Page 1

User’s

R

Manual

Model ZR202G

Integrated type

Zirconia Oxygen Analyzer

IM 11M12A01-04E

IM 11M12A01-04E

7th Edition

Page 2

Introduction

The EXAxt ZR Integrated type Zirconia Oxygen Analyzer has been developed for combustion control

in various industrial processes. There are several version of this analyzer so you can select one that

matches your application.

Optional accessories are also available to improve measurement accuracy and automate calibration.

An optimal control system can be realized by adding appropriate options.

This instruction manual describes almost all of the equipment related to the EXAxt ZR. You may skip

any section(s) regarding equipment which is not included in your system.

Regarding the HART Communication Protocol, refer to IM 11M12A01-51E.

IM11M12A01-51E has been published as ''Model EXAxt ZR series HART protocol''.

Regarding Separate type Zirconia Oxygen Analyzer, refer to IM 11M12A01-02E.

< Before using the equipment, please read any descriptions in this manual related to the equipment

and system that you have, on appropriate use and operation of the EXAxt ZR. >

Models and descriptions in this manual are listed below.

<Introduction>

i

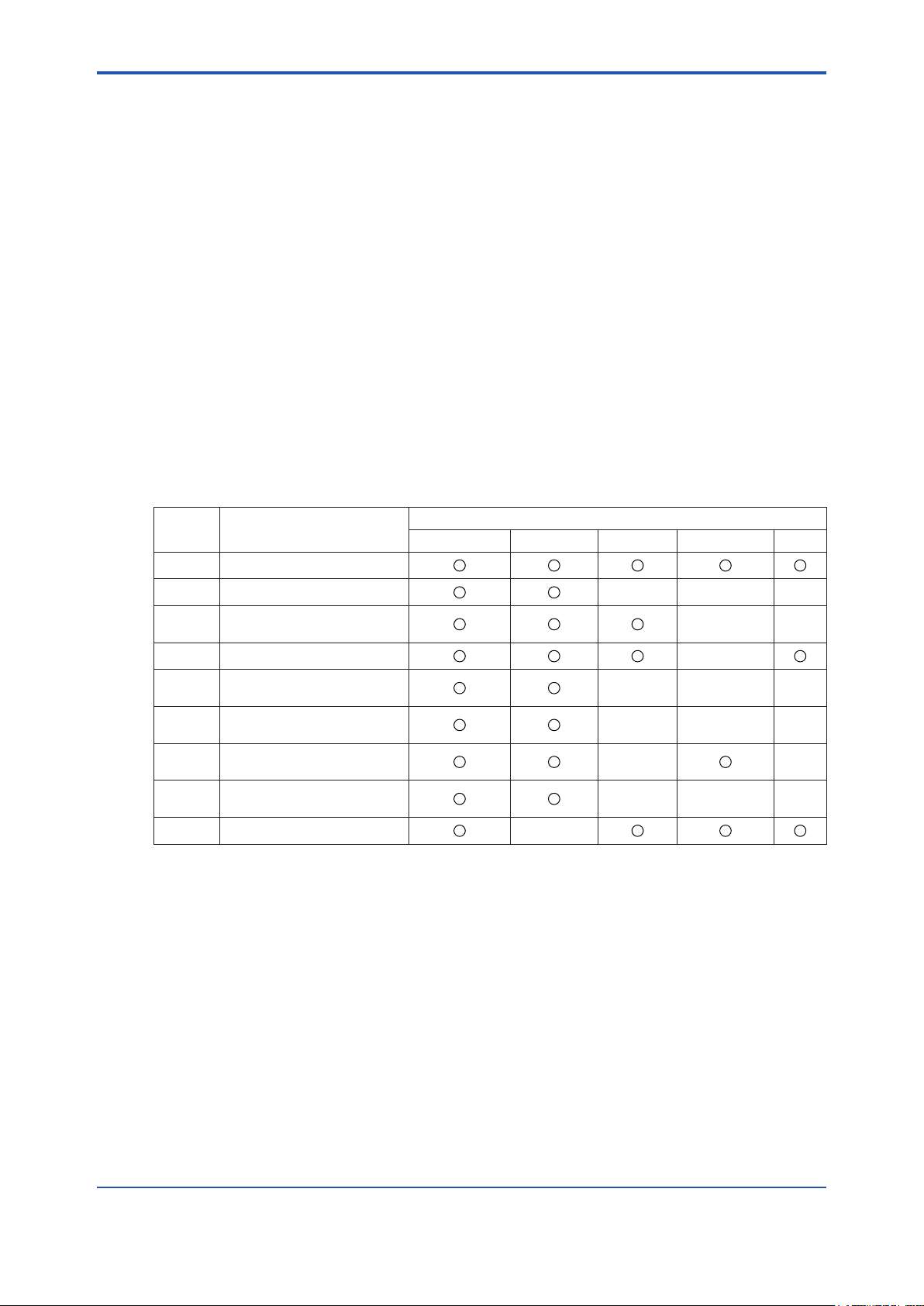

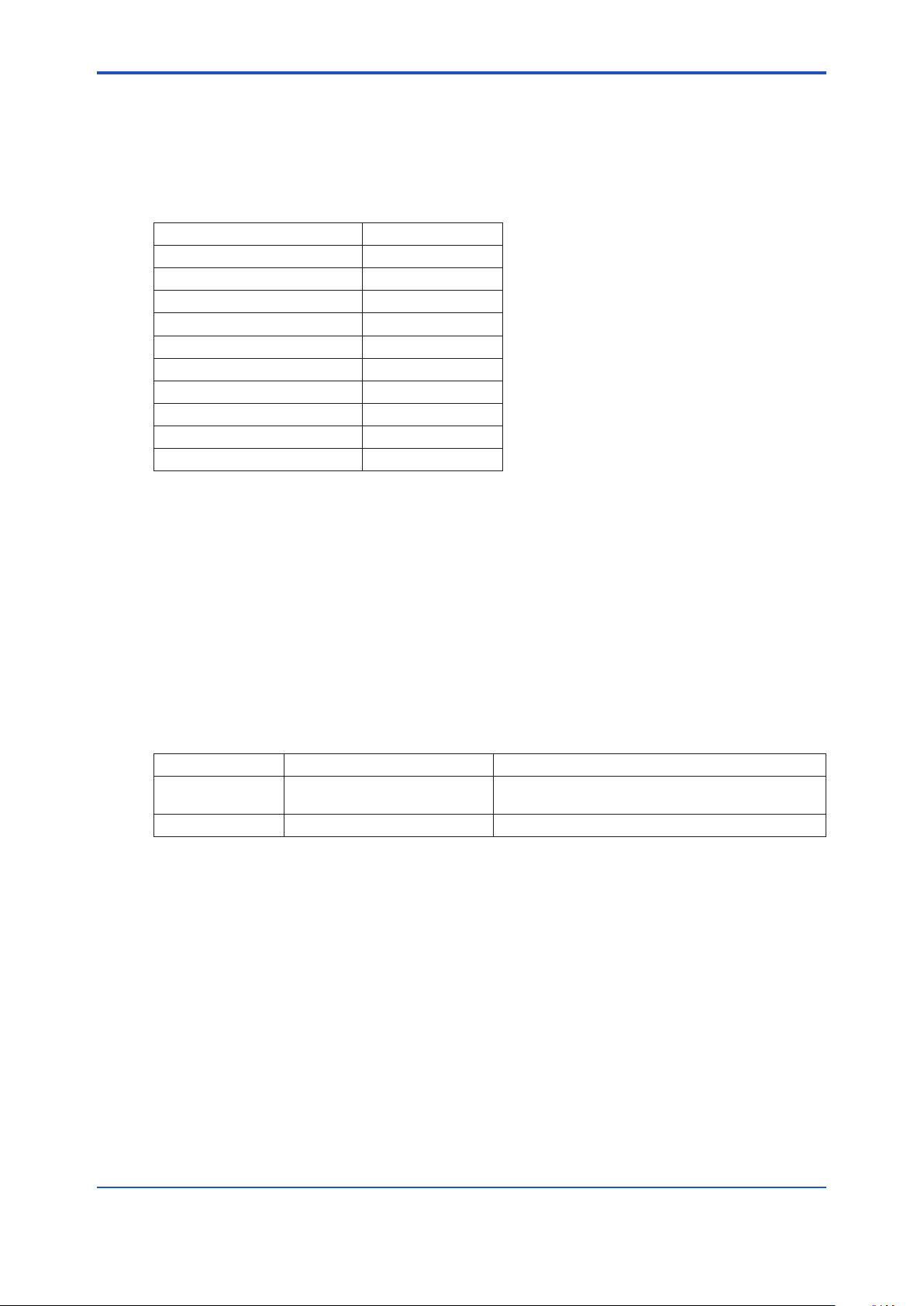

Model

ZR202G Integrated type Oxygen Analyzer

ZO21R Probe Protector

ZA8F Flow Setting Unit (for manual

ZR20H Automatic Calibration Unit

— Case Assembly for calibration

— Check valve (Part No. K9292DN,

— Dust Filter for the detector (Part

— Dust Guard Protector (Part No.

ZO21S Standard Gas Unit

CMPL: Customer Maintenance Parts List

Product Name

calibration use)

gas cylinder (Part No. E7044KF)

K9292DS)

No. K9471UA)

K9471UC)

Description in this manual

Specication Installation Operation Maintenance CMPL

Media No.IM 11M12A01-04E (CD) 7th Edition :March 2012 (YK)

All Rights Reserved Copyright © 2000, Yokogawa Electric Corporation

IM 11M12A01-04E

Page 3

ii

IM 11M12A01-04E

<Introduction>

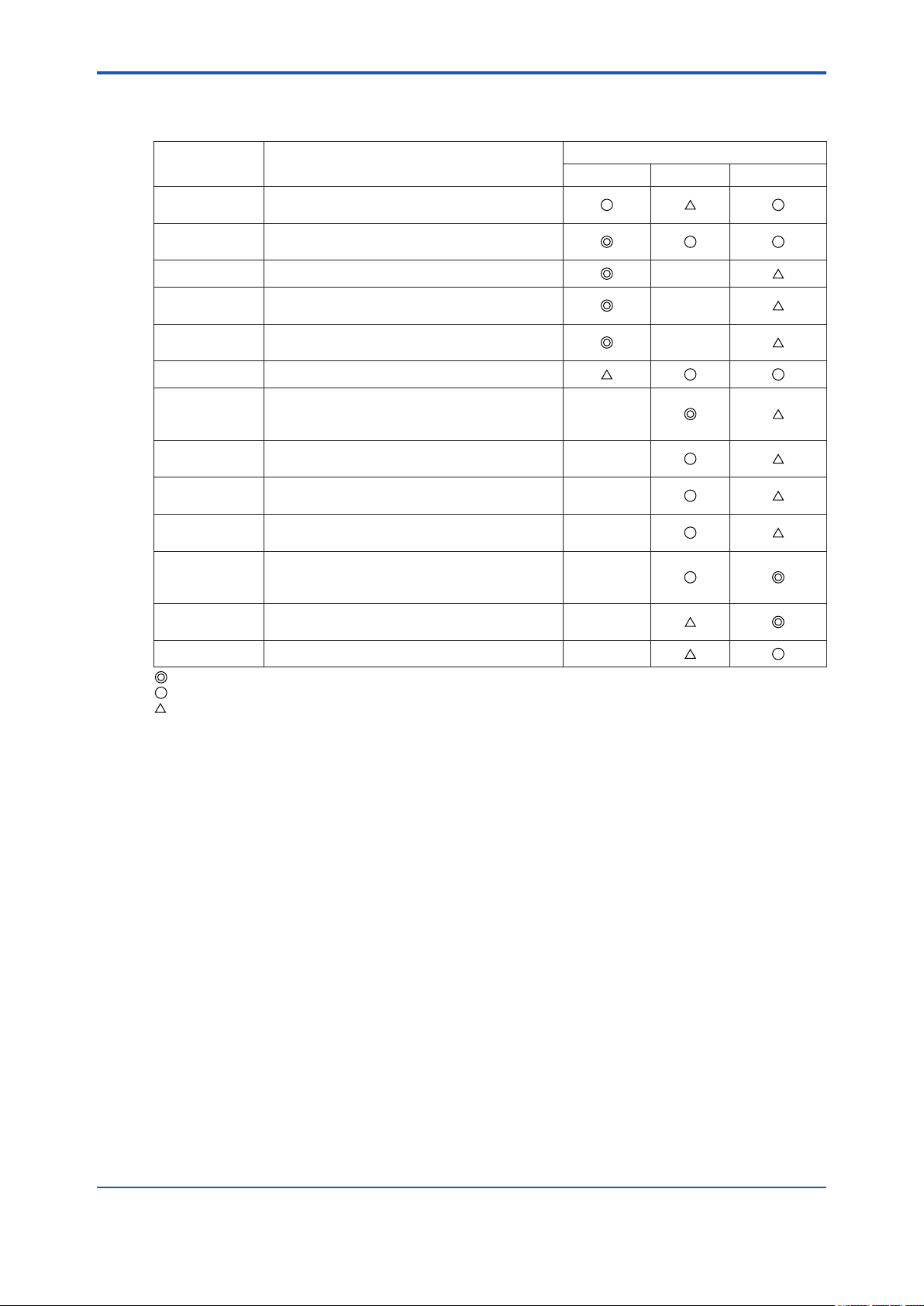

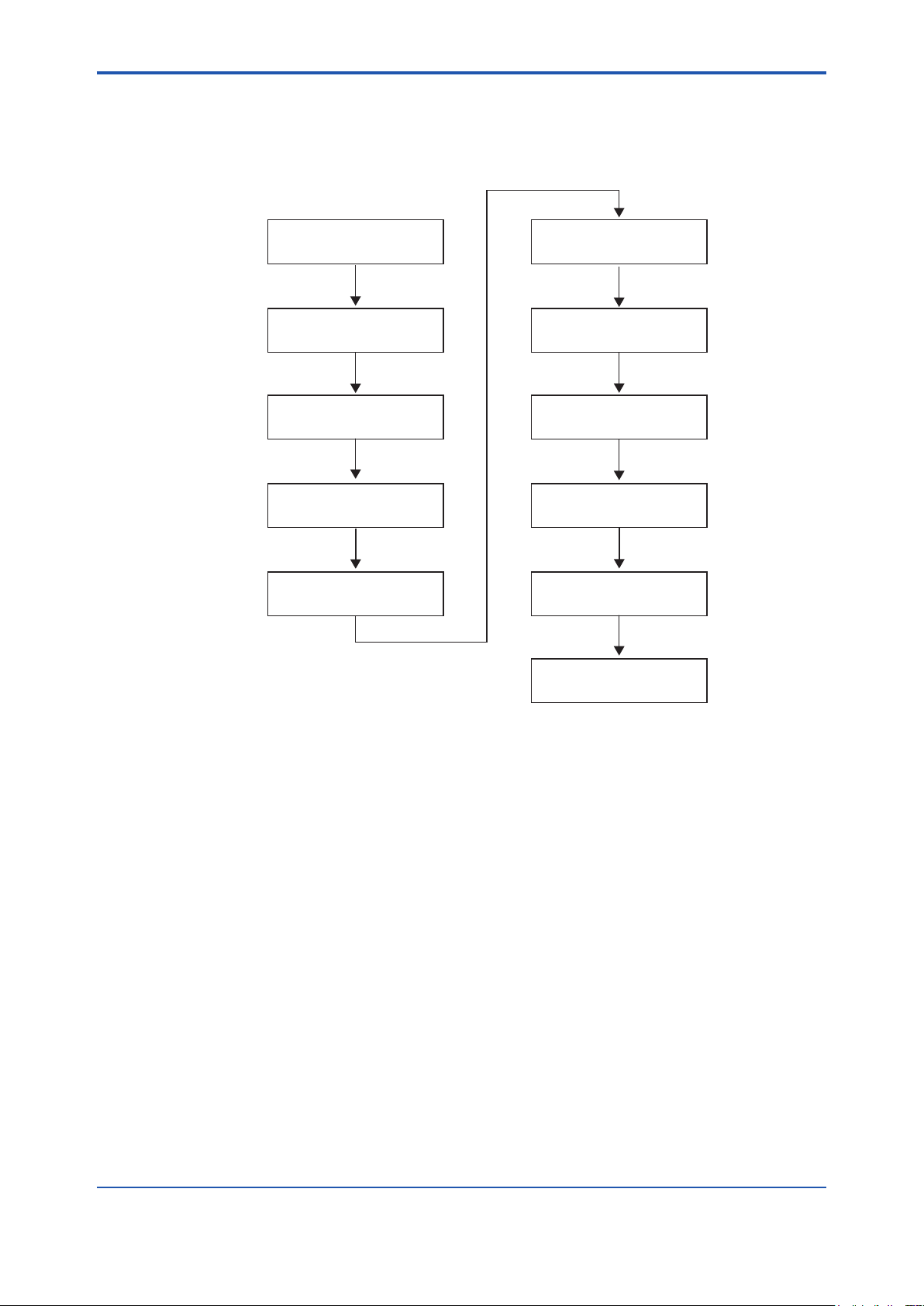

This manual consists of twelve chapters. Please refer to the reference chapters for installation, operation and maintenance.

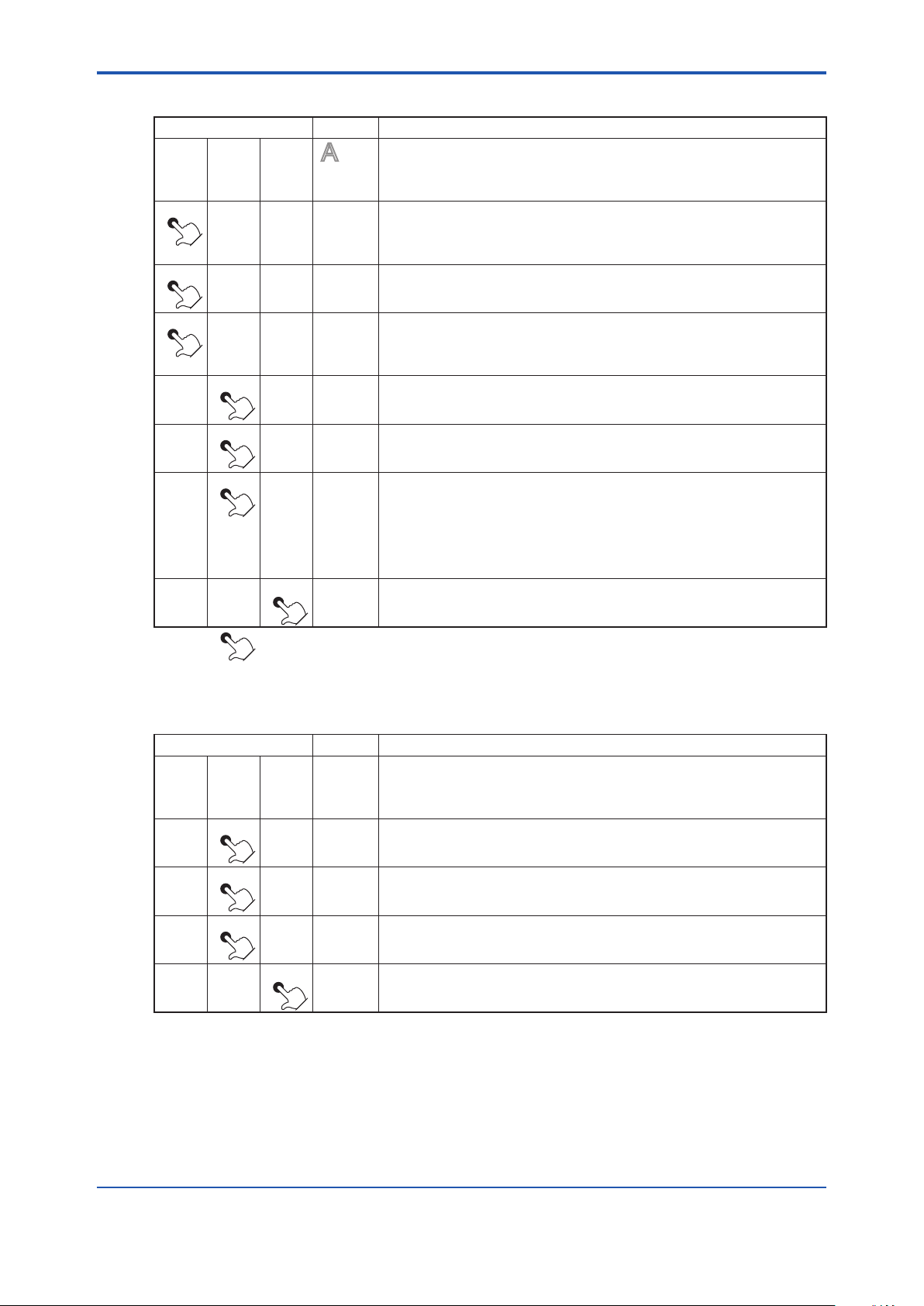

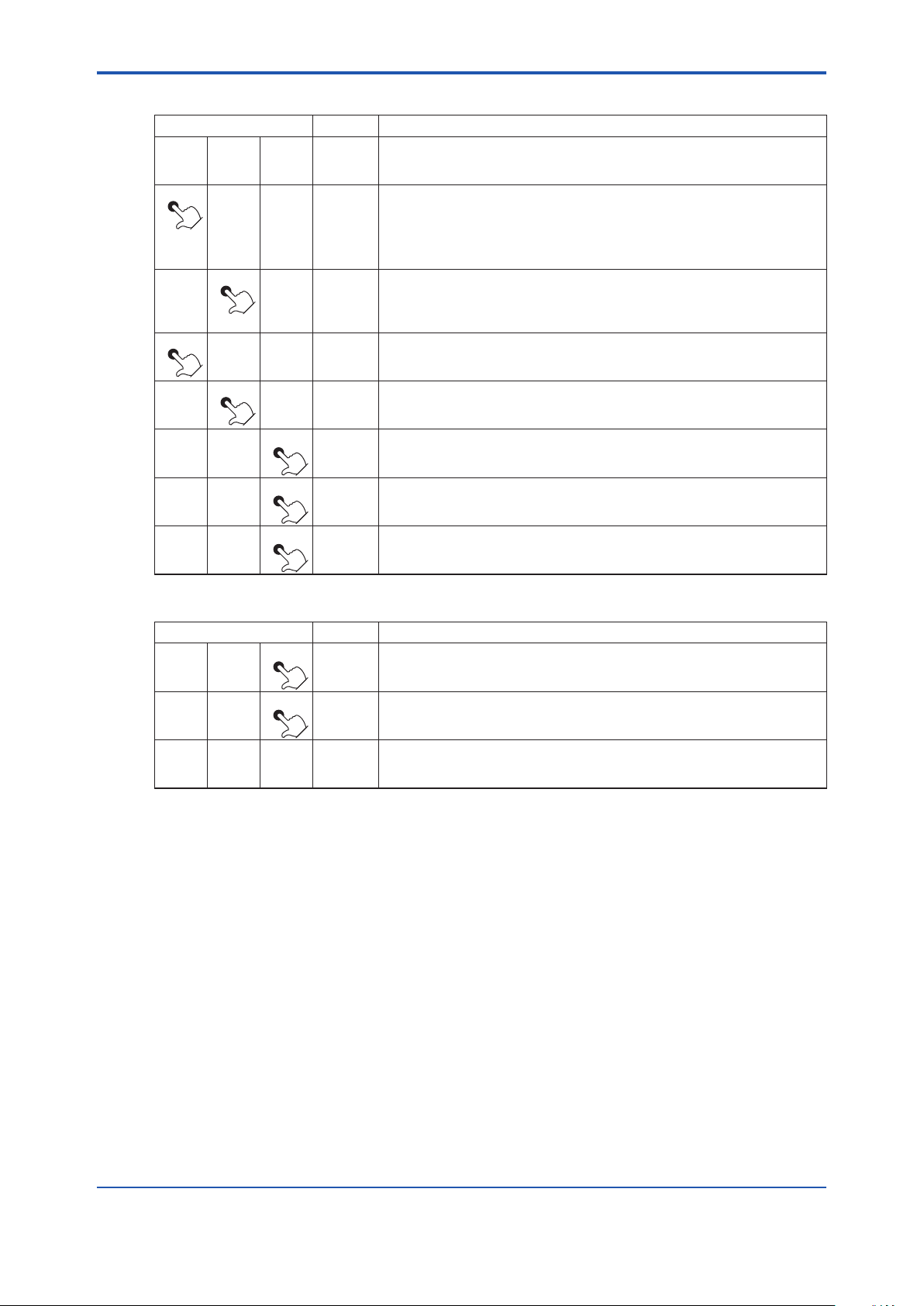

Chapter

1. Overview Equipment models and system conguration

examples

2. Specications Standard specication, model code (or part number),

3. Installation Installation method for each equipment

4. Piping Examples of piping in three standard system

5. Wiring Wiring procedures such as “Power supply wiring”,

6. Components Major parts and functions are described

7. Startup Basic procedure to start operation of EXAxt ZR.

8. Detailed Data

Setting

9. Calibration Describes the calibration procedure required in the

10. Other

Functions

11. Inspection

and

Maintenance

12. Troubleshoot-

ing

CMPL (parts list) User replaceable parts list

: Read and completely understand before operating the equipment.

: Read before operating the equipment, and refer to it whenever necessary.

: Recommended to read at least once.

dimension drawing for each equipment

congurations

“output signal wiring” or others

Chapter 7enables you to operate the equipment

immediately.

Details of key operations and displays

course of operation.

Other functions described

How to conduct maintenance of EXAxt ZR and

procedures for replacement of deteriorated parts

This chapter describes measures to be taken when an

abnormal condition occurs.

Outline

Relates to

Installation Operation Maintenance

Page 4

For the safe use of this equipment

WARNING

CAUTION

EXAxt ZR is very heavy. Be sure not to accidentally drop it. Handle safely to avoid injury.

Connect the power supply cord only after conrming that the supply voltage matches the rating of this

equipment. In addition, conrm that the power is switched off when connecting power supply.

Some process gas is dangerous to people. When removing this equipment from the process line for

maintenance or other reasons, protect yourself from potential poisoning by using a protective mask or

ventilating the area well

The cell (sensor) at the tip of the probe is made of ceramic (zirconia element). Do not drop the equipment or subject it to pressure stress.

<Introduction>

iii

• Do NOT allow the sensor (probe tip) to make contact with anything when installing the analyzer.

• Avoid water dropping directly on the probe (sensor) of the analyzer when installing it.

• Check the calibration gas piping before introducing the calibration gas to ensure that there is no

leakage of the gas. If there is any leakage of the gas, the moisture drawn from the sample gas

may damage the sensor.

• The probe (especially at the tip) becomes very hot. Be sure to handle it with gloves.

(1) About This Manual

The contents of this manual shall not be reproduced or copied, in part or in whole, without per-

mission.

This manual explains the functions contained in this product, but does not warrant that those will

suit the particular purpose of the user.

Every effort has been made to ensure accuracy in the preparation of this manual. However,

should any errors or omissions come to the attention of the user, please contact the nearest

Yokogawa Electric representative or sales ofce.

This manual does not cover the special specications. This manual may not be changed on any

change of specication, construction and parts when the change does not affect the functions or

performance of the product.

If the product is used in a manner not specied in this manual, the safety of this product may be

impaired.

IM 11M12A01-04E

Page 5

iv

IM 11M12A01-04E

<Introduction>

WARNING

CAUTION

IMPORTANT

NOTE

(2) Safety and Modication Precautions

Follow the safety precautions in this manual when using the product to ensure protection and

safety of personnel, product and system containing the product.

The following safety symbols and wordings are used on the product as well as in this manual.

(3) The following safety symbols are used in this manual.

Throughout this user’s manual, you will find several different types of symbols are used to identify

different sections of text. This section describes these icons.

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe practices.

Indicates that operating the hardware or software in this manner may damage it or lead to system

failure.

Draws attention to information essential for understanding the operation and features.

TIP

Identies additional information.

SEE ALSO

Identies a source to be referred to.

Clicking a reference displayed in green can call up its source, while clicking a reference displayed

in black cannot.

Page 6

<Introduction>

9

8

7

6

5

4

3

2

1

0

W

V

U

T

S

R

Q

P

O

N

M

L

K

J

I

H

G

F

E

D

C

B

A

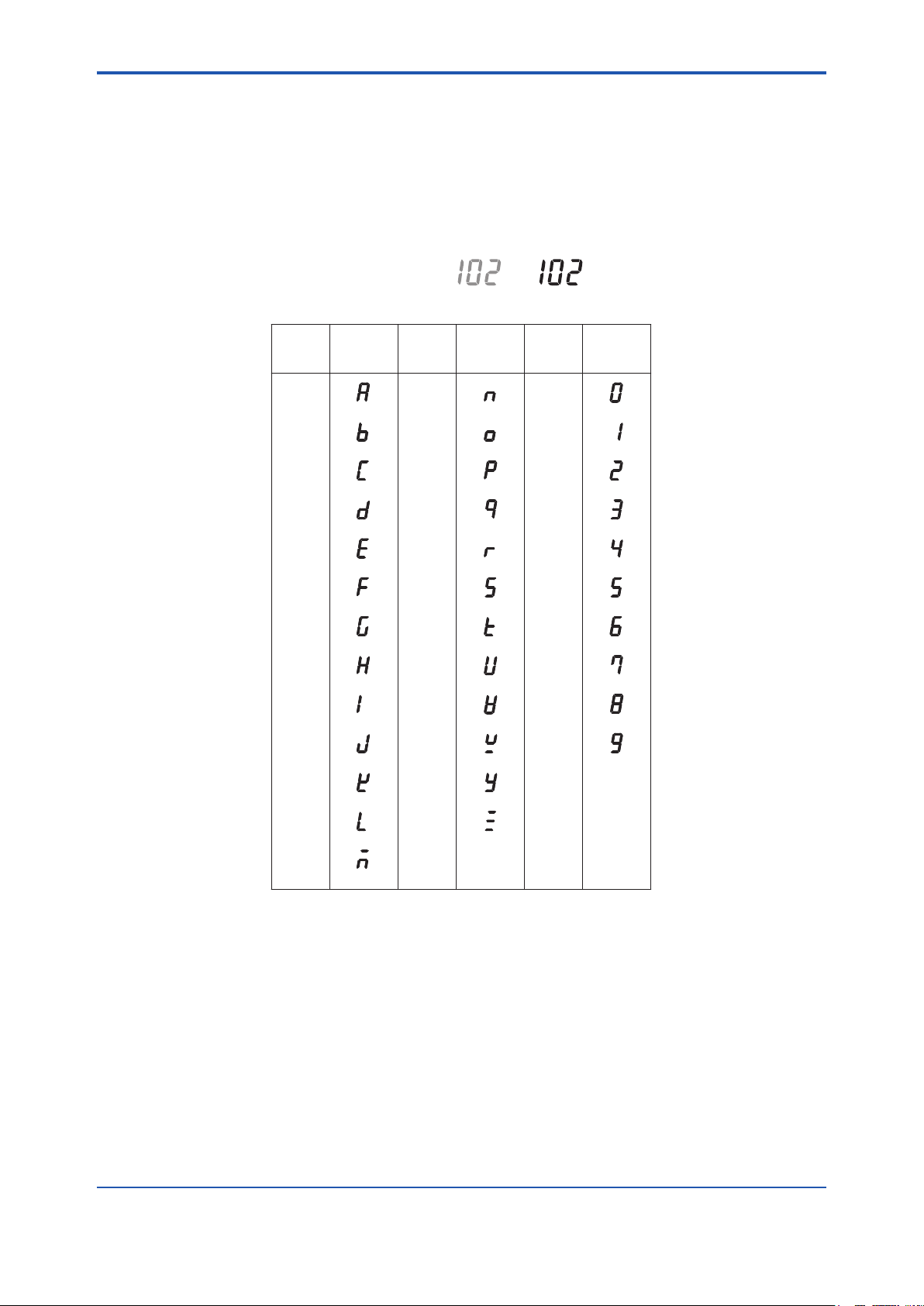

Alphanumerics Alphanumerics AlphanumericsLED Display LED Display LED Display

Z

Y

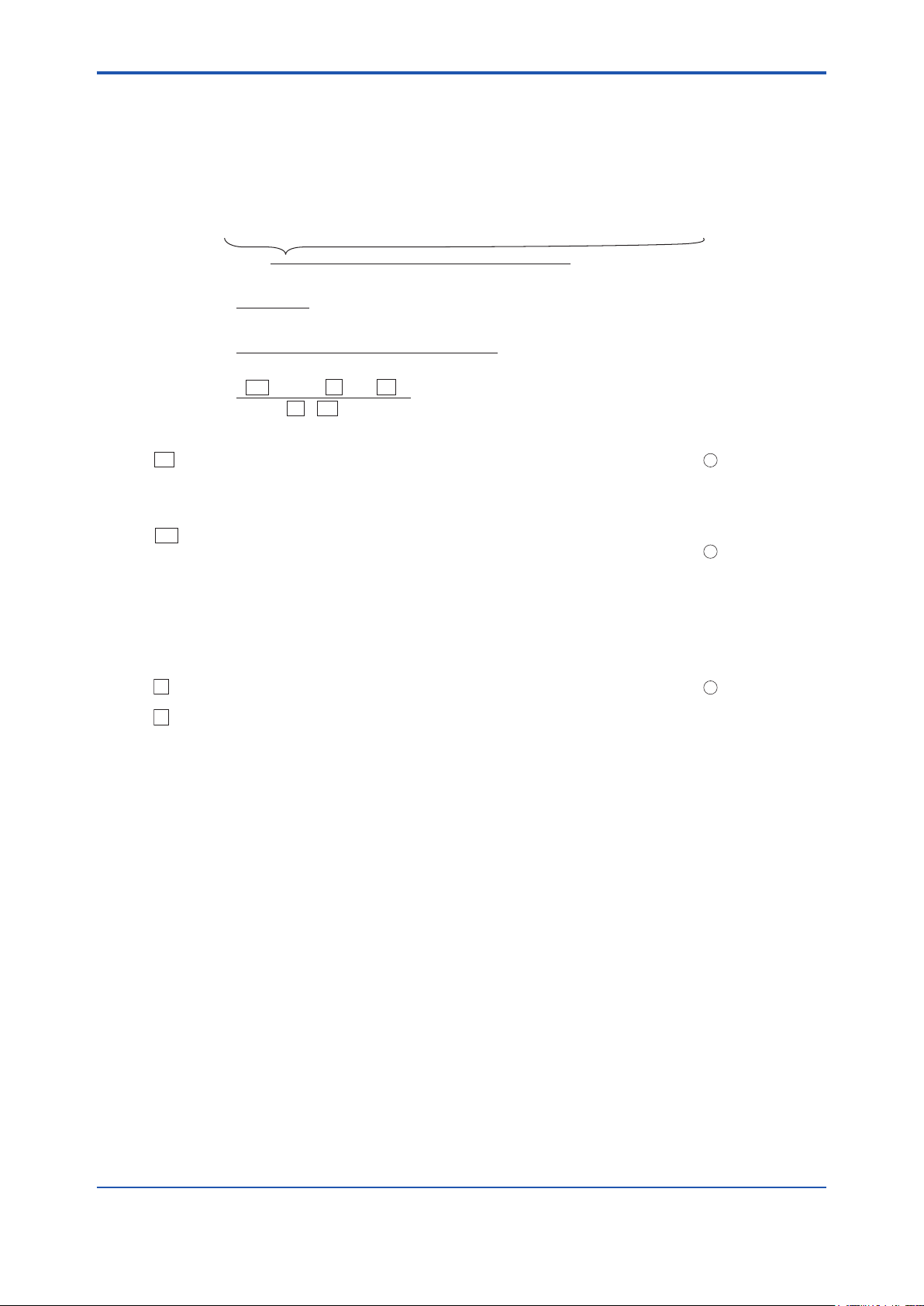

Special descriptions in this manual

This manual indicates operation keys, displays and drawings on the product as follows:

v

• Operation keys, displays on the panel

Enclosed in [ ]. (Ex. "MODE" key)

(Ex. message display → "BASE")

(Ex. data display → "102" lit, "102" ashing)

• Drawing for ashing

Indicated by gray characters (Flashing) (lit)

• Displays on the LCD display panel

IM 11M12A01-04E

Page 7

vi

IM 11M12A01-04E

<Introduction>

NOTICE

• Specication check

When the instrument arrives, unpack the package with care and check that the instrument has not

been damaged during transportation. In addition, please check that the specication matches the

order, and required accessories are not missing. Specications can be checked by the model codes

on the nameplate. Refer to Chapter 2 specications for the list of model codes.

• Details on operation parameters

When the EXAxt ZR Integrated type Zirconia Oxygen Analyzer arrives at the user site, it will operate

based on the operation parameters (initial data) set before shipping from the factory.

Ensure that the initial data is suitable for the operation conditions before conducting analysis.

Where necessary, set the instrument parameters for appropriate operation. For details on setting data,

refer to Chapters 7 to 10.

When user changes the operation parameter, it is recommended to note down the changed setting

data.

• How to dispose the batteries:

This is an explanation about the new EU Battery Directive (DIRECTIVE 2006/66/EC). This directive is

only valid in the EU.

Batteries are included in this product. Batteries incorporated into this product cannot be removed by

yourself. Dispose them together with this product.

When you dispose this product in the EU, contact your local Yokogawa Europe B.V.ofce. Do not

dispose them as domestic household waste.

Battery type: silver oxide battery

Notice:

The symbol (see above) means they shall be sorted out and collected as ordained in ANNEX II in

DIRECTIVE 2006/66/EC

Page 8

After-Sales Warranty

Do not modify the product.

During the warranty period, for repair under warranty carry or send the product to the local sales

representative or service ofce. Yokogawa will replace or repair any damaged parts and return

the product to you.

Before returning a product for repair under warranty, provide us with the model name and serial

number and a description of the problem. Any diagrams or data explaining the problem would

also be appreciated.

If we replace the product with a new one, we won’t provide you with a repair report.

Yokogawa warrants the product for the period stated in the pre-purchase quotation. Yokogawa

shall conduct dened warranty service based on its standard. When the customer site is located

outside of the service area, a fee for dispatching the maintenance engineer will be charged to the

customer.

In the following cases, customer will be charged repair fee regardless of warranty period.

• Failure of components which are out of scope of warranty stated in instruction manual.

• Failure caused by usage of software, hardware or auxiliary equipment, which Yokogawa Elec-

tric did not supply.

<Introduction>

vii

• Failure due to improper or insufcient maintenance by user.

• Failure due to modication, misuse or outside-of-specications operation which Yokogawa

does not authorize.

• Failure due to power supply (voltage, frequency) being outside specications or abnormal.

• Failure caused by any usage out of scope of recommended usage.

• Any damage from re, earthquake, storms and oods, lightning, disturbances, riots, warfare,

radiation and other natural changes.

Yokogawa does not warrant conformance with the specic application at the user site. Yokogawa

will not bear direct/indirect responsibility for damage due to a specic application.

Yokogawa Electric will not bear responsibility when the user congures the product into systems

or resells the product.

Maintenance service and supplying repair parts will be covered for ve years after the production

ends. For repair for this product, please contact the nearest sales ofce described in this instruc-

tion manual.

IM 11M12A01-04E

Page 9

viii

<Introduction>

IM 11M12A01-04E

Page 10

<CONTENTS>

Model ZR202G

Integrated type Zirconia Oxygen Analyzer

IM 11M12A01-04E 7th Edition

CONTENTS

Introduction ..............................................................................................................i

For the safe use of this equipment .............................................................................. iii

NOTICE ........................................................................................................................... vi

After-Sales Warranty .................................................................................................... vii

1. Overview .................................................................................................... 1-1

1.1 <EXAxtZR>SystemConguration ............................................................... 1-1

1.1.1 System 1 ............................................................................................

1.1.2 System 2 ............................................................................................

1.1.3 System 3 ............................................................................................

1.2 < EXAxt ZR > System Components ................................................................

1.2.1 System Components .........................................................................

1.2.2 Oxygen Analyzer and Accessories ....................................................

Toc-1

1-1

1-2

1-3

1-4

1-4

1-4

2. Specications ........................................................................................... 2-1

2.1 GeneralSpecications ..................................................................................... 2-1

2.1.1 StandardSpecications .....................................................................

2.1.2 ZR202G Integrated type Zirconia Oxygen Analyzer ..........................

2.1.3 ZO21R Probe Protector .....................................................................

2.2 ZA8F Flow Setting Unit and ZR20H Automatic Calibration Unit ................

2.2.1 ZA8F Flow Setting Unit ....................................................................

2.2.2 ZR20H Automatic Calibration Unit ...................................................

2.3 ZO21S Standard Gas Unit ..............................................................................

2.4 Other Equipment .............................................................................................

2.4.1 Dust Filter for Oxygen Analyzer (part no. K9471UA) .......................

2.4.2 Dust Guard Protector (part no. K9471UC) ......................................

2.4.3 Stop Valve (part no. L9852CB or G7016XH) ...................................

2.4.4 Check Valve (part no. K9292DN or K9292DS) ................................

2.4.5 Air Set ...............................................................................................

2.4.6 Zero Gas Cylinder (part no. G7001ZC) ...........................................

2.4.7 Pressure Regulator (G7013XF or G7014XF) for Gas Cylinder .......

2.4.8 Case Assembly (E7044KF) for Calibration gas Cylinder .................

2.4.9 ZR202A Heater Assembly ...............................................................

2-1

2-2

2-9

2-10

2-10

2-12

2-14

2-15

2-15

2-15

2-16

2-16

2-17

2-18

2-18

2-19

2-19

IM 11M12A01-04E

Page 11

Toc-2

<CONTENTS>

3. Installation ................................................................................................. 3-1

3.1 Installation of ZR202G Zirconia Oxygen Analyzer ........................................3-1

3.1.1 Installation Location ...........................................................................

3.1.2 Probe Insertion Hole ..........................................................................

3.1.3 Installation of the Probe .....................................................................

3.1.4 Installation of the Dust Filter (K9471UA), Dust Guard Protector

(K9471UC) Probe Protector (ZO21R) ...............................................3-3

3.2 Installation of ZA8F Flow Setting Unit ............................................................

3.2.1 Installation Location ...........................................................................

3.2.2 Mounting of ZA8F Flow Setting Unit ..................................................

3.3 Installation of ZR20H Automatic Calibration Unit .........................................

3.3.1 Installation Location ...........................................................................

3.3.2 Mounting of ZR20H Automatic Calibration Unit .................................

3.4 Installation of the Case Assembly (E7044KF) for

Calibration Gas Cylinder ..................................................................................3-9

3.4.1 Installation Location ...........................................................................

3.4.2 Mounting ............................................................................................

3.5 Insulation Resistance Test .............................................................................

3-1

3-2

3-2

3-5

3-5

3-6

3-7

3-7

3-7

3-9

3-9

3-10

4. Piping ......................................................................................................... 4-1

4.1 Piping for System 1 ...........................................................................................4-1

4.1.1 Piping Parts for System 1 ..................................................................

4.1.2 Piping for the Calibration Gas ............................................................

4.1.3 Piping for the Reference Gas

4.2 Piping for System 2 ...........................................................................................

4.2.1 Piping Parts for System 2 ..................................................................

4.2.2 Piping for the Calibration Gas ............................................................

4.2.3 Piping for the Reference Gas

4.3 Piping for System 3 ...........................................................................................

4.4 Piping for the Oxygen Analyzer with Pressure Compensation ...................

4.4.1 Piping Parts for Oxygen Analyzer with Pressure Compensation ......

4.4.2 Piping for the Calibration Gas ............................................................

4.4.3 Piping for the Reference Gas

.............................................................4-2

.............................................................4-4

.............................................................4-8

4-2

4-2

4-3

4-3

4-3

4-4

4-6

4-8

4-8

5. Wiring ......................................................................................................... 5-1

5.1 General ...............................................................................................................5-1

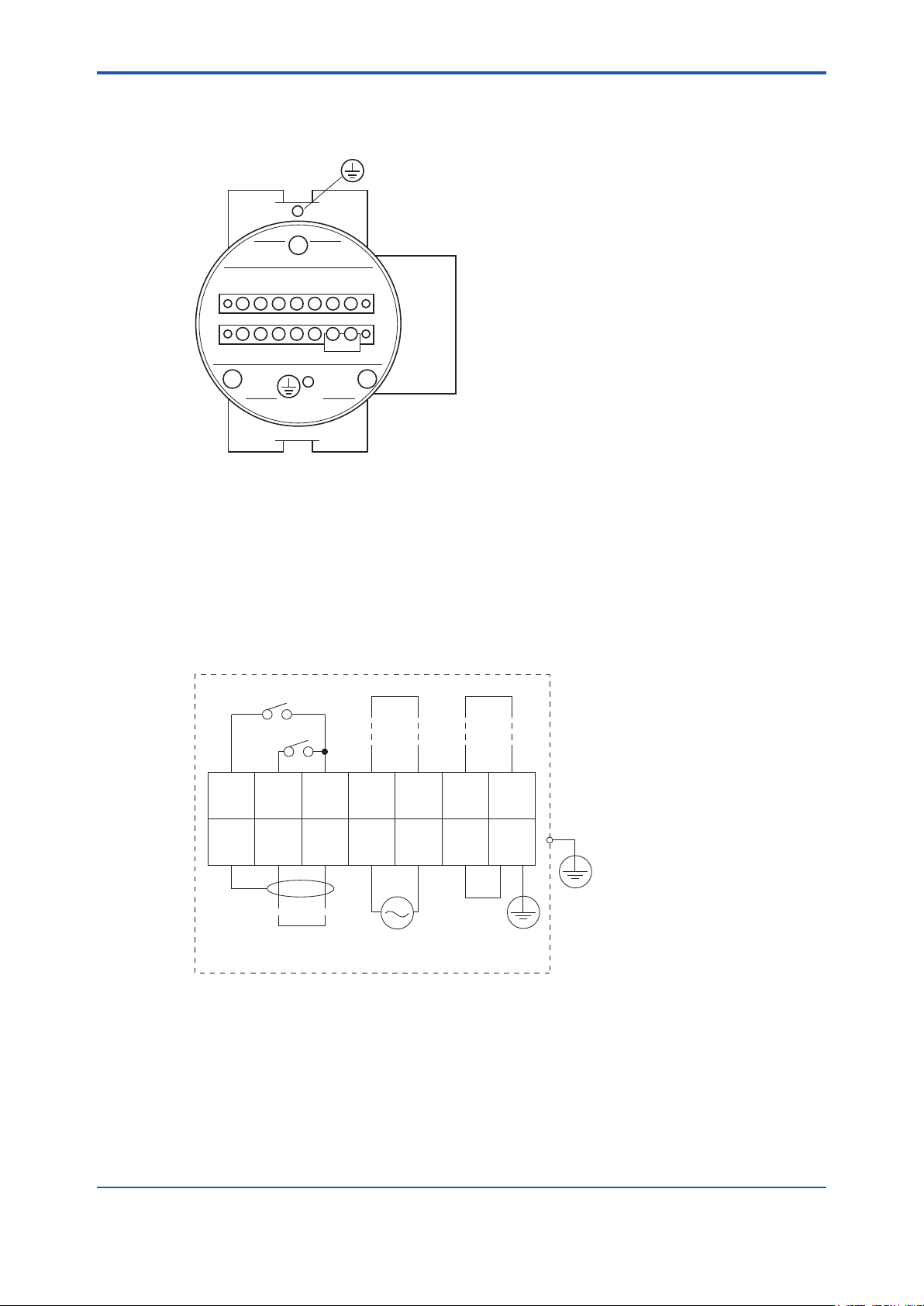

5.1.1 Terminals for the External Wiring .......................................................

5.1.2 Wiring .................................................................................................

5.1.3 Mounting of Cable Gland ...................................................................

5.2 Wiring for Analog Output .................................................................................

5.2.1 Cable Specications ..........................................................................

5.2.2 Wiring Procedure ...............................................................................

5-2

5-2

5-3

5-3

5-3

5-3

IM 11M12A01-04E

Page 12

<CONTENTS>

5.3 Wiring Power and Ground Terminals .............................................................5-4

5.3.1 Wiring for Power Line .........................................................................

5.3.2 Wiring for Ground Terminals ..............................................................

5.4 Wiring for Contact Output ................................................................................

5.4.1 Cable Specications ..........................................................................

5.4.2 Wiring Procedure ...............................................................................

5.5 Wiring for Contact Input ...................................................................................

5.5.1 Cable Specications ..........................................................................

5.5.2 Wiring Procedure ...............................................................................

Toc-3

5-4

5-4

5-5

5-5

5-5

5-5

5-5

5-6

6. Components ............................................................................................. 6-1

6.1 ZR202G Zirconia Oxygen Analyzer .................................................................6-1

6.1.1 Integrated type Zirconia Oxygen Analyzer ........................................

6.2 ZA8F Flow Setting Unit, ZR20H Automatic Calibration Unit ........................

6-1

6-2

7. Startup ....................................................................................................... 7-1

7.1 Checking Piping and Wiring Connections .....................................................7-2

7.2 Valve Setup ........................................................................................................

7.3 Supplying Power to Converter ........................................................................

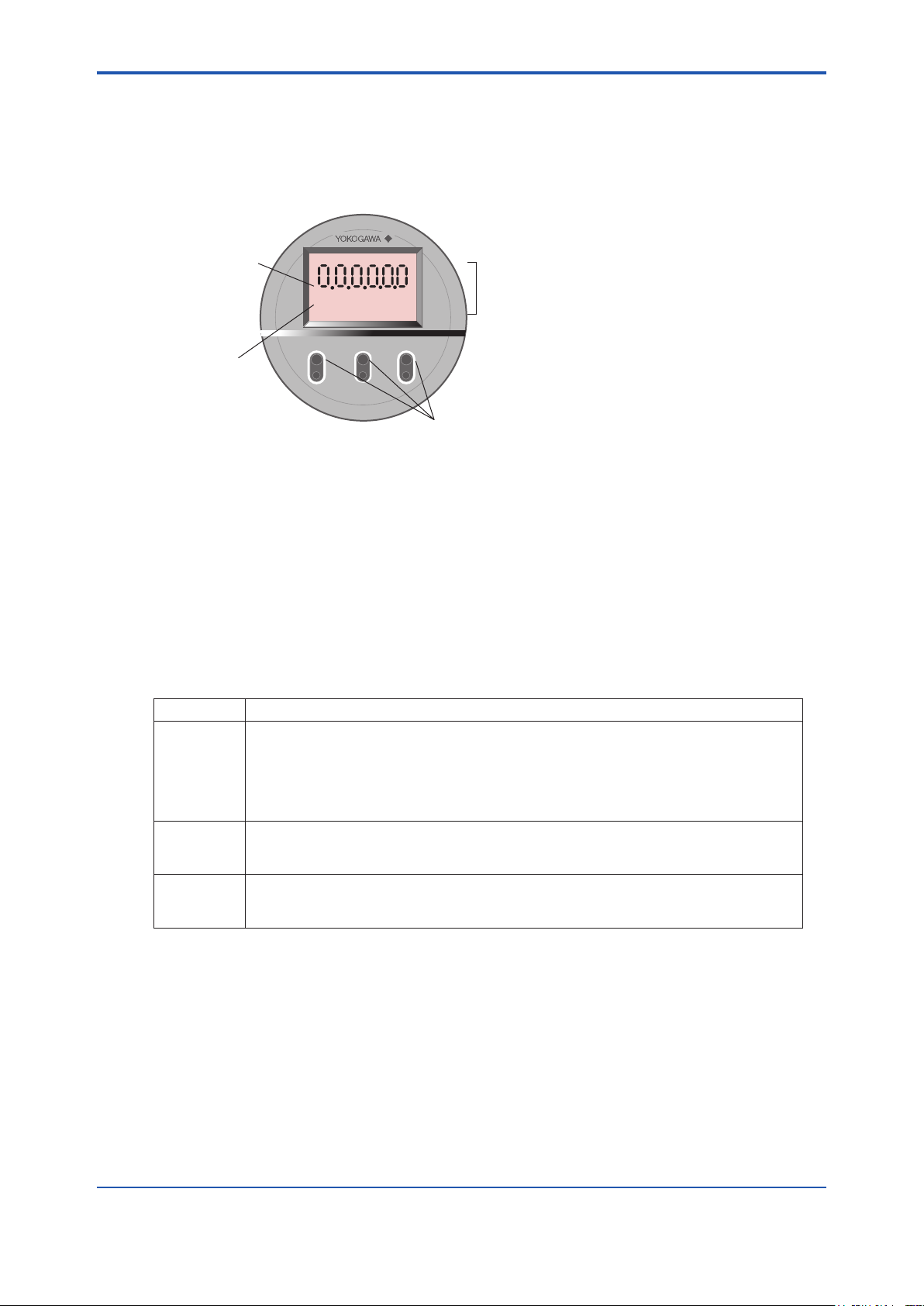

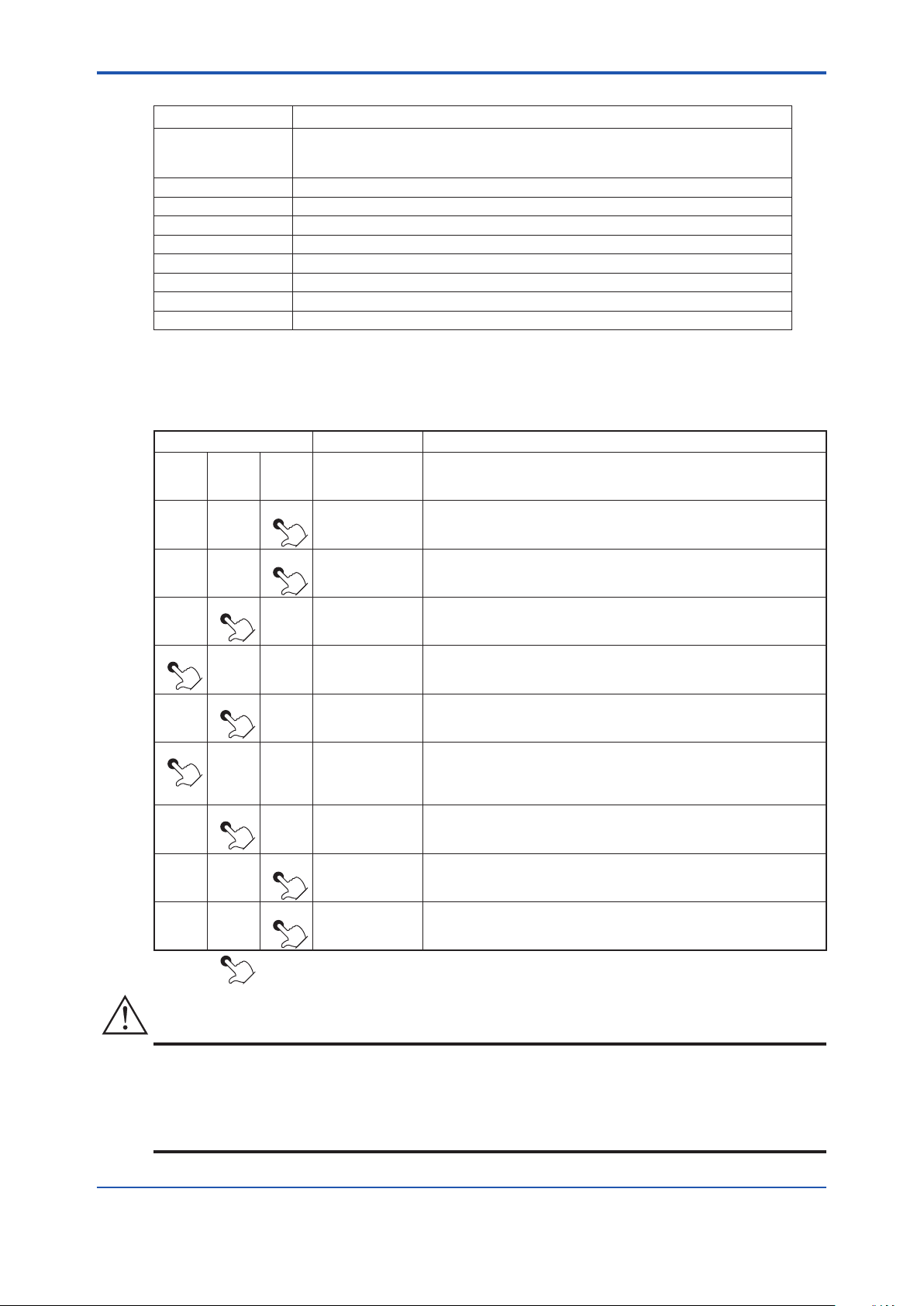

7.4 Operation of Infrared Switch ...........................................................................

7.4.1 Display and Switches .........................................................................

7.4.2 Display Conguration .........................................................................

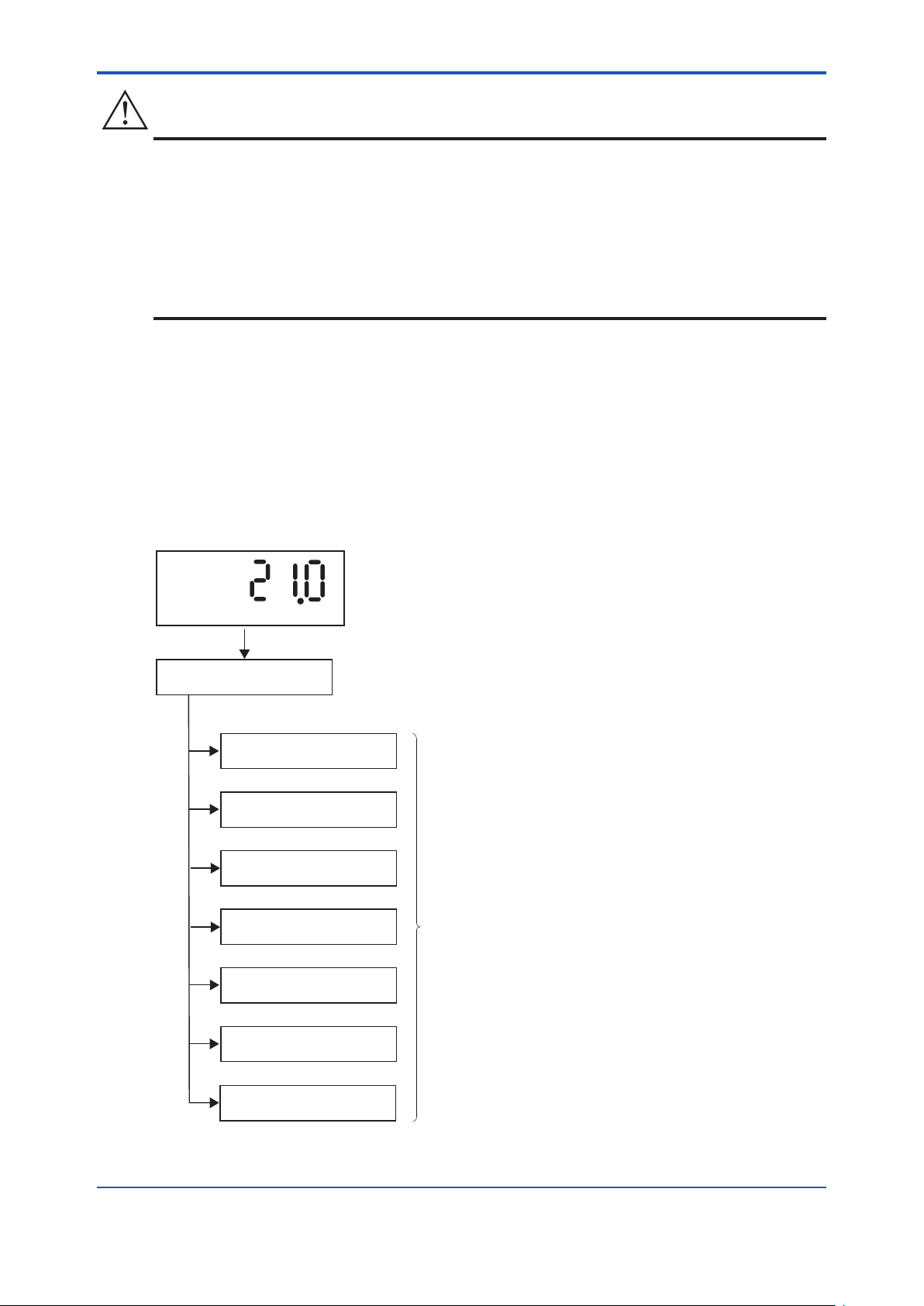

7.4.3 Entering Parameter Code Selection Display .....................................

7.4.4 Selecting Parameter Codes ...............................................................

7.4.5 Changing Set Values .........................................................................

7.5 Conrmation of Equipment Type Setting .......................................................

7.6 Selection of Measurement Gas .......................................................................

7.7 Output Range Setting .......................................................................................

7.7.1 Minimum Current (4 mA) and Maximum Current (20 mA) Settings ..

7.8 Checking Current Loop ..................................................................................

7.9 Checking Contact I/O ......................................................................................

7.9.1 Contact Output Check .....................................................................

7.9.2 Checking Calibration Contact Output ..............................................

7.9.3 Checking Input Contacts ..................................................................

7.10 Calibration .......................................................................................................

7.10.1 Calibration Setup .............................................................................

7.10.2 Manual Calibration ...........................................................................

7-2

7-2

7-3

7-3

7-4

7-5

7-6

7-6

7-8

7-9

7-9

7-9

7-11

7-11

7-12

7-13

7-14

7-15

7-15

7-17

IM 11M12A01-04E

Page 13

Toc-4

<CONTENTS>

8. Detailed Data Setting ............................................................................... 8-1

8.1 Setting Display Item ..........................................................................................8-1

8.2 Current Output Setting .....................................................................................

8.2.1 Setting Minimum Oxygen Concentration ( at 4 mA) and Maximum

Oxygen Concentration ( at 20 mA) ....................................................8-2

8.2.2 Entering Output Damping Constants .................................................

8.2.3 Selection of Output Mode ..................................................................

8.2.4 Default Values ....................................................................................

8.3 Output Hold Setting ..........................................................................................

8.3.1 Denition of Equipment Status ..........................................................

8.3.2 Preference Order of Output Hold Value .............................................

8.3.3 Output Hold Setting ............................................................................

8.3.4 Default Values ....................................................................................

8.4 Setting Oxygen Concentration Alarms

8.4.1 Alarm Values ......................................................................................

8.4.2 Alarm Output Actions .........................................................................

8.4.3 Alarm Setting

8.4.4 Default Values ....................................................................................

8.5 Output Contact Setup .......................................................................................

8.5.1 Output Contact ...................................................................................

8.5.2 Setting Output Contact ......................................................................

8.5.3 Default Values ..................................................................................

8.6 Input Contact Settings ....................................................................................

8.6.1 Setting Input Contact .......................................................................

8.6.2 Default Values ..................................................................................

8.7 Other Settings .................................................................................................

8.7.1 Setting the Date-and-Time ...............................................................

8.7.2 Setting Periods over which Average Values are Calculated and Periods

over which Maximum and Minimum Values Are Monitored.............8-13

8.7.3 Setting Fuels ....................................................................................

8.7.4 Setting Purging ................................................................................

......................................................................................8-7

...........................................................8-6

8-1

8-2

8-2

8-2

8-3

8-3

8-5

8-5

8-5

8-6

8-6

8-8

8-8

8-8

8-9

8-10

8-11

8-11

8-11

8-12

8-12

8-14

8-18

9. Calibration ................................................................................................. 9-1

IM 11M12A01-04E

9.1 Calibration Briefs ..............................................................................................9-1

9.1.1 Principle of Measurement ..................................................................

9.1.2 Calibration Gas ..................................................................................

9.1.3 Compensation ....................................................................................

9.1.4 Characteristic Data from a Sensor Measured During Calibration .....

9.2 Calibration Procedures ....................................................................................

9.2.1 Calibration Setting ..............................................................................

9.2.2 Calibration ..........................................................................................

9-1

9-2

9-2

9-4

9-5

9-5

9-8

Page 14

<CONTENTS>

Toc-5

10. Other Functions ...................................................................................... 10-1

10.1 Detailed Display ..............................................................................................10-1

10.1.1 Air Ratio

10.1.2 Cell Temperature ..............................................................................

10.1.3 C. J. Temperature

10.1.4 Amount of Water Vapor in Exhaust Gas ..........................................

10.1.5 Cell Voltage ......................................................................................

10.1.6 Thermocouple Voltage .....................................................................

10.1.7 Cold Junction Voltage ......................................................................

10.1.8 Current Output .................................................................................

10.1.9 Response Time ................................................................................

10.1.10 Cell’s Internal Resistance ...............................................................

10.1.11 Robustness of a Cell .......................................................................

10.1.12 Heater On-Time Ratio .....................................................................

10.1.13 Oxygen Concentration (with time constant) ....................................

10.1.14 Maximum Oxygen Concentration ...................................................

10.1.15 Minimum Oxygen Concentration ....................................................

10.1.16 Average Oxygen Concentration ......................................................

10.1.17 Span and Zero Correction Ratios ...................................................

10.1.18 History of Calibration Time ..............................................................

10.1.19 Time .................................................................................................

10.1.20 Software Revision ...........................................................................

10.2 Operational Data Initialization ......................................................................

10.3 Initialization Procedure ..................................................................................

10.4 Reset .................................................................................................................

10.5 Handling of the ZO21S Standard Gas Unit .................................................

10.5.1 Standard Gas Unit Component Identication ................................

10.5.2 Installing Gas Cylinders .................................................................

10.5.3 Calibration Gas Flow ......................................................................

10.6 Methods of Operating Valves in the ZA8F Flow Setting Unit ...................

10.6.1 Preparation Before Calibration ......................................................

10.6.2 Operating the Span Gas Flow Setting Valve .................................

10.6.3 Operating the Zero Gas Flow Setting Valve ..................................

10.6.4 Treatment After Calibration ............................................................

............................................................................................10-3

10-3

.............................................................................10-3

10-3

10-4

10-4

10-4

10-4

10-5

10-5

10-5

10-6

10-6

10-6

10-6

10-6

10-6

10-7

10-7

10-7

10-7

10-8

10-9

10-16

10-16

10-16

10-17

10-19

10-19

10-19

10-19

10-20

11. Inspection and Maintenance ................................................................. 11-1

11.1 Inspection and Maintenance of the Detector ............................................... 11-1

11.1.1 Cleaning the Calibration Gas Tube ..................................................

11.1.2 Replacing the Sensor Assembly ......................................................

11.1.3 Replacement of the Heater Assembly .............................................

11.1.4 Replacement of Dust Filter ..............................................................

11.1.5 Replacement of O-ring .....................................................................

11.1.6 Stopping and Re-starting Operation ................................................

11-1

11-2

11-4

11-6

11-6

11-6

IM 11M12A01-04E

Page 15

Toc-6

<CONTENTS>

11.2 Inspection and Maintenance of the Converter ............................................ 11-8

11.2.1 Replacing Fuses ..............................................................................

11.3 Replacement of Flowmeter for ZR20H Automatic Calibration Unit ........

11-8

11-10

12. Troubleshooting ..................................................................................... 12-1

12.1 Displays and Measures to Take When Errors Occur .................................. 12-1

12.1.1 What is an Error? .............................................................................

12.1.2 Measures to Take When an Error Occurs .......................................

12.2 Displays and Measures to Take When Alarms are Generated ...................

12.2.1 What is an Alarm? ............................................................................

12.3 Measures When Measured Value Shows an Error ......................................

12.3.1 Measured Value Higher Than True Value ........................................

12.3.2 Measured Value Lower Than True Value ......................................

12.3.3 Measurements Sometimes Show Abnormal Values .....................

12-1

12-2

12-4

12-4

12-9

12-9

12-10

12-10

Customer Maintenance Parts List ........................................CMPL 11M12A01- 04E

Customer Maintenance Parts List ........................................CMPL 11M12A01-12E

Customer Maintenance Parts List ...........................................CMPL 11M3D1- 01E

Revision Information ...............................................................................................i

IM 11M12A01-04E

Page 16

<1.Overview>

~

ZR202G Integrated type Zirconia Oxygen Analyzer

ZO21S Standard gas unit

Stop valve

Calibration gas

F1.1E.ai

~

100 to 240 V AC

100/110/115

200/220/240 V AC

Contact input

Analog output, contact output

Digital output (HART)

1. Overview

The EXAxt ZR Integrated type Zirconia Oxygen Analyzer is used to monitor and control the oxygen

concentration in combustion gases, in boilers and industrial furnaces, for wide application in industries

which consume considerable energy-such as steel, electric power, oil and petrochemical, ceramics,

pulp and paper, food, or textiles, as well as incinerators and medium/small boilers. It can help conserve

energy in these industries. The EXAxt ZR also contributes to preservation of the earth’s environment

in preventing global warming and air pollution by controlling complete combustion to reduce CO2, SOx

and NOx.

The EXAxt ZR Integrated type Zirconia Oxygen Analyzer integrates both probe and converter. The

analyzers need not use a sampling device, and allow direct installation of the probe in the wall of a ue

or furnace to measure the concentration of oxygen in the stack gas of the temperature up to 700°C.

The probe uses a high-reliability Zirconia sensor and a heater assembly that can be replaced on site.

The analyzer is equipped with three infrared switches, which enable the user to operate the equipment

without opening the cover on site. Analyzer calibration can also be fully automated and the automatic

calibration unit is provided. Choose the equipment which best suits your needs so that an optimal

combustion control system can be obtained.

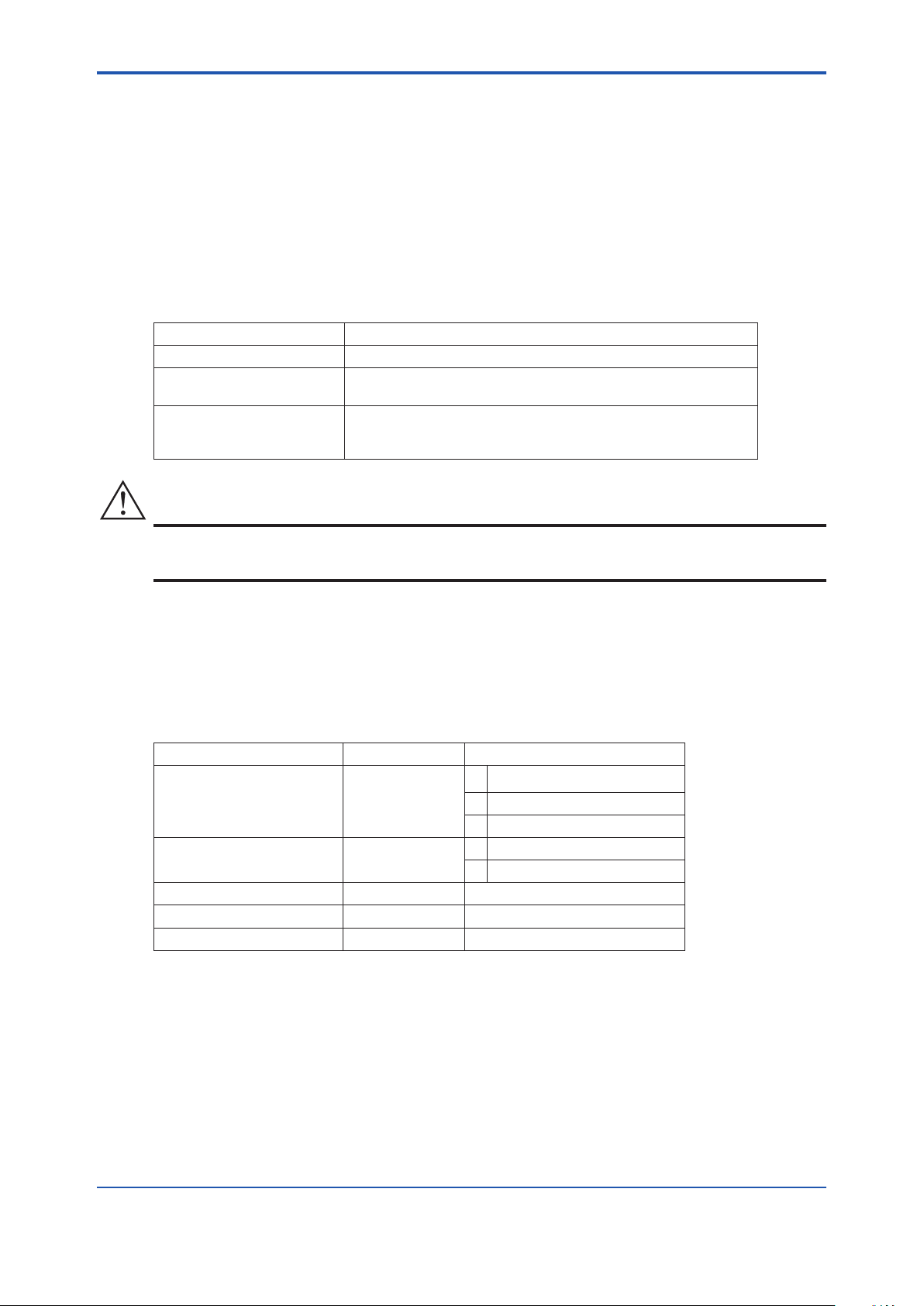

Some examples of typical system conguration are illustrated below:

1-1

1.1 <EXAxtZR>SystemConguration

The system configuration should be determined by the conditions; e.g. whether the calibration is to

be automated, and whether flammable gas is present and requires safety precautions. The system

conguration can be classied into three basic patterns as follows:

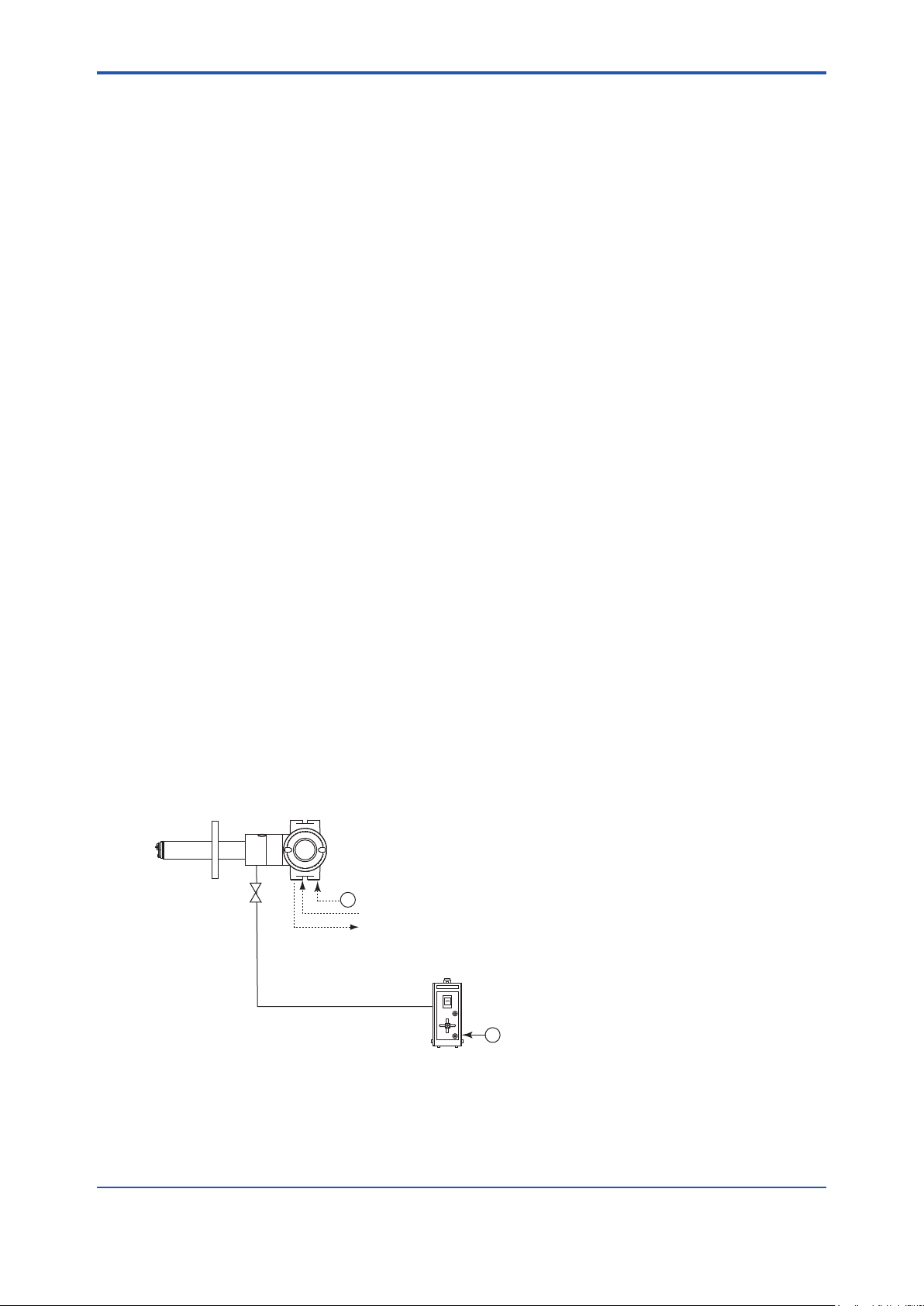

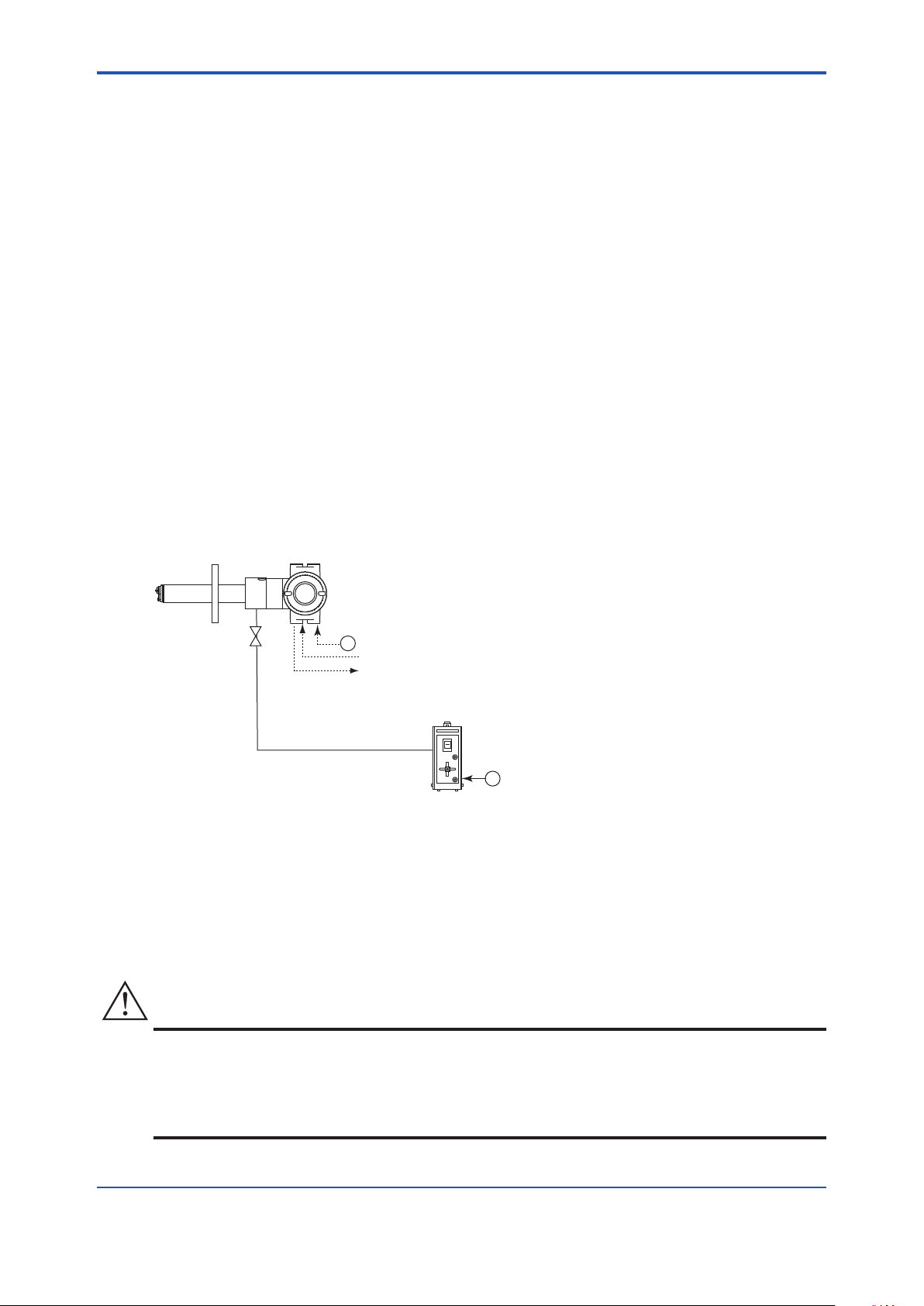

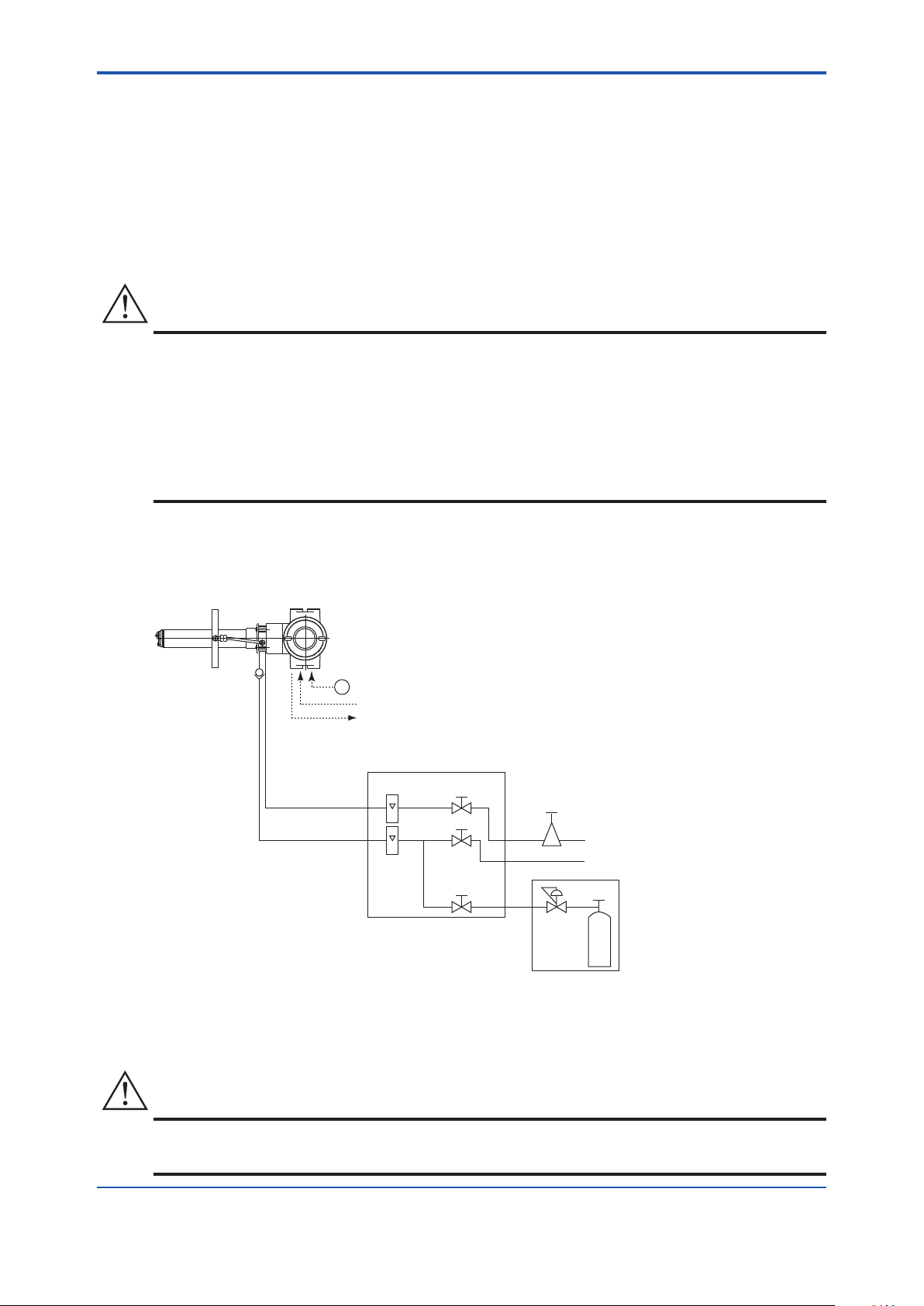

1.1.1 System 1

This is the simplest system consisting of an integrated type analyzer. This system can be implemented

for monitoring oxygen concentration in the combustion gases boiler. No piping is required for the

reference gas (air) which is fed in at the installation site. The ZO21S standard gas unit is used for

calibration.

Zero gas from this unit and span gas (air) is sent to the probe through a tube which is connected

during calibration.

Figure1.1 ExampleofSystem1

IM 11M12A01-04E

Page 17

<1. Overview>

1-2

IM 11M12A01-04E

CAUTION

~

ZR202G Integrated type Zirconia Oxygen Analyzer

F1.2E.ai

ZA8F flow setting unit

Reference gas

Calibration gas

Needle

valve

Flowmeter

Instrument air

Air Set

Calibration

gas pressure

regulator

Zero gas cylinder

Calibration gas unit case

Stop valve

or

Check valve

Span gas(Same as Zero gas calibration)

100 to 240 V AC

Contact input

Analog output, contact output

Digital output (HART)

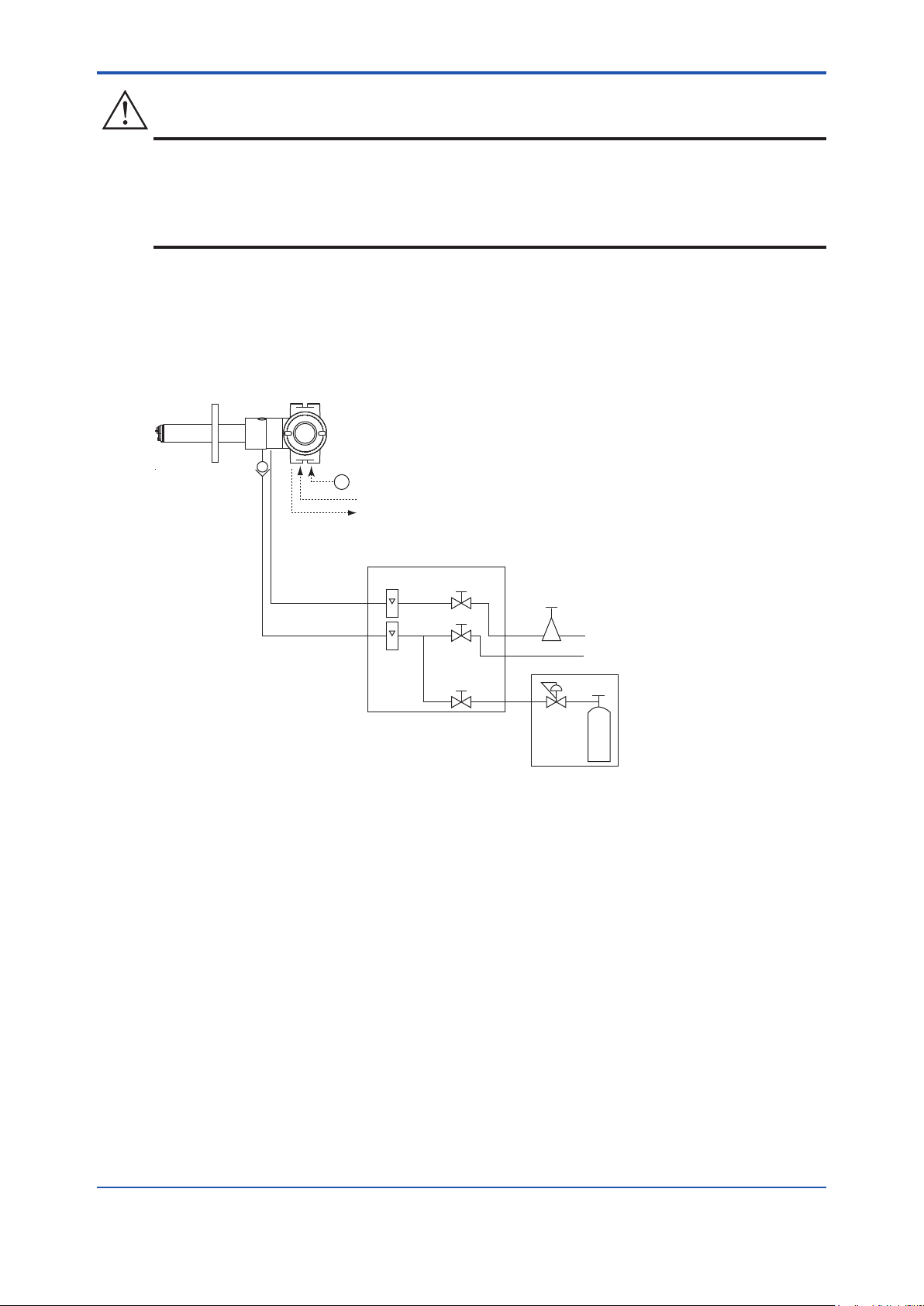

• As this system uses ambient air for the reference gas, measuring accuracy will be affected by

the installation location.

• A stop valve should be connected to the calibration gas inlet of the equipment. The valve should

be fully closed unless calibration is in progress.

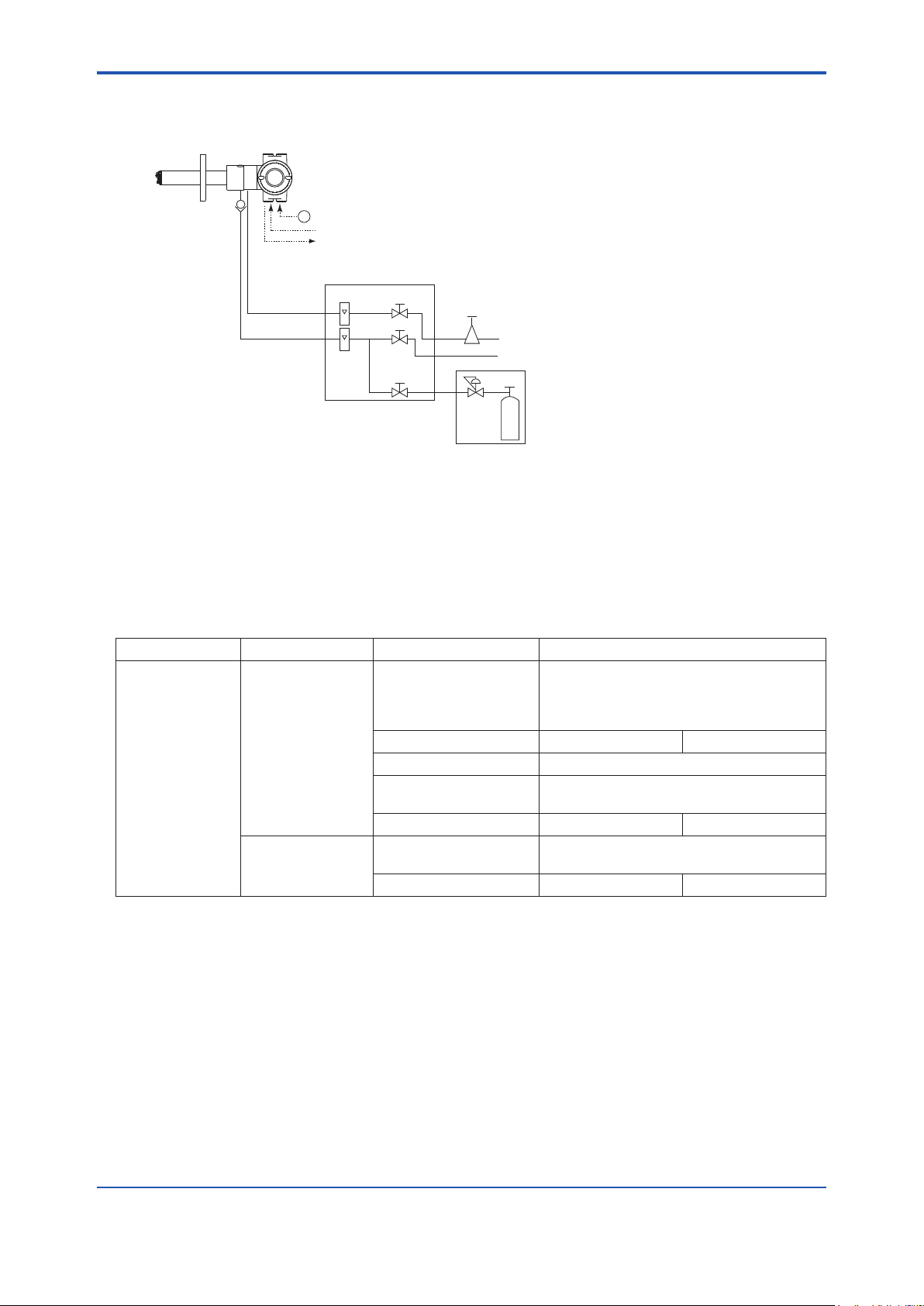

1.1.2 System 2

This system is for monitoring and controlling oxygen concentration in the combustion gases of a

large-size boiler or heating furnace. Instrument air (clean and dry air of oxygen concentration 21%)

is used as the reference gas and the span gas for calibration. Zero gas is fed from a cylinder during

calibration. The gas ow is controlled by the ZA8F ow setting unit (for manual valve operation).

Figure 1.2 Example of System 2

Page 18

<1.Overview>

~

100 to 240 V AC

Automatic calibration unit

Reference gas

Calibration gas (Zero)

Contact input

Analog output, contact output

Digital output (HART)

Air Set

Instrument air

Calibration gas unit case

Calibration

gas pressure

regulator

Zero gas cylinder

ZR202G Integrated type Zirconia Oxygen Analyzer

with automatic calibration unit (ZR202G-□-□-□-A-□-□-□-□-A)

F1.3E.ai

Span gas

ZR20H

*3

Note:

The installation temperature limits range for integrated type analyzer is -20 to 55°C.

*2

*1

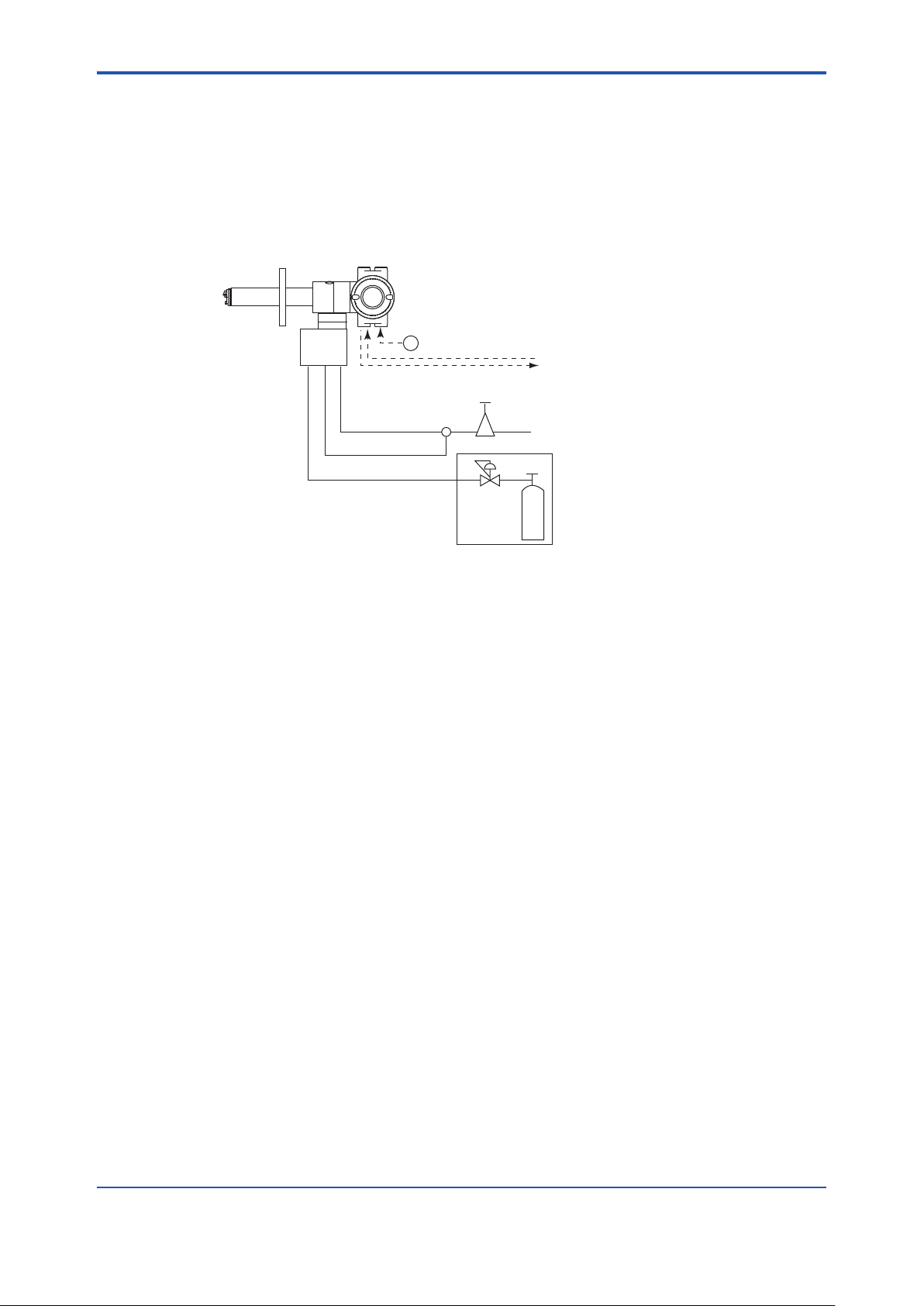

1.1.3 System 3

This example, System 3, represents typical applications in large boilers and heating furnaces, where

is a need to monitor and control oxygen concentration. The reference gas and calibration-time span

gas are (clean, dry) instrument air. Zero gas is supplied from a gas cylinder.

System 3 uses the ZR20H automatic calibration unit, with auto-switching of the calibration gas.

A “combustible gas detected” contact input turns off power to the heater. There’s also contact output

from the converter that can be used to operate a purge gas valve to supply air to the sensor.

1-3

*1 Shield cable:

Use shielded signal cables, and connect the shields to the FG terminal of the converter.

*2 Select the desired probe from the Probe Conguration table on page 1-4.

*3 When a zirconia oxygen analyzer is used, 100% N

Use approx. 1 vol% O2 gas (N2-based).

gas cannot be used as the zero gas.

2

Figure 1.3 Example of System 3

IM 11M12A01-04E

Page 19

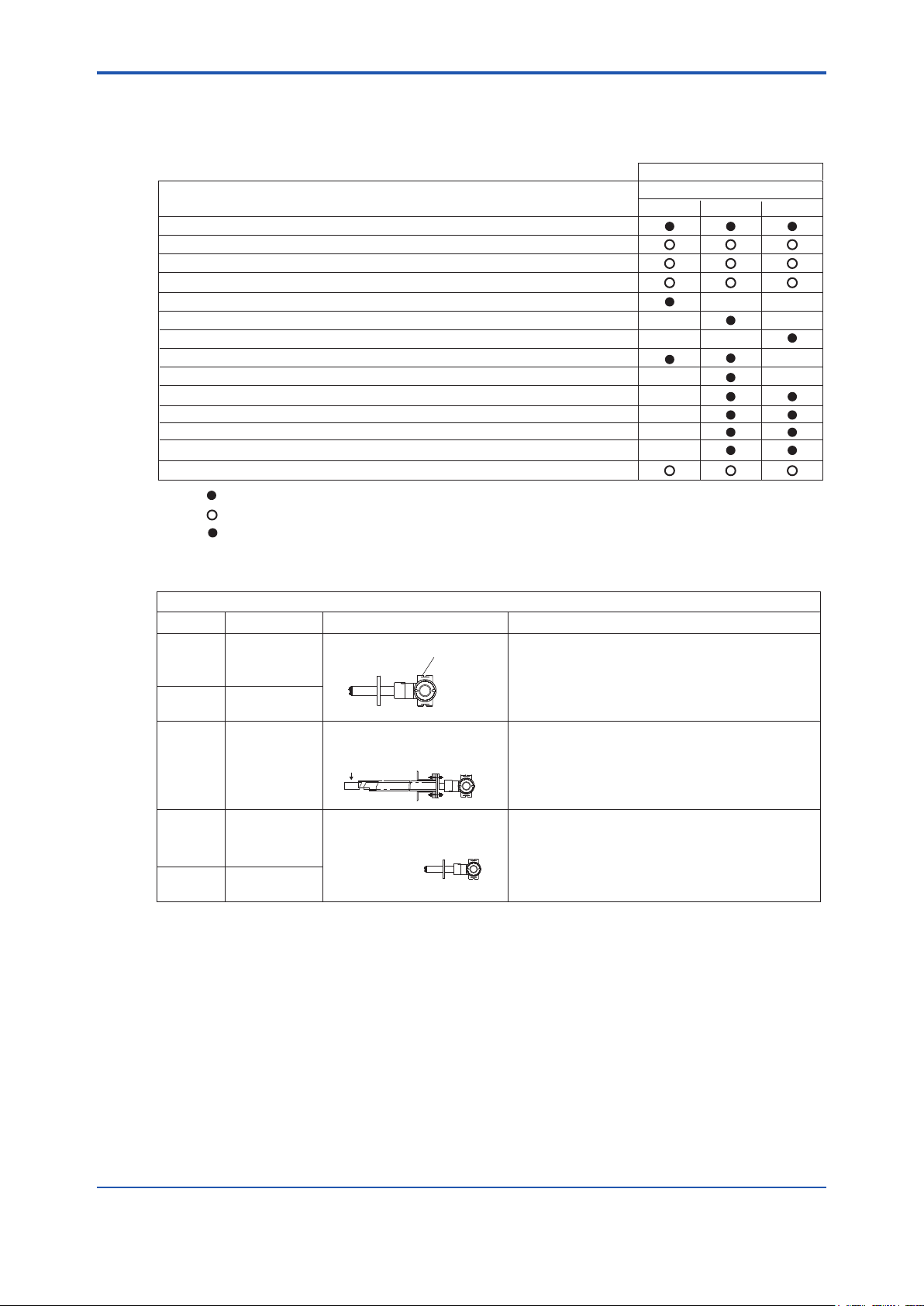

1-4

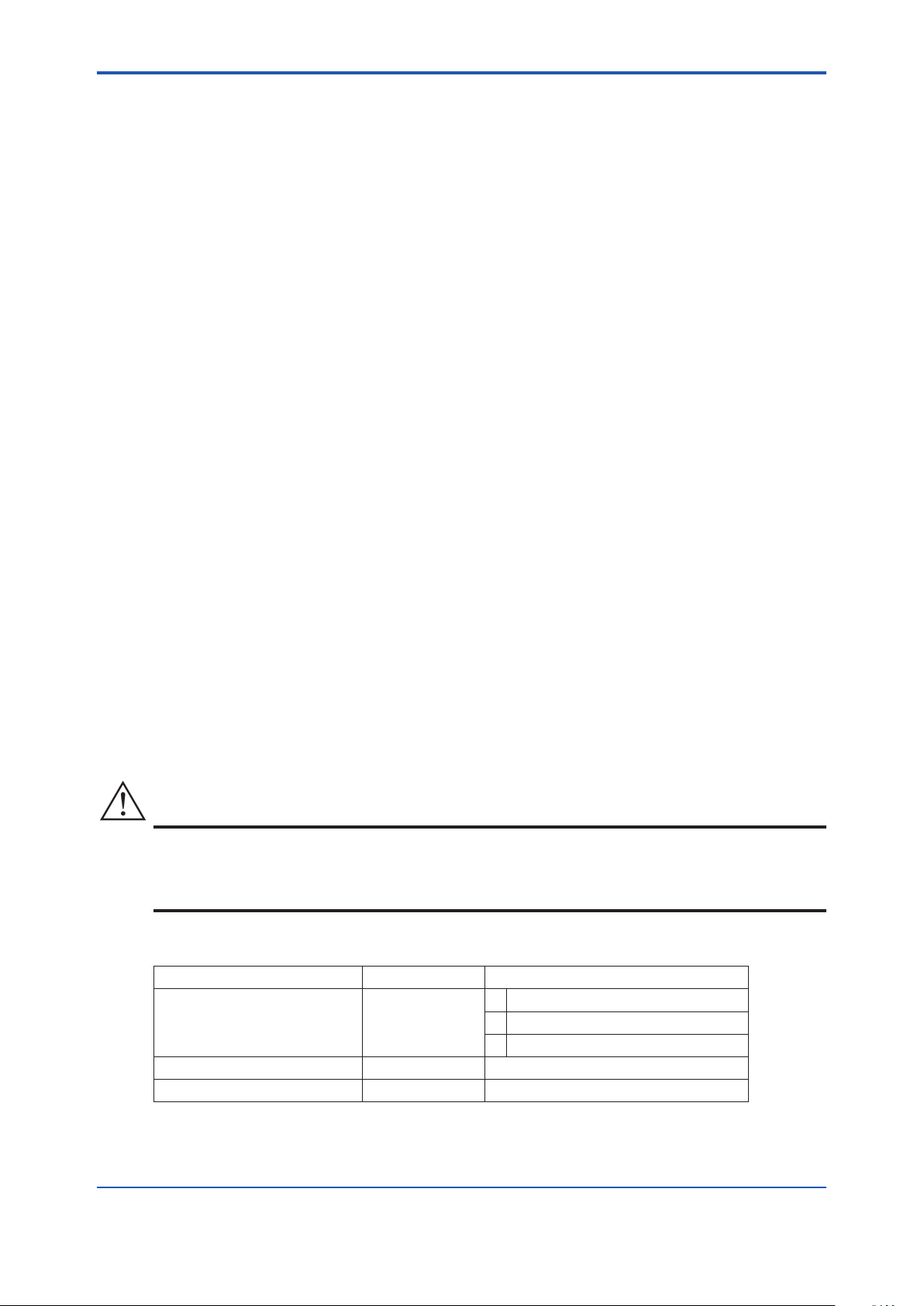

System Components

ZR202G Integrated type Zirconia Oxygen Analyzers

ZO21R Probe Protector for Zirconia Oxygen Analyzers

K9471UA Dust Filter for Oxygen Analyzer

ZO21S Standard Gas Unit

ZA8F Flow Setting Unit for manual calibration

ZR20H Automatic Calibration Unit for Integrated type Analyzer

L9852CB, G7016XH Stop Valve for Calibration gas line

K9292DN,K9292DS Check Valve for Calibration gas line

G7003XF/K9473XK, G7004XF/K9473XG Air Set

G7001ZC Zero gas Cylinder

G7013XF, G7014XF Pressure Regulator for Gas Cylinder

E7044KF Case Assembly for Calibration gas Cylinder

Integrated type

System configuration

Example 3Example 1

Example 2

( )

( )

T1.1.ai

: Items required for the above system example

: To be selected depending on each application. For details, refer to corresponding chapter.

: Select either

( )

ZR202A Heater Assembly (Spare Parts for ZR202G)

K9471UC Dust Guard Protector

F1.4E.ai

Detector

(ZR202G)

Detector

(ZR202G)

Detector(ZR202G)

Probe Protector

(ZO21R)

Dust Filter

(K9471UA)

or

Dust Guard

Protector

(K9471UC)

+

Sample gas temperature 0 to 700°C

Mounting

Insertion length

General-use Probe

Application

Horizontal

to

vertical

Horizontal

to

vertical

Horizontal

to

vertical

Vertical

Vertical

0.4

to

2 m

0.4

to

2 m

2.5 m

or more

3 m

or less

2.5 m

or more

• Boiler

• Heating furnace

• For pulverized coal boiler with gas flow velocity

10 m/sec or more

• Cement Kiln

• Black liquid recovery boiler

• Cement Kiln

Gas Flow

Sample inlet

<1. Overview>

1.2 < EXAxt ZR > System Components

1.2.1 System Components

1.2.2 Oxygen Analyzer and Accessories

IM 11M12A01-04E

Page 20

<2. Specications>

2. Specications

This chapter describes the specications for the following:

ZR202G General-use Integrated type Zirconia Oxygen Analyzer (See Section 2.1.2)

ZO21R-L Probe Protector (See Section 2.1.3)

ZA8F Flow Setting Unit (See Section 2.2.1)

ZR20H Automatic Calibration Unit (See Section 2.2.2)

ZO21S Standard Gas Unit (See Section 2.3)

K9471UA Dust Filter for Oxygen Analyzer (See Section 2.4)

2.1 General Specications

2.1.1 Standard Specications

Measured Object: Oxygen concentration in combustion exhaust gas and mixed gas (excluding

inammable gases). May not be applicable corrosive gas such as ammonia,

chlorine is present-check with YOKOGAWA.)

2-1

Measured System: Zirconia system

Oxygen Concentration: 0.01 to 100 vol% O

Output Signal: 4 to 20 mA DC (maximum load resistance 550Ω)

Measurement Range: Any setting in the range of 0 to 5 through 0 to 100 vol% O

partial range

Digital Communication (HART): 250 to 550Ω, depending on number of eld devices connected to the

loop (multi-drop mode).

Note: HART is a registered trademark of the HART Communication Foundation.

Display Range: 0 to 100 vol% O

Warm-up Time: Approx. 20 min.

Repeatability: (Excluding the case where the reference gas is by natural convection)

± 0.5% Maximum value of set range; less than 0 to 25 vol% O2 range

± 1 % Maximum value of set range; 0 to 25 vol%

Linearity: (Excluding standard gas tolerance)

(Excluding the case where the reference gas is by natural convection)

(Use oxygen of known concentration (with in the measuring range) as the

zero and span calibration gases.)

± 1% Maximum value of set range; less than 0 to 25 vol% O2 range

± 3% Maximum value of set range; 0 to 25 vol% O2 or more and less than 0

± 5% Maximum value of set range; 0 to 50 vol %O2 or more and up to 0 to

2

(in 1 vol%O2), or

2

2

O2 or more and up to 0 to

100 vol% O2 range

(Sample gas pressure: within ± 4.9 kPa)

to 50 vol% O2 range

(Sample gas pressure: within ± 0.49 kPa)

100 vol% O2 range

(Sample gas pressure: within ± 0.49 kPa)

IM 11M12A01-04E

Page 21

<2. Specications>

2-2

IM 11M12A01-04E

Drift: (Excluding the rst two weeks in use)

(Excluding the case where the reference gas is by natural convection.)

Both zero and span ± 2% Maximum value of set range/month

Response Time: Response of 90% within 5 seconds. (Measured after gas is introduced from

calibration gas inlet and analog output starts changing.)

2.1.2 ZR202G Integrated type Zirconia Oxygen Analyzer

Can be operated in the eld without opening the cover using optical switches.

Display: 6-digit LCD

Switch: Three optical switches

Output Signal: 4 to 20 mA DC, one point (maximum load resistance 550 Ω)

Digital Communication (HART): 250 to 550 Ω, depending on quantity of eld devices connected to the

loop (multi-drop mode).

Note: HART is a registered trademark of the HART Communication Foundation.

Contact Output Signal: Two points (one is fail-safe, normally open)

Contact Input Signal: Two points

Sample Gas Temperature: 0 to 700°C

It is necessary to mount the cell using Inconel cell-bolts when the

temperature measures more than 600°C.

High-temperature service ― greater than 700°C ― is not available.

Sample Gas Pressure: -5 to +250 kPa (When the pressure in the furnace exceeds 3 kPa, it is

recommended to compensate the pressure. When the pressure in the

furnace exceeds 5 kPa, you must perform pressure compensation.)

No pressure uctuation in the furnace be allowed.

Note: When the detector is used in conjunction with a check valve and the ZA8F Flow Setting Unit, the maximum pressure of sample

gas is 150 kPa. When with a check valve and the ZR20H Automatic Calibration Unit, it is 200 kPa. If the pressure of your sample

gas exceeds these limits, consult with Yokogawa.

Probe Length: 0.4, 0.7, 1.0, 1.5, 2.0, 2.5, 3.0 m

Probe Material: SUS 316 (JIS)

Ambient Temperature: -20 to +55°C (- 5 to +70°C on the case surface)

Storage Temperature: -30 to +70°C

Humidity Range: 0 to 95%RH (non-condensing)

Installation Altitude: 2000 m or less

Category based on IEC 1010: II (Note)

Pollution degree based on IEC 1010: 2 (Note)

Note: Installation category, called over-voltage category, species impulse withstand voltage. Category II is for electrical equipment.

Pollution degree indicates the degree of existence of solid, liquid, gas or other inclusions which may reduce dielectric strength.

Degree 2 is the normal indoor environment.

Power Supply Voltage: Ratings; 100 to 240 V AC

Acceptable range; 85 to 264 V AC

Power Supply Frequency: Ratings; 50/60 Hz

Acceptable range; 45 to 66 Hz

Power Consumption: Max. 300 W, approx. 100 W for ordinary use.

Page 22

<2. Specications>

CAUTION

Safety and EMC conforming standards

Safety: EN61010-1, CSA C22.2 No.61010-1,

EMC: EN 61326 Class A,

CISPR 11

KC Marking: Korea Electromagnetic Conformity Standard

This instrument is a Class A product, and it is designed for use in the industrial environment. Please

use this instrument in the industrial environment only.

Reference Gas System: Natural Convection, Instrument Air, Pressure Compensation

Instrument Air System (excluding Natural Convection):

Pressure; 200 kPa + the pressure inside the furnace (It is recommended

to use air which is dehumidied by cooling to dew point -20°C or

less, and dust or oil mist are removed.)

Consumption; Approx. 1Nl/min

EN 55011 Class A Group 1, EN 61000-3-2, AS/NZS

UL61010-1

2-3

Material in Contact with Gas: SUS 316 (JIS), Zirconia, SUS 304 (JIS) (ange), Hastelloy B, (Inconel

600, 601)

Construction: Heater and thermocouple replaceable construction. Non explosion-proof JIS

C0920 / equivalent to IP44D. Equivalent to NEMA 4X/IP66 (Achieved when

the cable entry is completely sealed with a cable gland in the recirculation

pressure compensated version.)

Gas Connection: Rc 1/4 or 1/4 FNPT

Wiring Connection: G1/2, Pg13.5, M20 by 1.5mm, 1/2 NPT select one type (4 pieces)

Installation: Flange mounting

Probe Mounting Angle: Horizontal to vertically downward.

When the probe insertion length is 2 m or less, installing at angles from

horizontal to vertically downward is available.

When the probe insertion length is 2.5m or more, mount vertically downward

(within ± 5°), and if installing at angles from horizontal to vertically downward

(within ± 5°), use a probe protector.

Case: Aluminum alloy

Paint Color: Cover; Mint green (Munsell 5.6BG3.3/2.9)

Case; Mint green (Munsell 5.6BG3.3/2.9)

Finish: Polyurethane corrosion-resistance coating

Insertion length of 0.4m: approx. 8 kg (JIS 5K 65) / approx. 13 kg (ANSI 150 4)

Insertion length of 1.0m: approx. 10 kg (JIS 5K 65) / approx. 15 kg (ANSI 150 4)

Insertion length of 1.5m: approx. 12 kg (JIS 5K 65) / approx. 17 kg (ANSI 150 4)

Insertion length of 2.0m: approx. 14 kg (JIS 5K 65) / approx. 19 kg (ANSI 150 4)

Insertion length of 3.0m: approx. 17 kg (JIS 5K 65) / approx. 22 kg (ANSI 150 4)

Weight:

IM 11M12A01-04E

Page 23

<2. Specications>

2-4

IM 11M12A01-04E

Functions

Display Function: Displays values of the measured oxygen concentration, etc.

Alarm, Error Display: Displays alarms such as “AL-06” or errors such as “Err-01” when any such

status occurs.

Calibration Functions: Auto-calibration; Requires the Automatic Calibration Unit. It calibrates

Maintenance Functions: Can operate updated data settings in daily operation and checking. Display

Setup Functions: Initial settings suit for the plant conditions when installing the converter.

Display and setting content:

Display Related Items: Oxygen concentration (vol% O2), Output current value (mA), air ratio,

automatically at specied intervals.

Semi-auto Calibration; Requires the Automatic Calibration Unit. Input

calibration start signal by optical switch or contact, then it calibrates

automatically afterwards.

Manual Calibration; Calibration with opening/closing the valve of calibration

gas in operation interactively with the optical switch.

data settings, calibration data settings, test settings (current output loop

check, input/output contact check).

Current output data settings, alarm data settings, contact data settings, other

settings.

moisture quantity (in hot gases) (vol% H2O), Cell temperature (°C ),

thermocouple reference junction temperature (°C ), maximum/minimum/

average oxygen concentration (vol% O2), cell e.m.f. (mV), cell internal

resistance (Ω), cell condition (in four grades), heater on-time rate (%),

calibration record (ten times), time (year/month/day/hour/minute)

Calibration Setting Items: Span gas concentration (vol% O2), zero gas concentration (vol%O2),

calibration mode (auto, semi-auto, manual), calibration type and method

(zero-span calibration, zero calibration only, span calibration only),

stabilization time (min.sec), calibration time (min.sec), calibration period

(day/hour), starting time (year/month/day/hour/minute)

Output Related Items: Analog output/output mode selection, output conditions when warming-up/

maintenance/calibrating/abnormal, 4 mA/20 mA point oxygen concentration

(vol% O2), time constant, preset values when warming-up/maintenance/

calibrating/abnormal, output preset values on abnormal

Alarm Related Items: Oxygen concentration high alarm/high-high alarm limit values (vol%

Oxygen concentration low alarm/low-low alarm limit values (vol% O2),

Oxygen concentration alarm hysteresis (vol% O2), Oxygen concentration

alarm detection, alarm delay (seconds)

Contact Related Items: Selection of contact input 1 and 2, selection of contact output 1 and

2 (abnormal, high-high alarm, high alarm, low alarm, low-low alarm,

maintenance, calibrating, range switching, warming-up, calibration gas

pressure decrease, ameout gas detection (answer-back of contact input)

O2),

Page 24

<2. Specications>

Converter Output: One mA analog output point (4 to 20 mA DC (maximum load resistance of

550Ω)) with mA digital output point (HART) (minimum load resistance of

250Ω).

2-5

Range; Any setting between 0 to 5 through 0 to 100 vol%

O2 in 1 vol% O2,

and partial range is available (Maximum range value/minimum

range value 1.3 or more)

For the log output, the minimum range value is xed at 0.1 vol% O2.

4 to 20 mA DC linear or log can be selected. Input/output isolation.

Output damping; 0 to 255 seconds.

Hold/non-hold selection, preset value setting possible with hold.

Contact Output: Two points, contact capacity 30V DC 3A, 250V AC 3A (resistive load)

One of the output points can be selected to ether normally energized or normally de-energized status.

Delayed functions (0 to 255 seconds) and hysteresis function (0 to 9.9 vol%

O2) can be added to high/low alarms.

The following functions are programmable for contact outputs.

(1) Abnormal, (2) High-high alarm, (3) High alarm, (4) Low-low alarm, (5)

Low alarm, (6) Maintenance, (7) Calibration, (8) Range switching answerback, (9) Warm-up, (10) Calibration gas pressure decrease (answer-back of

contact input), (11) Flameout gas detection (answer-back of contact input).

Contact Input: Two points, voltage-free contacts

The following functions are programmable for contact inputs:

(1) Calibration gas pressure decrease alarm, (2) Range switching (switched

range is xed), (3) External calibration start, (4) Process alarm (if this signal

is received, the heater power turns off)

Self-diagnosis: Abnormal cell, abnormal cell temperature (low/high), abnormal calibration,

A/D converter abnormal, digital circuit abnormal

Calibration: Method; zero/span calibration

Calibration mode; Auto, semi-auto and manual (All are operated using

optical switches). Either zero or span can be skipped.

Zero calibration gas concentration setting range; 0.3 to 100 vol% O2 (in 0.01

vol% O2).

Span calibration gas concentration setting range; 4.5 to 100 vol% O2 (in 0.01

vol% O2).

Use nitrogen-balanced mixed gas containing 0 to 10 vol% O2 scale of

oxygen for standard zero gas and 80 to 100 vol% O2 scale of oxygen for

standard span gas.

Calibration period; date/time setting: maximum 255 days

IM 11M12A01-04E

Page 25

<2. Specications>

2-6

IM 11M12A01-04E

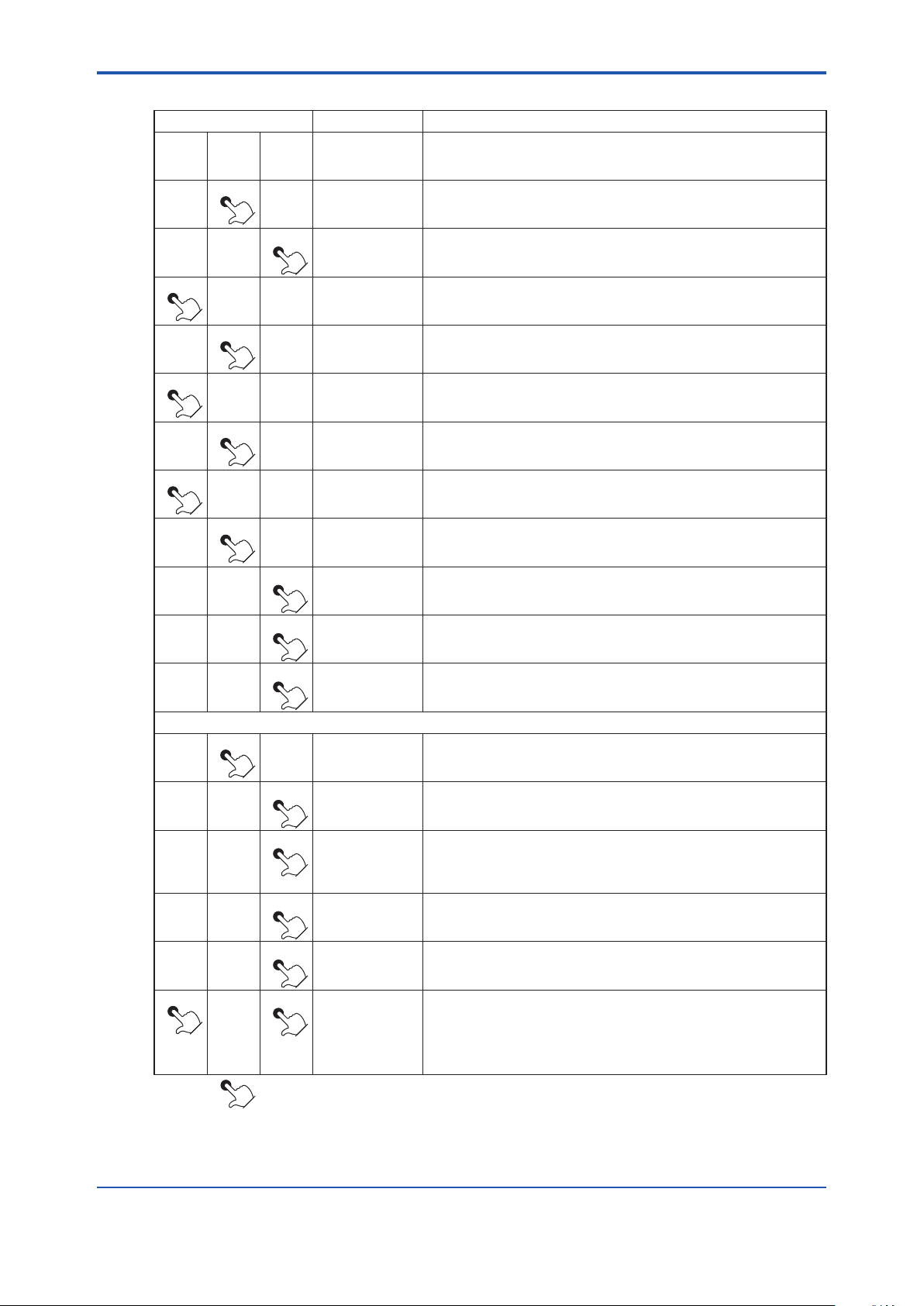

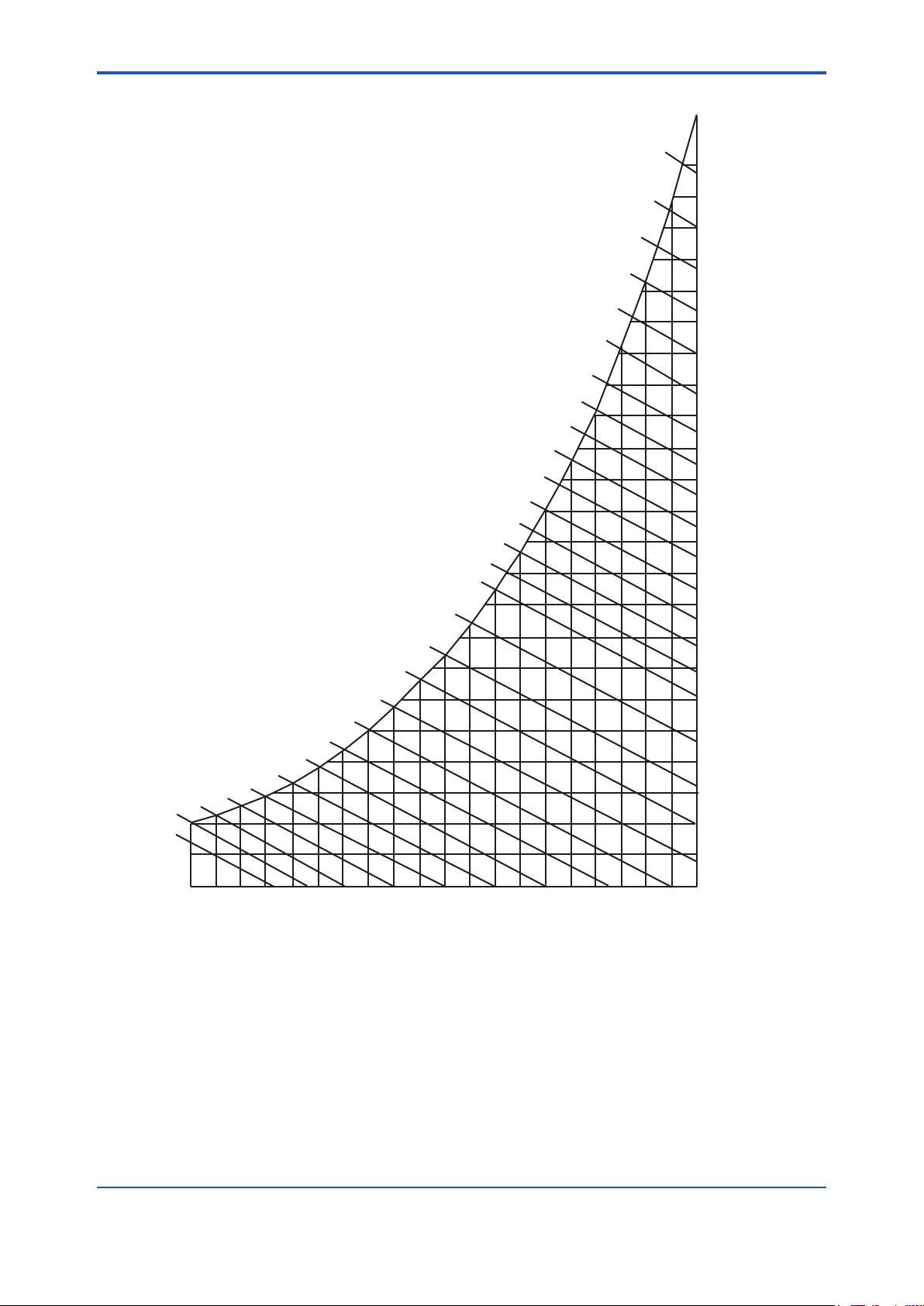

Model and Codes

Model Sufx code Option code Description

ZR202G - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - Integrated type Zirconia Oxygen Analyzer

Length -040

Wetted material -S

Flange

(*2)

Auto Calibration -N

Reference gas -C

Gas Thread -R

Connection box thread -P

Instruction manual -J

-- -A - - - - - - - - - - Always -A

Options

Valves

Tag plates

NAMUR NE43 compliant

-070

-100

-150

-200

-250

-300

-C

-A

-B

-C

-E

-F

-G

-K

-L

-M

-P

-R

-S

-W

-A

-B

-E

-P

-T

-G

-M

-T

-E

-C

*1 For the horizontally installed probe whose insertion length is 2.5 m or more, use the Probe Protector. Be sure to specify

ZO21R-L-200-. Specify the ange sufx code either -C or -K.

*2 The thickness of the ange depends on its dimensions.

*3 Inconel probe bolts and U shape pipe are used. Use this option for high temperature use (ranging from 600 to 700°C).

*4 Specify either /CV or /SV option code.

*5 Specify either /SCT or /PT option code.

*6 No need to specify the option codes, /CV and /SV, since the check valves are provided with the Automatic Calibration Unit.

Automatic calibration cannot be used when natural convection is selected as reference gas.

*7 Sun shield hood is still effective even if scratched. Hood is necessary for outdoor installation out of sun shield roof.

*8 Recommended if sample gas contains corrosive gas like chlorine.

*9 Piping for reference gas must be installed to supply reference gas constantly at a specied ow rate.

*10 Output signal limits: 3.8 to 20.5 mA. Specify either /C2 or /C3 option code.

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

/C Inconel bolt (*3)

/CV

/SV

/H Hood (*7)

/F1

/F2

/SCT

/PT

/C2

/C3

0.4 m

0.7 m

1.0 m

1.5 m

2.0 m

2.5 m (*1)

3.0 m (*1)

SUS316

Stainless steel with Inconel calibration gas tube (*8)

ANSI Class 150 2 RF SUS304

ANSI Class 150 3 RF SUS304

ANSI Class 150 4 RF SUS304

DIN PN10 DN50 A SUS304

DIN PN10 DN80 A SUS304

DIN PN10 DN100 A SUS304

JIS 5K 65 FF SUS304

JIS 10K 65 FF SUS304

JIS 10K 80 FF SUS304

JIS 10K 100 FF SUS304

JPI Class 150 4 RF SUS304

JPI Class 150 3 RF SUS304

Westinghouse

Not required

Horizontal mounting (*6)

Vertical mounting (*6)

Natural convection

External connection (Instrument air) (*9)

Pressure compensated (*9)

Rc 1/4

1/4 NPT (Female)

G1/2

Pg13.5

M20x1.5 mm

1/2NPT

Japanese

English

Chinese

Check valve (*4)

Stop valve (*4)

Dust Filter

Dust Guard Protector

Stainless steel tag plate (*5)

Printed tag plate (*5)

Failure alarm down-scale:

Output status at CPU failure and hardware error is 3.6 mA or less

(*10)

Failure alarm up-scale:

Output status at CPU failure and hardware error is 21.0 mA or more

(*10)

Page 26

<2. Specications>

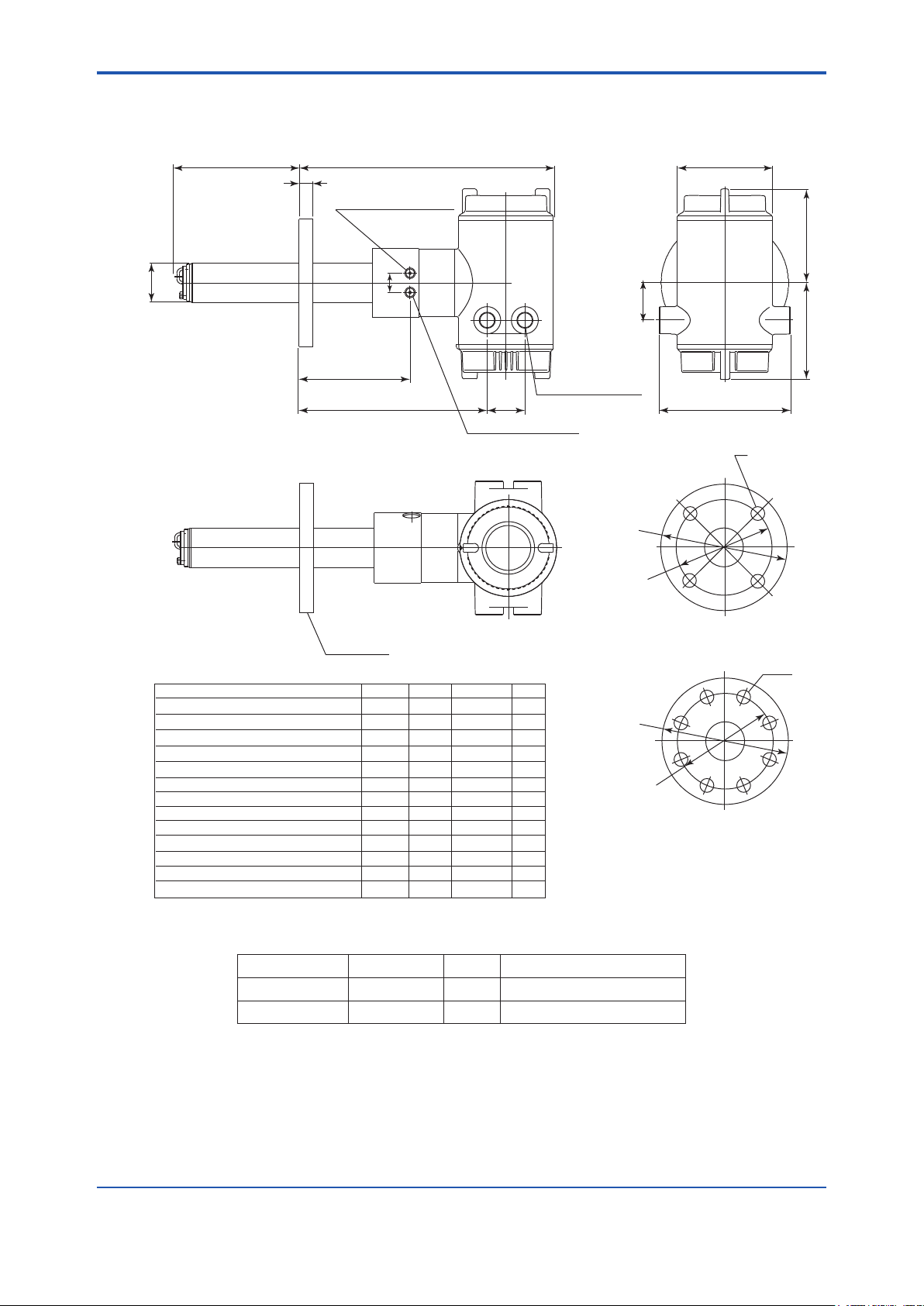

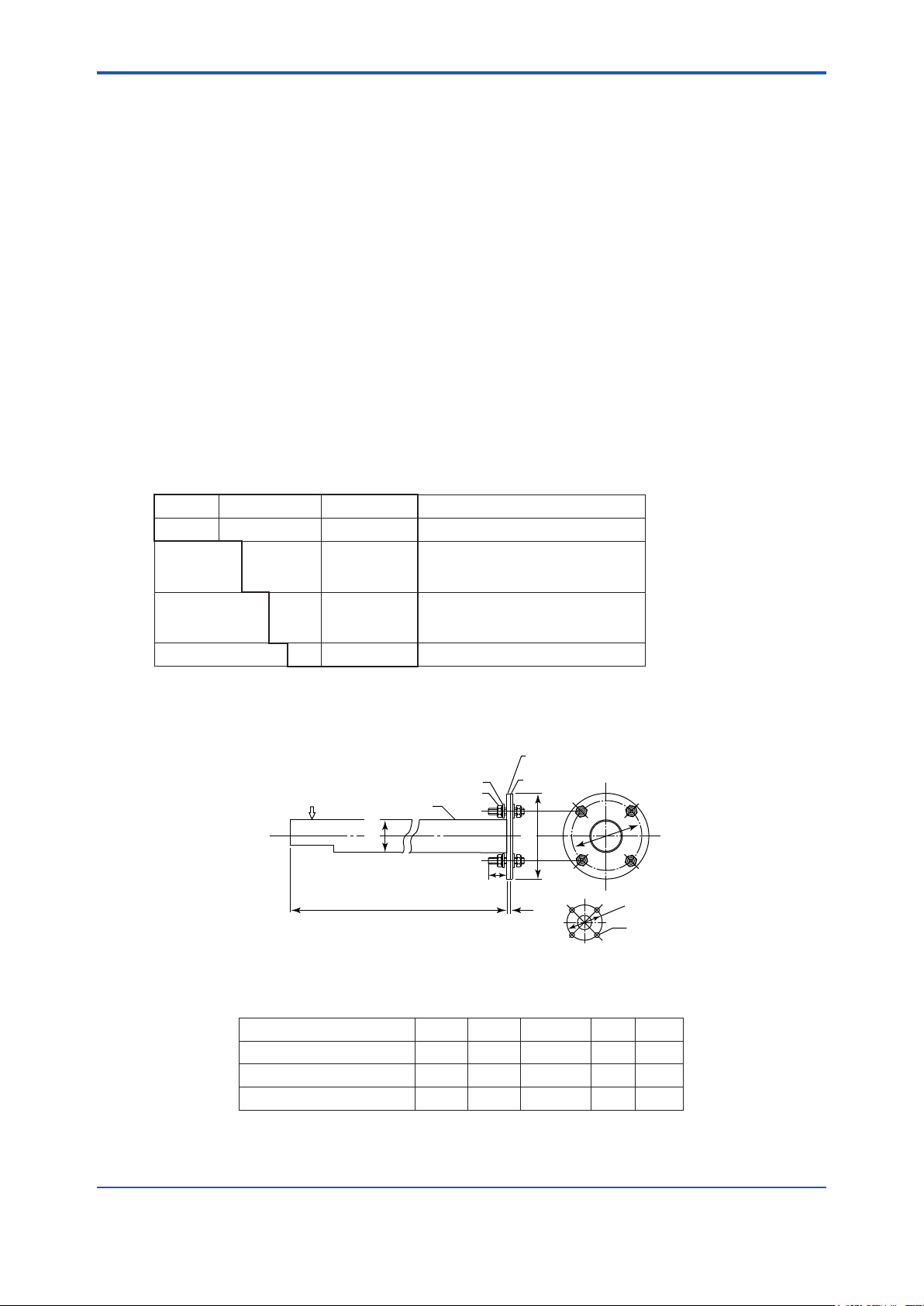

F11_01.ai

25

t

153 to 164

125

L

170

252 to 265

49

48.5

338 to 351

122

L= 0.4, 0.7,

1.0, 1.5, 2.0,

2.5, 3.0 (m)

4-G1/2,2-1/2NPT etc.

Cable connection port

Display side

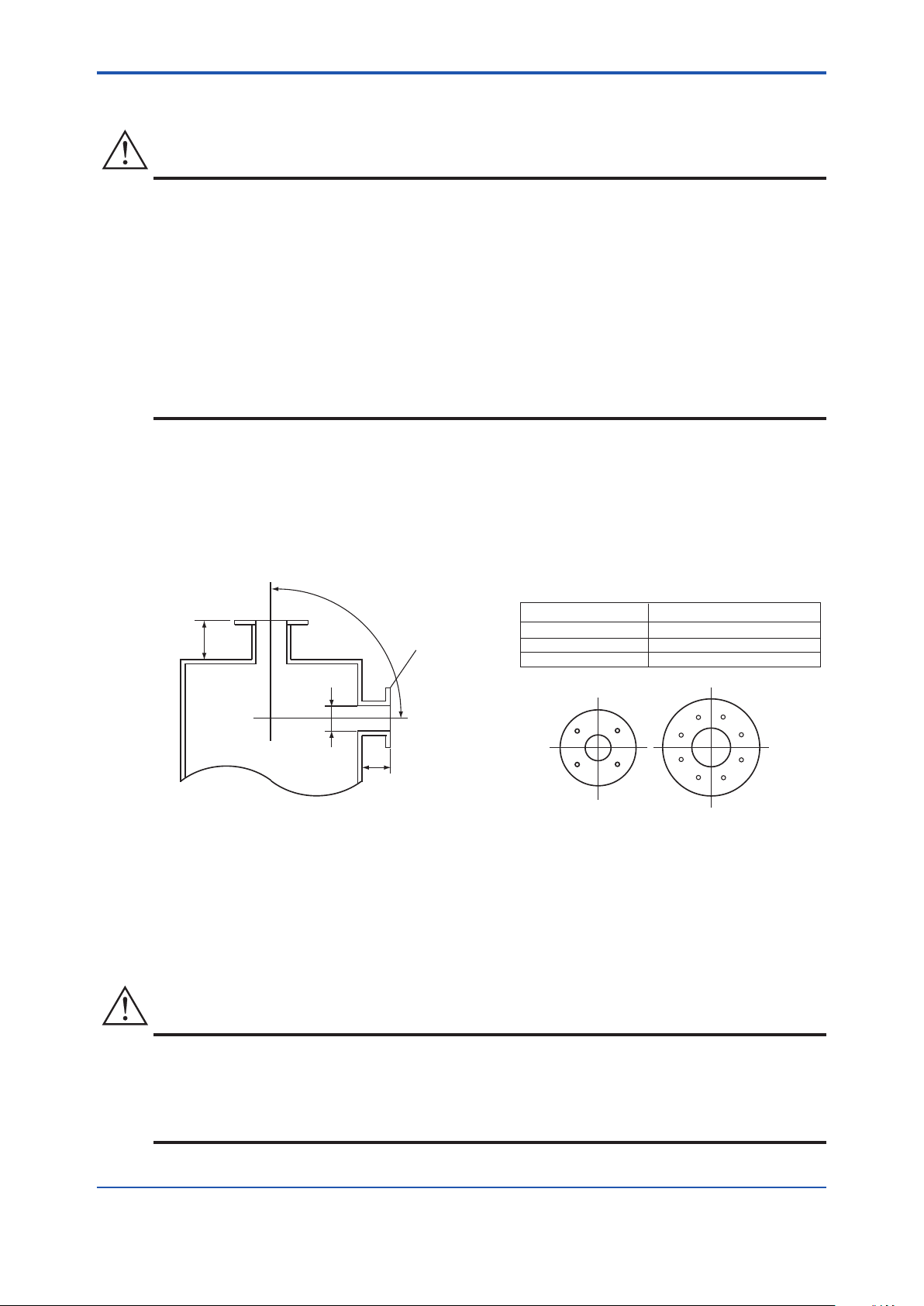

ANSI Class 150 2 RF SUS304

ANSI Class 150 3 RF SUS304

ANSI Class 150 4 RF SUS304

DIN PN10 DN50 A SUS304

DIN PN10 DN80 A SUS304

DIN PN10 DN100 A SUS304

JIS 5K 65 FF SUS304

JIS 10K 65 FF SUS304

JIS 10K 80 FF SUS304

JIS 10K 100 FF SUS304

JPI Class 150 4 RF SUS304

JPI Class 150 3 RF SUS304

Westinghouse

152.4

190.5

228.6

165

200

220

155

175

185

210

229

190

155

120.6

152.4

190.5

125

160

180

130

140

150

175

190.5

152.4

127

4 - Ø19

4 - Ø19

8 - Ø19

4 - Ø18

8 - Ø18

8 - Ø18

4 - Ø15

4 - Ø19

8 - Ø19

8 - Ø19

8 - Ø19

4 - Ø19

4 - Ø11.5

A B C

19

24

24

18

20

20

14

18

18

18

24

24

14

t

Ø50.8

Rc1/4 or 1/4NPT

Reference gas inlet

Rc1/4 or 1/4NPT

Calibration gas inlet

Ø123

Terminal side

C

Flange

Flange

Ø

B

C

Flange

Ø

A

Flange

Ø

A

Ø

B

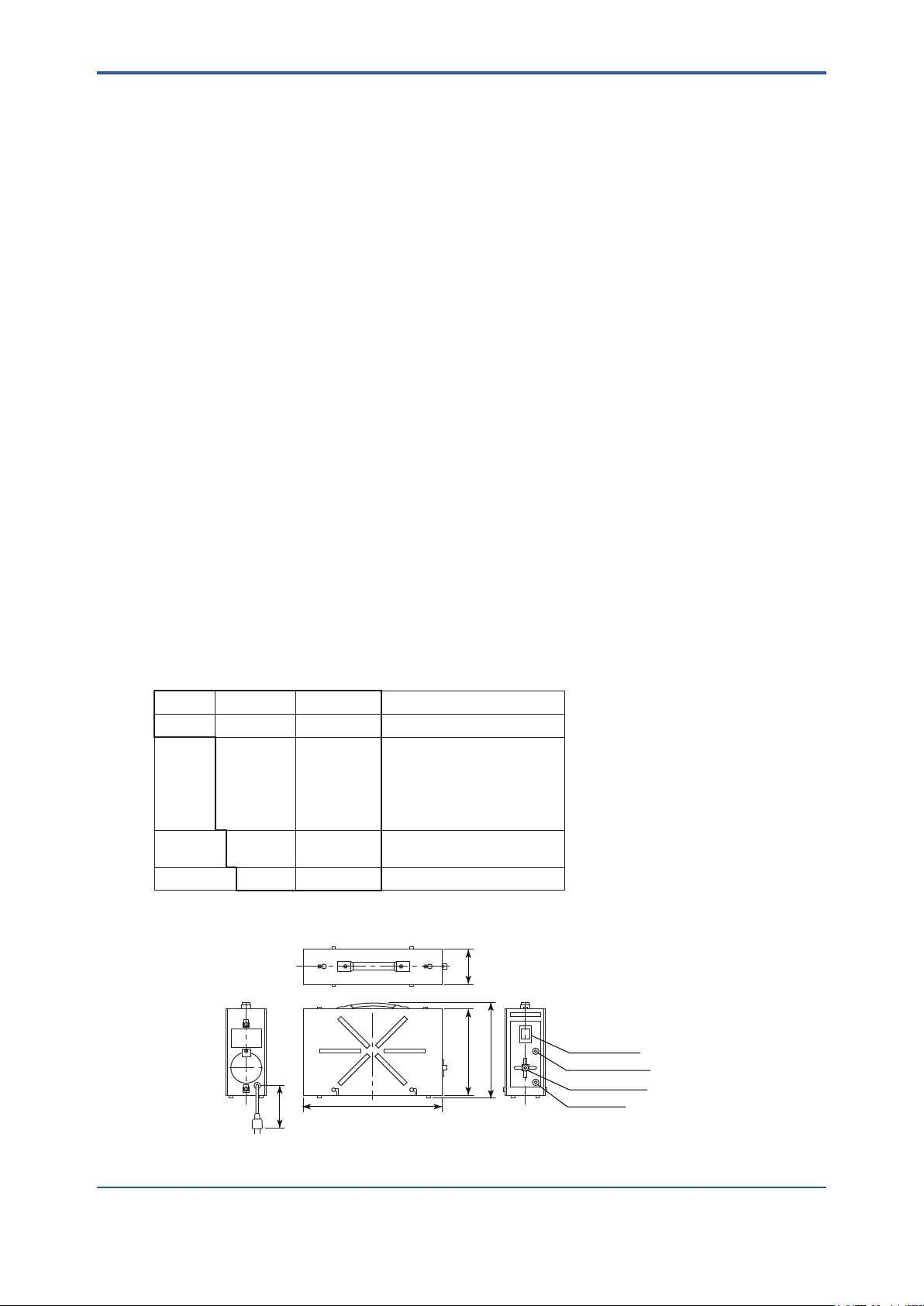

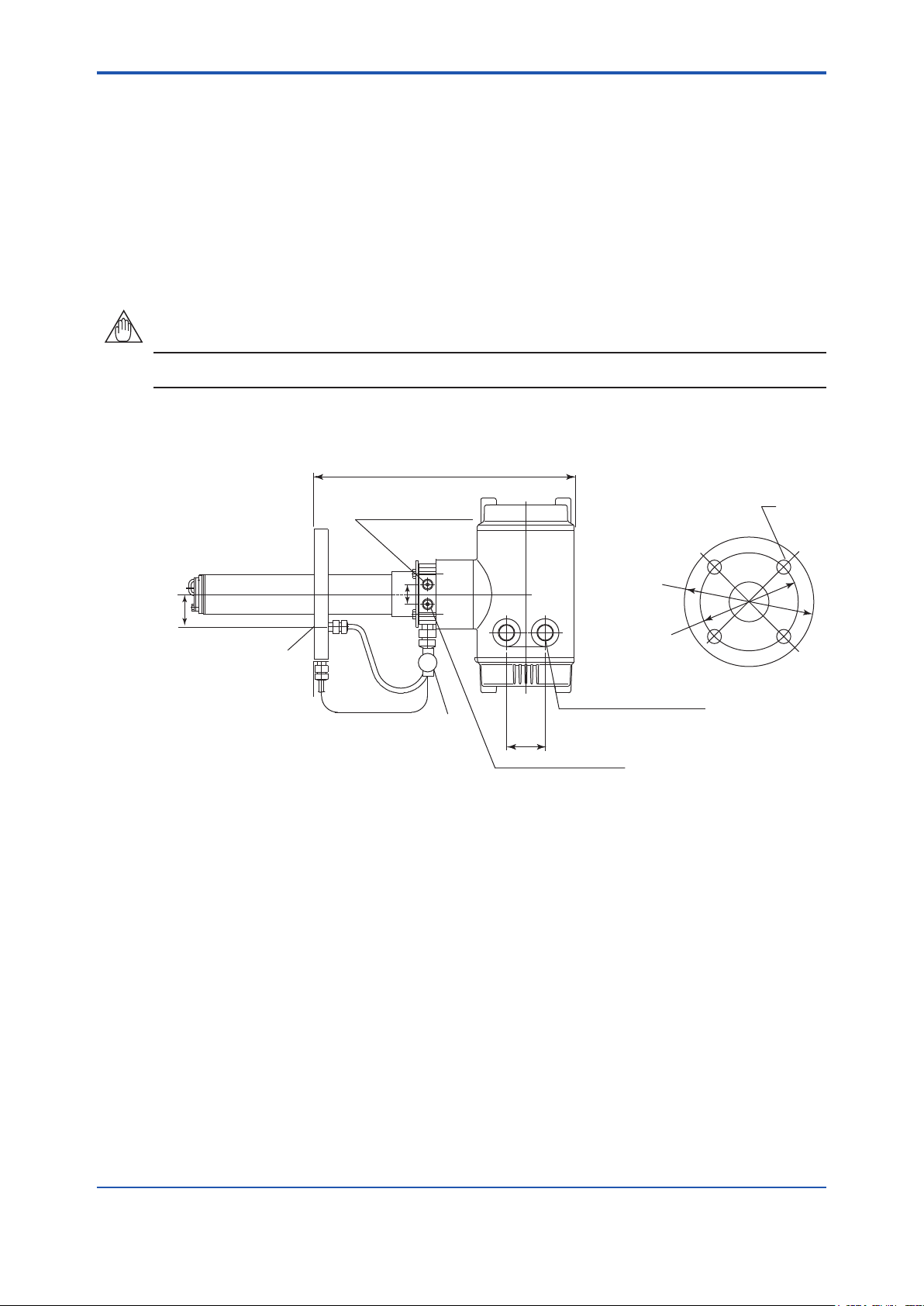

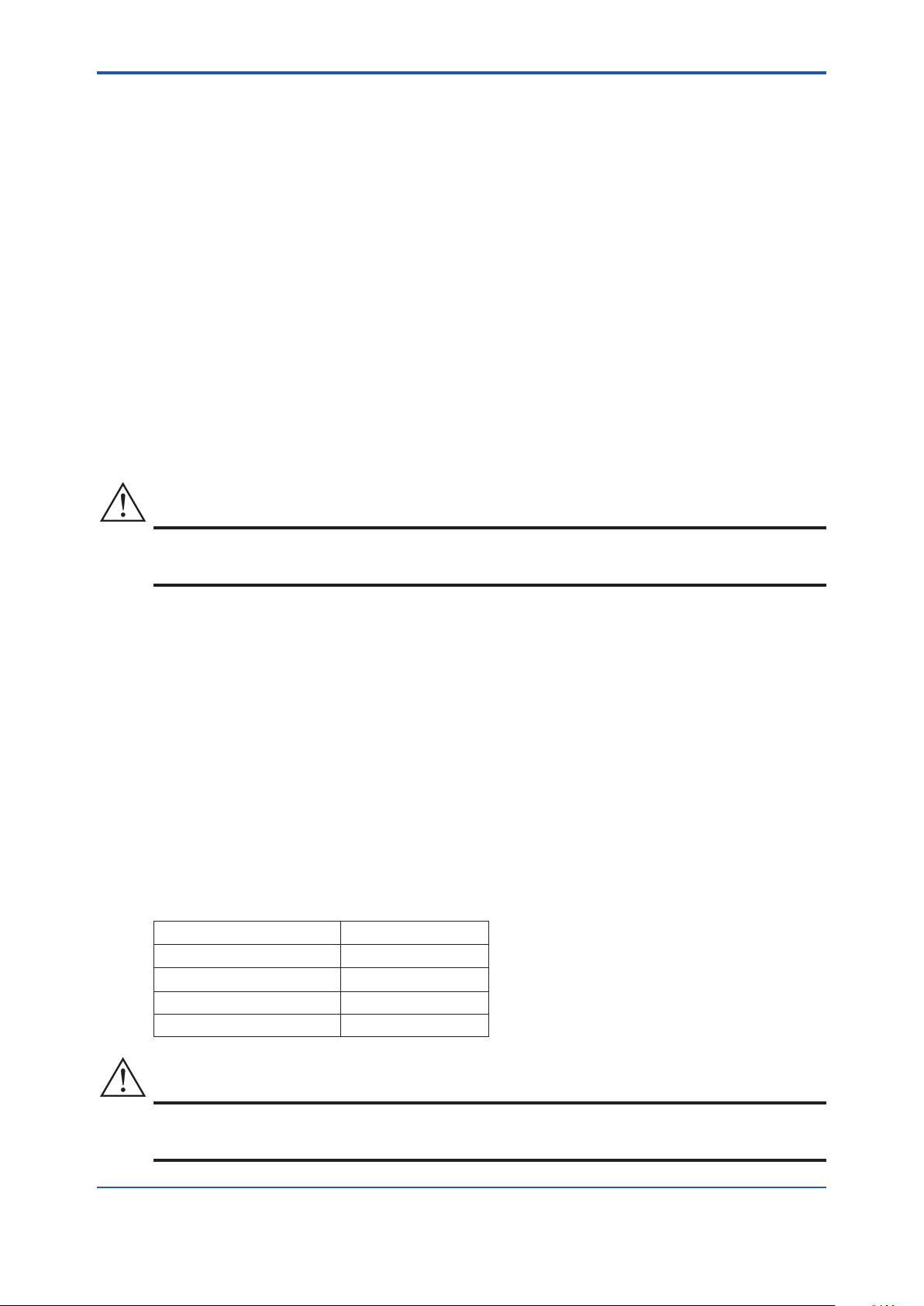

• External Dimensions

Model ZR202G Integrated type Zirconia Oxygen Analyzers Unit: mm

2-7

• Standard Accessories

Fuse A1113EF 1 3.15 A

Allen wrench L9827AB 1 For lock screw

Item Parts. No. Q'ty Description

IM 11M12A01-04E

Page 27

<2. Specications>

2-8

IM 11M12A01-04E

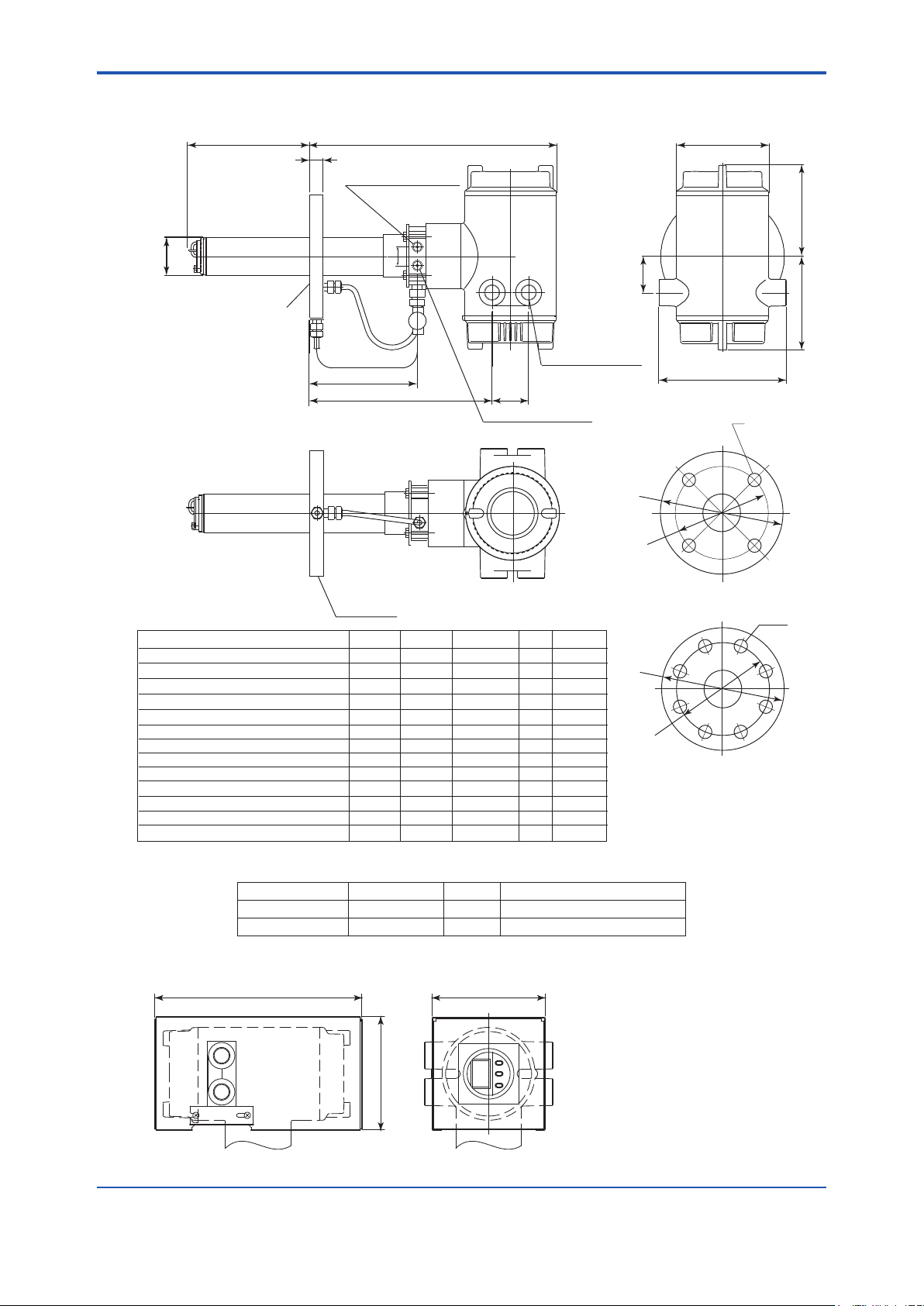

F11_02.EPS

Flange

156 ± 3

125

170

256 ± 4

49

48.5

Ø123

342 ± 4

25

t

122

Terminal side

PIPING:A

PIPING

:B

PIPING

A

B

B

A

B

B

A

A

B

B

B

B

A

ANSI Class 150 2 RF SUS304

ANSI Class 150 3 RF SUS304

ANSI Class 150 4 RF SUS304

DIN PN10 DN50 A SUS304

DIN PN10 DN80 A SUS304

DIN PN10 DN100 A SUS304

JIS 5K 65 FF SUS304

JIS 10K 65 FF SUS304

JIS 10K 80 FF SUS304

JIS 10K 100 FF SUS304

JPI Class 150 4 RF SUS304

JPI Class 150 3 RF SUS304

Westinghouse

152.4

190.5

228.6

165

200

220

155

175

185

210

229

190

155

120.6

152.4

190.5

125

160

180

130

140

150

175

190.5

152.4

127

4 - Ø19

4 - Ø19

8 - Ø19

4 - Ø18

8 - Ø18

8 - Ø18

4 - Ø15

4 - Ø19

8 - Ø19

8 - Ø19

8 - Ø19

4 - Ø19

4 - Ø11.5

A B C

19

24

24

18

20

20

14

18

18

18

24

24

14

t

L

L= 0.4, 0.7,

1.0, 1.5, 2.0,

2.5, 3.0 (m)

4-G1/2,2-1/2NPT etc.

Cable connection port

Ø50.8

Rc1/4 or 1/4NPT

Reference gas inlet

Rc1/4 or 1/4NPT

Calibration gas inlet

Reference gas outlet

Display side

C

Flange

ØB

C

Flange

ØA

Flange

Stop

valve

ØA

ØB

274

150

150

± 4

± 3

± 3

F13.ai

Material of HOOD : Aluminum Food Weight : Approx. 800g

Model ZR202G...-P Integrated type Zirconia Oxygen Analyzer with pressure compensation

Unit: mm

• Standard Accessories

• Hood (Option code /H) Unit: mm

Item Parts. No. Q'ty Description

Fuse A1113EF 1 3.15 A

Allen wrench L9827AB 1 For lock screw

Page 28

<2. Specications>

F2-3E.ai

D

Ø

B

C

Ø

B

Flange <1>

(with bolts, nuts and washer)

gasket (t1.5)

SUS316

Dimensions of

holes on opposing surface

ØA

Gas flow

Washer (12)

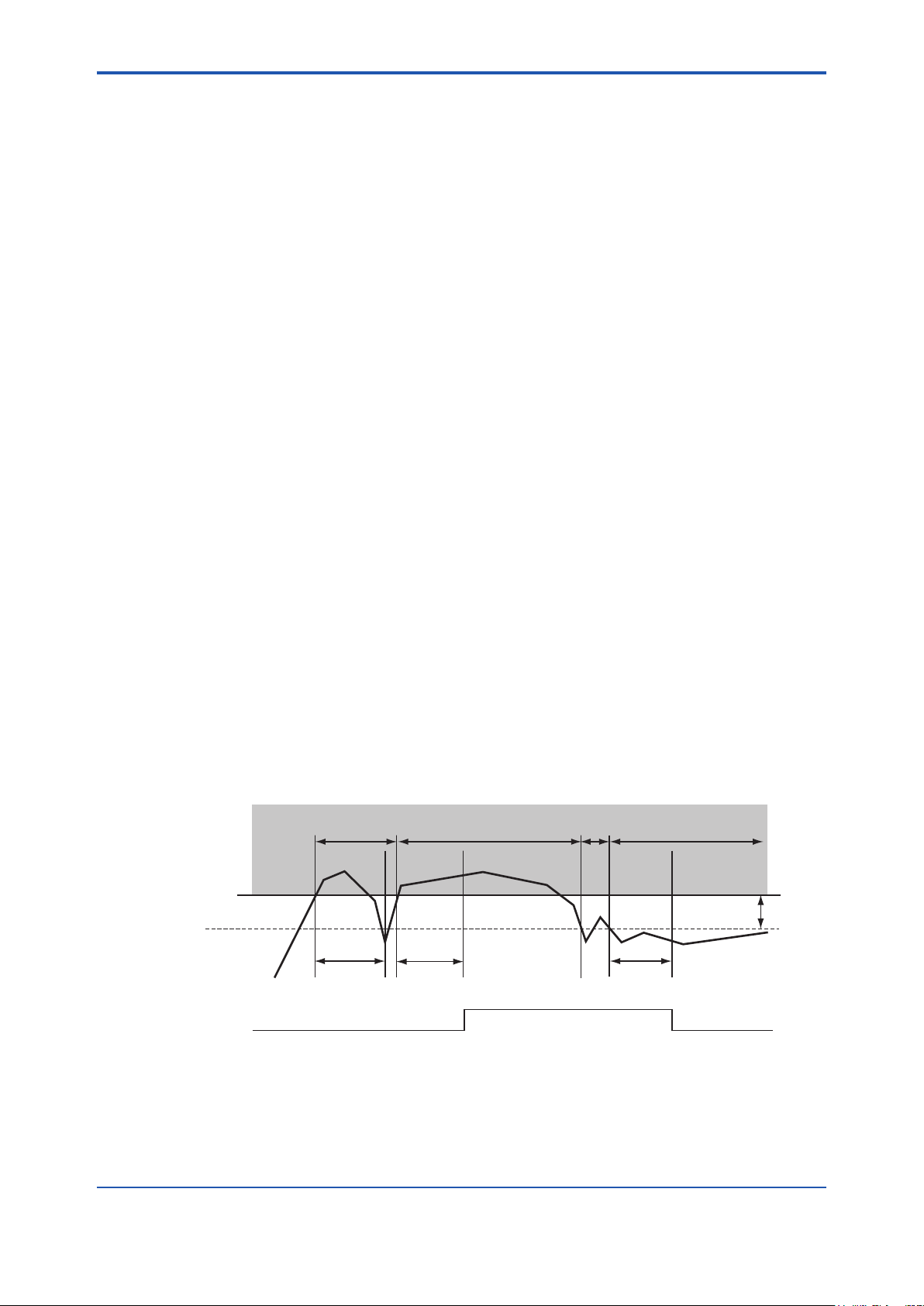

Mounting nut (M12)

l (Insert length)

l=1050,1550,2050

Ø60.5

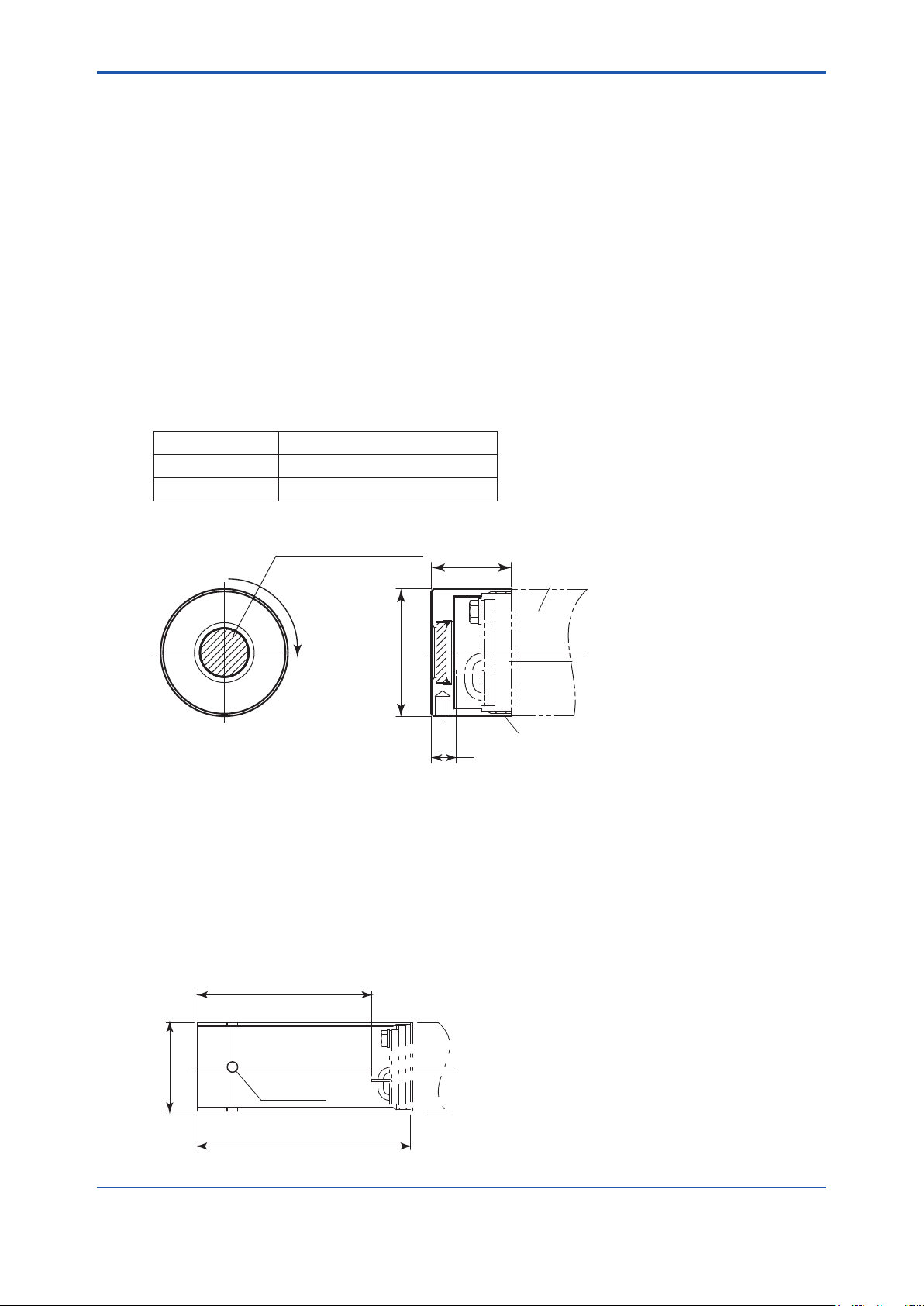

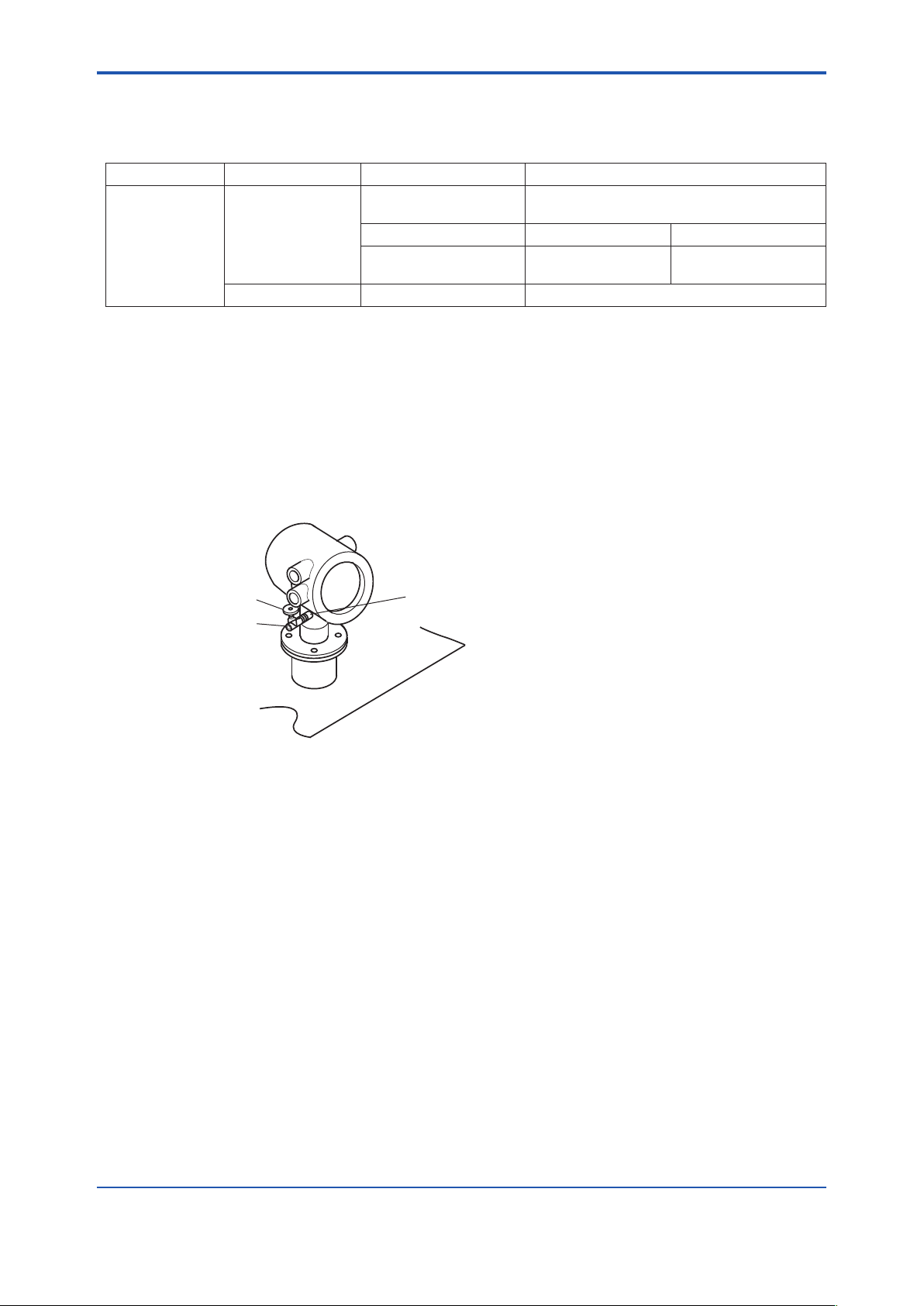

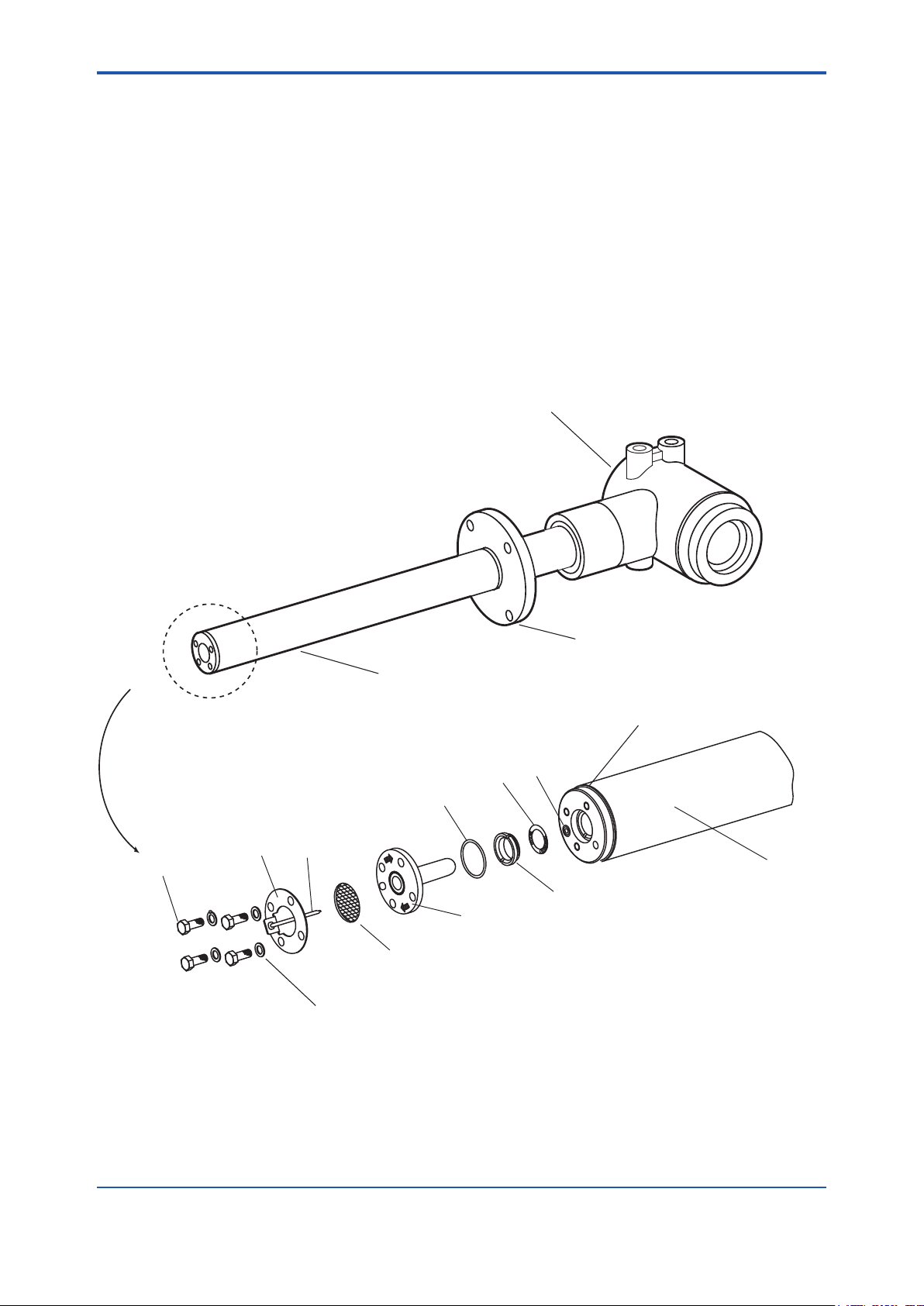

2.1.3 ZO21R Probe Protector

This probe protector is required for the general-use detector when it is used for oxygen concentration

measurements in powdered coal boilers or in uidized furnaces to prevent abrasion due to dust

particles when gas ow exceeds 10 m/sec.

When probe length of the ZR202G is 2.5 m or more and mounted horizontally, be sure to select a

probe protector ZO21R-L-200-*B to support the probe.

Insertion Length: 1.05 m, 1.55 m, 2.05 m.

Flange: JIS 5K 65A FF equivalent, ANSI Class 150 4 FF (without serration)

equivalent or DIN PN10 DN50A equivalent. However, ange thickness is

different.

Material: SUS316 (JIS), SUS304 (JIS) (Flange)

2-9

Weight: 1.05m; Approx. 6/10 kg (JIS/ANSI), 1.55 m; Approx. 9/13 kg

Installation: Bolts, nuts, and washers are provided for detector, probe adapter and

• Model and Codes

Model Sufx code Option code Description

ZO21R -L - - - - - - - - - - - - Probe Protector(0 to 700°C)

Insertion

length

Flange ( *1) -J

Style code *B - - - - - - - - - - - - Style B

*1 Thickness of ange depends on dimensions of ange.

• External Dimension

(JIS/ANSI), 2.05 m; Approx. 12/16 kg (JIS/ANSI)

process-side ange.

-100

-150

-200

-A

-E

- - - - - - - - - - - -

- - - - - - - - - - - -

- - - - - - - - - - - -

- - - - - - - - - - - -

- - - - - - - - - - - -

- - - - - - - - - - - -

1.05 m (3.5 ft)

1.55 m (5.1 ft)

2.05 m (6.8 ft)

JIS 5K 65 FF SUS304

ANSI Class 150 4 FF SUS304

DIN PN10 DN50A SUS304

Unit: mm

Flange<1> A B C t D

JIS 5K 65 FF SUS304 155 130 4 - Ø15 5 40

ANSI Class 150 4 FF SUS304 228.6 190.5 8 - Ø19 12 50

DIN PN10 DN50A SUS304 165 125 4 - Ø18 12 50

IM 11M12A01-04E

Page 29

<2. Specications>

2-10

IM 11M12A01-04E

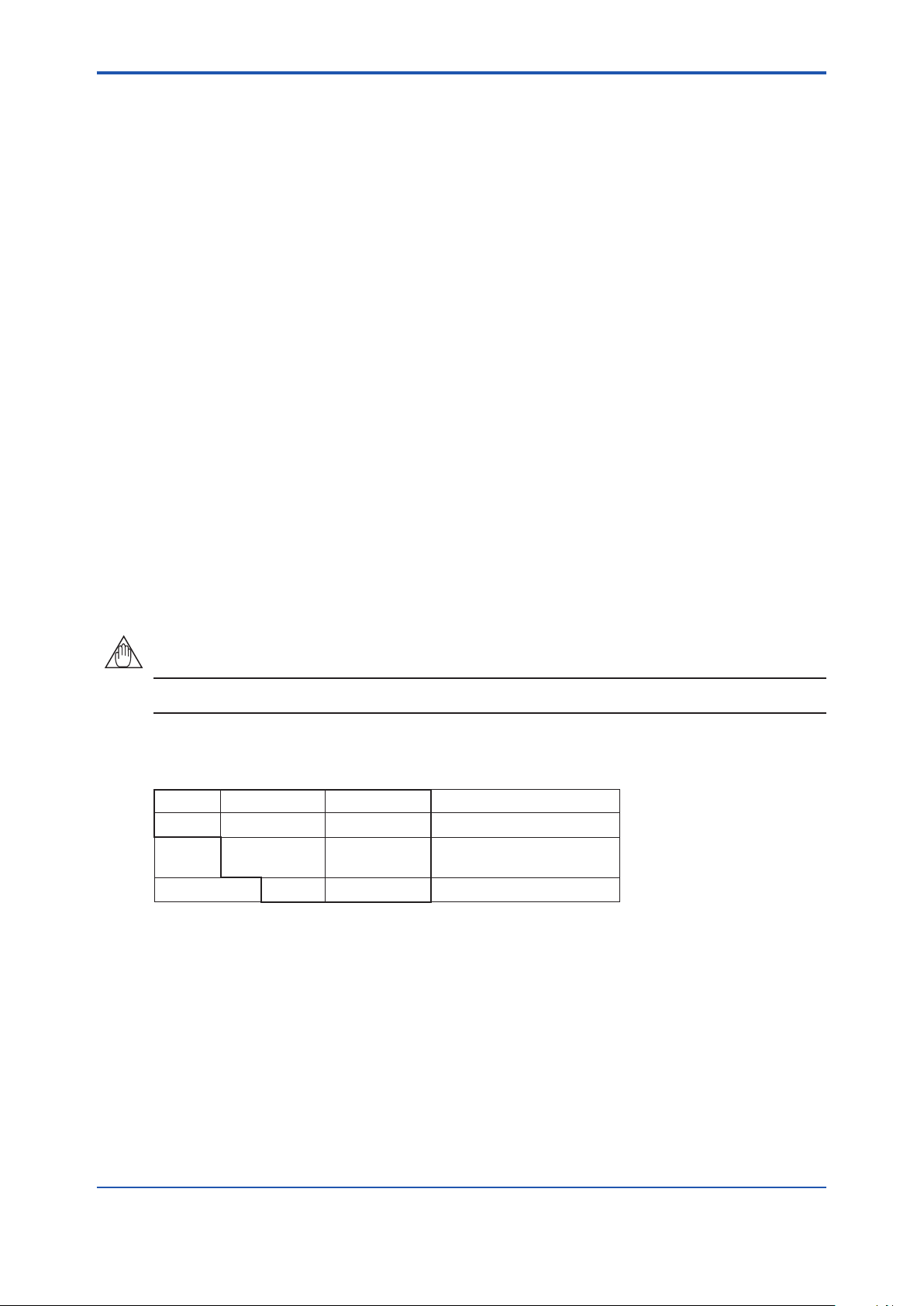

NOTE

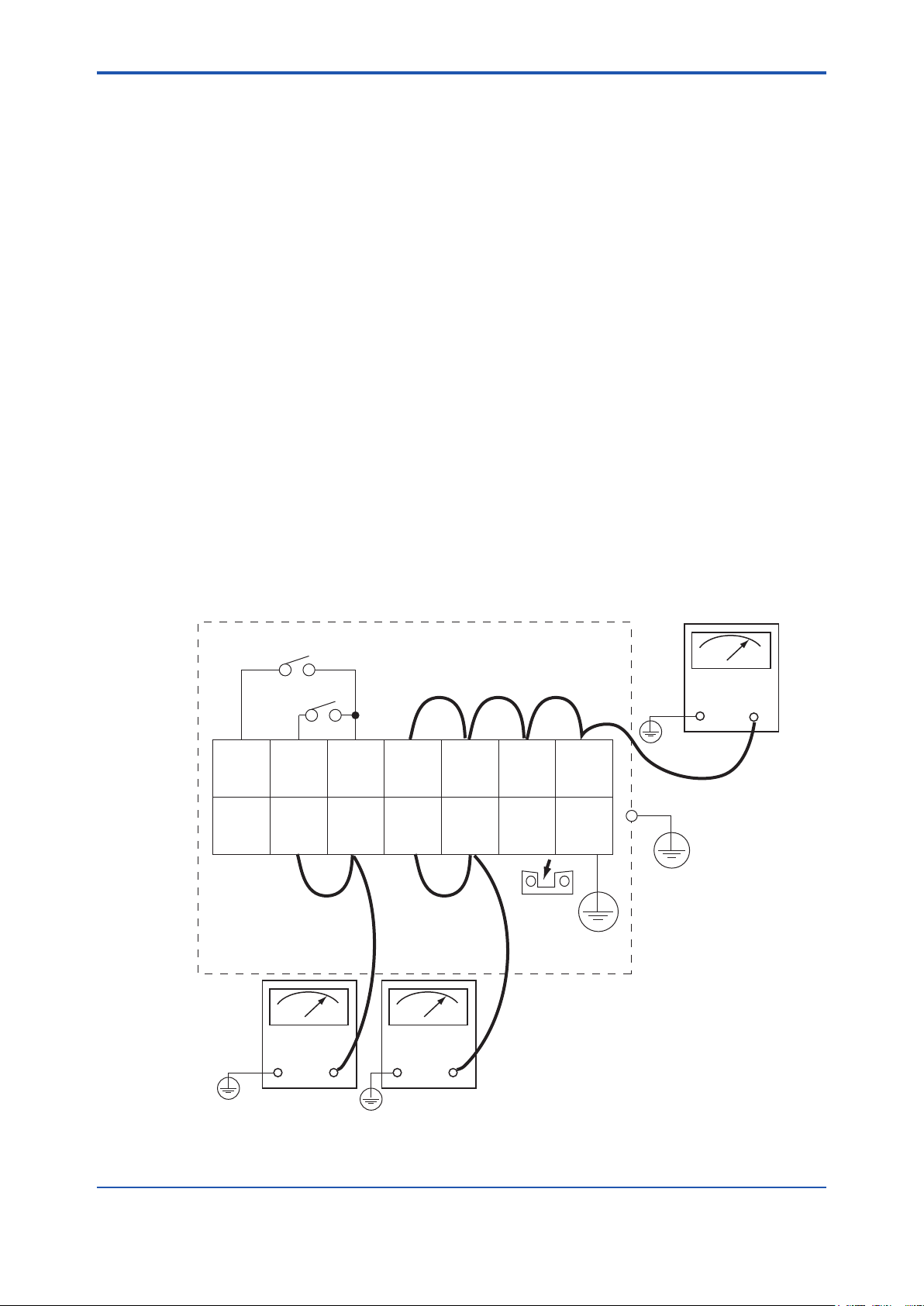

2.2 ZA8F Flow Setting Unit and ZR20H Automatic Calibration Unit

2.2.1 ZA8F Flow Setting Unit

This ow setting unit is applied to the reference gas and the calibration gas in a system conguration

(System 2).

This unit consists of a owmeter and ow control valves to control the ow of calibration gas and

reference gas.

• Standard Specications

Flowmeter: Calibration gas; 0.1 to 1.0 l/min. Reference gas; 0.1 to 1.0 l/min.

Construction: Dust-proof and rainproof construction

Case Material: SPCC (Cold rolled steel sheet)

Painting: Baked epoxy resin, Dark-green (Munsell 2.0 GY 3.1/0.5 or equivalent)

Tube Connections: Rc1/4 or 1/4FNPT

Reference Gas Pressure: Clean air supply of sample gas pressure plus approx. 50 kPa G (or

sample gas pressure plus approx.150 kPa G when a check valve is used,

maximum pressure rating is 300 kPa) (pressure at inlet of the automatic

calibration unit)

Air Consumption: Approx. 1.5 l/min

Weight: Approx. 2 kg

Used instrument air for span calibration gas, if without instrument air is used, contact YOKOGAWA.

• Model and Codes

Model Sufx code Option code Description

ZA8F - - - - - - - - - - - - - - - - - - - - - - - Flow setting unit

Joint

Style code *C - - - - - - - - - - - - Style C

-J

-A

- - - - - - - - - - - -

- - - - - - - - - - - -

Rc 1/4

With 1/4 NPT adapter

Page 30

<2. Specications>

CHECK

OUT

REF

OUT

REFERENCE

SPAN

ZERO

REFERENCE CHECK

AIR

IN

ZERO

IN

SPAN

IN

CHECK

OUT

PIPNG INSIDE THE FLOW SETTING UNIT

Unit : mm (inch)

Weight : Approx. 2.3 kg

Flowmeter Flowmeter

ZERO

GAS IN

AIR IN

Instrument air

Approx. 1.5 l/min.

Air Set

REF

OUT

SPAN

GAS IN

20

2035

35

35

35

35

70

32

7

222.8

235.8

140

180

7

Reference gas outlet

Calibration gas outlet

ø6 Hole

Span gas inlet

Zero gas inlet

2B mounting pipe

Instrument air inlet

F2.6E.ai

Air pressure ;

without check valve ; sample gas pressure + approx.50 kPaG

with check valve ; sample gas pressure + approx.150 kPaG

Piping connection port A

ZA8F-J*C

ZA8F-A*C

5 - Rc1/4

5 - 1/4NPT

Model

Piping connection port A

• External Dimensions

2-11

IM 11M12A01-04E

Page 31

<2. Specications>

2-12

IM 11M12A01-04E

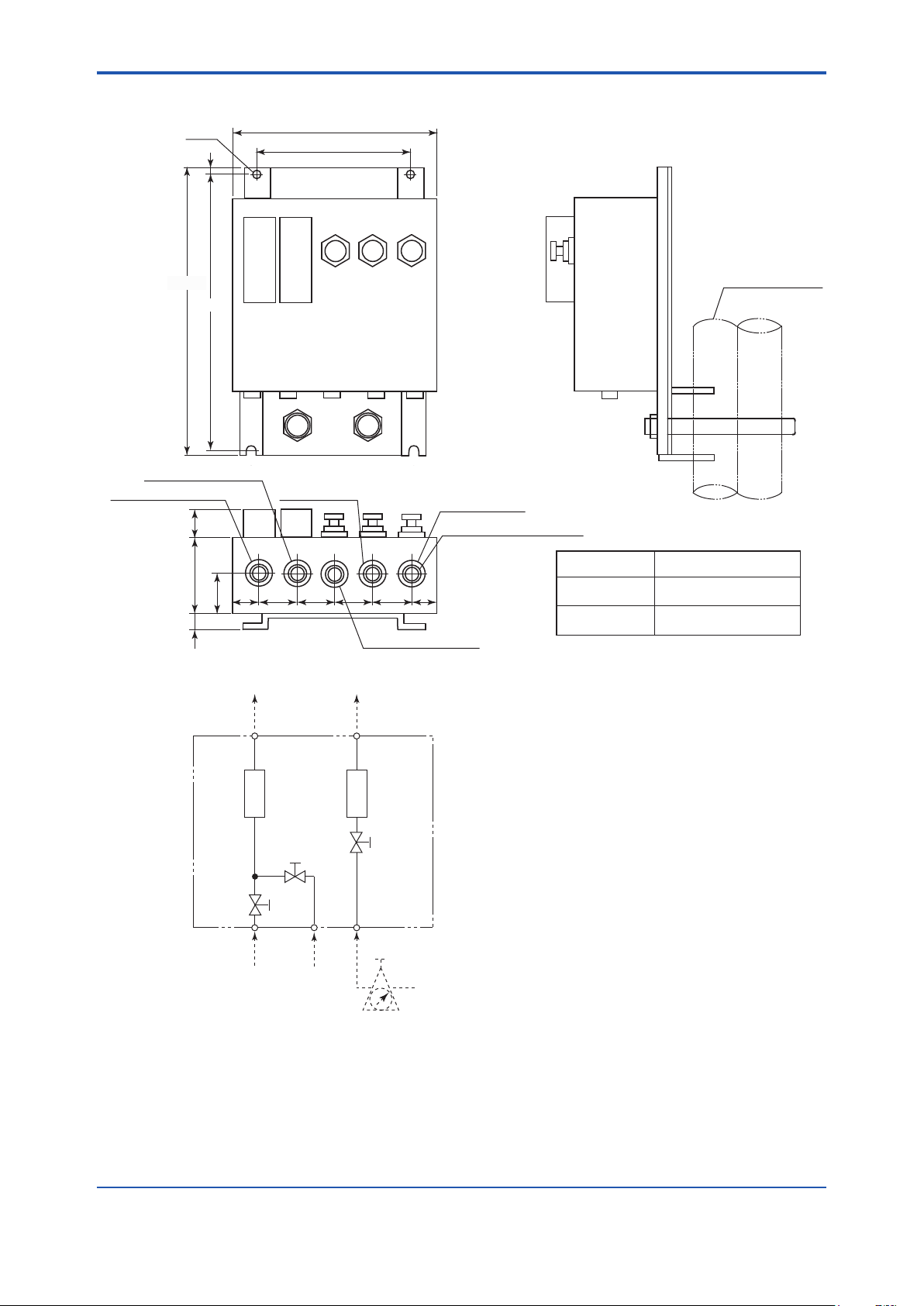

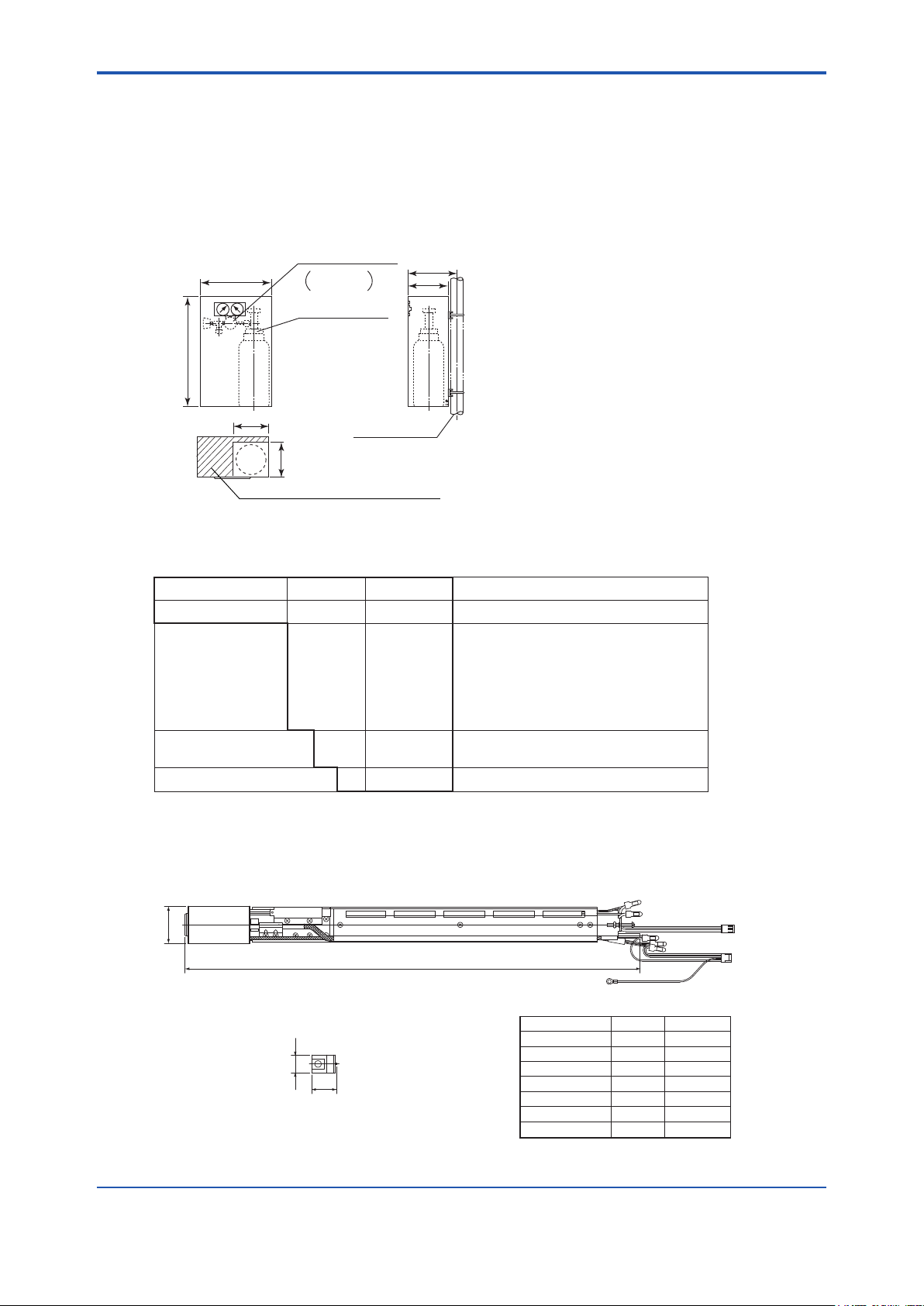

2.2.2 ZR20H Automatic Calibration Unit

This automatic calibration unit is applied to supply specied ow of reference gas and calibration gas

during automatic calibration to the detector in a system conguration (System 3).

• Specications

Equipped with the analyzer when automatic calibration is specied in the sufx code of the ZR202G

Integrated type by selecting either “-A (Horizontal mounting)” or “-B (Vertical mounting)”. The ZR20H

should be arranged when automatic calibration is to be required after the ZR202G has been installed.

Ask Yokogawa service station for its mounting.

Construction: Dust-proof and rainproof construction; NEMA4X/IP67 (excluding owmeter)

Mounting: Mounted on ZR202G, no vibration

Materials: Body; Aluminum alloy, Piping; SUS316 (JIS), SUS304 (JIS), Flowmeter;

Finish: Polyurethane corrosion-resistance coating

Piping Connection: Rc 1/4 or 1/4 NPT

Power Supply: 24V DC (from ZR202G)

Power consumption: Approx.1.3 W

Reference Gas Pressure: Sample gas pressure plus Approx. 150 kPa (690 kPa max.), (Pressure at

Air Consumption: Approx. 1.5 l/min

Weight: Approx. 2 kg

Ambient Temperature: -20 to +55°C, no condensing and freezing

Ambient Humidity: 0 to 95% RH

Storage Temperature: -30 to +65°C

• Model and Codes

Model Sufx code Option code Description

ZR20H - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Gas piping

connection-R-T

Reference gas *2 -E

Mounting -A

– -A - - - - - - - - - - - -

*1 Ask Yokogawa service station for additional mounting of ZR20H to the preinstalled ZR202G.

*2 Select the appropriate reference gas of ZR20H according to the one of ZR202G.

MA (Methacrylate resin), Bracket; SUS304 (JIS)

Case; Mint green (Munsell 5.6 BG3.3 /2.9)

Cover; Mint green (Munsell 5.6 BG3.3/2.9)

inlet of automatic calibration unit)

Automatic calibration unit for ZR202G *1

- - - - - - - - - - - -

- - - - - - - - - - - -

-P

-B

- - - - - - - - - - - -

- - - - - - - - - - - -

- - - - - - - - - - - -

- - - - - - - - - - - -

Rc 1/4

1/4 NPT

Instrument air

Pressure compensated

Horizontal mounting

Vertical mounting

Always -A

Page 32

<2. Specications>

Rc1/4 or 1/4NPT(Female)

Rc1/4 or 1/4NPT(Female)

Rc1/4 or 1/4NPT(Female)

Rc1/4 or 1/4NPT(Female)

Rc1/4 or 1/4NPT(Female)

Rc1/4 or 1/4NPT(Female)

SPAN IN REF IN ZERO IN

AUTO CAL. UNIT

-20 TO 558C

ZR20HMODEL

SUFFIX

STYLE

AMB.TEMP

NO.

S1

SUPPLY 690kPa MAX.

USED WITHZR202G

ZR202GUSED WITH

690kPa MAX.SUPPLY

S1

NO.

AMB.TEMP

STYLE

SUFFIX

MODEL ZR20H

-20 TO 558C

AUTO CAL. UNIT

SPAN IN REF IN ZERO IN

[ 84

166.5

Ø80

243

258

166.5

5644

180MAX444040 66.5

49111

66.540 40

Ø84

Span gas inlet

Zero gas inlet

Reference gas inlet

Zero gas inlet

Reference gas inlet

Span gas inlet

MAX

(2) Vertical Mounting (-B)

Unit: mm

Ø80

44

SPAN IN

REF. IN

ZERO IN

F4.11E.ai

Calibration gas

Reference gas

ZR202G body

Span gas

solenoid valve

Span gas flowmeter

Reference gas flowmeter

To Air set

To Zero gas cylinder

Needle valve

Automatic calibration unit

Zero gas flowmeter

Zero gas

solenoid valve

Check valve

External Dimensions

(1) Horizontal Mounting (-A)

2-13

PIPNG INSIDE THE AUTOMATIC CALIBRATION UNIT

IM 11M12A01-04E

Page 33

<2. Specications>

2-14

IM 11M12A01-04E

92

228

253

1600

354

Flow checker

Span gas valve

Zero gas valve

Gas outlet

F24.ai

Zero gas cylinder (6 cylinder): E7050BA

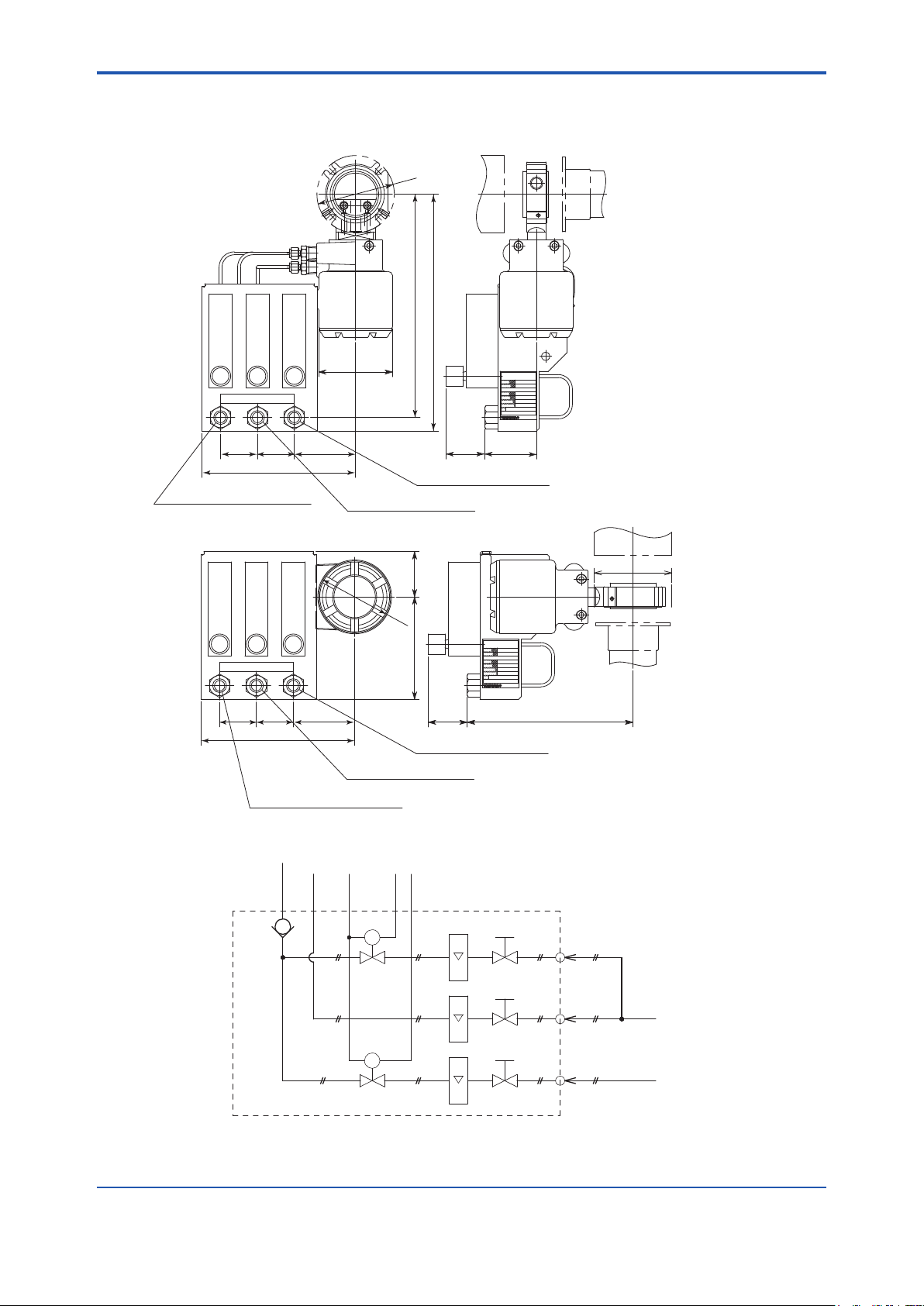

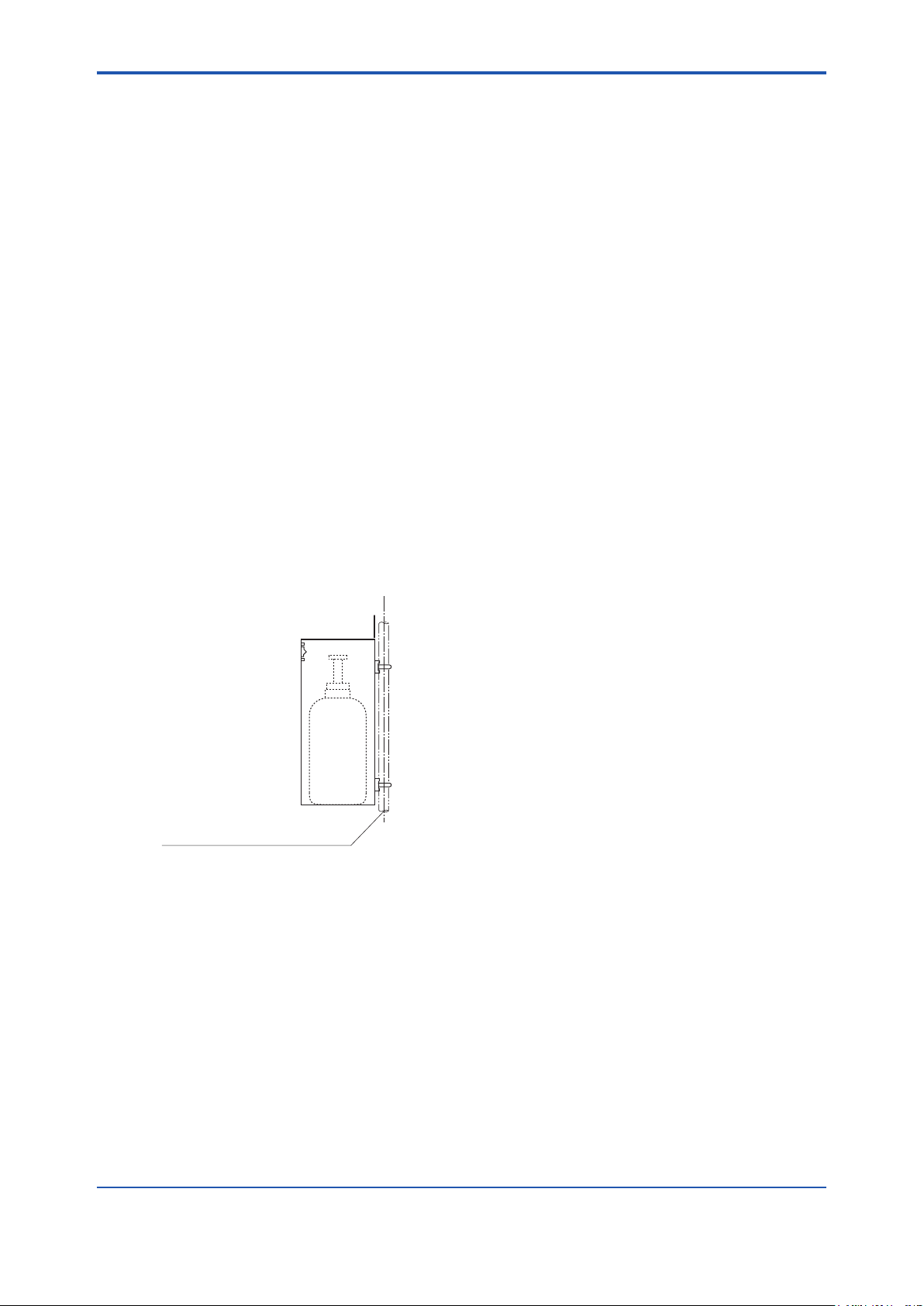

2.3 ZO21S Standard Gas Unit

This is a handy unit to supply zero gas and span gas to the detector in a system conguration based

on System 1. It is used in combination with the detector only during calibration.

• Standard Specications

Function: Portable unit for calibration gas supply consisting of span gas (air) pump, zero

gas cylinder with sealed inlet, ow rate checker and ow rate needle valve.

Sealed Zero Gas Cylinders (6 provide): E7050BA

Capacity: 1 l

Filled pressure: Approx. 686 kPa G (at 35 °C)

Composition: 0.95 to 1.0 vol% O

Power Supply: 100, 110, 115, 200, 220, 240V AC± 10%, 50/60 Hz

Power Consumption: Max. 5 VA

Case material: SPCC (Cold rolled steel sheet)

Paint: Epoxy resin, baked

Paint Color: Mainframe; Munsell 2.0 GY3.1/0.5 equivalent

Piping: Ø6 x Ø4mm exible tube connection

Weight: Approx. 3 kg

Span gas: Internal pump draws in air from atmosphere, and feeds to detector.

* Non CE Mark.

• Model and Codes

Model Sufx code Option code Description

ZO21S - - - - - - - - - - - - - - - - - - - - - Standard gas unit

-2

Power

supply

Panel

Style code *A - - - - - - - - - - - Style A

-3

-4

-5

-7

-8

balance

2+N2

Cover; Munsell 2.8 GY6.4/0.9 equivalent

- - - - - - - - - - -

- - - - - - - - - - -

- - - - - - - - - - -

- - - - - - - - - - -

- - - - - - - - - - -

- - - - - - - - - - -

-J

-E

- - - - - - - - - - -

- - - - - - - - - - -

200 V AC 50/60 Hz

220 V AC 50/60 Hz

240 V AC 50/60 Hz

100 V AC 50/60 Hz

110 V AC 50/60 Hz

115 V AC 50/60 Hz

Japanese version

English version

• External Dimensions

Page 34

<2. Specications>

Ø51

32

10

Carborundum filter (SiC)

Increasing of insertion length

F31.EPS

Screw

Detector

Attach the filter

unit to the tip of

the detector

by screwing

it clockwise.

4-Ø6

122

Ø50.8

100

Increasing of insertion length

F11-1.ai

2.4 Other Equipment

2.4.1 Dust Filter for Oxygen Analyzer (part no. K9471UA)

This lter is used to protect the detector sensor from corrosive dust components or from a high

concentration of dust when the oxygen concentration in utility boilers or concrete kilns are to be

measured.

This lter requires the measuring gas ow of 1 m/sec or faster to replace gas inside zirconia sensor.

• Standard specications

Applicable detector: Standard-type detector for general-use (the sample gas ow should be

approximately perpendicular to the probe.)

Mesh: 30 microns

Material: Carborundum (Filter), SUS316 (JIS)

Weight: Approx. 0.2 kg

Part No. Description

K9471UA Filter

K9471UX Tool

2-15

Unit: mm

2.4.2 Dust Guard Protector (part no. K9471UC)

Recommended to be used when sample gas is likely to ow directly into the cell due to its ow

direction in the stack or the like, ammable dust may go into the cell, or water drops are likely to fall

and remain in the cell during downtime or the like due to the installation position.

Material: SUS316 Unit: mm

Weight: Approx. 0.3 kg

IM 11M12A01-04E

Page 35

<2. Specications>

2-16

IM 11M12A01-04E

F15.ai

55

(Full open length)

40

Rc1/4 or 1/4NPT

Ø43

K9292DN : Rc 1/4(A),R 1/4(B)

K9292DS : 1/4FNPT(A),1/4NPT(Male)(B)

F30.EPS

Approx. 19 Approx. 54

Unit: mm

A

B

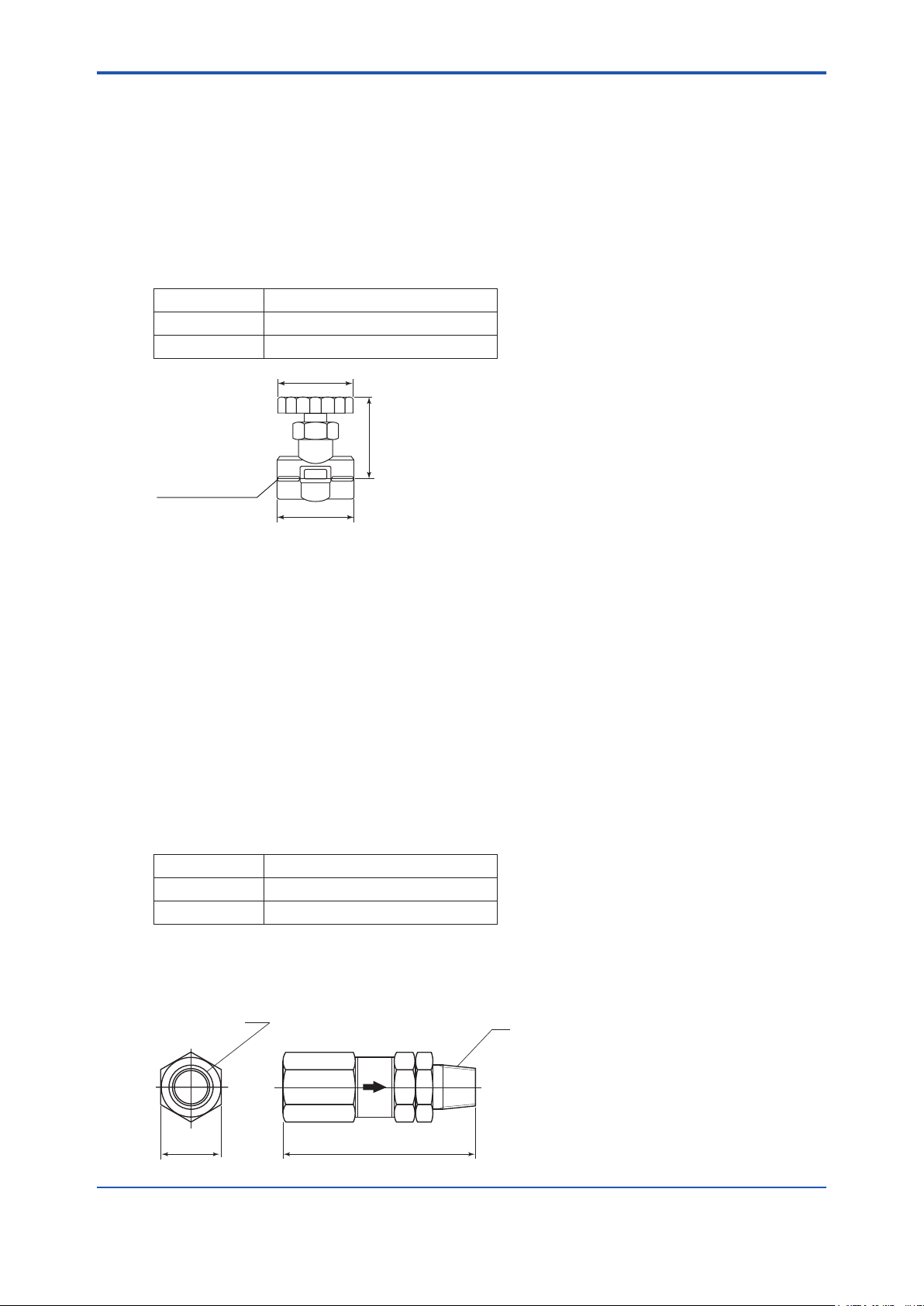

2.4.3 Stop Valve (part no. L9852CB or G7016XH)

This valve is mounted on the calibration gas line in the system to allow for one-touch calibration. This

is applied to a system conguration (System 1).

• Standard Specication

Connection: Rc 1/4 or 1/4 FNPT

Material: SUS 316 (JIS)