Page 1

TECHNICAL GUIDE

SUNLINE ULTRA™

SINGLE PACKAGE AIR-COOLED

AIR CONDITIONERS

3, 4 AND 5 NOMINAL TON

D1HE/D1HG036, 048 and D2HE/D2HG060

12.2 THROUGH 13.2 SEER

®

DHG MODEL SHOWN

036-21216-003-A-0204

FLEXIBLE LIGHT COMMERCIAL UNIT

GENERAL

YORK’s Sunline Ultra package units are designed to handle applications ranging from residential to light commercial and any in between. The Sunline Ultra is a unit that

gives you the flexibility and choices you need in today’s

market.

FEATURING

• COOLING ONLY UNITS

• COOLING/GAS HEATING UNITS (NATURAL GAS

OR PROPANE)

• LOW PROFILE

• QUIET OPERATION

• COMMON FOOTPRINT

• OPTIONAL FACTORY INSTALLED ECONOMIZERS

• OPTIONAL SLIDE IN MOTORIZED DAMPERS

• OPTIONAL SLIDE IN ECONOMIZERS

• OPTIONAL ELECTRIC HEATERS

• OPTIONAL PROPANE CONVERSION KIT

• OPTIONAL HIGH ALTITUDE GAS OR PROPANE KIT

• OPTIONAL NOx KIT

• MODULAR ELECTRICAL CONNECTIONS FOR

EASY OF INSTALLATION

• FULL PERIMETER BASE RAILS

• TROUBLE FREE UTILITY CONNECTIONS

• 1” OR 2” THROWAWAY FILTERS

• 5 YEAR LIMITED WARRANTY ON COMPRESSOR

• 10 YEAR LIMITED WARRANT ON GAS-FIRED HEAT

EXCHANGERS

• 1 YEAR LIMITED WARRANTY ON ALL REPLACEMENT PARTS

FOR DISTRIBUTION USE ONLY - NOT TO BE USED AT POINT OF RETAIL SALE

Page 2

TABLE OF CONTENTS

036-21216-003-A-0204

DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

FACTORY-INSTALLED OPTION . . . . . . . . . . . . . . . 4

FIELD-INSTALLED ACCESSORIES. . . . . . . . . . . . . 4

MECHANICAL SPECIFICATIONS . . . . . . . . . . . . . 24

LIST OF FIGURES

Fig. Pg.

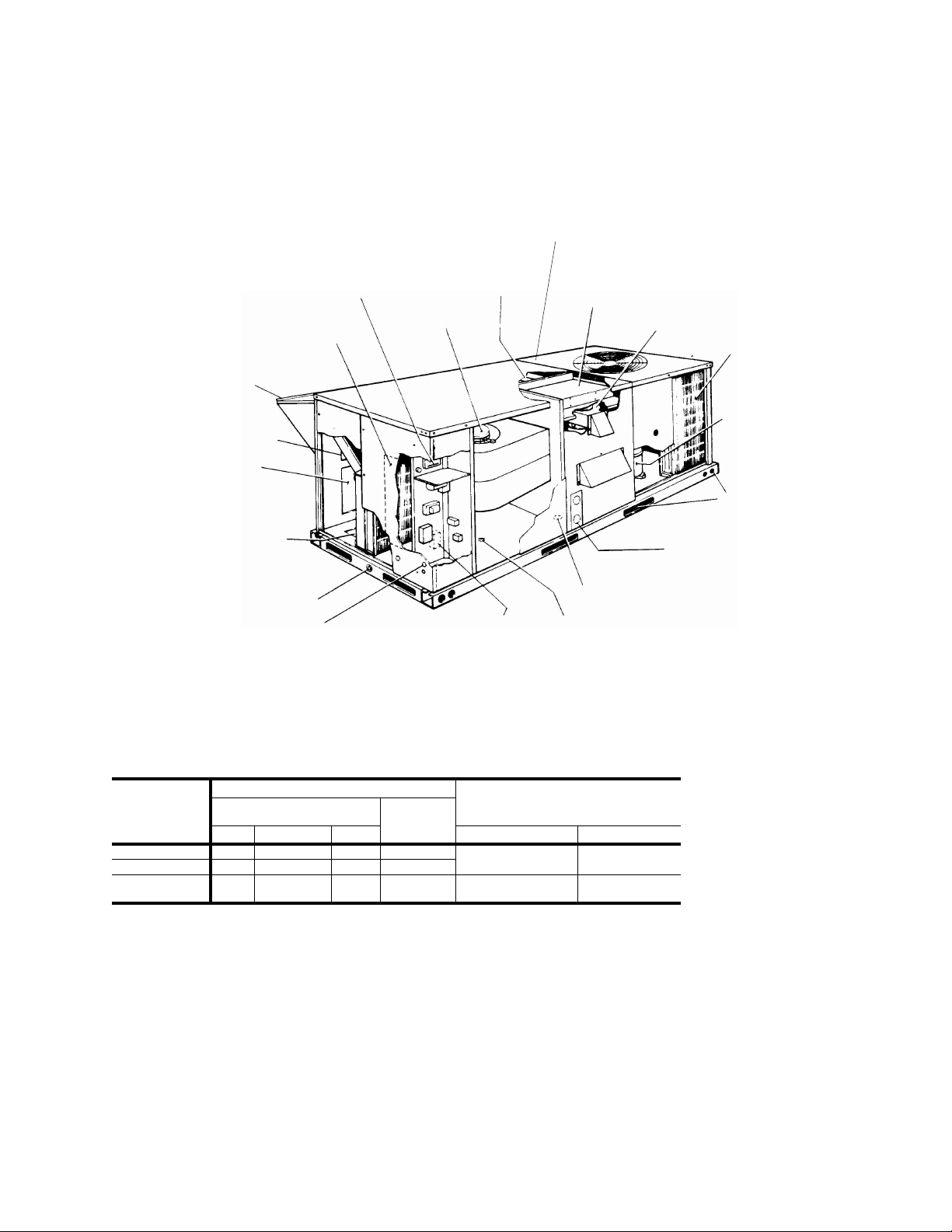

1 SUNLINE ULTRA CUTAWAY (MODEL DHG

GAS HEATING). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 FIELD POWER WIRING . . . . . . . . . . . . . . . . . . . . . . . . 16

3 CONTROL WIRING COOLING ONLY . . . . . . . . . . . . . 16

4 CONTROL WIRING SINGLE STAGE. . . . . . . . . . . . . . 17

5 CONTROL WIRING COOLING/HEATING . . . . . . . . . . 17

6 CONTROL WIRING MULTI-STAGE . . . . . . . . . . . . . . . 17

7 DHE UNIT DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . 18

8 ACCESS PANELS AND DISCONNECT . . . . . . . . . . . . 18

9 UNIT DIMENSIONS DHG UNIT . . . . . . . . . . . . . . . . . . 19

10 REAR DIMENSIONS OF DHE AND DHG

UNITS 3, 4 & 5 TON UNITS . . . . . . . . . . . . . . . . . . . . .20

11 UNIT DIMENSIONS WITH ECONOMIZER

RAINHOOD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

12 DETAIL “B” UNIT WITH FIXED OUTDOOR

AIR/MOTORIZED DAMPER RAINHOOD. . . . . . . . . . . 21

13 UNIT AND CURB APPLICATION . . . . . . . . . . . . . . . . . 21

14 ROOF CURB DIMENSIONS DHE/DHG

3, 4 & 5 TON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

15 CENTER OF GRAVITY AND CORNER WEIGHTS . . . 22

16 TYPICAL APPLICATIONS . . . . . . . . . . . . . . . . . . . . . . 23

17 TYPICAL ROOF-TOP INSTALLATION (DHG) . . . . . . . 23

LIST OF TABLES

Tbl. Pg.

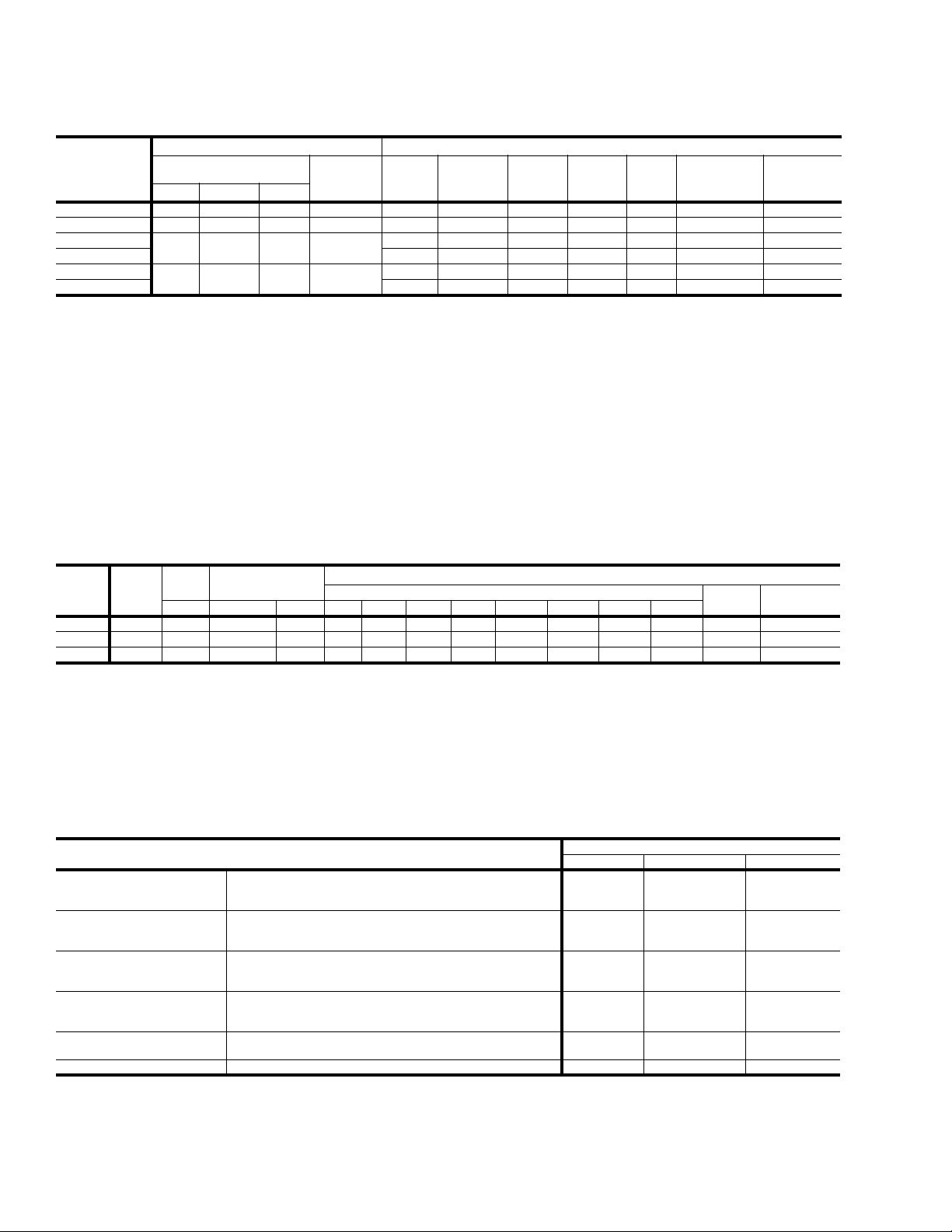

1 CAPACITY RATING - COOLING / ELECTRIC HEAT . . 5

2 CAPACITY RATINGS - COOLING / GAS HEATING . . . 6

3 SOUND POWER RATINGS . . . . . . . . . . . . . . . . . . . . . . 6

4 PHYSICAL DATA - BASIC UNIT . . . . . . . . . . . . . . . . . . 6

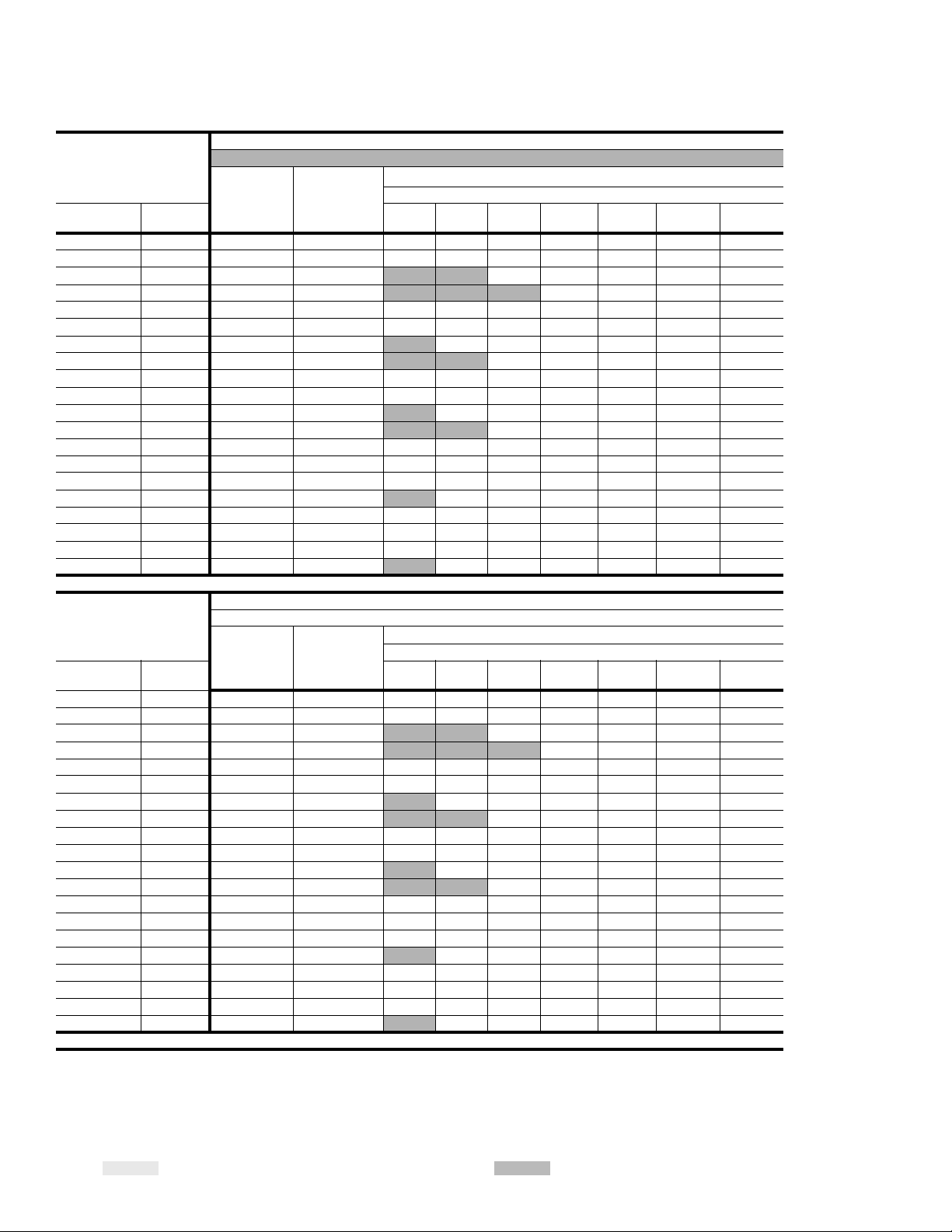

5 COOLING CAPACITIES - MODELS

DHE/DHG 036 - 85°F - 95ºF. . . . . . . . . . . . . . . . . . . . . . 7

6 COOLING CAPACITIES - MODELS

DHE/DHG 036 - 105°F - 115ºF. . . . . . . . . . . . . . . . . . . . 8

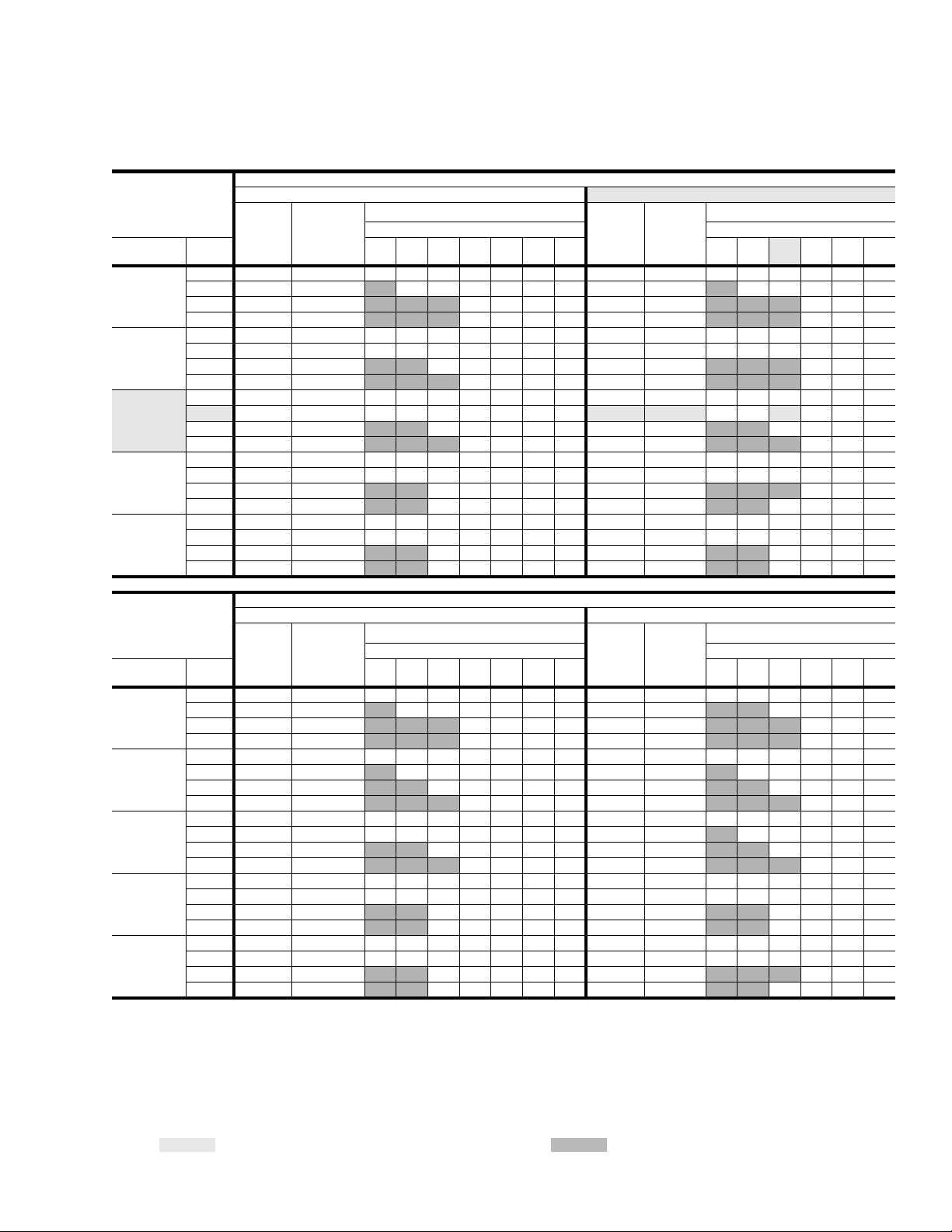

7 COOLING CAPACITIES - MODELS DHE/DHG048 . . . 9

8 COOLING CAPACITIES - MODELS DHE/DHG060 . . 10

9 SUPPLY AIR BLOWER PERFORMANCE -

DHE/DHG036 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

10 SUPPLY AIR BLOWER PERFORMANCE

DHE/DHG048 (4 TON GAS HEAT MODELS) . . . . . . . 12

11 SUPPLY AIR BLOWER PERFORMANCE

DHE/DHG060 (5 TON GAS HEAT MODELS) . . . . . . . 13

12 ACCESSORY STATIC RESISTANCE . . . . . . . . . . . . . 13

13 MOTOR AND DRIVE DATA - BELT-DRIVE BLOWER 14

14 ELECTRICAL DATA - BASIC UNIT . . . . . . . . . . . . . . . 14

15 ELECTRICAL DATA - COOLING/ELECTRIC

HEAT DHE036 & 048 . . . . . . . . . . . . . . . . . . . . . . . . . . 15

16 ELECTRIC HEAT CORRECTION FACTORS

(DHE048) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

17 FUSE BLOCK ACCESSORY . . . . . . . . . . . . . . . . . . . . 15

18 ELECTRICAL DATA - COOLING/ELECTRIC

HEAT DHE060 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

19 UTILITIES ENTRY DATA . . . . . . . . . . . . . . . . . . . . . . . 18

20 CLEARANCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

21 BASIC UNIT WEIGHT . . . . . . . . . . . . . . . . . . . . . . . . . 22

22 ACCESSORIES WEIGHT . . . . . . . . . . . . . . . . . . . . . . 22

2 Unitary Products Group

Page 3

036-21216-003-A-0204

DESCRIPTION

YORK Sunline Ultra units are high efficiency, convertible, single package air conditioners with a common cabinet and a

common roof curb for the 3, 4 and 5 ton sizes. The units were

designed for residential, light commercial and commercial

applications. They can easily be installed on a roof curb, slab,

roof jack or frame.

All units are self-contained and assembled on rigid full perimeter base rails with fork lift slots on three sides and holes for

overhead rigging. Every unit is completely piped, wired,

charged and tested at the factory to provide for a quick and

easy field installation.

The units are available in cooling only, and cooling with gas

heat. Electric heaters are available as field--installed acces

sories.

Both bottom and side duct connections are available without

having to swap panels. The installer simply removes the duct

covers for the desired configuration. Economizers may be

used on either bottom and side duct applications with no

modifications required.

All models include a 5-year limited warranty on compressors,

a 10-year limited warranty on gas-fired heat exchangers and

a 1-year limited warranty on all replacement parts.

-

FEATURES

COMMON FOOTPRINT/COMMON CABINET - All model

sizes and configurations share a common cabinet and a com

mon roof curb. The installer has the flexibility of setting one

curb and placing the proper tonnage unit on that curb after

the internal load has been determined. He can even decide

between gas or electric heat after the curb has been set.

HIGH EFFICIENCY - Units have a high cooling efficiency of

as high as 13.2 SEER and gas / electric models have a mini

mum AFUE of 80.3%. All efficiencies exceed legislated minimum levels and provide low operating costs.

CONVERTIBLE AIRFLOW DESIGN - Both the side and bottom duct openings are covered when they leave the factory. If

a side supply / side return is desired, you simply remove the

two side duct covers from the outside of the unit and discard

them. If a bottom supply / bottom return is desired, you simply

remove the two knockout panels from the base of the unit and

discard them. No panel cutting or swapping is required! Con

vertible airflow design allows maximum field flexibility and

minimum inventory.

FACTORY--INSTALLED OPTIONS - Economizers can be

installed at the factory. The economizers are shipped

installed and wired. Only the rain hood needs to be field

assembled and installed. Field labor dollars can be saved by

having the components arrive already installed.

FIELD--INSTALLED ACCESSORIES - Accessories were

designed for quick and easy installation. The motorized

damper and economizers simply slide in, and electrical con

nections are made by modular plugs. Electric heaters mount

easily, and knockouts are provided in the internal partitions to

connect the elements to the control box single point kit.

The motorized air damper includes a slid-in/plug-in damper

assembly with a rainhood and filters. The outdoor air damp

ers open when the indoor fan motor is energized. The

damper is capable of providing 0% through 100% of outdoor

return air opening.

The manual outdoor damper provides 0% through 35% or 0%

through 100% of return air opening (field adjustable).

Designed for duct mounted side or bottom supply/return

applications. Includes rain hood assembly and filter.

The 14" high roof curb is shipped knocked down. An insulated deck is not required because the bottom of the unit is

insulated.

Low ambient controls are available to provide stable unit

operation at outdoor temperatures down to 0F.

Propane, high altitude and low NOx kits are also available to

cover all gas heating applications.

WIDE RANGE OF INDOOR AIRFLOWS - All models operate

over a wide range of design conditions with the use of belt-drive blowers. The variable pitch pulley on the blower motor

can be adjusted to obtain the desired supply air CFM.

FULL PERIMETER BASE RAILS - The permanently attached

base rails provide a solid foundation for the entire unit and

-

protect the unit during shipment. The rails provide fork lift

access from 3 sides, and rigging holes are also provided so

that an overhead crane can be used to place the units on a

roof.

SYSTEM PROTECTION - Internal overload protection is

standard on all compressors. Every unit has a liquid line filter-

-

-drier, high and low pressure/loss of charge switches and a

suction line freezestat to protect all system components. All

units will provide cooling at ambient temperatures down to

45F.

UTILITY CONNECTIONS MADE EASY - Gas and electric

utility knockouts are provided in the unit base as well as the

side of the unit. A clearly identified location is provided to

mount a field supplied electrical disconnect switch. Utility

connections can be made quickly and with a minimum

-

amount of field labor.

SIMPLE CONTROL CIRCUIT - A low voltage printed circuit

board contains a compressor lockout indicator light and a low

voltage terminal strip. An additional set of pin connectors is

also provided to simplify the field interface of external con

trols. Mate-n-lock plug connectors are used where line and

low voltage wires pass through internal bulkheads. This

allows for easier troubleshooting and component replacement. The electrical control box is not located in the compressor compartment so the access cover can be removed for

-

-

-

Unitary Products Group 3

Page 4

036-21216-003-A-0204

troubleshooting without affecting the normal system operating pressures.

AIR FILTERS - Units are shipped with 1" throwaway filters.

The unit filter racks can accommodate 1" or 2" filters without

any modifications

FACTORY-INSTALLED OPTION

ECONOMIZERS: Units equipped with a factory-installed

economizer option have dampers that are positioned by a

spring return, fully modulating damper actuator and are capa

ble of introducing up to 100% outdoor air. As the outdoor air

intake dampers open, the return air dampers close. The

changeover from mechanical refrigeration to economizer

operation is determined by a single input electronic enthalpy

control or by a dual input electronic enthalpy control. Simulta

neous compressor and economizer operation is also possible.

The single enthalpy system contains a sensor that monitors

the outdoor air which automatically operates the damper

actuator allowing the dampers to open or close.

The dual enthalpy system contains a second sensor that

monitors both the temperature and the humidity of the return

air in addition to the outdoor air sensor described for a single

enthalpy system. The logic module compares the inputs from

both sensors and switches to economizer operation when

ever the outdoor air is cooler than the return air for maximum

efficiency of the economizer system.

The economizer is completely wired and installed at the factory. Only the outdoor air hood, including its filters, need be

assembled and installed in the field.

-

FIELD-INSTALLED ACCESSORIES

SINGLE INPUT ELECTRONIC ENTHALPY ECONOMIZER Includes a slide-in / plug-in damper assembly with fully modu

lating spring return motor actuator capable of introducing up

to 100% outdoor air, one outdoor air electronic enthalpy sen

sor and a rain hood with filters. The rain hood is painted to

match the basic unit and must be field-assembled before

installation. Economizer dampers are 2% low leakage type.

DUAL INPUT ELECTRONIC ENTHALPY ECONOMIZER Includes the same damper system and rain hood with filters

as described for a single enthalpy economizer except this

accessory contains two enthalpy sensors. It uses a differen

tial enthalpy control that compares the outdoor air versus the

return air. The logic module then optimizes the economizer

operation for additional savings over the single input economizer.

MOTORIZED AIR DAMPER - Includes a slid-in/plug-in

damper assembly with a rainhood and filters. The outdoor air

dampers open when the indoor fan motor is energized. The

damper is capable of providing 0% through 100% of outdoor

return air opening.

-

MANUAL OUTDOOR DAMPER - Provides 0% through 35%

or 0% through 100% of return air opening (field adjustable).

Designed for duct mounted side or bottom supply/return

applications. Includes rain hood assembly and filter.

ELECTRIC HEATERS - Include nickel chromium elements, a

terminal block, fuses (where required by UL), all the neces

sary connectors and hardware. All heaters utilize single point

power supply hookup. Capacities from 5 KW thru 30 KW

heating are available.

FUSE BLOCK KITS - These kits have a fuse box with a fuse

block and fuses. They're available for all 460-3-60 volt heat

ers and 208/230-3-60 volt heaters 7 KW and smaller.

OUTDOOR THERMOSTAT - A 24-volt thermostat providing

two stages of control for units equipped with electric heat

accessories.

ROOF CURB - This 14" high full perimeter roof curb is

shipped knocked down for field assembly and contains duct

supports that can easily be

shifted for the desired unit duct arrangement. No insulated

deck is required because the unit underside is insulated.

START ASSIST KIT - Provides increased starting torque for

single phase units in areas with low voltage conditions. It con

tains a 12.5 OHM PTCR temperature resistor with a support

clip and hardware for mounting.

LOW AMBIENT KIT - A head pressure controller maintains

stable system operation by reducing the speed of the con

denser fan motor when the outdoor temperature is between

45 and 0F. Condenser fan motors with ball bearings and

heavier windings are also available for these low ambient

applications.

ANTI-RECYCLE TIMER - A timer to prevent the unit compressor from short cycling. It assures a 5-minute off-time

between compressor cycles.

-

PROPANE CONVERSION KIT - Converts a gas-fired heater

from natural gas to propane. It contains main burner orifices,

a pilot orifice and a regulator spring.

LOW NOx KIT (natural gas furnaces only) - Contains five

stainless steel expanded metal sheets for mounting into the

heat exchanger tubes to meet the California low nitrous oxide

emission requirements.

HIGH ALTITUDE CONVERSION (NATURAL AND PROPANE) - Provides orifices for proper furnace operation at altitudes up to 6000 feet. For propane applications, the propane

conversion kit will also be required.

GAS PIPING - This kit contains 1/2" pipe nipples, fittings and

gas cock (including panel access gaskets) required for bot

tom gas supply connection with external shut-off.

OUTDOOR COIL GUARD - Consists of grille-type sections

for installation over the outdoor coil to protect it from damage.

-

-

-

-

-

4 Unitary Products Group

Page 5

036-21216-003-A-0204

S

WALL THERMOSTAT - The units are designed to operate

with 24-volt electronic and electro-mechanical thermostats.

2 0 G A U G E A L U M I N I Z E D

S T E E L T U B U L A R H E A T

X C H A N G E R

E

C T R I C A L D I S C O N N E C T

E L E

M O U N T I N G L O C A T I O N

( F i e l d I n s t a l l e d )

E C O N O M I Z E R H O O D

O U T D O O R A I R O P E N I N G

F O R S L I D E - I N / P L U G - I N

I N T N E R A L E C O N O M I Z E R

D E R E T U R N A I R

S I

D U C T O P E N I N G

B O T T O M R E T U R N A I R

D U C T O P E N I N G

L O W V O L T A G E R E L A Y B O A R D

A N D T E R M I N A L S T R I P

B E L T D R I V E

B L O W E R M O T O R

All units can operate with single stage heat / single stage cool

thermostats - with or without the economizer.

.

L O N G L A S T I N G

P O W D E R P A I N T F I N I S H

E L E C T R I C H E A T

A C C E S S O R Y

L O C A T I O N

( E l e c / E l e c U n i t s )

P O W E R V E N T E R M O T O R

W I T H P O S T P U R G E C Y C L E

C O P P E R T U B E /

A L U M I N U M F I N

C O N D E N S I N G C O I L

H I G H E F F I C I E N C Y

C O M P R E S S O R S

F U L L P E R I M E T E R B A S E

R A I L S W I T H F O R K L I F T

S L O T S A N D L I F T I N G H O L E

K N O C K O U T F O R S I D E

G A S S U P P L Y E N T R Y

3 / 4 " P V C F E M A L E

C O N D E N S A T E D R A I N

N O C K O U T S F O R

K

S I D E P O W E R A N D

C O N T R O L E N T R Y

T E R M I N A L B L O C K

( F o r S i n g l e P o i n t P o w e r

S u p p l y o n E l e c / E l e c U n i t s )

K N O C K O U T F O R B O T T O M

G A S S U P P L Y E N T R Y

K N O C K O U T F O R B O T T O M

P O W E R E N T

FIGURE 1 - SUNLINE ULTRA CUTAWAY (Model DHG gas heating)

TABLE 1: CAPACITY RATING - COOLING / ELECTRIC HEAT

EER

1

SOUND

RATING

5

(dBels)MBH

NOMINAL ELECTRIC HEAT CAPACITY

3

(kW)

240V 480V

5, 7, 10,

15 & 20

5, 7, 10,

15, 20 & 30

MODEL

COOLING CAPACITY

80 / 67-95°F

4

SEER

DHE036 42.5 12.25 11 .10 86

DHE048 46.5 13.20 11 .40 87

DHE060 57.0 12.20 10.60 86

ARI RATINGS

1.

Certified in accordance with the Unitary Small Equipment certification program, which is

based on ARI Standard 210/240.

2.

Heaters are available as accessories - all with single point power supply.

3.

Rated in accordance with ARI Standard 270.

4.

SEER = Seasonal Energy Efficiency Ration - the total cooling output in BTU’s during a normal annual usage period for cooling divided by the total electric power input in watt-hours

during the same period.

5.

EER = Energy Efficiency Ration - the cooling capacity in Btu’s per hour (Btuh) divided by

the power input in watts at any given set of rating conditions, expressed in BTUH per watt

(BTUH/watt).

R Y

7, 10,

15 & 20

7, 10, 15,

20 & 30

2

Unitary Products Group 5

Page 6

036-21216-003-A-0204

TABLE 2: CAPACITY RATINGS - COOLING / GAS HEATING

ARI RATINGS

MODEL

DHG036N040 42.5 12.25 11.1 86 50 40 80.0 81.6 77.3 15-45 1/2

DHG036N079 42.5 12.25 11.1 86 100 79 80.5 80.8 77.9 40-70 1/2

DHG048N060

DHG048N099 125 99 80.3 80.6 77.9 45-75 1/2

DHG060N079

DHG060N099 125 99 80.3 80.6 77.9 35-65 1/2

1.

Certified in accordance with the Unitary Small Equipment certification program, which is based on ARI Standard 210/240.

2.

Rated in accordance with ARI Standard 110, utilization range “A”.

3.

AFUE = Annual Fuel Utilization Efficiency - determined in accordance with DOE test procedure.

4.

S.S.E. = Steady State Efficiency. (Percent Output)

5.

S.E. = California Seasonal Efficiency - determined in accordance with test procedures as specified by the State of California

COOLING CAPACITY

80 / 67-95°F

MBH

SEER6EER

46.5 13.20 11 .40 87

57.0 12.20 10.60 86

1

SOUND

RATING

7

(dBels)

INPUT

2

(MBH)

75 59 80.9 81.6 77.3 25-55 1/2

100 79 80.5 80.8 73.6 25-55 1/2

DOE

OUTPUT

(MBH)

Energy Commission. Furnaces are available with a low NOx accessory.

6.

SEER = Seasonal Energy Efficiency Ratio - the total cooling output in BTU’s during a normal annual usage period for cooling

divided by the total electric power input in watt-hours during the same period.

7.

EER = Energy Efficiency Ratio - the cooling capacity in Btu’s per hour (Btuh) divided by the power input in watts at any given set of

rating conditions, expressed in BTUH per watt (BTUH/watt).

GAS HEAT CAPACITY

3

AFUE

(%)

S.S.E.

(%)

4

S.E.

(%)

5

TEMP. RISE

(°F)

GAS

LINE SIZE

(in. O.D.)

TABLE 3: SOUND POWER RATINGS

UNIT

SIZE

036 1200 0.60 LOW 0.60 84 84 74 67 69 62 57 52 74 41

048 1600 0.55 HIGH 0.80 85 85 75 68 70 63 58 53 75 42

060 2000 0.45 HIGH 1.00 86 86 76 69 71 64 59 54 76 43

CFM

1.

These values have been accessed using a model of sound propagation from a point source into the hermispheric free field. The

ESP BLOWER

IWG SPEED kW 63 125 250 500 1000 2000 4000 8000

1

OCTAVE BAND CENTERLINE FREQUENCY (Hz)

SOUND POWER (dB 10

-12

Watts)

SWL

dB(A)

dBA values provided are to be used for reference only. Calculation of dBA values cover matters of system design and the fan

manufacturer has no way of knowing the details of each system. This constitutes an exception to any specification or guarantee

requiring a dBA value or sound data in any other form than sound power level ratings.

2.

At a distance of 10 feet from the blower.

TABLE 4: PHYSICAL DATA - BASIC UNIT

MODELS

EVAPORATOR

BLOWER

EVAPORATOR

COIL

CONDENSER

FAN

AIR

1

FILTERS

SYSTEM

CHARGE

COMPRESSOR QUANTITY PER UNIT (Hermetic Type) 1 / Recpt. 1 / Recpt. 1/Recpt.

1.

Filter racks are adapted for 1” or 2” thick filters.

CENTRIGUGAL BLOWER (Dia. x Wd. in.)

FAN MOTOR HP (BELT-DRIVE)

ROWS DEEP

FINS PER INCH

FACE AREA (Sq. Ft.)

PROPELLER DIA. (in.)

FAN MOTOR HP

NOM. CFM TOTAL

QUANITY PER UNIT (15” X 20” X 1”)

QUANTITY PER UNIT (14” X 25” X 1”)

TOTAL FACE AREA (square feet)

REFRIGERANT 22 (pounds/ounces) 10/8 10/*4 10/14

036 048 060

12 x 10

1.5

4

13

4.3

24

1/2

4,500

2

1

6.6

DHE/DHG

12 x 10

1.5

4

13

5.1

24

1/2

4,200

2

1

6.6

dBA

@ 10 ft.

12 x 10

1.5

4

13

5.1

24

1/2

4,200

2

1

6.6

2

6 Unitary Products Group

Page 7

036-21216-003-A-0204

TABLE 5: COOLING CAPACITIES - MODELS DHE/DHG 036 - 85°F - 95ºF

AIR ON

EVAPORATOR

COIL

CFM

1500

1350

1200

1050

900

WB

°F

TOTAL

CAP.

MBH

1

POWER

INPUT

72 55.2 3.18 35.2 30.7 26.2 21.8 17.3 #N/A #N/A

67 49.1 3.13 41.7 37.2 32.8 28.3 23.8 19.4 14.9

62 44.7 3.05 44.7 43.6 39.1 34.6 30.1 25.7 21.2

57 42.4 3.05 42.4 42.4 42.4 37.9 33.4 29.0 24.5

72 55.2 3.18 35.2 30.7 26.2 21.8 17.3 #N/A #N/A

67 49.1 3.13 41.7 37.2 32.8 28.3 23.8 19.4 14.9

62 44.7 3.05 44.7 43.6 39.1 34.6 30.1 25.7 21.2

57 42.4 3.05 42.4 42.4 42.4 37.9 33.4 29.0 24.5

72 51.9 -3.15 30.0 26.5 23.0 19.5 16.0 #N/A

67 46.1 3.10 35.7 32.2 28.7 25.2 21.7 18.2 14.7

62 42.0 3.02 41.2 37.7 34.2 30.7 27.2 23.7 20.2

57 39.8 3.03 39.8 39.8 37.3 33.8 30.3 26.8 23-3

72 49.4 3.12 27.3 24.3 21.2 182 15.2 #N/A

67 43.9 3.07 32.6 29.6 26.5 23.5 20.5 17.4 14.4

62 40.0 2.99 37.7 34.7 31.6 28.6 25.6 22.5 19.5

57 37.9 3.00 37.9 37.0 34.5 31.4 28.4 25.4 22.3

72 46.9 3.09 24.6 22.1 19.5 16.9 14.4 #N/A

67 41.7 3.04 29.5 26.9 24.4 21.8 19.2 16.7 14.1

62 38.0 2.96 34.2 31.6 29.1 26.5 23.9 21.4 18.8

57 36.0 2.97 36.0 34.2 31.7 29.1 26.5 24.0 21.4

TEMPERATURE OF AIR ON CONDENSER COIL

85°F

2

86 83 80 77 74 71 68

SENSIBLE CAPACITY

ENTERING DRY BULB, °F

3

AIR ON

EVAPORATOR

COIL

CFM

1500

1350

1200

1050

900

TEMPERATURE OF AIR ON CONDENSER COIL

95°F

SENSIBLE CAPACITY

ENTERING DRY BULB, °F

WB

°F

TOTAL

CAP.

MBH

POWER

INPUT

86 83 80 77 74 71 68

72 51.5 3.44 34.1 29.7 25.2 20.7 16.2 #N/A #N/A

67 45.8 3.35 40.2 35.7 31.3 26.8 22.3 17.8 13.4

62 41.2 3.30 41.2 41.2 38.8 34.3 29.8 25.3 20.9

57 39.9 3.35 39.9 39.9 39.9 35.4 31.0 26.5 22.0

72 50.0 3.41 31.5 27.5 23.6 19.6 15.6 #N/A #N/A

67 44.5 3.32 37.2 33.2 29.2 25.3 2 13 17.3 13.3

62 40.0 3.27 40.0 39.2 36.3 32.3 28.3 24.3 20.3

57 38.8 3.32 38.8 38.8 37.5 33.5 29.6 25.6 21.6

72 48.6 3.38 28.9 25.4 21.9 18.4 14.9 #N/A ' #N/A

67 43.2 3.29 34.2 30.7 27.2 23.7 20.2 16.7 13.2

62 38.9 3.23 38.9 37.2 33.7 30.2 26.7 23.2 19.8

57 37.6 3.29 37.6 37.6 35.1 31.6 28.1 24.6 21.1

72 46.4 3.36 26.2 23.2 20.2 17.2 14.1 #N/A #N/A

67 41.2 3.27 31.1 28.1 25.0 22.0 19.0 16.0 12.9

62 37.1 3.21 36.2 34.1 31.1 28.0 25.0 22.0 18.9

57 35.9 3.27 35.9 34.9 32.3 29.3 26.3 23.2 20.2

72 44.2 3.34 23.6 21.0 18.4 15.9 13.3 #N/A #N/A

67 39.3 3.25 28.0 25.4 22.9 20.3 17.7 15.2 12.6

62 35.4 3.20 33.5 30.9 28.4 25.8 23.2 20.7 18.1

57 34.2 3.25 34.2 32.1 29.5 27.0 24.4 21.8 19.3

1.

These capacities are gross ratings. For net capacity, determine the KW of the supply air blower motor from the Blower Performance Table, multiply

this value by 3.415 MBH / KW to determine the motor heat, and deduct this heat from the gross capacity of the unit

2.

These ratings include the compressor and the condenser fan motors but not the supply air blower motor. The total condenser fan motor power input

is 0.36kW. Refer to Tables 10 and 11 for the kW of the supply air blower motor.

3.

These capacities are gross ratings. For net capacity, determine the kW of the supply air blower from Tables 10 and 11, multiply this value by 3.415

MBH/kW to determine the motor heat, and deduct this heat from the gross capacity of the unit.

NOMINAL RATING ALL SENSIBLE CAPACITY

Unitary Products Group 7

Page 8

036-21216-003-A-0204

TABLE 6: COOLING CAPACITIES - MODELS DHE/DHG 036 - 105°F - 115ºF

AIR ON

EVAPORATOR

CFM

COIL

WB

°F

TOTAL

CAP.

MBH

1

POWER

INPUT

1500 72 47.6 3.65 32.3 27.8 23.3 18.9 14.4 #N/A #N/A

67 42.5 3.56 39.0 34.5 30.0 25.6 21.1 16.6 12.1

62 38.0 3.49 38.0 38.0 36.6 32.1 27.6 23.1 18.7

57 37.4 3.54 37.4 37.4 37.4 32.9 28.5 24.0 19.5

1350 72 46.5 3.62 29.7 25.8 21.8 17.8 13.8 #N/A #N/A

67 41.6 3.53 36.0 32.0 28.0 24.0 20.1 16.1 12.1

62 37.1 3.46 37.1 36.6 34.1 30.1 26.1 22.2 18.2

57 36.5 3.52 36.5 36.5 35.2 31.2 27.2 23.3 19.3

1200 72 45.4 3.60 27.2 23.7 20.2 16.7 12.2 #N/A #N/A

67 40.6 3.51 33.0 29.5 26.0 22.5 19.0 15.5 12.0

62 36.2 3.44 36.2 35.2 31.7 28.2 24.7 21.2 17.7

57 35.7 3.49 35.7 35.7 33.0 29.5 26.0 22.5 19.0

1050 72 43.2 3.57 24.6 21.6 18.5 12.5 #N/A #N/A

67 38.7 3.48 29.9 26.9 23.8 20.8 17.8 14.7 11 .7

62 34.5 3.41 33.9 32.1 29.0 26.0 23.0 19.9 16.9

57 34.0 3.47 34.0 32.9 30.3 27.2 24.2 21.2 18.1

900 72 41.1 3.54 22.0 19.4 16.8 14.3 11 .7 #N/A #N/A

67 36.7 3.45 26.8 24.2 21.7 19.1 16.5 14.0 11 .4

62 32.8 3.39 31.5 28.9 26.4 23.8 21.2 18.7 16.1

57 32.3 3.44 32.3 30.1 27.5 24.9 22.4 19.8 17.2

TEMPERATURE OF AIR ON CONDENSER COIL

105°F

SENSIBLE CAPACITY

2

ENTERING DRY BULB, °F

86 83 80 77 74 71 68

3

AIR ON

EVAPORATOR

COIL

CFM

WB

°F

TOTAL

CAP.

MBH

POWER

INPUT

86 83 80 77 74 71 68

115 °F

SENSIBLE CAPACITY

ENTERING DRY BULB, °F

1500 72 43.6 3.85 30.4 26.0 21.5 17.0 12.5 #N/A #N/A

67 39.3 3.76 37.8 33.3 28.8 24.3 19.9 15.4 10.9

62 34.8 3.67 34.8 34.8 34.4 29.9 25.4 20.9 16.5

57 34.9 3.73 34.9 34.9 34.9 30.5 26.0 21.5 17.0

1350 72 42.9 3.83 28.0 24.0 20.0 16.0 12.0 #N/A #N/A

67 38.6 3.74 34.8 30.8 26.8 22.8 18.8 14.9 10.9

62 34.2 3.66 34.2 34.0 32.0 28.0 24.0 20.0 16.0

57 34.3 3.72 34.3 34.3 32.9 28.9 24.9 21.0 17.0

1200 72 42.2 3.82 25.5 22.0 18.5 15.0 11 .5 #N/A #N/A

67 37.9 3.73 31.8 28.3 24.8 21.3 17.8 14.3 10.8

62 33.6 3.64 33.6 33.1 29.6 26.1 22.6 19.1 15.6

57 33.7 3.70 33.7 33.7 30.9 27.4 23.9 20.4 16.9

1050 72 40.1 3.78 22.9 19.9 16.9 13.8 10.8 #N/A #N/A

67 36.1 3.69 28.7 25.7 22.6 19.6 16.6 13.5 10.5

62 32.0 3.61 31.6 30.0 27.0 23.9 20.9 17.9 14.9

57 32.1 3.67 32.1 30.9 28.2 25.1 22.1 19.1 16.0

900 72 38.0 3.75 20.4 17.8 15.2 12.7 10.1 #N/A #N/A

67 34.2 3.66 25.6 23.0 20.4 17.9 15.3 12.7 10.2

62 30.3 3.58 29.5 26.9 24.4 21.8 19.2 16.7 14.1

57 30.4 3.64 30.4 28.0 25.4 22.9 20.3 17.7 15.2

TEMPERATURE OF AIR ON CONDENSER COIL

1.

These capacities are gross ratings. For net capacity, determine the KW of the supply air blower motor from the Blower Performance

Table, multiply this value by 3.415 MBH / KW to determine the motor heat, and deduct this heat from the gross capacity of the unit

2.

These ratings include the compressor and the condenser fan motors but not the supply air blower motor. The total condenser fan motor

power input is 0.36kW. Refer to Tables 10 and 11 for the kW of the supply air blower motor.

3.

These capacities are gross ratings. For net capacity, determine the kW of the supply air blower from Tables 10 and 11, multiply this value

by 3.415 MBH/kW to determine the motor heat, and deduct this heat from the gross capacity of the unit.

NOMINAL RATING ALL SENSIBLE CAPACITY

8 Unitary Products Group

Page 9

036-21216-003-A-0204

TABLE 7: COOLING CAPACITIES - MODELS DHE/DHG048

AIR ON

EVAPORATOR

COIL

CFM

2000

1800

1600

1400

1200

TOTAL

WB

CAP.

MBH

°F

72 59 3.3 46 40 34 28 23 - - 55 3.5 43 37 32 26 20 67 53 3.2 53 49 43 38 32 26 21 49 3.4 49 47 41 35 30 24

62 47 3.2 47 47 47 42 36 30 25 44 3.4 44 44 44 38 32 26

57 47 3.1 47 47 47 41 35 29 24 43 3.3 43 43 43 37 31 26

72 58 3.3 42 37 32 27 22 - - 54 3.5 40 35 30 25 20 67 53 3.2 50 46 41 35 30 25 20 48 3.4 47 44 39 33 28 23

62 47 3.2 47 47 46 41 36 31 26 43 3.4 43 43 43 38 33 28

57 46 3.1 46 46 46 41 35 30 25 42 3.3 42 42 42 37 32 27

72 57 3.3 39 34 30 25 21 - - 53 3.5 37 33 28 23 19 67 52 3.2 47 42 38 33 29 24 19 48 3.4 45 41 36 32 27 22

62 46 3.2 46 46 45 41 36 32 27 42 3.4 42 42 43 39 34 30

57 45 3.1 45 45 45 40 36 31 27 41 3.3 41 41 41 37 32 28

72 54 3.2 35 31 27 23 19 - - 51 3.5 34 30 26 22 17 67 49 3.1 43 39 35 31 27 23 19 45 3.4 41 37 33 29 25 21

62 43 3.1 43 43 42 38 34 30 26 40 3.4 40 40 40 36 32 28

57 43 3.1 43 43 41 37 33 29 25 39 3.3 39 39 38 34 30 26

72 51 3.2 32 29 25 22 18 - - 48 3.5 30 27 23 20 16 67 46 3.1 39 35 32 28 25 21 18 42 3.5 37 34 30 27 23 20

62 41 3.1 41 41 38 35 31 28 24 38 3.4 38 38 36 33 29 26

57 40 3.0 40 40 38 34 31 27 24 37 3.4 37 37 35 31 28 24

POWER

1

INPUT

2

86 83 80 77 74 71 68 86 83 80 77 74 71

TEMPERATURE OF AIR ON CONDENSER COIL

85°F 95°F

SENSIBLE CAPACITY

ENTERING DRY BULB, °F ENTERING DRY BULB, °F

3

TOTAL

CAP.

MBH

POWER

1

INPUT

2

SENSIBLE CAPACITY

3

AIR ON

EVAPORATOR

COIL

CFM

2000

1800

1600

1400

1200

1.

These capacities are gross ratings. For net capacity, determine the KW of the supply air blower motor from the Blower Performance

TOTAL

WB

CAP.

MBH

°F

72 50 3.8 41 35 30 24 18 - - 45 4.0 39 33 28 22 16 67 45 3.7 45 44 39 33 27 22 16 40 4.0 40 40 37 31 25 20

62 39 3.6 39 39 39 34 28 22 17 35 3.8 35 35 35 30 24 18

57 39 3.6 39 39 39 33 27 22 16 35 3.8 35 35 35 29 23 18

72 50 3.8 38 33 28 23 18 - - 45 4.0 36 31 26 21 16 67 44 3.7 44 41 36 31 26 21 16 40 4.0 40 39 34 29 24 19

62 39 3.6 39 39 40 35 30 25 20 35 3.9 35 35 37 32 27 22

57 38 3.6 38 38 38 33 28 23 18 34 3.8 34 34 34 29 24 19

72 49 3.8 35 31 26 21 17 - - 45 4.1 33 29 24 20 15 67 44 3.7 43 39 34 30 25 20 16 40 4.1 40 37 32 27 23 18

62 39 3.6 39 39 41 37 32 27 23 35 3.9 35 35 39 34 30 25

57 38 3.6 38 38 38 33 29 24 19 34 3.8 34 34 34 30 25 20

72 47 3.8 32 28 24 20 16 - - 43 4.0 30 26 22 18 14 67 42 3.7 39 35 31 27 23 19 15 38 4.0 37 34 29 25 21 17

62 37 3.6 37 37 38 33 29 25 21 33 3.8 33 33 35 31 27 23

57 36 3.5 36 36 35 31 27 23 18 33 3.7 33 33 31 27 23 19

72 44 3.7 29 25 22 18 15 - - 41 3.9 27 24 20 17 13 67 40 3.7 36 32 29 25 21 18 14 36 3.9 34 30 27 23 20 16

62 35 3.6 35 35 34 30 27 23 20 32 3.8 32 32 32 28 25 21

57 34 3.5 34 34 32 28 25 21 18 31 3.7 31 31 29 25 22 18

POWER

1

INPUT

2

105°F 115 °F

86 83 80 77 74 71 68 86 83 80 77 74 71

TEMPERATURE OF AIR ON CONDENSER COIL

SENSIBLE CAPACITY

ENTERING DRY BULB, °F ENTERING DRY BULB, °F

3

TOTAL

CAP.

MBH

POWER

1

INPUT

2

SENSIBLE CAPACITY

Table, multiply this value by 3.415 MBH / KW to determine the motor heat, and deduct this heat from the gross capacity of the unit

2.

These ratings include the compressor and the condenser fan motors but not the supply air blower motor. The total condenser fan

motor power input is 0.36kW. Refer to Tables 10 and 11 for the kW of the supply air blower motor.

3.

These capacities are gross ratings. For net capacity, determine the kW of the supply air blower from Tables 10 and 11, multiply

this value by 3.415 MBH/kW to determine the motor heat, and deduct this heat from the gross capacity of the unit.

3

NOMINAL RATING ALL SENSIBLE CAPACITY

Unitary Products Group 9

Page 10

TABLE 8: COOLING CAPACITIES - MODELS DHE/DHG060

AIR ON

EVAPORATOR

COIL

CFM

2500

2250

2000

1750

1500

WB

°F

72 82 4.3 56 50 43 37 30 - - 76 4.6 54 48 41 34 28 - 67 70 4.2 67 61 54 48 41 34 28 65 4.5 65 58 51 45 38 31 25

62 67 4.0 67 67 66 59 52 46 39 62 4.5 62 62 62 55 49 42 35

57 66 4.0 66 66 66 59 52 46 39 61 4.4 61 61 61 54 47 41 34

72 78 4.3 53 47 41 35 29 - - 73 4.6 50 44 38 32 26 - 67 67 4.2 63 57 51 45 39 33 27 62 4.5 60 54 48 42 36 30 24

62 64 4.0 64 64 62 56 50 44 38 60 4.4 60 60 59 53 47 41 35

57 63 4.0 63 63 63 57 51 45 39 58 4.4 58 58 58 52 46 40 34

72 75 4.3 49 43 38 33 27 - - 70 4.6 46 41 36 30 25 - 67 64 4.2 58 53 48 42 37 32 26 60 4.5 56 50 45 39 34 29 23

62 61 4.0 61 61 58 52 47 42 36 57 4.4 57 57 55 50 45 39 34

57 60 4.0 60 60 59 54 49 43 38 56 4.4 56 56 56 50 45 39 34

72 72 4.3 44 40 35 30 25 - - 67 4.6 43 38 33 28 24 - 67 62 4.2 53 49 44 39 34 30 25 58 4.5 51 46 41 37 32 27 22

62 59 4.0 59 57 53 48 44 39 34 55 4.4 55 54 51 46 42 37 32

57 58 4.0 58 57 55 50 45 40 36 54 4.4 54 54 51 47 42 37 32

72 69 4.2 40 36 32 28 24 - - 65 4.6 39 34 30 26 22 - 67 59 4.1 48 44 40 36 32 28 23 56 4.5 46 42 38 34 30 26 21

62 56 4.0 56 53 49 44 40 36 32 53 4.4 53 51 47 43 39 35 30

57 55 4.0 55 54 50 46 42 37 33 52 4.4 52 51 47 43 39 35 30

TOTAL

CAP.

MBH

85°F 95°F

POWER

1

INPUT

2

SENSIBLE CAPACITY

ENTERING DRY BULB, °F ENTERING DRY BULB, °F

86 83 80 77 74 71 68 86 83 80 77 74 71 68

TEMPERATURE OF AIR ON CONDENSER COIL

3

TOTAL

CAP.

MBH

036-21216-003-A-0204

POWER

1

INPUT

2

SENSIBLE CAPACITY

3

AIR ON

EVAPORATOR

COIL

CFM

2500

2250

2000

1750

1500

1.

These capacities are gross ratings. For net capacity, determine the KW of the supply air blower motor from the Blower Performance

TOTAL

CAP.

WB

MBH

°F

72 68 5.0 51 44 38 31 25 - - 61 5.3 48 41 35 28 21 - 67 60 4.8 60 55 49 42 35 29 22 55 5.1 55 53 46 39 33 26 20

62 56 4.8 56 56 56 49 43 36 29 50 5.1 50 50 50 43 37 30 23

57 55 4.7 55 55 55 48 42 35 28 49 5.0 49 49 49 43 36 29 23

72 67 4.9 48 42 36 30 24 - - 60 5.3 45 39 33 27 21 - 67 58 4.8 57 52 46 40 34 28 22 54 5.1 53 50 44 38 32 26 20

62 55 4.7 55 55 54 48 42 36 30 49 5.0 49 49 49 43 37 31 25

57 54 4.7 54 54 53 47 41 35 29 49 5.0 49 49 49 43 37 31 25

72 65 4.9 44 39 33 28 23 - - 60 5.2 42 36 31 26 20 - 67 57 4.8 54 48 43 38 32 27 22 54 5.1 52 47 41 36 30 25 20

62 53 4.7 53 53 52 46 41 36 30 49 5.0 49 49 48 43 37 32 26

57 52 4.7 52 52 52 46 41 36 30 48 5.0 48 48 48 42 37 32 26

72 62 4.9 40 35 31 26 21 - - 56 5.2 38 33 28 24 19 - 67 54 4.8 49 44 40 35 30 25 21 51 5.0 47 42 38 33 28 23 19

62 51 4.7 51 50 48 43 38 33 29 46 5.0 46 46 44 39 34 30 25

57 50 4.6 50 50 48 43 38 33 29 46 4.9 46 46 44 39 34 29 25

72 59 4.9 36 32 28 24 20 - - 53 5.2 34 30 26 22 18 - 67 52 4.7 44 40 36 32 28 24 20 48 5.0 43 38 34 30 26 22 18

62 48 4.7 48 47 43 39 35 31 27 43 4.9 43 43 40 36 32 27 23

57 47 4.6 47 47 43 39 35 31 27 43 4.9 43 43 40 36 31 27 23

POWER

1

INPUT

2

105°F 115°F

SENSIBLE CAPACITY

ENTERING DRY BULB, °F ENTERING DRY BULB, °F

86 83 80 77 74 71 68 86 83 80 77 74 71 68

TEMPERATURE OF AIR ON CONDENSER COIL

3

TOTAL

CAP.

MBH

POWER

1

INPUT

2

SENSIBLE CAPACITY

Table, multiply this value by 3.415 MBH / KW to determine the motor heat, and deduct this heat from the gross capacity of the unit

2.

These ratings include the compressor and the condenser fan motors but not the supply air blower motor. The total condenser fan

motor power input is 0.36kW. Refer to Tables 10 and 11 for the kW of the supply air blower motor.

3.

These capacities are gross ratings. For net capacity, determine the kW of the supply air blower from Tables 10 and 11, multiply

this value by 3.415 MBH/kW to determine the motor heat, and deduct this heat from the gross capacity of the unit.

3

NOMINAL RATING ALL SENSIBLE CAPACITY

10 Unitary Products Group

Page 11

036-21216-003-A-0204

TABLE 9: SUPPLY AIR BLOWER PERFORMANCE -DHE/DHG036

AVAILABLE EXTERNAL STATIC PRESSURE - IWG

AVAILABLE EXTERNAL STATIC PRESSURE - IWG

MODEL

DHE/DHG

036

MODEL

DHE/DHG

AIR

FLOW

0.20 0.30 0.40 0.50 0.60 0.70 0.80

CFM

RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS

2000 843 860 880 925 919 1005 956 1065 993 1145 1030 1195 1067 1235

1900 817 775 854 850 893 920 930 995 970 1065 1008 1125 1046 1170

1800 790 700 828 760 867 840 906 905 944 980 985 1040 1025 1100

1700 - - 802 670 840 745 881 815 920 900 961 970 1001 1030

1600 - - - - 818 665 858 740 898 820 940 890 980 950

1500 - - - - - - 842 695 882 755 922 835 962 895

1400 - - - - - - 833 650 867 705 904 765 942 820

1300 - - - - - - - - 858 665 893 725 932 785

1200 - - - - - - - - 847 640 880 680 916 730

AIR

FLOW

0.90 1.00 1.10 1.20 1.30 1.40 1.50

CFM

RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS

1

2

2

2000 1103 1270 - - - - - - - - - - - -

1900 1085 1210 - - - - - - - - - - - -

1800 1064 1145 1102 1180 - - - - - - - - - -

1700 1040 1075 1081 1115 1121 1140 - - - - - - - -

036

1600 1020 1005 1060 1050 1100 1085 - - - - - - - -

1500 1003 945 1044 995 1086 1035 - - - - - - - -

1400 982 880 1024 920 1067 965 1107 1000 - - - - - -

1300 970 835 1010 870 1053 920 1099 960 - - - - - -

1200 953 780 992 815 1034 855 1080 905 - - - - - -

1.

For 208 Volts multiply values by 0.95.

2.

Includes allowances for a wet evaporator coil, 1” filters, and the heat exchangers. Refer to Table 12 for resistance values on applications other than gas / electric units with side duct airflows.

Unitary Products Group 11

Page 12

036-21216-003-A-0204

TABLE 10: SUPPLY AIR BLOWER PERFORMANCE DHE/DHG0481 (4 TON GAS HEAT MODELS)

UNIT

SIZE

(MBH

048

AIR

FLOW

CFM

2000 843 860 880 925 919 1005 956 1065 993 1145 1030 1195 1067 1235

1900 817 775 854 850 893 920 930 995 970 1065 1008 11 25 1046 1170

1800 790 700 828 760 867 840 906 905 944 980 985 1040 1025 110 0

1700 - - 802 670 840 745 881 815 920 900 961 970 1001 1030

1600 - - - - 818 665 858 740 898 820 940 890 980 950

1500 - - - - - - 842 695 882 755 922 835 962 895

1400 - - - - - - 833 650 867 705 904 765 942 820

1300 - - - - - - - - 858 665 893 725 932 785

1200 - - - - - - - - 847 640 880 680 916 730

0.20 0.30 0.40 0.50 0.60 0.70 0.80

RPM Watts RPM Watts RPM Watts RPM Watts RPM Watts RPM Watts RPM Watts

AVAILABLE EXTERNAL STATIC PRESSURE - IWG

2

UNIT

SIZE

(MBH

048

AIR

FLOW

CFM

2000 11 03 1270 - - - - - - - - - - - 1900 1085 1210 - - - - - - - - - - - 1800 1064 11 45 110 2 11 80 - - - - - - - - - 1700 1040 1075 1081 1115 11 21 1140 - - - - - - - 1600 1020 1005 1060 1050 110 0 1085 - - - - - - - 1500 1003 945 1044 995 1086 1035 - - - - - - - 1400 982 880 1024 920 1067 965 11 07 1000 - - - - - 1300 970 835 1010 870 1053 920 1099 960 - - - - - 1200 953 780 992 815 1034 855 1080 905 - - - - - -

1.

Models shown at 230/460 Volts with side duct connections.

2.

Includes allowances for a wet evaporator coil, 1” filters, and the heat exchangers. Refer to the static resistances table for resis-

0.90 1.00 1.10 1.20 1.30 1.40 1.50

RPM Wat ts RPM Watts RPM Watts RPM Watts RPM Watts RPM Wa tts RPM Watts

AVAILABLE EXTERNAL STATIC PRESSURE - IWG

2

tance values on applications other than gas/electric units with side duct airflows.

12 Unitary Products Group

Page 13

036-21216-003-A-0204

TABLE 11: SUPPLY AIR BLOWER PERFORMANCE DHE/DHG0601 (5 TON GAS HEAT MODELS)

UNIT

SIZE

(MBH)

060

AIR FLOW

CFM

2500 1059 1560 1077 1590 1095 1630 1114 1650 11 34 1660 11 58 1685 1181 1720

2400 1032 1405 1054 1470 1074 1525 1094 1560 1116 1595 11 40 1620 1167 1640

2300 1005 1260 1024 1275 1049 1370 1069 1440 1090 1475 1116 1505 1142 1535

2200 980 116 0 1002 117 0 1022 119 0 1044 1250 1066 1350 1090 1410 1117 1440

2100 930 1060 957 1070 983 1080 1010 11 00 1039 11 60 1064 1260 1092 1340

2000 877 950 908 975 941 1000 976 1020 1009 1050 1040 1100 1070 1225

1900 - - - - 894 885 940 940 980 980 1014 1020 1047 1095

1800 - - - - 855 815 903 860 950 905 988 940 1022 970

1700 - - - - - - 884 815 925 850 964 880 1001 910

1600 - - - - - - 864 770 908 805 948 835 987 870

1500 - - - - - - - - 882 740 926 780 965 830

0.20 0.30 0.40 0.50 0.60 0.70 0.80

RPM Watts RPM Watts RPM Watts RPM Watts RPM Watts RPM Watts RPM Watts

AVAILABLE EXTERNAL STATIC PRESSURE - IWG

2

UNIT

SIZE

(MBH)

AIR FLOW

CFM

2500 - - - - - - - - - - - - - 2400 1193 1665 - - - - - - - - - - - 2300 1170 1580 1202 1620 - - - - - - - - - 2200 1148 1480 11 80 1530 - - - - - - - - - 2100 1121 1385 11 55 1425 11 90 1475 - - - - - - - -

060

1.

2.

2000 1100 1285 11 33 1340 11 69 1385 1205 1445 - - - - - 1900 1079 11 80 111 0 1240 11 43 1280 1178 1330 1222 1375 - - - 1800 1058 1060 1090 11 35 11 22 119 0 1158 1240 119 6 1295 - - - 1700 1035 960 1071 1030 11 03 11 00 1134 11 40 116 4 117 5 11 97 1205 - 1600 1020 900 1056 965 1088 1035 1118 1065 1145 1105 11 70 1130 1198 11 50

1500 1004 860 1038 880 1070 925 1101 980 11 30 1045 11 58 1075 1184 111 0

Models shown at 230/460 Volts with side duct connections.

Includes allowances for a wet evaporator coil, 1” filters and the heat exchangers. Refer to Table 12 for resistance values on appli-

0.90 1.00 1.10 1.20 1.30 1.40 1.50

RPM Watts RPM Watts RPM Watts RPM Watts RPM Watts RPM Watts RPM Watts

cations other than gas / electric units with side duct airflows.

TABLE 12: ACCESSORY STATIC RESISTANCE

DESCRIPTION

ECONMIZER

ELECTRIC

HEATERS

BOTTOM DUCT CONNECTIONS

1.

2.

3

COOLING ONLY

Deduct these resistance values from the available external static pressure shown in Tables 10 and 11.

The pressure through the economizer is greater for 100% outdoor air than for 100% return air. If the resistance of the return air

1 2

5-15 kW 0.04 0.05 0.06 0.07 0.08 0.10 0.12 0.14 0.16 0.19 0.22

20 - 30 kW 0.06 0.07 0.08 0.09 0.11 0.13 0.15 0.17 0.20 0.23 0.26

1

2

duct system is less than 0.25 IWG, the unit will deliver less CFM during full economizer operation.

3.

Add these resistance values to the available static resistance values on Tables 10 and 11.

1000 1200 1400 1600 1800 2000 2200 2400 2600 2800 3000

0.07 0.08 0.09 0.11 0.13 0.15 0.17 0.20 0.23 0.26 0.30

0.06 0.07 0.08 0.09 0.10 0.11 0.12 0.14 0.16 0.19 0.22

0.08 0.10 0.12 0.14 0.16 0.18 0.20 0.23 0.26 0.29 0.32

AVAILABLE EXTERNAL STATIC PRESSURE IWG

EXTERNAL STATIC PRESSURE DROP

RESISTANCE, IWG

CFM

1

Unitary Products Group 13

Page 14

TABLE 13: MOTOR AND DRIVE DATA - BELT-DRIVE BLOWER

1

MODEL

DHE/DHG 036 780 - 1120

DHE/DHG048 790 - 1,120

DHE/DHG060 850 - 1,220

1.

All motors have solid bases and are inherently protected. These motors can be selected to operate into their service factor

RANGE

(RPM)

HP RPM

1/

1

2

1/

1

2

1/

1

2

BLOWER

MOTOR

FRAME

SIZE

SERVICE

FACTOR

1,725 56 1.15 2.4 - 3.4

1,725 56 1.15 2.4 - 3.4

1,725 56 1.15 2.4 - 3.4

because they are located in the moving air, upstream of any heating device

ADJUSTABLE

MOTOR PULLEY

PITCH

DIA.

(in.)

TABLE 14: ELECTRICAL DATA - BASIC UNIT

MODEL

DHE/

DHG

036

048

060

1.

Rated in accordance with ARI Standard 110, utilization range “A”..

2.

Dual element, time delay type.

POWER

SUPPLY

208/230-3-60 187 253 14.1 11 0 2.3 5.3 25.2 35 35

460-3-60 414 504 7.1 54 1.4 3.1 13.3 20 20

208/230-3-60 187 253 10.0 110.0 2.3 5.2 23.9 35 35

460-3-60 414 504 5.2 54.0 1.4 2.6 12.4 15 15

208/230-3-60 187 253 16.0 137.0 2.3 6.0 28.3 40 40

460-3-60 414 504 8.3 69.0 1.4 3.0 14.8 20 20

LIMITATIONS

MIN. MAX. RLA LRA

VO LTAG E

1

COMPRESSOR

COND.

FAN

MOTOR

FLA

BORE

(in.)

7/

8

7/

8

7/

8

SUPPLY

AIR

AMPACITY

AMPS

036-21216-003-A-0204

FIXED

BLOWER PULLEY

PITCH

DIA.

(in.)

BORE

(in.)

5.7 1 37.3 A36

5.7 1 37.3 A36

5.2 1 37.3 A36

TOTAL

UNIT

AMPACITY

AMPS

MAX.

FUSE

SIZE

AMPS

PITCH

LENGHT

(in.)

2

BELT

MAX.

HACR

BREAKER

SIZE

AMPS

DESIG-

NATION

14 Unitary Products Group

Page 15

036-21216-003-A-0204

TABLE 15: ELECTRICAL DATA - COOLING/ELECTRIC HEAT DHE036 & 048

MODEL

DHE

036

048

1.

Dual element, time delay type.

2.

Standard circuit breakers may be used in Canada and on applications over 60 amps where the heaters are separately fused.

3.

These electric heaters DO NOT include a fuse box. If a fuse box is required to meet a local code (e.g. Chicago), refer to Table 17

POWER

SUPPLY

208-3-60

230-3-60

460-3-60

208-3-60

230-3-60

460-3-60

HEATER

ACCESSORY

MODEL

NUMBER

2CE04500525

2CE04500725

2CE04501025 8.0 1 22.1 34.2 35 35

2CE04501525 11. 9 2 33.1 48.1 50 50

2CE04502025 15.9 2 44.2 61.9 70 70

2CE04500525

2CE04500725

2CE04501025 10.6 1 25.5 38.5 40 40

2CE04501525 15.9 2 38.2 54.4 60 60

2CE04502025 21.2 2 51.0 70.4 80 80

2CE04500746

2CE04501046

2CE04501546

2CE04502046

2CE04500525

2CE04500725

2CE04501025 8.0 1 22.1 35.3 35 35

2CE04501525 11. 9 2 33.1 48.8 50 50

2CE04502025 15.9 2 44.2 62.7 70 70

2CE04500525

2CE04500725

2CE04501025 10.6 1 25.5 39.4 40 40

2CE04501525 15.9 2 38.2 55.3 60 60

2CE04502025 21.2 2 51.0 71.2 80 80

2CE04500746

2CE04501046

2CE04501546

2CE04502046

SUPPLY

AIR

BLOWER

MOTOR

3

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

FLA

5.3

5.3

3.1

6.0

6.0

3.0

for fuse block accessories available for field installation.

4.

These electric heaters DO NOT include a fuse box. If a fuse box is required to meet a local code (e.g. Chicago), refer to Table 17

for fuse block accessories available for field installation.

ELECTRIC HEATERS

kW STAGES

4.0 1 11. 0 25.2 35 35

5.6 1 15.6 26.2 35 35

5.3 1 12.7 25.2 35 35

7.5 1 18.0 29.2 35 35

6.8 1 8.2 14.1 20 15

10.1 1 12.1 19.1 20 20

13.6 1 16.4 24.3 25 25

19.5 2 23.5 33.2 35 35

4.0 1 11. 0 26.0 35 35

5.6 1 15.6 26.9 35 35

5.3 1 12.7 26.0 35 35

7.5 1 18.0 30.1 35 35

6.8 1 8.2 14.0 15 15

10.1 1 12.1 18.9 20 20

13.6 1 16.4 24.2 25 25

19.5 2 23.5 33.1 35 35

TOTAL

AMPS

TOTAL

UNIT

AMPACITY

AMPS

MAX.

FUSE

SIZE

AMPS

MAX.

SIZE

1

HACR

AMPS

2

TABLE 16: ELECTRIC HEAT CORRECTION FACTORS (DHE048)

NOMINAL VOLTAGE VOLTAGE

208 208 1.00

240 230 0.92

480 460 0.92

600 575 0.92

kW CAP

MULTIPLIER

TABLE 17: FUSE BLOCK ACCESSORY

2FB04700425 208/240 Volts

2FB04700546 460 Volts

Unitary Products Group 15

Page 16

TABLE 18: ELECTRICAL DATA - COOLING/ELECTRIC HEAT DHE060

R V

Y C

G F

R

Y 1

B

Y 2

T H E R M O S T A T

1

T E R M I N A L S

U N I T T E R M I N A L

S T R I P T B 1

2 4 V O L T

T R A N S F O R M E R

C O O L I N G O N L Y ( 2 4 V O L T T H E R M O S T A T )

1 2 4 V O L T T H E R M O S T A T 2 T H 0 7 7 0 1 0 2 4 I F T H E U N I T H A S A N E C O N O M I Z E R ,

R E M O V E J U M P E R J 1 F R O M T E R M I N A L S 8 A N D 1

0 O N T H E R E L A Y B O A R D

T O P R E V E N T S I M U L T A N E O U S O P E R A T I O N O F T H E C O M P R E S S O R A N D

T H E E C O N O M I Z E R . I F Y O U W

A N T T O C O N T R O L T H E E C O N O M I Z E R O N A

S E C O N D S T A G E O F C O O L I N G

, U S E T H E T H E R M O S T A T 2 T H 0 4 7 0 1 2 2 4 .

SUPPLY

AIR

BLOWER

MOTOR

FLA

6.0

MODEL

DHE

POWER

SUPPLY

208-3-60

HEATER

ACCESSORY

MODEL

NUMBER

2CE04500525

2CE04500725

3

4

2CE04501025 8.0 1 22.1 35.1 40 40

2CE04501525 11 .9 2 33.1 48.9 50 50

2CE04502025 15.9 2 44.2 62.7 70 70

2CE04503025 22.2 2 61.7 84.6 90 90

4

4

6.0

060

230-3-60

2CE04500525

2CE04500725

2CE04501025 10.6 1 25.5 39.4 40 40

2CE04501525 15.9 2 38.2 55.3 60 60

2CE04502025 21.2 2 51.0 71.2 80 80

2CE04503025 29.6 2 71.2 96.5 100 100

2CE04500746

2CE04501046

460-3-60

2CE04501546

2CE04502046

2CE04503046

1.

Dual element, time delay type.

2.

Standard circuit breakers may be used in Canada and on applications over 60 amps where the heaters are separately fused.

3.

These electric heaters DO NOT include a fuse box. If a fuse box is required to meet a local code (e.g. Chicago), refer to Table 17

4

4

4

4

4

3.0

for fuse block accessories available for field installation.

ELECTRIC HEATERS

kW STAGES

4.0 1 11.0 26.0 40 40

5.6 1 15.6 26.9 40 40

5.3 1 12.7 26.0 40 40

7.5 1 18.0 30.1 40 40

6.8 1 8.2 14.0 20 20

10.1 1 12.1 18.9 20 20

13.6 1 16.4 24.2 25 25

19.5 2 23.5 33.1 35 35

28.8 2 34.6 47.1 50 50

TOTAL

AMPS

TOTAL

UNIT

AMPACITY

AMPS

036-21216-003-A-0204

MAX.

FUSE

SIZE

AMPS

MAX.

SIZE

1

HACR

2

AMPS

FIGURE 2 - FIELD POWER WIRING

16 Unitary Products Group

FIGURE 3 - CONTROL WIRING COOLING ONLY

Page 17

036-21216-003-A-0204

R C

R H

Y 1

Y 2

W 1

W 2

G

L E D 1

L E D 2

C O M

A 1

A 2

T

T

B

R

Y 1

Y 2

G

B

X

N

W 2

W 1

T H E R M O S T A T

1

T E R M I N A L S

U N I T T E R M I N A L

S T R I P T B 1

2 4 V O L T

T R A N S F O R M E R

T O R E M O T E S E N S O R

2 T H 0 4 0 7 0 2 2 2 4 I F U S E D

N O T

U S E D

A D D

J U M P E R

A D D

J U M P E R

4

4

3

2

1

E L E C T R O N I C P R O G R A M M A B L E T H E R M O S T A T 2 E T 0 4 7 0 0 2 2 4 ( I N C L U D E S S U B B A S E )

2

S E C O N D S T A G E C O O L I N G I S N O T R E Q U I R E D O N U N I T S L E S S E C O N O M I Z E R .

3

S E C O N D S T A G E H E A T I N G I S O N L Y R E Q U I R E D O N U N I T S W I T H A T W O S T A G E

E L E C T R I C H E A T E R .

4

R E M O V E J U M B E R J 2 F R O M T E R M I N A L S 4 A N D 9 O N J U M P E R P L U G C O N N E C T O R

P 6 O N U N I T S W I T H E C O N M I Z E R . T E R M I

N A L S A 1 A N D A 2 P R O V I D E A R E L A Y

O U T - P U T T O C L O S E T H E O U T D O O R E C O N O M I Z E R D A M P E R S W H E N T H E

T H E R M O S T A T

S W I T C H E S T O T H E S E T - B A C K P O S I T I O N .

C O O L I N G / H E A T I N G ( E L E C T R O N I C T H E R M O S T A T )

S I N G L E S T A G E

T H E R M O S T A T

T E R M I N A L S

A D D

J U M P E R

1

E L E C T R O N I C P R O G R A M M A B L E T H E R M O S T A T 2 E T 0 7 7 0 1 0 2 4 ( I N C L U D E S S U B B A S E ) .

I F T H I S U N I T H A S A N D E C O N O M I Z E R , R

1 0 O N T H E R E L A Y B O A R D T O P R E V E N T S I M U L T A N E O U S O P E R A T I O N O F T H E

C

O M P R E S S O R A N D T H E E C O N O M I Z E R . I F Y O U W A N T T O C O N T R O L T H E

E C O N O M I Z E R O N A S E C O N D S T A G E O F C O O L I N G , U S

1

U N I T T E R M I N A L

R H

R C

Y

W

G

S T R I P T B 1

R

Y 1

W 1

G

B

2 4 V O L T

T R A N S F O R M E R

E M O V E J U M P E R J 1 F R O M T E R M I N A L S 8 A N D

E T H E R M O S T A T 2 E T 0 4 7 0 0 2 2 4 .

FIGURE 4 - CONTROL WIRING SINGLE STAGE

C O O L I N G / H E A T I N G ( 2 4 V O L T T H E R M O S T A T )

T H E R M O S T A T

T E R M I N A L S

A D D

J U M P E R

1

R H

R C

U N I T T E R M I N A L

S T R I P T B 1

R

FIGURE 6 - CONTROL WIRING MULTI-STAGE

Y

W

G

1

2 4 V O L T T H E R M O S T A T 2 T H 0 7 7 0 1 0 2 4 . I F T H E U N I T H A S A N E C O N O M I Z E R ,

R E M O V E J U M P E R J 1 F R O M T E R M I N A L S 8 A N D

T O P R E V E N T S I M U L T A N E O U S O P E R A T I O N O F T H E C O M P R E S S O R A N D

T H E E C O N O M I Z E R . I F Y O U W

S E C O N D S T A G E O F C O O L I N G O R H A V E A N D E L E C T R I C H E A T A C C E S S O R Y

O S T A G E S O F H E A T , U S E T H E R M O S T A T 2 T H 0 4 7 1 0 2 4

W I T H T W

Y 1

Y 2

W 1

W 2

G

B

A N T T O C O N T R O L T H E R E C O N O M I Z E R O N A

2 4 V O L T

T R A N S F O R M E R

1 0 O N T H E R E L A Y B O A R D

FIGURE 5 - CONTROL WIRING COOLING/HEAT-

ING

Unitary Products Group 17

Page 18

036-21216-003-A-0204

(

)

R E T U R N A I R

S U P P L Y A I R

O U T D O O R A I R

O U T D O O R A I R

E c o n o m i z e r

All dimensions are in inches. They are

subject to change without notice. Certified dimensions will be provided upon

request.

FIGURE 7 - DHE UNIT DIMENSIONS

TABLE 19: UTILITIES ENTRY DATA

HOLE

A

B 2”

C 1-5/8” Gas Piping (Front)

D 1-1/2” Gas Piping (Bottom)

1.

Knockouts in the bottom of the unit can be located by

the slice in the insulation

2.

DO NOT remove the 2” knockout ring.

KNOCKOUT

SIZE (DIA.)

1

7/8”

Control Wiring (Side or

Power Wiring (Side or

USED FOR

Bottom)

Bottom)

2

FIGURE 8 - ACCESS PANELS AND DISCONNECT

NOTE: Units and ductwork of DHE models are approved for

zero clearance to combustible materials when

equipped with electric heaters

18 Unitary Products Group

Page 19

036-21216-003-A-0204

(

)

R E T U R N A I R

S U P P L Y A I R

O U T D O O R A I R

O U T D O O R A I R

E c o n o m i z e r

All dimensions are in inches. They are

subject to change without notice. Certified dimensions will be provided upon

request.

FIGURE 9 - UNIT DIMENSIONS DHG UNIT

TABLE 20: CLEARANCES

FRONT

BACK

LEFT SIDE (Filter Access)

RIGHT SIDE (Cond. Coil) 24”

BELOW UNIT

ABOVE UNIT

1.

1

2

Units may be installed on combustible floors made from

wood or class A, B, or C roof covering material.

2.

Units must be installed outdoors. Overhanging structures or shrubs should not obstruct condenser air discharge outlet.

DHE UNITS 24”

DHG UNITS 32”

12” (Less Economizer)

36” (With Economizer or

Fixed Air/Motorized

Damper)

24” (Less Economizer)

36” (With Economizer)

72” (For Condenser Air

Discharge)

NOTE: DHG modes must be provided a 1” clearance

between any combustible material and the supply

air ductwork for a distance of 2 feet from the unit.

The products of combustion must not be allowed to accumulate with a confined space and recirculate. Locate unit so that

the vent air outlet hood is at least.

• Three feet above any forced air inlet located within 10

0”

horizontal feet (excluding those integral to the unit).

• Four feet below, 4 horizontal feet from, or 1 foot above

any door or gravity air inlet into the building.

• Four feet from electric meters, gas meters, regulators

and relief equipment.

Unitary Products Group 19

Page 20

11-1/2

036-21216-003-A-0204

3

17-1/2

6-1/2

17-1/2

7-7/8

FIGURE 10 - REAR DIMENSIONS OF DHE AND DHG UNITS 3, 4 & 5 TON UNITS

Duct covers - units are shipped with all air duct openings covered.

For side duct applications:

• Remove and discard the supply and return air duct

covers.

• Connect ductwork to duct flanges on the rear of the unit.

2 7 - 1 / 2

For bottom duct applications:

• remove the side supply air duct cover to gain access to

the bottom supply air knockout panel.

• Remove and discard the bottom knockout panel.

• Replace the side duct cover.

• With filter section access panel removed from the unit,

remove and discard the bottom return air knockout

panel.

• Replace the filter Access panel.

1 - 5 / 8

11-1/2

4-5/8

2 7 - 1 / 2

1 9 - 3 / 4

1 9 - 1 / 2

4 4 - 7 / 8

FIGURE 11 - UNIT DIMENSIONS WITH ECONOMIZER RAINHOOD

20 Unitary Products Group

Page 21

036-21216-003-A-0204

2 7 - 1 / 2

R E A R V I E W

7 - 1 / 4

2 7 - 1 / 2

1 9 - 1 / 8

1 0 - 1 / 4

" A "

4 4 - 7 / 8

L . H . E N D V I E W

D I M E N S I O N " A "

F I X E D

O U T D O O R

1 2

A I R D A M P E R

M O T O R I Z E D

D A M P E R

1 6 - 1 / 2

FIGURE 12 - DETAIL “B” UNIT WITH FIXED OUTDOOR AIR/MOTORIZED DAMPER RAINHOOD

3 - 1 / 2

8 - 1 / 4

4 - 3 / 8

3.69"

3.56"

BASE RAIL

FIGURE 13 - UNIT AND CURB APPLICATION

Unitary Products Group 21

Page 22

036-21216-003-A-0204

FIGURE 14 - ROOF CURB DIMENSIONS DHE/DHG 3, 4 & 5 TON

C O R N E R " D "

C O R N E R " A "

4 4 - 7 / 8

4 0 - 3 / 4

C O R N E R " B "

8 2 - 1 / 4

FIGURE 15 - CENTER OF GRAVITY AND CORNER WEIGHTS

TABLE 21: BASIC UNIT WEIGHT

UNIT

DHG036 665 188 185 145 147

DHG048 680 192 189 148 152

DHG060 715 202 199 155 159

DHE036 565 160 157 123 125

DHE048 610 172 169 133 136

DHE060 645 182 179 140 144

1.

UNIT

WEIGHT

(lbs.)

Weight = Unit with economizer and high heat.

CORNER WEIGHTS

“A” “B” “C” “D”

1

TABLE 22: ACCESSORIES WEIGHT

ECONOMIZER 50

MOTORIZED OUTDOOR AIR DAMPER 26

ELECTRIC HEAT

(nom. kW DHE only)

ROOF MOUNTNG CURB 92

RELIEF/FIXED AIR DAMPER 10

C O R N E R " C "

C O N D E N S E R C O I L

E N D O F U N I T

1 9 - 3 / 4

DESCRIPTION WEIGHT (lbs.)

5-7 kW 18

10-15 kW 23

20-30 kW 28

22 Unitary Products Group

Page 23

036-21216-003-A-0204

ROOF JACK

INSTALLATION

ROOF CURB

INSTALLATION

SLAB ON GROUND

INSTALLATION

FIGURE 16 - TYPICAL APPLICATIONS

FIGURE 17 - TYPICAL ROOF-TOP INSTALLATION (DHG)

Unitary Products Group 23

Page 24

036-21216-003-A-0204

MECHANICAL SPECIFICATIONS

GENERAL DESCRIPTION

Single packaged outdoor mounted rooftop with built in field

convertible duct connections for vertical discharge/return air

or horizontal discharge/return air configuration. Cooling per

formance shall be rated in accordance with DOE and ARI test

procedures. Units shall be CSA Certified to ANSIZ21.47 stan

dards and UL 1995/CAN/CSA No. 236-M90 conditions.

EQUIPMENT

Factory-assembled, single-piece heating and cooling unit.

Unit shall be factory wired, piped, charged with R-22 refriger

ant and factory tested prior to shipment. Enclosed in each

unit shall be a factory test log sheet consisting of the unit

tested pressures, temperatures and amps, as tested prior to

shipment.

Unit Cabinet:

1. Unit cabinet shall be constructed of galvanized steel,

with exterior surfaces coated with a powered paint finish

certified at 750 hours salt spray test per ASTM-B117

standards.

2. Indoor blower section shall be insulated with a minimum

thick insulation, coated on the air side. Aluminum foil

faced insulation shall be used in the furnace compartment and be fastened with ridged fasteners to prevent

entering the air stream.

3. Cabinet panels shall be large size and easily removable

for servicing.

4. Perimeter base rails shall be provided to assure reliable

transit of equipment, rigging, and proper sealing to roof

on curb applications.

5. Disposable filters (1") shall be furnished and be accessible through a removable access door sealed air tight.

Units filter track shall be designed to accommodate both

1" and 2" filters.

6. Fan performance access ports shall be provided on cabinet to allow accurate air measurements of evaporator

fan performance without removing panels or creating air

by-pass of the coils.

7. Units vertical discharge duct configuration shall be

designed to fit between standard 24" O.C. beams without

modification to building structure, duct work and base

unit.

8. Condensate pan shall be internally sloped and confirm to

ASHARE 62-89 Standards. Condensate connection shall

be a minimum of and be a rigged mount connection

secured to the base unit.

-

Indoor (evaporator) fan assembly:

1. Fan shall be a belt driven assembly and include an

adjustable-pitch motor pulley. Job site selected (B.H.P.)

brake horse power shall not exceed the motors name

plate horse power rating plus the service factor. Units are

designed not to operate into service factor.

2. Fan wheel shall be double-inlet type with forward-curved

-

-

blades which are dynamically balanced.

3. Bearings shall be sealed, permanently lubricated for

longer life and no maintenance.

Outdoor (condenser) fan assembly:

1. Outdoor (condenser) fan shall be of the direct-driven propeller type and shall discharge air vertically upward.

2. Outdoor (condenser) fan motor shall be totally enclosed

with permanently lubricated bearings and internally pro

tected to overload conditions.

3. Outdoor (condenser) fan shall have aluminum blades riveted to corrosion resistant steel spiders and shall be

dynamically balanced.

Refrigerant components:

1. Compressor:

a. Fully hermetic type, internally protected with internal

high-pressure relief and over temperature protec

tion.

b. Factory mounted on internal spring mounted on

independent dedicated mounting isolation.

2. Coils:

a. Evaporator and condenser coils shall have alumi-

num plate fins mechanically bonded to seamless

internally-enhanced copper tubes with all joints

brazed. Special Phenolic coating available as a fac

tory option.

b. Evaporator coil shall be of the full face active

design.

3. Refrigerant Safety Components:

Refrigerant circuit components shall include:

a. Balance-port thermostatic expansion valve with

independent circuit feed system.

b. Filter drier/ strainer to eliminate any moisture or for-

eign matter.

c. Service gage connections on suction, discharge

lines to charge, evacuate, and contain refrigerant

during necessary servicing.

4. Unit Controls:

a. Unit shall be complete with self contained low-volt-

age control circuit protected by a fuse on the 24 volt

transformer side.

-

-

-

-

24 Unitary Products Group

Page 25

036-21216-003-A-0204

b. Unit shall incorporate a lock-out circuit which pro-

vides reset capability at the space thermostat,

should any of the following standard safety devices

trip and shut off compressor:

I.AUTO RESET - Compressor over temperature, over

current.

II.Loss-of-charge/low-pressure switch.

III.Freeze-protection thermostat, evaporator coil.

IV.High-pressure switch.

The lockout protection shall be easily disconnected at

the control board, if necessary.

Heating Section:

1. Induced draft combustion with Post purge logic and

energy saving direct spark ignition, redundant main gas

valve with venter wheel constructed of stainless steel

material.

2. The heat exchanger shall be of the tubular type constructed of a minimum of 18 gage steel coated with a

nominal 1.2 mil aluminum-silicone alloy for corrosion

resistance. Warranty shall be of 10-years.

3. Burners shall be of the in-shot type constructed of aluminum coated steel and contain air mixture adjustments.

4. All gas piping shall enter the unit cabinet at a single location, and be capable of side or bottom entry without

major unit field modifications.

5. A Integrated control board shall provide timed control of

evaporator fan functioning and burner ignition. An LED

(light-emitting diode) shall provide diagnostic information.

6. Heating section shall be provided with the following minimum protection:

a. High-temperature limit switch.

b. Induced draft motor speed sensor.

c. Flame roll out switch (automatic reset).

d. Flame proving controls.

Operating Characteristics:

1. Unit shall be capable of starting and running at 125 F

ambient outdoor temperature, exceeding maximum load

criteria of ARI Standard 210/240.

2. Compressor with standard controls shall be capable of

operation down to 45 F ambient outdoor temperature.

Accessory low ambient kit operated to 0 F.

3. Unit provided with fan time delay to prevent cold air

delivery before heat exchanger warms up. (Gas heat

only)

Electrical Requirements:

All unit power wiring shall enter unit cabinet at a single factory-pre drilled location and be capable of side or bottom

entry without major unit field modifications

Unitary Products Group 25

Page 26

036-21216-003-A-0204

26 Unitary Products Group

Page 27

036-21216-003-A-0204

Unitary Products Group 27

Page 28

Subject to change without notice. Printed in U.S.A. 036-21216-003-A-0204

K

Copyright © 2004 by Unitary Products Group. All rights reserved. Supersedes: 036-21216-002 (0601)

Unitary 5005 Norman

Products York O

Group Drive 73069

Loading...

Loading...