Page 1

User’s

Manual

RXA10-01 and RXA10-02

Conguration Software

IM 04P01B01-61E

5th Edition

Page 2

Foreword

Notes

Thank you for purchasing the RXA10 Configuration Software (Model: RXA10, hereafter

referred to as the “configuration software”).

This manual explains how to use the Configuration software. Please read this manual

carefully before operating the software to ensure its correct use.

After you have read this manual, keep it in a safe place where it can be referred to

anytime a question arises.

• This manual describes the RXA10 that is used with the µR10000 and µR20000,

version number 1.31 or before.

• The contents of this manual are subject to change without prio

continuing improvements to the performance and functions.

• Every ef

of its contents. However, should you have any questions or nd any errors, please

contact your nearest YOKOGAWA dealer as listed on the back cover of this manual.

• Copying or reproducing all or any part of the contents of this m

permission of Yokogawa Electric Corporation is strictly prohibited.

• T

• Yokogawa Electric Corporation provides no guarantees other than for physical

deciencies found on the original disk upon opening the product package.

• Y

losses or damage, direct or indirect, caused by the use or any unpredictable defect of

the product.

• Serial numbers will not be reissued. Please keep the serial nu

fort has been made in the preparation of this manual to ensure the accuracy

ransfer or loan of the software to a third party is prohibited.

okogawa Electric Corporation shall not be held responsible by any party for any

r notice as a result of

anual without the

mber in a safe place.

Trademarks

Revisions

• vigilantplant, μR10000, and μR20000 are registered trademarks or trademarks of

Yokogawa Electric Corporation.

• Microsoft and Windows are registered trademarks or trademar

Corporation in the United States and/or other countries.

• Adobe and

Incorporated.

• Company and product names that appear in this manual are r

trademarks of their respective holders.

• The company and product names used in this manual are not

registered trademark or trademark symbols (® and ™).

1st Edition February 2005

2nd Edition January 2006

3rd Edition June 2006

4th Edition December 2007

5th Edition October 2010

Acrobat are registered trademarks or trademarks of Adobe Systems

ks of Microsoft

egistered trademarks or

accompanied by the

5th Edition: October 2010 (YK)

All Rights Reserved, Copyright © 2005Yokogawa Electric Corporation

IM 04P01B01-61E

i

Page 3

ii

IM 04P01B01-61E

Products Described in This Manual

Product Version and Principal Changes

2nd Edition

• Recorder version: before 1.31

• Configuration software: R2.0x

No. Principal Changes Reference Section

1 The printout/display format of the date can be changed. 2.4

2 Selectable range of alarm values during linear scaling is

–5% to 105% of the scale span.

3 French and German added to suffix code -2. 2.7

4 Calibration correction (/CC1 option) added. 2.3, 2.4, and 2.7

3rd Edition

• Recorder version: before 1.3x

• Configuration software: Up to R3.02

No. Principal Changes Reference Section

1 Header printout (/BT1 option) added. 2.3, 2.6, and 2.7

2 Customized menu added. 2.7

4th Edition

• Recorder version: before 1.3x

• Configuration Software: R3.0x

• CopyTool: R3.0x

No. Principal Changes Reference Section

1 Support for Windows Vista. 1.2

2 Addition of CopyTool. Chapter 4

2.7

5th Edition

• Recorder version: before 1.3x

• Configuration Software: R3.04.01

• CopyTool: R3.04.01

No. Principal Changes Reference Section

1 Support for Windows 7 1.2

2 Change of the Installer 1.3, 4.2

Page 4

Terms and Conditions of the Software License

Yokogawa Electric Corporation, a Japanese corporation (hereinafter called “Yokogawa”), grants permission to use this Yokogawa Software

Program (hereinafter called the “Licensed Software”) to the Licensee on the conditions that the Licensee agrees to the terms and conditions

stipulated in Article 1 hereof.

You, as the Licensee (hereinafter called “Licensee”), shall agree to the following terms and conditions for the software license (hereinafter called

the “Agreement”) based on the use intended for the Licensed Software.

Please note that Yokogawa grants the Licensee permission to use the Licensed Software under the terms and conditions herein and in no event

shall Yokogawa intend to sell or transfer the Licensed Software to the Licensee.

Licensed Software Name:

Number of License:

Article 1 (Scope Covered by these Terms and Conditions)

1.1 The terms and conditions stipulated herein shall be applied to any Licensee who purchases the Licensed Software on the condition that the

Licensee consents to agree to the terms and conditions stipulated herein.

1.2 The “Licensed Software” herein shall mean and include all applicable programs

technology, algorithms, and know-how such as a factor, invariant or process contained therein.

Article 2 (Grant of License)

2.1 Yokogawa grants the Licensee, for the purpose of single use, non-exclusive and non-transferable license of the Licensed Software with the

license fee separately agreed upon by both parties.

2.2 The Licensee is, unless otherwise agreed in writing by

Licensed Software.

2.3 The Licensed Software shall not be copied in whole or in part except for keepin

secure or supervise the copy of the Licensed Software by the Licensee itself with great, strict, and due care.

2.4 I

n no event shall the Licensee dump, reverse assemble, reverse compile, or reverse engineer the Licensed Software so that the Licensee may

translate the Licensed Software into other programs or change it into a man-readable form from the source code of the Licensed Software.

Unless otherwise separately agreed by Yokogawa, Yokogawa shall not provide the Licensee the source code for the Licensed Software.

2.5 The Licensed Software and its related documentation shall be the proprietary p

grants Yokogawa the rights. In no event shall the Licensee be transferred, leased, sublicensed, or assigned any rights relating to the Licensed

Software.

2.6 Y

okogawa may use or add copy protection in or onto the Licensed Software. In no event shall the Licensee remove or attempt to remove

such copy protection.

2.7 The Licensed Software may include a software program licensed for re-use by

which may include any software program from afliates of Yokogawa made or coded by themselves.) In the case that Yokogawa is granted

permission to sublicense to third parties by any licensors (sub-licensor) of the Third Party Software pursuant to different terms and conditions

than those stipulated in this Agreement, the Licensee shall observe such terms and conditions of which Yokogawa noties the Licensee in

writing separately.

2.8 In no event shall the Licensee modify

including any copy thereof.

Article 3 (Restriction of Specic Use)

3.1 The Licensed Software shall not be intended specically to be designed, developed, constructed, manufactured, distributed or maintained for

the purpose of the following events:

a) Operation of any aviation, vessel, or support of those operations from the ground;,

Operation of nuclear products and/or facilities;,

b)

c) Operation of nuclear weapons and/or chemical weapons and/or biological weapons; or

d) Operation of medical instrumentation directly utilized for humankind or the human body.

3.2 Even if the Licensee uses the Licensed Software for the purposes in the preceding Paragraph 3.1, Yokogawa has no liability to or

responsibility for any demand or damage arising out of the use or operations of the Licensed Software, and the Licensee agrees, on its own

responsibility, to solve and settle the claims and damages and to defend, indemnify or hold Yokogawa totally harmless, from or against any

liabilities, losses, damages and expenses (including fees for recalling the Products and reasonable attorney’s fees and court costs), or claims

arising out of and related to the above-said claims and damages.

Article 4 (Warranty)

4.1 The Licensee shall agree that the Licensed Software shall be provided to the Licensee on an “as is” basis when delivered. If defect(s), such

as damage to the medium of the Licensed Software, attributable to Yokogawa is found, Yokogawa agrees to replace, free of charge, any

Licensed Software on condition that the defective Licensed Software shall be returned to Y

within seven (7) days after opening the Package at the Licensee’s expense. As the Licensed Software is provided to the Licensee on an “as

is” basis when delivered, in no event shall Yokogawa warrant that any information on or in the Licensed Software, including without limitation,

data on computer programs and program listings, be completely accurate, correct, reliable, or the most updated.

Notwithstanding the preceding Paragraph 4.1, when third party software is incl

4.2

and conditions that apply shall be those established by the provider of the third party software.

4.3 When

4.4 Notwithstanding the preceding Paragraph 4.3, in no event shall

4.5 THE FOREGOING W

4.6 Correction of nonconformity in the manner and for the period of time provided a

IM 04P01B01-61E

Yokogawa decides in its own judgement that it is necessary, Yokogawa may from time to time provide the Licensee with Revision

upgrades and Version upgrades separately specied by Yokogawa (hereinafter called “Updates”).

renovation or improvement of the Licensed Software.

WRITTEN, ORAL, OR IMPLIED, AND ALL OTHER WARRANTIES INCLUDING ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED BY YOKOGAWA AND ALL THIRD PARTIES LICENSING THIRD

PARTY SOFTWARE TO YOKOGAWA.

any failure of Yokogawa to comply with its obligations and shall constitute fulllment of all liabilities of Yokogawa and any third party licensing

the Third Party Software to Yokogawa (including any liability for direct, indirect, special, incidental or consequential damages) whether in

warranty, contract, tort (including negligence but excluding willful conduct or gross negligence by Yokogawa) or otherwise with respect to or

arising out of the use of the Licensed Software.

RXA10 Conguration Software

1

and documentation, without limitation, all proprietary

Yokogawa, not entitled to copy, change, sell, distribute, transfer, or sublicense the

g one (1) copy for back-up purposes. The Licensee shall

roperty or trade secret of Yokogawa or a third party which

a third party (hereinafter called “Third Party Software”,

, remove or delete a copyright notice of Yokogawa and its licenser contained in the Licensed Software,

okogawa’

s specied authorized service facility

uded in the Licensed Software, the warranty period and terms

Yokogawa provide Updates where the Licensee or any third party conducted

ARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES OF QUALITY AND PERFORMANCE,

bove shall be the Licensee’s sole and exclusive remedy for

iii

Page 5

iv

IM 04P01B01-61E

Terms and Conditions of the Software License

Article 5 (Infringement)

5.1 If and when any third party should demand injunction, initiate a law suit, or demand compensation for damages against the Licensee under

patent right (including utility model right, design patent, and trade mark), copy right, and any other rights relating to any of the Licensed

Software, the Licensee shall notify Yokogawa in writing to that effect without delay.

In the case of the preceding Paragraph 5.1, the Licensee shall assign to

5.2

with the claiming party. Furthermore, the Licensee shall provide Yokogawa with necessary information or any other assistance for Yokogawa’

s defense and negotiation. If and when such a claim should be attributable to Yokogawa, subject to the written notice to Yokogawa stated in

the preceding Paragraph 5.1, Yokogawa shall defend the Licensee and negotiate with the claiming party at Yokogawa’s cost and expense and

be responsible for the nal settlement or judgment granted to the claiming party in the preceding Paragraph 5.1.

5.3 When any assertion or allegation of the infringement of the third party’s rights dened in Paragraph 5.1 is made, or when at

judgment there is possibility of such assertion or allegation, Yokogawa will, at its own discretion, take any of the following countermeasures at

Yokogawa’s cost and expense.

a) T

o acquire the necessary right from a third party which has lawful ownership of the right so that the Licensee will be able to continue to use

the Licensed Software;

b) T

o replace the Licensed Software with an alternative one which avoids the infringement; or

c) To remodel the Licensed Software so that the Licensed Software can avoid the infringement of such third party’s right.

5.4 If and when Yokogawa fails to take either of the countermeasures as set forth in the preceding subparagraphs of Paragraph 5.3, Yokogawa

shall indemnify the Licensee only by paying back the price amount of the Licensed Software which Yokogawa has received from the Licensee.

THE FOREGOING PARAGRAPHS STATE THE ENTIRE LIABILITY OF YOKOGAWA AND ANY THIRD PARTY LICENSING THIRD PARTY

SOFTWARE TO YOKOGAWA WITH RESPECT TO INFRINGEMENT OF THE INTELLECTUAL PROPERTY RIGHTS INCLUDING BUT NOT

LIMITED TO, PATENT AND COPYRIGHT.

Article 6 (Liabilities)

6.1 If and when the Licensee should incur any damage relating to or arising out of the Licensed Software or service that Yokogawa has provided

to the Licensee under the conditions herein due to a reason attributable to Yokogawa, Yokogawa shall take actions in accordance with this

Agreement. However, in no event shall Yokogawa be liable or responsible for any special, incidental, consequential and/or indirect damage,

whether in contract, warranty, tort, negligence, strict liability, or otherwise, including, without limitation, loss of operational prot or revenue,

loss of use of the Licensed Software, or any associated products or equipment, cost of capital, loss or cost of interruption of the Licensee’

s business, substitute equipment, facilities or services, downtime costs, delays, and loss of business information, or claims of customers of

Licensee or other third parties for such or other damages. Even if Yokogawa is liable or responsible for the damages attributable to Yokogawa

and to the extent of this Article 6, Yokogawa’s liability for the Licensee’s damage shall not exceed the price amount of the Licensed Software

or service fee which Yokogawa has received. Please note that Yokogawa shall be released or discharged from part or all of the liability

under this Agreement if the Licensee modies, remodels, combines with other software or products, or causes any deviation from the basic

specications or functional specications, without Yokogawa’s prior written consent.

All causes of action against

6.2

Yokogawa is notied of the claim within one (1) year of its occurrence.

6.3 In no event, regardless of cause, shall

between the Licensee and its customers.

Yokogawa arising out of or relating to this Agreement or the performance or breach hereof shall expire unless

Yokogawa assume responsibility for or be liable for penalties or penalty clauses in any contracts

Article 7 (Limit of Export)

Unless otherwise agreed by Yokogawa, the Licensee shall not directly or indirectly export or transfer the Licensed Software to any countries other

than those where Yokogawa permits export in advance.

Article 8 (Term)

This Agreement shall become effective on the date when the Licensee receives the Licensed Software and continues in effect unless or until

terminated as provided herein, or the Licensee ceases using the Licensed Software by itself or with Yokogawa’s thirty (30) days prior written notice

to the Licensee.

Article 9 (Injunction for Use)

During the term of this Agreement, Yokogawa may, at its own discretion, demand injunction against the Licensee in case that Yokogawa deems

that the Licensed Software is used improperly or under severer environments other than those where Yokogawa has rst approved, or any other

condition which

Yokogawa may not permit.

Article 10 (Termination)

Yokogawa, at its sole discretion, may terminate this Agreement without any notice or reminder to the Licensee if the Licensee violates or fails to

perform this Agreement. However, Articles 5, 6, and 11 shall survive even after the termination.

Article 11 (Jurisdiction)

Any dispute, controversies, or differences between the parties hereto as to interpretation or execution of this Agreement shall be resolved amicably

through negotiation between the parties upon the basis of mutual trust. Should the parties fail to agree within ninety (90) days after notice from

one of the parties to the other, both parties hereby irrevocably submit to the exclusive jurisdiction of the Tokyo District Court (main ofce) in Japan

for settlement of the dispute.

Article 12 (Governing Law)

This Agreement shall be governed by and construed in accordance with the laws of Japan. The Licensee expressly agrees to waive absolutely

and irrevocably and to the fullest extent permissible under applicable law any rights against the laws of Japan which it may have pursuant to the

Licensee’s local law.

Article 13 (Severability)

In the event that any provision hereof is declared or found to be illegal by any court or tribunal of competent jurisdiction, such provision shall be null

and void with respect to the jurisdiction of that court or tribunal and all the remaining provisions hereof shall remain in full force and effect.

Yokogawa all of the rights to defend the Licensee and to negotiate

Yokogawa’s

Page 6

Checking the Contents of the Package

RXA10 Configuration Software

and

CopyTool

(CD)

RXA10-01, RXA10-02

Configuration Software

User's Manual

Interface Unit

(for the RXA10-02 model)

Please check the contents of the package before using this product. If some of the

contents are not correct or missing or if there is physical damage, contact the dealer from

which you purchased them.

• Contents of the Package

• MODEL and SUFFIX Code

Model Suffix Code Note

RXA10 -01 Configuration software

-02 Configuration software (with interface unit)

IM 04P01B01-61E

v

Page 7

How to Use This Manual

Structure of This Manual

This user’s manual consists of the following sections.

Chapter Title Description

1 Before Using the Software Describes the PC system requirements for using

2 Configuring the Recorder Describes how to create the setup data of the

3 Troubleshooting Describes the error messages and their corrective

4 Using CopyTool Explains how to use CopyTool to copy settings from

Index Gives an index.

Scope of the Manual

This manual does not cover the basic operations of the operation systems. For such

information, see the Windows user’s guide or other relevant documents.

Conventions Used in This Manual

• Unit

K: Denotes 1024. Example: 100 KB

k: Denotes 1000.

the configuration software, the software installation

procedure, and the procedure for connecting to the

recorder.

recorder and configure the recorder or save the data.

actions.

one recorder to another.

• Notations of Menus, Commands, Dialog Boxes, and Buttons

Typed in boldface in the operating procedure.

• Note

Note Gives useful tips on the operation of the software.

vi

IM 04P01B01-61E

Page 8

Contents

Foreword ............................................................................................................................................i

Products Described in This Manual ..................................................................................................ii

Terms and Conditions of the Software License................................................................................ iii

Checking the Contents of the Package.............................................................................................v

How to Use This Manual .................................................................................................................. vi

Chapter 1 Before Using the Software

1.1 Overview of the Configuration Software .............................................................................. 1-1

1.2 PC System Requirements ................................................................................................... 1-2

1.3 Installing the Configuration Software ................................................................................... 1-3

1.4 Connecting the Recorder and the PC .................................................................................. 1-4

Chapter 2 Configuring the Recorder

2.1 Starting/Closing the Software and Showing Version Information ........................................ 2-1

2.2 Setting the Communication Mode for Connecting to the Recorder ..................................... 2-2

2.3 Loading the Setup Data or Creating New Setup Data ......................................................... 2-4

2.4 Setting the Measurement Channels .................................................................................... 2-7

2.5 Setting the Computation Channels (/M1 Option) ............................................................... 2-14

2.6 Setting the Items in Setting Mode and the Data Display Me

2.7 Setting the Items in Basic Setting Mode ............................................................................ 2-24

2.8 Checking the Consistency of the Settings ......................................................................... 2-35

2.9 Sending Setup Data to the Recorder ................................................................................. 2-36

2.10 Saving the Setup Data ....................................................................................................... 2-37

2.11

Printing the Setup Data ...................................................................................................... 2-38

2.12 Characters

That Can Be Used ........................................................................................... 2-39

thod ...................................... 2-17

Chapter 3 Troubleshooting

3.1 Error Messages ................................................................................................................... 3-1

Chapter 4 Using CopyTool

4.1 Overview of CopyTool .......................................................................................................... 4-1

4.2 Installing CopyTool and Checking the Version ..................................................................... 4-2

4.3 Copying Recorder Settings .................................................................................................. 4-3

4.4 Error Messages ......................................................................................................

Index

............. 4-9

IM 04P01B01-61E

vii

Page 9

1

Chapter 1 Before Using the Software

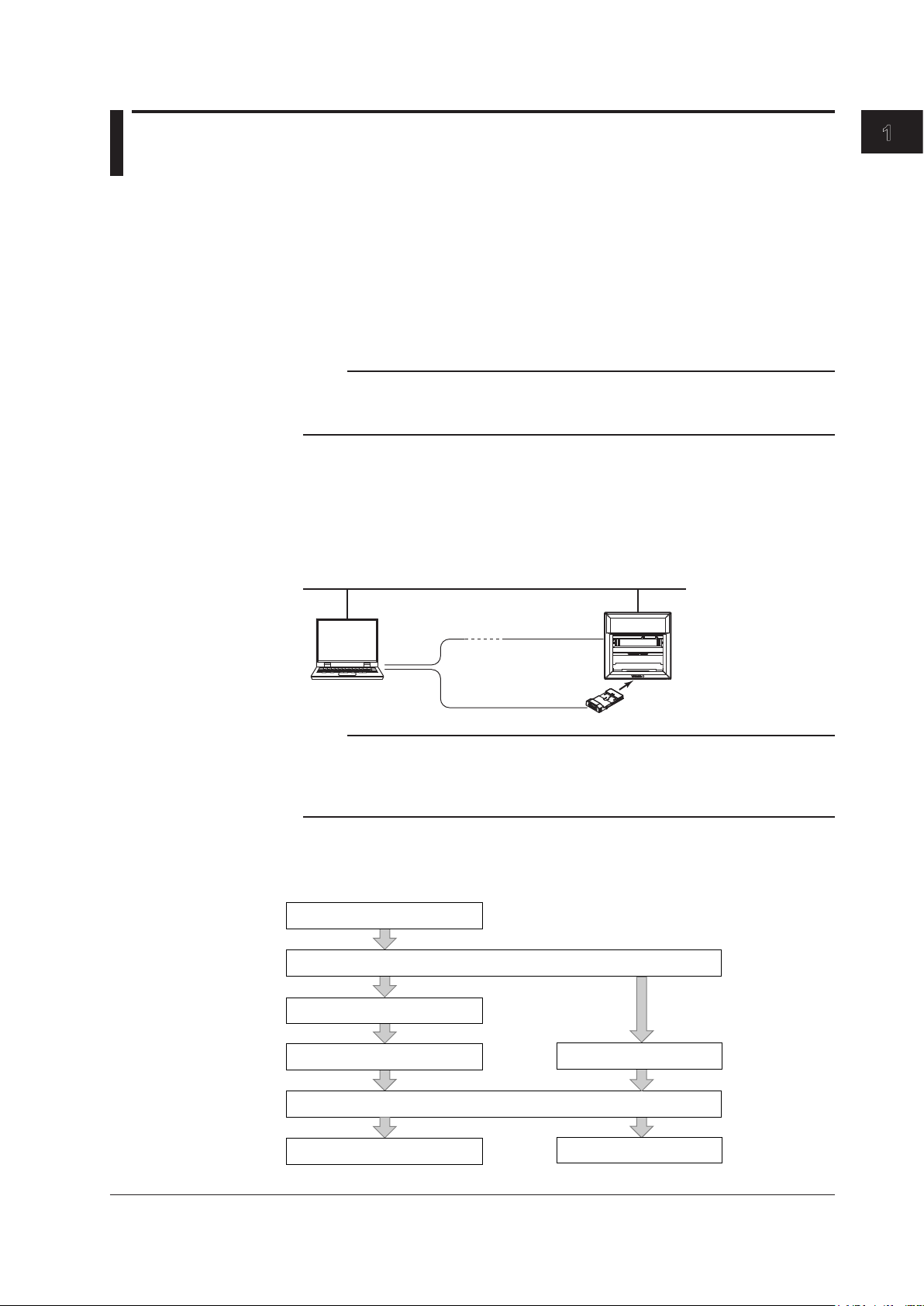

PC

Ethernet

Communication

Interface (/C7)

RS-422/485

Communication

Interface (/C3)

Interface unit

µR10000, µR20000

Connecting the recorder and the PC

Starting the software

Setting the communication mode

Loading setup data of the recorder

Changing the settings

Sending setup data to the recorder

Opening a setup data file

Saving the satup data

To change the settings of the recorder

To change a setup data file

(Section 2.1)

(Section 2.2)

(Section 2.3)

(Sections 2.4 to 2.8)

(Section 2.9)

(Section 1.4)

(Section 2.3)

(Section 2.10)

1.1 Overview of the Configuration Software

Function

This software program is used to configure the µR10000 and µR20000 from a PC.

The setup data can be created using any of the methods below to configure the recorder.

• Load the setup data from the connected recorder and change

• Open a saved setup data and change the settings.

• Create new setup data.

The setup data can be saved to the hard disk on the PC. The setup information can also

be printed.

Note

This program cannot be used to set the following items.

• Date/Time (Setting mode)

• RS-422/485, Ethernet, and pen and dot printing position adjustment (Basic Setting mode)

Connecting to the Recorder

A connection to a PC can be made using the RS-422/485 communication interface

(/C3 option) or the Ethernet communication interface (/C7 option) of the recorder. In

the case of the RXA10-02, the interface unit can be used to connect to the recorder

through the RS-232 communication interface of the PC even if the recorder is not

equipped with a communication interface.

Before Using the Software

the settings.

Flow of Operation

Note

When using the interface unit, turn OFF the device that is connected to the RS-422/485

communication interface (/C3 option) on the recorder rear panel or disconnect the cable. Data

may be sent to the device connected to the RS-422/485 communication interface on the rear

panel when the interface unit is communicating.

The flow of operation of the program is shown below.

IM 04P01B01-61E

1-1

Page 10

1-2

IM 04P01B01-61E

1.2 PC System Requirements

Hardware

• PC

When Using Windows 2000 or Windows XP

CPU: Pentium III 600-MHz or higher (800-MHz Pentium III or higher recommended).

Memory: 512 MB or more.

Hard disk: Free disk space of 10 MB or more.

When Using Windows Vista

CPU:

Memory: 1 GB or more.

Hard disk: Free disk space of 200 MB or more.

When Using Windows 7

32-bit

CPU: Intel Pentium IV, 3.0 GHz or faster x64 or x86 processor

Memory: 2 GB or more.

64-bit edition:

CPU: Intel x64 processor that is equivalent to Intel Pentium IV, 3.0 GHz or faster

Memory: 2 GB or more.

Hard disk: Free disk space of 200 MB or more.

• CD-ROM drive

A CD-ROM drive supported by the OS.

• Mouse

A mouse supported by the OS.

• Monitor

When Using Windows 2000 or Windows XP

A monitor supported by the OS of 1024 × 768 dpi or higher and 32K colors or more (64

When Using Windows Vista or Windows 7

A mo

• Communication port

An RS-232 port or an Ethernet port supported by the OS.

• Printer

A printer supported by the OS. An appropriate printer driver for the OS is also required.

Pentium IV, 3.0 GHz or faster

edition:

Pentium IV, 3.0 GHz or faster

K colors recommended).

nitor supported by the OS of 1024 × 768 dpi or higher and 65,536 colors or more.

Operating System

• Windows 2000 SP4

• Windows XP Home Edition SP3

• Windows XP Professional SP3 (excluding Windows XP Professional x64 Edition)

• Windows Vista Home Premium SP1, SP2 (excluding the 64-bit edition)

• Windows Vista Business SP1, SP2 (excluding the 64-bit edition)

• Windows 7 Home Premium (32-bit and 64-bit editions)

• Windows 7 Professional (32-bit and 64-bit editions)

Note

The PC must have Courier New font installed.

Page 11

1

1.3 Installing the Configuration Software

A serial number is required to install the configuration software. The serial number is

indicated on the CD-ROM case. Please have the serial number ready.

Installing the Software

Start Windows. Log onto Windows as an administrator.

1.

Insert the CD-ROM containing the software into the CD-ROM drive.

2.

The installation program starts automatically.

Click the Run button for the Configuration Installation. Proceed with the

3.

installation according to the instructions that appear on the screen.

If the installation program does not start automatically, carry out the procedures

.

below

Double-click the CD-ROM icon from “My Computer” to open the CD-ROM drive

4.

window.

Double-click the “Setup.exe” file in the root directory. The installation will start after

5.

a short time. Then, follow the instructions on the screen.

Note

• Exit memory resident programs such as virus protection programs before installation.

• Set the OS and program languages to the same language. Normal operation cannot be

guaranteed if you install the software under a different language than the OS.

• When reinstalling the software, uninstall it first.

• To uninstall the program, follow the procedures below.

Double-click “Add/Remove Programs” in the Control Panel and uninstall the program.

1.

As necessary, back up the setup data files with .pul extension in the directory in which

2.

the configuration software was installed to a different directory.

Delete the files (various data files and subdirectories) that were created after the

3.

installation of the program. Also, delete the directory in which the program was installed.

Before Using the Software

IM 04P01B01-61E

1-3

Page 12

1-4

IM 04P01B01-61E

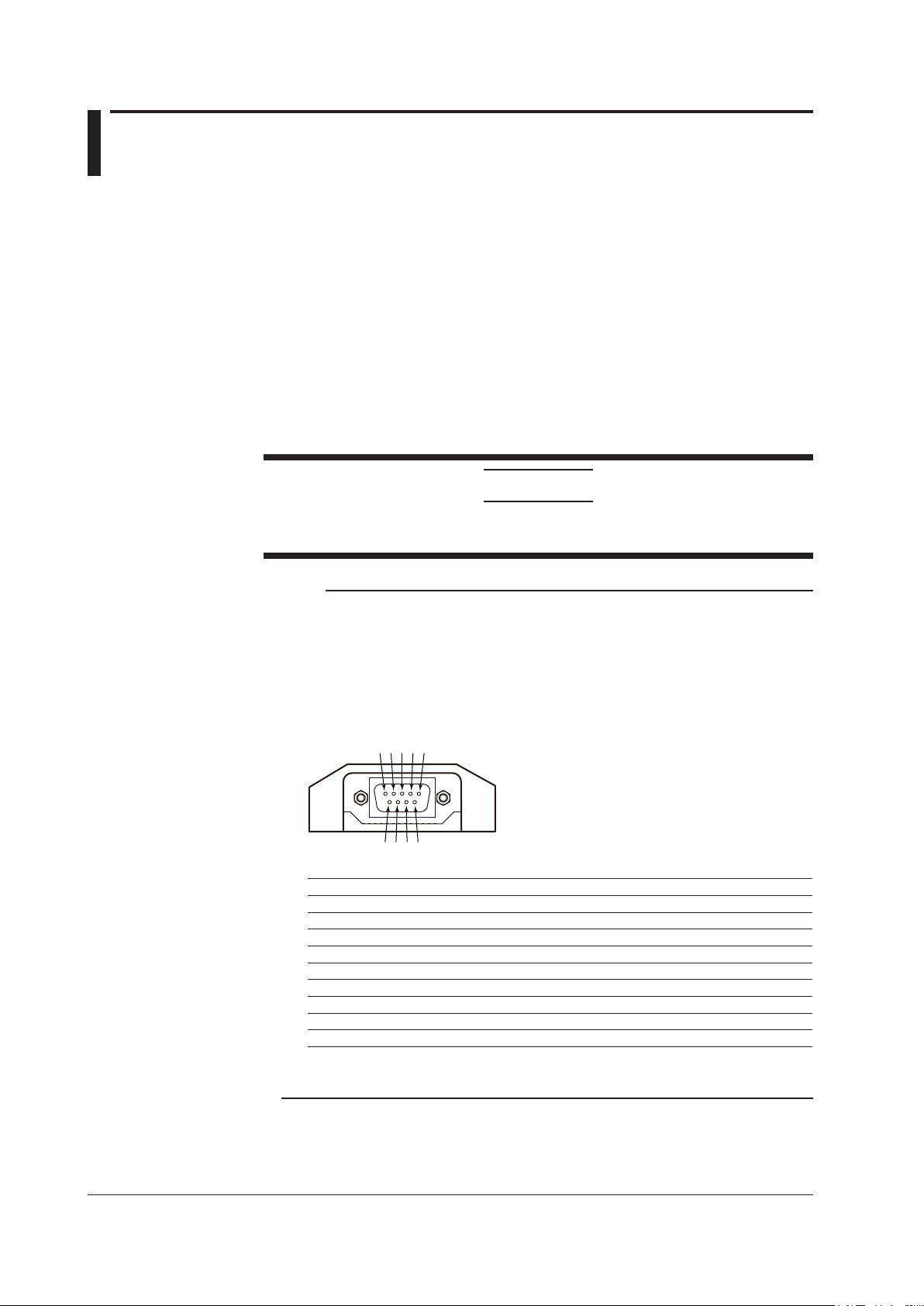

1.4 Connecting the Recorder and the PC

1 2 3 4 5

6 7 8 9

Interface unit (D-Sub 9-pin plug)

Using the Ethernet Communication Interface (/C7 Option)

For the procedure to connect the recorder and the PC, see section 2.2, “Connecting the

Ethernet Interface” in the µR10000/µR20000 Communication Interface User’s Manual (IM

04P01B01-17E).

Using the RS-422/485 Communication Interface (/C3 Option)

For the procedure to connect the recorder and the PC, see section 3.2, “Terminal

Arrangement and Signal Names and the Connection Procedure of the RS-422/485

Communication Interface” in the µR10000/µR20000 Communication Interface User’s

Manual (IM 04P01B01-17E).

Using the Interface Unit (For the RXA10-02)

CAUTION

Do not insert or remove the interface unit while the recorder is turned ON. If you do,

the internal circuit of the recorder and/or the interface unit may be damaged.

Note

• When using the interface unit, turn OFF the device that is connected to the RS-422/485

communication interface (/C3 option) on the recorder rear panel or disconnect the cable.

Data may be sent to the device connected to the RS-422/485 communication interface on

the rear panel when the interface unit is communicating.

• Use a D-Sub 9-pin RS-232 cable (cross cable) to connect the PC and the interface unit (The

connector on the interface unit is a D-Sub 9-pin plug (male)).

Pin Assignments

1 CD Carrier Detect

2 RXD Receive Data

3 TXD Transmit Data

4 DTR Data Terminal Ready

5 GND System Ground

6 SDR Data Set Ready

7 RTS Request to Send

8 CTS Clear to Send

9 RI Ring Indicator

Pins 4 and 6 are shorted internally

Pins 7 and 8 are shorted internally

.

.

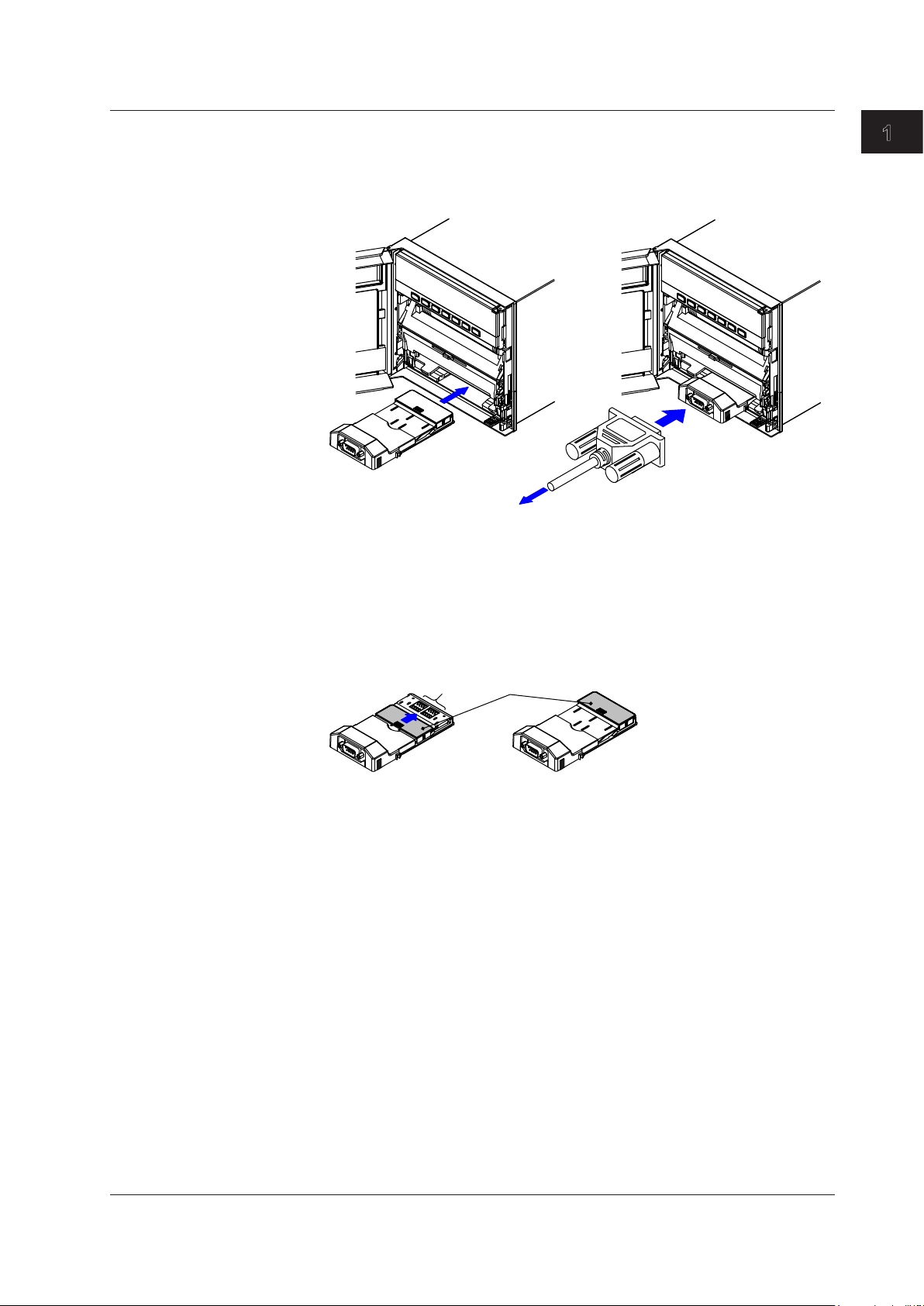

Page 13

1

Interface unit

Interface unit

RS-232 Cable

To the PC

Cover

Terminal

section

1.4 Connecting the Recorder and the PC

• Connecting the Recorder and the PC

Turn OFF the recorder and the PC.

1.

Insert the interface unit in the opening under the chart cassette.

2.

Insert it until it clicks in place.

Before Using the Software

• Disconnecting the Recorder from the PC

Connect the interface unit and the PC’s RS-232 connector with an RS-232 cable.

3.

Turn ON the recorder first and then the PC.

4.

Turn OFF the recorder and the PC.

1.

Pull out the interface unit.

2.

Place the cover over the terminal section of the interface unit.

3.

IM 04P01B01-61E

1-5

Page 14

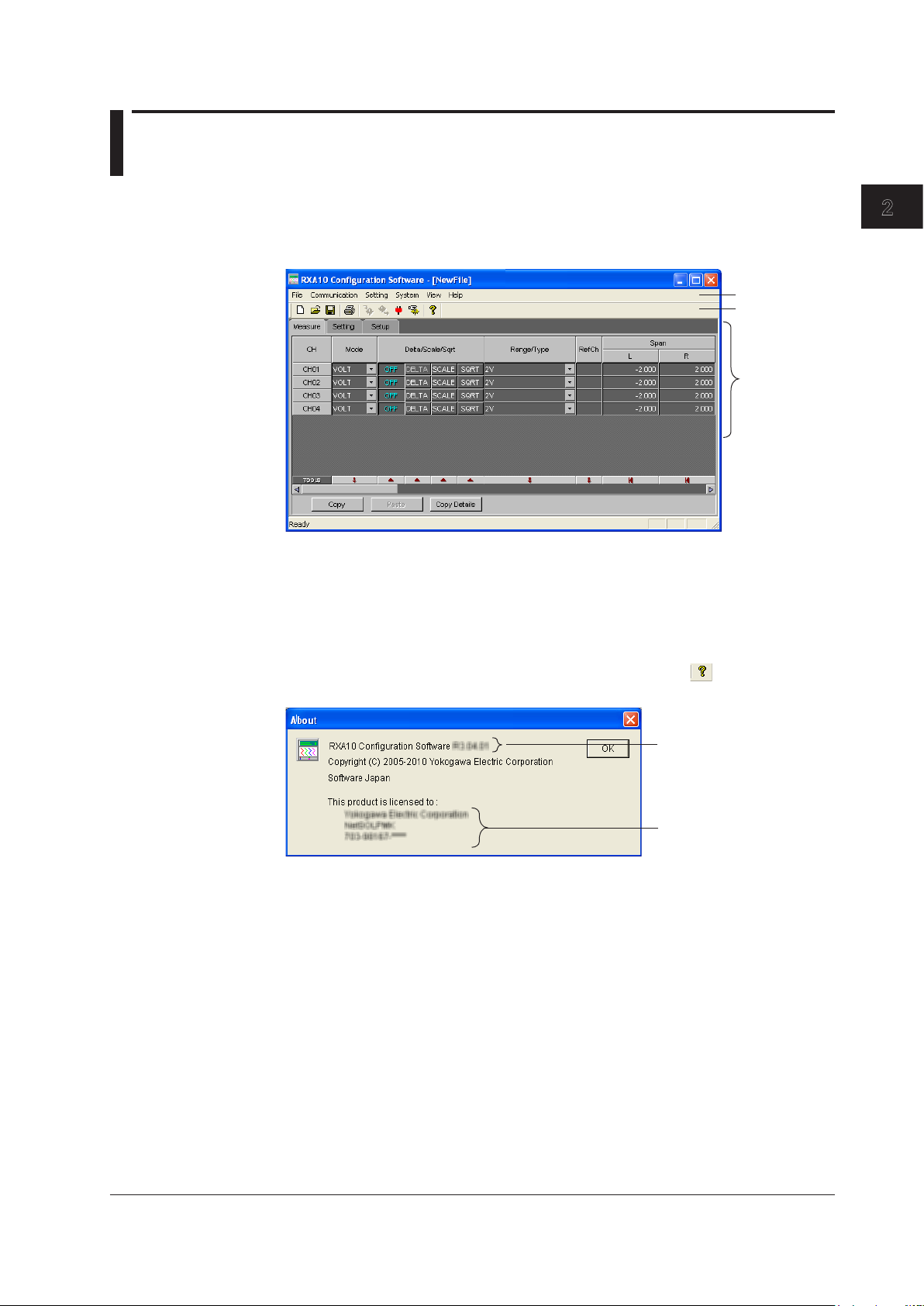

1

2

Setup data

Toolbar

Menu bar

Displays the serial number.

Displays the version number.

Chapter 2 Configuring the Recorder

2.1 Starting/Closing the Software and Showing

Version Information

Starting the Software

From the task bar, click Start, point to Programs, and choose RXA10 Configuration

Software in RXA10 Configuration Software folder.

The software starts.

Configuring the Recorderr

Closing the Software

From the File menu, choose Exit, or click the X button.

The configuration software window closes.

Showing Version Information

From the Help menu, choose About. You can also click the icon ( ) on the toolbar.

The About dialog box opens.

Click OK to close the dialog box.

IM 04P01B01-61E

2-1

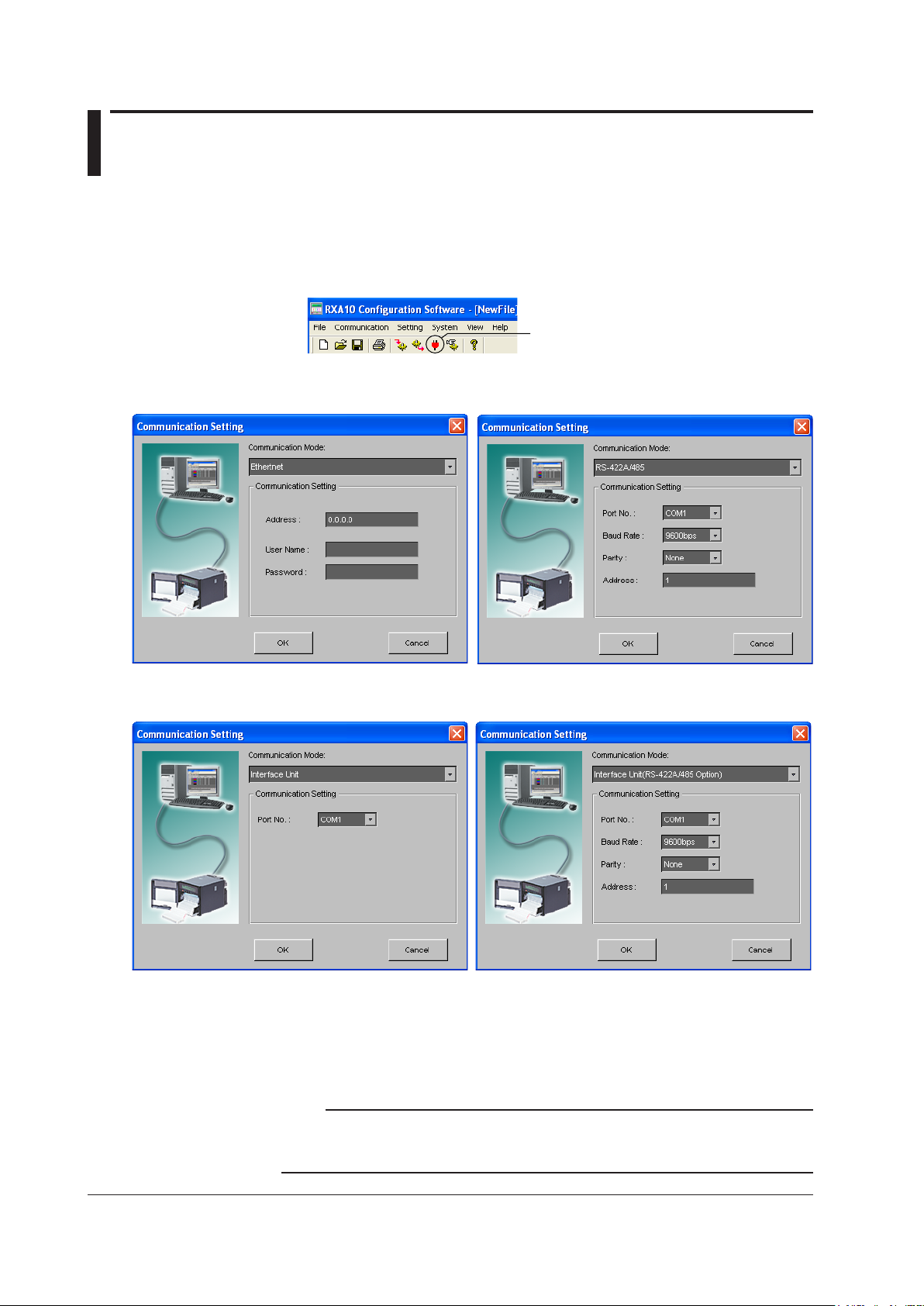

Page 15

2-2

IM 04P01B01-61E

2.2 Setting the Communication Mode for

Communication setting icon

When using Ethernet (/C7 option) When using the RS-422/485 interface (/C3 option)

When using the interface unit

When using the interface unit on a model with the

RS-422/485 interface (/C3 option)

Connecting to the Recorder

Set the communication mode and parameters according to the type of connection

between the PC and the recorder.

From the Communication menu, choose Communication Setting. You can

1.

also click the Communication Setting icon on the toolbar. The Communication

Setting dialog box opens.

Set the communication mode and parameters.

2.

Click OK.

3.

The dialog box closes, and the communication between the PC and the recorder

Click Cancel to cancel the settings and close the dialog box.

is enabled.

Note

After starting the program, be sure to check the communication settings and click OK.

After the communication settings are checked, Receive setting and Send setting of the

Communication menu become selectable.

Page 16

1

2

2.2 Setting the Communication Mode for Connecting to the Recorder

• Ethernet

• Address

Enter the IP address or host name of the recorder.

• User Name and Password

• When using the login function on the recorder

Login as an administrator.

• When not using the login function on the recorder

Login with the user name “Admin.”

Password is not necessary.

• RS-422/485

• Port No.

Select the port from COM1 to COM9.

• Baud Rate and Parity

Set the same values as the recorder.

• Address

Enter the recorder’s address.

• Interface Unit

• Port No.

Select the port from COM1 to COM9.

Configuring the Recorderr

• Interface Unit (RS-422/485 Option)

• Port No.

Select the port from COM1 to COM9.

• Baud Rate and Parity

Set the same values as the recorder.

• Address

Enter the recorder’s address.

IM 04P01B01-61E

2-3

Page 17

2-4

IM 04P01B01-61E

2.3 Loading the Setup Data or Creating New Setup

Receive setting icon

Data

The following three methods are available for creating setup data.

• Load the setup data of the recorder

• Open a setup data le.

• Create new setup data.

Loading the Setup Data of the Recorder

Before carrying out the following procedure, check to see that the communication

mode and parameters are set correctly. For details, see section 2.2, “Setting the

Communication Mode for Connecting to the Recorder.”

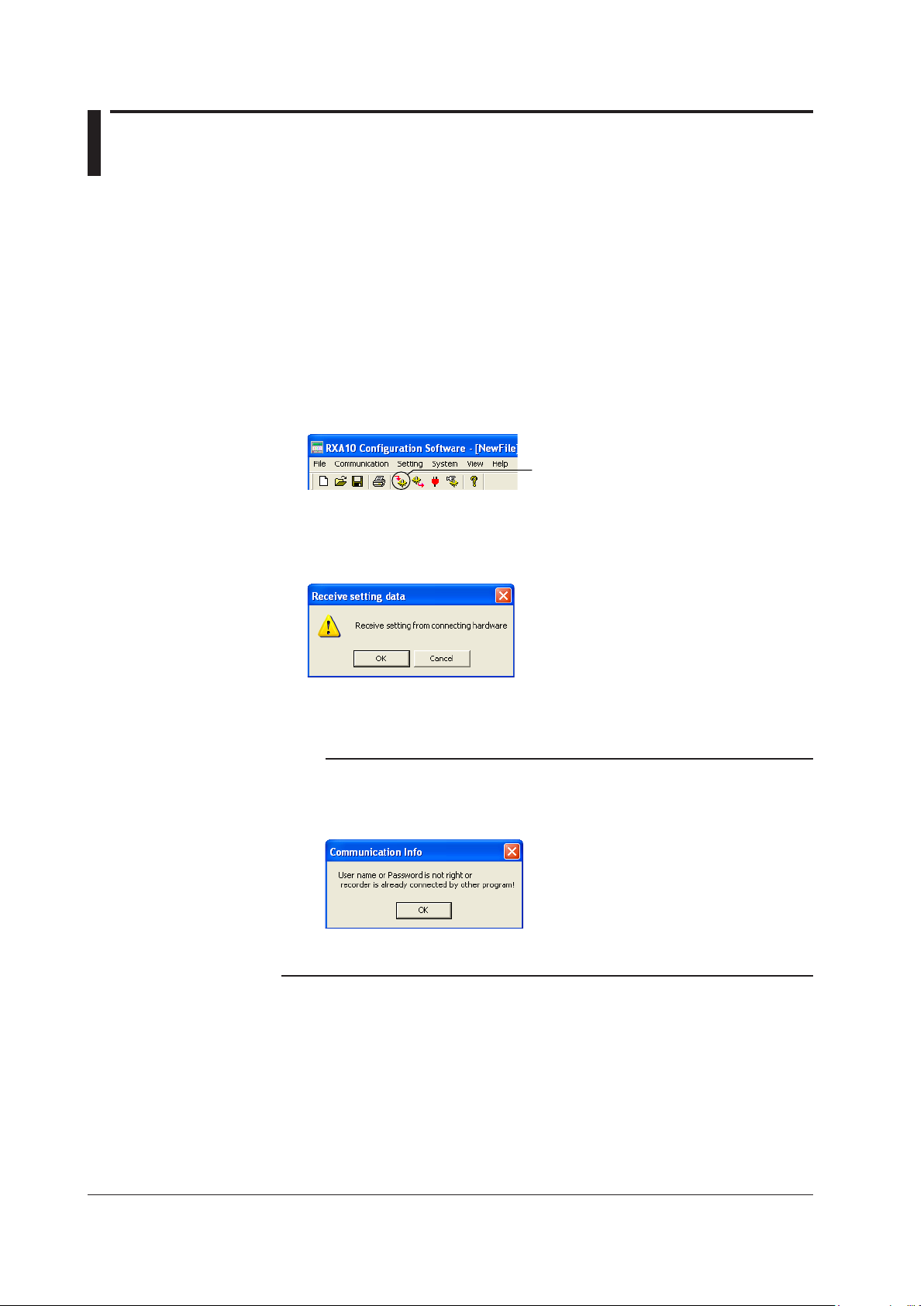

From the Communication menu, choose Receive Setting. You can also click

1.

the Receive setting icon on the toolbar. A confirmation dialog box for receiving

settings opens.

Click OK.

2.

The reception starts. When the reception of the settings is complete, a message

appears to indicate it.

Click OK.

3.

The loaded setup data is displayed.

Note

• If the message in the figure below appears, check the following:

• That the communication settings are matched with the settings on the recorder.

• That there are no users accessing the recorder or that the maximum number of users is

• Note that if setup data is received when the recorder is in Basic Setting mode, the setup

data in the middle of the configuration will be received.

not exceeded.

Page 18

1

2

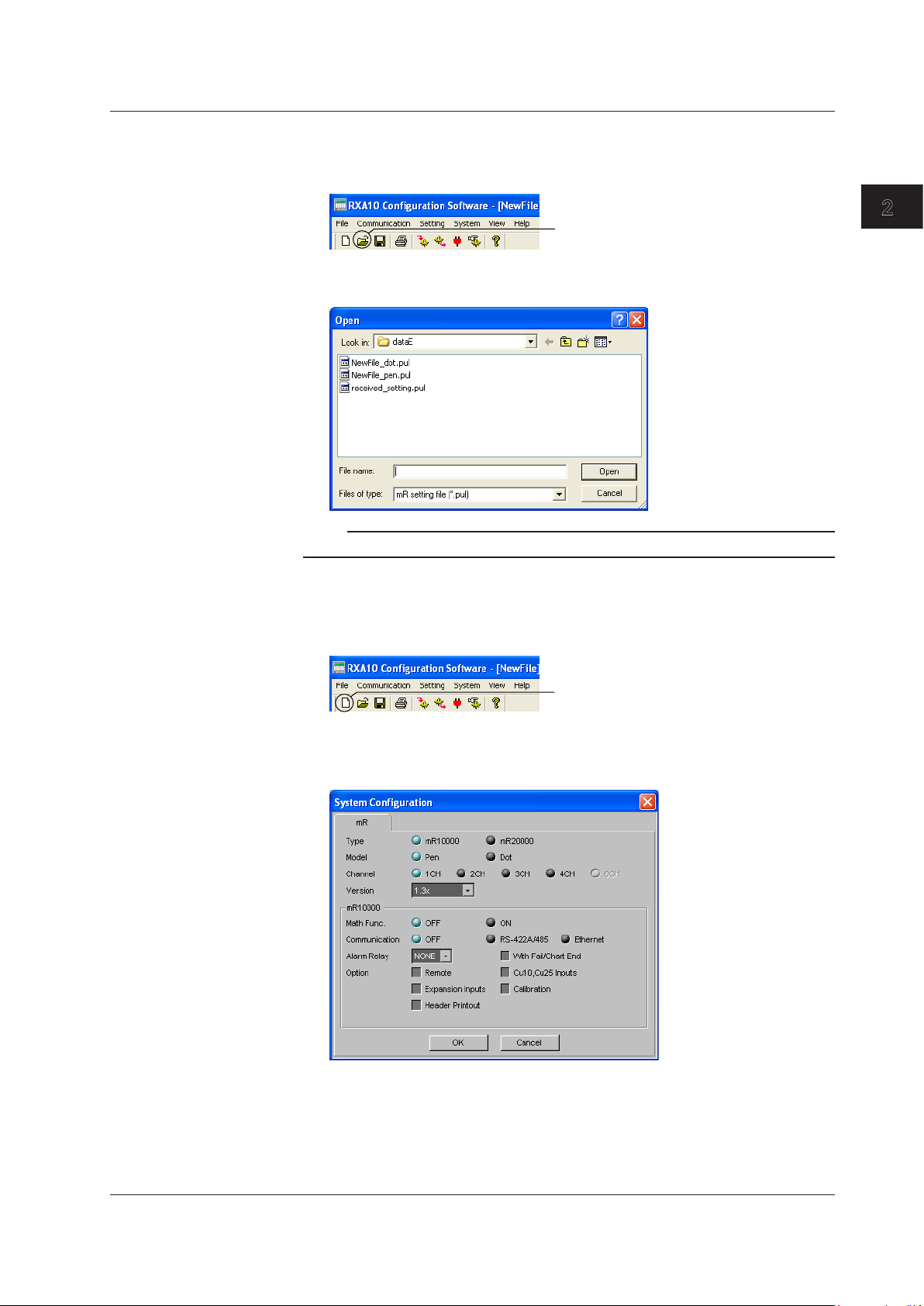

Opening a Setup Data File

Open icon

New icon

From the File menu, choose Open. You can also click the Open icon. The Open

1.

dialog box opens.

2.3 Loading the Setup Data or Creating New Setup Data

Select the desired file, and click Open.

2.

The setup data is displayed.

Note

The extension to setup data files is .pul.

Creating New Setup Data

From the File menu, choose New. You can also click the New icon. The System

1.

Configuration dialog box opens.

Configuring the Recorderr

• Type, Model, Channel, and Style

Type: Recorder types.

Model: Pen model or dot model.

Channel: The number of measurement channels on the recorder.

Style: The style number of the recorder.

Set the system configuration of the recorder, and click OK.

2.

A setup window with the specified system configuration opens with the settings

set to default values.

IM 04P01B01-61E

2-5

Page 19

2-6

IM 04P01B01-61E

2.3 Loading the Setup Data or Creating New Setup Data

• Options

Math Func.: Computation function (/M1 option)

Communication RS-422/485: RS-422/485 Communication Interface (/C3)

Communication Ethernet: Ethernet Communication Interface (/C7)

Alarm Relay 2p: Alarm output relay 2 points (/A1)

Alarm Relay 4p: Alarm output relay 4 points (/A2)

Alarm Relay 6p: Alarm output relay 6 points (/A3)

Alarm Relay 12p: Alarm output relay 6 points (/A4, µR20000)

Alarm Relay 24p: Alarm output relay 6 points (/A5, µR20000)

With FAIL/Chart End: FAIL/Chart End Detection and Output (/F1)

Remote: Remote Control Input (/R1)

Cu10, Cu25 Inputs: Cu10, Cu25 RTD Input (/N1)

Expansion Inputs: Expansion Inputs (/N3)

Calibration:* Calibration Correction (/CC1)

Header Printout:** Header Printout (/BT1)

* Function available on recorders with firmware version 1.21 or later.

** Function available on recorders with firmware version 1.31 or later.

Checking/Changing the System Configuration of the Setup Data

• Checking the System Configuration

With the setup data displayed in the window, choose System Conguration from the

System menu.

The System Conguration dialog box opens.

Check the system conguration that is shown, and click OK.

The dialog box closes.

• Changing the System Configuration

With the setup data displayed in the window, choose System Conguration from the

System menu.

The System Conguration dialog box opens.

Change the system conguration, and click OK.

The conrmation dialog box opens. Click OK to open a setup window with the

specied system conguration with the settings set to default values.

Initializing the Settings

1.

The Initialize dialog box opens.

2.

Note

For the default settings, see section 4.3, “Menu Structure, Settings, and List of Default

From the Setting menu, choose Initialize.

Click OK to initialize the settings.

Values” in the µR10000 Recorder User’s Manual (IM 04P01B01-01E) or µR20000 Recorder

User’s Manual (IM 04P02B01-01E).

Page 20

1

2

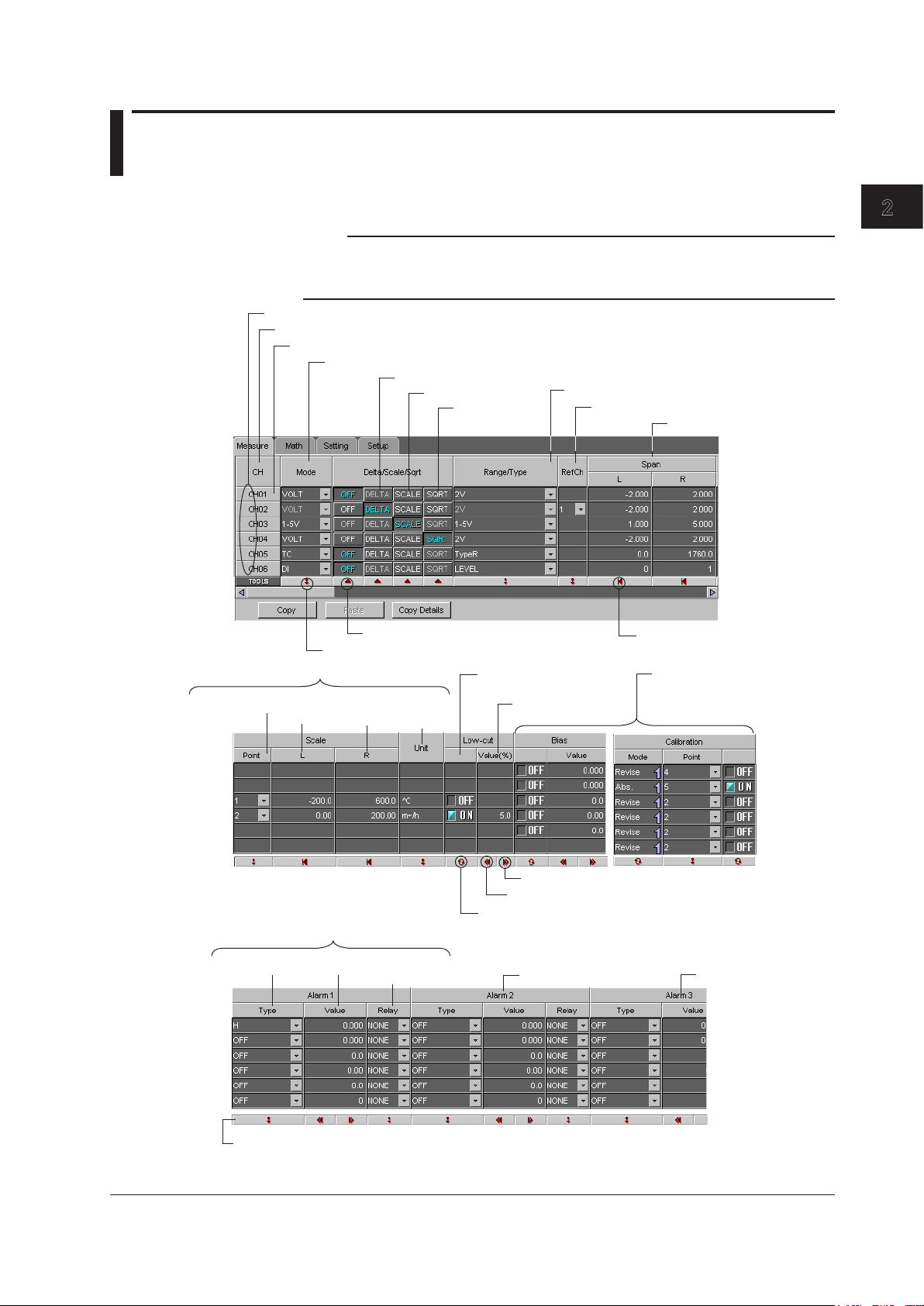

2.4 Setting the Measurement Channels

Click twice to unselect the channel.

Double-click to open a setup dialog box for the respective channel.

Delta input

Linear scaling

Square root

computation

Recording span

Input type

Input range

Alarm 2

Reference channel for delta input

Scale value of linear scaling

Rightmost

value

Leftmost

value

Decimal point

position

Turns the low-cut

function ON/OFF

Either “Bias” or “Calibration”

(/CC1 option) is displayed

depending on the settings in

Basic Setting mode (see page

2-25).

Low-cut value

Alarm 3

Sets the default value.

Sets the settings of the first channel to the other channels.

Set collectively.

Drag the pointer while holding down the left mouse button to select multiple channels.

Sets the minimum possible value.

Sets the maximum possible value.

Toggles ON/OFF collectively for each click.

The tool buttons apply to the selected range of channels when channels are selected.

They apply to all channels when a channel is not selected.

Unit

Alarm 1

Output relay

number

Alarm valueAlarm type

Click the Measure tab. You can also choose Measure Channels from the Setting menu.

Note

The following items may be shown or hidden depending on the settings in the Basic Setting

mode.

Low-cut, Bias, Calibration Correction (/CC1 option), Alarm Delay, and Partial.

Configuring the Recorderr

IM 04P01B01-61E

2-7

Page 21

2-8

IM 04P01B01-61E

Partial expanded recording

Bar graph display mode

Channel recording color (dot model)

Turns trend recording ON/OFF (dot model)

Turns ON/OFF periodic printout

Types of measured values

to be printed periodically

Sampling count of moving average (dot model)

or filter time constant (pen model)

Alarm 4

Tag

Alarm delay time

Recording zone

Click twice to unselect the correction points.

Correction value

Value at the correction point

Set the settings of the first point in the selected range

to the other points.

Given channels are copied and pasted to other channels.

Channel range to be copied.

Drag the pointer while holding down the left mouse button to select multiple correction points.

Channel range to be pasted.

Click OK to copy and paste.

2.4 Setting the Measurement Channels

Correction Points for Calibration Correction (/CC1 Option)*

* For recorders with firmware version 1.21 or later

Set the correction points for each channel to use the calibration correction. You can set

these points after setting the Calibration on the Measure tab.

Click the Calibration tab. You can also choose Calibration from the Setting menu.

Page 22

1

2

Input (Mode, Range/Type, and Span)

Set the input type (Mode, Range/Type) and the recording span (Span).

Mode Relevant Settings

VOLT (voltage) Range/Type, Span L, and Span R

TC (thermocouple) Range/Type, Span L, and Span R

RTD (resistance temperature detector) Range/Type, Span L, and Span R

1-5V (1-5V) Range/Type, Span L, and Span R

DI (voltage level/contact input) Range/Type, vpan L, and Span R

SKIP (Measurement OFF) None

Note

• Click the Default button ( ) for Span L to set the minimum value within the measurable

range. Click the Default button for Span R to set the maximum value within the measurable

range.

• The span L and R values that have been changed are displayed in orange, but the values

are valid. When data adjustment (see section 2.8) is executed, the values change back to

white.

• When a value outside the measurable range is entered or when the span L and span R

values are set to the same value, they are corrected when the data is checked.

• If SKIP is selected, other settings are discarded.

Delta Computation (Delta and RefCh)

Measures the difference between the input value of its own channel and that of the reference

channel. Delta computation can be specified when the Mode setting is VOLT, TC, or RTD.

Delta/Scale/Sqrt

Select DELTA.

2.4 Setting the Measurement Channels

Configuring the Recorderr

RefCh

Select the reference channel.

Specify a channel that is smaller in channel number than itself for the reference channel.

Square Root Computation

The square root of the input value is calculated, the result is scaled to a value in the

appropriate unit, and used as the measured value of the channel. Also, the low-cut function

can be used. This setting can be used only when the input mode is set to VOLT.

Delta/Scale/Sqrt

Select SQRT.

Low-cut

This appears when low-cut is enabled (see page 2-25) in Basic Setting mode.

For Square Root Computation

ON: Sets measured values below the specified value to 0 (the leftmost value of

the scale).

Value (%):

The measured value to be low-cut. Set the value in the range of 0.0% to 5.0%

of the recording span.

For 1-5V Input

ON: Sets measured values below 0% input to 0 (the leftmost value of the scale).

Linear Scaling

Scale (Point, L, and R)

The input values are scaled to values in the appropriate unit to be used as measured

values. Set the leftmost value of the scale (L) and the rightmost value of the scale (R)

using a mantissa and decimal point position.

Mantissa:

Decimal position:

IM 04P01B01-61E

–20000 to 30000

0 (the number of digits right of the decimal is 0) to 4 (the number of

digits to the right of the decimal is 4)

2-9

Page 23

2-10

IM 04P01B01-61E

9.8°C

90.5°C

10.0°C

90.0°C

0.2°C

–0.5°C

10.0°C

90.0°C

Datum

(Correction point)

Value after Correction Value (Correction value)

when Mode is Revise when Mode is Abs.

2.4 Setting the Measurement Channels

Note

The L and R values that have been changed are displayed in orange, but the values are valid.

When data adjustment (see section 2.8) is executed, the values change back to white.

Unit

Enter the unit using up to six characters. The characters that can be used are as follows

(see section 2.12):

Alphabet, numbers, symbols (%, #, °, @, +, –, *, /, (, ), µ, Ω,

Bias

This appears when bias is enabled (see page 2-25) in Basic Setting mode.

ON/OFF and Value

Select ON to use bias.

The range of bias that can be specified is ±10% of the measurable range of the input

range. For example, the range is –0.4 V to 0.4 V for the 2 V input range. For channels on

which scaling is set, the range is ±10% of the scaling range span. A bias cannot be set

on channels set to ON/OFF input (DI).

2, 3

, .), and space

Calibration

(/CC1 Option)*

* For recorders with firmware version 1.21 or later

Settings on the Measure Tab

Setting items are displayed when the calibration correction is enabled in Basic Setting

mode (see page 2-25).

• Mode

Select Revise or Abs. to specify correction values. See the table below.

• Point

Input number of correction points (up to 16 points) including rst and last points.

• ON/OFF

Select ON to use the calibration correction.

Settings on the Calibration Tab

• Datums

Set a value of the correction point (input value). Follow the conditions below.

Datum of rst correction point < Datum of second correction point ≤ Datum of third

correction point ≤ Datum of fourth correction point ≤ ......

• Value

Set a correction value corresponding to the datum. Follow the conditions below.

• When Mode is set to Revise

“Datum + Value” of rst correction point < “Datum + Value” of second correction

point < “Datum + Value” of third correction point < ......

• When Mode is set to Abs.

Value of of rst correction point < Value of of second correction point < Value of

third correction point < ......

The table below shows some examples.

Note

If the difference between values of the correction points, or the difference between values after

correction, are small, for example several digits, an error may occur when you send the setup

data to the recorder. In that case, change the set values.

Page 24

1

2

Alarm 1 to 4

2.4 Setting the Measurement Channels

Four alarms (Alarm 1 to 4) can be specied on each channel.

Type

Type Values Description

H An alarm occurs when the measured value exceeds the specified value.

L An alarm occurs when the measured value falls below the specified value.

h(dH)* An alarm occurs when the difference in the input values of two channels is

greater than or equal to the specified value.

l(dL)* An alarm occurs when the difference in the input values of two channels is

less than or equal to the specified value.

R(RH) The rate-of-change of the measured values is checked over a certain time

(interval). An alarm occurs if the rate-of-change of the measured value in the

rising direction is greater than or equal to the specified value.

r(RL) The rate-of-change of the measured values is checked over a certain time

(interval). An alarm occurs if the rate-of-change of the measured value in the

falling direction is greater than or equal to the specified value.

T** An alarm occurs when the measured value remains above the alarm value for

the specified time period.

t** An alarm occurs when the measured value remains below the alarm value for

a specified time period.

*

Can be specified on channels set to delta computation.

T and t can be selected when the alarm delay function is enabled in Basic Setting mode.

**

Alarm Value

Alarm is generated using the specified value as the boundary. The selectable range of

alarm values vary depending on the input mode and range.

Configuring the Recorderr

Relay

To output relays, select the output relay number. Otherwise, select NONE.

Alarm Delay

An alarm occurs when the measured value remains above or below the alarm value for a

specified time period (alarm delay time).

Filter and Moving Average

Filter (Pen Model)

To use the input filter, select the time constant (2 s, 5 s, or 10 s).

Moving Average (Dot Model)

To use the moving average, select the sampling count (2 to 16).

Tag

Enter the tag using up to 7 characters. The characters that can be used are as follows (see

section 2.12):

Alphabet, numbers, symbols (%, #, °, @, +, –, *, /, (, ), µ, Ω,

Note

The setting of whether to use channel numbers or tags for printing is specified in Print Setting

under the Setup tab.

Zone

Sets the zone in which the measured values of each channel are recorded. Set the

position (mm) on the chart paper for the leftmost value of the recording zone (L) and

rightmost value of recording zone (R).

•

Selectable range: 0 to 100 mm (µR10000), 0 to 180 mm (µR2

Set R to a value greater than L, and make the zone width (R – L) greater than or equal

to 5 mm.

2, 3

, .), and space

0000)

IM 04P01B01-61E

2-11

Page 25

2-12

IM 04P01B01-61E

2.4 Setting the Measurement Channels

Bar Graph

Selects the display mode of the bar graph.

Normal: Sets the base point of the graph to the smaller of the values Span L or Span R (or

Scale L or Scale R).

Center: Sets the base point of the bar graph to the 50% position of the span.

Partial

This appears when partial expanded recording is enabled in Basic Setting mode.

Expand (%)

Set the boundary position for the partial expanded recording. The range is from 1 to 99%.

Boundary

Set the boundary value to a value within the span (within the scale when linear scaling is

used).

Color (Dot Model)

Click the appropriate box in the Color column to open the Recording Color dialog box.

Select the recording color of the respective channel.

Print Out

Trend (Dot Model)

Turns trend recording ON/OFF.

Periodic Printout

Periodic

Turns periodic printout ON/OFF.

Selects the type of measured values to be printed in periodic printout. This setting is

activated when Mode for Periodic Print in Print Setting (see page 2-24) in Basic Setting

mode is set to Report.

Mode

AVE: Average value over the interval.

MIX: Minimum, maximum, and average values over the interval.

SUM: Sum value over the interval.

MIN: Minimum value over the interval.

MAX: Maximum value over the interval.

INST: Instantaneous value

SUM Scale

When the mode is SUM, set the sum scale.

SUM sums the data every computation interval. For flow values that have units /s, /min, /h,

or /day, a simple summation results in the actual value not matching the computed result,

because the scan interval and the unit of the input values are different. In such cases, set

the sum scale to match the unit of the input value. In effect, the sum value with the same

unit as that of the input value is calculated.

For example, if the scan interval is 1 s, and the input value is 100 m

summation would add 100 every 1 s resulting in 6000 after one minute. However, if the

sum scale is set to /min, then 1 s/60 s is multiplied every scan interval before the value is

added giving a result with an m

OFF: Simply sums the measured values.

/s: Sums by converting the measured values to a value over 1 second.

/min: Sums by converting the measured values to a value over 1 minute.

/h: Sums by converting the measured values to a value over 1 hour.

/day: Sums by converting the measured values to a value over 1 day.

3

/min unit.

3

/min, a simple

Page 26

1

2

Copying and Pasting the Settings

Channel number

Set each item, and click here.

Applies the settings.

Applies the settings specified on the [Measure] tab.

The settings specified for a given channel can be copied and pasted to other channels.

Click the copy source channel number. To select multiple channels, drag the

1.

pointer while holding down the left mouse button.

Click Copy ( ).

2.

Click the copy destination channel number. To select multiple channels, drag the

3.

pointer while holding down the left mouse button.

Click Paste ( ).

4.

The items that are to be copied/pasted can be limited

Click Copy Details to open the Channel Copy Details dialog box.

Select the check boxes for the items you wish to copy/paste, and click OK.

2.4 Setting the Measurement Channels

Configuring the Recorderr

Setting Each Channel

Double-click a channel number. The dialog box for that channel opens.

IM 04P01B01-61E

The settings in this dialog box are the same as those on the Measure tab.

2-13

Page 27

2-14

IM 04P01B01-61E

2.5 Setting the Computation Channels (/M1 Option)

Tag

Alarm delay time

Channel recording color (dot model)

Turning ON/OFF computation

Equation

Constants used

in equations

Click twice to unselect the channel.

Double-click to open a setup dialog box for the respective channel.

Drag the pointer while holding down the left mouse button to select multiple channels.

Recording span

Rightmost

value

Unit

Leftmost

value

Decimal point

position

Alarm 1

Output relay

number

Alarm valueAlarm type

Sets the settings of the first channel in the selected

range to the other channels.

Partial expanded recording

Bar graph display mode

Turns ON/OFF periodic printout

Types of measured values

to be printed periodically

Turn trend recording ON/OFF (dot model)

Recording zone

Alarm 4

Sets the default value.

Toggles ON/OFF collectively for each click.

Sets the minimum possible value.

Sets the maximum possible value.

The tool buttons apply to the selected range of channels when channels are selected.

They apply to all channels when a channel is not selected.

Click the Math tab. You can also choose Math Channels from the Setting menu.

Page 28

1

2

Turning ON/OFF Computation

Turns ON/OFF computation.

Expression

Enter the expression using up to 120 characters. For details on the expression, see

section 9.2, “Setting the Computing Equation” in the µR10000 Recorder User’s Manual (IM

04P01B01-01E) or µR20000 Recorder User’s Manual (IM 04P02B01-01E).

Constant

Sets the constants to be used in computing equations. Up to 30 constants can be

specied.

Range of values (maximum significant digits is 5):

–9.9999E+29 to –1.0000E–30, 0, 1.0000E–30 to 9.9999E+29

Span

Set the recording span.

Span (Point, L, and R)

Set the leftmost value of the span (L) and the rightmost value of the span (R) using a

mantissa and decimal point position.

Mantissa: –9999999 to 99999999

Decimal position:

2.5 Setting the Computation Channels (/M1 Option)

Configuring the Recorderr

0 (the number of digits right of the decimal is 0) to 4 (the number of

digits to the right of the decimal is 4)

Unit

Enter the unit using up to six characters. The characters that can be used are as follows

(see section 2.12):

Alphabet, numbers, symbols (%, #, °, @, +, –, *, /, (, ), µ, Ω,

Alarm 1 to 4

For the procedure, see section 2.4, “Setting the Measurement Channels.”

The alarm types that can be specified on a computation channel is high limit (H), low limit

(L), delay high limit (T), and delay low limit (t).

TLOG Computation (TLOG)

Sets TLOG computation and the printing of the computed values.

Timer

Sets the timer used in TLOG computation and printout to Periodic (periodic printout

timer), 1 (timer 1), or 2 (timer 2). For a description of the timer setting, see page 2-24.

SUM Scale

Sets the sum scale when determining the sum value in TLOG computation. For a

description of sum scale, see page 2-12.

Tag, Zone, Bar Graph, Partial, Color (Dot Model), and Trend

For the procedure, see section 2.4, “Setting the Measurement Channels.”

2, 3

, .), and space

Copying and Pasting the Settings

The settings specified for a given channel can be copied and pasted to other channels.

For the procedure, see “Copying and Pasting the Settings” on page 2-13.

IM 04P01B01-61E

2-15

Page 29

2-16

IM 04P01B01-61E

Buttons to select

the operator type

Operator buttons

<Select Operator dialog box>

2.5 Setting the Computation Channels (/M1 Option)

Setting Each Computation Channel

Double-click a channel number. The dialog box for that channel opens.

Setting the Equation

Click the Ope. button to open the Select Operator dialog box.

Select the operator type to switch the displayed operator buttons. Click a operator button

to enter the operator in Exp.

The items in the math channel tab can be configured for each channel. The settings in

this dialog box are the same as those on the Math tab.

Page 30

1

2

2.6 Setting the Items in Setting Mode and the Data

Click here (or choose [Setting] > [SET [Regular] Setting] > [Chart Speed]/[Trend Interval])

Chart speed

Secondary chart speed

Trend interval (dot model)

Display Method

Click the Setting tab. You can also select the item by choosing SET [Regular] Setting

from the Setting menu.

Chart Speed/Trend Interval

Chart Speed

• Pen Model

The chart speed can be selected from 82 settings shown below.

Chart speed on the pen model (unit: mm/h)

5 6 8 9 10 12 15 16 18 20

24 25 30 32 36 40 45 48 50 54

60 64 72 75 80 90 96 100 120 125

135 150 160 180 200 225 240 250 270 300

320 360 375 400 450 480 500 540 600 675

720 750 800 900 960 1000 1080 1200 1350 1440

1500 1600 1800 2000 2160 2250 2400 2700 2880 3000

3600 4000 4320 4500 4800 5400 6000 7200 8000 9000

10800 12000

• Dot Model

The chart speed can be set in the range of 1 to 1500 mm/h in 1 mm steps.

Configuring the Recorderr

Trend Interval (Dot Model)

Auto: The trend recording interval is set according to the chart speed in the range of

10 s to 90 s so that the dots do not overlap.

Fix: The trend recording interval is fixed to 10 s/6 dots. On models with the

computation function (/M1 option), the dot printing interval varies depending on

the number of measurement and computation channels to be trend recorded.

IM 04P01B01-61E

2-17

Page 31

2-18

IM 04P01B01-61E

Click here (or choose Setting > SET [Regular] Setting > Message)

Message

Format text box

Click the button to enter the displayed

character string in the text box.

Click a text box from 1 to 5. A dialog box used to set

the message format opens.

Copies/Pastes messages.

Click twice to unselect the message.

Drag the pointer while holding down the left mouse button to select multiple

messages.

2.6 Setting the Items in Setting Mode and the Data Display Method

Message

Messages

Set a message using up to 16 characters.

The characters that can be used are as follows (see section 2.12):

Alphabet, numbers, symbols (%, #, °, @, +, –, *, /, (, ), µ, Ω,

2, 3

, .), and space

Page 32

1

2

H:M 5 H:M:S 8

M/D H:M 11 M/D H:M:S 14

D/M H:M 11 D/M H:M:S 14

D.M H:M 11 D.M H:M:S 14

M.D H:M 12 M.D H:M:S 15

Y/M/D H:M:S 19 M/D/Y H:M:S 19

D/M/Y H:M:S 19 D.M.Y H:M:S 19

M.D.Y H:M:S 20

H, M, and S are hour, minute, and second, respectively, for H:M and H:M:S.

M, D, and Y are month, day, and year, respectively for M/D, D/M, D.M , M.D,

Y/M/D, M/D/Y, D/M/Y, D.M.Y, and M.D.Y.

Format symbols and number of characters used

Num. of

Chars

Symbol Num. of

Chars

Symbol Num. of

Chars

Symbol

01 to 24 7

L01 to L16 1 to 16

0A to 1P 9

10th and 11th characters of the message

string (9 characters already used, so this

represents the next characters.)

Message 1 string of the standard function:

Process-1°C

Message 1 printout result: 06/30 10:10 Process-1 134.8°C

Message format 1: M/D H:M L09 01L02

Message value on CH1 (no unit)

Space (number of characters: 1)

Space

1-9th characters of the message string

Date/Time

2.6 Setting the Items in Setting Mode and the Data Display Method

Message Format (/BT1 Option)*

* Function available on recorders with firmware version 1.31 or later.

Set the message format.

Click a text box from 1 to 5. A dialog box used to set the message format opens. Set the

format using the selectable items displayed in the dialog box and space.

Number of characters per message: Up to 35 (µR10000) and up to 69 (µR20000).

Setup Example

Configuring the Recorderr

IM 04P01B01-61E

2-19

Page 33

2-20

IM 04P01B01-61E

Click here (or choose [Setting] > [SET [Regular] Setting] > [Data Display Setup])

Screen tab

When display type is [Flag]

When display type is [Multiple display]

Displayed channel switching interval

Display type

Display of the top section Display of the bottom section

Display type

Displayed channel switching interval

Display channel

Selects the channels on which flag is to be displayed.

2.6 Setting the Items in Setting Mode and the Data Display Method

Data Display Setup

Pict1 Tab to Pict15 Tab

Corresponds to Screen 01 to Screen 15.

• Type

The following display types available. For details on the display types, see section

12.4, “Display Function Specications” in the µR10000 Recorder User’s Manual (IM

04P01B01-01E) or µR20000 Recorder User’s Manual (IM 04P02B01-01E).

Display Type Display Type

Skip (the screen is not displayed) Time/Chart speed

1 CH digital DI/DO

2 CH digital Multiple display (Display in which different screens

4 CH digital

6 CH digital (6-dot models) Tag_1 CH digital

12 CH digital (12/18/24-dot models, µR20000) Tag_2 CH digital

1 CH digital + 1 CH bargraph Tag_1 CH digital + 1 CH bargraph

1 CH digital + 4 CH bargraph (pen models) Tag_1 CH digital + 4 CH bargraph (pen models)

2 CH digital + 2 CH bargraph Status

4 CH bargraph (pen models) System

6 CH bargraph (dot models, µR10000) Batch Name*

Flag Lights out (display with no contents)

Channel alarm status

* Selectable on recorders with firmware version 1.31 or later and header printout (/BT1 option).

can be assigned to the top and bottom sections)

Page 34

1

2

• Interval

Click here (or choose [Setting] > [SET [Regular] Setting] > [Brightness]/[DST])

VFD brightness

Brightness of the internal illumination

For recorders with firmware version 1.02 or earlier

For recorders with firmware version 1.11 or later

Sets the displayed channel switching interval. This item appears when the display

Auto 1s to Auto 5s:

Manual: Switch the channel manually.

• Display (For Flag)

Selects the channels on which ag is to be displayed.

• Channel No. (L)/Channel No. (R) (For Multiple display)

Species the channels to be displayed simultaneously.

Brightness and DST

2.6 Setting the Items in Setting Mode and the Data Display Method

type requires this setting.

Switches the channel at the specied time interval.

Configuring the Recorderr

VFD Display

The brightness can be set to an integer between 1 and 8. The darkest setting is 1; the

brightest setting is 8.

Light

The brightness of the internal light can be set to an integer between 1 and 4. The darkest

setting is 1; the brightest setting is 4. Select OFF to turn off the internal light.

DST

Sets the date/time for switching between standard time and DST.

• For recorders with firmware version 1.02 or earlier

Summer: Date/Time when switching from standard time to DST

Winter: Date/Time when switching from DST to standard time

• For recorders with firmware version 1.11 or later

Start Time: Date/Time when switching from standard time to DST. Specify the day

as n th day of the week of the month.

End T

ime: Date/Time when switching from DST to standard time. Specify the day

as n th day of the week of the month.

IM 04P01B01-61E

2-21

Page 35

2-22

IM 04P01B01-61E

Click here (or choose [Setting] > [SET [Regular] Setting] > [Batch])

Click the text box and enter the text.

Click twice to unselect the line.

Drag the pointer while holding down the left mouse button to select multiple lines.

Copies/Pastes the text.

Displayed only for

End and End2.

2.6 Setting the Items in Setting Mode and the Data Display Method

Batch (/BT1 Option)*

* Function available on recorders with firmware version 1.31 or later.

This appears when batch function is enabled (see page 2-33) in Basic Setting mode.

Set the contents of the start printout and end printout.

The Start2 and End2 tabs are valid when Dual Comment is enabled in Basic Setting

mode.

Batch No.

Enter the batch number using up to 26 characters.

The characters that can be used are as follows (see section 2.12):

Alphabet, numbers, symbols (%, #, °, @, +, –, *, /, (, ), µ, Ω,

Lot No.

This appears when Digit of lot number is specified (see page 2-33) in Basic Setting

mode.

Set the number in the range of 0000 to 9999 or 000000 to 999999. Digit of lot number is

set in Basic Setting mode.

Batch Comment

Set the batch comment using up to 32 characters by 5 lines (µR10000) or 64 characters

by 5 lines (µR20000).

The characters that can be used are as follows (see section 2.12):

Alphabet, numbers, symbols (%, #, °, @, +, –, *, /, (, ), µ, Ω,

Batch Printout

• Batch Name

On: Prints the batch name.

• Chart Speed

On: Prints the chart speed.

• Date/Time

On: Prints the date and time.

2, 3

, and .), and space

2, 3

, and .), and space

Page 36

1

2

2.6 Setting the Items in Setting Mode and the Data Display Method

Batch Action

• Feed Amount

Set the length of chart paper to be fed out before start printout or after end printout in

1-mm steps up to 50 mm.

• Lot No. Auto Increment

On: Increments the lot number when the header printout is completed.

• Ejection of POC

On: Records the portion of the data that remains after recording stops when the pen

offset compensation function is enabled on the pen model.

• Chart feed speed at POC

Species the chart feed speed when recording the portion of the data that remains.

Configuring the Recorderr

IM 04P01B01-61E

2-23

Page 37

2-24

IM 04P01B01-61E

2.7 Setting the Items in Basic Setting Mode

Click here (or choose [Setting] > [SETUP [Basic] Setting] > [Alarm]/[Remote Action])

Click twice to unselect the channel.

Drag the pointer while holding down the left mouse button to select

multiple lines.

Copy/Paste the action.

Click the Setup tab. You can also select the item by choosing SETUP [Basic] Setting

from the Setting menu.

Alarm/Relay/Remote

Diagnosis

ON: Alarm output relay I01 is used for diagnosis output.

Reflash

ON: Alarm output relays I01, I02, and I03 are set to reflash alarm operation.

Relay AND

Set the range of relays (from alarm output relay I01) to take the AND operation. If NONE

is selected, no relays are set to AND operation. All relays are set to OR operation.

Relay Action

Sets whether the output relay is energized or de-energized when an alarm occurs.

Alarm Relay Behavior

Nonhold: Releases the relay output at the same time the alarm is released.

Hold: Holds the relay output until the alarm ACK operation is executed.

Alarm Indicator

Nonhold: Releases the alarm indication at the same time the alarm is released.

Hold: Holds the alarm indication until the alarm ACK operation is executed.

Rate of Change Increase and Rate of Change Decrease

Set the interval of the high limit and low limit on rate-of-change alarm to an integer

between 1 and 15. The interval is set to scan interval × (1 to 15).

The scan interval on the pen model is 125 ms. The scan interval on the dot model is 1 s

or 2.5 s.

Page 38

1

2

2.7 Setting the Items in Basic Setting Mode

Measure Alarm Hysteresis

Sets the alarm hysteresis of measurement channels in the range of 0.0% (OFF) to 1.0%

of the recording span in 0.1 steps. The hysteresis applies to all high limit and low limit

alarms of measurement channels.

Math Alarm Hysteresis (Models with the Computation Function (/M1

Option))

Sets the alarm hysteresis of computation channels in the range of 0.0% (OFF) to 1.0%

of the recording span in 0.1 steps. The hysteresis applies to all high limit and low limit

alarms of computation channels.

Remote (Models with Remote Control Input (/R1 Option))

Remote 1 to Remote 5 corresponds to remote control input terminals 1 to 5. The

following functions can be assigned.

Display Description

NONE No function is assigned.

Record On/Off Starts/stops recording.

Chart speed Changes the chart speed.

Time adjust Adjusts the internal clock to the nearest hour.

MATH start/stop Starts/stops the computation on the computation function

(/M1 option).

MATH reset Resets the computed result of the computation function

(/M1 option).

Manual print Executes manual printout.

Alarm ACK Executes alarm output release.

message # Prints message # (where # is a value between 1 and 5).

Priority to Remote Recording* Starts/stops recording.

Switching Batch Comment* Switches between start printout and start printout 2. Or,

switches between end printout and end printout 2.

*

Selectable on recorders with firmware version 1.31 or later and heade

r printout (/BT1 option).

Configuring the Recorderr

IM 04P01B01-61E

2-25

Page 39

2-26

IM 04P01B01-61E

Click here (or choose [Setting] > [SET [Basic] Setting] > [Burnout]/[RJC])

Click twice to unselect the channel.

Drag the pointer while holding down the right mouse button to select multiple lines.

Copies/Pastes the

settings of a channel to

other channels.

2.7 Setting the Items in Basic Setting Mode

Channel

Burnout

Up: Records off the scale on the 100% side when a thermocouple burnout is

detected.

Down: Records of

OFF: Disable the burnout detection function.

f the scale on the 0% side when a thermocouple burnout is detected.

RJC

• Type

Internal: Uses the RJC function of the recorder.

External: Uses an external RJC function.

• Volt (uV)

Sets the compensation voltage when using an external RJC function. The

compensation voltage can be set in the range of –20000 µV to 20000 µV.

Page 40

1

2

Key Lock

Click here (or choose [Setting] > [SETUP [Basic] Setting] > [Key Lock])

Select the keys to apply the key lock function

2.7 Setting the Items in Basic Setting Mode

Configuring the Recorderr

Key Lock

Specify whether to use key lock.

Password

Sets the password for releasing the key lock. Set the password using numbers and

spaces up to 4 digits.

Note

Note that if the firmware version of the µR10000 is 1.01, a password that starts with spaces

is read with the spaces removed on the recorder. The firmware version of the recorder can be

checked on the system display (see “Data Display Setup” on page 2-20).

Keys That Can Be Locked

Below are operations in the FUNC key menu.

• Alarm ACK: Alarm ACK operation

• Math: Math start, stop, and reset operations

• Print Out: Printout start/stop operation

• Message: Message printout operation

• Buffer clear: Operation for clearing the printout buffer memory

• Periodic: Operation for clearing the report data of the periodic printout

• Pen exchange: Operation for moving the pen to a position that is easily accessible

for replacement (pen model)

• Ribbon exchange:

* For recorders with firmware version 1.11 or later

Operation for moving the printer to a position that is easily

accessible for ribbon cassette replacement (dot model)*

IM 04P01B01-61E

2-27

Page 41

2-28

IM 04P01B01-61E

Click here (or choose [Setting] > [SETUP [Basic] Setting] > [Customized Menu])

Turn ON/OFF the menu item

2.7 Setting the Items in Basic Setting Mode

Customized Menu*

* Function available on recorders with firmware version 1.31 or later.

Customized Menu

The FUNC key menu and Setting mode menu can be customized to display only the

menus that you use.

• Customized Menu

Set whether or not to use this function.

• Password

This is the password used to release the customized menu or to enter Basic Setting

mode. Set the password using a number up to 4 digits and space.

• Pen/Dot print pos. adjust

Use: Use the pen position adjustment (pen model) and dot printing position adjustment

(dot model) without the password.

Not: Enter the password to enter Basic setting mode to use the pen position

adjustment (pen model) and dot printing position adjustment.

• Setting Mode Menu

Menu items of Setting mode.

OFF: Hides the menu items.

• FUNC Key Menu

Menu items using the FUNC key.

OFF: Hides the menu items.

Page 42

1

2

Timer