Page 1

TC10

48

48

48

PV

AT

1411

8 mm max.

Optional

gasket

65 mm min.

2.56 in min.

45

+0.6

mm

1.78

+0.023

in

45

+0.6

mm

1.78

+0.023

in

65 mm mi

n.

2.56 in min.

RS485

TERMINALS

Pin connector

∅

1.4 mm max.

(0.055 in.)

Stripped wire

L: 5.5 mm

(0.21 in.)

L

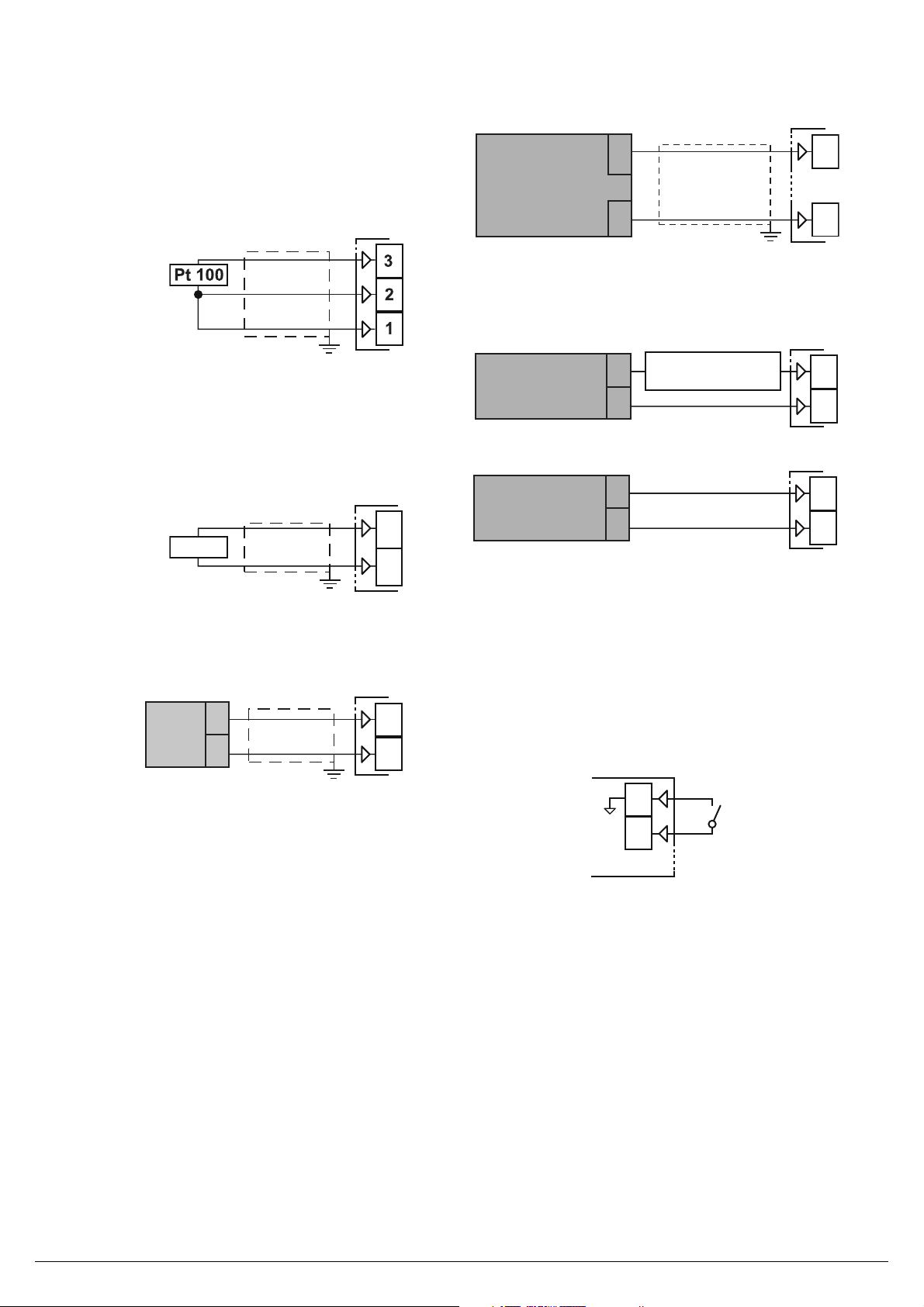

ELECTRICAL CONNECTIONS

Thermocouple

DI1

OP3

Limiter

OP4

(note)

Output 4: 0-12V DO

Analogue input

mV, V mA

Note: Terminal 4 can be programmed as:

- 0 to 12 V SSR Drive Output (OP4) connecting

the load between terminals 4 and 16;

- 12 Vdc (20 mA) transmitter power supply

connecting the 2 wire transmitter between

terminals 4 and 1; for 3 wire transmitter connect

terminal 4 to transmitter power supply inputand

terminal 1 and2 to transmitter signal output.

Neutral

Line

12VDC

(note)

PV

4 to 20 mA

3 wire transmitter

12VDC

(note)

PV

Pt100Pt1000

100 to 240 Vac

4 to 20 mA

2 wire transmitter

OP1

Output 1: 4-20 mA

Output

1

2

+

_

TC 10 - L

LIMIT CONTROL TYPE

Engineering Manual

Code: IM 05C01E81-12EN

1.3 MOUNTING REQUIREMENTS

This instrument is intended for permanent installation, for

indoor use only, in an electrical panel which encloses the

rear housing, exposed terminals and wiring on the back.

Select a mounting location having the following characteristics:

1. It should be easily accessible;

2. There is minimum vibrations and no impact;

3. There are no corrosive gases;

4. There are no water or other fl uids (i.e. condensation);

5. The ambient temperature is in accordance with the

operative temperature (0 to 50°C);

6. The relative humidity is in accordance with the instrument

specifi cations (20 to 90%);

The instrument can be mounted on panel with a maximum

thickness of 8 mm.

When the maximum front protection (IP65) is

desired, the optional gasket must be mounted.

This is mandatory for FM approval.

First edition:

Nov. 2019

Yokogawa Electric Corporation

2-9-32 Nakacho, Musashino-shi, Tokyo 180-8750 Japan

www.yokogawa.com/ns

1. OUTLINE DIMENSIONS (mm)

1.1 INSTRUMENT DIMENSIONS

1.2 PANEL CUT-OUT

2. CONNECTION DIAGRAM

2.1 GENERAL NOTES ABOUT WIRING

1. Do not run input wires together with power cables.

2. External components (like zener barriers, etc.) connected

between sensor and input terminals may cause errors in

measurement due to excessive and/or not balanced line

resistance or possible leakage currents.

3. When a shielded cable is used, it should be connected at

one point only.

4. Pay attention to the line resistance; a high line resistance

may cause measurement errors.

Yokogawa Electric Corporation - TC10-L - ENGINEERING MANUAL - PAG. 1

2.2 INPUTS

2.2.1 Termocouple Input

External resistance: 100W max., maximum error 25 µV.

Continuity detection current: 250 nA.

Cold junction: automatic compensation between 0 to 55°C.

Page 2

Cold junction accuracy: 0.04°C/°C after a warm-up of

2

3

Pt1000

mV

V

+

_

+

_

1

2

+

_

4 to 20 mA

Passive

transmitter

4

1

+

_

+

_

1

2

0/4 to 20 mA

Passive

transmitter

_

External

PWS

+

0/4 to 20 mA

Active

transmitter

+

_

+

_

1

2

Digital

Input 1

15

16

20 minutes.

Input impedance: > 1 MW.

Burn out: full scale

Calibration: According to EN 60584-1.

Note: For TC wiring use proper compensating cable

preferable shielded.

2.2.2 RTD Pt 100 Input

Input circuit: Current injection (135 µA).

Line resistance: Automatic compensation up to 20W/wire

with maximum error ±0.1% of the input span.

Calibration: According to EN 60751/A2.

Note: The resistance of the 3 wires must be the same.

2.2.3 RTD Pt 1000 Input

2.2.5 mA Input

0/4 to 20 mA input wiring for passive transmitter

using the auxiliar

Input impedance: < 53W.

Internal auxiliary PWS: 12 VDC (±10%), 20 mA max..

0/4 to 20 mA input wiring for passive transmitter

using an external pws

0/4 to 20 mA input wiring for active transmitter

y pws

Line resistance: Not compensated.

Pt 1000 input circuit: Current injection (15,5 µA).

Pt 1000 calibration: According to EN 60751/A2.

2.2.4 V and mV Input

Input impedance: > 1 MW for mV Input

500 kW for Volt Input.

Yokogawa Electric Corporation - TC10-L - ENGINEERING MANUAL - PAG. 2

2.2.6 Logic Input

Safety notes:

– Do not r

– The instrument needs 150 ms to recognize a contact

status variation;

– Logic inputs are NOT isolated by the measuring input.

A double or reinforced isolation between logic inputs and

power line must be assured by the external elements.

Logic inputs driven by dry contact

Maximum contact resistance: 100W.

Contact rating: DI1 = 10 V, 6 mA;

un logic input wiring together with power cables;

2.3 OUTPUTS

Safety notes:

– To avoid electrical shocks, connect power line at last.

– For supply connections use No. 16 AWG or larger wires

rated for at last 75°C.

– Use copper conductors only.

– SSR outputs are not isolated. A reinforced isolation must

be assured by the external solid state relays.

– For SSR, mA and V outputs if the line length is longer than

30 m use a shielded wire.

– Do not short-circuit the terminals of the SSR output.

WARNING! Before connecting the output actuators,

we recommend to confi gure the parameters to

Page 3

suit your application (e.g.: input type, Control

mA

+

-

7

8

V

+

-

7

8

C

NO

13

14

C

NO

11

12

SSR

+

-

4

Out4

4

16

D +

D -

D +

D -

D +

D -

D +

D -

RS-485

5

6

Power Supply

9

10

Neutral

Line

strategy, alarms, etc.).

2.3.1 Output 1 (OP1)

Function: retransmission

Output type: isolated output

Current Analog Output

2.4 SERIAL INTERFACE

mA output:

0/4... 20 mA, galvanically isolated, RL max. 600W.

Voltage Analog Output

V output: 0/2... 10 V

, galvanically isolated

2.3.2 Output 2 (OP2)

Function: limiter output

Relay Output

Contact rating: • 2 A /250 V cosϕ = 1;

• 1 A /250 V cosϕ = 0.4.

Operation: 1 x 105.

2.3.3 Output 3 (OP3)

Relay Output

Contact rating: • 2 A /250 V cosϕ = 1;

• 1 A /250 V cosϕ = 0.4.

Operation: 1 x 105.

, RL min.: 500W.

Interface type: Isolated (50 V) RS-485;

Voltage levels: According to EIA standard;

Protocol type: Modbus RTU;

Byte format: 8 bit with no parity;

Stop bit: 1 (one);

Baud rate:

Address: Programmable between 1 to 254.

Notes: 1. RS-485 interface allows to connect up to 30

2. The cable length must not exceed 1.5 km at

Programmable between 1200 to 38400 baud;

devices with one remote master unit.

9600 baud.

2.5 POWER SUPPLY

Supply Voltage: 100 to 240 VAC (-15 to +10%).

Notes: 1. Before connecting the instrument to the power

line, make sure that line voltage is equal to the

voltage shown on the identifi cation label;

2. The polarity of the power supply has no importance;

3. The power supply input is NOT fuse protected.

Please, provide a T type 1A, 250 V fuse externally.

2.3.4 Output 4 (OP4)

SSR Output

Logic level 0: Vout < 0.5 VDC;

Logic level 1: 12 V ±20%, 20 mA max..

Note: Overload protected.

Yokogawa Electric Corporation - TC10-L - ENGINEERING MANUAL - PAG. 3

Page 4

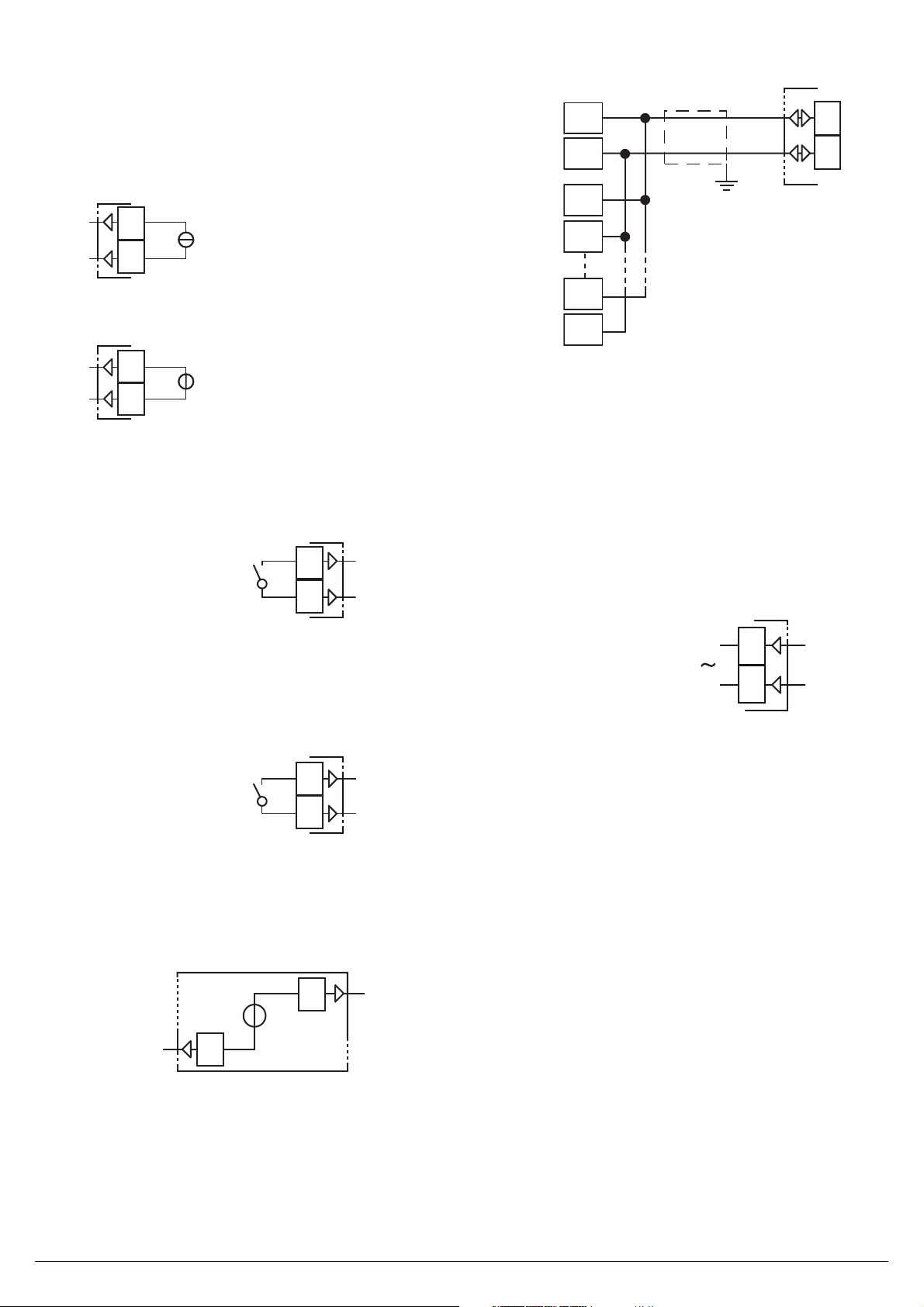

3. TECHNICAL CHARACTERISTICS

4. MODEL AND SUFFIX CODES

3.1 TECHNICAL SPECIFICATION

Case:

Front protection: IP 65 (when the optional panel gasket is

mounted) for indoor locations according to EN 60070-1;

Terminals protection: IP 20 according to EN 60070-1;

Installation: Panel mounting;

Terminal block:

0.25 to 2.5 mm2 (AWG22 to AWG14) with connection diagram,

tightening torque 0.5 Nm;

Dimensions: 48 x 48, depth 73 mm, (1.89 x 1.89 x 2.87 in.)

Panel cutout: 45[-0, +0.6] x 45[-0, +0.6] mm

(1.78[- 0.000, +0.023] x 1.78[- 0.000, +0.023] in.)

Weight: 180 g max..

Power supply: 100 to 240 VAC (-15 to +10% of the

nominal value);

Power consumption: 6.0 VA max. (100 to 240 VAC);

Insulation voltage: 2300 V rms according to EN 61010-1;

Display updating time: 500 ms;

Sampling time: 130 ms;

Resolution: 30000 counts;

Total Accuracy: ±0.5% F.S.V. ±1 digit @ 25°C of room

temperature;

Plastic, self-extinguishing degree: V-0 according to UL 94;

16 screw terminals for cables of

Model Code

TC10 -L

Fixed code -L Always "-L"

Power supply H 100 to 240 VAC

Fixed code C Always "C"

Retransmission

Limit control output R limit control relay output

Alarm output 1 - 2

Fixed code D

Serial communication

Fixed code F Always “F”

Option Code /GK Panel gasket for IP65

Suffix codes Description

oCo o oDo

N None

A PV retrans. output 4 to 20 mA

F Temperature Controller

N None

R

S RS485 Modbus

N None

Alarm output:2 Points (OT3 relay

+ OT4 SSR drive)

Always "D"

Electromagnetic compatibility and safety requirements

Compliance: directive EMC 2004/108/CE (EN 61326-1),

directive LV 2006/95/CE (EN 61010-1),

UL 61010-1 CSA 61010-1;

Note: During the test, the instrument continues to operate at

the measurement accuracy within specifi cation.

Installation category: II;

Pollution category: 2;

Temperature drift: It is part of the global accuracy;

Operating temperature: 0 to 50°C (32 to 122°F);

Storage temperature: -20 to +70°C (-4 to +158°F);

Humidity: 20 to 95% RH, not condensing.

Yokogawa Electric Corporation - TC10-L - ENGINEERING MANUAL - PAG. 4

Page 5

5. CONFIGURATION PROCEDURE

SP

HYS

PV

(A) (B) (C) (A) (B)(D)

EXCEEDED

LAMP

OUT

LAMP

lit

off

OUTPUT

RELAY

confirmation

(accepted)

confirmation

(not accepted)

lit

off

Energized

De-energized

OFF

OFFOFF

Lit

OFF

Lit

OFF

ON

OFF

Lit

OFF

Power

ON

OFF

SP

HYS

PV

(A) (B) (D)(C)

EXCEEDED

LAMP

OUT

LAMP

lit

off

OUTPUT

RELAY

confirmation

(accepted)

lit

off

Energized

De-energized

OFF

OFF

OFF

Lit

ON

OFF

Lit

OFF

Power

ON

OFF

OFF

ON

OFF

5.1 INTRODUCTION

When the instrument is powered, it starts immediately

to work according to the parameters values loaded in its

memory.

The instrument behaviour and its performance are governed

by the value of the stored parameters.

At the fi rst start up the instrument will use a “default” parameter set (factory parameter set); this set is a generic one

(e.g. a TC J input is programmed).

WARNING! Before connecting the output actuators, we

recommend to confi gure the parameters to

suit your application (e.g.: input type, Control

strategy, alarms, etc.).

To change these parameters you need to enter the “Confi guration mode”.

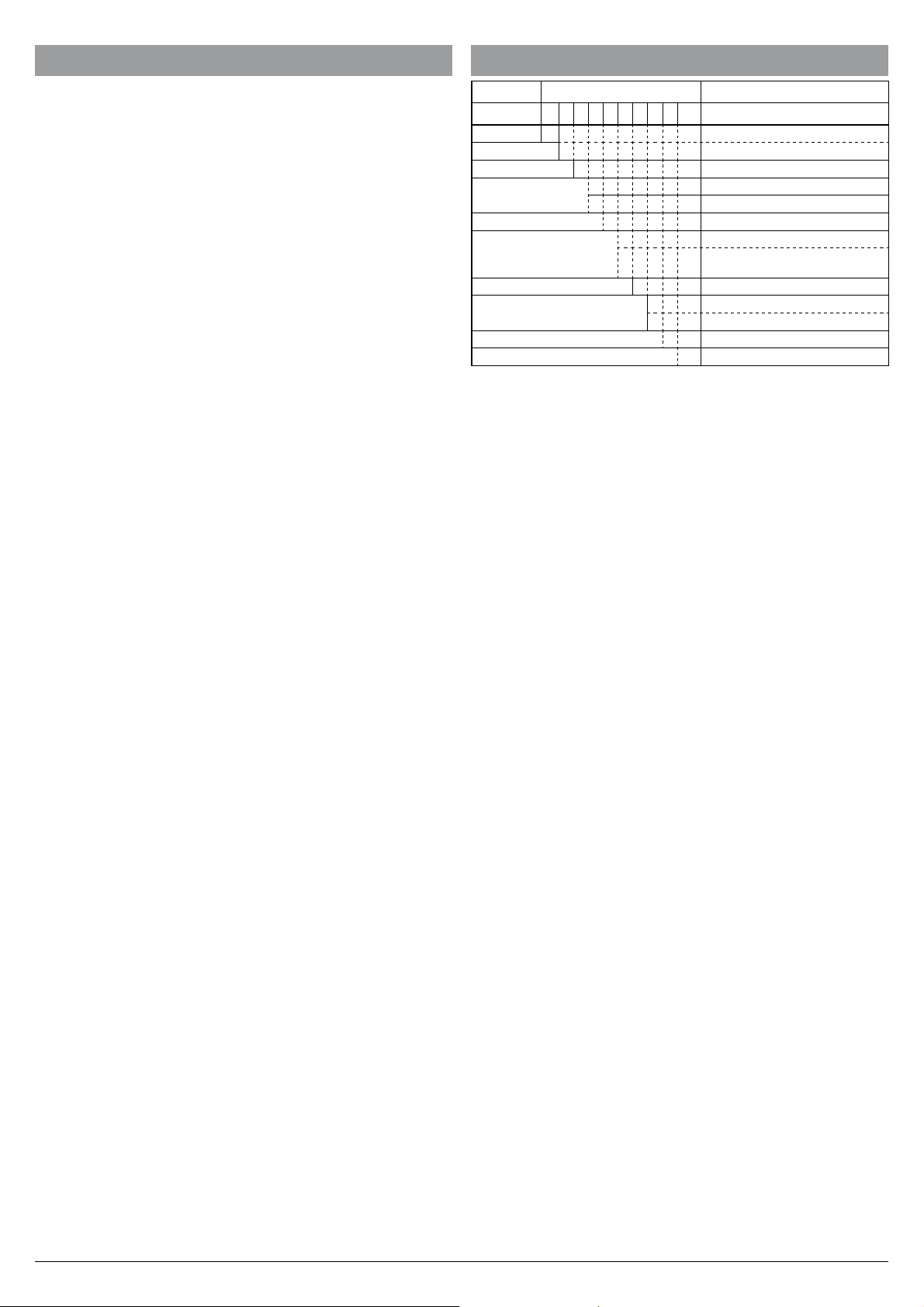

5.2 INSTRUMENT BEHAVIOUR AT POWER

ON

At power ON the instrument can operate in two different

mode according to the value assigned to [34] r.md parameter [34] r.md equal to 0

(Limit output is de-energized at power on in any cases.)

The output relay is always de-energized (opened) at poweron,even if PV does not exceed SP(A). The output (OUT)

display lamp is lit. If thePV does not exceed SP, after the

confi rming operation, output relay will be energized (closed)

and the output (OUT) display lamp turns off .

5.3 HOW TO ENTER THE

“CONFIGURATION MODES”

The confi guration procedure allows to take advantage of all

instrument features.

The instrument have one complete parameter set.

We call this set “confi guration parameter set” (or

“confi guration parameters”).

The access to the confi guration parameters is

password.

5.3.1 Complete confi guration procedure

The confi guration parameters are collected in various

groups. Every group defi nes all parameters related with a

specifi c function (e.g.: control, alarms, output functions).

1. Push the button for more than 3 seconds. The upper

display will show PASS while the lower display will show 0.

2. Using and buttons set the programmed password.

Notes: 1. The factory default password for confi guration

parameters is equal to 30.

3. Push the button

If the password is correct the display will show the acronym

protected by a

[34] r.md equal to 1(Limit output is de-energized at power on

in any cases.)The state of output relay is energized (closed)

and the output (OUT) display lamp turns off if the PV does

not exceed SP at power-on.

of the fi rst parameter group preceded by the symbol:

In other words the upper display will show:

]inp

]

.

(group of the Input parameters).

The instrument is in confi guration mode.

5.4 HOW TO EXIT THE “CONFIGURATION

MODE”

Push button for more than 3 seconds, the instrument will

come back to the “standard display”.

5.5 KEYBOARD FUNCTIONS DURING

PARAMETER CHANGING

A short press allows to exit from the current parameter

group and select a new parameter group.

A long press allows you to close the confi guration

parameter procedure (the instrument will come back

to the “standard display”).

When the upper display is showing a group and the

lower display is blank, this key allows to enter in the

selected group.

When the upper display is showing a parameter and

Yokogawa Electric Corporation - TC10-L - ENGINEERING MANUAL - PAG. 5

Page 6

the lower display is showing its value, this key allows

to store the selected value for the current parameter

and access the next parameter within the same group.

Allows to increase the value of the selected parameter.

Allows to decrease the value of the selected parameter.

+ These two keys allow to return to the previous

group. Proceed as follows:

Push the button and maintaining the pressure,

then push the button; release both the buttons.

Note: The group selection is cyclic as well as the selection

of the parameters in a group.

5.6 FACTORY RESET - DEFAULT

PARAMETERS LOADING PROCEDURE

Sometime, e.g. when you re-confi gure an instrument

previously used for other works or from other people or when

you have made too many errors during confi guration and

you decided to re-confi gure the instrument, it is possible to

restore the factory confi guration.

This action allows to put the instrument in a defi ned

condition (the same it was at the fi rst power ON).

The default data are those typical values loaded in the

instrument prior to ship it from factory.

To load the factory default parameter set, proceed as follows:

1. Press the

display will show PASS while the lower display shows 0;

2. Using

3. Push

4. The instrument will turn OFF all LEDs for a few seconds,

then the upper display will show dFLt (default) and then

all LEDs are turned ON for 2 seconds. At this point the

instrument restarts as for a new power ON.

The procedure is complete.

Note: The complete list of the default parameters is available

in Appendix A.

button for more than 5 seconds. The upper

and buttons set the value -481;

button;

5.7 CONFIGURING ALL THE PARAMETERS

In the following pages we will describe all the parameters of

the instrument. However, the instrument will only show the

parameters applicable to its hardware options in accordance

with the specifi c instrument confi guration (i.e. setting AL1t

[Alarm 1 type] to nonE [not used], all parameters related to

alarm 1 will be skipped).

]inP Group - Main and auxiliary input confi guration

[1] SEnS - Input type

Available: Always.

Range: • When the code of the input type is equal to c

(see paragraph “How to order”).

J TC J (-50... +1000°C/-58... +1832°F);

crAL TC K (-50... +1370°C/-58... +2498°F);

S TC S (-50... 1760°C/-58... +3200°F);

r TC R (-50... +1760°C/-58... +3200°F);

t TC T (-70... +400°C/-94... +752°F);

n TC N (-50...1300°C/-58...2372°F);

Pt1 RTD Pt 100 (-200... 850°C/-328... 1562°F);

Pt10 RTD Pt 1000 (-200... 850°C/-328... 1562°F);

0.60 0... 60 mV linear;

12.60 12... 60 mV linear;

0.20 0... 20 mA linear;

4.20 4... 20 mA linear;

0.5 0... 5 V linear;

1.5 1... 5 V linear;

0.10 0... 10 V linear;

2.10 2... 10 V linear.

Notes: 1. When a TC input is selected and a decimal fi gure

is programmed (see the next parameter) the max.

displayed value becomes 999.9°C or 999.9°F.

2. Every change of the SEnS parameter will

produces a change of the related parameter and

in particular:

• [7] bS (PV bias) will be forced to zero

• [11] Ao1L and [12] Ao1H (when the analog

retransmission is present) will be forced to the

Ex.Range limits.

• [13] AL1 and [30] AL2 will be forced to :

– for an absolute maximum alarm, them will be

forced to the maximum input span

– for an absolute minimum alarm, them will be

forced to the minimum input span

– for all other alarm, them will be forced to zero

• [14] HAL1 and [31] HAL2 will be forced equal

to the 0.5% of the input span

• [28] AL2L extended limit low

• [29] AL2H extended limit high

• [35] HYS will be forced equal to 0.05 % of the

input span

• [37] SPLL and [38] SPHL

• [39] SP

• the CAL group will be reset [51]A.L.P, [52]

A.L.O, [53] A.H.P, [54] A.H.O

[2] dP - Decimal point position

Available: Alw

Range: 0 to 3 when [1] SenS = Linear input;

0 or 1 when [1] SenS different from linear input.

Note: Every change of the dP parameter setting will produce

a change of the parameters related with it (e.g.: set

points, proportional band, etc.).

ays.

[3] SSc - Initial scale read-out for linear inputs

Available: When a linear input is selected b

Range: -1999 to 9999.

Notes: 1. SSc allows the scaling of the analog input to set

the minimum displayed/measured value.

The instrument will show a measured value up to

5% less than SSc value and then it will show an

underrange error.

2. It is possible to set a initial scale read-out higher

than the full scale read-out in order to obtain a

reverse read-out scaling.

E.g.:

0 mA = 0 mBar and 20 mA = -1000 mBar (vacuum).

y [1] SenS.

[4] FSc - Full scale read-out for linear input

Available: When a linear input is selected by [1] SenS.

Range: -1999 to 9999.

Notes: 1. Fsc allows the scaling of the analog input to set

the maximum displayed/measured value.

The instrument will show a measured value up to

5% higher than [4] FSc value and then it will show

Yokogawa Electric Corporation - TC10-L - ENGINEERING MANUAL - PAG. 6

Page 7

an overrange error.

2. It is possible to set a full scale read-out lower

than the initial scale read-out in order to obtain a

reverse read-out scaling.

E.g.:

0 mA = 0 mBar and 20 mA = -1000 mBar (vacuum).

[5] unit - Engineering unit

Available: When a temperature sensor is selected by [1]

SenS parameter.

Range: °C = Celsius;

°F = Fahrenheit.

[6] FiL - Digital fi lter on the measured value

Available: Alw

Range: oFF (No fi lter);

0.1 to 20.0 s.

Note: This is a fi rst order digital fi lter applied on the

measured value. For this reason it will affect the

measured value but also the control action and the

alarms behaviour.

[7] bS -

Available: Always.

Range: In Engineering unit, it is programmable from -100 to

ays.

PV input bias

100 % of the input span

[8] di.A - Digital Input Action

Available: Always.

Range: 0 = DI1 Direct action,

1 = DI1 Reverse action,

]out Gr

oup - Output parameters

[9] o1.t - Out 1 type

Available: When the out 1 is a linear output.

Range: 0.20 0 to 20 mA;

4.20 4 to 20 mA;

0.10 0 to 10 V;

2.10 2 to 10 V.

[10] o1F - Out 1 function

Available: Alw

Range: • When the out 1 is a linear output:

nonE =

r.inP = Measured value Analog retransmission.

r.Err = Analog retransmission of the measured

r.SP = Analog retransmission of the operative set

r.SEr = Analog retransmission of a value coming

ays.

Output not used. With this setting the status

of this output can be driven directly from

serial link;

error (PV-SP);

point;

from serial link;

[11] Ao1L - Initial scale value of the analog

retransmission

Available: When Out 1 is a present

Rang

e: -1999 to [12] Ao1H.

[12] Ao1H

- Full scale value of the analog

retransmission

Available: When Out 1 is present

Range: [11] Ao1L to 9999.

[13] o3F - Out 3 function

Available: When the instrument has out 3 option.

Range: nonE = Output not used. With this setting the status

of the this output can be driven directly

from serial link;

AL = Alarm output;

or.bo = Out-of-range or burn out indicator;

P.FAL = Power failure indicator;

bo.PF = Out-of-range, burn out and Power failure

indicator;

[14] o3AL - Alarms linked up with Out 3

Available: When [13] o3F = AL.

Range: 0 to 15 with the following rule:

+1 = Alarm 1;

+2 = Alarm 2;

+4 = Sensor break (burn out);

+8 = Overload on Out 4 (short circuit on out 4);

[15] o3Ac - Out 3 action

Available: when [13] o3F is diff

Range: dir = Direct action;

rEU = Reverse action;

Notes: 1. Direct action: the output repeats the status of the

driven element. Example: the output is an alarm

output with direct action. When the alarm is ON,

the relay will be energized (logic output 1).

2. Reverse action: the output status is the opposite

of the status of the driven element. Example:

the output is an alarm output with reverse

action. When the alarm is OFF, the relay will be

energized (logic output 1). This setting is usually

named “fail-safe” and it is generally used in

dangerous process in order to generate an alarm

when the instrument power supply goes OFF or

the internal watchdog starts.

erent from “nonE”.

[16] o4F - Out 4 function

Available: Alw

Range: nonE = Output not used. With this setting the status

AL = Alarm output;

or.bo = Out-of-range or burn out indicator;

P.FAL = Power failure indicator;

bo.PF = Out-of-range, burn out and Power failure

On = Output ever ON (it is used as auxiliary

ays

of the this output can be driven directly

from serial link.

indicator;

power supply for TX).

[17] o4AL - Alarms linked up with Out 4

Available: When [16] o4F = AL.

Rang

e: 0 to 7 with the following rule.

+1 = Alarm 1;

+2 = Alarm 2;

+4 = Sensor break (burn out);

[18] o4Ac - Out 4 action

Available: When [16] o4F is diff

Range: dir = Direct action;

rEU = Reverse action;.

erent from “nonE”.

Yokogawa Electric Corporation - TC10-L - ENGINEERING MANUAL - PAG. 7

Page 8

For more details see [15] o3.Ac parameter.

LoAb

OUT

AL1

AL1

PV

HAL1

time

HiAb

offoffoff

OUT

AL1

AL1

PV

HAL1

time

offoffoff

ON ON ON ON

LHAo

PV

AL1H

HAL1

time

offoffoff

LHdo

OUT

AL1

AL1L

HAL1

PV

AL1H

SP

HAL1

time

OUT

AL1

-AL1L

HAL1

offoffoff

ON ON ON ON

PWR ON

AL1

PV

time

offoff

Ab1 = +1

Ab1 = +0

offoff

ON ON

ON

Sp2

Sp1

PV

time

Ab1 = +8

Ab1 = +0

ON

offoff

AL1

offoffoff

AL1

ON

ON ON

ON

]AL1 Group - Alarm 1 parameters

[19] AL1t - Alarm 1 type

Available: Always.

Range:

nonE = Alarm not used;

LoAb = Absolute low alarm;

HiAb = Absolute high alarm;

LHAo = Absolute band alarm with alarm indication

out of the band;

LHAi = Absolute band alarm with alarm indication

inside the band;

SE.br = Sensor break;

LodE = Deviation low alarm (relative);

HidE = Deviation high alarm (relative);

LHdo = Relative band alarm with alarm indication

out of the band;

LHdi = Relative band alarm with alarm indication

inside the band.

Notes: 1. The relative and deviation alarms are “relative” to

the operative set point value.

2. The (SE.br) sensor break alarm will be ON when

the display shows ---- indication.

[20] Ab1 - Alarm 1 function

Available: When [28] AL1t is diff

Range: 0 to 3 with the following rule:

+1 = Not active at power up;

+2 =

Relative alarm not active at set point change.

Notes: 1. The “not active at power up” selection allows to

inhibit the alarm function at instrument power up

The alarm will be automatically enabled when the

measured value reaches, for the fi rst time, the

alarm threshold ±hysteresis (in other words, when

the initial alarm condition disappears).

2. A relative alarm not active at set point change” is

an alarm that masks the alarm condition after a

set point change until process variable reaches

the alarm threshold ±hysteresis.

Yokogawa Electric Corporation - TC10-L - ENGINEERING MANUAL - PAG. 8

erent from “nonE”.

3. The instrument does not store in EEPROM the

alarm status. For this reason, the alarm status

will be lost if a power down occurs.

[21] AL1L - For High and low alarms it is the low

limit of the AL1 threshold

-

For band alarm it is low alarm threshold

Available: When [19] AL1t is different from “nonE”.

Range: From -1999 to [22] AL1H engineering units.

[22] AL1H

- For High and low alarms, it is the high

limit of the AL1 threshold

- For band alarm, it is the high alarm

threshold

Available: When [19] AL1t is diff

Range: From [21] AL1L to 9999 engineering units.

erent from “nonE”.

[23] AL1- Alarm 1 threshold

Available: When:

[19] AL1t = LoAb - Absolute low alarm;

[19] AL1t = HiAb - Absolute high alarm;

[19] AL1t = LodE - Deviation low alarm (relative);

[19] AL1t = HidE - Deviation high alarm (relative).

Range: From [21] AL1L to [22] AL1H engineering units.

[24] HAL1 - Alarm 1 hysteresis

Available: When [19] AL1t is diff

Range: 1 to 9999 engineering units.

Notes: 1.

The hysteresis value is the difference between

the Alarm threshold value and the point the Alarm

automatically resets.

2. When the alarm threshold plus or minus the

hysteresis is out of input range, the instrument

will not be able to reset the alarm.

Example: Input range 0 to 1000 (mBar).

– Set point equal to 900 (mBar);

– Deviation low alarm equal to 50 (mBar);

– Hysteresis equal to 160 (mBar) the theoretical reset point is

900 - 50 + 160 = 1010 (mBar) but this value is out of range.

The reset can be made only by turning the instrument

OFF, removing the condition that generate the alarm and

then turn the instrument ON again;

– All band alarms use the same hysteresis value for both

thresholds;

– When the hysteresis of a band alarm is bigger than the

programmed band, the instrument will not be able to reset

the alarm.

Example: Input range 0 to 500 (°C).

– Set point equal to 250 (°C);

– Relative band alarm;

– Low threshold equal to 10 (°C);

– High threshold equal to 10 (°C);

– Hysteresis equal to 25 (°C).

erent from “nonE”.

Page 9

[25] AL1d - Alarm 1 delay

SP

HYS

PV

(A) (B) (C) (A) (B)(D)

EXCEEDED

LAMP

OUT

LAMP

lit

off

OUTPUT

RELAY

confirmation

(accepted)

confirmation

(not accepted)

lit

off

Energized

De-energized

OFF

OFFOFF

Lit

Lit

OFF

Lit

ON

OFF

ON

OFF

Lit

OFF

Available: When [19] AL1t is different from “nonE”.

Range: From oFF (0) to 9999 seconds.

Note: The alarm goes ON only when the alarm condition

persists for a time longer than [25] AL1d time but the

reset is immediate.

]AL2 Group - Alarm 2 parameters

[26] AL2t - Alarm 2 type

Available: A

Range:

Note: The relative alarm are “relative” to the current set

ways.

nonE = Alarm not used;

LoAb = Absolute low alarm;

HiAb = Absolute high alarm;

LHAo = Absolute band alarm with alarm indication

out of the band;

LHAi = Absolute band alarm with alarm indication

inside the band;

SE.br = Sensor break;

LodE = Deviation low alarm (relative);

HidE = Deviation high alarm (relative);

LHdo = Relative band alarm with alarm indication

out of the band;

LHdi = Relative band alarm with alarm indication

inside the band.

point.

reset is immediate.

]rEG gr

oup - Control parameters

[33] Hi.Lo - Control type:

Available: Always.

Range:

Hi = Hi limit;

Lo = Low limit

High limit control

When a measured value (PV) exceeds a set point

(SP),“EXCEEDED” [EX]lamp lights, “OUT” lamp turns ON

and the limit output relay (Out 2) is de-energized.

“EXCEEDED” [EX] lamp turns off when PV goes into normal

condition, while the output [OUT] display lamp stays on as

it is (b). The output [OUT] display lamp turns off when a

confi rming operation (rearm) is done by an operator.

The way to confi rm are: pressing

(according to the <<diS>> parameter setting).

The confi rming operation is not accepted during PV exceeds

SP (D) (during EXCEEDED lamp lights*). State of output

relay is de-energized whenever “OUT” lamp is on.

.

key or by DI1

[27] Ab2 - Alarm 2 function

Available: When [26] AL2t is diff

Range: 0 to 3 with the following rule:

+1 = Not active at power up;

+2 =

[28] AL2L

Relative alarm not active at set point change.

- For High and low alarms it is the low

erent from “nonE”.

limit of the AL2 threshold

- For band alarm it is low alarm threshold

Available: When [26] AL2t is different from “nonE”.

Range: -1999 to [29] AL2H engineering units.

[29] AL2H

- For High and low alarms it is the high

limit of the AL2 threshold

-

For band alarm it is high alarm threshold

Available: When [26] AL2t is different from “nonE”.

Range: From [28] AL2L to 9999 engineering units.

[30] AL2 - Alarm 2 threshold

Available: When:

[26] AL2t = LoAb Absolute low alarm;

[26] AL2t = HiAb Absolute high alarm;

[26] AL2t = LodE Deviation low alarm (relative);

[26] AL2t = HidE Deviation high alarm (relative).

Range: From [28] AL2L to [29] AL2H engineering units.

[31] HAL2 - Alarm 2 hysteresis

Available: When [26] AL2t is diff

Range: 1 to 9999 engineering units.

Note: For other details see [24] HAL1 parameter.

erent to “nonE” or [26] AL2t

is different from “SE.br”.

When the EXCEED lamp is ON but PV is lower than SP, the

upper display will be in green value and it shows that the PV

is in the hysteresis area.

Low limit control

When a measured value (PV) exceeds a setpoint (SP),

“EXCEEDED” lamp (c) lights, and “OUT” lamp (b) turns ON .

The limit output relay is de-energizedthen.

“EXCEEDED” lamp turns off when PV goes into normal

condition, while the output (OUT) display lamp stays on

as it is. The output (OUT) display lamp turns off when a

confi rming operation is done by an operator.

The way to confi rm are:

- pressing

key or

- by DI1 (according to the <<diS>> parameter setting).

The confi rming operation is not accepted during PV exceeds

SP (D) (during EXCEEDED lamp lights*). State of output

relay is de-energized whenever “OUT” lamp is on.

[32] AL2d - Alarm 2 delay

Available: When [26] AL2t type is diff

Range: From oFF (0) to 9999 seconds.

Note: The alarm goes ON only when the alarm condition

persist for a time longer than [32] AL2d time but the

Yokogawa Electric Corporation - TC10-L - ENGINEERING MANUAL - PAG. 9

erent form “nonE”.

Page 10

SP

HYS

PV

(A) (B) (C) (A) (B)(D)

EXCEEDED

LAMP

OUT

LAMP

lit

off

OUTPUT

RELAY

confirmation

(accepted)

confirmation

(not accepted)

lit

off

Energized

De-energized

OFF

OFFOFF

Lit

Lit

OFF

Lit

ON

OFF

ON

OFF

Lit

OFF

When the EXCEED lamp is ON but PV is Higher than SP,

the upper display will be in green value and it shows that the

PV is in the hysteresis area.

[34] r.md – Limit output status at power ON (Re-

start mode)

Available: A

Range: 0 = limit output is ON in any cas

[35] HyS – Hysteresis of the control output

Available: Available: always

Range: In engineering unit from 0.0 to 100 % of the input

vailable: always

1 = Limit output is OFF at power on when PV

doesn’t exceed SP.

span

[36] oP.SL – Operating display selection.

Available: A

vailable: always

Range:

Range: PU.SP = (0) PV (upper display) and SP (lower

display)

PU = (1) SP only (lower display)

Note: When you change the [37] SPLL value, the nstrument

checks the local set points (SP parameters). If SP

is out of this range, the instrument forces it to the

maximum acceptable value

[37] SPLL – Minimum set point value

Available: A

Range: from -1999 to [38] SPHL

Note: When you change the [37] SPLL value, the instrument

vailable: always

checks the local set points (SP parameters). If SP

is out of this range, the instrument forces it to the

minimum acceptable value.

[38] SPHL – Maximum set point value

Available: Available: always

Range: from [37] SPLL to 9999.

[39] SP - Set point.

Available: A

Range: from [37] SPLL to [38] SPHL

vailable: always

[40] diS– the way of confi rming operation

Available: Available: always

Range: but = by keyboard

di = by digital input

[41] tim – time duration of the last exceeded period.

Available: A

Range: from 00.00 to 99.59 (HH.mm).

vailable: always but it is a read only parameter.

[42] Hi- maximum measured value

Available: Available: when [33] Hi.Lo = Hi (high limit) but it is

a read only parameter.

Range: Engineering unit within the input range

[43] Lo – minimum measured value

Available: A

Range: Engineering unit within the input range.

vailable: when [33] Hi.Lo = Lo (low limit) but it is

a read only parameter.

]PAn group - Operator HMI

[44] PAS2 - Level 2 password:

Available: Always.

Range: oFF = Level 2 not protected by password

(as level 1 = Operator level) 1 to 200.

[45] PAS3

- Level 3 password:

Complete confi guration level

Available: Alw

Range: 3 to 200.

Note: Setting [44] PAS2 equal to [45] PAS3, the level 2 will

be masked.

ays.

[46] di.CL - Display color

Available: Always.

Range: 0 = the display color is used to show the

Exceed condition.

When no exceed condition is present, the

upper display will be green.

when [33] Hi.Lo = Hi (high limit ) and PV >

SP the upper display will be red.

when [33] Hi.Lo = Lo (low limit ) and PV <

SP the upper display will be red.

1 = Display red (fi x);

2 = Display green (fi x);

3 = Display orange (fi x).

[47] diS.t - Display time out

Available: Alw

Range: oFF = The display is ever ON;

0 (OFF) to 99.59 minutes and seconds.

Note: This function allows to turn OFF the display when no

alarm is present and no action is made on the instrument.

When diS.t is different from OFF and no button is

pressed for more than the programmed time out, the

display goes OFF and only 4 segments of the less

signifi cant digit are turned ON in sequence in order to

show that the instrument is working correctly.

If an alarm occurs or a button is pressed, the display

will come back to the normal operation.

ays.

]Ser group - Serial link parameter

[48] Add - Instrument address

Available: Always.

Range: oFF = Serial interface not used;

1 to 254.

[49] bAud - Baud rate

Available: When [48] Add diff

Range: 1200 = 1200 baud;

2400 = 2400 baud;

erent from oFF.

Yokogawa Electric Corporation - TC10-L - ENGINEERING MANUAL - PAG. 10

Page 11

9600 = 9600 baud;

AH.P 100°C

AH.o = 2

AL.o = -1

AH.P 10°C

Real curve

Modified curve

19.2 = 19200 baud;

38.4 = 38400 baud.

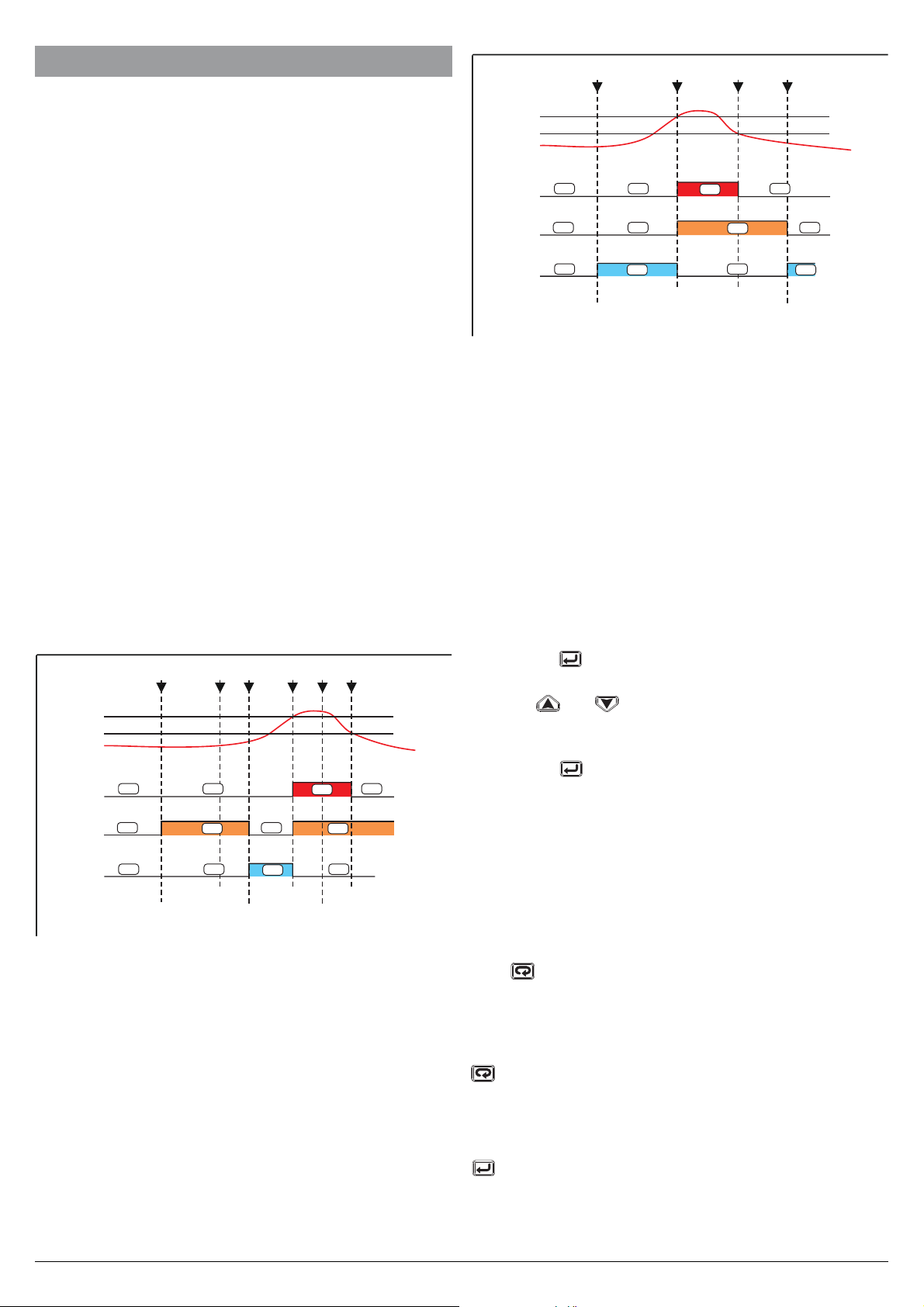

]CAL group - User calibration group

This function allows to calibrate the complete measuring

chain and to compensate the errors due to:

– Sensor location;

– Sensor class (sensor errors);

– Instrument accuracy.

[50] A.L.P - Adjust Low Point

Available: Alw

Range: -1999 to (A.H.P - 10) engineering units.

Note: The minimum difference between A.L.P and A.H.P is

equal to 10 Engineering Units.

[51] A.L.o - Adjust Low Offset

Available: Always.

Range: -300 to +300 engineering units.

[52] A.H.P - Adjust High Point

Available: Alw

Range: From (A.L.P + 10) to 9999 engineering units.

Note: The minimum difference between A.L.P and A.H.P is

equal to 10 Engineering Units.

ays.

ays.

• Push

button for more than 3 s. The instru-

ment will come back to the “standard display”.

[53] A.H.o - Adjust High Offset

Available: Always.

Range: -300 to +300 Engineering Units.

Example: Environmental chamber with an operative range:

10 to 100°C.

1. Insert in the chamber a reference sensor connected with

a reference instrument (usually a calibrator).

2. Start the control of the instrument, and set a set point equal to

the minimum value of the operative range (e.g.: 10°C). When

the temperature in the chamber is steady, take note of the

temperature measured by the reference system (e.g.: 9°C).

3. Set [50] A.L.P = 10 (low working point) and [140] A.L.o = -1

(it is the difference between the reading of the instrument

and the reading of the reference system). Note that after

this set the measured value of the instrument is equal to

the measured value of the reference system.

4. Set a set point equal to the maximum value of the

operative range (e.g. 100°C). When the temperature

in the chamber is steady, take note of the temperature

measured by the reference system (e.g. 98°C).

5. Set [52] A.H.P = 100 (low working point) and [142]

A.H.o = +2

instrument and the reading of the reference system). Note

that after this set the measured value of the instrument is

equal to the measured value of the reference system.

(it is the difference between the reading of the

The most important step of the confi guration procedure is

completed.

In order to exit from confi guration parameter procedure,

proceed as follows:

• Push

button.

Yokogawa Electric Corporation - TC10-L - ENGINEERING MANUAL - PAG. 11

Page 12

6. OPERATIVE MODES

PV

SP

Process Value

(in eng. units)

Set Point

(a)

(Editing mode)

Limit

Control

High

Limiter

Exceeded

indication

EX

OUT

PK

HI AL1 AL2

TC10-L

Output

(b)

(c)

(d)

(e)

SP

HYS

PV

(A) (B) (C) (A) (B)(D)

EXCEEDED

LAMP

OUT

LAMP

lit

off

OUTPUT

RELAY

confirmation

(accepted)

confirmation

(not accepted)

lit

off

Energized

De-energized

OFF

OFFOFF

Lit

Lit

OFF

Lit

ON

OFF

ON

OFF

Lit

OFF

SP

HYS

PV

(A) (B) (C) (A) (B)(D)

EXCEEDED

LAMP

OUT

LAMP

lit

off

OUTPUT

RELAY

confirmation

(accepted)

confirmation

(not accepted)

lit

off

Energized

De-energized

OFF

OFFOFF

Lit

Lit

OFF

Lit

ON

OFF

ON

OFF

Lit

OFF

The TC10-L is an FM (both FM3545 and FM3810) approved

limit controller that can be confi gured either as a high limit or

as a low limit controller by a user.

The relay of the output 2 operates in fail-safe mode (relay

de-energized during shutdown condition) and latching mode.

OUT 2 turns OFF (in this document this condition will be

named shutdown) when:

The instrument is confi gured as a high limiter (Hi.Lo = Hi)

and the measured value is greater than limiter threshold

[“SP” parameter] or.

The instrument is confi gured as a low limiter (Hi.Lo = Lo)

and the measured value is lower than limiter threshold.

Out 2 remains OFF until the condition which generated the

shutdown, no longer exists and the Confi rming action (rearm) has been performed.

During a shutdown (Out 2 is OFF) the upper display will be

red.

Confi rming action (rearm) can be performed in two different

way:

- by pressing the

key [when “diS” parameter is set to

“but”] but it will be accepted only when the condition which

generated the shutdown, no longer exists (EX lamp is OFF)

and the set point is shown on the lower display (see “normal

display” in “Navigation access”)

- by momentarily closing the digital input (by an external dry

contact) [when diS parameter is set to “di”] but it will be accepted only when the condition which generated the shutdown, no longer exists.

We defi ne also that the time duration of the shutdown condition, stored by the instrument, will be the time from Out 2

goes OFF (shutdown start) and the condition that generate

the shutdown no longer exists.

The confi rmation action is not part of this time count.

The time duration of the shutdown condition and max/min

measured values are stored in memory and available for

viewing (see “navigation access”) until the next shutdown

condition occurs.

These informations are lost at power down.

6.1 HIGH LIMIT CONTROL

- by DI1.

Output relay is de-energized whenever “OUT” lamp is on.

Check the “HYS” parameter value if the EX lamp (e) is not

turn off when PV (a) is lower than SP (b).

When the EX lamp (e) is ON but PV (a) is lower than SP (b),

the upper display will be in green color and it shows that the

PV is in the hysteresis area

6.2 LOW LIMIT CONTROL

The HI lamp (d) is OFF

When a measured value (a) is lower than the set point (b),

“EX” lamp (e) lights, and “OUT” lamp (c) turns ON and the

limit output relay is de-energized.

“EX” (e) lamp turns off when PV goes into normal condition,

while the “OUT” lamp (c) lamp stays on as it is.

The out (c) lamp turns off only when the EX lamp (e) is off

and a confi rming operation (rearm) has been done by an

operator.

The way to confi rm are (according to the “dis” parameter):

- pressing

- by DI1.

The confi rming operation is not accepted during PV exceeds

SP (D) (during EXCEEDED lamp lights*). State of output

relay is de-energized whenever “OUT” lamp is on.

Output relay is de-energized whenever “OUT” lamp is on.

Check the “HYS” parameter value if the EX lamp (e) is not

turn off when PV (a) is lower than SP (b).

key for more than 3 seconds or

The HI lamp (d) is ON

When a measured value (a) is higher then the set point

(b),“EX” lamp (e) lights, “OUT” lamp (b) turns ON and the

limit output relay (Out 2) is de-energized.

EX lamp (e) turns off when PV goes into normal condition,

while the ”OUT” lamp (c) stays on as it is.

The out (c) lamp turns off only when the EX lamp (e) is off

and a confi rming operation (rearm) has been done by an

operator.

The way to confi rm are (according to the “diS” parameter):

- pressing

key for more than 3 seconds or

Yokogawa Electric Corporation - TC10-L - ENGINEERING MANUAL - PAG. 12

When the EX lamp (e) is ON but PV (a) is higher than SP

(b), the upper display will be in green color and it shows that

the PV is in the hysteresis area

Page 13

6.3 ACCESS LEVELS AND SPECIFIC

PARAMETERS

The instrument is showing the “standard display”

This instrument is equipped with 3 different access

levels:Level 1 – Operator Mode.(not protected by password)

Level 2 – Operator modify parameter (protected by a programmable password [default 20])

Level 3 – Confi guration parameters mode (protected by programmable password [default 30])

• The operator area (Level 1) allows: confi rmation

action, to see and to reset the << tim >> parameter

(time duration of the last shutdown condition detected)

and to see and to reset the << Min/max >> (minimum

or maximum measured value during last shutdown

condition detected).

Note: when a new shutdown condition is detected, the

instrument automatically reset << tim>> and << min/

max >> parameters and start to memorize the values

related with the new shutdown condition only. At the

end of the shut down condition, <<tim>> and <<min/

max>> can be read and reset.

• The Level 2 area encompasses the following

parameters:

Param. Description

SP Set point (shutdown set point) dP

For high or low alarm, it is the low limit of AL1

AL1L

AL1H

AL2L

AL2H

threshold

For band alarm, it is low alarm threshold

For high or low alarm, it is the high limit of AL1

threshold

For band alarm, it is high alarm threshold

AL1 Alarm 1 threshold dP

For high or low alarm, it is the low limit of AL2

threshold

For band alarm, it is low alarm threshold

For high or low alarm, it is the high limit of AL2

threshold

For band alarm, it is high alarm threshold

AL2 Alarm 2 threshold dP

HyS

Fil Digital filter on the measured value 1

bS PV input bias

Hysteresis of the shutdown control (relay hyster-

esis for control output)

Dec.

Point

dP

dP

dP

dP

dP

6.4 ENTER THE “OPERATOR MODIFY

ARAMETER”

P

The instrument is showing the “standard display”.

1. Press the button for more than 3 seconds;

2. The upper display will show PASS while the lower display

will show 0;

3. By

and

buttons set the value assigned to [44]

PAS2 (Level 2 password).

Notes: 1. The factory default password for confi guration

parameters is equal to 20.

2. All parameter modifi cation are protected by a

time out. If no button is pressed for more than

30 second the instrument comes automatically

back to the Standard display, the new value of the

last selected parameter is lost and the parameter

modifi cation procedure is closed.When you

desire to remove the time out (e.g. for the fi rst

confi guration of an instrument) you can use a

password equal to 1000 plus the programmed

password (e.g. 1000 + 20 [default] = 1020).It is

always possible to manually End the parameter

confi guration procedure (see below).

4. Push

button.

5. The instrument will show on the upper display the

acronym of the fi rst parameter promoted to this level and

on the lower display its value.

6. By

and

buttons assign to this parameter the

desired value.

7. Press the

button in order to memorize the new value

and go to the next parameter.

8. When you want to come back to the “standard display”

push the button for more than 3 s.

6.5 HOW TO SEE BUT NOT MODIFY THE

“OPERATOR MODIFY PARAMETERS

ACCESS PARAMETERS”

Sometime it is necessary to let the possibility to see the

value assigned to the Operator Modify Parameter but it is

important that changes are made by authorized personnel

only.In this cases, proceed as follows:

1. Press the

2. The upper display will show PASS while the lower display

will show 0;

3. By

and

4. Push button;

5. The upper display will show the acronym of the fi rst

parameter promoted to the level 2 and lower display will

show its value;

6. Using

to all parameter present in level 2 but it will not be

possible to modify it;

7. It is possible to come back to the “standard display” by

pushing the

pushing no pushbutton for more than 30 seconds.

button for more than 3 seconds;

button set the value -181;

button it is possible to see the value assigned

button for more than 3 seconds or by

Yokogawa Electric Corporation - TC10-L - ENGINEERING MANUAL - PAG. 13

Page 14

6.6 LIST OF POSSIBLE ERRORS

ErAT Fast Auto-tune cannot start. The measure value is too

close to the set point.

Push the button in order to delete the error message.

ouLd Overload on the out 4

The messages shows that a short circuit is present on

the Out 4 when it is used as output or as a transmitter

power suply.

When the short circuit disappears the output restart to

operate.

NoAt Auto-tune not fi nished within 12 hours.

ErEP Possible problem of the instrument memory.

The messages disappears automatically.

When the error continues, send the instrument to your

supplier.

RonE Possible problem of the fi rmware memory.

When this error is detected, send the instrument to

your supplier.

Errt Possible problem of the calibration memory.

When this error is detected, send the instrument to

your supplier.

7. HARDWARE SPECIFICATIONS

7.6.1 Measuring input

Thermocouples

Type: J,K,S,R,T,N programmable.

Continuity detection current: 250 nA

Engineering Unit: °C or °F programmable.

CJ: automatic compensation from 0 to +55 °C.

CJ temperature drift : 0,04 °C/°C @ 25 °C after a warm-up

(instrument ON) equal to 20 minutes.

Burn-out: full scale.

Calibration: EN584-1, DIN 43710 - 1977

TC

Type

J -50 to 1000 °C -50.0 to 999.9 °C -58 to 1832 °F -58.0 to 999.9°F

K -50 to 1370 °C -50.0 to 999.9 °C -58 to 2498 °F -58.0 to 999.9 °F

S -50 to 1760 °C -50.0 to 999.9 °C -58 to 3200 °F -58 to 999.9 °F

R -50 to 1760 °C -50.0 to 999.9 °C -58 to 3200 °F -58.0 to 999.9 °F

T -70 to 400 °C -70.0 to 400.0 °C -94 to 752 °F -94.0 to 752.0 °F

N -50 to1300°C -50.0 to 999.9°C -58 to 2372°F -58.0 to 999.9 °F

RTD (Resistive Temperature Detector)

Type: Pt 100 - 3 wires

Current injection: 135 µA.

Line resistance: Automatic compensation (PT100 only) up to

20 Ohm/wire with maximum error <+0.1% input span.

Engineering unit: °C or °F programmable.

Burn-out: full scale.

Calibration: DIN 43760, EN 60751/A2

Pt 1000 - 2 wires.

RTD type Ranges

Pt 100 3 wires

PT 1000

- 200.0 to 850.0 °C -328.0 to 999.9 °F

- 200.0 to 850.0 °C -328.0 to 999.9 °F

Ranges

-200 to 850 °C -328 to 1562 °F

-200 to 850 °C -328 to 1562 °F

Linear inputs

Type: 0/12-60 mV, 0/4-20 mA, 0/1-5V, 0/2-10V.

Readout:

programmable from -1999 to 9999

Decimal point: programmable

Input type Input impedance

0/12 to 60 mV > 1 MOhm

0/4 to 20 mA 53 Ohm

0/1 to 5 V or 0/2 to 10 V > 500 kOhm

Digital input

Type: contact free of voltage

contact resistance: 100 Ohm.

Max.

Contact rating: 10 V, 6 mA.

Outputs

Out 1

Available: Optionally

Output action: direct/reverse programmable

Function: retransmission

Output type: 0-20 mA, 4-20 mA, 0-10 V or 2-10V programmable

Isolation: isolated output

Maximum load: 500 Ohm

Yokogawa Electric Corporation - TC10-L - ENGINEERING MANUAL - PAG. 14

Page 15

Out 2

Function: Limiter output

Available: Ever

Output action: Reverse

Output type: relay

Contatto: SPST (NO contact)

Contact rating: - 2A / 250 V c.a. on resistive load.

1 A / 250 V with cosf = 0.4

Out 3

Function: Alarm output

A

vailable: optionally

type : relay o SSR

a) Relay output

Contact type: SPST (No contact)

Contact rating: - 2A / 250 V c.a. on resistive load.

-1 A / 250 V with cosf = 0.4

b) Logic voltage for SSR drive.

Isolation: Output NOT isolated.

Protection: Output protected from short circuit.

1 logic status: 12 V ±20% @ 15 mA.

0 logic status: <0.5 V

Type: RS 485 optionally

Available: on request

Isolation: Isolated (50 V)

Protocol: Modbus RTU

Baud rate: from 1200 to 38400 baud

Multiple reading: max 16 word.

Multiple writing: max 16 word.

Parity: none

Data format: 8 bit

Start Bit : 1

Stop Bit: 1

Out 4 (when programmed)

Function: alarm output

A

vailable: ever

Type : SSR drive

Isolation: Not isolated

Protection : Output protected from short circuit.

Stato logico 1: 12 V ±20% @ 23 mA.

Stato logico 0: <0.5 V

Auxiliary power supply for TX

NOTE: this output is obtained by forcing the out 4 to ON.

Isolation:

Protection : Output protected from short circuit.

Voltage: 12 VDC

Current: 23 mA Max.

Not isolated

Serial interfaces

Type: TTL

A

vailable: ever

Isolation: Not isolated

Protocol: Modbus RTU

Baud rate: from 1200 to 38400 baud

Multiple reading: max 16 word.

Multiple writing: max 16 word.

Parity: none

Data format: 8 bit

Start Bit : 1

Stop Bit: 1

Yokogawa Electric Corporation - TC10-L - ENGINEERING MANUAL - PAG. 15

Page 16

8. GENERAL NOTES

8.1 PROPER USE

Every possible use not described in this manual must be

consider as a improper use.

This instrument is in compliance with EN 61010-1 “Safety

requirements for electrical equipment for measurement,

control and laboratory use”; for this reason it could not be

used as a safety equipment.

Whenever a failure or a malfunction of the control device

may cause dangerous situations for persons, thing or

animals, please remember that the plant has to be equipped

with additional safety devices.

Yokogawa Electric Corporation and its legal representatives do

not assume any responsibility for any damage to people, things

or animals deriving from violation, wrong or improper use or in

any case not in compliance with the instrument’s features.

8.2 WARRANTY

This product is under warranty against manufacturing

defects or faulty materials that are found within 18 months

from manufacturing date. The warranty is limited to the

replacement of the instrument.

The tampering of the instrument or an improper use of the

product will bring about the immediate withdrawal of the

warranty’s effects.

In the event of a faulty instrument, either within the period

of warranty, or further to its expiry, please contact our

sales department to obtain authorisation for sending the

instrument to our company.

8.3 DISPOSAL

Waste Electrical and Electric Equipment (WEEE)

Directive (This directive is valid in the EU

member states).

This product complies with the WEEE Directive

marking requirements.

The following marking indicates that you must

not discard this electrical/electronic product in domestic

household waste.

Product Category

With reference to the equipment types in the WEEE

directive, this product is classifi ed as a “Monitoring and

control instruments”.

Do not dispose of this product in domestic household waste.

When disposing of product in the EU, contact your Yokogawa

Europe B.V. offi ce.

Yokogawa Electric Corporation - TC10-L - ENGINEERING MANUAL - PAG. 16

Page 17

Appendix A

InP Group

N Param. Description Range value or selection list elements

J = TC J

crAL = TC K,

S = TC S,

r = TC R

t = TC T,

n = TC N

Pt1 = PT 100,

1 SEnS Measuring input

2 dP

3 SSc

4 FSc

5 unit

6 FiL

7 bS PV input bias -100 to 100 % of the input span dP

8 di.A Digital Input action

Decimal point figure

Note: For TC and RTD inputs the decimal figure must be 0 or 1 only.

Initial scale readout

NOTE: This parameter will be shown only when a linear input has been selected (mV, V or mA).

Full scale readout

NOTE: This parameter will be shown only when a linear input has been selected (mV, V or mA).

Engineering unit

NOTE: This parameter will be shown only when a TC or RTD input has been selected.

Digital filter on the measured value.

Note: This filter will affect the measured value but also the control action the analogue retransmission and the alarms behaviour.

OUT group

N Param. Description Range value or selection list elements

9 O1.t

10 o1F Out 1 function

11 Ao1L Retransmission – initial scale value -1999 to Ao1H dP

12 Ao1H Retransmission – full scale value Ao1L to 9999 dP

13 o3F

14 o3AL Alarms linked up with Out 3

15 o3Ac Out 3 action

16 o4F Out 4 function

Out 1 type

NOTE: this parameter will be shown only when Out 1 is present

Out 3 function

Available: when Out 3 is present.

0.20 = 0 to 20 mA

4.20 = 4 to 20 mA

0.10 = 0 to 10 Volt

2.10 = 2 to 10 Volt

nonE = Out not used

r.inP = Measure retransmission

r.Err = Error retransmission

r.SP = SP retransmission

r.SEr = Retransmission of a value coming from serial link

nonE = Out not used

AL = Alarm output

or.bo = Over-range and burn-out

P.FAL = Power failure

bo.PF = Over-range, Burn-out and power Fail

from 0 to 15

+1 = Alarm 1

+2 = Alarm 2

+4 = Burn-out

+8 = Overload of the Out 4

dir = Direct action

rEU = Reverse action

nonE = Out not used

AL = Alarm output

or.bo = Over-range and burn-out

P.FAL = Power failure

bo.PF = Over-range, Burn-out and power Fail

On = Output ever ON (usable as auxiliary PWS for a transmitter).

Pt10 = PT 1000,

0.60 = 0 to 60 mV,

12.60 = 12 to 60 mV,

0.20 = 0 to 20 mA,

4.20 = 4 to 20 mA,

0.5 = 0 to 5 V,

1.5 = 1 to 5 V,

0.10= 0 to 10 V

2.10 = 2 to 10 V,

0 to 3 dP

-1999 to 9999 dP

-1999 to 9999 (E.U.) dP

°C or °F

0( oFF) to 20.0 (s) 1

0 = DI1 direct

1 = DI1 reverse

Dec.

point

dP

Decimal

point

0

0

Yokogawa Electric Corporation - TC10 -L - ENGINEERING MANUAL - PAG. 17

Page 18

N Param. Description Range value or selection list elements

from 0 to 7

17 o4AL Alarms linked up with Out 4

+1 = Alarm 1

+2 = Alarm 2

+4 = Burn-out

18 o4Ac Out 4 action

dir = Direct action

rEU = Reverse action

AL1 Group

N Param. Description Range value or selection list elements

nonE = Alarm not used;

LoAb = Absolute low alarm;

HiAb = Absolute high alarm;

LHAo = Absolute band alarm with alarm indication out of the band;

19 AL1t Alarm 1 type

20 Ab1 Alarm 1 function

21 AL1L

22 AL1H

- For High and low alarms, it is the low limit of the AL1 threshold

- For band alarm, it is low alarm threshold

- For High and low alarms, it is the high limit of the AL1 threshold

- For band alarm, it is the high alarm threshold

23 AL1 Alarm 1 threshold AL1L to AL1H (E.U.) dP

24 HAL1 Alarm 1 hysteresis 1 to.9999 (E.U.) dP

25 AL1d Alarm 1 delay 0 (oFF) to 9999 (s) 0

LHAi = Absolute band alarm with alarm indication inside the band;

SE.br = Sensor break;

LodE = Deviation low alarm;

HidE = Deviation high alarm;

LHdo = Relative band alarm with alarm indication out of the band;

LHdi = Relative band alarm with alarm indication inside the band.

from 0 to 3

0 = no function

+1 = not active at power up

+2 = Relative alarm not active at set point change.

-1999 to AL1H (E.U.) dP

AL1L to 9999 (E.U.) dP

Decimal

point

0

Decimal

! gure

0

AL2 Group

N Param. Description Range value or selection list elements

nonE = Alarm not used;

LoAb = Absolute low alarm;

HiAb = Absolute high alarm;

LHAo = Absolute band alarm with alarm indication out of the band;

26 AL2t Alarm 2 type

LHAi = Absolute band alarm with alarm indication inside the band;

SE.br = Sensor break;

LodE = Deviation low alarm;

HidE = Deviation high alarm;

LHdo = Relative band alarm with alarm indication out of the band;

LHdi = Relative band alarm with alarm indication inside the band.

From 0 to 3

27 Ab2 Alarm 2 function

0 = no function

+1 = not active at power up

+2 = Relative alarm not active at set point change.

28 AL2L

29 AL2H

- For High and low alarms, it is the low limit of the AL2 threshold

- For band alarm, it is low alarm threshold

- For High and low alarms, it is the high limit of the AL2 threshold

- For band alarm, it is the high alarm threshold

-1999 to AL2H (E.U.) dP

AL2L to 9999 (E.U.) dP

30 AL2 Alarm 2 threshold AL2L to AL2H (E.U.) dP

31 HAL2 Alarm 2 hysteresis 1 to 9999 (E.U.) dP

32 AL2d Alarm 2 delay 0 (oFF) to 9999 (s) 0

rEG group

N Param. Description Range value or selection list elements

33 Hi.Lo Limit control type

34 r.md Restart mode

35 HyS Hysteresis of the control output From 0.0 to 100% of the input span dP

36 oP.SL Operative display selection

Hi = High limit.

Lo = Low limit.

0 = On > limit output is ON in any case (the instrument start in shutdown condition)

1 = oFF > limit output is OFF when, at power on, PV doesn’t exceed SP.

0 = PU.SP > PV and SP / SP only (lower display)

1 = SP > SP only (lower display)

Decimal

! gure

0

Decimal

! gure

Yokogawa Electric Corporation - TC10 - L - ENGINEERING MANUAL - PAG. 18

Page 19

N Param. Description Range value or selection list elements

37 SPLL Minimum set point value -1999 to SPHL ( E.U.) dP

38 SP.HL Maximum set point value SPLL to 9999 (E.U.) dP

39 SP Set point SPLL to SPHL dP

40 dis The way to confirming operation

41 tim

Duration time when in exceeded (in

shoutdown)

but = by keyboard (button)

di = by digital input

00.00 to 99.59 (HH.mm) 0

42 Hi Maximum measured value In Engineering Units dP

43 Lo Minimum measured value In Engineering Units dP

PAn Group

N Param. Description Range value or selection list elements

44 PAS2 Password level 2 0 (oFF) to 200 0

45 PAS3 Password level 3 3 to 200 0

0 = The display color is used to show the Exceeded condition.

46 di.CL Display color

1 = fixed red display

2 = fixed green display

3 = fixed amber display

47 diS.t Display time-out 0 (OFF) to 99.59 (mm.ss) 2

SEr group

N Param. Description Range value or selection list elements

48 Add Address 0 (oFF) to 254 0

1200

49 bAud Baud rate

2400

9600

19.2

38.4

Decimal

• gure

Decimal

• gure

0

Decimal

• gure

CAL group

N Param. Description Range value or selection list elements

50 A.L.P Adjust low Point -1999 to A.H.P-10 (E.U.) dP

51 A.L.o Adjust low Offset -300 to 300 (E.U.) dP

52 A.H.P Adjust High Point A.L.P +10 to 9999 (E.U.) dP

53 A.H.o Adjust High Offset -300 to 300 (E.U.) dP

Decimal

• gure

Yokogawa Electric Corporation - TC10 -L - ENGINEERING MANUAL - PAG. 19

Page 20

Yokogawa Electric Corporation - TC10 - L - ENGINEERING MANUAL - PAG. 20

Loading...

Loading...