Page 1

User's

Manual

Model VJQ8

Pulse to Analog Converter

(Isolated Single-output and Isolated Dualoutput Types)

Thank you for purchasing the JUXTA Signal Conditioner.

Please read through this manual before use for correct handling.

IM 77J01Q08-01E

4th Edition Mar. 2012(YK)

Network Solutions Business Division

2-9-32, Naka-cho Musashino-shi, Tokyo 180-8750 Japan

Phone: +81-422-52-7179 Facsimile: +81-422-52-6619

CAUTIONARY NOTES FOR SAFE USE OF

THE PRODUCT

This User’s Manual should be carefully read before installing

and operating the product. The following symbol is used on the

product and in this manual to ensure safe usage.

This symbol is displayed on the product when it is

necessary to refer to the User's Manual for information

on personal and instrument safety. This symbol is

displayed in the User's Manual to indicate precautions

to avoid danger to the operator, such as an electric

shock.

The following symbols are used only in this manual.

Note

Draws attention to essential information for

understanding the operations and/or functions of the

product.

CHECKING PRODUCT SPECIFICATIONS

AND PACKAGE

(1) Checking the Model and Product Specications

Check that the model and specications indicated on the

nameplate attached to the main unit are as ordered.

(2) Packaged Items

Check that the package contains the following items:

• VJQ8: 1

• Tag number label: 1

• Range label: 1

• Shunt resistor (when optional code “/R□” is specied): 1

• User's Manual (this manual)

GENERAL

This plug-in type pulse to analog converter receives contact

pulse, voltage pulse, or current pulse from the eld and converts

the signal into isolated DC current or voltage signals.

• Output-2 can be selected from DC voltage signal, DC current

signal, communication function (RS-485), or alarm output (2

relay contacts).

• Various parameters such as input range can be set and

modied using a PC (VJ77) or Handy Terminal (JHT200 and

the like).

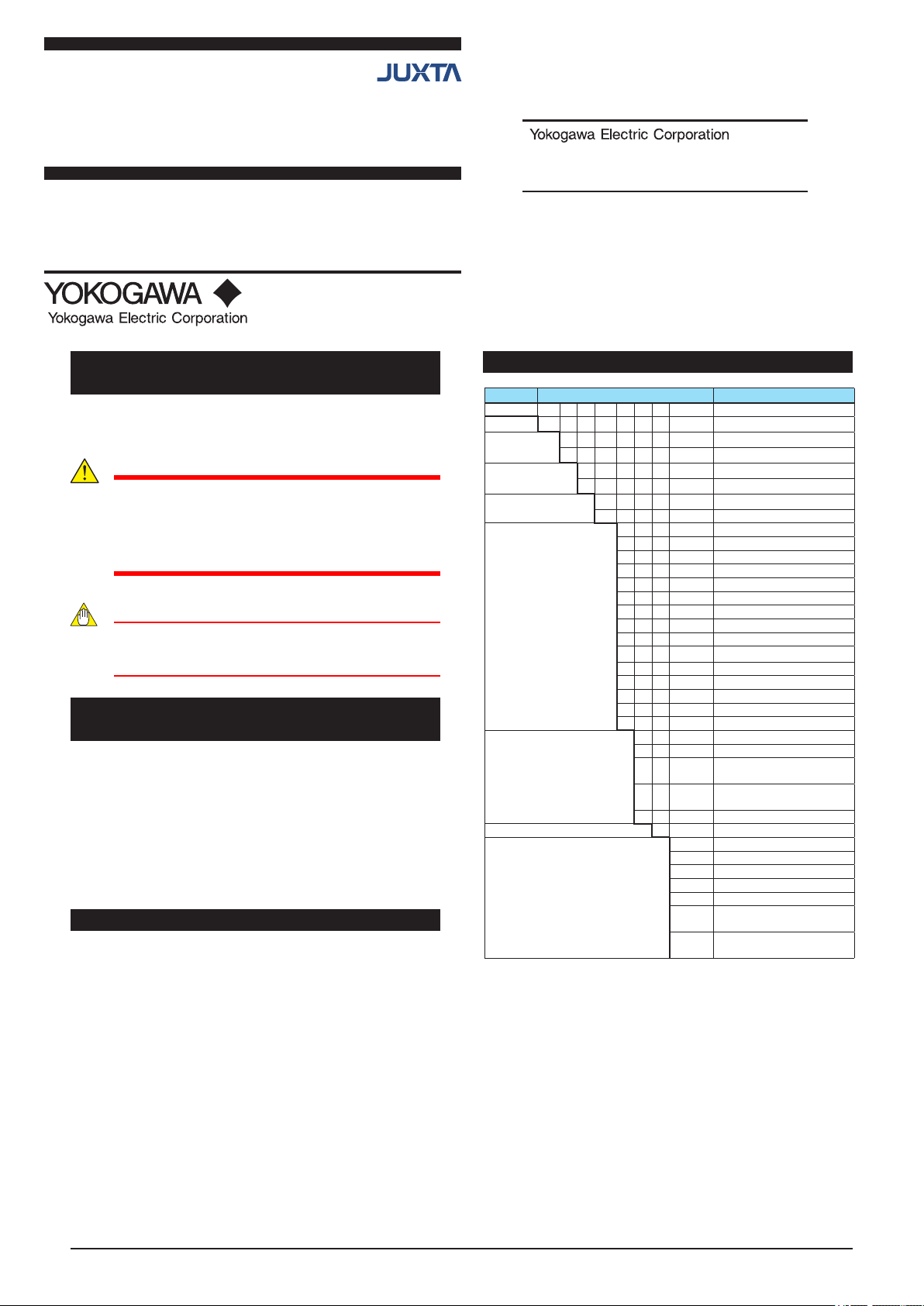

MODEL AND SUFFIX CODES

Model Sufx codes Description

VJQ8 -0 □ □ -□ □ □ 0 /□□ Pulse to Analog Converter

Output

conguration

Power supply 6 100-240 V AC/DC

Transmitter Power

Supply

Output-1 A 4 to 20mA DC

Output-2 A 4 to 20mA DC

Options Blank: With socket

*1 Operating range: 85-264 V

*2 Operating range: 12-36 V

*3 DC voltage signal or DC current signal

*4 Specify when current pulse input

-0 Always 0

1 Single

2 Dual

7 15-30V DC

-1 12V DC±10%

-2 24V DC±10%

B 2 to 10mA DC

C 1 to 5mA DC

D 0 to 20mA DC

E 0 to 16mA DC

F 0 to 10mA DC

G 0 to 1mA DC

1 0 to 10mV DC

2 0 to 100mV DC

3 0 to 1V DC

4 0 to 10V DC

5 0 to 5V DC

6 1 to 5 V DC

7 −10 to +10V DC

Z (Custom Order)

6 1 to 5V DC

P Communication function

T Alarm output

N None

0 Always 0

(RS-485)

(2 relay contacts)

/SN Without socket

/R100 With 100 Ω shunt resistor

/R220 With 220 Ω shunt resistor

/R510 With 510 Ω shunt resistor

/R1000 With 1000 Ω shunt resistor

(*4)

/R2200 With 2200 Ω shunt resistor

(*4)

[STYLE: S1]

(*1)

(*2)

(*3)

(*4)

(*4)

(*4)

1

Page 2

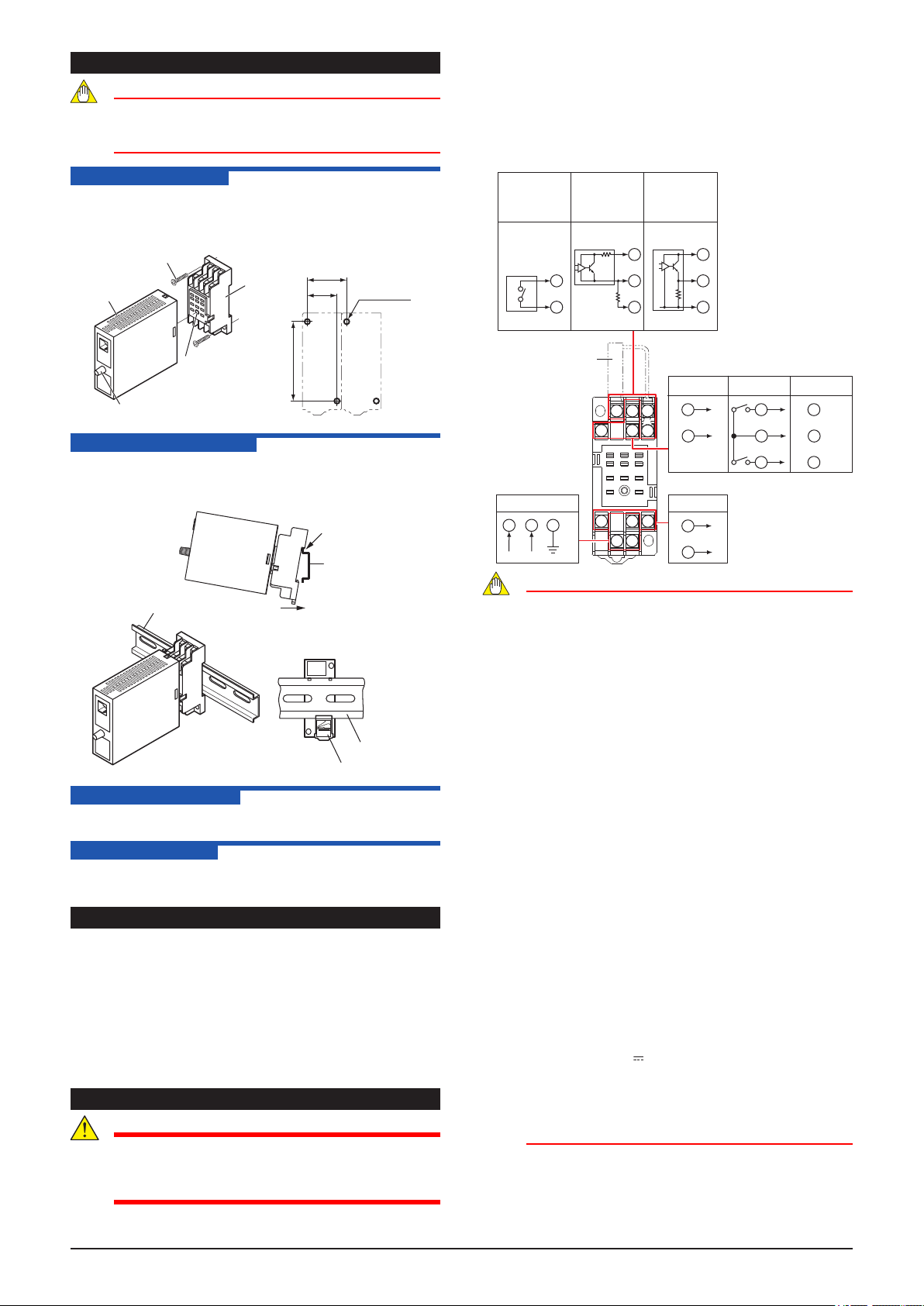

1. MOUNTING METHOD

Mounting

Input

Note

Insert/pull out the main unit into/from the socket

vertically to the face of socket. Otherwise the terminals

are bent and it may cause a bad contact.

Wiring should be connected to the terminals on the socket

of the product. The terminals for external connections are of

M3 screws. Use crimp-on terminal lugs for connections to the

terminals.

• Recommended cables: A nominal cross-sectional area of

2

or thicker for signal cables, and that of 1.25 mm2 or

0.5 mm

thicker for power cables.

1.1 Wall Mounting

Loosen the main unit-xing screw of the product and pull out the

main unit from the socket. Fix the socket on the wall with screws.

Next, insert the main unit into the socket and fasten the main unit

with the main unit-xing screw.

Mounting Dimensions

Socket

59±0.3

29.5 or more

22±0.2

Unit: mm

2-M4 or

2-ø4.5 or more

Main unit

screws

Main unit-fixing

screw

Threaded hole for

fixing the main unit

1.2 DIN Rail Mounting

Insert a DIN rail into the upper part of the DIN rail groove on the

rear of the socket, and then slide the slide lock at the lower part of

the socket upwards until the socket is xed into position as shown

below

Fit into here

DIN rail

DIN rail

Push

(Rear of socket)

DIN rail

Slide look

1.3 Mounting Using

When using a multi-mounting base, see the User's Manual for

VJCE (VJCE Mounting Base).

1.4 Using a Duct

When using a wiring duct, install the duct at least 30 mm away

from the top and bottom faces of the main unit.

2. INSTALLATION LOCATION

• Avoid the following environments for installation locations:

Areas with vibration, corrosive gases, dust, water, oil, solvents,

direct sunlight, radiation, a strong electric eld, and/or a strong

magnetic eld, altitude of more than 2000m above sea level.

• If there is any risk of a surge being induced into the power

line and/or signal lines due to lightning or other factors, a

dedicated lightning arrester should be used as protection for

both this converter and a eld-installed device.

• Operating temperature/humidity range: 0 to 50C/5 to 90%RH

(no condensation)

3. EXTERNAL WIRING

WARNING

Be sure to turn OFF the power supply before wiring to

avoid the risk of electric shock. Use a tester or similar

device to ensure that no power is being supplied to a

cable to be connected.

When receiving

non-voltage contact

signal or voltage

pulse

Transmitter

Shunt resistor

(at current pulse input)

Power supply

1110 8

N–

L+

Note

● Do not use output-2 for the single-output type.

● The power line and input/output signal lines should

be installed away from noise-generating sources.

Other wise accuracy cannot be guaranteed.

● The grounding resistance must be 100 Ω (JIS

Class D grounding). The length and thickness of

the grounding cable should be as short and thick

as possible. Directly connect the lead from the

ground terminal (terminal no. 8) of the product to the

ground. Do not carry out daisy-chained inter-ground

terminal wiring

● Use of the product ignoring the specications may

cause overheating or damage. Before turning on the

power, ensure the following:

Power supply voltage and input signal value applied to

The external wiring to the terminals and wiring to ground

● Do not operate the product in the presence of

ammable or explosive gases or vapors. To do so is

highly dangerous.

● The product is sensitive to static electricity;

exercise care in operating it. Before you operate

the product, touch a nearby metal part to discharge

static electricity.

● The use of inductance (L) loads such as auxiliary

relays and solenoid valves causes malfunction or

relay failure; always insert a CR lter or diode for

spark-removal into the line in parallel with the load.

Recommended CR

● For 15-30 V DC (±20%) power supply, as a safety

measure, always install a circuit breaker (an IEC

60947-compatible product, 1 A, 30 V DC) in an easily

accessible location near the instrument. Moreover,

provide indication that the switch is a device for

turning off the power to the instrument.

When receiving

current pulse by

running a transmiter

on an internal power

supply

Transmitter

+

3

−

4

R: Shunt resistor

GND

When receiving

voltage pulse by

running a transmiter

on an internal power

supply

PS+

Transmitter

1

+

3

−

R

4

3 2

1

56

4

789

1011

PS+

1

+

3

−

4

Output-2

Analog output

+

2

–

5

Output-1

Analog output

+

7

–

9

Alarm output

ALM1

2

COM

5

ALM2

6

RS-485

Communication

the product should meet the required specications.

are as specications.

• C: 0.5 to 1F against contact current 1A

• R: 0.5 to 1 against contact voltage 1V

B+

2

A–

5

6

COM

2

IM 77J01Q08-01E 4th Edition Mar. 02, 2012-00

Page 3

4. DESCRIPTION OF FRONT PANEL

How to connect with the setting tool

4.1 Front Panel

The communications connector in the front panel is used for

setting up parameters through a PC (VJ77 PC-based Parameters

Setting Tool) or the Handy Terminal.

Communications connector

Alarm-1 LED

Alarm-2 LED

4.2 Connector for Communication

Use the connector for communication when setting the

parameters using a PC (VJ77 Parameters Setting Tool) or the

Handy Terminal

JUXTA communication cable

with 5-pin connector (F9182EE)

JHT200

Handy Terminal

PC which is installed

with the VJ77

• Use the VJ77 of version R1.04 or later.

• The modular jack conversion adapter does not come with the

JHT200 Handy Terminal. It is sold separately.

[Provided with VJ77 and JHT200]

Modular jack conversion

adapter (E9786WH)

[Provided with VJ77]

Dedicated adapter (E9789HA)

[Provided with VJ77]

Dedicated cable (E9786WK)

[Provided with VJ77]

5.1.4 Sample Time

When the sample mode is set to “MANUAL”, set the sample

time in numerical value in [D21: SAMPLE TIME], Sample

time setting range: 0.1 to 100 seconds, by 0.1 second When

the sample mode is set to “AUTO”, the sample time is forcibly

decided on the following conditions.

0.1 second when F

(1/F

) 100 seconds when F

100

100 seconds when F

(100% input frequency) is 1kHz or more

100

100

is over 1Hz and below 1kHz

100

is 1Hz or less.

5.1.5 Input Range

Set the 0% value of input range in [D22: INPUT1L_RNG],

and 100% of input range in [D23: INPUT1H_RNG] within the

numerically specied range.

Note

In case the input range is changed after factory-ship,

the instrument may not work within the rated accuracy

range depending on the changed input range. Perform

the adjustment following the maintenance of this

instruction manual after changing the input range.

5.1.6 Input Filter

When the chattering noise is generated in input, the input lter

is used to restrain the inuence. Select and set “ON” in [D50:

INPUT FILTER], then the input lter for time constant of about

10ms will be connected.

5.1.7 Direction of Output Action

Analog output signals can be reversed. To reverse the

signal from output-1, set [D38: OUT1 DR] to REVERSE. For

output-2, set [D39 OUT2 DR] to REVERSE. To return the

output-1 signal to normal, set D38: OUT1 DR to DIRECT. For

output-2, set D39: OUT2 DR to DIRECT.

5. SETTING PARAMETERS

Set the parameters using a PC (VJ77 Parameter Setting Tool) or

the Handy Terminal. Refer to “8. LIST OF PARAMETERS” in this

manual and the User’s Manual for VJ77 PC-based Parameters

Setting Tool (IM 77J01J77-01E) or the User’s Manual for JHT200

Handy Terminal (IM JF81-02E). Parameters are indicated inside

the [ ].

5.1 Settings Related to Inputs and Outputs

5.1.1 Input Range Unit

When referring and setting the input range, select and set “Hz”

or “kHz” in [D10: UNIT]. Select “kHz” when input range is over

32000Hz.

5.1.2 Conversion Mode

Select and set the action of the instrument from “F/V

CONVERTER” (F/V conversion) or “INTEGRATOR” (pulse

integrator) in [D19: SELECT MODE].

F/V converter: Set when converting 0 to 100% of frequency

input to 0 to 100% of analog output, and

outputting it.

INTEGRATOR: Set when converting 0 to 100% of frequency

in put to 0 to 100% of analog output after

computing the average frequency from the

pulse number integrated per sample time, and

outputting it.

5.1.3 Sample Mode

Select and set “AUTO” or “MANUAL” in [D20: SAMPLE

MODE], when the conversion mode is set to “INTEGRATOR.”

AUTO: Outputs the sample time forcibly on the provided

MANUAL: Sets the sample time within setting range.

3

IM 77J01Q08-01E 4th Edition Mar. 02, 2012-00

Page 4

5.2 Settings Related to Communication

ON

Function

Set the following parameters when output-2 is specied

for communication function. For more information on the

communication function, see the Instruction Manual for VJ Series

Communication Function (IM 77J1J11-01E).

5.2.1 Communication Protocol

Set the communication protocol by selecting from among

PCLINK, PC-LINK WITH SUM, MODBUS ASCII, MODBUS

RTU, and LADDER in [F01: PROTOCOL].

5.2.2 Communication Address

Set the address number of the isolator numerically in a range

of 1 to 99 in [F02: ADDRESS].

5.2.3 Baud Rate

Set the baud rate by selecting from among 1200, 2400, 4800,

and 9600 bps in [F03: BAUD RATE].

5.2.4 Parity

Select and set NONE, EVEN, or ODD in [F04: PARITY].

5.2.5 Data Length

Select and set 7 bits or 8 bits in [F05: DATA LEN].

5.2.6 Stop Bit

Select and set 1 bit or 2 bits in [F06: STOP BIT].

5.2.7 Input Decimal Point Position

Number of digits of decimal places can be set.

Select and set among 0 to 5 digits in [F07: INPUT DEC PT].

5.3 Settings Related to Alarm Output

Set the following parameters when output-2 is specied for alarm

output.

5.3.1 Alarm Setpoints

Set the alarm setpoints of alarm-1 and alarm-2 in [E03: SET

POINT1] and [E04: SET POINT2] numerically.

Setting range: A range of 0 to 100% of input range

Setting resolution: 0.1%

5.3.2 Direction of Alarm Action

Select the direction of alarm-1 action and that of alarm-2

action from among HIGH ALM (high-limit alarm) and LOW

ALM (low-limit alarm) and set each in [E05: ALM1 ACTION]

(direction of alarm-1 action) or [E06: ALM2 ACTION]

(direction of alarm-2 action).

To activate alarm status when input signal ≥ alarm setpoint,

select HIGH ALM.

To activate alarm status when input signal ≤ alarm setpoint,

select LOW ALM.

5.3.3 Hysteresis

Set alarm-1 and alarm-2 hysteresis, in [E09: HYSTERESIS1]

and [E10: HYSTERESIS2]. Hysteresis is a value added to the

alarm setpoint in order for an alarm status to be released (to

normal) after the alarm status has been activated. The alarm

status will be released in the following conditions, depending

on the direction of alarm action.

* When HIGH ALM (high-limit alarm) is set: Alarm is released

when input signal < (alarm setpoint - hysteresis).

* When LOW ALM (low-limit alarm) is set: Alarm is released

when input signal > (alarm setpoint + hysteresis).

Setting range: A range of 0 to 100% of input range

Setting resolution: 0.1%

5.3.4 Alarm ON Delay and Alarm OFF Delay

Set alarm-1 and alarm-2 ON delays in [E11: ON DELAY1] and

[E12: ON DELAY2] and then alarm-1 and alarm-2 OFF delays

in [E13: OFF DELAY1] and [E14: OFF DELAY2]. An alarm

ON delay is a delay time from the establishment of alarm

condition to alarm output; an alarm OFF delay is a delay time

from the establishment of return-to-normal condition to output.

Setting range: 0 to 999 seconds

Setting resolution: 1 second (Note that about 0.2 second will

be added to set time to prevent erroneous operation.)

For example, when an alarm ON delay is set to 1 second,

alarm output is generated if alarm status continues for

more than 1 second after the input value exceeds the

alarm setpoint. Further, when an alarm OFF delay is set

to 2 seconds, alarm output is released if normal condition

continues for more than 2 seconds after the input value has

returned to normal from the alarm status.

5.3.5 Direction of Relay Action

Set the direction of relay energizing in alarm-1 normal

condition and alarm-2 normal condition by selecting from

among NRM DEENERGIZED (de-energized under normal

condition) and NRM ENERGIZED (energized under normal

condition) in [E15: RL1 ACTION] and [E16: RL2 ACTION]

and set them.

6. DESCRIPTION OF ALARM ACTIONS

This chapter describes examples of alarm actions under the

following conditions.

Item Alarm-1 Alarm-2

Direction of alarm

action

Alarm setting E03: SET POINT1 80% E04 : SET POINT2 15%

Hysteresis E09: HYSTERESIS1 10% E10 : HYSTERESIS2 5%

Alarm ON delay E11: ON DELAY1 1 sec. E12 : ON DELAY2 3 sec.

Alarm OFF delay E13: OFF DELAY1 2 sec. E14 : OFF DELAY2 4 sec.

Description of alarm

actions

Parameter

E05: ALM1 ACTION High-limit

The alarm sounds if the

condition where the input value

is 80% or more of high-limit

alarm continues for more than 1

second. After the alarm sounds,

when the condition where

input value is less than 70%of

the high-limit alarm continues

for more than 2 seconds, the

status returns to normal

Alarm conditions

established

[%]

100

80

60

40

20

15

0

Alarm-1 action

Alarm-2 action

High-limit alarm ON

Normal conditions established

[2]

[1]

1 sec.

Alarm-1

ON delay

Alarm-2 hysteresis (5%)

Normal

Alarm-1

OFF delay

Alarm-2 setpoint (15%)

Alarm

High-limit alarm OFF

2 sec.

Normal Normal

Setpoint

Parameter

E06: ALM2 ACTION Low-limit

alarm

The alarm sounds if the

condition where the input value

is 15% or less of low-limit

alarm continues for more than

3 seconds. After the alarm

sounds, when the condition

where input value is more than

20% of the low-limit alarm

continues for more than 4

seconds, the status returns to

normal.

[1]: Alarm status does not continue for more than 1 second after

the alarm conditions are established at alarm-1.

[2]: Normal status does not continue for more than 2 seconds after

the normal conditions are established at alarm-1.

[3]: Alarm status does not continue for more than 3 seconds after

the alarm conditions are established at alarm-2.

[4]: Normal status does not continue for more than 4 seconds after

the normal conditions are established at alarm-2.

Alarm-1 setpoint (80%)

Alarm-1 hysteresis (10%)

[3]

Low-limit alarm ON

Normal conditions

Alarm-2

ON delay

established

3 sec.

Normal

[4]

Alarm

Alarm conditions

established

Setpoint

alarm

Low-limit alarm OFF

Alarm-2

OFF delay

4 sec.

Elapsed time

7. TIMING CHART OF PULSE

INTEGRATION OPERATION

This timing chart shows an example of the integration operation

where input frequency is 0 to 10 Hz and sampling time is 2 sec.

10%

ON

ON ON ON ON

20%

5% 5%

Input pulse

Sampling

interval

Analog

output

ON ON

2 sec

0%

1 sec.

4

IM 77J01Q08-01E 4th Edition Mar. 02, 2012-00

Page 5

8. LIST OF PARAMETERS

Parameter Display Item

MODEL Model

TAG NO Tag no.

SELF CHK Self-check result

A DISPLAY1 Display1

A01 INPUT1 Input value 1

A05 OUTPUT1 Output value 1

A06 OUTPUT2 Output value 2

A07 ALM1 STATUS Alarm-1 status

A08 ALM2 STATUS Alarm-2 status

A31 COUNTER1 Integrating counter 1

A32 COUNTER2 Integrating counter 2

A33 COUNTER3 Integrating counter 3

A34 COUNTER4 Integrating counter 4

A54 STATUS Status

A56 REV NO Rev. no.

A58 MENU REV MENU REV

A60 SELF CHK Self-check result

B DISPLAY2 Display2

B01 INPUT1 Input value 1

B05 OUTPUT1 Output value 1

B06 OUTPUT2 Output value 2

B07 ALM1 STATUS Alarm-1 status

B08 ALM2 STATUS Alarm-2 status

B31 COUNTER1 Integrating counter 1

B32 COUNTER2 Integrating counter 2

B33 COUNTER3 Integrating counter 3

B34 COUNTER4 Integrating counter 4

B60 SELF CHK Self-check result

D SET (I/O) Setting (I/O)

D01 TAG NO.1 Tag no. 1

D02 TAG NO.2 Tag no. 2

D03 COMMENT1 Comment 1

D04 COMMENT2 Comment 2

D10 UNIT Range unit

D13 LOW CUT Low input cut point

D19 SELECT MODE Conversion mode

D20 SAMPLE MODE Sample mode

D21 SAMPLE TIME Sample time

D22 INPUT1 L_RNG Input low range

D23 INPUT1 H_RNG Input high range

D38 OUT1 DR Direction of output-1 action

D39 OUT2 DR Direction of output-1 action

D50 INPUT FILTER Input lter

D60 SELF CHK Self-check result

E SET(ALM) Setting (alarm output)

E03 SET POINT1 Alarm-1 setting

E04 SET POINT2 Alarm-2 setting

E05 ALM1 ACTION Direction of alarm-1 action

E06 ALM2 ACTION Direction of alarm-2 action

E09 HYSTERESIS1 Alarm-1 hysteresis

E10 HYSTERESIS2 Alarm-2 hysteresis

E11 ON DELAY1 Alarm-1 ON delay setting

E12 ON DELAY2 Alarm-2 ON delay setting

E13 OFF DELAY1 Alarm-1 OFF delay setting

E14 OFF DELAY2 Alarm-2 OFF delay setting

E15 RL1 ACTION Direction of alarm-1 relay

E16 RL2 ACTION Direction of alarm-1 relay

E60 SELF CHK Self-check result

F SET(COM) Setting (communication)

F01 PROTOCOL Communication protocol

F02 ADDRESS Address

F03 BAUD RATE Baud rate

F04 PARITY Parity

F05 DATA LEN Data Length

F06 STOP BIT Stop bit

F07 INPUT DEC PT Decimal point position of

F60 SELF CHK Self-check result

P ADJUST Adjustment

P12 OUT1 0% 0% adjustment of output-1

P13 OUT1 100% 100% adjustment of output-1

P14 OUT2 0% 0% adjustment of output-2

P15 OUT2 100% 100% adjustment of output-2

P60 SELF CHK Self-check result

(*2)

action

action

input

Q TEST Test

Q02 OUT1 TEST Forced output-1

Q03 OUT2 TEST Forced output-2

Q04 ALM1 TEST Forced output (alarm)

*1

Q05 ALM2 TEST Forced output (alarm)

Q60 SELF CHK Self-check result

*1 Instantaneous frequency is displayed even if conversion

mode is pulse integration.

*2 The Status is displayed for service personnel to see

history records.

*3 There are items not displayed depending on what output-2

is specied.

9. MAINTENANCE

The product starts running immediately when the power is turned

on; however, it needs 10 to 15 minutes of warm-up before it

meets the specied performance.

*1

*3

*3

*3

9.1 Calibration Apparatus

• A calibrator (Yokogawa 7561 or equivalent)

• A precision resistor of 250 Ω ±0.01%, 1W

• Setting tool for adjustment (Refer to “4.2 Connector for

Communication” in this manual.)

9.2 Calibration Procedure

1. Connect the instruments as shown below. First adjust the

output-1 signal and then the output-2 signal.

Output-2

2

3 2

Input

Calibrator

Power supply

L+

1110 8

N–

+

–

GND

3

4

1

56

4

789

1011

R: For current output using 250 Ω

2. Use the calibrator and apply input signals equivalent to 0, 25,

50, 75, and 100% of the input span to the product.

3. Check to see the corresponding output voltages are 0, 25, 50,

75, and 100% respectively and within the specied accuracy

rating. (“R” is used for current output.)

For alarm output, check the relay action by the alarm indicator

lamp or resistance of output terminals.

• Use the setting tool (VJ77 Parameter Setting Tool or JHT200

Handy Terminal) to adjust the input/output signals.

User’s Manual for VJ77 [Document No.: IM 77J01J77-01E];

however, use the VJ77 of version R1.04 or later.

User’s Manual for JHT200 [Document No.: IM JF81-02E]

+

R

Calibrator

–

5

Alarm-1

ALM1

2

5

COM

Alarm-2

ALM2

6

5

COM

Output-1

7

+

R

Calibrator

–

9

precision resistor

+

Calibrator

–

+

Calibrator

–

5

IM 77J01Q08-01E 4th Edition Mar. 02, 2012-00

Page 6

SAFETY AND EMC STANDARDS

CAUTION

This instrument is for Measurement Category I (CAT.I).

Do not use it for measurements in locations falling

under Measurement Categories II, III, and IV.

Entrance

Cable

Internal Wiring

III

IV

I

Outlet

II

T

Measurement

Description Remarks

category

I CAT.I For measurements performed

on circuits not directly connected

to MAINS.

II CAT.II For measurements performed

on circuits directly connected to

the low-voltage installation.

Appliances,

portable

equipments,

etc.

III CAT.III For measurements performed in

the building installation.

Distribution

board, circuit

breaker, etc.

IV CAT.IV For measurements performed

at the source of the low-voltage

installation.

An analog input signal is measurement category I (CAT.I).

Rated transient overvoltage: 1500 V

Note This is a reference safety standard value for

Measurement Category I of IEC/EN/CSA/UL61010-1.

This value is not necessarily a guarantee of instrument

performance.

(Note)

Overhead

wire, cable

systems, etc.

EMC standards: Complies with EN61326.

The above conformed instrument is only for voltage of 15 to 30

V DC.

* The instrument continues to operate at a measurement

accuracy of within ±20% of the range during testing.

6

IM 77J01Q08-01E 4th Edition Mar. 02, 2012-00

Loading...

Loading...