Young 26800 User Manual

METEOROLOGICAL INSTRUMENTS

INSTRUCTIONS

METEOROLOGICAL TRANSLATOR

MODEL 26800

R.M. YOUNG COMPANY 2801 AERO PARK DRIVE, TRAVERSE CITY, MICHIGAN 49686, USA TEL: (231) 946-3980 FAX: (231) 946-4772 WEB: www.youngusa.com

P/N: 26800-90

REV:K080613

MODEL 26800

METEOROLOGICAL

TRANSLATOR

1.0 INTRODUCTION

The Young 26800 Meteorological Translator is a programmable digital display and data recorder for use with a wide range of meteorological sensors.

FEATURES:

•All-in-one design

•Illuminated display with 8 screens

•Brightness and contrast control

•Large and small fonts, up to 240 characters per screen

•Simple, intuitive, easy-to-navigate menus

•16 single-ended or 7 differential voltage inputs in any combination

•4 pulse or frequency inputs in any combination

•4 analog outputs, voltage or current in any combination

•4 solid-state switch outputs

•Independent RS-232 and RS-485 serial communication ports

•Capacity for 512 user program instructions

•Capacity for over 2 million non-volatile floating point data records

•Simple setup via front panel or easy-to-use PC program Complete specifications are in APPENDIX A

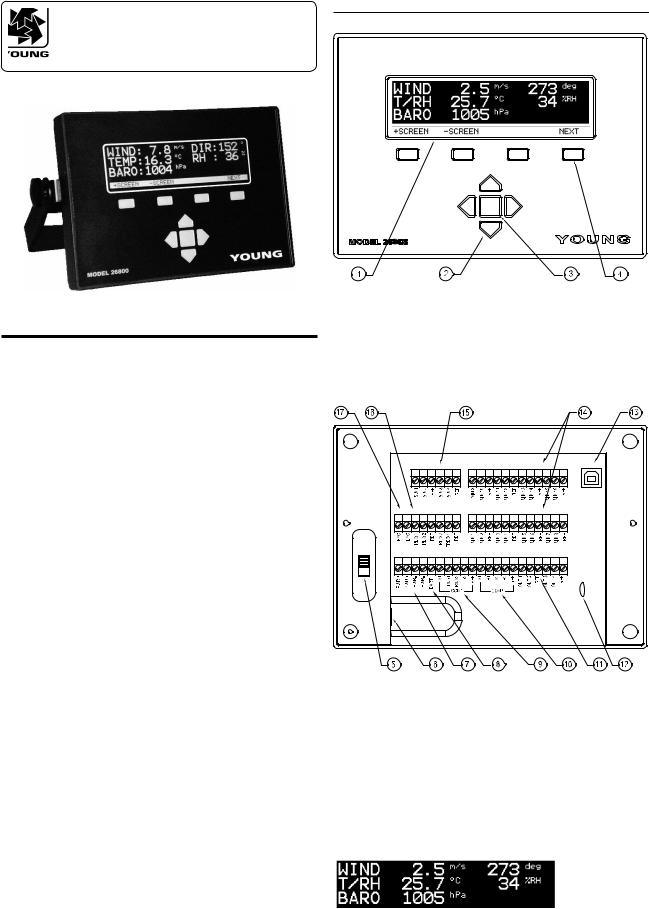

1.2 OPERATING CONTROLS

FRONT PANEL

1. |

Screen display |

Large font, 3 rows x 20 columns |

|

|

Small font, 6 rows x 40 columns |

2. |

ARROW keys |

Navigate screen, change values |

3. |

ENTER key |

Select highlighted item |

4. |

SOFT keys |

Select function indicated on screen |

BACK PANEL

1.1 PRECAUTIONS |

5. |

ON/OFF switch |

11. |

Voltage/Current outputs |

|

|

|

6. |

Power supply jack |

12. |

Cable tie-down point |

• Indoor use only unless operated in a suitable enclosure. |

7. |

Auxiliary power |

13. |

USB port |

|

8. |

Earth ground |

14. |

Voltage inputs |

||

• Always connect ground terminal to suitable earth ground. |

9. |

COM1 terminals |

15. |

Solid-state switch outputs |

|

• Switch power OFF before connecting sensor wires. |

10. |

COM2 terminals |

16. |

Pulse/Frequency inputs |

|

• Disconnect power before servicing unit. |

|

|

17. |

Excitation Voltage (5V) |

|

|

|

|

|

||

• Operating range is 0°C to 50°C, 0 to 95% RH |

1.3 |

GETTING STARTED |

|

||

• Some sensors may require connection to a proper earth ground |

|

||||

|

|

|

|

||

to prevent possible sensor damage or malfunction due to static |

Sensors and power supply adapter should be properly connected |

||||

discharge. Follow instructions provided with sensor. |

before operation (refer to APPENDIX B). Set power switch to ON |

||||

|

|

position. After 3 seconds, display appears: |

|||

Typical display with program installed

26800-90(K)

Page 1

The system is now operating. In OPERATE MODE, the 26800 |

|

SERIAL COMM lists serial port type and baud rate settings. |

|

executes USER PROGRAM instructions which may collect sensor |

|

COM1 may be set to operate as an RS-232 or RS-485 port. |

|

data, store records, process data, display results, produce outputs, |

|

COM2 is always RS-485. Select EDIT to change. Use UP and |

|

or communicate via serial ports. When the 26800 is powered up, it |

|

DOWN ARROW keys to change value. Select EXIT to leave. |

|

automatically enters OPERATE MODE. |

|

|

|

Typically, measured data will appear on the display. If multiple sen- |

|

UTILITY shows the UTILITY MENU where additional parameters |

|

|

may be examined or changed. |

||

sors are connected, data may appear on more than one screen. |

|

||

|

|

||

There are 8 display screens available. Use +SCREEN and |

|

3.0 UTILITY MENU |

|

–SCREEN soft-keys to select screen view. SCREEN SCROLL |

|

||

settings or USER PROGRAM instructions may limit the viewable |

|

The UTILITY MENU is a subset of the MAIN MENU. From the |

|

screens to less than 8. |

|

|

|

|

|

|

MAIN MENU, use ARROW keys to navigate to the UTILITY menu |

Press the NEXT soft-key to cycle through OPERATE MODE op- |

|

item. Press the ENTER key. |

|

tions: |

|

|

Use ARROW keys to navigate the UTILITY MENU. The ENTER |

|

|

|

|

+SCREEN/-SCREEN |

Selects screen. |

|

key selects the indicated menu item. |

+BRIGHT/-BRIGHT |

Sets display brightness. |

|

RECORD FIELDS defines the number of fields per record when |

+CONTRAST/-CONTRAST |

Sets display contrast. |

|

|

EXIT |

Exits OPERATE MODE to the |

|

recording data. Generally, one field is assigned for each value |

|

MAIN MENU |

|

that will be stored in a record. For example, if Date, Time, Wind |

|

|

|

Speed, and Wind Direction are recorded (4 separate values), |

2.0 MAIN MENU |

|

|

REC FIELDS would typically be set to 4. When records are |

|

|

retrieved, these 4 values will be grouped together on each line. |

|

|

|

|

|

|

|

RECORD ERASE deletes all recorded data. |

|

Reach the MAIN MENU from OPERATE MODE by pressing the |

|

||

NEXT soft-key until the EXIT option appears. Press the EXIT soft- |

|

PROGRAM CHECKSUM calculates a unique checksum signa- |

|

key. MAIN MENU appears. |

|

|

|

Use ARROW keys to navigate the MAIN MENU. Use the ENTER |

|

ture for the User Program. The signature value may be used to |

|

|

validate program integrity. |

||

key to select menu item. |

|

|

|

All parameters in the MAIN MENU may be also be set or examined |

|

PROGRAM INTERVAL determines how often, in seconds, |

|

using the RMYComm PC program included with the 26800. When |

|

the program is executed. The program interval must be long |

|

|

enough to execute all instructions. If the PGM INTERVAL is |

||

making extensive changes, we recommend using RMYComm |

|

||

|

not long enough for all instructions to execute and the PGM |

||

rather than the 26800 keypad. |

|

|

|

|

|

ERR HANDLE is set to STOP, an error message will appear. To |

|

|

|

|

|

You cannot harm the unit by examining or changing parameters |

|

eliminate this error, increase the number of seconds in the PGM |

|

|

INTERVAL or decrease the number of instructions. Note that dif- |

||

although altered settings will affect how the unit operates. |

|

||

|

ferent instructions require different amounts of time to execute. |

||

|

|

|

|

OPERATE returns to OPERATE MODE and begins executing the |

|

Some VOLTAGE INPUT measurement configurations require |

|

|

the longest execution time. A sample interval of 00 seconds |

||

user program. |

|

|

will run the program at maximum speed with no delay between |

DATE/TIME shows the current date and time to the nearest |

|

iterations. |

|

|

|

||

minute. Time is kept in 24-hour format. The internal clock runs |

|

IMPORTANT NOTE ABOUT PROGRAM INTERVAL: |

|

from a lithium battery when power is off. Depending on use, the |

|

User Program Instructions IF TIME INTERVAL and FLAG TIME |

|

battery will last up to 10 years. The internal clock automatically |

|

INTERVAL require a PROGRAM INTERVAL setting of 00 or 01 |

|

accounts for leap years. Select EDIT or EXIT. |

|

seconds so the time may be examined on every iteration of the |

|

USER PROGRAM shows program instructions that execute |

|

USER PROGRAM. |

|

|

|

||

|

PGM ERR HANDLE determines whether to STOP or SKIP er- |

||

in OPERATE MODE. Use ARROW keys to navigate instruc- |

|

||

tions. The instruction number appears in the upper-left corner. |

|

rors during OPERATE MODE. When set to STOP, an error mes- |

|

For further details about program instructions, see section 4.0 |

|

sage will appear with an option to edit the offending instruction. |

|

PROGRAMMING. |

|

|

A common technique is to set this parameter to STOP during |

SCREEN TEXT sets fixed text labels on each of the 8 display |

|

program development and SKIP during normal operation. |

|

|

Also see User Program Instruction LOC1=FUNCTION(LOC2) for |

||

screens. Use ARROW keys to navigate. Select screen number |

|

||

and press ENTER key. |

|

|

detecting and responding to errors in the user program. |

Select EDIT to change text or EXIT to leave. |

|

PROGRAM ERASE deletes all USER PROGRAM instructions. |

|

When editing: |

|

|

KEYPAD LOCKOUT defines front panel key behavior during |

RIGHT and LEFT ARROW select character. |

|

OPERATE MODE. When set to LOCKED, keys do not respond. |

|

UP and DOWN ARROW change character value |

|

When set to UNLOCKED keys respond normally. |

|

LARGE and SMALL select font size. |

|

|

|

LINE selects vertical row. |

|

|

Once LOCKED the keys may be reset to UNLOCKED in one of |

Select EXIT when finished. |

|

|

two ways. Method one: remove and re-apply power while press- |

|

|

ing the two outer-most soft-keys. The 26800 will go to the MAIN |

|

26800-90(K)

Page 2

MENU. Navigate to the KEYPAD LOCK parameter and set it to UNLOCKED. Method two: Use RMYComm to reset the KEYPAD

LOCKOUT parameter.

SCREEN SCROLL sets parameters that automatically scroll the display through one of 8 screens. END SCREEN also sets the last screen to show in manual scroll mode.

AUTO SCROLL: |

ON or OFF |

END SCREEN: |

Last screen to show, 1-8 |

PAUSE (SECONDS): |

Duration of pause, 01-99 |

4.0 PROGRAMMING

In OPERATE MODE, the 26800 executes a list of USER PRO-

GRAM instructions to make measurements, display data, manipulate data, record data, test for conditions, and produce output.

The instructions may be combined in any way for a broad range of applications.

The user program environment has three memory areas with various capacities.

Program Instruction: |

512 instructions |

Temporary Storage: |

256 data values |

Recorded Data: |

2,162,688 data values |

USER PROGRAM instructions may be entered, edited, or deleted using the front panel keys or remotely via serial communication and RMYComm.

IMPORTANT NOTE ABOUT PROGRAM DEVELOPMENT:

When developing your own programs, set PGM ERR HANDLE to STOP. This allows the 26800 to stop and identify sources of error in the USER PROGRAM when in OPERATE MODE. In most

cases, specific offending instructions and parameters will be identified. After your program has been developed and demonstrated to operate without error, you may set PGM ERR HANDLE to SKIP which will omit execution of instructions in which errors arise and

continue execution of other instructions.

VIEWING PROGRAM INSTRUCTIONS

From the MAIN MENU, navigate to USER PGM and press the

ENTER key. The first program instruction will appear.

Example:

i001 INPUT VOLTAGE

chan= |

16 |

rate= |

300Hz |

type= |

SE |

dloc= |

001 |

mult= |

1.00000 |

|

|

offs= |

0.00000 |

|

|

UP/DOWN navigation keys change value.

RIGHT/LEFT navigates characters in the field.

NEXT soft-key advances to the next parameter.

After progressing through each parameter, the 26800 will exit edit mode and return to view mode.

INSERTING PROGRAM INSTRUCTIONS

Press the INSERT soft-key to insert a new instruction ahead of the current instruction. Select the instruction to be inserted from the highlighted list:

UP/DOWN ARROW scrolls through the instruction list.

SELECT inserts the currently highlighted instruction. CANCEL cancels insertion and returns to view mode

Insertion forces instruction renumbering.

DELETING PROGRAM INSTRUCTIONS

Press the DELETE soft-key to delete the current instruction. Any instruction may be deleted except PGM END. Deletion forces instruction renumbering.

4.1 PROGRAM CONCEPTS

The 26800 executes USER PROGRAM instructions to measure, process data, display, record, produce calibrated output, or communicate with other devices.

A USER PROGRAM is assembled from a list of available instructions. Most instructions use TEMPORARY STORAGE LOCATIONS which allow instructions to share data values. There are 256 locations available. Any location may be identified as a destination or source (DLOC or SLOC) depending on context. Values in these locations exist only while the program operates. Recorded values are stored in a separate area.

A simple USER PROGRAM example follows:

i001 INPUT VOLTAGE |

|

|

chan= |

16 |

rate= 300Hz |

type= |

SE |

dloc= 001 |

mult= |

1.00000 |

|

offs= |

0.00000 |

|

i002 DISPLAY VALUE |

|

|

sloc= |

001 |

col= 30 |

scrn= |

1 |

width= 7 |

font= |

SMALL |

decpt= 2 |

row= 5 |

|

|

i003 PGM END

The i001 designation is the sequential instruction number which ranges from 001 to 512. The instruction description appears next.

Instruction parameters are below the instruction description. In this example, there are six parameters.

Use the LEFT and RIGHT ARROW keys to navigate the USER

PROGRAM. The last instruction is always PGM END. Navigation will wrap from end to beginning and vice versa. Press the EXIT soft-key to return to the MAIN MENU.

EDITING PROGRAM INSTRUCTIONS

Only parameters for an instruction may be edited. To replace an entire instruction, DELETE it then INSERT another instruction in its place.

To edit a parameter, press the EDIT soft-key. The selected character or field will be highlighted.

Labels i001, i002, and i003 indicate the sequential instruction number. As instructions are inserted or deleted, each one is renumbered in sequence. Use these numbers to navigate the USER PROGRAM.

The first instruction, INPUT VOLTAGE, makes a single-ended

(SE) voltage measurement on input channel 16. It measures at a sample-rate of 300Hz, multiplies the measurement by 1.00000, applies a 0.00000 offset, and stores the result in DLOC 001.

The second instruction, DISPLAY VALUE, displays the value in

SLOC 001 on screen 1, row 5, column 30, using a small font format seven characters wide with 2 digits after the decimal point.

PGM END designates program end.

Please see the APPENDIX C for a more extensive example.

26800-90(K)

Page 3

4.2 PROGRAM INSTRUCTIONS

Instruction names are listed below. Each instruction is followed by a detailed description of its function and parameter settings.

ALARM tests the value in a specified SLOC and activates one of the SOLID STATE SWITCH channels if the value meets conditions defined in the parameters.

SPAN determines how to compare the value in SLOC to the range defined by SETPOINT 1 and 2. INCL (inclusive) compares SLOC to values inside the range. EXCL (exclusive) compares SLOC to values outside the range. DELAY sets the duration the compare condition must be true in order to change the SW state. Use this to prevent switch chatter when the input value hovers near SETPOINT thresholds.

sloc= |

Source location (001-256) |

set1= |

Setpoint 1 |

set2= |

Setpoint 2 |

delay= |

Number of seconds (00-99) |

span= |

Span logic (INCL or EXCL) |

sw= |

SOLID STATE SWITCH channel (1-4) |

AVERAGE calculates the average of samples retrieved from

SLOC. Values are evaluated on each iteration of the instruction.

#SAMP is used on MOVING type averages only. BLOCK type calculates the result when FLAG 1 is set. The result is stored in

DLOC.

BLOCK type adds new values to an internal sum with each instruction iteration. When FLAG 1 is set, the average is calculated and stored in DLOC. Typically, FLAG 1 is set using the FLAG

TIME INTERVAL instruction.

MOVING type keeps a list of every sample. After #SAMP samples have been collected, the first average is calculated. After that, a new average is calculated for each new sample acquired.

The amount of internal memory used is proportional to #SAMP. An error message will appear if memory limits are reached.

ANGLE type temporarily converts unit vector angles to Cartesian form which are used for the actual calculation. Cartesian averages are then converted back to angles for the final result.

sloc= |

Source location (001-256) |

dloc= |

Destination location (001-256) |

type= |

BLOCK, BLOCK ANGLE, MOVING, MOVING ANGLE |

#samp= |

Number of samples, MOVING type only (0001-7000) |

BEEP produces from 1 to 9 beep sounds. It can be used to signal an event.

num= |

Number of beeps to sound (1-9) |

CHANGE TO SCREEN instructs the unit to change to a screen number based on the value in SLOC. The value in SLOC must be in the range of 1 to 8.

sloc= |

Source location (001-256) |

DELAY creates a millisecond delay in program execution to the nearest multiple of 5 milliseconds.

msec= Millisecond delay (5-9995)

DISPLAY FLAGS shows the condition of all 16 user flags in either HEX or BINary format. The flags are numbered 1 to 16 from right to left. Digit value 1=SET, 0=RESET.

scrn= |

Screen number (1-8) |

font= |

Font size (BIG or SMALL) |

row= |

Screen row (1-3 for BIG, 1-6 for SMALL) |

col= |

Screen column (1-20 for BIG, 1-40 for SMALL) |

DISPLAY NESW takes the angular wind direction value in degrees from SLOC and displays it in terms of compass point descriptions: N, NNE, NE, ENE, E, etc. Allow 3 character spaces on display screen.

sloc= |

Source location |

scrn= |

Screen number (1-8) |

font= |

Font size (BIG or SMALL) |

row= |

Screen row (1-3 for BIG, 1-6 for SMALL) |

col= |

Screen column (01-20 for BIG, 01-40 for SMALL) |

DISPLAY TEXT displays up to 25 text characters. Truncate to fewer than 25 characters by terminating with the ' \ ' (backslash) character. Otherwise, all 25 characters will be displayed even if most are blanks.

scrn= |

Screen number (1-8) |

row= |

Screen row (1-3 for BIG, 1-6 for SMALL) |

col= |

Screen column (01-20 for BIG, 01-40 for SMALL) |

text= |

Text to be displayed (up to 25 characters) |

font= |

Font size (BIG or SMALL) |

DISPLAY TIME displays time from the internal real time clock in hh:mm:ss format. Leap years are handled automatically.

scrn= |

Screen number (1-8) |

font= |

Font size (BIG or SMALL) |

row= |

Screen row (1-3 for BIG, 1-6 for SMALL) |

col= |

Screen column (01-20 for BIG, 01-40 for SMALL) |

DISPLAY VALUE displays the value in SLOC. WIDTH defines total character width on screen. DECPT defines the number of digits after the decimal point. Asterisks (*) are displayed if the value exceeds the defined WIDTH.

sloc= |

Source location (001-256) |

scrn= |

Screen number (1-8) |

font= |

Font size (BIG or SMALL) |

row= |

Screen row (1-3 for BIG, 1-6 for SMALL) |

col= |

Screen column (01-20 for BIG, 01-40 for SMALL) |

width= |

Maximum number of characters (1-9) |

decpt= |

Number of digits following decimal point (1-9) |

ELSE is used with IF statements as a branch when the associated IF test is false. Only one ELSE statement can be used with an IF statement. ELSE statements other than the first will be ignored and an ELSE without a preceding IF statement will generate an error when PGM ERR HANDLE is set to STOP.

Example:

IF LOC 10 = 100.0

BEEP 5

LOC 10 = 0

ELSE

LOC 10 = LOC 10 + 1.0

END IF

Count to 100 by 1s then beep and start over.

END IF marks the end of an IF block and must be used to conclude every IF statement. END IF without an IF will generate an error when PGM ERR HANDLE is set to STOP.

26800-90(K)

Page 4

|

|

|

IF LOC1 COMPARE VALUE compares the value in SLOC to a |

|||

IMPORTANT NOTE ABOUT FLAGS: |

||||||

fixed value. |

|

|||||

FLAG 01 is a special flag that triggers result calculation for AVER- |

|

|

|

|||

AGE, MINIMUM, MAXIMUM and STANDARD DEVIATION instruc- |

sloc1= |

Source location 1 (001-256) |

||||

tions when they use the BLOCK method. The flag has no effect |

comp: |

< |

less than |

|||

when the MOVING method is used. |

|

<= |

less than or equal to |

|||

|

|

|

|

>= |

greater than or equal to |

|

|

|

|

|

|||

FLAG SET is used to set a flag ON or OFF. Use flags to signify |

|

> |

greater than |

|||

|

<> |

not equal to |

||||

the occurrence of some event and trigger a response (see IF |

|

|||||

|

= |

equal to |

||||

FLAG). |

|

|

|

|||

|

|

val= |

Value to compare |

|||

flag#= |

Flag number (01 to 16) |

|||||

|

|

|

||||

state= |

Flag state (ON or OFF) |

IF LOC SPAN tests the value in SLOC against two setpoint val- |

||||

FLAG SET MASK sets the state of all flags using a hexadecimal |

ues. SPAN determines how to compare the value in SLOC to the |

|||||

range defined by SETPOINT 1 and 2. INCL (inclusive) compares |

||||||

mask. |

|

|

SLOC to values inside the range. EXCL (exclusive) compares |

|||

mask= |

Hexadecimal mask value (0000-FFFF) |

SLOC to values outside the range. DELAY sets the duration the |

||||

compare condition must be met to consider the comparison true. |

||||||

state= |

Flag state (ON or OFF) |

|||||

|

|

|

||||

FLAG TIME INTERVAL sets the state of FLAG# when current |

sloc= |

Source location (001-256) |

||||

set1= |

Setpoint 1 |

|||||

time aligns with an interval. When UNIT is set to MIN (minute), |

||||||

set2= |

Setpoint 2 |

|||||

TIME interval is limited to 1440 (equivalent to 24 hours). The |

||||||

delay= |

Time delay seconds (00-99) |

|||||

PROGRAM INTERVAL parameter must be set to 00 or 01 for |

||||||

span= |

Span logic (INCL or EXCL) |

|||||

this instruction to operate correctly. |

||||||

|

|

|

||||

unit= |

Time unit (SEC or MIN) |

IF TIME INTERVAL tests current time to against a time interval. |

||||

time= |

Time alignment (0001-9999) |

When UNIT is set to MIN (minutes), TIME interval is limited |

||||

flag#= |

Flag number (01-16) |

to 1440 (equivalent to 24 hours). The PROGRAM INTERVAL |

||||

state= |

Flag state (ON or OFF) |

parameter must be set to 00 or 01 for this instruction to operate |

||||

|

|

|

correctly. |

|

|

|

IMPORTANT NOTE ABOUT IF INSTRUCTIONS: |

|

|

||||

|

|

|

||||

All IF instructions must have a matching END IF instruction. Only |

unit= |

Time unit (MIN or SEC) |

||||

one optional ELSE instruction may be inserted between them. |

time= |

Time interval (0001-9999) |

||||

Example: |

|

|

|

|

|

|

IF FLAG |

|

|

INPUT FREQ measures pulses per second on FREQ INPUT |

|||

|

|

channels. LOW-AC configures the detector for a low-level AC |

||||

instruction(s)... |

||||||

signal. TTL/SW configures the detector for a TTL logic-level or |

||||||

ELSE (optional) |

||||||

switch-closure signal. Apply a multiplier and offset with MULT |

||||||

instruction(s)... (optional) |

||||||

and OFFS if needed. Result stored in DLOC. |

||||||

END IF |

|

|

||||

|

|

|

|

|

||

|

|

|

Switch-closures require a pull-up resistor. See appendix B for |

|||

IF FLAG tests whether FLAG# is ON or OFF. |

||||||

wiring examples. |

||||||

flag#= |

Flag number (01-16) |

chan= |

|

Frequency Input channel (1-4) |

||

state= |

Flag state (OFF or ON) |

|

||||

type= |

|

Input type (LOW-AC or TTL/SW) |

||||

|

|

|

|

|||

IF FLAG MASK tests all flags against a hexadecimal flag |

mult= |

|

Multiplier value |

|||

offs= |

|

Offset value |

||||

mask. LOGIC parameter determines whether ANY or ALL flags |

|

|||||

dloc= |

|

Destination location (001-256) |

||||

matching the mask will satisfy the condition. STATE parameter |

|

|||||

|

|

|

||||

determines whether we are looking for ON flags or OFF flags as |

INPUT PRECIP (TIPPING BUCKET) measures precipitation |

|||||

defined by the mask. |

||||||

from a tipping bucket sensor using FREQ INPUT channels. |

||||||

mask= |

Hexadecimal mask (0000 to FFFF) |

|||||

RESO parameter sets the resolution per tip. Apply a multiplier |

||||||

logic= |

Match logic (ANY or ALL) |

with MULT if needed. Current 1-hour precipitation is stored at |

||||

state= |

Comparison state (OFF or ON) |

DLOC. Additional results are stored in six locations following |

||||

IF KEYSWITCH tests whether any of the 3 user soft-keys are |

DLOC. DO NOT allow other instructions to store values in these |

|||||

locations. |

|

|

||||

pressed during OPERATE MODE. |

chan= |

|

Frequency input channel (1-4) |

|||

key= |

Key value (KEY1, KEY2, or KEY3) |

|

||||

reso= |

|

Tip resolution |

||||

|

|

|

|

|||

IF LOC1 COMPARE LOC2 compares the values in SLOC1 |

mult= |

|

Multiplier value |

|||

dloc= |

|

Destination location (001-256) |

||||

and SLOC2. |

|

|

||||

|

|

|

Current 1-hour precipitation |

|||

sloc1= |

Source location 1 (001-256) |

|

|

|||

dloc+1 |

|

Last 1-hour precipitation |

||||

comp: |

< |

less than |

|

|||

|

<= |

less than or equal to |

dloc+2 |

|

Current 24-hour precipitation |

|

|

>= |

greater than or equal to |

dloc+3 |

|

Last 24-hour precipitation |

|

|

> |

greater than |

dloc+4 |

|

1-hour rate based on 5-minute sample |

|

|

<> |

not equal to |

dloc+5 |

|

Rate total (used internally) |

|

|

= |

equal to |

dloc+6 |

|

Raw pulse count (used internally) |

|

sloc2= |

Source location 2 (001-256) |

|

|

|

||

|

|

|

|

|

26800-90(K) |

|

|

|

Page 5 |

|

|

||

INPUT PRECIP (SIPHON) measures precipitation from a

YOUNG siphon-type precipitation sensor using a VOLTAGE INPUT CHAN. Set voltage measurement TYPE as single-ended

(SE) or differential (DIFF). Set precipitation measurement UNIT to MM or INCH. Apply multiplier and offset with MULT and OFFS parameters if needed. Result is stored at DLOC.

chan= |

Voltage input channel (1-16) |

type= |

Input type (SE or DIFF) |

unit= |

Precipitation unit (MM or INCH) |

mult= |

Multiplier value |

offs= |

Offset value |

dloc= |

Destination location (001-256) |

INPUT SERIAL NMEA parses a NMEA sentence received on serial CHAN and stores results starting at DLOC. Numeric fields are stored as floating point numbers. Single-character ASCIIletter fields are stored as the equivalent decimal ASCII code. Example: 'A' = 65. HEADER text must match. WAIT defines the number of milliseconds to wait for an incoming NMEA string to appear. Parsing error codes are stored in the DLOC position just past the one used for the last field (dloc + #flds + 1).

chan= |

Serial I/O channel (COM1 or COM2) |

header= |

NMEA sentence header (text) |

#flds= |

Number of data fields in sentence (01-99) |

wait= |

Milliseconds to wait for serial data (0000-9999) |

dloc= |

First data field (001-256) |

dloc+1 |

Second data field |

dloc+2 |

Third etc. |

... |

|

dloc+flds+1 Error code

0No Error

1 Header does not match

2Bad checksum

5Timeout

6Asterisk not detected

7 No $ at beginning of sentence

8Null field detected

All received serial sentences are stored in an internal buffer. If

WAIT=0, new serial data will not be acquired. Instead, the existing buffer contents will be parsed. This scheme allows parsing for multiple headers by testing the error code for a match.

INPUT SERIAL NUM parses an ASCII text string received on serial CHAN and stores results starting at DLOC. #FLDS defines the number of data fields expected and will determine how many storage locations are used. DELIM defines the delimiter character between data fields in the string. ENDCHR defines the end-of-line characters. When ENDCHR is set to NONE, instruction will try to parse #FLDS. WAIT defines the number of milliseconds to wait for an incoming ASCII string to appear. The internal input buffer is limited to 128 characters.

chan= |

Serial I/O channel (COM1 or COM2) |

#flds= |

Number of data fields in string (1-99) |

delim= |

Field delimiter (SPACE, COMMA, TAB, NONE) |

endchr= |

End-of-line characters (CR, CR-LF, NONE) |

wait= |

Milliseconds to wait for serial data (0000-9999) |

dloc= |

First data field (001-256) |

dloc+1 |

Second data field |

dloc+2 |

Third etc. |

... |

|

26800-90(K)

INPUT SERIAL RMYT parses the RMYT binary string received on serial CHAN and stores results starting at DLOC. UNITS defines wind speed units. WAIT defines the number of milliseconds to wait for an incoming RMYT string to appear.

chan= |

Serial I/O channel (COM1 or COM2) |

units= |

Wind speed units (M/S, MPH, KM/H, KTS) |

wait= |

Number of milliseconds to wait for serial data |

dloc= |

Wind Speed destination location (001-256) |

dloc+1 |

Wind direction destination location (001-256) |

INPUT VOLTAGE measures voltage from 1 of 16 single-ended inputs or 7 differential inputs. Differential channels must always be set to an odd number to define the input pair (i.e. differential

5 means input pair 5 and 6). Use MULT and OFFS to apply a multiplier or offset to the measurement. RATE defines the sample rate. The default rate of 4800Hz provides the fastest

measurement. Slower rates provide greater noise immunity and additional effective resolution. The result is stored in DLOC.

chan= |

Voltage input channel (01-16) |

type= |

Input type (SE or DIFF) |

mult= |

Multiplier |

offs= |

Offset |

rate= |

Sample Rate (3.52kHz to 6.875Hz in 10 steps) |

dloc= |

Destination location (001-256) |

INPUT WIND DIR (VOLTAGE) measures wind direction using any single-ended voltage input channel 1 through 4. Designed for direct connection to a potentiometer transducer in the listed

YOUNG sensor models, this instruction automatically applies a compensated pull-down resistance to accommodate the potentiometer dead-band. Result in angular degrees is stored in DLOC.

chan= |

Input channel (1-4) |

sensor= |

Young (03xxx, 04xxx, 051xxx, 053xxx, 05108) |

dloc= |

Destination location (001-256) |

INPUT WIND SPEED (FREQ) measures wind speed of listed

YOUNG sensors using any FREQ INPUT channel 1 through 4.

This instruction pre-configures the FREQ INPUT channel for low-level AC.

chan= |

Frequency input channel (1-4) |

sensor= |

Young (03xxx, 04xxx, 051xxx, 053xxx, 05108) |

units= |

Wind speed units (M/S, MPH, KM/H, KTS) |

dloc= |

Destination location (001-256) |

LOC1 = LOC2 assigns the value in LOC2 to LOC1. |

|

loc1= |

Location 1 (001-256) |

loc2= |

Location 2 (001-256) |

LOC = VALUE assigns the number in VAL to LOC.

loc= |

Location 1 (001-256) |

val= |

Numerical value |

LOC1 = LOC2 OPER LOC3 performs a numerical operation using the values in LOC2 and LOC3 and stores the result in LOC1. POW raises the value in LOC2 to the power of the number in LOC3. MOD calculates the modulo using the value in LOC3.

loc1= |

Location |

where result is stored (001-256) |

loc2= |

Location |

(001-256) |

oper: |

Math operator (+, -, *, /, POW, MOD) |

|

loc3= |

Location (001-256) |

|

Page 6

LOC1 = LOC2 OPER VALUE performs a numerical operation on the value in LOC2 using the number in VAL and stores the result in LOC1. POW raises the value in LOC2 to the power of

VAL. MOD calculates modulo VAL.

loc1= |

Location |

where result is stored (001-256) |

loc2= |

Location |

(001-256) |

oper: |

Math operator (+, -, *, /, POW, MOD) |

|

val= |

Numerical value |

|

LOC1 = FUNCTION(LOC2) performs one of several complex functions on one or more values starting with LOC2 and stores the result in LOC1.

loc1= |

Location where first result is stored (001-256) |

|

func: |

ABS |

Absolute value of number in LOC2 |

|

COS |

Cosine of number in LOC2 |

|

SIN |

Sine of number in LOC2 |

|

ATAN2 |

Standard atan2 function calculates arc- |

|

|

tan of two Cartesian numbers in |

|

|

sequential storage locations. Result |

|

|

is in degrees. |

|

|

LOC2 = first value |

|

|

LOC2+1 = second value |

|

DEWPT |

Calculates dew point (°C) from RH% |

|

|

and temperature. Uses two sequential |

|

|

storage locations for input. |

|

|

LOC2 = RH% |

|

|

LOC2+1 = temperature (°C) |

|

WETBULB |

Calculates wetbulb temperature |

|

|

(°C) from RH%, temperature, and |

pressure. Uses three sequential storage locations for input.

LOC2 = RH%

LOC2+1 = temperature (°C)

LOC2+2 = pressure (hPa or mB)

RTD385 |

Calculates temperature of a 100-ohm |

|

|

0.385-alpha platinum RTD sensor |

|

|

using the ratio of RTD resistance in |

|

|

LOC2. A value of 1.0000 represents |

|

|

100 ohms. |

|

|

LOC2= RTD ohms |

|

P CORR |

Calculates sea level pressure |

|

|

correction in hPa when given altitude in |

|

|

meters. Add the correction to measured |

|

|

pressure to get sea level equivalent. |

|

|

LOC2= altitude (meters) |

|

ERRCODE |

Puts the ErrCode result of the previous |

|

|

instruction in LOC1. LOC2 is ignored. |

|

|

Values less than 200 correspond to the |

|

|

error code listed in section 6.0. Error |

|

|

code value >= 200 indicate incorrect |

|

|

instruction parameters. |

|

DATETIME |

Stores the date and time in successive |

|

|

locations starting with LOC1. |

|

|

LOC1= |

Year |

|

LOC+1= |

Month |

|

LOC+2= |

Day of Month |

|

LOC+3= |

Hour |

|

LOC+4= |

Minute |

|

LOC+5= |

Second |

|

LOC+6= |

1/100th of a second |

WAITFOR |

Waits until an interrupt-driven modulo |

|

|

counter matches the millisecond value |

|

|

in LOC2. The counter is updated every |

|

|

5 milliseconds therefore the millisecond |

|

|

value should be a multiple of 5. The |

|

|

modulo counter is reset to zero once per |

|

|

second. A 25 millisecond delay is added |

|

|

to every User Program execution cycle. |

|

WNDCHLL |

Calculates wind chill temperature |

|

(°C) from ambient temperature and |

|

wind speed using standard NWS |

|

formula. Uses two sequential storage |

|

locations for input. |

|

LOC2 = temperature (°C) |

|

LOC2+1 = wind speed (m/s) |

POLYNOM |

Calculates polynomial using the |

|

number in LOC2 and 5 coefficients in |

|

sequential storage locations. Result = |

|

A + B*X + C*X^2 + D*X^3 + E*X^4 |

|

LOC2= X |

|

LOC2+1= A |

|

LOC2+2= B |

|

LOC2+3= C |

|

LOC2+4= D |

|

LOC2+5= E |

RTD375 |

Calculates temperature of a 1000-ohm |

|

3.75-alpha platinum RTD sensor using |

|

the ratio of RTD resistance to 1000 in |

|

LOC2. A value of 1.0000 represents |

|

1000 ohms |

LOC2= Milliseconds (5-995)

MAXIMUM finds the algebraically highest value in a group of samples taken from SLOC. #SAMP defines the number of samples for MOVING only.

BLOCK type progressively examines new samples and stores the current maximum in DLOC. When FLAG 1 is set, the maximum is stored in DLOC+1 and reset with the value in SLOC.

MOVING type maintains a list of #SAMP samples. DLOC and

DLOC+1 are both set to the maximum value in the entire list.

The maximum is updated with every new sample. Each new sample displaces the oldest sample on the list. The number of samples that can be maintained in the list is limited by available memory. If PGM ERR HANDLE is set to STOP, an error will be generated when #SAMP exceeds available memory.

sloc= |

Source location (001-256) |

dloc1= |

Destination location(001-256) |

type= |

Max type (BLOCK or MOVING) |

#SAMP= |

Number of samples to examine (0001-7000) |

|

Limited to available memory for MOVING MAX. |

MINIMUM finds the algebraically lowest value in a group of LOC2= RTD ratio to 1000 ohms samples taken from SLOC. #SAMP defines the number of

samples for MOVING type only.

26800-90(K)

Page 7

BLOCK type progressively examines new samples and stores the current minimum in DLOC. When FLAG 1 is set, the minimum is stored in DLOC+1 and reset with the value in SLOC.

MOVING type maintains a list of #SAMP samples. DLOC and

DLOC+1 are both set to the minimum value in the entire list. The minimum is updated with every new sample. Each new sample displaces the oldest sample on the list. The number of samples that can be maintained in the list is limited by available memory.

If PGM ERR HANDLE is set to STOP, an error will be generated when #SAMP exceeds available memory.

sloc= |

Source location (001-256) |

dloc1= |

Destination location(001-256) |

type= |

Min type (BLOCK or MOVING) |

#SAMP= |

Number of samples to examine (0001-7000) |

|

Limited to available memory for MOVING MAX. |

OUTPUT MILLIAMPS produces output current in 1 of 4 analog output channels using the value in SLOC. MULT and OFFS may be used to scale the SLOC value with a multiplier and offset.

Output current is limited to 0.00 to 20.00 mA.

IMPORTANT NOTE ABOUT SERIAL INSTRUCTIONS:

All SERIAL BUFFER instructions (except SERIAL BUFFER OUT) add ACSII text to the serial output buffer. An internal buffer index increments with each new character added. This process continues until the 128-character buffer size limit is reached or a SERIAL BUFFER OUT instruction is executed. If the buffer limit is reached, no further text will be added and generate an error if PGM ERR

HANDLE is set to STOP. Any USER PROGRAM that adds text to the serial buffer should always include a SERIAL BUFFER OUT instruction. After executing a SERIAL BUFFER OUT instruction,

the internal index is reset to the beginning of the output buffer.

SERIAL BUFFER CHECKSUM calculates a checksum based on the contents of the serial output buffer and places it at the end. TYPE may be set to SIMPLE, CRC32, or NMEA. SIMPLE uses the arithmetic sum of ASCII values to produce a 5-digit integer. CRC32 uses CRC-32-IEEE 802.3 to produce an 8-character hex value. NMEA produces a marine NMEA 0183 standard checksum presuming that the sentence meets all other NMEA formatting requirements.

sloc= |

Source location (001-256) |

chan= |

Analog output channel (1-4) |

mult= |

Multiplier |

offs= |

Offset |

OUTPUT MILLIVOLTS produces output voltage in 1 of 4 analog output channels using the value in SLOC. MULT and OFFS may be used to scale the SLOC value with a multiplier and offset.

Output voltage is limited to 0 to 5000 mV.

sloc= |

Source location (001-256) |

chan= |

Analog output channel (1-4) |

mult= |

Multiplier |

offs= |

Offset |

OUTPUT SWITCH sets the state of 1 of 4 SOLID STATE SWITCH channels.

type= |

Checksum type (SIMPLE, CRC32, or NMEA) |

SERIAL BUFFER NESW takes angular wind direction (in degrees) from SLOC, translates it to a compass point description

(N, NNE, NE, ENE, E, etc...), and adds the 3-character string to the serial output buffer. DELIM defines the delimiter to be placed at the end of the field.

sloc= |

Source location |

delim= |

Field delimiter (SPACE, COMMA, TAB, NONE) |

SERIAL BUFFER OUT transmits the contents of the serial output buffer through serial CHAN COM1 or COM2. END-

CHR defines the termination characters sent at the end of the transmission. DELAY defines the number of milliseconds after transmission before the instruction continues program execution. After transmission, the internal output buffer index is reset to the beginning.

chan= |

Solid state switch channel (1-4) |

chan= |

Serial I/O channel (COM1 or COM2) |

endchr= |

Termination characters (CR, LF, NONE) |

||

state= |

State of switch (ON or OFF) |

delay= |

Millisecond delay (00-99) |

|

|

SERIAL BUFFER TEXT adds up to 25 characters to the to |

||

IMPORTANT NOTE ABOUT RECORD INSTRUCTIONS: |

||||

the serial output buffer. To truncate to less than 25 characters, |

||||

RECORD TIME and RECORD VALUE instructions store data to |

terminate the text string with the ' \ ' (backslash) character. |

|||

an internal serial flash device. Up to 2,162,688 single-precision |

|

|

||

floating point data values may be recorded. The storage scheme |

text= |

Text string |

||

is one large circular buffer with each RECORD instruction storing |

|

|

||

data in the next available location. When the end of memory is |

SER BUF TIME adds TIME or DATE text to the serial output |

|||

reached, the internal index starts back at the beginning. |

buffer. FRMT determines whether DATE or TIME is used. DATE |

|||

|

|

|||

|

|

produces yy-mm-dd (yy= year, mm=month, dd=day). TIME |

||

RECORD TIME records TIME or DATE to internal flash memory. |

produces hh:mm:ss (hh=hour, mm=minute, ss=seconds). DELIM |

|||

defines the delimiter placed at the end of the field. |

||||

DATE is encoded as a large integer. For example, 2008 May 27 |

|

|

||

is stored as 20080527. TIME is similarly stored in hundredths |

frmt= |

DATE or TIME |

||

of a second. For example, 15:23:07.00 is stored as 15230700. |

delim= |

Field delimiter (SPACE, COMMA, TAB, NONE) |

||

RMYComm can retrieve these values and convert them to con- |

|

|

||

ventional form. |

SERIAL BUFFER VALUE adds the number in SLOC to the |

|||

frmt= |

Record format (DATE or TIME) |

serial output buffer. WIDTH defines the total character width, |

||

DECPT defines the number of digits after the decimal point. |

||||

RECORD VALUE records the number stored in SLOC to internal |

DELIM defines the field delimiter inserted at the end. |

|||

sloc= |

Source location |

|||

flash memory. |

|

width= |

Number of characters |

|

|

|

decpt= |

Number of digits after decimal point |

|

sloc= |

Source location (001-256) |

delim= |

Field delimiter (SPACE, COMMA, TAB, NONE) |

|

26800-90(K)

Page 8

Loading...

Loading...