Page 1

Technical

TI 34P02K35-02E

TI 34P02K35-02E

Information

STARDOM

Engineering Guide (FCN-500/FCN-RTU)

© Copyright Apr. 2016 (YK)

1st Edition Apr.28.2016 (YK)

3rd Edition Jun. 6.2018 (YK)

Page 2

Blank Page

Page 3

i

IMPORTANT

Introduction

About this manual

This engineering guide is intended as a guide for system engineering of a

STARDOM system (FCN-500, FCN-RTU) based on given specifications.

It supplements the information contained in the following documents, which

are required for STARDOM engineering, and explains precautions and

pointers, following the engineering workflow sequence.

Related Documents

- GS 34P02Q02-01E FCN-RTU Autonomous Controller Functions

- GS 34P02Q03-01E FCN Autonomous Controller Functions (FCN-500)

- IM 34P02P25-01E NPAS POU – Overview

- IM 34P02Q01-01E STARDOM FCN/FCJ Guide

- TI 34P02A13-01E FCN-500 Technical Guide

- TI 34P02A14-01E FCN-RTU Technical Guide

- TI 34P02K13-02E STARDOM FCN-500/FCN-RTU

Primer – Fundamental

- TI 34P02K25-01E STARDOM Network Configuration Guide

- TI 34P02Q91-01E STARDOM FCN/FCJ Installation Guide

Notation in this document:

- The term “FCN-500” refers to the autonomous controllers with NFCP501/NFCP502

CPU module.

- The term “FCN-RTU” refers to the low power autonomous controllers with

NFCP050 CPU module.

All Rights Reserved. Copyright © 2001, Yokogawa Electric Corporation TI 34P02K35-02E Jun. 6, 2018-00

Page 4

ii

Copyrights and Trademarks

Copyrights

The copyrights of this document belong to Yokogawa Electric Corporation.

No part of this document may be transferred, sold, distributed (including delivery via

a commercial PC network or the like), or registered or recorded on videotapes.

Trademarks and Licensed Software

- STARDOM is a trademark.

- Company names and product names included in this document are trademarks

or registered trademarks of their respective owners.

- Registered trademarks or trademarks are not denoted with the ‘TM’ or ‘®’ mark

in this document.

TI 34P02K35-02E Jun. 6, 2018-00

Page 5

iii

TI 34P02K35-02E 3rd Edition

STARDOM

Engineering Guide (FCN-500/FCN-RTU)

CONTENTS

Introduction ................................................................................................ i

Copyrights and Trademarks .................................................................... ii

CONTENTS ............................................................................................... iii

1. Overview ........................................................................................... 1

2. Basic Design and Function Design ................................................ 3

2.1 Checking Hardware Specification ............................................................ 3

2.1.1 Current Consumption of FCN-500 and FCN-RTU Unit ................... 3

2.1.2 Checking Operation Specifications of I/O Modules ........................ 6

2.1.3 Checking Automatic Loading of I/O Modules .................................. 6

2.1.4 Measures for Duplexing .................................................................. 7

2.2 Pre-Application Creation Checklist .......................................................... 9

2.2.1 Checking Revisions of FCN-500, FCN-RTU and Tools .................. 9

2.2.2 Checking FCN-500, FCN-RTU Control Application Size .............. 12

2.2.3 Checking FCN-500, FCN-RTU Performance ................................ 13

2.2.4 Determining FCN-500, FCN-RTU Scan Cycle .............................. 15

2.2.5 Retentive Variable (Retain Data) Considerations ......................... 18

2.2.6 Time Synchronization .................................................................... 23

3. Hardware Setup .............................................................................. 25

3.1 Resource Configurator Setting ............................................................... 25

3.2 Setup in Web Browser ............................................................................. 27

4. Control Application Creation ......................................................... 29

4.1 Using Logic Designer Setup ................................................................... 29

4.1.1 Selecting a Template for a New Project ........................................ 29

4.1.2 Control Task Setup ........................................................................ 31

4.1.3 Multi-tasking .................................................................................. 34

4.1.4 Specifying Target FCN/FCJ........................................................... 35

4.1.5 Multi-resource Project ................................................................... 37

4.1.6 Application Size ............................................................................. 38

4.2 Application Programming Languages ................................................... 40

4.2.1 Programming Languages Supported by Logic Designer .............. 40

4.2.2 Selecting a Programming Language ............................................. 41

TI 34P02K35-02E Jun. 6, 2018-00

Page 6

iv

4.3 Principles of Application Creation .......................................................... 42

4.3.1 Principles of Application Creation ................................................. 42

4.3.2 Example of a Simple Application ................................................... 42

4.3.3 Bottom-up Application Creation .................................................... 45

4.4 Application Creation Know-how ............................................................. 46

4.5 Network Templates ................................................................................... 47

4.6 Application Encapsulation ...................................................................... 48

4.6.1 Features of Application Encapsulation .......................................... 48

4.6.2 Procedure for Creating a POU ...................................................... 50

4.6.3 Modifying Logic of a POU ............................................................. 54

4.7 Handling Compile Errors and Warnings ................................................ 58

4.8 Precautions About Downloading ............................................................ 60

4.8.1 Offline Download and Online Download ....................................... 60

4.8.2 Downloading Boot Project and Source ......................................... 62

4.8.3 Detailed Description of Download Dialog ..................................... 62

4.8.4 Importance of Boot Project ........................................................... 64

4.8.5 Importance of Source .................................................................... 65

4.9 Control Application Backup .................................................................... 66

5. Function Test (Debugging) ............................................................ 69

5.1 Equipment Used for Testing .................................................................... 69

5.1.1 Precautions of Testing When Using In-house Equipment ............. 70

5.1.2 Precautions of Testing When Using FCN/FCJ Simulator .............. 73

5.1.3 Precautions of Testing When Using Target Equipment ................. 75

5.1.4 Precautions of Migrating Testing from In-house Equipment to

Target Equipment .......................................................................... 77

5.2 Unit Test and Combination Test .............................................................. 79

5.3 Unit Test Precautions ............................................................................... 80

5.3.1 Pre-unit Test Checklist .................................................................. 80

5.3.2 Unit Test Methodology ................................................................... 81

5.3.3 Unit Test Know-how ...................................................................... 83

5.4 Combination Test Precautions ................................................................ 86

5.4.1 Combination Test Prerequisites .................................................... 86

5.4.2 Equipment Used for Combination Test ......................................... 86

5.4.3 Checking Log Files of FCN-500, FCN-RTU .................................. 87

5.4.4 System Failure Test ....................................................................... 87

5.5 Checking CPU Load and Application Size ............................................. 92

5.5.1 Checking CPU Load...................................................................... 92

5.5.2 Checking Application Size ............................................................. 93

TI 34P02K35-02E Jun. 6, 2018-00

Page 7

v

5.6 Logic Designer’s Debug Mode ................................................................ 95

5.6.1 Switching to Debug Mode ............................................................. 96

5.6.2 Basic Operation in Debug Mode ................................................... 99

5.6.3 Disconnecting I/O .......................................................................... 99

5.6.4 Entering and Checking Values of Device Label Variables .......... 101

5.7 Software Wiring ...................................................................................... 106

5.7.1 Overview of Software Wiring ....................................................... 106

5.7.2 Software Wiring Creation and Precautions ................................. 107

5.7.3 Precautions When Creating Software Wiring ............................. 109

5.8 Using Loop Check Tool ........................................................................... 110

5.8.1 Values Displayed in Loop Check Tool .......................................... 111

5.8.2 Locating Problems Using Loop Check Tool ................................. 112

6. User Acceptance Test (UAT) ........................................................ 114

6.1 Pre-UAT Checklist ................................................................................... 114

6.1.1 UAT Prerequisites ........................................................................ 114

6.1.2 UAT Implementation Guidelines................................................... 115

6.2 Items Requiring Prior Explanation to Users ......................................... 11 6

6.2.1 Differences in Equipment Used from Actual System ................... 116

6.2.2 Differences between Process I/O and Software Wiring ............... 117

6.2.3 Equipment Communicating with FCN-500, FCN-RTU ................. 11 7

7. System Delivery Precautions ...................................................... 118

7.1 System Delivery Checklist ...................................................................... 119

7.1.1 System Delivery Prerequisites ..................................................... 119

7.1.2 Forms of Delivery ......................................................................... 119

7.2 Delivery for New System ....................................................................... 121

7.2.1 Pre-Delivery Preparation ............................................................. 121

7.2.2 Control Application Backup ......................................................... 122

7.2.3 System Delivery .......................................................................... 123

7.3 Delivery for System Expansion ............................................................. 124

7.4 Delivery for System Modification .......................................................... 125

7.4.1 Pre-Delivery Preparation and Application Backup ...................... 125

7.4.2 System Delivery .......................................................................... 125

7.4.3 Preparation for On-site Installation ............................................. 125

7.4.4 On-site Installation ...................................................................... 126

7.5 Procedure Instruction Sheet and Rehearsal ....................................... 127

8. Detailed Description ..................................................................... 128

8.1 Checking Operation Specifications of I/O Modules ............................ 128

8.1.1 Checking Operation Specification of Analog/Digital Input .......... 128

8.1.2 Checking Operation Specification of Analog/Digital Output ........ 130

8.1.3 Checking Specification of Pulse Input......................................... 132

8.1.4 Checking Specification of Pulse Width Output ........................... 133

8.2 Checking Specification of Serial Communication .............................. 135

TI 34P02K35-02E Jun. 6, 2018-00

Page 8

vi

8.3 Precautions about Multi-tasking .......................................................... 137

8.4 Criteria for Selecting Programming Languages in Logic Designer .. 141

8.4.1 Selection Criteria for FBD, LD and ST ........................................ 141

8.4.2 Selecting between FBD and LD .................................................. 149

8.4.3 Combining FBD, LD and ST ....................................................... 150

8.4.4 Selecting between SFC and Stepped FBD or LD ....................... 152

9. Advanced Engineering ................................................................ 156

9.1 General Application Development Know-how ..................................... 156

9.1.1 Variable Definitions ..................................................................... 156

9.1.2 Local Variables versus Global Variables ..................................... 157

9.1.3 _RB and _BOOL Suffix Variables of Device Label Variables ...... 160

9.1.4 Execution Order of Control Application ....................................... 162

9.1.5 Inter-FCN/FCJ Communication Concept .................................... 169

9.1.6 How to Create User Data Types ................................................. 175

9.1.7 Jump, Connector and Return Functions ..................................... 178

9.1.8 Cross References ....................................................................... 182

9.1.9 Specifying Retain Data and OPC Property ................................. 185

9.1.10 Getting FCN-500, FCN-RTU Time .............................................. 186

9.1.11 Precautions When Using Terminal EN of Functions ................... 187

9.1.12 Logic for Saving Retain Data ...................................................... 190

9.1.13 Comparing Logic Designer Projects ........................................... 192

9.1.14 Avoidance of the Error during Execution .................................... 193

9.2 Know-how in Use of NPAS_POU .......................................................... 194

9.2.1 Scan Cycle and Control Cycle .................................................... 194

9.2.2 How to Detect Mode, Status and Alarm ...................................... 197

9.2.3 NPAS_POU Status Propagation ................................................. 202

9.2.4 Blocked NPAS_POU Status Propagation ................................... 207

9.2.5 Selection of Timers and Counters ............................................... 210

9.2.6 Engineering Parameters .............................................................. 211

Appendix 1 STARDOM Engineering Flow Chart ............................... 214

Revision Information ................................................................................. i

TI 34P02K35-02E Jun. 6, 2018-00

Page 9

<1. Overview>

1

TI 34P02K35-02E

Jun. 6, 2018-00

Check require-

ment spec.

User acceptance

test (UAT)

System delivery

Unit test

Integration test

System test

Detailed function

design of

application

software

Check requirement

spec.

Check system

configuration

- Verify that the requirement specification can be implemented using

the STARDOM system.

- Verify that the system configuration allows implementation of the

requirement specification.

- Based on the requirement specification, prepare basic specifications

for FCN/FCJ control applications, operation/monitoring applications

and communication functions.

- Based on basic functions, perform detailed design of each

application and prepare functional specification.

- Based on function specification, create applications.

- In unit test, check individual applications.

- In integration test, combine applications already tested in unit tests

and test the integrated STARDOM system as a whole.

- In system test, combine external equipment and control panels with

the STARDOM system, and perform function test, including

communication tests.

- Verify along with customer that the designed/created application

satisfies the function specification.

- After completion of UAT, deliver STARDOM system.

FCN/FCJ control

applications

Operation and

monitoring

applications

Communication

applications

Basic design and

function design

Application creationFunction test

1. Overview

STARDOM engineering can be divided into phases as shown in the diagram

below.

This engineering guide is intended as a guide for system engineering of a

STARDOM system based on given specifications. For this purpose, it describes

the precautions and checklist for each of the engineering phases after

specifications are confirmed, including basic design and function design,

application creation, function test, user acceptance test (UAT) and system

delivery.

This engineering guide focuses on FCN/FCJ control applications.

Details on the functions and use of the FCN-500 and FCN-RTU controller and

individual application programming tools can be found in their respective

instruction manuals (IM) and Technical Information (TI). Wherever necessary, this

manual will refer the reader to these documents for details on functions and

usage.

Page 10

Blank Page

Page 11

<2. Basic Design and Function Design>

3

TI 34P02K35-02E

Jun. 6, 2018-00

2. Basic Design and Function Design

The first thing to do in STARDOM engineering is to check whether a given

customer specification can be implemented using the hardware, application

programming tools, APPFs (application portfolios), and licenses provided

with the system.

2.1 Checking Hardware Specification

Review specifications for the hardware given in GS and IM documents to

confirm whether specification requirements are achievable.

2.1.1 Current Consumption of FCN-500 and FCN-RTU Unit

Calculate the current consumption of each FCN unit, and check that it does not

exceed the rated output current of the power supply module.

● Rated Output of Power Supply Module

The rated output current of the FCN-500 power supply module is given by:

System power supply: 0 A to 7.8 A

Analog field power supply: 4 A (max)

SEE ALSO

Chapter A1.3, “Power Supply Module” of IM “STARDOM FCN/FCJ Guide”

The rated output current of the FCN-RTU power supply module is given by:

NFPW426: System power supply: 0 A to 2.4 A

Analog field power supply: 0.54 A (max)

NFPW441: System power supply: 0 A to 7.8 A

Analog field power supply: 4 A (max)

SEE ALSO

Chapter A2.3, “Power Supply Module (NFPW426, NFPW444)” of IM “STARDOM FCN/FCJ Guide”

The power supply module mounted on a unit supplies power only to that unit so

the current consumption of each unit must be kept below the rated output

described above.

Page 12

<2. Basic Design and Function Design>

4

TI 34P02K35-02E

Jun. 6, 2018-00

● Calculating Current Consumption of an FCN Unit

The current consumption of the system power supply of an FCN unit can be

obtained by summing the current consumption values of the base module, as well

as the CPU modules, I/O modules, and E2 bus/SB bus modules installed on the

base module.

If I/O modules requiring analog field supply are mounted in the unit, the current

consumption of the analog field supply of the FCN unit should be calculated

additionally. The system power supply current consumption and analog field

supply current consumption values of individual modules given in the “STARDOM

FCN/FCJ Guide” can be used for these calculations.

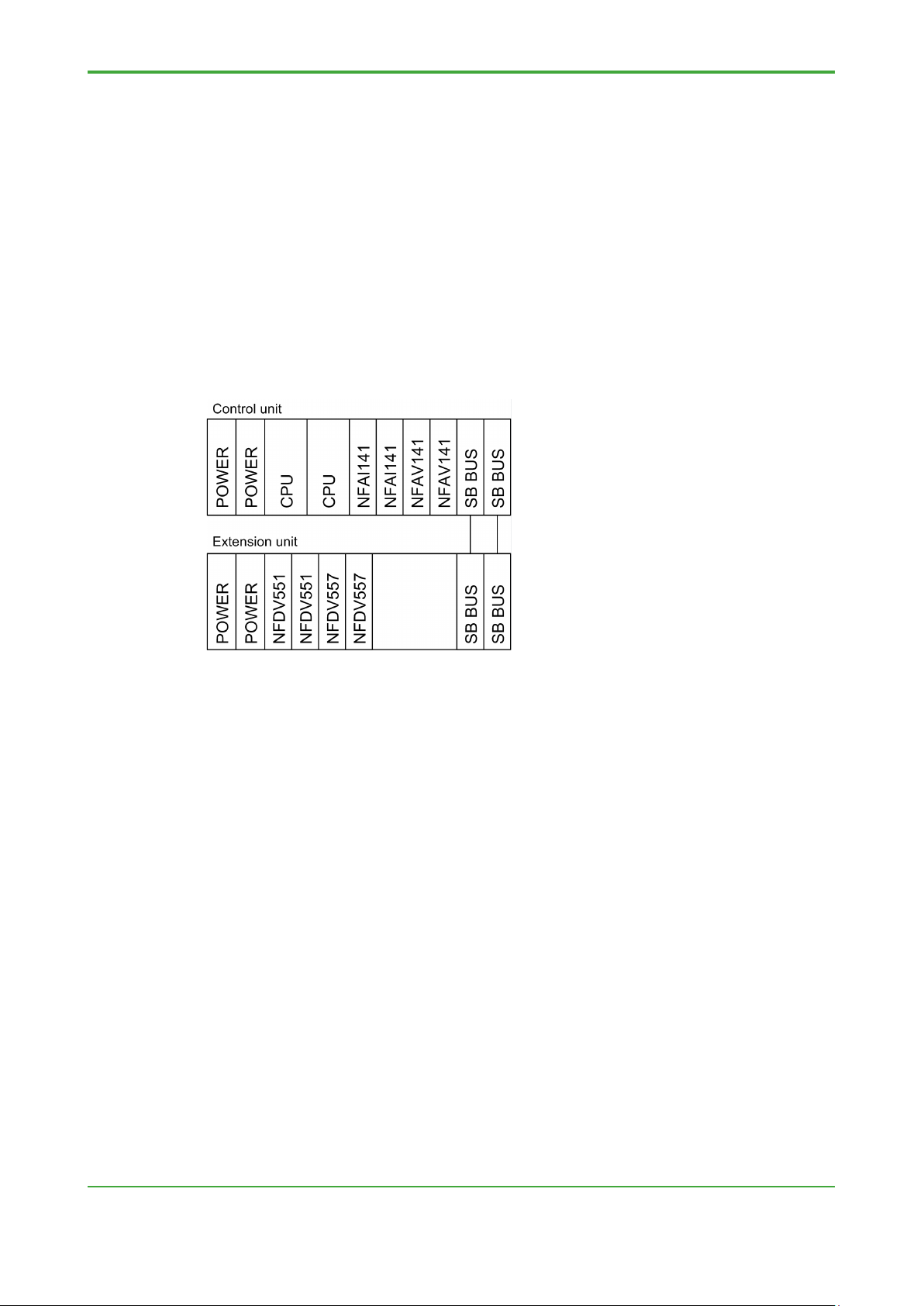

An example of current consumption calculation

This example calculates the current consumption of the control unit, as well as,

that of the extended unit, shown in the figure below.

- Calculating current consumption of control unit

System power supply

Current consumption of NFCP501 modules : 1200 mA×2 =2400 mA

Current consumption of NFAI141 modules : 310 mA×2 = 620 mA

Current consumption of NFAV141 modules : 350 mA×2 = 700 mA

Current consumption of SB bus repeat modules : 500 mA×2 =1000 mA

Total: 4720 mA < rated output current of 7.8A

Analog field power supply

Current consumption of NFAI141 : 450mA×2 = 900mA

Total: 900mA < rated output current of 4A

NFAV141 and SB bus repeat modules do not require analog field power and

are thus excluded from the calculation. (E2 bus interface module does not

require analog field power too)

- Calculating current consumption of extension unit

System power supply

Current consumption of NFDV551 modules : 700mA×2 = 1400mA

Current consumption of NFDV557 modules : 550mA×2 = 1100mA

Current consumption of SB bus repeat modules : 500mA×2 = 1000mA

Total: 3500mA < rated output current of 7.8A

Page 13

<2. Basic Design and Function Design>

5

TI 34P02K35-02E

Jun. 6, 2018-00

Analog field power supply

Current consumption of NFDV551 modules : 60mA×2 = 120mA

Current consumption of NFDV557 modules : 60mA×2 = 120mA

Total: 240mA

(For digital output cards, 24Vmust be supplied to each module)

SB bus repeat module does not require analog field power and are thus

excluded from the calculation. (E2 bus interface module does not require

analog field power too)

In this example, the current consumption of the system power supply, as well as

the current consumption of the analog field power supply, of both the control unit

and the extension unit, are below the rated output of the power supply modules so

there is no problem.

● I/O Modules Requiring Analog Field Power Supply

In the power consumption calculation example given above, some of the I/O

modules of the FCN-500 and FCN-RTU units require analog field power supply.

SEE ALSO

Section A1.13.3 "Field Power Supply" of IM “STARDOM FCN/FCJ Guide."

Any of such I/O modules, when used, require 24 V DC to be supplied to the power

supply module, in addition to the power supply used for control. Check the

hardware specification for 24 V DC power supply.

Page 14

<2. Basic Design and Function Design>

6

TI 34P02K35-02E

Jun. 6, 2018-00

2.1.2 Checking Operation Specifications of I/O Modules

Compare the operation specification of each I/O module against the requirement

specification to ensure that requirements can be met.

For more details, see Section 8.1, "Checking Operation Specifications of I/O

Modules;" Section 8.2, "Checking Serial Communication Specification" of Chapter

8, "Detailed Description," as well as the "STARDOM FCN/FCJ Guide."

2.1.3 Checking Automatic Loading of I/O Modules

Operation settings, device label names and all other configuration information of

I/O modules and communication modules are saved in the on-board flash

memory of the FCN-500 and FCN-RTU. Using Resource Configurator, whether to

automatically load configuration information into a new I/O module when an I/O

module is replaced can be specified.

If automatic loading is enabled, configuration information stored on the flash

memory is loaded and a replacement I/O module begins operations

automatically provided if the same model name I/O module being replaced.

Otherwise, confirmation information is not loaded automatically.

If automatic loading is disabled, configuration information stored on the flash

memory is not loaded automatically regardless of the model of the

replacement module.

In such case, redefine and download settings using the Resource Configurator

and rebooting the FCN-500 or FCN-RTU is required.

Page 15

<2. Basic Design and Function Design>

7

TI 34P02K35-02E

Jun. 6, 2018-00

2.1.4 Measures for Duplexing

Within a STARDOM system, the following components can be duplexed:

CPU of FCN-500

Power supply module of FCN-500 or FCN-RTU (used long base module only)

SB bus of FCN-500

Control network (control LAN) of FCN-500

Communication application

Check precautions described below for duplexed system components.

● FCN-500 Operation When Configured with Duplexed CPU

The operation specification and precautions applicable when the CPU of an FCN500 is duplexed are given in the following IM and TI documents:

Section B1.3.3, “Precautions on the Creation of Control Applications” of IM

“STARDOM FCN/FCJ Guide”

Chapter C2, “Duplex CPU Module (FCN-500)” of IM “STARDOM FCN/FCJ

Guide”

Section 7.2, “Operation using Duplex FCN CPU Modules" of TI “FCN-500

Technical Guide”

● FCN-500 and FCN-RTU Operation When Configured with Duplexed

Power Supply Module

Duplexing of the power supply module can be achieved by simply installing two

power supply modules on a long base module.

SEE ALSO

For details on the operation specification of an FCN-500 configured with duplexed power supply

module, see Section 3.1.2, “Power Supply Module” of TI “FCN-500 Technical Guide,” Section 3.1.2,

“Power Supply Module” of TI “FCN-RTU Technical Guide.”

● FCN-500 Operation When Configured with Duplexed E2 Bus/SB Bus

Duplexing of the E2 bus/SB bus can be achieved simply by configuration using

Resource Configurator.

SEE ALSO

For details on the operation specification of an FCN-500 configured with duplexed SB bus, see

Section 3.4, “SB Bus Repeat Module for FCN” of TI “FCN-500 Technical Guide.”

Page 16

<2. Basic Design and Function Design>

8

TI 34P02K35-02E

Jun. 6, 2018-00

● FCN-500 Operation and Precautions Regarding Duplexed Control

Network

For details on the operation specification and precautions applicable to a

STARDOM system configured with duplexed control network, see:

Section D2.2.2, “Control Network Duplexed Configuration” of IM “STARDOM

FCN/FCJ Guide”

Section 2.6 "Duplexing Control Network" of TI “STARDOM Network

Configuration Guide”

• Diagnostic communication interval

In a duplexed control network, diagnostic frames are transmitted periodically

through multicast communication.

If two successive diagnostic frame transmissions are unsuccessful, system

network failure is assumed, and control network switchover is performed.

One diagnostic frame is transmitted and one receive processing is performed

for each duplexed device within each cycle. When there are many duplexed

devices, the CPU load increases proportionally due to increased receive

processing of diagnostic frames. The diagnostic communication interval is

defined as 500 ms by default and can be lengthened as appropriate if many

duplexed devices are present on the network.

SEE ALSO

For details, see Section 2.6.1, “The Duplexed Network Function Provided on STARDOM” of TI

“Network Configuration Guide.”

● Operation and Precautions Regarding Duplexed Communication

Application

To implement duplexed communication with non-STARDOM equipment such

as FA-M3, third-party PLCs, and remote I/O, a communication application

must include logic for executing a transmission path switchover when a

communication error is detected.

SEE ALSO

For more details, see Section 2.6.2, “Duplexing Communications Using an Application” of TI

“Network Configuration Guide.”

Page 17

<2. Basic Design and Function Design>

9

TI 34P02K35-02E

Jun. 6, 2018-00

2.2 Pre-Application Creation Checklist

This section covers checking items on application programming tools,

application size, etc, before creating applications.

2.2.1 Checking Revisions of FCN-500, FCN-RTU and Tools

Before programming applications, check the revisions of the FCN/FCJ Basic

Software and each tool to be used in subsequent engineering. These include:

- FCN/FCJ Basic Software (stored on the system card)

- Resource Configurator

- Logic Designer

- Various application portfolios

The revision of the FCN/FCJ Basic Software should match the revision of the

CPU module (on-board flash memory).

SEE ALSO

For details on how to check the revision of the system card, see "● Revision of System Card Used”

of Section 5.1.1, “Precautions of Testing when Using In-house Equipment.”

● For New System Implementation

When implementing a new system, using the latest versions of the FCN/FCJ

Basic Software and tools listed above is recommended.

If application development is to be carried out using in-house development

equipment instead of the target equipment, upgrade the FCN-500, FCN-RTU,

Logic Designer and all software tools to the latest versions before starting

application creation.

● For System Modification

When modifying an existing application using in-house development equipment,

whether revisions of the FCN/FCJ Basic Software and the various tools listed

above of the in-house equipment match those of the existing system is needed to

be checked.

When carrying out engineering for system modification using in-house equipment

having revisions later than the existing system, beware of using new system

functions not supported in the existing system. Otherwise, the application may,

despite thorough testing on in-house equipment, fail to be downloaded to the

existing system or, even if successfully downloaded to the existing system, fail to

run or fail to run correctly.

Moreover, even if a function used in the modified application is present on the

existing system, its operation specification may be different because of functional

enhancements included in the revision upgrade so that the modified application

may behave differently when tested on in-house equipment and when executed

on the existing system after delivery.

Page 18

<2. Basic Design and Function Design>

10

TI 34P02K35-02E

Jun. 6, 2018-00

● For System Expansion

STARDOM allows intermixing of FCN-500 and FCN-RTU of different revisions

within a system. When implementing system expansion through addition of a new

FCN-500 and FCN-RTU to an existing system, consider whether to use the latest

revision for the new FCN-500 and FCN-RTU or to match the existing system

revision.

Consider the pros and cons described below, and decide whether to use the latest

revision for the new FCN-500, FCN-RTU and intermix different FCN-500, FCNRTU revisions within the system, to standardize revisions throughout the system

by downgrading the new FCN-500, FCN-RTU to match the existing system

revision, or to standardize to the latest revision throughout the system by

upgrading the existing system.

• Using the latest revision

In this case, all supported functions can be used.

However, beware that the operation specifications of some functions may

have changed due to functional enhancements included in the revision

upgrade so that the expanded system may behave differently from the existing

system. Furthermore, system revision control may be more tedious with

intermixing of FCN-500 and FCN-RTU s of different revisions.

• Matching the existing revision

In this case, the new FCN-500 and FCN-RTU will behave the same as the

existing system but new functionality included in the latest revision will not be

available. However, system revision control will be easier with a standardized

FCN-500 and FCN-RTU revision throughout the system.

The FCN-500 is used R4.02 or later.

● Procedure for System Downgrade

The procedures are essentially the same for downgrading and upgrading the

revision of in-house equipment to match the revision of an existing system for the

purpose of system modification or system expansion engineering.

When upgrading, use the DVD-ROM for the latest system revision; when

downgrading, use the DVD-ROM for the required system revision instead.

Observe the following precautions for downgrading the FCN/FCJ Basic Software.

• Precautions when downgrading FCN/FCJ Basic Software

FCN-500 can not be downgrading before than R4.02.

FCN-RTU can not be downgrading before than R2.10.

To downgrade a system, follow essentially the same procedure for system

upgrade by decompressing the Basic Software stored on the DVD-ROM for

the required revision to the PC, and then issuing an “FcxRevup” command at

the command prompt but include a “-s” option.

Page 19

<2. Basic Design and Function Design>

11

TI 34P02K35-02E

Jun. 6, 2018-00

If you execute the plain “FcxRevup” command without the “-s" option, as is

usually done when performing a revision upgrade, configuration information

stored on the flash memory will be retained after command execution. This

may cause an error if the existing configuration information cannot be

interpreted by the older revision after system downgrade. Therefore, when

downgrading a system, execute the "FcxRevup” command with the “-s" option

to perform a clean upgrade along with initialization of configuration

information.

● Checking Service Packs and Service Releases

Service releases or service packs may have been published for some system

revisions.

For new system implementation, after installing the latest system revision, check

for the presence of published service releases and service packs, and apply them

as required. Similarly, after having upgraded or downgraded the revision of inhouse equipment to match the existing system, check whether any service

releases and service packs have been previously applied to the existing system,

and apply them accordingly to the in-house equipment.

Page 20

<2. Basic Design and Function Design>

12

TI 34P02K35-02E

Jun. 6, 2018-00

2.2.2 Checking FCN-500, FCN-RTU Control Application Size

Estimate the size of an FCN500 or FCN-RTU control application from the

requirement specification and ensure that there is no problem.

SEE ALSO

For details on how to estimate the size of an application, see Section 4.5.2, “Calculation of Control

Application Capacity" of TI "FCN-500 Technical Guide," Section 4.5.2, “Calculation of Control

Application Capacity" of TI "FCN-RTU Technical Guide."

Estimate the control application size by estimating the ADLST size and retain data

size as described in TI “STARDOM Technical Guide.”

To investigate the utilization of application resources, calculate the respective

utilization rates of ADLST capacity of retain data capacity, and take the larger of

the two values as the system-wide utilization rate.

The checking items described in this section is based on calculated values, which

should be verified by checking the actual control application size during function

test.

SEE ALSO

For details, see Section 5.5.2, “Checking Application Size.”

• For projects using NPAS POUs

Projects using NPAS POUs usually exceed the ADLST size limit (if ever it is

exceeded) before exceeding the retain data size limit.

Therefore, first estimate the ADLST size, and if it is within the 4MB upper limit,

you can assume that there is no application size problem.

You can also use the ADLST utilization as an indicator of the utilization of the

control application.

• For projects not using NPAS POUs

For projects not using NPAS POUs, the ADLST size and retain data size

depend on how many variables are specified with OPC property and RETAIN

property during engineering.

In this case, estimate both ADLST size and retain data size and if both values

are within their respective upper limits, it can be assumed that there will be no

application size problem.

Furthermore, use the larger of the ADLST and retain data utilization rates as

an indicator of the utilization rate of the control application.

Page 21

<2. Basic Design and Function Design>

13

TI 34P02K35-02E

Jun. 6, 2018-00

NPAS_POU's execution time

Control task interval

CPU load (%) =

x 100%

2.2.3 Checking FCN-500, FCN-RTU Performance

Estimate the execution time of an FCN-500 or FCN-RTU control application from

the requirement specification and determine the CPU load.

SEE ALSO

For details on how to estimate performance, see Section 4.5.3, “Confirmation of Performance" of TI

"FCN-500 Technical Guide", Section 4.5.3, “Confirmation of Performance" of TI "FCN-RTU Technical

Guide".

The checking items described in this section is based on calculated values, which

should be verified by checking the actual CPU load during function test.

SEE ALSO

For details, see Section 5.5.1, “Checking CPU Load."

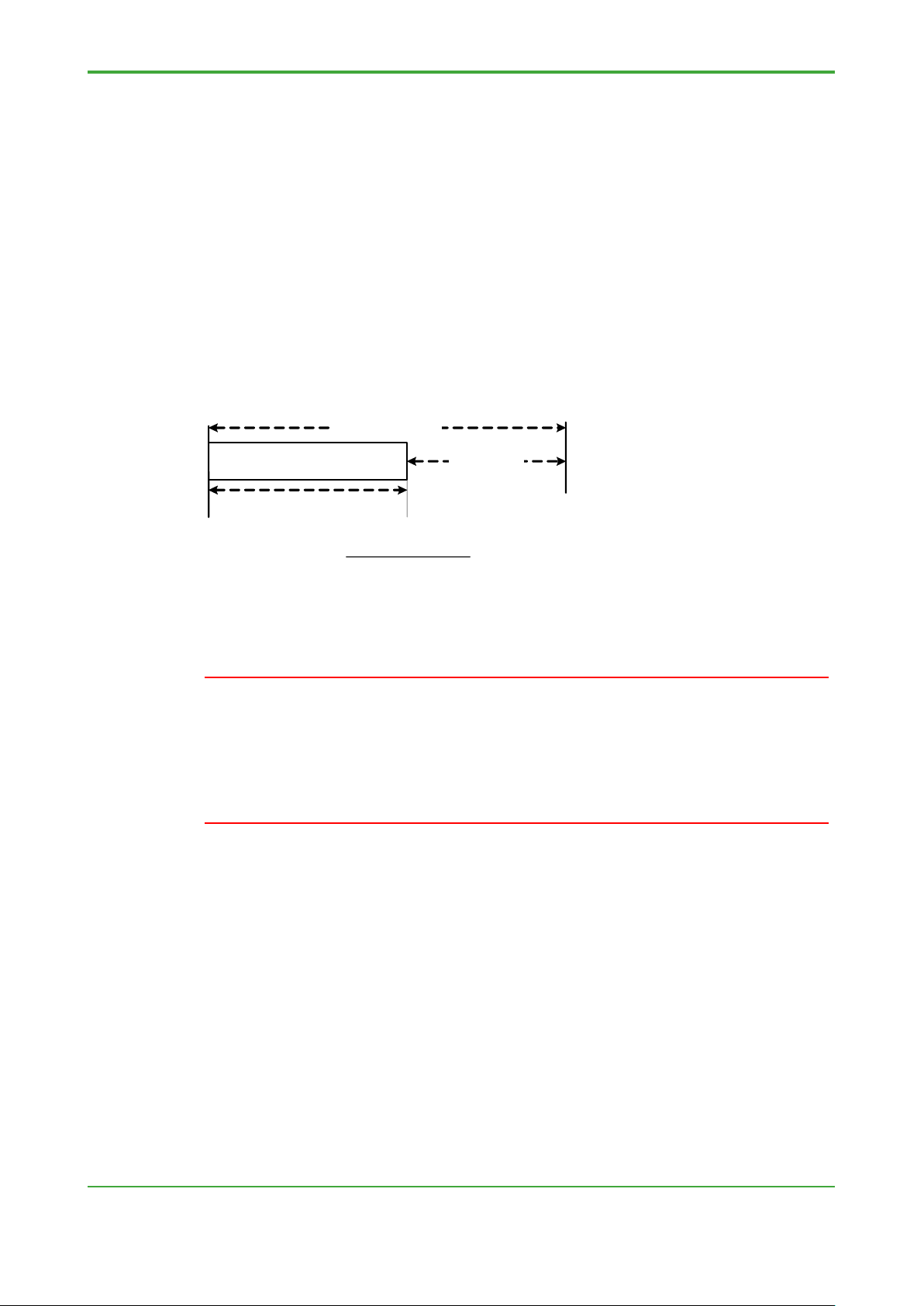

● Calculating Execution Time and CPU load of Control Application

The method for estimating the execution time of a control application depends on

whether the project uses NPAS POUs.

• For projects using NPAS POUs

For a project using NPAS POUs, determine the execution time as described in

the above-mentioned TI document, and calculate the CPU load using the

following formula:

• For projects not using NPAS POUs

The above-mentioned TI document does not describe how to calculate the

execution time of a project not using NPAS POUs. This is because the

execution time of non-NPAS_POU blocks are very short and hence need not

be considered during the estimation phase.

TIP

In the CPU function specification description of the GS document “FCN Autonomous Controller

Functions (FCN-500)” or “FCN-RTU Low Power Autonomous Controller Functions”, the execution

speed is given as:

FCN-500s Execution speed: Approx. 10 µs per kilosteps in an IL program

FCN-RTUs Execution speed: Approx. 50 µs per kilosteps in an IL program

This means that about 10 µs (FCN-500) or 50 µs (FCN-RTU) is required to process 1 kilosteps of an

IL program block.

Each function such as AND or OR coded in IL is equivalent to 3 steps.

Therefore, the execution time of 1000 functions is about 30 µs (FCN-500) or about 150 µs (50 µs x

3, FCN-RTU).

Based on this calculation, about 195,000 functions (FCN-500) or about 65,000 functions (FCN-RTU)

can be processed within 10 milliseconds.

Page 22

<2. Basic Design and Function Design>

14

TI 34P02K35-02E

Jun. 6, 2018-00

IMPORTANT

Execution time

Scan cycle

Idle time

Execution time

Scan cycle

CPU load ≤ 60%

Executes communication

● Recommended CPU Load

The following FCN-500 and FCN-RTU functions are executed during CPU idle

time:

- Ethernet communications of FCN-500 and FCN-RTU

- Communication with VDS/ASTMAC data server

- Inter- FCN-500 and FCN-RTU communication

- Various inter-device communications such as Modbus communications

using Ethernet or serial communications

- Operation or setup from Logic Designer or Resource Configurator

- Duolet function

- Downloading of boot project and source

To allow such processing, it is recommended that the CPU load be kept at 60% or

lower.

and Duolet functions

CPU load (%) =

x 100 %

The CPU load calculation described in this section considers only the execution

time of the control application. In an actual system, execution time also includes

CPU module and I/O module access time. Therefore, consider a CPU load slightly

higher than the value estimated here.

The I/O module access time varies with the number of I/O modules and normally

ranges between several milliseconds to 20 milliseconds.

Page 23

<2. Basic Design and Function Design>

15

TI 34P02K35-02E

Jun. 6, 2018-00

2.2.4 Determining FCN-500, FCN-RTU Scan Cycle

As described in the previous section 2.2.3, “Checking FCN-500 and FCN-RTU

Performance,” it is recommended that CPU load be kept at 60% or lower.

Check that the estimated CPU load is 60% or lower, and there is no problem with

the scan cycle stated in the requirement specification if applicable. If the CPU

load exceeds 60%, investigate rectification measures.

● Setting Range for Scan Cycle

The scan cycle of the FCN-500 can be set to a value between 5 ms and 32760

ms in 5 ms increments. The scan cycle of the FCN-RTU can be set to a value

between 10 ms and 32760 ms in 10 ms increments. When setting the scan cycle

to 4 seconds or longer, note the precautions described later.

● When a Required Scan Cycle is Stated in Requirement Specification

If a scan cycle is stated in the requirement specification, use the stated value to

estimate the CPU load and check that it is 60% or lower. If the CPU load exceeds

60%, consider whether it can be reduced using the methods described later.

● When no required scan cycle is stated in requirement specification

If no scan cycle is stated in the requirement specification the engineer is given the

responsbility, determine the scan cycle from the execution time of the control

application estimated as described in Section 2.2.3, “Checking FCN-500 and

FCN-RTU Performance.”

● Example for Determining Scan Cycle

If engineer is asked to decide on the scan cycle, use Logic Designer’s default

scan cycle of 100 ms as a baseline consideration.

Example 1: When estimated control execution time is 20 ms

Estimated CPU load = 20 ms/100 ms = 20%

Based on the estimated CPU load of 20%, even considering the time for

accessing I/O modules, the CPU load is expected to be below the

recommended limit of 60%. Therefore, the scan cycle of 100 ms should be

fine.

Example 2: When estimated control execution time is 50 ms

Estimated CPU load = 50 ms/100 ms = 50%

The estimated CPU load of 50% is below the recommended limit of 60%.

However, if the time for accessing I/O modules is taken into consideration, the

CPU load is expected to approach 60%, or even exceed 60% if many I/O

modules are installed.

In this example, we should look into reducing the CPU load using the methods

described hereafter.

If the scan cycle is set to 100 ms, download the application early on in application

creation to check that there is indeed no CPU load problem.

Page 24

<2. Basic Design and Function Design>

16

TI 34P02K35-02E

Jun. 6, 2018-00

Execution time

Scan cycle

CPU load

70 ms

100 ms

70%

70 ms

200 ms

35%

IMPORTANT

● Ways for Reducing CPU Load

Consider the ways described below for reducing CPU load.

• Lengthen the scan cycle

By lengthening the scan cycle, CPU load can be reduced even if the execution

time remains unchanged.

After changing the scan cycle, which is the most fundamental setting affecting

FCN-500 and FCN-RTU operation, always check that control is not adversely

affected.

• Define a task with long control cycle and move the application

For an application that can tolerate a long control cycle, define a task with a

longer cycle and move. By doing so, it reduces the overall CPU load.

Page 25

<2. Basic Design and Function Design>

17

TI 34P02K35-02E

Jun. 6, 2018-00

Control Cycle

Windup Time

100 ms

3 seconds

500 ms

15 seconds

1000 ms (= 1 minute)

30 seconds

2000 ms (= 2 minutes)

60 seconds (= 1 minute)

● Precautions When Using a Long Scan Cycle

• When scan cycle is 4 seconds or longer

Analog/digital output modules are defined with line access loss time of 4

seconds.

If the scan cycle is 4 seconds or longer, the interval between FCN-500 or

FCN-RTU CPU accesses of the output modules will be 4 seconds or longer.

Depending on individual setting, an output module may assume that a CPU

error has occurred and perform output fallback.

SEE ALSO

For details, see Section 8.1.2, "Checking Operation Specification of Analog/Digital Output” of

Chapter 8, “Detailed Description.”

• About windup of NPAS POUs

For NPAS POU, after an FCN-500 or FCN-RTU reboot, windup processing is

executed for 30 scan cycles before control computation begins.

As the windup time is proportional to the scan cycle, lengthening the scan

cycle delays the starting of control computation after an FCN-500 or FCN-RTU

boot.

Page 26

<2. Basic Design and Function Design>

18

TI 34P02K35-02E

Jun. 6, 2018-00

2.2.5 Retentive Variable (Retain Data) Considerations

Retain data of the FCN-500 and FCN-RTU may reside in the following locations:

- Non-volatile memory (factory setting)

- Volatile memory

- Flash memory

Based on the requirement specification, decide whether retain data is to reside in

volatile memory or non-volatile memory, as well as the procedure for saving retain

data to the flash memory.

SEE ALSO

For details on considerations of retain data in FCN-500 and FCN-RTU, see Section 4.3.5, “Retentive

Variables” of TI “FCN-500 Technical Guide,” Section 4.3.5, “Retentive Variables” of TI “FCN-RTU

Technical Guide.”

● Retain Data Residing in Memory

Retain data can be stored in either volatile memory or non-volatile memory using

Resource Configurator and is always resident in one of these locations.

By default factory setting, retain data is resident in non-volatile memory.

- Non-volatile memory

Retain data, when resident in non-volatile memory, is retained by a backup

battery even if the FCN-500 or FCN-RTU is powered off.

- Volatile memory

Data, including retain data, resident in the volatile memory is cleared when the

FCN-500 or FCN-RTU is powered off.

The management of retain data is rather different depending on whether it resides

in volatile or non-volatile memory.

● Saving Retain Data to Flash memory

Retain data residing in memory can also be backed up to the flash memory either

manually by an operator or by executing a save instruction from an application.

An operator can manually execute the backup using “Save Retain Data” from the

FCN/FCJ “Maintenance Menu” or, equivalently, set global variable

"GS_RETAIN_SV_SW” to TRUE in Logic Designer’s DEBUG mode.

Depending on the conditions present after an FCN-500 or FCN-RTU reboot, retain

data may be restored from the flash memory so saving retain data to the flash

memory is an important aspect of retain data management.

SEE ALSO

For details on executing a save instruction from an application, see Section 9.1.12, “Logic for Saving

Retain Data” of Chapter 9, "Advanced Engineering ".

In the FCN-500, the retain data is stored in the flash memory, and can be saved on the SD card. For

details, refer to D3.4 "Backup of all data to SD card (FCN-500)" of IM “STARDOM FCN/FCJ Guide”

Page 27

<2. Basic Design and Function Design>

19

TI 34P02K35-02E

Jun. 6, 2018-00

TIP

In subsequent description, the term "retain data on the flash memory" refers to retain data which

was current as at the time when it was saved to the system card but not necessarily the most up-todate.

For instance, if retain data was saved a week ago, “retain data on the flash memory" would be one

week old.

● Behavior of Retain Data when FCN-500 or FCN-RTU Power is Off/On

1. If retain data is resident in non-volatile memory

As described earlier, retain data residing in non-volatile memory is retained even

after the FCN-500 or FCN-RTU is powered off. When the FCN-500 or FCN-RTU

is powered on, the system reboots using retain data in the non-volatile memory so

retain data persistency is guaranteed.

However, under certain circumstances, retain data in the non-volatile memory

may not be restored. Instead, all retentive variables are first initialized to their

initial values after power on. If retain data has been previously saved to the flash

memory, that data is restored. Otherwise, the FCN-500 or FCN-RTU reboots with

all initial variable values. Some circumstances under which retain data in the nonvolatile memory will not be restored are listed below.

• If the structure of retain data of the application at startup does not match

the structure of retain data in the non-volatile memory

If the control application running before power off is inconsistent with the boot

project on the flash memory on the number, data type or some other aspect of

retain data, retain data in the non-volatile memory will not be restored after

power on.

• If the backup battery was removed

If the backup battery is removed when power is off, retain data, like all other

data residing in the non-volatile memory, will be lost and hence cannot be

restored at power up.

• If the CPU module or FCJ has been replaced

If the CPU module or FCJ is replaced, retain data residing in the non-volatile

memory of the hardware naturally cannot be restored.

2. If retain data is resident in volatile memory

Retain data stored in volatile memory is lost when the FCN-500 or FCN-RTU is

powered off.

After power on, all retentive variables are first initialized to their initial values. If

retain data has been previously saved to the flash memory, that data is restored.

Otherwise, the FCN-500 or FCN-RTU reboots with all initial variable values.

Page 28

<2. Basic Design and Function Design>

20

TI 34P02K35-02E

Jun. 6, 2018-00

● Behavior of Retain Data in FCN/FCJ Start Mode

Performing offline download to FCN-500 or FCN-RTU from Logic Designer stops

control on the FCN-500 or FCN-RTU. However, as power supply is not

interrupted, retain data, even if resident in volatile memory, retain their data. As

such, the behavior of retain data after data download in the FCN/FCJ start mode

is the same regardless of whether retain data is resident in volatile or non-volatile

memory.

1. If FCN/FCJ is warm started

1.1 If there is no change in retain data area

If there is no change in the retain data area, control is started using retain data

values current before offline download, even if the control application has been

changed.

1.2 If retain data structure has been changed

If the number or data type of retain data has been changed so that the retain

data structure is modified, retain data in the memory can no longer be used.

SEE ALSO Point 1 of TIP below

In this case, all retentive variables are first initialized to their initial values. If

retain data has been previously saved to the flash memory, control is restarted

using that data.

SEE ALSO Point 2 of TIP below

If no retain data is saved on the system card, the FCN-500 or FCN-RTU is

rebooted with initial values for retentive variables.

Page 29

<2. Basic Design and Function Design>

21

TI 34P02K35-02E

Jun. 6, 2018-00

TIP

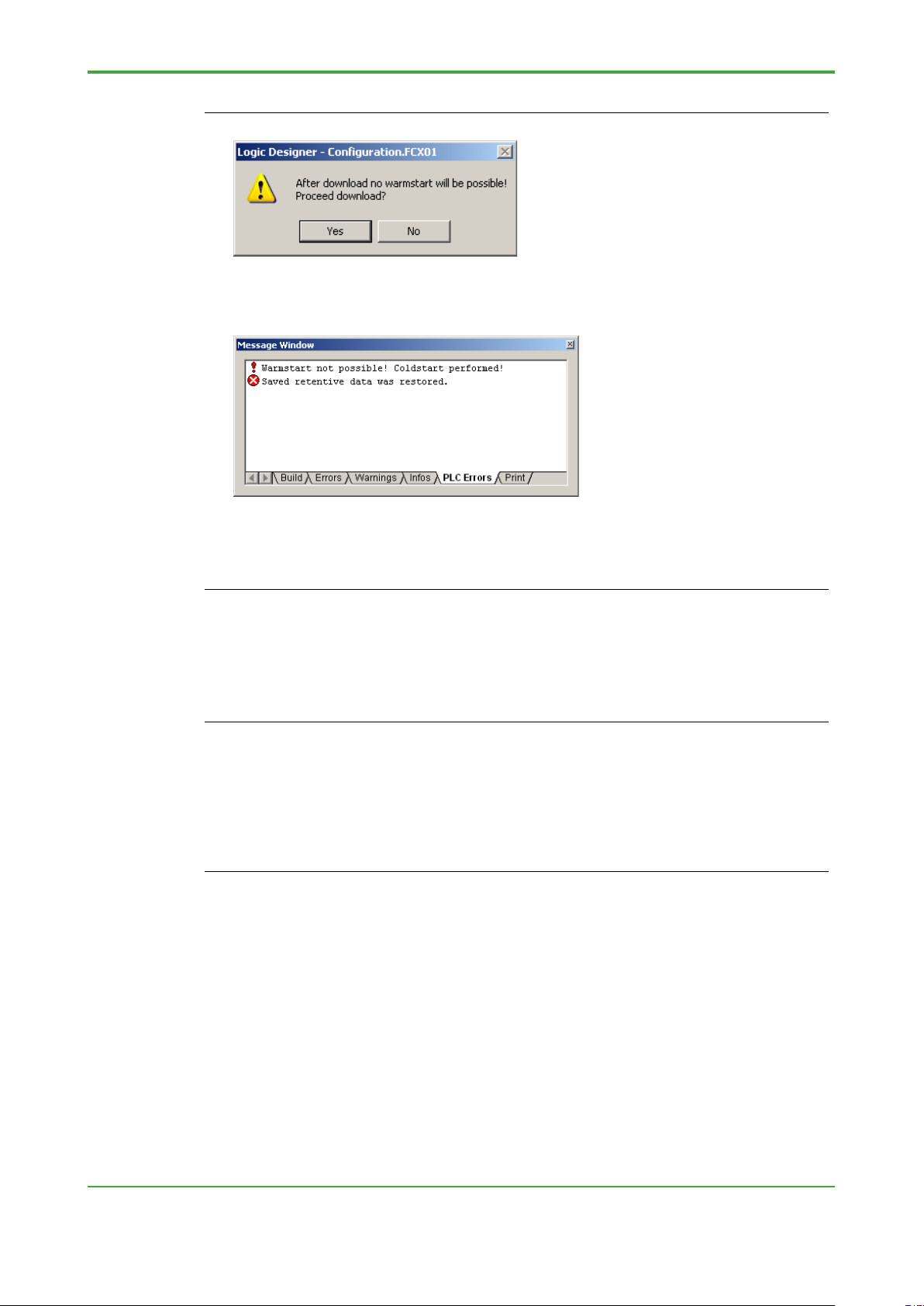

1. In the case of 1.2 described above, the following dialog is displayed before offline download:

This message indicates that warm start using retain data residing in the memory will not be

possible after downloading. It does not mean that warm start, in itself, is not allowed.

2. In this case, performing a warm start after completion of offline download generates the following

PLC error:

The first line of the message means that cold start was performed as warm start using retain

data in memory was not possible. The second line of the message means that the FCN-500 or

FCN-RTU was restarted using retain data saved on the flash memory.

From these two error messages, retain data saved on the flash memory was restored by a warm

start after an offline download is understood.

2. If FCN/FCJ is cold started

After a cold start, the FCN-500 or FCN-RTU initializes all variables and start

controlling. In other words, all retentive variables are initialized by a cold start.

TIP

The retain data structure will be changed by the following events:

- Adding or deleting an NPAS POU having one or more access parameters or engineering

parameters specified as retain data

- Specifying a non-retentive variable as a retentive variable or vice versa

- Changing the data type of a variable specified as retain data

The behavior of retain data on the FCN-500 or FCN-RTU start mode described above applies

similarly when the FCN-500 or FCN-RTU is stopped from Logic Designer’s Application Control

dialog,and then restarted without performing downloading.

Page 30

<2. Basic Design and Function Design>

22

TI 34P02K35-02E

Jun. 6, 2018-00

● Behavior of Retain Data on Online Download

Even if a modification involves a change in the retain data area, persistency of

retain data is guaranteed so long as the modification is online downloaded. Newly

added retentive variables, however, will be set to initial values.

● Relationship between Initial Value and Retained Value

After an FCN-500 or FCN-RTU warm start, even if initial values are specified for

retain dat, their retained values take precedence.

● Summary

By default setting, FCN-500 or FCN-RTU is configured so that retain data is

resident in non-volatile memory. As such, you can first review the specification on

this basis.

Data resident in non-volatile memory retain their values even after the FCN-500

or FCN-RTU is powered off because of a backup battery. These retained values

are restored at the next FCN-500 or FCN-RTU power on. In this way, the most upto-date data values are always maintained so keeping retain data resident in nonvolatile memory is the usual practice.

However, even if retain data is made resident in non-volatile memory, we

recommend saving retain data to the flash memory regularly as a safeguard

against unexpected situations where data retained in memory cannot be used. In

addition to saving retain data manually, saving data regularly using a control

application is also recommended.

SEE ALSO

For details, see Section 9.1.12, “Logic for Saving Retain Data” of Chapter 9, “Advanced

Engineering.”

If a backup of retain data is saved on the flash memory, in case of event that data

retained in non-volatile memory cannot be used for whatever reason, retained

data values as at the time of saving will be restored from the system card. by

doing so, it avoids the worst-case scenario where all retain data variables are

initialized.

Compared to keeping retain data resident in non-volatile memory, keeping retain

data reside in volatile memory enables a shorter execution time, and hence a

shorter scan cycle for FCN-500 or FCN-RTU operation. However, if the FCN-500

or FCN-RTU is powered off and on again, retain data values before power off is

lost and retain data values are always restored from the flash memory.

To prepare for unexpected contigency, save retain data to the flash memory

regularly, and also by manually whenever retain data is modified.

SEE ALSO

For details on scan cycle, see Section 2.2.4, “Determining FCN-500 and FCN-RTU Scan Cycle.”

Page 31

<2. Basic Design and Function Design>

23

TI 34P02K35-02E

Jun. 6, 2018-00

2.2.6 Time Synchronization

The FCN-500 or FCN-RTU allows time synchronization among external devices

supporting SNTP (Simple Network Time Protocol).

SEE ALSO

For details on time synchronization of FCN-500 or FCN-RTU, see:

- Section B1.9.4, “Time Synchronization Function” of IM “STA R DOM FCN/FCJ Guide”

- Section 2.3.3, “Time Synchronization Function” of TI “FCN-500 Technical Guide”

- Section 2.3.3, “Time Synchronization Function” of TI “FCN-RTU Technical Guide”

● For FCN-500 Running as SNTP Server

After setting through FCN-500 maintenance page, the FCN-500 time

synchronization server automatically runs and starts time reporting. Setting for

SNTP server is done through FCN-500 maintenance page. The following file is

modified to start SNTP sever.

However, the FCN-500 cannot provide highly accurate time reporting as its

reported time includes internal timer error of -17.5 to +12 seconds/day.

1. JEROS Basic Setting File (DOUNUS.PRP)

It specifies whether to start the SNTP server function. This setting is for only

FCN-500 only. Specify YES to start SNTP Server.

Setting item: Start the SNTP server function (SntpServer)

SntpServer = YES use the SNTP server function

SntpServer = NO not use the SNTP server function,

default value

SEE ALSO

For details of JEROS basic setting file, see online-help.

● For FCN-500 or FCN-RTU Running as SNTP Client

If the FCN-500 or FCN-RTU runs as an SNTP client. To setup from the

FCN/FCJ maintenance homepage to enable the FCN-500 or FCN-RTU to

receive reported time values from an SNTP server (as an SNTP client) and

perform time synchronization accordingly.

From the FCN/FCJ maintenance homepage, time synchronization settings are

implemented at the following two locations.

1. JEROS Basic Setting File (DOUNUS.PRP)

Configure for the use of SNTP client function.

2. SNTP Setting File (S NT P.PRP)

SEE ALSO

For details of JEROS basic setting file, see online-help.

Page 32

Blank Page

Page 33

<3. Hardware Setup>

25

TI 34P02K35-02E

Jun. 6, 2018-00

IMPORTANT

3. Hardware Setup

After reviewing and deciding on a desired FCN-500 and FCN-RTU hardware

configuration as described in Chapter 2, perform the actual FCN-500 and FCNRTU hardware setup by running Resource Configurator and by accessing the

FCN/FCJ maintenance homepage using a generic web browser.

3.1 Resource Configurator Setting

Among the hardware configuration items reviewed and described in Chapter 2, the

following items are configured using Resource Configurator:

- I/O module operation

- Enabling/disabling of automatic loading of I/O modules

- Duplexed operation

- Enabling/disabling of hardware backup of retain data

SEE ALSO

- Section 2.1.2,”Checking Operation Specifications of I/O Modules”

- Section 2.1.3,”Checking Automatic Loading of I/O Modules”

- Section 2.1.4,”Measures for Duplexing”

- Section 2.2.5,”Retentive Variable (Retain Data) Considerations”

Do not turn off the power to the FCN-500 and FCN-RTU controller while

downloading Resource Configuration.

It will take up to three minutes to complete the download operation.

For details on the Resource Configurator and how to use the Resource Configurator

Editor, read “STARDOM FCN-500/FCN-RTU Primer – Fundamental”(TI 34P02K1302) and the Resource Configurator online help documentation.

Page 34

<3. Hardware Setup>

26

TI 34P02K35-02E

Jun. 6, 2018-00

● Precautions When Using FCN-500 or FCN-RTU with No Actual I/O

Modules

Resource configurator R4.20 or later can maintain unimplemented I/O module

definition.

If FCN-500 or FCN-RTU is not installed with the required I/O modules and new

hardware configuration us downloaded using Resource Configurator R4.10 or

earlier, existing I/O module configuration already defined will be overwritten and lost.

As an example, consider the following scenario.

An engineer defines the required device labels and I/O settings for target equipment

installed with the required I/O modules, and downloads the project to the FCN-500

or FCN-RTU.

However, as application creation and debugging is to be carried out using an inhouse FCN-500 or FCN-RTU, he relocates the CPU module on the target FCN-500

or FCN-RTU to the in-house FCN-500 or FCN-RTU and reboots the FCN-500 or

FCN-RTU.

When the engineer connects to the in-house FCN-500 or FCN-RTU using Resource

Configurator at this stage, the system reads a state of no I/O module.

The engineer then downloads this information using Resource Configurator,

resulting in I/O module information being overwritten, and information defined

previously is lost permanently.

To prevent this, it is advisable not to modify hardware settings using Resource

Configurator when working with no I/O module installed or from using a different set

of I/O modules than what is currently defined in the configuration.

● Using Resource Configurator Editor

Resource Configurator works by first reading configuration information from a

running FCN-500 or FCN-RTU, and then downloading new configuration information

after it has been modified on a PC. As such, it cannot be used to perform hardware

setup without a running FCN-500 or FCN-RTU.

To perform hardware setup when an FCN-500 or FCN-RTU is not available, such as

in the early phase of engineering or in a job involving modification of an existing

system, use Resource Configurator Editor instead.

Settings defined using Resource Configurator Editor can be saved to a file, and

downloaded later using Resource Configurator when the FCN-500 or FCN-RTU is

available for connection.

Page 35

<3. Hardware Setup>

27

TI 34P02K35-02E

Jun. 6, 2018-00

3.2 Setup in Web Browser

Detailed setup and various FCN-500 or FCN-RTU operations can be achieved using

FCN/FCJ maintenance homepage through a generic web browser.

Among the hardware configuration items reviewed and decided as described in

Chapter 2, the following items can be configured by accessing the FCN/FCJ

maintenance homepage:

- Serial communication port

- Time synchronization

SEE ALSO

- Section 8.2, “Checking Serial Communication Specification (Serial Communication Port Settings)”

- Section 2.2.6, “Time Synchronization”

In addition to the above configuration items, setting system date and time, saving

retain data, read log files of the FCN-500 or FCN-RTU, reading various properties of

the FCN-500 or FCN-RTU , display CPU status and display resource configuration

can be achieved from the FCN/FCJ maintenance homepage.

SEE ALSO

For details on the operation and configuration items accessible on the maintenance homepage, see:

- Chapter B2, “Advanced Settings Using Web Browser“ of IM “STARDOM FCN/FCJ Guide”

- Section 4.1.6, “Settings of FCN/FCJ by Web Browser“ of TI “FCN-500 Technical Guide”

- Section 4.1.6, “Settings of FCN/FCJ by Web Browser“ of TI “FCN-RTU Tec h nical Guide”

Page 36

TI 34P02K35-02E

Jun. 6, 2018-00

Blank Page

Page 37

<4. Control Application Creation>

29

TI 34P02K35-02E

Jun. 6, 2018-00

4. Control Application Creation

Control applications executed by FCN-500 and FCN-RTU autonomous

controllers are created using Logic Designer and then downloaded to the

FCN-500 and FCN-RTU.

This chapter describes precautions on Logic Designer setup, as well as basic

principle, know-how and prohibitions on creating control applications.

For details on basic user operations of Logic Designer, see TI “STARDOM FCN500/FCN-RTU Primer – Fundamental" and the Logic Designer online help

documentation.

4.1 Using Logic Designer Setup

This section describes the required setup and selection using Logic Designer

before creating a control application, along with related precautions and

know-how information.

4.1.1 Selecting a Template for a New Project

When creating a new project using Logic Designer, select a project type from a list

of template projects.

For details on how to create a new project and select a template, see Section 4.1.2,

“Creating a New Project” of TI “STARDOM FCN-500FCN-RTU Primer –

Fundamental.”

● Template Types and Selection Criteria

When creating a new project, the project type can be selected from the following

three template projects.

• STARDOM FCX

This is the minimal template, which provides only system-defined functions and

function blocks. It does not include NPAS_POU, PAS_POU, serial

communication function blocks and function blocks for Foundation Fieldbus.

As such, select this template only when creating an application that uses neither

NPAS_POU nor PAS_POU.

• STARDOM FCN-500

It is the standard template for creating control application for the FCN-500.

Necessary functions for creating the control application has been prepared in

advance. (NPAS_POU, serial communication function block, function block for

Foundation Fieldbus, Turbomashinary, etc.)

If necessary, it is possible to add other library after creating a project.

Page 38

<4. Control Application Creation>

30

TI 34P02K35-02E

Jun. 6, 2018-00

• STARDOM FCX_A

It is the standard template for creating control application for the FCN-RTU.

Necessary functions for creating the control application has been prepared in

advance. (NPAS_POU, serial communication function block, function block for

Foundation Fieldbus, Turbomashinary, etc.)

If necessary, it is possible to add other library after creating a project.

● Adding Libraries

Logic Designer allows libraries to be added to a project to expand the available

functions.

Similarly, an application using an APPF can be created by installing the required

APPF from DVD-ROM to a PC running Logic Designer, and adding the relevant

libraries to the project.

Examples:

- To create an application using NPAS POUs, select the STARDOM FCX template

when creating the project, and then add the related NPAS_POU library.

Which library to add depends on the function to be aded. For details on the type of

library to be added and the procedure, see the online help documentation of each

function.

● Logic Designer Libraries and FCN-500, FCN-RTU Licenses

No license is required for adding a library to Logic Designer. In other words,

application development using a system function is allowed even if no license for

that function is registered in the FCN-500 or FCN-RTU.

However, a PLC error will be generated and the FCN-500 or FCN-RTU cannot run if

a project is downloaded to an FCN-500 or FCN-RTU without registering with the

required licenses for all functions used in the project.

When adding a library for functionality expansion, check that the required license is

registered in the FCN-500 or FCN-RTU .

SEE ALSO

Section 2.1.5, "Required Licenses”

Page 39

<4. Control Application Creation>

31

TI 34P02K35-02E

Jun. 6, 2018-00

4.1.2 Control Task Setup

Control applications created in Logic Designer are created by assigning to tasks and

turn into instances. This section describes task types and task settings.

● General Limitations of Control Tasks

All control tasks are subject to the following limitations.

• Limit on number of tasks

Up to 16 control tasks can be created for one FCN-500 or FCN-RTU. Running

only one control task on one FCN-500 or FCN-RTU is known as single-tasking,

while creating and running multiple control tasks concurrently on one FCN-500

or FCN-RTU is called multi-tasking.

• Task name

A task name consists of up to 7 alphanumeric and underscore (‘_’) characters

with the following restrictions:

- A task name cannot begin with a number.

- A task name cannot contain two contiguous underscore (‘_’) characters.

- A task name cannot end with an underscore (‘_’) character.

● Types of Control Tasks

There are three types of control tasks with different behaviors.

• Cyclic

A cyclic task is run at a specified interval, known as scan cycle. This task type is

used for most control applications.

• Default

A default task has the lowest execution priority among all control tasks. It is not

executed at fixed intervals. Instead, it is executed automatically when all other

control tasks are idle (not executing).

A default task is executed at variable execution intervals as its execution is

dependant on the operation of other control tasks. Hence, this task type is, in

general, not used in control applications.

• System

A system task is run when there is a change in the operating status of the FCN-

500 or FCN-RTU, or when an error is detected in the FCN-500 or FCN-RTU.

Page 40

<4. Control Application Creation>

32

TI 34P02K35-02E

Jun. 6, 2018-00

IMPORTANT

Execution triggers (status change or error) for a system tasks can be selected

from a list of predefined triggers.

System tasks are run only under specific FCN-500 or FCN-RTU conditions.

Hence, this task type is, in general, not used in control applications except for

some special-purpose applications.

As default and system task types are, in general, not used in control applications,

the description hereafter is limited to the cyclic task type.

Moreover, the term "control task" hereafter shall refers to a cyclic control task.

Page 41

<4. Control Application Creation>

33

TI 34P02K35-02E

Jun. 6, 2018-00

● Control Task Settings

The Task Settings dialog is used for specifying the execution interval, execution

priority, watchdog time and other settings of a control task.

For details on the relationship between the execution interval, priority and watchdog

time of a control task, and how these settings affect task execution, see Section

4.3.3, “Task Schedule” of TI “FCN-500 Technical Guide,” Section B4.3.3, “Task

Schedule” of TI “FCN-RTU Technical Guide.”

1. Execution interval of control task

Specify the execution interval of a control task in the [Interval] field on the Task

Settings dialog. The default execution interval for a new project is 100 ms. Modify it

according to the value decided as described in Section 2.2.4, ”Determining

FCN/FCJ Scan Cycle.”

2. Priority

When running multiple tasks concurrently on an FCN-500 or FCN-RTU, specify a

value (ranging from 0 to 31 in decreasing priority) for [Priority] on the task settings

dialog as the priority level of a task relative to other tasks during execution.

Assigning different priority values to individual tasks running in multi-tasking mode is

recommended.

3. Watchdog time

When the actual execution time of a control task exceeds the specified [Watchdog

Time], a watchdog error is generated and handled according to the setup described

in Section 4.1.4, “Specifying Target FCN/FCJ.”

Setting the watchdog time to 0 disables the watchdog timer.

Set the watchdog time to the same value as the control task execution interval as

described in Section 4.1.4, “Specifying Target FCN-500, FCN-RTU” is

recommended

4. Other Settings

The other settings on the Task Settings dialog including [Stack] and [Options] can be

left unchanged at default values.

Page 42

<4. Control Application Creation>

34

TI 34P02K35-02E

Jun. 6, 2018-00

4.1.3 Multi-tasking

This section describes the considerations and precautions for running multiple tasks

concurrently on an FCN-500 or FCN-RTU.

SEE ALSO

For details on the behavior of the FCN-500 or FCN-RTU when multiple tasks are created, see Section

4.3.3, “Task Schedule” of TI “FCN-500 Technical Guide,” Section 4.3.3, “Task Schedule” of TI “FCNRTU Technical Guide.”

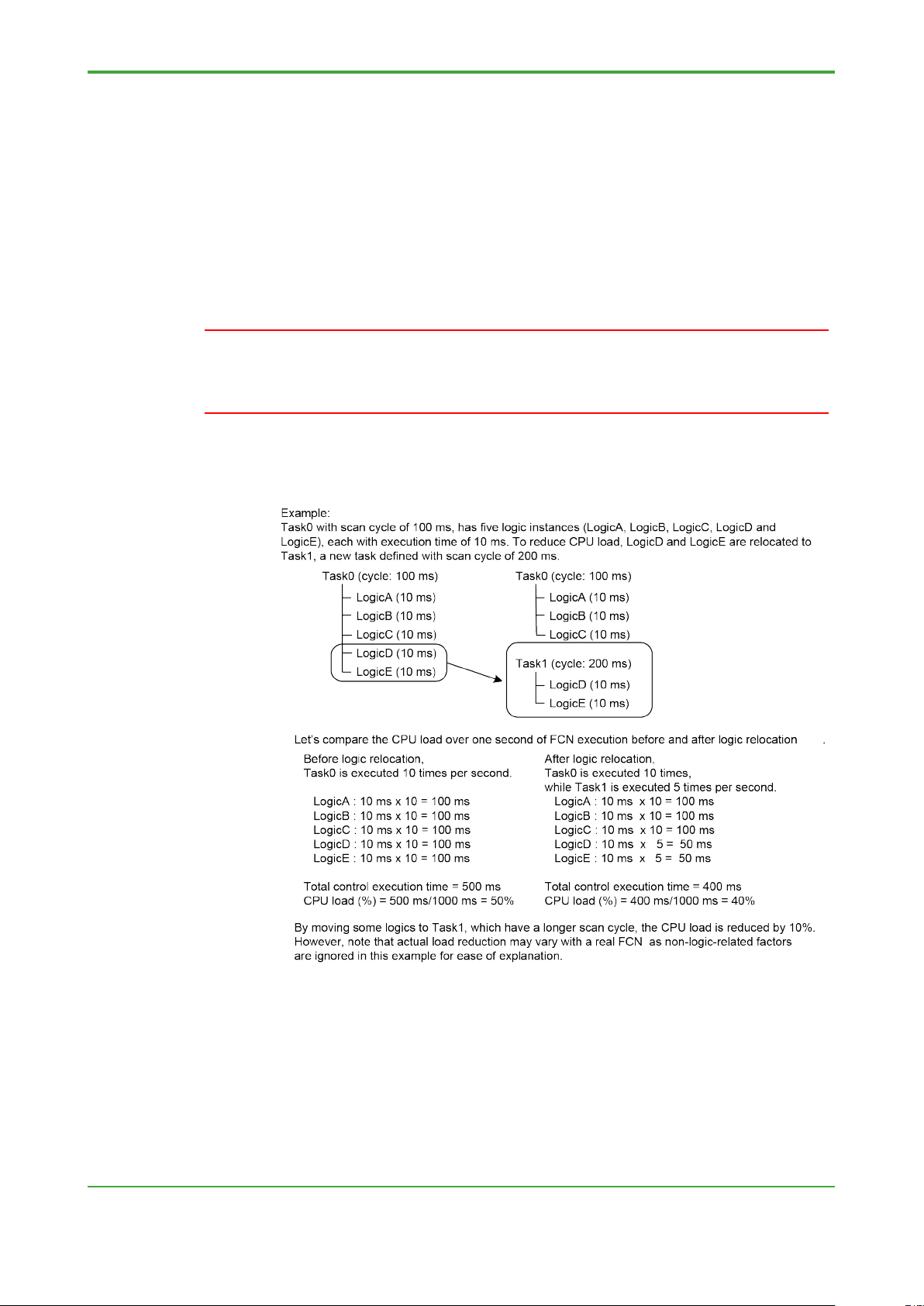

● Considerations Multi-tasking

Two possible reasons for considering implementing multi-tasking are given below:

1. To c reate control tasks having different execution intervals in an attempt to

reduce CPU load of the FCN-500 or FCN-RTU. For details, see Section

2.2.4, “Determining FCN-500, FCN-RTU Scan Cycle.”

2. To c reate control tasks having the same execution interval and priority

level for sorting control tasks to be instantiated by function.

The FCN/FCJ runs without problems even with multi-tasking. However, in multitasking mode, tasks are processed alternately at intervals of 30 ms in a time-sharing

manner as described in TI “STARDOM Technical Guide” and this complicates desk

investigation of control applications.

Therefore, running one task per FCN-500 or FCN-RTU is generally recommended.

When deciding on control application execution, start with single-tasking and

consider multi-tasking only if it is necessary.

Even when considering creating multiple tasks so as to reduce the CPU load of the

FCN-500 or FCN-RTU, listed as the first reason above, first consider the option of

lengthening the execution interval of a single control task, and consider multi-tasking

only if the first option is disallowed by the requirement specification.

Creating multiple tasks having the same execution interval and priority for sorting

purpose, listed as the second reason above, is unnecessary.

Multi-tasking not only complicates system operation, it may also increase CPU load

due to processing for sharing such as shared access to I/O modules.

For these reasons, it is best to avoid splitting a single task into multiple tasks having

the same execution interval and priority.

● Precautions When Multi-tasking

Pay attention to some precautions when using multi-tasking.

SEE ALSO

For details on precautions when multi-tasking, see Section 8.3, “Precautions about Multi-tasking" of

Chapter 8, “Detailed Description."

Page 43

<4. Control Application Creation>

35

TI 34P02K35-02E

Jun. 6, 2018-00

4.1.4 Specifying Target FCN/FCJ

The following Target dialog is used for specifying the IP address of the FCN-500 or

FCN-RTU.

Besides the IP address, this dialog also displays a checkbox with the message “The

task aborts when the execution time of a task exceeds a watch dog time.”

The checkbox setting is explained below.

SEE ALSO

For details on how the above setting affects system behavior in the event of a watchdog error, see

Section 4.3.3, “Task Schedule” of TI “FCN-500 Technical Guide,” Section 4.3.3, “Task Schedule” of TI

“FCN-RTU Technical Guide."

For details on how to specify the IP address of an FCN-500 or FCN-RTU, see Section 4.1.3,

“Specifying Target FCN-500, FCN-RTU (by Specifying IP Address)" of “FCN-500/FCN-RTU Primer –

Fundamental.”

● Defining Task Behavior upon a Watchdog Error Event

How a control task behaves when its execution time exceeds the specified

watchdog time described in Section 4.1.2, “Control Task Setup” differs whether the

“The task aborts when the execution time...” checkbox described above is ticked or

not.

• Common behavior regardless of whether checkbox is ticked or not

If the watchdog time described in Section 4.1.2, "Control Task Setup” is set to a

value other than 0 ms, a watchdog error will be generated when the execution

time of a control task exceeds the preset value.

At the same time, a watchdog error will be logged in the log file on the FCN-500

or FCN-RTU.

• Behavior when checkbox is ticked