Page 1

METEOROLOGICAL INSTRUMENTS

INSTRUCTIONS

WIND MONITOR

INTRINSICALLY SAFE WITH 4-20mA OUTPUTS

MODEL 05501LM

R.M. YOUNG COMPANY 2801 AERO PARK DRIVE, TRAVERSE CITY, MICHIGAN 49686, USA

TEL: (231) 946-3980 FAX: (231) 946-4772 WEB: www.youngusa.com

P/N: 05501-90

REV: D102811

Page 2

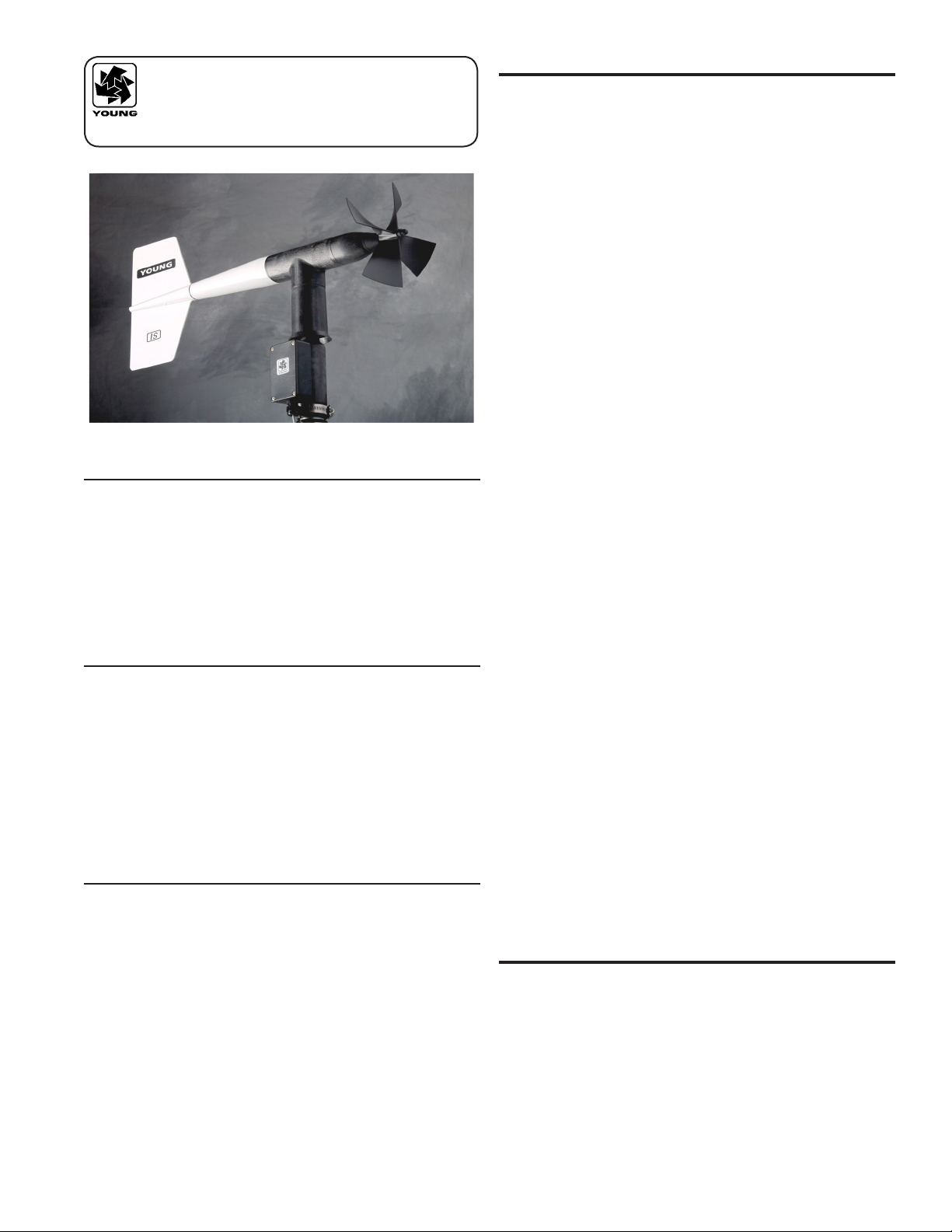

MODEL 05501LM

WIND MONITOR

Intrinsically Safe with 4-20 mA Outputs

INTRODUCTION

Model 05501LM Wind Monitor IS is an intrinsically safe wind sensor

that converts horizontal wind speed and direction measurements to

calibrated 4-20 mA signals. Each signal is derived from independent

2-wire loop-powered circuits. The sensor operates over a wide

ambient temperature range.

Intrinsic safety is achieved when the sensor is used with approved

barriers. Intrinsically safe systems are recognized as practical

and effective means of operating instruments in an explosive

environment. The technique limits the amount of energy available to

ignite explosive gases or ignitable mixtures. This is accomplished by

controlling the amount of voltage and current in the hazardous area.

When used with an approved Intrinsically Safe barrier, the Wind

Monitor IS can be used in Class 1, Division 1, Group A,B,C,D

hazardous areas. The categories are dened as follows:

WIND SPEED SPECIFICATION SUMMARY

Operating Range 0 to 60 m/s (134 mph)

Gust Survival 100 m/s (220 mph)

Sensor Type 18 cm diameter 4-blade helicoid

polypropylene propeller, 29.4 cm air

passage per revolution

Distance Constant 2.7 m (8.9 ft.) for 63% recovery

Threshold Sensitivity 1.0 m/s (2.2 mph)

Output Signal 4-20 mA for 0 to 50 m/s (100 m/s optional)

Power Requirement: 10 to 30 VDC at 20 mA max

WIND DIRECTION (AZIMUTH) SPECIFICATION SUMMARY

Range 360° mechanical,

355° electrical (5° open)

Sensor Balanced vane,

38 cm (15 in) turning radius.

Damping Ratio 0.3

Delay Distance 1.3 m (4.3 ft) for 50% recovery

Threshold Sensitivity 1.1 m/s (2.4 mph) at 10° displacement

Natural Wavelength 7.4 m (24.3 ft) Damped

7.2 m (23.6 ft) Undamped

Output Signal 4-20 mA for 0 to 360°

Power Requirement: 10 to 30 VDC at 20 mA max

GENERAL

Ambient Temperature -50 to 50°C (-58 to 122°F)

Intrinsic Safety Class I, Division 1, Groups A, B, C, D

when installed with approved

Intrinsically Safe Barrier

(see Wiring Diagram)

Entity Approval Vmax = 30V

Imax = 100 mA

Ci = 0.01 uF

Li = 0.0 uH

Class I Locations in which ammable gases or vapors are or may

be present in quantities sufcient to produce explosive or

ignitable mixtures.

Division 1 Locations in which hazardous concentrations in the air

exist continuously, intermittently, or periodically under

normal operating conditions.

Group A Atmospheres containing acetylene

Group B Atmospheres containing hydrogen, or gases or vapors of

equivalent hazard, such as manufactured gas.

Group C Atmospheres containing ethyl-ether vapors, ethylene, or

cyclo-propane

Group D Atmospheres containing gasoline, hexane, naptha,

benzine, butane, propane, alcohol, acetone, benzol,

lacquer solvent vapors, or natural gas.

The Wind Monitor IS is rugged and corrosion resistant, yet accurate

and lightweight. Housing, nose cone, propeller, and other components

are injection molded with U.V. stabilized plastic. Both the propeller

and vertical shafts use stainless steel precision grade ball bearings.

Propeller rotation produces an AC sine wave signal with frequency

proportional to wind speed. Internal circuitry converts this signal to a

calibrated 4 to 20 mA current output.

Vane position is sensed by a 10K ohm precision conductive plastic

potentiometer. This signal is also converted to 4 to 20mA output.

The instrument mounts directly on a standard one inch pipe, outside

diameter 34 mm (1.34"). An orientation ring is provided so the

instrument can be removed for maintenance and re-installed without

loss of wind direction reference. Both sensor and orientation ring

are secured to the mounting pipe by stainless steel band clamps.

Electrical connections are made in a junction box at the base.

INITIAL CHECK-OUT

When the instrument is unpacked, check it carefully for signs of

shipping damage.

Page 1

05501LM-90(D)

Page 3

Remove the plastic nut on the propeller shaft. Install the propeller on

×+=

360

164

angle

mA

4

360

355

168.19 +

×≈

the shaft with the serial number of the propeller facing forward (into

the wind). The instrument is aligned, balanced and fully calibrated

before shipment; however, it should be checked both mechanically

and electrically before installation. The vane and propeller should

easily rotate 360° without friction. Check vane balance by holding

the instrument base so the vane surface is horizontal. It should have

near neutral torque without any particular tendency to rotate. A slight

imbalance will not degrade performance.

INSTALLATION

PROPER ELECTRICAL CONNECTION IS CRITICAL

FOR SAFE USE IN HAZARDOUS LOCATIONS.

FAILURE TO DO SO COULD RESULT IN INJURY TO PERSONS

OR PROPERTY DAMAGE.

AN APPROVED INSTRINSICALLY SAFE BARRIER

MUST BE USED.

REFER TO WIRING DIAGRAM FOR CONNECTION DETAILS.

FOLLOW BARRIER MANUFACTURER'S GUIDELINES FOR

CORRECT INSTALLATION.

OBSERVE NEC CODES FOR WIRING IN HAZARDOUS

LOCATIONS OR EQUIVALENT.

The Wind Monitor IS must be connected through an approved

Intrinsically Safe barrier or its equivalent. Examples of approved

barriers include the following models from MTL (www.mtl-inst.com):

MTL 7087+ Passive diode barrier with resistors

MTL 7106 Diode barrier with active electronics

MTL 7206 Diode barrier with active electronics

MTL 5041 Isolated barrier with active electronics

MTL 5044 2-ch version of MTL5041

Entity Parameters for the Wind Monitor IS are as follows:

Accurate wind measurements require proper instrument placement.

Eddies from trees, buildings, or other structures can greatly inuence

wind speed and direction observations. To get meaningful data for

most applications, locate the instrument well above or upwind from

obstructions. As a general rule, the air ow around a structure is

disturbed to twice the height of the structure upwind, six times the

height downwind, and up to twice the height of the structure above

ground. For some applications it may not be practical or necessary to

meet these requirements.

Initial installation is most easily done with two people; one to adjust

the instrument position and the other to observe the indicating device.

After initial installation, the instrument can be removed and returned

to its mounting without realigning the vane since the orientation ring

preserves the wind direction reference. Install the Wind Monitor

following these steps:

1. MOUNT WIND MONITOR

a) Place orientation ring on mounting post. Do Not tighten

band clamp yet. Orientation ring may be omitted when portable

tripod is used.

b) Place Wind Monitor on mounting post. Do Not tighten band

clamp yet.

2. CONNECT SENSOR CABLE.

a) Refer to diagram W05501L located at back of manual.

3. ALIGN VANE

a) Connect instrument to indicator.

b) Choose a known wind direction reference point on the

horizon.

c) Sighting down instrument centerline, point nose cone at

reference point on horizon.

d) While holding vane in position, slowly turn base until

indicator shows proper value.

e) Tighten mounting post band clamp.

f) Engage orientation ring indexing pin in notch at instrument

base.

g) Tighten orientation ring band clamp.

Vmax = 30 VDC

Imax = 100 mA

Li = 0.0 uH

Ci = 0.01 uF

Any approved barrier may be used provided that its specications and

the wiring connections fulll the following relationship:

Vmax > Voc

Imax > Isc

La > Li + Lw

Ca > Ci + Cw

Where:

Vmax = 30 VDC Max Open Circuit Voltage of 05501LM

Imax = 100 mA Max Short Circuit Current of 05501LM

Li = 0.0 uH Inductance of 05501LM

Ci = 0.01 uF Capacitance of 05501LM

Lw = Connecting Wire Inductance

Cw = Connecting Wire Capacitance

Voc = Maximum Open Circuit Voltage of IS Barrier

Isc = Maximum Short Circuit Current of IS Barrier

La = Maximum Allowed Inductance of IS Barrier

Ca = Maximum Allowed Capacitance of IS Barrier

CALIBRATION CHECK

The Wind Monitor IS is fully calibrated before shipment and should

require no adjustments. Periodic calibration checks are desirable and

may be necessary if the instrument is used in programs which require

auditing of sensor performance.

WIND DIRECTION

Place the instrument on a Young Model 18112 Vane Angle Bench

Stand. Connect the instrument to a signal conditioning circuit

which indicates wind direction. Move the vane to various angular

orientations on the Vane Angle Bench Stand and observe the Wind

Monitor output. Indicated vane angle should agree with actual angle

within ±3°. If measuring current output, use the following formula:

Note that while the sensor mechanically rotates through a full 360°,

the active region of the sensor ends at 355°. This means that the

highest obtainable reading occurs at 19.8 mA.

05501LM-90(D)

Page 2

Page 4

WIND SPEED

×+=50164

speed

mA

RPMspeed ×= 0049.0

Remove the propeller and connect a Young Model 18802 Anemometer

Drive to the propeller shaft. Connect the instrument to a signal

conditioning circuit indicating wind speed.

Set the Anemometer Drive to various rates and observe the Wind Monitor

output. Indicated speed should agree with actual speed within ±0.5 m/s.

Use the following formulas:

Speed is in meters per second (m/s).

3. REMOVE POTENTIOMETER

a) Loosen set screw on potentiometer coupling and remove it from

potentiometer adjust thumbwheel.

b) Loosen set screw on potentiometer adjust thumbwheel and

remove it from potentiometer shaft.

c) Loosen two set screws at base of transducer assembly and

remove assembly from vertical shaft.

d) Unscrew potentiometer housing from potentiometer mounting

& coil assembly.

e) Push potentiometer out of potentiometer mounting &

coil assembly by applying firm but gentle pressure on

potentiometer shaft. Make sure that the shaft o-ring comes out

with the potentiometer. If not, then gently push it out from the

top of the coil assembly.

Details on checking bearing torque, which affects wind speed and

direction threshold, appear in the following section.

MAINTENANCE

Given proper care, the Wind Monitor should provide years of

service. The only components likely to need replacement due to

normal wear are the precision ball bearings and the wind direction

potentiometer. Only a qualied instrument technician should perform

the replacement. If service facilities are not available, return the

instrument to the company. Refer to the drawings to become familiar

with part names and locations. The asterisk * which appears in

the following outlines is a reminder that maximum torque on all set

screws is 80 oz-in.

ELECTRONIC REPAIR MAY BE PERFORMED

ONLY BY QUALIFIED TECHNICIANS.

SUBSTITUTION OF COMPONENTS

MAY IMPAIR INTRINSIC SAFETY.

POTENTIOMETER REPLACEMENT

The potentiometer has a life expectancy of fty million revolutions.

As it becomes worn, the element may begin to produce noisy signals

or become non-linear. When signal noise or non-linearity becomes

unacceptable, replace the potentiometer. Refer to exploded view

drawing and proceed as follows:

1. REMOVE MAIN HOUSING

a) Unscrew nose cone from main housing. Set o-ring aside for

later use.

b) Remove 4 screws attaching housing.

c) Gently push main housing latch.

d) While pushing latch, lift main housing up and remove It from

vertical shaft bearing rotor.

2. UNSOLDER TRANSDUCER WIRE

a) Remove junction box cover, exposing circuit board.

b) Remove screws holding circuit board.

c) Unsolder three potentiometer wires (white, green, black), two

wind speed coil wires (red, black), and earth ground wire (red)

from board.

4. INSTALL NEW POTENTIOMETER

a) Push new potentiometer into potentiometer mounting & coil

assembly making sure o-ring is on shaft.

b) Feed potentiometer and coil wires through hole in bottom of

potentiometer housing.

c) Screw potentiometer housing onto potentiometer mounting &

coil assembly.

d) Gently pull transducer wires through bottom of potentiometer

housing to take up any slack. Apply a small amount of silicone

sealant around hole.

e) Install transducer assembly on vertical shaft allowing 0.5 mm

(0.020") clearance from vertical bearing. Tighten set screws* at

bottom of transducer assembly.

f) Place potentiometer adjust thumbwheel on potentiometer shaft

and tighten set screw*.

g) Place potentiometer coupling on potentiometer adjust

thumbwheel. Do Not tighten set screw yet.

5. RECONNECT TRANSDUCER WIRES

a) Using needle-nose pliers or a paper clip bent to form a small

hook, gently pull transducer wires through hole in junction box.

b) Solder wires to circuit board according to wiring diagram.

Observe color code.

c) Secure circuit board in junction box using two screws removed

in step 2b. Do not overtighten.

6. REPLACE MAIN HOUSING

a) Place main housing over vertical shaft bearing rotor. Be careful

to align indexing key and channel in these two assemblies.

b) Place main housing over vertical shaft bearing rotor until

potentiometer coupling is near top of main housing.

c) Turn potentiometer adjust thumbwheel until potentiometer

coupling is oriented to engage ridge in top of main housing.

Set screw on potentiometer coupling should be facing the front

opening.

d) With potentiometer coupling properly oriented, continue pushing

main housing onto vertical shaft bearing rotor until main

housing latch locks into position with a “click”.

7. ALIGN VANE

a) Connect excitation voltage and signal conditioning electronics

to terminal strip according to wiring diagram.

b) With mounting post held in position so junction box is facing

due south, orient vane to a known angular reference. Details

appear in CALIBRATION section.

c) Reach in through front of main housing and turn potentiometer

adjust thumbwheel until signal conditioning system indicates

proper value.

d) Tighten set screw* on potentiometer coupling.

*Max set screw torque 80 oz-in

8. REPLACE NOSE CONE

a) Screw nose cone into main housing until o-ring seal is

seated. Be certain threads are properly engaged to avoid crossthreading.

05501LM-90(D)

Page 3

Page 5

FLANGE BEARING REPLACEMENT

If anemometer bearings become noisy or wind speed threshold

increases above an acceptable level, bearings may need

replacement. Check anemometer bearing condition using a Model

18310 Propeller Torque Disc. If necessary, bearings are replaced as

follows.

1. REMOVE OLD BEARINGS

a) Unscrew nose cone. Set o-ring aside for later use.

b) Loosen set screw on magnet shaft collar and remove magnet.

c) Slide propeller shaft out of nose cone assembly.

d) Remove front bearing cap which covers front bearing.

e) Remove both front and rear bearings from nose cone assembly.

Insert edge of a pocket knife under bearing ange and lift it out.

2. INSTALL NEW BEARINGS

a) Insert new front and rear bearings into nose cone.

b) Replace front bearing cap.

c) Carefully slide propeller shaft thru bearings.

d) Place magnet on propeller shaft allowing 0.5 mm (0.020")

clearance from rear bearing.

e) Tighten set screw* on magnet shaft collar.

f) Screw nose cone into main housing until o-ring seal is seated.

Be certain threads are properly engaged to avoid cross-

threading.

VERTICAL SHAFT BEARING REPLACEMENT

Vertical shaft bearings are much larger than the anemometer

bearings. Ordinarily, these bearings will require replacement less

frequently than anemometer bearings. Check bearing condition using

a Model 18331 Vane Torque Gauge.

WARRANTY

This product is warranted to be free of defects in materials and construction

for a period of 12 months from date of initial purchase. Liability is limited

to repair or replacement of defective item. A copy of the warranty policy

may be obtained from R. M. Young Company.

CE COMPLIANCE

This product has been tested and shown to comply with European CE

requirements for the EMC Directive (see Declaration of Conformity

below). Please note that shielded cable must be used.

Declaration of Conformity

R. M. Young Company

2801 Aero Park Drive

Traverse City, MI 49686 USA

Model 05501LM

The undersigned hereby declares on behalf of R. M.

Young Company that the above-referenced product, to

which this declaration relates, is in conformity with the

provisions of:

Council Directive 2004/108/EC (December 15, 2004)

on Electromagnetic Compatibility

Since this procedure is similar to POTENTIOMETER REPLACEMENT,

only the major steps are listed here.

1. REMOVE MAIN HOUSING.

2. UNSOLDER TRANSDUCER WIRES AND REMOVE TRANSDUCER

ASSEMBLY. Loosen set screws at base of transducer assembly

and remove entire assembly from vertical shaft.

3. REMOVE VERTICAL SHAFT BEARING ROTOR by sliding it up-

ward off vertical shaft.

4. REMOVE OLD VERTICAL BEARINGS AND INSTALL NEW BEAR-

INGS. When inserting new bearings, be careful not to apply pressure to bearing shields.

5. REPLACE VERTICAL SHAFT BEARING ROTOR.

6. REPLACE TRANSDUCER & RECONNECT WIRES.

7. REPLACE MAIN HOUSING.

8. ALIGN VANE.

9. REPLACE NOSE CONE.

David Poinsett

R&D Manager

05501LM-90(D)

Page 4

Page 6

Page 5

05501LM-90(D)

Page 7

BEARING REPLACEMENT & POTENTIOMETER ADJUSTMENT

05501LM-90(D)

Page 6

Page 8

GENERAL ASSEMBLY & REPLACEMENT PARTS

Page 7

05501LM-90(D)

Loading...

Loading...