Page 1

User’s

Manual

YFGW410

Field Wireless

Management Station

IM 01W02D01-01EN

IM 01W02D01-01EN

2nd Edition

Page 2

Blank Page

Page 3

YFGW410 Field Wireless Management Station

IM 01W02D01-01EN 2nd Edition

CONTENTS

Introduction ..............................................................................................................i

Safety Precautions ..................................................................................................ii

Documentation Conventions ................................................................................iii

Information of User’s Manual Revision ...............................................................iv

Toc-1

Part A Outline of Field Wireless System Conguration

A1. Minimum System Conguration ...........................................................A1-1

A2. Minimum System Conguration with Redundant Field Wireless

Network ...................................................................................................A2-1

A3. YFGW410 in Redundant Conguration ...............................................A3-1

A4. YFGW410 in High-Level Redundancy Conguration .........................A4-1

IM 01W02D01-01EN

Page 4

Part B YFGW410 Product Description

B1. Introduction .............................................................................................B1-1

B2. YFGW410 Function Outline ...................................................................B2-1

B2.1 System Manager ............................................................................................ B2-1

B2.2 Security Manager ........................................................................................... B2-1

B2.3 Gateway .......................................................................................................... B2-1

B2.4 Wireless Network Conguration and Management Functions and

Others .............................................................................................................. B2-2

B3. Structure and Parts of YFGW410 ..........................................................B3-1

B3.1 Front View ....................................................................................................... B3-1

B3.2 Top View .......................................................................................................... B3-1

B3.3 Side and Rear Views ...................................................................................... B3-2

B3.4 RS-485 Conguration Switches ................................................................... B3-2

B3.5 Outline of Component Functions ................................................................. B3-3

B3.6 Reset Switch ................................................................................................... B3-3

B3.7 Shutdown Switch ........................................................................................... B3-3

Toc-2

B4. Checking the Product ............................................................................B4-1

IM 01W02D01-01EN

Page 5

Part C Installation

C1. Installation Environment .......................................................................C1-1

C2. Power Supply and Grounding ..............................................................C2-1

C2.1 Power Supply ................................................................................................. C2-1

C2.2 Grounding ....................................................................................................... C2-2

C3. Mounting .................................................................................................C3-1

C3.1 Mounting Direction ........................................................................................ C3-1

C3.2 Mounting to DIN Rails .................................................................................... C3-2

C3.3 Installation of the YFGW410 ......................................................................... C3-3

C4. Wiring .......................................................................................................C4-1

C4.1 Terminals and Communication Ports Connection ..................................... C4-1

C4.2 Power Supply Cable Connection ................................................................. C4-2

C4.3 Grounding ....................................................................................................... C4-6

C4.4 Communication Cable Connection .............................................................. C4-8

C5. Explosion-Proof Wiring .........................................................................C5-1

Toc-3

IM 01W02D01-01EN

Page 6

Part D System Construction

D1. Engineering Procedures........................................................................D1-1

D2. Tools to be Used for the Engineering ...................................................D2-1

D2.1 Overview of the Tools .................................................................................... D2-1

D2.2 Using the Field Wireless Management Console ........................................ D2-2

D2.2.1 System Requirements .................................................................... D2-3

D2.2.2 Launching the Tool .......................................................................... D2-3

D3. Constructing a Field Wireless System .................................................D3-1

D3.1 Setting Operation Items ............................................................................... D3-1

D3.2 Detail of Conguration ................................................................................. D3-2

D3.2.1 YFGW410 Settings ........................................................................ D3-2

D3.2.2 Operation Mode ........................................................................... D3-14

D3.2.3 Hopping Patterns ......................................................................... D3-14

D3.2.4 Field Wireless Networks .............................................................. D3-19

D3.2.5 Graphic Editor .............................................................................. D3-34

D3.2.6 Alert Settings ................................................................................ D3-46

D3.2.7 Sampling Data .............................................................................. D3-47

D3.2.8 Modbus Settings ........................................................................... D3-58

D3.2.9 Resource ...................................................................................... D3-65

D3.2.10 Downloading Wireless Network Settings ...................................... D3-66

D3.2.11 Other Setting Operations ............................................................. D3-69

Toc-4

D4. Starting up the Field Wireless System .................................................D4-1

D4.1 Procedure for System Start-up ..................................................................... D4-1

D4.2 Wireless Network Management ................................................................... D4-2

D4.2.1 Monitor Functions ........................................................................... D4-2

D4.2.2 The Monitor Start up Window ......................................................... D4-4

D4.2.3 Graphic Viewer ............................................................................... D4-6

D4.2.4 Topology Viewer ............................................................................ D4-21

D4.2.5 Backbone Device List ................................................................... D4-22

D4.2.6 Field Device List ............................................................................ D4-24

D4.2.7 Log Viewer .................................................................................... D4-26

D4.2.8 Functions Called from the Menu Bar ............................................ D4-29

IM 01W02D01-01EN

Page 7

Part E Operation and Maintenance

E1. Routine Maintenance .............................................................................E1-1

E1.1 Routine Maintenance ......................................................................................E1-1

E1.1.1 Operation Status of Wireless System ..............................................E1-1

E1.1.2 YFGW410 Maintenance ..................................................................E1-1

E1.2 Handling a Device in the Abnormal Status ..................................................E1-2

E1.3 Handling a Device in the Warning Status .....................................................E1-2

E2. Adding and Replacing a Device ............................................................E2-1

E2.1 Field Wireless Device .....................................................................................E2-1

E2.2 Field Wireless Access Point (YFGW510) ......................................................E2-2

E2.3 Field Wireless Management Station (YFGW410).........................................E2-2

E3. YFGW410 Maintenance in Hazardous Area .........................................E3-1

E4. Parts with Dened Life Spans ...............................................................E4-1

Toc-5

IM 01W02D01-01EN

Page 8

Part F Troubleshooting

F1. Field Wireless System ...........................................................................F1-1

F2. YFGW410 .................................................................................................F2-1

F2.1 Status Information ..........................................................................................F2-1

F2.2 Status Indicators and Actions .......................................................................F2-2

Toc-6

IM 01W02D01-01EN

Page 9

Part G Specications

G1. YFGW410 ................................................................................................ G1-1

G1.1 Standard Specication .................................................................................. G1-1

G1.2 Model and Sufx Codes ................................................................................ G1-3

G1.3 External Dimensions .....................................................................................G1-4

G2. Field Wireless Network ......................................................................... G2-1

G2.1 Field Wireless Network Specication .......................................................... G2-1

G2.2 Network Form (Topology) ............................................................................. G2-2

G2.2.1 Star Topology .................................................................................. G2-2

G2.2.2 Mesh Topology ................................................................................G2-2

G2.3 Precautions on Conguring a Wireless Network .......................................G2-3

G2.3.1 Route Specication ......................................................................... G2-3

G2.3.2 Redundancy of Wireless Route ...................................................... G2-3

G2.3.3 Support of Large-Scale Wireless System .......................................G2-3

G2.3.4 Hopping Pattern ..............................................................................G2-3

G2.3.5 Number of Hops .............................................................................. G2-4

G2.3.6 Communication between Devices .................................................. G2-4

G2.4 Duocast (ISA100.11a Standard) ....................................................................G2-4

G2.5 Standard Battery Life ..................................................................................... G2-5

G2.6 Restrictions .................................................................................................... G2-5

G2.6.1 Restrictions on Number of Connectable Devices by Network

Resources .......................................................................................G2-5

G2.6.2 Maximum Number of Host Systems ...............................................G2-6

G2.6.3 Duocast and Auto I/O Device .......................................................... G2-6

G2.7 Recommended Device List ........................................................................... G2-7

Toc-7

G3. Glossary of Terms and Abbreviations ................................................ G3-1

IM 01W02D01-01EN

Page 10

<Read Me First>

Introduction

This document describes the YFGW410 Field Wireless Management Station (hereafter simply

refered to as YFGW410), which is a core component of the eld wireless system that based on

ISA100.11a, the wireless communication standard for industrial automation specied by the

International Society of Automation (ISA).

Functions of the YFGW410 are explained in the outline of the eld wireless system, and in the

installation, conguration, startup and operations of the eld wireless network.

The operation of Field Wireless Management Console, which is built in to the YFGW410 and

used as a tool for setup and management of a eld wireless network through YFGW410, is also

explained in this document.

i

IM 01W02D01-01EN

Page 11

<Read Me First>

Safety Precautions

IMPORTANT

Be sure to read the safety precautions for this product described in “Read Me First (IM

01W02D01-11EN)”.

n Transportation of products containing lithium batteries:

This product contains lithium batteries. Primary lithium batteries are subject to transportation

regulations by the U.S. Department of Transportation, and are also covered by the International

Air Transport Association (IATA), the International Civil Aviation Organization (ICAO), and the European Ground Transportation of Dangerous Goods (ARD). It is the responsibility of the shipper

to ensure compliance with these or any other local requirements. Consult current regulations and

requirements regarding lithium batteries before shipping.

ii

n How to dispose of batteries:

The following is an explanation about the new EU Battery Directive (DIRECTIVE 2006/66/EC).

This directive is only valid in the EU.

Batteries are included in this product. Batteries in this product cannot be removed by yourself.

Dispose of them together with this product.

If you dispose of this product within the EU, contact your local Yokogawa Europe B.V. ofce.

Do not dispose of them as domestic household waste.

Battery type: lithium thionyl chloride primary battery

CAUTION

The symbol (see above) means they shall be sorted out and collected as ordained in ANNEX II in

DIRECTIVE 2006/66/EC.

IM 01W02D01-01EN

Page 12

<Read Me First>

Documentation Conventions

n Typographical Convention

The following typographical conventions are used throughout the manuals:

l Conventions commonly used throughout manuals

Character string to be entered

The characters to be entered are shown in one-byte characters as follows:

Example:

FIC100.SV=50.0

“” mark

Indicates a space between character strings to be entered.

Example:

AL PIC010 -SC

Character string enclosed in curly brackets ({ })

Indicates an optional characters that can be omitted.

Example:

iii

PR TAG {. Sheet name}

l Conventions used to show key or button operations:

Characters enclosed in square brackets ([ ])

Characters enclosed in square brackets show the names of buttons used during the explanation

of the software operation.

Example:

To execute the command, click [OK].

Characters enclosed in angle brackets (< >)

Characters enclosed in angle brackets show the title of the screen during the explanation of the

software operation.

Characters enclosed in corner brackets ([ ])

Characters enclosed in corner brackets show a tab or an item of the screen during the explanation of the software operation.

n Symbols used in the manual

The symbol used in the manual are described in “Read Me First” (IM 01W02D01-11EN).

n Drawing Conventions

Some drawings may be partially emphasized, simplied, or omitted, for the convenience of description.

Some screen images depicted in the manual may have different display positions or character

types (e.g., the upper/lower case). Also note that some of the images contained in this manual

are display examples.

IM 01W02D01-01EN

Page 13

<Read Me First>

Information of User’s Manual Revision

Material Name : YFGW410 Field Wireless Management Station

Material Number : IM 01W02D01-01EN

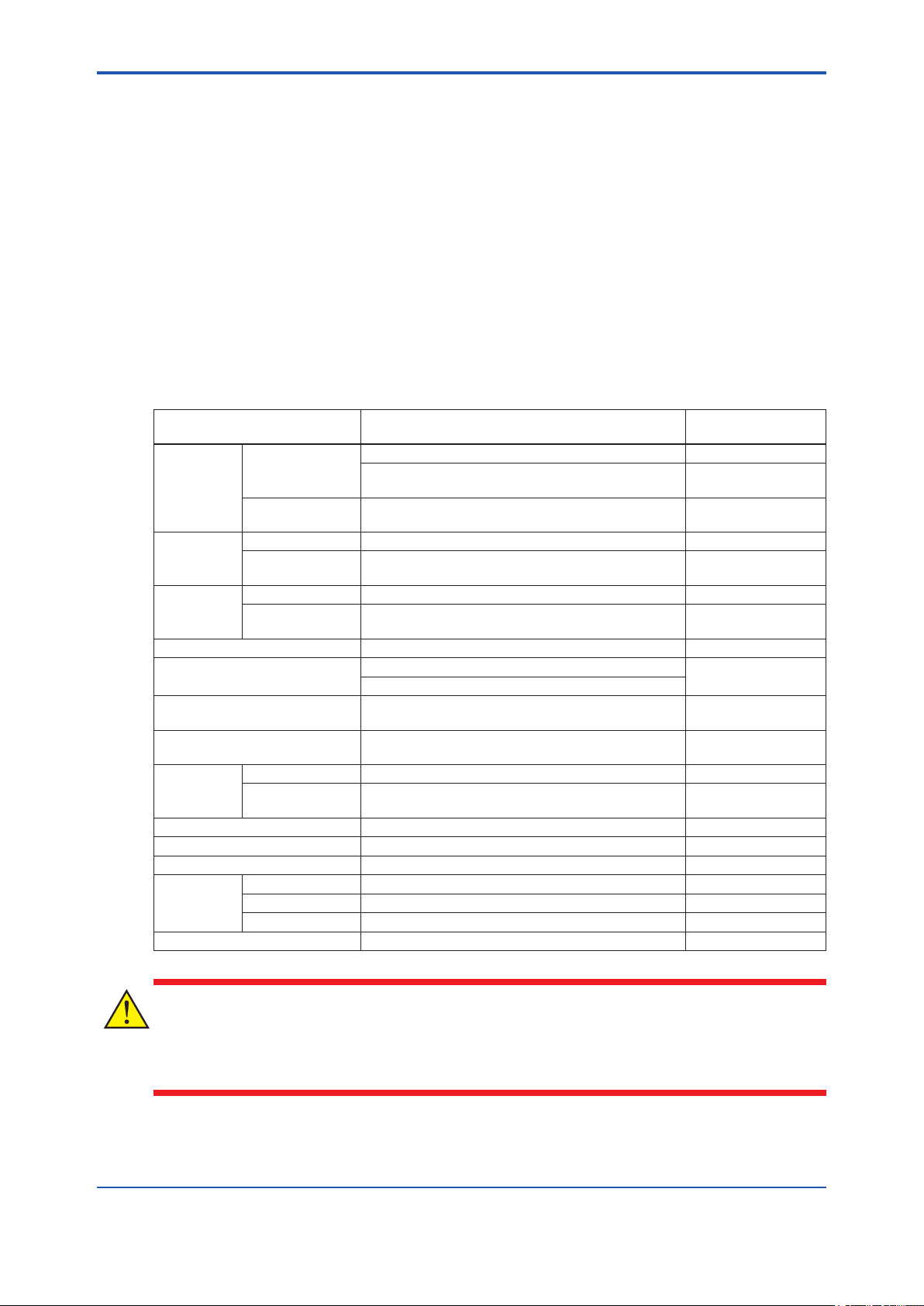

Edition Date Page Revised Item

1st August 2012 - New Issue

2nd February 2013 -

Part A

B3-2, C4-8

D3-15

D4-29, D4-31

G1-1, G1-3

G2-1, G2-2

G2-5

G2-6

G3-1

Revise descriptions about a number of connectable devices,

and typography.

Change a number of connectable devices.

Add description about RS-485.

Revised descriptions about HoppingPattern.

Add description about a radio prohibit function.

Change communication services and its capability.

Change a number of connectable devices, and add list of

communication services.

Add description about a number of connectable output devices.

Add description about a capablity for the host system.

Add Glossary

iv

IM 01W02D01-01EN

Page 14

<A1. Minimum System Conguration>

Part A Outline of Field Wireless System

Conguration

The YFGW410, the YFGW510 Field Wireless Access Point (hereafter simply refered to as

YFGW510), the YFGW610 Field Wireless Media Converter (hereafter simply refered to as

YFGW610) and eld wireless devices are used to build an industrial wireless network that based

on to ISA100.11a, the wireless communication standard for industrial automation specied by the

International Society of Automation (ISA).

This part describes the typical conguration of eld wireless system that can be established using

these devices.

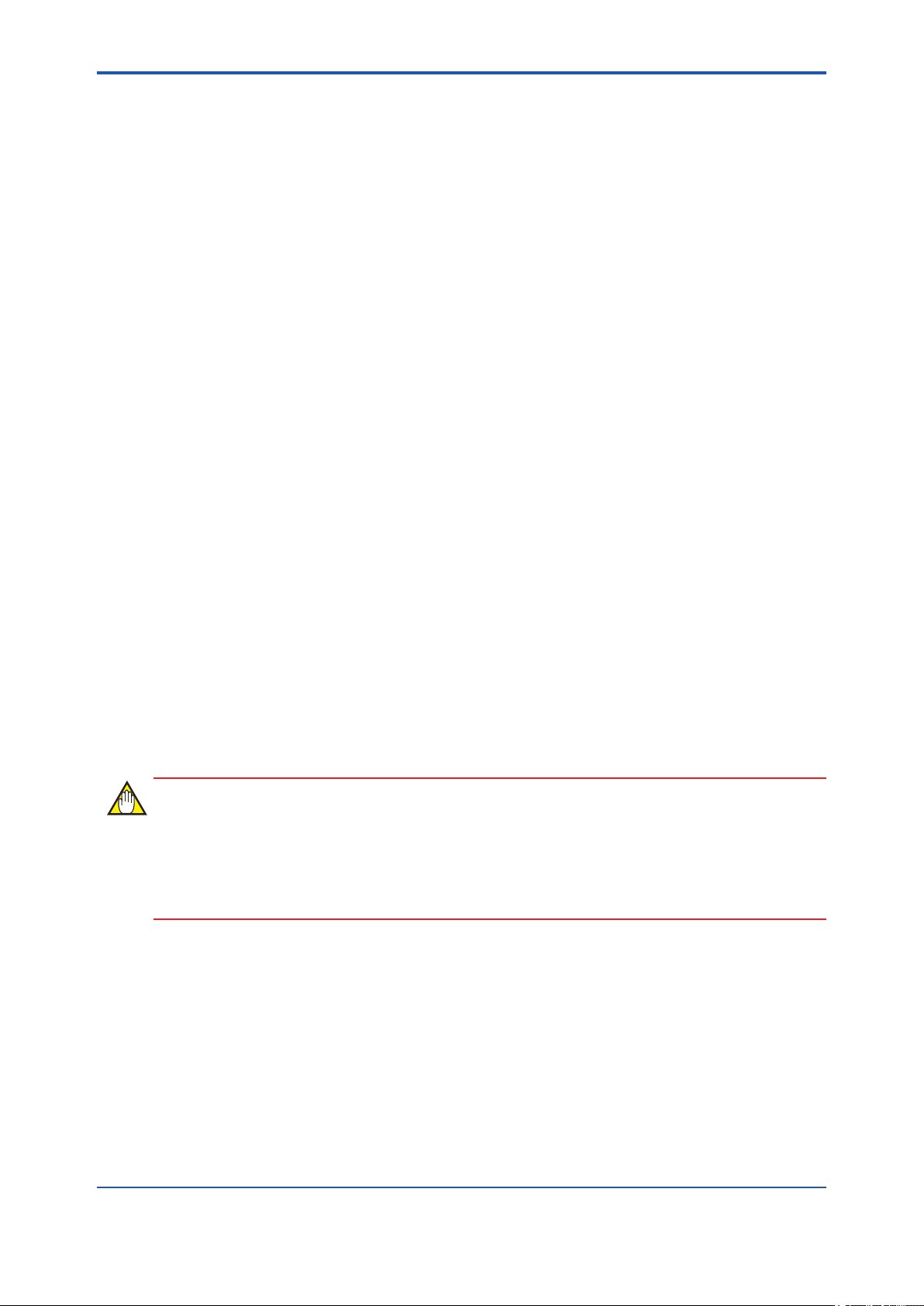

A1. Minimum System Conguration

Host system

A1-1

Field Wireless

Management Station

(YFGW410)

Field Wireless

Management Console

Field Wireless

Access Point

Field wireless network

(ISA100.11a)

Field wireless device

Figure A1-1 Minimum system conguration example (The eld wireless backbone using metal network)

(YFGW510)

FA0101.ai

This is the minimum conguration to monitor and record the process data of eld wireless devices.

This system consists of eld wireless devices, the YFGW510, YFGW410, and data monitoring

and recording devices (DAQSTATION, STARDOM and others) or the host system (DCS, SCADA

and others) supporting the Modbus/TCP communication.

The eld wireless subnet (the eld wireless network consisting of the YFGW510 and eld wireless devices) can be connected up to 100 eld wireless devices. In this conguration, up to 100

eld wireless devices can be connected.

IM 01W02D01-01EN

Page 15

<A1. Minimum System Conguration>

Up to 20 eld wireless subnets can be connected to the YFGW410.

Any of the three types of eld wireless backbone can be selected for between YFGW410 and

YFGW510.

• The metal network composed of the YFGW510 (100BASE-TX model), shown in Figure

A1-1

• The optical ber network shown in Figure A1-2, composed of the YFGW610 connected to

the YFGW410, uses the YFGW510 (100BASE-FX model) for signal transmission via optical

ber cables.

• The wireless LAN network shown in Figure A1-3, composed of other manufactures’ wireless

LAN access point (connected to the YFGW410) for wireless LAN communication with the

YFGW510 (wireless LAN client model).

The Field Wireless Management Console, which is the program built in to the YFGW410, is used

for conguration and management of a eld wireless network. This program can be started and

operated by the PC connected via the eld network interface or via the maintenance interface of

the YFGW410.

Certain parameters need to be set on the following devices to congure and start the wireless

network. For the relevant procedure, see the Provisioning and Conguration section.

• YFGW410 The device parameters, wireless network conguration, commu-

nication with host system, and others

A1-2

• YFGW510 The device parameters

Wireless LAN parameters if the wireless LAN client model is

selected

• Field wireless devices Provisioning and sensor parameters, and others

Once the eld wireless network has started, the eld wireless device parameters can be set and

those devices can be managed from the Plant Resource Manager (PRM) connected to the host

network. If the security policy for the host system is acceptable, the FieldMate can be used for

parameter setup and maintenance. The FieldMate is connected to the YFGW410 via the maintenance interface.

IMPORTANT

When CENTUM VP is running, set and adjust the parameters of the eld wireless device from

PRM.

When CENTUM VP is not running, or when a non-Yokogawa host system is connected, the parameters can be set and adjusted using FieldMate.

IM 01W02D01-01EN

Page 16

<A1. Minimum System Conguration>

Host system

Field Wireless

Management Station

(YFGW410)

Field Wireless

Management Console

Field Wireless

Media Converter

(YFGW610)

A1-3

Optical network

Field wireless network

(ISA100.11a)

Field wireless device

Field Wireless

Access Point

(YFGW510)

FA0102.ai

Figure A1-2 Minimum system conguration example (The eld wireless backbone using optical network)

In this conguration, YFGW610 and YFGW510 are connected through optical network cables.

The YFGW610 needs to be installed near YFGW410 for media conversion between optical

network and metal network.This is a useful method if the distance is too far from YFGW410 to

YFGW510. Also in order to eliminate the inuence of electromagnetic noise due to lightning and

keep transmission distance.

IM 01W02D01-01EN

Page 17

<A1. Minimum System Conguration>

Host system

Field Wireless

Management Station

(YFGW410)

Subnet A Subnet B

Wireless LAN access point

(other manufactures)

Wireless LAN access point

(other manufactures)

Wireless LANWireless LAN

Field Wireless

Management Console

A1-4

Field wireless

network

(ISA100.11a)

Field Wireless

Access Point

(YFGW510)

Field wireless

network

(ISA100.11a)

Field wireless deviceField wireless device

Field Wireless

Access Point

(YFGW510)

FA0103.ai

Figure A1-3 Minimum system conguration example (The eld wireless backbone using wireless LAN

network)

In this conguration example, the wireless LAN access point (other manufactures) is installed on

the eld wireless backbone, and each YFGW510 is connected to the eld wireless backbone via

the wireless LAN. If YFGW510 are connected via the wireless LAN, a single YFGW510 can be

connected to a single eld wireless subnet. Using YFGW510 wireless LAN redundancy model

and two wireless LAN access points, the wireless LAN communication can be made redundant.

Similar to the other eld wireless backbone network, up to 20 eld wireless subnets can be connected to the YFGW410. Up to 100 eld wireless devices can be connected in each eld wireless

subnet, and up to 500 eld wireless devices can be connected to the YFGW410.

For the recommended wireless LAN access points, see Section G2.7 Recommended Device

List.

IM 01W02D01-01EN

Page 18

<A2. Minimum system conguration with redundant eld wireless network>

A2-1

A2. Minimum System Conguration with

Redundant Field Wireless Network

Host system

Field Wireless

Management Station

(YFGW410)

Field Wireless

Management Console

Subnet A

Field Wireless

Access Point

(YFGW510)

Field wireless

network

(ISA100.11a)

Field wireless device

Field Wireless

Access Point

(YFGW510)

FA0201.ai

Figure A2-1 Minimum system conguration with redundant eld wireless network

This is redundant eld wireless network conguration. Two YFGW510 are installed in the eld

wireless network, and the eld wireless devices communicate with the both YFGW510 (Duocast). The communication path from the eld wireless devices to the YFGW410 is made redundant.

This system redundancy can prevent various types of interference in the eld wireless network

environment and can maintain the high quality connection.

Up to 100 eld wireless devices can be connected to a single eld wireless subnet.

IM 01W02D01-01EN

Page 19

<A3. YFGW410 in Redundant Conguration>

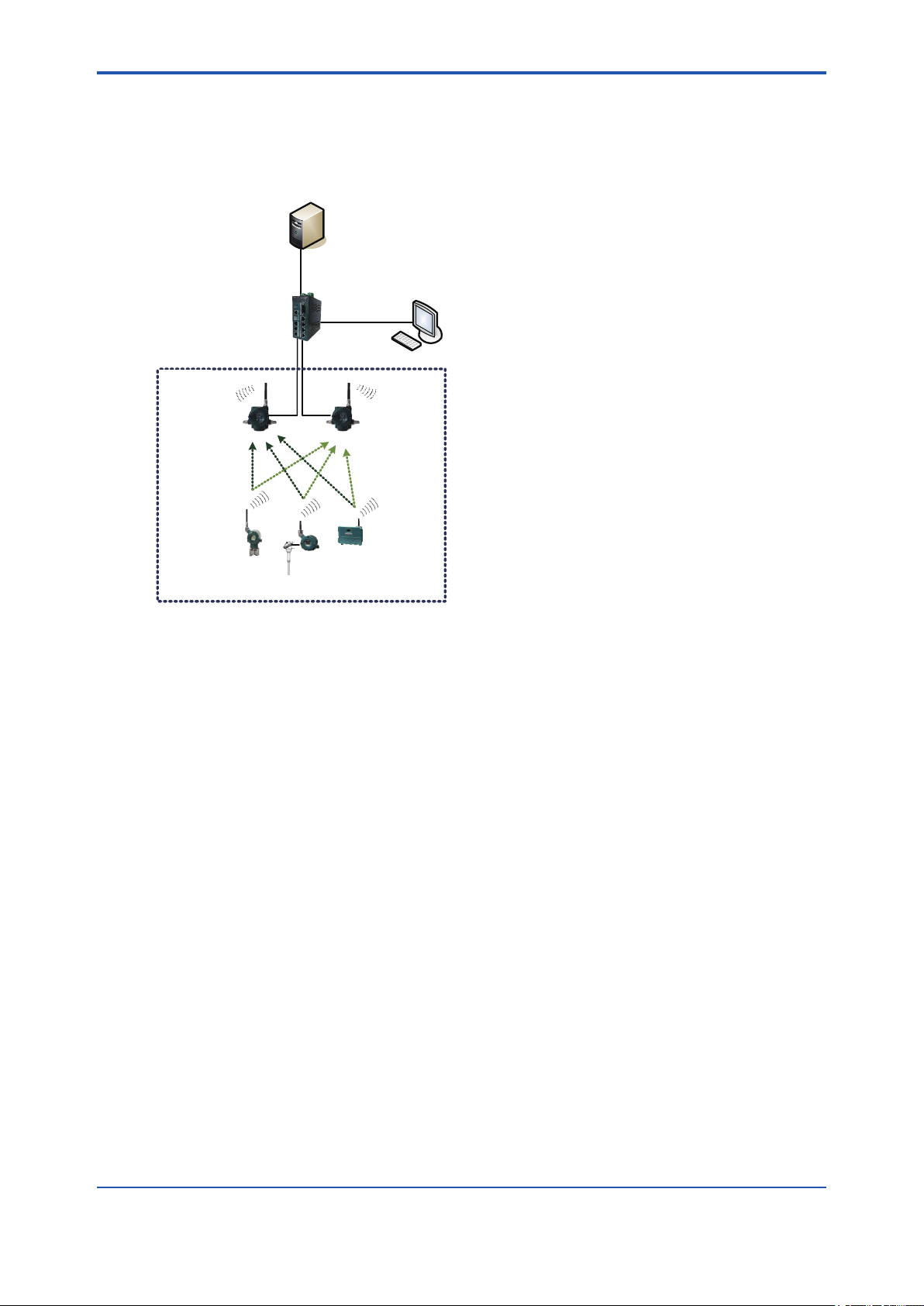

A3. YFGW410 in Redundant

Conguration

A3-1

HIS HIS/ENG PRM

Control network (Ethernet)

Subnet A

Field Wireless

Access Point

(YFGW510)

Field wireless

network

(ISA100.11a)

L2SWL2SW

Cable for Redundancy

FCS

ALE111×2

Field Wireless

Management Station

(YFGW410)

Field Wireless

Access Point

(YFGW510)

"Field wireless management PC

- Field Wireless Management Console"

L3SW

NTP server

Ethernet

Field wireless device

FA0301.ai

Figure A3-1 Redundant system conguration of YFGW410

In this example, the both of YFGW410 and YFGW510 are made redundant system. In using the

Duocast, the eld wireless devices are made fully redundant and a highly reliable system.

Two YFGW410 virtually operate as a single machine, and the backbone devices and host system

devices access to this virtual machine.

When one of YFGW410 is out of service by failure, another YFGW410 continue operation. One

failure does not affect a eld wireless system.

Up to 100 eld wireless devices can be connected to a single eld wireless subnet even in the

redundant conguration. Up to 500 eld wireless devices can be connected to YFGW410.

The host system is DCS, SCADA system, or the device management application.

IMPORTANT

When CENTUM VP is running, set and adjust the parameters of the eld wireless device from

PRM. When CENTUM VP is not running, or when a non-Yokogawa host system is connected,

the parameters can be set and adjusted using FieldMate.

IM 01W02D01-01EN

Page 20

<A3. YFGW410 in Redundant Conguration>

IMPORTANT

When CENTUM VP is used with YFGW410 in redundant conguration, CENTUM VP R5.02.00

or higher is required. For details, see the Communication with Subsystems Using FIO user’s

manual (IM 33K03L20-50E).

A3-2

IM 01W02D01-01EN

Page 21

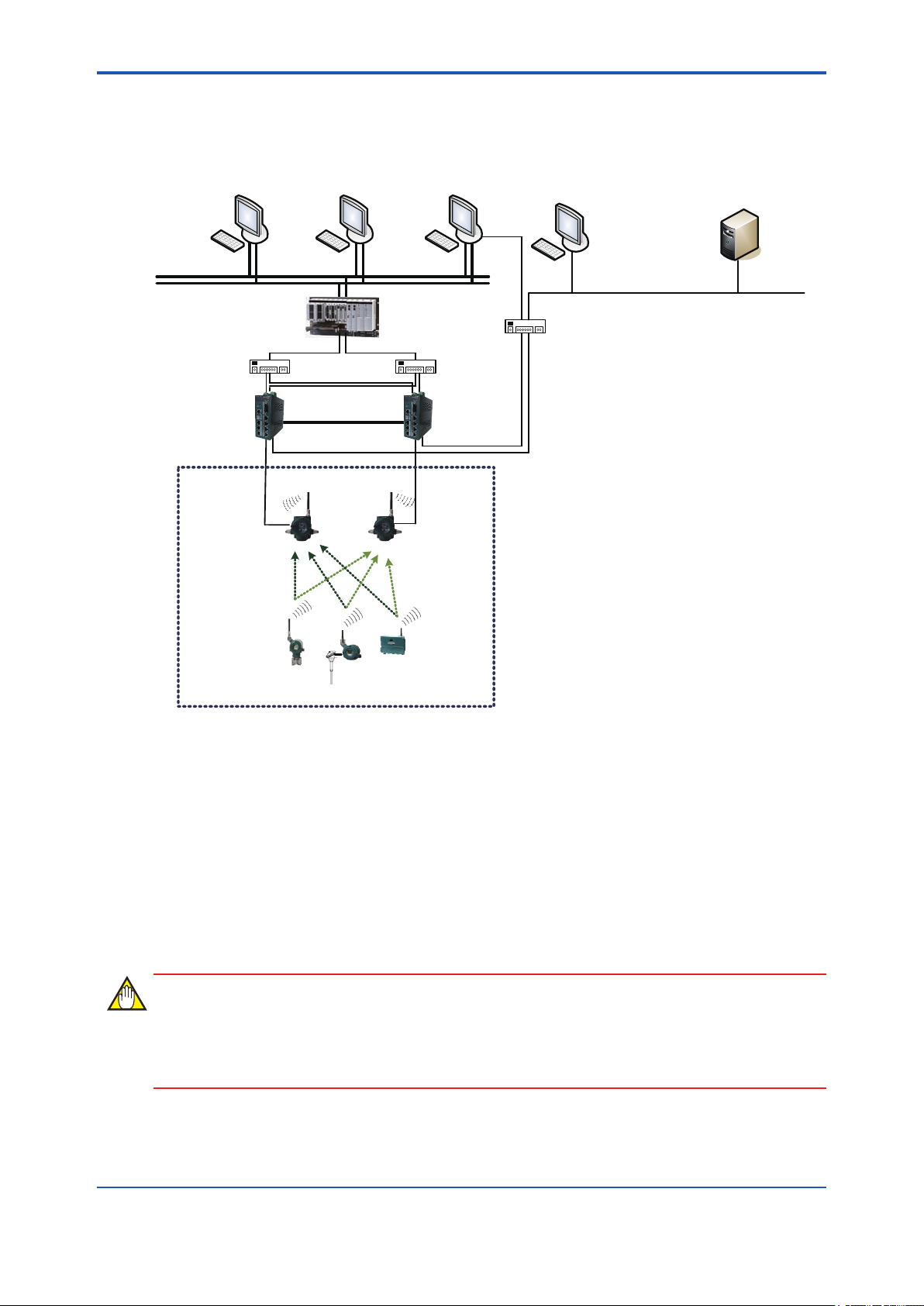

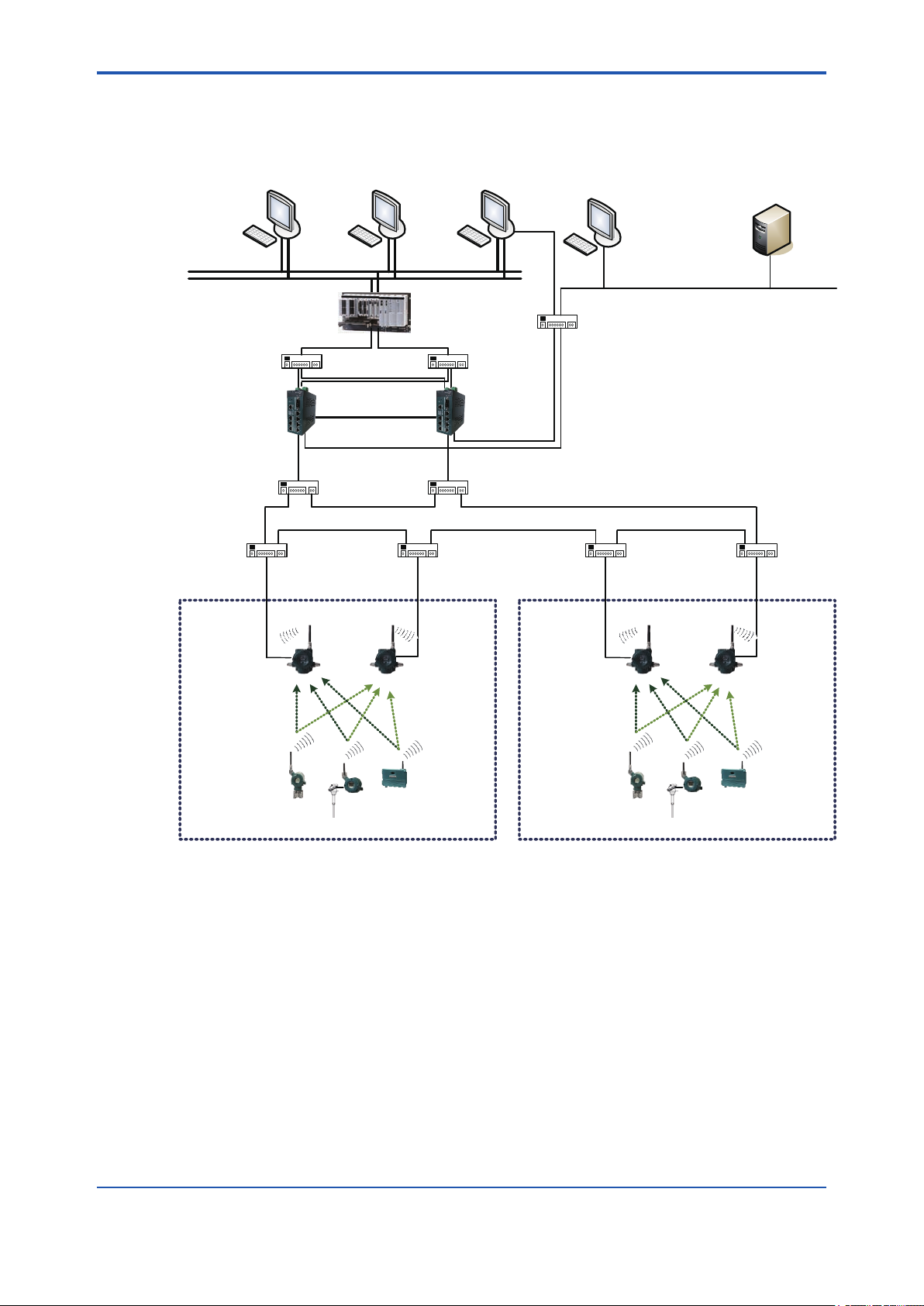

<A4. YFGW410 in High-Level Redundancy Conguration>

A4-1

A4. YFGW410 in High-Level Redundancy

Conguration

HIS HIS/ENG PRM

Control network (Ethernet)

FCS

ALE111×2

L2SW L2SW

Cable for Redundancy

L2SW (IEEE 1588) L2SW (IEEE 1588)

L2SW (IEEE 1588) L2SW (IEEE 1588) L2SW (IEEE 1588) L2SW (IEEE 1588)

Subnet A

Field Wireless

Access Point

(YFGW510)

Field Wireless

Access Point

Management Station

(YFGW510)

Field Wireless

(YFGW410)

Subnet B

Field Wireless

Access Point

(YFGW510)

"Field wireless management PC

- Field Wireless Management Console"

L3SW

NTP server

Ethernet

Field Wireless

Access Point

(YFGW510)

Field wireless network

(ISA100.11a)

Field wireless device

Field wireless network

(ISA100.11a)

Field wireless device

Figure A4-1 High-Level redundancy system conguration of YFGW410

In this conguration, the system consists of redundant YFGW410 and redundant Modbus/TCP

client of the host system. Yokogawa’s Modbus/TCP client can be made redundant using the FCS

(Field Control Station) of CENTUM VP. For details, see the CENTUM VP User’s Manual

(IM 33K03L20-50E for R5, or IM 33M01A30-40E for R4).

The YFGW410 in redundant conguration operates as a single virtual machine for the Modbus/

TCP clients. Although the YFGW410 has the L2SW functions, the eld wireless backbone network can be expanded by adding another L2SW between the eld wireless backbone devices.

The L2SW needs to be used which supports the IEEE 1588 v2 precision time protocol and the

RSTP or another loop detect functions. If a L2SW is used that is not supporting the IEEE 1588 v2

protocol and RSTP function, its operation is not guaranteed. Enable the IEEE 1588 v2 precision

time protocol of L2SW, and operate the switch in E2E 2-step TC mode. Also, enable the RSTP or

another loop detect function.

FA0401.ai

IM 01W02D01-01EN

Page 22

<A4. YFGW410 in High-Level Redundancy Conguration>

In the redundant YFGW410, need to connect the system to the YFGW510 using following method:

• Direct connection between YFGW410 and YFGW510 (shown in Figure A3-1)

• A single L2SW is installed for each backbone device. The L2SW have to connect as a loop.

(shown in Figure A4-1).

For the recommended L2SWs whose operations have been proven on the eld wireless backbone system, see Section G2.7 Recommended Device List. If a non-recommended L2SW is

used, its operation is not guaranteed even when the above functional requirements are satised.

IMPORTANT

When connecting the L2SW between YFGW410 and YFGW510, requirements for operation to

the backbone network are the following.

- Use IEEE1588 v2 compliant product to L2SW.

- Enable Rapid Spanning Tree Protocol (RSTP) or another loop detection function.

A4-2

IMPORTANT

When CENTUM VP is running, set and adjust the parameters of the eld wireless device from

PRM.

When CENTUM VP is not running, or when a non-Yokogawa host system is connected, the parameters can be set and adjusted using FieldMate.

IMPORTANT

When CENTUM VP is used with YFGW410 in redundant conguration, CENTUM VP R5.02.00

or higher is required. For details, see the Communication with Subsystems Using FIO user’s

manual (IM 33K03L20-50E).

IM 01W02D01-01EN

Page 23

<B1. Introduction>

Part B YFGW410 Product Description

B1. Introduction

This chapter outlines the functions and hardware conguration of the YFGW410.

YFGW410 is a core device in the eld wireless network, and it is used for conguration and management of a eld wireless network and for data transfer to the host system. A single YFGW410

is always required for the eld wireless network, and two YFGW410s are required for redundacy

system.

The YFGW410 can be mounted on the DIN rails, and it is usually mounted on the panel or wall in

the cabinet.

B1-1

IM 01W02D01-01EN

Page 24

<B2. YFGW410 Function Outline>

B2. YFGW410 Function Outline

The following outlines the YFGW410 functions.

YFGW410 has the System Manager, Security Manager, and Gateway functions. Also, this device

has the switching hub functions to connect the host system, PC to operate Field Wireless Management Console and other applications.

B2.1 System Manager

The System Manager controls the wireless communication of eld wireless devices, congures

the eld wireless backbone devices, and provides the database function.

The management function of the eld wireless device establishes a communication path to each

eld wireless device, monitors the Join or Leave status of each eld wireless device, and noties

the Field Wireless Management Console with an abnormality. Also, this function determines the

communication availability in conjunction with the Security Manager.

The management function of the eld wireless backbone device is used to initialize the IP address, network address and others of the YFGW410 and YFGW510.

The database function of the eld wireless network is used to manage the network information data contained in the YFGW410 and to control the data synchronization during redundant

YFGW410 system conguration.

B2-1

B2.2 Security Manager

The Security Manager has the functions for eld wireless device authentication and for encryption key management.

The Security Manager allows eld wireless devices to join to the network with the Join key, Session key and others. This manager is used to create, update, and delete an authentication/encryption key during communication.

B2.3 Gateway

The YFGW410 bridges between the eld wireless network and the host system.

During Modbus communication, the eld wireless device data is transmitted to the host system.

The Read Input Register, Read Holding Register, and Write Holding Register functions are supported. Before transmitting data to the host system, it is necessary to map the transmission process value, device status, alert information and other data to registers.

In the ISA100.11a protocol communication, the information about eld wireless network state and

device state of this network is transmitted when requested by the host system. Also, the gateway

relays a request and its response between the host system and eld wireless devices.

The Gateway can cache the diagnosis data acquired through communication with the eld wireless device in the YFGW410’s internal memory. The efcient communication to wireless eld

devices can use a wireless band exibly and improve the response to the host system.

IMPORTANT

When access to the Modbus registers that are not mapped in YFGW410, a non-zero data may

be contained.

IM 01W02D01-01EN

Page 25

<B2. YFGW410 Function Outline>

IMPORTANT

Writing to the Holding Register of Modbus by CENTUM VP requires R5.02.00 or higher. For details, see the Communication with Subsystems Using FIO user’s manual (IM 33K03L20-50E).

B2.4 Wireless Network Conguration and

Management Functions and Others

The YFGW410 has the software tools for conguration and management of eld wireless network on the Web page of this device. Connect to YFGW410 via Internet Explorer (IE) that are

installed on the eld wireless management PC.

B2-2

IM 01W02D01-01EN

Page 26

<B3. Structure and Parts of YFGW410>

B3. Structure and Parts of YFGW410

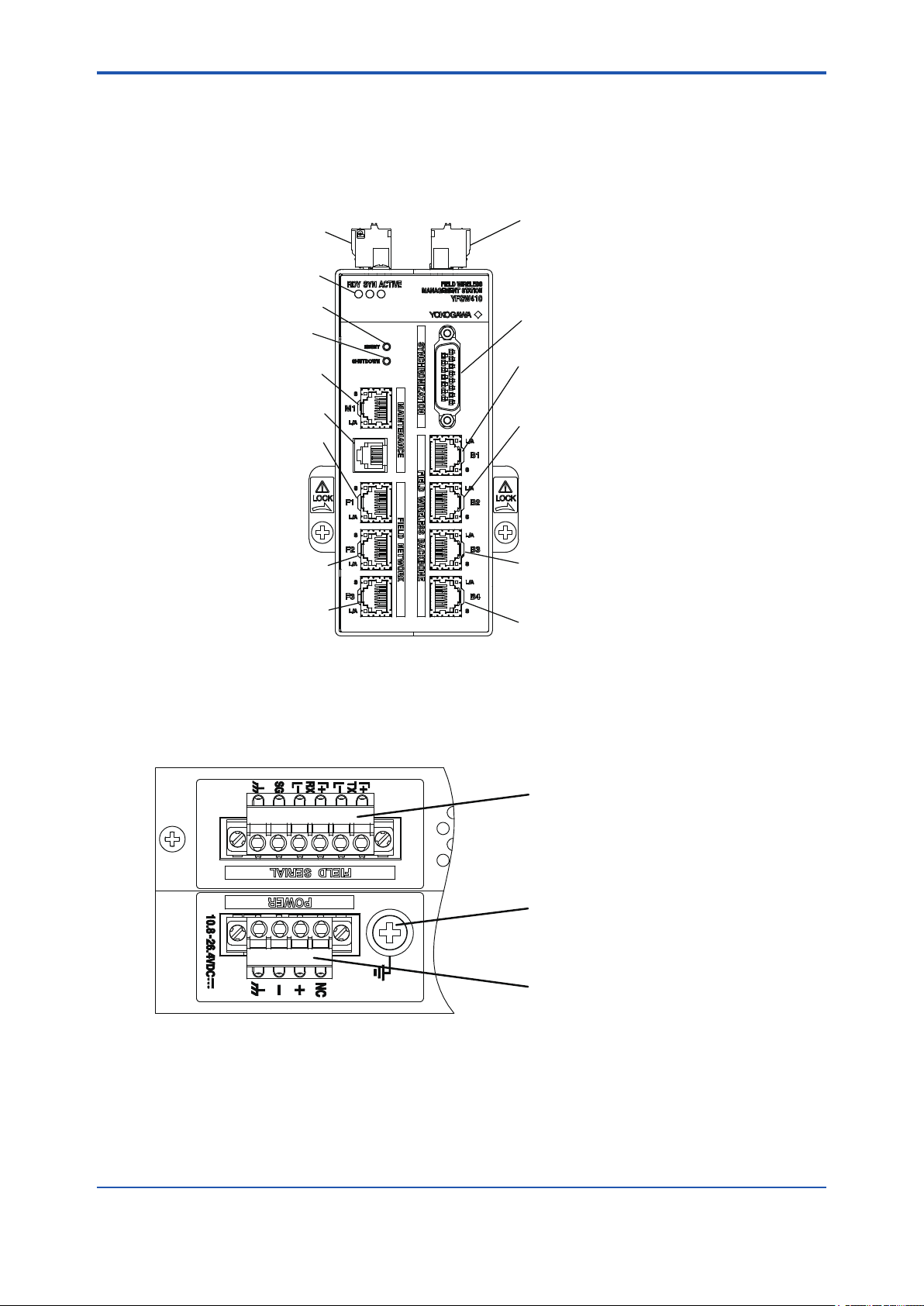

B3.1 Front View

B3-1

RS-485 connector

Status indicator LED

Reset switch

Shutdown switch

Maintenance interface

Serial port

Field network interface 1

Field network interface 2

Field network interface 3

Figure B3-1 YFGW410 front view

Power supply connector

Synchronization connector

Field wireless

backbone interface 1

Field wireless

backbone interface 2

Field wireless

backbone interface 3

Field wireless

backbone interface 4

FB0301.ai

B3.2 Top View

Figure B3-2 YFGW410 top view

RS-485 connector

Ground terminal

Power supply connector

FB0302.ai

IM 01W02D01-01EN

Page 27

<B3. Structure and Parts of YFGW410>

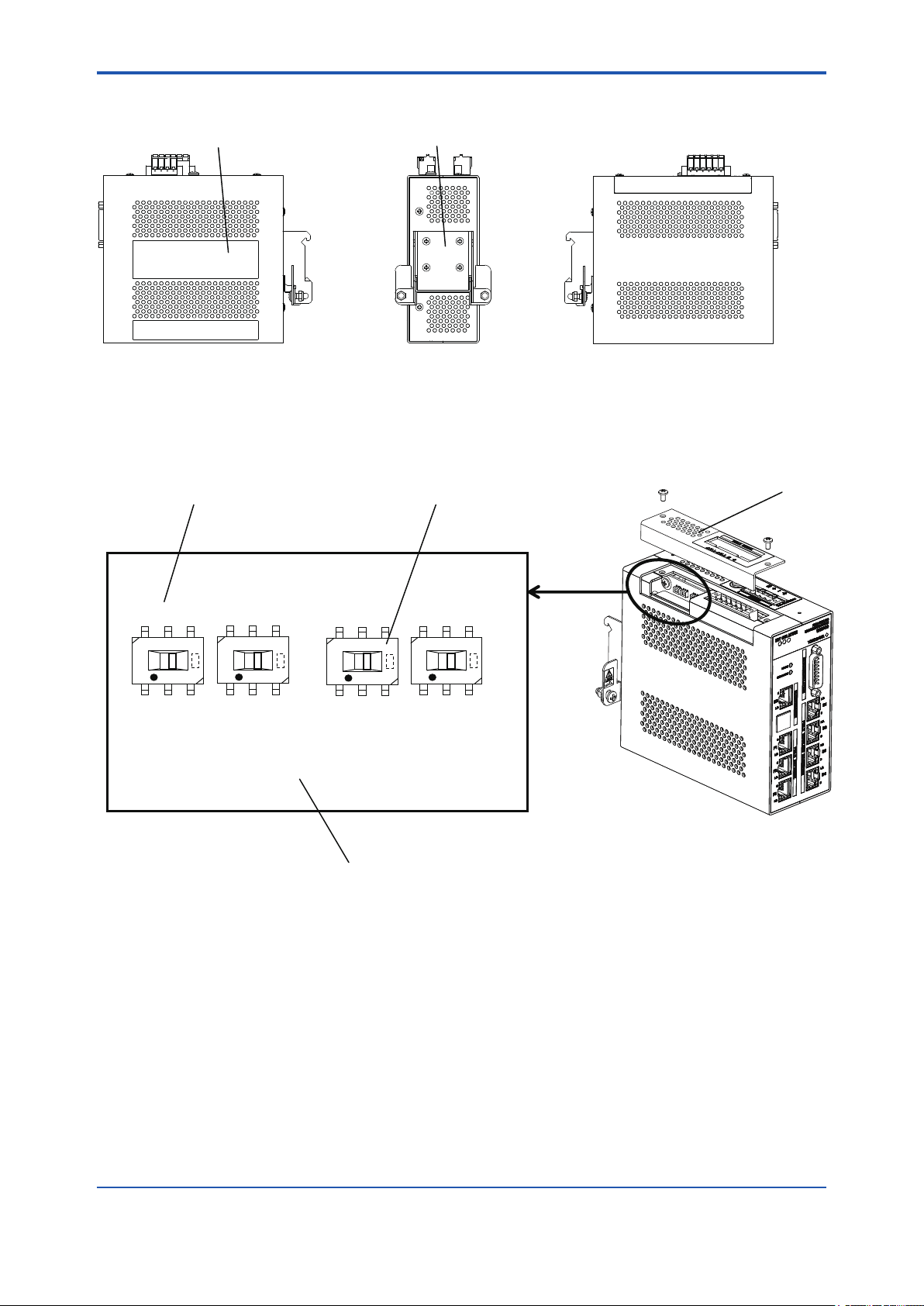

B3.3 Side and Rear Views

Name plate DIN rail mounting bracket

B3-2

Right side Rear

Figure B3-3 YFGW410 side and rear views

B3.4 RS-485 Conguration Switches

Switch number RS-485 configuration switches

SW602

SW604

SW603

SW605

Left side

FB0303.ai

Top cover

Circuit board

Figure B3-4 RS-485 Conguration Switches

FB0304.ai

IM 01W02D01-01EN

Page 28

<B3. Structure and Parts of YFGW410>

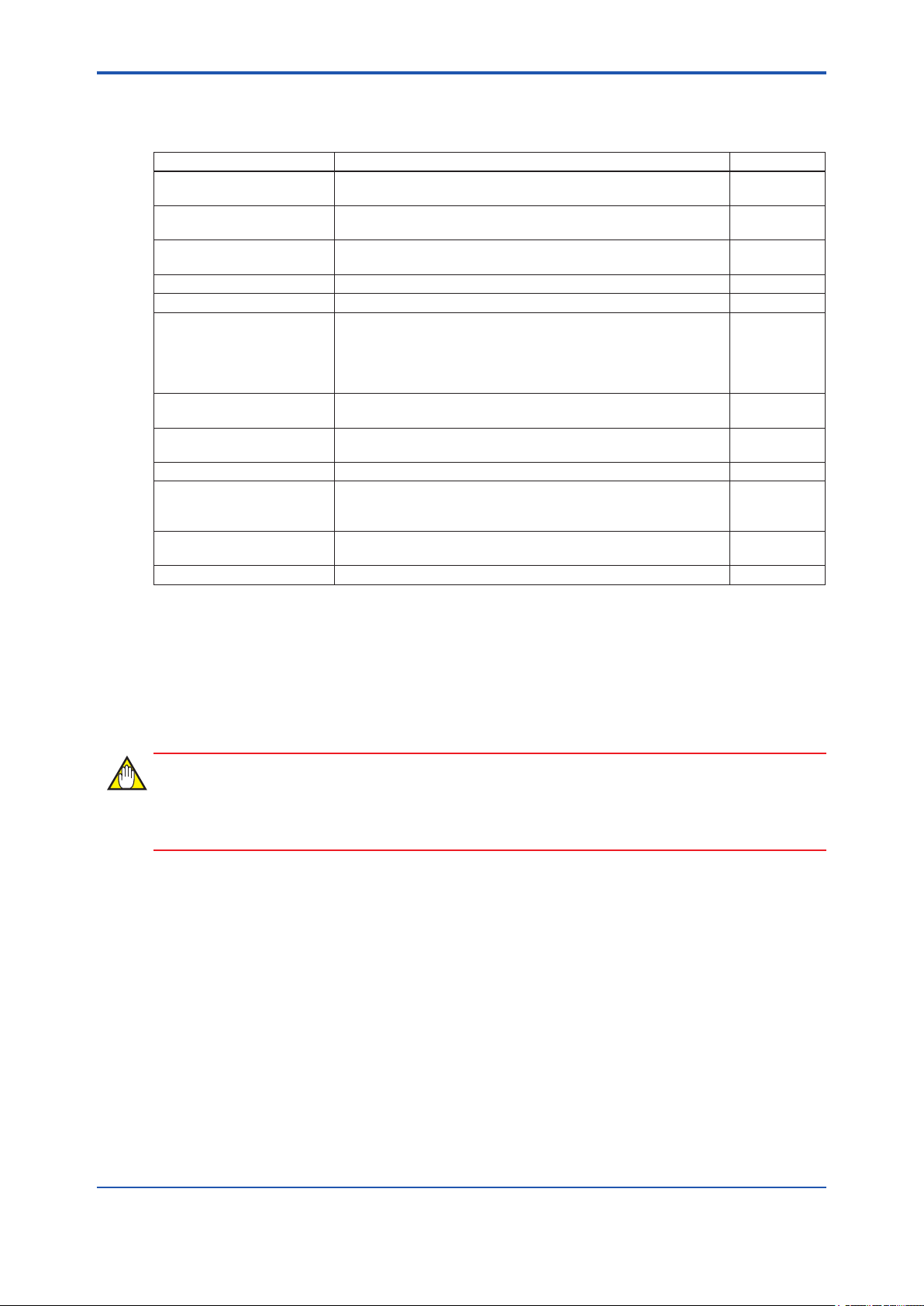

B3.5 Outline of Component Functions

Table B3-1 Outline of the YFGW410 component functions

Name Function Reference

RS-485 connector Connects to the host system that uses Modbus/RTU communi-

RS-485 conguration

switches

Status indicator LED A combination of three RDY, SYN, and ACTIVE LEDs indicates

Reset switch Resets the YFGW410. B3.6

Shutdown switch Shuts down the YFGW410. B3.7

Maintenance interface Connects the Field Wireless Management Console for setup and

Serial port Used for YFGW410 maintenance only. (Do not use this port dur-

Field network interface 1 to 3 Connects to the host system that uses the Modbus/TCP, ISA100.

Power supply connector Supplies electric power to the YFGW410. C4.2

Synchronization connector Connects two YFGW410 devices to each other for synchronous

Field wireless backbone

interface 1 to 4

DIN rail mounting bracket Secures the YFGW410 onto DIN rails using brackets. C3.3

cation.

Congures connection type to the host system (4-wire / 2-wire) C4.4

the YFGW410 operation status.

maintenance of a eld wireless network.

The PC, that has the FieldMate for setup and management of

eld wireless devices via wireless network, can also be connected (if used for the system without CENTUM VP).

ing normal network conguration and operation.)

11a or other protocol communication.

communication in the redundancy conguration. Plug the terminating connector into it if the system is not redundant.

Connects YFGW510, YFGW610, and the wireless LAN access

point to congure the eld wireless backbone.

B3-3

C4.4

F2.2

C4.4

C4.1

C4.4

C4.4

C4.4

B3.6 Reset Switch

Resets YFGW410. Hold the Reset switch for more than six seconds, the database in the

YFGW410 is initialized. If the database is initialized, the entire setup information of the device is

cleared. Always make a backup copy of the database before starting its initialization.

IMPORTANT

When initializing the database, don’t power off until RDY LED becomes green. Otherwise initialization will be failed and YFGW410 may not work correctly.

B3.7 Shutdown Switch

Shuts down YFGW410. Hold the Shutdown switch more than six seconds. Once shut down the

YFGW410, start it again by turning the power supply OFF rst, and then turn it ON again.

IM 01W02D01-01EN

Page 29

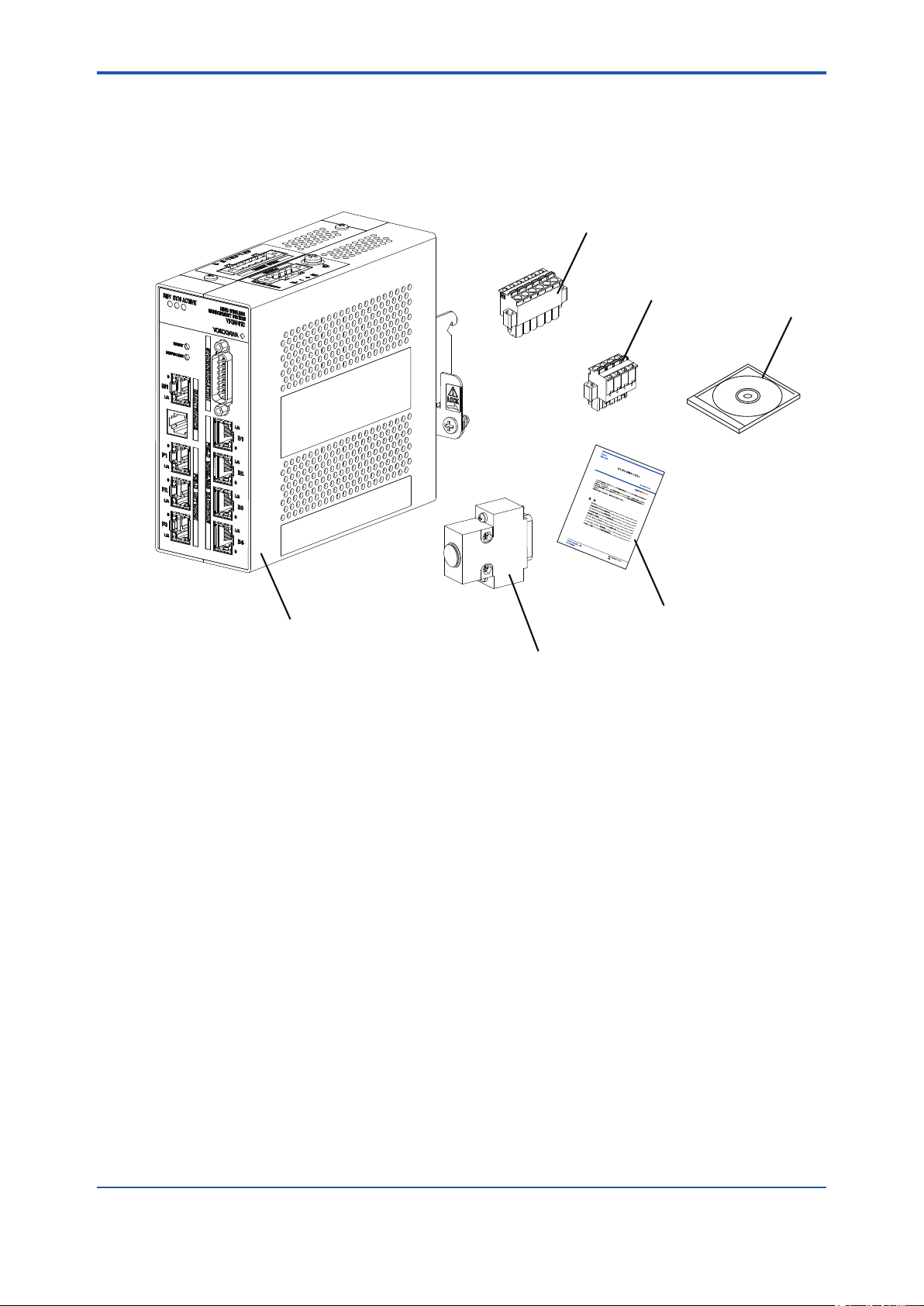

<B4. Checking the Delivered Products>

B4. Checking the Product

When you receive the product, please check the contents.

Check that the product specications match your order, that all parts are included, and that there

is no damage, stains, or other problems.

RS-485 connector

Power supply connector

B4-1

DVD-ROM

YFGW410

Read Me First

Terminator or Cable for Redundancy

Figure B4-1 Checkout of delivered products

● Read Me First (IM01W02D01-11EN Read Me First)

When specied manual language as an English.

● DVD-ROM (F9194TA)

When specied Software Media as DVD-ROM.

● Terminator or Cable for Redundancy

It depends on selection of Sync Connector Termination.

If With Terminator is specied, Terminator is included. Otherwise Cable for Redundancy is

included.

● Power supply connector and RS-485 connector

These are included as standard.

FB0401.ai

IM 01W02D01-01EN

Page 30

<C1. Installation Environment>

Part C Installation

This part describes the installation of the YFGW410.

Follow the steps below to use of the product.

1. YFGW410 installation

2. Power, ground, and signal cable connection

C1. Installation Environment

The system must be installed in an appropriate environment to ensure stable system operation.

The following denes the detailed specications of the YFGW410 installation environment.

Table C1-1 Installation environment specications

Item Specications Applicable

Ambient

temperature

Ambient

humidity

Temperature

gradient

Protection class IP20 IEC529

Vibration resistance 0.15 mm P-P (5 to 58 Hz)

Impact resistance 15 G, 11 ms (no conductive, and 3-direction half sine

Altitude Up to 3000 meters (due to restricted ambient tem-

Noise level Electric eld 3 V/m or less (80 MHz to 1 GHz)

Grounding Class D grounding

Cooling Natural cooling

Mounting Mounted on DIN rails.

Power

supply

Power consumption 10 W

Operating -40 to 65°C (at altitude below 2000 meters)

-40 to 55°C (at altitude between 2000 and 3000

meters)

Transport or storage

Operating 5 to 95% relative (without condensing)

Transport or stor-

age

Operating Within +/-10°C per hour JEIDA 29 Class B

Transport or stor-

age

Electrostatic

discharge

Voltage range 10.8 to 26.4 VDC

Rated voltage 24 VDC

Allowable ripple Less than 1% p-p

-40 to 85°C

5 to 95% relative (without condensing)

Within +/-20°C per hour

1 G (58 to 150 Hz)

waves)

perature)

4 kV or less (contact discharge), 8 kV or less (aerial

discharge)

IEC68-2-6

IEC68-2-27

C1-1

standards

CAUTION

When ambient temperature is beyond 50 °C, a temperature of the surface is very high. Please be

careful not to touch with bare hands.

IM 01W02D01-01EN

Page 31

<C1. Installation Environment>

IMPORTANT

• The temperature specication during operation indicates the criterion of the temperature

at the air intake of the bottom portion of modules. Do not block ventilation holes, as it may

hinder the air-cooling capabilities of the body. When installing YFGW410 in a cabinet, note

that the temperature specication is not in respect to the ambient temperature of the cabinet. Provide cooling fans in the cabinet if needed.

• Avoid exposing YFGW410 to direct sunlight.

• Prevent condensation under any circumstance.

• The dust level of the room should not exceed 0.3 mg/m

3

. Under any circumstance, avoid

iron akes, carbon particles, or any other type of dust that are conductive.

• Avoid existence of corrosive gases such as hydrogen sulde, sulfurous acid gas, chlorine,

and ammonia.

• YFGW410 should not share a ground wire with other devices.

n YFGW410 Vibration Criteria

C1-2

Ensure that if the frequency of vibration at the installation location is 58 Hz or less, the total amplitude is maintained less than 0.15 mm. If the vibration frequency is greater than 58 Hz, nd a

location that will meet the following condition:

Acceleration (m/s

2

) = 2π2 x A x F2 x 10-3 < 9.8 (=1 G)

A: Total amplitude (mm)

F: Frequency (Hz)

The range of allowable total amplitudes is shown below.

mm

0.2

0.15

0.1

Allowable range

0.05

Total amplitude

0

10 30 50 70 90 110 130 150Hz

Vibration frequency

FC0101.ai

Figure C1-1 Allowable Vibration Range

IM 01W02D01-01EN

Page 32

<C1. Installation Environment>

n Radio Device Noise to YFGW410

The following shows general requirements when using a radio device such as transceivers;

however, as a general rule, close the cabinet door when using a radio device:

• Transceivers that have 3 W of output power or less should be at least 1 m away. Transceivers that have 10 W of output power or less should be at least 2 m away.

• Radio devices that have 1 W of output power or less including cellular phones and cordless

phones should be at least 1 m away.

• The eld wireless device radio output is about 10 mW. There is no impact for YFGW410,

but keep to 1m than the same way as the 1 W output radio device.

C1-3

IM 01W02D01-01EN

Page 33

<C2. Power Supply and Grounding>

C2. Power Supply and Grounding

An appropriate power supply is necessary for the stable operation of YFGW410.

C2.1 Power Supply

Connect the power source to the spring terminal block located on the top of YFGW410.

SEE

For power supply and current consumption of the YFGW410, also see GS 01W02D01-01EN

ALSO

n Inrush current

When starting up, inrush current may run into the device. As shown in the table below, this current is, even though short-lived, signicantly larger (10 times or more) than the steady state current. Make sure that the power supply and protector can endure the inrush current.

Table C2-1 Inrush current specications

Item Specications Remarks

Inrush current 30 A, 2 ms or less At 26.4 VDC

C2-1

SEE

For wiring of the YFGW410 power supply, see Section C4.2 Power Supply Cable Connection.

ALSO

WARNING

• Conguration data may be corrupted if a power failure occurs during download to

YFGW410, YFGW510 and eld wireless devices. Conguration data is not corrupted even if

a power failure occurs at the time of the usual operation.

• When power failure is detected, the system may take a certain amount of time to recover to

the normal operation status.

• Please supply the power from the permanent power supply to avoid.

IMPORTANT

- YFGW410 does not have a power switch. Provide a breaker or switch for the external power

line to turn ON/OFF the device.

- The overcurrent protection circuit of the power supply, it is recommended to use the automatic-recover type with the reverse L-shaped.

IM 01W02D01-01EN

Page 34

<C2. Power Supply and Grounding>

C2.2 Grounding

Appropriate grounding is necessary for the stable operation of YFGW410. Class D grounding

(the third class grounding) with the ground resistance of 100 ohms or less is necessary. To connect the ground cable to YFGW410 directly, use the frame ground (FG) terminal on the top side

of the mainbody.

SEE

For grounding of the YFGW410, see Section C4.3 Grounding.

ALSO

C2-2

IM 01W02D01-01EN

Page 35

<C3. Mounting>

C3. Mounting

YFGW410 can be mounted on the DIN rails, and it is usually mounted on the panel or wall in the

cabinet.

No other type of mounting is allowed.

C3.1 Mounting Direction

YFGW410 is designed to be cooled by natural air. Install an YFGW410 so that the ventilation air

ows upward from its bottom to top as shown below. Mount in the correct direction.

Up

Air flow

C3-1

Air flow

Down

Figure C3-1 YFGW410 mounting direction

FC0301.ai

IMPORTANT

• Be sure to turn off the power before installing or removing YFGW410.

• Do not install the body blocking the ventilation holes on the top and bottom.

• At the top side, to prevent the cooling air current from being blocked, be sure to place the

body at least 150 mm away from other devices. This space is also used as a work area for

the power supply cable connection.

• At the bottom side, to prevent the cooling air current from being blocked, be sure to place

the body at least 100 mm away from other devices.

• At the side panel, to prevent the cooling air current from being blocked, be sure to place the

body at least 50 mm away from other devices. This space is also used as a work area for

the power supply cable connection.

• Do not expose to direct sunlight.

IM 01W02D01-01EN

Page 36

<C3. Mounting>

C3.2 Mounting to DIN Rails

First, install the DIN rails on the panel or the cabinet wall. Secure the DIN rails by tightening the

appropriate number of screws. Be careful that the rails do not get bent or deformed due to the

weight of the YFGW410 or cable tension.

To securely ground YFGW410, insert an insulation bushing between the DIN rails and mounting

panel and tighten the screws. Insulate the DIN rails from the metal surface of the mounting panel.

Insulation bushing

DIN rail

Insulation bushing

FC0302.ai

Figure C3-2 Use of insulation bushing

C3-2

IM 01W02D01-01EN

Page 37

<C3. Mounting>

C3.3 Installation of the YFGW410

1. Loosen the screws at both sides of the DIN rail mounting bracket (located on the rear panel

of the YFGW410), by rotating these screws in the reverse direction from the “Lock” position.

The screws do not drop even when fully loosened.

2. As shown in Figure C3-3, hook the top edge of the DIN rail mounting bracket onto the top of

the DIN rail, and return the YFGW410 back to the horizontal position. Then, hook the bottom

edge of the mounting bracket onto the bottom of the DIN rail.

3. Tighten the screws at both ends of the DIN rail mounting bracket, by rotating them toward

the “Lock” position. Tighten screws securely to ensure there is no clearance between the

bracket and the DIN rails.

4. Remove the YFGW410 by following the procedure described above in reverse.

After you have tightened the screws, loosen them by three turns.

C3-3

Figure C3-3 Mounting of the YFGW410 on DIN rails

FC0303.ai

IM 01W02D01-01EN

Page 38

<C3. Mounting>

FC0304.ai

Figure C3-4 Mounting example

C3-4

Figure C3-5 Mounting example (in redundant conguration)

FC0305.ai

IM 01W02D01-01EN

Page 39

<C4. Wiring>

C4. Wiring

This chapter explains the power, grounding, and communication cable connection to the

YFGW410.

C4.1 Terminals and Communication Ports

Connection

The YFGW410 has spring terminals to connect the power supply cable and serial communication

cables. Use the screw to connect the ground terminal with a ring-type crimp to the frame ground.

Use the RJ-45 connectors for Ethernet, and connect the metal network cables to the eld wireless backbone device interface, eld network interface, and maintenance interface.

Plug the cable for redundancy or the terminator to the synchonization connector.

The customer does not need to connect any cable to the serial port.

C4-1

RS-485 connector

Maintenance interface

Field network interface

Power supply connector

Synchronization connector

Field wireless

backbone interface

Figure C4-1 Terminals and Communication Ports View

FC0401.ai

IM 01W02D01-01EN

Page 40

<C4. Wiring>

C4.2 Power Supply Cable Connection

The YFGW410 has a 4-pin power supply connector (with a spring terminal; Phoenix Contact’s

FKC 2.5/4-STF) and the socket on the mainbody. The spring terminal base is secured by two

screws at both ends. To separate the terminal from the socket, loosening these screws.

There is enough space for cabling at the top and side panels of the YFGW410, leave the spring

terminals on the mainbody (as shown in Figure C4-2) and connect the positive and negative

power lines as indicated.

If there is insufcient space, separate the spring terminals from the socket, route the cables, and

secure the mainbody.

IMPORTANT

Be careful to connect the power supply cable with correct polarity. Because the YFGW410 does

not have a power switch, add a power switch or a circuit breaker to the external power line.

C4-2

1

2

3

4

Figure C4-2 Power supply cable connection procedure

FC0402.ai

IM 01W02D01-01EN

Page 41

<C4. Wiring>

To disconnect the power supply cable from the spring terminal, push down the orange areas

around the cable inlet and pull out the power supply cable from the socket.

FC0403.ai

C4-3

Figure C4-3 Disconnecting the power supply cable

l Applicable cables

Insulated cables for industrial equipment such as;

• 600 V polyvinyl chloride insulated wires (IV); JIS C3307

• Polyvinyl chloride insulated wires for electrical apparatus (KIV); JIS C3316

• 600 V grade heat-resistant polyvinyl chloride insulated wires (HIV); JIS C3317

• Heatproof vinyl insulated wires VW-1 (UL1015/UL1007)

• Control cables (vinyl insulated vinyl sheath cable) (CVV); JIS C3401

l Wire Size

Without sleeve: 0.2 mm2 to 2.5 mm2 (AWG24 to 14)

With sleeve: 0.2 mm

2

to 2.5 mm2 (AWG24 to 14)

IM 01W02D01-01EN

Page 42

<C4. Wiring>

l Wiring to spring terminals:1 (without sleeve)

- When using a solid conductor, strip the insulated cover and connect it.

Cable

Strip the solid conductor by 10 mm.

- When using a stranded conductor, strip the

insulated cover and twist and connect it.

Core

Length of exposed wire

Strip the stranded conductor for 10 mm.

Never solder the stranded conductor when connecting cables.

Be careful not to cause the loosely stranded conductor to come in contact with adjacent

terminals or others. Insert the cable leads into the terminal block securely.

l Wiring to spring terminals:2 (with sleeve)

The sleeve can prevent cable leads from untwist when you connect the cable. Select a sleeve to

match the cable size. If the length of cable leads does not match the length of sleeve (I

cable to the correct length. Strip the cable for a length so that the core wire slightly extends from

the metal tube of the sleeve. If this causes the length of the metal tube of the sleeve to be slightly

shorter than the stripping length, this is no problem.

C4-4

FC0404.ai

), strip the

2

The wiring cables and applicable sleeves are listed in the table below.

Use the same manufacturer for sleeves and tools.

Example of tool: Phoenix Contact’s CRIMPFOX 6

For details on sleeves and crimp tools, contact to Phoenix Contact Inc.

l

1

l

2

1

d

1

s

2

s

1

d

FC0405.ai

IM 01W02D01-01EN

Page 43

<C4. Wiring>

Table C4-1 List of power cables

Cable Dimensions (mm)

Section

area

2

(mm

)

AWG

Strip

length

(mm)

I

1

I

2

d

1

S

1

d

2

S

2

0.25 24 10 10.5 6.0 0.8 0.15 2.0 0.25 AI 0.25-6 BU

0.34 22 10 10.5 6.0 0.8 0.15 2.0 0.25 AI 0.34-6 TQ

10 12.5 8.0 0.8 0.15 2.0 0.25 AI 0.34-8 TQ

0.5 20 10 12.0 6.0 1.1 0.15 2.5 0.25 AI 0.5-6 WH

10 14.0 8.0 1.1 0.15 2.5 0.25 AI 0.5-8 WH

10 16.0 10.0 1.1 0.15 2.5 0.25 AI 0.5-10 WH

0.75 20 10 12.0 6.0 1.3 0.15 2.8 0.25 AI 0.75-6 GY

10 14.0 8.0 1.3 0.15 2.8 0.25 AI 0.75-8 GY

10 16.0 10.0 1.3 0.15 2.8 0.25 AI 0.75-10 GY

1.0 18 10 12.0 6.0 1.5 0.15 3.0 0.3 AI 1-6 RD

10 14.0 8.0 1.5 0.15 3.0 0.3 AI 1-8 RD

10 16.0 10.0 1.5 0.15 3.0 0.3 AI 1-10 RD

1.5 16 10 12.0 6.0 1.8 0.15 3.4 0.3 AI 1.5-6 BK

10 14.0 8.0 1.8 0.15 3.4 0.3 AI 1.5-8 BK

10 18.0 10.0 1.8 0.15 3.4 0.3 AI 1.5-10 BK

2.5 14 10 14.0 8.0 2.3 0.15 4.2 0.3 AI 2.5-8 BU

10 16.0 10.0 2.3 0.15 4.2 0.3 AI 2.5-10 BU

C4-5

Phoenix

Contact's type

IMPORTANT

• Use the same manufacturer for sleeves and tools.

• Use sleeve tools that match the wire thickness.

• Insert the wire to be connected completely into the pressure clamp terminal and attach it

securely.

• Secure the cable to cable clamps, etc. so that the weight of the cable applied to the terminal

is minimized.

• Strip the cable for a length so that the core wire slightly extends from the metal tube of the

sleeve. If this causes the length of the metal tube of the sleeve to be slightly shorter than the

stripping length, this is no problem.

IM 01W02D01-01EN

Page 44

<C4. Wiring>

C4.3 Grounding

Appropriate grounding is necessary for the stable operation of YFGW410. The YFGW410 has

two ground terminals: the frame ground (FG) terminal secured by the M4 screw at the side of

power supply connector (on the top side of the mainbody), and the ground terminal at the power

supply spring terminal.

Connect the ground cable from the frame ground (FG) terminal to the ground. Connect the cable

shield or others to the power supply spring terminal.The internal wiring of YFGW410 mainbody is

connected as shown in the following gure.

C4-6

Ground

terminal

Power supply

+

NC

connector

YFGW410 Housing

SG

RX RX +

TX TX +

RS-485

connector

FC0406.ai

Figure C4-4 Internal connection of the ground terminal

To ensure stable grounding, insulate the panel or DIN rails with YFGW410 from the metal surface

of external cabinet, rack and others by using insulation bushings or others. Then, connect the cable from YFGW410 to the ground. Class D grounding (the third class grounding) with the ground

resistance of 100 ohms or less is necessary. To connect the ground cable to YFGW410 directly,

use the frame ground (FG) terminal on the top side of the mainbody. YFGW410 should not share

a ground wire with other devices.

IM 01W02D01-01EN

Page 45

<C4. Wiring>

C4-7

Figure C4-5 Ground terminal connection procedure

FC0407.ai

IM 01W02D01-01EN

Page 46

<C4. Wiring>

l Applicable cables

Insulated cables for industrial equipment such as;

• 600V polyvinyl chloride insulated wires (IV); JIS C3307

• Polyvinyl chloride insulated wires for electrical apparatus (KIV); JIS C3316

• 600V grade heat-resistant polyvinyl chloride insulated wires (HIV); JIS C3317

• Heatproof vinyl insulated wires VW-1 (UL1015/UL1007)

l Wire Size

Core: AWG14 to 13 (2 mm2 to 2.6 mm2)

l Termination

Use a ring tongue terminal for M4 terminals: with an insulation sleeve

C4.4 Communication Cable Connection

C4-8

n Field wireless backbone device

Connect the 100BASE-TX compliance cable, terminated with an RJ-45 connector, to the eld

wireless backbone device interface on the front panel of the YFGW410.

Figure C4-6 Connection to eld wireless backbone

n Field network

Connect the 100BASE-TX compliance cable, terminated with an RJ-45 connector, to the eld

network interface on the front panel of the YFGW410.

Generally, connect the host system which transmits data using the ISA100.11a protocol to the F1

port of YFGW410. Connect the host system which transmits data using the Modbus/TCP protocol to the F2 or F3 port.

FC0408.ai

n RS-485

YFGW410 supports to communicate with the host system, which supports Modbus/RTU communication, via the RS-485 connector on top of the main body. 4-wire and 2-wire types are provided

for connection with the host system. Selecting connection type is set by RS-485 conguration

switches. YFGW410 supports only 1 to 1 connection.

RS-485 connector is a 6-pin connector with a spring terminal (Phoenix Contact FKC 2.5/6-STF).

For details of wiring, see C4.2 Power Supply Cable Connection. Regarding RS-485 communi-

IM 01W02D01-01EN

Page 47

<C4. Wiring>

cation cables, use shielded twisted pair cables (cables for RS-422/RS-485 communication are

recommended).

IMPORTANT

All RS-485 conguration switches are set to OFF by default. When connecting cables to the RS485 connector, set RS-485 conguration switches to t actual connection before power on.

l Connection in 4-wrie Type

YFGW410 Host System

TX+

TX-

TX+

R2

TX-

C4-9

RX+

R1

RX-

SG

FG

R1: Termination resistance of 120 Ω (comes with YFGW410)

R2: According to the instruction on the external equipment

Figure C4-7 Connection and Conguration in 4-wire Type

l Connection in 2-wire Type

YFGW410 Host System

TX+

TX-

RX+

R1

RX-

R2

TX+

TX-

RX+

RX-

R2

RX+

RX-

SG

FG

RS-485 Configuration Switches

SW602 SW603SW604 SW605

OFF OFF OFF ON

FC0409.ai

RS-485 Configuration Switches

SW602 SW603SW604 SW605

SG

FG

R1: Termination resistance of 120 Ω (comes with YFGW410)

R2: According to the instruction on the external equipment

Figure C4-8 Connection and Conguration in 2-wire Type

l Modbus/RTU

Following table shows Modbus/RTU communication parameter of YFGW410. The host system

should be congured in accordance with following parameters.

.

SG

FG

ON OFF ON ON

FC0410.ai

IM 01W02D01-01EN

Page 48

<C4. Wiring>

Table C4-2 Modbus/RTU Communication Parameters of YFGW410

Item Description Note

Serial Communication Boat rate: 38.4kbps

Parity: Even

Stop bit: 1 bit

Modbus/RTU Modbus Slave

Modbus/RTU Address: 1

Fixed values

Congure the host system as Modbus Master.

Modbus/RTU address of the host

system should be except 1.

IMPORTANT

Modbus/RTU supports to access up to 125 words at once. However, part of information may not

be accessed through Modbus/RTU, because number of accessible words depended on a Modbus/RTU client. For details, see users’ manual of the host system.

n Maintenance interface

C4-10

Connect the 100BASE-TX compliance cable, terminated with an RJ-45 connector, to the maintenance interface (M1) on the front panel of the YFGW410. Connect the Field Wireless Management Console to this port for conguration of a eld wireless network and the YFGW410.

IMPORTANT

When CENTUM VP is running, set and adjust the parameters of the eld wireless device from

PRM.

When CENTUM VP is not running, or when a non-Yokogawa host system is connected, the parameters can be set and adjusted using FieldMate.

n Synchronization connector

In order to build redundancy YFGW410, connect an attached cable for redundancy to the synchronization connector in the front of YFGW410. When using single YFGW410, connect the

terminator to the synchronization connector. If nothing has connected with a synchronization connector, YFGW410 does not operate.

IMPORTANT

• The cable for redundancy has the D-sub 15-pin connector at both ends. Secure the cable

connector to the synchronization connector using screws. When cables other than an attached cable for redundancy are connected, these operation is not guaranteed.

• If nothing has connected with a synchronization connector, YFGW410 does not operate.

IM 01W02D01-01EN

Page 49

<C5. Explosion-Proof Wiring>

C5. Explosion-Proof Wiring

- Application pending -

(Left blank intentionally)

C5-1

IM 01W02D01-01EN

Page 50

<D1. Engineering Procedures>

Part D System Construction

This part describes the ow and work content of the engineering in order to construct a Field

Wireless System.

D1. Engineering Procedures

Shippment

D1-1

Engineering of host system

System

(CENTUM VP, FAST/TOOLS,

engineer

DAQSTATION, and so on)

Backup file

Startup engineer or

wireless engineer

Modbus

registers file

Startup engineer or

wireless engineer

Startup engineer or

wireless engineer

Person in

charge of devices

Startup engineer or

wireless engineer

User or

startup engineer

Start-up

Engineering of field wireless network

(Configurator and YFGW410)

Configuration data

download to YFGW410

(Configurator)

Engineering of YFGW510

(Field wireless access point setup tool)

YFGW410

YFGW510

YFGW610

installation

Check and adjust wireless connection

Save the communication quality data

(Monitor)

Backup configuration data

(Configurator)

(Monitor)

Provisioning file

Field wireless device

(FieldMate)

Set device parameters

(FieldMate PRM)

Field wireless device installation

Set and adjust device parameters

(FieldMate PRM)

Loop check

Person in

charge of devices

Person in

charge of devices

Person in

charge of devices

Person in

charge of devices

User or

startup engineer

Operation

Operators

Device management

Maintenance staff

FD0101.ai

Figure D1-1 Engineering Flow for Wireless System Construction

The explanations in this document are based on the assumption that all engineering in the network construction is executed after the delivery of the components for the Field Wireless System

to the customer. When Yokogawa Electric Corporation receives an order that includes the engineering, the procedure may differ from the ow shown in Figure D1-1.

As shown in Figure D1-1, in order to construct a Field Wireless System that has been specically

designed according to a customer’s request, the following types of engineering are necessary:

(1) Provisioning and setting of the eld wireless device

(2) Construction of the Field Wireless System

(3) Engineering of the host system

IM 01W02D01-01EN

Page 51

<D1. Engineering Procedures>

n (1): Provisioning and Setting of the Field Wireless Device

Provisioning is conguration of the required information into a eld wireless device in order to

integrate it with the eld wireless network. This task is necessary in order to prevent third parties from making improper connections to the eld wireless network through methods such as

tampering or spoong. Devices on which provisioning has not been carried out or onto which the

incorrect information is congured cannot be integrated with the eld wireless network.

As shown in Figure D1-1, the following tasks are necessary before installing a eld wireless

device.

• Provisioning

Using FieldMate, the information that the eld wireless device requires in order to be integrated with the eld wireless network is congured via infrared data communication. This

task must be executed before the device is installed. Using the Provisioning Device tool on

FieldMate, provisioning is executed for the eld wireless device via infrared data communication.

• Setting and Adjustment of parameters

In the case of eld wireless devices manufactured by Yokogawa Electric Corporation, the

person in charge of devices can make settings and adjust the parameters via infrared data

communication before installing the device, by using FieldMate. This task can also be performed via a eld wireless network after the device is installed.

When performing these tasks before installing the device, use FieldMate R2.03.00 or later versions. For a eld wireless system, use applicable version of FieldMate and Device Files checked

by the website (http://www.eld-wireless.com/) For details, see Part I ISA100.11a Device Conguration in the FieldMate User’s Manual (IM 01R01A01-01E).

D1-2

n (2): Construction of the Field Wireless System

This task comprises the construction of a eld wireless network by the wireless system engineer

(including the start-up engineer) based on the detailed design information of the eld wireless

network by setting the YFGW410, the YFGW510 Field Wireless Access Point, and the eld wireless device.

The task includes constructing the network for the Field Wireless System, downloading information to the YFGW410, setting the YFGW510, verifying the startup and running status of the eld

wireless network, and, if necessary, correcting the network conguration, and setting and adjusting the parameters of the eld wireless device via the eld wireless network. The task of network

construction includes enabling or disabling redundancy in the YFGW410, registering and setting

the functions of the eld wireless device, setting up the communication paths, and dening process data in the Modbus registers.

For the detailed procedures, see Sub-section D3.2.8 “Setting Modbus” in this document.

The tasks of downloading information to the YFGW410 and verifying the startup and running status of the eld wireless network are assumed to be performed by the wireless system engineer

(including the start-up engineer) after the device has been delivered to the user’s plant site and

installed.

The task of setting and adjusting the device parameters is supposed to be performed by the

person in charge of the devices.

IM 01W02D01-01EN

Page 52

<D1. Engineering Procedures>

n (3): Engineering of the Host System

This task is the engineering of the host (control/monitoring) system by the system engineer.

The task targets system applications for which process data can be read/written using Modbus,

as well as applications for which the process values and parameters of the eld wireless device

can be read/written using the ISA100.11a protocol.

Some examples of target applications are shown below.

Modbus/TCP STARDOM, FA-M3R, DAQWORX, DAQSTATION, DAQMASTER,

CENTUM VP, FAST/TOOLS, other companies’ implementations of DCS/

SCADA

Modbus/RTU DAQMASTER and other companies’ implementations of DCS/SCADA

ISA100.11a PRM, FieldMate

OPC Applications that correspond to OPC servers (CENTUM VP, FAST/

TOOLS, etc.)

For details, see the User’s Manual for the relevant host system.

IMPORTANT

When CENTUM VP R4 is used, R4.02.30 or higher is required. For details, see Reference Subsystem Communication (Using FIO) (IM 33M01A30-40E).

D1-3

When CENTUM VP R5 is used, R5.02.00 or higher is required.

If CENTUM VP is used with YFGW410 in redundant conguration or writing output values to eld

wireless devices, CENTUM VP R5 is required. For details, see the Communication with Subsystem Using FIO user’s manual (IM 33K03L20-50E).

IM 01W02D01-01EN

Page 53

<D2. Tools to be Used for the Engineering>

D2-1

D2. Tools to be Used for the Engineering

In Figure D1-1 Engineering Flow for Wireless System Construction, the tools described in this

User’s Manual are shown in parentheses alongside the tasks.

This chapter describes the following tools included in Figure D1-1.

• Congurator

• Monitor

• Field wireless access point setup tool

• FieldMate

• PRM (Plant Resource Manager)

D2.1 Overview of the Tools

n Congurator

This tool is included in the Field Wireless Management Console that is built into the YFGW410. It

is used for constructing the eld wireless network.

It creates the conguration information for the wireless network conguration that is managed by

the YFGW410 based on the detailed design information of the wireless network. It also creates

conguration data based on the provisioning information of the eld wireless device, which contain information such as the devices to be integrated into the network, the roles of those devices,

the function settings for the data renewal cycles, etc., data allocations for the Modbus registers,

and other information.

These pieces of information are downloaded to the YFGW410 and the eld wireless device.

Congurator is launched from the Field Wireless Management Console on the YFGW410 via an

instance of Internet Explorer on a PC that is connected to maintenance interface or eld network

interface.

n Monitor

This tool is included with the Field Wireless Management Console that is built into the YFGW410.

It is used for monitoring the running status of Field Wireless System constructed .

Monitor displays the Packet Error Rate (PER), the Received Signal Strength Indicator (RSSI),

and the eld wireless network conguration gures for each wireless communication path, as

well as displaying information about the eld wireless device such as the battery life.

It is used for determining the communication stability when the Field Wireless System is started

and for monitoring daily status during operation.

Monitor is launched from the Field Wireless Management Console on the YFGW410 via an

instance of Internet Explorer on a PC that is connected to maintenance interface or eld network

interface.

IM 01W02D01-01EN

Page 54

<D2. Tools to be Used for the Engineering>

n Field wireless access point setup tool

The eld wireless access point setup tool makes the settings that YFGW510 requires in order to

be integrated with the eld wireless network (device tag and password).

This tool is a Windows PC application that is provided with YFGW510.

In the case of the wireless LAN option, it is also used to set parameters related to wireless LAN

(SSID, network key, etc.).

For details of operation, see the YFGW510 User’s Manual (IM01W02E01-01JA).

n FieldMate

This is a separately provided application for setting the parameters of the eld device.

In the Field Wireless System, the eld wireless device is provisioned and congured via infrared

data communication. Prepare the infrared adapter specied in the FieldMate User’s Manual (IM

01R01A01-01E).

If the host system for YFGW410 is not CENTUM VP manufactured by Yokogawa and there is

no PRM (mentioned later in this document), you can set the parameters by connecting a PC on

which FieldMate is installed to maintenance interface of YFGW410.

For details of operation, see the FieldMate User’s Manual (IM 01R01A01-01E).

D2-2

n PRM (Plant Resource Manager)

This is a separately provided application for monitoring the status of the eld device, and setting

and managing the parameters. It is used to create FDT projects on the FDT framework. Monitoring, conguration, and control are provided via a connection to the eld wireless device using

DTM.

The PC on which PRM is installed is connected to eld network interface of YFGW410.

For details of operation, see the Plant Resource Manager Reference (IM 33Y05Q10-11E).

D2.2 Using the Field Wireless Management

Console

The Field Wireless Management Console that is built into YFGW410 contains two tools: Congurator and Monitor.

The basic usage rights for the tool are as follows:

l Field Wireless Management Console: 1 license

l Congurator: 1 client

l Monitor: 3 clients

IM 01W02D01-01EN

Page 55

<D2. Tools to be Used for the Engineering>

D2.2.1 System Requirements

l PC environment

Item Recommended system requirements

CPU Intel Core 2 Duo 2.66 GHz or equivalent, or higher

RAM 2 GB or more

HDD 40 GB or larger (at least 15 GB of free space)

Communication interface Ethernet-compatible network ports

Display Color: True Color (24 bits or more) recommended

Resolution: 1280 x 800 recommended

D2-3

l PC software system requirements

OS Type

Windows 7 Professional Service Pack 1 32/64 bit

Windows Vista Business Edition Service Pack 2 32 bit

Windows Server 2008 Enterprise Service Pack 2 32 bit

Windows Server 2008 R2 Enterprise 32/64 bit

*1: Japanese or English versions are supported.

*2: Microsoft .NET Framework 3.5 Service Pack 1 must be installed.

*3: The 64 bit OS is compatible when using WOW64 (Windows 32-bit on Windows 64-bit).

*1*2*3

l Internet Explorer (IE) compatibility requirements

The tool works with the IE version bundled with each OS.

Target OS IE version

Windows 7 Professional SP1 (32/64 bit) IE 8.0

Windows Vista Business Edition SP2 (32 bit) IE 7.0

Windows Server 2008 Enterprise SP2 (32 bit) IE 7.0

Windows Server 2008 R2 Enterprise (32/64 bit) IE 8.0

D2.2.2 Launching the Tool

l Connecting and launching YFGW410

When YFGW410 is factory default, before power on, connecting the power, synchronization connector and eld network interface 1 is required. In addition, for a redundant conguration, two

YFGW410s should be connected each other with Cable for Redundancy.

The host system should be connected to eld network interface 1, and the PC which executes

the Field Wireless Management Console should be directly connected to maintenance interface.

If there is no host system, connect the PC which executes the Field Wireless Management Console to eld wireless interface 1.

For details, see Part A Outline of Field Wireless System Conguration and C4 Wiring.

IM 01W02D01-01EN

Page 56

<D2. Tools to be Used for the Engineering>

IMPORTANT

When launching YFGW410, if nothing is connected to eld network interface 1, or if the connected device is not running, YFGW410 may detect an error and may not launch properly.

IMPORTANT

The network should be congured that the PC which executes the Field Wireless Management

Console can access to YFGW410 through a eld network interface, during an operational state.

l PC settings