Page 1

Instruction

Manual

Models 4370

µR1800 Recorder

IM 4H3B1-01E

Yokogawa Electric Corporation

IM 4H3B1-01E

8th Edition

Page 2

INTRODUCTION

Thank you for purchasing the µR1800 Recorder.

To take full advantage of all functions of the µR1800 Industrial Recorder, and to operate

this instrument correctly and efficiently, please read this Instruction Manual carefully

before use.

NOTES • YOKOGAWA reserves the right to change this manual at any time without notice.

• If you find any ambiguities or errors in this manual, please inform YOKOGAWA.

• This manual is the eighth edition, July 1998.

Previous editions were released as follows:

November ’92 first edition

May ’93 second edition

October ’93 third edition

April ’94 fourth edition

October ’95 fifith edition

April ’96 sixth edition

May ’98 seventh edition

July ’98 eighth edition

Disk No. MR07

8th Edition : July 1998 (YG)

All Rights Reserved, Copyright © 1992, Yokogawa Electric Corporation

IM 4H3B1-01E

1

Page 3

SAFETY PRECAUTIONS

• The µR1800 is a Component Type instrument and should be mounted on a panel.

• The µR1800(except portable type) is a Safety ClassI instrument (provided with

terminal for protective earthing).

• The µR1800(except portable type) is an EN55011(EMI standard) Group 1, Class A

instrument.

• This instrument complies with Inatallation Category ll.

The following general safety precautions must be observed during all phases of

operation, service, and repair of this instrument. Failure to comply with these

precautions or with specific WARNINGS given elsewhere in this manual violates safety

standards of design, manufacture, and intended use of the instrument.

YOKOGAWA Electric Corporation assumes no liability for the customer’s failure to

comply with these requirements.

General definitions of safety symbols used on equipment and in manuals

Explanation: To avoid injury, death of personnel or damage to the instrument, the

operator must refer to an explanation in the instruction manual.

Protective grounding terminal: To protect against electrical shock in case of a fault.

This symbol indicates that the terminal must be connected to ground before operation of

equipment.

WARNING

CAUTION

High temperature: To avoid injury caused by hot surface, don't touch the heatsink.

A WARNING sign denotes a hazard. It calls attention to a procedure, practice,

condition or the like, which, if not correctly performed or adhered to, could result

in injury or death of personnel.

A CAUTION sign denotes a hazard. It calls attention to a procedure, practice,

condition or the like, which, if not correctly performed or adhered to, could result

in damage to or destruction of part of the product.

2 IM 4H3B1-01E

Page 4

WARNING

Power Supply

Ensure the source voltage matches the voltage of the power supply before

turning on the power.

Protective Grounding

Make sure to connect the protective grounding to prevent an electric shock

before turning on the power.

Necessity of Protective Grounding

Never cut off the internal or external protective grounding wire or disconnect the

wiring of protective grounding terminal. Doing so poses a potential shock

hazard.

Defect of Protective Grounding and Fuse

Do not operate the instrument when protective grounding or fuse might be

defective.

Fuse

To prevent a fire, make sure to use the fuse with specified standard (current,

voltage, type). Before replacing the fuse, turn off the power and disconnect the

power source. Do not use a different fuse or short-circuit the fuse holder.

Do not Operate in an Explosive Atmosphere

Do not operate the instrument in the presence of flammable liquids or vapors.

Operation of any electrical instrument in such an environment constitutes a

safety hazard.

Never Touch the Interior of the Instrument

Inside this instrument there are areas of high voltage; therefore, never touch the

interior if the power supply is connected. This instrument has an internal

changeable system; however, internal inspection and adjustments should be

done by qualified personnel only.

External Connection

To ground securely, connect the protective grounding before connecting to

measurement or control unit.

IM 4H3B1-01E

3

Page 5

CONTENTS

INTRODUCTION ................................................................................................. 1

SAFETY PRECAUTIONS .................................................................................. 2

HOW TO USE THIS MANUAL ......................................................................... 6

Chapter 1 FEATURES AND FUNCTIONS

1.1 Features ....................................................................................................... 1 - 1

1.2 Summary of Functions ............................................................................... 1 - 2

Chapter 2 BEFORE OPERATION

2.1 Handling Precautions ................................................................................. 2 - 1

2.2 Checking the Contents .............................................................................. 2 - 2

Chapter 3 INSTALLATION

3.1 Installation Site/Mounting .......................................................................... 3 - 1

3.2 Wiring ........................................................................................................... 3 - 4

!

!

!

!

!

!

Chapter 4 COMPONENT NAMES AND FUNCTIONS

4.1 Front Panel .................................................................................................. 4 - 2

4.2 Display.......................................................................................................... 4 - 4

Chapter 5 DAILY OPERATION

5.1 How to Switch the Power ON/OFF .......................................................... 5 - 1

5.2 How to Install (& Replace) Chart, Pens,

5.3 Basic Operation (Operation Mode) .......................................................... 5 - 7

5.4 How to Use the Key-lock .................................................................... 5 - 17

Chapter 6 HOW TO ENTER SETTINGS

6.1 Explanation of Modes ................................................................................ 6 - 1

6.2 Concept of Setting Parameters ................................................................ 6 - 2

6.3 Flow Charts ................................................................................................. 6 - 3

6.4 Setting Parameters in SET Mode ............................................................ 6 - 6

6.5 List of Initial Setting Values ................................................................ 6 - 7

Chapter 7 BASIC SETTINGS

7.1 How to Set Input Range and Recording Span....................................... 7 - 1

2.2.1 Checking Accessories and Appearance ..................................................... 2 - 2

2.2.2 Removing Packings ................................................................................ 2 - 3

2.2.3 Checking Model Code ............................................................................. 2 - 3

3.1.1 Installation Site ....................................................................................... 3 - 1

3.1.2 Mounting ............................................................................................... 3 - 2

3.1.3 Dimensional Drawings ............................................................................. 3 - 3

3.2.1 Rear Panel Arrangement ......................................................................... 3 - 4

3.2.2 Power Supply Wiring ......................................................................................... 3 - 5

3.2.3 Input Wiring ....................................................................................................... 3 - 6

3.2.4 Alarm Output Wiring .......................................................................................... 3 - 9

3.2.5 FAIL/Chart End Wiring ...................................................................................... 3 - 10

3.2.6 Remote Control Wiring ............................................................................ 3 - 11

Ribbon Cassette and Battery.................................................................... 5 - 2

5.2.1 How to Load (& Replace) the Chart ........................................................... 5 - 2

5.2.2 How to Install (& Replace) Pens and Ribbon Cassette................................. 5 - 4

5.2.3 How to Replace the Battery...................................................................... 5 - 6

5.3.1 How to Start/Stop the Recording ............................................................... 5 - 7

5.3.2 How to Feed the Chart ............................................................................ 5 - 7

5.3.3 How to Get a Manual Printout................................................................... 5 - 7

5.3.4 How to Get a List Printout ........................................................................ 5 - 8

5.3.5 How to Get a SET UP List Printout ............................................................ 5 - 10

5.3.6 How to Get a Message Printout ................................................................ 5 - 12

5.3.7 How to Acknowledge an Alarm ................................................................. 5 - 13

5.3.8 How to Select the Display ................................................................................. 5 - 14

5.3.9 How to Cope with FAIL/Chart End ............................................................ 5 - 16

6.3.1 Flow Chart of Operation Mode .................................................................. 6 - 3

6.3.2 Flow Chart of SET Mode ......................................................................... 6 - 4

6.3.3 Flow Chart of SET UP Mode .................................................................... 6 - 5

7.1.1 SKIP Setting .......................................................................................... 7 - 2

7.1.2 Voltage Measurement Setting (VOLT Setting) ............................................ 7 - 3

7.1.3 Thermocouple and Resistance Temperature Detector Setting

(TC, RTD Setting) ................................................................................... 7 - 4

7.1.4 Digital Input Setting (DI Setting) ................................................................ 7 - 5

7.1.5 Difference Computation Setting (DELT Setting) .......................................... 7 - 6

4 IM 4H3B1-01E

Page 6

7.1.6 Scale Setting (SCL Setting)...................................................................... 7 - 7

7.1.7 Setting to Obtain Square Root (SQRT Setting) ........................................... 7 - 8

7.2 How to Set Alarms ............................................................................. 7 - 10

7.3 How to Assign Units ................................................................................... 7 - 12

7.4 How to Set the Chart Speed ..................................................................... 7 - 13

7.5 How to Set the Clock ................................................................................. 7 - 14

7.6 How to Copy Channel Settings to Another Channel ............................. 7 - 15

7.7 How to Set the Remote RJC (For /N5 Model) .................................... 7 - 16

Chapter 8 AUXILIARY SETTINGS (AUX)

8.1 Settings for Analog Recording.................................................................. 8 - 1

8.1.1 How to Adjust the Trend Recording Format ................................................ 8 - 2

8.1.2 How to Set Zone Recording ..................................................................... 8 - 3

8.1.3 How to Set Partial Expanded Recording .................................................... 8 - 4

8.2 Settings for Digital Printing........................................................................ 8 - 6

8.2.1 How to Select the Periodic Printout ON/OFF .............................................. 8 - 6

8.2.2 How to Set a Tag .................................................................................... 8 - 8

8.2.3 How to Set Messages ............................................................................. 8 - 9

8.3 How to Set the Chart Speed Used When Change-on-alarm

or Remote Control is Selected ........................................................... 8 - 10

Chapter 9 CHANGING INITIAL SETTINGS

These settings are entered during manufacturing and seldom need to be changed.

9.1 How to Change Initial Settings for the Alarm Function......................... 9 - 1

9.1.1 How to Select the Reflash Function ON/OFF.............................................. 9 - 2

9.1.2 How to Select the Output Relay to be of AND/OR Type ............................... 9 - 3

9.1.3 How to Select the Output Relay to be Energizing/De-energizing on Alarm

9.1.4 How to Select the Alarm Output Relay to be of HOLD/NON-HOLD Type ....... 9 - 5

9.1.5 How to Select the Alarm Indicator to be of HOLD/NON-HOLD Type .............. 9 - 6

9.1.6 How to Set the Sampling Interval for Rate-of-change Alarms ........................... 9 - 7

9.1.7 How to Select Alarm Hysteresis ON/OFF ................................................... 9 - 8

9.2 How to Change Initial Settings for the Input ....................................... 9 - 9

9.2.1 How to Set the A/D Integration Time ......................................................... 9 - 9

9.2.2 How to Set Upscale/Downscale TC Burnout ..................................................... 9 - 10

9.2.3 How to Set Internal or External RJC .......................................................... 9 - 11

9.2.4 How to Select the Input Filter (Pen Model) ................................................. 9 - 12

9.2.5 How to Select a Moving Average (Dot Model) ............................................ 9 - 13

9.3 How to Change Initial Settings for Analog Recording .......................... 9 - 14

9.3.1 How to Select Pen Offset Compensation ON/OFF (Pen Model) .................... 9 - 14

9.3.2 How to Assign Different Colors to Channels (Dot Model) ............................. 9 - 15

9.4 How to Change Initial Settings for Digital Printouts .............................. 9 - 16

9.4.1 How to Select Channel Numbers or Tag Printout ........................................ 9 - 16

9.4.2 How to Select Scales Printout ON/OFF ..................................................... 9 - 16

9.4.3 How to Select the New Chart Speed Printout ON/OFF ................................ 9 - 17

9.4.4 How to Select the Record Start Time Printout ON/OFF ................................ 9 - 17

9.4.5 How to Select Alarm Settings and Alarm Printout ............................................. 9 - 18

9.4.6 How to Select to Trigger the Periodic Printout .................................................. 9 - 18

9.5 How to Select the Type of Bargraph ....................................................... 9 - 20

9.6 How to Change the Temperature Unit (for USA) ............................... 9 - 21

9.7 How to Initialize Settings ........................................................................... 9 - 21

9.8 How to Change Initial Settings for the REMOTE Option .................... 9 - 22

9.9 How to Select to Trigger the Recording to Start/Stop ........................ 9 - 23

9.10 How to Change Key-lock Settings ...................................................... 9 - 24

Chapter 10 GENERAL SPECIFICATIONS

Chapter 11 MAINTENANCE

11.1 Periodic Maintenance ................................................................................ 11 - 1

!

11.2 Fuse Replacement ..................................................................................... 11 - 2

11.3 Pen Adjustment (Pen Model) .................................................................... 11 - 3

11.4 Printer Carriage Adjustment (Dot Model) ............................................... 11 - 4

11.5 Calibration .................................................................................................... 11 - 5

11.6 Cleaning the Plotter Carriage Shaft (Pen Model) ................................... 11 - 7

11.7 Lubrication (Dot Model) ............................................................................. 11 - 7

Chapter 12 TROUBLESHOOTING

12.1 Error Message Table ................................................................................. 12 - 1

12.2 Troubleshooting Flow Chart ...................................................................... 12 - 2

.......

Chapter 1 Chapter 2 Chapter 3 Chapter 4 Chapter 5 Chapter 6 Chapter 7 Chapter 8 Chapter 9 Chapter 10 Chapter 11 Chapter 12

9 - 4

TERMINOLOGY

INDEX

IM 4H3B1-01E

TERMINOLOGY

INDEX

5

Page 7

HOW TO USE THIS MANUAL

This manual describes the standard functions, operation procedures and some of the

optional functions of the pen model and dot printing model of the µR1800 recorder.

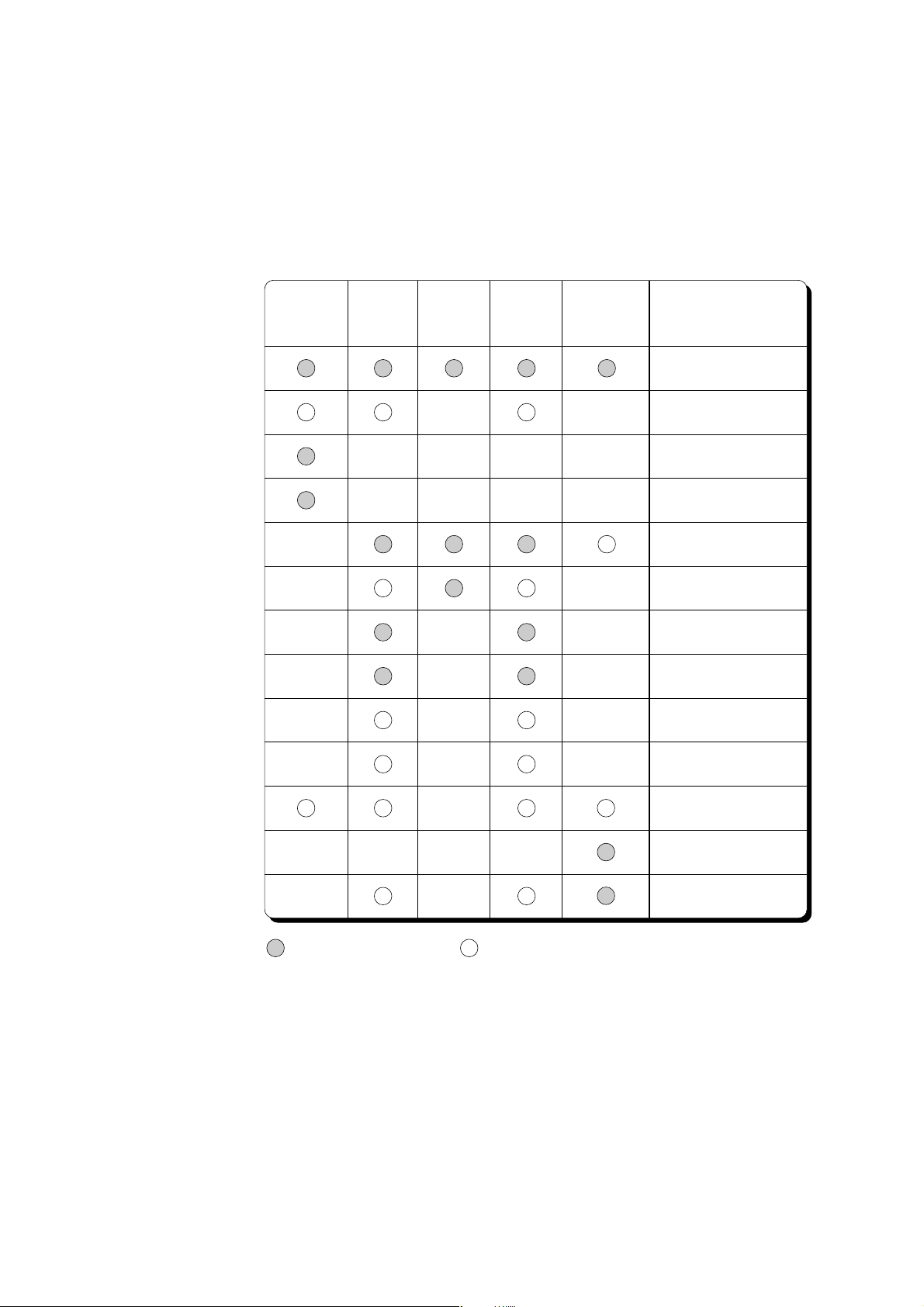

To use this manual in the most efficient way, please refer to the following table. In this

table the aim of the user is broken down into five broad categories. Please check which

are applicable to you and refer to the corresponding chapters.

Purchase &

Installation

First Time

Setting

Daily

Operation

Changing

Settings

Maintenance

& Trouble-

shooting

Chapters

Safety Precautions

1 Features and

Functions

2 Before Operation

3 Installation

4 Component Names

and Functions

5 Daily Operation

6 How to Enter

Settings

7 Basic Settings

8 Auxiliary Settings

(AUX)

9 Changing Initial

Settings

10 General

Specifications

11

Maintenance

Troubleshooting

12

necessary to read optional to read

::

For operation procedures of options, which are not described in this manual, refer to

specific option manuals.

6 IM 4H3B1-01E

Page 8

1.1 Features

Chapter 1 FEATURES AND FUNCTIONS

1.1 Features

This chapter describes the main features and functions of the µR1800 recorder. The

µR1800 is equipped with all the functions which can be expected in a modern recorder,

whereas its functions also reflect the latest user requirements.

The µR1800 recorder is a precision measuring instrument that is equipped with many

outstanding features:

Compact sized, high reliability: Its compact size (depth 220mm) allows you to

install the µR1800 where only a limited space is available. In case of the pen model, a

contact-free potentiometer and a brushless-DC servomotor contribute to its high

reliability. In case of the dot printing model, high reliability is obtained by the use of

high break down voltage solid-state relays.

Universal inputs: Inputs like DC-voltage, Thermocouple (TC), Resistance

Temperature Detector (RTD), and Digital Input (contact) can all be conveniently used.

There is no need to change any dipswitches; the type of input can be set using the keyboard.

Easy interactive setting: The setting procedure has been made very easy, by using

only panel keys. The µR1800 asks you to select the desired settings, without the need

for remembering difficult setting-codes.

Large informative operator display: The large sized, VFD, display shows the

measured data (including the engineering units) or clock, and bargraph at the same time.

There are two types of bargraph available: percentage-display, and center-zero display.

Because of its 1%-resolution, the bargraph displays very accurately.

1. FEATURES AND FUNCTIONS

Continuous pen recording for up to four channels (pen model only):

Depending on your µR1800 model type, the µR1800 can measure up to four channels

simultaneously. This allows you to decrease the number of recorders you require.

Universal power supply (except for /P1 model): The µR1800 accepts 90 to

250VAC (except 132 to 180VAC), and 50/60Hz without any problems, or need to turn

switches. Therefore the µR1800 is compatible with a wide variety of power supplies.

High performance: The sampling speed of the µR1800 pen model is high at 125 ms,

whereas the recording cycle of the µR1800 dot printing model is 6 ch./10 seconds, or

12ch./15sec., 18ch./20sec. or 24ch./30sec. depending on the model.

The µR1800 is equipped with many functions. Special functions can be ordered as an

option. Furthermore, its power consumption is low (4pen model; 30VA under normal

operation conditions).

Easy maintenance: Because of the use of many contact-free parts, the need for

maintenance has been decreased. The µR1800 is designed in modules, which decreases

the time needed for maintenance extensively.

Closed case: The closed case of the µR1800 allows it to be used in many

environments. The front door is in accordance with DIN 40050-IP54.

Computer interface and memory card: If equipped with this option, the µR1800

can store and retrieve measured data as well as setting data, using an IC memory card or

directly from your PC. The available interface is RS-422-A.

IM 4H3B1-01E

Based on international safety standards: The µR1800 (except portable type) is

based on international safety standards, such as the IEC 348.

1 - 1

Page 9

1.2 Summary of Functions

This paragraph describes a summary of the main functions, together with a recording

example.

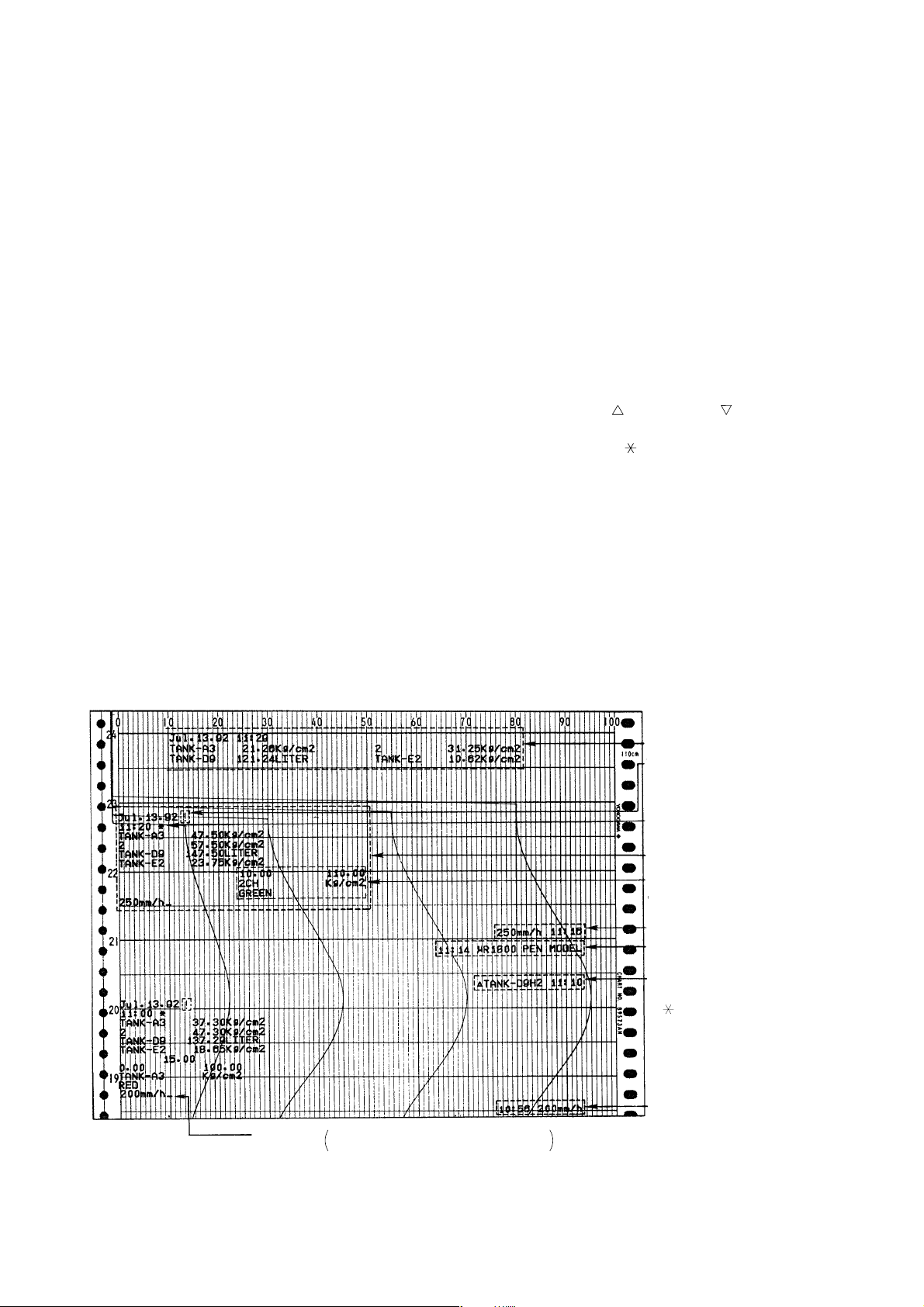

RECORDING

Trend: records in a way that the dots do not overlap (dot model only)

Zone: records on different bands (zones) for individual channels

Partial: expands part of the recording range for detailed examination

POC: Pen Offset Compensation: removes the time-axis offset between pens (pen model only)

PRINTOUT

Channel printout: contains channel No. besides analog recording (dot model only)

List printout: contains date, time, chart speed (1 & 2), channel No. or tag, range, span values, scale

values, partial values and contents of messages (for example, see 5.3.4)

Manual printout: contains date and time, channel No., type of alarm, latest measured values, units (for all

channels)

Alarm printout: contains channel or tag No., type of alarm, level, mark ( for occurence, for recover;

in case of the dot model, red and blue respectively) and alarm ON/OFF-time

Periodic printout: contains date & time, tag or channel No., POC ON mark ( ; for pen model only), unit,

scale markings (may not be printed while alarm occurs), chart speed, measured values

and recording color (for pen model) and time tick (for dot model)

Message printout: contains time and message

Recording start printout: contains time when recording starts

Chart speed change: contains time and new chart speed

SET UP List printout: contains initial settings concerning analog recording, digital printing, alarms, burnout,

RJC and options (for example, see 5.3.5)

NOTE The alarm, channel (for dot model), periodic, message, recording start and chart speed

change printout depend on the chart speed. The size of the characters varies depending

on the chart speed.

Manual printout

Time tick cancel mark (!)

appears when chart feed/speed

has been changed during

periodic printout

POC ON mark

Periodic printout

Scale printout an Recording

color

Chart speed change printout

Message printout

Alarm printout

Note: When an asterisk appears

( ), the memory buffer is full

and some data will not be printed.

This asterisk may appear in the

alarm printout, message printout,

recording start time printout and

the chart speed change printout.

Recording start time

Time tick (–)

Figure 1.1 Recording Example for Pen Model

always corresponding to pen No.1 when POC is OFF.

Corresponding to all pens when POC is ON.

1 - 2 IM 4H3B1-01E

Page 10

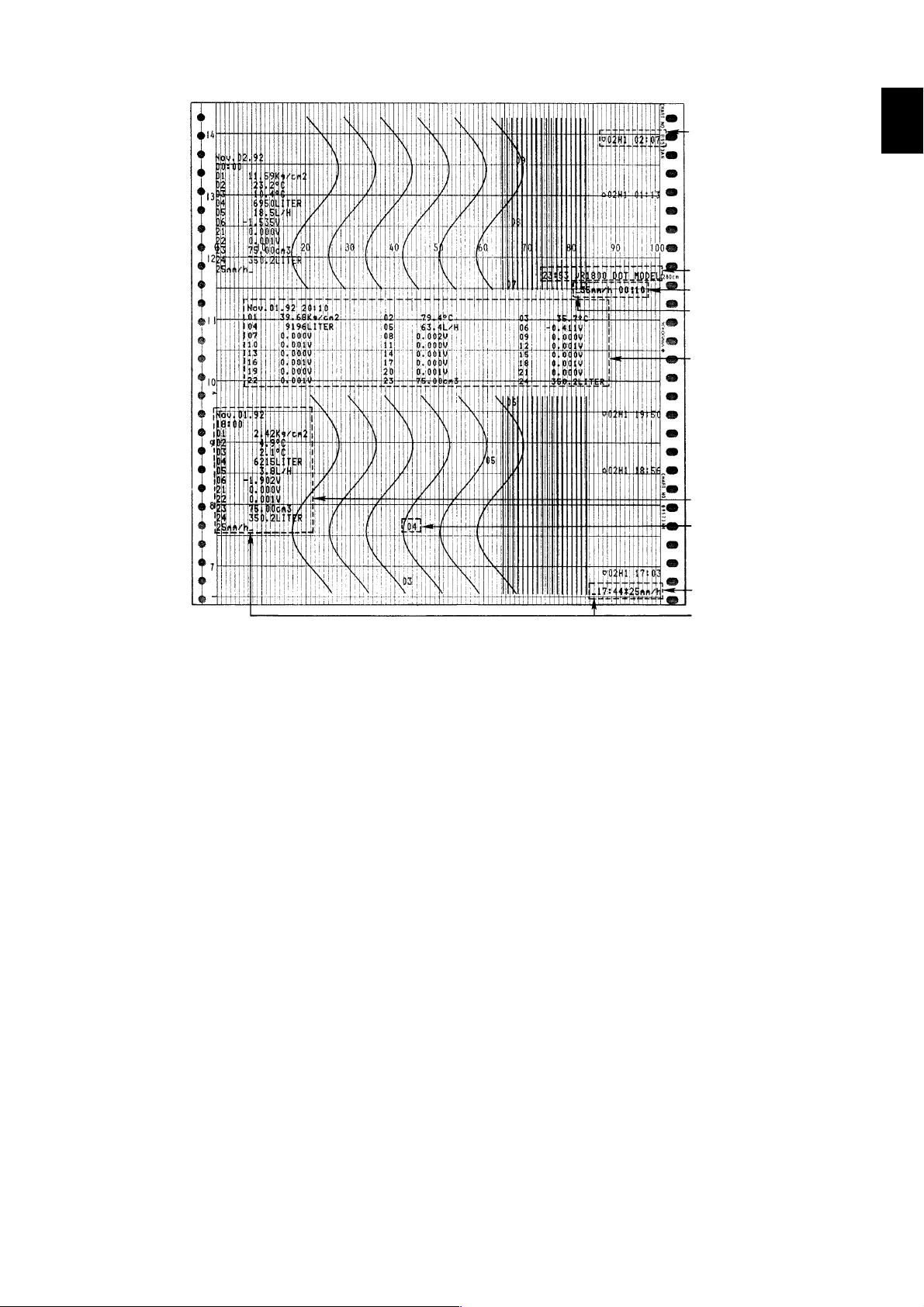

1.2 Summary of Functions

Alarm printout

Note: When an asterisk

appears (✴), the memory

buffer is full and some data will

not be printed. This asterisk

may appear in the alarm

printout, message printout,

recording start time printout

and the chart speed change

printout.

Message printout

Chart speed change

printout

Time tick (–)*

Manual printout

1

1. FEATURES AND FUNCTIONS

Periodic printout

Channel printout

Recording start time

✴1: will not be printed when the time does not correspond with the correct place on the chart.

Figure 1.2 Recording Example for Dot Model

Time tick (–)*

ALARM

Type of alarms: H: high limit

L: low limit

h: high difference limit

l: low difference limit

R: rate-of-change limit on increasing signal

r: rate-of-change limit on decreasing signal

Hysteresis: hysteresis value as a % of span which can be 0% or approx. 0.5%

Alarm output relay: when alarm occurs, the relay will be activated (optional)

Reflash: monitors repeating alarm occurrences among a group of alarms sharing the

same output relay (optional)

FAIL/Chart-end output: output relay is activated when chart reaches its end and/or when failure of

equipment occurs (optional)

INPUT

Type of inputs: TC: Thermocouple

RTD: Resistance Temperature Detector

DC-voltage

DC-current: using optional external shunt resistor

DI: Digital Input (contact)

Burnout: when TC-wire is broken, pens will move to left or right side

Filter: (signal damping) selects the time constant of signal damping (for pen model)

Moving average: selects the number of samples for moving average (for dot model)

1

IM 4H3B1-01E

1 - 3

Page 11

DISPLAY

Left-referenced bargraph: measured data are displayed as a %, on a 0 to 100% scale

Center-zero bargraph: center of the recording span is reference and deviation is displayed as a bargraph

Clock: year/month/day and hours/minutes/seconds

Measured data: AUTO: all channels will be shown alternately

MAN: a specified channel only will be shown

Alarm: channel No., type of alarm (display), channel No. (underneath bargraph, for dot model)

Status indicators: RCD: illuminated when recording is in progress

POC: illuminated when POC is being used (for pen model)

SET: illuminated when in SET Mode

AUTO:illuminated when AUTO display is used

MAN: illuminated when Manual display is used

CLK: illuminated when Clock display is used

ALM: illuminated/flashing when alarm occurs

CHT: illuminated when approx. 2cm are left till chart end (option)

BAT: illuminated/flashing when battery needs to be replaced

CALCULATION

Difference calc (DELT): takes the difference between the measured values of two channels

Linear scaling (SCL): sets different scale (and unit) to a specific range

Square root (SQRT): takes the square root of measured data

MATH: calculates basic arithmetic computations, SQRT, ABS, LOG, EXP, logical and

relational computation (optional)

TLOG: calculates statistic computation for time axis (optional)

COMPUTER INTERFACE (Optional)

RS-422-A

IC MEMORY CARD (Optional)

Storage and retrieval of setting parameters and measured data

REMOTE CONTROL (Optional)

Message printout, manual printout, periodic printout, recording ON/OFF, chart speed

change, TLOG START/STOP, IC memory card trigger.

1 - 4 IM 4H3B1-01E

Page 12

Chapter 2 BEFORE OPERATION

This chapter describes the preparations to be made before you can operate the µR1800

recorder. To use the µR1800, it is necessary to read this chapter first.

2.1 Handling Precautions

Cleaning

The µR1800 contains many plastic parts, like door window and panels. Therefore never

attempt to clean the µR1800 with chemicals like benzene or thinner.

Static electricity

Do not bring any objects charged with static electricity near the signal terminals. This

might cause malfunction.

Insecticide sprays, etc.

Do not allow any volatile substances such as insecticides etc. to come in contact with

the front door, the operation panel, etc. Do not allow rubber or vinyl to remain in

contact with the recorder for long periods.

After use

Ensure that the power switch is turned to the OFF position.

2.1 Handling Precautions

2. BEFORE OPERATION

In case of malfunction

Never continue to use the instrument if there are any symptoms of malfunction such as

unusual sounds, smell, or smoke coming from the instrument. Immediately disconnect

the power supply and stop further use of the instrument. If such abnormal symptoms

occur, contact your sales representative or nearest service center.

IM 4H3B1-01E

2 - 1

Page 13

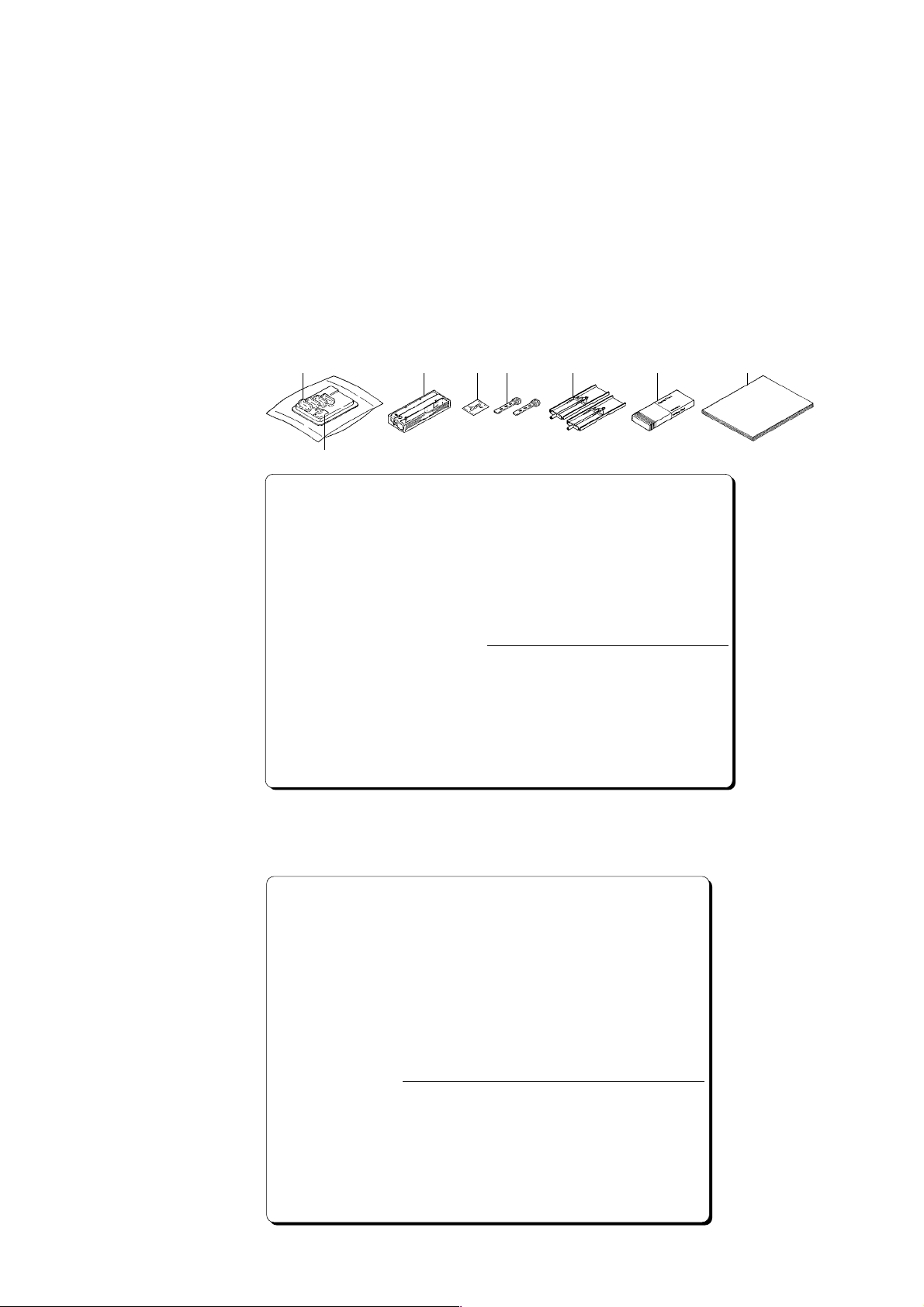

2.2 Checking the Contents

This µR1800 was thoroughly inspected before it was shipped from the factory.

However, when you receive the µR1800, check that all accessories are present and in

the correct quantities. Also check the external appearance of the µR1800 to ascertain

that no damage has occurred.

2.2.1 Checking Accessories and Appearance

The µR1800 should be accompanied by the accessories indicated in figure 2.1.

Check that all are present in the correct quantities. Also check the external appearance

of the µR1800 to ascertain that no damage has occurred. If you discover any problem

concerning the quantity of accessories or external appearance, please contact your sales

representative or the nearest service center. Addresses may be found on the back cover

of this Instruction Manual.

1

2

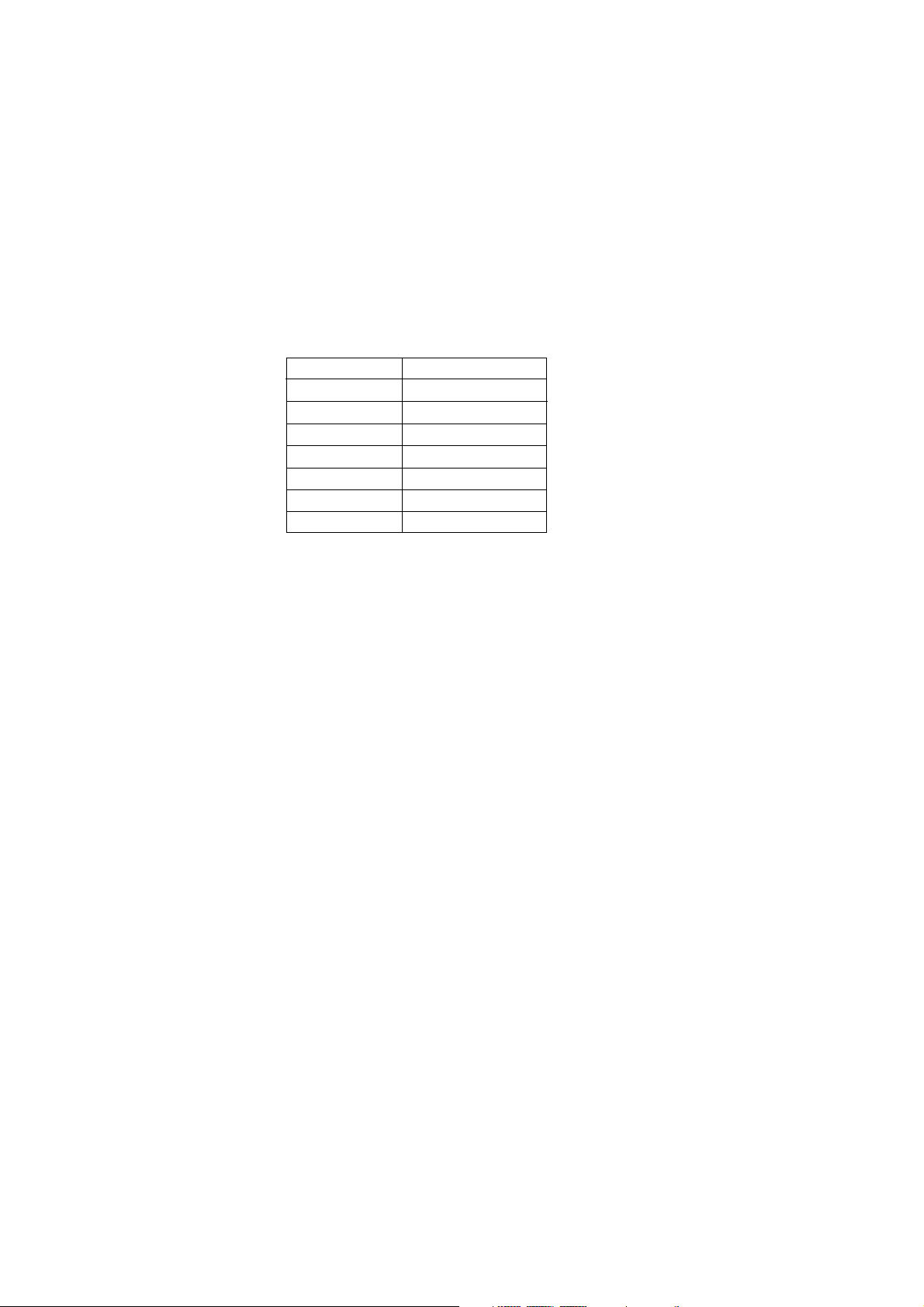

No. Description Quantity Remarks

1.

disposable felt pen (for pen model)

• 1 pen model

• 2 pen model

• 3 pen model

• 4 pen model

2.

plotter pen (for pen model)

3.

ribbon cassette (for dot model)

4.

fuse

key

5.

mounting brackets

6.

Z-fold chart paper

7.

Instruction Manual and Quick

8.

Reference power cord

3 4 5 6 7 8

red

1

red, green

2

red, green, blue

3

red, green, blue, violet

4

purple

1

1

250V 750mA time lag

1

(except for /P1 model)

250V 5A time lag

1

(for /P1 model)

Recorders with a gray power switch

250V 800mA time lag

1

(except for /P1 model)

250V 5A time lag

1

(for /P1 model)

Recorders with a white power switch

key-lock

2

2

approx. 20 meters

1

one each

1

for portable type

1

Figure 2.1 Accessories

Table 2.1 Spares

Name Part Number Description

Z-fold chart paper

disposable felt-pen

disposable felt-pen

disposable felt-pen

disposable felt-pen

plotter pen

ribbon cassette

fuse

mounting brackets

key (for key-lock)

lubricating oil

B9573AN

B9902AM

B9902AN

B9902AP

B9902AQ

B9902AR

B9906JA

A1438EF

A1102EF

A1512EF

A1513EF

B9900CW

B9900HZ

B9901AZ

(1 chart/unit), order quantity: 6 units

red (3 pcs./unit), order quantity: 1 unit

green (3 pcs./unit), order quantity: 1 unit

blue (3 pcs./unit), order quantity: 1 unit

violet (3 pcs./unit), order quantity: 1 unit

(3 pcs./unit), order quantity: 1 unit

(1 pc./unit), order quantity: 1 unit

(4pcs./unit), order quantity : 1 unit

250V 750mA time lag

(except for /P1 model)

(4pcs. /unit), order quantity : 1 unit

250V 5A time lag

(for /P1 model)

Recorders with a gray power switch

(4pcs. /unit), order quantity : 1 unit

250V 800mA time lag

(except for /P1 model)

(4pcs. /unit), order quantity : 1 unit

250V 5A time lag

(for /P1 model)

Recorders with a white power switch

(1 pc./unit), order quantity: 2 units

(1 pc./unit), order quantity: 2 units

(1 pc./unit), order quantity: 1 unit

2 - 2 IM 4H3B1-01E

Page 14

2.2.2 Removing Packings

The internal assembly is secured in position by packings to safeguard against damages

during transit. When you unpack the recorder, remove the packings as follows:

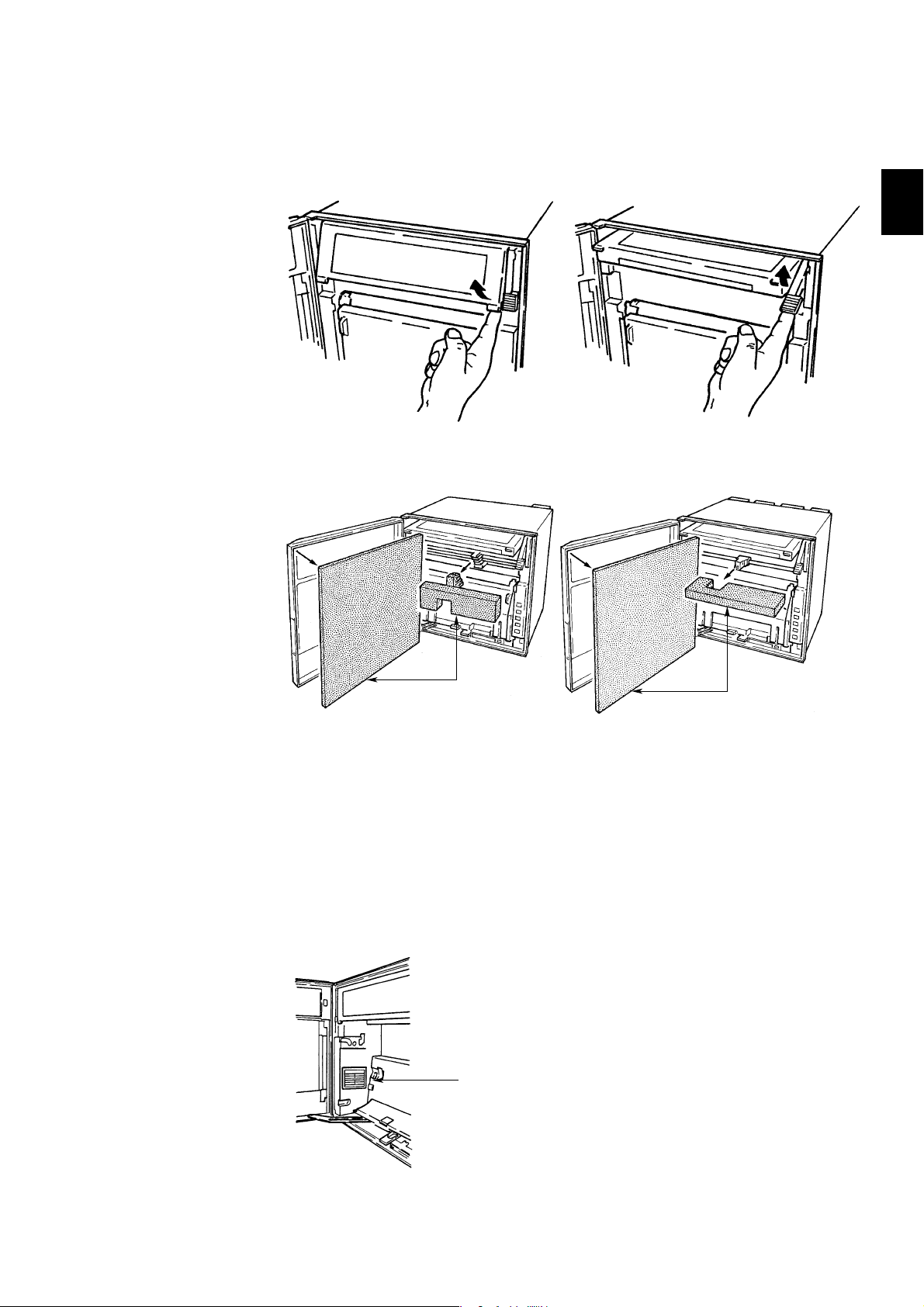

Open the µR1800 front door and swing open the display by grabbing the tabs located at

the lower right and left side of the display and pulling these tabs up. See figure 2.2a.

Figure 2.2a Swinging Up the Display Figure 2.2b Closing the Display

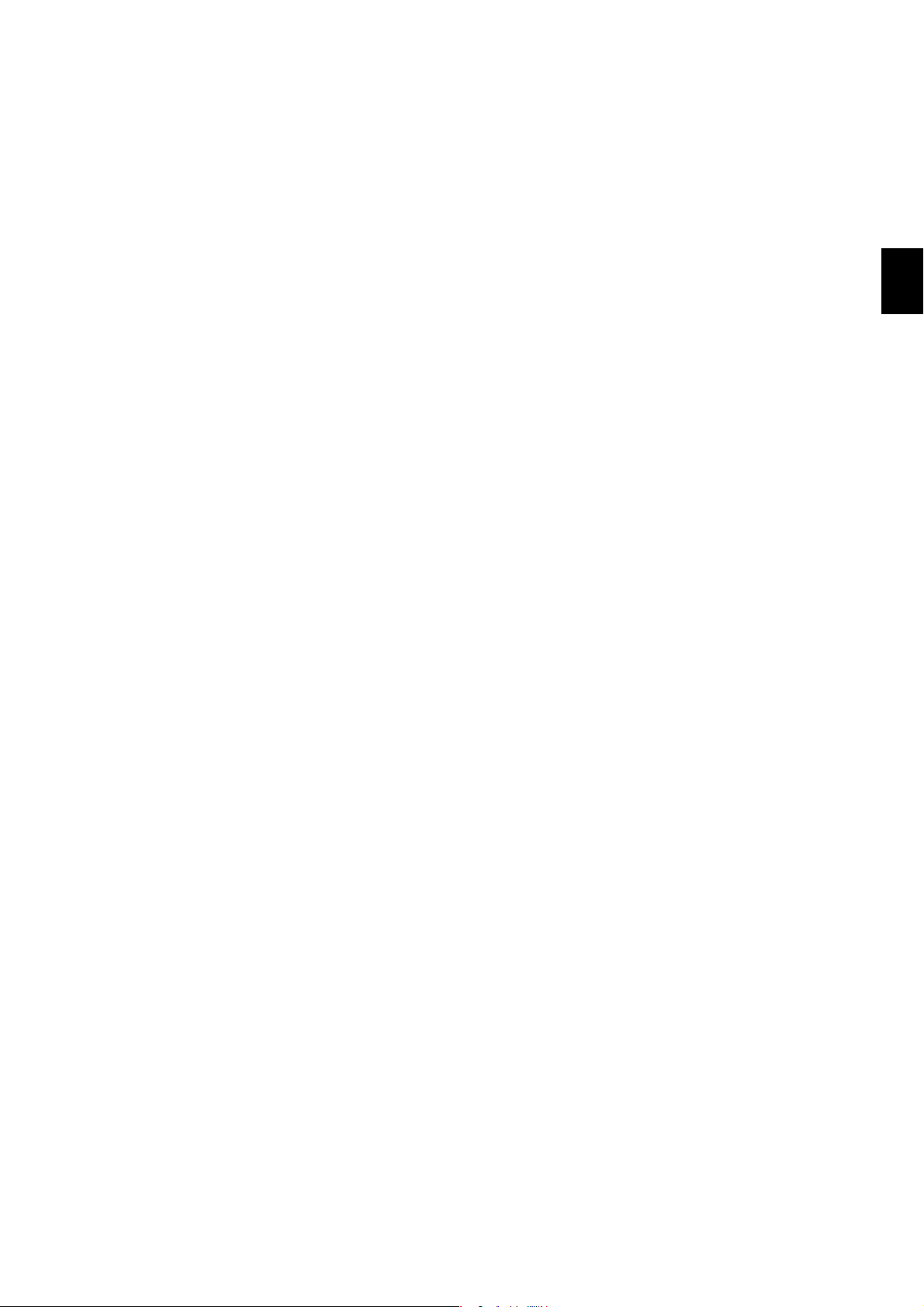

Then remove all the packings as shown in figure 2.3.

2.2 Checking the Contents

2. BEFORE OPERATION

Figure 2.3a Removing Packings in

After having removed the packings, close the display by pulling the 'release'-handle

until this handle is at the same level as the display. Then push the display back into

its normal position until the tabs click shut. See figure 2.2b.

2.2.3 Checking Model Code

When you receive your µR1800, check the information on the nameplate to make sure

that it is as specified by your order. If you open the front door and remove the chart

cassette, you will find the model code mentioned on the nameplate located as shown in

figure 2.4. Please check if model code (MODEL) is correct.

case of Pen Model

Packings

Nameplate

Packings

Figure 2.3b Removing Packings in

case of Dot Model

IM 4H3B1-01E

Figure 2.4 Checking Model Code

2 - 3

Page 15

Chapter 3 INSTALLATION

This chapter describes the installation of the µR1800, like the installation site, the

mounting and wiring. To install the µR1800 properly, it is necessary to read this

chapter.

3.1 Installation Site/Mounting

3.1.1 Installation Site

The µR1800 installation site should be chosen to meet the following conditions as close

as possible:

Installation site should be panel-mounted only. The µR1800 is especially designed for

panel mounting.

The µR1800 should be placed in a well ventilated area.

The µR1800 will be adversely affected if the unit is exposed to direct sunlight or

installed near a heater. Choose a location near room temperature (23°C) with minimal

temperature fluctuations.

3.1 Installation Site/Mounting

3. INSTALLATION

To expose the µR1800 to soot, steam, moisture, dust, corrosive gases etc. will adversely

affect it.

To use the µR1800 within strong electro-magnetic fields may cause malfunction. Please

avoid installing near electro-magnetic objects.

To install the µR1800 in a location susceptible to mechanical vibrations will adversely

affect the mechanical parts and the quality of recording. Please choose an installation

site characterized by minimal mechanical vibrations.

This µR1800 must be installed horizontally (however, mounting may be inclined up to

30° backwards from vertical).

To use the µR1800 within domestic establishments and within establishments directly

connected to a low voltage power supply network which supplies buildings used for

domestic purposes may cause malfunction of other equipments. Please avoid using in

domestic environment.

IM 4H3B1-01E

3 - 1

Page 16

3.1.2 Mounting

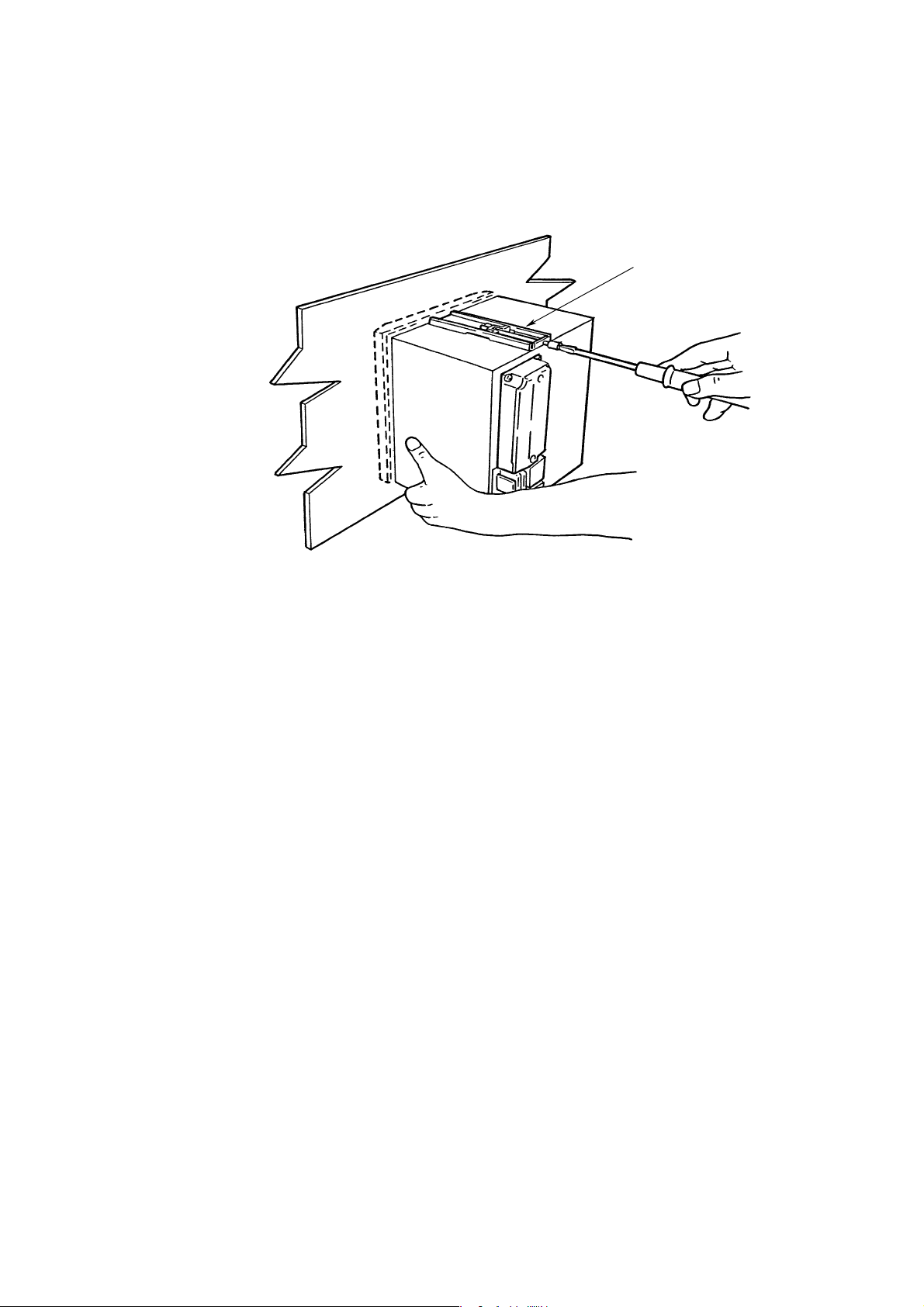

1 The µR1800 should be mounted on at least 2mm (and up to 26mm) thick steel panel.

2 Insert the µR1800 into the panel cutout.

3 Hold the bottom of the µR1800 and mount it on the panel using the mounting brackets

supplied, as shown in figure 3.1. (If still in place, remove the seals covering the holes

for the mounting brackets.)

Mounting bracket

Figure 3.1 Mounting

3 - 2 IM 4H3B1-01E

Page 17

3.1.3 Dimensional Drawings

3.1 Installation Site/Mounting

3. INSTALLATION

Figure 3.2 Panel Cutout and Spacing (including mounting brackets)

NOTE • The µR1800 should be mounted by only two brackets, either on the top & bottom of

the recorder, or on the left & right side of the recorder.

• The portable type has different dimensions.

IM 4H3B1-01E

3 - 3

Page 18

3.2 Wiring

!

This paragraph describes the wiring at the rear panel.

3.2.1 Rear panel arrangement

3.2.2 Power supply wiring

3.2.3 Input wiring

3.2.4 Alarm output wiring

3.2.5 FAIL/Chart end output wiring

3.2.6 Remote control wiring

CAUTION

employ some kind of strain relief between the rear wall and the recorder.

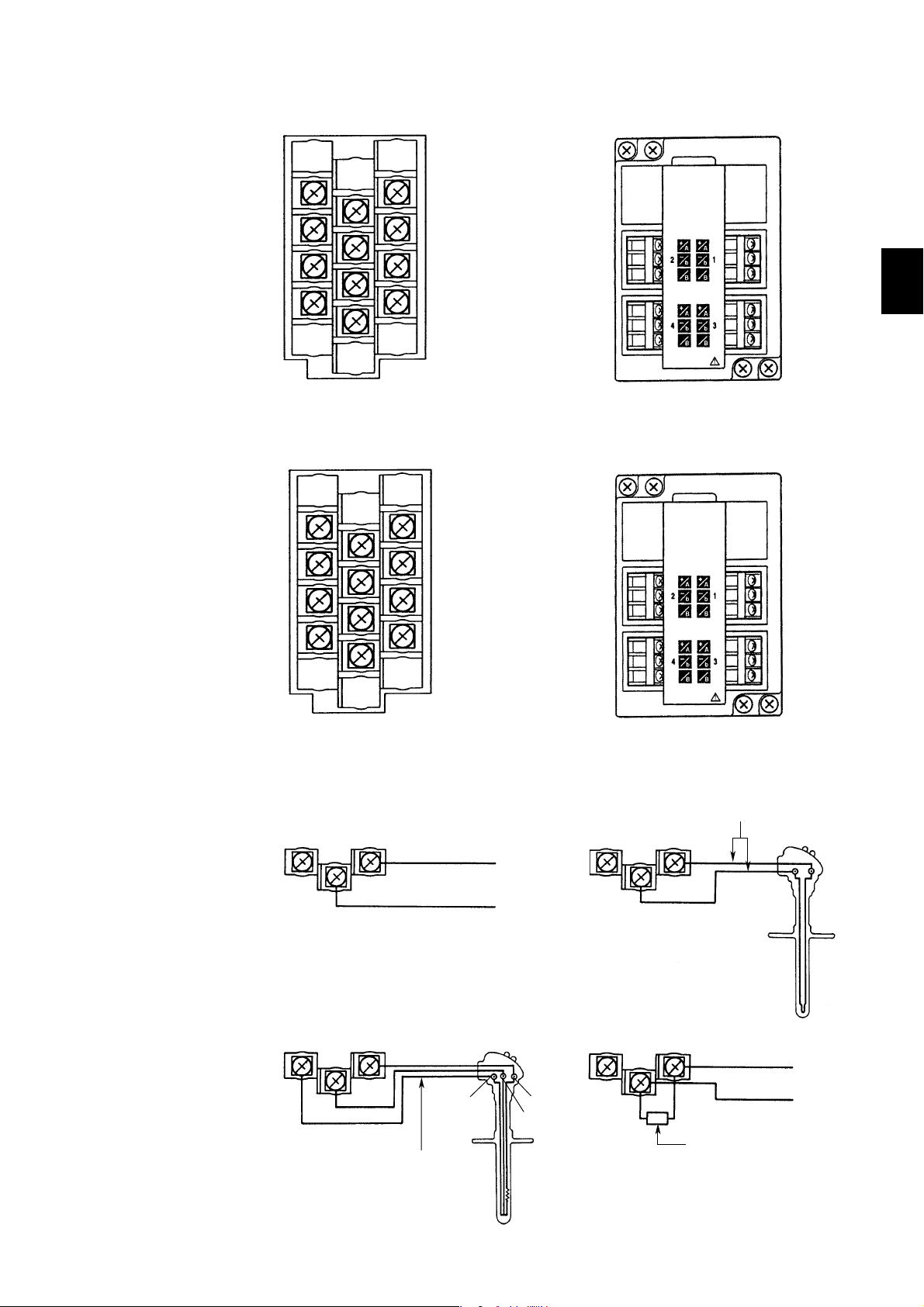

3.2.1 Rear Panel Arrangement

Power supply

terminal Block

Make sure to fasten the wiring at the rear wall of the mounting panel and

for /P1 model

Each terminal block can be

removed for easy wiring

by loosening these screws.

To ensure proper contact,

make sure to fasten the

screws properly.

Used terminal screws:

ISO M4, length: 6mm

DC24V

+

−

/B

+/A

-/b

1

2

3

4

Figure 3.3a Rear Panel Arrangement in case of Pen Model

Power supply

terminal block

for /P1 model

Each terminal block can be

removed for easy wiring

by loosening these screws.

To ensure proper contact,

make sure to fasten the

screws properly.

Do NOT change the place of

the terminal block!

Used terminal screws:

ISO M4, length: 6mm

Figure 3.3b Rear Panel Arrangement in case of Dot Model

+

−

DC24V

3 - 4 IM 4H3B1-01E

Page 19

3.2 Wiring

3.2.2 Power Supply Wiring

1 Make sure the power switch is turned OFF and remove the transparent cover at the

rear of the µR1800.

2 Connect the power supply wires and the protective ground wire to the power terminals

and the ground terminals as shown in figure 3.4.

3 Replace the transparent cover.

for /P1 model

+

−

DC24V

Figure 3.4 Power Supply Wiring

NOTE • Do not apply power supply of 132 to 180VAC. This might affect the measuring

accuracy.

• In case of portable type, plug the female end of power cord into the socket on the rear

panel.

• To prevent an emission of electromagnetic disturbances, separate the power supply

wires from the other wires at least 0.1m. Over 0.5m is recommended.

!

Power supply wires

L

N

Protective ground wire

3. INSTALLATION

WARNING

To prevent an electric shock, ensure the main power supply is turned OFF and

connect the ground terminal using a class 3 resistance of 100Ω or less.

For power and ground wiring termination, use “crimp on” lugs (for 4mm screws)

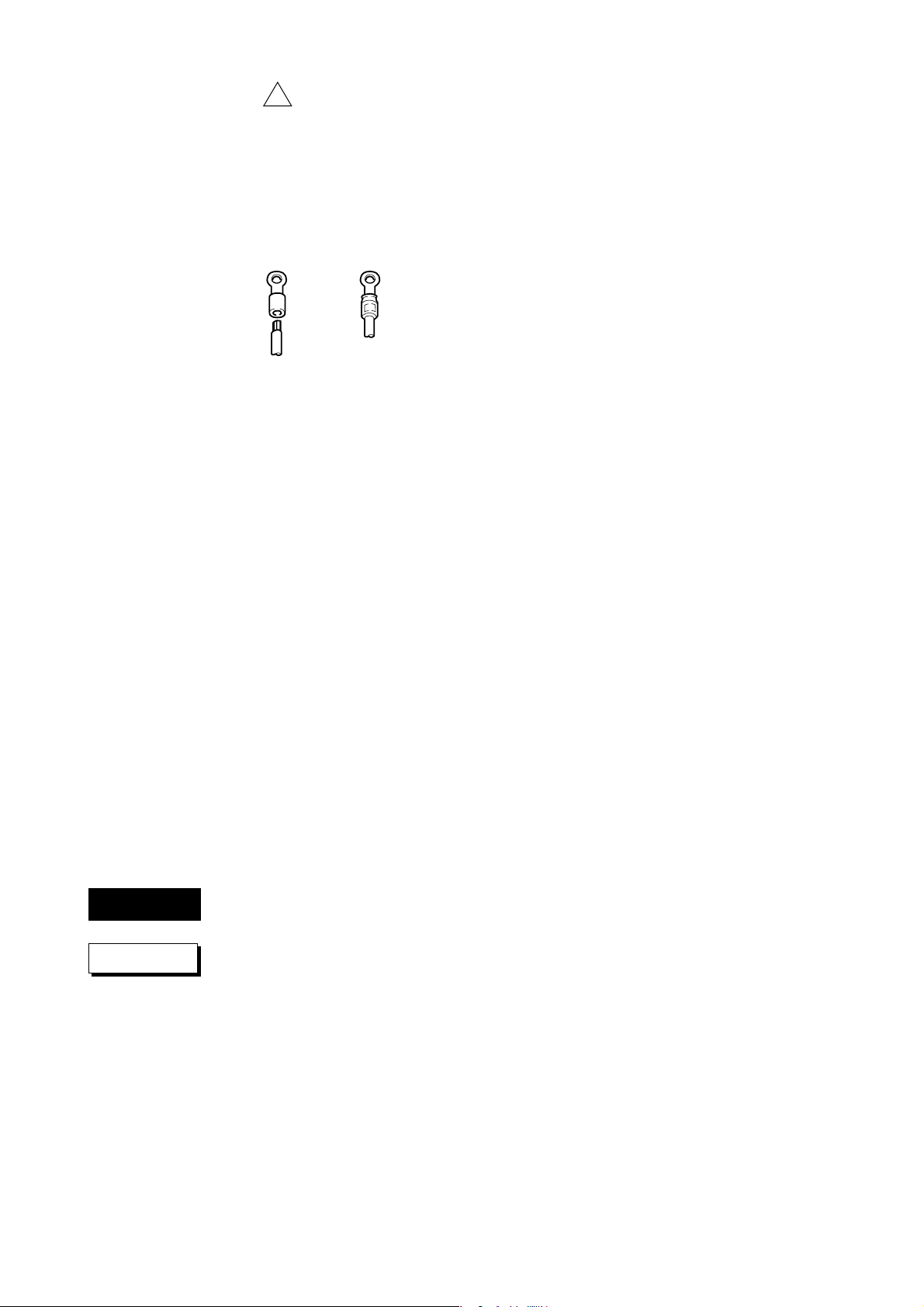

with insulation sleeves (see figure 3.5).

To prevent fire, use 600V PVC insulated wire (AWG18) for power and ground

wiring (cross sectional area of 0.83mm2 or thicker, anti-galvanic corrosion finish,

insulation thickness should be more than 0.8mm, insulation resistance should

be more than 50MΩKm at 20°C, approved EN60 320 (VDE0625), and do not

remove the transparent cover.

Make sure to apply a power switch in the power supply cord with the following

characteristics:

Others than /P1 model

• rated power current > 1A

• rated rush current > 60A

• fuse(s) of 2A to 15A is (are) necessary.

/P1 model

• rated power current > 3A

• rated rush current > 70A

• fuse(s) of 5A to 15A is (are) necessary.

The power switch and fuse used in the power supply cord should be

• CSA approved (for use in North America)

• VDE approved (for use in Europe).

IM 4H3B1-01E

3 - 5

Page 20

3.2.3 Input Wiring

!

1 Make sure the power switch is turned OFF and remove the transparent cover at the

rear of the µR1800.

2 Connect the input wires to the input terminal.

3 Replace the transparent cover.

It is recommended that “crimp on” lugs (for 4mm screws) with insulation sleeves be

used for leadwire ends. See figure 3.5.

Figure 3.5 “Crimp on” Lugs

In case of clamped input terminals, do not use “crimp on” lugs.

Since the input terminal will be affected by changes in temperature (e.g. because of

wind), make sure to replace the transparent cover after wiring.

Even after replacement, take care not to expose the terminals to fans, etc.

Suggestions to minimize noise pickup:

• The measuring circuit wiring should be run as remote as possible from the power

and ground wires.

• It is recommended that shielded wires be used to minimize noise pickup from an

electrostatic induction source. The shielding wire of the cable should be connected

to the µR1800 ground terminal (only one ground line).

• To minimize noise from an electromagnetic induction source, twist the measuring

line cables in short and equal spaces.

• The to be measured object should be free from noise. However, if it isn’t, make

sure the measuring circuit is isolated and the to be measured object is grounded.

WARNING

CAUTION

If TC and RJC is used, the temperature of the input terminals should be as stable as

possible. Therefore, make sure to use the transparent cover. The thermal capacity of

the wiring should be small (recommended ø ≤ 0.3mm).

Refrain from wiring the input parallel. However, if you do, then

• do not use the burnout function

• ground the equipments at the same point

•turning ON/OFF the power might cause malfunction

• RTD cannot be wired parallel.

To prevent an electric shock, ensure the main power supply is turned OFF

and connect the ground terminal using a class 3 resistance of 100Ω or less.

If you have an input of DC ≤ 2V or a TC, don’t apply an input voltage exceeding ±10VDC.

Do not apply a max. common mode voltage more than 250VAC rms (50/

60Hz). The recorder and measured values will be adversely affected.

Add following to 'CAUTION'

This instrument complies with Inatallation Category ll.

NOTE To prevent an emission of electromagnetic disturbances, separate the input wires from

the other wires at least 0.1m. Over 0.5m is recommended.

3 - 6 IM 4H3B1-01E

Page 21

Pen Model

3.2 Wiring

+

–

max. wiring ø ≤ 2.5mm

1 ch.

2 ch.

+

2 ch.

3 ch.

4 ch.

Standard Input Terminal Clamped Input Terminal (/H2 option)

Figure 3.6 DC V, Thermocouple and Contact Input in case of Pen Model

A

b

B

–

+

4 ch. 3 ch.

–

max. wiring ø ≤ 2.5mm

+

–

+

–

1 ch.

1 ch.

2 ch.

A

b

1 ch.

B

3 ch.

2 ch.

A

b

B

3. INSTALLATION

4 ch.

4 ch.

A

b

B

Standard Input Terminal

Figure 3.7 Resistance Temperature Detector Input in case of Pen Model

DC Voltage Input/DI Input (contact)

+

–

Resistance Temperature Detector Input DC Current Input

B

A

b

+

DC voltage input

–

B

A

b

Clamped Input Terminal (/H2 option)

Thermocouple Input

+

–

+

–

A

b

B

Compensation lead

DC current input

3 ch.

+

–

IM 4H3B1-01E

Leadwire resistance:

10Ω max./leadwire

Three wire resistances

should be approx. equal.

Figure 3.8 Wiring Input Terminals in case of Pen Model

Shunt resistor

NOTE: For 4 to 20mA input, shunt resistance

value should be 250Ω ±0.1%.

3 - 7

Page 22

Dot Printing Model

+

–

max.wiring ø ≤ 2.5mm

1 ch.

+

1 ch.

–

2 ch.

2 ch.

+

–

3 ch.

4 ch.

5 ch.

4 ch.

6 ch.

+

–

+

–

6 ch.

Standard Input Terminal

Figure 3.9 DC V, Thermocouple and Contact Input in case of Dot Model

BAb

Clamped Input Terminal (/H2 option)

max.wiring ø ≤ 2.5mm

1 ch.

A

2 ch.

2 ch.

B

b

3 ch.

A

B

4 ch.

5 ch.

6 ch.

4 ch.

6 ch.

b

A

B

b

+

3 ch.

–

+

5 ch.

–

A

1 ch.

B

b

A

B

3 ch.

b

A

5 ch.

B

b

Standard Input Terminal

Figure 3.10 Resistance Temperature Detector Input in case of Dot Model

DC Voltage Input/DI Input (contact)

DC voltage input

Resistance Temperature Detector Input DC Current Input

Leadwire resistance:

10Ω max./leadwire

Three wire resistances

should be approx. equal.

Clamped Input Terminal (/H2 option)

Thermocouple Input

Compensation lead

NOTE: For 4 to 20mA input, shunt resistance

value should be 250Ω ±0.1%.

DC current input

Shunt resistor

NOTE: In case of 3 leg isolated RTD (/N2 option), there is no difference between B and b.

However, A and b are designated to be the current line for measurements.

Figure 3.11 Wiring Input Terminals in case of Dot Model

3 - 8 IM 4H3B1-01E

Page 23

3.2 Wiring

3.2.4 Alarm Output Wiring

1 Make sure the power switch is turned OFF and remove the transparent cover at the rear

of the µR1800.

2 Connect the alarm output wires to the alarm output terminal. Do NOT change the place

of the therminal block!

3 Replace the transparent cover.

Depending on your option, your alarm output terminal will be arranged like one of the

following:

ALARM

NO NCC

1

NO NCC

2

!

ALARM

NO NCC

1

NO NCC

2

NO NCC

3

NO NCC

4

ALARM

NO NCC

1

NO NCC

2

NO NCC

3

NO NCC

4

NO NCC

5

NO NCC

6

3. INSTALLATION

WARNING

!

option /A1

2 contacts

Figure 3.12 Alarm Output Terminals

option /A2

4 contacts

!

option /A3

6 contacts

!

CHARACTERISTICS:

Output type: relay transfer contact (energize/de-energize type switchable)

Output capacity: 250VAC (50 or 60Hz), 3A

250VDC, 0.1A (resistive load)

Dielectric strength: 1500VAC (50 or 60Hz) for one minute between output terminal

and ground terminal

To adjust initial settings, see 9.1.

• To prevent an electric shock, ensure the main power supply is turned OFF

during wiring and ensure the ground terminal is connected using a class 3

resistance of 100Ω or less.

• Ensure the ground terminal is connected using a class 3 resistance of 100Ω or

less.

• Use "crimp-on" lugs with insulation sleeves for all connections if a voltage of

more than 30 VAC or 60 VDC is applied to the alarm output or fail/memory end

output. Furthermore, use doubleinsulated wires (withstand voltage

performance: more than 2300VAC) for those wires which apply 30 VAC or

60VDC. All other wires can be basic-insulated (withstand voltage performance:

more than 1350VAC). To prevent electric shock, do not touch the terminal after

wiring and make sure to re-attach the cover.

IM 4H3B1-01E

NOTE To prevent an emission of electromagnetic disturbances, separate the alarm output wires

from the power supply and input wires at least 0.1m. Over 0.5m is recommended.

3 - 9

Page 24

3.2.5 FAIL/Chart End Wiring

1 Make sure the power switch is turned OFF and remove the transparent cover at the rear

of the µR1800.

2 Connect the FAIL/Chart end output wires to the FAIL/Chart end output terminal.

3 Replace the transparent cover.

The FAIL/Chart end terminals (option) are arranged as follows:

CHART

NO NCC

FAIL

NO NCC

!

WARNING

!

Figure 3.13 FAIL/Chart End Output Terminal

The FAIL/Chart End output relay is of the de-energize type. See 5.3.9 for details.

• To prevent an electric shock, ensure the main power supply is turned OFF

during wiring and ensure the ground terminal is connected using a class 3

resistance of 100Ω or less.

• Ensure the ground terminal is connected using a class 3 resistance of 100Ω or

less.

• Use "crimp-on" lugs with insulation sleeves for all connections if a voltage of

more than 30 VAC or 60 VDC is applied to the alarm output or fail/memory end

output. Furthermore, use doubleinsulated wires (withstand voltage

performance: more than 2300VAC) for those wires which apply 30 VAC or

60VDC. All other wires can be basic-insulated (withstand voltage performance:

more than 1350VAC). To prevent electric shock, do not touch the terminal after

wiring and make sure to re-attach the cover.

NOTE To prevent an emission of electromagnetic disturbances, separate the FAIL/Chart end

wires from the power supply and input wires at least 0.1m. Over 0.5m is recommended.

3 - 10 IM 4H3B1-01E

Page 25

3.2 Wiring

3.2.6 Remote Control Wiring

1 Make sure the power switch is turned OFF and remove the transparent cover at the rear

of the µR1800.

2 Connect the REMOTE output wires to the REMOTE output terminal. Make sure to

connect every terminal with the c(ommon) terminal. Use shielded wires to prevent

electromagnetic interference.

3 Replace the transparent cover.

The remote control terminal (option) is arranged as follows:

REMOTE

132

4C5

!

3. INSTALLATION

WARNING

!

Figure 3.14 Remote Control Terminal

CHARACTERISTICS:

Input signals: dry contact or open-collector (TTL or transistor)

Input types for each function

(1) recording start/stop level

(2) change chart speed level

(3) start/stop TLOG computation level

(4) printout messages trigger

(5) get a manual printout trigger

(6) get a periodic printout trigger

250 ms minimum

(7) trigger IC Memory Card trigger

Input conditions: ON voltage (0.5V maximum) (30mA DC)

Leakage current in OFF state (0.25mA maximum)

Signal duration (250 msec minimum)

Input type: Photocoupler isolation (one side common)

Internal isolated power source (5V ±5%)

Dielectric strength: 500VDC between input terminal and ground terminal, 1min.

To adjust initial settings, see 9.8.

To prevent an electric shock, ensure the main power supply is turned OFF

during wiring and ensure the ground terminal is connected using a class 3

resistance of 100Ω or less.

The outer conductor must be grounded at the ground terminal.

IM 4H3B1-01E

NOTE To prevent an emission of electromagnetic disturbances, separate the remote control

wires from the power supply and input wires at least 0.1m. Over 0.5m is recommended.

3 - 11

Page 26

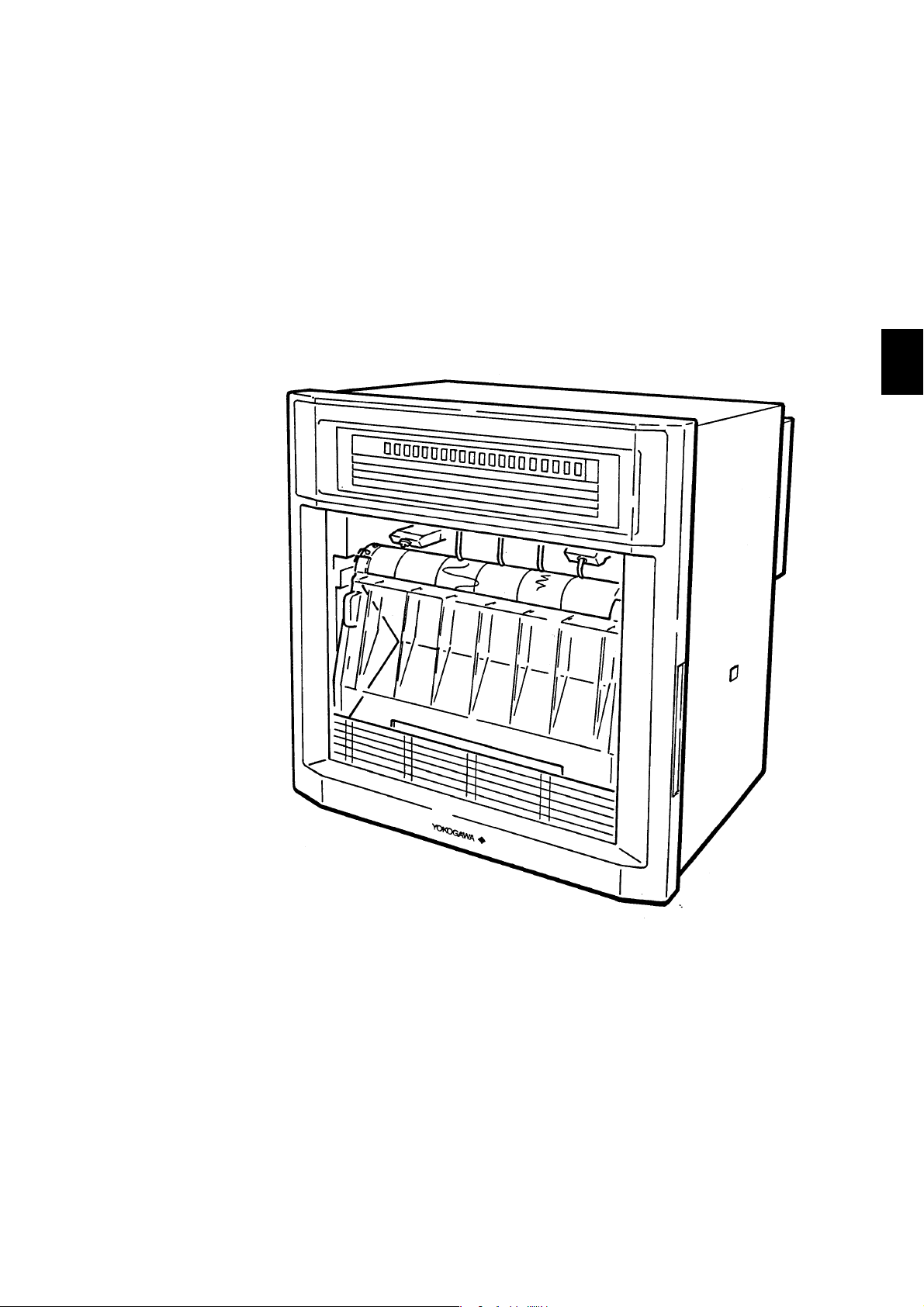

Chapter 4 COMPONENT NAMES AND

FUNCTIONS

This chapter describes the names of components, together with a short summary of their

functions.

4. COMPONENT NAMES AND FUNCTIONS

IM 4H3B1-01E

Figure 4.1 External View (pen model)

4 - 1

Page 27

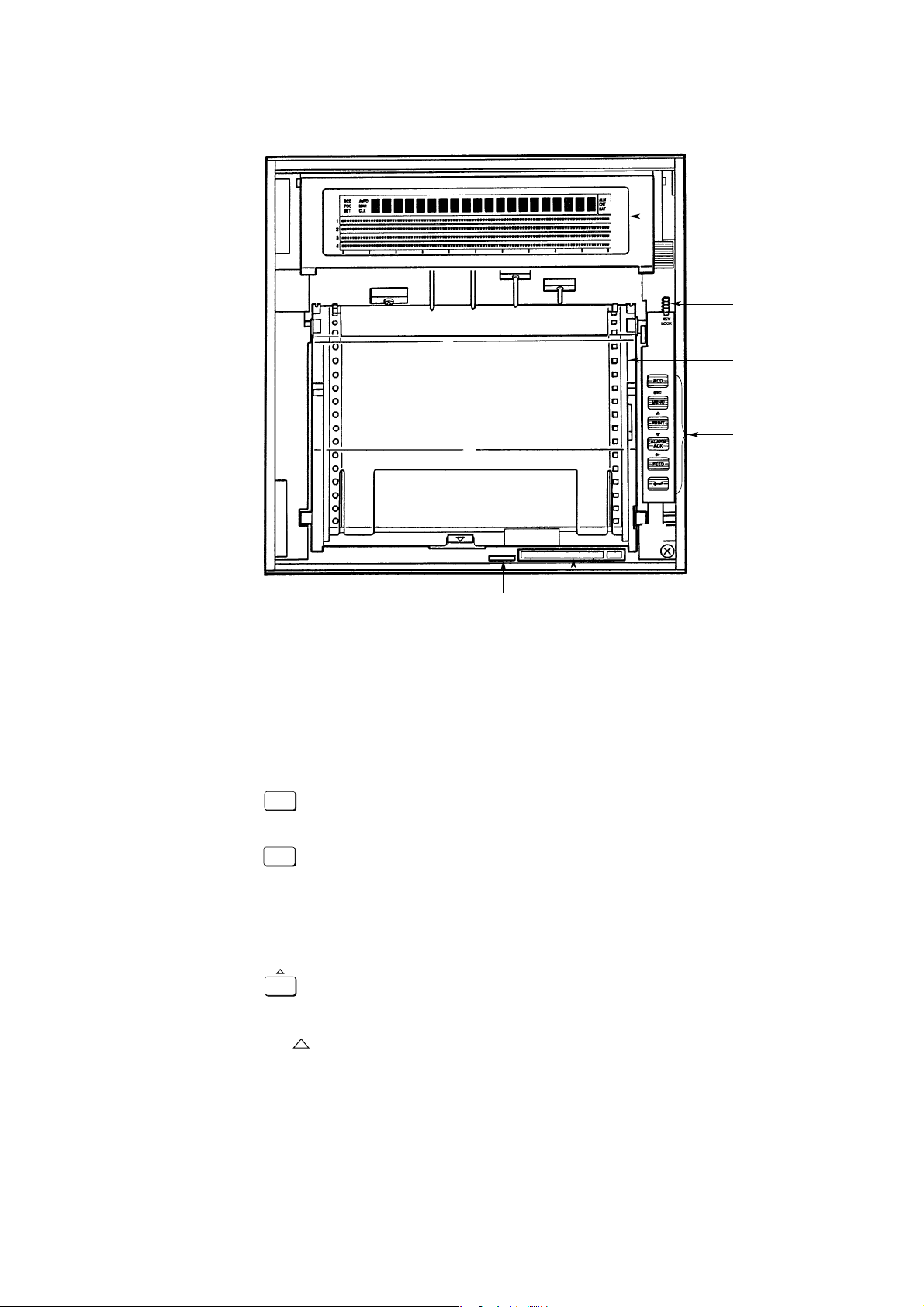

4.1 Front Panel

3

6

4

2

1

Figure 4.2 Front Panel (4 pen model)

5

1 Power switch

Pressing this button will result in switching the power ON or OFF.

2 Keyboard

The keyboard consists of six keys:

RCD

(RCD-key)

Pressing this key will result in starting or stopping the recording.

ESC

MENU

(Menu-key/Esc-key)

The MENU function is to select the type of display (see 5.3.8), to start SET UP List

printout and message printout (see 5.3.5, 5.3.6) etc., and to switch between Operation

and SET modes (see 6.1).

The ESC function is to escape to the previous level in the (setting) flow while entering

parameters.

PRINT

(Print-key/Cursor Up-key)

The PRINT function is used to get a manual printout or list printout printed onto the

chart (see 5.3.3, 5.3.4).

The function: The display is designed in an interactive way, which means that it

will ask you to enter the necessary data. In case there are several possibilities to

choose from (e.g. ON or OFF), use this key to show the next choice.

4 - 2 IM 4H3B1-01E

Page 28

4.1 Front Panel

ALARM

ACK

(Ack-key/Cursor Down-key)

The ‘ACK’-function is used to acknowledge alarms. Note that this function is only

effective if the alarm relay is in the hold-mode (see 5.3.7), and if the indicator status

is in the hold-mode (see 5.3.7). When you press this key in case an alarm occurs and

the ALM-indicator is flashing, the current alarm situation will be indicated and the

relay will be reset.

The function: The display is designed in an interactive way, which means that it

will ask you to enter the necessary data. In case there are several possibilities to

choose from (e.g. ON or OFF), use this key to show the previous choice.

FEED

(Feed-key/Move to Next Digit-key)

The ‘FEED’-function feeds the chart paper until this key is released (see also 5.3.2).

The function moves the cursor to the next digit while setting parameters. Please

note that there is not a back-space key provided. For that reason, the cursor moves

from the last digit to the first digit again (see 6.2).

(Ent-key)

The ‘ENT’-function allows you to keep the data you entered during the setting

procedure. Pressing ‘ENT’ results in moving to the next display in the same

(setting-) flow. Pressing ‘ENT’ after the ‘SET OK’-display appears, results in

starting the same (setting-) flow again.

3 Large sized VFD (Vacuum Fluorescent Display)

The display can show characters, bargraphs, and functions.

The backside of this display also illuminates the chart.

4 Chart and chart cassette

The recorder uses a Z-fold chart, 20 meter in length, with an effective analog trend

recording width of 180mm. The chart is stored inside a chart cassette.

5IC Memory card slot (optional)

IC Memory cards are inserted into this slot for use.

6 Key-lock

The key supplied with the recorder should be removed from the key-hole to lock the

recorder. See 5.4. To use the key-lock, see 9.10.

4. COMPONENT NAMES AND FUNCTIONS

IM 4H3B1-01E

4 - 3

Page 29

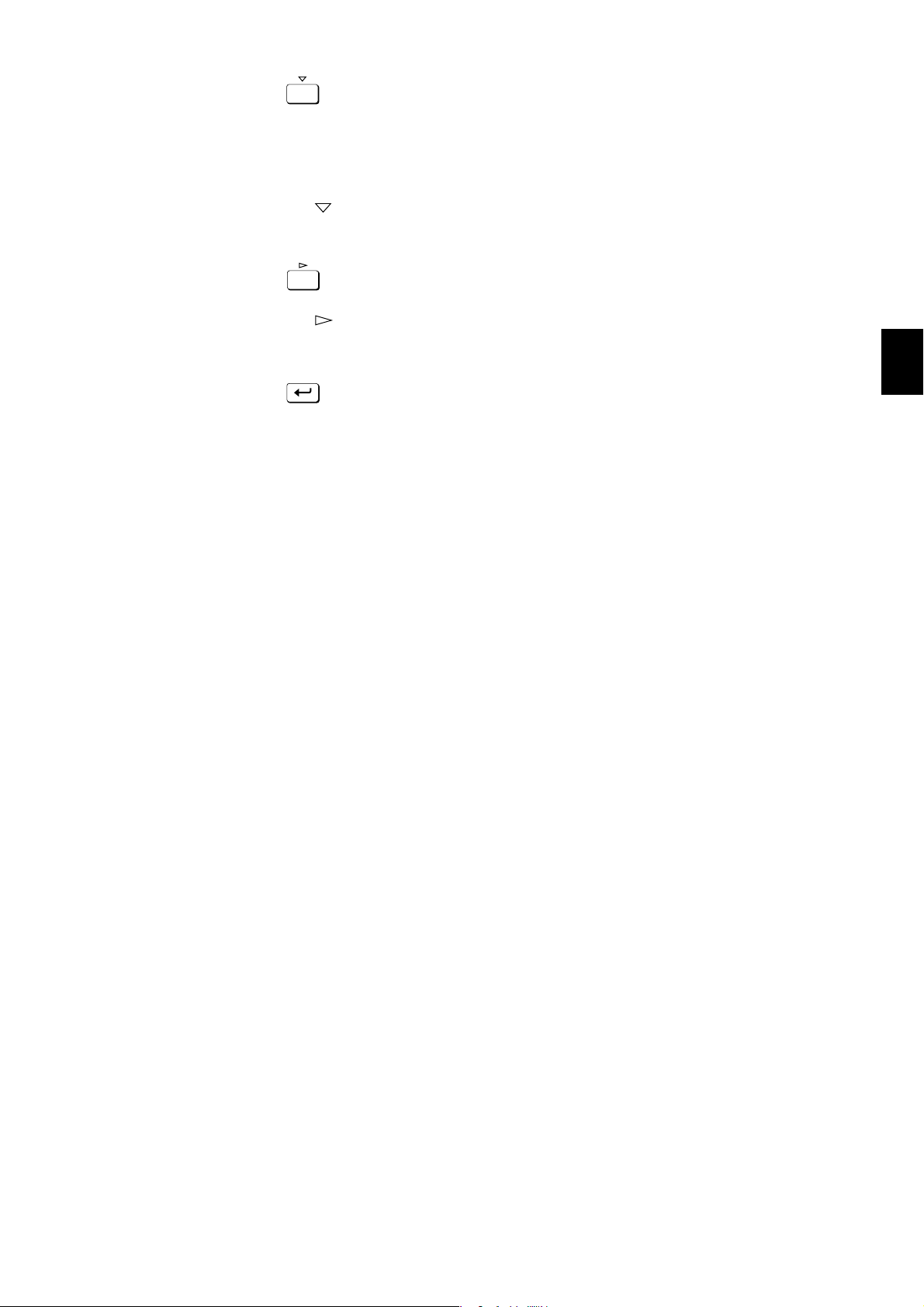

4.2 Display

1

AUTO

RCD

MAN

3

2

POC

CLK

SET

1

2

3

4

Figure4.3a Display (4 pen model)

1

AUTO

RCD

MAN

3

POC

SET

CLK

2

1

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

Figure 4.3b Display (dot model)

15 × 7 dot matrix (20 characters)

Used for data display, clock display, monitor display and setting display (see also 5.3.8).

Data display: Channel No. or tag, type of alarm, measured data, units

Clock display: (year, month, day) and (hour, minutes, seconds)

Monitor display: Operating conditions of IC Memory Card and TLOG function

Setting display: Every parameter can be set by interactive display.

ALM

CHT

BAT

ALM

CHT

BAT

3

3

2 Bargraph

Measured values of each channel will be displayed with 1% resolution (analog display).

The alarm set points will also be displayed. The colors of the bargraph correspond to

the colors of the pens. Two ways of display can be selected:

Left-referenced (%) bargraph Center-zero bargraph

(center of the recording span is reference

and the deviation is displayed as a bargraph)

1

2

The squares underneath the bargraph show the occurrence of an alarm in the

corresponding channel. They illuminate/flash in the same way as the ALM-indicator.

3Status indicators

RCD: Illuminated when recording is in progress.

POC: Illuminated when Pen Offset Compensation is being used (only for pen model).

SET: Illuminated when you are working in the SET Mode.

AUTO: Illuminated when the AUTO display is used.

MAN: Illuminated when the Manual display is used.

CLK: Illuminated when the Clock display is used.

ALM: This VFD will flash or illuminate when an alarm occurs.

Hold-mode: If the ACK-key is pressed, the flashing will stop and the VFD

will illuminate. After the alarm stops, the VFD will turn off. (If

the ACK-key is not pressed, the flashing stays even if the alarm

recovers, see also 5.3.7).

Non-hold-mode: VFD will illuminate until the alarm recovers (pressing the

ACK-key in this case will have no effect, see also 5.3.7).

CHT: Illuminated when there are approx. 2cm left till chart end (option).

BAT: Illuminated when the battery for setting data backup needs to be replaced.

Flashes when the battery of the IC Memory Card needs to be replaced.

4 - 4 IM 4H3B1-01E

Page 30

5.1 How to Switch the Power ON/OFF

Chapter 5 DAILY OPERATION

This chapter describes the daily operation of the µR1800, excluding settings.

Please read this chapter carefully before operation.

5.1 How to Switch the Power ON/OFF

The power switch is located behind the door, at the front side, in the middle of the lower

front (see figure 5.1a.). The power is supplied to the instrument when the power switch

is in the position as shown in figure 5.1b. The power is OFF when the power switch is

in the position as shown in figure 5.1b. The power can be turned ON/OFF by alternately

pressing the switch. When you do not use the instrument, please turn ‘OFF’ the power.

ON

5. DAILY OPERATION

CAUTION

Power switch

OFF

Figure 5.1a Figure 5.1b

NOTE After turning ON the power, the µR1800 will first perform a self diagnostic check for

several seconds.

The warm-up time is approx. 30 minutes. (However, just after finishing the

wiring, it might take longer. Especially if you removed the input terminals during

wiring.)

If the input wiring is connected parallel with other equipments, switching the

power ON/OFF should not be done.

If error message appears on the display or is printed on the chart, please refer

to the Error Message Table at sect.12.1.

IM 4H3B1-01E

5 - 1

Page 31

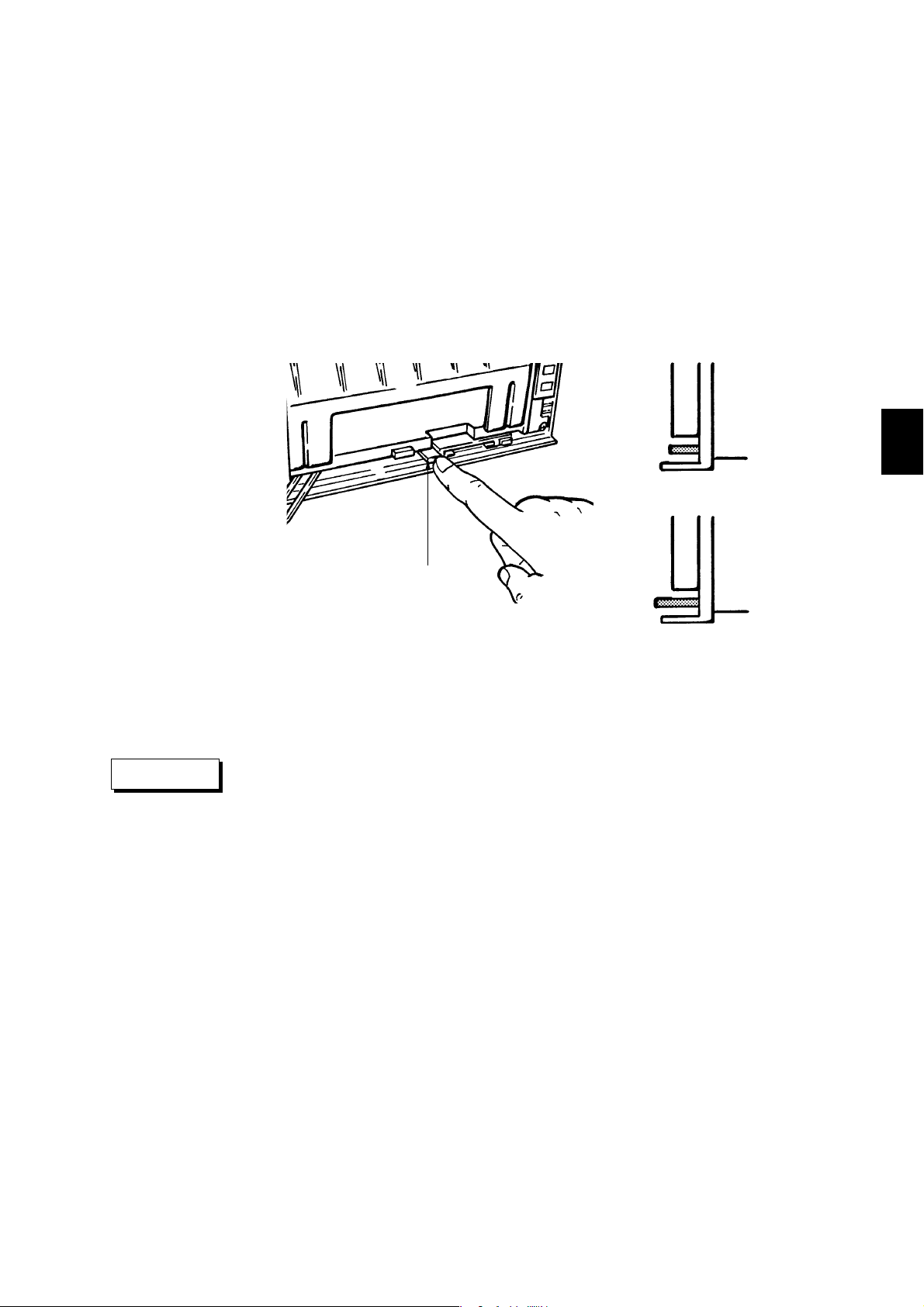

5.2 How to Install (& Replace) Chart, Pens, Ribbon Cassette and Battery

5.2.1 How to Load (& Replace) the Chart

1 Open the front door of the unit.

2 The power can be either ‘ON’ or ‘OFF’, but recording should be ‘OFF’.

3 Fan chart paper thoroughly at both ends before loading.

4 While gently pressing the chart paper compartment lock tab, located in the middle at the

lower front, in the direction of the arrow, swing and lift the compartment away from the

unit (see figure 5.2).

Lock tab

Figure 5.2

5 Press the tabs of the chart guide plate at the top rear of the chart compartment and swing

the guide plate up (see figure 5.3).

6 At the front, pull/swing the front transparent chart guide down and swing the small

transparent chart guides open (see figure 5.3).

Tabs

Top hopper

Small transparent

chart guides

Front transparent chart guide

Figure 5.3

7 Load the chart paper into the top hopper making sure that the sprocket teeth of the chart

drive are properly engaged in the chart paper perforation holes. Take care not to insert

the paper backwards (see figure 5.4).

Figure 5.4

5 - 2 IM 4H3B1-01E

Page 32

5.2 How to Install (& Replace) Chart, Pens, Ribbon Cassette and Battery

8 Place the rear chart guide plate back into position. Press the rear chart guide plate down

and towards you and load the chart.

9 Place the front transparent chart guides back into position (see figure 5.5).

Figure 5.5

10 Replace the chart paper compartment back into the unit. Slide the protruding knurls of

the chart paper compartment into the cutout grooves located on the support brackets.

Push/swing the compartment into the unit until the lock tab clicks shut (see figure 5.6).

5. DAILY OPERATION

Figure 5.6

11 Press the FEED-key (when the power is ON) until 2 leaves of paper are fed (or until the

chart is not curled anymore) and confirm that the chart is fed continuously. If not, repeat

the procedure from step 4.

NOTE A red band is printed at the end of the chart with the heading ‘RENEW CHART’ to

notify you when it is time to prepare a new chart.

IM 4H3B1-01E

5 - 3

Page 33

5.2.2 How to Install (& Replace) Pens and Ribbon Cassette

In case of felt-tip pens:

Normal procedure:

1 Open the front door and make sure the recording is not in progress (by pressing the

RCD-key; power can be either ‘ON’ or ‘OFF’).

2 Swing up the display by grasping and pulling the tabs located at the lower left and right

corner.

3 Grasp the protruding part of the felt-tip pen cartridge and gently pull/slide it out of the

cartridge holder (see figure 5.7).

4 Remove the pen cap before replacing the cartridge with a new one.

Insert a new felt pen cartridge in the pen cartridge holder (see figure 5.7). Start with the

smallest pen.

Felt pen

Figure 5.7

Pen cartridge holder

Pen 1 : red

Pen 2 : green

Pen 3 : blue

Pen 4 : violet

CAUTION

5 Close the display by pulling the 'release'-handle until this handle is at the same level as

the display. Then push the display back into its normal position until the tabs click shut.

6 To (re)start the recording, press the RCD-key.

2nd procedure when the pens are located at a place where it is difficult to replace them:

1 Open the front door and make sure the recording is not in progress (by pressing the

RCD-key; power must be ‘ON’).

2 Press the MENU-key. Use the UP/DOWN-keys to select the display

‘MENU=SELECT_FUNCTION’. Press the ENT-key.

3 Use the UP/DOWN-keys to select the display ‘CHANGE_PEN’. Press the ENT-key.

The pens will move to 55% of the chart, where it is easy to replace them. Note that this

will leave a line on the chart.

4 Handle as described in ‘Normal procedure’, steps 2, 3, 4 and 5.

5 The display ‘PRESS_ENT’ will appear. After finishing, press the ENT-key.

6 To (re)start the recording, press the RCD-key.

To protect the pens and the internal mechanism, never grasp the pen tip nor

apply excessive force to the cartridge holder. Always make sure to remove the

pen cap.

5 - 4 IM 4H3B1-01E

Page 34

5.2 How to Install (& Replace) Chart, Pens, Ribbon Cassette and Battery

In case of plotter pen:

1 Open the front door and make sure the recording is not in progress (by pressing the

RCD-key; power can be either ‘ON’ or ‘OFF’).

2 Swing up the display by grasping and pulling the tabs located at the lower left and right

corner.

3 While grasping the plotter holder, gently slide the plotter out of the holder (see figure

5.8).

4 Remove the pen cap and insert a new plotter pen in the holder (see figure 5.8).

If it is difficult to replace the plotter pen, try the 2nd procedure as described above.

5 Close the display by pulling the 'release'-handle until this handle is at the same level as

the display. Then push the display back into its normal position until the tabs click shut.

Plotter pen

Figure 5.8

Pen holder

In case of the ribbon cassette:

1 Open the front door and make sure the power is OFF.

2 Swing up the display by grasping and pulling the tabs located at the lower left and right

corner.

3 Hold the back section of the carriage assembly and move the assembly to the right.

4 Press the lock tab to the right and use the lower left part of the cassette as a handle to

pull it out of the holder. See figure 5.9.

Ribbon cassette

5. DAILY OPERATION

CAUTION

IM 4H3B1-01E

Printer carriage

Figure 5.9

5 Insert the right side of the new ribbon cassette into the cassette holder.

6 Insert the left side of the ribbon cassette into the cassette holder (clicking it into its

place). If the ribbon cassette does not click into its place easily, adjust the ribbon

feeding knob so that the peg fits the hole.

7 If necessary, turn the ribbon feeding knob to stretch/tighten the ribbon.

8 Close the display by pulling the 'release'-handle until this handle is at the same level as

the display. Then push the display back into its normal position until the tabs click shut.

If the ribbon cassette is not inserted correctly:

• data may be printed in the wrong color

• ribbon edge is used to print out data, which damages the ribbon.

5 - 5

Page 35

5.2.3 How to Replace the Battery

The ‘BAT’ indicator on the VFD-display can either remain illuminated or flash.

In case of illumination, the lithium battery needs to be replaced. However, this battery

will last for ten years under normal operation conditions. For replacement, please

contact the nearest Sales & Service Office. Addresses may be found on the back cover

of this manual.

In case of flashing, you have to replace your IC Memory Card battery (option).

In case of replacement, please refer to the IC Memory Card Instruction Manual IM

4H3B1-30E.

WARNING

To avoid injury, never replace the lithium battery yourself.

5 - 6 IM 4H3B1-01E

Page 36

5.3 Basic Operation (Operation Mode)

5.3.1 How to Start/Stop the Recording

Pressing the RCD-key will cause the recording to start or stop. However, if the Start/

Stop function is controlled by remote control, this key will not work.

(For the status of the initial recording settings, see 6.5)

5.3.2 How to Feed the Chart

The paper can be fed by operating the FEED-key. The paper will be fed as long as the

FEED-key is pressed.

5.3.3 How to Get a Manual Printout

A manual printout contains:

• date & time

• channel number or tag / type of occured alarm / latest measured values / units (for all

channels)

To get a manual printout, press the PRINT-key, select ‘MANUAL_PRINT_START’

using the PRINT-key and press the ENT-key.

When the writing of this printout starts, the display will return to the previous one.

When the writing of this printout is finished, the manual printout function is cancelled

automatically and the µR1800 returns to the recording previously in progress.

5.3 Basic Operation (Operation Mode)

5. DAILY OPERATION

When you want to cancel the manual printout function while in progress, press the

PRINT-key again, and the display ‘MANUAL_PRINT_STOP’ will appear. Press the

ENT-key, and the instrument returns to the recording previously in progress.

During the writing of the manual printout, the analog recording will stop. However,

scanning of the input and detection of alarms will still continue. When alarms occur

during the manual printout, the printing of these alarms will be done after the analog

recording (re)starts.

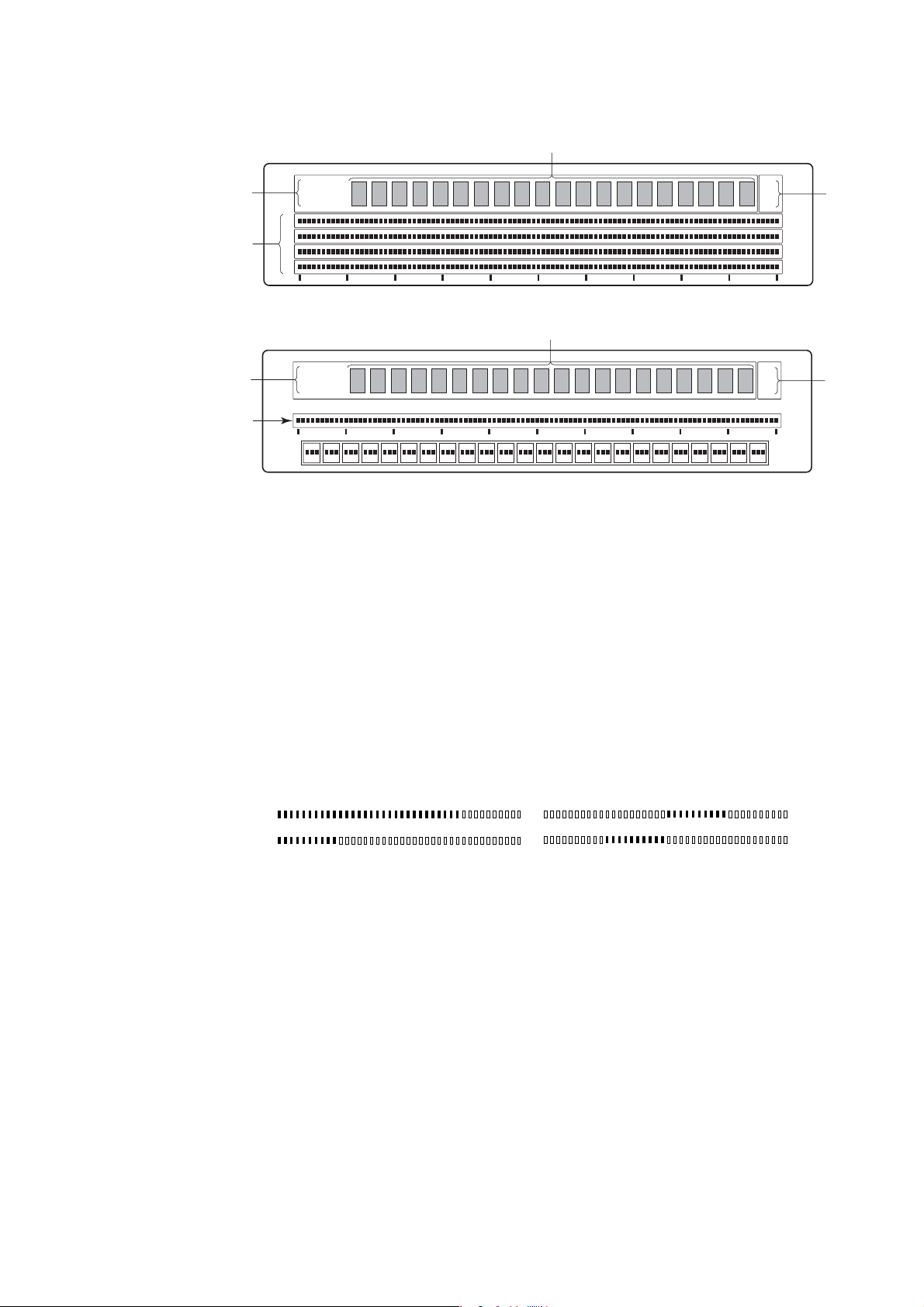

Figure 5.10a Manual Printout Example in case of the Pen Model (two columns appear when tags are

Figure 5.10b Manual Printout Example in case of the Dot Model (two columns appear when tags are

set, three columns appear in case of channel numbers)

set, three columns appear in case of channel numbers)

IM 4H3B1-01E

5 - 7

Page 37

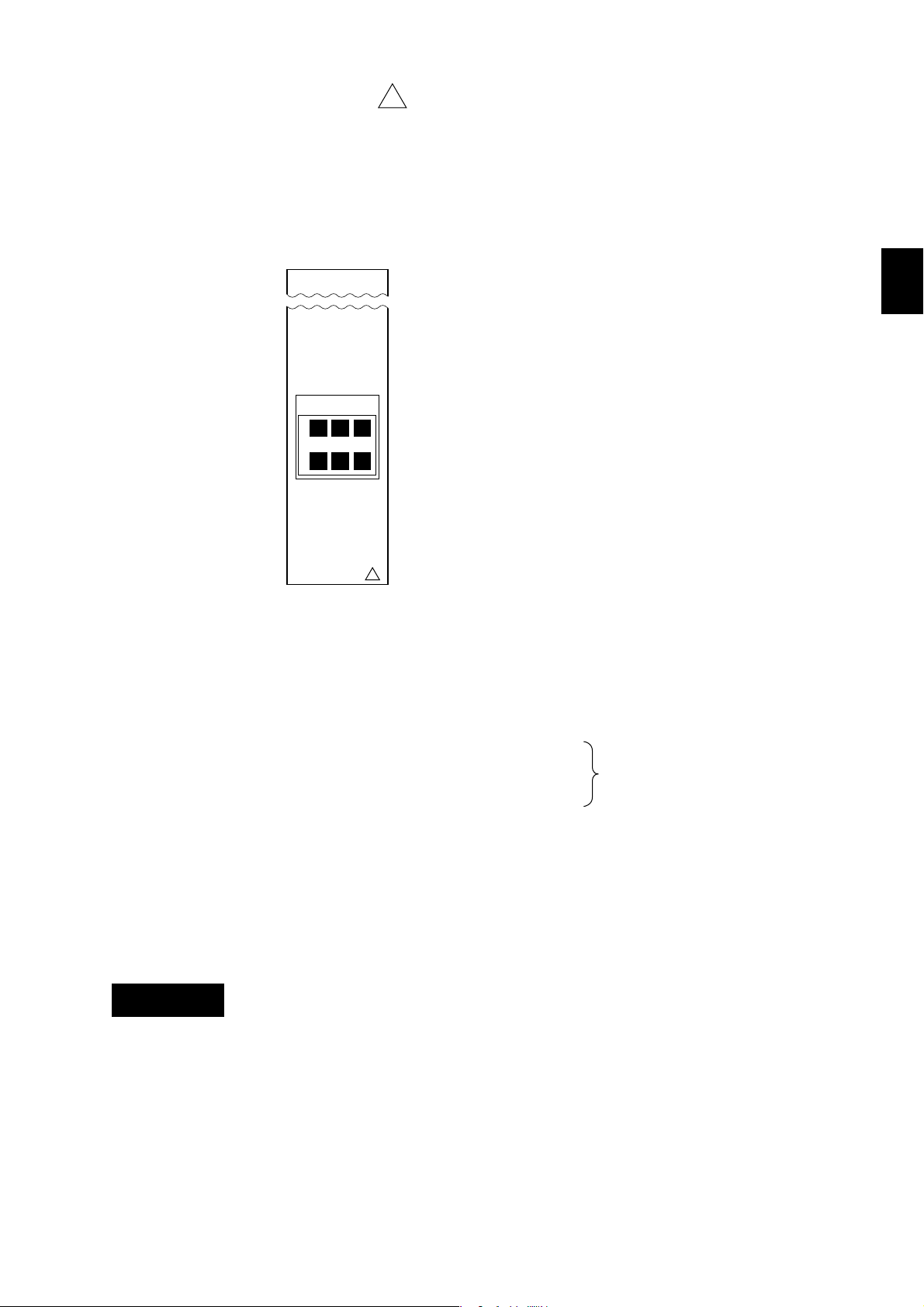

5.3.4 How to Get a List Printout

A list printout contains:

•date, time and chart speed (1 & 2) and in case of the dot model, the trend recording

interval.

•Ch.No. / tag / range / span / scaling values / unit

• type of alarm and values, zone values, partial values, periodic printout ON/OFF

• contents of messages (for all channels).

To get a list printout, press the PRINT-key, select ‘LIST_PRINT_START’ using the

PRINT-key and press the ENT-key.

When the writing of this printout starts, the display will return to the previous one.

When the writing of this printout is finished, this list printout function is cancelled

automatically and the µR1800 returns to the recording previously in progress.

When you want to cancel this list printout function while in progress, press the PRINT-

key again, and the display ‘LIST_PRINT_STOP’ will appear. Press the ENT-key and

the µR1800 returns to the recording previously in progress.

During the writing of the list printout, the analog recording will stop. However,

scanning of the input and detection of alarms will still continue. When alarms occur

during this printout, the printing of these alarms will be done after the analog recording

(re)starts.

Figure 5.11a List Printout Example in case of Pen Model

5 - 8 IM 4H3B1-01E

Page 38

5.3 Basic Operation (Operation Mode)

5. DAILY OPERATION

Figure 5.11b List Printout Example in case of Dot Model

IM 4H3B1-01E

5 - 9

Page 39

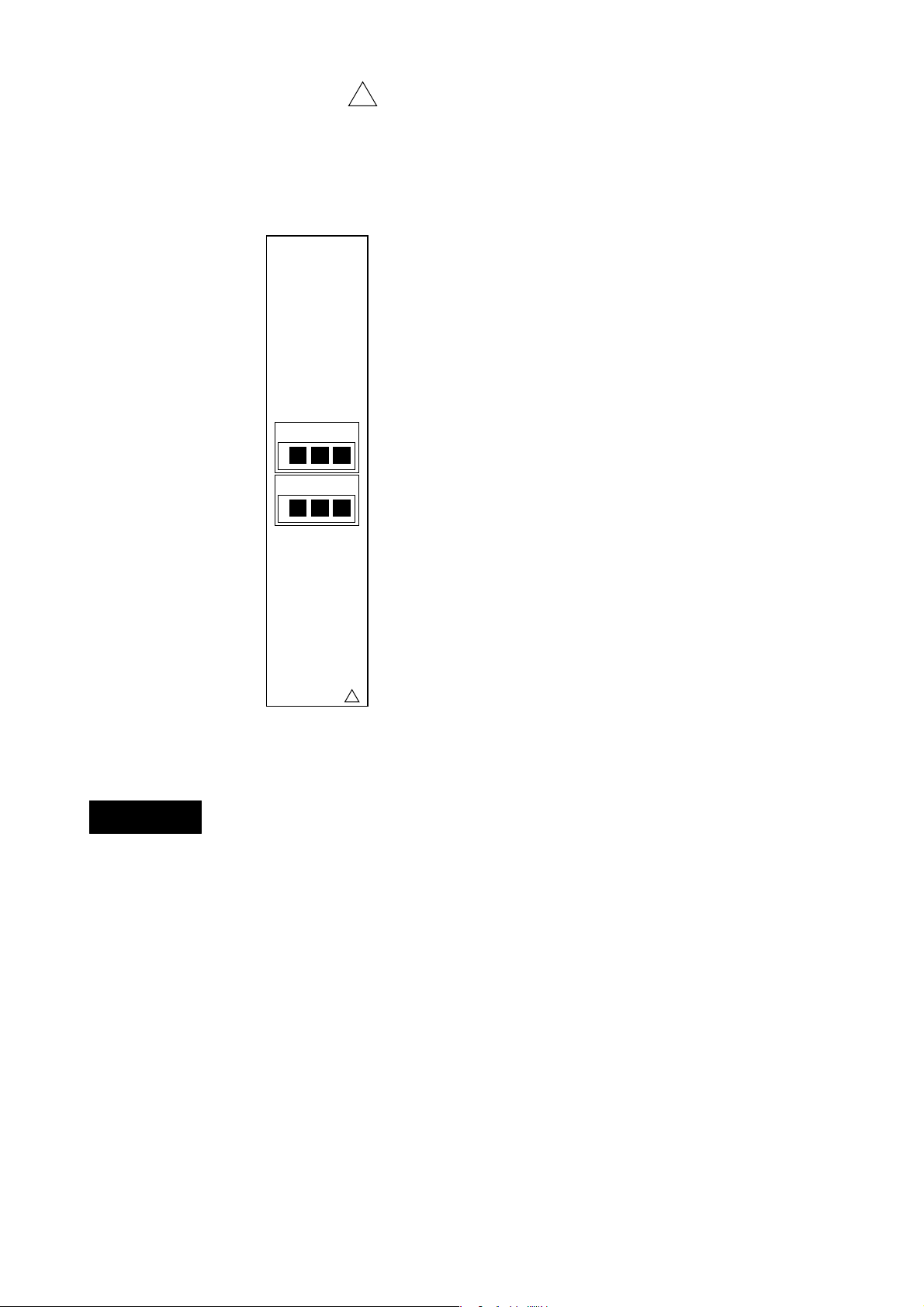

5.3.5 How to Get a SET UP List Printout

A SET UP list printout contains:

• initial settings; analog recording

• initial settings; digital printing

• initial settings; alarms

• initial settings; burnout, RJC and others

• initial settings; options, if installed.

To get the SET UP list printout, proceed as follows:

Press the MENU-key and select the ‘MENU=SELECT_FUNCTION’ display using the

UP/DOWN- keys. Then press the ENT-key. Select the ‘PRINT_SETUP_LIST’

display using the UP/DOWN-keys. Press the ENT-key, and the printing will start.

When the writing of this printout starts, the display will return to the previous one.

When the writing of this printout is finished, this SET UP list printout function is

cancelled automatically and the µR1800 returns to the recording previously in progress.

When you want to cancel this SET UP list printout function while in progress, press the

MENU-key again, select the ‘MENU=SELECT_FUNCTION’ display and press the

ENT-key. Then the ‘STOP_SETUP_LIST’ display will appear and press the ENT-

key. The µR1800 returns to the recording previously in progress.

During the writing of the SET UP list printout, the analog recording will stop.

However, scanning of the input and detection of alarms will still continue. When alarms

occur during this printout, the printing of these alarms will be done after the analog

recording (re)starts.

Figure 5.12a SET UP List Printout Example in case of Pen Model

5 - 10 IM 4H3B1-01E

Page 40

5.3 Basic Operation (Operation Mode)

5. DAILY OPERATION

Figure 5.12b SET UP List Printout Example in case of Dot Model

IM 4H3B1-01E

5 - 11

Page 41

5.3.6 How to Get a Message Printout

The contents of a message must be entered first.

To set or change a message, see 8.2.3.

To get a message printed on the chart, proceed as follows:

Press the MENU-key and select the ‘MENU=SELECT_FUNCTION’ display using the

UP/DOWN-keys. Then press the ENT-key.

Select the ‘PRINT_MESSAGE’ display using the UP/DOWN-keys. Press the ENTkey, and select which message you want to print out, since up to five messages can be

set. Press the ENT-key and the printing will start.

Note that no messages will be printed when the chart speed exceeds 1500 mm/h, in case

of the pen model, or 100 mm/h in case of the dot model, or when recording is OFF.

When the writing of this printout starts, the display will return to the previous one.

When the writing of this printout is finished, the µR1800 returns to the recording

previously in progress.

You cannot cancel this printout once started.

Messages can be triggered by the keyboard, as described above, and by remote control

(option). When several messages are triggered by remote control in a short time, they

will be stored in a buffer memory before printing on the chart. It is possible to clear this

buffer, which can be useful for example in case the printing will take too much time.

When the buffer is full, this will be indicated by an asterisk ( ) in the latest message

printout. As a result the next message is lost and will not be printed.

To clear the buffer memory, proceed as follows:

Press the MENU-key.

Select the display ‘MENU=SELECT_FUNCTION’ using the UP/DOWN-keys. Press

the ENT-key.

Select the display ‘CLEAR_MESSAGE_BUFFER’ using the UP/DOWN-keys. Press

the ENT-key.

The buffer is cleared. The display will return to the previous one used.

Figure 5.13a Message Printout Example in case of Pen Model

Figure 5.13b Message Printout Example in case of Dot Model

Message printout

NOTE The µR1800 will store up to 5 messages in a buffer memory, regardless whether

recording is ON or OFF. If more messages are generated, the new ones will not be kept

in the buffer memory.

5 - 12 IM 4H3B1-01E

Page 42

5.3.7 How to Acknowledge an Alarm

HOLD

NON-HOLD

Alarm ON

Alarm OFF

ACK ACK

or

Relay set

Relay reset

or

Indicator flash

Indicator ON

Indicator OFF

or

(see 9.1.4, 9.1.5)

(see 9.1.4, 9.1.5)

ACK

When an alarm occurs, the output relays (if installed) will be activated and the alarm

indicator will behave as described below (see also figure 5.14):

Non-hold Type (for hold/non-hold selection, see 9.1.4 and 9.1.5):

when alarm occurs: the output relay will be activated

when alarm recovers: the output relay will be reset

Pressing the ACK-key has no effect.

Hold Type (for hold/non-hold selection, see 9.1.4 and 9.1.5):

when alarm occurs: the output relay will be activated

when alarm recovers: the output relay will be kept activated; however, pressing the

5.3 Basic Operation (Operation Mode)

the indicator will lighten

the indicator will stop lighting

the indicator will start flashing; however, pressing the

ACK-key results in showing the current alarm status (alarm in

progress = ON, alarm recovered = OFF)

ACK-key results in resetting the relay.

the indicator will keep flashing; however, pressing theACK-key

results in showing the current alarm status (alarm in progress =

ON, alarm recovered = OFF)

5. DAILY OPERATION

IM 4H3B1-01E

Figure 5.14

When an alarm occurs, you will see this on the display and alarm data will be printed on

the chart. See 1.2 for an example.

When several alarms are generated in a short time, they will be stored in a buffer

memory before printing on the chart. It is possible to clear this buffer, which can be

useful for example in case the printing will take too much time. When the buffer is full,

this will be indicated by an asterisk ( ) in the latest alarm printout. As a result the next

alarm is lost and will not be printed.

To clear the buffer memory, proceed as follows:

Press the MENU-key.

Select the display ‘MENU=SELECT_FUNCTION’ using the UP/DOWN-keys. Press

the ENT-key. Select the display ‘CLEAR_ALARM_BUFFER’ using the UP/DOWNkeys. Press the ENT-key.

The buffer is cleared. The display will return to the previous one used.

NOTE The µR1800 will store up to 8 (pen model) or 12 (dot model) alarms in a buffer

memory. If more alarms are generated, the new ones will not be kept in the buffer

memory.

5 - 13

Page 43

5.3.8 How to Select the Display

Four different displays can be selected. These are:

DISPLAY AUTO:

Channel number or tag, measured values and units will appear on the display

alternately. Every channel will be shown for approximately 2 sec. If the input is greater

than the upper limit of the recording span, + will appear.

If the input is less than the lower limit of the recording span, – will appear.

Depending on whether you set tags (and specified this as explained in 9.4.1), the display