Page 1

METEOROLOGICAL INSTRUMENTS

INSTRUCTIONS

WIND SYSTEM CALIBRATION

RECOMMENDED CALIBRATION INTERVAL,

PROCEDURE, AND TEST EQUIPMENT

MODEL 18860-90

INCLUDES INSTRUCTIONS FOR THE FOLLOWING

MODEL 18802/18811 ANEMOMETER DRIVE

MODEL 18112/18212 VANE ANGLE FIXTURE

MODEL 18310/18312 TORQUE DISC

MODEL 18331 VANE TORQUE GAUGE

R.M. YOUNG COMPANY 2801 AERO PARK DRIVE, TRAVERSE CITY, MICHIGAN 49686, USA

TEL: (231) 946-3980 FAX: (231) 946-4772 WEB: www.youngusa.com

P/N: 18860-90

REV: B062309

Page 2

R. M. YOUNG COMPANY

WIND SYSTEM CALIBRATION

Recommended Calibration Interval, Procedure, and Test Equipment

RECOMMENDED CALIBRATION INTERVAL

Operational Accuracy Research Accuracy

WS ± 0.5 m/s WD ± 5° WS ± 0.3 m/s WD ± 3°

TOWER CHECK 6 months 3 months

TRAILER CHECK 12 months 6 months

LABORATORY CHECK 24 months 12 months

MANUFACTURER CHECK N/A 24 months

OPERATIONAL ACCURACY

Manufacturer’s standard calibration is within operational accuracy limits. Perform tower check at initial installation. Tower check and trailer

check intervals are recommended minimums for optimum performance.

RESEARCH ACCURACY

Sensor requires wind tunnel calibration by manufacturer, or other recognized calibration laboratory, prior to initial installation. Tower check

and trailer check intervals are recommended minimums. Perform tower check at initial installation.

OUTPUT SIGNAL MEASUREMENTS

Wind speed signals vary among sensors. The signals may be frequency related for magnet/coil and photochopper transducers or

voltage related for tachometer generator transducers. Wind direction signals from potentiometer transducers are voltage related and are

dependent upon stable excitation voltage. To monitor wind speed and direction signals, use a suitable indicator. It may be a frequency meter,

voltmeter, calibrated wind indicator, data logger with display, or some combination of these instruments. As a general rule the resolution of

the indicator should be equal to the smallest unit being measured and the accuracy of the indicator should be 5 to 10 times better than that

required by the calibration. If necessary quantiy and account for any additional error introduced by the indicating device.

WIND SPEED SENSOR TYPES

The following procedures refer to a propeller type wind speed sensor, however they are equally applicable to a cup wheel type sensor. To

check wind speed threshold of a cup wheel anemometer using the torque disc, hold or mount the sensor with the cup wheel shaft horizontal.

Page 1

18860-90

Page 3

TOWER CHECK

Perform tower check for each initial installation regardless of prior calibration interval.

PROCEDURE

Wind Speed Threshold:

Wind Speed Signal:

Wind Direction Threshold:

Wind Direction Signal:

In calm weather blow gently on propeller. Watch for obvious high torque

or irregular rotation.

Remove propeller or cupwheel. Drive shaft at known rpm, representing

mid range of sensor. Compare output signal to established calibration.

In calm weather blow gently on vane. Watch for obvious high torque or

irregular motion.

Visually align vane with known reference. Compare output signal. Align

vane with additional reference points or cardinal points marked on housing. Compare output signal to established calibration.

None

Anemometer Drive

None

Survey of visible landmarks, accurate magnetic compass, or solar

noon orientation.

TRAILER CHECK

Sensors are removed from tower and connected to signal conditioning modules with sensor cable patch cords.

EQUIPMENT

Wind Speed Threshold:

Wind Speed Signal:

Wind Direction Threshold:

Wind Direction Signal:

PROCEDURE

Remove propeller. Set torque disc for proper torque according to table and

curves supplied. Install torque disc on propeller shaft and check rotation

of disc. See instructions on torque disc drawing.

Remove propeller. Drive shaft at 200 rpm. Check output for measurable

signal. Drive shaft at rpm representing mid range of sensor. Compare

output signal to established calibration.

Hold or mount sensor on desk top with n horizontal to check vane balance. Adjust if required. After balancing vane assembly, mount sensor

on bench stand on level surface. Determine proper torque according to

table and curves supplied. Place torque gauge on vane housing and apply steady force to end of leaf spring. Record maximum torque value for

both CW and CCW rotation. See instructions on torque gauge drawing.

Mount sensor on Bench Stand. Rotate xture through 360 degrees comparing output signal at 30 degree intervals.

EQUIPMENT

Propeller Torque Disc

Anemometer Drive

Vane Torque Gauge

Vane Angle Bench Stand

Vane Angle Bench Stand

18860-90

Page 2

Page 4

LABORATORY CHECK

Sensors and signal conditioning modules are removed from eld site to calibration lab equipped with calibration xtures and test equipment

and operated by a qualied instrument technician.

Wind Speed Threshold:

Wind Speed Signal:

Wind Direction Threshold:

Wind Direction Signal:

PROCEDURE

Remove propeller. Set torque disc for proper torque according to table and

curves supplied. Install torque disc on propeller shaft and check rotation.

See instructions on torque disc drawing.

Drive propeller shaft at 200 rpm, observe output on oscillioscope for

minimum signal level and proper form. Drive propeller shaft at a minimum

of three other rpm values throughout the working range of the propeller,

checking output signal at each speed. Compare to established calibration.

Check vane balance and adjust if required. After balancing vane assembly,

mount sensor on bench stand on level surface. Determine proper torque

according to table and curves supplied. Place torque gauge on vane

housing and apply steady force to end of leaf spring. Record maximum

torque value for both CW and CCW rotation. See instructions on torque

gauge drawing.

Install sensor on vane angle xture. Check output signal at 30° intervals

with additional checks at 340°, 350°, and 355°.

Propeller Torque Disc

Oscilloscope

Anemometer Drive

Vane Torque Gauge

Vane Angle Bench Stand

Vane Angle Fixture

EQUIPMENT

MANUFACTURER CHECK

Return sensors to manufacturer or other recognized calibration lab. These tests are performed at manufacturer's facilities or calibration

lab facilities on a fee basis.

Wind Speed Threshold:

Wind Speed Signal:

Wind Direction Threshold:

Wind Direction Signal:

PROCEDURE

Check and adjust propeller balance. Install sensor on threshold xture.

Measure and record starting and stopping wind speed values.

Install sensor in wind tunnel. Measure and record output signal at 1, 2,

3, 4, 5, 6, 8, 10, 12, 14, 16, 20, and 25 and 30 m/s. Tabulate wind tunnel speed vs. sensor output. Calculate and record slope and intercept.

Measure vane torque and record equivalent threshold wind speed.

Install sensor on master vane angle xture. Measure and record output

signal through complete 360° rotation. Measure and record electrical

function angle.

EQUIPMENT

Threshold xture

Wind tunnel facility

Vane torque xture

Master vane angle xture

Page 3

18860-90

Page 5

18860-90

Page 4

Page 6

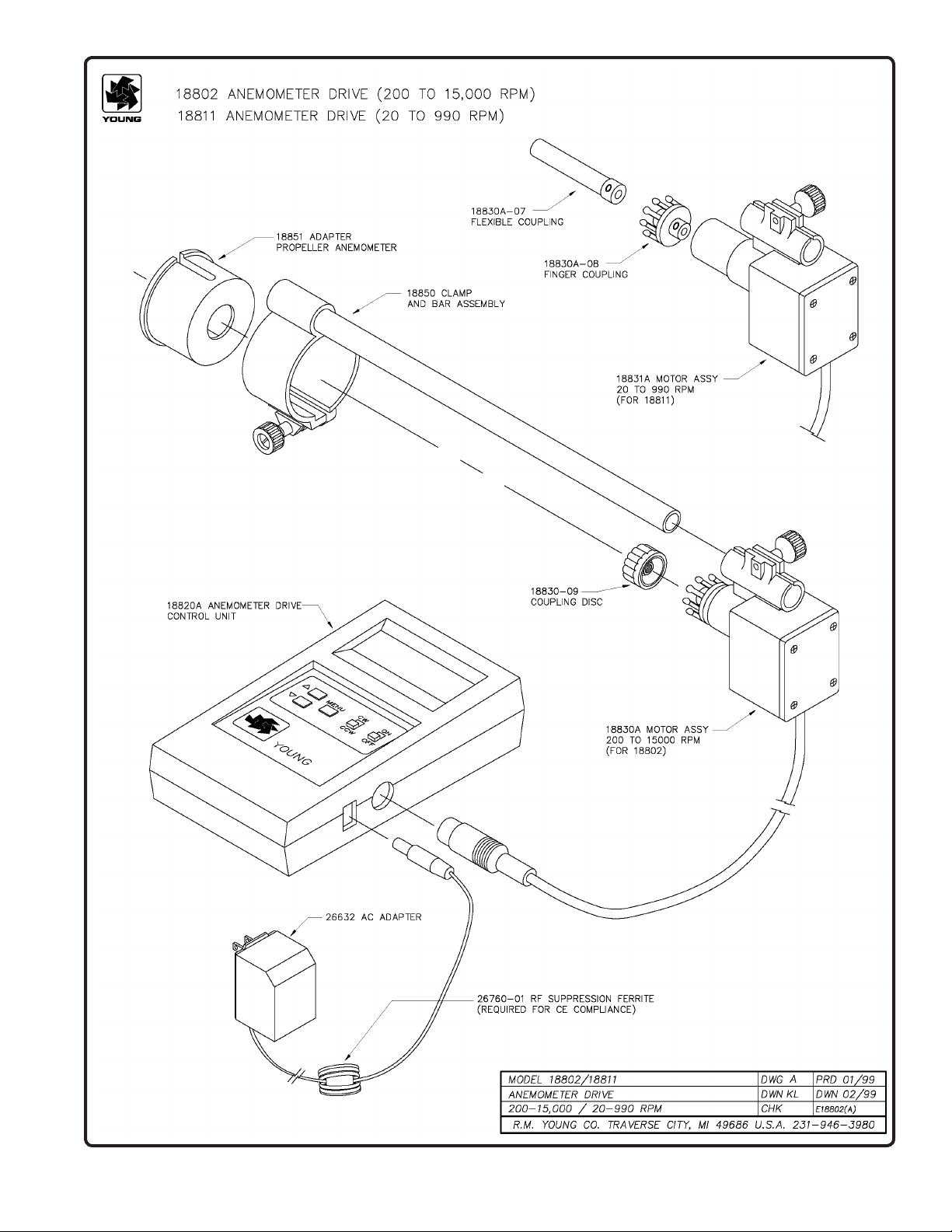

MODEL 18802/18811

SELECTABLE SPEED

ANEMOMETER DRIVE

SPECIFICATIONS

Operating Range: 200 - 15,000 RPM (18802)

20.0 - 990.0 RPM (18811)

Resolution: 1 RPM (18802)

0.1 RPM (18811)

Power Requirement: 12 to 30 VDC (2W n om in al , 6W

max)

Battery Power: Two 9-V

INTRODUCTION

The YOUNG S electable Speed Anemometer Drive provi des a

convenient and accurate way to rotate an anemometer shaft at a

known rate. The device consists of a control/display unit and a

variable speed motor with integral high-resolution optical encoder.

Two models are available: Model 18802 has an operating range

of 200 to 15,000 RPM for use with propeller type anemometers.

Model 18811 has a l ower RPM ra ng e for u se with cup ty pe

anemometers. The control unit is the same in each case. High and

low speed motors are available separately, permitting operation in

both speed ranges with a single display unit.

The control u ni t automatica ll y senses mo to r a ssembly ty pe

(high or low speed) and adjusts display and controlling circuits

automatically. Operating parameters for each motor type include

MAX & MIN RPM, STEP SIZE, and 9 PRESET speeds. Settings

for these parameters are saved when power is off.

A front panel CW-CCW switch selects rotation direction (as seen

facing anemometer). Motor speed is selected using the UP-DOWN

keys. Th e display s hows th e targe t and actua l RPM. Motor

rotation and measurement are referenced to a crystal oscillator for

stability and accuracy. Current limiting circuits protect the motor

from damage due to overload or stalling.

OPERATION

For proper o peration, the coupling on the motor must be

carefully aligned with the anemometer shaft. Misalignment,

particularly at low RPM rates, causes instability and stalling.

Alignment xtures included with the device allow the motor to be

attached directly to YOUNG anemometers. Attach the alignment

xture to the sensor as follows:

1) Remove propeller or cup-wheel from anemometer shaft and

attach coupling disc to shaft.

2) Mount clamp and bar xture on sensor and gently tighten

clamp. Do not overtighten!

3) Attach motor to xture. Carefully align anemometer and

motor coupling and gently tighten motor clamp. DO NOT

OVERTIGHTEN.

4) Turn unit ON and use the UP-DOWN keys to set target RPM.

5) Within several seconds display should show actual RPM

within ± 1 RPM of target setting. If not, carefully adjust

alignment until display shows proper value. This can be

performed while motor is running.

If the calibrating unit is used with an anemometer which does not

t the alignment xture, the motor may be held in place by hand.

Good results can be achieved if the motor and anemometer shafts

are well aligned.

MENU

Access the Setup Menu by pressing and holding the MENU key

for about five seconds. The motor will stop and the Setup Menu

will appear on the display. Each menu item and its function is listed

below.

Use the UP-DOWN keys to scroll between items on the menu list.

To EDIT a value, press the MENU key then use the UP-DOWN

keys to change it. When you are finished editing, press MENU

again. To return to O PERATE mode, repeatedly press th e UP

key until OPERATE appears on the display then press MENU.

The 18802 stores the new settings and within several seconds

will begin operating at its lowest speed. You MUST return to

OPERATE mode to retain new settings.

MENU ITEM DESCRIPTION

OPERATE Press MENU to return to OPERATE mode.

You MUS T ret urn t o OPE RATE

mode to retain new settings.

MAX RPM Max im um RP M allowed during opera ti on .

Once the maximum is reached, pressing the

UP ke y has no effec t. Limited to operatin g

range of motor.

MIN RPM Mi ni mum RPM a ll owed d ur in g oper at io n.

Once the minimum is reached, pressing the

DOWN key has no effect. Limited to operating

range of motor.

STEP SIZE The number of RP M a dd ed or subtracte d

when the UP- DO WN key s are pre ss ed to

change target RPM during operation.

PRESET YES/NO determines whether preset

RPM sett in gs are us ed. If YES, p ressing

the UP-DOWN keys selects preset speeds 1

through 9. If NO, UP-DOWN changes speed

by STEP SIZE increments.

The 18802 is powered from an AC wall adapter (included). For

completely portable operation, two internal 9-V batteries power the

unit. Use lithium type for longest life. When batteries are low, the

controller stops the motor and alerts the user on the display.

Page 5

PRESET1-9 Preset RPM values. Each PRESET may be

set to any value in operating range of motor.

18860-90

Page 7

WARRANTY

This product is warranted to be free of defects in materials and

construction for a period of 12 months from date of initial purchase.

Liability is limited to repair or replacement of defective item. A copy

of the warranty policy may be obtained from R. M. Young Company.

CE COMPLIANCE

This product has been tested and shown to comply with European

CE requirements for the EMC Directive.

Declaration of Conformity

R. M. Young Company

2801 Aero Park Drive

Traverse City, MI 49686 USA

Model 18802 ANEMOMETER DRIVE

The undersigned hereby declares on behalf of R. M.

Young Company that the above-referenced product, to

which this declaration relates, is in conformity with the

provisions of:

Council Directive 2004/108/EC (December 15, 2004)

on Electromagnetic Compatibility

David Poinsett

R&D Manager

18860-90

Page 6

Page 8

Page 7

18860-90

Page 9

18860-90

Page 8

Page 10

R. M. YOUNG COMPANY

TYPICAL TORQUE VALUES

For Checking Anemometer Bearing and Transducer Condition

threshold of:

Instrument (Standard Models) Sensor Transducer Torque Threshold 0.5 m/s 1.0 m/s

gm-cm m/s gm-cm gm-cm

03101-5 Wind Sentry Anemometer 03110 AC Coil 0.3 0.5 0.3 1.0

05103 Wind Monitor 08234 AC Coil 2.4 1.0 2.6

05106 Wind Monitor - MA 08234 AC Coil 2.9 1.1

05305 Wind Monitor - AQ 08254 AC Coil 0.3 0.3 1.0 3.8

05701 Wind Monitor - RE 08274 AC Coil 0.3 0.2 1.3 5.0

09101 Wind Monitor - SE 08234 AC Coil 2.4 1.0 2.6

09305 Wind Monitor - AQ - SE 08254 AC Coil 0.3 0.3 1.0 3.8

12102 Cup Anemometer 12170C 2400 mV Tach-Gen 0.4 0.5 0.4 1.4

12102D Cup Anemometer 12170C Photo Chopper 0.1 0.3 0.4 1.4

27106 Propeller Anemometer 08274 500 mV Tach-Gen 0.5 0.3 1.3 5.0

1

New Instrument

2

Max torque for

27106T Propeller Anemometer 08254 500 mV Tach-Gen 0.5 0.4 1.0 3.8

08274 Photo Chopper 0.3 0.2 1.3 5.0

NOTES:

1. New instrument torque and threshold specications are maximum values

2. Values shown are maximum torque to maintain instrument threshold at or below 0.5 m/s and 1.0 m/s respectively.

3. EPA and NRC instrument specications designate 0.5 m/s wind speed starting threshold. ASTM D5096-90 "Standard

Test Method for Determining the Performance of a Cup Anemometer or Propeller Anemometer" denes "starting

threshold" and outlines a method for its determination.

SENSORS:

03110 Wind Sentry 75 cm Cup Wheel Assembly

08234 18 X 30 cm Polypropylene Propeller (PP)

08254 20 X 30 cm Carbon Fiber Thermoplastic Propeller (CFT)

08274 22 X 30 cm Expanded Polystyrene Propeller (EPS)

12170C 100 cm Cup Wheel Assembly

STANDARD BEARINGS:

Model 05103 Wind Monitor / 09101 Wind Monitor-SE : Double Teon seals & lubricated with M-28 low torque grease

Model 05106 Wind Monitor - MA : Double Teon seals & lubricated with "Sta-lube" waterproof grease.

All other models : Double metal shields & lubricated with LOI instrument oil

Page 9

18860-90

Page 11

18860-90

Page 10

Page 12

Page 11

18860-90

Page 13

R. M. YOUNG COMPANY

TYPICAL TORQUE VALUES

For Checking Anemometer Bearing and Transducer Condition

Instrument (Standard Models) Torque Threshold 0.5 m/s @ 10° 1.0 m/s @ 10°

gm-cm m/s @ 10° gm-cm gm-cm

05103 Wind Monitor 30 1.1

05106 Wind Monitor - MA 30 1.1

05305 Wind Monitor - AQ 9 0.5 11 40

05701 Wind Monitor - RE 7 0.4 11 40

09101 Wind Monitor - SE 30 1.1

09305 Wind Monitor - AQ - SE 9 0.5 11 40

12302/5 Microvane 11 0.4 18 66

1

New Instrument

2, 3

Max torque for threshold of:

NOTES:

1. New instrument torque and threshold specications are maximum values

2. Values shown are maximum torque permitted to maintain instrument threshold at or below 0.5 m/s and 1.0 m/s

respectively at 10° displacement.

3. EPA and NRC instrument specications designate windvane threshold measurement at 10° displacement from

equilibrium position. ASTM D5366-93 “Standard Test Method for Determining the Dynamic Performance of a Wind

Vane” denes “starting threshold” and outlines a method for its determination.

STANDARD BEARINGS:

Models 05103 Wind Monitor / 05106 Wind Monitor-MA / 09101 Wind Monitor-SE:

Double Teon seals lubricated with LY-48 wide temperature range grease

Models 05305 Wind Monitor-AQ / 05701 Wind Monitor-RE / 09305 Wind Monitor-AQ-SE:

Double metal shields lubricateD with LOI instrument oil

All other models - Double Teon seals lubricated with LOI instrument oil

18860-90

Page 12

Page 14

Page 13

18860-90

Page 15

18860-90

Page 14

Page 16

Page 15

18860-90

Loading...

Loading...