Page 1

®

SUNLINE 2000

ELECTRIC / ELECTRIC & GAS / ELECTRIC

SINGLE PA CKAGE AIR CONDITIONERS

(Constant Air Volume)

INSTALLATION INSTRUCTION

208/230/460

VOLT ONLY

SAFETY CONSIDERATIONS

Due to system pressure, moving parts and electrical components,

installation and servicing of air conditioning equipment can be

hazardous. Only qualified, trained, service personnel should

install, repair, maintain or service this equipment.

‘YORK Model DCE and DCG units are single package air

conditioners d esig ned for outdoor inst alla tion on a roo ft op o r a

slab and is manufactured under ISO 9002 Quality System

Cert ification. The DCE models are coo ling only and can be

equipped with factory installed electric heaters for cooling /

heating applications. The DCG models are gas-fired central

heating furnaces wit h co ol in g.

The units are co mplete ly asse mbl ed on rig id, permanen tly at tach ed

base rails. All piping , refrigerant charge , and electrical wiring is factory

installed and test ed. All units require electric po wer , duct connections

and fixed outdoor air intake damper (units without economizer or

motorized damper option only) at the point of installation.

The DCG units ad ditionally req uire gas connecti on, installat ion of the

combustion air inlet hood and the flue gas outlet hoods at the point of

installation . The gas-fired h eaters ha ve al uminized-st eel tub ular heat

exchangers and spark ignition with proven pilot.

Supplemental electric heaters for DCE units have nickel-chrome

elements and utilize single point power connections.

The following safety precautions apply to DCG units:

FOR Y OUR SAFETY

If you smell gas:

1. Open windows.

2. Don’t touch electrical switches; do not use

any phones in the area of the gas leak.

3. Extinguish any open flame.

4. Immediatel y call y our gas supplier fr om another

location. Follow your gas supplier’s

instructions.

5. If you cannot reach y our gas supplier , call the

fire department.

Supersedes: 530.18-N11Y (195)

MODELS D2CE & D2CG300

(8.5 EER)

DCG MODEL

SHOWN

INSPECTION

As soon as a unit is received, it should be inspected for

possible damage during transit. If damage is evident, the

extent of the damage should be noted on the carrier’s freight

bill. A separate request for inspection by the carrier’s agent

should be made in writing. Refer to Form 50.15-NM for

additional information.

REFERENCE

Additional information on the design, installation, operation and

service of this equipment is available in the following reference forms:

44-320-10 - Barometric Relief Damper Accessory

•

530.18-N6.1V - Propane Conversion Accessory

•

530.18-N6.2V - High Altitude Accessory (Nat. Gas)

•

530.18-N6.3V - High Altitude Accessory (Propane)

•

530.18-n13y - Coil Guard In st al la ti on

•

Renewal Parts:

Refer to the Renewal Par ts Manual for comple te listing of

•

replacement parts on this equi pm ent.

All forms referenced in this instruction may be ordered from:

Publications Distribution Center

Unitary Products Group

P.O. Box 1592, York, Pa. 17405

APPROVALS

Design certified by ETL & CGA as follows:

1. For use as a central cooling only unit with or without

supplemental electric heat. (DCE models)

2. For use as a forced air furnace with cooling unit. (DCG models)

3. For use with natural gas or pro pa ne gas. (DCG mod el s)

4. For outdoor installat io n on ly.

5. For installation on combustible ma te ria l.

THIS PRODUCT MUST BE INSTALLED IN STRICT COMPLIANCE WITH

THE ENCLOSED INSTALLATION INSTRUCTIONS AND ANY

APPLICABLE LOCAL, ST ATE, AND NATIONAL CODES INCLUDING, BUT

NOT LIMITED TO , BUILDING, ELECTRICAL, AND MECHANICAL CODES.

CAUTION

530.18-N11Y (399)

035-16133

208/230/575

VOLT ONLY

Do not store o r use gasoline or ot her flammable

vapors and liquids in the vicinity of this or any

other appliance

Installer should pay particular attention to the words: NOTE, CAUTION and WARNING. Notes are inte nd ed t o clarify or m ake

the installa tion ea sier .

and/or equipment damage may result if installation pr ocedure is not handled properly.

FOR Y OUR SAFETY

INCORRECT INSTALLATION MAY CREATE A CONDITION

WHERE THE OPERATION OF THE PRODUCT COULD CAUSE

PERSONAL INJURY OR PROPERTY DAMAGE

.

Cautions are gi ven t o pre vent equipmen t damage . W arnings are giv en to ale rt installer that personal i njury

WARNING

Page 2

530.18-N11Y

TABLE OF CONTENTS

General................................................................................ 1

Inspection.............................................................................1

Reference............................................................................. 1

Approvals ............................................................................. 1

Nomenclature.......................................................................2

INSTALLATION

Limitations............................................................................ 3

Location ...............................................................................3

Rigging and Handling .......................................................... 3

Clearances........................................................................... 3

Ductwork .............................................................................. 3

Fixed Outdoor Air Intake Damper........................................ 4

Condensate Drain................................................................4

Compressors........................................................................4

Filters ................................................................................... 4

Service Access .................................................................... 4

Thermostat...........................................................................5

Power and Control Wiring.................................................... 5

Optional Electric Heaters (DCE Models)............................. 5

Combustion Disch arge (DCG Model s)................................5

Gas Piping (DCG Models)................................................... 6

Gas Connection (DCG Models)........................................... 6

L.P. Units, Tanks and Piping (DCG Models)......................... 6

Vent and Combustion Air Hoods (DCG Model s) ................. 7

Econ. / Mot. Damp er Rai n Hoo d Accy. (1EH0401)..............7

Econ. / Power Rain Hood Accy. (1EH0402)......................... 9

OPERA T ION

Cooling System.................................................................. 15

Preliminary Opera tion Cooling........................................... 15

Cooling Sequence of Operation........... ..............................15

Safety Controls (Cooling)................................................... 15

Electric Heating - Sequence of Operation ......................... 15

Heating Anticipat or Set poin ts....... .. .. .................. .. .............16

Gas Heating - Sequence of Op er at io n......... .. .. .. .. .............16

Safety Contro ls (Heat ing). .................. .. .. .................. .. .. ...... 16

Heat Antici pator Setpoints ................................................. 17

Pre-Start Check List........................................................... 17

START-UP

Operating Instructions........................................................ 17

Post-Start Check List.........................................................17

Manifold Ga s Pressure Adjustment...................... .............17

Pilot Checkout.................................................................... 18

Burner Instructions.............................................................18

Burner Air Shutter Adjustment...........................................18

Checking Supply Air CFM....... .. .................. .. .. .................. .18

Adjustment of Temperature Rise........................................ 19

Checking Gas Input ........................................................... 19

Secure Owner’s Approval .................................................. 19

MAINTENANCE & TROUBLESHOO TING

Normal Maintenance ......................................................... 20

Cleaning Flue Passages and Heating Elements...............20

Troubleshooting.................................................................. 2 1

Replacement Parts ..................................... .................. .. ... 23

TABLES

No. Description Page

1 Unit Application Data.................................. 3

2 Gas Heat Application Data ......................... 6

3 Pipe Sizing.................................................. 6

4 Physical Data.............................................. 10

5 Electrical Data - Basic Units...................... 10

6 Electrical Data - Units Wi th Ele c. Heat ...... 10

7 Four and Six Point Loads............................ 13

8 Supply Air Blower Performance .............. ... 13

9 Static Resistances ...................................... 14

10 Pow er Exh au st Performance....... .. .. .. ......... 14

11 Blower Motor and Drive Data...................... 14

12 Heat Anticipator Setpoint............................ 16

13 Limit Control Setting ................................... 17

14 Gas Rate - Cubic Feet Per Hour................. 19

FIGURES

No. Description Page

1 Typical Rigging....... ........................ ............. 3

2 Center of Gravi ty............................. .. .......... 3

3 Fixed Out door Air Dam pe r.............. .. .. .. ...... 4

4 Recommended Drain Piping....................... 4

5 Typical Field Wiring ..................................... 5

6 External Supply Connection ....................... 6

7 Bottom Supply Connection......................... 7

8 Vent and Combustion Air Hoods................. 8

9 Adjusting Enthalpy Setpoint.................... .. .. 9

10 Dimensions and Clearan ces...... .. ............... 11

Dimensions and Clearances (cont’d).......... 12

11 Four and Six Point Loads............................ 13

12 Gas V a lv e Pipin g................ .... .... .... .. .... .... ... 16

13 Gas Valve and Controls .............................. 17

14 Typical Gas Valve................... .... ...... ...... ..... 17

15 Proper Flame Adjustment................ .. ......... 18

16 Typical Flam e App ea ra nc e........ ................. 18

17 Belt Adjustment............................ .. .. ........... 18

18 Pressure Drop versus Supply Air CFM ...... 19

19 Typical Flue Baffle Installation .......... .......... 20

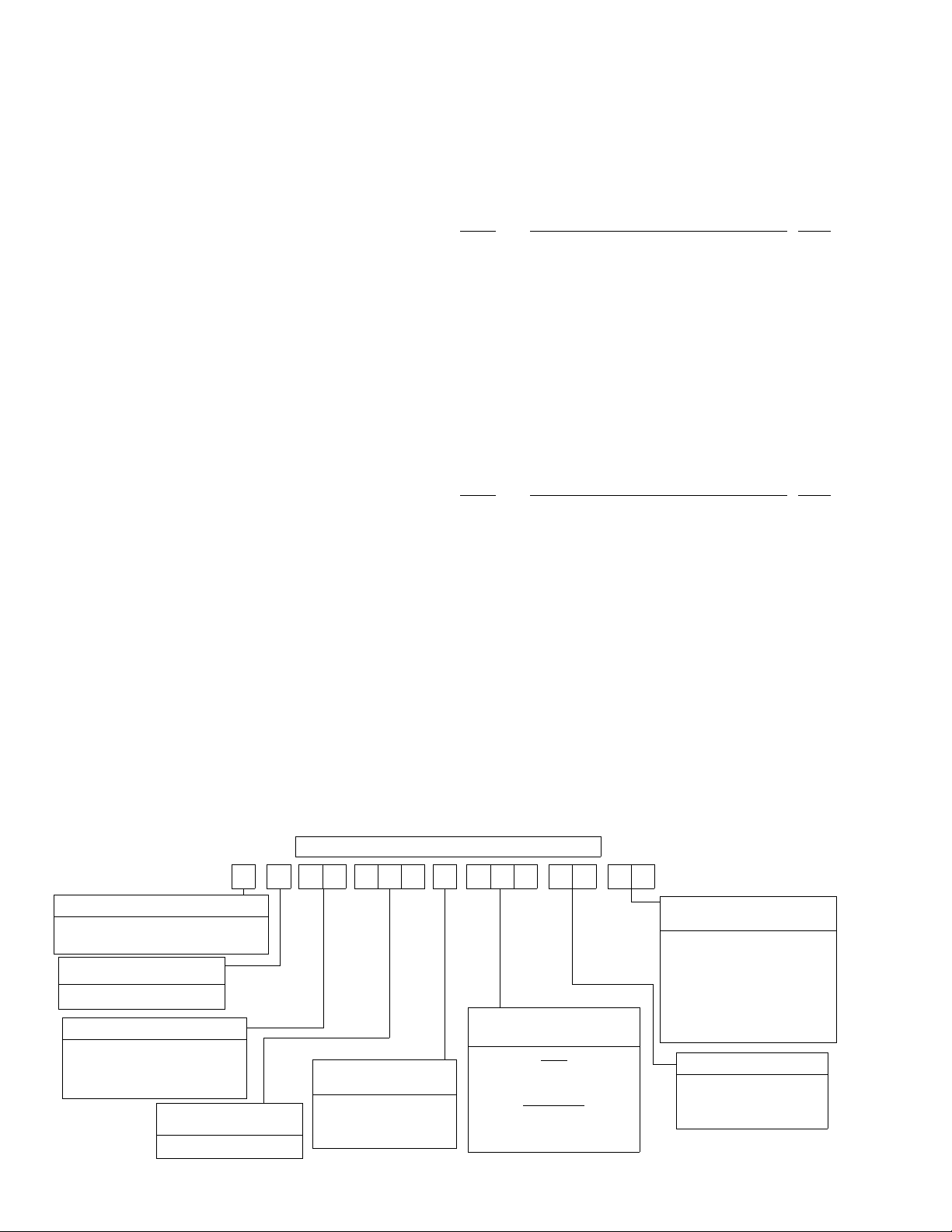

PRODUCT NOMENCLATURE

D 2 C G E C4N

PRODUCT CATEGORY

D = Single Package Air Conditioner

(Air Cooled)

PRODUCT GENERATION

2 = 2nd Generation

PRODUCT IDENTIFIER

CG = Gas/Electric

CE = Cooling only or

Electric / Electric

NOMINAL COOLING

CAPACITY

300 = 25 Tons

2 Unitary Products Group

FACTORY INSTALLED

HEAT

A = No Heat

N = Natural Gas

E = Electric

2 003 0 2 5

NOMINAL HEATING

OUTPUT CAPACITY

GAS

240 = 240 MBH

320 = 320 MBH

ELECTRIC

018 = 18 KW

036 = 36 KW

054 = 54 KW

072 = 72 KW

FACTORY INSTALLED

OPTION CODE

EC = Sing. Input Economiz er

DK = Diff. Input Economiz er

FD = Sing. Input Economizer

w/Power Exhaust

CF = Diff. Input Economizer

w/Power Exhaust

BG = Motorized Outdoor Air

Damper

VOLTAGE CODE

25 = 208/230-3-60

46 = 460-3-60

58 = 575-3-60

Page 3

INSTALLATION

LIMITATIONS

These units must be installed in accordance with the following

applicable national and local safety codes:

In U.S.A.:

1. Nati on al Elec trica l Cod e ANSI/ NFPA No. 70.

2. National Fuel Gas Code Z223.1.

3. Gas-Fired Central Furnace Standard ANSI Z21.47a.

4. Local gas and electric utility requirements.

In Canada:

1. Current Canadian Electrical Code C22.1.

2. Current Gas Installation Codes CAN/CGA-B149.1 and .2

3. Local plumbing and waste water codes.

4. Other applicable lo ca l co de s .

Refer to the Unit Application Data T able and to the Gas Heat Application

Data T ab le.

After installation, units with gas heat must be adjusted to obtain a

temperature rise within the range specified on the unit rating plate.

If components are to be added to a unit to meet local codes, they

are to be installed at the dealer’s and/or the customer’ s e xpense.

Size of unit for prop os ed in st al la ti on sh ou ld be ba se d on hea t

loss/heat g ain calcul ation made a ccording to the method s of

the Air Conditioning Contractors of America (ACCA).

This furnace is not to be used for temporary heating of buildings

or structures under construction.

TABLE 1

V oltage V ariation,

Min. / Max.

Supply Air CFM, Min. / Max. 8,000 / 12,000

Wet Bulb Temperature (°F) of Air on

Evaporator Coil, Min. / Max.

Dry Bulb T emperature (°F) of Air on

Condenser Coil, Min.

1

Utilization range “A” in accordance with ARI Standard 110.

2

A low ambient accessory is available for applica tio ns down to 0°F.

LOCATION

Use the following guidelines to sele ct a suitable location for

these units.

1. Unit is designed for outdoor installation only .

2. Condenser coils must have an unlimited supply of air.

3. For ground level installation, use a level concrete slab with

WARNING: Excessive exposure of this furnace to contami-

4. Roof structures must be able to support the weight of the

- UNIT APPLICATION DATA

208/230-3-60 187 / 253

1

Where a choice of location is possible, position the unit on

either north or east side of bu il di ng.

a minimum thickness of 4 inches. The length and width

should be at le ast 6 inc hes g rea ter t han the unit bas e ra ils .

Do not tie slab to the building foundation.

nated combus tion air may res ult in equipment d amage or personal injury. Typical contaminates include: permanent wave solutions, chlorinated

waxes and cleaners, chlorine based swimming

pool chemicals, water soft ening chemica ls, carbon

tetrachloride, Halogen type refrigerants, cleaning

solvents (e.g. perchloroethylene), printing inks,

paint removers, varnishes, hydrochloric acid, cements and glues, antistatic fabric softeners for

clothes dryers, ma sonry acid washing materials.

unit and its opti ons and/or accessori es. Unit must be installed on a solid level roof curb or appropriate angle iron

frame.

460-3-60 414 / 506

575-3-60 518 / 630

57 / 72

2

/ Max.

25 / 120

530.18-N11Y

CAUTION: If a unit is t o b e i ns tall ed on a ro of cu rb o r spec ia l

frame, gasketing mu st be applied to all surfaces

that come in contact with the unit underside.

5. Maintain lev el tole rance t o 1/2 " maximu m across the ent ire

length or width of the unit.

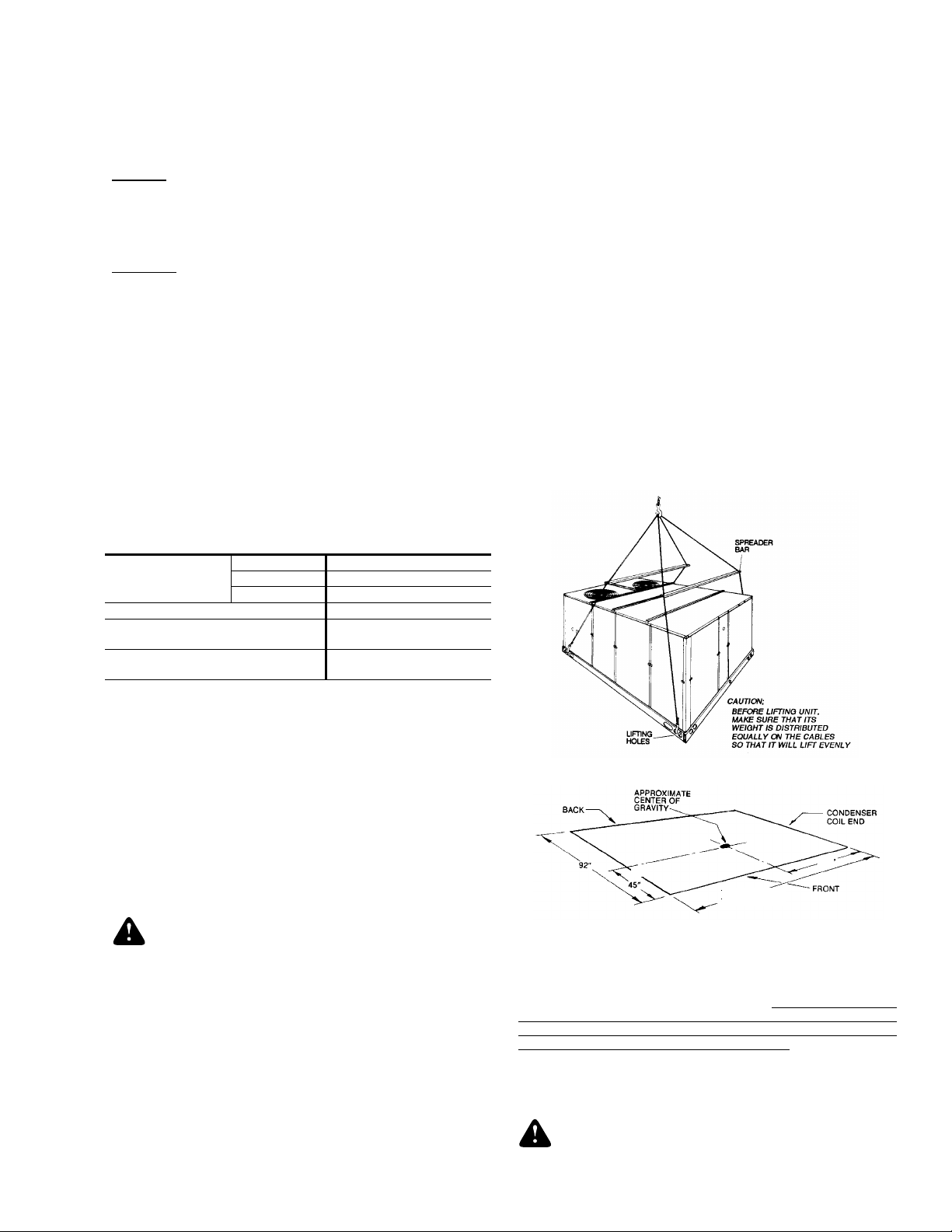

RIGGING AND HANDLING

Exercise care when moving the unit. Do not remove any

packaging until the unit is near the place of installation. Rig the

unit by attaching chain or cable slings to the round lifting holes

provided in t he base rails. Spreaders, wh ose length exceed s

the largest di mension ac ross the uni t,

be used acros s

MUST

the top of the unit.

Units may also be moved or lifted with a forklift, from the front

or rear only, providing that an accessory skid is used.

LENGTH OF FORKS MUST BE A MINIMUM OF 90".

CAUTION: On gas heating units, an adhesive backed label is

provided over the outside of the combustion air inlet

opening to prevent moisture from entering the unit

which could cause damage to electrical

components. Allow this closure label to remain in

place until the combustion air hood is to be

installed.

FIG. 1

- TYPICAL RIGGING

5

FIG. 2

- CENTER OF GRAVITY

4

136-1/4"

CLEARANCES

All units require certain clearances for proper operation and

service. Installer must make provisions for adequate combustion

and ventilation air in accordance with

Combustion and V entilation of the National Fuel Gas Code , ANSI

Z223.1 (in U.S.A.) or Sections 7.2, 7.3 or 7.4 of Gas Installation

Codes CAN/CGA-B149.1 and .2 (in Canada) and/or applicable

provisions of the local building codes. Refer to Dimensions and

Clearances table for the clearances required for combustible

construction, servicing, and proper unit operation.

WARNING:Do not permit o verhanging struct ure s or sh rubs to

obstruct ou tdoor air discharge ou tlet, combustion

air inlet or vent outlets.

Section 5.3, Air for

Unitary Products Group 3

Page 4

530.18-N11Y

DUCTWORK

Ductwork should be designed and sized according to the

methods in Manual Q of the Air Conditioning Contractors of

America (ACCA).

A closed return duct system shall be used. This shall not

preclude u se of ec onomizers or outd oor fres h air inta ke. The

supply and r eturn air duct connections at t he unit should be

made with flexible joints to minimize noise.

The supply and return air duct systems should be designed for

the CFM and static requirements of the job. They should

be sized to matc h the dime nsions of the duct connect ions on

the unit.

CAUTION: When fastening ductwork to side duct flanges on

unit, insert screws through duct flanges only. DO

NOT insert screws through casing.

Outdoor ductwork must be insulated and

waterproofed.

Refer to the Dimensions and Clearances figure for information

concerning side and bottom supply and return air duct openings.

It is recommended that, in Canada, the outlet duct on gas

heating units be provided with a removable access panel. It is

recommended that this opening be accessible when the unit

is installed in service, and of a size such that smoke or

reflected light may be observed inside the casing to indicate

the presence of leaks in the heat exchanger. The cover should

be attached in a ma nn er ad eq uate to preven t le ak ag e .

NOT

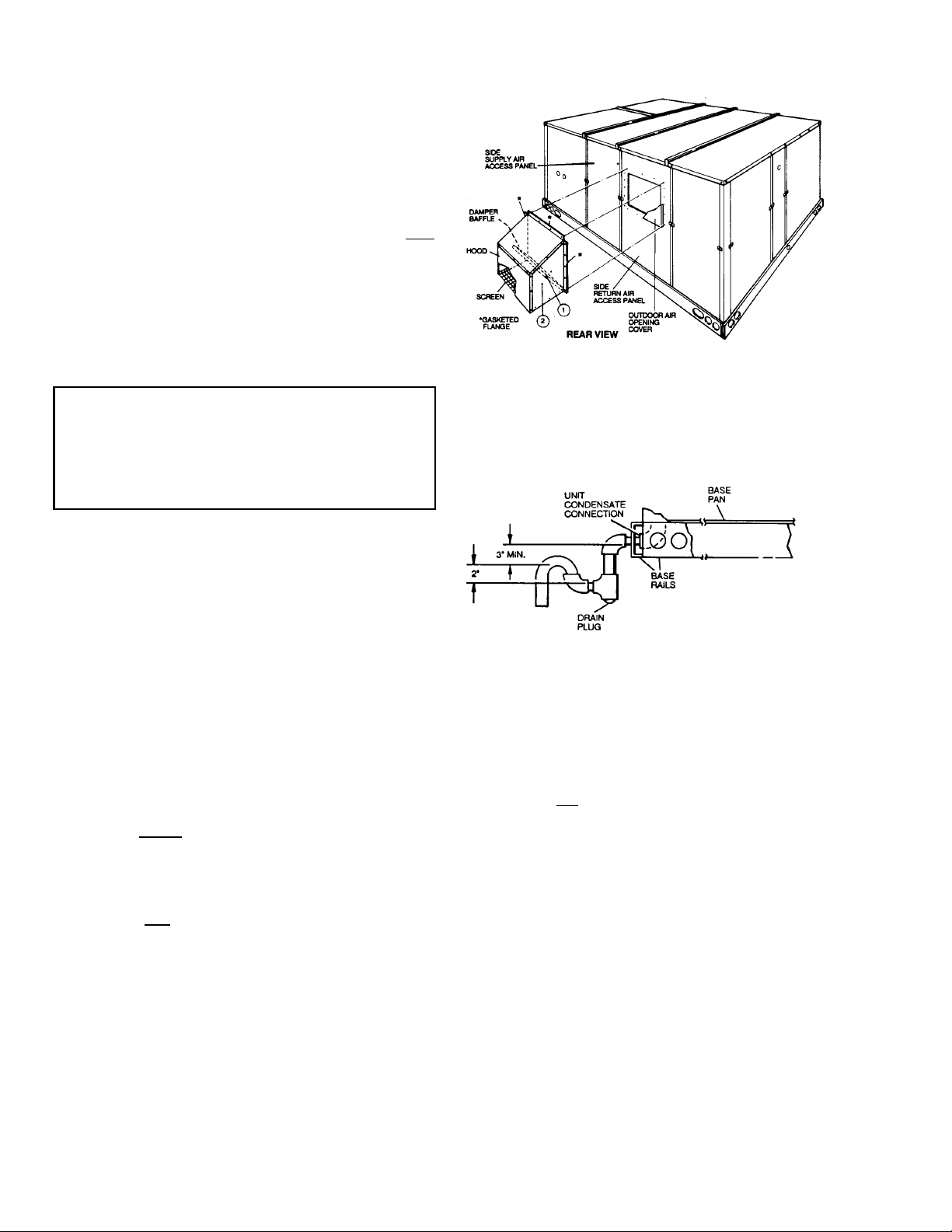

FIXED OUTDOOR AIR INTAKE DAMPER

FIG. 3

- FIXED OUTDOOR AIR DAMPER

CONDENSATE DRAIN

Plumbing must conform to local codes. Use a sealing

compound on male pipe threads. Install a condensate drain line

from the 1" NPT f emale connection on the unit to an op en drain.

This damper is shipped inside the return air compartment on units

that are not provided with an economizer or a motorized damper

option. It is completely assembled and ready for installation. A

damper baffle inside of the hood is adjustable to provide v ariable

amounts of outdoor air intake.

Gasketing and mounting screws are provided in a parts bag

attached to the hood assembly. Apply gasketing to the three

flange surfaces on the hood prior to installing the hood. Extend

gasketing 1/4" beyond the top and bottom of the two side

flanges to insure adequate sealing.

Adjusting the damper to the desired air flow may be done before

mounting the hood into position or (after installation) by

removing the front hood panel or the screen on the bottom of

the hood. Damper baffle in po siti on 1 will allow appr oximatel y

10% recirculated air f low , posit ion 2 appro ximatel y 15% and, to

allow approximately 25%, remove the damper baffle.

On units with

assembly o v er the o peni ng in the side retu rn air a ccess pane l.

Remove and discard the opening cover and the covering over

the hood moun ti ng h ol es (u se d for ship pi ng ) be fore inst al li ng .

Secure with the screws provided.

On units with side r eturn air appl ications, install th e damper

assembly on th e return air duc twork as close to the unit as

possible. Cut an opening 16" high by 18" wide in the ductwork

to accommodate the damper. Using the holes in the hood

flanges as a template, drill 9/64" dia. (#26 drill) holes into the

ductwork and secu re with the screws provide d.

CAUTION: If outdoor air intake will not be required on units

bottom return air appl icat ions , i nstall the d ampe r

with bottom return air applications, the damper

assembly s hould still be moun ted on the side return

air access panel, per the instructions above, to

insure mois ture is not drawn into the unit du ring

operation. The covering over the mounting holes

only need be removed. Do not remove the opening

cover.

FIG. 4 -

NOTE: The condensate drain line MUST be trapped to provide

RECOMMENDED DRAIN PIPING

proper drainage.

COMPRESSORS

Units are ship ped with comp ressor mounting s facto ry-adjusted

and ready for operation.

CAUTION: Do

Not loosen compressor moun ting bolts.

FILTERS

2" filters are su pplied with each uni t. Filt ers must alwa ys be installed

ahead of the evaporator coil and must be kept clean or replaced

with same size an d type. Dirty filters will redu ce the cap acity of t he

unit and will result in frosted coils or safety shutdown. Minimum filter

area and required si zes a re sho wn in t he Ph ysic al Dat a Table.

SERVICE ACCESS

Access to all serviceable components is provided by the

follo w in g rem o vable panels:

Compressor compartment

•

Electri c Heat compartment - DCE models

•

Gas Heat compartment (Two panels) - DCG models

•

Side Supply & Return Air compartments (Two panels)

•

Blower compartment (Three panels)

•

Main control box

•

Filter compartment

•

Outdoor Air compartment (Two panels)

•

Refer to th e Di mensio ns an d Cl eara nces fi gure for location of t hese

access panel s.

CAUTION: Make sure that all screws and panel latches are

replaced and properly positioned on the unit to

maintain an air-ti gh t se al.

4 Unitary Products Group

Page 5

530.18-N11Y

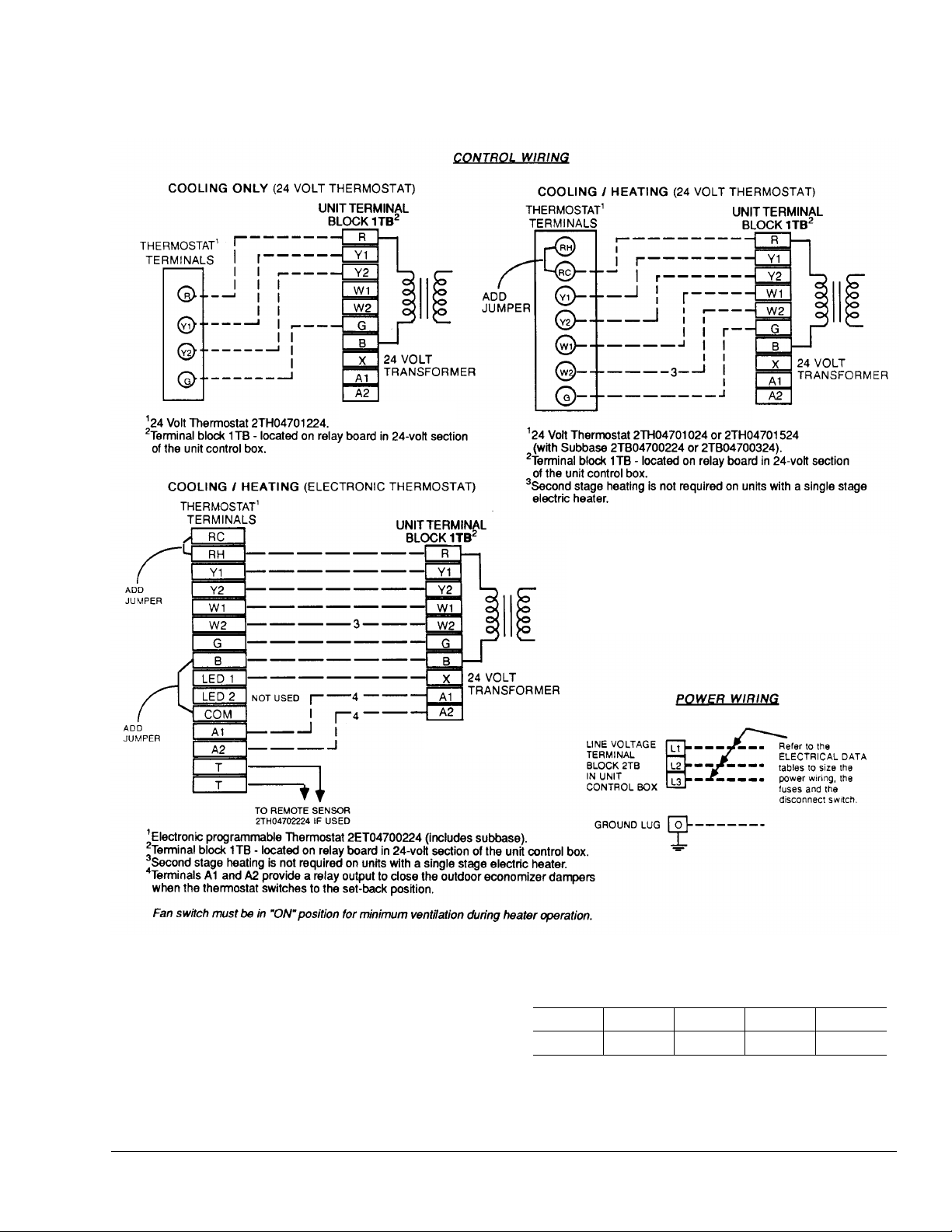

CONTROL WIRE SIZES

Wire Size1 AWG. Gauge

22 20 19 18 16

25 40 50 65 100

Maximum Wire Length2 Feet

Notes:

1. Solid, Class II copper wire

FIG. 5

- TYPICAL FIELD WIRING

Unitary Products Group 5

Page 6

530.18-N11Y

THERMOSTA T

The room thermostat should be located on an inside wall

approximately 56" above the floor where it will not be subject

to drafts, sun exposure or heat from electrical fixtures or

appliances. Follow manufacturer’s instructions enclosed with

thermostat for general installation procedure. Seven color

coded insulate d wires should be used to conn ect thermostat to

unit.

POWER AND CONTR OL WIRING

Field wiring to the unit must conform to provisions of the

National Electrical Code, ANSI / NFPA No. 70 (in U.S.A.),

current Cana dian Electrical Cod e C22.1 (in Canada) and/or

local ordinances. The unit must be electrically grounded in

accordance with NEC and CEC (as specified above) and/ or

local codes. Voltage tolerances which must be maintained at

the compressor terminals during starting and running

conditions are in dicated on the unit Ratin g Pla t e.

The internal wiring harness furnished with this unit is an integral

part of a ETL and CGA design certified unit. Field alteratio n to

comply with electrical codes should not be required.

A fused disconnect switch should be field provided for the unit.

The switch must be separate from all other circuits. Wire entry

at knockout openings require conduit fittings to comply with

NEC (in U.S.A.), CEC ( in Cana da) an d/or loc al co des. If any

of the wire suppl ied with the unit must be replaced, repla cement

wire must be of th e type shown on the wiring diagram and the

same minimum gauge as the replaced wire.

Electri cal line must be sized proper ly to carr y the load . Each

unit must be wired with a separate branch circuit fed directly

from the meter panel and properly fused.

CAUTION: When connecting electrical power and control

wiring to the unit, waterproof type connectors

MUST BE USED so that water or moisture cannot

be drawn into the unit during normal operat ion. The

above waterproofing conditions will also apply

when installing a field-supplied disconnect switch.

Refer to Typical Field Wiring Figure for typical field wiring and to

the appropriate unit wiring diagram for control circuit and power

wiring information.

OPTIONAL ELECTRIC HEATERS (DCE Models)

The factory installed heaters are wired for single point power

supply. Po wer supply need only be brought in to the singl e point

terminal block and thermostat w iring to the lo w volta ge terminal

block located in the upper portion of the unit control box.

These ETL an d CGA a pp roved he ater s ar e lo ca te d w ithi n th e

central compartment of the unit with the heater elements

extending into the supply air chamber. Refer to the Dimension

and Clearances figure for access panel location.

Fuses are supp li ed , whe r e req ui red , by the factory. Some KW

sizes require fuses and others do not. Refer to the Unit

Applicatio n Data Table 1 for minmum CFM limi tations an d to

Electrical Data T able.

TABLE 2

2,000 Feet

Sea Leve l

Max. Min. Max. Min. Max. Max. Min. Max.

300 150 270 135 240 213 279 20 50

400 200 360 180 320 281 372 30 60

NOTE: Heaters are shipped available for natural gas , but can be converted to

L.P. / Propane with Kit Model No. 1NP0418.

1

MBH rating should be red uce d at the ra te of 4 pe rce nt f o r ea ch 1, 000 feet above 4,500 feet.

2

Based on maximum input and 1075 Btu/Ft3.

3

The air flow must be adjusted to obtain a temperature rise within the range shown.

- GAS HEAT APPLICATION DATA

Input Capacity (Mbh) Output Capacity (Mbh)

0 T o

Above

2,000 To

4,500 Feet

Above

Sea Leve l

2,000 Feet

1

Sea Level

0 T o

Above

2,000 To

4,500 Feet

Above

Sea Leve l

1

Gas

Rate

(Ft.3/Hr.)

Temp.

2

Rise °F

At

Full Input

3

COMBUSTION DISCHARGE (DCG Models)

The products of combustion are discharged horizontally

through two screened (hooded) openings on the upper gas

heat access panel.

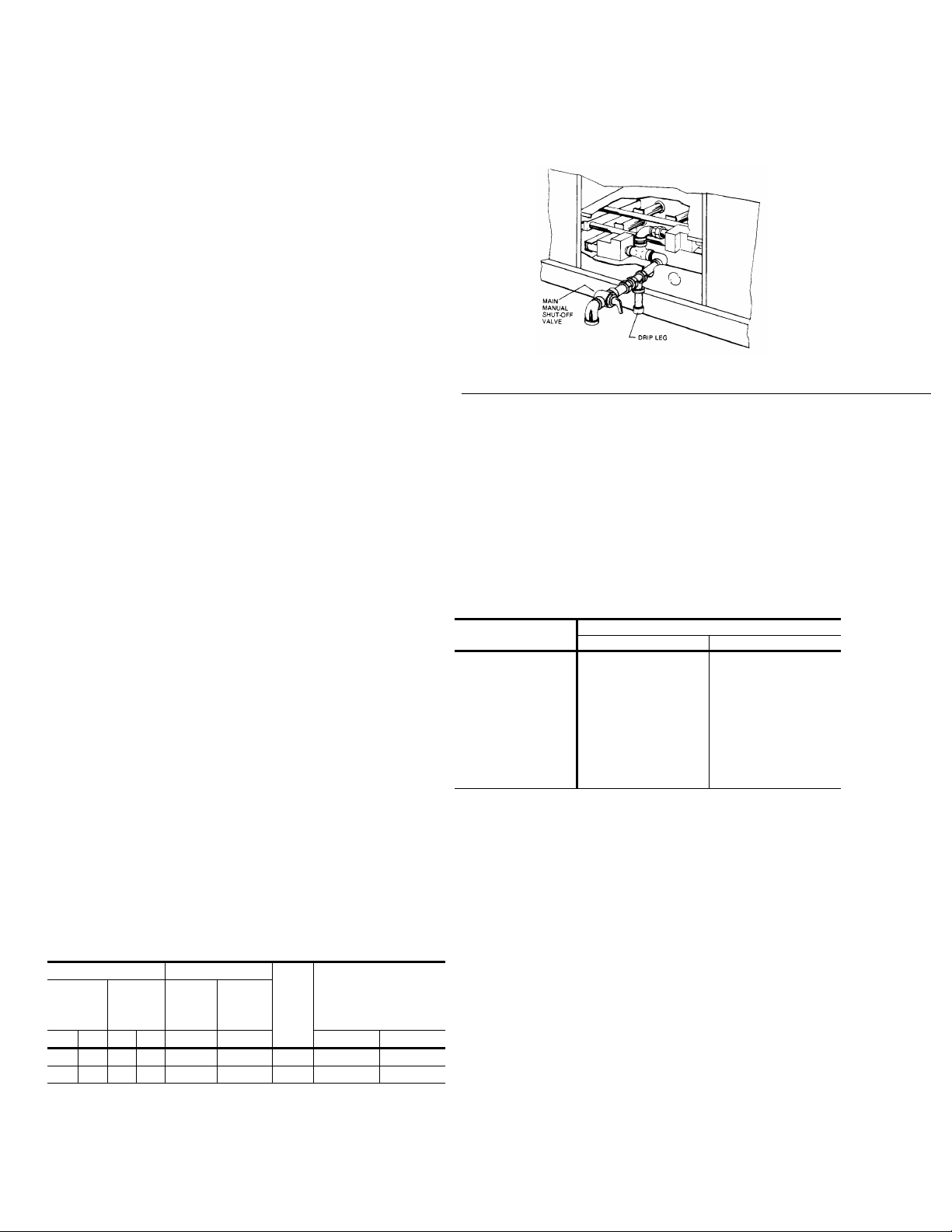

FIG. 6

- EXTERNAL SUPPLY CONNECTION

EXTERNAL SHUT-OFF

GAS PIPING (DCG Models)

Proper sizing of gas piping depends on the cubi c f eet pe r hour

of gas flow requir ed , sp ec ific gravity of th e ga s an d th e lengt h

of run. “National Fuel Gas Code” Z223.1 (in U.S.A.) or the

current Gas Installation Codes CAN/ CGA-B149.1 and .2 (in

Canada) should be followed in all cases unless superseded by

local codes or gas ut il ity requirements. See Pipe Sizin g t able.

The heating value of the gas may differ with locality. The value

should be chec ked with the local ga s ut ility.

NOTE : There may be a loca l gas utility requi rement specif ying

a minimum diameter for gas piping. All units re quire a

1 inch pipe connec ti on at th e entrance fitting.

TABLE 3

Maximum capacity of pipe in cubic feet of gas per hour. (Based upon a pressure drop of 0.3

inch water column and 0.6 specific gravity gas).

- PIPE SIZING

Length in Feet

10

20

30

40

50

60

70

80

90

100

Nominal Iron Pipe Size

1 in. 1-1/4 in.

520

350

285

245

215

195

180

170

160

150

1,050

730

590

500

440

400

370

350

320

305

GAS CONNECTION (DCG Models)

The gas supply line can be routed through the knockouts

located on the front of the unit or through the opening provided

in the unit’s base. Typical supply piping arrangements are

shown in the Supp ly C onn ecti on fi gures. All pipe, fitt ings, e tc.

are field-supplied.

T wo grommets are shipped in the blower compartment (in parts

bag taped to the blower housing) of every unit with gas heat

and should be used in the knockouts when the gas piping

enters through the front of the unit.

After the gas supply piping has been installed, the bottom

opening in t he unit should be sealed to prevent water fro m

leaking into the building.

Gas piping recommendations:

1. A drip leg and a ground joint union must b e installed in t he

gas piping.

2. When required by local co des, a man ual shut-of f val ve ma y

have to be in st al led outside of the unit.

3. U se w rough t ir on or st eel pipe for all ga s lines. Pipe compound should be ap plied sparingly to male thre ad s on ly.

6 Unitary Products Group

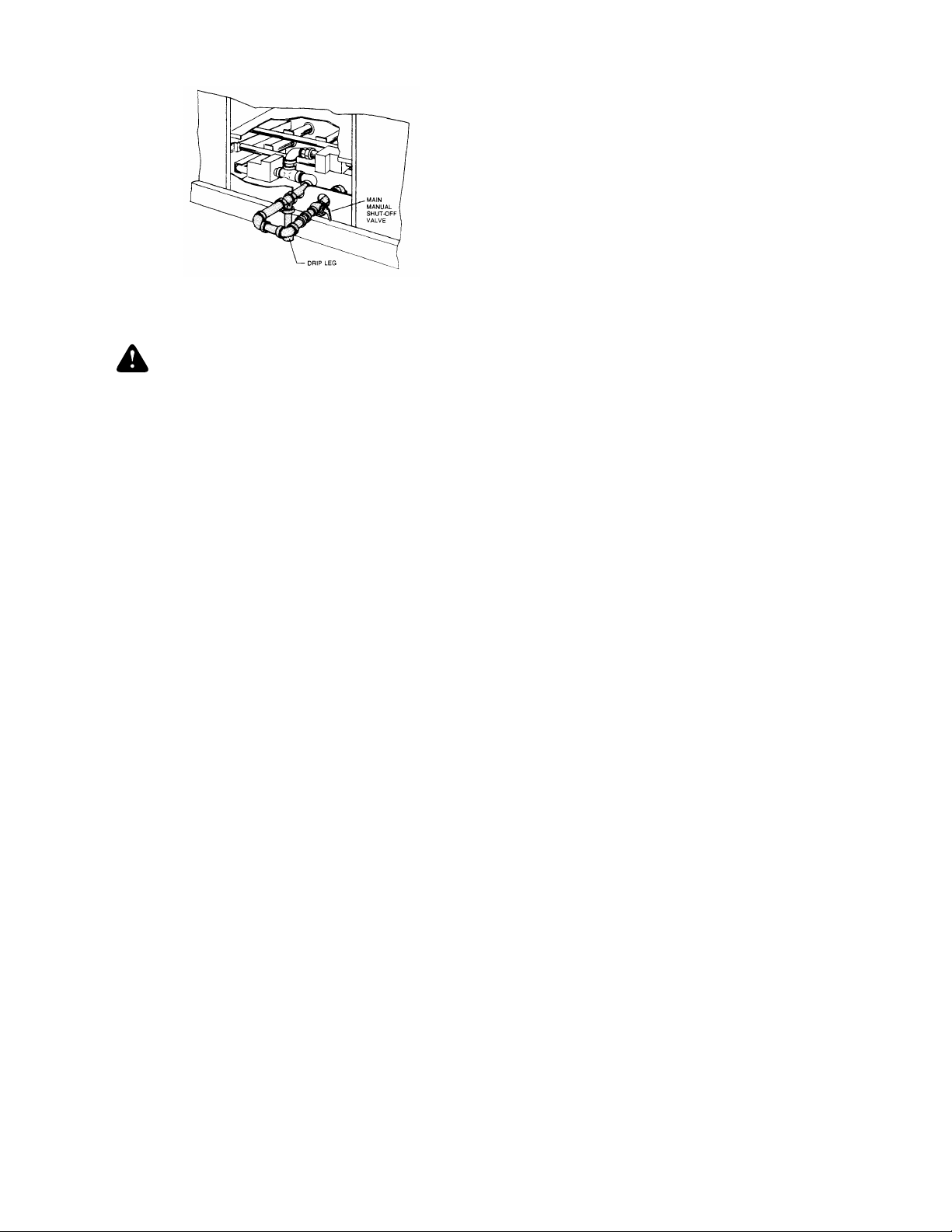

Page 7

FIG. 7

- BOTTOM SUPPLY CONNECTION

EXTERNAL SHUT-OFF

WARNING:Natural gas may contain some propane. Propane,

being an excellent solvent, will quickly dissolve

white lead or most standard commercial

compounds. Therefore, a special pipe com pound

must be applied when wrought iron or steel pipe is

used. Shellac base compounds such as Gask olac

or Stalastic, and compounds such as Rectorseal

#5, Cyde’s or John Crane ma y be us ed.

4. All piping should be clea ned of dirt and scale b y hammering

on the outside of th e pipe and bl owing out the loose dirt and

scale. Before i nitial start-up , be sure t hat al l of t he ga s lin es

external to the un it have been purged of air.

5. The gas supply should be a separate line and installed in

accordance with all safety codes as prescribed under

“Limitations”. After the gas connections have been

completed, open the main shut-off valve admitting normal

gas pressure to the mains. Check all joints for leaks with

soap solution or other material suitable for the purpose.

NEVER USE A FLAME.

6. T he fur nac e and its indiv idual m anual sh ut-off valve must

be disconnect ed fro m t he ga s sup ply p ipin g syst em d uring

any pressure testing of that system at test pressures in

excess of 1/2 psig (3.48kPa).

The furnace must be isolated from the gas supply piping

system by closing its individual manual shut-off valve during

any pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig (3.48kPa).

7. A 1/8 inch NPT plugged tapping, accessible for test gage

connection, m ust be in st alle d imme dia tely upst ream o f t he

gas supply connection to the furnace.

530.18-N11Y

L.P. UNITS, TANKS AND PIPING (DCG Models)

All gas heat units are shipped from the factor y equipped for

natural gas use only. The unit may be converted in the field for

use with L.P./ propane gas with access ory kit model nu mber

1NP0418.

All L. P./propane gas equipment must conform to the safety

standards of the Nat io nal Fire Protection Association.

For satis factory operat ion, L.P ./propane gas pressure must be

8.8 inch W.C at the unit under full load. Maintainin g proper gas

pressure depends on three main factors:

1. The vaporization rate which depends on (a) the temperature of the li quid and (b) the “wetted sur face” area of the

container or containers.

2. The proper pressure regulation. (Two-stage regulation is

recommende d from the standpoint of both cost and efficiency.)

3. The pressure drop in the lines between regulators and

between the second stage regulator and the appliance.

Pipe size required will depend on the length of the pipe run

and the total load of al l ap pl iances.

Complete infor mation regarding tank sizing for vaporization,

recommended regulator settings, and pipe sizing is available

from most regulator manufacturers and L.P./propane gas

suppliers.

L.P./propane gas is an excellent solvent and special pipe

compound must be us ed w he n a ss em bling pi pi ng for this ga s

as it will quickly dissolve white lead or most standard

commercial compounds. Shellac base compounds such as

Rectorseal #5 are satisfactory for this type of gas.

Check all connections for leaks when piping is completed,

using a soap solution. NEVER USE A FLAME.

Unitary Products Group 7

Page 8

530.18-N11Y

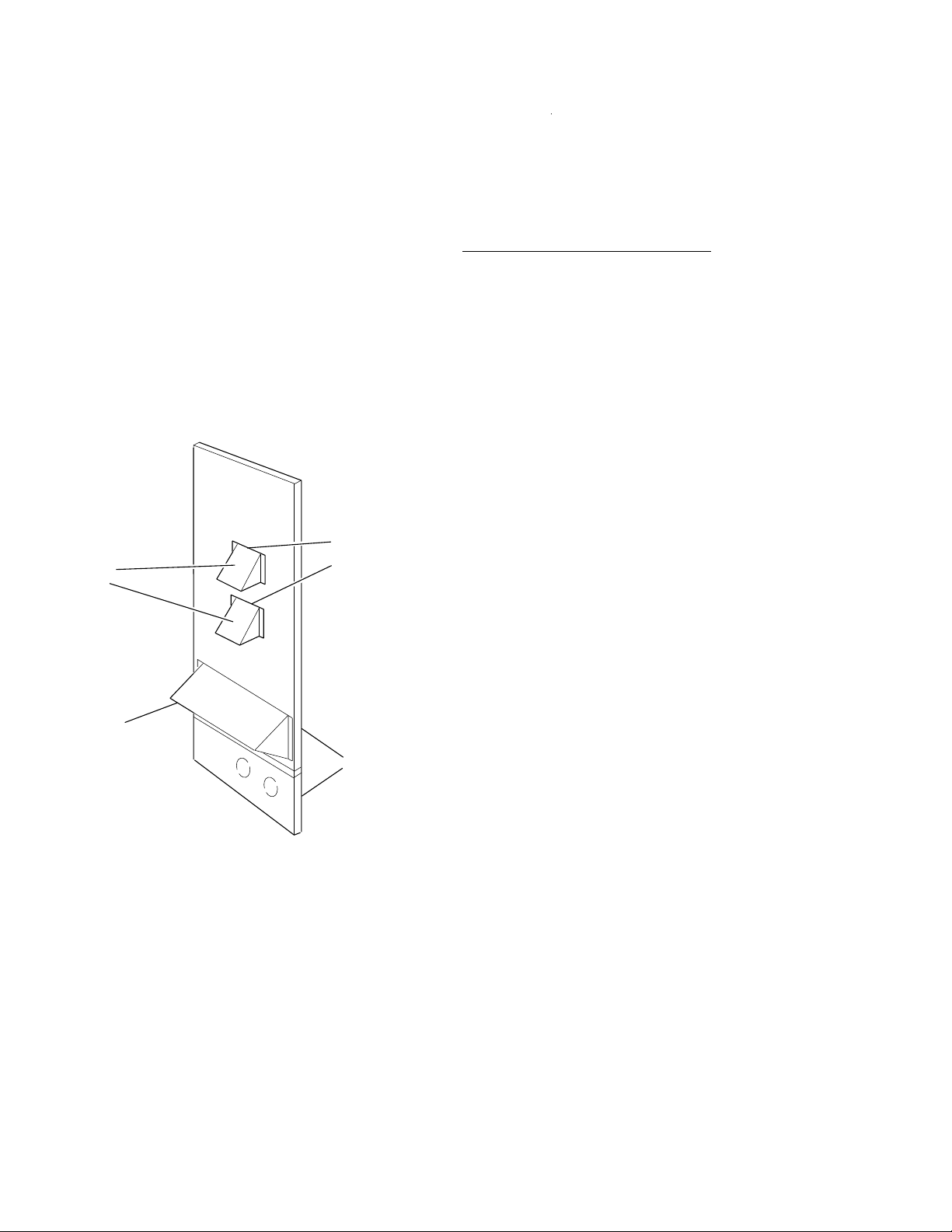

VENT AND COMBUSTION AIR HOODS

(DCG Models)

Two vent hoods and a combustion air hood (with screens) are

shipped attached to the blower housing in the blower

compartment. Thes e hoods must be ins talled to as sure pro per

unit function. All hoods must be fastened to the outside of the

gas heat access panel with the screws provided in the bag also

attached to the blower housing.

The screen f or the comb ustion air i ntake hood is secured to the

inside of the access panel op en in g w it h four fa st eners and the

screws used f or moun ting the hood t o the pane l. The top flange

of this hood s li ps i n under the top o f t he access panel o pe ning

when installing. Refer to the V ent and Combustion Hood figure.

OPTIONAL ECONOMIZER/MOTORIZED DAMPER

RAIN HOOD

The instru ction for the optional economizer/motorized damper

rain hood can be found in form 44-320-2. Use these instructions

when field a ssembling an econom izer rain hood ont o a unit.

The outdoor and return air damp ers, the damper actuator, the

damper linkage, the outdoor and return air divider baffles, and

all the control sensors are factory mounted as part of the

"Fac to ry install ed " ec on om izer option.

ENTHALPY SET POINT ADJUSTMENT

Remove the economizer access panel from the unit to check

the following adjustments. Loosen but do not remove the two

panel latches .

Each vent hood is installed by inserting the top flange of the

hood into the s lotted op ening i n the acce ss panel and sec uring

in place.

SLOTTED

VENT AIR

OUTLET

HOODS

COMBUSTION

AIR INTAKE

HOOD

OPENINGS IN

ACCESS PANEL

GAS HEAT

ACCESS

PANELS

CAUTI ON: Extreme care must be ex ercise d in turning both the

setpoint and m inimum p osition adjustin g scre ws to

prevent twisting them off.

1. T he enthalpy set point may now be set by selecting the

desired se tpoint shown in the Ent halpy figure. Adjust a s

follows:

For a single en thalpy operation, carefully turn the set

•

point adjusting screw to the “A”, “B”, “C” or “D” setting

corresponding t o th e le tt ere d cu rve.

For a dual enthalpy operation, carefully turn the set point

•

adjusting screw fully clockwise past the “D” setting.

2. To check that the damper blades m ove smoothly without

binding, carefully turn the minimum position adjusting

screw fully cl ockwise and then energize and de -energize

terminals “R” to “G”. With terminals “R” to “G” energized,

turn the minimum position screw counterclockwise until the

desired mini mum position has been attained.

3. Replace the economizer access panel. Reposition the two

latches horizontally and retighten the screws.

POWER EXHAUST/BAROMETRIC RE LIEF DAMPER

AND RAIN HOOD OPTION

The instructions for the power exhaust/barometric relief

damper and ra in hood can be found in form 44-320-10. The

exhaust fan, all supporting brackets, angles, and the wiring are

factory installed as part of the power exhaust option.

All of the components, including the dampers, hardware, and

mounting inst ructions are shipp ed in a single p ackag e e xternal

FIG. 8

- VENT AND COMBUSTION AIR HOODS

from the unit. The hood must be field a ssemble d and installe d.

Power exhaust is not available as a field installed option.

8 Unitary Products Group

Page 9

530.18-N11Y

FIG. 9

- ENTHALPY SETPOINT ADJUSTMENT

Unitary Products Group 9

Page 10

(1)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

530.18-N11Y

TABLE 4

- PHYSICAL DATA

MODELS

EV APORATOR

BLOWER

EV APORATOR

COIL

CONDENSER

FAN

(Two Per Unit)

CONDENSER

COIL

COMPRESSOR

(Qty. Per Unit)

CENTRIFUGAL BLOWER (Dia. x Wd. in.) 18 x 15

F AN MOTOR HP 15

ROWS DEEP 4

FINS PER INCH 13.5

FACE AREA (Sq. Ft.) 25.0

PROPELLER DIA. (in.) (Each) 30

FA N MOTOR HP (Each) 1

NOM. CFM TOTAL (Each) 7200

ROWS DEEP 3

FINS PER INCH 15

FACE AREA (Sq. Ft.) 43.3

12.5-TON TANDEM 2

QUANTITY PER UNIT (16" X 20" X 2") 2

AIR

FIL TERS

QUANTITY PER UNIT (16" X 25" X 2") 4

QUANTITY PER UNIT (14" X 20" X 2") 3

TO TAL FACE AREA (sq. ft.) 21.4

CHARGE

This compressor will be energized first.

*

TABLE 5

REFRIGERANT

22 (lbs./oz.)

- ELECTRICAL DATA - BASIC UNITS

MODEL NO.

D2CE300 208/230-3-60 41.4 312 1 4.2 15 38.6 139.5 175

& D2CG300 460-3-60 20.0 140 1 2.1 15 19.3 68.3 80

DCE/DCG

300

OPERATING WEIGHTS (LBS.) 25 T ON

DCE (Cooling only) 2730

Basic Unit

DCG

(Gas /

Electric)

N240 2930

N320 2970

Economizer 160

Economizer with

Power Exhaust

Options

Motorized Damper 150

Electric

Heater

(DCE only)

18 KW 25

36 KW 30

54 KW 35

72 KW 40

Roof Curb 185

Barometric Damper 45

Economizer/Motorized

Accessories

Damper Rain Hood

Economizer/P o wer E xhaust

Rain Hood

SYSTEM NO. 1 20/8

Wood Skid 220

SYSTEM NO. 2 20/0

POWER

SUPP LY

COMPRESSORS

QTY. 2

COND. FAN

#1 & #2

RLA LRA HP FLA AMPACITY DEVICE

ea.

ea.

ea.

SUPPLY AIR MINIMUM MAXIM UM

BLOWER MOTOR

ea.

HP RLA

CIRCUIT OV ERCURRENT

AMPS

AMPS

575-3-60 16.4 108 1 2.0 15 15.4 56.1 70

245

55

90

TABLE 6

- ELECTRICAL DATA - UNITS w/ELECTRIC HEAT

MODEL POWER CIRCUIT OVERCURRENT

D2CE SUPPL Y AMPA CITY DEVIC E ( 1)

300A25 208-3-60 E018 13.5 1 37.5 139.5 175

300A25 208-3-60 E036 27.0 2 75.1 142.1 175

300A25 208-3-60 E054 40.6 2 112.6 189.0 200

300A25 208-3-60 E072 54.1 2 150.1 198.4 225

300A25 230-3-60 E018 18.0 1 43.3 139.5 175

300A25 230-3-60 E036 36.0 2 86.6 156.5 175

300A25 230-3-60 E054 54.0 2 129.9 178.2 200

300A25 230-3-60 E072 72.0 2 173.2 221.5 250

300A46 460-3-60 E018 18.0 1 21.7 68.3 80

300A46 460-3-60 E036 36.0 2 43.3 78.3 80

300A46 460-3-60 E054 54.0 2 65.0 89.1 100

300A46 460-3-60 E072 72.0 2 86.6 110.7 125

300A58 575-3-60 E018 18.0 1 17.3 56.1 70

300A58 575-3-60 E036 36.0 2 34.6 62.6 70

300A58 575-3-60 E054 54.0 2 52.0 71.2 80

300A58 575-3-60 E072 72.0 2 69.3 88.5 100

ELEC TRIC HEAT ER OPTION

MODEL kW(1) STAGES AMPS

MINIMUM MAXIMUM

(AMPS) (AMPS)

VOLT AGE

LIMITATIONS**

**

Utilization Range “A” in accordance with ARI Standard 110.

NOMINAL VOLT A GE VOL TAGE KW CAP . MULTIPLIER

POWER SUPPLY

208/230-3-60 187 253

460-3-60 414 506

575-3-60 518 630

208 208 1.00

240 230 0.92

480 460 0.92

600 575 0.92

MIN. MAX.

VOLT AGE

10 Unitary Products Group

Page 11

BLOW ER

BLOW ER MOTOR

ACCESS

BLOW ER

CO M PARTM ENT

ACCESS

(A u x ilia r y )

DOT PLUG

(F o r p re s s ure

Drop Reading)

ACCESS

FR O NT

VIEW

UNIT BASE W ITH RAILS

Show n separately to illustrate

Bottom D uct openings and P ow er

C onnection locations

NOTE:

For curb m ounted units, refer to the curb hanger

dim ensions of the curb for the proper size of the

s u p p ly a n d re tu r n a ir d u c t c o n n e c tio n s .

BLOW ER

ACCESS

FIELD-SUPPLIED

BLOW ER MOTOR

ACCESS

BLOW ER

CO M PARTM ENT

ACCESS

(A u x ilia ry )

DOT PLUG

(F o r p re s su re

Drop Reading)

GAS HEAT

ACCESS

VENT AIR

OUTLET

HOODS

COM BUSTION

AIR INLET

HOOD

(C )

GAS SUPPLY

ENTRY

DISCONNECT SW ITCH

LO C A TIO N

136-1/4

CONTROL BOX

ACCESS

FR O N T

VIEW

UNIT BASE W ITH RA ILS

Show n separately to illustrate

Bottom D uct openings, P ow er

and G as P iping C onnection

lo c a tio n s

NOTE:

For curb m ounted units, refer to the curb hanger

dim ensions of the curb for the proper size of the

s u p p ly a n d r e tu rn a ir d u c t c o n n e c tio n s .

(D )

GAS SUPPLY

ENTRY

FIELD-SUPPLIED

DISCONNECT SW ITCH

LO C A TIO N

136-1/4"

ELECTRIC HE AT

ACCESS

CONTROL BOX

ACCESS

6-3/8"

35"

35-1/4

33"

11-1/8"

46-5/8"

35"

35-1/4"

33"

21"

5"

7-1/8"

9-3/4"

5-7/8"

46-5/8"

RETURN

AIR

2-3/4" 21-1/2"

12-1/2"

E C O N O M IZ E R / M O T O R IZ E D D A M P E R ,

FIXED O UTDO O R IN TAKE AIR AND

POW ER EXH AUST RAIN HO O DS

(See detail "Y")

21"

5"

9-3/4"

5-7/8"

11-1/2"

RETURN

AIR

SUPPLY

2-3/4" 21-1/2"

9-1/4"

AIR

9-1/4"

12-1/2"

E C O N O M IZ E R / M O T O R IZ E D D A M P E R ,

FIXED O UTDO O R INTAKE AIR AND

POW ER EXH AUST RAIN HO O DS

(See detail "Y ")

92"

11-1/2"

BOTTOM SUPPLY

AND RETURN

AIR OPENING S

(See Note)

SUPPLY

AIR

8-1/8"

9-3/4"

92"

BOTTOM SUPPLY

AND RETURN

AIR O PEN ING S

(See N ote)

8-1/8"

9-3/4"

COM PRESSOR

ACCESS

(See detail "X ")

52-5/8

(A )

CONTROL W IRING

ENTRY

(B )

POW ER W IRING

ENTRY

3-3/4"

(B )

POW ER W IRING

ENTRY

(A )

CONTROL W IRING

ENTRY

COM PRESSOR

ACCESS

(See detail "X")

52-5/8"

CONDENSER

COILS

(A )

CONTROL W IRING

ENTRY

(B )

POW ER W IRING

ENTRY

3-3/4"

(B )

POW ER W IRING

ENTRY

(A )

CONTROL W IRING

ENTRY

OPTIONAL

COIL GUARD

CONDENSER

COILS

All dimensions are in inches. They are subject to change without notice. Cert ified dimensions will be provided upon request.

OPTIONAL

COIL GUARD

RETURN AIR

SUPPLY AIR

CONDENSER AIR

OUTDOOR AIR

(Economizer)

UTILITIES ENTRY DATA

HOLE

A

B

C 2-3/8" KO Gas Piping (Front)

D 1-11/16" Hol e Gas Piping (Bottom)*

Opening in the bottom of the unit can be located by the slice

*

in the insulation.

OPENING

SIZE

USED FOR

(DIA.)

1-1/8" KO

3/4" NPS (Fem.) B ottom

3-5/8" KO

3" NPS (Fem.) Bottom

Control

Wiring

Power

Wiring

CLEARANCES

Front 36"

Back

Left Side (Filter Access)

Right Side (Cond. Coil) 36"

Below Unit

Above Unit

1

Units (applicable in U.S .A. only) may be installed on combustible floo rs

made from wood or class A, B or C roof covering material.

2

Units must be installed oudo ors. Overhanging structu re s or shrubs sho uld

not obstruct condenser air discharge outlet.

3

If economizer is factory installed, the assembled hood kit must be removed

prior to final installation. This hood is 54" long.

NOTE:

DCE Models: Units and ductwork are appro v ed f o r ze ro cle arance to combustible materials when equipped with electric heaters.

DCG Models: A 1" clearance must be provided between any combustible

material an d the supply air ductwork for a distance of 3 feet from the un it.

The products of comb ust ion mu st no t be al lo we d to accum u lat e wi th in a

confined space and re ci rcu lat e .

Locate unit so that the vent air outlet hood is at least:

Three (3) feet above any forced a ir inlet loca ted within 10 horizontal feet

•

(excluding those integral to the unit).

Four (4) feet below, 4 horizontal feet from, or 1 foot above any door or gravity

•

air inlet into the building.

Four (4) feet from electric meters, gas meters, regulators and relief equip-

•

ment.

1

2

24" (Less Economizer)

49" (With Economizer)

24" (Less Economizer)

3

36"

(With Economizer)

20"

72" With 36" Maximum

Horizontal Overhang

(For Condenser Air

Discharge)

530.18-N11Y

Front

Front

Cont’d.

FIG. 10

Unitary Products Group 11

- DIMENSIONS & CLEARANCES - DCE & DCG

Page 12

530.18-N11Y

GAUGE LINE

ACCESS

40-3/8"

COMPRESSOR

ACCESS

SUPPLY AIR

ACCESS

5-1/2"

CONDENSER

SECTION

RETURN AIR

ACCESS

REAR

VIEW

SUPPLY

AIR

18-5/8"

5-1/8"

RETURN

AIR

27-3/4"

EVAPORATOR

SECTION

DUCT COVERS - Units are shipped with the bottom

duct openings covered. An accessory flange kit is avail-

DOT PLUG

(For pressure

drop reading)

able for connecting side ducts.

For

1. Remove the side panels from the supply and return

air compartments to gain access to the bottom

FILTER

ACCESS

supply and return air duct covers.

2. Remove and discard the bottom duct covers. (Duct

openings are closed with sheet metal covers except

when the unit includes a power exhaust option. T he

covering consists of a heavy black paper composition.)

OUTDOOR

AIR

40-1/2"

3. Replace the side supply and return air compartment

panels.

For

1. Replace the side panels on the supply and return air

compartments with the accessory flange kit panels.

2. Connect ductwork to the duct flanges on the rear of

the unit.

29-5/8" (15 TON)

39-5/8

39-5/8" (20 TON)

OUTDOOR AIR

COMPARTMENT

ACCESS

1" NPT FEMALE

COND. DRAIN

CONNECTION

DETAIL “X”

ACCESSORY SIDE SUPPLY AND RETURN AIR OPENINGS

bottom duct applications:

side duct applications;

FIG. 10

ECONOMIZER

SUPPLY AIR

COMPARTMENT

POWER

EXHAUST

RAIN

HOOD

Return Air Compartment)

(on

MOTORIZED

DAMPER

RAIN HOOD

(on Outdoor Air Compartment)

36"

66-1/2"

2"

34-1/4"

5"

ECONOMIZER

AND

REAR VIEW

DETAIL "Y"

UNIT WITH RAIN HOODS

DET AIL “Y”

UNIT WITH RAIN HOODS

- DIMENSIONS & CLEARANCES (Cont’d.)- DCE & DCG

MOTORIZED DAMPER

/

POWER EXHAUST RAIN HOODS

FIXED

OUTDOOR

HOOD

INTAKE

(located on

Return Air

Compartment)

16-1/8"

36-1/4"

AIR

92"

LH VIEW

1" CONDENSTATE

DRAIN

(Must be trapped)

12 Unitary Products Group

Page 13

(

g)

(

)

(kW)

(iwg)

(

)

(kW)

(iwg)

(

)

(kW)

(iwg)

(

)

(kW)

(iwg)

(

)

(kW)

g

y

530.18-N11Y

B

FIG. 11

A

D

FRONT

4 POINT LOADS

- FOUR AND SIX POINT LOADS

TABLE 7

- FOUR AND SIX POINT LOADS

UNIT

TOTAL A B C D

C

4 - POINT LOADS (LBS)

A

300 3,130 615 671 962 882

NOTE: These weights are with economizer, high heat, and the largest blower motor available.

UNIT

TOTAL A B C D E F

300 3,130 418 438 533 628 603 510

6 - POINT LOADS (LBS)

NOTE: These weights are with economizer, high heat, and the largest blower motor available.

F

FRONT

6 POINT LOADS

B

E

D

C

TABLE 8

BLOWER PULLEY

SPEED TURNS ESP OUTPUT INPUT ESP OUTPUT INPUT ESP OUTPUT INPUT ESP OUTPUT INPUT ESP OUTPUT INPUT

NOTES:

- SUPPLY AIR BLOWER PERFORMANCE

7500 CFM 8750 CFM 10000 CFM 11250 CFM

rpm)OPEN:(iw

975 6.0* 1.4 5.9 4.9 1.0 7.3 6.0 0.5 8.8 7.2 - - - - - -

1005 5.0 1.6 6.2 5.1 1.2 7.7 6.3 0.7 9.2 7.6 0.1 10.9 8.9 - - 1040 4.0 1.8 6.6 5.4 1.4 8.1 6.7 0.9 9.7 8.0 0.3 11.4 9.4 - - 1070 3.0 2.0 6.9 5.7 1.6 8.5 7.0 1.1 10.2 8.3 0.6 11.9 9.8 - - 1100 2.0 2.1 7.3 6.0 1.8 8.9 7.3 1.3 10.6 8.7 0.8 12.4 10.2 0.2 14.3 11.7

1135 1.0 2.4 7.7 6.3 2.0 9.3 7.6 1.6 11.1 9.1 1.0 13.0 10.6 0.4 14.9 12.2

1165 0.0 2.6 8.0 6.6 2.2 9.7 8.0 1.8 11.6 9.5 1.3 13.5 11.0 0.7 15.5 12.7

1140 6.0 2.4 7.7 6.3 2.1 9.4 7.7 1.6 11.2 9.2 1.1 13.1 10.7 0.5 15.0 12.3

1180 5.0 2.7 8.2 6.7 2.3 9.9 8.1 1.9 11.8 9.7 1.4 13.7 11.2 0.8 15.8 12.9

1215 4.0 2.9 8.6 7.0 2.6 10.4 8.5 2.2 12.3 10.1 1.7 14.3 11.7 1.1 16.4 13.5

1255 3.0 3.2 9.1 7.4 2.9 11.0 9.0 2.5 12.9 10.6 2.0 15.0 12.3 1.4 17.2 14.1

1290 2.0 3.4 9.5 7.8 3.1 11.5 9.4 2.7 13.5 11.1 2.2 15.6 12.8 - - 1330 1.0 3.7 10.0 8.2 3.4 12.0 9.9 3.0 14.1 11.6 2.6 16.4 13.4 - - 1365 0.0 3.9 10.5 8.6 3.7 12.6 10.3 3.3 14.7 12.1 2.9 17.0 13.9 - - -

Blower performance is based on co ol i ng only unit, with fixed outdoor air, 2" T/A filters and a dry evaporator coil.

Refer to pa

ESP - External Static Pressure available for the suppl

blower.

* FACTORY SETTING

e 14 for additional static resistances.

bhp

bhp

and return air duct system. All internal unit resistances have been deducted from the total static pressure of the

DCE300

STANDARD DRIVE:

ACCESSORY DRIVE:

- BOT TOM DUCT CO NNECTIONS

bhp

bhp

(

COOLI NG APPLICATIONS)

12500 CFM

bhp

Unitary Products Group 13

Page 14

(

)

(

)

(

)

(

)

(

)

(

(

(

(

)

(

g)

(

)

(kW)

(iwg)

(

)

(kW)

(iwg)

(

)

(kW)

(iwg)

(

)

(kW)

(iwg)

(

)

(kW)

g

y

530.18-N11Y

TABLE 9

- SUPPLY AIR BLOWER PERFORMANCE

BLOWER PULLEY

SPEED TURNS ESP OUTPUT INPUT ESP OUTPUT INPUT ESP OUTPUT INPUT ESP OUTPUT INPUT ESP OUTPUT INPUT

rpm)OPEN:(iw

975 6.0 1.2 5.9 4.9 0.5 7.3 6.0 - - - - - - - - 1005 5.0 1.4 6.2 5.1 0.7 7.7 6.3 - - - - - - - - 1040 4.0 1.6 6.6 5.4 0.9 8.1 6.7 0.2 9.7 8.0 - - - - - 1070 3.0 1.8 6.9 5.7 1.1 8.5 7.0 0.4 10.2 8.3 - - - - - 1100 2.0 2.0 7.3 6.0 1.3 8.9 7.3 0.6 10.6 8.7 - - - - - 1135 1.0 2.2 7.7 6.3 1.6 9.3 7.6 0.8 11.1 9.1 - - - - - 1165 0.0 2.4 8.0 6.6 1.8 9.7 8.0 1.0 11.6 9.5 0.2 13.5 11.0 - - -

1140 6.0 2.2 7.7 6.3 1.6 9.4 7.7 0.9 11.2 9.2 - - - - - 1180 5.0 2.5 8.2 6.7 1.9 9.9 8.1 1.2 11.8 9.7 0.3 13.7 11.2 - - 1215 4.0 2.7 8.6 7.0 2.1 10.4 8.5 1.4 12.3 10.1 0.6 14.3 11.7 - - 1255 3.0 3.0 9.1 7.4 2.4 11.0 9.0 1.7 12.9 10.6 0.9 15.0 12.3 - - 1290 2.0 3.2 9.5 7.8 2.7 11.5 9.4 2.0 13.5 11.1 1.2 15.6 12.8 - - 1330 1.0 3.5 10.0 8.2 3.0 12.0 9.9 2.3 14.1 11.6 1.5 16.4 13.4 - - 1365 0.0 3.7 10.5 8.6 3.2 12.6 10.3 2.6 14.7 12.1 1.8 17.0 13.9 - - -

NOTES:

Blower performance is based on cooling only unit, with fixed outdoor air, 2" T/A filters and a dry evaporator coil.

Refer to pa

ESP - External Static Pressure available for the suppl

blower.

* FACTORY SETTING

7500 CFM 8750 CFM 10000 CFM 11250 CFM 1 2500 CFM

bhp

e 14 for additional static resistances.

and return air duct system. All internal unit resistances have been deducted from the total static pressure of the

DCG300

bhp

-BOTTOM DUCT CONNECTIONS(COOLING APPLICATIONS)

STANDARD DRIVE:

ACCESSORY DRIVE:

bhp

bhp

bhp

TABLE 10

- STATIC RESISTANCES*

DESCRIPTION

7500 8750 10000 11250 12500

ESP ESP ESP ESP ESP

IWG

AIRFLOW

IWG

IWG

CFM

IWG

IWG

DEDUCTIO NS: ( SUBTRACT VALUES BELOW FROM UNIT'S AVAILABLE ESP)

ALLOWANCE FOR WET COIL: 0.10 0.10 0.10 0.10 0.10

ECONOMIZER

RETURN DUCT): 0.06 0.09 0.11 0.14 0.18

18kW ELECTRIC HEAT: 0.31 0.43 0.56 0.71 0.87

36kW ELECTRIC HEAT: 0.38 0.52 0.68 0.87 1.07

54kW ELECTRIC HEAT: 0.62 0.84 1.10 1.39 1.72

72kW ELECTRIC HEAT: 0.68 0.93 1.21 1.54 1.90

ADDI T I ONS: (ADD VALUES BELOW TO UNIT'S A V AILA BL E ESP)

HORIZONT AL

HORIZONT AL

TABLE 11

MOTOR

SPEED

SIDE) SUPPLY DUCT: 0.31 0.26 0.27 0.31 0.41

SIDE) RETURN DUCT: 0.05 0.05 0.05 0.05 0.05

- POWER EXHAUST PERFORMANCE

STATIC RESISTANCE OF RETURN DUCTWORK, IWG

0.20.30.40.50.6

CFM KW CFM KW CFM KW CFM KW CFM KW

HIGH* 5250 0.83 4500 0.85 4200 0.88 3750 0.93 3000 0.99

MEDIUM 4900 0.77 3900 0.79 3500 0.82 2900 0.85 - -

LOW 44000.7237000.7430000.78 - - - -

Factory Setting

*

Power Exhaust motor is a 3/4 HP, PSC type with sleeve bearings, a 48 frame and inherent protection.

TABLE 12

MODEL

SIZE

25 TON

1

All motors have a nominal speed of 1800 RPM, a 1.15 service factor and a solid base. They can operate to the limit of their service factor because they are located in the mov ing air, upstream

of any heating device.

- BLOWER MOTOR AND DRIVE DATA

1

BLOWER

MOTOR

DRIVE

Stan-

Speed

dard

High

RANGE

(RPM)

975/1165

HP FRAME

15 254T 91 1LVP58B70A 7.5

EFF.

(%)

1140/1365 1B5V94 9.7 9.5 1-7/16 5VX840 84.0 1

Access

ADJUSTABLE MOTOR PULLEY FIXED BLOWER PULLEY

DESIG-

NATION

OUTSIDE

DIA.

(IN.)

PITCH

DIA.

(IN.)

BORE

(IN.)

DESIG-

NATION

OUTSIDE

DIA.

(IN.)

PITCH

DIA.

(IN.)

1B5V110 11. 3 11.1 1-7/16 5VX860 86.0 1

6.2-

1-5/8

7.4

BORE

(IN.)

DESIGNATION

14 Unitary Products Group

BELT

(NOTCHED)

PITCH

LENGTH

(IN.)

QTY.

Page 15

OPERATION

COOLING SYSTEM

The cooling section is a complete factory package utilizing an

air-cooled condenser. The system is factory-charged with

Refrigerant-22.

The compresso rs are hermetically sealed, internally sp rung

and base-mounted with rubber-insulated hold-down bolts.

Compressors have inherent (internal) protection. If there is an

abnormal temperature rise in a compressor, the protector will

open to shut down the compressor.

PRELIMINARY OP ERATION COOLING

After the ini tial installa tion, the compres sors should be gi ven

three false starts (energized just long enough to make a few

revolutions) with 5-7 minutes delay between each start, before

being put into ful l ti me service .

COOLING SEQUENCE OF OPERATION

NO OUTDOOR AIR OPTIONS - When the room ther mostat

calls f or “first-stage” cooling, the low voltage control circuit from

“R” to “G” and “Y1" is completed to energiz e compressors #1/2

(50% capacity), condenser fan motor #1, and the supply air

blower motor (if the fan switch on the room thermostat is set in

the ”A U TO" position).

When the thermostat calls for “second-stage” cooling, the low

voltage con trol circui t from “R” to “Y2" is completed to energize

compressor #3/4.

After the thermostat is satisfied and opens, all components will

stop simultaneously. The blower motor will continue to operate

if the fan switch on the room thermostat is set in the “ON”

position.

ECONOMIZER WITH SINGLE ENTHALPY SENSOR - When

the room thermostat calls for “first-stage” cooling, the low

voltage control circuit from “R” to “G” and “Y1" is completed.

The ”R" to “G” circuit energizes the blower motor (if the fan

switch on the room thermostat is set in the “AUTO” position)

and drives the economizer dampers from fully closed to their

minimum positi on. If the enthalp y of the ou tdoor air is be low the

setpoint of the enthalpy controller (previously determined), “Y1"

energizes the economizer. The dampers will modulate to

maintain a constant supply air temperature as monitored by the

discharge air sensor. If the outdoor air enthalpy is above the

setpoint, ”Y1" energiz es compressors #1/2, and co ndenser f an

motor #1.

When the thermostat calls for “second-stage” cooling, the low

voltage control circuit from “R” to “Y2" is completed. If the

enthalp y of the outdoor ai r is below t he setpoi nt of the e nthalp y

controller ( i .e. first stage ha s e ne r gi zed the ec on om izer ) , ”Y2"

will energize compressors #1/2. If the outdoor air is above the

setpoint, “Y2" will energize compressor #3/4.

After the thermostat is satisfied and opens, all components will

stop simultaneously. The blower motor will continue to operate

if the fan switch on the room thermostat is set in the “ON”

position.

ECONOMIZER WITH DUAL ENTHALPY SENSORS - The

operation with the dual enthalpy sensors is identical to the

single sensor e xcept that a second ent halpy se nsor is mounted

in the retur n air. This return air sens or allows the economizer

to choose between outdoor air and return air, whichever has

the lowest enthalpy value, to provide maximum operating

efficiency.

ECONOMIZER (SINGLE OR DUAL) WITH POWER

EXHAUST - Thi s system op erates as specifie d abov e with o ne

530.18-N11Y

addition. The power exhaust motor is energized whenever the

economizer is chosen by the enthalpy sensor for first stage

cooling, “Y1". As always, the ”R" to “G” connection pr ovides

minimum position but does not provide power exhaust

operation.

MOTORIZED OUTDOOR AIR DAMPERS - This system

operation i s th e sa me a s th e un it s wi th no ou tdoo r ai r op ti on s

with one exception. When the “R” to “G” circuit is comp lete , the

motorized damp er driv es open to a po siti on s et b y the d ampe r

motor adjustment. When the “R” to “G” circuit i s opened, the

damper spring ret urns fu ll y cl os ed .

CONTINUOUS BLOWER - Continuous blower operation is

possible by closing the R to G circuit on the thermostat.

SAFETY CONTROLS

Each refrigerant system is equipped with the following safety

controls:

1. A Suction Line Freezestat to protect against low evaporator

temperatures due to a low air flow or a low return air

temperature. (Opens at 26°F + 5°F and resets at 38°F +

5°F)

2. A High Pressure Cutout Switc h to protect against excessiv e

discharge p ressu res due to a blocked conden ser c oil or a

condenser moto r failure. (Opens at 380 psig + 10 and rese ts

at 300 psig +10)

3. A Low Pressure Switch/Loss Of Charge to protect against

loss of refrigerant charge. (Opens at 7 psig + 3 and resets

at 22 psig + 5)

If either one of th e abo v e sa f et y cont rol s open s, that indi vidu al

refrigerant system will be locked out. The other refrigerant

system will con tinue in operat ion un less it too is e ff ected b y the

same fault. The lock out of either system can be reset by

opening the 24V circui t ei th er a t t he roo m t he rmostat or at the

unit disconnect.

ELECTRIC HEATING - SEQUENCE OF OPERATION

WITH POWER TO UNIT AND THERMOSTAT IN THE

HEATING MODE

Single-stage heating: (applies only to 18 KW heater, all other

heaters MUST use a two-s ta ge t he rmostat :)

a) If the fan switch is in the “ON” position, the evaporator

blower motor contactor (3M) will be energized through

terminal G to provide continuous blower operation. If the fan

switch is in the “AUTO” position, the blower will operate only

when there is a call for heating by the thermostat.

NOTE: All 240 & 480V heaters are provided with manual

reset backup protection limits. These will de-energize the heaters should the primary limit fail to open

or the contactors fail to open in a failure mode.

b) Upon a call f or h eat by the thermostat , the heater co ntactor

(6M) will be energized.

c) The thermostat will cycle the electric heat to satisfy the

heating requirem en ts of th e co nd it ioned space.

Two-stage heating: (applies to all heaters except 18 KW):

a) If the fan switch is in the “ON” position, the evaporator

blower motor contactor (3M) will be energized through

terminal G to provide continuous blower operation. If the fan

Unitary Products Group 15

Page 16

530.18-N11Y

switch is in the “AUTO” position, the blower will operate only

when there is a call for heating by the thermostat.

b) Upon a call for first-stage heat by the thermostat, the heater

contactor (6M) (6M & 7M on 72 KW, 240V) will be

energized.

If the second stage of heat is required, heater contactor

(7M) will be energized. Note that on the 54 KW, 240V

heater , heater contactors (7M & 8M) wi ll b e en erg ized and

on the 72 KW, 240V heater, heater contactors (8M & 9M)

TABLE 9

- HEAT ANTICIPATOR SETTING

HEATER

KW

18

36 0.29 0.29

54 0.29 0.58

72 0.58 0.58

18

36 0.29 0.29

54 0.29 0.29

72 0.29 0.29

18

36 0.29 0.29

54 0.29 0.29

72 0.29 0.29

VOLT AGE

208/230-3-60

460-3-60

575-3-60

SETTING, AMPS

TH1 TH2

0.29 -

0.29 -

0.29 -

will be energize d.

c) The thermostat will cycle the electric heat to satisfy the

heating requirem en ts of th e co nd it ioned space.

HEAT ANTICIPATOR SETPOINTS

It is important that the anticipator setpoint be correct. Too high of

a setting will result in longer heat cycles and a greater temperature

swing in the co nditioned space. Reducing the value below th e

correct setpoint will give shorter “ON” cy cles and ma y resul t in the

lowering of the te mpertur e withi n the co ndit ioned s pace. Refer to

the Heat Anticipator Setpoints table for the required .

GAS HEATING SEQUENCE OF OPERATION

The following sequence describes the operation of the gas heat

section.

CONTINUOUS BLOWER

With the room thermostat switch set to “ON”, the supply air

blower will operate cont inuousl y. The normally cl osed cont act

“K5-1" provides 24 volt po wer to the “3M” cont actor . The “3M-1,

2 & 3" power contact s clos e an d the blower motor operates.

INTERMITTENT BLOWER

With the room thermostat system switch set to the “AUTO” or “HEAT”

position and the fan switch set to “AUTO”, the supply air blower will

operate after the room thermostat calls for heat and the time delay

relay cl oses.

The “TH1" closes, the heat relay ”RW1" is energized. The “RW1-1”

power contact cl oses energizin g the line voltage draft moto r. Th e

“RW1-2" contact is also closed. As the speed of the draft motor

reaches ap proximatel y 2500 RPM, the centrif ugal switch contact

located on the end of the draft mot or shaft closes to power the first

stage ignition module “IC1”.

After a brief pre-purge time, ignition module “IC1" will start the first

stage ignitor sparking and will open the redundant valve located

inside the first st age main g as va lve “GV1” to allow a flow of gas to

only the first stage c arr yover tube. Only after the pilot flam e has

been ignited a nd th e p r es en ce of pi lo t flame detected at th e “IC1”

by a signal sent back through the flame sensor is sparking

terminated and the first stage mai n gas v alv e open ed.

Gas flows into each of the main burners and is ignited from

the carryover tube flame.

If “IC1” fails to detect a pilot flame, it will continue to try for a maximum

of 85 seconds to ignite the pilot tube. If the pilot flame is not detected,

then “IC1" will lock out furnace operation for 5 minutes, then retry

ignition sequence.

At the same time power was supplied to the “RW1”, a parallel

circuit activates “ETD” which closes the “ETD” contact after

approximately 35 seconds and energizes “K5" which closes

”K5-2" and starts the blow er by energizing “3M”.

When “TH2" closes, heat relay ”RW2" is energized. The

“RW2-1" contact is closed energizing the second stage ignition

module ”IC2". “IC2" will immediately start the second stage

ignitor sparking and will open the redundant valve located

inside the second stage main gas valve ”GV2" to allow a flow

of gas to the second sta ge carryo ver tube. Only after the pilot

flame has been ig nited and the presence of pi lot flame dete cted

at “IC2" by a signal sent back through the flame sensor is

sparking terminated and the main gas valve opened.

Gas flows into each of th e se cond stage main burn ers and i s

ignited from the carryo ver tube flame.

If “IC2" fails to detect a pilot fl ame, it will c ontinue to tr y for a

maximum of 85 seconds to ignite the pilot tube. If the pilot flame

is not detected, then ”IC2" will lock out furnace operation for 5

minutes, then retry ignition sequence. Note that the sec ond

stage furnace can operate even if first st age has locked out.

When the heating cycle is complete, “TH2" opens de-energizing

the ”RW2" then “TH1" opens de-energizing ”RW1" and “ETD”,

FIG. 12

REDUNDANT

VALVE

GAS MAIN

GAS

VALVE

TO PILOT BURNER

- GAS VALVE PIPING

MAIN VALVE

TO MAIN

BURNER

thus closing all gas valves. The blower motor will continue to

run (approximately 45 seconds after the furnace is shut down)

until “ETD” opens, de-energizing the “K5" relay and ”3M"

contactor. The draft motor will continue to run for a brief

post-purge cycle.

SAFETY CONTROLS

The control circuit includes the following safety controls:

1. Limit Control (LS). This control is located inside the heat exchanger

compartment and is set to open at the temperature indicated in

the Limit Control Setting Table. It resets automatically. The limit

switch operates when a high temperature condition, caused by

inadequate supply air flow occurs, thus shutting down the ignition

control and closing the main gas valves and energizing the blower .

2. Centrifugal Switch (CS). If the draft motor should fail, the

centrifugal switch attached to the shaft of the motor prevents

the ignition controls and gas valves from being energized.

3. Redundant Gas Valve. There are two separate gas valves

in the furnace. Eac h valv e cont ains a mai n and a red undant

valve. The red undant valves are loca ted upstream of th e

main gas valves. Should either or both of the main gas

valves fail in the open position the redundant valves serve

as back-ups and sh ut s off the flow of gas.

4. Flame Sensor Rod / 100% Ignition Control Lock-Out. If an

ignition cont rol fai ls to detec t a signal from the flame sen sor

indicating the pilot flame is properly ignited, then the main

gas valve will not open. It will continue to try and ignite the

pilot for a ma ximum of 85 secon ds, th en if the pilot f lame is

not detected, the ignition control will lock out furnace

operation until 24V power is removed from the module

either at the unit or by resetting the room thermostat.

5. Rollout Switch. This switch is located above the main burners in the control compartment which in the event of a

sustained ma in bur ner roll out sh uts of f and locks out both

ignition controls closing both gas valves. The ignition controls lock out furnace op eration un til 24V pow er is remov ed

from the controls either at the unit or by resetting the room

thermostat. Note th e auto reset rollou t switch must reset

before allowing furnace operation.

16 Unitary Products Group

Page 17

530.18-N11Y

FIG 13

IGN. CONTROL #2

IG N . C O N T R O L # 1

R O LLO U T S W .

SENSO R #1

GV2

GAS

VALVE

IG NITOR #2

BURNER COM PARTM ENT

-GAS VALVE AND CONTROLS

GV 1

GAS

VALVE

IG NITOR #1

SENSO R #2

TABLE 10

- LIMIT CONTROL SETTING

Capacity, MBH

Input Output

300 240 195

400 320 195

HEAT ANTICIPATOR SETPOINTS

It is important that th e an ti ci pa tor setpoint be correct. Too high of

a setting will result in longer heat cycles and a greater

temperature swing in the conditioned space. Reducing the value

below the correct setpoint will give shorter “ON” cycles a nd may

result in the lowering of the temper ture within the conditioned

space.

Gas Valve

Honeywell VR8440

White-Rodgers 36C68

Anticipator Setpoint

1st Stage 2nd Stage

0.30 amp 0.11 amp

PRE-START CHECK LIST

Complete the following checks before starting the unit.

1. C heck the type of gas being su pplied. Be sure that it is the

same as listed on the unit nameplate.

2. Make sure that the vent and combustion air hoods have been

properly instal le d.

START-UP

Limit Control

Opens, °F

6. Auxiliary Limit Switch (AUX) This control is located inside

the heat exchanger compartment and is set to open at

190°F. It is a manual reset switch. If A UX limit trips, then the

primary limit has not functioned correctly., Replace the

primary limit

OPERATING INSTRUCTIONS

CAUTION: This fur na ce i s eq uipp ed w ith an i ntermittent pilo t

and automatic re-i gnition sys tem. DO NO T att empt

to manually light the pilot.

TO LIGHT PILOT AND MAIN BURNERS:

1. Turn “off” electric power to unit.

2. Turn room thermostat to lowest sett ing.

3. Turn gas valve kn ob t o “on” position.

4. Turn “on” electric power to unit.

5. Set room thermostat to d esired temperature.

(If thermostat “set” temperature is above room temperature,

pilot burner ignition will occur and, after an interval to prove

pilot flame, main burners will ignite).

TO SHUT DOWN:

1. Turn “off” electric power to unit.

2. Depress knob of gas valve while t urning to “off” position.

POST-START CHECK LIST (GAS)

After the entire control circuit has been energized and the

heating section is operating, make the follo w in g ch ecks:

1. Check for gas le aks in the uni t pipi ng as wel l as t he supp ly

piping.

2. Check for correct manifold gas pressures. See “Checking

Gas Input”.

3. Check the supply gas pres sure. It m u st be w it hin the limits

shown on rating nameplate. Supply pressure should be

checked w ith all g as applia nces in the b uildi ng at f ull fire. At

no time should the standby gas line pressure exceed 13",

nor the operating pressur e drop below 5.0" for natural gas

units. If gas pressure is outside these limits, contact the

ON-OFF CONTROL

HIGH FIRE ADJ.

(UNDER SCREW)

PILOT ADJ.

(UNDER SCREW)

FIG. 14

- TYPICAL GAS VALVE

local gas utility for correctiv e action.

MANIFOLD GAS PRESSURE ADJUSTMENT

Small adjustments to the high-fire gas flow may be made by

turning the pressure regul ator adjusting scre w on the automatic

gas valve. Refer to figure below.

Adjust as follows:

1. Remove the cap on the regulator. It’s located next to the

push-on electrical terminals.

2. To decrease the gas pressure, turn the adjusting screw

counterclockwise.

Unitary Products Group 17

Page 18

530.18-N11Y

BURNER ASSEMBLY BRACKET

Reve rse the abo ve procedure t o replace the asse mblie s. M ake

sure that burners are level and seat at the rear of the heat

exchanger.

FLAME SENSOR BULB

1/8" GAP BETWEEN CARRY-OVER

TUBE AND FLAME SENSOR BULB

CARRY-OVER TUBE

FIG. 15

- PROPER FLAME ADJUSTMENT

3. To increase the gas pressure, turn the adjusting screw

clockwise.

NOTE: The correc t manifold pressure for these furnaces is

3.65 IWG ±0.3.

PILOT CHECKOUT

The pilot flame should envelope the end of the flame sensor . Refer

to Proper Flame Adjustment figure. To adjust pilot flame, (1)

remove pilot adjustment cover scre w, (2) increase or decrease the

clearance for air to the desired level, (3) be sure to replace cover

screw after adjustment to prevent possib le gas leakage.

Put the system into oper ation and ob serve th rough compl ete

cycle to be sure all co nt rol s fu nc ti on pr op erly.

BURNER AIR SHUTTER ADJUSTMENT

Adjust burn er shutters so no yellow fla me is obser ved in the

heat exchanger tubes.

CHECKING SUPPLY AIR CFM

The RPM of the supply air blower will depend on the required CFM,

the unit accessories or options and the static resistances of both

the supply and the return air duct systems. With this information,

the RPM for the supply air blower and the motor pulley adjustment

(turns open) can be deter mined from the Blower Performance

Data Table.

A high speed drive accessory 1LD0435 (containing a smaller

blower pulley and shorter belts) is available for applications

requiring the supply air blo wer to pro duce high er CFM’s and/or

higher static pressures. Refer to the Blower M otor and Drive

Data T able.

Note the following:

BURNER INSTRUCTIONS

To check or change burners, pilot or orifices, CLOSE MAIN

MANUAL SHUT-OFF V ALVE AND SHUT OFF ALL ELECTRIC

POWER T O THE UNIT.

1. R emove the screws holding ei ther end of the man ifold to

the burner supports.

2. Op en the un io n f itti ng in the g as su pp ly li ne ju st up str ea m

of the unit gas v alve an d downstream f rom the main manu al

shut-off valve.

3. Remove the gas pipi ng clo su re pa ne l.

4. Disconnect wiring to the gas valves and spark ignitors.

Remove the manifold-bur ner ga s valve assembly by lift in g

up and pulling back.

Burners are now accessible for service.

FIG.17 -

BELT ADJUSTMENT

1. The supply air CFM mus t be w ithin the l imitat ions s hown in

Unit Application DataTab le.

2. Pulleys can be adjusted in half turn increments.

3. The tension on the belts should be adjusted as shown in

the belt adjustmen t fi gu re be low.

Start the supply air blower motor. Adjust the resistances in both

the supply an d the retur n air du ct system s to balanc e the air

distribution throughout the conditioned space. The job

specifications may require that this balancing be done by

someone other tha n the equipment installe r.

T o check the supply air CFM after the initial balancing has been

completed:

FIG. 16

- TYPICAL FLAME APPEARANCE

18 Unitary Products Group

1. Remove the two 5/16 " dot plugs fro m the blo wer motor a nd

the filter access pan el s .

Page 19

2. Insert at least 8" of 1/4 inch tubing in to each of thes e holes

for sufficient pene tration into the air flow on both side s of

the indoor coil.