Page 1

User's

Manual

Model ZR22G, ZR402G

Separate type

Zirconia High Temperature Humidity Analyzer

IM 11M12A01-03E

IM 11M12A01-03E

7th Edition

Page 2

Introduction

The EXAxt ZR Separate-type Zirconia High-temperature Humidity Analyzer has been

developed for humidity control in various industrial processes. This analyzer basically

consists of a detector and a converter. You can select between several versions based

upon your application.

Optional accessories are also available to improve measurements and automate calibration. An optimal control system can be realized by adding appropriate options.

This instruction manual refers to almost all of the equipment related to the EXAxt ZR.

You may skip any section(s) on the equipment which is/are not included in your system.

Regarding the HART communication protocol,refer to the IM 11M12A01-51E.

IM 11M12A01-51E has been published as Model EXAxt ZR Series HART Protocol

The all-in-one version (with sensor and analyzer integrated in one body) is described in

IM 11M12A01-05E

< Before using the equipment, please read any related descriptions in this manual for the

equipment and the system you have, on appropriate use and operation of the EXAxt ZR. >

Models and descriptions in this manual are as follows:

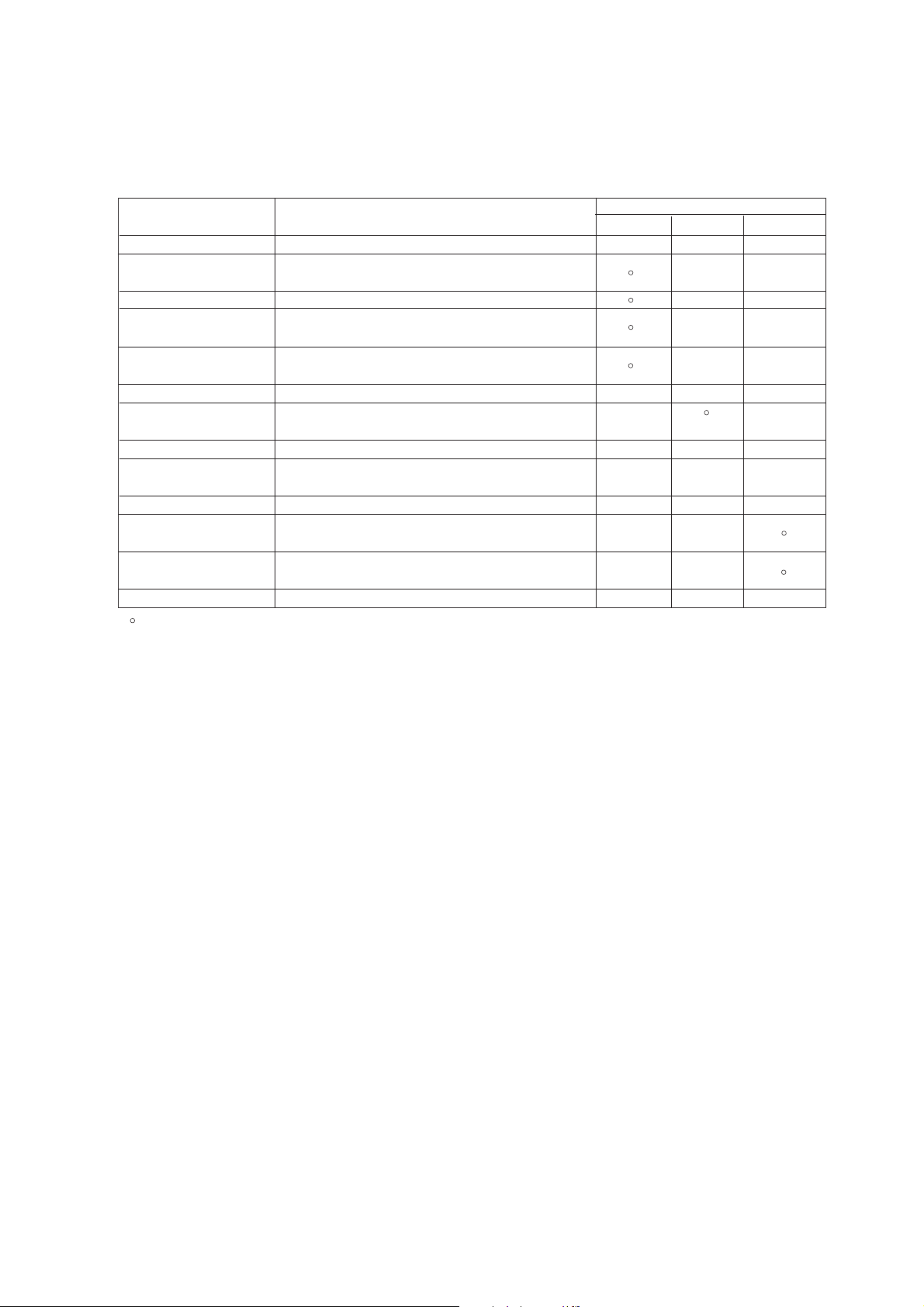

Models and descriptions in this manual

Description in this manual

Model Product Name Specification Installation Operation Maintenance CMPL

ZR22G General-use detector s s s s

ZR402G Converter s s s s s

ZH21B Dust protector s s

ZA8F Flow setting unit (for manual calibration use) s s s

ZR40H Automatic Calibration unit s s s s

- Calibration gas unit case (Part No. E7044KF) s s

- Check valve (Part No. K9292DN, K9292DS) s s

ZO21S Standard gas unit s s s s

T.Int.1E

CMPL : Customer Maintenance Parts List

IM 11M12A01-03E

7th Edition: Sep. 2006 (YK)

All Rights Reserved, Copyright © 2000, Yokogawa Electric Corporation

IM 11M12A01-03E

i

Page 3

This manual consists of twelve chapters. Please refer to the reference chapters for

installation, operation and maintenance.

Table of Contents

References

Chapter Outline Installation Operation Maintenance

1. Overview Equipment models and system configuration examples

2. Specifications Standard specification, model code (or part number),

dimension drawing for each equipment

3. Installation Installation method for each equipment

4. Piping Examples of piping in three standard system

configurations

5. Wiring Wiring procedures such as Power supply wiring , output

signal wiring or others

6. Components These are described in this manual

7. Startup Basic procedure to start operation of EXAxt ZR. Chapter 7

enables you to operate the equipment immediately.

8. Detailed Data Setting Details of key operations and displays

9. Calibration Describes the calibration procedure required in the course

of operation.

10. Other Functions Other functions described

11. Inspection and How to conduct maintenance of EXAxt ZR and procedures

Maintenance for replacement of deteriorated parts

12. Troubleshooting This chapter describes measures to be taken when an

abnormal condition occurs.

CMPL (parts list) User replaceable parts list

: Read and completely understand before operating the equipment.

s

: Read before operating the equipment, and refer to whenever necessary.

s

: Recommended to read it at least once.

n

s

s

s

s

s

n

n

s

s

s

s

s

s

s

n

n

s

s

n

n

n

s

n

n

n

n

s

s

s

T.Int.2E

ii

IM 1M12A01-03E

Page 4

r For the safe use of this equipment

CAUTION

The cell (sensor) at the tip of the detector is made of ceramic (zirconia element). Do not

drop the detector or subject it to pressure stress.

• Do NOT allow the sensor (probe tip) to make contact with anything when installing

the detector.

• Avoid any water dropping directly on the probe (sensor) of the detector when installing it.

• Check the calibration gas piping before introducing the calibration gas to ensure that

there is no leakage of the gas. If there is any leakage of the gas, the moisture drawn

from the measuring gas can damage the sensor.

• The detector (especially at the tip) becomes very hot. Be sure to handle it with gloves.

EXAxt ZR is very heavy. Handle it with care. Be sure not to accidentally drop it.

Handle safely to avoid injury.

DANGER

(1) About This Manual

Connect the power supply cord only after confirming that the supply voltage matches

the rating of this equipment. In addition, confirm that the power is switched off when

connecting power supply.

Some process gas is dangerous to people. When removing this equipment from the

process line for maintenance or other reasons, protect yourself from potential

poisoningby using a protective mask or ventilating the area well.

• This manual should be passed on to the end user.

• The contents of this manual are subject to change without prior notice.

• The contents of this manual shall not be reproduced or copied, in part or in whole,

without permission.

• This manual explains the functions contained in this product, but does not warrant that

those will suit the particular purpose of the user.

• Every effort has been made to ensure accuracy in the preparation of this manual.

However, should any errors or omissions come to the attention of the user, please

contact the nearest Yokogawa Electric representative or sales office.

• This manual does not cover the special specifications. This manual may not be

changed on any change of specification, construction and parts when the change does

not affect the functions or performance of the product.

• If the product is used in a manner not specified in this manual, safety of this product

may be impaired.

IM 11M12A01-03E

iii

Page 5

(2) Safety and Modification Precautions

• Follow the safety precautions in this manual when using the product to ensure protection and safety of personnel, product and system containing the product.

(3) The following safety symbols are used on the product as well as in this manual.

DANGER

This symbol indicates that the operator must follow the instructions laid out in this

manual in order to avoid the risk of personnel injuries or fatalities such as electric shock.

The manual describes what special care the operator must exercise to prevent such risks.

WARNING

This symbol indicates that the operator must refer to the instructions in this manual in

order to prevent the instrument (hardware) or software from being damaged, or a system

failure from occurring.

CAUTION

This symbol draws attention to information essential for understanding the operation and

functions.

Tip

This symbol gives information that complements the present topic.

SEE ALSO

This symbol identifies a source to which to refer.

Protective Ground Terminal

Function Ground Terminal (Do not use this terminal as the protective ground

terminal.)

Alternating current

iv

IM 1M12A01-03E

Page 6

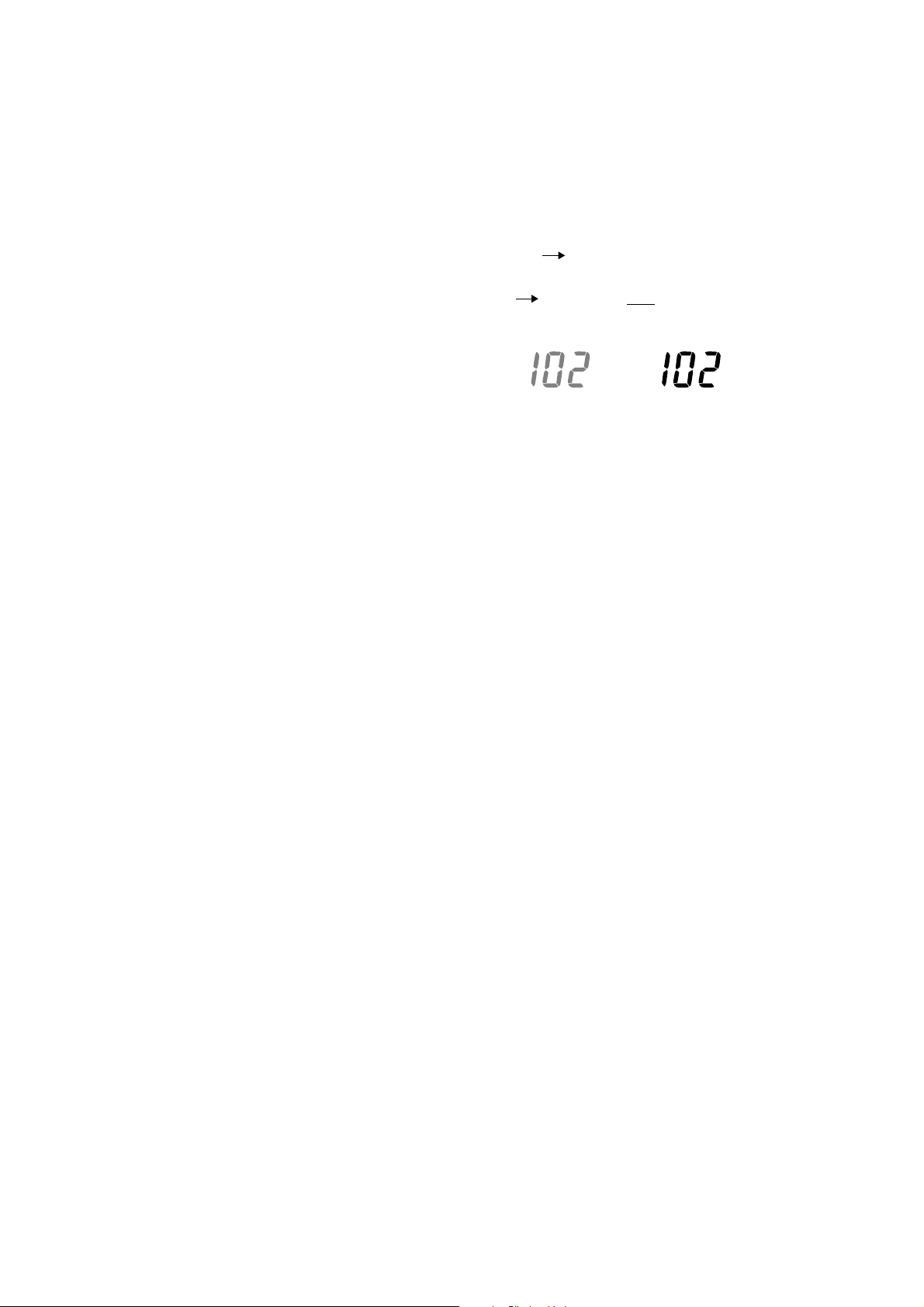

• Special descriptions in this manual

This manual indicates operation keys, displays and drawings on the product as follows:

• Operation keys, Enclosed in [ ], displays on the panel 0 0.

• Drawing for flashing

Indicated by gray characters. (Flashing) (lit)

(Ex. [MODE] key)

(Ex. message display 0 BASE 0)

(Ex. data display 0 102 0 lit, 0 102 0 flashing)

IM 11M12A01-03E

v

Page 7

r NOTICE

• Specification check

When the instrument arrives, unpack the package with care and check that the

instrument has not been damaged during transportation. In addition, please check that

the specification matches the order, and required accessories are not missing. Specifications can be checked by the model codes on the nameplate. Refer to Chapter 2

Specifications for the list of model codes.

• Details on operation parameters

When the EXAxt ZR Separate-type High Temperature Humidity Analyzer arrives at

the user site, it will operate based set before shipping parameters (initial data) on the

departure from the factory.

Ensure that the initial data is suitable for the operation conditions before conducting

analysis. Where necessary, set the instrument parameters for appropriate operation.

For details of setting data, refer to chapters 7 to 10.

When user changes the operation parameter, it is recommended to note down the

changed setting data.

r After -Sales Warranty

d Do not modify the product.

d During the warranty period, for repair under warranty carry or send the product to the

local sales representative or service office. Yokogawa will replace or repair any

damaged parts and return the product to you.

d Before returning a product for repair under warranty, provide us with the model

name and serial number and a description of the problem. Any diagrams or data

explaining the problem would also be appreciated.

d If we replace the product with a new one, we won’t provide you with a repair report.

d Yokogawa warrants the product for the period stated in the pre-purchase quotation.

Yokogawa shall conduct defined warranty service based on its standard. When the

customer site is located outside of the service area, a fee for dispatching the maintenance engineer will be charged to the customer.

d In the following cases, customer will be charged repair fee regardless of warranty

period.

• Failure of components which are out of scope of warranty stated in instruction

manual.

• Failure caused by usage of software, hardware or auxiliary equipment, which

Yokogawa Electric did not supply.

• Failure due to improper or insufficient maintenance by user.

• Failure due to modification, misuse or outside-of-specifications operation which

Yokogawa does not authorize.

• Failure due to power supply (voltage, frequency) being outside specifications or

abnormal.

• Failure caused by any usage out of scope of recommended usage.

• Any damage from fire, earthquake, storms and floods, lightning, disturbances, riots,

warfare, radiation and other natural changes.

vi

IM 1M12A01-03E

Page 8

d Yokogawa does not warrant conformance with the specific application at the user

site. Yokogawa will not bear direct/indirect responsibility for damage due to a specific

application.

d Yokogawa Electric will not bear responsibility when the user configures the product

into systems or resells the product.

d Maintenance service and supplying repair parts will be covered for five years after

the production ends. For repair for this product, please contact the nearest sales office

described in this instruction manual.

IM 11M12A01-03E

vii

Page 9

Contents

Introduction........................................................................................................................... i

r For the safe use of this equipment ............................................................................... iii

r NOTICE.........................................................................................................................vi

r After-Sales Warranty ................................................................................................... vi

1. Overview ...................................................................................................................... 1-1

1.1 < EXAxt ZR > System Configuration............................................................ 1-2

1.1.1 System 1 .................................................................................................. 1-2

1.1.2 System 2 .................................................................................................. 1-3

1.1.3 System 3 .................................................................................................. 1-4

1.2 < EXAxtZR > System Components ............................................................... 1-5

1.2.1 System Components ................................................................................ 1-5

1.2.2 Detectors and Accessories ....................................................................... 1-5

2. Specifications ............................................................................................................... 2-1

2.1 General Specifications .................................................................................... 2-1

2.1.1 Standard Specifications ........................................................................... 2-1

2.2 General-use Separate-type Detector and Related Equipment ........................ 2-3

2.2.1 ZR22G General-use Separate-type Detector ........................................... 2-3

2.2.2 ZH21B Dust Protector ............................................................................. 2-8

2.3 ZR402G Separate-type Converter ................................................................... 2-9

2.3.1 Standard Specifications ........................................................................... 2-9

2.3.2 Function ................................................................................................. 2-10

2.4 ZA8F Flow Setting Unit and ZR40H Automatic Calibration Unit ............. 2-16

2.4.1 ZA8F Flow Setting Unit........................................................................ 2-16

2.4.2 ZR40H Automatic Calibration Unit ...................................................... 2-18

2.5 ZO21S Standard Gas Unit ............................................................................ 2-21

2.6 Other Equipment ........................................................................................... 2-22

2.6.1 Stop Valve (Part Number: L9852CB or G7016XH) ............................ 2-22

2.6.2 Check Valve (Part Number: K9292DN or K9292DS) ......................... 2-23

2.6.3 Air Set................................................................................................... 2-24

2.6.4 Zero-gas Cylinder (Part Number: G7001ZC) ....................................... 2-26

2.6.5 Pressure Regulator for Gas Cylinder

(Part Number: G7013XF or G7014XF) .............................................. 2-26

2.6.6 Case Assembly for Calibration-gas Cylinder

(Part Number: E7044KF)..................................................................... 2-27

2.6.7 Model ZR22A Heater Assembly ........................................................... 2-28

3. Installation ................................................................................................................... 3-1

3.1 Installation of the Detector ............................................................................. 3-1

3.1.1 Location ................................................................................................... 3-1

3.1.2 Probe Insertion Hole ................................................................................ 3-2

3.1.3 Installation of the Detector ...................................................................... 3-3

3.1.4 Installation of ZH21B Dust Protector ..................................................... 3-3

viii

IM 1M12A01-03E

Page 10

3.2 Installation of the Converter ........................................................................... 3-4

3.2.1 Location .................................................................................................. 3-4

3.2.2 Mounting of the Converter ...................................................................... 3-4

3.3 Installation of ZA8F Flow Setting Unit ......................................................... 3-7

3.3.1 Location ................................................................................................... 3-7

3.3.2 Mounting of ZA8F Flow Setting Unit .................................................... 3-7

3.4 Installation of ZR40H Automatic Calibration Unit........................................ 3-9

3.4.1 Location ................................................................................................... 3-9

3.4.2 Mounting of ZR40H Automatic Calibration Unit .................................. 3-9

3.5 Installation of E7044KF Case Assembly for

the Calibration-gas Cylinder ......................................................................... 3-11

3.5.1 Location ................................................................................................. 3-11

3.5.2 Mounting................................................................................................ 3-11

3.6 Insulation Resistance Test ............................................................................. 3-12

3.7 External Dimensions of Detectors with Pressure Compensation................. 3-13

4. Piping............................................................................................................................4-1

4.1 Piping for System 1 ........................................................................................ 4-1

4.1.1 Parts Required for Piping in System 1 ................................................... 4-2

4.1.2 Connection to the Calibration Gas Inlet ................................................. 4-2

4.1.3 Connection to the Reference Gas Inlet ................................................... 4-2

4.2 Piping for System 2 ........................................................................................ 4-3

4.2.1 Piping Parts for System 2........................................................................ 4-3

4.2.2 Piping for the Calibration Gas ................................................................ 4-4

4.2.3 Piping for the Reference Gas .................................................................. 4-4

4.3 Piping for System 3 ........................................................................................ 4-5

5. Wiring ........................................................................................................................... 5-1

5.1 General ............................................................................................................ 5-1

5.1.1 Terminals for the External Wiring in the Converter .............................. 5-3

5.1.2 Wiring ...................................................................................................... 5-3

5.1.3 Mounting of Cable Gland........................................................................ 5-4

5.2 Wiring for Detector Output ............................................................................. 5-5

5.2.1 Cable Specifications ................................................................................ 5-5

5.2.2 Connection to the Detector...................................................................... 5-6

5.2.3 Connection to the Converter ................................................................... 5-7

5.3 Wiring for Power to Detector Heater ............................................................. 5-8

5.3.1 Cable Specifications ................................................................................ 5-8

5.3.2 Connection to Detector............................................................................ 5-8

5.3.3 Connection to Converter ......................................................................... 5-9

5.4 Wiring for Analog Output ............................................................................. 5-10

5.4.1 Cable Specifications .............................................................................. 5-10

5.4.2 Wiring Procedure................................................................................... 5-10

5.5 Power and Grounding Wiring....................................................................... 5-11

5.5.1 Power Wiring......................................................................................... 5-11

5.5.2 Grounding Wiring ................................................................................. 5-11

5.6 Wiring for Contact Output............................................................................ 5-12

5.6.1 Cable Specifications .............................................................................. 5-12

5.6.2 Wiring Procedure................................................................................... 5-12

5.7 Wiring for ZR40H Automatic Calibration Unit ........................................... 5-13

5.7.1 Cable Specifications .................................................................................. 5-14

5.7.2 Wiring Procedure ...................................................................................... 5-14

IM 11M12A01-03E

ix

Page 11

5.8 Wiring for Contact Input ............................................................................... 5-15

5.8.1 Cable Specifications .............................................................................. 5-15

5.8.2 Wiring Procedure................................................................................... 5-15

5.9 Temperature Input Wiring ............................................................................ 5-16

5.9.1 Applicable Temperature Transmitter .................................................... 5-16

5.9.2 Cable Specifications .............................................................................. 5-16

5.9.3 Wiring Procedure................................................................................... 5-16

6. Components ................................................................................................................. 6-1

6.1 ZR22G Detector .............................................................................................. 6-1

6.1.1 General-purpose Detector ........................................................................ 6-1

6.2 ZR402G Converter.......................................................................................... 6-2

6.3 ZA8F Flow Setting Unit, ZR40H Automatic Calibration Unit ..................... 6-3

7. Startup..........................................................................................................................7-1

7.1 Checking Piping and Wiring Connections ..................................................... 7-1

7.2 Checking Valve Setup ..................................................................................... 7-1

7.3 Supplying Power to the Converter .................................................................. 7-2

7.4 Touchpanel Switch Operations ....................................................................... 7-3

7.4.1 Basic Panel and Switch ........................................................................... 7-3

7.4.2 Display Configuration (for High-temperature Humidity Analyzer) ....... 7-4

7.4.3 Display Functions .................................................................................... 7-5

7.4.4 Entering Numeric and Text Data ............................................................ 7-5

7.5 Confirmation of Converter Type Setting........................................................ 7-7

7.6 Confirmation of Detector Type Setting .......................................................... 7-8

7.7 Current Output Setting.................................................................................... 7-8

7.7.1 Analog Output Setting ............................................................................. 7-8

7.7.2 Minimum Current (4 mA) and Maximum Current (20 mA) Settings ... 7-9

7.8 Setting Display Item ..................................................................................... 7-10

7.9 Checking Current Loop ................................................................................. 7-12

7.10 Checking Contact I/O ................................................................................... 7-13

7.10.1 Checking Contact Output ...................................................................... 7-13

7.10.2 Checking Calibration Contact Output................................................... 7-14

7.10.3 Checking Input Contacts ....................................................................... 7-14

7.11 Calibration ..................................................................................................... 7-15

7.11.1 Calibration Setup................................................................................... 7-15

7.11.2 Manual Calibration................................................................................ 7-16

8. Detailed Data Setting.................................................................................................. 8-1

8.1 Current Output Setting.................................................................................... 8-1

8.1.1 About Input Ranges ................................................................................. 8-1

8.1.2 Setting Minimum Current (4 mA) and Maximum Current (20 mA) ..... 8-4

8.1.3 Entering Output Damping Constants ...................................................... 8-4

8.1.4 Selection of Output Mode ....................................................................... 8-4

8.1.5 Default Values ......................................................................................... 8-5

8.2 Output Hold Setting ........................................................................................ 8-6

8.2.1 Definition of Equipment Status ............................................................... 8-6

8.2.2 Preference Order of Output Hold Value ................................................. 8-7

8.2.3 Output Hold Setting................................................................................. 8-8

8.2.4 Default Values ......................................................................................... 8-8

x

IM 1M12A01-03E

Page 12

8.3 Alarm Setting .................................................................................................. 8-9

8.3.1 Alarm Values ........................................................................................... 8-9

8.3.2 Alarm Output Actions ............................................................................. 8-9

8.3.3 Alarm Setting Procedure ....................................................................... 8-10

8.3.4 Default Values ....................................................................................... 8-11

8.4 Output Contact Setup .................................................................................... 8-12

8.4.1 Output Contact....................................................................................... 8-12

8.4.2 Setting Procedure................................................................................... 8-12

8.4.3 Default Values ....................................................................................... 8-15

8.5 Input Contact Settings................................................................................... 8-16

8.5.1 Input Contact Functions ........................................................................ 8-16

8.5.2 Setting Procedure................................................................................... 8-17

8.5.3 Default Values ....................................................................................... 8-17

8.6 Other Settings................................................................................................ 8-18

8.6.1 Setting the Date-and-Time .................................................................... 8-18

8.6.2 Setting Periods over which Average Values Are Calculated and Periods over

which Maximum and Minimum Values Are Monitored ...................... 8-19

8.6.3 Setting Measurement Gas Temperature and Pressure .......................... 8-20

8.6.4 Setting Purging ...................................................................................... 8-22

8.6.5 Setting Passwords .................................................................................. 8-23

9. Calibration ...................................................................................................................9-1

9.1 Calibration Briefs ............................................................................................ 9-1

9.1.1 Measurement Principle of Zirconia Humidity Analyzer ........................ 9-1

9.1.2 Calibration Gas ........................................................................................ 9-3

9.1.3 Compensation .......................................................................................... 9-4

9.1.4 Characteristic Data from a Sensor Measured During Calibration .......... 9-5

9.2 Calibration Procedures .................................................................................... 9-6

9.2.1 Calibration Setting ................................................................................... 9-6

9.2.2 Default Values ......................................................................................... 9-9

9.2.3 Calibration ............................................................................................. 9-10

10.Other Functions ........................................................................................................ 10-1

10.1 Display........................................................................................................... 10-1

10.1.1 Detailed Display .................................................................................... 10-1

10.1.2 Trend Graph ........................................................................................... 10-5

10.1.3 Auto(matic) Display-Revert Time......................................................... 10-7

10.1.4 Entering Tag Name ............................................................................... 10-8

10.1.5 Language Selection ............................................................................... 10-8

10.2 Blowback....................................................................................................... 10-9

10.2.1 Blowback Setup..................................................................................... 10-9

10.3 Operational Data Initialization.................................................................... 10-13

10.4 Reset ............................................................................................................ 10-17

10.5 Handling of the ZO21S Standard Gas Unit................................................ 10-18

10.5.1 Standard Gas Unit Component Identification ..................................... 10-18

10.5.2 Installing Gas Cylinders ...................................................................... 10-19

10.5.3 Calibration Gas Flow........................................................................... 10-20

10.6 Methods of Operating Valves in the ZA8F Flow Setting Unit .................. 10-23

10.6.1 Preparation Before Calibration ............................................................ 10-23

10.6.2 Operating the Span Gas Flow Setting Valve...................................... 10-23

10.6.3 Operating the Zero Gas Flow Setting Valve ...................................... 10-24

10.6.4 Operation After Calibration................................................................. 10-24

IM 11M12A01-03E

xi

Page 13

11.Inspection and Maintenance .................................................................................... 11-1

11.1 Inspection and Maintenance of the Detector ................................................ 11-2

11.1.1 Cleaning the Calibration Gas Tube....................................................... 11-2

11.1.2 Replacing the Sensor Assembly ............................................................ 11-3

11.1.3 Replacement of the Heater Unit .......................................................... 11-5

11.1.4 Replacement of O-ring .......................................................................... 11-8

11.1.5 Stopping and Re-starting Operation ........................................................ 11-8

11.2 Inspection and Maintenance of the Converter.............................................. 11-9

11.2.1 Replacing Fuses..................................................................................... 11-9

11.2.2 Cleaning............................................................................................... 11-10

11.2.3 Adjust LCD screen contrast ................................................................ 11-10

11.3 Replacing Flowmeter in ZR40H Autocalibration Unit .............................. 11-11

12.Troubleshooting.........................................................................................................12-1

12.1 Displays and Measures to Take When Errors Occur ................................... 12-1

12.1.1 What is an Error? .................................................................................. 12-1

12.1.2 Measures to Take When an Error Occurs ............................................. 12-2

12.2 Displays and Measures to Take When Alarms are Generated ..................... 12-5

12.2.1 What is an Alarm? ................................................................................. 12-5

12.2.2 Measures Taken When Alarms are Generated.................................. 12-7

12.3 Countermeasures When Measured Value Shows Error ............................. 12-13

12.3.1 Measured Value Higher Than True Value.......................................... 12-13

12.3.2 Measured Value Lower Than True Value .......................................... 12-14

12.3.3 Measurements Sometimes Show Abnormal Values........................... 12-14

Customer Maintenance Parts List ................................................ CMPL 11M12A01-03E

Customer Maintenance Parts List ................................................ CMPL 11M12C01-01E

Customer Maintenance Parts List ................................................ CMPL 11M12A01-11E

Customer Maintenance Parts List .................................................... CMPL 11M3D1-01E

Revision Record .................................................................................................................... i

xii

IM 1M12A01-03E

Page 14

1. Overview

The EXAxt ZR Separate-type Zirconia High-temperature Humidity Analyzer is used to

measure the humidity of hot gases continuously in driers which use hot gas or electricity

as the heat source. It can also be used in a variety of manufacturing applications in

humidifiers, as well as in driers, for humidity measurement and control. It can help

improve productivity in these application fields.

The ZR402G Separate-type converter is equipped with an LCD touchpanel which has

various setting displays, a calibration display, humidity trend display, with easier

operation and improvement of display functions. The converter is equipped with various

standard functions such as measurement and calculation as well as maintenance functions including a self-test. Analyzer calibration can also be fully automated and ZR40H,

the automatic calibration unit, is provided. Choose the detector which best suits your

needs so that an optimal humidity control system can be obtained.

Some examples of typical system configuration are illustrated following pages :

1. Overview

IM 11M12A01-03E

1-1

Page 15

1.1 < EXAxt ZR > System Configuration

The system configuration should be determined by the conditions; e.g. whether the

calibration gas flow should be automated. The system configuration can be classified

into three basic patterns as follows:

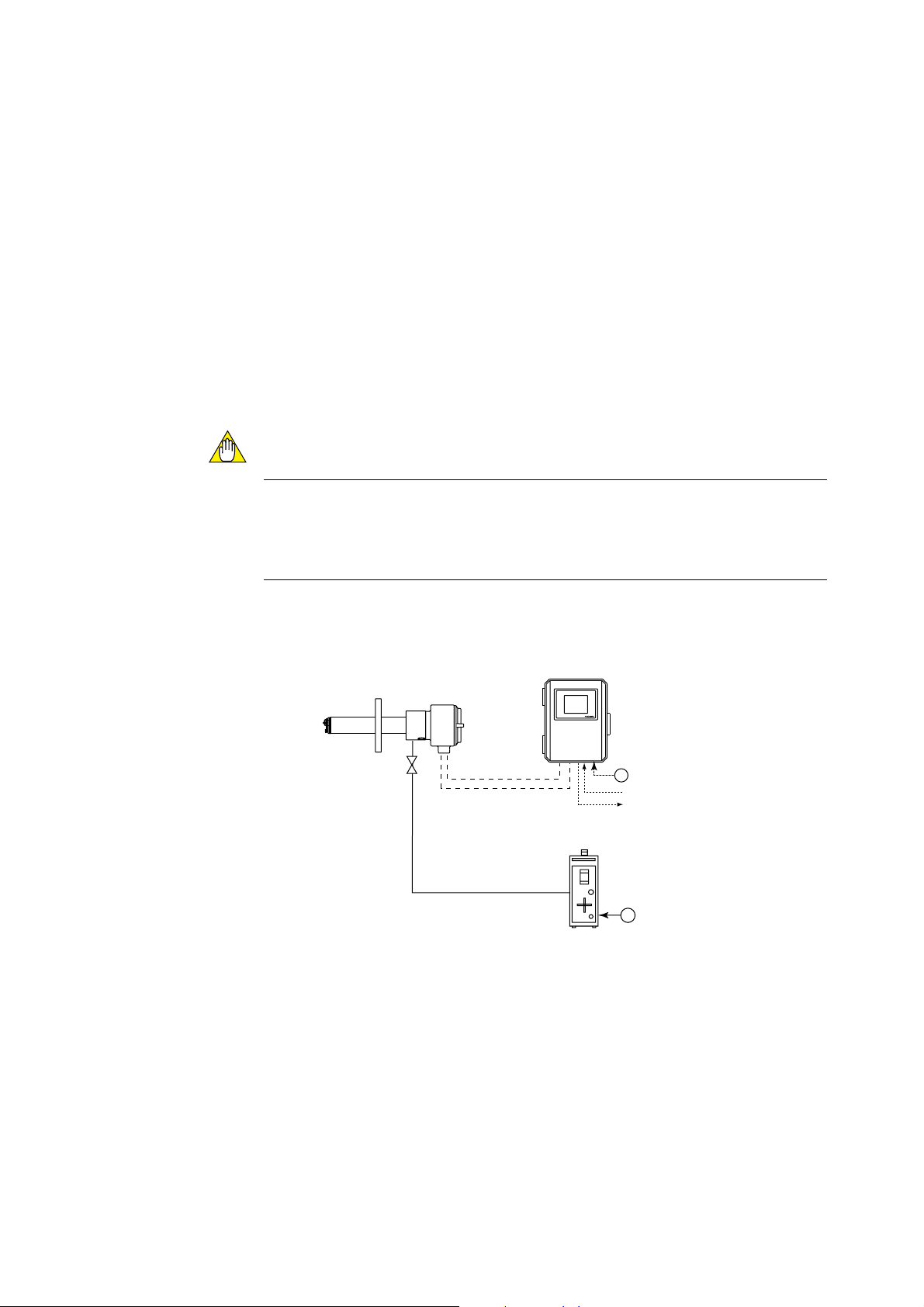

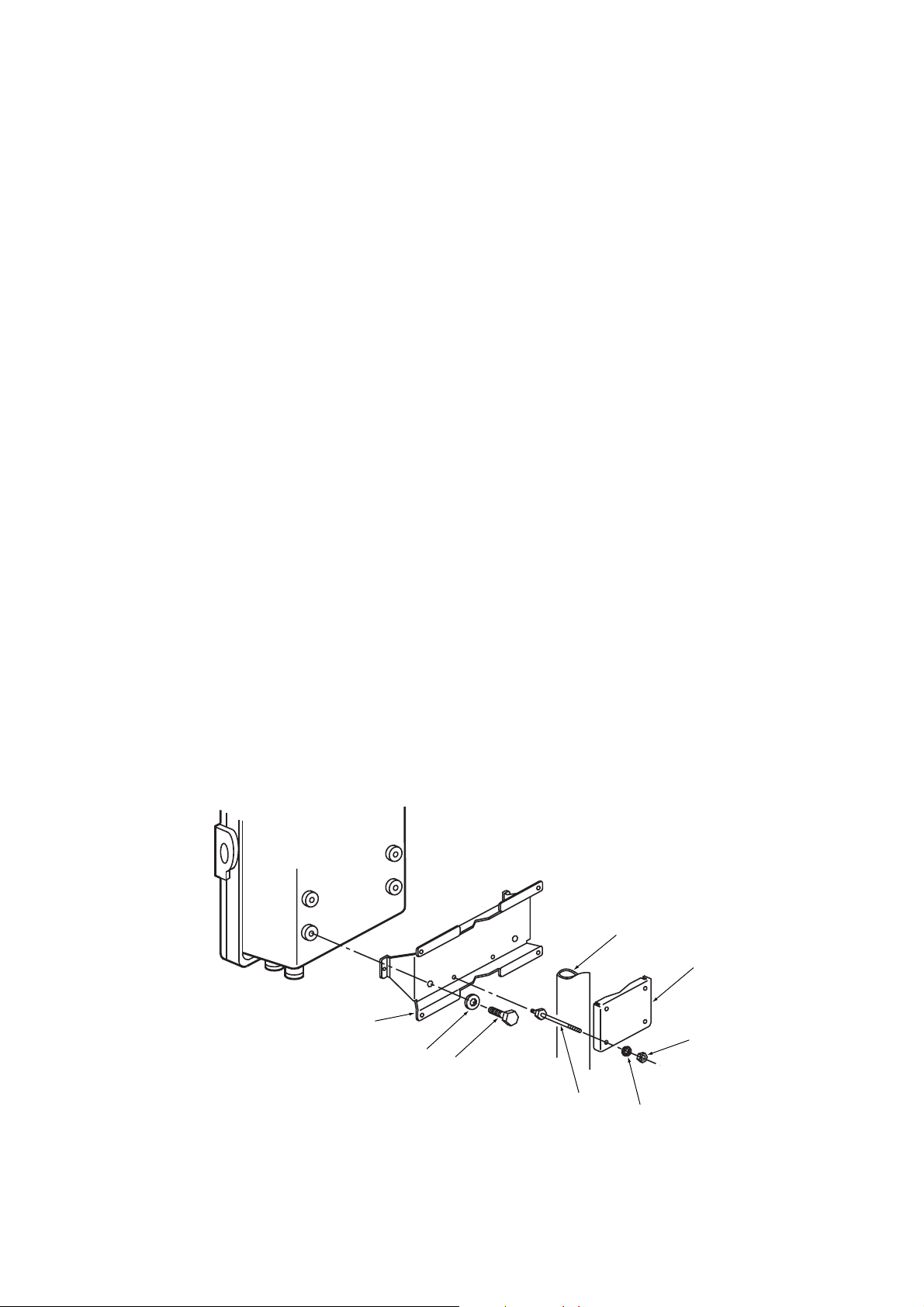

1.1.1 System 1

This is the simplest system consisting of a detector and a converter. This system can be

implemented for monitoring humidity in a production process such as food production.

No piping is required for the reference gas (air) which is fed in at the installation site.

The handy ZO21S standard gas unit is used for calibration.

Zero gas from this unit and span gas (air) is sent to the detector through a tube which is

connected during calibration.

CAUTION

• A needle (stop) valve should be connected to the calibration gas inlet of the detector.

The valve should be fully closed unless calibration is in progress.

• As this system uses ambient air for the reference gas, measuring accuracy will be

affected by the installation location.

Separate type Zirconia

High Temperature Humidity Analyzer,

Model ZR22G Detector

Stop valve

Signal

(6-core shield cable)

Heater (2-core)

Calibration gas

Figure 1.1

Model ZR402G Converter

EXA

ZR402G

100 to 240 V AC

,

Contact input

Analog outout, contact output

Digital output (HART)

Model ZO21S Standard gas unit

,

F1.1E.EPS

1-2

IM 11M12A01-03E

Page 16

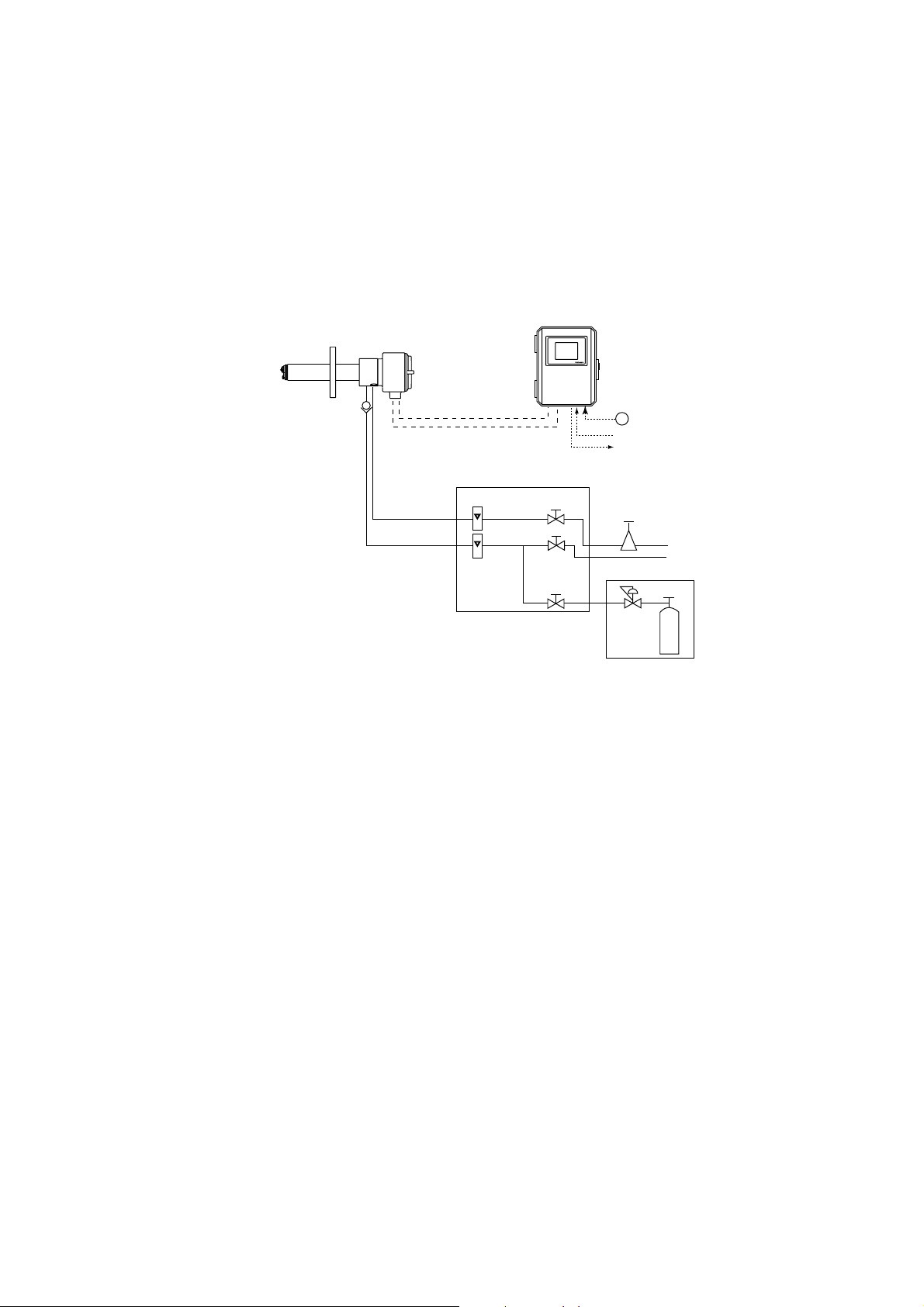

1.1.2 System 2

1. Overview

This system is for accurate monitoring and controlling humidity when the installation

environment is polluted with gases other than the air. Instrument air (clean and dry air

of oxygen concentration 21%) is used for the reference gas and the span gas for calibration. Zero gas is fed in from a cylinder during calibration. The gas flow is controlled by

the ZA8F flow setting unit (for manual valve operation).

Separate type Zirconia

High Temperature Humidity Analyzer,

Model ZR22G Detector

Check valve

or Stop valve

Calibration gas

Signal

(6-core shield cable)

Heater (2-core)

Reference

gas

Model ZA8F flow setting unit

Figure1.2

Model ZR402G Converter

Flowmeter

Needle

EXA

ZR402G

valve

100 to 240 V AC

,

Contact input

Analog outout, contact output

Digital output (HART)

Air Set

Instrument air

Span gas (Same as Zero gas

calibration unit)

Calibration gas pressure regulator

Calibration gas

unit case

Zero gas cylinder

F1.2E.EPS

IM 11M12A01-03E

1-3

Page 17

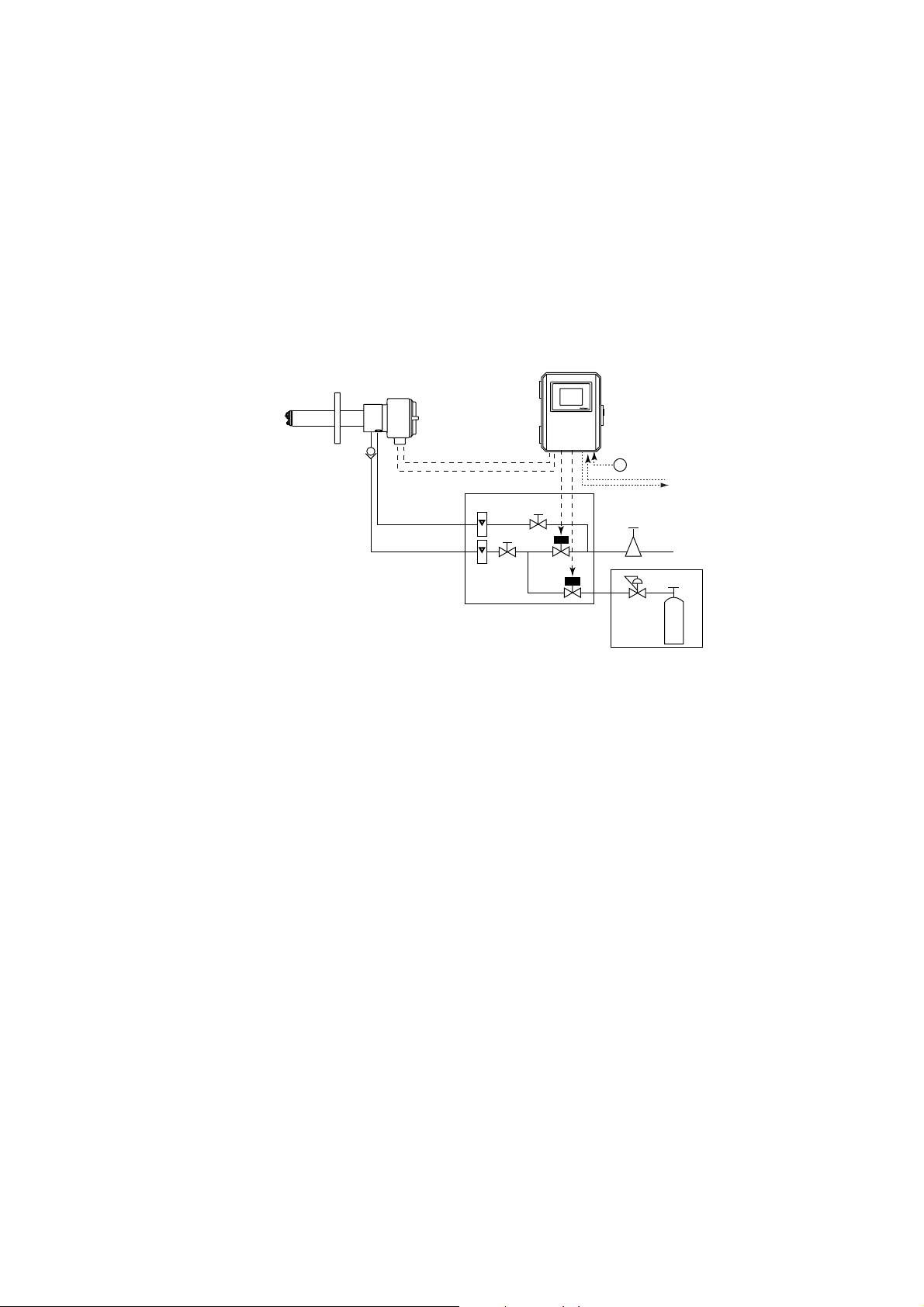

1.1.3 System 3

This system is for accurate monitoring and controlling of humidity. Instrument air

(clean and dry air) is used for the reference gas and the span gas for calibration. Zero

gas is fed in from a cylinder during calibration. The calibration gas flow is controlled

automatically by the ZR40H automatic calibration unit.

This system is similar to system 2, except that the calibration gas flow is automated

using the ZR40H automatic calibration unit.

Separate type Zirconia

High Temperature Humidity Analyzer,

Model ZR22G Detector

Check valve

*2

Reference gas

Calibration gas

Signal

(6-core shield cable)

Heater (2-core shield cable)

*1

Model ZR40H Auto-Calibration unit

Flowmeter

Model ZR402G Converter

EXA

ZR402G

,

Needle

vaive

Air Set

*3

100 to 240 V AC

Contact input

Analog output, contact output

Digital output (HART)

lnstrument air

Calibration gas pressure regulator

Calibration gas

unit case

Zero gas cylinder

F1.3E.EPS

Figure1.3

*1 Shield cable : Use shielded signal cables, and connect the shield to the FG terminal

of the converter.

*2 Select the desired probe from the Probe Configuration table on page 1-5

1-4

*3 100% N2 gas cannot be used as the zero gas. Use approximately 1% of O2 gas (N2 based).

IM 11M12A01-03E

Page 18

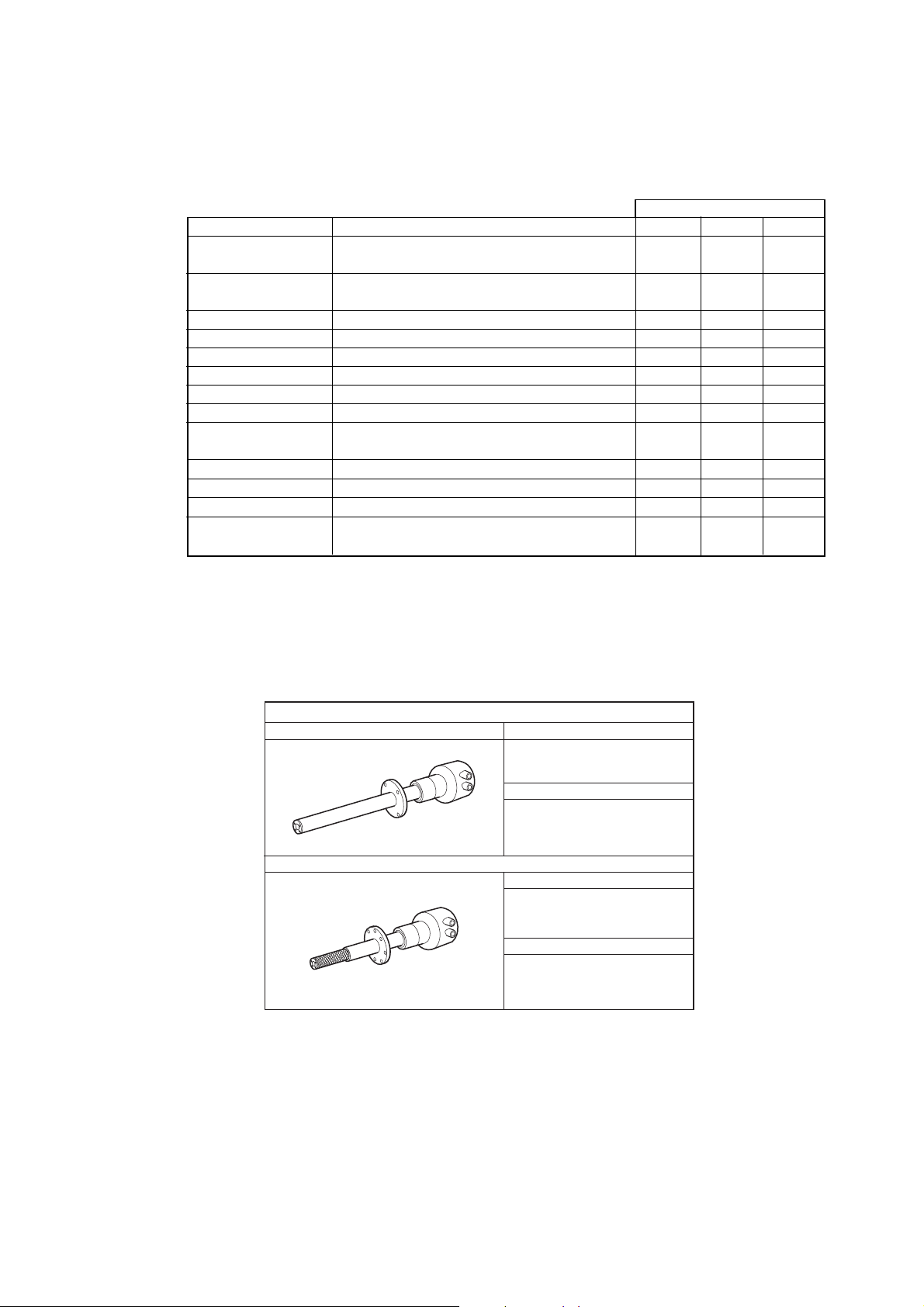

1.2 < EXAxtZR > System Components

1.2.1 System Components

Model or Part No. Product Name System 1 System 2 System 3

ZR22G Detector, Separate-type High-temperature

Humidity Analyzer, Detector

ZR402G Converter, Separate-type High-temperature

Humidity Analyzer, Converter

ZH21B Dust protector

ZO21S Standard gas unit

ZA8F Flow setting unit (for manual calibration)

ZR40H Automatic calibration unit (for separate type)

L9852CB/G7016XH Stop valve

K9292DN/K9292DS Check valve

K9473XH/K9473XJ, Air set

G7004XF/K9473XG

G7001ZC Zero gas cylinder

G7013XF/G7014XF Pressure regulator for gas cylinder

E7044KF Case assembly for calibration-gas cylinder

ZR22A Heater Assembly

(Spare parts for Model ZR22G)

d : The essential products for the system

s : Selected depending on your applications

(d) : Select either

1. Overview

Separate type

d d d

d d d

s s s

d

d

d

d (d)

(d) d

d d

d d

d d

d d

s s s

T1.1E.EPS

1.2.2 Detectors and Accessories

dGeneral-use Detector (sample gas temperature: 0 to 7008C)

Standard detector Model

ZR22G

Mounting angle

The probe insertion length: 0.4 to 2m

Vertical to horizontal

The probe insertion length: 2.5 to 3m

Vertical

Detector with dust protector

Model

ZR22G-040

and

ZH21B

Mounting angle

Vertical to horizontal

(The probe insertion length: 0.4m)

F1.4E.EPS

IM 11M12A01-03E

1-5

Page 19

Page 20

2. Specifications

This chapter describes the specifications for the following:

ZR22G General-use separate-type detector (See Section 2.2.1)

ZH21B Dust protector (See Section 2.2.2)

ZR402G Separate-type converter (See Section 2.3)

ZA8F Flow setting unit (See Section 2.4.1)

ZR40H Automatic calibration unit(See Section 2.4.2)

ZO21S Standard gas unit(See Section 2.5)

2.1 General Specifications

2.1.1 Standard Specifications

High Temperature Humidity Analyzer

Oxygen concentration in mixed gas which consists of water vapor and air is proportional

to the volume rate of air, so the volume rate of water vapor can be calculated by the

oxygen concentration.

2. Specifications

Measured Object:Water vapor (in vol%) in mixed gases (air and water vapor)

Measured System: Zirconia system

Measured Range: 0.01 to 100 vol% O2, 0 to 100 vol% H2O or 0 to 1.000 kg/kg

Output Signal: 4 to 20 mA DC (maximum load resistance 550V) Oxygen concentration;

Any setting in the range of 0 to 5 through 0 to 100 vol%O2 (in 1

vol% O2), or partial range.

Moisture quantity: 0 to 25 through 0 to 100 vol% H2O (in 1 vol% H2O), or partial

range.

Mixture ratio 0 to 0.2 through 0 to 1.000 kg/kg (in 0.001 kg/kg), or

partial range.

Digital Communication (HART): 250 to 550V, depending on quantity of field devices

connected to the loop (multi-drop mode).

(Note) HART is a registered trademark of the HART Communication

Foundation.

Display Range: Oxygen concentration; 0 to100 vol% O2 , Moisture quantity; 0 to 100

vol% H2O

Mixture ratio; 0 to 1 kg/kg

Relative humidity; 0 to 100 %RH

Dew point; -40 to 3708 C

(Note) Those values are calculated by temperature and absolute

pressure. Then accurate temperature and pressure value must be

input to the converter.

Warm-up Time: Approx. 20 min.

(Note) These characteristics are calculated by oxygen concentration

measured in air which include water vapor.

IM 11M12A01-03E

2-1

Page 21

Repeatability: (Note1)

61 vol% H2O (sample gas pressure 2 kPa or less)

Linearity: (Excluding standard gas tolerance)

(Note1)

(Use oxygen of known concentration (in the measuring range) as the

zero and span calibration gas.)

62 vol% H2O; (Sample gas pressure: within 60.49 kPa)

63 vol% H2O; (Sample gas pressure: 2 kPa or less)

Drift: (Excluding the first two weeks in use)

(Note1)

both zero and span 63 vol% H2O/month

Response Time: Response of 90 % within 5 seconds. (Measured after gas is introduced

from calibration-gas inlet and analog output starts changing.)

(Note1) These tolerances do not apply to the pressure compensated

version, or where natural convection is used for the reference air.

2-2

IM 11M12A01-03E

Page 22

2.2 General-use Separate-type Detector and Related Equipment

The “Detector with dust protector” consists of ZR22G general-use separate-type detector

and ZH21B dust protector (refer to Section 2.2.2).

2.2.1 ZR22G General-use Separate-type Detector

Sample Gas Temperature: 0 to 7008 C (Probe only)

It is necessary to mount the cell using Inconel cell-bolts when the

temperature is 6008 C or greater.

Sample Gas Pressure: -5 to +20 kPa (When the pressure in the process exceeds 3kPa,

it is recommended that you compensate the pressure. When the pressure

in the process exceeds 5kPa, you must perform pressure compensation.)

No pressure fluctuation in the process should be allowed.

Probe Length: 0.4, 0.7, 1.0, 1.5, 2.0, 2.5, 3.0 m

Probe Material: SUS 316 (JIS)

Ambient Temperature: -20 to +1508 C

Reference Air System: Natural Convection, Instrument Air

Instrument Air System (excluding Natural Convection):

Pressure; 200 kPa + the pressure inside the dryer, (It is recommended to

use air which has been dehumidified by cooling to dewpoint -208 C or

less, and with dust or oil mist removed.)

Consumption; Approx. 1Nl/min

Note: When the detector is used in conjunction with a check valve and a

ZA8F Flow Setting Unit, the maximum pressure of sample gas is 150

kPa. When with a check valve and a ZR40H Auto Calibration Unit, it is

200 kPa. If the pressure of your sample gas exceeds these limits, consult

with Yokogawa.

Material in Contact with Gas: SUS 316 (JIS), Zirconia, SUS 304 (JIS) (flange),

Hastelloy B, (Inconel 600, 601)

Construction: Heater and thermocouple replaceable construction. Non explosion-proof

JIS C0920 / equivalent to IP44D. Equivalent to NEMA 4X / IP66

(Achieved when the cable entry is completely sealed with a cable

gland in the recirculation pressure compensated version.)

2. Specifications

IM 11M12A01-03E

Terminal Box Case: Material; Aluminium alloy

Terminal Box Paint Color:

Case; Mint green (Munsell 5.6BG3.3/2.9)

Cover; Mint green (Munsell 5.6BG3.3/2.9)

Finish: Polyurethane corrosion-resistant coating

Gas Connection: Rc 1/4 or 1/4 FNPT

Wiring Connection: G1/2, Pg13.5, M20 by 1.5mm, 1/2 NPT

Installation: Flange mounting

2-3

Page 23

Probe Mounting Angle: Horizontal to vertically downward.

When the probe insertion length is 2 m or less, installing at angles from

horizontal to vertically downward is available.

When the probe insertion length exceeds 2.5 m, mount vertically down-

ward (within 658 ) and use a probe protector.

Weight:

Insertion length of 0.4 m: approx. 6 kg (JIS 5K 65) / approx. 11 kg (ANSI 150 4)

Insertion length of 1.0 m: approx. 8 kg (JIS 5K 65) / approx. 13 kg (ANSI 150 4)

Insertion length of 1.5 m: approx. 10 kg (JIS 5K 65) / approx. 15 kg (ANSI 150 4)

Insertion length of 2.0 m: approx. 12 kg (JIS 5K 65) / approx. 17 kg (ANSI 150 4)

Insertion length of 3.0 m: approx. 15 kg (JIS 5K 65) / approx. 20 kg (ANSI 150 4)

2-4

IM 11M12A01-03E

Page 24

2. Specifications

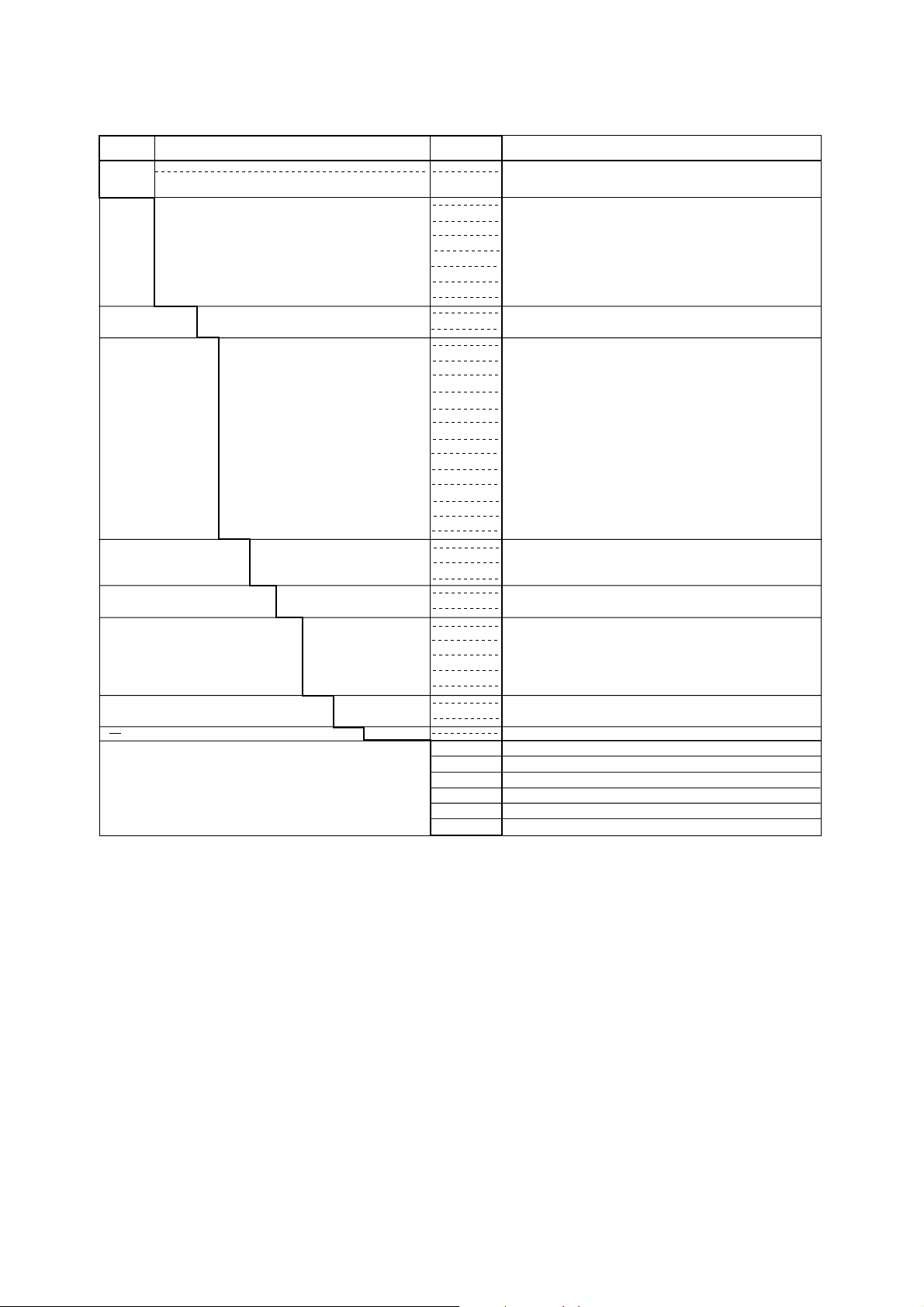

Model and Codes

Model

ZR22G

Suffix code

Option

code

Description

Separate type Detector of Zirconia High Temperature Humidity

[ Style : S2 ]

Analyzer

Length

-040

-070

-100

-150

-200

-250

-300

Wetted material

-S

-C

Flange

(*2)

-A

-B

-C

-E

-F

-G

-K

-L

-M

-P

-R

-S

-W

Reference air

-C

-E

-P

Gas Thread

-T

Connection box thred

-P

-G

-M

-T

-Q

Instruction manual

-J

-E

-A

Options

/D

/C

/CV

/SV

/PT

-R

/SCT

0.4 m

0.7 m

1.0 m

1.5 m

2.0 m

2.5 m (*1)

3.0 m (*1)

SUS316

Stainless steel with lnconel calibration gas tube

ANSI Class 150 2 RF SUS304

ANSI Class 150 3 RF SUS304

ANSI Class 150 4 RF SUS304

DIN PN10 DN50 SUS304

DIN PN10 DN80 SUS304

DIN PN10 DN100 SUS304

JIS 5K 65 FF SUS304

JIS 10K 65 FF SUS304

JIS 10K 80 FF SUS304

JIS 10K 100 FF SUS304

JPI Class 150 4 RF SUS304

JPI Class 150 3 RF SUS304

Westinghouse

Natural convection

External connection (Instrument air) (*8)

Pressure Compensation (*8)

Rc 1/4

1/4 NPT(F)

G1/2

Pg13.5

M20 x1.5 mm

1/2NPT

Quick connect (*6)

Japanese

English

Always-A

DERAKANE coating (*7)

Inconel bolt (*3)

Check valve (*4)

Stop valve (*4)

Stainless steel tag plate (*5)

Printed tag plate (*5)

*1 When installing horizontally the probe whose insertion length is 2.5 meters or more, use the Probe Protector. Be sure to specify

ZO21R-L-hhh-h. Specify the flange suffix code either -C or -K.

*2 The thickness of the flange depends on its dimensions.

*3 Inconel probe bolts and U shape pipe for calibration are used. Use this option for high temperature use (ranging from 600 to 700 8C).

*4 Specify either /CV or /SV option code.

*5 Specify either /SCT or /PT option code.

*6 Not waterproof, protect from rain.Operating maximum temperature is 80 8C. Available only in the U.S.

*7 Available only in the U.S. DERAKANE is a registered trademark of the Dow Chemical Company.

*8 Piping for reference air must be installed to supply reference air constantly at a specified flow rate.

T2.1E.EPS

IM 11M12A01-03E

2-5

Page 25

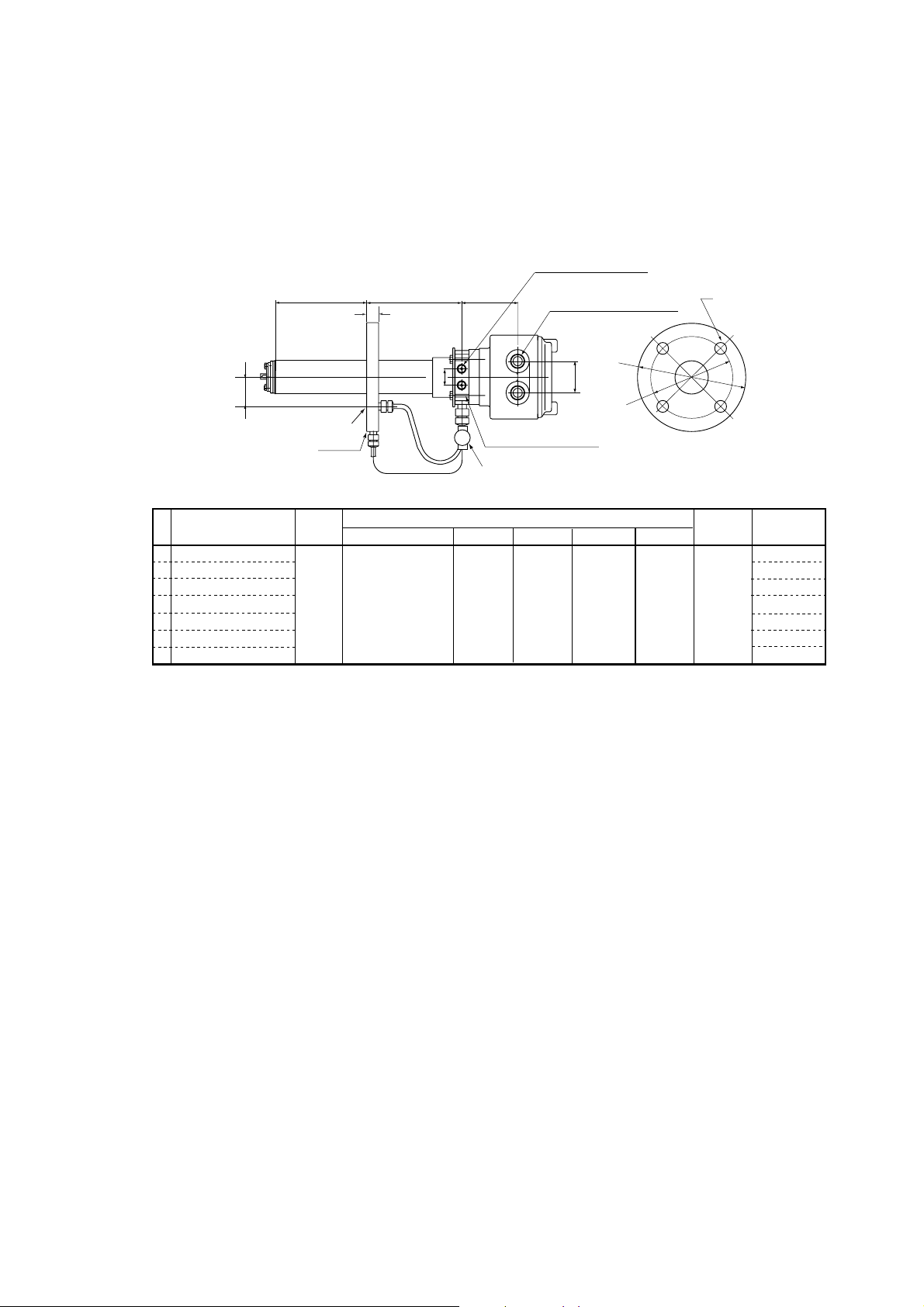

EXTERNAL DIMENSIONS

Model ZR22G Detectors Separate type Zirconia High Temperature Humidity Analyzer

[50.8

L=0.15, 0.4, 0.7, 1.0,

1.5, 2.0, 2.5, 3.0 (m)

L

t

Flange

283 to 292

155 to 163 69

25

85

Rc1/4 or 1/4NPT

Reference air inlet

2-G1/2,2-1/2NPT etc.

Cable connection port

48

Rc1/4 or 1/4NPT

Calibration gas inlet

[124

C

[A

[B

Flange

Flange

ANSI Class 150 2 RF SUS304

ANSI Class 150 3 RF SUS304

ANSI Class 150 4 RF SUS304

DIN PN10 DN50 SUS304

DIN PN10 DN80 SUS304

DIN PN10 DN100 SUS304

JIS 5K 65 FF SUS304

JIS 10K 65 FF SUS304

JIS 10K 80 FF SUS304

JIS 10K 100 FF SUS304

JIS 5K 32 FF SUS304

JPI Class 150 4 RF SUS304

JPI Class 150 3 RF SUS304

Westinghouse

AB C

152.4

190.5

228.6

165

200

220

155

175

185

210

115

229

190

155

120.6

152.4

190.5

125

160

180

130

140

150

175

90

190.5

152.4

127

4 - [19

4 - [19

8 - [19

4 - [18

8 - [18

8 - [18

4 - [15

4 - [19

8 - [19

8 - [19

4 - [15

8 - [19

4 - [19

4 - [11.5

19

24

24

18

20

20

14

18

18

18

24

24

14

t

[A

[B

Flange

5

C

F07_01.EPS

2-6

IM 11M12A01-03E

Page 26

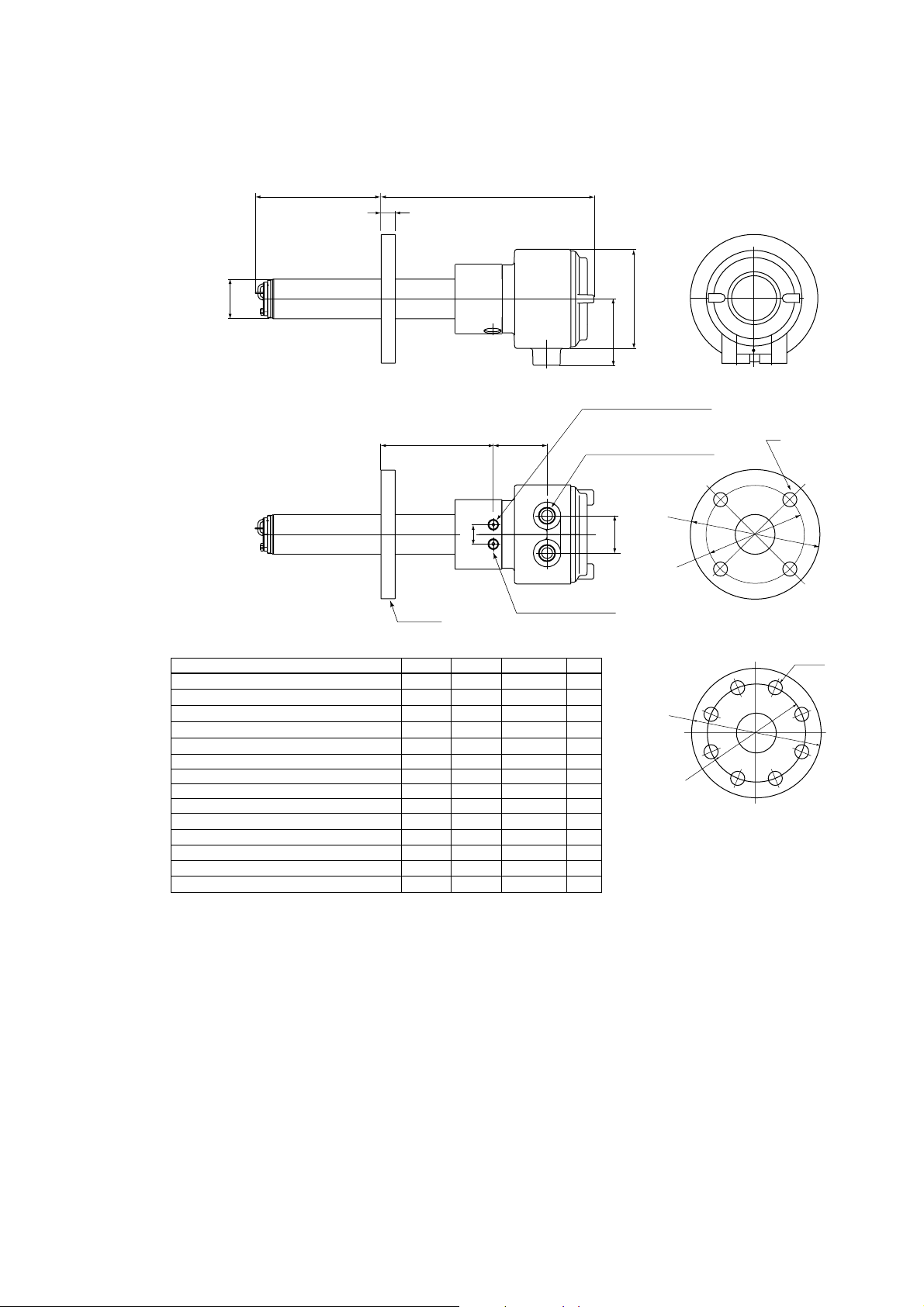

2. Specifications

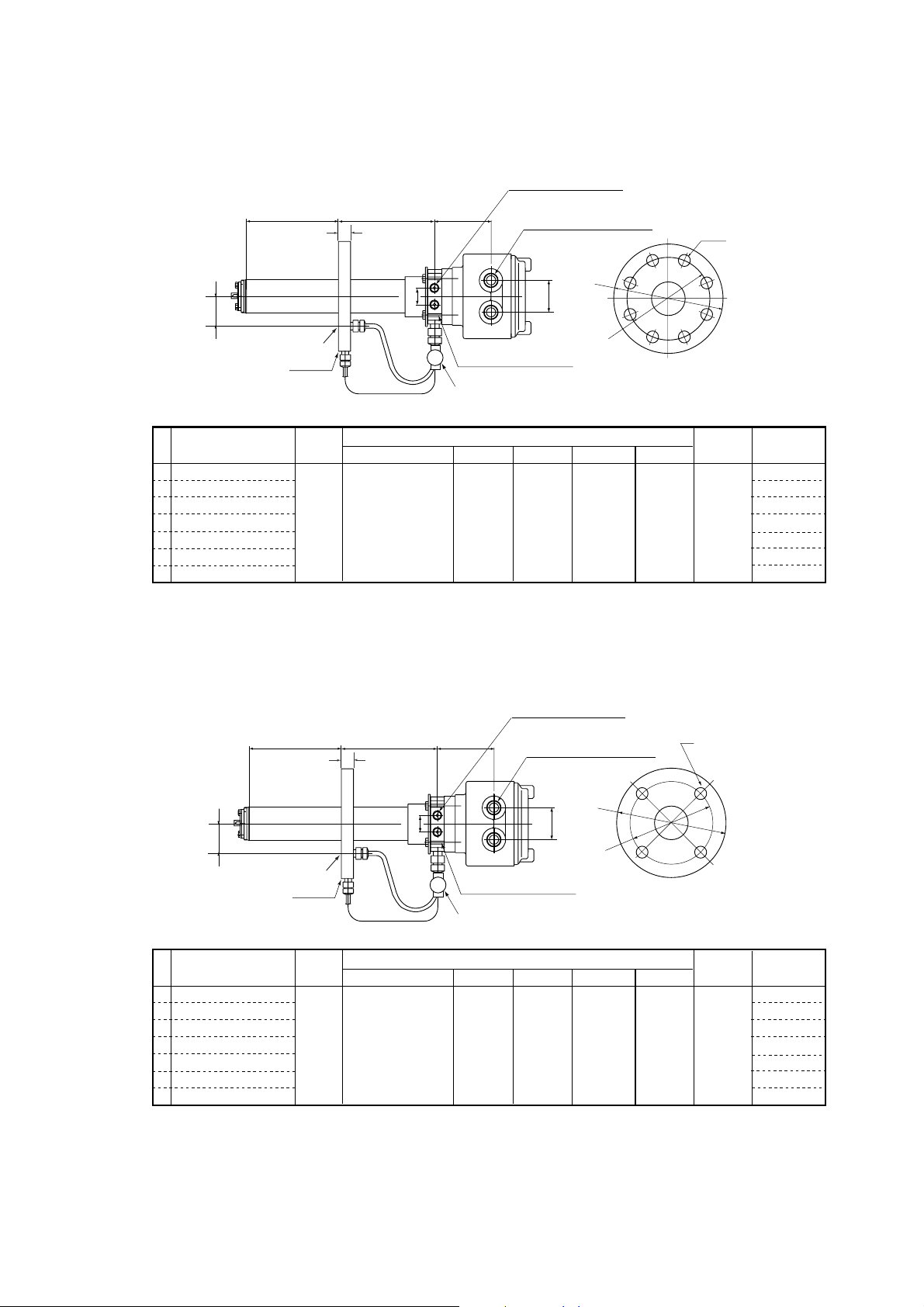

Model ZR22G...-P Detectors(with pressure compensation), Separate type Zirconia High Temperature

Humidity Analyzer, Detectors

L

f50.8

L=0.15, 0.4, 0.7, 1.0,

1.5, 2.0, 2.5, 3.0 (m)

L

Reference gas outlet

Flange

ANSI Class 150 2 RF SUS304

ANSI Class 150 3 RF SUS304

ANSI Class 150 4 RF SUS304

DIN PN10 DN50 SUS304

DIN PN10 DN80 SUS304

DIN PN10 DN100 SUS304

JIS 5K 65 FF SUS304

JIS 10K 65 FF SUS304

JIS 10K 80 FF SUS304

JIS 10K 100 FF SUS304

JPI Class 150 4 RF SUS304

JPI Class 150 3 RF SUS304

Westinghouse

Flange

t

303

156

t

25

PIPING

:B

PIPING : A

AB C

152.4

190.5

228.6

165

200

220

155

175

185

210

229

190

155

120.6

152.4

190.5

190.5

152.4

125

160

180

130

140

150

175

127

4 - [19

4 - [19

8 - [19

4 - [18

8 - [18

8 - [18

4 - [15

4 - [19

8 - [19

8 - [19

8 - [19

4 - [19

4 - [11.5

85

Rc1/4 or 1/4NPT

Reference air inlet

87

2-G1/2, 2-1/2NPT etc.

Cable connection port

48

Rc1/4 or 1/4NPT

Calibration gas inlet

Stop Valve

t

PIPING

19

24

24

18

20

20

14

18

18

18

24

24

14

A

B

B

A

B

B

A

A

B

B

B

B

A

f124

C

[A

[B

Flange

C

[A

[B

Flange

F07_02.EPS

IM 11M12A01-03E

2-7

Page 27

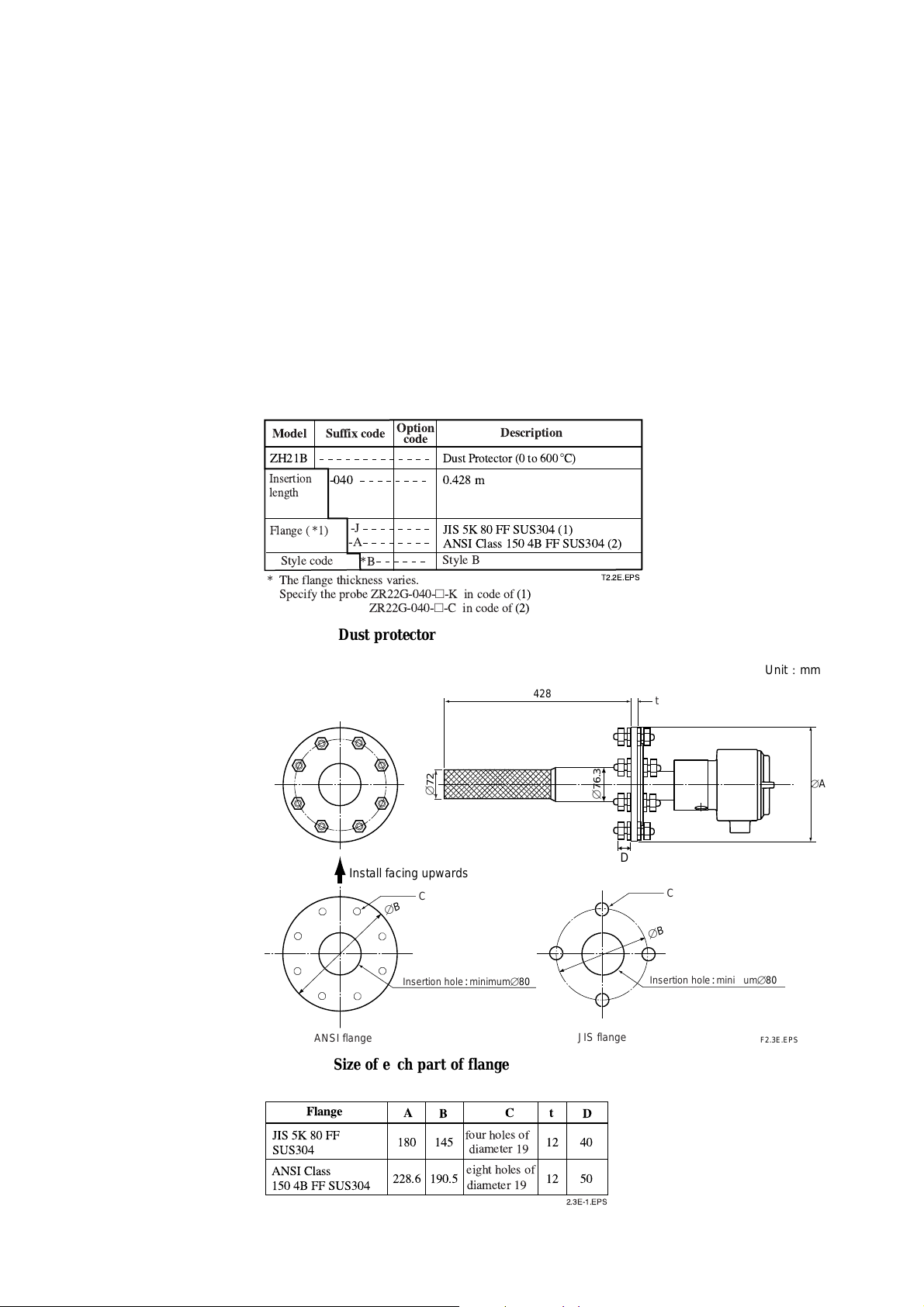

2.2.2 ZH21B Dust Protector

This protector is designed to protect the probe output from dust agitation (i.e., to prevent

combustible materials from entering the probe cell where humidity measurements are

made) in a dusty environment.

d Standard Specification

Insertion length: 0.428m

Flange: JIS 5K 80 FF SUS304 or ANSI Class 150 4 FF SUS304 (However,

Material: SUS 316(JIS), SUS 304(JIS) (flange)

Weight: Approximately 6kg (JIS), approximately 8.5kg (ANSI)

Mounting: Mounted on the probe or process flange with bolts and associated

flange thickness is different)

nuts and washers.

Model Suffix code

ZH21B

Insertion

length

Flange ( *1)

Style code

* The flange thickness varies.

Specify the probe ZR22G-040-h-K in code of (1)

-040 0.428 m

-A

Option

code

Dust Protector (0 to 6008C)

-J

*B

ZR22G-040-h-C in code of (2)

JIS 5K 80 FF SUS304 (1)

ANSI Class 150 4B FF SUS304 (2)

Style B

Dust protector

72

[

Install facing upwards

C

[B

Description

428

T2.2E.EPS

76.3

[

D

[B

Unit ; mm

t

[

A

C

2-8

Insertion hole;minimum[80

ANSI flange

Size of each part of flange

Flange

JIS 5K 80 FF

SUS304

ANSI Class

150 4B FF SUS304

A

180

228.6

B

145

190.5

four holes of

diameter 19

eight holes of

diameter 19

Ct

12

12

2.3E-1.EPS

JIS flange

D

40

50

Insertion hole;minimum[80

F2.3E.EPS

IM 11M12A01-03E

Page 28

2.3 ZR402G Separate-type Converter

2.3.1 Standard Specifications

Operated using an LCD touchscreen on the converter.

Display: LCD display of size 320 by 240 dot with touchscreen.

Output Signal: 4 to 20 mA DC, two points (maximum load resistance 550 V)

Contact Output Signal: four points (one is fail-safe, normally open)

Contact Input: two points

Analog Input: one point (thermal input 4-20 mA)

Auto-calibration Output: Two points (for dedicated auto-calibration unit)

Ambient Temperature: -20 to +558C

Storage Temperature: -30 to +708C

Humidity Ambient: 0 to 95%RH (Non-condensing)

Installation Altitude: 2000 m or less

Category based on IEC 1010: II (Note)

2. Specifications

Pollution degree based on IEC 1010: 2 (Note)

Note: Installation category, called over-voltage category, specifies impulse withstanding voltage. Category II is for electrical equipment.

Pollution degree indicates the degree of existence of solid, liquid, gas or other

inclusions which may reduce breakdown voltage. Degree 2 is the normal indoor

environment.

Power Supply Voltage: Ratings; 100 to 240 V AC

Acceptable range; 85 to 264 V AC

Power Supply Frequency: Ratings; 50/60 Hz Acceptable range; 45 to 66 Hz

Power Consumption: Max. 300 W, approx. 100 W for ordinary use.

Safety and EMC conforming standards

Safety: EN61010-1

CSA C22.2 No.61010-1

UL61010-1

EMC: EN 61326 Class A

EN 55011 Class A Group 1

EN 61000-3-2

AS/NZS CISPR 11

Maximum Distance between Probe and Converter: Conductor two-way resistance must

be 10 V or less (when a 1.25 mm2 cable or equivalent is used, 300 m or less.)

Construction: Outdoor installation, equivalent to NEMA 4 (with conduit holes

completely sealed with a plastic cable gland optional)

Wiring Connection: G1/2, Pg13.5, M20 by 1.5 mm, 1/2 NPT, eight holes

Installation: Panel, wall or 2B pipe mounting

Case: Aluminum alloy

Paint Color: Door: Sliver gray (Munsell 3.2PB7.4/1.2)

Case: Sliver gray (Munsell 3.2PB7.4/1.2)

Finish: Polyurethane corrosion-resistant coating

Weight: Approx. 6 kg

IM 11M12A01-03E

2-9

Page 29

2.3.2 Function

Display Functions:

Value Display; Displays values of the measured Oxygen concentration,

moisture quantity, mixture ratio etc.

Graph Display; Displays trends of measured oxygen concentration moisture

quantity, mixture ratio etc.

Data Display; Displays various useful data for maintenance, such as cell

temperature, reference junction temperature, maximum/

minimum moisture quantity and the like.

Status Messages; Indicates an alarm or error occurrence with flashing of the corre-

sponding icon. Indicates status such as warming-up, calibrating,

or the like by symbols.

Alarm, Error Display: Displays alarms such as “Abnormal moisture quantity” or

errors such as “Abnormal cell e.m.f.” when any such status

occurs.

Calibration Functions:

Auto-Calibration; Requires the Auto-calibration Unit. It calibrates automatically at

specified intervals.

Semi-auto Calibration; Requires the Auto-calibration Unit. Input calibration direction

on the touchpanel or contact, then it calibrates automatically

afterwards.

Manual Calibration; Calibration with opening/closing the valve of calibration gas in

operation interactively with an LCD panel.

Blowback Function:

Output through the contact at a set period and time. Auto/semi-auto

selectable.

Maintenance Functions:

Can update data settings during daily operation and checking.

Display data settings, calibration data settings, blowback data settings,

current output loop check, input/output contact check.

Setup Functions:

Initial settings suit for the plant conditions when installing the con

verter. Equipment settings, current output data settings, alarm data

settings, contact data settings, other settings.

Self-diagnosis:

This function diagnoses conditions of the converter or the probe and

indicates when any abnormal condition occurs.

Password Functions:

Enter your password to operate the analyzer excepting data display.

Individual passwords can be set for maintenance and setup.

2-10

IM 11M12A01-03E

Page 30

Display and setting content:

Measuring-related items: Oxygen concentration (vol% O2), moisture quantity(vol% H2O),

Display Related Items: Oxygen concentration (vol% O2), Moisture quantity (vol% H2O),

Calibration Setting Items: Span gas concentration (vol% O2), zero gas concentration

Output Related Items: Analog output/output mode selection, value conditions when

Alarm Related Items: Oxygen concentration high-alarm/high-high alarm limit values

2. Specifications

mixture ratio (kg/kg), relative humidity (%RH) and dew point (8 C)

mixture ratio (kg/kg), relative humidity (%RH), dew point (8 C), cell temperature (8 C), thermocouple reference junction temperature (8 C), maximum/

minimum/average oxygen concentration (vol% O2), maxi-mum/minimum/

average moisture quantity (vol% H2O), maximum/minimum/average mixture

ratio (kg/kg), cell e.m.f. (mV), output 1, 2 current (mA), cell response time

(seconds), cell internal resistance (V), cell condition (in four grades), heater ontime ratio (%), calibration history (ten times), time (year/month/day/hour/

minute)

(vol% O2), calibration mode (auto, semi-auto, manual), calibration type and

method (zero-span calibration, zero calibration only, span calibration only),

stabilization time (min.sec), calibration time (min.sec), calibration period (day/

hour), starting time (year/month/day/hour/minute)

warming-up/maintenance/calibrating(or blowback)/abnormal, oxygen concentration at 4mA/20mA (vol% O2), moisture quantity at 4mA/20mA (vol% H2O),

mixture ratio at 4mA/20mA (kg/kg), time constant.

(vol% O2), Oxygen concentration low-alarm/low-low alarm limit values (vol%

O2), moisture quantity high-alarm/high-high alarm limit values (vol% H2O),

moisture quantity low-alarm/low-low alarm limit values (vol% H2O), mixture

ratio high-alarm/high-high alarm limit value (kg/kg), mixture ratio low-alarm/

low-low alarm limit values (kg/kg), oxygen concentration alarm hysteresis

(vol% O2), moisture quantity alarm hysteresis (vol% H2O), mixture ratio alarm

hysteresis (kg/kg), oxygen concentration/moisture quantity/mixture ratio alarm

detection, alarm delay (seconds).

Contact Related Items: Selection of contact input 1 and 2, selection of contact output 1

to 3 (abnormal, high-high alarm, high-alarm, low-alarm, low-low alarm,

maintenance, calibrating, range switching, warming-up, calibration-gas pressure-decrease, temperature high-alarm, blow back, unburnt gas detected)

Converter Output: Two points mA analog output (4 to 20 mA DC (maximum load

resistance of 550V) and one of two mA digital output points (HART) (minimum load resistance of 250V).

Range: any setting between 0 to 5 through 0 to 100 vol% O2, 0 to 25 through 0 to 100

vol% H2O, 0 to 0.200 through 0 to 1.000 kg/kg or partial range is available.

For the log output, the minimum range values are fixed at 0.1 vol% O2 for the

oxygen concentration, 0.1 vol% H2O for the moisture quantity, and 0.01 kg/kg

for the mixture ratio.

4 to 20 mA DC linear or log can be selected.

Input/output isolation provided.

Output damping 0-255 (sec.)

Can select hold or non-hold, and set preset value for hold.

IM 11M12A01-03E

2-11

Page 31

Contact Output: Four points, contact capacity 30V DC 3A, 250V AC 3A

(resistive load).

Three of the output points can be selected to either normally energized or

normally de-energized status.

Delayed functions (0 to 255 seconds) and hysteresis function (0 to 9.9 vol% O

can be added to high/low-alarms.

The following functions are programmable for contact outputs.

(1) Abnormal, (2) High-high alarm, (3) High-alarm, (4) Low-low alarm, (5)

Low-alarm, (6) Maintenance, (7) Calibration, (8) Range switching answer-back,

(9) Warm-up, (10) Calibration-gas pressure decrease (answerback of contact

input), (11) Temperature high-alarm, (12) Blowback start, (13) Flameout gas

detection (answerback of contact input), (14) Calibration coefficient alarm, (15)

Startup power stabilization timeout alarm

Contact output 4 is set to normally operated, and fixed error status.

Converter Input: Thermal input one point (4 to 20 mA DC)

Contact Input: Two points, voltage-free contact inputs

The following functions are programmable for contact inputs:

(1) Calibration-gas pressure decrease alarm, (2) Range switching (switched

range is fixed), (3) External calibration start, (4) Process alarm (if this signal is

received, the heater power turns off), (5) Blowback start

Contact capacity: Off-state leakage current: 3 mA or less

Self-diagnosis: cell abnormal , cell temperature abnormal (low/high), calibration

abnormal, A/D converter defective, digital circuit defective

2

Calibration:Method; zero/span calibration

Calibration mode; automatic, semi-automatic and manual (All are operated

interactively with an LCD touchpanel). Either zero or span can be skipped.

Zero calibration-gas concentration setting range: 0.3 to 100 vol% O2 (minimum

in 0.01 vol%).

Span calibration-gas concentration setting range: 4.5 to 100 vol% O2 (minimum

in 0.01 vol%).

Use nitrogen-based mixed gas containing about 10% of oxygen for standard

zero-gas, and 80 to 100 % of oxygen for standard span-gas.

Calibration period; date/time setting: maximum 255 days

2-12

IM 11M12A01-03E

Page 32

d Model and Suffix Codes

Model

Suffix code

ZR402G

Converter

thread

-P

-G

-M

-T

Display

-J

-E

-G

-F

Instruction manual

Options

Tag plates

*1 Specify either /SCT or /PT option code.

*2 Sun shield hood is still effective even if scratched.

*3 Be sure to use the equipment with the option code /HS.

Option

code

Description

Separate type Zirconia High Temperature

Humidity Analyzer, Converter

G1/2

Pg13.5

M20x1.5 mm

1/2NPT

Japanese

English

German

French

-J

-E

-A

/HS

/H

/SCT

/PT

Japanese

English

Always -A

Set for Humidity Analyzer (*3)

Hood (*2)

Stainless steel tag plate (*1)

Printed tag plate (*1)

2. Specifications

T2.4E.EPS

IM 11M12A01-03E

2-13

Page 33

280

d External Dimensions

Unit ;mm

1 to 6 (Panel Thickness)

2-inch mounting pipe

EXA

ZR402G

4 - f 6 holes

for Wall mounting

126.5

100

120.2

8

228

10

57.3

136.3

36

54.7

(1/2NPT)

111

40

40 40

8-G1/2, 8-1/2NPT etc

(Wiring connection)

2346

38 2414 38

( for wall mounting)

190

Wall mounting

d Accessories

Item

Fuse

Bracket for mounting

Screw for Bracket

126.5

Part. No.

A1113EF

F9554AL

F9123GF

4 - f 6 holes

Qty

1

1

1

4-R8 to R10

or

4-C5 to C8

+2

183

0

Panel Cut-out

Description

3.15A

for pipe mounting, panel mounting

or wall mounting

+2

0

274

F2.5E.EPS

2-14

IM 11M12A01-03E

Page 34

2. Specifications

d Hood (Option / H)

64

243

6362

12355

ZR402G

64

251.5

6263

3994.5

205.5

64

155.5

Unit ;mm

63

Hood material : Aluminum

IM 11M12A01-03E

2-15

Page 35

2.4 ZA8F Flow Setting Unit and ZR40H Automatic Calibration Unit

2.4.1 ZA8F Flow Setting Unit

This flow setting unit is applied to the reference gas and the calibration gas in a system

configuration (System 2).

This unit consists of a flow meter and flow control valves to control the flow of calibration gas and reference air.

• Standard Specifications

FIowmeter: Calibration gas; 0.1 to 1.0 l/min. Reference air; 0.1 to 1.0 l/min.

Construction: Dust-proof and rainproof construction

Case Material: SPCC (Cold rolled steel sheet)

Painting: Baked epoxy resin, Dark-green (Munsell 2.0 GY 3.1/0.5 or equivalent)

Pipe Connections: Rc1/4 or 1/4FNPT

Reference Air pressure: Clean air supply of measured gas pressure plus approx. 50 kPa G

(or measured gas pressure plus approx. 150kPa G when a check valve is used)

pressure at inlet of the auto-calibration unit (Maximum 300 kPaG).

Air Consumption: Approx. 1.5 l/min

Weight: Approx. 2kg

Calibration gas (zero gas,span gas) flow : 0.7 l/min (at calibration time only)

d Model and Codes

Model Suffix code Option code Description

ZA8F

Joint

Style code

-J

-A

*B

Flow setting unit

Rc 1/4

With 1/4" NPT adapter

Style A

T2.5E.EPS

2-16

IM 11M12A01-03E

Page 36

d External Dimensions

2. Specifications

Reference air outlet

f6 hole

7

235.8

222.8

Zero gas outlet

REFERENCE CHECK

Span gas inlet

180

140

REFERENCE

SRAN

Unit: mm

ZERO

Zero gas inlet

268

70

ZERO

GAS IN

35

20 2035 35

35

CHECK

OUT

Flow

meter

SPAN

GAS IN

4-Rc1/4

Piping connection

port

35

Instrument air inlet

REF

OUT

Flow

meter

AIR IN

IM 11M12A01-03E

Airset

Instrument air

Approx 1.5 l/min.

Air pressure:

without check valve ; measured gas pressure 1 approx.50 kPaG

with check valve ; measured gas pressure 1 approx.150 kPaG

F2.6E.EPS

2-17

Page 37

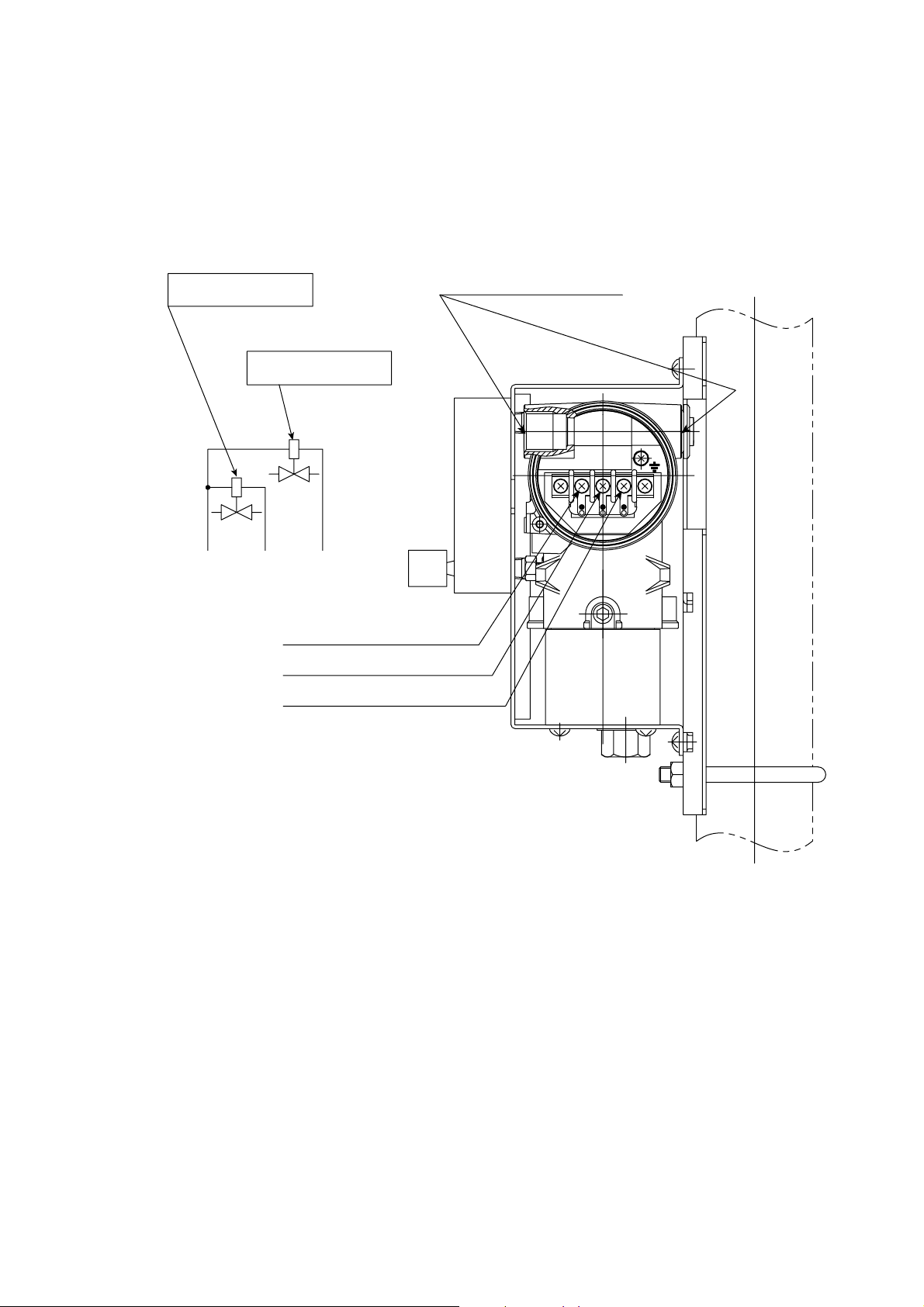

2.4.2 ZR40H Automatic Calibration Unit

This automatic calibration unit is applied to supply specified flow of reference gas and

calibration gas during automatic calibration to the detector in a system configuration

(System 3).

• Specifications

Used when auto calibration is required for the separate type and instrument air is

provided. The solenoid valves are provided as standard.

Construction: Dust-proof and rainproof construction:

NEMA4X/IP67 solenoid valve only (excluding flowmeter)

Mounting: 2-inch pipe or wall mounting, no vibration

Materials: Body; Aluminum alloy, Piping; SUS316 (JIS), SUS304 (JIS), Flowmeter; MA

Finish: Polyurethane corrosion-resistance coating, mint green (Munse11 5.6BG3.3/2.9)

Piping Connection: Refer to Model and Suffix Codes

Power Supply: 24V DC (from ZR402G), Power consumption; Approx. 1.3W

Reference Air Pressure: Sample gas pressure plus Approx. 150 kPa (690 kPa max.),

(Pressure at inlet of auto-calibration unit)

(acrylic resin), Bracket ; sus304 (JIS)

Air Consumption: Approx. 1.5 l/min

Weight: Approx. 3.5 kg

Ambient Temperature: -20 to +558 C, no condensation or freezing

Ambient Humidity: 0 to 95% RH

Storage Temperature: -30 to +658 C

d Model and Codes

Model Suffix code Option code Description

ZR40H

Gas piping connection

Wiring connection

-

-R

-T

-P

-G

-M

-T

-A

Automatic calibration unit for ZR402G

Rc 1/4

1/4" NPT

Pipe connection (G1/2)

Pg 13.5

20 mm (M20 x 1.5)

1/2 NPT

Always -A

T2.5-1E.EPS

2-18

IM 11M12A01-03E

Page 38

d External Dimensions

2B pipe mounting example

*1 with four M6 screws can wall-mount

54 71.526

41.2 41.2

Flowmeter

Setting Valve for

reference air

wiring inlet ; 2-G1/2,Pg13.5,M2031.5 or 1/2NPT(Female)

(wiring inlet is at same position on rear)

90 116.5

*1

4-

f

6.5

12223

250

140

2. Specifications

Unit : mm

49.5

OCK

Setting Valve for

calibration gas

calibration gas outlet

Rc1/4 or 1/4 NPT(Female)

Zero gas air inlet

Rc1/4 or 1/4 NPT(Female)

102 MAX58

42

26

3040 47.5 25

46 16

IM 11M12A01-03E

reference air outlet

Rc1/4 or 1/4 NPT(Female)

reference gas inlet

Rc1/4 or 1/4 NPT(Female)

F2.6-2E.EPS

2-19

Page 39

Piping

CHECK

OUT

flow

meter

REF

OUT

flow

meter

*2 *2

EV1 EV2

ZERO GAS IN

AIR IN

Instrument air Approx.

1.5 l/min.

*2 Needle valve is supplied as accessory with flow meter.

F2.6-3E.EPS

2-20

IM 11M12A01-03E

Page 40

2.5 ZO21S Standard Gas Unit

This is a handy unit to supply zero gas and span gas to the detector in a system configuration based on System 1. It is used in combination with the detector only during

calibration.

d Standard Specifications

Function: Portable unit for calibration gas supply consisting of span gas (air) pump, zero

gas cylinder with sealed inlet, flow rate checker and flow rate needle valve.

Sealed Zero Gas Cylinders (6 provided): E7050BA

Capacity: 1 l

Filled pressure: Approx. 686 kPa G (at 35 8 C)

Composition: 0.95 to 1.0 vo1% O2+N2 based

Power Supply: l00, 110, 115, 200, 220, 240 V AC6 10%, 50/60 Hz

Power Consumption: Max. 5 VA

Case Material: SPCC (Cold rolled steel sheet)

2. Specifications

Point: Epoxy resin, baked

Paint Color:

Mainframe; Munsell 2.0 GY3.1/0.5 equivalent

Cover; Munsell 2.8 GY6.4/0.9 equivalent

Piping: f 63f 4mm flexible tube connection

Span Gas: Internal pump draws in air from atmosphere, and feeds to detector.

Weight: Approx. 3 kg

p Non CE Mark.

d Model and Codes

Model

ZO21S

Power

supply

Panel

Style code

Suffix code Option code

-2

-3

-4

-5

-7

-8

-J

-E

*A

Description

Standard gas unit

200 V AC 50/60 Hz

220 V AC 50/60 Hz

240 V AC 50/60 Hz

100 V AC 50/60 Hz

110 V AC 50/60 Hz

115 V AC 50/60 Hz

Japanese version

English version

Style A

T2.6E.EPS

IM 11M12A01-03E

2-21

Page 41

d External Dimensions

1600

Zero gas cyilnder (6 cyilnder): E7050BA

354

Unit : mm

92

228

253

Flow checker

Span gas valve

Zero gas valve

Gas outlet

F2.7E.EPS

2.6 Other Equipment

2.6.1 Stop Valve (Part Number: L9852CB or G7016XH)

This valve is mounted on the calibration gas line in the system to allow for one-touch

calibration. This applies to the system configuration shown for system 1 in section 1.

Standard Specifications

Connection: Rc 1/4 or 1/4 FNPT

Material: SUS 316 (JIS)

Weight: Approx. 80 g

Part No.

L9852CB

G7016XH

Joint: RC 1/4, Material: SUS 316 (JIS)

Joint:

43

Description

1/4 NPT,

55

Material:

SUS 316 (JIS)

Unit: mm

T2.9E.EPS

2-22

Rc1/4 or 1/4NPT

40

(Full open length)

F15.EPS

IM 11M12A01-03E

Page 42

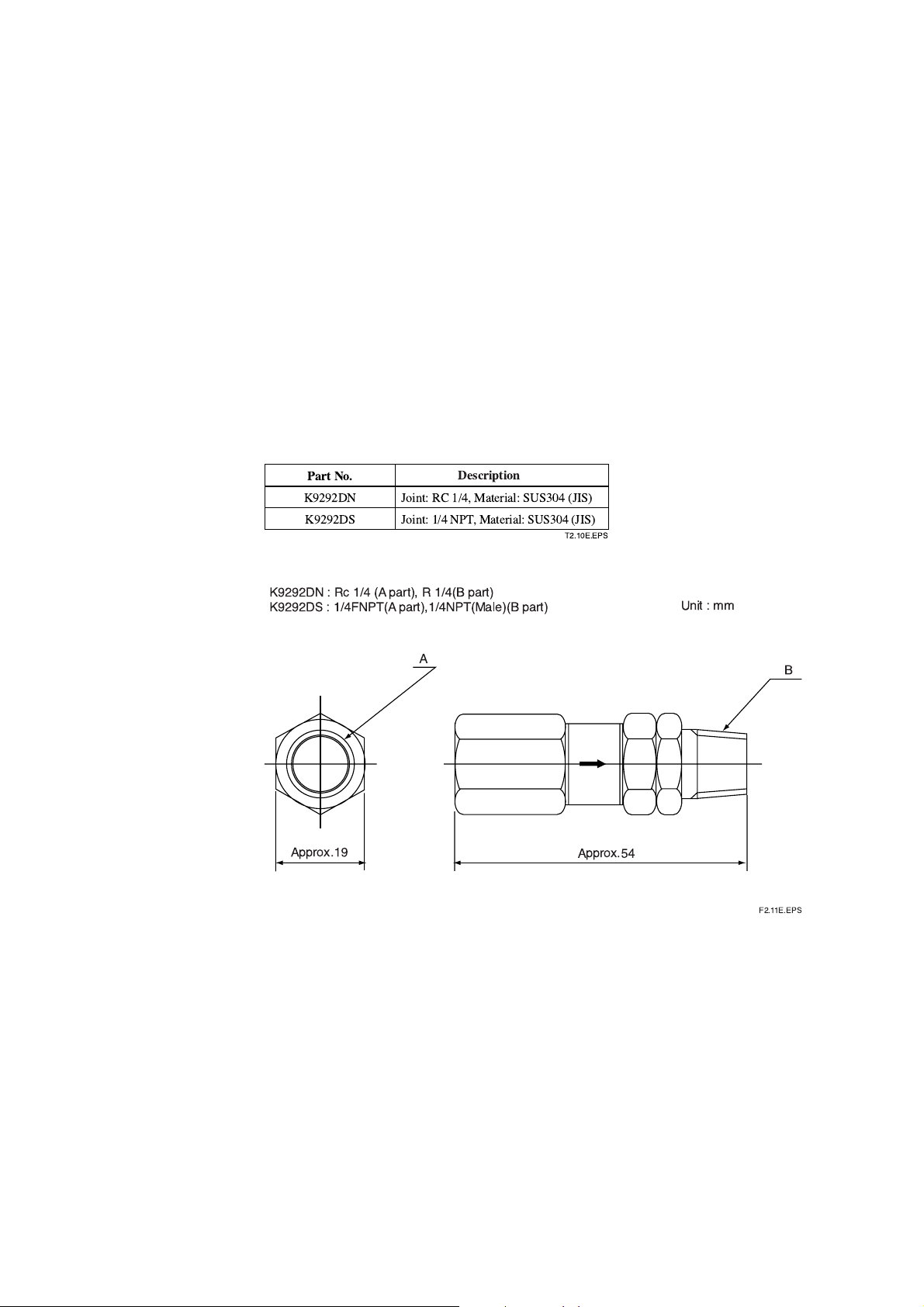

2.6.2 Check Valve (Part Number: K9292DN or K9292DS)

This valve is mounted on the calibration gas line (directly connected to the detector).

This is applied to a system based on the (System 2 and 3) system configuration.

This valve prevents the process gas from entering the calibration gas line. Although it

functions as a stop valve, operation is easier than a stop valve as it does not require

opening/closing at each calibration.

Screw a check valve into the calibration gas inlet of the detector instead of the stop

valve.

Standard Specifications

Connection: Rc1/4 or 1/4FNPT

Material: SUS304 (JIS)

Pressure: 70 kPa G or more,and 350 kPa G or less

Weight: Approx. 40 g

2. Specifications

1/4 NPT

A

Description

, Material:

SUS304

Part No.

K9292DN

K9292DS

K9292DN : Rc 1/4 (A part), R 1/4(B part)

K9292DS : 1/4FNPT(A part),1/4NPT(Male)(B part)

Approx.19

Joint: RC 1/4, Material: SUS304 (JIS)

Joint:

(JIS)

T2.10E.EPS

Unit : mm

B

Approx.54

F2.11E.EPS

IM 11M12A01-03E

2-23

Page 43

2.6.3 Air Set