Page 1

User’s

Manual

Model TB750G

Right Angle Scattered Light

Turbidimeter

Quick Start Manual

IM 12E01A06-02E

IM 12E01A06-02E

1st Edition

Page 2

◆ INTRODUCTION

■ Structure of this Manual

This is a supplementary manual to TB750G Right Angle Scattered Light Turbidimeter

for User's Manual IM 12E01A06-01E. This manual describes the specifications,

installation, operation, maintenance, and troubleshooting. To use this instrument

correctly, read this manual and User's Manual IM 12E01A06-01E thoroughly.

■ Before Measurement

The TB750G turbidimeter is preset with defaults prior factory shipment. Before

measurement, verify that these factory default settings meet the operating conditions and

if necessary, reconfigure parameters.

◆ Symbol and Notations Used in this Manual

■ Symbol

The following symbol is used in this manual.

CAUTION

■ Notations

Indicates that damage to software or hardware, or system failures could occur if

instructions are not followed.

In this manual, operation keys, display messages, indicators, and LED lamps on the

instrument are denoted in the following manner.

1. Operation keys are denoted by brackets [ ] – for example:

YES

: [YES] key

2. Indicators, messages, and numerical data on the display are denoted as follows:

Message display: {*WASH}

Data display: {2.05} (when lit), {2.05} (when flashing)

1st Edition: Apr. 2006 (YK)

All Rights Reserved, Copyright © 2006, Yokogawa Electric Corporation

IM 12E01A06-02E

1

Page 3

◆ Notice

■ About this Manual

●This manual should be passed on to the end user.

●This manual should be read thoroughly before operating the instrument.

●This manual explains the functions contained in this product, but does not warrant

that they will suit the particular purpose of the user.

●The contents of this manual shall not be reproduced or copied, in part or in whole,

without permission.

●The contents of this manual are subject to change without prior notice.

●Every effort has been made to ensure the accuracy in the preparation of this manual.

However, if any errors or omissions are noticed, please contact the nearest Yokogawa

representative or sales office.

■ Protection, Safety, and Modification of the Product

●The safety instructions described in this manual should be strictly observed to ensure

safety both of the product and the system controlled by the product.

●A protection or safety circuit should be installed externally, if needed. Do not attempt

to modify or add such circuit to the inside of the equipment.

■ Limitation of Liability

●Yokogawa grants no warranties other than the express warranty set forth under the

warranty provisions.

●Yokogawa shall not be liable to you or any third party for any damage, including

consequential or incidental damages, arising out of or in connection with the use of

this equipment, defects beyond our knowledge, or any other contingency beyond our

control.

2

IM 12E01A06-02E

Page 4

Contents

Contents

◆ INTRODUCTION.......................................................................................................... 1

◆ Symbols and Notations Used in this Manual ................................................................ 1

◆ Notice ............................................................................................................................. 2

1. OVERVIEW................................................................................................................... 5

1.1 Features ...............................................................................................................5

1.2 Measurement Principle ........................................................................................ 5

2. PIPING AND WIRING ................................................................................................. 6

2.1 Piping ................................................................................................................... 6

2.1.1 System Using Open Head Tank and Zero Turbidity Filter ........................ 6

2.1.2 System without Head Tank and Zero Turbidity Filter ...............................7

2.2 Wiring..................................................................................................................8

2.2.1 Wiring Required for TB750G .....................................................................8

2.2.2 Wiring for Detector .....................................................................................8

2.2.3 Wiring for Converter ................................................................................... 9

3. OPERATION ............................................................................................................... 11

3.1 Preparation ......................................................................................................... 11

3.1.1 Outline ....................................................................................................... 11

3.1.2 Converter Operation Panel ........................................................................12

3.1.3 Calibration ................................................................................................. 12

3.1.4

3.1.5 Performing 2-point Calibration Using Standard Solution ........................17

3.2 Normal Operation.............................................................................................. 18

3.2.1 When Sample Water Supply is Cut Off ...................................................18

3.2.2 Shutdown ...................................................................................................18

3.2.3 Restart ........................................................................................................ 18

Performing Zero/span Calibration Using Filtered Water as Zero Reference ...

13

4. PARAMETER SETTING ............................................................................................ 19

4.1 Outline of Operation, Setting, and Service Levels...........................................19

4.2 Operation Level.................................................................................................20

4.3 Setting Level ..................................................................................................... 21

4.4 Service Level.....................................................................................................22

4.5 Procedures for Setting Parameters ....................................................................24

5. MAINTENANCE......................................................................................................... 27

5.1 Lamp Replacement............................................................................................ 27

5.2 Calibration ......................................................................................................... 28

5.2.1 Outline ....................................................................................................... 28

5.2.2 2-point Calibration Using Turbidity Standard Solutions..........................28

6. TROUBLESHOOTING ............................................................................................... 29

Revision Record .................................................................................................................... 1

IM 12E01A06-02E

3

Page 5

Contents

4

IM 12E01A06-02E

Page 6

1. OVERVIEW

1.1 Features

The TB750G is a process turbidimeter employing the right angle light scattering method,

and has the following features.

• Highly reliable measurement with excellent linearity and repeatability

- Linearity: ±2% of reading or ±0.01 NTU, whichever is greater

- Repeatability: ±1% of reading or ±0.002 NTU, whichever is greater

- Display resolution: 0.001 NTU

• Easy-to-clean measurement cell

• Compact, lightweight converter and detector

• User configurable analog output range

- Analog output range: 0-0.2 NTU to 0-100 NTU

• Analog output range switching (2 or 3 ranges)

• Enhanced self-diagnostic function as standard

- Light source failure, input element failure, calibration failure, various circuit failures,

etc.

• Detector designed to remove influence of air bubbles

• A wide range of measurement conditions

- Low flow rate: 0.05 to 20 l/min {0.8 to 317 gal/h}

- High pressure: Up to 500 kPa {72 psi}

- Sample temperature: 0 to 50°C {32 to 122°F}

• Detector can be connected for in-line analysis

• 2 analog outputs, 3 relay contact outputs, and 1 serial communication

• Many options available upon request

• Ultrasonic transducer and oscillator for ultrasonic cleaning

• Various head tanks to accommodate application requirements

1. OVERVIEW

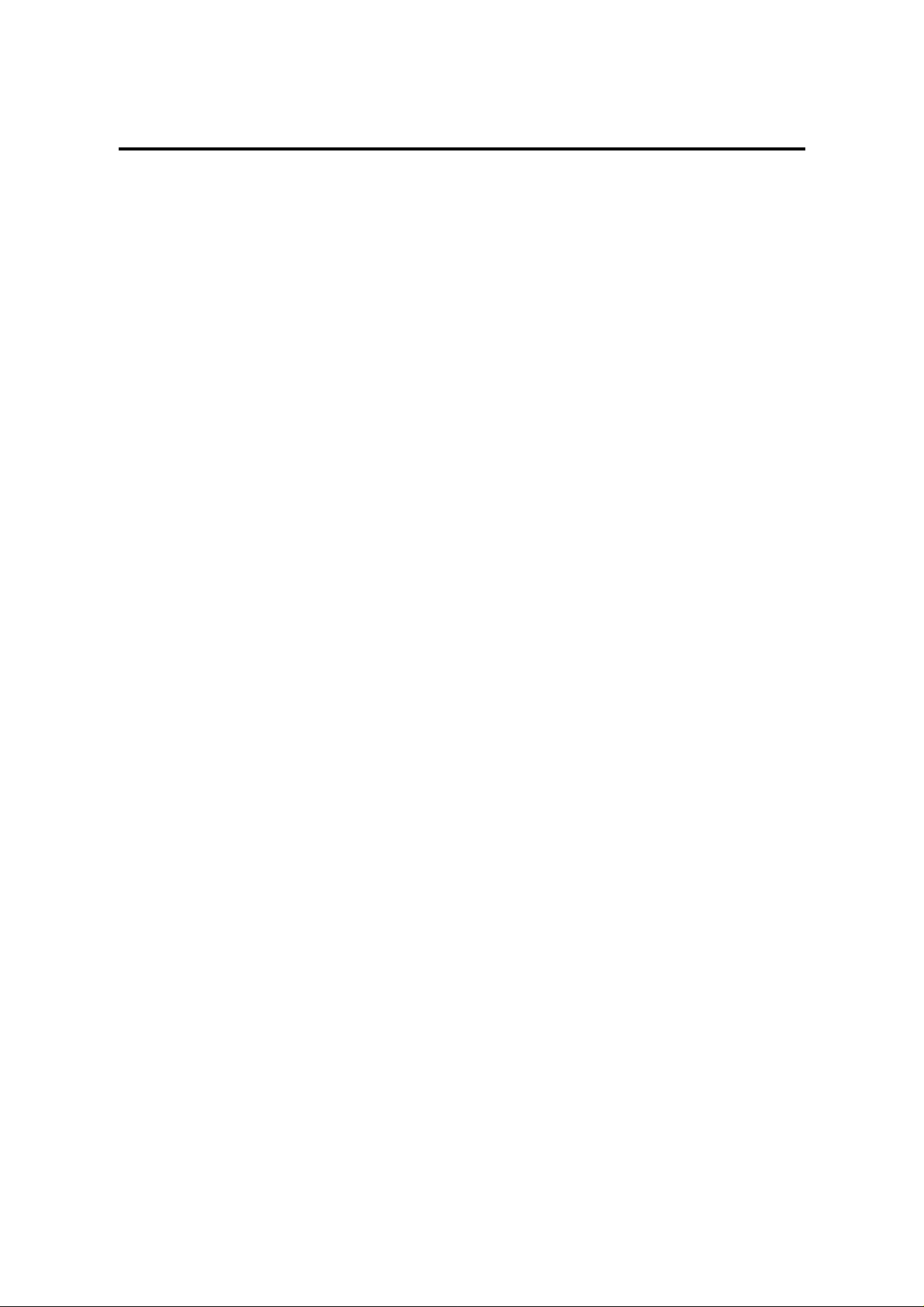

1.2 Measurement Principle

The measuring system of the TB750G turbidimeter, comprised of a detector and a

converter, complys with USEPA 180.1.

Scatted Light Detection Element

Measuring

Water

IM 12E01A06-02E

Light Source

(Lamp)

Figure 1.1 Measurement Principle

Lens

Scatted Light Detector

Receiver (Darkroom)

Measurement Window (Glass)

F0101.EPS

5

Page 7

2. PIPING AND WIRING

2. PIPING AND WIRING

2.1 Piping

Piping methods depend on the application, select the appropriate system configuration,

and install pipes accordingly following examples.

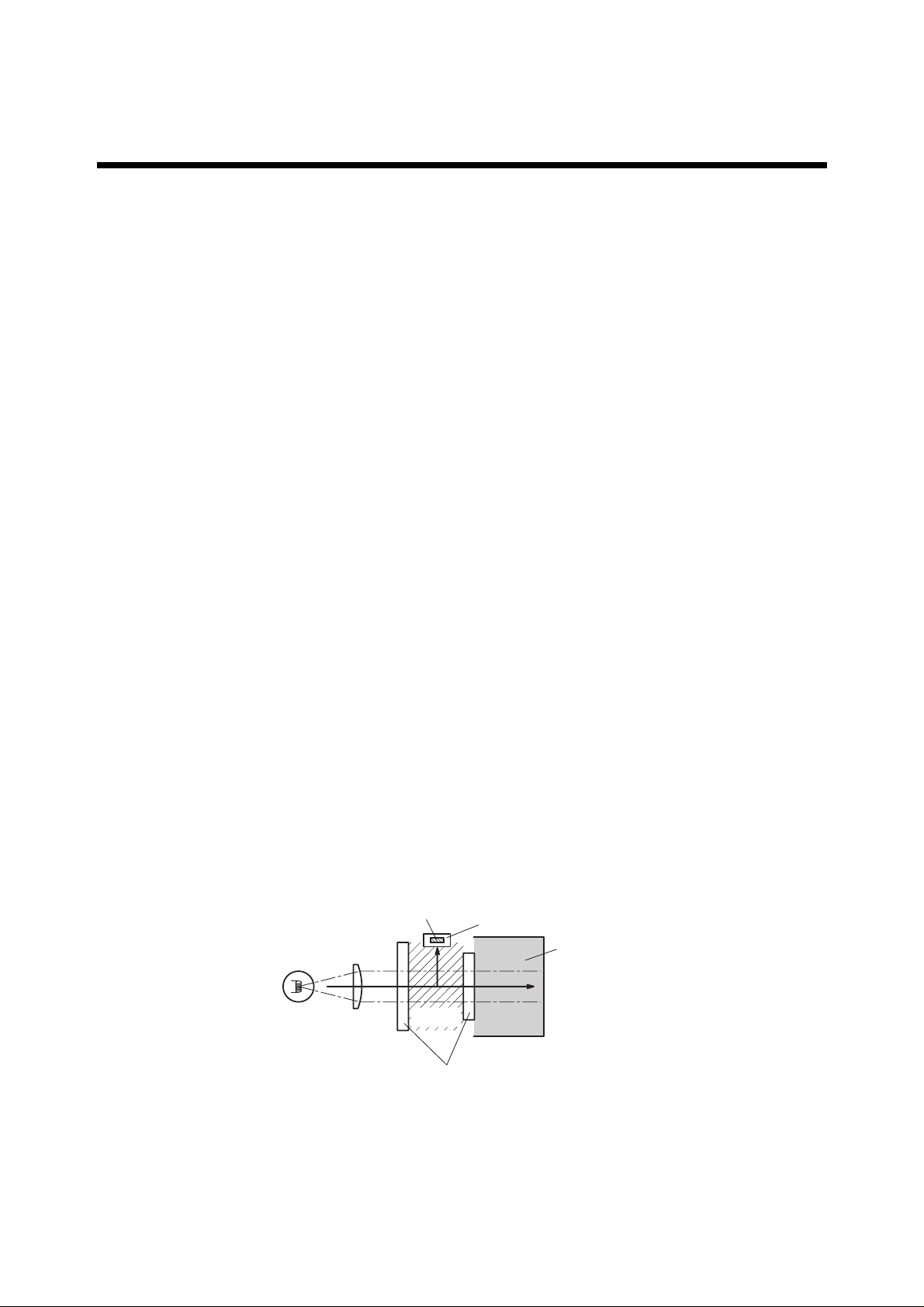

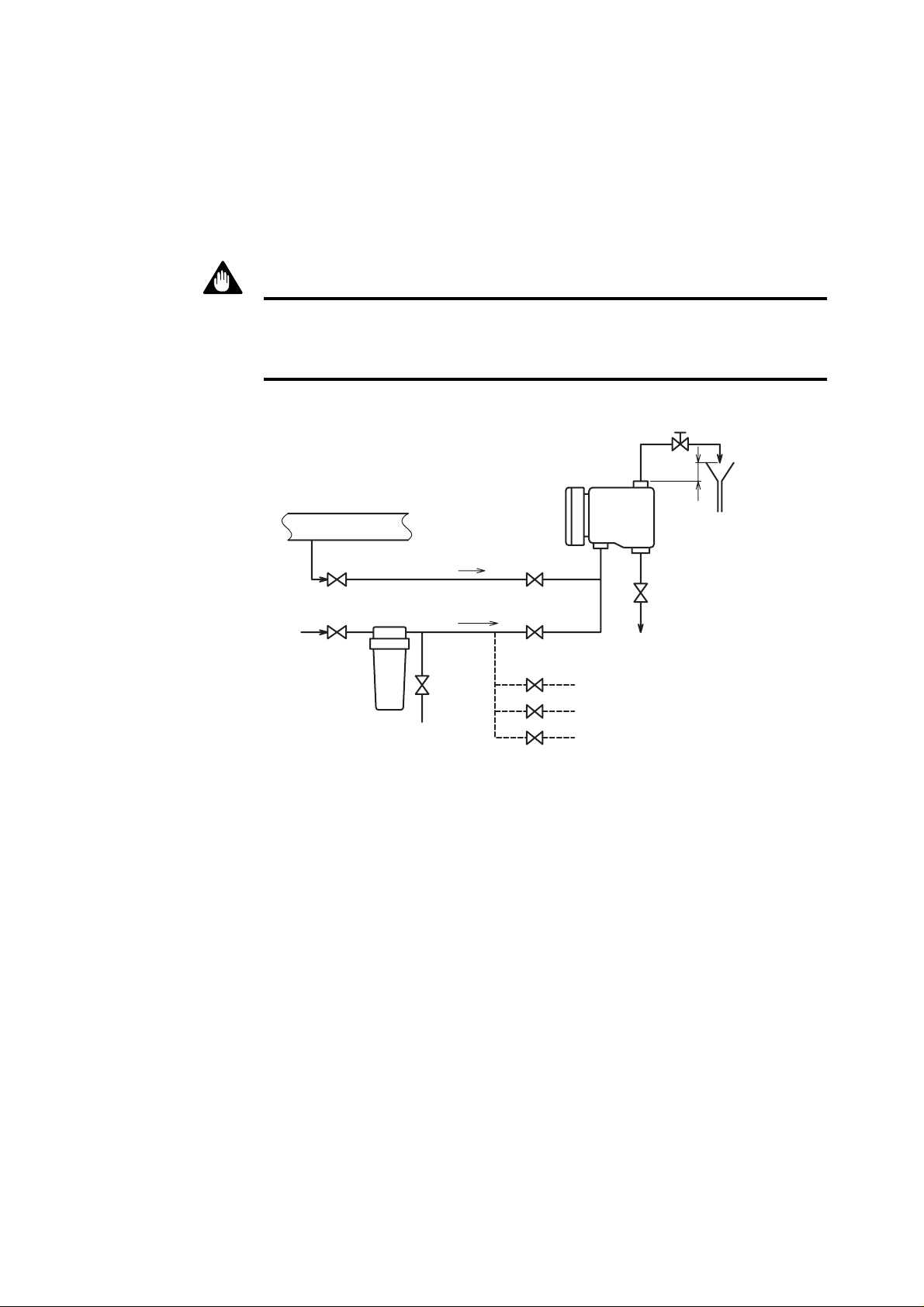

2.1.1 System Using Open Head Tank and Zero Turbidity Filter

This is a typical system. A piping diagram is shown in Figure 2.1. Air bubbles in a

water sample are removed by an open head tank and the water sample is introduced into

the detector at a stable flow rate.

Sample

Water

T ap

Water

Head Tank

Sample Water

Valv e

T ap W ater

Valv e

Zero Turbidity

Filter

Drain

Valv e

Drain

Sample Water

Zero Water

Zero Water

Drain Valv e

H

Drain

Sample Water

Inlet

Sample Water

Supply Valv e

Zero Water Supply Valv e

Flow Control Valve

Sample Water

Outlet

TB750G

Detector

Other Turbidity Detectors

h

Drain Port

Drain Valv e

Drain

Sample Water

Effluent

Drain

F0320.EPS

Figure 2.1 Piping Diagram

• To prevent corrosion of water inside the zero turbidity filter, allow water to flow

through the filter and flow out from the zero water drain valve continuously at a flow

rate of approximately 10 ml/min.

• When using filtered water as zero reference, install a filter with the appropriate pore

size depending on the measuring range.

Measuring range of less than 2 NTU: 0.2 µm

Measuring range of 2 NTU or greater: 1 µm

6

IM 12E01A06-02E

Page 8

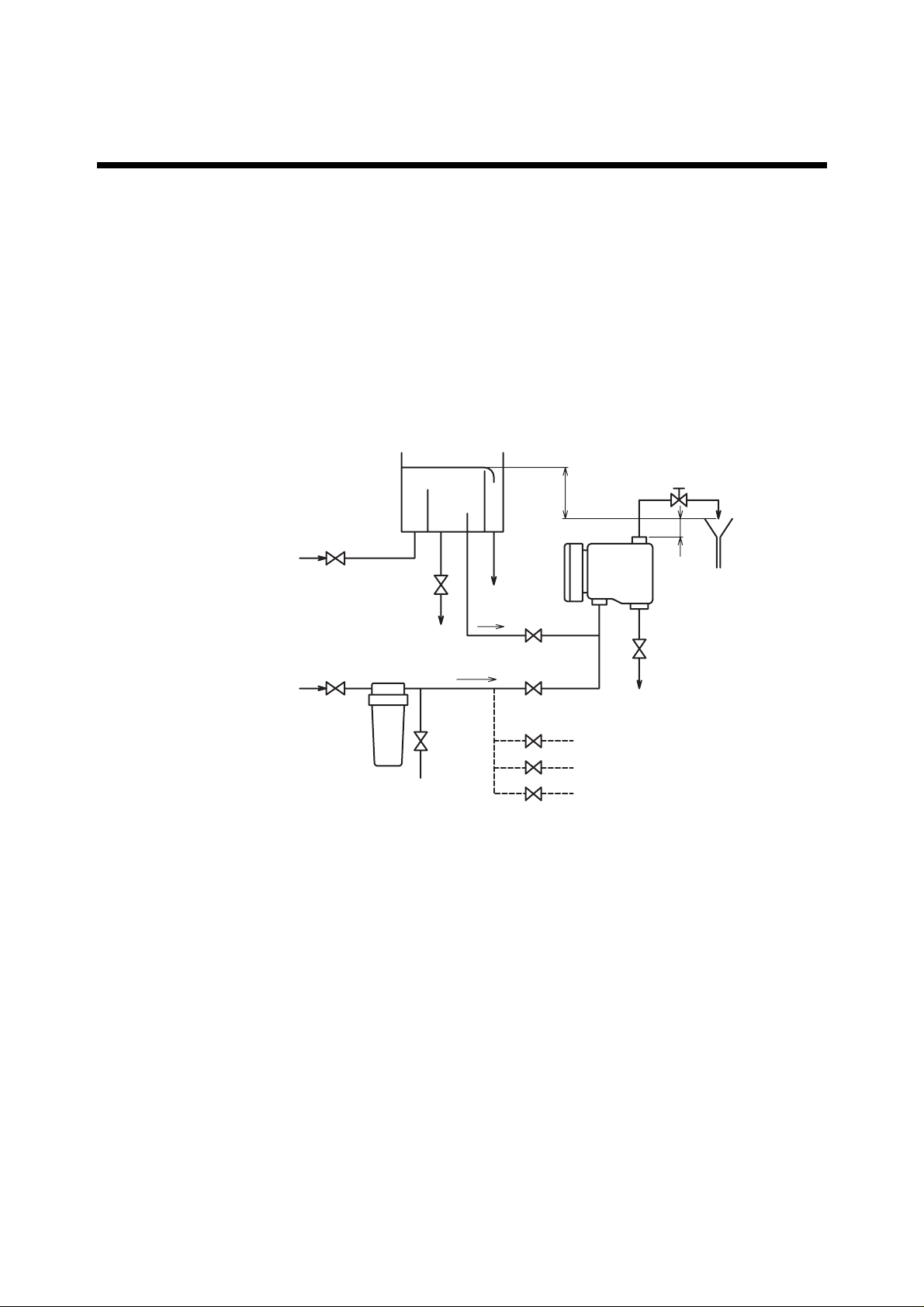

2.1.2 System without Head Tank and Zero Turbidity Filter

This is a simple system where a water sample is taken from the process and directly

introduced into the detector. This system configuration can be used when a water sample

contains a negligible amount of air bubbles or when the turbidity of a water sample is

high and the effect of air bubbles is nonsignificant.

CAUTION

Sample water conditions and ambient temperature must meet the specifications:

maximum pressure: 500 kPa; sample temperature: 0 to 50°C; ambient temperature: -5 to

50°C.

Process Piping

Flow Control Valve

Sample Water

Outlet

TB750G

Detector

2. PIPING AND WIRING

Sample Water

Effluent

h

Drain

Sample

Water

T ap W ater

Sample Water

Valv e

T ap W ater

Valv e

Zero Turbidity

Filter

Sample Water

Zero Water

Zero Water

Drain Valv e

Sample Water

Supply Valv e

Zero Water Supply Valv e

Sample Water

Inlet

Other Turbidity Detectors

Drain Port

Drain Valv e

Drain

F0325.EPS

Figure 2.2 Piping Diagram

• The flow control should not be done on the inlet side of the detector.

• To prevent corrosion inside the zero turbidity filter, allow water to flow through the

filter and flow out from the zero water drain valve continuously at a flow rate of

approximately 10 ml/min.

IM 12E01A06-02E

7

Page 9

2. PIPING AND WIRING

2.2 Wiring

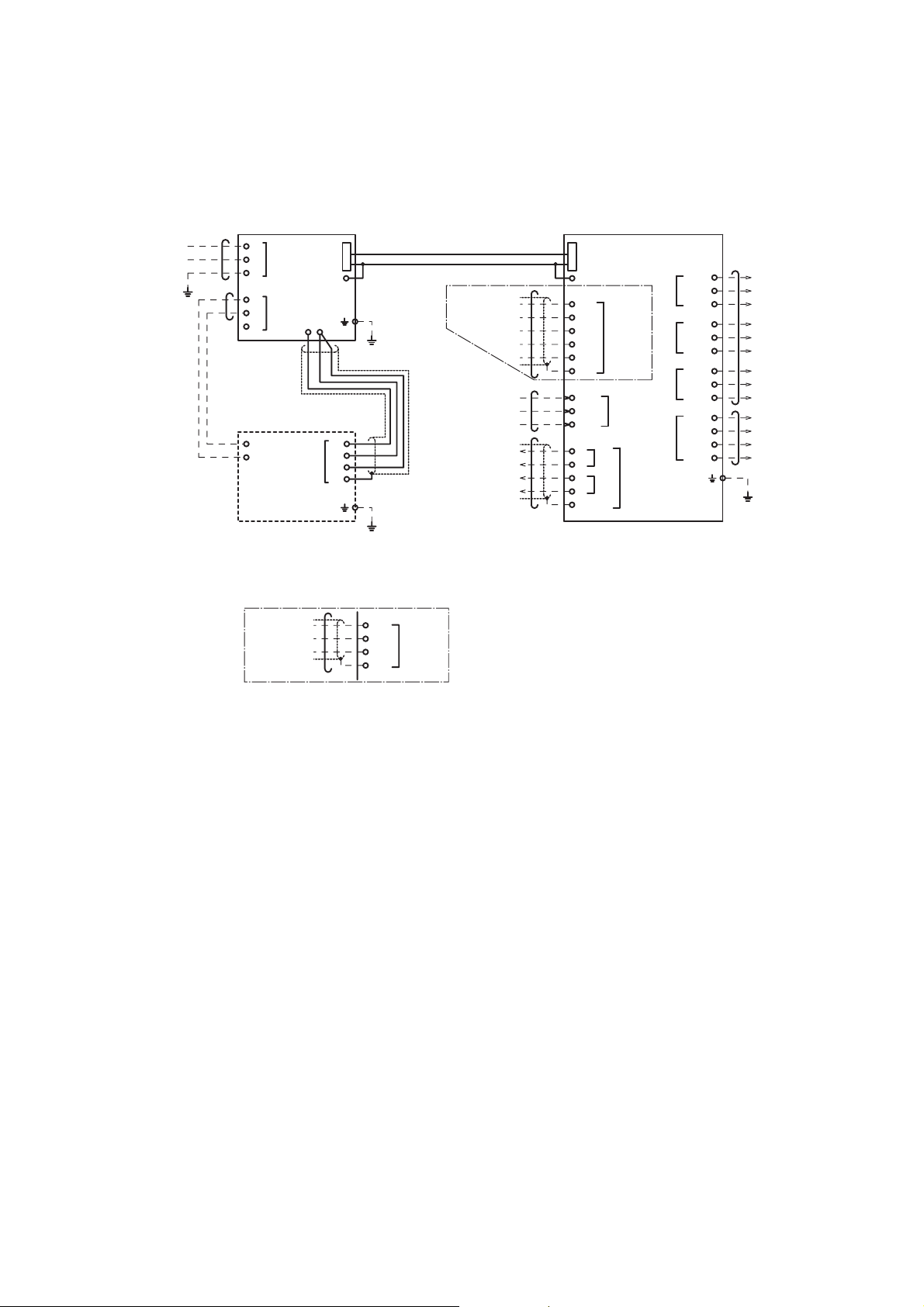

2.2.1 Wiring Required for TB750G

TB750G Turbidity converterTB750G Turbidity detector

Power

supply *

Grounding *

(100V or less)

L

5

1

Power supply

cable

N

G

L

N

G

CONVERT-

POWER

TUS

ER

U1U2

TUS400G Ultrasonic Oscillator

L2

L1

(Note) Dotted wiring is external wiring. Use cable with 6 to 12 mm OD for wiring.

*1 Power terminal "G" on detector, detector case, and converter case must be grounded (ground resistance: 100V or less).

*2 External grounding terminal of ultrasonic oscillator must be grounded (ground resistance: 100V or less).

*3 Use 2-conductor shielded cable for analog output wiring and serial communication wiring.

*4 The wiring configuration is described below in case that RS-232C serial communication is selected.

Serial com-

munication

(RS-232C)

U1

U2

U3

S

Dedicated cable (1/2/3m)

Grounding *

(100V or less)

5

*

Grounding *

(100V or less)

TXD

RXD

SG

G

1

Ultrasonic transducer

connecting cable

(maximum length: 15m)

(customer wiring)

2

RS-232C

Serial commu-

Analog output 1

(4-20mA DC) *

Analog output 2

(4-20mA DC or

0-20mA DC) *

3 *4

nication *

(RS-422)

Contact input

SENSOR

GG

RX+

RX-

RS-422

TX+

TX-

SG

G

IN1

INPUT

IN2

COM

3

3

+

-

+

-

G

mA1

mA2

RANGE

OUTPUT

S1

S2

FAIL

NO

NC

COM

NO

NC

COM

NO

NC

COM

A

B

C

COM

Contact

output S1

Contact

output S2

Contact

output FAIL

Range

contact output

Grounding *

(100V or less)

1

*5 When option code "/US" is specified, TUS400G should be purchased separately.

When TUS400G is used in system, the power supply to TB750G should be the same as the supply voltage specified in

the MS Code of TUS400G.

Figure 2.3 Connection Diagram

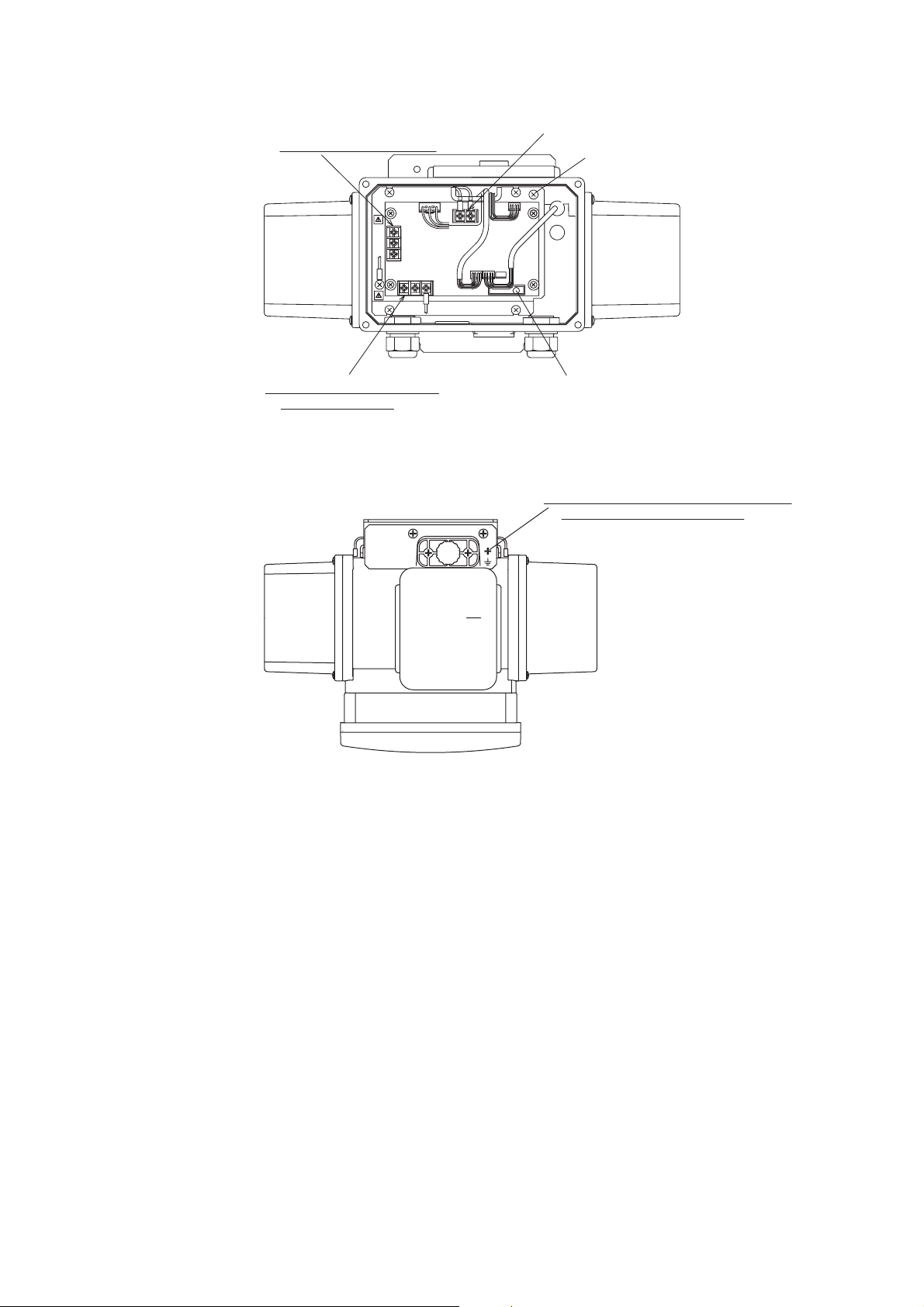

2.2.2 Wiring for Detector

Wire for connections to the following terminals:

(1) Power supply terminals;

(2) Power supply terminals for ultrasonic oscillator (when option code "/US" is

specified); and,

(3) External grounding terminal.

F18.EPS

8

IM 12E01A06-02E

Page 10

(1) Power Supply Terminals

2. PIPING AND WIRING

Terminals TM3 (Power to Lamp)

Terminal G

(For Converter 2 Detector

Connecting Cable)

(2) Power Supply Terminals for

Ultrasonic Oscillator

Connector for Converter 2 Detector Cable

Figure 2.4 Internal View of Detector

(3) External Grounding Terminal (M5 Screw)

(Norminal size of at least 2 mm

Figure 2.5 Grounding Terminal of Detector

F0310.EPS

2

)

F0319.EPS

2.2.3 Wiring for Converter

Wire for connections to the following terminals:

(1) Analog output/contact input terminals;

(2) Contact output/range contact output terminals;

(3) Serial communication terminals (when in use); and,

(4) Grounding terminal.

IM 12E01A06-02E

9

Page 11

r

2. PIPING AND WIRING

(A)

Converter 2 Detector

Front Cover

Connecting Cable

Serial Communication

Terminals

Front Cover

Terminal Cover

(B)

Terminal G

(For Converter 2

Detector Connecting Cable)

(1) Analog Output/Contact Input Terminals

How to Remove the Terminal Cover

Disconnect the converter-detector connecting cable (A) and its grounding wire (B) from the converter.

Remove the terminal cover by sliding it slightly to the left and pulling it forward.

Connector for

Converter 2 Detector Cable

(3) Serial Communication

Terminals

(2) Contact Output/

Range Contact

Output Terminals

Analog Output/Contact Input Terminals

Figure 2.6 Internal View of Converter

F0309.EPS

Toothed Lock Washe

(4) Grounding Terminal (M4 Screw)

Figure 2.7 Grounding Terminal of Converter

Contact Output (S1, S2 and FAIL) Wiring

• Be sure to use the contacts meeting the conditions below.

• Functions of contact outputs S1 and S2 should be set in Codes 40 and 41 at service

level. Refer to section 4.3.

Table 2.1 Contact Rating

Contact maximum permissible voltage

Contact maximum permissible current

Contact maximum permissible power

(resistance load)

Table 2.2 Contact Operation

Status

In action

Not in action

Power OFF

LED NO NC

OFF

OFF

Contact S1, S2

ON

Closed

Open

Open

LED NO NC

Open

Closed

OFF

Closed

OFF

250 V

2 A

125 VA

Contact FAIL

ON

Open

Closed

Open

AC

Closed

Open

Closed

T01.EPS

Grounding Wire

(Nominal Size of at least 2 mm

F0318.EPS

DC

30 V

3 A

60 W

T0303.EPS

2

)

10

IM 12E01A06-02E

Page 12

3. OPERATION

3.1 Preparation

3.1.1 Outline

3. OPERATION

1. Installation Check

2. Piping Check

3. Wiring Check

4. Supplying Power

5. Warm-up

6. Setting and Checking Parameters

7. Calibration

8. Supplying a Water Sample and

adjusting the flow rate

• Make sure that TB750G converter and detector

are fixed fimly.

• Unused cable inlets should be plugged to

prevent moisture from entering.

• Note that the TB750G does not have an internal

power switch.

• Upon power up, allow the meter to warm up for

at least one hour.

• When using zero turbidity filter, allow water to

run through it for at least one hour.

• For details of parameter settings, refer to

chapter 4.

• For details of calibrations, refer to the following

pages.

• Adjust the opening of the valve at the sample

water out of the detector.

9. Operation check

• Make sure that the system is free of defects.

F3.1.EPS

IM 12E01A06-02E

11

Page 13

3. OPERATION

3.1.2 Converter Operation Panel

HOLD FAILTEMP. MAN

YES NO MODE

YES NO

ENT

ENT

FNU

UNIT

mg/lNTU

MODE SET UP

MEASURE

SETPOINTS

CAL

RANGE

CAL START

SET HOLD

WASH START

CAL / WASH

SERVICE

DISPLAY

HOLD

CONTACTS

S1

S2

FAIL

Turbidity Unit Indication

Operation Key

([*]: To enter the operation level

from measurement mode)

Contact Status LED

3.1.3 Calibration

LCD Screen

Operation Key

F0504.EPS

(1) When performing a calibration using 0.2 or 1.0 µm filtered water as zero reference,

refer to section 3.1.4.

(2) When performing a 2-point calibration using standard solutions, refer to section

3.1.5. Use this method to perform a calibration complying with EPA 180.1.

Note:The instrument has been pre-calibrated using 0.2 µm filtered water as zero

reference at the factory before shipment.

Calibration Flow Chart

Start calibration

Is filtered water used

as zero reference?

YES

Perform span/zero calibration

using filtered water

Perform zero calibration

NO

Perform 2-point calibration

using standard solutions*

Perform point calibration

first using zero solution

12

Is span calibration performed

Standard Solution

using check block or

standard solution?

Check block

Perform span calibration

using check block.

Refer to Section 3.1.4.

Perform span calibration

using standard solution.

Refer to Section 3.1.4.

End calibration

* Calibration complying with EPA Method 180.1.

Perform second point

calibration using span solution.

Refer to Section 3.1.5.

F3.2.EPS

IM 12E01A06-02E

Page 14

3. OPERATION

3.1.4 Performing Zero/span Calibration Using Filtered Water as Zero Reference

START

• Supply power

• Warm-up (at least 1 hour)

• Allow water to run through the zero filter

• Supply zero water

• Prepare span solution, if necessary

[MODE]

CALB

[YES]

X.XXX

STD.CAL

[YES]

X.XXX

ZERO

• Confirm reading has stabilized (3 to 5 min)

[YES]

Automatically goes into

maintenance mode and holds

the output.

0.000

VALUE

[ENT]

X.XXX

ZERO

X.XXX

CAL.END

[NO] [YES]

A

To span calibration

using check block

{0.000} None configurable

Auto-adjustment

Zero calibration is complete

B

To span calibration

using standard solution

F3.3.EPS

IM 12E01A06-02E

13

Page 15

3. OPERATION

Span calibration using check block

Note:For span calibration using standard solution, refer to next page.

From zero calibration

A

X.XXX

STD.CAL

[YES]

X.XXX

ZERO

[NO]

X.XXX

SPAN

• Stop supplying zero water

• Drain zero water

• Install check block *

• Supply zero water

• Confirm reading has stabilized (3-5 min)

[YES]

XX.XX

VALUE

[ENT]

XX.XX

SPAN

XX.XX

CAL.END

[YES]

HOLD

[NO]

END

{XX.XX} None configurable

• Check that display re ads the value of check block

Auto-adjustment

Span calibration is complete

Release HOLD **

* How to install check block

1. Remove the rubber cover from the top of the detector.

2. Remove the retaining plate on the window of the top cover

by loosening the 2 setscrews.

3. Detach the observation window and replace it with the

check block. Fix it with the 2 setscrews securely.

Check block

14

** Be sure to release HOLD

F3.4.EPS

IM 12E01A06-02E

Page 16

Span calibration using standard solution (1/2)

From zero calibration

B

HOLD

[YES]

HOLD

[*] at least second

*SETP

[NO]

[NO]

[NO]

(3 times)

*SERV

[YES]

Before performing span calibration using

standard solution, standard solution/check

block selection should be set to "0 (standard

solution)" in CODE 16 as shown below.

To enter operation level

{*SETP} -> {*RANGE} -> {*HOLD} -> {*SERV}

3. OPERATION

16

*CODE

0

*CAL.TP

*SERV

HOLD

HOLD

C

[m]

[c]

• Enter "16" using [m]and [c] keys

[YES]

[m]

• Enter "0" using [m] key

[ENT]

[MODE]

[YES]

[MODE]

F3.5.EPS

IM 12E01A06-02E

15

Page 17

3. OPERATION

Span calibration using standard solution (2/2)

C

CALB

[YES]

X.XXX

STD.CAL

[YES]

X.XXX

ZERO

[NO]

X.XXX

SPAN

• Remove top cover (6 setscrews)

• Rinse the cell with span solution and drain

• Fill the cell with span solution to 90% *

• Replace top cover with setscrews

• Confirm reading has stabilized (3-5 min)

[YES]

00.00

VALUE

[ENT]

20.00

VALUE

[ENT]

XX.XX

SPAN

XX.XX

CAL.END

[YES]

HOLD

[NO]

END

[c]

• Set decimal point using [c] key

[m]

**

[c]

• Enter value of span calibration using [m] and [c] keys

Auto-adjustment

Span calibration is complete

Release HOLD ***

* How to pour span solution

Pour span solution into the measurement cell very

slowly, using a funnel or relevant equipment, taking

care not to allow air bubbles to enter the cell.

** Number in the figure is an example.

*** Be sure to release HOLD

F3.6.EPS

16

IM 12E01A06-02E

Page 18

3.1.5 Performing 2-point Calibration Using Standard Solution

START

• Supply power

• Warm-up (at least 1 hour)

• Wash the cell

• Prepare zero and span solutions

[MODE]

CALB

[YES]

X.XXX

STD.CAL

[NO]

X.XXX

SMP.CAL

[YES]

X.XXX

ZRSPAN

• Remove top cover (6 setscrews)

• Rinse the cell with zero solution and drain

• Fill the cell with zero solution to 90% *

• Replace top cover with screws

• Confirm reading has stabilized (3-5 min)

[YES]

0.000

VALUE.Z

0.020

VALUE.Z

X.XXX

ZERO

[c]

• Set decimal point using [c] key

[ENT]

**

[m]

[c]

• Enter value of zero calibration using [m] and [c] keys

[ENT]

Auto-adjustment

3. OPERATION

X.XXX

SPAN

• Remove top cover (6 setscrews)

• Rinse the cell with zero solution and drain

• Fill the cell with zero solution to 90% *

• Replace top cover with screws

• Confirm reading has stabilized (3-5 min)

[YES]

00.00

VALUE.S

20.00

VALUE.S

XX.XX

SPAN

XX.XX

CAL.END

HOLD

END

[c]

• Set decimal point using [c] key

[ENT]

[m]

**

[c]

• Enter value of span calibration using [m] and [c] keys

[ENT]

Auto-adjustment

Span calibration is complete

[YES]

Release HOLD ***

[NO]

* How to pour zero solution

Pour a span solution into the measurement cell very

slowly, using a funnel or relevant equipment, taking

care not to allow air bubbles to enter the cell.

** Numbers in the figures are examples.

*** Be sure to release HOLD

F3.7.EPS

IM 12E01A06-02E

17

Page 19

3. OPERATION

3.2 Normal Operation

The TB750G turbidimeter does not normally require any manual operations except when

periodic cleaning/calibration is performed or when a failure occurs.

3.2.1 When Sample Water Supply is Cut Off

The turbidity measurement is not affected by temporary suspension of sample water

supply, but long-term suspension may interfere with the accuracy of the instrument.

Since the TB750G cannot detect whether the sample water supply is stopped or not,

periodical check of the sample line is needed.

3.2.2 Shutdown

The parameter settings and other information set in the turbidimeter are retained even if

power is turned off. If the instrument will be out of operation for a long period, power

should be removed. Dirt and/or stains on the instrument should be washed off

thoroughly when the turbidimeter is to be removed from the site. Rinse the inside of the

measurement cell, and then empty the cell or keep zero water running through the cell.

3.2.3 Restart

When power is returned, the turbidimeter is put into the measurement state. It requires at

least one hour for warm-up. Check that the reading stabilizes well, before performing

calibration.

18

IM 12E01A06-02E

Page 20

4. PARAMETER SETTING

4. PARAMETER SETTING

4.1 Outline of Operation, Setting, and Service Levels

Parameters should be set in the relevant mode classified into three levels: operation,

setting and service.

Measurement Mode

[MODE] key [ * ] For at least second

Operation Level

CALIB (Calibration)

DISP (Message display)

STEP (Alarm setting)

HOLD (Hold selection)

Setting Level

STEP (Alarm setting)

RANGE (Analog output)

HOLD (Hold selection)

Service Level

CODE XX

F0501.EPS

Figure 4.1 Transition between Measurement Mode and Three Levels

IM 12E01A06-02E

19

Page 21

4. PARAMETER SETTING

4.2 Operation Level

This is the level where, basically, operations regarding routine inspections and

maintenance, such as calibration and manual cleaning, can be done. Also, the desired

display item on the message display can be selected at this operation level.

Measurement

mode

[MODE]

[NO]

DISP

[NO]

*1

[NO]

*2

HOLD

[NO]

[YES]

[YES]

[YES]

[YES]

Calibration mode

Message display selection mode

Alarm setting mode

Hold selection mode

[YES]

[YES]

[YES]

[YES]

HOLDCALIB

HOLDSETP

*3

*1: Skipped if alarm setting function is set to “0: Disabled” in Code 51 at service level, or unless

either of functions of contact output S1 or S2 is set to “1: Alarm” in Code 40 or 41 at service

level.

*2: Skipped if hold function is set to “*H.OFF: Disabled” in SET HOLD mode at setting level.

*3: If [YES] key is pressed, analog output is held in measurement mode.

Table 4.1 Setting Parameters at Operation Level

Setting ParameterMode Display Setting Range

CAL Calibration

Using turbidity standards, or

using water sample

Start

Turbidity value

Self-adjustment in process

End

CAL START

WASH START

DISPLAY Message display selection

Analog output 1 current

Analog output 2 current

Switchable output range state

(No pointer at Alarm setting

mode display) High alarm setpoint

Low alarm setpoint

HOLD Hold selection

Hold selection

CALIB

STD.CAL or

SMP.CAL

ZERO or SPAN

or ZRSPN

VALUE

ZERO or SPAN

CAL.END

DISP

XX.XmA1

XX.XmA2

RNG1/2-A/B/C

SETP

*

S.TB-H

*

S.TB-L

*

HOLD

0.001 to 2000[NTU]

Not available

Not available

–010.0 to 2200.0[NTU]

–010.0 to 2200.0[NTU]

*1

Output 1 current

*2

*3

2200.0

*1

-010.0

*1

*4

F0601.EPS

Default

(NTU)

(NTU)

(Disabled)

*1: Although setting range is up to 2000 NTU, measuring range is up to 100 NTU.

*2: Skipped if analog output range switching selection {*RNGPR} is set to “0: Fixed” in CODE 30 at service level.

*3: Skipped if alarm setting function is set to “0: Disabled” in Code 51 at service level, or if either function of contact

output S1 or S2 is not set to “1: Alarm” in Code 40 or 41 at service level.

*4: Skipped if hold function is set to “*H.OFF: Disabled” in SET HOLD mode at setting level.

20

T0501.EPS

IM 12E01A06-02E

Page 22

4.3 Setting Level

There are modes where parameters regarding output signals and contact outputs can be

set.

Measurement

*1

*RANGE

4. PARAMETER SETTING

*2

mode

[ * ] For at least second

*SETP

*HOLD

*SERV

*1: Skipped unless either of functions of contact output S1 or S2 is set to “1: Alarm” in

*2: Skipped if hold function is set to “*H.OFF: Disabled” in SET HOLD mode at setting

*3: For service level, see Section 4.4.

[YES]

[NO]

[YES]

[NO]

[YES]

[NO]

[YES]

[NO]

Code 40 or 41 at service level.

level.

SETPOINTS Mode

RANGE Mode

SET HOLD Mode

*3

Service Level

HOLD

F0605.EPS

Table 4.2 Setting Parameters at Setting Level

Setting ParameterMode Display Setting Range

SETPOINTS Alarm setting

High alarm setpoint

Low alarm setpoint

RANGE Analog output range setting

Fixed range for output 1, or

fixed range for output 2

Zero point

Span point

Local range selection

Local range for output 1, or

local range for output 2

SET HOLD Hold parameter setting

Hold function enabled, or

hold function disabled

Last measured value, or

fixed value

Fixed value for output 1

Fixed value for output 2

CAL/WASH

SERVICE

SETP

*

S.TB-H

*

S.TB-L

*

RANGE

*

FIXR.1 or

*

*FIXR.2

ZERO

*

SPAN

*

LOCAL

*

*LCL.1 or

*LCL.2

HOLD

*

H.ON or

*

H.OFF

*

H.LST or

*

H.FIX

*

H.mA1

*

H.mA2

*

–010.0 to 2200.0[NTU]

–010.0 to 2200.0[NTU]

0000.00 to 2000.00[NTU]

0000.00 to 2000.00[NTU]

0: Range A, 1: Range B, 2: Range C

* H.ON

(Enabled)

* H.OFF

* H.LST

* H.FIX

02.0 to 22.0[mA]

00.0 to 22.0[mA](0-20mA)

02.0 to 22.0[mA](4-20mA)

Not available

(Disabled)

(Last measured value)

(Fixed value)

*1

*1

*1

* H.ON

*2

Default

2200.0

(NTU)

-010.0

(NTU)

0000.00

(NTU)

0100.00

(NTU)

0

:Range A

:Enabled

* H.LST

:Last

measured value

22.0

(mA)

22.0

(mA)

*1: Skipped if alarm setting function is set to "0: Disabled" in Code 51 at service level, or if either function of contact

output S1 or S2 is not set to "1: alarm" in Code 40 or 41 at service level.

*2: For service level, see Section 4.4.

IM 12E01A06-02E

T0502.EPS

21

Page 23

4. PARAMETER SETTING

4.4 Service Level

The TB750G turbidimeter has various functions. At this level there are modes where

functions can be selected according to need for the operation.

Table 4.3 Setting Parameters at Service Level (1/2)

Setting ParameterCode Display Setting Range

CODE02 Input voltage display

Transmitted light detection element input display

Scattered light detection element input display

End

CODE08 Spike detection parameter setting

Spike detection function enabled or disabled

Limit value

Hold time

Sampling time

CODE11 Zero calibration factor display

Zero calibration factor display

CODE12 Slope display

Slope display

CODE13 Zero correction factor setting

Zero correction factor setting

CODE14 Sensitivity correction factor setting

Sensitivity correction factor setting

CODE16 Standard solution/check block selection

Standard solution or check block

CODE17 Check block turbidity setting

Check block turbidity

CODE30 Analog output range

switching parameter setting

Range switching output selection

Range switching function selection

Range A setting

Zero point for range A

Span point for range A

Range B setting

Zero point for range B

Span point for range B

Range C setting

Zero point for range C

Span point for range C

Automatic range switching point

CODE33 Analog output 2 range selection

Range selection for output 2

Fixed value for hold

Fixed value for hold during failure

IN1

*

IN2

*

END

*

SPIKE

*

LIMIT

*

HLD-T

*

SMP-T

*

*CAL.A

SL

*

*CAL.B

*CAL.K

*CAL.TP

*PLATE

RNGPR

*

*RSET

RSET.A

*

ZERO

*

*SPAN

RSET.B

*

*ZERO

SPAN

*

RSET.C

*

ZERO

*

SPAN

*

*AUTOR

*mA2

*H.mA2

*FH.mA2

0: Disabled, 1: Enabled

000.000 to 999.999

005 to 600[s]

001 to 600[s]

–9.000 to 09.000[NTU]

0.2500 to 4.0000

0: Standard Solution, 1: Check Block

0.001 to 2000[NTU]

0: Fixed, 1: AO1, 2: AO2

0: Local, 1: Automatic, 2: Remote

2RNG, 3: Remote 3RNG

0000.00 to 2000.00[NTU]

0000.00 to 2000.00[NTU]

0000.00 to 2000.00[NTU]

0000.00 to 2000.00[NTU]

0000.00 to 2000.00[NTU]

0000.00 to 2000.00[NTU]

070 to 100[%]

0: 4.0-20.0mA, 1: 0.0-20.0mA

00.0 to 22.0[mA](0-20mA)

02.0 to 22.0[mA](4-20mA)

00.0 to 22.0[mA](0-20mA)

02.0 to 22.0[mA](4-20mA)

Default

0

:Disabled

999.999

(NTU)

030

(s)

030

(s)

Depends on MS Code

100.0

(%)

00.000

(NTU)

1.0000

1

:Check Block

0

:Fixed

1

:Automatic

0000.00

(NTU)

0010.00

(NTU)

0000.00

(NTU)

0100.00

(NTU)

0000.00

(NTU)

1000.00

(NTU)

080

(%)

0:

4.0-20.0mA

22.0

(mA)

22.0

(mA)

T0503_1.EPS

22

IM 12E01A06-02E

Page 24

Table 4.3 Setting Parameters at Service Level (2/2)

Setting ParameterCode Display Setting Range

CODE35 Hold during failure parameter setting

Hold function enabled or disabled

Last measured value, or

fixed value

Fixed value for output 1

Fixed value for output 2

CODE37 Time constant setting

Time constant in measurement

Time constant in maintenance

CODE40 Contact output S1 function selection

Function of contact output S1

CODE41 Contact output S2 function selection

Function of contact output S2

CODE44 Delay time/hysteresis setting

Delay time

Hysteresis

CODE50

Auto return function enabled or disabled

CODE51 Alarm setting function selection

Alarm setting function enabled or disabled

CODE52 Password setting

Password

CODE54 Negative nondisplay/nonoutput selection

CODE61 Turbidity unit selection

Turbidity unit

CODE64 Software version display

Software version display

CODE66 Error “E2xx” error level selection

Error levels of errors “E201” to “E206”

CODE67 Error “E3xx” error detection selection

Error detection for “E301” to “E306”

Error detection for “E307”

Error detection for “E311” to “E316”

Error detection for “E317”

CODE71 Analog output test

Start test for output 1

Test current flowing

End

Start test for output 2

Test current flowing

End

CODE72 Contact output test

Test 1

Test 2

CODE73 Contact input test

Test

CODE79 Initialization

Start

Default loading

Auto return function selection

Negative nondisplay/nonoutput enabled or disabled

FHOLD

*

*FH.LST /

*FH.FIX

*FH.mA1

*FH.mA2

*TC

*TC-M

S1

*

S2

*

D.TIME

*

HYST

*

*RET

MODE

*

*PASS

*MINUS

*UNIT

*VER

*201-6

*301-6

*307

*311-6

*317

*AO1.T

*END

*AO2.T

*END

*DO.T1

*DO.T2

*DI.T

*LOAD

*WAIT

4. PARAMETER SETTING

0: Disabled, 1: Enabled

* FH.LST

(Last measured value)

* FH.FIX

(Fixed value)

02.0 to 22.0[mA]

00.0 to 22.0[mA](0-20mA)

02.0 to 22.0[mA](4-20mA)

000 to 120[s]

000 to 120[s]

0:None , 1: Alarm, 2: Automatic

calibration/washing, 3: Maintenance

0:None , 1: Alarm, 2: Automatic

calibration/washing, 3: Maintenance

000 to 199[s]

000 to 100[%]

0: Disabled, 1: Enabled

0: Disabled, 1: Enabled

0:No password, 1:111, 2:333, 3:777,

4:888, 5:123, 6:957, 7:331, 8:546, 9:847

0: Disabled, 1: Enabled

0: NTU, 1: FNU, 2: mg/l

0: Disable, 1: Level 1, 2: Level 2

0: Disabled, 1: Enabled

0: Disabled, 1: Enabled

0: Disabled, 1: Enabled

0: Disabled, 1: Enabled

0: Non-action, 1: Action

0: Non-action, 1: Action

Default

1

: Enabled

*FH.FIX

:Fixed value

22.0

(mA)

22.0

(mA)

020

(s)

006

(s)

1

: Alarm

3

: Maintenance

000

(s)

002

(%)

0

: Disabled

0

: Disabled

0.0.0

0.0

: Disabled.Disabled

0

: NTU

1.00

1.1.2.2.2.2

1.1.1.1.1.1

1

1.1.1.1.1.1

1

Last measured value held

Last measured value held

T0503_2.EPS

IM 12E01A06-02E

23

Page 25

4. PARAMETER SETTING

4.5 Procedures for Setting Parameters

An example for setting parameters, the procedures are described in following modes. For

more detail on the other functions, refer to User's Manual IM 12E01A06-01E Section 6.

(1) CAL Mode: {CALIB}

(2) HOLD Mode: {HOLD}

(3) RANGE Mode: {*RANGE}

(1) CAL Mode: {CALIB}

CALIB

[YES]

[NO]

[YES]

[NO]

[YES]

[ENT]

Self-adjustment

or [ENT]

[YES]

*2

*4 *5

*6

X.XXX

SPAN

[YES]

0.000

VALUE

[ENT]

X.XXX

SPAN

Self-adjustment

or [ENT]

X.XXX

SMP.CAL

[NO]

[c]

[m]

X.XXX

ZRSPN

*5

0.000

VALUE.Z

X.XXX

ZERO

X.XXX

SPAN

*5 *7

0.000

VALUE.S

X.XXX

SPAN

*6 *6

[YES]

[YES]

[ENT]

Self-adjustment

or [ENT]

[YES]

[ENT]

Self-adjustment

or [ENT]

[NO]

X.XXX

STD.CAL

*1

X.XXX

ZERO

*3

0.000

VALUE

X.XXX

ZERO

X.XXX

CAL.END

*7

HOLD

[NO]

[NO]

[c]

[m]

[c]

[m]

*6

X.XXX

ZERO

[YES]

*5

0.000

VALUE

[ENT]

X.XXX

ZERO

Self-adjustment

or [ENT]

[NO]

*5

[c]

[m]

*6 *6

X.XXX

SPAN

[YES]

0.000

VALUE

[ENT]

X.XXX

SPAN

Self-adjustment

or [ENT]

[NO]

[c]

[m]

24

Measurement

mode

*1: During the time between [YES] key press on {STD.CAL} display and [YES] or [NO] key press on

{CAL.END} display or on error code display or [MODE] key press to abort, data display shows turbidity

based on sensitivity correction factor (K)=1 and zero correction factor (B)=0. (Value not affected by

SMP.CAL: Display by T1={(S0/(SL/100)}*(V-A), not by T2=K(T1+B))

*2: Span calibration in {STD.CAL} is performed using turbidity standards or check block that has been

selected in CODE16.

*3: In zero calibration, calibration value should be “0.000” and cannot be changed. Only [ENT] key is

accepted to confirm.

*4: In span calibration using check block, calibration value cannot be changed. Only [ENT] key is accepted

to confirm.

*5: First determine the decimal point using [>] key and then set value in the range of 0.000 to 20000 NTU.

*6: Pressing [ENT] key during self-adjustment will abort the procedure, and the turbidity when [ENT] key is

pressed will be used for calibration factor calculation.

*7: Only [YES] key is accepted to confirm.

Note: Calibration factor will be updated when the calibration procedure is completed without cancellation or

errors. If [YES]/[NO] key is pressed on error code display, the instrument goes to {CALIB} display.

Error E203 or E204 appears after the instrument once returns to measurement display.

Figure 4.2 CAL Mode Flow Chart

IM 12E01A06-02E

F0602.EPS

Page 26

(2) HOLD Mode: {HOLD}

In this mode whether the analog output is held or not in measurement mode, can be

selected. This function is available when the hold function is set to “1: Enabled” in SET

HOLD mode at the setting level. If the function is set to “0: Disabled,” this mode will

be skipped.

4. PARAMETER SETTING

HOLD

[YES]

HOLD

Hold disabled in

measurement mode

Measurement

mode

(Flashing)

[YES][NO]

Hold enabled in

measurement mode

HOLD status indicator turns on.

F0604.EPS

Figure 4.3 HOLD Mode Flow Chart

If the hold function has been set to “1: Enabled” in SET HOLD mode at the setting

level, the instrument automatically goes into this HOLD mode when it returns from any

level to measurement mode, with the exception of DISPLAY mode.

IM 12E01A06-02E

25

Page 27

4. PARAMETER SETTING

(3) RANGE Mode: {*RANGE}

In this mode, an output range corresponding to analog output 1 and 2 can be set. Enter

turbidity values corresponding to a 4 mA (or 0 mA) output signal (zero point) and a 20

mA output signal (span point).

*RANGE

*1 *2 *3

XXXX.XX

XXXX.XX

*1: Skipped if analog output range switching selection {*RNGPR} is set to “1: Analog output 1” in

CODE 30 at service level.

*2: Skipped if analog output range switching selection {*RNGPR} is set to “2: Analog output 2” in

CODE 30 at service level.

*3: Displayed only if analog output range switching selection {*RNGPR} is set to “1: Analog output 1”

or “2: Analog output 2” and range switching function selection {*RSET} is set to “0: Manual” in

CODE 30 at service level.

*4: Displayed only if analog output range switching selection {*RNGPR} is set to “1: Analog output 1”

in CODE 30 at service level.

*5: Displayed only if analog output range switching selection {*RNGPR} is set to “2: Analog output 2”

in CODE 30 at service level.

*6: Zero and span points should be set together. Only after span point has been entered, both zero and

span points are accepted. Cancellation by pressing [MODE] key during the procedure will not

change either of the points.

[YES]

[NO]

[c]

XXXX.XX

[YES]

[ENT]

[m]

[c]

[m]

XXXX.XX

*ZERO

*SPAN

*6 *6

[YES][YES]

*ZERO

*SPAN

[NO][NO]

*LOCAL*FIXR.2*FIXR.1

*4

[c]

[YES]

[ENT]

[m]

[c]

[m]

X

*LCL.1

*5

X

*LCL.2

[YES]

[YES]

[ENT]

Local range for output 1

[m]

X: 0(Range A), 1(Range B)

or 2(Range C)

Local range for output 2

[m]

X: 0(Range A), 1(Range B)

or 2(Range C)

F0607.EPS

Figure 4.4 RANGE Mode Flow Chart

26

IM 12E01A06-02E

Page 28

5. MAINTENANCE

5.1 Lamp Replacement

CAUTION

Wait for some time to replace lamp assembly because lamp temperature is high just after

lamp power was turned off.

Although the lamp has a normal service life of more than one year, it is recommended

that the lamp be replaced at an interval of one year in terms of preventive maintenance.

Some lamps may fail within one year.

The following describes how to replace the lamp.

(1) Remove power from the TB750G turbidimeter.

(2) Remove the cover of the light source unit on the left side of the detector by

loosening the 4 setscrews.

(3) Disconnect the terminals for lamp from the terminal block. Remove the lamp

assembly by loosening the 2 setscrews.

(4) Replace the lamp assembly with a new one. Mount the new lamp assembly with the

2 setscrews. Connect the terminals for lamp to the terminal block (LAMP).

(5) Supply power to the TB750G turbidimeter.

(6) Check that the lamp is lit. Replace and fix the cover of the light source unit by

tightening the 4 setscrews.

(7) After the lamp replacement, allow the turbidimeter to warm up for at least one hour.

Then, perform calibrations instructed in Sections 3.

(8) Lamp replacement is now complete.

5. MAINTENANCE

IM 12E01A06-02E

Cover for

Terminal

Setscrews (2)

[View A]

Lamp Assembly

Ter minal Block

Cover of the Light Source Unit

A

Setscrews (2)

Ter minal Block

Figure 5.1 Lamp Replacement

Lamp Assembly

F0704.EPS

27

Page 29

5. MAINTENANCE

5.2 Calibration

5.2.1 Outline

CALIB STD.CAL ZERO

(1)

SPAN

Zero calibration using zero turbidity

water

Span calibration using check block

Span calibration using standard

solution

Calibration

using

filtered

water as

zero

reference

SMP.CAL ZRSPN

(2)

(3)

ZERO

SPAN

2-point calibration using standard

solutions

Zero point correction

Sensitivity correction

Figure 5.2 Calibration Methods

(1) Select when performing a calibration using 0.2 or 1.0 µm filtered water as zero

reference.

(2) Select when performing a 2-point calibration using standard solutions. Use this

method to perform a calibration complying with EPA 180.1.

(3) Select when performing a zero point or sensitivity correction after calibration (1) or

(2). This method is used to adjust the meter reading to reflect the lab data in a grab

sample calibration.

Note:The instrument has been pre-calibrated using 0.2 µm filtered water as zero

reference at the factory before shipment.

5.2.2 2-point Calibration Using Turbidity Standard Solutions

F0705.EPS

28

A 2-point calibration of the TB750G is performed with turbidity standard solutions

equivalent to zero solution and to span solution. After accepting both zero and span

values, the meter calculates a calibration factor.

When user-prepared zero and span solutions are used for calibrations, the turbidity of

diluting water for calibration should be measured with a calibrated lab turbidimeter in

advance. Prepare a formazin standard solution as a span solution. If the turbidity of

diluting water is high against the measurement accuracy, add the turbidity of diluting

water to the nominal turbidity of the prepared formazin standard solution. Use diluting

water as zero solution and a formazin solution as span solution for the calibration.

Refer to Section 3, “Operation” for concrete operating procedures.

IM 12E01A06-02E

Page 30

6. TROUBLESHOOTING

Table 6.1 Error Code List (1/2)

6. TROUBLESHOOTING

Flash memory

E101

fail u re

EEPROM write

E102

failure

RAM failure

E103

AD converter

E104

failure

Input voltage

E201

failure

Disconnection or

E202

detection element

failure

Lamp life expired

E203

Lamp intensity

E204

failure

Calibration failure

E205

ErrorNo. Occurrence

When power is turned

on.

All modes

When power is turned

on.

All modes

All modes

All modes

Zero calibration

coefficient A rewriting

timing. (excluding

when E301 or E311

occurs.)*1

E301 to E307, E311

to E317, E321 during

PC communication

occurrence timing

SUM results of flash memory do not match

programmed SUM values 5 consecutive times.

Data is written in EEPROM and verified, and

write failure occurs 3 consecutive times.

RAM area failure (3 consecutive times).

AD converter failure (3 consecutive times).

Either IN1 or IN2 input voltage is outside the

range of -0.15 to 1.2 V (fixed), including

abnormal value 0x7FFF or 8000, for 5

consecutive seconds.

Either IN1 or IN2 input voltage is less than PD

check voltage for 5 consecutive seconds.

During zero calibration self-adjustment, input

voltage IN1 is less than lamp life check voltage

for 5 consecutive seconds. (Not detected when

E301 is occurring.) Rewriting of zero calibration

coefficient A is performed.

Any of E301 to E307, E321 during PC

communication is occurring.

ReturnProblem

When power is turned off

and then on again, and

problem is eliminated.

(Without [YES]/[NO] key

press.)

When problem is

eliminated for 5

consecutive seconds.

When [YES]/[NO] key is

pressed, error code

display disappears, at the

same time during failure,

error is once removed.

When problem is

eliminated. When

[YES]/[NO] key is

pressed, error code

display disappears, at the

same time during failure,

error is once removed.

T0804-1.EPS

IM 12E01A06-02E

29

Page 31

6. TROUBLESHOOTING

ErrorNo. Occurrence ReturnProblem

Tu r bidity zero

E301

calibration

coefficient A

failure

T urbidity slope

E302

SL failure

Turbidity check

E303

block failure

Turbidity zero

E304

correction

factor B failure

Turbidity

E305

sensitivity

correction

factor K failure

Turbidity

E306

reference

sensitivity SO

failure

T urbidity

E307

response time

failure

Communication

E321

error

Analog output

E351

range setting

failure

Parameter

E352

setting failure

Table 6.1 Error Code List (2/2)

During zero

calibration (zero

water).

During span

calibration (standard

solution)

During span

calibration (check

block)

During zero shift

calibration

During span

calibration

(sensitivity

correction)

During turbidity

reference sensitivity

calibration

All calibrations

During

communication with

PC

During parameter

setting in RANGE

mode or CODE 30.

During parameter

setting

Turbidity zero calibration coefficient A newly

determined after zero calibration (zero water or

lamp OFF) is outside of the range of 0 to 5, or each

coordinate value of newly determined linearized

table is outside of the range of -99999 to 999999.

Turbidity slope value SL newly determined after

span calibration (standard solution) is outside of the

range of 25 to 200%, or each coordinate value of

newly determined linearized table is outside of the

range of -99999 to 999999.

Turbidity slope value SL newly determined after

span calibration (check block) is outside of the

range of 50 to 150%, or each coordinate value of

newly determined linearized table is outside of the

range of -99999 to 999999.

Turbidity zero correction factor B newly determined

after zero shift calibration is outside of the range of

-9 to 9.

Turbidity sensitivity correction factor K newly

determined after span calibration (sensitivity

correction) is outside of the range of 0.25 to 4.

Turbidity reference sensitivity SO newly set after

span calibration (check block) is outside of the

tolerance of 0.0001 to 2000, or each coordinate

value of newly determined linearized table is outside

of the range of -99999 to 999999.

Turbidity self-adjustment is not complete before self-

adjustment time has elapsed.

Any communication error during communication

with PC.

Either of:

(1) Zero point ≥ span point, or

(2) Span point - zero point < 20% of span point or

0.20, whichever is greater (for turbidity) or ( span

point - zero point < 5.00 (for color).

When automatic range is selected in CODE 30, also

possible:

(3) At each span point, Range A ≥ Range B, or

(4) at each span point, Range B ≥ Range C

Value outside the setting range is set in setting

other than AO range setting.

When problem is

eliminated. When

[YES]/[NO] key is pressed,

error code display

disappears, at the same

time during failure, error is

once removed.

When problem is

eliminated in the next

communication (only one

time is OK). When

[YES]/[NO] key is pressed,

error code display

disappears, at the same

time during failure, error is

once removed. (excluding

RS signal during

communication with

calibration/cleaning

controller.)

When [YES]/[NO] key is

pressed, error code

display disappears and

error is removed.

T0804-2.EPS

30

Refer to the user's manual IM 12E01A06-01E for details.

IM 12E01A06-02E

Page 32

Revision Record

Manual Title : Model TB750G Right Angle Scattered Light Turbidimeter Quick Start Manual

Manual Number : IM 12E01A06-02E

Edition Date Remark (s)

1st Apr. 2006 Newly published

Loading...

Loading...