Page 1

User’s

Manual

IM XL120E

XL100

(XL121/XL122/XL124)

Portable Data Station (Datum-Y)

(XL111/XL112/XL114)

Portable Data Logger (Datum-Y)

IM XL120E

1st Edition: April 2007 (MC)

Page 2

Introduction

Notes

Thank you for purchasing our XL100 Portable Data Station or Portable Data Logger.

This User’s Manual describes the functions of the XL100 as well as its operating

methods and handling precautions. Read this manual thoroughly before using the

XL100, to ensure correct use.

In addition to this manual, the Quick Setup Manual and Communication Function Manual

(contained in the CD-ROM as with this User’s Manual) are available separately.

The Quick Setup Manual briefly describes the main functions and the basic procedures

for performing such tasks as setup and measurement operations.

Use the Quick Setup Manual together with this in-depth User’s Manual. For details on

the communication functions, see the Communication Function Manual (contained in the

same CD-ROM). The Communication Function Manual is used on the XL121, XL122,

and XL124.

After reading this manual, keep it in an easily accessible place for later reference. This

manual will come in handy when you are unsure of how to operate the product.

• The contents of this manual are subject to change without prior notice.

• Figures and illustrations representing display views in this manual may differ from

actual views.

• Every effort has been made to ensure accuracy in the preparation of this manual.

However, should any doubts arise or errors come to your attention, please contact the

vendor from which you purchased the product.

• The contents of this manual may not be transcribed or reproduced, in part or in their

entirety, without prior permission.

Trademark Acknowledgements

The company and product names referred to in this document are either trademarks or

registered trademarks of their respective holders.

Revision Information

First Edition: April, 2007

1st Edition: April 2007 (MC)

All Rights Reserved, Copyright © 2005, Yokogawa Meters & Instruments Corporation

IM XL120E

1

Page 3

Checking the Contents of the Package

After opening the package, be sure to check the product as instructed below before use.

Should the product you have received be the wrong model, lack any items, or show any

problems in its appearance, contact the vendor from whom you purchased the product.

Instrument Main Unit

Check the model and suffix code printed on the nameplate on the rear panel to ensure

that the XL100 is exactly as specified in your purchase order.

Model

XL100

No.

When inquiring about the product to the vender,

please give the vendor the instrument number.

Model and Suffix Codes

Model Specifications

XL121 With a terminal block unit (8 channels)

XL122 With a terminal block unit (16 channels)

XL124 With a M3 screws terminal block unit (16 channels)

XL111 With a terminal block unit (8 channels), no SD card storage/communication function

XL112 With a terminal block unit (16 channels), no SD card storage/communication function

XL114 With a M3 terminal block unit (16 channels), no SD card storage/communication

* The XL111, XL112, and XL114 are only sold in Japan.

function

Accessories

Instrument Number

An instrument number is also printed on the nameplate. When inquiring about the

product to the vender, please also give the vendor this number.

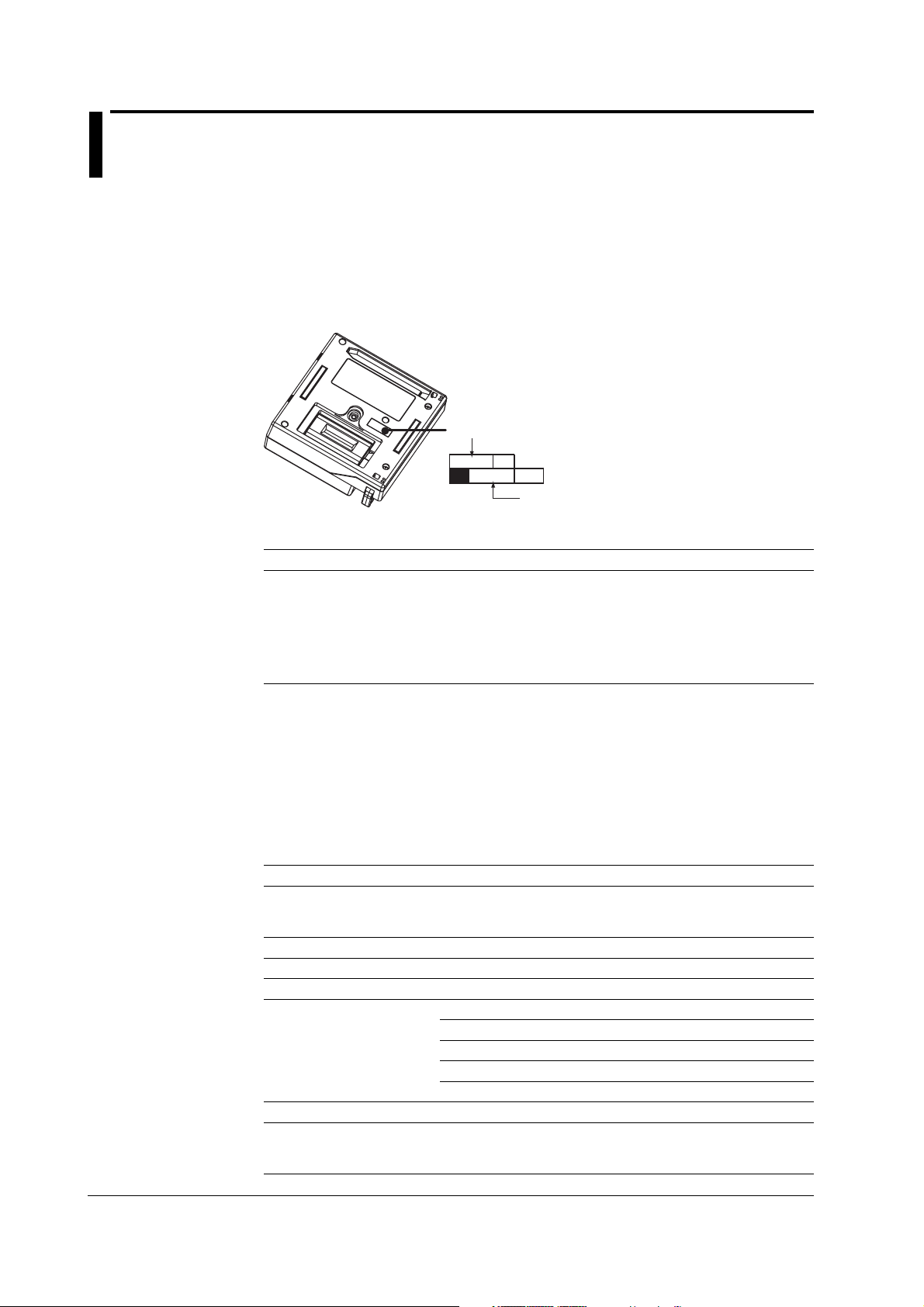

Make sure that the package contains all the accessories listed below and that they are

all free from any damage.

No. Name Part No. Remarks

1 Terminal block unit 95052/95053 95052, 95053, and 95055 when the model is

/95055 XL111,XL112, and XL114 or XL121,XL122, and

XL124, respectively

2 Rubber boot 93036 For impact resistance

3 Side cover – Supplied with the XL121, XL122, and XL124

4 Screwdriver for terminals –

5 AC adapter 94010-D UL/CSA standard

-F VDE standard

-R SAA standard

-S BS standard

-H GB standard

6 Quick Setup Manual IM XL120P-E

7 CD-ROM – Contains Standard Software and PDF manuals

(User’s Manual (this manual), Quick Setup

Manual, and Communication Function Manual)

2

IM XL120E

Page 4

Checking the Contents of the Package

1.

+

c

h

1

-

b

+

c

h

2

-

b

+

c

h

3

-

b

+

c

h

4

-

b

+

c

h

5

-

b

+

c

h

6

-

b

+

c

h

7

-

b

+

c

h

8

-

2.

(Example: 95052)

5.

Note: Accessory items 1 to 3 come installed in the XL100.

Accessories and Spare Parts (Optional)

The products listed below are available as optional accessories and spare parts. For

technical and ordering inquiries concerning accessories and spare parts, contact the

vendor from whom you purchased the product.

Accessories

Name Part No. Remarks

Type-K TC 90060 5 m 4 sets

Carrying case 93037 For storing the XL100 and accessories

Lithium ion battery 94009 Voltage: 7.4 V. Capacity: 2400 mAh

Digital I/O cable 91029 For pulse input, logic input, and alarm output.

Communication cable 91011 For RS-232 communication with a PC. Number of

Printer 97010 With 1 thermal paper roll and battery pack

AC adapter (for printer, Europe) 94006

AC adapter (for printer, USA) 94007

RS-232C cable 91010 For connecting the printer. Number of pins: 9 pins

Thermal paper for printer 97080 10 rolls

Stand 93039 Supports tilted installation on the desktop, wall

Application software XL900 For online data acquisition and data analysis

(Datum-LOGGER)

3.

6.

7.

4.

Length: 3 m

pins: 9 pins

mounting, and DIN rail mounting

IM XL120E

Spare Parts

Name Part No. Remarks

Terminal block unit (8 channels) 95052 8 channels, clamp terminal type

Terminal block unit (16 channels) 95053 16 channels, clamp terminal type

M3 screws terminal block unit 95055 16 channels, M3 screws terminal type

(16 channels)

Rubber boot 93036 For impact resistance

AC adapter 94010-D UL/CSA standard

-F VDE standard

-R SAA standard

-S BS standard

-H GB standard

TIP

It is advisable that the packing box be saved, as it is useful when you transport the product.

3

Page 5

Safety Precautions

When operating the instrument, be sure to observe the cautionary notes given below to

ensure correct and safe use of the instrument. If you use the instrument in any way other

than as instructed in this manual, the instrument’s protective measures may be impaired.

Yokogawa Meters & Instruments Corporation is by no means liable for any damage

resulting from use of the instrument in contradiction to these cautionary notes.

The following safety symbols are used on the instrument and in this manual.

Danger! Handle with Care. This symbol indicates that the operator must refer to

an explanation in the User’s Manual or Service Manual in order to avoid risk of

injury or death of personnel or damage to the instrument.

This symbol indicates DC voltage/current.

This symbol indicates AC voltage/current.

This symbol indicates ON (power).

This symbol indicates OFF (power).

WARNING

Indicates a hazard that may result in the loss of life or serious injury of the user

unless the described instruction is abided by.

CAUTION

Indicates a hazard that may result in an injury to the user and/or physical damage

to the product or other equipment unless the described instruction is abided by.

Note

Indicates information that is essential for handling the instrument or, should be

noted in order to familiarize yourself with the instrument’s operating procedures

and/or functions.

TIP

Indicates information that complements the present topic.

SEE ALSO

Indicates the reference location(s) for further information on the present topic.

4

IM XL120E

Page 6

Safety Precautions

Strictly observe the following cautionary notes in order to avoid the risk of injury or death

of personnel or damage to the instrument due to hazards such as electrical shock.

WARNING

• Do Not Remove the Case

Do not remove the case from the instrument or disassemble/modify the

instrument.

For inspection and/or adjustment of the internal assembly, contact the vendor

from which you purchased the instrument.

• Do Not Operate in an Explosive Atmosphere

Do not operate the instrument in a location where any flammable or explosive

gas/vapor is present. It is extremely hazardous to operate it in such an atmosphere.

• Use the Correct Power Supply

Before turning on the instrument, always make sure the voltage of the power

source to be applied matches the instrument’s supply voltage.

• Unplug If Abnormal Behavior Occurs

If the instrument begins to emit smoke, becomes too hot, or gives off an

unusual smell, immediately turn it OFF and disconnect the power cord from

the outlet. Also turn off power to the object under measurement that is connected to the instrument’s input terminals. Never attempt to use the instrument

again. If any such anomalies as noted above occurs, contact the vendor from

which you purchased the instrument.

Do not attempt to repair the instrument yourself, as doing so is extremely

dangerous.

• Do Not Damage the Power Cord

•To prevent electric shock or fire, be sure to use the power cord supplied by

YOKOGAWA.

• Do not place any load on the power cord or allow the power cord to come into

contact with any heat source. When unplugging the power cord from the outlet,

hold its plug, rather than holding and pulling the cord itself.

• If the power cord is damaged, contact the vendor from which you purchased

the instrument.

IM XL120E

5

Page 7

Language Setting at Startup

Language Setting at Startup

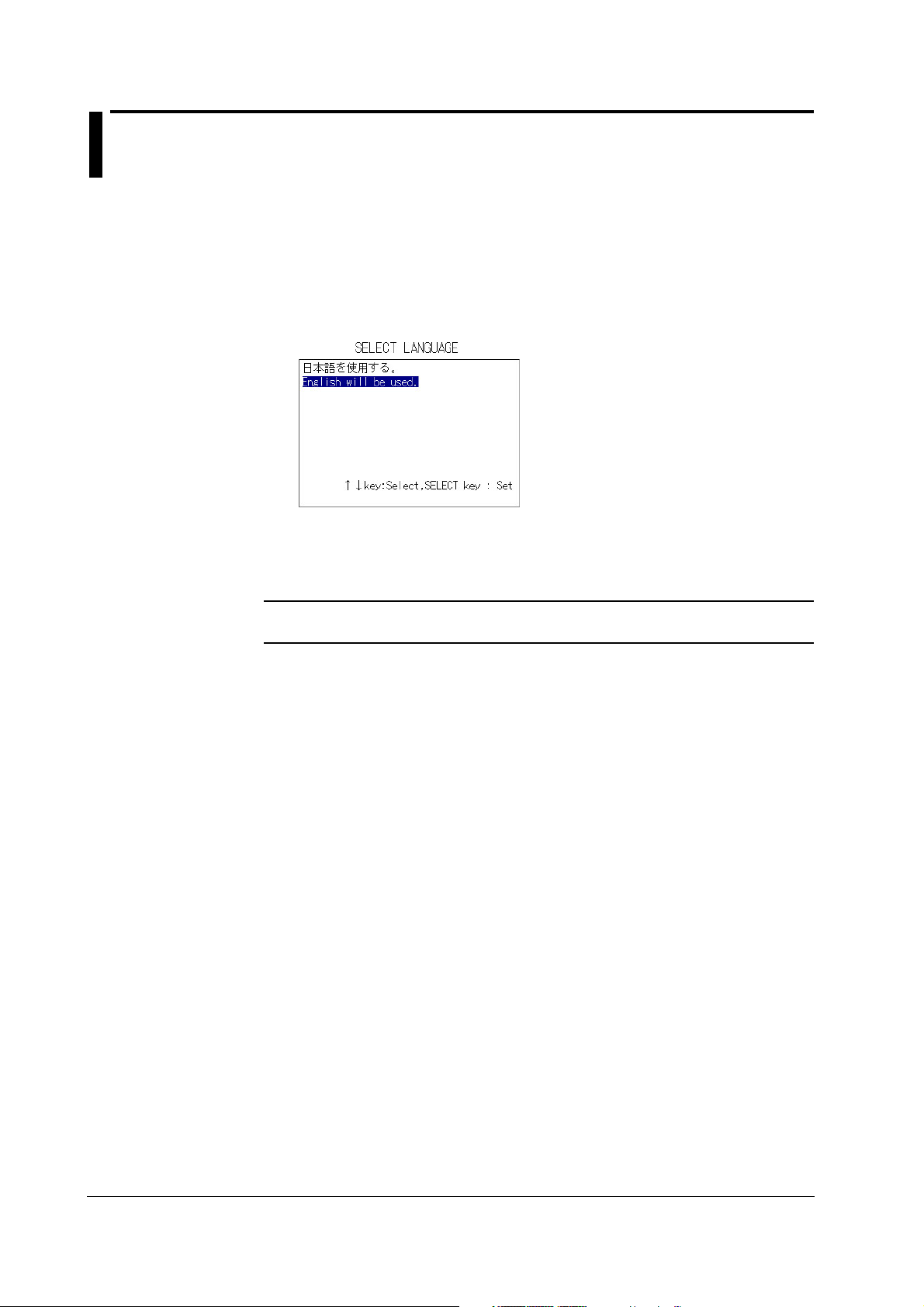

When you start up the XL100 for the first time (the first time you turn on the XL100 after

purchase), you must set the language that you are going to use. Follow the procedure

below to set the language.

Once you set the language, the XL100 will start up using the specified language the next

time.

1. When you turn the power switch ON, the following screen appears.

2. Use the arrow keys to select the language, and press SELECT.

3. The language is set, and a self-test starts automatically.

TIP

To change the language once you set it, press SETTING, select HARDWARE >

LANGUAGE, and change the setting.

6

IM XL120E

Page 8

3

10

11

12

13

App

Index

Contents

1

Checking the Contents of the Package .......................................................................................... 2

Safety Precautions ......................................................................................................................... 4

Language Setting at Startup ........................................................................................................... 6

2

3

Chapter 1 Explanation of Functions

1.1 Overview of the XL100 ..................................................................................................... 1-1

1.2 Functions of the Input Section ......................................................................................... 1-2

1.3 Display Function .............................................................................................................. 1-5

1.4 Alarm Function ................................................................................................................. 1-9

1.5 Data Save/Load Function and File Operation Function ................................................. 1-11

1.6 Calculation Function ...................................................................................................... 1-13

1.7 Setup Function ............................................................................................................... 1-14

1.8 Communication Function (Supported only on the XL121, XL122, and XL124) ............. 1-17

1.9 Other Main Functions ..................................................................................................... 1-19

Chapter 2 Part Names and Functions

2.1 Front Panel and Terminal Block Unit ............................................................................... 2-1

2.2 Side Panel and Rear Panel .............................................................................................. 2-3

2.3 Data Display ..................................................................................................................... 2-4

2.4 Setup Display ................................................................................................................. 2-19

Chapter 3 Handling Precautions and Wiring

3.1 Handling Precautions ....................................................................................................... 3-1

3.2 Operating Environment .................................................................................................... 3-2

3.3 Wiring the Input Signal Cable .......................................................................................... 3-4

3.4 Wiring the Pulse Input, Logic Input, and Signal Cables .................................................. 3-7

3.5 Wiring the External I/O Signal Cables .............................................................................. 3-8

3.6 Connecting the Power Supply ........................................................................................ 3-10

3.7 Handling of the Lithium Ion Battery (Sold Separately) ................................................... 3-11

3.8 Connecting Communication Cables

(Supported only on the XL121, XL122, and XL124) ...................................................... 3-12

3.9 Connecting the USB Memory ........................................................................................ 3-16

4

5

6

7

8

9

10

11

12

Chapter 4 Basic Operation

4.1 Turning ON/OFF the Power Switch ................................................................................. 4-1

4.2 Basic Key Operations ...................................................................................................... 4-4

4.3 Setting the Date and Time ............................................................................................. 4-16

4.4 Resetting the System (Initializing the Settings) .............................................................. 4-18

4.5 Setting the Display Backlight ......................................................................................... 4-19

4.6 Locking the Keys ............................................................................................................ 4-20

4.7 Inserting and Removing the External Storage Media .................................................... 4-21

Chapter 5 Setting the Input Channels

5.1 Setting the Analog Input Channels .................................................................................. 5-1

5.2 Setting the Pulse Input Channel ...................................................................................... 5-5

5.3 Setting the Logic Input Channel ....................................................................................... 5-9

5.4 Directly Setting the Range, Span, and Scale Using the RANGE key ............................ 5-11

IM XL120E

13

App

Index

7

Page 9

Contents

Chapter 6 Setting Alarms

6.1 Setting the Alarm on Analog Input Channels ................................................................... 6-1

6.2 Setting the Alarm on Pulse Input Channels ..................................................................... 6-3

6.3 Setting the Alarm on Logic Input Channels ...................................................................... 6-5

6.4 Setting Alarms on Calculation and Communication Channels (Communication channels

are supported only on the XL121, XL122, and XL124) .................................................... 6-7

6.5 Setting Alarm Output and Display .................................................................................... 6-9

6.6 Searching Alarms ........................................................................................................... 6-11

Chapter 7 Setting the Displayed Contents and Operating the Displays

7.1 Switching the Operation Mode and Display ..................................................................... 7-1

7.2 Setting Groups ................................................................................................................. 7-3

7.3 Setting the Background Color, Grid, and Bar Graph Base Position ................................. 7-5

7.4 Setting Alarm Lines .......................................................................................................... 7-7

7.5 Switching the Time Scale ................................................................................................. 7-9

Chapter 8 Setting the Calculation of Measured Data

8.1 Setting the Calculation ..................................................................................................... 8-1

8.2 Setting the Statistical Calculation ..................................................................................... 8-4

Chapter 9 Setting and Controlling the Data Saving and Loading Operations

9.1 Setting the Save Operation of Measured and Calculated Data ....................................... 9-1

9.2 Loading Measurement or Calculation Data Files ............................................................. 9-8

9.3 Manually Saving Measured and Calculated Data ............................................................ 9-9

9.4 Saving the Alarm Summary Data ................................................................................... 9-10

9.5 Saving the Log Data ...................................................................................................... 9-11

9.6 Saving and Loading Setup Data .................................................................................... 9-12

9.7 Renaming Files .............................................................................................................. 9-13

9.8 Deleting Files ................................................................................................................. 9-14

9.9 Copying Data ................................................................................................................. 9-15

9.10 Formatting the External Storage Media or Internal Memory .......................................... 9-17

9.11 Initializing Log Information ............................................................................................. 9-18

9.12 Automated Measurement and Save Function................................................................ 9-19

Chapter 10 Setting the Communication Function

10.1 Selecting the Communication Interface ......................................................................... 10-1

10.2 Setting the Serial Communication (RS-232, RS-485, Modbus, and Communication

Channel) ........................................................................................................................ 10-3

10.3 Setting the USB ID ......................................................................................................... 10-7

10.4 Setting the Ethernet Interface ........................................................................................ 10-8

10.5 Setting the FTP Client .................................................................................................. 10-12

10.6 Setting the Web Server ................................................................................................ 10-14

10.7 Setting the E-mail Transmission .................................................................................. 10-16

8

IM XL120E

Page 10

3

10

11

12

13

App

Index

Contents

Chapter 11 Other Functions

11.1 Setting the Print Output and Executing the Print Operation (Supported only on the XL121,

XL122, and XL124) ........................................................................................................ 11-1

11.2 Setting the Beep Sound ................................................................................................. 11-4

11.3 Set the ID Number ......................................................................................................... 11-5

11.4 Setting the Language ..................................................................................................... 11-6

11.5 Setting the Temperature Unit ......................................................................................... 11-7

11.6 Registering Users .......................................................................................................... 11-8

11.7 Setting and Executing Key Login/Logout and ................................................................ 11-9

11.8 Displaying System Information .................................................................................... 11-11

11.9 Setting the Filter ........................................................................................................... 11-12

Chapter 12 Troubleshooting

12.1 Troubleshooting ............................................................................................................. 12-1

12.2 Messages and Their Corrective Actions ........................................................................ 12-2

12.3 Disposing the Product .................................................................................................... 12-6

1

2

3

4

5

6

Chapter 13 Specifications

13.1 Input Specifications ........................................................................................................ 13-1

13.2 Display Specifications .................................................................................................... 13-4

13.3 Data Storage Specifications........................................................................................... 13-6

13.4 Alarm Specifications ...................................................................................................... 13-8

13.5 Communication Specifications

(Supported only on the XL121, XL122, and XL124) ...................................................... 13-9

13.6 Specifications of Other Functions ................................................................................ 13-11

13.7 General Specifications ................................................................................................. 13-12

13.8 External Dimensions .................................................................................................... 13-14

7

8

9

Appendix

Index

Appendix 1 A List of Settings and User Registration Privileges ........................................... App-1

Appendix 2 System Reset and Initialized Items When the Terminal Block Is Changed .......App-8

10

11

12

13

App

Index

IM XL120E

9

Page 11

Chapter 1 Explanation of Functions

1.1 Overview of the XL100

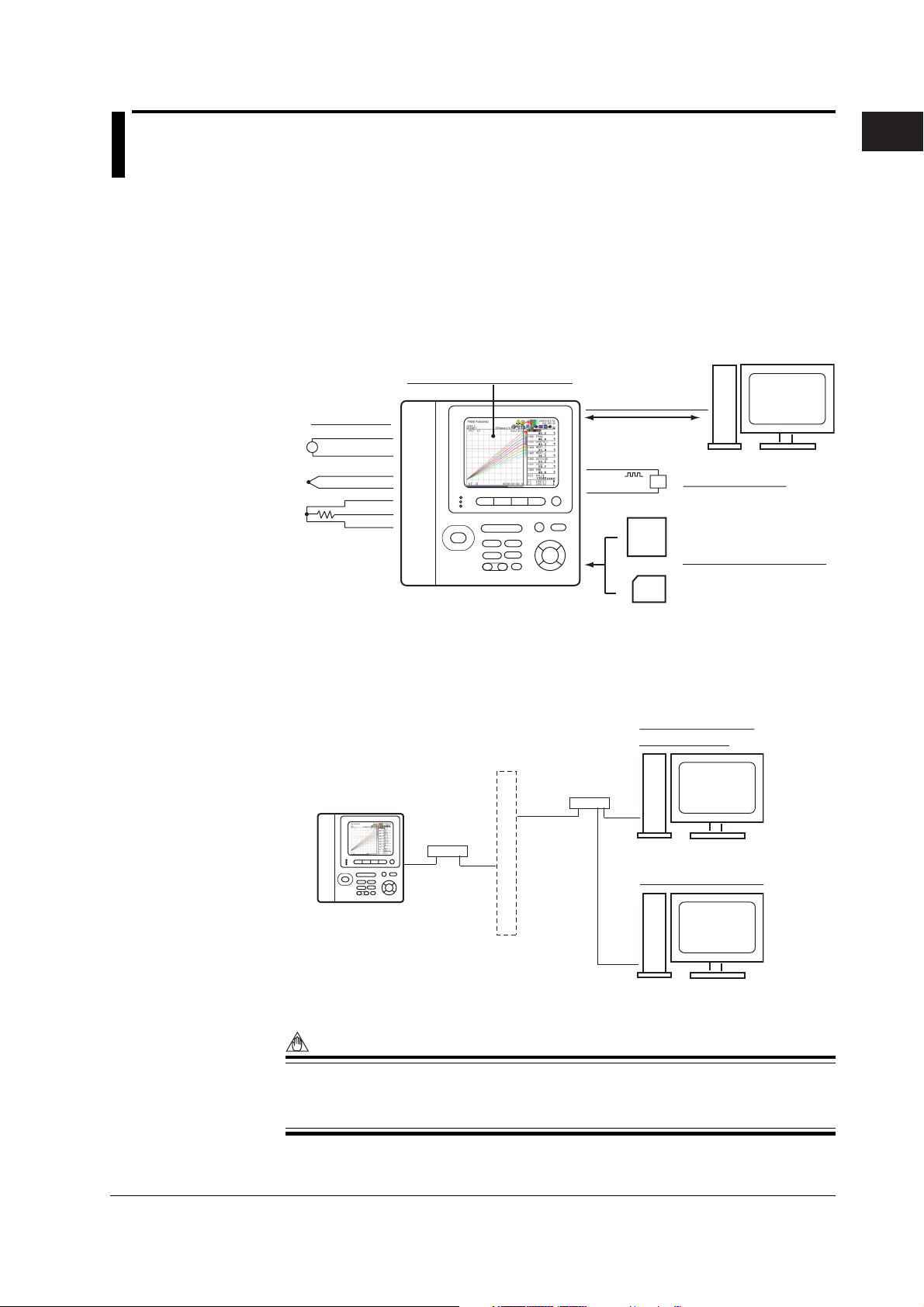

The XL100 is a handheld data logger that (1) periodically samples DC voltage or analog

input such as thermocouples and RTDs, (2) acquires the sampled measured data in the

internal memory, and (3) displays the measured data on a LCD in the form of

waveforms, digital display, and bar graphs. The measured data can also be saved to

external storage media such as CF cards and SD cards. The saved data can be loaded

into the XL100 to be displayed or displayed on a PC using the accompanying software

program.

Displays the measured data

Analog input

DC voltage

Thermocouple

RTD

V

Data communication

Pulse/Logic input

CF

Save the measured data

1

Explanation of Functions

PC

SD

By using the Ethernet interface that comes standard with the XL100, the measured data

can be automatically transmitted to a server on a network. The Ethernet interface can

also be used to retrieve the measured data saved on the XL100 internal memory or an

external storage medium into a PC on the network.

Automatically save

measured data

Ethernet

Hub

Hub

Load measured data

Server

PC

IM XL120E

Note

The function for saving the measured data to the SD card and general communication

functions including the Ethernet interface are supported only on the XL121, XL122, and

XL124.

1-1

Page 12

1.2 Functions of the Input Section

Number of Measurement Channels and Sampling Interval

There are two types of analog input terminals, 8 channels or 16 channels.

Terminal block unit (8 ch): 95052 Terminal block unit (16 ch): 95053

+

ch1

-

b

+

ch2

-

b

+

ch3

-

b

+

ch4

-

b

+

ch5

-

b

+

ch6

-

b

+

ch7

-

b

+

ch8

-

The sampling interval (scan interval and data storage interval) varies depending on the

number of input channels as shown in the table below.

Number of Channels Sampling Interval

8 100, 200 ,500 ms, 1 , 2, 5, 10, 20, 30 s, 1, 2, 5, 10, 20 , 30 min, or 1 h

16 200 ,500 ms, 1 , 2, 5, 10, 20, 30 s, 1, 2, 5, 10, 20 , 30 min, or 1 h

Input Type and Calculation

As shown in the table below, the available input types are analog input, which includes DC

voltage, thermocouple, and RTD, and other inputs, which consist of pulse signal (1 channel) and

logic signals (2 channels). Also, addition, subtraction, multiplication, and division between two

inputs can be calculated and assigned to a calculation channel and displayed in the same

fashion as measured values. The statistics of measured values can also be displayed.

Input/Calculation Description

DC voltage Measures a DC voltage in the range of ±100 mV to ±50 V.

Thermocouple Selectable from the following types: R, S, B, K, E, J, T, N, W, L, and U.

RTD Selectable from Pt100 and JPt100 types.

Pulse signal Displays the pulse input as number of revolutions, integrated value, or

Logic signal Displays the logic waveform by taking input voltage less than or equal to 0.9 V

Arithmetic calculation When the input type is set to DC voltage, thermocouple, RTD, or pulse

Statistical calculation Calculates and displays the maximum, minimum, average, peak (P-P),

Input Range and Measurable Range

Set the input range or type for analog inputs (DC voltage, thermocouple, and RTD) and

set the measurable range for a pulse signal digital input.

• DC voltage

Select from the input ranges listed in the following table.

Input Range Measurable Range Maximum Display Resolution

100 mV –100.00 to 100.00 mV 10 µV

500 mV –500.0 to 500.0 mV 100 µV

1 V –1.0000 to 1.0000 V 100 µV

5 V –5.000 to 5.000 V 1 mV

10 V –10.000 to 10.000 V 1 mV

50 V –50.00 to 50.00 V 10 mV

1-5V/f.s. 1.000 to 5.000 V 1 mV

f.s.: measurable range

1-2

instantaneous value.

to be OFF (0) and input voltage greater than or equal to 2.1 V to be ON (1).

input, addition, subtraction, multiplication, and division can be performed

with a measured value of another channel, and the result displayed as

the measured value of that channel.

or rms value of the measured value.

M3 screws terminal block unit (16 ch): 95055

IM XL120E

Page 13

1.2 Functions of the Input Section

• Thermocouple or RTD

Select from the thermocouple types or RTD types listed in the following table.

Input Type Type Measurable Range

Thermocouple R 0 to 1768 °C

S0 to 1768 °C

B 600 to 1800 °C

K–200.0 to 1372.0 °C

E–200.0 to 1000.0 °C

J–200.0 to 1200.0 °C

T–200.0 to 400.0 °C

N–200.0 to 1300.0 °C

W0 to 2315 °C

L–200.0 to 900.0 °C

U–200.0 to 400.0 °C

RTD Pt100 –200.0 to 850.0 °C

JPt100 –200.0 to 500.0 °C

• Pulse Signal

Measures the following items on the rising edge (from low to high) of the input pulse.

• Pulse (instantaneous value): Counts and displays the number of pulses per

sampling interval.

• Pulse (integrated value): Sums and displays the number of pulses per

sampling interval from the start of the logging

operation.

• Number of revolutions: Counts the number of pulses per second, converts

the number to number of revolutions, and displays

the result.

Input Type Range Maximum Number of Input Pulses

Pulse (instantaneous value) None 50 k/sampling interval

Pulse (integrated value) 50 kc/f.s. 50 k/sampling interval

500 kc/f.s.

5 Mc/f.s.

50 Mc/f.s.

500 Mc/f.s.

Number of revolutions 500 rpm/f.s. 50 k/sec

5 krpm/f.s.

50 krpm/f.s.

500 krpm/f.s.

f.s.: measurable range

1

Explanation of Functions

IM XL120E

• Logic Signal

Fixed as follows:

Low: 0.9 V or less or shorting of the input terminal

High: 2.1 V or more or opening of the input terminal

Scaling

For DC voltage, thermocouple, RTD and pulse input, the measured values can be scaled

to a value in the appropriate unit and displayed. Set the upper and lower limits of the

input’s display span, the upper and lower limits after scaling, and the unit. For pulse

input, set the conversion ratio, offset value, upper and lower limits of the scale after the

conversion, and unit.

Burnout

When measuring temperature using a thermocouple and the thermocouple burns out,

the measured result is fixed to positive over range (shown as “+*****”).

1-3

Page 14

1.2 Functions of the Input Section

Reference Junction Compensation (RJC)

When measuring temperature with a thermocouple, the XL100 uses its internal reference

junction compensation function.

Average Function

The average function performs moving average defined by the equation below on the

measured data to suppress the effects of noise riding on the signal. Use this function

when the displayed values of the measured data are fluctuating and difficult to read.

D

= (M

n

Dn: Displayed value obtained by linearly averaging m points of numeric data

M

n–(m–1):

•••

M

n–2:

M

n–1:

M

n:

m

:

Filter Function

Digital filter with the cutoff frequencies shown in the table below. The cutoff frequency

varies depending on the number of measurement channels and sampling frequency.

Set the frequency (50 Hz or 60 Hz) to match the frequency of the power supply that you

are using.

When the noise level is high due to the object under measurement or the environment,

this filter function can eliminate the noise components allowing correct measurements.

n–(m–1)

+ ... M

n–2+Mn–1+Mn

)/m

from the n–(m–1)th to nth time

Numeric data of the n–(m–1)th time

Numeric data of the n–2th time

Numeric data of the n–1th time

Numeric data of the nth time

Average count (select 1, 2, 5, 10, or 20)

Sampling Interval vs. Cutoff Frequency Table

Sampling interval 100 msec 200 msec 500 msec 1 sec 2 sec 5 sec 10 sec ≥ 20 sec

8 ch

16 ch

2560 Hz50 Hz

2560 Hz60 Hz 731 Hz 290 Hz 144 Hz 60 Hz 50 Hz 10 Hz 10 Hz

–50 Hz

–60 Hz 2560 Hz 731 Hz 290 Hz 144 Hz 60 Hz 60 Hz 10 Hz

2560 Hz8 ch Filter OFF 2560 Hz 2560 Hz 2560 Hz 2560 Hz 2560 Hz 2560 Hz 2560 Hz

2560 Hz16 ch Filter OFF 2560 Hz 2560 Hz 2560 Hz 2560 Hz 2560 Hz 2560 Hz 2560 Hz

731 Hz 290 Hz 144 Hz 50 Hz 50 Hz 10 Hz 10 Hz

2560 Hz 731 Hz 290 Hz 144 Hz 50 Hz 50 Hz 10 Hz

1-4

IM XL120E

Page 15

1.3 Display Function

Display

The XL100 is equipped with a 3.5-inch color LCD monitor (320 dots horizontal × 240 dots

vertical). The screen consists of the status display section and the data display section.

• Status Display Section

Displays the screen name, date/time, internal memory and external storage media

usage, communication condition, operation mode, alarm occurrence, key lock, user

name (key login function), calculation, power condition, etc.

• Data Display Section

Displays the waveform display, digital display, bar graph display as well as alarm, log,

and file information of the measured/calculated data. Displays the setting menu and

settings when configuring the functions of the XL100.

1

Explanation of Functions

Status display section

Data display section

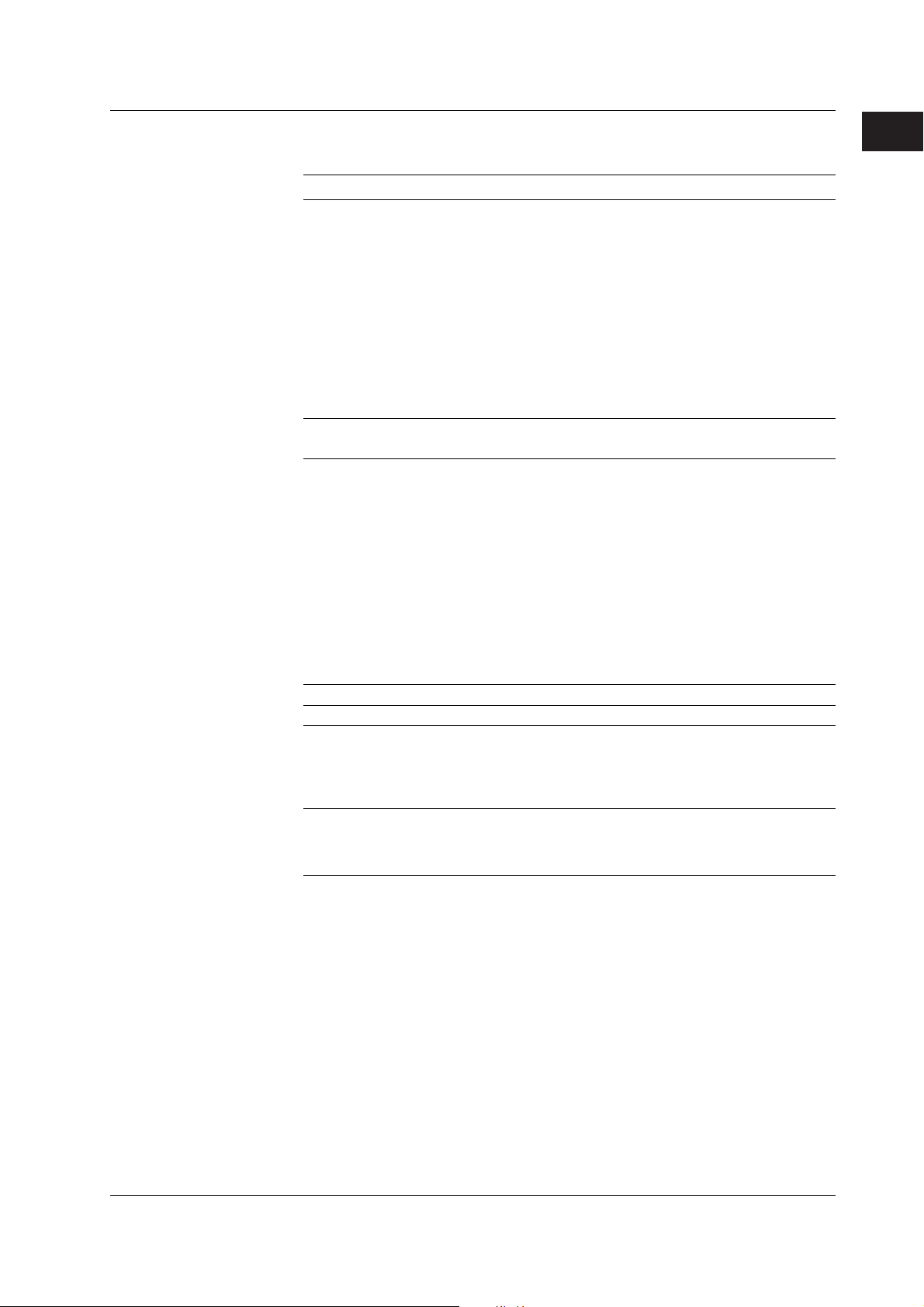

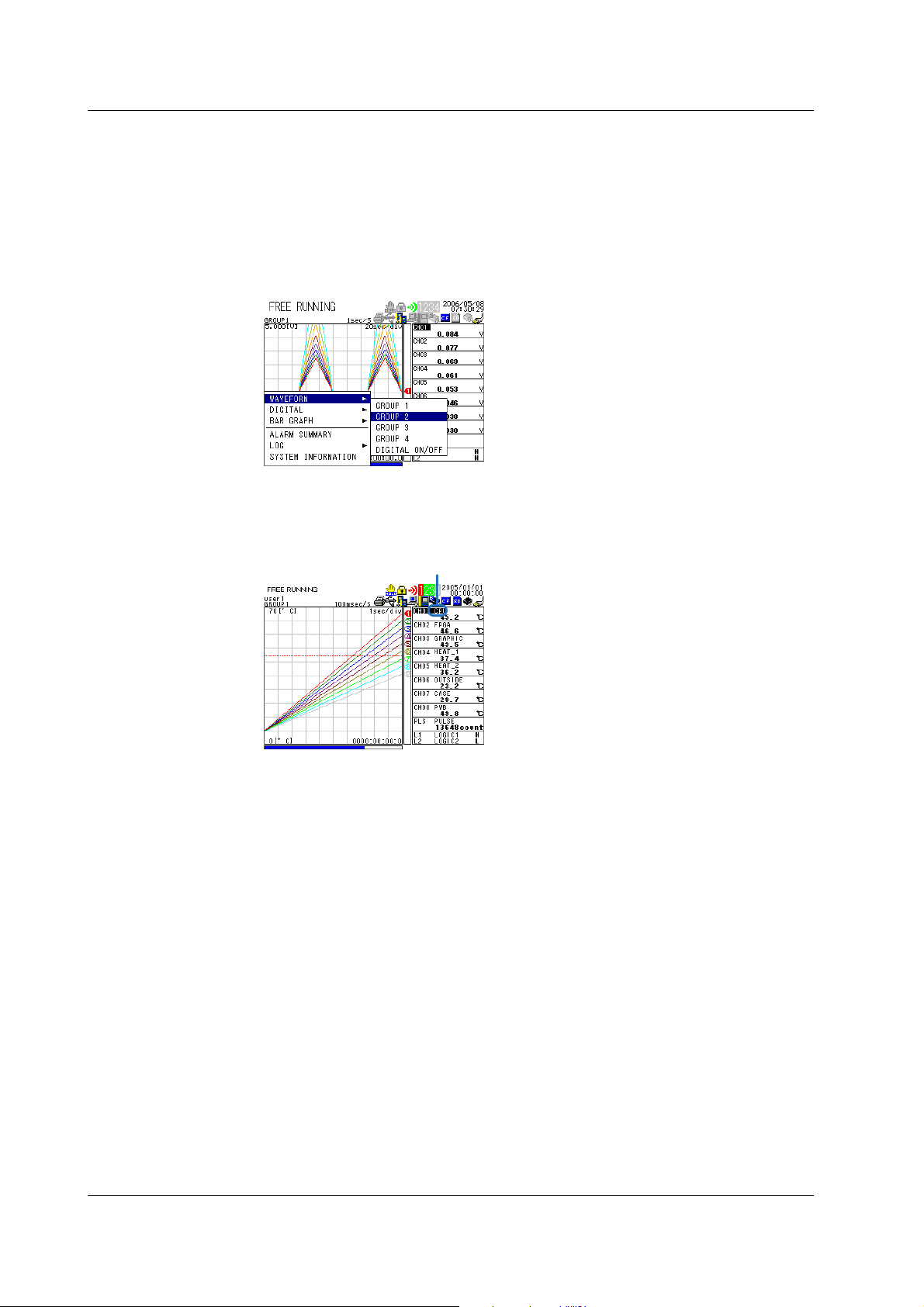

Operation Mode and Display

As shown in the figure below, the XL100 has six operation modes: (1) Free Running

Mode in which instantaneous values are measured, (2) Logging Mode in which

continuous measurement is performed by setting the start and end of data saving, (3)

Logging & Review Mode in which past measured data can be viewed during continuous

measurement, (4) Review Mode in which saved data is analyzed, (5) File Operation

Mode in which file operations such as saving and loading of the setup data is performed,

and (6) Setting Mode in which various settings such as the measurement conditions are

specified. The displayed contents vary depending on the operation mode.

HOME

Free Running Mode

Waveform

Digital

Bar graph

Alarm summary

Log

System

information

START

/ STOP

Logging Mode

Waveform

Digital

Bar graph

Alarm summary

Log

System

information

Switch the

display

Switch the

display

REVIEW

Review Mode

Marker

measurement

Statistical

calculation

FILE

File Operation Mode

File operation

menu

Select

Set

Rename files

Delete files

Setup file

Copy data files

Copy backup memory

Format

Initialize log

SETTING

Setting Mode

Setting menu

Set

Input

Display

Data Save

Alarm

Calculation

Communication

Select

Hardware

System

IM XL120E

REVIEW

Logging & Review Mode

Marker measurement

Statistical

calculation

1-5

Page 16

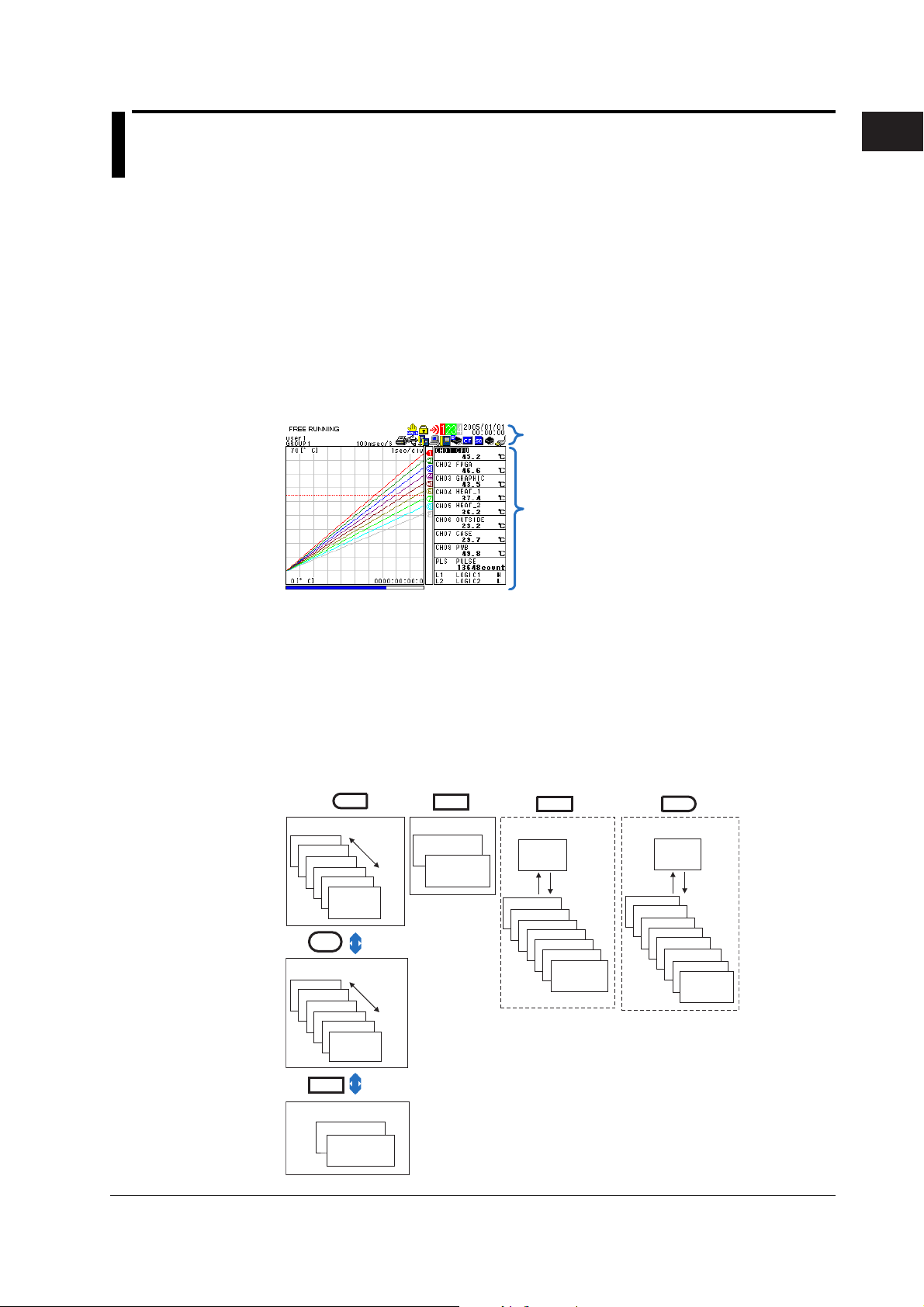

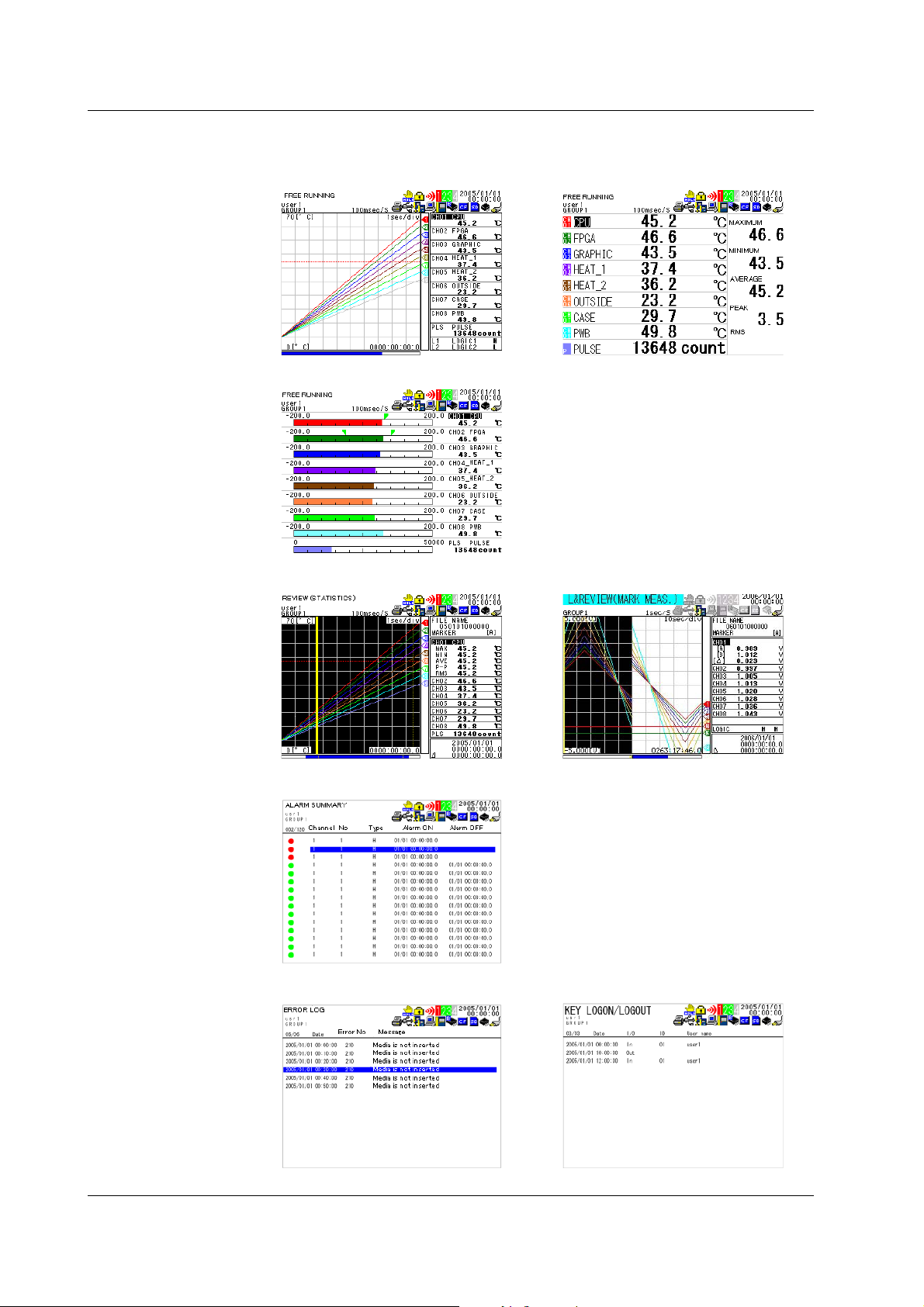

1.3 Display Function

The displays shown below are available. For a description of the displayed contents, see

section 2.3, “Data Display” and 2.4, “Setup Display.”

• Waveform & Digital Display • Digital Display

• Bar Graph Display

• Review display • Logging & Review Display

• Alarm Summary Display

• Log (Error) Display • Log (Key Login/Logout) Display

1-6

IM XL120E

Page 17

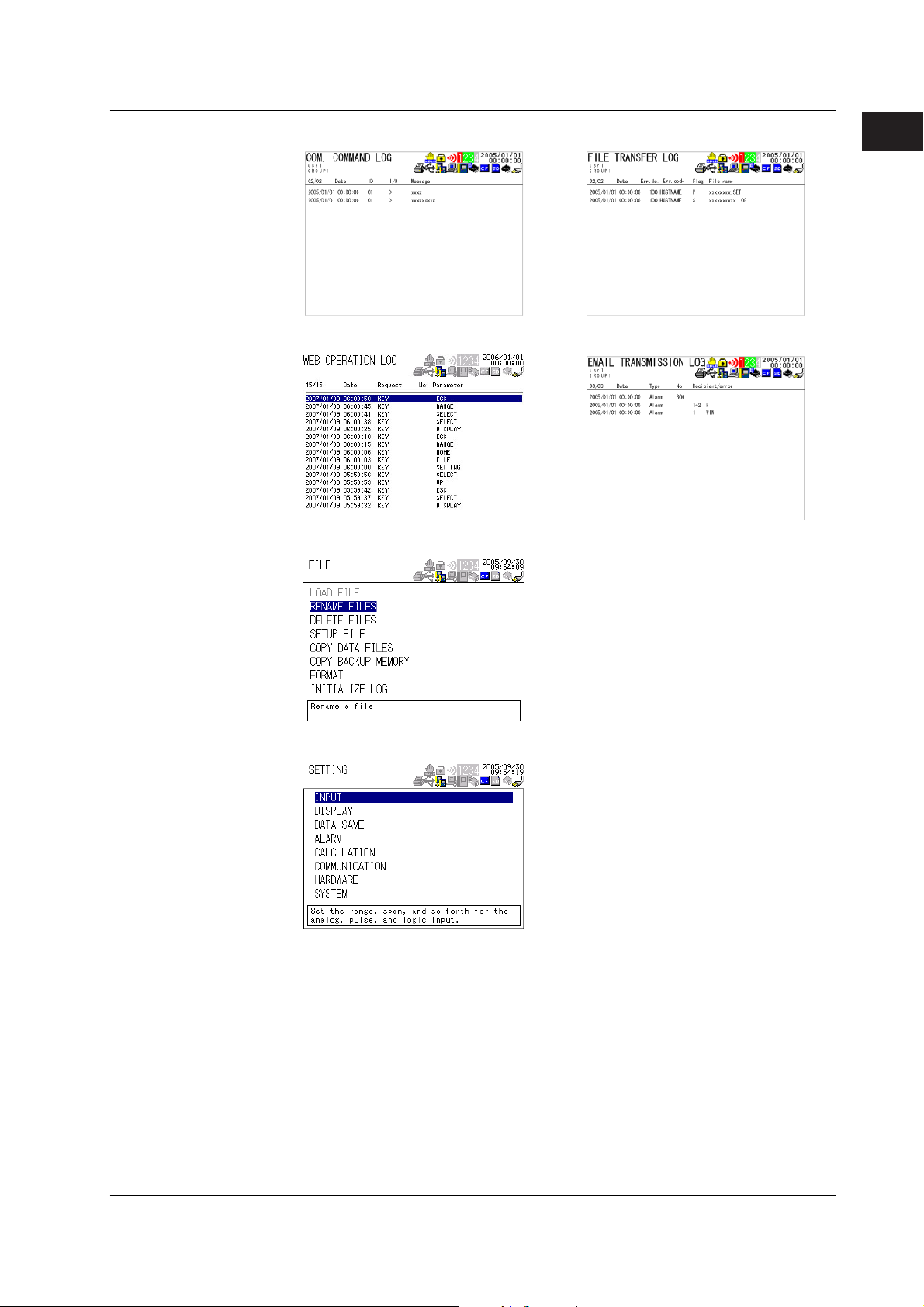

1.3 Display Function

• Log (Communication Command) Display • Log (FTP Client) Display

• Log (Web Operation) Display • Log (E-mail Transmission) Display

• File Operation Screen

1

Explanation of Functions

• Setup Display

IM XL120E

1-7

Page 18

s

1.3 Display Function

Group Display

On the waveform display, digital display, and bar graph display, the data of up to eight

channels can be shown on a single screen. The eight channels can consist of a

combination of analog input channels (hereafter referred to as “measurement channels”),

calculation channels (see section 1.6, “Calculation Function), and communication

channels (see section 1.8, “Communication Function). You can assign the measurement

channels, calculation channels, and communication channels to four groups and switch

the displayed group to show the data of 32 channels.

Tag Display

You can assign easily identifiable tags (using up to eight characters) to channels and

display them along with the channel numbers.

Display using tag

1-8

IM XL120E

Page 19

1.4 Alarm Function

This function generates an alarm when the measured/calculated value meets a certain

condition. When an alarm occurs, information notifying the alarm occurrence is displayed

on the screen. In addition, an alarm signal can be delivered from the output terminal

(digital I/O connector) on the rear panel of the XL100.

Number of Alarms

An alarm can be set for each channel.

Alarm Conditions

You can select from the conditions given in the following table.

Input Type Setting Alarm Condition

Level OFF Not set alarm conditions.

or Hi An alarm occurs when the measured/calculated value is

Pulse greater than or equal to the alarm value.

Lo An alarm occurs when the measured/calculated value is less than

Window IN An alarm occurs when the measured/calculated value is within

Window OUT An alarm occurs when the measured/calculated value is outside

Logic OFF Not set alarm conditions.

Hi An alarm occurs when the logic input changes from low

Lo An alarm occurs when the logic input changes from high

1

Explanation of Functions

or equal to the alarm value.

the lower limits and upper limits of the alarm range.

the lower limits and upper limits of the alarm range.

to high.

to low.

Hi

Alarm occurrence

Alarm release

Measured value

Window IN

Alarm occurrence

Measured value

Alarm value

Alarm value

Alarm release

Lo

Measured

value

Alarm occurrence

Window OUT

Measured

value

Alarm release

Alarm release

Alarm value

Alarm occurrence

Alarm value

Alarm Display

On the display, an alarm icon is shown in the status display section, and the alarm status

is shown in the data display section such as the waveform, digital, and bar graph

displays. In addition, the details of the alarm are shown on the alarm summary display.

There are two methods for displaying alarms. One method is to clear the alarm display

when the cause of the alarm is no longer met (non-hold display). The other method is to

keep displaying the alarm until the alarm acknowledge operation is carried out (hold

display).

IM XL120E

1-9

Page 20

1.4 Alarm Function

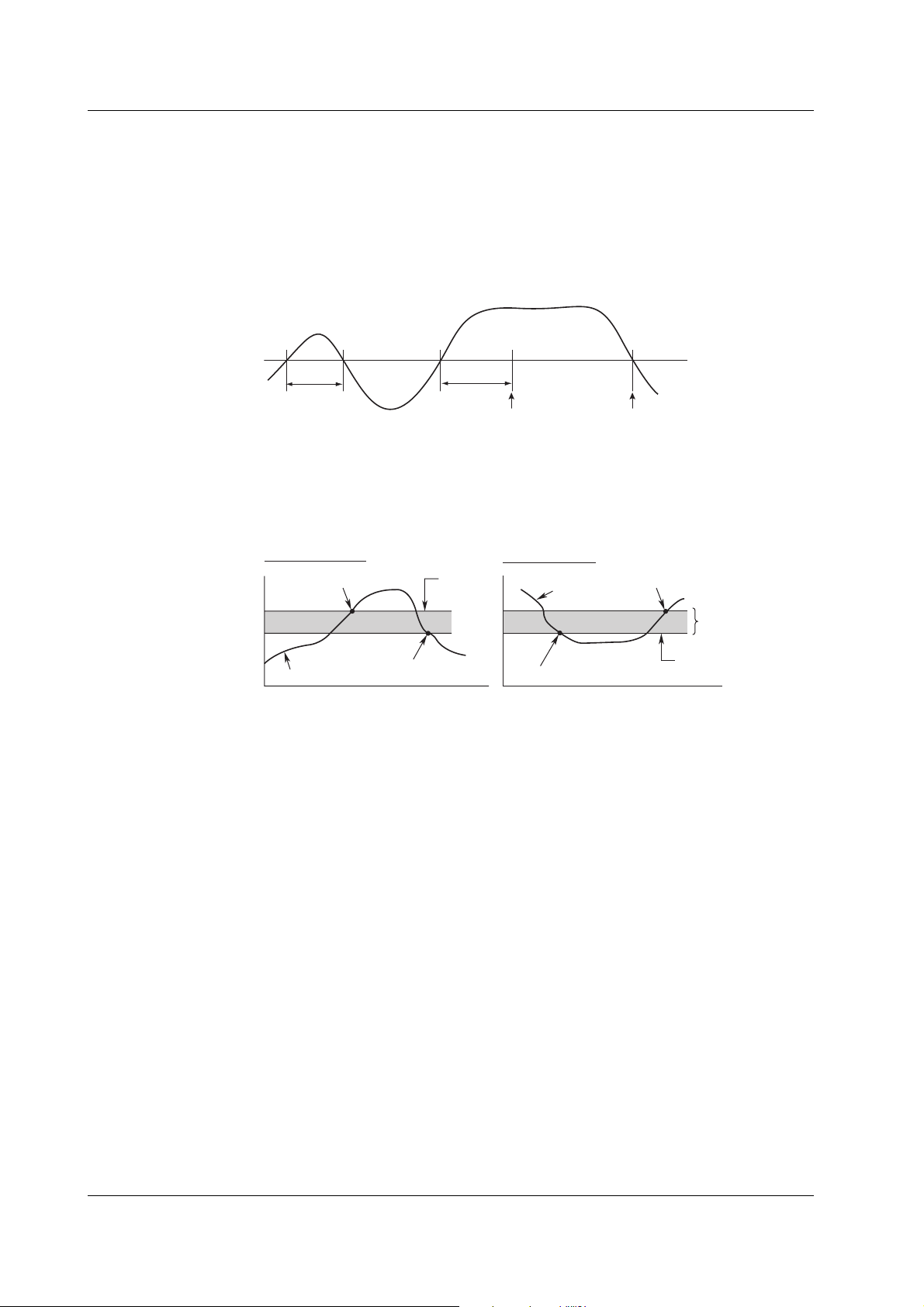

Delay Alarm

An alarm occurs when the measured/calculated value remains above (or below) the

alarm value for a specified time period (delay period).

In the figure below, the measured value exceeds the alarm value during period T1, but

no alarm is generated, because the condition does not last longer than the specified

delay period T. At time X2, the input exceeds the alarm value. However, no alarm is

generated, because the delay period has not elapsed. An alarm occurs at time X3 when

the delay period elapses.

Measured value or

calculated value

X1 X2 X3 X4

T1

T

Alarm value

Alarm releaseAlarm occurrence

Alarm Hysteresis

A width (hysteresis) can be specified to the values for activating and releasing the alarm.

Alarm hysteresis prevents frequent activation and release of alarms when the measured/

calculated value is unstable around the alarm value. The hysteresis is fixed to 0.5% of

the display span (display scale width if the range is set to scale).

When set to high

Alarm occurrence

Measured value

Alarm

value

Alarm release

When set to low

Measured value

Alarm occurrence

Alarm release

Hysteresis

(Approx. 0.5%)

Alarm

value

AND/OR of Alarm Output

When a single alarm output is shared among multiple alarms, you can select either of the

conditions below for activating the alarm output.

AND: Activated when all assigned alarms are occurring simultaneously.

OR: Activated when any of the specified alarms is occurring.

Hold/Non-Hold of Alarm Output

The method of clearing the alarm output from an alarm generated condition can be set to

either of the following settings.

Non-hold: Turn the output OFF when the alarm is cleared.

Hold: Hold the output ON until the alarm acknowledge operation is carried out.

Hold/Non-Hold of Alarm Display

The method of clearing the alarm display from an alarm generated condition can be set

to either of the following settings.

Non-hold: Clear the alarm display when the alarm is cleared.

Hold: Hold the alarm display until the alarm acknowledge operation is carried out.

1-10

Alarm Buzzer

A buzzer can be sounded when an alarm occurs.

Alarm Search

By using alarm markers in Review Mode, alarms can be searched on the review display.

IM XL120E

Page 21

1.5 Data Save/Load Function and File Operation Function

Measured data, calculated data, setup data, and so forth can be saved to the XL100

internal memory or an external storage medium (CF card or SD card) that is inserted in

the XL100

Save the data

CF

SD

Types of Data That Can Be Saved

Type Description

Logging data The instantaneous values of the measured/calculated data can be saved

at a specified sampling interval in Logging Mode. The data save operation

is started or stopped with the START/STOP key. The save operation can

also be started or stopped when a specific event (trigger) occurs. The

logging data contains alarm information.

Data format: Binary or ASCII

Manual sample data The measured/calculated data (instantaneous values) of all channels can

be saved by pressing the SAVE key in Free Running Mode.

Data format: ASCII

Alarm data The same information as the alarm summary display can be saved by

pressing the SAVE key during alarm summary display.

Data format: ASCII

Screen image data The image data of the screen being displayed can be saved by pressing

the SAVE key in Free Running Mode, etc.

Data format: BMP

Setup data The setup data of the XL100 can be saved in File Operation mode.

Data format: Binary

Log data The same information as the log display can be saved by pressing the

SAVE key during log data display.

Data format: ASCII

Backup file If the data save operation is not carried out normally to the internal

memory or external storage medium (CF card or SD card), the data is

saved to the backup memory of the XL100. The saved data can be copied

to an external storage medium.

Data format: Same format as the logging data

1

Explanation of Functions

IM XL120E

1-11

Page 22

1.5 Data Save/Load Function and File Operation Function

Triggers

In addition to using the keys to start or stop the logging (data save operation), a trigger

for starting (or stopping) the save operation of the logging data (measured/calculated

data) can be configured for automatic operation.

The trigger can be selected from the list below and configured. If multiple trigger

conditions are selected, the data save operation starts (or stops) when any of the trigger

conditions is met.

Type Description

None Not set trigger conditions.

External A trigger is activated by applying a signal to the external trigger

Level High limit A trigger is activated when the measured value is greater than or

Lower limit A trigger is activated when the measured value is less than or

Window IN A trigger is activated when the measured value is within the

Window OUT A trigger is activated when the measured value is outside the

Alarm A trigger is activated when any of the alarms occur.

Time A trigger is activated at the specified time.

Timer The time at which the data save operation is stopped can be

input terminal.

equal to the specified value.

equal to the specified value.

specified lower and high limits.

specified lower and high limits.

specified. Logging is stopped after the specified time elapses.

The XL100 has a pre-trigger function that saves data before a trigger is activated and a

trigger delay function that starts the data save operation the specified number of samples

after a trigger is activated.

In addition, you can select single-shot trigger that saves data once to a file when a

trigger is activated or continuous trigger that saves data to a new file each time a trigger

is activated.

File Operations

The following file operations are available.

Function Description

Rename Renames files saved on an external storage medium (CF card or

Save setup data Saves setting data to an external storage medium (CF card or SD

Load setup data Loads the setting data saved on an external storage medium (CF

Copy data Copies the files saved to the internal memory to an external

Copy backup memory Copies the files saved to the backup memory (memory to which

Format Formats an external storage medium (CF card or SD card),

Initialize log Clears all log data.

SD card) internal memory, or setting memory.

card) or setting memory.

card or SD card) or setting memory and changes the settings.

storage medium (CF card, SD card, or USB memory).

data is saved when data cannot be saved to an external storage

medium or internal memory) to an external storage medium (CF

card or SD card).

internal memory, or backup memory.

1-12

TIP

• The SD card is supported only on the XL121, XL122, and XL124.

• The XL100 has three types of memories, an internal memory for saving measured

data, a setting memory for saving setting data, and backup memory for saving

measured data when the measured data cannot be saved to the specified storage

medium.

IM XL120E

Page 23

1.6 Calculation Function

A

Arithmetic Calculation

Arithmetic calculation on variables such as measured data and calculated data (the

result of the calculation) and constants that you can arbitrarily define can be executed.

The result of the calculation can be displayed on (save to) any of the 32 channels

provided specifically for calculation (hereafter referred to as calculation channels). The

arithmetic calculation is executed every sampling interval. The available arithmetic

calculations are addition, subtraction, multiplication, and division.

Statistical Calculation

The statistical calculations below can be executed, and the result can be displayed on

(save to) the specified channel. The statistical calculation is executed every sampling

interval.

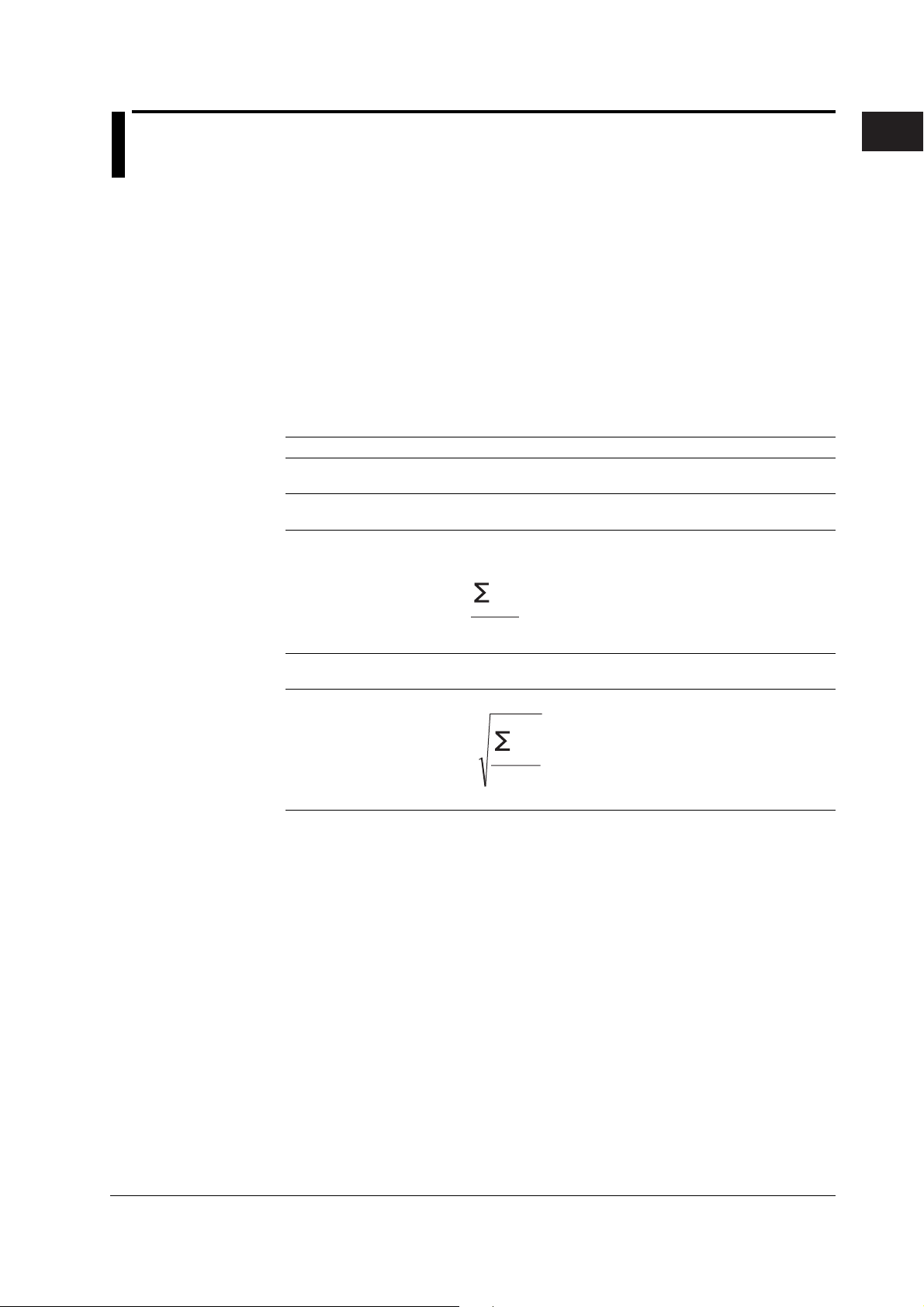

Calculated Item Description

Maximum Calculates the maximum value from the start of the logging operation to the

Minimum Calculates the minimum value from the start of the logging operation to the

Average Calculates the simple average from the start of the logging operation to the

Peak Calculates the peak value (maximum – minimum) from the start of the

Rms Calculates the rms value from the start of the logging operation to the end.

end.

end.

end.

=

VE

where di is the ith data and n is the number of data values

logging operation to the end.

=

RMS

where di is the ith data and n is the number of data values

1

Explanation of Functions

n

di

i=

1

n

n

2

di

i=

1

n

IM XL120E

1-13

Page 24

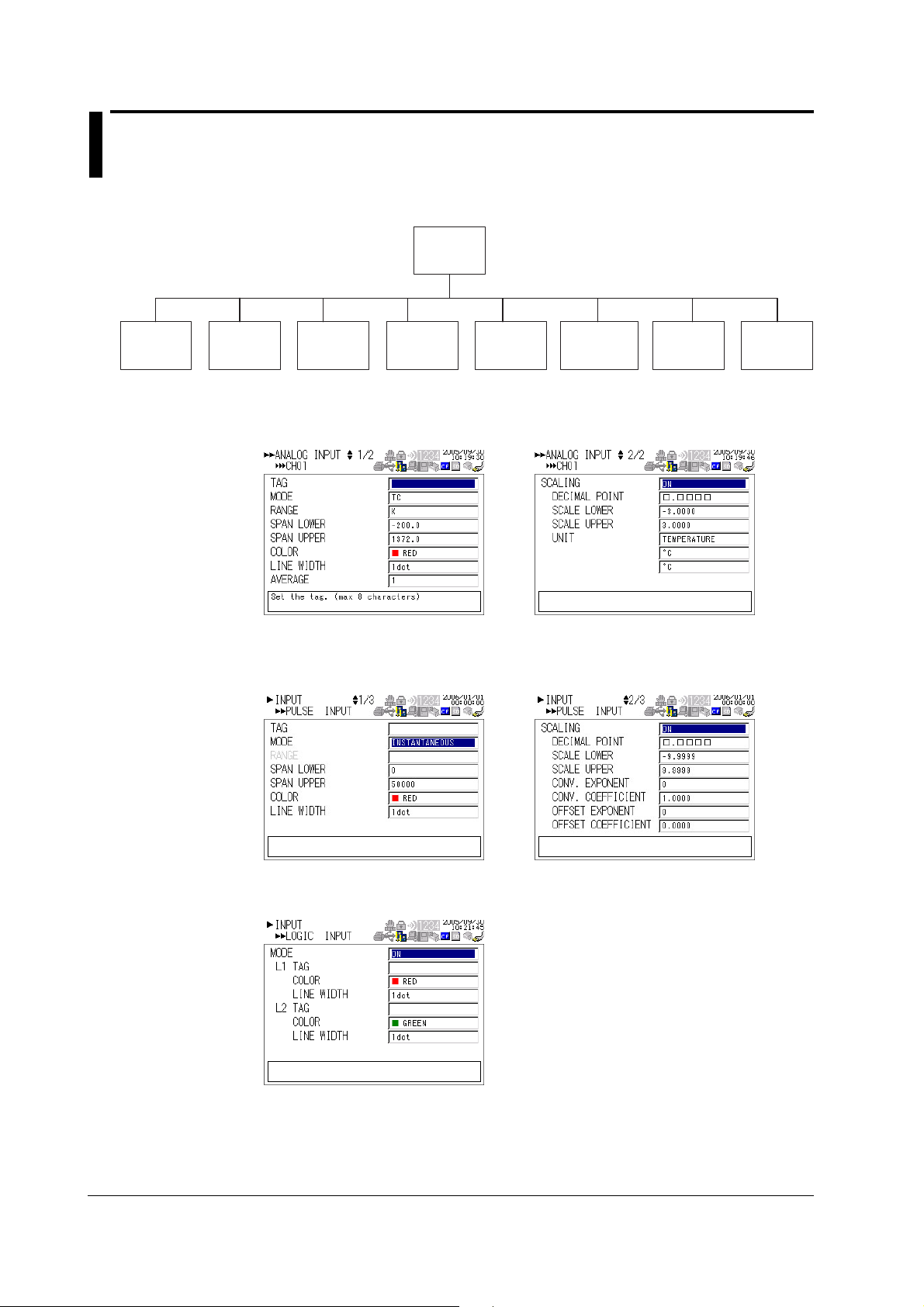

1.7 Setup Function

You can specify various settings shown below using keys in Setting Mode.

Setup TOP

Input

settings

Display

settings

Data Save

settings

Alarm

settings

Calculation

settings

Communication

settings

Hardware

settings

INPUT > ANALOG INPUT

Set the tag, input type (mode), input range, span upper and lower values, color, line

width, average, and scaling for the analog input.

INPUT > PULSE INPUT

Set the tag, input type (mode), span upper and lower values, color, line width, and

scaling for the pulse input.

System

settings

1-14

Input settings > Logic input settings

Set the tag name, color, and line width for the logic input.

IM XL120E

Page 25

1.7 Setup Function

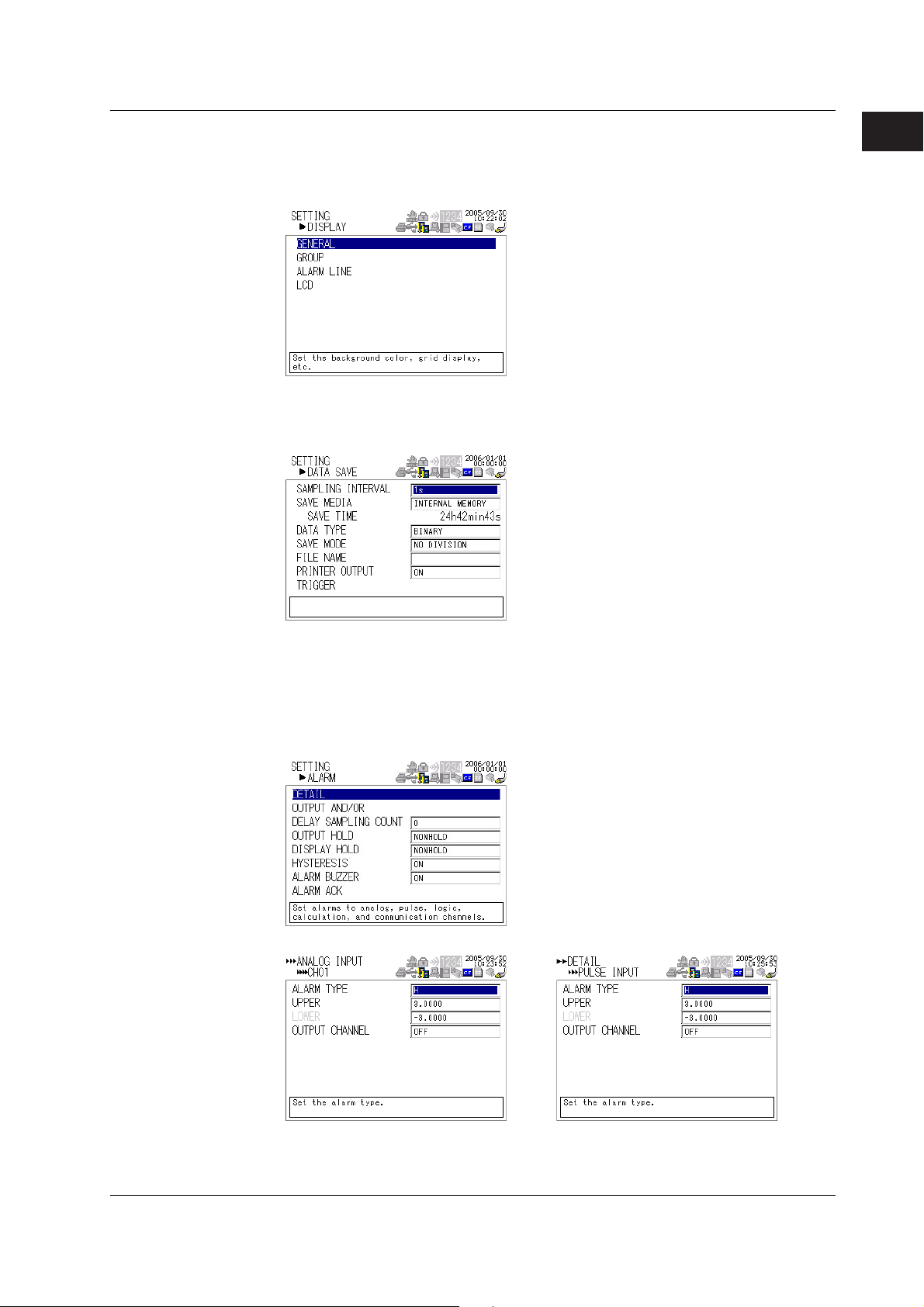

DISPLAY

Specify general display settings (background color, grid, and bar graph base position),

group settings (group name and channel assignments), alarm line settings (alarm line

display ON/OFF, color, and line width), and LCD setting (LCD backlight auto OFF).

DATA SAVE

Set the sampling interval, data save destination, data type, file name, printer output ON/

OFF, and trigger.

1

Explanation of Functions

ALARM

For the Alarm detailed settings, set the alarm type, alarm value, and output channel for

each of the measurement, calculation, pulse input, logic input, and communication input

channels. For other settings, set the output AND/OR, delay time, output/display hold,

hysteresis ON/OFF, and alarm buzzer ON/OFF. Carry out an alarm acknowledge

operation to clear alarms.

Alarm detailed settings of each channel

IM XL120E

1-15

Page 26

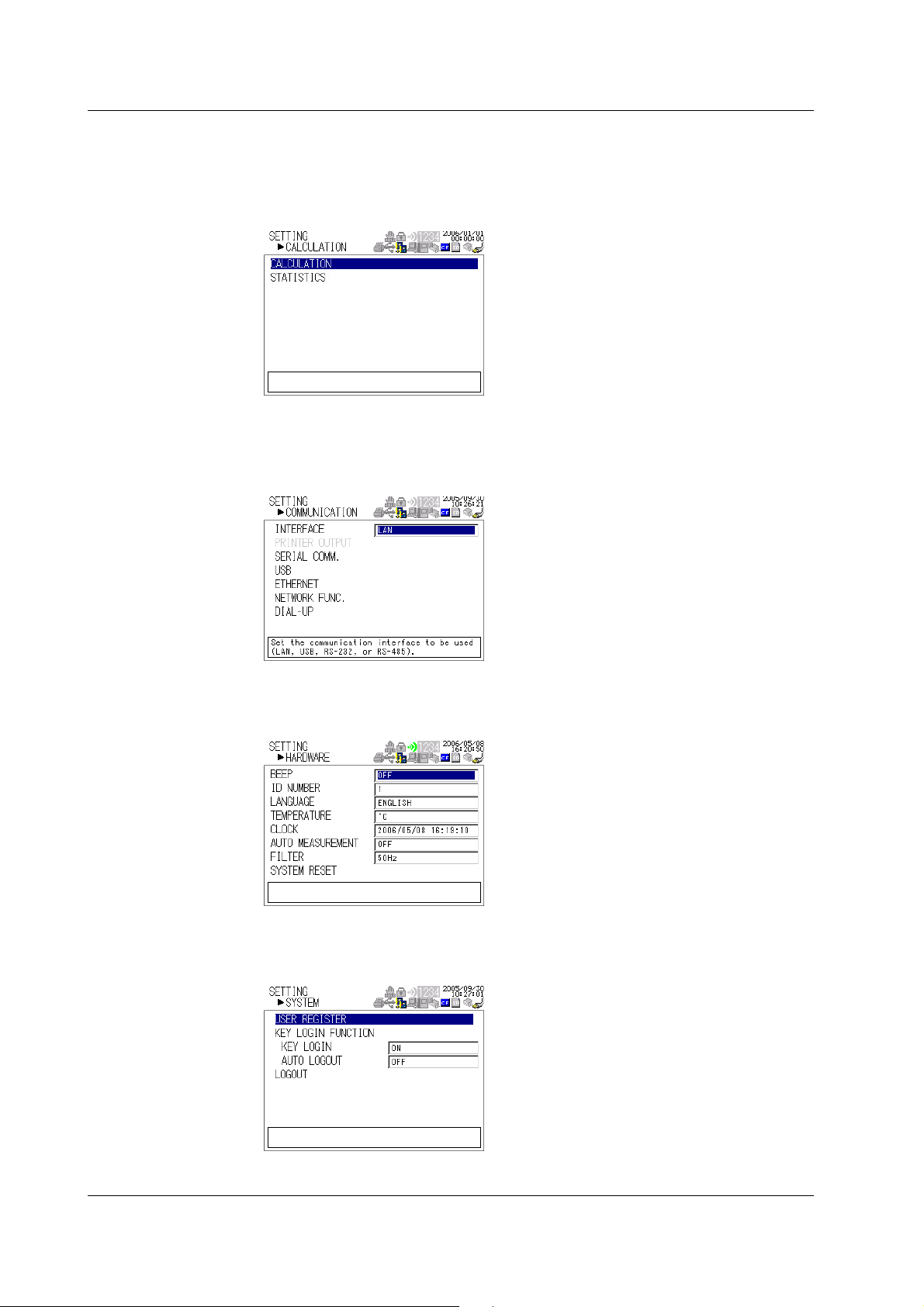

1.7 Setup Function

CALCULATION

Specify calculation settings (assignment of the calculation items 1 and 2, tag, calculation

method, constant exponent, and constant coefficient, decimal place, span upper and

lower values, unit, color, and line width) and statistical calculation settings (ON/OFF of

each statistical calculation item).

COMMUNICATION

Specify interface settings (communication interface selection), serial communication

settings, USB settings (USB ID number), Ethernet settings, and network function settings

(FTP client settings, Web server settings, and E-mail transmission settings).

HARDWARE

Set the beep sound, ID number, display language, date/time, automated measurement

function, and filter. Carry out system reset to reset the settings to their default values.

SYSTEM

Register users (registration of the administrator and users for the Ethernet login, Web

browsing, and key login functions) and set the key login/logout function.

1-16

IM XL120E

Page 27

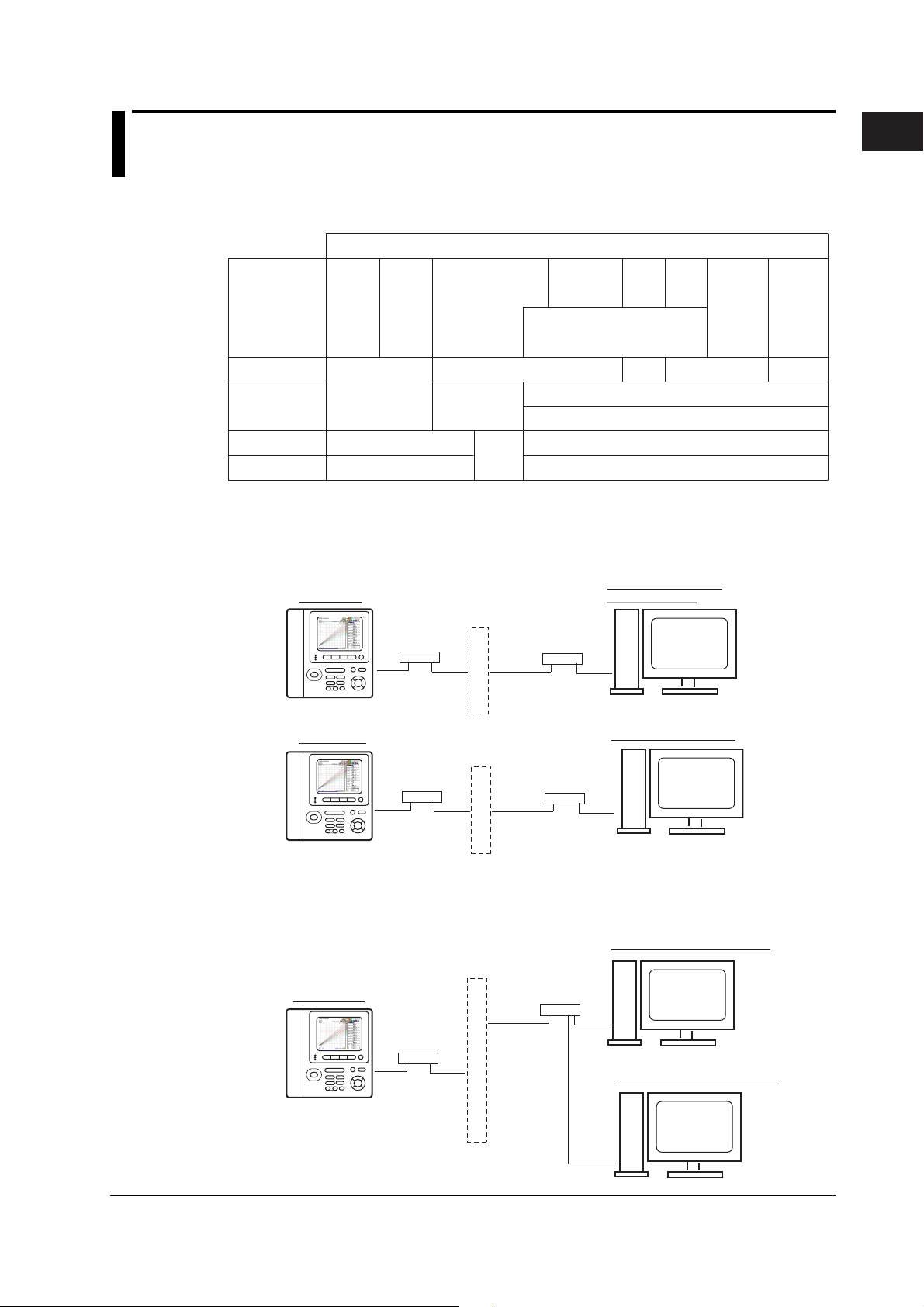

1.8 Communication Function

(Supported only on the XL121, XL122, and XL124)

The XL100 comes standard with an Ethernet interface, USB interface, and serial

interface (RS-232 and RS-485).

XL100 Communication Functions

Setting/Measurement

Application

Upper layer protocol

Lower layer

protocol

Upper interface

Lower interface

The Ethernet interface can be used to automatically transfer measurement data files to

an FTP server connected to the network or access the XL100 from a PC through FTP to

retrieve data on the external storage medium of the XL100.

MODBUS

Slave

MODBUS Protocol

MODBUS

Master

Serial

RS-232/RS-485

server

Standard protocol

Serial

communication

control

USB

Maintenance/

Test server

Login

(User authentication/

access privileges granting)

Web

server

HTTP

10BASE-T/100BASE-TX

FTP

server

TCP

IP

Ethernet

FTP client

FTP SMTP

E-mail client

1

Explanation of Functions

FTP client

measured data

Ethernet

Automatically save

Hub

FTP server

Hub

FTP server

Load measured data

Ethernet

Hub

Hub

PC

By configuring the XL100 to be a Web server, the XL100 screen can be shown on the

PC. You can monitor the measured data and control the XL100 (for example, switch the

display) from the PC.

Monitor the measured data

Ethernet

Web server

Hub

PC

IM XL120E

Hub

Monitor the measured data

PC

1-17

Page 28

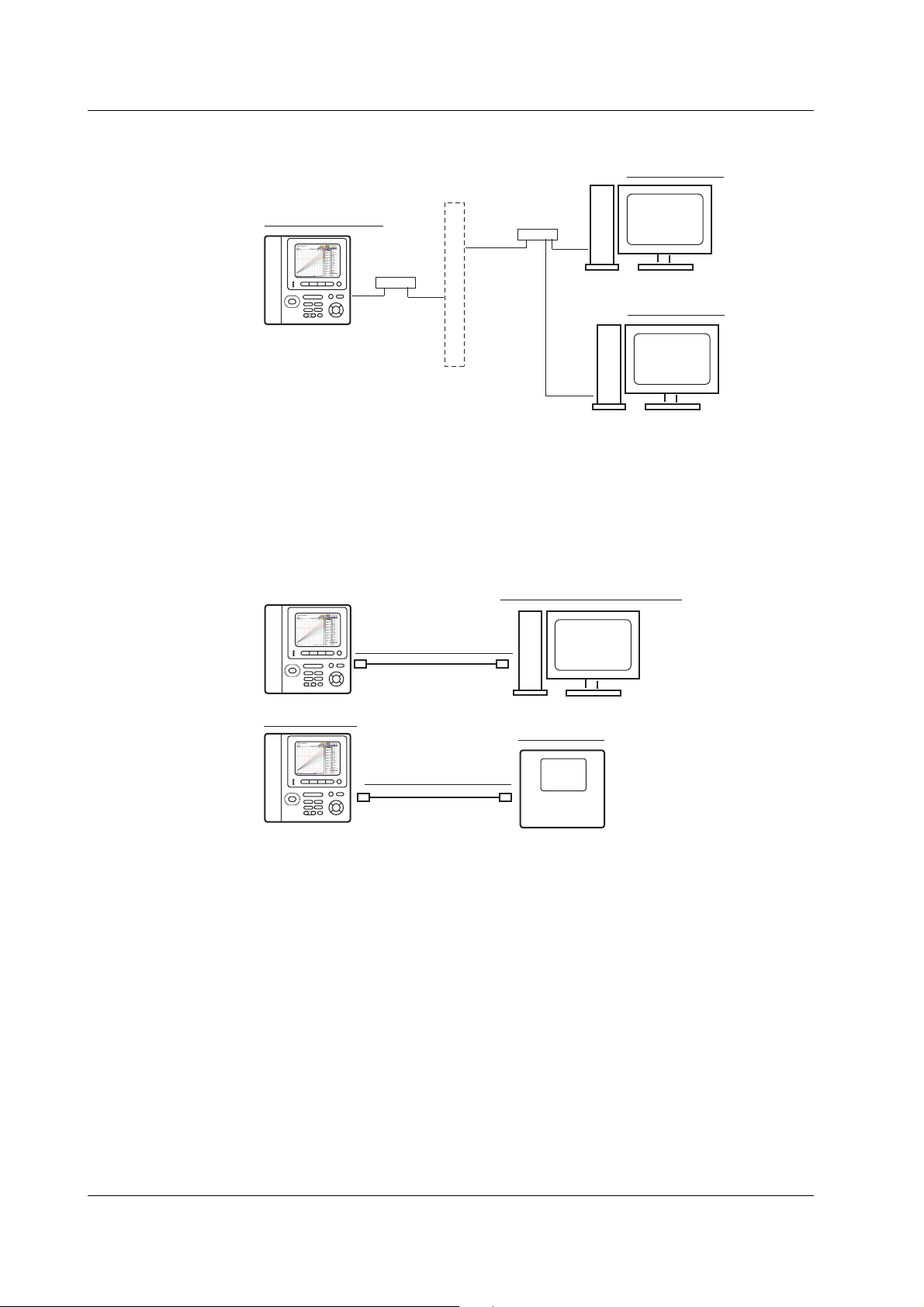

1.8 Communication Function

In addition, e-mail can be sent automatically from the XL100 when an alarm occurs.

E-mail reception

Ethernet

E-mail transmission

Hub

Hub

PC

E-mail reception

PC

The USB interface or serial interface can be used to change the XL100 settings from a

PC or retrieve data into the PC through command communication. In addition, Modbus

communication is possible on the serial interface. The Modbus master function enables

the measured data of a measuring instrument connected as a Modbus slave to be

retrieved as communication input data. The data can be displayed on a communication

input data channel (communication channel) on the XL100 in a similar fashion to

measurement and calculation channels.

Change settings and load data

Command communication

PC

Modbus master

USB, RS-232, RS-485

Modbus communication

RS-232, RS-485

Modbus slave

Measurement

instrument

1-18

IM XL120E

Page 29

1.9 Other Main Functions

Setting the Displayed Language

The displayed language can be switched between English and Japanese. If English is

specified, you can set the temperature unit to °C or °F.

Printer Output (Supported only on the XL121, XL122, and XL124)

Measured data and screen image data can be printed on a dedicated printer (97010)

sold separately by using the RS-232 interface.

Setting the Clock

The year, month, day, and time (hour:minute:second) are shown on the display

according to the specified clock time. If the XL100 is connected to a network through the

Ethernet interface, the clock can be corrected at any time by accessing the NTP server.

Display Hold

A displayed value can be held through a given key operation.

Key Login/Logout

You can set the XL100 so that only certain users can operate the instrument. A user is

identified by the user name and password registered in advance. Seven users,

administrator and user1 to user6, can be registered. The key login/logout status can be

confirmed on the log (key login/logout) display.

1

Explanation of Functions

Key Lock

Explanation of FunctionsAll key operations except the key lock release operation can be

disabled through a given key operation.

Lithium Ion Battery Operation

In addition to the AC power supply, the XL100 can operate on an internal lithium battery

(sold separately). The lithium ion battery is automatically charged when the AC adapter

is connected.

Automated Measurement Function

When the automated measurement function is turned ON, the XL100 automatically loads

the AUTRUN.SET file saved to the external storage medium (CF card, SD card, or USB

memory) and starts the logging operation (data save operation). After the logging

measurement is finished, the measured data that was saved is copied to the external

storage medium. (The SD card is supported only on the XL121, XL122, and XL124.)

Synchronized Logging Operation

The XL100 has an external trigger input/output function. By applying the external trigger

output signal to multiple XL100s as external trigger input, the logging (data save)

operation of measured data among multiple XL100s can be synchronized.

IM XL120E

1-19

Page 30

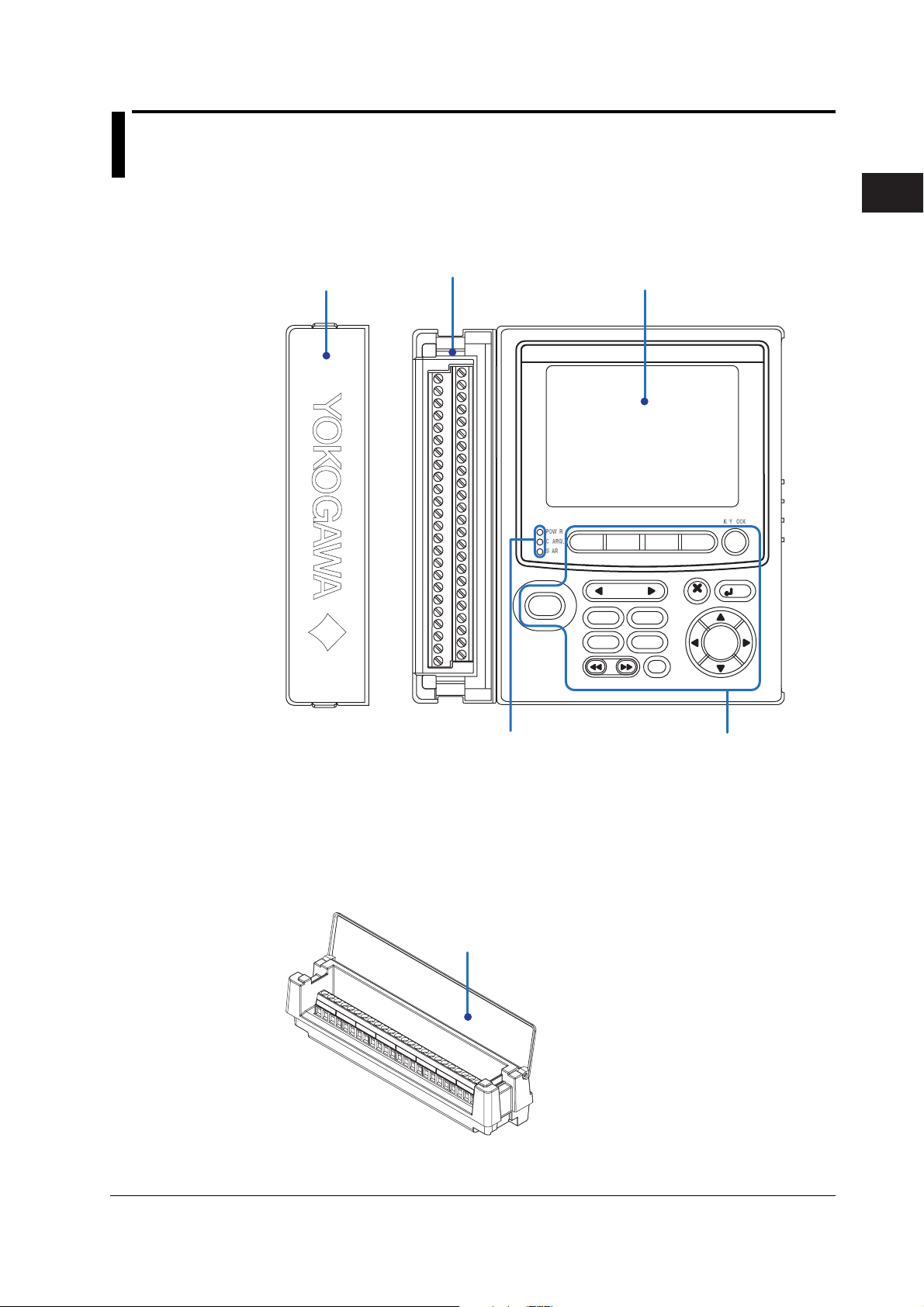

1

Chapter 2 Part Names and Functions

2.1 Front Panel and Terminal Block Unit

Front Panel

Terminal cover

(Cannot be removed

from the terminal

block unit)

Terminal block unit

A terminal block unit for connecting

analog input signal wires. Can be

removed from the XL100.

For the input signal wiring,

see section 3.3.

HOME REVIEW FILE

START

/ STOP

RANGE

SAVE

Display

Displays measured data, operation

status, setting menu, settings, etc.

The displayed contents vary

depending on the operation mode.

For the displayed contents,

see section 2.3.

HOLD

SETTING

TIME / DIV

DISPLAY

GROUP

MARK

SET

ESC

SELECT

2

Part Names and Functions

Operation status LED

POWER: Illuminates when the power is ON

CHARGE: Illuminates when the battery is being

charged

START: lluminates while logging

Keys

Name and function of

each key are described

on the next page.

(Blinks at logging standby)

Terminal Block Unit

8 ch (95052): Clamp screw 16 ch (95053): Clamp screw

16 ch (95055): M3 screw

Terminal cover

+

ch1

-

b

+

ch2

-

b

+

ch3

-

b

+

ch

4

-

b

+

ch

5

-

b

+

ch

6

-

b

+

ch

7

-

b

+

ch

8

-

IM XL120E

2-1

Page 31

2.1 Front Panel and Terminal Block Unit

Keys

1

HOME REVIEW FILE

3

2

4

SETTING

HOLD

9

START

/ STOP

10

12

RANGE

SAVE

TIME / DIV

14

6

DISPLAY

GROUP

MARK

15

13

11

7

5

SET

ESC

SELECT

16

8

1. HOME Key

Press this key to enable Free Running Mode for measuring instantaneous values.

2. REVIEW Key

Press this key to enable Logging & Review Mode in which past data can be viewed

while logging (saving measured data) or enable Review Mode in which saved data

can be analyzed.

3. FILE Key

Press this key to enable File Operation Mode in which file names can be changed,

measured data can be copied, setup data can be saved or loaded, and so on.

4. SETTING Key

Press this key to enter the setting mode and set conditions for saving measured

data, alarm conditions, etc.

5. HOLD Key

Press this key to hold the display so that the measured values are not updated or to

release the display. In addition, hold this key down to enable or disable key lock.

6. TIME/DIV Key

Press this key to switch the time scale (the time per grid (division)).

7. ESC Key

Press this key to cancel a key operation.

8. SET Key

Press this key to set settings entered through the keys.

9. START/STOP Key

Press this key to start/stop logging (saving the measured data).

10. RANGE Key

Press this key to change the input range or span (scale).

11. DISPLAY Key

Press this key to switch the displayed information in Free Running Mode or Logging

Mode. Press this key also to switch between marker display and statistical

calculation display in Review Mode.

12. SAVE Key

Press this key to manually save or print the measured data or screen data.

13. GROUP Key

Press this key to switch the displayed group of measurement channels.

14. Fast Forward Key

Press this key to move the marker to the left or right by 1 division on the review display.

15. MARK Key

Press this key to select a marker to be activated on the Review Mode display.

16. Arrow/SELECT Key

Press the arrow keys to select items on the display. Press this key also to move the

marker to the left or right on the review display. Press SELECT to confirm a selection.

2-2

IM XL120E

Page 32

1

2.2 Side Panel and Rear Panel

Side Panel

USB port for USB memory

For a description, see section 3.9.

Ethernet port*

For a description, see section 3.8.

USB port for connecting a PC*

For a description,

see section 3.8.

CF card slot

For a description, see section 4.7.

SD card slot*

For a description, see section 4.7.

USB

DC INPUT

20W MAX

12V

POWER

Power switch

For a description,

see section 4.1.

AC adapter jack

For a description,

see section 3.6.

USB

CF

SG

RS485 RS232LAN

LOGIC/PULSE

ALARM

SD

IN

GND

TRIGGER

OUT

Trigger input/output terminal

For a description, see section 3.5.

Digital I/O connector

For a description, see sections 3.3 and 3.4.

RS-232 connector*

For a description, see section 3.8.

RS-485 terminal block*

For a description, see section 3.8.

*Supported only on the XL121, XL122, and XL124.

2

Part Names and Functions

Rear Panel

Screwdriver for terminals (accessory)

Press the screwdriver towards the spring

(right in this figure) to detach it.

Name plate

Battery cover

Holds the lithium ion

battery sold separately

(94009).

For the procedure to load

the battery, see section 3.7.

IM XL120E

2-3

Page 33

2.3 Data Display

Status Display Section

2

3

1

Status display section

Data display section

5

7

4

6

8

1. Operation Mode

Displays the mode name: Free Running, Logging, Logging & Review, Setup, or File

Operation. For Logging and Logging & Review modes, the text background turns

light blue to indicate that logging is in progress.

2. User Name

Displays the login user name when the key login function is turned ON.

3. Group Name

Displays the group name of the displayed measurement channel.

4. Alarm Status

The status is displayed using different icon colors as follows:

Gray: No alarm setting

Yellow-green: Alarm setting enabled

Red: Alarm activated

5. Alarm Output Status

The status is displayed using different icon colors for each alarm output channel as

follows:

Gray: No alarm output setting

Yellow-green: Alarm output setting enabled

Red: Alarm outputting

6. Date/Time

Displays the year, month, day, hour, minute, and second. For the procedure to set

the date/time, see section 4.3, “Setting the Date/Time.”

7. Sampling Interval

Displays the sampling interval in the format “xxxyyyy/S” (where xxx is 1, 2, 5, 10, 20,

30, 100, 200, or 500 and yyyy is msec, sec, min, or h) when in Free Running,

Logging, or Logging & Review Mode.

2-4

IM XL120E

Page 34

1

2.3 Data Display

8. Various Icons

The following icons are used to display the operation status, interface usage status,

etc.

An icon shown when the data save destination is set to internal memory. The

icon blinks when there is access to the internal memory. The icon is gray when

the data save destination is not set to internal memory.

An icon shown when the data save destination is set to internal memory and the

save mode is set to DIVISION. The icon blinks when there is access to the

internal memory.

An icon shown when the data save destination is set to internal memory and the

memory full operation is set to REPEAT. The icon blinks when there is access to

the internal memory.

An icon shown when the data save destination is set to internal memory and the

memory full operation is set to DELETE. The icon blinks when there is access to

the internal memory.

An icon shown when the data save destination is set to internal memory, the

save mode is set to DIVISION, and the memory full operation is set to REPEAT.

The icon blinks when there is access to the internal memory.

2

Part Names and Functions

An icon shown when the data save destination is set to internal memory, the

save mode is set to DIVISION, and the memory full operation is set to DELETE.

The icon blinks when there is access to the internal memory.

An icon shown when the data save destination is set to CF card. The icon blinks

when there is access to the CF card. The icon is gray when the data save

destination is not set to CF card.

An icon shown when the data save destination is set to CF card and the save

mode is set to DIVISION. The icon blinks when there is access to the CF card.

An icon shown when the data save destination is set to CF card and the

memory full operation is set to REPEAT. The icon blinks when there is access to

the CF card.

An icon shown when the data save destination is set to CF card and the

memory full operation is set to DELETE. The icon blinks when there is access to

the CF card.

An icon shown when the data save destination is set to CF card, the save mode

is set to DIVISION, and the memory full operation is set to REPEAT. The icon

blinks when there is access to the CF card.

An icon shown when the data save destination is set to CF card, the save mode

is set to DIVISION, and the memory full operation is set to DELETE. The icon

blinks when there is access to the CF card.

An icon shown when the data save destination is set to SD card. The icon blinks

when there is access to the SD card. The icon is gray when the data save

destination is not set to SD card. (Supported only on the XL121, XL122, and

XL124.)

An icon shown when the data save destination is set to SD card and the save

mode is set to DIVISION. The icon blinks when there is access to the SD card.

(Supported only on the XL121, XL122, and XL124.)

IM XL120E

2-5

Page 35

2.3 Data Display

An icon shown when the data save destination is set to SD card and the

memory full operation is set to REPEAT. The icon blinks when there is access to

the SD card. (Supported only on the XL121, XL122, and XL124.)

An icon shown when the data save destination is set to SD card and the

memory full operation is set to DELETE. The icon blinks when there is access to

the SD card. (Supported only on the XL121, XL122, and XL124.)

An icon shown when the data save destination is set to SD card, the save mode

is set to DIVISION, and the memory full operation is set to REPEAT. The icon

blinks when there is access to the SD card. (Supported only on the XL121,

XL122, and XL124.)

An icon shown when the data save destination is set to SD card, the save mode

is set to DIVISION, and the memory full operation is set to DELETE. The icon

blinks when there is access to the SD card. (Supported only on the XL121,

XL122, and XL124.)

An icon shown when there is data saved in the backup memory. The icon blinks

when there is access to the backup memory. The icon is gray when there is no

data saved to the backup memory.

An icon shown when the interface is set to LAN, LAN/RS-232, or LAN/RS-485.

For other cases, the icon is gray. (Supported only on the XL121, XL122, and

XL124.)

An icon shown when the interface is set to USB. For other cases, the icon is

gray. (Supported only on the XL121, XL122, and XL124.)

An icon shown when the communication protocol is set to Modbus (slave). The

icon is gray when set to Modbus (master). (Supported only on the XL121,

XL122, and XL124.)

An icon shown when the communication protocol is set to Modbus (master). The

icon is gray when set to Modbus (slave). (Supported only on the XL121, XL122,

and XL124.)

An icon shown when the printer output is turned ON and the sampling interval is

greater than or equal to 1 minute. The icon is gray when the printer output is

OFF. (Supported only on the XL121, XL122, and XL124.)

An icon shown when the printer output is turned ON and the sampling interval is

less than or equal to 30 seconds. This indicates that only manual print is valid

using the SAVE key. (Supported only on the XL121, XL122, and XL124.)

An icon shown when the display update is held. The icon is gray when the

display is not held.

An icon shown when key lock is enabled. The icon is gray when key lock is

disabled.

2-6

An icon shown when the AC adapter is connected.

An icon shown when the AC adapter is not connected, and the XL100 is running

on a battery. Shows the remaining battery power using four levels

(

→ → → ).

IM XL120E

Page 36

1

Data Display Section

Waveform & Digital Display

8

2.3 Data Display

12

10

1

4

3

2

6

2

11

5

Part Names and Functions

7

1. Waveform

Waveforms of measured data, calculated data, and communication input data. The display

position of logic input waveforms is fixed to the bottom of the display as shown below.

2. Time Scale

The specified time scale (time per grid (division)) is displayed in the format “xxyyy/

div” (where xx is the value and yyy is sec, min, or h).

3. Alarm Line

Displayed with a dotted line using a specified color at the position of the alarm value

of the selected channel (active channel).

4. Scale Upper Limit

The scale upper limit of the active channel. If scaling is turned OFF, the span upper

limit is displayed.

5. Scale Lower Limit

The scale lower limit of the active channel. If scaling is turned OFF, the span lower

limit is displayed.

6. Pen

Displayed at the current value position of each channel. The active channel is shown

highlighted in reverse video.

7. Usage Indication Bar of the Storage Media

Displays using a blue bar the amount of space used with respect to the total space on

the storage medium that is specified to be the save destination of the measured data.

Total space on the save

destination medium

Used space

9

Free space

8. Grid

The grid can be turned ON/OFF.

9. Elapsed Time

The time elapsed from the start of the logging operation is displayed in the format

“wwww:xx:yy:z” (where wwww is the hour, xx is the minute, yy is the second, and z is

one-tenth of a second).

10. Digital Display

Displays the current values of the measured data, calculated data, and

communication input data using numeric values. When an alarm is occurring, the

value is shown in red in reverse video.

IM XL120E

2-7

Page 37

2.3 Data Display

11. Unit

Displays preset characters such as °C or an arbitrary specified characters (up to 6

characters).

12. Channel No./Tag

Displays the channel number and the specified tag (up to 8 characters). The active

channel is shown highlighted in reverse video.

Waveform Display

4

3

1

2

6

8

5

7

9

1. Waveform

Waveforms of measured data, calculated data, and communication input data.

2. Time Scale

The specified time scale (time per grid (division)) is displayed in the format “xxyyy/

div” (where xx is the value and yyy is sec, min, or h).

3. Alarm Line

Displayed with a dotted line using a specified color at the position of the alarm value

of the selected channel (active channel).

4. Scale Upper Limit

The scale upper limit of the active channel. If scaling is turned OFF, the span upper

limit is displayed.

5. Scale Lower Limit

The scale lower limit of the active channel. If scaling is turned OFF, the span lower

limit is displayed.

6. Pen

Displayed at the current value position of each channel. The active channel is shown

highlighted in reverse video.

7. Usage Indication Bar of the Storage Media

Displays using a blue bar the amount of space used with respect to the total space

on the storage medium that is specified to be the save destination of the measured

data.

8. Grid

The grid can be turned ON/OFF.

9. Elapsed Time

The time elapsed from the start of the logging operation is displayed in the format

“wwww:xx:yy:z” (where wwww is the hour, xx is the minute, yy is the second, and z is

one-tenth of a second).

2-8

IM XL120E

Page 38

1

2.3 Data Display

Digital Display

2

1. Digital Display

2. Channel No.

3. Tag

4. Unit

5. Statistical Calculation Value

34

Displays the current values of the measured data, calculated data, and

communication input data using numeric values. When an alarm is occurring, the

value is shown in red in reverse video.

Displays the channel number in the specified color.

Displays the specified tag (up to 8 characters). The active channel is shown

highlighted in reverse video.

Displays preset characters such as °C or an arbitrary specified characters (up to 6

characters).

Displays the maximum, minimum, average, peak (P-P), and rms values of the active

channel. Displays “OFF” when statistics is set to OFF.

1

5

2

Part Names and Functions

IM XL120E

2-9

Page 39

2.3 Data Display

Bar Graph Display

6

1

7

5

3

2

4

1. Bar

Displays the current values of the measured data, calculated data, and

communication input data using bars. The reference position of the bar can be set to

normal (left edge of the scale) or center. The color of the bars are the same as the

waveform colors.

When the reference position of the bar is set to center

2. Channel No./Tag

Displays the channel number and the specified tag (up to 8 characters). The active

channel is shown highlighted in reverse video.

3. Numeric Value

Displays the current values of the measured data, calculated data, and

communication input data using numeric values. When an alarm is occurring, the

value is shown in red in reverse video.

4. Unit

Displays preset characters such as °C or an arbitrary specified characters (up to 6

characters).

5. Scale Upper Limit

The scale upper limit for each channel. If scaling is turned OFF, the span upper limit

is displayed.

6. Scale Lower Limit

The scale lower limit for each channel. If scaling is turned OFF, the span lower limit

is displayed.

7. Alarm Mark

Displays arrow marks at the positions corresponding to the specified alarm values. If

an alarm is occurring, the alarm marks are displayed in red.

2-10

IM XL120E

Page 40

1

Review Display

4

10

11

12

5

22

2.3 Data Display

2

7

1

3

17

6

2

8

9

14

15

16

19

18

20

21

Part Names and Functions

13

1. Waveform

Waveforms of measured data, calculated data, and communication input data.

2. Time Scale

The specified time scale (time per grid (division)) is displayed in the format “xxyyy/

div” (where xx is the value and yyy is sec, min, or h).

3. Alarm Line

Displayed with a dotted line using a specified color at the position of the alarm value

of the selected channel (active channel).

4. Scale Upper Limit

The scale upper limit of the active channel. If scaling is turned OFF, the span upper

limit is displayed.

5. Scale Lower Limit

The scale lower limit of the active channel. If scaling is turned OFF, the span lower

limit is displayed.

6. Pen

Displayed at the current value position of each channel. The active channel is shown

highlighted in reverse video.

7. Grid

The grid can be turned ON/OFF.

8. File Name

Displays the file name of the data currently being reviewed.

9. Active Marker

Displays the marker name currently active.

10. Marker A

Displayed with a yellow solid line.