Page 1

Serial communication protocol

Modbus® for TC10

Document number: IM 05C01E81-03EN

Third edition: Feb. 2018

Yokogawa Electric Corporation - TC10 - PROTOCOL MANUAL 1

Page 2

Yokogawa Electric Corporation TC10 Communication Protocol

TC10 COMMUNICATION PROTOCOL

Index

1 Preface ...................................................................................................................3

2 Physical connection ..............................................................................................3

2.1 Interface ................................................................................................................................3

2.2 Line ........................................................................................................................................ 3

3 Communication protocol ...................................................................................... 3

3.1 Function code 3: read multiple registers (max. 16 registers for TC10) .................................. 4

3.2 Function code 6: write a single word (one location) ..............................................................5

3.3 Function code 16: preset multiple registers (maximum 16 registers for TC10) .....................5

3.4 The exception reply ...............................................................................................................6

3.5 Cyclic redundancy check (CRC) ...........................................................................................6

4 Data exchange ....................................................................................................... 8

4.1 Some definitions .................................................................................................................... 8

4.2 Memory zones ....................................................................................................................... 8

4.3 Variables zones .....................................................................................................................8

4.4 Most important changes ........................................................................................................ 8

2 Yokogawa Electric Corporation - TC10 - PROTOCOL MANUAL

Page 3

Yokogawa Electric Corporation TC10 Communication Protocol

1 PREFACE

TC10 uses Modbus® RTU communication protocol. Modbus is a royalty free protocol and is easy to be implemented. For Modbus RTU a

vast literature is available also in internet.

The Modbus protocol represent all data in hexadecimal format. All communication string finish with a check sum type CRC (cyclic

redundancy check).

Each device on a line must have different address. The protocol allows one master only and up to 255 slaves

Only the Master unit can start the transmission by sending the address of the unit and the command to be executed. Only the unit having

the correct address will answer to the master.

The transmission characteristics are usually programmable:

Device address: From 1 to 255.

Baud rate: bit per second.

byte format:

– 1 start bit;

– 8 data bitis;

– 2 final bits composed as follows:

1 parity bit (even or odd);

1 stop bit;

or

no parity bit;

2 stop bits.

The TC10 allows to configure:

– address (1 to 254);

– Baud rate (1200 – 2400 – 9600 – 19200 – 38400).

The byte format is fixed: 8 bits without parity and 1 stop bit.

This document is intended to describe the TC10 controllers using the Modbus protocol in their communication capability and is mainly

directed to technicians, system integrators and software developers.

2 PHYSICAL CONNECTION

2.1 Interface

TC10 controllers are provided with a RS485 serial communication interface, insulated so that any problem arising from ground potential is

removed.

While at rest, the instruments are in a receive condition and are revert to transmission after a correct message has been decoded that

matches the configured address.

2.2 Line

The instruments are equipped with 2 terminals named A and B.

The connection between TC10s has to be carried on in parallel, i.e. all A terminals have to be connected between them so as B terminals.

A termination resistor of 120W is required to maintain the quiescent condition on the line.

Adopted baud rates range 1200 to 38400 baud, that is very satisfactory for application performances, yet very slow for RS485 interface.

This fact allows the wiring of the line with a medium quality twisted pair cable: total capacity of the line should not exceed 200 nF.

The line can be up to 1000 meters in length.

3 COMMUNICATION PROTOCOL

The protocol adopted by

protocol, so that connections are easy for many commercial PLCs and supervisory programs.

For users needing to develop their own communication software, all information is available as well as implementation hints.

The Modbus RTU (JBUS) communication functions implemented in TC10 series are:

Function 3 Read n register;

Function 6 Preset one register;

Function 16 Preset multiple registers.

These functions allow the supervisory program to read and modify any data of the controller. The communication is based on messages

sent by the master station (host) to the slave stations (TC10) and viceversa. The slave station that recognises the message as sent to it,

analyses the content and, if it is formally and semantically correct, generates a reply message directed back to the master.

TC10

is a subset of the widely used Modbus RTU (JBUS, AEG Schneider Automation, Inc. registered trade mark)

Yokogawa Electric Corporation - TC10 - PROTOCOL MANUAL 3

Page 4

Yokogawa Electric Corporation TC10 Communication Protocol

The communication process involves five types of messages:

From master to slave From slave to master

Function 3: read n registers request Function 3: read n registers reply

Function 6: preset one register request Function 6: preset one register reply

Function 16: preset multiple registers request Function 16: preset multiple registers reply

Exception reply (as reply to all functions in abnormal conditions)

All messages contain four fields:

◊ Slave address (from 1 to 255): Modbus RTU (JBUS) reserves address 0 for broadcasting messagesand it is implemented in the TC10 series;

◊ Function code: contains 3, 6 or 16 for specified functions;

◊ Information field: contains data like word addresses and word values as required by function in use;

◊ Control word: a cyclic redundancy check (CRC) performed with particular rules for CRC16.

The characteristics of the asyncronous transmission are 8 bits, no parity, one stop bit.

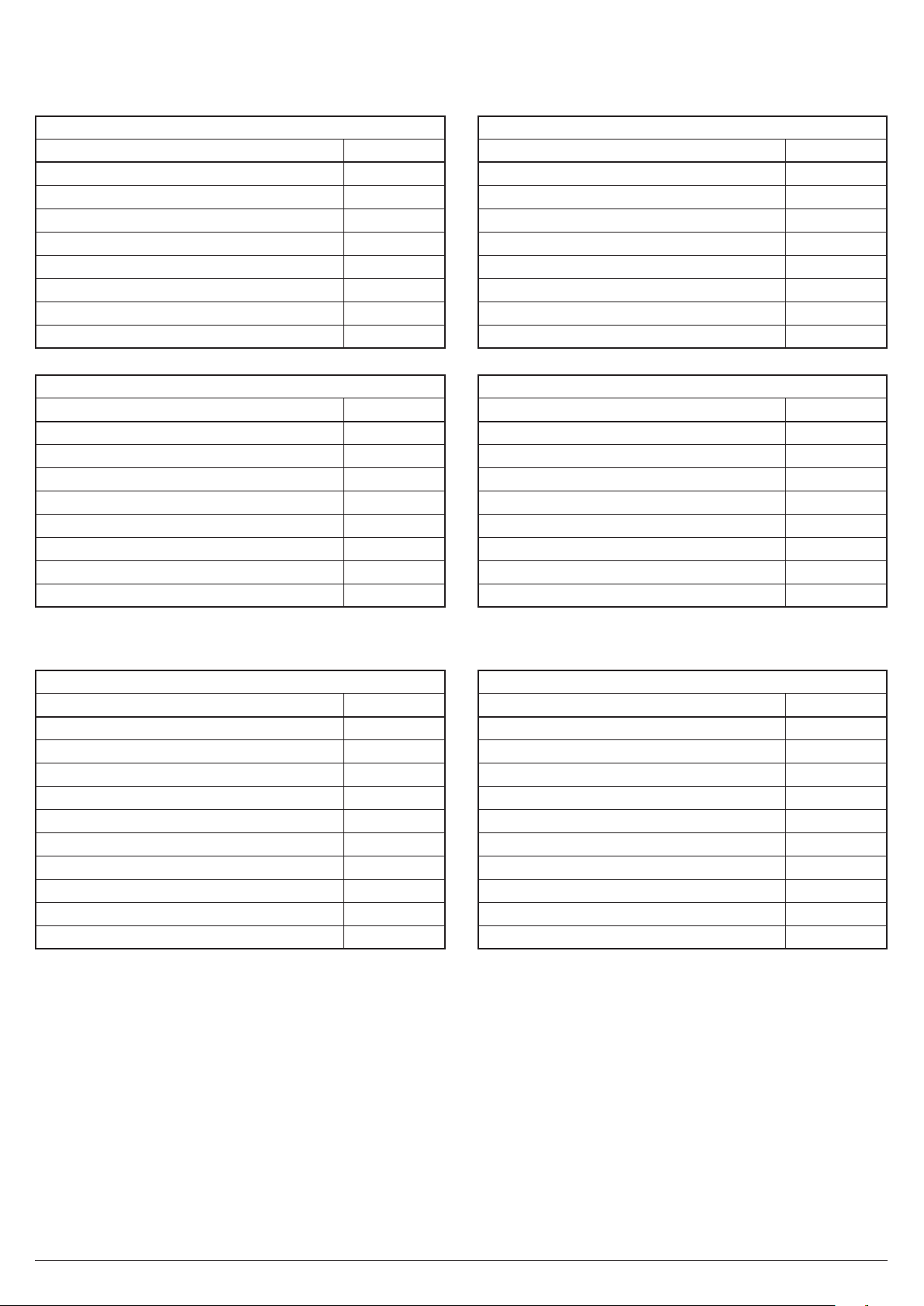

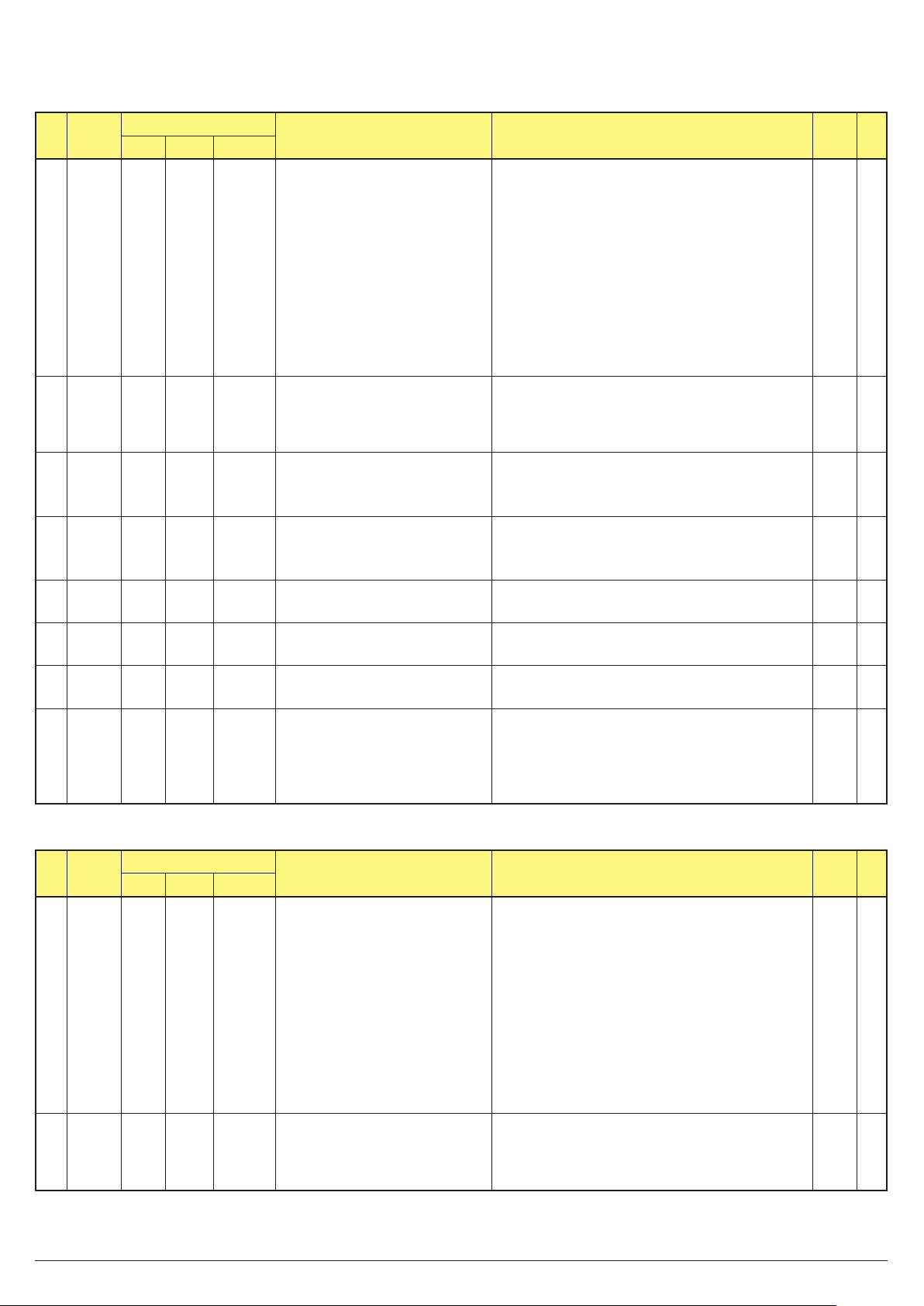

3.1 Function code 3: read multiple registers (max. 16 registers for TC10)

This function code is used by the master to read a group of sequential registers present in the slave.

Master request Slave reply

Data Byte Data Byte

Slave address (1 to 255) 1 Slave address (1 to 255) 1

Function code (3) 1 Function code (3) 1

First register address (MSB = Most Significant Byte)

First register address (LSB = Less Significant Byte)

Number of requested registers (MSB) 1 CRC-16 (LSB) 1

Number of requested registers (LSB) 1 CRC-16 (MSB) 1

CRC-16 (LSB) 1

CRC-16 (MSB) 1

In the “Data(s)” fild the values of the requested registers are presented in word format [2 byte]: the first byte represent the MSB (Most

Significant Byte) while the second byte represent the LSB (Less Significant Byte). This mode will be the same for all requested locations.

Example: The master requires to the address 1 the value of the locations 25 and 26 (0x19 and 0x1A).

1 Byte number (n) 1

1 Data(s) n

Master request Slave reply

Data Byte (Hex) Data Byte (Hex)

Slave address 01 Slave address 01

Function code (3 = read) 03 Function code (3 = read) 03

First register address (MSB)

First register address (LSB)

Number of requested registers (MSB) 00 Value of the first register (LSB) 0A

Number of requested registers (LSB) 02 Value of the second register (MSB) 00

CRC-16 (LSB) 15 Value of the second register (LSB) 14

CRC-16 (MSB) CC CRC-16 (LSB) DA

The slave replay means:

The value of the location 25 = 10 (0x000A hexadecimal)

The value of the location 26 = 20 (0x0014 hexadecimal)

00 Byte number 04

19 Value of the first register (MSB) 00

CRC-16 (MSB) 3E

4 Yokogawa Electric Corporation - TC10 - PROTOCOL MANUAL

Page 5

Yokogawa Electric Corporation TC10 Communication Protocol

3.2 Function code 6: write a single word (one location)

Master request Slave reply

Data Byte (Hex) Data Byte (Hex)

Slave address 01 Slave address (1-255) 1

Function code (6) 06 Function code (6) 1

Register address (MSB)

Register address (LSB)

Value to write (MSB) 00 Written value (MSB) 1

Value to write (LSB) 0A Written value (LSB) 1

CRC-16 (MSB) A8 CRC-16 (MSB) 1

CRC-16 (LSB) 49 CRC-16 (LSB) 1

Example: The master unit asks to the slave 1 to write in the memory location 770 (0x302) the value 10 (0x0A).

Master request Slave reply

Data Byte (Hex) Data Byte (Hex)

Slave address 01 Slave address 01

Function code (6) 06 Function code (6) 06

Register address (MSB)

Register address (LSB)

Value to write (MSB) 00 Written value (MSB) 00

Value to write (LSB) 0A Written value (LSB) 0A

CRC-16 (MSB) A8 CRC-16 (MSB) A8

CRC-16 (LSB) 49 CRC-16 (LSB) 49

03 Register address (MSB) 1

02 Register address (LSB) 1

03 Register address (MSB) 03

02 Register address (LSB) 02

3.3 Function code 16: preset multiple registers (maximum 16 registers for TC10)

This function code allows to preset 16 registers at a time.

Master request Slave reply

Data Byte (Hex) Data Byte (Hex)

Slave address (1-254) 1 Slave address (1-254) 1

Function code (16) 1 Function code (16) 1

First register address (MSB)

First register address (LSB)

Number of requested registers (MSB) 1 Number of written registers (MSB) 1

Number of requested registers (LSB) 1 Number of written registers (LSB) 1

Byte count 1 CRC-16 (LSB) 1

Values n CRC-16 (MSB) 1

CRC-16 (LSB) 1

CRC-16 (MSB) 1

Example: The master unit requires to the slave 1 to write in the registers 10314 (0x284A) and 10315 (0x284B) the values 100 (0x64) and

200 (0xC8)

1 First register address (MSB) 1

1 First register address (LSB) 1

Yokogawa Electric Corporation - TC10 - PROTOCOL MANUAL 5

Page 6

Yokogawa Electric Corporation TC10 Communication Protocol

Master request Slave reply

Data Byte (Hex) Data Byte (Hex)

Slave address 01 Slave address 01

Function code (16) 10 Function code (16) 10

First register address (MSB) 28 First register address (MSB) 28

First register address (LSB) 4A First register address (LSB) 4A

Number of requested registers (MSB) 00 Number of written registers (MSB) 00

Number of requested registers (LSB) 02 Number of written registers (LSB) 02

Byte count 04 CRC-16 (LSB) 69

Value 1 (MSB) 00 CRC-16 (MSB) BE

Value 1 (LSB) 64

Value 2 (MSB) 00

Value 2 ((LSB) C8

CRC-16 (LSB) C9

CRC-16 (MSB) A8

3.4 The exception reply

TC10 replies with an exception when the request is formally correct, but cannot be satisfied standing particular situations; the reply

contains a code indicating the cause of the missing regular reply, the frame is:

Exception replay

Data Byte (Hex)

Slave address 1

Function code 1

Error code 1

CRC-16 (LSB) 1

CRC-16 (MSB) 1

TC10 adopts a subset of Modbus RTU (JBUS) exception code:

– unknown function code 1

– invalid memory address 2

– invalid data field 3

– controller not ready 6

3.5 Cyclic redundancy check (CRC)

CRC is a check word that permits to verify the integrity of a message. Every message, sent or received, has in the two last characters the

CRC check word.

After receiving a request, the controller checks the validity of the received message comparing the received CRC with the calculated one.

When a reply is ready the controller calculates the CRC word and adds two characters to the prepared message. CRC calculation is

performed on every character of the message, excluding the last two.

6 Yokogawa Electric Corporation - TC10 - PROTOCOL MANUAL

Page 7

Yokogawa Electric Corporation TC10 Communication Protocol

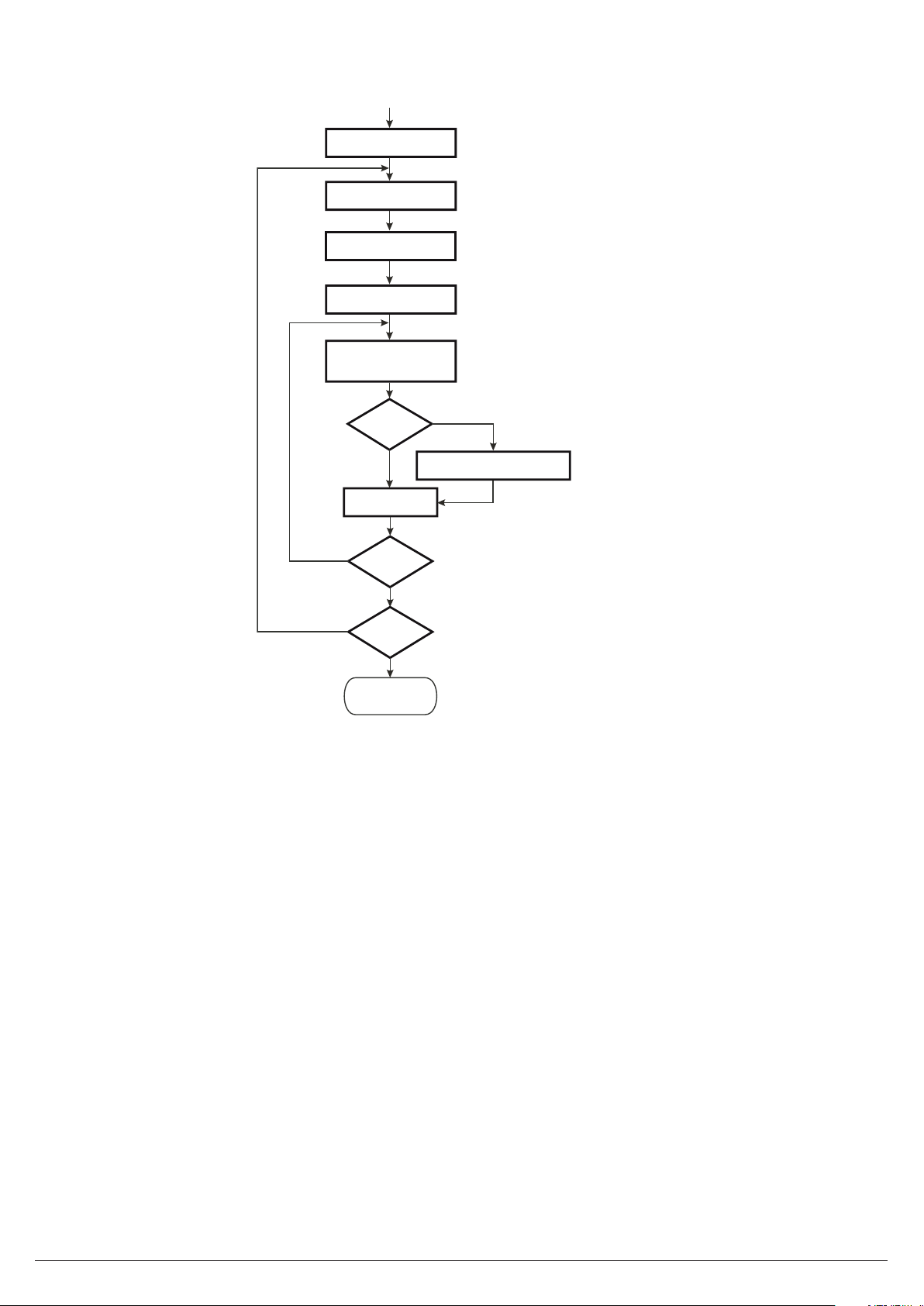

Being Modbus RTU (JBUS) compatible, TC10 controllers adopt an identical algorithm for CRC calculation, sketched in following diagram:

CRC = FFFF hex

next character

CRC = CRC exor char

n = 0

Shift on the left of

CRC in the carry

Carry = 1?

NO

n = n + 1

YES

N < 8?

YES

Other

character?

The CRC

calculation

is finished

YES

CRC = CRC exor POLY

NO

NO

The polinomial adopted by Modbus RTU (JBUS) is 1010 0000 0000 0001.

Note: The first transmitted character of the CRC word is the least significant between calculated bytes.

A subrutine made with “C” able to calculate the CRC-16 follows.

/* --------------------------------------------------------------crc_16 Calculation of CRC-16

Input parameters:

buffer: character string to compute the CRC-16

length: number of bytes in the string

This function returns the value of the CRC-16

--------------------------------------------------------------- */

unsigned int crc_16 (unsigned char *buffer, unsigned int length)

{

unsigned int i, j, temp_bit, temp_int, crc;

crc = 0xFFFF;

for (i = 0; i < length; i++){

temp_int = (unsigned char) *buffer++;

crc ^= temp_int;

for (j = 0; j < 8; j++) {

temp_bit = crc & 0x0001;

crc >>= 1;

if (temp_bit != 0)

crc ^= 0xA001;

}

}

return (crc);

}

Note: All numerical values in the format 0x.... are expressed in hexadecimal format.

Yokogawa Electric Corporation - TC10 - PROTOCOL MANUAL 7

Page 8

Yokogawa Electric Corporation TC10 Communication Protocol

4 DATA EXCHANGE

This section contains informations about data exchanged with TC10 series controllers concerning numerical and not numerical data, with

their formats and limits.

4.1 Some definitions

All exchanged data are in the form of 16 bit words.

Two types of data are distinguished: numerical and symbolic (or not numerical).

Numerical data represents the value of a quantity (e.g. the measured variable, the set point).

Symbolic data represents a particular value in a set of values (e.g. the thermocouple type in the set of available ones: J, K, S, etc.).

Both types are coded as integers number: signed numbers for numerical and unsigned numbers for symbolic.

A numerical data, coded as an integer, is coupled with appropriate number of decimal digits to represent a quantity with the same

engineering units adopted aboard the instrument.

Numerical data are in fixed point representation; however we make a distinction between two kind of data:

◊ The first kind has determined and unmodifiable decimal point position;

◊ The second has programmable decimal point position (dP parameter).

4.2 Memory zones

All readable and writable data appear to be allocated as 16 bit words in the memory of the instrument.

The memory map has three zones:

◊ Varaibles,

◊ Parameters,

◊ Instrument identification code.

Following parameters explore the characteristics of each zone.

4.3 Variables zones

In this zone there is a collection of main TC10 controller variables, it is a group of frequently computed or updated data residing in volatile

memory.

4.4 Most important changes

A) During parameter modification by push-button, the serial interface continue to operate without any “limit” (you can see

by serial link the value of all parameters and you can set it also).

B) When you write a value in a location the instrument will operate as follows:

B.1) If you write a value within parameter range, the instrument will accept it; the new value will be memorized and the

instrument will send back the standard answer.

B.2) If you try to write a value OUT of parameter range, the instrument will refuse the new value; the new value will NOT be

memorized and the instrument will send an exception message to the master.

8 Yokogawa Electric Corporation - TC10 - PROTOCOL MANUAL

Page 9

Yokogawa Electric Corporation TC10 Communication Protocol

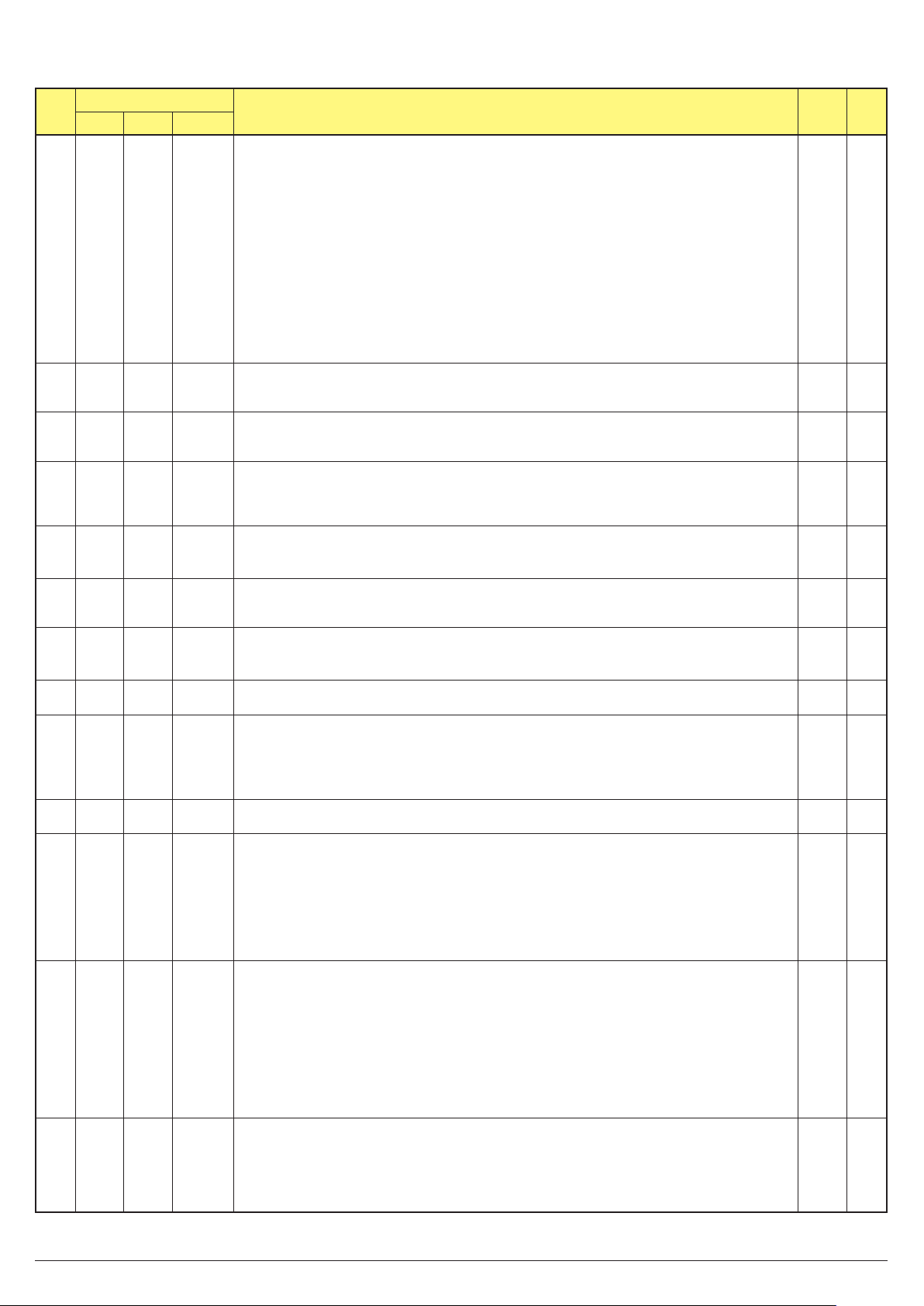

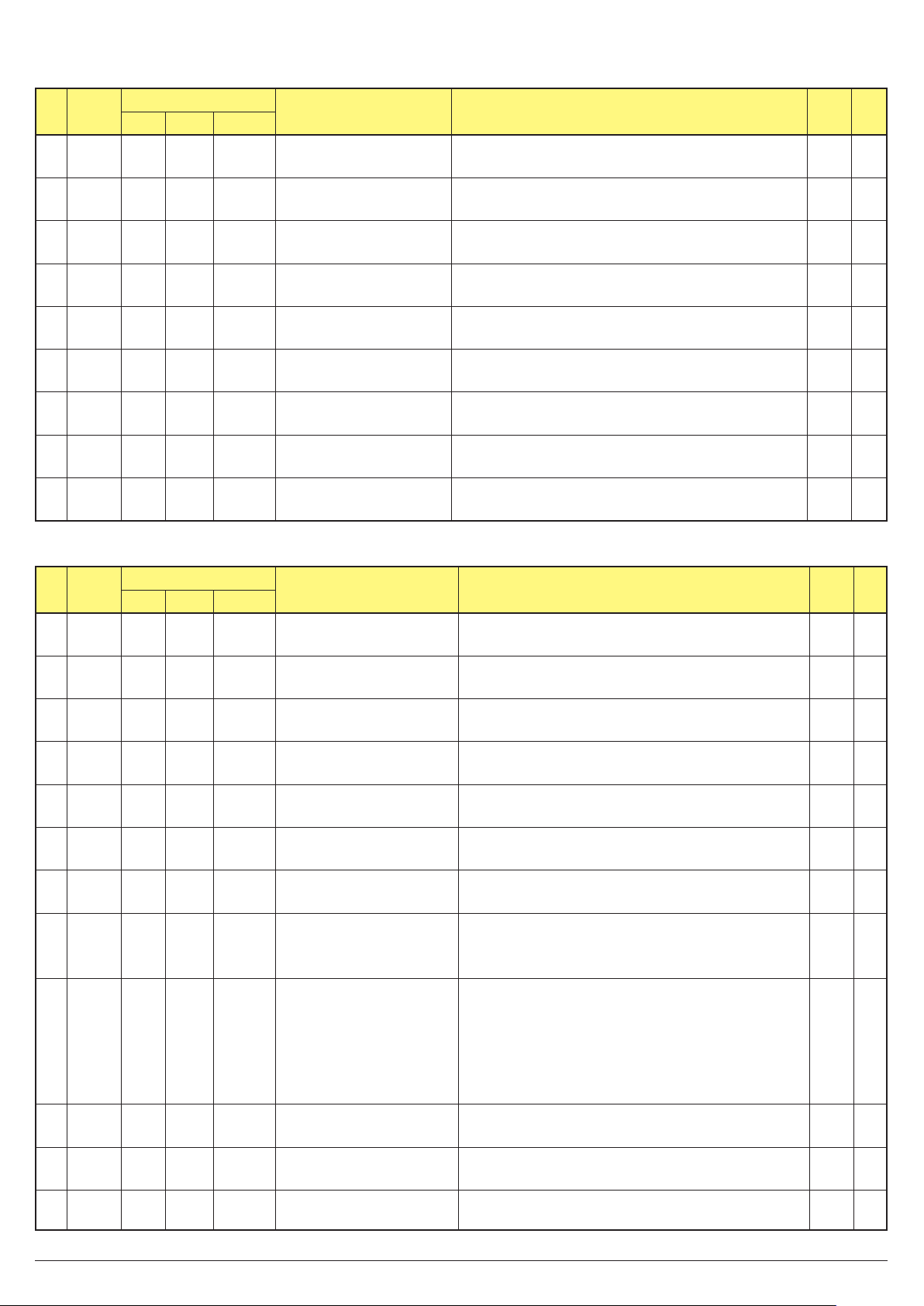

5 ADDRESS MAP

The instrument use only words:

Initial address Final address

Hex Dec Hex Dec

1 1 1D 29 Numeric values calculated and dinamically updated. Available in read and write operations

200 512 250 592 Numeric values calculated and dinamically updated. Available in read and write operations

280 640 31B 795 Configuration parameters: Numeric and symolic values. Available in read and write operations

Mining

2800 10240 289B 10395

5.1 Common Variables

no.

1A 1 1 40002

2A 2 2 40003

3A 3 3 40004

4A 4 4 40005

5A 5 5 40006

6A 6 6 40007

7A 7 7 40008

8A 8 8 40009

9A 9 9 40010

10A A 10 40011

11A B 11 400412

Address

Hex Dec Ref. no.

PV: Measured value

Note: When a measuring error is detected the instrument sends:

Number of decimal figures of the measured value

Operative set point (value)

Power output

Range: -100.00 to 100.00 (%)

Note: This parameter is always writeable but it will be active only when the instrument

Active set point selection

0 = SP

1 = SP 2

2 = SP 3

3 = SP 4

SP

Range: SPLL to SPLH

SP 2

Range: SPLL to SPLH

SP 3

Range: SPLL to SPLH

SP 4

Range: SPLL to SPLH

Alarms status

bit 0 = Alarm 1 status

bit 1 = Alarm 2 status

bit 2 = Alarm 3 status

bit 3 to 8 = Reserved

bit 9 = LBA status

bit 10 = power feilure indicator

bit 11 = Generic error

bit 12 = Overload alarm

bit 13 to 15 = Reserved

Outputs status (physical outputs)

bit 0 = Output 1 status

bit 1 = Output 2 status

bit 3 = Output 3 status

bit 4 = Output 4 status

bit 5 = Output 5 status

bit 6 to 15 = Reserved

When an output is driven by serial link, the relative bit will remain equal to 0.

Repetition of the configuration parameters: Numeric and symolic values. Available in read and write

operations

Description

• 10000 = Underrange

• 10000 = Overrange

• 10001 = Overflow of the A/D converter

• 10003 = Variable not available

operates in Manual mode.

Dec.

Point

r

0 r

dP r

2 r/w

0 r/w

dP r/w

dP r/w

dP r/w

dP r/w

0 r

0 r

r/w

Yokogawa Electric Corporation - TC10 - PROTOCOL MANUAL 9

Page 10

Yokogawa Electric Corporation TC10 Communication Protocol

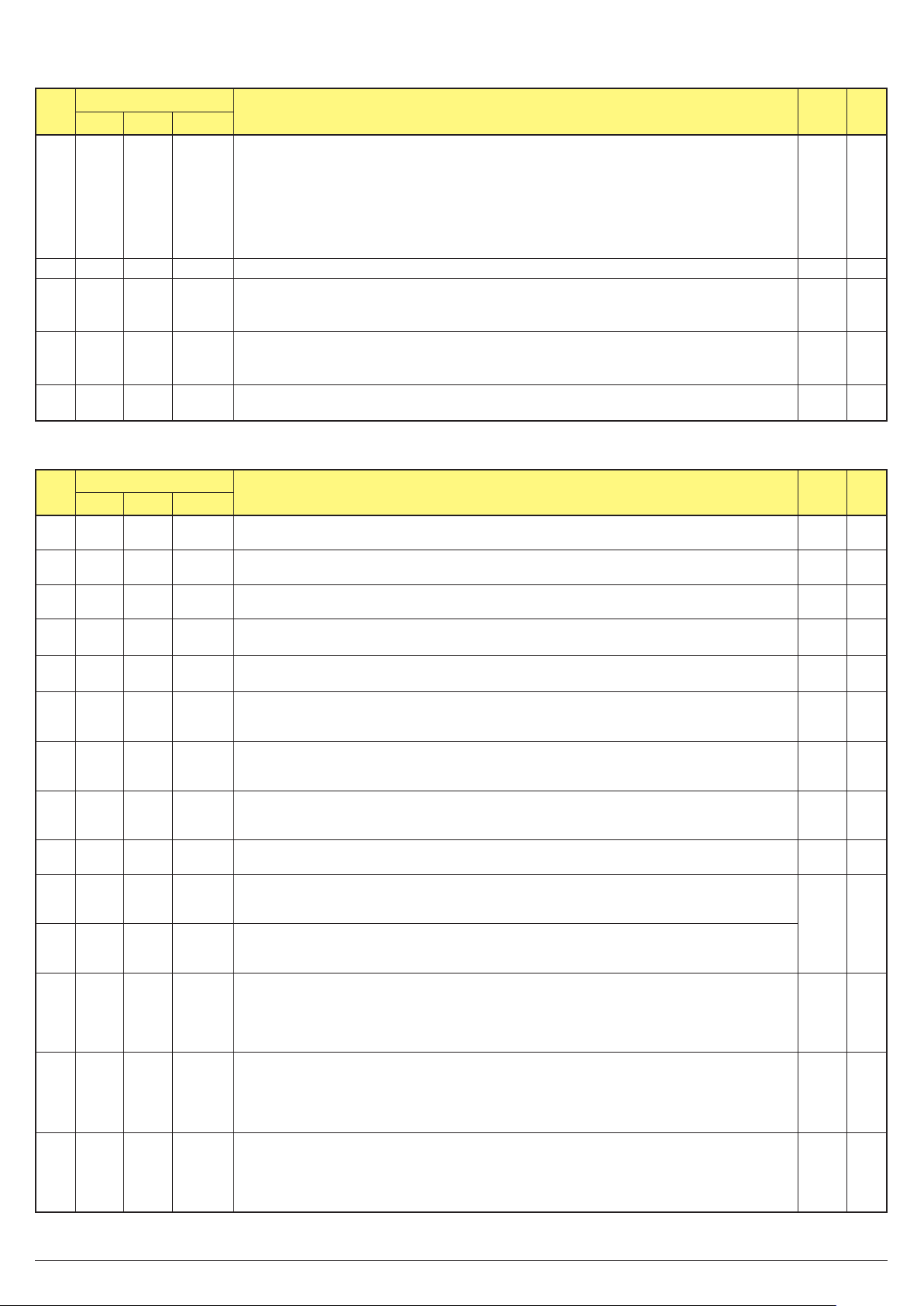

no.

12A C 12 40013

13A D 13 40014

14A E 14 40015

15A F 15 40016

16A 10 16 40017

17A 11 17 40018

18A 12 18 40019

19A 13 19 40020

20A 14 20 40021

21A 15 21 40022

22A 16 22 40023

23A 17 23 40024

24A 18 24 40025

Address

Hex Dec Ref. no.

Description

Instrument status

bit 0 = Automatic

bit 1 = manual

bit 2 = Standby

bit 3 = Remote Set point (temporary) used

bit 4 = Auto-tuning active

bit 5 = Self tuning active

bit 6 = Reserved

bit 7 = Reserved

bit 8 = Soft start running

bit 9 = Ramp for set point change (up or down) running

bit 10 = Delay at start up (od) running

bit 11 = Reserved

bit 12 = Measure status (0 = OK while 1 = error).

bit 13 to 15 = Reserved

Alarms reset

0 = Not resetted

1 = Resetted

Alarms acknowledge

0 = Not acknowledged

1 = Acknowledged

Control status

0 = Automatic

1 = Manual

2 = Stand-by

Remote set point (temporary) (from serial link)

Range: SPLL to SPLH

Note: the remote set point is stored in RAM

Auto tuning activation

0 = not active

1 = active

Power output used when a measuring error is detected.

Range: -100 to 100

Note: This value is stored in RAM

Default parameters loading.

481 = Default parameter loading

Parameters table identification code

Range: 0 to 65535

Note: The word is composed by two parts:

- Low byte – Version of the parameter table

- High byte – Version of the family protocoll

Instrument identification code

20 = TC10

First temporary code for speed configuration

The code is composed by two distinct 4 digits subcodes:

AABB where:

= Input type: 0 to 25

AA

BB = Control type and service functions 0 to 21

Note: 10000 = Temporary value not inserted

The programmed codes will be activated only after both have been correctly be programmed. The order has no importance.

Second temporary code for speed configuration

The code is composed by two distinct 4 digits subcodes:

CDEF where:

= Alarm type 1: 0 to 9

C

D = Alarm type 2: 0 to 9

E = Alarm type 3: 0 to 9

F = Enabling service functions: 0 to 4

Note: 10000 = Temporary value not inserted

The programmed codes will be activated only after both have been correctly be programmed. The order has no importance.

First final code for speed configuration

When programmed, the code is composed by two distinct 4 digits subcodes:

AABB where:

= Input type: 0 to 25

AA

BB = Control type and service functions: 0 to 21

If not programmed, the return value is -1 = Code not programmed.

Dec.

Point

0 r

0 r/w

0 r/w

0 r/w

dP r/w

0 r/w

0 r/w

0 r/w

0 r

0 r

0 r/w

0 r/w

0 r

r/w

10 Yokogawa Electric Corporation - TC10 - PROTOCOL MANUAL

Page 11

Yokogawa Electric Corporation TC10 Communication Protocol

no.

25A 19 25 40026

26A 1A 26 40027

27A 1B 27 40028

28A 1C 28 40029

29A 1D 29 40030

Address

Hex Dec Ref. no.

Second temporary code for speed configuration

When programmed, the code is composed by two distinct 4 digit subcodes:

CDEF where:

= Alarm type 1: 0 to 9

C

D = Alarm type 2: 0 to 9

E = Alarm type 3: 0 to 9

F = Enabling service functions: 0 to 4

If not programmed, the return value is -1 = Code not programmed.

Reserved

Manual autotuning start request pending for Od or Soft start

Range: 0 = No pending request waiting for the execution;

1 = Pending request waiting for the execution

Autotuning start request pending for setpoint change for Od or Soft start

Range: 0 = No pending request waiting for the execution;

1 = Pending request waiting for the execution

Value to be retransmitted on the analogue Output

Range: Ao1L to Ao1H

5.2 Common variables (continued)

no.

1B 0200 512 40513

2B 0201 513 40514

3B 0202 514 40515

4B 0203 515 40516

5B 0204 516 40517

6B 0205 517 40518

7B 0206 518 40519

8B 0207 519 40520

9B 0208 520 40521

10B 020A 522 40523

11B 020E 526 40527

12B 020F 527 40528

13B 0224 548 40549

14B 0225 549 40550

Address

Hex Dec Ref. no.

PV : Measured value

As address 1

Number of decimal figure of the measured value

As address 2

Power output

As address 4

Power output of the heating output

Range: 0 to 100.00 (%)

Power output of the cooling output

Range: 0 to 100.00 (%)

Alarm 1 status

0 = OFF

1 = ON

Alarm 2 status

0 = OFF

1 = ON

Alarm 3 status

0 = OFF

1 = ON

Operative set point

As address 3

LBA status

0 = OFF

1 = ON

Overload alarm status

0 = OFF

1 = ON

Controller status

0 = Stand-by

1 = Auto

2 = Tuning

3 = Manual

Status/remote control of the Output 1

0 = OFF

1 = ON

Note: This parameter is writeable when out 1 is “not used” by the controller (o1F output 1

function = nonE). This parameter is stored in RAM

Status/remote control of the Output 2

0 = OFF

1 = ON

Note: This parameter is writeable when out 2 is “not used” by the controller (o2F output 1

function = nonE). This parameter is stored in RAM

Description

Description

Dec.

Point

0 r

0 r

0 r

0 r

0 r/w

Dec.

Point

dP r

0 r

2 r

2 r

2 r

0 r

0 r

0 r

DP r

0 r

0 r

0 r/w

0 r/w

r/w

r/w

Yokogawa Electric Corporation - TC10 - PROTOCOL MANUAL 11

Page 12

Yokogawa Electric Corporation TC10 Communication Protocol

no.

15B 0226 550 40551

16B 0227 551 40552

17B 0240 576 40577

18B 0241 577 40578

19B 0244 580 40581

20B 0245 581 40582

21B 0246 582 40583

22B 0247 583 40584

23B 0248 584 40585

24B 0249 585 40586

25B 024A 586 40587

26B 024B 587 40588

27B 024C 588 40589

28B 0250 592 40593

Address

Hex Dec Ref. no.

Description

Status/remote control of the Output 3

0 = OFF

1 = ON

Note: This parameter is writeable when out 3 is “not used” by the controller (o3F output 1

function = nonE). This parameter is stored in RAM

Status/remote control of the Output 4

0 = OFF

1 = ON

Note: This parameter is writeable when out 4 is “not used” by the controller (o4F output 1

function = nonE). This parameter is stored in RAM

Digital input 1 status

0 = OFF

1 = ON

Note: Digital input 1status can be read from the serial port even if the input is not used by

the controller

Digital input 2 status

0 = OFF

1 = ON

Note: Digital input 2 status can be read from the serial port even if the input is not used by

the controller

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Wattmeter:

The meaning of this parameter is defined by the CO.ty parameter setting.

0 CO.ty = 0ff

kW CO.ty = 1

kWh CO.ty = 2

CO.ty = 3 Reserved

Worked days CO.ty = 4

Worked hours CO.ty = 5

Reserved

Days counted with the controller Powered ON

Range: 0 to 9999

Power output when the instrument is in manual mode

Range:-10000 to 10000 (%)

Dec.

Point

0 r/w

0 r/w

0 r/w

0 r/w

0 r

0 r

0 r

2 r/w

r/w

5.3 Parameters Setting: Addresses from 280 hex (640 dec) and 2800 hex (10240 dec)

5.3.1 inP GROUP - Main and auxiliary input configuration

no. Param.

1 SEnS

2 dp

Address

Hex Dec Ref. no.

280

2800

281

2801

640

10240

641

10241

40641

40642

Description Values

Input Type

Decimal Point Position (linear inputs)

Decimal Point Position (different

than linear inputs)

0 = J = TC J,

1 = crAL = TC K,

2 = S = TC S,

3 = r = TC R,

4 = t = TC T,

5 = Reserved,

6 = Reserved,

7 = Pt1 = RTD Pt100,

8 = Pt10 = RTD Pt1000,

9 = 0.60 = 0 to 60 mV,

10 = 12.60 = 12 to 60 mV,

11 = 0.20 = 0 to 20 mA,

12 = 4.20 = 4 to 20 mA,

13 = 0.5 = 0 to 5 V,

14 = 1.5 = 1 to 5 V,

15 = 0.10 = 0 to 10 V,

16 = 2.10 = 2 to 10 V

0 to 3

0/1

Dec.

Point

0 r/W

0 r/w

r/w

12 Yokogawa Electric Corporation - TC10 - PROTOCOL MANUAL

Page 13

Yokogawa Electric Corporation TC10 Communication Protocol

no. Param.

3 SSC

4 FSc

5 unit

6 Fil

7 inE

8 oPE

9 IO4.F

10 diF1

11 diF2

12 di.a

Address

Hex Dec Ref. no.

282

2802

283

2803

284

2804

285

2805

286

2806

287

2807

288

2808

289

2809

28A

280A

31C

289C

642

10242

643

10243

644

10244

645

10245

646

10246

647

10247

648

10248

649

10249

650

10250

796

10396

40643

40644

40645

40646

40647

40648

40649

40650

40651

40797

Description Values

Initial scale read-out for linear inputs

Full Scale Readout for linear inputs -1999 to 9999 dP r/w

Engineering unit

Digital filter on the measured value

Note: This filter affects the control

action, the PV retransmission

and the alarms action.

Sensor error used to enable the

safety output value

Safety output value (% of the output)

I/O 4 function

Digital Input 1 function

Digital Input 2 function

Digital Inputs Action

(DI2 only if configured)

-1999 to 9999 dP r/w

0 = C = °C

1 = F = °F

0 (OFF) to 200 (in seconds) 1 r/w

or = Over range

ou = Under range

our = Over and under range

-100 to 100 0 r/w

0 = on = Output used as PWS for TX,

1 = out4 = Output 4 (digital output 4),

2 = dG2c = Digital input 2 driven by contact,

3 = dG2U = Digital input 2 driven by voltage

0 = oFF = Not used,

1 = Alarm reset,

2 = Alarm acknowledge (ACK),

3 = Hold of the measured value,

4 = Stand by mode,

5 = Manual mode,

6 = HEAt with SP1 and CooL with SP2,

7 to 17 = Reserved,

18 = Sequential SP selection,

19 = SP1 - SP2 selection,

20 = SP1 to SP4 binary selection,

21 = Digital inputs in parallel to / keys

0 = oFF = Not used,

1 = Alarm reset,

2 = Alarm acknowledge (ACK),

3 = Hold of the measured value,

4 = Stand by mode,

5 = Manual mode,

6 = HEAt with SP1 and CooL with SP2,

7 to 17 = Reserved,

18 = Sequential SP selection,

19 = SP1 - SP2 selection,

20 = SP1 to SP4 binary selection,

21 = Digital inputs in parallel to / keys

0 = DI1 direct action, DI2 direct action

1 = DI1 reverse action, DI2 direct action

2 = DI1 direct action, DI2 reverse action

3 = DI1 reverse action, DI2 reverse action

Dec.

Point

0 r/w

0 r/w

0 r/w

0 r/w

0 r/w

0 r/w

r/w

Yokogawa Electric Corporation - TC10 - PROTOCOL MANUAL 13

Page 14

Yokogawa Electric Corporation TC10 Communication Protocol

5.3.2 Out group

no. Param.

13

14 o1F

15

16

17 o1AL

18 o1Ac

19 o2F

20 o2AL

21 o2Ac

22 o3F

23 o3AL

24 o3Ac

25 o4F

26 o4AL

27 o4Ac

Address

Hex Dec Ref. no.

28B

280B

28C

280C

28D

280D

28E

280E

28F

280F

290

2810

291

2811

292

2812

293

2813

294

2814

295

2815

296

2816

297

2817

298

2818

299

2819

651

10251

652

10252

653

10253

654

10254

655

10255

656

10256

657

10257

658

10258

659

10259

660

10260

661

10261

662

10262

664

10264

664

10264

665

10265

40652

40653

40654

40655

40656

40657

40658

40659

40660

40661

40662

40663

40664

40665

40666

Description Values

0 = 0-20 = 0 to 20 mA

Output 1 type

(when Out 1 is an analog output)

Out 1 function

(when Out 1 is an analog output)

Out 1 function

Initial scale value of the analog

retransmission

analog output)

Full scale value of the analog

retransmission

analog output)

Alarms linked up with the out 1

Out 1 action

Out 2 function See the values of 14 = o1F parameter 0 r/w

Alarms linked up with the out 2 See the values of 17 = o1AL parameter 0 r/w

Out 2 action See the values of 18 = o1Ac parameter 0 r/w

Out 3 function See the values of 14 = o1F parameter 0 r/w

Alarms linked up with the out 3 See the values of 17 = o1AL parameter 0 r/w

Out 3 action See the values of 18 = o1Ac parameter 0 r/w

Out 4 function See the values of 14 = o1F parameter 0 r/w

Alarms linked up with the out 4 See the values of 17 = o1AL parameter 0 r/w

Out 4 action See the values of 18 = o1Ac parameter 0 r/w

(when Out 1 is an

(when Out 1 is an

1 = 4-20 = 4 to 20 mA

2 = 0-10 = 0 to 10 V

3 = 2-10 = 2 to 10 V

0 = NonE = Output not used

1 = H.rEG = Heating output

2 = c.rEG = Cooling output

3 = r.inP = Measure retransmission

4 = r.Err = Error (sp - PV) retransmission

5 = r.SP = Set point retransmission

6 = r.SEr = Serial value retransmission

0 = NonE = Output not used

1 = H.rEG = Heating output

2 = c.rEG = Cooling output

3 = AL = Alarm output

4 to 11 = Reserved,

12 = or.bo = Out-of-range or burn out

indicator

13 = P.FAL = Power failure indicator

14 = bo.PF =

Power failure indicator

15 = St.bY = Stand by status indicator

16 = diF.1 =

input 1 status

17 = diF.2 =

input 2 status

18 = on = Out 1 always ON

-1999 ... Ao1H dp r/w

Ao1L ... 9999 dp r/w

0 to 63

+1 = Alarm 1

+2 = Alarm 2

+4 = Alarm 3

+8 = Loop break alarm

+16 = Sensor Break

+32 = Overload on output 4

0 = dir = Direct action

1 = rEU = Reverse action

2 = dir.r = Direct with reversed LED

3 = ReU.r = Reverse with reversed LED

Out-of-range, burn out and

The output repeats the digital

The output repeats the digital

Dec.

Point

0 r/w

0 r/w

0 r/w

0 r/w

r/w

14 Yokogawa Electric Corporation - TC10 - PROTOCOL MANUAL

Page 15

Yokogawa Electric Corporation TC10 Communication Protocol

5.3.3 AL1 group

no. Param.

28 AL1t

29 Ab1

30 AL1L

31 AL1H

32 AL1

33 HAL1

34 AL1d

35 AL1o

Address

Hex Dec Ref. no.

29A

281A

29B

281B

29C

281C

29D

281D

29E

281E

29F

281F

2A0

2820

2A1

2821

666

10266

667

10267

668

10268

669

10269

670

10270

671

10271

672

10272

673

10273

40667

40668

40669

40670

40671

40672

40673

40674

Description Values

0 = nonE = Alarm not used

1 = LoAb = Absolute low alarm

2 = HiAb = Absolute high alarm

3 = LHAo = Windows alarm in alarm outside the

windows

4 = LHAI = Windows alarm in alarm inside the

Alarm 1 type

Alarm 1 function

- For High and low alarms, it is the

low limit of the AL1 threshold;

- For band alarm, it is low alarm

threshold

- For High and low alarms, it is the

high limit of the AL1 threshold;

- For band alarm, it is high alarm

threshold

AL1 threshold From AL1L to AL1H (E.U.) dP r/w

AL1 hysteresis 1 to 9999 (E.U.) dP r/w

AL1 delay From 0 (oFF) to 9999 (s) 0 r/w

Alarm 1 enabling during Stand-by

mode and out of range conditions

windows

5 = SE.br = Sensor Break

6 = LodE = Deviation low alarm (relative)

7 = HidE = Deviation high alarm (relative)

8 = LHdo = Relative band alarm in alarm out of

the band

9 = LHdi = Relative band alarm in alarm inside

the band

0 to 15

+1 = Not active at power up

+2 = Latched alarm (manual reset)

+4 = Acknowledgeable alarm

+8 = Relative alarm not active at set point change

From -1999 to AL1H (E.U.) dP r/w

From AL1L to 9999 (E.U.) dP r/w

0 = Alarm 1 disabled during Stand by and out of

range

1 = Alarm 1 enabled in stand by mode

2 = Alarm 1 enabled in out of range condition

3 = Alarm 1 enabled in stand by mode and in

over range condition

Dec.

r/w

Point

0 r/w

0 r/w

0 r/w

5.3.4 AL2 group

no. Param.

36 AL2t

37 Ab2

Address

Hex Dec Ref. no.

2A2

2822

2A3

2823

674

10274

675

10275

40675

40676

Description Values

Alarm 2 type

Alarm 2 function

0 = nonE = Alarm not used

1 = LoAb = Absolute low alarm

2 = HiAb = Absolute high alarm

3 = LHAo = Windows alarm in alarm outside the

windows

4 = LHAI = Windows alarm in alarm inside the

windows

5 = SE.br = Sensor Break

6 = LodE = Deviation low alarm (relative)

7 = HidE = Deviation high alarm (relative)

8 = LHdo = Relative band alarm in alarm out of

the band

9 = LHdi = Relative band alarm in alarm inside

the band

0 to 15

+1 = Not active at power up

+2 = Latched alarm (manual reset)

+4 = Acknowledgeable alarm

+8 = Relative alarm not active at set point change

Dec.

r/w

Point

0 r/w

0 r/w

Yokogawa Electric Corporation - TC10 - PROTOCOL MANUAL 15

Page 16

Yokogawa Electric Corporation TC10 Communication Protocol

no. Param.

38 AL2L

39 AL2H

40 AL2

41 HAL2

42 AL2d

43 AL2o

Address

Hex Dec Ref. no.

2A4

2824

10276

2A5

2825

10277

2A6

2826

10278

2A7

2827

10279

2A8

2828

10280

2A9

2829

10281

5.3.5 AL3 group

no. Param.

44

AL3t

45

Ab3

46 AL3L

47 AL3H

48 AL3

49 HAL3

50 AL3d

51 AL3o

Address

Hex Dec Ref. no.

2AA

282A

10282

2AB

282B

10283

2AC

282C

10284

2AD

282D

10285

2AE

282E

10286

2AF

282F

10287

2B0

2830

10288

2B1

2831

10289

Description Values

676

40677

677

40678

678

40679

679

40680

680

40681

681

40682

682

40683

683

40684

684

40685

685

40686

686

40687 AL3 threshold From AL3L to AL3H (E.U.) dP r/w

687

40688

688

40689 AL3 delay From 0 (oFF) to 9999 (s) 0 r/w

689

- For High and low alarms, it is the

low limit of the AL2 threshold;

- For band alarm, it is low alarm

threshold

- For High and low alarms, it is the

high limit of the AL2 threshold;

- For band alarm, it is high alarm

threshold

AL2 threshold From AL2L to AL2H (E.U.) dP r/w

AL2 hysteresis 1 to 9999 (E.U.) dP r/w

AL2 delay From 0 (oFF) to 9999 (s) 0 r/w

Alarm 2 enabling during Stand-by

mode and out of range conditions

Description Values

Alarm 3 type

Alarm 3 function

- For High and low alarms, it is the

low limit of the AL3 threshold;

- For band alarm, it is low alarm

threshold

- For High and low alarms, it is the

high limit of the AL3 threshold;

- For band alarm, it is high alarm

threshold

AL3 hysteresis 1 to 9999 (E.U.) dP r/w

Alarm 3 enabling during Stand-by

mode and out of range conditions

From -1999 to AL2H (E.U.) dP r/w

From AL2L to 9999 (E.U.) dP r/w

0 = Alarm 2 disabled during Stand by and out of

range

1 = Alarm 2 enabled in stand by mode

2 = Alarm 2 enabled in out of range condition

3 = Alarm 2 enabled in stand by mode and in

over range condition

0 = nonE = Alarm not used

1 = LoAb = Absolute low alarm

2 = HiAb = Absolute high alarm

3 = LHAo = Windows alarm in alarm outside the

windows

4 = LHAI = Windows alarm in alarm inside the

windows

5 = SE.br = Sensor Break

6 = LodE = Deviation low alarm (relative)

7 = HidE = Deviation high alarm (relative)

8 = LHdo = Relative band alarm in alarm out of

the band

9 = LHdi = Relative band alarm in alarm inside

the band

0 to 15

+1 = Not active at power up

+2 = Latched alarm (manual reset)

+4 = Acknowledgeable alarm

+8 = Relative alarm not active at set point change

From -1999 to AL3H (E.U.) dP r/w

From AL3L to 9999 (E.U.) dP r/w

0 = Alarm 3 disabled during Stand by and out of

range

1 = Alarm 3 enabled in stand by mode

2 = Alarm 3 enabled in out of range condition

3 = Alarm 3 enabled in stand by mode and in

over range condition

Dec.

r/w

Point

0 r/w

Dec.

r/w

Point

0 r/w

0 r/w

0 r/w

16 Yokogawa Electric Corporation - TC10 - PROTOCOL MANUAL

Page 17

Yokogawa Electric Corporation TC10 Communication Protocol

5.3.6 LBA group - Loop Break Alarm Parameters

no. Param.

52 LbAt

53 LbSt

54 LbAS

55 LbcA

Address

Hex Dec Ref. no.

2B2

2832

2B3

2833

2B4

2834

2B5

2835

690

10290

691

10291

692

10292

693

10293

40691

40692

40693

40694

LBA time From 0 (oFF) to 9999 (s) 0

Delta measure used by LBA during Soft

start

Delta measure used by LBA 1 to 9999 (E.U.) dP

Condition for LBA enabling

5.3.7 rEG group - Control Parameters

no. Param.

56 cont

57 Auto

58 Aut.r

59 SELF

60 HSEt

61 cPdt

62 Pb

63 ti

64 td

65 Fuoc

66 tcH

Address

Hex Dec Ref. no.

2B6

2836

2B7

2837

2B8

2838

2B9

2839

2BA

283A

2BB

283B

2BC

283C

2BD

283D

2BE

283E

2BF

283F

2C0

2840

694

10294

695

10295

696

10296

697

10297

698

10298

699

10299

700

10300

701

10301

702

10302

703

10303

704

10304

40695

40696

40697

40698

40699

40700

40701

40702

40703 Derivative time From 0 (oFF) to 9999 (s) 0 r/w

40704

40705

Description Values

Control type

Autotuning selection

Manual start of the Autotuning

Self tuning enabling

Hysteresis of the ON/OFF

control

Time for compressor

protection

Proportional band 1 to 9999 (E.U.) dP

Integral time From 0 (oFF) to 9999 (s) 0 r/w

Fuzzy overshoot control 0 to 200 2 r/w

Heating output cycle time 10 to 1300 (s) 1 r/w

Description Values

From 0 (oFF) to 9999 (E.U.) dP

0 = uP = Active when Pout = 100%

1 = dn = Active when Pout = -100%

2 = both = Active in both cases

0 = Pid = PID (heat and/or)

1 = On.FA = ON/OFF asymmetric hysteresis

2 = On.FS = ON/OFF symmetric hysteresis

3 = nr = Heat/Cool ON/OFF control with neutral zone

4 = Reserved

Oscillating auto-tune with automaticrestart

-4 =

at power up and after all point change

-3 =

Oscillating auto-tune with manual start

-2 = Oscillating -tune with auto-matic start at the first

power up only

-1 =

Oscillating auto-tune with auto-matic restart

at every power up

0 = Not used

1 = Fast auto tuning with automatic restart at every

power up

2 = Fast auto-tune with automatic start the first

power up only

3 = FAST auto-tune with manual start

4 = FAST auto-tune with automatic restart

at power up and after a set point change

5 = Evo-tune with automatic restart at every power up

6 =

Evo-tune with automatic start the first power up only

7 = Evo-tune with manual start

8 = Evo-tune with automatic restart at power up

and after a set point change

0 = oFF = Autotuning Not active

1 = on = Autotuning Active

0 = no = The instrument does not perform the

self-tuning

1 = YES = The instrument is performing the self-tuning

0 to 9999 (E.U.) dP

From 0 (oFF) to 9999 (s) 0 r/w

Dec.

r/w

Point

0

Dec.

Point

0 r/w

0 r/w

0 r/w

0 r/w

r/w

Yokogawa Electric Corporation - TC10 - PROTOCOL MANUAL 17

Page 18

Yokogawa Electric Corporation TC10 Communication Protocol

no. Param.

67 rcG

68 tcc

69 rS

70

71

72 od

73 St.P

74 SSt

75 SS.tH

Address

Hex Dec Ref. no.

2C1

2841

2C2

2842

2C3

2843

2C4

2844

2C5

2845

2C6

2846

2C7

2847

2C8

2848

2C9

2849

705

10305

706

10306

707

10307

708

10308

709

10309

710

10310

711

10311

712

10312

713

10313

40706

40707

40708

40709

40710

40711

40712

40713

40714

Description Values

Power ratio between heating and cooling action

Cooling output cycle time 1 to 1300 (s) 1 r/w

Manual reset (Integral

pre-load)

Reserved

Reserved

Delay at power up From 0.00 (oFF) to 9959 (hh.mm) 2 r/w

Maximum power output

used during soft start

Soft start time 0 (oFF) to 800 = inF (h.mm) 2 r/w

Threshold for soft start

disabling

1 to 9999 2 r/w

-1000 to +1000 (%) 1 r/w

-100 to 100 (%) 0 r/w

-2000 (oFF) to 9999 (E.U.) dP r/w

Dec.

Point

r/w

5.3.8 SP group - Set point parameters

no. Param.

76 nSP

77 SPLL

78 SPHL

79 SP

80 SP 2

81 SP 3

82 SP 4

83 A.SP

84 SP.rt

85 SPLr

86 SP.u

87 SP.d

Address

Hex Dec Ref. no.

2CA

284A

2CB

284B

2CC

284C

2CD

284D

2CE

284E

2CF

284F

2D0

2850

2D1

2851

2D2

2852

2D3

2853

2D4

2854

2D5

2855

10314

10315

10316

10317

10318

10319

10320

10321

10322

10323

10324

10325

714

715

716

717

718

719

720

721

722

723

724

725

40715

40716

40717

40718

40719

40720

40721

40722

40723

40724

40725

Description Values

Number of used set points 1 to 4 0 r/w

Minimum set point value From -1999 to SPHL dP r/w

Maximum set point value From SPLL to 9999 dP r/w

Set point 1 From SPLL to SPLH dP r/w

Set point 2 From SPLL to SPLH dP r/w

Set point 3 From SPLL to SPLH dP r/w

Set point 4 From SPLL to SPLH dP r/w

Selection of the active set

point

Remote set point type

Local/remote set point selection

Rate of rise for POSITIVE

set point change (ramp UP)

Rate of rise for NEGATIVE set

point change (ramp DOWN)

Dec.

r/w

Point

0 = SP

1 = SP 2

2 = SP 3

3 = SP 4

0 = RSP =

1 = trin =

2 = PErc = The value coming from serial link will be

0 = Loc = local

1 = rEn = remote

0.01 to 99.99 (inF) engineering units per minute 2 r/w

0.01 to 99.99 (inF) engineering units per minute 2 r/w

The value coming from serial link is used as

remote set point

The value coming from serial link will be

added to the local set point selected by A.SP and

the sum becomes the operative set point

scaled on the input range and this value will be

used as remote SP

0 r/w

0 r/w

0 r/w

18 Yokogawa Electric Corporation - TC10 - PROTOCOL MANUAL

Page 19

Yokogawa Electric Corporation TC10 Communication Protocol

5.3.9 Reserved Parameters

no. Param.

88

to

117

Hex Dec Ref. no.

2D6 to 2F3

2856 to

2873

Address

726 to 755

10326 to 10355

40727 to 40756

5.3.10 PAn group - Operator HMI parameters

no. Param.

118 PAS2

119 PAS3

120 PAS4

121 uSrb

122 diSP

123 di.cL

124 AdE

125 di.St

126 fiLd

127

128 dSPu

Address

Hex Dec Ref. no.

2F4

2874

2F5

2875

2F6

2876

2F7

2877

2F8

2878

2F9

2879

2FA

287A

2FB

287B

2FC

287C

2FD

287D

2FE

287E

756

10356

757

10357

758

10358

759

10359

760

10360

761

10361

762

10362

763

10363

764

10364

765

10365

766

10366

40757

40758

40759

40760

40761

40762

40763

40764

40765

40766

40767

Description Values

Level 2 password

(limited access level)

Level 3 password

(complete configuration level)

Level 4 password

(CODE configuration

level)

button function

during RUN TIME

Display

management

Display colour

Deviation for display

colour management

Display

Timeout

Filter on the

displayed value

Reserved

Instrument status at

power ON

Description Values

Reserved

oFF (Level 2 not protected by password)

1 to 200

3 to 200 0 r/w

201 to 400 0 r/w

0 = nonE = No function

1 = tunE = Auto-tune/self-tune enabling. A single press

(longer than 1 second) starts the auto-tune

2 = oPLo =

instrument in manual mode (OPLO) while a second one

puts the instrument in Auto mode

3 = AAc = Alarm reset

4 = ASi = Alarm acknowledge

5 = chSP = Sequential set point selection

6 = St.by =

instrument in stand by mode while a second one puts

the instrument in Auto mode.

7 to 10 = Reserved

0 = nonE = Standard display

1 = Pou = Power output

2 = SPF = Final set point

3 = Spo = Operative set point

4 = AL1 = Alarm 1 threshold

5 = AL2 = Alarm 2 threshold

6 = AL3 = Alarm 3 threshold

7 to 12 = Reserved,

13 = PErc = Percent of the power output used during soft

start (when the soft start time is equal to infinite, the

limit is ever active and it can be used also when ON/

OFF control is selected)

14 = Reserved

0 = The display colour changes to point out the actual

deviation (PV - SP)

1 = Display red (fix)

2 = Display green (fix)

3 = Display orange (fix)

1 to 9999 Dp r/w

0 = oFF (display always ON) to 9959 (mm.ss) 2 r/w

0 = oFF (filter disabled) to 100 Dp r/w

0 = AS.Pr = Starts in the same way it was prior to the power

down

1 = Auto = Starts in Auto mode

2 = oP.0 = Starts in manual mode with a power output equal

to zero

3 = St.bY = Starts in stand-by mode

Manual mode. The first pressure puts the

Stand by mode. The first press puts the

Dec.

Point

Dec.

Point

0 r/w

0 r/w

0 r/w

r/w

r/w

r/w

Yokogawa Electric Corporation - TC10 - PROTOCOL MANUAL 19

Page 20

Yokogawa Electric Corporation TC10 Communication Protocol

no. Param.

129 oPr.E

130 oPEr

Address

Hex Dec Ref. no.

2FF

287F

300

2880

767

10367

768

10368

40768

40769

Description Values

Operative modes

enabling

Operative mode

selection

5.3.11 Ser group - Serial link parameters

no. Param.

131 Add

132 bAud

133 trSP

Address

Hex Dec Ref. no.

301

2881

302

2882

303

2883

769

10369

770

10370

771

10371

40770

40771

40772

Description Values

Instrument address 0 (oFF) to 254 0 r/w

baud rate

Selection of the

value to be retransmitted (Master)

0 = ALL = All modes will be selectable by the next

parameter

1 = Au.oP = Auto and manual (OPLO) mode only will be

selectable by the next parameter

2 = Au.Sb = Auto and Stand-by modes only will be selectable

by the next parameter

0 = Auto = Auto mode

1 = oPLo = Manual mode

2 = St.bY = Stand by mode

0 = 1200 = 1200 baud

1 = 2400 = 2400 baud

2 = 9600 = 9600 baud

3 = 19.2 = 19200 baud

4 = 38.4 = 38400 baud

0 = nonE = Retransmission not used (the instrument is a slave)

1 = rSP =

2 = PErc = The instrument become a Master and it

The instrument becomes a Master and retransmits

the operative set point

retransmits the power output

Dec.

Dec.

r/w

r/w

Point

0 r/w

0 r/w

Point

0 r/w

0 r/w

5.3.12 COn group - Consumption parameters

no. Param.

134 Co.tY

135 UoLt

136 cur

137 h.Job

Address

Hex Dec Ref. no.

304

2884

305

2885

306

2886

307

2887

772

10372

773

10373

774

10374

775

10375

40773

40774

40775

40776

Description Values

0 = oFF = Not used

1 = Instantaneous power (kW)

2 = Power consumption (kW/h)

3 = Reserved

4 = Total worked days with threshold. It is the number of

5 = Total worked hours with threshold. It is the number of

6 = Total worked days with threshold: number of hours the

7 = Total worked hours with threshold: number of hours that

Measurement type

8 = Totalizer of control relay worked days: number of hours the

9 = Totalizer of control relay worked hours: number of hours

10 = Totalizer of control relay worked days with threshold: num-

11 = Totalizer of control relay worked hours with threshold:

Nominal Voltage of

the load

Nominal current of

the load

Threshold of the

working period

1 to 9999 (V) 0 r/w

1 to 999 (A) 0 r/w

0 (oFF) to 999 0 r/w

hours that the instrument is turned ON divided for 24

hours that the instrument is turned ON

instrument is turned ON divided by 24, the controller

is forced in standby when Co.ty value reaches the

threshold set in [137] h.Job.

the instrument is turned ON, the controller is forced in

stand-by when Co.ty value reaches the threshold set in

[137] h.Job.

control relay has been in ON condition, divided by 24.

the control relay has been in ON condition.

ber of hours the control relay has been in ON condition

divided by 24, the controller is forced in stand-by when

Co.ty value reaches the threshold set in [137] h.Job.

number of hours the control relay has been in ON

condition, the controller is forced in stand-by when Co.ty

value reaches the threshold set in [137] h.Job.

Dec.

Point

0 r/w

r/w

20 Yokogawa Electric Corporation - TC10 - PROTOCOL MANUAL

Page 21

Yokogawa Electric Corporation TC10 Communication Protocol

no. Param.

138 t.Job

Address

Hex Dec Ref. no.

308

2888

776

10376

40777

Description Values

Worked time (not

resettable)

0 to 9999 0 r

5.3.13 CAl group - User calibration parameters

no. Param.

139 A.L.P

140 A.L.o

141 A.H.P

142 A.H.o

Address

Hex Dec Ref. no.

309

2889

30A

288A

30B

288B

30C

288C

777

10377

778

10378

779

10379

780

10380

40778

40779

40780

40781

Description Values

Adjust Low Point -1999 to (A.H.P - 10)(E.U.) dP r/w

Adjust Low Offset -300 to +300 (E.U.) dP r/w

Adjust High Point From (A.L.P + 10) to 9999 (E.U.) dP r/w

Adjust High Offset -300 to +300 (E.U.)

Dec.

Dec.

r/w

r/w

Point

Point

dP r/w

Yokogawa Electric Corporation - TC10 - PROTOCOL MANUAL 21

Page 22

Yokogawa Electric Corporation TC10 Communication Protocol

22 Yokogawa Electric Corporation - TC10 - PROTOCOL MANUAL

Page 23

Yokogawa Electric Corporation TC10 Communication Protocol

Yokogawa Electric Corporation - TC10 - PROTOCOL MANUAL 23

Page 24

Yokogawa Electric Corporation TC10 Communication Protocol

All rights reserved. No parts of this publication may be reproduced, in any form, without Yokogawa Electric Corporation written permission.

Every care has been taken preparing this manual; the document has been carefully reviewed for technical accuracy. In the event that technical or typographical errors exist Yokogawa Electric Corporation

reserves the right to make changes without any notice.

In no event shall Yokogawa Electric Corporation be liable for any damages arising out of or related to

this document or the information contained in it.

If errors are suspected, please contact Yokogawa Electric Corporation at the above address.

Yokogawa Electric Corporation

9-32, Nakacho 2-chome, Musashino-shi, Tokyo 180-8750, Japan

www.yokogawa.com

24 Yokogawa Electric Corporation - TC10 - PROTOCOL MANUAL

Loading...

Loading...