Page 1

Instruction

Manual

Model YF100

Vortex Flowmeter

Fieldbus Communication Protocol

IM 1F2F4-01E

IM 1F2F4-01E

1st Edition

Page 2

CONTENTS

CONTENTS

1. INTRODUCTION ......................................................................................................1-1

䊏 Regarding This Manual ....................................................................... 1-1

䊏 Safety Precautions............................................................................... 1-2

䊏 Warranty .............................................................................................. 1-3

2. PARTS OF THE AMPLIFIER ................................................................................2-1

3. ABOUT FIELDBUS .................................................................................................3-1

3.1 Outline ................................................................................................. 3-1

3.2 Internal Structure of YF100................................................................. 3-1

3.2.1 System/network Management VFD ............................................. 3-1

3.2.2 Function Block VFD ..................................................................... 3-1

3.3 Correlation of Each Block ................................................................... 3-2

3.4 Wiring System Configuration .............................................................. 3-2

4. FOR NOVICE USERS .............................................................................................4-1

4.1 Connection of Equipment.................................................................... 4-1

4.2 Host Setting......................................................................................... 4-3

4.3 Bus Power ON .................................................................................... 4-3

4.4 Integration of DD................................................................................. 4-4

4.5 Reading the Parameters ..................................................................... 4-4

4.6 Continuous Record of Settings ........................................................... 4-4

4.7 Generation of Alarm............................................................................ 4-4

5. CONFIGURATION ...................................................................................................5-1

5.1 Network Design................................................................................... 5-1

5.2 Network Definition ............................................................................... 5-2

5.3 Definition of Combining Function Blocks ............................................ 5-3

5.4 Setting of Device Tag and Node Address .......................................... 5-4

5.5 Communication Setting ....................................................................... 5-5

5.6 Block Setting ....................................................................................... 5-7

5.6.1 Link Object ................................................................................... 5-7

5.6.2 Trend Object ................................................................................. 5-8

5.6.3 View Object .................................................................................. 5-9

5.6.4 Function Block Parameters ........................................................ 5-13

6. IN-PROCESS OPERATION ...................................................................................6-1

6.1 Mode Transition .................................................................................. 6-1

6.2 Generation of Alarm............................................................................ 6-1

6.2.1 Indication of Alarm ....................................................................... 6-1

6.2.2 Alarms and Events ....................................................................... 6-2

6.3 Simulation Function............................................................................. 6-3

APPENDIX 1. LIST OF PARAMETERS FOR EACH BLOCK OF THE YF100 .A-1

A1.1 Resource Block ....................................................................................A-1

A1.2 Al Function Block .................................................................................. A-3

FD No. IM 1F2F4-01E

1st Edition: Dec. 1998 (YK)

All Rights Reserved, Copyright © 1998, Yokogawa Electric Corporation

A1.3 Transducer Block .................................................................................. A-5

i

Page 3

APPENDIX 2. APPLICATION, SETTING AND CHANGE OF

BASIC PARAMETERS .......................................................................A-8

A2.1 Applications and Selection of Basic Parameters .................................A-8

A2.2 Setting and Change of Basic Parameters ............................................ A-9

A2.3 Setting the AI Function Block.............................................................A-10

A2.4 Setting the Transducer Block ............................................................. A-12

APPENDIX 3. OPERATION OF EACH PARAMETER IN THE

EVENT OF FAILURE ........................................................................A-13

ii

IM 1F2F4-01E

Page 4

1. INTRODUCTION

This manual contains a description of the YF100 Vortex Flowmeter Fieldbus

Communication Protocol. The Fieldbus communication protocol is based on the

same sensing features as that of the BRAIN communication protocol, which is

employed as the measurement principle, and is similar to the BRAIN communication protocol in terms of basic performance and operation. This manual describes

only those topics that are required for operation of the Fieldbus communication

protocol and that are not contained in the BRAIN communication protocol instruction manual. Refer to each of the following instruction manuals for topics common

to the BRAIN communication and Fieldbus communication protocols.

Regarding This Manual

• This manual should be passed on to the end user.

• The contents of this manual are subject to change without prior notice.

• All rights reserved. No part of this manual may be reproduced in any form

without Yokogawa’s written permission.

• Yokogawa makes no warranty of any kind with regard to this manual, including,

but not limited to, implied warranty of merchantability and fitness for a particular

purpose.

• If any question arises or errors are found, or if any information is missing from

this manual, please inform the nearest Yokogawa sales office.

• The specifications covered by this manual are limited to those for the standard

type under the specified model number break-down and do not cover custommade instrument.

• Please note that changes in the specifications, construction, or component parts

of the instrument may not immediately be reflected in this manual at the time of

change, provided that postponement of revisions will not cause difficulty to the

user from a functional or performance standpoint.

1. INTRODUCTION

IM 1F2F4-01E

1-1

Page 5

Safety Precautions

• For the protection and safety of the operator and the instrument or the system

• For the intrinsically safe equipment and explosionproof equipment, in case the

• The following safety symbol marks are used in this Manual:

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION

including the instrument, please be sure to follow the instructions on safety

described in this manual when handling this instrument. In case the instrument is

handled in contradiction to these instructions, Yokogawa does not guarantee

safety.

instrument is not restored to its original condition after any repair or modification

undertaken by the customer, intrinsically safe construction or explosionproof

construction is damaged and may cause dangerous condition. Please contact

Yokogawa for any repair or modification required to the instrument.

Indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury. It may also be used to alert against unsafe practices.

CAUTION

This instrument is tested and certified as explosionproof type. Please note that the

construction of the instrument, installation, external wiring, maintenance or repair is

strictly restricted, and non-observance or negligence of these restriction would

result dangerous condition.

IMPORTANT

Indicates that operating the hardware or software in this manner may damage it or

lead to system failure.

NOTE

1-2

Draws attention to information essential for understanding the operation and

features.

IM 1F2F4-01E

Page 6

1. INTRODUCTION

■ Warranty

The warranty shall cover the period noted on the quotation presented to the

purchaser at the time of purchase. Problems occurred during the warranty period

shall basically be repaired free of charge.

• In case of problems, the customer should contact the Yokogawa representative

from which the instrument was purchased, or the nearest Yokogawa office.

• If a problem arises with this instrument, please inform us of the nature of the

problem and the circumstances under which it developed, including the model

specification and serial number. Any diagrams, data and other information you

can include in your communication will also be helpful.

• Responsible party for repair cost for the problems shall be determined by

Yokogawa based on our investigation.

● The purchaser shall bear the responsibility for repair costs, even during the warranty period, if

the malfunction is due to:

• Improper and/or inadequate maintenance by the purchaser.

• Failure or damage due to improper handling, use or storage which is out of

design conditions.

• Use of the product in question in a location not conforming to the standards

specified by the Yokogawa, or due to improper maintenance of the installation

location.

• Failure or damage due to modification or repair by the party except Yokogawa

or who is requested by Yokogawa.

• Malfunction or damage from improper relocation of the product in question after

delivery.

• Reason of force majeure such as fires, earthquakes, storms/floods, thunder/

lightening, or other natural disasters, or disturbances, riots, warfare, or radioactive contamination.

IM 1F2F4-01E

1-3

Page 7

2. PARTS OF THE AMPLIFIER

Refer to the individual instruction manuals for detailed descriptions of the parts.

This section describes the topics applicable to the Fieldbus communication protocol.

(1)The Fieldbus communication type has no local key access.

(2)The Fieldbus communication protocol has a simulation function. A SIMULATE-

ENABLE jumper is mounted in the YF100 amplifier to discourage attempts to

trigger the simulation function during operation. Refer to Section 6.3, “Simulation Function” for details of the simulation function.

2. PARTS OF THE AMPLIFIER

Figure 2.1 Shape of the CPU Assembly

IM 1F2F4-01E

2-1

Page 8

3. ABOUT FIELDBUS

3.1 Outline

Fieldbus is a bi-directional digital communication protocol for field devices. Fieldbus

is a dramatic advance in implementation technologies for process control systems

and is widely employed by numerous field devices. It is expected to replace the

standard 4 to 20 mA analog communication protocol.

3. ABOUT FIELDBUS

YF100 Series Fieldbus communication protocol employs the specification

(FOUNDATION

Fieldbus, and provides interoperability between Yokogawa devices and those

produced by other manufacturers. Fieldbus comes with software consisting of AI

function block, providing the means to implement a flexible instrumentation system.

For information on other features, engineering, design, construction work, startup

and maintenance of Fieldbus, refer to “The Fieldbus Reference Manual” (TI

38K3A01-01E).

TM*1

Fieldbus Low Voltage Mode) standardized by the Foundation

3.2 Internal Structure of YF100

The YF100 contains virtual field devices (VFD) that share the following functions.

3.2.1 System/network Management VFD

• Sets node addresses and device tags necessary for communication.

• Controls the execution of function blocks.

• Manages operation parameters and communication resources (Virtual Communication Relationship: VCR).

3.2.2 Function Block VFD

(1) Resource block

• Manages the status of YF100 hardware.

• Automatically informs the host of the detected faults or other problems.

(2) Transducer block

• Converts sensor output to flow signal and delivers to AI function block.

(3) AI function block

• Outputs flow signals.

• Carries out scaling, and damping.

*1: FOUNDATION is a registered trademark of the Foundation Fieldbus.

IM 1F2F4-01E

3-1

Page 9

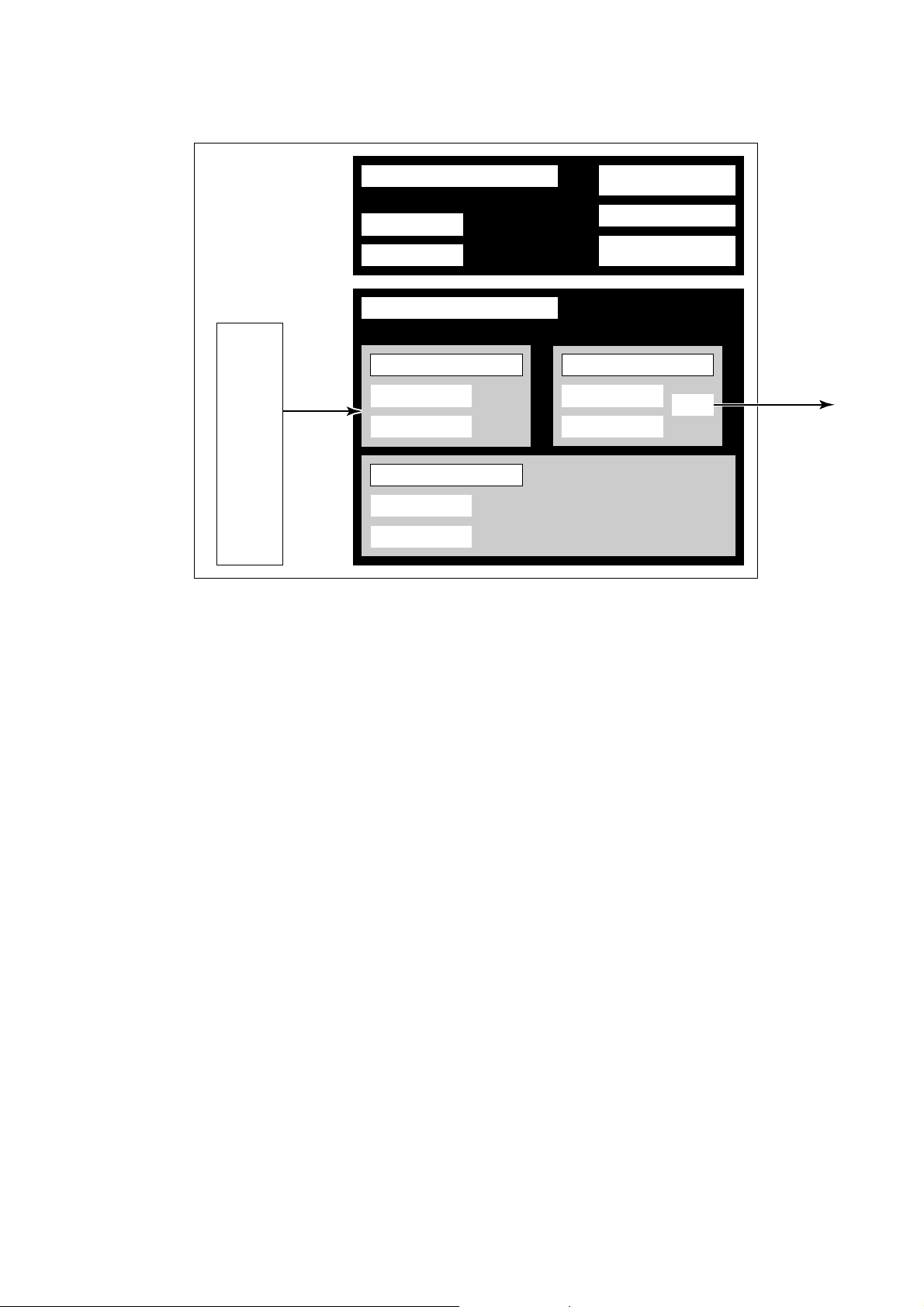

3.3 Correlation of Each Block

YF100

Sensor

Sensor

Input

Management VFD

Device Tag

Node Address

Function Block VFD

Transducer Block

Block Tag

Parameters

Resource Block

Block Tag

Parameters

Communication

Parameters

VCR

Function Block

Execution Schedule

AI function block

AI Function Block

Block Tag

Parameters

OUT

Output

F0301.EPS

Figure 3.1 Correlation of Each Block

Setting of various parameters, node address, and device tag shown in Figure 3.1

is required before starting operation.

3.4 Wiring System Configuration

The number of devices that can be connected to a single bus and the cable length

vary depending on system design. When constructing systems, both the fundamental and overall design, must be carefully considered to allow device performance to be fully exhibited.

3-2

IM 1F2F4-01E

Page 10

4. FOR NOVICE USERS

Fieldbus is fully dependent upon digital communication protocol and differs in

operation from conventional 4 to 20 mA transmission and the BRAIN communication protocol. It is recommended that novice users use field devices in accordance

with the procedures described in this section. The procedures assume that field

devices will be used for laboratories or similar experimental purposes.

4.1 Connection of Equipment

The following equipment is required for use with Fieldbus devices:

• Power supply: Fieldbus requires a dedicated power supply. It is recommended

that current capacity should be well over the total value of the

maximum current consumed by all devices (including the host).

Conventional DC current cannot be used as power supply.

• Terminator: Fieldbus requires two terminators. Refer to the supplier for

details of terminators that are attached to the host.

• Field devices: Connect Fieldbus communication type YF100. Two or more

YF100 (devices) or other devices can be connected.

• Host: Used for accessing field devices. A dedicated host (such as

DCS) is used for an instrumentation line while dedicated communication tools are used for experimental purposes. For

operation of the host, refer to the instruction manual for each

host. No details of the host are explained in the rest of this

material.

• Cable: Used for connecting equipment. Refer to “Guide to Fieldbus” (TI

38K3A01-01E) for details of instrumentation cabling. If the total

length of the cable is in a range of 2 to 3 meters for laboratory

or other experimental use, the following simplified cable (a

twisted pair wire with a cross section of 0.8 mm2 or more (#18

AWG) and cycle period of within 5 cm (2 inches) may be used.

Termination processing depends on the type of device being

deployed. For YF100, use an M3.5 screw terminal claw. Some

hosts require a connector.

4. FOR NOVICE USERS

IM 1F2F4-01E

Refer to Yokogawa when making arrangements to purchase the recommended

equipment.

Connect the equipment as shown in Figure 4.1. Connect the terminators at both

ends of the trunk, with a minimum length of the spur laid for connection.

Be care that the polarity of the terminal is correct.

4-1

Page 11

Fieldbus power

supply

Terminator

YF100

HOST

Terminator

F0401.EPS

Figure 4.1 Cabling

Note: No CHECK terminal is used for Fieldbus communication YF100. Do not connect the field

indicator and check meter.

Before using a Fieldbus configuration tool other than the existing host, confirm it

does not affect the loop functionality in which all devices are already installed in

operation. e.g. disconnect the relevant control loop from the bus.

IMPORTANT

Connecting a Fieldbus configuration tool to a loop with its exsisting host may

cause communication data scrambles resulting in a functional disorder or a system

failure.

4-2

IM 1F2F4-01E

Page 12

4.2 Host Setting

To activate Fieldbus, the following settings are required for the host.

Note: Care must be taken not to turn off the power immediately after setting. If the power is turned off

within 30 seconds after setting is made, the modified parameters are not saved and the settings

revert back to the original values.

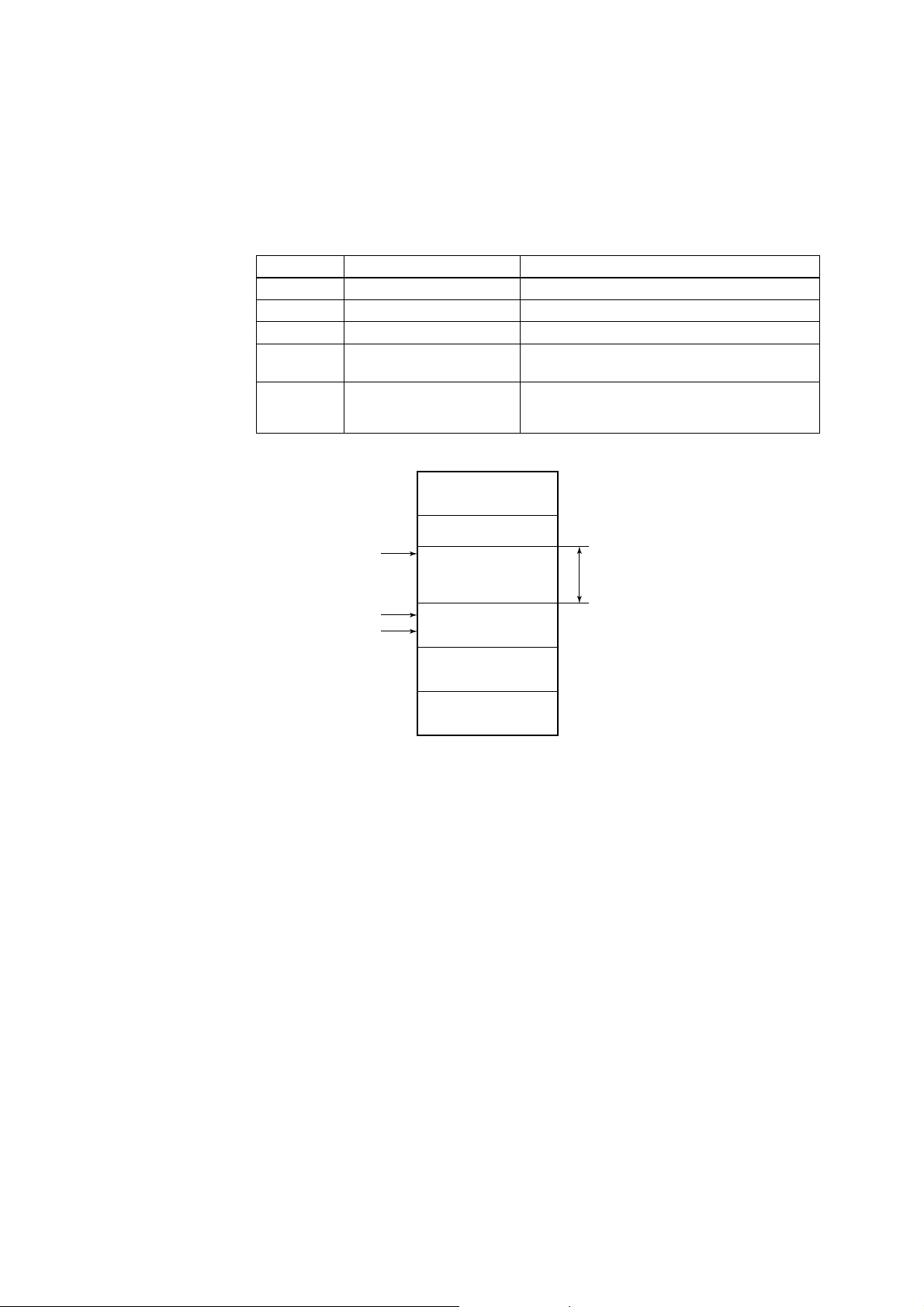

Table 4.1 Operation Parameters

Symbol Parameter Description and Settings

V (ST) Slot-Time

V (MID) Minimum-Inter-PDU-Delay

V (MRD) Maximum-Reply-Delay

V (FUN) First-Unpolled-Node

V (NUN) Number-of-consecutive-

Unpolled-Node

0x00

4. FOR NOVICE USERS

Set 4 or greater value.

Set 4 or greater value.

Set so that V (MRD) x V (ST) is 12 or greater

Indicate the address next to the address range

used by the host. Set hex. 15 or greater.

Unused address range. YF100 address is factory-

set to hex. F5. Set this address to be within the

range of the BASIC device in Figure 4.2.

T0401.EPS

Not used

V(FUN)

V(FUN)+V(NUN)

YEWFLO(0xF5)

Note 1: LM device: with bus control function (Link Master function)

Note 2: BASIC device: without bus control function

Figure 4.2 Available Range of Node Address

4.3 Bus Power ON

Turn on the power of the host and the bus. Where the YF100 is equipped with an

LCD indicator, first all segments are lit, then the display begins to operate. If the

indicator is not lit or abnormal current flows, check the polarity of the power supply.

Using the host device display function, check that YF100 is in operation on the

bus. Unless otherwise specified, the following settings are in effect when shipped

from the factory.

0x10

BASIC device

0xF7

0xF8

Default address

0xFB

0xFC

Portable device address

0xFF

LM device

Not used V(NUN)

F0402.EPS

IM 1F2F4-01E

Device tag: FI1001

Node address: 245 (hexadecimal F5)

Device ID: 5945430002xxxxxxxx (xxxxxxxx = a total of 8 alphanumeric

characters)

If no YF100 is detected, check the available address range and the polarity of the

power supply. If two YF100s are connected at a time, only one YF100 will be

detected if both YF100s have the same initial address. Separately connect each

YF100 and set a different address for each.

4-3

Page 13

4.4 Integration of DD

If the host supports DD (Device Description), the DD of the YF100 needs to be

included. Check if the following directory is placed under the directory where the

host DD is to be contained.

594543\0002

(Of this directory, 594543 is the manufacturer number of Yokogawa Electric

Corporation, and 0002 is the YF100 device number, respectively.)

In the absence of this directory, no DD of YF100 has been included. Create the

above directory and copy the DD file (0101.ffo,0101.sym) (option) into the directory.

Once the DD is included in the directory, the name and attribute of all parameters

of the YF100 are displayed.

4.5 Reading the Parameters

To read YF100 parameters, select the AI block of the YF100 from the host screen

and read the OUT parameter. The current flow is displayed.

(Check that MODE_BLK of the function block resource block is set to AUTO.)

4.6 Continuous Record of Settings

If the host has a function of continuously recording the indications, use this function to list the indications (values). Depending on the host being used, it may be

necessary to set the schedule of Publish (the function that transmits the indication

on a periodic basis).

4.7 Generation of Alarm

If the host is allowed to receive alarms, generation of an alarm can be attempted

from YF100. In this case, set the reception of alarms on the host side. YF100’s

VCR-7 and link object-3 are factory-set for this purpose. For practical purposes, all

alarms are placed in a disabled status; for this reason, it is recommended that you

first use one of these alarms on a trial basis.

Since the LO_PRI parameter (index 629) of the AI block is set to “0”, try setting

this value to “3”. Select the Write function from the host in operation, specify an

index or variable name, and write “3” to it.

The LO_LIM parameter (index 630) of the AI block determines the limit at which

the lower bound alarm for the process value is given. In usual cases, a very small

value is set to this limit. Set 10 (meaning 10 kg/min) to the limit. Since the flow is

almost 0, a lower bound alarm is raised. Check that the alarm can be received at

the host. When the alarm is confirmed, transmission of the alarm is suspended.

4-4

The above-mentioned items are a description of the simple procedure to be carried

out until YF100 is connected to Fieldbus. In order to take full advantage of the

performance and functionality of the device, it is recommended that it be read

together with Chapter 5, which describes how to use the YF100.

IM 1F2F4-01E

Page 14

5. CONFIGURATION

This chapter contains information on how to adapt the function and performance of

the YF100 to suit specific applications. Because two or more devices are connected to Fieldbus, settings including the requirements of all devices need to be

determined. Practically, the following steps must be taken.

(1)Network design

Determines the devices to be connected to Fieldbus and checks the capacity of

the power supply.

(2)Network definition

Determines the tag and node address for all devices.

(3)Definition of combining function blocks

Determines the method for combination between each function block.

(4) Setting tag and address

Sets the device address and node address one by one for each device.

(5)Communication setting

Sets the link between communication parameters and function blocks.

(6)Block setting

Sets the parameters for function blocks.

5. CONFIGURATION

The following section describes each step of the procedure in the order given.

Using a dedicated configuration tool allows the procedure to be significantly

simplified. This section describes the procedure to be assigned for a host which

has relatively simple functions.

5.1 Network Design

Select the devices to be connected to the Fieldbus network. The following equipment is necessary for operation of Fieldbus.

• Power supply: Fieldbus requires a dedicated power supply. It is recommended

• Terminator: Fieldbus requires two terminators. Refer to the supplier for

• Field devices: Connect the field devices necessary for instrumentation. YF100

• Host: Used for accessing field devices. A minimum of one device with

• Cable: Used for connecting equipment. Refer to “Guide to Fieldbus” for

that current capacity should be well over the total value of the

maximum current consumed by all devices (including the host).

Conventional DC current cannot be used as power supply.

details of terminators that are attached to the host.

has passed the interoperability test conducted by the Foundation

Fieldbus. In order to smoothly start Fieldbus, it is recommended

that the devices used satisfy the requirements of the above test.

bus control function is needed.

details of instrumentation cabling. Provide a cable sufficiently

long to connect all devices. For field branch cabling, use terminal boards or a connection box as required.

IM 1F2F4-01E

5-1

Page 15

First, check the capacity of the power supply. The power supply capacity must be

greater than the sum of the maximum current consumed by all devices to be

connected to Fieldbus. The maximum current consumed (power supply voltage 9 V

to 32 V) for YF100 is 17 mA. The cable must have the spur in a minimum length

with terminators installed at both ends of the trunk.

5.2 Network Definition

Before connection of devices with Fieldbus, define the Fieldbus network. Allocate

device tags and node address to all devices (excluding such passive devices as

terminators).

The device tag is the same as the conventional one used for the device. Up to 32

alphanumeric characters may be used for definition. Use a hyphen as a delimiter

as required.

The node address is used to specify devices for communication purposes. Because data is too long for a device tag, the host uses the device tag in place of the

node address for communication. A range of 16 to 247 (or hexadecimal 10 to F7)

can be set. The device (LM device) with bus control function (Link Master function)

is allocated from a smaller address number (16) side, and other devices (BASIC

device) without bus control function allocated from a larger address number (247)

side respectively. Place YF100 in the range of the BASIC device. Set the range of

address to be used to the LM device. Set the following parameters.

Table 5.1 Parameters for Setting Address Range

V (FUN) First-Unpolled-Node

V (NUN) Number-of-consecutive-

Unpolled-Node

Indicates the address next to the address range

used for the host or other LM device.

Unused address range

T0501.EPS

The devices within the address range written as “Unused” in Figure 5.1 cannot

participate in Fieldbus. For other address ranges, the range is periodically checked

to identify when a new device is mounted. Care must be taken not to allow the

address range to become wider, which can lead to exhaustive consumption of

Fieldbus communication performance.

0x00

Not used

V(FUN)

V(FUN)+V(NUN)

0x10

0xF7

0xF8

0xFB

0xFC

0xFF

LM device

Not used V(NUN)

BASIC device

Default address

Portable device address

F0501.EPS

5-2

Figure 5.1 Available Range of Node Address

IM 1F2F4-01E

Page 16

5. CONFIGURATION

To ensure stable operation of Fieldbus, determine the operation parameters and

set them to the LM devices. While the parameters in Table 5.2 are to be set, the

worst-case value of all the devices to be connected to the same Fieldbus must be

used. Refer to the specification of each device for details. Table 5.2 lists YF100

specification values.

Table 5.2 Operation Parameter Values of the YF100 to be Set to LM Devices

Symbol Parameters Description and Settings

V (ST) Slot-Time

V (MID) Minimum-Inter-PDU-Delay

V (MRD) Maximum-Reply-Delay

Indicates the time necessary for immediate reply of

thje device. Unit of time is in octets (256 µs). Set

maximum specification for all devices. For YF100,

set a value of 4 or greater.

Minimum value of communication data intervals.

Unit of time is in octets (256 µs). Set the maximum

specification for all devices. For YF100, set a value

of 4 or greater.

The worst case time elapsed until a reply is

recorded. The unit is Slot-time; set the value so

that V (MRD) xV (ST) is the maximum value of the

specification for all devices. For YF100, the setting

must be a value of 12 or greater.

T0502.EPS

5.3 Definition of Combining Function Blocks

The input/output parameters for function blocks are combined. For the YF100, the

output parameter (OUT) for AI block is subject to combination. They are combined

with the input of the control block as necessary. Practically, setting is written to the

YF100 link object with reference to “Block setting” in Section 5.6 for details. It is

also possible to read values from the host at proper intervals instead of connecting

the YF100 block output to other blocks.

The combined blocks need to be executed synchronously with other blocks or the

communications schedule. In this case, change the YF100 schedule according to

the following table. Enclosed values in the table are factory-settings.

Table 5.3 Execution Schedule of the YF100 Function Blocks

Index Parameters Setting (Enclosed is factory-setting)

269 (SM) MACROCYCLE_DURATION

276 (SM) FB_START_ENTRY.1

A maximum of 100ms is taken for execution of AI block. For scheduling of communications for combination with the next function block, the execution is so arranged

as to start after a lapse of longer than 100ms.

Cycle (MACROCYCLE) period of control or

measurement. Unit is 1/32 ms. (32000 = 1 s)

AI block startup time. Elapsed time from the start of

MACROCYCLE specified in 1/32 ms. (0 = 0 s)

T0503.EPS

IM 1F2F4-01E

5-3

Page 17

Macrocycle (Control Period)

LI103 LI100

OUT IN

LC100 LIC100

FC102 FIC100 FC100

BKCAL_IN

CAS_IN

BKCAL_OUT

FI101 FI100

Function Block

Schedule

Communication

Schedule

OUT

IN

BKCAL_IN

Unscheduled Communication

Figure 5.2 Function Block Schedule and Communication Schedule

5.4 Setting of Device Tag and Node Address

This section describes the steps in the procedure to take to set device tags and

node addresses to the YF100. There are three states of Fieldbus devices as

shown in Figure 5.3, and if the state is other than the lowest SM_OPERATIONAL

state, no function block is executed. YF100 must be transferred to this state when

an YF100 Device Tag or Node Address is changed.

(No Device Tag nor Node Address is set)

UNINITIALIZED

BKCAL_OUT

Scheduled

Communication

F0502.EPS

5-4

Device Tag clear Tag setting

INITIALIZED

(Only Tag is set)

Node Address clear

SM_OPERATIONAL

(Tag and address are retained, and

the function block can be executed.)

Node Address setting

F0503.EPS

Figure 5.3 Status Transition by Setting Device Tag and Node Address

YF100 has a device tag (FI1001) and node address (245, or hexadecimal F5) that

are set upon shipment from the factory (unless otherwise specified). To change

only the node address, clear the address once and then set a new node address.

To set the device tag, first clear the node address and clear the device tag, then

set the device address and node address again.

Devices whose node address was cleared will await the default address (randomly

chosen from a range of 248 to 251, or from hexadecimal F8 to FB). At the same

time, it is necessary to specify the device ID in order to correctly specify the

device. The device ID of the YF100 is 5945430002xxxxxxxx. (The xxxxxxxx at the

end of the above device ID is a total of 8 alphanumeric characters.)

IM 1F2F4-01E

Page 18

5.5 Communication Setting

To set the communication function, it is necessary to change the database residing

in SM-VFD.

VCR Setting

Set VCR (Virtual Communication Relationship), which specifies the called party for

communication and resources. YF100 has 8 VCRs whose application can be

changed, except for the first VCR, which is used for management. Each VCR has

the parameters listed in Table 5.4. Parameters must be changed together for each

VCR because modification for each parameter may cause inconsistent operation.

Table 5.4 VCR Static Entry

Subindex Parameter Description

1 FasArTypeAndRole

2 FasDllLocalAddr

3 FasDllConfiguredRemoteAddr

4 FasDllSDAP

5 FasDllMaxConfirmDelayO

nConnect

6 FasDllMaxConfirmDelayO

nData

7 FasDllMaxDlsduSize

8 FasDllResidualActiviey

Supported

9 FasDllTimelinessClass

10 FasDllPublisherTimeWin

dowSize

11 FasDllPublisherSynchro

nizaingDlcep

12 FasDllSubsriberTimeWin

dowSize

5. CONFIGURATION

Indicates the type and role of communication (VCR)

employed. The following 3 types may be used for

YF100.

0x32: Server (Responds to requests from host.)

0x44: Source (Transmits alarm or trend.)

0x66: Publisher (Sends AI block output to other

blocks.)

Set the local address. A range of 20 to F7 in

hexadecimal.

Sets the node address of the called party for

communication and the address (DLSAP or

DLCEP) used to specify VCR in that address. For

DLSAP or DLCEP, a range of 20 to F7 in

hexadecimal is used. Addresses in Subindex 2 and

3 need to be set to the same contents of the VCR

as the called party (local and remote are reversed).

Specifies the quality of communication. Usually,

one of the following types is set.

0x2B: Server

0x01: Source (Alert)

0x03: Source (Trend)

0x99: Publisher

To establish connection for communication, a

maximum wait time for the called party's response

is set in ms. Typical value is 60 seconds (60000).

For request of data, a maximum wait time for the

called party's response is set in ms. Typical value

is 60 seconds (60000).

Specifies maximum DL Service Data Unit Size

(DLSDU). Set 256 for Server and Trend VCR, and

64 for other VCRs.

Specifies whether connection is monitored. Set

YES (0xff) for Server. This parameter is not used

for other communication.

Not used for YF100.

Not used for YF100.

Not used for YF100.

Not used for YF100.

T0504-1.EPS

IM 1F2F4-01E

5-5

Page 19

Subindex Parameter Description

13 FasDllSubscriberSynchr

Not used for YF100.

onizationDlcep

14 FmsVfdId

Sets VFD in YF100 to be used. VfdID of YF100 is

0x1234.

15 FmsMaxOutstandingServi

ceCalling

16 FmsMaxOutstandingServi

ceCalled

17 FmsFeaturesSupported

Set 0 to Server. It is not used for other

applications.

Set 1 to Server. It is not used for other

applications.

Indicates the type of services in the application

layer. In the YF100, it is automatically set

according to specific applications.

Eight VCRs are factory-set as shown in the Table 5.5.

Table 5.5 VCR List

T0504-2.EPS

Index

(SM)

VCR Number Factory Setting

293 For system management (Fixed)1

294 Server (LocalAddr = 0xF3)2

295 Server (LocalAddr = 0xF4)3

296 Server (LocalAddr = 0xF7)4

297 Trend Source (LocalAddr = 0x07)5

298 Publisher (LocalAddr = 0x20)6

299 Al Alert Source (LocalAddr = 0x07)7

300 Server (LocalAddr = 0xF9)8

T0505.EPS

5-6

IM 1F2F4-01E

Page 20

5.6 Block Setting

Set the parameter for function block VFD.

5.6.1 Link Object

Link object combines the data voluntarily sent by the function block with VCR.

YF100 has five link objects. A single link object specifies one combination. Each

link object has the parameters listed in Table 5.6. Parameters must be changed

together for each VCR because the modifications made to each parameter may

cause inconsistent operation.

Table 5.6 Link Object Parameters

Subindex Parameters Description

1 LocalIndex

2 VcrNumber

3 RemoteIndex

4 ServiceOperation

5 StaleCountLimit

Five link objects are factory-set as shown Table 5.7. Usually, settings may be used

as they are and do not need to be changed.

5. CONFIGURATION

Sets the index of function block parameters to be

combined; set “0” for Trend and Alert.

Sets the index of VCR to be combined. If set to “0”,

this link object is not used.

Not used in YF100. Set to “0”.

Set one of the following. Set only one each for link

object for Alert or Trend.

0: Undefined

2: Publisher

6: Alert

7: Trend

Not used in YF100. Set to “0”.

T0506.EPS

Table 5.7 Factory-Settings of Link Objects

Index Link Object # Factory Settings

2000 AI.OUT → VCR#61

2001 Trend → VCR#52

2002 Alert → VCR#73

2003 Not used4

2004 Not used5

T0507.EPS

IM 1F2F4-01E

5-7

Page 21

5.6.2 Trend Object

It is possible to set the parameter so that the function block automatically transmits

Trend. YF100 has three Trend objects, all of which are used for Trend in analog

mode parameters. A single Trend object specifies the trend of one parameter.

Each Trend object has the parameters listed in Table 5.8. The first four parameters

are the items to be set. Before writing to a Trend object, it is necessary to release

the WRITE_LOCK parameter.

Table 5.8 Parameters for Trend Objects

Three trend objects are factory-set as shown Table 5.9.

subindex Parameters Description

1 Block Index

2 Parameter Relative Index

3 Sample Type

4 Sample Interval

5 Last Update

6 to 21 List of Status

21 to 37 List of Samples

Sets the leading index of the function block that

takes a trend. If the YF100, 600 is only available.

Sets the index of parameters taking a trend by a

value relative to the beginning of the function

block. In the YF100, the following three types of

trends are possible.

7: PV

8: OUT

19: FIELD_VAL

Specifies how trends are taken. Choose one of the

following 2 types:

1: Sampled upon execution of a function block.

2: The average value is sampled.

Specifies sampling intervals in units of 1/32 ms.

Set the integer multiple of the function block

execution cycle.

The last sampling time.

Status part of a sampled parameter.

Data part of a sampled parameter.

T0508.EPS

5-8

Table 5.9 Trend Object are Factory-Set

Index Trend Object # Factory Settings

2200 AI OUT1

2201 Not used.2

2202 Not used.3

T0509.EPS

IM 1F2F4-01E

Page 22

5.6.3 View Object

5. CONFIGURATION

This is the object to form groups of parameters in a block. One of advantage

brought by forming groups of parameters is the reduction of load for data transaction. YF100 has four View Objects for each Resource block, Transducer block and

AI1.AI2 function block, and each View Object has the parameters listed in Table

5.10 to 5.12.

Table 5.10 View Object for Resource Block

Relative Index Parameter Mnemonic VIEW_1 VIEW_2 VIEW_3 VIEW_4

1 ST_REV 2

2 TAG_DESC

3 STRATEGY

4 ALERT_KEY

5 MODE_BLK 4

6 BLOCK_ERR 2

7 RS_STATE

8 TEST_RW

9 DD_RESOURCE

10 MANUFAC_ID

11 DEV_TYPE

12 DEV_REV

13 DD_REV

14 GRANT_DENY

15 HARD_TYPES

16 RESTART

17 FEATURES

18 FEATURE_SEL

19 CYCLE_TYPE

20 CYCLE_SEL

21 MIN_CYCLE_T

22 MEMORY_SIZE

23 NV_CYCLE_T

24 FREE_SPACE

26 SHED_RCAS

27 SHED_ROUT

29 SET_FSAFE

30 CLR_FSAFE

31 MAX_NOTIFY

32 LIM_NOTIFY

33 CONFIRM_TIME

34 WRITE_LOCK

35 UPDATE_EVT

36 BLOCK_ALM

38 ACK_OPTION 2

39 WRITE_PRI 1

40 WRITE_ALM

11

425 FREE_TIME

128 FAIL_SAFE

837 ALARM_SUM

2

2

2

1

4

4

4

4

4

4

1

2

4

2

4

1

8

2

2

1

4

2

1

1

2

2

1

4

2

4

IM 1F2F4-01E

Totals (# bytes)

22 32 22 31

T0510.EPS

5-9

Page 23

Table 5.11 View Object for Transducer Block

Relative Index Parameter Mnemonic VIEW_1 VIEW_2 VIEW_3 VIEW_4

1 ST_REV 2

2 TAG_DESC

3 STRATEGY

4 ALERT_KEY

5 MODE_BLK 4

6 BLOCK_ERR 2

7 UPDATE_EVT

8 BLOCK_ALM

9

12 COLLECTION_DIRECTORY

13 PRIMARY_VALUE_TYPE

15 PRIMARY_VALUE_RANGE

16 CAL_POINT_HI

17 CAL_POINT_LO

18 CAL_MIN_SPAN

19 CAL_UNIT

20 SENSOR_TYPE

21 SENSOR_RANGE

22 SENSOR_SN

23 SENSOR_CAL_METHOD

24 SENSOR_CAL_LOC

25 SENSOR_CAL_DATE

26 SENSOR_CAL_WHO

27 LIN_TYPE

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

TRANSDUCER_DIRECTORY

SECONDARY_VALUE

SECONDARY_VALUE_UNIT

SIZE_SELECT

FLUID_TYPE

K_FACTOR_VALUE

K_FACTOR_UNIT

VISCOSITY_VALUE

VORTEX_FREQ_VALUE

FLOW_VELOCITY_VALUE

REYNOLDS_NUM_VALUE

MIN_DENITY_VALUE

DENSITY_UNIT

TEMPERATURE_F_VALUE

TEMPERATURE_UNIT

DENSITY_F_VALUE

SPE_ENTHALPY_VALUE

ENTHALPY_UNIT

TEMPERATURE_N_VALUE

210 TRANSDUCER_TYPE

111 XD_ERROR

514 PRIMARY_VALUE

4

4

2

2

2

4

4

1

1

4

1

4

1

4

1

4

4

1

4

2

4

2

2

1

5

5

4

4

4

2

2

1

2

11

4

2

2

11

4

1

2

4

T0511_1.EPS

5-10

IM 1F2F4-01E

Page 24

5. CONFIGURATION

Relative Index Parameter Mnemonic VIEW_1 VIEW_2 VIEW_3 VIEW_4

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

PRESSURE_F_VALUE

PRESSURE_N_VALUE

DEVIATION

NOISE_BALANCE_VALUE

TRIGGER_LEVEL_VALUE

AMPLIFIER_GAIN_VALUE

INSTRUMENTAL_ERR_ADJ

REYNOLDS_NUM_ADJ

ADJACENT_PIPE_EFFECT

EXPANSION_CORRECTION

HIGH_CUT_FILTER_VALUE

LOW_CUT_FLOW

NOISE_JUDGE_CONTROL

ADJ_FREQUENCY_1_VALUE

ADJ_DATA_1_VALUE

ADJ_FREQUENCY_2_VALUE

ADJ_DATA_2_VALUE

ADJ_FREQUENCY_3_VALUE

ADJ_DATA_3_VALUE

ADJ_FREQUENCY_4_VALUE

ADJ_DATA_4_VALUE

ADJ_FREQUENCY_5_VALUE

ADJ_DATA_5_VALUE

V_F_OUTPUT_SEL

V_F_FREQUENCY_VALUE

MODEL

DISPLAY_MODE

DISPLAY_CYCLE

ALARM_SUM

4

4

4

1

1

1

1

1

1

1

4

4

1

IM 1F2F4-01E

Totals (# bytes)

24

56

33

64

T0511_2.EPS

5-11

Page 25

Table 5.12 View Object for AI Function Block

Relative Index Parameter Mnemonic VIEW_1 VIEW_2 VIEW_3 VIEW_4

1 ST_REV 2

2 TAG_DESC

3 STRATEGY

4 ALERT_KEY

5 MODE_BLK 4

6 BLOCK_ERR 2

7PV

8 OUT 5

9 SIMULATE

10 XD_SCALE

11 OUT_SCALE

12 GRANT_DENY

13 IO_OPTS

14 STATUS_OPTS

15 CHANNEL

16 L_TYPE

17 LOW_CUT

18 PV_FTIME

20 UPDATE_EVT

21 BLOCK_ALM

23 ACK_OPTION

24 ALARM_HYS

25 HI_HI_PRI

26 HI_HI_LIM

27 HI_PRI

28 HI_LIM

29 LO_PRI

30 LO_LIM

31 LO_LO_PRI

32 LO_LO_LIM

33 HI_HI_ALM

34 HI_ALM

35 LO_ALM

36 LO_LO_ALM

37 PULSE_VAL

38 RESET

39 TOTAL

55

519 FIELD_VAL

822 ALARM_SUM

11

11

2

2

2

4

2

5

5

8

2

2

1

2

2

2

1

4

4

2

4

1

4

1

4

1

4

1

4

5-12

Totals (# bytes)

31 26 31 46

T0512.EPS

IM 1F2F4-01E

Page 26

5.6.4 Function Block Parameters

Function block parameters can be read from the host or can be set. For a list of

the parameters of blocks held by the YF100, refer to “List of parameters for each

block of the YF100” in Appendix 1. The following are a list of important parameters

with a guide to how to set them.

MODE_BLK: Indicates the three types of function block modes;

CHANNEL: This is the parameter of the transducer block to be input to the

XD_SCALE: Scale of input from the transducer block. The calibrated range

L_TYPE: Specifies the operation function of the AI block. If set to “Di-

PV_FTIME: Sets the time constant of the damping function within AI block

OUT_SCALE: Sets the range of output (from 0% to 100%). The unit can also

Alarm Priority: Indicates the priority of the process alarm. If a value of 3 or

Alarm Threshold: Sets the threshold at which a process alarm is generated. The

5. CONFIGURATION

Out_Of_Service, Manual, and Auto. In Out_Of_Service mode,

the AI block does not operate. The Manual mode does not

allow values to be updated. The Auto mode causes the measured value to be updated. Under normal circumstances, set

the Auto mode to take effect. The Auto mode is the factory

default.

AI block. AI block is assigned flow, respectively. Do not change

this setting.

is factory set (from 0 point to 100% point). Usually, the unit is

set in kg/min. Changing the unit (can be set only in flow unit)

also causes the unit within the transducer block to be automatically changed. (The unit is automatically changed according to

the unit selected by AI.)

rect”, the input delivered to CHANNEL is directly reflected on

OUT. If set to “Indirect”, scaling by XD_SCALE and

OUT_SCALE is carried out and is reflected on OUT. If set to

“Indirect SQRT”, after scaling by XD_SCALE, the square root is

extracted and the value scaled by OUT_SCALE is reflected on

OUT.

Square root is not utilized for YEWFLO.

(primary delay) in seconds.

be set with ease.

greater is set, an alarm is transmitted. The factory default is 1.

Four types of alarm can be set: HI_PRI, HI_HI_PRI, LO_PRI,

and LO_LO_PRI.

factory default setting is a value that does not generate an

alarm. Four types of alarm can be set: HI_LIM, HI_HI_LIM,

LO_LIM, and LO_LO_LIM.

IM 1F2F4-01E

5-13

Page 27

6. IN-PROCESS OPERATION

This chapter describes the procedure performed when changing the operation of

the function block of the YF100 in process.

6.1 Mode Transition

When the function block mode is changed to Out_Of_Service, the function block

pauses and a block alarm is issued.

When the function block mode is changed to Manual, the function block suspends

updating of output values. In this case alone, it is possible to write a value to the

OUT parameter of the block for output. Note that no parameter status can be

changed.

6. IN-PROCESS OPERATION

6.2 Generation of Alarm

6.2.1 Indication of Alarm

When the self-diagnostics function indicates that a device is faulty, an alarm

(device alarm) is issued from the resource block. When an error (block error) is

detected in each function block or an error in the process value (process alarm) is

detected, an alarm is issued from each block. If an LCD indicator is installed, the

error number is displayed as AL.XX. If two or more alarms are issued, multiple

error numbers are displayed in 2-second intervals.

F0601.EPS

IM 1F2F4-01E

Figure 6.1 Error Identified by Built-in Indicator

6-1

Page 28

Table 6.1 List of Error Messages for Built-in Indicators

LCD

AL-01

AL-02 Amplifier or hardware failure.

AL-03 EEPROM is faulty.

AL-20 The function block is not scheduled.

AL-21 The resource block is in O/S mode.

AL-22 The transducer block is in O/S mode.

AL-23 AI function block is in O/S mode.

AL-41

AL-42

AL-61 Out of the range of the built-in indicator display.

AL-62 Al function blocks are in Simulate mode.

AL-63

6.2.2 Alarms and Events

Following alarm or event can be reported by YF100 as an alert if allowed.

Analog Alerts (Generated when a process value exceeds threshold)

By AI Block Hi-Hi Alarm, Hi Alarm, Low Alarm, Low-Low Alarm

Discrets Alerts (Generated when an abnormal condition is detected)

By Resource Block Block Alarm, Write Alarm

By Transducer Block Block Alarm

By AI Block Block Alarm

Content of Alarms

Noise judgement circuit is faulty.

Out of flow range.

Out of span setting range for maximum and minimum.

Al function block is in MAN mode.

T0601.EPS

Update Alerts (Generated when a important (restorable) parameter is updated)

By Resource Block Update Event

By Transducer Block Update Event

By AI Block Update Event

An alert has following structure:

Table 6.2 Alert Object

Subindex

of Analog

Alert

1 Block Index

2 Alert Key

3 Standard

4 Mfr Type

5

6 Priority

7 Time Stamp

8 Subcode

9 Value

10 Relative Index

11 Unit Index

Subindex of

Discrete

Alert

1

2

3

4

5 Message

6

7

8

9

10

11 9

Subindex of

Update

Alert

1

2

3

4

5

6

7

8

Parameter

Name

Type

Type

Static

Revision

Explanation

Index of block from which alert is

generated

Alert Key copied from the block

Type of the alert

Alert Name identified by manufacturer

specific DD

Reason of alert notification

Priority of the alarm

Time when this alert is first detected

Enumerated cause of this alert

Value of referenced data

Relative index of referenced data

Value of static revision (ST_REV) of

the block

Unit code of referenced data

T0602.EPS

6-2

IM 1F2F4-01E

Page 29

6.3 Simulation Function

The simulation function simulates the input of a function block and lets it operate

as if the data was received from the transducer block. It is possible to conduct

testing for the downstream function blocks or alarm processes.

A SIMULATE_ENABLE jumper is mounted in the YF100 amplifier as a key for

disabling the accidental operation of this behavior. When this jumper is shortcircuited with a pin, simulation is enabled. To initiate the same action from a

remote terminal, if REMOTE LOOP TEST SWITCH is written to the 9th element (a

string of 32 characters) of the TEST_RW parameter (index 308) of the resource

block, the resulting action is the same as the one taken when the above jumper is

mounted. Note that this parameter value is lost when the power is turned OFF. In

simulation enabled status, an alarm is generated from the resource block, and

other device alarms will be masked; for this reason the simulation must be disabled immediately after using this function.

The SIMULATE parameter of AI block consists of the elements listed in Table 6.3

below.

Table 6.3 SIMULATE Parameter

Subindex Parameters Description

1 Simulate Status

2 Simulate Value

3 Transducer Status

4 Transducer Value

5 Simulate En/Disable

When Simulate En/Disable in Table 6.3 above is set to 2, the applicable function

block uses the simulation value set in this parameter instead of the data from the

transducer block. This setting can be used for propagation of the status to the

trailing blocks, generation of a process alarm, and as an operation test for trailing

blocks.

6. IN-PROCESS OPERATION

Sets the data status to be simulated.

Sets the value of the data to be simulated.

Displays the data status from the transducer block.

It cannot be changed.

Displays the data value from the transducer block.

It cannot be changed.

Controls the simulation function of this block.

1: Simulation disabled (standard)

2: Simulation started

T0603.EPS

IM 1F2F4-01E

6-3

Page 30

APPENDIX 1. LIST OF PARAMETERS FOR EACH BLOCK OF YF100

APPENDIX 1. LIST OF PARAMETERS

FOR EACH BLOCK OF THE

YF100

Note: The Write Mode column contains the modes in which each parameter is write enabled.

O/S: Write enabled in O/S mode.

MAN: Write enabled in Man mode and O/S mode.

AUTO: Write enabled in Auto mode, Man mode, and O/S mode.

A1.1 Resource Block

Offset Index ExplanationWrite ModeFactory DefaultParameter Name

0 300 TAG:“RS”Block Header

1 301 –ST_REV

2 302 NullTAG_DESC

3 303 0STRATEGY

4 304 0 1 to 255ALERT_KEY

5 305 AUTOMODE_BLK

6 306 –BLOCK_ERR

7 307 –RS_STATE

8 308 NullTEST_RW

9 309 NullDD_RESOURCE

10 310 0x00594543MANUFAC_ID

11 311 2DEV_TYPE

12 312 1DEV_REV

13 313 1DD_REV

14 314 0GRANT_DENY

15 315 Scalar input

16 316 –RESTART

17 317 Soft write lock

18 318 Soft write lock

HARD_TYPES

FEATURES

supported

Report supported

FEATURE_SEL

supported

Report supported

Block Tag

= O/S

–

AUTO

AUTO

AUTO

AUTO

–

AUTO

–

–

–

–

–

AUTO

–

Valid Range

Information on this block such as Block Tag, DD

Revision, Execution Time etc.

The revision level of the static data associated with the

resource block. The revision value is incremented each

time a static parameter value in this block is changed.

The user description of the intended application of the

block.

The strategy field can be used to identify grouping of

blocks. This data is not checked or processed by the

block.

The identification number of the plant unit. This

information may be used in the host for sorting alarms,

etc.

The actual, target, permitted, and normal modes of the

block.

This parameter reflects the error status associated with

the hardware or software components associated with a

block. It is a bit string, so that multiple errors may be

shown.

State of the resource block state machine.–

Read/write test parameter-used only for conformance

testing and simulation.

String identifying the tag of the resource which contains

the Device Description for this resource.

Manufacturer identification number-used by an interface

device to locate the DD file for the resource.

Manufacturer’s model number associated with the

resource-used by interface devices to locate the DD file

for the resource.

Manufacturer revision number associated with the

resource-used by an interface device to locate the DD

file for the resource.

Revision of the DD associated with the resource-used

by an interface device to locate the DD file for the

resource.

Options for controlling access of host computer and

local control panels to operating, tuning and alarm

parameters of the block.

The types of hardware available as channel numbers.–

Allows a manual restart to be initiated. Several degrees

of restart are possible. They are 1: Run, 2: Restart

resource, 3: Restart with defaults, and 4: Restart

processor.

Used to show supported resource block options.–

Used to select resource block options.AUTO

TA0101-1.EPS

IM 1F2F4-01E

A-1

Page 31

Offset Index ExplanationWrite Mode Valid RangeFactory DefaultParameter Name

19 319 ScheduledCYCLE_TYPE

20 320 ScheduledCYCLE_SEL

21 321 3200 (100ms)MIN_CYCLE_T

22 322 0MEMORY_SIZE

23 323 0NV_CYCLE_T

24 324 0FREE_SPACE

25 325 0FREE_TIME

26 326 –SHED_RCAS

27 327 –SHED_ROUT

28 328 1FAULT_STATE

29 329 1SET_FSTATE

30 330 1CLR_FSTATE

31 331 3MAX_NOTIFY

32 332 3LIM_NOTIFY

33 333 5000 (ms)CONFIRM_TIM

34 334 Unlocked

35 335 –UPDATE_EVT

36 336 –BLOCK_ALM

37 337 EnableALARM_SUM

38 338 0ACK_OPTION

39 339 0 0, 1, 3 to 15 only WRITE_PRI

40 340 –WRITE_ALM

WRITE_LOCK

–

AUTO

–

–

–

–

–

AUTO

AUTO

–

AUTO

AUTO

–

AUTO

AUTO

–

–

AUTO

AUTO

–

1(No Change)

2(Change) only

1(No Change)

2(Change) only

0–MAX_NOTIFY

1(Unlocked)

2(Locked) only

Identifies the block execution methods available for this

resource.

Used to select the block execution method for this

resource.

Time duration of the shortest cycle interval of which the

resource is capable.

Available configuration memory in the empty resource.

To be checked before attempting a download.

Interval between writing copies of NV parameters to

non-volatile memory. Zero means never.

Percent of memory available for further configuration.

YF100 has zero which means a preconfigured resource.

Percent of the block processing time that is free to

process additional blocks. YF100 does not support this.

Time duration at which to give up on computer writes to

function block RCas locations. YF100 does not support

this.

Time duration at which to give up on computer writes to

function block ROut locations. YF100 does not support

this.

Condition set by loss of communication to an output

block, failure promoted to an output block or a physical

contact. When fail-safe condition is set, Then output

function blocks will perform their FSAFE actions.

Allows the fail-safe condition to be manually initiated by

selecting Set.

Writing a Clear to this parameter will clear the device

fail-safe state if the field condition, if any, has cleared.

Maximum number of unconfirmed notify messages

possible.

Maximum number of unconfirmed alert notify messages

allowed.

The minimum time between retries of alert reports.AUTO

If set, no writes from anywhere are allowed, except to

clear WRITE_LOCK. Block inputs will continue to be

updated

This alert is generated by any change to the static data.–

The block alarm is used for all configuration, hardware,

connection failure or system problems in the block. The

cause of the alert is entered in the subcode field. The

first alert to become active will set the Active status in

the Status attribute. As soon as the Unreported status is

cleared by the alert reporting task, another block alert

may be reported without clearing the Active status, if

the subcode has changed.

The current alert status, unacknowledged states,

unreported states, and disabled states of the alarms

associated with the function block.

Priority of the alarm generated by clearing the write

lock.

This alert is generated if the write lock parameter is

cleared.

TA0101-2.EPS

A-2

IM 1F2F4-01E

Page 32

A1.2 Al Function Block

APPENDIX 1. LIST OF PARAMETERS FOR EACH BLOCK OF YF100

Offset Index ExplanationWrite Mode Valid RangeParameter Name

0 600 TAG: “AI”Block Header

1 601 –ST_REV

2 602 (blank)TAG_DESC

3 603 0STRATEGY

4 604 0 1 to 255ALERT_KEY

5 605 AUTOMODE_BLK

6 606 –BLOCK_ERR

7 607 –PV

8 608 –OUT

9 609 DisableSIMULATE

10 610 Specified at the

11 611 Specified at the

XD_SCALE

OUT_SCALE

Factory Default

time of order

time of order

Block Tag

= O/S

–

AUTO

AUTO

AUTO

AUTO

–

–

Value =

MAN

AUTO

MAN

MAN

Information on this block such as Block Tag, DD

Revision, Execution Time etc.

The revision level of the static data associated with the

function block. The revision value will be incremented

each time a static parameter value in the block is

changed.

The user description of the intended application of the

block.

The strategy field can be used to identify grouping of

blocks. This data is not checked or processed by the

block.

The identification number of the plant unit. This

information may be used in the host for sorting alarms,

etc.

The actual, target, permitted, and normal modes of the

block.

This parameter reflects the error status associated with

the hardware or software components associated with a

block. It is a bit string, so that multiple errors may be

shown.

Either the primary analog value for use in executing the

function, or a process value associated with it.

May also be calculated from the READBACK value of

an AO block.

The primary analog value calculated as a result of

executing the function.

Allows the transducer analog input or output to the

block to be manually supplied when simulate is

enabled. When simulation is disabled, the simulate

value and status track the actual value and status.

The high and low scale values, engineering units code,

and number of digits to the right of the decimal point

used with the value obtained from the transducer for a

specified channel.

The high and low scale values, engineering units code,

and number of digits to the right of the decimal point to

be used in displaying the OUT parameter and

parameters which have the same scaling as OUT.

12 612 0GRANT_DENY

13 613 0IO_OPTS

14 614 0STATUS_OPTS

15 615 1CHANNEL

16 616 Specified at the

17 617 0LOW_CUT

18 618 2sec

L_TYPE

time of order

AUTO

O/S

O/S

O/S

MAN

AUTO

AUTO

1 only

1 to 3 only

The value > 0

The value > 0PV_FTIME

Options for controlling access of host computers and

local control panels to operating, tuning and alarm

parameters of the block.

Options which the user may select to alter input and

output block processing

Options which the user may select in the block

processing of status

The number of the logical hardware channel that is

connected to this I/O block. This information defines

the transducer to be used going to or from the physical

world.

Determines if the values passed by the transducer

block to the AI block may be used directly (Direct) or if

the value is in different units and must be converted

linearly (Indirect), or with square root (Ind Sqr Root),

using the input range defined by the transducer and the

associated output range.

Limit used in square root processing. A value of zero

percent of scale is used in block processing if the

transducer value falls below this limit, in % of scale.

This feature may be used to eliminate noise near zero

for a flow sensor.

Time constant of a single exponential filter for the PV, in

seconds.

TA0102-1.EPS

IM 1F2F4-01E

A-3

Page 33

Offset Index ExplanationWrite Mode Valid Range

19 619

20 620 –UPDATE_EVT

Parameter Name

Factory Default

–FIELD_VAL

–

–

Raw value of the field device in percent of thePV range,

with a status reflecting the Transducer condition, before

signal characterization (L_TYPE) or filtering

(PV_FTIME).

This alert is generated by any change to the static data.

21 621 –BLOCK_ALM

22 622 EnableALARM_SUM

23 623 0ACK_OPTION

24 624 0.5% ALARM_HYS

25 625 0HI_HI_PRI

26 626 +INFHI_HI_LIM

27 627 0HI_PRI

28 628 +INFHI_LIM

29 629 0LO_PRI

30 630 –INFLO_LIM

31 631 0LO_LO_PRI

32 632 –INF

33 633 –HI_HI_ALM

34 634 –HI_ALM

LO_LO_LIM

–

–

AUTO

AUTO

AUTO

AUTO

AUTO

AUTO

AUTO

AUTO

AUTO

AUTO

–

–

0 to 50

0, 1, 3 to 15

Note 1

0, 1, 3 to 15

Note 1

0, 1, 3 to 15

Note 2

0, 1, 3 to 15

Note 2

The block alarm is used for all configuration, hardware,

connection failure or system problems in the block. The

cause of the alert is entered in the subcode field. The

first alert to become active will set the Active status in

the Status attribute. As soon as the Unreported status is

cleared by the alert reporting task, another block alert

may be reported without clearing the Active status, if

the subcode has changed.

The current alert status, unacknowledged states,

unreported states, and disabled states of the alarms

associated with the function block.

Selection of whether alarms associated with the block

will be automatically acknowledged.

Amount the PV must return within the alarm limits

before the alarm condition clears. Alarm Hysteresis is

expressed as a percent of the PV span.

Priority of the high high alarm.

The setting for high high alarm in engineering units.

Priority of the high alarm.

The setting for high alarm in engineering units.

Priority of the low alarm.

The setting for the low alarm in engineering units.

Priority of the low low alarm.

The setting of the low low alarm in engineering units.

The status for high high alarm and its associated time

stamp.

The status for high alarm and its associated time stamp.

35 635 –LO_ALM

36 636 –LO_LO_ALM

37 637 5 (E+5)PULSE_VAL

38 638 0 (OFF)

39 639 –TOTAL

Note 1: When Min (OUT_SCALE.EU0, OUT_SCALE.EU100) ≤ set value ≤ + INF, it is write-able.

Note 2: When -INF ≤ set value ≤ Max (OUT_SCALE .EU0,OUT_SCALE.EU100), it is write-able.

–

–

O/S

AUTO

–

0 to 13

0 (Off), 1 (Reset) onlyRESET

The status of the low alarm and its associated time

stamp.

The status of the low low alarm and its associated time

stamp.

Set the factor per totalized value count when a totalized

flow is necessary.

Totalized value (display & RAM data) are reset when

this function is executed.

Totalized value.

TA0102-2.EPS

A-4

IM 1F2F4-01E

Page 34

A1.3 Transducer Block

Offset Index ExplanationWrite Mode Valid RangeFactory DefaultParameter Name

0 400 TAG: “TB”Block Header

1 401 –ST_REV

2 402 (blank)TAG_DESC

3 403 0STRATEGY

4 404 1 1 to 255ALERT_KEY

5 405 AUTOMODE_BLK

6 406 –BLOCK_ERR

7 407 –UPDATE_EVT

8 408 –BLOCK_ALM

9 409 –TRANSDUCER_

10 410 104: Flow with

11 411 –XD_ERROR

12 412 –COLLECTION_

13 413 100: Mass flow

14 414 –PRIMARY_

15 415 Range of flowPRIMARY_

16 416 Max rangeCAL_POINT_HI

17 417 Min. rangeCAL_POINT_LO

18 418 FlowCAL_MIN_SPAN

19 419 1349: m

20 420 Vortex

21 421 Flow rangeSENSOR_

22 422 Serial No.SENSOR_SN

23 423 100: VolumetricSENSOR_CAL_

24 424 SENSOR_CAL_

25 425 SENSOR_CAL_

26 426 –SENSOR_CAL_

27 427 1LIN_TYPE

28 428 –SECONDARY_

29 429 1088: kgSECONDARY_

30 430 25 mm

DIRECTORY

TRANSDUCER_

TYPE

DIRECTORY

PRIMARY_

VALUE_TYPE

VALUE

VALUE_RANGE

RANGE

METHOD

LOC

DATE

WHO

VALUE

VALUE_UNIT

SIZE_SELECT

Calibration

101: Volumetric flow

3

/hCAL_UNIT

–

–

Block Tag

= O/S

–

AUTO

AUTO

AUTO

AUTO

–

–

–

–

O/S

–

–

–

O/S

O/S

O/S

–

APPENDIX 1. LIST OF PARAMETERS FOR EACH BLOCK OF YF100

Information on this block such as Block Tag, DD

Revision, Execution Time etc.

The revision level of the static data associated with the

function block. The revision value will be incremented

each time a static parameter value in the block is

changed.

The user description of the intended application of the

block

The strategy field can be used to identify grouping of

blocks. This data is not checked or processed by the

block.

The identification number of the plant unit.

This information may be used in the host for sorting

alarms, etc.

The actual, target, permitted, and normal modes of the

block.

This parameter reflects the error status associated with

hardware or software components associated with a

block. It is a bit string, so that multiple errors may be

shown.

This alert is generated by any change to the static data.–

The block alarm is used for all configuration, hardware,

connection failure or system problems in the block. The

cause of the alert is entered in the subcode field. The

first alert to become active will set the Active status in

the Status attribute.

A directory that specifies the number and starting

indices of the transducers.

104: Flow with

Calibration

100 to 109

Note 1

Note 2

Note 3

112:Vortex onlySENSOR_TYPE

100 to 106

0, 1, 255

Only displayed units

are write enabled

0:15 mm to

16:200 mmHPT

Identifies transducer.–

The error code in transducer.–

A directory that specifies the number, starting indices,

and DD Item Ids of the data collections in each

transducer within a transducer block.

The type of measurement represented by primary

value.

The measured value and status available to the function

block.

The High and Low range limit values, engineering units

code and the number of digits to the right of the decimal

point to be used to display the primary value.

The highest calibrated value.O/S

The lowest calibrated value.O/S

The minimum calibration span value allowed.–

The engineering unit for the calibrated values.–

The type of sensor.–

The High and Low range limit values, engineering units

code and the number of digits to the right of the decimal

point for the sensor.

The sensor serial number.–

The method of the last sensor calibration.O/S

The location of the last sensor calibration.

The date of the last sensor calibration.

The name of the person responsible for the last sensor

calibration.

The secondary value (totalized value) of transducer.–

The engineering unit of secondary value.–

The nominal size of combined detector.O/S

TA0103-1.EPS

IM 1F2F4-01E

A-5

Page 35

Offset Index ExplanationWrite Mode Valid RangeFactory DefaultParameter Name

31 431 Steam MFLUID_TYPE

32 432 68.6K_FACTOR_

VALUE

33 433 P/LK_FACTOR_

UNIT

34 434 1VISCOSITY_

VALUE

35 435 –VORTEX_FREQ

_VALUE

36 436 –FLOW_VELOCITY

_VALUE

37 437 –REYNOLDS_

NUM_VALUE

38 438 1MIN_DENSITY_

VALUE

39 439 Kg/m

DENSTY_UNIT

40 440 15TEMPERATURE_

F_VALUE

41 441 DegCTEMPERATURE_

UNIT

42 442 1DENSITY_F_

VALUE

43 443 1SPE_ENTHALPY

_VALUE

44 444 Kcal/kgENTHALPY_

UNIT

45 445 15TEMPPERATURE

_N_VALUE

46 446 1.0332PRESSURE_F_

VALUE

47 447 1.0332PRESSURE_N

VALUE

48 448 1DEVIATION

49 449 0NOISE_BALANCE

_VALUE

50 450 0TRIGGER_LEVEL

_VALUE

51 451 0AMPLIFIER_

GAIN_VALUE

52 452 0INSTRUMENTAL_

ERR_ADJ

53 453 0REYNOLDS_

NUM_ADJ

54 454 0ADJACENT_PIPE

_EFFECT

55 455 0EXPANSION_

CORRECTION

56 456 0HIGH_CUT_

FILTER_VALUE

57 457 0.06122LOW_CUT_

FLOW

58 458 1NOISE_JUDGE_

CONTROL

59 459 0ADJ_

FREQUENCY_

1_VALUE

60 460 0ADJ_DATA_1_

VALUE

61 461 0ADJ_

FREQUENCY_2

_VALUE

The type of flow fluid.O/S

The K-factor value (KM) at 15degC for combined

detector.

The unit of K-factor.O/S

O/S

0:Stream M to 7:Liq M

0 to 32000

0:p/L, 1:p/gal,

2:p/lmpGal

O/S

0 to 32000

The viscosity coefficient of low fluid to output the

Reynolds number.

The vortex frequency.–

The flow velocity value.–

The reynolds number–

0 to 32000

3

1097:kg/m

1107:lb/ft

3

3

The minimum density value under operating condition.O/S

The density unit under operating condition.O/S

1108:lb/gal

–500 to 1000

1001:degC

The fluid temperature under operating condition.O/S

The temperature unitO/S

1002:degF

0 to 32000

0 to 32000

1515:kcal/kg

The density value under operationg condition.O/S

The value of specific enthalpy.O/S

The unit of specific enthalpy.O/S

1208:kJ/kg

1516:Btu/lb

The fluid temperature under standard condition.O/S

The absolute pressure value (kg/cm

2

abs) under

operating condition.

The absolute pressure value (kg/cm2 abs) under

standard condition.

The deviation factor.O/S

The noise balance adjustment.O/S

The trigger level adjustment.O/S

The flowmeter gain can be adjusted.O/S

The parameter to correct the instrumental error.O/S

The parameter to correct the reynolds number’s shift

error.

The parameter to correct the measurement errors

caused by pipe schedules 10, 40, and 80

The parameter to corrects the deviation from the ideal

gas law when measuring a compressibility gas by mass

O/S

O/S

O/S

O/S

O/S

–500 to 1000

0 to 32000

0 to 32000

0 to 10

–5 to 10

–1 to 2

Note 4

0:Off, 1:On

0:Off, 1:On

0:Off to

6:Flange Sch80

0:Off, 1:On

flow and standard condition.

–

–

O/S

O/S

O/S

O/S

Note 5

0 to

XD_SCALE.EU100

0:Off, 1:On

0 to 32000

–100 to 100

0 to 32000

The control high cut filter to minimize the effect of high

frequency noise.

The parameter to eliminate noise in the low-frequency

(low flow rate) area.

The parameter to eliminate pipe vibration effect when

flowrate is close to zero.

The first break-point frequency for the instrumental error

adjustment.

The correcting value (%) at the first break-point

frequency for the instrumental error adjustment.

The second break-point frequency for the instrumental

error adjustment.

TA0103-2.EPS

A-6

IM 1F2F4-01E

Page 36

Offset Index ExplanationWrite Mode Valid RangeFactory DefaultParameter Name

62 462 0 –100 to 100ADJ_DATA_2_

VALUE

63 463 0ADJ_

FREQUENCY_3

_VALUE

64 464 0ADJ_DATA_3_

VALUE

65 465 0ADJ_

FREQUENCY_4

_VALUE

66 466 0ADJ_DATA_4_

VALUE

67 467 0ADJ_

FREQUENCY_5

_VALUE

68 468 0ADJ_DATA_5_

VALUE

69 469 0V_F_OUTPUT_

SEL

70 472 –V_F_

FREQUENCY_

VALUE

71 471 YF100*EMODEL

O/S

O/S

O/S

O/S

O/S

O/S

O/S

–

–

APPENDIX 1. LIST OF PARAMETERS FOR EACH BLOCK OF YF100

The correcting value (%) at the second break-point

frequnecy for the instrumental error adjustment.

0 to 32000

–100 to 100

0 to 32000

–100 to 100

0 to 32000