Page 1

The

Dissolved Oxygen

Handbook

a practical guide to dissolved oxygen measurements

YSI.com/weknowDO

Page 2

CONTENTS

Introduction .......................................................................................................1

Dissolved Oxygen Sensors ................................................................................ 3

Optical Sensors ..............................................................................................5

YSI Optical Dissolved Oxygen Instruments ............................................6

Optical Sensing Element ............................................................................ 7

How an Optical Sensor Measures Dissolved Oxygen ............................. 9

Electrochemical Sensors .............................................................................10

YSI Electrochemical Instruments ........................................................... 10

Electrochemical Membranes ................................................................... 12

How an Electrochemical Sensor Measures Dissolved Oxygen ............ 15

Advancements in Steady-state Electrochemical Sensors ...................... 20

Comparing Steady-state Polarographic and Galvanic Sensors ............ 21

Comparing Optical and Electrochemical Sensing Technologies ................ 25

Measurement Accuracy ..............................................................................25

Approved Methodology .............................................................................. 28

Response Time ............................................................................................. 29

Flow Dependence ........................................................................................32

Warm-Up Time ............................................................................................ 34

Calibration Frequency ................................................................................ 34

Measurement Interferences ........................................................................ 35

Maintenance Requirements ........................................................................ 35

Power Consumption....................................................................................35

Summary .....................................................................................................35

Measuring Dissolved Oxygen with Either Sensor Type ............................... 37

Variables that Affect Dissolved Oxygen Measurements .......................... 38

Temperature .................................................................................................39

Page 3

Salinity .......................................................................................................... 40

Electrode Maintenance ............................................................................67

Correcting for Salinity .............................................................................42

Barometric Pressure .................................................................................... 43

Using Barometric Pressure for DO Calibration ....................................44

Local DO % Measurements ..................................................................... 46

Calibration ........................................................................................................ 46

Calibration Frequency ................................................................................ 46

Calibration Methods ..................................................................................47

Winkler Titration Calibration .................................................................48

Air-saturated Water Calibration ............................................................. 49

Water-saturated Air Calibration ............................................................49

Two Point Calibration .............................................................................. 54

Calibration Musts .......................................................................................55

Calibration Musts for Electrochemical Sensors ....................................55

Calibration Musts for Optical Sensors ..................................................56

Errors During Calibration .......................................................................... 57

Probe Care and Maintenance for Optical Sensors ...................................69

Storage ..........................................................................................................70

Final Words .......................................................................................................70

Appendix A - Oxygen Solubility Table ..........................................................72

Appendix B – Calibration Values for Various Atmospheric Pressures and

Altitudes ............................................................................................................74

References ......................................................................................................... 76

GLP (Good Laboratory Practices) File ...................................................... 58

Taking Measurements ...................................................................................... 59

BOD Measurements .................................................................................... 60

Measurement Precautions and Interferences ...........................................61

Biofouling .................................................................................................. 61

Coating Materials .....................................................................................61

Probe Attacking Liquids .......................................................................... 62

Interfering Gases .....................................................................................63

Membrane and Sensing Element Integrity ............................................ 63

Probe Care and Maintenance .......................................................................... 64

Probe Care and Maintenance for Electrochemical Sensors ....................64

Changing a Membrane ............................................................................. 64

Page 4

THIS PAGE LEFT INTENTIONALLY BLANK

INTRODUCTION

YSI has a long history in developing and manufacturing sensors that

measure dissolved oxygen in aqueous solutions and has had many firsts

over the years including the invention and commercialization of the first

portable dissolved oxygen instrument in 1963. This instrument utilized a

membrane-covered Clark Polarographic sensor, commonly referred to as a

Clark electrode, which was developed in 1956 by Dr. Leland Clark (figure

1), a researcher at Antioch College who was working in collaboration with

YSI scientists. Before the introduction of the Clark electrode, methods for

measuring dissolved oxygen were laborious, time-consuming and highly

susceptible to interference. Today the world continues to benefit from Dr.

Clark’s invention as the Clark electrode is still used by many manufacturers

and in several YSI instruments. In addition to the variety of Clark electrodes

offered, YSI also manufactures optical based dissolved oxygen sensors

for laboratory, spot sampling and long term monitoring applications. See

figure 2 for a brief overview of other YSI milestones in dissolved oxygen

measurement technologies over its 60 year history.

This booklet describes in detail the different types of dissolved oxygen sensing

technologies available. It also covers, in general terms, recommended

calibration methods, regular maintenance procedures that can be performed

by the user and how to take a measurement in order to obtain accurate

data. For instrument specific instructions and recommendations, please

refer to the instrument’s instruction manual.

YSI offers seminars on the topic of dissolved oxygen measurement

technologies which may apply to continuing education units depending on

the certifying agency. If you would like to schedule a seminar for your group

or organization, please contact YSI at environmental@ysi.com, 1-800-8974151 or +1 937-767-7241.

1

Page 5

2

3

Figure 1. Dr. Leland Clark, inventor of the Clark polarographic electrode.

Notable Events in YSI’s History of Developing Sensing

Technologies for Measuring Dissolved Oxygen

1956 – Dr. Leland Clark invents the membrane covered Polarographic

electrode while working with YSI Scientists.

2006 – YSI releases the ROX® optical dissolved oxygen sensor. The

sensor has a dedicated wiper for long term monitoring on multi-parameter

sondes.

2007 – YSI releases a galvanic electrochemical sensor for use on the Pro

Series handheld product family.

2008 – YSI releases the ProODO® optical dissolved oxygen instrument for

spot sampling and laboratory applications.

Figure 2. YSI’s Dissolved Oxygen Time line.

DISSOLVED OXYGEN SENSORS

There are two primary types of dissolved oxygen sensing technologies

available: the optical based sensing method which is commonly referred

to as luminescent and the Clark electrochemical or membrane-covered

electrode. Within these two types of technologies, there are slight variations

available. For example, there are two types of optical sensors. Both types

of optical sensors measure luminescence as it is affected by the presence

of oxygen; however, one sensor measures the lifetime of the luminescence

while the other sensor measures the intensity of the luminescence.

1965 – YSI develops the first biological oxygen monitor. Considered a

breakthrough for modern medicine and surgery, this instrument enabled

physicians to perform open-heart surgery for the first time because immediate

blood oxygen measurements could be taken real-time in the operating room

rather than having a sample drawn and taken to a lab for analysis.

1993 – YSI patents first long-term, in-situ, stirring independent oxygen sensor

(Rapid PulseTM DO) and packages it with multiparameter instruments.

1993 – YSI patents first stirring independent micro-electrode oxygen sensor

(Micro-Electrode Array or MEA) for spot sampling applications.

2002 – YSI releases polyethylene membranes for use on polarographic

dissolved oxygen sensors. This advancement in membrane material

lowered the stirring dependence and quickened the sensor’s response time

over traditional Teflon® membranes.

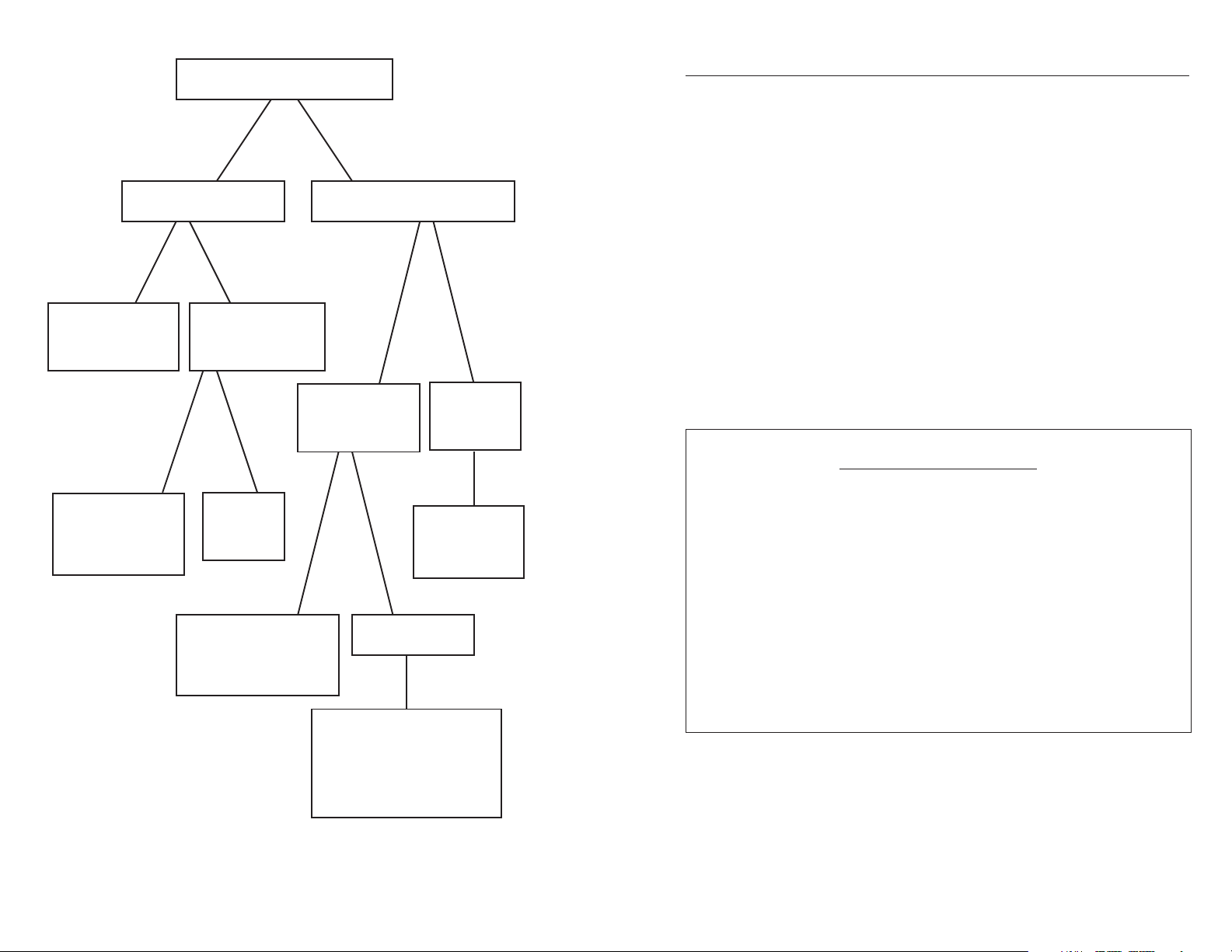

The two types of Clark electrochemical sensors available are Polarographic

and Galvanic. Additionally, YSI manufacturers two types of Polarographic

sensors: Steady-state and the patented Rapid Pulse sensor. Refer to figure 3

for a diagram of the various sensor types.

Page 6

4

5

Dissolved Oxygen Sensors

Optical Sensors

Electrochemical Sensors

Intensity-based

Optical Sensors

Lifetime-based

Optical Sensors

Polarographic

Sensors

Galvanic

Sensors

ROX - available

on most 6-series

sondes

ProODO

Rapid Pulse -

available on some

6-series sondes

Steady-state

Available on

Pro20 and

ProPlus

Available on several

instruments including:

ProPlus, Pro20, 550A,

DO200 and 5100

OPTICAL SENSORS

Lifetime and intensity optical measurement methods detect dissolved oxygen

based on the well documented principle that dissolved oxygen quenches

both the lifetime and intensity of the luminescence associated with carefullychosen chemical dyes. When there is no oxygen present, the lifetime and

intensity of the signal are at their maximum. As oxygen is introduced

to the sensing element, both the lifetime and intensity of the luminescence

become shorter. Therefore, the lifetime and intensity of the luminescence

are inversely proportional to the amount of oxygen present. The relationship

between the oxygen pressure outside the sensor and the lifetime or intensity

of the luminescence in the dye layer of the sensing element can be generally

quantified by the Stern-Volmer equation (figure 4). However, the SternVolmer equation implies an inversely linear relationship which is not strictly

true especially at higher oxygen concentrations; therefore, YSI employs the

use of a 3rd order polynomial to correct for this non-linearity and to obtain

the desired range of dissolved oxygen readings.

Figure 3. Diagram of Dissolved Oxygen Sensors.

The Stern-Volmer Relationship

Io/I = 1 + kqt0 * O2

Where:

Io =Intensity or lifetime of luminescence without the quenching molecule

(O2).

I = Intensity or lifetime of luminescence with the quenching molecule (O2).

kq = Is the quencher rate coefficient.

t0 = Is the luminescence lifetime of the chemical (the dye) to be quenched.

O2 = The concentration of oxygen.

Figure 4. Stern-Volmer equation.

Given that the sensing elements of the two optical sensor types are identical,

the primary advantage of the lifetime method over the intensity method is

that a lifetime sensor will be more stable in the long term. This is because the

Page 7

6

7

degradation of the dye in the sensing element has less effect on the lifetime

based measurement than the intensity based measurement. Therefore, the

intensity method will require more frequent calibrations - particularly at zero

oxygen.

YSI OPTICAL DISSOLVED OXYGEN INSTRUMENTS

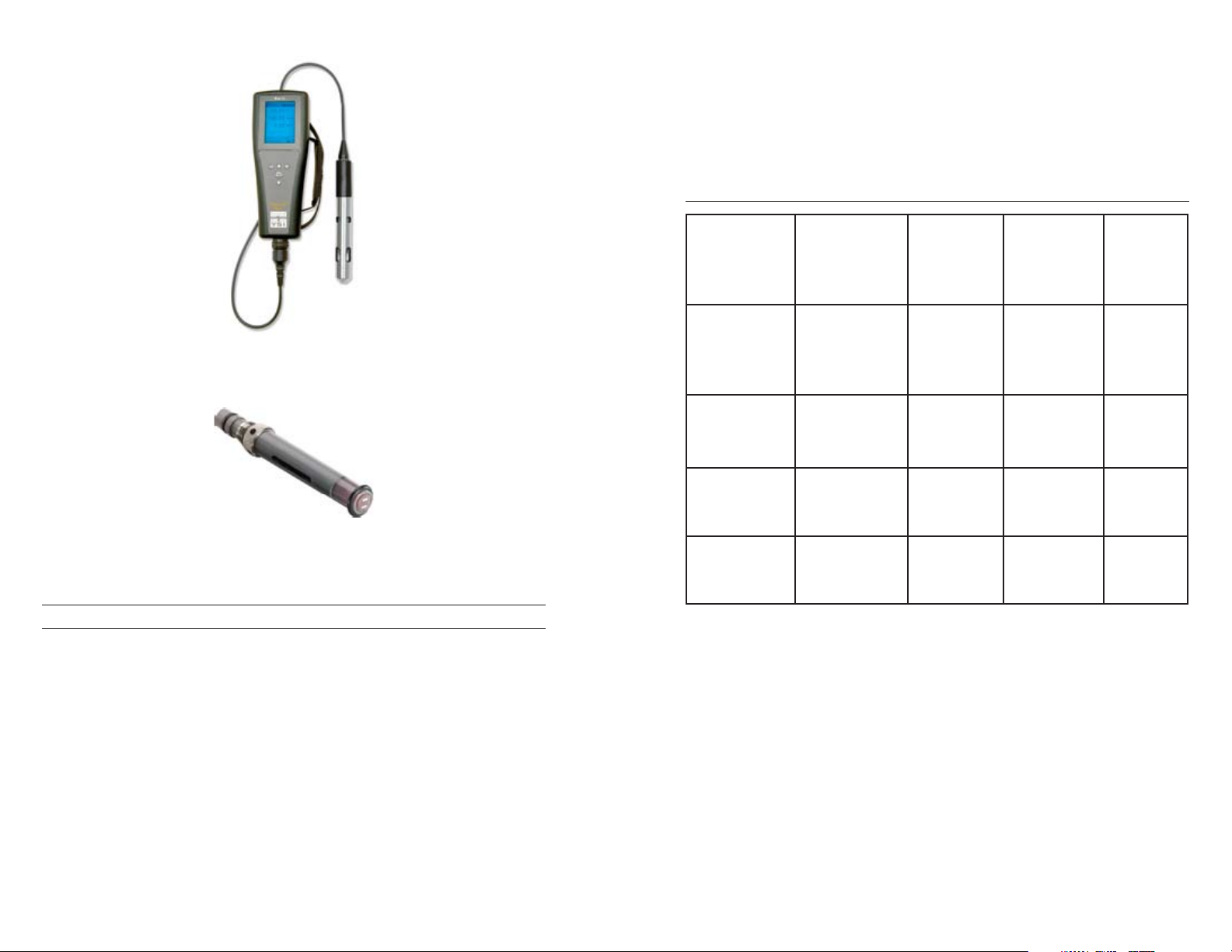

YSI offers two lifetime optical sensors: the ProODO (figure 5) sampling

instrument and the 6150 ROX® (figure 6) sensor which can be used on

most 6-series sondes that have an optical port. In addition, there will be an

optical BOD-style sensor available for use on the ProODO in early 2010.

ROX

Sensor

Figure 5. The ProODO is a compact, handheld instrument designed to withstand

the harshest field conditions yet is accurate enough for use in a laboratory.

Figure 6. The ROX sensor’s dedicated wiper and anti-fouling accessories help extend

deployment times while protecting data integrity making it ideal for unattended,

remote and real time monitoring applications.

OPTICAL SENSING ELEMENT

YSI’s two optical dissolved oxygen sensors utilize sensing elements that are

similar in function but slightly different in design. The ProODO’s sensing

element is referred to as a Sensor Cap due to its screw on cap design (figure

7). The ROX’s sensing element is referred to as a ROX Membrane (figure 8)

and is held in place by 3 screws.

Figure 7. ProODO Sensor Cap.

Sensor Cap

Page 8

8

9

Figure 8. ROX membrane.

Oxygen is constantly diffusing

through the paint layer, affecting the

luminescence of the sensing layer.

Each sensing element has two layers. The outer layer is a paint that acts

as an oxygen permeable diffusion layer which allows oxygen molecules

to pass through while protecting the dye layer. The sensing layer is an

immobilized polystyrene dye layer that luminesces when excited with light

of a proper wavelength (figure 9). The degradation of this dye layer over

time is what causes the sensor cap to need replacement and all lifetime

based optical sensors require that this dye layer be replaced periodically.

YSI sensing elements are warranted for 1 year but may last much longer.

The working life of a sensing element may be extended by keeping it clean

and properly stored between uses. See the Probe Care and Maintenance

section of this booklet for more information on cleaning and storage.

The sensing elements are factory calibrated at YSI and a calibration

code specific to each individual sensing element is determined during the

manufacturing process. The calibration code consists of coefficients that

are preloaded into the sensor at the factory for increased measurement

accuracy. Replacement sensing elements are supplied with their unique

calibration codes which can easily be entered into the instrument and probe

without the need to return it to the factory. The unique codes and instructions

for entering them into the instrument can be found on the instruction sheet

provided with the replacement sensing element.

The lifetime of the

luminescence is measured

by the sensor and compared

against a reference.

The amount of oxygen passing through

to the sensing layer is inversely

proportional to the lifetime of the

luminescence in the sensing layer.

Figure 9. Illustration of how a YSI optical sensor measures oxygen.

HOW AN OPTICAL SENSOR MEASURES DISSOLVED OXYGEN

The probe measures dissolved oxygen by emitting a blue light of the proper

wavelength that causes the dye in the sensing element to luminesce or glow

red. Oxygen dissolved in the sample continually passes through the diffusion

layer to the dye layer, affecting the luminescence of the dye both in intensity

and lifetime. The YSI sensor measures the lifetime of the dye’s luminescence

as it is affected by the presence of oxygen with a photodiode (light detector)

in the probe and compares that reading to a reference (figure 9).

To increase the accuracy and stability of the measurement, the sensor also

emits a red light that is reflected by the dye layer back to the photodiode in

the sensor. The sensor measures the reflected light and uses that reading

as the reference value for comparison to the previously measured lifetime

luminescent value. The lifetime of the luminescence from excitation by the

blue light is compared to that of the reference value (red light) and a stable

dissolved oxygen concentration is calculated by the probe.

Although the accuracy of an optical sensor’s measurement is not dependent

on flow, it is dependent on temperature. This temperature dependence

Page 9

10

11

is removed by proprietary algorithms in the system software. As for any

oxygen probe, the mg/L concentration is calculated from the sensor’s %

saturation reading (temperature compensated), temperature, and salinity

after the calibration of the system using barometric pressure. The effects of

these factors on dissolved oxygen readings are described in the Measuring

Dissolved Oxygen with Either Sensor Type section of this booklet.

ELECTROCHEMICAL SENSORS

YSI offers three types of field rugged electrochemical sensors: steady-state

galvanic, steady-state polarographic, and Rapid Pulse polarographic (figure

3). In addition to several different field probes, YSI offers a BOD-style

laboratory polarographic probe with a built in stir bar.

Dr. Leland Clark first invented the Polarographic electrode in 1956 and

variations of this electrode are still used by many manufacturers today. Figure

10 shows a picture of a YSI 5739 polarographic sensor which is currently

offered by YSI and is similar in design to the original Clark electrode.

The Professional Plus and Pro20 as well as other YSI instruments can be

equipped with either a field or lab BOD-style sensor (figure 11). This

flexibility allows for the convenience and cost-savings of having one

instrument for both applications. Additionally, these two instruments utilize

a screw-on cap membrane which makes membrane changes simple and

easy to perform. The third electrochemical sensor type, the Rapid Pulse

sensor, can be used on several of the 6-series multiparameter sondes (figure

13).

Figure 10. Model 5739 polarographic sensor.

YSI ELECTROCHEMICAL INSTRUMENTS

YSI offers numerous instruments that utilize an electrochemical sensor. Most

notably are the Professional Plus multiparameter and the Pro20 dissolved

oxygen and temperature instruments (figure 11 and 12). These two models

are the most versatile YSI handheld dissolved oxygen instruments since they

can use either a polarographic or galvanic sensor. Deciding between a

polarographic and galvanic sensor depends on the application and user

preference. See the Comparing Steady-state Polarographic and Galvanic

Sensors section to understand the advantages and disadvantages of using

one type of sensor over the other.

Figure 11. The Professional Plus multiparameter instrument with a BOD-style

sensor. The Professional Plus can be outfitted with several different single and

multi-parameter cables including the Quatro which can measure dissolved oxygen,

temperature, conductivity, and two ISEs at the same time and on the same cable.

Page 10

12

13

thicknesses and materials offered by YSI and their corresponding response

times, flow dependences, and required flow rates. For tips on how to

overcome flow dependence, see the Taking Measurements section. The

topics of flow dependence and response time are discussed further in the

Comparing Optical and Electrochemical Sensing Technologies section.

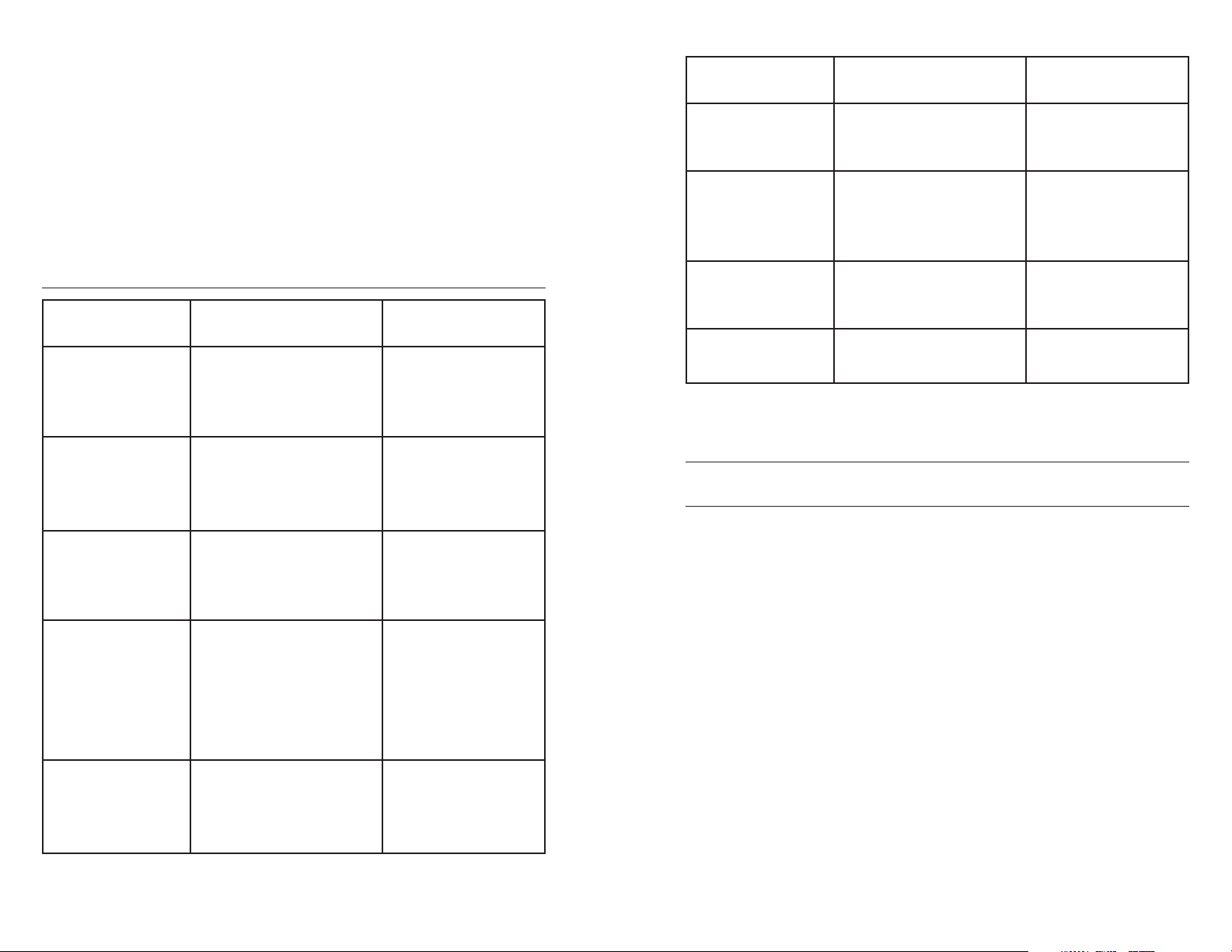

Membrane Comparison Table

Figure 12. The Pro 20 as well as the Pro Plus can be outfitted with a polarographic

or galvanic sensor.

Figure 13. Rapid Pulse sensor for use on some 6-series sondes.

ELECTROCHEMICAL MEMBRANES

An electrochemical membrane is a thin semi-permeable material, stretched

over the sensor that isolates the electrodes from the environment while

allowing gases to enter. YSI offers several different types of dissolved

oxygen membranes of varying design, thickness and material.

The two types of membrane designs include the traditional, sheet-like stretch

membrane that is held in place by an o-ring and the plastic screw-on cap

membrane that has the membrane material pre-stretched at the factory.

The membrane’s material and thickness affect the sensor’s flow dependence

and response time. The table in figure 14 shows the various membrane

Sensor Membrane

Material

Color of Cap

Optical Diffusion layer

and sensing

element

Response

Time 100 to

0% (T-95)

40

seconds*

Flow

Dependence

after 4

minutes

0 (zero)

Non-

Required

Flow Rate

0 (zero)

consumptive

Steady-state

Galvanic or

Polarographic

Steady-state

Galvanic or

Polarographic

Steady-state

Galvanic or

Polarographic

1.0 mil Teflon

Black Cap

1.25 mil PE

Yellow Cap

2.0 mil PE

Blue Cap

18 seconds 45% 12 inches

per

second

8 seconds 25% 6 inches

per

second

17 seconds 18% 3 inches

per

second

Figure 14. Newer membrane caps are made of polyethylene notated as PE in the

table. The response time in this table is listed as T-95 which is the amount of time

it takes for the sensor to get to 95% of the desired reading when moved from a 100%

saturated sample to a 0 oxygen environment.

*YSI studies have shown that stirring an optical sensor can lower its response

time. For example, using a magnetic stirrer or stir bar could result in an

optical response time of 22 seconds or less for T-95.

The type of membrane that can be used with a particular instrument is

dictated by the sensor type in use and by the instrument’s microprocessor.

Using an incorrect membrane could result in erroneous readings so care

Page 11

14

15

should be taken when ordering replacement membranes. Refer to figure

15 for a guide to ordering the proper membrane for a specific instrument

and sensor. If you have an instrument that can use more then one type of

membrane, refer to figure 14 to determine which option is best for your

application based on the response times and required flow rates of the

membranes available for use on your instrument. For instruments that can

use more than one membrane, it should be noted that the instrument must be

properly configured for the membrane installed in order to obtain accurate

readings.

Membrane Selection Guide

Membrane Model #

(Item #)

5680

(060745)

5775

(098094)

5776

(098095)

5906

(059880)

Type, Thickness, Material Instrument and

probes it is used with

Stretch Membrane,

2.0 mil Teflon

Stretch Membrane,

1.0 mil Teflon

Stretch Membrane,

0.5 mil Teflon

Black Cap Membrane,

1.0 mil Teflon

Probes: 5719, 5739,

and 5750 when used

with a model 58

instrument only.

Instrument: 55

Probes: 5719, 5739,

5750, and Rapid

Pulse

Probes: 5719, 5739,

and 5750 when used

with a model 58

instrument only.

Instrument: 85,

550, 556 MPS,

and Pro Plus with a

Polarographic sensor.

Probes: 5239, 5905

and 5010

Membrane Model #

(Item #)

5909

(059882)

5912

(605912)

5913

(605913)

5914

(605914)

Figure 15. Newer membrane caps are made of polyethylene notated as PE in the

table.

Type, Thickness, Material Instrument and

probes it is used with

Blue Cap Membrane,

2.0 mil Polyethylene (PE)

Black Cap Membrane,

1.0 mil Teflon

Yellow Cap Membrane,

1.25 mil Polyethylene (PE)

Blue Cap Membrane,

2.0 mil Polyethylene (PE)

Instruments: 556

Probes: Pro Series

Polarographic sensors

Pro Series Galvanic

sensor when used

with a Pro Plus

instrument only

Pro Series Galvanic

sensors

Pro Series Galvanic

sensors

HOW AN ELECTROCHEMICAL SENSOR MEASURES DISSOLVED OXYGEN

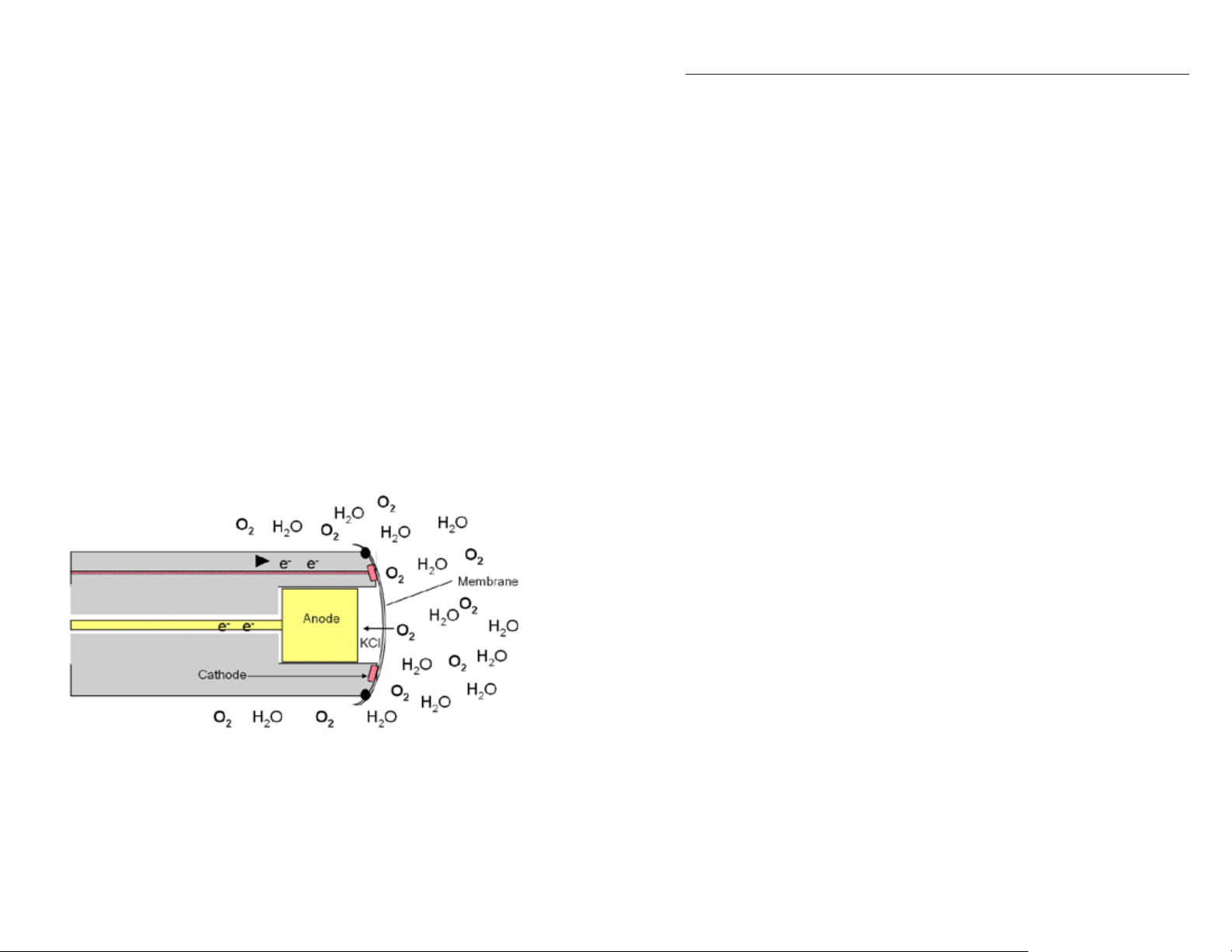

Electrochemical sensors, both polarographic and galvanic, consist of an

anode and a cathode that are confined in electrolyte solution by an oxygen

permeable membrane. Oxygen molecules that are dissolved in the sample

diffuse through the membrane to the sensor at a rate proportional to the

pressure difference across it. The oxygen molecules are then reduced at

the cathode producing an electrical signal that travels from the cathode to

the anode and then to the instrument. Since oxygen is rapidly reduced or

consumed at the cathode, it can be assumed that the oxygen pressure under

the membrane is zero. Therefore, the amount of oxygen diffusing through

the membrane is proportional to the partial pressure of oxygen outside the

membrane.

5908

(059881)

Yellow Cap Membrane,

1.25 mil Polyethylene (PE)

Instruments: DO200,

550A, and 556

Probes: Pro Series

Polarographic sensors

For example, in air or air-saturated water at sea level, the oxygen partial

pressure is approximately 160 mmHg (21% of 760 mmHg), while the

pressure under the membrane is zero. This difference in oxygen pressures

produces the current that is read by the instrument. As the oxygen pressure

varies, so does the oxygen diffusion through the membrane which causes

Page 12

16

17

the probe current to change proportionally. Figure 16 is a dissection of

a Clark electrode and illustrates how an electrochemical sensor, either

polarographic or galvanic, works.

It is important to recognize that oxygen dissolved in the sample is consumed

during the measurement with a steady-state electrochemical sensor. This

results in a measurement that is dependent on flow. It is therefore essential

that the sample be continuously stirred at the sensor tip. If stagnation occurs,

the readings will be artificially low. The flow dependence and therefore the

rate of stirring required for an accurate measurement varies by membrane,

see figure 14. The topics of flow dependence and response time are

discussed further in the Comparing Optical and Electrochemical Sensing

Technologies section. For tips on how to overcome flow dependence, see

the Taking Measurements section.

Electrochemical dissolved oxygen measurements are also affected by

barometric pressure and the temperature and salinity of the sample. These

three factors and how they affect dissolved oxygen readings are described

in detail in Measuring Dissolved Oxygen with Either Sensor Type section.

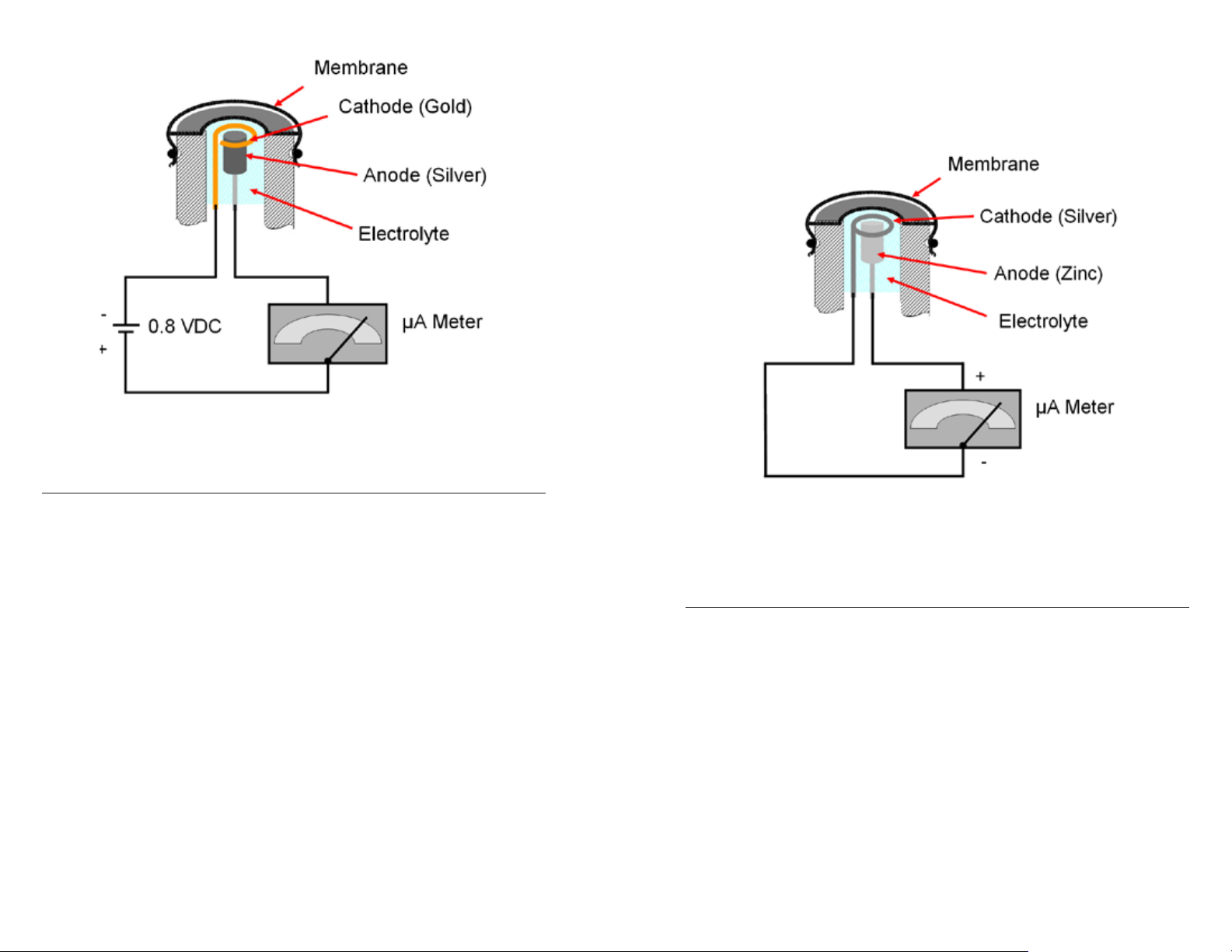

Steady-State Polarographic Sensors

In a polarographic sensor, the cathode is gold and the anode is silver. The

system is completed by a circuit in the instrument that applies a constant

voltage of 0.8 volts to the probe, which polarizes the two electrodes, and a

meter to read the dissolved oxygen response from the sensor.

The electrolyte held under the membrane allows the electrical signal to travel

from the cathode to the anode. The signal continues down to the meter

as shown by the basic circuit diagram in figure 17. The polarographic

sensor operates by detecting a change in this current caused by the variable

pressure of oxygen while the potential is held constant at 0.8 V. The more

oxygen passing through the membrane and being reduced at the cathode,

the greater the electrical signal (current) read by the probe. As oxygen

increases, the signal increases and, conversely, as oxygen decreases, the

signal decreases. Chemically, this is described as the oxidation of the silver

and reduction of oxygen at the gold cathode as follows:

Silver Anode Reaction: 4Ag + 4Cl- 4AgCl + 4e

Gold Cathode Reaction: O2 + 2H2O +4e- 4OH

-

-

Overall reaction: O2 + 2H2O + 4Ag + 4KCl 4AgCl + 4KOH

Figure 16. An illustration of an electrochemical sensor.

Page 13

18

19

Zinc Anode reaction: 2Zn 2Zn

2

+ 4e

-

+

Sliver Cathode reaction: O2 + 2H2O + 4e- 4OH

-

Figure 17. A simplified diagram of a polarographic sensor and circuit.

Steady-State Galvanic Sensors

In the YSI galvanic sensor, the cathode is silver and the anode is zinc. The

anode may be a different material, such as lead, in different manufacturers’

sensors. Figure 18 is an illustration of a galvanic sensor.

Overall reaction: O2 + 2H2O + 2Zn 2Zn(OH)

2

Figure 18. A simplified diagram of a galvanic sensor and circuit.

A circuit completes the measurement, but, unlike the polarographic sensor,

the galvanic sensor does not have or need a constant voltage applied to it.

In the Galvanic sensor, the electrodes are dissimilar enough to self-polarize

and reduce oxygen molecules without an applied voltage. It is similar in

function to a battery.

A galvanic dissolved oxygen system uses a meter to read the electrical signal

coming back from the probe and this signal is proportional to the amount

of oxygen passing through the membrane. Oxygen passing through the

membrane and being reduced at the cathode increases the electrical signal

(current) read by the probe. As oxygen increases, the signal increases and

as oxygen decreases, the signal decreases. Chemically, this is described

as the oxidation of the zinc and reduction of oxygen at the silver cathode

as follows:

Rapid Pulse Polarographic Sensors

The third type of electrochemical sensor offered by YSI is the patented Rapid

Pulse polarographic sensor. This sensor is like the steady-state polarographic

sensor in that it has a gold cathode, silver anode and utilizes electrolyte

solution that is held in place by an oxygen permeable membrane. Also,

similar to the traditional polarographic sensor, a voltage of 1.0 V is applied

to the electrodes and oxygen passing through the membrane is reduced at

the cathode. This reduction causes a change in the electrical signal read by

the instrument. The amount of oxygen passing through the membrane and

being reduced at the cathode is directly proportional to the electrical signal

sent back to the instrument.

Page 14

20

21

The Rapid Pulse sensor differs from a steady-state sensor in that it pulses

on and off during the measurement allowing the oxygen to replenish at

the membrane surface. The voltage is only applied for 40 milliseconds; it

is then turned off for 3960 milliseconds for a total measurement cycle of 4

seconds. This results in a sensor with almost zero flow dependence and

therefore does not require stirring or sample movement in order to obtain

accurate dissolved oxygen readings. It also uses digital electronics for

processing data as opposed to analog electronics like the two steady-state

electrochemical sensors previously discussed.

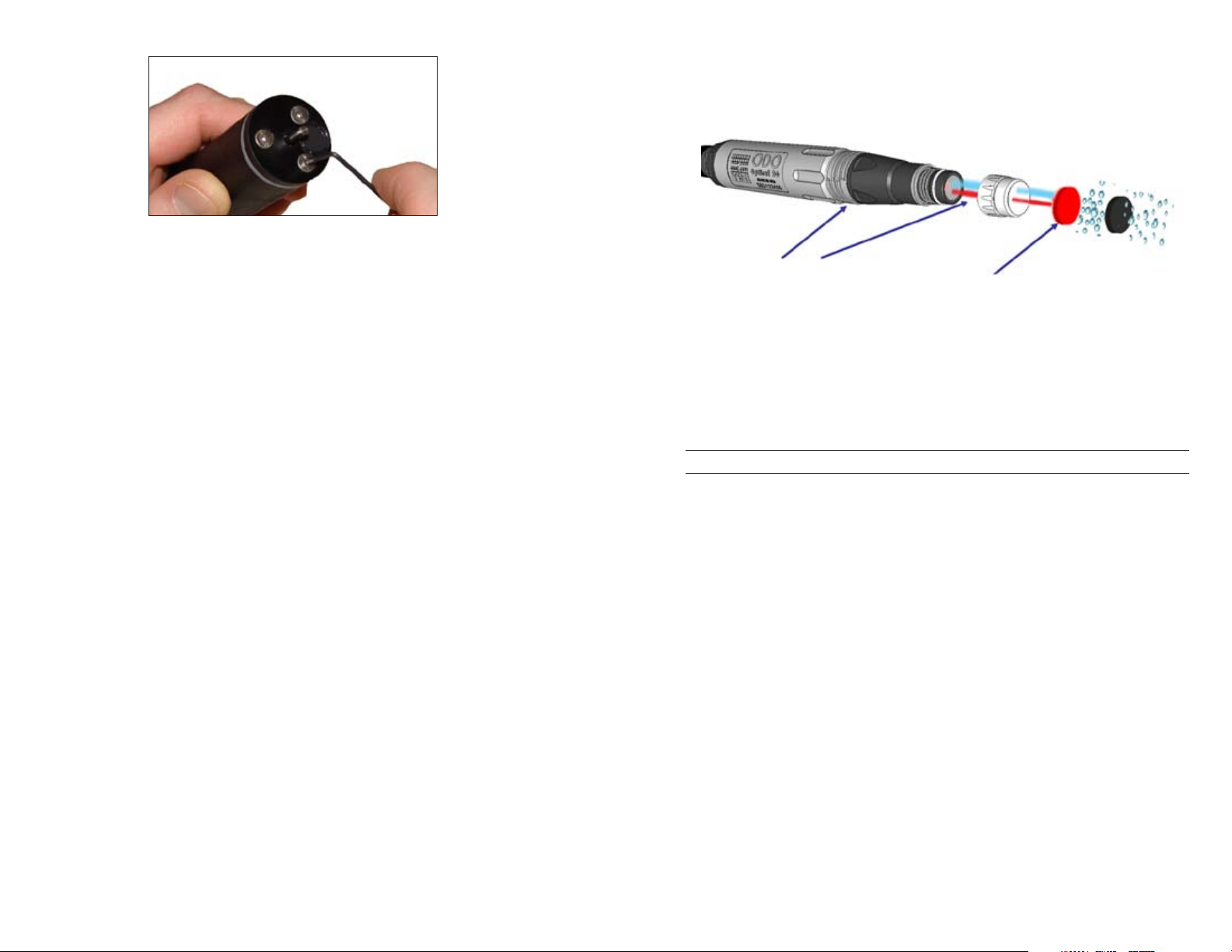

The Rapid Pulse sensor is also unique in the fact that it uses a third electrode,

see figure 19. The third electrode is a silver reference electrode that is

separate from the silver anode as opposed to the steady-state polarographic

and galvanic sensors where the reference electrodes and anodes are

combined. The three electrode configuration is required to polarize and

de-polarize the electrodes consistently and for a very short period of time,

the feature that makes the Rapid Pulse sensor function as a flow independent

sensor.

1

2

by the user. Most YSI electrochemical sensors manufactured today utilize

this screw-on membrane cap design. Since the cap has a membrane that

is pre-stretched at the factory, there is no need to worry about stretching

the membrane too much or not enough when installing it on a sensor.

Further, the cap is filled with electrolyte and then screwed on to the sensor

as opposed to filling the sensor and then stretching the membrane over the

solution. This design minimizes the chances of an air bubble getting trapped

underneath the membrane which could result in inaccurate readings. See

the Probe Care and Maintenance Section for more information on changing

a membrane.

The next advancement in the steady-state sensor was the release of

polyethylene membranes in 2002. This new membrane material lowered

the stirring dependence and reduced the response time of a sensor when

compared to traditional Teflon membranes. This resulted in a faster, more

accurate dissolved oxygen measurement.

Additionally, the dissolved oxygen sensor and cable are now manufactured

to be detachable so the sensor can be replaced without affecting the cable,

lowering the overall total cost of ownership. Further, no tools are required

to change sensors on YSI’s newest instruments, the Professional Plus and

Pro20, making the sensors truly field replaceable. Newer instruments also

include sensor diagnostics and error messages to help the user determine

when to change a membrane or recondition the electrodes, see the GLP

(Good Laboratory Practices) File section for more information on sensor

diagnostics.

3

Figure 19. Illustrating the 3 electrodes of a Rapid Pulse Sensor.

ADVANCEMENTS IN STEADYSTATE ELECTROCHEMICAL

SENSORS

The design of the electrochemical sensor has undergone many enhancements

over the years. The first YSI advancement in electrochemical sensors was

the redesign of the electrodes and membrane so that the membrane could

be pre-stretched into a plastic cap at the factory for easier replacement

COMPARING STEADYSTATE POLAROGRAPHIC AND GALVANIC

SENSORS

In terms of physical configuration and general performance, YSI galvanic

dissolved oxygen sensors are very similar to the polarographic sensors

which YSI pioneered and has sold for 40 years. The main advantage of

using galvanic sensors is convenience. Galvanic sensors provide an instanton sensor without the need for a warm-up time but this factor also adversely

affects the life of the sensor. Polarographic sensors last longer and have

a longer warranty but require a 5-15 minute warm-up time before use or

calibration. This section describes the similarities and differences between

these two technologies. These points are also summarized in figure 20.

Page 15

22

23

Similarities

First, both the polarographic and galvanic sensors are ‘steady-state’. This

means that when the instrument is turned on in the instance of a polarographic

sensor or, in the case of a galvanic sensor without the instrument being

turned on, the electrodes are continuously polarized or in ‘steady-state’.

Second, both sensor types reduce or consume oxygen at the cathode and

are therefore dependent on flow across the sensor tip. Flow dependence

is caused by the reduction of oxygen at the cathode which depletes

oxygen at the membrane surface in the sample. The oxygen depletion

at the membrane surface results in the need for sample movement across

the membrane in order to get accurate dissolved oxygen measurements.

If enough sample movement is not supplied by the natural flow of the

medium, manual agitation of the sensor by the user, a mechanical stirrer, or

some combination of these factors, then the sensor will continue to deplete

oxygen at the membrane surface which will result in artificially low DO

readings. The flow dependence is dictated by the membrane in use. The

flow dependence and required flow for each type of membrane is listed in

figure 14. The topics of flow dependence and response time are discussed

further in the Comparing Optical and Electrochemical Sensing Technologies

section. Tips on how to overcome flow dependence to obtain accurate

readings can be found in the Taking Measurements section.

Lastly, both sensors utilize electrolyte solution that allows an electrical current

to flow between the cathode and anode and is held in place by an oxygen

permeable membrane.

Differences

A major difference between polarographic and galvanic sensors is that

the galvanic sensor does not require a polarizing voltage to be applied in

order to reduce the oxygen that has passed through the membrane. Rather,

the electrode materials for the galvanic sensor have been chosen so that

their electrode potentials are dissimilar enough to reduce oxygen without

an applied voltage. Thus, the cathode and anode of the galvanic sensor

are made from silver and zinc (a highly reducing metal), respectively, while

the cathode and anode for the polarographic sensor are gold and silver (a

much less reducing metal), respectively.

Given that the galvanic sensor does not require an external voltage for

polarization, it therefore does not require the “warm-up” polarization time

that the polarographic sensor requires. Since a galvanic sensor doesn’t

require a “warm-up” time, the instrument is ready to measure when it is

powered on and, therefore, users are not required to wait to calibrate

or to take readings when using a galvanic sensor. Conversely, when an

instrument with a polarographic sensor is turned on, the polarizing potential

is applied to the sensor and a substantial “warm-up” period is required

before the sensor is stable enough for calibration and measurements. The

polarization warm-up time for a polarographic sensor is between 5-15

minutes depending on the age and condition of the electrodes. Thus, there

is an advantage of galvanic sensors over polarographic sensors in terms of

convenience of use.

Another difference between the two sensor types is in the oxidation of their

anodes. To balance the reduction reaction associated with oxygen at the

cathode, there is a corresponding oxidation reaction at the anode which

converts the zinc to zinc hydroxide (for galvanic sensors) or the silver to silver

chloride (for polarographic sensors). The practical difference between the

two types of anode oxidations is that the silver chloride remains attached

to the anode in a polarographic sensor while much of the zinc hydroxide

detaches from the anode in a galvanic sensor and forms a suspension of

white solid in the electrolyte. Thus, visual inspection of the electrolyte

at the tip of a galvanic sensor is likely to show the presence of a white

solid while the electrolyte for a polarographic sensor will be clear. The

amount of solid which is visible in the electrolyte for a galvanic sensor and

attached to the anode for a polarographic sensor is directly proportional

to the total current from the reduction of oxygen. Eventually, the formation

of oxidized anode material, either on the anode for polarographic sensors

or in the electrolyte for galvanic sensors, will cause degradation of sensor

performance. This degradation usually is indicated by low sensor output

and/or slightly jumpy readings. When these symptoms occur, the user

must remove the old membrane, clean the sensor anode if necessary, and

install a new membrane and electrolyte to restore proper performance. The

presence of the solid in galvanic sensors is likely to require a somewhat

more frequent membrane/electrolyte replacement than for polarographic

sensors due to degradation of overall system performance, giving an

advantage to polarographic sensors in this area. However it should be

Page 16

24

25

noted that (a) YSI has demonstrated 2-3 months of good galvanic sensor

performance even when there is considerable solid present in the electrolyte

and (b) the membrane/electrolyte replacement is very simple and relatively

inexpensive. Thus, the polarographic advantage is likely to be minor. See

Probe Care and Maintenance for more information on routine maintenance

procedures for electrochemical sensors and the recommended intervals for

performing these actions.

The last main difference between the two sensors is their theoretical sensor

life. Because the galvanic sensor’s electrodes are continuously polarized,

it is always ‘on’ even when the instrument is turned off. This results in a

degradation of the consumable anode which could result in a theoretically

shorter sensor life. Since the Polarographic sensors are not self-polarizing,

the sensor is off when the instrument is off and, therefore, the consumable

anode is not being continuously degraded which results in a longer

theoretical sensor life. Therefore, theoretically, the polarographic sensor

may have some advantage over galvanic in overall sensor longevity. In

practical terms, the anode of a YSI galvanic sensor should last for several

years so the advantage is minor; however, it should be noted that a YSI

polarographic sensor is warranted for 1 year while a YSI galvanic sensor

is warranted for 6 months.

Steady-State Polarographic versus Steady-State Galvanic Sensors

Similarities:

Steady-State Polarographic versus Steady-State Galvanic Sensors

Differences:

• Galvanic sensors do not require a warm-up time and are ready for

immediate use after being powered on.

• Polarographic sensors require warm up period before use.

• Galvanic sensors continually consume the anode, even when the

instrument is off. Thus, they have a shorter theoretical sensor life and are

warranted for 6 months

• The consumption of polarographic sensors stops when the instrument

is turned off. Thus, they have a longer theoretical sensor life and are

warranted for 1 year.

Figure 20.

C O M PA R I N G O P T I C A L A N D E L E C T R O C H E M I C A L S E N S I N G TECHNOLOGIES

There are many advantages and disadvantages associated with each

sensing technology and these should be considered when selecting an

instrument. This section describes how the two technologies compare in

accuracy, approval for compliance purposes, and general use.

• Both sensors are Steady-state.

• Both reduce oxygen, thus they require stirring or sample movement for

accurate readings.

• Both use electrolyte that is held in place by an oxygen-permeable

membrane.

MEASUREMENT ACCURACY

Electrochemical and optical dissolved oxygen sensing technologies produce

nearly identical results across a wide measurement range as long as you

provide enough sample movement when using a steady state electrochemical

sensor.

Refer to the graphs in figure 21, the top graph represents dissolved oxygen

measurements from a stirred steady state electrochemical sensor at six

different dissolved oxygen concentrations. The bottom graph represents

measurements of the same samples taken with a lifetime optical sensor.

Each concentration was measured by each sensor seven times. As shown

by the data in the graphs, the two technologies measured dissolved oxygen

equivalently across the wide measurement range.

Page 17

26

27

CON SIST ENCY OF M EM BRANE EL ECT RODE READING S FOR VARIOUS DO

CON CENT RATIO NS

0

1

2

3

4

5

6

7

8

9

0 1 2 3 4 5 6 7 8

BOTTLE #

DO CONCENTRATION, MG/L

CONC 1

CONC 2

CONC 3

CONC 4

CONC 5

CONC 6

CONS IST ENCY O F YS I OPT ICAL READING S FO R VARIOUS DO C ONCENT RATIO NS

0

1

2

3

4

5

6

7

8

9

0 1 2 3 4 5 6 7 8

BOTTLE #

DO CONCENTRATION, MG/L

CONC 1

CONC 2

CONC 3

CONC 4

CONC 5

CONC 6

Figure 22 further illustrates that the two sensor technologies perform

equivalently. In this example, a ROX optical sensor and a Teflon covered

Rapid Pulse polarographic sensor were deployed continuously for 52 days.

Since the Rapid Pulse sensor was used, stirring or sample movement was

not required. Both sensors were equipped with wipers to minimize the

effects of bio-fouling. The data between the two sensors (blue circles for the

Rapid Pulse sensor and red circles for the ROX sensor) tracked consistently

with each other even during a low DO event. A manual spot check of DO

was periodically taken during the test and is represented on the graph with

black triangles. There are a few apparent discrepancies for the manual

readings, which could be the result of insufficient sample movement or

improper calibration of the instrument used to take the manual reading. In

general, the three types of measurements track well.

Figure 21. Studies were performed by YSI Scientists for the Standard Methods

Review Panel.

Figure 22. Source: South Carolina Department of Natural Resources – Waddell

Mariculture Center; Research funded by National Institute of Standards and

Te ch no l og y1.

Even though the two technologies perform equivalently in the field, optical

sensors are slightly more accurate then electrochemical sensors under

controlled conditions in the 0-20 mg/L measurement range as is shown in

YSI’s published specifications, see figure 23.

Page 18

28

29

Optical

% DO Saturation 0-500% 0.1%

mg/L 0-50 mg/L 0.01 mg/L

Electrochemical

% DO Saturation 0-500% 0.1%

Range Resolution Accuracy

Range Resolution Accuracy

0 - 200%: ±1%

of reading or 1%

Saturation, whichever is

greater.

200 - 500%: ±15% of

reading.

0 - 20 mg/L: ±0.1mg/L

or 1% of reading,

whichever is greater.

20 - 50 mg/L: ±15% of

reading.

0 - 200%: ±2%

of reading or 2%

Saturation, whichever is

greater.

Test Protocol) Coordinator for individual approval. Submitting an application

to your Regional ATP Coordinator is typically all that is required but, in some

cases, you may have to submit data in order to get approval to use this

method for compliance reporting. ASTM International has approved the

optical method for measuring dissolved oxygen in water, method D888-05,

but it has not yet been approved by Standard Methods for the Examination

of Water and Wastewater. A Standard Method will likely be adopted in

the near future.

The electrochemical method has been used for decades and is therefore a

proven technology. It is approved for monitoring and compliance reporting

by the US EPA and can be used without contacting a regional US EPA office.

This factor gives it a slight advantage over the optical method.

RESPONSE TIME

The response time of a sensor should be considered when selecting an

instrument since this feature will dictate the amount of time required to

conduct a sampling session. A faster responding sensor could save time

and therefore money if used instead of a slower responding sensor.

200 - 500%: ±6% of

reading.

mg/L 0-50 mg/L 0.01 mg/L

Figure 23.

0 - 20 mg/L: ±0.2

mg/L or 2% of reading,

whichever is greater.

20 - 50 mg/L: ±6% of

reading

APPROVED METHODOLOGY

At the time of publication, the optical sensing method is not nationally

approved by the United States Environmental Protection Agency (US EPA)

for compliance monitoring and reporting. It has gained interim approval in

many EPA regions, but you must contact your Regional EPA ATP (Alternative

The table in figure 24 shows the typical response times of optical and

steady-state electrochemical sensors. The table further illustrates the

response time of an electrochemical sensor when used with various types

of membranes. The response time is expressed as T-95 which is the length

of time it takes to reach 95% of the final (true) reading when a sensor is

transferred from a fully saturated sample to a zero oxygen environment. As

shown, an optical sensor’s response time is about twice as long as a Teflon

covered electrochemical sensor and five times as long as a polyethylene

(PE) covered electrochemical sensor. The varying sensor response times

are also demonstrated in the graph in figure 25 where you can see the

polyethylene covered electrochemical sensor responded much quicker then

the other two sensors.

Although 40 seconds is a relatively short period of time to take one reading,

the table in figure 26 illustrates how much longer it would take to measure

dissolved oxygen in 500 samples with an optical sensor versus a polyethylene

or Teflon covered electrochemical sensor. If using a polyethylene covered

Page 19

30

31

sensor, 500 samples could be measured in about 1 hour where it would

DO Response Time

0

10

20

30

40

50

60

70

80

90

100

1 10 19 28 37 46 55

Time in Seconds

Dissolved Oxygen % Saturation

Teflon Membrane

1.25 PE Membrane

Optical Sensor

take over 5 hours to measure 500 samples with an unstirred optical sensor.

It should be noted that YSI studies have shown that stirring an optical sensor

can lower its response time. For example, using a magnetic stirrer or stir

bar could result in an optical response time of 22 seconds or less for T-95.

Therefore, reading 500 samples with a stirred optical BOD sensor (OBOD)

could take about 3 hours to perform.

Sensor Type Membrane Material Response Time

100 to 0%

(T-95)

Optical Sensing element with

40 seconds**

diffusion layer

Galvanic or

Polarographic

Galvanic or

Polarographic

Galvanic or

Polarographic

1.0 mil Teflon

Black cap

1.25 mil PE

Yellow Cap

2.0 mil PE

Blue Cap

18 seconds

8 seconds

17 seconds

Figure 25. A graph displaying DO measurements over time for three sensors that

were transferred from 100% saturated water to a zero oxygen environment.

Figure 24. A table defining the measurement response time of various sensors and

membranes.

** YSI studies have shown that stirring an optical sensor can lower its

response time. For example, using a magnetic stirrer or stir bar could result

in an optical response time of 22 seconds or less for T-95.

Sensor Type Number of

Polarographic

Samples

500 18 2.5

T-95 Response

in seconds

Total Time in

hours

with 1.0 mil Teflon

membrane

Polarographic

500 8 1.1

with 1.25 mil PE

membrane

Optical 500 40 5.6

Figure 26. The data in the table demonstrates the amount of time it would take to

measure 500 samples with three different sensors.

Page 20

32

33

FLOW DEPENDENCE

As mentioned, steady-state electrochemical sensors consume oxygen during

measurement and therefore require sample movement or the readings will

be artificially low. This is commonly referred to as flow dependence since

the sensor is dependent on flow or water movement across the membrane

in order to obtain accurate readings. Optical sensors, however, use a

non-consumptive method for dissolved oxygen measurements resulting in a

sensing method with zero flow dependence or stirring requirement.

The graphs in figure 27 and 28 illustrate this advantage of the optical sensor.

Figure 27 is a graph of data measured with a steady-state polarographic

sensor in an air-saturated water sample where adequate sample movement

was provided by a mechanical stir bar. When the stirring mechanism was

turned off, the readings began to fall resulting in artificially low dissolved

oxygen measurements. Figure 28 is a graph of data measured with

an optical sensor in the same air-saturated water sample where sample

movement was provided by a stir bar. When the stirring mechanism was

turned off for the optical measurements, the readings remained constant

and accurate proving the optical sensor is not dependent on flow. This

is a considerable advantage of the optical sensor especially for low flow

applications or applications where probe stirring or sample movement is

difficult such as down well.

Figure 28. A graph, created in YSI Data Manager software program, illustrating

the flow independence of an optical sensor.

For steady-state electrochemical sensors, the membrane material and

thickness dictates the degree of the sensor’s flow dependence. For example,

polyethylene membranes, frequently notated as PE, require less movement or

flow then traditional Teflon membranes as illustrated by the graph in figure

29. In this graph, three different sensors were placed in fully aerated water

with a stir bar. Once the stirring was ceased, the steady-state electrochemical

readings began to fall. Notice how the Teflon covered sensor fell further

and more rapidly then the PE covered sensor. The stirring dependence

of each sensor and membrane type, along with the recommended stirring

rates, is listed in figure 14. For tips on how to overcome flow dependence,

see Taking Measurements.

Figure 27. A graph, created in YSI’s Data Manager software program ,illustrating

the flow dependence of a steady state electrochemical sensor.

Page 21

34

35

Figure 29. Flow dependence comparison graph.

60%

100%

Percent

Saturation

Remove Stirring

Steady State Response

Teflon Response

PE Response

Optical

Time in seconds

WARM-UP TIME

A key advantage of the optical sensor for sampling applications is that it

does not have a warm up time since there are no electrodes to polarize.

So, similar to a galvanic sensor, an optical sensor can be calibrated and

used immediately after being turned on. A polarographic sensor, however,

requires 5-15 minutes for the electrodes to polarize before a calibration or

measurement can be performed.

CALIBRATION FREQUENCY

MEASUREMENT INTERFERENCES

Some gases, including hydrogen sulfide, can permeate the membrane of

an electrochemical sensor interfering with the electrodes and the readings.

A list of these gases can be found in the Measurement Precautions and

Interference section. Optical sensors, on the other hand, are unaffected

by the presence of hydrogen sulfide and other gasses that interfere with

the traditional electrochemical method. This gives the optical sensor the

ability to sample in environments with hydrogen sulfide like wastewater,

lake bottoms and wetlands.

MAINTENANCE REQUIREMENTS

The optical sensor requires much less maintenance then traditional

electrochemical sensors. With the optical sensor, the sensing element only

needs to be replaced about once per year where an electrochemical sensor

usually requires a membrane change every 2-8 weeks. Further, there is no

need to clean or resurface electrodes in an optical sensor as is required

when using an electrochemical sensor. For more information on performing

routine maintenance tasks, see the Probe Care and Maintenance section.

POWER CONSUMPTION

Optical sensors have a higher power consumption rate than the

electrochemical sensors. This results in a shorter battery life which could be

a disadvantage for the optical sensor in some sampling applications.

The optical measurement method experiences very little calibration drift

when compared to electrochemical sensors and this advantage results

in less frequent calibrations. In fact, optical sensors are so stable they

are capable of holding their calibration for many months, although YSI

recommends verifying the calibration regularly to ensure the highest data

accuracy. Steady-state electrochemical sensors require a calibration each

day they are used in a spot sampling application. Although this can be

considered a disadvantage of the electrochemical method, it must be noted

that a dissolved oxygen calibration is simple and easy to perform. See the

Calibration section for additional information.

SUMMARY

As you can see, there are several advantages and disadvantages associated

with each sensing method and these factors as well as some additional

points have been summarized in figure 30. It is important to analyze your

specific application needs to help determine which sensor is best for your

specific application. See the figure 31 for a table that outlines the best

suited applications for each sensing method.

Page 22

36

37

Electrochemical Sensors

Advantages Disadvantages

Proven technology. Approved

by the US EPA for compliance

monitoring and reporting.

Faster measurement response time

than an optical sensor.

Lower power consumption than an

optical sensor.

Lower initial acquisition cost than

an optical sensor.

Advantages Disadvantages

Instant on – no warm up time

required.

Exhibits very little calibration drift

and can hold a calibration for

several months.

Not susceptible to interferences like

hydrogen sulfide.

Non consumptive method – no

need to stir or provide sample

movement.

Less maintenance than traditional

electrochemical sensors.

Figure 30. Summary of advantages and disadvantages associated with each sensor

type.

Steady-state sensors are flow

dependent and therefore require

sample movement for accurate

readings.

Requires more frequent calibrations

than an optical sensor.

The measurement is susceptible to

interferences from gases such as

hydrogen sulfide.

The electrodes require periodic

maintenance.

The membrane requires regular

changes.

Optical

Not approved by the US EPA

for compliance monitoring and

reporting.

Higher initial acquisition cost.

Slower measurement response time

than traditional electrochemical

sensors.

Higher power consumption than

traditional electrochemical sensors.

Best Suited Application for each Dissolved Oxygen Sensor

Type

Sensor Type Membrane Material Best Application (in general)

Optical Sensing element with

diffusion layer

Galvanic or

Polarographic

Galvanic or

Polarographic

Figure 31. Best suited application per sensor type.

1.25 mil PE Sampling applications that

2.0 mil PE Sampling applications

Deep water profiling•

Shallow water where •

stirring is difficult

Low flow applications•

Samples that are small in •

volume

Samples with hydrogen •

sulfide

Continuous long-term •

deployments with the

ROX sensor

require the fastest response

time

that require a lower flow

dependence

MEASURING DISSOLVED OXYGEN WITH EITHER SENSOR TYPE

Dissolved oxygen sensors, both electrochemical and optical, do not measure

the concentration of dissolved oxygen in mg/L or ppm (parts per million

which is equivalent to mg/L). Instead, the sensors measure the pressure of

oxygen that is dissolved in the sample. To simplify the readings displayed

by an instrument, the pressure of the dissolved oxygen is expressed as DO

% Saturation. The instrument converts the dissolved oxygen pressure value

from the sensor to % Saturation by dividing the sensor output in mmHg by

160*** (the pressure of oxygen in air at 760 mmHg) and then multiplying

Page 23

38

39

by 100. Thus, a measured oxygen pressure of 150 mmHg would be

displayed by a YSI instrument as 93.8 % Saturation (150/160 * 100).

The fact that the sensor measures oxygen pressure and not dissolved oxygen

concentration is known to be true because a sample of fresh water can

dissolve more oxygen than a sample of sea water at the same temperature

and at the same altitude (or under the same barometric pressure); however,

the sensor’s output signal is identical in both samples since the oxygen

pressure is identical in both media. See figure 32 for an example of this

concept.

***The pressure of oxygen at sea level is 160 mmHg because oxygen is

about 21% of the earth’s atmosphere and 21% of 760 (average sea level

barometric pressure) is about 160 mmHg.

and field use with the use of additional sensors and/or instrument software

settings. The effect of flow dependence has been overcome by advances

in measurement technologies. Newer, optical dissolved oxygen sensors

have no flow dependence. For electrochemical based sensors, users

need to provide sample movement to overcome flow dependence or the

measurements could be artificially low. The stirring dependence and

recommended stirring rates of each sensor and membrane type are listed in

figure 14. For tips on how to overcome flow dependence, see the Taking

Measurements section.

Barometric pressure primarily affects the calibration of dissolved oxygen

sensors as it defines the pressure of oxygen in the calibration environment.

Generally, there is no need to be concerned about changes in barometric

pressure that take place after calibration, except if reporting DO% Local

with a YSI 556 or 650 as explained in the Barometer section.

DO Sensors Measure % Saturation

If two samples, one of fresh water and one of sea water, are fully

saturated with oxygen the dissolved oxygen concentration will be:

Fresh water at 25ºC = 8.26 mg/L

Sea water (36 ppt) at 25ºC = 6.27 mg/L

However, the signal output from either sensor type will be identical in the

two samples. Since both are 100% saturated, % saturation (or oxygen

pressure) is what both sensors are measuring.

Figure 32. DO sensors measure % saturation.

VARIABLES THAT AFFECT DISSOLVED OXYGEN MEASUREMENTS

There are several factors that affect the measurement of dissolved oxygen.

These variables include temperature, salinity, flow or stirring dependence,

and barometric pressure.

Temperature and salinity are compensated for during instrument calibration

TEMPERATURE

The most significant variable for dissolved oxygen measurements is

temperature; therefore, it is important to ensure the temperature sensor on the

instrument is measuring accurately. Temperature affects DO measurements

in two ways.

First, due to the increase or decrease in molecular activity, diffusion of

oxygen through the membrane of an electrochemical probe or sensing

element of an optical probe changes with temperature. The change in

diffusion rate based on temperature can be up to approximately 4% per

degree Celsius depending on the membrane material for steady-state

electrochemical sensors, 1% per degree Celsius for Rapid Pulse sensors, and

is approximately 1.5% per degree Celsius for optical sensors. For example,

if the temperature of a sample changes from 20°C to 15°C, the probe

signal would decrease by varying rates depending on the sensor in use,

giving a lower DO % saturation reading even though the % saturation of the

water has not changed. Therefore, the sensor signal must be compensated

for changes in temperature. This is done by adding a thermistor to the circuit

of older, analog instruments. For newer, digital instruments, the software

compensates for temperature changes with proprietary algorithms that use

the temperature readings from the probe’s thermistor.

Page 24

40

41

The adjustment described so far only compensates for temperature’s effect

on the oxygen diffusion rate through a membrane or sensing element. In

addition to this effect, temperature also affects the ability of water to dissolve

oxygen. It is a scientific fact that the solubility of oxygen in water is directly

proportional to temperature; see Oxygen Solubility Table in Appendix

A. Warmer water cannot dissolve as much oxygen as colder water. For

example, in an oxygen saturated sample of water at sea level (exposed to

760 mmHg of barometric pressure), the % saturation value will be 100%

regardless of the temperature because it is fully saturated. However, the

dissolved oxygen mg/L concentration will change with temperature because

the solubility of oxygen in water changes with temperature. For instance, at

15 ºC water can dissolve 10.08 mg/L while 30 ºC water can only dissolve

7.56 mg/L of oxygen even though the % saturation value is 100% in both

samples. Therefore, we must compensate the mg/L concentration reading

per the temperature of the sample.

Both of these temperature effects are factored into the conversion of the probe

signal to a mg/L concentration. For newer, digital instruments, the software

compensates for both of these temperature-related factors after instrument

calibration and during readings. The temperature compensation for the

% saturation reading is empirically derived, while the conversion from %

saturation, temperature and salinity to a mg/L concentration is automatically

carried out by the instrument’s firmware using formulae available in Standard

Methods for the Examination of Water and Wastewater2. The calculation

for converting % Saturation to mg/L and an example is provided in figure

33.

SALINITY

The second variable that affects DO concentration is the salinity of the water

sample. While the % saturation reading is not a function of the salinity

(or dissolved solids content) of the water, the mg/L concentration changes

significantly with salinity. As the salinity of water increases, its ability to

dissolve oxygen decreases. For example, oxygen saturated freshwater with

0 salinity at 25ºC contains 8.26 mg/L of oxygen while oxygen saturated

sea water (36 ppt) at the same pressure and temperature contains only

6.72 mg/L of dissolved oxygen.

Thus, salinity (along with temperature) must be factored into the instrument’s

calculation of mg/L. This calculation is based on the % saturation reading,

temperature reading, and the measured or entered salinity value using

formulae found in Standard Methods for the Examination of Water and

2

Wastewater

. The calculation for converting % to mg/L and an example is

provided in figure 33.

Determining DO mg/L from % Saturation

The following explains how to convert % Saturation to mg/L (also

referred to as ppm).

In order to perform this conversion, the temperature and salinity of the

sample must be known.

Step one: Determine the % saturation, temperature, and salinity of

the sample.

Step two: Multiply the % saturation reading by the value in

appropriate column (depends on salinity) and row

(depends on temperature) of the Oxygen Solubility Table

in Appendix A.

Example:

Step one: Sample is measured to have: 80% DO saturation

0 salinity

20º C

Step two: Multiply .80 (which is the DO %) by 9.09 (value from

oxygen solubility table at 0 salinity and 20º C) = 7.27

mg/L.

Result: 7.27 is the mg/L value that corresponds to an 80% DO-

Saturation reading of a sample with zero salinity at 20º

C.

Figure 33. Calculating mg/L from % saturation, temperature and salinity.

Page 25

42

43

CORRECTING FOR SALINITY

The salinity value used by the instrument in the calculation of mg/L is

obtained one of two ways, depending on the instrument being used. For

YSI dissolved oxygen instruments that also measure conductivity, the salinity

value measured by the conductivity sensor is used for the mg/L calculation.

Therefore, it is important to ensure the conductivity sensor is calibrated and

reading accurately in order to obtain accurate DO mg/L readings.

dissolved oxygen instrument that also measures conductivity for highest

data accuracy. A dissolved oxygen instrument that also has a conductivity

sensor will use the real-time salinity readings from the conductivity sensor

for every mg/L calculation. This will make sampling easier since it will not

be necessary to manually change the correction factor at each sampling

new site.

BAROMETRIC PRESSURE

For YSI dissolved oxygen instruments that do not have a conductivity sensor,

the salinity value of the sample must be manually entered by the end user.

See the salinity guide in figure 34 for a list of typical salinity values for

various types of water.

Salinity Guide - Average salinity by water type3

Water Type Average Salinity

Fresh water <0.5 ppt****

Brackish water 0.5 to 30 ppt

Sea water 33 to 37 ppt

Saline water 30 to 50 ppt

Brine > 50 ppt

Figure 34. Average salinity of different types of water.

****Salinity is a unitless measurement determined from conductivity and

temperature readings according to the Practical Salinity Scale which can be

found in Standard Methods for the Examination of Water and Wastewater2.

Historically, salinity values determined via the Practical Salinity Scale were

given the designation “ppt” because these values were very close to those

determined by the previously used method where the mass of dissolved salts

in a given mass of water (parts per thousand) were reported. Today, ppt is

commonly replaced by psu (Practical Salinity Units) as the preferred unit to

describe salinity calculated by the Practical Salinity Scale; however, these

values are equivalent since they are determined by the same method.

When sampling water of varying salinity, for example in brackish waters

such as estuaries or coastal wetlands, it is recommended that you use a

The final factor with regard to dissolved oxygen calibration and measurement

is barometric pressure. Barometric pressure affects the pressure of oxygen

in a sample of air or water. For example, the percentage of oxygen in

air is always 21%, but the actual pressure of oxygen varies with changes

in barometric pressure. At sea level, the pressure of oxygen is 160 mmHg

(.21 x 760 mmHg). In a fully aerated sample, under these conditions, the %

saturation measured by a sensor would be 100% (160/160 x 100%, see

Measuring Dissolved Oxygen with Either Sensor Type). If the temperature

of the sample is 25 ºC, the instrument would calculate the dissolved oxygen

concentration as 8.26 mg/L based on the Oxygen Solubility table. As

the sample is moved up in altitude and kept air-saturated, the barometric

pressure would decrease and so would the pressure of oxygen in the

sample. At 1126 ft of elevation, the pressure of oxygen would be 153

mmHg (.21 x 730 mmHg) and the % saturation relative to sea level read by

the probe would be 95.6% (153/160 x 100%) in the fully aerated sample.

If the temperature of the sample is 25 ºC, the instrument would calculate a

dissolved oxygen concentration of 7.92 mg/L or 96% of 8.26 based on the

Oxygen Solubility table.

The effect of barometric pressure is overcome by proper sensor calibration.

Barometric pressure is used in the majority of dissolved oxygen sensor

calibrations as described in the Calibration section since it determines

the absolute pressure of oxygen in a sample of air or water at the time of

calibration and it is this pressure which is measured by all oxygen sensors.

When calibrating oxygen sensors, the sensor’s output is set to this known

pressure of oxygen. If the sensor output changes after calibration, then

the instrument would calculate a % saturation based on a simple linear

regression calculation. Thus, as long as the system does not drift, the

sensor’s output can always be used to define the oxygen pressure in any

Page 26

44

45

medium after performing a proper calibration and the use of the barometric

pressure (or altitude) at the time of calibration is the key factor in setting

the proper calibration coefficient. Therefore, it is not necessary to correct

for changes in barometric pressure after performing a proper calibration in

order to obtain accurate readings in the field.

In summary, as barometric pressure changes due to a change in altitude

or local weather front, the pressure of oxygen changes. However, there is

never any reason to compensate for this change if a proper calibration has

already been performed and the sensor has not drifted.

Note: If DO% Local is being measured with a YSI 6-series sonde or 556

it may be necessary to recalibrate the instrument after extreme changes in

barometric pressure or altitude in order to keep the DO% Local value at

100% in a fully saturated environment. This is not a requirement if only mg/L

values are being recorded since these values will remain accurate without

recalibrating Local DO %. If reporting DO% Local with newer instruments

such as the Professional Plus, ProODO, or Pro20, it is not necessary to

recalibrate after a significant barometric pressure change in order to

report an accurate DO% Local since these instruments have an on-board

barometer that is read by the instrument continuously. See the Local DO %

Measurement section for more information on this reporting option.

When performing a % air saturation calibration on instruments without

an internal barometer, the user inputs either the local “true” barometric

pressure or local altitude into the instrument during the calibration process.

Local altitude is used on some of YSI’s older instruments and barometric

pressure is used on newer instruments. Although entering altitude as

opposed to barometric pressure during calibration is a little less accurate

(up to .1 mg/L), it should provide enough accuracy for most applications.

In either situation, the calibration of the instrument in % saturation is handled

automatically by the system’s software or microprocessor based on either

the internal barometer reading or the value entered by the user at the time

of calibration.

A third method for calibrating DO to barometric pressure is used on

older, box-style instruments that only report mg/L and not % saturation.

In this method, the operator places the probe in either air-saturated water

or water-saturated air and manually corrects for barometric pressure by