Page 1

FORM 201.23-EG1 (1007)

�

Air Cooled Screw Liquid Chillers

140-200 Tons

60Hz

R134a

150 - 385 TONS

(527 - 1354 kWi)

2 and 3 Compressor

50 and 60 Hz

ASHRAE 90.1 Compliant

Page 2

Table of Contents

Introduction ........................................................................................................................................................................................................... 3

Specications ....................................................................................................................................................................................................... 4

Accessories and Options ................................................................................................................................................................................... 7

Nomenclature........................................................................................................................................................................................................ 9

Temperatures and Flows ................................................................................................................................................................................... 10

Water Pressure Drop .......................................................................................................................................................................................... 12

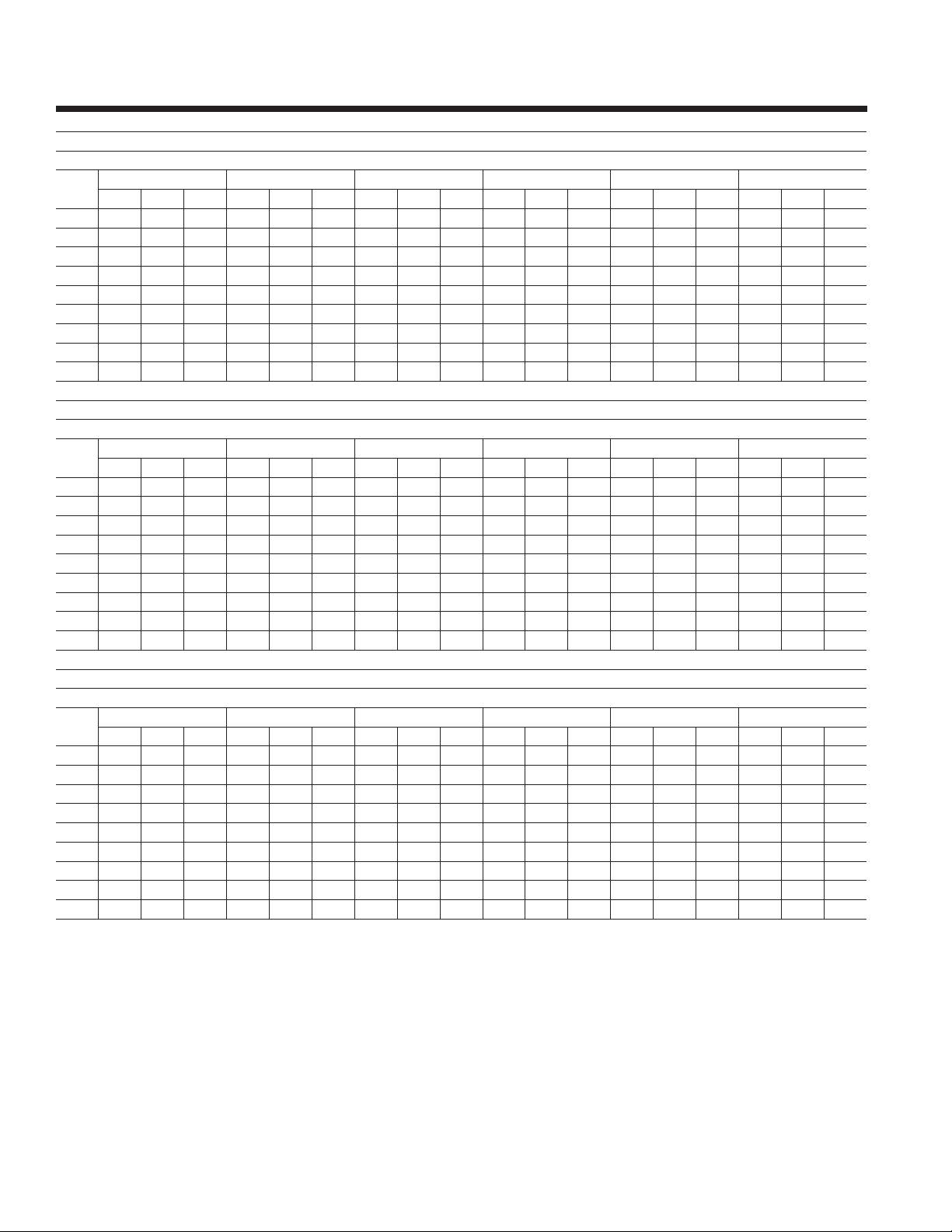

Standard Efciency Ratings – English - 460V/60Hz ....................................................................................................................................... 16

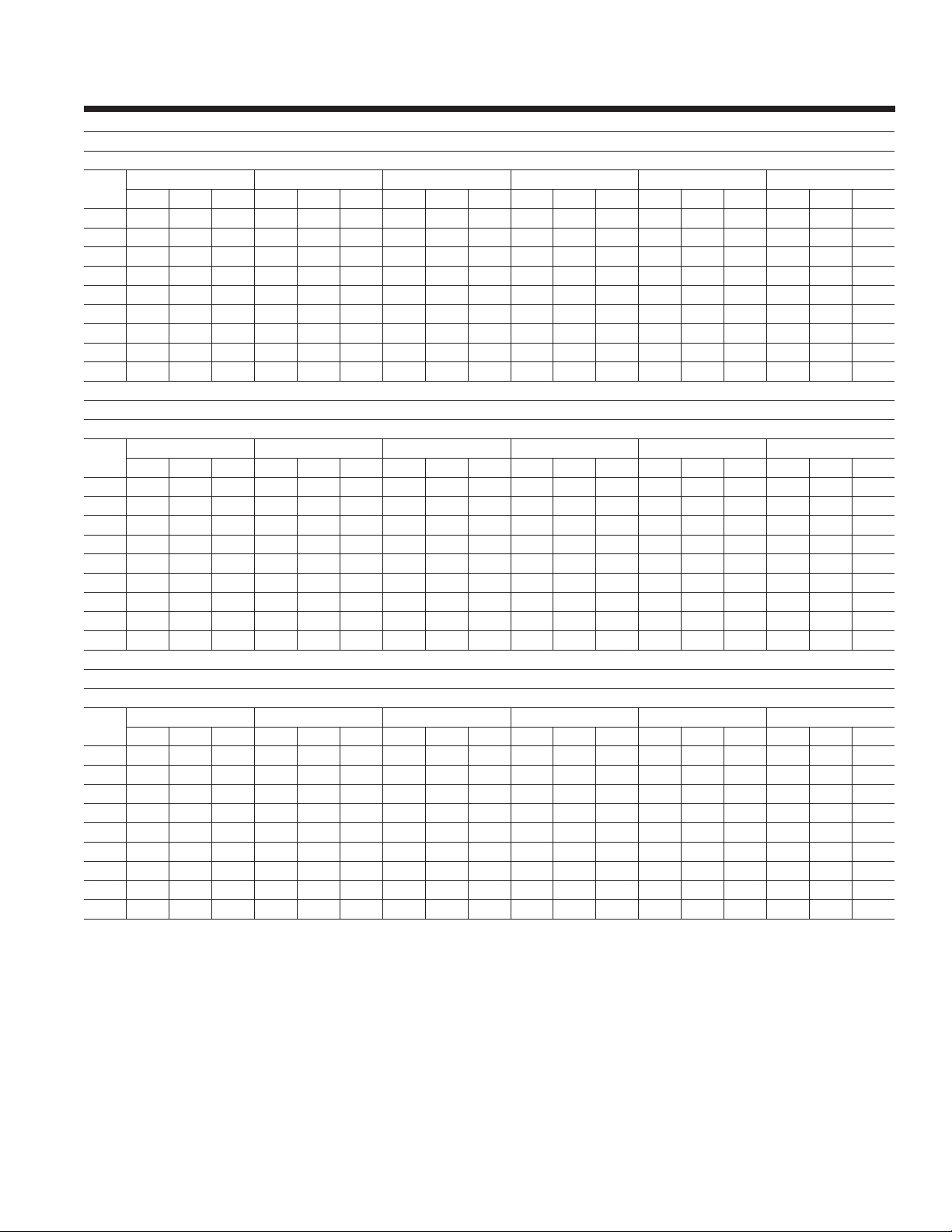

High Efciency Ratings – English - 460V/60Hz............................................................................................................................................... 20

Standard Efciency Ratings – SI - 460V/60Hz................................................................................................................................................. 24

High Efciency Ratings – SI - 460V/60Hz

Standard Efciency Ratings – SI - 400V/50Hz................................................................................................................................................. 32

High Efciency Ratings – SI - 400V/50Hz ........................................................................................................................................................ 36

Standard Efciency Ratings – English - 380V/60Hz ....................................................................................................................................... 40

High Efciency Ratings – English - 380V/60Hz

Standard Efciency Ratings – SI - 380V/60Hz................................................................................................................................................. 48

High Efciency Ratings – SI - 380V/60Hz ........................................................................................................................................................ 52

Physical Data (English - Standard Efciency) ................................................................................................................................................. 56

Physical Data (English - High Efciency)......................................................................................................................................................... 58

Physical Data (SI - Standard Efciency)........................................................................................................................................................... 60

Physical Data (SI - High Efciency) .................................................................................................................................................................. 62

Dimensions – English ........................................................................................................................................................................................ 64

Dimensions – SI .................................................................................................................................................................................................. 84

Isolator Locations – English ............................................................................................................................................................................ 104

Isolator Locations – SI ..................................................................................................................................................................................... 108

Isolator Details ...................................................................................................................................................................................................112

Electrical Data - 2 Comp Standard Efciency .................................................................................................................................................116

Electrical Data - 2 Comp High Efciency ........................................................................................................................................................118

Electrical Data - 3 Comp Standard Efciency ................................................................................................................................................ 120

Electrical Data - 3 Comp High Efciency ....................................................................................................................................................... 122

Electrical Notes................................................................................................................................................................................................. 124

Power Wiring ..................................................................................................................................................................................................... 125

Typical Control Wiring - Two Compressor ..................................................................................................................................................... 128

Typical Control Wiring - Three Compressor .................................................................................................................................................. 130

Application Data ............................................................................................................................................................................................... 132

Guide Specications ........................................................................................................................................................................................ 133

........................................................................................................................................................ 28

............................................................................................................................................... 44

JOHNSON CONTROLS2

Page 3

Introduction

YORK YCIV Air Cooled Screw Liquid Chillers

FORM 201.23-EG1 (1007)

YORK has a proud history of innovation in both compressor design and variable-speed-drive (VSD)

technology. The LatitudeTM air cooled chiller uses the best of modern screw compressor design

and manufacturing techniques and combines them with the latest in a long line of chiller variable

speed drives. The result is superior control and industry leading efciency at real world conditions.

In addition, by slowing the speed of the chiller to match system requirements at off-design conditions, the chiller sound output is reduced when it is the most sensitive to neighbors – evenings and

weekends.

With the introduction of the YCIV model air cooled chiller, system designers are given the Latitude™to

design around the traditional benets of air cooled chillers and still offer building owners energy efcient system design. In the past, the choice to use an air cooled chiller came with the expectation

of compromise, where simplicity of design and maintenance were traded for performance and ef-

ciency. Now combining the best of both worlds can provide a design that truly delivers the lowest

total cost of ownership.

JOHNSON CONTROLS

3

Page 4

Specications

POWER AND ELECTRICAL

• Johnson Controls has over 25 years of experience

designing variable speed drives specically for chiller

applications. The result is an extremely reliable air

cooled chiller system that offers industry leading ef-

ciency at real world operating conditions, valve-less

compressor loading/unloading, excellent capacity

control, high power factor and soft start.

• All controls and motor starting equipment necessary

for unit operation shall be factory wired and function

tested.

• VSD Power/Control Panel includes main power

connection(s), VSD and fan motor contactors, current overloads, and factory wiring. Standard design

includes NEMA 3R (IP55) rating, powder painted steel

cabinet with hinged, latched, and gasket sealed outer

doors equipped with wind struts for safer servicing.

• VSD section of power panel includes a dedicated

inverter for each compressor.

• The panel includes control display access door so

display and control features can be accessed without

opening main cabinet doors.

• Two and three compressor models come standard with

single point power connection. In addition, all models

are supplied with a factory mounted and wired control

transformer that will supply all unit control voltage from

the main unit power supply. The transformer utilizes

scheduled line voltage on the primary side and provides 115V/1Ø on secondary.

• The standard power panel is equipped with terminal

block electrical connections at the point of incoming

power. An optional factory mounted circuit breaker is

available, at point of incoming single point connection,

that provides the means to disconnect power and short

circuit protection. The optional lockable operating

handle extends through the power panel door so that

power may be disconnected without opening any panel

doors.

• Short Circuit Withstand Rating of the chiller electri-

cal enclosure is 30,000 Amps for standard terminal

block connection. Ratings IAW (in accordance with)

UL508. (See Accessories and Options section: Can

be increased to 65,000 Amps for 380, 400 & 460V).

• Compressor motors are powered by a variable speed

drive. Therefore, motor current never exceeds the

rated load amps (RLA), providing soft starts with no

electrical inrush. This eliminates the motor heating

and stress always found with conventional motor

starters. In addition, by eliminating the heat build up

during starting, the required off-time between starts is

reduced to a maximum of two minutes.

• Many utility companies charge an additional fee

if power factor is below 0.95. These power factor

adjustments/penalties can affect both regular tariff

rates, as well as demand charges. All YCIV models

have a full load power factor of 95% and maintain this

level throughout the operating range. Specications

should always require the installing contractor to be

responsible for additional cost to furnish and install

power factor correction capacitors if they are not factory mounted and wired.

S E M I - H E R M E T I C Y O R K T W I N S C R E W

COMPRESSORS

Johnson Controls Engineered Systems’ Chiller Design

Team has developed a world class compressor with unequaled performance:

• Continuous function, microprocessor controlled, VSD

provides valveless, smooth capacity control from 100%

down to 10% of chiller capacity for two compressor

chillers and 100% down to 7.5% for three compressor

chillers. In addition, elimination of the slide valve and

associated unloading components resulted in a 50%

reduction in compressor moving parts.

• Compressors are direct drive, semihermetic, rotary

twin-screw type, including: mufer, temperature actuated ‘off-cycle’ heater, rain-tight (IP55) terminal

box, discharge shut-off service valve, and precision

machined cast iron housing mounted on neoprene

isolators.

• Reliable suction gas cooled, high efciency, accessible hermetic compressor motor, full suction gas ow

through 0.006” maximum mesh screen, with inherent

internal thermal overload protection and external current overload on all three phases.

• Suction gas screen and serviceable, 0.5 micron full

ow oil lter within the compressor housing.

• Cast iron compressor housing precisely machined

for optimal clearances and superb efciency. Entire

compressor, from suction to discharge has a Design

Working Pressure of 350 PSIG (24 bar) or higher.

REFRIGERANT CIRCUIT

• Independent refrigerant circuits per compressor, each

using copper refrigerant pipe formed on computer

controlled bending machines. This eliminates over

60% of system piping brazed joints as compared to

designs that use ttings, resulting in a highly reliable

and leak resistant system.

• Liquid line components include: liquid line shut-off

valve with charging port, low side pressure relief device, high adsorption removable core lter-drier, sight

glass with moisture-indicator, and electronic expansion

valve.

JOHNSON CONTROLS4

Page 5

FORM 201.23-EG1 (1007)

• Discharge line provided with manual compressor

shutoff service valve (See Options and Accessories for

suction line valve). Suction line equipped with closed-

cell insulation.

• Insulated external oil separators with no moving parts,

450 PSIG (31 bar) design working pressure, and UL

listing. Refrigerant system differential pressure pro-

vides oil ow through service replaceable, 0.5 micron,

full ow, cartridge type oil lter internal to compres-

sor.

• Oil cooling provided by dedicated air cooled nned

tube type heat exchanger located in the condenser

section of the machine.

• A ash tank is located in each refrigerant circuit to

increase the system efciency. The design working

pressure is 450 PSIG (31 bar).

• Suction lines, oil separators and ash tanks are covered with closed-cell insulation.

EVAPORATOR

• High efciency, direct-expansion type cooler with re

frigerant in tubes and chilled liquid through the bafed

shell. Independent circuits provided for each compressor.

• Design working pressure of the shell waterside is 150

PSIG (10.3 bar), and 235 PSIG (16 bar) for the refrig-

erant side. Constructed and tested IAW applicable

sections of ASME Pressure Vessel Code, Section VIII,

Division (1). Water side exempt per paragraph U-1, ©,

(6).

• Removable heads allow access to internally-enhanced, seamless, copper tubes. Water vent and drain

connections included.

• The evaporator is equipped with a thermostatically

controlled heater for protection to -20°F (-29°C) ambient, and shell is covered with 3/4” (19mm), exible,

closed-cell insulation, thermal conductivity of 0.26k

(BTU/HR-Ft2-°F/in.) maximum.

• Water nozzles have grooves for mechanical (ANSI/

AWWA C-606) couplings, and shall be insulated by

Contractor after pipe installation. (See the Accessories

and Options section for ange options.

CONDENSER SECTION

• Condenser fans are dynamically and statically bal

anced, direct drive, corrosion resistant glass ber

reinforced composite blades molded into low noise,

full airfoil cross section, providing vertical air discharge

from extended orices. Guards of heavy gauge, PVC

(polyvinyl chloride) coated.

• Standard and reduced sound level models have

condensers tted with single speed fans. Low sound

models have two speed fans tted.

• The fan motors are the high efciency, direct drive, 6

pole on standard sound models and 8 pole on reduced

and low sound models, 3 phase, Class-“F”, current

overload protected, totally enclosed (TEAO) type with

double sealed, permanently lubricated, ball bearings

• Fin and tube condenser coils of seamless, internally

enhanced, high condensing coefcient, corrosion resistant copper tubes arranged in staggered rows and

mechanically bonded to corrosion resistant aluminum

alloy ns with full height n collars. Design working

pressure is 450 PSIG (31 bar).

MICROPROCESSOR CONTROLS

• Microprocessor control system provides automatic

control of chiller operation including compressor start/

stop and load/unload, anti-recycle timers, condenser

fans, evaporator pump, evaporator heater, unit alarm

contacts and run signal contacts.

-

• Chiller automatically resets to normal chiller operation

after power failure.

• Unit operating software is stored in non-volatile

memory. Field programmed set points are retained

in lithium battery backed regulated time clock (RTC)

memory for minimum 5 years.

• Alarm contacts are provided to remote alert contacts

for any unit or system safety fault.

• Display and Keypad:

♦ 80 character liquid crystal display that is both view-

able in direct sunlight and has LED backlighting for

nighttime viewing. One keypad and display panel

is provided with every chiller.

♦ Display and keypad is accessible through display

access door without opening main control/electrical

cabinet doors.

♦ Display provides unit setpoints, status, electrical

data, temperature data, pressures, safety lockouts and diagnostics without the use of a coded

display.

♦ Descriptions in English (or available language op-

tions), numeric data in English (or Metric) units.

♦ Sealed keypad shall include unit On/Off switch.

• Programmable Setpoints (within Manufacturer limits):

display language; leaving chilled liquid temperature:

setpoint, control range; local or remote control; units of

measure; compressor lead/lag; and maximum chilled

water setpoint reset temperature range.

• Display Data: Chiller liquid return and leaving tempera-

tures, ambient, lead compressor identication, clock

JOHNSON CONTROLS

5

Page 6

Specications (Continued)

and schedule, (variable) out of range, remote input

indication, chilled liquid reset setpoint, and history

data for last ten shutdown faults. Compressor suction, discharge, and oil pressures and temperatures,

suction and discharge superheats, percent of full-load,

operating hours, starts, and anti-recycle timer status.

Status Messages for manual override, unit switch off,

compressor run, run permissive, remote controlled

shut down, no cooling load, daily/holiday shut down,

anti-recycle timer.

• During extreme or unusual conditions (i.e. blocked

condenser coils, ambient above scheduled maximum,

etc.) the chiller control system will avoid safety shutdown by varying the chiller controls and cooling load

output to stay online and avoid safety limits being

reached. This allows maximum possible cooling capacity until the unusual condition is cleared and avoids

costly shutdowns. The system monitors the following

parameters and maintain the maximum cooling output

possible without shutdown of the equipment: motor

current, suction pressure and discharge pressure.

• System Safeties are provided for individual compres-

sor systems to perform auto-reset shut down (manual

reset required after the third trip in 90 minutes). Safeties include: high discharge pressure or temperature,

low suction pressure, high / low motor current, high

motor temperature, high pressure switch, high / low

differential oil pressure, high oil temperature, low suction superheat, critical sensor malfunction, low or high

current, phase loss/single phase power, overload of

motor windings, and low voltage.

• Unit Safeties are provided for the chiller to perform

auto-reset shut down for the following conditions: high

or low ambient, low leaving chilled liquid temperature,

under voltage, and ow switch operation.

COMPLETE FACTORY PACKAGE

• These air cooled chillers are shipped as a complete

factory package. Each unit is completely assembled

with all interconnecting refrigerant piping and internal

wiring, ready for eld installation:

• Each compressor is installed on its own independent

refrigerant circuit, which is factory pressure tested,

evacuated, then fully charged with R134a refrigerant

and oil.

• After assembly, an operational test is performed with

water owing through the cooler to ensure each circuit

operates correctly.

• Unit panels, structural elements, control boxes and

heavy gauge structural base shall be constructed

of galvanized steel. Unit panels, control boxes and

structural base are nished with a baked on powder

paint. All painted surfaces shall be coated with baked

on powder paint which, when subject to ASTMB117,

1,000 hour, 5% salt spray test, yields minimum ASTM

1654 rating of “6”.

• Design is IAW applicable sections of ASME Pressure

Vessel Code, NFPA 70 (National Electrical Code), U.L.

and cU.L. Standards , and ASHRAE/ANSI-15 Safety

Code for Mechanical Refrigeration.

• Units are Rated (all) and Certied (140 - 200 tons) IAW

ARI Standard 550/590-98.

•Design is IAW ASHRAE 90.1 Energy Standard for

Building Except Low-Rise Residential Buildings and

ARI 70 Sound Rating of Large Outdoor Refrigeration

and Air Conditioning Equipment.

• YCIV chillers are designed within EN ISO 9001 and

built within an EN ISO 9002 accredited manufacturing

organization.

• All exposed power wiring routed through liquid-tight,

UV-stabilized, non-metallic conduit.

• When required, chillers have the option available to

conform with the following European Directives (50

Hz only):

♦ Machinery Directive (89/9/EEC)

♦ Low Voltage Directive (7//EEC, EN 600)

♦ EMC Directive (89/6/EEC)

♦ Pressure Equipment Directive (97//EC)

♦ Safety Code for Mechanical Refrigeration (EN78)

JOHNSON CONTROLS6

Page 7

Accessories and Options

FORM 201.23-EG1 (1007)

SOUND REDUCTION OPTIONS – The standard chiller

has fans that operate at normal speed, no compressor

enclosure, and is typically used in non-sensitive sound

areas such as industrial areas or locations with loud trafc

background noise. One or more of the following sound re-

duction options may be employed by the system designer

as normally generated machine noise is considered in the

overall project design.

Ultra Quiet Fans (Factory Mounted) – With this option,

the basic chiller is equipped with specially designed fans

and motors to provide lower sound levels and retain appropriate airow. The result is reduced fan generated

noise with no adverse effect on the chiller capacity or

efciency performance.

Two-Speed Fans (Factory Mounted) – With this option,

the basic chiller is equipped with fans designed with two

operating speeds. At high ambient conditions the fans

operate at the normal speed with sound levels equivalent

to Ultra Quiet Fans. As the ambient temperature falls the

fans automatically reduce to slow speed reducing sound

levels. If very low sound is required at all ambient condi-

tions normal fan speed can be inhibited.

Reduced Sound Option (Factory Mounted) – With this

option the chiller is equipped with an unlined compressor enclosure. This option is typically used for daytime

operation where background noise is lower than normal

city trafc etc.

Low Sound Option (Factory Mounted) – This option

is only available with the selection of Ultra Quiet Fans or

Two-Speed Fans. The chiller is equipped with an acousti-

cally lined compressor enclosure. This option is typically

for locations near residential areas, hotels, or hospitals

etc where background noise is limited. When paired with

the Two-Speed Fan option the unit can operate at normal

speed during the day, when background noise levels are

noticeable, and at low speed in the evening and at night

when background levels are lower.

SilentNight™ - Standard variable speed compressors

result in a chiller system that has lower part load sound

values than conventional air-cooled chillers. Over 99%

of chiller operating hours occur when building loads are

less than design and/or ambient temperatures are less

than design. As a result, all YCIV model chillers will

operate with less than full load sound output nearly all

the time – this is especially important on evenings and

weekends when neighbors are home the most. Due to

time of day based sound regulations it may be desirable

to force the chiller to a lower sound level on demand.

The SilentNight™ control option provides a control input

to limit sound output of the chiller based on time of day.

This feature is programmable at the chiller panel or can

be controlled remotely via signal (4-20mA or 0-10 VDC)

from a BAS system.

CIRCUIT BREAKER – Power panel will come equipped

with a factory mounted circuit breaker at point of incom-

ing single or multi-point connection that provides the

following:

• Means to disconnect power mounted on chiller.

• Circuit breaker sized to provide the motor branch

circuit protection, short circuit protection and ground

fault protection for the motor branch-circuit conductors,

the motor control apparatus and the motors. (Chiller

mounted circuit breaker option sized for branch circuit

protection eliminates the need to provide a separate

‘line of sight’ disconnect and separate branch circuit

protection device.)

• Lockable operating handle that extends through power

panel door so that power may be disconnected without

opening any panel doors.

• Short Circuit Withstand Rating of the chiller electrical

enclosure when using circuit breaker option is 380,

400, & 460V: 65,000 Amps. Rating IAW UL508.

CONDENSER COIL PROTECTION – Standard con-

denser coil construction materials include aluminum ns,

copper tubes, and galvanized tube supports for generally

good corrosion resistance. However, these materials are

not adequate for all environments. The system designer

can take steps to inhibit coil corrosion in harsh applica-

tions and enhance equipment life by choosing from these

options based on project design parameters and related

environmental factors. (Factory Mounted)

• PRE-COATED FIN CONDENSER COILS – The air

cooled condenser coils are constructed of epoxy-

coated aluminum ns. This can provide corrosion

resistance comparable to copper-n coils in typical

seashore locations. Either these or the post coated

coils (below), are recommended for units being installed at the seashore or where salt spray may hit

the unit.

• POST-COATED EPOXY DIPPED CONDENSER

COILS – The unit is built with dipped-cured epoxy

condenser coils. This is another choice for seashore

and other corrosive applications (with the exception

of strong alkalies, oxidizers and wet bromine, chlorine and uorine in concentrations greater than 100

ppm).

• COPPER FIN CONDENSER COILS – The unit con-

structed with copper tube condenser coils, which have

copper ns. (This is not recommended for units in

areas where they may be exposed to acid rain.)

PROTECTIVE CHILLER PANELS:

• Wire Panels (full unit) – UV stabilized black polyvi-

nyl chloride coated, heavy gauge, welded wire mesh

guards mounted on the exterior of the unit. Protects

condenser coil faces and prevents unauthorized access to refrigerant components (compressors, pipes,

JOHNSON CONTROLS

7

Page 8

Accessories and Options (Continued)

cooler, etc.), yet provides free air ow. This can cut

installation cost by eliminating the need for separate,

expensive fencing. (Factory mounted)

• Louvered Panels (condenser coils only) – Painted

steel to match unit panels, louvered panels are

mounted over the exterior condenser coil faces on the

sides of the unit to visually screen and protect coils.

(Factory mounted)

• Louvered Panels (full unit) – Painted steel to match

unit panels, to protect condenser coils from incidental

damage, visually screen internal components, and

prevent unauthorized access to internal components.

(Factory mounted)

• Louvered (Condensers)/Wire Panels (Mechanical)

– Louvered steel panels on external condenser coil

faces, painted to match unit panels. Heavy gauge,

welded wire-mesh, coated to resist corrosion, around

base of machine to restrict unauthorized access. (Fac-

tory Mounted)

EVAPORATOR OPTIONS:

• 1-1/2” Insulation – Double thickness insulation provided. (Factory Mounted)

• Raised Face Flange Accessory for cooler nozzles:

♦ 150 PSIG (10.3 bar), welded anges (eld kit,

matching pipe ange by contractor).

♦ 150 PSIG (10.3 bar) companion weld anges. (eld

kit - Not available with 460V units).

♦ 150 PSIG (10.3 bar), ANSI/AWWA C-606 COU-

PLINGS (eld kit, matching pipe ange by contrac-

tor).

BUILDING AUTOMATION SYSTEM INTERFACE:

• Chiller to accept 4 to 20mA or 0 to 10 VDC input to

reset the leaving chilled liquid temperature. (Factory

Mounted)

MULTI-UNIT SEQUENCE CONTROL:

Separate sequencing control center provided to permit

control of up to eight chillers in parallel based of mixed

liquid temperature (interconnecting wiring by others).

(Field Mounted)

VIBRATION ISOLATION:

• Neoprene Isolation – Recommended for normal in-

stallations. Provides very good performance in most

applications for the least cost. (Field mounted)

• 1” Spring Isolators – Level adjustable, spring and

cage type isolators for mounting under the unit base

rails. 1” nominal deection may vary slightly by appli-

cation. (Field mounted)

• 2” Seismic Spring Isolators – Restrained Spring-Flex

Mountings incorporate a rugged welded steel housing with vertical and horizontal limit stops. Housings

designed to withstand a minimum 1.0g accelerated

force in all directions to 2” (51mm). Level adjustable,

deection may vary slightly by application. (Field

mounted)

BUY AMERICAN ACT COMPLIANCE - In keeping with

the “Buy America Act”, products will be comprised of 50%

or more U.S. content and manufactured (nal assembly)

in the U.S.A.

• Opposite Handed evaporator water connections

for ease of installation. Standard water connections

are on the left-hand side of the unit, when viewed from

the control panel end.

FLOW SWITCH ACCESSORY : Vapor proof SPDT, NEMA

3R switch, 150 PSIG (10.3 bar) DWP, 20°F to 250°F

(-28.9°C to 121.1°C) with 1” NPT (IPS) connection for

upright mounting in horizontal pipe (This ow switch or

equivalent must be furnished with each unit). (Field

Mounted).

DIFFERENTIAL PRESSURE SWITCH - Alternative to the

paddle-type ow switch. 3-45 PSIG (0.2-3 bar) range with

1/4" NPTE pressure connections. (Field Mounted)

SERVICE ISOLATION VALVE – Service suction isolation added to unit for each refrigerant circuit. (Factory

Mounted)

CHICAGO CODE RELIEF VALVE - Special relief valves

per Chicago code. (Factory Mounted)

PRESSURE RELIEF (CE/PED) SERVICE VALVE KIT

- Each relief valve is mounted on a sealable ball valve to

aid maintenance. (Factory Mounted)

JOHNSON CONTROLS8

Page 9

Nomenclature

The Model Number denotes the following characteristics of the unit:

FORM 201.23-EG1 (1007)

NOMENCLATURE

JOHNSON CONTROLS

9

Page 10

Temperatures and Flows

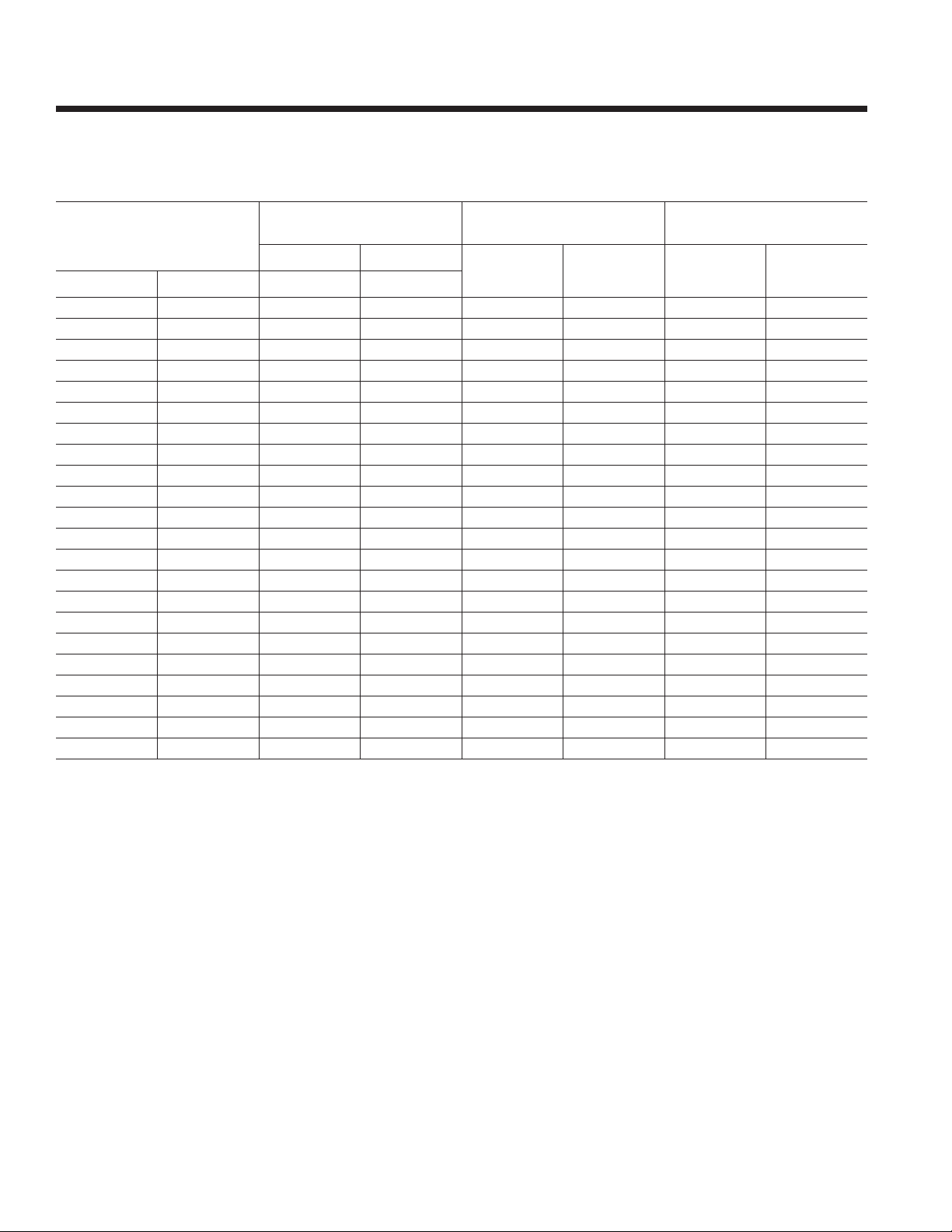

TEMPERATURE AND FLOWS

(English Units)

MODEL

NUMBER

YCIV

LEAVING WATER

TEMPERATURE (°F)

1

MIN.

MAX.

2

COOLER3 FLOW

(GPM)

MIN. MAX. MIN. MAX

AIR ON CONDENSER (°F)

50 Hz 60 Hz

0600(S/P) 0157(S/P) 40 60 140 675 0 125

0590(E/V) 0157(E/V) 40 60 160 750 0 125

0650(S/P) 0177(S/P) 40 60 160 750 0 125

0630(E/V) 0177(E/V) 40 60 160 750 0 125

0720(S/P/) 0187(S/P) 40 60 160 750 0 125

0700(E/V) 0187(E/V) 40 60 160 750 0 125

0760(E/V) 0197(E/V) 40 60 180 750 0 125

0770(S/P) 0207(S/P) 40 60 180 800 0 125

0800(E/V) 0207(E/V) 40 60 180 750 0 125

0840(S/P) 0227(S/P) 40 60 180 800 0 125

0830(E/V) 0227(E/V) 40 60 180 750 0 125

0920(S/P) 0247(S/P) 40 60 180 800 0 125

0930(E/V) 0247(E/V) 40 60 180 800 0 125

1000(S/P) 0267(S/P) 40 60 180 800 0 125

1050(E/V) 0267(E/V) 40 60 250 1200 0 125

1070(S/P) 0287(S/P) 40 60 250 1200 0 125

1120(E/V) 0287(E/V) 40 60 250 1200 0 125

1180(S/P) 0307(S/P) 40 60 300 1200 0 125

1220(E/V) 0327(E/V) 40 60 300 1200 0 125

1340(S/P) 0357(S/P) 40 60 300 1200 0 125

1380(E/V) 0357(E/V) 40 60 300 1200 0 125

1500(S/P) 0397(S/P) 40 60 300 1200 0 125

NOTES:

1. For leaving brine temperature below 40°F (4.4°C), contact your nearest Johnson Controls ofce for application requirements.

2. For leaving water temperature higher than 60°F (15.6°C), contact the nearest Johnson Controls ofce for application guidelines.

3. The evaporator is protected against freezing to -20°F (-28.8°C) with an electric heater as standard.

JOHNSON CONTROLS10

Page 11

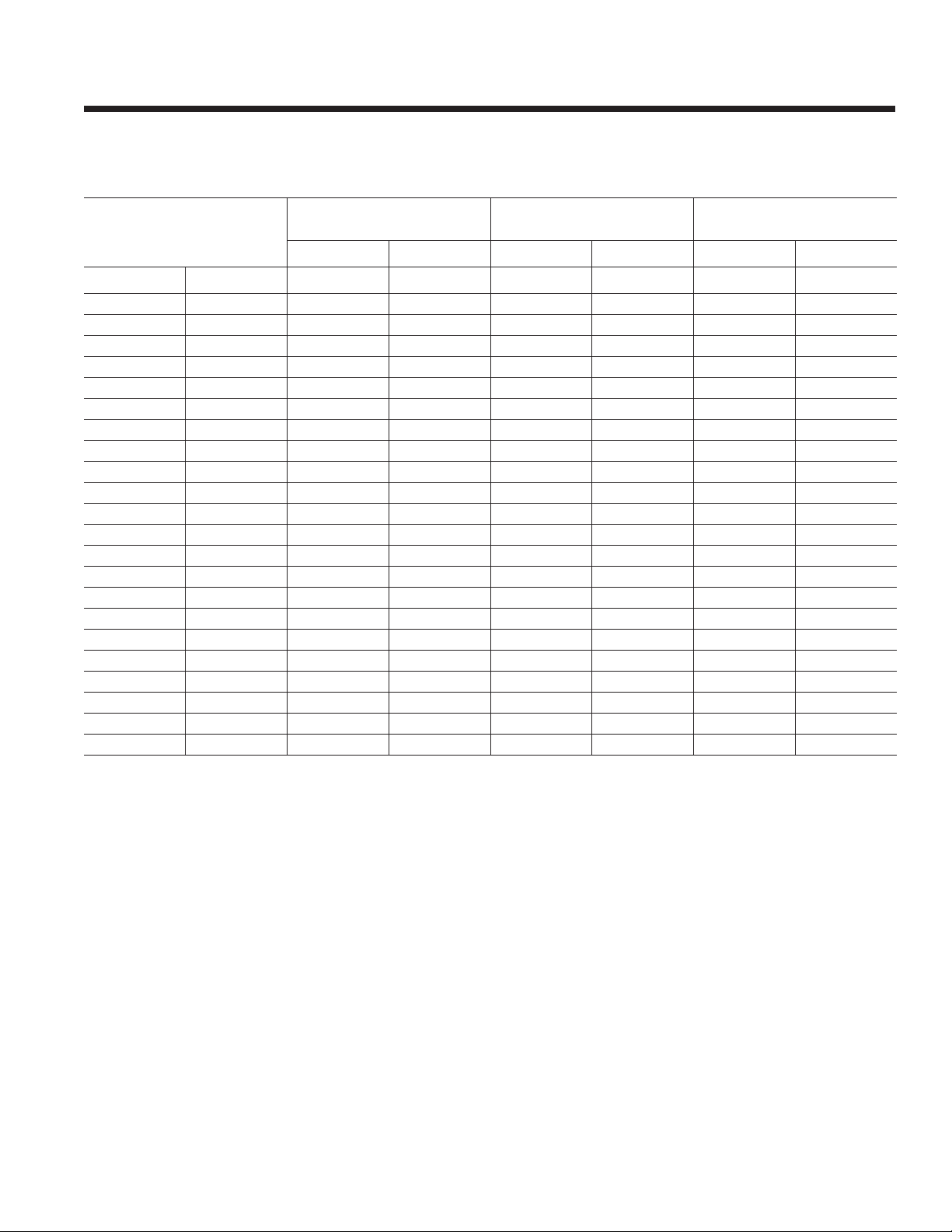

TEMPERATURE AND FLOWS

(SI Units)

FORM 201.23-EG1 (1007)

MODEL

NUMBER

YCIV

LEAVING WATER

TEMPERATURE (°C)

1

MIN.

MAX.

COOLER3 FLOW

(l/s)

2

MIN. MAX. MIN. MAX

AIR ON CONDENSER (°C)

50 Hz 60 Hz

0600(S/P) 0157(S/P) 4.4 15.6 8.8 42.6 -17.8 51.7

0590(E/V) 0157(E/V) 4.4 15.6 10.1 47.3 -17.8 51.7

0650(S/P) 0177(S/P) 4.4 15.6 10.1 47.3 -17.8 51.7

0630(E/V) 0177(E/V) 4.4 15.6 10.1 47.3 -17.8 51.7

0720(S/P/) 0187(S/P) 4.4 15.6 10.1 47.3 -17.8 51.7

0700(E/V) 0187(E/V) 4.4 15.6 10.1 47.3 -17.8 51.7

0760(E/V) 0197(E/V) 4.4 15.6 11.4 47.3 -17.8 51.7

0770(S/P) 0207(S/P) 4.4 15.6 11.4 50.5 -17.8 51.7

0800(E/V) 0207(E/V) 4.4 15.6 11.4 47.3 -17.8 51.7

0840(S/P) 0227(S/P) 4.4 15.6 11.4 50.5 -17.8 51.7

0830(E/V) 0227(E/V) 4.4 15.6 11.4 47.3 -17.8 51.7

0920(S/P) 0247(S/P) 4.4 15.6 11.4 50.5 -17.8 51.7

0930(E/V) 0247(E/V) 4.4 15.6 10.1 47.3 -17.8 51.7

1000(S/P) 0267(S/P) 4.4 15.6 11.4 50.5 -17.8 51.7

1050(E/V) 0267(E/V) 4.4 15.6 11.4 50.5 -17.8 51.7

1070(S/P) 0287(S/P) 4.4 15.6 15.8 75.7 -17.8 51.7

1120(E/V) 0287(E/V) 4.4 15.6 15.8 75.7 -17.8 51.7

1180(S/P) 0307(S/P) 4.4 15.6 18.9 75.7 -17.8 51.7

1220(E/V) 0327(E/V) 4.4 15.6 18.9 75.7 -17.8 51.7

1340(S/P) 0357(S/P) 4.4 15.6 18.9 75.7 -17.8 51.7

1380(E/V) 0357(E/V) 4.4 15.6 18.9 75.7 -17.8 51.7

1500(S/P) 0397(S/P) 4.4 15.6 18.9 75.7 -17.8 51.7

NOTES:

1. For leaving brine temperature below 4.4°C, contact your nearest Johnson Controls ofce for application requirements.

2. For leaving water temperature higher than 15.6°C, contact the nearest Johnson Controls ofce for application guidelines.

3. The evaporator is protected against freezing to -28.8°C with an electric heater as standard.

JOHNSON CONTROLS

11

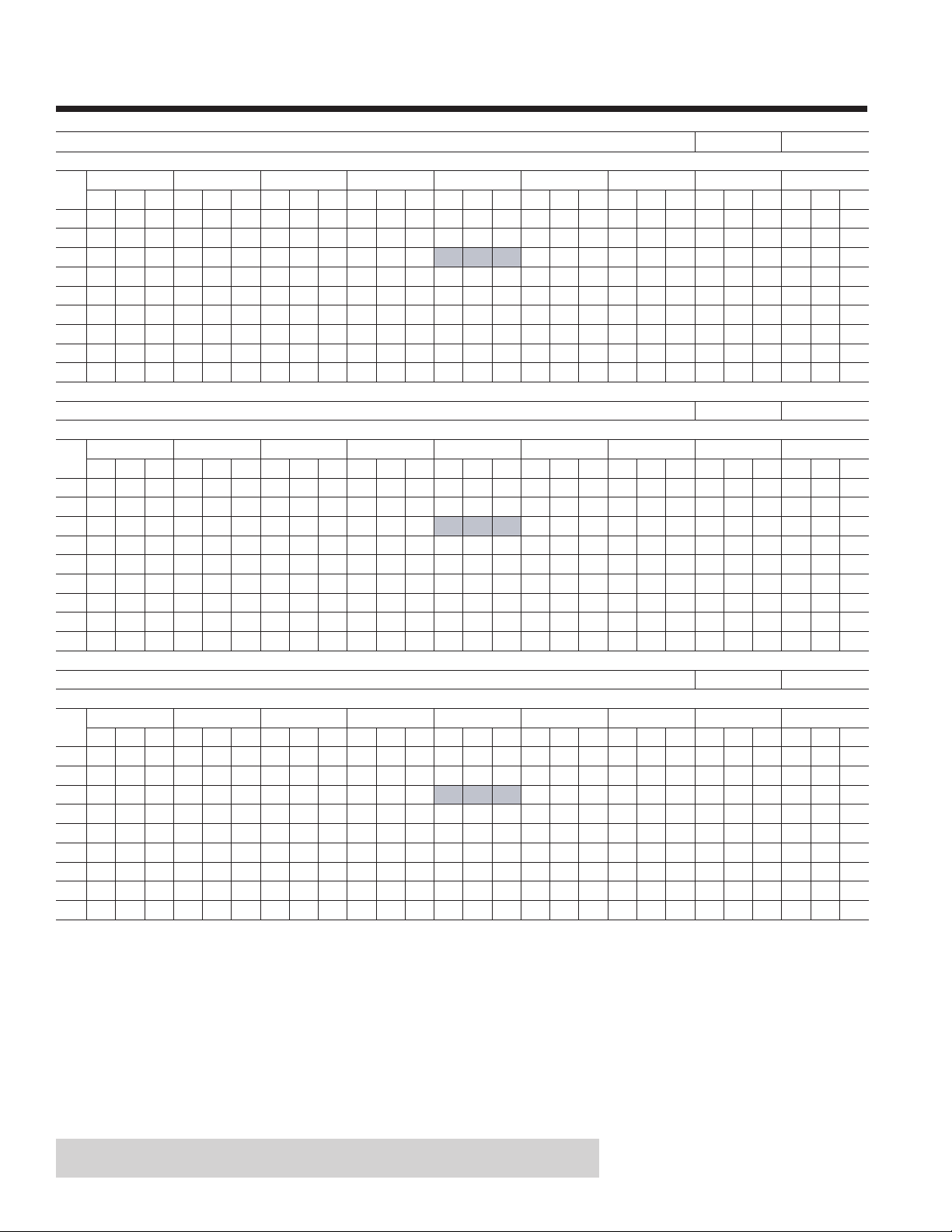

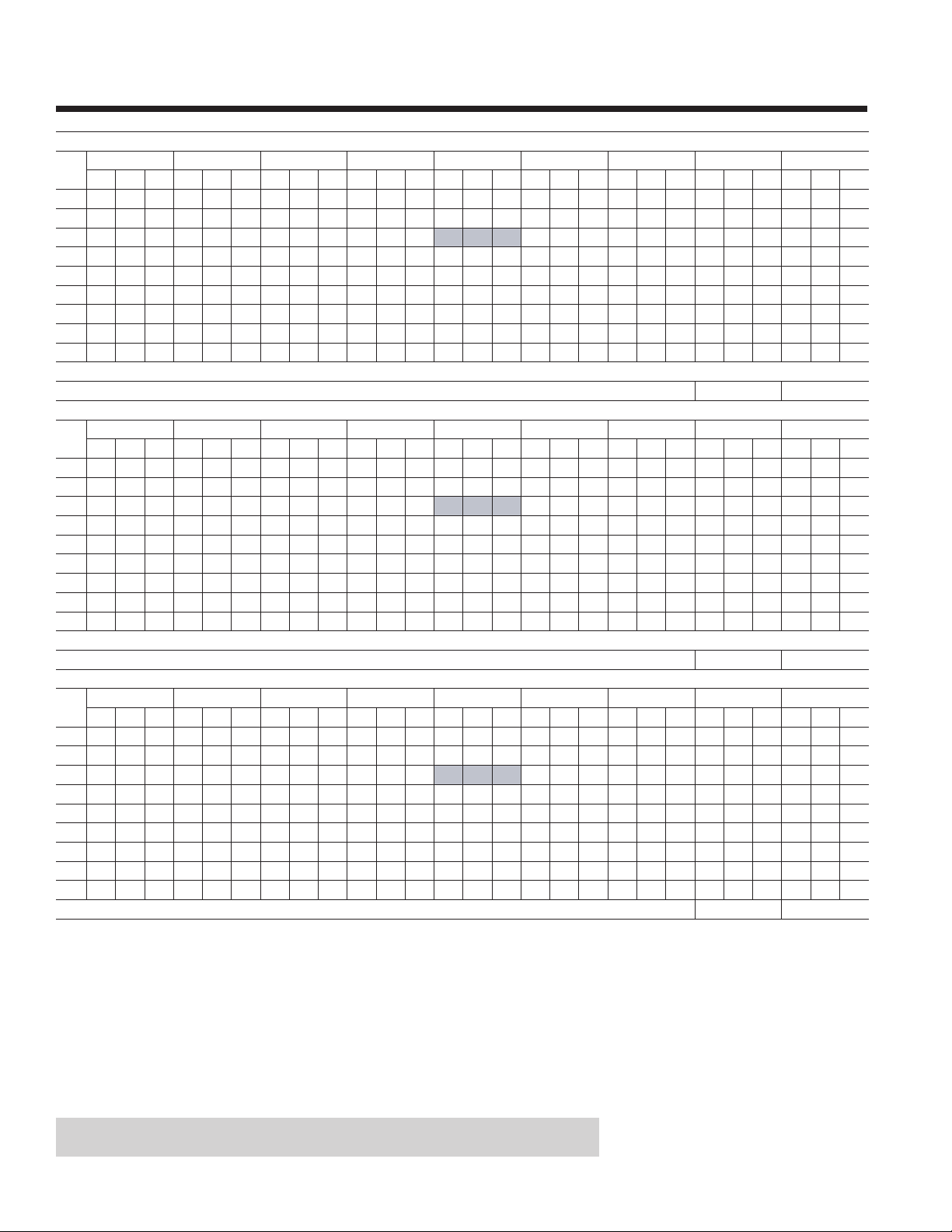

Page 12

Water Pressure Drop

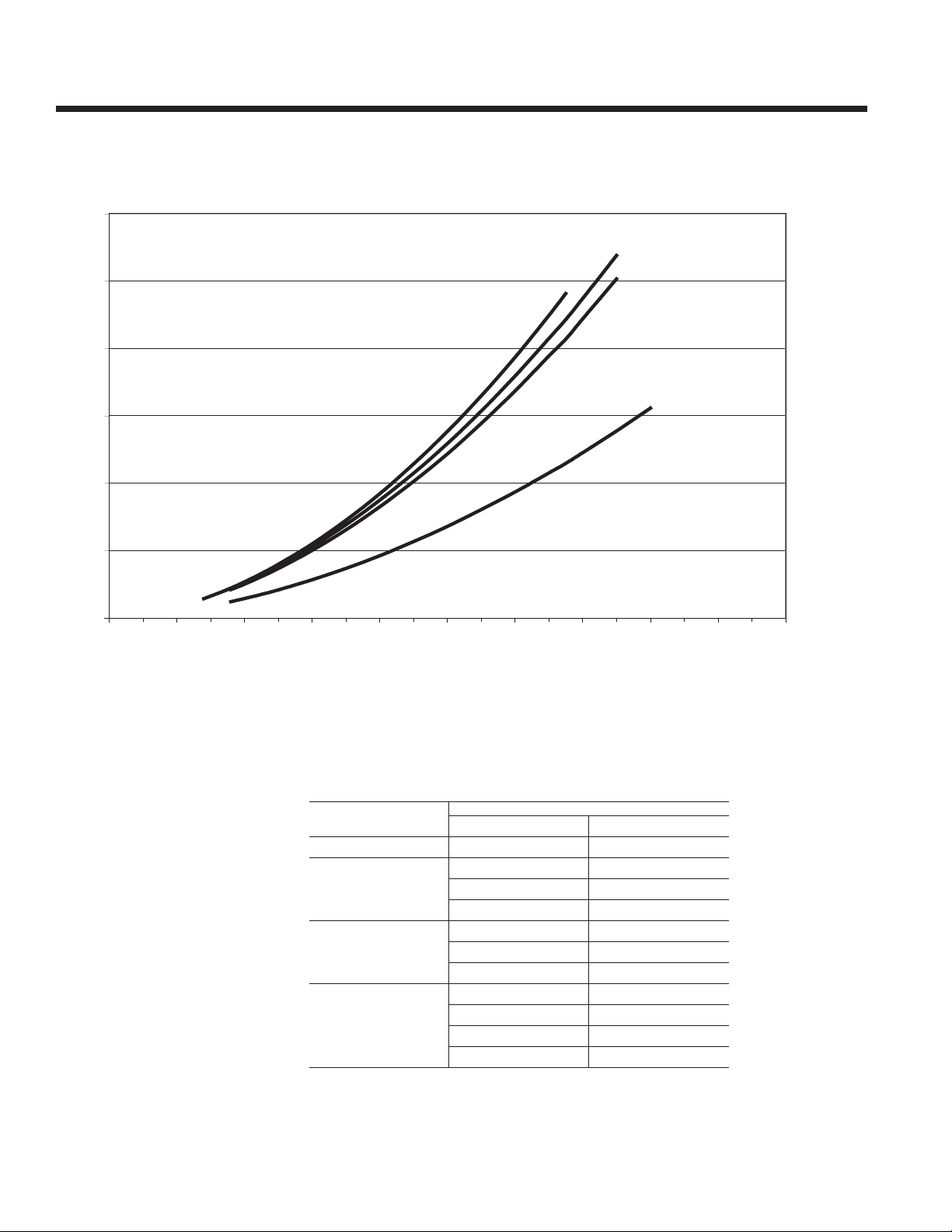

ENGLISH UNITS

COOLER

A 0157(S/P) 0600(S/P)

B

C

D

MODEL NUMBER YCIV

60Hz 50Hz

0157(E/V) 0590(E/V)

0177(S/P/E/V) 0630(E/V), 0650(S/P)

0187(S/P/E/V) 0700(E/V), 0720(S/P)

0197(E/V) 0760(E/V)

0207(E/V) 0800(E/V)

0227(E/V) 0830(E/V)

0207(S/P) 0770(S/P)

0227(S/P) 0840(S/P)

0247(S/P/E/V) 0920(S/P), 0930(E/V)

0267(S/P) 1000(S/P)

JOHNSON CONTROLS12

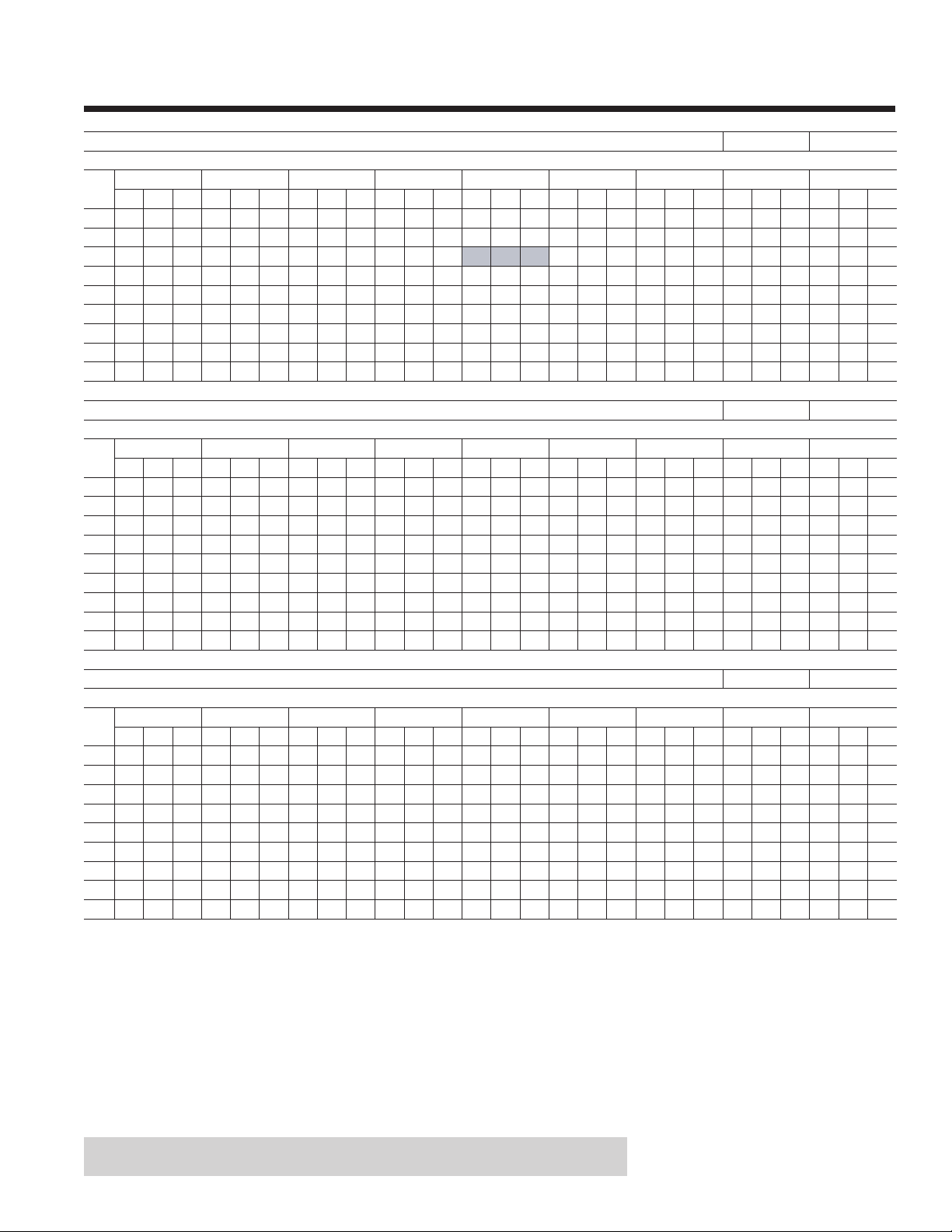

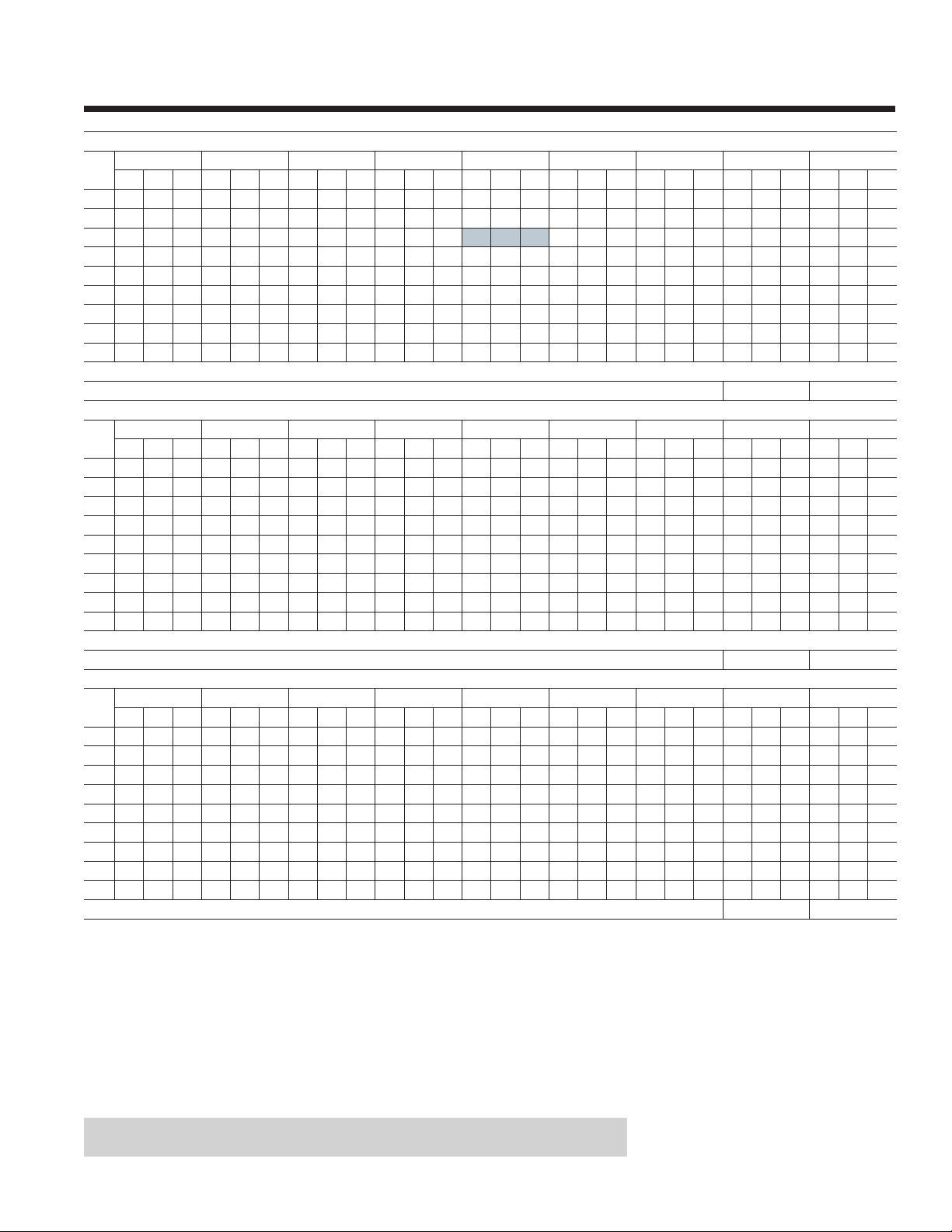

Page 13

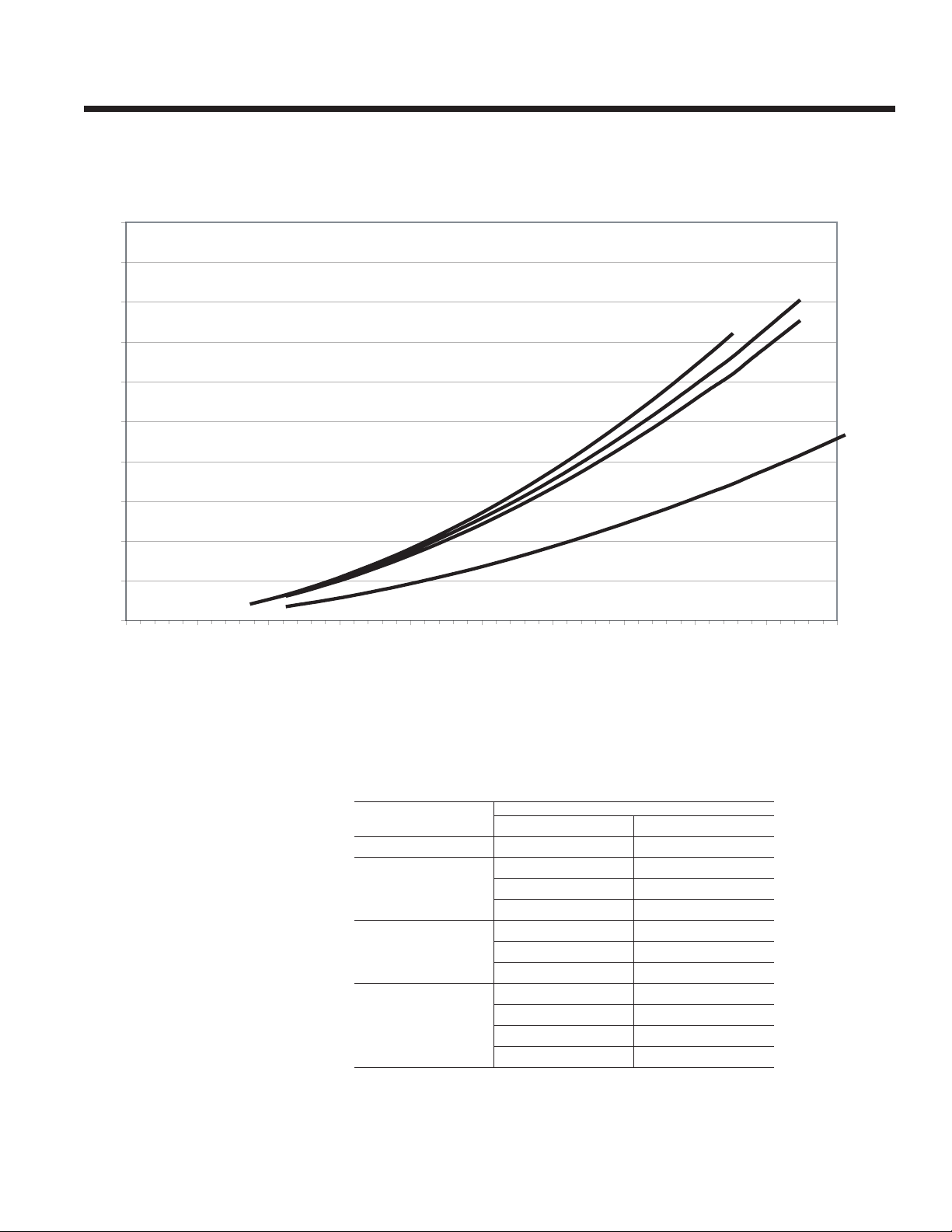

SI UNITS

FORM 201.23-EG1 (1007)

COOLER

A 0157(S/P) 0600(S/P)

B

C

D

MODEL NUMBER YCIV

60Hz 50Hz

0157(E/V) 0590(E/V)

0177(S/P/E/V) 0630(E/V), 0650(S/P)

0187(S/P/E/V) 0700(E/V), 0720(S/P)

0197(E/V) 0760(E/V)

0207(E/V) 0800(E/V)

0227(E/V) 0830(E/V)

0207(S/P) 0770(S/P)

0227(S/P) 0840(S/P)

0247(S/P/E/V) 0920(S/P), 0930(E/V)

0267(S/P) 1000(S/P)

JOHNSON CONTROLS

13

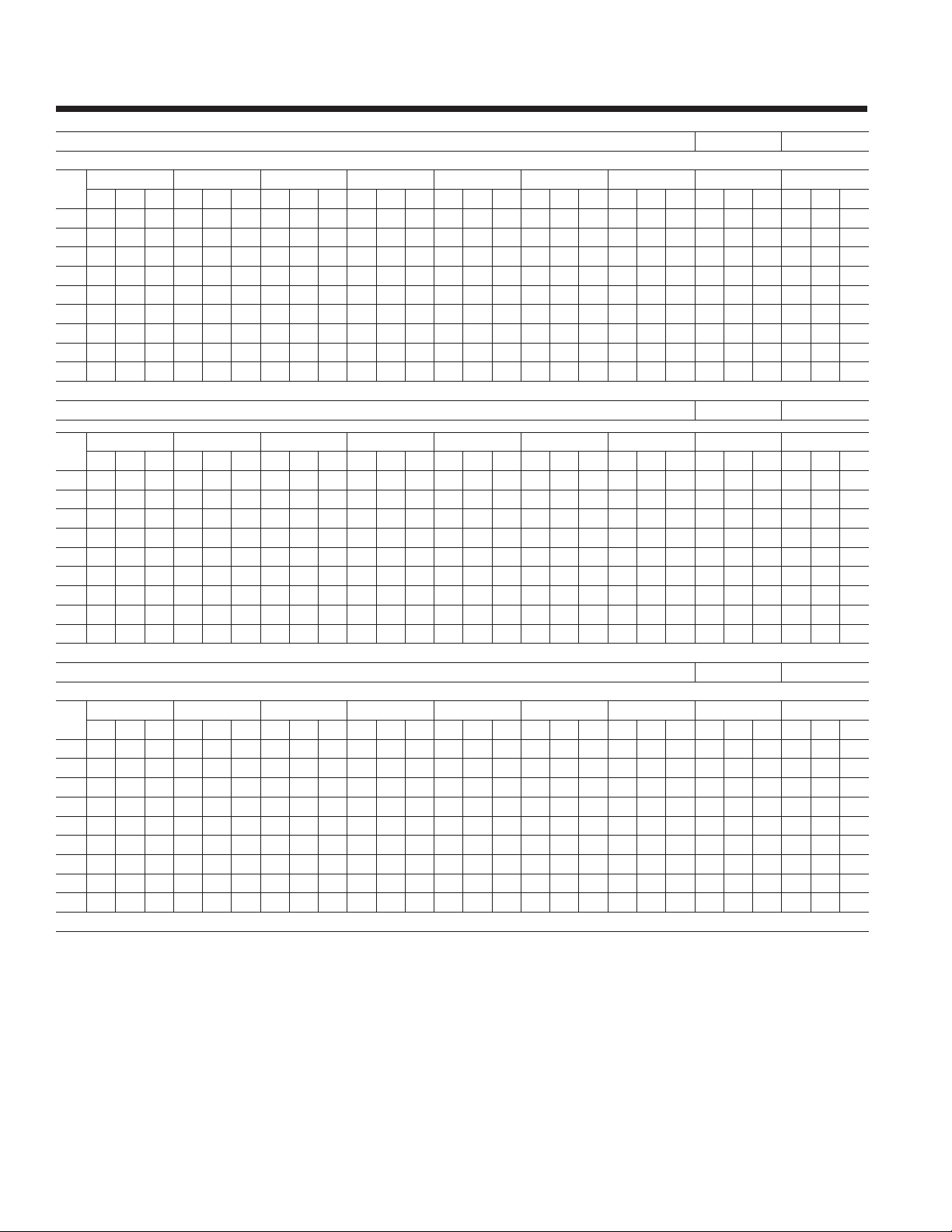

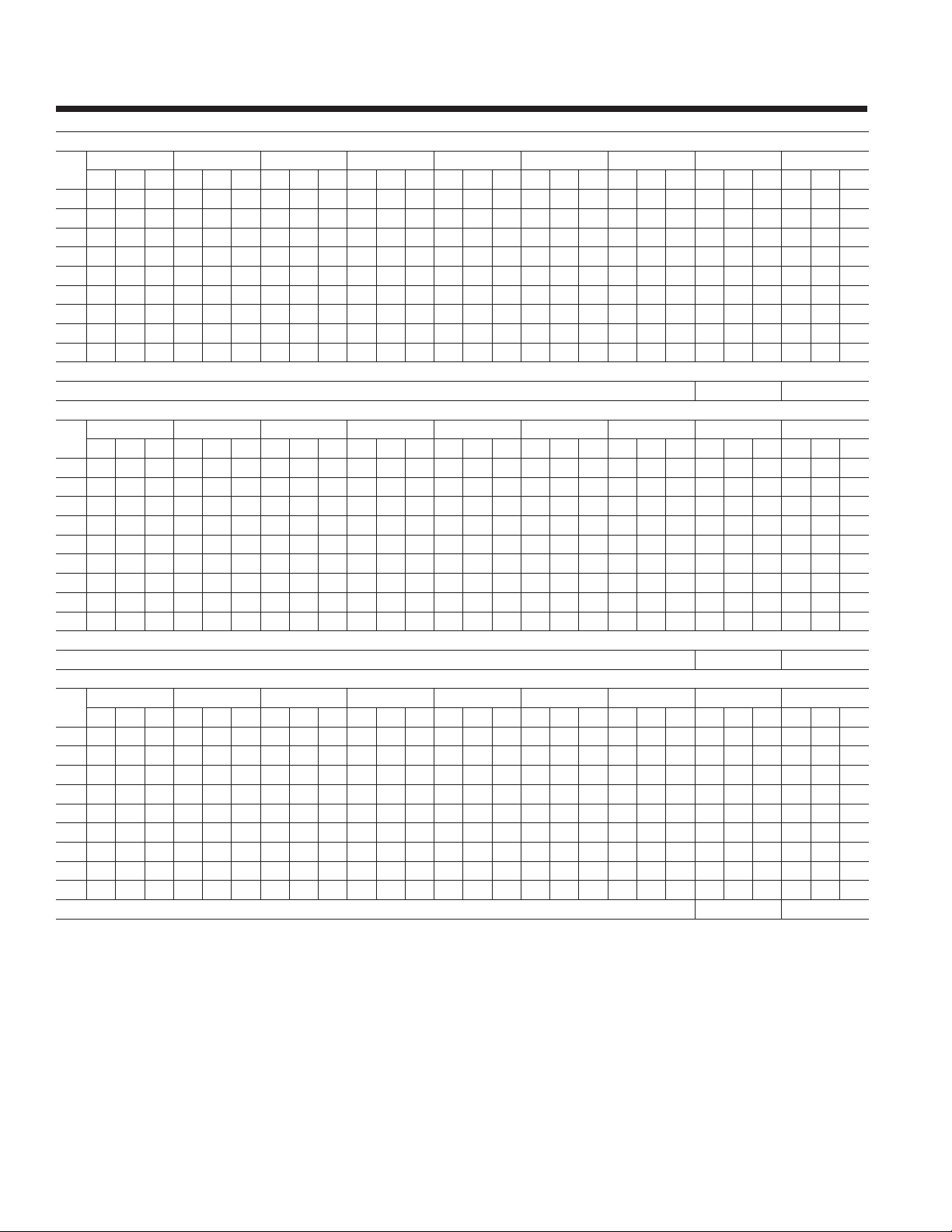

Page 14

1

10

100

100 1000

Water Flow Rate (GPM)

Pressure Drop

(f

t H2

O)

2000

A

B

Pressure Drop Through Three Circuit YCIV Evaporators

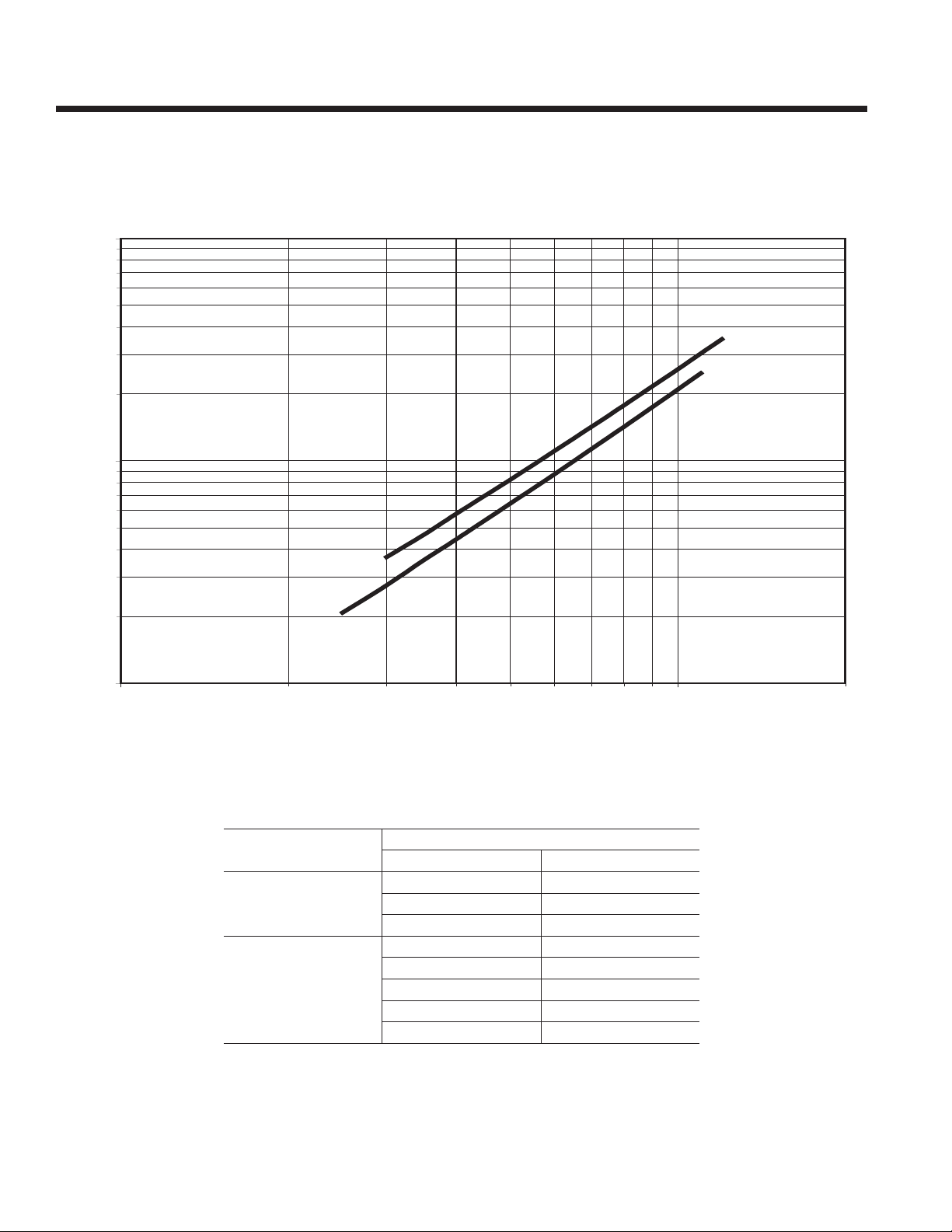

Water Pressure Drop – continued

ENGLISH UNITS

EVAP

A

B

YCIV MODELS

60Hz 50Hz

0267EA/VA 1050(E/V)

0287SA/PA 1070(S/P)

0287EA/VA 1120(E/V)

0307SA/PA 1180(S/P)

0327EA/VA 1220(E/V)

0357SA/PA 1340(S/P)

0357EA/VA 1380(E/V)

0397SA/PA 1500(S/P)

JOHNSON CONTROLS14

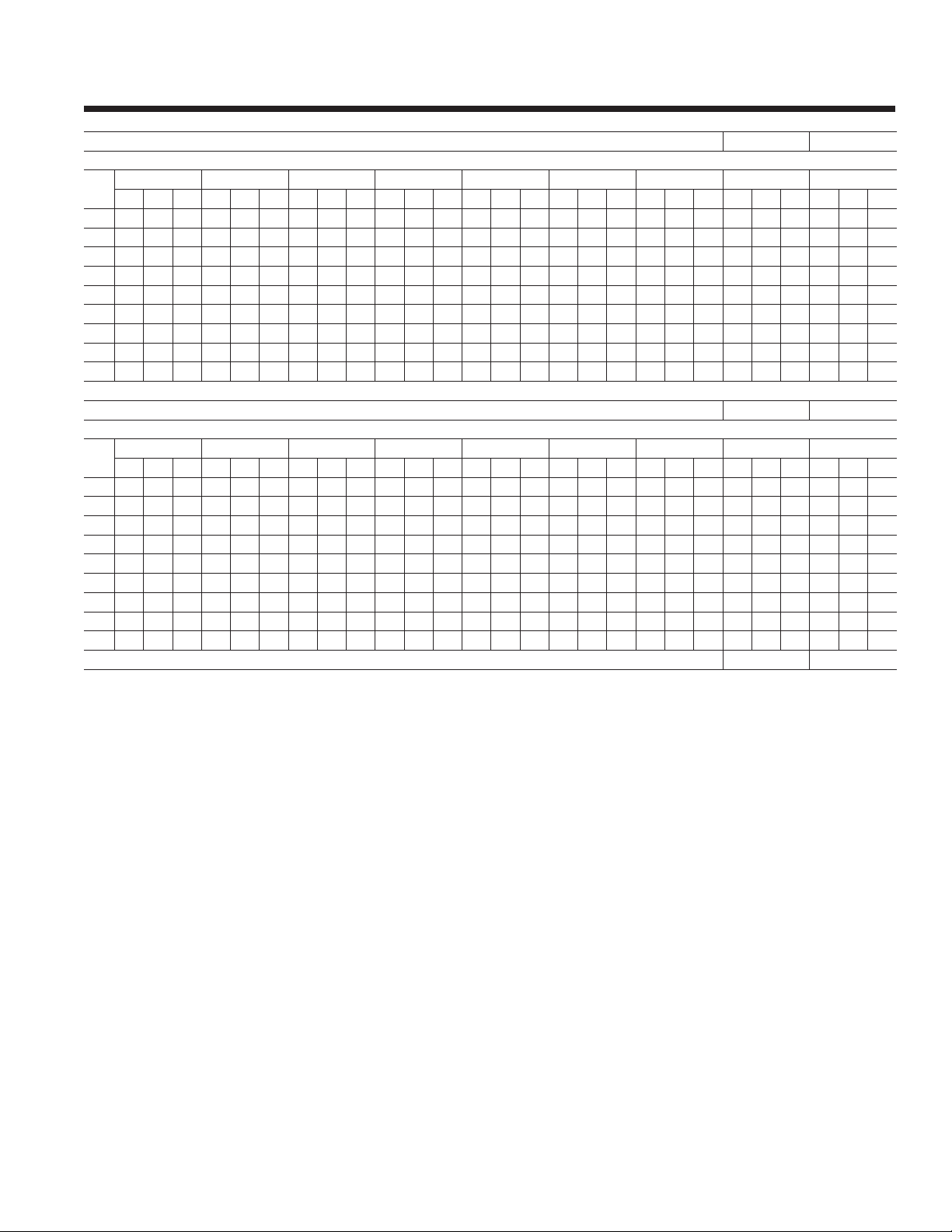

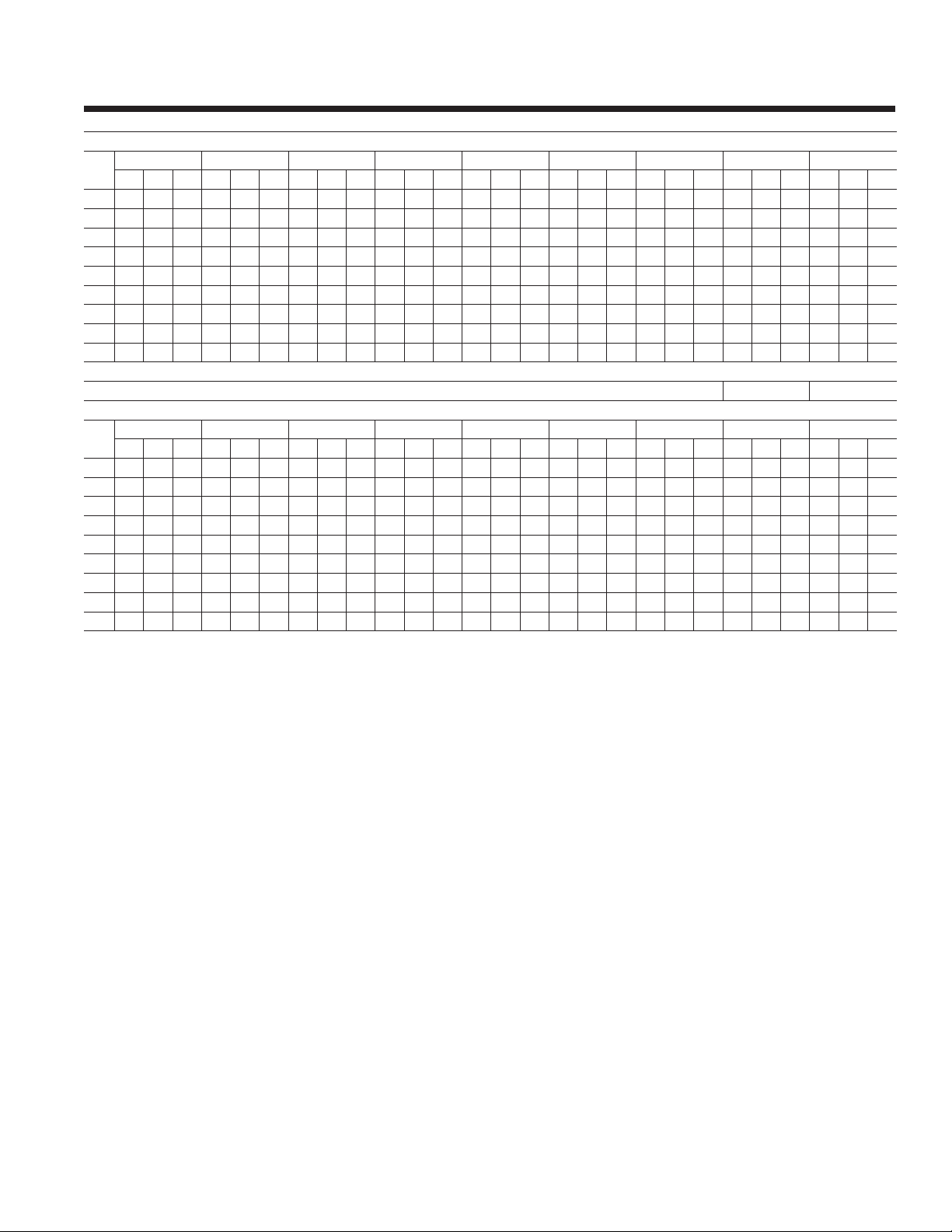

Page 15

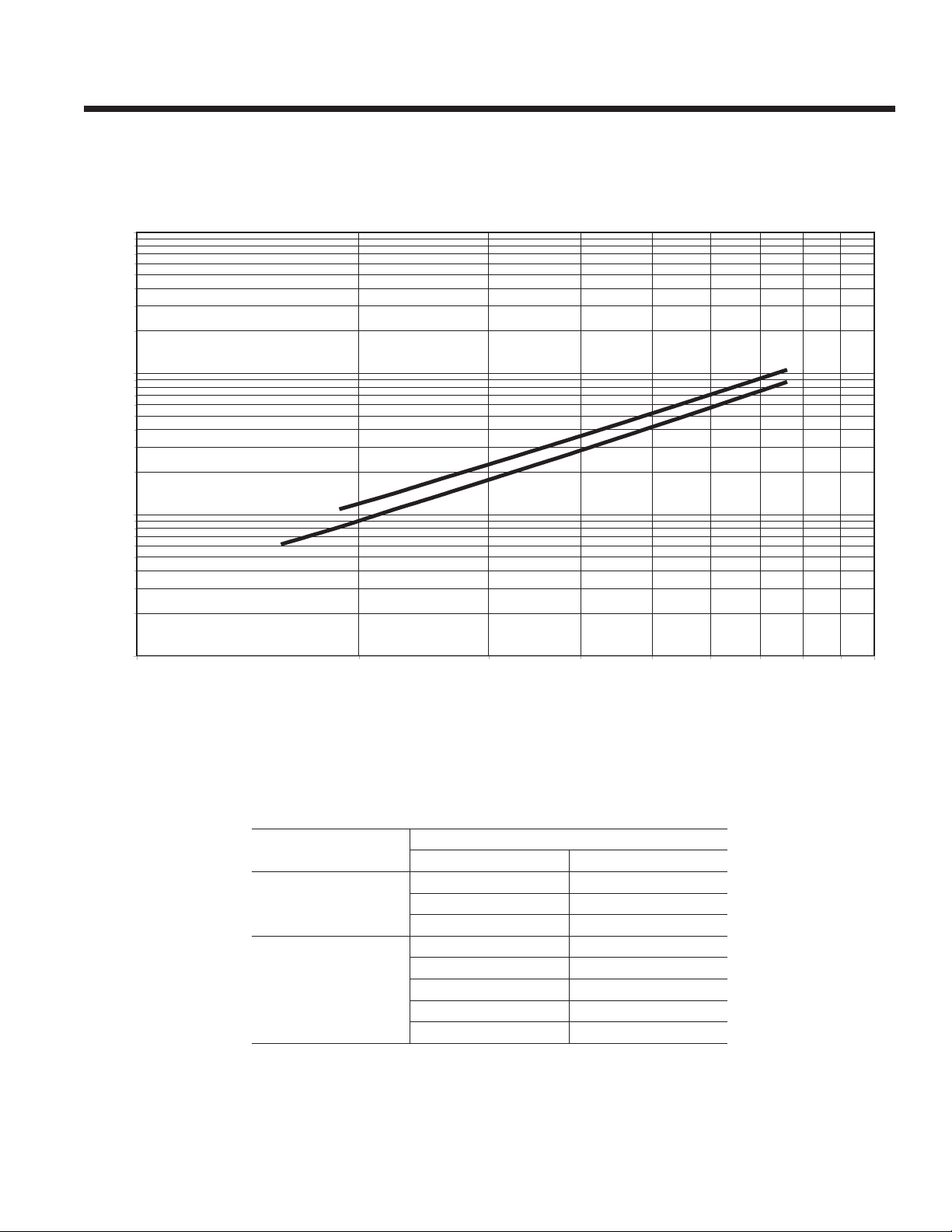

SI UNITS

FORM 201.23-EG1 (1007)

YCIV MODELS

EVAP

A

B

60Hz 50Hz

0267EA/VA 1050(E/V)

0287SA/PA 1070(S/P)

0287EA/VA 1120(E/V)

0307SA/PA 1180(S/P)

0327EA/VA 1220(E/V)

0357SA/PA 1340(S/P)

0357EA/VA 1380(E/V)

0397SA/PA 1500(S/P)

JOHNSON CONTROLS

15

Page 16

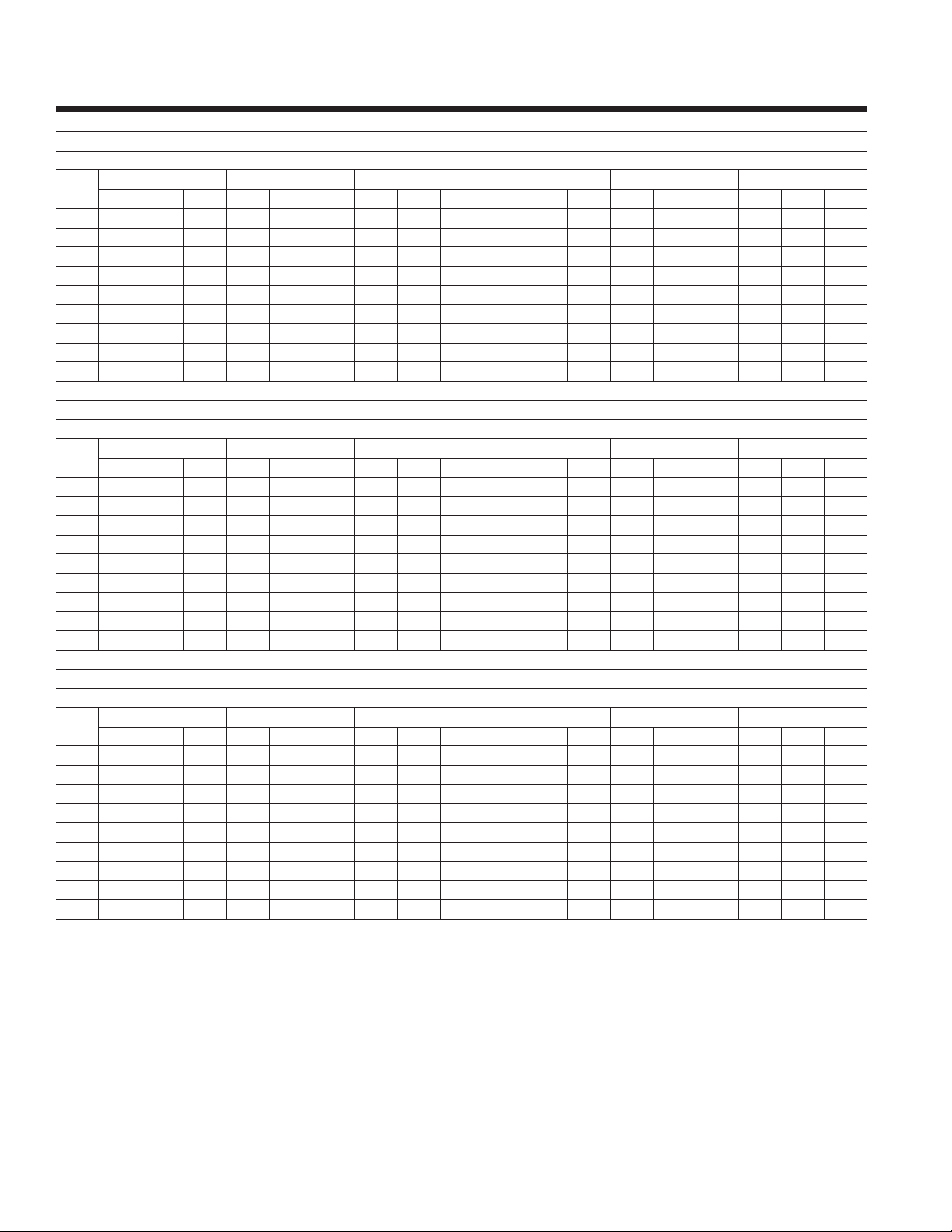

Standard Efciency Ratings – English - 460V/60Hz

MODEL: YCIV0157S/P

AIR TEMPERATURE ON - CONDENSER (°F)

LCWT 75.0 80.0 85.0 90.0 95.0 100.0 105.0 110.0 115.0

(°F) TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER

149.1 131.5 12.3 148.0 141.8 11.4 146.7 152.6 10.6 145.4 164.1 9.8 143.9 176.0 9.1 142.2 189.4 8.4 138.9 202.0 7.7 133.5 212.3 7.1 127.9 223.1 6.5

40.0

153.7 132.5 12.6 152.5 142.6 11.7 151.2 153.5 10.9 149.8 165.0 10.1 148.2 177.0 9.3 146.5 190.5 8.6 142.7 202.7 7.9 137.0 213.2 7.3 131.3 223.9 6.6

42.0

158.3 133.5 12.9 157.1 143.6 12.0 155.7 154.4 11.1 154.3 165.9 10.3 152.6 177.9 9.6 150.8 191.5 8.8 146.5 203.4 8.1 140.6 214.0 7.4 134.7 224.7 6.8

44.0

160.7 134.0 13.1 159.4 144.1 12.1 158.1 154.9 11.3 156.5 166.4 10.4 154.9 178.4 9.7 153.0 192.0 8.9 148.4 203.7 8.2 142.5 214.3 7.5 136.5 225.0 6.9

45.0

163.1 134.6 13.2 161.8 144.6 12.3 160.4 155.4 11.4 158.8 166.9 10.6 157.1 178.9 9.8 155.2 192.5 9.0 150.4 204.0 8.3 144.3 214.7 7.6 138.3 225.4 6.9

46.0

167.9 135.7 13.5 166.6 145.7 12.6 165.1 156.5 11.7 163.5 167.9 10.8 161.7 180.0 10.0 159.7 193.6 9.3 154.3 204.7 8.5 148.1 215.4 7.8 141.8 226.3 7.1

48.0

172.8 137.0 13.8 171.4 146.9 12.8 169.9 157.7 11.9 168.2 169.0 11.1 166.4 181.1 10.3 164.3 194.7 9.5 158.2 205.4 8.7 151.9 216.1 7.9 145.5 227.0 7.3

50.0

177.8 138.4 14.0 176.4 148.2 13.1 174.8 158.9 12.2 173.1 170.2 11.3 171.2 182.3 10.5 168.6 195.6 9.7 162.2 206.1 8.9 155.8 216.8 8.1 149.2 227.6 7.4

52.0

185.4 140.6 14.4 184.0 150.3 13.5 182.3 160.8 12.6 180.5 172.1 11.7 178.5 184.1 10.8 175.0 196.8 10.0 168.3 207.2 9.2 161.7 217.8 8.4 151.7 218.9 7.8

55.0

MODEL: YCIV0177S/P

AIR TEMPERATURE ON - CONDENSER (°F)

LCWT 75.0 80.0 85.0 90.0 95.0 100.0 105.0 110.0 115.0

(°F) TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER

165.7 144.7 12.6 164.2 156.2 11.6 162.4 168.5 10.7 160.5 181.2 9.9 158.4 194.4 9.1 154.6 205.6 8.5 149.9 214.6 7.9 143.5 222.1 7.3 130.1 211.5 6.9

40.0

170.9 145.7 12.9 169.3 157.3 11.9 167.5 169.5 11.0 165.5 182.3 10.1 163.3 195.6 9.4 159.1 206.2 8.7 154.0 215.3 8.1 147.5 222.8 7.5 131.8 207.2 7.2

42.0

176.1 146.8 13.2 174.6 158.3 12.2 172.8 170.6 11.3 170.7 183.5 10.4 168.4 196.8 9.6 163.8 206.8 8.9 158.3 215.8 8.3 151.5 223.4 7.7 133.6 203.1 7.4

44.0

178.8 147.5 13.3 177.2 158.9 12.3 175.4 171.1 11.4 173.3 184.0 10.5 171.0 197.5 9.7 166.1 207.1 9.0 160.5 216.0 8.4 153.5 223.7 7.8 134.5 200.9 7.5

45.0

181.5 148.2 13.5 179.9 159.5 12.5 178.1 171.7 11.5 175.9 184.6 10.7 173.5 197.8 9.9 168.5 207.3 9.2 162.6 216.2 8.5 155.6 224.0 7.9 135.3 198.6 7.7

46.0

186.9 149.5 13.8 185.4 160.8 12.8 183.5 173.0 11.8 181.3 185.9 10.9 178.4 198.3 10.1 173.3 207.9 9.4 167.0 216.6 8.7 159.8 224.5 8.1 137.0 194.3 7.9

48.0

192.4 151.0 14.0 190.8 162.2 13.0 189.0 174.3 12.1 186.7 187.2 11.2 183.4 198.8 10.4 178.2 208.4 9.6 171.5 217.0 8.9 162.8 221.6 8.3 138.3 189.5 8.2

50.0

198.0 152.6 14.3 196.4 163.7 13.3 194.5 175.8 12.3 192.2 188.6 11.4 188.5 199.4 10.6 183.1 209.0 9.9 176.0 217.4 9.1 164.7 216.6 8.6 139.6 184.9 8.4

52.0

206.4 155.2 14.7 204.9 166.1 13.7 202.9 178.1 12.7 200.6 190.9 11.8 196.2 200.4 11.0 190.7 209.9 10.2 182.9 217.9 9.5 167.5 209.1 9.0 141.5 178.2 8.9

55.0

S_IPLV = 13.2 P_IPLV = 14.5

S_IPLV = 13.0 P_IPLV = 14.8

MODEL: YCIV0187S/P

AIR TEMPERATURE ON - CONDENSER (°F)

LCWT 75.0 80.0 85.0 90.0 95.0 100.0 105.0 110.0 115.0

(°F) TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER

180.3 156.2 12.6 178.8 168.2 11.7 177.1 181.1 10.8 175.3 194.7 10.0 173.4 208.9 9.3 171.1 224.9 8.6 166.1 236.3 7.9 159.4 245.3 7.3 152.8 253.9 6.8

40.0

185.9 157.4 12.9 184.4 169.4 12.0 182.6 182.3 11.1 180.7 195.8 10.3 178.7 210.1 9.5 176.4 226.2 8.8 170.5 236.8 8.1 163.7 245.8 7.5 156.9 254.5 7.0

42.0

191.7 158.8 13.2 190.0 170.7 12.3 188.2 183.5 11.4 186.3 197.1 10.5 184.2 211.3 9.8 181.7 227.5 9.0 175.1 237.3 8.3 168.0 246.3 7.7 160.9 255.1 7.1

44.0

194.6 159.6 13.4 192.9 171.4 12.4 191.1 184.2 11.5 189.1 197.7 10.7 186.9 212.0 9.9 184.3 228.0 9.1 177.4 237.5 8.4 170.2 246.5 7.8 163.0 255.4 7.2

45.0

197.5 160.4 13.5 195.8 172.1 12.5 193.9 184.9 11.6 191.9 198.4 10.8 189.7 212.7 10.0 186.9 228.3 9.2 179.7 237.7 8.5 172.5 246.7 7.9 165.1 255.6 7.3

46.0

203.5 162.1 13.8 201.7 173.7 12.8 199.8 186.3 11.9 197.6 199.8 11.0 195.3 214.1 10.2 191.9 228.9 9.4 184.5 238.1 8.7 177.0 247.1 8.1 169.5 256.1 7.5

48.0

209.5 163.8 14.1 207.7 175.3 13.1 205.7 187.8 12.2 203.5 201.3 11.3 201.1 215.5 10.5 196.8 229.3 9.7 189.3 238.4 9.0 181.6 247.5 8.3 171.2 249.6 7.8

50.0

215.7 165.8 14.3 213.8 177.1 13.3 211.7 189.5 12.4 209.4 202.8 11.5 206.9 217.0 10.7 201.9 229.8 9.9 194.1 238.9 9.2 186.3 247.9 8.5 172.9 242.8 8.0

52.0

225.2 169.0 14.7 223.2 180.0 13.7 221.0 192.2 12.8 218.6 205.4 11.9 215.9 219.6 11.0 209.6 230.6 10.2 201.5 239.5 9.5 193.4 248.5 8.8 175.7 233.3 8.5

55.0

NOTES:

1. kWi = Compressor Input Power

2. EER = Chiller EER (includes power from compressors, fans, and control panels 0.8 KWi)

3. LCWT = Leaving Chilled Water Temperature

4. Ratings based on 2.4 GPM cooler water per ton

5. Rated IAW ARI Standard 550/590-98

6. Certied IAW the ARI Water-Chilling Packages Using the Vapor Compression Cycle Certication Program,

which is based on ARI Standard 550/590.

S_IPLV = 13.1 P_IPLV = 14.9

JOHNSON CONTROLS16

Page 17

FORM 201.23-EG1 (1007)

MODEL: YCIV0207S/P

S_IPLV = 13.2 P_IPLV = 14.7

AIR TEMPERATURE ON - CONDENSER (°F)

LCWT 75.0 80.0 85.0 90.0 95.0 100.0 105.0 110.0 115.0

(°F) TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER

194.8 168.3 12.7 192.9 182.2 11.7 190.9 197.4 10.8 188.7 213.5 9.9 186.4 230.3 9.1 181.9 244.1 8.4 176.0 254.8 7.8 168.7 261.6 7.3 149.2 238.0 7.1

40.0

200.9 169.6 13.1 199.0 183.3 12.0 196.8 198.2 11.1 194.6 214.3 10.2 192.1 231.2 9.4 187.1 244.4 8.7 180.7 254.7 8.0 173.2 261.8 7.5 151.0 232.8 7.3

42.0

207.2 171.2 13.3 205.2 184.5 12.3 202.9 199.3 11.4 200.5 215.2 10.4 197.6 231.3 9.6 192.4 244.6 8.9 185.4 254.4 8.3 177.7 261.8 7.7 152.8 227.3 7.6

44.0

210.4 172.0 13.5 208.3 185.2 12.5 206.0 199.8 11.5 203.6 215.7 10.6 200.4 231.4 9.8 195.0 244.7 9.0 187.9 254.3 8.4 180.0 261.8 7.8 153.7 224.5 7.7

45.0

213.6 173.0 13.6 211.5 185.9 12.6 209.1 200.4 11.6 206.6 216.3 10.7 203.2 231.5 9.9 197.8 244.8 9.1 190.3 254.1 8.5 182.0 260.9 7.9 154.6 221.8 7.8

46.0

220.2 175.1 13.9 218.0 187.6 12.9 215.5 201.8 11.9 212.9 217.5 11.0 208.9 231.7 10.2 203.3 245.0 9.4 195.3 253.7 8.7 184.0 254.4 8.2 156.2 216.6 8.1

48.0

226.9 177.4 14.1 224.5 189.6 13.2 222.0 203.5 12.2 219.2 218.9 11.2 214.8 232.1 10.4 208.8 245.0 9.6 200.4 253.2 9.0 186.1 247.7 8.5 157.8 211.5 8.4

50.0

233.7 180.1 14.4 231.3 191.8 13.4 228.6 205.3 12.4 225.7 220.5 11.5 220.7 232.5 10.7 214.2 244.6 9.9 205.5 252.8 9.2 188.1 241.3 8.8 159.3 206.5 8.6

52.0

244.3 184.7 14.7 241.7 195.6 13.8 238.8 208.5 12.8 235.4 222.5 11.9 229.8 233.6 11.1 222.4 244.2 10.3 213.4 252.2 9.6 191.0 232.5 9.3 161.6 199.2 9.0

55.0

MODEL: YCIV0227S/P

S_IPLV = 12.9 P_IPLV = 14.7

AIR TEMPERATURE ON - CONDENSER (°F)

LCWT 75.0 80.0 85.0 90.0 95.0 100.0 105.0 110.0 115.0

(°F) TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER

211.3 180.4 12.9 209.4 194.3 11.9 207.3 209.2 11.0 205.1 224.8 10.2 202.7 241.3 9.4 199.9 259.8 8.7 193.1 269.8 8.1 185.3 277.1 7.6 177.5 283.8 7.1

40.0

218.0 182.0 13.2 216.0 195.7 12.2 213.8 210.5 11.3 211.4 226.2 10.4 208.9 242.7 9.7 206.0 261.3 8.9 198.2 270.0 8.3 190.2 277.4 7.8 182.1 284.2 7.3

42.0

224.9 183.7 13.5 222.7 197.3 12.5 220.4 212.0 11.6 218.0 227.7 10.7 215.3 244.2 9.9 211.9 262.1 9.1 203.5 270.1 8.5 195.2 277.6 8.0 186.9 284.5 7.4

44.0

228.3 184.7 13.6 226.2 198.2 12.6 223.8 212.8 11.7 221.3 228.5 10.8 218.5 245.1 10.0 214.7 262.2 9.2 206.2 270.2 8.6 197.7 277.7 8.1 189.3 284.6 7.5

45.0

231.8 185.7 13.7 229.6 199.1 12.8 227.2 213.7 11.8 224.6 229.3 11.0 221.8 245.9 10.1 217.5 262.2 9.4 208.9 270.2 8.7 200.3 277.7 8.2 191.8 284.7 7.6

46.0

238.9 187.8 14.0 236.7 201.1 13.0 234.2 215.4 12.1 231.4 231.0 11.2 228.5 247.5 10.4 223.2 262.4 9.6 214.4 270.3 9.0 205.6 277.8 8.4 195.3 281.4 7.9

48.0

246.2 190.1 14.3 243.8 203.1 13.3 241.2 217.4 12.4 238.4 232.8 11.5 235.3 249.2 10.6 229.0 262.5 9.8 219.9 270.4 9.2 210.9 277.8 8.6 197.2 274.6 8.1

50.0

253.6 192.7 14.5 251.2 205.4 13.6 248.5 219.5 12.6 245.5 234.9 11.7 242.3 251.2 10.8 234.9 262.7 10.1 225.6 270.4 9.4 216.3 277.8 8.8 199.3 267.5 8.4

52.0

264.9 196.7 14.9 262.4 209.2 13.9 259.5 223.0 13.0 256.4 238.2 12.1 253.1 254.3 11.2 243.9 263.0 10.5 234.3 270.6 9.8 224.6 277.9 9.1 202.2 256.3 8.9

55.0

MODEL: YCIV0247S/P

S_IPLV = 12.7 P_IPLV = 14.8

AIR TEMPERATURE ON - CONDENSER (°F)

LCWT 75.0 80.0 85.0 90.0 95.0 100.0 105.0 110.0 115.0

(°F) TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER

231.8 198.8 12.8 229.8 213.8 11.9 227.6 229.8 11.0 225.2 246.7 10.2 222.7 264.4 9.4 219.7 284.3 8.7 213.4 297.6 8.1 206.3 308.8 7.6 199.1 319.5 7.1

40.0

239.1 200.6 13.1 236.9 215.6 12.1 234.6 231.5 11.3 232.1 248.4 10.4 229.5 266.1 9.7 226.4 286.1 8.9 219.3 298.4 8.3 211.9 309.5 7.8 204.4 320.4 7.2

42.0

246.5 202.6 13.4 244.3 217.4 12.4 241.9 233.3 11.5 239.2 250.2 10.7 236.4 268.0 9.9 232.9 287.5 9.1 225.3 299.1 8.5 217.6 310.3 7.9 208.9 318.7 7.4

44.0

250.2 203.7 13.5 248.0 218.4 12.6 245.5 234.3 11.7 242.8 251.2 10.8 239.9 268.9 10.0 236.1 287.8 9.2 228.3 299.4 8.6 220.5 310.7 8.0 210.1 315.4 7.6

45.0

254.0 204.8 13.7 251.7 219.4 12.7 249.2 235.2 11.8 246.5 252.1 10.9 243.5 269.9 10.1 239.2 288.2 9.4 231.4 299.7 8.7 223.4 311.1 8.1 211.3 311.8 7.7

46.0

261.7 207.1 13.9 259.4 221.6 13.0 256.7 237.3 12.0 253.9 254.1 11.2 250.8 271.9 10.4 245.7 288.9 9.6 237.6 300.4 8.9 229.4 311.7 8.3 213.6 304.4 7.9

48.0

269.6 209.5 14.2 267.1 223.9 13.2 264.4 239.5 12.3 261.4 256.2 11.4 258.2 274.0 10.6 252.2 289.6 9.8 243.9 301.1 9.2 235.5 312.4 8.5 215.8 296.4 8.2

50.0

277.6 212.2 14.4 275.1 226.4 13.5 272.2 241.9 12.5 269.1 258.5 11.7 265.8 276.2 10.8 258.9 290.4 10.1 250.3 301.8 9.4 241.7 313.0 8.8 217.8 288.1 8.5

52.0

289.9 215.9 14.8 287.2 230.3 13.9 284.2 245.7 12.9 281.0 262.2 12.0 277.4 279.7 11.2 269.0 291.7 10.4 260.2 302.9 9.7 251.2 314.1 9.1 220.5 275.9 9.0

55.0

NOTES:

1. kWi = Compressor Input Power

2. EER = Chiller EER (includes power from compressors, fans, and control panels 0.8 KWi)

3. LCWT = Leaving Chilled Water Temperature

4. Ratings based on 2.4 GPM cooler water per ton

5. Rated IAW ARI Standard 550/590-98

6. Certied IAW the ARI Water-Chilling Packages Using the Vapor Compression Cycle Certication Program,

which is based on ARI Standard 550/590.

JOHNSON CONTROLS

17

Page 18

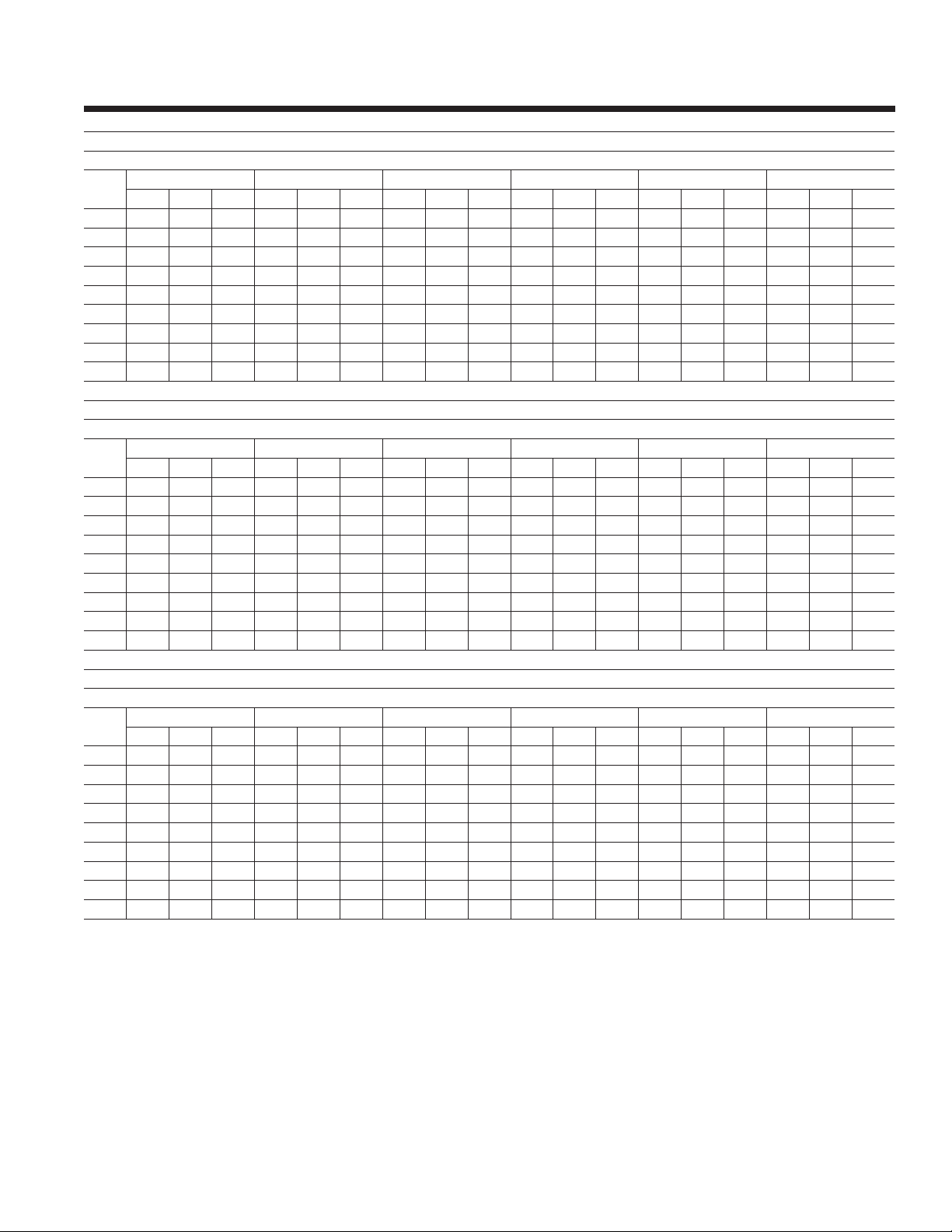

Standard Efciency Ratings – English - 460V/60Hz

MODEL: YCIV0267S/P

AIR TEMPERATURE ON - CONDENSER (°F)

LCWT 75.0 80.0 85.0 90.0 95.0 100.0 105.0 110.0 115.0

(°F) TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER

252.3 217.0 12.8 250.2 233.1 11.9 247.9 250.3 11.0 245.4 268.3 10.2 242.7 287.2 9.5 239.6 308.5 8.7 233.9 325.1 8.1 227.3 340.0 7.6 220.8 354.7 7.1

40.0

260.2 219.0 13.1 258.0 235.2 12.1 255.6 252.2 11.3 252.9 270.4 10.4 250.1 289.2 9.7 246.8 310.7 9.0 240.4 326.4 8.3 233.6 341.3 7.8 226.8 356.2 7.2

42.0

268.2 221.2 13.3 265.9 237.3 12.4 263.3 254.3 11.5 260.6 272.4 10.7 257.6 291.5 9.9 254.0 312.6 9.2 247.1 327.6 8.5 240.1 342.6 7.9 231.8 354.5 7.4

44.0

272.2 222.5 13.5 269.9 238.4 12.5 267.3 255.5 11.6 264.5 273.6 10.8 261.4 292.5 10.0 257.5 313.2 9.3 250.5 328.3 8.6 243.4 343.2 8.0 233.0 350.2 7.5

45.0

276.3 223.6 13.6 273.9 239.5 12.7 271.3 256.6 11.8 268.4 274.7 10.9 265.3 293.6 10.1 261.0 313.9 9.4 253.9 328.9 8.7 246.7 344.0 8.1 234.2 345.8 7.7

46.0

284.6 226.1 13.9 282.1 242.0 12.9 279.4 258.9 12.0 276.4 276.9 11.2 273.1 296.0 10.4 268.2 315.2 9.6 260.9 330.1 8.9 253.4 345.2 8.3 236.7 336.8 8.0

48.0

293.1 228.7 14.1 290.5 244.5 13.2 287.7 261.3 12.3 284.6 279.3 11.4 281.1 298.4 10.6 275.5 316.5 9.8 267.9 331.5 9.1 260.2 346.5 8.5 239.1 327.9 8.2

50.0

301.7 231.6 14.4 299.1 247.1 13.4 296.1 264.0 12.5 292.9 281.8 11.6 289.3 300.9 10.8 282.9 317.8 10.0 275.1 332.8 9.4 267.2 347.8 8.7 241.5 319.2 8.5

52.0

315.0 234.9 14.8 312.1 251.1 13.8 309.0 268.1 12.9 305.6 286.0 12.0 301.9 304.8 11.1 294.2 320.1 10.4 286.1 334.8 9.7 277.9 349.8 9.0 244.8 307.1 9.0

55.0

MODEL: YCIV0287S/P

AIR TEMPERATURE ON - CONDENSER (°F)

LCWT 75.0 80.0 85.0 90.0 95.0 100.0 105.0 110.0 115.0

(°F) TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER

268.2 228.0 12.9 265.7 246.5 11.9 262.9 266.4 10.9 259.9 287.2 10.1 256.7 308.8 9.3 251.3 328.6 8.6 244.3 345.3 8.0 234.1 356.5 7.4 209.5 332.8 7.1

40.0

276.6 229.7 13.2 274.1 248.0 12.2 271.2 267.7 11.2 268.0 288.6 10.4 264.6 310.3 9.6 258.7 329.7 8.8 250.9 345.8 8.2 240.4 357.3 7.6 211.9 325.4 7.3

42.0

285.2 231.6 13.5 282.6 249.6 12.5 279.6 269.2 11.5 276.3 290.0 10.6 272.7 311.7 9.8 266.3 330.6 9.1 257.7 346.2 8.4 246.8 357.8 7.8 214.8 318.9 7.6

44.0

289.6 232.6 13.7 286.9 250.5 12.6 283.9 270.0 11.7 280.6 290.8 10.8 276.7 312.1 9.9 270.2 331.0 9.2 261.2 346.3 8.5 250.0 358.2 7.9 216.1 315.4 7.7

45.0

294.0 233.7 13.8 291.3 251.4 12.8 288.3 270.8 11.8 284.9 291.6 10.9 280.7 312.5 10.1 274.1 331.5 9.3 264.7 346.4 8.6 253.4 358.4 8.0 217.5 311.9 7.8

46.0

303.0 236.1 14.1 300.2 253.5 13.1 297.1 272.7 12.1 293.5 293.3 11.2 288.9 313.4 10.3 282.0 332.3 9.6 271.7 346.6 8.9 258.9 355.8 8.2 220.1 304.8 8.1

48.0

312.1 238.8 14.4 309.3 255.8 13.4 306.0 274.7 12.4 302.4 295.2 11.4 297.2 314.4 10.6 290.1 333.3 9.8 278.9 346.7 9.1 261.9 347.2 8.5 222.4 297.7 8.4

50.0

321.4 241.7 14.6 318.5 258.5 13.6 315.2 277.1 12.7 311.4 297.4 11.7 305.7 315.5 10.9 298.2 334.0 10.1 286.2 346.8 9.3 264.9 338.8 8.8 224.6 290.7 8.6

52.0

335.7 246.8 15.0 332.7 262.8 14.0 329.2 280.9 13.0 325.3 300.9 12.1 318.6 317.4 11.3 310.1 334.5 10.4 297.4 346.9 9.7 269.4 327.1 9.3 227.7 280.5 9.0

55.0

S_IPLV = 12.3 P_IPLV = 14.9

S_IPLV = 13.0 P_IPLV = 14.7

MODEL: YCIV0307S/P

AIR TEMPERATURE ON - CONDENSER (°F)

LCWT 75.0 80.0 85.0 90.0 95.0 100.0 105.0 110.0 115.0

(°F) TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER

298.0 251.5 13.0 295.2 272.2 12.0 292.2 294.8 11.0 289.0 318.9 10.1 285.6 344.0 9.3 279.8 366.7 8.6 271.4 384.3 8.0 260.3 394.8 7.5 229.5 358.3 7.2

40.0

307.4 253.3 13.3 304.5 273.7 12.3 301.3 296.0 11.3 297.9 320.0 10.4 294.3 345.1 9.6 287.9 367.5 8.8 278.6 384.1 8.2 267.2 395.1 7.7 232.1 349.9 7.5

42.0

317.0 255.6 13.6 314.0 275.5 12.6 310.6 297.5 11.6 307.1 321.3 10.7 302.9 345.6 9.8 296.2 368.1 9.1 286.0 383.8 8.4 274.2 395.1 7.9 235.1 342.1 7.7

44.0

321.9 256.9 13.8 318.8 276.5 12.8 315.4 298.3 11.8 311.7 322.0 10.8 307.3 345.8 10.0 300.4 368.5 9.2 289.7 383.6 8.5 277.7 395.0 8.0 236.5 338.1 7.8

45.0

326.9 258.2 13.9 323.7 277.6 12.9 320.2 299.2 11.9 316.4 322.7 11.0 311.7 346.1 10.1 304.7 368.8 9.3 293.5 383.3 8.7 280.1 392.1 8.1 237.9 334.0 8.0

46.0

336.9 261.3 14.2 333.6 280.0 13.2 329.9 301.2 12.2 326.0 324.5 11.2 320.6 346.9 10.4 313.4 369.4 9.6 301.2 382.7 8.9 283.2 382.4 8.4 240.7 326.4 8.3

48.0

347.2 264.7 14.5 343.7 282.9 13.5 339.9 303.5 12.5 335.8 326.6 11.5 329.8 347.7 10.7 322.0 369.6 9.8 309.0 382.1 9.1 286.4 372.5 8.7 243.0 318.5 8.5

50.0

357.7 268.6 14.7 354.1 286.1 13.7 350.1 306.2 12.7 345.8 328.8 11.8 339.1 348.7 10.9 330.3 369.0 10.1 317.0 381.4 9.4 289.6 362.8 9.0 245.3 311.0 8.8

52.0

373.9 275.3 15.0 370.0 291.6 14.1 365.8 310.9 13.1 360.8 332.0 12.2 353.5 350.8 11.3 343.0 368.4 10.5 329.2 380.5 9.8 294.2 349.6 9.5 248.8 300.0 9.2

55.0

NOTES:

1. kW = Compressor Input Power

2. EER = Chiller EER (includes power from compressors, fans, and control panels 0.8 KWi)

3. LCWT = Leaving Chilled Water Temperature

4. Ratings based on 2.4 GPM cooler water per ton

5. Rated IAW ARI Standard 550/590-98

S_IPLV = 12.6 P_IPLV = 14.6

JOHNSON CONTROLS18

Page 19

FORM 201.23-EG1 (1007)

MODEL: YCIV0357S/P

AIR TEMPERATURE ON - CONDENSER (°F)

LCWT 75.0 80.0 85.0 90.0 95.0 100.0 105.0 110.0 115.0

(°F) TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER

336.3 288.0 12.8 333.4 309.9 11.9 330.1 333.5 11.0 326.6 358.2 10.2 322.9 384.1 9.4 318.6 413.2 8.7 309.3 432.1 8.1 298.3 446.9 7.6 287.4 460.8 7.1

40.0

346.9 290.6 13.1 343.8 312.4 12.2 340.4 335.8 11.3 336.7 360.5 10.4 332.8 386.5 9.7 328.3 415.8 8.9 317.7 433.0 8.3 306.3 447.8 7.7 295.0 462.0 7.2

42.0

357.7 293.3 13.4 354.5 315.0 12.4 350.9 338.3 11.5 347.1 363.1 10.7 342.9 389.0 9.9 338.1 418.1 9.1 326.3 433.8 8.5 314.6 448.7 7.9 302.8 463.1 7.4

44.0

363.2 294.8 13.6 359.9 316.4 12.6 356.3 339.6 11.7 352.3 364.3 10.8 348.1 390.4 10.0 342.7 418.5 9.2 330.7 434.1 8.6 318.7 449.1 8.0 304.8 459.0 7.5

45.0

368.8 296.5 13.7 365.4 317.8 12.7 361.7 341.0 11.8 357.6 365.7 10.9 353.3 391.7 10.1 347.2 418.9 9.3 335.1 434.5 8.7 322.9 449.5 8.1 306.7 454.4 7.6

46.0

380.1 299.7 14.0 376.6 320.9 13.0 372.7 343.8 12.1 368.5 368.5 11.2 363.9 394.5 10.4 356.5 419.7 9.6 344.0 435.2 8.9 331.5 450.3 8.3 310.2 444.4 7.9

48.0

391.6 303.2 14.2 387.9 324.2 13.3 383.9 347.0 12.3 379.5 371.4 11.4 374.8 397.4 10.6 366.0 420.5 9.8 353.1 435.9 9.2 340.2 450.9 8.5 313.5 433.3 8.2

50.0

403.4 307.0 14.5 399.6 327.7 13.5 395.4 350.3 12.6 390.8 374.5 11.7 385.9 400.4 10.8 375.7 421.3 10.1 362.4 436.7 9.4 349.2 451.6 8.8 316.5 421.3 8.5

52.0

421.3 312.6 14.9 417.2 333.5 13.9 412.9 355.6 13.0 408.1 379.9 12.0 402.9 405.5 11.2 390.4 422.8 10.4 376.6 437.8 9.7 362.8 452.6 9.1 320.4 402.9 8.9

55.0

MODEL: YCIV0397S/P

AIR TEMPERATURE ON - CONDENSER (°F)

LCWT 75.0 80.0 85.0 90.0 95.0 100.0 105.0 110.0 115.0

(°F) TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER

377.3 324.5 12.8 374.2 348.7 11.9 370.7 374.4 11.0 366.9 401.4 10.2 362.9 429.8 9.5 358.2 461.7 8.7 350.0 486.9 8.1 340.3 509.2 7.6 330.6 531.2 7.1

40.0

389.1 327.5 13.1 385.8 351.6 12.1 382.2 377.3 11.3 378.2 404.5 10.4 374.0 432.8 9.7 369.0 464.8 8.9 359.8 488.8 8.3 349.7 511.2 7.8 339.5 533.5 7.2

42.0

401.2 330.7 13.3 397.8 354.8 12.4 394.0 380.3 11.5 389.8 407.5 10.7 385.3 436.0 9.9 380.1 468.1 9.2 369.8 490.8 8.5 359.3 513.2 7.9 348.7 535.6 7.4

44.0

407.4 332.4 13.5 403.8 356.4 12.5 399.9 382.1 11.6 395.7 409.1 10.8 391.0 437.7 10.0 385.4 469.1 9.3 374.9 491.7 8.6 364.2 514.2 8.0 350.8 530.1 7.5

45.0

413.5 334.3 13.6 410.0 358.1 12.7 406.0 383.7 11.8 401.6 410.9 10.9 396.9 439.3 10.1 390.7 470.2 9.4 380.0 492.6 8.7 369.2 515.1 8.1 352.7 523.5 7.6

46.0

426.1 337.9 13.9 422.4 361.6 12.9 418.2 387.1 12.0 413.7 414.2 11.2 408.7 442.9 10.4 401.5 472.0 9.6 390.5 494.5 8.9 379.2 517.2 8.3 356.3 510.3 7.9

48.0

439.0 341.8 14.2 435.1 365.5 13.2 430.8 390.7 12.3 426.0 417.8 11.4 420.9 446.4 10.6 412.6 474.0 9.8 401.1 496.5 9.1 389.5 519.0 8.5 360.0 496.9 8.2

50.0

452.0 346.1 14.4 448.0 369.4 13.5 443.5 394.7 12.5 438.6 421.5 11.7 433.2 450.1 10.8 423.8 476.0 10.0 411.9 498.5 9.3 400.0 521.0 8.7 363.7 483.8 8.5

52.0

471.7 350.8 14.9 467.3 375.7 13.8 462.8 400.7 12.9 457.8 427.6 12.0 452.3 455.9 11.2 441.0 479.4 10.4 428.7 501.5 9.7 416.1 524.0 9.0 368.8 465.1 8.9

55.0

MODEL: YCIV0157E/V

S_IPLV = 13.5 P_IPLV = 15.1

S_IPLV = 13.2 P_IPLV = 15.2

E_IPLV = 13.5 V_IPLV = 14.6

NOTES:

1. kW = Compressor Input Power

2. EER = Chiller EER (includes power from compressors, fans, and control panels 0.8 KWi)

3. LCWT = Leaving Chilled Water Temperature

4. Ratings based on 2.4 GPM cooler water per ton

5. Rated IAW ARI Standard 550/590-98

JOHNSON CONTROLS

19

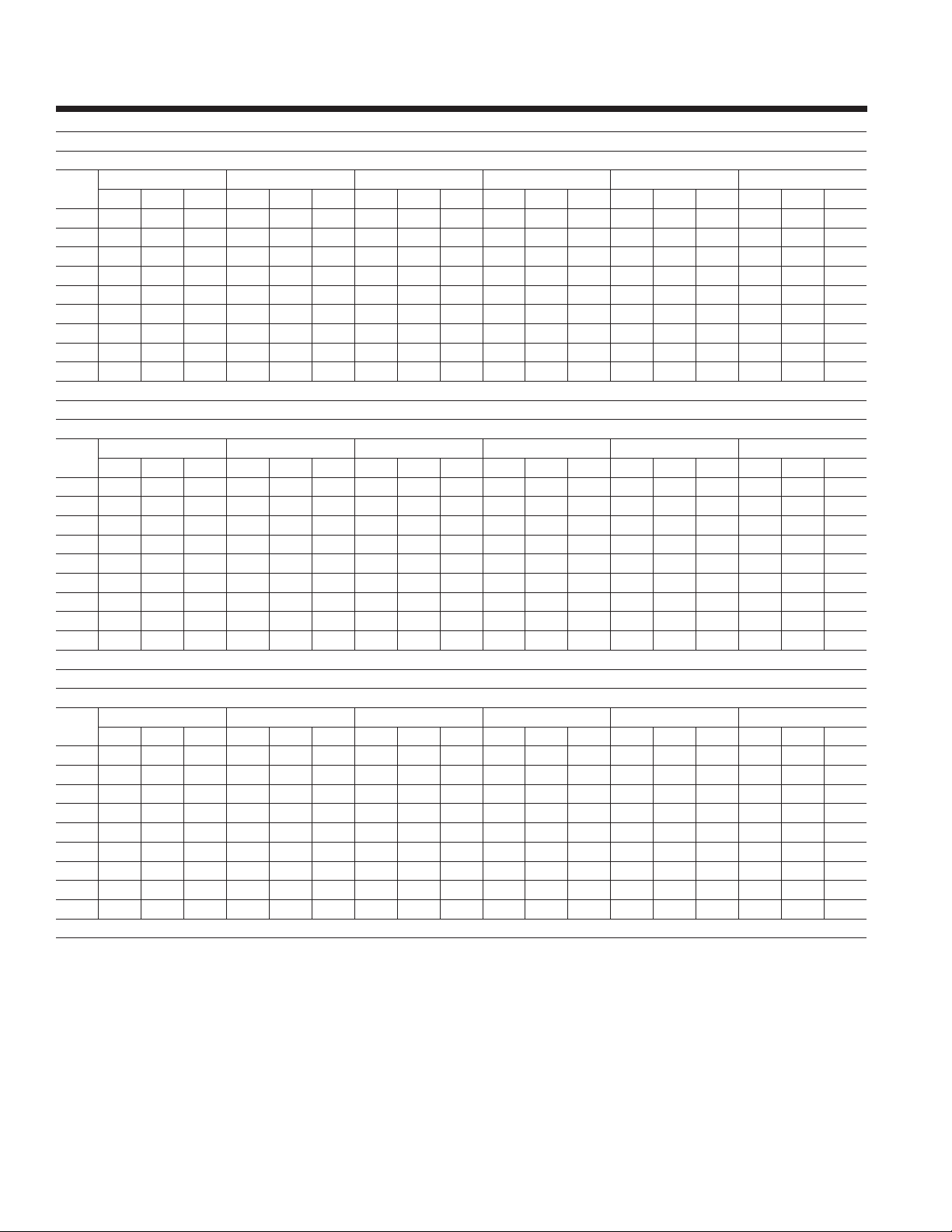

Page 20

High Efciency Ratings – English - 460V/60Hz

AIR TEMPERATURE ON - CONDENSER (°F)

LCWT 75.0 80.0 85.0 90.0 95.0 100.0 105.0 110.0 115.0

(°F) TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER

148.1 121.7 13.1 146.8 130.5 12.2 145.2 139.6 11.4 143.4 149.1 10.6 141.4 158.9 9.8 139.1 170.1 9.1 136.1 181.5 8.4 130.1 190.6 7.7 124.0 200.1 7.0

40.0

152.7 122.8 13.4 151.5 131.6 12.5 149.9 140.8 11.7 148.1 150.3 10.9 146.1 160.2 10.1 143.7 171.4 9.3 140.1 182.5 8.6 133.9 191.5 7.8 127.6 200.9 7.1

42.0

157.4 123.9 13.8 156.2 132.8 12.8 154.7 142.0 11.9 152.8 151.6 11.1 150.8 161.6 10.3 148.3 172.8 9.6 144.2 183.5 8.8 137.7 192.5 8.0 131.3 201.8 7.3

44.0

159.8 124.4 13.9 158.6 133.4 13.0 157.1 142.6 12.1 155.2 152.2 11.2 153.2 162.2 10.5 150.7 173.5 9.7 146.3 184.0 8.9 139.7 193.0 8.1 133.2 202.2 7.4

45.0

162.2 125.1 14.1 161.0 134.0 13.1 159.5 143.2 12.2 157.7 152.9 11.4 155.6 162.9 10.6 153.0 174.2 9.8 148.3 184.5 9.0 141.7 193.5 8.2 135.1 202.6 7.5

46.0

167.0 126.2 14.4 165.9 135.2 13.4 164.4 144.6 12.5 162.6 154.2 11.6 160.4 164.3 10.8 157.9 175.6 10.0 152.5 185.5 9.2 145.7 194.5 8.4 138.9 203.6 7.7

48.0

171.9 127.3 14.7 170.8 136.4 13.7 169.3 145.9 12.8 167.5 155.7 11.9 165.4 165.8 11.1 162.7 177.2 10.2 156.7 186.5 9.4 149.8 195.5 8.6 142.7 204.7 7.9

50.0

176.8 128.5 15.0 175.8 137.7 14.0 174.4 147.2 13.0 172.6 157.1 12.1 170.4 167.2 11.3 167.7 178.7 10.5 161.0 187.6 9.6 153.9 196.5 8.8 146.7 205.7 8.0

52.0

184.4 130.2 15.4 183.5 139.6 14.4 182.1 149.2 13.4 180.3 159.2 12.5 178.1 169.5 11.7 174.8 180.6 10.8 167.5 189.3 9.9 160.2 198.1 9.1 152.8 207.2 8.3

55.0

MODEL: YCIV0177E/V

AIR TEMPERATURE ON - CONDENSER (°F)

LCWT 75.0 80.0 85.0 90.0 95.0 100.0 105.0 110.0 115.0

(°F) TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER

157.1 131.4 13.0 156.3 137.3 12.3 155.0 147.6 11.4 153.5 158.6 10.6 151.9 170.1 9.8 150.0 183.2 9.1 147.0 195.7 8.4 142.2 207.3 7.7 136.2 217.9 7.0

40.0

162.5 128.7 13.6 161.3 138.3 12.6 159.9 148.5 11.7 158.3 159.4 10.9 156.6 171.0 10.1 154.7 184.1 9.3 151.2 196.5 8.6 146.1 207.9 7.9 139.9 218.6 7.2

42.0

167.6 129.9 13.9 166.3 139.3 12.9 164.8 149.5 12.0 163.2 160.4 11.2 161.5 171.9 10.4 159.4 185.0 9.6 155.6 197.2 8.8 150.1 208.5 8.1 143.6 219.3 7.4

44.0

170.2 130.5 14.0 168.9 139.9 13.1 167.4 150.1 12.2 165.7 160.9 11.3 163.9 172.4 10.5 161.8 185.5 9.7 157.8 197.6 8.9 152.1 208.8 8.2 145.5 219.6 7.4

45.0

172.8 131.2 14.2 171.4 140.5 13.2 169.9 150.6 12.3 168.2 161.4 11.4 166.4 172.9 10.6 164.3 186.0 9.8 160.0 198.0 9.0 154.1 209.1 8.3 147.5 219.9 7.5

46.0

178.0 132.6 14.5 176.7 141.8 13.5 175.1 151.8 12.6 173.4 162.5 11.7 171.5 174.0 10.9 169.1 186.9 10.0 164.6 198.7 9.2 158.3 209.7 8.4 151.4 220.5 7.7

48.0

183.4 134.1 14.8 182.0 143.1 13.8 180.4 153.0 12.9 178.6 163.7 12.0 176.6 175.1 11.1 173.9 187.8 10.3 169.2 199.6 9.5 162.5 210.3 8.7 154.4 218.2 7.9

50.0

188.9 135.7 15.0 187.5 144.6 14.1 185.8 154.4 13.2 183.9 165.0 12.3 181.9 176.3 11.4 178.7 188.7 10.5 173.9 200.5 9.7 166.8 210.9 8.9 156.2 212.7 8.2

52.0

197.4 138.4 15.4 195.8 147.0 14.5 194.1 156.6 13.6 192.2 167.0 12.7 190.0 178.3 11.8 186.2 190.2 10.9 180.8 201.5 10.0 173.3 211.9 9.2 158.8 204.8 8.7

55.0

MODEL: YCIV0187E/V

AIR TEMPERATURE ON - CONDENSER (°F)

LCWT 75.0 80.0 85.0 90.0 95.0 100.0 105.0 110.0 115.0

(°F) TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER

174.7 145.0 13.1 173.7 152.7 12.3 172.2 164.6 11.4 170.5 177.2 10.5 168.7 190.5 9.8 166.5 205.3 9.0 163.0 217.8 8.3 158.0 227.5 7.8 151.4 235.7 7.2

40.0

180.2 146.1 13.4 179.2 153.6 12.6 177.7 165.4 11.7 175.9 178.0 10.8 174.0 191.3 10.0 171.7 206.3 9.2 167.8 218.3 8.6 162.4 227.9 8.0 155.6 236.2 7.4

42.0

185.8 147.5 13.7 184.8 154.7 12.9 183.2 166.4 12.0 181.4 178.9 11.1 179.4 192.1 10.3 177.0 207.2 9.5 172.7 218.7 8.8 166.9 228.3 8.2 159.9 236.6 7.6

44.0

189.0 144.5 14.1 187.6 155.3 13.1 186.0 166.9 12.2 184.2 179.4 11.3 182.1 192.6 10.4 179.7 207.7 9.6 175.2 218.8 8.9 169.2 228.4 8.3 162.1 236.8 7.7

45.0

191.8 145.2 14.2 190.4 155.8 13.2 188.8 167.4 12.3 187.0 179.9 11.4 184.9 193.1 10.6 182.5 208.1 9.7 177.7 219.0 9.0 171.5 228.5 8.4 164.3 237.0 7.8

46.0

197.5 146.7 14.5 196.2 157.1 13.5 194.5 168.6 12.6 192.6 180.9 11.7 190.5 194.1 10.8 188.0 209.1 10.0 182.8 219.4 9.3 176.2 228.7 8.6 168.7 237.3 8.0

48.0

203.4 148.3 14.8 202.0 158.6 13.8 200.3 169.8 12.9 198.4 182.1 12.0 196.2 195.2 11.1 193.3 209.5 10.2 188.0 219.7 9.5 181.0 228.9 8.8 173.3 237.5 8.2

50.0

209.3 150.0 15.1 207.9 160.1 14.1 206.2 171.3 13.2 204.2 183.4 12.2 202.0 196.4 11.4 198.6 210.0 10.5 193.2 220.1 9.8 185.8 229.1 9.1 177.4 236.6 8.4

52.0

218.4 153.0 15.4 217.0 162.7 14.5 215.3 173.6 13.6 213.2 185.5 12.6 210.9 198.4 11.8 206.8 210.7 10.9 201.2 220.7 10.2 193.2 229.4 9.4 180.3 227.5 8.9

55.0

MODEL: YCIV0197E/V

E_IPLV = 13.5 V_IPLV = 14.7

E_IPLV = 13.2 V_IPLV = 15.1

E_IPLV = 12.9 V_IPLV = 15.0

NOTES:

1. kW = Compressor Input Power

2. EER = Chiller EER (includes power from compressors, fans, and control panels 0.8 KWi)

3. LCWT = Leaving Chilled Water Temperature

4. Ratings based on 2.4 GPM cooler water per ton

5. Rated IAW ARI Standard 550/590-98

6. Certied IAW the ARI Water-Chilling Packages Using the Vapor Compression Cycle Certication Program,

which is based on ARI Standard 550/590.

JOHNSON CONTROLS20

Page 21

FORM 201.23-EG1 (1007)

AIR TEMPERATURE ON - CONDENSER (°F)

LCWT 75.0 80.0 85.0 90.0 95.0 100.0 105.0 110.0 115.0

(°F) TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER

189.8 153.1 13.4 188.2 165.6 12.4 186.4 179.5 11.4 184.5 194.4 10.5 182.5 210.2 9.6 180.1 227.8 8.8 176.4 243.2 8.1 169.4 250.7 7.6 162.4 257.3 7.1

40.0

195.8 154.3 13.7 194.1 166.4 12.7 192.2 180.0 11.7 190.3 194.8 10.8 188.1 210.6 9.9 185.6 228.4 9.1 181.3 242.8 8.4 174.0 250.6 7.8 166.7 257.5 7.3

42.0

201.9 155.8 14.0 200.1 167.5 13.0 198.2 180.8 12.0 196.1 195.4 11.1 193.9 211.0 10.2 191.3 228.9 9.3 186.2 242.3 8.6 178.7 250.3 8.0 171.2 257.5 7.5

44.0

205.0 156.6 14.2 203.2 168.2 13.2 201.3 181.3 12.2 199.1 195.7 11.2 196.8 211.2 10.4 194.2 229.1 9.5 188.7 242.1 8.7 181.1 250.1 8.1 173.5 257.4 7.6

45.0

208.1 157.6 14.3 206.3 168.8 13.3 204.3 181.8 12.3 202.2 196.0 11.4 199.8 211.5 10.5 197.1 229.4 9.6 191.2 241.8 8.9 183.6 249.9 8.3 175.8 257.3 7.7

46.0

214.5 159.6 14.6 212.6 170.4 13.6 210.6 182.9 12.7 208.3 196.9 11.7 205.8 212.2 10.8 203.0 230.0 9.9 196.4 241.2 9.1 188.5 249.4 8.5 180.5 256.9 7.9

48.0

221.0 162.1 14.8 219.1 172.3 13.9 216.9 184.3 12.9 214.5 198.1 12.0 212.0 213.1 11.1 209.0 230.9 10.1 201.6 240.6 9.4 193.5 248.8 8.7 185.3 256.5 8.1

50.0

227.7 164.8 15.0 225.7 174.5 14.2 223.4 186.1 13.2 221.0 199.4 12.3 218.3 214.2 11.3 215.2 231.7 10.4 206.9 240.1 9.7 198.5 248.2 9.0 190.2 255.9 8.4

52.0

237.9 169.6 15.3 235.8 178.3 14.5 233.4 189.1 13.6 230.8 201.8 12.7 228.0 216.1 11.7 223.7 231.3 10.8 214.9 239.4 10.1 206.3 247.4 9.4 197.7 255.0 8.7

55.0

MODEL: YCIV0207E/V

E_IPLV = 13.4 V_IPLV = 15.0

AIR TEMPERATURE ON - CONDENSER (°F)

LCWT 75.0 80.0 85.0 90.0 95.0 100.0 105.0 110.0 115.0

(°F) TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER

201.7 161.2 13.5 200.1 173.9 12.5 198.3 187.9 11.5 196.4 203.1 10.6 194.4 219.0 9.8 192.0 237.1 9.0 188.3 252.6 8.3 182.0 262.6 7.8 174.6 269.6 7.3

40.0

208.1 162.5 13.8 206.4 175.0 12.8 204.5 188.7 11.8 202.5 203.7 10.9 200.4 219.6 10.1 197.9 237.7 9.3 193.7 252.8 8.6 186.9 262.5 8.0 179.3 269.8 7.5

42.0

214.6 164.1 14.1 212.8 176.2 13.1 210.9 189.7 12.2 208.8 204.4 11.2 206.5 220.3 10.4 203.9 238.4 9.5 199.2 253.0 8.8 191.9 262.3 8.2 184.1 269.8 7.7

44.0

217.9 165.0 14.3 216.1 176.9 13.3 214.1 190.2 12.3 211.9 204.8 11.4 209.6 220.6 10.5 206.9 238.8 9.7 202.0 253.0 8.9 194.5 262.2 8.3 186.6 269.7 7.8

45.0

221.3 165.9 14.4 219.4 177.6 13.4 217.4 190.8 12.5 215.1 205.4 11.5 212.8 221.1 10.7 210.0 239.2 9.8 204.8 253.1 9.1 197.1 262.0 8.4 189.0 269.7 7.9

46.0

228.1 168.1 14.7 226.1 179.3 13.7 224.0 192.2 12.8 221.7 206.5 11.8 219.2 222.0 10.9 216.2 239.8 10.0 210.6 253.2 9.3 202.3 261.6 8.7 194.0 269.4 8.1

48.0

235.0 170.4 14.9 233.0 181.3 14.0 230.8 193.8 13.0 228.4 207.7 12.1 225.8 223.0 11.2 222.3 240.0 10.3 216.2 252.8 9.6 207.7 261.1 8.9 199.1 269.0 8.3

50.0

242.1 173.1 15.2 240.0 183.4 14.3 237.7 195.6 13.3 235.2 209.2 12.4 232.5 224.3 11.5 228.5 240.3 10.6 221.8 252.4 9.8 213.1 260.7 9.2 203.0 265.7 8.6

52.0

252.7 177.6 15.5 250.6 187.2 14.6 248.2 198.7 13.7 245.6 211.9 12.8 242.7 226.5 11.9 238.0 241.0 11.0 230.5 251.9 10.2 221.4 260.0 9.5 206.3 254.8 9.1

55.0

MODEL: YCIV0227E/V

E_IPLV = 13.1 V_IPLV = 15.0

AIR TEMPERATURE ON - CONDENSER (°F)

LCWT 75.0 80.0 85.0 90.0 95.0 100.0 105.0 110.0 115.0

(°F) TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER

209.5 167.1 13.4 207.9 179.8 12.5 206.1 193.4 11.6 204.2 208.1 10.7 202.1 223.5 10.0 199.8 241.0 9.2 197.2 259.1 8.5 190.9 269.7 7.9 183.3 277.2 7.4

40.0

216.1 168.5 13.7 214.5 181.0 12.8 212.6 194.6 11.9 210.6 209.1 11.0 208.4 224.5 10.2 205.9 242.0 9.4 203.2 260.3 8.7 196.1 269.8 8.1 188.3 277.4 7.6

42.0

222.9 170.1 14.1 221.2 182.3 13.1 219.2 195.8 12.2 217.1 210.2 11.3 214.9 225.6 10.5 212.2 243.1 9.7 209.4 261.4 8.9 201.5 269.9 8.3 193.4 277.4 7.8

44.0

226.4 171.0 14.2 224.6 183.1 13.3 222.6 196.4 12.3 220.4 210.8 11.5 218.1 226.1 10.6 215.4 243.7 9.8 212.4 261.7 9.0 204.2 269.8 8.4 196.0 277.5 7.9

45.0

229.8 171.9 14.4 228.0 183.9 13.4 226.0 197.1 12.5 223.8 211.4 11.6 221.4 226.8 10.8 218.6 244.2 9.9 215.2 261.7 9.2 206.9 269.8 8.6 198.6 277.5 8.0

46.0

236.9 173.9 14.7 235.0 185.6 13.7 232.9 198.7 12.8 230.6 212.8 11.9 228.1 228.0 11.0 225.2 245.5 10.2 221.0 261.7 9.4 212.5 269.8 8.8 203.9 277.4 8.2

48.0

244.0 176.0 14.9 242.1 187.5 14.0 239.9 200.3 13.1 237.6 214.2 12.2 235.0 229.3 11.3 232.0 246.8 10.4 226.9 261.7 9.7 218.1 269.7 9.0 209.3 277.4 8.4

50.0

251.1 178.3 15.2 249.2 189.5 14.3 247.0 202.1 13.3 244.6 215.9 12.4 242.0 230.8 11.6 238.9 248.2 10.7 232.9 261.7 9.9 223.9 269.6 9.3 214.8 277.2 8.7

52.0

262.1 182.1 15.6 260.1 192.9 14.6 257.8 205.1 13.7 255.3 218.6 12.8 252.5 233.3 12.0 249.2 250.5 11.0 242.1 261.8 10.3 232.7 269.6 9.6 223.2 277.1 9.0

55.0

MODEL: YCIV0247E/V

E_IPLV = 12.8 V_IPLV = 14.9

NOTES:

1. kW = Compressor Input Power

2. EER = Chiller EER (includes power from compressors, fans, and control panels 0.8 KWi)

3. LCWT = Leaving Chilled Water Temperature

4. Ratings based on 2.4 GPM cooler water per ton

5. Rated IAW ARI Standard 550/590-98

6. Certied IAW the ARI Water-Chilling Packages Using the Vapor Compression Cycle Certication Program,

which is based on ARI Standard 550/590.

JOHNSON CONTROLS

21

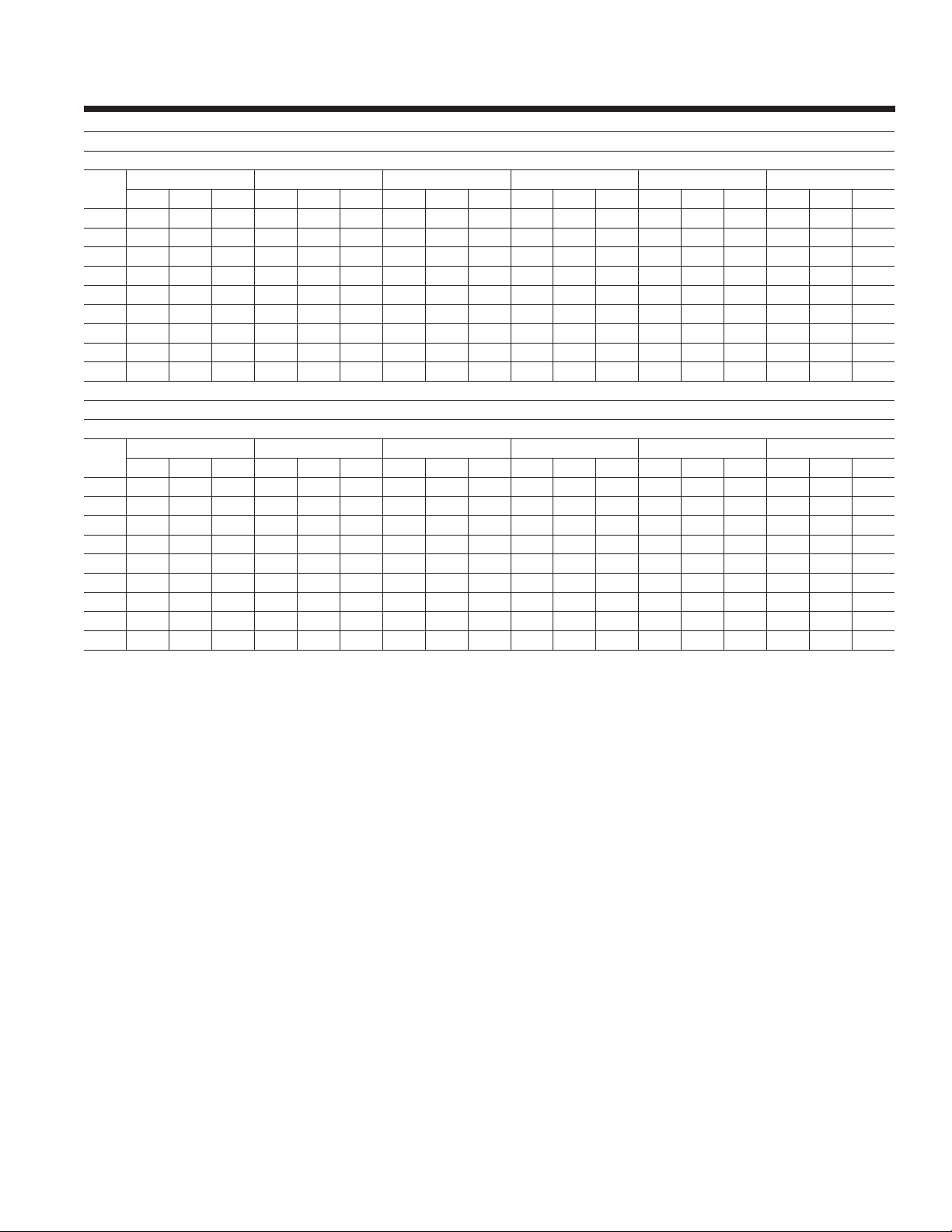

Page 22

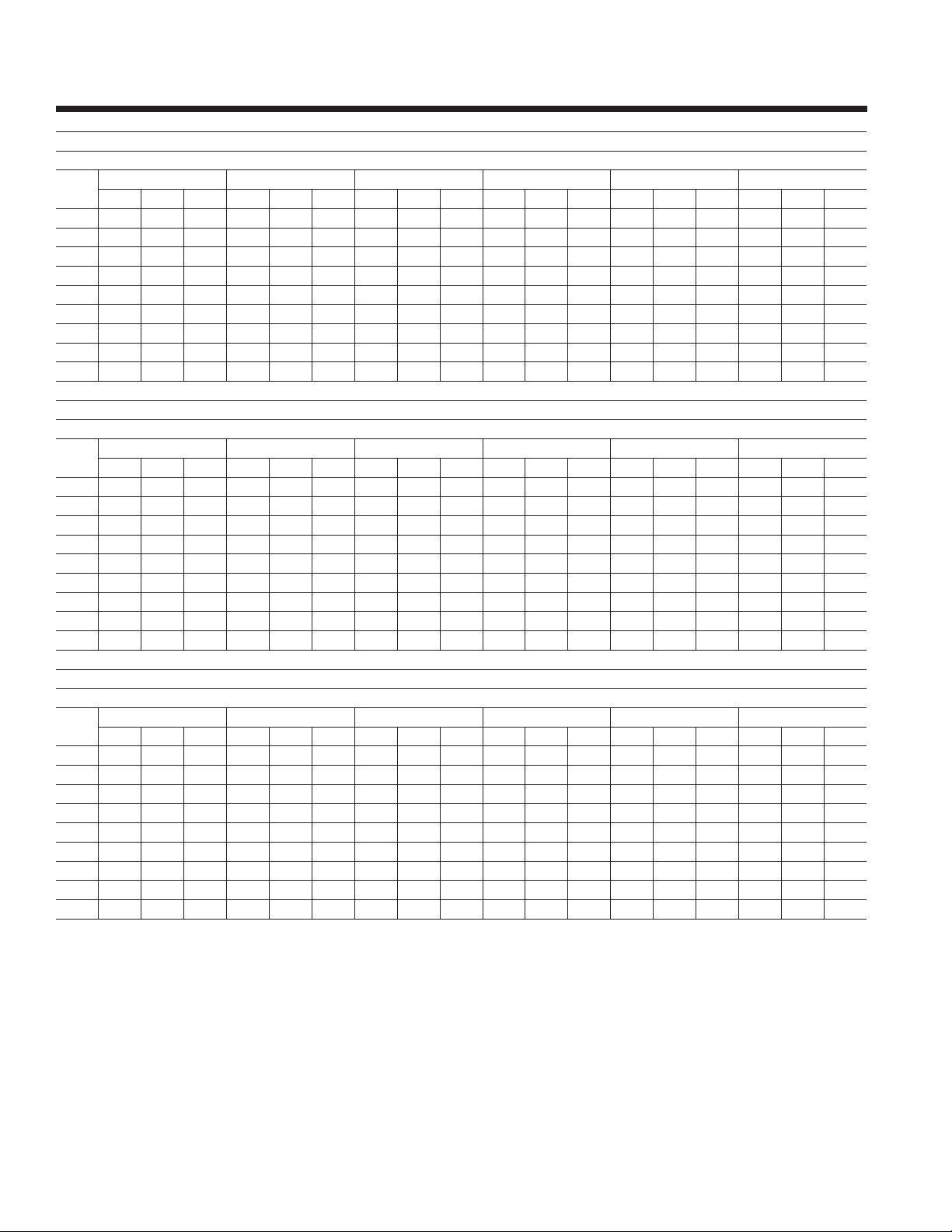

High Efciency Ratings – English - 460V/60Hz

AIR TEMPERATURE ON - CONDENSER (°F)

LCWT 75.0 80.0 85.0 90.0 95.0 100.0 105.0 110.0 115.0

(°F) TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER

232.7 192.6 13.1 230.8 206.9 12.2 228.7 222.3 11.3 226.4 238.6 10.5 223.9 255.8 9.7 221.1 275.2 9.0 216.9 292.5 8.3 210.2 305.1 7.8 202.9 316.2 7.2

40.0

240.0 194.4 13.4 238.0 208.6 12.5 235.8 223.9 11.6 233.4 240.2 10.8 230.8 257.3 10.0 227.9 276.8 9.2 223.2 293.8 8.5 216.0 305.8 8.0 208.5 317.0 7.4

42.0

247.4 196.3 13.7 245.4 210.4 12.8 243.1 225.6 11.9 240.6 241.8 11.0 237.9 259.0 10.2 234.7 278.3 9.4 229.7 294.9 8.7 221.9 306.4 8.2 213.0 315.2 7.6

44.0

251.2 197.4 13.9 249.1 211.4 12.9 246.8 226.5 12.0 244.2 242.7 11.1 241.4 259.9 10.3 238.1 278.9 9.6 232.8 295.2 8.9 225.0 306.8 8.3 214.3 311.7 7.7

45.0

255.1 198.5 14.0 252.9 212.3 13.1 250.5 227.4 12.1 247.9 243.6 11.3 245.1 260.7 10.5 241.5 279.6 9.7 236.0 295.5 9.0 228.0 307.1 8.4 215.6 308.1 7.9

46.0

262.8 200.8 14.3 260.6 214.5 13.3 258.1 229.4 12.4 255.4 245.4 11.5 252.4 262.6 10.7 248.4 280.9 9.9 242.4 296.1 9.2 234.2 307.7 8.6 218.0 300.5 8.2

48.0

270.8 203.3 14.5 268.5 216.8 13.6 265.9 231.5 12.7 263.1 247.5 11.8 260.0 264.5 11.0 255.5 282.2 10.1 248.9 296.8 9.4 240.5 308.3 8.8 220.2 292.4 8.5

50.0

278.9 205.9 14.8 276.5 219.2 13.9 273.8 233.8 12.9 270.9 249.6 12.0 267.7 266.6 11.2 262.8 283.6 10.4 255.5 297.5 9.7 246.9 308.9 9.0 222.2 284.1 8.8

52.0

291.2 209.7 15.2 288.7 223.1 14.2 285.9 237.5 13.3 282.8 253.1 12.4 279.5 269.8 11.6 273.9 286.0 10.7 265.7 298.6 10.0 256.7 309.9 9.3 225.0 272.3 9.2

55.0

MODEL: YCIV0267E/V

AIR TEMPERATURE ON - CONDENSER (°F)

LCWT 75.0 80.0 85.0 90.0 95.0 100.0 105.0 110.0 115.0

(°F) TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER

264.2 211.7 13.5 261.9 228.6 12.5 259.3 246.9 11.5 256.4 266.4 10.6 253.3 286.8 9.8 249.7 309.7 9.0 244.9 331.1 8.3 234.7 343.0 7.7 224.5 353.9 7.1

40.0

272.6 213.3 13.8 270.3 229.9 12.8 267.6 248.0 11.8 264.6 267.4 10.9 261.3 287.9 10.1 257.6 310.9 9.2 251.8 331.4 8.5 241.3 343.4 7.9 230.7 354.6 7.3

42.0

281.2 215.2 14.1 278.8 231.4 13.1 276.0 249.2 12.1 272.9 268.5 11.2 269.5 288.9 10.4 265.6 312.2 9.5 258.9 331.4 8.8 247.9 343.6 8.1 237.1 355.1 7.5

44.0

285.5 216.3 14.3 283.1 232.3 13.3 280.3 249.9 12.3 277.2 269.1 11.4 273.7 289.5 10.5 269.7 312.7 9.6 262.4 331.4 8.9 251.3 343.7 8.2 240.3 355.3 7.6

45.0

289.9 217.4 14.4 287.4 233.2 13.4 284.6 250.7 12.5 281.4 269.8 11.5 277.9 290.1 10.6 273.8 313.4 9.8 266.0 331.5 9.0 254.7 343.8 8.3 243.5 355.5 7.7

46.0

298.8 219.9 14.7 296.3 235.3 13.7 293.4 252.4 12.8 290.1 271.2 11.8 286.5 291.4 10.9 282.2 314.7 10.0 273.3 331.4 9.2 261.7 343.8 8.5 250.2 355.6 7.9

48.0

307.8 222.7 15.0 305.3 237.6 14.0 302.3 254.4 13.1 299.0 273.0 12.1 295.2 293.0 11.2 290.8 316.1 10.3 280.7 331.3 9.5 268.8 343.8 8.8 256.9 355.8 8.1

50.0

317.0 225.8 15.3 314.5 240.3 14.3 311.5 256.6 13.3 308.0 274.9 12.4 304.2 294.7 11.5 299.6 317.8 10.5 288.2 331.3 9.7 276.0 343.8 9.0 263.8 355.8 8.3

52.0

331.1 231.1 15.6 328.5 244.8 14.7 325.4 260.5 13.8 321.9 278.2 12.8 317.9 297.6 11.9 312.4 319.0 10.9 299.8 331.4 10.1 287.1 343.7 9.4 274.4 355.8 8.7

55.0

MODEL: YCIV0287E/V

AIR TEMPERATURE ON - CONDENSER (°F)

LCWT 75.0 80.0 85.0 90.0 95.0 100.0 105.0 110.0 115.0

(°F) TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER

281.2 222.4 13.6 278.8 240.6 12.6 276.1 260.6 11.6 273.1 282.2 10.7 270.0 304.7 9.8 266.3 330.2 9.0 261.8 354.9 8.3 251.2 365.8 7.7 240.7 375.4 7.2

40.0

290.1 224.2 14.0 287.6 241.7 12.9 284.8 261.4 11.9 281.7 282.7 11.0 278.4 305.4 10.1 274.6 331.0 9.3 269.1 354.4 8.5 258.1 365.7 7.9 247.2 375.7 7.4

42.0

299.3 226.2 14.3 296.7 243.2 13.3 293.8 262.4 12.3 290.5 283.5 11.3 287.1 306.0 10.4 283.1 331.8 9.5 276.5 353.7 8.8 265.1 365.4 8.1 253.9 375.8 7.6

44.0

303.9 227.4 14.4 301.3 244.2 13.4 298.3 263.1 12.4 295.0 284.0 11.5 291.5 306.4 10.5 287.4 332.2 9.6 280.3 353.4 8.9 268.7 365.1 8.3 257.3 375.7 7.7

45.0

308.6 228.7 14.6 305.9 245.2 13.6 302.9 263.9 12.6 299.6 284.5 11.6 296.0 306.8 10.7 291.8 332.6 9.8 284.1 353.0 9.0 272.4 364.8 8.4 260.8 375.6 7.8

46.0

318.1 231.7 14.9 315.4 247.4 13.9 312.2 265.5 12.9 308.8 285.7 11.9 305.0 307.8 11.0 300.7 333.6 10.1 291.8 352.3 9.3 279.8 364.2 8.6 267.8 375.1 8.0

48.0

327.8 235.1 15.1 325.0 250.0 14.2 321.8 267.5 13.2 318.2 287.4 12.2 314.3 309.2 11.3 309.8 334.6 10.3 299.7 351.5 9.5 287.3 363.4 8.9 274.9 374.6 8.3

50.0

337.8 239.0 15.3 334.8 253.2 14.4 331.5 269.9 13.5 327.8 289.4 12.5 323.8 310.7 11.6 319.1 335.8 10.6 307.7 350.8 9.8 295.0 362.6 9.1 282.2 373.9 8.5

52.0

353.0 245.8 15.6 349.9 258.6 14.8 346.5 274.4 13.9 342.7 292.8 12.9 338.4 313.4 12.0 333.2 337.9 11.0 320.0 349.8 10.2 306.7 361.6 9.5 293.5 372.7 8.9

55.0

MODEL: YCIV0327E/V

E_IPLV = 13.3 V_IPLV = 14.9

E_IPLV = 12.9 V_IPLV = 14.8

E_IPLV = 13.8 V_IPLV = 14.8

NOTES:

1. kW = Compressor Input Power

2. EER = Chiller EER (includes power from compressors, fans, and control panels 0.8 KWi)

3. LCWT = Leaving Chilled Water Temperature

4. Ratings based on 2.4 GPM cooler water per ton

5. Rated IAW ARI Standard 550/590-98

JOHNSON CONTROLS22

Page 23

FORM 201.23-EG1 (1007)

AIR TEMPERATURE ON - CONDENSER (°F)

LCWT 75.0 80.0 85.0 90.0 95.0 100.0 105.0 110.0 115.0

(°F) TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER TONS KW EER

305.7 244.9 13.5 303.0 264.3 12.5 300.2 285.6 11.5 297.2 308.6 10.6 293.9 332.8 9.8 290.2 360.1 9.0 283.6 382.0 8.3 273.3 395.7 7.8 262.0 405.9 7.3

40.0

315.4 246.9 13.8 312.6 265.9 12.8 309.7 286.8 11.8 306.4 309.5 10.9 303.0 333.8 10.1 299.1 361.2 9.2 291.6 382.1 8.6 280.6 395.6 8.0 269.0 406.3 7.5

42.0

325.4 249.3 14.1 322.5 267.8 13.1 319.3 288.4 12.2 315.9 310.7 11.2 312.3 334.8 10.4 308.2 362.3 9.5 299.7 382.2 8.8 288.1 395.4 8.2 276.1 406.4 7.6

44.0

330.4 250.7 14.3 327.5 268.8 13.3 324.3 289.2 12.3 320.8 311.4 11.4 317.1 335.4 10.5 312.8 362.9 9.6 303.9 382.1 8.9 292.0 395.2 8.3 279.7 406.4 7.7

45.0

335.5 252.1 14.4 332.5 270.0 13.4 329.2 290.1 12.5 325.7 312.3 11.5 321.9 336.1 10.6 317.5 363.6 9.8 308.1 382.2 9.0 295.9 395.0 8.4 283.4 406.3 7.9

46.0

345.9 255.3 14.7 342.8 272.5 13.7 339.4 292.2 12.8 335.6 313.9 11.8 331.6 337.6 10.9 326.7 364.4 10.0 316.6 382.0 9.3 303.7 394.5 8.6 290.9 406.0 8.1

48.0

356.6 258.9 15.0 353.3 275.5 14.0 349.7 294.7 13.1 345.8 315.9 12.1 341.7 339.2 11.2 335.8 364.4 10.3 325.0 381.4 9.6 311.7 393.8 8.9 298.5 405.5 8.3

50.0

367.5 262.9 15.2 364.0 278.9 14.3 360.3 297.4 13.3 356.2 318.2 12.4 351.9 341.2 11.5 345.0 364.6 10.6 333.5 380.8 9.8 319.9 393.2 9.1 304.6 401.2 8.5

52.0