Page 1

D*V Model Air Cooled Self

Page 1

Contained Indoor Packaged Units

2-25 Tons

Preliminary Application Data

July 28, 2008

Page 2

PROJECT: TAG:

Page 2

1 of 4

Gross Cooling Capacity [Btuh]: 95,000*

Design CFM: 3,200

Evaporator Coil Face Area: 8.67 [sq ft]

Rows/FPI : 3/10

Refrigerant Control: TX Valve

Energy Efficiency Ratio: 11.55 EER**

Net Cooling Capacity [Btuh]: 92,000**

Net Cooling CFM: 3,200

Evaporator Fan No./Type: 1/CENTRIFUGAL

Diameter x Width [in]: 12x15

Drive: Adjustable Belt

Motor HP : 1.5 / 2.0

[Standard/Oversized]

Condenser Fan No./Type: 2/CENTRIFUGAL

Diameter x Width [in]: 12x11

Drive: tleB elbatsujdA

Motor HP : 2.0

[Standard]

*Cooling performance is rated at 95°F ambient, 80°F entering dry bulb, 67°F wet bulb

and CFM listed. Gross capacity does not include the effect of fan motor heat.

**Rated in accordance with ARI Standard 360-2000

Condenser Coil Face Area: 12.28 [sq ft]

Rows/FPI: 4/14

Compressor No./Type: 2/Scroll

Refrigerant Circuits: 2 / Independent

Refrigerant: R22

Charge: 8.75 Lbs./ circuit

Filters - Qty./Size: 4/14x25x2

Operating Weight [lbs.]: 1005

Shipping Weight [lbs.]: 1060

Condensate Connection: 3 / 4 NPT

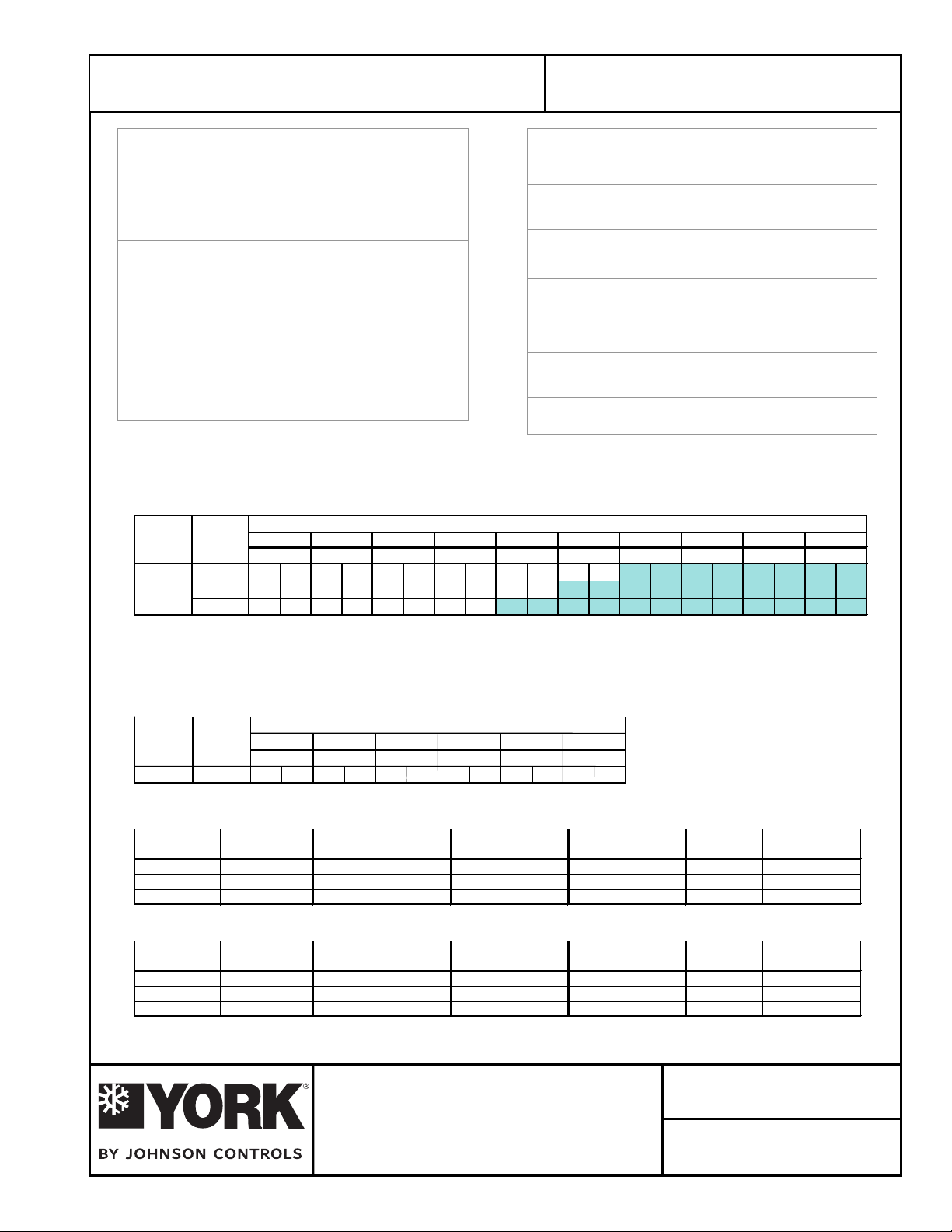

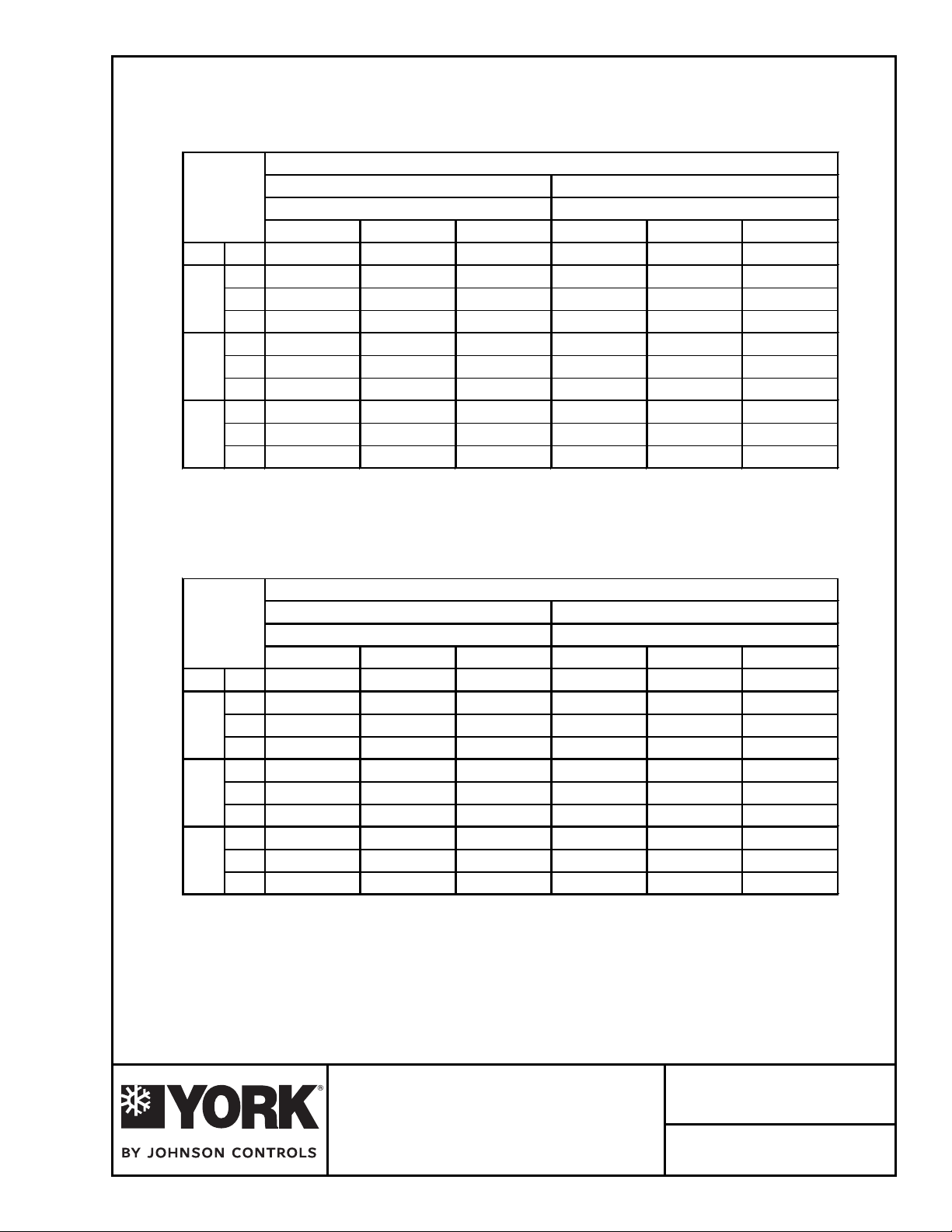

EVAPORATOR FAN PERFORMANCE

MODEL SUPPLY 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0

# CFM RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

3000

734 0.76 809 0.89 881 1.02 950 1.17 1016 1.32 1079 1.47 1139 1.63 1196 1.79 1251 1.97 1303 2.17

3200DPV096

771 0.90 843 1.03 911 1.17 977 1.32 1040 1.47 1101 1.63 1159 1.81 1214 2.01 ----

811 1.06 879 1.20 944 1.35 1007 1.50 1068 1.66 1128 1.83 1187 2.01

3400

EXTERNAL STATIC PRESSURE - Inches W.C.

- - ----

NOTE:

1. At high evaporator air flows, and wet bulb conditions, condensate carry-over may occur. Adjust airflow downward as necessary.

2. Values include pressure drop from wet coil and clean filters.

3. Shaded areas indicate oversize motors.

CONDENSER FAN PERFORMANCE

EXTERNAL STATIC PRESSURE - Inches W.C.

MODEL OUTDOOR 0.2 0.4 0.6 0.8 1.0 1.2

# CFM RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

DPV096

4700

737 1.19 811 1.38 882 1.59 951 1.82 1017 2.07 - -

ELECTRICAL DATA – STANDARD MOTOR

MODEL

#

DPV096

DPV096

DPV096

VOLTAGE COMPRESSOR EVAPORATOR FAN CONDENSER FAN MIN. CCT. MAX FUSE /

QTY RLA LRA HP FLA HP FLA AMPACITY CCT. BKR. AMP

208-230/3/60 2 @ 13.9 88.0 1.50 4.5 2.00 5.9 41.68 50

460/3/60 2 @ 7.1 44.0 1.50 2.1 2.00 2.8 20.97 25

575/3/60 2 @ 5.4 34.0 1.50 1.7 2.00 2.2 15.94 20

ELECTRICAL DATA – OVERSIZED MOTOR

MODEL

#

DPV096

DPV096

DPV096

Johnson Controls maintains a continuous product improvement policy, therefore specifications are subject to change without notice.

VOLTAGE COMPRESSOR EVAPORATOR FAN CONDENSER FAN MIN. CCT. MAX FUSE /

208-230/3/60 2 @ 13.9 88.0

460/3/60 2 @ 7.1 44.0

575/3/60 2 @ 5.4 34.0

QTY RLA LRA HP FLA HP FLA AMPACITY CCT. BKR. AMP

2.00

5.9 2.00 5.9 43.08 50

2.00 2.8 2.00 2.8 21.67 25

2.00 2.2 2.00 2.2 16.44 20

DESCRIPTION:

Form YK145.12-PA4 (308)

DPV096 VERTICAL UNIT

AIR-COOLED SELF-CONTAINED

March 2008

Page 3

2 of 4

Page 3

"DPV" SERIES VERTICAL INDOOR SYSTEM

GENERAL MECHANICAL SPECIFICATIONS

GENERAL

All models 5-15 tons ship as factory-charged unitized packages. The 20 ton model shall be shipped as

separate evaporator and condensing unit modules (nitrogen holding charge only). All units may be field

split and installed as separate modules to suit on-site requirements. All packages are designed for freestanding mounting on the floor, or on a field fabricated structural steel stand. The 5, 8, and 10 ton models

are shipped with vertical evaporator fan discharge as standard. The 12, 15, and 20 ton models are

shipped horizontal discharge as standard.

CABINET

All cabinets are completely constructed of heavy gauge galvanized steel. The entire unit interior ( both

evaporator and condensing section ) is insulated with 1/2" thick,

are

equipped with lifting handles for ease of removal and handling. Duct flanges for condenser discharge,

condenser intake, and evaporator discharges, are provided with the unit for field installation. Duct flange

on evaporator return is incorporated into the filter frame.

COMPRESSORS

All models utilize "Scroll" type hermetic compressors. Compressors are mounted on rubber isolators to

minimize vibration transmission. Internal overload protection is provided. External high pressure and low

pressure cutout switches are included in each compressor control circuit. Crankcase heaters are

standard on all models.

2 lb. density insulation. Service panels

REFRIGERANT CIRCUITS

The 5 ton units have a single refrigeration circuit. The 8-20 ton units feature two independent refrigeration

circuits. Each refrigeration circuit includes

equali

zer), liquid line filter drier, sight glass/moisture indicator, and service gauge ports.

EVAPORATOR AND CONDENSER COILS

The evaporator and condenser coils are constructed of internally enhanced copper tubes mechanically

bonded to rippled aluminum plate fins. Both coils are employed in a draw-thru configuration. Large

evaporator coil face area minimizes potential water blow-off.

INDOOR/OUTDOOR FANS

Forward curved, double inlet and double width centrifugal blowers are used for both evaporator and

condenser air movement. Blower wheels are fabricated of galvanized steel. Blowers employ solid steel

shafts, supported in permanently lubricated ball bearing. All blowers are belt driven. Variable-pitch motor

sheaves allow for field adjustment

ELECTRI

All units are completely factory wired with all necessary controls. Manual reset protection is provided on

both evaporator and condenser motors. A manual reset circuit is also provided on each compressor

control circuit in the event of high/low pressure cutout. A 24 volt control circuit, with oversize transformer,

is provided for field connection.

FILTERS

All models are shipped with 2-inch thick medium-efficiency throwaway filters factory installed. Filter rack

is external to the cabinet (shipped loose).

CAL/CONTROLS

of blower rpm.

an adjustable thermal expansion valve (with external

Johnson Controls maintains a continuous product improvement policy, therefore specifications are subject to change without notice.

DESCRIPTION:

Form YK145.12-PA4 (308)

MECHANICAL SPECIFICATIONS

DPV096 VERTICAL UNIT

AIR-COOLED SELF-CONTAINED

DATE:

March 2008

Page 4

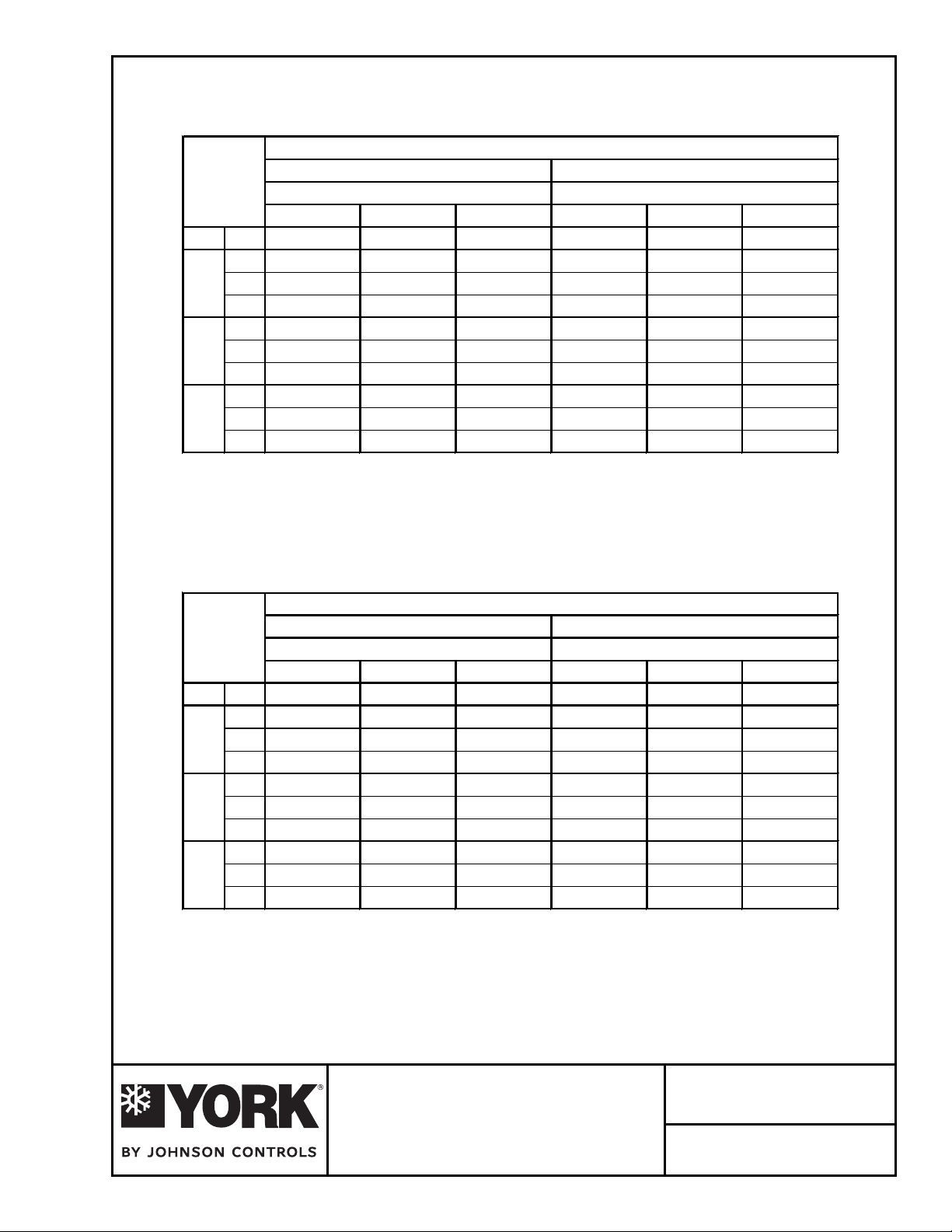

8 TON

Page 4

CFM EDB

75°F

3000 80°F

85°F

75°F

3200 80°F

85°F

75°F

3400 80°F

85°F

3 of 4

Ambient Condenser Air Temperature

F°59F°58

BWEBWE

62°F 67°F 72°F 62°F 67°F 72°F

TC SC TC SC TC SC TC SC TC SC TC SC

90.0 72.0 97.5 57.3 106.7 43.8 86.8 70.6 94.1 55.9 102.5 42.2

91.3 86.7 98.2 71.6 107.6 57.8 88.4 85.8 94.7 70.2 103.4 56.2

96.6 96.6 99.1 86.8 108.2 72.4 93.7 93.7 95.6 85.2 103.7 70.9

91.1 74.1 98.3 58.5 107.1 44.1 87.7 72.6 94.8 57.0 102.8 42.5

92.7 90.0 99.0 73.5 108.2 58.8 89.1 87.8 95.5 72.1 103.6 57.3

98.3 98.3 100.1 89.4 108.6 74.3 95.3 95.3 96.5 87.9 104.0 72.7

91.8 76.0 99.0 59.6 107.5 44.4 88.2 74.5 95.4 58.2 103.0 42.7

93.4 92.0 99.7 75.4 108.4 59.8 92.3 92.3 96.1 74.0 103.8 58.2

99.8 99.8 100.9 92.0 108.8 76.0 96.8 96.8 97.2 90.4 104.1 74.5

8 TON

CFM EDB

75°F

3000 80°F

85°F

75°F

3200 80°F

85°F

75°F

3400 80°F

85°F

Ambient Condenser Air Temperature

F°511F°501

BWEBWE

62°F 67°F 72°F 62°F 67°F 72°F

TC SC TC SC TC SC TC SC TC SC TC SC

83.3 69.1 90.3 54.3 97.9 40.5 79.4 67.4 86.2 52.7 92.7 38.5

84.6 83.4 90.9 68.7 98.6 54.5 82.6 82.6 86.7 67.0 93.4 52.6

90.7 90.7 91.8 83.6 98.9 69.1 87.3 87.3 87.7 81.8 93.5 67.3

83.9 71.0 91.0 55.5 98.0 40.8 79.7 69.2 86.7 53.8 92.7 38.8

87.5 87.5 91.5 70.6 98.7 55.5 84.0 84.0 87.2 69.0 93.3 53.6

92.1 92.1 92.5 86.2 99.1 71.0 88.7 88.7 88.1 84.3 93.5 69.1

84.3 72.9 91.5 56.6 98.2 41.0 81.4 72.1 87.2 54.9 92.7 39.0

88.9 88.9 92.2 92.2 98.7 56.4 85.2 85.2 87.6 70.8 93.1 54.5

93.5 93.5 93.0 88.6 99.0 72.7 89.9 89.9 90.3 87.8 93.2 62.6

DESCRIPTION:

COOLING PERFORMANCE DATA

DPV096 VERTICAL UNIT

AIR-COOLED SELF-CONTAINED

Form YK145.12-PA4 (308)

DATE:

March 2008

Page 5

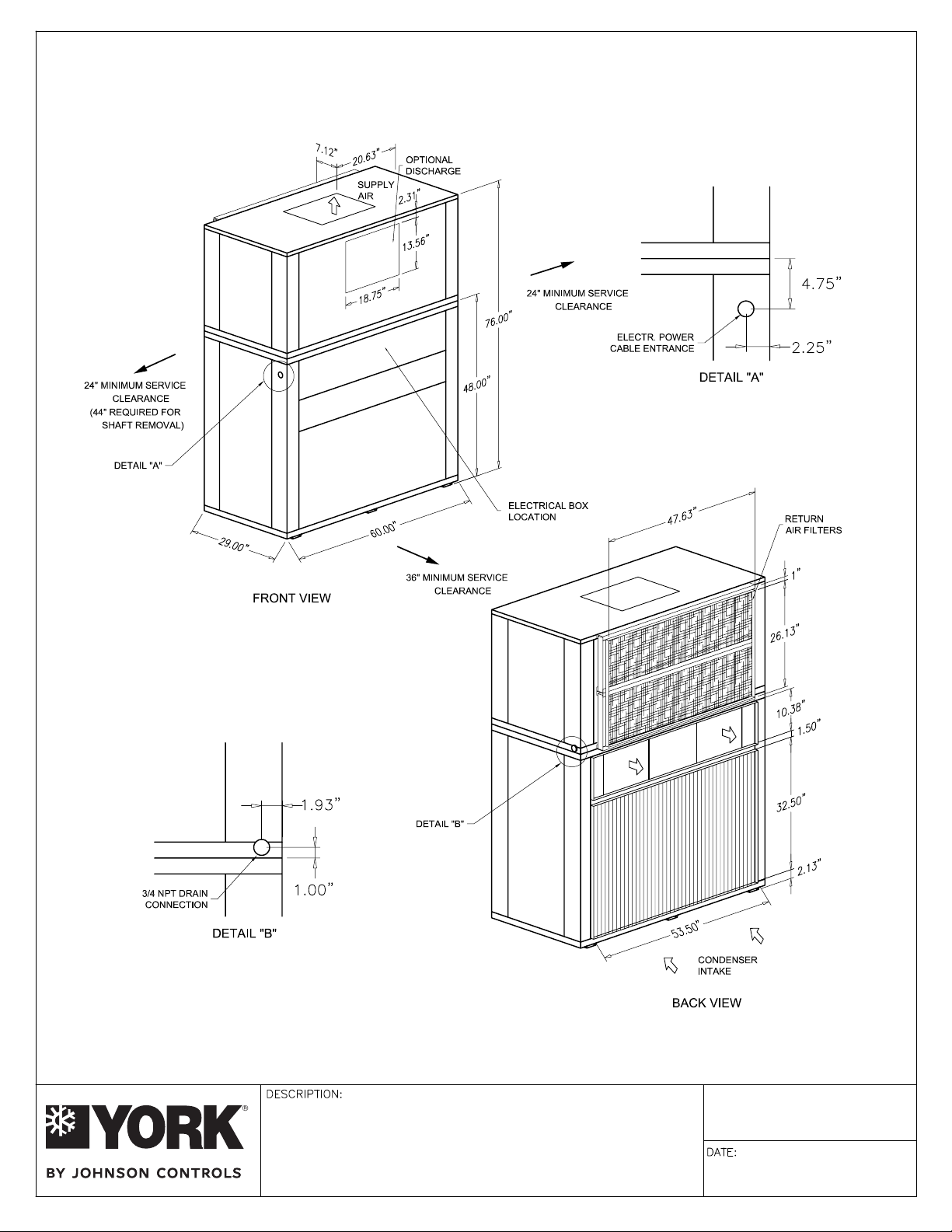

DPV096 AND DPV120 DIMENSIONAL DATA

Page 5

4 of 4

DIMENSIONAL DATA

DPV096 & DPV120 VERTICAL UNIT

AIR-COOLED SELF-CONTAINED

Form YK145.12-PA4 (308)

March 2008

Page 6

PROJECT: TAG:

Page 6

1 of 4

Gross Cooling Capacity [Btuh]: 122,000*

Design CFM: 4,000

Evaporator Coil Face Area: 8.67 [sq ft]

Rows/FPI : 4/10

Refrigerant Control: TX Valve

Energy Efficiency Ratio: 10.60 EER**

Net Cooling Capacity [Btuh]: 117,000**

Net Cooling CFM: 3,600

Evaporator Fan No./Type: 1/CENTRIFUGAL

Diameter x Width [in]: 12x15

Drive: Adjustable Belt

Motor HP : 2.0 / 3.0

[Standard/Oversized]

Condenser Fan No./Type: 2/CENTRIFUGAL

Diameter x Width [in]: 12x11

Drive: tleB elbatsujdA

Motor HP : 3.0

[Standard]

*Cooling performance is rated at 95°F ambient, 80°F entering dry bulb, 67°F wet bulb

and CFM listed. Gross capacity does not include the effect of fan motor heat.

**Rated in accordance with ARI Standard 360-2000

Condenser Coil Face Area: 12.28 [sq ft]

Rows/FPI: 4/14

Compressor No./Type: 2/Scroll

Refrigerant Circuits: 2 / Independent

Refrigerant: R22

Charge: 9.5 Lbs./ circuit

Filters - Qty./Size: 4/14x25x2

Operating Weight [lbs.]: 1065

Shipping Weight [lbs.]: 1110

Condensate Connection: 3 / 4 NPT

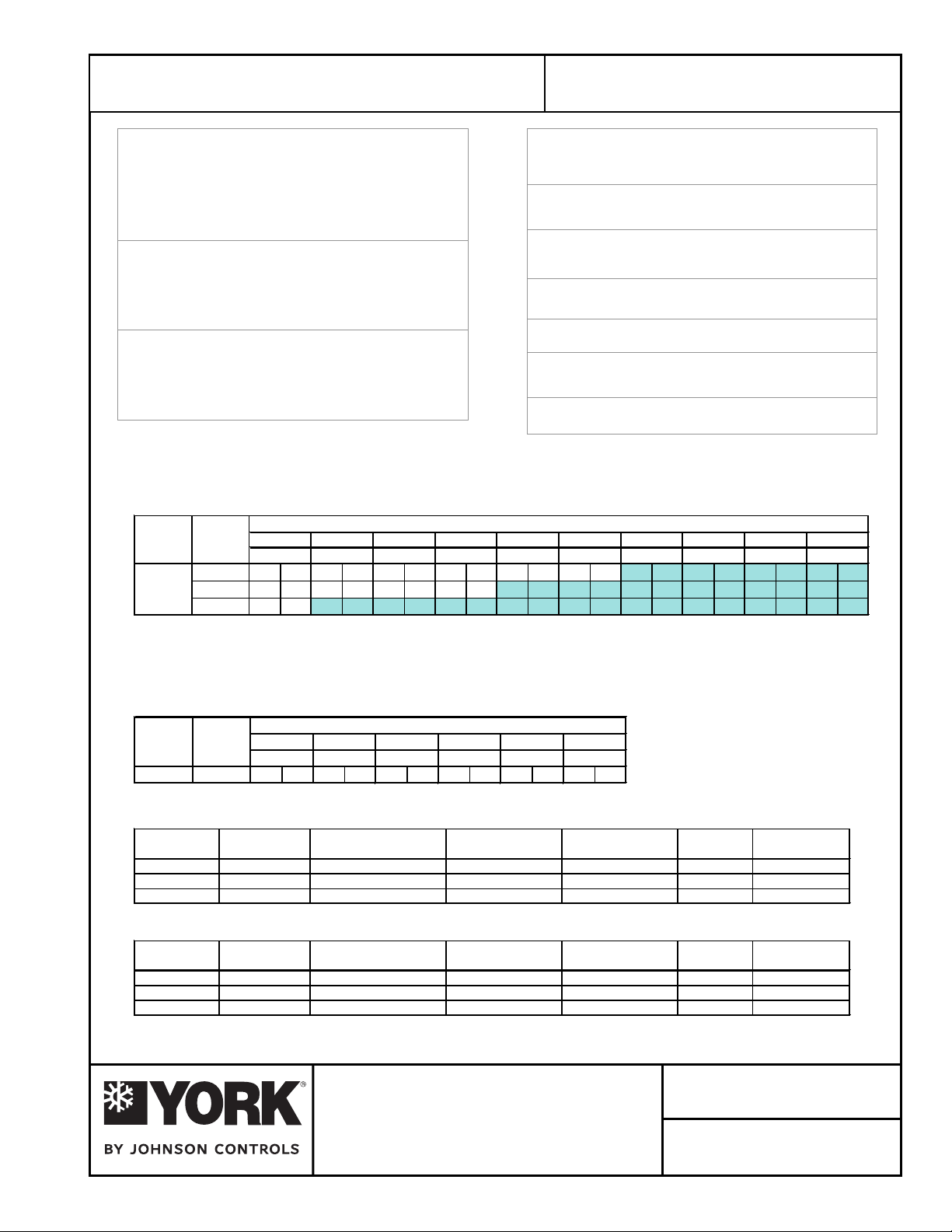

EVAPORATOR FAN PERFORMANCE

MODEL SUPPLY 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0

# CFM RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

3600

DPV120

800 1.13 867 1.28 931 1.43 993 1.59 1052 1.74 1100 1.88 1158 2.11 1225 2.25 1245 2.50 1335 2.66

4000

876 1.52 937 1.68 996 1.85 1052 2.01 1100 2.23 1154 2.31 1200 2.55 1263 2.72 1304 2.93 1367 3.12

951 1.98 1007 2.16 1062 2.35 1120 2.52 1178 2.76 1204 2.92 1263 3.15

4400

EXTERNAL STATIC PRESSURE - Inches W.C.

------

NOTE:

1. At high evaporator air flows, and wet bulb conditions, condensate carry-over may occur. Adjust airflow downward as necessary.

2. Values include pressure drop from wet coil and clean filters.

3. Shaded areas indicate oversize motors.

CONDENSER FAN PERFORMANCE

EXTERNAL STATIC PRESSURE - Inches W.C.

MODEL OUTDOOR 0.2 0.4 0.6 0.8 1.0 1.2

# CFM RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

DPV120

5500

804 1.71 873 1.94 941 2.19 1008 2.46 1073 2.75 1136 3.06

ELECTRICAL DATA – STANDARD MOTOR

MODEL

#

DPV120

DPV120

DPV120

VOLTAGE COMPRESSOR EVAPORATOR FAN CONDENSER FAN MIN. CCT. MAX FUSE /

QTY RLA LRA HP FLA HP FLA AMPACITY CCT. BKR. AMP

208-230/3/60 2 @ 19.3 123.0 2.00 5.9 3.00 8.7 58.03 70

460/3/60 2 @ 7.5 49.5 2.00 2.8 3.00 4.0 23.68 30

575/3/60 2 @ 6.4 40.0 2.00 2.2 3.00 3.2 19.80 25

ELECTRICAL DATA – OVERSIZED MOTOR

MODEL

#

DPV120

DPV120

DPV120

Johnson Controls maintains a continuous product improvement policy, therefore specifications are subject to change without notice.

VOLTAGE COMPRESSOR EVAPORATOR FAN CONDENSER FAN M IN. CCT. MAX FUSE /

208-230/3/60 2 @ 19.3 123.0 3.00 8.7 3.00 8.7 60.83 80

460/3/60 2 @ 7.5 49.5

575/3/60 2 @ 6.4 40.0

QTY RLA LRA HP FLA HP FLA AMPACITY CCT. BKR. AMP

3.00

3.00

4.0 3.00 4.0 24.88 30

3.2 3.00 3.2 20.80 25

DESCRIPTION:

Form YK145.12-PA5 (308)

DPV120 VERTICAL UNIT

AIR-COOLED SELF-CONTAINED

March 2008

Page 7

2 of 4

Page 7

"DPV" SERIES VERTICAL INDOOR SYSTEM

GENERAL MECHANICAL SPECIFICATIONS

GENERAL

All models 5-15 tons ship as factory-charged unitized packages. The 20 ton model shall be shipped as

separate evaporator and condensing unit modules (nitrogen holding charge only). All units may be field

split and installed as separate modules to suit on-site requirements. All packages are designed for freestanding mounting on the floor, or on a field fabricated structural steel stand. The 5, 8, and 10 ton models

are shipped with vertical evaporator fan discharge as standard. The 12, 15, and 20 ton models are

shipped horizontal discharge as standard.

CABINET

All cabinets are completely constructed of heavy gauge galvanized steel. The entire unit interior ( both

evaporator and condensing section ) is insulated with 1/2" thick, 2

are

equipped with lifting handles for ease of removal and handling. Duct flanges for condenser discharge,

condenser intake, and evaporator discharges, are provided with the unit for field installation. Duct flange

on evaporator return is incorporated into the filter frame.

COMPRESSORS

All models utilize "Scroll" type hermetic compressors. Compressors are mounted on rubber isolators to

minimize vibration transmission. Internal overload protection is provided. External high pressure and low

pressure cutout switches are included in each compressor control circuit. Crankcase heaters are

standard on all models.

lb. density insulation. Service panels

REFRIGERANT CIRCUITS

The 5 ton units have a single refrigeration circuit. The 8-20 ton units feature two independent refrigeration

circuits. Each refrigeration circuit includes

equali

zer), liquid line filter drier, sight glass/moisture indicator, and service gauge ports.

EVAPORATOR AND CONDENSER COILS

The evaporator and condenser coils are constructed of internally enhanced copper tubes mechanically

bonded to rippled aluminum plate fins. Both coils are employed in a draw-thru configuration. Large

evaporator coil face area minimizes potential water blow-off.

INDOOR/OUTDOOR FANS

Forward curved, double inlet and double width centrifugal blowers are used for both evaporator and

condenser air movement. Blower wheels are fabricated of galvanized steel. Blowers employ solid steel

shafts, supported in permanently lubricated ball bearing. All blowers are belt driven. Variable-pitch motor

sheaves allow for field adjustment

ELECTRI

All units are completely factory wired with all necessary controls. Manual reset protection is provided on

both evaporator and condenser motors. A manual reset circuit is also provided on each compressor

control circuit in the event of high/low pressure cutout. A 24 volt control circuit, with oversize transformer,

is provided for field connection.

FILTERS

All models are shipped with 2-inch thick medium-efficiency throwaway filters factory installed. Filter rack

is external to the cabinet (shipped loose).

CAL/CONTROLS

of blower rpm.

an adjustable thermal expansion valve (with external

Johnson Controls maintains a continuous product improvement policy, therefore specifications are subject to change without notice.

DESCRIPTION:

MECHANICAL SPECIFICATIONS

DPV120 VERTICAL UNIT

AIR-COOLED SELF-CONTAINED

Form YK145.12-PA5 (308)

DATE:

March 2008

Page 8

10 TON

Page 8

CFM EDB

75°F

3600 80°F

85°F

75°F

4000 80°F

85°F

75°F

4400 80°F

85°F

3 of 4

Ambient Condenser Air Temperature

F°59F°58

BWEBWE

62°F 67°F 72°F 62°F 67°F 72°F

TC SC TC SC TC SC TC SC TC SC TC SC

115.4 91.5 124.8 73.0 134.5 53.8 111.0 89.6 120.2 71.1 129.8 52.2

116.6 109.7 125.8 90.9 136.1 72.4 112.6 107.8 120.9 89.0 131.3 70.6

122.5 122.5 126.8 109.4 136.8 90.2 118.8 118.8 121.9 107.4 131.8 88.4

117.2 95.9 126.7 75.7 136.5 56.3 112.5 93.8 121.6 73.6 131.7 54.4

118.8 115.5 127.4 95.2 138.2 75.1 114.7 113.4 122.5 93.2 133.2 73.3

126.2 126.2 128.6 115.3 138.8 94.5 122.3 122.3 123.4 113.1 133.5 92.6

118.4 100.0 127.9 78.1 138.3 57.3 114.9 98.7 122.9 76.1 133.3 55.5

121.7 121.1 128.8 99.3 140.0 77.6 119.1 119.1 123.5 97.2 134.7 75.7

129.4 129.4 129.9 120.7 140.2 98.6 125.1 125.1 126.4 119.5 134.8 96.7

10 TON

CFM EDB

75°F

3600 80°F

85°F

75°F

4000 80°F

85°F

75°F

4400 80°F

85°F

Ambient Condenser Air Temperature

F°511F°501

BWEBWE

62°F 67°F 72°F 62°F 67°F 72°F

TC SC TC SC TC SC TC SC TC SC TC SC

106.3 87.5 115.2 69.1 124.9 50.5 101.1 85.2 109.9 66.9 119.8 49.6

107.2 105.0 115.9 87.0 126.2 68.7 103.4 103.0 110.5 84.8 121.0 66.8

114.8 114.8 116.8 105.3 126.6 86.5 110.6 110.6 111.4 103.1 121.3 84.6

108.6 92.4 116.5 71.6 126.5 52.5 103.5 90.1 111.0 69.4 121.3 50.6

111.8 111.8 117.2 91.2 128.0 71.4 107.4 107.4 111.6 89.0 122.5 69.5

118.0 118.0 119.5 111.8 128.1 90.7 113.6 113.6 114.4 109.4 122.6 88.8

109.9 96.5 117.4 117.4 128.0 53.5 104.6 94.1 111.7 71.7 122.6 51.6

114.5 114.5 118.1 95.2 129.0 73.9 109.8 109.8 112.2 93.0 123.3 71.9

120.7 120.7 121.4 117.1 129.4 94.8 116.1 116.1 117.5 115.5 123.9 92.8

DESCRIPTION:

COOLING PERFORMANCE DATA

DPV120 VERTICAL UNIT

AIR-COOLED SELF-CONTAINED

Form YK145.12-PA5 (308)

DATE:

March 2008

Page 9

DPV096 AND DPV120 DIMENSIONAL DATA

Page 9

4 of 4

DIMENSIONAL DATA

DPV096 & DPV120 VERTICAL UNIT

AIR-COOLED SELF-CONTAINED

Form YK145.12-PA5 (308)

March 2008

Page 10

PROJECT: TAG:

Page 10

1 of 4

Gross Cooling Capacity [Btuh]: 150,000*

Design CFM: 4,800

Evaporator Coil Face Area: 13.03 [sq ft]

Rows/FPI : 3/10

Refrigerant Control: TX Valve

Energy Efficiency Ratio: 10.65 EER**

Net Cooling Capacity [Btuh]: 144,000**

Net Cooling CFM: 4,800

Evaporator Fan No./Type: 2/CENTRIFUGAL

Diameter x Width [in]: 12x9

Drive: Adjustable Belt

Motor HP : 2.0 / 3.0

[Standard/Oversized]

Condenser Fan No./Type: 2/CENTRIFUGAL

Diameter x Width [in]: 15x15

Drive: tleB elbatsujdA

Motor HP : 3.0

[Standard]

*Cooling performance is rated at 95°F ambient, 80°F entering dry bulb, 67°F wet bulb

and CFM listed. Gross capacity does not include the effect of fan motor heat.

**Rated in accordance with ARI Standard 360-2000

Condenser Coil Face Area: 15.82 [sq ft]

Rows/FPI: 4/14

Compressor No./Type: 2/Scroll

Refrigerant Circuits: 2 / Independent

Refrigerant: R22

Charge: 12.13 Lbs./ circuit

Filters - Qty./Size: 2/14x20x2 & 4/14x25x2

Operating Weight [lbs.]: 1335

Shipping Weight [lbs.]: 1395

Condensate Connection: 3 / 4 NPT

EVAPORATOR FAN PERFORMANCE

MODEL SUPPLY 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0

# CFM RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

4300

717 1.06 792 1.23 862 1.41 928 1.58 989 1.75 1049 1.93 1100 2.10 1165 2.30 1210 2.50 1245 2.60

4800DPV144

5300

781 1.42 850 1.62 915 1.81 976 2.00 1035 2.20 1091 2.39 1144 2.58 1197 2.79 1245 2.96 - -

848 1.87 912 2.08 972 2.29 1030 2.57 1085 2.72 1138 2.94 1189 3.15

EXTERNAL STATIC PRESSURE - Inches W.C.

- --- - -

NOTE:

1. At high evaporator air flows, and wet bulb conditions, condensate carry-over may occur. Adjust airflow downward as necessary.

2. Values include pressure drop from wet coil and clean filters.

3. Shaded areas indicate oversize motors.

CONDENSER FAN PERFORMANCE

EXTERNAL STATIC PRESSURE - Inches W.C.

MODEL OUTDOOR 0.2 0.4 0.6 0.8 1.0 1.2

# CFM RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

DPV144

6600

675 1.77 735 2.06 792 2.46 848 2.60 900 3.00 - -

ELECTRICAL DATA – STANDARD MOTOR

MODEL

#

DPV144

DPV144

DPV144

VOLTAGE COMPRESSOR EVAPORATOR FAN CONDENSER FAN MIN. CCT. M AX FUSE /

QTY RLA LRA HP FLA HP FLA AMPACITY CCT. BKR. AMP

208-230/3/60 2 @ 20.7 156.0 2.00 5.9 3.00 8.7 61.18 80

460/3/60 2 @ 10.0 75.0 2.00 2.8 3.00 4.0 29.30 35

575/3/60 2 @ 8.2 54.0 2.00 2.2 3.00 3.2 23.85 30

ELECTRICAL DATA – OVERSIZED MOTOR

MODEL

#

DPV144

DPV144

DPV144

Johnson Controls maintains a continuous product improvement policy, therefore specifications are subject to change without notice.

VOLTAGE COMPRESSOR EVAPORATOR FAN CONDENSER FAN MIN. CCT. M AX FUSE /

208-230/3/60 2 @ 20.7 156.0

460/3/60 2 @ 10.0 75.0

575/3/60 2 @ 8.2 54.0

QTY RLA LRA HP FLA HP FLA AMPACITY CCT. BKR. AMP

DESCRIPTION:

3.00

3.00

3.00

8.7 3.00 8.7 63.98 80

4.0 3.00 4.0 30.50 40

3.2 3.00 3.2 24.85 30

Form YK145.12-PA6 (308)

DPV144 VERTICAL UNIT

AIR-COOLED SELF-CONTAINED

DATE:

March 2008

Page 11

2 of 4

Page 11

"DPV" SERIES VERTICAL INDOOR SYSTEM

GENERAL MECHANICAL SPECIFICATIONS

GENERAL

All models 5-15 tons ship as factory-charged unitized packages. The 20 ton model shall be shipped as

separate evaporator and condensing unit modules (nitrogen holding charge only). All units may be field

split and installed as separate modules to suit on-site requirements. All packages are designed for freestanding mounting on the floor, or on a field fabricated structural steel stand. The 5, 8, and 10 ton models

are shipped with vertical evaporator fan discharge as standard. The 12, 15, and 20 ton models are

shipped horizontal discharge as standard.

CABINET

All cabinets are completely constructed of heavy gauge galvanized steel. The entire unit interior ( both

evaporator and condensing section ) is insulated with 1/2" thick, 2

are

equipped with lifting handles for ease of removal and handling. Duct flanges for condenser discharge,

condenser intake, and evaporator discharges, are provided with the unit for field installation. Duct flange

on evaporator return is incorporated into the filter frame.

COMPRESSORS

All models utilize "Scroll" type hermetic compressors. Compressors are mounted on rubber isolators to

minimize vibration transmission. Internal overload protection is provided. External high pressure and low

pressure cutout switches are included in each compressor control circuit. Crankcase heaters are

standard on all models.

lb. density insulation. Service panels

REFRIGERANT CIRCUITS

The 5 ton units have a single refrigeration circuit. The 8-20 ton units feature two independent refrigeration

circuits. Each refrigeration circuit includes

equali

zer), liquid line filter drier, sight glass/moisture indicator, and service gauge ports.

EVAPORATOR AND CONDENSER COILS

The evaporator and condenser coils are constructed of internally enhanced copper tubes mechanically

bonded to rippled aluminum plate fins. Both coils are employed in a draw-thru configuration. Large

evaporator coil face area minimizes potential water blow-off.

INDOOR/OUTDOOR FANS

Forward curved, double inlet and double width centrifugal blowers are used for both evaporator and

condenser air movement. Blower wheels are fabricated of galvanized steel. Blowers employ solid steel

shafts, supported in permanently lubricated ball bearing. All blowers are belt driven. Variable-pitch motor

sheaves allow for field adjustment

ELECTRI

All units are completely factory wired with all necessary controls. Manual reset protection is provided on

both evaporator and condenser motors. A manual reset circuit is also provided on each compressor

control circuit in the event of high/low pressure cutout. A 24 volt control circuit, with oversize transformer,

is provided for field connection.

FILTERS

All models are shipped with 2-inch thick medium-efficiency throwaway filters factory installed. Filter rack

is external to the cabinet (shipped loose).

CAL/CONTROLS

of blower rpm.

an adjustable thermal expansion valve (with external

Johnson Controls maintains a continuous product improvement policy, therefore specifications are subject to change without notice.

DESCRIPTION:

MECHANICAL SPECIFICATIONS

DPV144 VERTICAL UNIT

AIR-COOLED SELF-CONTAINED

Form YK145.12-PA6 (308)

DATE:

March 2008

Page 12

12 TON

Page 12

CFM EDB

75°F

4300 80°F

85°F

75°F

4800 80°F

85°F

75°F

5300 80°F

85°F

3 of 4

Ambient Condenser Air Temperature

F°59F°58

BWEBWE

62°F 67°F 72°F 62°F 67°F 72°F

TC SC TC SC TC SC TC SC TC SC TC SC

140.0 108.7 151.6 87.4 167.1 66.6 135.4 106.7 146.6 85.3 160.8 64.5

145.8 132.3 152.8 108.0 168.5 88.6 139.8 129.4 147.1 106.0 162.2 86.2

148.1 148.1 153.1 128.8 169.4 109.7 143.9 143.9 147.7 126.6 163.0 107.3

143.1 114.2 154.1 90.5 168.7 69.2 138.1 112.0 148.9 88.4 162.3 66.8

144.8 137.4 155.0 113.0 170.4 91.5 138.6 134.4 150.0 111.0 163.7 89.0

152.8 152.8 156.8 137.3 171.2 114.5 148.4 148.4 151.5 134.9 164.3 112.1

145.1 119.0 156.2 93.4 170.0 70.1 139.7 116.7 150.6 91.2 163.3 67.7

147.8 144.5 157.3 117.9 171.4 94.0 142.5 141.4 151.6 115.7 164.4 91.5

156.8 156.8 159.0 143.7 172.1 119.1 152.2 152.2 153.4 141.2 164.9 116.6

12 TON

CFM EDB

75°F

4300 80°F

85°F

75°F

4800 80°F

85°F

75°F

5300 80°F

85°F

Ambient Condenser Air Temperature

F°511F°501

BWEBWE

62°F 67°F 72°F 62°F 67°F 72°F

TC SC TC SC TC SC TC SC TC SC TC SC

130.2 104.3 141.1 83.0 153.9 63.2 124.4 101.8 134.7 80.4 146.1 60.3

133.3 126.2 142.1 103.7 155.2 83.5 127.4 123.9 135.6 101.1 147.2 80.6

139.4 139.4 143.2 125.6 155.8 104.8 134.3 134.3 136.8 122.8 147.6 101.8

132.4 109.5 143.1 86.0 154.9 64.1 125.9 106.7 136.3 83.3 146.7 61.0

134.4 132.3 144.0 108.7 156.1 86.2 130.9 130.9 137.2 106.0 147.7 83.2

143.6 143.6 145.5 132.3 156.7 109.4 138.1 138.1 138.7 129.4 147.9 106.4

133.7 114.1 144.5 88.8 155.4 64.8 126.8 111.3 137.6 86.1 146.8 61.6

140.1 140.1 145.5 113.4 156.6 88.7 134.1 134.1 138.4 110.7 147.6 85.6

147.0 147.0 146.9 138.5 157.0 113.9 141.2 141.2 142.1 137.2 147.8 110.8

DESCRIPTION:

COOLING PERFORMANCE DATA

DPV144 VERTICAL UNIT

AIR-COOLED SELF-CONTAINED

Form YK145.12-PA6 (308)

DATE:

March 2008

Page 13

DPV0144 AND DPV180 DIMENSIONAL DATA

Page 13

4 of 4

DPV144

DPV180

DIMENSIONAL DATA

DPV144 & DPV180 VERTICAL UNIT

AIR-COOLED SELF-CONTAINED

Form YK145.12-PA6 (308)

March 2008

Page 14

PROJECT: TAG:

Page 14

1 of 4

Gross Cooling Capacity [Btuh]: 186,000*

Design CFM: 6,000

Evaporator Coil Face Area: 13.03 [sq ft]

Rows/FPI : 4/10

Refrigerant Control: TX Valve

Energy Efficiency Ratio: 9.80 EER**

Net Cooling Capacity [Btuh]: 178,000**

Net Cooling CFM: 5,500

Evaporator Fan No./Type: 2/CENTRIFUGAL

Diameter x Width [in]: 15x9

Drive: Adjustable Belt

Motor HP : 5.0 / NA

[Standard/Oversized]

Condenser Fan No./Type: 2/CENTRIFUGAL

Diameter x Width [in]: 15x15

Drive: tleB elbatsujdA

Motor HP : 5.0

[Standard]

*Cooling performance is rated at 95°F ambient, 80°F entering dry bulb, 67°F wet bulb

and CFM listed. Gross capacity does not include the effect of fan motor heat.

**Rated in accordance with ARI Standard 360-2000

Condenser Coil Face Area: 15.82 [sq ft]

Rows/FPI: 4/14

Compressor No./Type: 2/Scroll

Refrigerant Circuits: 2 / Independent

Refrigerant: R22

Charge: 13.83 Lbs./ circuit

Filters - Qty./Size: 2/14x20x2 & 4/14x25x2

Operating Weight [lbs.]: 1465

Shipping Weight [lbs.]: 1525

Condensate Connection: 3 / 4 NPT

EVAPORATOR FAN PERFORMANCE

MODEL SUPPLY 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0

# CFM RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

5400

765 1.93 818 2.16 870 2.41 920 2.70 970 2.90 1010 3.20 1050 3.46 1100 3.70 1145 3.90 1180 4.30

6000DPV180

824 2.52 873 2.77 920 3.03 967 3.30 1010 3.58 1052 3.90 1097 4.24 1137 4.59 1178 4.95 1220 5.33

903 3.33 947 3.60 991 3.89 1034 4.19 1076 4.49 1110 4.80 1150 5.10

6600

EXTERNAL STATIC PRESSURE - Inches W.C.

- -----

NOTE:

1. At high evaporator air flows, and wet bulb conditions, condensate carry-over may occur. Adjust airflow downward as necessary.

2. Values include pressure drop from wet coil and clean filters.

3. Shaded areas indicate oversize motors.

CONDENSER FAN PERFORMANCE

EXTERNAL STATIC PRESSURE - Inches W.C.

MODEL OUTDOOR 0.2 0.4 0.6 0.8 1.0 1.2

# CFM RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

DPV180

7500

725 2.35 780 2.67 834 3.01 886 3.37 936 3.76 983 4.18

ELECTRICAL DATA – STANDARD MOTOR

MODEL

#

DPV180

DPV180

DPV180

Johnson Controls maintains a continuous product improvement policy, therefore specifications are subject to change without notice.

VOLTAGE COMPRESSOR EVAPORATOR FAN CONDENSER FAN MIN. CCT. MAX FUSE /

QTY RLA LRA HP FLA HP FLA AMPACITY CCT. BKR. AMP

208-230/3/60 2 @ 28.6 196.0 5.00 13.7 5.00 13.7 91.75 110

460/3/60 2 @ 14.2 100.0 5.00 6.6 5.00 6.6 45.15 50

575/3/60 2 @ 9.7 90.0 5.00 5.3 5.00 5.3 32.43 40

DESCRIPTION:

Form YK145.12-PA7 (308)

DPV180 VERTICAL UNIT

AIR-COOLED SELF-CONTAINED

DATE:

March 2008

Page 15

2 of 4

Page 15

"DPV" SERIES VERTICAL INDOOR SYSTEM

GENERAL MECHANICAL SPECIFICATIONS

GENERAL

All models 5-15 tons ship as factory-charged unitized packages. The 20 ton model shall be shipped as

separate evaporator and condensing unit modules (nitrogen holding charge only). All units may be field

split and installed as separate modules to suit on-site requirements. All packages are designed for freestanding mounting on the floor, or on a field fabricated structural steel stand. The 5, 8, and 10 ton models

are shipped with vertical evaporator fan discharge as standard. The 12, 15, and 20 ton models are

shipped horizontal discharge as standard.

CABINET

All cabinets are completely constructed of heavy gauge galvanized steel. The entire unit interior ( both

evaporator and condensing section ) is insulated with 1/2" thick, 2

are

equipped with lifting handles for ease of removal and handling. Duct flanges for condenser discharge,

condenser intake, and evaporator discharges, are provided with the unit for field installation. Duct flange

on evaporator return is incorporated into the filter frame.

COMPRESSORS

All models utilize "Scroll" type hermetic compressors. Compressors are mounted on rubber isolators to

minimize vibration transmission. Internal overload protection is provided. External high pressure and low

pressure cutout switches are included in each compressor control circuit. Crankcase heaters are

standard on all models.

lb. density insulation. Service panels

REFRIGERANT CIRCUITS

The 5 ton units have a single refrigeration circuit. The 8-20 ton units feature two independent refrigeration

circuits. Each refrigeration circuit includes

equali

zer), liquid line filter drier, sight glass/moisture indicator, and service gauge ports.

EVAPORATOR AND CONDENSER COILS

The evaporator and condenser coils are constructed of internally enhanced copper tubes mechanically

bonded to rippled aluminum plate fins. Both coils are employed in a draw-thru configuration. Large

evaporator coil face area minimizes potential water blow-off.

INDOOR/OUTDOOR FANS

Forward curved, double inlet and double width centrifugal blowers are used for both evaporator and

condenser air movement. Blower wheels are fabricated of galvanized steel. Blowers employ solid steel

shafts, supported in permanently lubricated ball bearing. All blowers are belt driven. Variable-pitch motor

sheaves allow for field adjustment

ELECTRI

All units are completely factory wired with all necessary controls. Manual reset protection is provided on

both evaporator and condenser motors. A manual reset circuit is also provided on each compressor

control circuit in the event of high/low pressure cutout. A 24 volt control circuit, with oversize transformer,

is provided for field connection.

FILTERS

All models are shipped with 2-inch thick medium-efficiency throwaway filters factory installed. Filter rack

is external to the cabinet (shipped loose).

CAL/CONTROLS

of blower rpm.

an adjustable thermal expansion valve (with external

Johnson Controls maintains a continuous product improvement policy, therefore specifications are subject to change without notice.

DESCRIPTION:

MECHANICAL SPECIFICATIONS

DPV180 VERTICAL UNIT

AIR-COOLED SELF-CONTAINED

Form YK145.12-PA7 (308)

DATE:

March 2008

Page 16

15 TON

Page 16

CFM EDB

75°F

5400 80°F

85°F

75°F

6000 80°F

85°F

75°F

6600 80°F

85°F

3 of 4

Ambient Condenser Air Temperature

F°59F°58

BWEBWE

62°F 67°F 72°F 62°F 67°F 72°F

TC SC TC SC TC SC TC SC TC SC TC SC

175.4 138.5 189.7 110.0 207.4 82.9 168.8 135.5 182.8 107.8 200.6 81.8

177.1 165.8 191.0 137.5 209.1 111.5 171.2 163.1 184.0 134.7 201.4 108.4

185.6 185.6 192.5 165.4 210.0 139.1 180.0 180.0 185.6 162.4 202.6 135.9

178.1 145.0 192.4 114.6 209.1 86.2 171.2 142.0 185.1 111.6 200.0 82.9

180.6 174.7 193.7 144.0 210.6 115.1 174.3 171.8 186.3 141.1 201.5 111.8

191.3 191.3 195.5 174.2 211.2 145.0 185.4 185.4 187.9 171.1 201.9 141.8

180.0 151.2 194.5 118.3 209.9 87.1 174.8 149.4 186.9 115.3 200.7 83.8

184.9 183.4 195.8 150.2 211.3 118.3 180.4 180.4 188.2 147.2 201.6 114.8

196.1 196.1 197.6 182.5 211.9 150.9 189.9 189.9 192.2 180.6 202.0 147.5

15 TON

CFM EDB

75°F

5400 80°F

85°F

75°F

6000 80°F

85°F

75°F

6600 80°F

85°F

Ambient Condenser Air Temperature

F°511F°501

BWEBWE

62°F 67°F 72°F 62°F 67°F 72°F

TC SC TC SC TC SC TC SC TC SC TC SC

161.6 132.3 175.0 104.6 189.4 78.3 153.0 128.5 166.3 101.0 178.7 74.3

162.9 158.9 176.1 131.5 190.9 104.8 156.5 155.5 167.3 128.0 180.0 100.8

173.9 173.9 177.6 159.0 191.4 132.3 166.9 166.9 168.7 155.4 180.4 128.3

163.3 138.6 177.2 108.4 190.0 79.2 156.7 136.0 167.9 104.7 178.7 75.1

169.0 169.0 178.0 137.8 191.3 108.0 162.1 162.1 168.7 134.3 179.8 104.0

178.9 178.9 181.5 168.9 191.6 138.2 171.5 171.5 173.1 164.9 180.0 134.2

167.0 145.9 178.7 112.0 190.2 80.0 158.3 141.9 169.0 108.2 178.6 75.8

173.6 173.6 179.6 143.9 191.0 111.1 165.8 165.8 170.0 140.3 178.8 106.9

183.0 183.0 184.5 177.0 191.2 143.8 175.4 175.4 177.6 174.3 178.9 139.7

DESCRIPTION:

COOLING PERFORMANCE DATA

DPV180 VERTICAL UNIT

AIR-COOLED SELF-CONTAINED

Form YK145.12-PA7 (308)

DATE:

March 2008

Page 17

DPV144 AND DPV180 DIMENSIONAL DATA

Page 17

4 of 4

DPV144

DPV180

DIMENSIONAL DATA

DPV144 & DPV180 VERTICAL UNIT

AIR-COOLED SELF-CONTAINED

Form YK145.12-PA7 (308)

March 2008

Page 18

PROJECT: TAG:

Page 18

1 of 4

Gross Cooling Capacity [Btuh]: 244,000*

Design CFM: 8,000

Evaporator Coil Face Area: 19.00 [sq ft]

Rows/FPI : 4/10

Refrigerant Control: TX Valve

Energy Efficiency Ratio: 10.10 EER**

Net Cooling Capacity [Btuh]: 236,000**

Net Cooling CFM: 6,800

Evaporator Fan No./Type: 2/CENTRIFUGAL

Diameter x Width [in]: 15x15

Drive: Adjustable Belt

Motor HP : 5.0 / 7.5

[Standard/Oversized]

Condenser Fan No./Type: 2/CENTRIFUGAL

Diameter x Width [in]: 18x13

Drive: tleB elbatsujdA

Motor HP : 7.5

[Standard]

*Cooling performance is rated at 95°F ambient, 80°F entering dry bulb, 67°F wet bulb

and CFM listed. Gross capacity does not include the effect of fan motor heat.

**Rated in accordance with ARI Standard 360-2000

Condenser Coil Face Area: 20.55 [sq ft]

Rows/FPI: 4/14

Compressor No./Type: 2/Scroll

Refrigerant Circuits: 2 / Independent

Refrigerant: R22

Charge: 18.35 Lbs./ circuit

Filters - Qty./Size: 6/20x25x2

Operating Weight [lbs.]: 1720

Shipping Weight [lbs.]: 1805

Condensate Connection: 3 / 4 NPT

EVAPORATOR FAN PERFORMANCE

MODEL SUPPLY 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0

# CFM RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

7200

657 1.89 717 2.19 774 2.51 829 2.84 875 3.18 933 3.53 972 3.89 1024 4.26 1072 4.63 1113 5.02

8000DPV240

717 2.51 772 2.84 825 3.20 875 3.55 924 3.92 976 4.31 1022 4.72 1062 5.15 1105 5.60 1145 6.07

778 3.27 830 3.64 878 4.01 925 4.40 970 4.79 1015 5.20 1067 5.63 1102 6.08 1140 6.54 1183 7.03

8800

EXTERNAL STATIC PRESSURE - Inches W.C.

NOTE:

1. At high evaporator air flows, and wet bulb conditions, condensate carry-over may occur. Adjust airflow downward as necessary.

2. Values include pressure drop from wet coil and clean filters.

3. Shaded areas indicate oversize motors.

CONDENSER FAN PERFORMANCE

EXTERNAL STATIC PRESSURE - Inches W.C.

MODEL OUTDOOR 0.2 0.4 0.6 0.8 1.0 1.2

# CFM RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

DPV240

10200

656 3.72 700 4.12 741 4.50 781 4.91 820 5.32 857 5.73

ELECTRICAL DATA – STANDARD MOTOR

MODEL

#

DPV240

DPV240

DPV240

VOLTAGE COMPRESSOR EVAPORATOR FAN CONDENSER FAN MIN. CCT. MAX FUSE /

QTY RLA LRA HP FLA HP FLA AMPACITY CCT. BKR. AMP

208-230/3/60 2 @ 33.6 225.0 5.00 13.7 7.50 22.2 111.50 125

460/3/60 2 @ 17.3 114.0 5.00 6.6 7.50 10.8 56.33 70

575/3/60 2 @ 13.5 80.0 5.00 5.3 7.50 8.2 43.88 50

ELECTRICAL DATA – OVERSIZED MOTOR

MODEL

#

DPV240

DPV240

DPV240

Johnson Controls maintains a continuous product improvement policy, therefore specifications are subject to change without notice.

VOLTAGE COMPRESSOR EVAPORATOR FAN CONDENSER FAN MIN. CCT. MAX FUSE /

208-230/3/60 2 @ 33.6 225.0

460/3/60 2 @ 17.3 114.0

575/3/60 2 @ 13.5 80.0

QTY RLA LRA HP FLA HP FLA AMPACITY CCT. BKR. AMP

7.50

7.50

7.50

22.2 7.50 22.2 120.00 150

10.8 7.50 10.8 60.53 70

8.4 7.50 8.4 47.18 60

DESCRIPTION:

Form YK145.12-PA8 (308)

DPV240 VERTICAL UNIT

SELF-CONTAINED AIR-COOLED

DATE:

March 2008

Page 19

2 of 4

Page 19

"DPV" SERIES VERTICAL INDOOR SYSTEM

GENERAL MECHANICAL SPECIFICATIONS

GENERAL

All models 5-15 tons ship as factory-charged unitized packages. The 20 ton model shall be shipped as

separate evaporator and condensing unit modules (nitrogen holding charge only). All units may be field

split and installed as separate modules to suit on-site requirements. All packages are designed for freestanding mounting on the floor, or on a field fabricated structural steel stand. The 5, 8, and 10 ton models

are shipped with vertical evaporator fan discharge as standard. The 12, 15, and 20 ton models are

shipped horizontal discharge as standard.

CABINET

All cabinets are completely constructed of heavy gauge galvanized steel. The entire unit interior ( both

evaporator and condensing section ) is insulated with 1/2" thick, 2

are

equipped with lifting handles for ease of removal and handling. Duct flanges for condenser discharge,

condenser intake, and evaporator discharges, are provided with the unit for field installation. Duct flange

on evaporator return is incorporated into the filter frame.

COMPRESSORS

All models utilize "Scroll" type hermetic compressors. Compressors are mounted on rubber isolators to

minimize vibration transmission. Internal overload protection is provided. External high pressure and low

pressure cutout switches are included in each compressor control circuit. Crankcase heaters are

standard on all models.

lb. density insulation. Service panels

REFRIGERANT CIRCUITS

The 5 ton units have a single refrigeration circuit. The 8-20 ton units feature two independent refrigeration

circuits. Each refrigeration circuit includes

equali

zer), liquid line filter drier, sight glass/moisture indicator, and service gauge ports.

EVAPORATOR AND CONDENSER COILS

The evaporator and condenser coils are constructed of internally enhanced copper tubes mechanically

bonded to rippled aluminum plate fins. Both coils are employed in a draw-thru configuration. Large

evaporator coil face area minimizes potential water blow-off.

INDOOR/OUTDOOR FANS

Forward curved, double inlet and double width centrifugal blowers are used for both evaporator and

condenser air movement. Blower wheels are fabricated of galvanized steel. Blowers employ solid steel

shafts, supported in permanently lubricated ball bearing. All blowers are belt driven. Variable-pitch motor

sheaves allow for field adjustment

ELECTRI

All units are completely factory wired with all necessary controls. Manual reset protection is provided on

both evaporator and condenser motors. A manual reset circuit is also provided on each compressor

control circuit in the event of high/low pressure cutout. A 24 volt control circuit, with oversize transformer,

is provided for field connection.

FILTERS

All models are shipped with 2-inch thick medium-efficiency throwaway filters factory installed. Filter rack

is external to the cabinet (shipped loose).

CAL/CONTROLS

of blower rpm.

an adjustable thermal expansion valve (with external

Johnson Controls maintains a continuous product improvement policy, therefore specifications are subject to change without notice.

DESCRIPTION:

MECHANICAL SPECIFICATIONS

DPV240 VERTICAL UNIT

AIR-COOLED SELF-CONTAINED

Form YK145.12-PA8 (308)

DATE:

March 2008

Page 20

20 TON

Page 20

CFM EDB

75°F

7200 80°F

85°F

75°F

8000 80°F

85°F

75°F

8800 80°F

85°F

3 of 4

Ambient Condenser Air Temperature

F°59F°58

BWEBWE

62°F 67°F 72°F 62°F 67°F 72°F

TC SC TC SC TC SC TC SC TC SC TC SC

230.3 184.1 248.7 146.4 269.3 108.2 221.9 180.3 239.8 142.7 258.3 104.3

233.3 221.4 250.2 182.6 270.6 146.3 223.9 216.6 241.0 178.9 259.4 142.1

262.7 262.7 257.8 222.3 278.1 185.8 256.4 256.4 249.3 218.7 266.7 181.7

233.4 193.0 251.7 151.6 270.0 111.9 224.6 189.1 242.4 147.9 258.0 107.4

237.1 233.3 253.1 191.3 271.6 150.9 229.0 228.3 243.4 187.5 259.7 146.6

274.3 274.3 262.9 235.0 279.6 194.2 267.2 267.2 253.9 231.3 267.7 190.0

238.2 203.1 254.1 156.6 269.4 112.7 229.5 199.0 244.2 152.7 256.9 108.2

245.1 245.1 255.4 199.7 271.2 155.0 237.2 237.2 245.4 195.8 258.4 150.5

283.8 283.8 267.3 247.1 279.9 202.1 276.1 276.1 261.2 245.1 267.1 197.7

20 TON

CFM EDB

75°F

7200 80°F

85°F

75°F

8000 80°F

85°F

75°F

8800 80°F

85°F

Ambient Condenser Air Temperature

F°511F°501

BWEBWE

62°F 67°F 72°F 62°F 67°F 72°F

TC SC TC SC TC SC TC SC TC SC TC SC

212.7 176.3 229.6 138.6 245.6 101.9 204.5 173.1 218.5 134.1 231.2 96.6

215.3 212.5 230.8 174.9 246.5 137.4 208.0 208.0 219.3 170.3 231.9 132.1

249.3 249.3 239.8 214.8 253.8 177.1 241.6 241.6 229.1 210.4 239.2 171.9

217.3 186.4 231.7 143.6 244.6 102.6 207.0 181.7 220.0 139.0 229.6 97.1

223.1 223.1 232.9 183.4 246.1 141.7 214.4 214.4 220.6 178.7 230.7 136.4

259.5 259.5 246.4 228.9 254.1 185.3 250.9 250.9 236.3 224.2 238.8 180.0

219.6 194.6 233.2 148.4 242.7 103.0 208.7 189.7 220.1 143.6 226.8 97.3

228.4 228.4 234.1 191.6 244.2 145.5 218.7 218.7 224.8 188.5 227.9 139.9

267.4 267.4 251.9 240.8 252.9 192.9 257.9 257.9 241.6 236.0 236.5 187.5

DESCRIPTION:

COOLING PERFORMANCE DATA

DPV240 VERTICAL UNIT

AIR-COOLED SELF-CONTAINED

Form YK145.12-PA8 (308)

DATE:

March 2008

Page 21

DPV240 DIMENSIONAL DATA

Page 21

4 of 4

DIMENSIONAL DATA

DPV240 VERTICAL UNIT

AIR-COOLED SELF-CONTAINED

Form YK145.12-PA8 (308)

March 2008

Page 22

PROJECT: TAG:

Page 22

1 of 4

Gross Cooling Capacity [Btuh]: 304,000*

Design CFM: 10,000

Evaporator Coil Face Area: 19.797 [sq ft]

Rows/FPI : 4/10

Refrigerant Control: TX Valve

Energy Efficiency Ratio: 9.60 EER**

Net Cooling Capacity [Btuh]: 286,000**

Net Cooling CFM: 8,800

Evaporator Fan No./Type: 2/CENTRIFUGAL

Diameter x Width [in]: 15x15

Drive: Adjustable Belt

Motor HP : 7.5 / 10.0

[Standard/Oversized]

Condenser Fan No./Type: 2/CENTRIFUGAL

Diameter x Width [in]: 18x13

Drive: tleB elbatsujdA

Motor HP : 7.5

[Standard]

*Cooling performance is rated at 95°F ambient, 80°F entering dry bulb, 67°F wet bulb

and CFM listed. Gross capacity does not include the effect of fan motor heat.

**Rated in accordance with ARI Standard 360-2000

Condenser Coil Face Area: 24.13 [sq ft]

Rows/FPI: 4/14

Compressor No./Type: 3/Scroll

Refrigerant Circuits: 3 / Independent

Refrigerant: R22

Charge: 14.65 Lbs./ circuit

Filters - Qty./Size: 8/20x20x2

Operating Weight [lbs.]: 1995

Shipping Weight [lbs.]: 2080

Condensate Connection: 3 / 4 NPT

EVAPORATOR FAN PERFORMANCE

MODEL SUPPLY 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0

# CFM RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

9000 785 3.42 836 3.80 884 4.18 930 4.56 975 4.97 1019 5.38 1068 5.81 1100 6.26 1143 6.75 1184 7.24

10000DPV300

11000

861 4.59 907 5.00 952 5.43 994 5.85 1035 6.27 1076 6.73 1116 7.19 1155 7.66 1198 8.15 1225 8.66

938 6.02 981 6.48 1022 6.94 1061 7.39 1100 7.87 1137 8.34 1174 8.82 1210 9.32 1246 9.83 1281 10.34

EXTERNAL STATIC PRESSURE - Inches W.C.

NOTE:

1. At high evaporator air flows, and wet bulb conditions, condensate carry-over may occur. Adjust airflow downward as necessary.

2. Values include pressure drop from wet coil and clean filters.

3. Shaded areas indicate oversize motors.

CONDENSER FAN PERFORMANCE

MODEL OUTDOOR 0.2 0.4 0.6 0.8 1.0 1.2

# CFM RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

DPV300

11500

687 4.76 728 5.20 767 5.64 805 6.09 841 6.52 876 6.97

EXTERNAL STATIC PRESSURE - Inches W.C.

ELECTRICAL DATA – STANDARD MOTOR

MODEL

#

DPV300

DPV300

DPV300

VOLTAGE COMPRESSOR EVAPORATOR FAN CONDENSER FAN MIN. CCT. MAX FUSE /

QTY RLA LRA HP FLA HP FLA AMPACITY CCT. BKR. AMP

208-230/3/60 3 @ 32.1 195.0 7.50 22.2 7.50 22.2 148.73 175

460/3/60 3 @ 16.4 95.0 7.50 10.8 7.50 10.8 74.90 90

575/3/60 3 @ 12.0 80.0 7.50 8.2 7.50 8.2 55.40 60

ELECTRICAL DATA – OVERSIZED MOTOR

MODEL

#

DPV300

DPV300

DPV300

Johnson Controls maintains a continuous product improvement policy, therefore specifications are subject to change without notice.

VOLTAGE COMPRESSOR EVAPORATOR FAN CONDENSER FAN MIN. CCT. MAX FUSE /

208-230/3/60 3 @ 32.1 195.0 10.00 25.6 7.50 22.2 152.13 175

460/3/60 3 @ 16.4 95.0

575/3/60 3 @ 12.0 80.0

QTY RLA LRA HP FLA HP FLA AMPACITY CCT. BKR. AMP

10.00

10.00

11.6 7.50 10.8 75.70 90

9.6 7.50 8.2 56.80 60

DESCRIPTION:

Form YK145.12-PA9 (308)

DPV300 VERTICAL UNIT

AIR-COOLED SELF-CONTAINED

DATE:

March 2008

Page 23

2 of 4

Page 23

"DPV" SERIES VER

TICAL INDOOR SYSTEM

GENERAL MECHANICAL SPECIFICATIONS

GENERAL

All models 5-15 tons ship as factory-charged unitized packages. The 20 ton model shall be shipped as

separate evaporator and condensing unit modules (nitrogen holding charge only). All units may be field

split and installed as separate modules to suit on-site requirements. All packages are designed for freestanding mounting on the floor, or on a field fabricated structural steel stand. The 5, 8, and 10 ton models

are shipped with vertical evaporator fan discharge as standard. The 12, 15, and 20 ton models are

shipped horizontal discharge as standard.

CABINET

All cabinets are completely

evaporator

are equipped with lifting handles for ease of removal and handling. Duct flanges for condenser discharge,

condenser intake, and evaporator discharges, are provided with the unit for field installation. Duct flange

on evaporator return is incorporated into the filter frame.

COMPRESSORS

All models utilize "Scroll" type hermetic compressors. Compressors are mounted on rubber isolators to

minimize vibration transmission. Internal overload protection is provided. External high pressure and low

pressure cutout switches are included in each compressor control circuit. Crankcase heaters are

standard on all models.

REFRIGERANT CIRCUITS

The 5 ton units

circuits.

equalizer), liquid line filter drier, sight glass/moisture indicator, and service gauge ports.

and condensing section ) is insulated with 1/2" thick, 2 lb. density insulation. Service panels

have a single refrigeration circuit. The 8-20 ton units feature two independent refrigeration

Each refrigeration circuit includes an adjustable thermal expansion valve (with external

constructed of heavy gauge galvanized steel. The entire unit interior ( both

EVAPORATOR AND CONDENSER COILS

The evaporator and condenser coils are constructed of internally enhanced copper tubes mechanically

bonded to rippled aluminum plate fins. Both coils are employed in a draw-thru configuration. Large

evaporator coil face area minimizes potential water blow-off.

INDOOR/OUTDOOR FANS

Forward curved, double inlet and double width centrifugal blowers are used for both evaporator and

condenser air movement. Blower wheels are fabricated of galvanized steel. Blowers employ

shafts,

sheaves allow for field adjustment of blower rpm.

ELECTRICAL/CONTROLS

All units are completely factory wired with all necessary controls. Manual reset protection is provided on

both evaporator and condenser motors. A manual reset circuit is also provided on each compressor

control circuit in the event of high/low pressure cutout. A 24 volt control circuit, with oversize transformer,

is provided for field connection.

FILTERS

All models are shipped with 2-inch thick medium-efficiency throwaway filters factory installed. Filter rack

is external to the cabinet (shipped loose).

supported in permanently lubricated ball bearing. All blowers are belt driven. Variable-pitch motor

Johnson Controls maintains a continuous product improvement policy, therefore specifications are subject to change without notice.

DESCRIPTION:

MECHANICAL SPECIFICATIONS

DPV300 VERTICAL UNIT

AIR-COOLED SELF-CONTAINED

Form YK145.12-PA9 (308)

DATE:

solid steel

March 2008

Page 24

25 TON

Page 24

CFM EDB

75°F

9000 80°F

85°F

75°F

10000 80°F

85°F

75°F

11000 80°F

85°F

3 of 4

Ambient Condenser Air Temperature

F°59F°58

BWEBWE

62°F 67°F 72°F 62°F 67°F 72°F

TC SC TC SC TC SC TC SC TC SC TC SC

285.6 225.4 308.9 180.1 339.4 136.0 275.0 220.8 297.5 175.4 325.1 133.6

291.7 271.6 311.4 224.0 342.3 182.2 281.0 267.2 299.6 219.3 327.5 176.7

304.3 304.3 314.2 269.9 344.0 227.1 294.8 294.8 302.6 265.0 329.0 221.8

290.5 236.1 313.5 186.4 341.9 140.9 279.2 231.3 301.6 181.7 326.7 135.2

297.4 286.2 315.8 234.3 344.8 187.9 286.0 281.3 303.7 229.7 329.2 182.2

313.5 313.5 319.3 284.1 346.0 236.7 303.4 303.4 306.8 279.0 330.2 231.3

291.3 244.8 317.1 192.3 344.4 142.8 279.6 240.0 304.7 187.5 328.3 136.9

301.6 298.9 319.4 244.1 346.7 193.2 296.7 296.7 306.8 239.4 330.6 187.6

321.2 321.2 320.7 296.4 347.7 246.2 310.6 310.6 311.0 293.2 330.9 240.5

25 TON

CFM EDB

75°F

9000 80°F

85°F

75°F

10000 80°F

85°F

75°F

11000 80°F

85°F

Ambient Condenser Air Temperature

F°511F°501

BWEBWE

62°F 67°F 72°F 62°F 67°F 72°F

TC SC TC SC TC SC TC SC TC SC TC SC

263.1 215.6 285.0 170.3 309.2 127.7 249.6 209.8 270.6 164.5 291.5 121.1

266.8 259.8 286.9 214.3 311.3 170.8 255.5 254.0 272.2 208.6 293.1 164.3

284.4 284.4 289.4 259.5 312.6 216.0 272.7 272.7 274.6 253.5 293.9 209.5

266.4 225.8 288.2 176.3 309.8 129.1 255.4 221.7 273.3 170.5 290.9 122.1

273.7 273.5 290.2 224.5 312.1 176.1 266.2 266.2 274.9 218.7 292.6 169.2

292.3 292.3 295.5 275.4 312.8 225.4 279.9 279.9 281.6 268.8 292.9 218.7

270.4 236.7 290.8 182.0 310.6 130.5 256.8 230.6 275.2 176.0 291.2 123.5

284.5 284.5 292.6 234.1 312.5 181.2 270.9 270.9 276.7 228.3 292.2 174.3

298.8 298.8 297.1 286.7 312.6 234.4 285.8 285.8 287.5 283.3 291.4 227.5

DESCRIPTION:

COOLING PERFORMANCE DATA

DPV300 VERTICAL UNIT

AIR-COOLED SELF-CONTAINED

Form YK145.12-PA9 (308)

DATE:

March 2008

Page 25

DPV300 DIMENSIONAL DATA

Page 25

4 of 4

DIMENSIONAL DATA

DPV300 VERTICAL UNIT

AIR-COOLED SELF-CONTAINED

Form YK145.12-PA9 (308)

March 2008

Loading...

Loading...