Page 1

User’s

Manual

YTA70

Temperature Transmitter

IM 01C50C03-01EN

7th Edition: July 2011 (YK)

All Rights Reserved, Copyright © 1999, Yokogawa Electric Corporation

IM 01C50C03-01EN

7th Edition

YOKOGAWA ELECTRIC CORPORATION

Headquarters

2-9-32, Nakacho, Musashino-shi, Tokyo, 180-8750 JAPAN

Branch Sales Offices

Nagoya, Osaka, Hiroshima, Fukuoka, Sendai, Ichihara, Toyota,

Kanazawa, and Kitakyusyu.

YOKOGAWA CORPORATION OF AMERICA

2 Dart Road, Newnan, Georgia 30265-1094, U.S.A.

Phone : 1-800-888-6400 Fax : 1-770-254-0928

YOKOGAWA EUROPE B. V.

Euroweg 2, 3825 HD Amersfoort, THE NETHERLANDS

Phone : 31-88-4641000 Fax : 31-88-4641111

Branch Sales Offices / Wien (Austria), Zaventem (Belgium),

Ratingen (Germany), Madrid (Spain), Runcorn (United Kingdom),

Milano (Italy), Velizy-Villacoublay (France), Budapest (Hungary),

Stockholm (Sweden), Sola (Norway), Warszawa (Poland),

Vila Nova de Gaia (Portugal), Bucharest (Romania), Dublin (Ireland)

YOKOGAWA AMERICA DO SUL LTDA.

Praca Acapulco, 31 - Santo Amaro. Sao Paulo/SP - BRAZIL

Phone : 55-11-5681-2400 Fax : 55-11-5681-4434

YOKOGAWA ELECTRIC ASIA PTE. LTD.

5 Bedok South Road, 469270 SINGAPORE

Phone : 65-6241-9933 Fax : 65-6241-2606

YOKOGAWA ELECTRIC KOREA CO., LTD.

14-1, Yangpyongdong-4Ga, Youngdeungpo-Gu, Seoul, 150-866 KOREA

Phone : 82-2-2628-6000 Fax : 82-2-2628-6400

YOKOGAWA AUSTRALIA PTY. LTD.

Tower A, 112-118 Talavera Road, Macquarie Park,

N.S.W.2113, AUSTRALIA

Phone : 61-2-8870-1100 Fax : 61-2-8870-1111

YOKOGAWA INDIA LTD.

Plot No.96 Electronic City Complex, Hosur Road, Bangalore 560100, INDIA

Phone : 91-80-4158-6000 Fax : 91-80-2852-1442

YOKOGAWA CHINA CO., LTD.

3F TowerD Cartelo Crocodile Building

No.568 West Tianshan Road, Shanghai 200335, CHINA

Phone : 86-21-62396262 Fax : 86-21-62387866

June '10

SAFETY INSTRUCTIONS

Ex/I.S. installation:

• For correct use and installation the manufacturer’s manual must be followed.

When programming the Transmitter by PC and communication interface or a

HART® terminal the intrinsically safe data shall be observed.

• The designation galvanic isolation between the transducer input and the

loop supply indicates signal isolation only. It shall not be interpreted as an

Intrinsically Safe galvanic isolation like an isolating barrier. Therefore ordinary

care in selecting barrier and grounding shall be considered.

• The apparatus must be installed in an enclosure with an Ingress Protection of

at least IP 20.

• The terminals 1 and 2 of the equipment have to be electrically connected to a

linear barrier located in the non hazardous area.

• For Ex/I.S. data, see chapter 7. Approvals Options.

The YTA70 is a head mount type of temperature transmitter that accepts

thermocouple or RTD input and converts it to a 4 to 20 mA DC signal for

transmission. The YTA70 species HART communication protocol for remote

conguration.

It is imperative that usres observe the instructions in this manual to ensure the

protection and safety of operators.

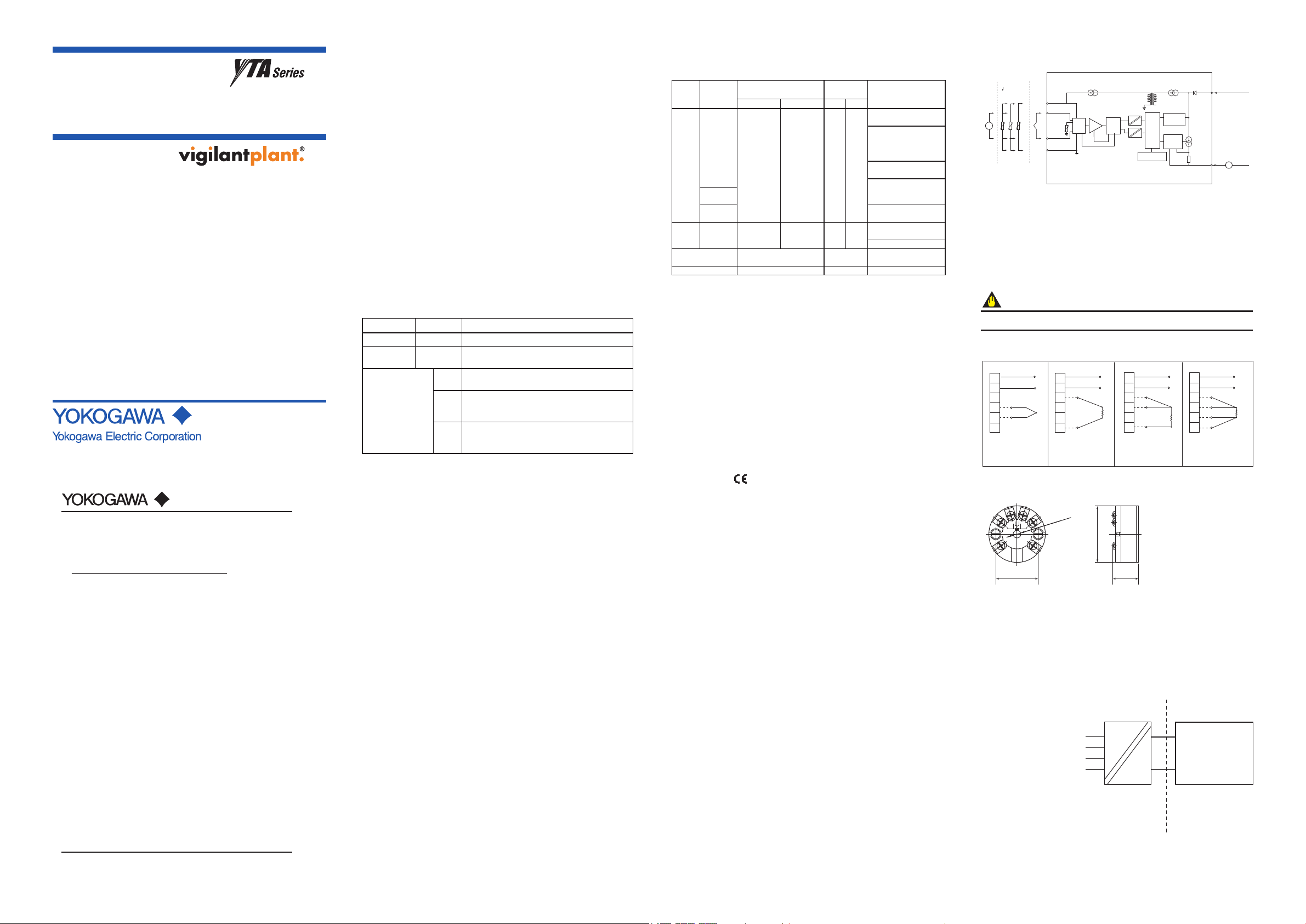

1. Model and Sufx Codes

Model Sufx code Descriptions

YTA70 . . . . . . . . . . Temperature Transmitter

Output Signal -E . . . . . . . . 4 to 20mA DC with digital communication

(HART protocol)

Optional

Specications

/KS2 CENELEC ATEX (KEMA) intrinsically safe

approval

/DS2 FM intrinsically safe/Nonincendive and CENELEC

ATEX (KEMA) intrinsically safe approval

combination

/SS2 IECEx intrinsically safe, FM intrinsically safe/

Nonincendive, and CENELEC ATEX (KEMA)

intrinsically safe approval combination

2. Warranty

The warranty period of the instrument is as of condition shown when purchasing.

Any trouble arising during the warranty period shall be replaced at free of charge.

The following problems or troubles shall not be eligible of charge-exempt repair.

• Caused by improper usage or storage of the customer which exceeds the

specication requirements.

• Caused by mishandling or modication.

• Caused by re, earthquake or other acts of God that are not directly a result of

problems of the instrument.

3. Handling Precautions

(1) Read this manual throughly and carefully before handling the instruments.

Observe the instructions.

(2) Store the product in location that meets the following requirements.

• No exposure to rain or water

• No major mechanical vibration or shock

• Humidity and Temperature limitations

• Ordinary conditions(25°C, 65%) is preferable.

Otherwise, as of specied in “Standard Specications.”

(3) Avoid corrosive atmosphere for storage and installation.

(4) For safe installation of the transmitter in hazardous area, the

following must be observed. The module must only be installed by qualied

personnels who are familiar with the national and international laws, directives,

and standards that apply to this area.

(5) Yokogawa will not be liable for malfunctions or damage resulting from any

modication made to this instrument by the customer.

4. Standard Specications

Accuracy (see table below)

Sensor

Standard

type

<T/C>

B IEC584 400 to 1820 752 to 3308 200 360 ±0.1% of span or ±1.0°C

E -100 to 1000 -148 to 1832 50 90 ±0.1% of span or ±0.5°C

J -100 to 1200 -148 to 2192 50 90

K -180 to 1372 -292 to 2502 50 90

N -180 to 1300 -292 to 2372 100 180

R -50 to 1760 -58 to 3200 200 360 ±0.1% of span or ±1.0°C

S -50 to 1760 -58 to 3200 200 360

T -200 to 400 -328 to 752 50 90 ±0.1% of span or ±0.5°C

L DIN43710 -100 to 900 -148 to 1652 50 90

U -200 to 600 -328 to 1112 75 135

W3 ASTM 0 to 2300 32 to 4172 200 360 ±0.1% of span or ±1.0°C

W5 0 to 2300 32 to 4172 200 360

<RTD>

Pt100 IEC751 -200 to 850 -328 to 1562 10 18 ±0.1% of span or ±0.1°C

Ni100 DIN43760 -60 to 250 -76 to 482 10 18 ±0.1% of span or ±0.2°C

DC Voltage -800 to 800 [mV] 2.5 [mV] ±0.1% of span or

Resistance 0 to 7000 [Ω] 25 [Ω] ±0.1% of span or ±0.1Ω

Input ranges

°C °F °C °F

Cold Junction Compensation Accuracy(For T/C only)

±1°C (±1.8°F)

Ambient Temperature Effects (per 10°C Change)

For E, J, K, L, N, T and U thermocouple inputs:

±0.05% of span or ±0.25°C, whichever is greater

For R, S, B, W3 and W5 thermocouple inputs:

±0.05% of span or ±1°C, whichever is greater

For Pt100 and Ni100 RTD inputs:

±0.05% of span or ±0.05°C, whichever is greater

For DC voltage input:

±0.05% of span or ±5µV, whichever is greater

For Resistance(ohm) input:

±0.05% of span or ±0.05Ω, whichever is greater

Power Supply Effects

±0.005% of FS per Volt

RFI Effects

Tested per EN 61326, eld intensity up to 10 V/m.

EMC Conformity

EN 61326

Maximum Zero Offset

±50% of the maximum temperature

Input Signal Source Resistance (for T/C input)

10 MΩ, or 3 kΩ at power-off

Input Lead Wire Resistance (for RTD input)

5 Ω per wire or lower

Burnout

High(NAMUR NE43 upscale) , Low(NAMUR NE43 downscale) or value within

3.5 to 20 mA

Output

Two wire 4 to 20 mA DC

Response Time

1 to 60 sec programmable

Ambient Temperature Limits (Option code may affect limit)

–40 to 85°C (–40 to 185°F)

Ambient Humidity Limits

5 to 90% RH at 40°C (104°F)

Supply Voltage

8 to 35 V DC

8 to 30 V DC for Intrinsically safe type

13.8 to 35 V DC for digital communication

Load Resistance

Limitation: 0 to (E–8)/0.0236 [Ω], where E is power supply voltage.

Isolation

Input/output isolated to 1500 V AC.

Mounting

DIN form B head mounting

Terminals

M3 screws

Weight

50 g (0.11 lb)

Minimum

span

Accuracy

(value whichever is greater)

±0.01mV

5. Block Diagram

0_16

mA

1

2

supply +

8–35VDC

supply -

4–20 mA

A

F01E.ai

mV

mV

RTD.lin.R

+

-

-

Wire

4 3 2

TC

6

5

+

Int.

MUX

CJC

-

4

3

PGA

A/D

CPU

EEPROM

4 mA

HART

Comm.

D/A

YTA70

6. Wiring

See wiring diagram. For output signal, use twisted pair or cables with performance

equivalent to 600V vinyl insulate cable. For wiring in high or low temperature, use

a wire or cable suitable for such temperature. Use cables and wires which meet

atmospheric conditions. Take necessary measure to avoid corrosion or damage of

cables and wires.

IMPORTANT

When mounting on a sensor head, do not overtighten the screws.

Wiring Diagram

n

1

SUPPLY

2

3

(–)

4

5

(+)

6

T/C or

DC milivolts

Dimensions

n

+

−

3

3

−

2

33 (1.30)

(+)

(–)

+

5 4

1

1

2

3

4

5

6

RTD or ohm

Ø6

6

(0.24)

SUPPLY

(B)

(A)

Two-wire

(+)

(–)

Ø 44 (1.73)

20.2

(0.80)

1

2

3

4

5

6

(+)

SUPPLY

(–)

(B)

(B)

(A)

Three-wire

RTD or ohm

Unit : mm (approx. inch)

1

2

3

(B)

4

(B)

5

(A)

6

(A)

Four-wire

RTD or ohm

F03E.ai

(+)

SUPPLY

(–)

F02E.ai

7. Approvals Options

7.1 CENELEC ATEX (KEMA) Intrinsically safe model (/KS2,

/DS2, /SS2)

ATEX Certicate: KEMA 10 ATEX0027

Applicable Standard: EN 60079-0: 2006, EN 60079-11: 2007,

EN 60079-26: 2007, EN 61241-0: 2006, EN 61241-11: 2006

[ Installation diagram ]

Zone 0, 1, 2, 20, 21, 22

T4: -40 ≤ Ta ≤ 85°C

T6: -40 ≤ Ta ≤ 60°C

Terminal: 3, 4, 5, 6

Uo: 9.6 VDC

Io: 28 mA

Po: 67 mW

Lo: 35 mH

Co: 3.5 μF

6

5

4

3

YTA70

Terminal: 1, 2

Ui: 30 VDC

Ii: 120 mA

Pi: 0.84 W

Li: 10 μ H

Ci: 1.0 nF

Non-hazardous AreaHazardous Area

1 +

2 -

Barrier

F04E.ai

1

Page 2

Maximum Ambient Temperature for gas-proof

For T4: 85°C, For T6: 60°C

Maximum Surface Temperature for dust-proof

For T4: T105°C (Ambient Temperature: –40 to 85°C)

For T6: T85°C (Ambient Temperature: –40 to 60°C)

7.2 FM Intrinsically safe/Nonincendive model (/DS2, /SS2)

Applicable Standard: FM 3600, FM 3610, FM 3611, FM 3810

Installation diagram

[ Intrinsically safe ]

Hazardous (Classified) Location

Class I,Division1, Groups, A,B,C,D

Class II Division 1 Groups E,F,G or

Class I, Zone 0, IIC

Ambient temperature limits

T4: -40 to +85 deg. Celcius

T6: -40 to +60 deg. Celcius

Terminal 3,4,5,6

Vt or Uo: 9.6 V

It or Io: 28 mA

Pt or Po: 67.2 mW

Ca or Co: 3.5 uF

La or Lo: 35 mH

sensor

6

5

YTA70

4

3

Terminal: 1 , 2

Vmax or Ui: 30 V

Imax or Ii: 120 mA

Pmax or Pi: 0.84 W

Ci: 1 nF

Li: 10 uH

Non-hazardous Location

Associated Apparatus

1 +

2 -

entity Parameters:

UM ≤ 250V

Voc or Uo ≤ Vmax or Ui

Isc or Io ≤ Imax or Ii

Po ≤ Pi

Ca or Co ≥ Ci + C cable

La or Lo ≥ Li + L cable

This device must not be

connected to any

associated apparatus

which uses or generates

more than 250 VRMS

or Barrier

with

[ Nonincendive ]

Hazardous (Classified) Location

Class I,Division2, Groups, A,B,C,D

Class I, Zone 2, IIC

Ambient temperature limits

T4: -40 to +85 deg. Celcius

T6: -40 to +60 deg. Celcius

6

5

4

sensor

3

YTA70

Terminal: 1 , 2

Vmax: 35 V

Ci: 0 μ F

Li: 10 uH

Non-hazardous Location

Associated Apparatus

1 +

Voc or Vt ≤ Vmax

2 -

Ca ≥ Ci + C cable

La ≥ Li + L cable

This device must not be

connected to any

associated apparatus

which uses or generates

more than 250 VRMS

or Barrier

F05E.ai

7.3 IECEx Scheme Intrinsically safe model (/SS2)

Certicate No.: IECEx KEM 10.0086

Applicable Standard: IEC 60079-0:2007-10, IEC 60079-11:2006,

IEC 60079-26:2006, IEC 61241-11:2005

[ Installation diagram ]

Zone 0, 1, 2, 20, 21, 22

T4: -40 ≤ Ta ≤ 85°C

T6: -40 ≤ Ta ≤ 45°C

Terminal: 3, 4, 5, 6

Uo: 9.6 VDC

Io: 28 mA

Po: 67 mW

Lo: 35 mH

Co: 3.5 μF

6

5

4

3

YTA70

Terminal: 1, 2

Ui: 30 VDC

Ii: 120 mA

Pi: 0.84 W

Li: 10 μ H

Ci: 1.0 nF

Non-hazardous AreaHazardous Area

1 +

2 -

Barrier

F06E.ai

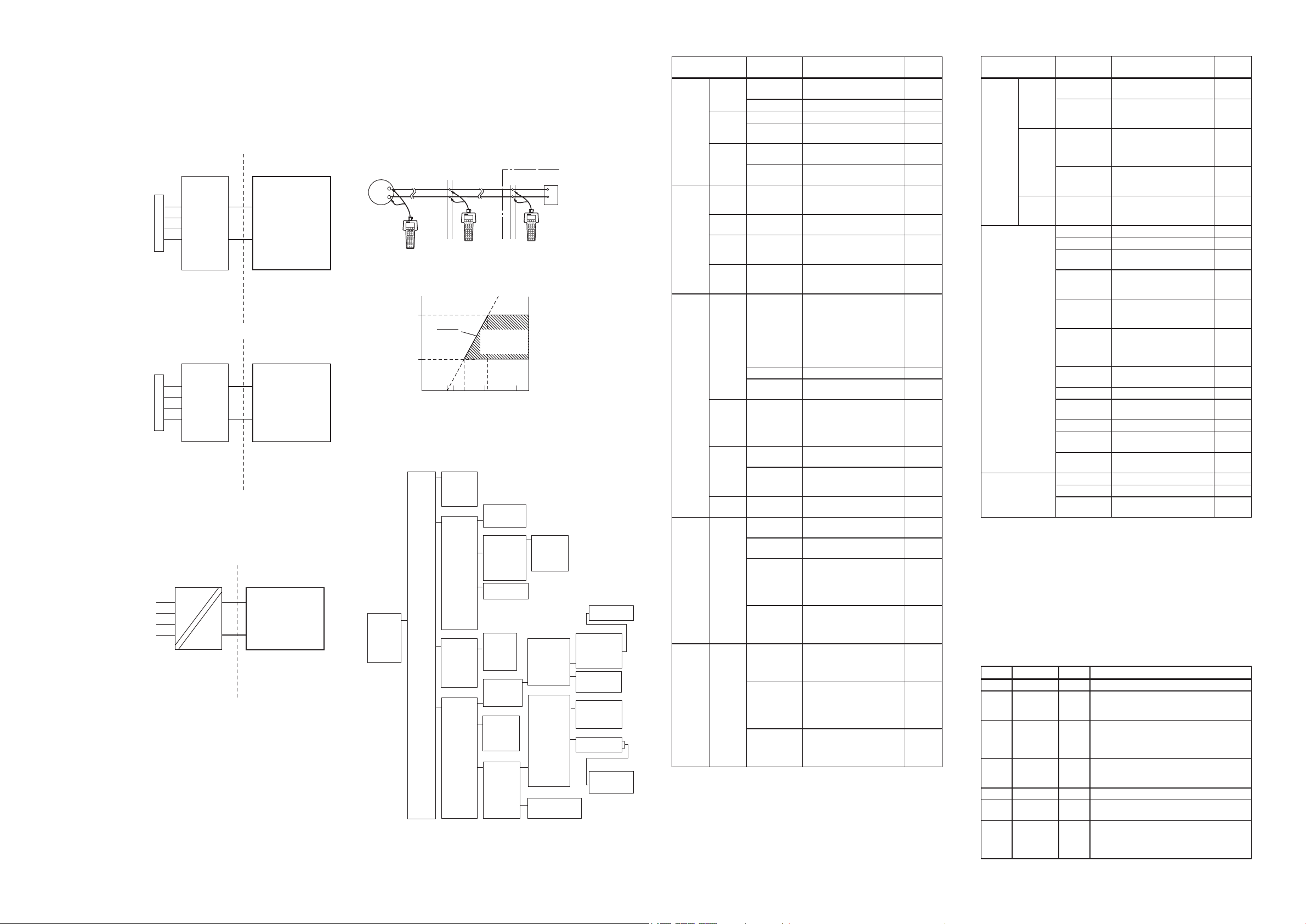

8. HART Communication

8.1 Connection and Requirements

A standard HART communicator can be used for programming the YTA70. The

HART communicator must be loaded with the appropriate DDL driver for YTA70.

Minimum loop resistance is 250Ω. If the receiving equipment has a lower

resistance, a serial resistor must be inserted to communicate with the HART

communicator.

Control room

Relaying

terminals

+

−

YTA70

HART

communicator

communicator

Connection

600

E-8

R=

External

load

resistance

(Ω)

R

0.0236

250

8.0

Power supply voltage E (V DC)

Communication requirement

8.2 Parameters

Online Menu

1.Device

setup

2.PV

3.Electr

4.Snsr1

5.PV AO

6.PV %rnge

(Device setup)

1.Process

Variable

2.Diag/

Service

3.Basic

Setup

4.Detailed

Setup

5.Review

(Process Variables)

1.PV

2.Electr

3.Snsr1

4.PV AO

5.PV % rnge

(Diag/Service)

1.Status

2.Loop test

3.Calibration

4.Write

Protection

5.Read

max/min log

6.Reset

max/min

(Basic Setup)

1.Tag

2.Range

values

3.Sensor

config

4.PV Damp

5.Snsr s/n

(Detailed setup)

1.Sensors

2.Signal

condition

3.Output

condition

4.Device

information

HART

13.8

Terminal board

communicator

Digital

Communication

range

21.8

(Status)

1.Sensor errors

2.ADC errors

3.Misc. errors

(Calibration)

1.Range values

2.D/A trim

3.Scaled

D/A trim

4.Override

D/A trim

1.Write protect

2.New password

(Range values)

1.PV LRV

2.PV URV

3.PV unit

4.LSL

5.USL

(Sensors)

1.Process

sensor

2.Electr

(Signal condition)

1.PV LRV

2.PV URV

3.PV unit

4.PV % rnge

5.PV Damp

(Output condition)

1.Analog

output

2.HART

output

Distributor

HART

35.0

F08E.EPS

(Range values)

1.PV LRV

2.PV URV

3.PV unit

4.LSL

5.USL

(Process sensor)

1.PV

2.Snsr1

3.PV unit

4.Sensor setup

5.Sensor info

(Analog output)

1.PV AO

2.Output rnge

3.Sensor error

values

4.Loop test

5.Scaled

D/A trim

6.D/A trim

7.Override

D/A trim

(HART output)

1.Poll addr

2.Num req preams

3.Num resp preams

F07E.ai

(Cable resistance)

1.Enter value

2.Measure value

(Sensor setup)

1.Sensor config

2.Error detection

3.Cable

resistance

4.Snsr s/n

1.USL

2.LSL

3.Min span

(Output range)

1.AO 0%

2.AO 100%

3.AO lo lim

4.AO up lim

(Sensor error values)

1.Broken sensor

2.Shorted sensor

(Broken/shorted

sensor)

1.Br(Sh) sensor

2.NAMUR down

3.NAMUR up

F09E.ai

Parameters List

HART

Communicator

PV Measured variables in engineering

Process

Variable

Item

Process

Variable

Electr Terminal temperature —

Output

value

PV AO Output value in mA —

PV % rnge Output value with respect to the

PV Log Read max/min log Reads the maximum/minimum PV

Reset max/min Clears the PV maximum/minimum

Signal

Condition

Range

value

PV LRV/PV URV Lower/upper range value to

Range Limit LSL/USL Shows the max./min. usable value

Unit PV unit Engineering unit to be displayed

Damping PV Damp Damping time constant in seconds

Sensor

Setup

Sensor

cong

Sensor type

(wire, unit)

RTD factor For RTD only. Leave it to “1.” 1

Cold Junction

Compensation

Sensor

Errors

Cable

resistance

Error detection Type of sensor errors to be

Enter value Enter new value of the RTD/ohm

Measure value Actually measure the cable

Output

Condition

Minimum

span limit

Analog

Output

range

Min.span Minimum settable span —

AO 0%(100%) Output value for 0%(100%) in mA. 4(0%)

AO lo(up) lim Output lower(upper) limit in mA.

Sensor Error

values

Loop test Change the output manually for

Diagnostics Error status Sensor errors Show error status related to a

ADC errors Show error status related to

Misc. errors Show error status related to a

Selection/Setting Range

unit.

range in %

stored in the memory

log and restart logging

denes the 0%/100% value of the

measurement

for upper/lower range value

with such digital value as PV, URV,

LRV, USL, LSL,min.span, etc.

applied to the digital value. 0 to

62.5(s)

Sensor type and related settings.

[When T/C or milivolts is selected]

Always select “single” for a

measurement type.

[When RTD or ohm is selected]

Always select 2-, 3- or 4-wire but

others for the number of sensor

wires.

For T/C only. Always leave it to

“1.internal sensor.”

detected for burnout operation.

(1)No test performed, (2)broken

sensor, (3)shorted sensor*3, or

(4)broken & shorted*3

cable resistance for compensation.

resistance of 2-wire RTD/ohm for

compensation.

NAMUR, or 3.8 to 23mA

Enter or select the output value

when sensor error is detected.

NAMUR upscale, NAMUR

downscale, or value within 3.5

to 23mA

testing the loop.

4mA, 20mA, or value within 3.5

to 23mA

sensor. When any one of the errors

turns "ON", check the sensor and

wiring.

analog to digital conversion.

When any one of the errors turns

"ON", Repower the device. If error

remains, replace the device.

device. When any one of the errors

turns "ON", Re-power the device. If

error remains, replace the device.

Initial

Setting

—

—

—

—

LRV: 0

URV:100

*1

—

°C

0.43(s) *1

Pt100

3-wire

°C

*1

Internal

sensor

broken

sensor

5 (ohm)

—

20(100%)

NAMUR

NAMUR

upscale

[high]

*1

—

—

—

—

Item

Calibration Write

protection

Apply trim D/A trim Allows the calibration of a selected

Clear trim Override D/A trim Overrides any previous

HART

Communicator

Write protect Write-protects the device, if correct

New password Sets a new password for wirte

Scaled D/A trim Allows the calibration of the analog

Selection/Setting Range

password is entered. *2

protection, if correct password is

entered.

analog output with an external

reference at the operating

endpoint.

output with the external reference

which is scaled at 0 to 100%.

D/A trimming by restoring factory

calibration values.

Initial

Setting

Not

protected

—

—

—

—

Device information Manufacturer Manufacturer identication code Yokogawa

Model Model name YTA70-E

TAG Tag number, up to 8

Descriptor Text which can be used by user in

Message Text which can be used by user in

Date Date information. MM/DD/YY. Not

Write protect Indicates whether the device is

alphanumerical characters.

any way. Up to 16 alpha-numerical

characters

any way. Up to 32 alpha-numerical

characters

inclemented. The date is updated

whenever changing conguration

via PC congurator.

write-proteced.

—

—

—

Factory

calibration

date

Not

protected

Snsr s/n Not used. 0

Final assembly

number

Not used. 0

Distributor — Yokogawa

Revision #'s Software/hardware revision

Status Error stauts (see “Error status” in

number

this table.)

—

—

Review Input info List of input variables —

Output info List of output variables —

Device information See “Device information” in this

table.

—

*1: Or as specied upon ordering.

*2: The initial setting of password upon shipment is "********".

*3: With T/C or milivolts for sensor type, the alarm is generated when the input

signal drops down below 2.5 mV.

Revision Record

● Manual No. : IM 01C50C03-01EN

● Title : YTA70 Temperature Transmitter

Edition Date Page Revised item

1st Mar. 1999 — New Publication.

2nd June 1999 1

3rd Feb. 2000 2,3

4th Mar. 2002 12Change Optional code KS1 and DS1 to KS2 and DS2

5th July 2003 1,5,6 Delete code "/KS1" and "/DS1".

6th Feb. 2007 2,3,6 Add handling precaution.

7th July 2011 Change marking for KS2 and DS2.

Add code "/DS1" in the table

Add "7.2 FM intrinsically safe model"

6

Add "note 2" .

10

Revise accuracy & temperature effect.

Correct "Isolation".

4

Add explanation

9

Add "Note".

11

respectively.

Add description(4) based on ATEX directives.

Change specications of FM Intrinsically safe model.

Change Certicate number and applicable standard.

Change electrical data.

Add 7.3 IECEx scheme approval.

2

Loading...

Loading...