Page 1

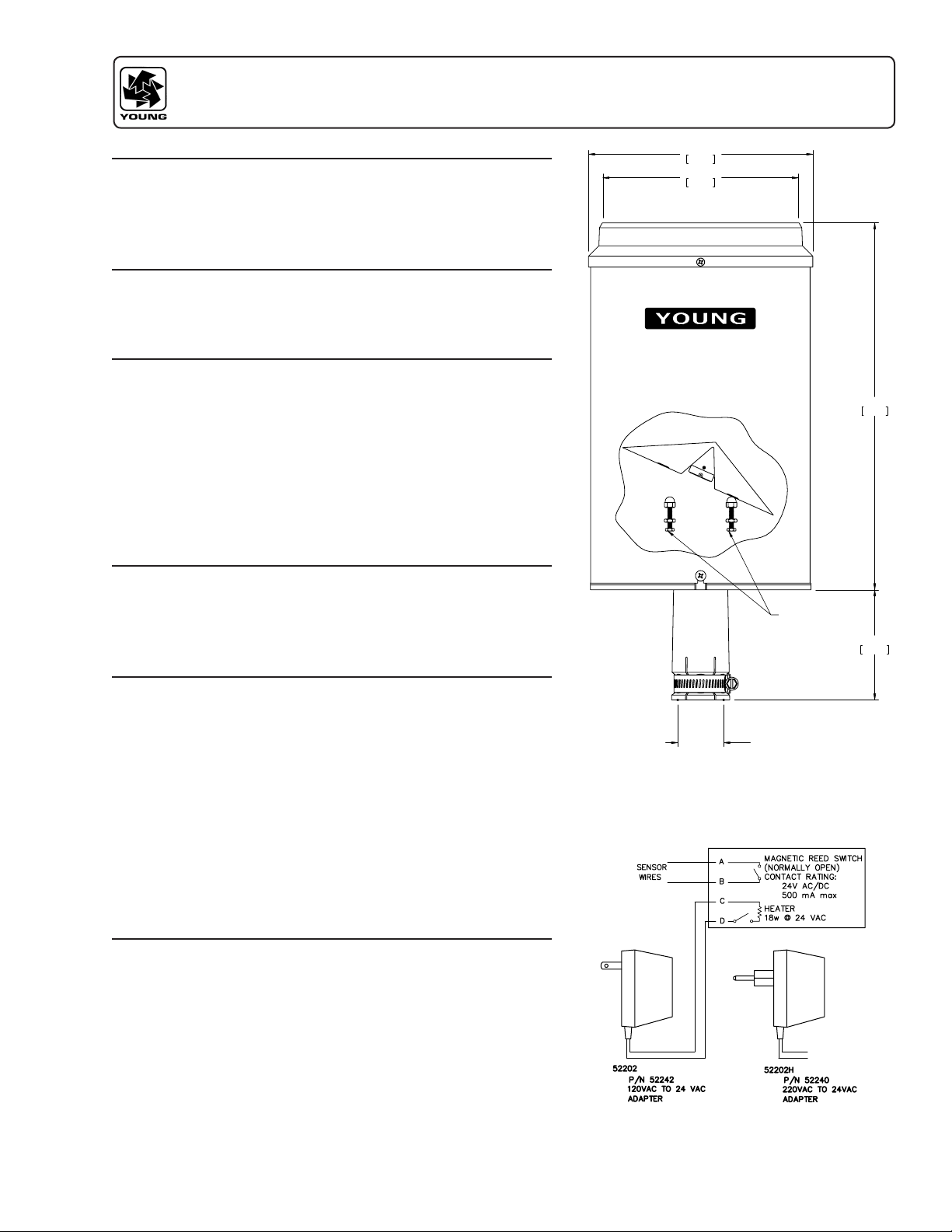

MODEL 52202 / 52202H / 52203

TIPPING BUCKET RAIN GAUGE

INSTRUCTION SHEET 52202-90

REV H041411

INTRODUCTION

The YOUNG Mod el 52 20 2 / 52203 Tipping Bucket Rain Gauge meets the

specifications of the World Meteorological Organization (WMO). Extensive

use of molded thermoplastic components gives maximum performance and

resistance to corrosion. Model 52202 is heated for year-round use, Model 52203

is unheated for use in temperate climates.

LOCATION OF RAIN GAUGE

Precipitation measurement is greatly affected by location of the rain gauge.

Select a location that is naturally protected from gusts and crosswinds. Avoid a

site prone to contamination from debris such as falling leaves, dirt, etc...

INSTALLATION

The Model 52202 / 52203 is fully calibrated at the factory. The movable bucket

is retained to prevent damage during shipment. On installation, the following

procedure should be followed.

1. Loosen 3 screws that retain housing to base assembly. Carefully lift housing

free of base.

2. Remove shipping retainer from bucket. Verify that bucket tips freely.

3. Attach sensor wires and heater wires (when used) to terminals as shown in

wiring diagram.

4. Adjust leveling screws until bulls eye level is centered.

5. Replace housin g. If hea ted, hea te r wires (gray) must be a ttached to

terminals C & D before housing is fully engaged. Retighten screws.

MAINTENANCE

The r ain gauge shoul d be inspe cted peri odicall y. Accum ulate d di rt and

debris should be cleaned from funnel, screen and bucket assembly. Electrical

conn ectio ns sho uld be i nspec te d an d cl eaned . Le velin g scre ws m ay b e

rea djusted at this time. Periodic r ecalibration may be d esirable to ensure

measurement accuracy.

CALIBRATION

18.5 cm

7.3 in

16 cm

6.3 in

CALIBRATING

SCREW

30 cm

12 in

9 cm

3.5 in

To check or recalibrate the rain gauge, Model 52260 Rain Gauge Calibrator will

simplify the process. If a calibration device is not available, the following steps

will yield satisfactory results:

1. With the rain ga uge properly l eveled, slowly pour a measur ed volume

of water into the collection funnel. The rate should not exceed 10 ml per

minute which is approximately 1 inch per hour. The bucket should tip 5 times

for each 10 ml of water. For example, 100 ml should give a count of 50 ±1.

Bucket tips may be counted manually or with a counter connected to the

rain gauge terminals.

2. If the count shows an error of more than 2%, adjust the calibrating screws to

correct the error. Raise the screws if the count is low, lower the screws if the

count is high. Always adjust both screws equally.

SPECIFICATIONS

CATCHMENT AREA: 200 cm

RESOLUTION: 0.1 mm per tip

ACCURACY: 2 % up to 25 mm / hr, 3% up to 50 mm/hr

OUTPUT: Magnetic reed switch, normally open

CONTACT RATING: 24V AC / DC 500 mA MAX

OPER. TEMP: -20°C to + 50°C (heated)

POWER: 18 Watts @ 24 VAC for heater only

MOUNTING: Standard 1 Inch Pipe Size, 34mm (1.34") Dia.

2

MOUNTING:

STANDARD 1 INCH IRON PIPE

SIZE 34mm (1.34") DIAMETER

Power Supplies for

Heated Models

R. M. YOUNG COMPANY 2801 Aero Park Drive , Traverse City, Michigan 49686 USA

TEL (231) 946-3980 FAX (231) 946-4772

Page 2

BIRD PROTECTION

Model 52250 Bird Wire Assembly will discourage bird perching on the

funnel rim. Contact your YOUNG supplier to order this accessory.

WARRANTY

Thi s produc t is wa rranted to be f ree of defects in mater ials and

construction for a period of 12 months from date of initial purchase.

Liability is limited to repair or replacement of defective item. A copy

of the warranty policy may be obtained from R. M. Young Company.

CE COMPLIANCE

This product has been tested and shown to comply with European

CE requirements for the EMC Directive. Please note that shielded

cable must be used.

Declaration of Conformity

R. M. Young Company

2801 Aero Park Drive

Traverse City, MI 49686 USA

Model 52202/52203 Tipping Bucket Rain Gauge

The undersigned hereby declares on behalf of R. M.

Young Company that the above-referenced product, to

which this declaration relates, is in conformity with the

provisions of:

Council Directive 2004/108/EC (December 15, 2004)

on Electromagnetic Compatibility

David Poinsett

R&D Manager

Loading...

Loading...