Page 1

User's

Manual

YTA Series

Temperature T ransmitter s

(Hard ware)

[Style: S2]

IM 01C50B01-01E

Yokogawa Electric Corporation

IM 01C50B01-01E

8th Edition

Page 2

Page 3

CONTENTS

CONTENTS

1. PREFACE ......................................................................................................1-1

䊏 Notes on the Instruction Manual............................................................... 1-1

䊏 Notes on Safety and Modifications ........................................................... 1-1

䊏 For Safety Using ....................................................................................... 1-1

䊏 Warranty.................................................................................................... 1-2

䊏 Trade Mark................................................................................................ 1-2

2. NOTES ON HANDLING ................................................................................2-1

2.1 Nameplate ........................................................................................... 2-1

2.2 Transport ............................................................................................. 2-1

2.3 Storage................................................................................................ 2-1

2.4 Choosing the Installation Location...................................................... 2-1

2.5 Use of a Transceiver........................................................................... 2-2

2.6 Insulation Resistance Test and Withstand Voltage Test.................... 2-2

2.6.1 Insulation resistance test procedure ............................................ 2-2

2.6.2 Withstand voltage test procedure ................................................ 2-3

2.7 Installation of Explosion Protected Type Transmitters ....................... 2-3

2.7.1 CSA Certification .......................................................................... 2-3

2.7.2 CENELEC ATEX (KEMA) Certification ........................................ 2-5

2.7.3 CENELEC (KEMA) Certification................................................... 2-8

2.7.4 FM Certification ............................................................................ 2-9

2.7.5 JIS Certification .......................................................................... 2-11

2.7.6 SAA Certification ........................................................................ 2-11

2.8 EMC Conformity Standards .............................................................. 2-12

3. PART NAMES AND FUNCTIONS ................................................................3-1

3.1 Part Names ......................................................................................... 3-1

3.2 Setting the Hardware Error Burnout Change-over Switch ................. 3-2

3.3 Built-in Indicator Display Function ...................................................... 3-2

4. INSTALLATION.............................................................................................4-1

5. WIRING..........................................................................................................5-1

5.1 Notes on Wiring .................................................................................. 5-1

5.2 Loop Construction ............................................................................... 5-1

5.3 Cable Selection ................................................................................... 5-2

5.3.1 Input signal Cable Selection ........................................................ 5-2

5.3.2 Output Signal Cable Selection ..................................................... 5-2

5.4 Cable and Terminal Connections ....................................................... 5-2

5.4.1 Input Terminal Connections ......................................................... 5-2

5.4.2 Output Terminal Connection ........................................................ 5-3

5.5 Wiring Cautions................................................................................... 5-4

5.6 Grounding............................................................................................ 5-5

FD No. IM 01C50B01-01E

8th Edition: May 2002(YK)

All Rights Reserved, Copyright © 1998, Yokogawa Electric Corporation

i

IM 01C50B01-01E

Page 4

CONTENTS

6. MAINTENANCE............................................................................................. 6-1

6.1 General................................................................................................ 6-1

6.2 Calibration ........................................................................................... 6-1

6.2.1 Selection of Equipment for Calibration ........................................ 6-1

6.2.2 Calibration Procedure................................................................... 6-1

6.3 Disassembly and Assembly ................................................................ 6-2

6.3.1 Replacement of Built-in Indicator ................................................. 6-3

6.3.2 Replacement of CPU Assembly................................................... 6-3

6.4 Troubleshooting................................................................................... 6-4

6.4.1 Basic Troubleshooting Flow ......................................................... 6-4

6.4.2 Example of Troubleshooting Flow................................................ 6-4

6.5 Integral Indicator and Error Display .................................................... 6-6

7. STANDARD SPECIFICATIONS .................................................................... 7-1

7.1 Standard Specifications ...................................................................... 7-1

7.2 Model and Suffix Codes...................................................................... 7-5

7.3 Optional Specifications........................................................................ 7-5

7.4 Dimensions.......................................................................................... 7-7

INSTALLATION AND OPERATING PRECAUTIONS FOR JIS FLAMEPROOF

EQUIPMENT........................................................................................ EX-B03E

Customer Maintenance Parts List ..................................... CMPL 01C50B01-02E

REVISION RECORD

ii

IM 01C50B01-01E

Page 5

1. PREFACE

1. PREFACE

The YTA temperature transmitter is fully factory-tested

according to the specifications indicated on the order.

In order for the YTA temperature transmitter to be

fully functional and to operate in an efficient manner,

the instruction manual must be carefully read to

become familiar with the functions, operation, and

handling of the YTA.

This Instruction Manual gives instructions on handling,

wiring and maintenance of YTA110, YTA310 and

YTA320 temperature transmitters. Changing the

parameter settings requires a terminal dedicated to the

HART Protocol or the BRAIN Protocol. For details on

how to set the parameters of these transmitters, refer to

the “BRAIN Protocol” IM 0lC50T03-01E or “HART

Protocol” IM 01C50T01-01E.

For FOUNDATION Fieldbus communication type,

please refer to IM 01C50T02-01E in addition to this

manual.

Notes on the Instruction Manual

• This manual should be delivered to the end user.

• The information contained in this manual is subject

to change without prior notice.

• The information contained in this manual, in whole

or part, shall not be transcribed or copied without

notice.

• In no case does this manual guarantee the merchant

ability of the transmitter or its adaptability to a

specific client need.

• Should any doubt or error be found in this manual,

submit inquiries to your local dealer.

•No special specifications are contained in this

manual.

• Changes to specifications, structure, and components

used may not lead to the revision of this manual

unless such changes affect the function and performance of the transmitter.

Notes on Safety and Modifications

• Before handling the YTA, it is absolutely imperative

that users of this equipment read and observe the

safety instructions mentioned in each section of the

manual in order to ensure the protection and safety

of operators, the YTA itself and the system containing the transmitter. We are not liable for any

accidents arising out of handling that does not

adhere to the guidelines established in the safety

instructions.

• No maintenance should be performed on explosionproof type temperature transmitters while the

equipment is energized. If maintenance is required

with the cover open, always first use a gas detector

to check that no explosive gases are present.

• If the user attempts to repair or modify an

explosionproof type transmitter and is unable to

restore it to its original condition, damage to the

explosionproof features result, leading to dangerous

conditions. Contact your authorized Yokogawa

Electric Corporation representative for repairs or

modifications of an explosionproof type transmitter.

For Safety Using

Please give your attention to the followings.

(a) Installation

• The instrument must be installed by an expert

engineer or a skilled personnel. The procedures

described about INSTALLATION are not permitted

for operators.

•In case of high process temperature, care should be

taken not to burn yourself because the surface of the

case reaches a high temperature.

• All installation shall comply with local installation

requirement and local electrical code.

(b) Wiring

• The instrument must be installed by an expert

engineer or a skilled personnel. The procedures

described about WIRING are not permitted for

operators.

• Please confirm that voltages between the power

supply and the instrument before connecting the

power cables and that the cables are not powered

before connecting.

(c) Maintenance

• Please do not carry out except being written to a

maintenance descriptions. When these procedures

are needed, please contact nearest YOKOGAWA

office.

•Care should be taken to prevent the build up of drift,

dust or other material on the display glass and

name plate. In case of its maintenance, soft and dry

cloth is used.

1-1

IM 01C50B01-01E

Page 6

1. PREFACE

Symbols used in this Instruction Manual

The YTA temperature transmitter and this manual use

the following safety related symbols and signals.

WARNING

Contains precautions to protect against the

chance of explosion or electric shock which, if

not observed, could lead to death or serious

injury.

CAUTION

Contains precautions to protect against danger,

which, if not observed, could lead to personal

injury or damage to the instrument.

IMPORTANT

Contains precautions to be observed to protect

against adverse conditions that may lead to

damage to the instrument or a system failure.

NOTE

Contains precautions to be observed with regard

to understanding operation and functions.

Some of the diagrams in this instruction manual are

partially omitted, described in writing, or simplified for

ease of explanation. The screen drawings contained in

the instruction manual may have a display position or

characters (upper/lower case) that differ slightly from

the full-scale screen to an extent that does not hinder

the understanding of functions or monitoring of

operation.

Warranty

• The warranty period of the instrument is written on

the estimate sheet that is included with your purchase. Any trouble arising during the warranty

period shall be repaired free of charge.

• Inquiries with regard to problems with the instrument shall be accepted by the sales outlet or our

local dealer representative.

• Should the instrument be found to be defective,

inform us of the model name and the serial number

of the instrument together with a detailed description

of nonconformance and a progress report. Outline

drawings or related data will also be helpful for

repair.

• Whether or not the defective instrument is repaired

free of charge depends on the result of our inspection.

The following conditions shall not be

eligible for charge-exempt repair.

• Problems caused by improper or insufficient

maintenance on the part of the customer.

• Trouble or damage caused by mishandling, misusage, or storage that exceeds the design or specification requirements.

• Problems caused by improper installation location or

by maintenance conducted in a non-conforming

location.

• Trouble or damage was caused by modification or

repair that was handled by a party or parties other

than our consigned agent.

• Trouble or damage was caused by inappropriate

relocation following delivery.

•Trouble or damage was caused by fire, earthquake,

wind or flood damage, lightning strikes or other acts

of God that are not directly a result of problems with

this instrument.

Trade Mark

• HART is a trademark of the HART Communication

Foundation.

• Registered trademarks or trademarks appearing in

this manual are not designated by a TM or ®

symbol.

• Other company names and product names used in

this manual are the registered trademarks or trademarks of their respective owners.

1-2

IM 01C50B01-01E

Page 7

2. NOTES ON HANDLING

2. NOTES ON HANDLING

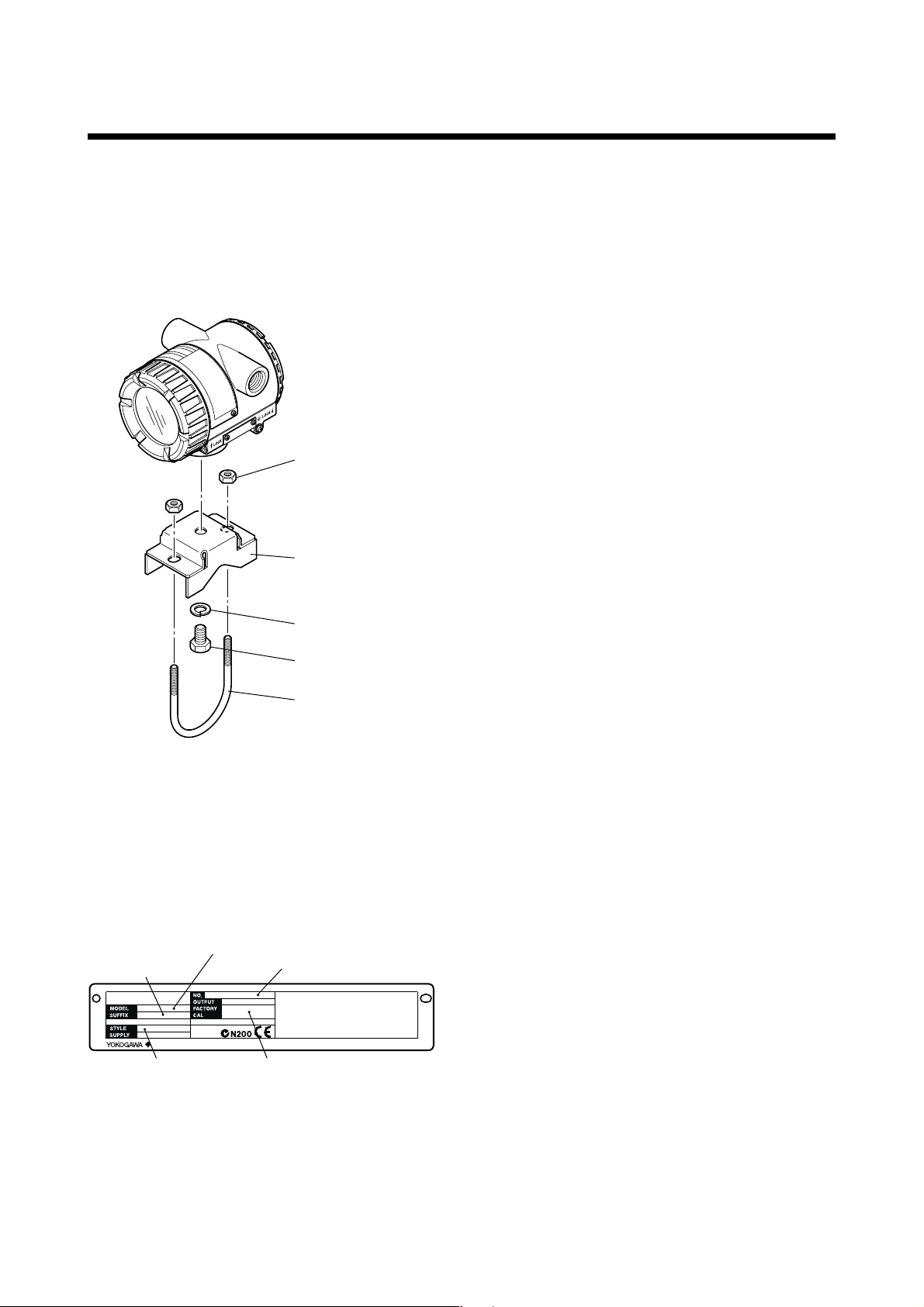

The YTA temperature transmitter is fully factory-

tested upon shipment. When the YTA is delivered,

check the appearance for damage, and also check that

the transmitter mounting parts shown in Figure 2.1 are

included with your shipment. If “No Mounting

Bracket” is indicated, no transmitter mounting bracket

is included.

Nut for U-bolt

Mounting bracket

Spring washer

2.2 Transport

To prevent damage while in transit, leave the transmitter in the original shipping container until it reaches

the installation site.

2.3 Storage

When an extended storage period is expected, observe

the following precautions:

1. If at all possible, store the transmitter in factoryshipped condition, that is, in the original shipping

container.

2. Choose a storage location that satisfies the following requirements.

•A location that is not exposed to rain or water.

•A location subject to a minimum of vibration or

impact.

• The following temperature and humidity range is

recommended. Ordinary temperature and humidity

(25°C, 65%) are preferable.

Temperature: No Integral indicator –40 to 85°C

With Integral indicator –30 to 80°C

Humidity: 5 to 100% RH (at 40°C)

Transmitter fastening bolt

U-bolt

F0201.EPS

Figure 2.1 Transmitter mounting parts

2.1 Nameplate

The model name and configuration are indicated on

the nameplate. Verify that the configuration indicated

in the “Model and Suffix Code” in Chapter 7 is in

compliance with the specifications written on the order

sheet.

Specification code

TEMPERATURE

TRANSMITTER

YTA

DC24V

Made in Japan

Style code

Figure 2.2 Name plate

Model name

4~20mA DC

Serial No.

Factory-shipped range and unit

F0202.EPS

3. The performance of the transmitter may be impaired if stored in an area exposed to direct rain and

water. To avoid damage to the transmitter, install it

immediately after removal from shipping container.

Follow wiring instructions in Chapter 5.

2.4 Choosing the Installation

Location

Although the temperature transmitter is designed to

operate in a vigorous environment, to maintain

stability and accuracy, the following is recommended:

(1) Ambient Temperature

It is preferable to not to expose the instrument to

extreme temperatures or temperature fluctuations. If

the instrument is exposed to radiation heat a thermal

protection system and appropriate ventilation is

recommended.

(2) Environmental Requirements

Do not allow the instrument to be installed in a

location that is exposed to corrosive atmospheric

conditions. When using the instrument in a corrosive

environment, ensure the location is well ventilated.

The unit and its wiring should be protected from

exposure to rainwater.

2-1

IM 01C50B01-01E

Page 8

2. NOTES ON HANDLING

(3) Impact and Vibration

It is recommended that the instrument be installed in a

location that is subject to a minimum amount of impact

and vibration.

2.5 Use of a Transceiver

Although the temperature transmitter is designed to

resist influence from high frequency noise; use of a

transceiver in the vicinity of installation may cause

problems. Installing the transmitter in an area free from

high frequency noise (RFI) is recommended.

2.6 Insulation Resistance Test and Withstand Voltage Test

CAUTION

(1) Overvoltage of the test voltage that is so

small that it does not cause an dielectric

breakdown may in fact deteriorate insulation

and lower the safety performance; to prevent

this it is recommended that the amount of

testing be kept to a minimum.

(2) The voltage for the insulation resistance test

must be 500 VAC or lower, and the voltage

for the withstand voltage test must be 500

VAC or lower. Failure to heed these guidelines may cause faulty operation.

(3) Where a built-in arrester is provided (suffix

code: /A), the voltage for the insulation

resistance test must be 100 VDC or lower,

and the voltage for the withstand voltage test

must be 100 VAC or lower. Failure to heed

these guidelines may cause faulty operation.

Follow the steps below to perform the test, the wiring

of the transmission line must be removed before

initiating testing.

2.6.1 Insulation resistance test procedure

Testing between the output terminal and

input terminal

1. Lay transition wiring between the + terminal, the -

terminal, and the check terminal of the terminal box.

2. Lay wiring across terminals 1, 2, 3, and 4 of the

terminal box.

3. Connect the insulation resistance meter (with the

power turned OFF) between the transition wiring of

Steps 1 and 2 above. The polarity of the input

terminals must be positive and that of the output

terminals must be negative.

4. Turn the power of the insulation resistance meter

ON and measure the insulation resistance. The

duration of the applied voltage must be the period

during which 100M⍀ or more is confirmed (or

20M⍀ if the unit is equipped with a built-in

arrester).

5. Upon completion of the test, remove the insulation

resistance meter, connect a 100K⍀ resistor between

the transition wiring, and allow the electricity to

discharge. Do not touch the terminal with your bare

hands while the electricity is discharging for more

than 1 second.

Testing between the output terminal and

grounding terminal

1. Lay transition wiring between the + terminal, the terminal, and the check terminal of the terminal box,

then connect an insulation resistance meter (with the

power turned OFF) between the transition wiring

and the grounding terminal. The polarity of the

transition wiring must be positive and that of the

grounding terminal must be negative.

2. Turn the power of the insulation resistance meter

ON and measure the insulation resistance. The

duration of the applied voltage must be the period

during which 100M⍀ or more is confirmed (or

20M⍀ if the unit is equipped with a built-in

arrester).

3. Upon completion of the test, remove the insulation

resistance meter, connect a 100K⍀ resistor between

the transition wiring and the grounding terminal, and

allow the electricity to discharge. Do not touch the

terminal with your bare hands while the electricity is

discharging for more than 1 second.

Testing between the input terminal and

grounding terminal

1. Lay transition wiring between terminals 1, 2, 3, 4

and 5 of the terminal box, and connect the insulation

resistor (with the power turned OFF) between the

transition wiring and the grounding terminal. The

polarity of the transition wiring must be positive and

that of the grounding terminal must be negative.

2. Turn the power of the insulation resistance meter

ON and measure the insulation resistance. The

duration of the applied voltage must be the period

during which 100M⍀ or more is confirmed (or

20M⍀ if the unit is equipped with a built-in

arrester).

3. Upon completion of the test, remove the insulation

resistance meter, connect a 100K⍀ resistor between

the transition wiring and the grounding terminal, and

allow the electricity to discharge. Do not touch the

terminal with your bare hands while the electricity is

discharging for more than 1 second.

2-2

IM 01C50B01-01E

Page 9

2. NOTES ON HANDLING

2.6.2 Withstand voltage test procedure

Testing between the output terminal and the

input terminal

1. Lay transition wiring between the + terminal, the –

terminal, and the check terminal of the terminal box.

2. Lay transition wiring between terminals 1, 2, 3, 4

and 5 of the terminal box.

3. Connect the withstand voltage tester (with the power

turned OFF) between the transition wiring shown in

Steps 1 and 2 above.

4. After setting the current limit value of the withstand

voltage tester to 10mA, turn the power ON, and

carefully increase the impressed voltage from 0V to

the specified value.

5. The voltage at the specified value must remain for a

duration of one minute.

6. Upon completion of the test, carefully reduce the

voltage so that no voltage surge occurs.

Testing between the output terminal and the

grounding terminal

1. Lay the transition wiring between the + terminal, the

- terminal and the check terminal of the terminal

box, and connect the withstand voltage tester (with

the power turned OFF) between the transition wiring

and the grounding terminal. Connect the grounding

side of the withstand voltage tester to the grounding

terminal.

2. After setting the current limit value of the withstand

voltage tester to 10mA, turn the power ON, and

gradually increase the impressed voltage from 0V to

the specified value. .

3. The voltage at the specified value must remain for a

duration of one minute.

4. Upon completion of the test, carefully reduce the

voltage so that no voltage surge occurs.

Testing between the input terminal and the

grounding terminal

1. Lay the transition wiring across terminals 1, 2, 3, 4,

and 5 of the terminal box and connect the withstand

voltage tester (with the power turned OFF) between

the transition wiring and the grounding terminal.

Connect the grounding side of the withstand voltage

tester to the grounding terminal.

2. After setting the current limit value of the withstand

voltage tester to 10mA, turn the power ON, and

gradually increase the impressed voltage from 0V to

the specified value.

3. The voltage at the specified value must remain for a

duration of one minute.

4. Upon completion of the test, carefully reduce the

voltage so that no voltage surge occurs.

2.7 Installation of Explosion Protected T ype Transmitters

In this section, further requirements and differences

and for explosionproof type instrument are described.

For explosionproof type instrument, the description in

this chapter is prior to other description in this users

manual.

CAUTION

To preserve the safety of explosionproof equipment requires great care during mounting,

wiring, and piping. Safety requirements also

place restrictions on maintenance and repair

activities. Please read the following sections very

carefully.

2.7.1 CSA Certification

Model YTA110/CU1, YTA310/CU1 and YTA320/CU1

temperature transmitters can be selected the type of

protection (CSA Intrinsically Safe, Non-incendive, or

Explosionproof) for use in hazardous locations.

Note 1. For the installation of this transmitter,

once a particular type of protection is

selected, any other type of protection

cannot be used. The installation must be

in accordance with the description about

the type of protection in this instruction

manual.

Note 2. In order to avoid confusion, unnecessary

marking is crossed out on the label other

than the selected type of protection when

the transmitter is installed.

a) CSA Intrinsically Safe Type/Non-incendive

Type

Caution for CSA Intrinsically safe type. (Following

contents refers “DOC No. ICS008-A13 P.1-1 and P.12”)

Note 1. Model YTA110/CU1, YTA310/CU1 and

YTA320/CU1 temperature transmitters

are applicable for use in hazardous

locations:

• Intrinsically Safe for Class I, II, III, Division 1,

Groups A, B, C, D, E, F & G.

• Non-incendive for Class I, II, Division 2, Groups A,

B, C, D, E, F & G, Class III, Division 1.

• Encl. “Type 4X”

• Temperature Class: T4

• Ambient temperature: –40 to 60°C

2-3

IM 01C50B01-01E

Page 10

2. NOTES ON HANDLING

Note 2. Entity Parameters (Electrical/Non-

incendive field wiring parameters)

• [Supply Circuit]

Vmax = 30 V, Imax = 165 mA, Pmax = 0.9 W

Ci = 18 nF, Li = 730 µH

• [Associated apparatus]

Voc 30 V, Isc 165 mA, Pmax 0.9 W

• [Sensor Circuit]

Voc = 9 V, Isc = 40 mA, Po = 90 mW,

Ca = 1 µF, La = 10 mH

Note 3. Installation

• All wiring shall comply with Canadian Electrical

Code Part I and Local Electrical Codes.

• For the sensor circuitry, the above parameters for

sensor circuit must be taken into account.

• Dust-tight conduit seal must be used when installed in

class II and III environments.

• In any used safety barrier, output current must be

limited by a resistor 'R' such that Isc=Voc/R.

• The safety barrier must be CSA certified, and the

input voltage of the barrier must be less than

250Vrms/Vdc.

• For non-incendive type, general purpose equipment

must be CSA certified and the equipment which have

non-incendive field wiring parameters.

• The instrument modification or parts replacement by

other than authorized representative of Yokogawa

Electric Corporation is prohibited and will void

Canadian Standards Intrinsically safe and

nonincendive Certification.

[Intrinsically Safe]

Hazardous

Location

YTA Series

Temperature

Transmitter

1

2

3

Sensor

4

5

Hazardous

Location

+

Supply

–

[Non-incendive]

Nonhazardous

Location

Safety Barrier

+

+

–

–

Nonhazardous

Location

General

Purpose

Equipment

+

–

b) CSA Explosionproof Type

Caution for CSA Explosionproof type

Note 1. Model YTA110/CU1, YTA310/CU1 and

YTA320/CU1 temperature transmitters

are applicable for use in hazardous

locations:

• Explosionproof for Class I, Division 1, Groups B,

C and D.

• Dust-ignitionproof for Class II, Groups E, F and G,

Class III.

• Encl “Type 4X”

• Temperature Class: T6

• Ambient Temperature: –40 to 60°C

• Supply Voltage: 42 V dc max.

• Output Signal: 4 to 20 mA

Note 2. Wiring

• All wiring shall comply with Canadian Electrical

Code Part I and Local Electrical Codes.

• In hazardous location, wiring shall be in conduit as

shown in the figure.

WARNING: A SEAL SHALL BE INSTALLED

WITHIN 50 cm OF THE ENCLOSURE. UN SCELLEMENT DOIT

ÊTRE INSTALLÉ À MOINS DE

50 cm DU BOÎTIER.

• When installed in Division 2, “FACTORY

SEALED, CONDUIT SEAL NOT REQUIRED”.

Note 3. Operation

• Keep strictly the “WARNING” on the label

attached on the transmitter.

WARNING: OPEN CIRCUIT BEFORE RE-

MOVING COVER. OUVRIR LE

CIRCUIT AVANT D´ENLEVER LE

COUVERCLE.

• Take care not to generate mechanical spark when

access to the instrument and peripheral devices in

hazardous location.

Note 4. Maintenance and Repair

• The instrument modification or parts replacement

by other than authorized representative of

Yokogawa Electric Corporation is prohibited and

will void Canadian Standards Explosionproof

Certification.

YTA Series

Temperature

Transmitter

1

2

3

4

Sensor

5

Supply

+

–

Not Use

Safety Barrier

General

Purpose

Equipment

+

–

F0204.EPS

2-4

IM 01C50B01-01E

Page 11

2. NOTES ON HANDLING

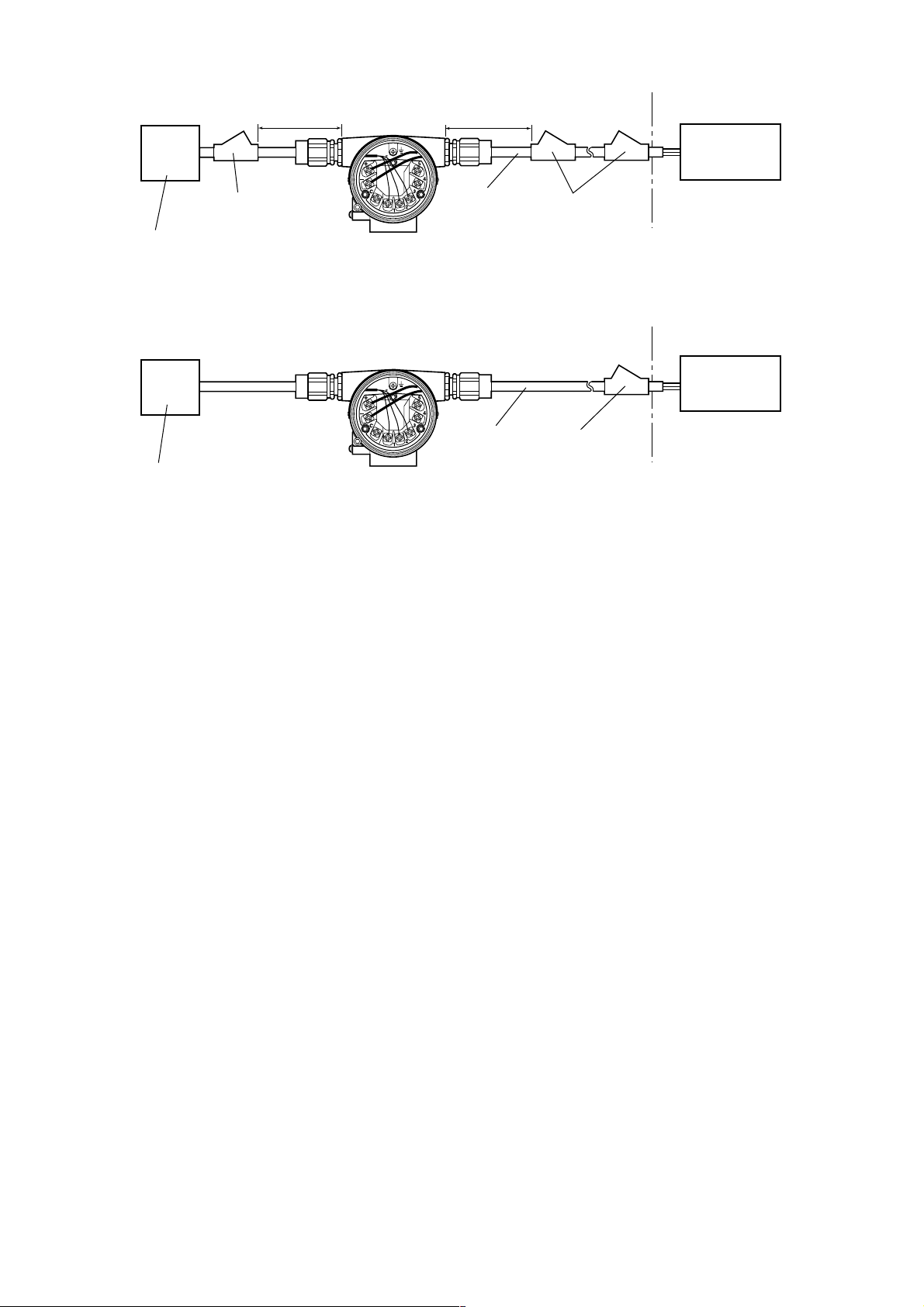

HAZARDOUS LOCATIONS DIVISION 1

50 cm Max.

Sensor

Sealing Fitting

Certified/Listed Temper ature Sensor

Explosionproof Class I, Groups C and D

Dustignitionproof Class II, Groups E, F and G, Class III

Wiring method shall be suitable for the specified hazardous locations.

Sensor

Certified/Listed Temper ature Sensor

Explosionproof Class I, Groups C and D

Dustignitionproof Class II, Groups E, F and G, Class III

Wiring method shall be suitable for the specified hazardous locations.

YTA Series

HAZARDOUS LOCATIONS DIVISION 2

YTA Series

50 cm Max.

Conduit

Conduit

Sealing Fitting

Sealing Fitting

NON-HAZARDOUS

LOCATIONS

Non-hazardous

Location

Equipment

42 V DC Max.

4 to 20 mA DC

Signal

NON-HAZARDOUS

LOCATIONS

Non-hazardous

Location

Equipment

42 V DC Max.

4 to 20 mA DC

Signal

F0203.EPS

2.7.2 CENELEC ATEX (KEMA) Certification

Model YTA110/KU2, YTA310/KU2 and YTA320/

KU2 temperature transmitters can be selected the type

of protection (CENELEC ATEX(KEMA) Intrinsically

Safe or CENELEC ATEX(KEMA) Flameproof or

CENELEC ATEX Type of Protection “n”) for use in

hazardous locations.

Note 1. For the installation of this transmitter,

once a particular type of protection is

selected, any other type of protection

cannot be used. The installation must be

in accordance with the description about

the type of protection in this instruction

manual.

Note 2. In order to avoid confusion, unnecessary

marking is crossed out on the label other

than the selected type of protection when

the transmitter is installed.

(1) Technical Data

a) CENELEC ATEX (KEMA) Intrinsically Safe

Type

Caution for CENELEC ATEX (KEMA) Intrinsically

safe type

Note 1. Model YTA110/KU2, YTA310/KU2 and

YTA320/KU2 temperature transmitters for

potentially explosive atmospheres:

• No. KEMA 02ATEX1026X

•Type of Protection and Marking code: II 1G EEx ia

IIC T5, T4

• Temperature Class: T5, T4

• Ambient Temperature: –40 to 70°C for T4, –40 to

50°C for T5

• Enclosure: IP67

Note 2. Electrical Data

•In type of explosion protection intrinsic safety II 1G

EEx ia IIC only for connection to a certified

intrinsically safe circuit with following maximum

values:

• [Supply circuit]

Ui = 30 V Ii = 165 mA

Pi = 900 mW

Effective internal capacitance, Ci = 20 nF

Effective internal inductance, Li = 660 µH

• [Sensor circuit]

Uo = 8.6 V Io = 30 mA

Po = 70 mW

Max. allowed external capacitance, Co = 3 µF

Max. allowed external inductance, Lo = 20 mH

Note 3. Installation

•All wiring shall comply with local installation

requirements. (Refer to the installation diagram)

Note 4. Maintenance and Repair

• The instrument modification or parts replacement by

other than authorized representative of Yokogawa

Electric Corporation is prohibited and will void

KEMA Intrinsically safe Certification.

2-5

IM 01C50B01-01E

Page 12

2. NOTES ON HANDLING

s

Note 5. Special condition for safe use

• Because the enclosure of the Temperature

Transmitter is made of aluminium, if it is mounted

in an area where the use of category 1G apparatus is

required, it must be installed such, that, even in the

event of rare incidents, ignition source due to impact

and friction sparks are excluded.

[Installation Diagram]

Hazardous

Location

Transmitter

1

2

3

4

Sensor

5

*1: In any safety barriers used the output current must be limited by

a resistor “R” such that Imaxout-Uz/R.

+

Supply

–

Nonhazardou

Location

Safety Barrier

+

–

*1

F0208.EPS

b) CENELEC ATEX (KEMA) Flameproof Type

Caution for CENELEC ATEX (KEMA) Flameproof

Type

Note 1. Model YTA110/KU2, YTA310/KU2 and

YTA320/KU2 temperature transmitters for

potentially explosive atmospheres:

• No. KEMA 02ATEX2155

• Type of Protection and Marking Code: II 2G EEx d

IIC T5, T6

• Temperature Class: T5, T6

• Ambient Temperature: –40 to 80°C for T5, –40 to

75°C for T6

• Enclosure: IP67

Note 2. Electrical Data

• Supply voltage: 42 V dc max.

• Output signal: 4 to 20 mA

Note 3. Installation

•All wiring shall comply with local installation

requirement.

•The cable entry devices shall be of a certified

flameproof type, suitable for the conditions of use.

Note 4. Operation

• Keep strictly the “WARNING” on the label on the

transmitter.

WARNING: AFTER DE-ENERGIZING, DELAY

5 MINUTES BEFORE OPENING.

WHEN THE AMBIENT TEMP. ⭌

70⬚C, USE THE HEATRESISTING CABLES OF HIGHER THAN

90⬚C.

• Take care not to generate mechanical spark when

access to the instrument and peripheral devices in

hazardous location.

Note 5. Maintenance and Repair

• The instrument modification or parts replacement by

other than authorized representative of Yokogawa

Electric Corporation is prohibited and will void

KEMA Flameproof Certification.

c) CENELEC ATEX Type of Protection “n”

WARNING

When using a power supply not having a nonincendive circuit, please pay attention not to

ignite in the surrounding flammable atmosphere.

In such a case, we recommend using wiring

metal conduit in order to prevent the ignition.

Caution for CENELEC ATEX Type of Protection “n”

Note 1. Model YTA110/KU2, YTA310/KU2 and

YTA320/KU2 temperature transmitters for

potentially explosive atmospheres:

• Type of Protection and Marking Code: II 3G EEx

nL IIC T5, T4

• Temperature Class: T5, T4

• Ambient Temperature: –40 to 50°C for T5, –40 to

70°C for T4

• Enclosure: IP67

Note 2. Electrical Data

[Supply circuit]

Ui = 30 V

Effective internal capacitance, Ci = 20 nF

Effective internal inductance, Li = 660 µH

[Sensor circuit]

Uo= 8.6 V Io = 30 mA Po = 70 mW

Max. allowed external capacitance, Co = 3 µF

Max. allowed external capacitance, Lo = 20 mH

Note 3. Installation

•All wiring shall comply with local installation

requirements. (refer to the installation diagram)

2-6

IM 01C50B01-01E

Page 13

2. NOTES ON HANDLING

s

Note 4. Maintenance and Repair

• The instrument modification or parts replacement by

other than authorized representative of Yokogawa

Electric Corporation is prohibited and will void

Type of Protection “n” Certification.

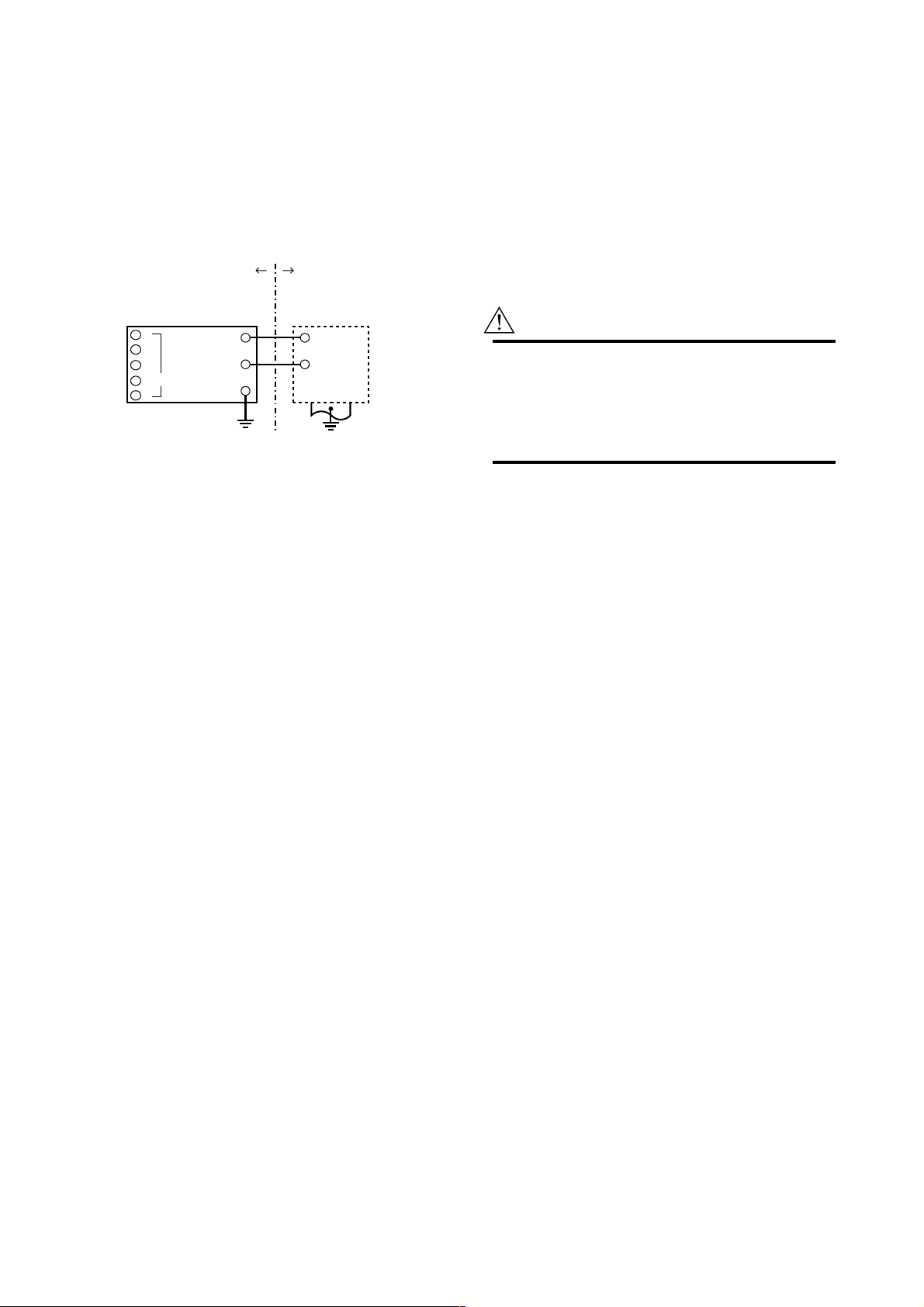

[Installation Diagram]

Hazardous

Location

Nonhazardou

Location

(Zone 2 only)

Temperature

Transmitter

+

Power Supply

+

Suppry

–

–

F0212.EPS

Ratings of the Power Supply are as follows:

Maximum Voltage: 30 V

(2) Electrical Connection

The type of electrical connection is stamped near

the electrical connection port according to the

following marking.

(5) Maintenance and Repair

WARNING

The instrument modification or parts replacement

by other than authorized Representative of

Yokogawa Electric Corporation is prohibited and

will void the certification.

(6) Name Plate

Name plate for type n protection

TEMPERATURE

TRANSMITTER

YTA

10.5⫺30 (42) V DC

TOKYO 180-8750 JAPAN

:Refer to USER’S MANUAL.

4⫺20 mA DC

0344

II

1G

No. KEMA 02ATEX1026 X

EEx ia IIC T5

Tamb -40 TO 50⬚C

EEx ia IIC T4

Tamb -40 TO 70⬚C

ENCLOSURE: IP67

SUPPLY INPUT

Ui=30V, Ii=165mA, Pi=900mV

Ci=20nF, Li=660H

SENSOR OUTPUT

Uo=8.6V, Io=30mA, Po=70mW

Co=3F, Lo=20mH

2GII II 3G

No. KEMA 02ATEX2155

EEx d IIC T6

Tamb -40 TO 75⬚C

EEx d IIC T5

Tamb -40 TO 80⬚C

ENCLOSURE: IP67

WARNING

AFTER DE-ENERGIZING, DELAY

5 MINUTES BEFORE OPENING.

WHEN THE AMBIENT TEMP.⭌70⬚C,

USE THE HEAT-RESISTING

CABLES⭌90⬚C.

Cross out unnecessary marking other than the selected type

of protection. When II 3G is selected, cross out 0344.

EEx nL IIC T5

Tamb -40 TO 50⬚C

EEx nL IIC T4

Tamb -40 TO 70⬚C

ENCLOSURE: IP67

SUPPLY INPUT

Ui=30V

Ci=20nF, Li=660H

SENSOR OUTPUT

Uo=8.6V, Io=30mA

Po=70mW, Co=3F

Lo=20mH

F0298.EPS

MODEL: Specified model code.

SUFFIX: Specified suffix code.

STYLE: Style code.

SUPPLY: Supply voltage.

NO.: Serial number and year of production*1.

OUTPUT: Output signal.

FACTORY CAL: Specified calibration range.

TOKYO 180-8750 JAPAN:

The manufacturer name and the

address*2.

Location of the marking

F0200.EPS

(3) Installation

WARNING

All wiring shall comply with local installation

requirement and local electrical code.

(4) Operation

WARNING

• OPEN CIRCUIT BEFORE REMOVING

COVER. INSTALL IN ACCORDANCE WITH

THIS USER’S MANUAL

• Take care not to generate mechanical sparking

when access to the instrument and peripheral

devices in hazardous locations.

*1: (a) The production year for the serial number

starting with other than “S.”

The third figure from the last shows the last one

figure of the year of production. For example, the

production year of the product engraved in “NO.”

column on the name plate as follows is 2001.

12A819857 132

The year 2001

(b) The production year for the serial number

starting with “S.”

The third and fourth figures from the left show the

last two figures of the year of production. For

example, the production year of the product

engraved in “NO.” column on the name plate as

follows is 2001.

S201D0229335

The year 2001

*2: “180-8750” is a zip code which represents the

following address.

2-9-32 Nakacho, Musashino-shi, Tokyo Japan

2-7

IM 01C50B01-01E

Page 14

2. NOTES ON HANDLING

s

2.7.3 CENELEC (KEMA) Certification

Model YTA110/KU1, YTA310/KU1 and YTA320/

KU1 temperature transmitters can be selected the type

of protection (CENELEC (KEMA) Intrinsically Safe or

CENELEC (KEMA) Flameproof or IEC(KEMA) Type

of Protection “n”) for use in hazardous locations.

Note 1. For the installation of this transmitter,

once a particular type of protection is

selected, any other type of protection

cannot be used. The installation must be

in accordance with the description about

the type of protection in this instruction

manual.

Note 2. In order to avoid confusion, unnecessary

marking is crossed out on the label other

than the selected type of protection when

the transmitter is installed.

a) CENELEC (KEMA) Intrinsically Safe Type

Caution for CENELEC (KEMA) Intrinsically safe type

Note 1. Model YTA110/KU1, YTA310/KU1 and

YTA320/KU1 temperature transmitters for

potentially explosive atmospheres:

• Type of Protection and Marking code: EEx ia IIC

• Temperature Class: T4, T5

• Ambient Temperature: –40 to 70°C for T4, –40 to

50°C for T5

Note 2. Electrical Data

• In type of explosion protection intrinsic safety EEx

ia IIC only for connection to a certified intrinsically

safe circuit with following maximum values:

• [Supply circuit]

Ui = 30 V Ii = 165 mA

Pi = 0.9 W

Effective internal capacitance, Ci = 20 nF

Effective internal inductance, Li = 660 µH

• [Sensor circuit]

Uo = 8.6 V Io = 30 mA

Po = 70 mW

Max. allowed external capacitance = 3 µF

Max. allowed external inductance = 20 mH

Note 3. Installation

•All wiring shall comply with local installation

requirements. (Refer to the installation diagram)

Note 4. Maintenance and Repair

• The instrument modification or parts replacement by

other than authorized representative of Yokogawa

Electric Corporation is prohibited and will void

KEMA Intrinsically safe Certification.

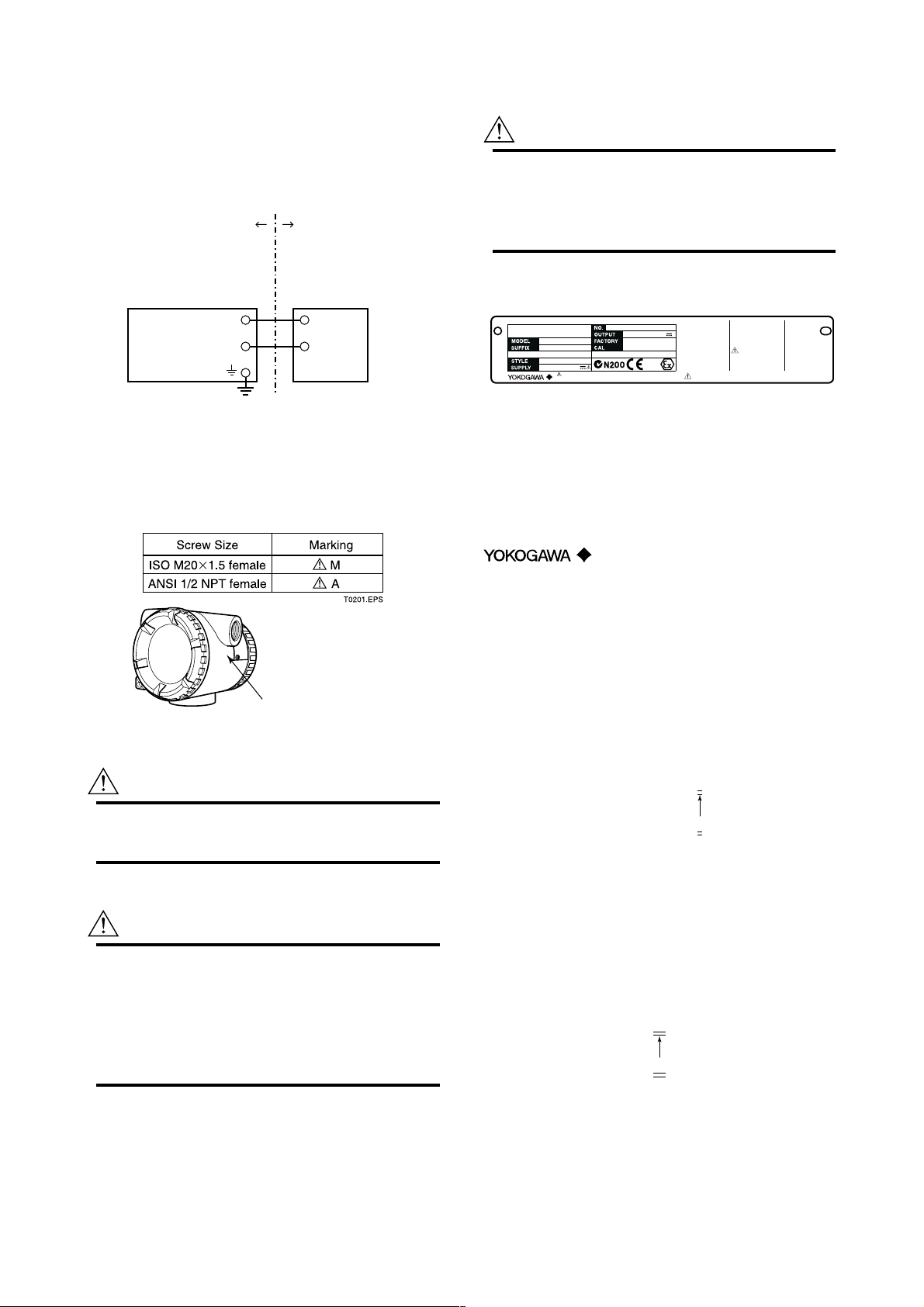

[Installation Diagram]

Hazardous

Location

Transmitter

1

2

3

4

Sensor

5

*1: In any safety barriers used the output current must be limited by

a resistor “R” such that Imaxout-Uz/R.

+

Supply

–

Nonhazardou

Location

Safety Barrier

+

–

*1

F0208.EPS

b) CENELEC (KEMA) Flameproof Type

Caution for CENELEC (KEMA) Flameproof Type

Note 1. Model YTA110/KU1, YTA310/KU1 and

YTA320/KU1 temperature transmitters for

potentially explosive atmospheres:

• Type of Protection and Marking Code: EEx d IIC T6

Temperature Class: T6

• Ambient Temperature: –40 to 75°C

Note 2. Electrical Data

• Supply voltage: 42 V dc max.

Output signal: 4 to 20 mA

Note 3. Installation

•All wiring shall comply with local installation

requirement.

•The cable entry devices shall be of a certified

flameproof type, suitable for the conditions of use.

Note 4. Operation

• Keep strictly the “WARNING” on the label on the

transmitter.

WARNING: WAIT 5 MIN. AFTER POWER-

DISCONNECTION, BEFORE

OPENING THE ENCLOSURE.

WHEN THE AMBIENT TEMP. ⭌

70⬚C, USE THE HEATRESISTING CABLES OF HIGHER

THAN 90⬚C

• Take care not to generate mechanical spark when

access to the instrument and peripheral devices in

hazardous location.

Note 5. Maintenance and Repair

• The instrument modification or parts replacement by

other than authorized representative of Yokogawa

Electric Corporation is prohibited and will void

KEMA Flameproof Certification.

2-8

IM 01C50B01-01E

Page 15

2. NOTES ON HANDLING

s

c) IEC (KEMA) Type of Protection “n”

Caution for IEC (KEMA) Type of Protection “n”

Note 1. Model YTA110/KU1, YTA310/KU1 and

YTA320/KU1 ditemperature transmitters

for potentially explosive atmospheres:

• Type of Protection and Marking Code: Ex nC IIC

T5, T4

• Temperature Class: T5, T4

• Ambient Temperature: –40 to 50°C for T5, –40 to

70°C for T4

• Enclosure: IP67

Note 2. Electrical Data

Ui = 30 V Ii = 150 mA

(terminals + and –)

Note 3. Installation

•All wiring shall comply with local installation

requirements. (refer to the installation diagram)

Note 4. Operation

• Keep strictly the “WARNING” on the label on the

transmitter.

WARNING: WAIT 5 MIN. AFTER POWER-

DISCONNECTION, BEFORE

OPENING THE ENCLOSURE.

WHEN THE AMBIENT TEMP. ⭌

70⬚C, USE THE HEATRESISTING CABLES OF HIGHER

THAN 90⬚C

Note 5. Maintenance and Repair

• The instrument modification or parts replacement by

other than authorized representative of Yokogawa

Electric Corporation is prohibited and will void

KEMA Type of Protection “n” Certification.

[Installation Diagram]

Hazardous

Location

(Zone 2 only)

Temperature

Transmitter

+

Suppry

–

Ratings of the Power Supply are as follows:

Maximum Voltage: 30 V

Maximum Current: 150 mA

Nonhazardou

Location

Power Supply

+

–

F0212.EPS

2.7.4 FM Certification

a) FM Intrinsically Safe Type

Caution for FM Intrinsically safe type.

Note 1. Model YTA /FU1 temperature transmitter

is applicable for use in hazardous

locations

• Intrinsically Safe for Class I, Division 1, Groups A,

B, C & D.

Class II, Division 1, Groups E, F & G and Class III,

Division 1 Hazardous Locations.

• Outdoor hazardous locations, NEMA 4X.

• Temperature Class: T4

• Ambient temperature: –40 to 60°C

Note 2. Entity Parameters of the temperature

transmitter:

• Supply Circuit (+ and -) •Sensor Circuit ( 1 to 5 )

Vmax : 30 V Voc/Vt : 9 V

Imax : 165 mA Isc/It : 40 mA

Pmax : 0.9 W Ca : 1 µF

Ci : 18 nF La : 10 mH

Li : 730 µH

• For the sensor input circuitry, these entity parameters

must be taken into account when installed.

• Installation Requirements between temperature

transmitter and safety barrier:

Voc Vmax, Isc Imax, Ca Ci + Ccable, La

Li + Lcable

Voc , Isc, Ca and La are parameters of the safety

barrier.

Note 3. Installation

• The safety barrier must be FM approved.

• Input voltage of the safety barrier must be less than

250 Vrms/Vdc.

•Installation should be in accordance with ANSI/ISA

RP12.6 “Installation of Intrinsically Safe Systems

for Hazardous (Classified) Locations” and the

National Electric Code (ANSI/NFPA 70).

• Intrinsically safe sensor must be FMRC Approved or

be simple apparatus (a device which will neither

generate nor store more than 1.2 V, 0.1 A, 25 mW

or 20 µJ, ex. switches, thermocouples, LED’s or

RTD’s).

• Dust-tight conduit seal must be used when installed

in a Class II and III environments.

Note 4. Maintenance and Repair

• The instrument modification or parts replacement by

other than authorized representative of Yokogawa

Electric Corporation is prohibited and will void

Factory Mutual Intrinsically safe and Nonincendive

Approval.

2-9

IM 01C50B01-01E

Page 16

2. NOTES ON HANDLING

[Intrinsically Safe]

Hazardous

Location

Class I, II, III, Division 1,

Groups A, B, C, D, E, F and G

Intrinsically

Safe Sensor

or Simple

Apparatus

Temperature

Transmitter

1

2

3

4

Sensor

5

Supply

+

–

C

Nonhazardous

Location

General

Purpose

Equipment

+–

Safety Barrier

+

+

–

–

F0210.EPS

b) FM Non-incendive Type

Caution for FM Non-incendive type.

Note 1. Model YTA /FU1 temperature transmitter

is applicable for use in hazardous

locations

• Non-incendive for Class I, Division 2, Groups A, B,

C & D.

Class II, Division 2, Groups E, F & G and Class III,

Division 1 Hazardous Locations.

• Outdoor hazardous locations, NEMA 4X.

• Temperature Class: T4

• Ambient temperature: –40 to 60°C

Note 2. Non-incendive field wiring Parameters of

the temperature transmitter:

• Supply Circuit (+ and -) •Sensor Circuit ( 1 to 5 )

Vmax : 30 V Voc/Vt : 9 V

Imax : 165 mA Isc/It : 40 mA

Pmax : 0.9 W Ca : 1 µF

Ci : 18 nF La : 10 mH

Li : 730 µH

• For the sensor input circuitry, these non-incendive

parameters must be taken into account when

installed.

• Installation Requirements between temperature

transmitter and general purpose equipment:

Voc Vmax, Isc Imax, Ca Ci + Ccable, La

Li + Lcable

Voc , Isc, Ca and La are non-incendive field wiring

parameters of general purpose equipment.

Note 3. Installation

• The general purpose equipment must be FM approved which have non-incendive field wiring

parameters.

•Installation should be in accordance with ANSI/ISA

RP12.6 “Installation of Intrinsically Safe Systems

for Hazardous (Classified) Locations” and the

National Electric Code (ANSI/NFPA 70).

• non-incendive sensor must be FMRC Approved or

be simple apparatus (a device which will neither

generate nor store more than 1.2 V, 0.1 A, 25 mW

or 20 µJ, ex. switches, thermocouples, LED’s or

RTD’s).

• Dust-tight conduit seal must be used when installed

in a Class II and III environments.

Note 4. Maintenance and Repair

• The instrument modification or parts replacement by

other than authorized representative of Yokogawa

Electric Corporation is prohibited and will void

Factory Mutual Intrinsically safe and Nonincendive

Approval.

[Nonincendive]

Hazardous

Location

Class I, II, Division 2,

Groups A, B, C, D, E, F and G

Class III, Division 1.

Non-incendive

Sensor

or Simple

Apparatus

Temperature

Transmitter

1

2

3

4

Sensor

5

+

Supply

–

C

Nonhazardous

Location

General

Purpose

Equipment

+

–

c) FM Explosionproof Type

Caution for FM Explosionproof type

Note 1. Model YTA /FU1 and YTA /FF1 tempera-

ture transmitters are applicable for use in

hazardous locations:

• Explosionproof for Class I, Division 1, Groups A, B,

C, and D.

• Dust-ignitionproof for Class II/III, Division 1,

Groups E, F and G.

• Enclosure rating: NEMA 4X.

• Temperature Class: T6

• Ambient Temperature: –40 to 60°C

• Supply Voltage: 42 V dc max.

• Output signal: 4 to 20 mA

Note 2. Wiring

• All wiring shall comply with National Electrical

Code ANSI/NEPA70 and Local Electrical Codes.

• “FACTORY SEALED, CONDUIT SEAL NOT

REQUIRED”.

2-10

IM 01C50B01-01E

F0211.EPS

Page 17

2. NOTES ON HANDLING

Note 3. Operation

• Keep strictly the “WARNING” on the nameplate

attached on the transmitter.

WARNING: OPEN CIRCUIT BEFORE RE-

MOVING COVER. “FACTORY

SEALED, CONDUIT SEAL NOT

REQUIRED”. INSTALL IN ACCORDANCE WITH THE INSTRUCTION

MANUAL IM 1C50B1.

• Take care not to generate mechanical spark when

access to the instrument and peripheral devices in

hazardous location.

Note 4. Maintenance and Repair

• The instrument modification or parts replacement by

other than authorized representative of Yokogawa

Electric Corporation is prohibited and will void

Factory Mutual Explosionproof Approval.

2.7.5 JIS Certification

a) JIS Flameproof Type

The model YTA /JF3 temperature transmitter, which

has obtained certification according to technical criteria

for explosion-protected construction of electric machinery and equipment (Standards Notification No.556

from the Japanese Ministry of Labor) conforming to

IEC standards, is designed for hazardous areas where

explosive gases and/or inflammable vapors may be

present. (This allows installation in Division 1 and 2

areas)

To preserve the safety of flameproof equipment

requires great care during mounting, wiring, and

piping. Safety requirements also place restrictions on

maintenance and repair activities. Users absolutely

must read “Installation and Operating Precautions for

JIS Flameproof Equipment” at the end of this manual.

WARNING

The terminal cover should not be opened at

least for three minutes after the power is turned

off.

The terminal section of the flameproof YTA

series is made of resin-filled, explosion-protected

construction. The technical standards for this

flameproof construction require that the possibility of explosion resulting from a prospective

short-circuit current*2 of up to 4000 A be prevented even for cases when external power

supply circuits are short-circuited accidentally.

Install a fuse or a circuit breaker having a

breaking capacity of at least 4000 A in the

higher-order power line connected to the YTA

series. The breaking capacity refers to the upper

limit of current that can be cut off. Normally, a

fuse or a circuit breaker having a breaking

capacity of greater than 5000 A is used in power

supply circuits. Confirm that this is true with your

factory. No extra measures need be taken after

the confirmation.

Note that the rated current of the YTA series in

terms of explosion protection is 4 to 20 mA;

keep the input current of the YTA series within

the appropriate range.

*2: Refers to a current that flows when a fuse in a circuit is

substituted with a connecting metal piece having virtually no

impedance and the circuit is then shorted. For AC circuits, this

current is represented by a root-mean-square value (JIS C6575).

2.7.6 SAA Certification

Model YTA110/SU1, YTA310/SU1 and YTA320/SU1

temperature transmitters can be selected the type of

protection (SAA Intrinsically Safe, Type of Protection

“n” or Flameproof) for use in hazardous locations.

Note 1. For the installation of this transmitter,

once a particular type of protection is

selected, any other type of protection

cannot be used. The installation must be

in accordance with the description about

the type of protection in this instruction

manual.

Note 2. In order to avoid confusion, cross out

unnecessary marking on the label other

than the selected type of protection when

the transmitter is installed.

a) SAA Intrinsically Safe/Type N Type

Caution for SAA Intrinsically safe/Type n type

Note 1. Model YTA110/SU1, YTA310/SU1 and

YTA320/SU1 temperature transmitters for

potentially explosive atmospheres:

• Type of Protection and Marking code:

Ex ia IIC T4 (Tamb=70°C) IP66/67 Zone 0

Ex n IIC T4 (Tamb=70°C) IP66/67 Zone 2

• Ambient Temperature: –40 to 70°C

Note 2. Entity Parameter

• In type of explosion protection only for connection

to a certified intrinsically safe/type n circuit with

following maximum values:

[Input parameters (terminals +&-/C)]

Maximum Input Voltage(Ui) = 30 V

Maximum Input Current(Ii) = 165 mA

Maximum Input Power(Pi) = 0.9 W

Maximum Internal Capacitance(Ci) = 30.2 nF

Maximum Internal Inductance(Li) = 738 µH

2-11

IM 01C50B01-01E

Page 18

2. NOTES ON HANDLING

NOTE

[Output parameters (terminals 1 to 5)]

Maximum Output Voltage(Uo) = 8.6 V

Maximum Output Current(Io) = 30 mA

Maximum Output Power(Po) = 62 mW

Maximum External Capacitance = 1 µF

Maximum External Inductance = 20 mH

Maximum External Connected L/R = 0.5mH/⍀

Note 3. Installation

•All wiring shall comply with Australian Standards.

• The input and output cables are to be installed either

as seperate cables or as seperate screened circuits.

• Certified IP66/67 glands or plugs must be used on

the enclosure cable entries.

Note 4. Maintenance and Repair

•The instrument modification or parts replacement by other

than authorized representative of Yokogawa Electric

Corporation is prohibited and will void SAA Certification.

[Installation Diagram for intrinsically safe type]

Hazardous Location

(Zone 0)

Transmitter

1

2

3

Sensor

4

5

Hazardous Location

(Zone 2)

Transmitter

*1: In any safety barriers used the output current must be limited by

a resistor “R” such that Imaxout-Uz/R.

+

Supply

–

[ Installation Diagram for Type n ]

+

+

Suppry Power Supply

–

–

Nonhazardous Location

Safety Barrier

+

–

Nonhazardous Location

+

+

–

–

*1

F2013.EPS

b) SAA Flameproof Type

Caution for SAA Flameproof Type

Note 1. Model YTA110/SU1, YTA310/SU1 and

YTA320/SU1 temperature transmitters for

potentially explosive atmospheres:

• Type of Protection and Marking Code:

Ex d IIC T6(Tamb 75°C) IP66/67 Zone 1

• Ambient Temperature: –40 to 75°C

Note 2.Electrical Data

• Supply voltage: 42 V dc max.

• Output signal: 4 to 20 mA

Note 3. Installation

•All wiring shall comply with Australian Standards.

•The cable entry devices shall be of a certified

flameproof type, suitable for the conditions of use.

Note 4. Operation

• Keep strictly the “WARNING” on the label on the

transmitter.

WARNING: WAIT 5 MIN. AFTER POWER-

DISCONNECTION, BEFORE

OPENING THE ENCLOSURE.

WHEN THE AMBIENT TEMP.

⭌ 70⬚C, USE THE HEATRESISTING CABLES OF HIGHER THAN

90⬚C

• Take care not to generate mechanical spark when

access to the instrument and peripheral devices in

hazardous location.

Note 5. Maintenance and Repair

• The instrument modification or parts replacement by

other than authorized representative of Yokogawa

Electric Corporation is prohibited and will void SAA

Certification.

2.8 EMC Conformity Standards

EN61326, AS/NZS 2064

YOKOGAWA recommends customer to apply

the Metal Conduit Wiring or to use the twisted

pair Shield Cable for signal wiring to conform the

requirement of EMC Regulation, when customer

installs the YTA Series Transmitters to the plant.

2-12

IM 01C50B01-01E

Page 19

3. PART NAMES AND FUNCTIONS

3. PART NAMES AND FUNCTIONS

3.1 Part Names

Burn out output direction

setting pin upon hardware failure

Name plate

Stud bolt

CPU assembly

Terminal cover

LCD assembly

(with indicator)

Grounding

Amp. cover

Lock screw

Wiring connector

(input signal side)

terminal

Tag plate

Grounding

terminal

Wiring connector

(output signal side)

Figure 3.1 Part Names

Built-in indicator display

Output signal terminal

3-1

Input signal terminal

F0301.EPS

F0301.EPS

IM 01C50B01-01E

Page 20

3. PART NAMES AND FUNCTIONS

3.2 Setting the Hardware Error Burnout Change-over Switch

The temperature transmitter is equipped with a hardware error burnout function used to set the output

direction upon hardware error, and a sensor burnout

function that sets the direction of the output in the

event of burnout of the temperature sensor. When

factory-shipped under normal conditions, the output of

both hardware error burnout and sensor burnout are set

to HIGH, but if suffix code /C1 is specified, the

hardware error burnout is set to LOW (-5%) output,

and sensor burnout is set to LOW (-2.5%) output,

respectively. The setting of the direction of output from

burnout can be changed.

To change the direction of output arising from burnout,

switch the setting pin on the CPU assembly (see Figure

3.1 and Table 3.1). To change the direction of output

arising out of sensor burnout, a dedicated hand-held

terminal is required to rewrite the parameters within

the transmitter. For details, refer to the separate

instruction manual, IM 01C50T01-01E “HART

Protocol” or IM 01C50T03-01E “BRAIN Protocol”.

Table 3.1 Output Direction Setting Pins for Hardware

Error Burnout

Pin

position

H

L

H

L

burnout

direction

HIGH

LOW

Hardware error

burnout

output

110% or more

(21.6 mA DC)

-5% or less

(3.2 mA DC)

RemarkHardware error

Set to HIGH upon

shipment from the

factory

Set to LOW when

suffix code /C1

is provided

T0301.EPS

3.3 Built-in Indicator Display

(1)Output bar chart display

The output value is displayed in a bar chart. Resolution

of the bar chart is to the extent of 32 divisions (each

increment is about 3.125%). If the output exceeds 0%

or 100%,䉲 is lit. The bar chart can be toggled ON/

OFF using the bar chart display parameter.

(2) Communication protocol display

The indicator is on in accordance with each communication protocol.

(3)Operation mode display

Lit when each operation mode is activated.

M.D.:Lit when the multidrop mode of HART commu-

nication specification is activated.

B.M.: Lit during burst mode transfer of HART commu-

nication specification.

F.O.: Lit when manual mode is active.

W.P.: Lit when write protect status is active.

(4)Input display

Indicates the type of input in accordance with the value

shown in the column in Item (5).

Sns1: Meant to show the process variable allocated to

Sensor 1.

Sns2: Meant to show the process variable allocated to

Sensor 2. (Can be displayed only with the

YTA320.) .

Term: Meant to show the temperature of the terminal

box of the temperature transmitter.

Avg: Meant to show the average of the process

variable allocated to Sensor1 and Sensor2. (Can

be displayed only with the YTA320.).

Function

Communication protocol display

Output bar chart display

Operation mode

display

Input display

Process variable display

Unit display

Display of sensor type and

number of wire connections

Figure 3.2 Built-in Indicator Display Function

F0302.EPS

Dif: Meant to show the difference of the process

variable allocated to Sensor1 and Sensor2. (Can

be displayed only with the YTA320.)

(5)Process variable display

Displays the process variable or output value. The

value is displayed down to the second decimal position

if the integer part is less than three digits, or down to

the first decimal position if the integer part is 4 digits.

If the value is negative, the minus (⫺) sign is lit. For

process variables, the indicators for each item specified

in the column of input display in Item (4) and the unit

column in Item (6) are lit. For output value, % or mA

in the unit column in Item (6) is lit. When burnout of

the temperature sensor is identified, or the temperature

transmitter is found abnormal, an error code flashes.

For a list of error codes, refer to “Error code table” in

Section 6.4.

3-2

IM 01C50B01-01E

Page 21

3. PART NAMES AND FUNCTIONS

(6)Unit display

The unit specified as the unit of process in the process

variable display column in Item (5) is lit. The output

display is fixed to mA or %.

(7)Display of sensor type and number of wire

connections

Displays process variable/output items, the number of

sensor wiring connections and the multidrop address in

dot matrix (only applies to HART communication). In

the event of hardware error, “FAIL” is displayed.

Process variable: To display the process variable

value in the process variable

display in Item (5), display the type

of applicable process variable

(“PV”, “SV”, “TV”).

Output display: To display the output value in the

process variable display in Item

(5), display “OUT”. During the

output of sensor burnout, “Abn”

and “OUT” are alternately dis

played.

Upon shipment from the factory, the indicator is set as

follows.

Table 3.2 Setting of Indicator upon Shipment from the

Factory

Display location

Output bar chart display

Input display

Process variable display

Unit display

Display of sensor type and

number of wire connections

Output bar chart display is on.

Sns1 is lit.

PV value and output value

(mA) are alternately displayed.

The unit specified upon

shipped from factory and mA

are lit.

“PV” and “OUT” are displayed

alternately.

Contents

T0302.EPS

WIRE: Displays the number of wiring

connections. There are two wiring

connections for thermocouple

input, while there are two to four

connections for thermometer

resistor; these are displayed

alternately with the sensor type.

The display can be hidden by

setting an applicable parameter.

Note that the DIF and AVG display

does not allow the sensor type to

be displayed.

TYPE: Displays the type of sensor. Note

that the DIF and AVG display does

not allow the sensor type to be

displayed. If the sensor is customordered, “Z1” and “Z2” are

displayed.

Multidrop address: If the multidrop address is 1

through 15 in HART communication, the output display brings up

these addresses instead of display

ing “OUT”.

3-3

IM 01C50B01-01E

Page 22

4. INSTALLATION

4. INSTALLATION

IMPORTANT

• When performing on-site pipe fitting work that

involves welding, use care to prevent outflow

of the welding current into the transmitter.

• Do not use the transmitter as a foothold for

installation.

• For details of choosing the installation location, refer

to the guidelines outlined in Section 2.4, “Choosing

the installation location”.

• The mounting bracket shown in Figure 4.1 is used

for the transmitter and is installed on 50A (2B) pipe.

It can be installed either on a horizontal pipe and a

vertical pipe or on a wall.

• To install the mounting bracket on the transmitter,

torque the transmitter lock screw (1) to about 20 to

30N⭈m.

Horizontal Pipe Mounting

U-bolt nut

Mounting bracket

Spring washer

Transmitter lock scraps

2B pipe

(60.5dia.)

U-bolt

Vertical Pipe Mounting

Wall Mounting

Note: Wall mounting bolts are user-

supplied.

Figure 4.1 Mounting the Transmitter

4-1

F0401.EPS

IM 01C50B01-01E

Page 23

5. WIRING

F0501.EPS

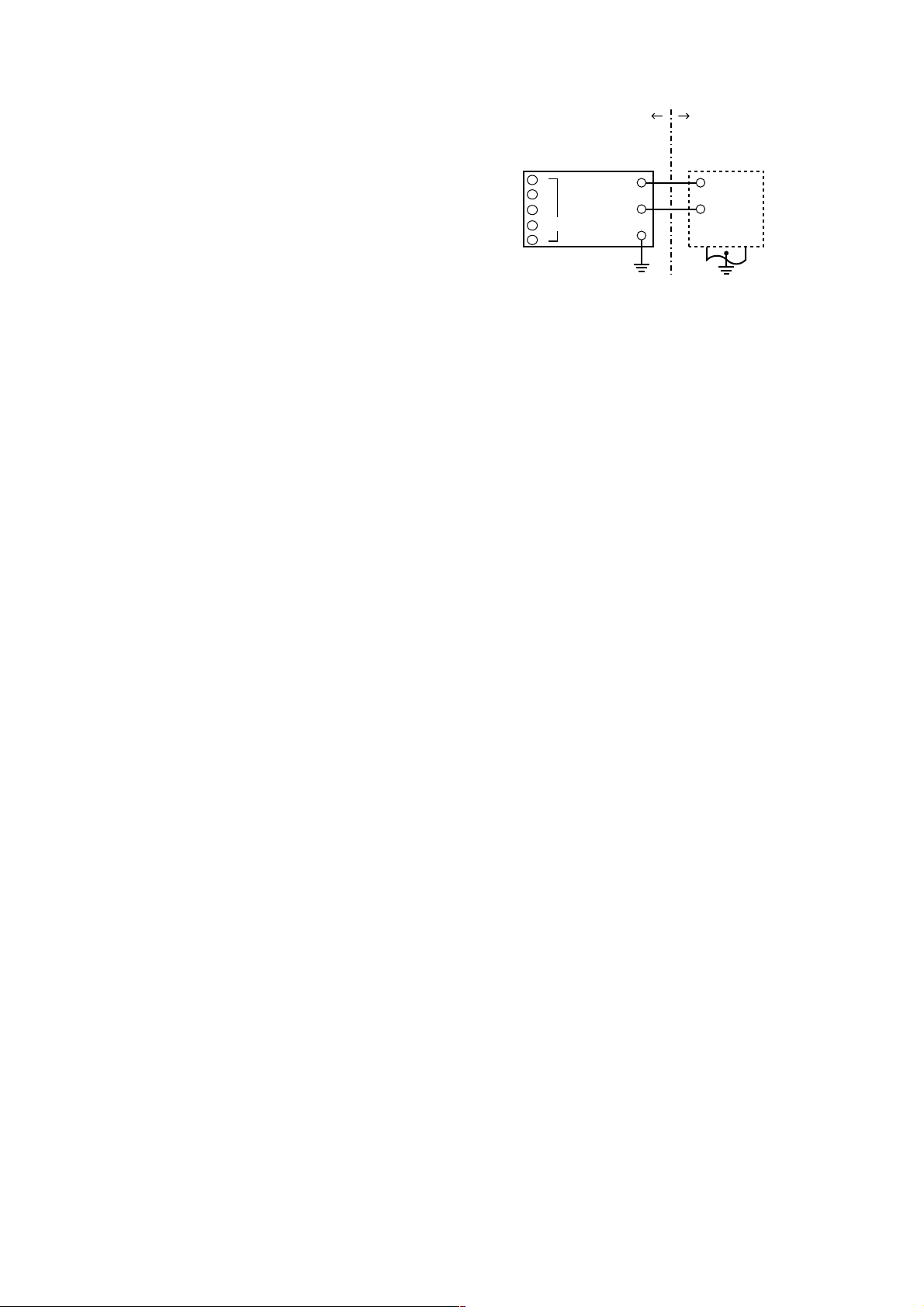

<Hazardous location> <Nonhazardous location>

+

Output signal

–

Distributor

(power supply unit)

Receiver

Input signal

(thermocouple,

RTD, mV, etc.)

F0502.EPS

<Hazardous location> <Nonhazardous location>

+

Output signal

–

Distributor

(power supply unit)

Receiver

Safety

barrier

Input signal

(thermocouple,

RTD, mV, etc.)

5.1 Notes on Wiring

IMPORTANT

• Apply a waterproofing sealant to the

threads of the connection port. (It is recommended that you use non-hardening sealant

made of silicon resin for waterproofing.)

• Lay wiring as far away as possible from

electrical noise sources such as large transformers, motors and power supplies.

• Remove the wiring connection dust-caps

before wiring.

• To prevent electrical noise, the signal cable

and the power cable must not be housed in

the same conduit.

• The terminal box cover is locked by an Allen

head bolt (a shrouding bolt) on CENELEC,

SAA and JIS flameproof type transmitters.

When the shrouding bolt is driven clockwise

by an Allen wrench, it is going in and cover

lock is released, and then the cove can be

opened by hands. See Subsection 6.3

“Disassembly and Reassembly” for details.

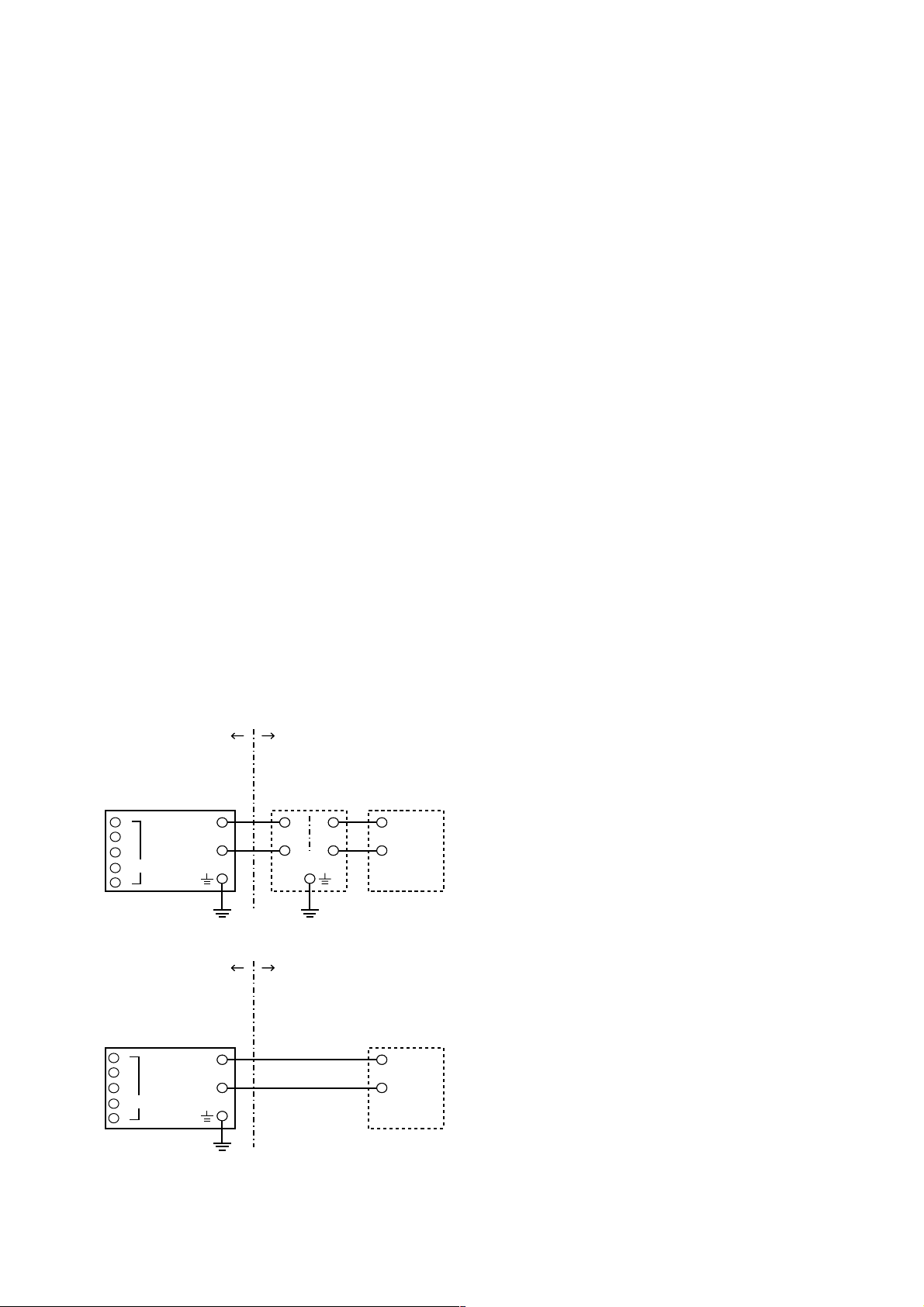

5.2 Loop Construction

The YTA is a two-wire temperature transmitter that

uses the output power supply wiring and signal wiring

alternately.

5. WIRING

Figure 5.1 Loop Construction (for General-use Type and

Figure 5.2 Loop Construction (for Intrinsically Safe

resistance

Flameproof Type)

Type)

600

External

load

250

R

(⍀)

R=

E–10.5

0.0236

Communication

applicable range

BRAIN and HART

The transmission loop requires DC power. Connect the

transmitter with the distributor as shown in Figure 5.1

or Figure 5.2.

For the transmission loop, the load resistance of the

distributor or other instrument to be installed in the

loop and the lead wire must be within the range shown

in Figure 5.3.

For details of communication requirements, refer to the

additional reference materials, IM 01C50T03-01E “YTA

Series BRAIN Communication”, and IM 01C50T01-01E

“YTA Series HART Communication”.

10.5 16.4 24.7 42

Power supply voltage E (V DC)

Figure 5.3 Relation between Power Supply Voltage and

Note: For intrinsic safe explosion-proof type units, the internal

5-1

Load Resistance

resistance of the safety barrier is also included in the load

resistance.

IM 01C50B01-01E

F0503.EPS

Page 24

5. WIRING

5.3 Cable Selection

5.3.1 Input signal Cable Selection

A dedicated cable is used for connection between the

temperature sensor and the temperature transmitter.

When a thermocouple is used as the temperature

sensor, a compensation wire must be used that it

appropriate for the type of thermocouple (refer to

compensating cables for JIS C 1610/IEC584-3 thermocouples). When a resistance temperature sensor (RTD)

is used as the temperature sensor, 2-core/3-core/4-core

cable must be used (refer to resistance thermometer

sensor JIS C 1604/IEC751). The terminal of the

dedicated cable is a 4 mm screw.

5.3.2 Output Signal Cable Selection

• With regard to the type of wire to be used for

wiring, use twisted wires or cables with performance equivalent of 600V vinyl insulated cable

(JIS C3307).

• For wiring in areas susceptible to electrical noise,

use shielded wires.

• For wiring in high or low temperature areas, use

wires or cables suitable for such temperatures.

• For use in an atmosphere where harmful gases or

liquids, oil, or solvents are present, use wires or

cables made of materials resistant to those substances.

• It is recommended that a self-sealing terminal with

insulation sleeve (4-mm screw) be used for lead

wire ends.

CAUTION

When wiring, pay attention not to damage the

cable and cores. All the cores of the cable must

have the sufficient insulation around them.

STEP 1

(1)

a. Cable connection to thermometer resistor(RTD),

3-wire

STEP 2

(2)

b. Power supply cable connection

Figure 5.4 Terminal Connection Pro cedure

F0504.EPS

WARNING

If the YTA is JIS flameproof and the ambient

temperature is 50°C or more, use an external

cable having a maximum allowable heat resistance of at least 70°C in consideration of the

instrument’s generation of heat or the cable’s

self-heating.

5.4 Cable and Terminal Connections

5.4.1 Input Terminal Connections

NOTE

It is recommended that the terminals be connected in the order of input terminal (1) and

output terminal (2).

䊏 The temperature sensor is to be connected

as shown in Figures 5.6 and 5.7.

Figure 5.5 Terminal diagram

5-2

IM 01C50B01-01E

F0505.EPS

Page 25

5. WIRING

Sensor1(YTA110, YTA310)

1

(+)

2

3

(–)

4

5

Thermocouple and

DC voltage

(A)

1

(B)

2

(B)

3

4

5

RTD and resistance

(3-wire)

RTD and resistance

1

2

3

4

5

1

2

3

4

5

(A)

(B)

(2-wire)

(A)

(A)

(B)

(B)

RTD

(4-wire)

F0506.EPS

Figure 5.6 YTA110 and YTA310 Input Terminal Wire

Connection Diagram

1 input (YTA320)

1

(+)

2

3

(–)

4

5

Thermocouple and

DC voltage

(A)

1

(B)

2

(B)

3

4

5

RTD and resistance

(3-wire)

(A)

1

2

(B)

3

4

5

RTD and resistance

(2-wire)

(A)

1

(A)

2

(B)

3

(B)

4

5

RTD

(4-wire)

5.4.2 Output Terminal Connection

(1) Connection of output signal/power supply

cable

Connect the output signal cable (shared with the

power supply cable) to the – terminal and the +

terminal. For details, refer to Figure 5.2, “Loop

construction”.

(2) Connection of wiring for field indicator

Connect the lead wire for the field indicator with

the – terminal and the C terminal.

Note: Use a field indicator with an internal resistance of 10W or less.

Field indicator

Power

supply

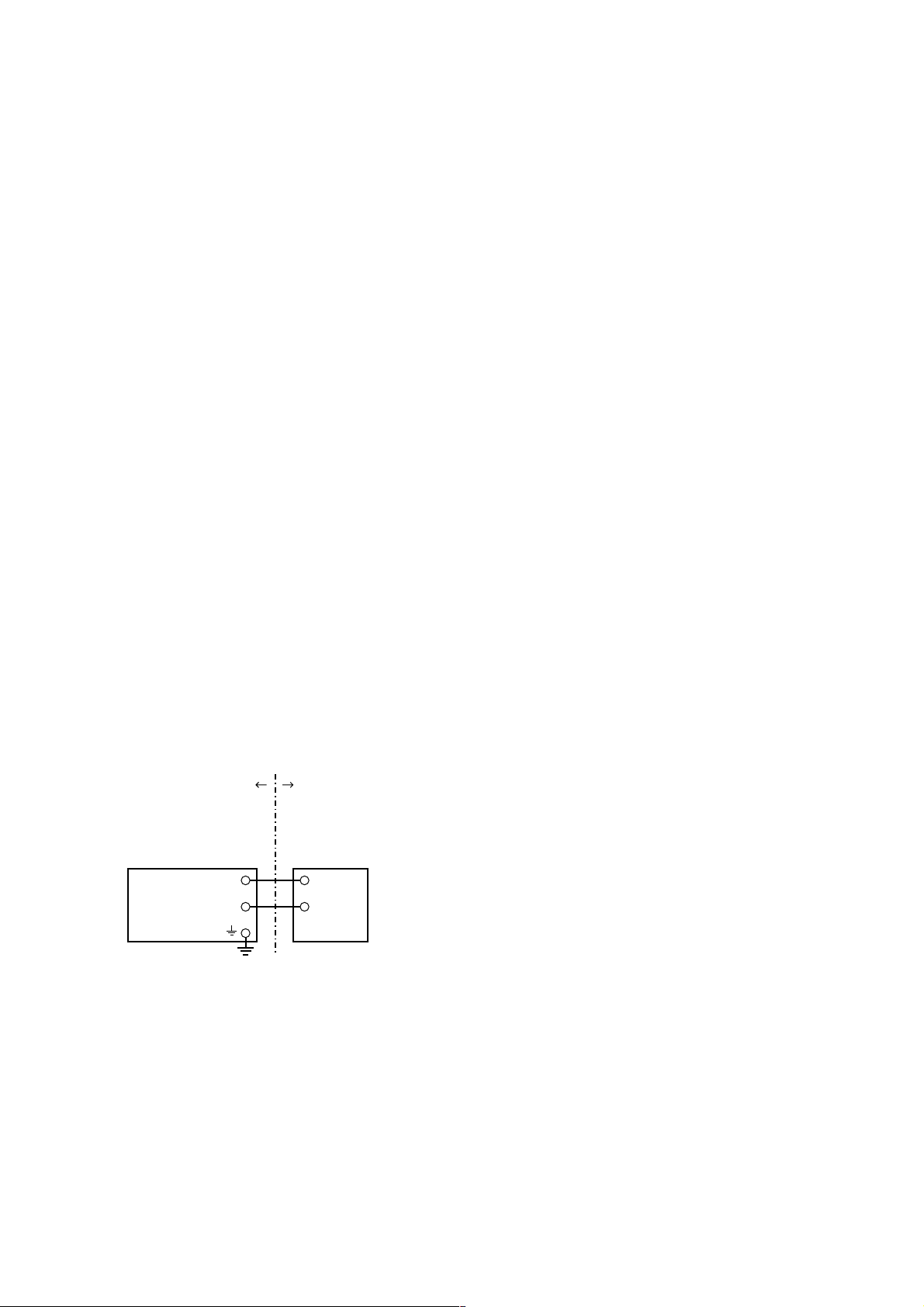

+

Figure 5.8 Connection to Field Indicator

(3) Connection of check meter

Connect the check meter with the – terminal and

the C terminal.

The current signal of output signal 4 to 20 mA DC

is output from the – terminal and the C terminal.

Note: Use a check meter with internal resistance of 10⍀ or less.

Check meter

––+

F0508.EPS

2 input (YTA320)

(+)

1

2

(–)

3

4

(+)

5

Thermocouple and

DC voltage

(+)

1

(–)

2

3

4

5

(B)

(B)

(A)

Thermocouple +

RTD and resistance

(A1)

1

(B1)

2

(B1)

3

(B2)

4

(B2)

5

(A2)

RTD and resistance

(3-wire)

(A1)

1

(B1)

2

3

(B2)

4

(A2)

5

RTD and resistance

(2-wire)

(3-wire)

Figure 5.7 YTA320 Input Terminal Wire Connection

Diagram

Figure 5.9 Check Meter Connection

+

–

Power

supply

F0509.EPS

5-3

IM 01C50B01-01E

Page 26

5. WIRING

5.5 Wiring Cautions

(1) General-use Type and Intrinsically Safe

Type

Use metal conduit wiring or a waterproof gland

(metal wiring conduit JIS F 8801) for cable wiring.

•Apply nonhardening sealant to the threads of the

wiring tap and a flexible fitting for secure waterproofing. Figure 5.10 shows an example of wiring

on the output side. This example also applies to the

wiring on the input side.

Flexible fitting

Wiring conduit

Apply a nonhardening

sealant to the threads for

waterproofing.

Figure 5.10 Example of Wiring Using a Wiring Conduit

(2) JIS Flameproof Type

Wire cables through a flameproof packing adapter,

or using a flameproof metal conduit.

Tee

Drain plug

F0510.EPS

Table 5.1 Flameproof Packing and Appropriate Cable

Wiring Port

Thread

Diameter

G1/2

Outer Diameters

Appropriate

Cable Outer

Diameter (mm)

8 -10

10.1-12

Identifying

Mark

16168-10

10-12

Part

Number

G9601AM

T0501.EPS

Follow the procedure below to install the flameproof