Page 1

User’s

Model 735201

Manual

TB200

OPTICAL POWER METER

IM 735201-01E

3rd Edition

Page 2

Foreword

Thank you for purchasing the TB200 Optical Powermeter. This user’s manual

contains useful information about the functions and operating procedures of the

TB200 and lists the handling precautions of the instrument. To ensure correct use,

please read this manual thoroughly before beginning operation. After reading this

manual, keep it in a convenient location for quick reference in the event a

question arises during operation.

Notes

The contents of this manual are subject to change without prior notice as a result

of continuing improvements to the instrument’s performance and functions.

Display contents illustrated in this manual may differ slightly from what actually

appears on your screen.

In this manual, the descriptions are based on Windows 2000.

Every effort has been made in the preparation of this manual to ensure the

accuracy of its contents. However, should you have any questions or find any

errors, please contact your nearest YOKOGAWA dealer as listed on the back

cover of this manual.

Copying or reproducing all or any part of the contents of this manual without the

permission of Yokogawa Electric Corporation is strictly prohibited.

A warranty sheet is included. It cannot be reissued. After reading the sheet,

keep it in a safe location.

Trademarks

Windows is either a trademark or registered trademark of Microsoft Corporation

in the United States and/or other countries.

Adobe, Adobe Acrobat, and PostScript are registered trademarks of Adobe

Systems incorporated.

The company and product names used in this manual are not accompanied by

the trademark or registered trademark symbols (TM and ®).

Other company and product names are trademarks or registered trademarks of

their respective companies.

Revisions

● First Edition July, 2005

● Second Edition September, 2005

● Third Edition November, 2010

3rd Edition : November 2010 (YK)

All Rights Reserved, Copyright © 2005 Yokogawa Electric Corporation

All Rights Reserved, Copyright © 2010 Yokogawa Meters & Instruments Corporation

IM 735201-01E

i

Page 3

Terms and Conditions of the Software License

NOTICE - PLEASE READ CAREFULLY BEFORE USE

Thank you very much for purchasing this medium containing a software program and related documentation provided by

Yokogawa Electric Corporation and Y okogawa Meters & Instruments Corporation (hereinafter called "Y okogawa"), and the

program contained, embedded, inserted or used in the medium (hereinafter called the "Y okogawa Software Program").

By opening this package or plastic wrapping (hereinafter called "Package") enclosing the Yokogawa Sof tware Program, you

acknowledge that you understand and agree to the "T erms and Conditions of the Software License" (hereinafter called "Terms

and Conditions") which is written in the documentation and separately attached. Accordingly, the Terms and Conditions bind you.

The Yokogawa Sof tware Program and its related documentation including ownership of copyright shall remain the exclusive

property of Yokogawa or those third p arties from whom sublicensed software in the Y okogawa Software Program is licensed.

Yokogawa hereby grants you permission to use the Y okogawa Software Program on the conditions that you agree to the T erms

and Conditions before you open the Package and/or install it in or onto a computer.

IF YOU DO NOT AGREE TO THE TERMS AND CONDITIONS, YOU CANNOT OPEN THE P ACKAGE, A ND MUST

IMMEDIATEL Y RETURN IT T O YOKOGAWA OR ITS DESIGNA TED PARTY .

Terms and Conditions of the Soft ware License

Yokogawa Electric Corporation and Y okogawa Meters & Instruments Corporation, Japanese corporations (her einafter called

"Yokogawa"), grant permission to use this Yo kogawa Software Program (hereinafter called the "Licensed Sof tware") to the

Licensee on the conditions that the Licensee agrees to the terms and conditions stipulated in Article 1 hereof.

You, as the Licensee (hereinafter called "Lice nsee"), shall agree to the following terms and conditions for the sof tware license

(hereinafter called the "Agreement") based on the use intended for the Licensed Software.

Please note that Yokogawa grants the Licensee permission to use the Licensed Software under the terms and conditions herein

and in no event shall Yokogawa intend to sell or transfer the Licensed Software to the Licensee.

Licensed Software Name: TB200

Number of License: 1

Article 1 (Scope Covered by these Terms and Conditions)

1.1 The terms and conditions stipulated herein shall be applied to any Licensee who purchases the Licensed Software on the

condition that the Licensee consents to agree to the terms and conditions stipulated herein.

1.2 The "Licensed Software" herein shall mean and include all applicable programs and documentation, without limitation, all

proprietary technology, algorithms, and know -how such as a factor , invariant or process cont ained therein.

Article 2 (Grant of License)

2.1 Yokogawa grants the Licensee, for the purpose of single use, non-exclusive and non-transferable license of the Licensed

Software with the license fee separately agreed upon by both parties.

2.2 The Licensee is, unless otherwise agreed in writing by Yokogawa, not entitled to copy , change, sell, distribute, transfer , or

sublicense the Licensed Software.

2.3 The Licensed Software shall not be copied in whole or in part except for keeping one (1) copy for back-up purposes. The

Licensee shall secure or supervise the copy of the Licensed Software by the Licensee itself with great, strict, and due care.

2.4 In no event shall the Licensee dump, reverse assemble, reverse compile, or reverse engineer the Licensed Software so that

the Licensee may translate the Licensed Software into other programs or change it into a man-readable form from the

source code of the Licensed Software. Unless otherwise separately agreed by Y okogawa, Y okogawa shall not provide the

Licensee the source code for the Licensed Software.

2.5 The Licensed Software and its related documentation shall be the proprietary property or trade secret of Y okogawa or a third

party which grants Y okogawa the rights. In no event shall the Licensee be transferred, leased, sublicensed, or assigned any

rights relating to the Licensed Software.

2.6 Yokogawa may use or add copy protection in or onto the Licensed Software. In no even t shall the Licensee remove or

attempt to remove such copy protection.

2.7 The Licensed Software may include a software program licensed for re-use by a third party (hereinafter called "Third Party

Software", which may include any software program from affiliates of Y okogawa made or coded by themselves.) In the

case that Yokogawa is granted permission to sublicense to third parties by any licen sors (sub-licensor) of the Third Party

Software pursuant to different terms and conditions than those stipulated in this Agreement, the Licensee shall observe such

terms and conditions of which Yokogawa notifies the Licensee in writing separately .

2.8 In no event shall the Licensee modify, remove or delete a copyright notice of Y o kogawa and its licenser contained in the

Licensed Software, including any copy thereof.

ii

Utility

IM 735201-01E

Page 4

Article 3 (Restriction of Specific Use)

3.1 The Licensed Software shall not be intended specifically to be designed, developed, constructed, manufactured, distributed

or maintained for the purpose of the following events:

a. Operation of any aviation, vessel, or support of those operations from the ground;,

b. Operation of nuclear products and/or facilities;,

c. Operation of nuclear weapons and/or chemical weapons and/or biological weapons; or

d. Operation of medical instrumentation directly utilized for humankind or the human body.

3.2 Even if the Licensee uses the Licensed Software for the purposes in the preceding Paragraph 3.1, Yokogawa has no liability

to or responsibility for any demand or damage arising out of the use or operations of the Licensed Software, and the

Licensee agrees, on its own responsibility, to solve and settle the claims and damages and to defend, indemnify or hold

Yokogawa totally harmless, from or against any liabilities, losses, damages and expenses (including fees for recalling the

Products and reasonable attorney’s fees and court costs), or claims arising out of and related to the above-said claims and

damages.

Article 4 (Warranty)

4.1 The Licensee shall agree that the Licensed Software shall be provided to the Licensee on an "as is" basis when delivered. If

defect(s), such as damage to the medium of the Licensed Software, attributable to Yokogawa is found, Yokogawa agrees to

replace, free of charge, any Licensed Software on condition that the defective Licensed Software shall be returned to

Yokogawa’s specified authorized service facility within seven (7) days after opening the Package at the Licensee’s expense.

As the Licensed Software is provided to the Licensee on an "as is" basis when delivered, in no event shall Yokogawa

warrant that any information on or in the Licensed Software, including without limitation, data on computer programs and

program listings, be completely accurate, correct, reliable, or the most updated.

4.2 Notwithstanding the preceding Paragraph 4.1, when third party software is included in the Licensed Software, the warranty

period and terms and conditions that apply shall be those established by the provider of the third party software.

4.3 When Yokogawa decides in its own judgement that it is necessary, Yokogawa may from time to time provide the Licensee

with Revision upgrades and Version upgrades separately specified by Yokogawa (hereinafter called "Updates").

4.4 Notwithstanding the preceding Paragraph 4.3, in no event shall Yokogawa provide Updates where the Licensee or any third

party conducted renovation or improvement of the Licensed Software.

4.5 THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES OF QUALITY AND

PERFORMANCE, WRITTEN, ORAL, OR IMPLIED, AND ALL OTHER WARRANTIES INCLUDING ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED

BY YOKOGAWA AND ALL THIRD PARTIES LICENSING THIRD PARTY SOFTWARE TO YOKOGAWA.

4.6 Correction of nonconformity in the manner and for the period of time provided above shall be the Licensee’s sole and

exclusive remedy for any failure of Yokogawa to comply with its obligations and shall constitute fulfillment of all liabilities of

Yokogawa and any third party licensing the Third Party Software to Yokogawa (including any liability for direct, indirect,

special, incidental or consequential damages) whether in warranty, contract, tort (including negligence but excluding willful

conduct or gross negligence by Yokogawa) or otherwise with respect to or arising out of the use of the Licensed Software.

Article 5 (Infringement)

5.1 If and when any third party should demand injunction, initiate a law suit, or demand compensation for damages against the

Licensee under patent right (including utility

relating to any of the Licensed Software, the Licensee shall notify Yokogawa in writing to that effect without delay.

5.2 In the case of the preceding Paragraph 5.1, the Licensee shall assign to Yokogawa all of the rights to defend the Licensee

and to negotiate with the claiming party. Furthermore, the Licensee shall provide Yokogawa with necessary information or

any other assistance for Yokogawa’s defense and negotiation. If and when such a claim should be attributable to Yokogawa,

subject to the written notice to Yokogawa stated in the preceding Paragraph 5.1, Yokogawa shall defend the Licensee and

negotiate with the claiming party at Yokogawa’s cost and expense and be responsible for the final settlement or judgment

granted to the claiming party in the preceding Paragraph 5.1.

5.3 When any assertion or allegation of the infringement of the third party’s rights defined in Paragraph 5.1 is made, or when at

Yokogawa’s judgment there is possibility of such assertion or allegation, Yokogawa will, at its own discretion, take any of the

following countermeasures at Yokogawa’s cost and expense.

a. To acquire the necessary right from a third party which has lawful ownership of the right so that the Licensee will be able to

continue to use the Licensed Software;

b. To replace the Licensed Software with an alternative one which avoids the infringement; or

c. To remodel the Licensed Software so that the Licensed Software can avoid the infringement of such third party’s right.

5.4 If and when Yokogawa fails to take either of the countermeasures as set forth in the preceding subparagraphs of Paragraph

5.3, Yokogawa shall indemnify the Licensee only by paying back the price amount of the Licensed Software which

Yokogawa has received from the Licensee. THE FOREGOING PARAGRAPHS STATE THE ENTIRE LIABILITY OF

YOKOGAWA AND ANY THIRD PARTY LICENSING THIRD PARTY SOFTWARE TO YOKOGAWA WITH RESPECT

TO INFRINGEMENT OF THE INTELLECTUAL PROPERTY RIGHTS INCLUDING BUT NOT LIMITED TO, PATENT

AND COPYRIGHT.

model right, design patent, and trade mark)

IM 735201-01E

, copy right, and any other rights

iii

Page 5

Article 6 (Liabilities)

6.1 If and when the Licensee should incur any damage relating to or arising out of the Licensed Software or service that

Yokogawa has provided to the Licensee under the conditions herein due to a reason attributable to Yokogawa, Yokogawa

shall take actions in accordance with this Agreement. However, in no event shall Yokogawa be liable or responsible for any

special, incidental, consequential and/or indirect damage, whether in contract, warranty, tort, negligence, strict liability, or

otherwise, including, without limitation, loss of operational profit or revenue, loss of use of the Licensed Software, or any

associated products or equipment, cost of capital, loss or cost of interruption of the Licensee’s business, substitute

equipment, facilities or services, downtime costs, delays, and loss of business information, or claims of customers of

Licensee or other third parties for such or other damages. Even if Yokogawa is liable or responsible for the damages

attributable to Yokogawa and to the extent of this Article 6, Yokogawa’s liability for the Licensee’s damage shall not exceed

the price amount of the Licensed Software or service fee which Yokogawa has received. Please note that Yokogawa shall

be released or discharged from part or all of the liability under this Agreement if the Licensee modifies, remodels, combines

with other software or products, or causes any deviation from the basic specifications or functional specifications, without

Yokogawa’s prior written consent.

6.2 All causes of action against Yokogawa arising out of or relating to this Agreement or the performance or breach hereof shall

expire unless Yokogawa is notified of the claim within one (1) year of its occurrence.

6.3 In no event, regardless of cause, shall Yokogawa assume responsibility for or be liable for penalties or penalty clauses in any

contracts between the Licensee and its customers.

Article 7 (Limit of Export)

Unless otherwise agreed by Yokogawa, the Licensee shall not directly or indirectly export or transfer the Licensed Software to any

countries other than those where Yokogawa permits export in advance.

Article 8 (Term)

This Agreement shall become effective on the date when the Licensee receives the Licensed Software and continues in effect

unless or until terminated as provided herein, or the Licensee ceases using the Licensed Software by itself or with Yokogawa’s

thirty (30) days prior written notice to the Licensee.

Article 9 (Injunction for Use)

During the term of this Agreement, Yokogawa may, at its own discretion, demand injunction against the Licensee in case that

Yokogawa deems that the Licensed Software is used improperly or under severer environments other than those where

Yokogawa has first approved, or any other condition which Yokogawa may not permit.

Article 10 (Termination)

Yokogawa, at its sole discretion, may terminate this Agreement without any notice or reminder to the Licensee if the Licensee

violates or fails to perform this Agreement. However, Articles 5, 6, and 11 shall survive even after the termination.

Article 11 (Jurisdiction)

Any dispute, controversies, or differences between the parties hereto as to interpretation or execution of this Agreement shall be

resolved amicably through negotiation between the parties upon the basis of mutual trust. Should the parties fail to agree within

ninety (90) days after notice from one of the parties to the other, both parties hereby irrevocably submit to the exclusive jurisdiction

of the Tokyo District Court (main office) in

Article 12 (Governing Law)

This Agreement shall be governed by and construed in accordance with the laws of Japan. The Licensee expressly agrees to

waive absolutely and irrevocably and to the fullest extent permissible under applicable law any rights against the laws of Japan

which it may have pursuant to the Licensee’s local law.

Article 13 (Severability)

In the event that any provision hereof is declared or found to be illegal by any court or tribunal of competent jurisdiction, such

provision shall be null and void with respect to the jurisdiction of that court or tribunal and all the remaining provisions hereof shall

remain in full force and effect.

Japan for settlement of

the dispute.

iv

IM 735201-01E

Page 6

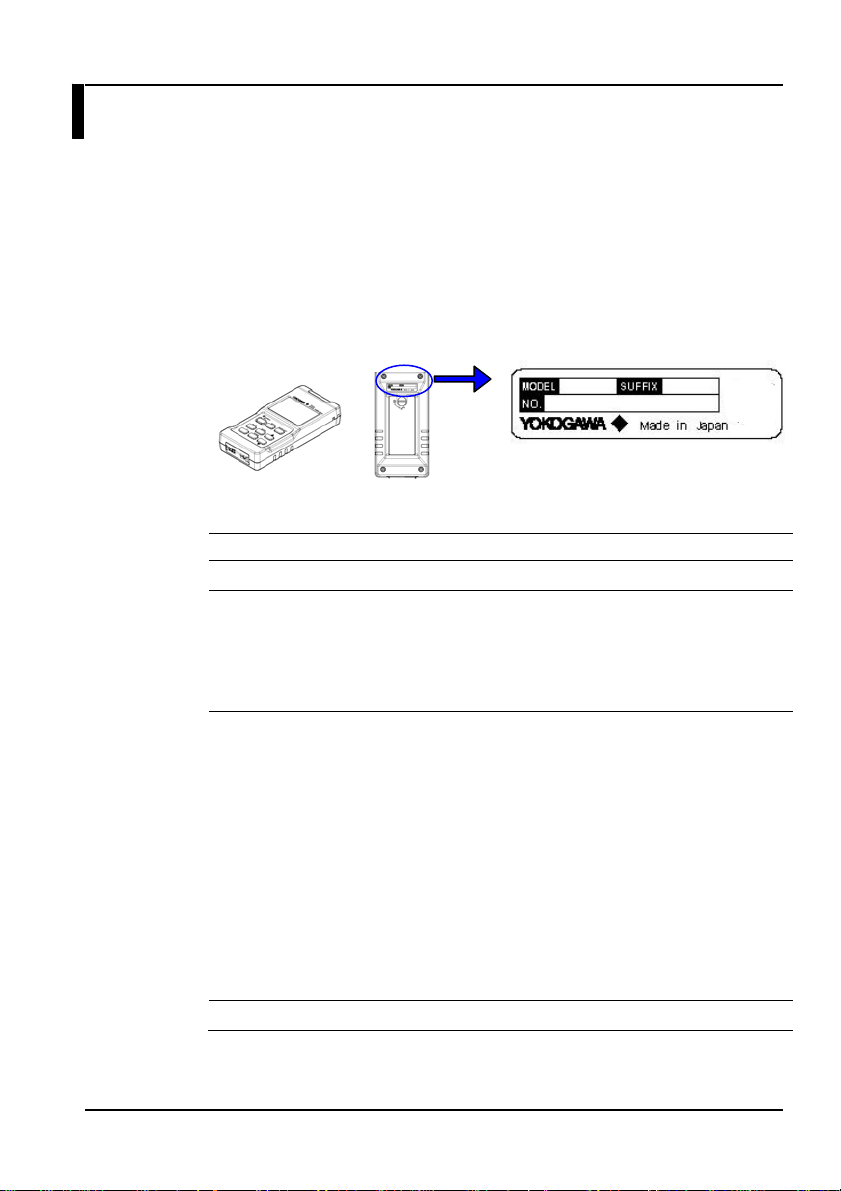

Checking the Contents of the Package

After opening the package, check the following items before beginning use. If

any of the contents are incorrect, missing, or appear to be abnormal, please

contact your Yokogaw a dealer or representa tive.

TB200 Main Unit

Check that the model and suffix code on the name plate on the rear of the

instrument match those of your order. Please have the instrument number

(NO.) ready when contacting your deal er or re presenta tive.

TB200 main unit

Models and Suffix Codes

Model Suffix Code Description

735201

Power cord - M

With/without sensor

head

Options /PR Protector (with stand)

Main unit

rear panel

AC adapter PSE Conforming (2 pin)

- C

- F

- G

- J

- CA0

- CA1

- CA3

AC adapter UL/CSA compliant (UL2P)

AC adapter VDE compliant (CEE-C2)

AC adapter AS compliant (AS2P)

AC adapter BS compliant (BS2P) angle

Without sensor head (when ordering main

unit only)

With sensor head (405 nm, 1 wavelength

calibration)

Inaccuracy under standard conditions:

±2.5%

With sensor head (405/660/785 nm, 3

wavelength calibration), inaccuracy under

standard conditions

405 nm:±2.5%

660 nm:±3.0%

785 nm:±3.0%

Name plate

IM 735201-01E

v

Page 7

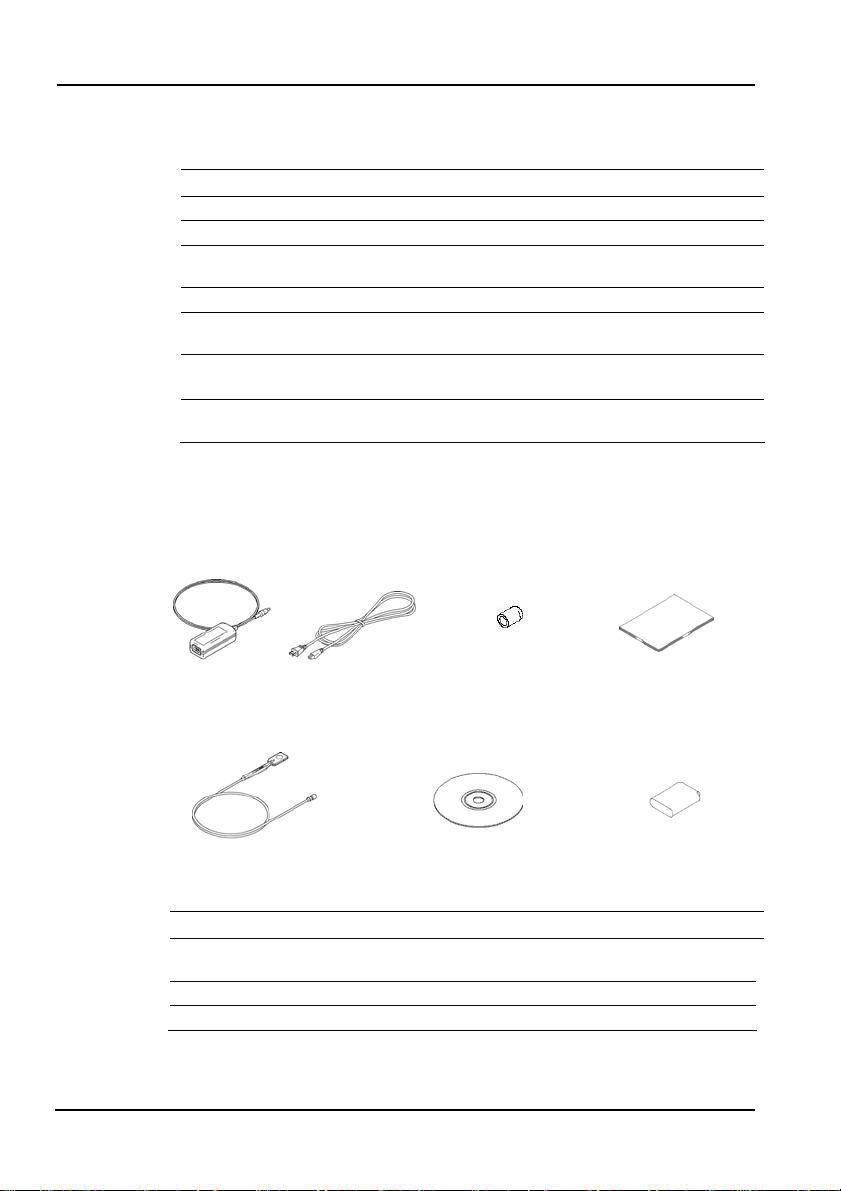

Standard Accessories

The following accessories come standard.

Product Name Model Qty. Note

AC adapter SU2007A 1

Power cord - 1

UM connector

protective cap

User's manual IM735201-01E 1 This manual

Sensor head 735201 1

Software

(TB200 Utility)

Sensor protective

cap

Note) The model when purchasing the sensor head by itself is 735221.

Sensor head

(when purchased together

Options (Sold Separately)

The following options are available for purchase separately.

Name Model Notes

Sensor head 735221

Protector SU2002A Protector with stand

Soft carrying case SU2006A

1 Attached to TB200 main unit

When purchasing together with

the TB200

-

-

Power cordAC adapter

UM connector protective cap

(on the TB200 main unit)

Software

(TB200 Utility)

Available on the sensor head

1

accessory CD.

1 Attached to the sensor head

User’s manual

(this document)

Sensor protective cap

(on sensor head)

Model when ordering only the

sensor head

vi

IM 735201-01E

Page 8

Safety Precautions

To ensure safe and correct operation of the instrument, you must take the safety

precautions given below. The instrument’s protective functions may not work if

used in a manner not described in this manual. Yokogawa bears no responsibility

for, nor implies any warranty against damages occurring as a result of failure to

take these precautions.

The following safety symbols and wording is used in this manual.

Warning: Handle with care. Refer to the user’s manual or service

manual. This symbol appears on dangerous locations on the

instrument which require special instructions for proper handling

or use. The same symbol appears in the corresponding place in

the manual to identify those instructions.

Direct current

Alternating current

IM 735201-01E

vii

Page 9

The following precautions must be taken to prevent potentially fatal accidents.

Use the Correct Power Supply

Check that the supply voltage of the instrument m atches that of the p ower

supply to be used before turning the power ON.

Use the Correct AC Power Cord and Adapter

To prevent electric shock or fire when using the AC adapter, only use the

dedicated AC adapter and pow er cord supplied with the instrument.

Also do not use the power cord and AC adapter that came with the

instrument on any other device.

Do Not Use Near Flammable Gases

Never use the instrument in locations with flammable or explosive gases or

vapors. Doing so is extremely dangerous.

Do Not Remove the Case

Only qualified Yo kogawa te chnicians may remove the case.

Handle the Item under Test Properly

The instrument measures devices that emit lasers. To prevent exposure

to radiation from lasers, operate the item under test strictly according to the

device’s user’s manual. Also, take care when handling the lens and other

optical devices as doing so can cause damage to the eye.

To prevent fire or electric shock, do not insert or drop metallic objects into the

opening.

When connecting to commercial power, conn ect directly to a ded icated outlet.

Do not use extension cords as they can overheat and cause fires.

Do Not Place the Power Cord on or Near Heaters

Heat can degrade the insulating coating resulting in fires or electric shock.

Do Not Damage or Modify the Pow er Cord

=> Fire or electric shock can result.

Do Not Use Extension Co rds or Splitte rs

=> Cables can overheat, causing fires.

Do Not Bend, Twist, or Forcibly Pu ll the Cable

=> Fire or electric shock can result.

Do Not Plug or Unplug the Power Cord with Wet Hands

=> Electric shock can result.

Insert the Power Plug Completely and Securely into the Outlet

=> If metal or other objects are allowed to contact the power supply plug,

fire or electric shock can result.

WARNIN G

viii

IM 735201-01E

Page 10

Safety Precautions

Do not remove the case. The instrument's internal components carry high

voltages and are extremely dangerous.

For internal inspection or adjustment, contact your nearest YOKOGAWA

dealer.

If there are any symptoms of trouble such as strange smells or smoke coming

from the instrument, turn the power OFF immediately, and remove the battery

pack or the power cord from the outlet. If such an irregularit y occurs, co ntact

your YOKOGAW A dealer .

Nothing should be placed on the power cord. The cord should be kept away from

any heat sources. When unplugging the pow er cord from the outlet, neve r pull

by the cord itself. Always hold and pull by the plug. If the power cord is

damaged, contact your dealer for re placement.

Always unplug the power cord from the outlet, and check that all externally

connected wires and cables are removed before moving the instrument.

=> Otherwise, the cords can become damaged, causing fire or electric

shock.

Be sure to unplug the power co rd from the outlet during lightning storms.

=> Fire, electric shock, or malfunction can result.

Do not use old and new batteries at the same time.

=> Explosion or leakage of the batteries can result, caus ing fire, injury, or

contamination of the surrounding area.

Check the polarity of the batteries (plus/minus orientation) before installing them.

=> Incorrect orientation can result in explos ion or leakage of the batteries,

causing fire, injury, or contamination of the surrounding area.

If the instrument experiences an abnormality, do not attempt to repair the

instrument your self.

=> Electric shock or damage can result. Also, any repairs conducted without

authorized consent will not be covered by the product warranty.

Never disassemble or rework the instrument.

=> Fire, electric shock, or malfunction can result.

When handling parts that open and close, such as when changing the battery,

take care not to pinch or injure your finger.

See below for operating environment limitations.

This product is a Class A (for industrial envir onments) produ ct. Operat ion of

this product in a residential area may cause radio interference in which case

the user will be required to corre ct the interference .

CAUTION

IM 735201-01E

ix

Page 11

General Handling Precautions

Take care not to damage the instrument by dropping it.

Unplug During Periods of Extended Non-Use

Unplug the power cord from the outlet. Remove the dry cells. Failure to

remove the battery pack during long periods of non-use can cause the

battery fluid to leak into the instrument, causing damage.

Do not place any other instrument or anything containing liquid on top of the

instrument. Doing so can lead to malfunction.

Since the LCD screen is very vulnerable and can be easily scratched, do not

allow any sharp objects near it. Also never expose it to vibrations and shocks.

Do Not Install the Instrument in Any of the Following Places

・ Humid or dusty areas

・ On an unstable surface

・ In direct sunlight or in locations such as automobiles where the

temperature can become high

・ In a location where it may become vibrated or shocked

・ Near sources of heat such as heating appliances

The IEC61010-1 pollution degree and overvoltage category of the instrument are

as follows.

・ Pollution degree 2

Pollution degree refers to the degree of adherence by a solid, liquid, or

vapor that reduces the withstand voltage or surface resistance factor. It

is a number that expresses the degree to which an instrument or one

of its components may become poluted while being used.

Pollution degree 2 applies to normal indoor atmospheres. It

applies only to normal or non-conductive pollution, but

conductivity may occur temporarily depending on

concentrations.

・ Overvoltage category II

Overvoltage category (installation category) is a number that defines

excessive voltage, and includes regulations for impulse withstand

voltage.

Overvoltage category II applies to electrical equipment that is powered

by a fixed installation such as a distribution board.

● ● Read this section before using the instrument for the first time.

If this instrument is used in a manner not specified in this manual, the

protective features provided by the instrument may be impaired.

CAUTION

x

IM 735201-01E

Page 12

Safety Markings

Safety Markings

The following markings are used in this manual.

WARNING

CAUTION

Note Calls attention to information that is important for proper

Bolded Characters

Bold characters and symbols used in the Procedure sections indicate the text

and symbols on the keys of the instrument.

Items set in boldface mainly refer to controls on the instrument and other devices,

or on-screen interface elements such as menu commands with which the user

interacts.

Improper handling or use can lead to injury to the user or

damage to the instrument. This symbol appears on the

instrument to indicate that the user must refer to the user's

manual for special instructions. The same symbol

appears in the corresponding place in the user's manual to

identify those instructions. In the manual, the symbol is

used in conjunction with the word “WARNING” or

“CAUTION.”

Calls attention to actions or conditions that could cause

serious or fatal injury to the user, and precautions that can

be taken to prevent such occurrences.

Calls attentions to actions or conditions that could cause

light injury to the user or damage to the instrument or user's

data, and precautions that can be taken to prevent such

occurrences.

operation of the instrument.

IM 735201-01E

xi

Page 13

Contents

Foreword ......................................................................................................i

Terms and Conditions of the Software License .........................................ii

Checking the Contents of the Package......................................................v

Safety Precautions ....................................................................................vii

Safety Markings..........................................................................................xi

Chapter 1 Explanation of Functions

1.1 Names and Functions of Parts ..............................................1-1

1.2 List of Functions...................................................................... 1-6

Chapter 2 Preparing for Measurement

2.1 Handling Precautions............................................................. 2-1

2.2 Connection Procedure ...........................................................2-3

2.3 Turning the Power Supply ON and OFF............................... 2-5

Chapter 3 Measurement

3.1 Entering Measurement Conditions........................................ 3-1

3.1.1 Setting the Wavelength ....................................................3-2

3.1.2 Setting the NA (Numerical Aperture) Correction Coefficient

........................................................................................... 3-3

3.1.3 Entering Averaging Settings............................................. 3-5

3.2 Modes ..................................................................................... 3-6

3.2.1 List of Modes..................................................................... 3-6

3.2.2 Diagram of Relationship between Modes .......................3-6

3.3 Absolute Value Measurement................................................ 3-7

3.3.1 Measuring Optical Power .................................................3-7

3.3.2 Changing Units .................................................................3-7

3.3.3 Fixing the Measuring Range (Range Hold)..................... 3-8

3.3.4 Displaying Maximum Values (MAX Hold)........................3-9

3.3.5 Measuring after Setting the CAL Value.......................... 3-10

3.4 Relative Value Measurement............................................... 3-12

xii

IM 735201-01E

Page 14

Chapter 4 Measuring Using USB (Remote Control)

4.1 USB Communication Function...............................................4-1

4.2 Installing USB Drivers .............................................................4-2

4.3 List of Commands...................................................................4-4

4.4 Sample Program.....................................................................4-9

4.4.1 Installing the DLL...............................................................4-9

4.4.2 Sample Software...............................................................4-9

Chapter 5 Notes When Purchasing the Sensor Head by

Itself

5.1 Uploading Sensor Specific Data.............................................5-1

5.2 Displaying the Sensor Head Serial Number..........................5-3

Chapter 6 Maintenance

6.1 Error Messages.......................................................................6-1

6.2 Troubleshooting ......................................................................6-3

6.3 Periodic Calibration.................................................................6-4

Chapter 7 Specifications

7.1 Specifications ..........................................................................7-1

7.2 External Dimensions...............................................................7-5

Appendix

Appendix 1 Table of NA Correction Coefficients.......................... App-1

Appendix 2 Table of 7-Segment Display Characters ..................App-4

IM 735201-01E

xiii

Page 15

Chapter 1 Explanation of Functions

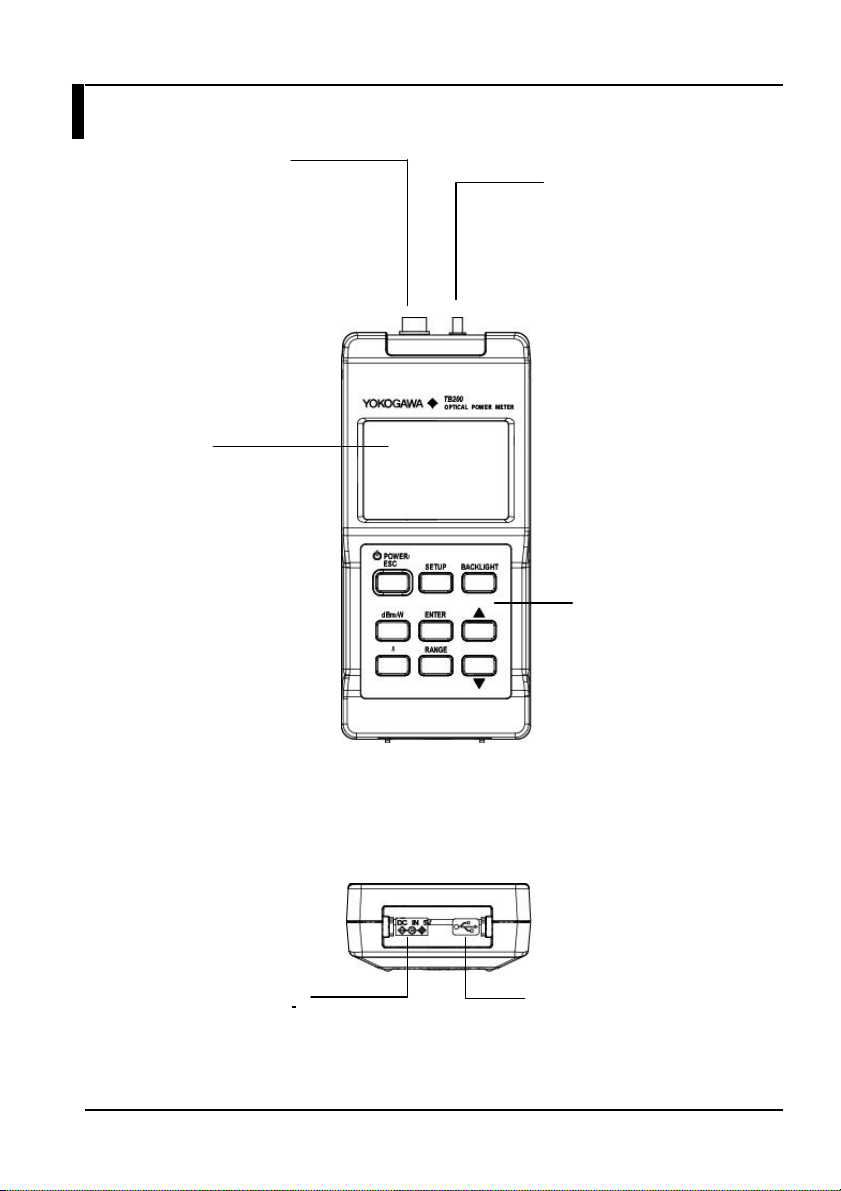

1.1 Names and Functions of Parts

Sensor Connector

IM 735201-01E

Connects to the

sensor head.

⇒See p. 2-4

Display

Displays measured

results and various

settings.

=> See p.1-4 and

p.1-5

AC Adapter Terminal

For connecting the AC

Keys

adapter.

Analog Out Terminal

(UM Connector)

Outputs a voltage

according to the

sensor head output.

=> See p. 1-7 and

1-8

Keys

Nine keys for

operating the

instrument.

=> See p.1-2 and

p.1-3

USB Terminal

For connecting the USB

cable.

1-1

Page 16

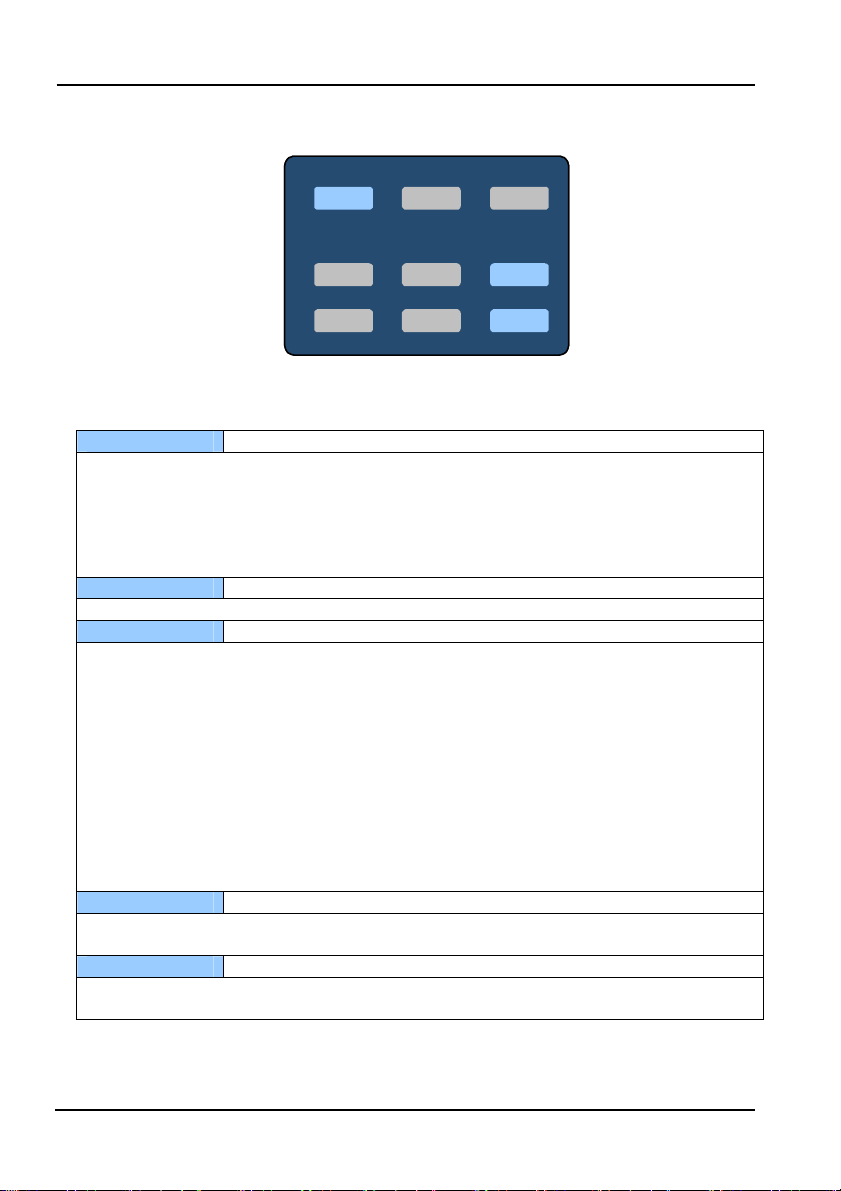

1.1 Names and Functions of Parts

Keys

POWER/ESC SETUP

POWER/ESC SETUP

dBm/W

dBm/W

λ

λ

ENTER

ENTER

RANGE

RANGE

POWER/ESC

Power supply and escape key

This key turns the power ON and OFF. Press the key to start the instrument with the power

save function set. If you hold down the button until the power save indicator “PWR SAVE”

disappears, the instrument starts with the power save function disabled. To turn the

instrument OFF, hold down the key until the LCD display goes out.

You can press the key once during operation to return to normal measurement mode (ESC

function).

BACKLIGHT

Backlight key

Press this key to turn ON the backlight. Press again to turn it OFF.

dBm/W

Unit selection key

This key switches the units for absolute value measurement mode (dBm or W). Each time

you press the key, the selected units change as follows:

dBm display => W display (switches automatically between mW, µW, and nW) => mW

display (fixed) => dBm display

Also, if you hold down the ENTER key while pressing this key, the instrument enters relative

value measurement mode. The measured value at the moment the key is pressed is set as

the reference value for relative value measurement. The instrument enters relative value

measurement mode (and displays the difference in the measured value from the reference

value) from the next measurement thereafter. Every time the key is pressed, the reference

value is updated. In relative value measurement mode, this key switches to absolute value

measurement mode.

(Related keys: ENTER)

λ

Wavelength key

Press this key to enter a mode for entering wavelength settings. Change values using the

UP and DOWN keys, then press the ENTER key to enter the selection.

RANGE

Range hold key

Press this key to fix the measuring range. Press it again to release the range. Press the

UP and DOWN keys to change the range.

BACKLIGHT

BACKLIGHT

▲

▲

▼

▼

1-2

IM 735201-01E

Page 17

1.1 Names and Functions of Parts

SETUP

Press this key to change to the Setup mode, in which various settings can be entered.

In absolute value measurement mode, measurement conditions can be entered in the

following order:

Averaging setting, max hold setting, NA correction coefficient setting, sensor serial number

display.

(Related keys: UP/DOWN, ENTER)

ENTER

Enters various kinds of selectable settings.

(Related keys: UP/DOWN, SETUP, dBm/W)

▲, ▼ Selection keys (UP/DOWN)

Use these keys to turn items ON and OFF, and to enter values.

Press once to change the selection UP or DOWN. Hold down to quickly scroll UP or DOWN

through the selections.

(Related keys: SETUP, ENTER)

Setup mode key

Entry key

IM 735201-01E

1-3

Page 18

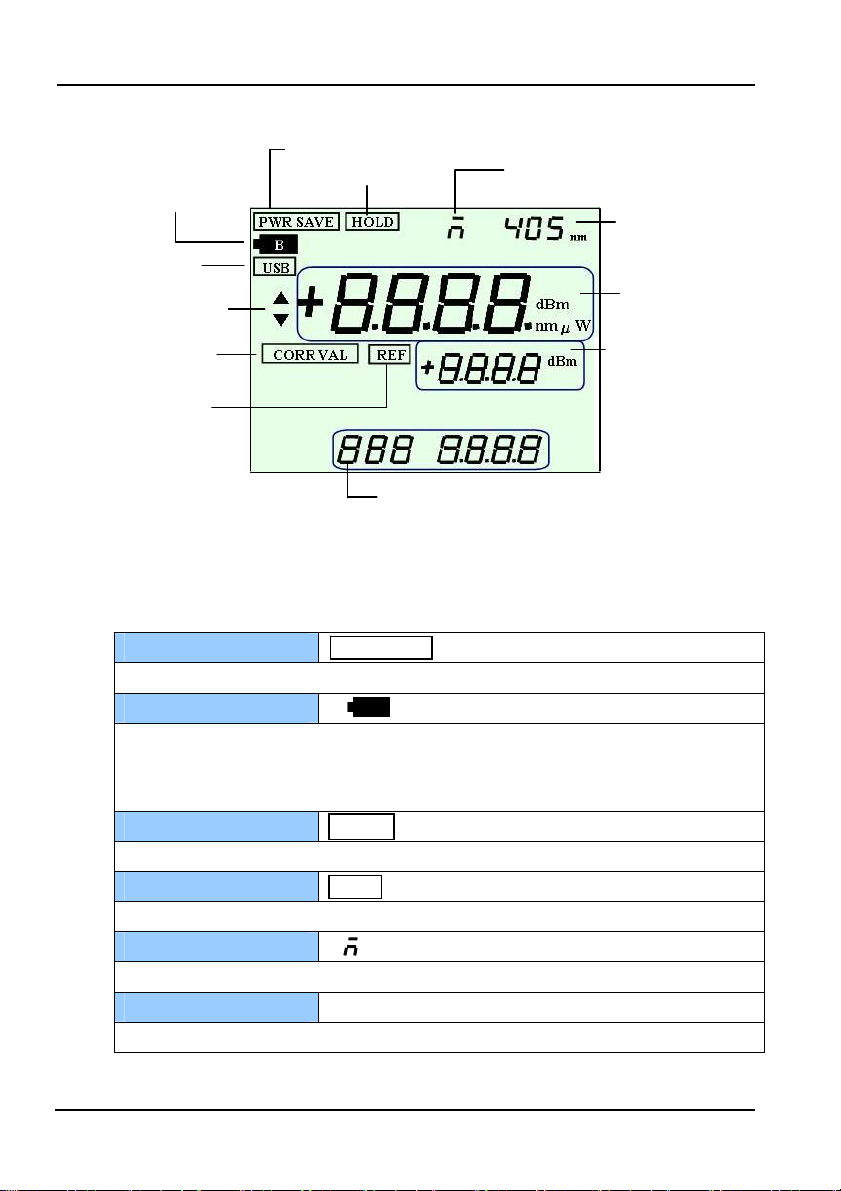

1.1 Names and Functions of Parts

r

e

play

Screens

Battery alarm

USB

communication

Arrow key indicator

User calibration

Relative value

measurement

Power save

“PWR SAVE” is displayed when the power save function is set.

Battery alarm

The indicator above blinks when the remaining battery charge is too low to provide

sufficient power for operation. Change the batteries or connect the AC adaptor. During

alarms, resuming is disabled.

Range fixing

The “HOLD” indicator is displayed when range switching is held.

USB communication

The “USB” indicator is displayed when in USB mode.

MAX hold

The mark above is displayed when the MAX hold function is set.

Wavelength setting

Displays the set wavelength (nm).

Power save

Range hold

PWR SAVE

HOLD

USB

“405 nm”

MAX hold

Measured

wavelength

Measured value

dis

Set value display

Rel. val. meas. ref. val.

Fixed range

NA correction value

MAX hold value

CAL valu

Setup mode display

Averaging ON/OFF

NA correction ON/OFF

Sensor serial numbe

BB

1-4

IM 735201-01E

Page 19

1.1 Names and Functions of Parts

Arrow key indicators “▲” “▼”

Displayed when various kinds of selectable settings are available.

Measured value display

Displays the measured value and its units. Messages appearing during errors and entry

of settings are also displayed here. (Related keys: dBm/W)

Correction value setting

The “CORR VAL” indicator is displayed when the correction value has been set using

the user calibration function.

Relative value

measurement

The “REF” indicator is displayed when in relative value measurement mode.

Setting value display

The reference value is displayed when in relative value measurement mode.

Also displays setting values and selection messages.

Setup mode display

Displays NA correction ON/OFF and the sensor serial number.

“+8.8.8.8.dBm nmµW”

CORR VAL

REF

“8.8.8.8”

“8 8 8 8.8.8.8”

IM 735201-01E

1-5

Page 20

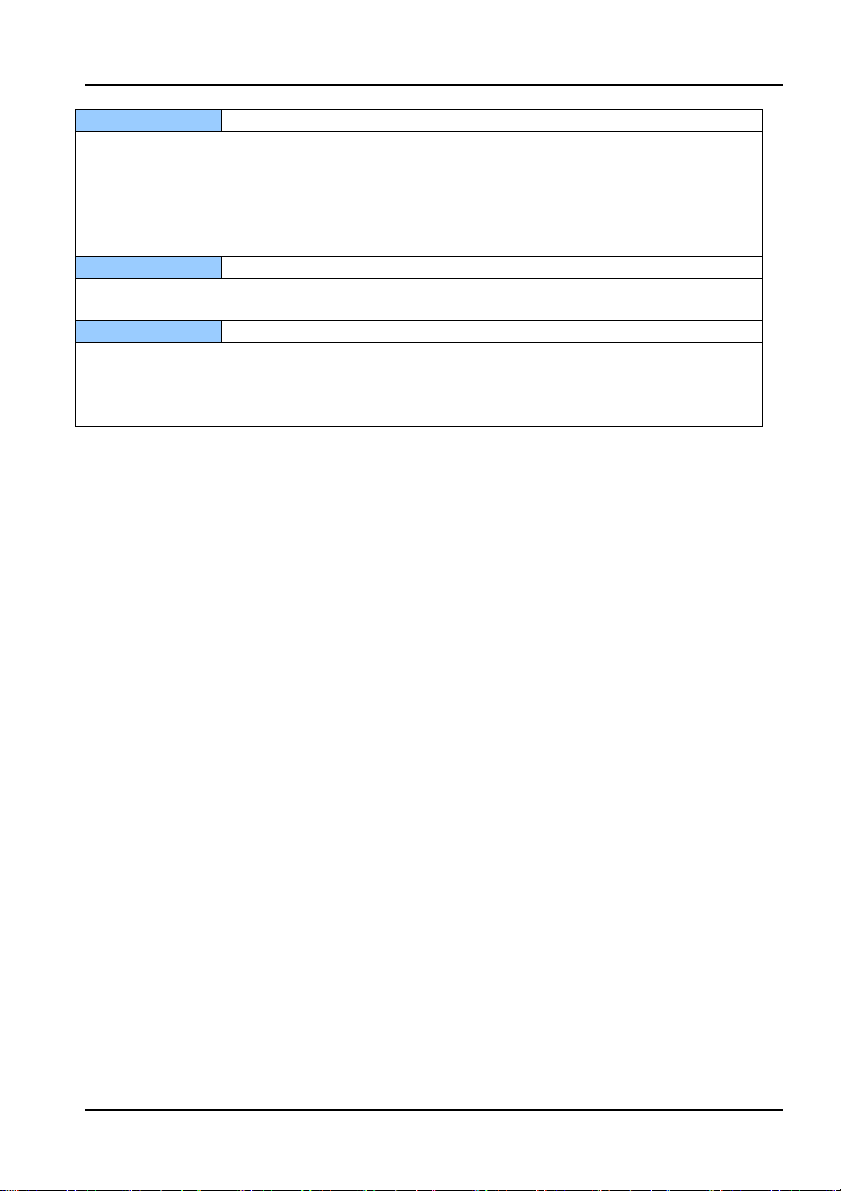

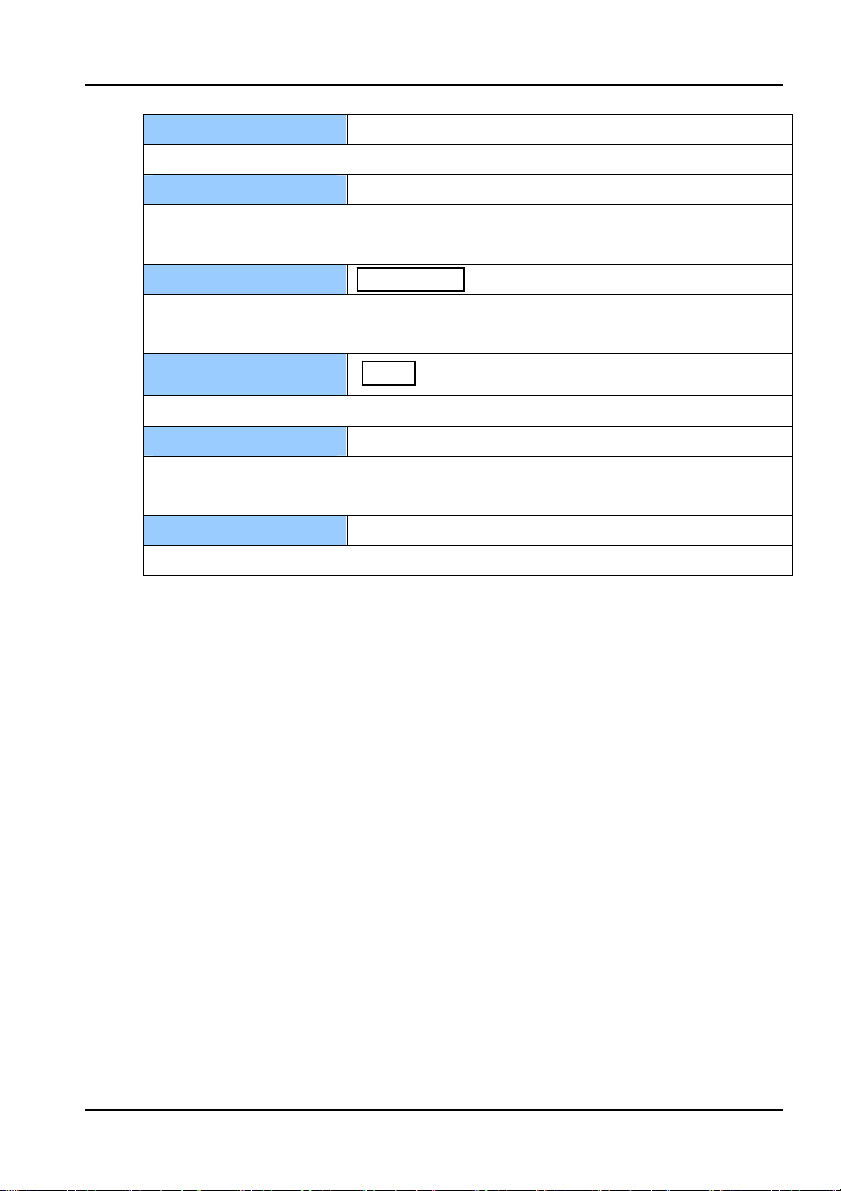

1.2 List of Functions

Function Overview/Description

Optical power level

measurement

Range setting Sets the range automatically according to the level of received

Auto zero set Automatically sets zero when the power is turned ON.

Wavelength sensitivity

correction

Relative value

measurement

Absolute value

measurement

unit switching

Averaging Averages measured values internally and displays them.

Max hold Displays the maximum value during measurement.

NA (aperature)

correction

Sensor head

S/N display

User calibration Adds setting values displayed in normal measurement mode

Backlight Turning the backlight ON allows you to see the display in the

Displays the optical power level of the light received by the

sensor head in the display.

light. You can specify a fixed range. The setting range is -30 dBm

to +20 dBm

The user need not set zero manually.

The wavelength sensitivity can be corrected in the range from

400 to 850 nm (in 1 nm steps). Accurate measurements can be

obtained by matching with the wavelength of the light source

being measured.

You can set a reference value and display the change in level

relative to the reference value (units: dB).

You can switch the displayed units between dBm and W.

When W is selected, mW, uW, or nW is automatically selected

and displayed according to the optical power.

You can also fix the displayed units at mW.

The number of measured data values averaged is fixed at 20.

A moving average is taken every measurement interval.1

When measuring at high NA, you can correct error due to

angular incidence characteristics of the sensor. The setting range

is 0.500 to 2,000 (in 0.001 steps). However, the correction value

must be selected from the NA correction coefficient table in

appendix 1.

Displays the serial number of the sensor head connected to the

instrument.

and displays them. The available setting range is -10 dB to +10

dB.

dark.

1-6

IM 735201-01E

Page 21

1.2 List of Functions

A

a

Power save

(only when using a

battery)

Battery alarm

(only when using a

battery)

Resume

Analog output3 Outputs an analog voltage for each range according to the

USB communication Lets you edit settings and acquire measured values via USB

2

The settings that were active when the power was turned OFF

When running on dry cells, the power turns OFF automatically if

a key is not pressed within ten minutes.

The battery indicator blinks when the battery runs low.

are saved and restored the next time the power is turned ON (if

shutdown successfully).

The function is disabled when the battery alarm indicator is

displayed. In this case, the instrument saves the settings that

were last active when the power was turned OFF normally.

measured value.

(keys cannot be used for control when using this function).

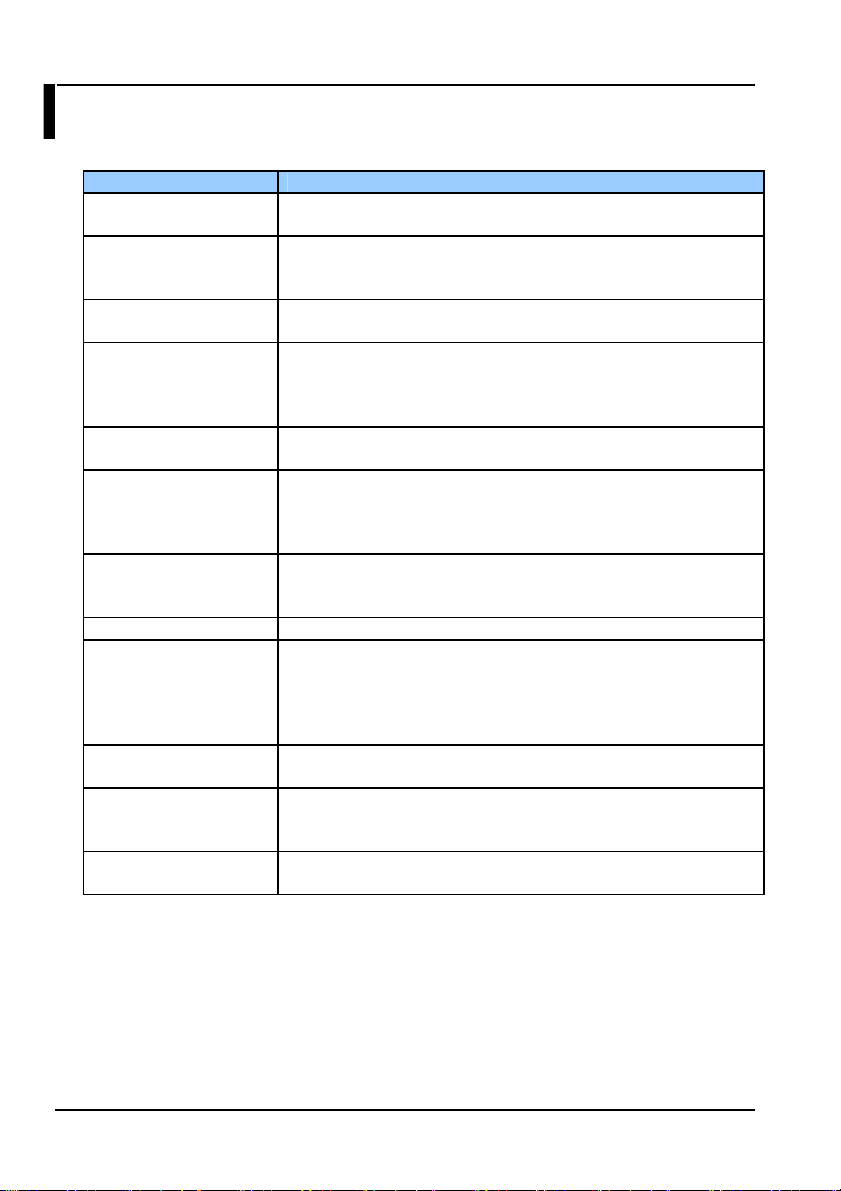

1. Moving average

Averages measured values from a determined number of measurements.

The average value is updated at all times as the most recent values are

loaded and the oldest ones are discarded.

Meas val 1 Meas val 2 Meas val 3

vg. over this are

Next, avg. over this area

Meas val N Meas val N+1

・・・

Then this area, and so on

Meas val N+2

N : No. of measurements (for this instrument, N =20)

2. The settings that are saved by the Resume function are as follows.

● Absolute value/relative value setting mode ● Range AUTO/HOLD

● Relative measurement value ● Range info. (only with range hold)

● Measurement wavelength ● NA correction value ON/OFF

● Last set detail wavelength ● Last set NA correction value

● Displayed units ● CAL setting ON/OFF

● Averaging ON/OFF ● Last set CAL value

● Turning MAX Hold ON/OFF

IM 735201-01E

1-7

Page 22

1.2 List of Functions

e

p

e

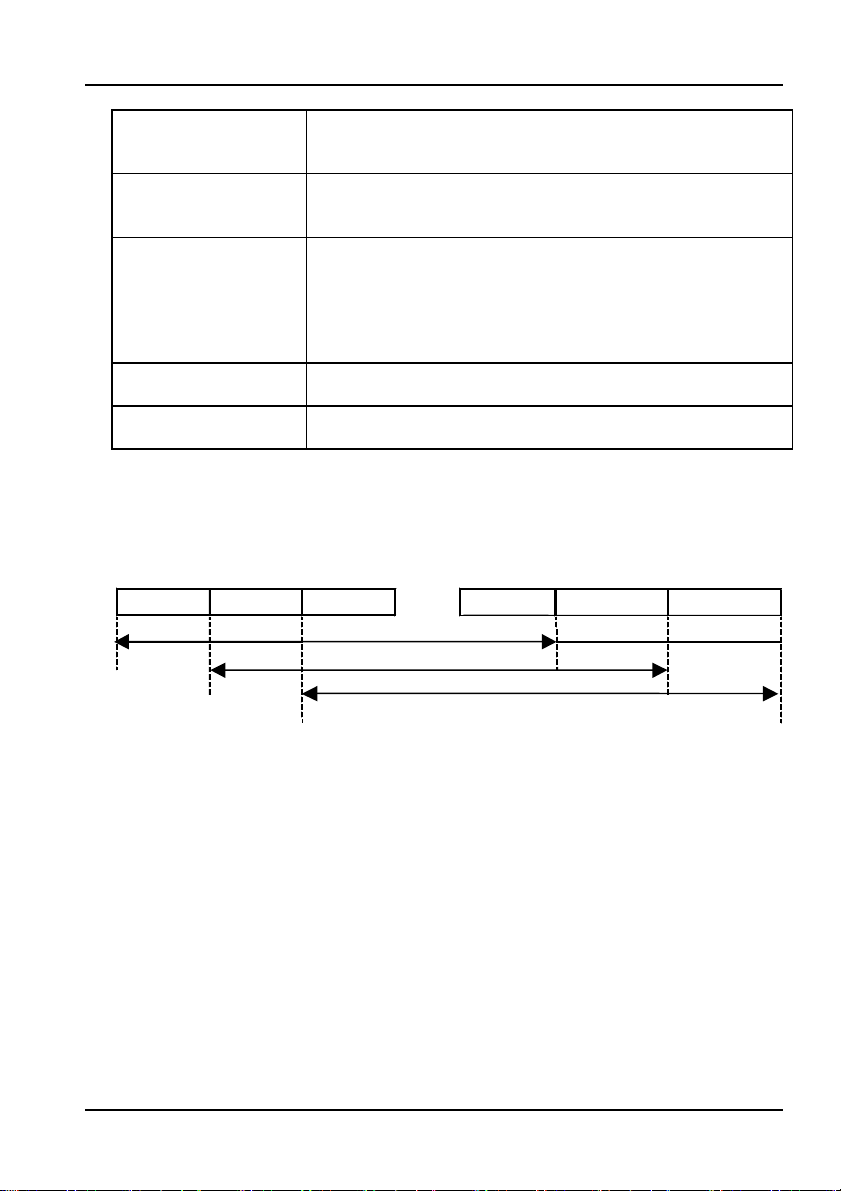

3. Analog Out

You can convert measured results to voltages of 0–2 V and output them. Output

values can be input to another device such as a recorder for comparison and trend

analysis. At each measuring range, the output value is the voltage from 0 to 2 V

that is proportional to the input value. With a fixed range, the output value is under

range at approximately 0.1 V and over range at approximately 2 V. When an

overrange occurs, a voltage of 2 V or over can be output from the analog out

terminal. Since with auto-switching the measuring range changes from

approximately 0.1 V to approximately 2 V, the output values are non-continuous.

(V)

2

ut valu

1

0.1

0

(V) Out

2

1

Output valu

0.1

0

-20 -10 103-40 0

-30 20 30

Input power (dBm)

Analog out when using automatic ranging

-20 -10 10-40 0

-30 20 30

Input power (dBm)

Analog out when using fixed measuring range (-20 dB)

1-8

IM 735201-01E

Page 23

Chapter 2 Preparing for Measurement

2.1 Handling Precautions

The following describes precautions that must be taken during use of the instrument.

This instrument utilizes ultra-precision optical components. In order for performance to

be guaranteed, please take note of the following.

Precautions during Use

1) Do not drop or expose the instrument to excessive physical shock. The

instrument is protected with plastic casing, but contains fragile optical

components.

2) Do not place the instrument in direct sunlight, or in high-temperature or highly

humid locations such as inside of a car for long periods of time.

3) Do not bring the instrument close to strong electromagnetic waves. Doing so

can lead to malfunction.

4) Do not use the instrument and mobile phones simultaneously in the same

vicinity.

5) The instrument is portable and can be used outdoors under battery power, but

is not waterproof. Never operate the instrument in the rain.

6) Do not disassemble the device.

7) Do not peer into the ends of the optical fiber, the beams as they travel through

the air, the optical connector, or other parts connected to the light source.

Doing so can result in injury to the eyes from lasers. Take appropriate caution

when handling.

8) Incidence of excessive or highly concentrated light outside of the optical power

measuring range can damage the sensor element.

9) When the optical power is expressed as an average the value appears low,

but the instantaneous power can be quite high. Take extra precaution with low

duty, high-cusp pulses.

10) If the surface of the sensor is soiled with dirt or grime, clean the end with

specialized optical connector cleaner or a dust-resistant cloth.

11) If any plastic parts become soiled, wipe with a soft and dry cloth.

12) When not using the instrument, attach the cap to protect the sensor from dirt,

grime, and other foreign particles.

13) To prevent damage when attaching or removing the optical input connector

cap, take care not to rub the connector against the cap.

14) Never insert or remove the sensor head while the power is ON.

15) Do not connect anything to the connectors (sensor head, analog out terminal,

etc.) other than the specified product. Damage can result.

16) The sensor head contains optical components that are easily scratched.

Take care not to scratch or crack any part of the sensor head.

17) Only turn ON the power if the sensor head is attached.

IM 735201-01E

2-1

Page 24

2.1 Handling Precautions

Precautions When Using the Batteries

1) If the plus or minus terminal of the battery holder is dirty, contact with the

battery will be weakened, possibly causing the power to cut out. If dirty, wipe

the plus and minus terminals clean with a dry cloth.

2) Do not allow the batteries to come into contact with water (including rain water

and sea water). Also, do not apply strong physical shocks.

3) Shorting the plus and minus terminals of the batteries with metal or other

conductive objects causes a large current to flow that can damage the

batteries and emit heat. Take care not to short the terminals when handling

the batteries.

4) Disassembling the batteries or placing them in fire is extremely dangerous and

must never be attempted.

5) Do not discard spent batteries together with general household waste (unless

your local laws permit doing so).

6) Check the polarity/orientation of the batteries carefully before inserting them

into the battery holder. Incorrectly oriented batteries can result in damage to

the instrument.

7) Remove the batteries during periods of extended non-use. Leakage from

batteries can occur, resulting in damage to the instrument.

8) Always operate the instrument in a way that is appropriate for the type of

batteries you are using.

Cautions When Using the AC Adapter

Use the AC adapter that came with the instrument, and the country-specific

power cable that was packaged together with the AC adapter. Connect a power

supply that meets the specifications of the AC adapter.

To use the cable and adapter, insert the power cable firmly into the inlet on the

AC adapter, and connect the output cable firmly to the AC adapter terminal on

the instrument. Also, only use these items indoors. Use them in the same

temperature range as is required for the instrument. Note that the safety standard

for the AC adapter specifies an operational temperature of 0–40°C. Never use an

AC adapter or power cable other than the dedicated ones available for use with

this instrument, as damage can result.

Precautions When Using the CD

This CD contains software, and is for use in a computer only. Do not play this on

an audio CD player as the high volume may damage your hearing or audio

speakers.

Precautions When Discarding the Instrument

Treat the instrument as general industrial waste, separate from household waste,

and dispose of the instrument according to relevant local laws.

2-2

IM 735201-01E

Page 25

2.2 Connection Procedure

Connecting the AC Adapter

Connect the AC adapter output terminal to the instrument’s AC adapter terminal

after opening the cap.

Figure 2-1 AC Adaptor Output Terminal

Installing the Batteries

When using batteries,

turn the screw on the rear

panel with a coin or other flat

object to remove the cover,

then install the batteries.

Turning the screw

locks/unlocks the cover as

shown in the figure.

Insert two AA batteries into

the holder following the

polarity markings. Always close the

cover after installing batteries.

If the low battery indicator blinks, you

must change the batteries

immediately. The instrument runs for

approximately twenty-four hours

when using alkaline AA batteries

(performance may vary depending

on the operating conditions).

-

+

+

-

Lock Unlock

Figure. 2-2 Installing the batteries

IM 735201-01E

2-3

Page 26

2.2 Connection Procedure

Connecting the Sensor Head

Connect the sensor head connector to the sensor

connector terminal on the instrument. Align the connector

tab with the groove, then push in. The connector head

cannot be connected if the tab is not properly aligned.

Figure 2-3 Sensor head connection diagram

● ● To remove the sensor head, hold and pull by the connector

Do not pull by the cable itself as it can break.

CAUTION

2-4

IM 735201-01E

Page 27

2.3 Turning the Power Supply ON and OFF

When Using the AC Adapter

When the power is OFF, press POWER/ESC key.

The instrument starts up in normal measurement mode.

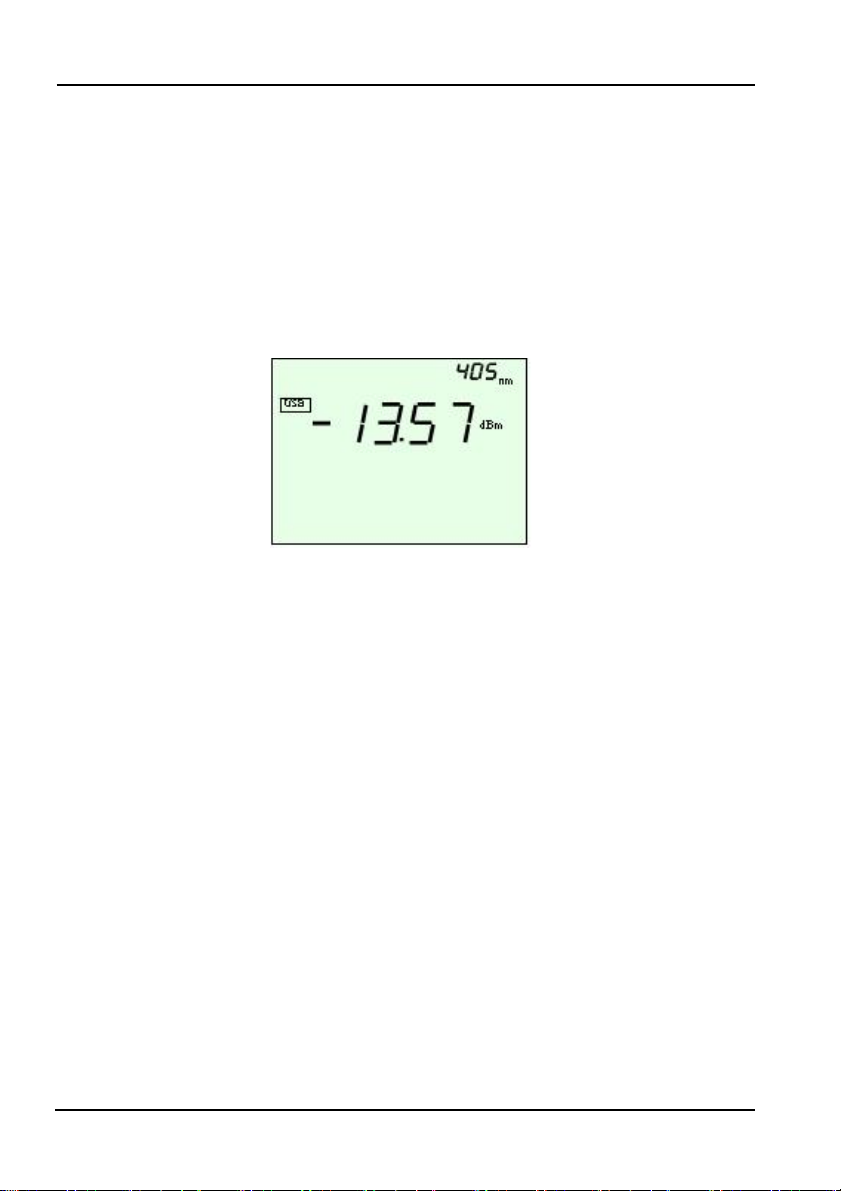

Figure 2-4 Example of the normal measurement mode screen

Never use an AC adapter or power cable other than the dedicated

ones available for use with this instrument, as damage can result.

When Using Batteries

When the power is OFF, press POWER/ESC.

The instrument starts up in normal measurement mode.

“PWR SAVE” is displayed in the upper left part of the screen.

Figure 2-5 Display example in power save mode

Note

To start up with the power save function OFF, make sure the power is

・

turned OFF, then hold down the POWER/ESC key until the “PWR

SAVE” display goes out.

This instrument features a zero adjust function (zero point adjustment)

・

that automatically removes the offset within the circuits. Thus, no zero

adjustment by the user is necessary

WARNING

Indicates that the power save function is

operating. The power turns OFF if no key is

pressed for ten minutes.

IM 735201-01E

2-5

Page 28

2.3 Turning the Power Supply ON and OFF

Starting Up in USB Mode

When the instrument is connected to a PC with a USB cable, the instrument

enters USB mode when the power is turned ON. It also enters this mode if the

cable is connected after the power is turned ON. Therefore, if a USB cable is

connected while the instrument is in normal measurement mode, it switches to

USB mode automatically. In USB mode, all keys are disabled except for the

POWER and BACKLIGHT keys.

The “USB” indicator is displayed when the instrument starts up in USB mode or

switches to that.

Figure 2-6 Display example in USB mode

Turning the Power OFF

1. Hold down the power key until the LCD display goes out.

2. Attach the sensor head protective cap.

3. When using the AC adapter, turn the instrument OFF with the power key

before disconnecting the adapter.

2-6

IM 735201-01E

Page 29

Chapter 3 Measurement

P

3.1 Entering Measurement Conditions

The following three measurement condition parameters can be set.

1) Wavelength setting (typical value, or switching of the wavelength in 1 nm

steps)

2) NA setting

3) Averaging setting

The conditions set here are stored until the next time you enter settings, even if

the power is turned OFF (Resume function.See p.1-7).

If you make a mistake, you can press the ESC or SETUP key.

ESC key: Return to normal measurement mode.

The setting procedures described all start from the initial screen in normal

measurement mode.

The initial screen in normal measurement mode.

Figure 3-1 Example of the initial screen in normal measurement mode.

key: Cancel setting and advance to the next setting.

SETU

Same screen as when first starting up.

Confirm that the screen shows the initial

settings, then begin the procedure for entering

measurement conditions.

IM 735201-01E

3-1

Page 30

3.1 Entering Measurement Conditions

3.1.1 Setting the Wavelength

You can set the correction wavelength for the sensor head to match the used

wavelength. The sensor element has wavelength sensitivity characteristics. To obtain

accurate measurements, the instrument is set to a wavelength that matches the

wavelength of the measured light.

Choosing a Typical Wavelength

1. Perform the operation from the initial screen in normal measurement mode

(Figure 3-1).

2. Press the λ key. The wavelength setting screen appears.。

Figure 3-2 Wavelength setting screen

3. Each time you press the UP key, the displayed wavelength cycles through

the following options: “405”, “660”, “785”, “Prev Val”, “Usr”, “405”, and so on.

Pressing the DOWN key cycles in the reverse order.

(Note: Previous value refers to the wavelength most recently set.)

4. After selecting a wavelength, press the ENTER key. The typical wavelength

setting is finalized.

Setting to an Arbitrary Wavelength. (Can Be Set in Units of 1 nm).

5. After setting the wavelength display to “USr”, press the ENTER key.

The detail wavelength setting screen appears.

Figure 3-3 Detail wavelength setting screen

6. Press the UP or DOWN key. Change the wavelength in units of 1 nm.

The available setting range is 400 to 850 nm.

7. Press the ENTER key. The detail wavelength settings are finalized.

3-2

IM 735201-01E

Page 31

3.1 Entering Measurement Conditions

3.1.2 Setting the NA (Numerical Aperture) Correction Coefficient

You can set the NA correction coefficient and correct the angle dependency of

the light accepted by the sensor head resulting from the aperture.

1. Perform the operation from the initial screen in normal measurement mode

(Figure 3-1).

2. Press the SETUP key. The setup mode screen appears.

3. Press the SETUP key two more times. The NA correction coefficient setting

ON/OFF screen appears.

Figure 3-4 Display example of the NA correction coefficient setting

ON/OFF screen

4. Each time you press the UP or DOWN key, “ON” or “OFF” blinks.

Select “ON”.

5. Press the ENTER key. The NA correction coefficient blinks.

Figure 3-5 Example of a display while setting the NA correction

coefficient

6. Press the UP or DOWN key to change the value. Determine the value from

the NA correction coefficient table (see appendix 1).

7. Press the ENTER key. The sensor serial number reference screen appears

(see Figure 5-1). The NA correction coefficient setting is finalized.

IM 735201-01E

3-3

Page 32

3.1 Entering Measurement Conditions

8. Press the ENTER key. The instrument returns to the normal measurement

mode screen.

Figure 3-6 Example of the display in normal measurement mode when

the NA correction coefficient setting is enabled.

Note

The NA correction coefficient differs depending on the NA and RIM of

・

the light source you are using.

Select a coefficient from the NA correction coefficient table in appendix

・

1 according to the conditions matching the light source.

NA

Stands for numerical aperture, and is a number that determines the

light-condensing characteristics of a lens.

The larger the NA, the more the beam is concentrated, allowing higher-density

recording.

3-4

IM 735201-01E

Page 33

3.1.3 Entering Averaging Settings

1. Perform the operation from the initial screen in normal measurement mode

(Figure 3-1).

2. Press the SETUP key. The averaging setting screen appears.

Figure 3-7 The averaging setting screen

3. Each time you press the UP or DOWN key, “ON” or “OFF” blinks.

Select “ON”.

4. Press the ENTER key. The MAX hold setting screen appears (see Figure

3-13). The averaging settings are finalized.

5. Press the ENTER key three times. The instrument returns to the normal

measurement mode screen.

Figure 3-8 Normal measurement mode screen when the averaging

Note

Averaging is performed on the instrument using a serial addition

・

averaging method.

・

The specified number of data from the measured values are averaged

and the result is displayed. After measurement begins, it is possible that

fewer than the specified number of data are measured.

3.1 Entering Measurement Conditions

setting is enabled

IM 735201-01E

3-5

Page 34

N

3.2 Modes

This instrument has five modes as shown in the table. When the power is turned

ON, the instrument starts up in normal measurement mode. You can press the

appropriate key to transition from normal measurement mode into the other

modes. When a USB cable is connected, the instrument switches to USB mode

automatically. When USB is disconnected, the instrument returns to normal

measuring mode.

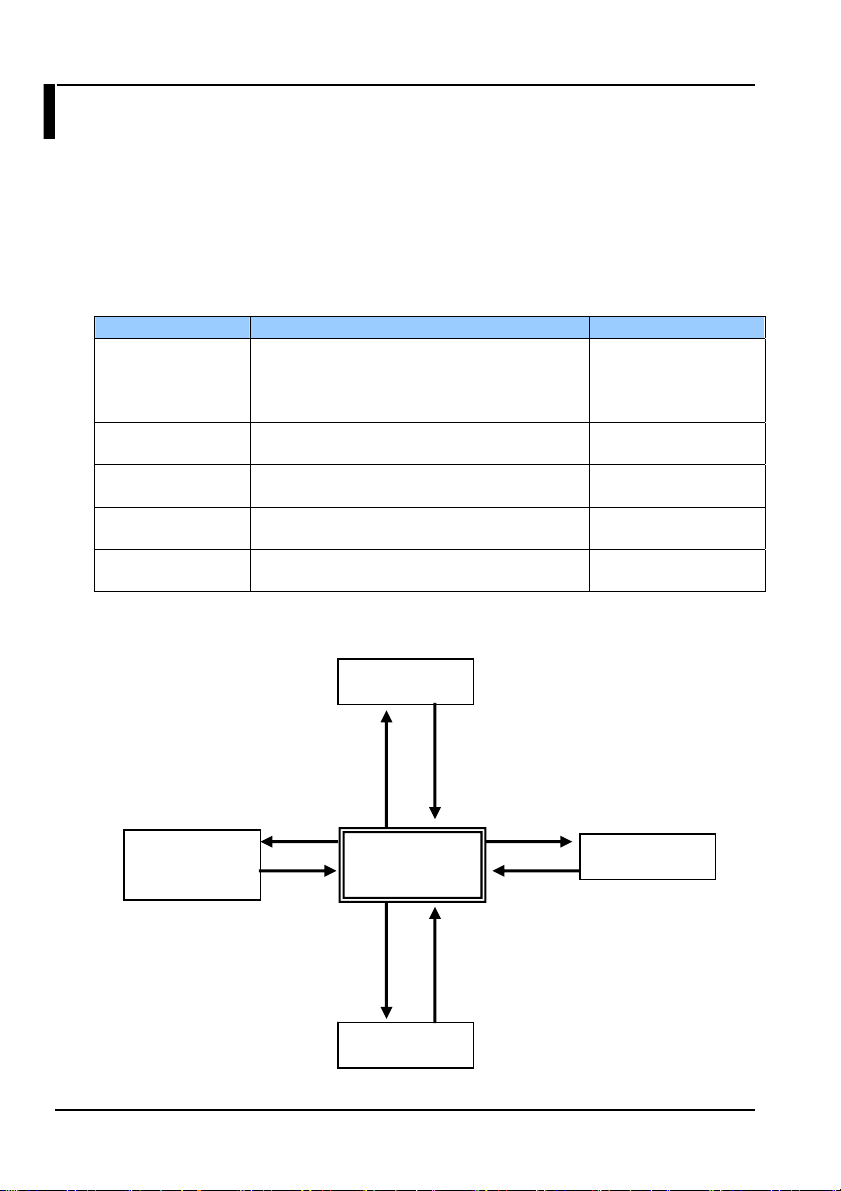

3.2.1 List of Modes

Mode Functions Included Entering the Mode

Normal

measurement

mode

Setup mode Averaging setting. MAX hold setting.

Wavelength

setting mode

CAL setting mode User calibration function setting.

USB mode Remote control. Uploading the sensor head

3.2.2 Diagram of Relationship between Modes

Wavelength

measurement

mode

ENTER+SETUP key

Optical power measurement. Absolute value

measurement. Relative value measurement.

Range fixing. Switching the display units to

dBm/W.

NA setting. Sensor serial number display.

Setting the measured wavelength.

specific data to the TB200 from the PC.

ENTER key

SETUP key

λ key

SETUP mode

ormal

measurement

mode

CAL mode

Press the ENTER or SETUP key

four times in a row

Turn power ON and connect cables

Turn power OFF,

disconnect cables

ENTER key

Power ON

Press the SETUP

key.

Press the λ key

Press ENTER +

SETUP

Turn power ON and

connect cable.

USB mode

3-6

IM 735201-01E

Page 35

3.3 Absolute Value Measurement

3.3.1 Measuring Optical Power

When the power to the instrument is turned ON, measurement begins.

The optical power level is displayed in the measured value display area.

Figure 3-9 Example of an optical power measurement screen

3.3.2 Changing Units

Each time you press the dBm/W key, the display cycles through the following

options: “dBm” -> “W” (auto units) -> “mW” (fixed units) -> “dBm”.

dBm display W display (auto) mW display (fixed)

Figure 3-10 Display example of unit settings

Note

If the units are dB, differential measurement (relative value

・

measurement mode) is indicated.

Press the dBm/W key to switch to optical power measurement

・

(absolute value measurement mode).

IM 735201-01E

3-7

Page 36

3.3 Absolute Value Measurement

r

3.3.3 Fixing the Measuring Range (Range Hold)

You can fix the measuring range (range hold). This is useful when using the

analog out function.

1. Perform the operation from the initial screen in normal measurement mode

(Figure 3-1).

2. Press the RANGE key. The “HOLD” display and current range value blink

for five seconds.

Figure 3-11 Example of the range value display during range hold

Blinks for 5 sec. in synch. with the range value display,

then stops blinking.

3. After blinking, “HOLD” is displayed, and the range value is no longer

displayed. The fixed range setting is finalized. The instrument enters range

hold mode.

Figure 3-12 Example of the display when in range hold mode

To Change the Range Value

4. Press the UP or DOWN key while in range hold mode. The range goes up

or down.

5. The range blinks for five seconds in the area shown in Figure 3-11, then the

original screen returns (if REF is set, the REF value is displayed again).

Note

If the measuring range is fixed and the incoming light exceeds the

・

measuring range, the measured value blinks. If the upper limit of the

range is exceeded, “▲” is displayed. If the lower limit is not exceeded

“▼” is displayed.

Press the RANGE key again to return to AUTO mode.

・

Range value display

Displays the current range value fo

5 sec. (blinks)

3-8

IM 735201-01E

Page 37

3.3.4 Displaying Maximum Values (MAX Hold)

1. Perform the operation from the initial screen in normal measurement mode

(Figure 3-1).

2. Press the SETUP key. The setup mode screen appears.

3. Press the SETUP key once again. The MAX hold setting ON/OFF screen

appears.

Figure 3-13 Max hold setting screen

4. Each time you press the UP or DOWN key, “ON” or “OFF” blinks. Select

“ON”.

5. Press the ENTER key. The screen changes to the NA correction coefficient

setting screen (see Figure 3-4). The MAX hold setting is finalized.

6. Press the ENTER key two times. The instrument returns to the normal

measurement mode screen.

Figure 3-14 Normal measurement mode screen when the MAX hold setting

is enabled

Note

The MAX hold and REF functions cannot be used at the same time on

・

the instrument.

If you turn ON the REF function while the MAX hold function is enabled,

・

MAX hold is cancelled and the REF function is enabled.

3.3 Absolute Value Measurement

IM 735201-01E

3-9

Page 38

3.3 Absolute Value Measurement

3.3.5 Measuring after Setting the CAL Value

You can add an arbitrarily set user calibration value (CAL value) to the values

displayed in normal measurement mode. The available setting range is -10 dB to

+10 dB. The active power range and the setting range for the relative value

measurement reference value is shifted by the value of CAL. The ON status of the

user calibration function and the CAL value are saved even when the power is

turned OFF. Use for the correction made when performing calibration.

1. Perform the operation from the initial screen in normal measurement mode

(Figure 3-1).

2. Press the SETUP key while holding down the ENTER key. The CAL

setting ON/OFF screen appears. However, it does not appear when in

relative measurement mode. The transition only occurs from absolute

value measurement mode. If you transition to CAL setting mode, “CAL” is

displayed, and the display to the lower right of “CAL” blinks.

3. Each time you press the UP key, the display to the lower right of “CAL”

cycles through the following options: “OFF”, “Prev Val”, “Usr”, “OFF”.

Pressing the DOWN key cycles in the reverse order.

4. After selecting a CAL value (previous value), press the ENTER key.

The typical CAL setting is finalized.

Figure 3-15 Example of the CAL value setting screen

3-10

IM 735201-01E

Page 39

3.3 Absolute Value Measurement

5. You can set an arbitrary CAL value in 0.01 dB steps.

After setting the display to the lower right of “CAL” to “USr”, press the

ENTER key. The CAL detail setting screen appears.

6. Press the UP or DOWN key. The CAL value changes in steps of 0.01 dB.

The available setting range is -10 dBm to +10 dBm

Figure 3-16 Example of the CAL value detail setting screen

7. Press the ENTER key. The instrument returns to normal measurement

mode. The CAL detail setting is finalized.

Figure 3-17 Example of the normal measurement mode screen when

the CAL setting is enabled

IM 735201-01E

3-11

Page 40

3.4 Relative Value Measurement

Measuring the Optical Power Differential

You can display the difference (dB) from a reference value (REF).

1. In absolute value measurement mode, press the dBm/W key while holding

down the ENTER key. The measured value at the time the key was

pressed is set as the reference value, and relative measurement begins.

2. The units for relative measurement reference value are fixed at dBm.

There is no W unit display.

Absolute value measurement mode When REF is set

Figure 3-18 Example of display in absolute value measurement mode

when setting the reference (REF)

Note

To return to absolute value measurement, press the dBm/W key.

・

Each time you press the dBm/W key while holding down the ENTER

・

key, the reference value is updated.

Only measured values can be set as the reference value. Arbitrary

・

values cannot be specified.

3-12

IM 735201-01E

Page 41

Chapter 4 Measuring Using USB (Remote Control)

4.1 USB Communication Function

You can control the instrument using USB. You can read data and enter various

parameters from the PC. Also, a DLL and sample software are available on the

TB200 Utility CD in order to install the TB200 dedicated USB driver and easily

create control software. The following provides the USB communication

specifications and explains how to install the driver.

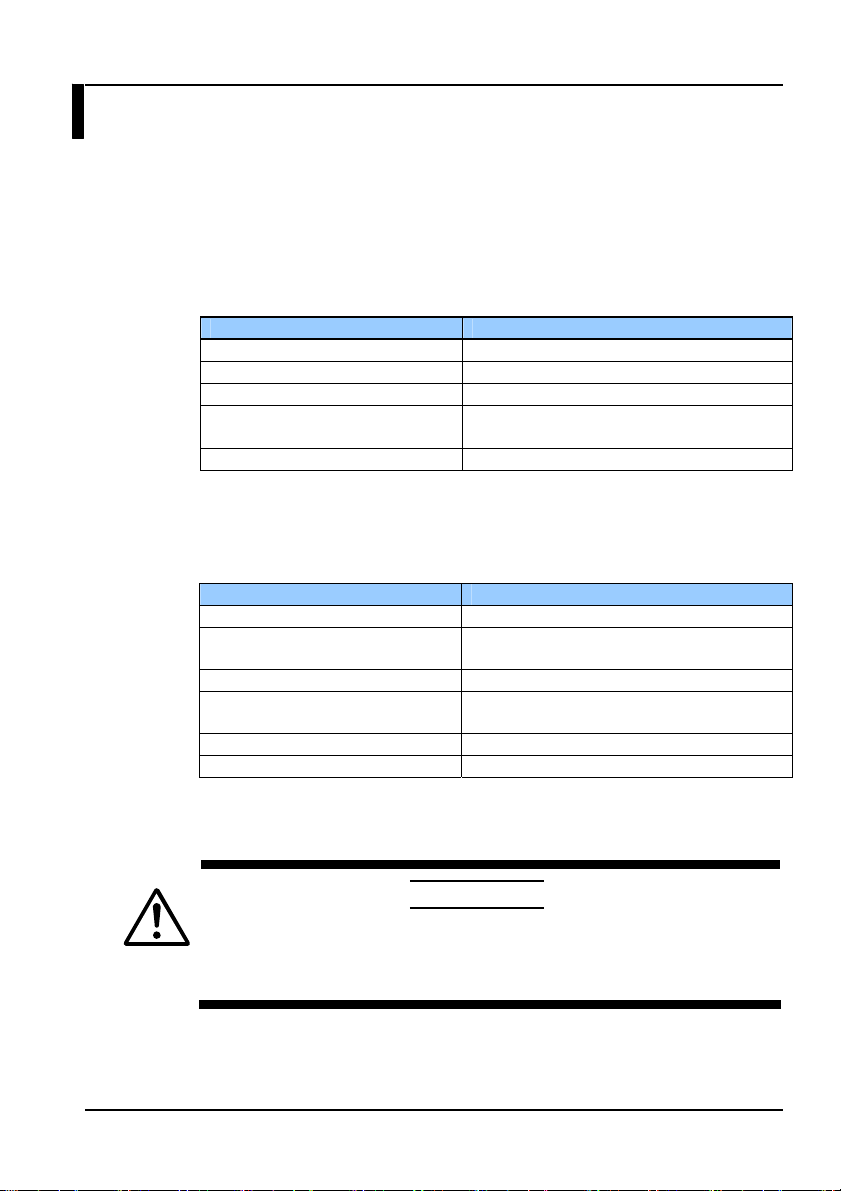

USB Communication Specification

Item Specification

USB standard Conforms to USB Version 1.1

Connector type B

Remote control function Provided (bulk transfer)

USB driver TB200 dedicated driver comes standard

(for Windows 2000/XP)

USB cable length* 2 m or less (shielded type)

* Attach a ferrite core (TDK: ZCAT1325-0530A or equivalent) to one end of the

USB cable, close to the instrument’s USB connector.

Driver/DLL Specifications and Operating Environment

Item System Requirements

OS Windows 2000/XP

Languages Microsoft Visual C++ 6.0

Microsoft Visual Basic 6.0

RAM 32 MB or more

Interface Windows 2000/XP with TB200 dedicated

USB driver installed.

Send delimiter (TB200 -> PC) CR+LF

Receive delimiter (PC -> TB200) CR+LF or LF only

CAUTION

During USB communications, do not turn the power to the PC and

TB200 OFF.

The driver and DLL are not guaranteed to be compatible with all PCs,

hubs, and other hardware.

IM 735201-01E

4-1

Page 42

4.2 Installing USB Drivers

Install the USB driver on the PC. Use the TB200 Utility CD that comes standard.

Follow the on-screen instructions.

Preparation

Turn the instrument ON, then connect the instrument to the PC using a USB

cable (insert the cable connector completely and firmly into the receptacle). The

instrument automatically enters USB mode, and USB is displayed (see section

2.2 and figure 2-6).

* USB cable: shielded cable of 2 m or more in length.

Installation

1. Place the enclosed TB200 Utility CD in the CD-ROM drive.

2. Turn the instrument ON, then connect the instrument to the PC using a

USB cable (insert the cable connector completely and firmly into the

receptacle). The Found New Hardware Wizard is displayed.

3. Click Next

4. Select Search for a suitable driver for my device. Click Next.

4-2

IM 735201-01E

Page 43

4.2 Installing USB Drivers

5. Select CD-ROM drives. Click Next.

6. Click Next.

7. Click Finish. The installation is complete

IM 735201-01E

4-3

Page 44

4.3 List of Commands

The following describes the commands available on the TB200.

The TB200 offers ASCII character strings in addition to input and output commands.

Also, the return values for setting commands and query commands are separate, so

there is no need to send commands and queries separately.

Command Notation Conventions and Meanings

1) Commands begin with a colon ( : ).

2) <wsp> means, enter a space.

3) <Value> means, enter value here.

4) ON|OFF means, enter either ON or OFF.

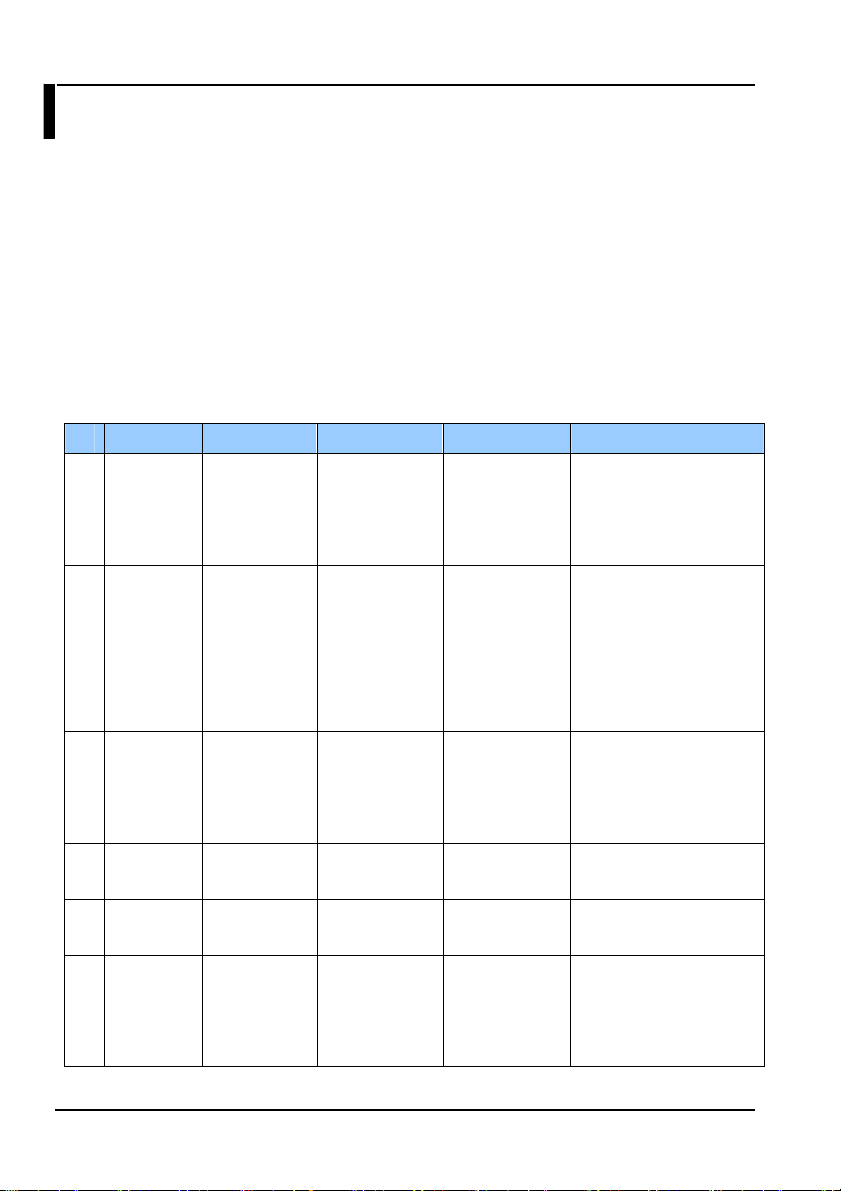

Command List

No.

Function Command Description Parameters Response

1 Data

request

2 Data

request with

status

3 Max value

data

request

4 Wavelength

setting

5 Check the

set

wavelength

6 NA

correction

function

enable/

disable

setting

:READ:POW? Returns the

:READ:POW:

STAT?

:READ:MAX? Returns the

:SENS:POW:

WAV<ws p>

<Value>

:SENS:POW:

WAV?

:SENS:CORR

:NA:STAT<ws

p> ON|OFF

current

measured value.

Returns the

current

measured value

and range

status.

current

maximum

measured value.

Sets the

wavelength

Returns the set

wavelength.

Turns NA

correction

function ON and

OFF

None Returns the current

None Returns the current

None

Returns the current

400-850

(1 step)

Units: nm

None Set as a three digit integer.

ON: Enabled

OFF: Disabled

measured value in Float

format. The units are the

same as those during

setting.

ERR#: See error list.

measured value in Float

format.

<Range status>

Over Range

Under Range

In Range

Average

ERR#: See error list.

maximum measured value

in Float format. The units

are the same as those

during setting.

ERR#: See error list.

OK: Setting complete

ERR#: See error list.

The units are fixed at nm.

ERR#: See error list.

OK: Setting complete

ERR#: See error list.

4-4

IM 735201-01E

Page 45

No.

Function Command Description Parameters Response

7 Check NA

correction

function

setting

status

8 Set NA

correction

Val ue

9 Check NA

correction

value

10 Setting the

measuring

range

11 Check

measuring

range

12 Set units of

measurement

13 Check units

of measurement

:SENS:CORR:

NA:STAT?

:SENS:CORR

:NA:VAL<wsp

><Value>

:SENS:CORR

:NA:VAL?

:SENS:POW:

RANG<wsp>

<Value>

:SENS:POW:

RANG?

:SENS:POW:

UNIT<wsp>

<Value>

:SENS:POW:

UNIT?

Returns the NA

correction

function setting

status.

Sets the NA

correction value.

Sets the data

internally

regardless of the

NA correction

function

ON/OFF.

Returns the

currently set NA

correction value.

Returns the

setting status of

the data

internally

regardless of the

NA correction

function

ON/OFF.

Sets

the measuring

range.

Returns the

status of the

current

measuring

range setting.

Sets the units for

the measured

value.

Returns the unit

setting status of

measured

values.

None ON: Enabled

0.500-2.000

:0.001step

None Decimal place 3 digits *.**

AUTO

+20 dBm

+10 dBm

0 dBm

-10 dBm

-20 dBm

-30 dBm

None AUTO

0: dBm

1: mW / µW /

nW auto

switching

2: mW fixed

display

None 0: dBm

4.3 List of Commands

OFF: Disabled

ERR#: See error list.

OK: Setting complete

ERR#: See error list.

ERR#: See error list.

OK: Setting complete

ERR#: See error list.

+20 dBm

+10 dBm

0 dBm

-10 dBm

-20 dBm

-30 dBm

ERR#: See error list.

OK: Setting complete

ERR#: See error list.

1: mW/µW/nW auto

switching

2: mW fixed display

ERR#: See error list.

IM 735201-01E

4-5

Page 46

4.3 List of Commands

No.

Function Command Description Parameters Response

14 Relative

value

measurement setting

15 Check

relative

setting

16 Check

relative

measurement

reference

value

17 User CAL

function

enable/

disable

setting

18 Check user

CAL

function

setting

status

19 Set user

CAL value

20 Check user

CAL value

21 Set

averaging

22 Check

averaging

setting

:SENS:POW:

REF:STAT

<wsp>ON|OF

F

:SENS:POW:

REF:STAT?

:SENS:POW:

REF:VAL?

:SENS:CORR

:CAL:STAT

<wsp>ON|OF

F

:SENS:CORR

:CAL:STAT?

:SENS:CORR

:CAL:VAL<ws

p><Value>

:SENS:CORR

:CAL:VAL?

:SENS:POW:

AVG < wsp >

ON|OFF

:SENS:POW:

AVG ?

Switches

between relative

and absolute

measurement.

Returns the

relative/absolute

value

measurement

status.

Returns the

relative

measurement

reference value.

Turns user CAL

function ON and

OFF

Returns the user

CAL function

setting status.

Sets the user

CAL value

Returns the user

CAL value.

Sets up

averaging.

Returns

the averaging

setting status.

ON: Relative

value

measurem

ent: dB

Absolute value

measurement

(dBm)

None ON: Relative value

None

***.** (symbol, 2-digit

ON: User CAL

ON status

OFF: User CAL

OFF status

None ON: User CAL ON status

***.** (symbol,

2-digit integer,

2-digit decimal).

The units are dB

Range: integer

from -10.00 to

+10.00, first 0 or

+ can be omitted

None ***.** (symbol, 2-digit

ON: Averaging

ON

OFF: Normal

measurement

None ON: Averaging ON

OK: Setting complete

ERR#: See error list.

measurement: dB

OFF: Absolute value

measurement: dBm

ERR#: See error list.

integer, 2-digit decimal).

units are dBm.

ERR#: See error list.

OK: Setting complete

ERR#: See error list.

OFF: User CAL OFF status

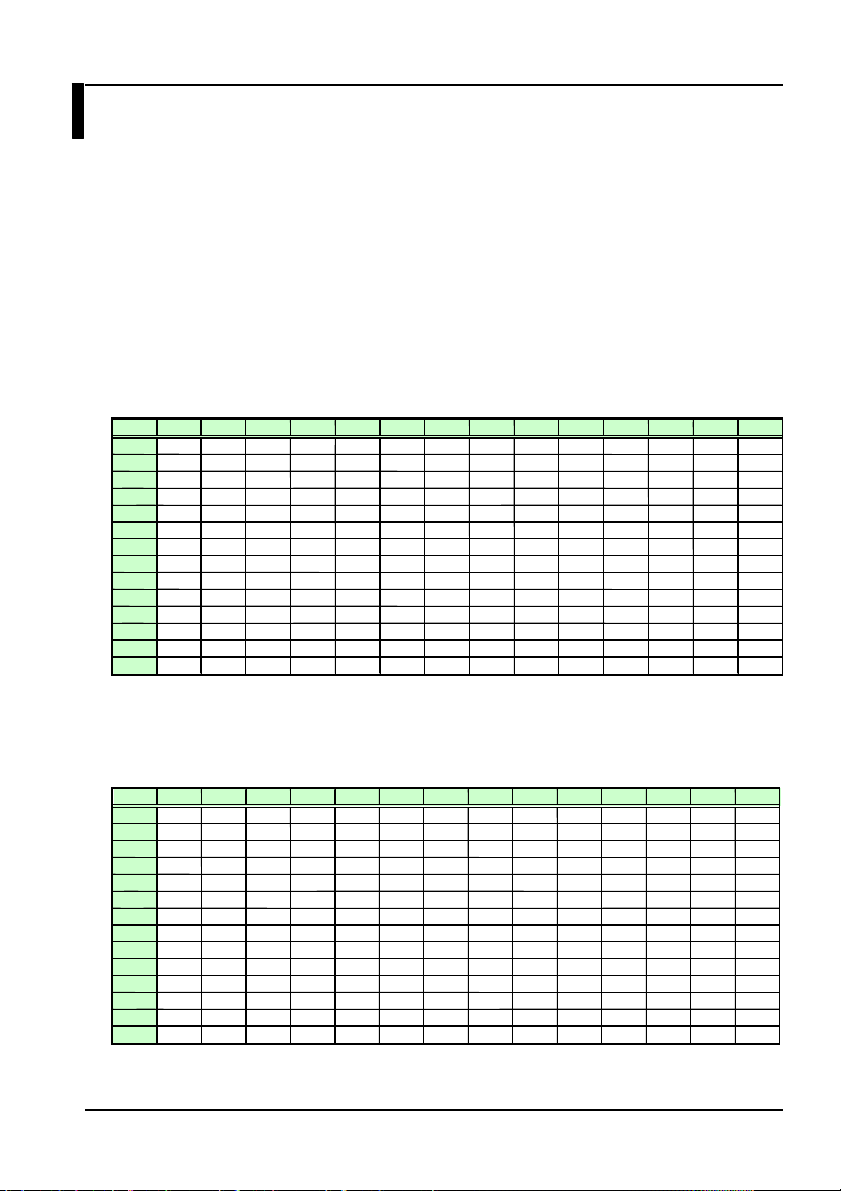

ERR#: See error list.