Page 1

General

Specications

Model TDLS8000

Tunable Diode Laser Spectrometer

GS 11Y01D01-01EN

n Overview

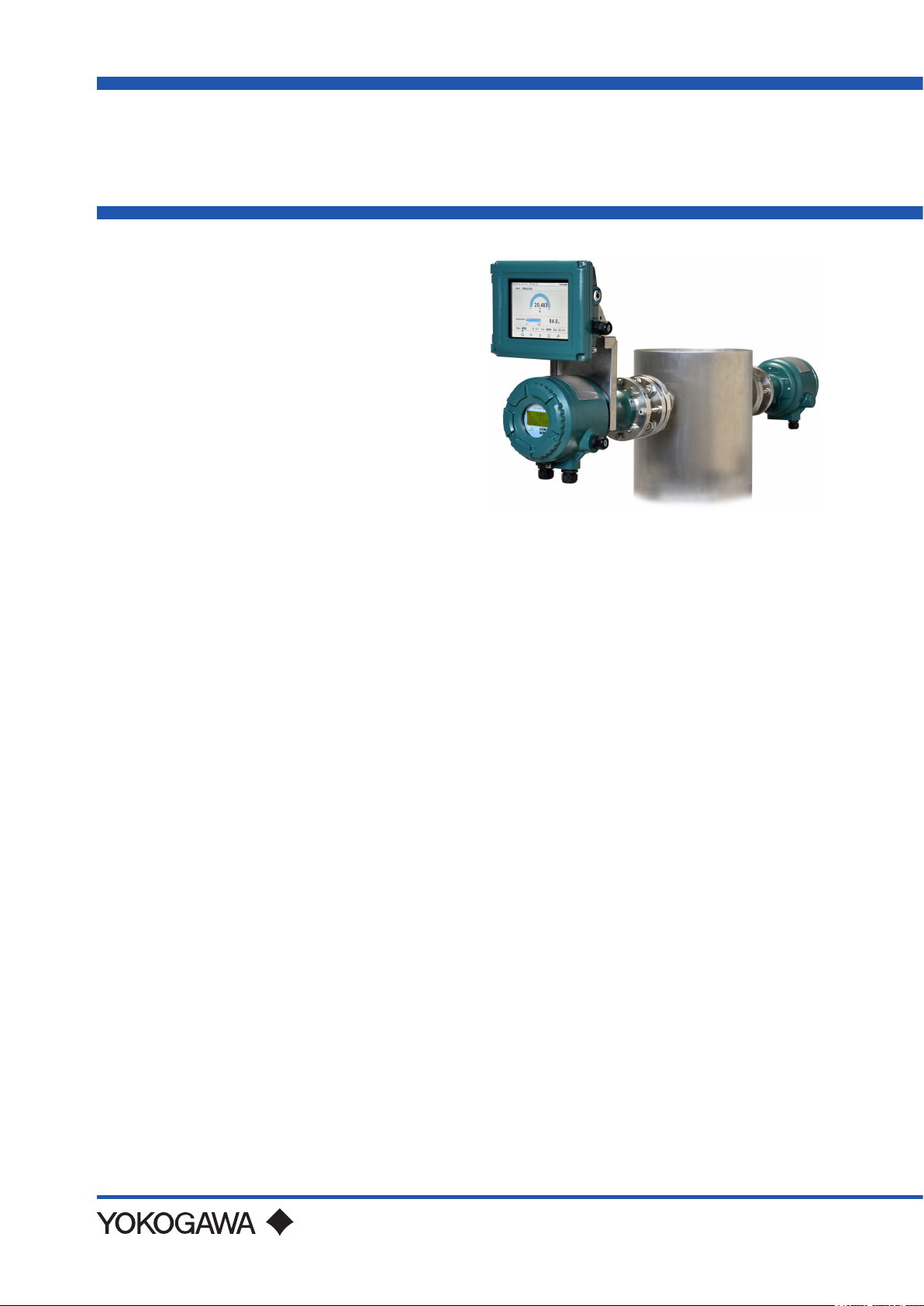

Yokogawa’s new TDLSTM8000 houses all of the

industry’s leading features in one robust device.

The platform design is for in situ measurements

which negate the need for sample extraction and

conditioning.

The non-contacting sensor allows for a variety of

process types including corrosive, abrasive and

condensing.

The rst generation platform has been proven in many

others for the measurements of O2, CO, CH4, NH3,

H2O and many more NIR absorbing gases.

This second generation platform has improved

reliability and ease of installation and maintenance

while still meeting or exceeding designed application

demands.

TDLS8000 with YH8000 HMI Unit

n Features

• SIL2, TruePeakTM combined with smart laser

technology

- Measurement integrates the area of the absorbance

and gets a true, interference-free analysis under

changing pressure, temperature and background

- Laser module is replaceable on site without any

calibration or adjustment

- Internal reference cell in the laser module ensures

peak locking during trace measurement

- Laser and Detector modules are sealed to protect

them from dirty purge gas

- On board diagnostics and low TCO(*1) (no moving

parts, high MTTF(*2) for components)

- IEC61508 SIL designed & approved, SIL 2 capability

for single analyzer use, SIL 3 capability for dual

analyzer use

• Intuitive touchscreen HMI

- Large HMI provides easy operation and control of

up to 4 analyzers at the same time·A standard mini

display at both sides enables easy optical alignment

• HART and Modbus TCP communications

standard

•8-stageauto-gainadaptstodicultapplications

- Auto-gain enables wide signal ranges against

dynamic variation of transmission.

•Fullyeldrepairablewith50daysofdataand

spectra storage

•Compactdesignforone-maninstallationwithout

sacricingruggedness

- IECEx, ATEX, FM(US, Canada), Korea Ex, NEPSI,

EAC, Japan hazardous area approvals based on

Nonincendive/Type n or Explosionproof/ame proof.

- Purge gas is no need for explosion protection.

• In-situorextractiveanalysisandfastresponse

(2-5seconds,1second(optional))

• Process pressures up to 1 MPa abs. and process

temperaturesupto1,500ºC(Note)

Note: Maximum process temperatures and pressures

will vary by application

*1: Total Cost of Ownership

*2: Mean Time To Failure

• 10 language display options

YH8000 oers easy touch screen operation and

simple menu structure in 10 languages. Menus of

display, execution and setting are displayed in a

selected language.

Typical gases measured include:

• Oxygen in process and combustion applications.

Process temperatures can be as high as 1,500ºC,

and process pressures can be as high as 1 MPa abs.

Measurement span is typically between 1% and 25%

oxygen.

• Carbon monoxide in process and combustion

applications. Process temperatures can be as high as

1,500ºC. Two versions are available, high sensitivity

with ppm detection limits, and standard sensitivity for

higher ppm and percent level CO measurement

Other applications and gas measurements are possible

with the TDLS8000. Please ll out the Application

Data Sheet at the end of this document and send to

Yokogawa.

TDLS, TruePeak are trademarks or registered trademarks of Yokogawa Electric Corporation.

All other company and product names mentioned in this document are trademarks or registered trademarks of their respective companies.

Please select appropriate equipment in accordance with the laws and regulations of the relevant country/region, when it is used in a location where explosive atmospheres may be present.

Yokogawa Electric Corporation

2-9-32, Nakacho, Musashino-shi, Tokyo, 180-8750 Japan

GS 11Y01D01-01EN

©Copyright Apr. 2015

13th Edition Aug. 28, 2020

Page 2

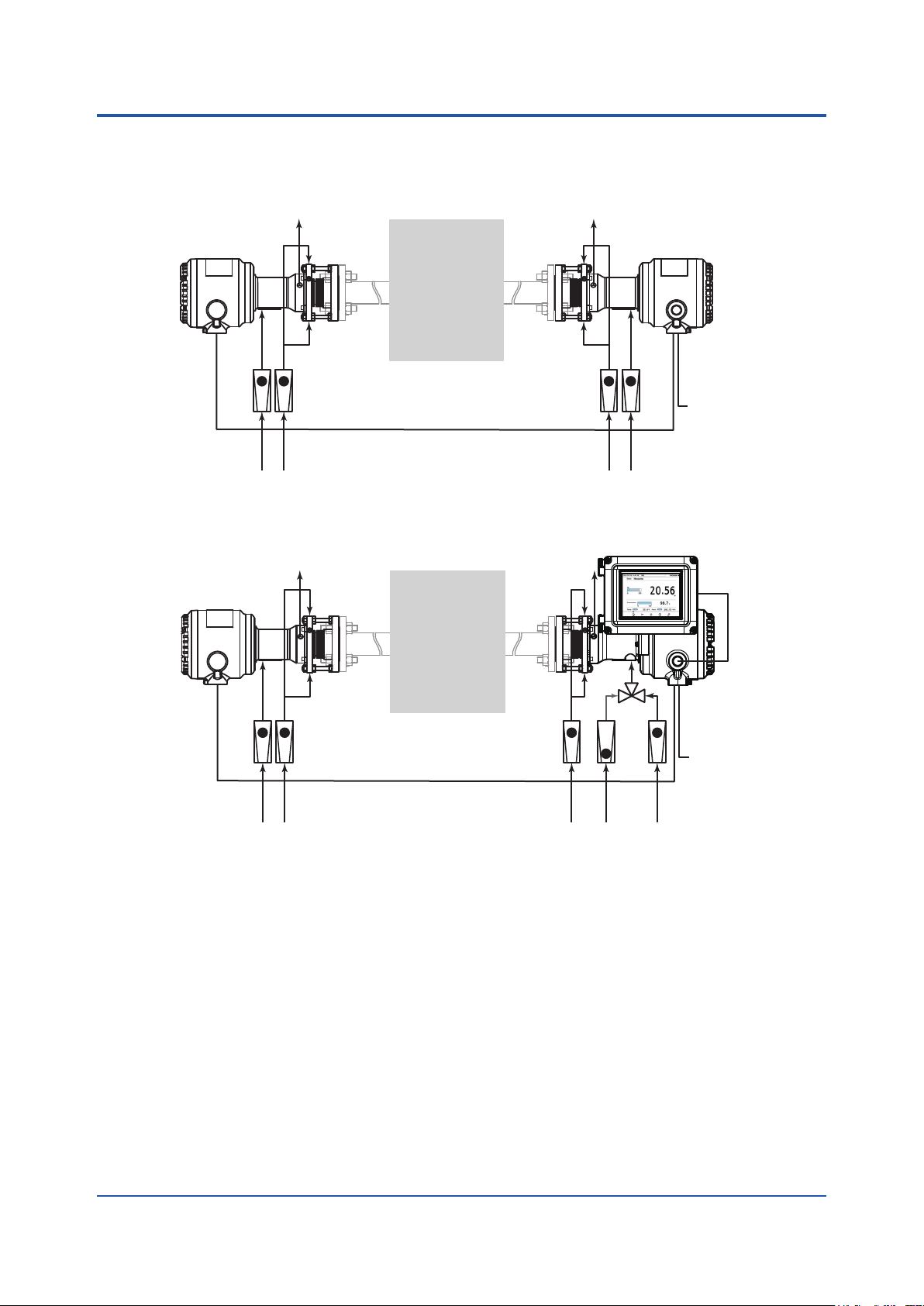

nSystemconguration

StandardSystemConguration

2

Laser unit (LU)

Measured gas

Flow meter Flow meter

Unit connection cable

Purge line for Optic Purge line for Optic

Purge line for Process window Purge line for Process window

Sensor control unit (SCU)

SystemCongurationwithYH8000HMIUnitandValidationgasline

Laser unit (LU)

Measured gas

Sensor control unit (SCU)

24V DC±10%

Flow meter Flow meter

Unit connection cable

Purge line for Optic Purge line for Optic

Purge line for Process window

Purge line for Process window

Check gas line

24V DC±10%

All Rights Reserved. Copyright © 2015, Yokogawa Electric Corporation GS 11Y01D01-01EN Aug 28, 2020-00

Page 3

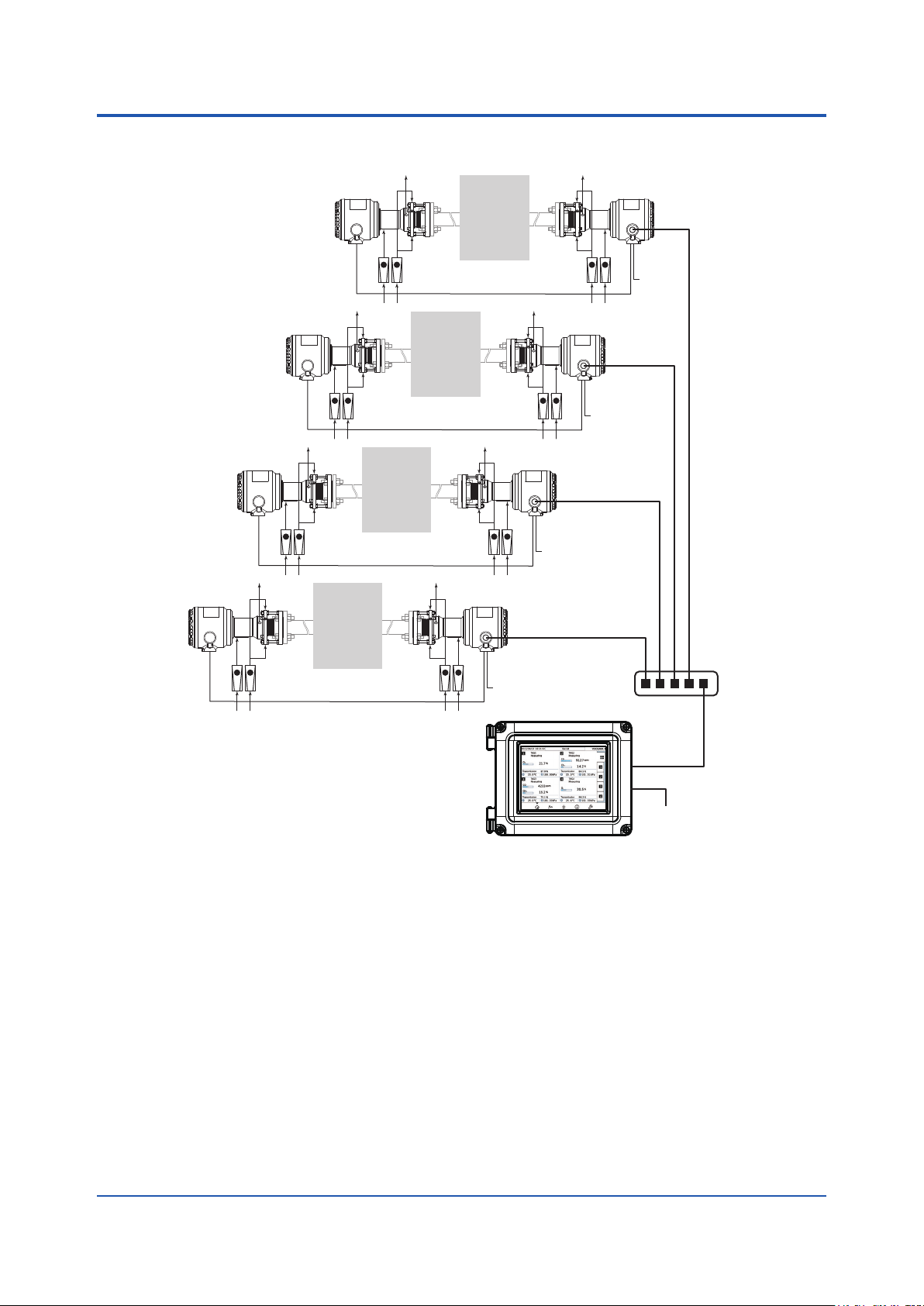

MultiAnalyzerCongurationwithRemoteHMI

Laser unit (LU) Sensor control unit (SCU)

Measured

Measured

gas

3

Measured

gas

24V DC

±10%

gas

24V DC±10%

24V DC±10%

Measured

gas

Flow meter Flow meter

Unit connection cable

Note: If power supply is 100 to 240 V AC, purchase the Universal Power Supply, separately.

If four multi analyzer conguration with remote HMI is made, ve universal power supply including YH8000 are needed.

24V DC±10%

Switching HUB

24V DC±10%

YH8000 HMI Unit

All Rights Reserved. Copyright © 2015, Yokogawa Electric Corporation GS 11Y01D01-01EN

Aug 28, 2020-00

Page 4

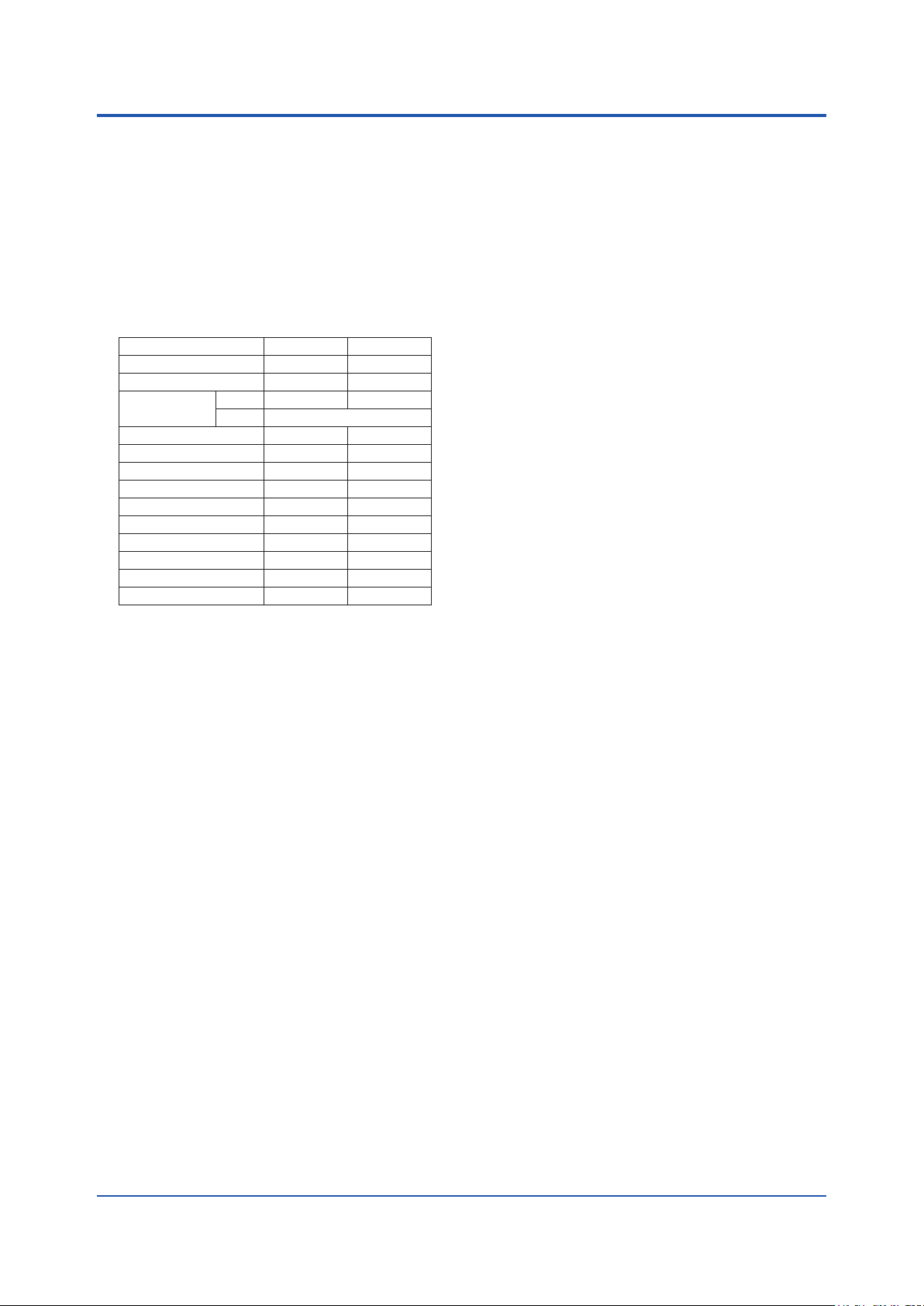

4

n STANDARD SPECIFICATIONS

TDLS8000 Tunable Diode Laser Spectrometer

Measurement object:

O2, CO, CO or CH4, CO2, CO + CO2,

H2O, NH3, H2S, HCl concentration in

combustion exhaust gas and process gas

If other gas measurements are required,

consult with Yokogawa

Measurement system:

Tunable diode laser spectroscopy

Light source; Near-infrared tunable diode laser

Measured components and ranges:

Measured component Min. range Max. range

O

2

CO (ppm) 0-200 ppm 0-10,000 ppm

CO or CH4 (*3)

NH

3

H2O (ppm) in non HC (*1) 0-30 ppm 0-30,000 ppm

H2O (ppm) in HC (*2) 0-30 ppm 0-30,000 ppm

CO (%) 0-20% 0-50%

CO (%) + CO2 (%) 0-30% 0-100%

H2S 0-5% 0-100%

CO2 (%) High Range 0-1% 0-5%

CO2 (%) Extend. Range 0-30% 0-50%

H2O (%) 0-10% 0-100%

HCl 0-50 ppm 0-5,000 ppm

*1: Non hydrocarbon background.

*2: Hydrocarbon background.

*3: Please consult with Yokogawa if CO or CH4

ingredient coexists.

CO 0-200 ppm 0-10,000 ppm

CH

4

Please consult with Yokogawa if the measuring range

for your sample gas is outside of the above ranges

Optical path length:

Optical distance between the laser unit

and the sensor control unit

Standard; 0.5 to 6 m (Application dependent)

Max; 30 m ( With optional Large Aperture

Optics (LAO))

Note: LAO unit can be selected only with analyzers for

If your optical path length is under 0.5 m or over

25 m (Zone 1/Div.1/Flameproof “d” with LAO)

O2, CO(ppm) and CO+CH

30 m, please consult with Yokogawa.

Safety, EMC, and RoHS conformity standards:

Safety conformity standards:

CE EN61010-1, EN61010-2-030

UL UL61010-1, UL 61010-2-030

CSA CAN/CSA-C22.2 No.61010-1, CAN/

CSA-C22.2 No.61010-2-030

GB GB30439 Part 1

Installation altitude: 2000 m or less

Installation category:

I (Anticipated transient overvoltage 330V)

Measuring category: O (Other)

Pollution degree: 2, Indoor/Outdoor use

Note: Installation category, called overvoltage category,

species impulse withstand voltage. Pollution

degree indicates the degree of existence of solid,

liquid, gas or other inclusions which may reduce

dielectric strength.

0-1% 0-25%

0-5%

0-30 ppm 0-5,000 ppm

4.

EMC conformity standards:

CE EN55011 Class A Group 1

EN61326-1 Class A Table 2 (For use in

industrial location), EN61326-2-3

RCM EN55011 Class A Group 1

KC KN11 Class A Group 1, KN61000-6-2

(Korea Electromagnetic Conformity)

RoHS conformity standards: EN50581

Information of the WEEE Directive

This product is purposely designed to be used in a

large scale xed installations only and, therefore,

is out of scope of the WEEE Directive. The WEEE

Directive does not apply.

The WEEE Directive is only valid in the EU.

Laser classication: CAN/CSA-E60825-1-15,

CE EN 60825-1:2014, FDA 21CFR part

1040.10, GB7247.1-2012, Class 1 laser

product

SIL Certication: The TDLS8000 expect digital output

(2 points), digital input (2 points), valve

control output (2 points), and digital

communications (HART, Modbus/TCP) are

certied in compliance with the following

standard.

IEC 61508:Functional safety of Electrical/

electronic/programmable electronic

related systems; SIL 2 capability for single

analyzer use, SIL 3 capability for dual

analyzer use.

Display:

128 x 64 dots LCD; On Sensor Control Unit

Status LEDs; 3 on Sensor Control Unit (Green:

Power, Orange: DO, Red: Fault)

4 digit 7-segment LEDs: On Laser Unit

Display items:

LCD on Sensor Control Unit; Gas concentration,

Transmission, Process gas temperature

(AI), Process gas pressure (AI), System

status, Alarm information, System

information (Product serial no., Laser

module serial no., Output signal, IP

address, HART address, Optical path

length, Analyzer internal temperature)

7-segment LEDs on Laser Unit; Transmission

Analog output: 2 points, 4 to 20 mA DC (Isolated from

the power supply and ground, Max. load

resistance 550 Ω)

Output types; Gas concentration, Transmission,

Process gas temperature, Process

gas pressure

Output range; 3.0 to 21.6 mA DC

Digital communications:

HART; On analog output signal 1 (AO-1)

Load resistance; 250 to 550 Ω (Include cable resistance)

Ethernet; RJ-45 connector in Sensor Control Unit

Protocol; Modbus/TCP

Communication speed; 100 Mbps

Digital output: 2 points, contact rating 24V DC, 1A

DO;

Function: Activate during Warning / Calibration

/ Validation / Warm up / Maintenance

conditions

Contact Specication: Relay contact output

(Isolated from the power supply and

ground), C-contact (NC/NO/COM)

All Rights Reserved. Copyright © 2015, Yokogawa Electric Corporation GS 11Y01D01-01EN

Aug 28, 2020-00

Page 5

5

Fault;

Function: Activate during Fault condition or when

the system power is o

Contact Specication: Relay contact output

(Isolated from the power supply and

ground), A-contact (NC/COM)

Valve control output: 2 points

Function; Activate calibration or validation solenoid

valves for zero, span or validation gas.

Output signal; 24V DC, 500 mA Max. per terminal

Alarm:

Warning;

Gas concentration low, Gas concentration

high, Transmission low, Process pressure

low, Process pressure high, Process

temperature low, Process temperature

high, Validation required, Validation

failure, Zero calibration error, Span

calibration error, Non process alarm,

External alarm

, Detector signal high,

Absorption too high

Fault;

Laser module temperature low, Laser

module temperature high, Laser

temperature low, Laser temperature high,

Peak center out of range, Reference peak

height low, Transmission lost, Reference

transmission low, Reference peak height

high, Laser unit failure, Laser module error,

File access error, E2PROM access error

Digital input: 2 points

Function; External Alarm/Calibration start/

Validation start/Stream switch (Valve

control)

Contact specication; Zero voltage contact input

(Isolated from the power supply and

ground)

Input signal; Open signal: 100 kΩ or more, Close

signal: 200 Ω or less

Analog input: 2 points

Signal type; 4 to 20 mA DC (Isolated from

the power supply and Ground), with

selectable powered/unpowered function

Input signal range; 2.4 to 21.6 mA DC

Input types; Process gas temperature, Process

gas pressure

Transmitter power supply;

15 V DC or higher (at 20 mA DC)

26 V DC or less (at 0 mA DC)

Note: This voltage is generated between the AI terminals

of TDLS8000. When calculating the minimum

operating voltage for transmitters, consider to allow

margins for voltage drop in external wiring.

Self-diagnostics:

Laser Unit temperature, Sensor Control

Unit temperature, Laser temperature,

Detector signal level, Memory read/write

function, Peak locking condition

Calibration:

Calibration method; Zero/Span calibration

Calibration mode; Manual, Auto (Time initiate,

Remote initiate (DI/Modbus)), Semi-Auto

(YH8000/HART)

Validation:

Validation method; Up to 2 points

Validation mode; Manual, Auto (Time initiated,

Remote initiate (DI/Modbus)), Semi-Auto

(YH8000/HART)

Note: Validation check is not available when Large

Aperture Optics “-LA” of the Optic Accessory

is specied or H20 ppm measurement “-H1” of

the Gas Parameter is specied. As well, when

gas concentration is unstable, please consult

Yokogawa.

Power supply: 24V DC +/-10%

If your power supply is 100 to 240 V AC,

Universal Power Supply, M1276WW (sold

separately), is required

Power consumption:

Max. 20W; TDLS8000 only

Max. 60W;

TDLS8000 with YH8000 and 2 solenoid valves

Protection degree: IP66, Type 4X

Material: Case; Aluminum alloy

Wetted materials:

316 SS, BK-7 glass, Teon encapsulated

FKM (O-ring for alignment ange), Silicone

(O-ring for LAO)

Paint color: Mint green (RAL 190 30 15 or equivalent)

Weight:

Sensor Control Unit; Approx. 8 kg

Laser Unit; Approx. 8 kg

Large Aperture Optics; Approx. 14 kg

ANSI Class 150-2-RF (Eq.) Alignment Flange;

Approx. 5 kg/pc

ANSI Class 150-3-RF (Eq.) Alignment Flange;

Approx. 7 kg/pc

ANSI Class 150-4-RF (Eq.) Alignment Flange;

Approx. 9 kg/pc

DIN PN16-DN50-A (Eq.) Alignment Flange;

Approx. 5 kg/pc

DIN PN16-DN80-A (Eq.) Alignment Flange;

Approx. 6 kg/pc

JIS 10K-50-FF (Eq.) Alignment Flange;

Approx. 5 kg/pc

JIS 10K-80-FF (Eq.) Alignment Flange;

Approx. 6 kg/pc

Flow Cell Alignment Flange; Approx. 5 kg/pc

Cable gland for Japan Ex “-J1”; (/JA1) Approx. 320 g/pc,

(/JB3, /JB4) Approx. 450 g/pc

Cable gland for Japan Ex “-J2”;

(/JC1, /JD1) Approx. 150 g/pc,

(/JE3, /JE4) Approx. 200 g/pc

Process gas condition:

Process gas temperature; Max. 1,500ºC,

Application dependent

Process gas pressure;

abs.,

Max.1 MPa abs., Min. 90 kPa

Application dependent

Max. 15 kPa G with LAO unit

Note:

When using TDLS8000 as CE marking compliance

product, it has following limitation.

General purpose model (-G1, -G2):

The upper limit of the measurement gas

ATEX model (-S1, -S2):

The upper limit of the measurement gas

An unstable gas in this context is a gas liable to

transform itself spontaneously, producing a sudden

pressure increase.

Such transformation as an example can result

from a relatively small variation of an operating

parameter (e.g. pressure, temperature, presence

of catalyzing material) in a conned volume.

This includes gases that are classied as

chemically unstable gases according to CLP

Regulation (EC) No 1272/2008 as amended.

pressure is 50kPa in gauge pressure.

Consult with Yokogawa Europe B.V. in the

case of witnessing high pressure in Europe.

pressure is 500kPa abs. The unstable gas

dened by following cannot be measured.

All Rights Reserved. Copyright © 2015, Yokogawa Electric Corporation GS 11Y01D01-01EN

Aug 28, 2020-00

Page 6

6

Typical examples of unstable gases: acetylene

(UN 1001), methyl acetylene (UN 1060),

vinyluoride (UN 1860), ozone and dinitrogen

oxide (UN 1067).

For further examples, see Table 35.1 of the UN

Manual of Tests and Criteria.

Dust in process gas; 20 g/m3 or less

(Dust loading levels are dependent

upon the application, OPL and other

installation factors)

Warm-up time: 5 min.

Installation condition:

Ambient operating temperature; -20 to 55ºC

Storage temperature; -30 to 70ºC

Humidity; 0 to 95%RH at 40ºC (Non-condensing)

Mounting ange type; ASME B16.5, DIN, JIS

Cable entries;

Sensor Control Unit:

1/2NPT or M20x1.5mm,one hole

3/4NPT or M25x1.5mm, three holes

Laser Unit: 3/4 NPT or M25x1.5mm, one hole

Purge gas connections;

1/4NPT or Rc1/4

If other gas connections are required,

please consult with Yokogawa.

Purge gas;

Theoretically, instrument air could be used as

a purge gas for all of the below applications

except for oxygen or H2O measurement.

Choosing between using nitrogen or

instrument air or purge gas will ultimately

depend upon further application details and

the desired precision of the measurement. All

gasses should be clean and dry.

Recommended purge gasses:

O2 analyzer: N2 (99.99% or greater, application

dependent)

H2O ppm analyzer: N2 (99.99% or greater with

< 20 ppm H2O for feed to the optional

dryer package)

CO, CO or CH4, CO2, CO + CO2, NH3, H2S, HCl

analyzer: N2 (99.99% or greater,

application dependent) or Instrument air

Purge gas ow rates;

Optic:

Application dependent (typ. 2 to 20L/min)

2 to 20L/min and 50 to 70mL/min

(Zone 1/Div.1/Flameproof “d”)

* Not more than 10kPa at the inlet for

Zone 1/Div.1/Flameproof “d” and Zone

2/Div.2/Type of protection “n”

Process window: Application dependent

(typ. 5 to 30L/min)

Hazardousareaclassications:

Division 1, Zone 1: Explosionproof

TDLS8000-D1 (FM Approval for US)

Division system:

Type of protection:

Explosionproof for Class I, Division 1,

Groups A, B, C, D, T5

Dust-Ignitionproof for Class II/III,

Division 1, Groups E, F, G, T5

Enclosure rating: Type4X

Applicable standards:

FM Class 3600: 2018

FM Class 3615: 2018

FM Class 3616: 2011

FM Class 3810: 2018

ANSI/NEMA250: 2013

Zone system:

Type of protection:

Class I, Zone 1, AEx db [op is T6 Ga]

IIC T5 Gb

Zone 21, AEx tb [op is T85˚C Da] IIIC

T100˚C Db

Enclosure rating: IP66

Applicable standards:

ANSI/UL 60079-0:2019

ANSI/UL 60079-1:2015

ANSI/UL 60079-28:2017

ANSI/UL 60079-31:2015

ANSI/IEC 60529:2004

TDLS8000-C1 (FM Approval for Canada)

Type of protection:

Ex db [op is T6 Ga] IIC T5 Gb

Class II/III, Division 1, Groups E, F, G, T5

Ex tb [op is T85˚C Da] IIIC T100˚C Db

Enclosure rating: IP66, Type4X

Applicable standards:

CAN/CSA-C22.2 No.0:2010 (R2015)

CSA-C22.2 No. 0.4:2017

CSA C22.2 No. 0.5:2016

CSA C22.2 No. 25:2017

CSA C22.2 No.94.2:2015

CAN/CSA-C22.2 No.61010-1:2012

CAN/CSA-C22.2 No.61010-2-030:2012

CAN/CSA-C22.2 No.60529:2016

CSA C22.2 No.60079-0:2019

CAN/CSA-C22.2 No.60079-1:2016

CAN/CSA-C22.2 No.60079-28:2016

CAN/CSA-C22.2 No.60079-31:2015

ANSI/ISA 12.27.01:2011

TDLS8000-S1 (ATEX)

Type of protection:

II 2(1) G Ex db [op is T6 Ga] IIC T5 Gb

II 2(1) D Ex tb [op is T85˚C Da] IIIC

T100˚C Db

Enclosure rating:

IP66 (In Accordance with EN 60529)

Applicable standards:

EN IEC 60079-0:2018

EN 60079-1:2014, EN 60079-28:2015,

EN 60079-31:2014

TDLS8000-E1 (IECEx)

Type of protection:

Ex db [op is T6 Ga] IIC T5 Gb

Ex tb [op is T85˚C Da] IIIC T100˚C Db

Enclosure rating:

IP66 (In Accordance with IEC 60529)

Applicable standards:

IEC 60079-0:2017, IEC 60079-1:2014,

IEC 60079-28:2015, IEC 60079-31:2013

TDLS8000-J1 (Japan Ex)

Type of protection:

Ex d IIC T5 Gb

Applicable standards:

JNIOSH-TR-46-1:2015

JNIOSH-TR-46-2:2015

TDLS8000-Q1, -R1 (EAC)

Type of protection:

1Ex d [op is T6 Ga] IIC T5 Gb X

Ex tb IIIC T100 ºC Db X

Enclosure rating:

IP66 (In accordance with GOST 14254-96)

All Rights Reserved. Copyright © 2015, Yokogawa Electric Corporation GS 11Y01D01-01EN

Aug 28, 2020-00

Page 7

7

Applicable standards:

GOST R IEC 60079-0-2011

GOST IEC 60079-1-2011

GOST 31610.28-2012

GOST IEC 60079-31-2013

Division 2, Zone 2: Nonincendive/Type n

TDLS8000-D2 (FM Approval for US)

Division system:

Type of protection:

Nonincendive for Class I, Division 2,

Groups A, B, C, D, T5

Dust-Ignitionproof for Class II/III,

Division 1, Groups E, F, G, T5

Enclosure rating: Type 4X

Applicable standards:

FM Class 3600: 2018

FM Class 3611: 2018

FM Class 3616: 2011

FM Class 3810: 2018

ANSI/NEMA250: 2013

Zone system:

Type of protection:

Class I, Zone 2, AEx nA nC [op is T6

Ga] IIC T5 Gc

Zone 21, AEx tb [op is T85˚C Da] IIIC

T100˚C Db

Enclosure Rating: IP66

Applicable standards:

ANSI/UL 60079-0:2019

ANSI/UL 60079-15:2013

ANSI/UL 60079-28:2017

ANSI/UL 60079-31:2015

ANSI/IEC 60529:2004

TDLS8000-C2 (FM Approval for Canada)

Type of protection:

Ex nA nC [op is T6 Ga] IIC T5 Gc

Ex tb [op is T85˚C Da] IIIC T100˚C Db

Enclosure rating: IP66, Type 4X

Applicable standards:

CSA C22.2 No. 25:2017

CSA C22.2 No.94.2:2015

CAN/CSA-C22.2 No.60529:2016

CAN/CSA-C22.2 No. 60079-0:2019

CAN/CSA-C22.2 No.60079-15:2016

CAN/CSA-C22.2 No.60079-28:2016

CAN/CSA-C22.2 No.60079-31:2015

CAN/CSA-C22.2 No.61010-1:2012

ANSI/ISA 12.27.01:2011

TDLS8000-S2 (ATEX)

Type of protection:

Enclosure rating:

IP66 (In accordance with EN 60529)

Applicable standards:

EN IEC 60079-0:2018,

Class II/III, Division 1, Groups E, F, G, T5

CAN/CSA-C22.2 No.61010-2-030:2012

II 3(1) G Ex nA nC [op is T6 Ga] IIC T5 Gc

II 2(1) D Ex tb [op is T85˚C Da] IIIC

T100˚C Db

EN 60079-15: 2010,

EN 60079-28: 2015,

EN 60079-31: 2014

TDLS8000-E2 (IECEx)

Type of protection:

Ex nA nC [op is T6 Ga] IIC T5 Gc

Ex tb [op is T85˚C Da] IIIC T100˚C Db

Enclosure rating:

IP66 (In accordance with IEC 60529)

Applicable standards:

TDLS8000-K2 (Korea Ex)

Type of protection: Ex nA nC IIC T5

Ex tD A21 T100 ºC

Enclosure rating:

IP66 (In accordance with IEC 60529)

Applicable standards:

TDLS8000-N2 (NEPSI)

Type of protection:

Ex nA nC [op is T6 Ga] IIC T5 Gc

Ex tD A21 IP66 T100ºC

Enclosure rating:

IP66 (In accordance with GB 4208)

Applicable standards:

GB 3836.1-2010, GB 3836.8-2014,

TDLS8000-Q2, -R2 (EAC)

Type of protection:

2Ex nA nC [op is T6 Ga] IIC T5 Gc X

Enclosure rating:

Applicable standards:

GOST R IEC 60079-0-2011

TDLS8000-J2 (Japan Ex)

Type of protection:

Applicable standards:

JNIOSH-TR-46-8:2015

JNIOSH-TR-46-9:2015

Enclosure rating:

IP66 (In accordance with IEC 60529)

IEC 60079-0:2017, IEC 60079-15: 2010,

IEC 60079-28: 2015, IEC 60079-31: 2013

Notice of Ministry of Labor No. 2013-54

Harmonized with IEC 60079-0: 2011,

IEC 60079-15: 2010, IEC 60079-28:

2015, IEC 60079-31: 2013

GB 12476.1-2013, GB 12476.5-2013,

IEC 60079-28:2015

Ex tb IIIC T100 ºC Db X

IP66 (In accordance with GOST 14254-96)

GOST R IEC 60079-15-2010

GOST 31610.28-2012

GOST IEC 60079-31-2013

Ex nA nC IIC T5 Gc

Ex tb IIIC T100

JNIOSH-TR-46-1:2015

ºC

Db

All Rights Reserved. Copyright © 2015, Yokogawa Electric Corporation GS 11Y01D01-01EN

Aug 28, 2020-00

Page 8

8

PERFORMANCE

Repeatability / Linearity:

Measured gas Repeatability Linearity

O

2

CO (ppm)

CO or

CH

4

NH

3

H2O (ppm) in

non HC

H2O (ppm) in HC+/- 2% reading or +/- 0.1 ppm

CO (%)

CO (%)

+ CO2

(%)

H2S

CO2 (%)

High Range

CO2 (%)

Extend. Range

H2O (%)

HCl

Measurement conditions: Gas temperature; 25 ºC, Gas

Data Update Cycle:

Standard; Approx. 2 seconds (Response

If less than 2 seconds response is

Zero Drift: Typically <0.1% of the minimum range

Inuences on the Measurement - Application

dependent

A. Temperature: The temperature of the measured

gas should be taken into account by the analyzer

so that the reading can be corrected on a real

time basis. The eect is specic to each dierent

measurement gas.

a. If the gas temperature is constant at the

desired measurement condition, then a xed

gas temperature may be programmed into the

analyzer. This xed value can be used in real

time by the analyzer to provide a temperaturecompensated reading.

b. If the gas temperature is relatively equal to the

ambient temperature, then an integral sensor

value may be utilized by the analyzer. This

active ambient value is used real time by the

analyzer to provide a temperature compensated

reading.

+/- 1% reading or +/- 0.01

%O2, whichever is greater

+/- 2% reading or +/- 1 ppm

CO, whichever is greater

+/- 2% reading or +/- 1 ppm

CO

CO, whichever is greater

+/- 4% reading or +/- 0.02%

CH

4

CH4, whichever is greater

+/- 2% reading or +/- 1 ppm

NH3, whichever is greater

+/- 2% reading or +/- 0.1 ppm

H2O, whichever is greater

H2O, whichever is greater

+/- 1% reading or +/- 0.01%

CO, whichever is greater

+/- 1% reading or +/- 0.1%

CO

CO, whichever is greater

+/- 1% reading or +/- 0.1%

CO

2

CO2, whichever is greater

+/- 1% reading or +/- 0.005%

H2S, whichever is greater

+/- 1% reading or +/- 0.005%

CO2, whichever is greater

+/- 1% reading or +/- 0.02%

CO2, whichever is greater

+/- 1% reading or +/- 0.004%

H2O, whichever is greater

+/- 1% reading or +/- 2.5 ppm

HCl, whichever is greater

pressure; 0.1 MPa, Optical path

length; 1 m

+/- 1% F.S.

+/- 1% F.S.

+/- 2% F.S.

+/- 4% F.S.

+/- 2% F.S.

+/- 1% F.S.

+/- 1% F.S

+/- 1% F.S.

+/- 1% F.S.

+/- 1% F.S.

+/- 1% F.S.

+/- 1% F.S.

+/- 1% F.S.

+/- 1% F.S.

+/- 2% F.S.

time may increase for non-standard

applications)

required, please consult with Yokogawa

over 24 months

c. If the gas temperature is variable, then an

external sensor value may be utilized by

the analyzer. This active input value can be

used in real time by the analyzer to provide a

temperature compensated reading.

B. Pressure: The pressure of the measured gas must

be taken into account by the analyzer so that the

reading can be corrected on a real time basis. The

eect is specic to each dierent measurement

gas.

a. If the gas pressure is constant at the desired

measurement condition, then a xed gas

pressure may be programmed to the analyzer.

This xed value can be used in real time by the

analyzer to provide a pressure compensated

reading.

b. If the gas pressure is variable, then an external

sensor value may be utilized by the analyzer.

This active input value can be used in real

time by the analyzer to provide a pressure

compensated reading.

● YH8000HMIUnit

The YH8000 is an HMI designed specically for the

TDLS8000 series. The YH8000 features an easy-touse touchscreen 7.5 inch color LCD which can be

used to display maintenance information, display alarm

statuses and records, and set all parameters of the

TDLS8000.

The YH8000 can be installed directly on the TDLS8000

series or installed remotely.

An Ethernet connection is used to connect the YH8000

to up to four TDLS8000 series simultaneously via a

hub.

Display: Touchscreen 7.5 inch TFT color LCD

panel, 640 x 480 (VGA)

Communication: Ethernet; RJ-45 connector

Communication speed; 100 Mbps

Case: Aluminum alloy

Paint color:

Protection degree of enclosure: IP65, Type 4X

Window: Polycarbonate

Weight: Approx. 4 kg

Cable gland for Japan Ex; (/JA1, /JA2) Approx. 320 g/pc

Mounting: Analyzer mount (Front, left-side, right-side)

Cable Entries: 1/2NPT or M20x1.5 mm, two holes

Installation conditions:

Ambient operating temperature; -20 to 55ºC

Storage temperature: -30 to 70ºC

Humidity: 10 to 90%RH at 40ºC (Non-condensing)

Power Supply: 24V DC +/-10%

Power consumption: Max.12 W

Safety, EMC, and RoHS conformity standards:

Safety conformitystandards:

CE EN61010-1

UL UL61010-1

CSA CAN/CSA-C22.2 No.61010-1

GB GB30439 Part 1

Installation Altitude: 2000 m or less

Installation category: I

Pollution degree: 2, Indoor/Outdoor use

Mint green (RAL 190 30 15 or equivalent)

with tilt function, Pipe mount, or Panel

mount (Stainless steel)

(Anticipated transient overvoltage 330 V)

All Rights Reserved. Copyright © 2015, Yokogawa Electric Corporation GS 11Y01D01-01EN

Aug 28, 2020-00

Page 9

9

EMC conformity standards:

CE EN55011 Class A Group 1

EN61326-1 Class A Table 2 (For use in

industrial location)

RCM EN55011 Class A Group 1

KC KN11 Class A Group 1, KN61000-6-2

(Korea Electromagnetic Conformity)

RoHS conformity standards: EN50581

Information of the WEEE Directive

This product is purposely designed to be used

in a large scale xed installations only and,

therefore, is out of scope of the WEEE Directive.

The WEEE Directive does not apply.

The WEEE Directive is only valid in the EU.

Hazardousareaclassications:

Division 2, Zone2: Nonincendive/Type n

YH8000-D2 (FM Approval for US)

Division system

Type of protection: Nonincendive for Class I,

Division 2, Groups A, B, C, D, T5

Enclosure rating: Type 4X

Applicable standards:

FM Class 3600: 2011, FM

Class 3611: 2004, FM Class

3810: 2005, NEMA 250: 2003

Zone system

Type of protection:

Class I, Zone 2, AEx nA ic IIC T5

Enclosure rating: IP65

Applicable standards: ANSI/ISA-60079-0-2013,

ANSI/ISA-60079-11-2014,

ANSI/ISA-60079-15-2012,

ANSI/IEC 60529-2004 (R2011)

YH8000-C2 (FM Approval for Canada)

Type of protection: Ex nA nL IIC T5

Enclosure rating: IP65, Type 4X

Applicable standards:

CAN/CSA-

CAN/CSACAN/CSA-

C22.2 No. 0-10 (R2015),

C22.2 No. 94.1-07 (R2012),

C22.2 No. 94.2-07 (R2012),

CAN/CSA-C22.2 No.60079-0:11,

CAN/CSA-C22.2 No.60079-15:12,

CAN/CSA-C22.2 No.61010-1-12,

CAN/CSA No. 60529-5 (2010)

YH8000-S2 (ATEX)

Type of protection: II 3 G Ex nA ic IIC T5 Gc

Enclosure rating:

IP65 (In accordance with EN 60529)

Applicable standards:

EN 60079-0: 2012+A11: 2013,

EN 60079-11: 2012, EN 60079-15: 2010

YH8000-E2 (IECEx)

Type of protection: Ex nA ic IIC T5 Gc

Enclosure rating:

IP65 (In accordance with IEC 60529)

Applicable standards: IEC 60079-0: 2011,

IEC 60079-11: 2011, IEC 60079-15: 2010

YH8000-J2 (Japan Ex)

Type of protection: Ex nA ic IIC T5 Gc

Enclosure rating:

IP54 (In accordance with IEC 60529) *1

*1: IP54 that is minimum requirement of Ex standards is

conrmed at the conformance assessment of Japan Ex.

YH8000 can be used in the environment required IP65.

Applicable standards: JNIOSH-TR-46-1:2015

JNIOSH-TR-46-6:2015

JNIOSH-TR-46-8:2015

YH8000-K2 (Korea Ex)

Type of protection: Ex nA nL IIC T5

Enclosure rating: IP65 (In accordance with

IEC 60529)

Applicable standards: Notice of Ministry of

LaborNo. 2013-54

Harmonized with IEC600790: 2011, IEC 60079-11:

2011, IEC 60079-15:2010

YH8000-N2 (NEPSI)

Type of protection: Ex nA ic IIC T5 Gc

Enclosure rating: IP65 (In accordance with

GB 4208)

Applicable standards: GB 3836.1-2010,

GB 3836.4-2010,

GB 3836.8-2014

YH8000-R2 (EAC)

Type of protection: 2Ex nA ic IIC T5 Gc X

Enclosure rating: IP65 (In accordance with

GOST 14254-96)

Applicable standards: GOST R IEC 60079-0-2011

GOST R IEC 60079-15-2010

● IF8000IsolationFlanges

A process isolation ange protects the TDLS8000

from the process gas pressure and the heat, dust,

and corrosive elements of the process gas. A process

isolation ange must be installed in the following

situations.

• When the process gas pressure exceeds 500 kPa

• When the process temperature is high and the

temperature of the process window area exceeds

55ºC even when process window purge is performed.

• When the process dust level is high and the

adherence of dust or intrusion of corrosive elements

cannot be prevented even when process window

purge is performed.

The IF8000 isolation anges can be used for additional

protection in in-situ or bypass installations.

Note: Must use in conjunction with alignment anges

Process connections: (see below table)

Heatresistance temperature: 200ºC max

Measured gas pressure: Max. 1 MPa abs.

Wetted materials:

Sapphire, 316 SS, Monel 400,

Kalrez (O-ring)

All Rights Reserved. Copyright © 2015, Yokogawa Electric Corporation GS 11Y01D01-01EN

Aug 28, 2020-00

Page 10

10

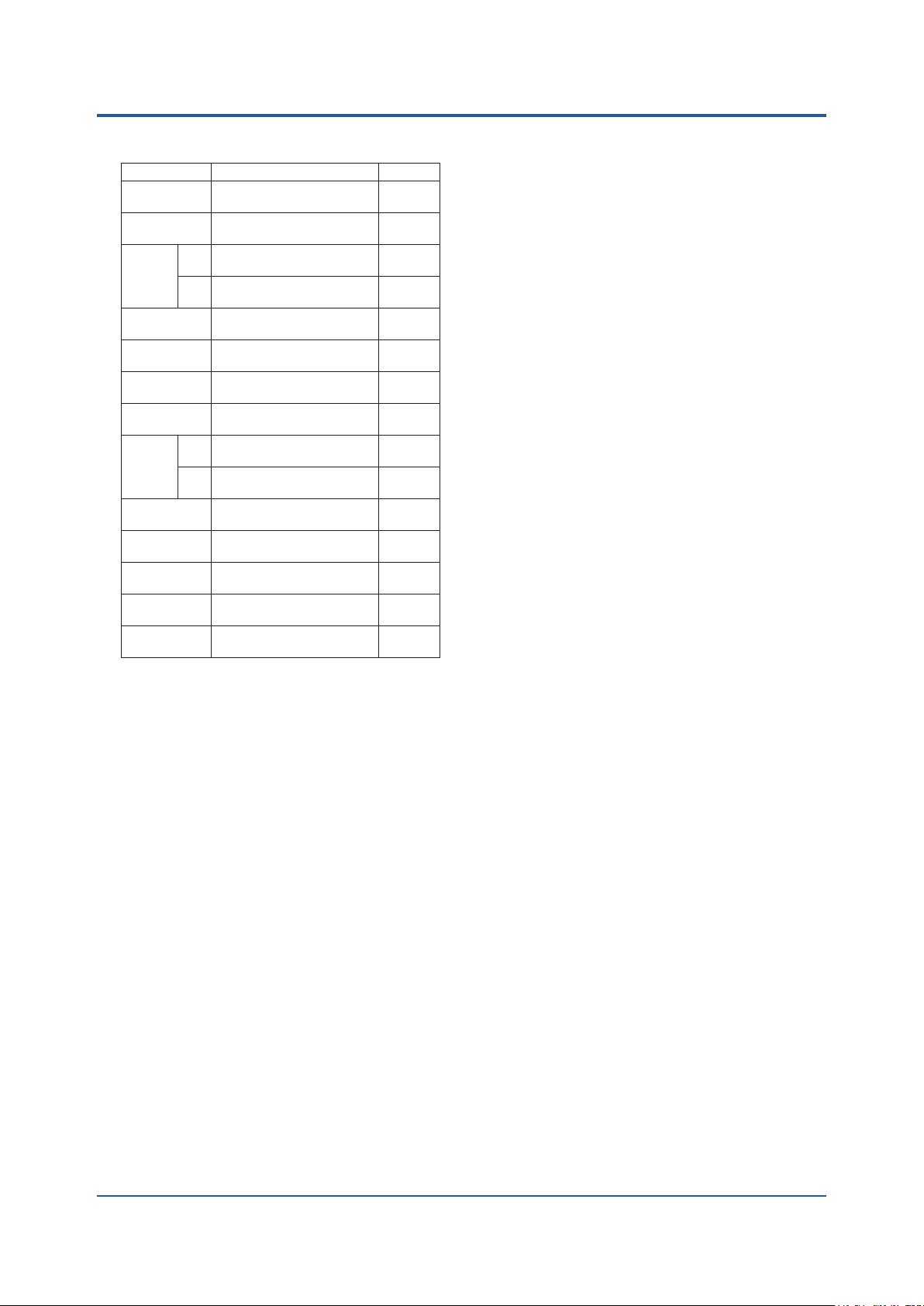

Weight;

Process

connection

ANSI Class 1502-RF Flange

ANSI Class 3002-RF Flange

ANSI Class 1503-RF Flange

ANSI Class 3003-RF Flange

ANSI Class 1504-RF Flange

DIN PN16-DN50

Flange

DIN PN16-DN80

Flange

JIS 10K-50-FF

Flange

JIS 10K-80-FF

Flange

Note: When using TDLS8000 as CE marking compliance

product, the upper limit of the measurement gas

pressure is 50kPa in gauge pressure.

Consult with Yokogawa Europe B.V. in the case of

witnessing high pressure in Europe.

Analyzer

connection

ANSI Class 1502-RF Flange

DIN PN16-DN50

Flange

Weight(Approx.)

316SS

5 kg/pc 6 kg/pc

7 kg/pc 7 kg/pc

8 kg/pc 9 kg/pc

11 kg/pc 12 kg/pc

12 kg/pc 14 kg/pc

7 kg/pc 7 kg/pc

10 kg/pc 11 kg/pc

7 kg/pc 7 kg/pc

9 kg/pc 10 kg/pc

Monel 400

● YC8000FlowCell

Used for extracting sample streams at any location.

Note: Must use in conjunction with alignment anges (“-FC”)

Gas temperature: 200ºC max

Gas pressure: Max. 1 MPa abs.

Wetted materials:

Weight;

Material/Optical

Path Length

Monel 400 Approx. 15 kg Approx. 18 kg

316 SS Approx. 14 kg Approx. 17 kg

Note: When using TDLS8000 as CE marking compliance

product, the upper limit of the measurement gas

pressure in YC8000 is 50kPa in gauge pressure.

Sapphire, 316 SS, Monel 400,

Kalrez (O-ring)

1016 mm

(40inch)

1524mm

(60inch)

● CalibrationCell

Used for o-line calibrations and validations.

Appropriate process windows are included on

calibration cell.

Optical Path Length: 660 mm

Material: 316 SS

Part No. Description Weight

K9772XA Calibration Cell with free-standing

K9772XB Calibration Cell with free-standing

K9772XC

K9772XD Calibration Cell with free-standing

K9772XE

K9772XF Calibration Cell with free-standing

K9772XG Calibration Cell with free-standing

K9772XH

K9772XJ Calibration Cell with free-standing

K9772XL

K9772XM Calibration Cell with free-standing

Note: When using TDLS8000 as CE marking compliance

frame for O

frame for O2 LAO

Calibration Cell with free-standing

frame for ppm H2O in non- hydrocarbon

frame for NH

Calibration Cell with free-standing

frame for ppm H2O in hydrocarbon

background

frame for ppm CO

frame for ppm CO LAO

Calibration Cell with free-standing frame for

CO (%) + CO2 (%), CO2 (%) Extend. Range

frame for HCl

Calibration Cell with free-standing

frame for CO(%), CO2 (%) High Range

frame for H2S

product, the upper limit of gas pressure in calibration

cell is 50kPa in gauge pressure.

2

3

Approx.

14 kg

● UnitConnectionCable

Use for interconnecting the Sensor Control Unit and the

Laser Unit.

Construction:

Note: When cable length is not more than 25m, Belden

Double-shielded (Overall shield and

Individual shields) 4-pair cable

Part No. Cable length

K9775XA 5 m

K9775XB 10 m

K9775XC 20 m

K9775XD 30 m

K9775XE 40 m

K9775XF 50 m

K9775XG 60 m

1475A may be used as Unit Connection Cable.

All Rights Reserved. Copyright © 2015, Yokogawa Electric Corporation GS 11Y01D01-01EN

Aug 28, 2020-00

Page 11

n MODEL AND CODES

● TDLS8000TunableDiodeLaserSpectrometer

Model SuxCode Option Code Description

TDLS8000 ..................................... ....................... Tunable Diode Laser Spectrometer

Type -G1

-G2

-GQ

-GR

-D2

-C2

-S2

-E2

-K2

-N2

-Q2

-R2

-D1

-C1

-S1

-E1

-J1

-J2

-Q1

-R1

Gas Parameter -X1

-X2

-C1

-C2

-C3

-C4

-C5

-A1

-S1

-D1

-D5

-H1

-H3

-H4

-L1

Optics Accessory -NN

-LA

-U2

-U3

-U4

-D5

-D8

-J5

-J8

-FC

I/O Interface -A1 ....................... Analog with HART+Modbus Ethernet

SI Unit -J

— -N ....................... Always -N

Option /D

*1: Type “-D1”, “-C1”, “- S1”, “-E1”, “-J1”, “-Q1”, “-R1” cannot be selected with “-H1” or “-H3”.

*2: When the process gas pressure is out of 90 to 130 kPa (abs.) or the process gas contains CO2 ≥ 40 % or H2 ≥ 20 % as

coexisting gas components, please contact YOKOGAWA.

*3: When CO or CH4 ingredient coexist, please contact YOKOGAWA.

*4: When “-NN” is selected, Zone2/Div2/Type of protection “n”, FM (Canada) Zone1 is not available.

-N

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

......................

......................

......................

.......................

.......................

......................

......................

......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

/RX

/RC

/SCT

/JA1

/JB3

/JB4

/JC1

/JD1

/JE3

/JE4

General Purpose, cable entry/piping:NPT

General Purpose, cable entry:Metric thread, piping:Rc

EAC with PA General Purpose, cable entry:Metric thread, piping:Rc

EAC General Purpose, cable entry:Metric thread, piping:Rc

FM (US) Class I Div 2, Zone2, cable entry/piping:NPT

FM (Canada) Class I Zone2, cable entry/piping:NPT

ATEX Type of protection “n”, cable entry:Metric thread, piping:Rc

IECEx Type of protection “n”, cable entry:Metric thread, piping:Rc

Korea Ex Type of protection “n”, cable entry:Metric thread, piping:Rc

NEPSI Type of protection “n”, cable entry:Metric thread, piping:Rc

EAC with PA Type of protection “n”, cable entry:Metric thread, piping:Rc

EAC Type of protection “n”, cable entry:Metric thread, piping:Rc

FM (US) Class I Div 1, Zone1, cable entry/piping:NPT (*1)

FM (Canada) Class I Zone1, cable entry/piping:NPT (*1)

ATEX Flameproof ”d”, cable entry:Metric thread, piping:Rc (*1)

IECEx Flameproof “d”, cable entry:Metric thread, piping:Rc (*1)

Japan Ex / Zone 1, cable entry:Metric thread, piping:Rc (*1) (*11)

Japan Ex / Zone 2, cable entry:Metric thread, piping:Rc (*11)

EAC with PA Flameproof “d”, cable entry:Metric thread, piping:Rc (*1)

EAC Flameproof “d”, cable entry:Metric thread, piping:Rc (*1)

O2 < 600°C, 0-25% (*2)

O2 < 1500°C, 0-25% Combustion

CO (%) 0-20%/0-50% <500°C

CO ppm 0-200ppm/0-10,000ppm <500°C (*3)

CO ppm <1500°C Combustion (*3)

CO ppm <1500°C or CH4 0-5% Combustion (*3)

CO (%) + CO2(%) 0-30%/0-100% <150°C

NH3 up to 0-5,000ppm <450°C DeNOX

H2S 0-5%/0-100% <100°C (*2)

CO2 High Range 0-1%/0-5% <100°C

CO2 Extend. Range 0-30/0-50% <150°C

H2O ppm non-Hydrocarbon Background (*1)

H2O ppm Hydrocarbon Background (*1)

H2O 0-10%/0-100% <500°C (*2)

HCl 0-50ppm/0-5,000ppm <500°C

Without Alignment Flanges (*4)

Large Aperture Optics, ANSI CLASS150-4-RF (*5) (*6)

ANSI CLASS150-2-RF(Eq.) Alignment Flange, pipng: NPT

ANSI CLASS150-3-RF(Eq.) Alignment Flange, pipng: NPT

ANSI CLASS150-4-RF(Eq.) Alignment Flange, pipng: NPT

DIN PN16-DN50-D(Eq.) Alignment Flange, pipng: Rc

DIN PN16-DN80-D(Eq.) Alignment Flange, pipng: Rc

JIS 10K-50-FF(Eq.) Alignment Flange, pipng: Rc

JIS 10K-80-FF(Eq.) Alignment Flange, pipng: Rc

Flow Cell Alignment Flange (*6)

Only SI Unit

SI Unit or non SI Unit (*7)

Diverging Beam without LAO (*8)

Reference Cell for O2 (*9)

Reference Cell for CO (*10)

Stainless Steel Tag Plate

Cable gland for Japan Ex “-J1” (Cable O.D. 8-12mm, G1/2) 1pc, for local HMI

Cable gland for Japan Ex “-J1” (Cable O.D. 10-16mm, G3/4) 3 pcs

Cable gland for Japan Ex “-J1” (Cable O.D. 10-16mm, G3/4) 4 pcs

Cable gland for Japan Ex “-J2” (Cable O.D. 6-9.5mm, M20) 1pc, for local HMI

Cable gland for Japan Ex “-J2” (Cable O.D. 8.5-13.4mm, M20) 1pc, for local HMI

Cable gland for Japan Ex “-J2” (Cable O.D. 9.5-15.4mm, M25) 3 pcs

Cable gland for Japan Ex “-J2” (Cable O.D. 9.5-15.4mm, M25) 4 pcs

11

All Rights Reserved. Copyright © 2015, Yokogawa Electric Corporation GS 11Y01D01-01EN

Aug 28, 2020-00

Page 12

*5: For applications whose optical path length is 6 m or longer, select the “-LA”. A condensing lens unit (LAO unit) is added to

the SCU side.

“-LA” can be selected when Oxygen or CO (-C2, -C3, -C4) analyzer is selected.

“-LA” can be selected with Zone 1/Div.1/Flameproof “d” when Gas Parameter “-X2”, “-C3”, “-C4” is selected.

*6: When FM (US) or FM (Canada) is specied, the connecting port for window purge is 1/4NPT.

When ATEX, IECEx, Korea Ex, NEPSI, EAC or Japan Ex is specied, the connecting port for window purge is Rc1/4.

*7: Available only to an end user located outside of Japan.

*8: The Option “/D” can be selected when Large Aperture Optics “-LA” of the Optic Accessory is not specied and Oxygen or

CO (-C2, -C3, -C4) analyzer is selected.

*9: The Option “/RX” can be used when Oxygen analyzer is selected. When both “-X2” of the Gas Parameter and “-LA” of the

Optics Accessory are selected, “/RX”must be specied.

*10: The Option “/RC” can be used when CO analyzer is selected. When both “-C3” or “-C4”of the Gas Parameter is selected,

“/RC” must be specied.

*11: For Japan Ex model (TDLS8000-J1, TDLS8000-J2), specied cable glands shall be attached to each cable entry for wiring.

Select one cable gland out of two types: (/JB3 or /JB4 for “-J1”, /JE3 or /JE4 for “-J2”). If you need, specify (/JA1 for “-J1”, /

JC1 or /JD1 for “-J2”) as well. For detailed information, refer to Japanese General Specications.

The Option “/JA1”, “/JB3” and “/JB4” can be used only when Japan Ex/Zone 1 model (TDLS8000-J1) is selected.

The Option “/JC1”, “/JD1”, “/JE3” and “/JE4” can be used only when Japan Ex/Zone 2 (TDLS8000-J2) model is selected.

If “/JA1”, “/JB3”, “/JB4”, “/JC1”, “/JD1”, “/JE3” or “/JE4” is necessary for other model, please contact Yokogawa.

● YH8000HMIUnit

Model SuxCode Option Code Description

YH8000 ...................... ....................... HMI Unit

Type -G1

Language -E ....................... English and 9 languages (*1)

— -N ....................... Always -N

Option /M

*1: These languages are message languages on the display.

One analyzer has English and 9 languages.

All languages are as follows; English, German, French, Spanish, Portuguese, Russian, Hungarian, Korean, Chinese and Japanese.

*2: For Japan Ex/Zone 2 certied model (YH8000-J2), specied cable glands shall be attached to each cable entry for wiring.

Select the Option “/JA1” or “/JA2”.

For detailed information, refer to Japanese General Specications (GS 11Y01D01-01JA).

The Option “/JA1” and “/JA2” can be used only when Japan Ex/Zone 2 certied model (YH8000-J2) is selected. If “/JA1” or

“/JA2” is necessary for other model, please contact Yokogawa.

*3: /M cannot be selected with TDLS8000 Type “-D1”, “-C1”, “-S1”, “-E1”, “-J1”, “-Q1” “-R1”.

-G2

-GR

-D2

-C2

-S2

-E2

-J2

-K2

-N2

-R2

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

/P

/W

/S

/C

/SCT

/JA1

/JA2

General Purpose, NPT thread for cable entry

General Purpose, Metric thread for cable entry

EAC General Purpose, Metric thread for cable entry

FM (US) Class I Div 2, Zone2, NPT thread for cable entry

FM (Canada) Class I Zone2, NPT thread for cable entry

ATEX Type of protection “n”, Metric thread for cable entry

IECEx Type of protection “n”, Metric thread for cable entry

Japan Ex/Zone 2, Metric thread for cable entry (*2)

Korea Ex Type of protection “n”, Metric thread for cable entry

NEPSI Type of protection “n”, Metric thread for cable entry

EAC Type of protection “n”, Metric thread for cable entry

Mounting kit for TDLS8000 series (*3)

Pipe mount

Wall mount

Sun Shield

Local HMI connection cable: 3m

Stainless Steel Tag Plate

Cable gland for Japan Ex (Cable O.D. 8-12mm, G1/2), 1 pc(*2)

Cable gland for Japan Ex (Cable O.D. 8-12mm, G1/2), 2 pc(*2)

12

All Rights Reserved. Copyright © 2015, Yokogawa Electric Corporation GS 11Y01D01-01EN

Aug 28, 2020-00

Page 13

● IF8000IsolationFlanges

Model SuxCode Option Code Description

IF8000 .................................................. ....................... Isolation Flange for TDLS8000 (2pcs/unit) (*1)

Process

Connection

(*2)

Analyzer Connection

(*3)

Material -MN

Sapphire Window Type -12

— -N ....................... Always -N

*1: IF8000 is delivered with two sets (for LU and SCU).

*2: When ANSI ange of the Process Connection is selected, the “-21” of Analyzer Connection must be specied.

When DIN or JIS of the Process Connection is selected, the “-50” of Analyzer Connection must be specied.

*3: The Analyzer Connection must be selected according to the ange size of TDLS8000.

-21

-23

-31

-33

-41

-50

-80

-J5

-J8

-21

-50

-SS

-13

-14

-15

-16

-17

-18

-20

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

ANSI CLASS150-2-RF(Eq.)

ANSI CLASS300-2-RF(Eq.)

ANSI CLASS150-3-RF(Eq.)

ANSI CLASS300-3-RF(Eq.)

ANSI CLASS150-4-RF(Eq.)

DIN PN16-DN50-D(Eq.)

DIN PN16-DN80-D(Eq.)

JIS 10K-50-FF(Eq.)

JIS 10K-80-FF(Eq.)

ANSI CLASS150-2-RF(Eq.)

DIN PN16-DN50-D(Eq.)

Monel 400

316/316L SS

Coated for O2 (-X1, -X2)

Coated for ppm H2O non Hydrocarbon background (-H1)

Coated for ppmNH3 (-A1)

Coated for ppm H2O Hydrocarbon background (-H3)

Coated for ppm CO (-C2, -C3, -C4)

Coated for % CO or % CO2 (-C5, -D5)

Coated for HCl (-L1)

Coated for -C1, -D1, -H4, -S1

13

● YC8000FlowCell

Model SuxCode Option Code Description

YC8000 ........................................................................ ....................... Flow Cell for TDLS8000

Flow Cell Type -EN ....................... Enhanced

Optical Path Length -40

-60

Material -MN

-SS

Port Conguration -3 ....................... 3 ports

Window Type -XX

-H3

-HH

-NH

-CC

-C2

-HC

-MC

Inside Wall Treatment -NN

-EP

— -N ....................... Always -N

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

.......................

Forty Inches

Sixty Inches

Monel 400

316/316L SS

Oxygen (-X1, -X2)

Moisture Hydrocarbon background (-H3)

Moisture non Hydrocarbon background (-H1)

NH3 (-A1)

ppm CO (-C2, -C3, -C4)

CO%+CO2% (-C5, -D5)

HCl (-L1)

-C1, -D1, -H4, -S1

No treatment (cleaned)

Electro-polish

All Rights Reserved. Copyright © 2015, Yokogawa Electric Corporation GS 11Y01D01-01EN

Aug 28, 2020-00

Page 14

14

n EXTERNAL DIMENSIONS

For the external dimensions of Japan Ex model (TDLS8000-J1, TDLS8000-J2, YH8000-J2), see Japanese General

Specications (GS 11Y01D01-01JA).

TDLS8000 with Alignment Flange

● LU

237

33

80

200

Ø180

33

198

SCU cable gland

3/4NPT or M25x1.5

Purge port (IN)

1/4NPT or Rc1/4

332

17

20

Flow restrictor *2

*1: The alignment flange varies according to specifications.

Other flanges may be added.

*2: The flow restrictors are attached in the case of

type -D1, -C1, -S1, -E1, -J1, -Q1 or -R1.

Purge port (OUT) x2

1/4NPT or Rc1/4

Alignment flange *1

Unit: mm

Measured

gas

34

All Rights Reserved. Copyright © 2015, Yokogawa Electric Corporation GS 11Y01D01-01EN Aug 28, 2020-00

Page 15

● SCU

15

Alignment

flange *1

Measured

gas

Purge port (OUT) x2

1/4NPT or Rc1/4

*1: The alignment flange varies according to specifications.

Other flanges may be added.

*2: The flow restrictors are attached in the case of

type -D1, -C1, -S1, -E1, -J1, -Q1 or -R1.

17

20

Flow restrictor *2

332

LU cable gland

3/4NPT or M25x1.5

For I/O signal

3/4NPT or M25x1.5

For power supply

3/4NPT or M25x1.5

1/2NPT or M20x1.5

Purge port (IN)

1/4NPT or Rc1/4

Unit: mm

198

62

196

Ø180

65

For YH8000

237

33

80

● Maintenance space

150

150 150

250

34

Unit: mm

600

All Rights Reserved. Copyright © 2015, Yokogawa Electric Corporation GS 11Y01D01-01EN

Aug 28, 2020-00

Page 16

● Alignment Flange

16

Purge port (IN) x2

1/4NPT or Rc1/4

TDLS8000 side

Optics Accessory code

(ange)

-U2 ANSI CLASS150-2-RF(Eq.) 4 19 120.7 19.5 150 87 1/4NPT

-U3 ANSI CLASS150-3-RF(Eq.) 4 19 152.4 24.3 190 92 1/4NPT

-U4 ANSI CLASS150-4-RF(Eq.) 8 19 190.5 23.9 228.6 92 1/4NPT

-D5 DIN PN16-DN50-D(Eq.) 4 18 125 18 165 86 Rc1/4

-D8 DIN PN16-DN80-D(Eq.) 8 18 160 20 200 88 Rc1/4

-J5 JIS 10K-50-FF(Eq.) 4 19 120 16 155 84 Rc1/4

-J8 JIS 10K-80-FF(Eq.) 8 19 150 18 185 86 Rc1/4

Hole QTYQHolehHole P.C.DCThicknesstOutside dia.DDistance

A (variable)

t

Q - h

ØD

Process side

Unit: mm

ØC

A

Ø61.7

Purge port

● LAO(LargeApertureOptics);OpticsAccessorycode“-LA”

This accessory is only for SCU side. For LU side, the Alignment ange ANSI CLASS150-4-RF (Eq.) will be mounted.

When piping is Rc1/4, a conversion adapter will be attached on the Alignment ange of the LU side.

Ø190.5

Instalation for process side

Ø108.2

Process side

8-Ø19 holes

Ø229

55

23.9

189 (Variable)

Purge port (IN) x2

1/4NPT or

Rc1/4 (with adapter)

TDLS8000 side

Unit: mm

All Rights Reserved. Copyright © 2015, Yokogawa Electric Corporation GS 11Y01D01-01EN

Aug 28, 2020-00

Page 17

■ YH8000HMIUnit

17

261

204

Earth terminal

MountingkitforTDLS8000series(Optioncode:/M)

261

Cable entry 2 (for Modbus)

1/2NPT or M20x1.5

65

75

87.5

Cable entry

1/2NPT or M20x1.5

185

75

4 - M6 depth 13

1 (for TDLS8000 series)

Unit: mm

Unit: mm

337

440

(198)

Front mounting

302

(198)

(200)

Right mounting

Available for left mounting

All Rights Reserved. Copyright © 2015, Yokogawa Electric Corporation GS 11Y01D01-01EN

Aug 28, 2020-00

Page 18

Pipemount(Optioncode:/P)

18

261

138

123

102

204 65 110

108.3

54.3

87.5

SunShield(Optioncode:/S)

197

318

46.3

Bracket

for pipe mount

2B pipe

Vertical or horizontal mounting

46.3

31

Stud for

sun shield

Bracket

for pipe mount

Unit: mm

Unit: mm

212.5

178

Wallmount(Option code:/W)

10

266

10

226 206 206

4 - Ø7.2 holes

*: The wall construction for mounting has to be designed for 4 times the weight of the YH8000.

Bracket for wall mount can be placed in lengthwise

105.4246

Bracket for wall mount

±0.5

2B pipe

Vertical or horizontal mounting

Unit: mm

246±0.5

4 - Ø6.0 to 7.2 holes

or M6

Installation for wall

All Rights Reserved. Copyright © 2015, Yokogawa Electric Corporation GS 11Y01D01-01EN

Aug 28, 2020-00

Page 19

SunShield(Optioncode:/S)

19

318

246

10

266

246

4 - Ø7.2 holes

When the sun shield is mounted, the bracket for wall have to be placed in widthwise.

20610

■ IF8000IsolationFlanges

Nut

5/8UNC, 3/4UNC

or M16

196

30

Bracket for wall mount

246

±0.5

Installation for wall

Q - h

Unit: mm

206±0.5

4 - Ø6.0 to 7.2 holes

or M6

Unit: mm

ØC

Ø38

ØD

t

L

TDLS8000 side

Process Connection code

(ange)

-21 ANSI CLASS150-2-RF(Eq.)

-23 ANSI CLASS300-2-RF(Eq.) 8

-31 ANSI CLASS150-3-RF(Eq.) 4

-33 ANSI CLASS300-3-RF(Eq.) 8

-41 ANSI CLASS150-4-RF(Eq.) 8

-50 DIN PN16-DN50-D(Eq.)

-80 DIN PN16-DN80-D(Eq.) 8 18 160 41.6 200 137

-J5 JIS 10K-50-FF(Eq.) 4 19 120 40.6 165 139

-J8 JIS 10K-80-FF(Eq.) 8 19 150 40.6 185 139

Process side

Analyzer Connection

code(ange)

ANSI

-21

CLASS150-2RF(Eq.)

DIN PN16-

-50

DN50-D(Eq.)

Hole QTYQHole

4

4 18

Purge port (IN) x2

1/4NPT or Rc1/4

Nut

h

19

5/8UNC

19

19

22 3/4UNC

19 5/8UNC

M16

Hole P.C.DCThicknesstOutside dia.DBolt lengthLPurge

120.7 39.6 150 127

127 39.6 165 137

152.4 39.6 190 137

168.3 39.6 210 146

190.5 39.1 228.6 137

125 41.6 165 137

Instalation for process side

port

1/4NPT

Rc1/4

All Rights Reserved. Copyright © 2015, Yokogawa Electric Corporation GS 11Y01D01-01EN

Aug 28, 2020-00

Page 20

■ YC8000FlowCell

TDLS8000 have to be assigned the dedicated Alignment ange (Optic Accessory: -FC).

When piping is Rc1/4, a conversion adopter will be attached on the Alignment ange.

20

86 (vaeiable)

1053 (Optical path length: -40) or 1561 (Optical path length: -60)

Pipe size: 1-1/2 Sch80

Sample inlet

35

(for 1/4” pipe)

Gas temp. or

pressure measurement port

(for 1/4” pipe)

Sample outlet

(for 1/4” pipe)

Ø152.4

Ø152.4

Flow cell aligenment

flange

(TDLS8000

Optics accessory

code “-FC”)

Unit: mm

■ CalibrationCell

Part number: K9772XA, K9772XB, K9772XC, K9772XD, K9772XE, K9772XF, K9772XG, K9772XH, K9772XJ,

K9772XL, K9772XM

Approx. 690

Sample port x2 (IN, OUT) 1/4NPT

Ø152.4

Unit: mm

Pipe size: 1-1/2 Sch80

Approx. 820

■ UnitConnectionCable

Part number: K9775XA, K9775XB, K9775XC, K9775XD, K9775XE, K9775XF, K9775XG

Ø13.5

L

L = 5, 10, 20, 30, 40, 50, 60 m

Approx.

410

210

Unit: mm

All Rights Reserved. Copyright © 2015, Yokogawa Electric Corporation GS 11Y01D01-01EN

Aug 28, 2020-00

Page 21

n WIRING

Wiring Laser Unit and Sensor Control Unit

Terminal A

21

Sensor Control Unit (SCU)Laser Unit (LU)

Ethernet port for

YH8000 or DCS

Terminal B

Terminal C

Earth for shield wire

Magnified Terminal A

LC MS-1 MS-2 VO

+-+-+

Connect to shield wire terminal

(Both side of cable)

Earth terminal

-

-

+

Earth for shield wire

Earth terminal

Magnified Terminal B

AO-1 AO-2 AI-1 AI-2 DI-1 DI-2 DO FAULT

-

+

+-+-+-+-+

Isolated

4-20mA

Output

-

+-+

4-20mA

Input for

Pressure

transmitter

4-20mA

Input for

Temperature

transmitter

-

Digital Input

+-+

Solenoid

Valve

Control for

Auto Cal

Solenoid

Valve

Control for

Auto Cal

Isolated

4-20mA

Output

With

HART

Magnified Terminal C

LC MS-1 MS-2 VO SV-1 SV-2

+-+

POWER

-

NC

-

+

Power

Supply

24V DC

COM

NO NC

COM

Digital

Output for

Digital

Output for

programmable

DO

-

FAULT

VO (HMI)

- -

+ +

24V DC Output for

YH8000 Power

All Rights Reserved. Copyright © 2015, Yokogawa Electric Corporation GS 11Y01D01-01EN

Aug 28, 2020-00

Page 22

Wiring the YH8000 HMI UNIT

LocalHMIconguration

22

Ethernet port

for DCS

Ethernet port

for TDLS8000 Series

Port1 Port2

Connection for power

Earth for shield wire

Modbus/TCP communication with DCS

Port1 Port2

w

e

-

P

o

-

+

r

+

Connect to shield wire terminal

Ethernet communication with TDLS8000 Series

24V DC power from TDLS8000 Series

• Connection cable between TDLS8000 Series and YH8000 must be use special cable which can be specied option code

“/C.”

• Maximum cable length between TDLS8000 Series and YH8000 is 3m.

• Maximum cable length between YH8000 and DCS is 100m.

RemoteHMIconguration

Ethernet communication with TDLS8000 Series

via switching HUB

Port1 Port2

-

P

o

-

w

+

e

r

+

24V DC power

Connect to shield wire terminal

• Maximum cable length between YH8000 and Switching HUB is 100m.

All Rights Reserved. Copyright © 2015, Yokogawa Electric Corporation GS 11Y01D01-01EN Aug 28, 2020-00

Page 23

23

TDLS8000 Tunable DiodeLase Gas Analyzer Inquiry Form

Thank you for your inquiry about our TDLS8000 Tunable Diode Laser Gas Analyzer. Please make inquiries by placing

checkmarks in the appropriate boxes and lling in the blanks. (The items with check mark and descriptions previously

lled on the underlines are xed requirements.)

1. GeneralInformation

Company :

Address :

Contact Person :

Email :

Telephone :

Fax :

Requested delivery date (day/month/year) :

Plant name :

Brief Description of application :

2. InstallationDetails(checkone-see drawing)

Cross Stack/Pipe. For measurement across the process.

Path length

Process Connection

Bypass Leg. Measurement across bypass leg located at process measurement point.

Path length

Process Connection

Extractive. Sample is extracted and transported (by others) to analyzer.

3. Analyzer Options:

YH8000 HMI Unit IF8000 Isolation Flanges YC8000 Flow Cell

Calibration Cell Unit Connection Cable

Cable length from Analyzer Unit to HMI Unit (specify units) :

Area Classication:

Ambient Temperature (Min-Max.) Specify units

4. Process Wetted Materials

Must Use

Must Not Use

5. StreamComposition(1sheetperstreamanalyzed)

Component Concentrations Units Measured

Name Min. Typ. Max. ppm(v)/vol% Yes/No

Range

If Measured

All Rights Reserved. Copyright © 2015, Yokogawa Electric Corporation GS 11Y01D01-01EN

Aug 28, 2020-00

Page 24

6. Physical Properties

Units Min. Typ. Max.

Temperature

Pressure

Dew Point

Water Vapor

Flow

Velocity

Particulate Concentration

Installation location: Indoor Outdoor

Ambient temperature: to ºC

7. General Application & Installation Notes/Comments:

24

All Rights Reserved. Copyright © 2015, Yokogawa Electric Corporation GS 11Y01D01-01EN

Subject to change without notice.

Aug 28, 2020-00

Loading...

Loading...