Page 1

Instruction

Manual

IM 77J01P08-01E

Model VJP8

Pulse Rate Converter (Multi-function)

1. CAUTIONARY NOTES FOR SAFE

USE OF THE PRODUCT

For the correct use of this product, read through this manual before

use. The following safety symbol is indicated on the product to ensure safe use.

CAUTION

If this symbol is indicated on the product, the operator

should refer to the explanation given in the instruction

manual in order to avoid personnel injury or death to either

themselves or other personnel, and/or damage to the instrument. The manual describes the special care the operator

should exercise to avoid shock or other dangers that may result in injury or loss of life.

The following symbol marks are used only in this manual.

IMPORTANT

Indicates that operating the hardware or software in a particular manner may damage it or result in a system failure.

NOTE

Draws attention to information that is essential for understanding the operations and/or features of the product.

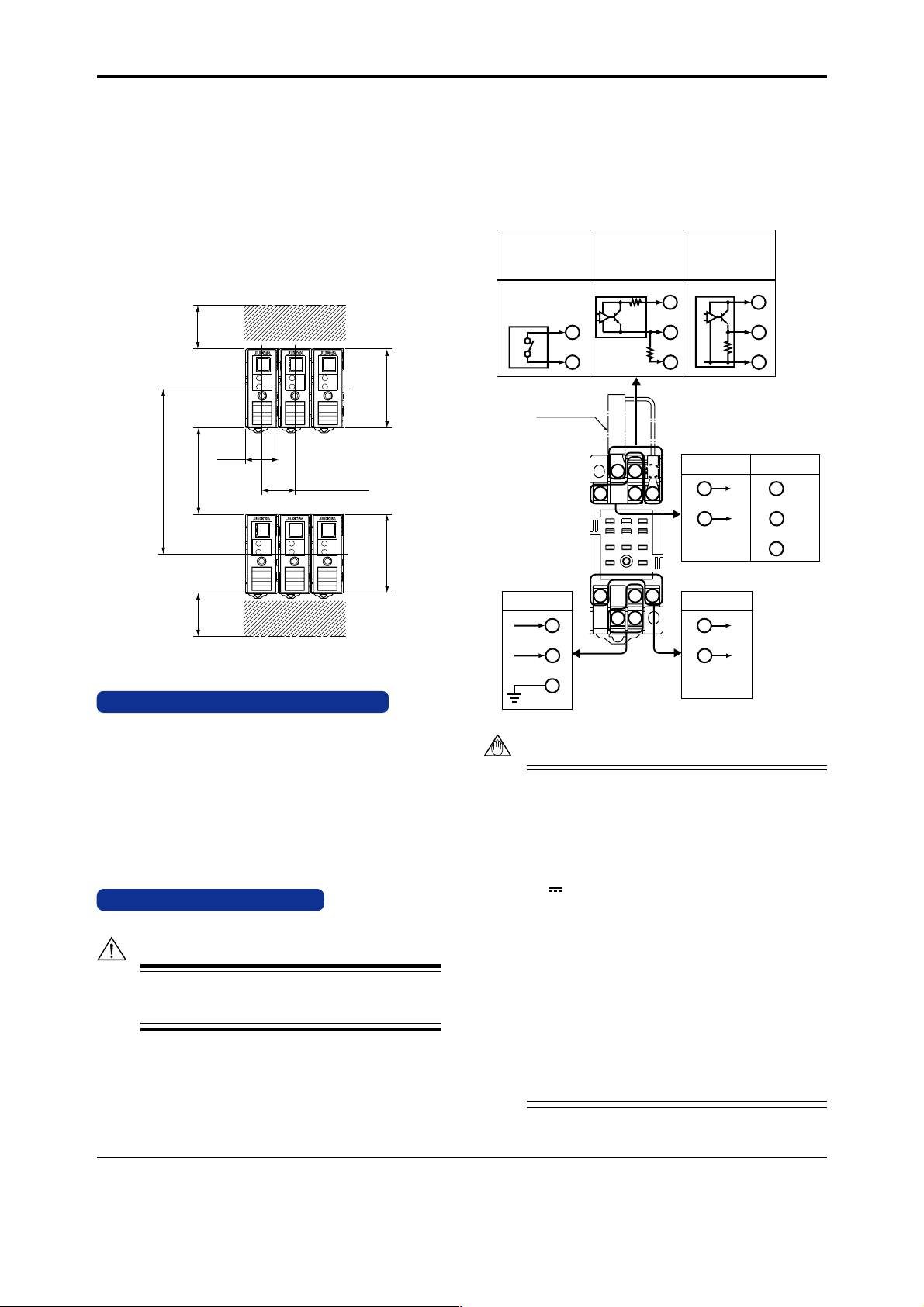

4. MOUNTING METHODS

4.1 Wall Mounting

Loosen the main unit-fixing screw of the converter to disconnect

the main unit from the socket. Next, anchor the socket onto the

wall with screws. Then, plug the main unit into the socket and secure the main unit with the main unit-fixing screw.

Socket

Threaded hole for

fixing the main unit

Main unit

Main

unit-fixing

screw

Fig. 4.1

4.1.1 Mounting Dimensions

29.5 or more

22±0.2

Unit: mm

2-M4 or 2-ø4.5 or more

Mounting

screws

2. CHECKING PRODUCT SPECIFICATIONS AND THE CONTENTS

OF PACKING

(1) Model Number and Specification Check

Check that the model number and specifications shown on the

nameplate attached on the side of the product are as ordered.

(2) Contents of the Packing

Check that the packing contains the following items:

● VJP8 main unit, 1

● Instruction Manual (IM 77J01P08-01E), 1

Accessories:

● Tag number label, 1

● Range label, 1

● Shunt registor (when optional code/R is specified), 1

3. GENERAL

The VJP8 is a plug-in pulse rate converter that receives contact, voltage or current pulse from a field, and converts it into isolated transistor-contact pulse or contactless AC switch pulse at a preset pulse rate.

The VJP8 can also be used as a pulse signal repeater by setting the

pulse rate and pulse width type.

The VJP8 pulse rate scaler features:

• Either pulse output or communication function (RS-485) is se-

lectable as Output-2.

Keep this manual in a safe place.

59±0.3

Fig. 4.2

4.2 DIN Rail Mounting

Locate the converter so that the DIN rail fits into the upper part of

the DIN-rail groove at the rear of the socket, and fasten the socket

using the slide lock at the lower part of the socket.

DIN rail

VIEW A

Fig. 4.3

VIEW A (Rear of socket)

DIN rail

Slide lock

Network Solutions Business Divisiion

2-9-32, Naka-cho Musashino-shi, Tokyo 180-8750 Japan

Phone: +81-422-52-7179 Facsimile: +81-422-52-6793

IM 77J01P08-01E

1st Edition Feb. 2000

2nd Edition June 2004

Page 2

2

NOTE

4.3 Mounting Using a Multi-mounting Base

For mounting using a multi-mounting base, see the Instruction

Manual for VJCE (VJ Mounting Base).

4.4 Using Ducts

Wiring ducts should be installed at least 30 mm away from the top

or bottom of the main unit.

4.5 I

n case of top-and-bottom close mounting

Transmitter should be mounted horizontally with its top and bottom slits being vertical. The top and bottom slits should not be

covered.

The area for wiring is required above and below the transmitter

(the area with slant lines).

40 or more40 or more

ALM1

ALM1

ALM2

ALM1

ALM2

ALM2

(72)

(29.5)

29.5 or more

78 or more

150 or more

ALM1

ALM1

ALM2

ALM1

ALM2

ALM2

(72)

Fig. 4.4

5. INSTALLATION LOCATION

• For installation, avoid any location where the product may be

subject to vibrations, corrosive gases, or large amounts of

dust, or where the product is exposed to water, oil, solvents,

direct sunlight, radioactive rays, or strong electric or magnetic

fields.

• If there is a possibility that lightning could induce a high surge

voltage on the power and signal lines, provide lightning arresters on the line between the field instrument and indoor instrument in order to protect the product. Install a dedicated arrester on the field side and another on the indoor side.

6. EXTERNAL WIRING

WARNING

Turn OFF the power supply and make sure that none of the

cables are not in the hot-line state before carrying out the

wiring to avoid the possibility of electric shock.

Wires are connected to the terminals of the isolator’s socket. M3

screw terminals are provided for the connection of external signals.

Attach a crimp-on lug to each wire for connection to the terminals.

• Recommended cables: A nominal cross-sectional area of 0.5

mm2 or thicker for signal cables, and that of 1.25 mm2 or

thicker for power cables, and shielded twisted-pair cables

(AWG24) for communication wiring cables.

• For mounting, use M3 screws and crimp-on terminals with insulating sleeves appropriate for the wires used.

Tool of the crimp-on terminals to be used should be appropriate for the crimp-on terminals.

• Mount a breaker on the external place.

Mount a switch or 5A circuit breaker on the place near by the

instrument, within operator’s reach. And attach the indication

that it is for disconnecting the instrument.

Input signal

When receiving nonvoltage contact signal

or voltage pulse

Transmitter

(Externally connected

for current pulse input)

Power supply

+

-

Shunt resistor

L+

10

N-

11

GND

8

3

4

When receiving

current pulse by

running a transmiter

on an internal power

supply

Transmitter

R

R:200Ω

23

654

8

9

11 10

PS+

1

7

1

+

3

-

4

When receiving

voltage pulse by

running a transmiter

on an internal power

supply

Transmitter

Output-2 signal

Pulse output

Output-1 signal

Pulse output

PS+

+

2

-

5

+

7

-

9

1

+

3

-

4

RS485

communication

2

5

6

B+

A-

COM

Fig. 6.1

● Keep all sources of noise away from the power and sig-

nal cables. Otherwise, accuracy cannot be assured.

● Provide grounding to a grounding resistance of 100 ⍀.

The length of the grounding cable should be 20 m or

less. Directly connect the lead from the ground terminal

(terminal no. 8) of the isolator to the ground. Do not

carry out daisy-chained inter-ground terminal wiring.

● Direct Current

●

“Overvoltage category (Installation category)” describes

a number which defines a transient overvoltage condition. It implies the regulation for impulse withstand voltage. “II” applies to electrical equipment which is supplied from the fixed installation like distribution board.

●

“Pollution degree” describes the degree to which a solid,

liquid, or gas which deteriorates dielectric strength or

surface resistivity is adhering. “2” applies to normal indoor atmosphere. Normally, only non-conductive pollution occurs. Occasionally, however, temporary conductivity caused by condensation must be expected.

● Rated fuse of 125VDC, 1A is stored. However, opera-

tors can not replace the fuse.

All Rights Reserved. Copyright © 1999, Yokogawa M&C Corporation IM 77J01P08-01E 3rd Edition Mar.31,1997-00

Page 3

3

IMPORTANT

● If this instrument is used in a manner not sepecified in

this manual, the protection provided by this instrument

may be impaired.

● If the product is operated by a power supply exceeding

the specifications, the product may become extremely

hot and, as a result, damaged. To prevent this, ensure

the following before turning on the power.

(a) The voltage of the supplied power and the input

signal level meet the specifications of the product.

(b) External wires are connected to the correct termi-

nals (refer to Chapter 5).

● Do not operate the product in the presence of flammable

or explosive gases or vapors. To do so is highly dangerous.

● The product is sensitive to static electricity; exercise

care in operating it. Before you operate the product,

touch a nearby metal part to discharge static electricity.

7. DESCRIPTION OF FRONT PANEL

AND CONNECTION OF SETTING

TOOLS

7.1 Front Panel

The communications connector in the front panel is used for setting up parameters through a PC (VJ77 PC-based Parameters Setting Tool) or the Handy Terminal.

Communications connector

* The LEDs are provided only when output-2

is specified for contact output.

Fig. 7.1 Front Panel

7.2 Connecting the Setting Tools

Connect the modular jack-to-connector adapter (E9786WH) to the

JUXTA communication cable with 5-pin connector (F9182EE)

and then connect this adapter to the communication connector of

JUXTA.

JUXTA communication cable with

5-pin connectors (F9182EE)

JHT200

Handy T erminal

Fig. 7.2 Connecting the Setting Tools

[Provided with VJ77, JHT200]

Modular jack conversion

adapter (E9786WH)

[Provided with VJ77]

Dedicated adapter (E9789HA)

[Provided with VJ77]

Dedicated cable (E9786WK)

[Provided with VJ77]PC

8. SETTING PARAMETERS

Set the parameters using a PC (VJ77 PC-based Parameters Setting

Tool) or the Handy Terminal. Refer to the list of parameters in this

manual and the Instruction Manual for Handy Terminal (IM JF8102E) and VJ77 PC-based Parameters Setting Tool (IM 77J01J7701E).

8.1 Settings Related to inputs and outputs

8.1.1 Input Display Unit

The input display unit is used for referring the input signal. Select

and set "Hz" or "kHz" in D10: UNIT.

8.1.2 Pulse Rate

Set the pulse rate within the numerically specified range in D41:

PULSE RATE.

Setting range: 0.0001 to 2.0000(settable up to 4 decimal

When the pulse width type is set to

"THROUGH" (no change), effective range

is 0.0001 to 1.0000.

8.1.3 Pulse Width Type

Select and set "THROUGH" or "ON PULSE" in D42: PULSE

TYPE..

THROUGH: Outputs ON-state pulse time of frequency

ON PULSE: Outputs ON-state pulse time after chang

When the instrument is used as a pulse signal repeater, set the

pulse width type to "THROUGH", and the pulse rate to "1."

8.1.4 Pulse Width Time

The pulse width time is set when the pulse width type is set to "ON

PULSE."

Select and set "12.5s", "50s", "100s", "12.5ms", "30ms",

"50ms", or "100ms" in D43: PULSE WIDTH.

8.1.5 Input Filter

When the chattering noise is generated in input, the input filter is

used to restrain the influence.

Select and set "ON" in D50: INPUT FILTER, then the input filter

for time constant of about 10ms will be connected.

8.2

Settings Related to Communication Function

Set the following parameters when output-2 is specified for communication function. For more information on the communication

function, see the Instruction Manual for VJ Series Communication

Function (IM 77J1J11-01E).

8.2.1 Communication Protocol

Set the communication protocol by selecting from among PCLINK, PC-LINK WITH SUM, MODBUS ASCII, MODBUS

RTU, and LADDER in F01: PROTOCOL.

8.2.2 Communication Address

Set the address number of the isolator numerically in a range of 1

to 99 in F02: ADDRESS.

8.2.3 Baud Rate

Set the baud rate by selecting from among 1200, 2400, 4800, and

9600 bps in F03: BAUD RATE.

8.2.4 Parity

Select and set NONE, EVEN, or ODD in F04: PARITY.

8.2.5 Data Length

Select and set 7 bits or 8 bits in F05: DATA LEN.

8.2.6 Stop Bit

Select and set 1 bit or 2 bits in F06: STOP BIT.

8.2.7 Input Decimal Point Position

Namber of digits of decimal places can be set.

Select and set among 0 to 5 digits in F07: INPUT DEC PT.

places)

as it is.

ing it to the set value.

All Rights Reserved. Copyright © 1999, Yokogawa M&C Corporation IM 77J01P08-01E 3rd Edition Mar.31,1997-00

Page 4

9.LIST OF PARAMETERS

No. Item Display Remarks No. Item Display Remarks

01 Model MODEL

02 Tag No. TAG NO

03 Self-check result SELF CHK

A Display1 DISPLAY1 B Display2 DISPLAY2

A01 Input value INPUT1 B01 Input value INPUT1

A33 Temporary memory 1 T1 B31 Integrating counter 1 COUNTER1

A34 Temporary memory 2 T2 B32 Integrating counter 2 COUNTER2

A54 Temporary memory 3 T3 B33 Integrating counter 3 COUNTER3

A55 Temporary memory 4 T4 B34 Integrating counter 4 COUNTER4

A54 Status STATUS *1 B60 Self-check result SELF CHK

A56 Rev. no REV NO

A58 MENU REV MENU REV

A60 Self-check SELF CHK

D Setting (I/O) SET(I/O) F Setting (communication) SET (COM)

D01 Tag no. 1 TAG NO.1 F01 Communication protocol PROTOCOL

D02 Tag no. 2 TAG NO.2 F02 Address ADDRESS

D03 Comment 1 COMMENT1 F03 Baud rate BAUD RATE

D04 Comment 2 COMMENT2 F04 Parity PARITY

D10 Range unit UNIT F05 Data length DATA LEN

D41 Pulse rate range PULSE RATE F06 Stop bit STOP BIT

D42 Pulse width type PULSE TYPE F07 Decimal point position of input

D43 Pulse width time PULSE TIME F60 Self-check result SELF CHK

D50 Input filter INPUT FILTER

D60 Self-check result SELF CHK

Adjusting items There are items not displayed depending on what output-2 is specified.

P Adjustment ADJUST1

P60 Self-check result SELF CHECK

4

Display items

*1 The Status is displayed for service personnel to see history records.

Setting items

INPUT DEC PT

10.MAINTENANCE

The product starts running immediately when the power is turned on;

however, it needs 10 to 15 minutes of warm-up before it meets the

specified performance.

For cleaning the instrument, use a soft and dry cloth.

10.1 Calibration Apparatus

Pulse generator (Yokogawa FG100 or the equivalent): 1

A counter(Yokogawa TC100 or the equivalent) or oscilloscope

(Yokogawa DL1540 or the equivalent): 1

A precision resistor (1k⍀, 1.6 k⍀): 1 each

6V battery: 1

10.2 Calibration Procedure

Connect the instruments as shown in Fig.10.1. First adjust the output-1 signal and then the output-2 signal.

Produce a rectangular pulse of any frequency from the pulse generator to measure the value using a counter or oscilloscope. (Connect the

counter or oscilloscope as the broken line shown in figure 10.1.)

Next, connect the counter to the terminals 7 and 9, or terminals 2 and

5, then check that the frequency (input frequency x set rate) is output.

When using a oscilloscope, the wave shaping of output pulse can be

confirmed.

3 2

56

1011

Power supply

L+

N-

GND

1110 8

Calibration for output-1

3

1

4

4

+

-

+

Pulse

Generator

Counter or

-

Osilloscope

7

9

789

Calibration for output-2

3

4

2

5

1kΩ

1.6kΩ

+

-

+

-

1kΩ

1.6kΩ

6V

Battery

Pulse

Generator

Counter or

Osilloscope

6V

Battery

Fig. 10.1

All Rights Reserved. Copyright © 1999, Yokogawa M&C Corporation IM 77J01P08-01E

Loading...

Loading...