Page 1

Y

User’s

YTA Series

Manual

Temperature Transmitter

(BRAIN Protocol)

IM 01C50T03-01E

IM 01C50T03-01E

okogawa Electric Corporation

5th Edition

Page 2

CONTENTS

CONTENTS

1. INTRODUCTION..........................................................................................1-1

■ Regarding This Manual ............................................................................. 1-1

■ For Safe Use of Product ........................................................................... 1-2

■ Warranty .................................................................................................... 1-2

■ ATEX Documentation................................................................................ 1-3

2. CONDITIONS OF COMMUNICATION LINE............................................... 2-1

2.1 Interconnection Between YTA and BT200 ......................................... 2-1

2.2 Communication Line Requirements.................................................... 2-1

3. OPERATION ................................................................................................ 3-1

3.1 Parameters Description....................................................................... 3-1

3.2 Setting Parameters ............................................................................. 3-4

3.2.1 Sensor Configuration .................................................................... 3-4

3.2.2 Process Variables Mapping ......................................................... 3-5

3.2.3 Unit Setting................................................................................... 3-6

3.2.4 Range Setting............................................................................... 3-6

3.2.5 Setting Damping Time Constant .................................................. 3-6

3.2.6 Tag Number and Memo Writing ................................................... 3-6

3.2.7 Forced Output Function ............................................................... 3-7

3.2.8 Integral Indicator Display Function ............................................... 3-7

3.2.9 Burn Out Function ...................................................................... 3-10

3.2.10 Reverse Output Function ........................................................... 3-10

3.2.11 Sensor Backup Function (For Model YTA320).......................... 3-10

3.2.12 Copy the Setting Data................................................................ 3-11

3.2.13 Write Protect Function ................................................................ 3-11

3.2.14 Sensor Trim................................................................................ 3-12

3.2.15 Output Trim ................................................................................ 3-13

3.2.16 CJC Selection............................................................................. 3-14

4. SELF-DIAGNOSTICS .................................................................................. 4-1

4.1 Error Message..................................................................................... 4-1

4.2 Warning ............................................................................................... 4-3

4.3 Logging Function................................................................................. 4-5

4.3.1 Error Log ...................................................................................... 4-5

4.3.2 Min/Max Log................................................................................. 4-5

4.3.3 Operation Time ............................................................................. 4-5

4.3.4 Power Check ................................................................................ 4-5

4.3.5 BRAIN communication BCC error occurrence rate ..................... 4-5

5. LIST OF PARAMETERS ............................................................................. 5-1

FD No. IM 01C50T03-01E

5th Edition: Sep. 2006 (KP)

All Rights Reserved, Copyright © 1998, Yokogawa Electric Corporation

i

IM 01C50T03-01E

Page 3

CONTENTS

APPENDIX A. OPERATION OF BRAIN TERMINAL BT200 ............................. A-1

A.1 Operation Key Arrangement ...............................................................A-1

A.2 Function of Operation Keys ................................................................A-2

A.2.1 Entry of Alphanumeric Characters ...............................................A-2

A.2.2 Function Keys...............................................................................A-3

A.3 Calling of Menu Address..................................................................... A-4

A.3.1 Data Display with BT200 .............................................................. A-5

A.3.2 Data Setting with BT200 .............................................................. A-5

APPENDIX B. THE SENSOR MATCHING FUNCTION ..................................... B-1

B.1 Specifications ......................................................................................B-1

B.2 Operations (The Sensor Matching Function)...................................... B-2

APPENDIX C. SAFETY INSTRUMENTED SYSTEMS INSTALLATION ......... C-1

C.1 Scope and Purpose ............................................................................ C-1

C.2 Using the YTA for an SIS Application ................................................C-1

C.2.1 Safety Accuracy ...........................................................................C-1

C.2.2 Diagnostic Response Time ..........................................................C-1

C.2.3 Setup ............................................................................................C-1

C.2.4 Required Parameter Settings .......................................................C-1

C.2.5 Proof Testing................................................................................ C-1

C.2.6 Repair and Replacement .............................................................C-2

C.2.7 Startup Time .................................................................................C-2

C.2.8 Firmware Update..........................................................................C-2

C.2.9 Reliability Data ............................................................................. C-3

C.2.10 Lifetime Limits ..............................................................................C-3

C.2.11 Environmental Limits ....................................................................C-3

C.2.12 Application Limits .........................................................................C-3

C.3 Terms and Definitions......................................................................... C-3

REVISION RECORD

ii

IM 01C50T03-01E

Page 4

1. INTRODUCTION

1. INTRODUCTION

Thank you for purchasing the YTA series Temperature

Transmitter.

The YTA temperature transmitter is fully factory-tested

according to the specifications indicated on your order.

This manual describes BRAIN communication functions of the model YTA110, YTA310, and YTA320

temperature transmitters and the various settings for

temperature transmitter functions that can be set via the

BT200 handheld terminal. The BT200 BRAIN terminal

is required to change the settings of internal transmitter

parameters.

In order for the YTA temperature transmitter to be

fully functional and to operate in an efficient manner,

read the instruction manual carefully to become

familiar with the functions and operation as well as

handling.

See User’s Manual IM 01C00A11-01E for details

related to using the BT200 BRAIN terminal. For

details of mounting, wiring and maintenance of this

transmitter, see the separate User’s Manual IM

01C50B01-01E.

䊏 Regarding This Manual

• The following safety symbol marks are used in this

Manual:

WARNING

Indicates a potentially hazardous situation which,

if not avoided, could result in death or serious

injury.

CAUTION

Indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate

injury. It may also be used to alert against

unsafe practices.

IMPORTANT

Indicates that operating the hardware or software

in this manner may damage it or lead to system

failure.

•This manual should be passed on to the end user.

• The contents of this manual are subject to change

without prior notice.

• All rights reserved. No part of this manual may be

reproduced in any form without Yokogawa’s written

permission.

• Yokogawa makes no warranty of any kind with

regard to this manual, including, but not limited to,

implied warranty of merchantability and fitness for a

particular purpose.

• If any question arises or errors are found, or if any

information is missing from this manual, please

inform the nearest Yokogawa sales office.

• The specifications covered by this manual are

limited to those for the standard type under the

specified model number break-down and do not

cover custom-made instrument.

• Please note that changes in the specifications,

construction, or component parts of the instrument

may not immediately be reflected in this manual at

the time of change, provided that postponement of

revisions will not cause difficulty to the user from a

functional or performance standpoint.

NOTE

Draws attention to information essential for

understanding the operation and features.

1-1

IM 01C50T03-01E

Page 5

1. INTRODUCTION

䊏 For Safe Use of Product

For the protection and safety of the operator and the

instrument or the system including the instrument,

please be sure to follow the instructions on safety

described in this manual when handling this instrument. In case the instrument is handled in contradiction

to these instructions, Yokogawa does not guarantee

safety. Please give your attention to the followings.

(a) Installation

• The instrument must be installed by an expert

engineer or a skilled personnel. The procedures

described about INSTALLATION are not permitted

for operators.

• In case of high process temperature, care should be

taken not to burn yourself because the surface of the

case reaches a high temperature.

• All installation shall comply with local installation

requirement and local electrical code.

(b) Wiring

• The instrument must be installed by an expert

engineer or a skilled personnel. The procedures

described about WIRING are not permitted for

operators.

• Please confirm that voltages between the power

supply and the instrument before connecting the

power cables and that the cables are not powered

before connecting.

(c) Maintenance

• Please do not carry out except being written to a

maintenance descriptions. When these procedures

are needed, please contact nearest YOKOGAWA

office.

•Care should be taken to prevent the build up of drift,

dust or other material on the display glass and

name plate. In case of its maintenance, soft and dry

cloth is used.

䊏 Warranty

•The warranty shall cover the period noted on the

quotation presented to the purchaser at the time of

purchase. Problems occurred during the warranty

period shall basically be repaired free of charge.

• In case of problems, the customer should contact the

Yokogawa representative from which the instrument

was purchased, or the nearest Yokogawa office.

• If a problem arises with this instrument, please

inform us of the nature of the problem and the

circumstances under which it developed, including

the model specification and serial number. Any

diagrams, data and other information you can

include in your communication will also be helpful.

• Responsible party for repair cost for the problems

shall be determined by Yokogawa based on our

investigation.

• The Purchaser shall bear the responsibility for repair

costs, even during the warranty period, if the

malfunction is due to:

- Improper and/or inadequate maintenance by the

purchaser.

- Failure or damage due to improper handling, use

or storage which is out of design conditions.

- Use of the product in question in a location not

conforming to the standards specified by

Yokogawa, or due to improper maintenance of

the installation location.

- Failure or damage due to modification or repair

by any party except Yokogawa or an approved

representative of Yokogawa.

- Malfunction or damage from improper relocation

of the product in question after delivery.

- Reason of force majeure such as fires, earthquakes, storms/floods, thunder/lightening, or

other natural disasters, or disturbances, riots,

warfare, or radioactive contamination.

(d) Modification

• Yokogawa will not be liable for malfunctions or

damage resulting from any modification made to

this instrument by the customer.

1-2

IM 01C50T03-01E

Page 6

1. INTRODUCTION

䊏 ATEX Documentation

This procedure is only applicable to the countries in

European Union.

GB

All instruction manuals for ATEX Ex related products

are available in English, German and French. Should

you require Ex related instructions in your local

language, you are to contact your nearest Yokogawa

office or representative.

DK

Alle brugervejledninger for produkter relateret til

ATEX Ex er tilgængelige på engelsk, tysk og fransk.

Skulle De ønske yderligere oplysninger om håndtering

af Ex produkter på eget sprog, kan De rette

henvendelse herom til den nærmeste Yokogawa

afdeling eller forhandler.

I

Tutti i manuali operativi di prodotti ATEX

contrassegnati con Ex sono disponibili in inglese,

tedesco e francese. Se si desidera ricevere i manuali

operativi di prodotti Ex in lingua locale, mettersi in

contatto con l’ufficio Yokogawa più vicino o con un

rappresentante.

E

Todos los manuales de instrucciones para los productos

antiexplosivos de ATEX están disponibles en inglés,

alemán y francés. Si desea solicitar las instrucciones de

estos artículos antiexplosivos en su idioma local,

deberá ponerse en contacto con la oficina o el

representante de Yokogawa más cercano.

NL

SF

Kaikkien ATEX Ex -tyyppisten tuotteiden käyttöhjeet

ovat saatavilla englannin-, saksan- ja ranskankielisinä.

Mikäli tarvitsette Ex -tyyppisten tuotteiden ohjeita

omalla paikallisella kielellännne, ottakaa yhteyttä

lähimpään Yokogawa-toimistoon tai -edustajaan.

P

Todos os manuais de instruções referentes aos produtos

Ex da ATEX estão disponíveis em Inglês, Alemão e

Francês. Se necessitar de instruções na sua língua

relacionadas com produtos Ex, deverá entrar em

contacto com a delegação mais próxima ou com um

representante da Yokogawa.

F

Tous les manuels d’instruction des produits ATEX Ex

sont disponibles en langue anglaise, allemande et

française. Si vous nécessitez des instructions relatives

aux produits Ex dans votre langue, veuillez bien

contacter votre représentant Yokogawa le plus proche.

D

Alle Betriebsanleitungen für ATEX Ex bezogene

Produkte stehen in den Sprachen Englisch, Deutsch

und Französisch zur Verfügung. Sollten Sie die

Betriebsanleitungen für Ex-Produkte in Ihrer

Landessprache benötigen, setzen Sie sich bitte mit

Ihrem örtlichen Yokogawa-Vertreter in Verbindung.

S

Alla instruktionsböcker för ATEX Ex (explosionssäkra)

produkter är tillgängliga på engelska, tyska och

franska. Om Ni behöver instruktioner för dessa

explosionssäkra produkter på annat språk, skall Ni

kontakta närmaste Yokogawakontor eller representant.

Alle handleidingen voor producten die te maken

hebben met ATEX explosiebeveiliging (Ex) zijn

verkrijgbaar in het Engels, Duits en Frans. Neem,

indien u aanwijzingen op het gebied van

explosiebeveiliging nodig hebt in uw eigen taal, contact

op met de dichtstbijzijnde vestiging van Yokogawa of

met een vertegenwoordiger.

GR

ATEX Ex

, .

Ex

Yokogawa .

1-3

IM 01C50T03-01E

Page 7

2. CONDITIONS OF COMMUNICATION LINE

2. CONDITIONS OF COMMUNICATION

LINE

2.1 Interconnection Between YTA

and BT200

WARNING

Do not attempt to use the BT200 in a dangerous

environment where explosive gas or inflammable

vapor is generated.

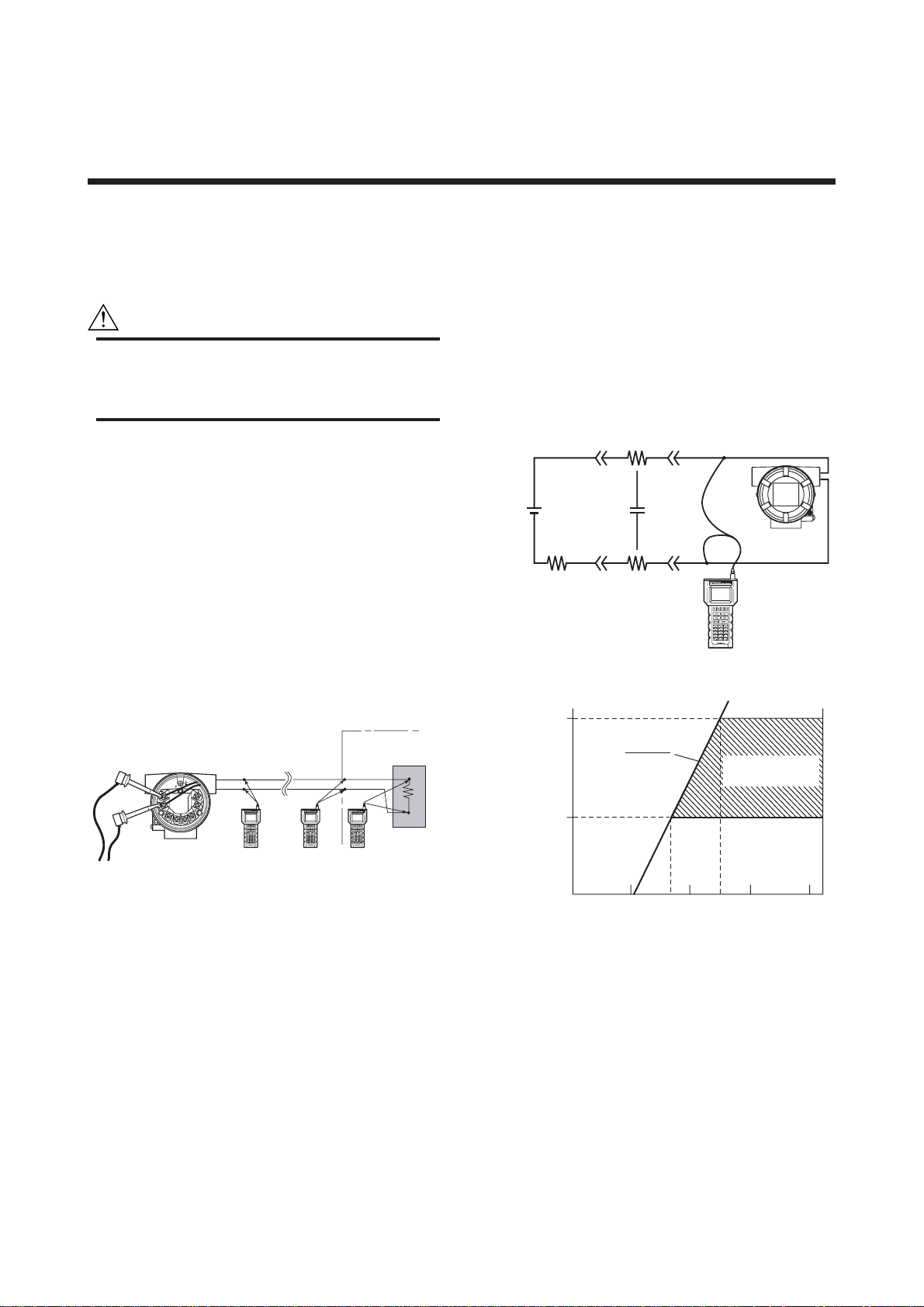

The BRAIN communication signal is superimposed

onto the 4 to 20 mA DC analog signal. Since the

modulated wave is a communication signal, superimposing it on the normal signal will, from basic principles, cause no error in the DC component of the

analog signal. Thus, monitoring can be performed via

the BT200 while the transmitter is on-line.

As shown in Figure 2.1, there are two methods of

connecting the transmitter and the BT200: the first is to

use the BT200 connection hook provided in the

terminal box and the other is to use a terminal board or

relay terminals on the transmission line.

Load impedance : 3.3 mH or less

Communication distance: 2 km (1.25 mile), when

CEV cable is used

Distance from the power line:

Output signal line : 15 cm (5.9 inch) or more

(do not use parallel wiring)

Input signal line : 100 cm (39.8 inch) or more

(do not use parallel wiring)

Input impedance of receiver connected to receiving

resistor: 10 kΩ more (at 2.4 kHz)

Rc

Power

supply

Figure 2.2 Communication line requirements

cc

YTA

RcR

BT200

F0202.EPS

4 to 20 mA DC

signal

Relay

terminals

YTA

BT200

Figure 2.1 Connecting the BT200

transmission

line

Control room

Terminal

board

Distributor

BT200BT200BT200

F0201.EPS

2.2 Communication Line Re-

quirements

Configure a loop that satisfies the following conditions

for mutual communication with the temperature

transmitter.

Power supply voltage : 16.4 to 42 V DC

Load resistance : R + 2Rc = 250 to 600 Ω

(See Figure 2.3 for the relationship between the

power supply voltage and load resistance.)

Load capacity : 0.22 µF or less

600

E–10.5

R=

Load

resistance

R

250

(Ω)

Figure 2.3 Relationship between power supply voltage

and load resistance

0.0236

10.5 16.4 24.7 42

Power supply voltage E (V)

Communication

applicable range

F0203.EPS

2-1

IM 01C50T03-01E

Page 8

3. OPERATION

IMPORTANT

Do not turn off the power to the transmitter

immediately after setting the data using the

BT200. If the transmitter is turned off less than

30 seconds after parameters have been set, the

setting data will not be stored in the transmitter.

3.1 Parameters Description

The following outlines the function of the BRAIN

parameters for the YTA.

• Sensor configuration See Page 3-4

When changing the sensor type from the current

setting to another, it is necessary to change parameter settings.

D10: SENSOR1 TYPE

D20: SENSOR1 WIRE

E10: SENSOR2 TYPE(YTA320 only)

E20: SENSOR2 WIRE(YTA320 only)

•Process variable mapping See Page 3-5

Process variables can be assigned as the primary

variable(PV), the secondary variable(SV), the

tertiary variable(TV), and the quaternary

variable(4V).

The following items can be mapped as the process

variables.

Sensor1, Sensor2*2, DIFFERENCE*2, AVERAGE*2,

Sensor1-Term, Sensor2-Term*2, Terminal Temp (*2:

These items are displayed for the model YTA320 only.)

B10: PV is, B20: SV is, B30: TV is, B40: 4V is

• Unit setting See Page 3-6

Choose the engineering unit for the process

variables assigned as the PV, SV, TV, and 4V from

degree C and Kelvin. When mV or ohm is specified

as an input type, the unit is automatically set to mV

or ohm.

B11: PV UNIT, B21: SV UNIT, B31: TV UNIT, B41: 4V

UNIT

• Range setting See Page 3-6

Changing the range of the PV as a 4 to 20mA DC

output. There are two ways to set the range value.

F10: LRV , F20: URV

F30: AUTO LRV , F35: AUTO URV

.............

.............

.......................

.........................

Sensor type setting

Wire connections setting

Setting by keypad

.

Setting by applying value

3. OPERATION

•

Damping time constant setting

See Page 3-6

Setting the response time of the transmitter smooths

the output with rapid changes in input.

The damping time constant can be set between 1

and 99 seconds.

B12: PV DAMPING, B22: SV DAMPING, B32: TV

DAMPING, B42: 4V DAMPING

• Tag Number, Memo, Description and Date

See Page 3-6

C10: TAG NO. ............... Tag number (16 characters)

O10: MEMO1, O20: MEMO2

...... MEMO (16 characters)

O30: DESCRIPTOR ...... DESCRIPTION (16 characters)

O40: DATE ..................... DATE (6 characters)

• Forced Output Function

(Manual Output mode) See Page 3-7

Setting the transmitter to output a fixed current

from -2.5 to 110 % in 0.1% increments for loop

checks.

G10: OUTPUT MODE, G20: OUPUT VALUE

•Integral Indicator Display Function

See Page 3-7

The input and output values can be displayed, as

can the type of temperature sensor and the number

of wire connections.

M10: PROCESS DISP ...... Process variable display

selection

M20: %/mA DISP ................ Output display selection

M30: MATRIX DISP ............ Sensor type/wire connec-

tions display selection

M40: BAR GRAPH ..............Output bar graph display

setting

M50: DISP UPDATE ........... Selection of a cycle speed

for display

M55: Err- NO DISP ............. Error code display

• Burn Out Function See Page 3-10

Configure the current output value in sensor failure.

Selectable from High, Low, and User setting

values.

F40: BURN OUT, F41: BURN OUT VAL, F50: TX

FAILURE

• Reverse Output Function See Page 3-10

To reverse the direction for a 4 to 20 mA DC

output relative to input.

H10: REVERSE OUT

3-1

IM 01C50T03-01E

Page 9

• Sensor Backup Function (YTA320 only)

See Page 3-10

Configure the transmitter to automatically transfer

the input from Sensor1 to Sensor2 when Sensor1

fails.

H20: SNSR BACKUP, H21: RETURN SNS1

• Copy the Setting Data to the BT200

See Page 3-11

Copy the setting data of one temperature transmitter

to another via the BT200. (Uploading & Downloading)

H30: UPLOAD SELCT

•Write Protect See Page 3-11

Configure the transmitter to enable/disable write

protection parameters

H40: WRITE PROTCT

•Sensor Trim See Page 3-12

Adjust the integral characterization curve stored in

memory.

J05: SNSR1 CLR, J10: SNSR1 ZERO, J20: SNSR1

GAIN ..... Sensor1 Trim

K05: SNSR2 CLR, K10: SNSR2 ZERO, K20: SNSR2

GAIN ... Sensor2 Trim (YTA320 only)

J07: IN TRIM MODE

3. OPERATION

• Output Trim See Page 3-13

Used for fine adjustment of a 4 to 20 mA DC

output.

L05: OUT CLR, J10: OUTPUT MODE, J20: OUT ZERO,

J30: OUT GAIN

• Error Messages See Page 4-1

To show that the transmitter has malfunctioned.

A60: SELF CHECK

• Warnings See Page 4-3

To show that incorrect settings entered for a

particular usage of the transmitter.

I59: WARNING, H50: WARNING ENBL

• Logging Function See Page 4-5

Store the errors and min/max process values.

3-2

IM 01C50T03-01E

Page 10

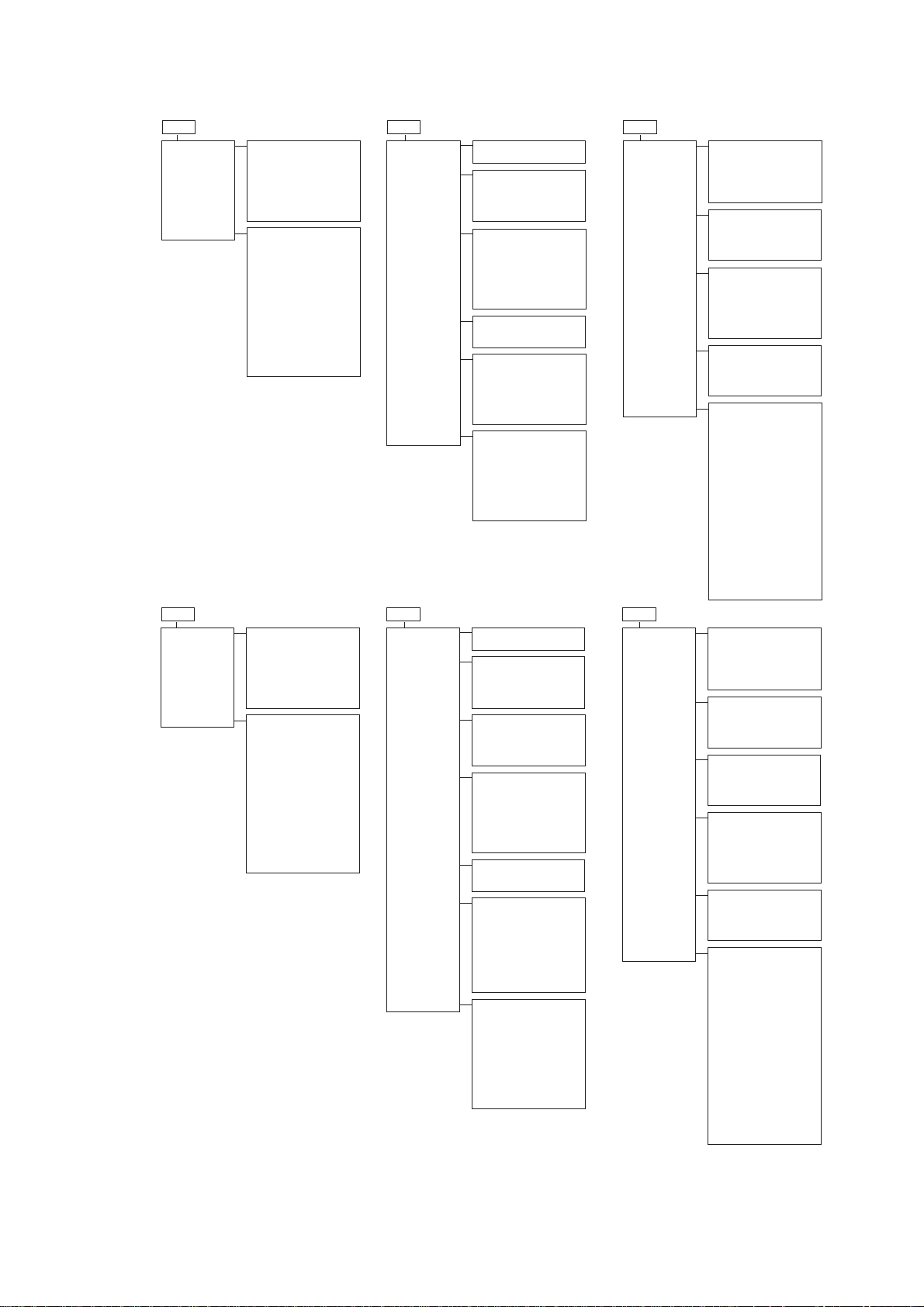

Menu tree for YTA110 & YTA310

3. OPERATION

HOME

A:VARIABLE

B:SET VAR CON.

Menu tree for YTA320

HOME

A:VARIABLE

B:SET VAR CON.

A10:PV

A11:mA of RANGE

A12:% of RANGE

A20:SV

A30:TV

A40:4V

A50: TERM

A60:SELF CHECK

B10:PV is

B11:PV UNIT

B12:PV DAMPING

B13:PV DMP POINT

B20:SV is

B21:SV UNIT

B22:SV DAMPING

B30:TV is

B31:TV UNIT

B32:TV DAMPING

B40:4V is

B41:4V UNIT

B42:4V DAMPING

B51:TERM UNIT

B60:SELF CHECK

A10:PV

A11:mA of RANGE

A12:% of RANGE

A20:SV

A30:TV

A40:4V

A50: TERM

A60:SELF CHECK

B05:SET DIFF

B10:PV is

B11:PV UNIT

B12:PV DAMPING

B13:PV DMP POINT

B20:SV is

B21:SV UNIT

B22:SV DAMPING

B30:TV is

B31:TV UNIT

B32:TV DAMPING

B40:4V is

B41:4V UNIT

B42:4V DAMPING

B51:TERM UNIT

B60:SELF CHECK

SET

C:SET TA G

D:SET SENSOR1

F:SET OUTPUT

G:FORCED OUT

H:SET MODE

I:INFORMATION

SET

C:SET TA G

D:SET SENSOR1

E:SET SENSOR2

F:SET OUTPUT

G:FORCED OUT

H:SET MODE

I:INFORMATION

C10:TAG NO.

C60:SELF CHECK

D10:SENSOR1 TYPE

D20:SENSOR1 WIRE

D40:SENSOR1

D41:SNSR1 UNIT

D60:SELF CHECK

F10:LRV

F20:URV

F30:AUTO LRV

F35:AUTO URV

F40:BURN OUT

F41:BURN OUT VAL

F50:TX FAILURE

F60:SELF CHECK

G10:OUTPUT MODE

G20:OUTPUT VALUE

G60:SELF CHECK

H01:CJC SELECT

H02: CNST CJC TMP

H10:REVERSE OUT

H30:UPLOAD SELCT

H40:WRITE PROTCT

H50:WARNING ENBL

H60:SELF CHECK

I10:PV LRL

I11:PV URL

I12:PV MIN SPAN

I20:SNSR1 LSL

I21:SNSR1 USL

I40:TERM LSL

I41:TERM USL

I59:WARNING

I60:SELF CHECK

C10:TAG NO.

C60:SELF CHECK

D10:SENSOR1 TYPE

D20:SENSOR1 WIRE

D40:SENSOR1

D41:SNSR1 UNIT

D60:SELF CHECK

E10:SENSOR2 TYPE

E20:SENSOR2 WIRE

E40:SENSOR2 TEMP

E41:SNSR2 UNIT

E60:SELF CHECK

F10:LRV

F20:URV

F30:AUTO LRV

F35:AUTO URV

F40:BURN OUT

F41:BURN OUT VAL

F50:TX FAILURE

F60:SELF CHECK

G10:OUTPUT MODE

G20:OUTPUT VALUE

G60:SELF CHECK

H01:CJC SELECT

H02: CNST CJC TMP

H10:REVERSE OUT

H20:SNSR BACKUP

H21:RETURN SNSR1

H30:UPLOAD SELCT

H40:WRITE PROTCT

H50:WARNING ENBL

H60:SELF CHECK

I10:PV LRL

I11:PV URL

I12:PV MIN SPAN

I20:SNSR1 LSL

I21:SNSR1 USL

I30:SNSR2 LSL

I31:SNSR2 USL

I40:TERM LSL

I41:TERM USL

I59:WARNING

I60:SELF CHECK

ADJ

J:CAL SENSOR1

L:CAL OUTPUT

M:SET METER

O:MEMO

P:RECORDS

ADJ

J:CAL SENSOR1

K:CAL SENSOR2

L:CAL OUTPUT

M:SET METER

O:MEMO

P:RECORDS

J05:SNSR1 CLR

J07:IN TRIM MODE

J10:SNSR1 ZERO

J20:SNSR1 GAIN

J30:SNSR1 SERIAL

J60:SELF CHECK

L05:OUT CLR

L10:OUTPUT MODE

L20:OUT ZERO

L30:OUT GAIN

L60:SELF CHECK

M10:PROCESS DISP

M20:%/mA DISP

M30:MATRIX DISP

M40:BAR GRAPH

M50:DISP UPDATE

M55:Err-NO DISP

M60:SELF CHECK

O10:MEMO1

O20:MEMO2

O30:DESCRIPTOR

O40:DATE

O60:SELF CHECK

P05:LOG CLEAR

P10:PV MIN LOG

P11:PV MAX LOG

P12:SV MIN LOG

P13:SV MAX LOG

P14:TV MIN LOG

P15:TV MAX LOG

P16:4V MIN LOG

P17:4V MAX LOG

P18:TERM MIN LOG

P19:TERM MAX LOG

P20:ERR LOG 1

P21:ERR LOG 2

P22:ERR LOG 3

P23:ERR LOG 4

P24:ERR LOG CLR

P30:OPERATE TIME

P31:POWER CHECK

P40:BCC ERROR %

P60:SELF CHECK

J05:SNSR1 CLR

J07:IN TRIM MODE

J10:SNSR1 ZERO

J20:SNSR1 GAIN

J30:SNSR1 SERIAL

J60:SELF CHECK

K05:SNSR2 CAL CLR

K10:SNSR2 ZERO

K20:SNSR2 GAIN

K30:SNSR2 SERIAL

K60:SELF CHECK

L05:OUT CLR

L10:OUTPUT MODE

L20:OUT ZERO

L30:OUT GAIN

L60:SELF CHECK

M10:PROCESS DISP

M20:%/mA DISP

M30:MATRIX DISP

M40:BAR GRAPH

M50:DISP UPDATE

M55:Err-NO DISP

M60:SELF CHECK

O10:MEMO1

O20:MEMO2

O30:DESCRIPTOR

O40:DATE

O60:SELF CHECK

P05:LOG CLEAR

P10:PV MIN LOG

P11:PV MAX LOG

P12:SV MIN LOG

P13:SV MAX LOG

P14:TV MIN LOG

P15:TV MAX LOG

P16:4V MIN LOG

P17:4V MAX LOG

P18:TERM MIN LOG

P19:TERM MAX LOG

P20:ERR LOG 1

P21:ERR LOG 2

P22:ERR LOG 3

P23:ERR LOG 4

P24:ERR LOG CLR

P30:OPERATE TIME

P31:POWER CHECK

P40:BCC ERROR %

P60:SELF CHECK

F0300.EPS

3-3

IM 01C50T03-01E

Page 11

3. OPERATION

3.2 Setting Parameters

3.2.1 Sensor Configuration

When the sensor type or the number of wire connections changes, the following parameters must be reset.

Sensor type setting;

D10: SENSOR1 TYPE, E10: SENSOR2 TYPE

Wire connections setting;

D20: SENSOR1 WIRE, E20: SENSOR2 WIRE

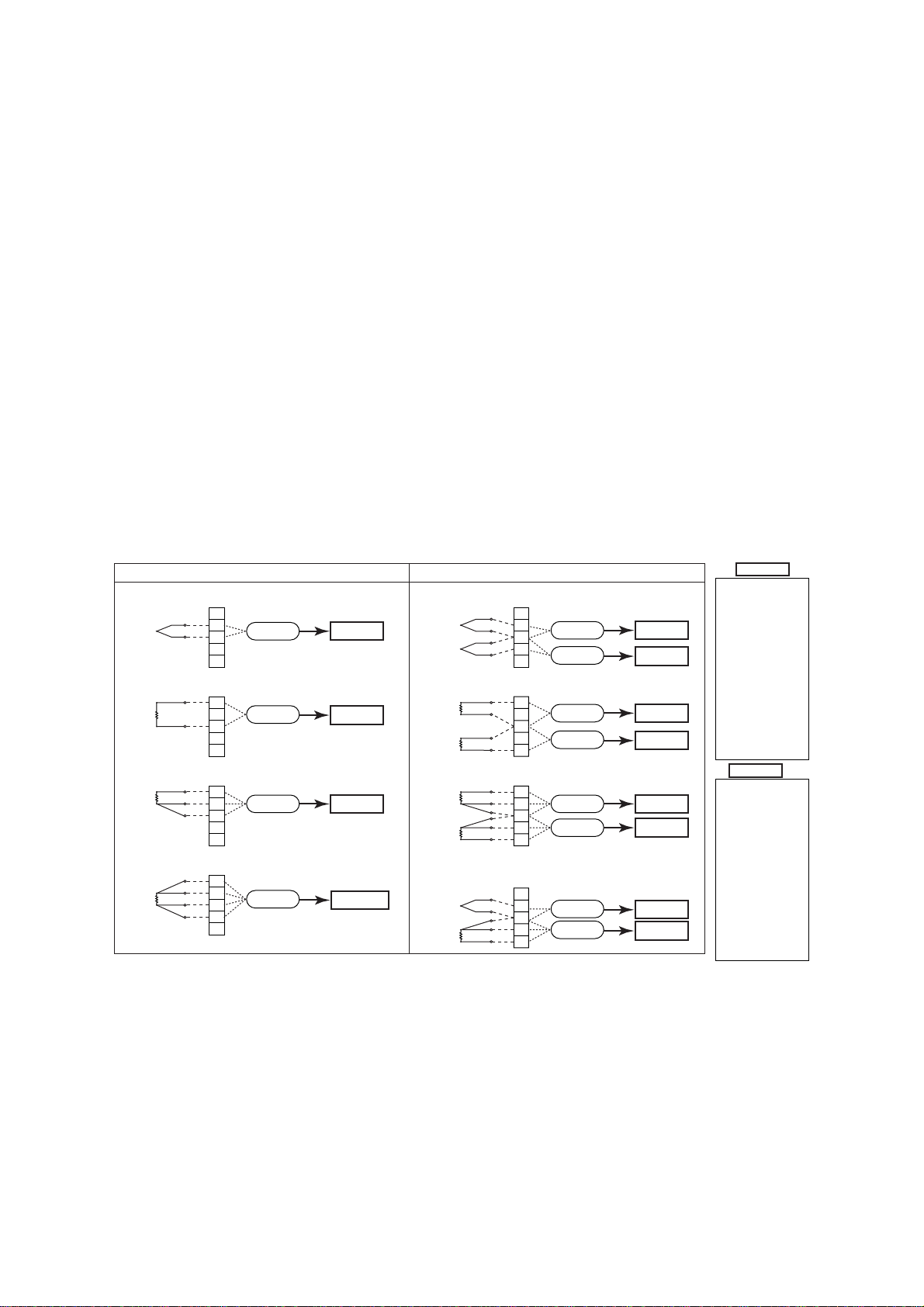

Figure 3.1 diagram shows the wire connections to the

input terminals of the transmitter and sensor type

selections for the parameters in each connection case.

Note that TCs and mV are categorized as Group A and

RTDs and ohm as Group B.

Check the connections between the input terminals and

temperature sensors and set the correct sensor type and

the number of wire connections for the parameters.

Sensor type selection

Thermocouple TYPE W3, W5 (ASTM988)

TYPE B, E, J, K, N, R, S, T

(IEC 584)

TYPE L, U (DIN 43710)

Resistance thermometer

Pt100, Pt200, Pt500

(IEC 751)

[2-, 3- or 4-wire] JPt100 (JIS)

Ni120 (STI INC), Cu

(SAMA RC21-4)

DC voltage mV

Resistance ohm [2- or 3-wire]

1-input model YTA110, YTA310, and YTA320

Thermocouple and DC voltage (TC & mV)

1

(+)

2

Sensor1

3

(–)

4

5

Resistance thermometer(RTD) and resistance (2-wire type)

Resistance thermometer(RTD) and resistance (3-wire type)

Resistance thermometer(RTD) (4-wire type)

(A)

1

Sensor1

2

(B)

3

4

5

(A)

1

(B)

(B)

(A)

(A)

(B)

(B)

Sensor1

2

3

4

5

1

2

Sensor1

3

4

5

Group A

Group B

Group B

Group B

* : Without ohm

Thermocouple and DC voltage (TC & mV)

Resistance thermometer(RTD) and resistance (2-wire type)

Resistance thermometer(RTD) and resistance (3-wire type)

Thermocouple(TC) &

Resistance thermometer(RTD) and resistance (3-wire type)

*

2-input model YTA320

(+)

1

2

(–)

3

4

(+)

5

(A1)

1

(B1)

2

3

(B2)

4

(A2)

5

(A1)

1

(B1)

2

(B1)

3

(B2)

4

(B2)

5

(A2)

(+)

1

(–)

2

(B)

3

4

(B)

5

(A)

Figure 3.1 Input terminal wire connection diagram and sensor type categories

Sensor1

Sensor2

Sensor1

Sensor2

Sensor1

Sensor2

Sensor1

Sensor2

Group A

Group A

Group B

Group B

Group B

Group B

Group A

Group B

Group A

TYPE B (IEC584)

TYPE W3 (ASTM988)

TYPE W5 (ASTM988)

TYPE E (IEC584)

TYPE J (IEC584

TYPE K (IEC584)

TYPE L (DIN43710)

TYPE N (IEC584)

TYPE R (IEC584)

TYPE S (IEC584)

TYPE T (IEC584)

TYPE U (DIN43710)

Pt100 (IEC751)

Pt200 (IEC751)

Pt500 (IEC751)

JPt100 (JIS)

Ni120 (STI INC)

Cu (SAMA RC21-4)

ohm

mV

Group B

TYPE B (IEC584)

TYPE W3 (ASTM988)

TYPE W5 (ASTM988)

TYPE E (IEC584)

TYPE J (IEC584

TYPE K (IEC584)

TYPE L (DIN43710)

TYPE N (IEC584)

TYPE R (IEC584)

TYPE S (IEC584)

TYPE T (IEC584)

TYPE U (DIN43710)

Pt100 (IEC751)

Pt200 (IEC751)

Pt500 (IEC751)

JPt100 (JIS)

Ni120 (STI INC)

Cu (SAMA RC21-4)

* Only for 2 or 3-wire type]

ohm [

mV

F0301.EPS

3-4

IM 01C50T03-01E

Page 12

3. OPERATION

● Example: Set Pt 100 and 4-wire type to Sensor1.

(model YTA320)

<1>

PARAM

D10:SENSOR1 TYPE

Pt200 (IEC751)

D20:SENSOR WIRE

3 WIRE

D40:SENSOR1 TEMP

23.56 degC

DATA DIAG PRNT ESC

<2>

SET

D10:SENSOR1 TYPE

Pt200 (IEC751)

<Pt100 (IEC751) >

<Pt200 (IEC751) >

<Pt500 (IEC751) >

<JPt100 (JIS ) >

<3>

SET

D20:SENSOR1 WIRE

3 WIRE

<3 WIRE >

<4 WIRE >

<2 WIRE >

TYPE B (IEC584)

TYPE W3(ASTM988)

TYPE W5(ASTM988)

TYPE E (IEC584)

TYPE J (IEC584)

TYPE K (IEC584)

TYPE L(DIN43710)

TYPE N (IEC584)

TYPE R (IEC584)

TYPE S (IEC584)

TYPE T (IEC584)

TYPE U(DIN43710)

Pt100 (IEC751)

Pt200 (IEC751)

Pt500 (IEC751)

JPt100 (JIS)

Ni120 (STI INC)

Cu (SAMA RC21-4)

ohm

mV

Non Connection

1. Select D: SET SENSOR1 to go

to the screen (1).

2. Select “D10” and press

[ENTER] to go to the

screen (2).

3. Select “Pt100” and press

[ENTER] twice.

4. Check that “Pt100” has been

set and press [OK].

ESC

5. To set the number of wire

connections, select

D20 and press [ENTER].

6. Select “4 WIRE” and press

ESC

[ENTER] twice.

7. Press [OK].

Note: D40 indicates input values of

the sensor based on the

settings at D10 and D20.

F0302.EPS

3.2.2 Process Variables Mapping

Process variable mapping;

B10: PV is, B20: SV is, B30: TV is, B40: 4V is

Process variables can be assigned as the primary

variable(PV), the secondary variable(SV), the tertiary

variable(TV), and the quaternary variable(4V). The PV

always outputs a 4 to 20mA DC analog signal corresponding to Lower Range Value and Upper Range

Value. Mapping process variables to the SV, TV, and

4V is optional.

The following items can be mapped as the process

variables.

Sensor1 : Sensor1 input value.

Sensor2 : Sensor2 input value.

DIFFERENCE

*1,*2,*4

: Difference between

Sensor1 and Sensor2.

(Sensor1-Sensor2 or

Sensor2-Sensor1; specified in B05: SET DIFF)

AVERAGE

*1,*4

: Average of Sensor1 and

Sensor2.

[(Sensor1 + Sensor2)/2]

Sensor1-Term

*4,*5

: Difference between

Sensor1 and terminal

temperature

Sensor2-Term

*1,*4,*5

: Difference between

Sensor2 and terminal

temperature

Terminal Temp : Terminal temperature

Not used

*3

: Showing that a process

variable is not assigned.

*1: This item is displayed only when the YTA320 2-input

temperature transmitter is used.

*2: The setting in B05 applies to the PV, SV, TV, and 4V.

*3: “Not used” is not displayed for B10 since the PV

requires process variable mapping.

*4: When this item is selected, the sensor types to be set

for D10(Sensor1) and E10(Sensor2) should be

selected from any one of the following three groups;

Temperature sensor(T/C and RTD), DC voltage or

resistance. The combination(for example, temperature

sensor and DC voltage input) would cause an incorrect

computation due to the different unit system and is not

allowed.

*5: When this item is selected, DC voltage and resistance

input should not be set for D10(Sensor1) or

E10(Sensor2).

● Example: Use two temperature sensors to map the

difference (Sensor2-Sensor1) between Sensor1

and Sensor2 to the PV (the primary variable).

Before mapping the process variable, complete the

setting of the temperature sensor to be connected

to Sensor1 and Sensor2.

Sensor1 setting: D10: SENSOR1 TYPE, D20:

SENSOR1 WIRE

Sensor2 setting: E10: SENSOR2 TYPE, E20:

SENSOR2 WIRE

PARAM

B05:SET DIFF

Sensor1-Sensor2

B10:PV is

Sensor1

B11:PV UNIT

degC

DATA DIAG PRNT ESC

SET

B05:SET DIFF

Sensor1-Sensor2

<Sensor1-Sensor2 >

<Sensor2-Sensor1 >

SET

B10:PV is

Sensor1

<Sensor1 >

<Sensor2 >

<DIFFERENCE >

<AVERAGE >

If the temperature sensor is correctly connected to Sensor1

and Sensor2,

the setting content is reflected on A10: PV.

1. Set the content of

“DIFFERENCE” for the

difference between Sensor1

and Sensor2.

Select B05: SET DIFF and

press [ENTER]

2. Select “Sensor2 - Sensor1” and

press [ENTER] twice.

3. Press [OK].

ESC

4. Select B10: PV is and press

[ENTER] for PV mapping.

5. Select “DIFFERENCE” and

ESC

press [ENTER] twice.

6. Press [OK].

F0303.EPS

3-5

IM 01C50T03-01E

Page 13

3. OPERATION

3.2.3 Unit Setting

B11: PV UNIT, B21: SV UNIT, B31: TV UNIT, B41: 4V

UNIT

Select the engineering unit for the process variables

assigned as PV, SV, TV, and 4V from degree C,

Kelvin, degree F* and degree R*. When mV or ohm is

specified as an input type, the unit is automatically set

to mV or ohms.

*: Degree F and degree R are available only when

optional code /D2 is specified.

3.2.4 Range Setting

(a) Changing the range with keypad

Lower range value setting;

F10: LRV, Upper range value setting; F20: URV

The range for the PV corresponding to the 4 to 20mA

output signal is set at the factory before shipment. The

procedure to rerange is as follows.

● Example: Changing the measurement range from

0 to 100°C to 0 to 150°C .

PARAM

F10:LRV

0 degC

F20:URV

100 degC

F30:AUTO LRV

DISABLE

DATA DIAG PRNT ESC

PARAM

F20:URV

0 degC

+ 150

DEL CLR ESC

Note : The unit selected in B11: PV UNIT is applied to the units used

for F10 and F20.

NOTE

When entering numeric values at the range

setting, the value of URV must be greater than

that of LRV.

Range Setting Condition: URV > LRV

1. Select F20: URV and press

[ENTER].

2. Input “150” and press [ENTER]

twice.

3. Press [OK].

F0304.EPS

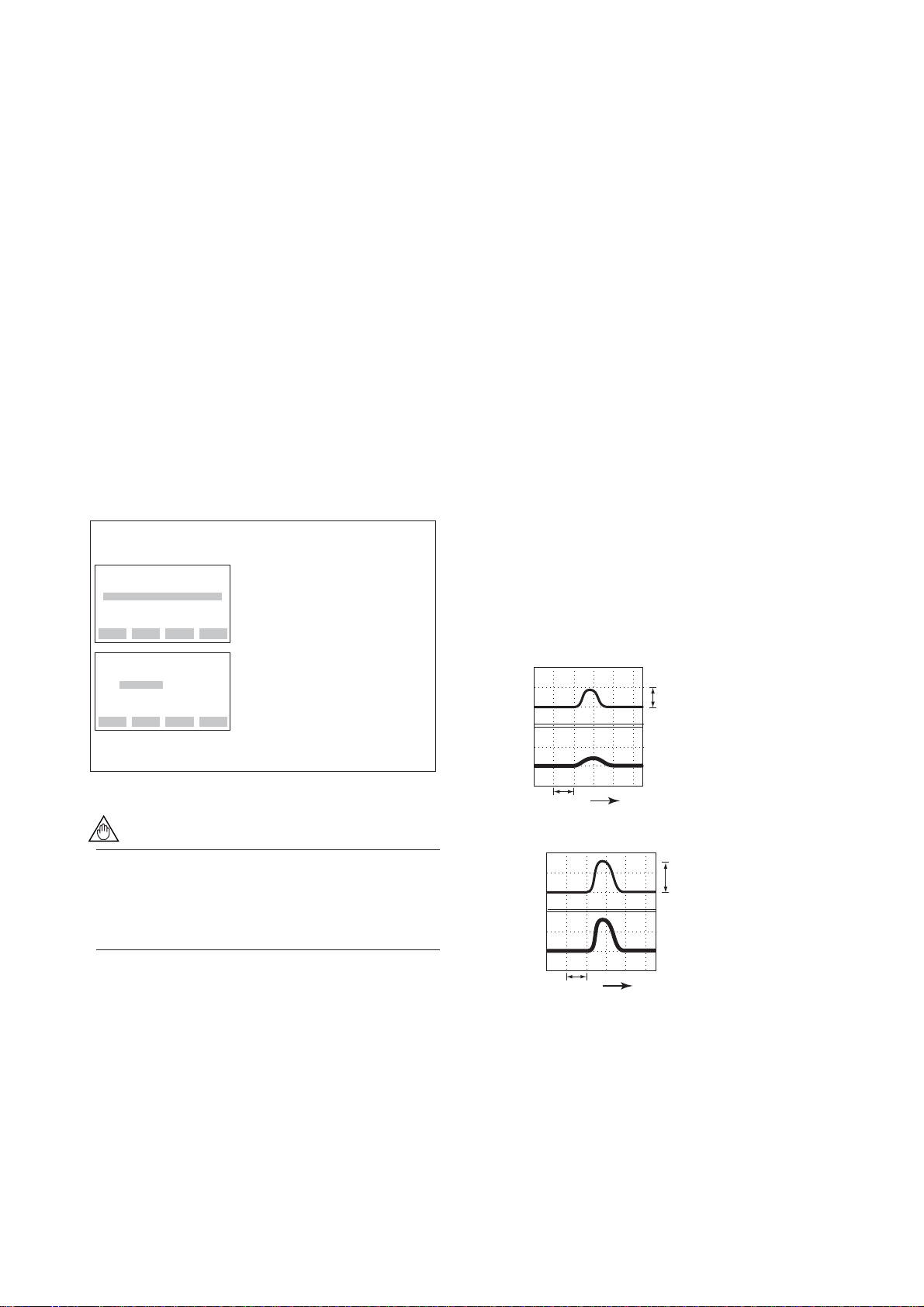

3.2.5 Setting Damping Time Constant

B12: PV DAMPING, B22: SV DAMPING,

B32: TV DAMPING, B42: 4V DAMPING

Setting the response time of each Process Variable to

make the output change very slowly with a rapid

change in input. Set the value from 0 to 99 seconds.

If the time constant is set to 2 seconds, the transmitter

calculates a reading every cycle using the damping

equation, in order to make the output 63 percent of the

input range after 2 seconds.

This damping time constant is normally set to work

when the temperature make a step change within 2

percent of the output range. The damping can be

changed using the “B13: PV DMP POINT” parameter.

● Setting Damping Holding Point

B13: PV DMP POINT

This parameter is used to set the point where the

transmitter conducts the PV damping operation,

depending on a magnitude of the change in the

input value. When the change value in percent

exceeds the setting value, the transmitter outputs

the signal without the damping operation.

Set the value as a percent of span.

● Example: Output pattern for the setting value of 10%

•Change value less then 10%

(C)

Input

10

0

(%)

Output

10

0

3 sec.

•Change value 10% or above

(C)

Input

10

0

(%)

Output

10

0

Time

9%

Assumed setting

Renge: 0 to 100 C

Damping time: 3 sec.

14%

(b) Changing the range while applying an

actual input

F30: AUTO LRV

F35: AUTO URV

This feature allows the lower and upper range values to

be setup automatically with the actual input applied.

3 sec.

Time

3.2.6 Tag Number and Memo Writing

Tag number (See Appendix A. Section A.3.2)

C10: TAG NO.

Up to sixteen alphanumeric characters can be entered.

The tag number is as specified upon shipment.

3-6

IM 01C50T03-01E

F0325.EPS

Page 14

3. OPERATION

Memo

O10: MEMO1, O20: MEMO2

Up to sixteen alphanumeric characters can be entered.

Description

O30: DESCRIPTOR

Up to sixteen alphanumeric characters can be entered.

Date

O40: DATE

Six numeric values can be entered. Only a date

recording function is provided; no internal clock

function is provided, thus the date is not updated.

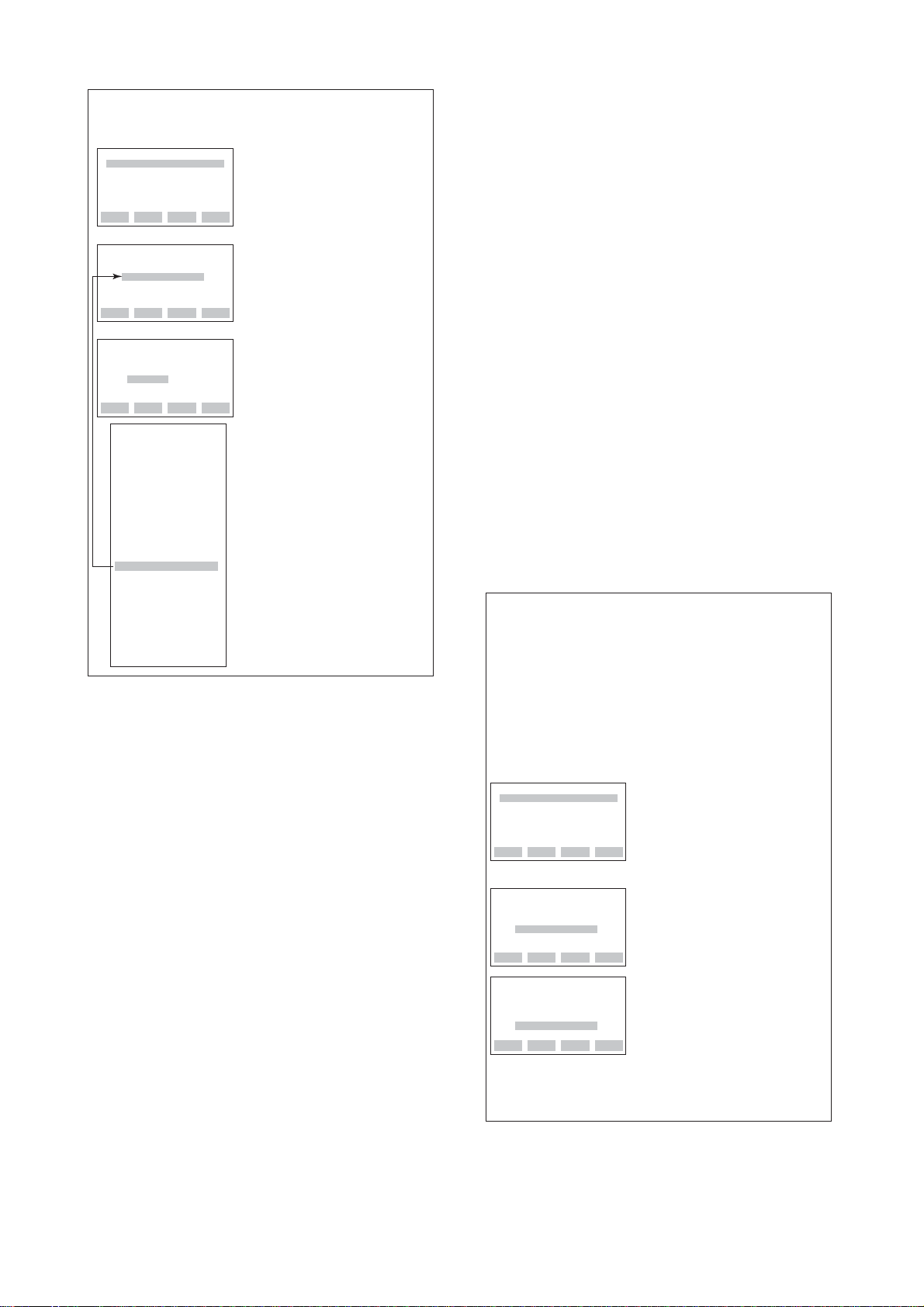

3.2.7 Forced Output Function

G10: OUTPUT MODE, G20: OUPUT VALUE

This feature can be used to output a fixed current from

3.6 mA (-2.5%) to 21.6 mA (110%) for loop checks.

● Example: Outputting 16 mA (75%) constant current

PARAM

G10:OUTPUT MODE

AUTOMATIC MODE

G60:SELF CHECK

GOOD

DATA DIAG PRNT ESC

SET

G10:OUTPUT MODE

AUTOMATIC MODE

<AUTOMATIC MODE >

<MANUAL MODE mA >

<MANUAL MODE % >

PARAM

G10:OUTPUT MODE

MANUAL MODE mA

G20:OUTPUT VALUE

4 mA

C60:SELF CHECK

GOOD

DATA DIAG PRNT ESC

SET

G20:OUTPUT VALUE

4 mA

+ 16

DEL CLR ESC

SET

G20:OUTPUT VALUE

16 mA

FEED NO OK

1. Select G10: OUTPUT MODE

and press [ENTER].

2. Set "MANUAL MODE mA."

ESC

3. G20: OUTPUT VALUE is

displayed.

Select G20: OUTPUT VALUE

and press [ENTER].

4. Set "16."

5. Pressing [ENTER] twice outputs

a constant current.

If the transmitter is equipped

with the integral indicator, the

LCD displays F.O.

6. Press [OK].

IMPORTANT

• Manual mode output is held for approximately

10 minutes and then released automatically

after the time has elapsed. Even if the BT200

power supply is turned off or the communication connector is disconnected during the test,

it is held for approximately 10 minutes.

• To release the test output immediately, set

“AUTOMATIC MODE” at G10 as seen in the

figure above or turn off the transmitter.

3.2.8 Integral Indicator Display Function

If the transmitter is equipped with the integral indicator, the following items can be displayed in parameter

settings.

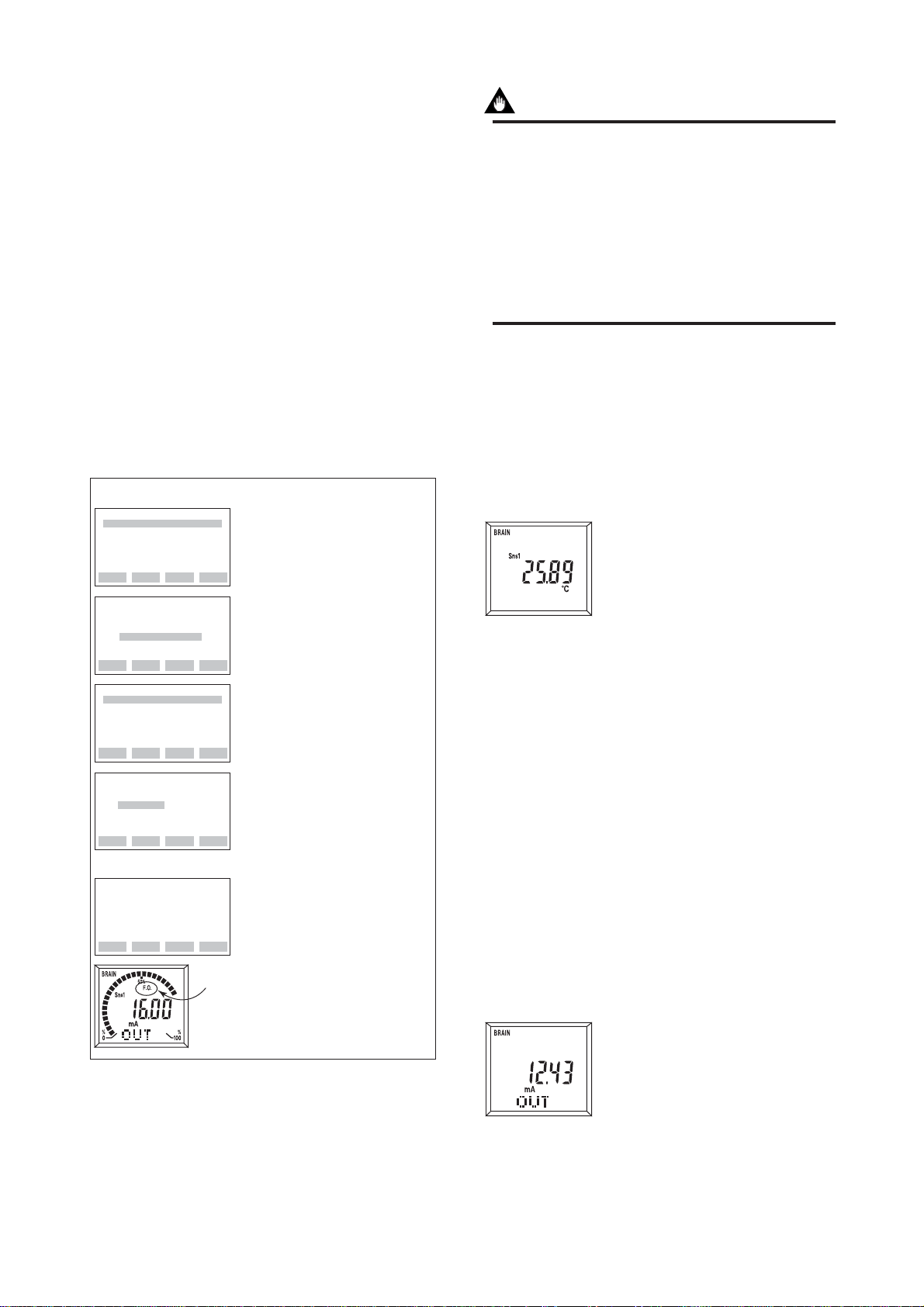

(a) Display process variable

M10: PROCESS DISP

Displays PV value.

Also, if the output value is selected at M20, the process

variable and output value are displayed alternately.

PV : Displays PV value

SV : Displays SV value

TV : Displays TV value

4V : Displays 4V value

PV, SV : Displays PV and SV

PV, SV, TV : Displays PV, SV and TV

PV, SV, TV, 4V : Displays PV, SV, TV, and

INHIBIT : The process variable is

Used to select the process variable

to be displayed on the LCD

indicator. If more than one process

is selected, they are displayed in

sequence as the display update

cycles. The appropriate unit is also

F03291

displayed for each process variable.

value alternately

value alternately

4V value alternately

not displayed.

"F.O." lit on.

F0305.EPS

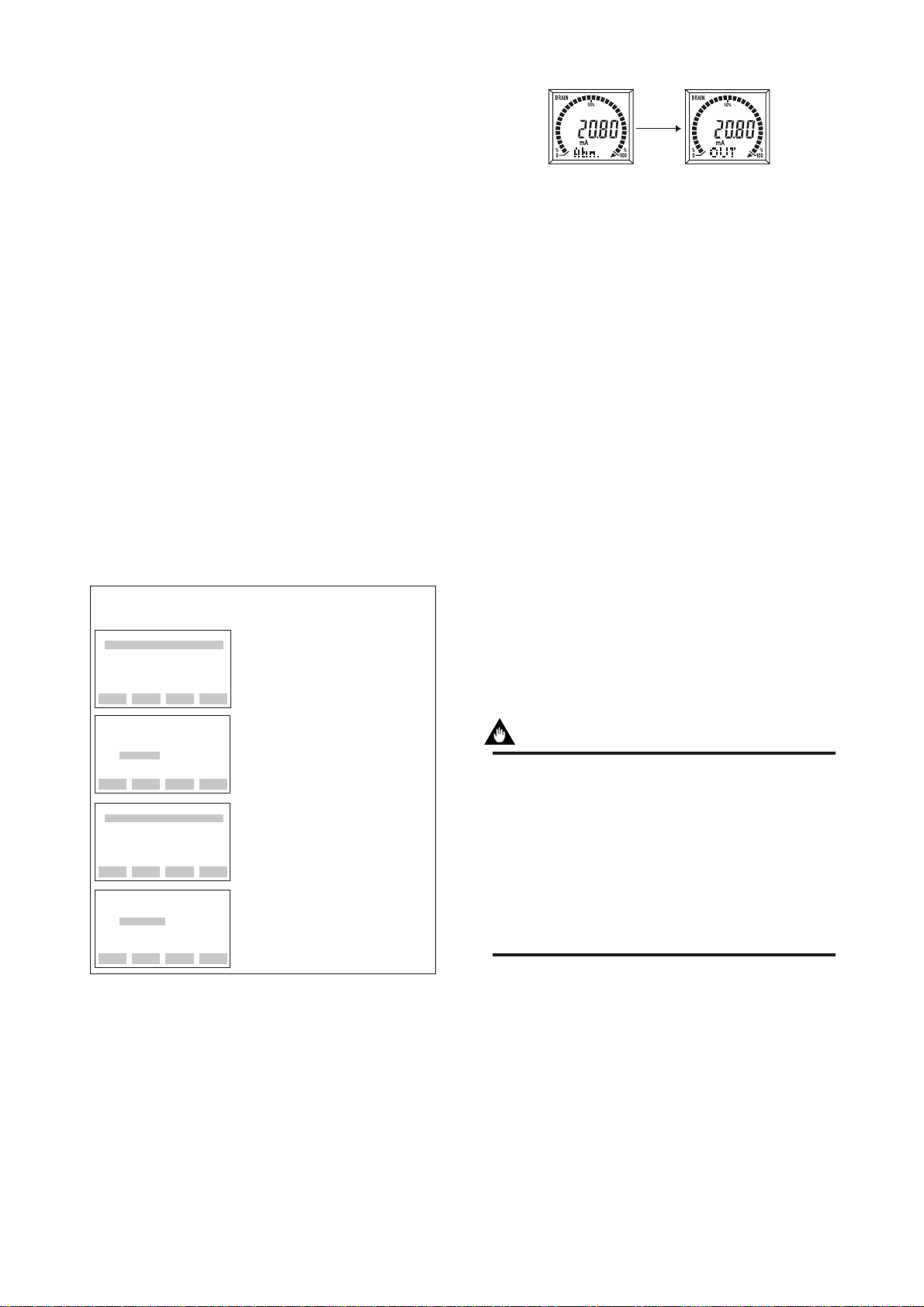

(b) Display output value

M20: %/mA DISP

Displays output value.

Used to select the output indications to be displayed on the LCD

indicator. If two output indications

are selected, they are displayed in

sequence as the display update

cycles.

F03292

3-7

IM 01C50T03-01E

Page 15

3. OPERATION

mA : Displays output value in mA

%: Displays output value in %

mA, % : Displays output value in

mA and % alternately

INHIBIT : The output value is not

displayed

(c) Display sensor type/number of wire

connections

M30: MATRIX DISP

Displays PV value and

sensor type

Used to select the input sensor type

and the number of wire connections to be displayed on the LCD

indicator. The displays of these

items are synchronized with the

process variable displays selected

F03293

at M10. Specifying “INHIBIT”

under M10 disables the function of M30 for the

display.

PROCESS : Displays process variables

(PV, SV, TV, or 4V.)

TYPE : Displays sensor type

WIRE : Displays number of wire

connections

PROCESS, TYPE : Displays process and

sensor type alternately

TYPE, WIRE : Displays sensor type and

number of wire

connections alternately

INHIBIT : the sensor type and the

number of wire

connections is not

displayed

FAST : 1/2 of the normal cycle

speed

NORMAL : Normal cycle speed

SLOW : 1.5 times of the normal

cycle speed

NOTE

When operating under –10°C(14°F), the display

response time may be reduced. In such a case,

set the display cycle speed to “NORMAL” or

“SLOW.”

(d) Display output bar graph

M40: BAR GRAPH

Displays bar graph.

Used to select output bar graph

display ON/OFF.

F03292

SHOW : Displays analog output bar

graph

INHIBIT : No bar graph display

(e) Select a cycle speed for display

M50: DISP UPDATE

Used to select the update rate for the display on the

LCD indicator. Process variables, output values, and

error codes are displayed using this cycle speed.

3-8

IM 01C50T03-01E

Page 16

(f) Display error code

M55: Err-NO DISP

If an error occurs, the error code is displayed on the

LCD indicator.

SHOW : Error code is displayed

INHIBIT : Error code is not displayed

●Example of LCD display cycle

The example of the LCD indicator is based on the following settings.

3. OPERATION

Integral indicator display parameter setting

M10: PROCESS DISP = PV, SV

M20: %/mA DISP = mA

M30: MATRIX DISP = PROCESS, TYPE

M40: BAR GRAPH = SHOW

Process variable display PV value PV value SV value SV value

%/mA display: mA

Matorix display: Process variable Sensor type Process variable Sensor type

Bar graph ON

Assumed current status and parameter settings

A10: PV = 50.0 degC

A11: mA of RANGE = 12.00 mA

A20: SV = 25.16 degC

B10: PV is = Sensor1

B20: SV is = Sensor1-Term

D10: SENSOR1 TYPE = TYPE B

F0306.EPS

3-9

IM 01C50T03-01E

Page 17

3.2.9 Burn Out Function

(a) Sensor burn out

Configure the burn out mode in the case of sensor

failure or disconnection. When the sensor failure is

detected, the transmitter will output one of the following values.

F40: BURN OUT

Select from the followings:

LOW : Outputs 3.6 mA (-2.5%)

HIGH : Outputs 21.6 mA (110%)

USER mA : Output user set value in mA.

Settable 3.6 to 21.6 mA in F41

USER % : Output user set value in %.

Settable -2.5 to 110 % in F41

OFF : The burn out output is NOT

defined

F41: BURN OUT VAL

When “USER mA” or “USER %” is selected at

F40:BURN OUT, F41:BURN OUT VAL is displayed.

The output value setting range is 3.6 to 21.6 mA (-2.5

to 110%).

3. OPERATION

Displays "Abn." Displays "OUT."

F0308.EPS

Figure 3.2 Integral Indicator Display in Sensor Burn Out

(b) Confirming the output direction if Hard-

ware error occurs

F50: TX FAILURE

The output status of the transmitter in hardware failure

is set by using a jumper on the CPU assembly. (See IM

01C50B01-01E section 3.2) The current setting can be

checked in parameter D50: TX FAILURE.

HIGH : When an error occurs,

110%(21.6mA) or higher is

output.

LOW : When an error occurs,

-5%(3.2mA) or lower is output.

3.2.10 Reverse Output Function

● Example: Setting output to 20.8 mA in the event of

sensor burn out

PARAM

F40:BURN OUT

HIGH

F50:TX FAILURE

HIGH

F60:SELF CHECK

GOOD

DIAG PRNT ESC

DATA

SET

F40:BURN OUT

HIGH

<HIGH >

<USER mA >

<USER % >

<OFF >

PARAM

F40:BURN OUT

USER mA

F41:BURN OUT VAL

21.6 mA

F50:TX FAILURE

HIGH

DIAG PRNT ESC

DATA

SET

F41:BURN OUT VAL

21.6 mA

+ 20.8

DEL CLR ESC

1. Select F40: BURN OUT and

press [ENTER].

2. Select "USER mA" and press

[ENTER] twice.

3. Press [OK].

ESC

4. Select F40: BURN OUT VAL

and press [ENTER].

5. Set “20.8” and press [ENTER]

twice.

6. Press [OK].

F0307.EPS

During sensor burn out time, the Sensor1 failure or the

Sensor2 failure error message is generated. (See

Section 4.1.1 for details.)

If the transmitter is equipped with the integral indicator, the LCD displays “Abn.” and “OUT” as shown in

Figure 3.2.

H10: REVERSE OUT

To reverse the direction for a 4 to 20 mA DC output

relative to input.

3.2.11 Sensor Backup Function (For Model YTA320)

IMPORTANT

To use sensor backup function, the following

conditions must be met.

• “Sensor1” is mapped as the PV at B10: PV is.

• “Sensor2” is mapped as the SV at B20: SV is.

• “Sensor1” and “Sensor2” are both correct

input status.

• “HIGH, LOW, User mA, or User %” is selected in the sensor burnout

parameter setting at F40: BURN OUT

The sensor backup command sets the transmitter to

automatically use Sensor2 as PV if Sensor1 fails.

When the transmitter is in the Sensor Backup operation

and switches to Sensor2, there will be no disruption in

the 4 to 20 mA output. The error code for Sensor1

failure is shown on the integral indicator, and also the

error message is sent to the BT200 that the Sensor1

failed and the sensor backup has been in operation. In

case Sensor2 fails during the backup operation, the

3-10

IM 01C50T03-01E

Page 18

3. OPERATION

transmitter will send the error code for Sensor2 failure

to the integral indicator and the BT200, and outputs the

“Sensor burnout” value.

(a) Setting of backup mode

H20: SNSR BACKUP

Set “ENABLE” at H20: SNSR BACKUP.

ENABLE : Activates backup mode, and

transmitter starts to observe.

DISABLE : Cancels backup mode.

IMPORTANT

Do not change the PV and SV mapping data

when the sensor backup mode is active. Cancel

the sensor backup mode to alter the mapping

data.

(b) Returning from Sensor2 to Sensor1 during

the sensor backup operation

H21: RETURN SNS1

Once the transmitter enters the sensor backup operation, H21:RETURN SNS1 appears on the BT200. This

parameter is used to retrieve the output to the Sensor1

input value. Ensure that Sensor1 and Sensor2 are both

correct input status, then;

Set “ENABLE” at H21:RETURN SNS1.

ENABLE : Switches to Sensor1 output.

DISABLE : Maintains Sensor2 output status.

SET PRAM ONLY : Uploads the parameters

with respect to the operation settings such as LRV

and the sensor type.

ALL PRAM : Uploads the all param-

eters.

See the parameter list at the end of this manual for

classification of the operation setting parameter groups

and the parameter group unique to the equipment. See

also the BT200 instruction manual, IM 1C0A11-01E,

for the setting procedure.

3.2.13 Write Protect Function

(a) Software Write Protect Function

H40: WRITE PROTCT

The write protect function is used to prevent unauthorized configuration data changes in the transmitter.

YES : Disables writing of all parameters

other than H40.

NO : Enables writing of all param-

eters.

If the transmitter is equipped with the integral indicator, the LCD displays “W.P.” when setting H40 to

YES.

● Example: Setting write protect on

SET

H40:WRIT PROTCT

NO

<NO >

<YES >

1. Select “YES” and press

[ENTER] twice to enter

the setting.

ESC

"W. P." lit on

IMPORTANT

In the sensor backup operation, even if the

Sensor1 recovers, the Sensor2 input value

continues to be output until “ENABLE” is set at

H21: RETURN SNS1 or the transmitter's power

is turned off and then on again.

3.2.12 Copy the Setting Data

H30: UPLOAD SELCT

This function is used to copy the setting data of one

temperature transmitter to another.

Connect the temperature transmitter with the BT200

and record (UPLOAD) the setting data to the BT200

nonvolatile memory. By connecting the BT200 to other

temperature transmitters, recorded data can be overwritten (DOWNLOAD) on the transmitters.

The YTA series temperature transmitter handles the

uploading data at two levels. It is necessary to specify

the desired one before uploading data.

(b) Hardware Write Protect Function

Hardware write protect function is set up by Switch

(SW2) on the CPU assembly. Under write protect

status, any change operation is denied. If the transmitter is equipped with the integral indicator, the LCD

displays “W.P.” when setting SW2 to “Y”.

3-11

IM 01C50T03-01E

F0309.EPS

Page 19

3. OPERATION

Pin position of SW2

W P

Y

SW2

N

W P

Y

SW2

N

SW1

Burnout output direction

upon hardware failure

CPU Assembly

Figure 3.3 SW2 setting

Write Protect Status

No

Yes

SW2

Hardware Write Protect

F0355.EPS

3.2.14 Sensor Trim

Each YTA transmitter is factory-characterized based on

the standard sensor curve and uses the information to

produce a process variable output. The sensor trim

function is used to adjust to the transmitters internal

interpretation of the input signal.

ZERO

Output

Input

One point trim

Figure 3.4 Trim function images

ZERO

Output

Input

Two points trim

(a) Zero/Gain Point Adjustment

J07: IN TRIM MODE

J10: SNSR1 ZERO, J20: SNSR1 GAIN

K10: SNSR2 ZERO, K20: SNSR2 GAIN ...YTA320 only

1) Connect the temperature transmitter and the

calibration device as shown in Figure 3.5 and warm

up for at least three minutes.

GAIN

F0310.EPS

a. Wiring of power supply and output

+ Output signal

–

Load resistance

Voltmeter

b. Example of wiring of thermocouple

or DC voltage input (1-input type)

1

2

3

4

5

c. Example of wiring of thermometer resistor

4-wire type (1-input type)

1

2

3

4

5

Figure 3.5 Example of wiring for calibration equipment

(+)

(–)

DC voltage generator

or thermocouple

(A)

(A)

(B)

(B)

Variable resistor

or thermometer resistor

F0311.EPS

2) Check the sensor type with the D: parameter.

3) Select the input trimming mode in J07:IN TRIM

MODE. The following selections are offered.

V.R./ZERO&GAIN

V.R./ZERO

TEMP/ZERO&GAIN

TEMP/ZERO

Select “V.R./ZERO&GAIN” or “V.R./ZERO” when

the calibration device is DC voltage generator or

Variable resistor, or select “TEMP/ZERO&GAIN”

or “TEMP/ZERO” when the device is Temperature

sensor.

4) Perform zero-point adjustment.

•When the input trimming mode is “V.R./

ZERO&GAIN” or “V.R./ZERO”, apply the value

for the zero-point shown in the Table 3.1 depending on the specified sensor type. Wait until the

input from the calibration device becomes stable.

•When the input trimming mode is “TEMP/

ZERO&GAIN” or “TEMP/ZERO”, expose the

temperature sensor to calibration temperature for

the zero-point. Wait until the input from the

temperature sensor becomes stable.

3-12

IM 01C50T03-01E

Page 20

3. OPERATION

Table 3.1 Zero and Gain point value for Sensor

trim

Sensor type

TC B,R,S,T +0[mV] +25[mV]

E,J,K,N,W3,W5,L,U, mV +0[mV] +75[mV]

RTD Pt100,JPt100,NI120,Cu +40[ohm] +330[ohm]

Pt200, Pt500, ohm +40[ohm] +1600[ohm]

Setting value

Zero-point Gain-point

T0301.EPS

5) Enter the current input value in J10: SNSR1 ZERO

(or K10: SNSR2 ZERO for YTA320).

6) Press [ENTER] twice and press [OK].

7) Perform gain-point adjustment if “V.R./

ZERO&GAIN” or “TEMP/ZERO&GAIN” is

selected in J07:IN TRIM MODE.

•When the input trimming mode is “V.R./

ZERO&GAIN” apply the value for the gain-point

shown in the Table 3.1 depending on the specified sensor type. Wait until the input from the

calibration device becomes stable.

•When the input trimming mode is “TEMP/

ZERO&GAIN”, expose the temperature sensor to

calibration temperature for the gain-point. Wait

until the input from the temperature sensor

becomes stable.

8) Enter the current input value in J20: SNSR1 GAIN

(or K20: SNSR2 GAIN for YTA320).

9) Press [ENTER] twice and press [OK].

NOTE

• First correct the ZERO point, then correct the

GAIN point in two points calibration. When the

GAIN point is adjusted, the ZERO point

correction amount is also updated and written

into the EEPROM.

• The calibration unit is changed to “mV” or

“ohm” depending on the type of connected

sensor when the input trimming mode is “V.R./

ZERO&GAIN” or “V.R./ZERO” or to temperature unit selected at D41:SNSR1 UNIT.

(b) Returning to the factory set value

J05: SNSR1 CLR

K05: SNSR2 CLR ...YTA320 only

To return to the factory set value, set “USER CAL

CLEAR” or “USER CAL IGNORE” at J05: SNSR1

CLR for the Sensor1 and K05: SNSR2 CLR for the

Sensor2.

USER CAL CLEAR : Clear user trim value

and return to the

factory set value.

USER CAL IGNORE : Ignore user trim value

and return to the

factory set value.

USER CAL ACT : Use user trim value.

NOTE

Regardless of restarting the transmitter, the

“USER CAL ACT” is always set and the user

trim value is used as the input signal unless it is

cleared by “USER CAL CLEAR.”

3.2.15 Output Trim

(a) Zero/Gain Point Adjustment

L10: OUTPUT MODE, L20: OUT ZERO, L30: OUT GAIN

The output adjustment function can match the 4 mA

and 20 mA output of the temperature transmitter to the

reference meter such as a voltmeter.

1) Connect the temperature transmitter, 250 Ω

resistance and the voltmeter as shown in Figure 3.2.

2) Select L10: OUTPUT MODE and press [OK].

3) Select “MANUAL MODE 4mA” and press

[ENTER] twice.

(4 mA output status continues for 10 minutes.)

Press [OK].

4) Select L20: OUT ZERO and press [OK].

5) Write the indicated value of the voltmeter to L20:

OUT ZERO and press [ENTER] twice.

(The temperature transmitter automatically corrects

the difference between this value and the operation

output.)

Press [OK].

6) Select L10: OUTPUT MODE and press [OK].

7) Select “MANUAL MODE 20mA” and press

[ENTER] twice.

(20 mA output status continues for 10 minutes.)

Press [OK].

8) Write the indicated value of the voltmeter at L30:

OUT GAIN and Press [ENTER] twice.

(The temperature transmitter automatically corrects

the difference between this value and the operation

output.) Press [OK].

Note 1: First correct the ZERO point, then correct the GAIN

point. If the ZERO point is not adjusted, GAIN point is

not corrected.

(b) Returning to the factory set value

L05: OUT CLR

To return to the factory set value;

USER CAL CLEAR : Clear user trim value

and return to the

factory set value.

3-13

IM 01C50T03-01E

Page 21

USER CAL IGNORE : Ignore user trim value

and return to the

factory set value.

USER CAL ACT : Use user trim value.

NOTE

Regardless of restarting the transmitter, the

“USER CAL ACT” is always set and the user

trim value is used as the input signal unless it is

cleared by “USER CAL CLEAR.”

3.2.16 CJC Selection

For thermocouple input, terminal temperature measured

by an internal sensor is used for Cold Junction Compensation function. In YTA, a constant value set by

users can be used for the compensation function in

place of the terminal temperature. If the constant value

is set to “0", the compensation is not applied.

3. OPERATION

H01 : CJC SELECT

Select “Constant CJC” to use the constant value in

place of terminal temperature;

INTERNAL CJC : Use the terminal tempera-

ture measured by an

internal sensor.

CONSTANT CJC : Use the constant value set

by users.

H02 : CNST CJC TMP

This parameter appears only when “CONSTANT CJC”

is selected for H01. Enter designated temperature value

used for CJC function. This value is a constant and not

incremented.

3-14

IM 01C50T03-01E

Page 22

4. SELF-DIAGNOSTICS

The temperature transmitter continually monitors its

own performance during normal operation. If an error

occurs, it displays and records the error to the logging

parameters, and with the integral indicator, an error

code corresponding to the error is displayed.

4.1 Error Message

An error message is displayed on the BT200 when

there is a problem with functions. The error message

can be checked with the parameter number of each

item ■60:SELF CHECK. In addition, the error code is

displayed when the transmitter is equipped with the

integral indicator. See Table 4.1 below for the error

contents corresponding to the error messages, error

codes, and their countermeasures.

4. SELF-DIAGNOSTICS

● Example: Checking by the BT200

PARAM

A10:PV

125.06 degC

A11:mA of RANGE

16.51 mV

A12:% of RANGE

50.25 %

DATA DIAG PRNT ESC

HOME

A60:SELF CHECK

ERROR

<ERROR >

<SENSOR1 FAILURE >

<Sns Backup Start>

<SENSOR2 FAILURE >

FEED PRNT ESC

1. Press [F2] (DIAG) to go to the

diagnostics panel

(A60: SELF CHECK).

2. Error messages are shown

when the error occurs.

● Example: Checking by the integral indicator

Error codes are shown when the errors occur.

F0401.EPS

Note : To display the error code, set M55: Err-NO DISP to SHOW.

F0402.EPS

4-1

IM 01C50T03-01E

Page 23

Table 4.1 List of Error Codes

Indicator

N/A GOOD

Er-01 Output Too Low

Er-02 Output Too High

Er-03 Sensor1 Failure

Er-04 Sensor2 Failure

(YTA320 only)

Er-05 S1 Signal Error

Er-06 S2 Signal Error

(only YT A320)

Er-07 Amb Temp Low

Er-08 Amb Temp High

Er-09 Sns Backup Start

(only YT A320)

Er-10 Illegal PV MAP

Er-11 Term Sns Failure

Er-12 EEPROM Failure

Er-13 CPU Failure

Er-14 AD Conv Failure

Er-15 Reverse Cal Fail

*1: See subsection 3.2.9 (a) ‘Sensor burn out.’

*2: See subsection 3.2.9 (b) ‘Confirming the output direction if Hardware error occurs.’

BT200 display Cause Output operation upon error Action

Input value is lower than the

PV low range value.

Input value is higher than the

PV Upper range value.

Sensor1 fails or disconnects

from the terminal box.

Sensor2 fails or disconnects

from the terminal box.

Outputs goes to minimum

value. (3.68 mA, –2.0%)

Outputs goes maximum

value. (20.8 mA, 105%)

If sensor1 is set as PV,

burnout value is output.

When sensor backup mode

is set in YTA320, sensor2

input is used as PV.

If sensor1 value is set as

PV, and the sensor backup

mode is effect, the sensor

burnout value is output.

Sensor1 input value greatly

exceeds sensor

measurement range. Sensor

Outputs goes to minimum

value (3.68 mA) or

maximum value (20.8 mA).

type or connection polarity

may be incorrect.

Sensor2 input value greatly

exceeds sensor

measurement range. Sensor

Outputs goes to minimum

value (3.68 mA) or

maximum value (20.8 mA).

type or connection polarity

may be incorrect.

The ambient temperature

exceeds the lower ambient

Continues to operate and

output.

temperature limit of the

transmitter.

The ambient temperature

exceeds the upper ambient

Continues to operate and

output.

temperature limit of the

transmitter.

Sensor backup mode is in

effect.

Sensor2 input is used as

PV. If sensor2 fails, the

transmitter operates with

burnout setting.

There is a problem with the

PV mapping setting.

Check output status

immediately before error is

stored.

Terminal block sensor has

failed.

EEPROM failed.

Continues operate and

output.

The output goes to the

value set by the hardware

error mode jumper.

Output circuit hardware

failure.

The output goes to the

value set by the hardware

error mode jumper.

Input circuit hardware failure.

The output goes to the

value set by the hardware

error mode jumper.

Confirmation calculation

result is bad.

The output goes to the

value set by the hardware

failure mode jumper.

4. SELF-DIAGNOSTICS

Check the LRV and adjust.

Check the URV and adjust.

• Check sensor for damage.

*1

• Check terminal connection.

• If in sensor backup mode

refer to “Er-09.”

• Check sensor for damage.

• Check terminal connection.

• If sensor backup mode is set,

*1

repair wiring or replace

damage sensors.

• Check sensor connections.

• Check sensor type selected.

• Check sensor connections.

• Check sensor type selected.

Use a heat source to raise the

temperature of the transmitter.

Use a cooling source to lower

the temperature of the

transmitter.

Repair or replace sensor1 then

enable sensor1 normal

connection parameters, or

repower the transmitter.

Correct the PV mapping.

Contact Service personnel.

Contact Service personnel.

*2

Contact Service personnel.

*2

Contact Service personnel.

*2

Contact Service personnel.

*2

T0401.EPS

4-2

IM 01C50T03-01E

Page 24

4. SELF-DIAGNOSTICS

●

●

●

●

●

●

●

●

●

●

●

●

●

4.2 Warning

1) Warning and contents

The YTA series has a warning display function.

The warning display function displays a warning when

there is an incorrect use status such that a setting is out

of the specified range. Also, when the instrument is

operated in other than standard operation mode, that

status is displayed as a warning. Factory default setting

is to not display the warning. To display the warning,

set parameter H55: WARNING ENBL. Use parameter

I59: WARNING to confirm the warning. See Table 4.2

for contents corresponding to warnings and countermeasures.

2) Setting warning display

Classified warnings can be displayed with H55:

WARNING ENBL. The warning is classified as

follows.

Setting : Occurs when an inappropriate

parameter setting is used such

as out of the specification range

of the transmitter.

Operation : Occurs when the input value for

the parameter setting is out of

the setting range.

Special : Occurs when the parameter of a

function unique to the YTA is set

during forced output operation or

reverse output operation.

Setting Operation status Special Data to set

× × × 00000000

× × 3F1C0000

×

× ×

×

×

= display, × = no display

× C0030800

× FF1F0800

00E00108

3FFC0108

C0E30908

FFFF0908

T0403.EPS

● Example: Displaying “Setting” and “Special” warning

SET

H50:WARNING ENBL

00000000

3FFC0108

DEL CLR ESC

SET

I59:WARNING

GOOD

SET

I59:WARNING

WARNING

< WARNING >

<Out Manual Mode >

<Can Write data >

1. Set “3FFC0108” in the Data to

set column for F combination in

the table above.

2. Press [ENTER] twice.

Warning can be checked with I59:

WARNING.

ESC

ESC

F0403.EPS

4-3

IM 01C50T03-01E

Page 25

Table 4.2 List of warnings

Parameter StatusClass

LRV Too Low

LRV Too High

URV Too Low

URV Too High

Setting

LRV>=URV setting

The LRV setting is lower than the temperature

range (GS stated value).

The LRV setting is higher than the

temperature range (GS stated value).

The URV setting is lower than the temperature

range (GS stated value).

The URV setting is higher than the

temperature range (GS stated value).

The LRV and URV settings are reversed.

4. SELF-DIAGNOSTICS

Countermeasure

Check the LRV setting.

Check the LRV setting.

Check the LRV setting.

Check the URV setting.

Set LRV < URV.

Operation

status

Special

Span Too Small

Illegal SV MAP

Illegal TV MAP

Illegal 4V MAP

Snsr1 Temp Low

Snsr1 Temp High

Snsr2 Temp Low

Snsr2 Temp High

Last SUM Area

Out Reverse Mode

Out Manual Mode

Snsr Backup Mode

Soft Not Protect

The setting is lower than the recommended

minimum span.

There is a problem with input (setting status)

specified to SV map.

There is a problem with input (setting status)

specified to TV map.

There is a problem with input (setting status)

specified to 4V map.

Sensor1 input temperature is lower than the

temperature range. The measurement range

is a YTA series specification but not a range

defined by sensor type.

Sensor1 input temperature is higher than the

temperature range. The measurement range

is a YTA series specification but not a range

defined by sensor type.

Sensor2 input temperature is lower than the

temperature range. The measurement range

is a YTA series specification but not a range

defined by sensor type.

Sensor2 input temperature is higher than the

temperature range. The measurement range

is a YTA series specification but not a range

defined by sensor type.

The EEPROM checksum field is using the

spare 4 (the last area). This means there is no

spare area for writing the EEPROM

checksum.

Output reverse mode operation is ongoing.

Forced output mode is on.

In this case, the forced output is active or

the output adjustment is performed.

The sensor backup mode is set.

This is the parameter write enable status.

Unexpected write cannot be prevented.

Set URV-LRV to be set to greater than minimum

span.

Correct SV mapping

Correct TV mapping

Correct 4V mapping

Check process temperature and set new LRV and

URV values. Verify correct sensor selection for

temperature range.

Check process temperature and set new LRV and

URV values. Verify correct sensor selection for

temperature range.

Check process temperature and set new LRV and

URV values. Verify correct sensor selection for

temperature range.

Check process temperature and set new LRV and

URV values. Verify correct sensor selection for

temperature range.

There is no problem with current operation. If

EEPROM is damaged an EEPROM FAILURE will

be indicated.

Turning output reverse mode OFF causes normal

output .

The transmitter is in manual output mode. Return

to normal operation if desired.

Turn the sensor backup mode OFF.

Set the protect parameter to YES to enable write

protect mode and prevent unexpected changes.

T0402.EPS

4-4

IM 01C50T03-01E

Page 26

4. SELF-DIAGNOSTICS

4.3 Logging Function

The YTA series has the capability to store useful

information for trouble shooting.

4.3.1 Error Log

Up to four error histories are stored in the transmitter

memory. The transmitter records an error that continues to occur for more than 6 minutes.

P20:ERR LOG 1

This parameter records the latest errors that occurred.

P21:ERR LOG 2

This parameter records the last errors that have

occurred.

P22:ERR LOG 3

This parameter records the 2nd to last error.

P23:ERR LOG 4

This parameter records the 3rd to last error.

P24: ERR LOG CLR ...... Error log clear processing

Clears all error logging data.

The % value is calculated from the number of BCC

errors that occurred in BRAIN communication reception frame and the number of transmissions/receptions.

Turning the power off clears the data.

*1 : This parameter should display the 0 % in normal operation. If

it consistently displays other than that, check the cable wiring

for the transmitter.

*2 : BBC = BRAIN Communication Check.

4.3.2 Min/Max Log

Minimum and Maximum values of the process variables and terminal temperature are stored in the

transmitter memory. The logged data for the process

variables except for the terminal temperature is reset at

every power off.

To clear the logging data for process variables, select

“ENABLE” at P05: ERR LOG CLR.

4.3.3 Operation Time

P30: OPERATE TIME

The transmitter’s operation time from the last power up

is counted. The information is reset at every power off.

The accuracy of time counting is not guaranteed. It is

simply a reference.

4.3.4 Power Check

P31: POWER CHECK

By setting this parameter to START after power up,

the transmitter can be checked to see if a temporary

loss of power has occurred. This parameter is always

reset to STOP at power off.

4.3.5 BRAIN communication BCC error occurrence rate

P40: BCC ERROR %

Displays the BCC error occurrence rate of BRAIN

communication.

4-5

IM 01C50T03-01E

Page 27

5. LIST OF PARAMETERS

● ● ●

● ● ●

● ● ●

● ● ●

● ● ●

● ● ●

● ● ●

● ● ●

● ● ●

● ● ●

● ● ●

● ● ●

● ● ●

● ● ●

● ● ● ● ●

● ● ● ● ●

● ● ● ● ●

● ● ● ● ●

● ● ● ● ●

● ● ● ● ●

● ● ● ● ●

● ● ● ● ●

● ● ● ● ●

● ● ● ● ●

● ● ● ● ●

● ● ● ● ●

● ● ● ● ●

● ● ● ● ●

● ● ●

● ● ●

● ● ● ●

● ● ●

● ● ●

● ● ● ● ●

● ● ● ● ●

● ● ●

● ● ● ● ●

● ●

● ●

● ●

● ●

● ●

● ●

● ●

● ●