Page 1

User’s

Manual

YFGW710

Field Wireless Integrated Gateway

IM 01W01F01-01EN

IM 01W01F01-01EN

7th Edition

Page 2

Blank Page

Page 3

YFGW710 Field Wireless Integrated Gateway

IM 01W01F01-01EN 7th Edition

CONTENTS

Introduction ..............................................................................................................i

Safety Precautions ..................................................................................................ii

Documentation Conventions ................................................................................vi

Information of User’s Manual Revision .............................................................viii

Use of Open Source License Software ..............................................................viii

Toc-1

PART-A HARDWARE OF YFGW710

A1. Introduction .............................................................................................A1-1

A2. Checking the Product ............................................................................A2-1

A3. YFGW710 Field Wireless Integrated Gateway ....................................A3-1

A3.1 Installation ...................................................................................................... A3-1

A3.1.1 Requirements for Installation Locations ..........................................A3-1

A3.1.2 Notes on Installation ........................................................................A3-2

A3.1.3 Mounting Procedure ........................................................................A3-3

A3.1.4 Set-up after Mounting ......................................................................A3-6

A3.2 Cable Connection .......................................................................................... A3-8

A3.2.1 Power Supply Cable Connection .....................................................A3-8

A3.2.2 Ground Cable Connection ...............................................................A3-9

A3.2.3 Network Cable Connection ............................................................A3-10

A3.2.3.1 Optical Network Cable Connection ..............................A3-10

A3.2.3.2 Metal Network Cable Connection .................................A3-12

A3.2.4 Mounting Antenna and Wiring .......................................................A3-13

A3.2.4.1 Mounting Antenna to YFGW710 Main Body ................A3-14

A3.2.4.2 Mounting and Wiring External Antenna ........................A3-15

A3.3 Wiring for Explosion Proof ......................................................................... A3-19

IM 01W01F01-01EN

Page 4

Toc-2

A3.4 Maintenance ................................................................................................. A3-20

A3.4.1 Routine Maintenance .....................................................................A3-20

A3.4.2 Maintenance in Hazardous Area ...................................................A3-20

A3.4.3 Communication Check ..................................................................A3-21

A3.4.4 About Parts Having Dened Life Spans ........................................A3-21

A3.5 Troubleshooting ........................................................................................... A3-22

A3.6 General Specication .................................................................................. A3-23

A3.6.1 Standard Specication ...................................................................A3-23

A3.6.2 Model and Sufx Code...................................................................A3-36

A3.6.3 Optional Specication ....................................................................A3-36

A3.6.4 Outline Diagram .............................................................................A3-38

A4. Field Wireless Network ..........................................................................A4-1

A4.1 Wireless Communication Ranges ............................................................... A4-1

A4.2 Wireless System Specication .................................................................... A4-2

IM 01W01F01-01EN

Page 5

PART-B ENGINEERING

B1. Engineering .............................................................................................B1-1

B1.1 System Engineering Flow Overview ............................................................ B1-2

B1.2 Basics .............................................................................................................. B1-4

B1.2.1 Preparations .....................................................................................B1-5

B1.2.2 Field Wireless Network Ofine Engineering ....................................B1-7

B1.2.2.1 Creating a Project Database ..........................................B1-7

B1.2.2.2 Registering YFGW710 ....................................................B1-9

B1.2.2.3 Registering Field Wireless Device ................................B1-12

B1.2.2.4 Loading a Capabilities File (CF) ...................................B1-12

B1.2.2.5 User Application Engineering .......................................B1-14

B1.2.3 Work before Installing Field Wireless Device ................................B1-16

B1.2.3.1 Task of Setting YFGW710 ............................................B1-16

B1.2.3.2 Task of Provisioning a Field Wireless Device ...............B1-18

B1.2.3.3 Adjusting and Setting Field Wireless Device

Parameters ...................................................................B1-20

B1.2.4 Downloading to YFGW710 ............................................................B1-20

B1.2.4.1 Registering Provisioning Information with

the Project Database ....................................................B1-20

B1.2.4.2 Downloading to YFGW710 ...........................................B1-24

B1.2.5 Task of Checking Field Wireless Network Operation Conditions ..B1-27

B1.2.5.1 Checking Join Status of Field Wireless Devices

to Field Wireless Network .............................................B1-27

B1.2.5.2 Checking Client/Server Communication between

YFGW710 and Field Wireless Device ..........................B1-28

B1.2.6 Task of Setting and Adjusting Field Wireless Device

Parameters ....................................................................................B1-29

B1.2.7 Task of Downloading the Process Data Communication

Denitions ......................................................................................B1-29

B1.2.8 Engineering of Control System ......................................................B1-32

B1.3 Applications .................................................................................................. B1-33

B1.3.1 Field Wireless Device Maintenance Task ......................................B1-33

B1.3.1.1 Task of Replacing a Field Wireless Device...................B1-33

B1.3.1.2 Task of Replacing YFGW710 .......................................B1-35

B1.3.1.3 Monitoring Field Wireless Device Status ......................B1-36

B1.3.2 Network Construction Task ............................................................B1-37

B1.3.2.1 Setting Device Role ......................................................B1-37

B1.3.2.2 Time Synchronization

(Connection with an NTP Server) .................................B1-40

B1.3.3 System Expansion .........................................................................B1-40

B1.3.3.1 Connecting with an OPC Server...................................B1-40

B1.3.3.2 Constructing Multiple Field Wireless Networks ............B1-41

B1.3.3.3 Security .........................................................................B1-42

Toc-3

IM 01W01F01-01EN

Page 6

Toc-4

B2. System Maintenance ..............................................................................B2-1

B2.1 Alarm ............................................................................................................... B2-1

B2.2 Troubleshooting and Recovery Task ........................................................... B2-2

IM 01W01F01-01EN

Page 7

PART-C ATTACHED SOFTWARE

C1. System Requirements of Provided Software ......................................C1-1

C2. Field Wireless Congurator .................................................................C2-1

C2.1 Introduction .................................................................................................... C2-1

C2.1.1 Document Purpose and Intended Users ........................................ C2-1

C2.1.2 Product Overview............................................................................ C2-1

C2.2 Installation ...................................................................................................... C2-2

C2.2.1 System Requirements .................................................................... C2-2

C2.2.2 Installation Procedure ..................................................................... C2-2

C2.3 Using the Field Wirless Congurator ......................................................... C2-5

C2.3.1 Authentication ................................................................................. C2-5

C2.3.2 Main Window .................................................................................. C2-6

C2.3.3 Working with Projects ..................................................................... C2-7

C2.3.3.1 Project Actions ............................................................... C2-7

C2.3.3.2 Project Properties .......................................................... C2-9

C2.3.3.3 Options ......................................................................... C2-10

C2.3.3.4 Creating a Project .........................................................C2-11

C2.3.3.5 Downloading Project Data to the YFGW710 ............... C2-19

C2.3.3.6 Error Checks ............................................................... C2-23

C2.3.3.7 Download Status.......................................................... C2-24

C2.3.3.8 Download History ......................................................... C2-25

C2.3.3.9 Project Log ................................................................... C2-26

C2.3.4 How To… ....................................................................................... C2-28

C2.3.4.1 Modifying a Project ...................................................... C2-28

C2.3.4.2 Add a Device to an Existing Project ............................. C2-28

C2.3.4.3 Delete One or More Devices ....................................... C2-29

C2.3.4.4 Modifying a device ....................................................... C2-29

C2.3.4.5 Replacing YFGW710 ................................................... C2-29

C2.3.4.6 Modifying Sampling Parameters ................................. C2-29

C2.3.4.7 Modifying the Modbus Register Map ........................... C2-30

C2.3.5 Users ............................................................................................. C2-30

C2.3.5.1 User Accounts .............................................................. C2-31

C2.3.5.2 Changing your password ............................................. C2-33

C2.3.6 Help Menu ..................................................................................... C2-33

Toc-5

IM 01W01F01-01EN

Page 8

Toc-6

C3. Field Wireless Management Tool..........................................................C3-1

C3.1 Introduction ................................................................................................... C3-1

C3.1.1 Document Purpose and Intended Users ........................................ C3-1

C3.1.2 Product overview ............................................................................ C3-1

C3.2 Installation ...................................................................................................... C3-1

C3.2.1 System Requirements .................................................................... C3-1

C3.2.2 Installation Procedure ..................................................................... C3-2

C3.3 Using the Field Wireless Management Tool ................................................ C3-5

C3.3.1 Authentication and Connection to YFGW710................................. C3-5

C3.3.1.1 Creating a New Connection ........................................... C3-6

C3.3.1.2 Deleting a Connection ................................................... C3-6

C3.3.2 Main Window .................................................................................. C3-7

C3.3.2.1 Action Menu ................................................................... C3-8

C3.3.2.1.1 Connecting to/Disconnecting from YFGW710 ....... C3-8

C3.3.2.1.2 Viewing the System Status (YFGW Status) ........... C3-8

C3.3.2.1.3 Upgrading the System (System Upgrade) ............. C3-9

C3.3.2.1.4 Changing Your Password (Change Password) ... C3-10

C3.3.2.2 View Menu ....................................................................C3-11

C3.3.2.2.1 Network Topology ................................................. C3-12

C3.3.2.2.2 Network Health ..................................................... C3-17

C3.3.2.2.3 Devices ................................................................. C3-19

C3.3.2.2.4 Readings .............................................................. C3-34

C3.3.2.2.5 Commands Log .................................................... C3-35

C3.3.2.2.6 User Accounts ...................................................... C3-37

C3.3.2.3 Help Menu .................................................................... C3-39

C4. Restriction of function ...........................................................................C4-1

C4.1 Field Wireless Congurator .......................................................................... C4-1

C4.1.1 Notice of Error Checks for Number of connected eld wireless

devices and Publication period (Update time) ................................ C4-1

IM 01W01F01-01EN

Page 9

<Read Me First>

Introduction

This document describes engineering related procedures including the installation and

wiring of YFGW710 Field Wireless Integrated Gateway and the setting and start-up of eld

wireless networks through YFGW710. YFGW710 Field Wireless Integrated Gateway is a

core component of eld wireless networks conforming to ISA100.11a, the wireless communication standard for industrial automation prescribed by the International Society of

Automation (ISA).

IMPORTANT

This manual consists of the following four parts.

l Part A Hardware of YFGW710

This part explains the hardware specications, installation, wiring, and maintenance works for the

YFGW710 Field Wireless Integrated Gateway, and the specications of the wireless network.

i

l Part B Engineering

This part explains the procedure for engineering work to build up and operate the Field Wireless

System.

l Part C Attached Software

This part explains the procedure of installation and operation of the Field Wireless Congurator

and the Field Wireless Management Tool. Both programs are attached to YFGW710 and referred

to from Part B Engineering as necessary.

Field Wireless Congurator: sets up the eld wireless system and its element devices

Field Wireless Management Tool: manages the operation of the eld wireless system

And this part explains the precautions of hardware and software.

IM 01W01F01-01EN

Page 10

<Read Me First>

Safety Precautions

IMPORTANT

Be sure to read the safety precautions for this product described in Read Me First (IM

01W01F01-11EN).

n Transportation of products containing lithium batteries :

This product contains lithium batteries. Primary lithium batteries are regulated in transportation

by the U.S. Department of Transportation, and are also covered by the International Air Transport Association (IATA), the International Civil Aviation Organization (ICAO), and the European

Ground Transportation of Dangerous Goods (ARD). It is the responsibility of the shipper to

ensure compliance with these or any other local requirements. Consult current regulations and

requirements before shipping.

ii

n How to dispose the batteries:

This is an explanation about the new EU Battery Directive (DIRECTIVE 2006/66/EC).This directive is only valid in the EU.

Batteries are included in this product. Batteries incorporated into this product cannot be removed

by yourself. Dispose them together with this product.

When you dispose this product in the EU, contact your local Yokogawa Europe B.V. ofce. Do not

dispose them as domestic household waste.

Battery type: lithium thionyl chloride primary battery

CAUTION

The symbol (see above) means they shall be sorted out and collected as ordained in ANNEX II in

DIRECTIVE 2006/66/EC.

IM 01W01F01-01EN

Page 11

<Read Me First>

n Cautions for Safely Applying the Device:

l EMC Conformity Standards

EN61326-1 Class A, Table 2 (For use in industrial locations), EN61000-6-2

CAUTION

This instrument is a Class A product, and it is designed for use in the industrial environment.

Please use this instrument in the industrial environment only.

l Low Voltage Directive

Applicable standard: EN61010-1

(1) Pollution Degree 2

“Pollution degree” describes the degree to which a solid, liquid, or gas which deteriorates dielectric strength or surface resistivity is adhering. “2” applies to normal indoor atmosphere. Normally,

only non-conductive pollution occurs. Occasionally, however, temporary conductivity caused by

condensation must be expected.

iii

(2) Installation Category I

“Overvoltage category (Installation category)” describes a number which denes a transient overvoltage condition. It implies the regulation for impulse withstand voltage.

“I” applies to electrical equipment which is supplied from the circuit when appropriate transient

overvoltage control means (interface) are provided.

l Regulatory Compliance for Radio and Telecommunication

Please conrm that a installation region fulls a standards, require additional regulatory information and approvals, contact to Yokogawa Electric Corporation.

• Radio and Telecommunications

Terminal Equipment Directive (R&TTE)

We, Yokogawa Electric Corporation hereby declare that this equipment, YFGW710 is in compliance with the essential requirements and other relevant provisions of Directive 1999/5/EC.

The CE declaration of conformity for R&TTE for this product can be found at http://www.

yokogawa.com/d/

IM 01W01F01-01EN

Page 12

<Read Me First>

l FCC compliance

This device complies with Part 15 pf FCC Riles. Operation is subject to the following two conditions: (1) this device may not cause interference, and (2) this device must accept any interference, including interference that may cause undesired operation of this device.

Co-located:

This transmitter must not be co-located or operated in conjunction with any other antenna or

transmitter.

FCC WARNING:

Changes or modications not expressly approved by the party responsible for compliance could

void the use’s authority to operate the equipment.

NOTE

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instruction manual, may cause harmful interferences to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense.

iv

IM 01W01F01-01EN

Page 13

<Read Me First>

l Industry Canada (IC) compliance

This Class A digital apparatus complies with Canadian ICES-003.

This device complies with Industry Canada licence-exempt RSS standard(s). Operation is subject to the following two conditions: (1) this device may not cause interference, and (2) this device

must accept any interference, including interference that may cause undesired operation of the

device.

Under Industry Canada regulations, this radio transmitter may only operate using an antenna of

a type and maximum (or lesser) gain approved for the transmitter by Industry Canada. To reduce

potential radio interference to other users, the antenna type and its gain should be so chosen that

the equivalent isotropically radiated power (e.i.r.p.) is not more than that necessary for successful

communication.

This radio transmitter IC Number 8999A-WIC001 has been approved by Industry Canada to

operate with the antenna types listed below with the maximum permissible gain and required antenna impedance for each antenna type indicated. Antenna types not included in this list, having

a gain greater than the maximum gain indicated for that type, are strictly prohibited for use with

this device.

Antenna type: Gain:

COLLINEAR 9dBi, 50Ω

Sleeve 2.14dBi, 50Ω

v

French:

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

Le présent appareil est conforme aux CNR d’Industrie Canada applicables aux appareils radio

exempts de licence. L’exploitation est autorisée aux deux conditions suivantes : (1) l’appareil ne

doit pas produire de brouillage, et (2) l’utilisateur de l’appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est susceptible d’en compromettre le fonctionnement.

Conformément à la réglementation d’Industrie Canada, le présent émetteur radio peut fonctionner avec une antenne d’un type et d’un gain maximal (ou inférieur) approuvé pour l’émetteur par

Industrie Canada. Dans le but de réduire les risques de brouillage radioélectrique à l’intention

des autres utilisateurs, il faut choisir le type d’antenne et son gain de sorte que la puissance

isotrope rayonnée équivalente (p.i.r.e.) ne dépasse pas l’intensité nécessaire à l’établissement

d’une communication satisfaisante.

Le présent émetteur radio IC Number 8999A-WIC001 a été approuvé par Industrie Canada pour

fonctionner avec les types d’antenne énumérés ci-dessous et ayant un gain admissible maximal et l’impédance requise pour chaque type d’antenne. Les types d’antenne non inclus dans

cette liste, ou dont le gain est supérieur au gain maximal indiqué, sont strictement interdits pour

l’exploitation de l’émetteur.

Antenne type: Gain:

COLLINEAR 9dBi, 50Ω

Sleeve 2.14dBi, 50Ω

n Insulation Resistance and Dielectric Strength Test

Insulation Resistance and dielectric strength test could not be carried out for YFGW710, due to

the circuit ground is connected directly to the frame of YFGW710 via RF cable shield.

IM 01W01F01-01EN

Page 14

<Read Me First>

Documentation Conventions

n Typographical Convention

The following typographical conventions are used throughout the user’s manuals:

l Conventions commonly used throughout user’s manuals

Character string to be entered

The characters to be entered are shown in one-byte characters as follows:

Example:

FIC100.SV=50.0

“”Mark

Indicates a space between character strings to be entered.

Example:

.AL PIC010 -SC

Character string enclosed by brackets ({ })

vi

Indicates an option that can be omitted.

Example:

.PR TAG {. Sheet name}

l Conventions used to show key or button operations:

Characters enclosed by brackets ([ ])

Characters enclosed by brackets within any description on a key or button operation, indicate

either a key on the HIS (Human Interface Station) keyboard, a key on the operation keyboard, a

button name on a window, or an item displayed on a window.

Example:

To alter the function, press the [ESC] key

Characters enclosed by angle-brackets (<>)

Characters enclosed by angle-brackets show the title of the screen during the explanation of the

software operation.

IM 01W01F01-01EN

Page 15

<Read Me First>

l Conventions used in command syntax or program statements:

The following conventions are used in a command syntax or program statement:

Characters enclosed by angle-brackets

Indicate character strings that user can specify freely according to certain guidelines.

Example:

#dene <Identier><Character string>

“...” Mark

Indicate that the previous command or argument may be repeated.

Example:

Imax (arg1, arg2, ...)

Characters enclosed by brackets ([ ])

Indicate that those character strings can be omitted.

Example:

sysalarm <format_string> [output_value ...]

Characters enclosed by separators (| |)

vii

Indicate that those character strings can be selected from more than one option.

Example:

opeguide <format_character_string> [, <output_value> ...]

OG,<element number> opeguide

n Symbols used in the manual

The symbol used in the manual are described in “Read Me First” (IM 01W01F01-11EN).

n Drawing Conventions

Some drawings may be partially emphasized, simplied, or omitted, for the convenience of description.

Some screen images depicted in the user’s manual may have different display positions or

character types (e.g., the upper/lower case). Also note that some of the images contained in this

user’s manual are display examples.

IM 01W01F01-01EN

Page 16

<Read Me First>

Information of User’s Manual Revision

Material Name: YFGW710 Field Wireless Integrated Gateway

Material Number: IM 01W01F01-01EN

Edition Date Page Revised Item

1st August 2010 New Issue

2nd October 2010 A3-24 Add “Explosion Proof Certications.”

3rd April 2011 v

A3-24

B1-2

B1-4

D3

4th September 2011 PART-A

PART-D

5th July 2012 iii

C3-26

6th March 2013 iii

A3-9

A3-15

A3-31

A3-32

A3-36

A3-38

7th Janualy 2014 iii

A3-33

A3-37

Added “Use of Open Source License Software”

Added electrical connection code 0

Modied the System Engineering Flow Overview gure

Added note regarding setting device information using infrared

communications in FieldMate R2.03.00

Deleted “Restriction of changing Dening Device Role”

Deleted “Notice of saving a project as different name”

Corrections made.

Deleted.

Add CE alert marking.

Add applicable country code table.

Add note for display of remaining battery power.

Delete CE alert marking.

Add tightening torque for power supply terminal.

Change gure A3-12.

Add control drawing.

Change hazardous class name plate.

Change applicable standard for ATEX Type n.

Add dimensional drawing for antenna mounting bracket.

Delete country name table

Change IECEx Certication

Change IECEx scheme

viii

Use of Open Source License Software

This product uses software based on the open source license of GPL (GNU General Public

License), etc.

GPL (the GNU General Public License) Provisions

For details on the GPL, see the following URL.

URL http://www.gnu.org/copyleft/gpl.html

Scope of Warranty and Responsibility

Yokogawa does not guarantee the operation of the open source software itself in accordance

with the GPL and related provisions.

Individual Information of the Open Source Software

For details on the module names and source codes of the open source software, contact your

nearest Yokogawa dealer.

IM 01W01F01-01EN

Page 17

<Read Me First>

n ATEX Documentation

This is only applicable to the countries in European Union.

ix

GB

DK

E

NL

SK

CZ

I

LT

LV

EST

PL

SF

P

F

D

S

SLO

H

BG

RO

M

GR

IM 01W01F01-01EN

Page 18

<A1. Introduction>

A1. Introduction

The YFGW710 Field Wireless Integrated Gateway and eld wireless devices are used to build an

industrial wireless network that conforms to ISA100.11a, the wireless communication standard

for industrial automation specied by the International Society of Automation (ISA).

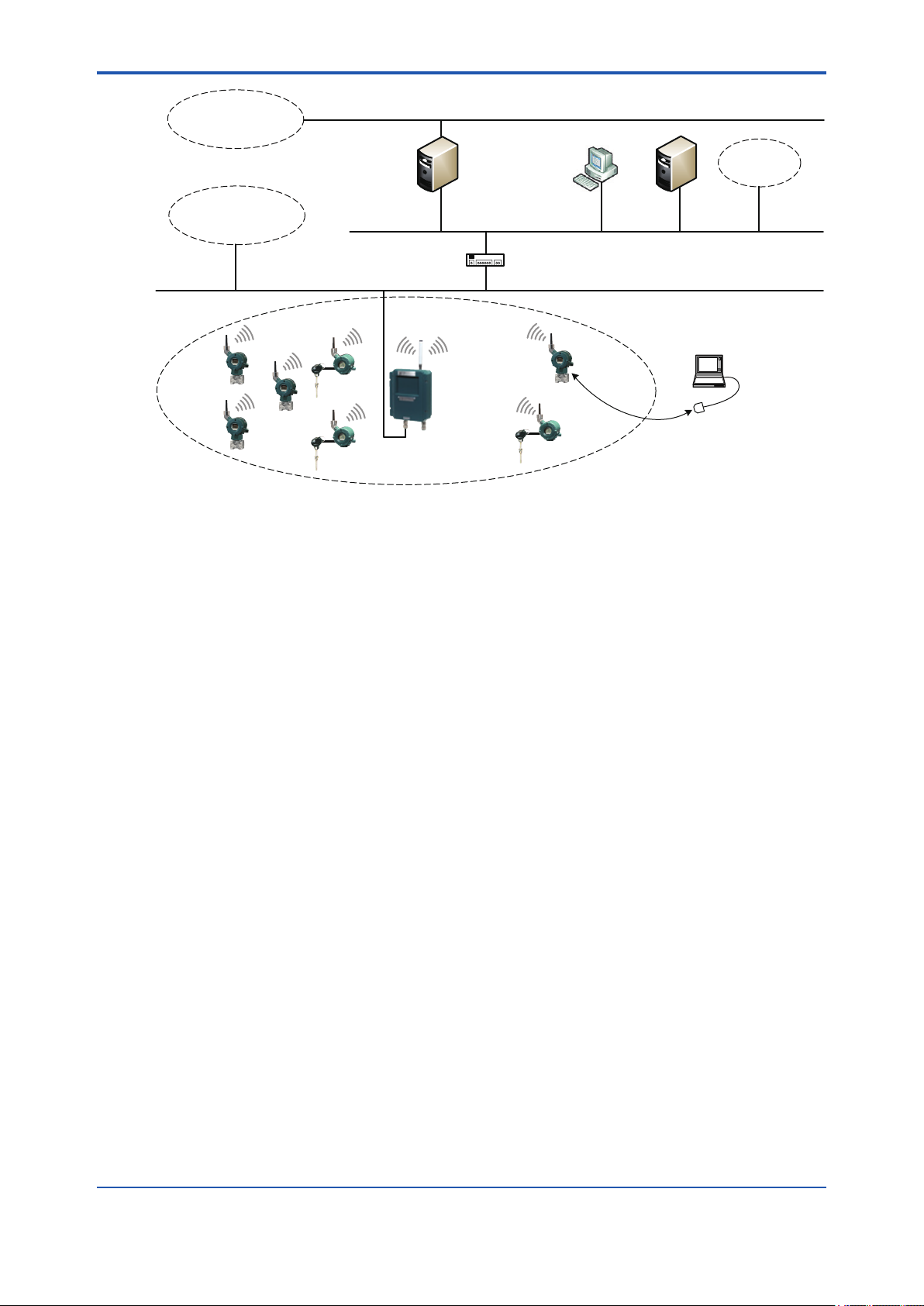

As shown in Fig. A1-1, the YFGW710 Field Wireless Integrated Gateway plays a key role in the

wireless network and has the following functions:

• Allows eld wireless devices to join the wireless network, forms and maintains communication routes, and manages the wireless network for monitoring the communication state

• Stores Publish*1 data of eld wireless devices in the Modbus register for transmitting it to

CENTUM VP or other host systems

• Transmits process data to the host system via a Modbus/TCP or dedicated OPC server

• Relays on-demand communication for parameter setting and management between eld

wireless devices and PRM

*1: Action to measure the process value at intervals preset in the eld wireless device itself and transmit it via wireless communi-

cation

This manual explains the YFGW710 Field Wireless Integrated Gateway (hereinafter referred to

as YFGW710) and the eld wireless network.

A1-1

Among eld wireless devices, our wireless EJX (Differential Pressure/Pressure Transmitter) and

wireless YTA (Temperature Transmitter) can communicate with the YFGW710. Devices certied

as compliant with the ISA100.11a standard can communicate with the YFGW710 and join the

wireless network.

For details of eld wireless devices, refer to the user’s manual of the respective devices.

For the overall system conguration including the eld wireless network and a host system, refer

to the general specications:

GS 01W01A01-01EN Overview of Field Wireless System

IM 01W01F01-01EN

Page 19

<A1. Introduction>

A1-2

Host system

(OPC interface)

(6)

Host system

(Modbus/TCP)

(2)

Field Wireless

OPC server

Field Wireless Network

Figure A1-1 Image of Field Wireless Network

Notes:

Management Tool

(1)

Field Wireless

Integrated

Gateway

(4)

Field Wireless

Layer 3 switch

EJX

Ir connection

YTA

(5)

NTP

server

FieldMate

Ir adapter

(3)

Ethernet

Device

management

tool

Ethernet

Ethernet

(7)

FA0101.ai

(1) Field Wireless Integrated Gateway (YFGW710): Core equipment in the wireless network

(2) Field wireless devices (wireless EJX and wireless YTA): Field instruments that measure

process values and send them wirelessly

(3) FieldMate: Software that performs “provisioning” (setting essential parameters) through

infrared data communication in advance to allow wireless eld devices to join the wireless

network

(4) Field Wireless Management Tool: Field Wireless Congurator congures the wireless net-

work and Field Wireless Management Tool manages it.

(5) NTP server: The Gateway refers to this server to synchronize its time with a reference time

source, which is a basic operation of a wireless network. Wireless communication between

eld wireless devices and YFGW710 can be established without an NTP server.

(6) Host system (Modbus/TCP): A system that uses process values measured by eld wireless

devices through the wireless network for monitoring, etc.

(7) Device management tool: An application that sets and manages the parameters of eld

wireless devices via a wireless network system

IM 01W01F01-01EN

Page 20

<A2. Checking the Product>

A2. Checking the Product

When you receive the product, please check the contents.

Check that the product specications match your order, all parts are included, and there is no

damage, stains, or other troubles.

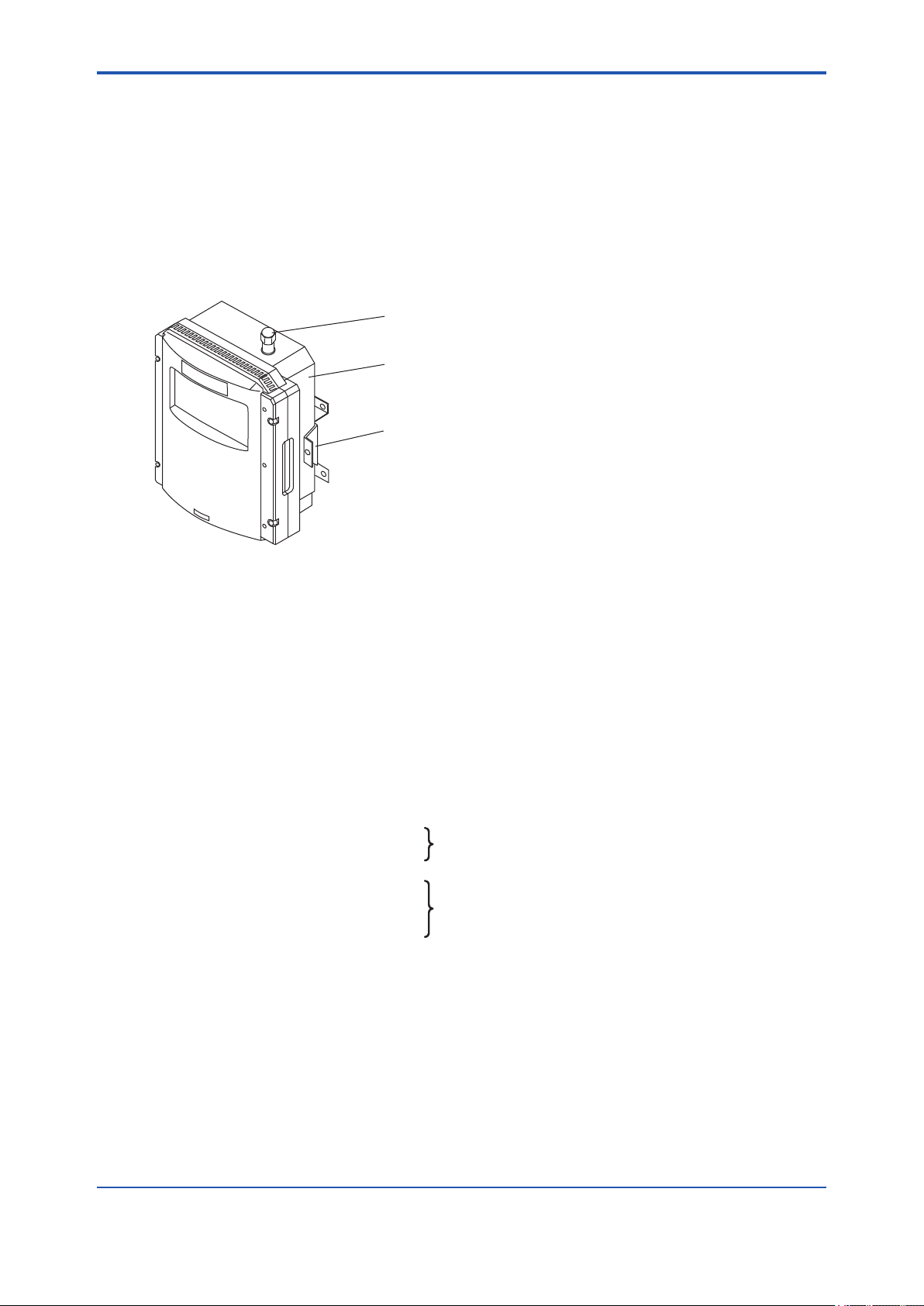

n Main unit

• YFGW710

Antenna connector (Capped)

Main unit of YFGW710

Bracket on the housing side

Provided when “2-inch (2B) pipe mounting bracket” is specified.

The bracket is secured to the main unit with screws.

A2-1

n Standard accessories

• Antenna 1

• User’s Manual 1 English or Japanese, as specied

• Software media 1 When “With Software Media” is specied

• Mounting bracket 1 When “2-inch (2B) pipe mounting” is specied

n Options

• External antenna cable

Antenna cable 1

Antenna mounting bracket 1

Antenna cable 2

Arrester 1 When “cable length: 4 m, 6 m or 13 m” is specied

Antenna mounting bracket 1

FA0201.ai

When “cable length: 1 m or 3 m” is specied

IM 01W01F01-01EN

Page 21

<A3. YFGW710 Field Wireless Integrated Gateway>

A3-1

A3. YFGW710 Field Wireless Integrated

Gateway

This chapter explains the installation of the YFGW710, antennas, cable connections, and maintenance.

A3.1 Installation

A3.1.1 Requirements for Installation Locations

The installation of YFGW710 and eld wireless devices must meet the following conditions:

• The eld wireless equipment should be mounted in the place where no obstacle exists

around the antenna. Especially, YFGW710 should be mounted in the condition that no obstacle exists around the antenna, in both cases of wall mounting and pipe mounting.

• If there is a pipe for mounting or plumbing in the direction except for the communication

partners, the antenna should be more than 30 cm apart from them.

• When the wall mounting does not satisfy the condition, use the extension cable to mount an

antenna in the place where there is no inuence from any objects.

• All antennas must be in the upright position.

• The antenna of eld wireless equipment must be installed at least 1.5 meter above the

ground (oor)

• The YFGW710 should be installed at a location as close as possible to the center of the eld

wireless network.

• Ensure that the eld wireless devices that are located within the wireless communication

range are within the line of sight of each other. In the star topology, the YFGW710 must

meet this condition.

IM 01W01F01-01EN

Page 22

<A3. YFGW710 Field Wireless Integrated Gateway>

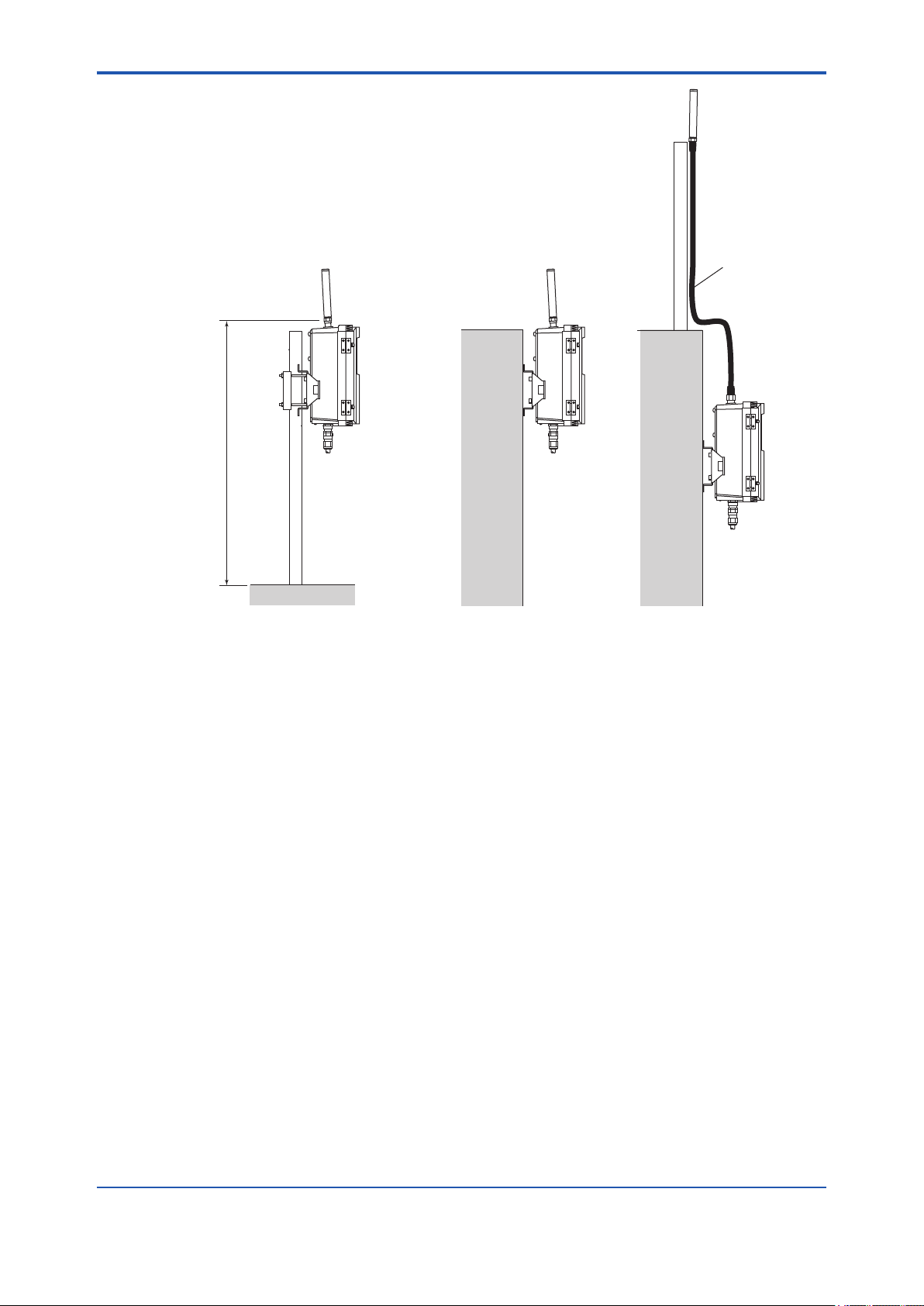

More than

1.5 m

A3-2

Extension

Cable

2-inch (2B) pipe Wall Mounting

Figure A 3-1 Mounting Example of Field Wireless Integrated Gateway

A3.1.2 Notes on Installation

Pay attention to the following points at the installation of YFGW710.

n Installation Location

This device is designed to work under the severe environmental condition. However, it is necessary to pay attention to the following conditions for the stable and long-term precise operation.

l Exposure to Direct Sunlight

If the device is placed at a location that may be exposed to direct sunlight, it is necessary

to make the insulation measure. However, the antenna must be covered with the material

which does not block the radio wave.

l Ambient Temperature

Avoid locations subject to wide temperature variations or a signicant temperature gradient.

If the location is exposed to radiant heat from plant equipment, provide adequate thermal

insulation and/or ventilation. Do not install the device in a location where high temperature

and high humidity may last for a long time.

FA0301.ai

l Ambient Atmosphere

Do not install the device in a corrosive atmosphere. If this cannot be avoided, there must

be adequate ventilation as well as measures to prevent the rain water from penetrating or

remaining in the conduits.

IM 01W01F01-01EN

Page 23

<A3. YFGW710 Field Wireless Integrated Gateway>

l Vibration and Impact

Although the device is designed to be resistant to vibration and impact, an installation site

should be selected where vibration and impact are kept to a minimum.

n Installation of Explosion Proof Compliant Device

The explosion proof compliant equipment can be installed in the hazardous area of specic

gases. This device must be installed in accordance with the regulations of the country where the

device is installed.

• Installation: Check that the ambient temperature is not beyond the limit.

• Wiring: Put all the power cables in protective ducts. If possible, also put the network cables

(optical ber cable or metal cable) in protective ducts.

• Maintenance: After conrming that there is no dangerous gas in the ambience, open the

housing or protective ducts.

A3.1.3 Mounting Procedure

Mount YFGW710 on the 2-inch (2B) pipe or the wall where the environment satises all the requirements for the wireless device.

SEE

For more information about the installation environment, see the General Specication of YFGW710 Field Wire-

ALSO

less Integrated Gateway (GS 01W01F01-01EN).

A3-3

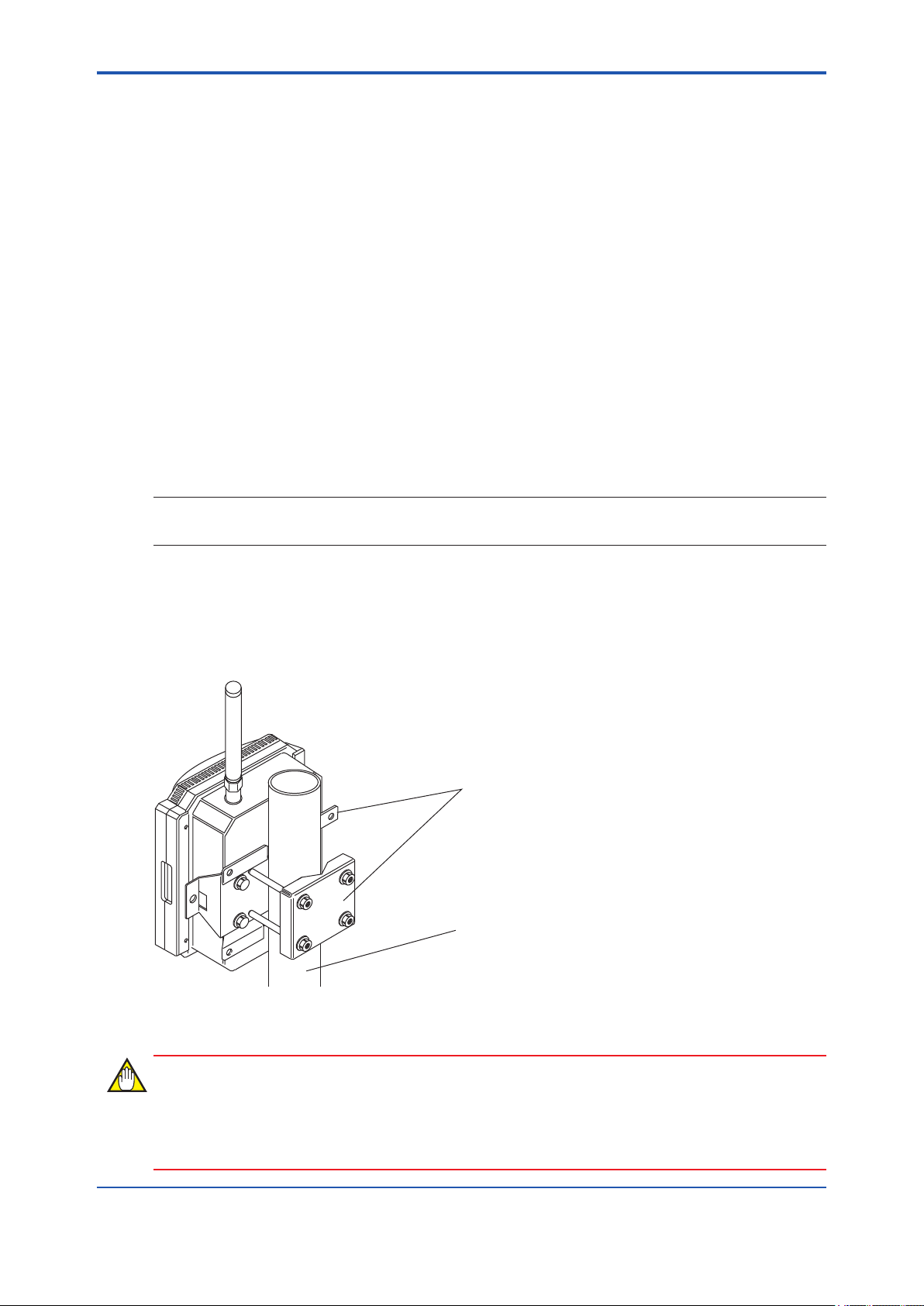

n Mounting to 2-inch (2B) Pipe with Bracket

When mounting the device on the 2-inch (2B) pipe, a dedicated bracket should be used. This

bracket is an option of YFGW710, see the model code list.

This bracket does not support the mounting to the horizontal piping.

Bracket

2-inch (2B) pipe

Fig. A 3-2 Mounting YFGW710 to 2-inch (2B) pipe

FA0302.ai

IMPORTANT

YFGW710 is a heavy device (5.1 kg). Ensure that the bracket and 2-inch (2B) pipes used for

mounting are xed rmly enough to withstand strong wind and vibration. The device must be

maintained in its upright position.

IM 01W01F01-01EN

Page 24

<A3. YFGW710 Field Wireless Integrated Gateway>

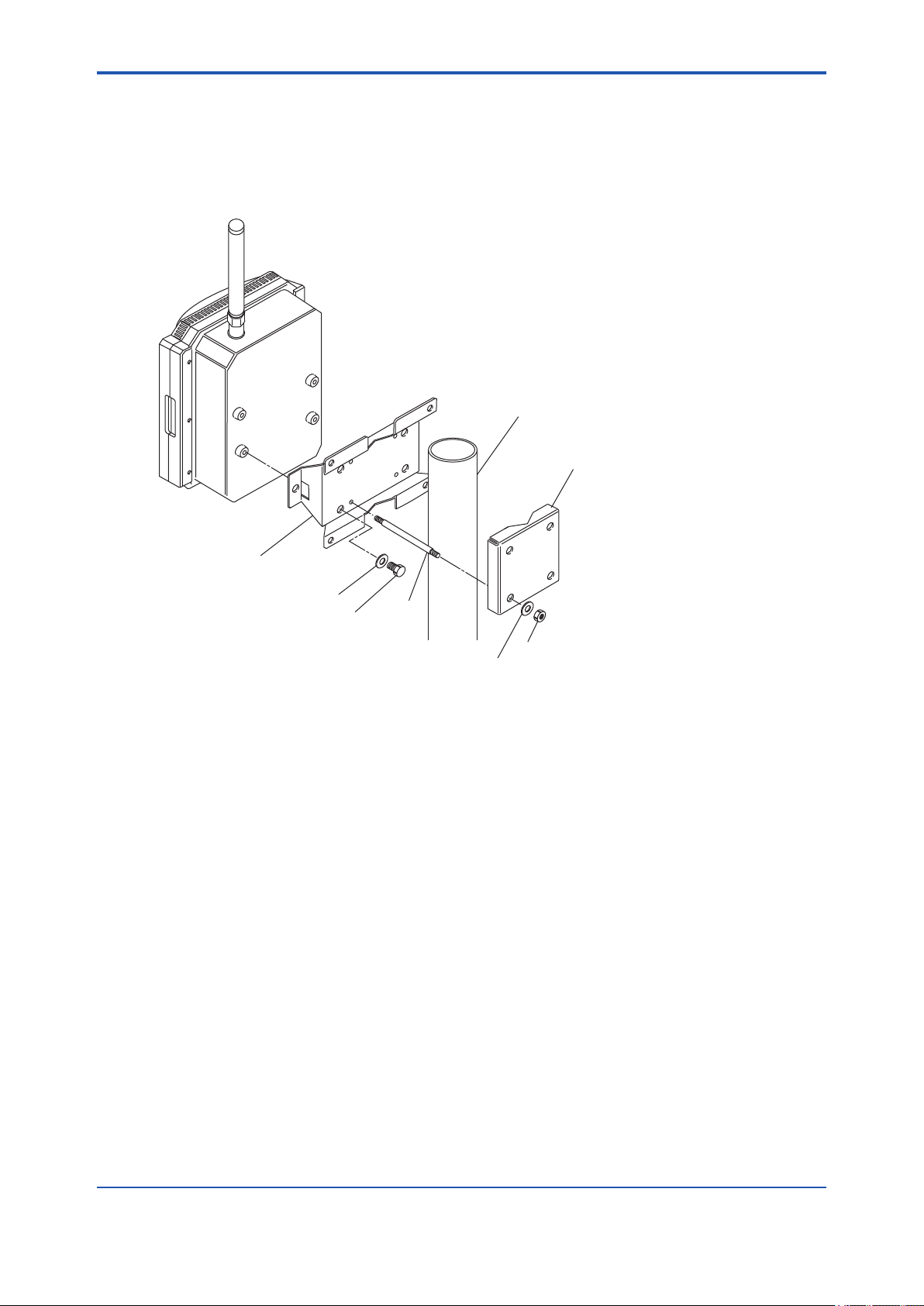

l Mounting procedure

1. Fix the bracket 1 for the housing to the back of Gateway with the 4 provided screws. When

you specify a unit with the bracket, the bracket is secured to the main body with screws.

2. Screw the 4 provided bolts into the bracket 1 as shown in the gure.

3. Hold 2-inch (2B) pipe by the bracket 1 and bracket 2, and tightly fasten the bolts with nuts.

2-inch (2B) pipe

Bracket 2

A3-4

Bracket 1 for housing

Washer

Screw

Bolt

Fig. A 3-3 Mounting to the 2-inch (2B) pipe

Washer

Nut

FA0303.ai

IM 01W01F01-01EN

Page 25

<A3. YFGW710 Field Wireless Integrated Gateway>

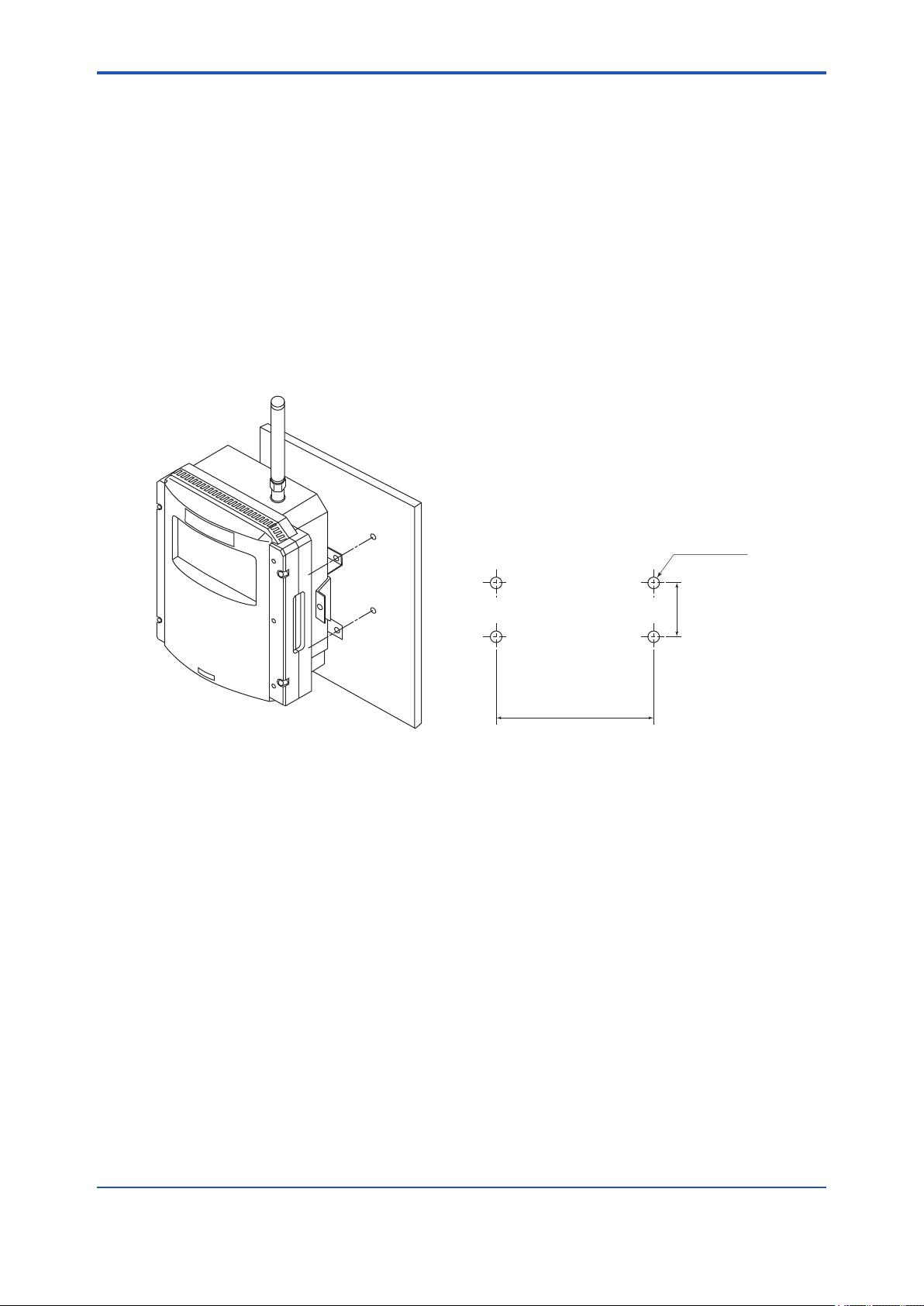

n Mounting to the Wall Using Bracket

When mounting YFGW710 to the wall, use the bracket for the housing. When the body is ordered, the bracket is specied by the model code. To avoid the communication problem caused

by the wall, mount the Gateway in the place where any obstacles do not exist around the antenna.

When no place satisfying the mounting condition, the antenna should be mounted in an appropriate place apart from the main body using the extension cable.

l Mounting Procedure

1. Fix the bracket for the housing using the 4 provided screws on the back of Gateway

2. Fix the Gateway to the wall using M5 screws through screw holes.

3. To avoid the vibration and wind and so on, x the antenna on the place apart from the wall

and obstacles according to the procedure described in A3.2.4.

Mount the main body on the wall with the

bracket and M5 screws.

The provided bolts and nuts are not used.

A3-5

Fig. A 3-4 Mounting to the wall

Ø6.5 hole

or M5 Screw

126.5

190

FA0304.ai

IM 01W01F01-01EN

Page 26

<A3. YFGW710 Field Wireless Integrated Gateway>

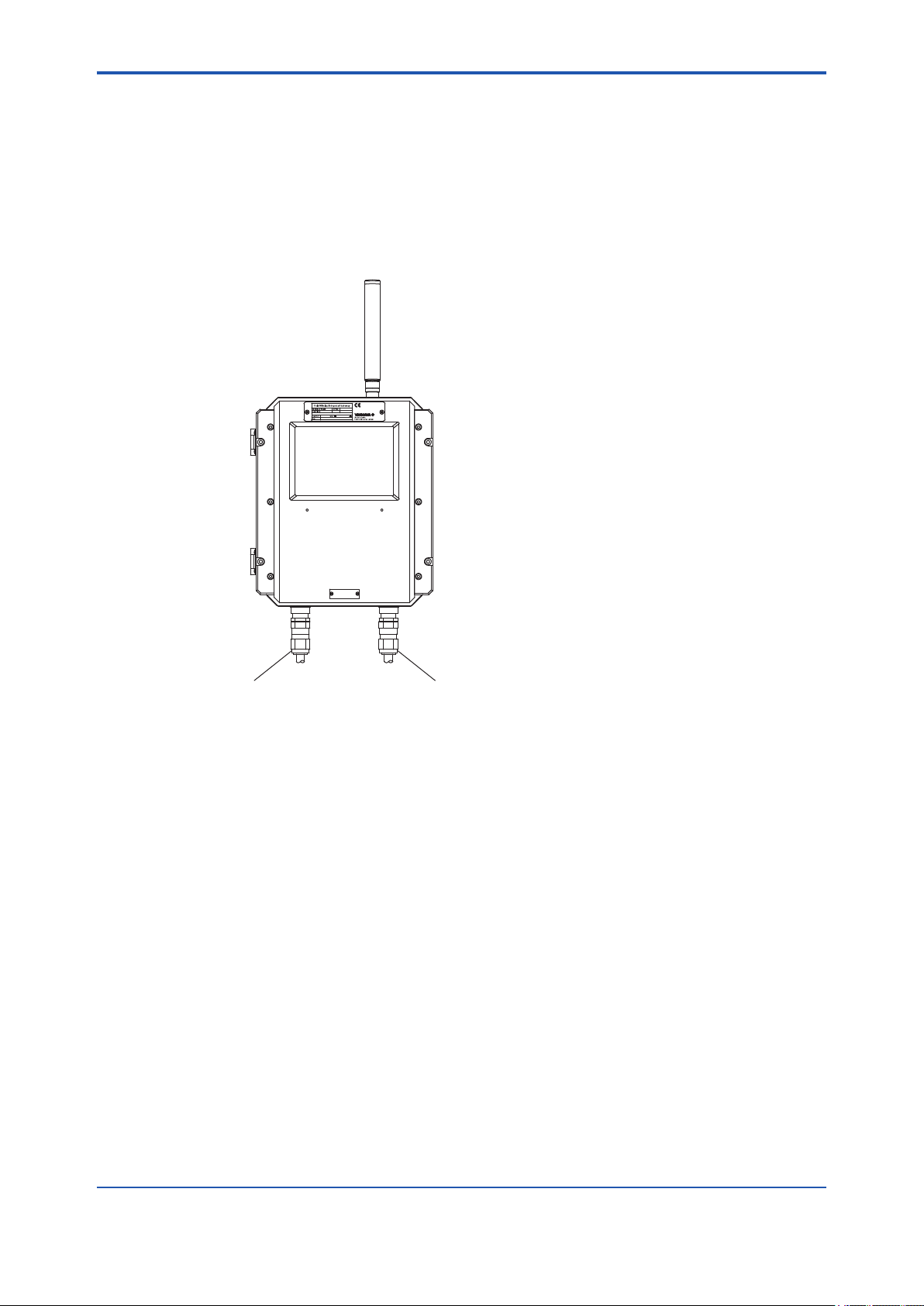

A3.1.4 Set-up after Mounting

The necessary procedure after mounting YFGW710 is explained.

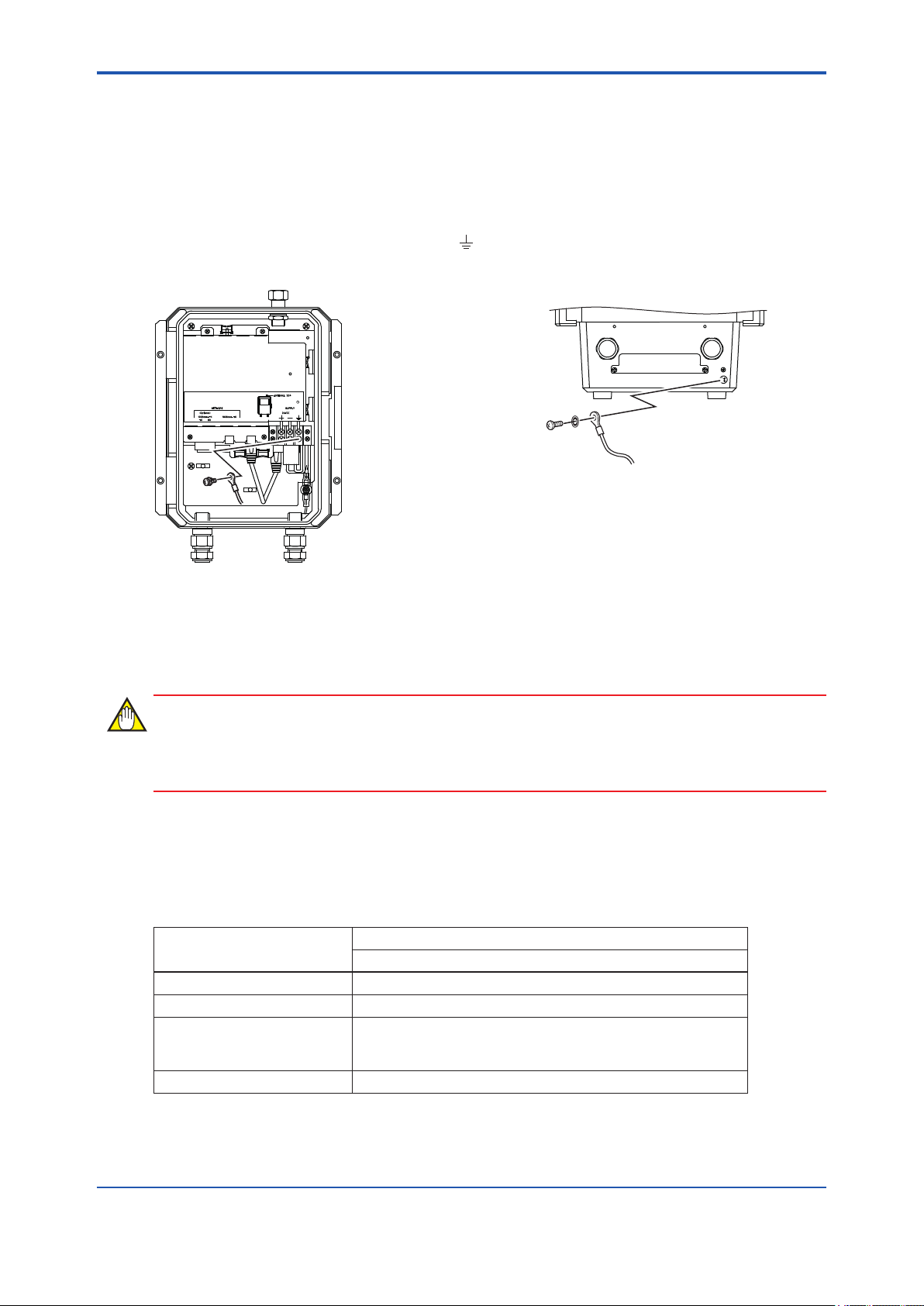

n Attaching Cable Glands

Attach the cable glands to the housing before connecting the cables to YFGW710 as necessary.

The left cable gland is for the communication cable and the right one is for the power supply

cable (see the label on the bottom of main housing).

A3-6

Cable Gland

for Communication

Fig. A 3-5 Attaching Cable Gland

Cable Gland

for Power Supply

FA0305.ai

IM 01W01F01-01EN

Page 27

<A3. YFGW710 Field Wireless Integrated Gateway>

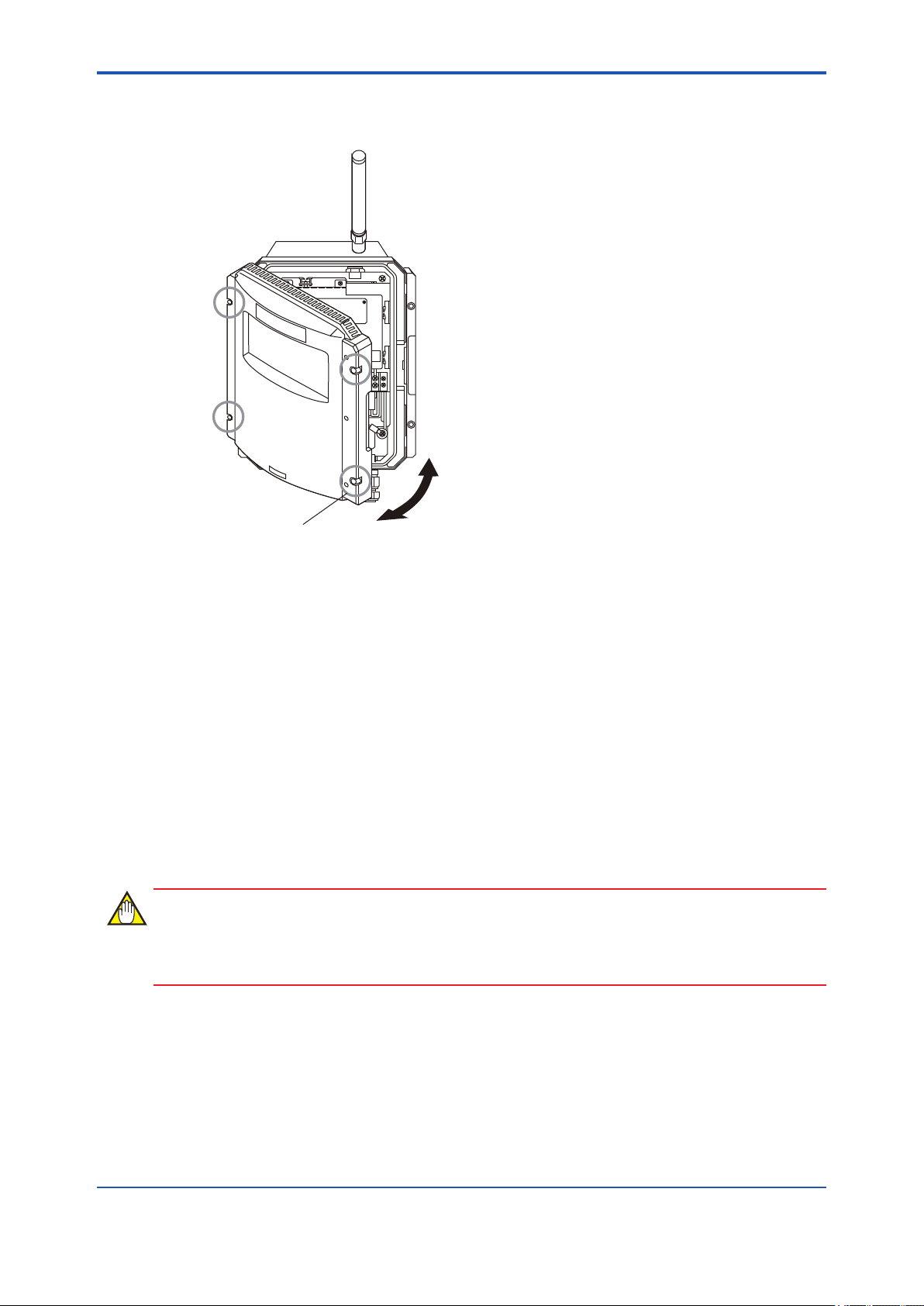

n Opening and Closing Front Door

Open and close the front door of the housing following the procedure below.

Close

A3-7

Four bolts to fix the front door

Fig. A 3-6 How to open/close the front door

Open

FA0306.ai

l How to open the front door

1. Unscrew the four M5 Hexagon socket head cap bolts at each corner of the front door. The

bolts do not get away from the screw hole. Use a hex wrench of 4 mm hexagon width across

ats to unscrew/tighten the bolts.

2. Open the door to the left.

l How to close the front door

1. Close the front door to the main housing with full attention not to get ngers pinched in the

hinge and between the front door and the main housing.

2. Tighten the four xing bolts pressing the right edge of the front door evenly with a torque of

2.8 N∙m ±0.2 N∙m.

IMPORTANT

When opening and closing the front door, be careful not to get ngers and/or a part of body

pinched in the hinge and/or between the door and the main unit.

IM 01W01F01-01EN

Page 28

<A3. YFGW710 Field Wireless Integrated Gateway>

A3.2 Cable Connection

This chapter describes the connection of the power supply cable, grounding cable, network cable, and antenna extension cable and also the mounting of the antenna.

l The explosion proof device must be wired according to the related laws and regulations.

A3.2.1 Power Supply Cable Connection

This section describes the power supply cable wiring.

l Wiring

Pull the power supply cable into the gateway through the power cable ground. Connect the

power supply cable to the power supply terminal in the gateway.

l Recommended power supply capacity

Output voltage range 12 – 24 V DC (Supplied to YFGW710)

Output Current More than 1.5 A DC

*1: This equipment ows the inrush current at start-up as explained below. Therefore, the power source should have enough current

output capacity several times as high as the normal current consumption.

l Inrush Current

The input current at the start up (inrush current) is signicantly larger than the steady state current (see the table). Ensure that the power supply and its protective device can accommodate

this inrush current.

*1

A3-8

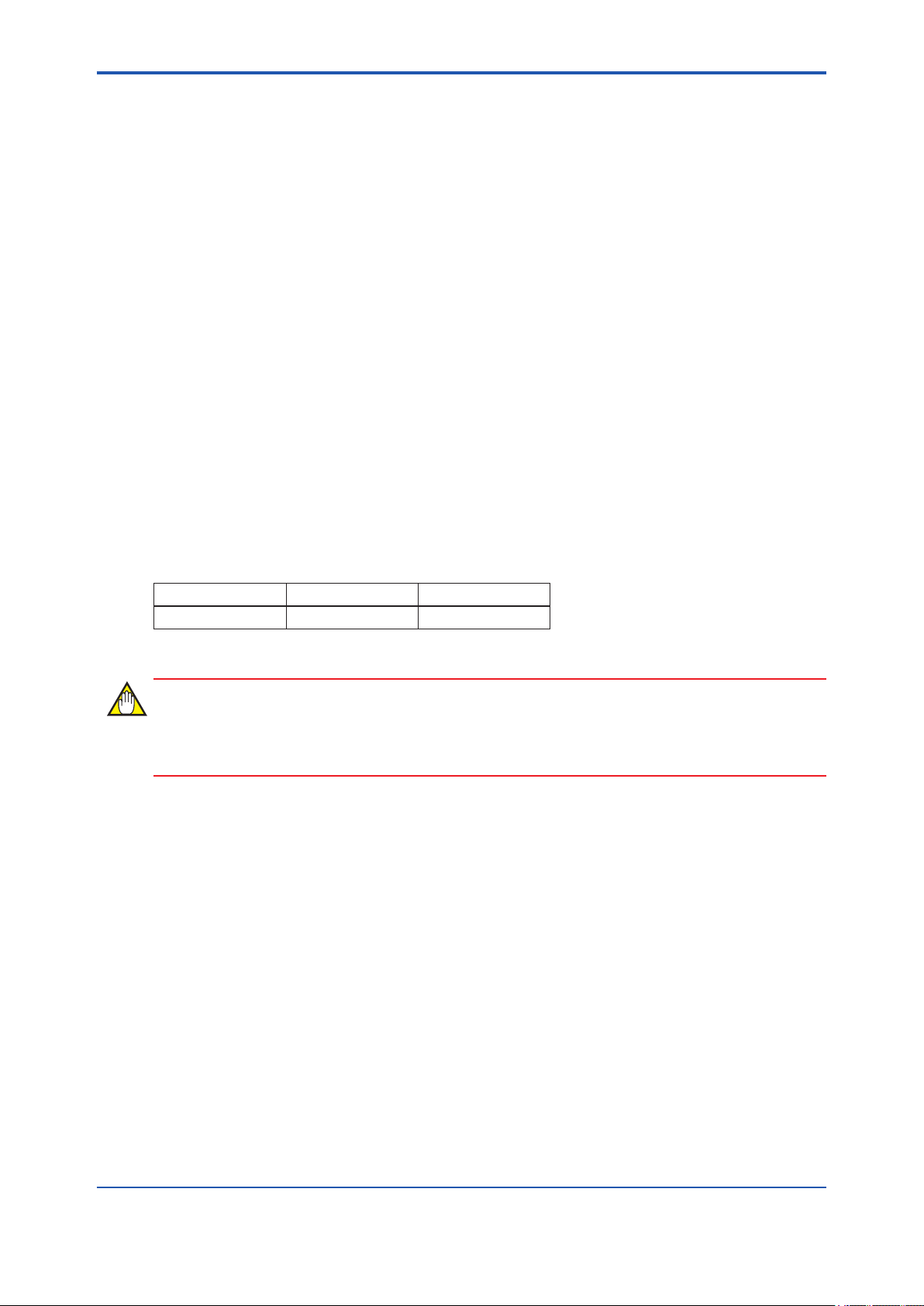

Table A 3-1 Inrush current of YFGW710

Item Specication Remarks

Inrush Current 30 A 2 ms

*2: This note corresponds when the power line breaker of YFGW710 is turned-on in condition the power source is running.

*2

at 24 V DC

IMPORTANT

YFGW710 does not have a power switch. Set a dedicated breaker for the external power line to

turn ON/OFF the device.

l Applicable Cable (Insulated wire for industrial equipment)

Examples:

• 600 V polyvinyl chloride insulated wires (IV): JIS C3307

• Polyvinyl chloride insulated wires for electrical apparatus (KIV): JIS C3316

• 600 V grade heat-resistant polyvinyl chloride insulated wires (HIV): JIS C3317

• Heatproof vinyl insulated wires VW-1 (UL1015/UL1007)

Wire Size

• Core: AWG14 to 13 (2 to 2.6 mm

2

)

Terminal Treatment

• Ring terminal for M4: With insulation covers

IM 01W01F01-01EN

Page 29

<A3. YFGW710 Field Wireless Integrated Gateway>

l Connection Procedure of Power Cable

1. Pull the power cable into the housing of YFGW710 through the power cable ground.

2. Connect + lead wire to + terminal and – lead wire to – terminal.

3. Tighten the terminal screw with a torque of 1.2 to 1.4 N∙m.

SUPPLY

A3-9

NETWORK

(Optional)

100Base-FX 100Base-FX

TX RX

ANTENNA50Ω

SUPPLY

Cable gland for power supply cable

Power supply cable

Fig. A 3-7 Power Supply Cable Connection

A3.2.2 Ground Cable Connection

This section describes ground wiring.

Class D grounding (the third class grounding) with the grounding resistance of 100 Ω or less is

necessary. To connect the grounding cable to YFGW710 directly, use the grounding terminal on

the right bottom of the main body. Do not share the ground wiring with other devices.

Connect the + and – wires to the + and –

terminals, respectively.

If the power cable is a shielded cable, the

shield should be grounded at terminal and

the grounding of the whole cable should be

restricted to this point only.

Power supply terminal

FA0307.ai

IMPORTANT

The explosion proof compliant device always needs the grounding.

l Applicable Cable (Insulated wire for industrial equipment)

Examples:

• 600 V polyvinyl chloride insulated wires (IV): JIS C3307

• Polyvinyl chloride insulated wires for electrical apparatus (KIV): JIS C3316

• 600 V grade heat-resistant polyvinyl chloride insulated wires (HIV): JIS C3317

• Heatproof vinyl insulated wires VW-1 (UL1015/UL1007)

Wire Size

• Core: AWG14 to 13 (2 to 2.6 mm

Terminal Treatment

• Ring terminal for M4: With insulation covers

2

)

IM 01W01F01-01EN

Page 30

<A3. YFGW710 Field Wireless Integrated Gateway>

l Connection of Cable

The grounding terminals are located on the inside and outside of the terminal area.

Connect the cable to grounding terminal in accordance with wiring procedure 1) or 2).

A3-10

1) Internal grounding terminal

If the power cable is a shielded cable, the shield

should be grounded at the terminal marked

as below.

Fig. A 3-8 Wiring Procedure for Grounding Terminals

A3.2.3 Network Cable Connection

2) External grounding terminal

M4 screw

(Bottom of the enclosure)

FA0308.ai

This section describes the connection of the optical and metal network cables.

IMPORTANT

According to the requirement of communication specication, select the optical Ethernet or the

metal Ethernet to communicate with the higher layer application.

A3.2.3.1 Optical Network Cable Connection

l Applicable Cable

Table A 3-2 Specication of Optical Network Cable

Item

Standard 100Base-FX

Connector SC Connector (1-pole x 2)

Applicable Cable

Transmission Range 2 km (Max.)

Multi Mode Fiber (Central wavelength: 1300 nm)

50/125 um or 62.5/125 um

Inner tension must be nonmetals, such as FRP.

*1

Specication

Optical Fiber Cable

*2

*1: 100Base-TX (Refer table A3-3) and 100Base-FX must be used exclusively.

*2: A double ferrule SC connector cannot be used. Be sure to use a single ferrule type.

IM 01W01F01-01EN

Page 31

<A3. YFGW710 Field Wireless Integrated Gateway>

IMPORTANT

The connection between the host system (CENTUM or STARDOM equipment and other application PCs) and YFGW710 requires an optical to metal Ethernet converter. Prepare an appropriate

converter which matches respective communication specications for converting 10BASET/100BASE-TX and 100BASE-FX. The recommended model is SLX-5ES-2SC of SIXNET.

l Wiring

1. Pull the optical ber network cable into YFGW710 through the cable ground for the network

cable.

2. Connect the optical ber communication cable to the optical connector.

Do not bend the optical ber communication cable at a tight angle; arrange it as shown in

the gure.

3. The optical ber communication cable is composed of a pair of wires that are used separately and exclusively for transmission and reception (TX/RX), as indicated on the internal

label of the pole of SC optical connector into YFGW710. Follow the indication on the label, if

shown. If there is no indication, you may connect them arbitrarily. The connection directions

can be changed easily in the optical converter of the host system.

A3-11

NETWORK

(Optional)

100Base-FX 100Base-FX

TX RX

Cable Gland for Network Cable

Optical Fiber communication cable

SC Optical Connecter

Fig. A 3-9 Connection of optical network cable

ANTENNA50Ω

SUPPLY

FA0309.ai

IM 01W01F01-01EN

Page 32

<A3. YFGW710 Field Wireless Integrated Gateway>

A3.2.3.2 Metal Network Cable Connection

l Caution for Use of Metal Network Cable

The metal network cable is for indoor operations only. To use it outdoors, the arrester is needed.

However, there is no appropriate arrester of the outdoor specication which can be installed

close to YFGW710.

Therefore, use the optical ber network cable for the outdoor wiring.

l Applicable Cable

Table A 3-3 Specication of Metal Network Cable

A3-12

Item

Standard 100Base-FX

Connector RJ-45

*2

*1

Specication

Metal Network Cable

Applicable Cable Category 5 or higher

Transmission Range 100 m (Max.)

*1: 100Base-TX and 100Base-FX (Refer table A3-2) must be used exclusively.

*2: RJ-45 connector must be connected to YFGW710 after putting the cable through the cable ground.

l Wiring

Connect the metal network cable according to the following procedure.

1. Pull the metal network cable into YFGW710 through the cable ground for network cable.

2. Apply pressure welding to connect the RJ-45 connector and the end of the metal network

cable.

3. Connect the metal network cable to the network connector. Use the metal cable conforming

to the standard of 100BASE-TX.

NETWORK

(Optional)

100Base-FX 100Base-FX

TX RX

Cable Ground for Network Cable

Metal Network Cable

Fig. A 3-10 Metal network cable connection

ANTENNA50Ω

SUPPLY

Ethernet Connector

FA0310.ai

IM 01W01F01-01EN

Page 33

<A3. YFGW710 Field Wireless Integrated Gateway>

A3.2.4 Mounting Antenna and Wiring

This section describes the mounting of the antenna to YFGW710 main body, the installation of

the external antenna, and their wiring.

IMPORTANT

The antenna connector is covered with a cap at the time of delivery. Keep the cap attached until

the installation of the antenna or antenna cables to protect the inside connection part. The unscrewed cap should be stored in order to replace it immediately after the antenna or antenna

cables are removed.

NOTE

To maintain the ultimate conditions of radio-frequency signal, protect the connectors of antenna,

extension antenna cable, and arrester from the corrosive atmosphere by the following treatment.

1. Clean the connection to be protected.

A3-13

2. Wind the butyl rubber self-bonding tape around the connection. See the manual of the tape

about the winding.

3. To protect the butyl rubber self-bonding tape from the environment such as ultraviolet rays

and so on, wind vinyl tape (or a vinyl type self-bonding tape) on it.

IM 01W01F01-01EN

Page 34

<A3. YFGW710 Field Wireless Integrated Gateway>

A3.2.4.1 Mounting Antenna to YFGW710 Main Body

Screw the provided antenna into the connector on the top of the body.

Conrm and waterproof the connection.

Antenna connector

A3-14

FA0311.ai

Fig. A 3-11 Mounting the antenna to the housing of YFGW710

l Mounting Procedure of Antenna

1. Unscrew the antenna connector cap on the antenna connector.

2. Screw the provided antenna into the antenna connector.

Tighten the antenna connector with a torque of 2 to 3 N∙m.

IM 01W01F01-01EN

Page 35

<A3. YFGW710 Field Wireless Integrated Gateway>

A3.2.4.2 Mounting and Wiring External Antenna

n Mounting of External Antenna

Mount the external antenna at the proper location according to the wireless environment described in “A3.1.1 Installation Condition” of this manual.

The mounting to the pipe such as 2-inch (2B) pipe needs to secure the enough strength to endure a strong wind, vibration and so on. The antenna must be mounted vertically.

l Fixing of External Antenna

Fix an external antenna appropriately using the bracket provided as the external antenna option.

2-inch pipe

Antenna

A3-15

U Bolt

Bracket

Washer

Nut

Fig. A 3-12 Example of xing external antenna

Nut

Antenna

Extension Cable

Vertical pipe

mounting

Horizontal pipe

mounting

FA0313.ai

l Mounting Procedure of External Antenna

1. Fix the antenna extension cable to the bracket with the provided nut as shown in the gure

A3-12 above.

2. Fix the bracket to the 2-inch (2B) pipe by using the provided a pair of U bolts and nuts.

3. Screw the antenna into the antenna connector of the antenna extension cable on the

bracket.

Tighten the antenna connector with a torque of 2 to 3 N∙m.

4. Protect the connection as necessary. For details of the protection, see “A3.2.4 Mounting

Antenna and Wiring.”

IM 01W01F01-01EN

Page 36

<A3. YFGW710 Field Wireless Integrated Gateway>

n Wiring External Antenna

l Specication for Extension Antenna Cable (Only by order of option)

• Specication: 8D-SFA(PE)

• Outside Diameter: 11.1 mm

• Minimum Bend Radius: 67 mm (when xing)

167 mm (when wiring)

• Cable End Treatment: N type connector, one end is male and the other is female.

* “When xing” shows the bending radius for xing (the state is maintained for a long time).

“When wiring” shows the bending radius while checking the wiring position. This bending

radius is set larger than that for xing in order to prevent damage to the cable because the

cable is likely to be repeatedly bent when checking the nal wiring position.

l Wiring of Extension Antenna Cable

1. Use the provided extension antenna cable to connect the antenna connector with the external antenna. Tighten the connector of the antenna extension cable with a torque of 2 to 3

N∙m. Refer to the specication about the limitation of bend radius when xing or wiring.

2. When using two extension cables, the provided arrester should be inserted between these

cables.

A3-16

3. Before the wiring work, conrm the polarities (male/female) of the connectors of antenna,

extension antenna cable, and arrester.

Tighten the connector of the antenna extension cable with a torque of 2 to 3 N∙m.

4. Protect the connectors of antenna, extension antenna cable, and arrester as necessary.

See “A3.2.4 Mounting Antenna and Wiring.”

5. Fix the extension antenna cable to the appropriate structure to protect the cable from the

vibration, wind, and so on.

IM 01W01F01-01EN

Page 37

<A3. YFGW710 Field Wireless Integrated Gateway>

External Antenna

External Antenna

Extension cable 2

Length: 10 m or 3 m

A3-17

Protect by

Self-bonding tape

Extension cable

Length: 3 m or 1 m

Housing of YFGW710

Fig. A 3-13 Wiring of external antenna

Protect by

Self-bonding tape

Housing of YFGW710

Arrester

Ground Wiring

Extension cable 1

Length: 3 m or 1 m

FA0314.ai

l Mounting of Arrester and Wiring

Mount an arrester between the extension cables and connect the grounding cable to the grounding terminal of the arrester.

Connect the grounding cable to the grounding terminal on the main body. Class D grounding (the

third class grounding) with the grounding resistance of 100 Ω or less is necessary. Do not share

the ground with other devices.

l Applicable Grounding Cable (Insulated wire for industrial equipment)

Examples:

• 600 V polyvinyl chloride insulated wires (IV): JIS C3307

• Polyvinyl chloride insulated wires for electrical apparatus (KIV): JIS C3316

• 600 V grade heat-resistant polyvinyl chloride insulated wires (HIV): JIS C3317

• Heatproof vinyl insulated wires VW-1 (UL1015/UL1007)

Wire Size

• Core: AWG14 to 13 (2 to 2.6 mm

2

)

Terminal Treatment

• Ring terminal for M4: With insulation covers

IM 01W01F01-01EN

Page 38

<A3. YFGW710 Field Wireless Integrated Gateway>

Antenna

Extension cable 2

Grounding wiring

Arrester

Extension cable 1

A3-18

YFGW710

FA0315.ai

Fig. A 3-14 Connection of the arrester and antenna extension cables

Antenna

Self-bonding tape

Grounding wiring

Main Body

FA0316.ai

Fig. A 3-15 Arrester protection by self-bonding tape

IM 01W01F01-01EN

Page 39

<A3. YFGW710 Field Wireless Integrated Gateway>

A3.3 Wiring for Explosion Proof

Refer to explosion proof certications section of this document.

A3-19

IM 01W01F01-01EN

Page 40

<A3. YFGW710 Field Wireless Integrated Gateway>

A3.4 Maintenance

This section describes the maintenance of YFGW710.

A3.4.1 Routine Maintenance

The following maintenance needs to be performed periodically.

IMPORTANT

If the YFGW710 is covered with dust or dirt, wipe with a soft cloth moistened by water or mild

soap.

n Antenna

When the antenna is covered with dirt or dust containing metal powder, the wireless communication may become unstable; therefore, the periodic cleaning and maintenance are necessary. In

cold regions, preventive measures against snow and ice problems as well as periodic maintenance should be provided periodically.

A3-20

A3.4.2 Maintenance in Hazardous Area

Refer to explosion proof certications section of this document.

IM 01W01F01-01EN

Page 41

<A3. YFGW710 Field Wireless Integrated Gateway>

A3.4.3 Communication Check

On the Field Wireless Network Manager, the status of wireless device connected to the wireless

network and the status of the communication route can be conrmed. Field Wireless Network

Manager is the provided software of YFGW710 and used in the PC connected to the YFGW710

of the Field Wireless System.

SEE

For more information about checking device and communication status, see “B1.2.5 Conrmation of Field Wire-

ALSO

less Network Operation”

A3.4.4 About Parts Having Dened Life Spans

The YFGW710 include no parts having dened life spans, which need to be replaced.

Read this section thoroughly and carry out the periodical replacement.

IMPORTANT

Precautions for parts having dened life spans

• The term “Parts having dened life spans” refers to parts that are expected to wear out or

break down within 10 years from the initial use under normal conditions of use and storage.

Therefore, parts with expected life spans of 10 years or more are excluded here.

A3-21

• The recommended replacement cycle is the cycle indicated for preventive maintenance. It

provides no guarantee against the accidental failures.

• The recommended replacement cycle is merely a guideline. The actual replacement cycle

depends on the usage conditions.

The recommended replacement cycle is subject to change according to the actual results in

the eld.

SEE

For more information about installing YFGW710, see the General Specication of YFGW710 Field Wireless

ALSO

Integrated Gateway (GS 01W01F01-01EN).

IM 01W01F01-01EN

Page 42

<A3. YFGW710 Field Wireless Integrated Gateway>

A3.5 Troubleshooting

When the malfunction occurs to the wireless communication in the start-up or during operation

and the Field Wireless Management Tool identies that it is caused by YFGW710, follow the

procedures below.

1. Turn off the power of YFGW710.

2. Check the antenna connection and the wiring of power supply, communication, and grounding. Correct problems, if any. There are no other checking points which users can correct in

YFGW710.

3. If any problems are not found but the failure remain unsolved, contact to Yokogawa’s service section in charge and request the measure such as replacing the unit.

A3-22

IM 01W01F01-01EN

Page 43

<A3. YFGW710 Field Wireless Integrated Gateway>

A3.6 General Specication

A3.6.1 Standard Specication

n Specication of Wireless Transmission

Item Specication

Antenna Connector N type

Antenna Impedance 50 ohm

For details of specication common with wireless transmission, see the table in A4.2 Wireless System Specication.

n Specication of Upper Layer Interface

Item Specication

Communication

Interface

Communication

Protocol

Maximum Connection

Number

*5

Standard

*1

Number of Port 1 1

Transmission Speed 100 Mbps 100 Mbps

Connector RJ-45 SC connector (1-pole x 2)

Cable Type Category5 Cable

Central wavelength - 1300 nm

Transmission Range 100 m Max. 2 km Max.

OPC Server for Field

Wireless

*4

Management, Conguration, so on

Modbus/TCP 4 clients

OPC Server for Field

Wireless

*4

100Base-TX 100Base-FX

Multimode ber

50/125 or 62.5/125 μm (2-core)

Modbus/TCP

Proprietary Protocol

Proprietary Protocol

10 systems

A3-23

*2

*3

*1: 100Base-TX and 100Base-FX must be used exclusively. Use 100Base-FX for the wiring outdoors.

*2: The 2-pole SC connector cannot be put in the cable end connection.

*3: Use an optical cable with non-metal tension member for outdoor wiring.

*4: Possible to connect in the OPC interface by using OPC Server for Field Wireless (GS 33M20S20-40), which is available separately.

*5: Possible to connect at the same time.

IM 01W01F01-01EN

Page 44

<A3. YFGW710 Field Wireless Integrated Gateway>

n Specication of Environment

Item Specication

Operating Ambient

Temperature Range

Operating Humidity Range 0-100%RH (without condensation)

Rating Voltage 24 V DC

Power Supply

Power Consumption 10 W Max.

Protection Degree IP66, NEMA4X

Grounding Class D Grounding (No sharing with others)

Vibration EC 60770-1: 10-60 Hz; 0.21 mmp-p, 60-2000 Hz 3G

Altitude Less than 2000 m

Voltage Range 10.0-26.4 V DC

Instant Power Failure Prompt shut down

Ripple Less than 1%p-p

-40 to +60°C

n Weight

Main Body: Approx. 5.1 kg (excluding cable grounds and brackets)

A3-24

n Housing Material

Cast aluminum alloy with polyurethane, mint-green paint

(Munsell 5.6BG 3.3/2.9 or its equivalent)

n Regulatory Compliance

l EMC Conformity Standards

EN61326-1 Class A, Table 2 (For use in industrial locations), EN61000-6-2

* Class A equipment is designed for industrial environments and cannot be used in any other

environment.

l Radio standard (Wireless Module Conformity Standard)

Technical Standard Conformity Certicate:

Wireless equipment specied in No.19, Clause 1, Article 2 of the Certication Rule; 2.4 GHz

Sophisticated Low Power Data Communication System

IMPORTANT

Specic wireless equipment (Approval No.: 007WWCUL0480) with the technical standard conformity certicate based on the Radio Act is used in this product.

IM 01W01F01-01EN

Page 45

<A3. YFGW710 Field Wireless Integrated Gateway>

R&TTE:

ETSI EN 300 328, ETSI EN 301 489-17, EN61010-1, EN62311

FCC:

Part15.247 Contains FCC ID: SGJ-WFC001

IC:

RSS-210 Contains IC: 8999A-WIC001

IMPORTANT

• Microwave ovens and other industrial, scientic, and medical equipment, as well as local

wireless stations (license required) and specic low power wireless stations (license not

required) for identifying mobile objects used in the production line of a factory, use the same

frequency band as this product. Prevent interference with other wireless stations.

• Check that local wireless stations and specic low power wireless stations are not being

used in the vicinity before using this product.

• If this product causes radio interference in a local wireless station used for identifying mobile

objects, change the working frequency or stop the emission of radio waves immediately. For

details on how to prevent radio interference, contact our service ofce.

A3-25

n Explosion Proof Certications

CAUTION

This instrument has been tested and certied as being explosion proof. Please note that severe

restrictions apply to this instrument’s construction, installation, external wiring, maintenance and

repair. A failure to abide by these restrictions could make the instrument a hazard to operate.

l FM Approval

Caution for FM nonincendive. (Following contents refer to “DOC.NO. NFM023-A14 P.1 AND

P.2.”)

Note 1. Model YFGW710 Field Wireless Integrated Gateway with optional code /FN17 is

applicable for use in hazardous (Classied) locations.

• Applicable standard: FM3600, FM3611, FM3810, ANSI/NEMA 250

• Nonincendive for

Class I, Division 2, Groups A, B, C and D.

Class II, Division 2, Groups F and G.

Class III, Division 1

hazardous (Classied) locations.

• Enclosure: NEMA 4X (Indoors and outdoors).

• Temperature Class: T4

• Ambient Temperature: –40 to 60°C

IM 01W01F01-01EN

Page 46

<A3. YFGW710 Field Wireless Integrated Gateway>

Note 2. Installation

WARNING

• The installation of the devices should be carried out by the engineers or other professional

personnel of the related expertise. The installation should not be carried out by operators or

other unprofessional personnel.

• The installation should be in accordance with NEC (the National Electric Code:

ANSI/NFPA-70) or local electric code.

• Make sure that the breakers are installed in the power supply circuits located in

non-hazardous areas so that the power can be shutoff when abnormality occurs.

• In the course of installation, the related documents of GS (General specications),TI (Technical Information of Installation Guidance) and IM (User’s Manuals) should be referenced

and the instructions described in the documents should be observed.

• YFGW710 should be installed in upright position.

• YFGW710 does not have the nonincendive Field Wiring. The conduit wiring is required for

the power cable and the metal network cable to be connected to YFGW710.

A3-26

• To satisfy type of protection and NEMA4X, apply suitable devices to the electrical connection port.

• YFGW710 does not have a power switch inside. Prepare a dedicated breaker for the external power line to turn ON/OFF the device.

• Note a warning label worded

“DO NOT REMOVE COVER WHILE CIRCUIT IS LIVE WHEN A FLAMMABLE OR COM-

BUSTIBLE ATMOSPHERE IS PRESENT.”

“INSTALL IN ACCORDANCE WITH DOC.NO. NFM023-A14 P.1 AND P.2”

• Electrostatic charge may cause an explosion hazard. Avoid any actions that cause the generation of electrostatic charge, such as rubbing with a dry cloth on coating face of product.

• Take care not to generate mechanical sparking when access to the instrument and peripheral devices in hazardous locations.

Note 3. Maintenance and Repair

WARNING

• The instrument modication or parts replacement by other than authorized Representative

of Yokogawa Electric Corporation is prohibited and will void FM Approvals approval.

• When opening the cover, the enclosure should be dry and clean to prevent from ingress

water or dust.

IM 01W01F01-01EN

Page 47

<A3. YFGW710 Field Wireless Integrated Gateway>

l CSA Certication

Caution for CSA nonincendive/Type n. (Following contents refer to “Doc No. NCS013”)

Note 1. Model YFGW710 Field Wireless Integrated Gateway with optional code /CN17 is appli-

cable for use in hazardous locations.

• Certicate: 2342292

[For CSA C22.2]

• Applicable standard: C22.2 No.0, C22.2 No.0.4, C22.2 No.25, C22.2 No.94, C22.2 No.213,

C22.2 No.61010-1

• Nonincendive for

Class I, Division 2, Groups A, B, C, D.

Class II, Division 2, Groups F, G.

Class III, Division 1

• Enclosure: Type 4X

• Temp. Code: T4

• Ambient Temperature: –40 to 60°C

[For CSA E60079]

A3-27

• Applicable standard: CAN/CSA E60079-0, CAN/CSA E60079-15, IEC60529:2001

• Ex nA nL IIC T4

• Enclosure: IP66

• Ambient Temperature: –40 to 60°C

Note 2. Electrical Connection

The type of electrical connection is depends on the model code sufx.

The model code sufx is shown on the main label in front of YFGW710.

The second character following the letter A shows the type of electrical connection as below.

Character b on Sufx: Aab-cdefghjkm The type of electrical connection

2 1/2 NPT female

4 M20 female

Note *1: 1/2 NPT is realized by the conversion adapter from M20 female to 1/2NPT female.

Note *2: When the cable glands or another device are necessary, user needs to prepare them which adapt to M20 female entry.

*1

*2

IM 01W01F01-01EN

Page 48

<A3. YFGW710 Field Wireless Integrated Gateway>

Note 3. Installation

WARNING

• The installation of the devices should be carried out by the engineers or other professional

personnel of the related expertise. The installation should not be carried out by operators or

other unprofessional personnel.

• The installation should be in accordance with Canadian Electrical Code Part I or Local Electrical Code.

• YFGW710 should be installed in upright position.

• To satisfy type of protection “n” and degree of protection provided by enclosure IP66, apply

suitable devices to the electrical connection port.

• Make sure that the breakers are installed in the power supply circuits located in non-hazardous areas so that the power can be shutoff when abnormality occurs.

• In the course of installation, the related documents of GS (General specications),TI (Technical Information of Installation Guidance) and IM (User’s Manuals) should be referenced

and the instructions described in the documents should be observed.

A3-28

• YFGW710 does not have the Nonincendive Field Wiring. The conduit wiring is required for

the power cable and the metal network cable to be connected to YFGW710.

• When the cable glands are necessary, user needs to prepare the cable glands. The cable

glands shall be certied in type of protection “n” suitable for the conditions of use and correctly installed.

• To maintain the degree of ingress protection IP66 according to IEC 60529, and TYPE4X according to CSA C22.2 No.94 special care must be taken to avoid water.

• Note a warning label worded

“DO NOT OPEN WHEN AN EXPLOSIVE ATMOSPHERE MAY BE PRESENT.”

“POTENTIAL ELECTROSTATIC CHARGING HAZARD – SEE INSTRUCTIONS.”

• Electrostatic charge may cause an explosion hazard. Avoid any actions that cause the generation of electrostatic charge, such as rubbing with a dry cloth on coating face of product.

• Take care not to generate mechanical sparking when access to the instrument and peripheral devices in hazardous locations.

Note 4. Maintenance and Repair

WARNING

• The instrument modication or parts replacement by other than authorized Representative

of Yokogawa Electric Corporation is prohibited and will void CSA certication.

• When Opening the cover, the enclosure should be dry and clean to prevent from ingress

water or dust.

IM 01W01F01-01EN

Page 49

<A3. YFGW710 Field Wireless Integrated Gateway>

l ATEX Declaration

(1) Technical Data

Caution for ATEX Type n.

Note 1. Model YFGW710 Field Wireless Integrated Gateway with optional code /KN27 is appli-

cable for use in hazardous area.

• Applicable standard: EN60079-0: 2009, EN60079-0: 2012, EN60079-11: 2012,

EN60079-15: 2010, EN60079-28: 2007

A3-29

• Marking:

II 3G Ex nA [ic] [op is] IIC T4 Gc (with 100BASE-FX)

II 3G Ex nA [ic] IIC T4 Gc (without 100BASE-FX)

• Ambient temperature: -40 to +60°C

• IP code: IP66

• Power supply: 10.0 V DC to 26.4 V DC (Rated voltage: 24.0 V DC)

• Um: 250 V

• Power dissipation: ≤ 10 W

• RF power: ≤ 20 mW (ISA100.11a; IEEE802.15.4)

• Cable parameters for antenna connection: Cc: 4 nF, Lc: 20 μH

• Specic condition of use:

Precautions shall be taken to minimize the risk from electrostatic discharge of painted parts.

Note 2. Electrical Connection

The type of electrical connection is depends on the model code sufx.

The model code sufx is shown on the main label in front of YFGW710.

The second character following the letter A shows the type of electrical connection as below.

Character b on Sufx: Aab-cdefghjkm The type of electrical connection

2 1/2 NPT female

4 M20 female

Note *1: 1/2 NPT is realized by the conversion adapter from M20 female to 1/2NPT female.

Note *2: When the cable glands or another device are necessary, user needs to prepare them which adapt to M20 female entry.

*1

*2

Note 3. Installation

WARNING

• The installation of the devices should be carried out by the engineers or other professional

personnel of the related expertise. The installation should not be carried out by operators or

other unprofessional personnel.

• The installation should be in accordance with EN60079-14 and Local Electrical Code.

• The equipment shall be installed in accordance with the user’s manual.

• YFGW710 should be installed in upright position.

IM 01W01F01-01EN

Page 50

<A3. YFGW710 Field Wireless Integrated Gateway>

• The thread type of the cable entries shall be conrmed according to the user’s manual.

• Cable glands, adapters and/or blanking elements shall be of type “n”, type “e” or type “d”

and shall be installed so as to maintain the specied degree of protection (IP code) of the

equipment.

• Keep the cap attached to the antenna connector (N type) until the installation of the antenna

or antenna cables to protect the inside of the connector from exposure of light. In case the

antenna or antenna cables are removed from the connector, the inside of the antenna connector should be protected from exposure of light.

• The antenna and the surge arrester shall be a simple apparatus in accordance with

EN60079-11. Li and Ci of the simple apparatus shall be negligible. Temperature class of

them shall be determined from Po = 20 mW.

• The equipment shall be earthed in accordance with EN60079-14, in order to maintain intrinsic safety. A cable lug or a similar device shall be used to maintain the secureness of the

connection to the equipment. Care should be taken to avoid multi-point earthing since the

equipment is not galvanically isolated from the power supply.

• YFGW710 does not have a power switch inside. Prepare a dedicated breaker for the external power line to turn ON/OFF the device.

• Make sure that the breakers are installed in the power supply circuits located in non-hazardous areas so that the power can be shutoff when abnormality occurs.

A3-30

• Note a warning label worded

“DO NOT OPEN WHEN AN EXPLOSIVE ATMOSPHERE MAY BE PRESENT.”

“POTENTIAL ELECTROSTATIC CHARGING HAZARD – SEE INSTRUCTIONS.”

• Electrostatic charge may cause an explosion hazard. Avoid any actions that cause the generation of electrostatic charge, such as rubbing with a dry cloth on coating face of product

and the antenna.

• Take care not to generate mechanical sparking when access to the instrument and peripheral devices in hazardous area.

IM 01W01F01-01EN

Page 51

<A3. YFGW710 Field Wireless Integrated Gateway>

[Control drawing]

A3-31

Hazardous Area

Zone 0/Zone 1/Zone 2

Electrical Equipment

(e.g.) “d”, “i”, “Type n” equipment

Radio wave

(IEEE802.15.4)

Hazardous Area

Zone 2 only

YFGW710

Field Wireless integrated gateway

Antenna

(*1)

Surge

Arrester

(*1, *2)

metal wiring

optical fiber

Nonhazardous or Hazardous Area

Zone 2 only

Control Equipment

or

Power Supply

wiring

*1: These apparatus are simple apparatus.