Page 1

User’s

Manual

YS1500 Indicating Controller

YS1700 Programmable

Indicating Controller

Operation Guide

Functional

Enhancement

IM 01B08B02-01EN

IM 01B08B02-01EN

4th Edition

Page 2

Product Registration

Thank you for purchasing YOKOGAWA products.

YOKOGAWA provides registered users with a variety of information and services.

Please allow us to serve you best by completing the product registration form accessible

from our homepage.

http://www.yokogawa.com/ns/reg/

Page 3

Page 4

Contents

Foreword ................................................................................................................................................................................ 3

Notice ...................................................................................................................................................................................... 3

Trademarks ............................................................................................................................................................................3

Authorised Representative in the EEA ....................................................................................................................................3

Revisions .................................................................................................................................................................................3

Safety Precautions ................................................................................................................................................................. 3

Handling Precautions for the Main Unit ..................................................................................................................................4

Checking the Contents of the Package .................................................................................................................................. 5

Symbols Used in This Manual ................................................................................................................................................ 6

About an Electronic Manual ................................................................................................................................................... 6

Introduction to Functions .....................................................................................................................................7

Part Names .............................................................................................................................................................8

Front Panel Part Names ..........................................................................................................................................................8

Swinging the Front Panel Up and Down ................................................................................................................................ 8

Part Names of the Internal Panel Seen with the Front Panel Swung up.................................................................................9

YS1500/YS1700 Operating Procedure ...............................................................................................................10

Basic Operation ...................................................................................................................................................11

Overview of Display Switching and Operation Keys ............................................................................................................. 11

Monitoring and Control of Regular Operations (Operation Display) ..............................................................16

Monitoring and Operating the Operation Display ................................................................................................................. 16

Monitoring and Operating the LOOP Display .................................................................................................................16

Monitoring and Operating the METER Display ............................................................................................................... 20

Monitoring and Operating the TREND Display .............................................................................................................. 24

Monitoring and Operating the ALARM Display ..............................................................................................................26

Monitoring and Operating the DUAL Display ................................................................................................................. 28

Switching of Operation Modes (Automatic Control (A), Manual Control (M), or Cascade Setting Automatic Control (C))....30

Switching by Keystroke ...................................................................................................................................................30

Switching in Response to Digital Input ..........................................................................................................................31

Operating the Tuning Displays ...........................................................................................................................32

Setting PID ........................................................................................................................................................................... 32

Displaying the Operation Display While the Tuning Display is being Shown .......................................................................33

Setting Alarms ....................................................................................................................................................................... 33

Operating the Engineering Displays..................................................................................................................36

Setting the Controller Mode ..................................................................................................................................................36

Setting the Control Type and Control Operation Formula ....................................................................................................37

Setting the Scale and Decimal Point Position for Process Variables ....................................................................................38

Registering a Tag and Units ..................................................................................................................................................39

Tuning Guide ........................................................................................................................................................40

Starting Operations by Manual Operation ............................................................................................................................ 40

PID Parameter Tuning Guide and Automatic Adjustment .................................................................................................... 41

Installation and Wiring ........................................................................................................................................42

Installation Location ..............................................................................................................................................................42

Mounting Method .................................................................................................................................................................43

Mounting the Instrument Main Unit ................................................................................................................................ 43

Installing an Expandable I/O Terminal ............................................................................................................................44

External Dimensions/Panel Cutout Dimensions ...................................................................................................................45

YS1500/YS1700 main unit .............................................................................................................................................45

IM 01B08B02-01EN

1

Page 5

Contents

Expandable I/O Terminal (YS010) .................................................................................................................................46

Expandable I/O Cable (YS011-03) .................................................................................................................................46

Wiring .................................................................................................................................................................................... 47

Wiring Precautions ..........................................................................................................................................................47

Terminal Diagrams of YS1500/YS1700 Single-loop, Cascade, and Selector Modes .................................................... 48

Terminal Diagrams of YS1700 Programmable Mode .....................................................................................................50

Expandable I/O Terminal Diagram (YS1700 Basic Type (with Expandable I/O)) ...........................................................52

Transmitter Supply Power Wiring ...................................................................................................................................52

Wiring for Digital Input/Output and FAIL Output..............................................................................................................53

Direct Input Wiring (Optional Code /A0) ..................................................................................................................... 54

Wiring for the Serial Communication Interface (Optional Code /A31) ........................................................................... 55

Wiring for Distributed Control System (DCS-LCS) Communication (Optional Code /A32) ............................................ 56

Wiring for Peer-to-peer Communication (YS1700, Optional Code /A31) ....................................................................... 56

Wiring for the Ethernet Communication Interface (Optional Code /A34) ........................................................................ 56

Wiring for Power Supply and Grounding ........................................................................................................................57

Installing the Terminal Cover ................................................................................................................................................57

Troubleshooting ..................................................................................................................................................58

How to Take Actions if the ALM Lamp or FAIL Lamp Lights up ............................................................................................ 58

Backup Operation in the Event of Instrument Failure ..........................................................................................................62

Recovery Operations after Power Failures .......................................................................................................................... 63

List of Parameters ...............................................................................................................................................64

<Tuning Parameters> ..........................................................................................................................................................65

<Engineering Parameters> .................................................................................................................................................. 74

The following are related manuals:

YS1500 Indicating Controller/YS1700 Programmable Indicating

Controller

User’s Manual (Electronic version)

Chapter 1 Control Function

Chapter 2 Auxiliary Control Function

Chapter 3 Auxiliary Input and Output Functions

Chapter 4 Display and Security Functions

Chapter 5 Adjusting of Direct Inputs (Temperature/Resistance/

Frequency)

Chapter 6 Processing during Power Failures

Chapter 7 Self-tuning Function

Chapter 8 Maintenance

Chapter9 Specications

YS1000 Series Communication Interface

User’s Manual (Electronic version)

Chapter 1 Overview

Chapter 2 Setting Communication Functions

Chapter 3

Chapter 4 Description of Ethernet Communication (Modbus/

Chapter 5 Description of DCS-LCS Communication (Optional

Chapter 6

Chapter 7 Functions and Application of YS1310/YS1350/

Appendix ASCII Code Table

Description of RS-485 Communication (Optional Code:

/A31)

TCP) (Optional Code: /A34)

Code: /A32)

Functions and Application of YS1500/YS1700 D-registers

YS1360 D-registers

YSS1000 Setting Software for YS1000 Series/

YS1700 Programmable Function

User’s Manual (Electronic version)

Chapter 1 Overview

Chapter 2 YSS1000 Operation Guide

Chapter 3 User Program Creation Guide

Chapter 4 Operation of Computation and Control Programs

Chapter 5 Basic Usage of Control Modules

Chapter 6 Applied Usage of Control Modules

Chapter 7 Operations and Application of Computing Module

(Instructions)

Chapter 8 Using Peer-to-peer Communication

Chapter 9 Maintenance

Chapter 10 Sample Program

Chapter 11 Worksheets / Program Sheets / Parameter Sheets

Chapter 12 List of Text Program Instructions

YS1000 Series Replacement Manual

(Electronic version)

Chapter 1 Overview

Chapter 2 Replacement with YS100-compatible Type

Chapter 3 Replacement with YS80 Internal Unit-compatible

Type and EBS, I, EK, or HOMAC-compatible Type

Chapter 4 Replacement with YS80-compatible Type

Chapter 5 Replacement with 100 Line-compatible Type

2

IM 01B08B02-01EN

Page 6

Foreword

Thank you for purchasing the YS1000 series single-loop controller

(hereinafter referred to as “YS1000”).

This manual describes the basic functions and operation methods of

the YS1500/YS1700. Please read though this user’s manual carefully

before using the product.

Note that the manuals for the YS1500/YS1700 comprise the following

vedocuments:

● Printedmanual

Manual Name Manual Number

YS1500/YS1700 Operation Guide IM 01B08B02-01EN

This manual describes the basic operation methods.

Precautions on the Use of the YS1000 Series

This manual is always delivered even if ‘without

manuals’ was selected.

● Electronicmanuals

Manual Name Manual Number

YS1500/YS1700 Operation Guide IM 01B08B02-01EN

This is identical to the printed manual.

YS1500/YS1700 User’s Manual IM 01B08B02-02EN

This manual describes the detailed functions and setting items. It

does not contain the user programs and communication functions.

YS1000 Series Communication Interface

User’s Manual

This manual describes how to use YS1000 in Ethernet, serial, and

DCS-LCS communications.

YSS1000 Setting Software/YS1700

Programmable Function User’s Manual

This manual describes how to use YSS1000 and YS1700’s

programmable function.

YS1000 Series Replacement Manual IM 01B08H02-01EN

This manual describes the compatibility of installation and wiring

with YS100, YS80, EBS, I, EK, HOMAC, and 100 line.

Precautions on the Use of the YS1000 Series

This manual is always delivered even if ‘without

manuals’ was selected.

User’s manuals for YS1000 are available on the following web site:

www.yokogawa.com/ns/ys/im/

You need Adobe Reader 7.0 or later (but the latest version is

recommended) installed on the computer in order to open and read

the manuals.

The printed versions of the electronic manuals are available for

purchase. Contact your nearest YOKOGAWA dealer for details.

● GeneralSpecications

General Specification Name GS Number

YS1700 Programmable Indicating Controller GS 01B08B02-01EN

YS1500 Indicating Controller GS 01B08C02-01EN

Thelasttwocharactersofthemanualnumberandgeneralspecication

*

number indicate the language in which the manual is written.

IM 01B08B02-91EN

IM 01B08J02-01EN

IM 01B08K02-02EN

IM 01B08B02-91EN

Notice

● Thecontentsofthismanualaresubjecttochangewithout

notice as a result of continuing improvements to the instrument’s

performance and functions.

● Everyeorthasbeenmadetoensureaccuracyinthepreparation

of this manual. Should any errors or omissions come to your

attention, however, please inform YOKOGAWA Electric’s sales

oceorsalesrepresentative.

● Undernocircumstancesmaythecontentsofthismanual,inpart

or in whole, be transcribed or copied without our permission.

4th Edition : Mar. 2018 YK

All Rights Reserved Copyright © 2014 Yokogawa Electric Corporation

IM 01B08B02-01EN

Trademarks

● Ourproductnamesorbrandnamesmentionedinthismanualare

the trademarks or registered trademarks of YOKOGAWA Electric

Corporation (hereinafter referred to as YOKOGAWA).

● Microsoft,MS-DOS,Windows,WindowsXP,andWindowsNT

are either registered trademarks or trademarks of Microsoft

Corporation in the United States and/or other countries.

● Adobe,Acrobat,andPostscriptareeitherregisteredtrademarks

or trademarks of Adobe Systems Incorporated.

● EthernetisaregisteredtrademarkofXEROXCorporation.

● WedonotusetheTMor®marktoindicatethesetrademarksor

registered trademarks in this user's manual.

● Allotherproductnamesmentionedinthisuser'smanual

are trademarks or registered trademarks of their respective

companies.

Authorised Representative in the EEA

Yokogawa Europe BV. (Address: Euroweg 2, 3825 HD Amersfoort,

The Netherlands) is the Authorised Representative of Yokogawa

Electric Corporation for this Product in the EEA.

Revisions

1st Edition: June 2014

2nd Edition: May 2015

3rd Edition: Mar. 2016

4th Edition: Mar. 2018

Safety Precautions

Thefollowingcontentsarefor the sux codes “-0”, “-1” and

“-2”

This instrument is a product of Installation Category II of IEC/

EN61010-1, IEC/EN61010-2-201 and IEC/EN61010-2-030 Safety

Standards and Class A (use in commercial and industrial areas) of

EN61326-1, EN55011 (EMC Standards) (use a ferrite core and an

arrester to comply with the standards).

CAUTION

This instrument is a class A product (use in commercial and

industrial areas). In a domestic environment this product may

cause radio interference in which case the user needs to take

adequate measures.

This instrument is designed to be used within the scope of

Measurement Category O (other) and is dedicated for indoor use.

* Measurement Category O (other)

This category applies to electric equipment that measures a

circuit connected to a low-voltage facility and receives power from

stationary equipment such as electric switchboards.

To use the instrument properly and safely, observe the safety precautions

described in this user’s manual when operating it. Use of the instrument

in a manner not prescribed herein may compromise protection features

inherent in the device. We assume no liability for or warranty on a fault

caused by users’ failure to observe these instructions.

This instrument is an FM Non-incendive or CSA Non-incendive Standard

certiedproduct.

FM nonincendive: Class 3600:2011

Class 3611:2004

Class 3810:2005

Locations: Class I, Division 2, Groups A,B,C and D

Class I, Zone 2, Groups II C

Temperature Code: T4

CSA nonincendive: C22. 2 No. 213-M1987

CAN/CSA-C22.2 No. 0-10

CAN/CSA-C22.2 No. 0.4-04

Locations: Class I, Division 2, Groups A,B,C and D

Temperature Code: T4

3

Page 7

Notes on the User’s Manual

“Handle with Care” (This symbol is attached to the part(s)

Direct current

• This user’s manual should be readily accessible to the end users

so it can be referred to easily. It should be kept in a safe place.

• Read the information contained in this manual thoroughly before

operating the product.

• The purpose of this user's manual is not to warrant that the

product is well suited to any particular purpose, but rather to

describe the functional details of the product.

Safety,Protection,andModicationoftheProduct

The following symbols are used in the product and user’s manuals to

indicate safety precautions:

of the product to indicate that the user’s manual should be

referred to in order to protect the operator and the

instrument from harm.)

Protective grounding terminal

Functional grounding terminal (Do not use this terminal as

a protective grounding terminal.)

Alternating current

• In order to protect the system controlled by this product and the

product itself, and to ensure safe operation, observe the safety

precautions described in this user’s manual. Use of the instrument

in a manner not prescribed herein may compromise the product's

functions and the protection features inherent in the device.

We assume no liability for safety, or responsibility for the product's

quality, performance or functionality should users fail to observe

these instructions when operating the product.

• Installation of protection and/or safety circuits with respect to a

lightning protector; protective equipment for the system controlled

by the product and the product itself; foolproof or failsafe design

of a process or line using the system controlled by the product

or the product itself; and/or the design and installation of other

protective and safety circuits are to be appropriately implemented

as the customer deems necessary.

• Be sure to use the spare parts approved by YOKOGAWA when

replacing parts or consumables.

• This product is not designed or manufactured to be used in critical

applicationsthatdirectlyaectorthreatenhumanlives.Such

applications include nuclear power equipment, devices using

radioactivity, railway facilities, aviation equipment, air navigation

facilities, aviation facilities, and medical equipment. If so used,

it is the user’s responsibility to include in the system additional

equipment and devices that ensure personnel safety.

• Modicationoftheproductisstrictlyprohibited.

WARNING

● PowerSupply

Ensure that the instrument’s supply voltage matches the voltage of

the power supply before turning ON the power.

● ProtectiveGrounding

Topreventelectricshock, alwaysconrmthatprotectivegroundingis

connected before turning ON the instrument’s power supply.

● NecessityofProtectiveGrounding

Donot cut o the internalor external protective grounding wireor

disconnect the wiring of the protective grounding terminal. Doing so

renders the protective functions of the instrument invalid and poses a

potential shock hazard.

● DefectsinProtectiveFunctions

If protective functions such as grounding are suspected to be

defective, do not operate the instrument. Ensure that all protective

functions are in working order before operating the instrument.

● DoNotUseinanExplosiveAtmosphere

Do not operate the instrument in locations with combustible

or explosive gases or steam. Operation in such environments

constitutes an extreme safety hazard. Use of the instrument in

environments with high concentrations of corrosive gas (H

etc.) for extended periods of time may cause a failure.

S, SOx,

2

● DoNotRemoveInternalUnit

The internal unit should not be removed by anyone other than YOKOGAWA's

service personnel. There are dangerous high voltage parts inside.

● ExternalConnection

Ensure that protective grounding is connected before connecting the

instrument to the device under measurement or to an external control circuit.

● DamagetotheProtectiveConstruction

Operation of the instrument in a manner not specied in this user ’s

manual may damage its protective construction.

Warning and Disclaimer

• YOKOGAWA makes no warranties regarding the product except

those stated in the WARRANTY that is provided separately.

• The product is provided on an "as is" basis. YOKOGAWA

assumes no liability to any person or entity for any loss or

damage, direct or indirect, arising from the use of the product or

from any unpredictable defect of the product.

Notes on Software

• YOKOGAWA makes no warranties, either expressed or implied,

with respect to the software’s merchantability or suitability for

anyparticularpurpose,exceptasspeciedinthetermsofthe

separately provided warranty.

• Thissoftwaremaybeusedononespecicmachineonly.

• To use the software on another machine, the software must be

purchased again separately.

It is strictly prohibited to reproduce the product except for backup purposes.

•

• Store the software CD-ROM (the original medium) in a safe place.

• All reverse-engineering operations, such as reverse compilation

or the reverse assembly of the product are strictly prohibited.

• No part of the product’s software may be transferred, converted,

or sublet for use by any third party, without prior written consent

from YOKOGAWA.

Handling Precautions for the Main Unit

•

The instrument comprises many plastic components. To clean it, wipe

it with a soft, dry cloth. Do not use organic solvents such as benzene

or thinner for cleaning, as discoloration or deformation may result.

• Keep electrically charged objects away from the signal terminals.

Not doing so may cause the instrument to fail.

• Do not apply volatile chemicals to the display area, operation

keys, etc. Do not leave the instrument in contact with rubber or

PVC products for extended periods. Doing so may result in failure.

• If the equipment emits smoke or abnormal smells or makes

unusual noises, turn OFF the instrument’s power switch

immediately and unplug the device. In such an event, contact

your sales representative.

Regarding the LCD

A small number of missing or steady-on LCD pixels and

minor variations in brightness uniformity is a normal display

characteristic and not a malfunction.

Protection of Environment

Waste Electrical and Electronic Equipment

(WEEE), Directive

Applicable models: YS1700-10x, -11x, -12x, -20x, -21x, -22x

YS1500-10x, -12x, -20x, -22x

However, except the option /A08.

This is an explanation of how to dispose of this product based on

Waste Electrical and Electronic Equipment (WEEE), Directive. This

directive is only valid in the EU.

● Marking

This product complies with the WEEE Directive

marking requirement. This marking indicates that

you must not discard this electrical/electronic

product in domestic household waste.

● ProductCategory

With reference to the equipment types in the

WEEE directive, this product is classified as a

“Small equipment” product.

Do not dispose in domestic household waste.

When disposing products in the EU, contact your

localYokogawaEuropeB.V.oce.

4

IM 01B08B02-01EN

Page 8

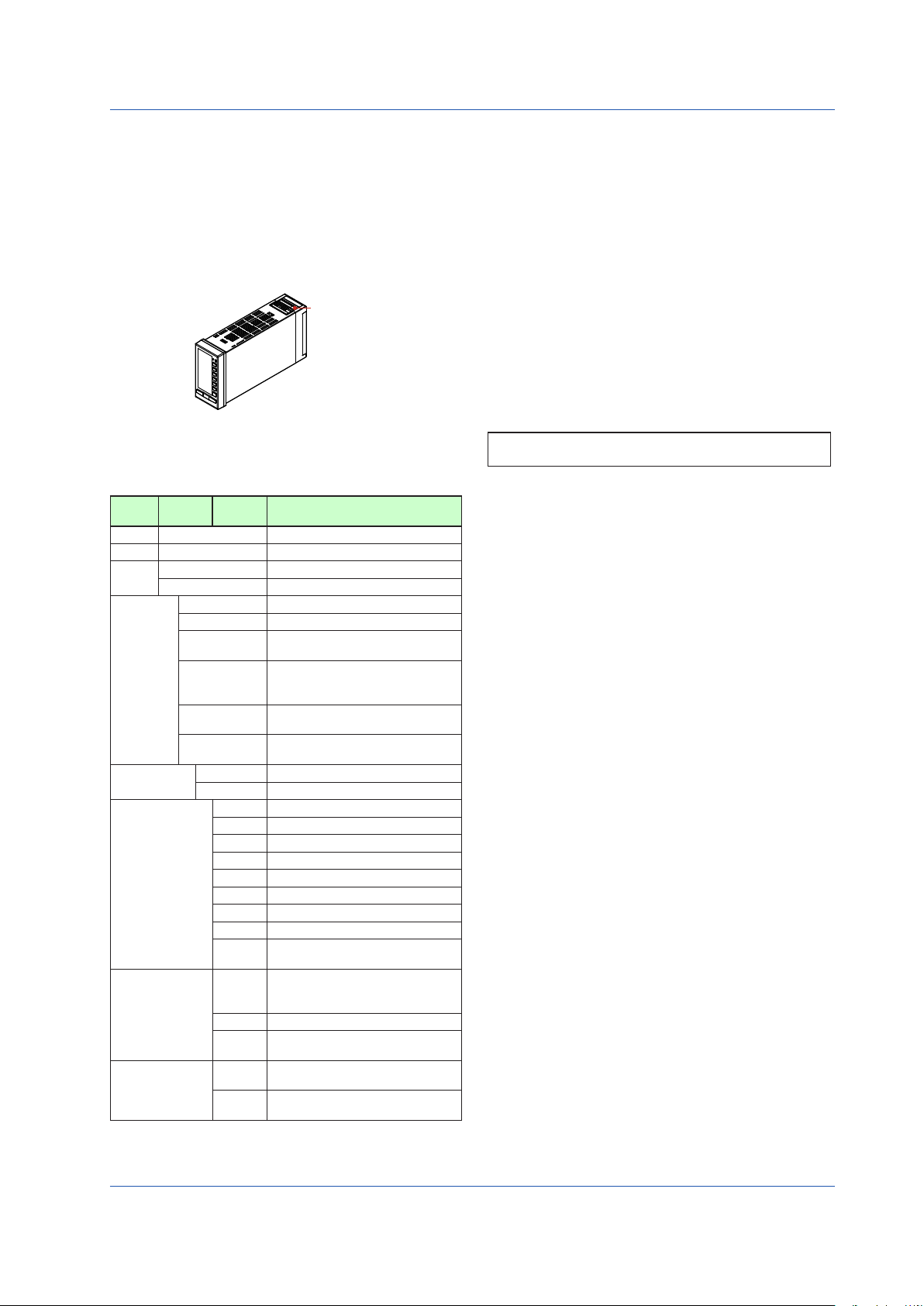

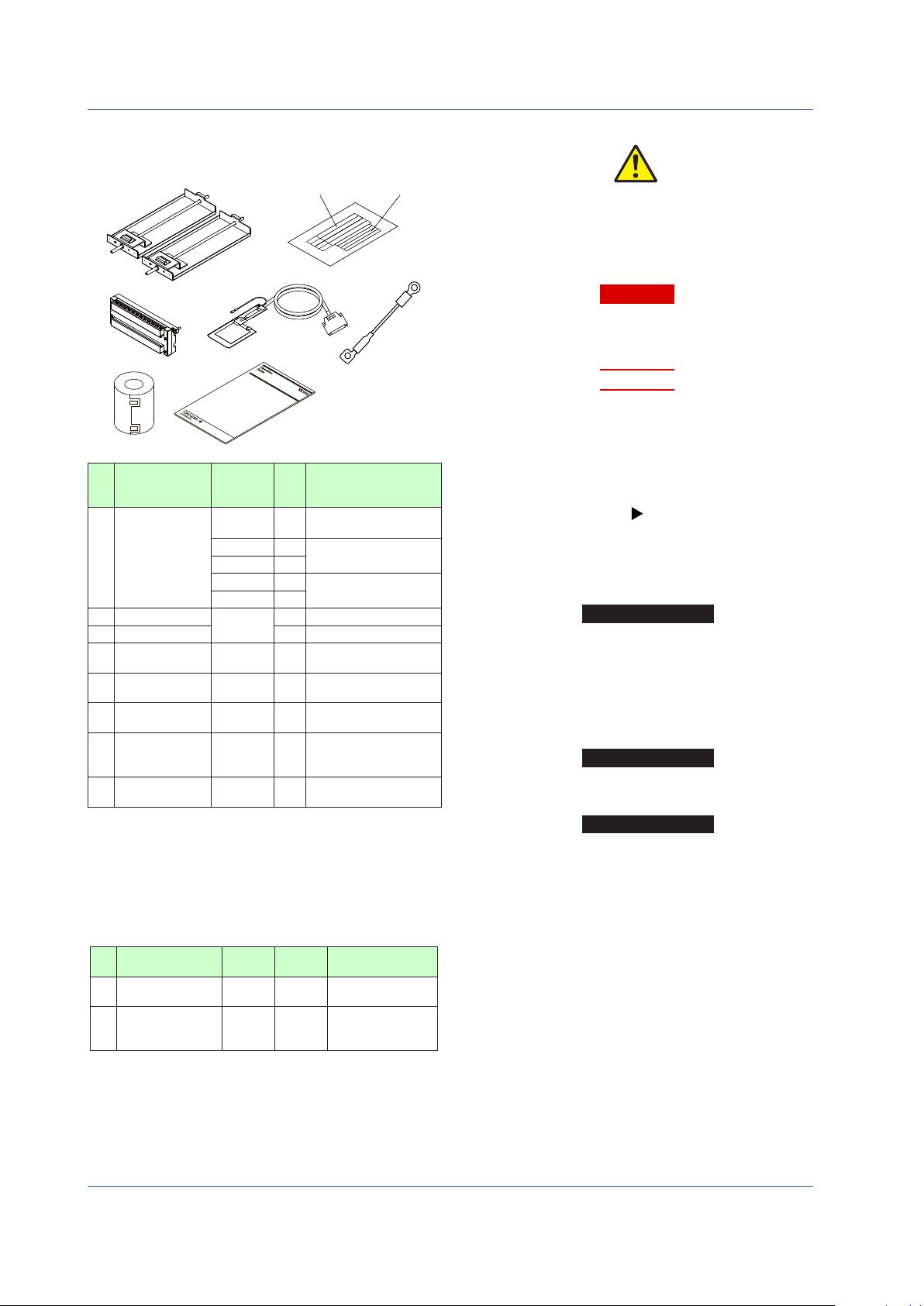

Checking the Contents of the Package

0001E.ai

Unpack the box and check the contents before using the product. If

theproductisdierentfromthatwhichyouhaveordered,ifanyparts

or accessories are missing, or if the product appears to be damaged,

contact your sales representative.

YS1500/YS1700 Main Unit

TheYS1000seriesmainunits havenameplatesaxedtothetopsof

the terminals.

Check the model and suffix codes inscribed on the nameplate to

conrmthattheproductreceivedisthatwhichwasordered.

Nameplate

No. (Instrument number)

When contacting your sales representative, inform them of this

number too.

ModelandSuxCodes

Model

YS1700

YS1500

Use

Type

Power supply

Direct input (*4)

Communication

Certification

*1

Suffix

-1

-2

Only YS1700 is compatible. The expandable I/O terminal (model YS010)

and expandable I/O cable (model YS011) (cable length: 3 m) are provided.

Code

0

1

2

3

4

5

0

1

Optional

Code

/A01

/A02

/A03

/A04

/A05

/A06

/A07

/A08

/DF

/A31

/A32

/A34

/FM

/CSA

Remarks

Programmable indicating controller

Indicating controller

With hard manual unit

Without hard manual unit

Basic type

Basic type with expandable I/O (*1)

Compatible type for YS100 (with

YS100 case)

Compatible type for YS80 internal unit/

compatible type for EBS, I, EK, and

HOMAC (*2)

Compatible type for YS80 (compatible

size for YS80 with YS100 terminal)

Compatible type for pneumatic 100

line (with YS100 terminal) (*3)

100 V AC, 24 V DC common power

220 V AC power

mV input

Thermocouple input

RTD input

Potentiometer input

Isolator

Two-wire transmitter input (isolated)

Two-wire transmitter input (non-isolated)

Frequency input (*11)

Direct input with Fahrenheit

temperature range function (*5)

RS-485 communication (PC-link,

Modbus, YS protocol, and Peer-toPeer) (*6)

DCS-LCS communication (*7)

Ethernet communication (Modbus/

TCP) (*8)

FM nonincendive approved (FM Class

I, Div 2) (*9)

CSA safety and nonincendive

approved (Class I, DIV 2) (*10)

*2 This type can be connected to the YS80 housing (model SHUP).

(The EK/HOMAC-compatible housing (SHUP-420) and EBS/I

series-compatible housing (SHUP-100) are sold separately.)

The 100 line-compatible housing (model YS006) is sold separately.

*3

*4 Direct input options can be combined only with suffix codes “-2,”

“-4,” or “-5.” Selection of multiple options is not possible.

Optional code /DF can be combined only with optional code /A02 or /A03.

*5

*6 A combination with suffix code “-3” is not possible. Optional

codes /A31 and /A32 cannot be simultaneously specified. Please

specify the communication options /A31 (RS-485 communication)

to directly communicate with the CENTUM CS3000/VP.

*7 Optional codes /A31 and /A32 cannot be simultaneously

specified. Please specify the communication options /A32 (DCSLCS communication) to communicate with the CENTUM CS3000/

VP through the SCIU.

Optional code /A34 can be specified only for suffix codes “-0” or “-1.”

*8

*9

Optional code /FM can be combined only with suffix codes “-0” or “-1.”

*10 This option can be combined only with suffix codes “-0,”

“-1,” “-2.” However, certification is planned for the

combination of suffix code -2 and optional code /CSA.

*11 When option code /A08 is specified, the conformity to CE marking

is excluded

For the installation and wiring of YS1500/YS1700-2, -3,

-4, or -5, see the YS1000 Series Replacement Manual.

■CustomizedProduct

/S#,/Z:Customizedproduct;detailsinFX1-XJYS1700.xxx*

* Contact your supplier in case your instrument has option /S#

(where‘#’is anumber),and youare notinthe possessionof FX1XJYS1700.xxx.(where "xxx"is a unique document number and

option/S#or/Zisidentiedbythecoverpageofthatdocument.)

IM 01B08B02-01EN

5

Page 9

Accessories

0002E.ai

1

2 3

The product is provided with the following accessories according to

themodelandsuxcodes(seethetablebelow).Checkthatnoneof

them are missing or damaged.

TAG NO.

TAG NO.

TAG NO.

TAG NO.

4 5

7

YS1500 Indicating Controller

YS1700 Programmable

Indicating Controller

Operation Guide

8

6

Symbols Used in This Manual

This symbol is used on the instrument. It indicates the possibility of

injuryto the userordamage to theinstrument,and signies thatthe

user must refer to the user’s manual for special instructions. The

same symbol is used in the user’s manual on pages that the user

needs to refer to, together with the term “WARNING” or “CAUTION.”

WARNING

Calls attention to actions or conditions that could cause serious or

fatal injury to the user, and indicates precautions that should be taken

to prevent such occurrences.

CAUTION

Calls attention to actions or conditions that could cause injury to

the user or damage to the instrument or property and indicates

precautions that should be taken to prevent such occurrences.

Note

Identiesimportantinformationrequiredtooperatetheinstrument.

No. Item Name

Part

Number/

Q’ty Remarks

Model

Metal clamps

1

L4041RA 2

E9760RJ 2

E9760RN 2

E9760RJ 1

E9760RP 1

Tag plate seals

2

Range entry seals

3

Expandable I/O

4

terminal

Expandable I/O

5

cable

RJC sensor

6

L4041UA

YS010 1

YS011-03 1

L3501RA 1

Ferrite core

7

YS1500/YS1700

8

Operation Guide

*1:

For the RJC mounting, see the chapter “Installation and Wiring” in this

A1179MN 1

– 1

manual or the YS1000 Series Replacement Manual.

For YS100-0, or

YS100-1

For YS100-2

For YS100-4

4 50 × 3.5 mm

4 34 × 2 mm

Supplied with YS1700-

.

1

Cable length: 3 m

Supplied with YS1700-1.

Supplied with products with

optional code /A02. (*1)

For direct input cable

(Supplied with products

with optional code /A0

This user’s manual, A4

size

Indicates related operations or explanations for the user’s reference.

Indicates a character string displayed on the display.

[ ]

Setting Display

Indicates a setting display and describes the keystrokes required to

display the relevant setting display.

Perform the operations in chronological order. This section describes

the procedure under the assumption that these steps are being

takenforthersttime.Therearecaseswherenotallofthestepsare

required, depending on the required operation.

.

)

Setting Details

Provides the descriptions of settings.

Description

Describes restrictions, etc. regarding a relevant operation.

Accessories (sold separately)

The following lists accessories that are sold separately. When

ordered, check that none of them are missing or damaged. To inquire

about the accessories or about how to place an order, contact your

sales representative.

No. Item Name Model

120Ωterminating

1

resistor (*1)

YS020 1

Sales

Unit

Remarks

For RS-485

communication

About an Electronic Manual

User’s manuals for YS1000 are available on the following web site:

www.yokogawa.com/ns/ys/im/

You need Adobe Reader 7.0 or later (but the latest version is

recommended) installed on the computer in order to open and read

the manuals.

For a built-in 24 V

250Ωshuntresistor

2

YS021 1

transmitter power

supply

*1 The instrument has a built-in terminating resistor, which can be

selected for use by setting the relevant parameter. If a terminating

resistor is used in another device at the termination of the same

communication system, an external terminating resistor needs to

be provided to match the terminating resistance of the YS1000’s

built-in terminating resistor.

6

IM 01B08B02-01EN

Page 10

Introduction to Functions

The YS1000 series is a series of single-loop controllers to meet the demands of users’ consistently advancing and diversifying

needs. It is capable of the flexible control computation required for process control.

Features

• Color LCD display

The monitoring and operation display is provided in color, and input and output values, various constants, and incorporated

control functions can be set freely using key switches on the front panel. The monitoring displays include LOOP Display,

TREND Display, ALARM Display, and METER Display which provides information in much the same way as analog meters.

• Failsafe function

Two CPUs are configured to provide manual operations and displays even if one of the CPUs becomes faulty. Moreover, be-

cause the instrument incorporates a hard manual circuit independent of the digital circuit, it can continue to generate manipulated output variables even if the digital circuit that includes the CPUs fails.

• AC/DC-common power supply with wide operating voltage range.

The instrument can be powered by either AC (100 V AC) or DC (24 V DC).

• The front panel is dust- and water-proof (conforming to IP54).

• Abundant communication functions

The instrument can incorporate Ethernet (Modbus/TCP) communication, serial communication (Modbus, PC-link, and YS

protocol), and DCS-LCS communication.

• Control functions and abundant computation functions

The instrument is capable of single-loop, cascade, selector, and programmable control functions.

It can also perform computations such as the four arithmetic operations, logic computation, exponent, logarithm, temperature

compensation, pressure correction, etc. and peer-to-peer communication. (Optional YSS1000 Setting Software is required.)

Introduction to Functions

• Number of I/O points

Use of YS1700’s expandable I/O terminal allows the use of a maximum of eight analog inputs, a maximum of four analog

outputs, and a maximum of 14 DIOs.

Definition of Terms

• PV: Process variable input from process

• SV: Setpoint regarded as a control target

• MV: Manipulated variable for operating control elements such as valves.

• PID control: Control system based on action which combined three elements: proportional (P) action, integral (I) action, and

derivative (D) action.

• M mode: Mode in which manipulated output variables are operated manually.

• A mode: Mode in which MV is automatically controlled based on YS1000’s setpoint

• C mode: Mode in which MV is controlled based on an external setpoint

• Multi-function mode: Modes of the three preinstalled functions (single-loop mode, cascade mode, and selector mode)

• Programmable mode: Mode in which input/output or control computation is programmed

• User program: A program created using the YSS1000 Setting Software (available as an option)

IM 01B08B02-01EN

7

Page 11

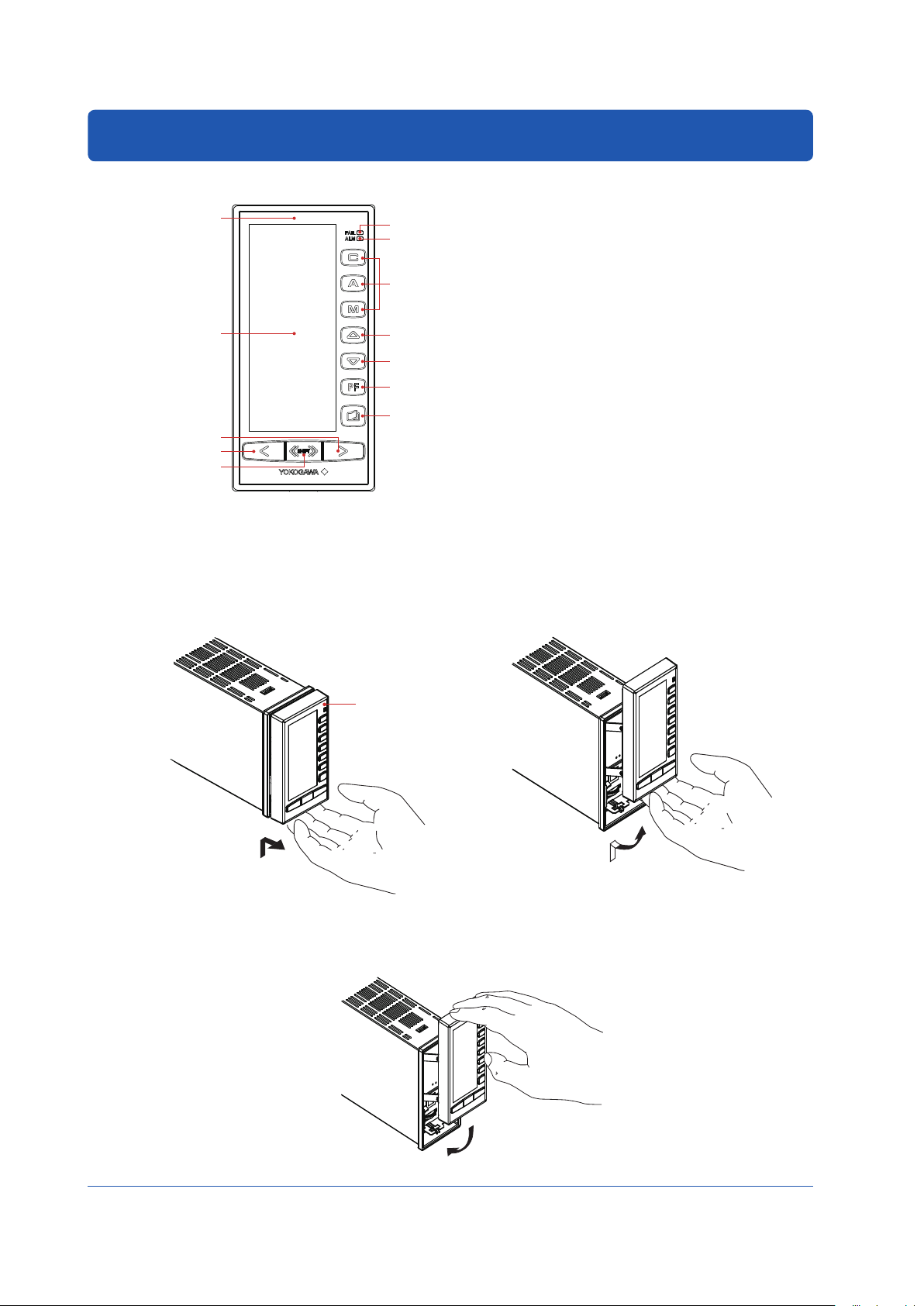

Part Names

0201E.ai

Front Panel

0202E.ai

0203E.ai

0204E.ai

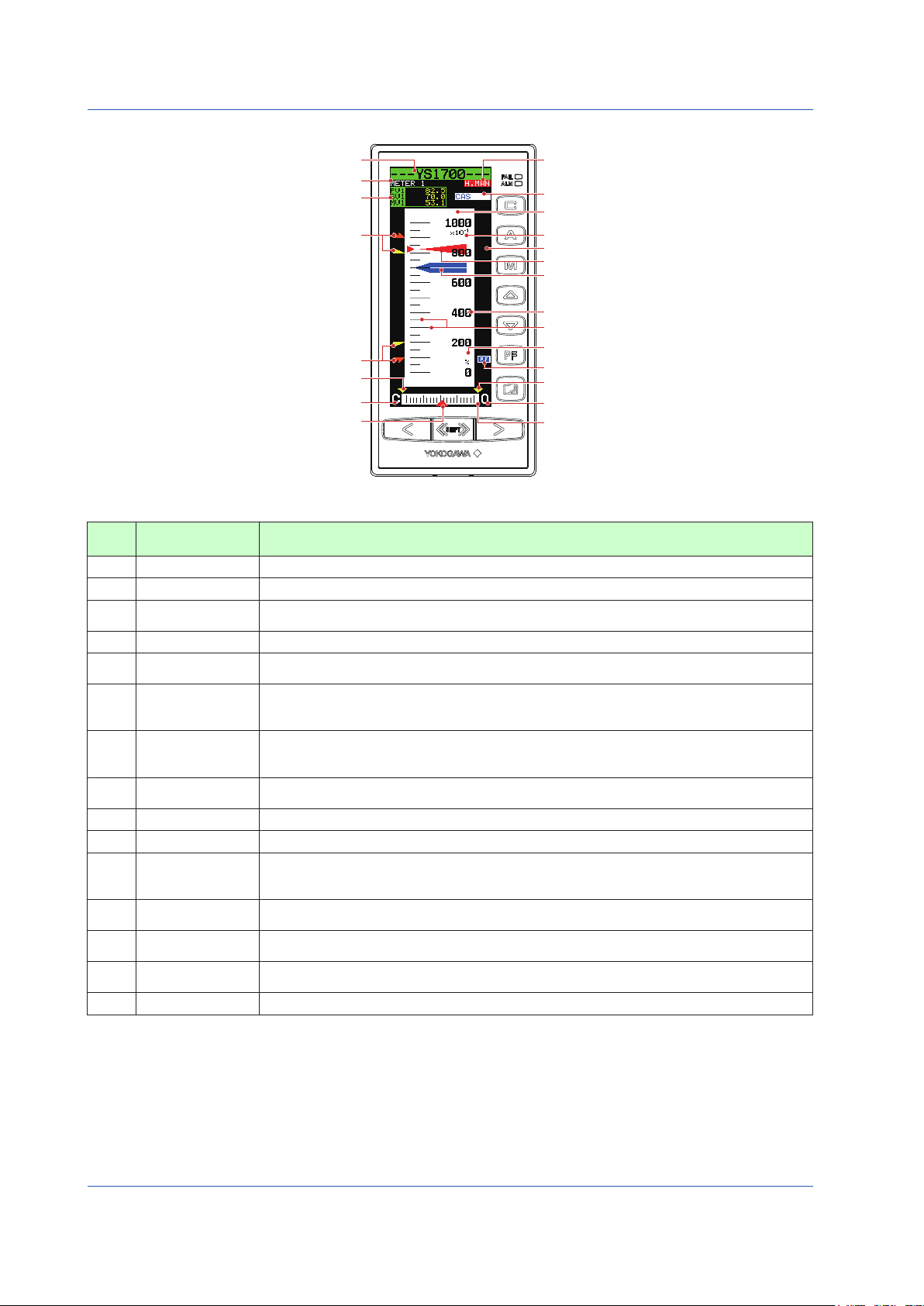

Front Panel Part Names

(12)

(1)

(9)

(10)

(11)

Figure 2.1

(2)

(3)

(4)

(5)

(6)

(7)

(8)

Swinging the Front Panel Up and Down

Swinging up the front panel

1.

Press upwards in the center of the bottom of the front panel. You can draw the front panel toward you until you feel a slight

resistance and the movement of the front panel will stop.

(You can swing up the front panel more smoothly if hold the top and bottom of the front panel.)

2.

Swing the front panel up and out from that position.

(1) Color LCD display: 120 × 320 dots

(2) FAIL lamp (LED: red)

(3) ALM lamp (LED: yellow)

(4) C mode key, A mode key, M mode key, and LED indicators

(C: green, A: green, M: yellow)

(5) SV increase key

(6) SV decrease key

(7) PF key and LED indicator

(8) Page key

(9) MV increase key

(10) MV decrease key

(11) Fast-change key/SHIFT key

(12) TAG label (recommended position to attach label)

► Forthefunctionsofeachpart:see“MonitoringandControl

of Regular Operations (Operation Display)” in this manual.

Figure 2.3

Figure 2.2

Swinging down the front panel

Push down on the center of the top of the front panel. When you feel a slight sense of resistance, stop pushing. Slide it forward

from that position. It will click into place, indicating that it is locked.

Figure 2.4

8

8

IM 01B08B02-01EN

Page 12

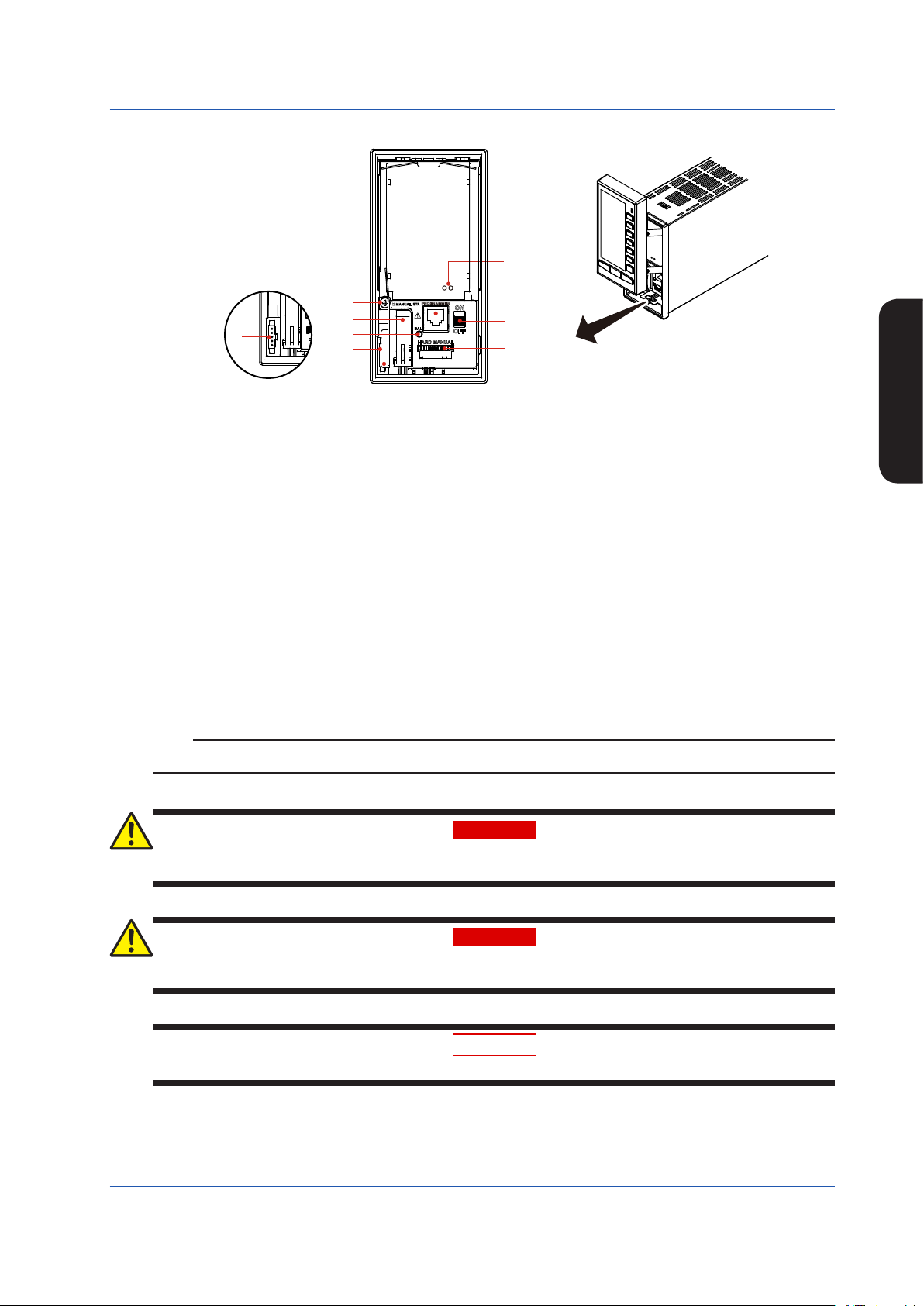

Part Names of the Internal Panel Seen with the Front Panel Swung up

0205E.ai

(9)

Part Names

(1)

(7)

(5)

(3)

(8)

(4)

(6)

(3)

(2)

Figure 2.5

(1) Connector for connection to a PC (PROGRAMMER)

This is a communication cable connector for downloading, uploading, or monitoring parameters or user programs set using

the YSS1000 Setting Software.

► YSS1000:YSS1000SettingSoftware/YS1700ProgrammableFunctionUser’sManual

(2) Metal lever

Touch the metal lever to discharge static electricity. Before you connect the cable to the YS110 connector, touch the metal

lever.

(3) Connector for YS110 standby manual station (MANUAL STA)

(4) Internal unit release lever

(5) Hard manual operation wheel (HARD MANUAL)

An operation wheel to manipulate an output

(6) MV balance lamp (BAL) (Color: green)

Lights up when a manipulated output variable and the hard manual unit’s output value agree with each other.

(7) Hard manual selector switch (ON/OFF)

The switch used to switch to a manipulated variable (MV) set using the hard manual operation wheel.

(8) An internal unit fixing screw

(9) LED and switch for repair

Contact us for repair.

► Regardingitems(2),(3),(5),(6),and(7)above:see“BackupOperationintheEventofInstrumentFailure”inthismanual.

Note

For products with suffix code -2xx, there are no hard manual unit-related parts ((5), (6), and (7)).

Part Names

Do not remove the internal unit from the instrument case. Contact YOKOGAWA’s sales office or sales representative when

removing the internal unit, as safety standard inspection is required.

Explosionhazard.

Do not remove or insert the internal unit in explosive atmospheres.

Products with optional code /FM or /CSA cannot satisfy the explosion protection standards if the internal unit is removed.

IM 01B08B02-01EN

WARNING

WARNING

CAUTION

9

Page 13

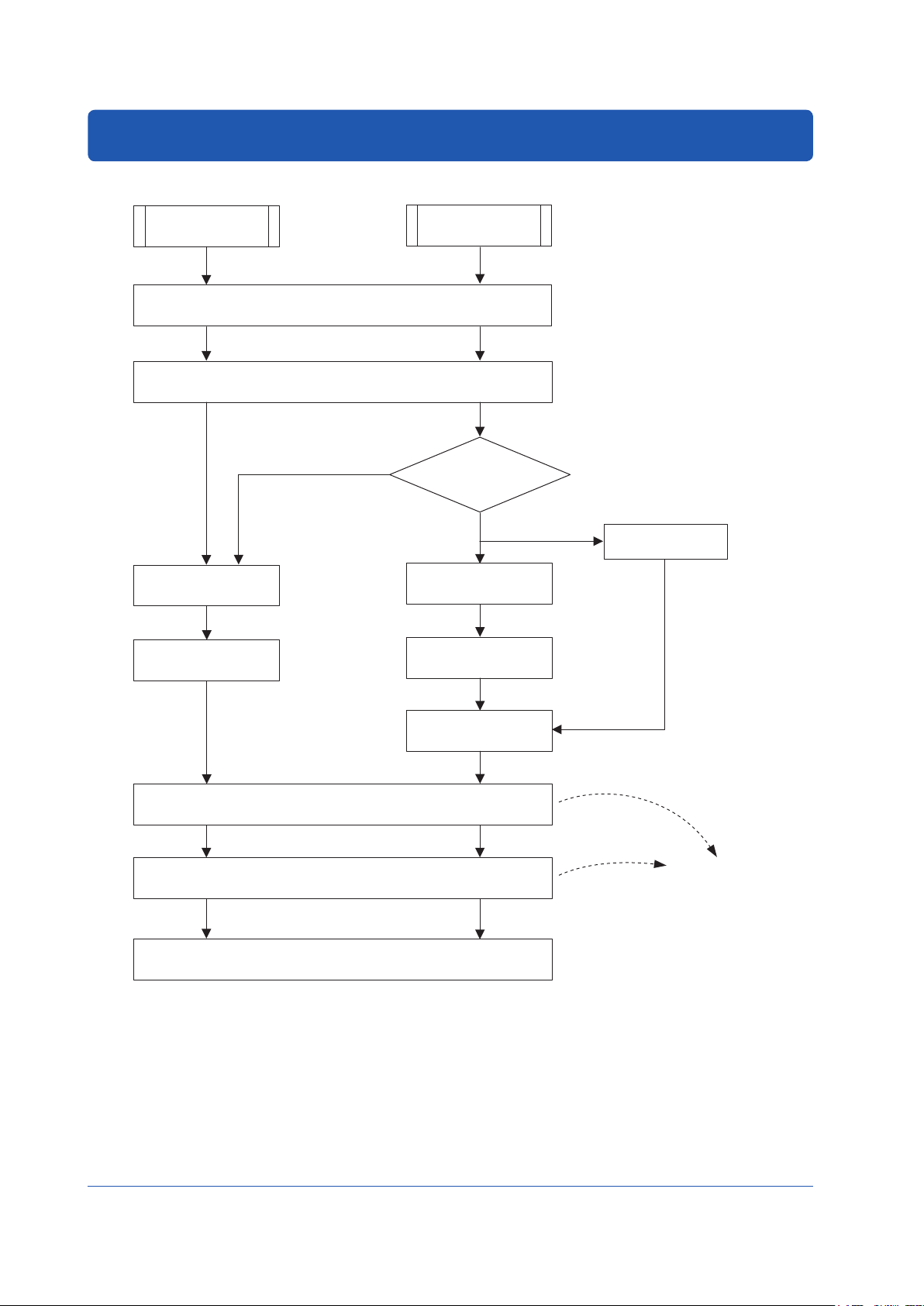

YS1500/YS1700 Operating Procedure

YS1500 or

YS1700

Tuning/operations can be

0301E.ai

When using the instrument for the first time, proceed according to the following sequence:

YS1500

Unpack the instrument and check the specifications

Turn ON power supply

Select the

multi-function mode

► Setting the Controller Mode (p.36)

Multi-function mode has

the following three modes:

• Single-loop mode

• Cascade mode

• Selector mode

Installation

No

YS1700

► Checking the Contents of the Package (p.5)

► Installation and Wiring (p.42)

Will you create

user programs?

Yes

YS1700

Turn ON power supply

Select the

programmable mode

► Seting the Controller Mode (p.36)

Write user programs

► YSS1000 Setting Software/YS1700 Programmable

Function User’s Manual

YSS1000

Setting Software (PC)

Create

user programs

► YSS1000 Setting

Software/YS1700

Programmable

Function User’s

Manual

10

10

Set up engineering constants

Start tuning/operation

Regular operation

► Operating the Engineering

Displays (from p.36)

set using the YSS1000

Setting Software.

► Operating the Tuning Displays

(from p.32)

Tuning Guide (from p.40)

► Monitoring and Control of Regular Operations (from p.16)

Figure 3.1

► YSS1000 Setting

Software/YS1700

Programmable Function

User’s Manual

IM 01B08B02-01EN

Page 14

Basic Operation

Power ON

0401E.ai

SHIFT

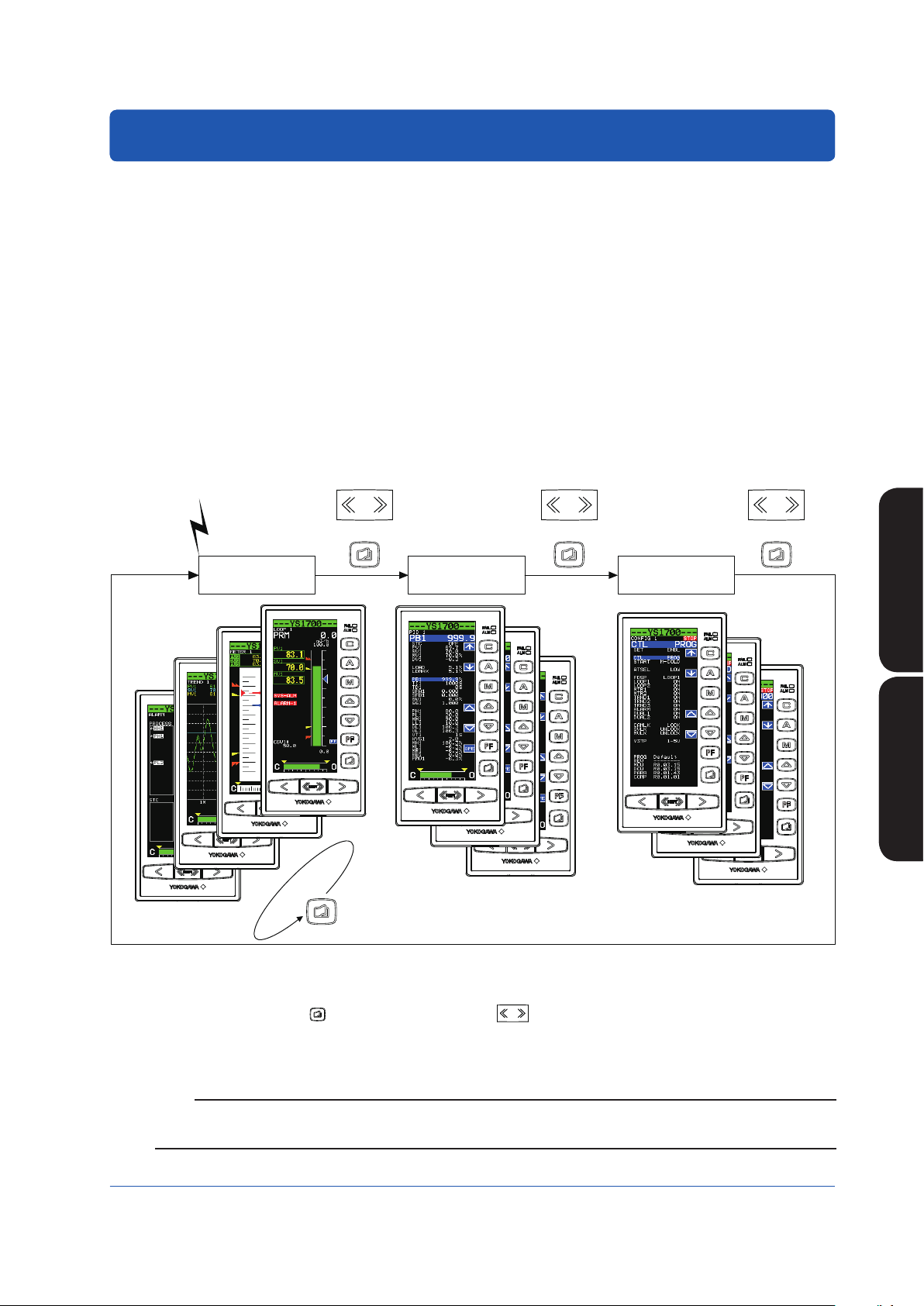

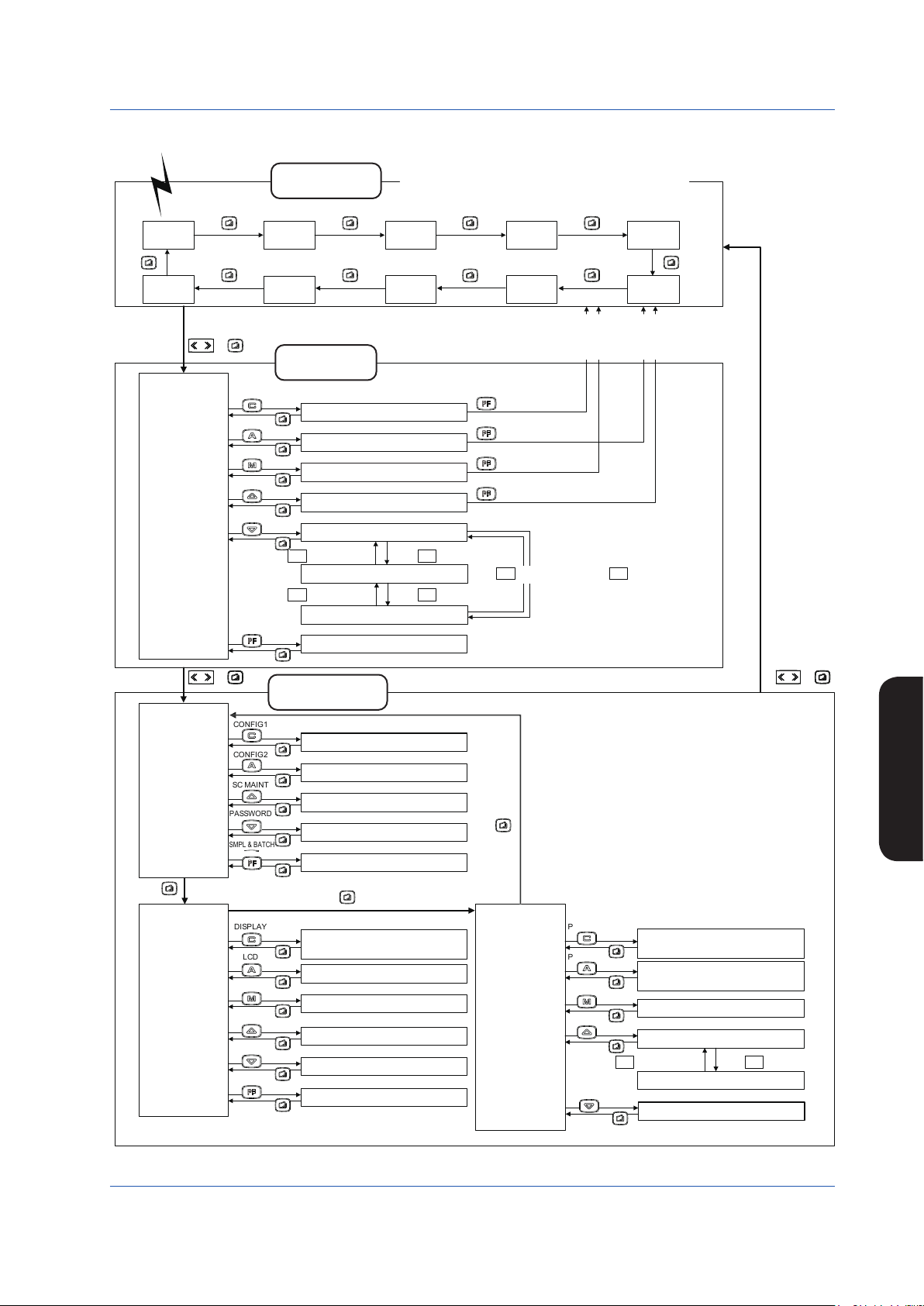

Overview of Display Switching and Operation Keys

The YS1000 has the following three display groups:

(1) Operation Display Group

This group has a LOOP Display which allows operation mode switching during control operation, SV setting, and MV opera-

tion; a TREND Display which displays the trends of PV, SV, and MV; an ALARM Display which displays detailed alarm infor-

mation; a LOOP Display which displays two loops simultaneously (operation is on a loop basis); and a METER Display which

displays PV, SV, and MV on a meter scale using a pointer.

(2) Tuning Display Group

This group has a display for setting and displaying control parameters such as PID, and a display for monitoring input/output

signals.

(3) Engineering Display Group

This group has a display for setting up functions as a controller, a display for setting and displaying various registers and vari-

ous tables, a display for setting input specifications and a password setting display.

Selecting a Display

The flow of display selecting operations is as follows:

SHIFT

SHIFT

SHIFT

+ + +

Operation Display

group

C

Tuning Display

group

For operations of the Tuning Display and Engineering Display groups, see

“Operating the Tuning Displays” and “Operating the Engineering Displays .”

Engineering Display

group

YS1500/YS1700 Operating

Procedure

Basic Operations

Basic Operations

Figure 4.1

When the instrument’s power is turned ON, the Operation Display appears.

1.

Each time the Page key ( ) is pressed with the SHIFT key (

2.

The display changes in the order of Operation Display, Tuning Menu Display, and Engineering Menu Display, after which the

Operation Display reappears.

) held down, the display is switched.

Note

Operation of the SHIFT key + Page key (a two key keystroke) implies that you should press the Page key with the SHIFT key

held down. Doing so in the opposite order does not switch the display.

IM 01B08B02-01EN

1111

Page 15

Basic Operations

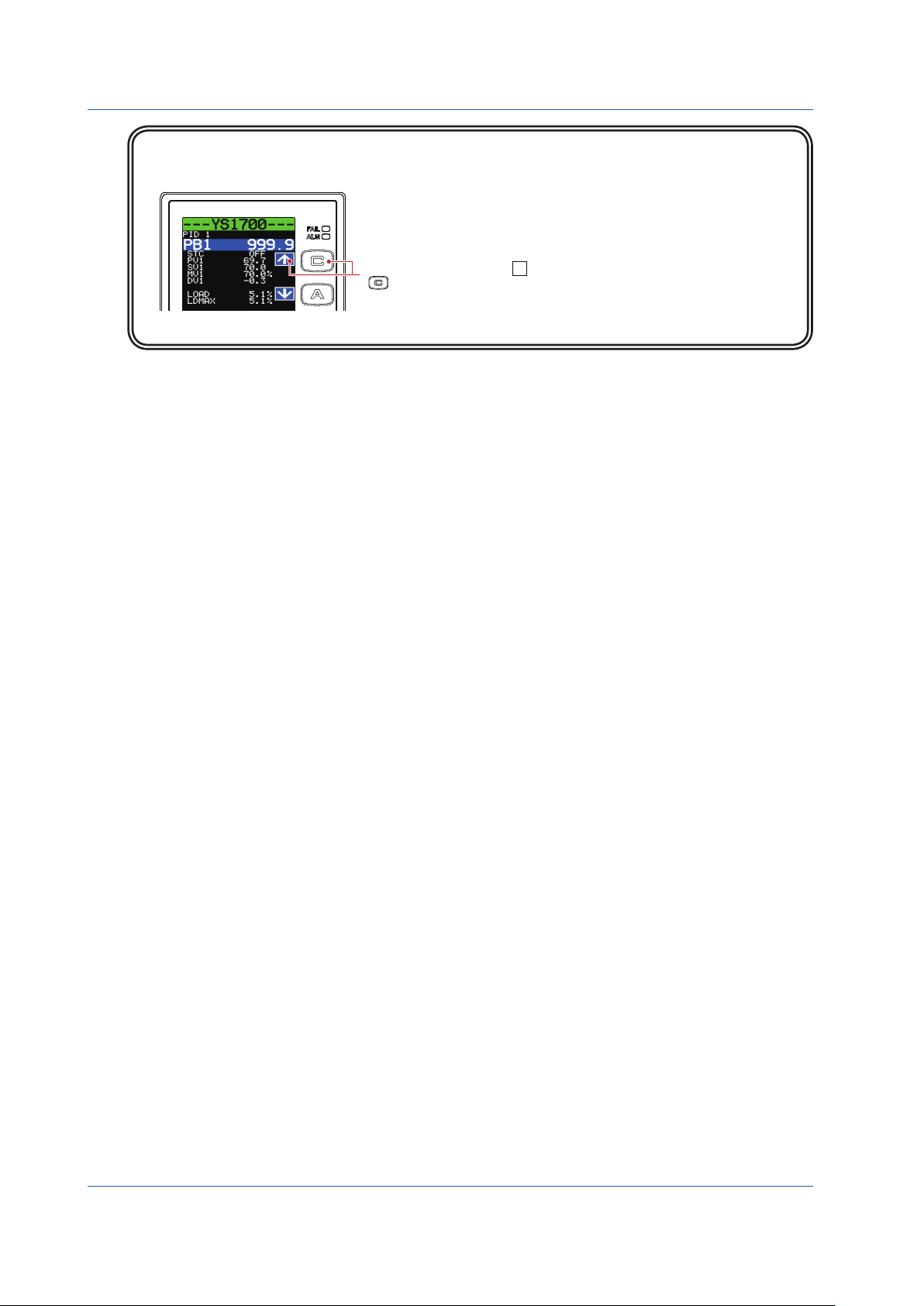

Software keys

Software keys are keys displayed on the LCD. The functions of the software keys are assigned to the operation keys on

the right of the display.

In the figure at the left, the ↑ (UP) software key corresponds with the

mode key.

Figure 4.2

0402E.ai

12

IM 01B08B02-01EN

Page 16

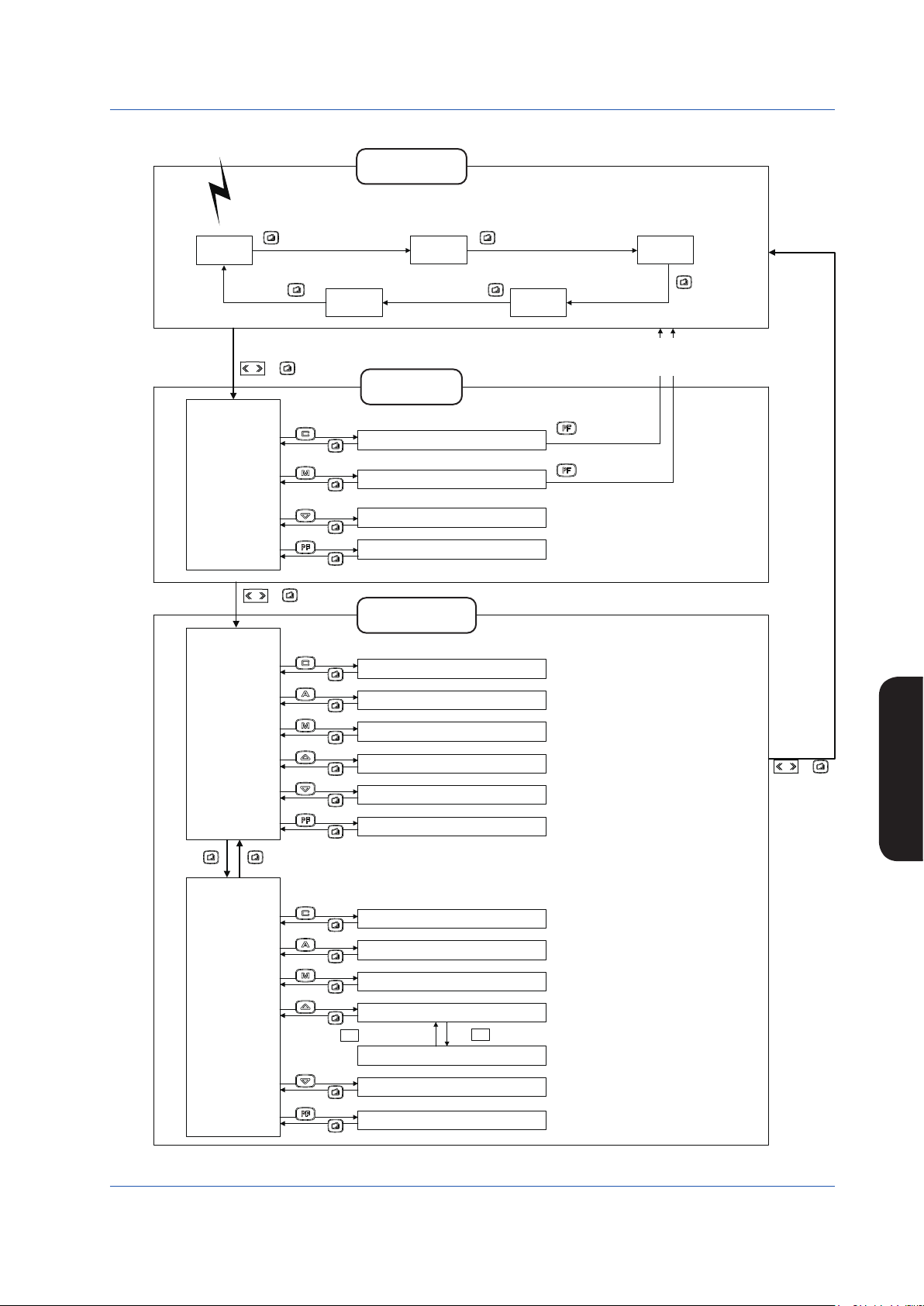

DisplaySwitchinginSingle-loopMode(YS1500’sfactorysetting)

Power ON

0403E.ai

Operation Display

LOOP1

Display

group

METER1

Display

The turning ON/OFF of each Operation Display and the initial

Operation Display which appears when the power is turned

on can be set.

► Settings and description: YS1500 Indicating Controller/

YS1700 Programmable Indicating Controller User’s

Manual

Basic Operations

TREND1

Display

SHIFT

Tuning Menu

Display

[PID1]

[STC1]

[PARAMETER]

[I/O DATA]

SHIFT

Engineering

Menu Display 1

[

CONFIG1]

[CONFIG2]

[CONFIG3]

[SC MAINT ]

[PASSWORD]

[SMPL]

+

PARAMETER

I/O DATA

+

CONFIG1

CONFIG2

CONFIG3

SC MAINT

PASSWORD

PID1

STC1

SMPL

ALARM

Display

Tuning Display

group

PID Setting Display 1

STC Setting Display 1

Parameter Setting Display

Input and Output Data Display

Engineering Display

group

Function Setting Display 1

Function Setting Display 2

Function Setting Display 3

Input Specification Setting Display

Password Setting Display

Sample Setting Display

TREND3

Display

To the LOOP 1, TREND 1, or METER 1 Display

(To an Operation Display on which the Tuning Menu

Display is selected for the first time)

OPE

OPE

Basic Operations

SHIFT

+

IM 01B08B02-01EN

Engineering

Menu Display 2

[DISPLAY]

[LCD]

[COMM]

[DI/DO]

[LCD MAINT]

[FX TABLE]

DISPLAY

LCD

COMM

DI/DO

Setting Display for Operation Display

LCD Setting Display

Communication Setting Display

DI/DO Setting Display 1/2

↑

Press at the first line and at the last line.

LCD MAINT

DI/DO Setting Display 2/2

↓

LCD Maintenance Display

FX TABLE

FX Table Setting Display

Figure 4.3

13

Page 17

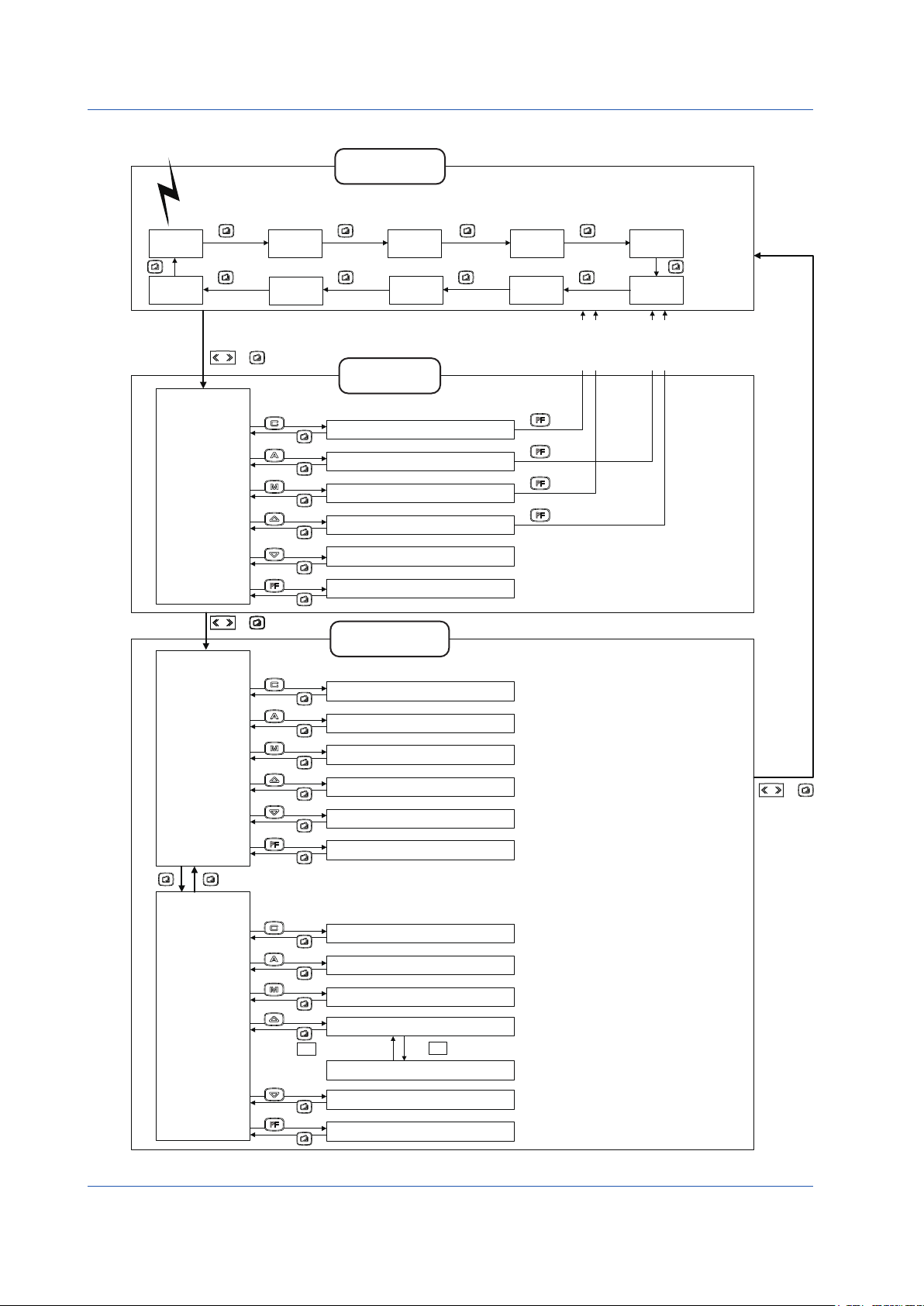

Power ON

Basic Operations

Display Switching in the Cascade or Selector Mode

Operation Display

group

+

STC2

PARAMETER

I/O DATA

LOOP2

Display

DUAL1

Display

PID1

PID2

STC1

Tuning Display

group

PID Setting Display 1

PID Setting Display 2

STC Setting Display 1

□

STC Setting Display 2

Parameter Setting Display

Input and Output Data Display

LOOP1

Display

□

DUAL2

Display

SHIFT

Tuning Menu

Display

[PID1]

[PID2]

[STC1]

[STC2]

[PARAMETER]

[I/O DATA]

METER1

Display

ALARM

Display

The turning ON/OFF of each Operation Display and the initial

Operation Display which appears when the power is turned

on can be set.

► Settings and description: YS1500 Indicating Controller/

YS1700 Programmable Indicating Controller User’s Manual

METER2

Display

TREND3

Display

To the LOOP1, TREND1, METER1,

or DUAL 1 Display (To an Operation

Display on which the Tuning Menu

Display is selected for the first time)

OPE

OPE

OPE

OPE

TREND1

Display

TREND2

Display

To the LOOP2, TREND2, METER2,

or DUAL 2 Display (To an Operation

Display on which the Tuning Menu

Display is selected for the first time)

SHIFT

Engineering

Menu Display 1

[CONFIG1]

[CONFIG2]

[CONFIG3]

[SC MAINT ]

[PASSWORD]

[SMPL]

Engineering

Menu Display 2

[DISPLAY]

[LCD]

[COMM]

[DI/DO]

[LCD MAINT]

[FX TABLE]

+

Engineering Display

group

CONFIG1

CONFIG2

CONFIG3

SC MAINT

PASSWORD

Function Setting Display 1

Function Setting Display 2

Function Setting Display 3

Input Specification Setting Display

Password Setting Display

SMPL

Sample Setting Display

DISPLAY

Setting Display for Operation Display

LCD

LCD Setting Display

COMM

DI/DO

Communication Setting Display

DI/DO Setting Display 1/2

↑

Press at the first line and at the last line.

LCD MAINT

FX TABLE

DI/DO Setting Display 2/2

LCD Maintenance Display

↓

FX Table Setting Display

* Not displayed in Selector mode.

SHIFT

+

0404E.ai

14

Figure 4.4

IM 01B08B02-01EN

Page 18

Display Switching in the Programmable Mode (YS1700’s factory setting)

Power ON

0405E.ai

The turning ON/OFF of each Operation Display and the

initial Operation Display which appears when the power is

turned on can be set.

► Settings and description: YS1500 Indicating Controller/

YS1700 Programmable Indicating Controller User’s Manual

METER1

Display

METER2

Display

LOOP1

Display

Operation Display

group

LOOP2

Display

Basic Operations

TREND1

Display

DUAL2

Display

SHIFT

Tuning Menu

Display

[PID1]

[PID2]

[STC1]

[STC2]

P&T REG]

[

[I/O DATA]

SHIFT

Engineering

Menu Display 1

[CONFIG1]

[CONFIG2]

[SC MAINT ]

[PASSWORD]

[SMPL & BATCH]

DUAL1

Display

+

Tuning Display

ALARM

Display

To the LOOP1, TREND1, METER1,

or DUAL 1 Display (To an Operation

Display on which the Tuning Menu

Display is selected for the first time)

group

PID1

PID2

STC1

STC2

PID Setting Display 1

PID Setting Display 2

STC Setting Display 1

STC Setting Display 2

P&T REG

P&T Register Display 1/3

↑

Press at the first line.

Press at the last line.

P&T Register Display 2/3

↑

Press at the first line. Press at the last line.

I/O DATA

P&T Register Display 3/3

I/O Data Display

+

Engineering Display

group

CONFIG1

CONFIG2

SC MAINT

PASSWORD

SMPL & BATCH

Function Setting Display 1

Function Setting Display 2

Input Specification Setting Display

Password Setting Display

Sample & Batch Setting Display

OPE

OPE

OPE

OPE

↓

Press at the last line.

↓

TREND3

Display

↓

TREND2

Display

To the LOOP2, TREND2, METER2,

or DUAL 2 Display (To an Operation

Display on which the Tuning Menu

Display is selected for the first time)

↑

Press at the first line.

SHIFT

+

Basic Operations

Engineering

Menu Display 2

[DISPLAY]

[LCD]

[COMM]

[

GX1 TABLE]

[GX2 TABLE]

[FX TABLE]

IM 01B08B02-01EN

DISPLAY

LCD

COMM

GX1 TABLE

GX2 TABLE

FX TABLE

Setting Display for Operation

Display

LCD Setting Display

Communication Setting Display

GX1 Table Setting Display

GX2 Table Setting Display

FX Table Setting Display

Engineering

Menu Display 3

[PGM1 SET]

PGM2 SET]

[

[

PID TABLE]

[

K CONST]

[LCD MAINT]

Figure 4.5

PGM1 SET

Program-setting-unit 1

PGM2 SET

Setting Display

Program-setting-unit 2

PID TABLE

K CONST

Setting Display

Preset PID Setting Display

K-constant Display 1/2

↑ ↓

Press at the first line. Press at the last line.

LCD MAINT

K-constant Display 2/2

LCD Maintenance Display

15

Page 19

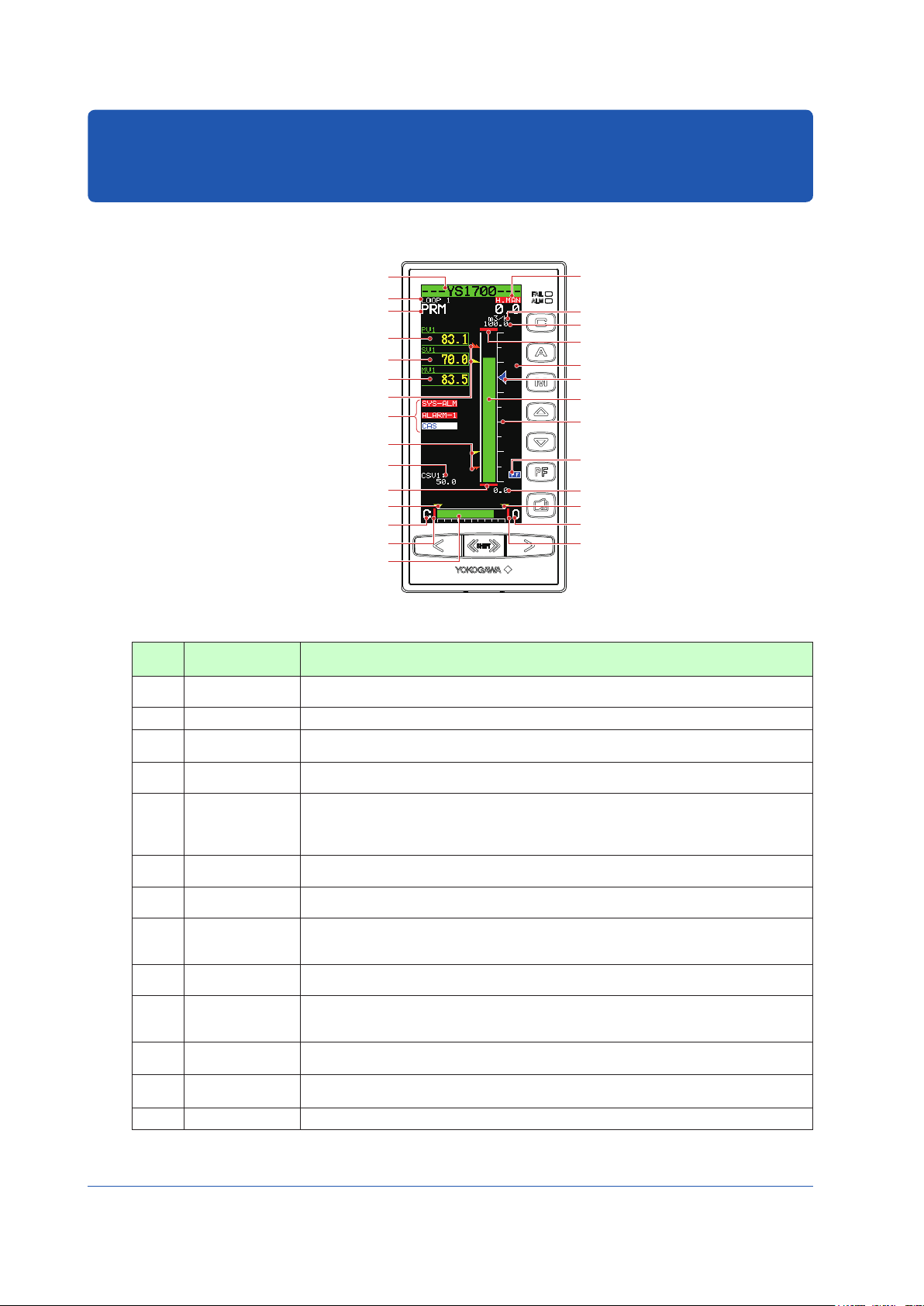

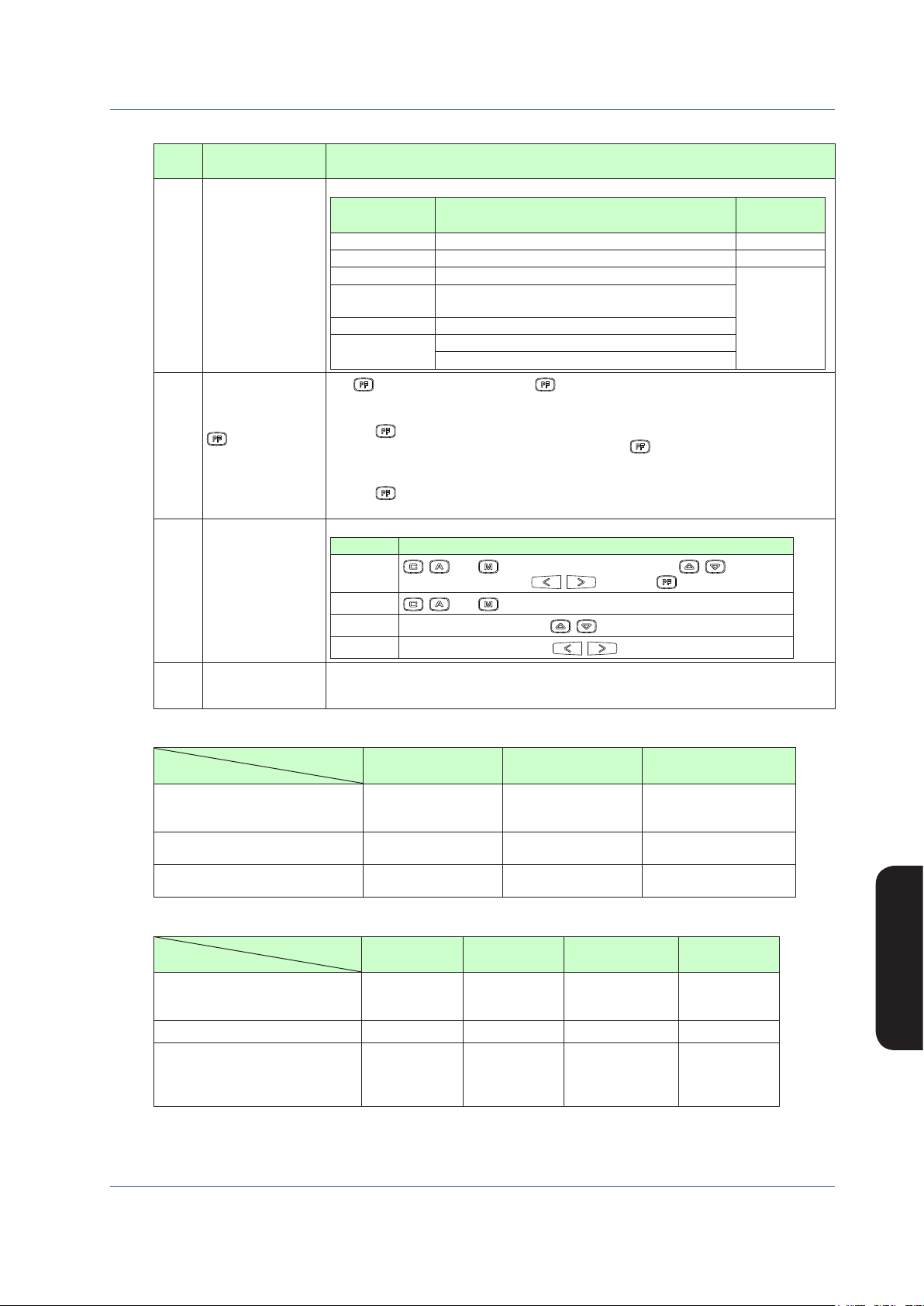

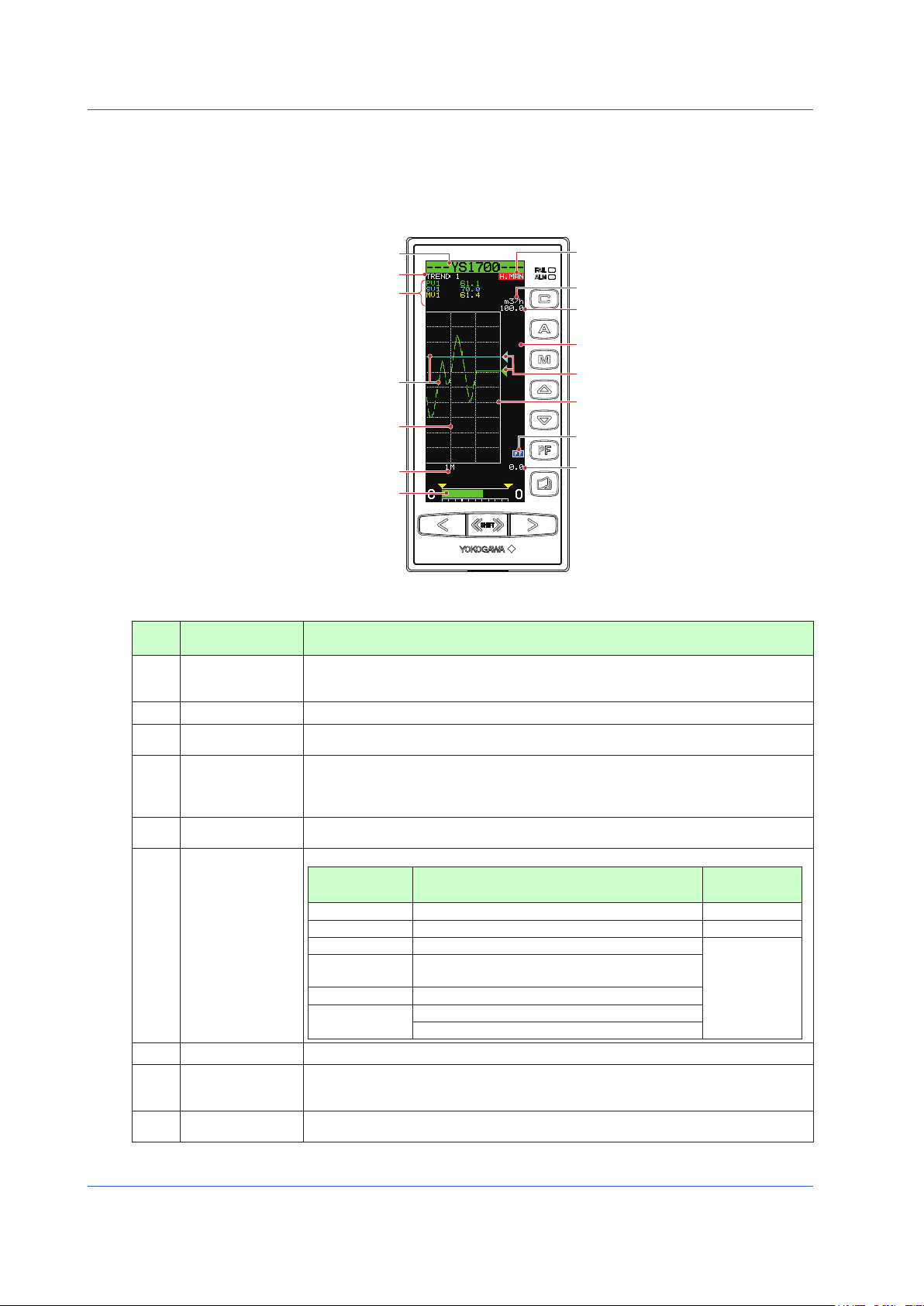

Monitoring and Control of Regular Operations

(22) Key LOCK status display

0501E.ai

(Operation Display)

Monitoring and Operating the Operation Display

Monitoring and Operating the LOOP Display

Tag number (1)

Display title (2)

P-register display (18)

PV digital display (3)

SV digital display (7)

MV digital display (9)

HH pointer, PH pointer (5)

Alarm generation display,

control status display

LL pointer, PL pointer (5)

Cascade setting input value (20)

PV underflow (6)

ML pointer (11)

MV valve direction (13)

MV underflow (12)

MV bar, MV scale (10)

(17)

(19) Operation status display

(14) Engineering units

(16) 100% value of scale

(6) PV overflow

(8) SV pointer

(4) PV bar

(15) PV bar scale

(21) PF key function display

(16) 0% value of scale

(11) MH pointer

(13) MV valve direction

(12) MV overflow

Figure 5.1

Table 5.1

No. in

Figure

(1) Tag number

Name Description

A tag number combining alphanumeric characters and symbols having a maximum of 12 digits

is displayed on a loop basis.

(2) Display title The title of the display being shown is indicated.

(3) PV digital display

(4) PV bar

A PV value is displayed in engineering units in a digital value of five significant digits (seven

digits including a sign and decimal point).

A PV value is displayed in a bar. The bar display is in 200 dots at full scale (100%) and

increases/decreases on a dot (0.5%) basis.

PH values (high limit alarm setpoints for PV) and PL values (low limit alarm setpoints for PV) are indicated

PH, PL, HH, and LL

(5)

pointers

with triangular pointers, while HH values (high-high limit alarm setpoints for PV) and LL values (low-low

limit alarm setpoints for PV) are indicated with pointers which are overlapped pairs of triangles. Pointers

are clipped and displayed at 0% if PV values are below 0%, or displayed at 100% if they exceed 100%.

PV underflow and

(6)

PV overflow

(7) SV digital display

A PV underflow is displayed if a PV value is below 0%, while a PV overflow is displayed if it

exceeds 100%.

An SV value is displayed in engineering units in a digital value of five significant digits (seven

digits including a sign and decimal point).

SV values are indicated with triangular pointers. The pointer display moves up and down with

(8) SV pointer

a resolution of 0.5%. Pointers are clipped and displayed at 0% if SV values are below 0%, or

displayed at 100% if they exceed 100%.

(9) MV digital display

MV bar

(10)

MV scale

(11) MH and ML pointers

MV underflow and

(12)

MV overflow

An MV value is displayed in a digital value of four significant digits (six digits including a sign

and decimal point, with the number of decimal places fixed to one digit) in a % display.

An MV value is displayed in a bar. The bar display is in 80 dots (100%) at full scale, divided into

20 blocks (5%) for display. It increases/decreases on a dot (1.25%) basis. A scale divided into

10 (10% segments) is also displayed.

MH values (high limit setpoints of MV) and ML values (low limit setpoints of MV) are indicated

with triangular pointers.

An MV underflow is displayed if an MV value is below 0%, while an MV overflow is displayed if it

exceeds 100%.

(13) MV valve direction MV valve direction is displayed as [C] (closed) or [O] (open). The valve direction can be set.

16

16

IM 01B08B02-01EN

Page 20

Monitoring and Control of Regular Operations (Operation Display)

Table 5.2

No. in

Figure

Name Description

(14) Engineering units Engineering units (UNIT) are displayed in a maximum of seven digits.

(15) PV bar scale The PV bar scale is displayed divided into a maximum of 10 segments (10% segments).

0% value of scale, 100%

(16)

value of scale

Alarm generation display,

(17)

Control status display

P-register display

(18)

0% value of scale (SCL) and 100% value of scale (SCH) are displayed in engineering units in

a digital value of five significant digits (seven digits including a sign and decimal point).

Alarm and control statuses are displayed in abbreviations. These vary according to

controller mode in the multi-function mode; or according to the control module in the

programmable mode. See Tables 5.3 to 5.5.

When this display is enabled, P register is displayed on the LOOP 1 and LOOP 2

Displays individually. This display is available in the programmable mode.

The controller operation status is displayed.

Display Description

[POWER DOWN] Power down is being detected. (1)

[H.MAN] Hard manual selector switch has been activated. (2)

Operation status display

(19)

(No indication) The instrument is operating.

[STOP] Operation stopped (such as while setting a

function on the Engineering Display, etc.)

Cascade setting input

(20)

value

[TEST1]

[TEST2]

When the instrument is used in the cascade mode, a cascade setting input value is

displayed in engineering units in a digital value of five significant digits (seven digits

including a sign and decimal point). No value is displayed in the programmable mode.

Test run mode 1 (only in the programmable mode)

Test run mode 2 (only in the programmable mode)

Simulation program is being executed

The key function is displayed. The key function display is different in the multifunction mode and the programmable mode.

1) Multi-function mode

The key function is set using the PF key function selection parameter [PFKEY].

(21)

key function display

When the STC mode selection is “not OFF” and the “ key has been set to STC”,

the function display becomes [STC]. In other cases, nothing is displayed.

2) Programmable mode

The key function can be defined in user programs.

The function display becomes [PF] in the programmable mode.

The key LOCK status is displayed.

Display Description

[ALLK]

Key LOCK status display

(22)

[MDLK]

[SVLK]

[MVLK]

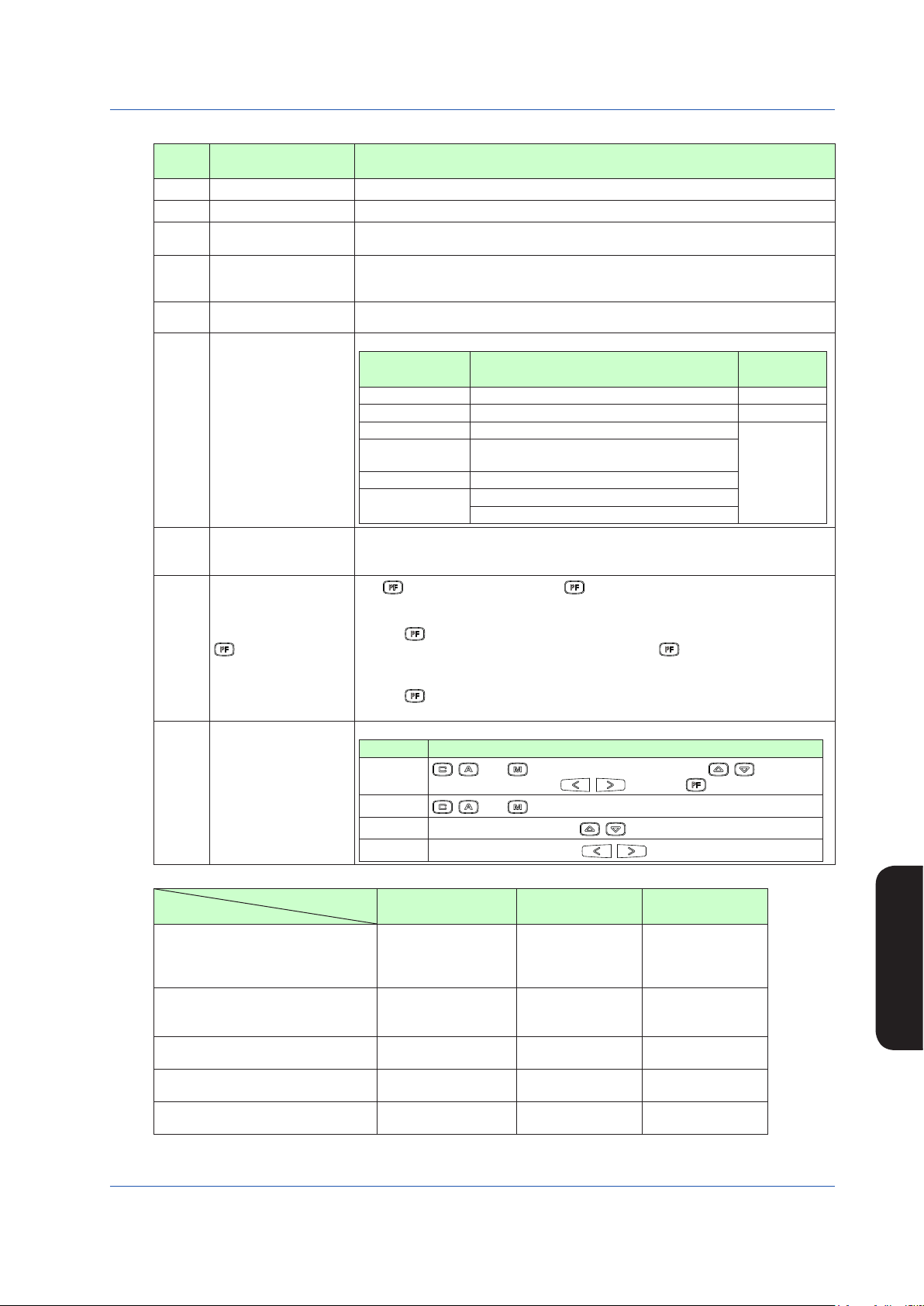

Table 5.3 Alarm Display and Control Status Display in the YS1500/YS1700 Multi-function Mode

Controller Mode

Display Item

SYS-ALM

Alarm generation display (Note 1)

STC-ALM

ALARM-1

CAS

Control status display (Note 2)

SPC, DDC

BUA, BUM

Control substatus display 1

Control substatus display 2

Control substatus display 3

Note 1: This display appears only if an alarm occurs. If multiple alarms occur simultaneously, they are indicated in multiple lines.

Note 2: Only when the operation mode is in cascade setting automatic control (C mode) is a control status displayed, while nothing is indicated in

automatic control (A mode) or manual control (M mode).

IM 01B08B02-01EN

EXT-MAN,EXT-AUT

EXT-PMV,EXT-TRK

SV TRK, PV TRK OPEN, CLOSE

STC-ON, STC-DSP,

ATSTUP

, , and keys, SV increase and decrease ( , ) keys, MV

increase and decrease ( , ) keys, and key are disabled.

, , and keys are disabled.

SV increase and decrease (

MV increase and decrease (

, ) keys are disabled.

, ) keys are disabled.

Single Loop Cascade Selector

SYS-ALM

STC-ALM

ALARM-1

ALARM-2

CAS

SPC, DDC

BUA, BUM

SYS-ALM

STC-ALM

ALARM-1

ALARM-2

CAS

SPC, DDC

BUA, BUM

EXT-TRK,EXT-PMV EXT-TRK,EXT-PMV

SV2-RMT, SV2-LCL

SEL1, SEL2

STC-ON, STC-DSP,

ATSTUP

STC-ON, STC-DSP

Display

Priority Order

(3)

Monitoring and Control of

Regular Operations

17

Page 21

Monitoring and Control of Regular Operations (Operation Display)

Table 5.4 Alarm Display and Control Status Display in the YS1700 Programmable Mode

Control Module

Display Item

Alarm generation display (Note 1)

Control status display (Note 2)

Control substatus display 1

Basic Control

(BSC1)

SYS-ALM

STC-ALM

ALARM-1

CAS

SPC, DDC

BUA, BUM

None None None None

Cascade Control

(CSC)

SYS-ALM

STC-ALM

ALARM-1

ALARM-2

CAS

SPC, DDC

BUA, BUM

Selector Control

(SSC)

SYS-ALM

STC-ALM

ALARM-1

ALARM-2

CAS

SPC, DDC

BUA, BUM

SYS-ALM

STC-ALM

ALARM-1

ALARM-2

CAS

SPC, DDC

BUA, BUM

SV2-RMT

Control substatus display 2

None

OPEN, CLOSE

SV2-LCL

SEL1, SEL2

None

SEL-EXT

Control substatus display 3

STC-DSP

ATSTUP

Note 1: This display appears only if an alarm occurs. If multiple alarms occur simultaneously, they are indicated in multiple lines.

Note 2: Only when the operation mode is in cascade setting automatic control (C mode) is a control status displayed, while nothing is indicated in

automatic control (A mode) or manual control (M mode).

Table 5.5 Meaning of Display Abbreviations

STC-ON

STC-ON

STC-DSP

ATSTUP

STC-ON

STC-DSP

STC-ON

STC-DSP

ATSTUP

Symbol Meaning Symbol Meaning

SYS-ALM

STC-ALM

ALARM-1

ALARM-2

CAS

SPC

DDC

BUA

BUM

EXT-MAN

EXT-AUT

EXT-PMV

EXT-TRK

A system alarm occurred.

An STC alarm occurred.

A loop 1 process alarm occurred.

A loop 2 process alarm occurred.

Remote operation being conducted in response to

external setpoint input

Remote operation being conducted in response to

SV from a high-level device

Remote operation being conducted in response to

MV from a high-level device

Transition to backup auto status

Transition to backup manual status

Transition to manual control in response to external

digital input

Transition to automatic control in response to

external digital input

Preset MV being output in response to external

digital input

Output being tracked in response to external digital

input

SV TRK

PV TRK

OPEN

CLOSE

SV2-RMT

SV2-LCL

SEL1

SEL2

SEL-EXT

STC-ON

STC-DSP

ATSTUP

SV being tracked

PV being tracked

(Internal) cascade open

(Internal) cascade closed

Loop 2’s SV2 remote setting

Loop 2’s SV2 local setting

Loop 1 side’s selection status

Loop 2 side’s selection status

External signal selection status

STC control operation being conducted

PID setting target value is indicated by STC.

STC auto startup being conducted

DUAL-loop

Control (BSC1,

BSC2)

► Forcausesofalarmsthathaveoccurredandactionstobetaken:see“Troubleshooting”inthismanual.

18

IM 01B08B02-01EN

Page 22

Monitoring and Control of Regular Operations (Operation Display)

Operating the LOOP Display

This section describes keystrokes for performing various settings and operations on the LOOP Display.

(1) Switching the operation mode

M mode key: Switches the operation mode to manual control (M mode).

A mode key: Switches the operation mode to automatic control (A mode).

C mode key: Switches the operation mode to cascade setting automatic control (C mode).

Moreover, the LED inside the operation mode key corresponding to the current operation mode lights up.

Note

Ifacascadeinputsignalis−6.3%orlessor106.3%ormore,theoperationmodecannotbeswitchedtoCmode.

► Forswitchingtheoperationmode:see“SwitchingofOperationModes”inthismanual.

(2) SV setting operation

The SV setting key changes the setpoint (SV).

This key is enabled when the operation mode is in the A or M mode.

SV increase key: Increases an SV value.

SV decrease key: Decreases an SV value.

(3) MV operation

The MV operation key is used to manually operate a manipulated output variable (MV). This key is enabled when the opera-

tion mode is in the M mode.

MV increase key: Increases an MV value.

MV decrease key: Decreases an MV value.

Moreover, pressing an MV operation key with the

increase/decrease speed.

SHIFT

(fast-change key/SHIFT key) held down accelerates the MV-value

(4) PF key functions

The PF key functions are different in the multi-function mode and the programmable mode.

Multi-functionmode:

The PF key function is set on the Function Setting Display 3 (CONFIG 3). There are the following two parameter designations:

(1) No function: The PF key does not function.

(2) STC ON/OFF: The PF key switches STC operation ON/OFF.

If STC ON/OFF is specified, when STC is ON the LED inside the PF key lights up.

Programmable mode:

The PF key function is defined by user programs then used. The LED in the PF key can be turned ON/OFF by the user pro-

grams.

For cascade control, selector control, or dual-loop control, the loop 1 can be operated on the LOOP 1 Display, while the loop 2

can be operated on the LOOP 2 Display.

Monitoring and Control of

Regular Operations

IM 01B08B02-01EN

19

Page 23

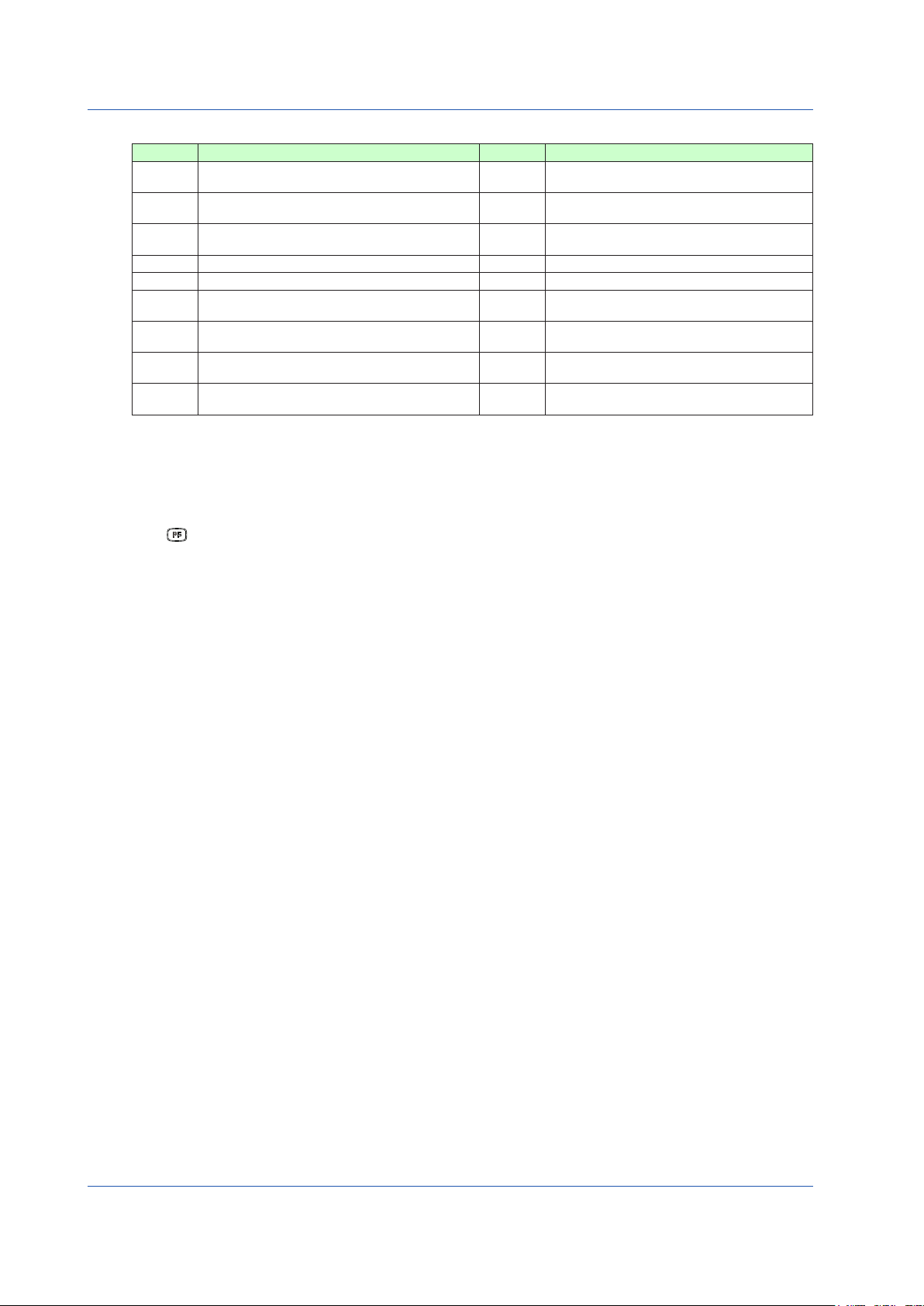

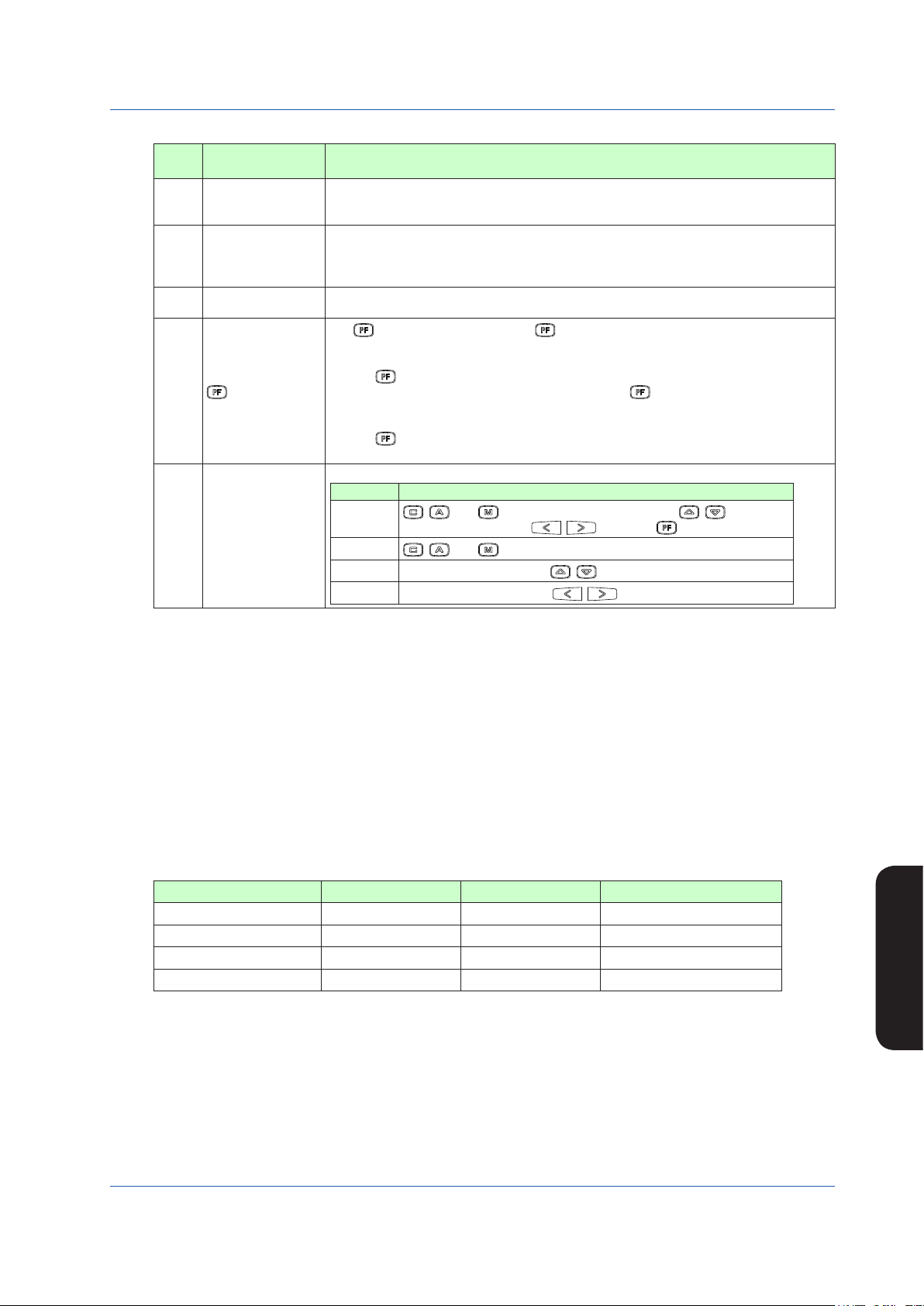

Monitoring and Control of Regular Operations (Operation Display)

P

0502E.ai

Monitoring and Operating the METER Display

Tag number (1)

Display title (2)

V, SV, MV digital display (3)

HH pointer, PH pointer (11)

LL pointer, PL pointer (11)

ML pointer (14)

MV valve direction (15)

MV pointer (13)

Figure 5.2

Table 5.6

No. in

Figure

Name Description

(1) Tag number As on the LOOP Display, a tag number appears here.

(2) Display title The title of the display being shown is indicated.

PV, SV, and MV

(3)

digital display

(4) PV meter scale

Main scale marks,

(5)

subscale marks

PV, SV, and MV digital values are displayed here.

The PV meter scale displays main and subscale marks, a numerical scale, a scale factor, and engineering units.

The main scale marks and subscale marks are determined by setting the variables to the 0% value of scale (SCL) and to

the 100% value of scale (SCH), which causes the scale to be automatically divided into divisions based on those values.

The scale range is clearly represented in the range of the number of numerical scale digits using the

(6) Scale factor

power of 10 (× 10n). It is possible to set the value of the power, however it can also be automatically

determined from the 0% value of scale (SCL) and 100% value of scale (SCH).

The numerical scale is automatically determined from the 0% value of scale (SCL) and 100% value of

(7) Numerical scale

scale (SCH), and is displayed centered and to the right of the main scale marks. The number of digits to

be displayed is three (or four digits if there is no decimal point).

(8) PV pointer

(9) SV pointer

A PV value is indicated by two pointers (at the left and right sides of the scale). The pointer display

moves up and down with a resolution of 0.5%.

An SV value is indicated with a pointer. The pointer display moves up and down with a resolution of 0.5%.

(10) Engineering units Engineering units (UNIT) are displayed in a maximum of seven digits.

PH, PL, HH, and LL

(11)

pointers

MV meter scale

(12)

MV pointer

(13)

MH and ML pointers

(14)

MV valve direction The MV valve direction is displayed as [C] (closed) or [O] (open). The valve direction can be set.

(15)

PH values (high limit alarm setpoints for PV) and PL values (low limit alarm setpoints for PV) are indicated

with triangular pointers, while HH values (high-high limit alarm setpoints for PV) and LL values (low-low limit

alarm setpoints for PV) are indicated with pointers which are overlapped pairs of triangles.

Scale marks are displayed on the MV meter scale. The mark at the far left is the 0% position and the

mark at the far right is the 100% position. Each scale division is 5%.

MV values are indicated with a pointer. Since the scale’s full scale is 80 dots (100%), the MV pointer

increases and decreases in a resolution of 1.25%.

MH values (high limit setpoints of MV) and ML values (low limit setpoints of MV) are indicated with

triangular pointers.

(16) Operation status display

(19) Control status display

(4) PV meter scale

(6) Scale factor

(18) Key LOCK status display

(8) PV pointer

(9) SV pointer

(7) Numerical scale

(5) Main scale marks, subscale marks

(10) Engineering units

(17) PF key function display

(14) MH pointer

(15) MV valve direction

(12) MV meter scale

20

IM 01B08B02-01EN

Page 24

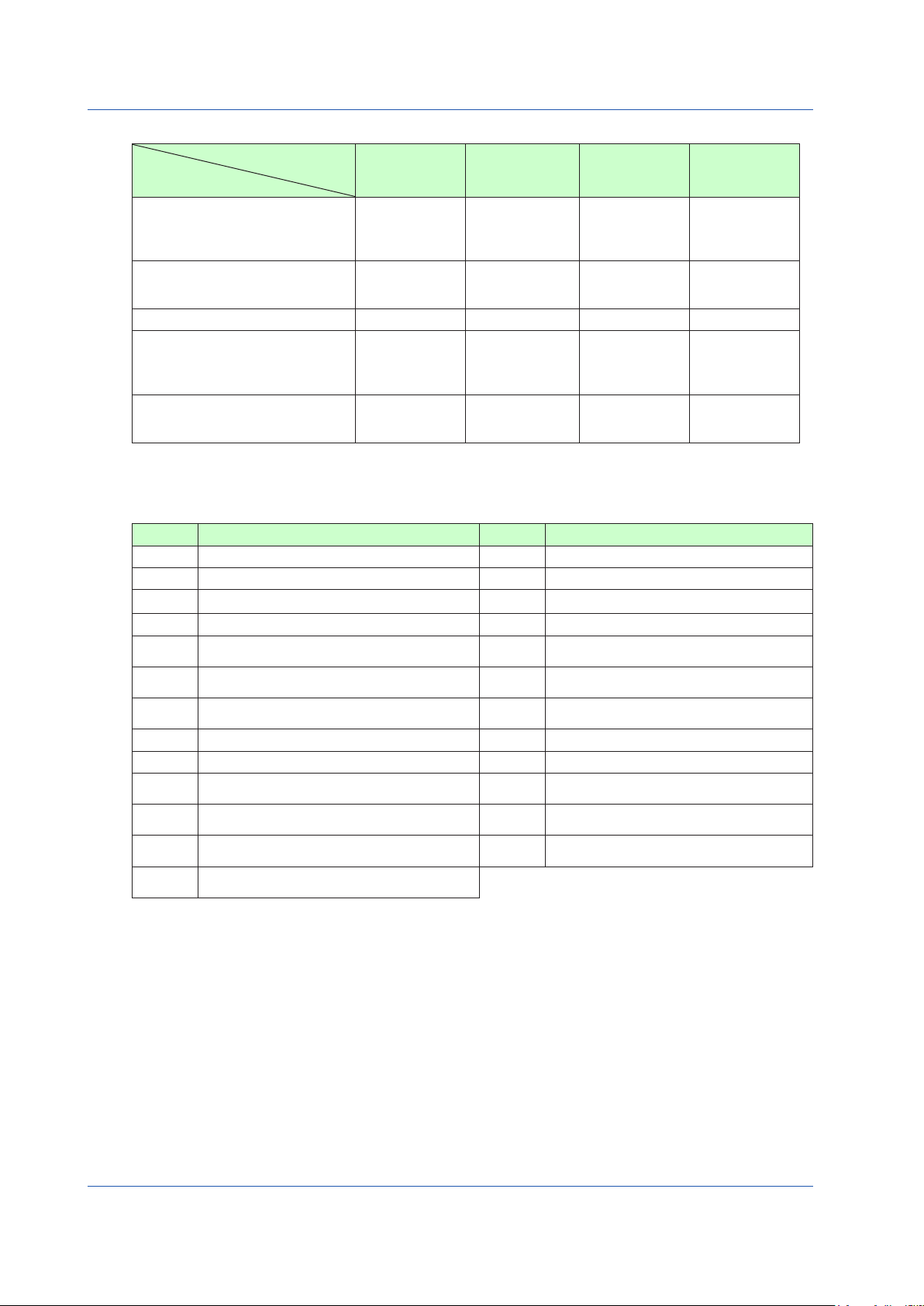

Table 5.7

No. in

Figure

(16)

(17)

(18)

(19)

Monitoring and Control of Regular Operations (Operation Display)

Name Description

The controller operation status is displayed.

Display Description

[POWER DOWN] Power down is being detected. (1)

Operation status

display

[H.MAN] Hard manual selector switch has been activated. (2)

(No indication) The instrument is operating.

[STOP] Operation stopped (such as while setting a function

on the Engineering Display, etc.)

[TEST1] Test run mode 1 (only in the programmable mode)

[TEST2]

Test run mode 2 (only in the programmable mode)

Simulation program is being executed

The key function is displayed. The key function display is different in the multi-function

mode and the programmable mode.

1) Multi-function mode

key function

display

The key function is set using the PF key function selection parameter [PFKEY].

When the STC mode selection is “not OFF” and the “ key has been set to STC”, the

function display becomes [STC]. In other cases, nothing is displayed.

2) Programmable mode

The key function can be defined in user programs.

The function display becomes [PF] in the programmable mode.

The key LOCK status is displayed.

Display Description

Key LOCK status

display

[ALLK]

[MDLK]

[SVLK]

[MVLK]

, , and keys, SV increase and decrease ( , ) keys, MV

increase and decrease ( , ) keys, and key are disabled.

, , and keys are disabled.

SV increase and decrease (

MV increase and decrease (

Control status is displayed in abbreviations. Control status display differs according to

Control status display

the controller mode in the multi-function mode; or according to the control module in the

programmable mode. See Tables 5.8 to 5.10.

Display

Priority Order

(3)

, ) keys are disabled.

, ) keys are disabled.

Table 5.8 Control Status Display in the YS1500/YS1700 Multi-function Mode

Controller Mode

Display Item

Control status display (Note 1)

Control substatus display 1 (Note 2)

Control substatus display 2 (Note 3)

Table 5.9 Control Status Display in the YS1700 Programmable Mode

Control Module

Display Item

Control status display (Note 1)

Control substatus display 1 (Note 2)

Single Loop Cascade Selector

CAS

SPC, DDC

BUA, BUM

EXT-MAN,EXT-AUT

EXT-PMV,EXT-TRK

SV TRK, PV TRK OPEN, CLOSE

Basic Control

CAS

SPC, DDC

BUA, BUM

CAS

SPC, DDC

BUA, BUM

None None

Cascade

Control

CAS

SPC, DDC

BUA, BUM

Selector Control

CAS

SPC, DDC

BUA, BUM

CAS

SPC, DDC

BUA, BUM

SV2-RMT, SV2-LCL

SEL1, SEL2

Dual-loop

CAS

SPC, DDC

BUA, BUM

None None None None

Control

SV2-RMT

Control substatus display 2 (Note 3)

None OPEN, CLOSE

SV2-LCL

SEL1, SEL2, SEL-

None

EXT

Note 1: Only when the operation mode is in cascade setting automatic control (C mode) is a control status displayed, while nothing is indicated in

automatic control (A mode) or manual control (M mode).

Note 2: When each control substatus is generated, one item is displayed. Nothing is displayed when a status is not generated.

Note 3: One of the control substatuses is always displayed.

Monitoring and Control of

Regular Operations

IM 01B08B02-01EN

21

Page 25

Monitoring and Control of Regular Operations (Operation Display)

Table 5.10 Meaning of Display Abbreviations

Symbol Meaning Symbol Meaning

CAS

SPC

DDC

BUA

BUM

EXT-MAN

EXT-AUT

EXT-PMV

EXT-TRK

► Forcausesofalarmsthathaveoccurredandactionstobetaken:see“Troubleshooting”inthismanual.

Remote operation being conducted in response to

external setpoint input

Remote operation being conducted in response to

SV from a high-level device

Remote operation being conducted in response to

MV from a high-level device

Transition to backup auto status

Transition to backup manual status

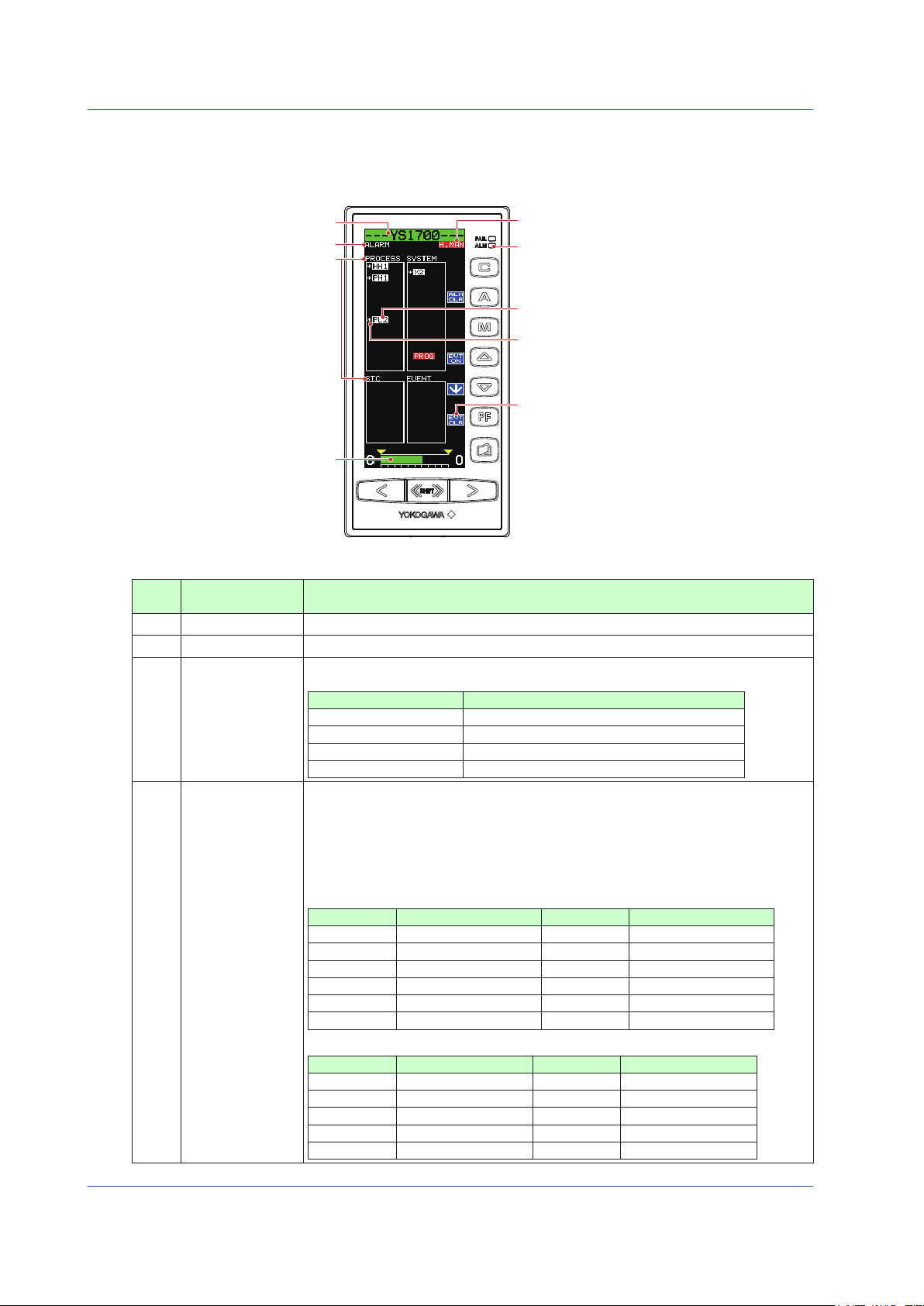

Transition to manual control in response to external

digital input

Transition to automatic control in response to