Page 1

Time Interval Analyzer

Yokogawa Electric Corporation

IM 704210-01E

1st Edition

Page 2

Foreword

Notices

Trademarks

Thank you for purchasing the YOKOGAWA TA320 Time Interval Analyzer.

This user’s manual contains useful information about the functions and operating methods of the

instrument. It also contains precautions that should be observed during use. To ensure correct use

of the instrument, please read this manual thoroughly before operating it.

Keep the manual in a safe place for quick reference whenever a question arises.

The following manual is provided with this instrument in addition to this manual.

Manual Name Manual No. Description

TA320 GP-IB Interface IM704210-12E Describes the communication functions for the GP-IB

User’s Manual interface.

• The contents of this manual are subject to change without prior notice as a result of

improvements in the instrument’s performance and functions. Display contents illustrated in

this manual may differ slightly from what actually appears on your screen.

• Every effort has been made in the preparation of this manual to ensure the accuracy of its

contents. However, should you have any questions or find any errors, please contact your

nearest YOKOGAWA representative as listed on the back cover of this manual.

• Copying or reproduction of all or any part of the contents of this manual without

YOKOGAWA’s permission is strictly prohibited.

• MS-DOS is a registered trademark of Microsoft Corporation.

• HP-GL is a registered trademark of Hewlett-Packard Company.

Revisions

• 1st Edition : December 1996

Disk No. HF07

1st Edition: December 1996 (YG)

All Rights Reserved, Copyright © 1996 Yokogawa Electric Corporation

IM 704210-01E

1

Page 3

Checking the Contents of the Package

Unpack the box and check the contents before operating the instrument. If the wrong instrument

or accessories have been delivered, if some accessories are missing or if they appear abnormal,

contact the dealer from which you purchased them.

Main Body

Check that the model name and suffix code given on the name plate of the rear panel match those

on your order.

Nameplate

MODEL (Type Name)

704210

SUFFIX (Suffix Code)

Item Suffix Code Specifications

Power voltage •••••••••••••••••••• 100-240 VAC

Power cord -D UL/CSA Standards Power Cord (Part No.: A1006WD)

-F VDE Standard Power Cord (Part No.: A1009WD)

-Q BS Standard Power Cord (Part No.: A1054WD)

-R SAA Standard Power Cord (Part No.: A1024WD)

[Maximum Rated Voltage: 125 V, Maximum Rated Current: 7 A]

[Maximum Rated Voltage: 250 V, Maximum Rated Current: 10 A]

[Maximum Rated Voltage: 250 V, Maximum Rated Current: 10 A]

[Maximum Rated Voltage: 240 V, Maximum Rated Current: 10 A]

NO. (Instrument No.)

When contacting the dealer from which you purchased your instrument, please quote the

instrument No.

Note

It is recommended that the packing box be kept in a safe place. The box can be used when you need to

transport the instrument somewhere.

2

IM 704210-01E

Page 4

Standard Accessories

Checking the Contents of the Package

The following standard accessories are supplied with the instrument. Make sure that all items are

present and undamaged.

Power cord (one of the following power cords

is supplied according to the instrument's suffix codes)

Optional Accessories

UL/CSA standard

A1006WD

D

VDE standard

A1009WD

F Q R

Rubber feet(2pcs)

(A9088ZM(1pc))

BS standard

A1054WD

User's manual

Communication interface

manual

SAA standard

A1024WD

(1pc)

(1pc)

The following optional accessories are available. On receiving these optional accessories, make

sure that all the items that you ordered have been supplied and that they are undamaged.

If you have any questions regarding optional accessories, or if you wish to place an order, contact

the dealer from whom you purchased them.

Part Name Part No. Minimum Q’ty Remarks

150 MHz passive probe 700996 1 Input impedance: 10 MΩ, Length: 1.5 m

BNC cable (1m) 366924 1 BNC-BNC, Length: 1 m

BNC cable (2m) 366925 1 BNC-BNC, Length: 2 m

Rack-mount kit 751533-E3 1 For EIA single mount

Rack-mount kit 751534-E3 1 For EIA dual mount

Rack-mount kit 751533-J3 1 For JIS single mount

Rack-mount kit 751534-J3 1 For JIS dual mount

IM 704210-01E

3

Page 5

Safety Precautions

This instrument is an IEC safety class I instrument (provided with terminal for protective

grounding).

The following general safety precautions must be observed during all phases of operation, service

and repair of this instrument. If this instrument is used in a manner not sepecified in this manual,

the protection provided by this instrument may be impaired. Also, YOKOGAWA Electric

Corporation assumes no liability for the customer’s failure to comply with these requirements.

The following symbols are used on this instrument.

To avoid injury, death of personnel

or damage to the instrument, the

operator must refer to an explanation

in the User’s Manual or Service

Manual.

Make sure to comply with the following safety precautions. Not complying might

result in injury, death of personnel or damage to the instrument.

Alternating current.

ON(power).

OFF(power).

WARNING

Power Supply

Ensure the source voltage matches the voltage of the power supply before turning ON the

power.

Power Cable and Plug

To prevent an electric shock or fire, be sure to use the power cord supplied by

YOKOGAWA. The main power plug must be plugged in an outlet with protective

grounding terminal. Do not invalidate protection by using an extension cord without

protective grounding.

Protective Grounding

Make sure to connect the protective grounding to prevent an electric shock before

turning ON the power.

Necessity of Protective Grounding

Never cut off the internal or external protective grounding wire or disconnect the wiring

of protective grounding terminal. Doing so poses a potential shock hazard.

Defect of Protective Grounding and Fuse

Do not operate the instrument when protective grounding or fuse might be defective.

Do not Operate in an Explosive Atmosphere

Do not operate the instrument in the presence of flammable liquids or vapors. Operation

of any electrical instrument in such an environment constitutes a safety hazard.

Do not Remove any Covers

There are some areas with high voltages. Do not remove any cover if the power supply is

connected. The cover should be removed by qualified personnel only.

External Connection

To ground securely, connect the protective grounding before connecting to measurement

or control unit.

4

IM 704210-01E

Page 6

Structure of the Manual

This User’s Manual consists of 12 chapters and an Index as described below.

Chapter1 Functions

Describes the measuring principles and functions of the instrument. No description is given for

operating methods, however it is recommended that this chapter be read before operating the

instrument to gain a basic understanding of what the instrument can do.

Chapter2 Name and Use of Each Part

Describes the name and function of each part of the instrument. For keys and rotary knob,

reference sections (or page numbers) are also given.

Chapter3 Before Starting Measurement

Describes usage precautions, how to install the instrument, connect the power cord, turn the

power switch ON/OFF, connect a probe and set the date and time.

Chapter4 Common Operations

Describes how to start and stop acquisition of a measuring input signal and set a numerical value

using the ten-key.

Chapter5 Setting the Sampling Mode and Measurement Function (Item)

Describes how to set the sampling mode and measurement function (item).

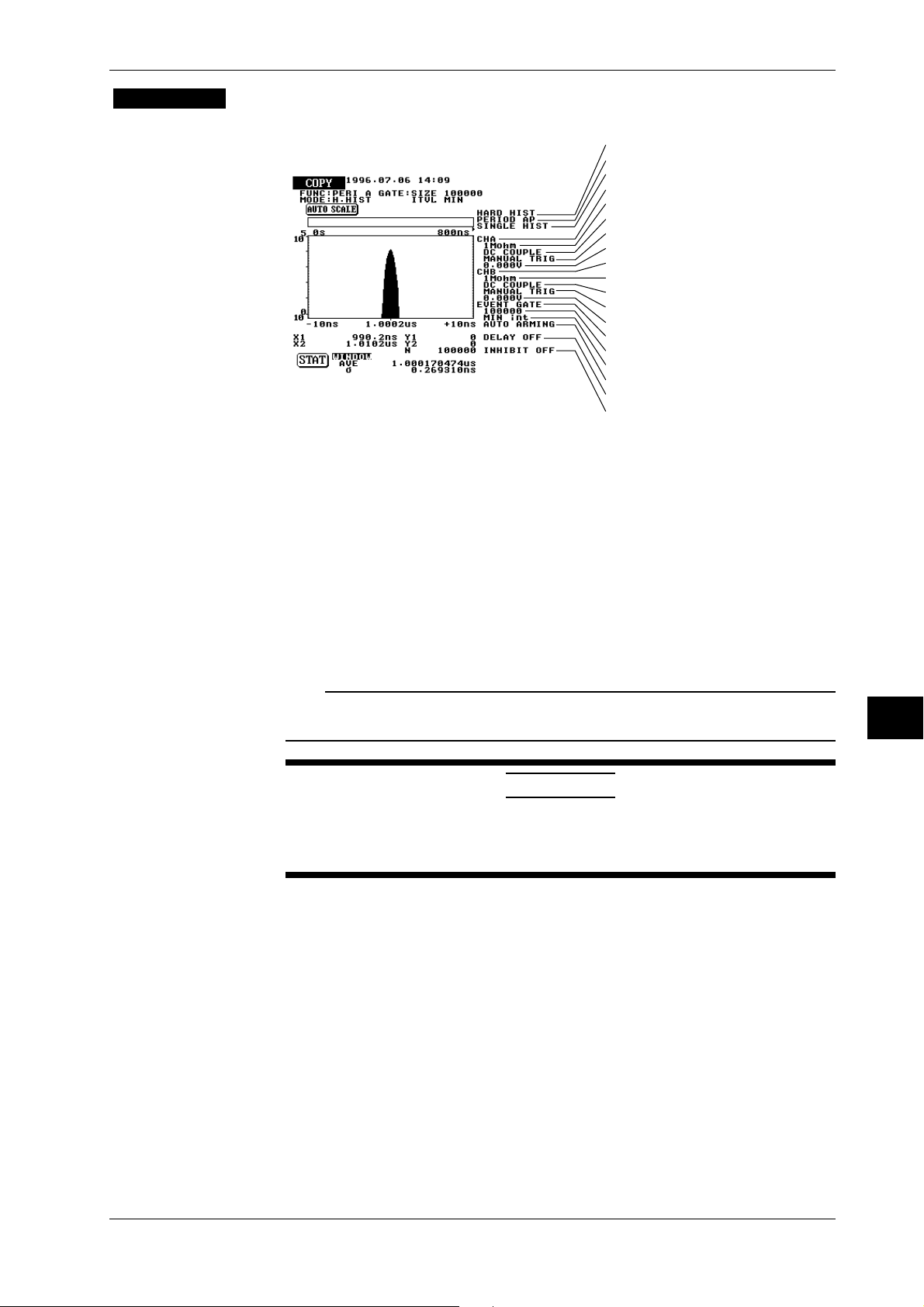

Chapter6 Setting the Acquisition Conditions for Input Signal to be Measured

Describes how to set the acquisition conditions for the input signal to be measured, including

input coupling, input impedance, trigger mode and trigger level, gate type, sample size and

sampling interval, arming source, slope, delay types, and inhibit.

Chapter7 Displaying the Measured/Computed Data

Describes how to display a histogram, time variation, list of measured data and statistic values,

and how to set multi-window, panorama display and histogram data addition functions.

Chapter8 Storing and Recalling the Set-up Information from the Internal Memory

Describes how to store the set-up information to the internal memory and how to recall the stored

set-up information and change it.

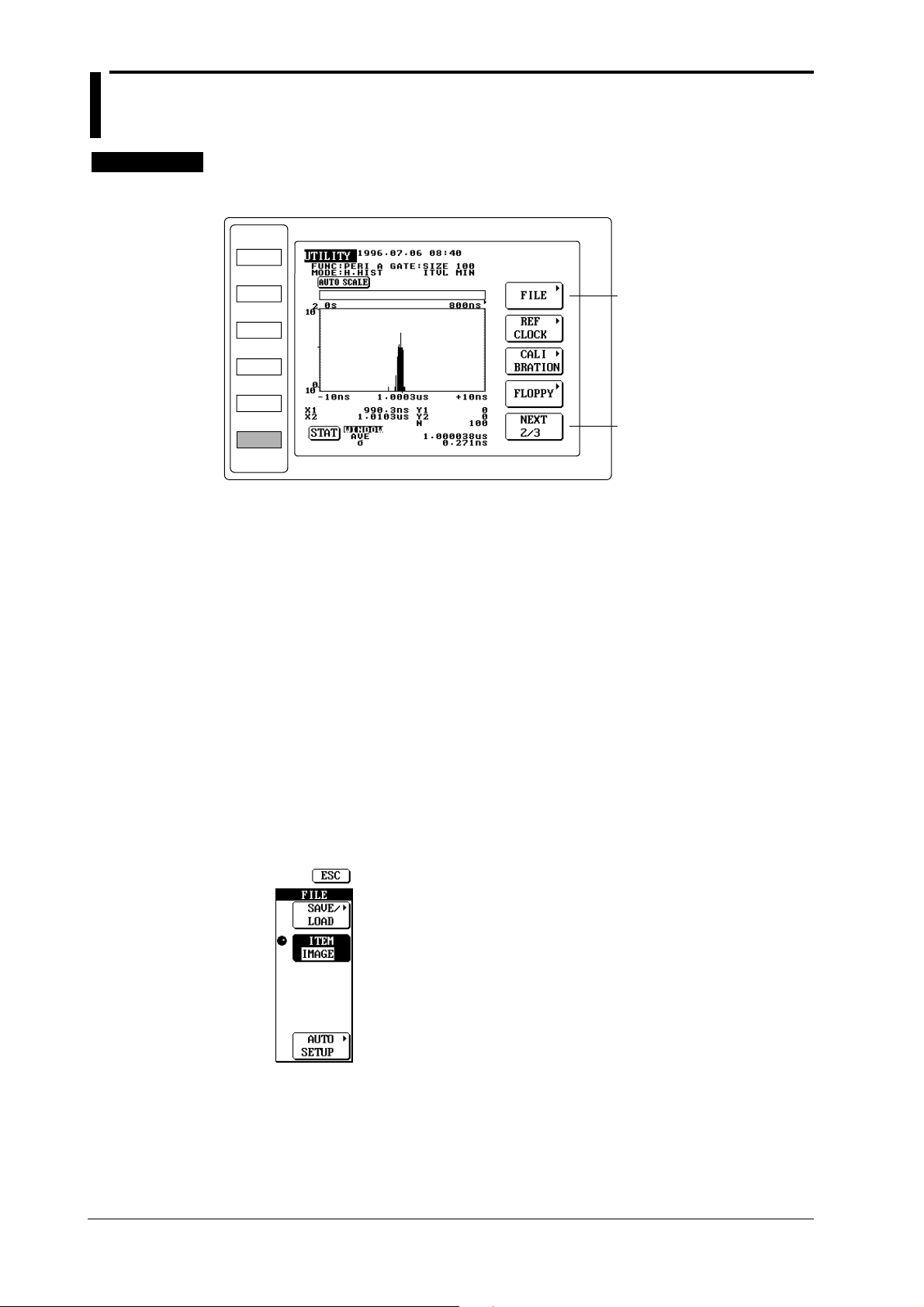

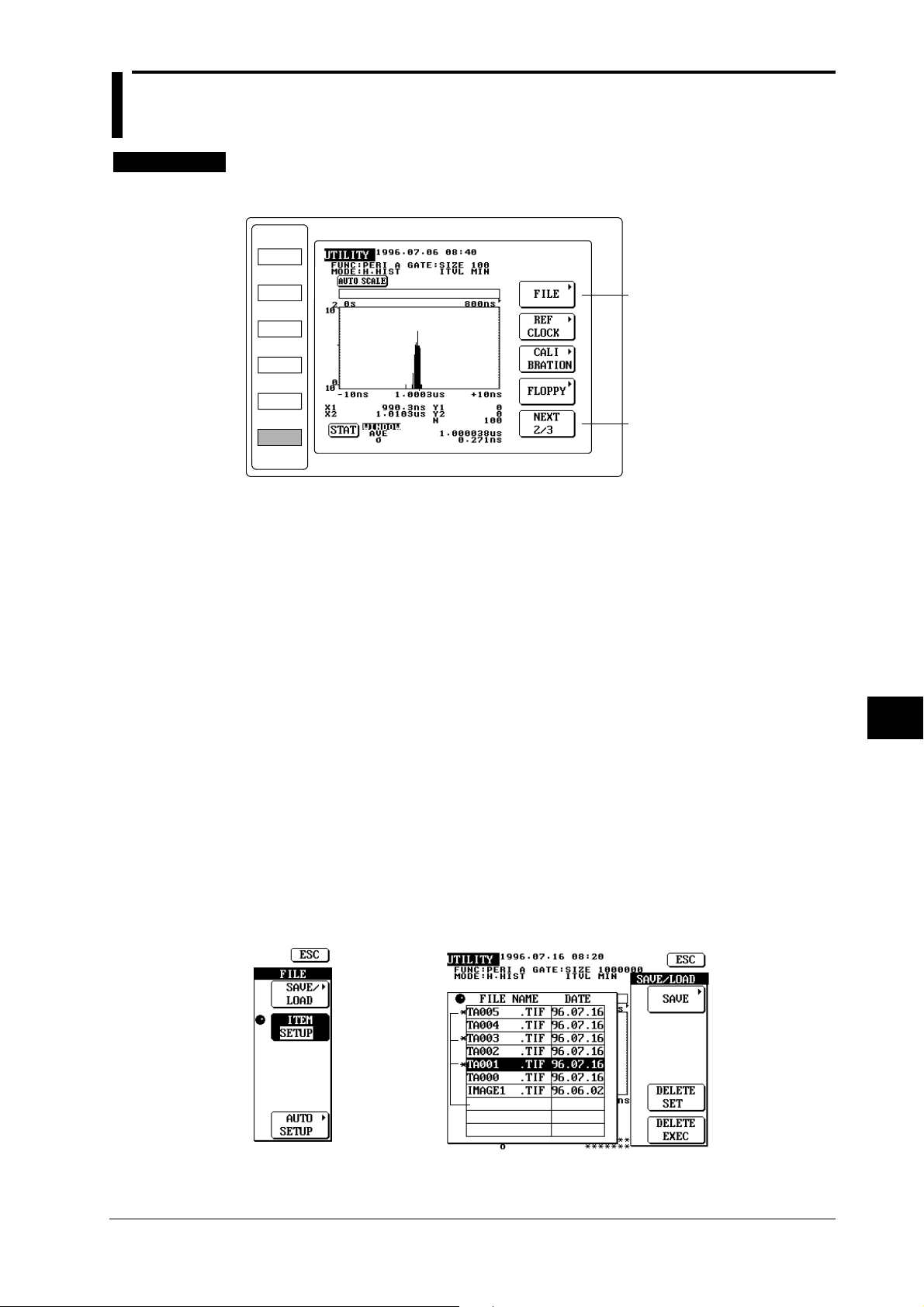

Chapter9 Saving and Loading the Data from a Floppy Disk

Describes how to save data such as set-up information, measured/computed results and screen

image to a floppy disk, load the saved data, format a floppy disk and delete data.

Chapter10 Using Other Functions

Describes how to output measured data to a plotter, input/output the reference signal, output

monitor signals, initialize the set-up information, calibrate the instrument, set the screen contrast

and set the touch key sound.

Chapter11 Troubleshooting and Maintenance

Describes corrective actions to be taken in case of problems and their causes, describes error

messages, how to use the error logging and self-test functions, adjust the time base, carry out the

performance test and reset the circuit breaker.

Chapter12 Specifications

Describes the specifications of the instrument.

Index

Describes important terms.

IM 704210-01E

5

Page 7

Notations and Symbols Used in this Manual

Procedure

Explanation

Unit

k :1000 (e.g. 100 kHz)

K :1024 (e.g. 640 KB (floppy disk memory capacity))

Symbols Used

The following symbols are used in this User’s Manual.

To avoid injury or death of personnel, or damage to the instrument, the

operator must refer to the User’s Manual. In the User’s Manual, these

symbols appear on the pages to which the operator must refer.

WARNING

CAUTION

Note

Symbols used on pages where description of operation is given

The following symbols are used in chapters 3 to 11, to classify descriptions.

Procedure

Explanation

Describes precautions that should be observed to prevent the danger of

serious injury or death to the user.

Describes precautions that should be observed to prevent the danger of

minor or moderate injury to the user, or the damage to the property.

Provides information that is important for proper operation of the

instrument.

Describes keys to be used and operating procedure. With some operating

procedures, it is not necessary to carry out the steps according to the order

in which they are described.

Gives a detailed description of settings and restrictions regarding

operations. No detailed description is given for the function. For a

detailed description of the function, refer to Chapter 1.

6

IM 704210-01E

Page 8

Contents

Foreword ........................................................................................................................................................................................ 1

Checking the Contents of the Package .......................................................................................................................... 2

Safety Precautions ................................................................................................................................................................... 4

Structure of the Manual .......................................................................................................................................................... 5

Notations and Symbols Used in this Manual ............................................................................................................... 6

Chapter 1 Functions

1.1 System Configuration and Block Diagram.........................................................................................................1-1

1.2 Measuring Principles and Sampling Mode......................................................................................................... 1-2

1.3 Measurement Functions (Measurement Items) .................................................................................................. 1-3

Period, Time Interval ............................................................................................................................................................... 1-3

Pulse Width, Phase Difference, Duty Ratio ............................................................................................................................. 1-4

1.4 Computation ....................................................................................................................................................... 1-5

Readout Function ..................................................................................................................................................................... 1-5

Calculation, Statistical Computation Items ............................................................................................................................. 1-6

1.5 Setting the Acquisition Conditions for Input Signal to be Measured .................................................................1-8

Input Coupling, Input Impedance, Measurement Block .......................................................................................................... 1-8

Trigger Mode/Trigger Level, Gate .......................................................................................................................................... 1-9

Sample Size (Number of Events), Sampling Interval, Arming, Arming Delay ..................................................................... 1-10

Inhibit ......................................................................................................................................................................................1-11

1.6 Displaying the Measured/Computed Data........................................................................................................ 1-12

Histogram Display, Multi-window .........................................................................................................................................1-12

Panorama Display, Histogram Data Addition, Time Variation Display ................................................................................ 1-13

List Display, Statistics Display ...............................................................................................................................................1-14

1.7 Other Functions

External Signal Input/Output (Rear Panel), Communications, Storing and Recalling of Set-up Information, Saving and

Loading Data from a Floppy Disk, Auto Loading of Set-up Information, Plotter Output, Initialization of Set-up

Information, Calibration .................................................................................................................................................. 1-16

Numeric Value Setting, Contrast, Touch-key Sound, Error Logging, Self-test ..................................................................... 1-17

1

2

3

4

5

6

7

8

9

Chapter 2 Name and Use of Each Part

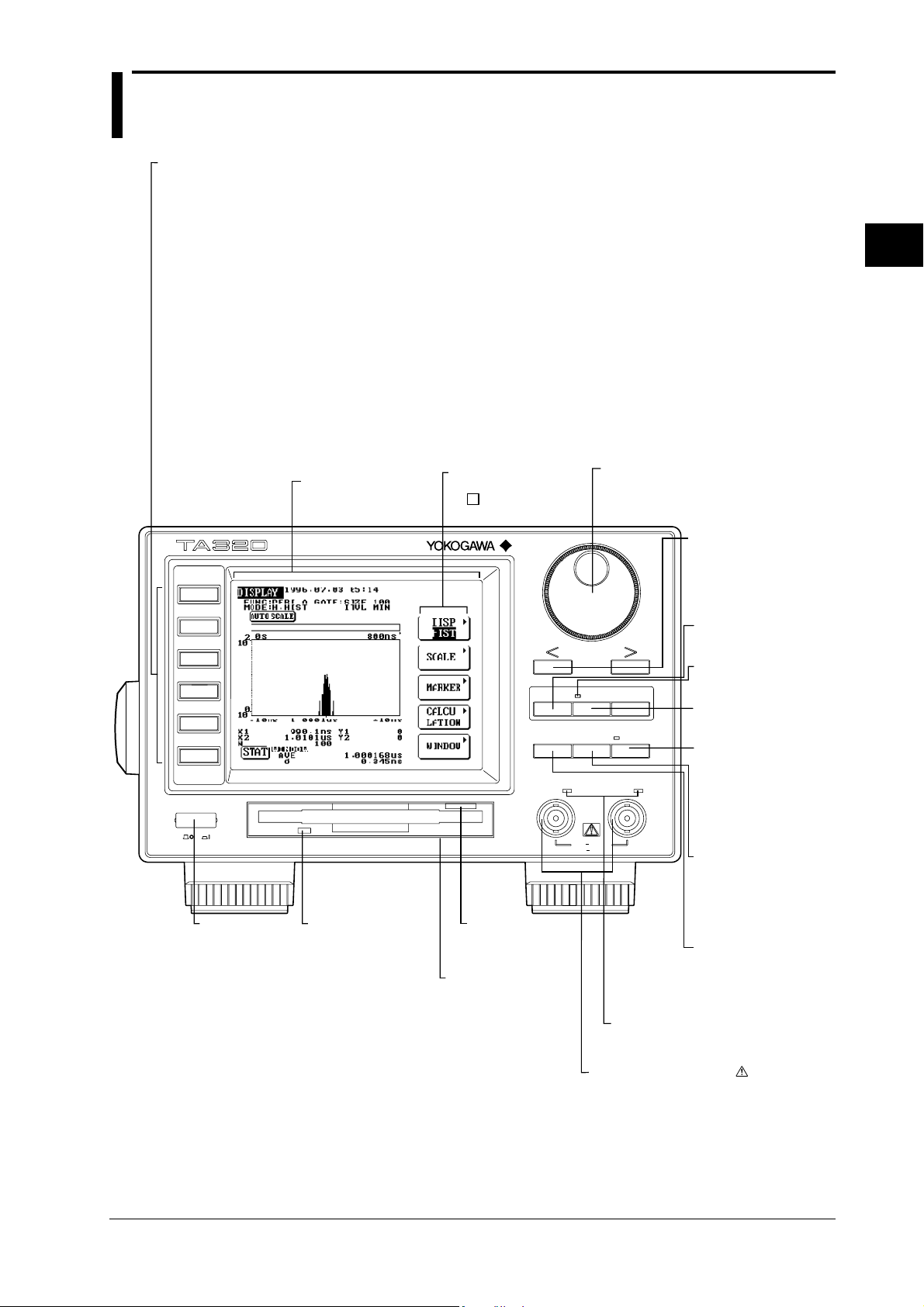

2.1 Front Panel.......................................................................................................................................................... 2-1

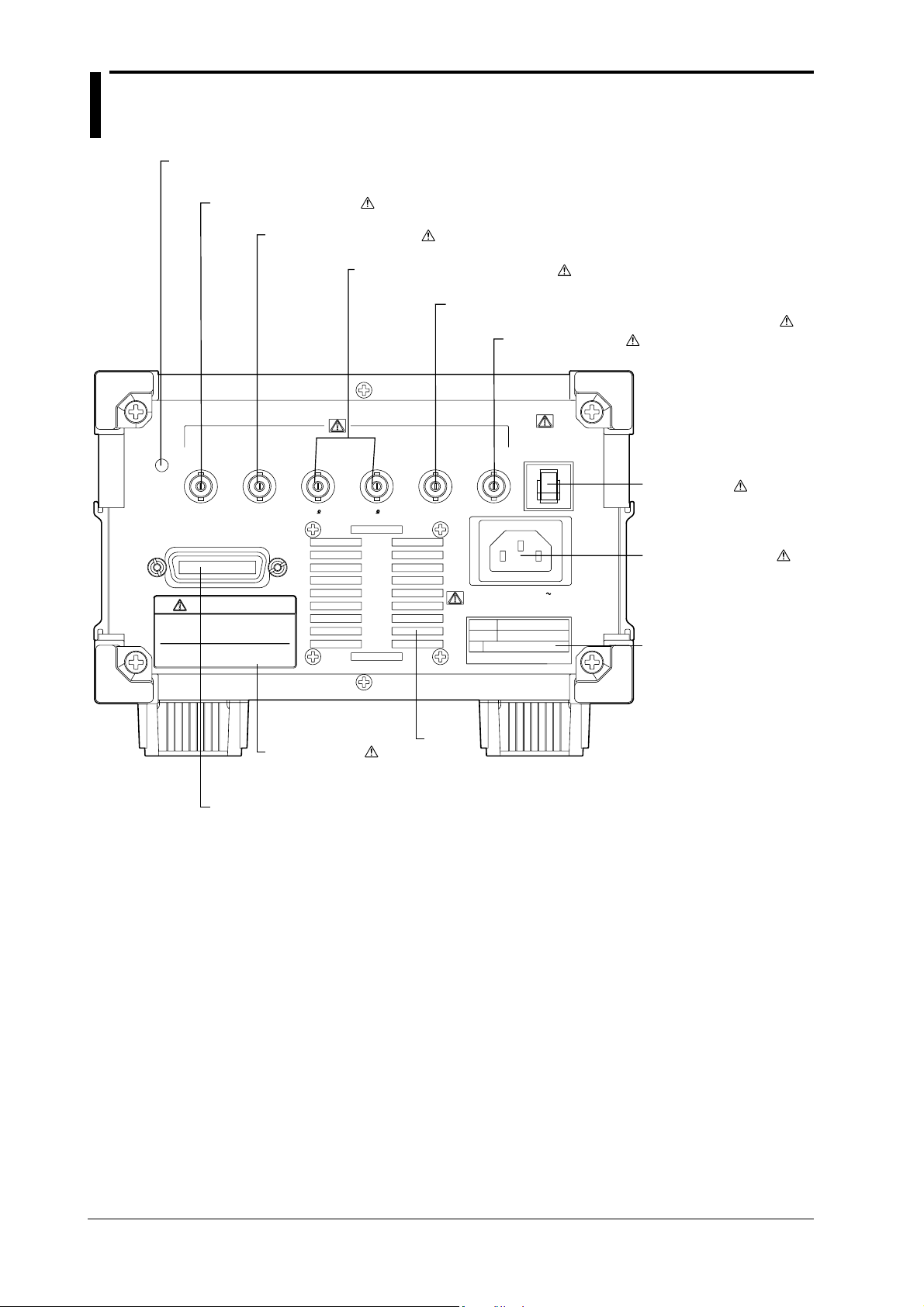

2.2 Rear Panel ........................................................................................................................................................... 2-2

Chapter 3 Before Starting Measurement

3.1 Usage Precautions .............................................................................................................................................. 3-1

3.2 Installing the Instrument .....................................................................................................................................3-2

3.3 Connecting the Power Cord................................................................................................................................ 3-4

3.4 Turning the Power Switch ON/OFF ...................................................................................................................3-5

3.5 Connecting the Cables/Probes ............................................................................................................................3-6

3-6 Compensating a Probe (Carrying Out Phase Correction)................................................................................... 3-7

3.7 Setting the Date and Time .................................................................................................................................. 3-9

10

11

12

Index

IM 704210-01E

7

Page 9

Contents

Chapter 4 Common Operations

4.1 Starting/Stopping Acquisition of a Measuring Input Signal .............................................................................. 4-1

4.2 Setting Numerical Values ...................................................................................................................................4-2

Chapter 5 Setting the Sampling Mode and Measurement Function (Item)

5.1 Selecting the Sampling Mode .............................................................................................................................5-1

5.2 Setting Period Measurement............................................................................................................................... 5-2

5.3 Setting Time Interval Measurement ................................................................................................................... 5-4

5.4 Setting Pulse Width Measurement .....................................................................................................................5-6

5.5 Setting Phase Difference Measurement.............................................................................................................. 5-8

5.6 Setting Duty Ratio Measurement .....................................................................................................................5-10

Chapter 6 Setting the Acquisition Conditions for Input Signal to be Measured

6.1 Setting the Input Coupling, Input Impedance, Trigger Mode and Trigger Level .............................................. 6-1

6.2 Setting the Gate Type, Sample Size and Sampling Interval ...............................................................................6-3

6.3 Setting the Arming Source, Slope and Delay Types .......................................................................................... 6-6

6.4 Setting the Inhibit Function ................................................................................................................................6-9

Chapter 7 Displaying the Measured/Computed Data

7.1 Setting the Histogram Display Function and Reading the Data (Readout) ........................................................7-1

7.2 Using the Multi-window Function ..................................................................................................................... 7-5

7.3 Using the Panorama Display Function ...............................................................................................................7-9

7.4 Carrying out Histogram Data Addition ............................................................................................................ 7-11

7.5 Setting the Time Variation Display Function and Reading the Data (Readout) .............................................. 7-13

7.6 Selecting the List Display Function and Displaying the Data ..........................................................................7-17

7.7 Selecting the Statistics Display Function and Reading the Statistic Data ........................................................7-19

7.8 Selecting the Histogram Display Function and Displaying the Statistic Data ................................................. 7-21

Chapter 8 Storing and Recalling the Set-up Information from the Internal Memory

8.1 Storing the Set-up Information in the Internal Memory .....................................................................................8-1

8.2 Recalling the Set-up Information from the Internal Memory ............................................................................ 8-2

Chapter 9 Saving and Loading the Data from a Floppy Disk

9.1 Points to Note during Use of the Floppy Disk Drive .........................................................................................9-1

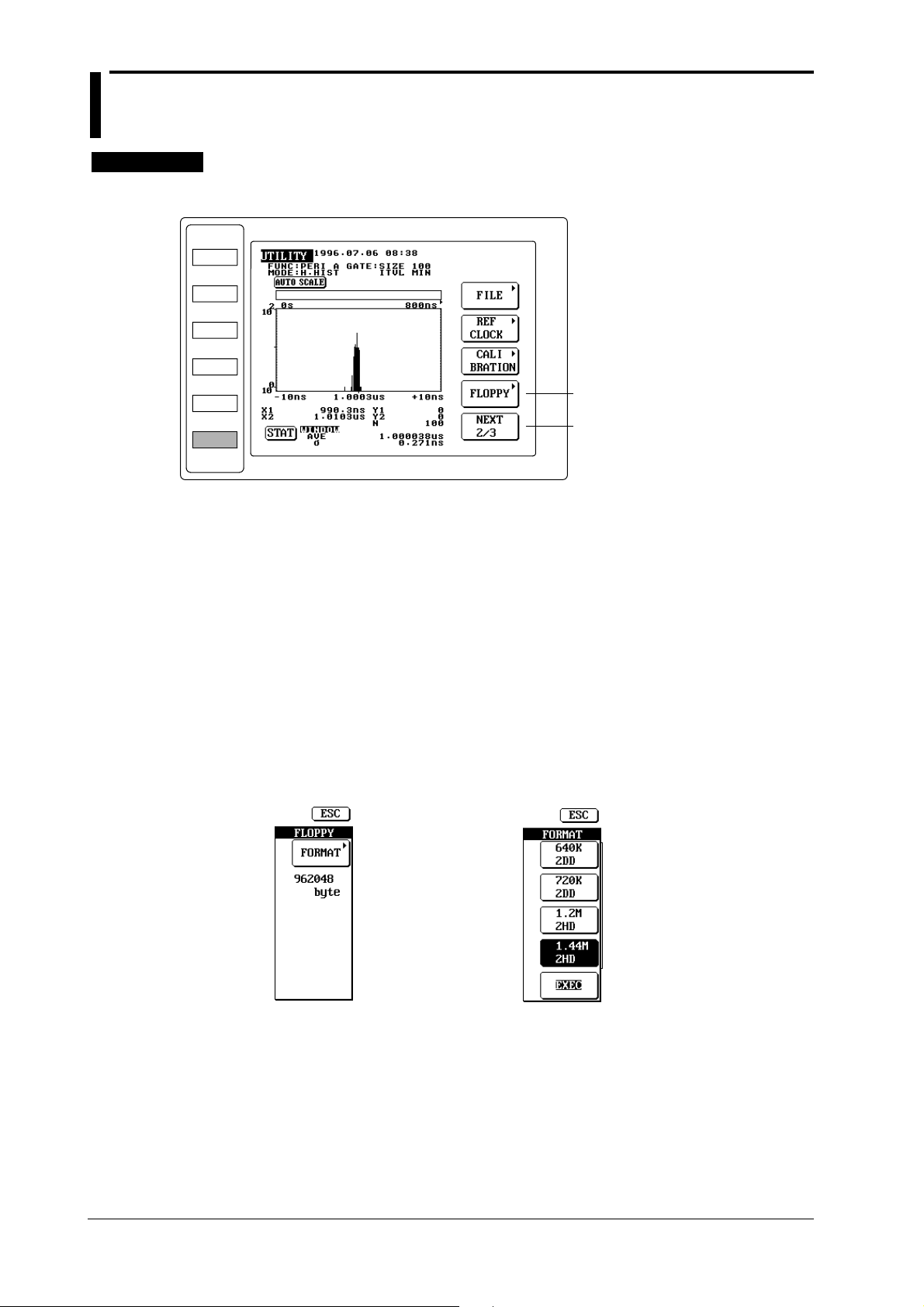

9.2 Formatting a Floppy Disk ...................................................................................................................................9-2

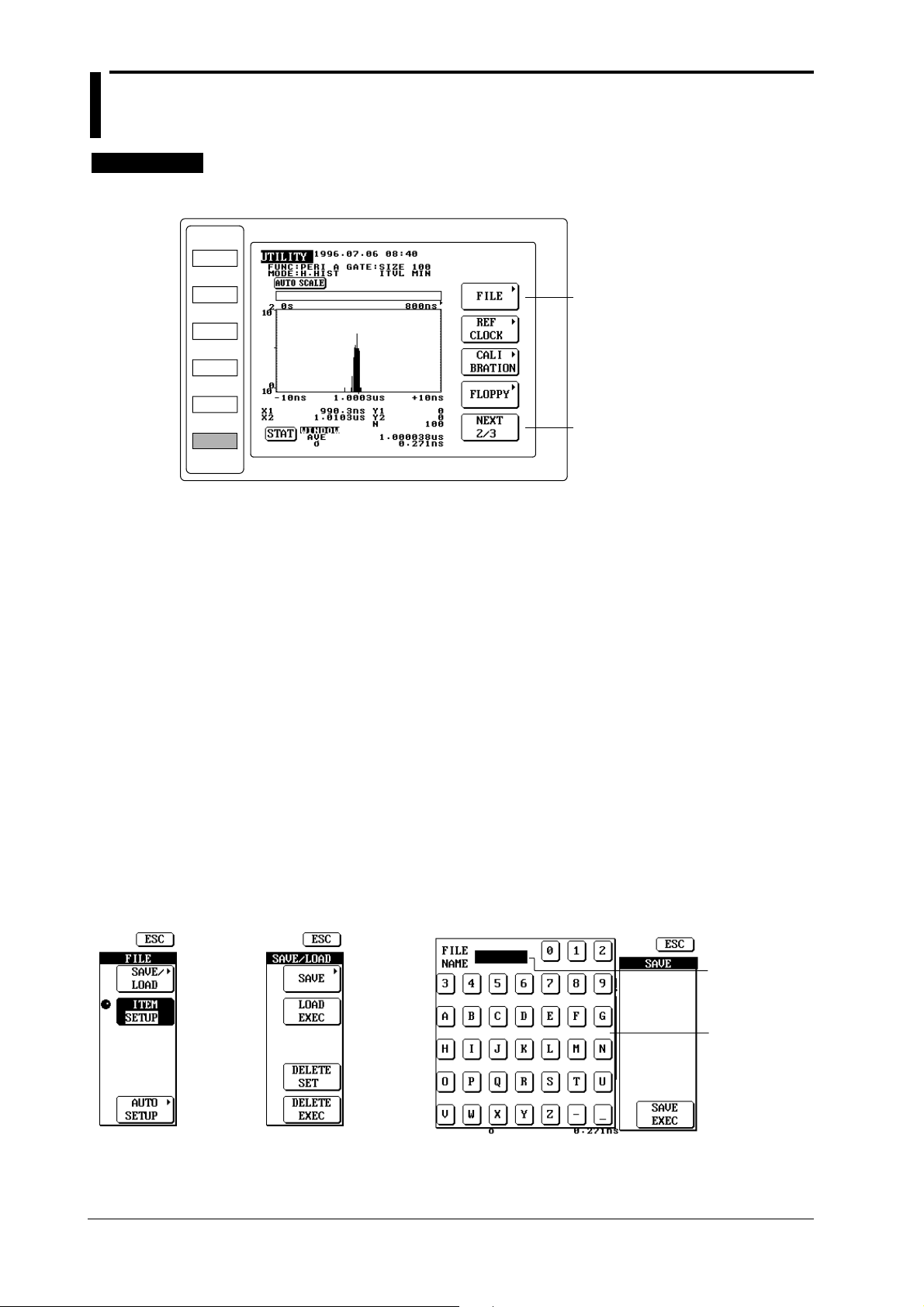

9.3 Saving, Loading and Auto Loading the Set-up Information .............................................................................. 9-4

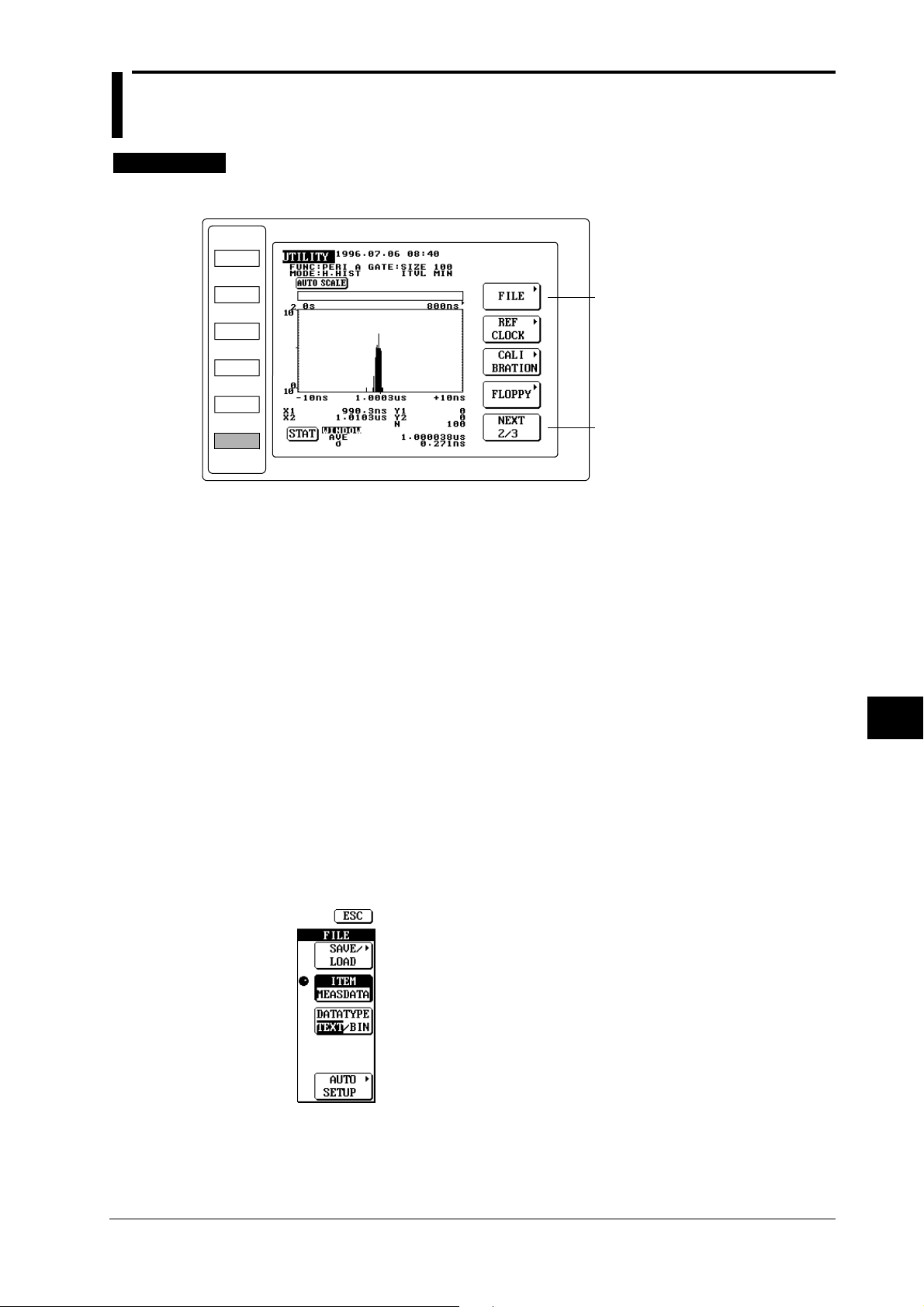

9.4 Saving and Loading the Measured and Computed Data .................................................................................... 9-7

9.5 Saving the Screen Image Data ..........................................................................................................................9-10

9.6 Auto Saving the Screen Image Data .................................................................................................................9-12

9.7 Deleting Saved Data .........................................................................................................................................9-13

Chapter 10 Using Other Functions

10.1 Outputting Data to a Plotter .............................................................................................................................. 10-1

10.2 Inputting and Outputting the Reference Signal ................................................................................................10-5

10.3 Outputting the Monitor Signal.......................................................................................................................... 10-7

10.4 Initializing the Set-up Information ...................................................................................................................10-8

10.5 Calibrating the Instrument ..............................................................................................................................10-10

10.6 Setting the Screen Contrast ............................................................................................................................ 10-11

10.7 Turning the Touch-key Sound ON/OFF......................................................................................................... 10-12

8

IM 704210-01E

Page 10

Chapter 11 Troubleshooting and Maintenance

11.1 Troubleshooting................................................................................................................................................11-1

11.2 Messages...........................................................................................................................................................11-2

11.3 Using the Error Logging Function ................................................................................................................... 11-4

11.4 Executing the Self-test ...................................................................................................................................... 11-5

11.5 Adjusting the Time Base .................................................................................................................................. 11-8

11.6 Carrying out the Performance Test................................................................................................................... 11-9

11.7 Circuit Breaker ............................................................................................................................................... 11-19

Chapter 12 Specifications

12.1 Measuring Inputs and Trigger .......................................................................................................................... 12-1

12.2 Measurement Functions (Measurement Items) ................................................................................................ 12-2

12.3 Gate, Arming, Inhibit ....................................................................................................................................... 12-4

12.4 Display .............................................................................................................................................................. 12-5

12.5 Inputs/Outputs (Rear Panel) ............................................................................................................................. 12-7

12.6 GP-IB Interface ................................................................................................................................................ 12-8

12.7 Time Base .........................................................................................................................................................12-8

12.8 Internal Memory Function ................................................................................................................................ 12-8

12.9 Built-in Floppy Disk Drive............................................................................................................................... 12-8

12.10 General Specifications ......................................................................................................................................12-9

12.11 External Dimensions ...................................................................................................................................... 12-10

Index

Contents

1

2

3

4

5

6

7

8

9

10

11

12

Index

IM 704210-01E

9

Page 11

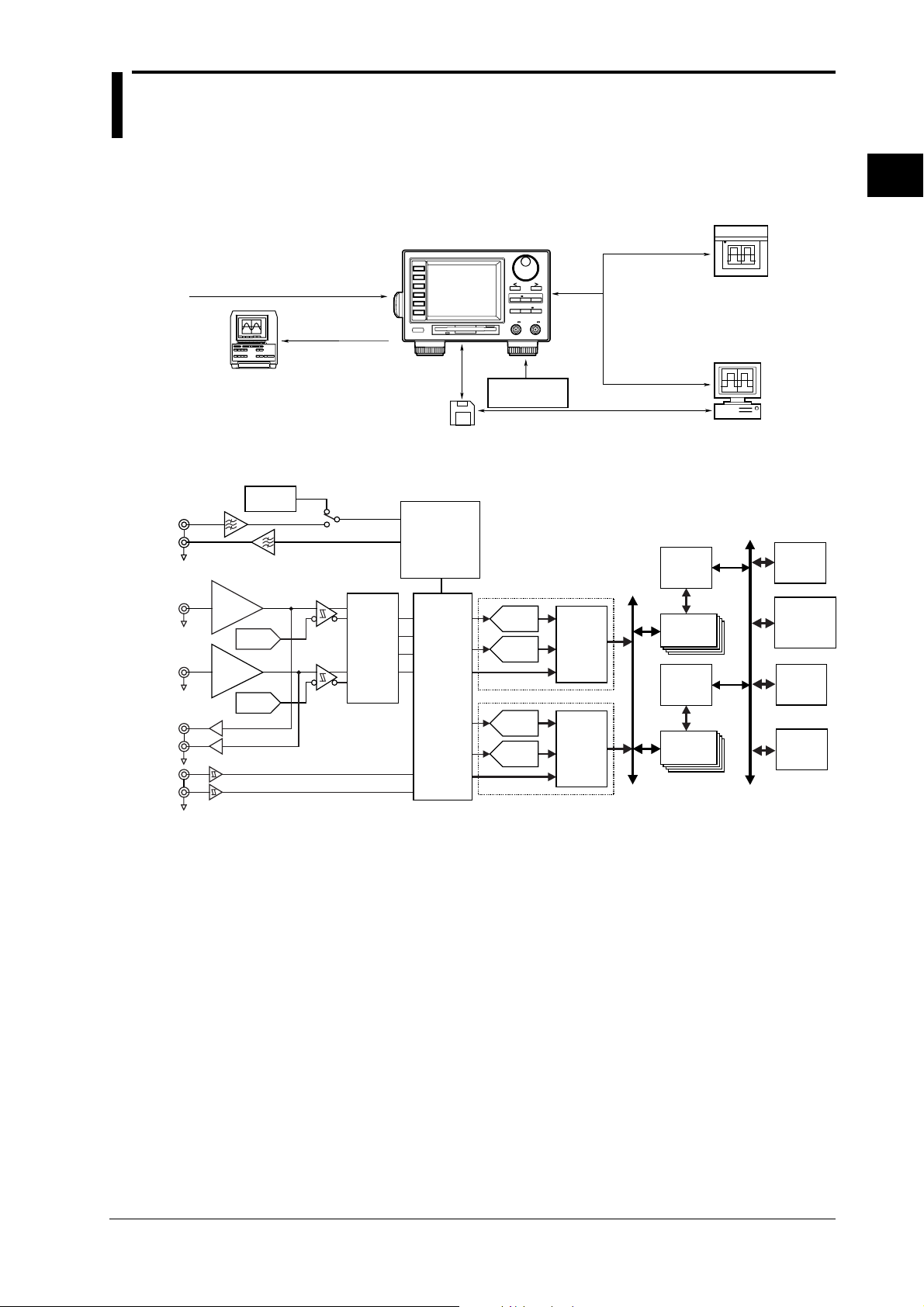

1.1 System Configuration and Block Diagram

System Configuration

HP-GL compatible plotter

• Hard copy

• Set-up information list

Inhibit input

External arming input (the terminal

is shared with external gate input)

Reference input

Block Diagram

IN

Ach IN

Bch IN

10MHz

10MHz

Amplifier

Amplifier

Reference

Reference

OUT

Ach Monitor

OUT

Bch Monitor

OUT

EXT ARM IN

INHIBIT IN

10MHz-TCXO

Reference

Clock

Input

Trigger

DAC

Input

Trigger

DAC

External Arming Signal

Inhibit Signal

Monitor output

Reference output

Comparator

Signal

Comparator

Multiplexer

PLL

Clock

Generator

Clock

Measuring

Controller

&

Fractional

Pulse

Generator

Input signal

Object to be

measured

Saving and loading of

data from a floppy disk

Time Measuring Unit 1

T/V

Converter

T/V

Converter

Time Measuring Unit 2

T/V

Converter

T/V

Converter

Counter

Generator

Counter

Generator

Personal computer

• Remote control

• Data collection/analysis

Communication

Contoroller

&

Data

Contoroller

Acquisition BUS

&

Data

Memory

Acquisition

Memory 1

Memory

Acquisition

Memory 2

CPU BUS

CPU

LCD

&

Touch Panel

GP-IB

FDD

1

Functions

IM 704210-01E

Signal Flow

The signal input to the input terminal (Ach IN, Bch IN) is converted into a low-impedance signal

by the input amplifier. It is then sent to the comparator, where it is converted to a binary signal.

At the same time, the signal from the input amplifier is output as a monitor signal via the output

terminal (Ach Monitor OUT, Bch Monitor OUT).

The signal multiplexer selects the binary signal according to the selected measurement function

(item), then the signal is input to the measuring controller. The measuring controller controls

measurement and creates fractional pulse according to the external arming signal and inhibit

signal. The width of the fractional pulse is measured, with a resolution of 100 ps, by the T/V

converter of the time measuring unit (1, 2), and then compared with the value on the digital

counter, to provide measured data. With continuous measurement, two time measuring units (1,

2) are activated alternately.

In time stamp mode (see the following page), both measured value and time stamp data (elapsed

time) are acquired in each acquisition memory (1, 2). In hardware histogram mode (see the

following page), the frequency of each measured value (i.e. number of the same measured values)

is acquired in each acquisition memory. The acquired data is then sent via the memory controller

to a CPU, where it is used for statistical computation or displayed on the LCD.

Either the signal from the internal crystal oscillator (compensated against temperature drift) or an

external reference signal (input to the Reference IN terminal) can be used as the reference clock.

In either case, the reference clock is output through the 10-MHz band pass filter to the Reference

OUT terminal.

1-1

Page 12

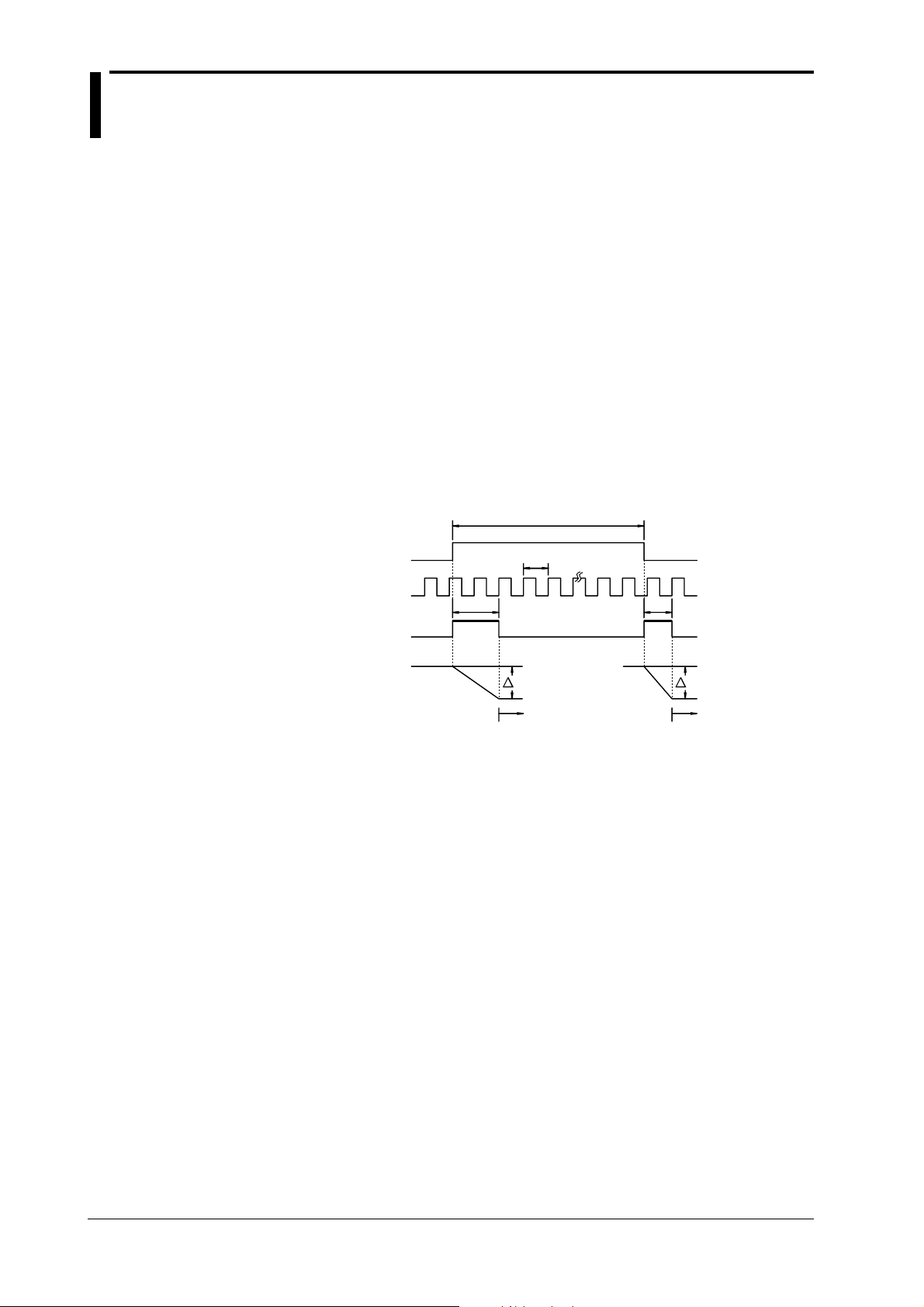

1.2 Measuring Principles and Sampling Mode

Measuring Principles

Time shorter than the period of the reference clock is called fractional time. In general, since the

signal to be measured is not synchronized with the reference clock, fractional time exists at both

beginning and end of measurement. This instrument generates a fractional pulse comprised of the

fractional time and the time equivalent to one cycle of the reference clock.

With the pulse width of the signal to be measured, period of the reference clock and time span of

each fractional pulse assumed to be T, t

multiplication of the period of the reference clock (N • t

and Tb) as shown below.

, Ta and Tb respectively, T can be separated into

0

) and period of each fractional pulse (T

0

a

T = N • t

With this instrument, T

+ (Ta – Tb)

0

and Tb, the time of fractional pulses generated at the beginning and end

a

of measurement, are converted into a voltage value, which is then converted into a digital value

by a 8-bit A/D converter. This enables measurement of the time of fractional pulse, with time

resolution of 100 ps per 1 LSB. T is calculated by substituting the measured time of each

fractional pulse for T

Signal to be measured

Reference clock

Fractional pulse

Time-voltage conversion

and Tb of the above formula.

a

12

T

a

V =k·T

aa

A/D conversion A/D conversion

T =N·t + (T –T )

k: A/D conversion factor

T

t

0

0

Sampling Mode ≡For operating procedure, refer to 5.1≡

Two sampling modes are available: time stamp mode and hardware histogram mode. The

sampling method (acquisition method of measured data) and display format (display method)

differ depending on the sampling mode. For a detailed description of display format, refer to 1.6,

“Displaying the Measured/Computed Data”.

N

T

b

V =k·T

b b

b

a

1-2

Time stamp mode

Measured values and their time stamps (i.e. the time on which measurement is taken) are acquired

into the acquisition memory, and used as time-series data. The maximum sample size (i.e. the

maximum allowable number of data items to be acquired) is 32,000, though it varies depending

on the measurement function (refer to section 1.3). The measured values can be displayed in four

formats (histogram, list (measured values and time stamp), time variation and statistic values.

* Time stamp is expressed as the elapsed time between that when arming is activated (refer to

section 1.5) and when measurement for one sample is completed.

Hardware histogram mode

The measured value and its occurrence frequency are acquired into the acquisition memory. The

maximum sample size (i.e. the maximum allowable number of data items to be acquired) is

99,999,999. The measured values can be displayed in three formats (histogram, list (measured

values and frequency) and statistic values.).

IM 704210-01E

Page 13

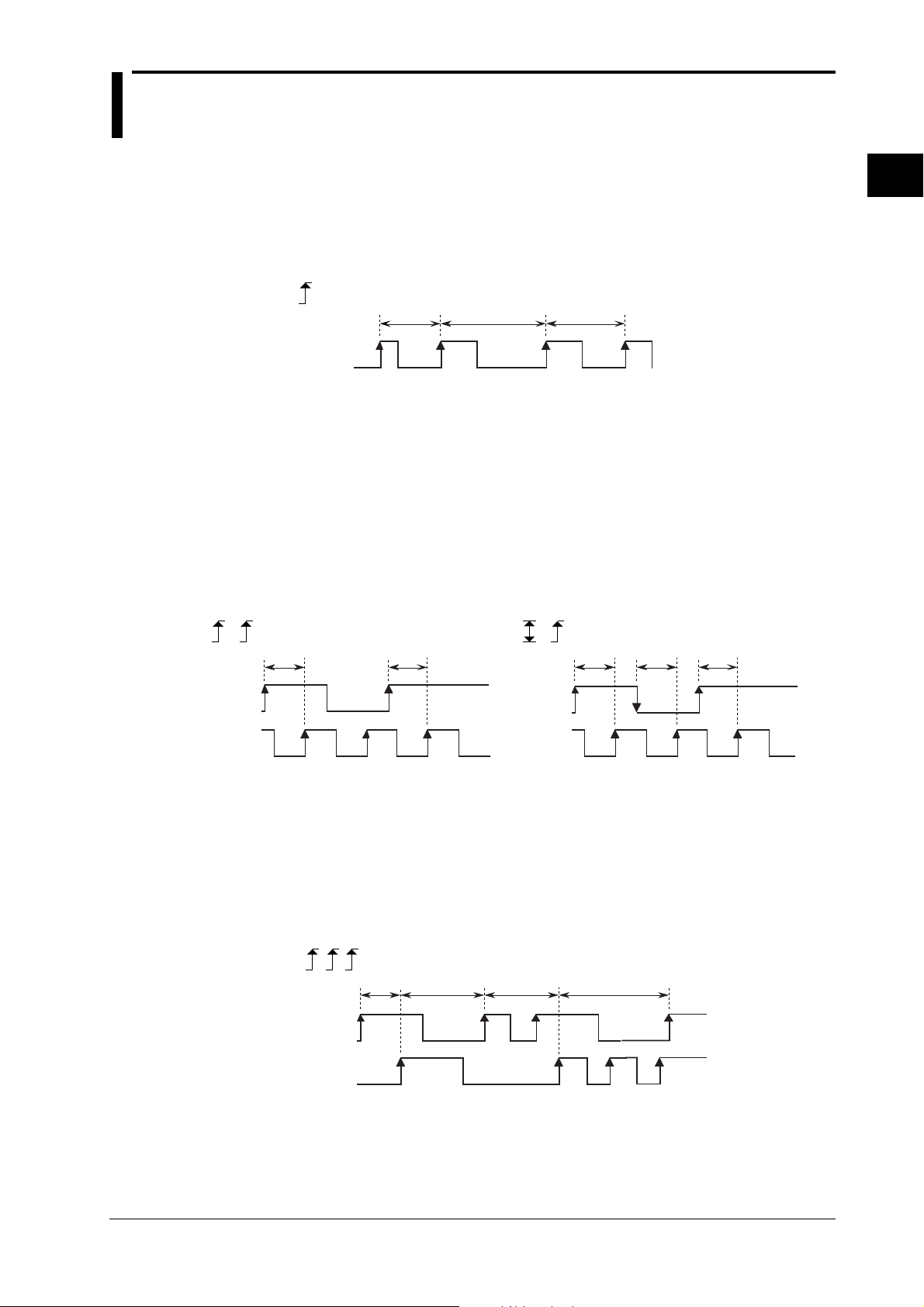

1.3 Measurement Functions (Measurement Items)

Period ≡For operating procedure, refer to 5.2≡

The time from a rising (or falling) edge to the next rising (or falling) edge of the input signal is

measured. Either rising or falling edge can be selected, and channel A or B can be selected for

measurement.

Example (rising slope is selected)

Measured Measured Measured

CH A/

CH B

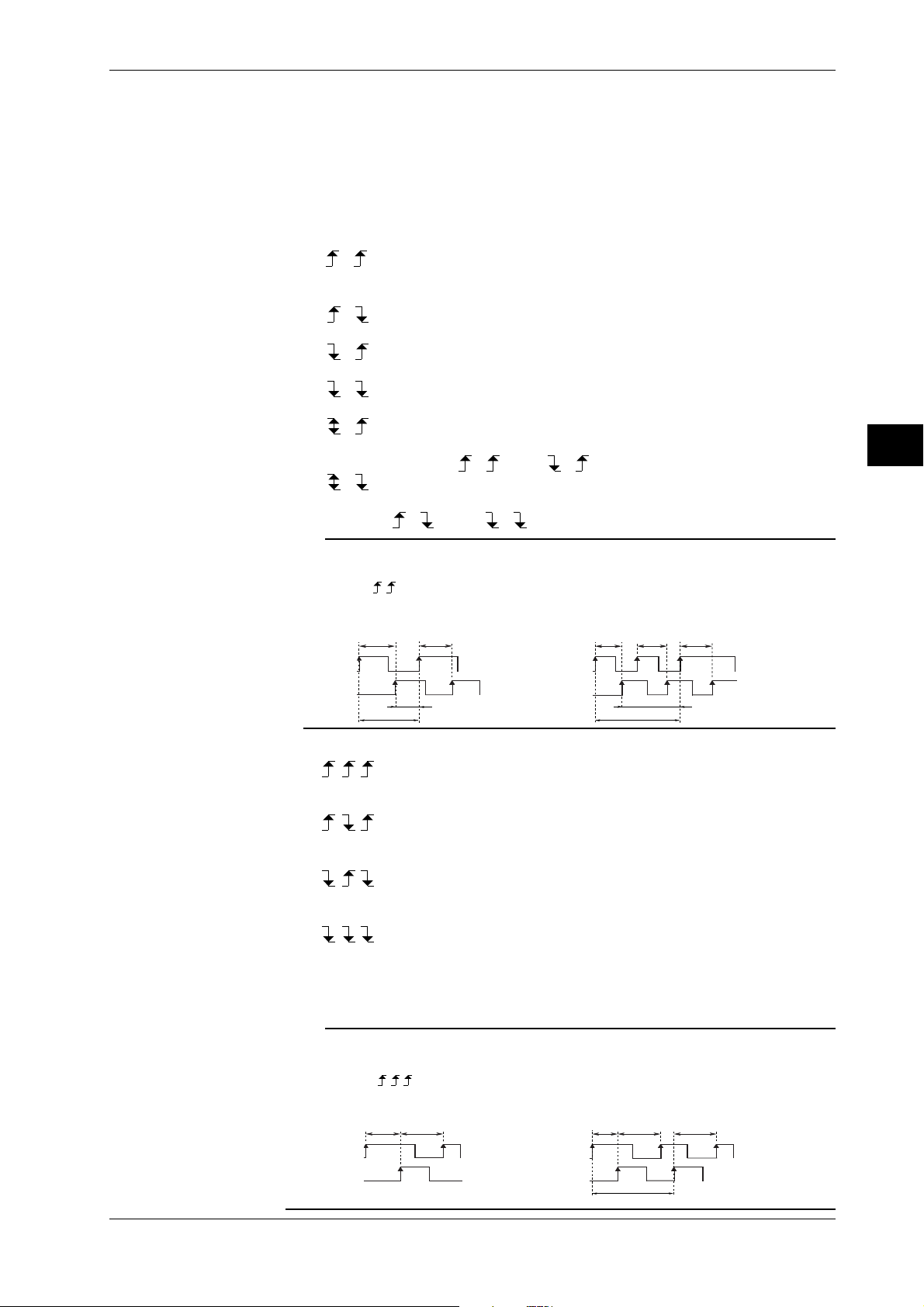

Time Interval ≡For operating procedure, refer to 5.3≡

The time interval between the signal input to channel A and that input to channel B is measured.

The following two types of time interval can be measured.

A-to-B interval

The time interval between an edge of the signal input to channel A and the first edge of the signal

input to channel B is measured. Various combinations of edges can be selected as follows. For a

description of combinations of slopes, refer to 5.3, “Setting Time Interval Measurement”.

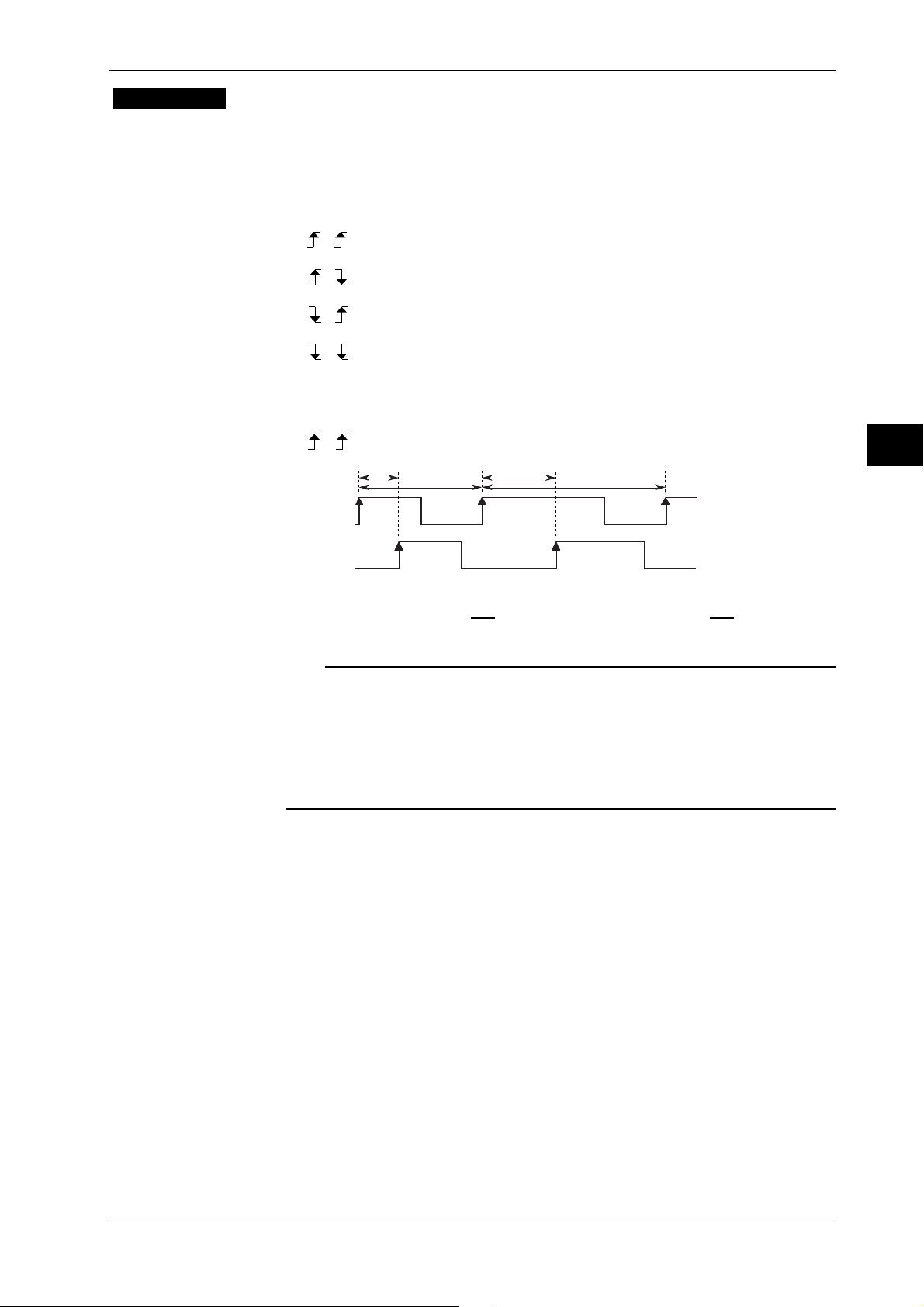

1

Functions

Example (Both channels A and B: rise)

AB

Measured

Measured

CH A

CH B

A-to-B-to-A interval

The time interval between an edge of the signal input to channel A and the first edge of the signal

input to channel B, and the time interval between an edge of the signal input to channel B and the

subsequent edge of the signal input to channel A are measured. For a description of combinations

of slopes, refer to 5.3, “Setting Time Interval Measurement”.

Example (All three edges: rise)

ABA

Measured

CH A

Example (Channel A: both rise and fall, channel B: rise)

A

B

Measured Measured Measured

CH A

CH B

MeasuredMeasured Measured

IM 704210-01E

CH B

1-3

Page 14

1.3 Measurement Functions (Measurement Items)

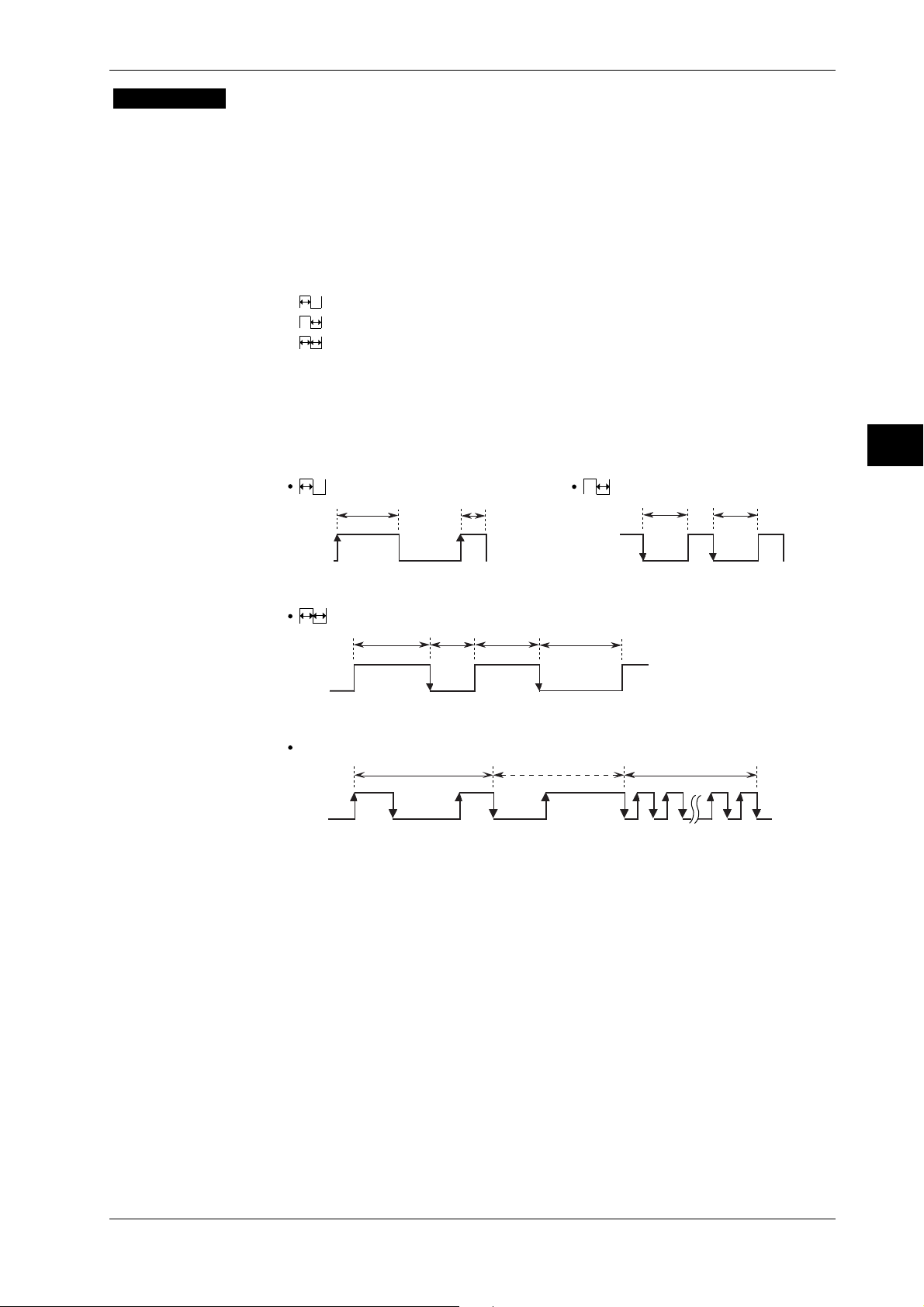

Pulse Width ≡For operating procedure, refer to 5.4≡

The time between a rising (or falling) edge and the next falling (or rising) edge of the input signal

is measured. For selection of combinations of polarity, refer to 5.4, “Setting Pulse Width

Measurement”. A special combination of polarity, in which a time constant T (see section 1.4) is

specified to carry out measurement only when the period of the pulse is within the specified time

range (22T±0.5T). This combination is called “22T”. For measurement of pulse width, channel

A or B can be selected.

Example (positive: rising to falling)

Measured Measured Measured Measured

CH A/

CH B

Example (22T)

22T

Measured when

within 22T ±0.5T

CH A/

CH B

Not measured when

not within 22T ±0.5T

Measured when

within 22T ±0.5T

Phase Difference ≡For operating procedure, refer to 5.5≡

The time between an edge of the signal input to channel A and an edge of the signal input to

channel B is measured, and the measured value is then expressed in phase difference (deg) in

relation to the period of the signal input to channel A which is set as 360 degrees. This

measurement is available only when time stamp mode is selected as the sampling mode. For a

description of combinations of slopes, refer to 5.5, “Setting Phase Difference Measurement”.

Example (Both channels A and B: rise)

AB

Duty Ratio

Measuredtp1

Measuredt1 Measuredt2

Measuredt

CH A

CH B

1[deg]=

≡≡

≡For operating procedure, refer to 5.6

≡≡

The ratio of the time between a rising (or falling) edge and the next falling (or rising) edge in

relation to one period of the input signal is measured. This measurement is available only when

time stamp mode is selected as the sampling mode. For measurement of duty ratio, channel A or

B can be selected.

t

t

p2

p1

× 360 2[deg]=

1

Phase difference

t

p2

× 360Phase difference

t

2

≡≡

≡

≡≡

1-4

Example (rising to falling)

CH A/

CH B

Measuredt

Duty ratio

p1

Measuredt

1

[

%

]=

t

p1

t

1

Measuredt

1

× 100

p2

Duty ratio

Measuredt

2[ ]=

%

2

t

p2

t

× 100

2

IM 704210-01E

Page 15

1.4 Computation

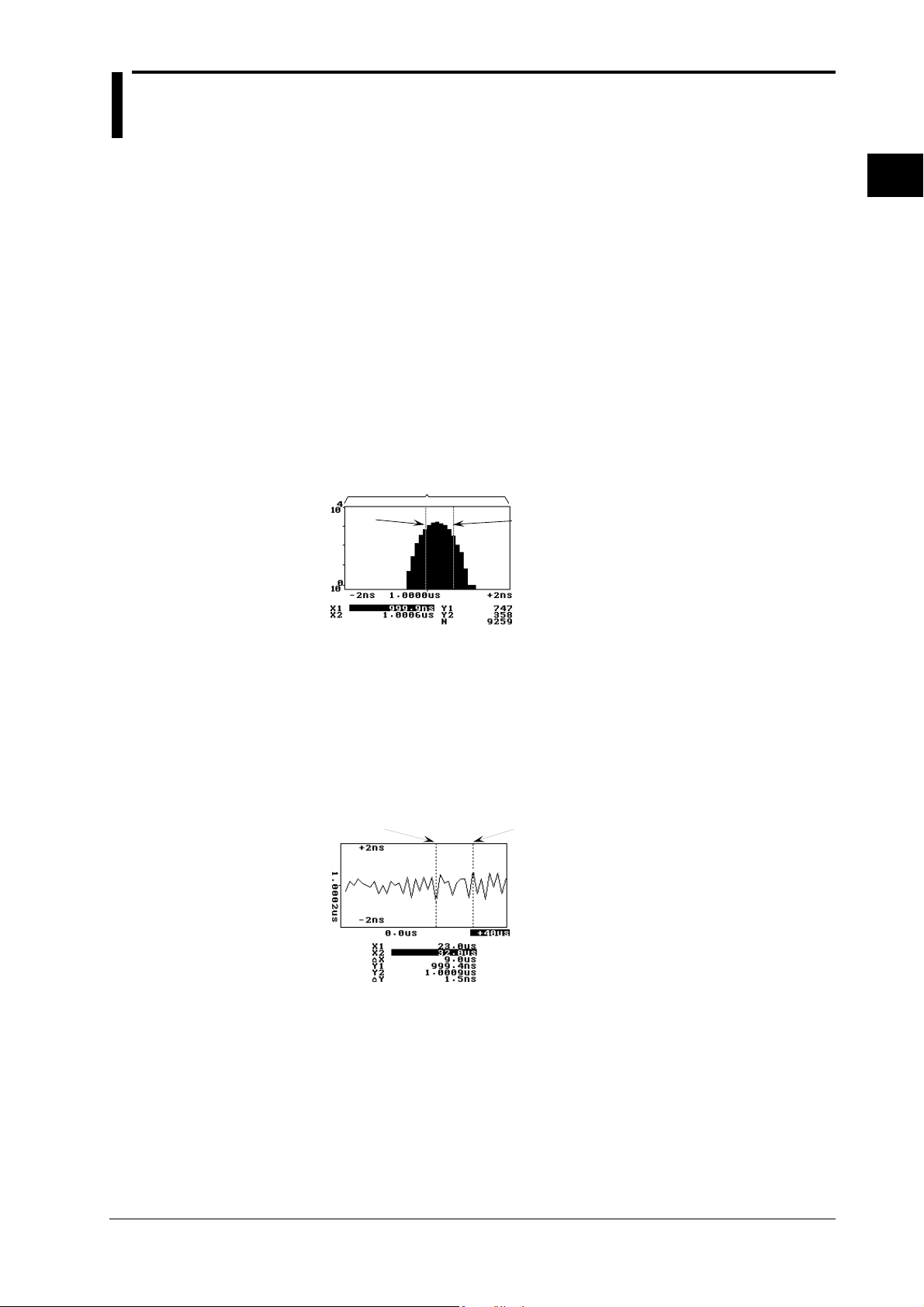

Readout Function ≡For operating procedure, refer to 7.1 and 7.5≡

If histogram or time variation display format is selected (see 1.6), two markers (X1 and X2) will

be displayed. This enables reading out of the coordinates of each cross-point of the markers and

the histogram (or time variation). In addition, selecting a calculation area (see the following

page) enables statistical computation for the area enclosed by the markers.

Histogram display format

The meaning of each value displayed at the bottom of the screen is given below.

X1: X-axis coordinate of X1 marker (measured value)

Y1: Y-axis coordinate of X1 marker (frequency of X1)

X2: X-axis coordinate of X2 marker (measured value)

Y2: Y-axis coordinate of X2 marker (frequency of X2)

N:

• WINDOW selected as calculation area: Total number of samples within the window

• MARKER selected as calculation area: Number of samples present within the area enclosed

by X1 and X2 markers

Window

X1 marker

X2 Marker

1

Functions

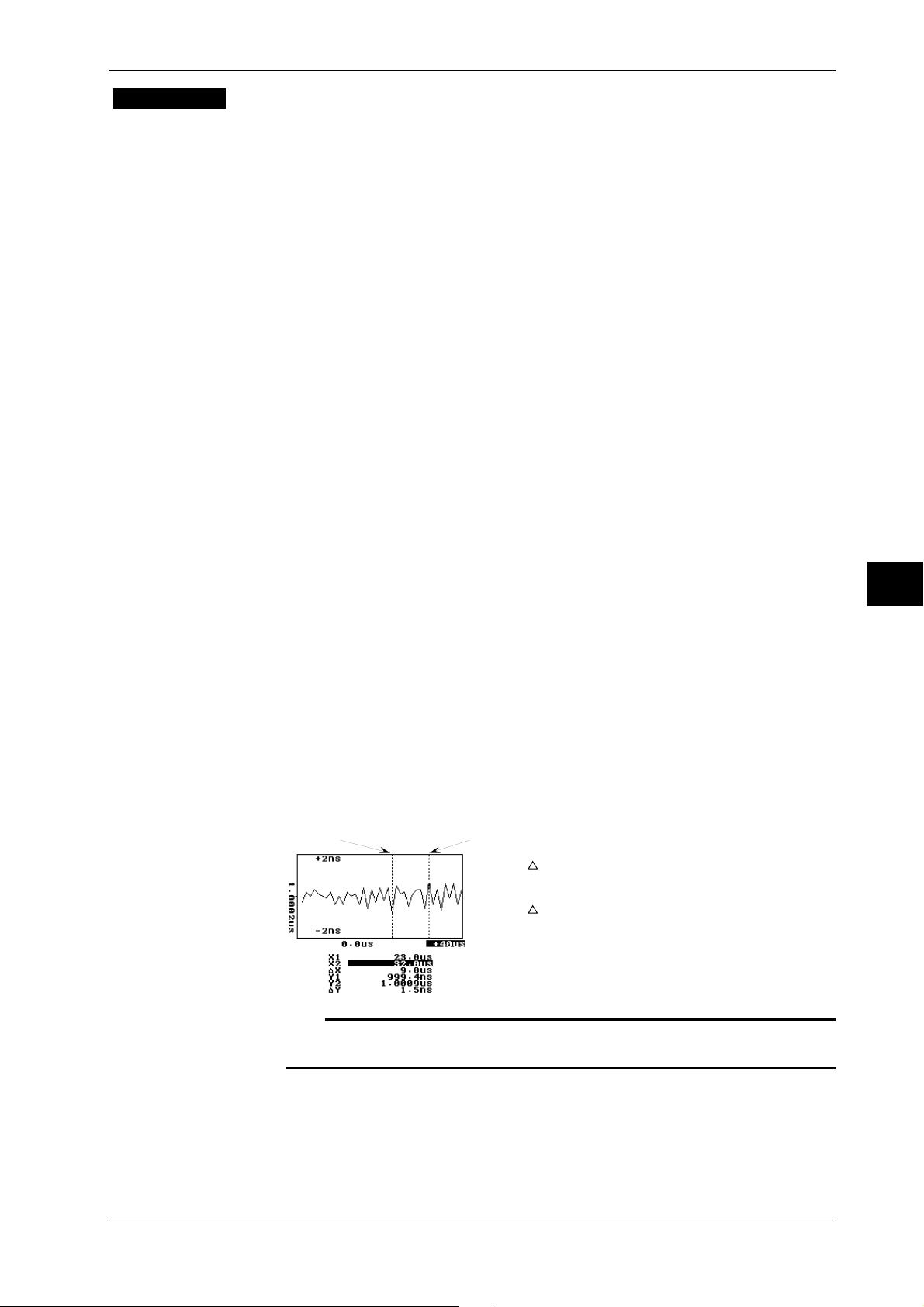

Time variation display format

The meaning of each value displayed at the bottom of the screen is given below.

X1: X-axis coordinate of X1 marker (time stamp)

X2: X-axis coordinate of X2 marker (time stamp)

∆X: X2 - X1

Y1: Y-axis coordinate of X1 marker (measured value)

Y2: Y-axis coordinate of X2 marker (measured value)

∆Y: |Y2 – Y1|

X1 marker

X2 Marker

IM 704210-01E

1-5

Page 16

1.4 Computation

Calculation ≡For operating procedure, refer to 7.1 and 7.7≡

The following functions are available to select/set parameters required for statistical computation.

Selecting the calculation area

This function allows the user to select whether to carry out statistical computation using the

measured values present in the entire window of a histogram or using those present within the

area enclosed by the markers.

Setting the constant

This function allows the user to set the constant T to be used for calculation of jitter 1 (σ/T) or

jitter 2 (|AVE - X

| / T) or the one to be used for measurement of pulse width (22T).

center

Statistical Computation Items ≡For operating procedure, refer to 7.1 and 7.8≡

Statistical computation can be carried out using measured values. Computation results can be

displayed if histogram or statistic display format is selected (see 1.6). The entire area of a

histogram (i.e. entire window area) or the area enclosed by the X1 and X2 markers can be used as

the calculation area. The formula may differ depending on the sampling mode.

Time stamp mode

In the following formulas, “n” indicates the number of samples and X

value for each sample.

indicates the measured

i

• Maximum value (MAX)

Indicates the largest value among the measured values.

MAX=[Xi]

max

• Minimum value (MIN)

Indicates the smallest value among the measured values.

MIN= [Xi]

min

• Average value (AVE)

Calculates the average of the measured values.

n

AVE =

• Standard deviation (

1

X

Σ

i

n

i=1

σσ

σ)

σσ

Calculates the standard deviation of the measured values. Standard deviation indicates degree of

dispersion.

n

σ =

1

n

Σ (

i=1

Xi– AVE)

2

• Peak to peak (P-P)

Calculates the difference between the maximum and minimum values.

1-6

P–P= MAX– MIN

•Flutter (

σσ

σ/AVE)

σσ

Calculates flutter. Flutter indicates degree of dispersion in percentage in relation to the average

value.

σ / AVE =

σ

AVE

× 100(%)

IM 704210-01E

Page 17

1.4 Computation

Hardware histogram mode

In the following formulas, “n” indicates the number of bins of a histogram. “Bin” refers to each

bar of the histogram and indicates frequency of the same measured data. X

indicates the class

i

value of each bin. The width of bins varies depending on the specified span of X-axis, and may

be as small as 100 ps. In this case, X

indicates the measured value. For details, refer to 1.6.

i

• Maximum value (MAX)

Indicates the largest value among the class values.

1

Functions

MAX=[Xi]

max

• Minimum value (MIN)

Indicates the smallest value among the class values.

MIN= [Xi]

min

• Average value (AVE)

Calculates the average value of the histogram. Pi indicates relative frequency (*).

n

Σ

i=1

Xi× P

i

AVE =

*Pi can be calculated using the formula “Pi = Ni / N” when the total number of samples to be

used for statistical computation is N and frequency (number of samples) of a bin is N

• Standard deviation (

σσ

σ)

σσ

Calculates the standard deviation of the histogram. Standard deviation indicates degree of

dispersion. P

indicates relative frequency.

i

n

1

=

σ

Xi– AVE)2× P

Σ (

n

i=1

i

• Peak to peak (P-P)

Calculates the difference between the maximum and minimum values.

.

i

P–P= MAX– MIN

• Flutter (

σσ

σ/AVE)

σσ

Calculates flutter of the histogram. Flutter indicates degree of dispersion in percentage in relation

to the average value.

σ

AVE

× 100(%)

• Jitter 1 (

σ / AVE =

σσ

σ/T)

σσ

Constant T is used to calculate jitter 1 of the histogram. Jitter 1 indicates degree of dispersion in

percentage in relation to constant T.

σ /T=

σ

T

× 100(%)

• Jitter 2 (MELE, Maximum Effect Length Error)

Constant T is used to calculate jitter 2 of the histogram. X

X-axis in the window. For details, refer to 1.6. X

means the value around which measured

center

values are distributed. Jitter 2 indicates deviation of the average value from X

indicates the center value of

center

center

in percentage

in relation with constant T.

ME LE=

| AVE–X

T

CENTER

|

× 100(%)

IM 704210-01E

1-7

Page 18

1.5 Setting the Acquisition Conditions for Input Signal to be Measured

Input Coupling ≡For operating procedure, refer to 6.1≡

When you want to measure only (AC components) of the input signal or only the signal

overlapping with the specified DC voltage, measurement can be facilitated if DC components are

removed from the signal. In other cases, you may want to measure all the AC and DC

components of the input signal. In these cases, an appropriate input coupling can be selected.

The following input coupling methods are available.

AC coupling

The signal is input to the amplifier through a capacitor. AC coupling is used to measure only the

amplitude of the input signal by removing DC components or measure only the signal which

overlaps the specified DC voltage.

Input terminal

DC coupling

The signal is input directly to the amplifier. DC coupling is used to measure all the AC and DC

components of the input signal

Input terminal

Input

amplifier

Input

amplifier

Input Impedance ≡For operating procedure, refer to 6.1≡

To reduce attenuation or distortion of the signal to be measured, an input impedance can be

selected from 50 Ω and 1 MΩ to match the output impedance of the source of the signal.

Measurement Block

The instrument carries out a series of processes, from measurement to data processing and

display, repeatedly. The minimum block of each series of processes is called “measurement

block”. When the number of samples (number of data items) for each series is assumed to be N,

each series of processes (measurement, processing and display of N samples) is called “one-block

measurement”.

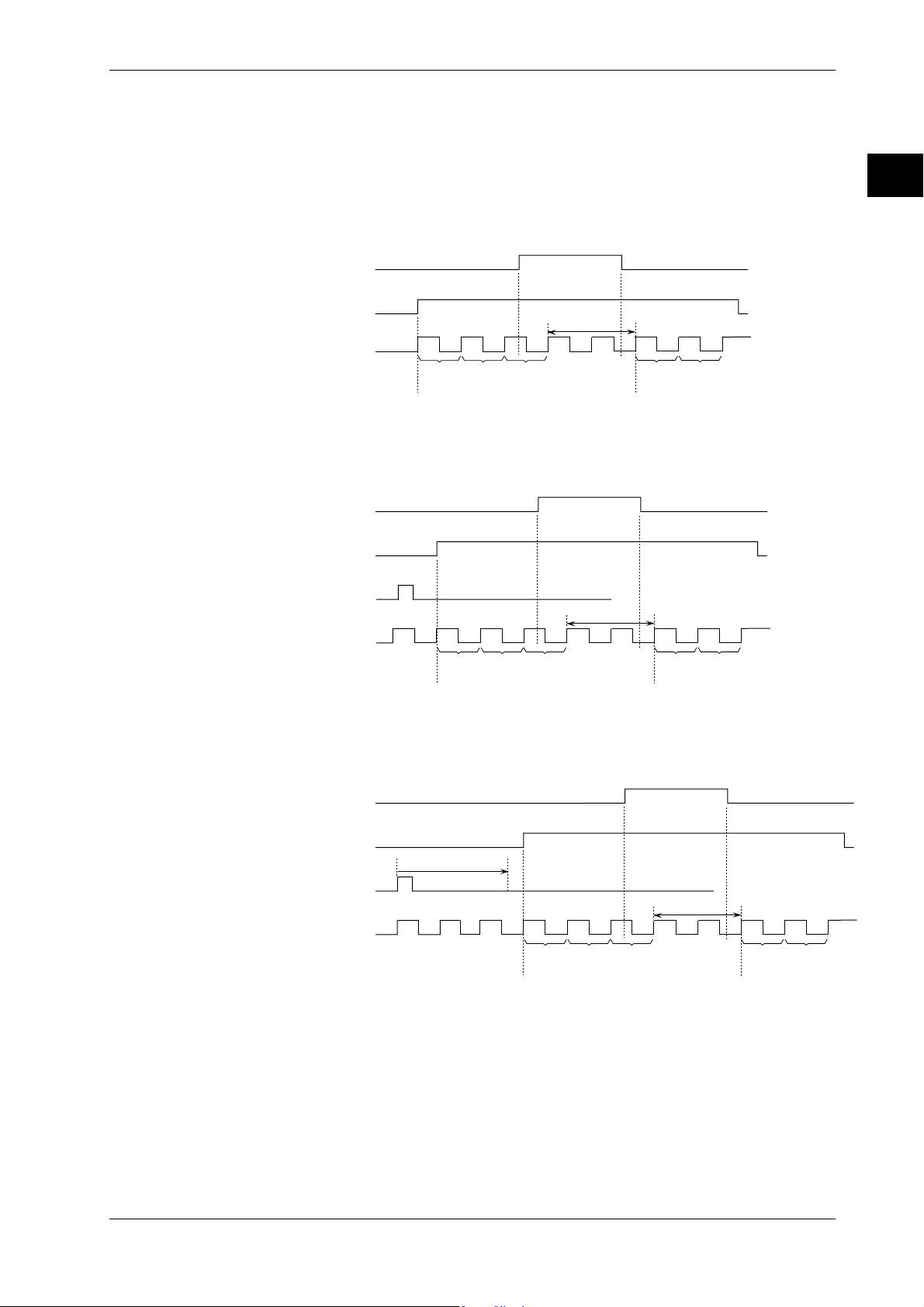

Samples S1, S2, S3 to SN within the measurement block are measured as shown below by

sampling pulses P1, P2, P3 to PN generated at the specified sampling intervals. (For setting the

sampling intervals, refer to page 1-10.)

1-8

Input signal

Sampling

pulse

When the period of the input signal is longer than the sampling interval

1 block 1 block

Measurement block Measurement block

S1 S2 S3 SN

P1 P2 P3 P4 P2 P3 P4

Sampling interval

Data processing,

display

Preparation

for measurement

S1 S2 S3

IM 704210-01E

Page 19

Half of

the amplitude

Half of

the amplitude

Amplitude

(Input signal)

Trigger level is set

Measurement block

A trigger is caused.

Trigger level

1.5 Setting the Acquisition Conditions for Input Signal to be Measured

When the period of the input signal is shorter than the sampling interval

Preparation

for measurement

Input signal

Sampling

pulse

1 block

Measurement block

S1

S2 S3 S4 SN S1 S2 S3 S4

P1 P2 P3 P4 P2 P3 P4

Sampling interval

Data processing,

display

Trigger Mode/Trigger Level ≡For operating procedure, refer to 6.1≡

The instrument allows the user to specify the level at which measurement is to be carried out.

This level is called trigger level.

Single auto trigger

The center level of the amplitude of the input signal is set as the trigger level automatically during

the cycle just before the first measurement block. This trigger level will be used for all the

subsequent measurement blocks.

Repeat auto trigger

The center level of the amplitude of the input signal is set as the trigger level automatically during

the cycle just before each measurement block. Unlike the single auto trigger, the trigger level is

set for each measurement block.

1 block

Measurement block

1

Functions

P1PN

Manual trigger

The level set using the rotary knob or front panel keys is set as the trigger level.

Gate ≡For operating procedure, refer to 6.2≡

The instrument allows the user to specify the size of measurement block. Measurement can be

carried out as many as the specified number of events or during the specified gating time (i.e.

while the gate is open). Three types of gate are available.

Event gate

Each sampling is called an event. For instance, one measurement of the period of the input signal

is counted as one event. Up to 32,000 events (16,000 events for duty ratio/phase difference

measurement) can be set in the case of time stamp mode and up to 99,999,999 events can be set in

the case of hardware histogram mode, within 320 seconds following the arming (see the following

page).

Time gate

Gating time of up to 10 seconds can be set. However, the maximum number of events allowed

for the sampling mode must not be exceeded.

External gate

The external arming input terminal (EXT ARM IN) is used to open/close the gate(See the

IM 704210-01E

following page). The gate can be opened for up to 320 seconds, as long as the maximum number

of events allowed for the sampling mode is not exceeded. In addition, it is possible to select

whether to open the gate using the positive or negative edge of the external arming signal.

1-9

Page 20

1.5 Setting the Acquisition Conditions for Input Signal to be Measured

Sample Size (Number of Events)≡For operating procedure, refer to 6.2≡

The allowable number of measured data items to be acquired into the acquisition memory is

called sample size. This setting is required if event gate is selected. Up to 32,000 events (16,000

events for duty ratio/phase difference measurement) can be set in the case of time stamp mode

and up to 99,999,999 events can be set in the case of hardware histogram mode.

Sampling Interval ≡For operating procedure, refer to 6.2≡

The sampling interval is the interval at which a sample is acquired. A sampling pulse (see

“Measurement Block”) is generated at sampling intervals, and measurement is carried out when

the input signal satisfies the trigger conditions (trigger level, slope etc.) after the sampling pulse.

The sampling interval can be set between approximately 71 ns (reciprocal of the maximum

sampling rate 14 MS/s) and 4 ms in the case of time stamp mode. For hardware histogram mode,

the sampling interval is fixed at approximately 71 ns.

Arming ≡For operating procedure, refer to 6.3≡

Measurement of a measurement block is started when arming is activated. Two arming methods

are available: auto arming in which measurement starts immediately when the START key is

pressed or START communication command is issued, and external arming in which

measurement starts when the external arming signal is input.

Auto arming

Arming is activated automatically after the START key is pressed or START communication

command is issued. For auto arming, the internal arming signal is used.

External arming

Arming is activated when the external arming signal is input to the EXT ARM IN terminal

following start of measurement. It is possible to select whether to activate arming using the rising

or falling edge of the external arming signal.

ArmingStart of measurement

Measurement

block

Arming Delay ≡For operating procedure, refer to 6.3≡

With the external arming method, it is possible to delay measurement until a certain time elapses

or the specified number of events occur following activation of arming. The following two

arming delay methods are available.

Time delay

Measurement starts after the specified time (up to 1 second) has elapsed.

Event delay

Measurement starts after the specified number of events (up to 30,000) have occurred.

1-10

IM 704210-01E

Page 21

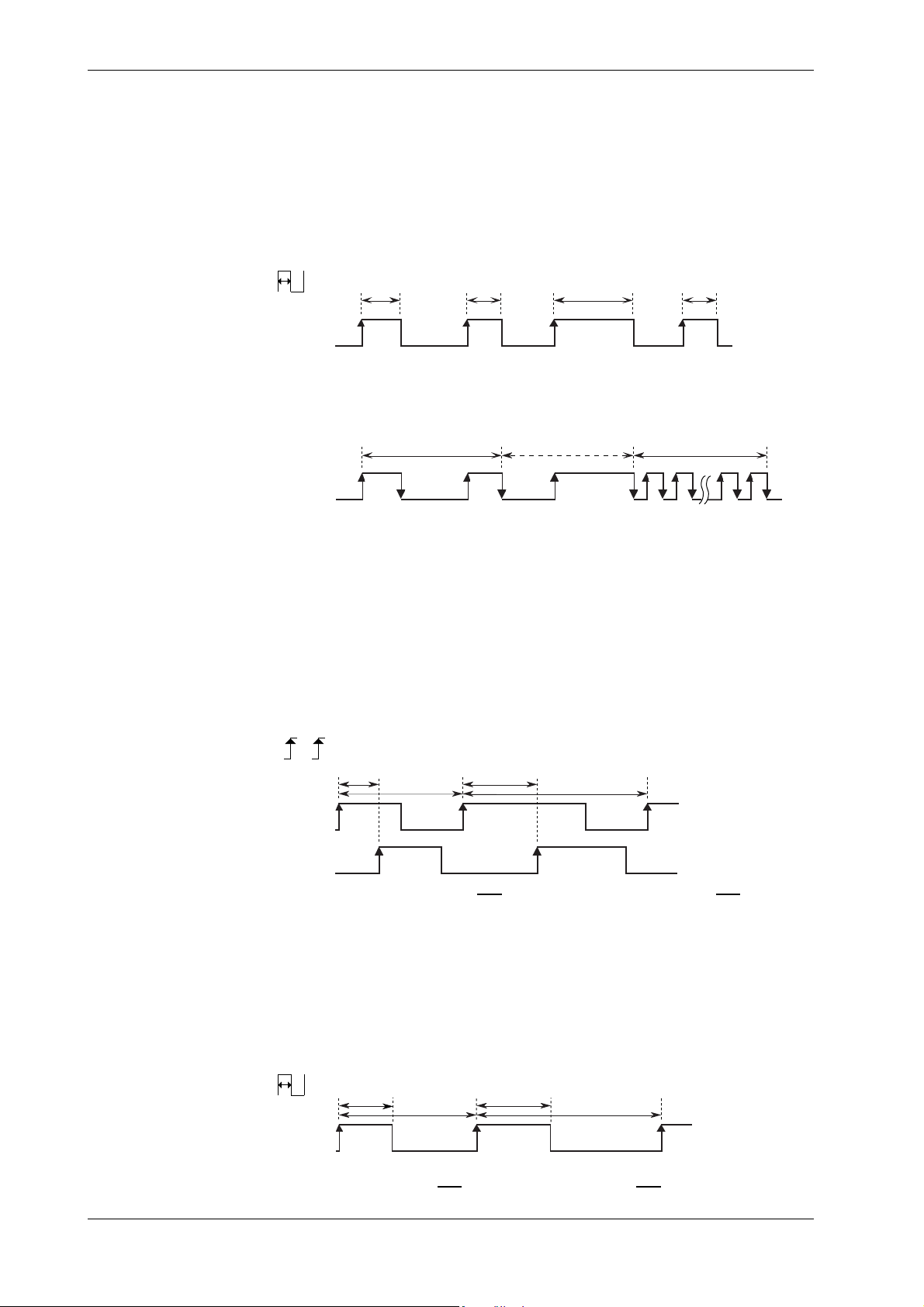

1.5 Setting the Acquisition Conditions for Input Signal to be Measured

Inhibit ≡For operating procedure, refer to 6.4≡

Measurement can be inhibited by inputting the inhibit signal to the INHIBIT IN terminal. This is

also possible while the gate is open or during measurement following the arming delay.

Measurement can be inhibited for up to 320 seconds. In addition, it is possible to select whether

to inhibit measurement using the positive or negative edge of the inhibit signal.

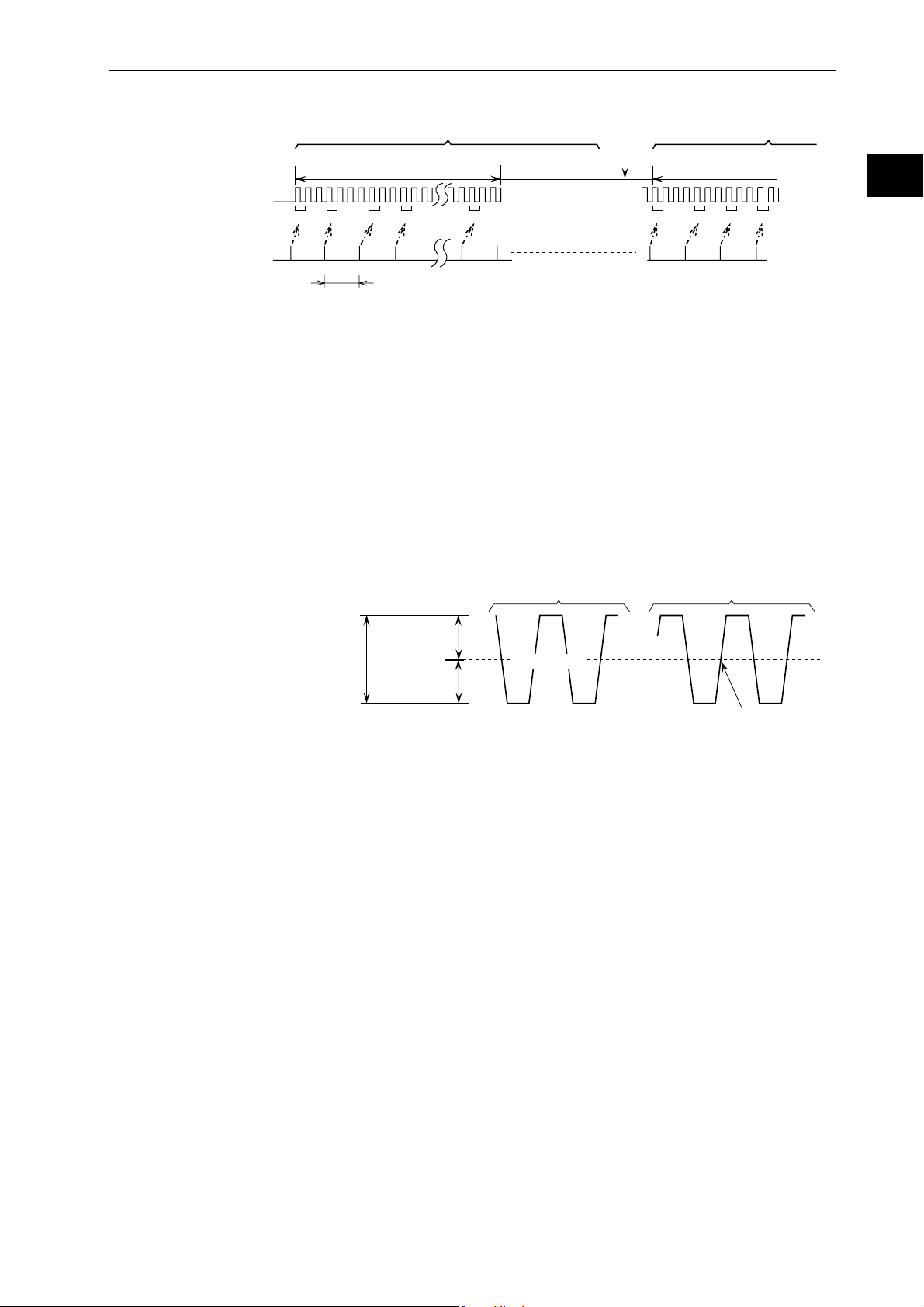

Relation between the inhibit signal and gating

Mesurement is inhibited.

Inhibit signal

1

Functions

Gate

Input signal

Gate is open.

S1 S2 S3

Start of measurement

Not counted as an

event during inhibition

of measurement.

Not measured.

S4 S5

Measurement is resumed.

Relation between the inhibit signal and gating/external arming

Inhibit signal

Gate is open.

Gate

External arming

Input signal

S1 S2 S3

Start of measurement

Mesurement is inhibited.

Not measured.

S4 S5

Measurement is resumed.

Not counted as an

event during inhibition

of measurement.

Relation between the inhibit signal and gating/external arming/arming delay

Mesurement is inhibited.

Inhibit signal

Gate is open.

Gate

Arming delay

External arming

Not measured.

Input signal

S1 S2 S3

Start of measurement

Not counted as an

event during inhibition

of measurement.

S4 S5

Measurement

is resumed.

IM 704210-01E

1-11

Page 22

1.6 Displaying the Measured/Computed Data

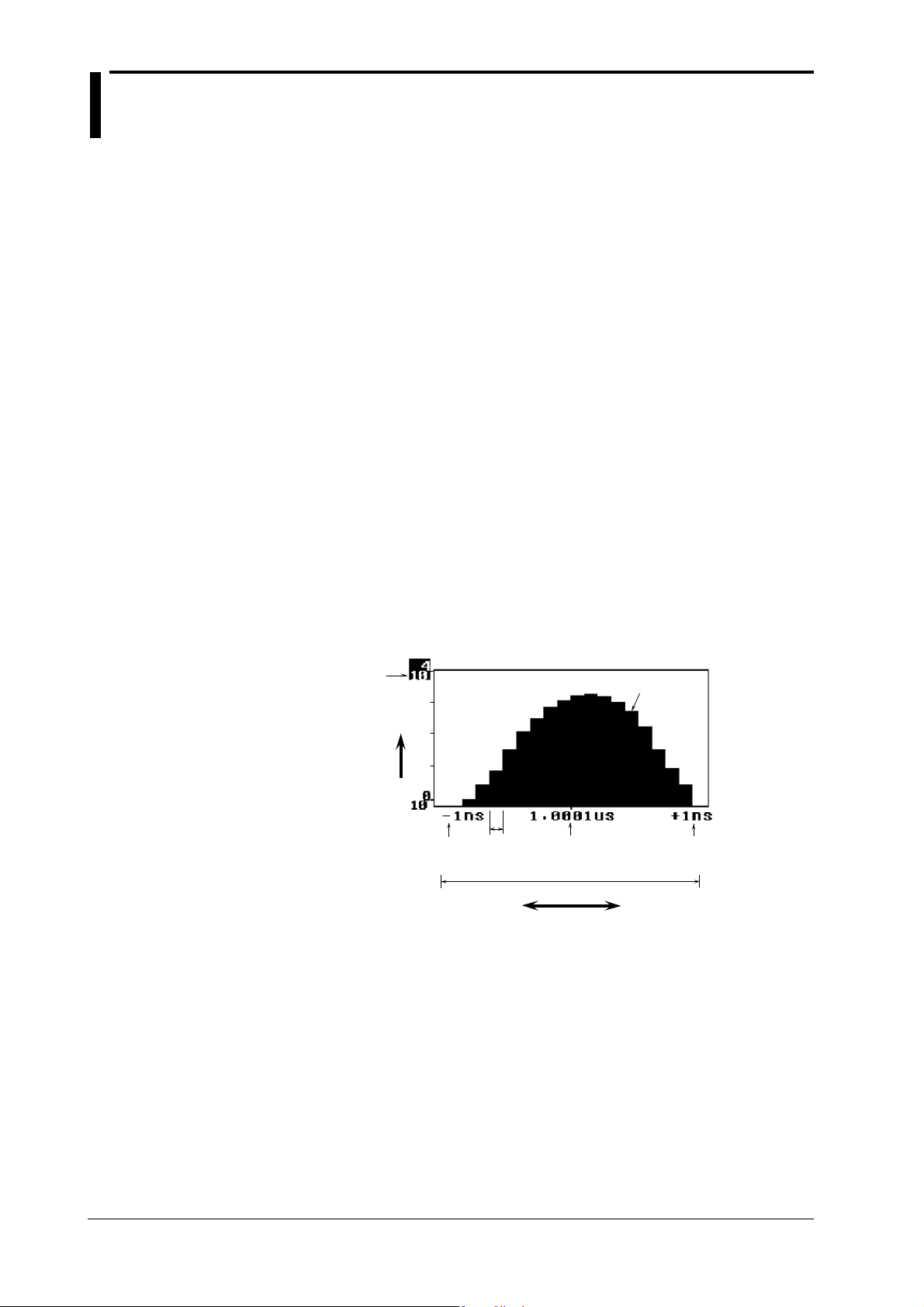

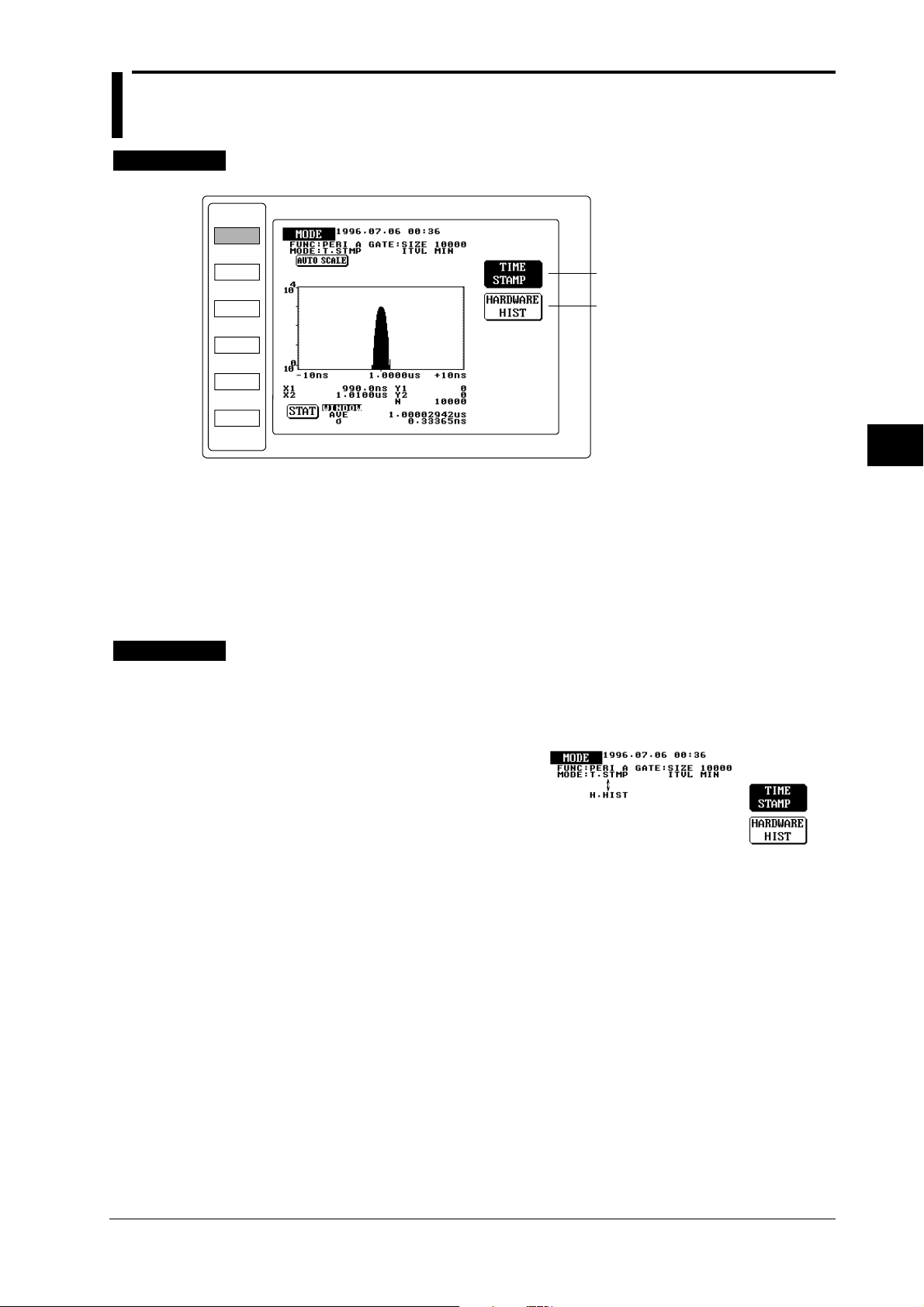

Histogram Display ≡For operating procedure, refer to 7.1≡

A histogram of measured data is displayed for each measurement block to allow the user to

observe data distribution. Although period, phase difference or duty ratio can be set for the

X-axis and frequency for the Y-axis manually, they can be set automatically using the auto

scaling function. The following items can be set manually.

•Center value of X-axis

• Span of X-axis

• Y-axis scale (linear or logarithmic scale)

• Maximum value of Y-axis

• Space between the center values of X-axis (This setting is required when you are using the

multi-window function in hardware histogram mode.) For a description of the multi-window

function, refer to “Multi-window” on this page.

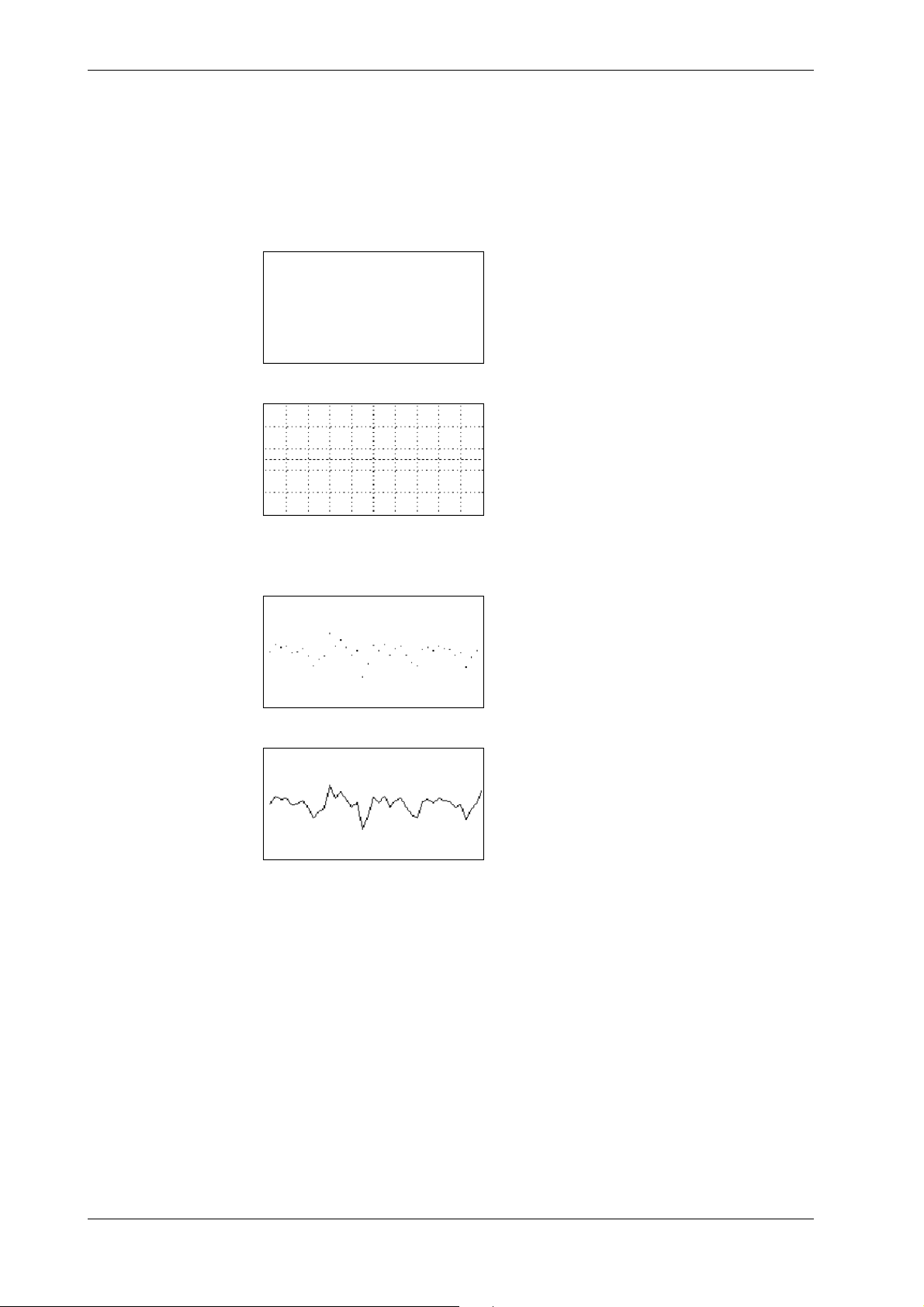

Histogram displayed when time stamp mode is selected or when hardware

histogram mode is selected and only one window is used (i.e. multi-window function

is OFF)

A histogram is displayed according to the settings made for the above items.

If a class has a time span, for instance, if the minimum and maximum values in the class are

505 ns and 515 ns, respectively, 510 ns will be treated as the class value, and samples in this class

are all considered as 510 ns. If the measured values in this class are all the same, they will be

treated as the class value. Each value given along the X-axis as shown below indicates either the

class value or displacement. A histogram is created as the number of samples in each class are

accumulated.

Y-axis scale (logarithmic scale is used in this example)

Maximum value of Y-axis

Y-axis

(frequency)

Class

Left-end value of X-axis

(negative displacement from

the center value of X-axis)

Span of X-axis (2 ns in this example)

Center value of X-axis

(Class value of

the center class)

X-axis (time)

Histogram displayed when hardware histogram mode is selected and more than two

windows are used (i.e. multi-window function is ON)

Refer to “Multi-window” and “Panorama Display” given in this section.

Multi-window ≡For operating procedure, refer to 7.2≡

If data for a measurement block is distributed along more than two center values of X-axis, more

than two histograms will be created. Although all the histograms can be displayed within one

window, it is possible to set more than two windows to allow each histogram to be displayed in its

own window. This function is called the multi-window function. Up to 16 windows can be set.

An example of a window is shown in “Panorama Display” on the following page.

Using the multi-window function in conjunction with the panorama display function enables the

user to recognize easily which histogram is currently displayed.

Each bar is called a bin.

Right-end value of X-axis

(positive displacement from

the center value of X-axis)

1-12

IM 704210-01E

Page 23

1.6 Displaying the Measured/Computed Data

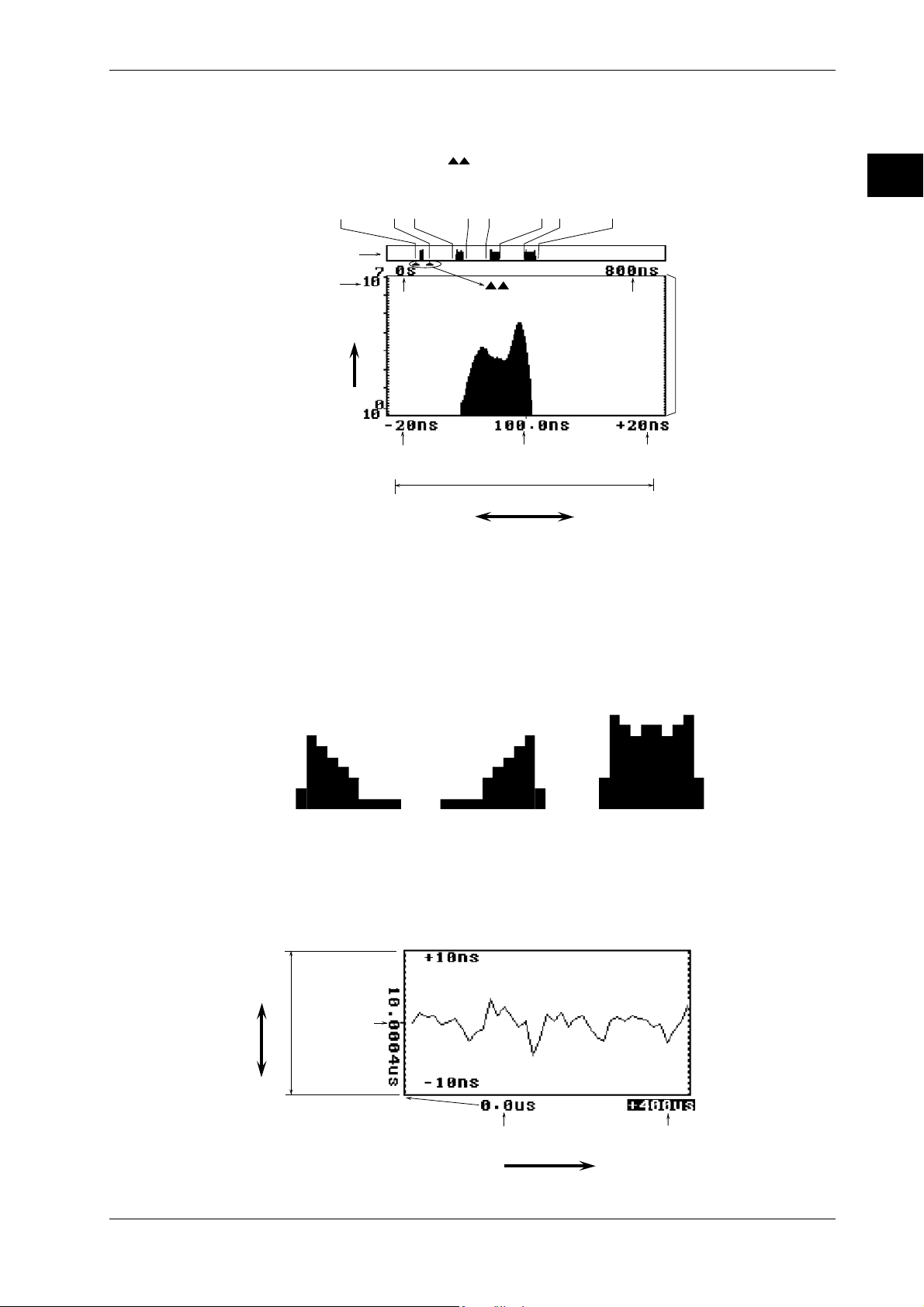

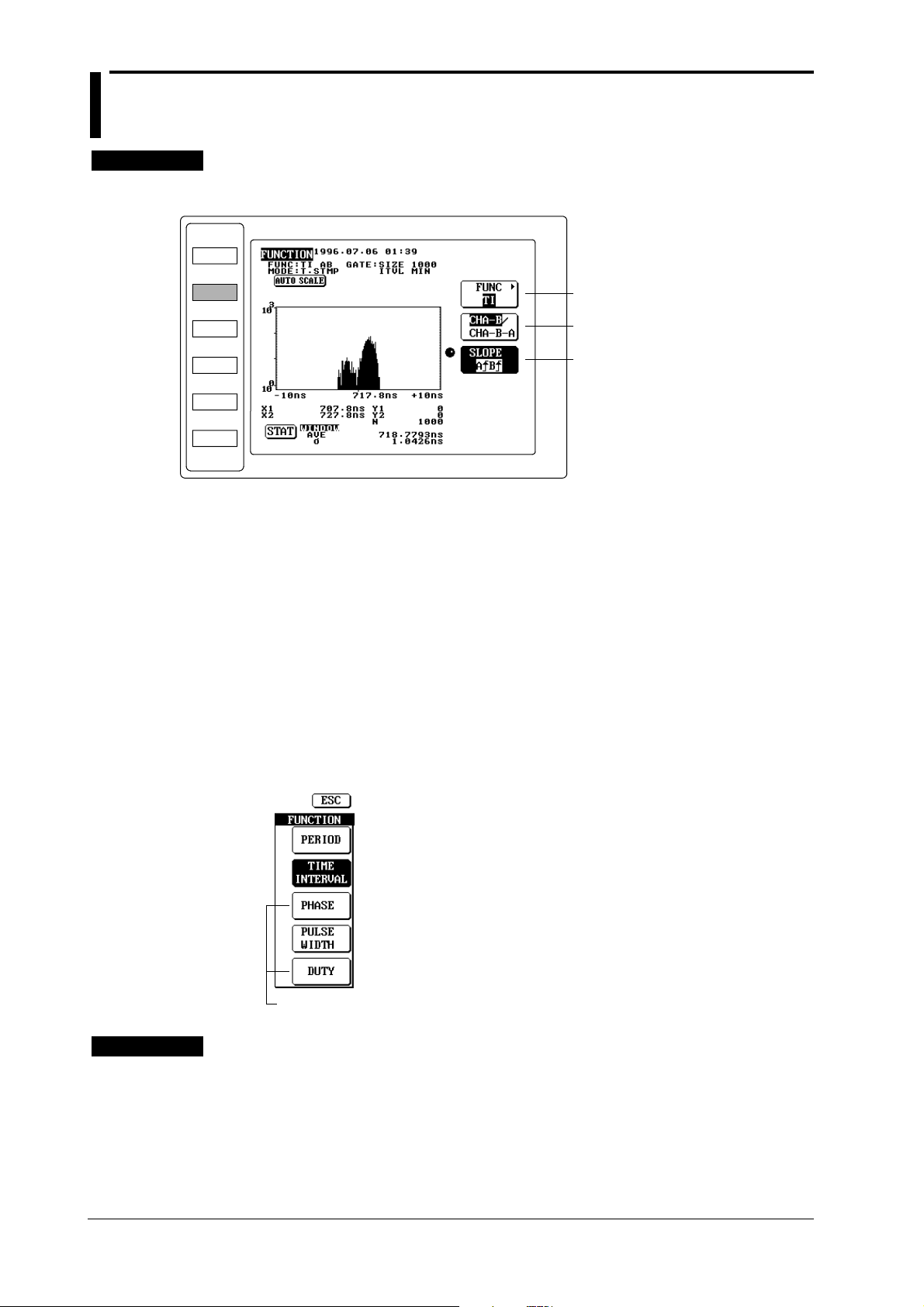

Panorama Display ≡For operating procedure, refer to 7.3≡

A panorama bar is displayed at the top of the screen during hardware histogram mode. The

panorama bar shows all the histograms of measured data. The histogram currently displayed in

the window is enclosed by “ marks,” so that the user can easily understand which histogram

is currently displayed.

Window 1 Window 2 Window 3 Window 4

Panorama bar

1

Functions

Maximum value of Y-axis

(frequency)

Left-end value of X-axis

(negative displacement from

the center value of X-axis)

Y-axis

Left-end value of

the panorama bar

Center value of X-axis

mark

Right-end value of

the panorama bar

(Class value of

the center class)

Span of X-axis

(40 ns in this example)

X-axis (time)

Right-end value of X-axis

from the center value of X-axis)

Histogram Data Addition ≡For operating procedure, refer to 7.4≡

It is possible to add the histogram of each window specified using the SIZE touch key during

multi-window setting, and display the resulting histogram in a single window. The frequency of

the bin located at the center value of X-axis of each histogram is added, and then the frequency of

each bin located on the left and right of that bin is similarly added. This enables comparison of

data distribution between histograms and global statistical computation of all the histograms.

Histogram for

window 1

Histogram for

window 2

Resulting histogram

Window

(Window 1 is displayed

in this example)

(positive displacement

+

=

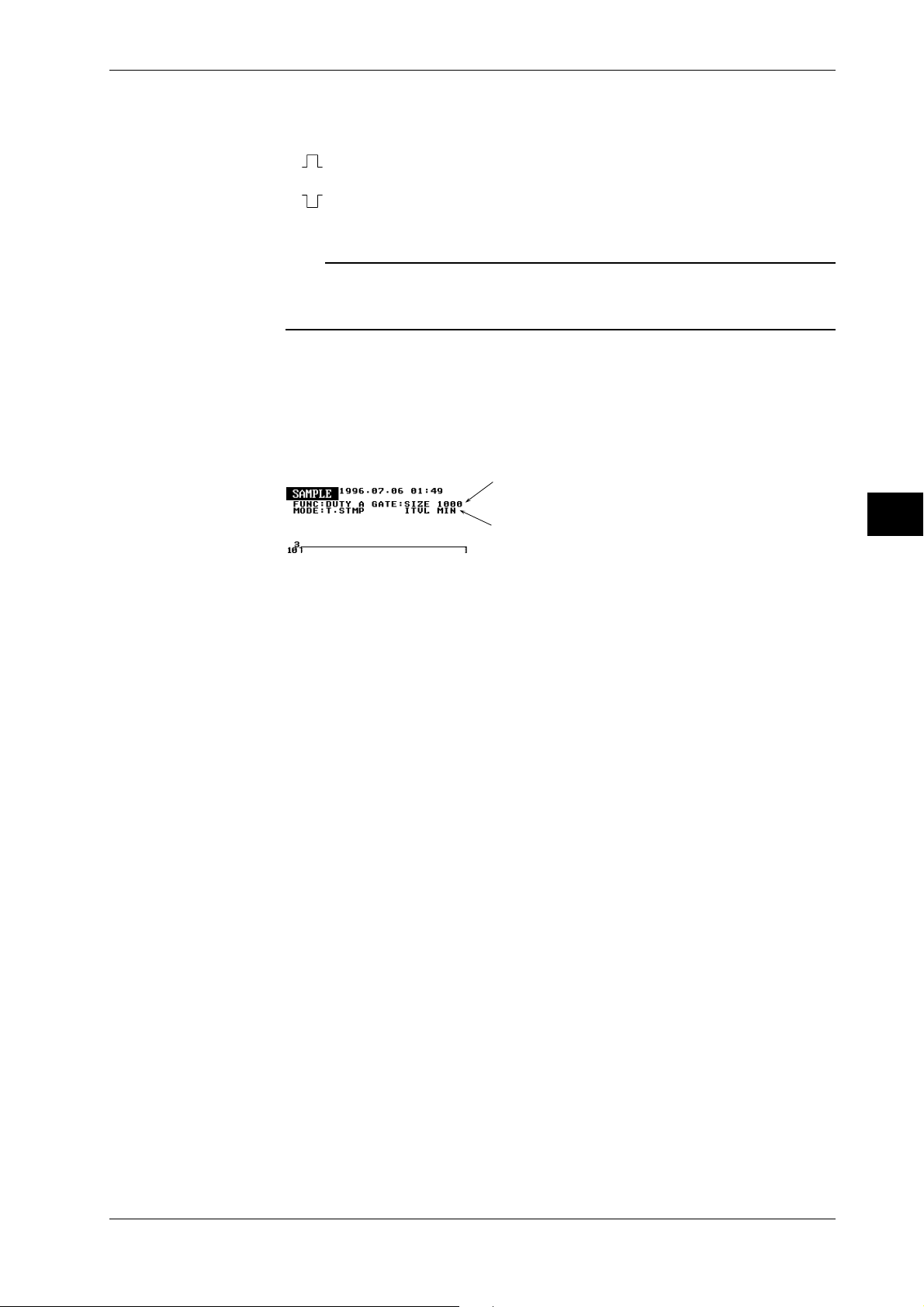

Time Variation Display ≡For operating procedure, refer to 7.5≡

During time stamp mode, measured values and time stamps are treated as data and acquired in the

acquisition memory. The time variation display function uses this time-series data to display

variation of measured values in relation to the elapsed time following the arming.

Span of Y-axis

(20 ns in this example)

(positive displacement from the

(measured value)

Y-axis

Center value

of Y-axis

IM 704210-01E

center value of Y-axis)

(negative displacement from the

center value of Y-axis)

Minimum value

of X-axis

X-axis (elapsed time)

Maximum value of X-axis

(positive displacement from

the minimum value of X-axis)

(Span: 400 µs in this example)

1-13

Page 24

1.6 Displaying the Measured/Computed Data

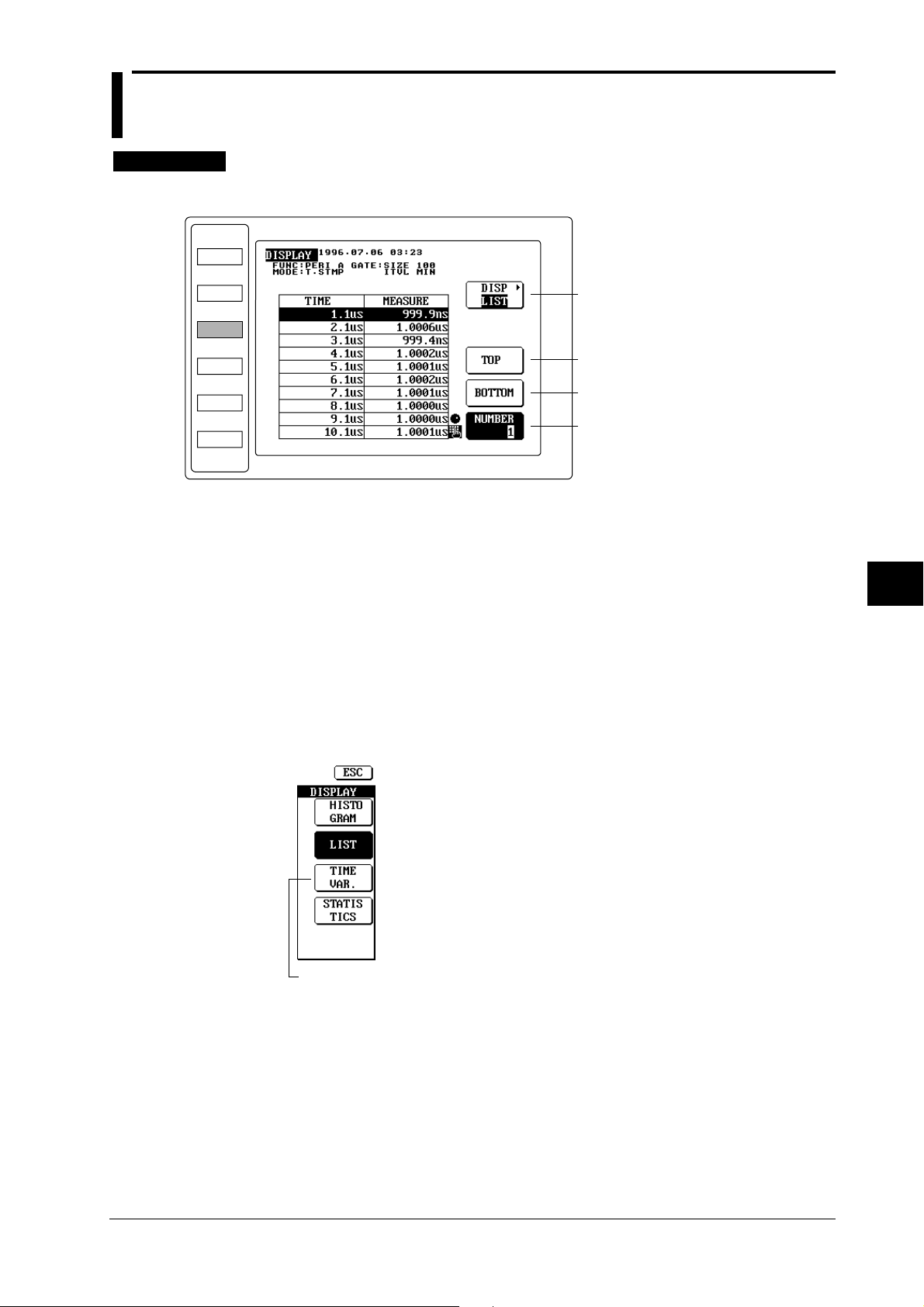

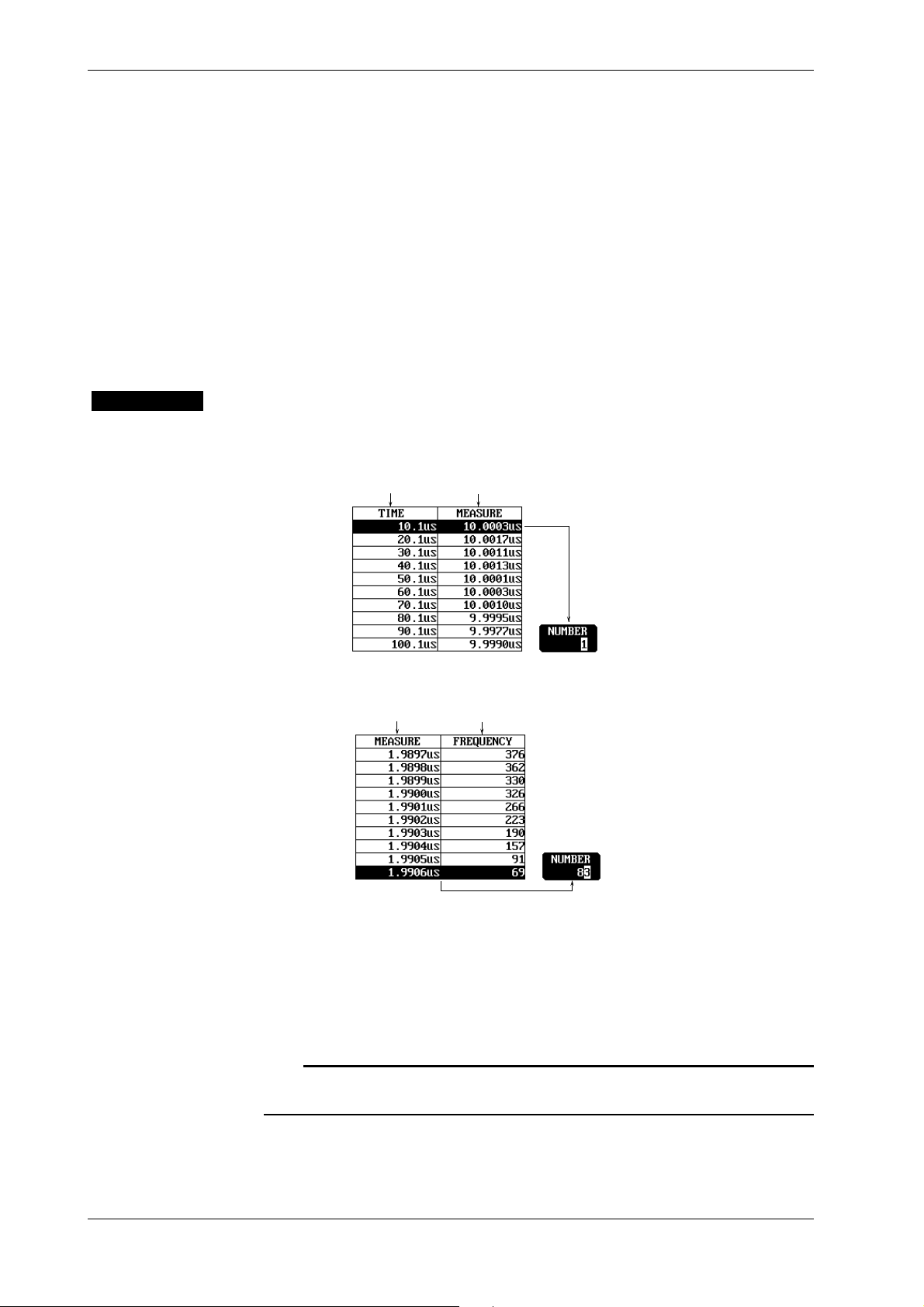

List Display ≡For operating procedure, refer to 7.6≡

A list of measured values is displayed. This function enables the user to jump to the top or

bottom data in the list, and set data numbers to locate/display the measured value of the desired

data number. The contents of the list vary according to the selected sampling mode.

Time stamp mode

A list of time stamps and their measured values for the number of events/time range specified in

gating setting (see 1.5) is displayed.

Time stamp Measured value

Data number

1

2

3

4

5

6

7

8

9

10

Hardware histogram mode

A list of measured values (class values of histogram) and their frequency within the span of Xaxis specified in histogram display setting is displayed.

The data number of the

highlighted data is displayed.

Class value Frequency

Data number

74

75

76

77

78

79

80

81

82

83

The data number of the

highlighted data is displayed.

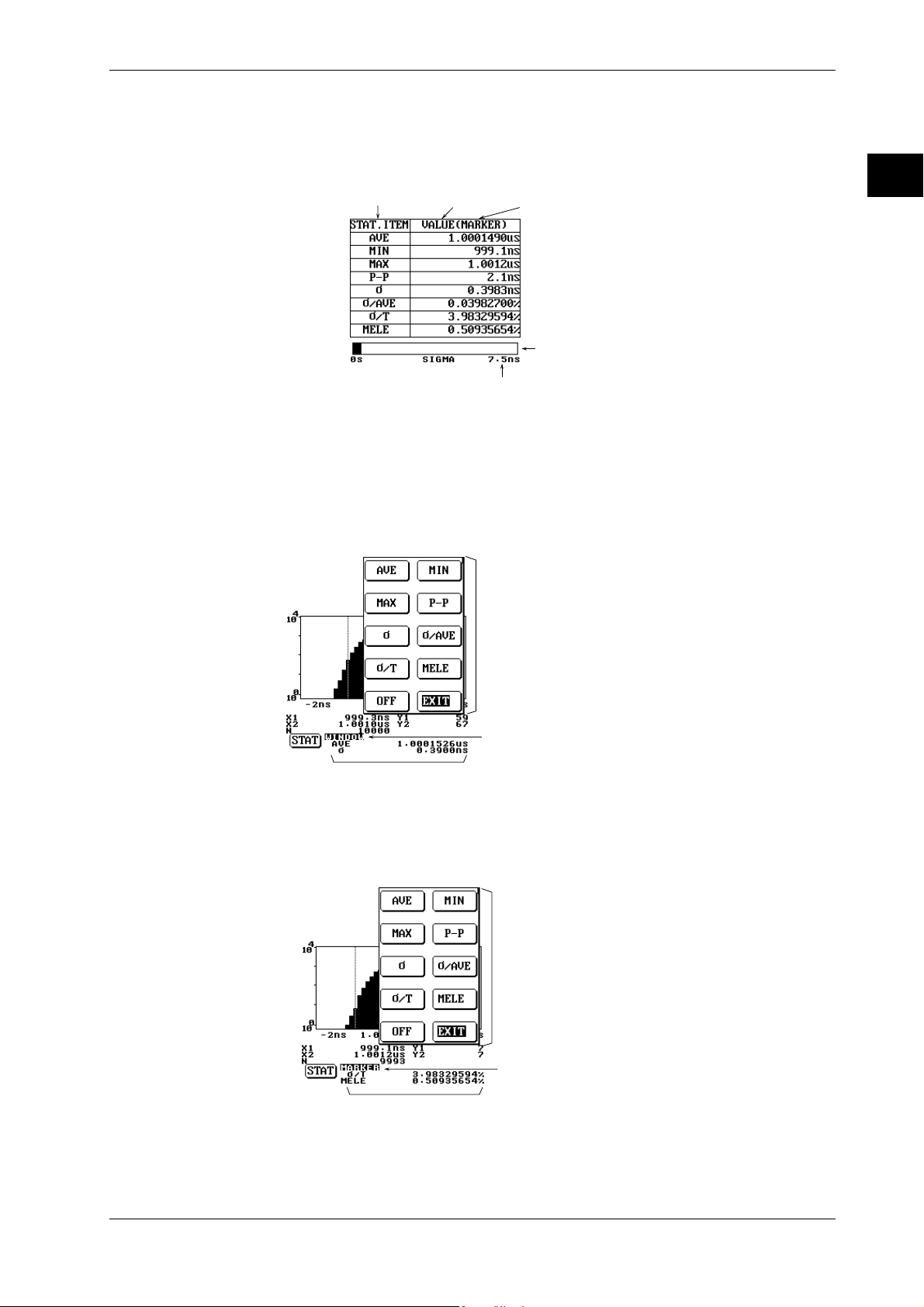

Statistics Display ≡For operating procedure, refer to 7.7 and 7.8≡

A list of statistic values is displayed. For statistical computation items, computation and

computation area, refer to 1.4, “Computation”. The contents of the list vary according to the

selected sampling mode.

Time stamp mode

No computation is carried out for jitter 1 (σ/T) and jitter 2 (MELE), so no results are displayed.

Statistical computation item Statistic value Statistical computation area

(The entire window is used for statistical

computation in this example. “MARKER”

will be displayed if the area enclosed by

the markers is used for statistical computation.)

1-14

No computation is carried out for jitter 1 and jitter 2.

IM 704210-01E

Page 25

Hardware histogram mode

A bar graph indicating the standard deviation (σ) is displayed below the list. The bar graph range

(maximum value) can be selected (see below).

Statistical computation item Statistic value

Bar graph range (maximum value)

Statistics values during histogram display

The statistical computation area and items (two items) are displayed while a histogram is

displayed. It is possible to select statistical computation items to be displayed.

1.6 Displaying the Measured/Computed Data

Statistical computation area

(The area enclosed by the markers

is used for statistical computation

in this example. “WINDOW” will be

displayed if the entire window is

used for statistical computation.)

Standard deviation (σ) is displayed in bar graph.

1

Functions

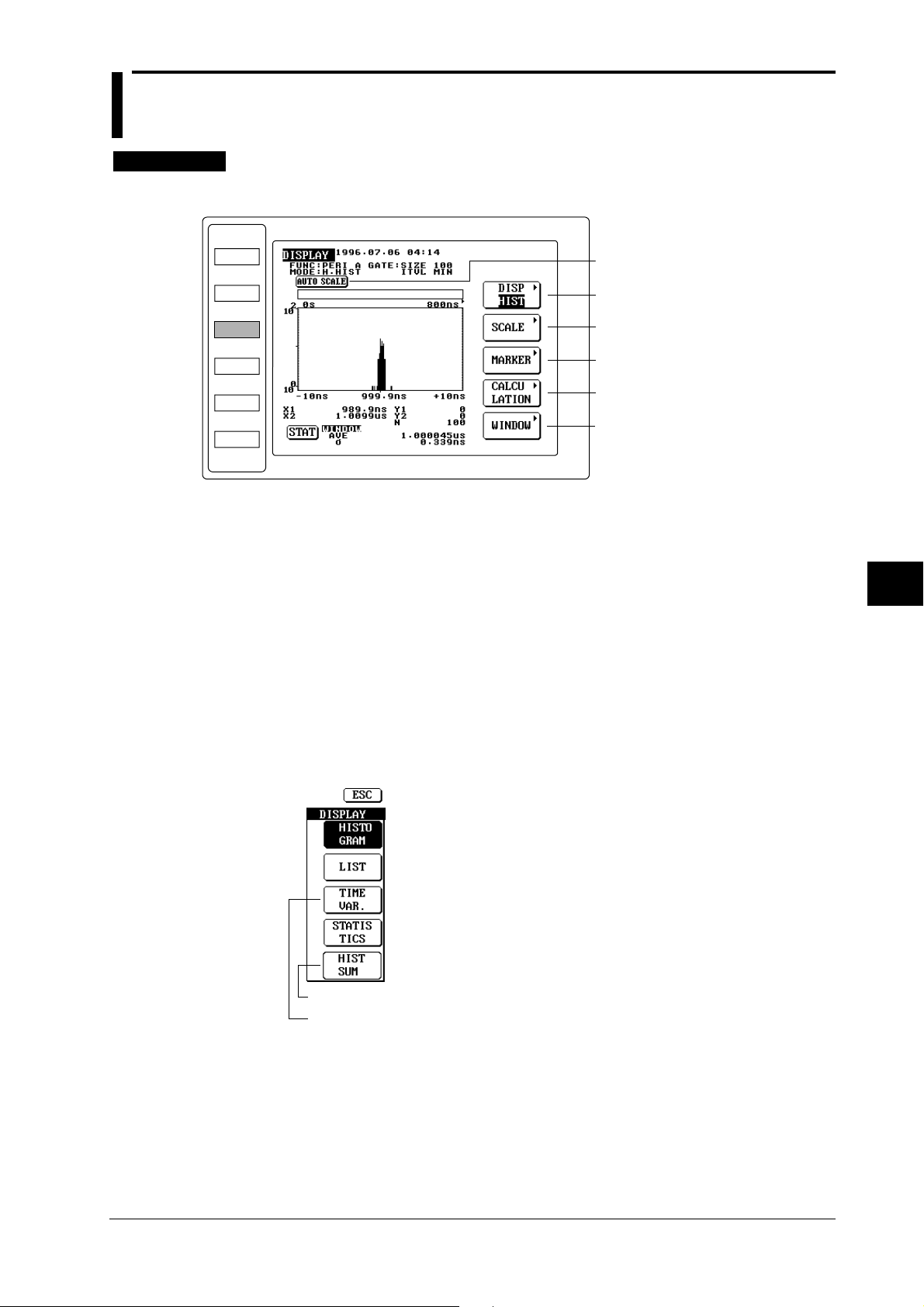

• Time stamp mode

Selected statistical

computation items

• Hardware histogram mode

Selects statistical computation items to be displayed.

(This menu is displayed when the STAT touch key

located at the bottom of the screen is pressed.)

Statistical computation area (The entire window is used

for statistical computation in this example. “MARKER”

will be displayed if the area enclosed by the markers is

used for statistical computation.)

Selects statistical computation items to be displayed.

(This menu is displayed when the STAT touch key located at

the bottom of the screen is pressed.)

IM 704210-01E

Selected statistical computation items

Statistical computation area

markers is used for statistical computation in this example.

“WINDOW” will be displayed if the entire window is used for

statistical computation.)

(The area enclosed by the

* “Touch key” is a key displayed on the LCD. Touching it with your finger will execute a certain

operation.

1-15

Page 26

1.7 Other Functions

External Signal Input/Output (Rear Panel)

The following input and output terminals (BNC) are provided on the rear panel, to communicate

with external devices. For location of each terminal, refer to 2.2, “Rear Panel”.

Reference input terminal (REFERENCE IN)

Although the instrument has an internal reference clock to be used for measurements, it is

possible to input an external signal (10 MHz) to this terminal and use it as the reference clock.

Reference output terminal (REFERENCE OUT)

The internal reference clock or external reference clock can be sent through a 10-MHz band pass

filter and then output from this terminal.

Monitor output terminals (MONITOR OUT CHA, CHB)

Signals input to the input terminals can be output directly from these terminals. They can be used

for observation of a waveform during phase correction of a probe.

External arming input/inhibit input terminals (EXT ARM IN, INHIBIT IN)

These signals are used to control measurement functions of the instrument. For the function of

external arming or inhibit signal, refer to 1.5, “Setting the Acquisition Conditions for Input Signal

to be Measured”.

≡For operating procedure, refer to 10.2 and 10.3≡

Communications ≡Refer to the GP-IB Interface User’s Manual (IM704210-12E)≡

The instrument is equipped with a GP-IB interface as a standard feature. Use of this interface

enables transmission of measured data to a personal computer to analyze it, and enables control of

this instrument using an external controller.

Storing and Recalling of Set-up Information

Up to 10 sets of set-up information can be stored in the internal non-volatile memory. It is also

possible to recall the stored set-up information to set up the instrument. This function is useful

when you want to use the set-up information repeatedly.

Saving and Loading Data from a Floppy Disk

The instrument is equipped with a floppy disk drive. This enables the user to save set-up

information and measured data to a floppy disk or load from it, whenever it is required. In

addition, it is also possible to save the screen image data in TIFF format. This enables the user to

import the saved screen image data to a document created by a DTP software application, to

create a report.

≡For operating procedure, refer to Chapter 8≡

≡For operating procedure, refer to Chapter 9≡

Auto Loading of Set-up Information ≡For operating procedure, refer to 9.3≡

Turning ON the power after a floppy disk containing the set-up information is inserted into the

floppy disk drive will load the set-up information to the instrument automatically. This is useful

to restore the set-up information in the instrument.

Plotter Output ≡For operating procedure, refer to 10.1≡

Measured data can be output to an external plotter via the GP-IB interface.

Initialization of Set-up Information ≡For operating procedure, refer to 10.4≡

The set-up information can be reset to the factory settings (default settings).

Calibration ≡For operating procedure, refer to 10.5≡

Calibration of the offset voltage of each input amplifier and conversion factor of each T/V

converter can be carried out using the internal calibration signal.

1-16

IM 704210-01E

Page 27

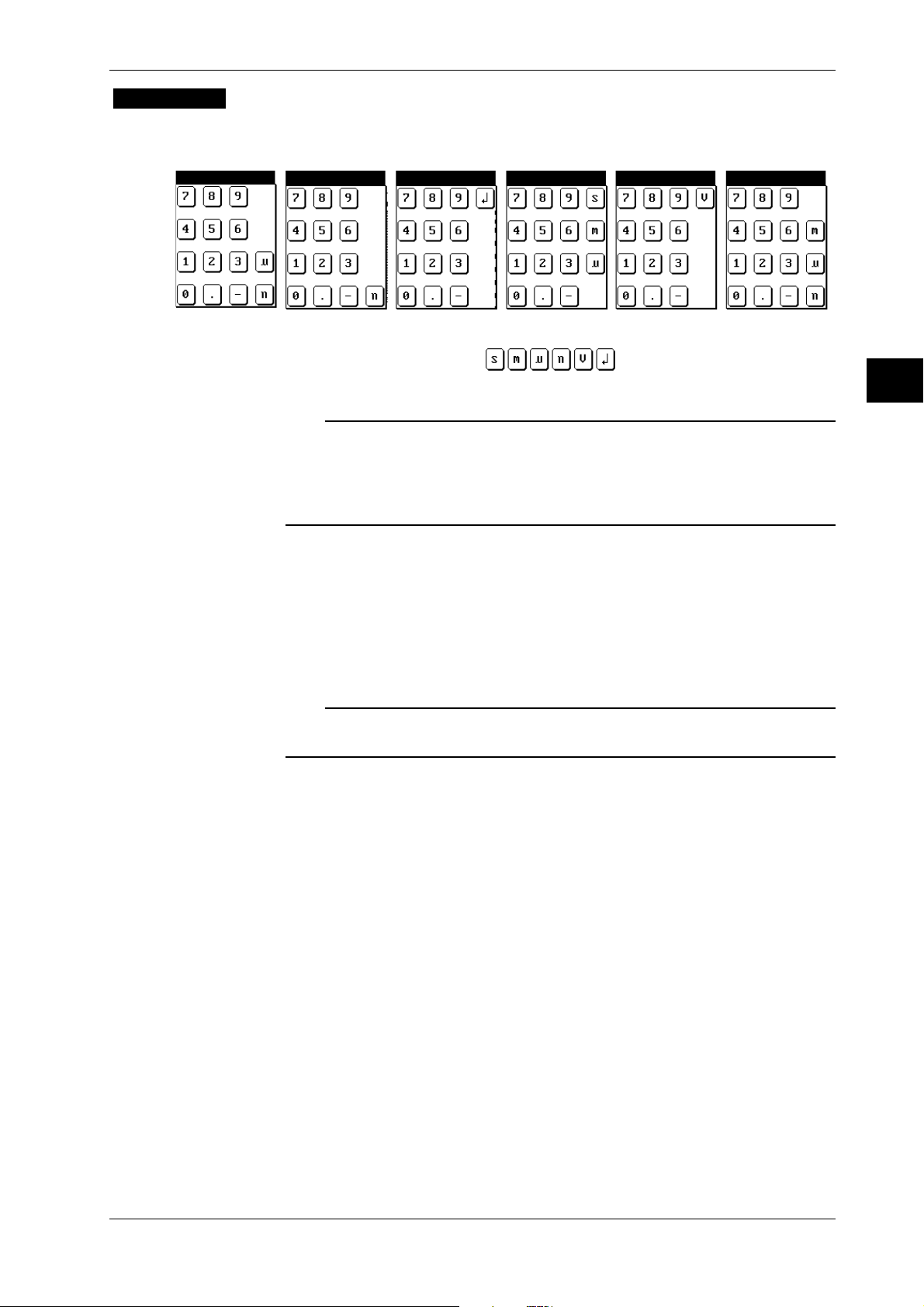

Numeric Value Setting ≡For operating procedure, refer to 4.2≡

A numerical value can be entered using the ten-key (displayed when the KEYBOARD key is

pressed) while a small ten-key icon is displayed on the left of the currently highlighted touch key.

This is useful when you need to set a value consisting of several digits. If a small icon is

displayed, a numerical value can be entered using the rotary knob.

Small rotary knob icon

Small ten-key icon

Contrast ≡For operating procedure, refer to 10.6≡

The contrast of the LCD display can be adjusted. Adjust it so that it suits the environment in

which the instrument is used.

Touch-key Sound ≡For operating procedure, refer to 10.7≡

A beeping sound is heard when a touch key is pressed (touched) or an error occurs. It is possible

to disable this beep.

1.7 Other Functions

1

Functions

Error Logging ≡For operating procedure, refer to 11.3≡

“!” mark appears in the upper right corner of the screen if a data error such as overflow of

measured data occurs or a communication error occurs. Error messages are recorded in the error

logging window, to enable the user to observe them later.

Self-test ≡For operating procedure, refer to 11.4≡

In case of a problem, a self-test can be carried out to enable the user to check the problem before

contacting YOKOGAWA. This function enables inspection of the memory, PC board and

display.

IM 704210-01E

1-17

Page 28

2.1 Front Panel

Top menu keys

Displays the corresponding top menu.

• MODE key

Displays the sampling mode selection screen. (See 5.1.)

• FUNCTION key

Displays menus for setting/selecting the measurement function, input channel and slope. (See chapter 5.)

2

• DISPLAY key

Displays menus for setting/selecting the display format, window axis, markers, calculation. (See chapter 7.)

• SAMPLE key

Displays menus for setting/selecting the gate, sample size, sampling interval, arming and inhibit. (See chapters 6.2, 6.3 and 6.4.)

• INPUT key

Displays menus for setting/selecting the input coupling, input impedance, trigger mode and trigger level. (See chapter 6.1.)

• UTILITY key

Displays menus for setting/selecting initialization of set-up information, storing and recalling of data in the internal memory,

configuration (communication, contrast, date/time, touch key sound), self-test, saving and loading of data from a floppy disk, reference

clock, calibration and initialization of a floppy disk. Also displays the error logging window and version No. (ROM version). (See 3.7,

chapters 8,9, and 10, and 11.3 to 11.5.)

LCD display

(Touch screen)

Touch key

Press the area enclosed

by to make various

Rotary knob

Sets a numerical value, moves markers and

selects a file. (See 4.2, chapters 7 and 9.)

settings and selections.

100ps resolution 14MS/s

TIME INTERVAL ANALYZER

Arrow keys

Moves from one digit to

another digit during setting

of a numerical value. Also

MODE

used as a back space key

(<). (See 4.2.)

FUNCTION

SINGLE key

Carries out measurement

DISPLAY

SAMPLE

INPUT

UTILITY

POWER

SINGLE START STOP

COPY LOCAL

50 5Vrms

1M 40Vpk

REMOTE

CH

B

KEY

BOARD

CH

A

only once. (See 4.1.)

Measurement indicator

Lights up during acquisition

of measured data.

START/STOP key

Starts/stops continuous

measurement. (See 4.1.)

LOCAL key

Cancels remote control

(REMOTE indicator lights

up during remote control

mode). Refer to the GP-IB

Interface User’s Manual

(IM704210-12E).

COPY key

Saves the screen image data

to a floppy disk/outputs the

screen image data to an

external plotter.

Power switch

(See 3.4.)

Access indicator

Blinks while the floppy

disk drive is in use.

Eject button

Used to remove the

floppy disk.(See 9.1.)

Floppy disk drive

(See 9.6 and 10.1.)

KEYBOARD key

Displays a ten-key (only

when a ten-key icon is

displayed on the left of a

touch key).(See 4.2.)

CHA/CHB input indicator

Blinks while the signal is input and a trigger

is caused.

CHA/CHB input terminal

Connect the input signal cables to these terminals.

(See 3.5.)

Name and Use of Each Part

IM 704210-01E

2-1

Page 29

2.2 Rear Panel

Adjustment hole for reference clock frequency

Used to adjust the time base. (See 11.5.)

Reference input terminal

The external reference clock is input to this terminal. (See 10.2.)

Reference output terminal

The reference clock is output from this terminal. (See 10.2.)

REF

ADJUST

REFERENCE

IN OUT

GP-IB ( IEEE488 )

WARNING

It is dangerous to operate this instrum

ent outside its environmental specificati

ons. Refer to manual.

(50 )10MHz 1Vp-p 10MHz 1Vp-p

CHA/CHB monitor output terminal

Input signals are output from these terminals. (See 10.3.)

MONITOR OUT

CH A CH B

(50 )

External arming input terminal (shared with the external

gating input)

(See 6.2 and 6.3.)

Inhibit input terminal

(See 6.4.)

CIRCUIT

EXT ARM INHIBIT

IN IN

BREAKER

250V AC 3A

Circuit breaker

( TTL ) ( TTL )

(See 11.7 for the

resetting method.)

Power cord connector

The power cord is connected

100 - 240V AC

125VA MAX 50/60Hz

to this connector. (See 3.3.)

Name plate

Refer to this name plate when

checking the contents of the

package. (See page 2.)

Vent

WARNING plate

holes

Safety Precautions. (See page 4.)

Usage Precautions. (See 3.1.)

GP-IB connector

Used to connect the instrument to an external device (e.g. personal computer).

Refer to the GP-IB Interface User’s Manual (IM704210-12E).

2-2

IM 704210-01E

Page 30

3.1 Usage Precautions

Safety precautions

• Be sure to read through the safety precautions given on page 4 of this manual before starting to

use the instrument.

• Never remove the instrument’s casing. The unit contains extremely hazardous high-voltage

components. Consult your nearest Yokogawa representative (see listing on rear cover) if the

instrument requires maintenance or adjustment.

• If the instrument emits smoke or unusual odors, or in any way behaves abnormally immediately

turn OFF the power switch and unplug the power cord from the outlet. Then consult your

nearest Yokogawa representative for assistance.

• If the cooling fan stops during operation, the instrument will display the error message shown

below. When you see this message, turn OFF the power immediately. The fan (on the rear

panel) may be jammed; check for and remove any obstructions, then restart. If the same error

recurs, turn OFF the power and contact your nearest Yokogawa representative.

• Never rest any objects on the power cord. Keep the cord clear of hot objects at all times. When

unplugging the power cord, pull on the plug area - never pull on the cord itself. If the cord is

damaged, contact your dealer and obtain a replacement. (Quote the part number indicated on

page 2 of this manual.)

3

Before Starting Measurement

Handling Precautions

• Never place liquid-filled containers or other potentially damaging objects on top of the

instrument.

• Avoid subjecting the instrument to vibration and strong impacts, as these can cause hardware

damage. Be especially careful if the instrument is equipped with a floppy disk drive. Also note

that any impact to terminals or connecting cables may cause electrical noise to the output

signal.

• Always keep terminals clear of electrically charged objects. Electrostatic at the terminals may

cause internal damage.

• If you do not plan to use the instrument for an extended period, unplug the power cord.

• If you need to lift and move the instrument, first disconnect the power cord and connecting

cables. Lift and carry by the handle, as shown. The instrument weighs approximately 5kg.

IM 704210-01E

• Never touch the LCD (touch screen) with pointed objects. Contact with sharp objects may

cause damage.

• Never clean plastic parts with benzene or other such solvents, as these may cause discoloration.

To clean the case or panel, wipe lightly with a soft dry cloth.

3-1

Page 31

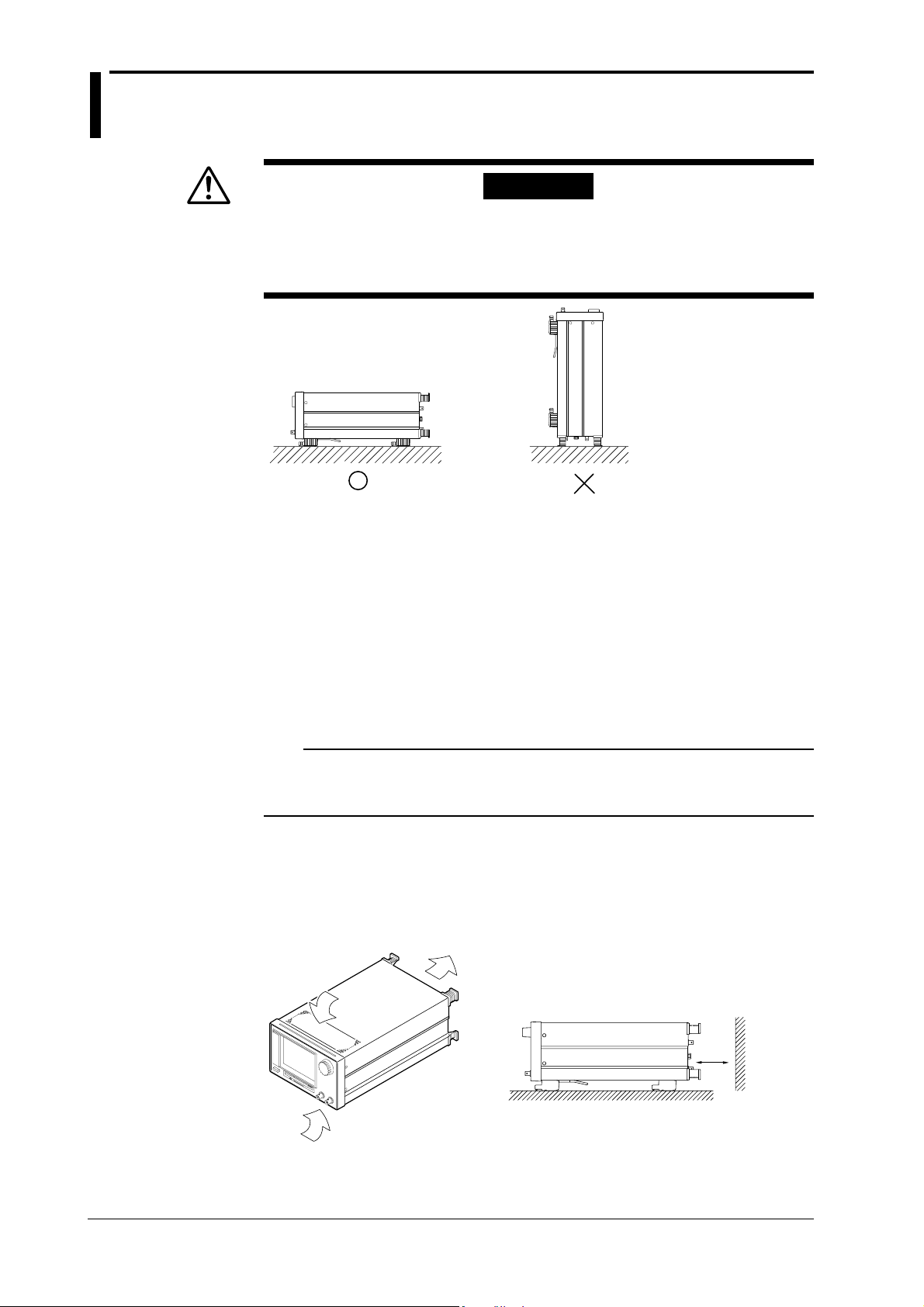

3.2 Installing the Instrument

You should never run the instrument in an upright position, with the fan vent facing

downward. If the instrument malfunctions while in this position, heat escaping from the

vent may cause a fire. If you really need to operate the instrument in this position, place

a metal plate or flame-retardant barrier (grade UL94-1 or higher) beneath it.

Installation Conditions

Be sure to install the instrument in a location that meets the environmental conditions described

below.

WARNING

Ambient temperature and humidity

Ambient temperature and humidity during operation should be within the following limits.

• Temperature: 5°C to 40°C

For high accurate measurement: 23±2ºC

• Humidity: 20% to 80% RH; no condensation

For high accurate measurement: 50±10% RH

Note

Condensation may occur when the instrument is moved from a cold, dry location to a warm, humid one or

when there is a rapid change in ambient temperature. If liquid condenses on the instrument, allow the

instrument to stand for at least one hour under stable ambient conditions before using.

Well-ventilated location

Vent holes are situated on the top and bottom of the instrument. In addition, vent holes for the

cooling fans are also situated in the rear panel. To prevent a rise in the internal temperature, the

vent holes should not be blocked and sufficient clearance should be maintained around them.

10cm

or more

3-2

IM 704210-01E

Page 32

Installation Position

3.2 Installing the Instrument

Install the instrument in a location that is:

• Away from direct sunlight and other heat sources.

• Away from oily smoke, steam, dust, corrosive gas, and other such contaminants.

• Away from strong magnetic fields.

• Away from high-voltage equipment and power lines.

• Away from mechanical vibrations.

• Stable surface.

Place the instrument in a horizontal position or tilted using the stand, as shown below. To install