York LA300, 480, 600, LB360 User Manual

®

036-21335-002-A-1102

TECHNICAL GUIDE

SPLIT-SYSTEM AIR-COOLED

EVAPORATOR BLOWER

25, 30, 40 & 50 TON

LA300, LB360, 480 & 600

PROVEN PERFORMANCE

GENERAL

The LA/LB line is a flexible performer. LA300, LB360 & 480

canbepositionedinupto12differentpositionsandsuspended in various positions. The LB600 can be positioned in

up to 7 different arrangements and suspended also. The LA/

LB line will give you the power to condition large amounts of

building space and the ability to conform to almost any situation.

FEATURING

• EASE OF SERVICE

•PUMP-OUTONSTART-UP

• BASE SECTIONS (25, 30 & 40 Ton only)

• SUSPENSION PACKAGES

• HOT WATER COILS

• STEAM COILS (LA300 & LB360 only)

• WIDE RANGE OF BLOWER MOTORS

• A VARIETY OF DRIVE PACKAGES

• CONTROL BOX WITH LOW VOLTAGE TRANSFORMER AND MOTOR STARTER (motor, motor drive

kit and motor overloads sold separately).

1

This product was manufactured in

a plant whose quality system is

certified/registered as being

in conformity with ISO9001.

FOR DISTRIBUTION USE ONLY - NOT TO BE USED AT POINT OF RETAIL SALE

036-21335-002-A-1102

TABLE OF CONTENTS

DESCRIPTION .............................4

MODULARDESIGN .........................4

FACTORY-MOUNTEDCOMPONENTS ..........4

ACCESSORIES.............................4

GUIDESPECIFICATIONS ...................23

LIST OF FIGURES

Fig. Pg.

1 PRODUCTNOMENCLATURE.................3

2 UNITINSTALLATION ........................4

3 DETAILS FOR SECURING BOTTOM MOUNTING

SUPPORTS ................................6

4 LA300/LB360 WEIGHT DISTRIBUTION . . . . . . . . .6

5 UNIT DIMENSIONS - LA300, LB360 & LB480 . . . .11

6 25 TON LIQUID LINE SOLENOID

WIRING ..................................11

7 30, 40 & 50 TON LIQUID LINE

SOLENOIDWIRING ........................11

8 LA300PIPINGCONNECTIONS ...............12

9 LB360PIPINGCONNECTIONS ...............12

10 LB480PIPINGCONNECTIONS ...............12

11 UNITDIMENSIONS-LB600..................13

12 LB600 PIPING CONNECTIONS - END PANEL

DETAIL...................................13

13 HOTWATERCOILDIMENSIONS .............14

14 STEAMCOILDIMENSIONS..................14

15 BASE SECTION DIMENSIONS . . . . . . . . . .. . . . .14

16 BLOWER CURVE LA300 & LB360 . . . . . . . . . . .. .19

17 BLOWER CURVE LB480 . . . . . . . . . . . . . . . . . . . . 21

18 BLOWER CURVE LB600 . . . . . . . . . . . . . . . . . . . . 22

LIST OF TABLES

Tbl. Pg.

1 STATIC RESISTANCES FOR UNIT ACCESSORIES . 5

2 UNITMOUNTINGDIMENSIONS.................5

3 CORNERWEIGHTS...........................7

4 ACCESSORY OPERATING WEIGHT DISTRIBUTION

(LBS) .....................................7

5 UNITBLOWERMOTORDATA ..................7

6 UNITDRIVEDATA ...........................8

7 MOTOROVERLOADELEMENTS................8

8 HOT WATER COIL CAPACITIES. . . . . . . . . . . . . . . . . 9

9 CAPACITY CORRECTION & PRESSURE DROP

VSGPM ...................................9

10 STEAM COIL CAPACITIES (LA300 & LB360 ONLY) 10

11 CORRECTION FACTORS FOR HIGH STEAM . . . . . 10

12 UNIT DIMENSIONS - LA300, LB360 & LB480 . . . . . 11

13 HOTWATERCOILDIMENSIONS...............14

14 STEAMCOILDIMENSIONS ...................14

15 BASE SECTIONS DIMENSIONS . . . . . . .. .. . . . . . . 15

16 PHYSICALDATA............................16

17 ELECTRICALDATA..........................17

18 FAN PERFORMANCE DATA (25TON) . . . . . . . . . . . 18

19 FAN PERFORMANCE DATA (30TON) . . . . . . . . . . . 18

20 FAN PERFORMANCE DATA (40TON) . . . . . . . . . . . 20

21 FAN PERFORMANCE DATA (50TON) . . . . . . . . . . . 20

2 Unitary Products Group

036-21335-002-A-1102

YORK SPLIT INDOOR PRODUCT NOMENCLATURE

L

A 300 C 00 A 6 A AA 1 A

Model #

Model Number

Description

Options

L Product Category L = Air Handling Unit - Cooling F = Air Handling Unit - Heat Pump

A Product Identifier

Nominal Cooling

300

Capacity

MBH

A =R-22 Standard Efficiency 2-Pipe

B =R-22 Standard Efficiency 4-Pipe

300 = 25 Ton

360 = 30 Ton

480 = 40 Ton

600 = 50 Ton

C Heat Type C = Cooling Only

Nominal Heating

00

Capacity

00 = No Heat Installed

A Airflow Options A=None

6 Voltage

0=None

5 = 575-3-60

6 = 208/230-460-3-60

A Factory Options A=None

AA Special Options AA = None

1 Product Generation 1 = First Generation 2 = Second Generation

FIGURE 1: PRODUCT NOMENCLATURE

NOTE: LB600 matches with both HB480 and HB600

Outdoor Condensing Units for maximum efficiency.

NOTE: LB480 Indoor and HB480 Outdoor Units do

match up,but do not meet ASHRAE 90.1 standards for efficiency.

Unitary Products Group 3

036-21335-002-A-1102

DESCRIPTION

Evaporator blower units are designed with two distinct modules to provide maximum application flexibility. The 25, 30

and40tonunitsareshippedassinglepackageswiththe

blower module mounted on top of the coil module, The

blower module can be repositioned in the field to meet almost

any installation requirement. Blower and coil modules for the

50 ton units are shipped separately to simplify handling.

These modules can be connected in the field with the same

flexibility as thesmaller units.

The blower module includes the blower wheels and room for

a field-mounted motor and drive. The coil module includes

direct expansion coils, 2 in. throwaway filters, liquid line solenoid valves for both capacity reduction and pumpdown, thermal expansion valves, distributors and a condensate drain

pan.

Every evaporator coil is pressurized with air to 325 psig and

leak tested under water. After the headers are brazed onto

the coil and the coil is installed in the unit, the coil is pressurized with a combination of Refrigerant-22 and nitrogen to 150

psig for pressure testing and additional leak testing. After the

coil is evacuated and dehydrated, it is pressurized with a

holding charge of Refrigerant-22 for storage and/or shipping.

Steamcoils, hot water coils, base sections, suspension hardware, blower motors and drive packages are available as

field-installed accessories to provide additional application

flexibility.

These evaporator blowers, combined with condensing units,

provide years of quiet, efficient and dependable operation.

These units are manufactured under ISO 9001 Quality System Certification.

For Indoor Unit Installation details,please see document 03518496-000.

MODULAR DESIGN

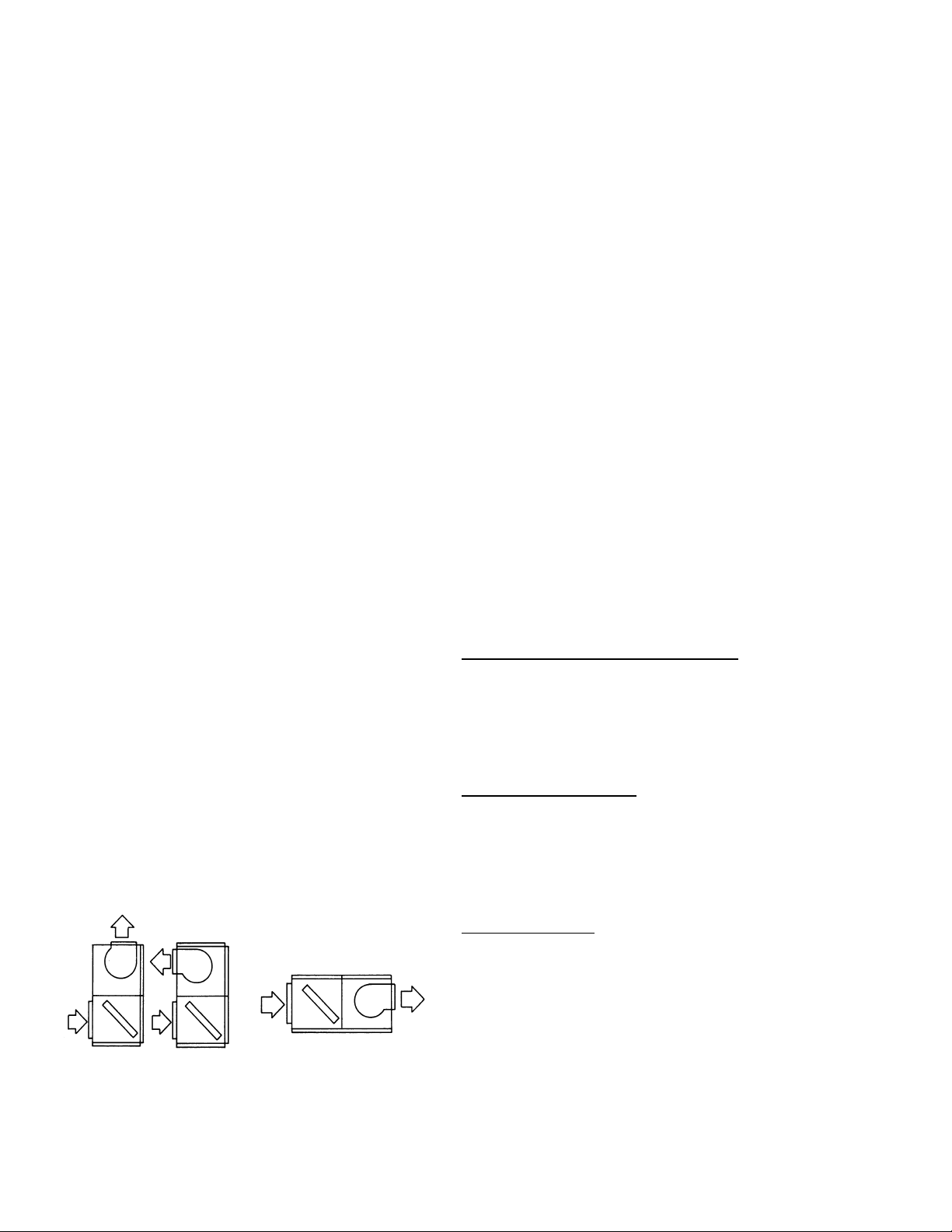

These evaporator blowers can bearranged for a variety o f air

discharge patterns in either the horizontal or vertical position.

Figure 2 shows three of the common installation arrangements. Refer to the unit installationinstructions for otherpossibilities.

Units may be bottom-supported or ceiling-suspended and

can be arranged to meet almost any space or duct requirements. Each unit is available with a choice of blower motors,

drive packages and other accessories to make them suitable

for most applications.

FACTORY-MOUNTED COMPONENTS

PART LOAD OPERATION These evaporator blowers have

multiple coils with pre-piped distributors, expansion valves

and solenoid valves. Field modifications are not required for

part load operations. Capacity reduction not only provides

economical operation, but also maintains more even temperature and humidity levels in the conditioned space.

EASY SERVICE Serviceable expansion valves are provided

on every unit. These superior valves are factory-installed to

provide many years of trouble-free operation. If service is

required, it is not necessary to unbrazeany joints.

PUMP-OUT Evaporator blowers include a solenoid valve for

non-recycling pump-out. When a cooling requirement in the

conditioned space is needed, the refrigerant is pumped into

the high side of the system before unit start-up.

ACCESSORIES

BASE SECTIONS (25, 30 and 40 ton only: Base sections

can be used to elevate units above the floor. If desired, outdoor air may be introduced through these sections by cutting

an access opening to accommodate the outdoor air duct connection. These bases have a durable finish to match the

evaporator blower unit. They may have to be insulated for

certain applications.

SUSPENSION PACKAGES:

to suspend horizontal units from above without interfering

with access to the unit. They can also be used for elevating a

floor-mounted unit (either horizontal or vertical) to provide

additional height for the installation of a trap at the condensate drain connection. All suspension packages can be used

with vibration isolators.

These accessoriescan be used

HOT WATER COILS:

field installation between the blower and the coil modules of

both horizontal and vertical units. Since their casings match

the dimensions and the finish of the basic units, they become

an integral part of the unit after installation. The coils slide out

of their casings for easy installation. Coils have c opper tubes

that have been mechanically expanded into aluminum fins.

Both headers are located on the same end of the coil. Coils

FIGURE 2: UNIT IN STALLATION

4 Unitary Products Group

are leak-tested at 325psig under water and dried before their

connections are capped for storage and shipping.

Drainable water coils are available for

036-21335-002-A-1102

STEAM COILS (LA300 & LB360 only): A steam coil is available on the 25 & 30 Ton for installation between the blower

rounding space. 5 HP motors are inherently protected. 7.5

HP - 15 HP require motor overload protection.

and coil modules of both horizontal and vertical units. Since

the casing matches the dimensions and the finish of the basic

unit, it becomes an integral part of the unit after installation.

The coil slides out of the casings for easy installation and is

pitched in the casings to facilitate condensate drainage. The

coil has copper tubes that have been mechanically expanded

into aluminum fins. Both headers are located on the same

end of the coil. The coil is leak-tested at 325 psig and dried

before the connections are capped for storage and shipping.

BLOWER MOTORS:

Different HP motors are available for

each unit to m eet almost any air delivery requirement. All

motors are UL approved, have permanently lubricated ball

bearings and are field-mounted within the insulated cabinet of

DRIVE PACKAGES:

available for each unit to provide a blower RPM range to

meet almost any air delivery requirement. Variable pitch

motorpulleyscanbeadjustedtoprovidetheproperblower

RPM. All drive packages are rated at least 25% above the

nominal HP rating of the blower motor. Two-groove pulleys

and two belts are provided on every drive package rated at 5

HP and above.

STARTERS AND HEATER ELEMENTS (7.5 - 15 HP):

blower motors that are available for the units do not have

inherent protection and require external motor overload protection. See details in Table 7.

the units to minimize the transmission of sound to the sur-

TABLE 1: STATIC RESISTANCES FOR UNIT ACCESSORIES

UNIT MODEL ACCESSORY CFM

8,000 9,000 10,000 11,000 12,000

LA300

LB360

LB480

LB600

Hot Water Coil 0.06 0.07 0.08 0.09 0.10

Steam Coil 0.11 0.14 0.17 0.20 0.23

10,000 11,000 12,000 13,000 14,000

Hot Water Coil 0.08 0.09 0.10 0.12 0.14

Steam Coil 0.17 0.20 0.23 0.27 0.31

12,800 14,400 16,000 17,600 19,200

Hot Water Coil 0.11 0.13 0.15 0.17 0.20

16,000 18,000 20,000 22,000 24,000

Hot Water Coil 0.15 0.18 0.21 0.24 0.28

Different size pulleys and belts are

The

TABLE 2: UNIT MOUN TING DIMENSIONS

LA/LB

UNIT

300

360

480

1.

See Figure 4 for dimensions AX, BX and CX.

Unitary Products Group 5

AX BX CX

69-1/4 49-1/16 26-5/8

69-1/4 49-1/16 26-5/8

84 50-9/16 34

1

DIMENSIONS, INCHES

NOTE: The following illustration shows how the channels

should be secured to the unit using the hardware

provided with the suspension accessory.

(2) 9/16 HOLES FOR 1/ 2

HANGER RODS

SUSPENSION

CHANNEL

036-21335-002-A-1102

5/16 NUT,

FLATWASHER

3/8 NUT (USED

AS SPACER)

SIDE

PANEL

3

UNIT ANGLE

5/16 NUT,

LOCKWASHER,

FLATWASHER

UNIT PANEL

5/16 BOLT,

FLAT-WASHER

FIGURE 3 : DETAILS FOR SECURING BOTTOM MOUNTING SUPPORTS

D

AX

AX

A

3

1-1/2

HOR IZONTAL

LE U 360 O R 480

UN IT S U S PE ND ED

FR OM ABOVE

T he s ame c hannels ca n be us ed in e ither pos ition. W hen us ed to

1

support at ve rtical u nit, the se c hannels s hould be cut to ma tch the

bottom dimens ion of the e vapora tor coil s ection.

The s us pens ion cha nnels h ave two s ets o f mounting holes to

ac commodate horizontal u nits with or without a h eating c oil. O n

2

a h orizontal unit without a h eating coil, th e s uspens ion cha nnels

will extend 3 " beyond both e nds of the unit.

3

EVAP. C OIL

S E CT ION

BX

VERTICAL LA300, LB360, LB480

UNIT SUPPORTED FROM BELOW

BX

C

HE AT ING C OIL

SUSPENSION

ANGLE S

2

A

1

D

B

BLOWER

S E CT ION

BLOWER

S E CT ION

BX

B

EVAP.

COIL

S E CT ION

4

CX

BX

C

T he s ame channe ls c an be u sed to s upport a horiz ontal, fl oor-

3

mounted unit from be low.

After these bottom c hannels are c ut per Note 1 , a new h ole will h ave

4

to be d rilled a t the cut e nd if the unit is to be mounted o n isola tors.

FIGURE 4 : LA300/LB360 WEIGHT DISTRIBUTION

6 Unitary Products Group

036-21335-002-A-1102

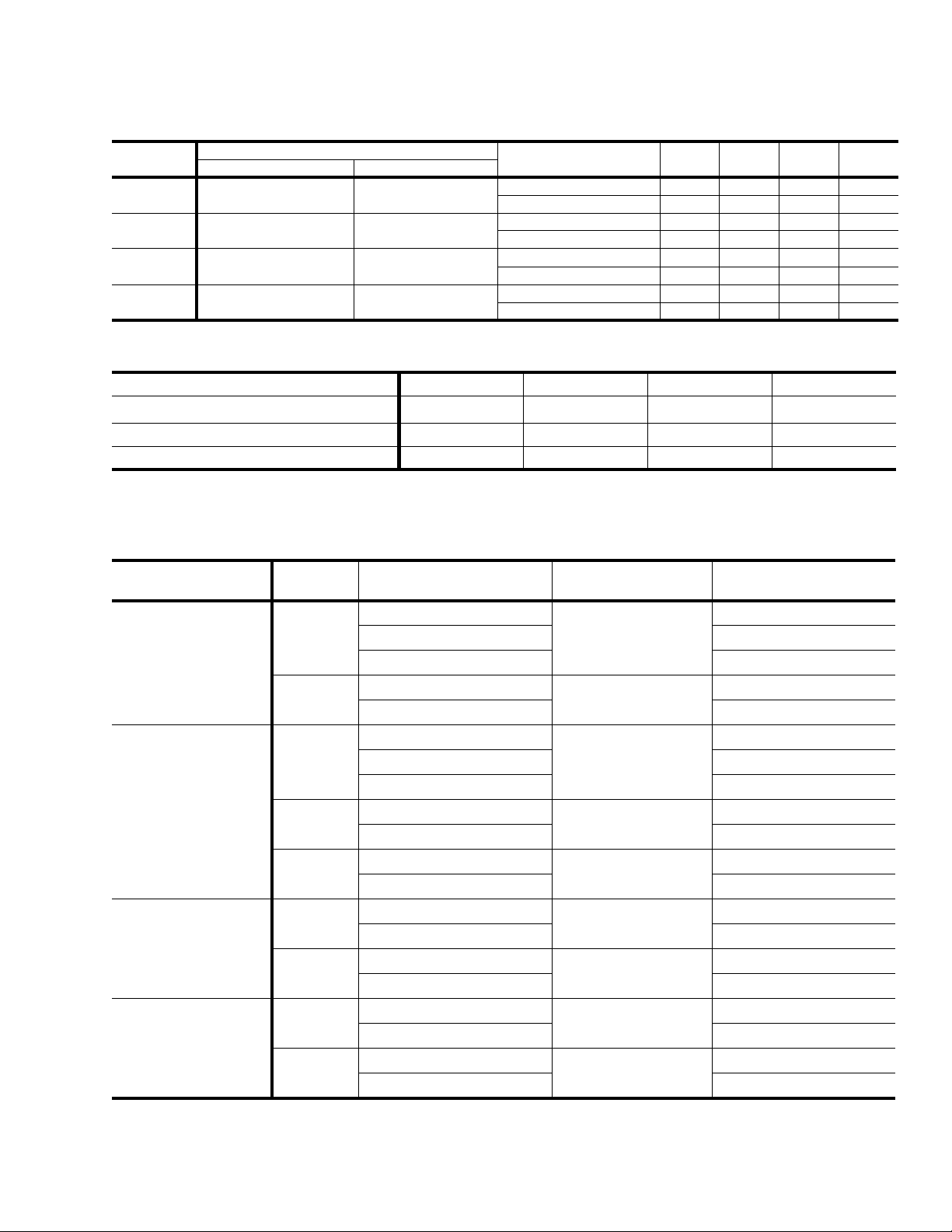

TABLE 3: CORNER WEIGHTS

UNIT-

MODEL

LA300 1180 1125

LB360 1180 1146

LB480 1510 1426

LB600 1572 1640

Unit Weight

Configuration A B C DShipping Operation

HORIZONTAL 276 317 285 247

VERTICAL 262 301 301 262

HORIZONTAL 281 323 290 252

VERTICAL 266 307 307 266

HORIZONTAL 348 414 361 303

VERTICAL 292 348 427 359

HORIZONTAL 451 386 370 433

VERTICAL 484 414 342 400

TABLE 4: ACCESSORY OPERATING WEIGHT DISTRIBUTION (LBS)

ACCESSORY

2

BASE

HOT WATER COIL

STEAM COIL 1 ROW

1.

These weights should be added to each point load in table 3.

2.

This accessory can only be applied on units installed in the vertical position.

LA300 LB360 LB480 LB600

25 25 30 45

35 35 45 35

30 30 35 50

TABLE 5: UNIT BLOWER MOTOR DATA

UNIT MODEL HP

5

LA300

7.5

5

LB360

7.5

10

7.5

LB480

10

10

LB600

15

MOTOR KIT

MODEL NUMBER

2LR04605032

2LR04605023 208

2LR04605158 575

2LP04607133

2LP04607158 575

2LR04605032

2LR04605023 208

2LR04605158 575

2LP04607133

2LP04607158 575

2LP04610133

2LP04610158 575

2LP04607133

2LP04607158 575

2LP04610133

2LP04610158 575

2LP04610133

2LP04610158 575

2LP04615133

2LP04615158 575

1

FRAMESIZE

184

213

184

213

215

213

215

215

254

VOLTAGE

(3PH-60HZ)

230/460

230/460

230/460

208/230/460

208/230/460

208/230/460

208/230/460

208/230/460

208/230/460

Unitary Products Group 7

036-21335-002-A-1102

TABLE 6: UNIT DRIVE DATA

ADJUSTABLE MOTOR PULLEY FIXED BLOWER PULLEY BELTS

UNIT

MODEL

DRIVE KIT

MODEL

NUMBER

1LD0440 600 - 750 4.0- 5.0 1 1/8 12.0 1 3/16 2 63.3 A62

LA300

1LD0407 700 - 850 4.2- 5.2 1 3/8 11.0 1 3/16 2 63.3 A62

1LD0442 780 - 940 5.3 - 6.3 1 3/8 12. 0 1 3/16 2 63.3 A62

1LD0415 636 - 795 4.0 - 5.0 1 1/8 11.0 1 3/16 2 63.3 A62

LB360

1LD0407 668 - 827 4.2 - 5.2 1 3/8 11.0 1 3/16 2 63.3 A62

1LD0408 827 - 986 5.3 - 6.3 1 3/8 11.0 1 3/16 2 59.7 A59

LB480 1LD0409 607 - 776 4.3 - 5.5 1 3/8 12.4 1 3/16 2 85.1 B84

1LD0410 776 - 917 5.4 - 6.6 1 3/8 12. 4 1 3/16 2 86.8 B85

LB600 1LD0411 692 - 833 4.8 - 6.0 1 3/8 12.4 1 3/16 2 78.6 B78

1LD0412 762 - 931 5.4 - 6.6 1 5/8 12. 4 1 3/16 2 76.8 B75

BLOWER

RPM

RANGE

PITCH DIA.

(IN.)

BORE

(IN.)

PITCH DIA.

(IN.)

BORE

(IN.) QTY.

PITCH

LENGTH

(IN.) DESIGNATION

TABLE 7: MOTOR OVERLOAD ELEMENTS

MOTOR HP VOLTAGE MODEL NUMBER

208 2MP04704600

5

7.5

10

15

230 2MP04704600

460 2MP04704900

575 2MP04705000

208 2MP04703700

230 2MP04704500

460 2MP04704300

575 2MP04704000

208 2MP04701600

230 2MP04704100

460 2MP04704200

575 2MP04704300

208 2MP04704400

230 2MP04701700

460 2MP04704500

575 2MP04704600

1

Do not operate the supply air blower motor above

its nominal HP rating when a unit is equipped with

a hot water coil a ccessory. Do not use steam in hot

water coils.

Do not operate the supply air blower above its

nominal HP rating when a unit is equipped with a

steam coil accessory.

Although these coils are suitable for a much higher

pressure, steam above 25 psig provides too much

heat that could damage the blower motor.

1.

These units are equipped from the factory with a correctly sized motor starter; overload elements are not

factory supplied.

Note: Three elements required per unit.

8 Unitary Products Group

Loading...

Loading...