Page 1

User’s

Manual

YVP110

Advanced Valve Positioner

IM 21B04C01-01E

IM 21B04C01-01E

10th Edition

Page 2

YVP110

Advanced Valve Positioner

IM 21B04C01-01E 10th Edition

CONTENTS

Introduction ..........................................................................................................viii

■ Notes on the User’s Manual ............................................................................. viii

■ For Safe Use of Product.................................................................................... viii

■ Warranty

■ Trade Mark

■ ATEX Documentation

PART I: HARDWARE

..............................................................................................................ix

..........................................................................................................ix

...........................................................................................x

i

1. Notes on Handling .................................................................................... 1-1

1.1 Nameplate ..........................................................................................................1-1

1.2 Transport ............................................................................................................1-1

1.3 Storage ............................................................................................................... 1-1

1.4 Choosing the Installation Location ................................................................. 1-1

1.5 Use of a Transceiver .........................................................................................1-1

1.6 Insulation Resistance Test and Withstand Voltage Test ..............................1-2

1.7 Notes for Saftey .................................................................................................1-2

1.8 EMC Conformity Standards .............................................................................1-3

1.9 Installation of Explosion Protected Type Positioner ....................................1-3

1.9.1 FM Certication ..................................................................................1-3

1.9.2 ATEX Certication ..............................................................................1-7

1.9.3 CSA Certication ..............................................................................1-12

1.9.4 TIIS Certication ..............................................................................1-12

2. Part Names ................................................................................................ 2-1

2.1 Appearance and Part Names ...........................................................................2-1

2.2 Block Diagram ...................................................................................................2-1

3. Installing YVP110 on Actuator ................................................................ 3-1

3.1 General ............................................................................................................... 3-1

3.2 Installing YVP110 on Actuator ......................................................................... 3-1

3.2.1 Installing YVP110 on Linear-motion Control Valve ............................3-1

3.2.2 Installing YVP110 on Rotary-motion Control Valve ...........................3-3

3.2.3 A/M Switching ....................................................................................3-5

10th Edition: Dec. 2013 (YK)

All Rights Reserved, Copyright © 2000, Yokogawa Electric Corporation

IM 21B04C01-01E

Page 3

4. Wiring and Piping ..................................................................................... 4-1

4.1 General ............................................................................................................... 4-1

4.2 Piping .................................................................................................................4-1

4.2.1 Air Supply ........................................................................................... 4-1

4.2.2 Pneumatic Piping ...............................................................................4-1

4.3 Wiring .................................................................................................................4-2

4.3.1 Recommended Cables ...................................................................... 4-2

4.3.2 Precautions on Wiring ........................................................................4-2

4.4 Grounding ..........................................................................................................4-4

5. Setup .......................................................................................................... 5-1

5.1 General ............................................................................................................... 5-1

5.2 Setting Basic Parameters ................................................................................5-1

5.3 Carrying out Tuning .........................................................................................5-2

5.4 Checking Valve Actions ...................................................................................5-4

5.5 Setting Parameters of Transducer Block .......................................................5-4

6. Maintenance .............................................................................................. 6-1

6.1 General ............................................................................................................... 6-1

6.2 Periodic Inspections .........................................................................................6-1

6.2.1 Cleaning the Fixed Nozzle .................................................................6-1

6.3 Part Replacement ..............................................................................................6-2

6.3.1 Replacing the Control Relay Assembly .............................................6-2

6.3.2 Replacing the Screen Filters ............................................................. 6-2

6.3.3 Replacing the Internal Air Filter ..........................................................6-2

6.3.4 Tuning the Pressure Balance of Control Relay .................................6-3

ii

7. Standard Specications .......................................................................... 7-1

PART II: FUNCTIONS

8. About Fieldbus ......................................................................................... 8-1

8.1 Outline ................................................................................................................ 8-1

8.2 Internal Structure of YVP110 ............................................................................8-1

8.2.1 System/network Management VFD .................................................. 8-1

8.2.2 Function Block VFD ...........................................................................8-1

8.3 Logical Structure of Each Block .....................................................................8-1

8.4 System Conguration ......................................................................................8-1

8.4.1 Connection of Devices .......................................................................8-2

8.5 Integration of DD ...............................................................................................8-2

9. Conguration ............................................................................................ 9-1

9.1 Network Design .................................................................................................9-1

9.2 Network Denition ............................................................................................9-1

9.3 Denition of Combining Function Blocks ...................................................... 9-2

IM 21B04C01-01E

Page 4

9.4 Setting of Tags and Addresses .......................................................................9-3

9.5 Communication Setting ...................................................................................9-4

9.5.1 VCR Setting .......................................................................................9-4

9.5.2 Function Block Execution Control ...................................................... 9-4

9.6 Block Setting .....................................................................................................9-5

9.6.1 Link Object .........................................................................................9-5

9.6.2 Trend Object ......................................................................................9-5

9.6.3 View Object ........................................................................................9-5

9.6.4 Function Block Parameters..............................................................9-12

10. Actions of YVP110 During Operation ................................................... 10-1

10.1 Block Modes ....................................................................................................10-1

10.2 Alarm Generation ............................................................................................10-2

10.3 Simulation Function .......................................................................................10-3

11. Resource Block ..................................................................................... 11-1

11.1 General ............................................................................................................11-1

11.2 Alarm Processing .......................................................................................... 11-1

11.3 Device Status .................................................................................................. 11-1

iii

12. Transducer Block ................................................................................... 12-1

12.1 General .............................................................................................................12-1

12.2 Forward Path ...................................................................................................12-1

12.2.1 Input from AO Block .........................................................................12-1

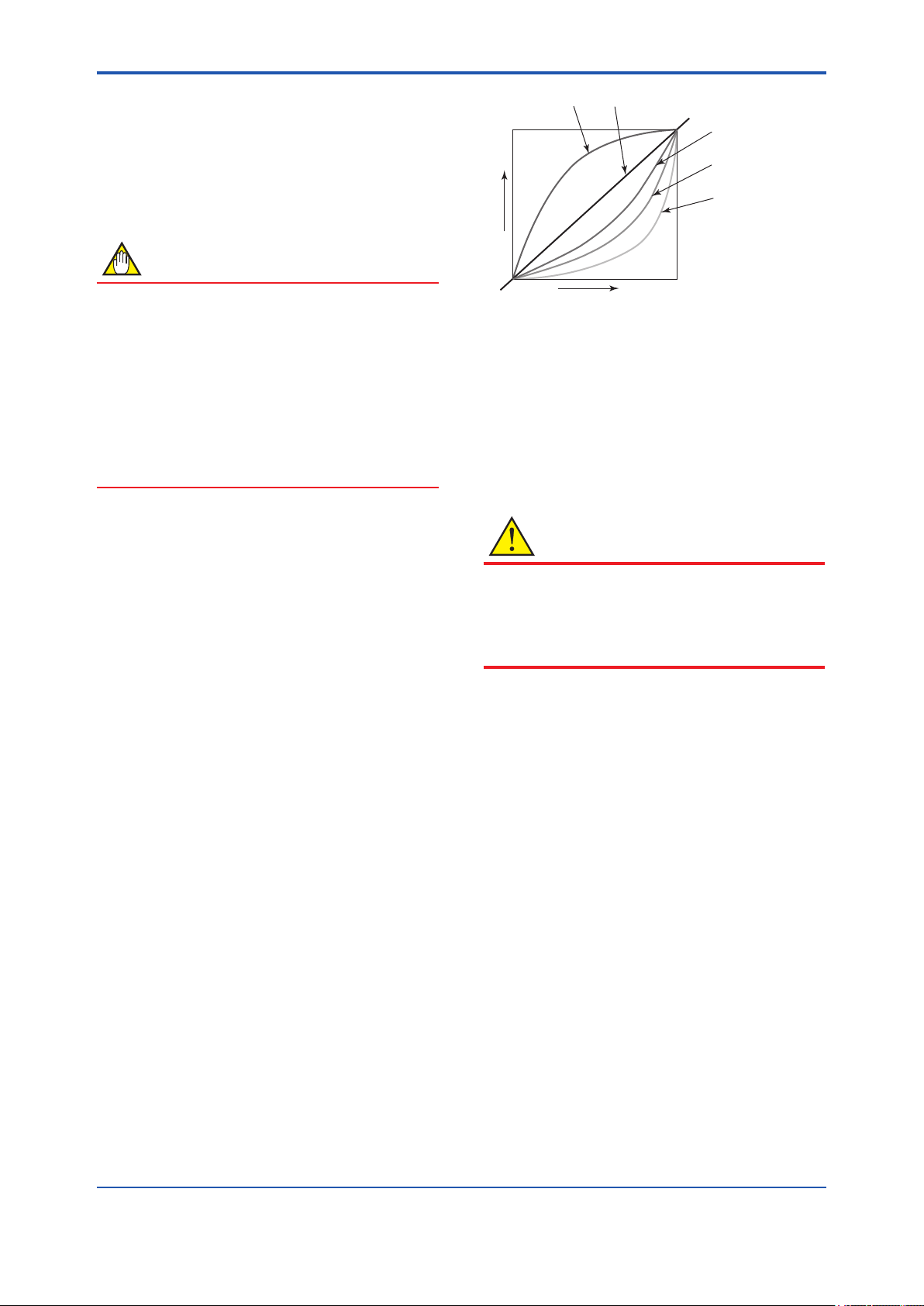

12.2.2 Position-to-ow Rate Characteristic Conversion .............................12-2

12.2.3 FINAL_VALUE and Range ..............................................................12-2

12.2.4 Tight-shut and Full-open Actions .....................................................12-2

12.3 Backward Path ................................................................................................12-2

12.3.1 FINAL_POSITION_VALUE .............................................................12-2

12.3.2 Limit Switches ..................................................................................12-2

12.4 Auto Tuning .....................................................................................................12-3

12.5 Travel Calibration ............................................................................................12-4

12.6 Online Diagnostics .........................................................................................12-4

12.6.1 XD_ERROR .....................................................................................12-4

12.6.2 Fail-safe Action.................................................................................12-5

12.6.3 Operation Result Integration ...........................................................12-5

12.6.4 Recording of Revisions ...................................................................12-5

12.7 Control Parameters .........................................................................................12-5

12.8 Temperature and Pressure Measurement ....................................................12-5

13. AO Function Block ................................................................................. 13-1

13.1 General .............................................................................................................13-1

13.2 Modes ...............................................................................................................13-1

13.3 Forward Path ...................................................................................................13-1

13.3.1 Fault state ........................................................................................13-1

13.4 Backward Path ................................................................................................13-2

IM 21B04C01-01E

Page 5

13.5 IO_OPTS and STATUS_OPTS ........................................................................13-2

13.6 Mode Shedding upon Computer Failure .....................................................13-3

13.7 Initialization at Start ........................................................................................13-3

13.8 Alarm Processing ..........................................................................................13-3

14. DI Function Block .................................................................................. 14-1

14.1 General .............................................................................................................14-1

14.2 Modes ...............................................................................................................14-1

14.3 PV Value (PV_D) ..............................................................................................14-1

14.4 Filtering ............................................................................................................14-1

14.5 Output ...............................................................................................................14-2

14.6 IO_OPTS and STATUS_OPTS ........................................................................14-2

14.7 Alarm Processing ..........................................................................................14-2

14.7.1 Block Alarms ....................................................................................14-2

14.7.2 Discrete Alarm ..................................................................................14-2

15. OS Function Block .................................................................................15-1

15.1 General .............................................................................................................15-1

15.2 Modes ...............................................................................................................15-1

15.3 Output Processing ..........................................................................................15-1

15.4 Backward Path (BKCAL_OUT) .....................................................................15-2

15.5 STATUS_OPTS ...............................................................................................15-2

15.6 Alarm Processing ..........................................................................................15-2

iv

16. PID Function Block ................................................................................16-1

16.1 General .............................................................................................................16-1

16.2 Modes ...............................................................................................................16-1

16.3 Input Processing .............................................................................................16-1

16.4 Setpoint (SP) Limiters ....................................................................................16-1

16.5 PID Computation .............................................................................................16-2

16.6 Control Output .................................................................................................16-2

16.7 Direction of Control Action ............................................................................16-2

16.8 Control Action Bypass ...................................................................................16-2

16.9 Feed-forward ...................................................................................................16-3

16.10 External-output Tracking (LO) .......................................................................16-3

16.11 Measured-value Tracking ...............................................................................16-3

16.12 CONTROL_OPTS ............................................................................................16-3

16.13 Initialization and Manual Fallback (IMan) .....................................................16-4

16.14 Manual Fallback ..............................................................................................16-4

16.14.1 STATUS_OPTS ...............................................................................16-4

16.15 Auto Fallback ...................................................................................................16-4

16.16 Mode Shedding upon Computer Failure ......................................................16-4

16.17 Alarms ..............................................................................................................16-5

16.17.1 Block Alarm (BLOCK_ALM) .............................................................16-5

16.17.2 Process Alarms ................................................................................16-5

IM 21B04C01-01E

Page 6

17. IS Function Block ................................................................................... 17-1

17.1 IS Function Block Schematic ........................................................................17-1

17.2 Input Section ...................................................................................................17-3

17.2.1 Mode Handling ................................................................................17-3

17.2.2 MIN_GOOD Handling .....................................................................17-3

17.3 Selection .........................................................................................................17-4

17.3.1 OP_SELECT Handling ...................................................................17-4

17.3.2 SELECTION Handling ....................................................................17-5

17.4 Output Processing .......................................................................................17-11

17.4.1 Handling of SELECTED ................................................................ 17-11

17.4.2 OUT Processing ............................................................................17-12

17.4.3 STATUS_OPTS ............................................................................17-13

17.5 Application Example ....................................................................................17-13

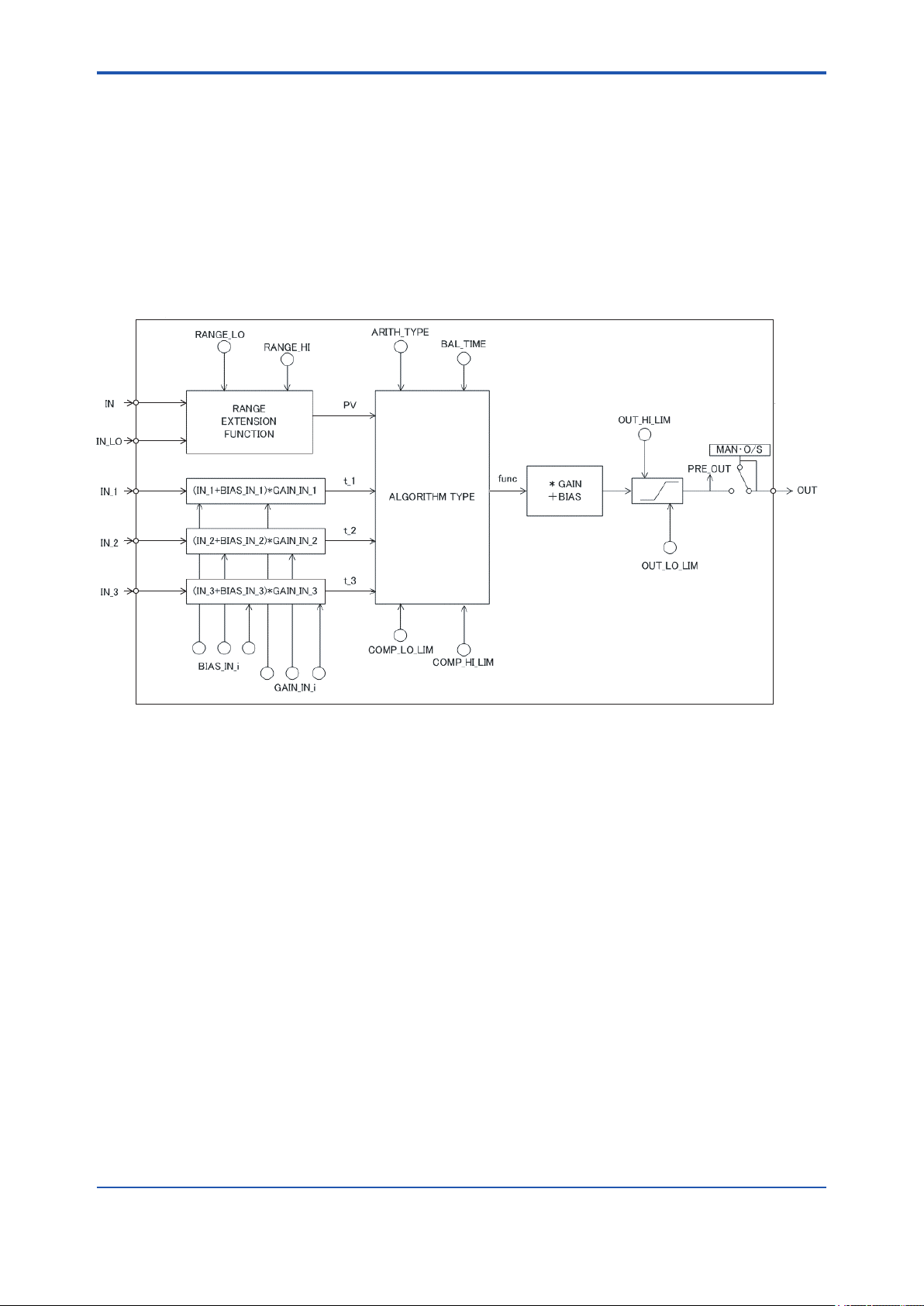

18. AR Function Block .................................................................................18-1

18.1 AR Function Block Schematic ......................................................................18-1

18.2 Input Section ...................................................................................................18-2

18.2.1 Main Inputs ......................................................................................18-2

18.2.2 Auxiliary Inputs ................................................................................18-2

18.2.3 INPUT_OPTS .................................................................................18-3

18.2.4 Relationship between the Main Inputs and PV ............................... 18-3

18.3 Computation Section .....................................................................................18-3

18.3.1 Computing Equations .....................................................................18-3

18.3.2 Compensated Values ......................................................................18-4

18.3.3 Average Calculation ........................................................................18-4

18.4 Output Section ...............................................................................................18-4

18.4.1 Mode Handling ................................................................................18-4

18.4.2 Status Handling ...............................................................................18-5

v

19. Diagnostics ............................................................................................. 19-1

19.1 Overview ..........................................................................................................19-1

19.2 Integration Functions .....................................................................................19-1

19.3 Signature Measurement Functions ..............................................................19-2

19.3.1 Signature Measurement Procedure ................................................ 19-2

19.3.2 Signatures and Relevant Parameters ............................................. 19-3

19.3.3 Signature Measuring Result ............................................................19-4

20. Troubleshooting ..................................................................................... 20-1

20.1 What to Do First ...............................................................................................20-1

20.2 Troubleshooting Communications ...............................................................20-1

20.3 Troubleshooting Function Block Parameters .............................................20-1

20.4 Troubleshooting Valve Control .....................................................................20-2

20.5 Troubleshooting Auto Tuning ........................................................................20-3

20.6 Troubleshooting Position, Pressure, and Temperature Sensors ..............20-3

IM 21B04C01-01E

Page 7

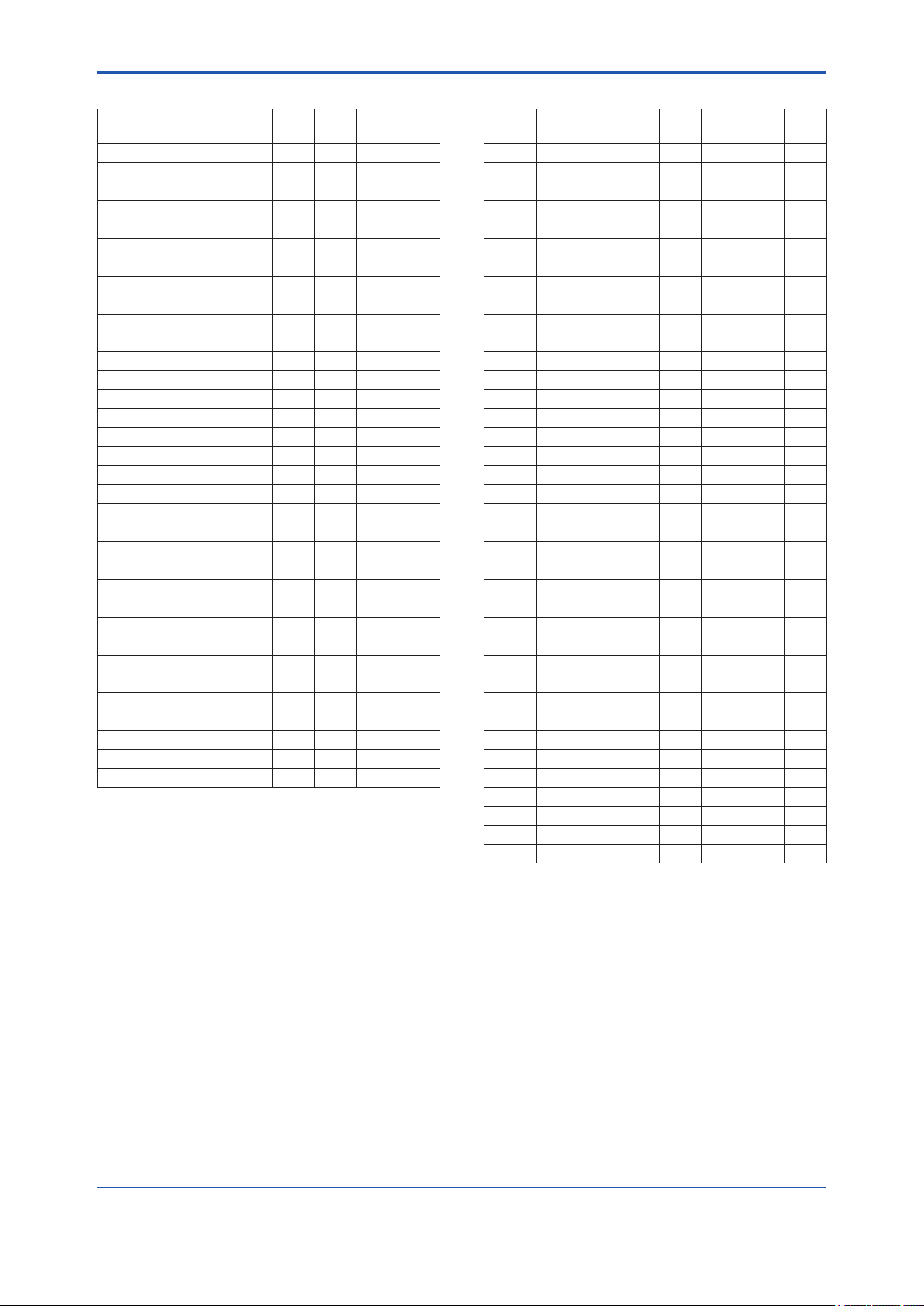

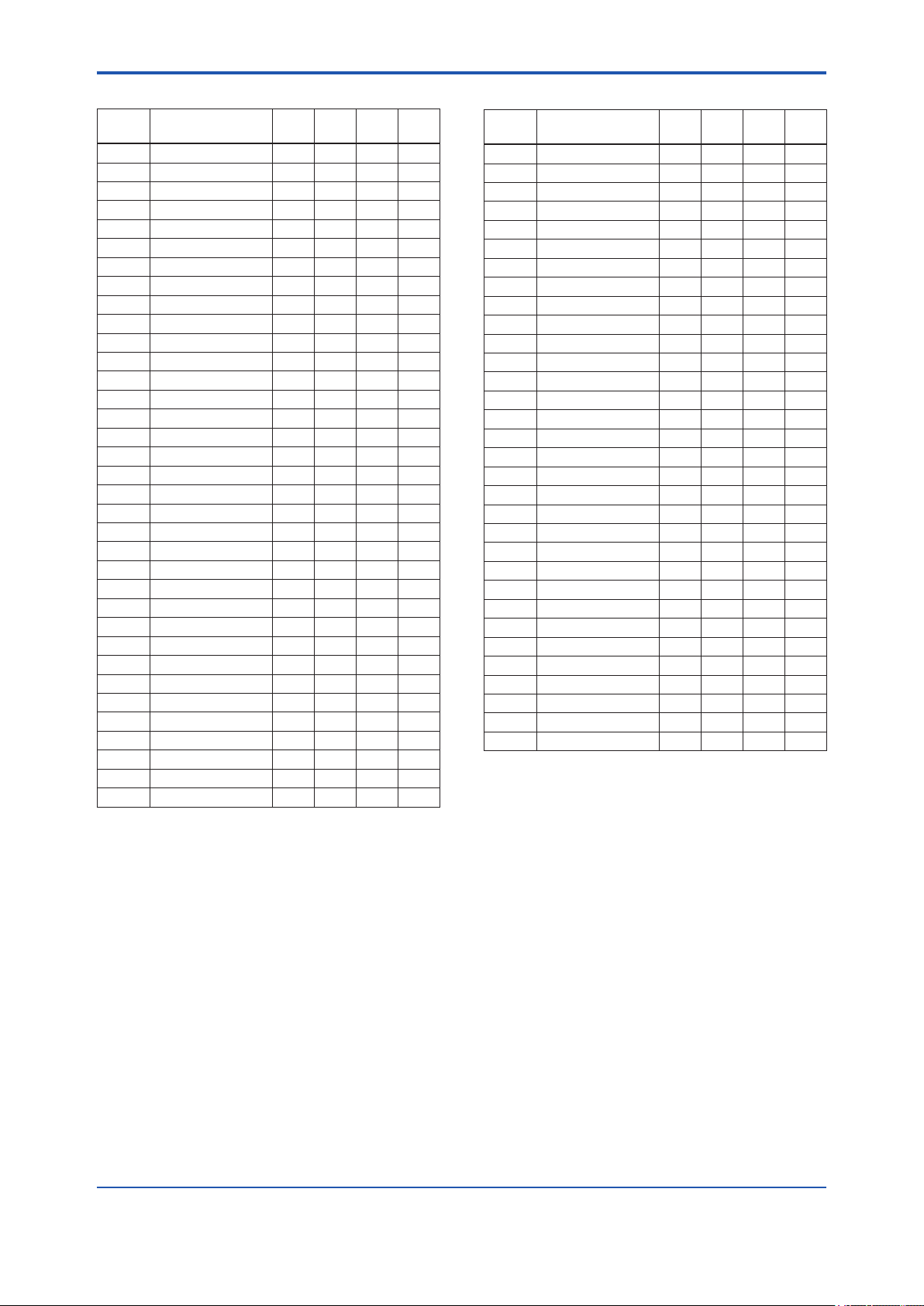

Appendix 1. Function Block Parameters ......................................................A-1

A1.1 Parameters of Resource Block ...................................................................... A-1

A1.2 Parameters of Transducer Block ................................................................... A-3

A1.3 Parameters of AO Block ................................................................................. A-8

A1.4 Parameters of DI Block ................................................................................. A-10

A1.5 Parameters of OS Block ................................................................................A-11

A1.6 Parameters of PID Block (Optional) ............................................................ A-12

A1.7 Parameters of IS Block .................................................................................. A-14

A1.8 Parameters of AR Block ................................................................................ A-16

A1.9 IO_OPTS - Availability of Options for Each Block ..................................... A-18

A1.10 STATUS_OPTS - Availability of Options for Each Block ........................... A-18

A1.11 CONTROL_OPTS - Availability of Options for Each Block ...................... A-18

Appendix 2. Link Master Functions .............................................................A-19

A2.1 Link Active Scheduler.................................................................................... A-19

A2.2 Link Master ..................................................................................................... A-19

A2.3 Transfer of LAS .............................................................................................. A-19

A2.4 LM Functions .................................................................................................. A-20

A2.5 LM Parameters ............................................................................................... A-21

A2.5.1 LM Parameter List ............................................................................A-21

A2.5.2 Descriptions for LM Parameters ......................................................A-22

A2.6 FAQs ................................................................................................................ A-25

vi

Appendix 3. DD Methods and DD Menu ......................................................A-26

A3.1 Overview ......................................................................................................... A-26

A3.2 DD Methods ................................................................................................... A-26

A3.2.1 Transducer Block .............................................................................A-26

A3.2.2 AO Block ..........................................................................................A-28

A3.2.3 OS Block ..........................................................................................A-29

Appendix 4. Software Download ..................................................................A-30

A4.1 Benets of Software Download .................................................................... A-30

A4.2 Specications ................................................................................................. A-30

A4.3 Preparations for Software Downloading ..................................................... A-30

A4.4 Software Download Sequence ..................................................................... A-30

A4.5 Download Files ............................................................................................... A-31

A4.6 Steps after Activating a Field Device ........................................................... A-31

A4.7 Troubleshooting ............................................................................................. A-32

A4.8 Resource Block’s Parameters Relating to Software Download ............... A-32

A4.9 System/Network Management VFD Parameters Relating to Software

Download ........................................................................................................ A-34

A4.10 Comments on System/Network Management VFD Parameters Relating to

Software Download ....................................................................................... A-35

Appendix 5. Position Adjustment of Feedback Lever ...............................A-37

IM 21B04C01-01E

Page 8

Appendix 6. Manual Tuning Guideline ........................................................A-38

A6.1 General ............................................................................................................ A-38

A6.2 Control Parameter Tuning Procedure.......................................................... A-38

A6.3 Examples of Tuning Control Parameters .................................................... A-40

A6.4 Description of Control Parameters .............................................................. A-41

Installation and Operating Precautions for TIIS Flameproof Equipment

.............................................................................................................EX-B03

Customer Maintenance Parts List

YVP110 Advanced Valve Positioner ................................................ CMPL21B04C01-01E

Revision Record

vii

IM 21B04C01-01E

Page 9

<Introduction>

Introduction

viii

The YVP110 advanced valve positioner is fully

factory-tested according to the specications

indicated upon the order.

This User’s Manual consists of two parts:

Hardware and Functions. The Hardware part

gives instructions on handling, wiring set-up and

maintenance of YVP110, and the Functions part

describes the software functions of YVP110.

In order for the YVP110 to be fully functional and

to operate in an efcient manner, both parts in

this manual must be carefully read, so that users

become familiar with the functions, operation, and

handling of the YVP110.

■ Notes on the User’s Manual

• This manual should be delivered to the end

user.

• The information contained in this manual is

subject to change without prior notice.

• The information contained in this manual, in

whole or part, shall not be transcribed or copied

without notice.

• In no case does this manual guarantee

the merchantability of the instrument or its

adaptability to a specic client need.

• Should any doubt or error be found in this

manual, submit inquiries to your local dealer.

• No special specications are contained in this

manual.

• Changes to specications, structure, and

components used may not lead to the revision

of this manual unless such changes affect the

function and performance of the instrument.

• Some of the diagrams in this instruction manual

are partially omitted, described in writing, or

simplied for ease of explanation. The drawings

contained in the instruction manual may have

a position or characters (upper/lower case)

that differ slightly from the what are actually

seen to an extent that does not hinder the

understanding of functions or monitoring of

operation.

l Symbols used in this manual

WARNING

Contains precautions to protect against the

chance of explosion or electric shock which,

if not observed, could lead to death or serious

injury.

CAUTION

Contains precautions to protect against danger,

which, if not observed, could lead to personal

injury or damage to the instrument.

IMPORTANT

Contains precautions to be observed to protect

against adverse conditions that may lead to

damage to the instrument or a system failure.

NOTE

Contains precautions to be observed with regard

to understanding operation and functions.

■ For Safe Use of Product

For the protection and safety of the operator

and the instrument or the system including the

instrument, please be sure to follow the instructions

on safety described in this manual when handling

this instrument. In case the instrument is handled

in contradiction to these instructions, Yokogawa

does not guarantee safety. Yokogawa will not be

liable for malfunctions or damage resulting from

any modication made to this instrument by the

customer. Please give your highest attention to the

followings.

(a) Installation

• The instrument must be installed by an expert

engineer or skilled personnel. The procedures

described about INSTALLATION are not

permitted for operators.

IM 21B04C01-01E

Page 10

<Introduction>

ix

• Some of the operations will stroke the valve.

Keep clear of the valve while the positioner is

pneumatically or electrically supplied, so as

not to be hit by unexpected movements of the

valve.

• In case where ambient temperature is high,

care should be taken not to burn yourself,

because the surface of the body of the

instrument reaches a high temperature.

• All installation shall comply with local installation

requirement and local electrical codes.

• Do not supply air at a pressure exceeding the

maximum rated air supply pressure. Doing so

may result in a high risk of damage or cause an

accident.

• To avoid injury or the process being affected

when installing or replacing a positioner on a

control valve, ensure that;

1) All inputs to the valve actuator and other

accessories of the valve and actuator,

including air supply and electrical signal, are

cut off;

2) The process has been shut down or the

control valve is isolated from the process by

using bypass valves or the like; and

3) No pressure remains in the valve actuator.

• Auto-Manual switch must not be moved by

anyone except for the authorized engineer.

(b) Wiring

• The instrument must be installed by an expert

engineer or skilled personnel. The procedures

described about WIRING are not permitted for

operators.

• Please conrm voltages between the power

supply and the instrument before connecting

the power cables and that the cables are not

powered before connecting.

(c) Operation

• Wait three minutes after power is turned off,

before opening the covers.

(d) Maintenance

• Only the procedures written in maintenance

descriptions are allowed for users. When

further maintenance is needed, please contact

nearest YOKOGAWA ofce.

• Care should be taken to prevent the build up of

drift, dust or other material on the data plate. In

case of its maintenance, use clean, soft and dry

cloth.

• The instrument modication or parts

replacement for explosion-protected type

instruments by other than authorized

representative of Yokogawa Electric

Corporation is prohibited and will void the

approval.

■ Warranty

• The warranty period of the instrument is written

on the estimate sheet that is included with

your purchase. Any trouble arising during the

warranty period shall be repaired free of charge.

• Inquiries with regard to problems with the

instrument shall be accepted by the sales outlet

or our local dealer representative.

• Should the instrument be found to be defective,

inform us of the model name and the serial

number of the instrument together with a

detailed description of nonconformance and

a progress report. Outline drawings or related

data will also be helpful for repair.

• Whether or not the defective instrument is

repaired free of charge depends on the result of

our inspection.

l The following conditions shall not be

eligible for charge-exempt repair.

• Problems caused by improper or insufcient

maintenance on the part of the customer.

• Trouble or damage caused by mishandling,

misusage, or storage that exceeds the design

or specication requirements.

• Problems caused by improper installation

location or by maintenance conducted in a nonconforming location.

• Trouble or damage was caused by modication

or repair that was handled by a party or parties

other than our consigned agent.

• Trouble or damage was caused by

inappropriate relocation following delivery.

• Trouble or damage was caused by re,

earthquake, wind or ood damage, lightning

strikes or other acts of God that are not directly

a result of problems with this instrument.

■ Trade Mark

• FOUNDATION Fieldbus is a trademark of the

Fieldbus Foundation.

• Registered trademarks or trademarks

appearing in this manual are not designated by

a TM or ® symbol.

• Other company names and product names

used in this manual are the registered

trademarks or trademarks of their respective

owners.

IM 21B04C01-01E

Page 11

<Introduction>

■ ATEX Documentation

This procedure is only applicable to the countries in European Union.

x

GB

DK

E

NL

SK

CZ

I

LT

LV

EST

PL

SF

P

F

D

S

SLO

H

BG

RO

M

GR

IM 21B04C01-01E

Page 12

<1. Notes on Handling>

1. Notes on Handling

1-1

The YVP110 advanced valve positioner is fully

factory-tested upon shipment. When the YVP110 is

delivered, visually check that no damage occured

during the shipment.

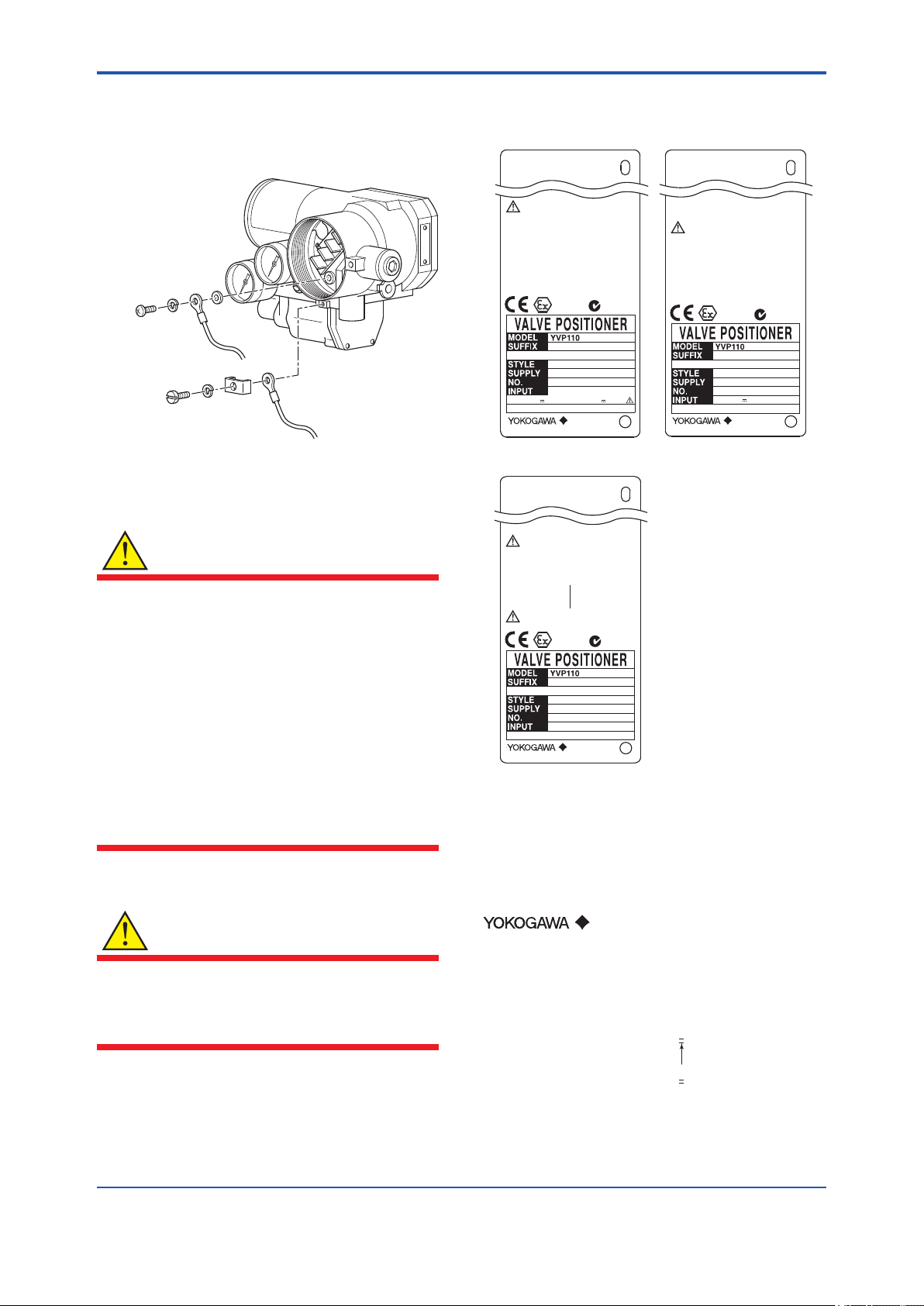

1.1 Nameplate

The model name and conguration are indicated

on the nameplate. Verify that the conguration

indicated in the “Model and Sufx Code” in Chapter

7 is in compliance with the specications written on

the order sheet.

F0101.ai

Figure 1.1 Nameplate

1.2 Transport

To prevent damage while in transit, leave the

positioner in the original shipping container until it

reaches the installation site.

(3) The performance of the positioner may be

impaired if stored in an area exposed to direct

rain and water.

To avoid damage to the positioner, install it

immediately after removal from the shipping

container. Follow wiring instructions in this

manual.

1.4 Choosing the Installation Location

Although the advanced valve positioner is

designed to operate in a vigorous environment,

to maintain stability and accuracy, the following is

recommended:

(1) Ambient Temperature

It is preferable not to expose the instrument

to extreme temperatures or temperature

uctuations. If the instrument is exposed to

radiation heat a thermal protection system and

appropriate ventilation is recommended.

(2) Environmental Requirements

Do not allow the positioner to be installed

in a location that is exposed to corrosive

atmospheric conditions. When using the

positioner in a corrosive environment, ensure

the location is well ventilated. The unit and its

wiring should be protected from exposure to

rainwater.

1.3 Storage

When an extended storage period is expected,

observe the following precautions:

(1) If at all possible, store the positioner in factory-

shipped condition, that is, in the original

shipping container.

(2) Choose a storage location that satises the

following requirements.

• A location that is not exposed to rain or water.

• A location subject to a minimum of vibration or

impact.

• The following temperature and humidity range

is recommended. Ordinary temperature and

humidity (25°C, 65%) are preferable.

Temperature: –40 to 85°C

Humidity: 5 to 100% RH (at 40°C)

(3) Impact and Vibration

It is recommended that the positioner is

installed in a location that is subject to a

minimum amount of impact and vibration.

1.5 Use of a Transceiver

Although the positioner is designed to resist

inuence from high frequency noise, use of a

transceiver in the vicinity of installation may cause

problems. Installing the transmitter in an area free

from high frequency noise (RFI) is recommended.

IM 21B04C01-01E

Page 13

<1. Notes on Handling>

1-2

1.6 Insulation Resistance Test and Withstand Voltage Test

CAUTION

(1) Overvoltage of the test voltage that is so

small that it does not cause an dielectric

breakdown may in fact deteriorate insulation

and lower the safety performance; to prevent

this it is recommended that the amount of

testing be kept to a minimum.

(2) The voltage for the insulation resistance test

must be 500V DC or lower, and the voltage

for the withstand voltage test must be 500V

AC or lower. Failure to heed these guidelines

may cause faulty operation.

(3) Where a built-in arrester is provided (sufx

code: /A), the voltage for the insulation

resistance test must be 100V DC or lower,

and the voltage for the withstand voltage test

must be 100V AC or lower. Failure to heed

these guidelines may cause faulty operation.

Withstand voltage test procedure

Testing between the input terminals and the

grounding terminal

1. Lay the transition wiring between the + terminal

and the − terminal, and connect the withstand

voltage tester (with the power turned OFF)

between the transition wiring and the grounding

terminal. Connect the grounding side of the

withstand voltage tester to the grounding

terminal.

2. After setting the current limit value of the

withstand voltage tester to 10 mA, turn

the power ON, and gradually increase the

impressed voltage from 0 V to the specied

value.

3. The voltage at the specied value must remain

for a duration of one minute.

4. Upon completion of the test, carefully reduce

the voltage so that no voltage surge occurs.

1.7 Notes for Saftey

Follow the steps below to perform the test, the

wiring of the communication line must be removed

before initiating testing.

Insulation resistance test procedure

1. Lay transition wiring between the + terminal and

the − terminal.

2. Connect the insulation resistance meter (with

the power turned OFF) between the transition

wiring of Step 1 above and ground terminal.

The polarity of the input terminals must be

positive and that of the ground must be

negative.

3. Turn the power of the insulation resistance

meter ON and measure the insulation

resistance. The duration of the applied voltage

must be the period during which 100 MΩ

or more is conrmed (or 20 MΩ if the unit is

equipped with a built-in arrester).

4. Upon completion of the test, remove the

insulation resistance meter, connect a 100

kΩ resistor between the transition wiring, and

allow the electricity to discharge. Do not touch

the terminal with your bare hands while the

electricity is discharging for more than one

second.

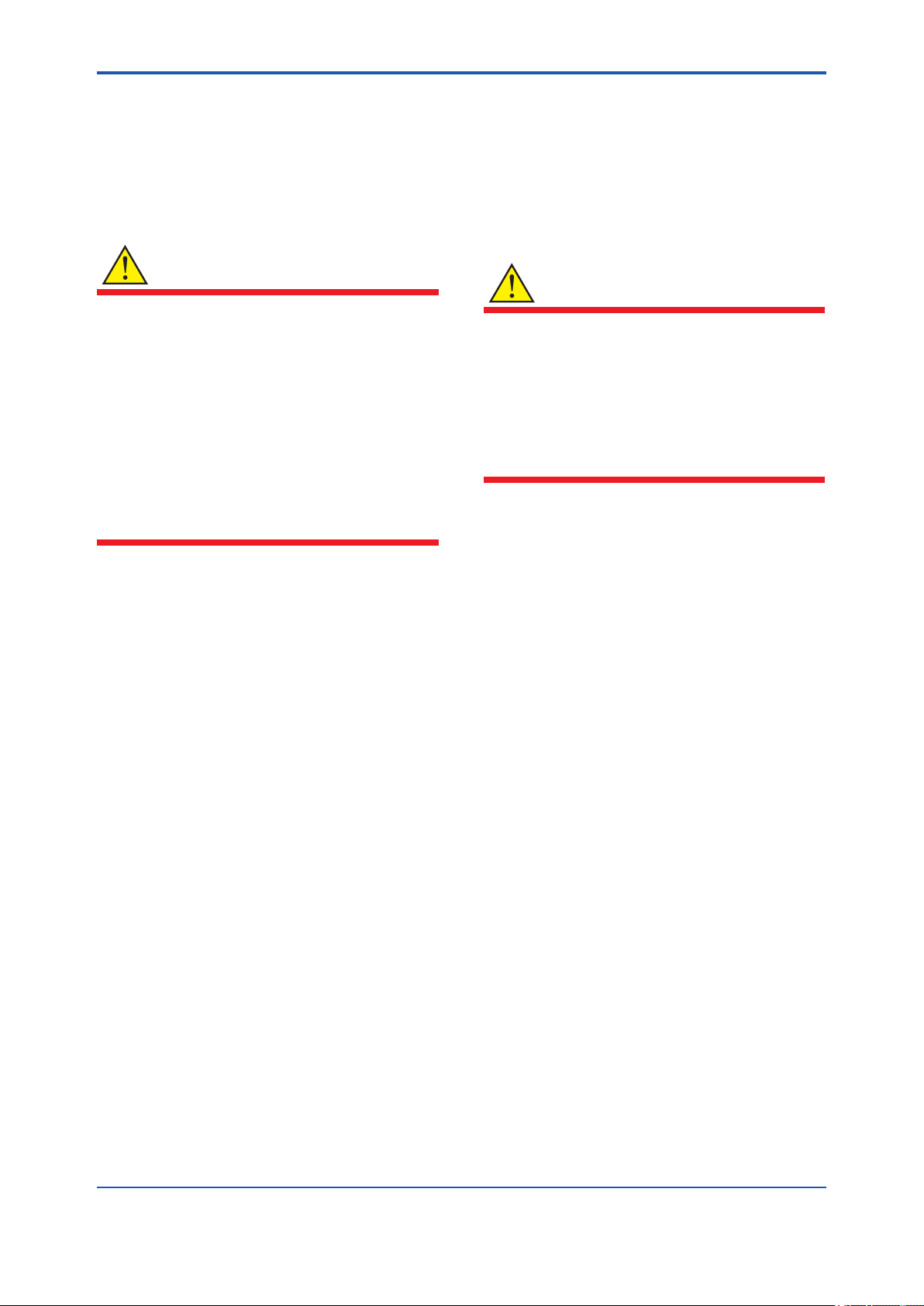

CAUTION

When air is supplied to a valve, do not touch

the moving part (a stem of the valve), as it may

suddently move.

CAUTION

• While A/M selection switch is set to manual

side (M), the pressure set in the regulator

for air supply will be directly output to the

actuator regardless of the control signal.

Before changing the mode from auto to

manual, check and conrm thoroughly that

there will be no effect which may cause

a danger in process or personal injury by

changing the mode.

• Do not change the mode by using auto/

manual switch during the operation. If the

mode is changed from auto to manual or

manual to auto, the valve stem will happnen

to move to the position which is different

from the control signal (the input signal to the

positioner), and thus dangerous.

• As soon as the manual operation is nished,

make it sure to change the mode to auto by

moving the A/M selection switch to Auto(A)

side.

IM 21B04C01-01E

Page 14

<1. Notes on Handling>

1-3

1.8 EMC Conformity Standards

EN61326-1 Class A, Table 2 (For use in industrial

locations)

CAUTION

This instrument is a Class A product, and it is

designed for use in the industrial environment.

Please use this instrument in the industrial

environment only.

1.9 Installation of Explosion Protected Type Positioner

CAUTION

To preserve the safety of explosionproof

equipment requires great care during mounting,

wiring and piping. Safety requirements also

place restrictions on maintenance and repair

activities. Please read the following section very

carefully.

1.9.1 FM Certication

or

Rating 2

For Groups A, B, C, D, E, F and G or Group IIC

Maximum Input Voltage Vmax: 17.5 V

Maximum Input Current Imax: 360 mA

Maximum Input Power Pmax: 2.52 W

Maximum Internal Capacitance Ci: 1.76 nF

Maximum Internal Inductance Li: 0 µH

or

Rating 3

For Groups C, D, E, F and G or Group IIB

Maximum Input Voltage Vmax: 17.5 V

Maximum Input Current Imax: 380 mA

Maximum Input Power Pmax: 5.32 W

Maximum Internal Capacitance Ci: 1.76 nF

Maximum Internal Inductance Li: 0 µH

• In the rating 1, the output current of the

barrier must be limited by a resistor “Ra”

such that

Io = Uo/Ra.

• In the rating 2 or 3, the output characteristics

of the barrier must be the type of trapezoid

which are certied as the FISCO model.

• The safety barrier may include a terminator.

• More than one eld instruments may be

connected to the power supply line.

A) FM Intrinsically Safe Type

Cautions for FM Intrinsically safe type. (Following

cotents refer “Doc No. IFM017-A12 P.1, 1-1, 2, 2-1,

and 2-2.”)

Note 1. Model YVP110 Advenced Valve Positioner

with optional code /FS15 are applicable for

use in hazardous locations.

• Applicable standard: FM3600, FM3610,

FM3611, FM3810, ANSI/NEMA250

• Intrinsically safe, with FISCO parameters, for

use in Class I, II, III, Division 1, Groups A, B,

C, D, E, F, G and Class I, Zone 0, AEx ia IIC

• Non-incendive for Class I, Division 2, Groups

A, B, C, D and Class I, Zone 2, Group IIC

• Indoor/Outdoor hazardous locations, NEMA

4X

• Ambient Temperature: –40 to 60°C

Note 2. Electrical Data

Rating 1

For Groups A, B, C, D, E, F and G or Group IIC

Maximum Input Voltage Vmax: 24 V

Maximum Input Current Imax: 250 mA

Maximum Input Power Pmax: 1.2 W

Maximum Internal Capacitance Ci: 1.76 nF

Maximum Internal Inductance Li: 0 µH

Note 3. Installation

• Dust-tight conduit seal must be used

when installed in Class II and Class III

environments.

• Control equipment connected to the

Assoiciated Apparatus must not use or

generate more than 250 Vrms or Vdc.

• Installation should be in accordance with

ANSI/ISA RP12.6 “Installation of Intrinsically

Safe Systems for Hazardous (Classied)

Locations” and the National Electrical Code

(ANSI/NFPA 70) Sections 504 and 505.

• The conguration of Associated Apparatus

must be Factory Mutual Research Approved

under FISCO Concept.

• Associated Apparatus manufacturer’s

installation drawing must be followed when

installing this equipment.

• The YVP series are approved for Class

I, Zone 0, applications. If connecting

AEx[ib] associated Apparatus or AEx ib I.S.

Apparatus to the YVP series the I.S. circuit

is only suitable for Class I, Zone 1, or Class

I, Zone 2, and is not suitable for Class I,

Zone 0, or Class I, Division 1, Hazardous

(Classied) Locations.

IM 21B04C01-01E

Page 15

<1. Notes on Handling>

1-4

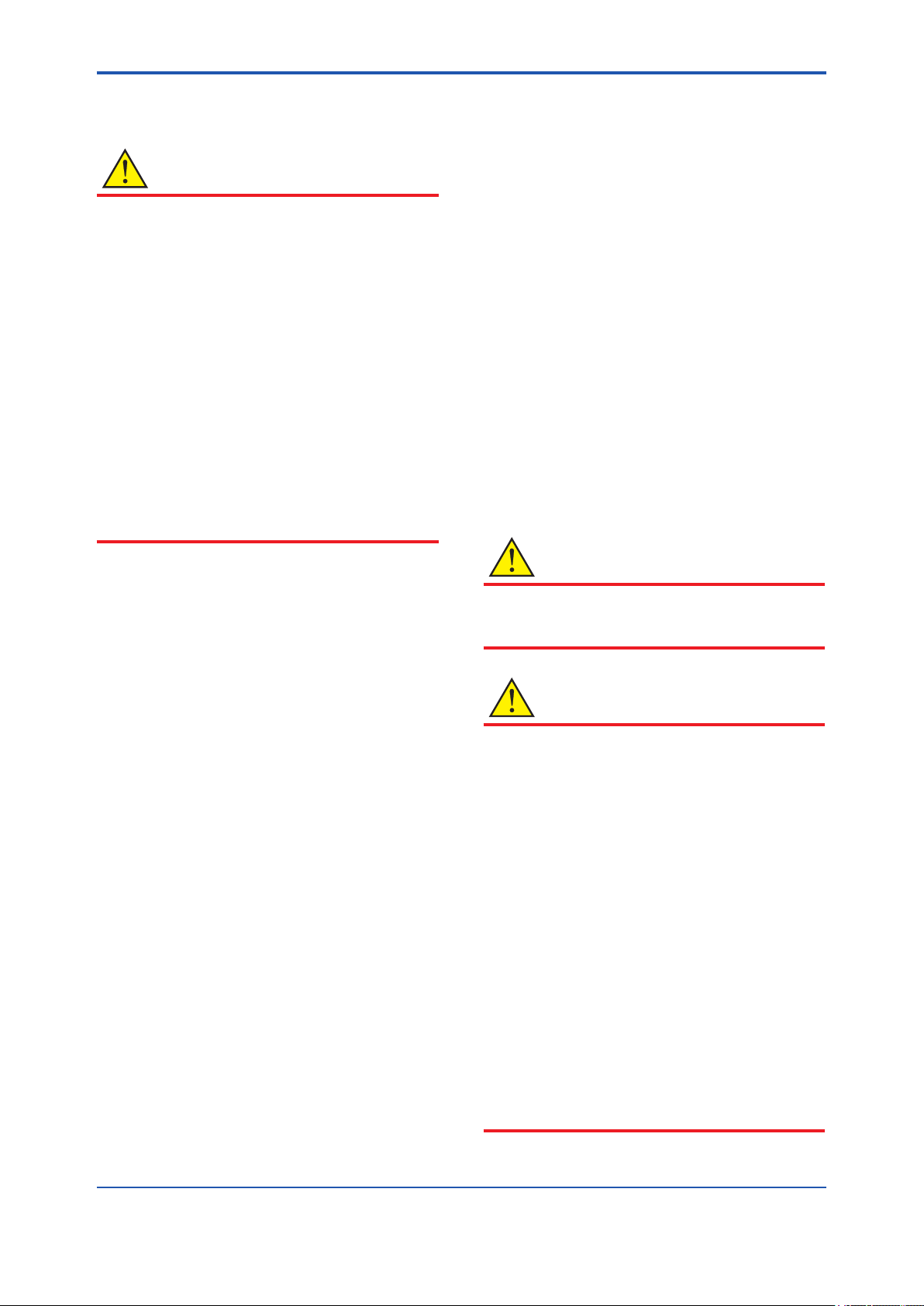

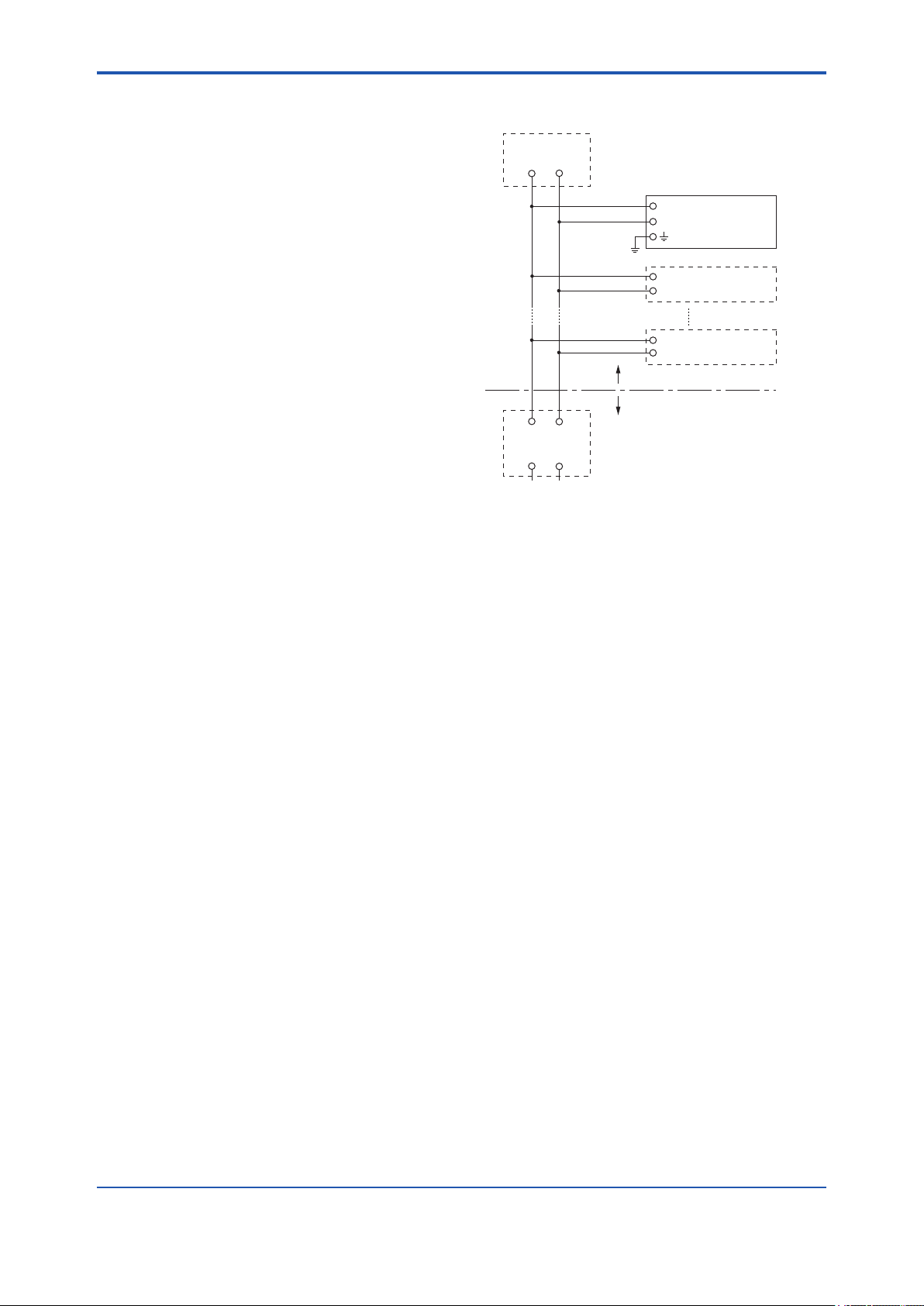

l Installation Diagram (Intrinsically safe,

Division 1 Installation)

Terminator

+

Valve Positioner

−

+

Transmitter

−

+

Transmitter

−

Hazardous Location

Non-hazardous Location

Terminator

−+

Safety Barrier

Note 4. FISCO rules

The FISCO concept allows the interconnection

of intrinsically safe apparatus to associated

apparatus not specically examined in

such combination. The criterion for such

interconnection is that the voltage (Ui), the

current (Ii) and the power (Pi) which intrinsically

safe apparatus can receive and remain

intrinsically safe, considering faults, must be

equal or greater than the voltage (Uo, Voc,

Vt), the current (Io) and the power (Po) which

can be provided by the associated apparatus

(supply unit). In addition, the maximum

unprotected residual capacitance (Ci) and

inductance (Li) of each apparatus (other than

the terminators) connected to the eldbus

must be less than or equal to 5 nF and 10 µH

respectively.

In each I.S. eldbus segment only one active

source, normally the associated apparatus, is

allowed to provide the necessary power for the

eldbus system. The allowed voltage Uo of the

associated apparatus used to supply the bus is

limited to the range of 14 V d.c. to 24 V d.c. All

other equipment connected to the bus cable

has to be passive, meaning that the apparatus

−+

F0102.ai

is not allowed to provide energy to the system,

except to a leakage current of 50 µA for each

connected device.

Supply unit

trapezoidal or rectangular output characteristic

only

Uo = 14 to 24 V (I.S. maximum value)

Io according to spark test result or other

assessment,

e.g. 133 mA for Uo = 15 V (Group IIC, rectangular

characteristic)

No specication of Lo and Co in the

certicate and on the label.

Cable

The cable used to interconnect the devices

needs to comply with the following parameters:

loop resistance R’: 15 to 150 Ω/km

inductance per unit length L’: 0.4 to 1 mH/km

capacitance per unit length C’: 80 to 200

nF/km

C’ = C’ line/line + 0.5 C’ line/screen, if both

lines are oating

or

C’ = C’ line/line + C’ line/screen, if the screen

is connected to one line

length of spur cable: max. 30 m (Group IIC)

or 120 m (Group IIB)

length of trunk cable: max. 1 km (Group IIC)

or 1.9 km (Group IIB)

Terminators

At each end of the trunk cable an approved

line terminator with the following parameters is

suitable:

R = 90 to 100 Ω

C = 0 to 2.2 µF

The resistor must be infallible according to IEC

60079-11. One of the two allowed terminators

might already be integrated in the associated

apparatus (bus supply unit).

System evaluation

The number of passive devices like

transmitters, actuators, hand held terminals

connected to a single bus segment is not

limited due to I.S. reasons. Furthermore, if the

above rules are respected, the inductance

and capacitance of the cable need not to be

considered and will not impair the intrinsic

safety of the installation.

IM 21B04C01-01E

Page 16

<1. Notes on Handling>

1-5

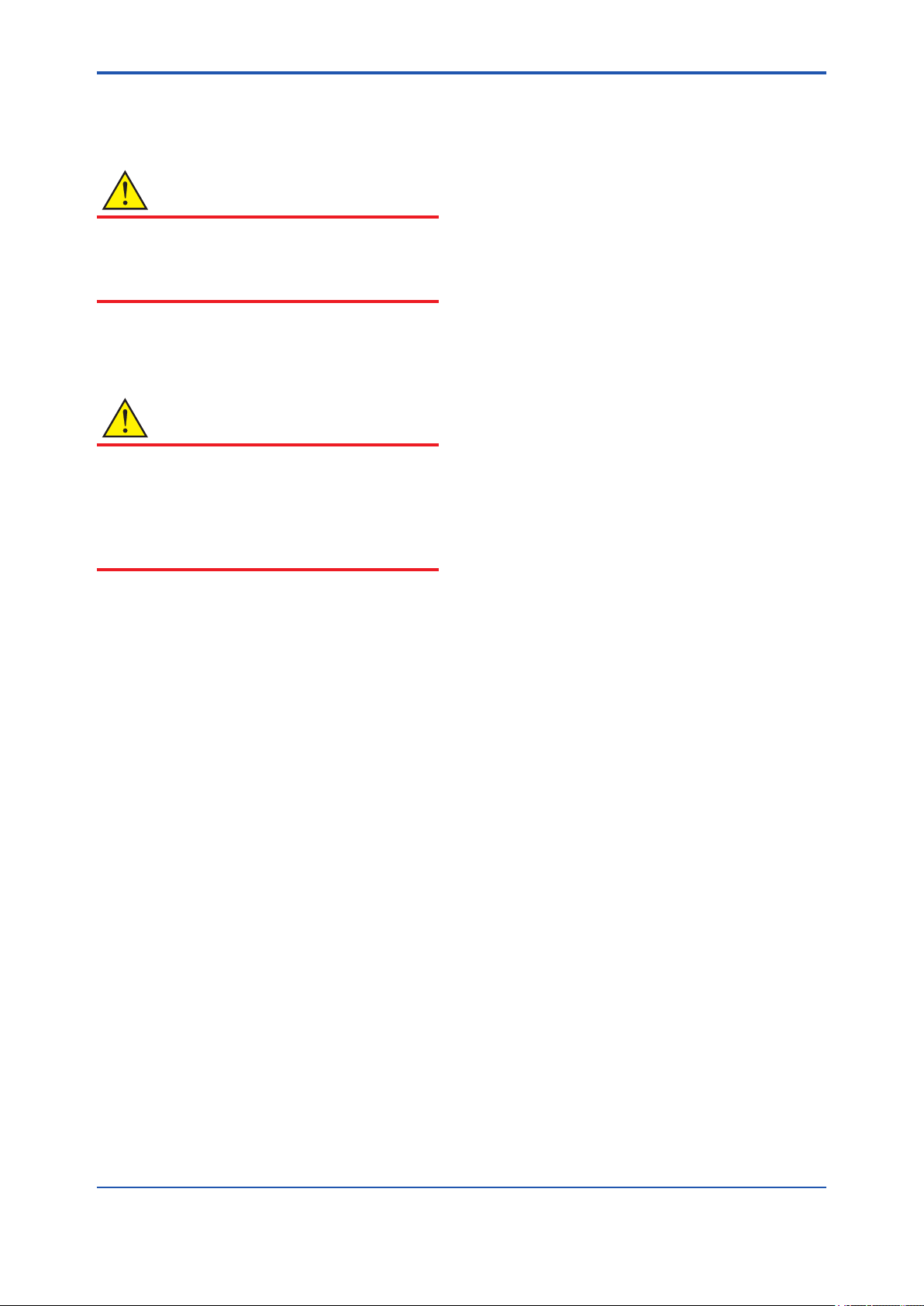

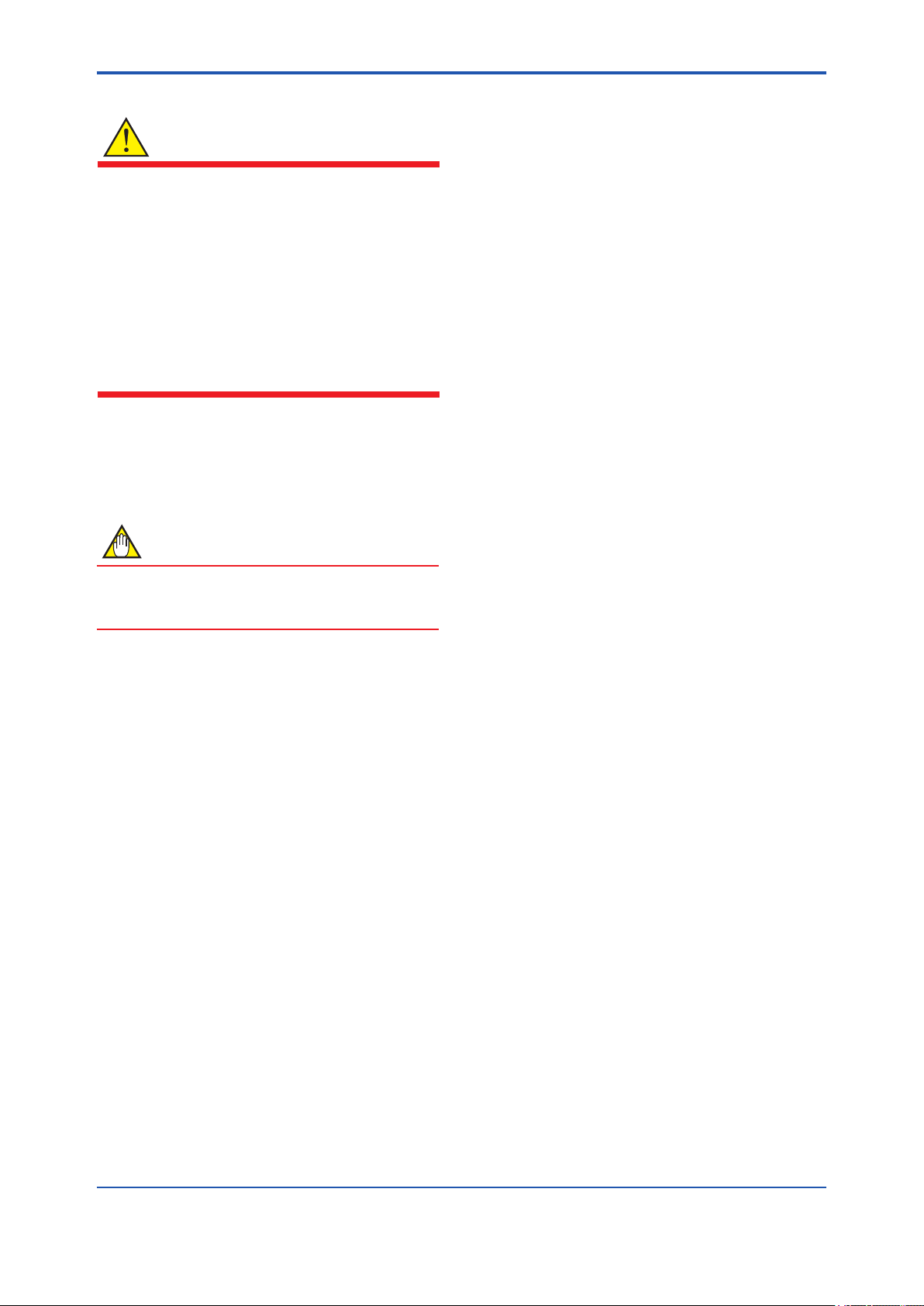

SAFE AREA HAZARDOUS AREA

Supply Unit

(FISCO Model)

U

U

I

Terminator

Data

Field Instruments

Terminator

(FISCO Model)

Ex i

(Passive)

Note 5. Maintenance and Repair

The instrument modication or parts

replacement by other than authorized

representative of Yokogawa Electric

Corporation is prohibited and will void Factory

Mutual Intrinsically Safe and Non-incendive

Approval.

l Installation Diagram (Nonincendive,

Division 2 Installation)

Terminator

+

Valve Positioner

−

+

Transmitter

−

F0103.ai

*1: Dust-tight conduit seal must be used when

installed in Class II and Class III environments.

*2: Installation should be in accordance with the

National Electrical Code® (ANSI/NFPA 70)

Sections 504 and 505.

*3: The conguration of Associated Nonincendive

Field Wiring Apparatus must be FM Approved.

*4: Associated Nonincendive Field Wiring

Apparatus manufacturer’s installation

drawing must be followed when installing this

equipment.

*5: No revision to drawing without prior FM

Approvals.

*6: Terminator and supply unit must be FM

Approved.

*7: If use ordinary wirings, the general purpose

equipment must have nonincendive eld wiring

terminal approved by FM Approvals.

*8: The nonincendive eld wiring circuit concept

allows interconection of nonincendive eld

wiring apparatus with associated nonincendive

eld wiring apparatus, using any of the wiring

methods permitted for unclassied locations.

*9: Installation requirements;

Vmax ≥ Voc or Vt

Imax = see note 10.

Ca ≥ Ci + Ccable

La ≥ Li + Lcable

*10: For this current controlled circuit, the parameter

(Imax) is not required and need not be aligned

with parameter (Isc or It) of the barrier or

associated nonincendive eld wiring apparatus.

Terminator

(Nonincendive)

Power Supply

+

Transmitter

−

Hazardous Location

Non-hazardous Location

FM Approved Associated

Nonincendive Field Wiring Apparatus

Vt or Voc

It or Isc

Ca

La

F0104.ai

Electrical Data:

Maximum Input Voltage Vmax: 32 V

Maximum Internal Capacitance Ci: 1.76 nF

Maximum Internal Inductance Li: 0 µH

B) FM Explosionproof Type

Caution for FM explosionproof type.

Note 1. Model YVP110 Valve Positioner with

optional code /FF1 are applicable for use in

hazardous locations.

• Applicable standard: FM3600, FM3615,

FM3810, ANSI/NEMA250

• Explosionproof for Class I, Division 1,

Groups A, B, C and D

• Dust-ignitionproof for Class II/III, Division 1,

Groups E, F and G

• Enclosure Rating: NEMA 4X

• Temperature Class: T6

• Ambient Temperature: –40 to 80°C

IM 21B04C01-01E

Page 17

<1. Notes on Handling>

1-6

Note 2. Wiring

• All wiring shall comply with National Electrical

Code ANSI/NEPA70 and Local Electrical

Codes.

• “FACTORY SEALED, CONDUIT SEAL NOT

REQUIRED.”

Note 3. Operation

• Note a warning label worded as follows;

WARNING: OPEN CIRCUIT BEFORE

REMOVING COVER.

• Take care not to generate mechanical spark

when accessing to the instrument and

peripheral devices in hazardous locations.

Note 4. Maintenance and Repair

• The instrument modication or parts

replacement by other than authorized

representative of Yokogawa Electric

Corporation is prohibited and will void

the approval of Factory Mutual Research

Corporation.

C) FM Nonincendive approval

Model YVP110 Advanced Valve Positioner with

optional code /FN15.

• Applicable standard: FM3600, FM3611,

FM3810

• Nonincendive Approval

Class I, Division 2, Groups A, B, C and D

Class II, Division 2, Groups F and G

Class III, Division 1 and

Class I, Zone 2, Group IIC in Hazardous

(Classied) Locations.

Temperature Class: T4

Ambient Temperature: –40 to 60°C

Enclosure: NEMA Type4X

• Electrical Parameters:

Vmax = 32 Vdc

Ci = 1.76 nF

Li = 0 µ H

• Caution for FM Nonincendive type.

(Following contents refer to “DOC. No.

NFM010-A12 p.1 and p.2”)

NFM010-A12

Installation Diagram:

Terminator

+

YVP

−

Valve Positioner

+

Field Instruments

−

+

Field Instruments

−

Hazardous Area

Safe Area

Nonincendive

Power Supply

F0105.ai

Note 1.

Dust-tight conduit seal must be used when

installed in Class II and Class III environments.

Note 2.

Installation should be in accordance with

National Electrical Code (ANSI/NFPA 70)

Sections 504, 505 and Local Electrical Code.

Note 3.

The conguration of Associated Apparatus must

be Factory Mutual Research Approved.

Note 4.

Associated Apparatus manufacturer's

installation drawing must be followed when

installing this equipment.

Note 5.

No revision to drawing without prior Factory

Mutual Research Approval.

Note 6.

Terminator and supply unit must be FM

approved.

Note 7.

Installation requirements;

Vmax ≥ Voc or Vt

Ca ≥ Ci + Ccable

La ≥ Li + Lcable

IM 21B04C01-01E

Page 18

<1. Notes on Handling>

1-7

1.9.2 ATEX Certication

WARNING

• Do not open the cover when energized.

• When the ambient temp.≥70°C,

Use the heat-resisting cable≥90°C

• Take care not to generate mechanical

sparking when access to the instrument and

peripheral devices in hazardous locations.

• Electrostatic charge may cause an explosion

hazard.

Avoid any actions that cause the generation

of electrostatic charge, such as rubbing with

a dry cloth on coating face of product.

(1) Technical Data

A) ATEX Intrinsically Safe Type (Ex ia)

Caution for ATEX Intrinsically Safe Type.

NOTE

Degree of Protection of the Enclosure: IP65

Electrical Parameters:

For Ex ia IIC or Ex iaD

Ui = 24.0 V, Ii = 250 mA, Pi = 1.2 W,

Cint = 1.76 nF, Lint = 0 μH

or

For Ex ia IIB/ IIC or Ex iaD (FISCO model)

Ui = 17.5 V, Ii = 380 mA, Pi = 5.32 W,

Cint = 1.76 nF, Lint = 0 μH

For II 1D Ex tD

Input signal: 32 Vdc,

Output current: 17 mA

Note 3. Installation

All wiring shall comply with local installation

requirements.

(Refer to the installation diagram)

Note 4. Maintenance and Repair

The instrument modication or parts

replacement by other than authorized

representative of Yokogawa Electric

Corporation is prohibited and will void KEMA

Intrinsically safe Certication.

Keep the safety use conditions for both 1G and

1D when used in the hazardous gas and dust

area.

Note1. Model YVP110 Advanced Valve Positioner

with optional code /KS25 for potentially

explosive atmospheres:

• Applicable standard: EN60079-0:2006,

EN60079-11:2007, EN60079-26:2007,

EN60079-27:2006, EN61241-0:2006,

EN61241-1:2004, EN61241-11:2006 and

EN60529

• Certicate: KEMA 08ATEX0114 X

Note 2. Ratings

Type of Protection:

II 1G Ex ia IIB/IIC T4

II 1D Ex iaD 20 IP65 T100°C

II 1D Ex tD A20 IP65 T100°C

Maximum Surface Temperature for dust proof.:

T100°C

Ambient Temperature Ex ia or Ex iaD:

–40°C to +60°C

Ambient Temperature Ex tD: –40°C to +80°C

Ambient Humidity: 0 to 100%RH

(No condensation)

Note 5. Special Conditions for Safe Use

Because the enclosure of the Valve Positioner

is made of aluminium, if it is mounted in an area

where the use of category 1G apparatus is

required, it must be installed such, that, even in

the event of rare incidents, ignition sources due

to impact and friction sparks are excluded.

Once used as apparatus of equipment category

1D in type of protection Ex tD, the valve

positioner is no longer suitable as apparatus

of equipment category 1G or 1D in type of

protection Ex ia or Ex iaD.

Note 6. Installation Instructions

When used in a potentially explosive

atmosphere, requiring the use of apparatus of

equipment category 1D, suitable certied cable

entry devices or certied blanking elements

with a degree of ingress protection of at least

IP6X according to EN 60529 shall be used and

correctly installed.

Note 7. Installation

When used in potentially explosive atmosphere

for category 1D, need not use safety barrier.

IM 21B04C01-01E

Page 19

<1. Notes on Handling>

1-8

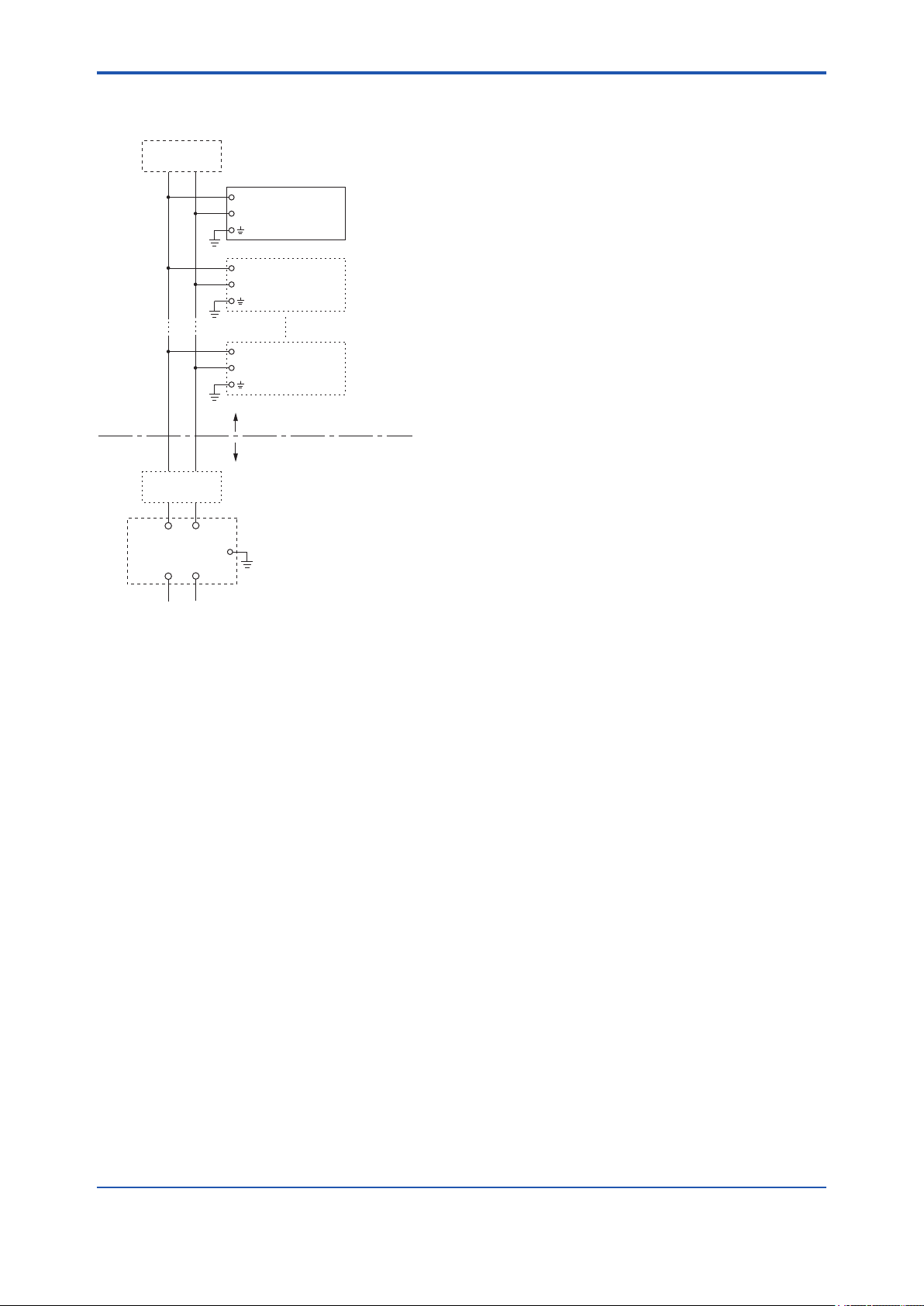

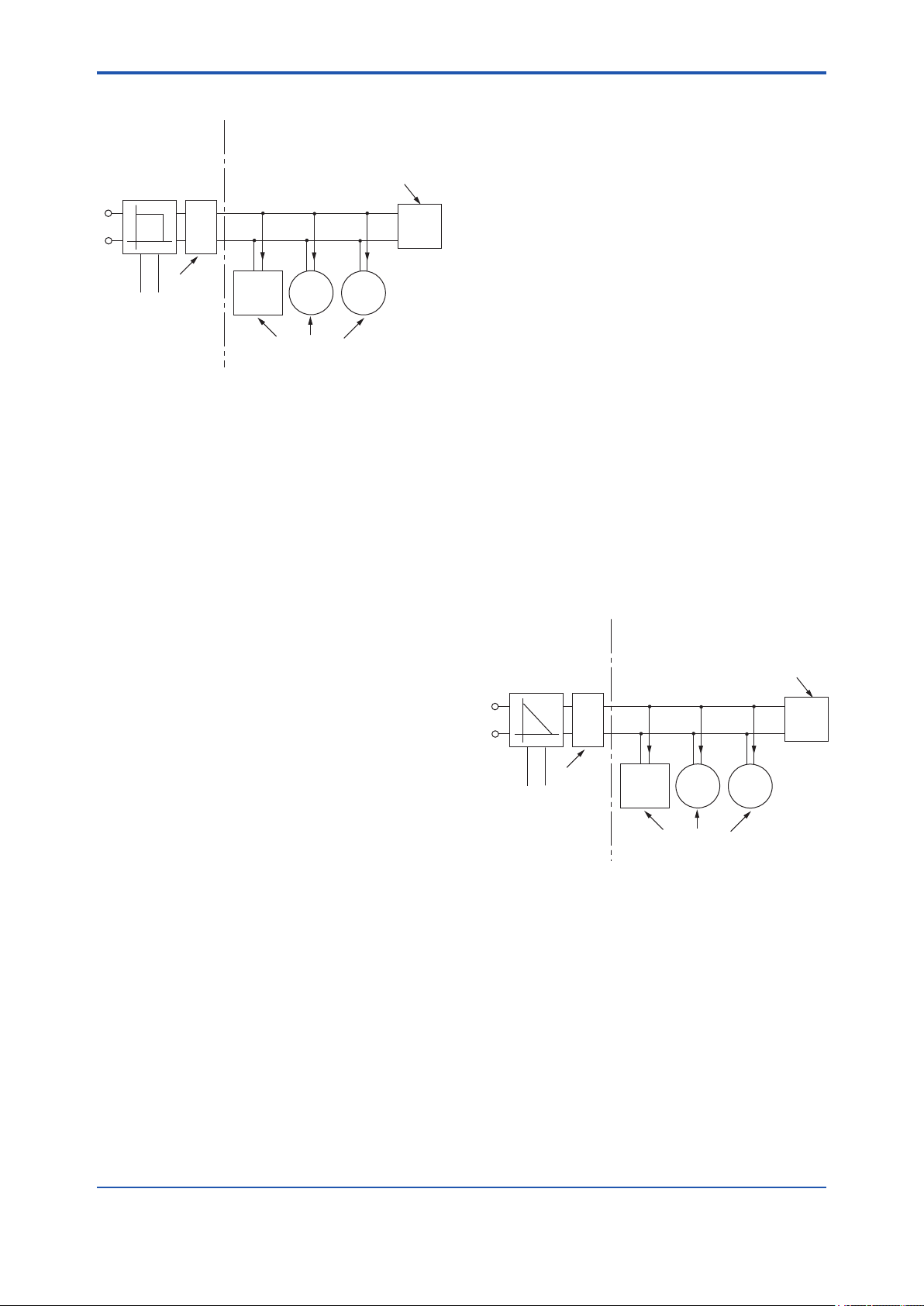

FISCO Model

Non-hazardous

Locations

Supply Unit

(FISCO Model)

U

U

I

Terminator

Data

I.S. eldbus system complying with FISCO

The criterion for such interconnection is that the

voltage (Ui), the current (Ii) and the power (Pi),

which intrinsically safe apparatus can receive,

must be equal or greater than the voltage (Uo),

the current (Io) and the power (Po) which can be

provided by the associated apparatus (supply unit).

In addition, the maximum unprotected residual

capacitance (Ci) and inductance (Li) of each

apparatus (other than the terminators) connected

to the eldbus line must be equal or less than 5 nF

and 10 µH respectively.

Supply unit

The supply unit must be certied by a notied body

as FISCO model and following trapezoidal output

characteristic is used.

Uo = 14 to 24 V (I.S. maximum value)

Io based on spark test result or other assessment,

ex. 133 mA for Uo = 15 V (Group IIC)

The maximum allowed Co and Lo are determined

by the combinations as specied below.

Cable

The cable used to interconnect the devices needs

to comply with the following parameters:

loop resistance R': 15 to 150 Ω/km

inductance per unit length L': 0.4 to 1 mH/km

capacitance per unit length C': 80 to 200 nF/km

C' = C' line/line + 0.5 C' line/screen, if both lines

are oating

Hazardous Locations

Terminator

(FISCO Model)

Ex i

Hand-

held-

Terminal

Field Instruments

(Passive)

F0106.ai

or

C' = C' line/line + C' line/screen, if the screen is

connected to one line

length of spur cable: max. 30 m (Ex ia IIC T4) or

120 m (Ex ia IIB T4)

length of trunk cable: max. 1 km (Ex ia IIC T4)

or 1.9 km (Ex ia IIB T4)

Terminators

The terminator must be certied by a notied body

as FISCO model and at each end of the trunk

cable an approved line terminator with the following

parameters is suitable:

R = 90 to 100 Ω

C = 0 to 2.2 µF

The resistor must be infallible according to EN

50020. One of the two allowed terminators might

already be integrated in the associated apparatus

(bus supply unit).

Number of Devices

The number of devices (max. 32) possible on a

eldbus link depends on factors such as the power

consumption of each device, the type of cable used,

use of repeaters, etc.

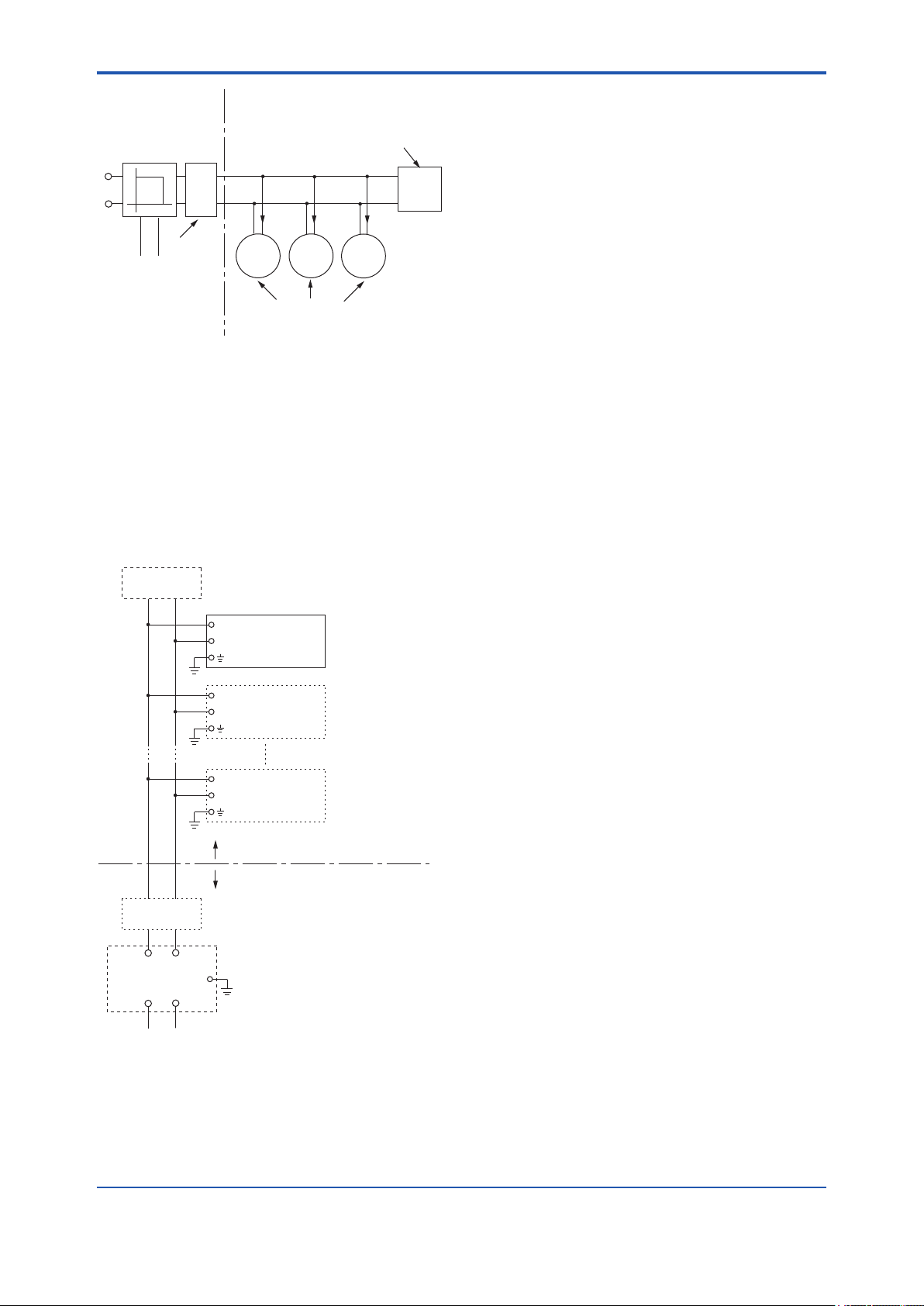

Entity Model

Non-hazardous

Locations

Supply Unit

U

U

I

Terminator

Data

I.S. eldbus system complying with Entity model

Hazardous Locations

Ex i

Hand-

held-

Terminal

Field Instruments

(Passive)

Terminator

F0107.ai

IM 21B04C01-01E

Page 20

<1. Notes on Handling>

1-9

I.S. values Power supply-eld device:

Po ≤ Pi, Uo ≤ Ui, Io ≤ Ii

Calculation of max. allowed cable length:

Ccable ≤ Co - ∑ci - ∑ci (Terminator)

Lcable ≤ Lo - ∑Li

Number of Devices

The number of devices (max. 32) possible on a

eldbus link depends on factors such as the power

consumption of each device, the type of cable used,

use of repeaters, etc.

B) ATEX Flameproof Type

Caution for ATEX ameproof type.

Note 1. Model YVP110 Valve Positioner with

optional code /KF2 is applicable for

potentially explosive atmospheres:

• Applicable standard:

EN60079-0:2009, EN60079-1:2007

• Certicate: KEMA 10ATEX0023 X

• Group: II

• Category: 2G

• Type of Protection and Marking Code:

Ex d IIC, T6 or T5 Gb

• Ambient Temperature: T6; –40 to 65°C

T5; –40 to 80°C

Note 2. Electrical Data

• Supply voltage: 32 V DC max.

• Output signal: 17 mA DC

Note 3. Installation Instructions

• The cable glands and blanking elements

shall be certied in type of protection

ameproof enclosure “d” suitable for the

conditions of use and correctly installed.

• With the use of conduit entries a sealing

device shall be provided either in the

ameproof enclosure or immediately on the

entrance thereto.

• To maintain the degree of ingress protection

IP65 according to EN 60529 special care

must be taken to avoid water entering the

breathing and draining device when the valve

positioner is mounted with the feedback shaft

in the upright position.

Note 4. Operation

• Keep strictly the WARNING on the label on

the positioner.

AFTER DE-ENERGIZING, DELAY 5

MINUTES BEFORE OPENING.

WHEN THE AMBIENT TEMP. ≥ 70°C,

USE HEAT-RESISTING CABLE & CABLE

GLAND ≥ 90°C.

Note 5. Maintenance and Repair

• The instrument modication or parts

replacement by other than authorized

representative of Yokogawa Electric

Corporation is prohibited and will void KEMA

Flameproof Certication.

C)

ATEX Intrinsically safe (Ex ic)/Type n (Ex nA)

Note 1. Model YVP110 Advanced Valve Positioner

with optional code /KN25

• Applicable standard:

EN60079-0:2009/EN60079-0:2012(Ex ic/Ex

nA), EN60079-11:2012(Ex ic)

EN60079-15:2010(Ex nA)

• Ex ic: II 3G Ex ic IIC T4 Gc (Intrinsically safe)

• Ex nA: II 3G Ex nA IIC T4 Gc (Non-sparking)

• Ambient Temperature: -30 to 75°C

• Ambient Humidity:

0 to 100%RH (No condensation)

• Enclosure: IP65

• Installation category: I

Note 2. Electrical Data

• Ex ic: Ui = 32 V, Ci = 3.52 nF, Li = 0 μH

• Ex nA: 32 V DC MAX

Note 3. For the installation of this positioner, once

a particular declared type of protection

is selected, the other type of protection

cannot be used. The installation must be in

accordance with the description about type

of protection in this instruction manual.

Note 4. In order to avoid confusion, unnecessary

marking is crossed out on the label other

than the selected type of protection when

positioner is installed.

Note 5. Installation Instructions

• Cable glands, adapters and/or blanking

elements shall be of Ex “n”, EX “e” or Ex “d”

and shall be installed so as to maintain the

specied degree of protection (IP Code) of

the equipment.

• To maintain the degree of protection IP65

according to IEC 60529, special care must

be taken to avoid water.

Note 6. Maintenance and Repair

• The instrument modication or parts

replacement by other than authorized

representative of Yokogawa Electric

Corporation is prohibited and will void ATEX

Ex ic and Ex nA.

IM 21B04C01-01E

Page 21

<1. Notes on Handling>

1-10

Note 7. Ex ic Installation

• All wiring shall comply with local installation

requirements (refer to the installation

diagram)

Installation Diagram

Hazardous Area

Valve Positioner

+

−

Non-hazardous Area

Associated Apparatus

+

−

Electrical Data: Ui = 32 V

Ci = 3.52 nF

Li = 0 μH

Note 8. Ex ic Specic Conditions of Use

WARNING

• Electrostatic charge may cause an explosion

hazard. Avoid any actions that cause the

generation of electrostatic charge, such as

rubbing with a dry cloth on coating face of

product.

• When the lightning protector option is

specied (/A), the apparatus is not capable

of withstanding the 500V insulation test

required by EN60079-11. This must be taken

into account when installing the apparatus.

• WHEN THE AMBIENT TEMP.≥70°C, USE

THE HEAT-RESISTING CABLE AND

CABLE GRAND≥90°C

• POTENTAIAL ELECTROSTATIC

CHARGING HAZARD – SEE USER’S

MANUAL

F0108.ai

Note 10. Ex nA Specic Conditions of Use

WARNING

• Electrostatic charge may cause an explosion

hazard. Avoid any actions that cause the

generation of electrostatic charge, such as

rubbing with a dry cloth on coating face of

product.

• WHEN THE AMBIENT TEMP.≥70°C, USE

THE HEAT-RESISTING CABLE AND

CABLE GRAND≥90°C

• POTENTAIAL ELECTROSTATIC

CHARGING HAZARD – SEE USER’S

MANUAL

• DO NOT OPEN IN AN EXPLOSIVE

ATMOSPHERE WHEN ENERGIZED

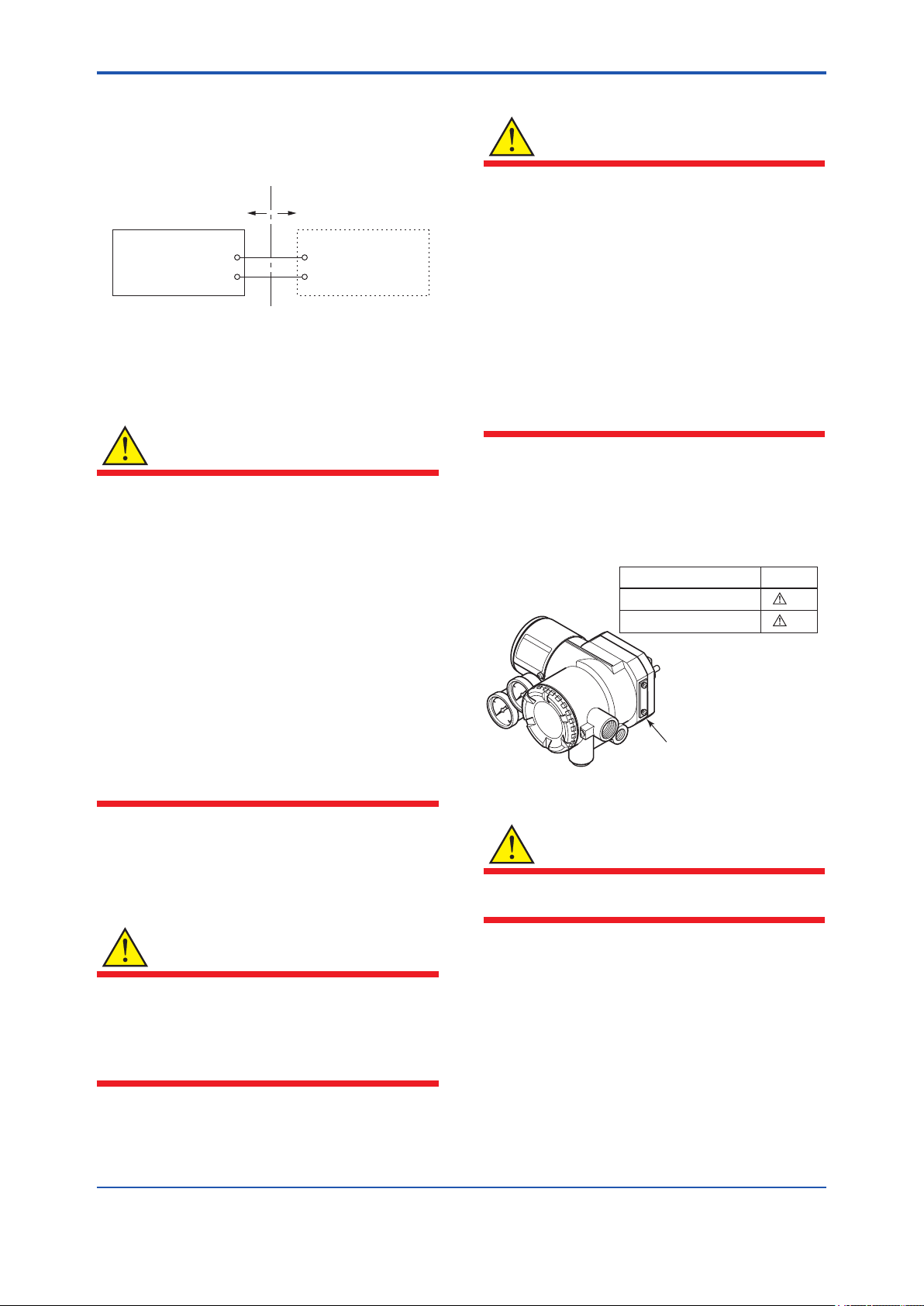

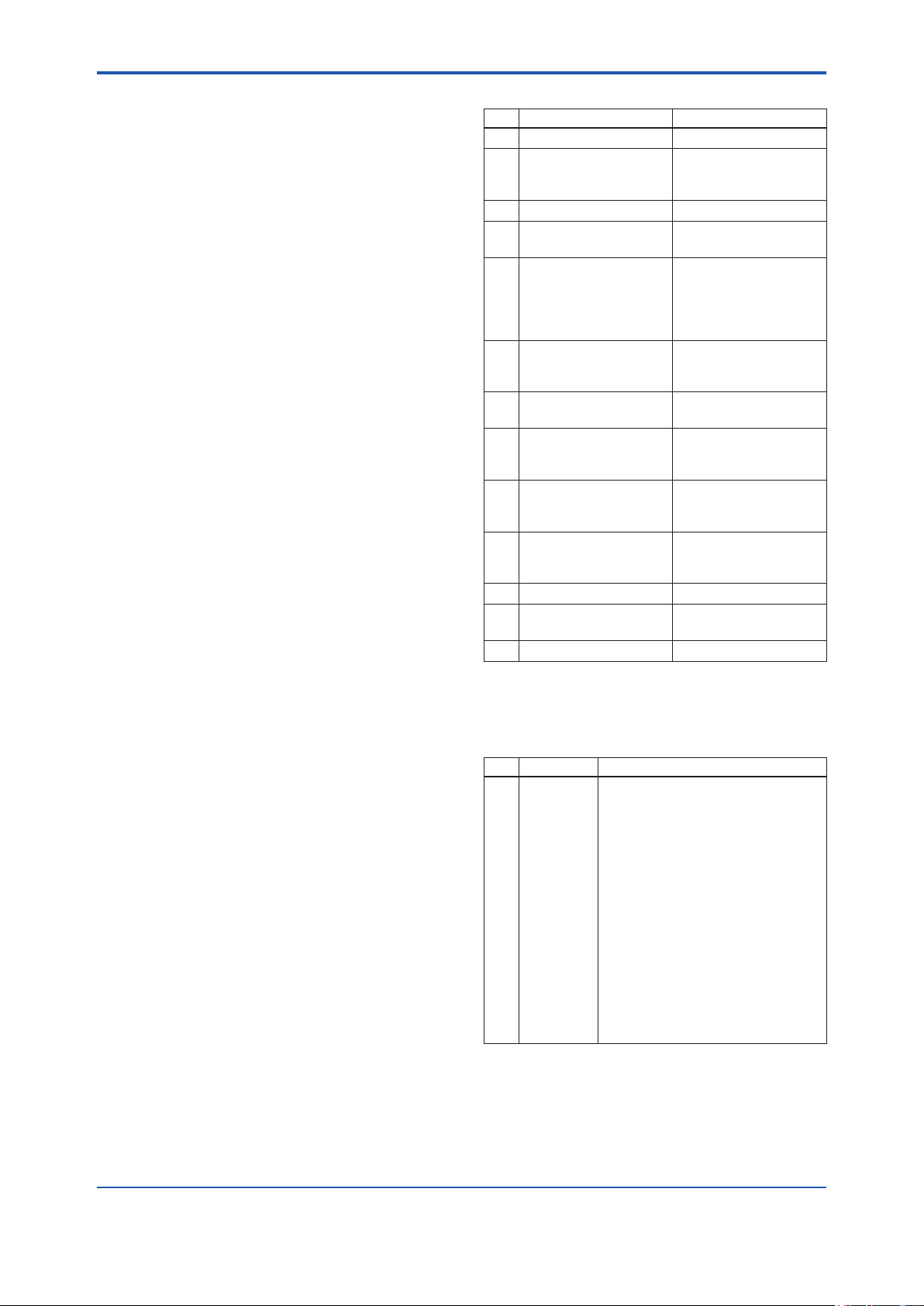

(2) Electrical Connection

The type of electrical connection is stamped near

the electrical connection port according to the

following marking.

Screw Size Marking

ISO M20

ANSI 1/2 NPT female

× 1.5 female

Location of the marking

M

N

F0109.ai

(3) Installation

Note 9. Ex nA Installation

• Screws of terminals for eld wiring

connections shall be tightened with specied

torque values: 1.2 N·m

WARNING

When using a power supply not having a

nonincendive circuit, please pay attention not to

ignite in the surrounding ammable atmosphere.

In such a case, we recommend using wiring

metal conduit in order to prevent the ignition.

WARNING

All wiring shall comply with local installation

requirement and local electrical code.

IM 21B04C01-01E

Page 22

<1. Notes on Handling>

1-11

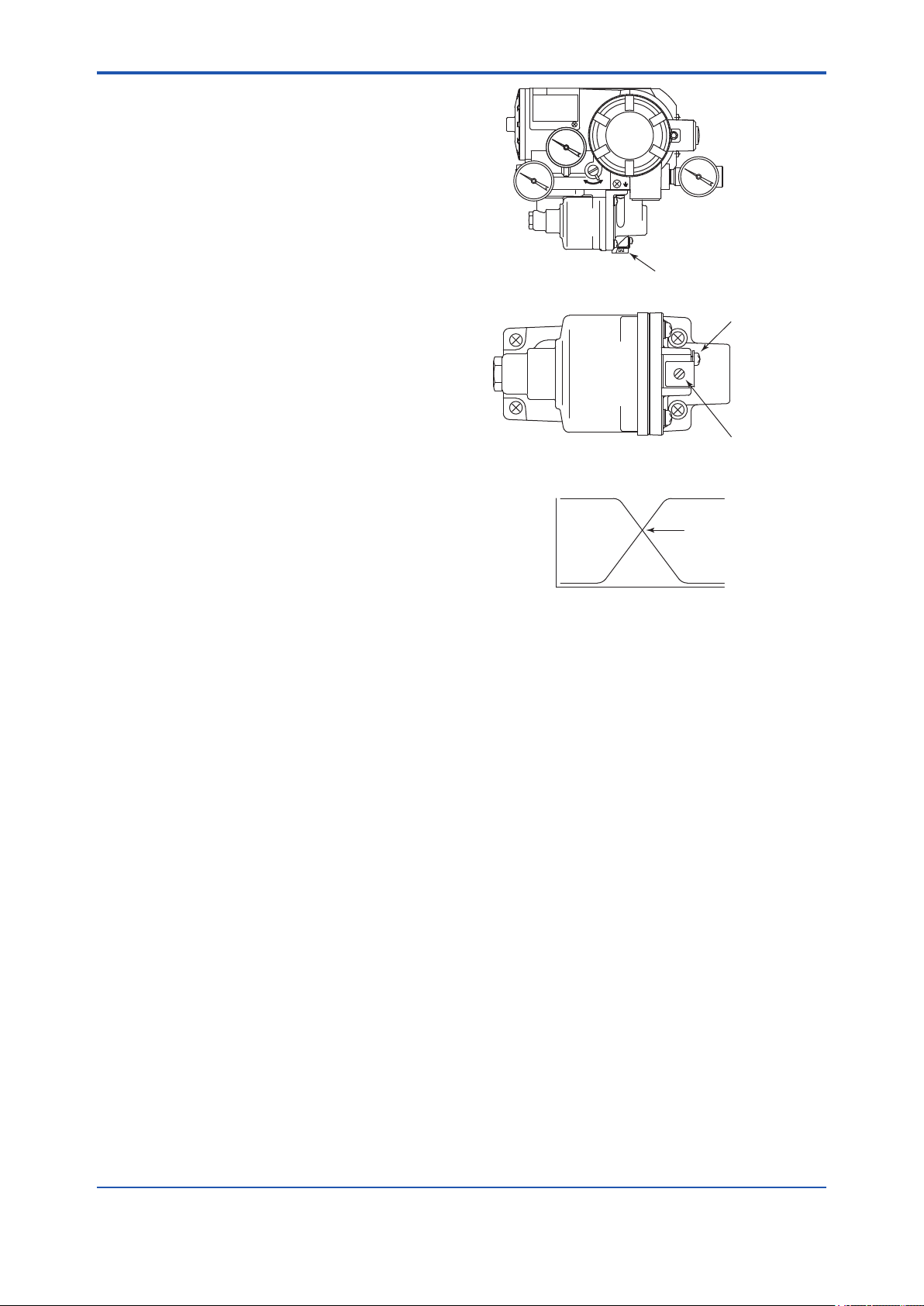

The grounding terminals are located on the inside

and outside of the terminal area.

Connect the cable to grounding terminal in

accordance with wiring procedure 1) or 2).

1) Internal grounding

terminal

2) External grounding

terminal

F0111.ai

Wiring Procedure for Grounding Terminals

(4) Operation

WARNING

• OPEN CIRCUIT BEFORE REMOVING

COVER. INSTALL IN ACCORDANCE WITH

THIS USER’S MANUAL

• Take care not to generate mechanical

sparking when access to the instrument and

peripheral devices in hazardous locations.

• Electrostatic charge may cause an explosion

hazard.

Avoid any actions that cause the generation

of electrostatic charge, such as rubbing with

a dry cloth on coating face of product.

• Carbon disulphide is excluded for enclosures

under gas atmosphere.

(5) Maintenance and Repair

WARNING

The instrument modication or parts replacement

by other than authorized Representative of

Yokogawa Electric Corporation is prohibited and

will void the certication.

(6) Name Plate

● Name plate for

intrinsically safe type

F91 76LL

YV P KS2 5

WARNING

DON'T OPEN WHEN ENERGIZED.

WHEN THE AMBIENT TEMP. ≥70°C

USE THE HEAT-RESISTING CABLE ≥90°C

No. KEMA 08ATEX0114 X

II 1G Ex ia IIB/IIC T4

II 1D Ex iaD 20 IP65 T100°C

II 1D Ex tD A20 IP65 T100°C

ENCLOSURE:IP65

For II 1G Ex ia IIC or II 1D Ex iaD

Ui=24V Ii=250mA Pi=1.2W Ci=1.76nF Li=0µH

For II 1G Ex ia IIC/IIB or II 1D Ex iaD (FISCO field device)

Ui=17.5V Ii=380mA Pi=5.32W Ci=1.76nF Li=0µH

For II 1D Ex tD

Input signal:32V Output current:17mA

0344

9-17.5(24)V DC (Ex ia, iaD) 9-32.0V DC (Ex tD)

TOKYO 180-8750 JAPAN

Tamb: −40 to 60°C

Tamb: −40 to 60°C

Tamb: −40 to 80°C

II 1G,1D

Foundation Fieldbus

*3

Made in Japan

N200

● Name plate for

/KN25 (Ex ic, Ex nA)

F91 76MQ

YV P KN2 5

WARNING

WHEN THE AMBIENT TEMP.≥70°C,

USE THE HEAT-RESISTING CABLE & CABLE GLAND ≥90°C.

POTENTIAL ELECTROSTATIC CHARGING HAZARD.

- SEE USER’S MANUAL

DO NOT OPEN IN AN EXPLOSIVE ATMOSPHERE WHEN

ENERGIZED

Ex nA IIC T4 Gc

Tamb −30 TO 75°C

ENCLOSURE : IP 65

SUPPLY 32V DC MAX

CROSS OUT UNNECESSARY MARKING OTHER

THAN THE SELECTED TYPE OF PRPTECTION

TOKYO 180-8750 JAPAN

Ex ic IIC T4 Gc

Tamb −30 TO 75°C

ENCLOSURE : IP 65

Ui=32V, Ci=3.52nF, Li=0µH

II 3G

Foundation Fieldbus

N200

*3

Made in Japan

● Name plate for

flameproof type

F91 76LK

YV P KF2

WARNING

AFTER DE-ENERGIZING, DELAY 5 MINUTES

BEFORE OPENING.

WHEN THE AMBIENT TEMP.≥70°C,

USE THE HEAT-RESISTING CABLE & CABLE GLAND ≥90°C.

POTENTIAL ELECTROSTATIC CHARGING HAZARD.

SEE USER’S MANUAL BEFORE USE.

No. KEMA 10ATEX0023X

Ex d IIC T6,T5 Gb

SUPPLY 32V DC MAX

Tamb −40 TO 65°C(T6),80°C(T5)

ENCLOSURE : IP 65

0344

TOKYO 180-8750 JAPAN

II 2G

9 - 32 V DC Foundation Fieldbus

*3

Made in Japan

N200

F0110.ai

MODEL: Specied model code.

SUFFIX: Specied sufx code.

STYLE: Style code.

SUPPLY: Air supply pressure.

NO.: Serial number and year of production*1.

INPUT: Type of electrical input (FOUNDATION

FIELDBUS).

TOKYO 180-8750 JAPAN:

The manufacturer name and the address*2.

*1: The third gure from the last of the serial number shows

the year of production. For example, the production year

of the product engraved in “NO.” column on the name

plate as follows is 2001.

12A220566 108

The year 2001

*2: “180-8750” is a zip code which represents the following

address.

2-9-32 Nakacho, Musashino-shi, Tokyo Japan

*3: The production year is shown on the place of *3 (for

example “2013.02).”

IM 21B04C01-01E

Page 23

<1. Notes on Handling>

1-12

1.9.3 CSA Certication

A) CSA Explosionproof Type

Cautions for CSA Explosionproof type.

Note 1. Model YVP110 Advanced Valve Positioner

with optional code /CF1 are applicable for

use in hazardous locations:

• Applicable standard: C22.2 No. 0, No. 0.4,

No. 0.5, No. 25, No. 30, No. 94, No. 1010.1

• Certicate: 1186507

• Explosionproof for Class I, Groups B, C and

D; Class II, Groups E, F and G; Class III.

• Enclosure Rating: Type 4X

• Temperature Code: T6 and T5

• Ambient Temperature: –40 to 75°C for T6,

–40 to 82°C for T5

Note 2. Wiring

• All wiring shall comply with National Electrical

Code ANSI/NFPA 70 and Local Electrical

Codes.

• “FACTORY SEALED, CONDUIT SEAL NOT

REQUIRED.”

• When the ambient temperature is 60°C

or more, use an external cable having a

maximum allowable heat-resistance of at

least 90°C.

1.9.4 TIIS Certication

A) TIIS Flameproof Type

The model YVP110 Valve Positioner with optional

code /JF3, which has obtained certication

according to technical criteria for explosionprotected construction of electric machinery and

equipment (Standards Notication No. 556 from

the Japanese Ministry of Labor) conforming to IEC

standards, is designed for hazardous areas where

inammable gases or vapors may be present. (This

allows installation in Division 1 and 2 areas)

To preserve the safety of ameproof equipment

requires great care during mounting, wiring, and

piping. Safety requirements also place restrictions

on maintenance and repair activities. Users

absolutely must read “Installation and Operating

Precautions for JIS Flameproof Equipment” at the

end of this manual.

CAUTION

When selecting cables for TIIS ameproof type

positioners, use cables having a maximum

allowable heat resistance of at least 70°C.

Note 3. Maintenance and Repair

• The instrument modication or parts

replacement by other than authorized

representative of Yokogawa Electric

Corporation is prohibited and will void CSA

Certication.

IM 21B04C01-01E

Page 24

<2. Part Names>

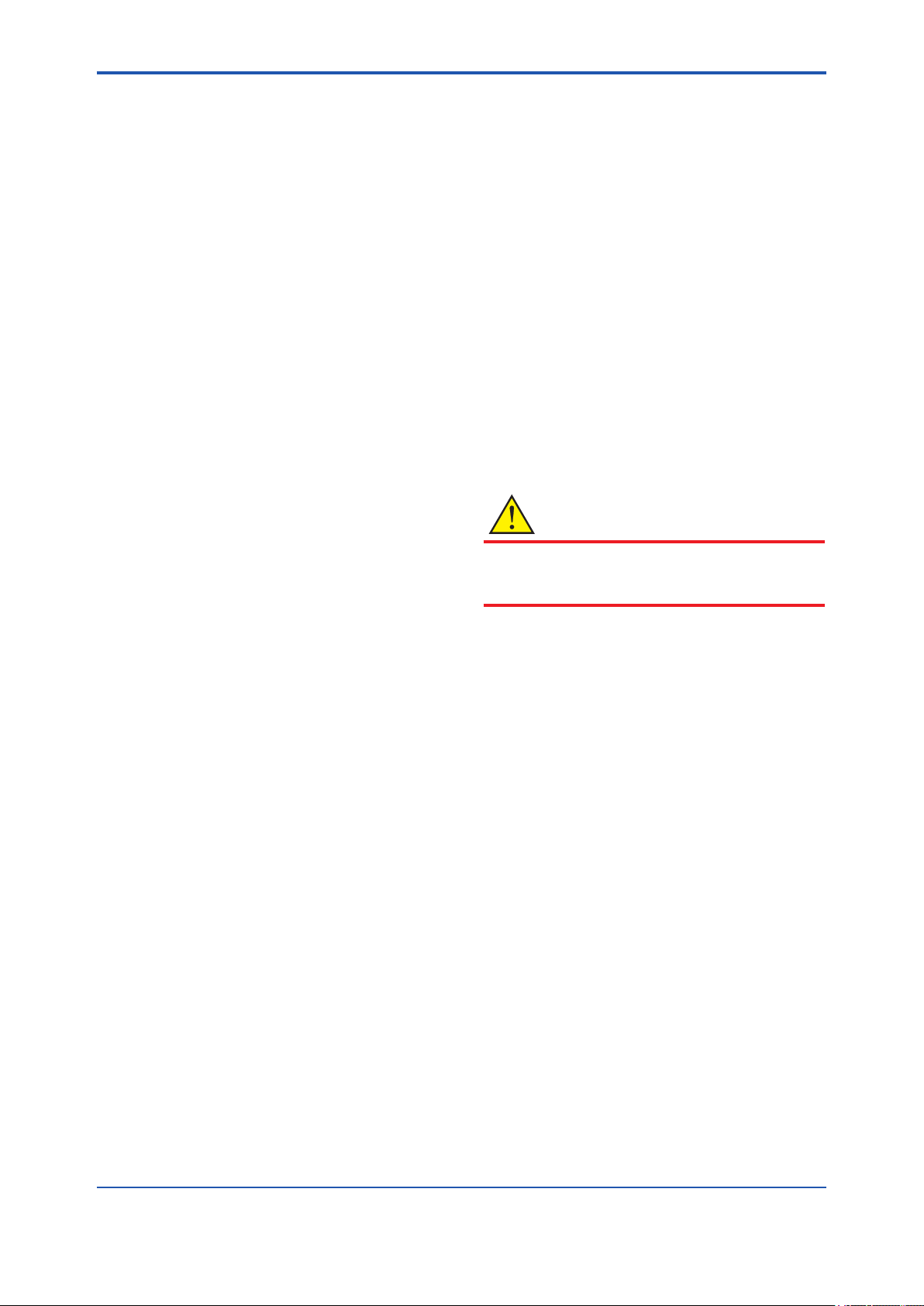

2. Part Names

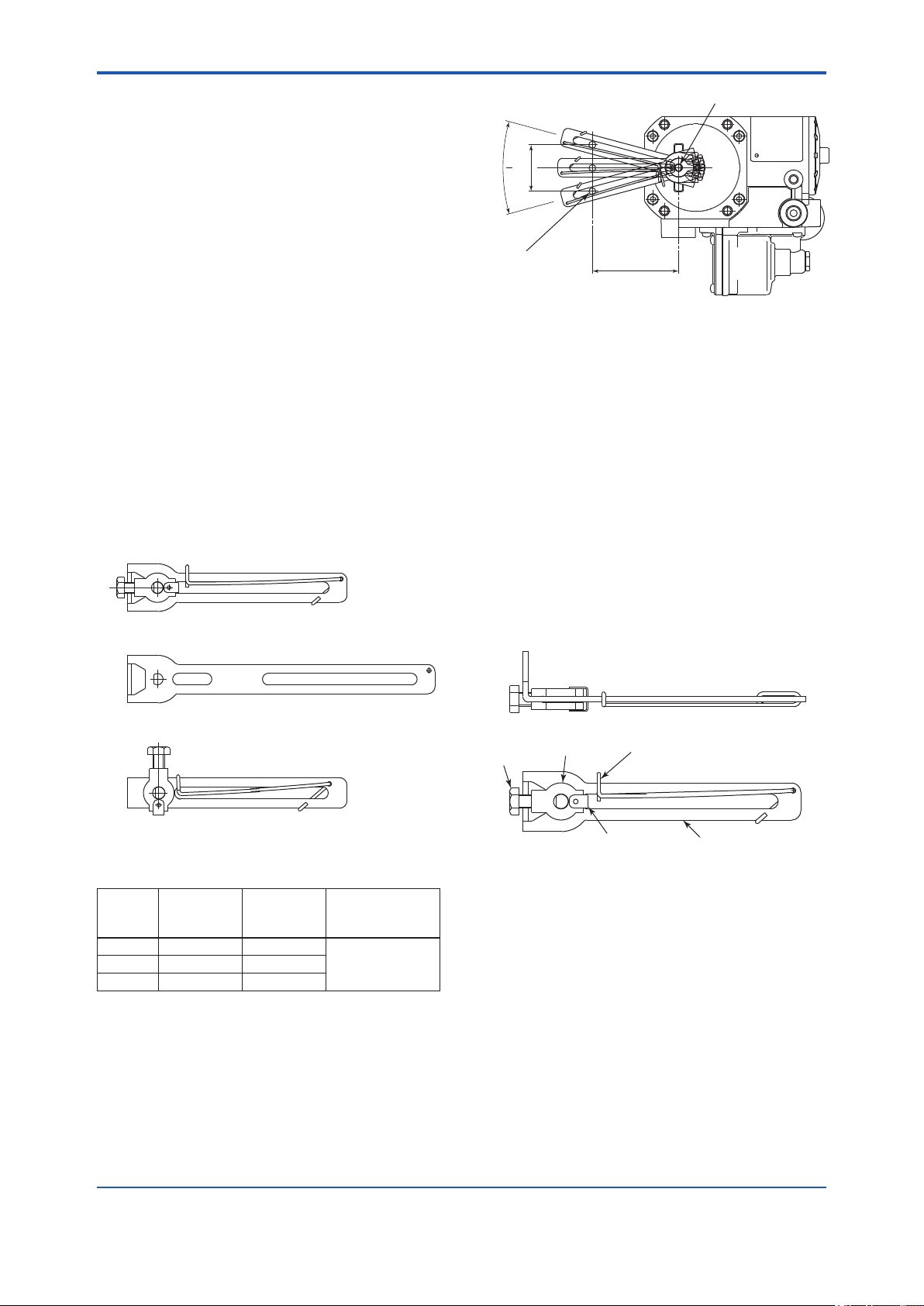

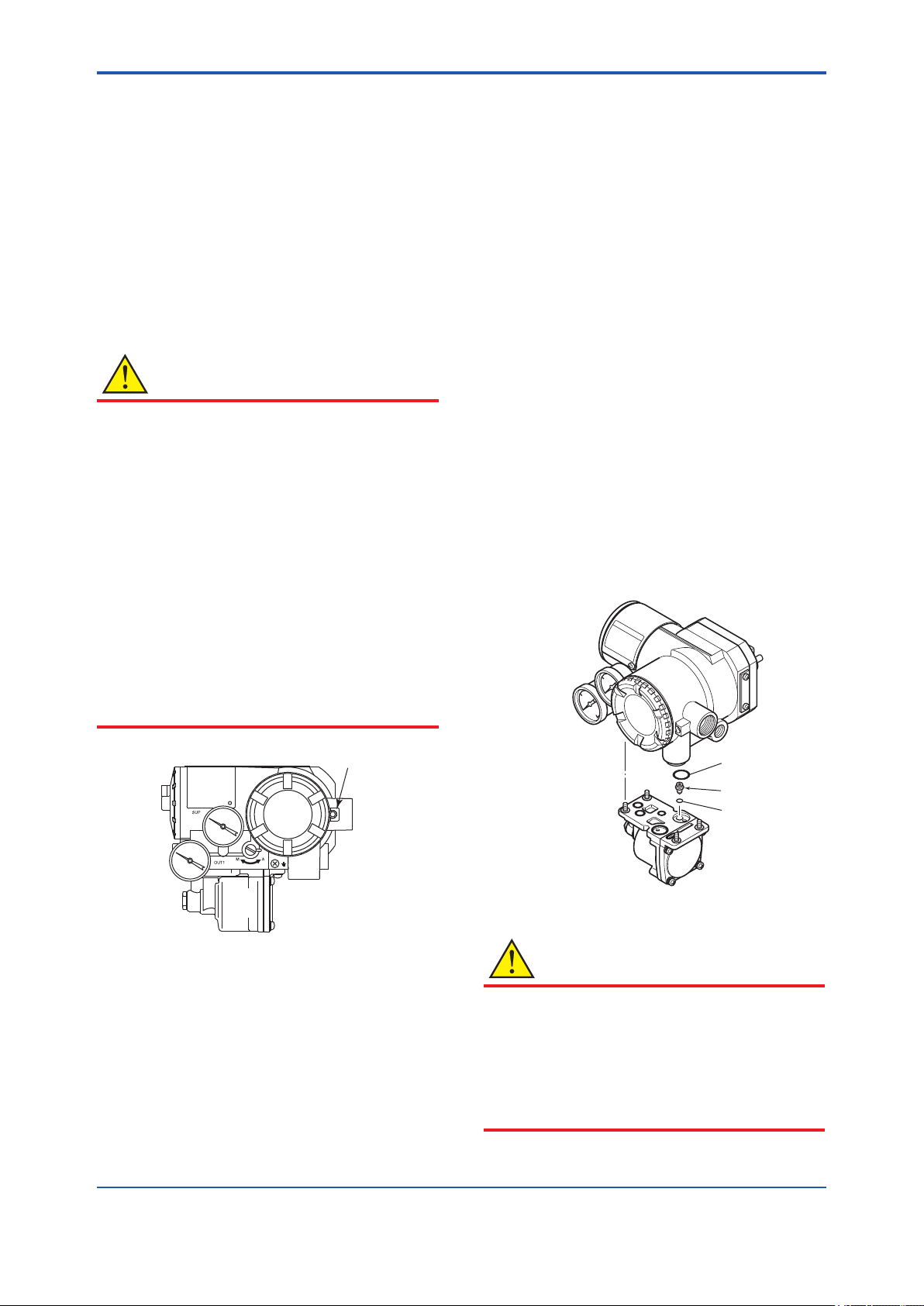

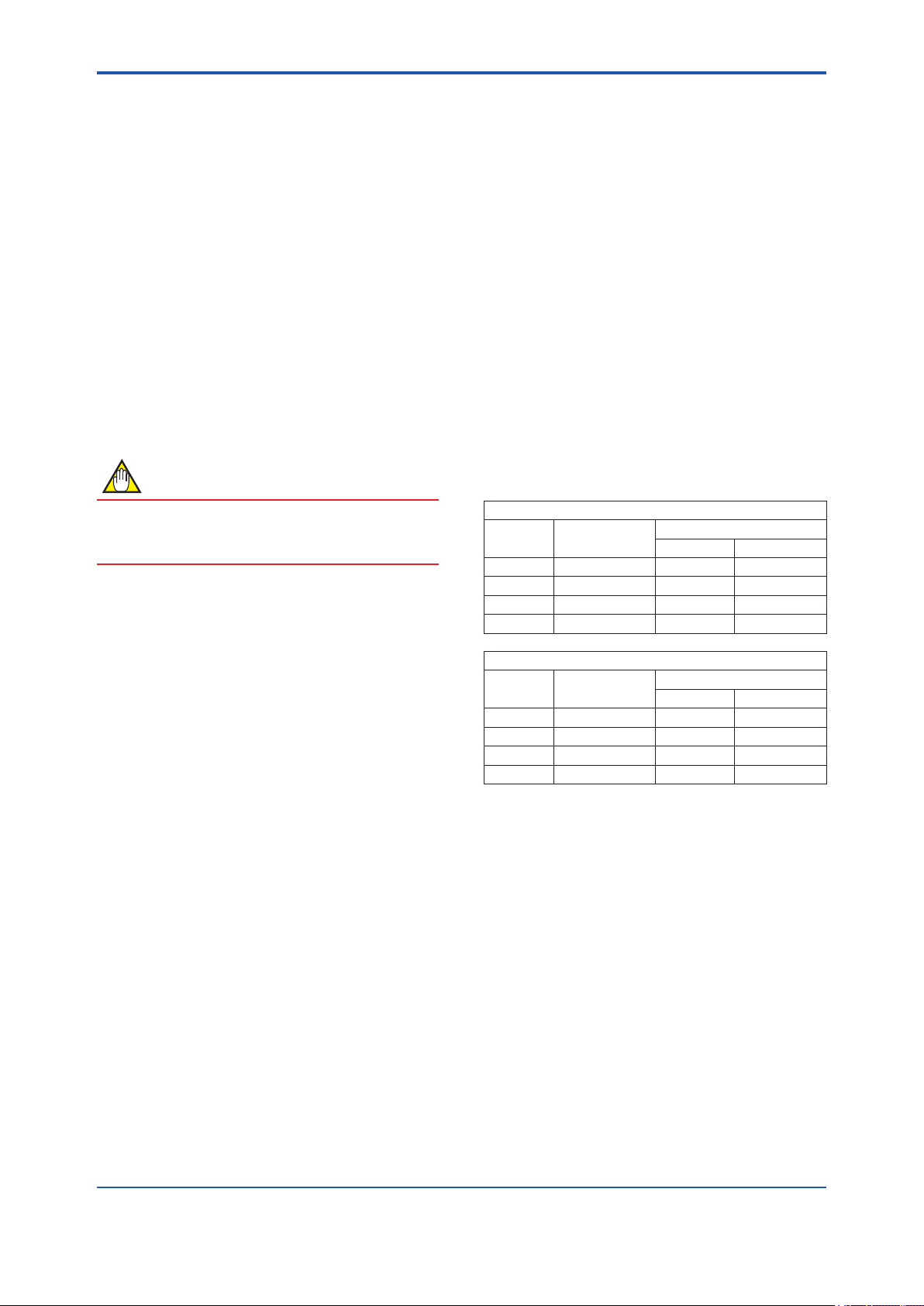

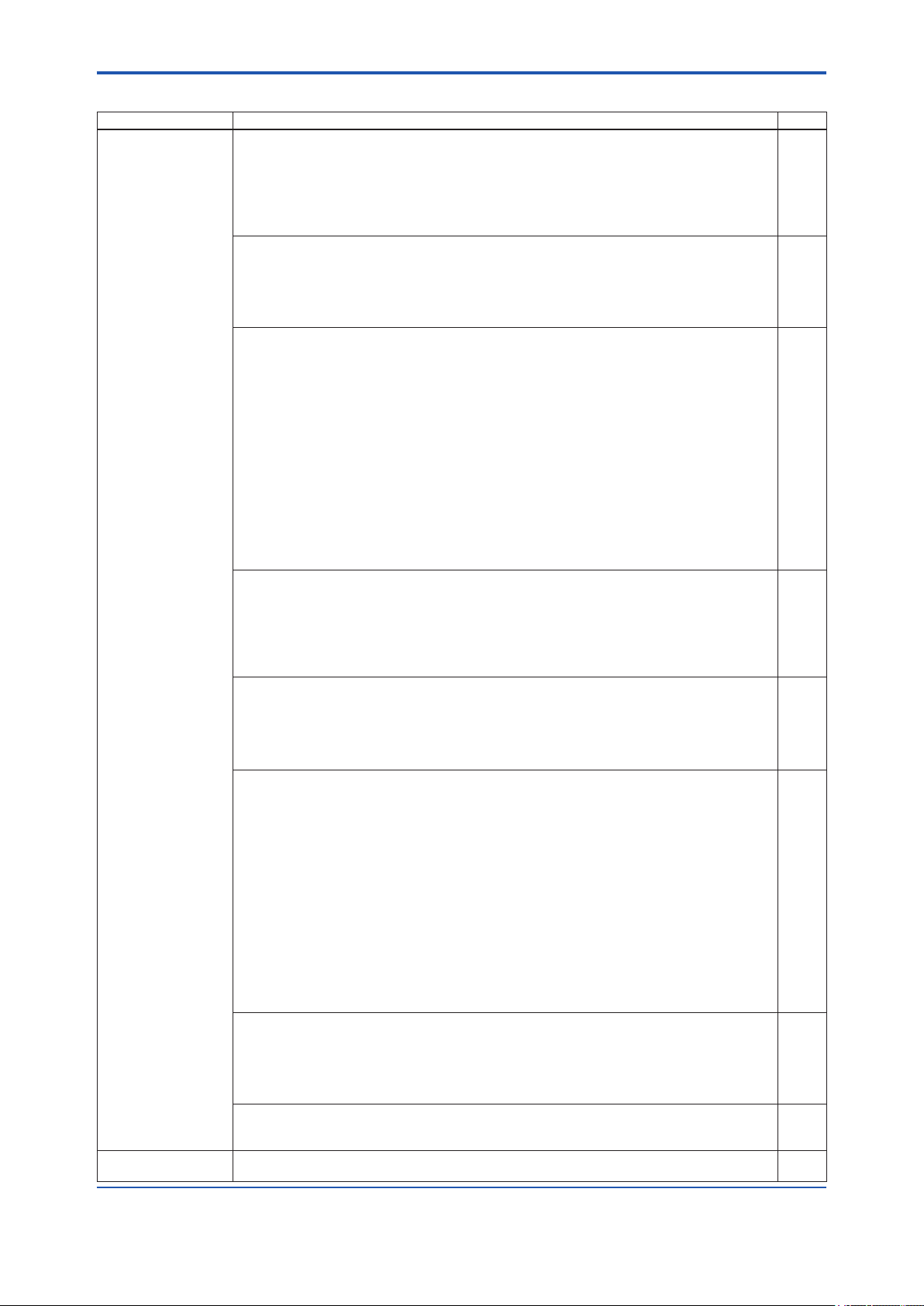

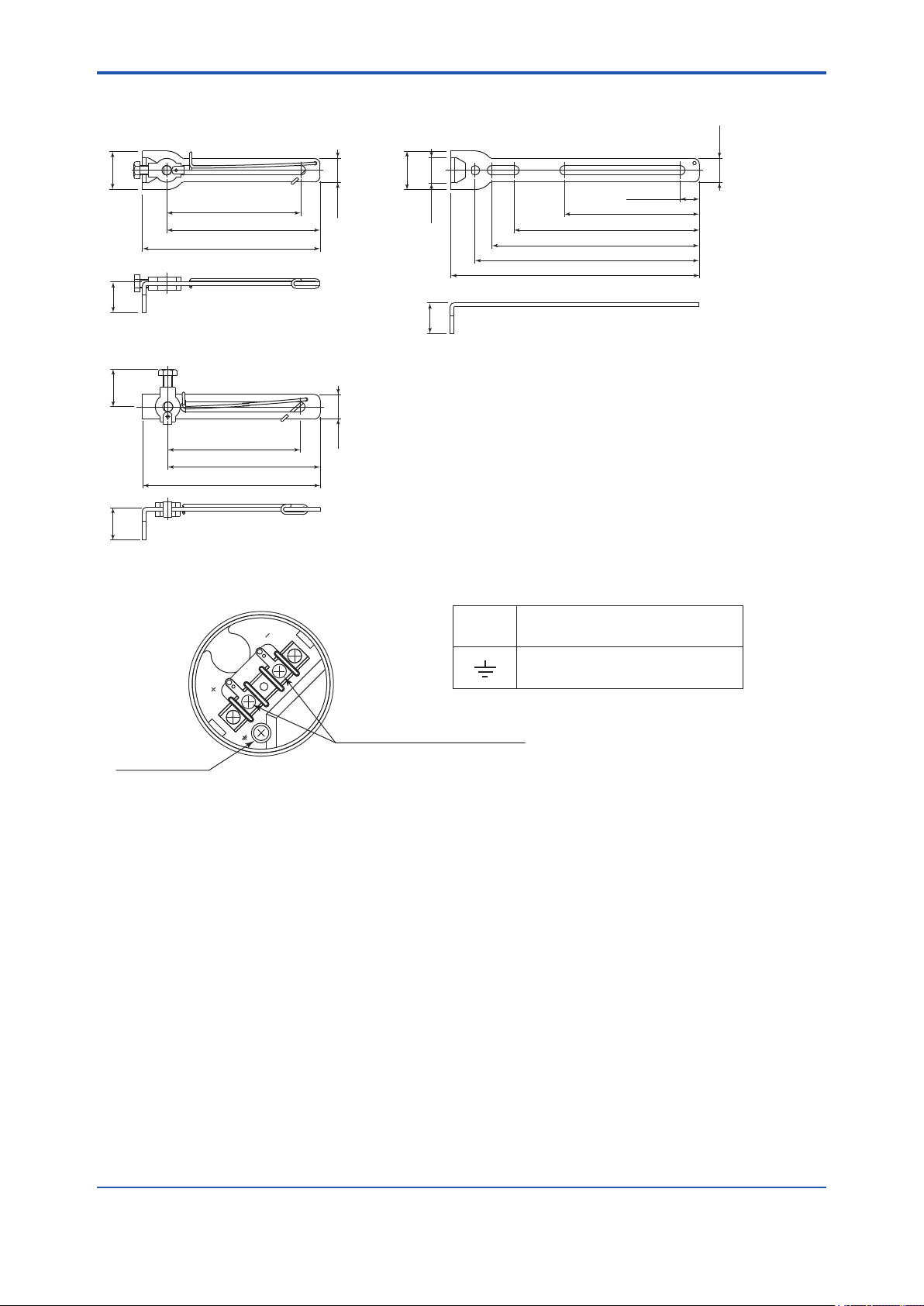

2.1 Appearance and Part Names

2-1

Single Acting Type

Name plate

Air supply

connection

Output pressure

connection

Output pressure

gauge (Optional)

Double Acting Type

Name plate

Air supply

connection

Output pressure

connection

Output pressure

gauge (Optional)

Feedback lever (Optional)

Terminal cover

Electrical

connection

Ground terminal

Air supply pressure gauge

(Optional)

Feedback lever (Optional)

Terminal cover

Output pressure

connection

Output pressure

gauge (Optional)

Electrical

connection

Ground terminal

Air supply pressure gauge

(Optional)

For M8 mounting bolt

Output pressure

gauge (Option)

Output pressure

connection

For mounting

(Normally not used)

Air supply connection

Feedback shaft

Control relay

For mounting

(Normally not used)

Air supply

connection

Feedback shaft

Control relay

For M8 mounting bolt

F0201.ai

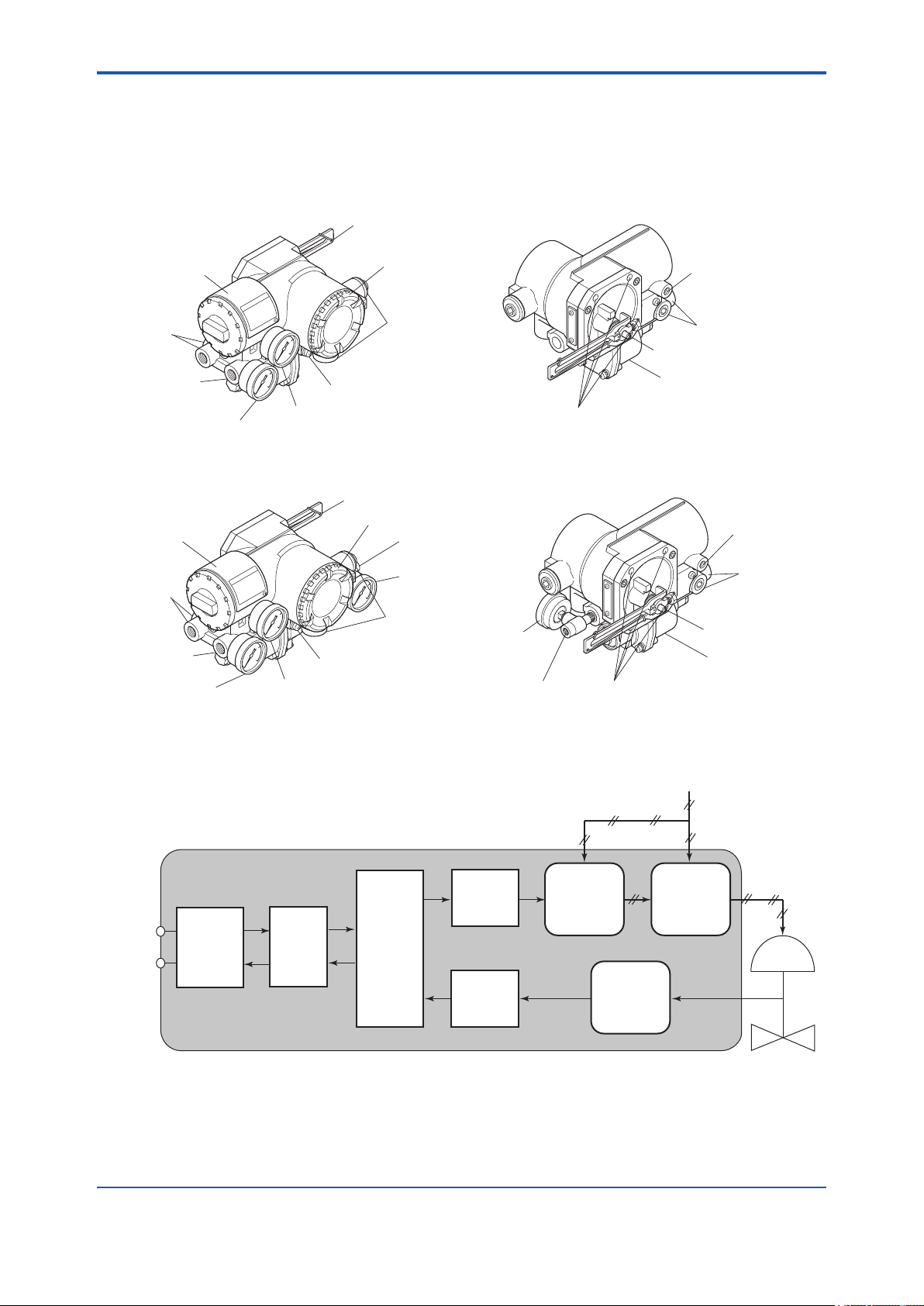

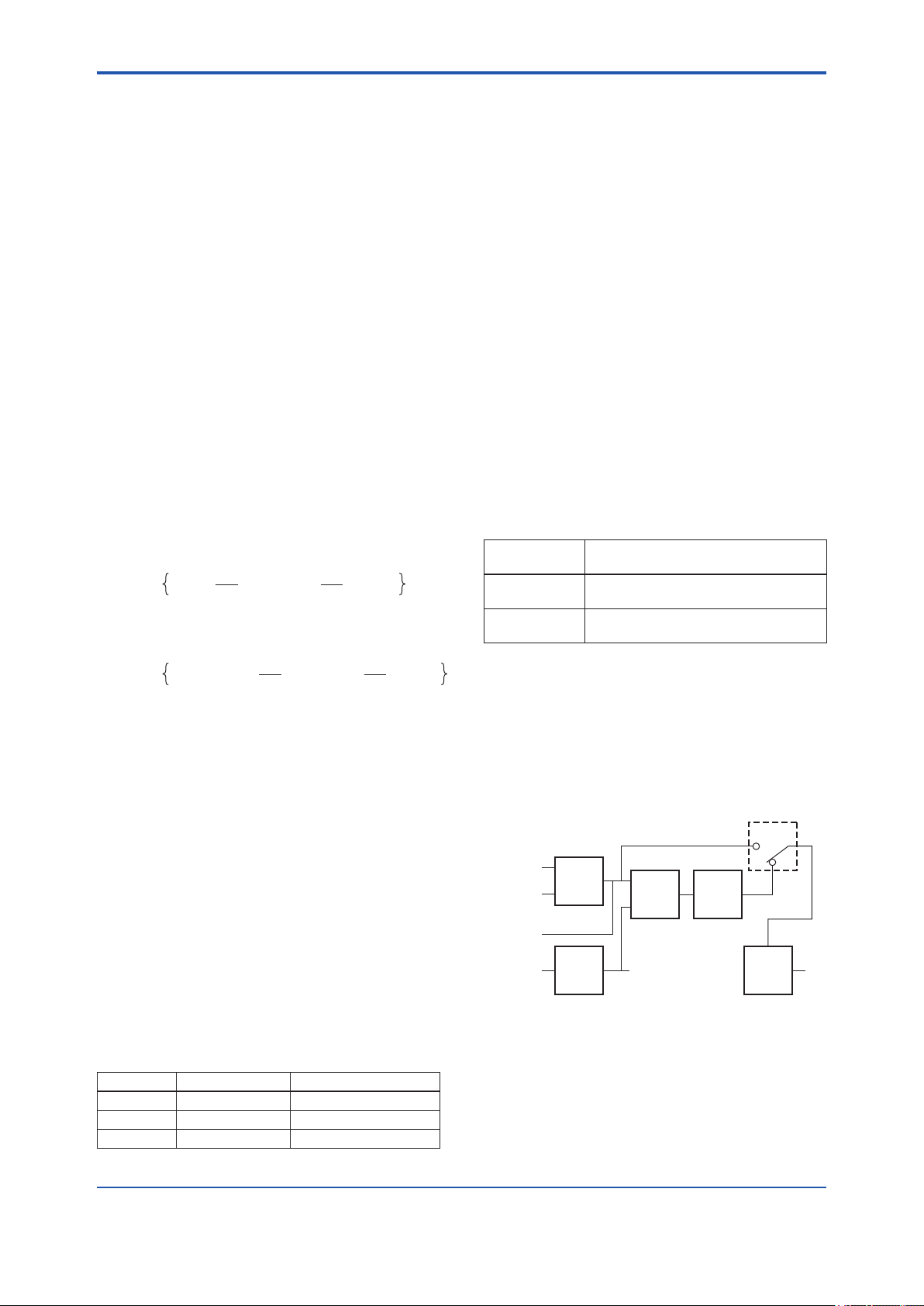

2.2 Block Diagram

YVP110

Fieldbus

Commu-

nication

Circuit

Regulator

Fieldbus

Modem

CPU

Digital

Processing

Unit

D/A

Conversion

A/D

Conversion

I/P Module

Supply Air Pressure

Control

Relay

Position

Sensor

F0202.ai

IM 21B04C01-01E

Page 25

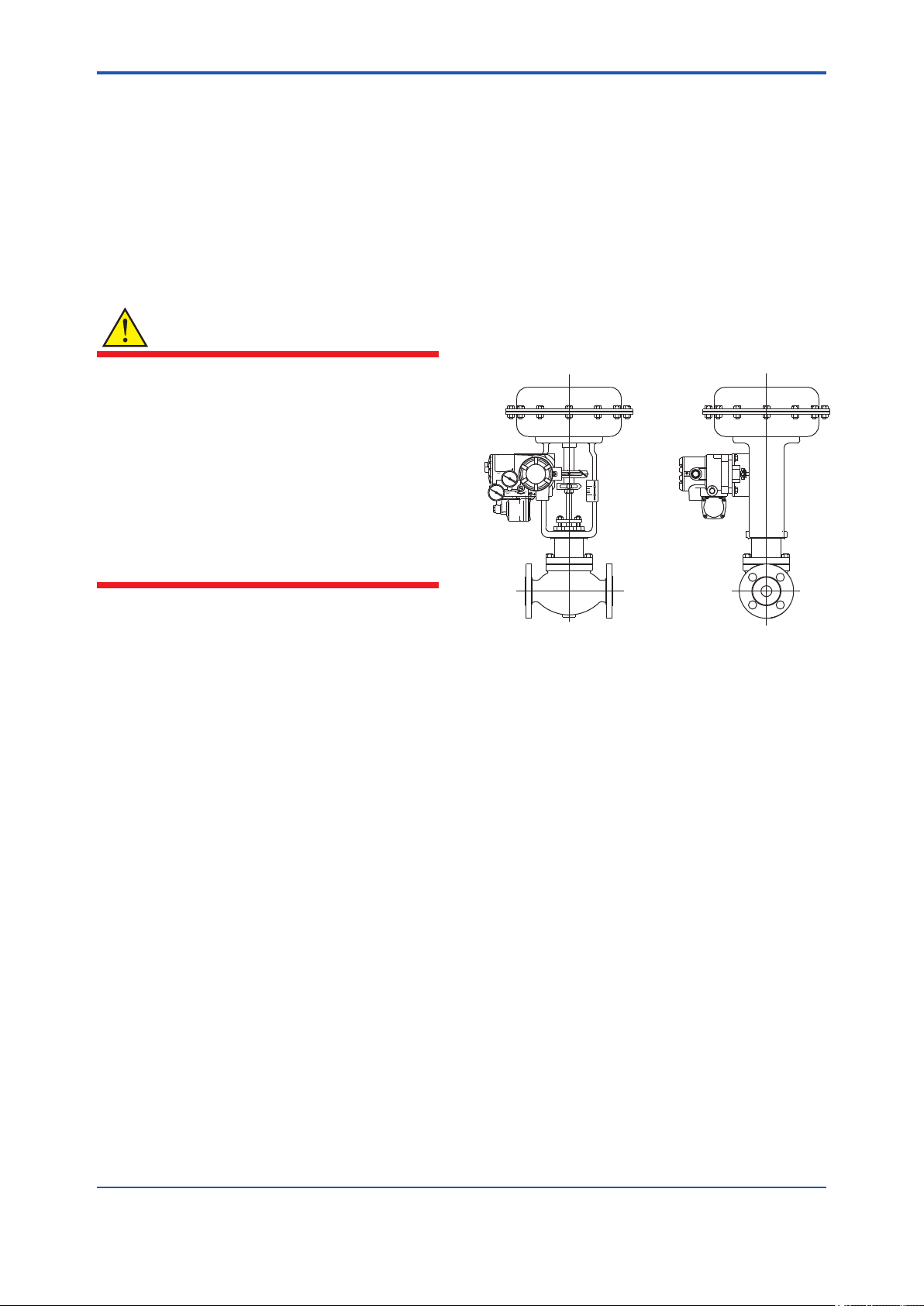

<3. Installing YVP110 on Actuator>

3. Installing YVP110 on Actuator

3-1

3.1 General

For installation of a YVP110, see Section 1.4,

“Choosing the Installation Location.” For the

ambient, environmental conditions required

for installation, see Chapter 7, “General

Specications.”

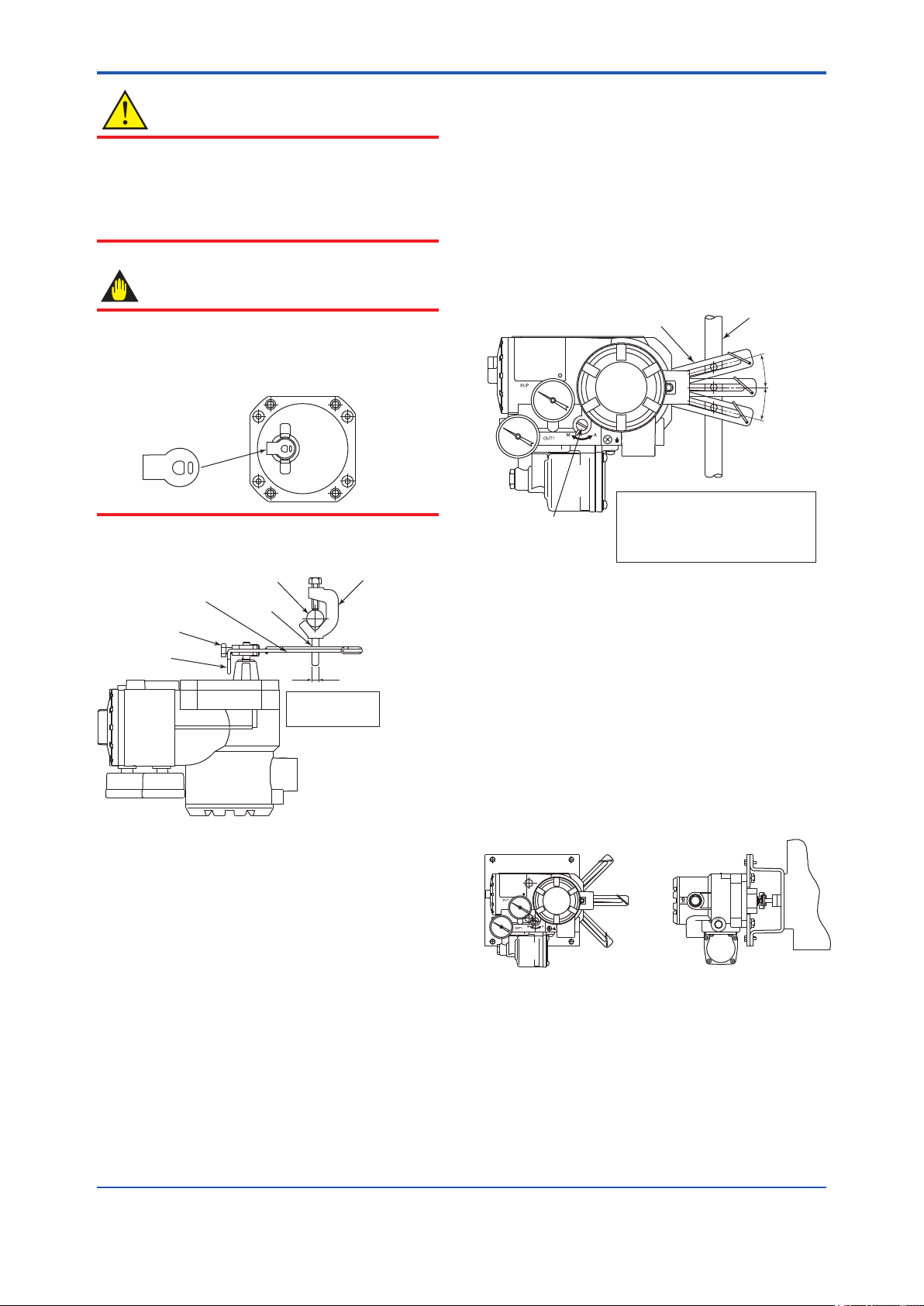

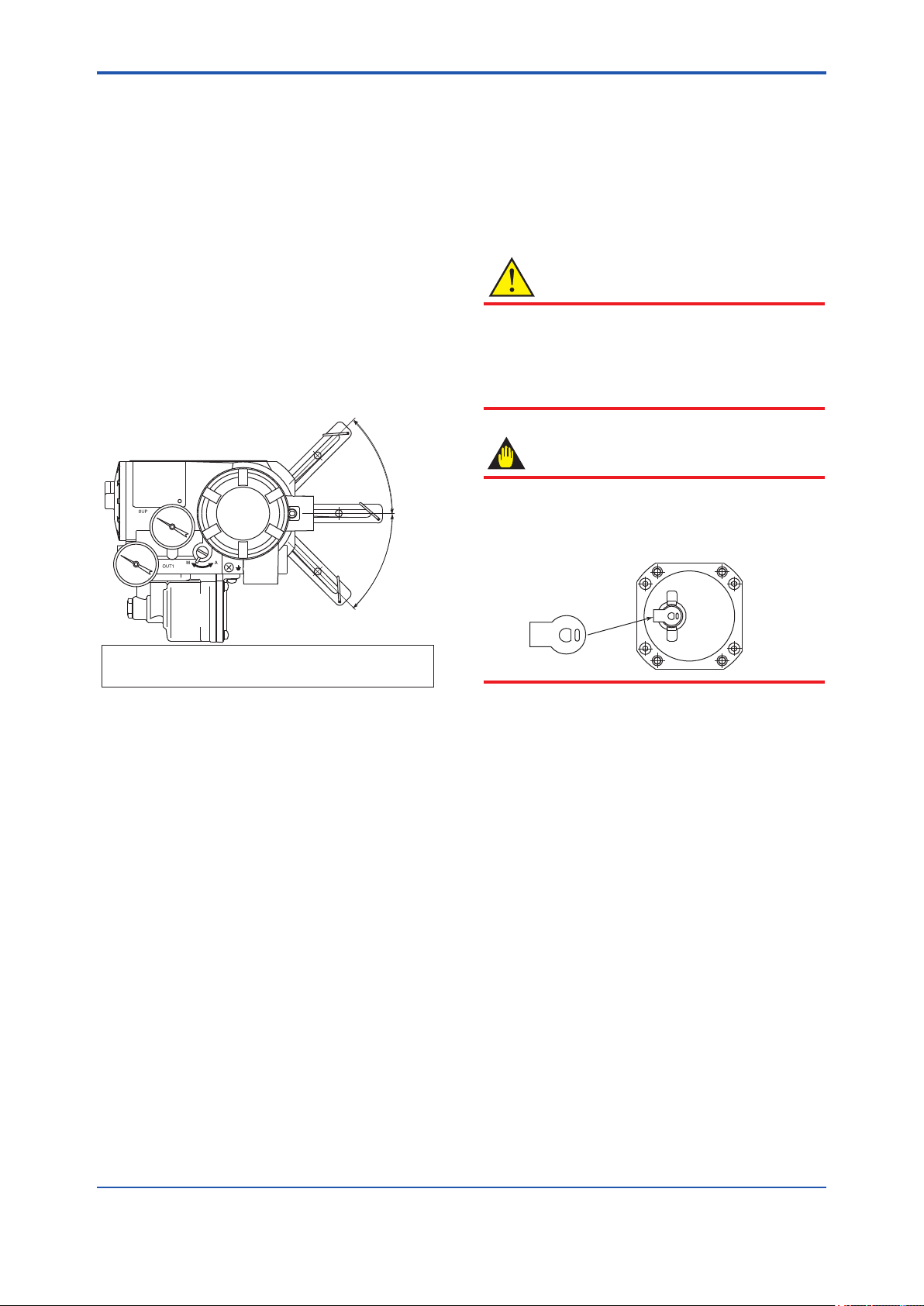

WARNING

To avoid injury or the process being affected

when installing or replacing a positioner on a

control valve, ensure that:

• All inputs to the valve actuator and other

accessories of the valve and actuator,

including the air supply and electric signal,

are cut off.

• The process has been shut down or the