Page 1

®

036-21359-001-B-0302

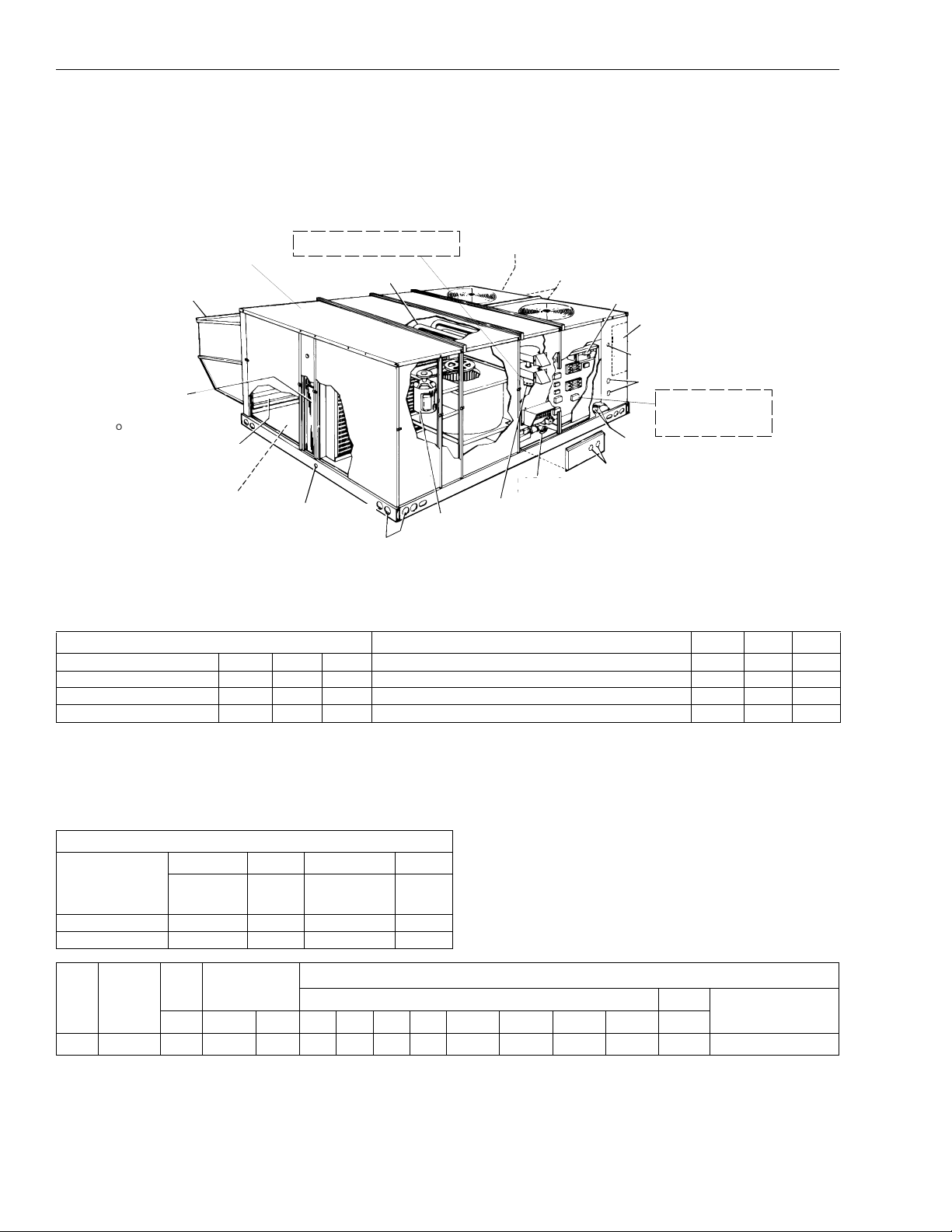

DESCRIPTION

Sunline™ 2000 series convertible package rooftop models have two independent refrigerant circuits for efficient

part load operation. Although the units are primarily

designed for curb mounting on a roof, they can also be

slab-mounted at ground level or set on steel beams above

a finished roof.

Technical Guide

SINGLE PACKAGE

GAS / ELECTRIC UNITS AND

SINGLE PACKAGE AIR CONDITIONERS

D2CE / D2CG 300 CONSTANT VOLUME

25 NOMINAL TONS

8.5 EER

SUNLINE 2000 ™

Cooling only, cooling with gas heat and cooling with electric

heat models are available with a wide variety of factorymounted options and field-installed accessories to make

them suitable for almost every application.

All units are self-contained and assembled on full perimeter

base rails with holes in the four corners for overhead

rigging.

Every unit is completely piped, wired, charged and tested

at the factory to simplify field installation and to provide

years of dependable operation. Powder paint cabinets provide an exceptionally durable finish with the 750 hour salt

spray process per ASTM-B117 test standard.

All models (including those with an economizer) are suitable for either bottom or horizontal duct connections. Models with power exhaust are suitable for bottom duct

connections only. For bottom duct, you remove the sheet

metal panels from the supply and return air openings

through the base of the unit. For horizontal duct, you

replace the supply and return air panels on the rear of the

unit with a side duct flange accessory.

All models are available with five different outdoor air

damper options:

• Single enthalpy economizer

• Differential (dual) enthalpy economizer

• Single enthalpy economizer with power exhaust

• Differential (dual) enthalpy economizer with

power exhaust

• Motorized outdoor air damper

A fixed outdoor air intake assembly is shipped in the return

air compartment of all units ordered without an economizer

or motorized outdoor air damper option. The assembly

includes a rain hood with a damper that can be set for 10,

15 or 25% outdoor air. With bottom duct connections, the

intake damper assembly should be mounted over the

opening in the return air panel. With horizontal ductwork, it

should be mounted on the return air duct.

FOR DISTRIBUTION USE ONLY - NOT TO BE USEDAT POINT OF RETAIL SALE

Page 2

036-21359-001-B-0302

All supply air blowers are equipped with a belt drive

that can be adjusted to meet the exact requirements of

the job. A high speed drive accessory is available for

applications with a higher CFM and/or static pressure

requirement.

All compressors include internal pressure relief. Every

refrigerant circuit includes an expansion valve, a liquid

line filter-drier, a discharge line high pressure switch

and a suction line with a freezestat and low pressure/

loss of charge switch. The unit control circuit includes

two 75 VA transformers, two 24-volt circuit breakers

and a relay board with two compressor lockout circuits,

a terminal strip for thermostat wiring, plus an additional

set of pin connectors to simplify the interface of additional field controls.

All 208/230 and 460-volt models are ETL approved. All

208/230 and 575-volt models are CGA approved.

All models include a 1-year limited warranty on the

complete unit. Compressors and electric heater elements carry an additional 4-year warranty. Aluminized

steel tubular heat exchangers carry an additional 9year warranty.

All gas heat models are built with two heating sections

for two equal stages of capacity control. Each section

includes a durable heat exchanger with aluminized

steel tubes, a redundant gas valve, spark ignition,

power venting, an ignition module for 100% shut-off

and all of the safety controls required to meet the latest

ANSI standards.

The gas supply piping can be routed into the heating

compartment through a hole in the base pan of the unit

or through a knockout in the piping panel on the front of

the unit.

All electric heat models are wired for a single power

source and include a bank of nickel chromium elements mounted at the discharge of the supply air

blower to provide a high velocity and uniform distribution of air across the heating elements. Every element

is fully protected against excessive current and temperature by fuses and two thermal limit switches.

The power supply wiring can be routed into the control

box through a threaded pipe connection in the base

pan of the unit or through a knockout in the wiring

panel on the front of the unit.

All internal factory wiring is color coded and numbered

for ease in servicing and troubleshooting.

FACTORY-INSTALLED OPTIONS

ECONOMIZERS

Interlocked outdoor and return air dampers are positioned by a fully modulating, spring return damper actuator capable of introducing up to 100% outdoor air with

nominal 1% leakage type dampers. As the outdoor air

intake dampers open, the return air dampers close.

The changeover from compressor to economizer cooling is determined by one or two solid state enthalpy

controls.

On single enthalpy, an outdoor air sensor determines

when the outdoor air is cool and dry enough to provide

“free” cooling. On differential enthalpy, one sensor

monitors the outdoor air while a second sensor monitors the return air. Whenever the outdoor air is cooler

and drier than the return air, the unit will switch to economizer operation. For either option, the first compressor stage can provide additional cooling during

economizer operation if the room thermostat calls for

second stage.

The dampers and controls are installed and wired at

the factory. Only the accessory rain hood needs to be

assembled and installed in the field.

These economizer options can be used on all duct configurations.

POWER EXHAUST

Both the single and differential economizer options are

available with power exhaust. Whenever the outdoor

air intake dampers are opened for free cooling, the

exhaust fan will be energized to prevent the conditioned space from being over-pressurized during economizer operation.

The exhaust fan, motor and controls are installed and

wired at the factory. Only the back-draft damper

assembly needs to be field installed and the accessory

rain hoods need to be assembled and installed in the

field.

The power exhaust option can only be used on bottom

duct configurations.

MOTORIZED OUTDOOR AIR INTAKE DAMPER

Interlocked outdoor and return air dampers are controlled by a 2-position, spring return damper actuator.

The outdoor damper will open to some pre-set position

whenever the supply air blower is operating and will

drive fully closed when the blower shuts down.

The damper and controls are installed and wired at the

factory. Only the accessory rain hood needs to be

assembled in the field.

This damper option can be used on all duct configura-

2 Unitary Products Group

tions.

Page 3

036-21359-001-B-0302

FIELD-INSTALLED ACCESSORIES

SINGLE INPUT ELECTRONIC ENTHALPY

ECONOMIZERS

ANTI-RECYCLE TIMERS

Two solid state timers prevent the compressors from

short-cycling. Once a compressor is de-energized, it

will remain de-energized for approximately five min-

Includes a slide-in/plug-in damper assembly with fully

utes.

modulating spring-return monitor actuator capable of

introducing up to 100% outdoor air with nominal 1%

leakage type dampers.

The enthalpy system contains one sensor that

monitors the outdoor air and determines when the air is

HIGH ALTITUDE NATURAL GAS

Burner orifices and pilot orifices are provided for proper

furnace operation at altitudes up to 6,000 feet.

PROPANE

cool enough and dry enough to provide “free” cooling.

Burner orifices, pilot orifices and gas valve parts are

The rainhood is painted to match the basic unit and

provided to convert a natural gas furnace to propane.

must be field-assembled before installing.

Power exhaust is not available as a field installed

option.

DUAL INPUT ELECTRONIC ENTHALPY

ECONOMIZERS

Includes a slide-in / plug-in damper assembly with fully

modulating spring-return monitor actuator capable of

introducing up to 100% outdoor air with nominal 1%

leakage type dampers.

This enthalpy system contains one sensor that monitors the outdoor air and one sensor that monitors the

return air. The logic module compares these two values and modulates the dampers providing the maximum efficiency of economizer system.

The rainhood is painted to match the basic unit and

must be field-assembled before installing.

Power exhaust is not available as a field installed

option.

MOTORIZED OUTDOOR AIR INTAKE DAMPER

Includes a slide-in/plug-in damper assembly with a

2-position, spring return motor actuator which opens to

some pre-set position whenever the supply air blower

is operating and will drive fully closed when the blower

unit shuts down.

The rain hood is painted to match the basic unit and

must be field assembled before installing.

Power exhaust is not available as a field installed

option.

ROOF CURBS

Fourteen inch high roof curbs provide a water-tight seal

between the unit and the finished roof. These full

HIGH ALTITUDE PROPANE

Burner orifices and pilot orifices are provided for proper

furnace operation at altitudes up to 6,000 feet. This

accessory supplements the basic propane conversion

kit.

SIDE DUCT FLANGES

One inch flanges replace the supply and return air panels on the rear of the unit to accommodate horizontal

duct connections. These flanges can also be used individually for bottom supply/horizontal return or horizontal supply/bottom return. They cannot be used on units

with power exhaust.

BAROMETRIC RELIEF DAMPER

This damper accessory can be used to relieve internal

air pressure on units with an economizer but no power

exhaust. This accessory includes a rain hood, a bird

screen and a fully assembled damper. With bottom

duct connections, the damper should be mounted over

the opening in the return air panel. With horizontal

ductwork, the accessory should be mounted on the

return air duct.

ECONOMIZER / POWER EXHAUST RAIN HOODS

A rain hood accessory must be used on units with an

economizer, a motorized damper, or a combined economizer with power exhaust option. These accessories

include all the hood panels, the necessary components

and hardware for field assembly.

HIGH SPEED DRIVE

A smaller blower pulley and a shorter belt increase the

speed of the supply air blower for applications with a

higher CFM and/or static pressure requirement.

perimeter curbs meet the requirements of the National

Roofing Contractors Association (NRCA) and are

shipped knocked-down for field assembly. They're

designed to fit inside the base rails of the unit and

include both a wood nailing strip and duct hanger supports.

Unitary Products Group 3

LOW AMBIENT CONTROLS TO 0°F

An autotransformer and a thermostat maintain stable

system operation by reducing the speed of the condenser fan motor at low outdoor temperatures. The kit

Page 4

036-21359-001-B-0302

O

also includes a 1-phase motor to replace the unit's

standard 3-phase condenser fan motor. Standard units

can operate down to 45°F.

COIL GUARD KIT

LO NG LASTING

POW DER PAIN T FINISH

ECONOMIZER HOOD

2" DISPOSA BLE

FILTER S

UTDOOR AIR OPENING

FOR SLIDE-IN /PLUG-IN

INTERNAL ECONOM IZER (OPTION)

SIDE AN D B O TTO M

SUPPLY & RETUR N AIR

D U C T O P E N IN G S ( S ID E X S ID E )

ELEC TR IC H EA TER LOC A TIO N

(O P T IO N A L E L E C T R IC /E L E C T R IC U N IT S )

20 G AU G E ALUM IN IZED STEEL

TUBULAR HEAT EXCHANGERS

NPT

I

1" N P T I

CONDENSATE DRAIN

FULL PER IM ETER 14 G UAG E BASE

R A IL S W IT H L IF T IN G H O L E S

Provides coil guard and fastners.

HIGH EFFICIENCY SCROLL COM PRESSORS

COPPER TUBE/ALUM INUM FIN

BELT-DR IVE

BLOW ER MOTOR

CONDENSER COILS

HOLE FOR BOTTOM

GAS SUPPLY ENTRY

POW ER VENTOR M O TO R

W ITH POST PURGE CYCLE

LOW VO LTAGE RELAY BOAR D

A N D T E R M IA N L S T R IP

ELECTRIC AL D ISCO N NECT

M O U N T IN G L O C A T IO N

(F ie ld in s t a lle d )

KNOCKOUT FOR

S ID E C O N T R O L W IR IN G E N T R Y

KNOCKOUT FOR

S ID E P O W E R W IR IN G E N T R Y S ID E

T E R M IN A L B L O C K

(F or S ingle P oint P ow er Supp ly

w ith E le c tric H e a t)

ELECTRIC/ELECTRIC UNITS

BOTTOM POW ER & CO NTROL

W IRING ENTRY

KNO CKO U TS FOR SIDE

GAS SUPPLY ENTRY

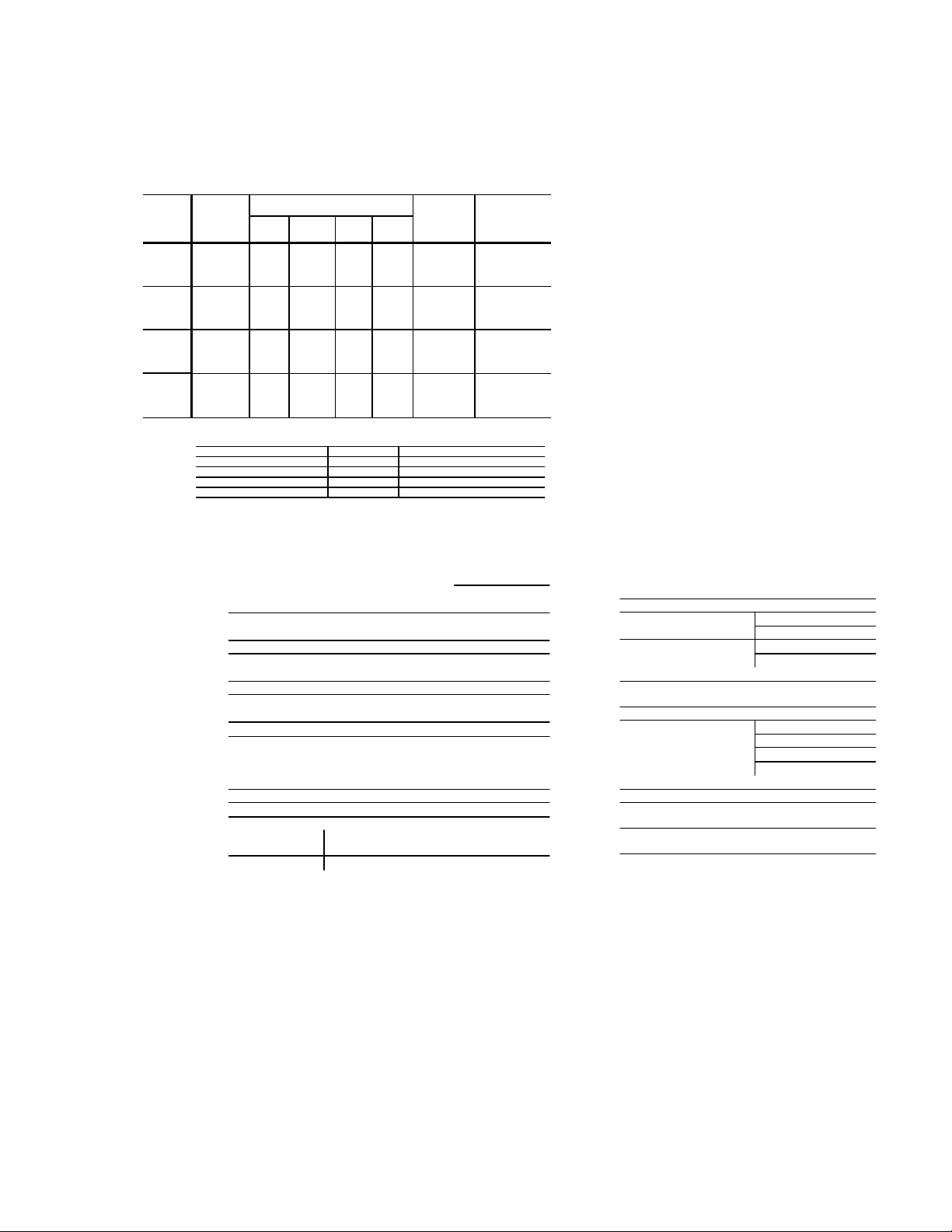

CAPACITY RATINGS - (ARI 360)

*

MODEL MBH EER IPLV MODEL MBH EER IPLV

COOLING WITH GAS HEAT COOLING WITH ELECTRIC HEAT

D2CG300N240 290 8.5 8.3 D2CE300E018 290 8.5 8.6

D2CG300N320 290 8.5 8.3 D2CE300E036 290 8.5 8.6

COOLING ONLY D2CE300E054 287 8.5 8.2

D2CE300 290 8.5 8.7 D2CE300E072 284 8.5 8.2

*.

Outside the scope of ARI Standard 340/360.

EER=Energy Efficiency Rating at full load-the cooling capacity in Btu’s per hour (Btuh) divided by the power input in watts, expressed in Btuh per

watt (Btuh/watt).

IPLV - Integrated part load value.

NOTE: All cooling is three stage.

GAS HEAT RATINGS

MBH Input MBH Output

MODEL

D2CG300N240 300 150 240 120

D2CG300N320 400 200 320 160

Unit

Size

CFM

)

Stage

1&2

Stage 1

ESP Blower

Stage

1&2

Stage 1

Octave Band Centerline Frequency (Hz) SWL db(A)

IWG RPM BHP 63 125 250 500 1,000 2,000 4,000 8,000 db(A)

Note: All gas units are two-stage heating. First stage is 50% of total.

All models are 80% Steady State Efficiency (S.S.E.).

Sound Power (db 10-

12

Watts)

@10Ft.

*

300 10,000 1.30 1,160 12.5 108 108 98 91 93 86 81 76 98 65

*.

At a distance of 10 ft.from the blower.

NOTE: These values have been derived using a model of sound propagation,

measuring the indoor ambient sound levels ten feet from the source. The dBA

values provided are for reference only. Calculation of dBA values cover matters

of system design and application. This constitutes an exception to any specifi-

cation or guarantee requiring a dBA value or sound data in any other form than

sound power level ratings.

4 Unitary Products Group

Page 5

036-21359-001-B-0302

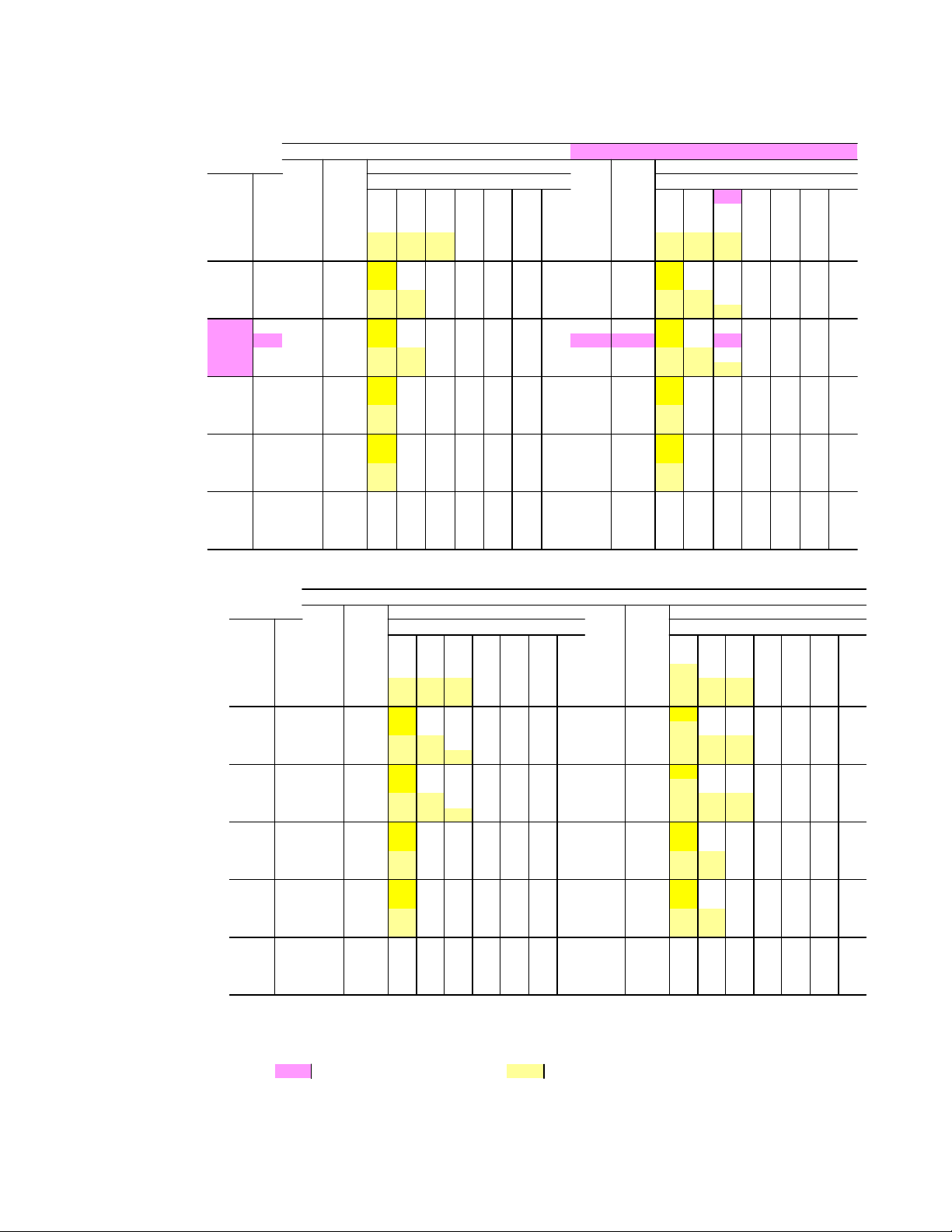

COOL ING CA PACI TIES -

Air On

Evapo ra tor

CFM

12,000

11,000

10,000

9,000

8,000

6,000

Coil

WB

?F

72 371 27.1 277 240 203 167 130 - - 354 28.8 268 231 195 158 122 - -

67 340 26.1 335 299 262 226 189 152 116 325 27.7 324 288 251 214 178 141 105

62 329 25.5 329 329 329 293 256 219 183 315 27.1 315 315 315 278 241 205 168

57 329 25.5 329 329 329 292 256 219 183 314 27.1 314 314 314 278 241 205 168

72 365 27.0 260 226 193 159 125 - - 348 28.6 257 223 189 155 122 - 67 336 25.9 317 283 249 216 182 148 114 321 27.5 312 279 245 211 178 144 110

62 324 25.3 324 324 313 279 245 212 178 309 26.9 309 309 307 273 239 206 172

57 324 25.3 324 324 315 281 247 214 180 309 26.9 309 309 309 275 242 208 174

72 359 26.8 244 213 182 151 120 - - 342 28.5 245 214 184 153 122 - 67 332 25.7 298 268 237 206 175 144 113 317 27.4 301 270 239 208 177 146 115

62 318 25.2 318 318 296 265 235 204 173 304 26.8 304 304 299 268 237 207 176

57 318 25.1 318 318 301 270 239 208 177 304 26.7 304 304 304 273 242 211 180

72 354 26.6 229 201 173 145 117 - - 338 28.2 228 200 172 144 116 - 67 326 25.5 280 252 224 196 168 141 113 312 27.1 279 251 223 195 167 139 111

62 314 25.0 314 306 282 254 226 198 170 300 26.5 300 295 280 253 225 197 169

57 314 25.0 314 308 286 258 230 203 175 300 26.5 300 297 285 257 229 201 173

72 349 26.4 215 190 165 140 115 - - 334 28.0 211 186 161 136 111 - 67 321 25.3 262 237 212 187 162 137 112 307 26.9 257 232 207 182 157 132 107

62 310 24.8 310 293 268 243 218 193 168 297 26.3 297 287 262 237 212 187 162

57 310 24.8 310 297 272 247 222 197 172 297 26.3 297 291 266 241 216 191 166

72 318 25.2 186 167 148 129 110 - - 304 26.8 177 158 138 119 100 - 67 290 24.0 226 206 187 168 149 130 111 277 25.5 213 194 175 156 137 118 99

62 282 23.7 277 258 240 221 201 192 163 270 25.2 262 243 225 206 187 167 148

57 282 23.7 281 262 243 224 205 186 167 270 25.2 266 247 228 209 190 171 152

To tal

Cap.

MBH

1

Power

In put

KW

2

86 83 80 77 74 71 68 86 83 80 77 74 71 68

25 TON (DCE / DCG300)

Tem pera ture of Air on Con denser Coil

85 ?F95?F

Sen si ble Ca pac ity

En ter ing Dry Bulb, ?F En ter ing Dry Bulb, ?F

1

, MBH

To tal

Cap.

MBH

1

Power

In put

KW

2

Sen si ble Ca pac ity

1

, MBH

Air On

Evapo ra tor

Coil

WB

CFM

105?F 115?F

To tal

Power

1

Cap.

In put

MBH

?F

KW

Sen si ble Ca pac ity

2

En ter ing Dry Bulb, ?F En ter ing Dry Bulb, ?F

86 83 80 77 74 71 68 86 83 80 77 74 71 68

Tem pera ture of Air on Con denser Coil

1

, MBH

To tal

Cap.

MBH

1

Power

In put

KW

2

Sen si ble Ca pac ity

1

, MBH

72 337 30.7 264 228 191 155 118 - - 320 32.6 261 224 188 151 114 - -

12,000

67 310 29.5 309 283 246 210 173 137 100 294 31.3 294 278 242 205 169 132 95

62 300 28.8 300 300 300 263 226 190 153 285 30.5 285 285 285 248 212 175 138

57 299 28.8 299 299 299 263 226 190 153 285 30.5 285 285 285 248 211 175 138

72 331 30.5 254 221 187 153 119 - - 315 32.3 252 218 185 151 117 - -

11,000

67 306 29.3 302 276 242 208 174 141 107 291 31.0 291 273 239 205 171 138 104

62 295 28.5 295 295 294 260 226 192 159 280 30.3 280 280 280 246 213 179 145

57 294 28.5 294 294 294 261 227 193 160 280 30.3 280 280 280 246 213 179 145

72 326 30.2 244 213 183 152 121 - - 310 32.1 243 212 181 151 120 - -

10,000

67 302 29.0 294 268 237 206 176 145 114 287 30.8 287 267 236 205 174 143 112

62 290 28.3 290 290 287 256 226 195 164 276 30.0 276 276 276 245 214 183 152

57 290 28.2 290 290 290 259 228 197 166 275 29.9 275 275 275 244 214 183 152

72 322 30.0 228 200 172 144 116 - - 306 31.8 228 200 172 144 116 - 67 297 28.8 276 251 223 195 167 139 111 283 30.5 274 251 223 195 167 139 111

9,000

62 286 28.1 286 284 271 243 215 187 159 272 29.8 272 272 262 234 206 178 150

57 286 28.1 286 285 273 245 217 189 161 272 29.7 272 272 261 234 206 178 150

72 319 29.8 212 187 162 137 112 - - 303 31.6 213 188 163 138 113 - 67 293 28.6 259 234 209 184 159 134 109 278 30.3 260 235 210 185 160 135 110

8,000

62 283 28.0 283 278 255 230 205 180 155 269 29.6 269 269 248 223 198 173 148

57 283 28.0 283 280 257 232 207 182 157 269 29.6 269 269 248 223 198 173 148

72 290 28.3 180 161 141 122 103 - - 276 30.0 183 164 145 125 106 - 67 264 26.9 224 200 181 162 142 123 104 251 28.5 222 203 194 165 146 127 108

6,000

62 258 26.6 258 241 223 204 184 165 146 245 28.2 245 239 220 201 182 163 144

57 258 26.6 258 242 224 205 186 167 148 245 28.2 245 240 221 202 182 163 144

1These ca paci ties are gross rat ings. For net ca pac ity, de duct the heat of the sup ply air blower mo tor, MBH = 3.415 x KW. Ref er to the ap pro pri ate Blower

Per form ance Ta ble for the KW of the sup ply air blower mo tor.

2These rat ings in clude the con denser fan mo tors (To tal 2.3 KW) and the com pres sor mo tors but not the sup ply air blower mo tor.

All Sen si ble Ca pac ityNomi nal Rat ing

Unitary Products Group 5

Page 6

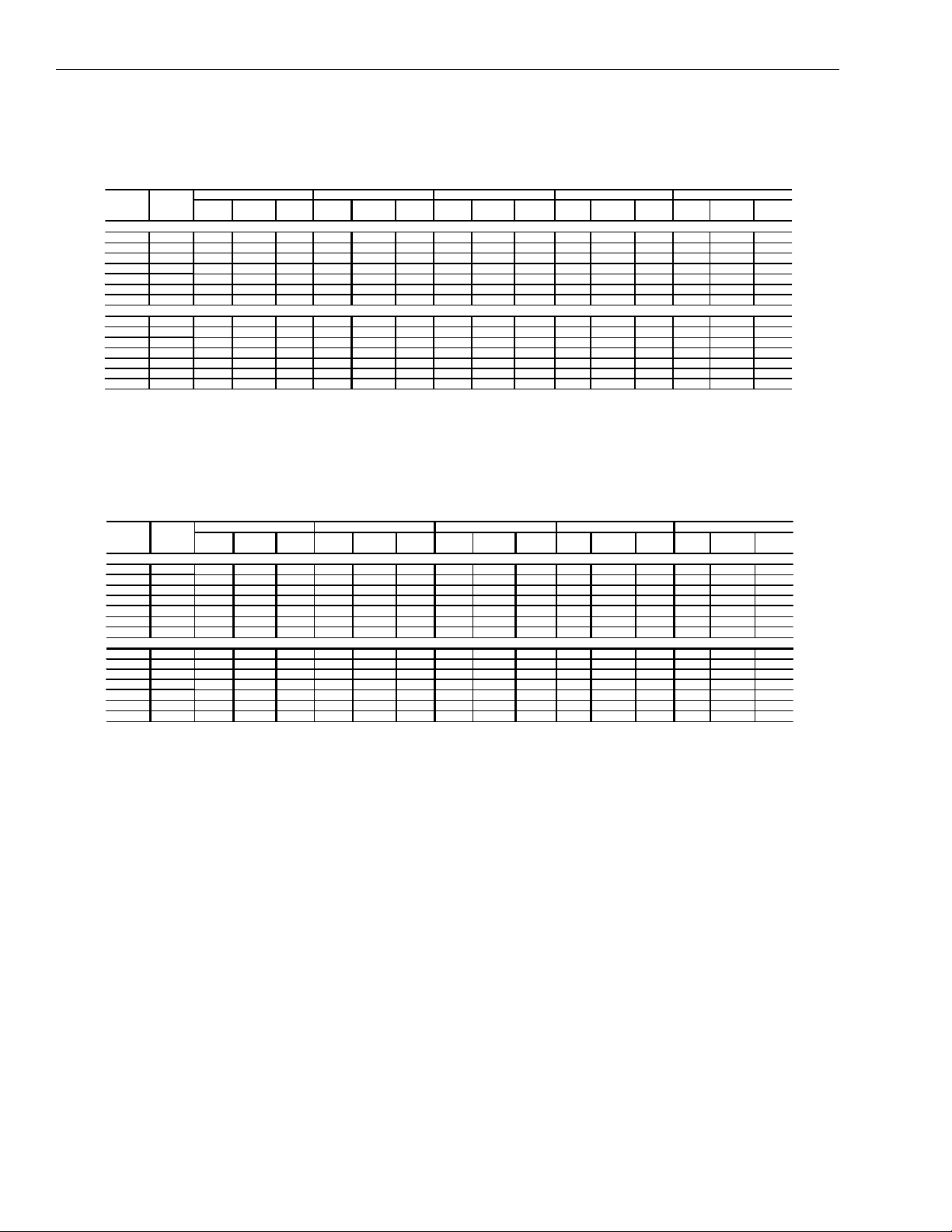

BLOWER PER FORM ANCE - 25 TON (DCE/DCG300)

M

M

036-21359-001-B-0302

DCE300

BLOWER PULLEY

SPEED TURNS ESP OUTPUT INPUT ESP OUTPUT INPUT ESP OUTPUT INPUT ESP OUTPUT INPUT ESP OUTPUT INPUT

(rpm) OPEN: (iwg) (bhp) (kW) (iwg) (bhp) (kW) (iwg) (bhp) (kW) (iwg) (bhp) (kW) (iwg) (bhp) (kW)

975 6.0* 1.4 5.9 4.9 1.0 7.3 6.0 0.5 8.8 7.2 - - - - - 1005 5.0 1.6 6.2 5.1 1.2 7.7 6.3 0.7 9.2 7.6 0.1 10.9 8.9 - - 1040 4.0 1.8 6.6 5.4 1.4 8.1 6.7 0.9 9.7 8.0 0.3 11.4 9.4 - - 1070 3.0 2.0 6.9 5.7 1.6 8.5 7.0 1.1 10.2 8.3 0.6 11.9 9.8 - - 1100 2.0 2.1 7.3 6.0 1.8 8.9 7.3 1.3 10.6 8.7 0.8 12.4 10.2 0.2 14.3 11.7

1135 1.0 2.4 7.7 6.3 2.0 9.3 7.6 1.6 11.1 9.1 1.0 13.0 10.6 0.4 14.9 12.2

1165 0.0 2.6 8.0 6.6 2.2 9.7 8.0 1.8 11.6 9.5 1.3 13.5 11.0 0.7 15.5 12.7

1140 6.0 2.4 7.7 6.3 2.1 9.4 7.7 1.6 11.2 9.2 1.1 13.1 10.7 0.5 15.0 12.3

1180 5.0 2.7 8.2 6.7 2.3 9.9 8.1 1.9 11.8 9.7 1.4 13.7 11.2 0.8 15.8 12.9

1215 4.0 2.9 8.6 7.0 2.6 10.4 8.5 2.2 12.3 10.1 1.7 14.3 11.7 1 .1 16.4 13.5

1255 3.0 3.2 9.1 7.4 2.9 11.0 9.0 2.5 12.9 10.6 2.0 15.0 12.3 1 .4 17.2 14.1

1290 2.0 3.4 9.5 7.8 3.1 11.5 9.4 2.7 13.5 11.1 2.2 15.6 12.8 - - 1330 1.0 3.7 10.0 8.2 3.4 12.0 9.9 3.0 14.1 11.6 2.6 16.4 13.4 - - 1365 0.0 3.9 10.5 8.6 3.7 12.6 10.3 3.3 14.7 12.1 2.9 17.0 13.9 - - -

NOTES:

BLOWER PERFORMANCE

DCG300

BLOWER PULLEY

SPEED TURNS ESP OUTPUT INPUT ESP OUTPUT INPUT ESP OUTPUT INPUT ESP OUTPUT INPUT ESP OUTPUT INPUT

(rpm) OPEN: (iwg) (bhp) (kW) (iwg) (bhp) (kW) (iwg) (bhp) (kW) (iwg) (bhp) (kW) (iwg) (bhp) (kW)

975 6.0* 1.2 5.9 4.9 0.5 7.3 6.0 - - - - - - - - 1005 5.0 1.4 6.2 5.1 0.7 7.7 6.3 - - - - - - - - 1040 4.0 1.6 6.6 5.4 0.9 8.1 6.7 0.2 9.7 8.0 - - - - - 1070 3.0 1.8 6.9 5.7 1.1 8.5 7.0 0.4 10.2 8.3 - - - - - 1100 2.0 2.0 7.3 6.0 1.3 8.9 7.3 0.6 10.6 8.7 - - - - - 1135 1.0 2.2 7.7 6.3 1.6 9.3 7.6 0.8 11.1 9.1 - - - - - 1165 0.0 2.4 8.0 6.6 1.8 9.7 8.0 1.0 11.6 9.5 0.2 13.5 11.0 - - -

1140 6.0 2.2 7.7 6.3 1.6 9.4 7.7 0.9 11.2 9.2 - - - - - 1180 5.0 2.5 8.2 6.7 1.9 9.9 8.1 1.2 11.8 9.7 0.3 13.7 11.2 - - 1215 4.0 2.7 8.6 7.0 2.1 10.4 8.5 1.4 12.3 10.1 0.6 14.3 11.7 - - 1255 3.0 3.0 9.1 7.4 2.4 11.0 9.0 1.7 12.9 10.6 0.9 15.0 12.3 - - 1290 2.0 3.2 9.5 7.8 2.7 11.5 9.4 2.0 13.5 11.1 1.2 15.6 12.8 - - 1330 1.0 3.5 10.0 8.2 3.0 12.0 9.9 2.3 14.1 11.6 1.5 16.4 13.4 - - 1365 0.0 3.7 10.5 8.6 3.2 12.6 10.3 2.6 14.7 12.1 1.8 17.0 13.9 - - -

NOTES:

- BOT TOM DUCT CON NEC TIONS (COOL ING AP PLI CA TIONS)

7500 CFM 8750 CFM 10000 CFM 11250 CF

STANDARD DRIVE:

ACCESSORY DRIVE:

Blower performance is based on cooling only unit, with fixed outdoor air, 2" T/A filters and a dry evaporator coil.

Refer to page 7 for additional static resistances.

ESP - External Static Pressure available for the supply and return air duct system. All internal unit resistances have been deducted from the total static pressure of the

blower.

* FACTORY SETTING

- 25 TON (DCE/DCG300)

- BOT TOM DUCT CON NEC TIONS (COOL ING AP PLI CA TIONS)

7500 CFM 8750 CFM 10000 CFM 11250 CFM 12500 CFM

STANDARD DRIVE:

ACCESSORY DRIVE:

Blower performance is based on cooling only unit, with fixed outdoor air, 2" T/A filters and a dry evaporator coil.

Refer to page 7 for additional static resistances.

ESP - External Static Pressure available for the supply and return air duct system. All internal unit resistances have been deducted from the total static pressure of the

blower.

* FACTORY SETTING

12500 CF

6 Unitary Products Group

Page 7

036-21359-001-B-0302

-

ELEC TRI CAL DATA

MODEL POWER CIRCUIT OVERCURRENT

D2CE SUPPLY AMPACITY DEVICE (1)

300A25 208-3-60 E018 13.5 1 37.5 139.5 175

300A25 208-3-60 E036 27.0 2 75.1 142.1 175

300A25 208-3-60 E054 40.6 2 112.6 189.0 200

300A25 208-3-60 E072 54.1 2 150.1 198.4 225

300A25 230-3-60 E018 18.0 1 43.3 139.5 175

300A25 230-3-60 E036 36.0 2 86.6 156.5 175

300A25 230-3-60 E054 54.0 2 129.9 178.2 200

300A25 230-3-60 E072 72.0 2 173.2 221.5 250

300A46 460-3-60 E018 18.0 1 21.7 68.3 80

300A46 460-3-60 E036 36.0 2 43.3 78.3 80

300A46 460-3-60 E054 54.0 2 65.0 89.1 10 0

300A46 460-3-60 E072 72.0 2 86.6 110.7 125

300A58 575-3-60 E018 18.0 1 17.3 56.1 70

300A58 575-3-60 E036 36.0 2 34.6 62.6 70

300A58 575-3-60 E054 54.0 2 52.0 71.2 80

300A58 575-3-60 E072 72.0 2 69.3 88.5 10 0

1

NOMI NAL VOLT AGE VOLT AGE KW CAP. MUL TI PLIER

ELECTRIC HEATER OPTION

MODEL kW(1) STAGES AMPS

208 208 1.00

240 230 0.92

480 460 0.92

600 575 0.92

Units With Elec tric Heat

MINIMUM MAXIMUM

(AMPS) (AMPS)

PHYSI CAL DATA

BA SIC UNITS

MOD ELS

EVAPO RA TOR

BLOWER

EVAPO RA TOR

COIL

CON DENSER

FAN

(Two Per Unit)

CON DENSER

COIL

COM PRES SOR

(Qty. Per Unit)

AIR

FIL TERS

CHARGE

CEN TRIFU GAL BLOWER (Dia. x Wd. in.) 18 x 15

FAN MO TOR HP 15

ROWS DEEP 4

FINS PER INCH 13.5

FACE AREA (Sq. Ft.) 25.0

PRO PEL LER DIA. (in.) (Each) 30

FAN MO TOR HP (Each) 1

NOM. CFM TO TAL (Each) 7200

ROWS DEEP 3

FINS PER INCH 15

FACE AREA (Sq. Ft.) 43.3

12.5 TON, SCROLL, HER METIC,

TAN DEM (2 STAGE, 50% ea.)

QUAN TITY PER UNIT (16" X 20" X 2") 2

QUAN TITY PER UNIT (16" X 25" X 2") 4

QUAN TITY PER UNIT (14" X 20" X 2") 3

TO TAL FACE AREA (sq. ft.) 21.4

RE FRIG ER ANT

22 (lbs./oz.)

DCE/DCG/DCV

300

SYS TEM NO. 1 20/8

SYS TEM NO. 2 20/0

OP ER AT ING WEIGHTS

MODEL SIZE (MBH) 300

DCE (Cool ing only) 2730

DCV (Cool ing only) 2795

Ba sic Unit

DCG (Gas / Elec tric)

DCV (Gas / Elec tric)

Econo mizer 160

Econo mizer with

Power Ex haust

Op tions Mo tor ized Damper 150

Elec tric Heater

2

(Elec/Elec only)

Roof Curb 185

Ba ro met ric Damper 45

Ac ces so -

Econo mizer/Mo tor ized Damper

Rain Hood

ries

Econo mizer/Power Ex haust Rain

Hood

Wood Skid 220

N240 2930

N320 2970

N240 2995

N320 3035

245

18 KW 25

36 KW 30

54 KW 35

72 KW 40

55

90

Unitary Products Group 7

Page 8

036-21359-001-B-0302

A

t

BLOWER MO TOR AND DRIVE DATA

1

MODEL

SIZE

25 TON

1All mo tors have a nomi nal speed of 1800 RPM, a 1.15 serv ice fac tor and a solid base. They can op er ate to the limit of their serv ice fac tor be cause they are lo cated in the mov ing air, up stream

of any heat ing de vice.

BLOWER

DRIVE

RANGE

(RPM)

Stan-

975/1165

dard

High

Speed

1140/1365 1B5V94 9.7 9.5 1-7/16 5VX840 84.0 1

Ac cess

MO TOR

HP FRAME

15 254T 91

AD JUST ABLE MO TOR PUL LEY FIXED BLOWER PUL LEY

OUT-

EFF.

(%)

DESIG-

NATION

1LVP58B70

A

SIDE

DIA.

(IN.)

7.5

PITCH

DIA.

(IN.)

6.2-

7.4

BORE

(IN.)

1 5/8

OUT SIDE

DESIG NATION

1B5V110 11.3 11.1 1-7/16 5VX860 86.0 1

DIA.

(IN.)

PITCH

DIA.

(IN.)

BORE

(IN.)

DESIG-

NATION

BELT

(NOTCHED)

PITCH

LENGTH

(IN.)

QTY.

STATIC RE SIS TANCES*

DESCRIPTION

DEDUCTIONS: (SUBTRACT VALUES BELOW FROM UNIT'S AVAILABLE ESP)

ALLOWANCE FOR WET COIL: 0.10 0.10 0.10 0.10 0.10

ECONOMIZER (RETURN DUCT): 0.06 0.09 0.11 0.14 0.18

18kW ELECTRIC HEAT: 0.31 0.43 0.56 0.71 0.87

36kW ELECTRIC HEAT: 0.38 0.52 0.68 0.87 1.07

54kW ELECTRIC HEAT: 0.62 0.84 1.10 1.39 1.72

72kW ELECTRIC HEAT: 0.68 0.93 1.21 1.54 1.90

ADDITIONS: (ADD VALUES BELOW TO UNIT'S AVAILABLE ESP)

HORIZONTAL (SIDE) SUPPLY DUCT: 0.31 0.26 0.27 0.31 0.41

HORIZONTAL (SIDE) RETURN DUCT: 0.05 0.05 0.05 0.05 0.05

7500 8750 10000 11250 12500

ESP ESP ESP ESP ESP

(IWG) (IWG) (IWG) (IWG) (IWG)

IRFLOW (CFM)

POWER EX HAUST PER FORM ANCE

MO TOR

SPEED

HIGH* 5250 0.83 4500 0.85 4200 0.88 3750 0.93 3000 0.99

ME DIUM 4900 0.77 3900 0.79 3500 0.82 2900 0.85 - -

LOW 4400 0.72 3700 0.74 3000 0.78 - - - -

*Fac tory Set ting

Power Ex haust mo tor is a 3/4 HP, PSC type with sleeve bear ings, a 48 frame and in her ent pro tec tion.

0.2 0.3 0.4 0.5 0.6

CFM KW CFM KW CFM KW CFM KW CFM KW

ELEC TRI CAL DATA

ELECTRICAL DATA - Cooling Only Units & Units With Gas Hea

MODEL NO.

D2CE300 208/230-3-60 41.4 312 1 4.2 15 38.6 139.5 175

& D2CG300 460-3-60 20.0 150 1 2.1 15 19.3 68.3 80

POWER

SUPPLY

575-3-60 16.4 108 1 2.0 15 15.4 56.1 70

STATIC RE SIS TANCE OF RE TURN DUCT WORK, IWG

-

Cool ing Only Units and Units With Gas Heat

COMPRESSORS

(QTY. 2)

RLA LRA HP FLA AMPACITY DEVICE (1)

(ea.) (ea.) (ea.) (ea.) (AMPS) (AMPS)

COND. FAN

(#1 & #2)

SUPPLY AIR MINIMUM MAXIMUM

BLOWER MOTOR

HP RLA

CIRCUIT OVERCURRENT

VOLT AGE

LIMI TA TIONS**

**Rated in ac cor dance with ARI Stan dard 110, utili za tion range “A”.

POWER SUP PLY

208/230- 3- 60 187 253

460- 3- 6 0 414 506

575- 3- 6 0 518 630

VOLT AGE

MIN. MAX.

8 Unitary Products Group

Page 9

036-21359-001-B-0302

FIELD WIRING - DCE/DCG ELECTRIC/ELECTRIC AND GAS/ELECTRIC UNITS

CONTROL W IRING

C O O L IN G O N L Y (2 4 V O L T T H E R M O S T A T )

THERM OSTAT

TER M IN ALS

1

UNIT TERMINAL

BLO CK 1TB

R

R

Y1

Y2

Y1

Y2

W1

W2

G

G

B

X

A1

1

24 V olt T herm ostat 2TH 04701224.

2

Term inal block 1TB - located on relay board in 24-volt section

of the unit control box.

A2

2

24 V O LT

TRAN SFO R M ER

C O O L IN G / H E A T IN G (2 4 V O L T T H E R M O S T A T )

THERM OSTAT

TER M IN ALS

RH

RC

1

UNIT TERMINAL

BLO CK 1TB

Y1

Y2

W1

ADD

JU M P E R

Y1

W2

G

Y2

W1

W2

3

A1

A2

G

R

B

X

24 V O LT

TRAN SFO R M ER

2

C O O L IN G / H E A T IN G (E L E C T R O N IC T H E R M O S T A T )

ADD

JUM PER

THERM OSTAT

TER M IN ALS

RC

RH

Y1

Y2

W1

W2

G

B

LED 1

LED 2

COM

1

NOT

USED

3

4

4

UNIT TERMINAL

BLO CK 1TB

2

R

Y1

Y2

W1

W2

24 V O LT

G

TRAN SFO R M ER

B

X

A1

A2

A1

A2

T

T

TO R EM OTE SENSO R

2TH 04702224 IF U SE D

1

Electronic program m able Therm ostat 2E T 04700224 (includes subbase).

2

Term inal block 1TB - located on relay board in 24-volt section of the unit control box.

3

Second stage heating is not required on units w ith a single stage electric heater.

4

Term inals A 1 and A 2 provide a relay output to close the outdoor econom izer dam pers

w hen the therm ostat sw itches to the set-back position.

Fan switch m ust be in "O N " position for m inim um ventilation during heater operation.

1

24 V olt T herm ostat 2TH 04701024 or 2TH 04701524

(w ith subbase 2TB 04700224 or 2TB 04700324).

2

Term inal block 1TB - located on relay board in 24-volt section

o f th e u n it c o n tro l b o x .

3

Second stage heating is not required on units w ith a single stage

electric heater.

POW ER W IRING

LINE VOLTAGE

TER M IN AL

BLO CK 2TB

IN U N IT

CONTROL BOX

GROUND LUG

L1

L2

L3

R e fe r to th e

ELECTRICAL

DATA

ta b le s to s iz e th e

power wiring, the

fuses an d th e

disconnect

sw itch.

O

Unitary Products Group 9

Page 10

BLOWER

R

R

BLOWER MOTOR

ACCESS

BLOWER

COMPARTMENT

ACCESS

(Auxiliary)

DOT PLUG

(For pressure

Drop Reading)

FRONT

VIEW

UNIT BASE WITH RAILS

Shown separate ly to illustrate

Bottom Duct openings and Power

Connection locations

NOTE:

For curb mounted units, refer to the curb hanger

dimensions of the curb for the proper size of the

supply and return air duct connections.

ACCESS

125-1/4" (15 TON)

136-1/4" (20 TON)

ELECTRIC HEAT

ACCESS

CONTROL BOX

ACCESS

24-1/4" (15 TON)

36-1/4" (20 TON)

FIELD-SUPPLIED

DISCONNECT SWITCH

LOCATION

35"

33"

21"

5"

9-3/4"

5-7/8"

RETURN

AIR

2-3/4" 21-1/2"

12-1/2"

ECONOMIZER / MOTORIZED DAMPER,

FIXED OUTDOOR INTAKE AIR AND

POWER EXHAUST RAIN HOODS

(See detail "Y")

92"

11-1/2"

BOTTOM SUPPLY

AND RETURN

AIR OPENINGS

(See Note)

SUPPLY

AIR

8-1/8"

9-1/4"

9-3/4"

COMPRESSOR

ACCESS

(See detail "X")

OPTIONAL COIL

GUARD KIT

48-5/8" (15TON)

52-5/8" (20TON)

CONDENSER

COILS

(A)

CONTROL WIRING

ENTRY

(B)

POWER WIRING

ENTRY

3-3/4"

(B)

POWER WIRING

ENTRY

(A)

CONTROL WIRING

ENTRY

036-21359-001-B-0302

All dimensions are in inches. They are

subject to change without notice. Certified

dimensions will be provided upon request.

UTILITIES ENTRY DATA

HOLE

11" pip ing MPT re quired

2 Open ing in the bot tom of the unit can be lo cated by the slice

in the in su la tion.

RETURN AIR

SUPPLY AIR

OUTDOOR AIR

OUTDOOR AIR

(Economizer)

OPEN ING

SIZE

(DIA.)

1-1/8" KO Con trol

A

3/4" NPS (Fem.) Bot tom

3-5/8" KO

B

3" NPS (Fem.) Bot tom

USED FOR

Wir ing

Power

Wir ing

Front

Front

C 2-3/8" KO Gas Pip ing (Front)

D 1-11/16" Hole

Gas Pip ing (Bot -

1,2

tom)

1

BLOWER

ACCESS

BLOWER MOTOR

ACCESS

BLOWER

COMPARTMENT

ACCESS

(Auxiliary)

DOT PLUG

(For pressure

Drop Reading)

GAS HEAT

ACCESS

VENT AIR

OUTLET

HOODS

COMBUSTION

AIR INLET

HOOD

(C)

GAS SUPPLY

ENTRY

FRONT

VIEW

UNIT BASE WITH RAILS

Shown separately to illu s t ra te

Bottom Duct openings, Power

and Gas Piping Connection

locations

NOTE:

For curb mounted units, refer to the curb hanger

dimensions of the curb for the proper size of the

supply and return air duct connections.

136-1/4

CONTROL BOX

ACCESS

(D)

GAS SUPPLY

ENTRY

FIELD-SUPPLIED

DISCONNECT SWITCH

LOCATION

6-3/8"

35"

35-1/4

11-1/8"

46-5/8"

7-1/8"

5-7/8"

RETURN

33"

2-3/4" 21-1/2"

ECONOMIZER / MOTORIZED DAMPER,

FIXED OUTDOOR INTAKE AIR AND

POWER EXHAUST RAIN HOODS

(See detail "Y")

21"

5"

9-3/4"

46-5/8"

BOTTOM SUPPLY

AIR

SUPPLY

AIR

9-1/4"

12-1/2"

92"

11-1/2"

AND RETURN

AIR OPENINGS

(See Note)

8-1/8"

9-3/4"

COMPRESSOR

ACCESS

(See detail "X")

OPTIONAL

COIL GUARD

KIT

52-5/8

CONDENSER

COILS

(A)

CONTROL WIRING

ENTRY

(B)

POWER WIRING

ENTRY

3-3/4"

(B)

POWER WIRING

ENTRY

(A)

CONTROL WIRING

ENTRY

CLEARANCES

Front 36"

Back

Left Side (Fil ter Ac cess)

Right Side (Cond. Coil) 36"

Be low Unit

Above Unit

1U nits (ap pli ca ble in U.S.A. only) may be in stalled on com bus ti ble floors

made from wood or class A, B or C roof cov er ing ma te rial.

2

Units must be in stalled ou doors. Over hang ing struc tures or shrubs should

not ob struct con denser air dis charge out let.

NOTE:

ELEC/ELEC Mod els

RETURN AIR

com bus ti ble ma te ri als when equipped with elec tric heat ers.

SUPPLY AIR

GAS/ELEC Mod els: A 1" clear ance must be pro vided be tween any

com bus ti ble ma te rial and the sup ply air duct work for a dis tance of 3 feet

OUTDOOR AI

from the unit.

OUTDOOR AI

The prod ucts of com bus tion must not be al lowed to ac cu mu late within a

(Economizer)

con fined space and re cir cu late.

Lo cate unit so that the vent air out let hood is at least:

? Three (3) feet above any forced air in let lo cated within 10 hori zon tal feet (ex -

clud ing those in te gral to the unit).

? Four (4) feet be low, 4 hori zon tal feet from, or 1 foot above any door or grav ity

air in let into the build ing.

1

2

: Units and duct work are ap proved for zero clear ance to

24" (Less Econo mizer)

49" (With Econo mizer)

24" (Less Econo mizer)

36" (With Econo mizer)

20"

72" With 36" Maxi mum

Ho ri zon tal Ov er hang

(For Con denser Air

Dis charge)

10 Unitary Products Group

Page 11

036-21359-001-B-0302

e

GAUGE LINE

ACCESS

COMPRESSOR

ACCESS

SUPPLY AIR

ACCESS

40-3/8"

5-1/2"

CONDENSER

SECTION

RETURN AIR

ACCESS

REAR

VIEW

SUPPLY AIR

CO M PAR TM ENT

SUPPLY

AIR

18-5/8"

5-1/8"

RETURN

AIR

OUTDOOR

AIR

27-3/4"

29-5/8" (15 TON)

39-5/8" (20 TON)

POW ER

RAIN

HOOD

Return Air C om partm ent)

(o n

EXHAU ST

EVAPORATOR

SECTION

DOT PLUG

(For pressur

drop reading)

FILTER

ACCESS

40-1/2"

1" NPT FEMALE

COND. DRAIN

CONNECTION

OUTDOOR AIR

COMPARTMENT

ACCESS

ECONOMIZER

MOTORIZED

DAMPER

RAIN HOO D

(on O utdoor A ir C om partm ent)

DUCT COVERS - Units are shipped with the bottom

duct openings covered. An accessory flange kit is available for

connecting side ducts.

For bottom

duct applications:

1 Remove the side panels from the supply and return air

compartments to gain access to the bottom supply and

return air duct covers.

2 Remove and discard the bottom duct covers. (Duct

openings are closed with sheet metal covers except

when the unit includes a power exhaust option. The

covering consists of a heavy black paper c omposition.)

3 Replace the side supply and return air compartment

panels.

For side duct applications;

1 Replace the s ide panels o n the supply and return air

compartments with the accessory flange kit panels.

2 Connect ductwork to the duct flanges on the rear of the

unit.

ECONOMIZER

AND

MOTORIZED DAM PER

/

POW ER EXHAUST RAIN HOODS

REAR VIEW

66-1/2"

34-1/4"

36"

2"

UNIT W ITH RAIN HOO DS

5"

D E T A IL " Y "

36-1/4"

16-1/8"

FIX ED

OUTDOOR

HOOD

IN T A K E

(located on

R e tu r n A ir

C om partm ent)

AIR

L H V IE W

1" C O N D EN STA TE

DRAIN

(M ust be trapped)

92"

Unitary Products Group 11

Page 12

036-21359-001-B-0302

B

F

A

FRO N T

D

C

A

B

E

C

4 Point Loads 6 Point Loads

DCE

UNIT

TOTAL A B C D

4 - POINT LOADS (LBS)

300 2,890 487 619 646 508

DCE

DCE

UNIT

TOTAL A B C D E F

6 - POINT LOADS (LBS)

300 2,890 415 471 528 551 492 433

NOTE: These weights are with economizerand 24kW electric heat.

D

FRO NT

DCG

UNIT

TOTAL A B C D

4-POINTLOADS(LBS)

300 3,130 615 671 962 882

DCG

UNIT

TOTAL A B C D E F

6 - POINT LOADS (LBS)

300 3,130 418 438 533 658 603 510

NOTE: These weights are with economizer, high heat and oversized motor.

12 Unitary Products Group

Page 13

036-21359-001-B-0302

3.69"

3.56"

BASE RAIL

Unitary Products Group 13

Page 14

036-21359-001-B-0302

14 Unitary Products Group

Page 15

036-21359-001-B-0302

MECHANICAL SPECIFICATIONS

GENERAL DESCRIPTION

Units shall be factory-assembled, single packaged,

(DCG Electric Cooling/Gas Heat, DCE Electric Cooling/

Optional Electric Heat), designed for outdoor mounted

installation. Units shall have minimum EER ratings of

8.5. They shall have built in field convertible duct connections for down discharge supply/return or horizontal

discharge supply/return, and be available with factory

installed options or field installed accessories.

The units shall be factory wired, piped, charged with R22 refrigerant and factory tested prior to shipment. All

unit wiring shall be both numbered and color coded.

Enclosed in each unit shall be a factory test log sheet

consisting of the unit tested pressures, temperatures

and amps, as tested prior to shipment.

All units shall be manufactured in a facility certified to

ISO 9001 standards and the cooling performance shall

be rated in accordance with DOE and ARI test procedures. Units shall be ETL & CGA listed, classified to

ANSIZ21.47 standards, UL 1995/CAN/CSA No. 236M90 conditions.

UNIT CABINET

7. Condensate pan shall be internally sloped and

conform to ASHARE 62-89 self-draining standards.

Condensate connection shall be a minimum of 1"

I.D. female and be a ridged mount connection.

8. Unit shall incorporate a fixed outdoor air damper

with an outdoor air intake opening covered with a

bird screen and a rain hood painted to match the

exterior of the unit.

INDOOR (EVAPORATOR) FAN ASSEMBLY

1. Fan shall be a belt drive assembly and include an

adjustable-pitch motor pulley. Job site selected

(B.H.P.) brake horse power shall not exceed the

motors nameplate horse power rating, plus the service factor. Units shall be designed not to operate

above service factor.

2. Fan wheel shall be double-inlet type with forwardcurved blades, dynamically balanced to operate

smoothly throughout the entire range of operation.

Airflow design shall be constant air volume.

3. Bearings shall be sealed and permanently lubricated for longer life and no maintenance.

1. Unit cabinet shall be constructed of G90 galva-

OUTDOOR (CONDENSER) FAN ASSEMBLY

nizedsteel,withexteriorsurfacescoatedwitha

non-chalking, powered paint finish, certified at 750

hours salt spray test per ASTM-B117 standards.

1. The outdoor fans shall be of the direct-driven propeller type, discharge air vertically, have blades

riveted to corrosion resistant steel spider brackets

2. Indoor blower section shall be insulated with up to

1" thick insulation, coated on the air side. Alumi-

and shall be dynamically balanced for smooth

operation.

num foil faced insulation shall be used in the furnace compartment and be fastened with ridged

fasteners to prevent insulation from entering the air

stream.

2. The 2 outdoor fan motors shall be totally enclosed

with permanently lubricated bearings, internally

protected against overload conditions and staged

independently.

3. Cabinet panels shall be “large” size, easily removable for servicing and maintenance.

REFRIGERANT COMPONENTS

1. Compressors:

4. Full perimeter base rails shall be provided to

assure reliable transit of equipment, overhead rigging and proper sealing on roof curb applications.

5. Disposable 2" filters shall be furnished and be

accessible through a removable access door,

sealed air tight. Units filter track shall be designed

to accommodate either 1" or 2" filters.

A. Shall be fully hermetic type, direct drive, internally

protected with internal high-pressure relief and over

temperature protection. The hermetic motor shall be

suction gas cooled and have a voltage range of + or

- 10% of the unit nameplate voltage.

B. Shall have internal spring isolation and sound muf-

fling to minimize vibration and noise, and be externally isolated on a dedicated, independent

mounting.

6. Fan performance measuring ports shall be provided on the outside of the cabinet to allow accu-

2Coils:

rate air measurements of evaporator fan

performance without removing panels or creating

air by-pass of the coils.

Unitary Products Group 15

A. Evaporator and condenser coils shall have alumi-

num plate fins mechanically bonded to seamless

internally-enhanced copper tubes with all joints

brazed. Special Phenolic coating shall be available

as a factory option.

Page 16

036-21359-001-B-0302

B. Evaporator and Condenser coils s hall be of the

direct expansion, draw-thru, design.

C. Condenser coils shall be protected with factory

installed coil guards

3. Refrigerant Circuit and Refrigerant Safety Components shall include:

A. Balance-port thermostatic expansion valve with

independent circuit feed system.

B. Filter drier/strainer to eliminate any moisture or for-

eign matter.

C. Accessible service gage connections on both suc-

tion and discharge lines to charge, evacuate, and

measure refrigerant pressure during any necessary

servicing or troubleshooting, without losing charge.

D. The refrigeration system shall provide at least 15 °F

of sub-cooling at design conditions.

E. All Models shall have two independent circuits..

4. Unit Controls:

A. Unit shall be complete with self contained low-volt-

age control circuit protected by a resetable circuit

breaker on the 24 volt transformer side.

resistance and allowing minimum mixed air entering temperature of 25 °F.

3. Burners shall be of the in-shot type, constructed of

aluminum coated steel and contain air mixture

adjustments.

4. All gas piping shall enter the unit cabinet at a single

location through either the side or curb, without any

field modifications.

5. An integrated control board shall provide timed

control of evaporator fan functioning and burner

ignition.

6. Heating section shall be provided with the following

minimum protection:

A. Primary and auxiliary high-temperature limit

switches.

B. Induced draft motor speed sensor.

C. Flame roll out switch (manual reset).

D. Flame proving controls.

7 Unit shall have two independent stages of capacity.

B. Unit shall incorporate a lock-out circuit which pro-

vides reset capability at the space thermostat or

base unit, should any of the following standard

safety devices trip and shut off compressor:

1. Loss-of-charge/Low-pressure switch.

2. High-pressure switch.

3. Freeze-protection thermostat, evaporator coil.

If any of the above safety devices trip, an LED (light-

emitting diode) indicator shall illuminate.

C. Unit shall incorporate “AUTO RESET” compressor

over temperature, over current protection.

D. Unit shall operate with conventional thermostat

designs and have a low voltage terminal strip for

easy hook-up.

GAS HEATING SECTION (DCG MODELS)

1. Shall be designed with induced draft combustion

with post purge logic and energy saving direct

spark ignition, redundant main gas valve. Ventor

wheel shall be constructed of stainless steel for

corrosion resistance.

ELECTRIC HEATING (DCE MODELS)

1. Nickel chromium electric heating elements shall be

provided as required by the application with 1 or 2

stage control, as required, from 13.5 KW to 72 KW

capacity.

2. The heating section shall have a primary limit control(s) and automatic reset to prevent the heating

element system from operating at an excessive

temperature.

3. Units with Electric Heating shall be wired for a single point power supply with branch circuit fusing

(where required).

UNIT OPERATING CHARACTERISTICS

1. Unit shall be capable of starting and running at 125

°F outdoor temperature, exceeding maximum load

criteria of ARI Standard 210/240.

2. The compressor, with standard controls, shall be

capable of operation down to 25 °F outdoor temperature. Accessory low ambient kit shall be available for operation to 0 °F.

2. The heat exchanger shall be of the tubular type,

constructed of T1-40 aluminized steel for corrosion

3. Unit shall be provided with fan time delay to prevent cold air delivery before heat exchanger warms

up. (Gas heat only)

16 Unitary Products Group

Page 17

036-21359-001-B-0302

ELECTRICAL REQUIREMENTS

All unit power wiring shall enter unit cabinet at a single

factory provided location and be capable of side or bottom entry, to minimize roof penetrations and avoid unit

field modifications. Separate side and bottom openings

shall be provided for the control wiring.

STANDARD LIMITED WARRANTIES

Compressor- 5 Years

Heat Exchanger - 10 Years

Elect. Heat. Elem.- 5 Years

Parts- 1 Year

OPTIONAL OUTDOOR AIR (Shall be made available

by either/or):

1 ELECTRONIC ENTHALPY AUTOMATIC ECON-

OMIZER - Outdoor and return air dampers that are

interlocked and positioned by a fully-modulating,

spring-return damper actuator. The maximum leakage rate for the outdoor air intake dampers shall

not exceed 2% when dampers are fully closed and

operating against a pressure differential of 0.5

IWG. A unit-mounted potentiometer shall be provided to adjust the outdoor and return air damper

assembly to take in CFM of outdoor air to meet the

minimum ventilation requirement of the conditioned

space during normal operation. During economizer

operation, a mixed-air temperature control shall

modulate the outdoor and return air damper

assembly to prevent the supply air temperature

from dropping below 55°F. Changeover from compressor to economizer operation shall be provided

by an integral electronic enthalpy control that feeds

input into the basic module. The outdoor intake

opening shall be covered with a rain hood that

matches the exterior of the unit. Water eliminator/

filters shall be provided. Simultaneous economizer/

compressor operation is also possible. Dampers

shall fully close on power loss.

2. DUAL INPUT DIFFERENTIAL ELECTRONIC

ENTHALPY AUTOMATIC ECONOMIZER -Outdoor and return air dampers that are interlocked

and positioned by a fully-modulating, spring-return

damper actuator. The maximum leakage rate for

the outdoor air intake dampers shall not exceed

2% when dampers are fully closed and operating

against a pressure differential of 0.5 IWG. A unit

mounted potentiometer shall be provided to adjust

the outdoor and return air damper assembly to take

in the design CFM of outdoor air to meet the minimum ventilation requirement of the conditioned

space during normal operation. During economizer

operation, a mixed-air temperature control shall

modulate the outdoor and return air damper

assembly to prevent the supply air temperature

from dropping below 55°F. Changeover from compressor to economizer operation shall be provided

by two integral electronic enthalpy controls - one

that senses outdoor air and one that senses indoor

air. Both enthalpy sensors supply input to the logic

module which modulates both sets of dampers for

maximum economizer savings. The outdoor intake

opening shall be covered with a rain hood that

matches the exterior of the unit. Water eliminator/

filters shall be provided. Simultaneous economizer/

compressor operation is also possible. Dampers

shall fully close on power loss.

3 MOTORIZED OUTDOOR AIR DAMPERS -Out-

door and return air dampers that are interlocked

and positioned by a 2-position, spring-return

damper actuator. The maximum leakage rate for

the outdoor air intake dampers shall not exceed

2% when dampers are fully closed and operating

against a pressure differential of 0.5 IWG. A unitmounted potentiometer shall be provided to adjust

the outdoor and return air damper assembly to take

in the design CFM of outdoor air to meet the ventilation requirements of the conditioned space during

normal operation. Whenever the indoor fan motor

is energized, the dampers open up to one of two

pre-selected positions - regardless of the outdoor

air enthalpy. Dampers return to the fully closed

position when the indoor fan motor is de-energized. Dampers shall fully close on power loss.

OTHER PRE-ENGINEERED ACCESSORIES AVAILABLE

1.

ROOF CURB - 14" high, full perimeter curb with

wood nailer (shipped knocked-down).

2.

BAROMETRIC RELIEF DAMPER -Containsarain

hood, air inlet screen, exhaust damper and mounting hardware. Used to relieve internal air pressure

through the unit during economizer operation.

3.

PROPANE CONVERSION KIT - Contains new ori-

fices and gas valve parts to convert from natural to

L.P. gas. One per unit required.

4.

HIGH ALTITUDE - NATURAL GAS -Containsorifices

required for applications between 2000 and 6000

feet altitude.

Unitary Products Group 17

Page 18

036-21359-001-B-0302

5. HIGH ALTITUDE - PROPANE GAS - Contains orifices

required for applications between 2000 and 6000

feet altitude. Must be used with propane conversion kit.

6.

BURGLAR BARS -Designedtoworkwithabove

roofcurbs, depending on unit model. Fits duct

openings of curb supply and return air openings.

7.

SIDE DUCT FLANGE - Supply and return air duct

flanges for side duct applications. Do not use on

units with power exhaust.

8.

HIGH SPEED DRIVE - Includes blower pulley and

belt for higher CFM and/or static pressure requirements.

9.

WOOD SKID - Allows unit to be handled with 90"

forks.

10.

ECONOMIZER/MOTORIZED DAMPER RAIN HOOD

(DCE/CG300 only)

- Contains all hood panels and

the hardware for assembling.

12.

ANTI-RECYCLE TIMER - Assures 5-minute off-time

between compressor cycles.

13.

LOW AMBIENT KIT - Provides unit cooling opera-

tion down to 0°F.

OTHER FACTORY INSTALLED OPTIONS

1 POWER EXHAUST OPTION - To work in conjunc-

tion with economizers.

2. TECHNICOAT PHENOLIC COATED COND. COIL

3. ELECTRONIC ENTHALPY ECONOMIZER

4. DUAL INPUT ELECTRONIC ENTHALPY ECONOMIZER

THERMOSTATS - Multiple models available from

11.

A.C.O., M.C.O., Electronic or Electrical Mechanical

versions.

18 Unitary Products Group

Page 19

036-21359-001-B-0302

Unitary Products Group 19

Page 20

036-21359-001-B-0302

20 Unitary Products Group

Page 21

036-21359-001-B-0302

Unitary Products Group 21

Page 22

036-21359-001-B-0302

22 Unitary Products Group

Page 23

036-21359-001-B-0302

Unitary Products Group 23

Page 24

Subject to change without notice. Printed in U.S.A. CD: 6-21359 036-21359-001-B-0302

Copyright © by Unitary Products Group 2002. All rights reserved. Supersedes: 036-21359-001-A-0302

Unitary 5005 Norman

Products York OK

Group Drive 73069

Loading...

Loading...