Page 1

User’s

Manual

TDLS200

Tunable Diode Laser Spectroscopy Analyzer

Start-up Manual

IM11Y01B01-11E-A

Yokogawa Corporation of America

Yokogawa Corporation of America

2 Dart Road, Newnan, Georgia U.S.A. 30265

Tel: 1-800-258-2552 Fax: 1-770-254-0928

IM11Y01B01-11E-A

5th Edition

Page 2

Blank Page

IM 11Y01B02-11E-A 5th Edition :June 5, 2012-00

Page 3

i

Introduction

Thank you for purchase the TDLS200 Tunable Diode Laser Analyzer. Please read the following respective

documents before installing and using the TDLS200.

Notes on Handling User’s Manuals

• This manual should be passed on to the end user.

• The contents of this manual are subject to change without prior notice.

• The contents of this manual shall not be reproduced or copied, in part or in whole, without permission.

• This manual explains the functions contained in this product, but does not warrant that they are suitable

for the particular purpose of the user.

• Every effort has been made to ensure accuracy in the preparation of this manual. However, when you

realize mistaken expressions or omissions, please contact the nearest Yokogawa Electric representative

or sales offi ce.

• This manual does not cover the special specifi cations. This manual may be left unchanged on any

change of specifi cation, construction or parts when the change does not affect the functions or

performance of the product.

• If the product is not used in a manner specifi ed in this manual, the safety of this product may be

impaired.

Yokogawa is not responsible for damage to the instrument, poor performance of the instrument or losses

|resulting from such, if the problems are caused by:

• Improper operation by the user.

• Use of the instrument in improper applications

• Use of the instrument in an improper environment or improper utility program

• Repair or modifi cation of the related instrument by an engineer not authorized by Yokogawa.

Drawing Conventions

Some drawings may be partially emphasized, simplifi ed, or omitted, for the convenience of description.

Some screen images depicted in the user’s manual may have different display positions or character types

(e.g., the upper / lower case). Also note that some of the images contained in this user’s manual are display

examples.

Media No. IM 11Y01B01-11E-A 5th Edition :June. 2012 (YCA)

All Rights Reserved Copyright © 2012, Yokogawa Corporation of America

IM 11Y01B01-11E-A 5th Edition :June 5, 2012-00

Page 4

ii

Safety Precautions

Safety, Protection, and Modifi cation of the Product

• In order to protect the system controlled by the product and the product itself and ensure safe operation,

observe the safety precautions described in this user’s manual. We assume no liability for safety if users

fail to observe these instructions when operating the product.

• If this instrument is used in a manner not specifi ed in this user’s manual, the protection provided by this

instrument may be impaired.

• If any protection or safety circuit is required for the system controlled by the product or for the product

itself, prepare it separately.

• Be sure to use the spare parts approved by Yokogawa Electric Corporation (hereafter simply referred to

as YOKOGAWA) when replacing parts or consumables.

• Modifi cation of the product is strictly prohibited.

• The following safety symbols are used on the product as well as in this manual.

DANGER

This symbol indicates that an operator must follow the instructions laid out in this manual in

order to avoid the risks, for the human body, of injury, electric shock, or fatalities. The

manual describes what special care the operator must take to avoid such risks.

WARNING

This symbol indicates that the operator must refer to the instructions in this manual in order

to prevent the instrument (hardware) or software from being damaged, or a system failure

from occurring.

CAUTION

This symbol gives information essential for understanding the operations and functions.

Note!

This symbol indicates information that complements the present topic.

This symbol indicates Protective Ground Terminal

"

#

Warning and Disclaimer

The product is provided on an “as is” basis. YOKOGAWA shall have neither liability nor responsibility to any

person or entity with respect to any direct or indirect loss or damage arising from using the product or any

defect of the product that YOKOGAWA cannot predict in advance.

IM 11Y01B02-11E-A 5th Edition :June 5, 2012-00

Page 5

iii

TDLS200

CAUTION

SAFETY should be considered fi rst and foremost importance when working on the equipment described in this

manual. All persons using this manual in conjunction with the equipment must evaluate all aspects of the task

for potential risks, hazards and dangerous situations that may exist or potentially exist. Please take appropriate

action to prevent ALL POTENTIAL ACCIDENTS.

AVOID SHOCK AND IMPACT TO THE ANALYZER THE LASERS CAN BE PERMANENTLY DAMAGED

Laser Safety & Classifi cation according to FDA Regulations. The TDLS200 is Registered with the United States

FDA as a Laser Product.

WARNING

THIS ANALYZER CONTAINS A LASER PRODUCT THAT IS GENERALLY IN ACCORDANCE WITH THE REGULATIONS FOR THE ADMINISTRATION AND ENFORCEMENT OF THE RADIATION CONTROL FOR HEALTH AND

SAFETY ACT OF 1968 (TITLE 21, CODE OF FEDERAL REGULATIONS, SUBCHAPTER J). REFER SECTION

1002.10 OF THE REGULATIONS REFERENCED ABOVE.

CAUTION INVISIBLE LASER RADIATION AVOID DIRECT EXPOSURE

MAXIMUM OUTPUT POWER < 1 MW (Oxygen)

MAXIMUM OUTPUT POWER < 20 mW (other Gases) DURING NORMAL OPERATION THIS ANALYZER IS:

CLASS I LASER PRODUCT (according to IEC 60825-1)

CAUTION

The Instrument is packed carefully with shock absorbing materials, nevertheless, the instrument may be

damaged or broken if subjected to strong shock, such as if the instrument is dropped. Handle with care.

Warranty and service

Yokogawa products and parts are guaranteed free from defects in workmanship and material under normal use

and service for a period of (typically) 12 months from the date of shipment from the manufacturer. Individual

sales organizations can deviate from the typical warranty period, and the conditions of sale relating to the original purchase order should be consulted. Damage caused by wear and tear, inadequate maintenance, corrosion,

or by the effects of chemical processes are excluded from this warranty coverage.

In the event of warranty claim, the defective goods should be sent (freight paid) to the service department of the

relevant sales organization for repair or replacement (at Yokogawa discretion). The following information must be

included in the letter accompanying the returned goods:

• Part number, model code and serial

• Number

• Original purchase order and date

• Length of time in service and a description of the process

• Description of the fault, and the circumstances of failure

• Process/environmental conditions that may be related to the failure of the device.

• A statement whether warranty or nonwarranty service is requested

• Complete shipping and billing instructions for return of material, plus the name and phone number of a

contact person who can be reached for further information.

Returned goods that have been in contact with process fl uids must be decontaminated/ disinfected before

shipment. Goods should carry a certifi cate to this effect, for the health and safety of our employees. Material

safety data sheets should also be included for all components of the processes to which the equipment has

been exposed.

IM 11Y01B02-11E-A 5th Edition :June 5, 2012-00

Page 6

iv

DANGER

Dont install “general purpose type” instruments in the hazardous area.

CAUTION

The intrument is packed carefully with shock absorbing materials, nevertheless, the instrument may be damaged

or broken if subjected to strong shock, such as if the instrument is dropped. Handle with care.

IM 11Y01B02-11E-A 5th Edition :June 5, 2012-00

Page 7

TOC-1

Model TDLS200

Tunable Diode Laser Spectroscopy Analyzer

Start-up Manual

IM 11Y01B01-11E-A 5th Edition

CONTENTS

Introduction .......................................................................................................................................................... i

Safety Precutions ............................................................................................................................................... ii

1 Instrument Check ......................................................................................................................................1-1

2 Quick Start ................................................................................................................................................2-1

3 Installation and Wiring .............................................................................................................................3-1

3.1 Process Measurement Point Considerations .....................................................................................3-1

3.2 Position of Process Flanges for Launch and Detect Units .................................................................3-2

3.3 Process Flange Welding Alignment and Line-Up ...............................................................................3-4

3.4 Process Flange Clear Aperture ...........................................................................................................3-5

3.5 Mounting the Launch and Detect Units to the Process Flange .........................................................3-5

3.5.1 Process Window Purge Gas Connection .....................................................................................3-6

3.6 Mounting the Process Interface .........................................................................................................3-6

3.7 Typical Purge Gas Confi guration, In-Situ ...........................................................................................3-7

3.8 Typical Purge Gas Confi guration, Extractive trace ppm H2O system.................................................3-7

3.9 Dimensional Drawings ........................................................................................................................3-8

3.10 Wiring Drawings ...............................................................................................................................3-15

3.11 Hazardous Area Systems .................................................................................................................3-19

3.11.1 Purging Analyzer for Hazardous Areas (with On-Line Validation) ..............................................3-20

3.11.2 Purging Analyzer for Hazardous Areas (without On-Line Validation) ..........................................3-20

3.11.3 Purging Analyzer and Universal Power Supply and/or URD for Hazardous Areas

(with On-Line Validation) .............................................................................................................3-21

3.11.4 Purging Analyzer and Universal Power Supply and/or URD (not using On-Line Validation) ......3-21

3.12 Cyclops Division 2/ zone 2 Purge Indicator, with Switch .................................................................3-22

Revison Record .................................................................................................................................................... i

IM 11Y01B02-11E-A 5th Edition :June 5, 2012-00

Page 8

1 INSTRUMENT CHECK

Upon delivery, unpack the instrument carefully and inspect it to ensure that it was not damaged during

shipment. If damage is found, retain the original packing materials (including the outer box) and then

immediately notify the carrier and the relevant Yokogawa sales offi ce.

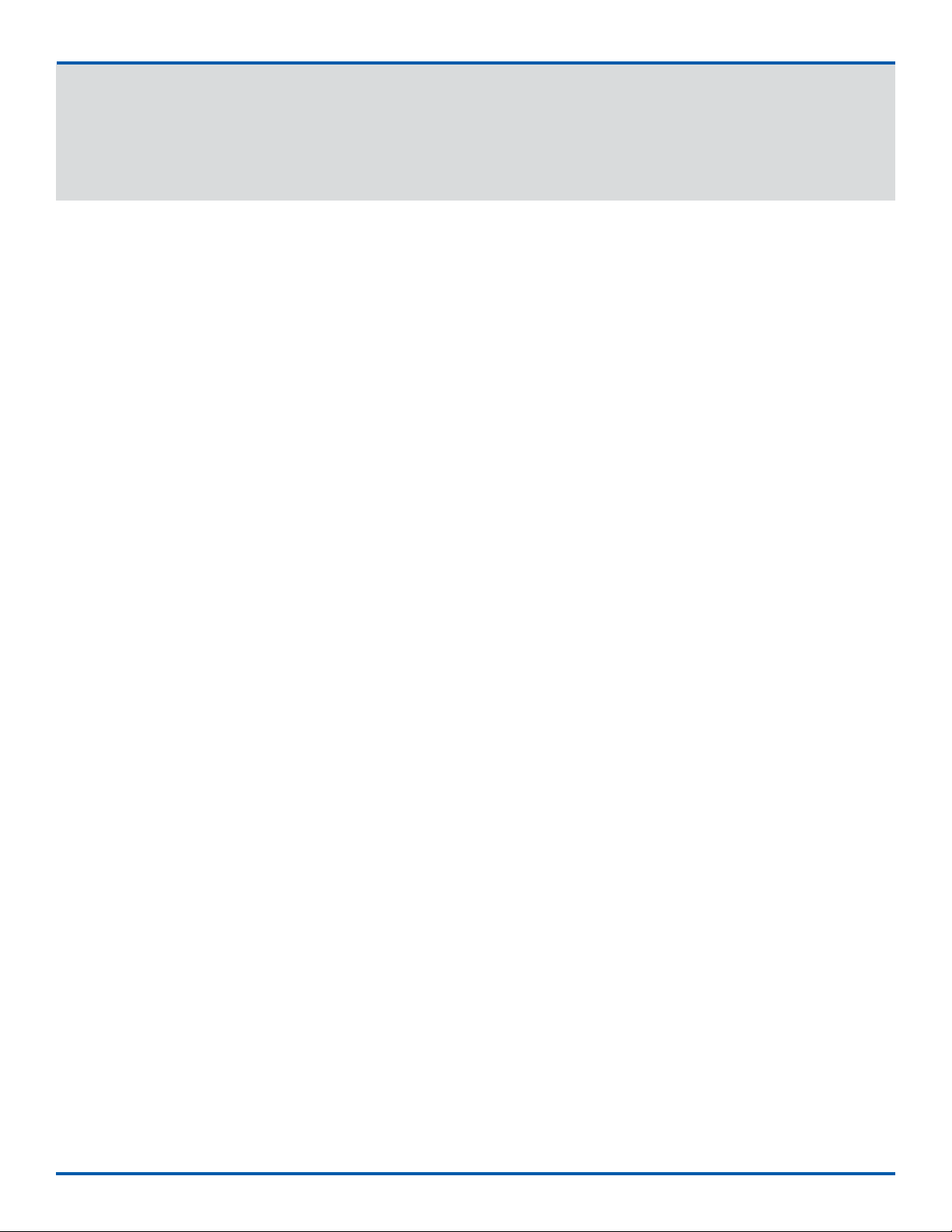

Make sure the model number on the

nameplate of the instrument agrees with your

order.

The nameplate will also contain the serial

number and any relevant certifi cation marks.

Be sure to apply correct power to the unit, as

detailed on the nameplate.

For products used within the European

Community or other countries requiring the CE

mark and/or ATEX classifi cation, the following

labels are attached (as appropriate):

1-1<1 INSTRUMENT CHECK>

For Zone 2 (CAT 3) ATEX use the following labels will be attached as appropriate:

IM 11Y01B02-11E-A 5th Edition :June 5, 2012-00

Page 9

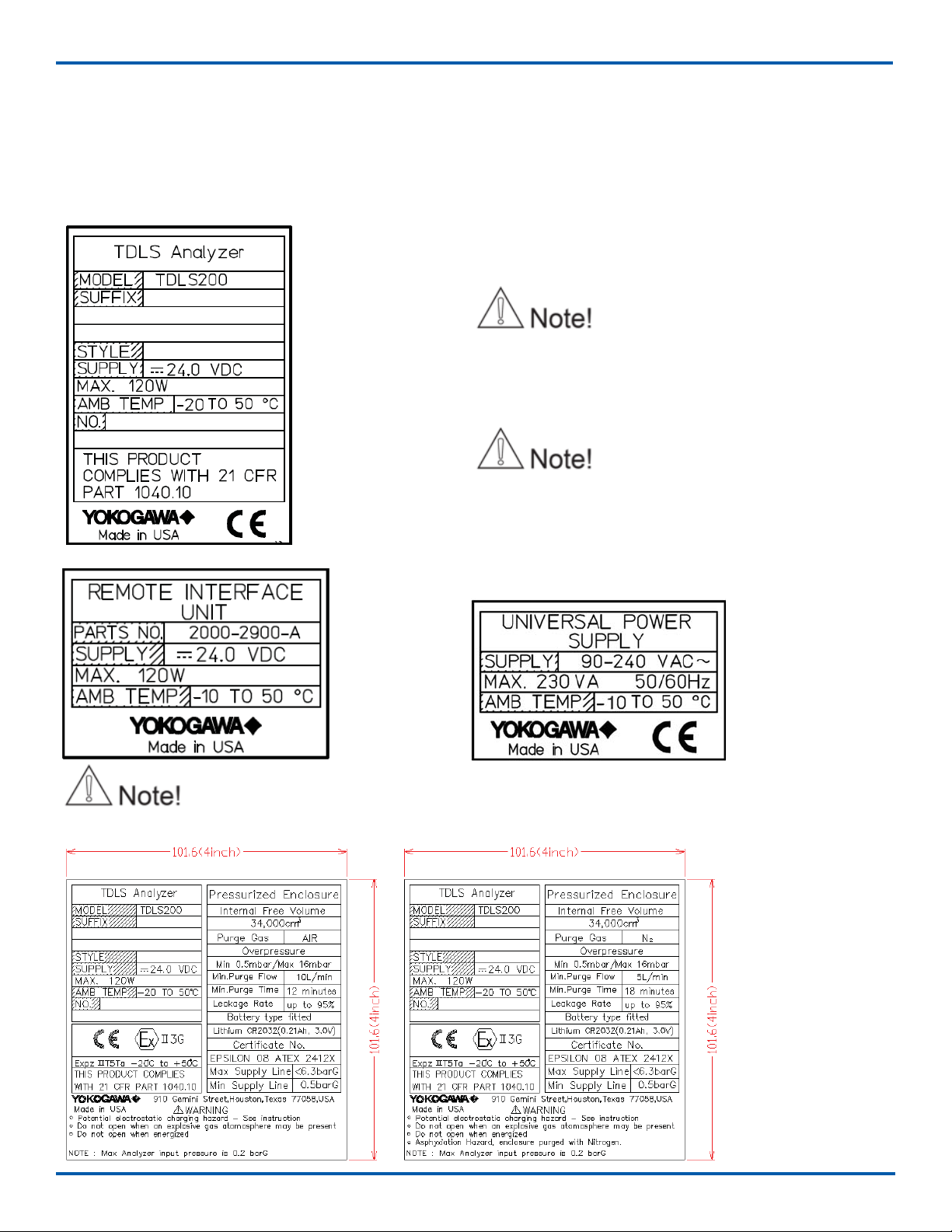

For YR-200 (Remote Interface Unit, RIU) Zone 2 (CAT 3) ATEX use the following labels will be attached

as appropriate:

1-2<1 INSTRUMENT CHECK>

CAUTION - For Cleaning of the labels and LCD window, please use wet cloth to avoid electrostatic

condition.

NOTE - ATEX Hazardous Area Operation:

Product MUST NOT be used in Zone 0 (CAT 1) locations

Product MUST NOT be used in Group I (Dust/Grain) locations

Product MUST NOT be used in Group III (Fibers) locations

Conditions of Certifi cation

On loss off purge an alarm shell be made to inform the user, action shall then be taken by the user to

ensure continued use is safe.

A functional test shall be carried out in accordance with clause 17.1 of EN 60079-2:2007 to verify the

parameters of the Purge Control Unit when fi tted.

A leakage test shall be carried out in accordance with clause 17.2 of EN 60079-2:2007. The

manufacturer shall record and retain these results.

Only Lithium batteries specifi ed in manual are to be used in this enclosure.

Special Conditions of Certifi cation:

A suitability certifi ed Purge Control Unit must be sued with the TDLS Analyzer that is capable providing

the requirements listed on label/certifi cate and that either provides a suitable exhaust through a particle

barrier of to a safe area.

When installed there shall be a minimum of two pressure regulators in the air/nitrogen supply line.

IM 11Y01B02-11E-A 5th Edition :June 5, 2012-00

Page 10

Materials of Construction

The analyzer incorporates a variety of materials in its construction and they should therefore be

used in an appropriate manner. Any chemicals (liquid or gas) that may have a detrimental effect on

the product’s structural integrity should not be allowed come in contact.

The electronic enclosures are constructed from Aluminum Alloy AL Si 12 (ASTM A413) and have a

protective epoxy powder coated surface fi nish.

The welded bodies are constructed of stainless steel grade 316

The fasteners are constructed of stainless steel grade 18-8

The windows (when fi tted) are constructed of laminated safety glass

Maintenance Work by Qualifi ed Personnel

Unqualifi ed work on the product may result in severe personal injury and/or extensive damage to

property. If the Warnings contained herein are not adhered to the result may also be severe

personal injury and/or extensive damage to property.

1-3<1 INSTRUMENT CHECK>

This product is designed such that maintenance work must be carried out by trained personnel.

Trained personnel are considered as below:

- Engineers familiar with the safety approaches of process analytical instrumentation (and/or

general automation technology) and who have read and understood the content of this

User Guide.

- Trained start-up/commissioning analyzer technicians who have read and understood the

content of this Instruction Manual.

WARNING – Battery replacement

Replacement Battery Installation (Type CR2032 located on CPU).

The battery MUST be factory installed and cannot be installed by others at site (soldered connections,

required) – Contact factory for further assistance

IM 11Y01B02-11E-A 5th Edition :June 5, 2012-00

Page 11

2-1<2 QUICK START>

2 QUCIK START

Step Title Description

1.0

1.1 Ensure the process connections match the supplied process interface.

1.2 Ensure the appropriate utilities are available and ready for connection. These may include electrical

1.3 Ensure you comply with any local and/or site specifi c safety requirements.

1.4

2.0

2.1 Attach the process interface (alignment fl anges) to the site installed fl anges (or isolation valves as

2.2 Carefully mount the Launch and Detect Units to their alignment fl anges using the quick connect

2.3 Mount optional equipment such as Universal Power Supply (UPS), Universal Remote Display (URD),

2.4

Preparation

Installation

Ambient

Temperature

3.0

3.1 Connect the appropriate electrical power supply.

3.2 Connect the Launch to Detect interconnect cable (supplied with analyzer) according to the supplied

3.3 Connect any analog I/O signals to the analog I/O Board. Outputs land on TB8 and Inputs land on TB9.

3.4 Connect any other equipment such as URD, Ethernet, solenoid valves, digital I/O, etc.

3.5

Wiring

Carefully un-pack and check equipment for any obvious damage. This includes fl anges, Cables, Power

Supplies, manuals and any other supplied options.

NOTES: There are 14 ferrules in the accessory bag for tubing-piping. The number of ferrule that are

required for actual tubing-piping are different by application. Please see tubing-piping fi gure

specifi c to project for exact detail.

power, nitrogen purge gas, instrument air, validation gas, etc.

Read the appropriate sections of the Instruction Manual BEFORE starting any installation work –

Contact Yokogawa Laser Analysis Division or Local Agent if any doubts!

If separate process isolation fl anges have been provided for corrosive service, then install to the

process/stack fl ange/isolation valves.

appropriate).

If installing Large Aperture Optics, ensure the detect system is correctly mounted and purged to

prevent damage to the large optical element.

coupling.

Remote Interface Unit (RIU), etc.

The analyzer and some accessories (such as LAO, RIU, UPS, URD, alignment fl anges, etc.) are

suitable for -20 to +50oC ambient operating temperature. Accessories and Options are available to

increase these the operating conditions – please consult Yokogawa for further details.

Ensure that all wiring will enable the analyzer launch and detect units to be freely moved from their

process location to an adjacent off-line calibration cell. This will entail the use of tray rated cables and/

or fl exible conduit and/or other suitable armored cable. Rigid conduit systems are not recommended.

• 24 VDC to TB1 on the analyzer (launch Unit) backplane. Check that the actual voltage

is >23.5VDC otherwise the SBC and other devices will not function!

• 110/240 50/60 Hz to UPS or URD, then take 24 VDC to analyzer

wiring detail (TB7 on the Launch and TB 13 on the Detect Unit).

Check terminations and ensure all cable shields are landed per supplied wiring details.

4.0

Utilities

4.1 Connect the appropriate process window purge gas (nitrogen for oxygen analyzers) and make site

4.2

4.3 Connect and check any other required utility connections (such as steam trace for heated isolation

NOTE! – All purge, Validation Gas and other gas utility lines should be thoroughly cleaned, dried

and purged prior to connecting to the analyzer

– Failure to do so can result in serious damage to the TDLS200 or contamination to the

internal optical elements.

Connect the appropriate analyzer purge gas (nitrogen for oxygen analyzers) and make site connections

per the supplied purge gas sequence details (including any Hazardous area purge system). Start the

purge gas fl ow accordingly.

ATEX purge requires dual regulators at the inlet purge gas supply to prevent overpressure damage in

the event of a single regulator failure!

connections per the supplied purge gas sequence details. Start the window purge gas fl ow

accordingly – ensuring that any isolation valves are open.

Connect the appropriate analyzer on-line check gas fl ow cell gas (nitrogen for oxygen analyzers) and

make site connections per the supplied purge gas sequence details. Start the purge gas fl ow

accordingly.

fl anges or fl ow cells) or secondary window purges for lethal service gases. Start other utilities

accordingly.

IM 11Y01B02-11E-A 5th Edition :June 5, 2012-00

Page 12

2-2<2 QUICK START>

4.4

5.0

5.1 Use the internal On-Off switch to power-up the analyzer.

5.2 Observe the various LED clusters on the backplane and FPGA boards. All blue LEDs located on the

5.3 Observe the Green power indicator on the SBC.

5.4

6.0

6.1 If there is an installed optional Mini Display (4x20 VFD) – Observe the status line message.

6.2 If there is no installed User Interface, then connect a laptop PC via Ethernet to the SBC mounted

6.3

Power-Up

Checking

Alignment

Leak-check all connections and ensure pressure ratings are not exceeded!

Apply power to the analyzer and using a multi-meter, check for 24VDC power at TB1 on the launch

unit back plane.

lower right side of the back-plane should be on.

Observe the LEDs on the analog I/O board.

If there is an installed optional 6.5” Display and Keypad – Observe the Main Menu messages and

status information.

on the backplane. Initiate the supplied VNC software from the laptop to initiate a VNC session with

the ‘blind’ analyzer and observe the analyzer Main Menu via the laptop.

At this time there may be one or more alarm message due to low transmission, out of range

parameters or other – fi nal system confi guration is still required!

Please also note that the analyzer laser temperature control is disabled for the initializing

period (5 minutes) – this means that even manual control of the laser temperature is disabled

during this period.

Initially, observe the Transmission value through the appropriate user interface. The objective is to

adjust alignment until the maximum transmission value is obtained. Perfect alignment in a clear

process gas will yield close to 100% transmission.

If the analyzer displays a Warning “Validation Required”, this indicates there is no target gas absorption peak found at start-up.

7.0

7.1 Start by adjusting the Launch unit alignment fl ange nuts up-down and left right. Look for increases

7.2 When it has been maximized at the launch side, adjust the detect unit accordingly.

7.3 Further adjustment can be made by maximizing the raw detector voltage signal (available at test

7.4

8.0

Alignment – check

Detector Gain

Confi gure

BASIC

8.1 Enter the Basic Menu and go to Confi gure.

8.2

8.3

8.4

8.5 If any other parameters are required to be set (such as analog I/O ranges, alarms levels, Auto

Optical Path

Gas Pressure

Gas Temperature

Introduce some measured gas into the optical path and re-start or perform a validation with target

gas. This will ensure that the analyzer is correctly tuned to the measurement gas absorption peak.

If this Warning cannot be cleared by either method, please contact Yokogawa Laser Analysis

Division or your local agent for further assistance.

If you have 100% certainty that the analyzer is already measuring the process gas and validation is

not currently possible then, this alarm can be cleared via the Advanced Calibrate & Validate menu.

Initially, observe the Transmission value through the appropriate user interface. The objective is

to adjust alignment until the maximum transmission value is obtained. Perfect alignment a clear

process gas will yield close to 100% transmission.

and decreases in transmission strength to aid in the alignment.

points on both launch and detect). The signal should be maximized and will not exceed 5.3V DC for

low temperature (<600C process) or 9.9V DC for high temperature (>600C process).

For Large Aperture Optics (LAO) systems, please refer to the Detector Gain Adjustment section of

this User Guide to ensure correct functionality and adjustment.

By way of the appropriate user interface, the correct process parameters and other parameters can

now be entered.

Enter in the correct optical path length.

Enter in the correct process gas pressure (if Active, see Advanced Confi gure).

Enter in the correct process gas temperature (if Active, see Advanced Confi gure).

Validation sequences) then the Advanced Menu needs to be accessed.

Advanced Menu access is Password protected and should only be used by skilled and

trained persons - Contact Yokogawa Laser Analysis Division or Local Agent if any doubts!

IM 11Y01B02-11E-A 5th Edition :June 5, 2012-00

Page 13

<2 QUICK START> 2-3

9.0

Confi gure

Using the correct password (Default 1234), enter in to the Advanced Menu, then the Confi gure.

ADVANCED

9.1 Select the desired measurement units (English or Metric selected on an individual parameter basis).

9.2

9.3

9.4

9.5 Confi gure the system I/O by entering in to the System I/O sub menu in Confi gure.

9.6 If the Analog I/O board is installed, then select Analog Output and set the appropriate 4mA and

9.7 Select what mode (Block, Track or Hold) the 4-20mA outputs are to be when the analyzer is in

9.8 Confi gure Digital outputs – Warnings and Faults. Many of these will be factory preset so if unsure

9.9

9.10 Go to the Trends screen and review/plot several of the listed parameters to check analyzer

9.11

Optical Path

Gas Pressure

Gas Temperature

Non- Process

Parameters

10.0

10.1 To Export Data, simply insert an empty USB memory stick in to a USB port on the launch unit back

Normal Operation

Enter in the correct optical path length.

Select Fixed or Active.

If Fixed, enter in the correct process gas pressure.

If Active, enter in the 4-20mA input signal range proportional to the pressure range.

“Control” mode is not applicable to TDLS200

Select Fixed or Active.

If Fixed, enter in the correct process gas temperature.

If Active, enter in the 4-20mA input signal range proportional to the temperature range.

Active ambient and Active Peaks may also be used, refer to project specifi c and application

specifi c details.

“Control” mode is not applicable to TDLS200

20mA values for Ch1 Concentration and Ch2 Transmission.

Warning, Fault and Calibration Modes.

about any settings then leave as Factory Default. Select and set level for Alarm Limit to either the

Measured Gas orTransmission.

Go to the Data screen and set the appropriate parameters for and ‘Spectrum Capture’. These will

ensure the analyzer stores important information during operation that may be used to verify

operation/status/diagnostics and other trouble shooting.

performance over a period of time.

If the application use gas containing the target gas (e.g. Oxygen measurement with

Instrument Air Purge) then the Non-Process parameters should be confi gured as detailed later in

this manual under the Software Section. Non-Process Parameters should also be confi gured if

using a linelocking gas in the validation cell (e.g. CO for combustion).

When the site/fi eld confi guration is complete and the analyzer has operated for at least two hours

without any functional alarms, then perform an export data routine.

plane. The data transfer may take several minutes.

DO NOT REMOVE THE MEMORY STICK DURING THIS TIME!

10.2 Close out the VNC software and disconnect the service PC – if connected.

10.3 Ensure the doors/lids are closed and tightly sealed.

10.4 The system is now in normal operation mode.

10.5

We RECOMMEND sending all the Exported Data fi les to Yokogawa Laser Analysis Division

along with any notes and comments. We will then be able to store these fi les on a master

record for future reference.

Please carefully read the appropriate Sections of this Instruction Manual. The TDLS200 Tunable Diode

Laser (TDL) Analyzer is a technologically advanced instrument that requires the appropriate care when

handling, installing and operating.

Failure to do so may result in damage and can void any warranties!

If there is any doubt about any aspect of the Instrument or its use, please contact Yokogawa Laser

Analysis Division and/or your authorized Representative/Distributor.

IM 11Y01B02-11E-A 5th Edition :June 5, 2012-00

Page 14

<3 INSTALLATION AND WIRING> 3-1

3 INSTALLATION AND WIRING

Detailed Installation, Wiring, Utility Drawings are included on a Project Basis. Please contact

Yokogawa for any project specifi c documentation to ensure correct installation. Drawings provided herein

are considered for standard installation use only

3.1 Process Measurement Point Considerations

The following criteria should be considered when selecting the installation point in respect to the process

conditions:

• Process Gas Flow Conditions – Laminar, homogenous gas concentration distribution conditions

across the measurement point are recommended.

For circular ducts/stacks this condition is generally at least three unimpaired diameters (D) before and

after a process bend. For rectangular cross sections, the hydraulic ductdiameter (D) is derived from:

D = (4 x duct cross sectional area) / duct circumference

If neither situation exists or is possible, then distribution of the unimpaired section of duct should be

66% on the inlet side and 34% on the outlet side. Profi ling of the proposed measurement point may be

required to ensure that a correct installation point is selected.

• Process Gas Temperature – It is recommended that the analyzer be installed at a location where

temperature fl uctuations are minimized. Generally as a guide, if the temperature of the gas at the point

where the analyzer is to be installed is to vary by more than +/-10˚C (+/-18˚F) then an “Active” input

signal should be used for compensation.

Ensure the analyzer has been selected and confi gured to suit the maximum operating gas temperature.

Lower gas temperatures generally lead to better measurements.

• Process Gas Pressure – It is recommended that the analyzer be installed at a location where pressure

fl uctuations are minimized. Generally as a guide, if the pressure of the gas at the point where the

analyzer is to be installed is to vary by more than +/- 0.05 Bar (+/- 0.725 psi) then an “Active” input

signal should be used for compensation.

Ensure the analyzer has been selected and confi gured to suit the maximum operating gas pressure.

Ensure the process isolation windows have been selected and confi gured to suite the maximum design

gas pressure.

Lower gas pressures generally lead to better measurements.

• Process Dust/Particulate Matter – It is recommended that the analyzer be installed at

a location where dust loadings are minimized. Dust and other particulate matter will

reduce the optical transmission of the measuring laser beam. Within limits, the loss of

optical transmission does not effect the measurement however a Warning alarm will

be initiated when the transmission falls below allowable limits. The amount of dust

loading is also dependant upon the optical path length – Consult Factory for further

details.

Lower dust loads generally lead to better measurements.

IM 11Y01B02-11E-A 5th Edition :June 5, 2012-00

Page 15

<3 INSTALLATION AND WIRING> 3-2

3.2 Position of Process Flanges for Launch and Detect Units:

Process fl anges should be located on the process such that the Launch and Detect Units can be installed,

accessed and removed in a safe and convenient manner.

The following criteria/Check List should be met at a minimum:

• Good, Safe Engineering practices

• Local codes and regulations for such equipment installation

• Appropriate hazardous area (if applicable) precautions

• Owner Company best practice and engineering standards

• Access for personnel to stand in front of launch and Detect Units

• Clearance for installation and removal of Launch and Detect (see below)

• Clearance for installation and removal of purge insertion tubes (if applicable)

• Access to process isolation valves

• Safe routing for interconnecting cables

• Ambient conditions in accordance with analyzer limits

• Access to appropriate utilities

• Adjacent space for mounting to Calibration Cell when off-line

Figure 1 - Launch and Detect Unit-In -Situ Installation Overview

Figure 2 - Launch and Detect Unit-In-Situ with Insertion Purge Tube Installation Overview

Figure 22 - and Detect Unit – In-Situ Installation Overview

IM 11Y01B02-11E-A 5th Edition :June 5, 2012-00

Page 16

3-3<3 INSTALLATION AND WIRING>

Figure 3 - Launch or Detect Unit Installation Dimensions

The standard fl ange sizes are either 2” or 3” 150# R.F. ANSI as well as DN50 and DN80. Please check the exact

fl ange size specifi ed and provided for the particular installation. Other fl ange sizes and a variety of materials (to

suit the process) are available so please check these details prior to installing the fl anges on the process.

Note: The process isolation valves should have at least a 1½” (38mm) diameter clear bore size

(aperture) to ensure there is suffi cient tolerance to align the laser beam after installation. Ducts and

Stacks that have thin and fl exible walls should be reinforced to ensure that the laser beam alignment is

maintained at all times. Rigid mounting for the process fl anges is highly recommended to ensure a

lignment is maintained.

In situations where the process fl anges are mounted to these thin and fl exible duct/stack walls, a larger

reinforcing plate should be welded around the mounting fl ange area to increase the attaching region. The fi gure

below depicts a typical suggestion however; it is the installer’s responsibility to ensure appropriately rigid

installation is provided for the analyzer.

Figure 4 - Suggested Reinforcing Plate for Launch or Detect Unit Flanges- reduce fl exing with mechnical

reinforcement to duck/stack walls

IM 11Y01B02-11E-A 5th Edition :June 5, 2012-00

Page 17

<3 INSTALLATION AND WIRING> 3-4

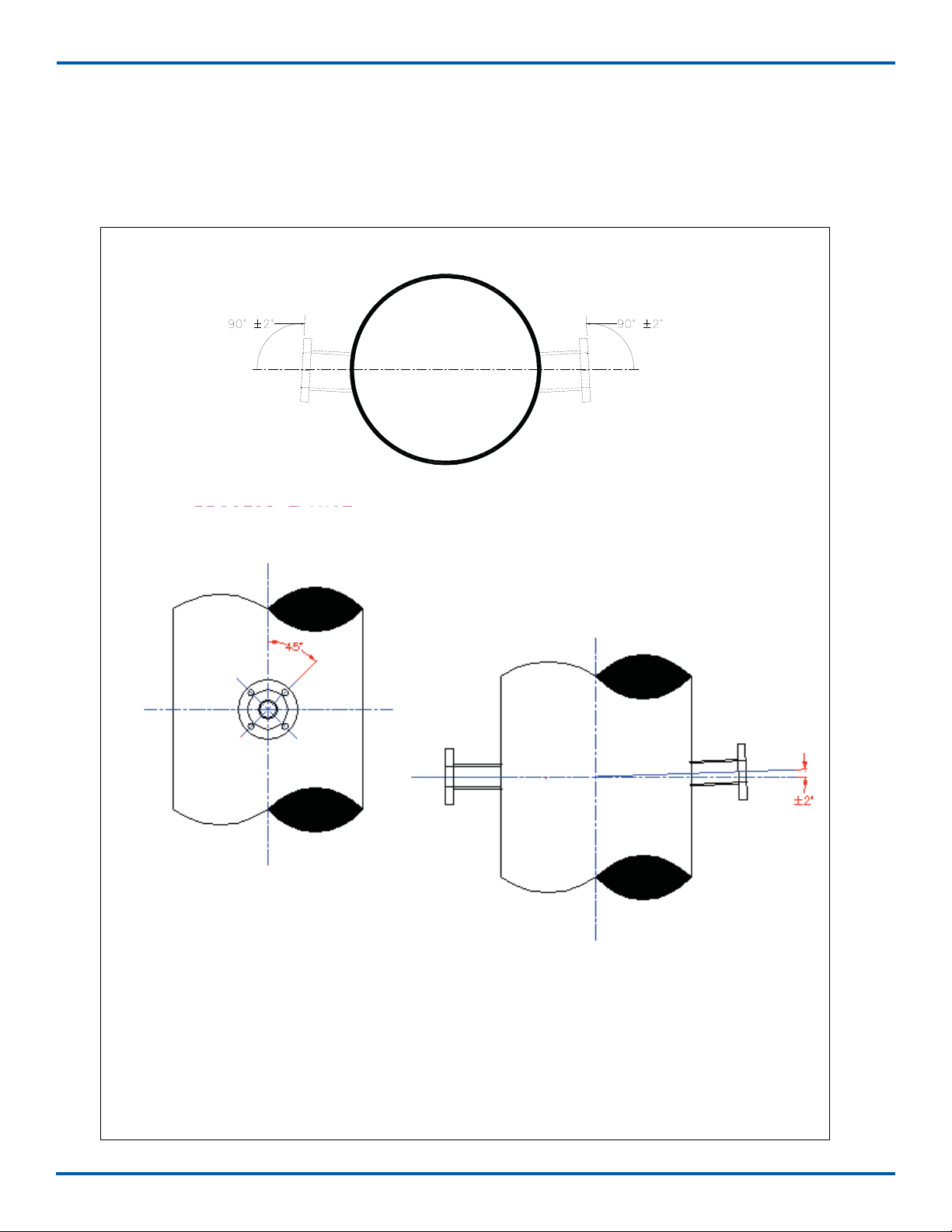

3.3 Process Flange Welding Alignment and Line-Up

The Launch and Detect units are provided with alignment mechanisms that allow for some manual adjustment

of the laser beam direction in both planes. It is however recommended that the following angular tolerances be

adhered to as closely as possible.

PROCESS FLANGE

ANGULAR TOLERANCE

Angular tolerance

PROCESS FLANGE

BOLT ALIGNMENT

NOZZLE FLANGE BOLT PATTERN MUST BE AS

INDICATED TO ASSURE PROPER MOUNTING OF

ANALYZER LAUNCH AND DETECT UNITS

COMBINED ANGULAR OFFSET OF BOTH NOZZLES

MUST NOT EXCEED 2” IN ANY DIRECTION. BEST

INSTALLATION WILL HAVE NO ANGULAR OFFSET

Figure 5 - Angular Alignment Tolerances for Launch or Detect Unit Flanges

IM 11Y01B02-11E-A 5th Edition :June 5, 2012-00

Page 18

3-5<3 INSTALLATION AND WIRING>

3.4 Process Flange Clear Aperture

The Launch and Detect unit fl anges (and insertion tubes if used) should be installed in such a way that a

minimum clear through aperture (opening) diameter of 1 ½” (38 mm) when the distance between the 2” 150#

fl ange faces does not exceed 6ft (~2 m).

Note: Larger clear through apertures may be required when operating over longer distances –

CONSULT FACTORY for further details.

PROCESS FLANGE

CLEAR APERTURE TOLERANCE

LATERAL OFFSET OF NOZZELS MUST BE MINIZED AS TO

ALLOW FOR MINMUM 1.75” [45MM] CLEAR APERTURE.

BEST INSTALLATION WILL HAVE NO LATEAL OFFSET.

Figure 6 - Clear Aperture for Launch or Detect Unit Flanges

3.5 Mounting the Launch and Detect Units to the Process Flange

Securely bolt the Launch and Detect Units to the process fl anges using the standard bolt holes provided. Ensure

the correct size bolts, nuts, and gasket are used in accordance with the fl ange specifi cations and in accordance

with the process specifi cations when applicable.

NOTE: If the process isolation valve fl ange is excessively hot due to the process temperature or radiant

heat, then a thermal insolating fl ange gasket should be used in order to minimize the heat transfer to the

analyzer fl ange face.

It is generally benefi cial to make the fl ange of the Launch and Detect Units and the fl ange of the process

concentric with each other. Due to the large clearance provided by standard fl anges and bolts, it is possible to

mount the two fl anges in an un-concentric manner – this should be avoided to aid laser beam alignment.

IM 11Y01B02-11E-A 5th Edition :June 5, 2012-00

Page 19

<3 INSTALLATION AND WIRING> 3-6

3.5.1 Process Window Purge Gas Connection

In order to keep the process windows clean (prevent fouling by process gas) it is necessary to purge the

windows with a clean dry gas of suffi ciently low dew point.

When measuring Oxygen, Nitrogen should be used for purging the windows. The purge gas or nitrogen should

be clean (<0.5 μ particulate), dry (-40˚C dew point), oil free.

The process fl anges are provided with two diagonally opposed inlet ports (typically ¼” OD tube). Use Swagelok

(or equal) double ferrule tube fi ttings and connect both ports with ¼” OD stainless steel tubing to the purge gas

supply. The exact purge gas fl ow rate will be dependant upon the process conditions that exist at the fl ange

connection and therefore, the fl ow rate could be anywhere from 5lts/min to 50lts/min

(~10 SCFH to ~100 SCFH).

Ensure the purge gas line is clean and dry prior to connecting to the fl ange to ensure any condensate or

debris is not blown on to the windows at initial start-up. The same applies to both Launch Unit and Detect

Unit process fl anges, with and without any insertion purge tubes installed.

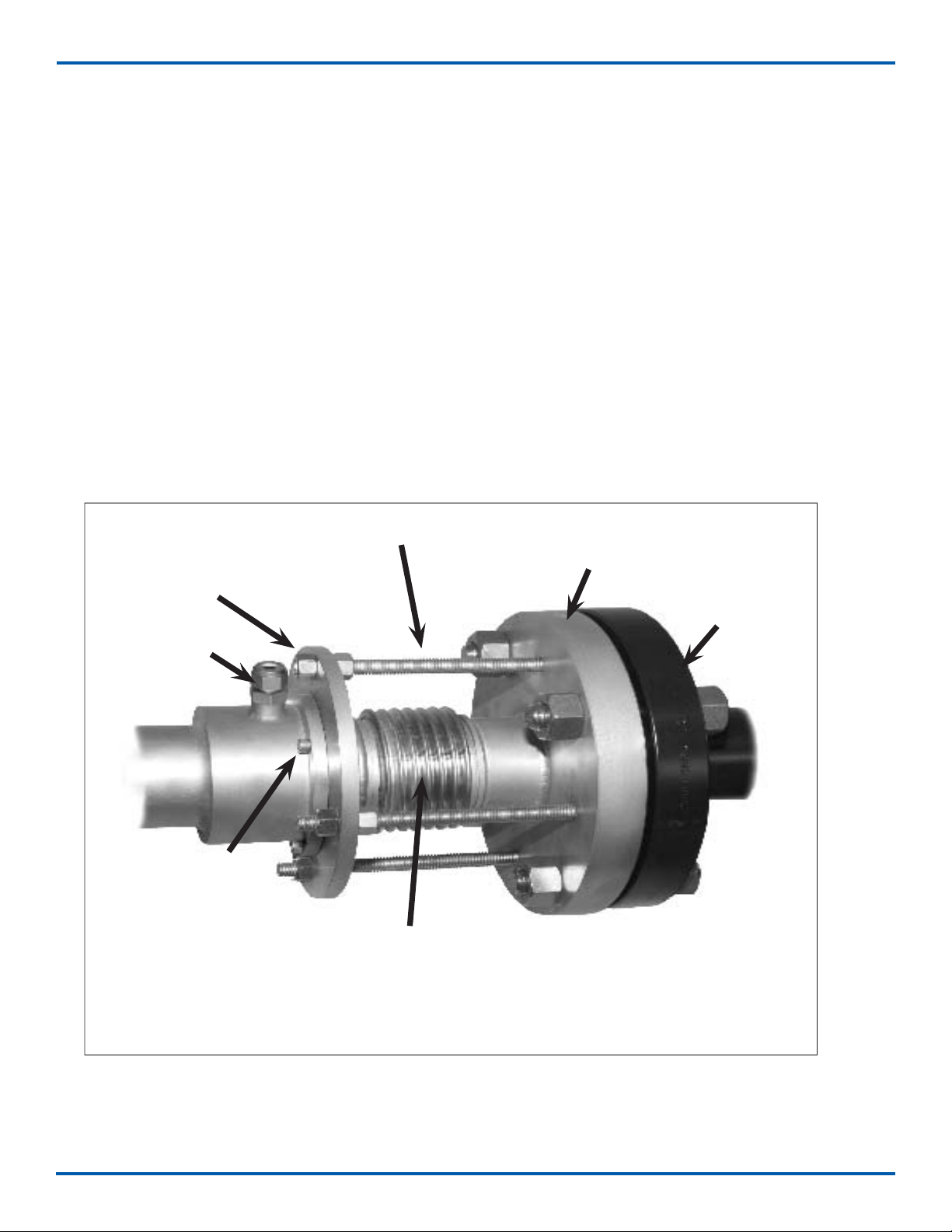

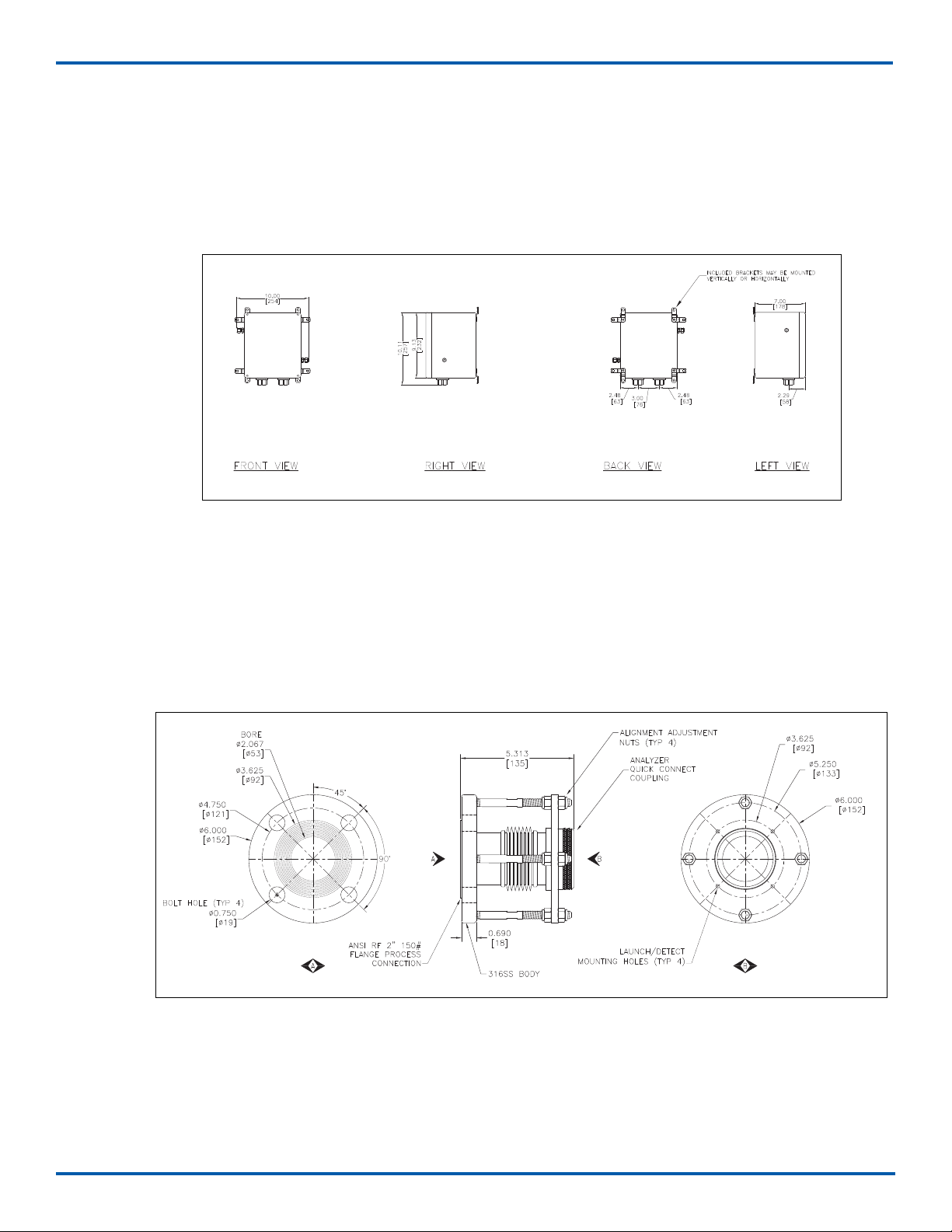

3.6 Mounting the Process Interface – standard 2”, 3”. 4” 150# ANSI RF or DN - 50/80

Alignment Nuts (x8)

Window Purge Port (x2)

Analyzer Quick Connect

Alignment Studs (x4)

Analyzer Mounting Flange

Process Flange

Alignment Bellows

Figure 7 3” 150# Welded Metal Bellows Alignment Flange Shown above, with analyzer quick connect

IM 11Y01B02-11E-A 5th Edition :June 5, 2012-00

Page 20

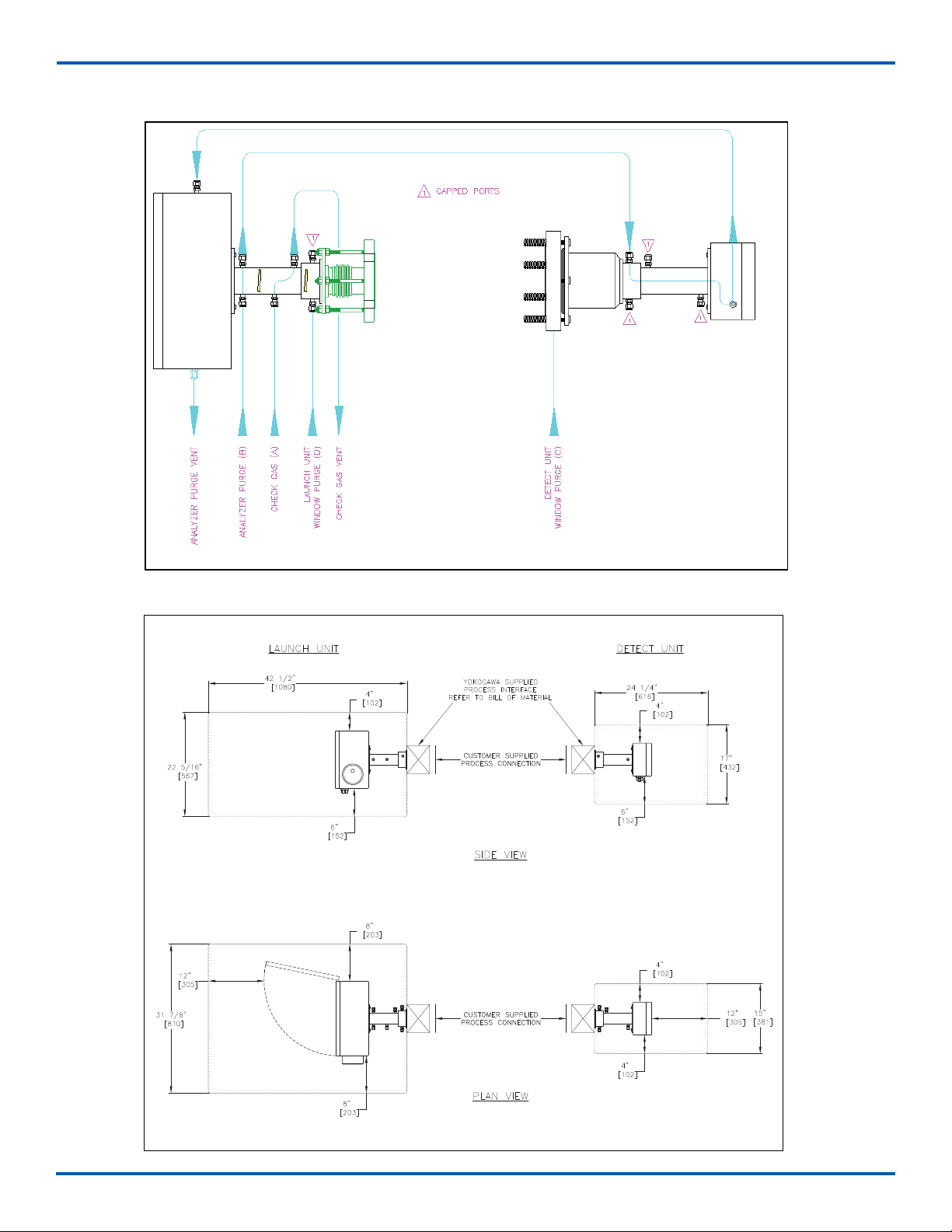

3.7 Typical Purge Gas Confi guration, In-Situ

Please refer to project specifi c details, the following is a typical standard in-situ confi guration:

3-7<3 INSTALLATION AND WIRING>

Figure 8

3.8 Typical Purge Gas Confi guration, Extractive trace ppm H2O system:

Please refer to project specifi c details, the following is a typical standard enhanced fl ow cell confi guration:

Figure 9

IM 11Y01B02-11E-A 5th Edition :June 5, 2012-00

Page 21

<3 INSTALLATION AND WIRING> 3-8

Typical Purge Large Aperture Optics (LAO) combustion O2, CO/CH

Figure 10

4

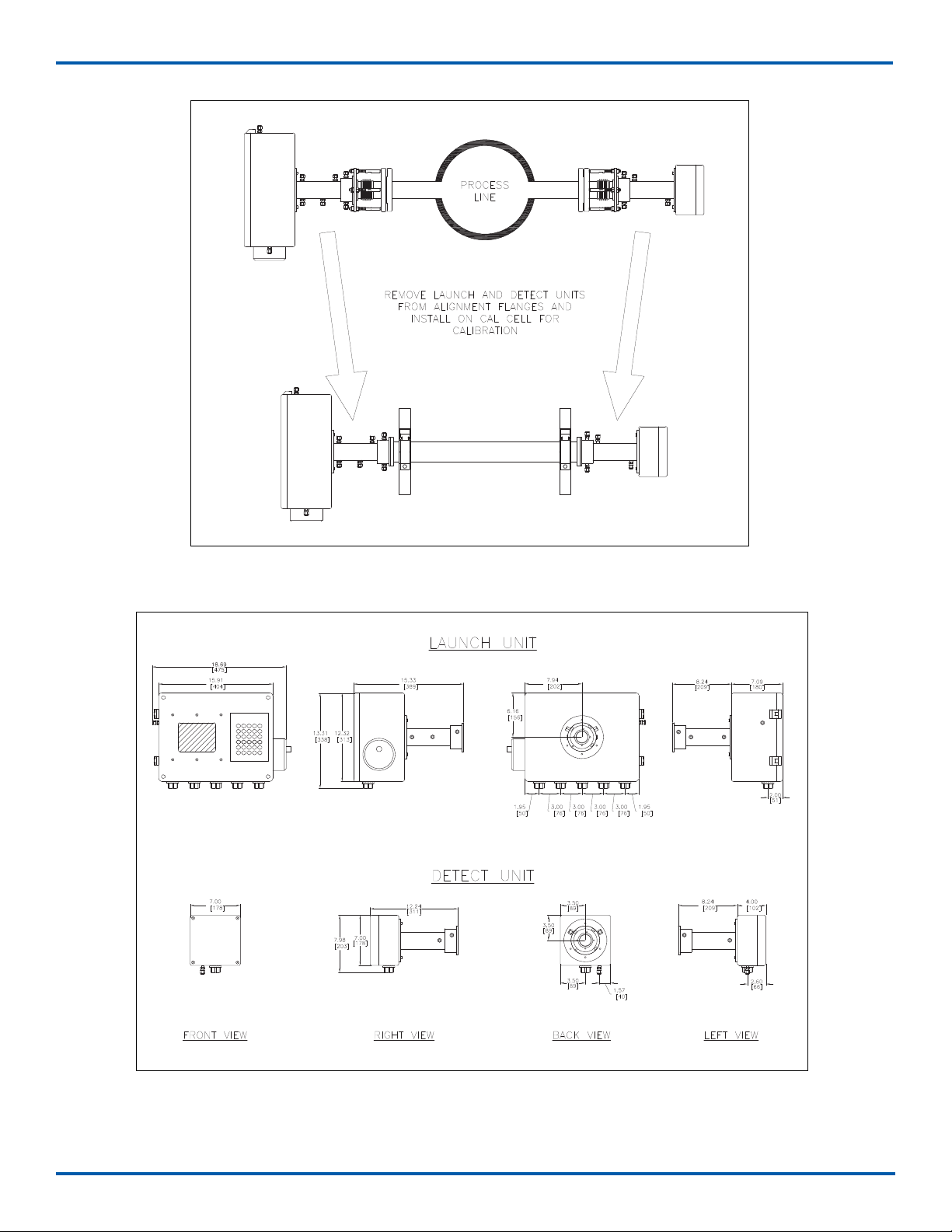

3.9 Dimensional Drawings

Figure 11 - General Installation Clearance Requirements

IM 11Y01B02-11E-A 5th Edition :June 5, 2012-00

Page 22

3-9<3 INSTALLATION AND WIRING>

Figure 12 -Off-Line Calibration Overview

Figure 13 - Launch and Detect unit Dimensions

IM 11Y01B02-11E-A 5th Edition :June 5, 2012-00

Page 23

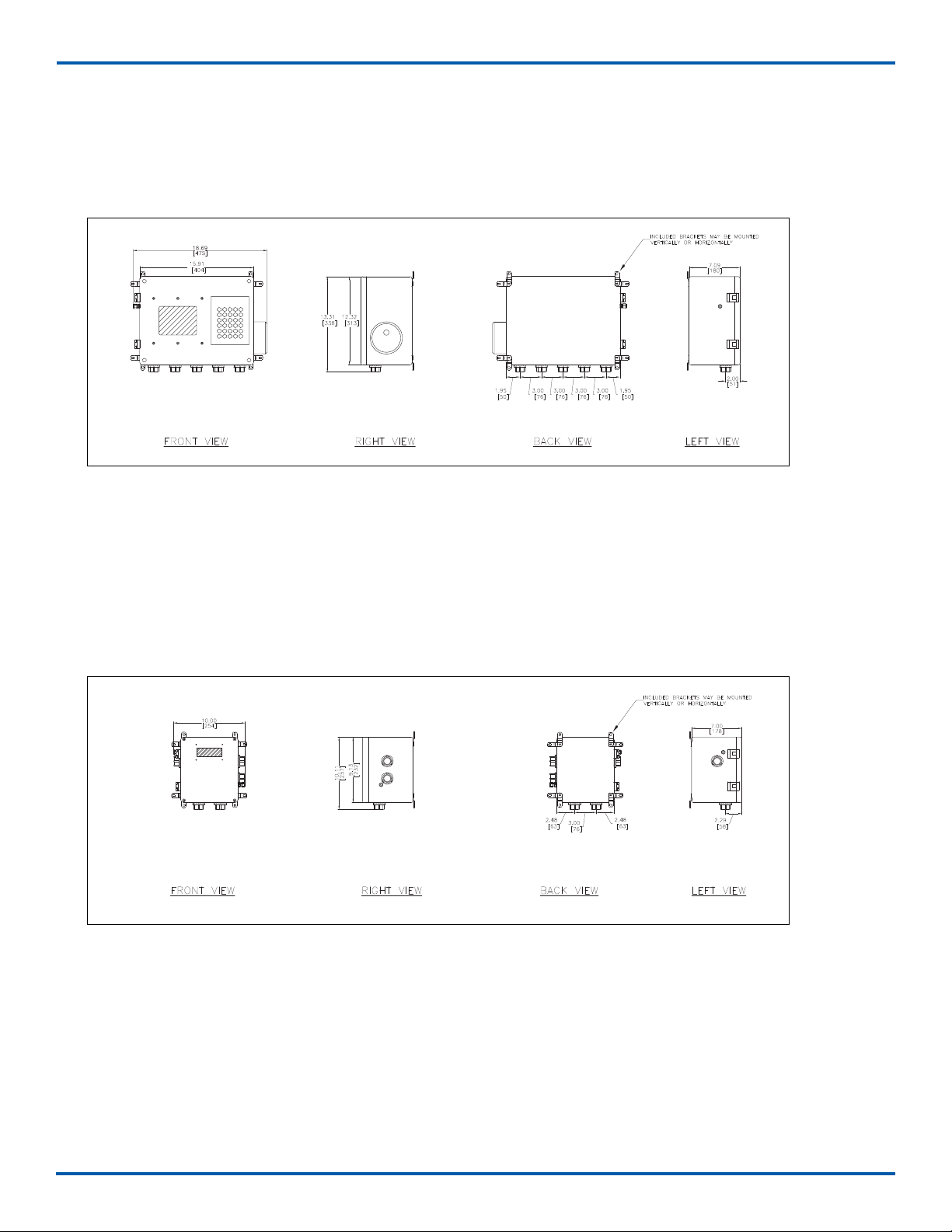

Figure 14 - Remote Interface Unit

<3 INSTALLATION AND WIRING> 3-10

Figure 15 - Universal remote Display (URD)

IM 11Y01B02-11E-A 5th Edition :June 5, 2012-00

Page 24

Figure 16 - Universal Power Supply (UPS)

3-11<3 INSTALLATION AND WIRING>

Figure 17 - Alignment Bellows * Other fl ange sizes available to meet application needs

IM 11Y01B02-11E-A 5th Edition :June 5, 2012-00

Page 25

<3 INSTALLATION AND WIRING> 3-12

Figure 18 - Large Apenture * Other fl ange sizes available to meet application needs

Figure 19 - Isolation Flanges, model IF200

IM 11Y01B02-11E-A 5th Edition :June 5, 2012-00

Page 26

Figure 20 - Insertion Tube Detail

3-13<3 INSTALLATION AND WIRING>

Figure 21 - Off-Line Calibration Gas and Purge Detail

IM 11Y01B02-11E-A 5th Edition :June 5, 2012-00

Page 27

<3 INSTALLATION AND WIRING> 3-14

Figure 22 - Utility Panel Tubing Detail Standard Single, Auto - validation

Figure 23 - Utility Panel Tubing Detail Standard Dual Auto - validation

IM 11Y01B02-11E-A 5th Edition :June 5, 2012-00

Page 28

3.10 Wiring

3.10.1 Wiring of Launch for the US version

3-15<3 INSTALLATION AND WIRING>

Figure 24

IM 11Y01B02-11E-A 5th Edition :June 5, 2012-00

Page 29

<3 INSTALLATION AND WIRING> 3-16

3.10.2 Launch and Detect Unit Wiring – Standard for CE/ATEX

SPECIAL NOTE: Noise sources magnetically coupled to the 4-pair launch to detect cable can cause errors to the

measurement if the frequency and applied total voltage meet or exceed the following; Frequency range of 0.1 to

7.5 MHz and Total induced voltage of 3Vrms.

A combination of these parameters will cause measurement error outside of the analyzer performance

specifi cation. In practice, these potential errors can be easily avoided by routing the 4-pair launch to detect cable

away from electromagnetic interference sources that could exhibit these parameters. Such sources might include

power transformers, electric motors, electric welding machinery, high voltage power lines, etc. Analyzer grounding

wires and any other I/O lines such as 8-pair launch to utility panel cable or A I/O cables to/from the DCS should

also be installed with similar basic practices to also ensure there is no additional adverse infl uence on any of the

I/O signals.

Launch Unit (to Detect) Terminations TB-7 (ensure 360˚ cable shield ground)

Detect Unit (to Launch) Terminations TB-7 (ensure 360˚ cable shield ground)

IM 11Y01B02-11E-A 5th Edition :June 5, 2012-00

Page 30

Launch and Detect Unit Wiring – Standard GP/Div2 (non CE/ATEX)

Launch Unit (to Detect) Terminations at TB-7

3-17<3 INSTALLATION AND WIRING>

Detect Unit (to Launch) Terminations at TB-13

IM 11Y01B02-11E-A 5th Edition :June 5, 2012-00

Page 31

<3 INSTALLATION AND WIRING> 3-18

3.10.3 Launch Unit Terminations CE/ATEX/GP/Div2 – all units:

SEE FOLLOWING NOTES:

Please NOTE that ALL analog output signals from TB-8 are POWERED BY THE ANALYER!

Outputs from TB-9 can be confi gured for POWERED inputs or LOOP POWERED external transmitter!

PLEASE CHECK CAREFULLY BEFORE APPLYING POWER TO THE ANALYZER!

IM 11Y01B02-11E-A 5th Edition :June 5, 2012-00

Page 32

3-19<3 INSTALLATION AND WIRING>

3.11 Hazardous Area Systems

The TDLS200 Analyzer requires a continuous nitrogen or I/A gas purge to prevent ambient oxygen ingress to the

optical path, when oxygen is the measured gas. The fl ow rate can be minimized as long as it prevents any ambient

oxygen ingress to the measurement optical path. Other purge gases may be used as long as they do not contain

any of the measured gas and are clean, dry, etc. If using a purge gas that also contains the measured gas (e.g.

purge with instrument air and measuring process/combustion oxygen) then the Non-Process Parameters software

feature/parameters will have to be implemented.

For hazardous area operation, the same nitrogen purge gas is used to purge the entire analyzer (including

non-optical path sections such as the electronics).

The process interface may also require purging to maintain clear windows, refer to Process Window Purge details

separately.

NOTE: Please also refer to any separate Purge System Original Manufacturers Operating Instructions and

Manuals in conjunction with this User Guide.

The Purge Systems are not manufactured by Yokogawa Laser Analysis Division.

Please also refer to separate detailed manufacturer’s instructions and start-up information for any Zone 1

or Division 1 automatic purge controller unit operational details. Failure to follow the manufacturer’s

guideline can result in damages and/or non-functionality of the purging system!

IM 11Y01B02-11E-A 5th Edition :June 5, 2012-00

Page 33

<3 INSTALLATION AND WIRING> 3-20

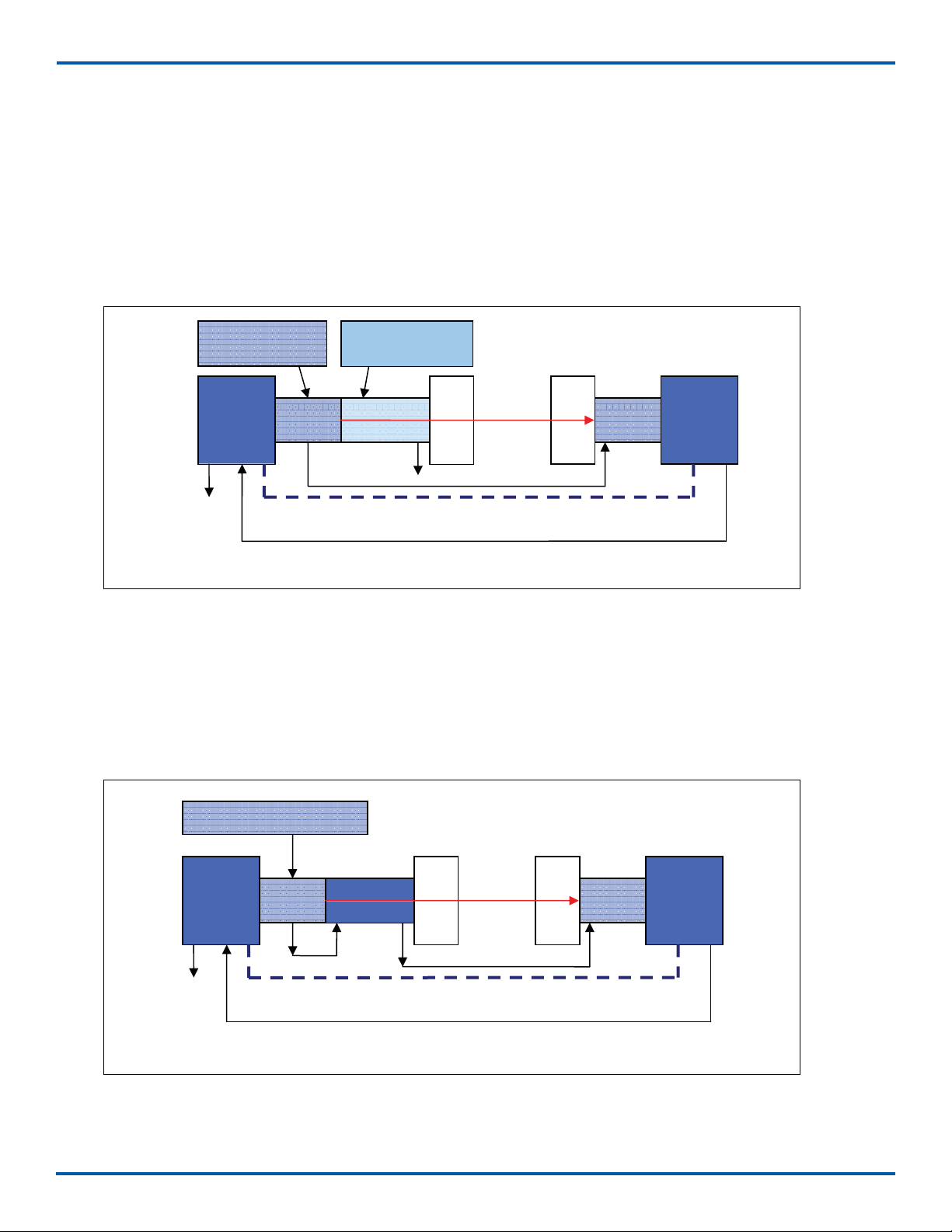

3.11.1 Purging Analyzer for Hazardous Areas (with On-Line Validation)

• NEC/CSA Class 1, Division 2, Groups A-D

• ATEX Zone 2 CAT 3 Dual regulators must be used on the inlet!

The block diagram below shows the sections of the analyzer that require nitrogen purging. A Z-Type purge control

system is fi tted the Launch Unit and it includes a local indicator (Bright Green, rugged light) and pressure switch

alarm contacts (open on loss of purge pressure). The purging should be carried in sequence typically as shown

below. All purge gas connections are ¼” od Tube fi ttings.

Nitrogen or I/A

Purge Gas

Main

Main

Electric

Electronic

Housing &

Housing

Purge

& Purge

System

System

Figure 25 - Purge Flow Diagram when using on line validation

Laser

Module

Nitrogen or I/A

Nitrogen or I/A Purge

Purge Gas

Gas

Check Gas

Flow Cell

Process

Interface

Process

Detect

Interface

Module

Detect

Electronic

Detect

Electronic

Housing

Housing

3.11.2 Purging Analyzer for Hazardous Areas (without On-Line Validation)

• NEC/CSA Class 1, Division 2, Groups A-D

• ATEX Zone 2 CAT 3 – Dual regulators must be used on the inlet!

The block diagram below shows the sections of the analyzer that require nitrogen purging. A Z-Type purge

control system is fi tted the Launch Unit and it includes a local indicator (Bright Green, rugged light) and pres-

sure switch alarm contacts (open on loss of purge pressure).

Nitrogen or I/A Purge Gas

Main

Main

Electronic

Electric

Housing &

Housing

Purge

& Purge

System

System

Figure 26 - Purge Flow Diagram when not using on line validation

Laser

Module

Check Gas

Check Gas

Flow Cell

Flow Cell

Process

Interface

Interface

Process

Detect

Module

IM 11Y01B02-11E-A 5th Edition :June 5, 2012-00

Detect

Detect

Electronic

Electronic

Housing

Housing

Page 34

<3 INSTALLATION AND WIRING>

3-21

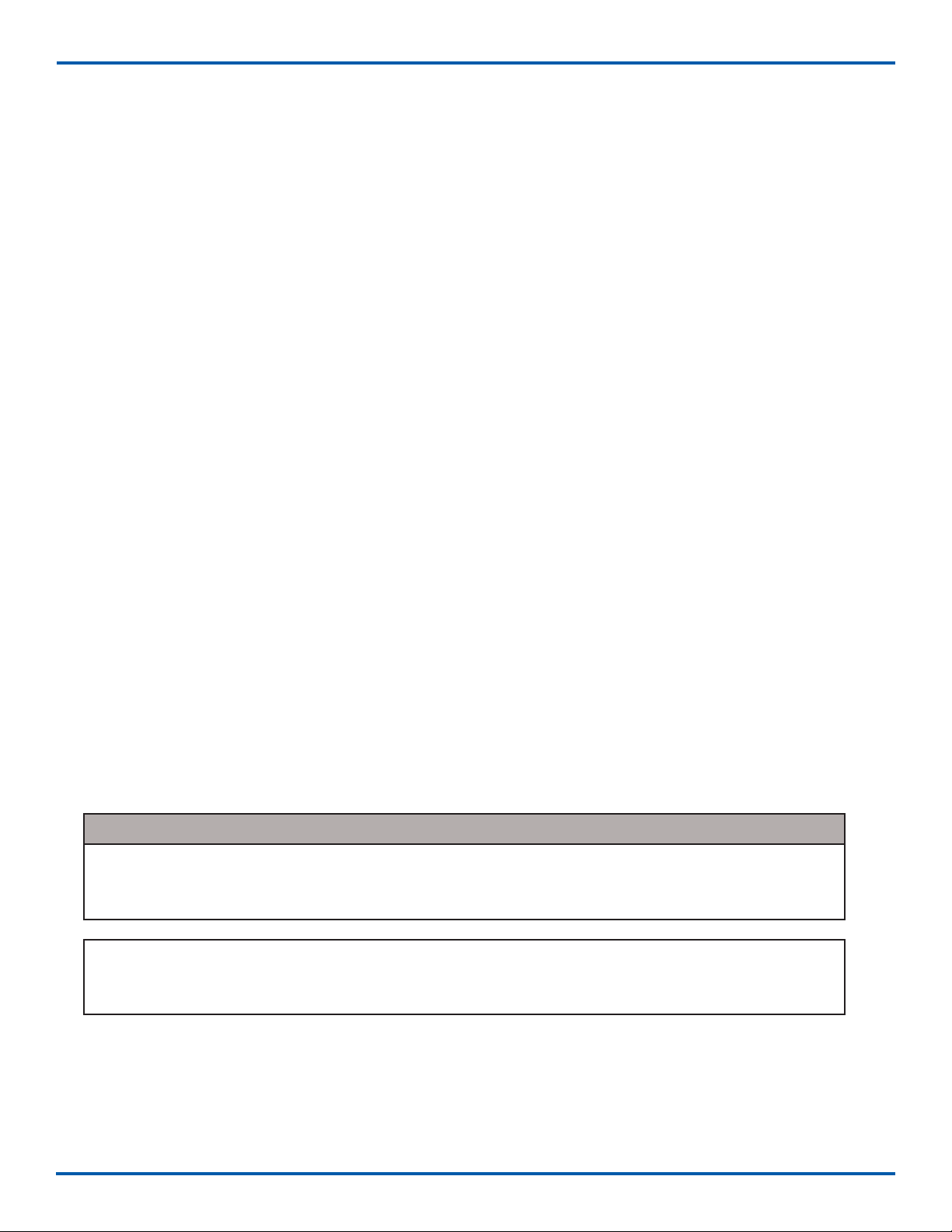

3.11.3 Purging Analyzer and Universal Power Supply and/or URD for Hazardous

Areas (with On-Line Validation)

• NEC/CSA Class 1, Division 2, Groups A-D

• ATEX Zone 2 CAT 3 – Dual regulators must be used on the inlet!

The block diagram below shows the sections of the analyzer that require nitrogen purging when using in

conjunction with either or the Universal Power Supply and Universal Remote Display. AZ-Type purge control

system is fi tted the Launch Unit and it includes a local indicator (Bright Green, rugged light) and pressure switch

alarm contacts (open on loss of purge pressure).

Nitrogen or I/A Purge

Gas

Main

Electronic

Housing &

Purge

System

Figure 27 - Purge Flow Diagram when using on line validation

Laser

Module

Nitrogen or I/A Purge

Nitrogen or I/A Purge

Gas

Gas

Check Gas

Check Gas

Flow Cell

Flow Cell

Power

Supply

or URD

Interface

Process

Detect

Process

Interface

Module

Detect

Detect

Electronic

Electronic

Housing

Housing

3.11.4 Purging Analyzer and Universal Power Supply and/or URD (not using On-Line Validation)

• NEC/CSA Class 1, Division 2, Groups A-D

• ATEX Zone 2 CAT 3 – Dual regulators must be used on the inlet!

The block diagram below shows the sections of the analyzer that require nitrogen purging. A Z-Type purge

control system is fi tted the Launch Unit and it includes a local indicator (Bright Green, rugged light) and

pressure switch alarm contacts (open on loss of purge pressure). The purging should be carried in sequence

typically as shown below. All purge gas connections are ¼” od Tube fi ttings.

Nitrogen or I/A Purge Gas

Main

Main

Electronic

Electronic

Housing &

Housing

Purge

& Pureg

System

System

Figure 28 - Purging Analyzer for Hazardous Areas -NO- On-Line Validation

Laser

Module

Check Gas

Check Gas

Flow Cell

Flow Cell

Process

Power

Power

Supply

Supply

or URD

or URD

Interface

Interface

Process

Detect

Detect

Detect

Module

Electronic

Electronic

Housing

Housing

IM 11Y01B02-11E-A 5th Edition :June 5, 2012-00

Page 35

<3 INSTALLATION AND WIRING> 3-22

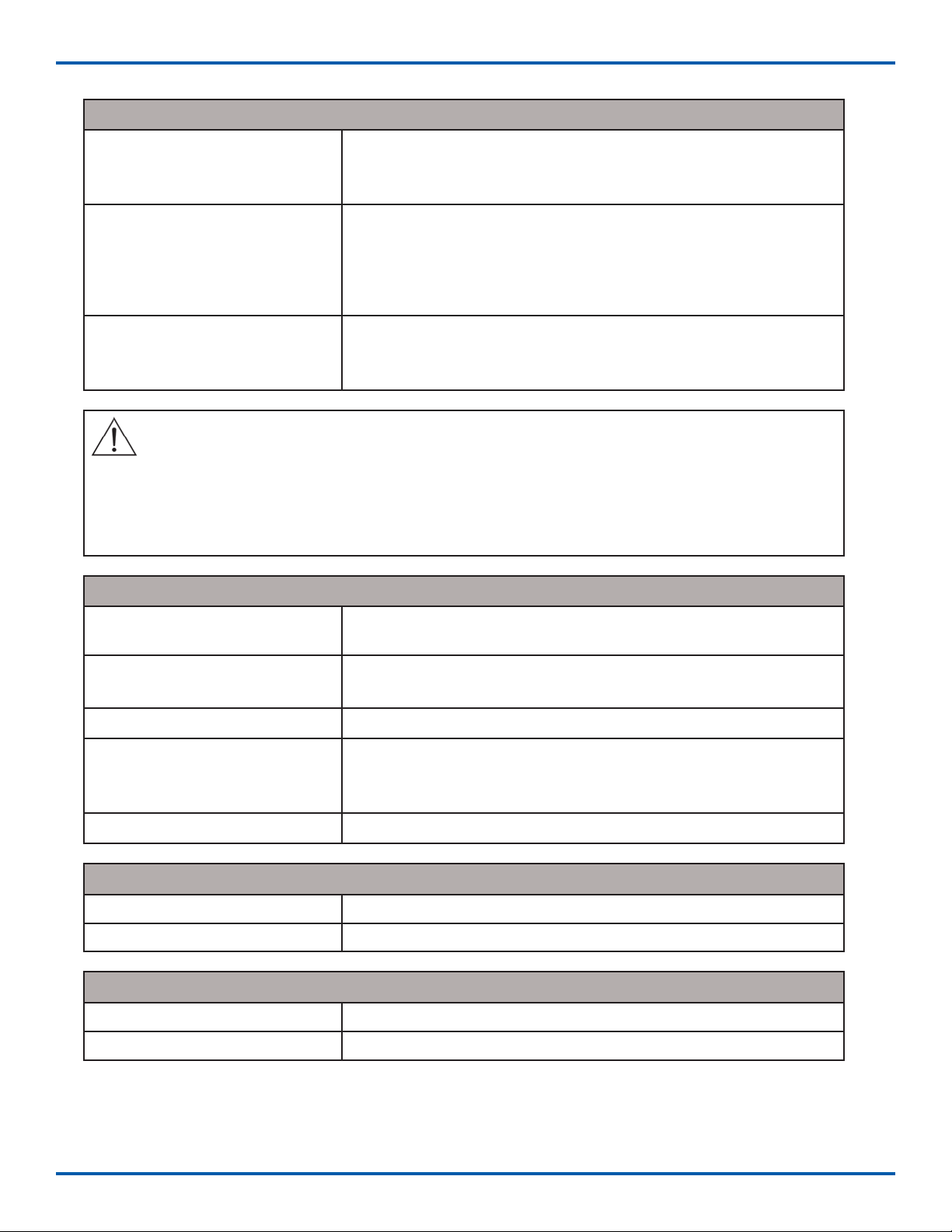

3.12 Cyclops Division 2/Zone 2 Purge Indictor, with switch

Type Z purging reduces the classifi cation within a protected electronics enclosures from Division 2 or Zone 2

to nonhazardous. Failure to maintain pressure within the protected enclosure shall be detected by an alarm

or indicator at the electronics enclosure. The dilution purge time shall be a manual operation and once the

electronics enclosure has been purged of ignitable or fl ammable concentrations, only positive pressure of at least

0.20 inches H

to remove power from the protected equipment upon the loss of purge pressure. The CYCLOPS

Z – Purge Indicator is used to provide safe monitoring of electrical equipment in Division 2 and Zone 2 hazardous

areas, which can be used to prevent the possibility of fi re or explosion inside the enclosure of energized electrical

equipment, a protective gas supply is used to dilute potentially fl ammable materials to an acceptable level,

creating a safe area for the electrical equipment within the enclosure. Positive pressure prevents the ingress

of fl ammable materials in the surrounding atmosphere from entering into the enclosure, as long as positive

pressure is maintained. After the enclosure is purged, power may be manually applied to the protected electrical

equipment.

The CYCLOPS Z – Purge Indicator provides an objective evidence of the presence of adequate positive purge

pressure within the electrical equipment enclosure. A normally open differential pressure switch continuously

compares the pressure inside the monitored electronics enclosure with respect to the atmospheric pressure

surrounding the electronics enclosure. When the monitored electronics enclosure register’s a pressure of at

least 0.20 inches H2O (0.50 mbar) above the reference atmospheric pressure a manually controlled dilution

time cycle may then begin. Typically, a minimum dilution time cycle is specifi ed to ensure that at least fi ve

times the volume of free space in the electronics enclosure is exchanged before power is manually applied to

the electrical equipment. (The number of exchanged volumes may be higher in some situations). After the

manual dilution time cycle has elapsed and the monitored electronics enclosure pressure is being maintained

above 0.20 inches H2O (0.50 mbar), power may be manually applied to the electrical equipment within the

purged electronics enclosure. The CYCLOPS Z – Purge Indicator is designed to indicate the presence of purge

pressure from one pressure reference point. Several electronics enclosures can be installed in series with purge

gas being introduced into the fi rst electronics enclosure and the CYCLOPS Z – Purge Indicator monitoring the

last electronics enclosure in the series; multiple electronics enclosures can now be monitored using only one

CYCLOPS Z – Purge Indicator. The pressure inside the monitored electronics enclosures must maintain at least

0.20 inches H2O (0.50 mbar) higher than the atmospheric pressure surrounding the electronics enclosure. This

ensures that hazardous materials are not going to ingress into the pressurized and now protected electronics

enclosures. If any of the electronics enclosures installed in the series door is opened, pressure will show to be

below the required 0.20 inches H2O (0.50 mbar) in all electronics enclosures. The exhaust vent which comes as

part of the CYCLOPS Z – Purge Indicator casing, can exhaust purge gas from enclosures with volumes up to 15

cubic feet (425 liters).

O (0.50 mbar) is required to be maintained within the electronics enclosure and it is not necessary

2

Cyclops Features

Certifi ed for installation and use in ATEX and IECEx for

Type Z – Purge, II 3 G Ex nA nL [pz] IIC T6

For Zone 2 gas hazardous areas

Certifi ed for installation and use in ATEX and IECEx for

Type Z – Purge, II 3 G Ex nA nL [pz] IIC T6

For Zone 2 gas hazardous areas

IM 11Y01B02-11E-A 5th Edition :June 5, 2012-00

Page 36

Normal Operating Conditions

3-23<3 INSTALLATION AND WIRING>

Power

Certifi ed for installation and use in ATEX and IECEx for

Type Z – Purge, II 3 G Ex nA nL [pz] IIC T6

For Zone 2 gas hazardous areas

Manual Dilution Cycle Time To

Energizing Electrical Equipment

CYCLOPS Z – Purge Indicator,

Minimum Pressure

WARNING: The number of exchanged volumes may be higher in some situations. Refer to

TDLS-200 ATEX Purge Warning Labels for Details.

NOTE: Instrument Air and Nitrogen purge gases have different purge time requirement. It is

important to use clean, dry purge gases to ensure the pressure switch contacts do not foul and

cause subsequent operating issues (i.e. non-functionality of the Cyclops).

Typically, dilution cycle time is to ensure that at least fi ve (5)

times the volume of free space in the enclosure of protective

gas supply is exchanged before power is applied to the

electrical equipment. Ten (10) times volumes for motors,

generators and other rotating electrical machinery.

Green indicator light remains on to show purge pressure being

maintained above 0.20 inches H2O (0.50 mbar) in electronics

enclosure being monitored.

Utility Requirements

Purge Protective Gas Supply

Pressure to Pressure Regulator

Purge Protective Gas Supply

Quality

Power Input / Consumption

Voltage

20 psig (1.4 Bar) minimum (Suggested to compensate for

enclosure leak rate)

Water and oil-free, - 40°F (- 40°C) dew point, particles ≤ 5μ, ISA

grade hydrocarbon free

0.5 Watts maximum

4VDC model (19VDC to 28VDC) 47 to 63 Hz

CYCLOPS Z – Purge Indicator

Mains Supply Fluctuation

Not to Exceed 10%

Environmental Conditions

Operating Temperature Range - 40°F to 150°F (- 40°C to 65°C)

Used and Mounted For Indoor and Outdoor Use

Casing Material Specifi cations

Anodized Aluminum Weight 2.48 lbs (1.13 kg)

Anodized Aluminum Protection NEMA 4 (IP66)

IM 11Y01B02-11E-A 5th Edition :June 5, 2012-00

Page 37

<REVISION RECORD> i

Manual Title: Model TDLS200 Tunable Diode Laser Spectroscopy Analyzer Start-up Manual

Manual Number: IM 11Y01B01-11E-A

Edi on Date Remark (s)

st

April 2008 Newly Published

1

nd

April 2009 Revisions: Forma ng was corrected.

2

rd

3

th

February 2012 Revisions:

4

5th June 2012 Revisions:

April 2010 Revisions:

Updated to include latest manual informa on.

Quick start sec on 1 was modifi ed.

1. Forma ng was corrected.

2. Introduc on and Safety Precau ons pages i-iv were added.

3. Instrument check, now sec on one was added.

4. Quick Start sec on changed to sec on 2.

5. Installa on and wiring sec on 3 was added.

6. Revision Record was added.

7. Back panel for CD holder was added.

IM 11Y01B02-11E-A 5th Edition :June 5, 2012-00

Page 38

Blank Page

IM 11Y01B02-11E-A 5th Edition :June 5, 2012-00

Page 39

TDLS200 TruePeak Series Electronic User’s Manaul IM 11Y01B01-21E-A

[Contents]

This CD-ROM contains information in PDF format that is necessary for sale and effective operation of the product.

www.yokogawa.com/us

WARNING: This CD-ROM contains software, and is for use in a computer only. Do not play this on an audio CD player,

as the high volume may damage your hearing or audio speakers.

copyright © 2012, Yokogawa Corporatoin of America. All Rights Reserved.

CD-R

Page 40

Yokogawa Corporation of America

North America

2 Dart Road, Newnan, GA 30265-1094, USA

Phone: 800-258-2552 Fax: 770-254-0928

12530 West Airport Blvd., Sugar Land, TX 77478

Phone: 281-340-3800 Fax: 281-340-3838

Mexico

Melchor Ocampo 193, Torre C, Ofi cina 3”B”

Veronica Anzures D.F., C.P. 11300

Phone: (55) 5260-0019, (55) 5260-0042

Yokogawa Canada, Inc.

Bay 4, 11133 40th Street SE, Calgary, AB Canada T2C2Z4

Phone: 403-258-2681 Fax: 403-258-0182

Yokogawa has an extensive sales and

distribution network.

Please refer to the website (www.

yokogawa.com/us) to contact your nearest

representative.

IM 11Y01B01-11E-A 05-1206 (A) I

Subject to change without notice Printed in The USA

Copyright

®

2012

IM 11Y01B02-11E-A 5th Edition :June 5, 2012-00

Loading...

Loading...