Page 1

METEOROLOGICAL INSTRUMENTS

INSTRUCTIONS

PROPELLER ANEMOMETER

MODEL 27106T

R.M. YOUNG COMPANY 2801 AERO PARK DRIVE, TRAVERSE CITY, MICHIGAN 49686, USA

TEL: (231) 946-3980 FAX: (231) 946-4772 WEB: www.youngusa.com

PN: 27106T-90

REV: C062309

Page 2

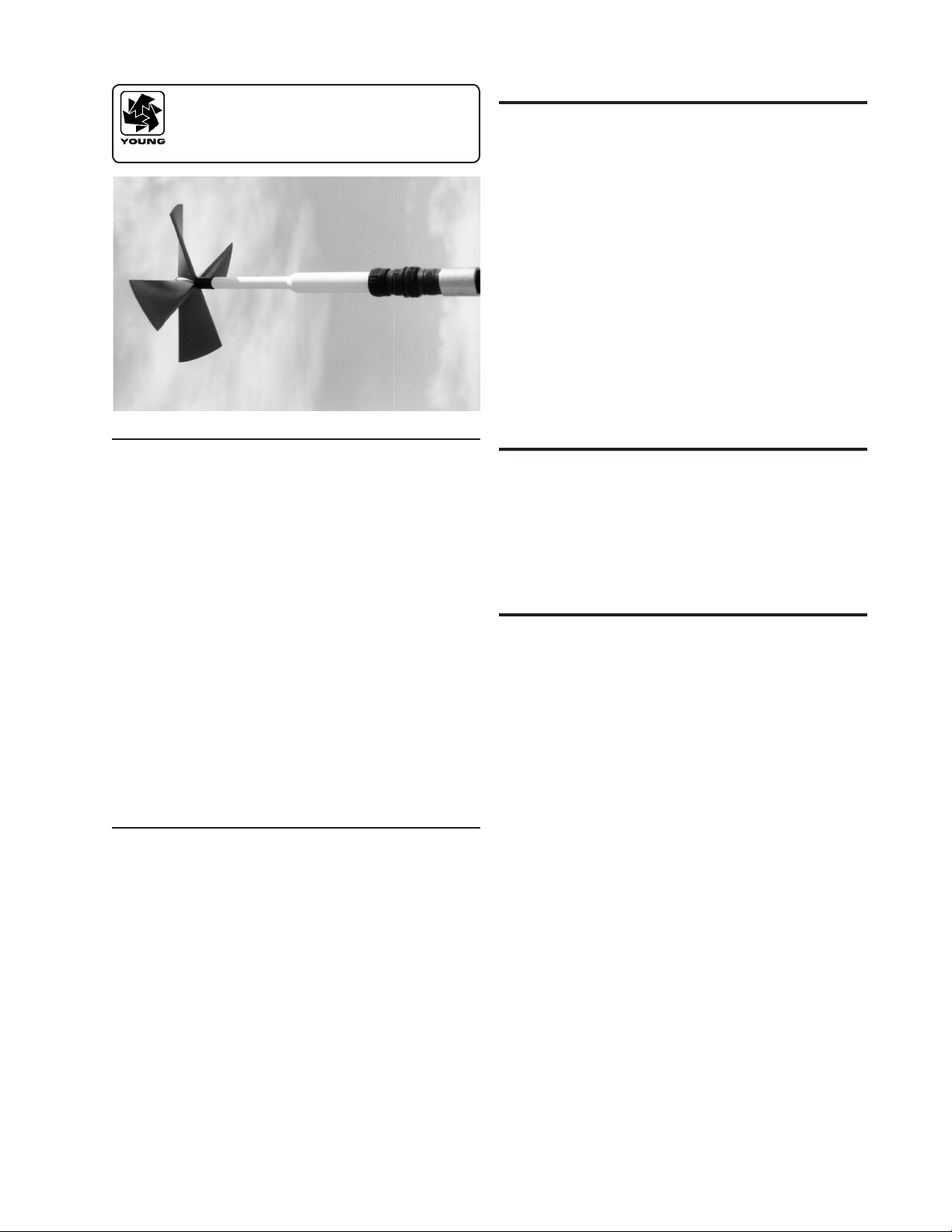

MODEL 27106T

GILL PROPELLER

ANEMOMETER

INTRODUCTION

The Gill Propeller Anemometer is a low threshold precision air

veloc it y sensor employing a fast resp onse helic oid propelle r.

The ins trume nt uses a high quality tech -gene rator transducer

which converts propeller rotation to a DC voltage that is linearly

proportional to air velocity. The output signal is suitable for a wide

range of signal translators and data logging devices.

Airow from any direction may be measured, however, the propeller

responds only to the component of the air ow which is parallel to

the axis of its rotation. Off-axis response closely approximates a

cosine curve (see accompanying graphs) with appropriate polarity.

With perpendicular air ow, the propeller does not rotate.

For detailed studies of low air speeds, optional propeller shaft

extensions improve response in the 90° stall region by improving

symmetry and reducing the stall angle.

The instrument mounts to 3/4 inch standard pipe. A rugged cable

connector provides both electrical and mechanical connection. A

dustcap is provided to protect the connector when the instrument

is removed.

SPECIFICATION SUMMARY

Range, Axial Flow 0-40 m/s (90 mph)

Range, All Angles 0-35 m/s (80 mph)

Propeller 20 cm diameter 4-blade helicoid propeller

Pitch 30.0 cm air passage per revolution

Distance Constant* 2.1 m (6.9 ft.)

Threshold Sensitivity* 0.4 m/s (0.8 mph)

Signal Output Analog DC voltage proportional to axial

Power Requirement Anemometer is self powered.

Specications represent nominal values determined in accordance

with ASTM standard procedures.

*

Threshold and Distance Constant values are for axial ow.

GENERAL

Operating Temperature: -50 to 50°C (-58 to 122°F)

molded of carbon ber thermoplastic

wind component. Polarity reverses with

reverse rotation.

1800 rpm (500 mV) = 9.0 m/s (20.1 mph).

INITIAL CHECKOUT

When the instrument is unpacked it should be carefully checked

for any signs of shipping damage. The propeller shaft should rotate

easily without friction.

Using the WIRING DIAGRAM as a guide, connect the instrument

to an ind icator or v oltmeter and check for proper signals from

the sensor. The calibration may be checked using the methods

outlined in the CALIBRATION section of this manual.

INSTALLATION

Generally, the instrument should be oriented with the propeller

facing the predominant ow of air being measured. In some cases

it is appropriate to orient the instrument so the predominant air ow

is perpendicular to the propeller such as in applications measuring

the vertical component of wind. Keep in mind that off-axis response

increases the effective threshold and distance constant.

For vertical measurements mount the instrument so the propeller

faces upward. This helps prevent moisture or dirt from entering

ar ou nd th e prope ller hu b an d po ten ti all y co ntami nat in g the

bearings.

If the instrument is used to measure high air velocity or left for

extended pe ri od s without a tt en ti on , tape the thr ea de d cable

connector collar to eliminate the possibility of loosening from

vibration. Th e threaded joint between th e generator and shaft

housings may also be taped.

For some applications commutator ripple from the tech-generator

may need to be reduced. Use a 500 uF 10 VDC non-polarized

capacitor connected across the sensor leads as shown in the wiring

diagram. Given the low internal resistance of the tech-generator

the effective time constant of this lter is approximately 15 mS and

will not degrade measurement accuracy to any signicant degree.

The instrument measures both forward and reverse air ow. Signal

polarity re lative t o the connecti on pins is sh own in the wi ring

diagram. In applications measuring horizontal air ow, most users

connect the sensor to produce a positive signal with flow from

the front (counterclockwise propeller rota tion). In applications

measuring vertical air flow, the sensor is usually connected so

downdrafts produce a negative signal, updrafts a positive signal.

Output from the tech-generator should be connected to a load

impedance of 10k ohms or higher.

Page 1

27106T-90

Page 3

CALIBRATION

Calibration is determined by propeller pitch and the output

characteristics of the tach-generator.

Both Model 08274 Expanded Polystyrene Propeller and Model

08254 Carbon Fiber Thermoplastic Propeller have a 29.4 cm/rev

pitch. This is equivalent to 0.0049 m/s per rpm and is accurate

to ±1%. Zero offset is insignicant. Formulas for other units of

measurement appear on the calibration chart included with this

manual.

The tach-generator output is set at the factory for 500 ±2 mV at

1800 rpm. Check the output by removing the propeller from the

anemometer and coupling an Anemometer Drive to the shaft.

Check linearity by taking measurements at several different

speeds. If the tech-generator is out of calibration it must be

replaced. See the following MAINTENANCE section for details on

replacement procedure.

Information on checking bearing and transducer torque, which

can affect propeller threshold, also appear in the MAINTENANCE

section.

When the propeller is used for measuring vertical wind component,

users may want to apply a 1.25 multiplier to the output signal.

This may be done numerically in data processing operations

or electronically in the signal conditioning. Using the multiplier

brings the anemometer output signal within ±3% of the cosine

response for elevation angles between -30 and +30 degrees.

Since the standard deviation of wind elevation angle in open

terrain rarely exceeds 12 degrees, 98% (2.5 standard deviations)

of observations will be within ±30 degrees. Using the multiplier

is NOT necessary when the anemometer is used in a UVW

conguration with YOUNG Model 26601 UVW Translator.

MAINTENANCE

Replace the tack-generator as follows:

Given proper care, the Gill Propeller Anemometer should

provide years of service. Components are conservatively rated

and require little maintenance. The only parts likely to need

replacement due to normal wear are the precision ball bearings

and the tach-generator. The replacement procedures are best

performed in a service facility and only by qualied technicians.

If service facilities are not available, return the instrument to the

factory.

Refer to the accompanying drawings to become familiar with part

names and locations.

PROPELLER

The Model 08274 Expanded Polystyrene (EPS) Propeller can be

easily damaged by careless handling, high winds, hail, or birds.

Damage from these causes is not covered by warranty. If the

EPS propeller is repeatedly damaged, consider using the more

durable though slightly less sensitive Model 08254 Carbon Fiber

Thermoplastic (CFT) Propeller.

Replace bearings as follows:

1. REMOVE OLD BEARINGS

a) Remove propeller from anemometer.

b) Unthread and separate shaft housing assembly from

generator housing.

c) Loosen set screw on shaft collar/coupling disk and

remove from propeller shaft.

d) Slide propeller shaft through both bearings and out of

housing.

e) Pull front bearing dust shield off housing.

f) Using the edge of a pocket knife, gently pry front and rear

bearings out of housing.

2. INSTALL NEW BEARINGS

a) Gently insert front bearing into housing.

b) Push front bearing dust shield back onto housing.

c) Carefully slide propeller shaft through front bearing and

into housing.

d) Slide rear bearing over propeller shaft and gently push it

into housing.

e) Place shaft collar/coupling disk on propeller shaft.

f) Allow 0.010 inch (0.25 mm) end play gap between shaft

collar/coupling disk and bearing.

Tighten set screw (80 oz in, 5600 gm-cm max torque).

9) Thread shaft housing assembly into generator housing.

Tighten rmly.

h) Check bearing torque to conrm it is within specications.

TACH-GENERATOR REPLACEMENT

When the tach-generator output becomes erratic (usually due

to brush failure) or begins to show signs of bearing failure (high

torque), the entire generator assembly should be removed and

replaced. If replacing the tach-generator due to excessive torque

make certain it is indeed caused by a worn tach-generator, not the

anemometer ange bearings.

Replace the tach-generator as follows:

1. REMOVE OLD GENERATOR ASSEMBLY

a) Remove propeller from anemometer.

b) Unthread generator housing collar. Pull generator

housing

away from sensor connector and generator assembly.

c) Note position of generator wires on sensor connector

pins. Unsolder wires from pins and remove old generator

assembly.

2. INSTALL NEW GENERATOR ASSEMBLY

a) Solder wires from new generator assembly onto proper

sensor connector pins. Verify correct polarity: CCW

rotation produces negative output voltage.

b) Slide generator housing over generator assembly. Firmly

tighten housing collar onto connector threads.

c) Check bearing torque to conrm it is within specication.

FLANGE BEARING REPLACEMENT

If anemometer bearings become noisy or wind speed threshold

increases above an acceptable level, bearings may need replacement. Check bearing condition using a Model 18310 Anemometer

Bearing Torque Disk. If, after replacing bearings, the torque is still

too high, check the tach-generator.

27106T-90

Page 2

Page 4

ADDITIONAL REFERENCES

WARRANTY

References containing additional information about the Gill

Propel ler Anemometer are listed below in chronological order:

Holmes, R. M., Gill, G. C., and Carson, H. W., “A Propeller Type

Vertical Anemometer”, Journal of Applied Meteorology, Vol 3,

1964, pp. 802-804.

Drinkow, R., “A Solution to the Paired Gill-Anemometer Response

Function”, Journal of Applied Meteorology, Vol 11, 1972,

pp. 7-80.

Hicks, B. B., “Propeller Anemometers as Sensors of Atmospheric

Turbulence”, Boundary-Layer Meteorology, Vol 3,1972,

pp. 214-228.

Fichtl, G. H., and Kumar, P., “The Response of Propeller

Anemometer to Turbulent Flow with the Mean Wind Vector

Per pendicular to the Axis of Rotation”, Boundary-Layer

Meteorol ogy, Vol 6,1974, pp. 363-379.

McMichael, J. M., and Klebanoff, P. S., “The Dynamic Response

of Helicoid Anemometers”, NBSIR 75-772, National Bureau of

Standards, 1975.

This product is warranted to be free of defects in materials and

construction for a period of 12 months from date of initial purchase.

Liability is limited to repair or replacement of d efective item. A

copy of the warranty policy may be obtained from R. M. Young

Company.

CE COMPLIANCE

This product has been tested and shown to comply with European

CE re qui remen ts f or the EM C Di recti ve (se e De cl ara tio n o f

Conformity below). Please note that shielded cable must be used.

Declaration of Conformity

R. M. Young Company

2801 Aero Park Drive

Traverse City, MI 49686 USA

Model 27106T Propeller Anemometer

The undersigned hereby declares on behalf of R. M.

Young Company that the above-referenced product, to

which this declaration relates, is in conformity with the

provisions of:

Council Directive 2004/108/EC (December 15, 2004)

on Electromagnetic Compatibility

David Poinsett

R&D Manager

Page 3

27106T-90

Page 5

27106T-90

Page 4

Page 6

Page 5

27106T-90

Page 7

27106T-90

Page 6

Page 8

Page 7

27106T-90

Loading...

Loading...