Page 1

IM 760201-01E

1st Edition

Power Analyzer

Page 2

Product Registration

Thank you for purchasing YOKOGAWA products.

YOKOGAWA provides registered users with a variety of information and

services.

Please allow us to serve you best by completing the product registration

form accessible from our homepage.

http://www.yokogawa.com/tm/

PIM 103-02E

Page 3

i

IM 760201-01E

Thank you for purchasing the WT500 Power Analyzer. The WT500 is an instrument

capable of measuring parameters such as voltage, current, and power with high

precision.

This user’s manual explains the features, operating procedures, and handling

precautions of the WT500. To ensure correct use, please read this manual thoroughly

before beginning operation. Keep this manual in a safe place for quick reference in the

event that a question arises.

This manual is one of two WT500 manuals. Please read both manuals.

Manual Title Manual No. Description

WT500 Power Analyzer

User’s Manual

IM760201-01E This manual. Explains all WT500 features,

except for the communication features, and

the operating procedures that relate to them.

WT500 Power Analyzer

Communication Interface

User’s Manual (CD-ROM)

IM760201-17E Explains the features related to using

communication commands to control the

WT500.

Notes

• The contents of this manual are subject to change without prior notice as a result

of continuing improvements to the instrument’s performance and functionality. The

appearance of the figures given in this manual may differ from the appearance of your

actual display.

•

Every effort has been made in the preparation of this manual to ensure the accuracy

of its contents. However, should you have any questions or find any errors, please

contact your nearest YOKOGAWA dealer.

•

Copying or reproducing all or any part of the contents of this manual without the

permission of YOKOGAWA is strictly prohibited.

•

The TCP/IP software of this product and the documents concerning it have been

developed/created by YOKOGAWA based on the BSD Networking Software, Release

1 that has been licensed from the Regents of the University of California.

Trademark Acknowledgements

• Microsoft, Internet Explorer, MS-DOS, Windows, Windows NT, and Windows Vista

are either registered trademarks or trademarks of Microsoft Corporation in the United

States and/or other countries.

•

Adobe, Acrobat, and PostScript are trademarks of Adobe Systems Incorporated.

• In this manual, the TM and ® symbols do not accompany their respective registered

trademark or trademark names.

•

Other company and product names are registered trademarks or trademarks of their

respective holders.

Revisions

• 1st Edition: June 2008

1st Edition : June 2008 (YK)

All Rights Reserved, Copyright © 2008 Yokogawa Electric Corporation

Page 4

ii

IM 760201-01E

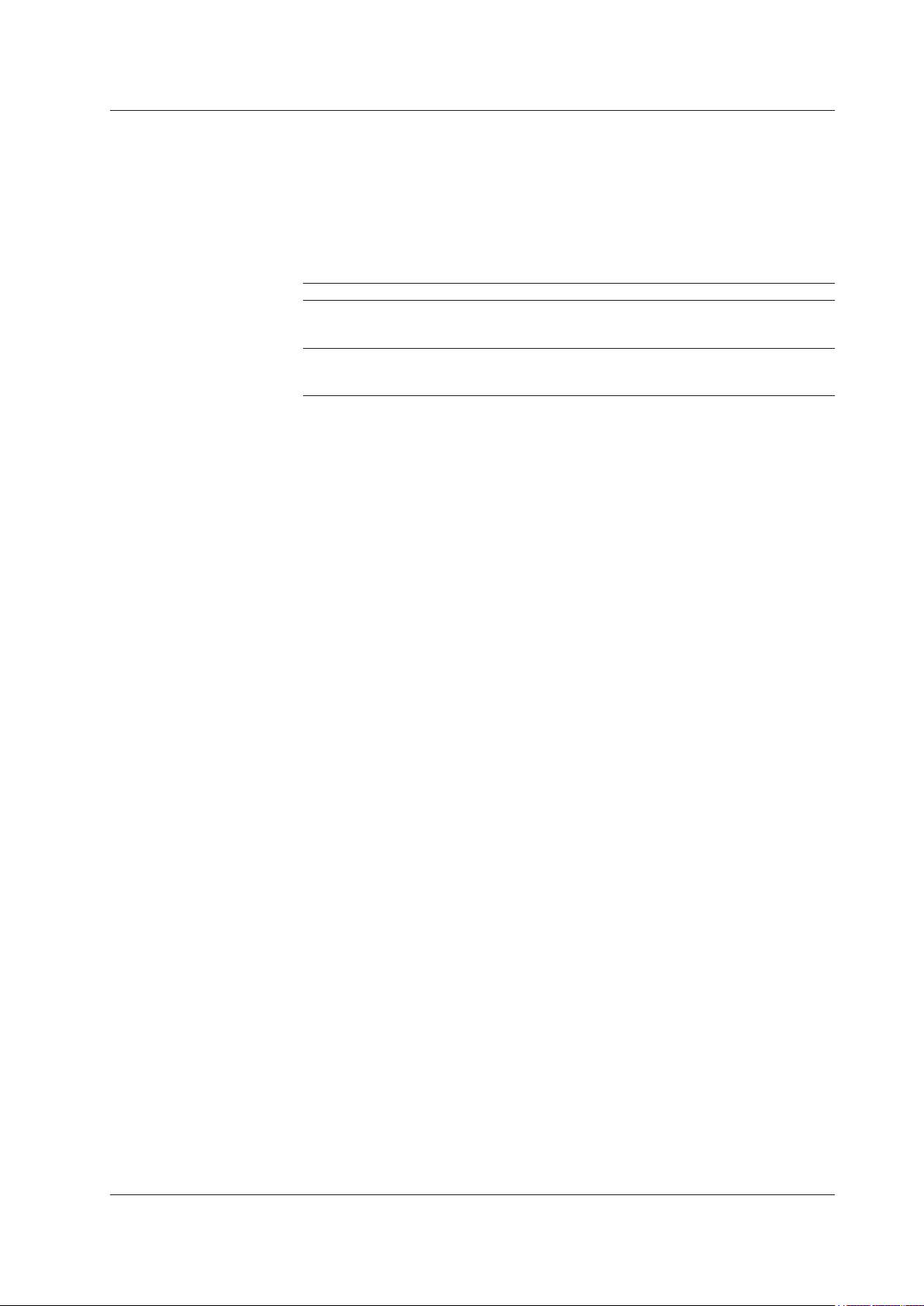

Checking the Package Contents

After receiving the product and opening the package, check the items described below.

If the wrong items have been delivered, if items are missing, or if there is a problem with

the appearance of the items, contact your nearest YOKOGAWA dealer.

WT500

Check that the model name and suffix code given on the name plate on the side panel

are the same as those on your order.

MODEL

SUFFIX

NO.

Made in Japan

MODEL

SUFFIX

NO.

Made in J apan

MODEL and SUFFIX Codes

Model/Item Suffix Code Description

760201

760202

760203

Number of installed input elements: 1

Number of installed input elements: 2

Number of installed input elements: 3

Power cord -D UL, CSA standard power cord

-F VDE standard power cord

-Q BS standard power cord

-R AS standard power cord

-H GB standard power cord (CCC-compatible)

Options /C1 GP-IB interface

/C7 Ethernet interface

/EX1 External sensor input (only selectable with the 760201)

/EX2 External sensor input (only selectable with the 760202)

/EX3 External sensor input (only selectable with the 760203)

/G5 Harmonic measurement

/DT Delta computation

/FQ Frequency measurement add-on (enables simultaneous

measurement of all input elements)

/V1 VGA output

Suffix Code Example

On a model with three input elements installed that comes with the GP

-IB interface, external

input sensor, and harmonic measurement options and a UL, CSA standard power cord, the

suffix code is 760203-D/C1/EX3/G5.

NO. (Instrument number)

When contacting the dealer from which you purchased the instrument, please give them

the instrument number.

Page 5

iii

IM 760201-01E

Standard Accessories

The WT500 is shipped with the following accessories.

Item Model/Part No. Quantity Note

Power cord One of the following power cords is included according to the suffix code on the previous

page.

A1006WD 1 UL, CSA standard power cord

Maximum rated voltage: 125 V, Maximum rated current: 7 A

A1009WD 1 VDE standard power cord

Maximum rated voltage: 250 V, Maximum rated current: 10 A

A1054WD 1 BS standard power cord

Maximum rated voltage: 250 V, Maximum rated current: 10 A

A1024WD 1 AS standard power cord

Maximum rated voltage: 250 V, Maximum rated current: 10 A

A1064WD 1 GB standard power cord (CCC-compatible)

Maximum rated voltage: 250 V, Maximum rated current: 10 A

Rubber feet A9088ZM 1 There are two feet in a pair

.

Current input protective

cover

B9319BX 1 Comes with two screws.

Safety terminal adapter set 758931 See the

note on

the right.

Same number of sets as the number of installed input

elements

760201:

One set with one hexagonal socket wrench

760202: Two sets with one hexagonal socket wrench

760203: Three sets with 1 hexagonal socket wrench

User’s Manual IM760201-01E 1 This manual

Communication Interface

User’s Manual

IM760201-17E 1 CD-ROM

(CD-ROM part number: B9319ZZ)

(Printed manuals can be purchased separately. Contact your nearest YOKOGAWA dealer.)

Rubber feet

A9088ZM

Current input

protective cover

B9318BX

Safety terminal

adapter set

758931

User’s Manual

(this manual)

IM760201-01E

Communication Interface

User’s Manual

IM760201-17 (CD-ROM)

A1006WD

(-D)

A1009WD

(-F)

A1024WD

(-R)

Power cord (One of the following power cords is included according to the suffix code)

A1054WD

(-Q)

A1064WD

(-H)

Checking the Package Contents

Page 6

iv

IM 760201-01E

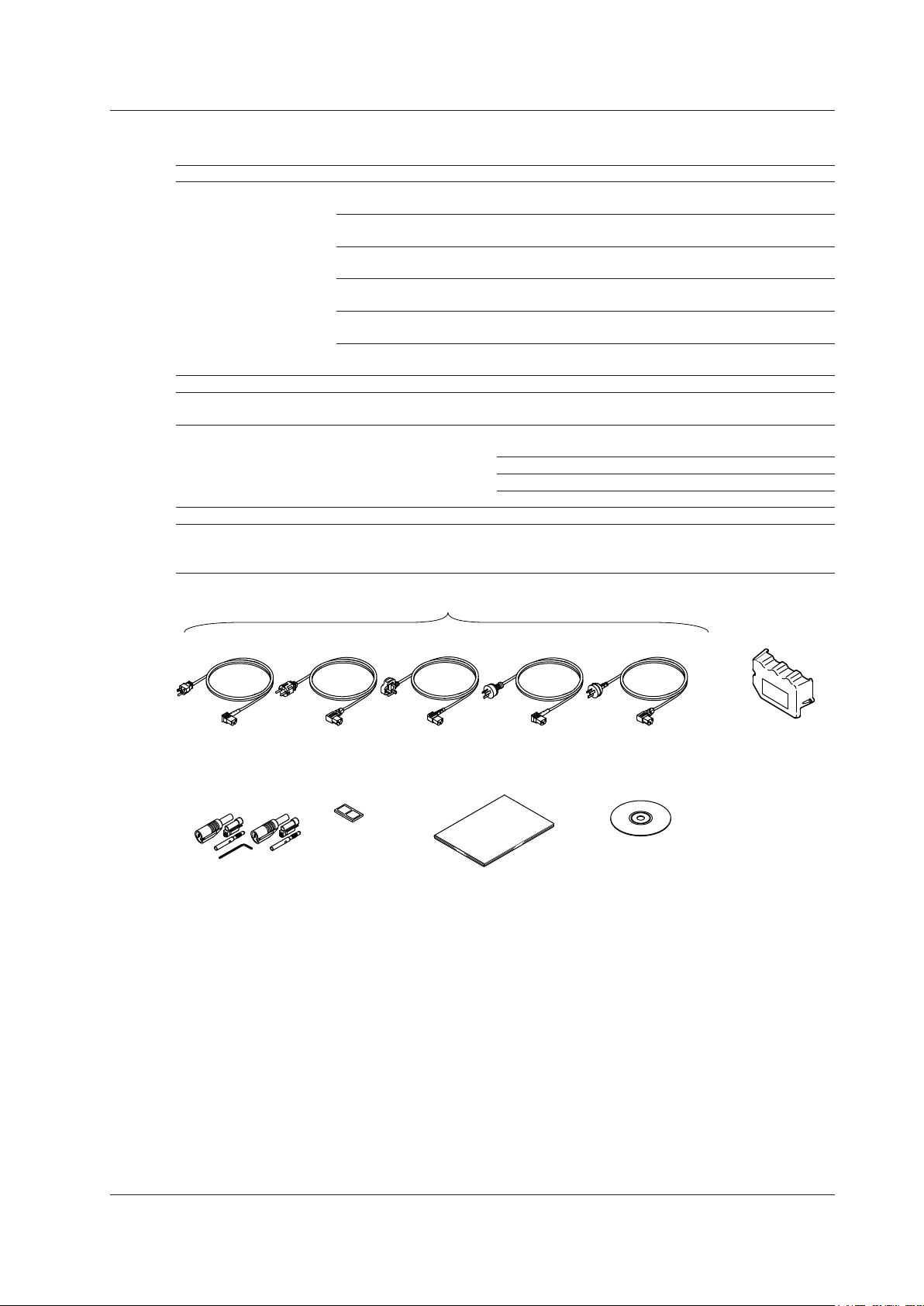

Optional Accessories (Sold separately)

The following optional accessories are available for purchase separately.

Item Model/Part

No.

Quantity

Sold

Note

Measurement lead 758917 1 Two leads in one set. Used with the

separately sold 758922 or 758929 adapter.

Length: 0.75 m. Rated voltage: 1000 V.

Safety terminal adapter set 758923 1 Two pieces in one set. Rated voltage 600 V.

758931 1 Two pieces in one set. Rated voltage

1000V.

Alligator clip adapter set 758922 1 Two pieces in one set. For the 758917

measurement lead.

Rated voltage: 300 V.

758929 1 Two pieces in one set. For the 758917

measurement lead.

Rated voltage: 1000V.

Fork terminal adapter set 758921 1 Two pieces in one set. For the 758917

measurement lead.

Rated voltage: 1000 V. Rated current: 25 A.

BNC-BNC 366924 1 42 V or less. Length: 1 m.

Measurement lead 366925 1 42 V or less. Length: 2 m.

External sensor cable B9284LK 1 For connecting the current sensor input

connector of the WT500.

Length: 0.5 m.

Conversion adapter 758924 1 BNC-4 mm socket adapter. Rated voltage:

500 V.

Measurement lead

758917

Alligator clip

adapter set

758922

Alligator clip

adapter set

758929

Fork terminal

adapter set

758921

Safety terminal

adapter set

758923

External sensor

cable

B9284LK

Safety terminal

adapter set

758931

BNC cable

366924 (1 m)

366925 (2 m)

Conversion adapter

758924

Checking the Package Contents

Page 7

v

IM 760201-01E

Safety Precautions

This instrument is an IEC safety class 01 instrument (provided with a terminal for

protective earth grounding).

The general safety precautions described herein must be observed during all phases

of operation. If the instrument is used in a manner not specified in this manual, the

protection provided by the instrument may be impaired. Yokogawa Electric Corporation

assumes no liability for the customer’s failure to comply with these requirements.

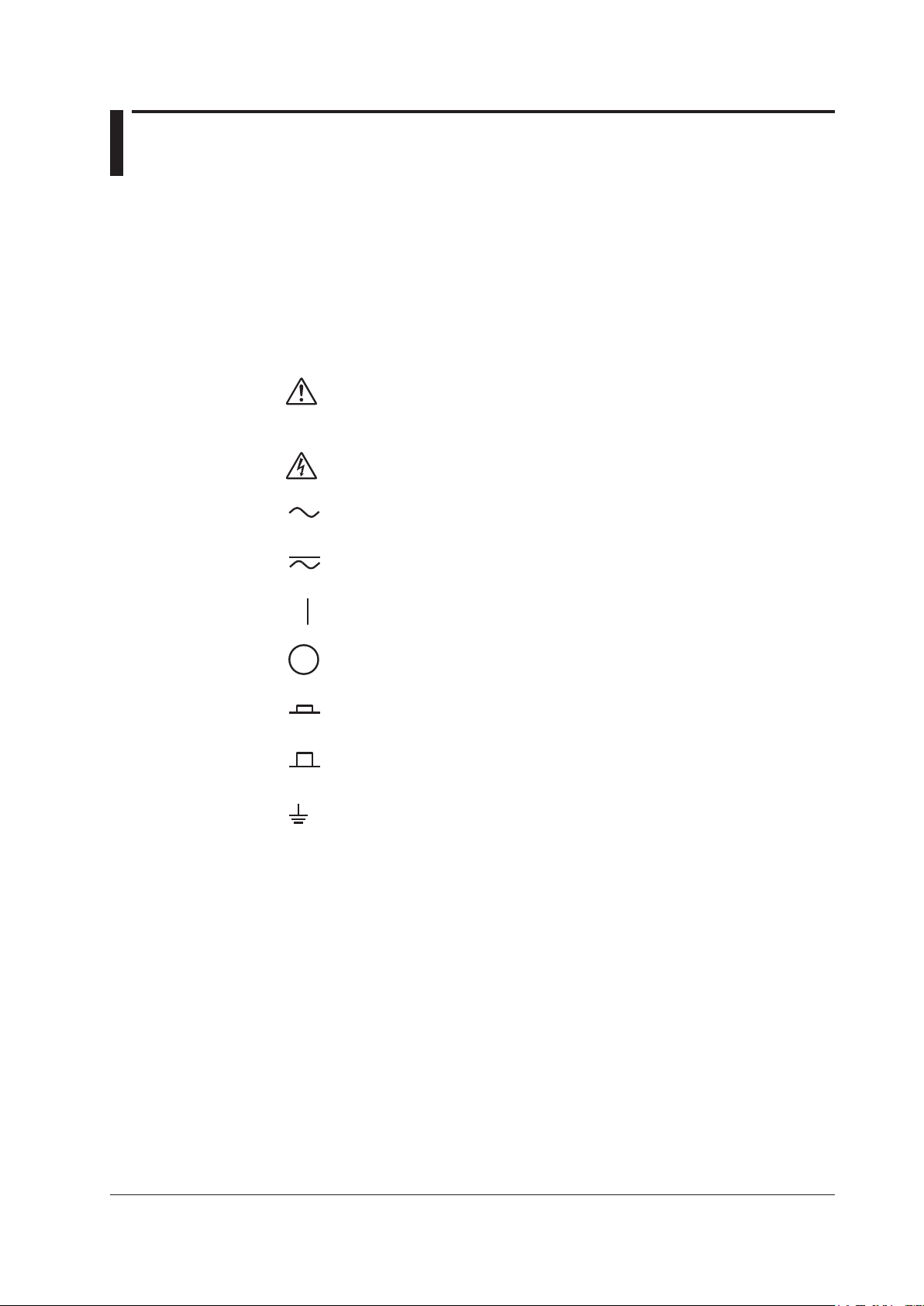

The following symbols are used on this instrument.

Handle with care. To protect the instrument and its users, refer to the explanation

in the User’s Manual or Service Manual.

Electric shock, danger

Alternating current

Both direct and alternating current

Power on

Power off

Power-on state

Power-off state

Grounding

Page 8

vi

IM 760201-01E

Failure to comply with the precautions below could lead to injury or death.

WARNING

Use the Correct Power Supply

Make sure that the power supply voltage matches the WT500 rated supply voltage

and that it does not exceed the maximum voltage range specified for the power

cord.

Use the Correct Power Cord and Plug

To prevent fire and electric shock, use the power cord supplied by YOKOGAWA.

The main power plug must be plugged into an outlet with a protective earth

terminal. The earth protection will be nullified if you use an ungrounded extension

cord.

Connect to a Protective Earth Terminal

To prevent electric shock, be sure to connect to a protective earth terminal before

turning on the power. The power cord that comes with the instrument is a threeprong cord. Connect the power cord to a properly grounded three-prong outlet.

Do Not Impair the Protective Grounding

Never cut off the internal or external protective earth wire or disconnect the wiring

to the protective earth terminal. Doing so may result in electric shock or damage to

the instrument.

Do Not Operate with Defective Protective Grounding or Fuses

Do not operate the instrument if its protective grounding or one of its fuses might be

defective. Check the grounding and the fuses before operating the instrument.

Do Not Operate in an Explosive Atmosphere

Do not operate the instrument in the presence of flammable gasses or vapors.

Doing so is extremely dangerous.

Do Not Remove Covers

Only qualified YOKOGAWA personnel should remove the instrument’s covers. The

inside of the instrument is dangerous because parts of it have high voltages.

Ground the Instrument before Making External Connections

Securely connect the protective grounding before connecting to the item under

measurement or to an external control unit. Before touching a circuit, turn off its

power and check that it has no voltage.

Operating Environment Limitations

CAUTION

This is a class A instrument designed for an industrial environment. Operation of

this equipment in a residential area can cause radio interference, in which case

users will be required to correct the interference.

Safety Precautions

Page 9

vii

IM 760201-01E

Waste Electrical and Electronic Equipment

Waste Electrical and Electronic Equipment (WEEE), Directive 2002/96/EC

(This directive is only valid in the EU.)

This product complies with the WEEE Directive (2002/96/EC) marking

requirement. This marking indicates that you must not discard this electrical/

electronic product in domestic household waste.

Product Category

With reference to the equipment types in the WEEE direct

ive Annex 1, this

product is classified as a “Monitoring and Control instrumentation” product.

Do not

dispose in domestic household waste. When disposing products in the EU,

contact your local Yokogawa Europe B. V. office.

Page 10

viii

IM 760201-01E

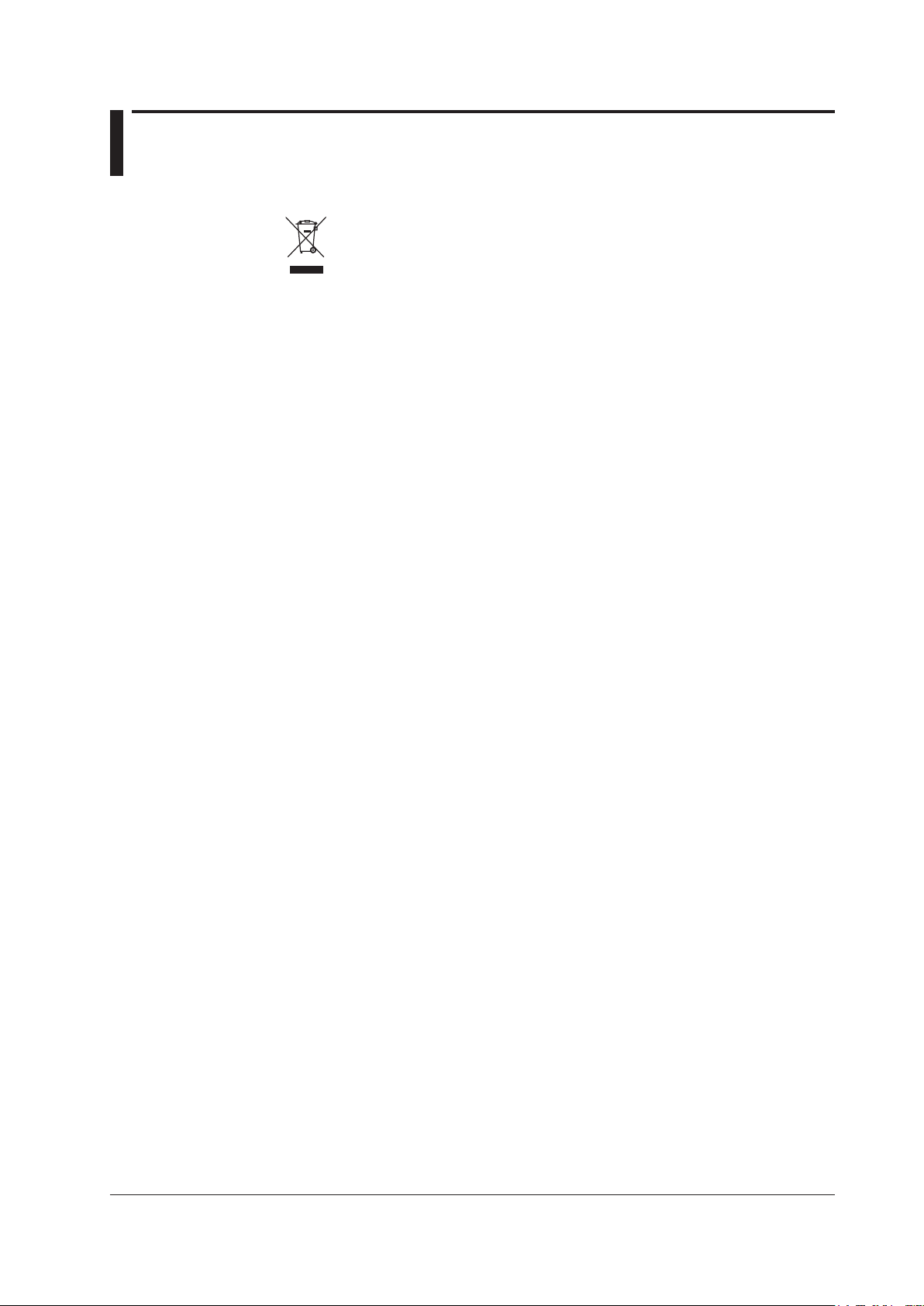

Conventions Used in This Manual

Notes and Cautions

The notes and cautions in this manual are categorized using the following symbols.

Improper handling or use can lead to injury to the user or damage

to the instrument. This symbol appears on the instrument to indicate

that the user must refer to the user’s manual for special instructions.

The same symbol appears in the corresponding place in the user’

s manual to identify those instructions. In the manual, the symbol is

used in conjunction with the word “WARNING” or “CAUTION.”

WARNING

Calls attention to actions or conditions that could cause serious or

fatal injury to the user, and precautions that can be taken to prevent

such occurrences.

CAUTION

Calls attention to actions or conditions that could cause light injury

to the user, or cause damage to the instrument or user’s data, and

precautions that can be taken to prevent such occurrences.

Note

Calls attention to information that is important for proper operation of

the instrument.

Symbols Used in Procedural Explanations

The procedural explanations in chapters 3 to 13 use the following symbols, characters,

and words to identify their contents.

Procedure

Follow the order of the step numbers when carrying out procedures.

Procedural explanations assume that the procedures are being

performed for the first time. You may not need to perform every step

in a procedure when you are altering settings that have already been

made before.

Explanation

Limitations and settings related to the procedure are explained here.

The feature itself is not usually explained here. For information about

the features themselves, see chapter 2.

Characters and Terminology Used in Procedural Explanations

Panel Keys and Soft Keys

Bold characters in procedural explanations are used to indicate panel keys that are used in the

procedure and menu items that appear on the screen.

SHIFT+Panel Key

When SHIFT+panel key appears in a procedural explanation, it means to press the shift key so

that it lights, and then to press the indicated panel key. The setup menu marked in purple below

the panel key that you pressed appears on the screen.

Units

k Denotes 1000. Example: 12 kg, 100 kHz

K Denotes 1024. Example: 459 KB (file size)

Page 11

ix

IM 760201-01E

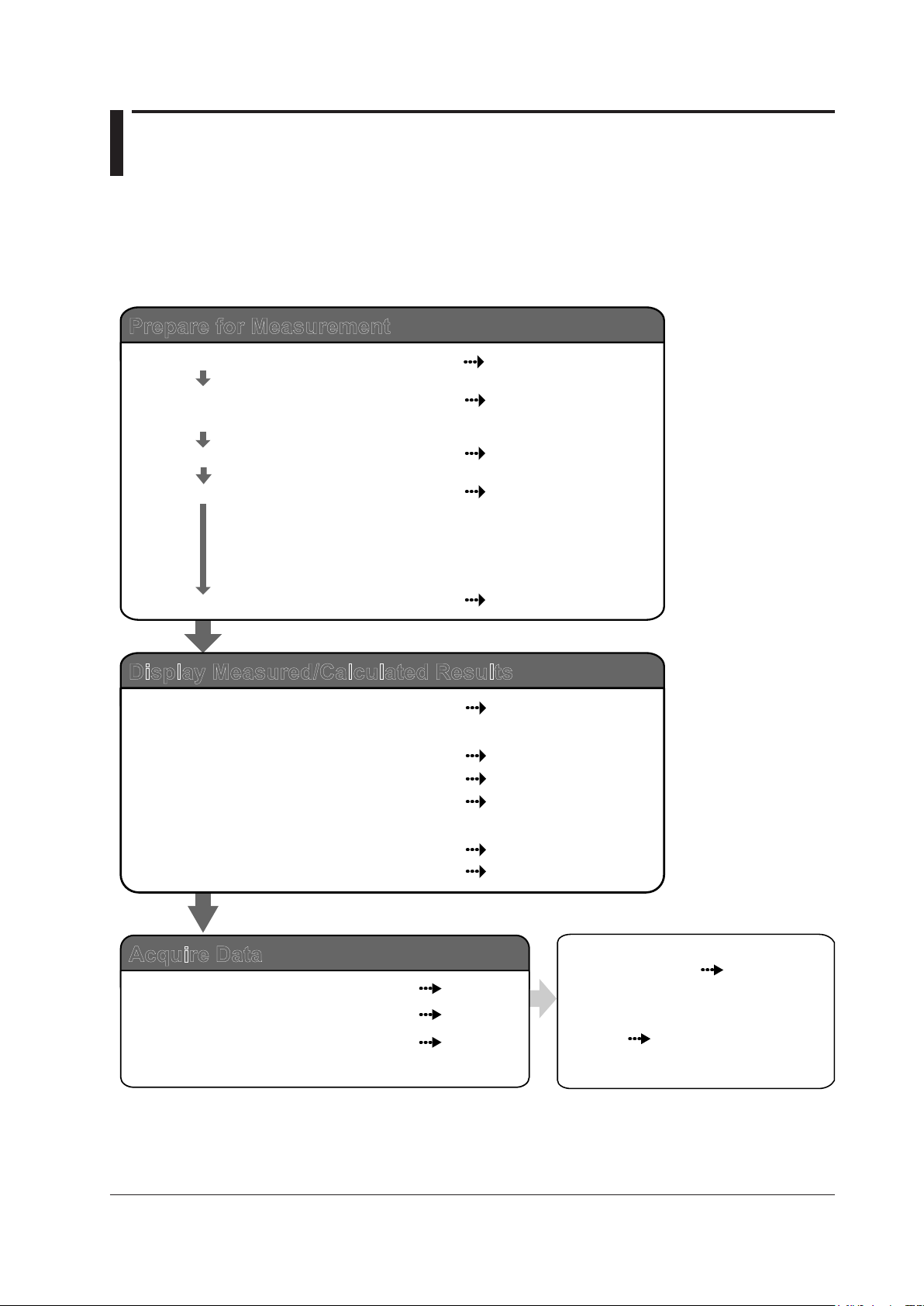

Workflow

The figure below is provided to familiarize the first-time user with the workflow of WT500

operation. For a description of an item, see the relevant section or chapter. In addition

to the sections and chapters that are referenced in the figure below, this manual also

contains safety precautions for handling the instrument and performing wiring work. Be

sure to observe the precautions.

Section 3.2

Sections 3.3 and 3.4

Section 3.8

Sections 3.9 to 3.11

Chapter 4

Sections 5.1 to 5.5 and

5.13 to 5.16

Sections 5.6 to 5.12

Section 5.17

Chapter 6

Chapter 7

Chapter 8

Install the instrument

Connect the power supply and

turn the power switch on

Select the measurement method

Wire the circuit that you will measure

Set the measurement conditions

Read the precautions in sections 3.5 and 3.7 thoroughly before connecting

the wires. Also, if necessary, assemble the input terminal adapter that

connects to the voltage input terminal (see section 3.6) before connecting

the wires.

RGB video signal (VGA)

output (optional)

Send data through USB or the

optional GP-IB or Ethernet interface.

Prepare for Measurement

Display Measured/Calculated Results

Measured power values

Integrated values

Delta computation (optional)

Harmonic measurements (optional),

bar graphs, vectors

Voltage/current waveforms

Trends

Chapter 11

Acquire Data

Store data to internal memory

Save data to USB memory

Send data through the optional

Ethernet interface

Communication Interface

User’s Manual

IM760201-17E (CD-ROM)

Section 12.1

Chapter 9

Chapter 10

Page 12

x

IM 760201-01E

Contents

Checking the Package Contents.......................................................................................................ii

Safety Precautions ............................................................................................................................v

Waste Electrical and Electronic Equipment .................................................................................... vii

Conventions Used in This Manual ................................................................................................. viii

Workow .......................................................................................................................................... ix

Chapter 1 Component Names and Functions

1.1 Front Panel, Rear Panel, and Top Panel .......................................................................... 1-1

1.2 Setup Menu Display and Operation Keys ........................................................................ 1-3

1.3

Screen Display ................................................................................................................. 1-8

Chapter 2 Features

2.1 SystemCongurationandBlockDiagram ........................................................................ 2-1

2.2 Measurement Functions and Periods ............................................................................... 2-3

2.3

Measurement Conditions ............................................................................................... 2-10

2.4

Power Measurement ...................................................................................................... 2-16

2.5

Computation ................................................................................................................... 2-19

2.6

Integration ...................................................................................................................... 2-22

2.7

Waveform Display .......................................................................................................... 2-26

2.8

Trend, Bar Graph, and Vector Displays .......................................................................... 2-33

2.9

Saving and Loading Data, and Other Miscellaneous Functions ..................................... 2-36

Chapter 3 Before You Start Measuring

3.1 Handling Precautions ....................................................................................................... 3-1

3.2 Installing the Instrument ................................................................................................... 3-3

3.3 Connecting the Power Supply .......................................................................................... 3-5

3.4 Turning the Power Switch On and Off .............................................................................. 3-6

3.5 Precautions for Wiring the Circuit That You Will Measure ................................................ 3-8

3.6 Assembling the Adapter for the Voltage Input Terminal .................................................. 3-10

3.7

Wiring for Accurate Measurements ................................................................................ 3-12

3.8

Guide for Selecting the Method Used to Measure the Power ........................................ 3-13

3.9

Wiring the Circuit That You Will Measure for Direct Input............................................... 3-14

3.10

Wiring the Circuit That You Will Measure with a Current Sensor ................................... 3-17

3.1

1 Wiring the Circuit That You Will Measure with a VT or CT ............................................. 3-21

3.12

Setting the Date and Time .............................................................................................. 3-24

3.13

Initializing the Settings .................................................................................................... 3-26

3.14

Entering Values and Character Strings .......................................................................... 3-27

3.15

Entering Character Strings on a USB Keyboard ............................................................ 3-29

3.16

Switching the Display ..................................................................................................... 3-31

3.17

Displaying a List of Setup Parameters ........................................................................... 3-33

3.18

Selecting the Message Language .................................................................................. 3-34

3.19

Setting the USB Keyboard Language ............................................................................ 3-35

Chapter 4 Measurement Conditions

4.1 Panel Keys and Setup Menus Used in This Chapter ....................................................... 4-1

4.2 Selecting a Wiring System ............................................................................................... 4-2

4.3

SelectingIndependentInputElementConguration ........................................................ 4-5

4.4

Setting the Measurement Ranges for Direct Input ........................................................... 4-7

Page 13

3

2

1

4

5

6

7

8

9

10

11

12

13

14

App

Index

xi

IM 760201-01E

xi

IM 760201-01E

4.5 Setting the Measurement Ranges for an External Current Sensor (Optional) ............... 4-13

4.6 Setting the Scaling Feature When Using a VT or CT ..................................................... 4-16

4.7 Setting the Measurement Period .................................................................................... 4-19

4.8 Selecting an Input Filter .................................................................................................. 4-22

4.9

Selecting the Data Update Rate ..................................................................................... 4-24

4.10

Selecting an Averaging Method ...................................................................................... 4-26

4.1

1 Selecting a Crest Factor ................................................................................................. 4-29

4.12

Holding the Display and Performing Single Measurements ........................................... 4-30

Chapter 5 Power Measurement

5.1 Panel Keys and Setup Menus Used in This Chapter ....................................................... 5-1

5.2 Displaying Numeric Data and Changing Displayed Items ................................................ 5-2

5.3

Setting the EquationforEfciency ................................................................................... 5-9

5.4

Setting the Equations for Apparent and Reactive Power ................................................5-11

5.5

Selecting a Phase Difference Display Format ................................................................ 5-13

5.6

Integration ......................................................................................................

................ 5-15

5.7 Setting Manual Integration ............................................................................................. 5-20

5.8

Setting Normal or Continuous Integration ...................................................................... 5-23

5.9

Setting Real-Time Integration or Real-Time Continuous Integration .............................. 5-26

5.10

Turning Integration Auto Calibration On or Off ............................................................... 5-30

5.1

1 Selecting a Watt Hour Integration Method for Each Polarity .......................................... 5-31

5.12

Selecting a Current Integration Mode ............................................................................. 5-32

5.13

Setting User-DenedFunctions ..................................................................................... 5-33

5.14

Setting the MAX Hold Feature ........................................................................................ 5-38

5.15

Measuring the Average Active Power ............................................................................. 5-40

5.16

Selecting What Frequency to Measure .......................................................................... 5-41

5.17

Setting Delta Computation (Optional) ............................................................................. 5-42

Chapter 6 Harmonic Measurement (Optional)

6.1 Panel Keys and Setup Menus Used in This Chapter ....................................................... 6-1

6.2 Changing Numeric Data Display Items ............................................................................ 6-2

6.3 Selecting the PLL Source ................................................................................................. 6-8

6.4 Setting the Measured Harmonic Orders ......................................................................... 6-10

6.5

Selecting a Distortion Factor Equation ........................................................................... 6-12

6.6

Setting the Anti-Aliasing Filter ........................................................................................ 6-13

6.7

Displaying Bar Graphs and Making Cursor Measurements ........................................... 6-15

6.8

Displaying Vectors .......................................................................................................

... 6-20

Chapter 7 Waveform Display

7.1 Panel Keys and Setup Menus Used in This Chapter ....................................................... 7-1

7.2 Displaying Waveforms ...................................................................................................... 7-2

7.3

Selecting Which Waveforms to Display ............................................................................ 7-3

7.4

Setting the Time Axis .......................................................................................................

. 7-4

7.5 Setting the Trigger ............................................................................................................ 7-5

7.6 Vertically Zooming and Shifting Waveforms ..................................................................... 7-9

7.7

Displaying Waveforms in Split Screens ...........................................................................7-11

7.8

Selecting a Graticule and Turning Interpolation, Scale Value Display, and

Wave Labels On or Off ................................................................................................... 7-13

7.9

Measuring with Cursors .................................................................................................. 7-17

Contents

Page 14

xii

IM 760201-01E

xii

IM 760201-01E

Contents

Chapter 8 Trend Display

8.1 Panel Keys and Setup Menus Used in This Chapter ....................................................... 8-1

8.2 Displaying Trends .......................................................................................................

...... 8-2

8.3 Selecting What Trend Data to Display .............................................................................. 8-3

8.4

Setting Which Measurement Functions to Display Using Trends ..................................... 8-4

8.5

Setting Trend Scaling ......................................................................................................

. 8-7

8.6 Setting the Time Axis .......................................................................................................

. 8-9

8.7 Displaying Trends in Split Screens ................................................................................. 8-10

8.8

Selecting a Graticule and Turning Interpolation, Scale Value Display, and

Wave Labels On or Off .

....................................................................................................... 8-11

8.9 Restarting Trends ......................................................................................................

..... 8-12

8.10 Measuring with Cursors ..................................................................................................... 8-13

Chapter 9 Storing Numeric Data and Saving Stored Numeric Data

9.1 Panel Keys and Setup Menus Used in This Chapter ....................................................... 9-1

9.2 Setting the Storage Mode ................................................................................................. 9-2

9.3

Setting What Numeric Data to Store ................................................................................ 9-3

9.4

Setting the Store Count, Store Interval, and the Scheduled Storage Start and

End Times ......................................................................................................

.................. 9-5

9.5 Choosing Where to Store Numeric Data .......................................................................... 9-8

9.6

Storing Numeric Data ..................................................................................................... 9-13

9.7

Converting a Stored Binary Format File to CSV Format ................................................ 9-15

Chapter 10 Saving and Loading Data

10.1 Panel Keys and Setup Menus Used in This Chapter ..................................................... 10-1

10.2 About USB Memory .......................................................................................................

. 10-2

10.3 Saving Setup Parameters, Waveform Display Data, and Numeric Data ........................ 10-4

10.4

Saving Screen Image Data .......................................................................................... 10-12

10.5

Loading Setup Parameters and Displaying File Properties .......................................... 10-16

10.6

Deleting Files .......................................................................................................

......... 10-19

10.7 Copying Files .......................................................................................................

......... 10-22

Chapter 11 Ethernet Interface (Optional)

11.1 Panel Keys and Setup Menus Used in This Chapter ......................................................11-1

11.2 Connecting to a Network .................................................................................................11-2

1

1.3 ConguringTCP/IP Settings ............................................................................................11-3

1

1.4 Accessing the WT500 from a PC or Workstation (FTP server feature) .........................11-12

1

1.5 Checking the MAC Address and Whether the WT500 Is Equipped with the

Ethernet Interface Option ..............................................................................................11-15

Chapter 12 RGB Video Signal (VGA) Output (Optional) and Other Features

12.1 Panel Keys and Setup Menus Used in This Chapter ..................................................... 12-1

12.2 RGB Video Signal (VGA) Output (Optional) ................................................................... 12-2

12.3

Zero-Level Compensation .............................................................................................. 12-3

12.4

NULL Feature ......................................................................................................

........... 12-4

12.5 Setting the Key and Shift Locks ..................................................................................... 12-5

12.6 Master and Slave Synchronized Measurement .............................................................. 12-6

Chapter 13 Troubleshooting, Maintenance, and Inspection

13.1 Troubleshooting .............................................................................................................. 13-1

13.2 Error Messages and Troubleshooting Methods .............................................................. 13-2

13.3

Self-Test ......................................................................................................

................... 13-6

Page 15

3

2

1

4

5

6

7

8

9

10

11

12

13

14

App

Index

xiii

IM 760201-01E

xiii

IM 760201-01E

Contents

13.4 Displaying the System Overview .................................................................................... 13-9

13.5

Recommended Part Replacement ............................................................................... 13-10

Chapter 14 Specications

14.1 Input ............................................................................................................................... 14-1

14.2 Display ............................................................................................................................ 14-2

14.3

Normal Measurement Functions (Measured Items) ....................................................... 14-3

14.4

Harmonic Measurement Functions (Measured Items) ................................................... 14-5

14.5

Accuracy ......................................................................................................................... 14-6

14.6

Functions ...................................................................................................................... 14-10

14.7

External Input and Output (Master and slave synchronization signals and

clock input) ......................................................................................................

............. 14-15

14.8 RGB Video Signal (VGA) Output (Optional) ................................................................. 14-15

14.9

USB PC Interface ......................................................................................................... 14-16

14.10

USB PERIPHERAL Interface ....................................................................................... 14-16

14.1

1 GP-IB Interface Option ................................................................................................. 14-16

14.12

Ethernet Interface Option ............................................................................................. 14-17

14.13

Safety Terminal Adapter ............................................................................................... 14-17

14.14

GeneralSpecications ................................................................................................. 14-18

14.15

External Dimensions .................................................................................................... 14-19

Appendix

Appendix 1 Symbols and Determination of Measurement Functions ...................................App-1

Appendix 2 List of Initial Settings and Numeric Data Display Order ..................................... App-7

Appendix 3

Power Basics (Power, harmonics, and AC RLC circuits) .................................App-13

Appendix 6

USB Keyboard Character Assignments ........................................................... App-29

Index

Page 16

1-1

IM 760201-01E

Component Names and Functions

1

Chapter 1 Component Names and Functions

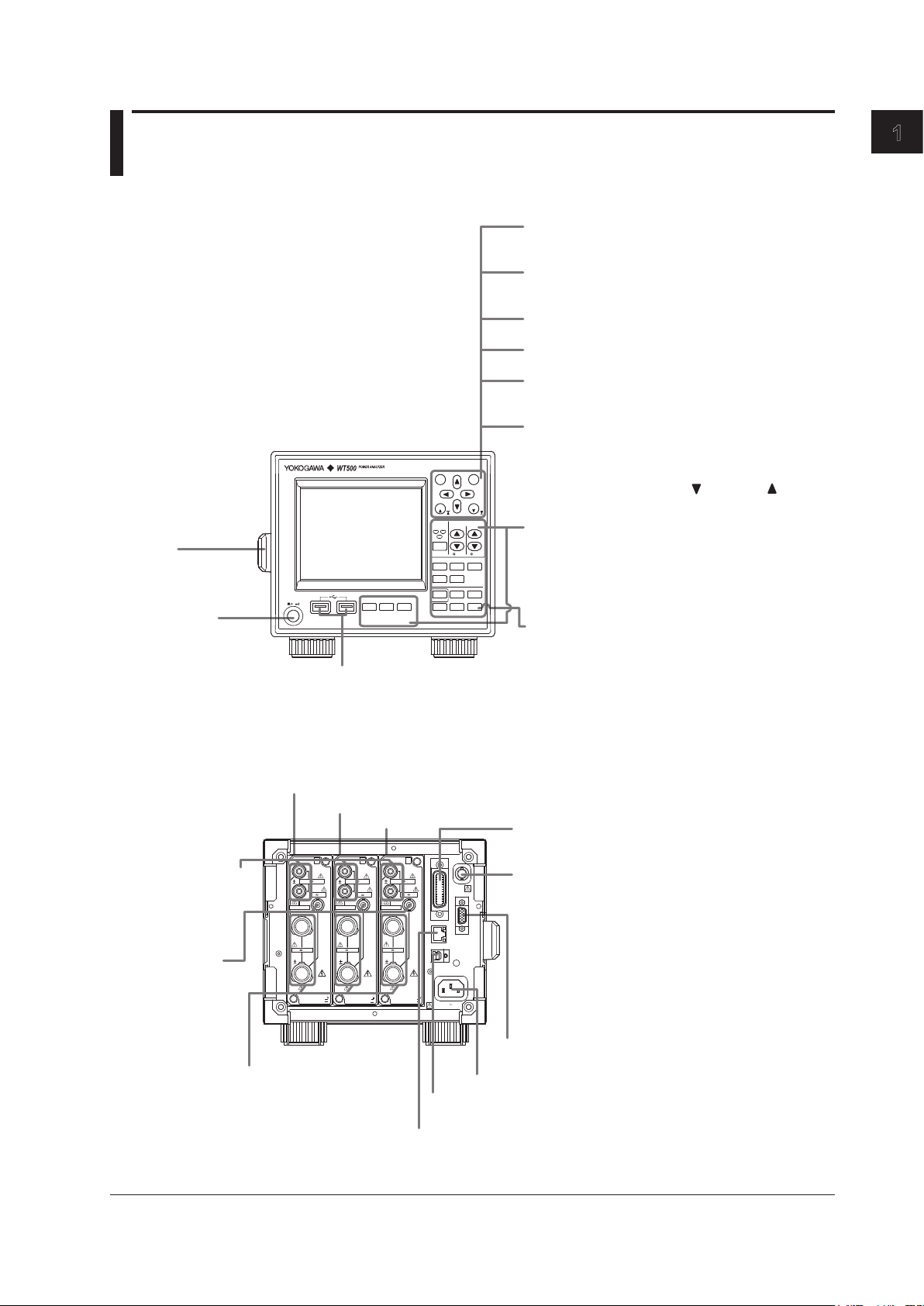

1.1 Front Panel, Rear Panel, and Top Panel

Front Panel

Power switch

(see section 3.4)

LCD

Handle

Use this handle to

move the WT500.

(see section 3.1)

Setup menu display and operation keys

These are the first keys that you press when you make

settings or perform operations. Pressing a setup menu

display key will display its corresponding setup menu.

Pressing an operation key will execute its

corresponding operation. (see section 1.2)

SHIFT key

When you press the SHIFT key, the key illuminates,

and pressing a panel keys produces the effect

indicated by the purple letters below it.

USB ports

Use to connect USB memory

or a USB keyboard.

ESC

RESET

SET

CAL

PAGE

PAGE

ELEMENT

1

2

3

ELEMENT

ALL

RANGE

VOLTAGE CURRENT

AUTO AUTO

DISPLAY

NUMERIC WAVE OT HERS

FORM ITE M

CURSOR

INTEGRATOR

SETUP

INPUT INF O

START/

STOP

RESET

HOLD

SINGLE

SHIFT

MISC

NULL

LOCAL

KEY LOCK

FILE IMAGE

MENU

STORE

STORE SET

POWER

Cursor keys

Set values (and select digits), move the cursor, and

select items in setup operations.

SET key

Enters or confirms the item or value selected using the

cursor keys.

SHIFT + SET (CAL) key combination

Executes zero-level compensation.

ESC key

Closes setup menus and dialog boxes.

SHIFT + ESC (RESET) key combination

Returns the item or value selected with the cursor to its

default value.

PAGE key

Because not all measured items can be displayed

on the screen at the same time, the WT500 uses

pages to display measured values. You can switch

between pages using PAGE and PAGE .

(see section 5.1)

Rear Panel

Input element 1

(see section 2.3)

Input element 2

Input element 3

Ethernet port (optional) (see section 11.2)

Power connector (see section 3.3)

USB port (PC) See the Communication Interface User’s Manual

IM760201-17E (CD-ROM).

External clock input/External start signal output

connector

• Receives the synchronization source (signal), which

defines the measurement period. (see section 4.7)

• Receives the external PLL source (signal) for

harmonic measurement. (see section 6.3)

• Used when performing master/slave synchronized

measurement.(see section 12.6)

• Receives the external trigger, which determines when

a waveform is displayed. (see section 7.5)

GP-IB Connector (optional; see the Communication

Interface User's Manual IM760201-17E on the

CD-ROM)

RGB video signal (VGA) output connector (optional)

Transmits image signals. (see section 12.2)

Current input terminal

For connecting current

measurement cables.

(see sections 3.8, 3.9,

and 3.11)

External current

sensor input

connector (optional)

For connecting the

external current

sensor cable.

(see section 3.10)

Voltage input terminal

For connecting voltage

measurement cables.

(see sections

3.8 to 3.11)

ELEME NT

VOLTAGE

1000V

MAX

EXT

CURREN T

ALL TE RMINA LS

1000V MAX

TO

CAT

II

EXT. CLK

GP-IB

(

IEEE 488

)

LINK/

ACT

VIDEO-OU T

(

VGA

)

100LINK

ETHERN ET 1 00BA SE-T X

USB

100- 240 V AC

50 VA MAX 50/60 Hz

10V

MAX

1000VMA X

40A

MAX

ELEME NT

VOLTAGE

1000V

MAX

EXT

CURREN T

ALL TE RMINA LS

1000V MAX

TO

CAT

II

10V

MAX

1000VMA X

40A

MAX

ELEME NT

VOLTAGE

1000V

MAX

EXT

CURREN T

ALL TE RMINA LS

1000V MAX

TO

CAT

II

10V

MAX

1000VMA X

40A

MAX

Page 17

1-2

IM 760201-01E

Top Panel

Handle

Vent holes (see section 3.2

for details)

There are inlet holes on the bottom panel.

1.1 Front Panel, Rear Panel, and Top Panel

Page 18

1-3

IM 760201-01E

Component Names and Functions

1

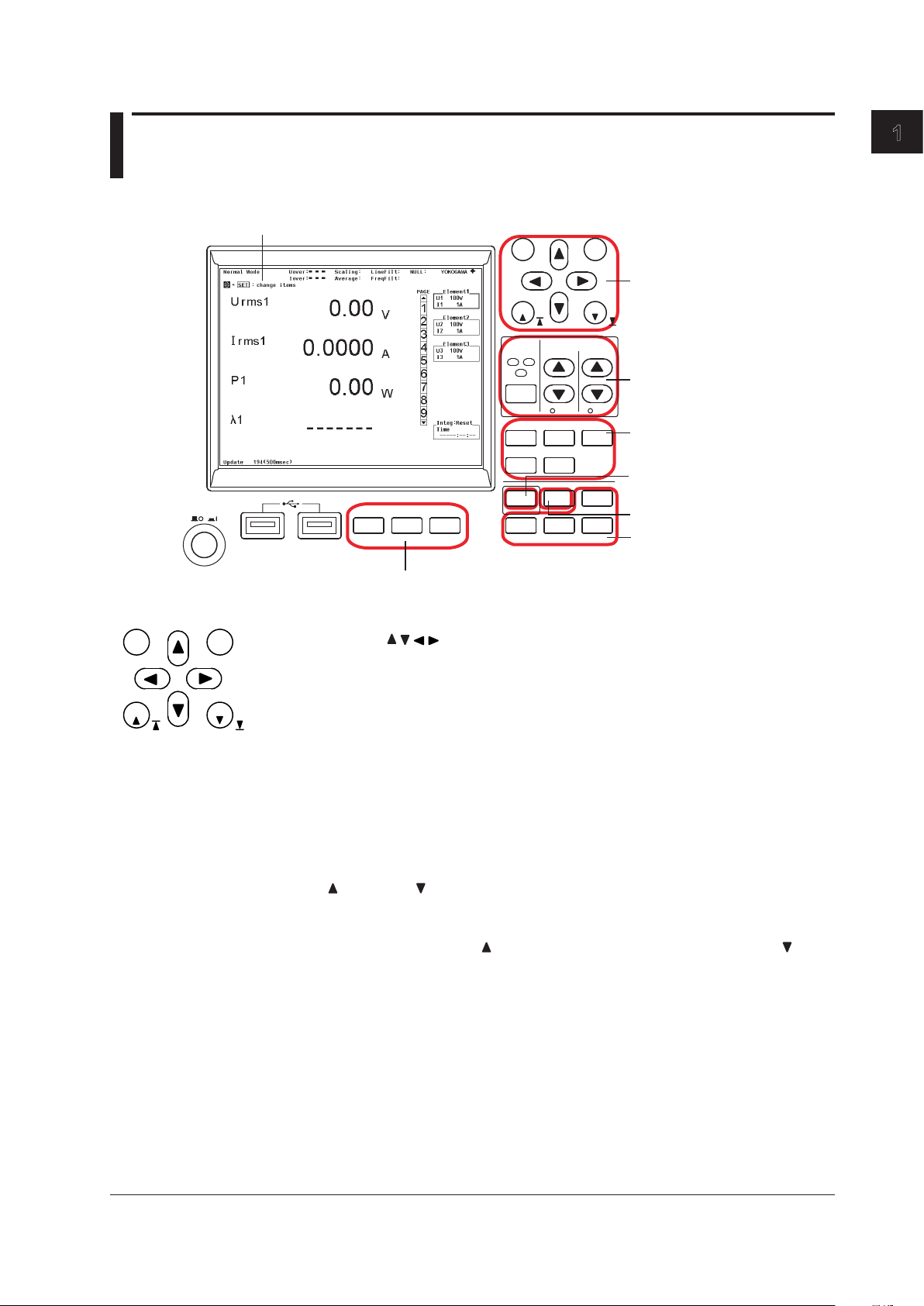

1.2 Setup Menu Display and Operation Keys

This section describes the WT500 panel keys and their functions.

Keys for data storage and saving

Display (see section 1.3)

Keys for setting measurement

conditions

Keys for setting the measurement

range

Keys for displaying

measured/calculated

results

Other keys

Integration key

Keys for changing the display

ESC

RESET

SET

CAL

PAGE

PAGE

ELEMENT

1

2

3

ELEM ENT

ALL

RANGE

VOLTAGE CURRENT

AUTO AUTO

DISPLAY

NUME RIC WAVE OTH ERS

FORM ITE M

CUR SOR

INTEGR ATOR

SETU P

INPU T INFO

START/

STOP

RESE T

HOLD

SING LE

SHIF T

MISC

NULL

LOC AL

KEY L OCK

FILE IMAGE

MENU

STOR E

STORE SET

POWE R

Keys for Changing the Display

ESC

RESET

SET

CAL

PAGE

PAGE

Cursor Keys ( )

Use these keys to move the cursor in setup menus and dialog boxes, to set values, to

select digits when setting numbers, and to select menu items.

SET

Use this key to display menus that you select with the cursor keys, confirm items and

values, and open a menu for changing displayed items when the menu display is turned

off in a numeric data display.

ESC

Use this key to close setup menus and dialog boxes, and to move up a level in a menu.

SHIFT+ESC (RESET) Key Combination

Use this key combination to return the item or value selected with the cursor to its default

value.

PAGE and PAGE

Use these keys in numeric value displays and other displays, when all of the measured

items do not fit into a single page, to change the displayed page. You can go to the first

page by pressing SHIFT+PAGE

and to the last page by pressing SHIFT+PAGE .

SHIFT+SET (CAL) Key Combination

Use this key combination to execute zero-level compensation. When zero level

compensation is executed, the WT500 creates a zero input condition in its internal

circuitry and sets the level at that point to the zero level.

Page 19

1-4

IM 760201-01E

1.2 Setup Menu Display and Operation Keys

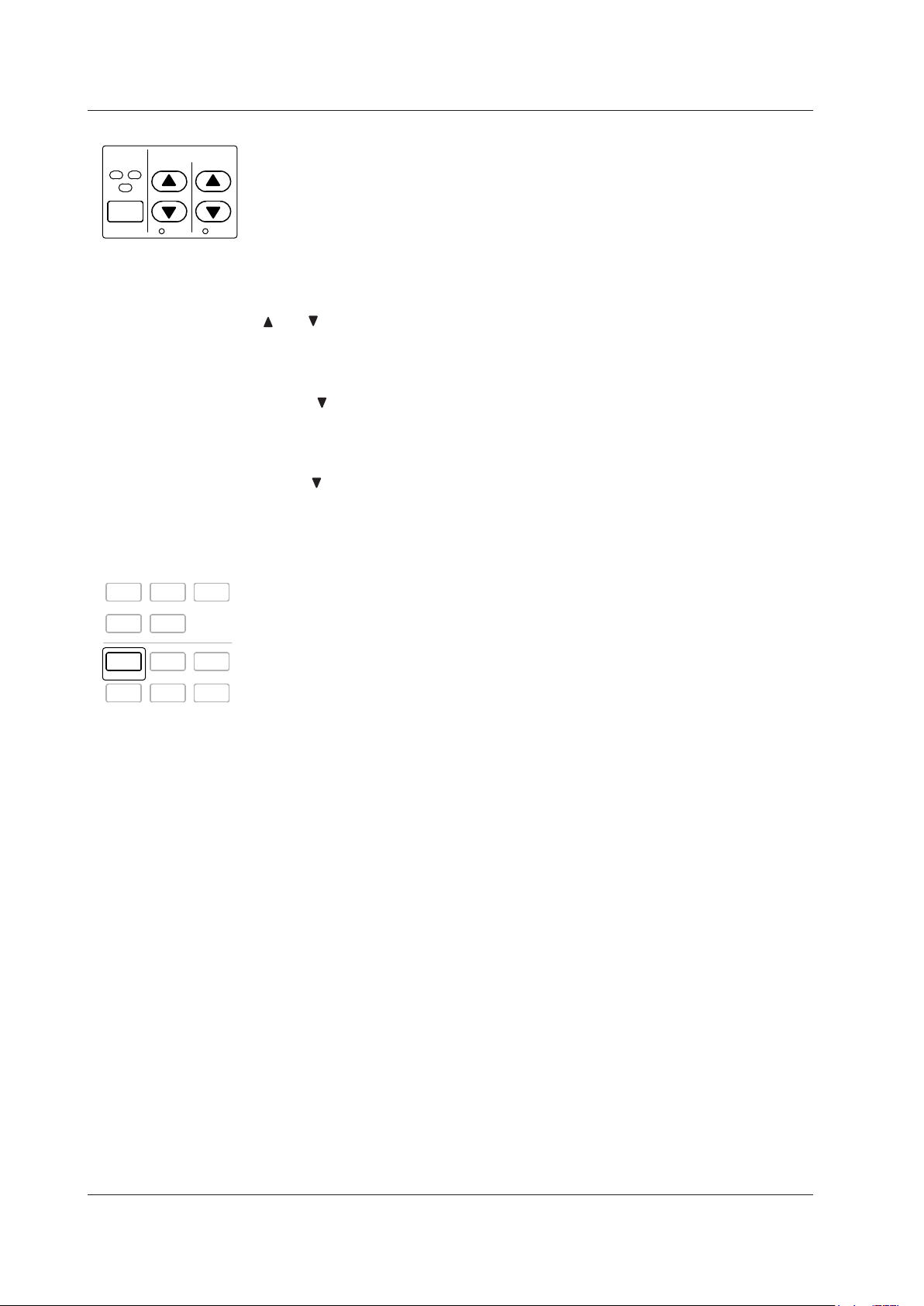

Keys for Setting the Measurement Range

ELEMENT

1

2

3

ELE MENT

ALL

RANGE

VOLTAGE CURRENT

AUTO A UTO

ELEMENT

• Use this key to select the input element that you want to set the measurement range

for. The selected input element will change each time you press ELEMENT.

•

When selecting a wiring system, the input elements that are part of the same wiring

system will be selected together.

SHIFT+ELEMENT (ALL) Key Combination

Use this key combination to set the voltage and current ranges of all elements at the

same time. Press ELEMENT again to make settings for individual elements.

and (See sections 4.3 and 4.4)

Use these keys to select the voltage, current, and current sensor ranges. The ranges

selected with these keys are valid when the AUTO indicators described below are not

lighted (when the manual range feature is being used).

SHIFT+ (AUTO) Key Combination

Use this key combination to activate the auto range feature (the AUTO indicator will light

when this feature is activated). This feature automatically sets the voltage, current, or

current sensor range depending on the amplitude of the received electrical signal. Press

SHIFT+

(AUTO) again to activate the manual range feature (the AUTO indicator light

will turn off).

Keys for Setting Measurement Conditions

SETU P

INPU T INFO

DISPLAY

NUM ERIC WAVE OTH ERS

FOR M ITEM

CUR SOR

INTEG RATOR

START /

STOP

RESE T

HOLD

SING LE

SHIF T

MIS C

NULL

LOC AL

KEY LOCK

SETUP

Use this key to display the Setup menu for setting measurement conditions. The following

items appear in the Setup menu:

• Wiring (See sections 4.1, 4.2, 5.7, and 5.8)

Select this item to display a menu for selecting the wiring system, configuring

individual input element settings, setting the efficiency equation, etc.

• Ranges (See sections 4.3 and 4.4)

You can select this item to set the voltage, current, or current sensor range, just as

you can with the panel RANGE keys. If you select AUTO, the auto feature will be

activated and the AUTO indicators underneath the RANGE keys will light.

• Scaling (See section 4.5)

Select this item to display a menu for setting the VT and CT ratios and the power

factor for each input element. The power coefficients are used to convert the VT/CT

output or the power derived from measuring the VT and CT outputs to the voltage,

current, and power of the object being measured.

• Sync Source (See section 4.7)

Select this item to display a menu for setting the synchronization source for each

wiring unit. The synchronization source defines the period (measurement period) over

which sampled data, which is used to produce numeric data (i.e., measured values

such as voltage, current, and power), is acquired.

• Filters (See section 4.8)

Select this item to display a menu for setting the line filter (which is inserted into the

measurement circuit) and the frequency filter (which is inserted into the frequency

measurement circuit) for each element.

• Update Rate (See section 4.9)

Select this item to display a menu for selecting the period (data update rate) at which

sampled data, which is used to produce numeric data (i.e., measured values such as

voltage, current, and power), is acquired.

• Averaging (See section 4.10)

Select this item to display a menu for setting the measured value averaging feature.

Page 20

1-5

IM 760201-01E

Component Names and Functions

1

• Integration (See sections 5.6 to 5.12)

Select this item to display a menu for setting the integration mode, integration auto

calibration, the integration timer, the reservation time, the watt hour integration method

for each polarity, and the ampere hour integration mode.

• Details.../Hide Details

Select this item to switch between displaying all menu items and only displaying a

portion of the menu items.

• Measure (See sections 5.3 to 5.5 and 12.6)

Select this item to display a menu for setting master/slave synchronized measurement

and for selecting the equation for apparent/reactive power and the format for phase

difference display.

• User Function (See sections 5.13 and 5.14)

Select this item to display a menu for setting user-defined functions and the MAX hold

feature.

• Freq Items (See section 5.16)

This item only appears on models without the frequency measurement option. Select

this item to display a menu for selecting which frequencies to measure. Because

models with the frequency measurement option measure all voltages and currents,

this menu will not appear.

• Harmonics (See sections 6.3 to 6.5)

This item only appears on models with the harmonic measurement option. Select this

item to display a menu for setting the PLL source, the measured harmonic orders, and

the equation for the harmonic distortion factor, in harmonic measurement.

• Delta Measure (See section 5.17)

This item only appears on models with the delta computation option. Select this item

to display a menu for selecting the delta computation type and the voltage or current

mode that will be the object of delta computation.

Note

While displaying any submenu in the Setup menu, you can press PAGE or PAGE to display

the previous or next menu. This feature is useful when you want to check the measurement

conditions set in each menu.

SHIFT+SETUP (INPUT INFO) Key Combination

Use this key combination to display a list of the conditions for acquiring the data from

a measured voltage or current signal, such as the wiring system for each element, the

wiring unit, the measurement range, the scaling, the synchronization source, and the

input filter.

1.2 Setup Menu Display and Operation Keys

Page 21

1-6

IM 760201-01E

Keys for Displaying Measured/Computed Results

SETU P

INPU T INFO

DISPLAY

NUM ERIC WAVE OTH ERS

FOR M ITEM

CUR SOR

INTEG RATOR

START /

STOP

RESE T

HOLD

SING LE

SHIF T

MIS C

NULL

LOC AL

KEY LOCK

NUMERIC (See sections 3.16, 5.1, and 6.2)

Use this key to display numeric data.

• Each time you press NUMERIC, the number of displayed items switches in this order:

4 Items > 8 Items > 16 Items > Matrix > All Items > Single List

*

> Dual List* > 4 Items >

and so on.

* Only appears on models with the harmonic measurement option.

• When you are displaying numeric data, you can press FORM, which is described later

in this section, to display a menu for changing the number of displayed items.

•

When you are displaying numeric data, you can press ITEM, which is described later

in this section, to display a menu for changing the displayed items.

WAVE (See sections 3.16, 6.7, and 7.2)

Use this key to display waveforms.

• Each time you press WAVE, the waveform display split screen setting switches in this

order: Single > Dual > Triad > Quad > Single > and so on.

•

When you are displaying waveforms, you can press FORM, which is described later

in this section, to display a menu for setting the time-axis of the displayed waveforms,

the trigger for waveform display, the number of waveform display split screens, and

the assignment of waveforms to split screens.

•

When you are displaying waveforms, you can press ITEM, which is described later

in this section, to display a menu for selecting and zooming in on the displayed

waveforms.

OTHERS (See sections 3.16, 6.7, 6.8, 7.2, and 8.2)

Use this key to switch between the Trend, Bar Graph*, and Vector* displays.

Each time you press OTHERS, the display switches in this order: Trend > Bar* > Vector*

> Trend > and so on.

* Only appears on models with the harmonic measurement option.

FORM (See sections 5.2, 6.2, 6.7, 6.8, 7.4, 7.5, 7.7, 7.8, and 8.6 to 8.9)

Use this key to display a menu for setting the format of the display that has been selected

using NUMERIC, WAVE, or OTHERS.

SHIFT+FORM (CURSOR) Key Combination (See sections 7.9 and 8.10)

Use this key when you are displaying waveforms, trends, or bar graphs* to display a

menu for using cursors to measure waveform and graph values.

* Only appears on models with the harmonic measurement option.

ITEM Key (See sections 5.2, 6.2, 6.7, 6.8, 7.3, 7.6, and 8.3 to 8.5)

Use this key to display a menu for setting the displayed items in the display that has

been selected using NUMERIC, WAVE, or OTHERS.

Keys for Data Storage/Saving

FILE IMA GE

MENU

STOR E

STOR E SET

FILE

Use this key to display a menu for saving and loading setup parameters, saving

measured data, deleting files, copying files, and so on.

IMAGE

Use this key to save the screen image data.

SHIFT+IMAGE (MENU) Key Combination

Use this key combination to display a menu for setting screen image data save options

such as the file name, data format, color mode, data compression, and comments.

STORE

Use this key to execute, stop, or reset a storage operation.

SHIFT+STORE (STORE SET) Key Combination

Use this key to display a setup menu for the storage feature.

1.2 Setup Menu Display and Operation Keys

Page 22

1-7

IM 760201-01E

Component Names and Functions

1

Other Keys

SETU P

INPU T INFO

DISPLAY

NUM ERIC WAVE OTH ERS

FOR M ITEM

CUR SOR

INTEG RATOR

START /

STOP

RESE T

HOLD

SING LE

SHIF T

MIS C

NULL

LOC AL

KEY LOCK

START/STOP Key

Use this key to start or end integration. You can view the integration condition in the

integration setup/condition display (see section 1.3).

SHIFT+START/STOP (RESET) Key Combination

Use this key combination to reset the integrated value.

HOLD (See section 4.12)

Press HOLD to stop data measurement and display operations and to hold the numeric

display (the HOLD key illuminates when the numeric display is held). During integration,

the numeric display is held but measurement is not stopped. Press HOLD again to allow

the numeric data display to be updated (the HOLD key will no longer be illuminated).

SHIFT+HOLD (SINGLE) Key Combination (See section 4.12)

Use this key combination while the display is held to measure the signal once at the set

data update rate, and then to re-hold the display.

LOCAL

Use this key to switch from remote mode (the REMOTE indicator will appear at the upper

right of the screen) to local mode (in which front panel key operations are valid). This key

is invalid when the WT500 is in local lockout mode.

SHIFT+LOCAL (KEY LOCK) Key Combination

Use this key combination to turn the key lock on or off. When the key lock is on, no keys

or key combinations other than SHIFT+LOCAL are valid, and LOCK appears in the upper

right of the screen.

MISC

Use this key to display a menu for viewing the system status, initializing setup

parameters, configuring or viewing the settings of remote control through communication

commands (using the USB, GP-IB, or Ethernet interface option), setting the date/time,

selecting the message and menu languages, selecting the crest factor, setting the USB

peripheral interface, setting the optional Ethernet interface, setting the self test, etc.

SHIFT+MISC (NULL) Key Combination

Use this key combination to activate the NULL feature, which removes the DC

component from the sampled data (the NULL indicator appears on the screen when the

NULL feature is activated). Press SHIFT+MISC (NULL) again to deactivate the NULL

feature (the NULL indicator will no longer appear).

SHIFT

When you press the SHIFT key, the key illuminates, and pressing a panel key produces

the effect indicated by the purple letters below it. Holding down SHIFT for 2 seconds or

more will lock the WT500 into the shifted state. Pressing SHIFT again will release the

shifted state (and the SHIFT key will no longer be illuminated).

1.2 Setup Menu Display and Operation Keys

Page 23

1-8

IM 760201-01E

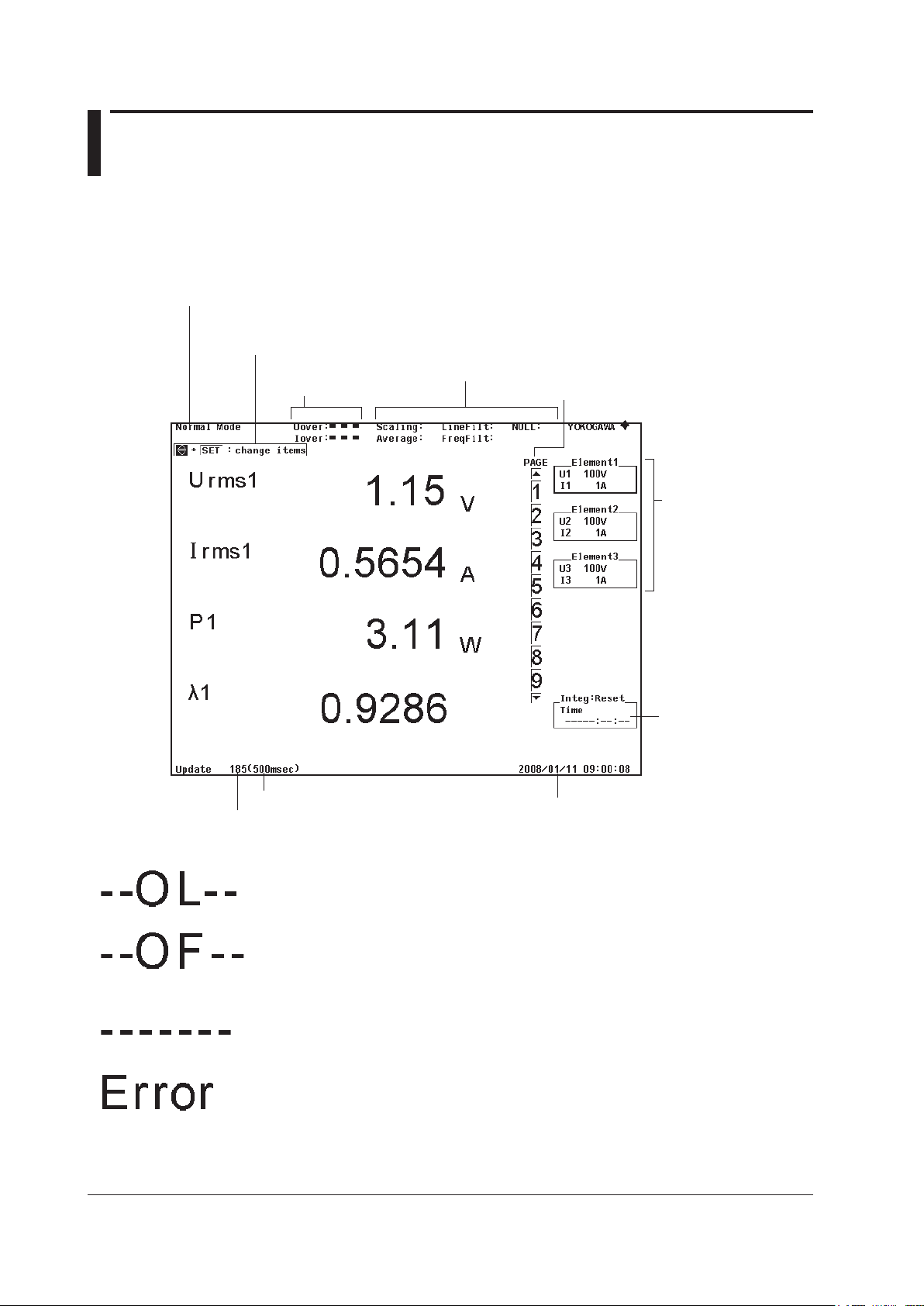

1.3 Screen Display

Display Example When Measuring Power (Numeric display) in Normal

Measurement Mode

For a description of the screens in other display modes, see the chapters that cover

those modes.

Date/time (see section 3.11)

Input peak over-range

indicator (see section 5.2)

Measurement mode (see section 7.2)

Display items that can

be changed directly

(see section 5.2)

Indication of on/off status of various features

• Scaling (see section 4.6)

• Averaging (see section 4.10)

• Line filter (see section 4.8)

• Frequency filter (see section 4.8)

• NULL feature (see section 12.4)

Page bar (see section 5.2)

Input element setup

parameters

• Measurement range

(see sections 4.4 to 4.5)

• Wiring system

(see section 4.2)

Integration setting/status

(see section 5.11)

Data update count (see section 5.2)

Data update rate (see section 4.9)

Non-Numeric Displays

Overload

Displayed if the measured value exceeds 140% of the measurement range.

Overflow

Displayed if the measured or computed result cannot be displayed using the specified

decimal place or unit.

No data

Displayed if a measurement function is not selected or if there is no numeric data.

Error

Displayed in cases such as when a measured value is outside of its determined range.

Page 24

2-1

IM 760201-01E

Features

2

1

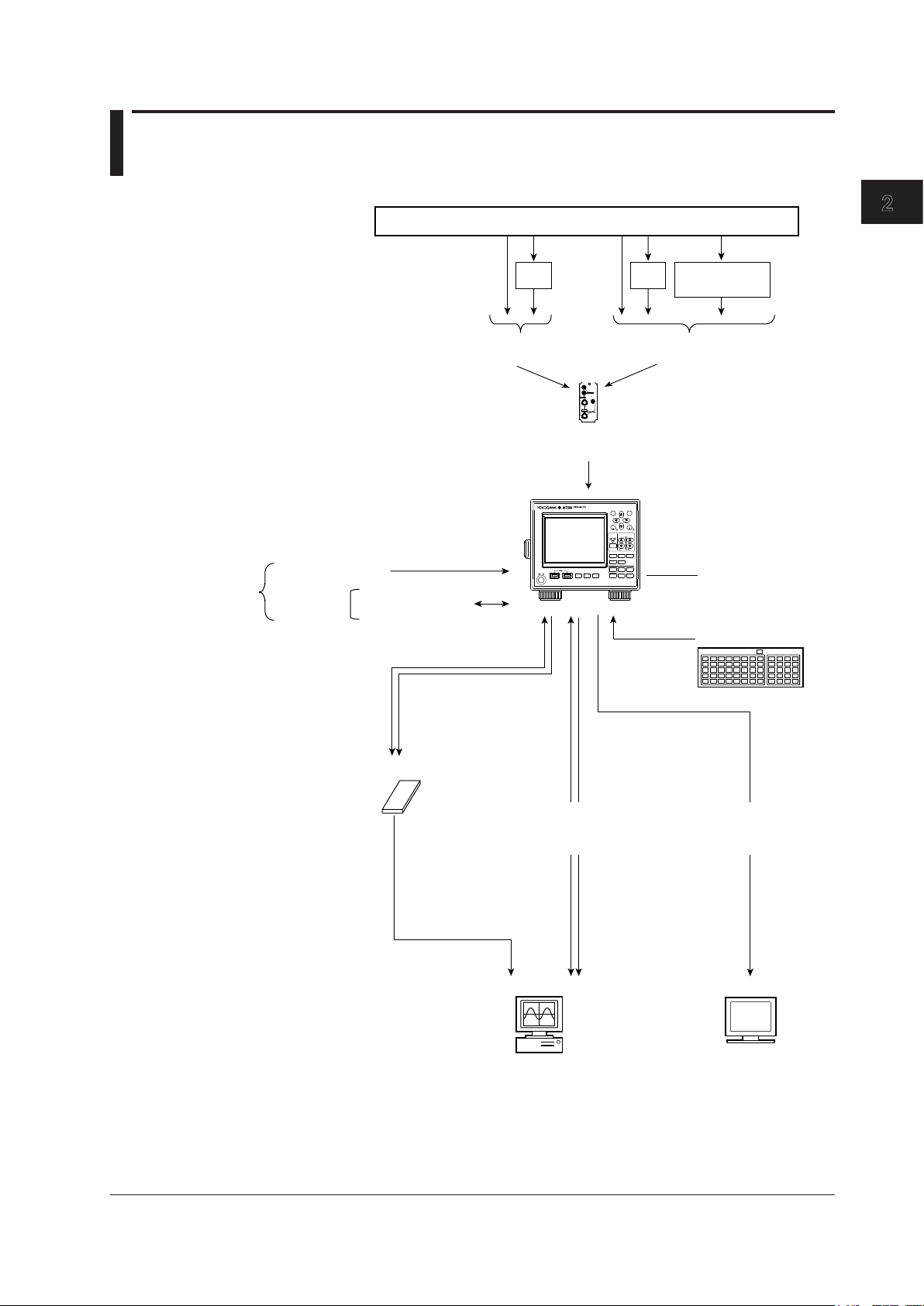

2.1 System Configuration and Block Diagram

System Configuration

ESC

RESET

SET

CAL

PAGE

PAGE

ELEMENT

1

2

3

ELEMENT

ALL

RANGE

VOLTAGE CURRENT

AUTO AUTO

DISPLAY

NUMERIC WAVE O THERS

FORM ITEM

CURSOR

INTEGRATOR

SETUP

INPUT INFO

START/

STOP

RESET

HOLD

SINGLE

SHIFT

MISC

NULL

LOCAL

KEY LOCK

FILE IMAGE

MENU

STORE

STORE SET

POWER

ELEMENT

VOLTAGE

±

±

CURRENT

EXT

Object Being Measured

VT

CT

Voltage

(Apply one or the other)

Current

(Apply one of them)

Current sensor

(optional)

Input element

External clock input

Master/slave

sync signal

USB keyboard

Internal memory

Stores numeric data

USB memory

CRT

Numeric data

Waveform display data

Screen image data

Stored data

Setup parameters

Numeric data

Waveform display data

Screen image data

Setup

parameters

PC

Measurement start/

Measurement stop

GP-IB interface (optional)/

Ethernet interface (optional)/

USB interface

RGB video signal (VGA)

output (optional)

Image signal

(Apply one or the other)

Chapter 2 Features

Page 25

2-2

IM 760201-01E

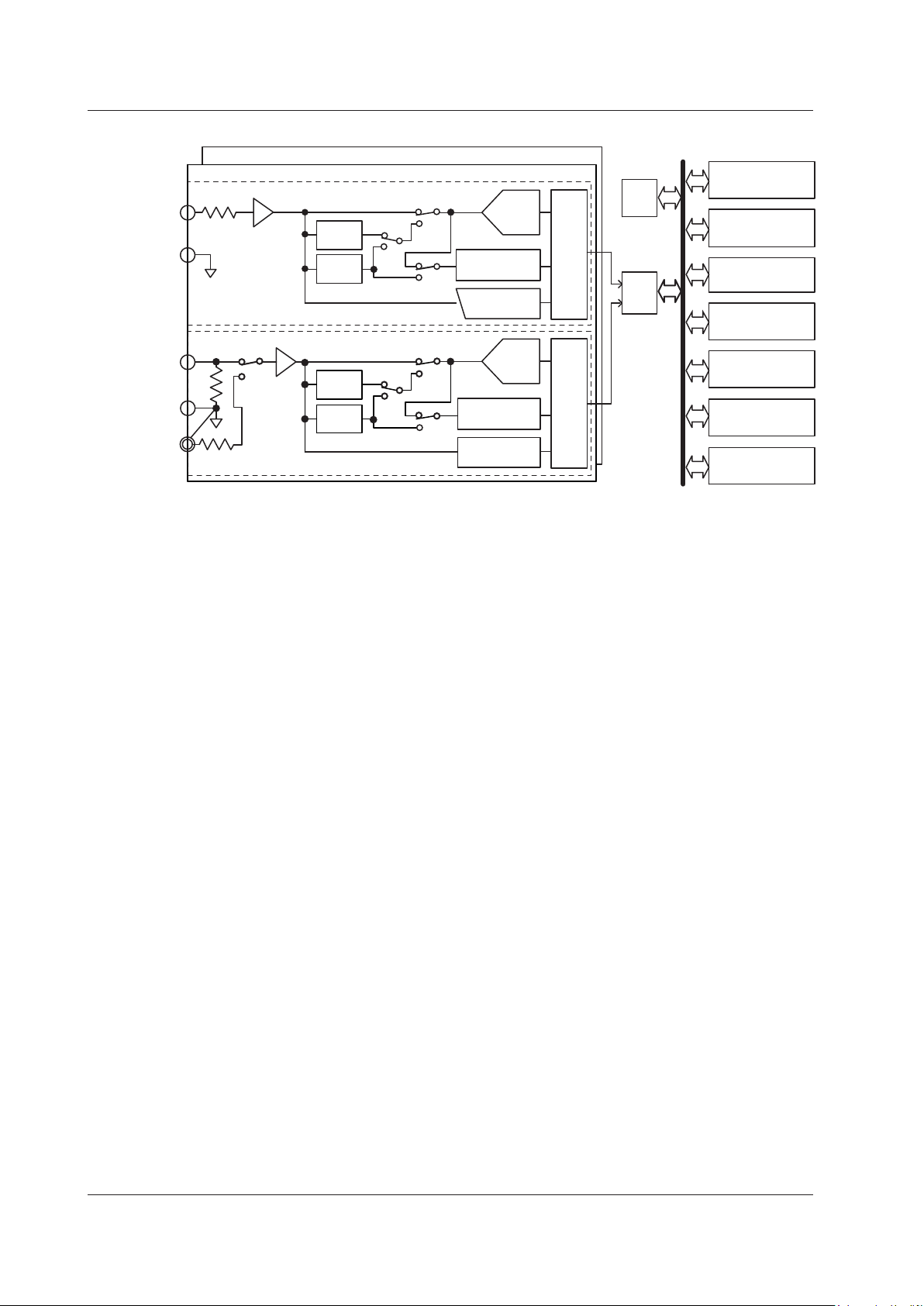

Block Diagram

U

±

L.P.F.

5.5 kHz

L.P.F.

500 Hz

L.P.F.

5.5 kHz

L.P.F.

500 Hz

A/D

Isolator Isolator

Zero-crossing

detector

Peak

detector

I

±

Current sensor

(EXT; optional)

Voltage input circuit

Current input circuit

Input element 1

Input elements 2 and 3

DSP

CPU

LCD

USB port

(for peripherals)

USB port

(PC)

GP-IB

(optional)

Ethernet

(optional)

VGA output

(optional)

KEY

Voltage Input

Current input

A/D

Zero-crossing

detector

Peak

detector

Input Signal Flow and Process

Input elements 1 through 3 consist of a voltage input circuit and a current input circuit.

The input circuits are mutually isolated. They are also isolated from the case.

The voltage signal that is applied to the voltage input terminal (U, ±) is normalized using

the voltage divider and the operational amplifier (op-amp) of the voltage input circuit . It is

then sent to a voltage A/D converter.

The current input circuit is equipped with two types of input terminals, a current input

terminal (I, ±) and an optional current sensor input connector (EXT). Only one can be

used at any given time. The voltage signal from the current sensor that is received at the

current sensor input connector is normalized using the voltage divider and the operational

amplifier (op-amp). It is then sent to a current A/D converter. The current signal that is

applied to the current input terminal is converted to a voltage signal by a shunt. Then, it

is sent to the current A/D converter in the same fashion as the voltage signal from the

current sensor.

The voltage signal that is applied to the voltage A/D converter and current A/D converter

is converted to digital values at an interval of approximately 10 µs. These digital values

are isolated by the isolator and passed to the DSP. In the DSP, the measured values

are derived based on the digital values. The measured values are then transmitted to

the CPU. The measured values and computed values are displayed and transmitted as

measurement functions of normal measurement.

The harmonic measurement functions are derived in the following manner (harmonic

measurement is an option). The voltage signal sent to the A/D converter is converted to

digital values at a sampling frequency that is determined by the PLL source signal. The

DSP derives the measured value of each harmonic measurement item by performing an

FFT on the converted digital values.

2.1 System Configuration and Block Diagram

Page 26

2-3

IM 760201-01E

Features

2

1

2.2 Measurement Functions and Periods

Measurement Functions

The physical values (such as rms voltage, average current, power, and phase difference)

that the WT500 measures and displays are called measurement functions. Each

measurement function is displayed using symbols that correspond to its physical value.

For example, “Urms” corresponds to the true rms voltage.

Types of Measurement Functions Used in Normal Measurement

The data of measurement functions (numeric data) is measured or computed from the

sampled data that is described in “Measurement Period” on page 2-9.

1

1 The WT500 samples the instantaneous values of the voltage and current signals at the

specified sample rate. The sampled data is processed as numeric data or data used to

display waveforms on the screen (waveform display data).

The sample rate is the number of data points that are sampled within 1 s. For example, at a

sample rate of 100 kS/s, 100000 data points are sampled every second.

Types of Measurement Functions

• Input Element Measurement Functions

The following 23 measurement functions are available. For details about the

determination of measurement function data, see appendix 1.

U (voltage Urms, Umn, Udc, Urmn, Uac), I (current Irms, Imn,

Idc, Irmn, Iac), P (active

power), S (apparent power), Q (reactive power), λ (power factor), f (phase difference),

fU/fI (also expressed as FreqU/FreqI; measures the frequencies of up to two voltage/

current signals),

2

U+pk/U-pk (maximum/minimum voltage values), I+pk/I-pk (maximum/

minimum current values), and CfU/CfI (crest factor of voltage/current; peak-to-rms

ratio)

2 The voltage and current frequencies of all input elements can be measured on models with

the frequency measurement add-on option.

• Wiring UnitΣ Measurement Functions (Σ Functions)

The following 15 measurement functions are available. For details about the

determination of measurement function data, see appendix 1.

UΣ (voltage average UrmsΣ, UmnΣ, UdcΣ, UrmnΣ, UacΣ), IΣ (current average IrmsΣ,

ImnΣ, IdcΣ, IrmnΣ, IacΣ), PΣ (sum of active powers), SΣ (sum of apparent powers),

QΣ (sum of reactive powers), λΣ (power factor average), and fΣ (phase difference

average)

•Efficiency (Σ functions) and User-Defined Functions

There are two ef

ficiency functions, η1 and η2. The available user-defined functions

are F1 to F8. For details, see section 2.5.

•

Integration Functions

See section 2.6.

• Delta Computation (Optional)

There are four delta functions, ΔF1 to Δ F4. For details, see section 5.17.

Page 27

2-4

IM 760201-01E

Determining Voltage and Current

The following five types of voltage (U) and current (I) measurement functions are

available.

•

Urms and Irms (True rms value)

These values are the true rms values of the voltage and current. The instantaneous

values over one period are squared and averaged. Then, the square root of the

average is determined. f(t) is the input signal as a function of time. T is the period of

the input signal.

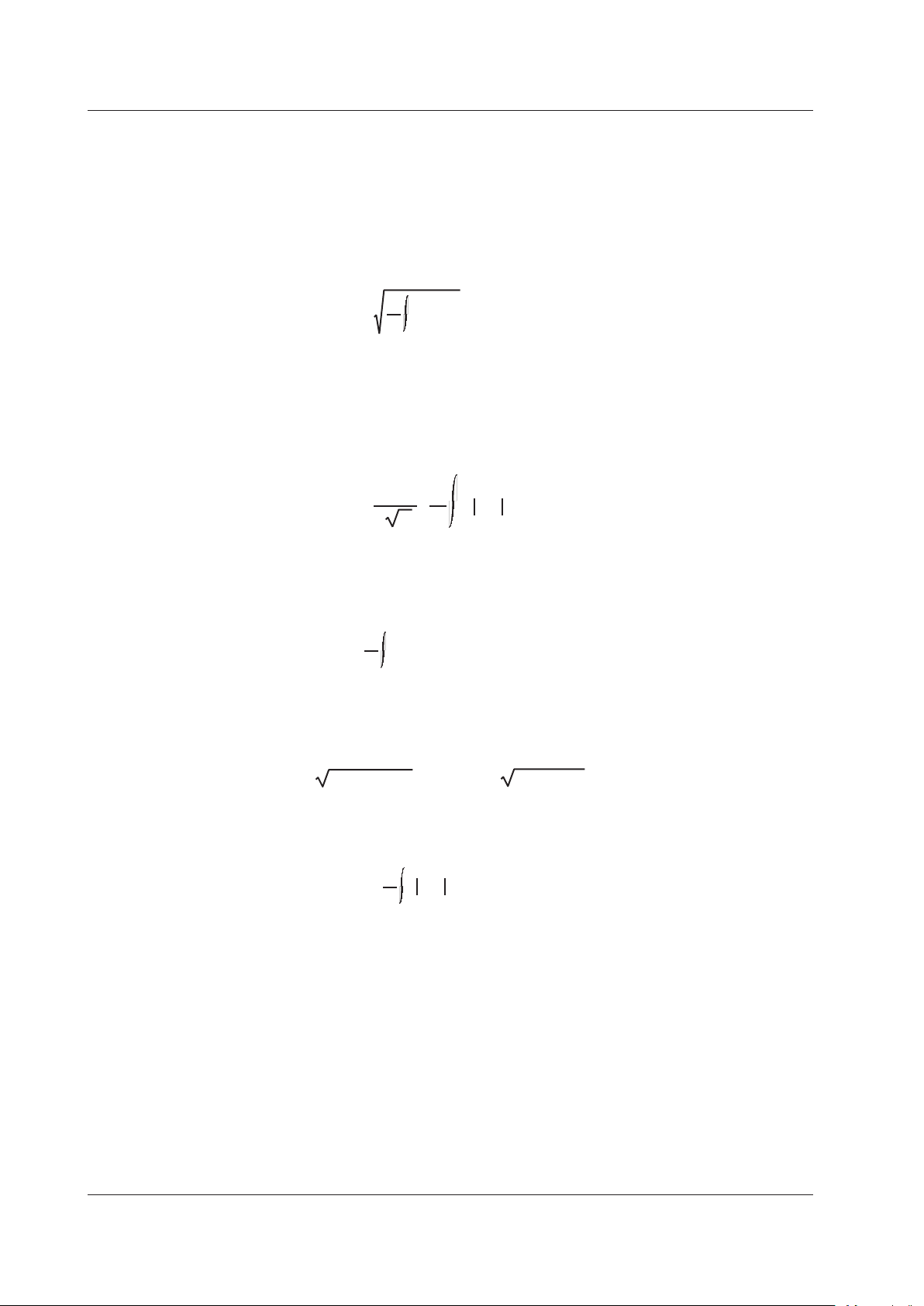

Urms or Irms =

1

T

0

T

f(t)2 dt

• Umn and Imn (Rectified mean value calibrated to the rms value)

This function rectifies one period of the voltage or current signal, determines the

average, and multiplies the result by a coefficient. The coefficient is a value that when

applied to a sinusoidal input signal, gives the true rms value. When the input signal is

a distorted or DC waveform, these values will differ from the true rms values. f(t) is the

input signal as a function of time. T is the period of the input signal.

Umn or Imn =

π

2

2

•

1

T

0

T

f(t) dt

• Udc and Idc (Simple average, DC)

These are the average values of the voltage and current signal over one period. This

function is useful when determining the average value of a DC input signal or the DC

component that is superimposed on an AC input signal.

Udc or Idc =

1

T

0

T

f(t) dt

• Uac and Iac (AC component)

This function determines the AC component of the voltage or current. The function

calculates the square root of the square of the true rms value minus the square of the

DC component.

Uac=

Urms

2

–Udc

2

Iac=

Irms

2

–Idc

2

, or

• Urmn and Irmn (Rectified mean value)

This function rectifies one period of the voltage or current signal and determines the

average.

Urmn or Irmn =

1

T

0

T

f(t) dt

Elements

Element refers to a set of input terminals that can receive a single phase of voltage and

current to be measured. The WT500 can contain up to three elements, numbered from

1 to 3. An element number is appended to the measurement function symbol for the

measured data that the WT500 displays, so that you can tell which data belongs to which

element. For example, “Urms1” corresponds to the true rms voltage of element 1.

Wiring Systems

You can specify five wiring systems on the WT500 to measure the power of various

single-phase and three-phase power transmission systems: single-phase, two-wire;

single-phase, three-wire; three-phase, three-wire; three-phase, four-wire; and threephase, three-wire with three-voltage, three-current method. For details, see section 2.3.

2.2 Measurement Functions and Periods

Page 28

2-5

IM 760201-01E

Features

2

1

Wiring Unit

The wiring unit is a set of two or three input elements of the same wiring system that

are grouped to measure three-phase power. The wiring unit is represented by Σ. The

measurement function of a wiring unit is called a Σ function.

For example, “UrmsΣ” corresponds to the average of the voltages of the input elements

that are assigned to the wiring unit. The average represents the true rms value.

•

Wiring System and Wiring Unit Configuration Example

Voltage

input

Current

input

Three-phase,

three-wire

3

Element 1

Element 2 Element 3

Single-phase,

two-wire

Wiring system

Wiring unit

2.2 Measurement Functions and Periods

Page 29

2-6

IM 760201-01E

Types of Measurement Functions Used in Harmonic Measurement (Optional)

The data of harmonic measurement functions (numeric data) is measured or computed

from the sampled data that is described later in “Measurement Period.”

*

* For information about sampled data, see the explanation under “Types of Measurement

Functions Used in Normal Measurement,” earlier in this section.

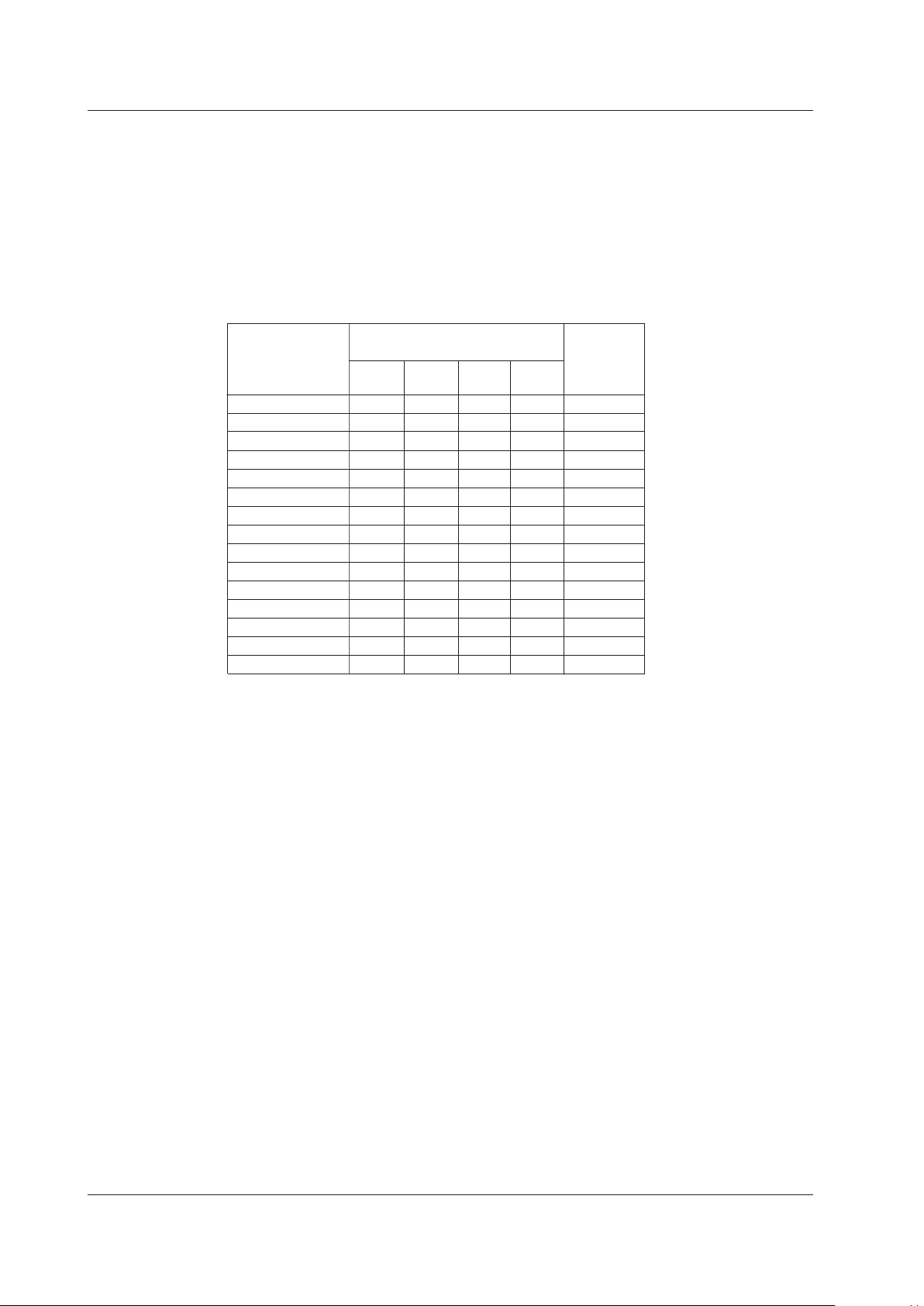

Types of Harmonic Measurement Functions

• Input Element Harmonic Measurement Functions

The following 15 harmonic measurement functions are available. For details about the

determination of measurement function data, see appendix 1.

dc

Yes

Yes

Yes

Yes

Always 0

Yes

No

No

No

Yes

Yes

Yes

No

No

No

1

Yes

Yes

Yes

Yes

Yes

Yes

Yes

No

No

Yes

Yes

Yes

No

No

No

Total

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

No

No

No

k

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

No

No

No

All

No

parentheses

No

No

No

No

No

No

No

No

No

No

No

No

Yes

Yes

Yes

U( )

I( )

P( )

S( )

Q( )

λ( )

φ( )

φU( )

φI( )

Uhdf( )

Ihdf( )

Phdf( )

Uthd

Ithd

Pthd

Characters or Numbers

in Parentheses

Measurement

Function

Yes: Numeric data available

No: No numeric data available

• Functions with parentheses will produce different values depending on which of the

following is contained in their parentheses.

•

total: The total value is displayed.

•

dc: The dc component numeric data is displayed.

• 1: The numeric data of the fundamental signal is displayed.

• k: The numeric data from harmonic orders 2 to N is displayed. N is the upper

limit of harmonic order analysis (see section 17.6 for details). The upper

limit of harmonic analysis is either set to an automatically determined value

or to the value that you set, whichever is smaller. It can go up to the 50th

harmonic order.

•

All: Functions without parentheses display numeric data.

• Functions Uhdf to Pthd are measurement functions that express values that

are unique to harmonics. For details about how the values are determined, see

appendix 1.

2.2 Measurement Functions and Periods

Page 30

2-7

IM 760201-01E

Features

2

1

• Harmonic Measurement Functions That Express the Voltage and Current Phase

Differences (f) between and within Input Elements

There are five kinds of harmonic measurement functions that e

xpress phase

differences:

fUi-Uj, fUi-Uk, fUi-Ii, fUi-Ij, fUi-Ik

(i, j, and k are input element numbers)

The following explanation of the five kinds of harmonic measu

rement functions is for

the case when the number of input elements in wiring unit Σ is three and their common

wiring system is three phase, four wire. Also, i = 1, j = 2, and k = 3.

In this case, the following numeric data for the phase dif

ferences between elements 1,

2, and 3 is calculated.

•

fU1-U2

The phase dif

ference between the fundamental voltage of element 1, U1(1), and

the fundamental voltage of element 2, U2(1).

•

fU1-U3

The phase dif

ference between the fundamental voltage of element 1, U1(1), and

the fundamental voltage of element 3, U3(1).

•

fU1-I1

The phase dif

ference between the fundamental voltage of element 1, U1(1), and

the fundamental current of element 1, I1(1).

• fU1-I2

The phase dif

ference between the fundamental voltage of element 1, U1(1), and

the fundamental current of element 2, I2(1).

•

fU1-I3

The phase dif

ference between the fundamental voltage of element 1, U1(1), and

the fundamental current of element 3, I3(1).

•

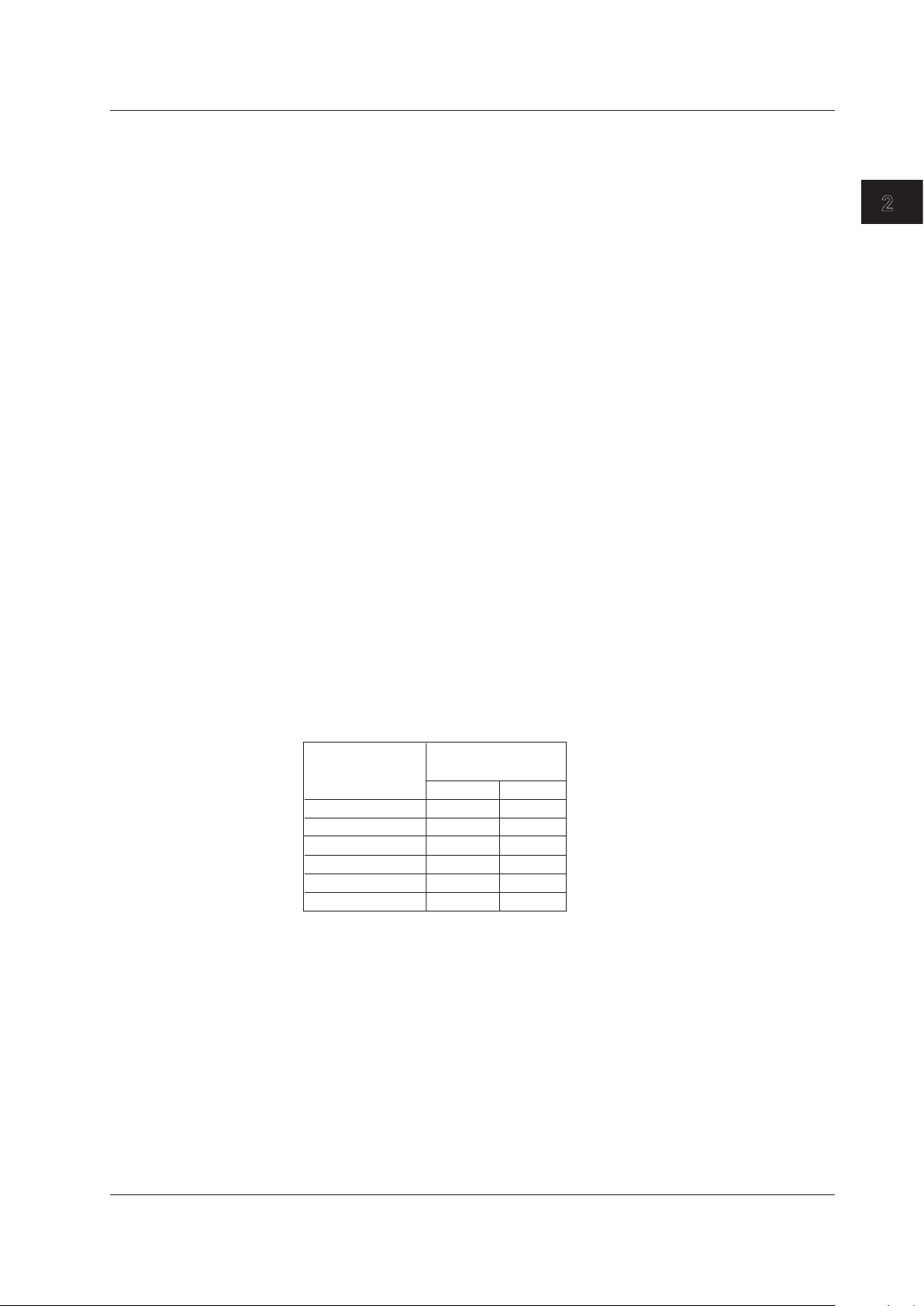

Functions for Averaging and Summing Input Elements (Σ functions)

The following six harmonic measurement functions are available. For details about

how the measurement function values are determined, see appendix 1.

1

Yes

Yes

Yes

Yes

Yes

Yes

Total

Yes

Yes

Yes

Yes

Yes

Yes

U3( )

I3( )

P3( )

S3( )

Q3( )

L3( )

Characters or number

in parentheses

Measurement

Function

Yes: Numeric data available

Functions with parentheses will produce different values depending on which of the

following is contained in their parentheses.

•

total: The total value is displayed.

• 1: The numeric data of the fundamental signal is displayed.

2.2 Measurement Functions and Periods

Page 31

2-8

IM 760201-01E

Elements

Element refers to a set of input terminals that can receive a single phase of voltage

and current to be measured. The WT500 can contain up to three elements, numbered

from 1 to 3. The element number follows the function symbols discussed in “Input

Element Harmonic Measurement Functions” earlier in this section. For example, “U1(2)”

corresponds to the voltage of the second harmonic of element 1.

Wiring Systems

The selectable wiring system patterns vary depending on the number of input elements

that are installed in the WT500.

Wiring Unit

The wiring unit is a set of two or three input elements of the same wiring system that

are grouped to measure three-phase power. The wiring unit is represented by Σ. The

measurement function of a wiring unit is called a Σ function.

For example, “UΣ(1)” corresponds to the average of the fundamental voltages of the

input elements that are assigned to the wiring unit.

PLL Source (See section 6.3 for operating instructions)

To measure harmonics, the fundamental period (the period of the fundamental

signal) that will be used to analyze the harmonics must be determined. The signal for

determining the fundamental period is the PLL (phase locked loop) source. For stable

harmonic measurement, choose an input signal for the PLL source that has as little

distortion and fluctuation as possible. The ideal signal when the crest factor is set to 3

(see section 5.11 for details) is a rectangular wave with an amplitude that is 50% or more

of the measurement range (see section 1.3 for details). When the crest factor is set to

6, the ideal signal is a rectangular wave with an amplitude that is 100% or more of the

measurement range.

Also, applying a clock signal (Ext Clk) with the same period as the waveform whose

harmonics are being measured makes stable harmonic measurement possible.

2.2 Measurement Functions and Periods

Page 32

2-9

IM 760201-01E

Features

2

1

Measurement Period (See section 4.7 for operating instructions)

Measurement Functions Used in Normal Measurement

• The measurement period is set within the data update interval between the first point

where the reference input signal (synchronization source) crosses the level zero point

(center of the amplitude) on the rising trigger slope (or falling trigger slope) and the

last point where the synchronization source crosses the level zero point (center of the

amplitude) on the rising slope (or falling slope).

1, 2

However, the measurement period

for determining the numeric data of the peak voltage or peak current is the entire span

of the data update interval. Therefore, the measurement period for the measurement

functions that are determined using the maximum voltage or current value (U+pk,

U-pk, I+pk, I-pk, CfU, and CfI) is also the entire span of the data update interval.

•

The WT500 determines whether to define the measurement period using the rising