WT3000

WT3000 Manual, Vol 3/3

Precision Power Analyzer

Expansion Function

IM 760301-51E

7th Edition

Note

Thank you for purchasing the WT3000 Precision Power Analyzer.

This Expansion Function User’s Manual contains useful information about the operating

procedures and lists the handling precautions of the expansion functions. To ensure

correct use, please read this manual thoroughly before beginning operation. After reading

the manual, keep it in a convenient location for quick reference whenever a question

arises during operation.

Three manuals, including this one, are provided as manuals for the WT3000. Please

read all of them.

Manual Title Manual No. Description

WT3000 Precision Power Analyzer

User’s Manual

(Vol 1/3)

WT3000 Precision Power Analyzer

Communication Interface

User’s Manual (CD-ROM)

(Vol 2/3)

WT3000 Precision Power Analyzer

Expansion Function

User’s Manual

(Vol 3/3)

IM 760301-51E Explains all functions and procedures

of the WT3000 excluding the expansion

functions and communication functions.

IM 760301-17E Explains the functions for controlling

the WT3000 using communication

commands.

IM 760301-51E This manual. Explains the expansion

functions (motor evaluation function

and options) of the WT3000 and their

operating procedures.

• The contents of this manual are subject to change without prior notice as a result of

continuing improvements to the instrument’s performance and functions. The figures

given in this manual may differ from those that actually appear on your screen.

•

Every effort has been made in the preparation of this manual t

o ensure the accuracy

of its contents. However, should you have any questions or find any errors, please

contact your nearest YOKOGAWA dealer.

• Copying or reproducing all or any part of the contents of this manual without the

permission of

• The TCP/IP

Yokogawa Electric Corporation is strictly prohibited.

software of this product and the document concerning the TCP/IP

software have been developed/created by YOKOGAWA based on the BSD Networking

Software, Release 1 that has been licensed from the University of California.

Trademarks

• Microsoft, Internet Explorer, MS-DOS, Windows, Windows NT, and Windows XP are

either registered trademarks or trademarks of Microsoft Corporation in the United

States and/or other countries.

•

Adobe, Acrobat, and PostScript are trademarks of

• For purposes of this manual, the ® and TM symbols do not accompany their

respective registered trademark names or trademark names.

• Other company and product names are registered trademarks or trademarks of their

respective holders.

Revisions

• 1st Edition December 2004

• 2nd Edition June 2005

• 3rd Edition January 2006

• 4th Edition December 2006

• 5th Edition March 2007

• 6th Edition May 2009

• 7th Edition February 2014

7th Edition: Februray 2014 (YMI)

All Rights Reserved, Copyright © 2004 Yokogawa Electric Corporation

All Rights Reserved, Copyright © 2014 Yokogawa Meters & Instruments Corporation

IM 760301-51E

Adobe Systems Incorporated.

i

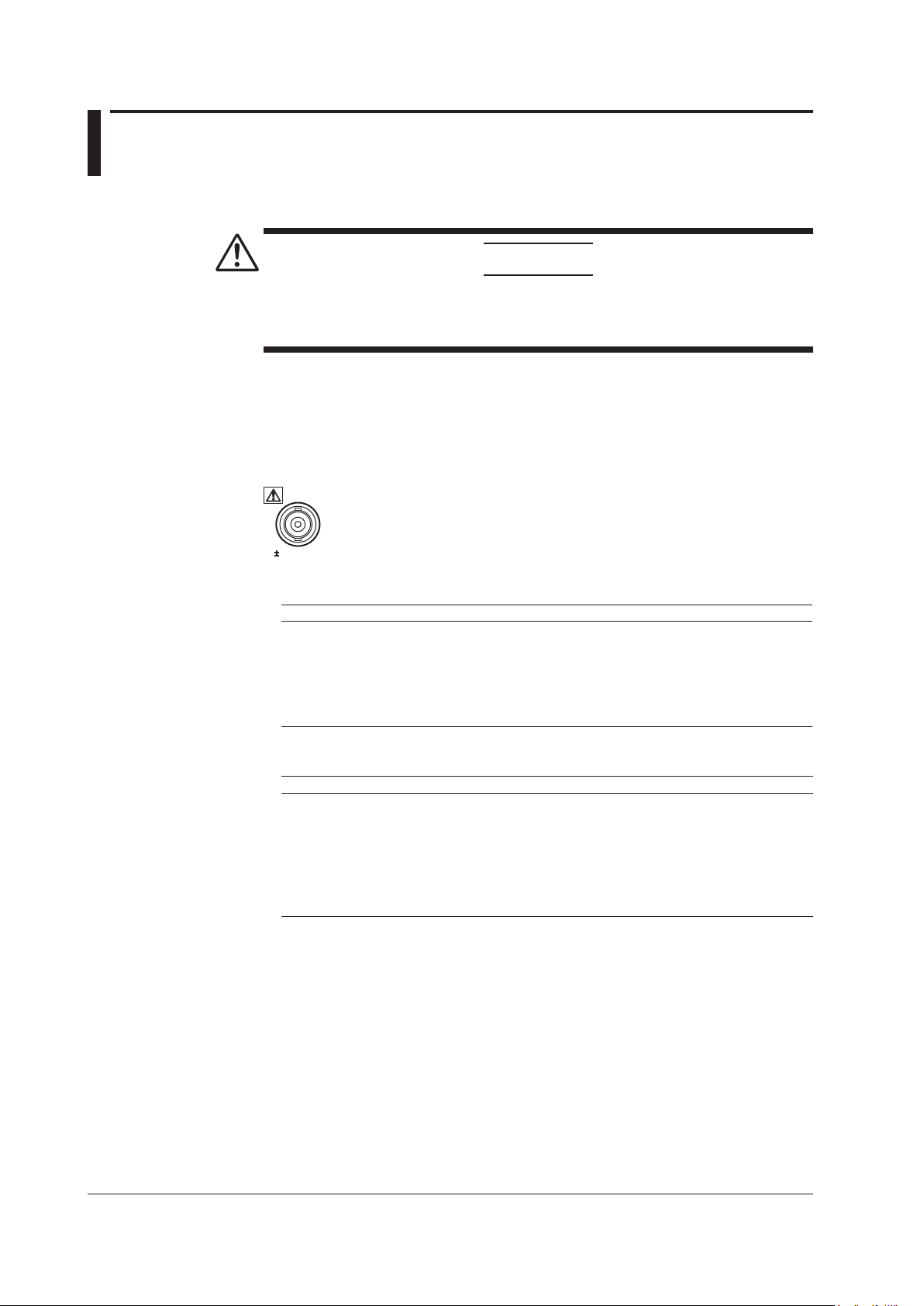

Safety Precautions

This instrument is an IEC safety class 01 instrument (provided with a terminal for

protective earth grounding).

The general safety precautions described in the User’s Manual IM760301-01E and

this manual (IM760301-51E) must be observed during all phases of operation. If the

instrument is used in a manner not specified in these manuals, the protection provided

by the instrument may be impaired. Yokogawa Electric Corporation assumes no liability

for the customer’s failure to comply with these requirements.

ii

IM 760301-51E

Conventions Used in This Manual

Safety Markings

The following markings are used in this manual.

Improper handling or use can lead to injury to the user or damage to

the instrument. This symbol appears on the instrument to indicate that

the user must refer to the user’s manual for special instructions. The

same symbol appears in the corresponding place in the user’s manual

to identify those instructions. In the manual, the symbol is used in

conjunction with the word “WARNING” or “CAUTION.”

Subheadings

WARNING

CAUTION

Calls attention to information that is important for proper operation of

Note

On pages that describe operating procedures, the following symbols, displayed

characters, and terminology are used to distinguish the procedures from their

explanations:

Procedure

Explanation

Calls attention to actions or conditions that could cause serious or

fatal injury to the user, and precautions that can be taken to prevent

such occurrences.

Calls attentions to actions or conditions that could cause light injury to

the user or damage to the instrument or user’s data, and precautions

that can be taken to prevent such occurrences.

the instrument.

Follow the numbered steps. All procedures are written with

inexperienced users in mind; experienced users may not need to

carry out all the steps.

This subsection describes the setting parameters and the limitations

on the procedures.

Unit

IM 760301-51E

Displayed Characters and Terminology Used in the Procedural Explanations

Panel Keys and Soft keys

Bold characters used in the procedural explanations indicate characters that are marked on the

panel keys or the characters of the soft keys or menus displayed on the screen.

SHIFT+Panel Key

SHIFT+key means you will press the SHIFT key to turn ON the SHIFT key followed by the

operation key. The setup menu marked in purple below the panel key that you pressed appears on

the screen.

k Denotes 1000. Example: 12 kg, 100 kHz

K Denotes 1024. Example: 459 KB (file data size)

iii

Contents

Safety Precautions ............................................................................................................................ii

Conventions Used in This Manual ................................................................................................... iii

Chapter 1 Motor Evaluation Function (Motor Version)

1.1 Names and Functions of Parts of the Motor Evaluation Function .................................... 1-1

1.2 Applying Signals of Rotating Speed and Torque .............................................................. 1-2

1.3 Selecting the Type of the Revolution and Torque Signals ................................................ 1-4

1.4 Selecting the Analog Range .............................................................................................

1.5 Selecting the Line Filter and Synchronization Source .................................................... 1-10

1.6 Setting the Pulse Range, Pulse Count, and Pulse Rating .............................................. 1-12

1.7 Setting the Scaling Factor and Unit ................................................................................ 1-17

1.8 Setting the Motor and Frequency Measurement Source fo

Speed and Slip ......................................................................................................

1.9

1.10 Specications

Chapter 2 Built-in Printer (Option)

2.1 Names and Functions of Parts of the Built-in Printer ....................................................... 2-1

2.2 Loading the Roll Paper and Feeding the Paper ............................................................... 2-2

2.3 Printing Screen Images on the Built-in Printer ................................................................. 2-7

2.4 Printing Numeric Data Lists on the Built-in Printer ........................................................... 2-9

2.5 Auto Print

2.6 Built-in

ComputingtheMotorEfciencyandTotalEfciency...................................................... 1-24

oftheMotorEvaluationFunction ............................................................ 1-25

.......................................................................................................

PrinterSpecications .......................................................................................... 2-18

r Computing the Sync

................. 2-12

1-7

......... 1-21

Chapter 3 D/A Output and Remote Control (Option)

3.1 Part Names and Functions of D/A Output ........................................................................ 3-1

3.2 Setting the D/A Output ...................................................................................................... 3-3

3.3 Setting the D/A Zoom ..................................................................................................... 3-10

3.4 Remote Control .............................................................................................................. 3-12

3.5 D/AOutputandRemoteControlSpecications ............................................................. 3-14

Chapter 4 RGB Video Signal (VGA) Output (Option)

4.1 Names and Functions of the Parts of the RGB Video Signal (VGA) Output .................... 4-1

4.2 RGBVideoSignal(VGA)OutputSpecications............................................................... 4-2

Chapter 5 Ethernet Communications (Option)

5.1 Connecting to the Network ............................................................................................... 5-1

5.2 Setting TCP/IP .................................................................................................................. 5-2

5.3 Saving Setup, Waveform Display

(FTP Client Function) ......................................................................................................

Printing Screen Images on a Network Printer ................................................................ 5-12

5.4

5.5 Sending E-mail ...............................................................................................................

5.6 Accessing the WT3000 from a PC or Workstation (FTP

5.7 Setting of the T

5.8

5.9 Setting the FTP Passive Mode and LPR/SMTP Timeout ............................................... 5-26

5.10 EthernetInterfaceSpecications .................................................................................... 5-28

Checking the Ethernet Communication Function (Option) Availability and

MAC Address ..................................................................................................................... 5-25

ime Difference from GMT or SNTP ........................................................ 5-23

, Numeric, and Image Data to the FTP Server

. 5-9

5-16

Server Function) ..................... 5-19

iv

IM 760301-51E

1

2

3

4

5

6

7

8

9

10

11

12

13

Index

Contents

Chapter 6 Delta Computation (Option)

6.1 Delta Computation Function ............................................................................................. 6-1

6.2 Setting the Delta Computation ......................................................................................... 6-2

6.3 Determination of Delta Computation ................................................................................ 6-5

6.4 Delta

ComputationSpecications .................................................................................... 6-6

Chapter 7 Harmonic Measurement in Normal Measurement Mode (Option)

7.1 Harmonic Measurement Function .................................................................................... 7-1

7.2 Setting the Measurement Mode and Displaying Numeric Data ...................................... 7-10

7.3 Setting the Number of Displayed Items, Page Scrolling the Display ..............................

7.4 Changing the Displayed Items of Numeric Data ............................................................ 7-16

7.5 Selecting the PLL Source ............................................................................................... 7-22

7.6 Setting the Measured Order ........................................................................................... 7-25

7.7 Selecting the Distortion Factor Equation ........................................................................ 7-27

7.8 Setting the

7.9 Displaying the Bar Graph and Making Cursor Measurements

7.10 Displaying Vectors

7.11 Harmonic

Anti-Aliasing Filter ........................................................................................

....................................... 7-30

.......................................................................................................... 7-35

MeasurementSpecications .......................................................................... 7-38

7-12

7-28

Chapter 8 Wide Bandwidth Harmonic Measurement (Option)

8.1 Wide Bandwidth Harmonic Measurement Function ......................................................... 8-1

8.2 Various Settings Related to Wide Bandwidth Harmonic Measurement ............................ 8-2

8.3 Selecting the Wide Bandwidth Harmonic Measurement Mode and

Displaying Numeric Data ..................................................................................................

8.4

Turning ON/OFF the

8.5 Wide

BandwidthHarmonicMeasurementSpecications ................................................. 8-6

Timeout Warning Display of the PLL Lock ...................................... 8-5

8-3

Chapter 9 IEC Harmonic Measurement (Option)

9.1 IEC Harmonic Measurement Function ............................................................................. 9-1

9.2 Various Settings Related to IEC Harmonic Measurement ................................................ 9-5

9.3 Selecting the IEC Harmonic Measurement Mode ............................................................ 9-6

9.4 Selecting the Measured Source ....................................................................................... 9-7

9.5 Selecting the V

9.6 IEC

HarmonicMeasurementSpecications ................................................................... 9-10

oltage/Current Grouping ...........................................................................

Chapter 10 Waveform Computation (Option)

10.1 Waveform Computation Function ................................................................................... 10-1

10.2 Various Settings Related to Waveform Computation ..................................................... 10-3

10.3 Setting the Waveform Computation Mode ......................................................................

10.4 Setting the Waveform Equation ......................................................................................

10.5 Setting the Scale, Unit, and Label of the Computed Waveform .....................................

10.6 Waveform

ComputationFunctionSpecications .......................................................... 10-13

9-8

10-4

10-5

10-9

IM 760301-51E

v

Contents

Chapter 11 FFT (Option)

11.1 FFT Function ...................................................................................................................11-1

11.2 Various Settings Related to FFT ......................................................................................11-4

11.3 Setting the FFT

11.4 Selecting the Power Spectrum to Be Displayed, Selecting

Setting the Label ......................................................................................................

11.5 Setting the Number of Computed Points and Time Window .........................................11-10

11.6 Setting the Display Range of the X-Axis (Frequency) and

the Y-Axis (Signal Amplitude) ........................................................................................11-12

1

1.7 Selecting the Display

11.8 Displaying the Power Spectrum on the Split Screen .....................................................

11.9 Cursor Measurement .....................................................................................................

11.10 FFT

FunctionSpecications ..........................................................................................11-20

Mode ......................................................................................................11-5

the FFT Source, and

the Scale Type of

Type of the Power Spectrum.......................................................11-14

Chapter 12 Voltage Fluctuation and Flicker Measurement (Option)

12.1 Voltage Fluctuation and Flicker Measurement Function ................................................ 12-1

12.2 Setting the Voltage Fluctuation and Flicker Measurement Mode ................................... 12-6

12.3 Setting the Measurement Conditions ............................................................................. 12-8

12.4 Setting the Judgement Conditions ............................................................................... 12-13

12.5 Executing the Normal V

12.6 Executing the Measurement of dmax Caused by Manual Switching ...........................

12.7 Voltage

FluctuationandFlickerMeasurementSpecications ...................................... 12-33

oltage Fluctuation and Flicker Me

asurement .......................... 12-18

.......1

11-16

11-17

12-25

1-7

Chapter 13 Cycle-by-Cycle Measurement (Option)

13.1 Cycle-by-Cycle Measurement Function ......................................................................... 13-1

13.2 Setting the Cycle-by-Cycle Measurement Mode ............................................................ 13-4

13.3 Setting the Measurement Conditions ............................................................................. 13-6

13.4 Executing the Cycle-by-Cycle Measurement ............................................................... 13-13

13.5 Cycle-by-Cycle

MeasurementSpecications ............................................................... 13-19

Index

vi

IM 760301-51E

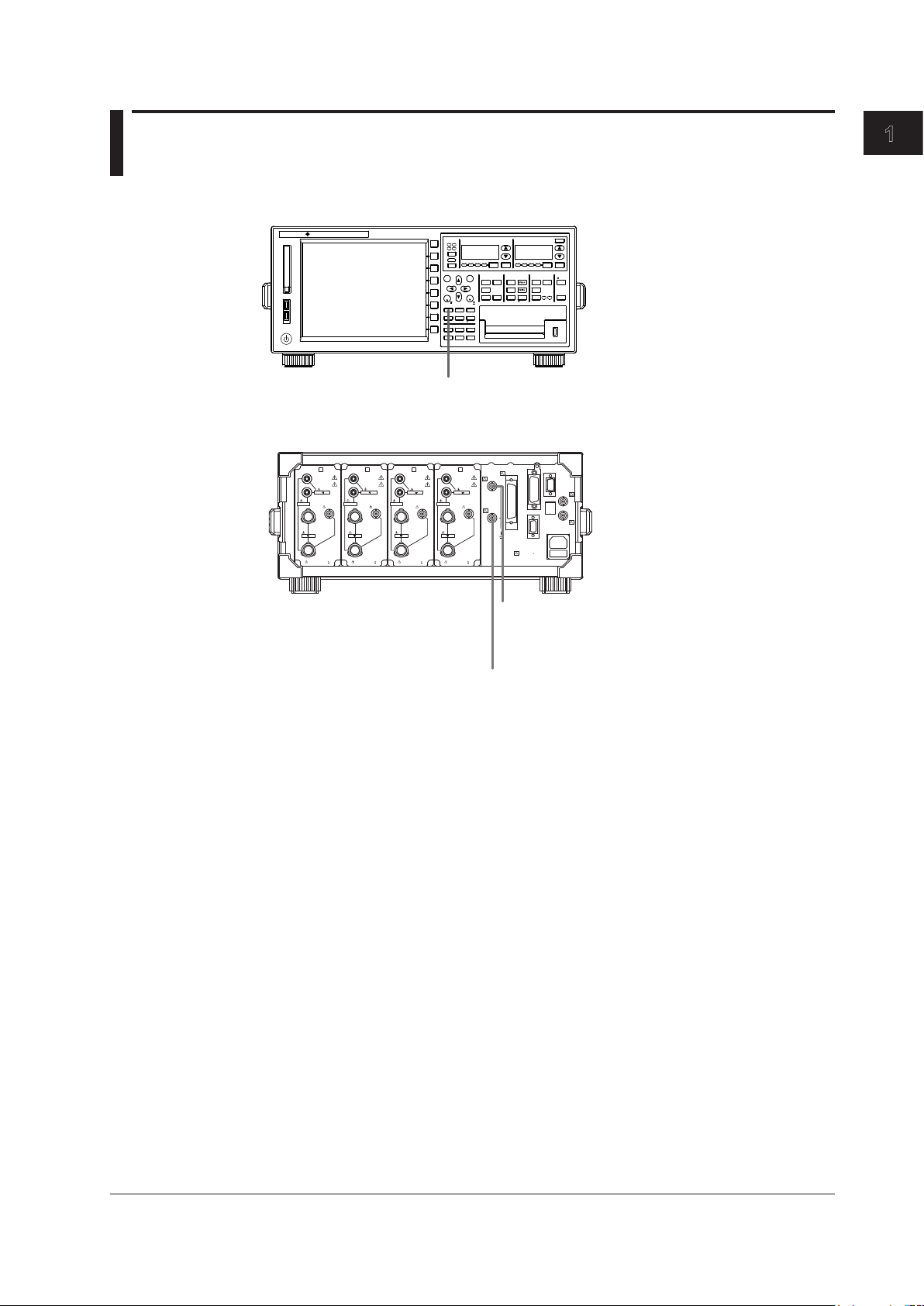

1

START STOP

REMOTE

CAL

SENSOR RATIO

MEASURING

RMS MEAN DC RMEAN

CURRENT RANGEVOLTAGE RANGE

MEASURING

RMS MEAN DC RMEAN

ALL

INPUT INFO.

MOTOR

SET

CURSOR NULL

MENU STORE SET

MENU

LOWER ITEM LOWER FORM ALLUSER SET

DISPLAY

ITEM & ELEMENT

2

3 4

COMPEN

ESC

ELEMENT

ELEMENT

1

WIRING

MODE AUTO MODE AUTO

EXT SENSOR

RESET SET

PAGE PAGE

SCALING

HRM SET

MEASURE

SYNC SOURCE

AVG

LINE FILTER

FREQ

FILTER

FILE

PRINT

MISC

STORE

IMAGE SAVE

HELP

NUMERIC WAVE

OTHERS

ITEM

FORM

U / I / P

WP/q/

TIME

USER

ELEMENT

UPDATE

RATE

HOLD

SINGLE

INTEG

LOCAL

SHIFT

YOKOGAWA

WT3 00 0

PRECI SIO N PO WER ANA LYZ ER

MOTOR VERS ION

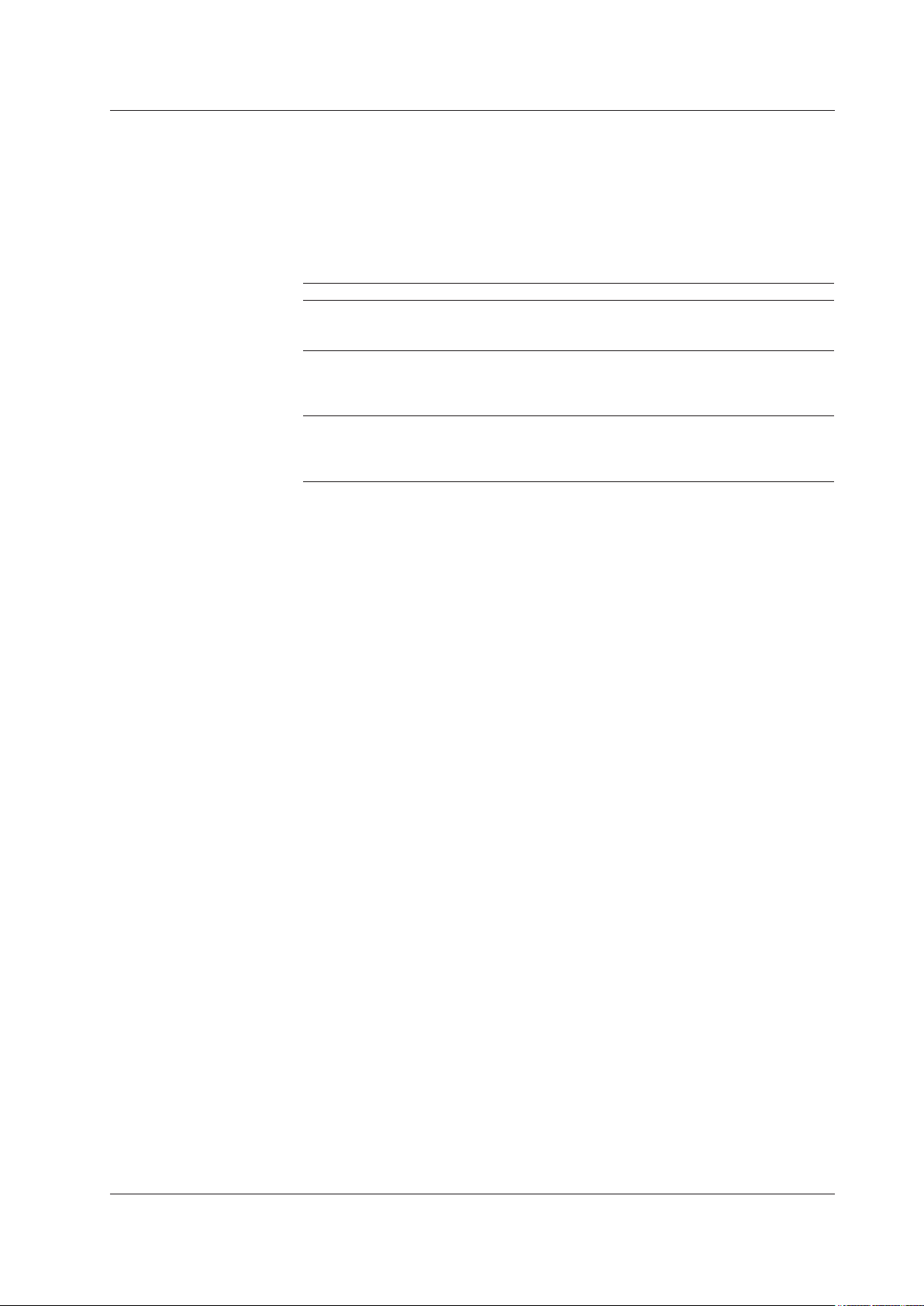

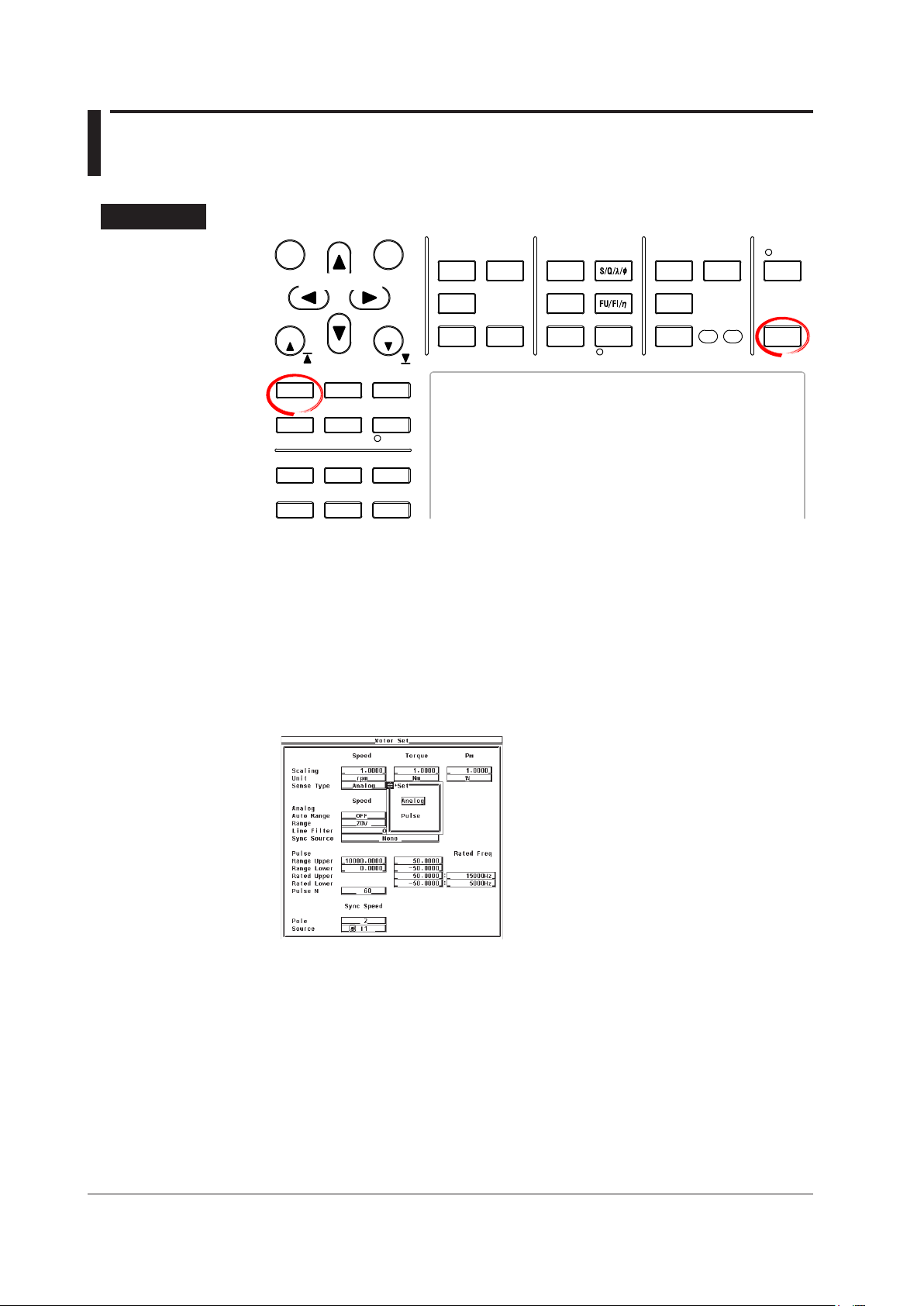

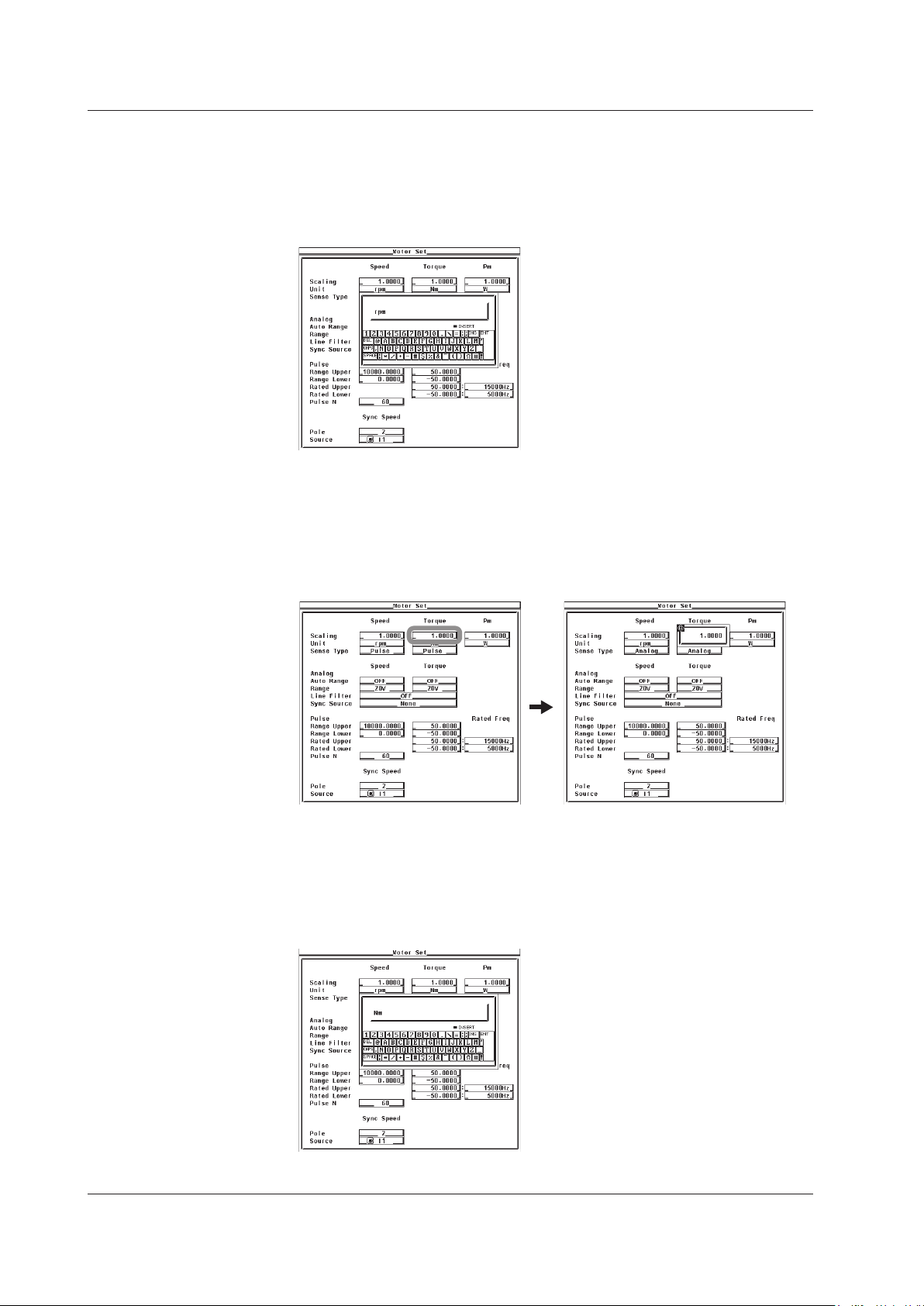

SHIFT+SCALING (MOTOR SET) key (motor version)

Sets items that are required in the motor evaluation such as torque,

number of rotations, and motor output.

ELEMENT

VOLTAGE

±

1000V

MAX

1000V

MAX

±

CURRENT

1

30A

MAX

EXT

CAT II

ALL TERMINALS

1000V MAX TO

ELEMENT

VOLTAGE

±

1000V

MAX

1000V

MAX

±

CURRENT

2

30A

MAX

EXT

CAT II

ALL TERMINALS

1000V MAX TO

ELEMENT

VOLTAGE

±

1000V

MAX

1000V

MAX

±

CURRENT

3

30A

MAX

EXT EXT

CAT II

ALL TERMINALS

1000V MAX TO

ELEMENT

VOLTAGE

±

1000V

MAX

1000V

MAX

±

CURRENT

4

30A

MAX

CAT II

ALL TERMINALS

1000V MAX TO

TORQUE

± 20V MAX

± 20V MAX

SPEED

42V

pk MAX

D/A OUTPUT

VIDEO-OUT

(VGA)

GP-IB

(IEEE488)

SERIAL

(RS-232)

/ USB

EXT. CLK

ETHERNET

100BASE-TX

MEAS. START

100-240V AC 50/60Hz

200VA MAX

FUSE 250V T 6.3A

Torque signal input connector (TORQUE)

(motor version)

Receives signals from torque meters when evaluating

motors.

Revolution signal input connector (SPEED)

(motor version)

Receives signals from revolution sensors when evaluating

motors.

Chapter 1

Motor Evaluation Function (Motor Version)

1.1 Names and Functions of Parts of the Motor Evaluation Function

Front Panel

Rear Panel

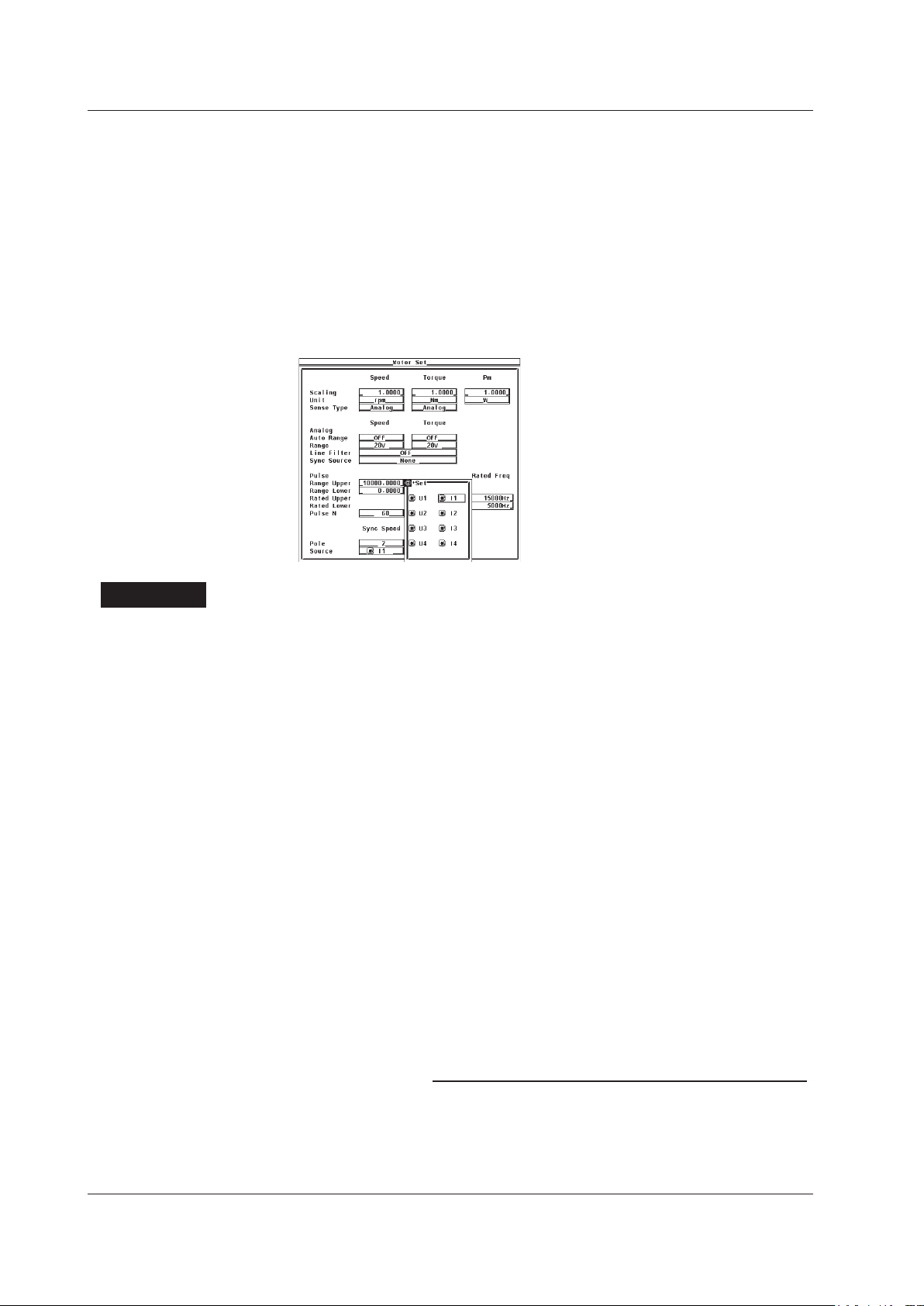

Motor Evaluation Function (Motor Version)

Functional Description

By using the motor evaluation function (motor version), the rotating speed, torque, and

output of a motor can be determined from the signal that is proportional to the rotating

speed of the motor, and the signal received from a torque meter, which is proportional to

the motor’s torque. The signal applied from the revolution sensor or torque meter to the

WT3000 can be selected from analog signal (DC voltage) or pulse signal. In addition,

the synchronous speed and slip of a motor can be determined by setting the motor’s

number of poles. Furthermore, the active power and frequency that are measured by the

WT3000 and the motor output can be used to compute the motor efficiency and the total

efficiency.

Types of Measurement Functions

Measurement functions consists of Speed (rotating speed), Torque, Pm (motor output

or mechanical power), SyncSp (synchronous speed), and Slip. For details on the

Limitations by Measurement Modes

IM 760301-51E

determination of the measurement functions, see section 1.10. Set equations for the

motor

the procedures in section 5.7 in the User’s Manual IM760301-01E.

Measurement functions of the motor evaluation function cannot be measured in wide

bandwidth harmonic measurement, IEC harmonics measurement, voltage fluctuation and

flicker measurement, and cycle-by-cycle measurement modes.

ficiency((Pm)/(PΣA)×100)andtotalefficiency((Pm)/(PΣB)×100)accordingto

ef

1-1

1-2

IM 760301-51E

1.2 Applying Signals of Rotating Speed and Torque

SPEED

20V MAX

CAUTION

Applying a voltage exceeding the maximum allowable input to the revolution signal

input connector (SPEED) or torque signal input connector (TORQUE) can damage

the instrument.

Revolution Signal Input Connector (SPEED)

Input the signal output from the revolution sensor (a DC voltage (analog signal) or a

pulse signal that is proportional to the rotating speed of the motor) according to the

following specifications.

• DC Voltage (Analog Input)

Item Specifications

Connector type

Input range

Effective input range

Input resistance

Maximum allowable input

Continuous maximum common mode voltage

Isolated BNC connector

1 V, 2 V, 5 V, 10 V, and 20 V

0% to ±110% of the measurement range

Approx.

±22 V

±42 Vpeak or less

• Pulse Input

Item Specifications

Connector type

Frequency range

Amplitude input range

Effective amplitude

Input waveform

Input resistance

Continuous maximum common mode voltage

Isolated BNC connector

2 Hz to 200 kHz

±12 Vpeak

1 V (peak to peak) or more

50% duty ratio rectangular wave

Approx.

±42 Vpeak or less

1

1

MΩ

MΩ

1

Torque Signal Input Connector (TORQUE)

TORQUE

20V MAX

Input the signal output from the torque meter (a DC voltage (analog or pulse signal) that

is proportional to the torque of the motor) according to the following specifications.

• DC Voltage (Analog Input)

Item Specifications

Connector type

Input range

Effective input range

Input resistance

Maximum allowable input

Continuous maximum common mode voltage

• Pulse Input

Item Specifications

Connector type

Frequency range

Amplitude input range

Effective amplitude

Input waveform

Input resistance

Continuous maximum common mode voltage

1.2 Applying Signals of Rotating Speed and Torque

Isolated BNC connector

1 V, 2 V, 5 V, 10 V, and 20 V

0% to ±110% of the measurement range

Approx.

±22 V

±42 Vpeak or less

Isolated BNC connector

2 Hz to 200 kHz

±12 Vpeak

1 V (peak to peak) or more

50% duty ratio rectangular wave

Approx.

±42 Vpeak or less

MΩ

1

1MΩ

Motor Evaluation Function (Motor Version)

IM 760301-51E

1-3

1-4

IM 760301-51E

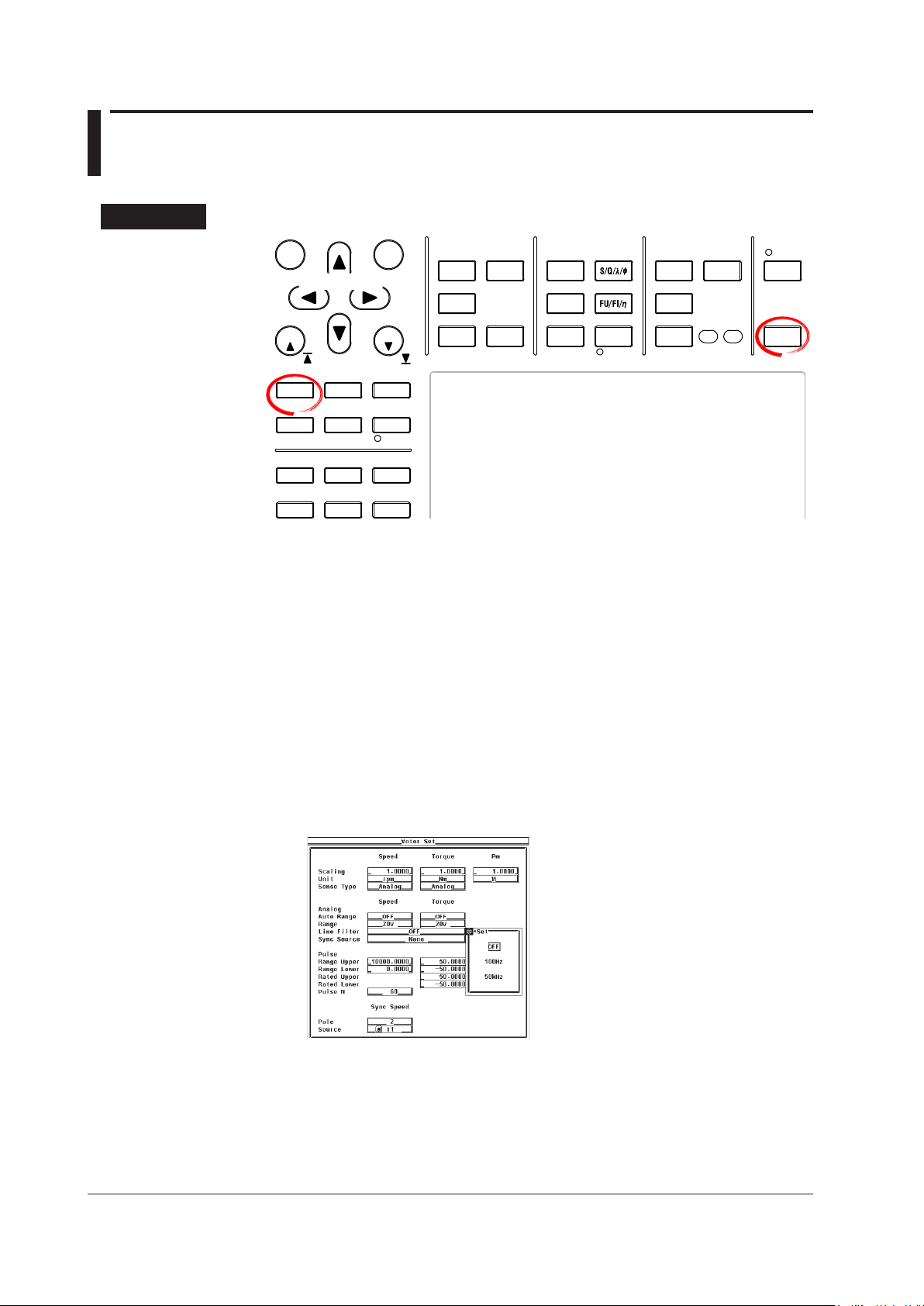

1.3 Selecting the Type of the Revolution and

START STOP

REMOTE

CAL

MOTOR

SET

CURSOR NULL

MENU STORE SET

MENU

LOWER ITEM LOWER FORM ALLUSER SET

DISPLAY

ITEM & ELEMENT

RESET SET

PAGE PAGE

SCALING

HRM SET

MEASURE

SYNC SOURCE

AVG

LINE FILTER

FREQ

FILTER

FILE

PRINT

MISC

STORE

IMAGE SAVE

HELP

NUMERIC

WAVE

OTHERS

ITEM

FORM

U / I / P

WP/q/

TIME

USER

ELEMENT

UPDATE

RATE

HOLD

SINGLE

INTEG

LOCAL

SHIFT

Cursor keys

To exit the menu during operation, press ESC located above the

soft keys.

In the procedural explanation below, the phrase “press the cursor

keys” may be used. This phrase refers to the procedures for

selecting items and entering values and character strings. For

details on the procedures, see section 3.14 in the User’s Manual

IM760301-01E.

Torque Signals

Procedure

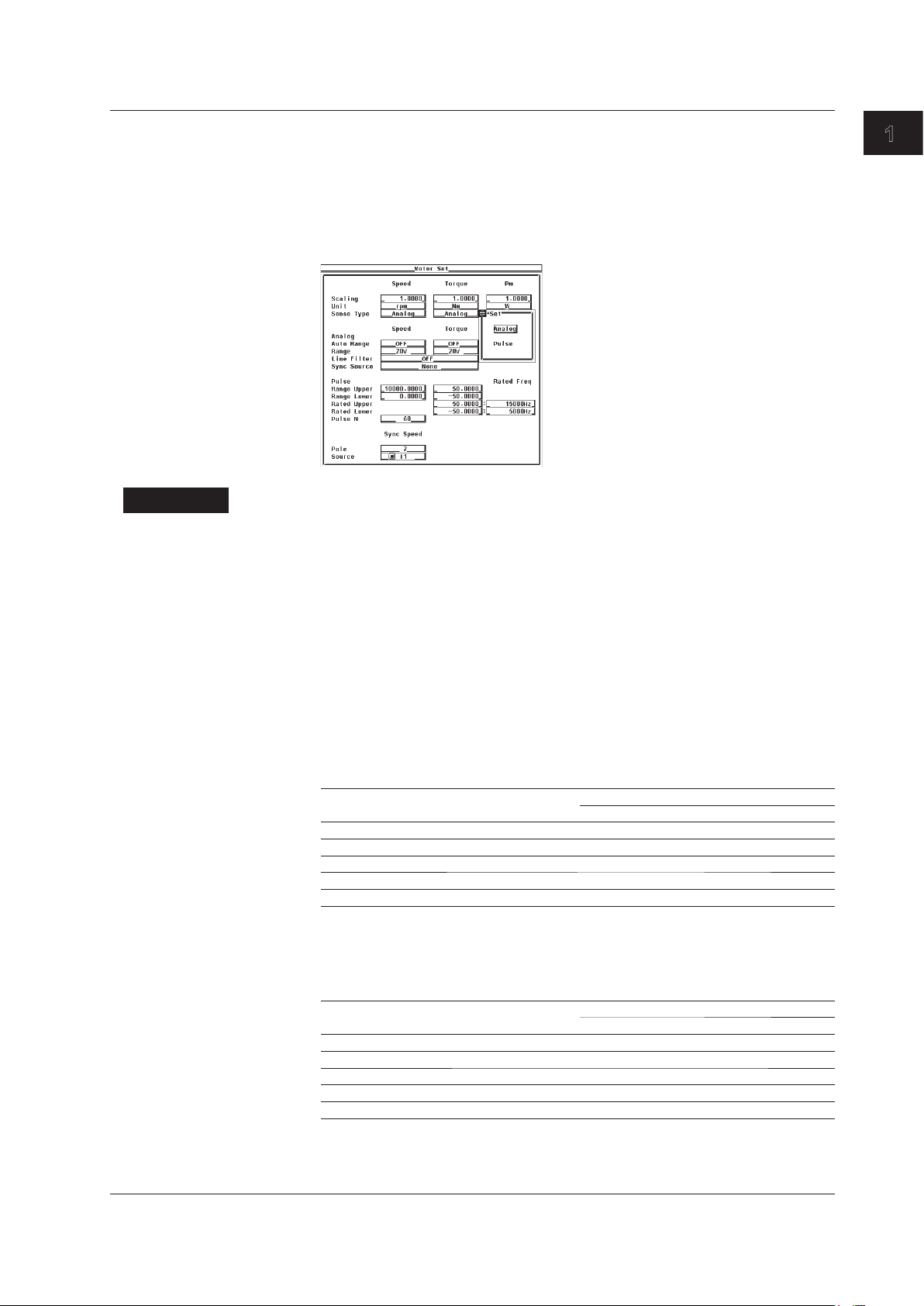

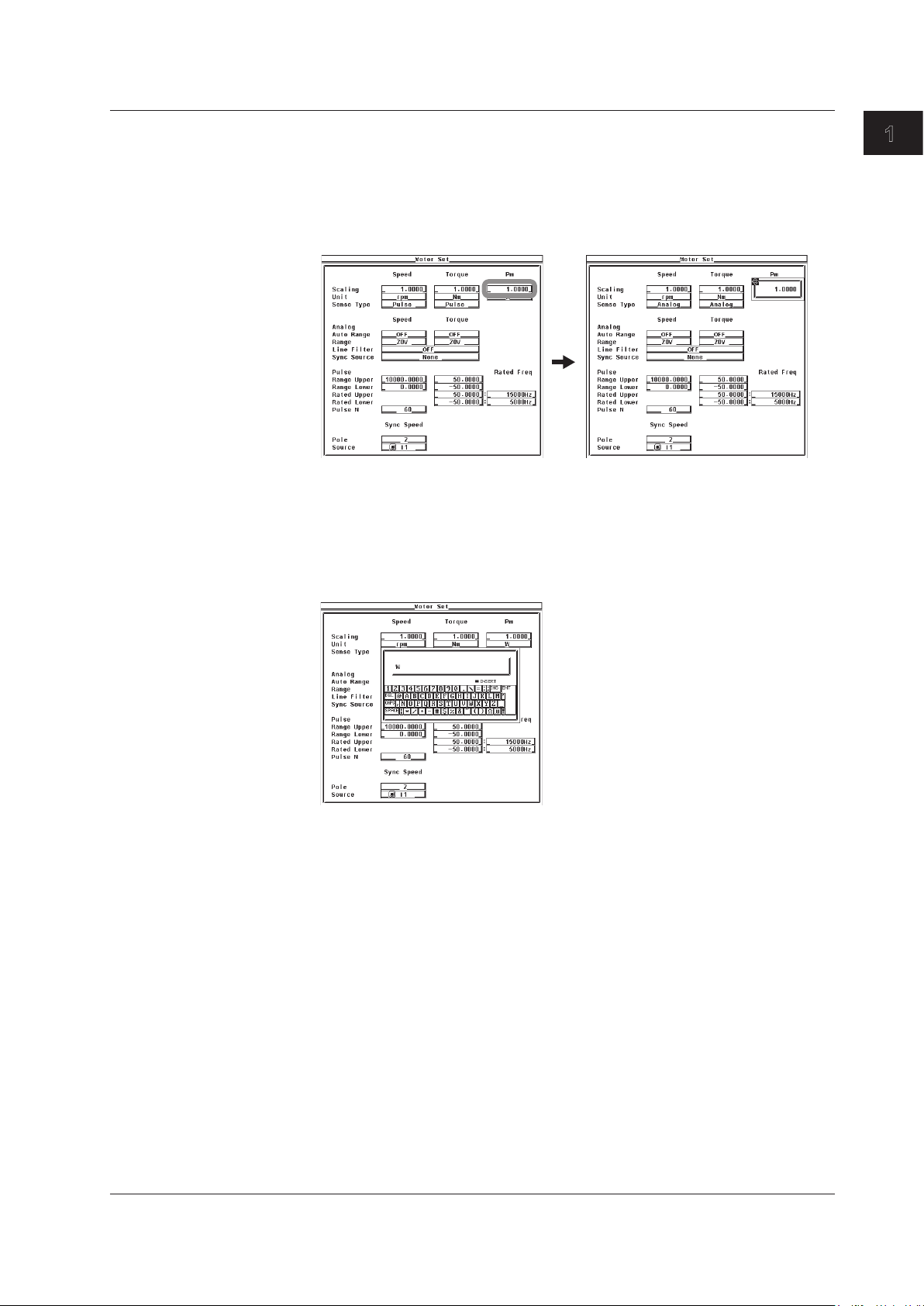

Press SHIFT+SCALING (MOTOR SET) to display the Motor Set dialog box.

1.

• Selecting the Revolution Signal Type

Press the cursor keys to select the Sense Type under Speed.

2.

Press SET. A signal type selection box appears.

3.

Press the cursor keys to select Analog or Pulse.

4.

Press SET to confirm the signal type.

5.

1

• Selecting the Torque Signal Type

Explanation

• Selecting the Signal Type

The signal applied from the revolution sensor or torque meter to the WT3000 can be

• Analog

•

1.3 Selecting the Type of the Revolution and Torque Signals

Press the cursor keys to select the Sense Type under Torque.

2.

Press SET. A signal type selection box appears.

3.

Press the cursor keys to select Analog or Pulse.

4.

Press SET to confirm the signal type.

5.

selected from the following two types.

Select this when the signal type is a DC voltage (analog signal).

Pulse

Select this when the signal type is a pulse signal.

Motor Evaluation Function (Motor Version)

• Signal Type and Setup Items

Some of the settings described in the subsequent sections are not required depending

on the signal type as described below.

• Settings Related to the Revolution Signal Type

Revolution Signal Type

Analog Pulse

Analog range (section 1.4) Required Not required

Line filter (section 1.5) Required Not required

Synchronization source (section 1.5) Required Recommended*

Pulse range (section 1.6) Not required Required

Pulse count per revolution (section 1.6) Not required Required

*

Measurement is possible using None (default), but it is recommended that you specify the

setting to improve the measurement accuracy

1.5.

• Settings Related to the Torque Signal Type

Analog range (section 1.4) Required Not required

Line filter (section 1.5) Required Not required

Synchronization source (section 1.5) Required Recommended*

Pulse range (section 1.6) Not required Required

Pulse rating (section 1.6) Not required Required

*

Measurement is possible using None (default), but it is recommended that you specify the

setting to improve the measurement accuracy

1.5.

. For details, see the explanation in section

Torque Signal Type

Analog Pulse

. For details, see the explanation in section

IM 760301-51E

1-5

1-6

IM 760301-51E

1.3 Selecting the Type of the Revolution and Torque Signals

• Common Settings Not Dependent on the Signal Type

• Motor’s number of poles and frequency measurement source (section 1.7)

• Scaling factor and unit (section 1.8)

1

1.4 Selecting the Analog Range

START STOP

REMOTE

CAL

MOTOR

SET

CURSOR NULL

MENU STORE SET

MENU

LOWER ITEM LOWER FORM ALLUSER SET

DISPLAY

ITEM & ELEMENT

RESET SET

PAGE PAGE

SCALING

HRM SET

MEASURE

SYNC SOURCE

AVG

LINE FILTER

FREQ

FILTER

FILE

PRINT

MISC

STORE

IMAGE SAVE

HELP

NUMERIC

WAVE

OTHERS

ITEM

FORM

U / I / P

WP/q/

TIME

USER

ELEMENT

UPDATE

RATE

HOLD

SINGLE

INTEG

LOCAL

SHIFT

Cursor keys

To exit the menu during operation, press ESC located above the

soft keys.

In the procedural explanation below, the phrase “press the cursor

keys” may be used. This phrase refers to the procedures for

selecting items and entering values and character strings. For

details on the procedures, see section 3.14 in the User’s Manual

IM760301-01E.

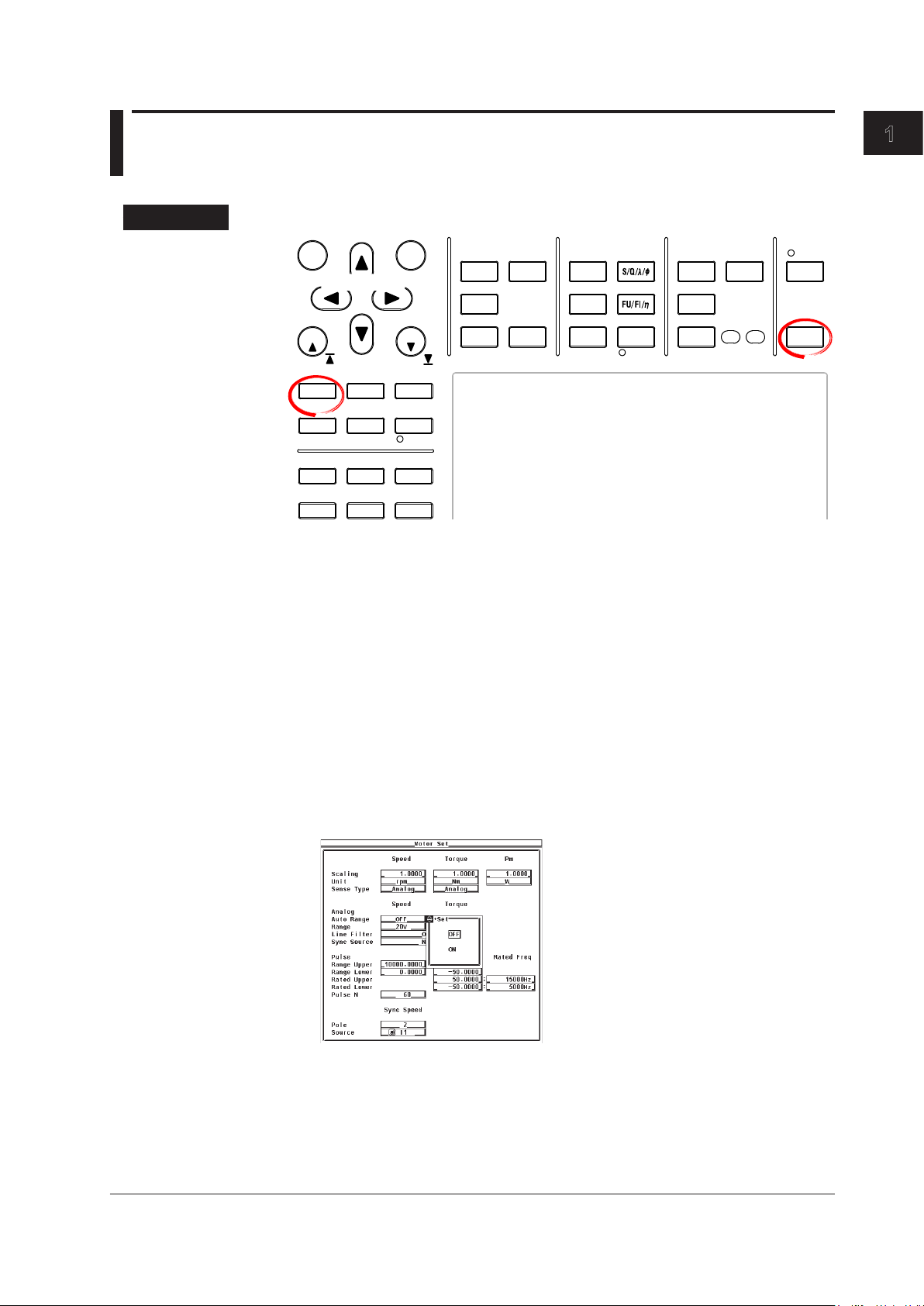

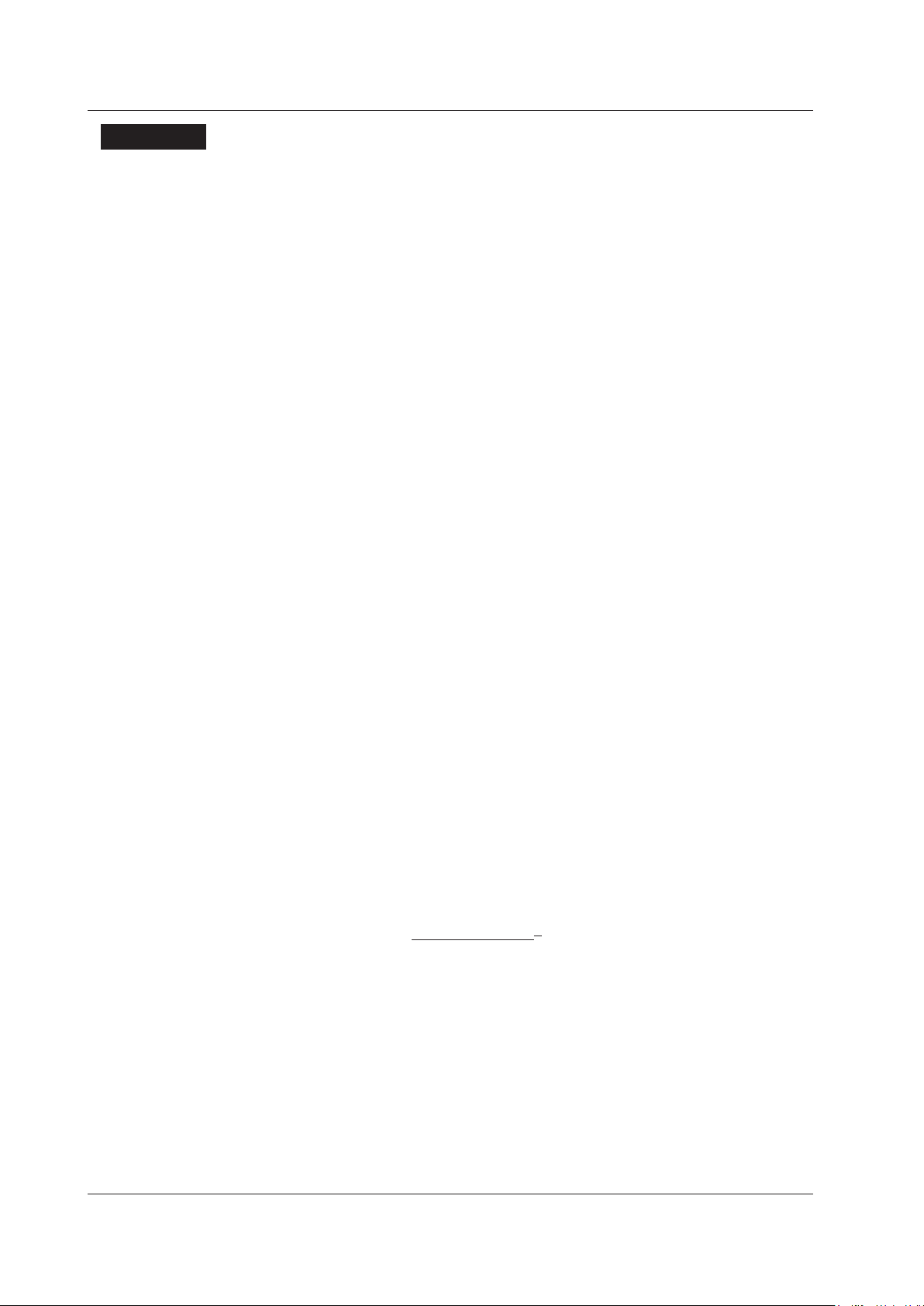

Procedure

The settings covered in this section apply to the case when the input signal type is set to

Analog. You do not have to specify the settings in this section if the input signal type is

set to Pulse.

Motor Evaluation Function (Motor Version)

• Selecting the Analog Input Range of the Revolution Signal

• Selecting Auto Range

Press SHIFT+SCALING (MOTOR SET) to display the Motor Set dialog box.

1.

Press the cursor keys to select Auto Range under Speed.

2.

Press SET. An auto range selection box appears.

3.

Press the cursor keys to select ON or OFF.

4.

Press SET to confirm the auto range setting.

5.

IM 760301-51E

1-7

1-8

IM 760301-51E

1.4 Selecting the Analog Range

• When Measuring Using a Fixed Range (When Auto Range Is Set to OFF)

6.

7.

8.

9.

• Selecting the Analog Input Range of the Torque Signal

• Selecting Auto Range

2.

3.

4.

5.

Press the cursor keys to select Range under Speed.

Press SET. An input range selection box appears.

Press the cursor keys to select a value between 20 V to 1 V.

Press SET to confirm the input range.

Press the cursor keys to select Auto Range under Torque.

Press SET. An auto range selection box appears.

Press the cursor keys to select ON or OFF.

Press SET to confirm the auto range setting.

• When Measuring Using a Fixed Range (When Auto Range Is Set to OFF)

6.

7.

8.

9.

Press the cursor keys to select Range under Torque.

Press SET. An input range selection box appears.

Press the cursor keys to select a value between 20 V to 1 V.

Press SET to confirm the input range.

1

1.4 Selecting the Analog Range

Explanation

• Selecting the Input Range of the Revolution and Torque Signals

Two types of range settings are available: fixed and auto.

• Fixed Range

Select the input range from the following:

20 V, 10 V, 5 V, 2 V, or 1 V

•

Auto Range

Select ON for the auto range setting to enable auto range. The range changes

automatically depending on the amplitude of the input signal.

• Range Increase

• When the rotating speed or torque data exceeds 1

measurement range, the measurement range is increased.

• When the peak value of the input signal exceeds approximately 150% of the

measurement range, the range is increased.

• Range Decrease

Wh

en the rotating speed or torque data is less than 30% of the measurement range

and the peak value of the input signal is less than 125% of the next lower range,

the measurement range is decreased.

10% of the current

Motor Evaluation Function (Motor Version)

Note

When non-periodic pulse waveforms are applied during auto range, the range may not remain

constant. If this happens, use the fixed range setting.

IM 760301-51E

1-9

1-10

IM 760301-51E

1.5 Selecting the Line Filter and Synchronization

START STOP

REMOTE

CAL

MOTOR

SET

CURSOR NULL

MENU STORE SET

MENU

LOWER ITEM LOWER FORM ALLUSER SET

DISPLAY

ITEM & ELEMENT

RESET SET

PAGE PAGE

SCALING

HRM SET

MEASURE

SYNC SOURCE

AVG

LINE FILTER

FREQ

FILTER

FILE

PRINT

MISC

STORE

IMAGE SAVE

HELP

NUMERIC

WAVE

OTHERS

ITEM

FORM

U / I / P

WP/q/

TIME

USER

ELEMENT

UPDATE

RATE

HOLD

SINGLE

INTEG

LOCAL

SHIFT

Cursor keys

To exit the menu during operation, press ESC located above the

soft keys.

In the procedural explanation below, the phrase “press the cursor

keys” may be used. This phrase refers to the procedures for

selecting items and entering values and character strings. For

details on the procedures, see section 3.14 in the User’s Manual

IM760301-01E.

Source

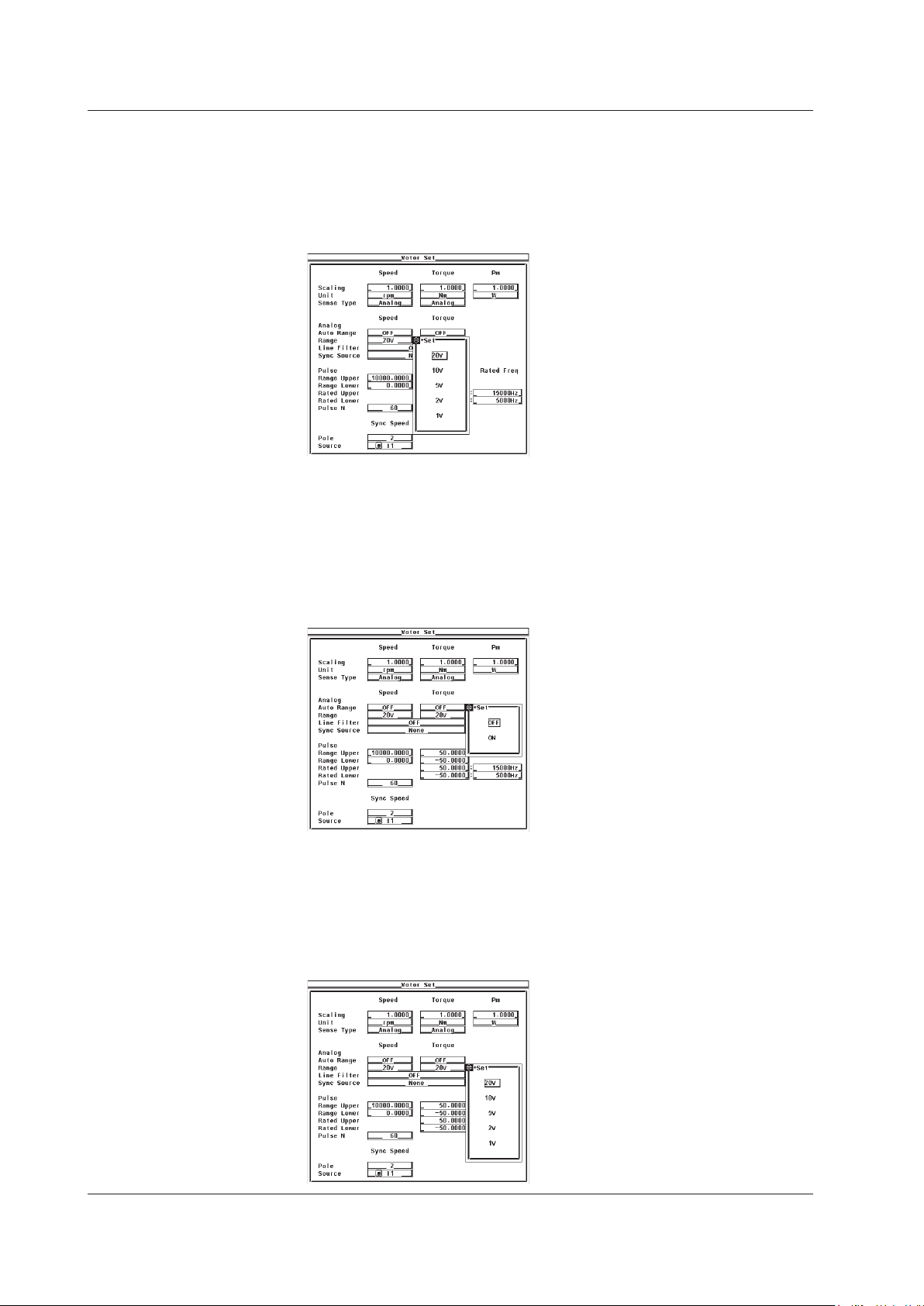

Procedure

The settings covered in this section apply to the case when the input signal type is set to

Analog. You do not have to specify the settings in this section if the input signal type is

set to Pulse.

Press SHIFT+SCALING (MOTOR SET) to display the Motor Set dialog box.

1.

• Selecting the Line Filter

Press the cursor keys to select Line Filter.

2.

Press SET. A line filter selection box appears.

3.

Press the cursor keys to select a value between OFF and 50 kHz.

4.

Press SET to confirm the line filter. The same filter is set to both the revolution

5.

signal and the torque signal.

• Selecting the Synchronization Source

Press the cursor keys to select Sync Source.

2.

3.

4.

5.

Press SET. A synchronization source selection box appears.

Press the cursor keys to select any of the elements/wiring units starting with U1.

Press SET to confirm the synchronization source.

1

Explanation

1.5 Selecting the Line Filter and Synchronization Source

• Selecting the Line Filter

A line filter can be inserted into the circuits that measure the revolution signal and

torque signal. It eliminates harmonic noise.

The cutoff frequency can be selected from the list of choices below

OFF, 100 Hz, and 50 kHz

Selecting OFF disables the filter.

.

Note

If the signal type (see section 1.3) is Pulse, the filter function does not work.

Motor Evaluation Function (Motor Version)

IM 760301-51E

• Line Filter and Measurement Mode

• The line filter setting is common to all measurement modes except cycle-by-cycle

measurement mode. The initial setting is OFF.

• The line filter setting in cycle-by-cycle measurement mode is independent of the

setting in other measurement modes.

The initial setting is 50 kHz.

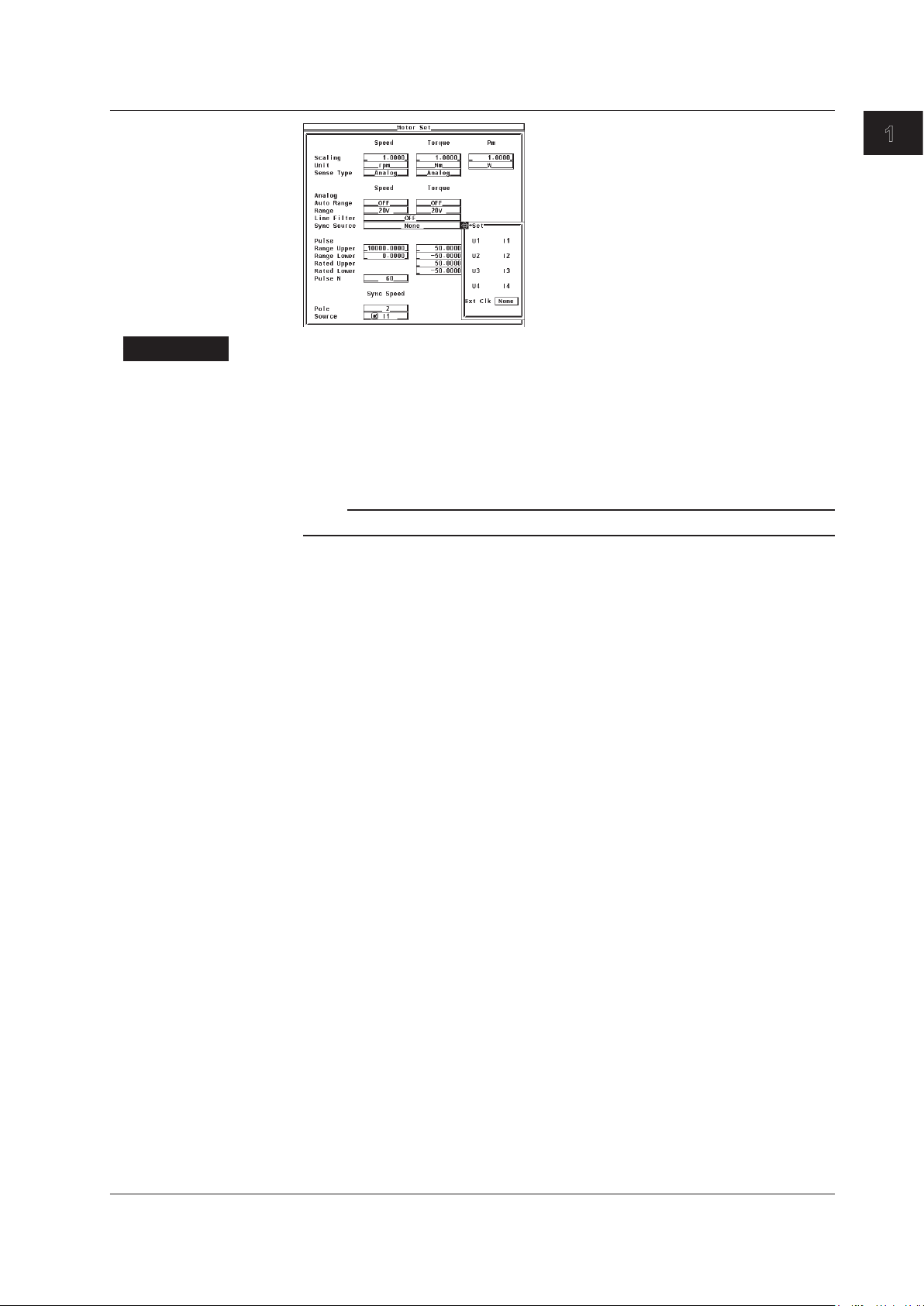

• Selecting the Synchronization Source

• Select which element’s input signal will be used as a synchronization source

(synchronized to the zero-crossing point of the selected signal) when measuring

the analog signal of the revolution signal and torque signal. Select the signal to

be the synchronization source from the choices below. The selectable items vary

depending on the installed elements.

U1, I1, U2, I2, U3, I3, U4, I4, Ext Clk (external clock)

* For the specifications of the Ext Clk (external clock), see the explanation in section

7.4.

• The measurement period determined by the synchronization source selected here

is used to measure the analog signal of the revolution signal and torque signal. If

you specify no synchronization source by selecting “None,” the entire sampled data

within the data update interval is the data used to determine the rotating speed and

torque. For details on the synchronization source, see appendix 6 in the User

Manual IM760301-01E.

•

If the rotating or torque signal is a pulse signal, the average of the pulse signal

interval over the measurement period determined by the synchronization source

elected here is the measured value of the rotating or torque signal. If the pulse signal

s

interval is not within this measurement period, the measured value is determined

from the previous interval.

•

To achieve stable measured values by matching the measurem

the measurement functions of voltage, current, active power, and so on such

as during the measurement of the motor efficiency, it is recommended that the

synchronization source be set to the same synchronization source specified in

section 4.7 in the User’s Manual IM760301-01E.

*

, and None

ent period with

’s

1-11

1-12

IM 760301-51E

1.6 Setting the Pulse Range, Pulse Count, and

START STOP

REMOTE

CAL

MOTOR

SET

CURSOR NULL

MENU STORE SET

MENU

LOWER ITEM LOWER FORM ALLUSER SET

DISPLAY

ITEM & ELEMENT

RESET SET

PAGE PAGE

SCALING

HRM SET

MEASURE

SYNC SOURCE

AVG

LINE FILTER

FREQ

FILTER

FILE

PRINT

MISC

STORE

IMAGE SAVE

HELP

NUMERIC

WAVE

OTHERS

ITEM

FORM

U / I / P

WP/q/

TIME

USER

ELEMENT

UPDATE

RATE

HOLD

SINGLE

INTEG

LOCAL

SHIFT

To exit the menu during operation, press ESC located above the

soft keys.

In the procedural explanation below, the phrase “press the cursor

keys” may be used. This phrase refers to the procedures for

selecting items and entering values and character strings. For

details on the procedures, see section 3.14 in the User’s Manual

IM760301-01E.

Cursor keys

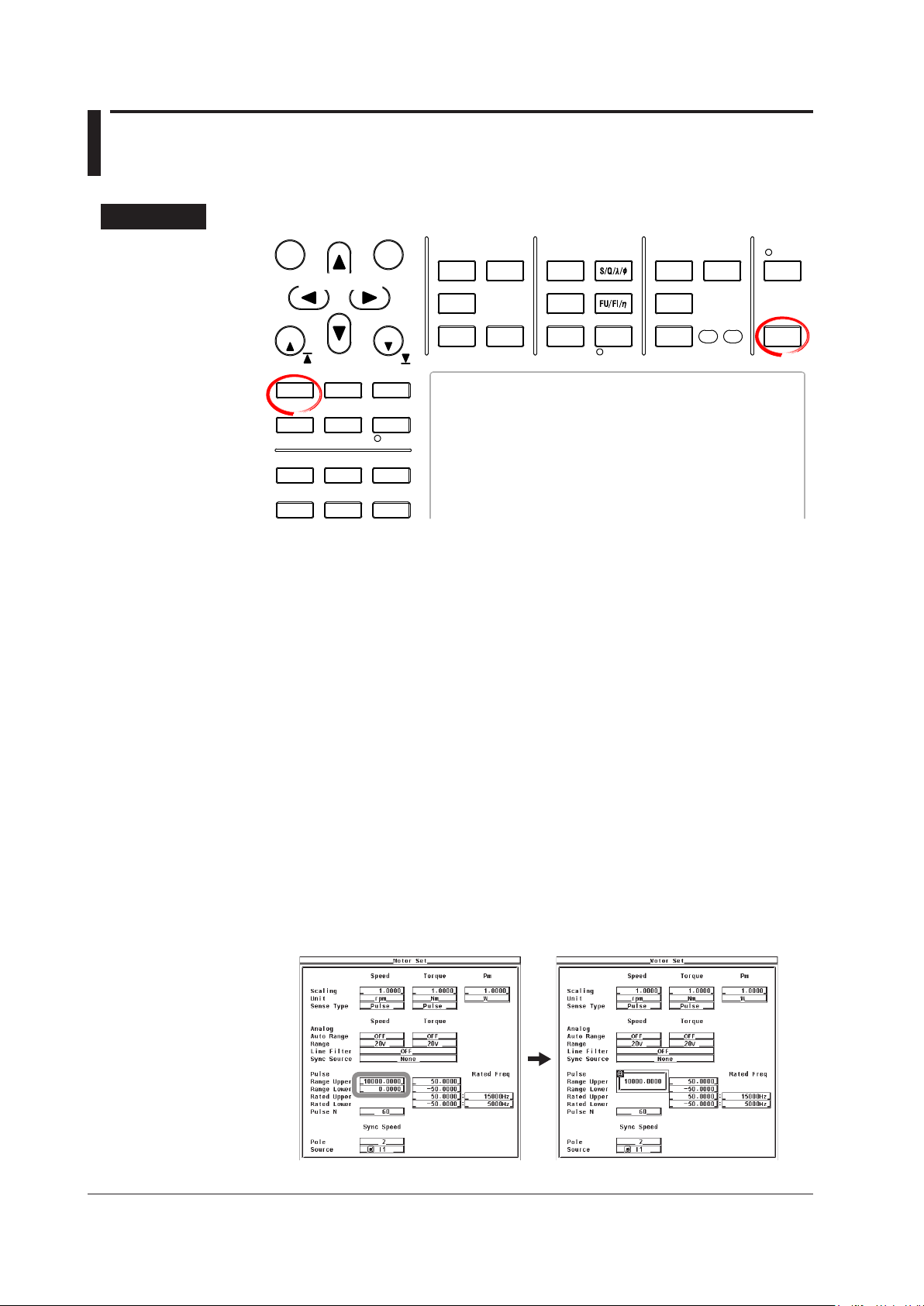

Pulse Rating

Procedure

The settings covered in this section apply to the case when the input signal type is set to

Analog. You do not have to specify the settings in this section if the input signal type is

set to Pulse.

Press SHIFT+SCALING (MOTOR SET) to display the Motor Set dialog box.

1.

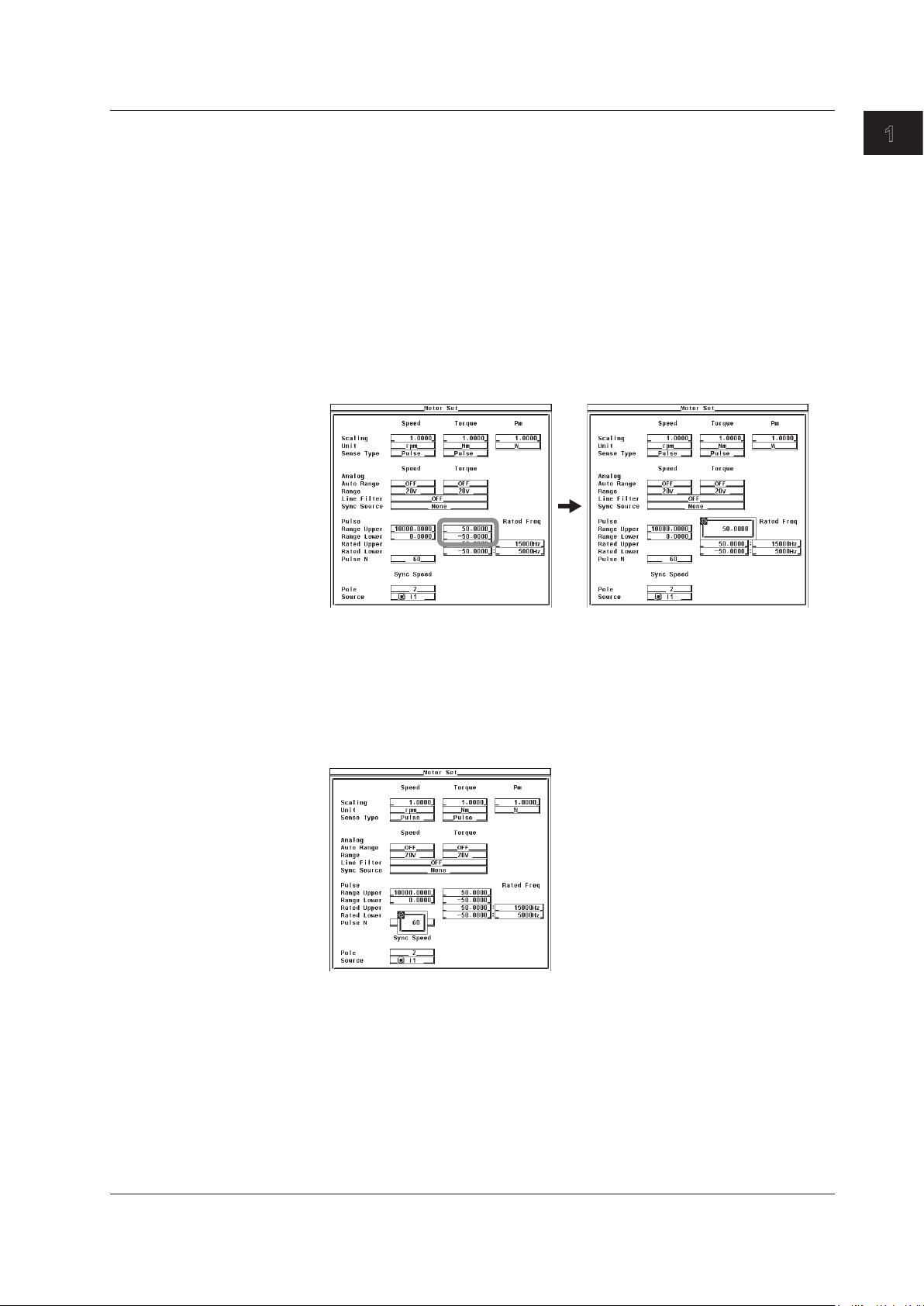

• Setting the Pulse Input Range of the Revolution Signal

If the revolution signal type is Pulse, set the upper and lower limits of the pulse input

range.

Press the cursor keys to select Pulse Range Upper under Speed.

2.

Press SET. A pulse input range setup box appears.

3.

Press the cursor keys to set the upper limit of the pulse input range.

4.

Press SET or ESC to close the box.

5.

Press the cursor keys to select Pulse Range Lower under Speed.

6.

Press SET. A pulse input range setup box appears.

7.

Press the cursor keys to set the lower limit of the pulse input range.

8.

Press SET or ESC to close the box.

9.

1

• Setting the Pulse Input Range of the Torque Signal

If the torque signal type is Pulse, set the upper and lower limits of the pulse input

range.

2.

3.

4.

5.

6.

7.

8.

9.

1.6 Setting the Pulse Range, Pulse Count, and Pulse Rating

Motor Evaluation Function (Motor Version)

Press the cursor keys to select Pulse Range Upper under Torque.

Press SET. A pulse input range setup box appears.

Press the cursor keys to set the upper limit of the pulse input range.

Press SET or ESC to close the box.

Press the cursor keys to select Pulse Range Lower under Torque.

Press SET. A pulse input range entry box appears.

Press the cursor keys to set the lower limit of the pulse input range.

Press SET or ESC to close the box.

• Setting the Pulse Count per Revolution of the Revolution Signal

2.

3.

4.

5.

Press the cursor keys to select Pulse N.

Press SET. A pulse count entry box appears.

Press the cursor keys to set the pulse count.

Press SET or ESC to close the box.

IM 760301-51E

1-13

1-14

IM 760301-51E

1.6 Setting the Pulse Range, Pulse Count, and Pulse Rating

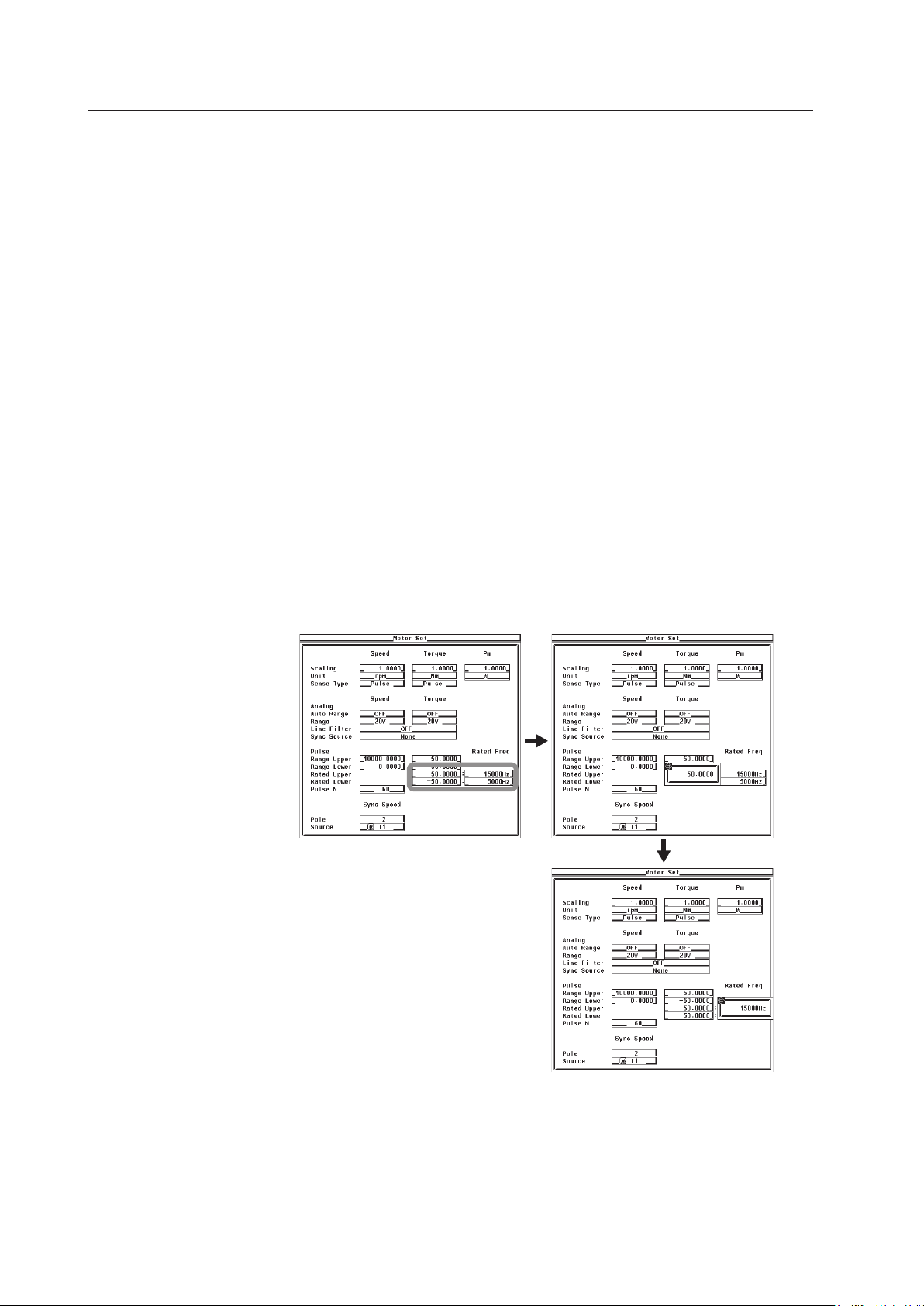

• Setting the Pulse Rating of the Torque Signal

Set the pulse rating of the torque sensor.

• Setting the Positive Rating

Press the cursor keys to select Pulse Rated Upper under Torque.

2.

Press SET. A pulse rating (torque) entry box appears.

3.

Press the cursor keys to set the positive pulse rating (torque).

4.

Press SET or ESC to close the box.

5.

Press the cursor keys to select Rated Upper under Rated Freq under Torque.

6.

Press SET. A pulse rating (pulse frequency) entry box appears.

7.

Press the cursor keys to set the positive pulse rating (pulse frequency).

8.

Press SET or ESC to close the box.

9.

• Setting the Negative Rating

Press the cursor keys to select Pulse Rated Lower under Torque.

2.

Press SET. A pulse rating (torque) entry box appears.

3.

Press the cursor keys to set the negative pulse rating (torque).

4.

Press SET or ESC to close the box.

5.

Press the cursor keys to select Rated Lower under Rated Freq under Torque.

6.

Press SET. A pulse rating (pulse frequency) entry box appears.

7.

Press the cursor keys to set the positive pulse rating (pulse frequency).

8.

Press SET or ESC to close the box.

9.

1

Explanation

1.6 Setting the Pulse Range, Pulse Count, and Pulse Rating

• Pulse Input Range

Set an appropriate range that includes the maximum and minimum values of the input

signal. For example, if you are measuring a signal whose rotating speed is between

120 rpms and 180 rpms and the torque is between –18 N·m to +18 N·m, set the pulse

input range of the rotating speed to 100 rpms to 200 rpms and that of the torque to

–20 N·m to +20 N·m.

The selectable range of pulse range of input signals is as follo

ws:

• Revolution signal: 0.0001 to 99999.9999 [rpm]

Torque signal: –10000.0000 to 10000.0000 [N·m]

•

If the input signal type is Pulse, the upper and lower limits of the waveform display are

set to the values specified here.

• On models with the D/A output (option), the rated value of the

D/A output is as

follows.

Input Signal of Rotating Speed or Torque D/A Output

Pulse Range Upper setting +5 V

PulseRange

Uppersetting×(–1) –5 V

• Setting the Rotation Pulse Count

Set the pulse count per rotation. Set the value in the range of 1 to 9999.

Motor Evaluation Function (Motor Version)

Rotating Speed =

Pulse count (pulse count per revolution)

* If the scaling factor is 1, the rotating speed is the number of rotations per minute (min

or rpm). In addition, if the revolution signal is a changed signal, you can set the scaling

factor (see section 1.7) to determine the rotating speed before the change.

Input pulse count from the revolution sensor per minute

×scalingfactor

*

• Pulse Rating of the Torque Signal

If the torque signal type is Pulse, set the positive and negative ratings of the torque

sensor. Refer to the torque sensor specifications to set the values.

The selectable range of the values is as follows:

•

Torque: –10000.0000 to 10000.0000 [N·m]

Pulse count: 1 to 100000000 [Hz]

•

Torque = (torque pulse coefficient*1×pulsefrequency+torquepulseoffset*1×scalingfactor

*1 The torque pulse count and torque pulse offset are set as shown in the figure on the next

page depending on the pulse rating of the torque signal.

*2 If the torque signal is a changed signal, you can set the scaling factor (see section 1.7) to

determine the torque before the change.

–1

*2

IM 760301-51E

1-15

1-16

IM 760301-51E

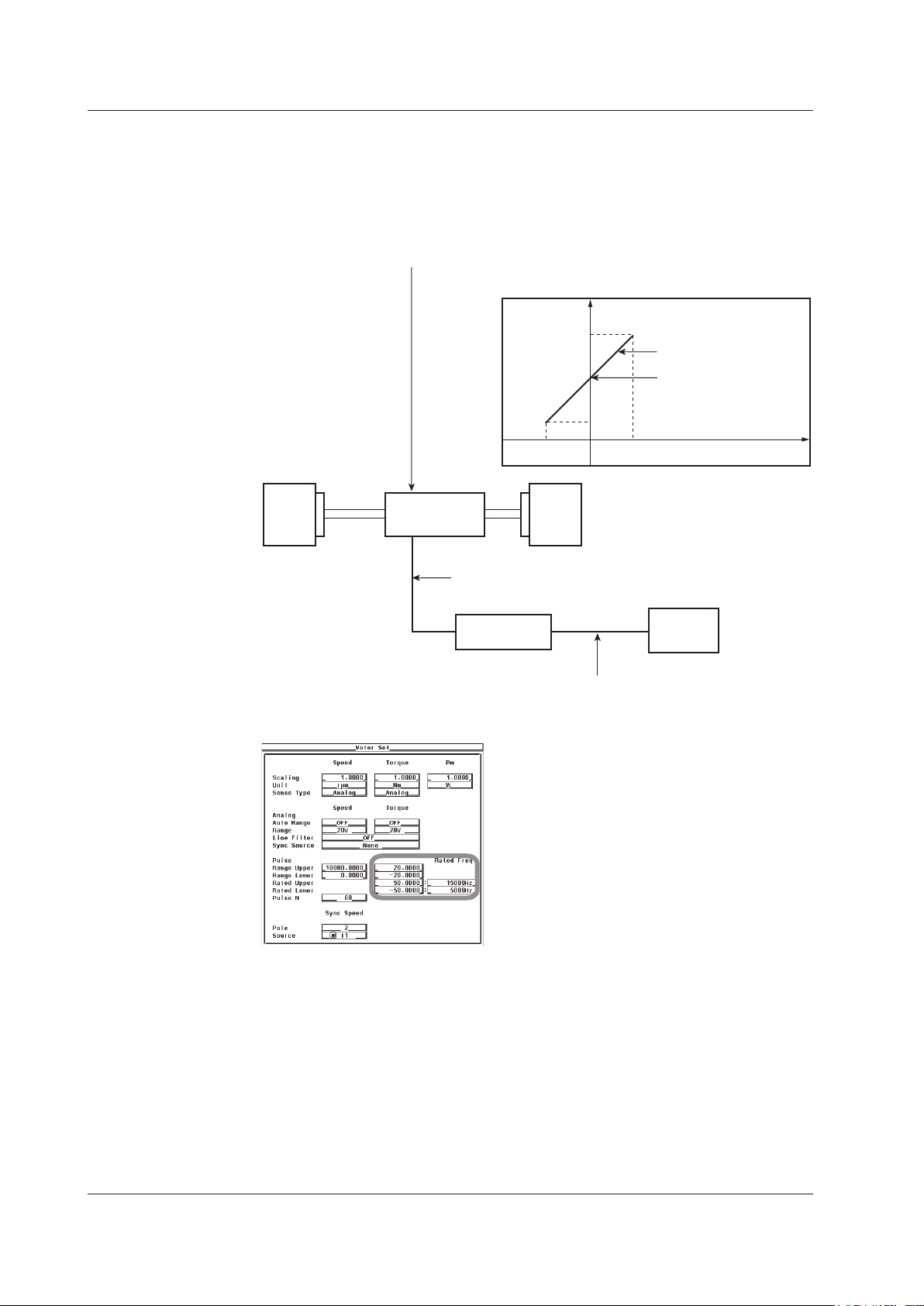

Specifications of the pulse output torque sensor

Pulse rating (positive): Outputs 15 kHz for 50 N·m

Pulse rating (negative): Outputs 5 kHz for –50 N·m

Torque pulse offset

Number of

output pulse

15 kHz

5 kHz

–50 N ·m

Output

axis

50 N· m Input torque

Torque signal to the WT3000

Pulse signal corresponding to –20 N· m to +20 N·m

D/A output signal to the recorder

5 V for –20 N·m to +20 N·m

Pulse input range and pulse rating

settings of the torque signal

Motor Load

WT3000

Recorder

Pulse output

torque sensor

Slope: Torque pulse

coefficient

1.6 Setting the Pulse Range, Pulse Count, and Pulse Rating

• Relationship between the Pulse Input Range and Pulse Rating of the

Torque Signal

If the torque sensor with the specifications below is used to measure the torque in the

range of –20 N·m to +20 N·m, the pulse input range and pulse rating settings are as

shown in the scree example below.

1

1.7 Setting the Scaling Factor and Unit

START STOP

REMOTE

CAL

MOTOR

SET

CURSOR NULL

MENU STORE SET

MENU

LOWER ITEM LOWER FORM ALLUSER SET

DISPLAY

ITEM & ELEMENT

RESET SET

PAGE PAGE

SCALING

HRM SET

MEASURE

SYNC SOURCE

AVG

LINE FILTER

FREQ

FILTER

FILE

PRINT

MISC

STORE

IMAGE SAVE

HELP

NUMERIC

WAVE

OTHERS

ITEM

FORM

U / I / P

WP/q/

TIME

USER

ELEMENT

UPDATE

RATE

HOLD

SINGLE

INTEG

LOCAL

SHIFT

To exit the menu during operation, press ESC located above the

soft keys.

In the procedural explanation below, the phrase “press the cursor

keys” may be used. This phrase refers to the procedures for

selecting items and entering values and character strings. For

details on the procedures, see section 3.14 in the User’s Manual

IM760301-01E.

Cursor keys

Procedure

Press SHIFT+SCALING (MOTOR SET) to display the Motor Set dialog box.

1.

Motor Evaluation Function (Motor Version)

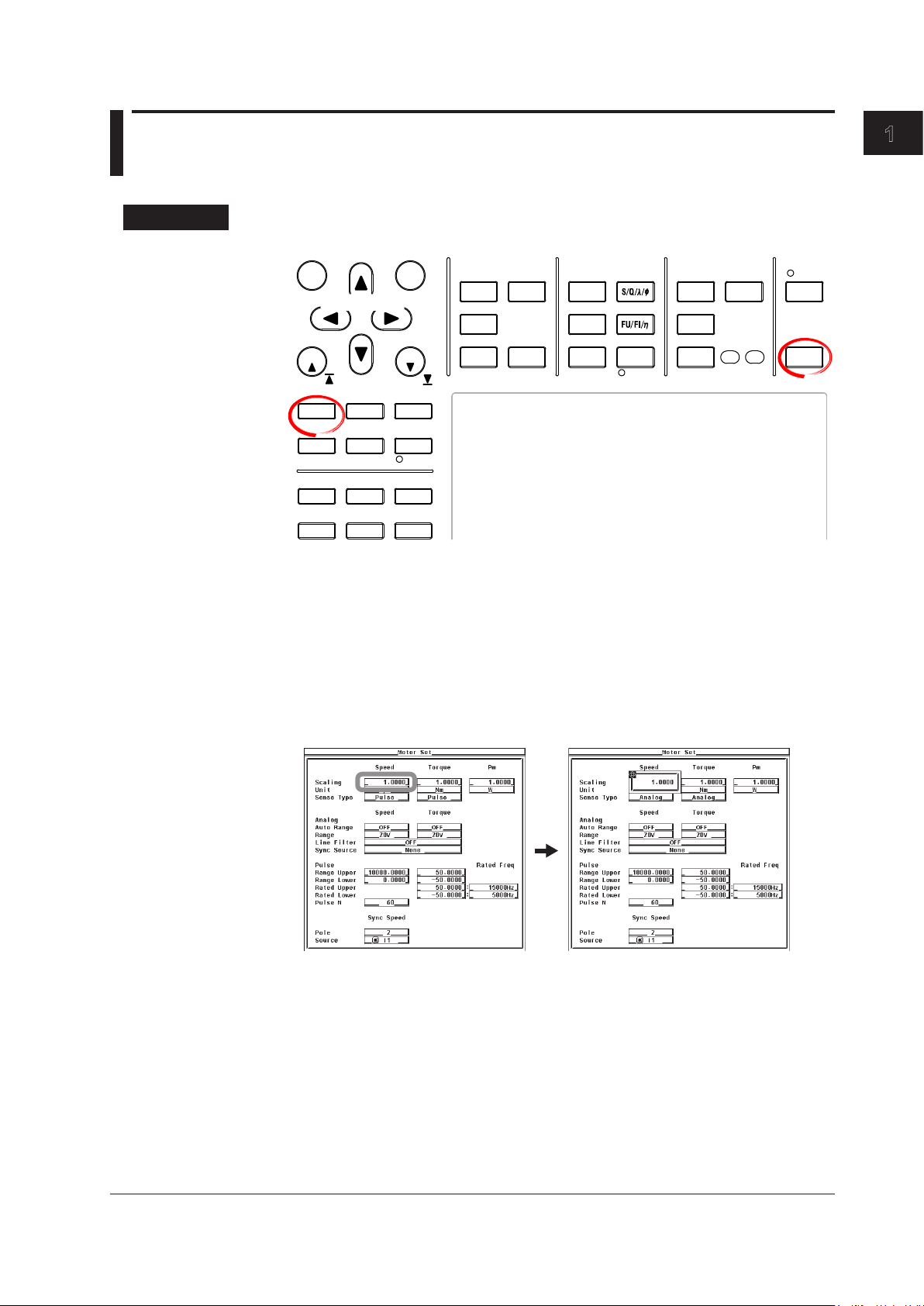

• Setting the Scaling Factor Used to Transform the Revolution Signal

Press the cursor keys to select Scaling under Speed.

2.

Press SET. A scaling factor entry box appears.

3.

Press the cursor keys to set the scaling factor.

4.

Press SET or ESC to close the box.

5.

IM 760301-51E

1-17

1-18

IM 760301-51E

1.7 Setting the Scaling Factor and Unit

• Setting the Unit of Rotating Speed

Press the cursor keys to select Unit under Speed.

2.

Press SET. A keyboard appears.

3.

Use the keyboard to set the unit.

4.

For keyboard operations, see section 3.14 in the User’s Manual IM760301-01E.

• Setting the Scaling Factor Used to Transform the Torque Signal

Press the cursor keys to select Scaling under Torque.

2.

Press SET. A scaling factor entry box appears.

3.

Press the cursor keys to set the scaling factor.

4.

Press SET or ESC to close the box.

5.

• Setting the Unit of Torque

Press the cursor keys to select Unit under Torque.

2.

Press SET. A keyboard appears.

3.

Use the keyboard to set the unit.

4.

For keyboard operations, see section 3.14 in the User’s Manual IM760301-01E.

1

• Setting the Scaling Factor Used to Compute the Motor Output

• Setting the Unit of Motor Output

1.7 Setting the Scaling Factor and Unit

Press the cursor keys to select Scaling under Pm.

2.

Press SET. A scaling factor entry box appears.

3.

Press the cursor keys to set the scaling factor.

4.

Press SET or ESC to close the box.

5.

Press the cursor keys to select Unit under Pm.

2.

Press SET. A keyboard appears.

3.

Use the keyboard to set the unit.

4.

For keyboard operations, see section 3.14 in the User’s Manual IM760301-01E.

Motor Evaluation Function (Motor Version)

IM 760301-51E

1-19

1-20

IM 760301-51E

1.7 Setting the Scaling Factor and Unit

Explanation

• Setting the Scaling Factor Used to Transform the Revolution Signal

Set the factor used to transform the revolution signal. Set the value in the range of

0.0001 to 99999.9999.

• When the Revolution Signal Type is

Analog

By setting the number of rotations per volt of input voltage, the rotating speed is

derived from the following equation.

Rotating

speed=Inputvoltagefromtherevolutionsensor×scalingfactor

• When the Revolution Signal Type is Pulse

The value is used as a scaling factor in the equation given in “Setting the Rotation

Pulse Count” in section 1.6

• Setting the Scaling Factor Used to Transform the Torque Signal

You can specify the scaling factor used to transform the torque signal to the torque of

the motor. Set the value in the range of 0.0001 to 99999.9999.

• When the Torque Signal T

By setting the torque per volt of input voltage, the torque is derived from the input

voltage from the torque meter using the following equation.

Torque

=Inputvoltagefromthetorquemeter×scalingfactor

• When the Torque Signal Type is Pulse

The value is used as a scaling factor in the equation given in “Setting the Torque

Signal Pulse Count” in section 1.6

ype is Analog

• Setting the Scaling Factor Used to Compute the Motor Output

You can specify the scaling factor used to compute the motor output (mechanical

power) from the rotating speed and torque. Set the value in the range of 0.0001 to

99999.9999.

The equation is indicated below

are set so that the unit of the rotating speed is min

. The scaling factors of the rotating speed and torque

–1

(or rpm) and the unit of torque

is N·m. When the scaling factor of the motor output specified here is 1, the unit of the

motor output Pm is W. Because the efficiency in section 1.9 is computed with the unit

of Pm to be W, it is recommended that the scaling factor of each item be set so that

the unit of Pm is W.

Motor output Pm =

60

*1 Rotating speed derived in section 1.6.

*2 Torque derived in section 1.6.

2×π×rotatingspeed

*1

×scalingfactor×torque

*2

• Setting the Unit of Rotating Speed, Torque, and Motor Output

• Number of Characters

Eight characters or less.

• Types of Characters

Characters that are displayed on the keyboard or spaces.

1

1.8 Setting the Motor and Frequency Measurement

START STOP

REMOTE

CAL

MOTOR

SET

CURSOR NULL

MENU STORE SET

MENU

LOWER ITEM LOWER FORM ALLUSER SET

DISPLAY

ITEM & ELEMENT

RESET SET

PAGE PAGE

SCALING

HRM SET

MEASURE

SYNC SOURCE

AVG

LINE FILTER

FREQ

FILTER

FILE

PRINT

MISC

STORE

IMAGE SAVE

HELP

NUMERIC

WAVE

OTHERS

ITEM

FORM

U / I / P

WP/q/

TIME

USER

ELEMENT

UPDATE

RATE

HOLD

SINGLE

INTEG

LOCAL

SHIFT

To exit the menu during operation, press ESC located above the

soft keys.

In the procedural explanation below, the phrase “press the cursor

keys” may be used. This phrase refers to the procedures for

selecting items and entering values and character strings. For

details on the procedures, see section 3.14 in the User’s Manual

IM760301-01E.

Cursor keys

Source for Computing the Sync Speed and Slip

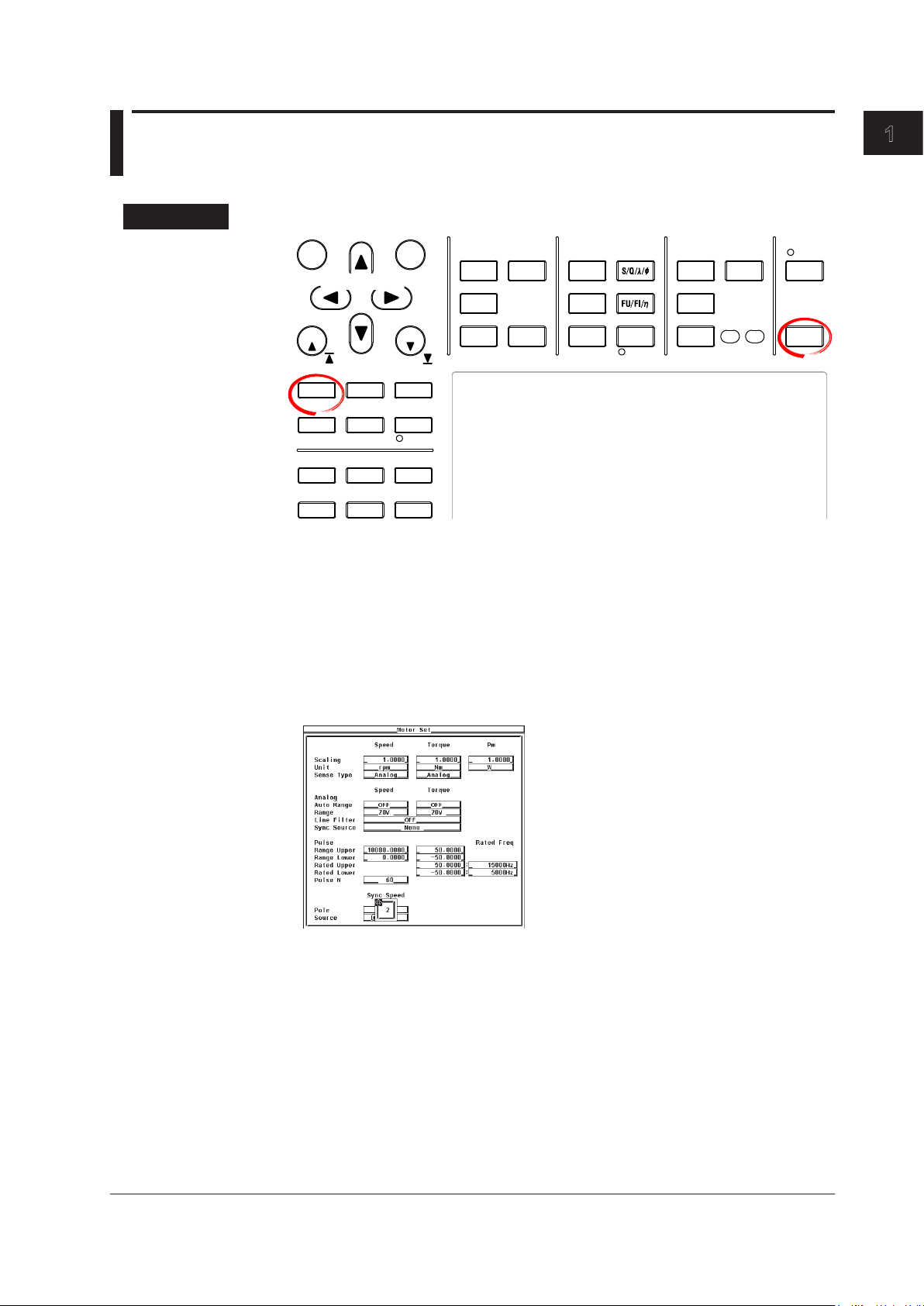

Procedure

Press SHIFT+SCALING (MOTOR SET) to display the Motor Set dialog box.

1.

Motor Evaluation Function (Motor Version)

• Setting the Motor’s Number of Poles

Press the cursor keys to select Pole.

2.

Press SET. A box for entering the number of poles appears.

3.

Press the cursor keys to set the number of poles.

4.

Press SET or ESC to close the box.

5.

IM 760301-51E

1-21

1-22

IM 760301-51E

120 × frequency of the frequency measurement source (Hz)

Motor’s number of poles

Rotating speed SyncSp (min

–1

) =

1.8 Setting the Motor and Frequency Measurement Source for Computing the Sync Speed and Slip

• Selecting the Frequency Measurement Source Signal (Voltage or

Current Signal Supplied to the Motor)

Press the cursor keys to select Sync Speed Source.

2.

Press SET. A frequency measurement source selection box appears.

3.

Press the cursor keys to select any of the target input signals for frequency

4.

measurement (see section 5.3 in the User’s Manual IM760301-01E).

When the button to the left of the input signal in the selection box is highlighted,

that is the source input signal for frequency measurement selected in section 5.3

in the User’s Manual IM760301-01E.

Press SET to confirm the frequency measurement source.

5.

Explanation

• Setting the Motor’s Number of Poles

The number can be set in the range of 1 to 99. Sets the number of poles for the motor

being measured.

• Setting the Frequency Measurement Source Signal

• Select the frequency measurement source from the choices below. The selectable

items vary depending on the installed elements.

U1, I1, U2, I2, U3, I3, U4, and I4

• Se

lect any of the source input signals for frequency measurement. When the button

to the left of the input signal in the frequency measurement source selection box is

highlighted, that is the source input signal for frequency measurement selected in

section 5.3 in the User’s Manual IM760301-01E. If you select an input signal that is

not a frequency measurement source, an error results.

•

In normal cases, the frequency measurement source (see section 5.3 in the

Manual IM760301-01E) is set to the voltage or current supplied to the motor. If

a frequency other than that of the voltage and current supplied by the motor is

specified, the synchronous speed may not be determined correctly.

User’s

• Equation for Deriving the Synchronous Speed

The unit of synchronous speed is fixed to min–1 (or rpm). The equation is indicated

below.

1

× 100

Synchronous speed (min

–1

) – rotating speed*(min–1)

Rotating speed (min

–1

)

Slip (%) =

* Rotating speed derived in section 1.6.

1.8 Setting the Motor and Frequency Measurement Source for Computing the Sync Speed and Slip

• Equation for Deriving the Slip

The unit of synchronous speed is fixed to min–1 (or rpm). Therefore, to determine the

slip, set the scaling coefficient of the rotating speed (see section 1.7) so that the unit

of rotating speed s also min

–1

(or rpm).

Note

Please select a stable voltage or current (supplied by the motor) with small distortion or noise

for the frequency measurement source.

Motor Evaluation Function (Motor Version)

IM 760301-51E

1-23

Loading...

Loading...