Page 1

User’s

Manual

WT310/WT310HC/WT330

Digital Power Meter

Getting Started Guide

IM WT310-02EN

1st Edition

Page 2

Product Registration

Thank you for purchasing YOKOGAWA products.

YOKOGAWA provides registered users with a variety of information and

services.

Please allow us to serve you best by completing the product registration

form accessible from our homepage.

http://tmi.yokogawa.com/

PIM 103-03E

Page 3

Thank you for purchasing the WT310, WT310HC, or WT330 Digital Power Meter (hereinafter, “WT310/

WT310HC/WT330” will refer to all of these products). The WT310/WT310HC/WT330 is a power

measurement instrument that can measure parameters such as voltage, current, and power.

This getting started guide primarily explains the handling precautions and basic operations of the

WT310/WT310HC/WT330. To ensure correct use, please read this manual thoroughly before

beginning operation.

Keep this manual in a safe place for quick reference in the event that a question arises.

This manual is one of three WT310/WT310HC/WT330 manuals. Please read all manuals.

Manual Title Manual No. Description

WT310/WT310HC/WT330 Digital

Power Meter User’s Manual

WT310/WT310HC/WT330 Digital

Power Meter Getting Started Guide

WT310/WT310HC/WT330 Digital

Power Meter Communication

Interface User’s Manual

IM WT310-01EN The manual explains all the WT310/WT310HC/WT330

features, except for the communication interface

features, and how to use them.

IM WT310-02EN This guide. Provided as a printed manual. The manual

explains the handling precautions and basic operations

of the WT310/WT310HC/WT330 and provides an

overview of its features.

IM WT310-17EN This manual explains the WT310/WT310HC/WT330

communication interface features and how to use them.

PDF files of all the manuals above are included in the accompanying CD.

Notes

• The contents of this manual are subject to change without prior notice as a result of continuing

improvements to the instrument’s performance and functionality. The figures given in this manual

may differ from those that actually appear on your screen.

•

Every effort has been made in the preparation of this manual t

contents. However, should you have any questions or find any errors, please contact your nearest

YOKOGAWA dealer.

• Copying or reproducing all or any part of the contents of this manual without the permission of

YOKOGA

• The TCP/IP

WA is strictly prohibited.

software of this product and the documents concerning it have been developed/created

by YOKOGAWA based on the BSD Networking Software, Release 1 that has been licensed from

the Regents of the University of California.

o ensure the accuracy of its

Trademarks

• Microsoft, Internet Explorer, MS-DOS, Windows, Windows NT, Windows XP, Windows Vista, and

Windows 7 are either registered trademarks or trademarks of Microsoft Corporation in the United

States and/or other countries.

•

Adobe and Acrobat are either registered trademarks or tradem

• In this manual, the TM and

® symbols do not accompany their respective registered trademark or

trademark names.

• Other company and product names are registered trademarks or trademarks of their respective

holders.

Revisions

• January 2013 1st Edition

1st Edition: January 2013 (YMI)

All Rights Reserved, Copyright © 2013 Yokogawa Meters & Instruments Corporation

IM WT310-02EN

arks of Adobe Systems Incorporated.

i

Page 4

ii

IM WT310-02EN

Checking the Contents of the Package

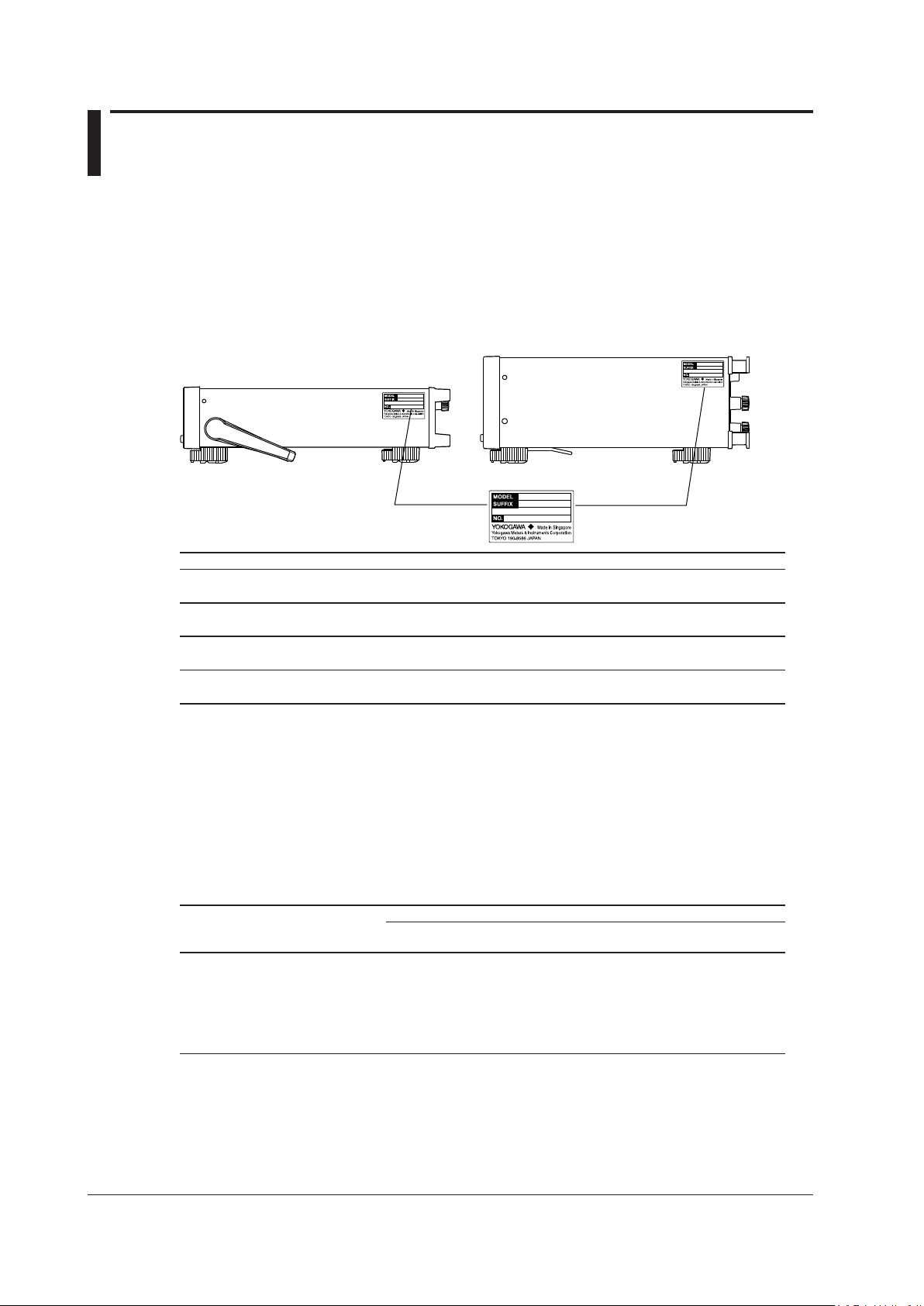

WT310/WT310HC WT330 (Model: WT332/WT333)

Unpack the box and check the contents before operating the instrument. If the wrong items have been

delivered, if items are missing, or if there is a problem with the appearance of the items, contact your

nearest YOKOGAWA dealer.

WT310/WT310HC/WT330

Check that the product that you received is what you ordered by referring to the model name and suffix

code given on the name plate on the left side panel.

The WT330 includes the WT332 and WT333.

Model Suffix Code Description

WT310 WT310 Digital Power Meter

One input element model

WT310HC WT310 Digital Power Meter

One input element/large current model

WT332 WT330 Digital Power Meter

Two input element model

WT333 WT330 Digital Power Meter

Power cord

Communication interface -C1 GP-IB interface

(The instrument is equipped

with one of these.)

Options /C7 Ethernet Communication

1

-D UL/CSA Standard power cord (Part No.: A1006WD)

-F VDE Standard power cord (Part No.: A1009WD)

-Q BS Standard power cord (Part No.: A1054WD)

-R AS Standard power cord (Part No.: A1024WD)

-H GB Standard power cord (Part No.: A1064WD)

-N NBR Standard power cord (Part No.: A1088WD)

-C2 RS-232 interface

/EX1

/EX2

/G5 Harmonic measurement

/DA4 DA output (4CH); for the WT310 or WT310HC

/DA12 DA output (12CH); for the WT332 or WT333

1 Make sure that the attached power cord meets the designated standards of the country and area

that you are using it in.

2 A single instrument cannot have both the /EX1 and /EX2 optio

Three input element model

Maximum rated voltage: 125 V

Maximum rated voltage: 250 V

Maximum rated voltage: 250 V

Maximum rated voltage: 250 V

Maximum rated voltage: 250 V

Maximum rated voltage: 250 V

2

2.5 V/5 V/10 V external input

2

50 mV/100 mV/200 mV/500 mV/1 V/2 V external input

ns.

No. (Instrument number)

When contacting the dealer from which you purchased the instrument, please give them the instrument

number.

Page 5

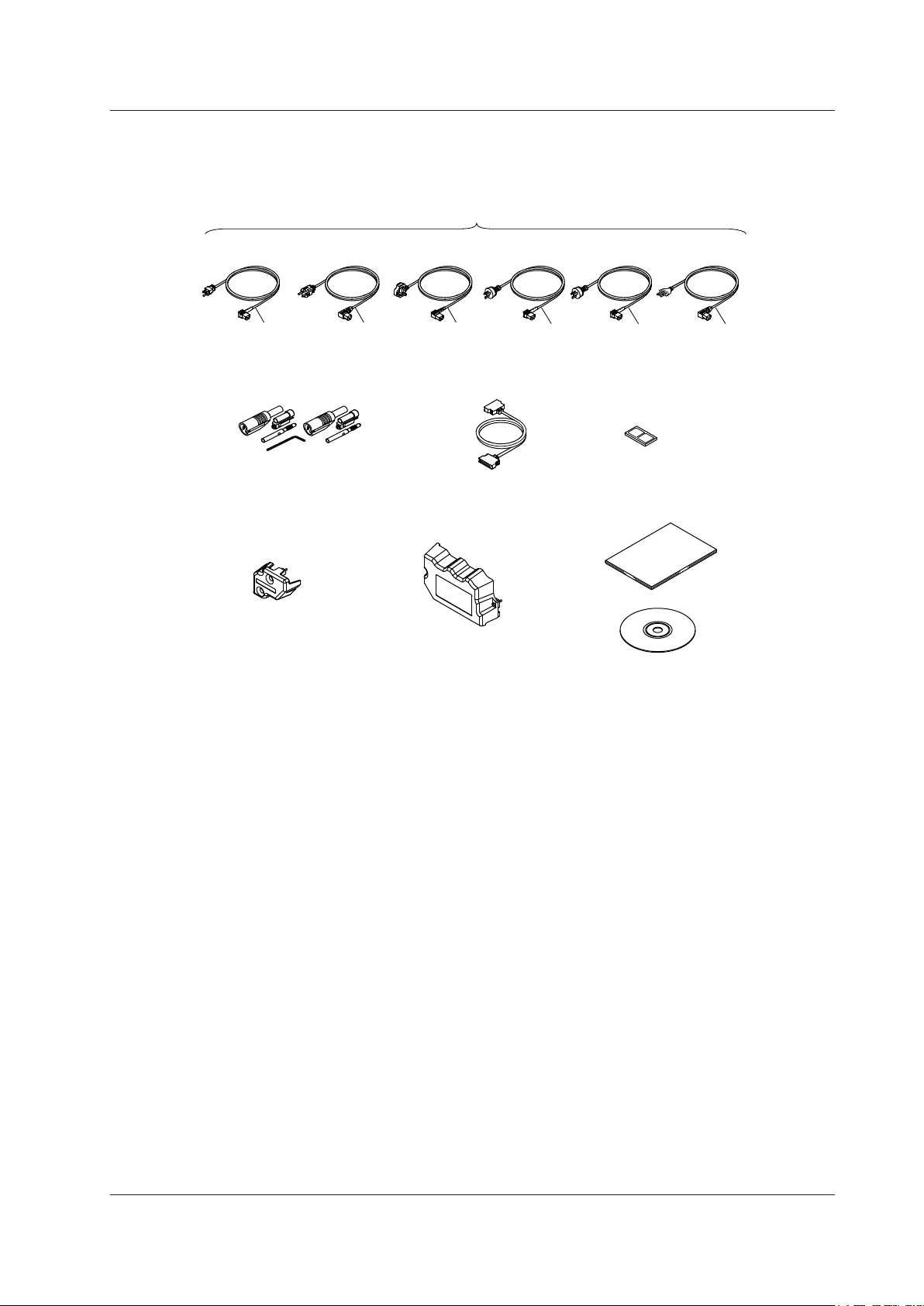

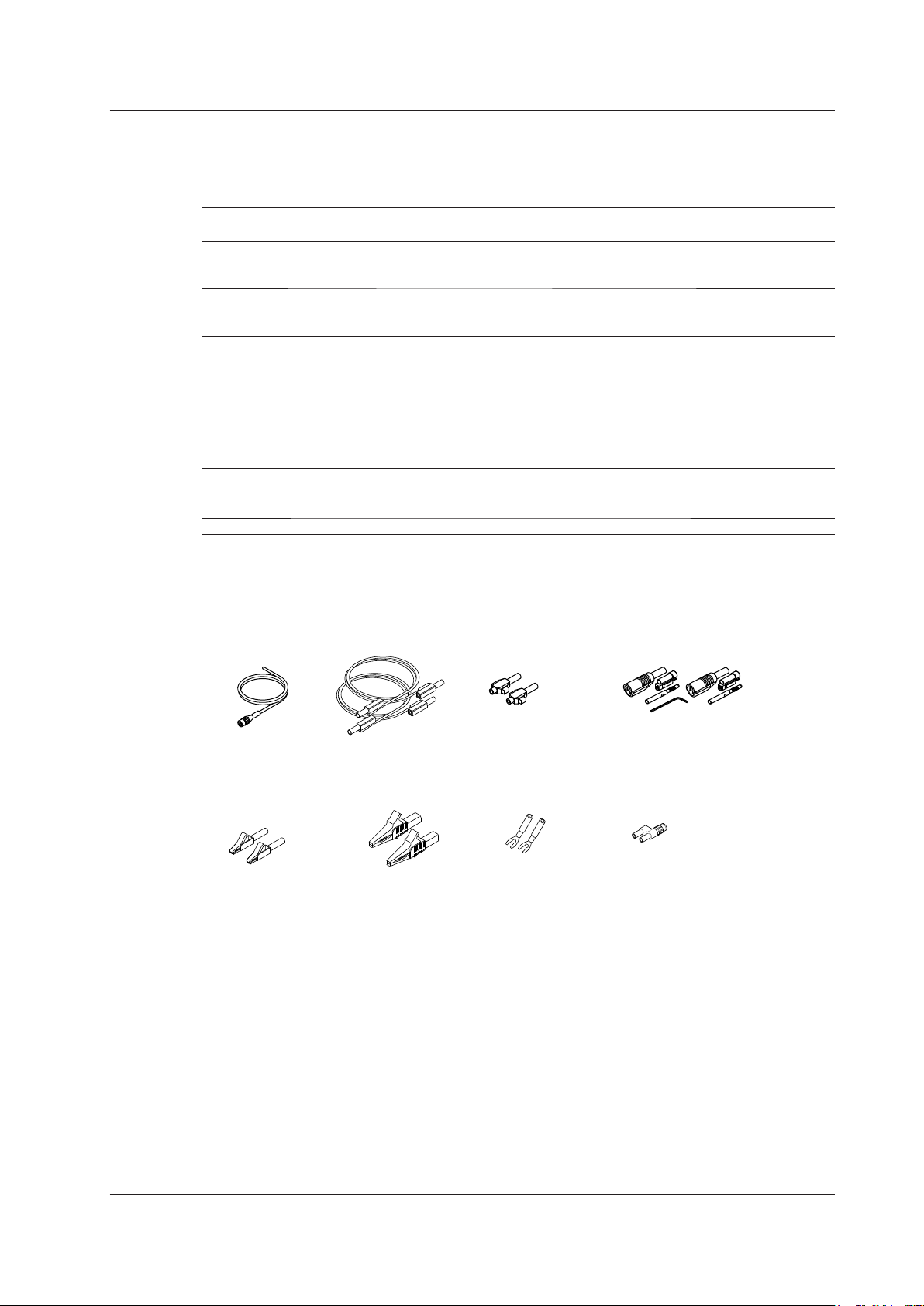

Standard Accessories

D/A cable

3

B9879SX

Current input protection

cover

4

B8212BX

Current input protection

cover

5

B8212FX

Rubber feet

A9088ZM

One set of manuals

6

Safety terminal adapter set

2

758931

UL/CSA Standard

A1006WD

VDE Standard

A1009WD

BS Standard

A1054WD

AS Standard

A1024WD

D

F

Q

R

Power cord (one cord that matches the suffix code is included)

1

GB Standard

A1064WD

H

NBR Standard

A1088WD

N

The instrument is shipped with the following accessories. Make sure that all accessories are present

and undamaged.

Checking the Contents of the Package

1 Make sure that the attached power cord meets the designated standards of the country and area

that you are using it in.

2 Same number of sets as the number of installed input elements

WT310: One set with one hexagonal socket wrench

WT310HC: One set with one hexagonal socket wrench

WT332: Two sets with one hexagonal socket wrench

WT333: Three sets with one hexagonal socket wrench

3

Included with models that have D/A output and remote control (/DA4 or /DA12)

4 For the WT310/WT310HC

5 For the WT332/WT333

6 For information on the types of printed manuals and manuals on the CD that are provided, see

page i.

IM WT310-02EN

iii

Page 6

iv

IM WT310-02EN

Checking the Contents of the Package

CD-R

The CD-R contains the data listed below. To view the PDF user’s manuals, you need Adobe Reader 5.0

or later.

PDFs of the WT310/WT310HC/WT330 User’s Manuals

These manuals are in the Manuals folder.

English

• WT310/WT310HC/WT330 Digital Power Meter User’s Manual

IM WT310-01EN

• WT310/WT310HC/WT330 Digital Power Meter Getting Started Guide

IM WT310-02EN

• WT310/WT310HC/WT330 Digital Power Meter Communication Interface User’s Manual

IM WT310-17EN

Japanese

• WT310/WT310HC/WT330 Digital Power Meter User’s Manual

IM WT310-01JA

• WT310/WT310HC/WT330 Digital Power Meter Getting Started Guide

IM WT310-02JA

• WT310/WT310HC/WT330 Digital Power Meter Communication Interface User’s Manual

IM WT310-17JA

Installer for the WTViewerFreePlus Application Software (For the

WT310/WT310HC/WT330)

• WTViewerFreePlus_Installer.exe

• WTViewerFreePlus (folder)

• YKMUSB (folder)

PDF of the Manual for the WTViewerFreePlus Application Software

These manuals are in the Manuals folder.

English

• Application Software WTViewerFreePlus for WT310/WT310HC/WT330 User’s Manual

IM 760121-02E

Japanese

• Application Software WTViewerFreePlus for WT310/WT310HC/WT330 User’s Manual

IM 760121-02

WARNING

Never play this CD-R on an audio CD player. Doing so may cause loss of hearing or speaker

damage due to the large sounds that may be produced.

Page 7

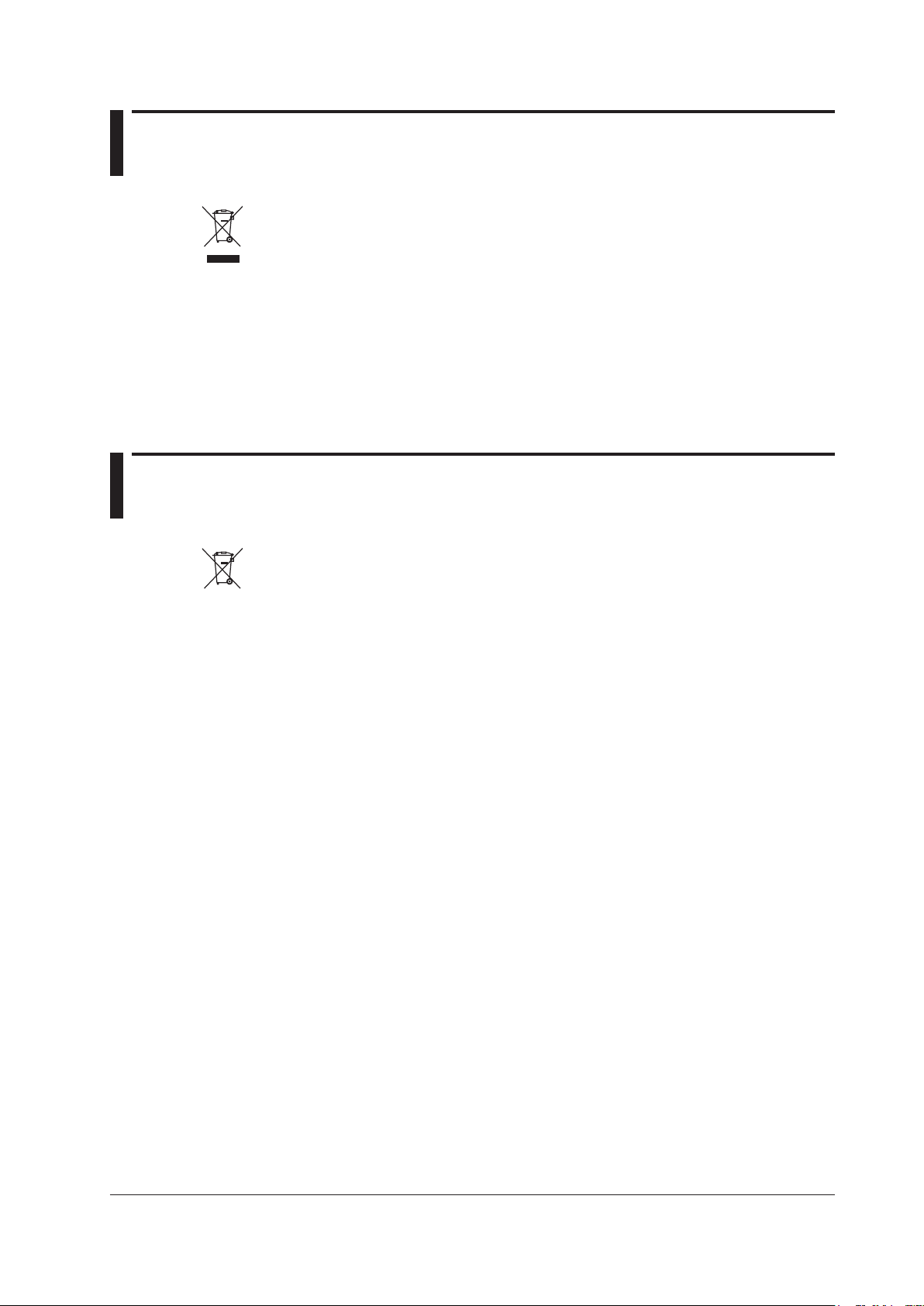

Measurement

lead

758917

Alligator clip

adapter set

758922

Alligator clip

adapter set

758929

Fork terminal

adapter set

758921

Safety terminal

adapter set

758923

External sensor

cable

B9284LK

Safety terminal

adapter set

758931

Conversion adapter

758924

Checking the Contents of the Package

Optional Accessories (Sold separately)

The following optional accessories are available for purchase separately.

For information about ordering accessories, contact your nearest YOKOGAWA dealer.

Item Model/ Min. Q’ty Note

Part No.

External sensor cable B9284LK 1 For connecting to the WT310/WT310HC/WT330’s

external current sensor input connector.

Length: 0.5 m.

Measurement lead 758917 1 Two leads in one set. Used with the 758922 or

758929 adapter (sold separately). Length: 0.75 m.

Rated voltage: 1000 V.*

Safety terminal adapter set 758923 1 Two pieces in one set. Rated voltage 600 V.*

758931 1 Two pieces in one set. Rated voltage 1000 V.*

Alligator clip adapter set 758922 1 Two pieces in one set. For use with measurement

lead 758917.

Rated voltage 300 V.*

758929 1 Two pieces in one set. For use with measurement

lead 758917.

Rated voltage 1000 V.*

Fork terminal adapter set 758921 1 Two pieces in one set. For use with measurement

lead 758917.

Rated voltage 1000 V.* Rated current: 25 A.

Conversion adapter 758924 1 BNC-4 mm socket adapter. Rated voltage: 500 V.*

* The actual voltage that can be used is the lowest voltage of the WT310/WT310HC/WT330 and

cable specifications.

IM WT310-02EN

v

Page 8

vi

IM WT310-02EN

Safety Precautions

This instrument is an IEC safety class I instrument (provided with a terminal for protective earth

grounding).

The general safety precautions described herein must be observed during all phases of operation.

If the instrument is used in a manner not specified in this manual, the protection provided by the

instrument may be impaired. YOKOGAWA assumes no liability for the customer’s failure to comply

with these requirements.

The WT310/WT310HC/WT330 is a power measurement instrument that can measure parameters

such as voltage, current, and power. Do not use this instrument for anything other than its intended

purpose.

The following symbols are used on this instrument.

Warning: handle with care. Refer to the user’s manual or service manual. This symbol appears

on dangerous locations on the instrument which require special instructions for proper handling

or use. The same symbol appears in the corresponding place in the manual to identify those

instructions.

Electric shock, danger

Ground (earth) or functional ground terminal (do not use this terminal as a protective ground

terminal.)

Alternating current

Both direct and alternating current

ON (power)

OFF (power)

Power-on state

Power-off state

Page 9

Safety Precautions

Failure to comply with the precautions below could lead to injury

or death.

WARNING

Use the Instrument Only for Its Intended Purpose

The WT310/WT310HC/WT330 is a power measurement instrument that can measure

parameters such as voltage, current, and power. Do not use this instrument for anything other

than as a power measurement instrument.

Check the Physical Appearance

Do not use the instrument if there is a problem with its physical appearance.

Use the Correct Power Supply

Make sure that the power supply voltage matches the instrument’s rated supply voltage and

that it does not exceed the maximum voltage range specified for the power cord.

Use the Correct Power Cord and Plug

To prevent the possibility of electric shock or fire, be sure to use the power cord supplied by

YOKOGAWA. The main power plug must be plugged into an outlet with a protective earth

terminal. Do not invalidate this protection by using an extension cord without protective earth

grounding.

Additionally, do not use the power cord supplied with this instrument with another instrument.

Connect the Protective Grounding Terminal

Make sure to connect the protective earth to prevent electric shock before turning on the

power. The power cord that comes with the instrument is a three-prong type power cord.

Connect the power cord to a properly grounded three-prong outlet.

Do Not Impair the Protective Grounding

Never cut off the internal or external protective earth wire or disconnect the wiring of the

protective earth terminal. Doing so may result in electric shock or damage to the instrument.

Do Not Operate with Defective Protective Grounding or Fuses

Do not operate the instrument if the protective earth or fuse might be defective. Check the

grounding and the fuse before operating the instrument.

Do Not Operate in an Explosive Atmosphere

Do not operate the instrument in the presence of flammable gasses or vapors. Doing so is

extremely dangerous.

Do Not Remove Covers

Only qualified YOKOGAWA personnel should remove the instrument’s covers. The inside of

the instrument is dangerous because parts of it have high voltages.

Ground the Instrument before Making External Connections

Securely connect the protective grounding before connecting to the item under measurement

or to an external control unit. Before touching a circuit, turn off its power and check that it has

no voltage.

IM WT310-02EN

Measurement Category

This instrument is a measurement category II product. Do not use it for measurement category

III or IV measurements.

Install or Use the Instrument in Appropriate Locations

•

Do not install or use the instrument outdoors or in locations subject to rain or water.

• Install the instrument so that you can immediately remove the

dangerous condition occurs.

power cord if an abnormal or

vii

Page 10

viii

IM WT310-02EN

Safety Precautions

Connect Cables Correctly

Power meters can measure large voltages and currents directly. If you use a voltage

transformer or a current transformer together with this power meter, you can measure even

larger voltages or currents. When you are measuring a large voltage or current, the power

capacity of the item under measurement becomes large. If you do not connect the cables

correctly, an overvoltage or overcurrent may be generated in the circuit under measurement.

This may lead to not only damage to the power meter and the item under measurement, but

electric shock and fire as well. Be careful when you connect the cables, and be sure to check

the following points.

Before you begin measuring (before you turn the item under measurement on), check that:

•

Cables have been connected to the power meter’s input terminals correctly.

Check that there are no voltage measurement cables that hav

current input terminals.

Check that there are no current measurement cables that have been connected to the

voltage input terminals.

If you are measuring multiphase power, check that there are no mistakes in the phase

wiring.

• Cables have been connected to the power supply and the item under measurement

correctly.

Check that there are no short circuits between terminals or between connected cables.

•

The cables are connected firmly to the current input terminals.

• There are no problems with the current input terminals and the crimping terminals, such as

the presence of foreign substances.

e been connected to the

During measurement (never touch the terminals and the connected cables when the item

under measurement is on), check that:

There no problems with the input terminals and the crimping terminals, such as the

•

presence of foreign substances.

• The input terminals are not abnormally hot.

• The cables are connected firmly to the input terminals.

The terminal connections may become loose over time. If this happens, heat may be

generated due to changes in contact resistance. If you are going to take measurements

using the same setup for a long time, periodically check that the cables are firmly

connected to the terminals. (Be sure to turn both the power meter and the item under

measurement off before you check the connections.)

After measuring (immediately after you turn the item under measurement of

After you measure a large voltage or current, power may rema

under measurement even after you turn it off. This remaining power may lead to electric

shock, so do not touch the input terminals immediately after you turn the item under

measurement off.

varies depending on the item.

The amount of time that power remains in the item under measurement

in for some time in the item

See below for operating environment limitations.

f):

CAUTION

This is a class A instrument designed for an industrial environment. Operation of this product

in a residential area may cause radio interference in which case the user will be required to

correct the interference.

Page 11

Waste Electrical and Electronic Equipment

Waste Electrical and Electronic Equipment (WEEE), DIRECTIVE 2002/96/EC

(This directive is valid only in the EU.)

This product complies with the WEEE Directive (2002/96/EC) marking requirement. This

marking indicates that you must not discard this electrical/electronic product in domestic

household waste.

Product Category

With reference to the equipment

as a “Monitoring and control instruments” product.

Do not dispose in domestic household waste. When disposing products in the EU, contact your

local Yokogawa Europe B. V. office.

types in the WEEE directive Annex I, this product is classified

New EU Battery Directive

New EU Battery Directive, DIRECTIVE 2006/66/EC

(This directive is valid only in the EU.)

Batteries are included in this product. This marking indicates they shall be sorted out and

collected as ordained in ANNEX II in DIRECTIVE 2006/66/EC.

Battery type: Lithium battery

You ca

nnot replace batteries by yourself. When you need to replace batteries, contact your

local Yokogawa Europe B.V.office.

IM WT310-02EN

ix

Page 12

x

IM WT310-02EN

Conventions Used in This Manual

Units

k: Denotes 1000. Example: 100 kS/s (sample rate)

K: Denotes 1024. Example: 720 KB (file size)

Notes

The notes and cautions in this manual are categorized using the following symbols.

Improper handling or use can lead to injury to the user or damage to the

instrument. This symbol appears on the instrument to indicate that the user must

refer to the user’s manual for special instructions. The same symbol appears in

the corresponding place in the user’s manual to identify those instructions. In the

user’s manual, the symbol is used in conjunction with the word “WARNING” or

“CAUTION.”

WARNING

CAUTION

Calls attention to information that is important for the proper operation of the

Note

Calls attention to actions or conditions that could cause serious or fatal injury to

the user, and precautions that can be taken to prevent such occurrences.

Calls attention to actions or conditions that could cause light injury to the user

or cause damage to the instrument or user’s data, and precautions that can be

taken to prevent such occurrences.

software.

Characters That Appear on the 7-Segment LED

Because this instrument uses a 7-segment LED display, numbers, letters, and mathematical symbols

are displayed using special characters. For details, see section 1.3, “Digital Numbers and Characters.”

Page 13

6.

4.

2.

(Display C)

Configure the storage feature.

(Display B)

1.

3.

5.

Confirm

the setting.

Close menu.

Conventions Used in This Manual

Symbols and Conventions Used in Procedural Explanations

The contents of the procedural explanations are indicated using the following symbols.

This mark appears on the right side of the page to indicate features and settings that can be

operated and configured using the WTViewerFreePlus application software, which comes with the

instrument.

Procedure

Operations are explained using flowcharts. See the example below for an

explanation of how various operations are indicated. All procedures are written

under the assumption that you are starting operation at the beginning of the

procedure, so you may not need to carry out all the steps in a procedure when

you are changing the settings.

Example: Operations for turning the storage feature on and off

The above flow chart indicates the following operations.

You can configure items that are blinking.

Press the SHIFT key so that it illuminates, and then press SETUP (UTILITY).

1.

A menu appears in display B.

Use ▲ or ▼ to select StorE.

2.

Pressing either key cycles through 9 menu items.

Press SET to confirm the selection of StorE.

3.

The StorE function menu that you selected in step 2 appears in display C.

Use ▲ or ▼ to select oFF or on.

4.

Pressing either key cycles through 3 menu items.

Press SET to confirm the selection of oFF.

5.

The selected or set item is confirmed when you press SET.

A menu appears in display B.

Press HOLD (ESC) to return the menu display to the measurement data display.

6.

• When you are making a number positive (no sign) or negative (–) or setting a number, when the

digit in the display that the input will be added to is blank, an underscore flashes at the position of

the digit.

• While you are performing menu operations, to leave the menu display, press HOLD (ESC). All

setting changes that you have confirmed by pressing the SET

Explanation

This section describes the setup items and the limitations regarding the

key will be reflected in the settings.

procedures. It may not give a detailed explanation of the feature. For a detailed

IM WT310-02EN

explanation of the feature, see chapter 1 in the User’s Manual, IM WT310-01EN.

xi

Page 14

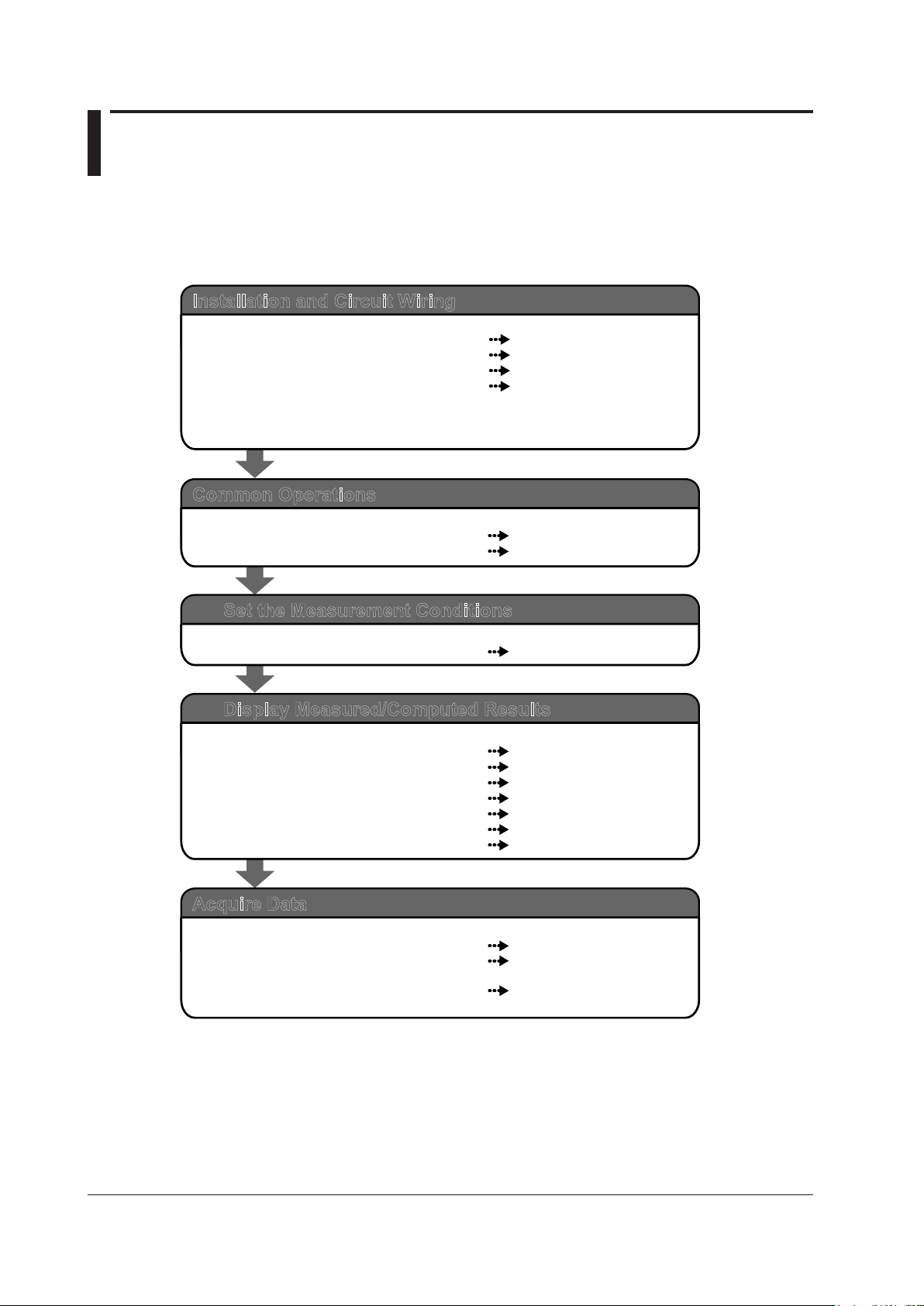

Workflow

Getting Started Guide

Section 2.2

Sections 2.3 and 2.4

Section 2.8

Sections 2.9 to 2.11

Installation and Circuit Wiring

Install the WT310/WT310HC/WT330.

Connect the power supply, and turn the power on.

Select the measurement method.

Wire the circuit under measurement.

Getting Started Guide

Sections 3.1 and 3.2

Section 3.3

Common Operations

Perform key operations.

Initialize settings.

User’s Manual

Chapter 2

Set the Measurement Conditions

Measurement conditions

User’s Manual

Section 4.1

Section 4.2

Section 4.3

Section 4.4

Section 4.5

Chapter 5

Chapter 6

Display Measured/Computed Results

Voltage, current, and active power

Apparent power, reactive power, and power factor

Phase angle and frequency

Peak value

Crest factor, etc.

Integrated power (watt hour)

Harmonic measurement

User’s Manual

Chapter 7

Section 8.4 and chapter 5 of the

Getting Started Guide

Communication Interface

User’s Manual

Acquire Data

Store data to internal memory.

Transmit data using D/A output (option).

Transmit data through the USB, GP-IB,

RS-232, or Ethernet interface.

Read the precautions in sections 2.5 and 2.7 thoroughly before connecting the wires.

Also, if necessary, assemble the input terminal adapter that connects to the voltage

input terminal (see section 2.6) before connecting the wires.

The figure below is provided to familiarize the first-time user with the workflow of WT310/WT310HC/

WT330 operation. For a description of an item, see the relevant section or chapter. In addition to

the sections and chapters that are referenced in the figure below, this manual also contains safety

precautions for handling and wiring the instrument. Be sure to observe the precautions.

xii

IM WT310-02EN

Page 15

1

2

3

4

5

6

7

App

Contents

Checking the Contents of the Package.............................................................................................ii

Safety Precautions ...........................................................................................................................vi

Waste Electrical and Electronic Equipment ..................................................................................... ix

New EU Battery Directive ................................................................................................................ix

Conventions Used in This Manual ....................................................................................................x

Workflow ......................................................................................................................................... xii

Chapter 1 Component Names and Functions

1.1 Front Panel, Rear Panel, and Top Panel .......................................................................... 1-1

1.2 Displayed Items ................................................................................................................ 1-5

1.3 Digital Numbers and Characters ...................................................................................... 1-7

1.4 Keys

Auto Range, Overrange, and Error Indications During Measurement ............................ 1-12

1.5

1.6 System Configuration .....................................................................................................

Chapter 2 Making Preparations for Measurements

2.1 Handling Precautions ....................................................................................................... 2-1

2.2 Installing the Instrument ................................................................................................... 2-3

2.3 Connecting the Power Supply .......................................................................................... 2-6

2.4 Turning the Power Switch On and Off .............................................................................. 2-7

2.5 Precautions When Wiring the Circuit under Measurement .............................................. 2-9

2.6 Assembling the Adapters for the Voltage Input Terminals .............................................. 2-12

2.7 Wiring for Accurately Measuring a Single-phase Device ................................................ 2-14

2.8 Guide for Selecting the Method Used to Measure the Pow

2.9 Wiring the Circuit under Measurement for Direct Input .................................................. 2-16

2.10 Wiring the Circuit under Measurement When Using Current Sensors ........................... 2-31

2.11 Wiring the Circuit under Measurement When Using a Voltage or Current Transformer . 2-38

2.12 Connecting to a PC via USB (Installing WTViewerFreePlus) ......................................... 2-44

Chapter 3 Common Operations

3.1 Key Operation and Functions ........................................................................................... 3-1

3.2 Entering Values ................................................................................................................ 3-3

3.3 Initializing the Settings ...................................................................................................... 3-4

................................................................................................................................. 1-8

1-14

er ........................................ 2-15

Chapter 4 Operating the WT310/WT310HC/WT330

4.1 Setting the Measurement Ranges .................................................................................... 4-1

4.2 Configuring the Wiring System Settings (Only on the WT330) ........................................ 4-4

4.3 Displaying the Voltage, Current, and Active Power on the WT310/WT310HC

4.4 Displaying Voltages, Currents, and Active Powers on the WT330 ...................................

Chapter 5 External I/0 (Option)

5.1 External I/O Connector Pin Arrangement and Pinout ....................................................... 5-1

5.2 Controlling the WT310/WT310HC/WT330 Remotely ....................................................... 5-3

5.3 Producing D/A Output ....................................................................................................... 5-4

IM WT310-02EN

................. 4-5

4-6

xiii

Page 16

xiv

IM WT310-02EN

Contents

Chapter 6 Troubleshooting, Maintenance, and Inspection

6.1 Troubleshooting ................................................................................................................ 6-1

6.2 Error Code Descriptions and Corrective Actions .............................................................. 6-2

6.3 Recommended Part Replacement ................................................................................... 6-3

6.4 Calibration and

Adjustment .............................................................................................. 6-4

Chapter 7 Specifications

7.1 Input ................................................................................................................................. 7-1

7.2 Measurement Items .......................................................................................................... 7-4

7.3 Accuracy ........................................................................................................................... 7-5

7.4

Functions .......................................................................................................................... 7-9

7.5

External Current Sensor Input (/EX1 and /EX2 options) ................................................ 7-14

7.6 D/A Output (/DA4, /DA12 Options)

Remote Control Input/Output Signal (/DA4, /DA12 Options) .......................................... 7-14

7.7

7.8 GP-IB Interface (Standard on -C1) ................................................................................. 7-15

7.9 Serial (RS-232) Interface (Standard on -C2) ..................................................................

7.10 USB PC Interface ........................................................................................................... 7-15

7.1

1 Ethernet Interface(/C7 Option) ....................................................................................... 7-15

7.12 Safety

7.13 General Specifications ................................................................................................... 7-17

7.14 External Dimensions ...................................................................................................... 7-19

Terminal Adapter .................................................................................................

................................................................................. 7-14

7-15

7-16

Appendix

Appendix 1 How to Make Accurate Measurements ..............................................................App-1

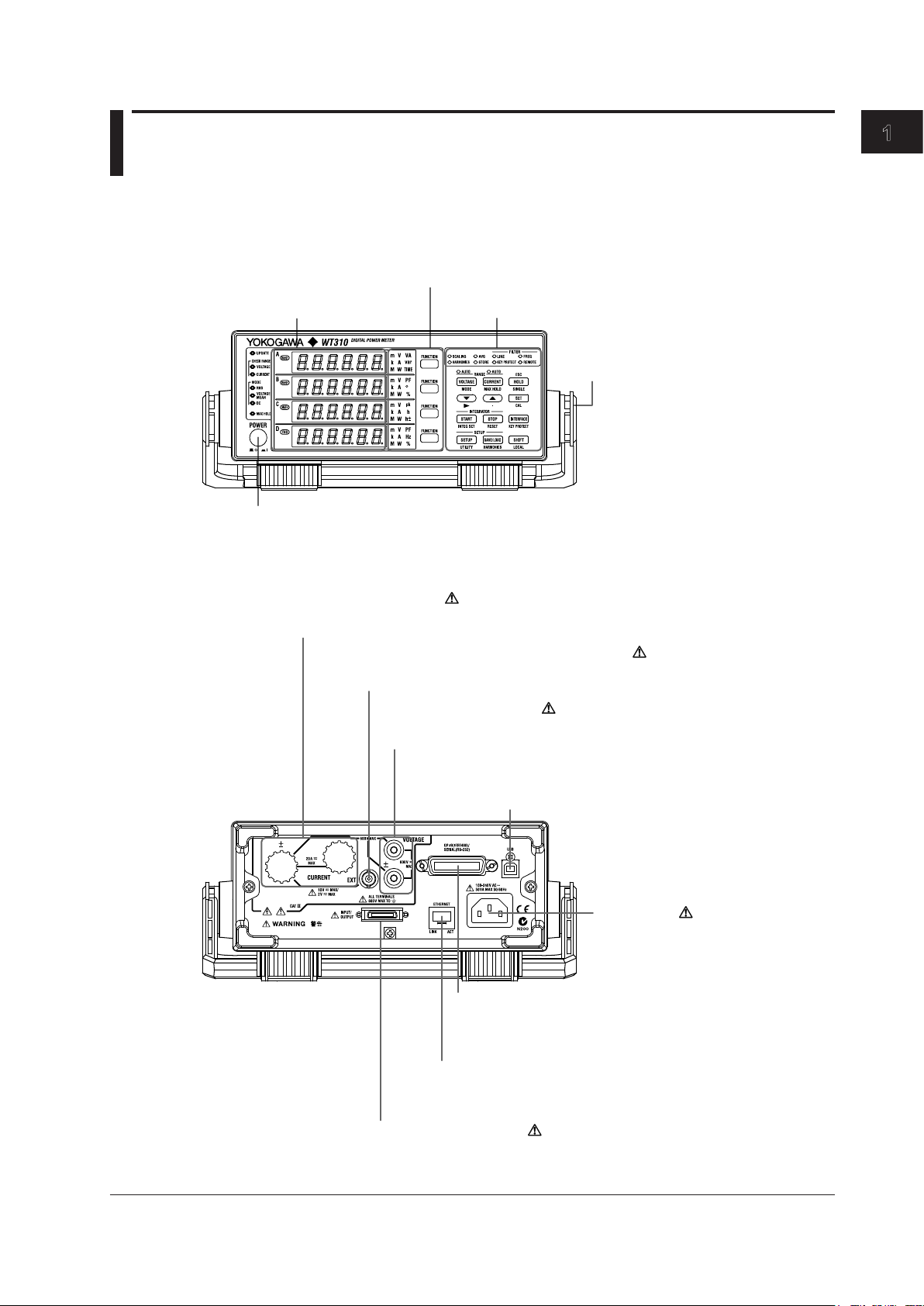

Page 17

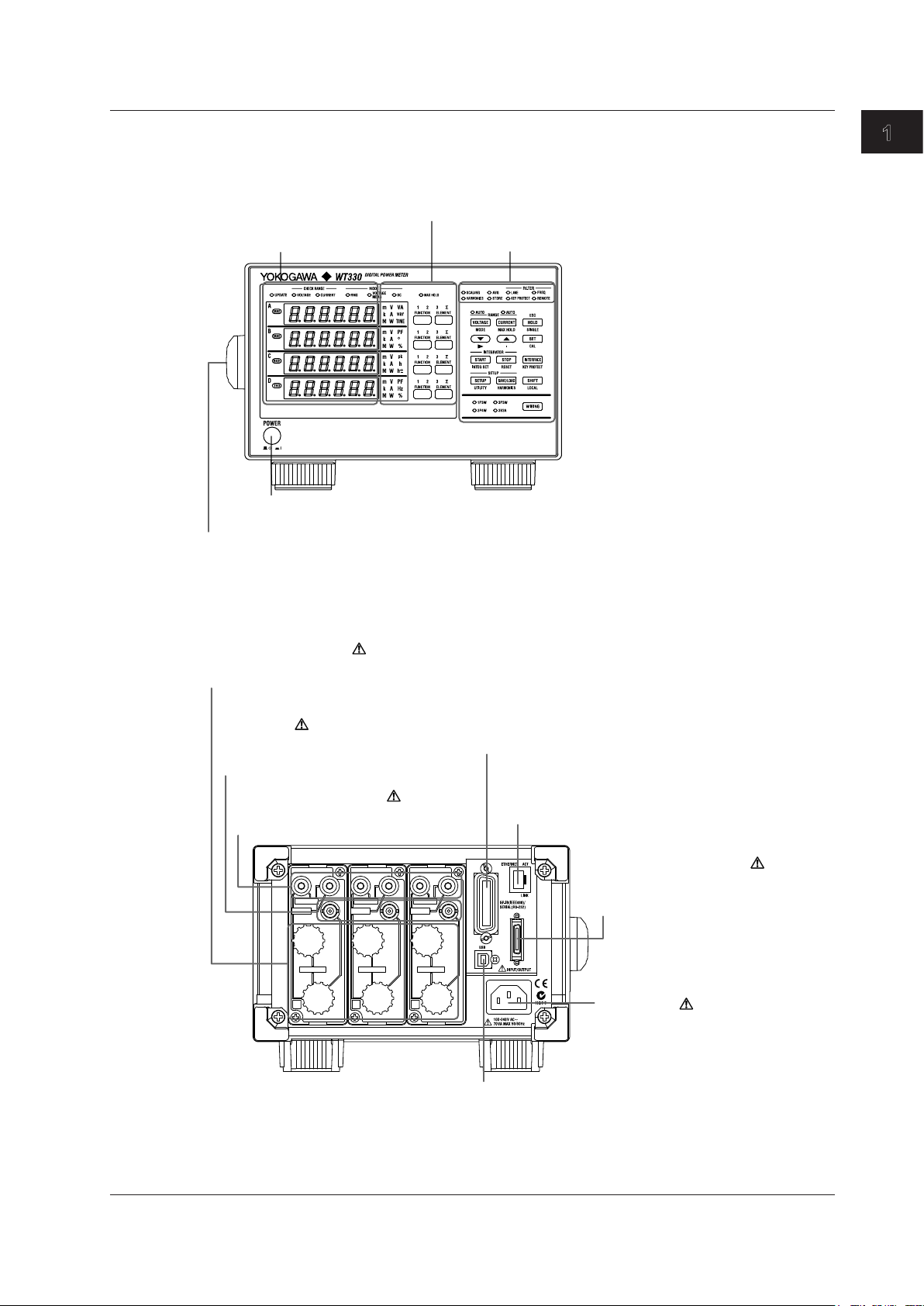

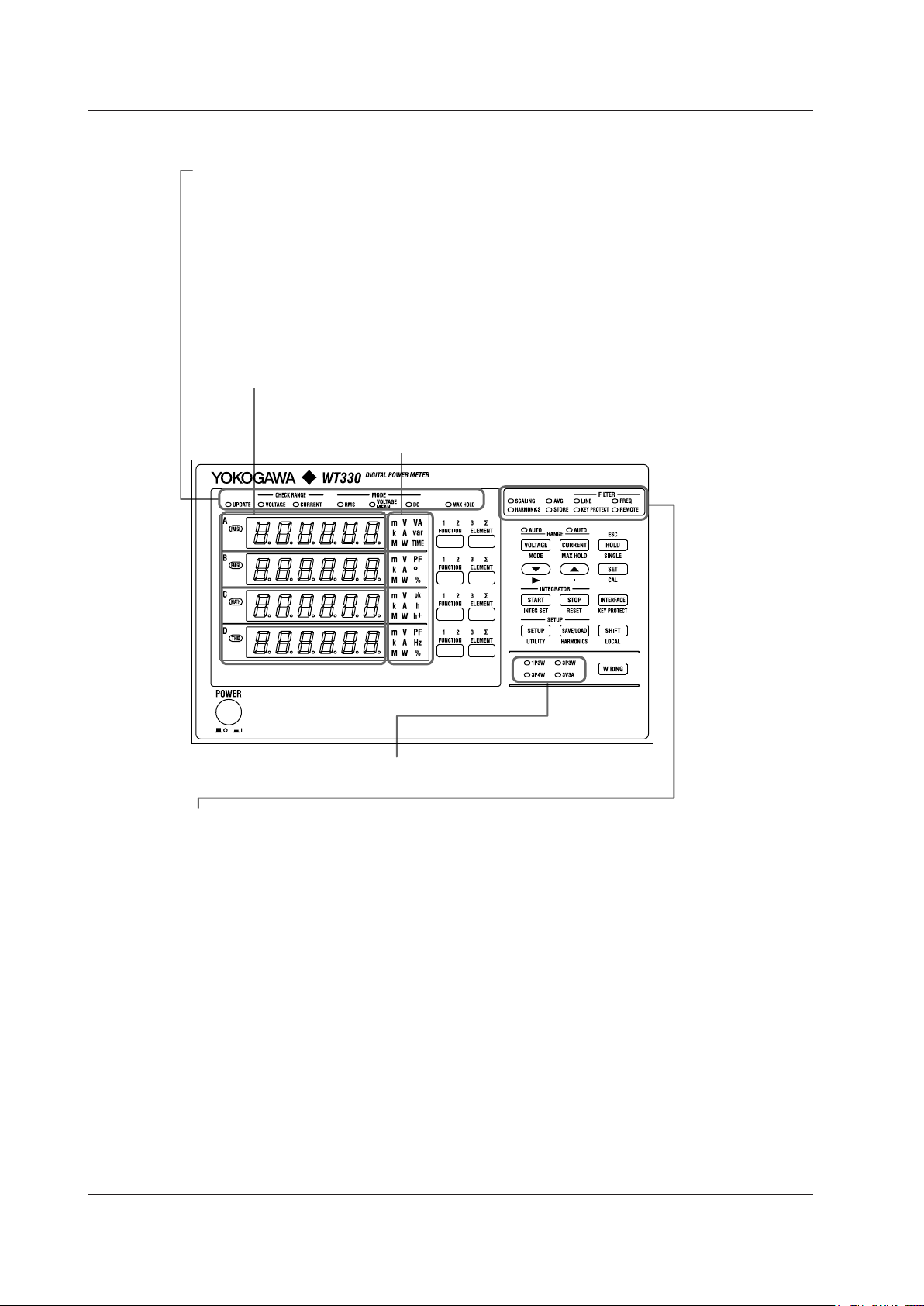

1

Power switch

→ section 2.4

Handle

Used to carry the

WT310/WT310HC/WT330

→ section 2.1

7-segment LED

display

→ section 1.2

Function and unit indicators

→ section 1.2

Keys

→ section 1.4

Power inlet

Power connection → section 2.3

GP-IB or RS-232 connector

Used to communicate with the WT310/WT310HC/WT330

through the GP-IB or RS-232 interface

→ Communication Interface User’s Manual

External I/O connector

For connecting D/A output and remote control cables

→ chapter 5

For connecting voltage measurement cables

→ sections 2.8 to 2.11

Voltage input terminals

Current input terminal

For connecting current measurement

cables → sections 2.8, 2.9, and 2.11

External current sensor input connector

For connecting cables from an external current sensor

→ section 2.10

Ethernet port

Used to connect the WT310/WT310HC/WT330 to a network

→ Communication Interface User’s Manual

USB port for PCs

Used to connect the WT310/WT310HC/WT330 to

a PC that has a USB port

→ Communication Interface User’s Manual

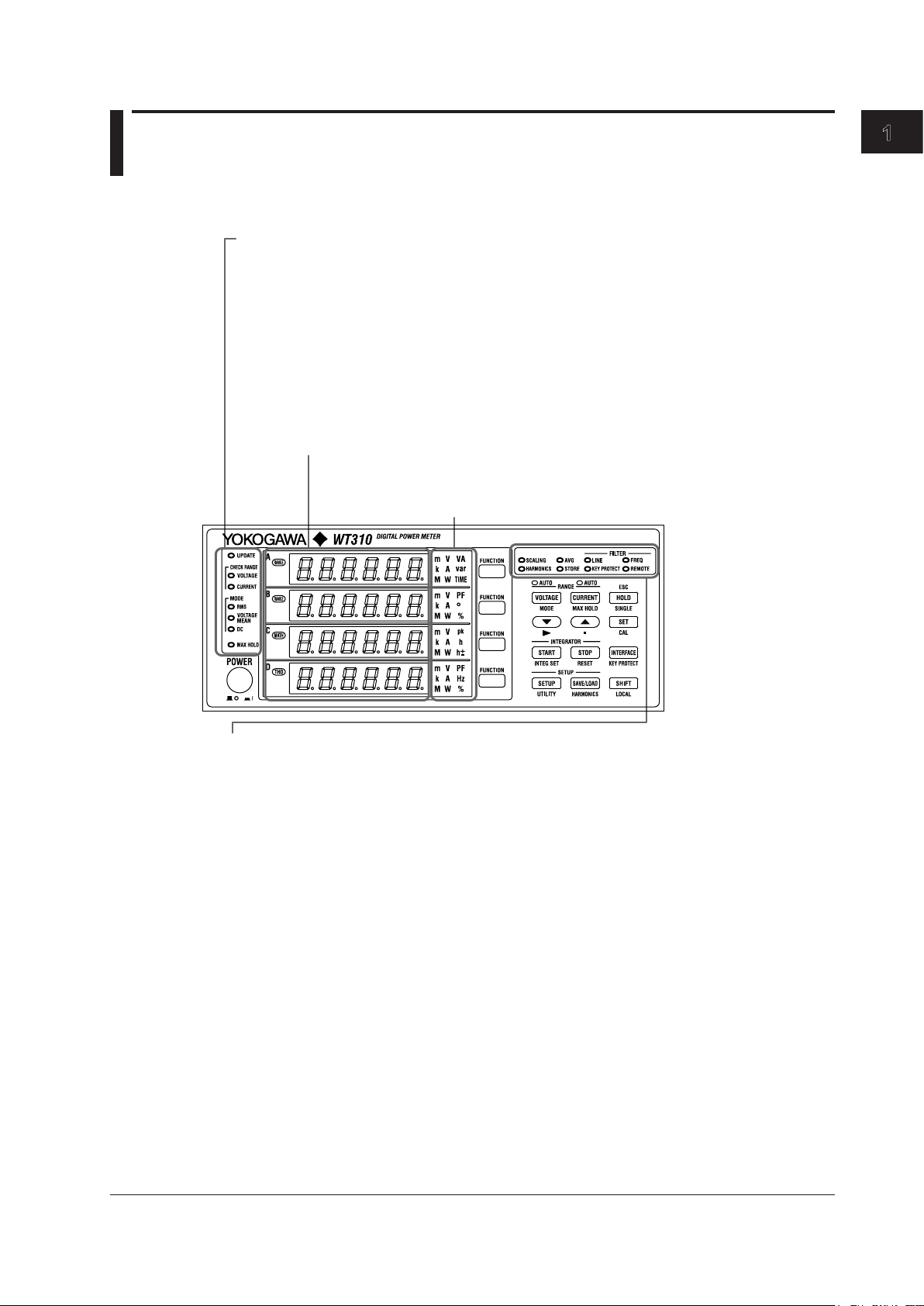

Chapter 1 Component Names and Functions

1.1 Front Panel, Rear Panel, and Top Panel

WT310/WT310HC

Front Panel

Component Names and Functions

Rear Panel

IM WT310-02EN

1-1

Page 18

1-2

IM WT310-02EN

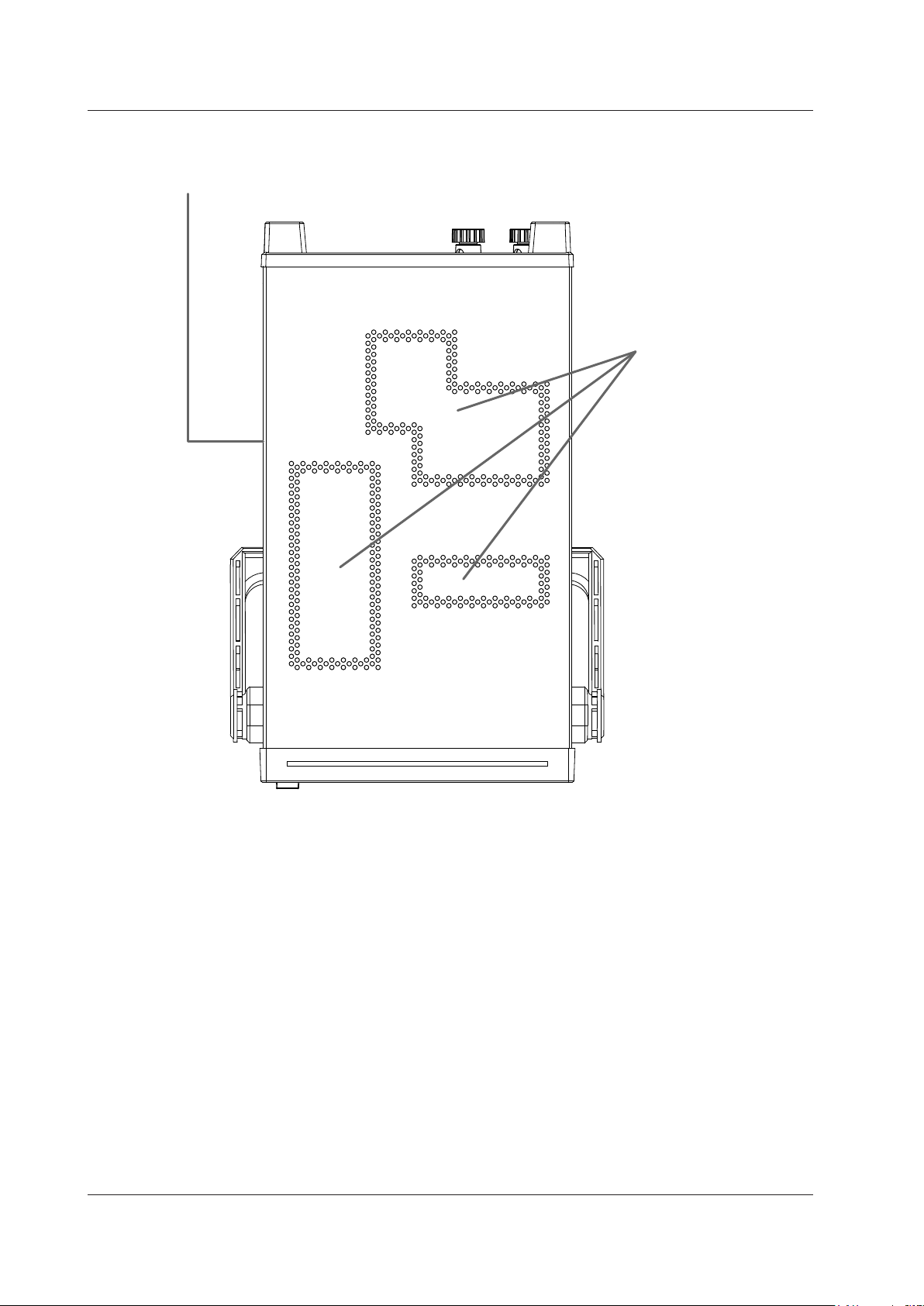

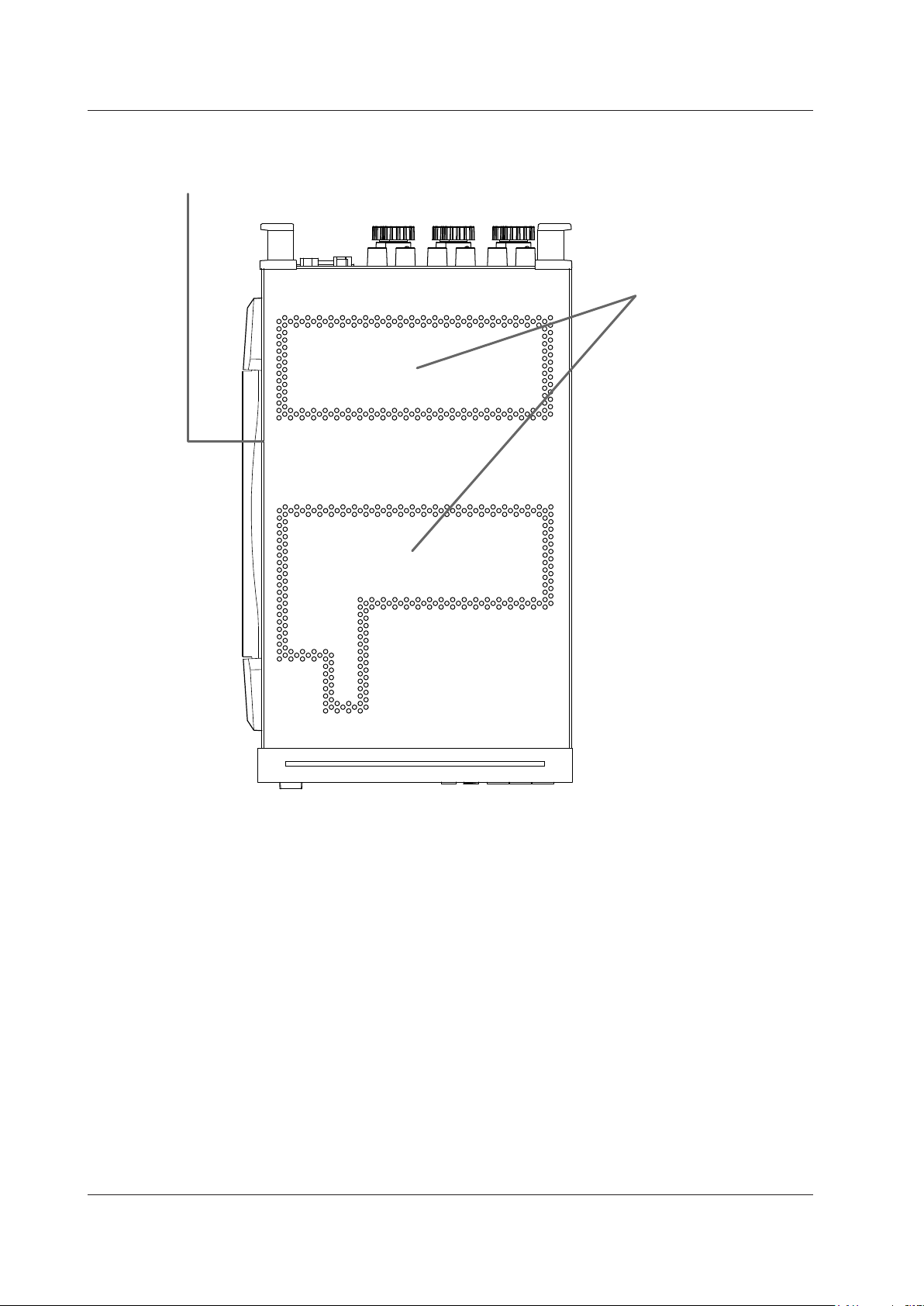

Vent holes → section 2.2

Inlet holes → section 2.2

(There are also inlet holes on the bottom panel.)

1.1 Front Panel, Rear Panel, and Top Panel

Top Panel

Page 19

1

Function, unit, and element indicators

→ section 1.2

Keys

→ section 1.4

Power switch

→ section 2.4

Handle

Used to carry the WT310/WT310HC/WT330

→ section 2.1

7-segment LED

display

→ section 1.2

Power inlet

Power connection → section 2.3

GP-IB or RS-232 connector

Used to communicate with the WT310/WT310HC/WT330

through the GP-IB or RS-232 interface

→ Communication Interface User’s Manual

External I/O connector

For connecting D/A output and remote

control cables

→ chapter 5

For connecting voltage measurement cables

→ sections 2.8 to 2.11

Voltage input terminals

Current input terminal

For connecting current measurement cables

→ sections 2.8, 2.9, and 2.11

External current sensor input

connector

For connecting cables from an

external current sensor

→ section 2.10

Ethernet port

Used to connect the WT310/WT310HC/WT330

to a network

→ Communication Interface User’s Manual

USB port for PCs

Used to connect the WT310/WT310HC/WT330 to a PC

that has a USB port

→ Communication Interface User’s Manual

WT330

Front Panel

1.1 Front Panel, Rear Panel, and Top Panel

Component Names and Functions

Rear Panel

IM WT310-02EN

1-3

Page 20

1-4

IM WT310-02EN

Vent holes → section 2.2

Inlet holes → section 2.2

(There are also inlet holes on the bottom panel.)

1.1 Front Panel, Rear Panel, and Top Panel

Top Panel

Page 21

1

1.2 Displayed Items

Auto range monitor (CHECK RANGE)

Lights when an input signal meets the conditions for auto range switching

Measurement mode indicator (MODE)

Indicates the voltage and current measurement modes

Data update indicator (UPDATE)

Blinks when measurement data is being updated.

MAX HOLD indicator (MAX HOLD)

Lights when MAX HOLD is enabled

Scaling indicator (SCALING)

Lights when scaling is enabled

Averaging indicator (AVG)

Lights when averaging is enabled

Line filter indicator (FILTER-LINE)

Lights when the line filter is enabled

Frequency filter indicator (FILTER-FREQ)

Lights when the frequency filter is enabled

Storage indicator (STORE)

When you start storage, this indicator blinks at the pace at which storage is taking place.

Remote indicator (REMOTE)

Lights when the WT310/WT310HC/WT330 is in remote mode

Harmonic measurement display indicator (HARMONICS)

Lights when the harmonic measurement display is on

Key protection indicator (KEY PROTECT)

Lights when the keys are locked

7-segment LED display

Displays the measured data for the function that you select using the function key

and displays menus when you are using menus to configure the settings

Function and unit indicators

Indicates the type of function and unit that are being shown on the

7-segment LED display

WT310/WT310HC

Component Names and Functions

IM WT310-02EN

1-5

Page 22

1-6

IM WT310-02EN

Auto range monitor (CHECK RANGE)

Lights when an input signal meets the conditions for auto range switching

Measurement mode indicator (MODE)

Indicates the voltage and current measurement modes

Data update indicator (UPDATE)

Blinks when measurement data is being updated.

MAX HOLD indicator (MAX HOLD)

Lights when MAX HOLD is enabled

Scaling indicator (SCALING)

Lights when scaling is enabled

Averaging indicator (AVG)

Lights when averaging is enabled

Line filter indicator (FILTER-LINE)

Lights when the line filter is enabled

Frequency filter indicator (FILTER-FREQ)

Lights when the frequency filter is enabled

Storage indicator (STORE)

When you start storage, this indicator blinks at the pace at which storage is taking place.

Remote indicator (REMOTE)

Lights when the WT310/WT310HC/WT330 is in remote mode

Harmonic measurement display indicator (HARMONICS)

Lights when the harmonic measurement display is on

Key protection indicator (KEY PROTECT)

Lights when the keys are locked

7-segment LED display

Displays the measured data for the function that you select using the function key and

displays menus when you are using menus to configure the settings

Function and unit indicators

Indicates the type of function and unit that are being shown on the

7-segment LED display

Wiring method indicator

Indicates the wiring method

1.2 Displayed Items

WT330

Page 23

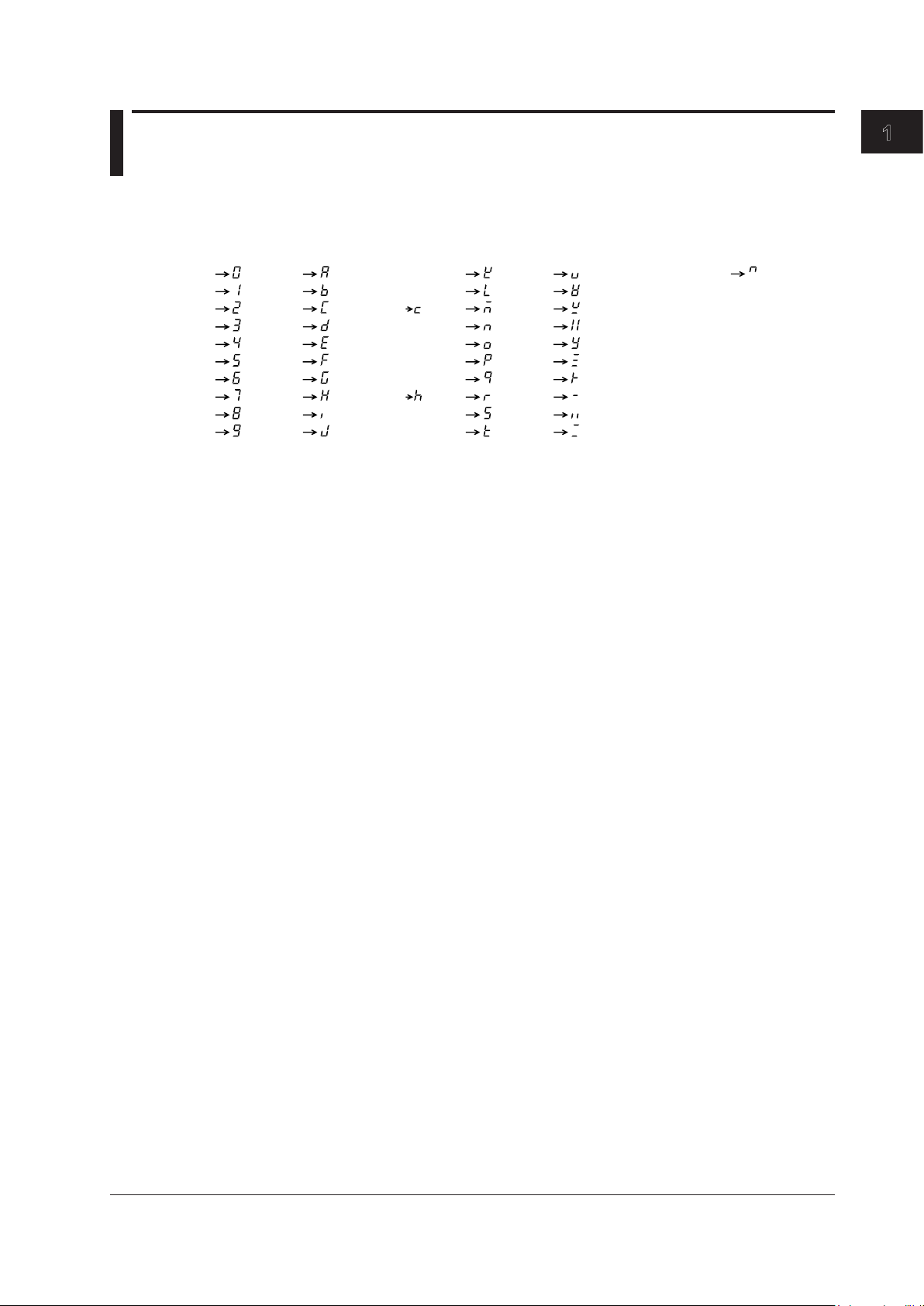

1

1.3 Digital Numbers and Characters

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

S

T

Lowercase c

Lowercase h

U

V

W

X

Y

Z

+

–

×

÷

^ (exponentiation)

Because this instrument uses a 7-segment LED display, numbers, letters, and mathematical symbols

are displayed using special characters in the manner shown below. Some of the characters shown

below are not used by this instrument.

Component Names and Functions

IM WT310-02EN

1-7

Page 24

1-8

IM WT310-02EN

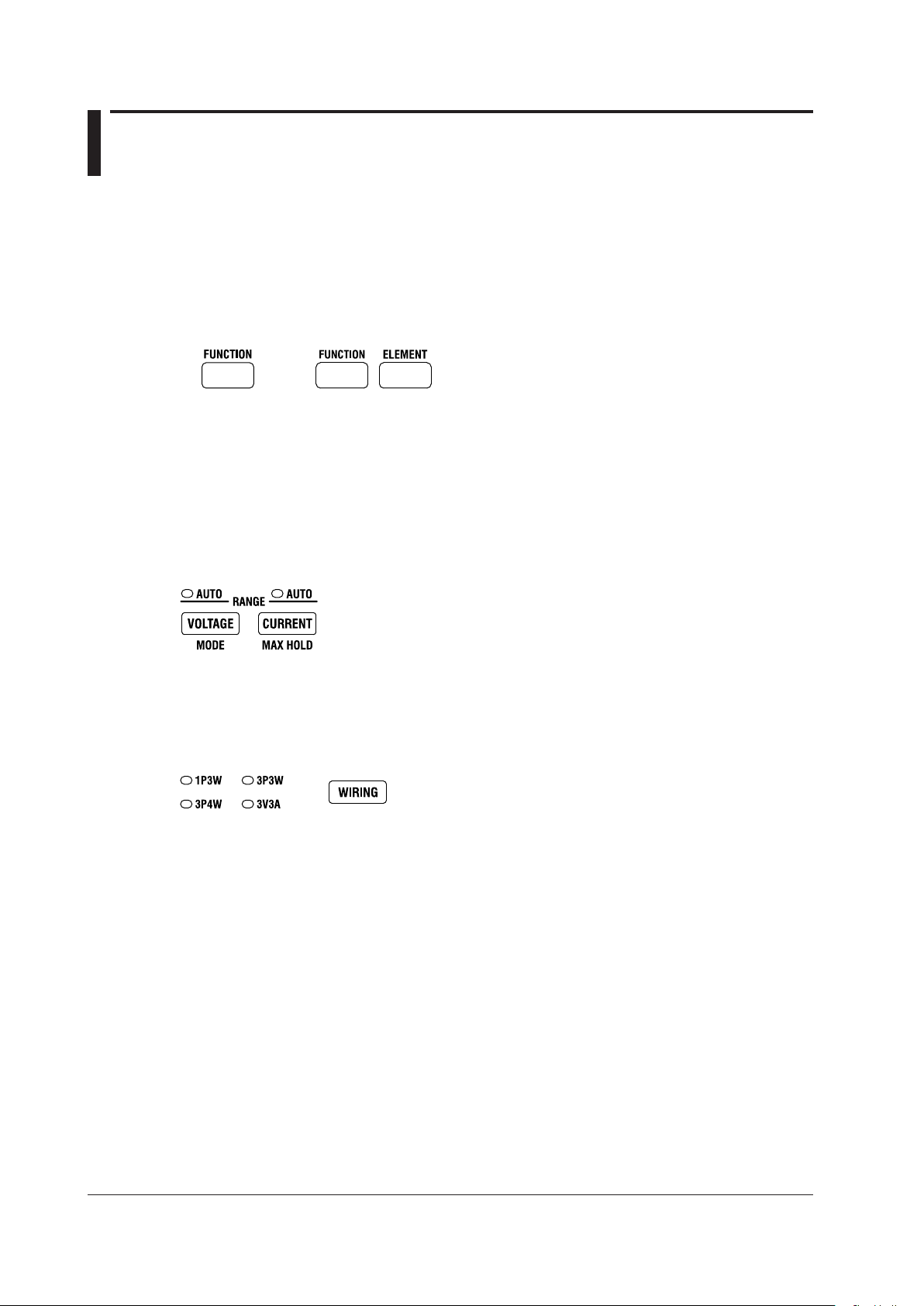

1.4 Keys

WT310/WT310HC WT330

Switching the Display

FUNCTION Key

Choose which function to display.

ELEMENT Key (Only on the WT330)

Choose which input element to display. The indicator of the selected element lights.

Measurement Range and Mode

VOLTAGE Key

Displays the voltage range setting menu. The AUTO indicator lights when the range is set to AUTO.

CURRENT Key

Displays the current range setting menu. The AUTO indicator lights when the range is set to AUTO.

SHIFT+VOLTAGE (MODE) Key

Switches the measurement mode.

Wiring System

WIRING Key (Only on the WT330)

Select the wiring system that corresponds to the wiring system you are using to connect to the voltage

and current terminals on the rear panel.

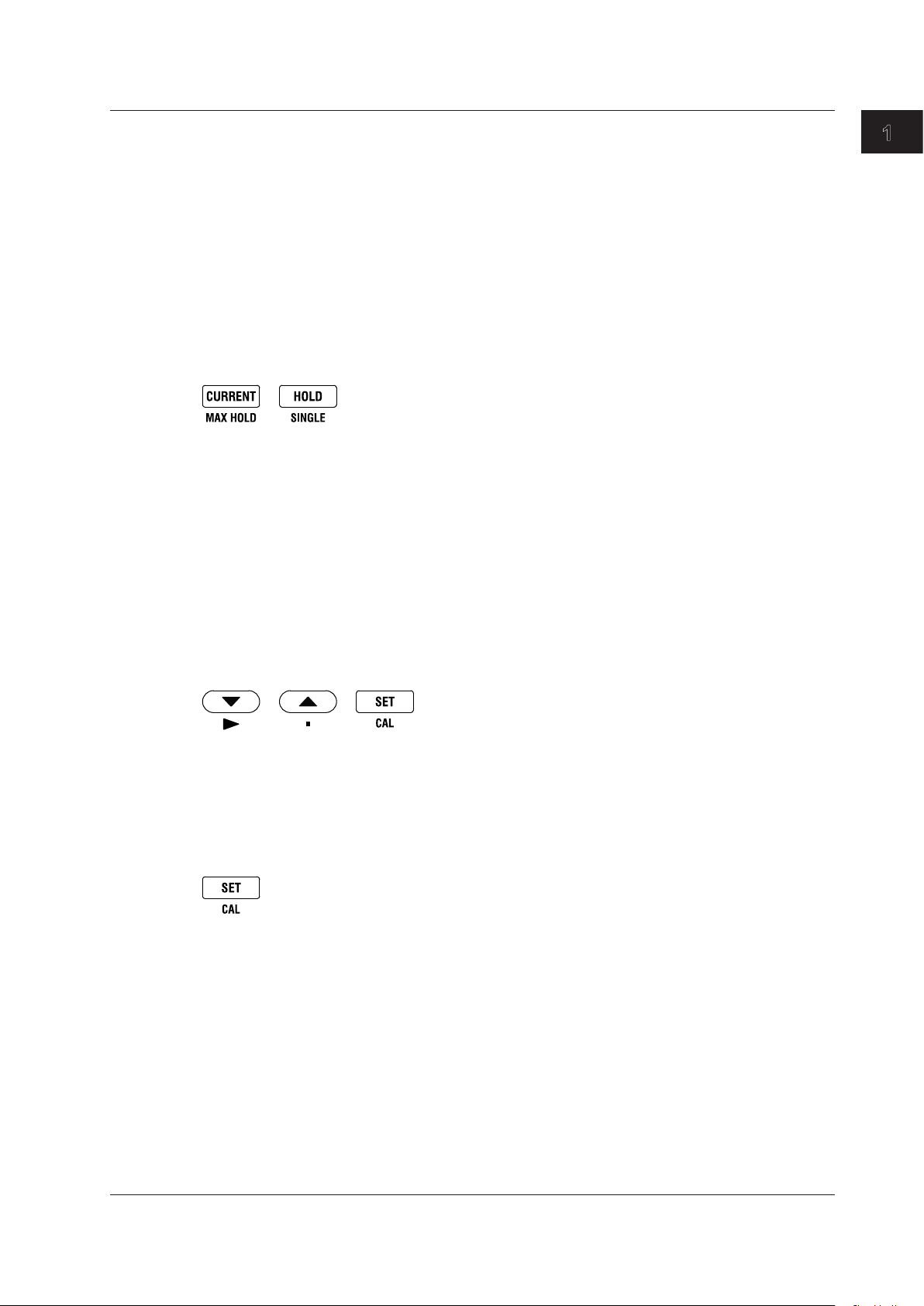

Page 25

1

Display Hold/MAX Hold

SHIFT+CURRENT (MAX HOLD) Key

Turns the MAX hold feature on and off. When the MAX hold feature is on, the MAX HOLD indicator

lights.

HOLD Key

Switches from updating the display after each data update interval to stopping the series of display

operations and holding the display of the numeric data. The HOLD key lights. If you press HOLD

again, the data starts getting updated again, and the HOLD key light turns off.

SHIFT + HOLD Key

While the numeric data is held, press SINGLE to measure data only once at the set data update

interval and then update and hold the displayed values.

General-Purpose Keys

▲ and ▼ Keys

Select features and set values.

SHIFT+▼ (►) Key

Moves the digit that is being set in a value to the right (or from the farthest right position back to the

farthest left position)

1.4 Keys

Component Names and Functions

SHIFT+▲ (.) Key

Moves the decimal point to the right (or from the farthest right position back to the farthest left position)

SET Key

Confirms the specified range, feature, or value

Zero-Level Compensation

SHIFT+SET Key (CAL)

Executes zero-level compensation. When zero-level compensation is executed, the WT310/WT310HC/

WT330 creates a zero input condition in its internal circuitry and sets the zero level to the level at that

point.

IM WT310-02EN

1-9

Page 26

1-10

IM WT310-02EN

1.4 Keys

Integrated Power (Watt hour)

START Key

Starts integration

STOP Key

Stops integration

SHIFT+START (INTEG SET) Key

Displays a menu for setting the integration mode, timer, and rated integration time

SHIFT+STOP Key (RESET)

Resets the integrated value and the elapsed integration time.

Communication Interface

INTERFACE Key

Displays the communication interface setting menu and connection information

Key Lock

SHIFT+INTERFACE (KEY PROTECT) Key

Turns key protection on and off.

The key protection indicator lights, and the front panel keys are locked. Press this key combination

again to unlock the keys.

Page 27

1

Other Features

SETUP Key

Set the measurement synchronization source, input filter, scaling, external sensor input, averaging,

computation, data update interval, etc.

SAVE/LOAD Key

Save or load setup data.

SHIFT+SETUP (UTILITY) Key

Displays a menu for displaying system information (model information, suffix code, instrument number,

and firmware version), initializing settings, setting the number of displayed digits, performing self-tests,

and configuring crest factor, storage, network, and D/A output settings.

SHIFT+SAVE/LOAD (HARMONICS) Key

Displays a setting menu for turning the harmonic measurement display on and off, setting the PLL

source, etc.

SHIFT Key

When you press the SHIFT key once, an indicator illuminates, and you can access the features that

are written in purple below each key. Pressing the key again disables the shifted state. Holding the key

for at least two seconds enables SHIFT lock.

SHIFT (LOCAL) Key

Press this key to switch from remote mode (in which the REMOTE indicator is illuminated) to local

mode (in which front panel key operations are valid). This key is disabled when the WT310/WT310HC/

WT330 is in local lockout mode.

1.4 Keys

Component Names and Functions

ESC Key

Pressing this key when a setup menu is showing returns the screen to the waveform data display.

IM WT310-02EN

1-11

Page 28

1-12

IM WT310-02EN

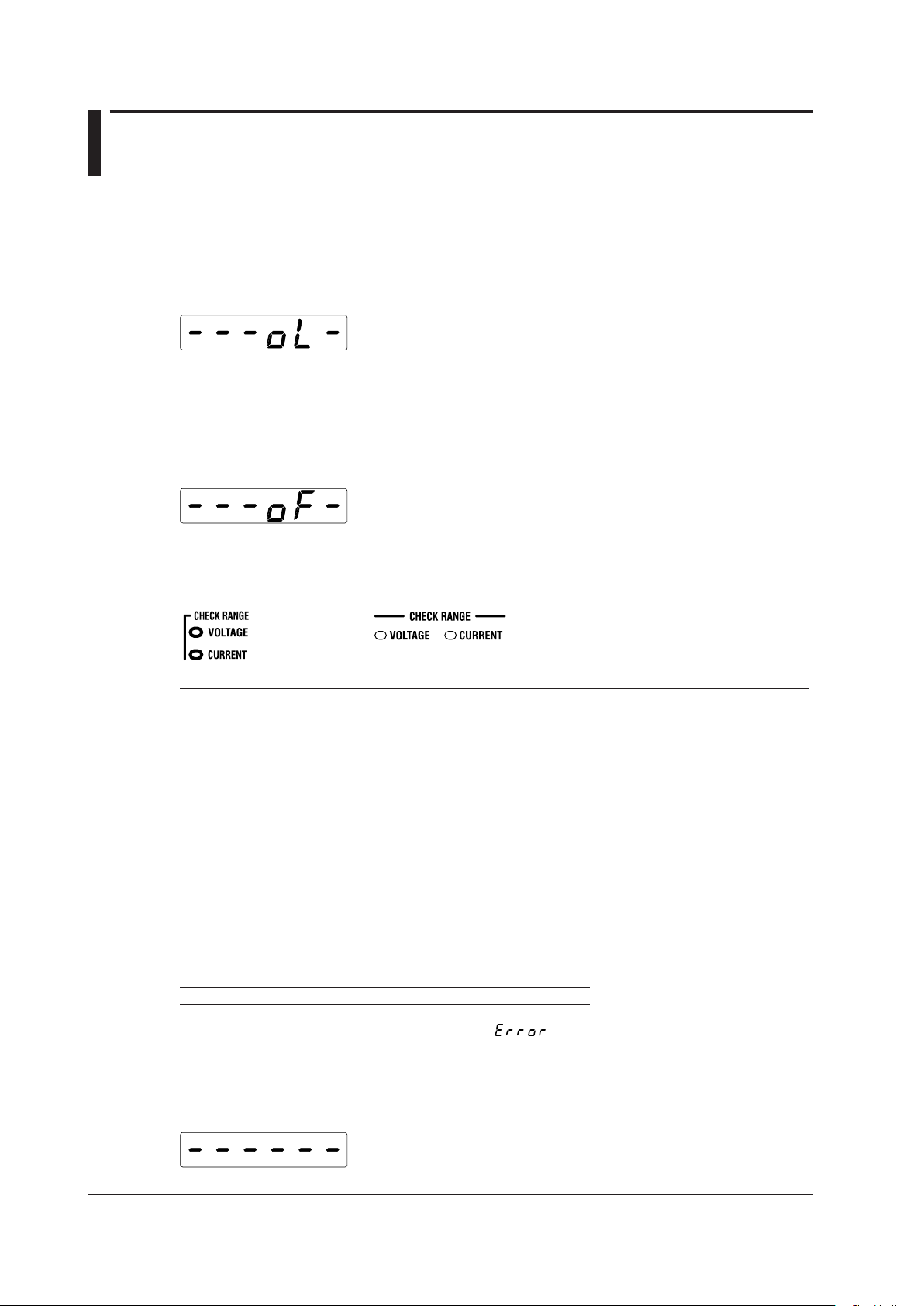

1.5 Auto Range, Overrange, and Error Indications

WT310/WT310HC WT330

During Measurement

Overrange Indication

The measured voltage and rated current values are determined to be overrange when they exceed

140% of their rated range.* When auto range is enabled, the range is automatically increased, but

if a values exceeds 140% of its maximum range, it is determined to be overrange, and the following

indication appears.

* On the WT310HC, the current is determined to be overrange when it exceeds 110% of the

maximum current range (40 A range).

Computation Overflow Indication

If a computed value cannot be displayed using the specified decimal place or unit, the following

indication appears.

Auto Range Monitor Indications

When an input signal meets the conditions for auto range switching, an indicator lights.

Colors and Meanings of Auto Range Monitor Indicators

Color Description

Red Peak overrange

Magenta Greater than 140% of the rated range (overrange)

Yellow Greater than 130% of the rated range and not more than 140% (condition for raising the auto range)

Cyan 30% or less of the rated range (condition for reducing the auto range)

If the range is already at the minimum measurement range, this indicator will not light even when

values are 30% or less of the rated range.

1 On the WT310HC, the current is determined to be overrange when it exceeds 110% of the maximum current

range (40 A range).

2 On the WT310HC, the current is determined to be overrange when it exceeds 100% of the maximum current

range (40 A range).

1

Indications When the Measured Value Is Too Small

When the measured voltage or current is 0.5% or less of the rated range (1% or less when the

crest factor is set to 6), the following indications appear. These indications only appear when the

measurement mode is RMS or VOTLAGE MEAN.

Function Indication

Voltage, current, apparent power, or reactive power A zero appears.

Power factor or phase angle

Measurement Suspension/No Data Indication (Dashes)

When the measurement range, function, or element is switched and the displayed contents change or

when there is no data to display, the following dashes are displayed temporarily.

2

Page 29

1

1.5 Auto Range, Overrange, and Error Indications During Measurement

Error

Displayed in cases such as when a measured value is outside of its determined range.

Component Names and Functions

IM WT310-02EN

1-13

Page 30

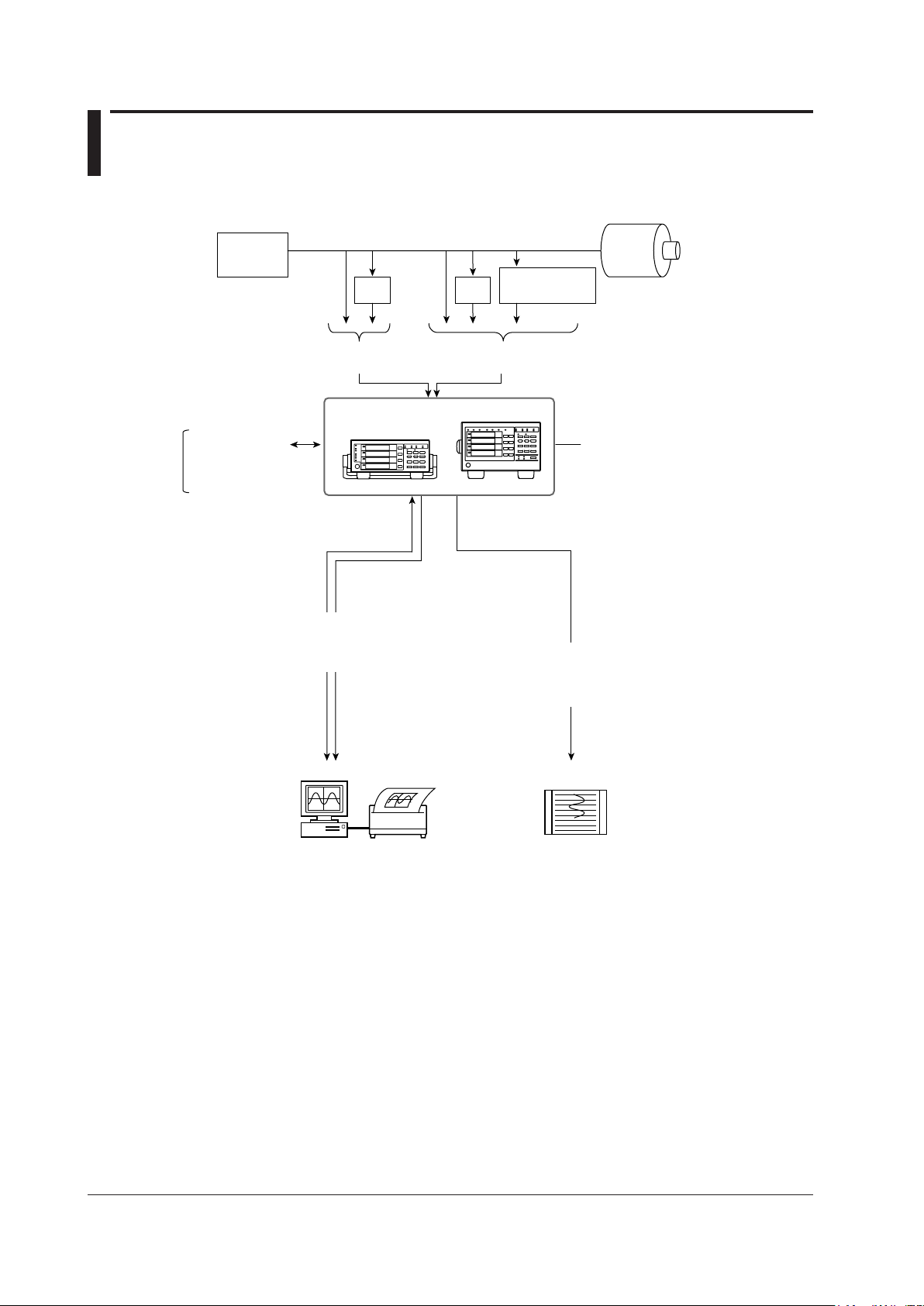

1.6 System Configuration

Power

Supply

Load

VT

CT

Voltage

(Apply one of them.)

Current

(Apply one of them.)

Current sensor

(optional)

Remote control signal

(optional)

Internal memory

Numeric data storage

Recorder

Numeric data

Setup parameters

PC

Printer

Integration start

Integration stop

Hold/

single

USB interface/

GP-IB interface

*

/

RS-232 interface*/

Ethernet interface (optional)

D/A output (option)

Measured values

are transmitted

as DC voltages.

WT310/WT310HC/WT330

* The WT310/WT310HC/WT330 is standard-equipped with a GP-IB or RS-232 interface (whichever

you choose).

1-14

IM WT310-02EN

Page 31

1

2

Chapter 2 Making Preparations for Measurements

2.1 Handling Precautions

Safety Precautions

If you are using this instrument for the first time, make sure to read “Safety Precautions” on pages vi to

viii.

Do Not Remove the Case

Do not remove the case from the instrument. Some parts of the instrument use high voltages and

are extremely dangerous. For internal inspection and adjustment, contact your nearest YOKOGAWA

dealer.

Unplug If Abnormal Behavior Occurs

If you notice smoke or unusual odors coming from the instrument, immediately turn off the power and

unplug the power cord. Also, turn off the power to any circuits under measurement that are connected

to the input terminals. Then, contact your nearest YOKOGAWA dealer.

Do Not Damage the Power Cord

Nothing should be placed on top of the power cord. The power cord should also be kept away from

any heat sources. When removing the plug from the power outlet, do not pull on the cord. Pull from the

plug. If the power cord is damaged, purchase a replacement with the same part number as the one

indicated on page iii.

Making Preparations for Measurements

General Handling Precautions

Do Not Place Objects on Top of the Instrument

Never stack the instrument or place other instruments or any objects containing water on top of it.

Doing so may damage the instrument.

Keep Electrically Charged Objects Away from the Instrument

Keep electrically charged objects away from the input terminals. They may damage the internal

circuitry.

Unplug during Extended Non-Use

Turn off the power to the circuit under measurement and the instrument and remove the power cord

from the outlet.

IM WT310-02EN

2-1

Page 32

2-2

IM WT310-02EN

WT310/WT310HC WT330

2.1 Handling Precautions

When Carrying the Instrument

First, turn off the circuit under measurement and remove the measurement cables. Then, turn off the

instrument and remove the power cord and any attached cables. When carrying the instrument, use

the handle as shown in the following figure, or use both hands to hold the instrument firmly.

When Cleaning the Instrument

When cleaning the case or the operation panel, turn off the circuit under measurement and the

instrument and remove the instrument’s power cord from the outlet. Then, wipe the instrument

lightly with a clean dry cloth. Do not use chemicals such as benzene or thinner. Doing so may cause

discoloring and deformation.

Page 33

1

2

2.2 Installing the Instrument

Installation Conditions

WARNING

• Do not install the instrument outdoors or in locations subject to rain or water.

• Install the instrument so that you can immediately remove the power cord if an abnormal or

dangerous condition occurs.

Install the instrument in an indoors environment that meets the following conditions.

Flat, Even Surface

Use the instrument on a stable surface that is level in all directions. If you use the instrument on an

unstable or tilted surface, the accuracy of its measurements may be impeded.

Well-Ventilated Location

Inlet and vent holes are located on the top and bottom of the instrument. To prevent internal

overheating, allow at least 20 mm of space around the inlet and vent holes.

When connecting measurement wires and other various cables, allow extra space for operation.

Making Preparations for Measurements

CAUTION

If you block the inlet or outlet holes on the instrument, it will become hot and may break down.

Ambient Temperature and Humidity

Ambient temperature: 5 to 40°C

Ambient humidity: 20 to 80% RH

(No condensation)

Do Not Install the Instrument in the Following Places

• In direct sunlight or near heat sources

• In an environment with excessive amounts of soot, steam, dust, or corrosive gas

• Near strong magnetic field sources

• Near high-voltage equipment or power lines

• In an environment that is subject to large levels of mechanical vibration

• On an unstable surface

• Outdoors or in locations subject to rain or water

Note

• For the most accurate measurements, use the instrument in the following kind of environment.

Ambient temperature: 23°C ± 5°C Ambient humidity: 30% RH to 75% RH (no condensation)

When using the instrument in a place where the ambient temperature is 5°C to 18°C or 28°C to 40°C, add the

temperature coefficient to the accuracy as specified in chapter 7.

• When installing the instrument in a place where the ambient humidity is 30% or less, take measures to

prevent static electricity such as using an anti-static mat.

• Condensation may occur if the instrument is moved to another place where the ambient temperature or

humidity is higher, or if the temperature changes rapidly. In these kinds of circumstances, wait for at least an

hour before using the instrument, to acclimate it to the surrounding temperature.

IM WT310-02EN

2-3

Page 34

2-4

IM WT310-02EN

1

2

3

4

5

6

7

8

1

3

Rotating base

Pull this out approximately 2 mm

to 3 mm, and rotate the handle.

Handle stop positions (We recommend that you use positions 1, 3, 5, and 8. Do not place a heavy load

on the WT310/WT310HC/WT330 when the handle is in stop position 2 or 4.)

Movable legs

2.2 Installing the Instrument

Storage Location

Do not store the instrument:

• Where the relative humidity is greater than 80% • Where the level of mechanical vibration is high

• In direct sunlight • Where there are corrosive or explosive gasses

• Where the temperature is 60°C or higher • Where an excessive amount of soot, dust, salt,

• Near a strong source of heat or moisture • Where water

We recommend that the instrument be stored in an environment where the temperature is between 5°C

and 40°C and the relative humidity is between 20% RH and 80% RH.

Installation Position

Desktop

Place the instrument in a horizontal position or tilt it on its handle or movable legs. Place the instrument

on a flat, level surface as shown in the figure below.

• WT310/WT310HC

To use the handle as a stand to tilt the instrument, first check that the handle is fixed in place,

and then position the instrument. To rotate the handle, first pull the handle’

approximately 2 mm to 3 mm on both the left and right sides of the instrument, and then rotate it

slowly to one of its stop positions.

or iron is present

, oil, or chemicals may splash onto

the instrument

s rotary axis out

• WT330

WARNING

• When adjusting the WT310/WT310HC handle, be careful not to injure your hand with the

edges of the handle.

• When you put away the handle or movable legs, be careful not to get your hand caught

between the handle or movable legs and the instrument.

• Handling the movable legs or handle without firmly supporting the instrument can be

dangerous. Please take the following precautions.

• Only handle the movable legs or handle when the instrument is on a stable surface.

• Do not handle the movable legs or handle when the instrument is tilted.

Do not place the instrument in any position other than those shown in the above figures.

•

Rubber Feet

If the instrument is installed so that it is flat as shown in the above figure, rubber stoppers can be

attached to the feet to prevent the instrument from sliding. One set of rubber stoppers (two stoppers)

are included in the package.

Page 35

1

2

Rotating base

To remove the handle, rotate

the handle to position 8, and

then pull out the rotating base

of the handle by approximately

10 mm on both sides.

WT310/WT310HC WT330

Cover

Cover

Handle

2.2 Installing the Instrument

Rack Mounting

To mount the instrument on a rack, use a rack mount kit (sold separately).

• For the WT310/WT310HC

Item Model Note

Rack mount kit 751533-E2 For EIA single mount

Rack mount kit 751533-J2 For JIS single mount

Rack mount kit 751534-E2 For EIA dual mount

Rack mount kit 751534-J2 For JIS dual mount

• For the WT330

Item Model Note

Rack mount kit 751533-E3 For EIA single mount

Rack mount kit 751533-J3 For JIS single mount

Rack mount kit 751534-E3 For EIA dual mount

Rack mount kit 751534-J3 For JIS dual mount

A summary of the procedure for mounting the instrument on a rack is given below. For detailed

instructions, see the manual that is included with the rack mount kit.

Remove the handle from the instrument.

1.

• WT310/WT310HC

Rotate the handle to position 8 (see the figure on the previous page), and then pull out the rotating base

of the handle by approximately 10 mm on both sides.

• WT330

Remove the handle attachment section cover, and remove the handle attachment screws.

Making Preparations for Measurements

2.

3.

4.

5.

6.

Note

• When rack-mounting the instrument, allow at least 20 mm of space around the inlet and exhaust holes to

• Make sure to provide adequate support from the bottom of the instrument. The support should not block the

For detailed instructions for the procedures below, see the manual that is included with the rack mount kit.

Remove the feet from the bottom of the instrument.

Peel off the seals over the rack mount attachment holes on both side panels of the instrument,

and pull out the rubber rivets.

Place seals over the feet and handle attachment holes.

Attach the rack mount kit to the instrument.

Mount the instrument on a rack.

prevent internal heating.

inlet and vent holes.

IM WT310-02EN

2-5

Page 36

2-6

IM WT310-02EN

2.3 Connecting the Power Supply

WT310/WT310HC WT330

Three-prong outlet

Before Connecting the Power Supply

To prevent electric shock and damage to the instrument, follow the warnings below.

WARNING

• Make sure that the power supply voltage matches the instrument’s rated supply voltage

and that it does not exceed the maximum voltage range specified for the power cord.

• Connect the power cord after checking that the power switch of the instrument is turned

OFF.

• T

o prevent fire and electric shock, only use a power cord supplied by YOKOGA

• To avoid electric shock, be sure to ground the instrument. Connect the power cord to a

three-prong power outlet with a protective earth terminal.

• Do not use an ungrounded extension cord. If you do, the instrument will not be grounded.

• Use an AC outlet that complies with the power cord provided a

protective grounding. If such an AC outlet is unavailable and protective grounding cannot

be furnished, do not use the instrument.

Connecting the Power Cord

Check that the instrument’s power switch is off.

1.

Connect the power cord plug to the power inlet on the rear panel of the instrument.

2.

Connect the other end of the cord to an outlet that meets the following conditions. Use a

3.

grounded three-prong outlet.

Item Specification

Rated supply voltage 100 VAC to 120 VAC, 200 VAC to 240 VAC

Permitted supply voltage range 90 VAC to 132 VAC, 180 VAC to 264 VAC

Rated power supply frequency 50/60 Hz

Permitted supply frequency range 48 Hz to 63 Hz

Maximum power consumption WT310/WT310HC: 50 VA, WT330: 70 VA

*

This instrument can use a 100 V or a 200 V power supply. The maximum rated voltage differs according

to the type of power cord. Before you use the instrument, check that the voltage supplied to it is less

than or equal to the maximum rated voltage of the power cord provided with it (see page v for the

maximum voltage rating).

WA.

nd securely connect the

Page 37

1

2

2.4 Turning the Power Switch On and Off

POWER

OFF ON

WT310/WT310HC WT330

Before Turning On the Power, Check That:

• Theinstrumentisinstalledproperly.→section2.2,“InstallingtheInstrument”

• Thepowercordisconnectedproperly.→section2.3,“ConnectingthePowerSupply”

Power Switch Location

The power switch is located in the lower left of the front panel.

Turning the Power Switch On and Off

The power switch is a push button. Press the button once to turn the instrument on and press it again

to turn the instrument off.

Making Preparations for Measurements

Operations Performed When the Power Is Turned On

When the power switch is turned on, a self-test starts automatically. When the self-test completes

successfully, the screen that was displayed immediately before the power was turned off appears.

Note

• After turning the power off, wait at least 10 seconds before you turn it on again.

When the Power-on Operation Does Not Finish Normally

• If the instrument does not operate as described above when the power switch is turned on, turn the power

switch off, and then:

• Check that the power cord is securely connected.

• Checkthatthecorrectvoltageiscomingtothepoweroutlet.→section2.3,“ConnectingthePower

Supply”

• After checking the above, try turning on the power while holding down SET to initialize the settings (reset

them to their factory defaults). For details about initializing the settings, see section 3.3, “Initializing

Settings.”

• If the instrument still does not work properly, contact your nearest YOKOGAWA dealer for repairs.

• If an error code is displayed, see section 6.2, “Error Code Descriptions and Corrective Actions,” and take

the appropriate actions.

• It may take a few seconds for the startup message to appear.

To Make Accurate Measurements

• Allow the instrument to warm up for at least 30 minutes after turning on the power switch.

• Aftertheinstrumentwarmsup,executezero-levelcompensation.→section8.3oftheUser’s

Manual, IM WT310-01EN

IM WT310-02EN

2-7

Page 38

2-8

IM WT310-02EN

All the LEDs light.

Power on

Measurement data display

Model: WT310, WT310HC, WT332, or WT333

Firmware version

1

2

3

2.4 Turning the Power Switch On and Off

Operations Performed When the Power Is Turned Off

After the power is turned off, the instrument stores the setup parameters in its memory before shutting

down. The same is true when the power cord is disconnected from the outlet. The next time the power

is turned on, the instrument powers up using the stored setup parameters.

Note

The instrument stores the settings using an internal lithium battery. When the lithium battery voltage falls

below a specified value, you will no longer be able to store setup parameters, and error code 901 will

appear on the screen when you turn on the power (see section 6.2, “Error Code Descriptions and Corrective

Actions”). If this message appears frequently, you need to replace the battery soon. Do not try to replace the

battery yourself. Contact your nearest YOKOGAWA dealer to have the battery replaced.

Power-on Messages

Page 39

1

2

2.5 Precautions When Wiring the Circuit under Measurement

To prevent electric shock and damage to the instrument, follow the warnings below.

WARNING

• Ground the instrument before connecting measurement cables. The power cord that comes

with the instrument is a three-prong cord. Insert the power cord into a grounded threeprong outlet.

•

Turn the circuit under measurement off before connecting and disconnecting cables to it.

Connecting or removing measurement cables while the power is on is dangerous.

Do not wire a current circuit to the voltage input terminal or a voltage circuit to the current

•

input terminal.

• Strip the insulation covers of measurement cables so that when they are wired to the input

terminals, the conductive parts (bare wires) do not protrude from the terminals.

sure to fasten the input terminal screws securely so that cables do not come loose.

• When connecting measurement cables to the voltage input ter

measurement cables that have safety terminals that cover their conductive parts. Using

a terminal with bare conductive parts (such as a banana plug) can be dangerous if the

terminal comes loose.

• When connecting cables to the external current sensor input terminals, only connect cables

that have safety terminals that cover their conductive parts. Using a connector with bare

conductive parts can be dangerous if the terminal comes loose.

• When you apply current directly to the current input terminals to measure it, the voltage of

the item under measurement appears at the external sensor input connector

electric shock, remove the cable connected to the external sensor.

• When the voltage of the circuit under measurement is being applied to the current input

terminals, do not touch the external current sensor input terminals. Doing so is dangerous

because the terminals are electrically connected inside the instrument.

• When connecting a measurement cable from an external current sensor to an external

current sensor input connector, remove the cables connected to the current input terminals.

Also, when the voltage of the circuit under measurement is being applied to the external

current sensor input terminals, do not touch the current input terminals. Doing so is

dangerous because the terminals are electrically connected inside the instrument.

•

When using an external voltage transformer (VT) or current transformer (CT), make sure

that it has enough dielectric strength for the voltage (U) being measured (2U + 1000 V

recommended). Also, make sure that the secondary side of the CT does not become an

open circuit while the power is being applied. If this happens, high voltage will appear at

the secondary side of the CT

•

When using an external current sensor, make sure to use a sensor that comes in a case.

The conductive parts and case should be insulated, and the sensor should have enough

dielectric strength for the voltage of the circuit under measurement. Using a bare sensor is

dangerous, because there is a high probability that you might accidentally touch it.

• When using a shunt-type current sensor as an external current sensor, turn off the circuit

under measurement before you connect the sensor

while the power is on is dangerous.

• When using a clamp-type current sensor as an external current sensor, make sure that

you understand the voltage of the circuit under measurement and the specifications and

handling of the clamp-type sensor, and then confirm that there are no dangers, such as

shock hazards.

• For safety reasons, when using the instrument after mounting it on a rack, furnish a switch

for turning off the circuit under measurement from the front side of the rack.

• For safety reasons, after you connect the measurement cable

attach the current input protection cover (screw tightening torque: 0.6 N•m). Make sure that

the conductive parts do not protrude from the protection cover.

, making it extremely dangerous.

. Connecting or removing the sensor

minals, only connect

s, use the included screws to

Also, make

. To prevent

Making Preparations for Measurements

IM WT310-02EN

2-9

Page 40

2-10

IM WT310-02EN

2.5 Precautions When Wiring the Circuit under Measurement

• To make the protective features effective, before applying the voltage or current from the

circuit under measurement, check that:

• The power cord provided with the instrument is being used to connect to the power

supply and that the instrument is grounded.

• The instrument is turned on.

•

The current input protection cover provided with the instrument is attached.

• When the instrument is turned on, do not apply a signal that e

to the voltage or current input terminals. When the instrument is turned off, turn the circuit

under measurement off. For information about other input terminals, see the specifications

in chapter 6.

Instantaneous maximum allowable input (within 20 ms)

Voltage input

Peak value of 2.8 kV or rms value of 2 kV, whichever is less.

Current input

Direct input

•

WT310 and WT330

When the crest factor is 3: 0.5 A to 20 A

When the crest factor is 6: 0.25 A to 10 A

Peak value of 450 A or rms value of 300 A, whichever is less.

• WT310

When the crest factor is 3: 5 mA to 200 mA

When the crest factor is 6: 2.5 mA to 100 mA

Peak value of 150 A or rms value of 100 A, whichever is less.

• WT310HC

When the crest factor is 3: 1 A to 40 A

When the crest factor is 6: 0.5 A to 20 A

Peak value of 450 A or rms value of 300 A, whichever is less.

External sensor input

Peak value less than or equal to 10 times the range.

xceeds the following values

Instantaneous maximum allowable input (1 s or less)

Voltage input

Peak value of 2 kV or rms value of 1.5 kV, whichever is less.

Current input

Direct input

WT310 and WT330

•

When the crest factor is 3: 0.5 A to 20 A

When the crest factor is 6: 0.25 A to 10 A

Peak value of 150 A or rms value of 40 A, whichever is less.

• WT310

When the crest factor is 3: 5 mA to 200 mA

When the crest factor is 6: 2.5 mA to 100 mA

Peak value of 30 A or rms value of 20 A, whichever is less.

• WT310HC

When the crest factor is 3: 1 A to 40 A

When the crest factor is 6: 0.5 A to 20 A

Peak value of 150 A or rms value of 44 A, whichever is less.

External sensor input

Peak value less than or equal to 10 times the range.

Page 41

1

2

2.5 Precautions When Wiring the Circuit under Measurement

Continuous maximum allowable input

Voltage input

Peak value of 1.5 kV or rms value of 1.0 kV, whichever is less.

Current input

Direct input

• WT310 and WT330

When the crest factor is 3: 0.5 A to 20 A

When the crest factor is 6: 0.25 A to 10 A

Peak value of 100 A or rms value of 30 A, whichever is less.

• WT310

When the crest factor is 3: 5 mA to 200 mA

When the crest factor is 6: 2.5 mA to 100 mA

Peak value of 30 A or rms value of 20 A, whichever is less.

• WT310HC

When the crest factor is 3: 1 A to 40 A

When the crest factor is 6: 0.5 A to 20 A

Peak value of 100 A or rms value of 44 A, whichever is less.

External sensor input

Peak value less than or equal to 5 times the range.

CAUTION

Use measurement cables with dielectric strengths and current capacities that are appropriate

for the voltage or current being measured.

Example: When making measurements on a current of 20 A, use copper wires that have a

conductive cross-sectional area of 4 mm

Attaching a measurement cable to this product may cause radio interference in which case

the user will be required to correct the interference.

2

or greater.

Making Preparations for Measurements

Note

• If you are measuring large currents or voltages or currents that contain high frequency components, take

special care in dealing with mutual interference and noise when you wire the cables.

• Keep measurement cables as short as possible to minimize the loss between the circuit under

measurement and the instrument.

• The thick lines on the wiring diagrams shown in sections 2.9 to 2.11 are the parts where the current flows.

Use wires that are suitable for the current levels.

• To make accurate measurements of the voltage of the circuit under measurement, connect the

measurement cable that is connected to the voltage input terminal to the circuit as closely as possible.

• To make accurate measurements, separate the measurement cables as far away from the ground wires

and the instrument’s case as possible to minimize static capacitance to the ground.

• To measure the apparent power and power factor more accurately on an unbalanced three-phase circuit,

we recommend that you use the three-voltage, three-current method (3V3A).

IM WT310-02EN

2-11

Page 42

2-12

IM WT310-02EN

2.6 Assembling the Adapters for the Voltage Input

Plug

Internal insulator

Cover

Cable

Internal insulator

Attachable cable

Covering: max. diameter 3.9 mm

Core wire: max. diameter 1.8 mm

10 mm

Insert the hexagonal wrench into the plug and tighten.

Plug

Hexagonal

wrench

Cable tip

Cover

Terminals

When connecting a measurement cable to a WT310/WT310HC/WT330 voltage input terminal, use the

included 758931 Safety Terminal Adapter or the 758923 Safety Terminal Adapter (sold separately).

758931 Safety Terminal Adapter

When using the 758931 Safety Terminal Adapter, assemble it according to the following procedure.

Assembling the Safety Terminal Adapter

Remove approximately 10 mm of the covering from the end of the cable and pass the cable

1.

through the internal insulator.

Insert the tip of the cable into the plug. Fasten the cable in place using the hexagonal wrench.

2.

Insert the plug into the internal insulator.

3.

Attach the external cover. Make sure that the cover does not come off.

4.

Note

Once you attach the cover, it is difficult to disassemble the safety terminal adapter. Use care when attaching

the cover.

Below is an illustration of the adapter after it has been assembled.

Page 43

1

2

Explanation

Voltage under

measurement

758921

758922

758917

758923

758931

758929

WT310/WT310HC

Voltage input terminals

WT330

Voltage input terminals

96030

96031

96001

(voltage output type)

751552

(current output type)

758917 758921

758924

Current under

measurement

Connecting a clamp-on probe

WT310/WT310HC

WT330

EXT input

terminal

Current input

terminals

Current input

terminals

EXT input terminal

96001 terminal

When you are connecting to the 96030, 96031,

or 758924, remove the terminal sleeves.

Sleeves

2.6 Assembling the Adapters for the Voltage Input Terminals

Wire the adapters that come with the WT310/WT310HC/WT330 or the adapters and various sensors

that are sold separately as shown below:

Wiring to a Voltage Input Terminal

Making Preparations for Measurements

Wiring to a Current Input Terminal

Use the clamp-on probes (sold separately) as shown below.

* The current input terminal and EXT input terminal cannot be wired (used) simultaneously.

IM WT310-02EN

2-13

Page 44

2-14

IM WT310-02EN

2.7 Wiring for Accurately Measuring a Single-

SOURCE

LOAD

U

I

C

V

LOAD

U

V

I

C

SOURCE

• Easily affected • Not easily affected

SOURCE

LOAD

U

I

C

V

SOURCE

LOAD

U

I

C

V

±

±

±

±

±

±

±

±

SOURCE

LOAD

U

I

C

V

LOAD

SOURCE

U

I

C

V

• When the measured current is

relatively large

Connect the voltage input terminal

between the current input terminal

and the load.

• When the measured current is

relatively small

Connect the current input terminal

between the voltage input terminal

and the load.

LOAD

U

V

I

C

SOURCE

SOURCE

LOAD

U

I

C

V

±

±

±

±

±

±

±

±

phase Device

When you are wiring a single-phase device, there are the four patterns of terminal wiring positions

shown in the following figures for wiring the voltage input and current input terminals. Depending on

the terminal wiring positions, the effects of stray capacitance and the effects of the measured voltage

and current amplitudes may become large. To make accurate measurements, refer to the items below

when wiring the voltage input and current input terminals.

Effects of Stray Capacitance