Page 1

User’s

Manual

IM 01B04K03-02E

Model SDAU (Style R)

Digital Alarm Unit

IM 01B04K03-02E

8th Edition

Page 2

Page 3

Toc-1

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

IM 01B04K03-02E 8th Edition

Model SDAU (Style R)

Digital Alarm Unit

CONTENTS

1. INTRODUCTION .................................................................................. 1-1

1.1 Inspection ............................................................................................. 1-2

1.2 Documentation Conventions ............................................................... 1-3

1.3 Notice .................................................................................................... 1-4

1.4 About Compatibility with the Conventional Model (Style E) ............. 1-6

2. GENERAL ............................................................................................. 2-1

2.1 Standard Specifications ....................................................................... 2-2

2.2 Model and Suffix Codes ............................................................................. 2-3

2.3 Accessory ...................................................................................................... 2-4

3. INSTALLATION .................................................................................... 3-1

3.1 External Wiring ..................................................................................... 3-1

4. FUNCTIONS ......................................................................................... 4-1

4.1 Operation Principle .............................................................................. 4-1

4.1.1 Hardware Block Diagram ........................................................... 4-1

4.2 Input Processing Function .................................................................. 4-3

4.3 Alarm Processing Function ................................................................. 4-5

4.3.1 Alarm-Detecting Sections .......................................................... 4-6

4.3.2 Alarm Connection / Output Sections .......................................... 4-7

4.3.3 Example of Setting the Alarm Functions .................................. 4-10

4.4 Retransmission Output Function (for /VLT and /CUR Options) ...... 4-11

4.5 Communication Function (for /COM Option) .................................... 4-12

4.6 Function of Recovery from Power Failure ........................................ 4-13

4.7 Self-Diagnostic Function ................................................................... 4-14

4.8 Alarm/Failure Outputs at Power-on and Power Failure .................... 4-15

5. SETTING ............................................................................................... 5-1

5.1 Names of Components ......................................................................... 5-3

5.2 Part Names of the Display Setter ......................................................... 5-4

5.3 Setting Jumpers ................................................................................... 5-6

5.3.1 Checking Setting Jumpers and their Locations ........................... 5-7

5.3.2 Change of Setting Jumper ......................................................... 5-8

5.4 Settings Done from the Front Panel of the Alarm Unit ....................... 5-9

5.4.1 How to Operate the Key Switches .............................................. 5-9

5.4.2 Settings Using Key Switches (Example) .................................. 5-10

Page 4

Toc-2

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

5.5 Parameter Change Disable Function................................................. 5-11

5.6 Various Display Modes ...................................................................... 5-12

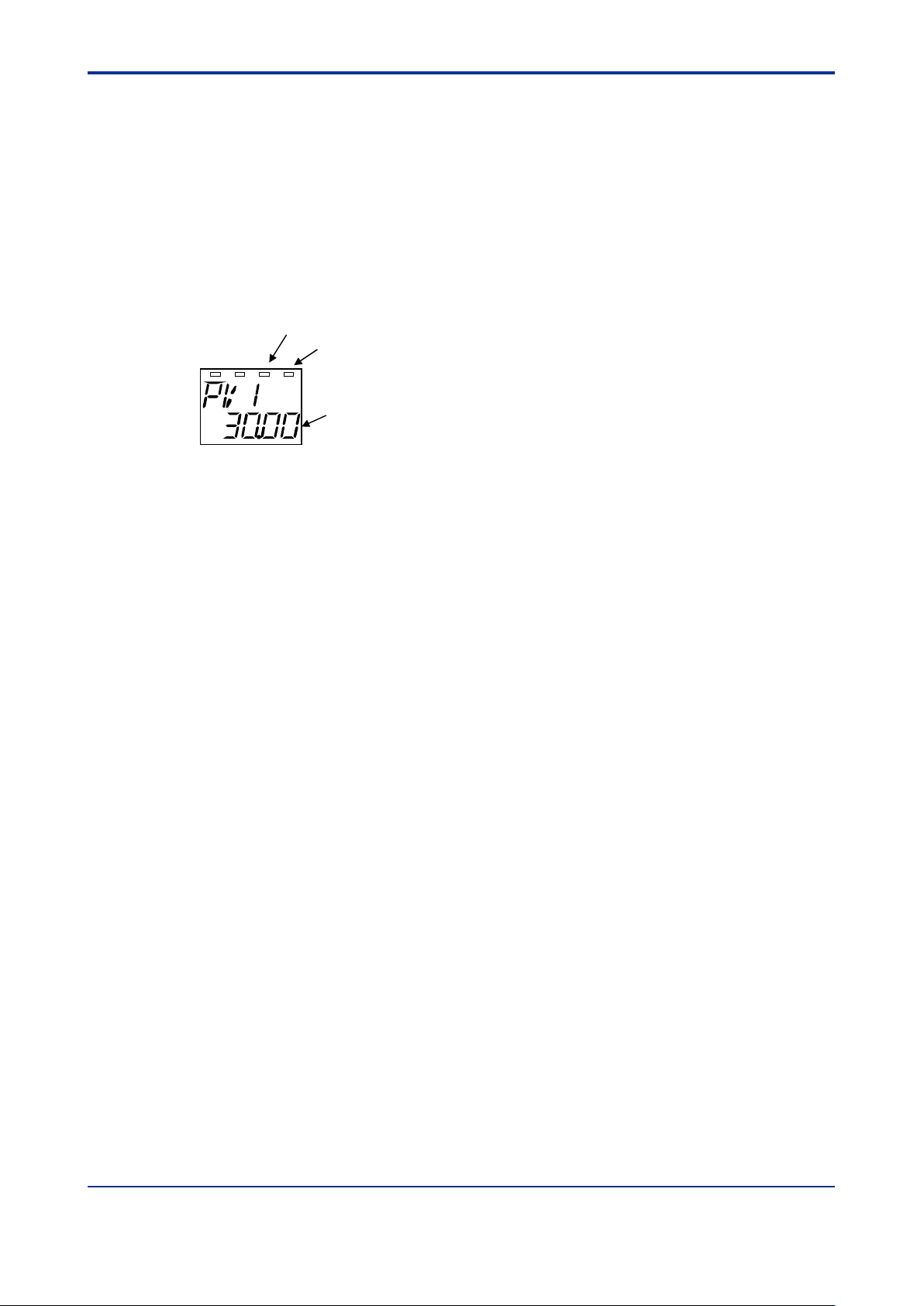

5.6.1 Display at Power ON ............................................................... 5-12

5.6.2 LOCK Display .......................................................................... 5-12

5.6.3 Display in Display Shutoff Mode .............................................. 5-12

5.6.4 Error Display ............................................................................ 5-13

5.6.5 Display of Self-Diagnostic Results ........................................... 5-13

5.6.6 Detailed Alarm Status Display .................................................. 5-14

5.7 Settings Using the JHT200 Handy Terminal ..................................... 5-16

5.8 Settings Using a PC (VJ77) ................................................................ 5-17

6. PARAMETERS ..................................................................................... 6-1

6.1 Configuration of Parameters ............................................................... 6-1

6.2 Display on Front Panel: Development View of Parameters ............... 6-2

6.3 Display on Front Panel: List of Parameters ........................................ 6-6

6.4 BRAIN Communication: List of Parameters ...................................... 6-22

7. MAINTENANCE ................................................................................... 7-1

7.1 Test Equipments ................................................................................... 7-1

7.2 Reference Table of Thermocouple and RTD ....................................... 7-1

7.3 Adjustment and Check ......................................................................... 7-1

7.3.1 Input Adjustment ........................................................................ 7-2

7.3.2 Correction of Input W iring Resistance ........................................ 7-4

7.4 Check of Reference Junction Temperature Compensation Action.... 7-6

7.5 List of Replaceable Parts ..................................................................... 7-7

8. TROUBLESHOOTING ........................................................................ 8-1

8.1 Actions under Fault Conditions .......................................................... 8-2

9. POWER SUPPLY TERMINAL CONNECTINS (Options /TB, /TB/A2

and /REK) ...................................................................................... 9-1

9.1 Names of Components and Power Terminal Symbols ....................... 9-2

9.2 Power Supply and Ground Wiring ...................................................... 9-3

General Specifications

Revision Information

Page 5

<1. INTRODUCTION >

1-1

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

1. INTRODUCTION

This manual describes the functions and operations of the SDAU Digital Alarm

Unit.

Intended Readers

This manual is intended for personnel in charge of:

Installation and wiring

Instrumentation and setup of functions

Operation and monitoring of the controller

Maintenance of equipment

Related Documents

The following documents all relate to the SDAU Digital Alarm Unit. Read them as

necessary. The codes enclosed in parentheses are the document numbers.

• Rack-Mounted Instruments (IM 1B4F2-01E)

Describes mounting and wiring for YS80 rack-mounted instruments.

• Model VJ77 PC-based Parameters Setting Tool (IM 77J01J77-01E)

Describes operation of the VJ77 parameters setting tool.

• Model JHT200 Handy Terminal (IM 77J50H01-01EN)

Describes operation of JHT200.

• YS80*R Rack-Mounted Instruments Communication Functions

Describes the communication functions of SDAU. (IM 01B04F01-20E)

Page 6

<1. INTRODUCTION >

1-2

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

1.1 Inspection

The SDAU digital alarm unit is shipped only after stringent inspection at the factory.

Visually inspect the product upon delivery to make sure it is not damaged in any way.

Store the box and inner packing material of the package in a safe place / they may be

needed if there is a problem with the product and it needs to be sent back for repair.

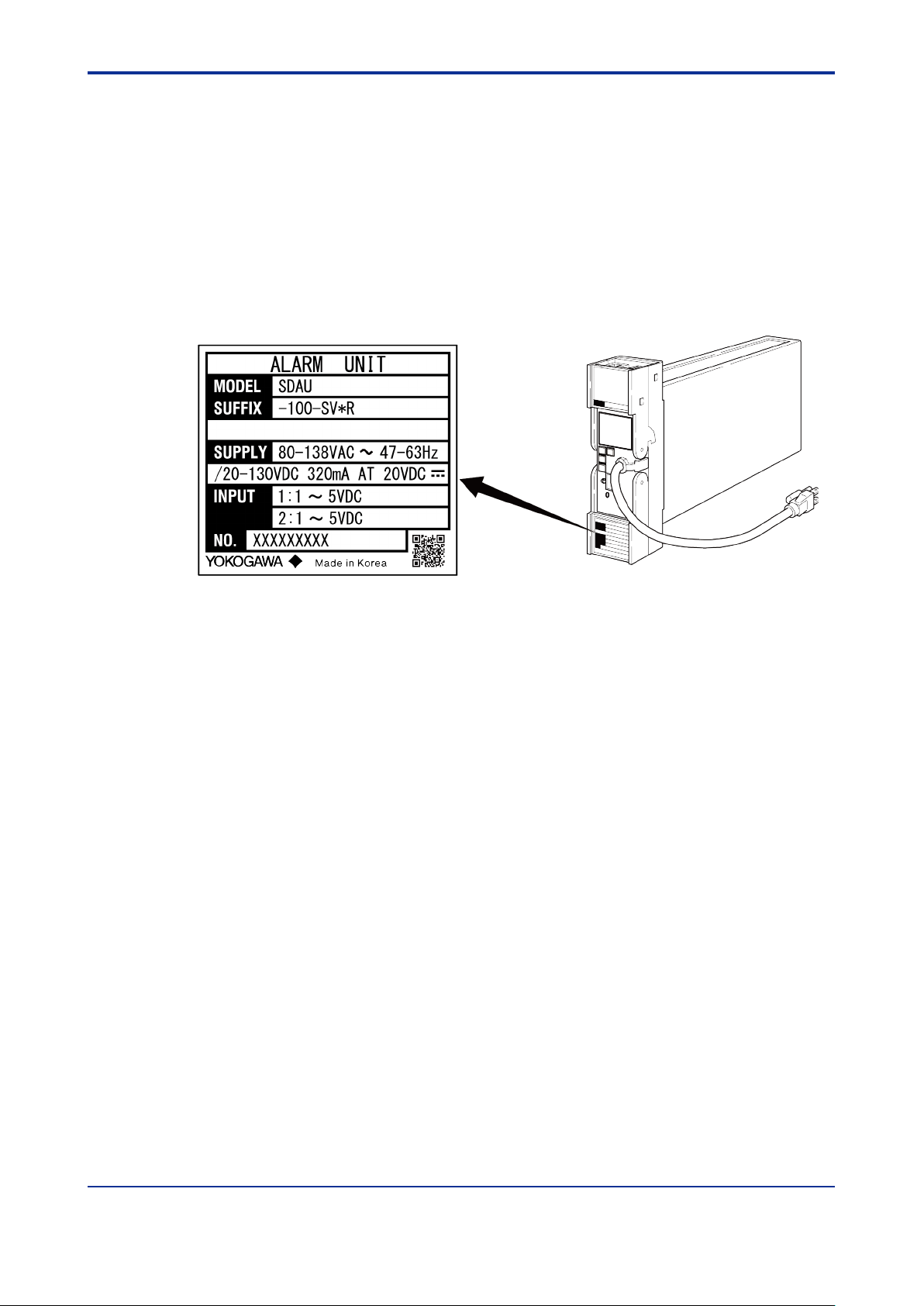

Check of Model and Suffix Codes

The model and suffix codes are indicated on the Name plate attached to the front cover

of the instrument. Crosscheck this information with the model and suffix codes of

Section 2.2 to ensure that the product is as specified in the order.

Figure1.1 Appearance and Name plate (Description example)

Confirmation of the Package Contents

Check the package contents against the list below. If anything is missing or damaged,

immediately contact the sales office from which you purchased the product or your

nearest Yokogawa representative.

• SDAU Digital Alarm Unit ................................................................................. 1

• Reference Junction Bracket (Parts No.: L4040EN)

(only for SDAU-120-xx*R/NHR or SDAU-270-xx*R/NHR) ............................. 1

• Alarm Label (Parts No.: L4040JA) .................................................................. 1 sheet

• Precautions on the Use of the YS80 Series.................................................... 1

Downloadable Electronic Manuals

You can download the latest manuals from the following website:

To view the User ’s Manuals, use Adobe Acrobat Reader of Adobe Systems Incorporated.

http://www.yokogawa.com/ns/ys/

Page 7

<1. INTRODUCTION >

1-3

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

1.2 Documentation Conventions

This manual uses the following notational conventions.

Symbols

The following symbols are used in this manual.

Indicates that operating the hardware or software in a particular manner may damage it

or result in a system failure.

Draws attention to information that is essential for understanding the operation and/or

features of the product.

TIP

Gives additional information to complement the present topic and/or describes terms

specific to this document.

See Also

Gives reference locations for further information on the topic.

Description of Displays

Some of the representations of product displays shown in this manual may be

exaggerated, simplified, or partially omitted for reasons of convenience when explaining

them.

QR Code

The product has a QR Code pasted for efficient plant maintenance work and asset

information management. It enables confirming the specifications of purchased products

and user’s manuals.

For more details, please refer to the following URL.

https://www.yokogawa.com/qr-code

QR Code is a registered trademark of DENSO WAVE INCORPORATED.

Page 8

<1. INTRODUCTION >

1-4

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

1.3 Notice

This User’s Manual

This manual should be passed on to the end user. Keep at least one extra copy of

the manual in a safe place.

Read this manual carefully to gain a thorough understanding of how to operate this

product before you start using it.

This manual is intended to describe the functions of this product. Yokogawa Electric

Corporation (hereinafter simply referred to as Yokogawa) does not guarantee that

these functions are suited to the particular purpose of the user.

Under absolutely no circumstances may the contents of this manual, in part or in

whole, be transcribed or copied without permission.

The contents of this manual are subject to change without prior notice.

Every effort has been made to ensure accuracy in the preparation of this manual.

Should any errors or omissions come to your attention however, please contact your

nearest Yokogawa representative or sales office.

Protection, Safety, and Prohibition against Unauthorized Modification

The following safety symbols are used on the product and in this manual.

If this symbol is indicated on the product, the operator should refer to the explanation

given in the user’s manual in order to avoid personal injury or death to either

themselves or other personnel, and/or damage to the instrument. The manual

describes that the operator should exercise special care to avoid shock or other

dangers that may result in injury or loss of life.

Protective ground terminal:

This symbol indicates that the terminal must be connected to ground prior to

operating the equipment.

Function ground terminal:

This symbol indicates that the terminal must be connected to ground prior to

operating the equipment.

AC voltage:

This symbol indicates that AC voltage is present.

DC voltage:

This symbol indicates that DC voltage is present.

Page 9

<1. INTRODUCTION >

1-5

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

In order to protect the product and the system controlled by it against damage and

ensure its safe use, make certain that all of the instructions and precautions relating

to safety contained in this document are strictly adhered to. Yokogawa does not

guarantee safety if products are not handled according to these instructions.

If protection/safety circuits are to be used for the product or the system controlled by

it, they should be externally installed on the product.

Do not turn off the power of the product during adjustment.

When you replace the parts or consumables of the product, only use those specified

by Yokogawa.

Do not modify the product.

Force Majeure

Yokogawa does not make any warranties regarding the product except those

mentioned in the WARRANTY that is provided separately.

Yokogawa assumes no liability to any party for any loss or damage, direct or

indirect, caused by the use or any unpredictable defect of the product.

Page 10

<1. INTRODUCTION >

1-6

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

1.4 About Compatibility with the Conventional

Model (Style E)

The operation and function differ from the conventional model.

Read this manual carefully to gain a thorough understanding of how to operate this

product before you start using it.

Be sure to confirm the parameters such as alarm set point and setting jumper

referring to ''6. PARAMETERS'' before installing the product in a system or plant.

After confirming them, install the product in a system or plant and turn on the power.

When replacing an internal unit with the old style code (SDAU-1xx-xx*E) with an

internal unit with the SDAU-120-xx*R or SDAU-270-UN*R style code, the reference

junction contact fitting (for contact with the RJC sensor) must be installed (or

replaced). For more information, see Section 2.3, “Accessory.”

Page 11

<2. GENERAL>

2-1

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

2. GENERAL

The SDAU Digital Alarm Unit accepts two input signals (freely selectable from 1 to

5 V, mV, thermocouple, and RTD), and six detection results present in alarmdetecting sections are freely AND-connected or OR-connected. These results are

then output to alarm relays (two points, or four points if the optional suffix is

specified).

Each alarm-detecting section detects high limit and low limit alarms of an input

absolute value, input rate-of-change, and two-input deviation. Either a normally

energized or de-energized state is selectable for alarm output relays.

The digital display and key switches on the front panel allow input values to be

displayed and parameters such as alarm setpoints to be set or changed.

Parameters can also be set or changed by using a PC (VJ77) or the JHT200 Handy

Terminal

The self-diagnostic function also allows failure outputs to be generated.

With the VJ77 Parameter Setting Tool you can do the following:

*1: The B T200 BRAIN Term inal of Yokogawa E lectric Corporati on can also be connected.

Modular jack adapter (part no.: E9786WH) is requi red t o connect a PC (VJ77), the JHT200 Handy Termin al or BT200

*1

.

· Read/write all parameters at once

· Save read parameters to a file

· Copy parameters to other devices of the same model and suffix code.

to the Digital Alarm Unit.

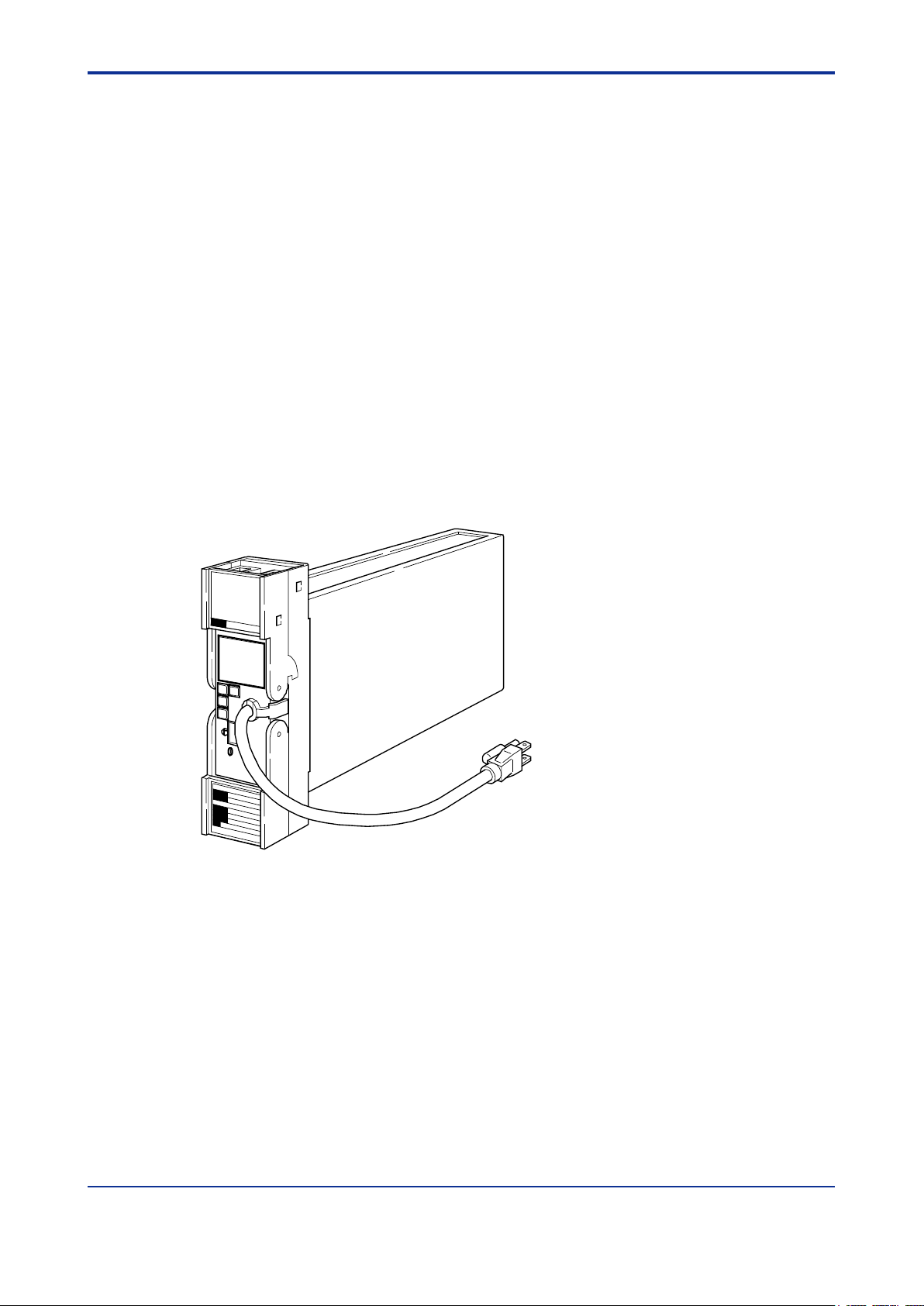

Figure 2.1 Appearance of the SDAU Digital Alarm Unit

Page 12

<2. GENERAL>

2-2

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

2.1 Standard Specifications

Please see the General Specifications (GS 01B04K03-02E) at the end of this manual.

Page 13

<2. GENERAL>

2-3

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

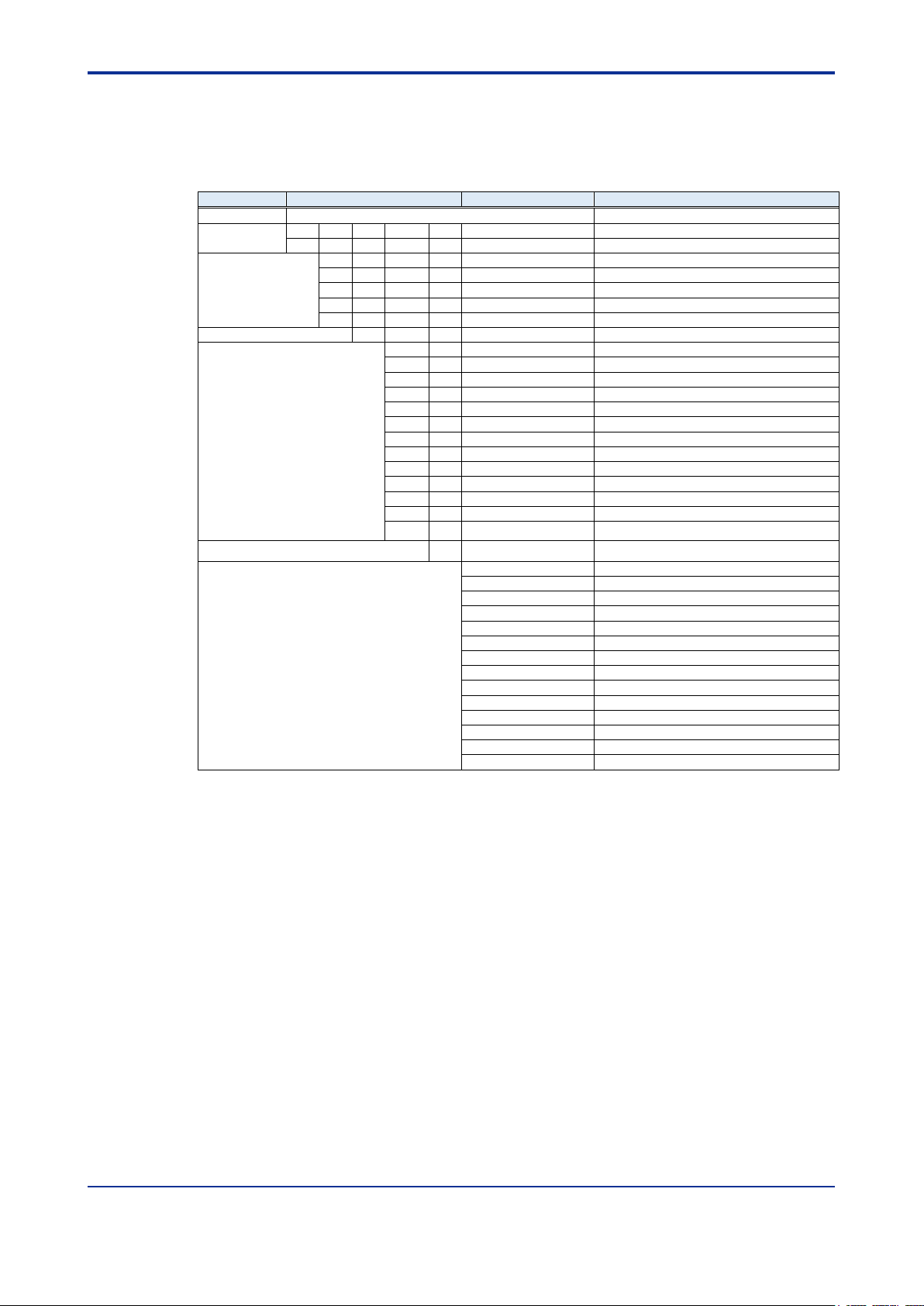

Model

Suf fix Codes

Optional Suf fix Codes

Description

SDAU

Digital Alarm Unit

-1 Input signal 2: 1 to 5 V

-2 Input signal 2: Universal (Note 3)

0

1 to 5 V

1

mV 2 TC (Thermoc ouple)

3

RTD 7 Universal (Note 3)

Always 0

0 Always 0

Auxiliary Codes

SDAU-270: -UN

-SV

Two points of 1 to 5 V inputs

-MV

mV input

-TK

Type K (ITS-90,JIS’95)

-TT

Type T (ITS-90,JIS’95)

-TJ

Type J (ITS-90,JIS’95)

-TE

Type E (ITS-90,JIS’95)

-TB

Type B (ITS-90,JIS’95)

-TR

Type R (ITS-90,JIS’95)

-TS

Type S (ITS-90,JIS’95)

-PA

JPt 100 (JIS’89)

-PB

Pt50 (JIS ’81)

-PD

Pt100 (ITS-90, JIS’97)

-UN

Universal (Note 3)

Style Code

*R Style R

/A2ER

220 V version power supply plug

/TB/A2

220 V version power supply terminal (Note 4)

/NHR

W ithout c ase

/FBP

Power supply fuse bypass

/LOCK

Power supply plug with lock

/WSW

With spring washer

/REK

Mount to same line with EK series rack

/TB

With power supply terminal

/VLT

With 1 to 5 V output (Note 1)

/CUR

With 4 to 20 mA output (Note 1)

/RLY4

Four points of alarm outputs (Note 1)

/COM

With RS-485 communication function

/BU

Burnout upscale ( Note 2)

/BD

Burnout downscale (Note 2)

2.2 Model and Suffix Codes

The following table shows the SDAU model and suffix codes.

Table 2.1 Model and Suffix Codes

Input Signal 2

Input Signal 1

Available Combination

Standard Specifications:

SDAU-100, SDAU-110

SDAU-120, SDAU-130

SDAU-270

Auxiliary Codes:

SDAU-100: -SV

SDAU-110: -MV

SDAU-120: from -TK to -TS

SDAU-130: from -PA to -PD

Common Options

Note 1: /VLT, and /CUR options can be combined with only –UN auxiliary c ode.

/RLY4 option can be combined with only –SV or –UN auxiliary codes.

/VLT, /CUR and RLY4 options can not be combined with each other.

Note 2: For two points of 1 to 5 V inputs (-SV), burnout upscale or burnout downscale is not selectable.

Note 3: For universal inputs, 1 to 5 V is not selec table.

Note 4: Specify the option codes /TB and /A2 at th e same tim e.

Page 14

<2. GENERAL>

2-4

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

2.3 Accessory

Reference junction bracket : 1

(For SDAU-120-xx*R/NHR or SDAU-270-xx*R/NHR)

Alarm label : 1

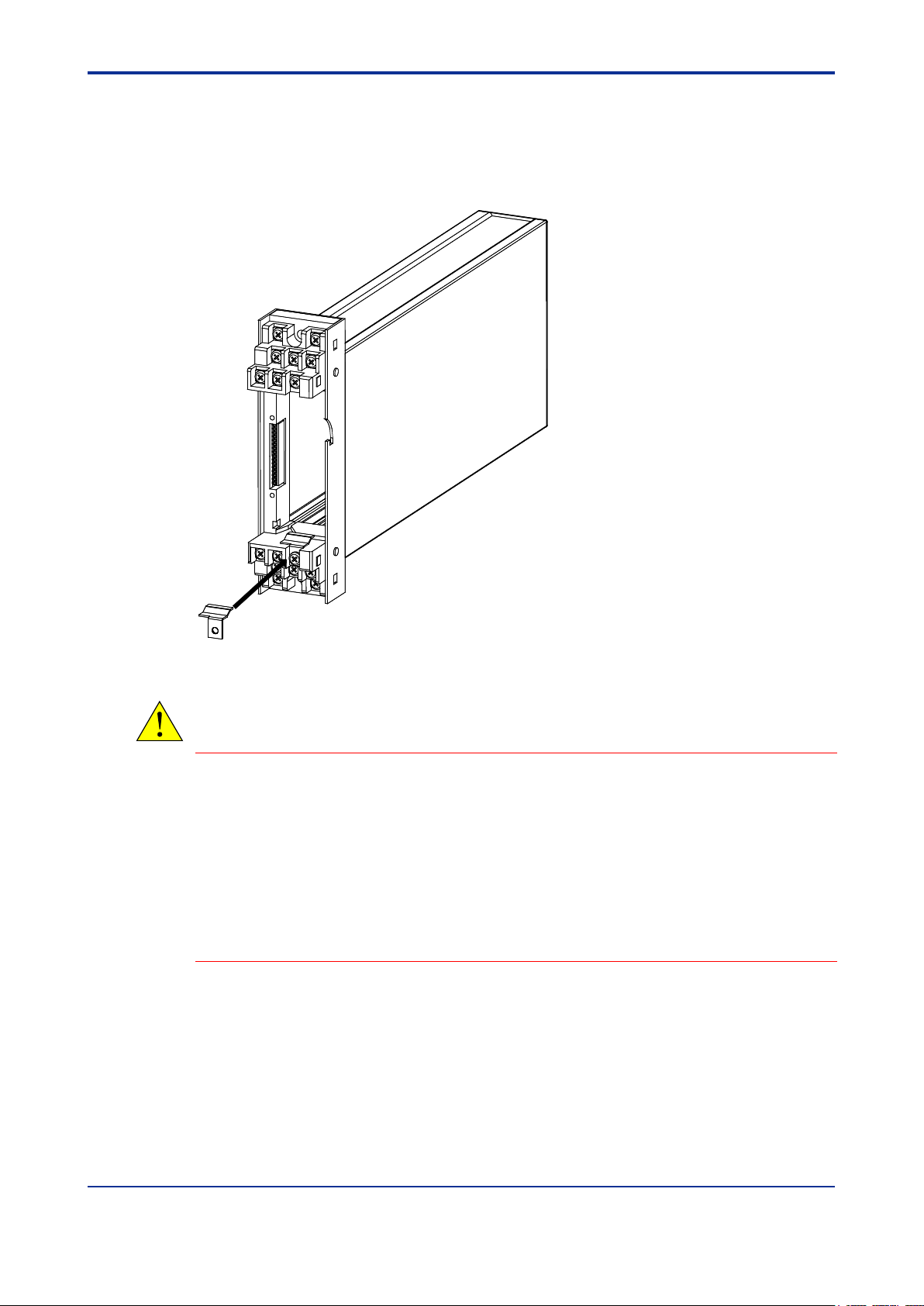

Figure 2.2 Location of the Reference Junction Bracket

CAUTION

• Notice when replacing the internal unit of a conventional model:

When replacing the internal unit of a conventional model (SDAU-1xx-xx*E) with that of SDAU-

120-xx*R or SDAU-270-UN*R, a reference junction bracket (for connection to the RJC sensor)

needs to be installed (replaced).

For SDAU-120-xx*E

Replace a reference junction bracket (for connection to the RJC sensor).

For models other than SDAU-120-xx*E

Install a reference junction bracket (for connection to the RJC sensor).

Page 15

<3. INSTALLATION>

3-1

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

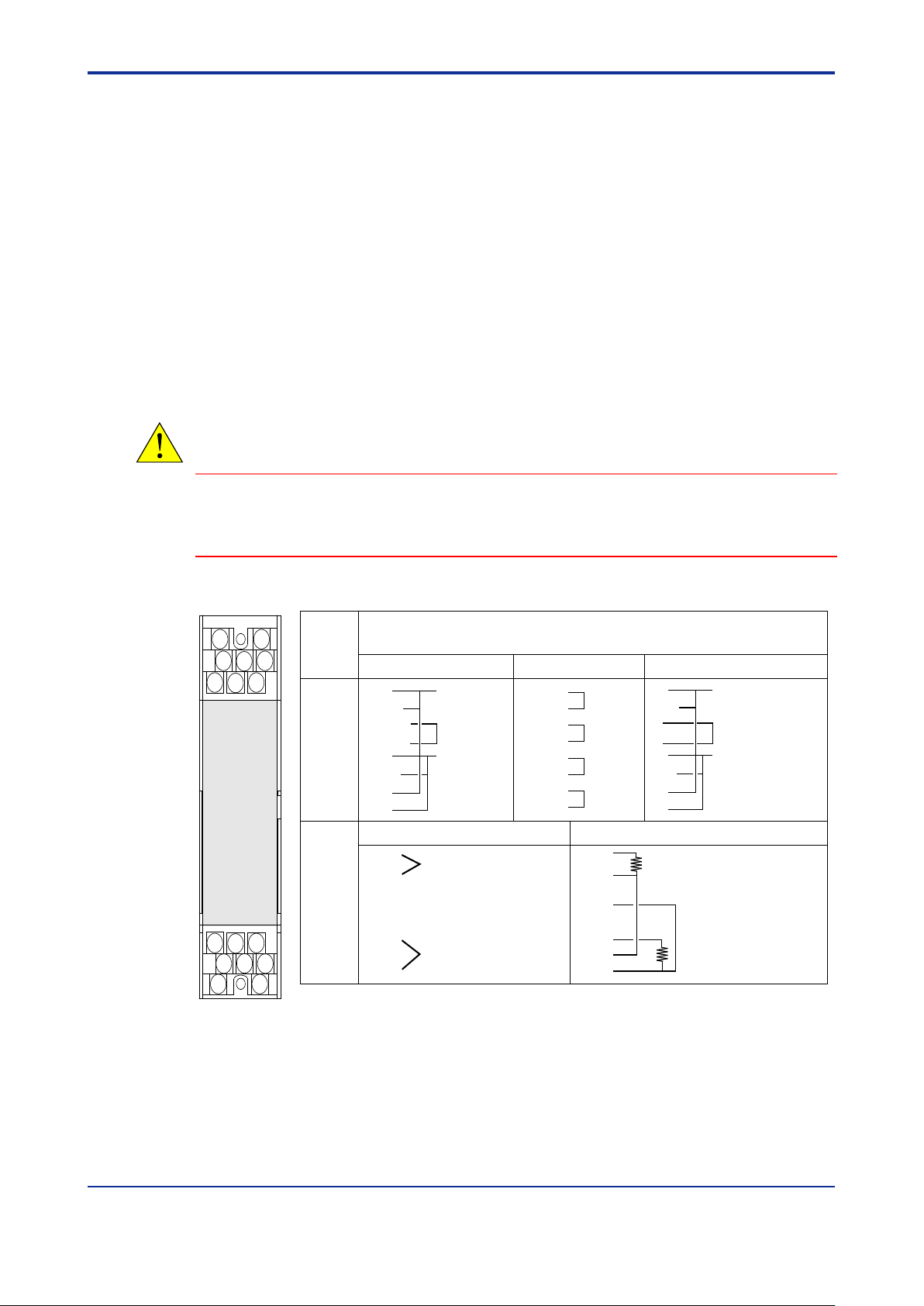

Alarm output 2

Alarm output 1

Failure output

1 to 5 V, mV, TC Input RTD Input

*1: Terminal for connecting the reference junction bracket.

*2: Switch NC/NO using jumper.

NC: Relay normally closed contact (closed when relay de-energized).

NO: Relay normally open contact (open when relay de-energized).

Terminal

Designation

Description

Excluding /RLY4, /VLT and /CUR

/RLY4 /VLT or /CUR

Alarm output 1

Retransmission output

1 to 5 V or 4 to 20 mA

Alarm output 2

Alarm output 1

Alarm output 4

Alarm output 2

Alarm output 3

Input 1

Input 2

Input 1

Input 2

A

C

F

B

D

H

J

K

1

3

5

2

4

6

7

8

A

B

C

D

F

H

J

K

NC

COM

NC,NO

COM

NC

COM

NO

NO

NC,NO

COM

NC,NO

COM

NC,NO

COM

COM

NC,NO

NC

COM

+

-

NC

COM

NO

NO

1

2

3

4

5

6

7

8

+

-

+

-

A

B

B

A

B

B

(*1)

(*2)

(*2)

(*2)

(*2)

(*2)

Front view

may differ

according to

device.

3. INSTALLATION

For details of the installation procedure and wiring precautions, refer to the

instruction manual “Installation of Rack-Mounted Instruments” (IM 1B4F2-01E).

3.1 External Wiring

(a) All cable ends must be furnished with crimp-on type solderless lugs (for 4mm

screws).

(b) Draw out the internal unit from the rack case.

(c) Connect the cable to the correct terminals referring to Figure 3.1.

(d) Return the internal unit into the rack case after completing the wiring.

(e) Always return the terminal block cover to its original position after completing the

wiring.

CAUTION

The terminal block cover cannot be returned to its original position if the internal unit is not installed

correctly inside in the rack case. Securely return the terminal block cover because it also functions as

lock for the internal unit.

Figure 3.1 Terminal Layout and Terminal Wiring

Page 16

<3. INSTALLATION>

3-2

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

B+

A-

COM

Figure 3.2 RS485 Communication Terminal Layout (/COM option)

Applicable Cables

(1) Signal circuit wiring

• Cross-sectional area of the cable conductor: 0.5 to 0.75 mm

• Examples of applicable cables: Single core PVC insulated flexible cable (VSF)

(2) Alarm circuit wiring

• Cross-sectional area of the cable conductor: 0.5 to 1.25 mm

• Examples of applicable cables: 600 V PVC insulated cable (IV) stranded wires (JIS

(3) Power supply wiring

• Cross-sectional area of the cable conductor: 1.25 to 2.00 mm

• Examples of applicable cables: 600 V PVC insulated cable (IV) stranded wires

2

stranded wires (JIS C 3306);

heat-resistant vinyl-insulated cable (UL style 1007)

2

C 3307);

PVC insulated cable for electric appliances (KIV)

stranded wires (JIS C 3316);

heat-resistant vinyl-insulated cable (UL style 1007)

2

(JIS C 3307)

Page 17

<4. FUNCTIONS >

4-1

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

4. FUNCTIONS

4.1 Operation Principle

Input signals are converted into digital data by an A/D converter circuit. This digital data

is signal processed (such as linearization or square root extraction) by a microprocessor

and then computed for alarm detection. Alarm relays are energized or de-energized

according to the alarm computation outputs.

For retransmission output, an input signal is pulse-width modulated after being signal

processed. It is then converted into 1 to 5 V DC or 4 to 20 mA DC signals via a photoisolation circuit.

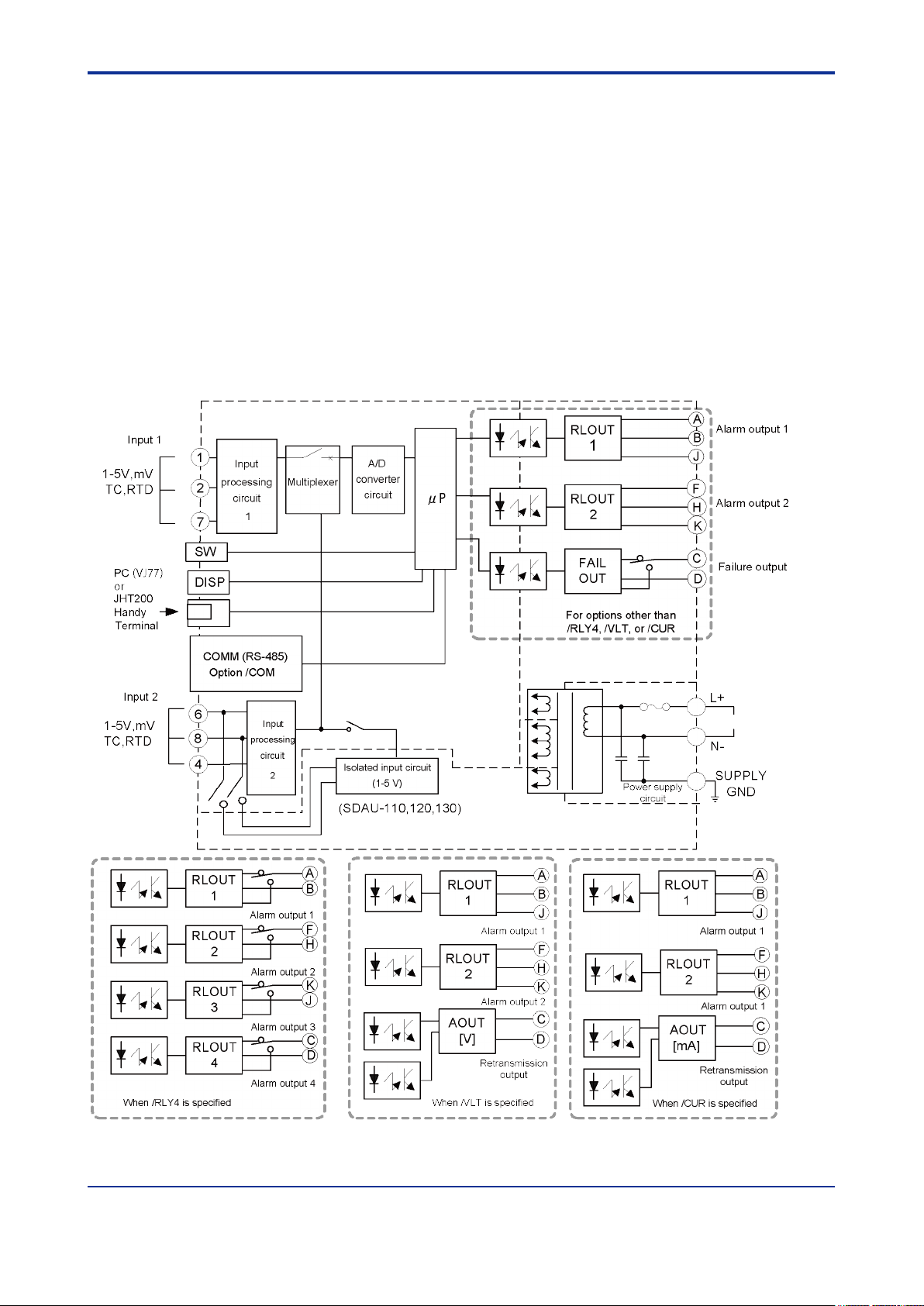

4.1.1 Hardware Block Diagram

Figure 4.1 Hardware Block Diagram

Page 18

<4. FUNCTIONS >

4-2

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

/RLY4

Input 1

Input 2

Input

processing

PV1

Input

processing

PV2

Alarm detection processing

Alarm connection/output processing

Alarm

output 1

Alarm

output 2

Alarm

output 3

Alarm

output 4

Retransmission

output

Retransmission

output

processing

Failure output

Terminal

symbol name

Parameter

displayed

/VLT,/CUR

When /RLY4,/VLT,or

/CUR is not specified

Self-

diagnosis

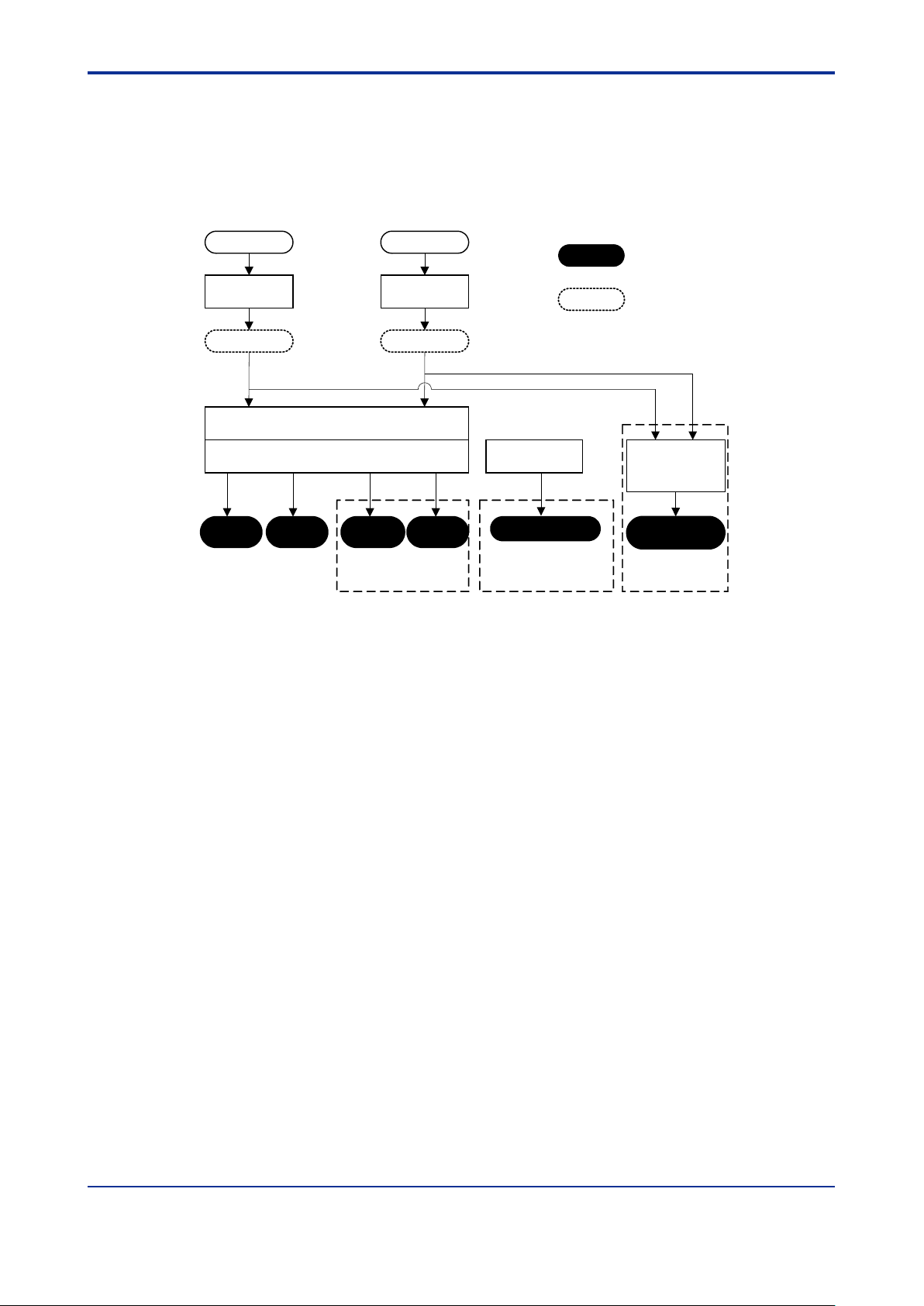

Internal Function Block Diagram

The following shows the internal function block diagram. For more information, see the

Description of Each Function section.

Figure 4.2 Internal Function Block Diagram

Page 19

<4. FUNCTIONS >

4-3

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

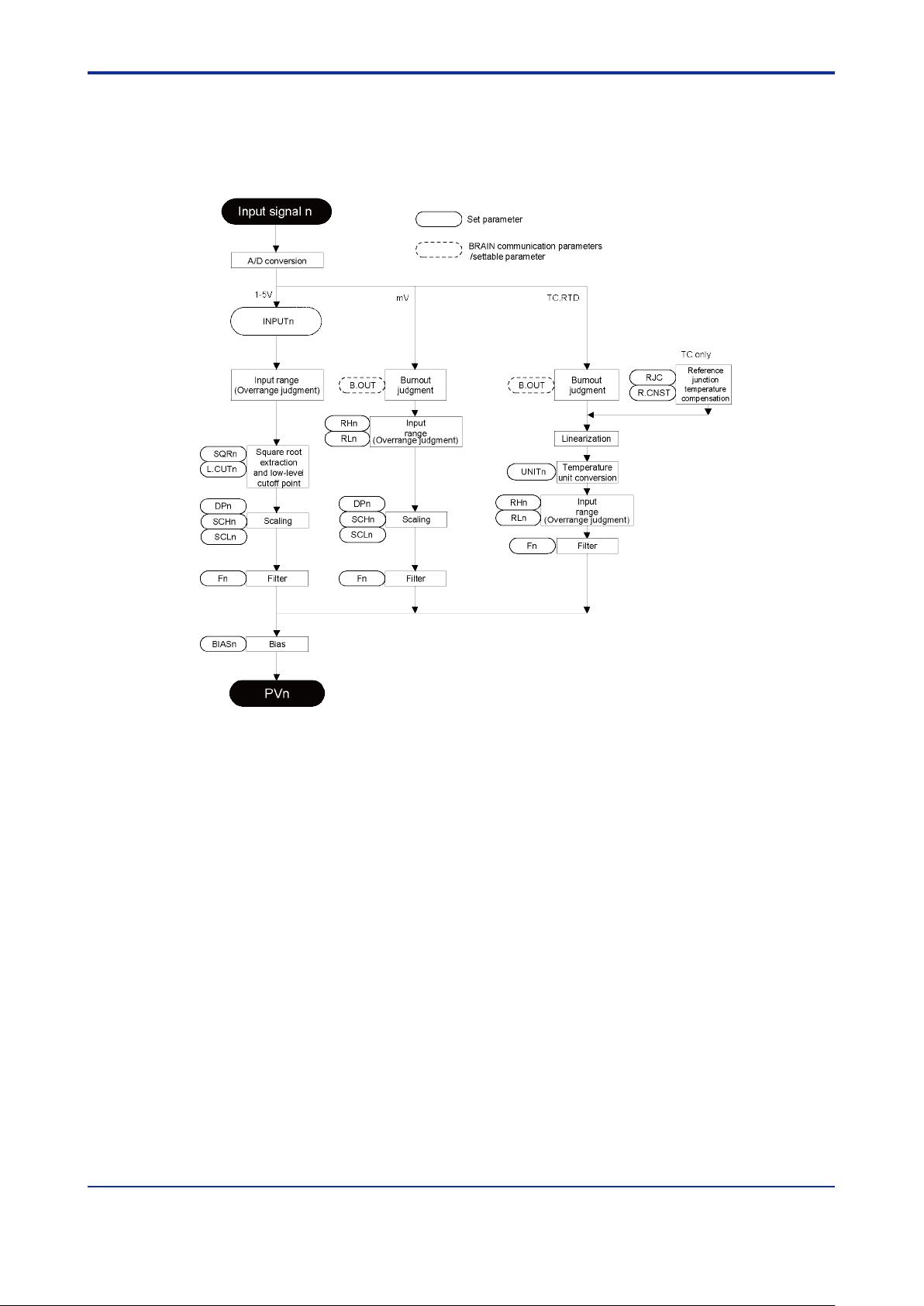

4.2 Input Processing Function

Two input points are provided. The following processing is done with respect to each

input (see Figure 4.3). Encircled symbols are parameter symbols appearing on the

display setter. "n" takes value 1 or 2.

Figure 4.3 Input Processing Function Block Diagram

Description of Each Function:

• A/D conversion: Performs A/D conversion of input signals.

• Burnout (B.OUT): If an input signal is mV, thermocouple, or RTD input, the action to

be taken in case of burnout can be set. (This can be specified according to an

option code. Settings can be changed via a PC (VJ77) or the JHT200 Handy

Terminal after delivery.)

• Temperature unit conversion (UNITn): Allows temperature units (°C, K or °F) to be

set if an input signal is thermocouple or RTD input.

Page 20

<4. FUNCTIONS >

4-4

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

0.0 mV (RL1) 100.0 mV (RH1)

Default input range

0.0 (SCL1) 100.0 (SCH1)

Default scale

10.0 mV (RL1) 80.0 mV (RH1)

Measuring input range

1000 (SCL1) 20000 (SCH1)

Measuring scale

Decimal point position registered at DP1.

• Input range (RHn, RLn): An input range should be set if an input signal is mV or

temperature input. If an input value is -6.25% or less, or greater than 106.25% of the

input range, an input overrange occurs. For actions to be taken in the event of an

input overrange, see Section 8.2, "Actions under Fault Conditions."

• Square root extraction (SQRn, L.CUTn): If an input signal is 1 to 5 V DC, the

availability of square root extraction and a low-level cutoff point can be specified.

Specification of a low-level cutoff point is enabled only when square root extraction

is available. For inputs below the low-level cutoff point, no square root is extracted.

(Linear characteristics apply for any inputs below the low-level cutoff point.)

• Filter (Fn): This is a first-order lag filter. The time constant can be set in the range of

0.0 to 200.0 seconds. Note that for the actual time constant, a hardware filter time

constant of approx. 0.1 second will be added to the noted setting.

• Scaling (DPn, SCHn, SCLn): If an input signal is mV or 1 to 5 V DC, scaling can be

applied to a range specified by the input range (RHn, RLn). A value converted by

scaling (a value obtained by adding bias to this value if bias is used) becomes PVn.

The initial value of scaling is 0.0 to 100.0 (DPn=1, SCHn=100.0, SCLn=0.0).

<How to Set Input Range and Scaling>

The following is the example when input range of 10.0 to 80.0 mV is scaled to 1000 to

20000.

(1) Set the input range at the parameters RL1 and RH1.

(Example: RL1=10.0, RH1=80.0)

(2) Set the input decimal point position matched to the unit system actually in use at

DP1.

(Example: DP1=0)

(3) Set the scale range at the parameters SCH1 and SCL1.

(Example: SCL1=20000, SCH1=1000)

(Example)

Figure 4.4 Scaling

Note: Reverse scal ing (SCH1 < S CL1) is also possible.

The al arm unit will not operate normal ly when SCH1 is set to equal SCL1. Change the setting.

• Bias (BIASn):

A bias value can be added to scaling values.

This allows error to be compensated when there is an error between the input value

and the indicated value.

Bias can be set within the range ±10% [(SCH1 - SCL1) x 0.1] of the scaling width.

• PVn:

The value obtained by adding bias to the scaling value.

Page 21

<4. FUNCTIONS >

4-5

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

Alarm

detection 3

Alarm

detection 2

Alarm

detection 1

HYS1

HI alarm

LO alarm

1H

1L

MOD1

Deviation

(PV1-PV2)

Rate-ofchange

PV1

Rate-of-

change

PV2

MOD3

HI alarm LO alarm

3H

3L

Set parameter

PV1

PV2

PV1

PV2

MOD2

HI alarm

LO alarm

2H 2L

PV1

PV2

DV

PV1.VL

PV2.VL

AND

ALn_H

ALn_L

OR

Connected to

AL1_H and

AL1_L

TMn

ACTn

Output timer

RL

NCCOMNO

AN.OR.n

ALMn

Lamp

TM1

ACT1

AND

AL1_H

AL1_L

OR

Connected to

AL1_H and

AL1_L

Output timer

RL

NCCOMNO

AN.OR.1

ALM1

Lamp

Parameter to be displayed

VL1.TM

HYS2

VL2.TM

HYS3

VL3.TM

TM.M

TM.M

ON.TM1

OFF.TM1

ON.TMn

OFF.TMn

Same connections as

MOD1

Same connections as

MOD1

Alarm output n (n=2 to 4. Note that n=3 or 4 is for /RLY4 only.)

Alarm output 1

Connected to 1H, 1L,

2H, 2L, 3H, and 3L

Alarm1

connection

result

Alarm n

connection

result

Alarm-detecting sectionsAlarm connection/output sections

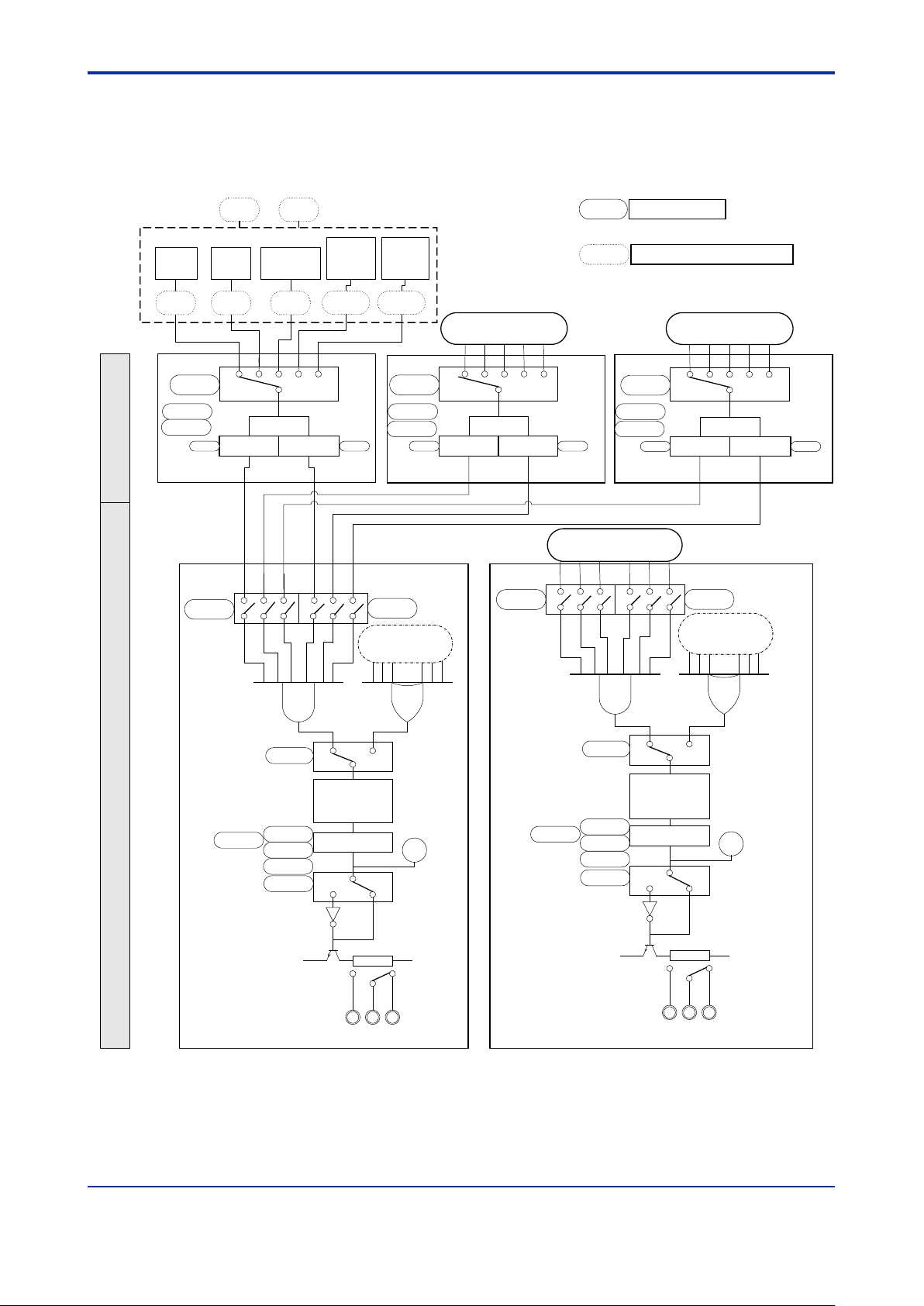

4.3 Alarm Processing Function

As shown in Figure 4.5, the SDAU's alarm function consists of the alarm-detecting

sections and alarm connection/output sections, each of which functions independent of

the others.

Figure 4.5 Alarm Processing Function Block Diagram

Page 22

<4. FUNCTIONS >

4-6

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

Low-limit alarm

provided

nL

nH

HYSn

HYSn

Input

High-limit alarm

provided

4.3.1 Alarm-Detecting Sections

There are three alarm-detecting sections, which set each of the following items (see

Figure 4.5). Those in parentheses show parameter symbols to be displayed on the

display setter. "n" takes value 1, 2, or 3.

• Input mode (MODn): Selects a target input at alarm detection-n from among input-1

absolute alarm, input-2 absolute alarm, deviation alarm (input 1 - input 2), input-1

rate-of-change alarm, and input-2 rate-of-change alarm.

If the same PVn rate-of-change alarm is set to the multiple MOD, the rate-of-change

of MODn having smaller n value is displayed in PVn.VL parameter.

For example, MOD1=MOD2=MOD3=4: Input 2 rate-of-change (PV2.VL), and

VL1.TM=10, VL2.TM=5, VL3.TM=3, PV2.VL displays PV2 rate-of-change for 10

seconds.

• Hysteresis (HYSn): Sets hysteresis at alarm detection-n in engineering units (range:

0 to 32000). (This is not applicable to rate-of-change alarms.)

• Rate-of-change alarm sampling time (VLn.TM): Available when the input mode is

set to rate-of-change alarm. A rate-of-change is obtained as follows:

Example: When MOD1 = PV1 rate-of-change alarm and VL1.TM = 10 sec. are set,

Rate-of-change = current value (present PV1 value) - previous value (PV1

value 10 sec. before)

• High-limit alarm setpoint (nH): Sets the high-limit setpoint at alarm detection-n in

engineering units (range: -19999 to 32000). High-limit alarm cannot be used as lowlimit alarm.

• Low-limit alarm setpoint (nL): Sets the low-limit setpoint at alarm detection-n in

engineering units (range: -19999 to 32000). Low-limit alarm cannot be used as highlimit alarm.

• Alarm detection repeatability: Same as input conversion accuracy

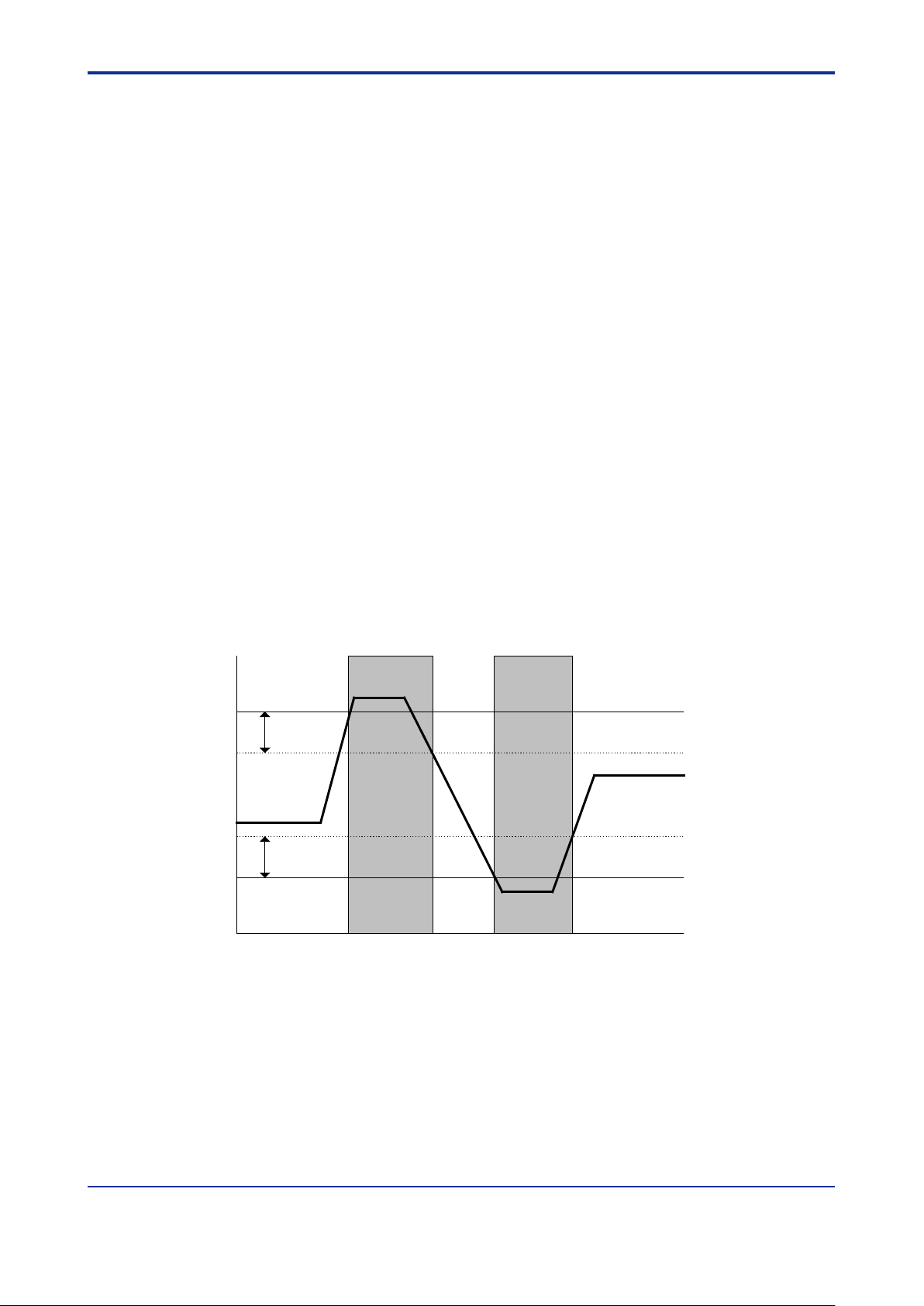

Figure 4.6 Alarm Action When Hysteresis is Set

Page 23

<4. FUNCTIONS >

4-7

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

[°C]

[Sec.]

Alarm action

when n.H = +30°C

Normal

Normal

100

80

60

40

20

0

V

Ln.TM

+40°C

+30°C

-20°C

-40°C

+30°C

Alarm action

when n.L = -20°C

Normal Normal

Alarm

Alarm

Alarm

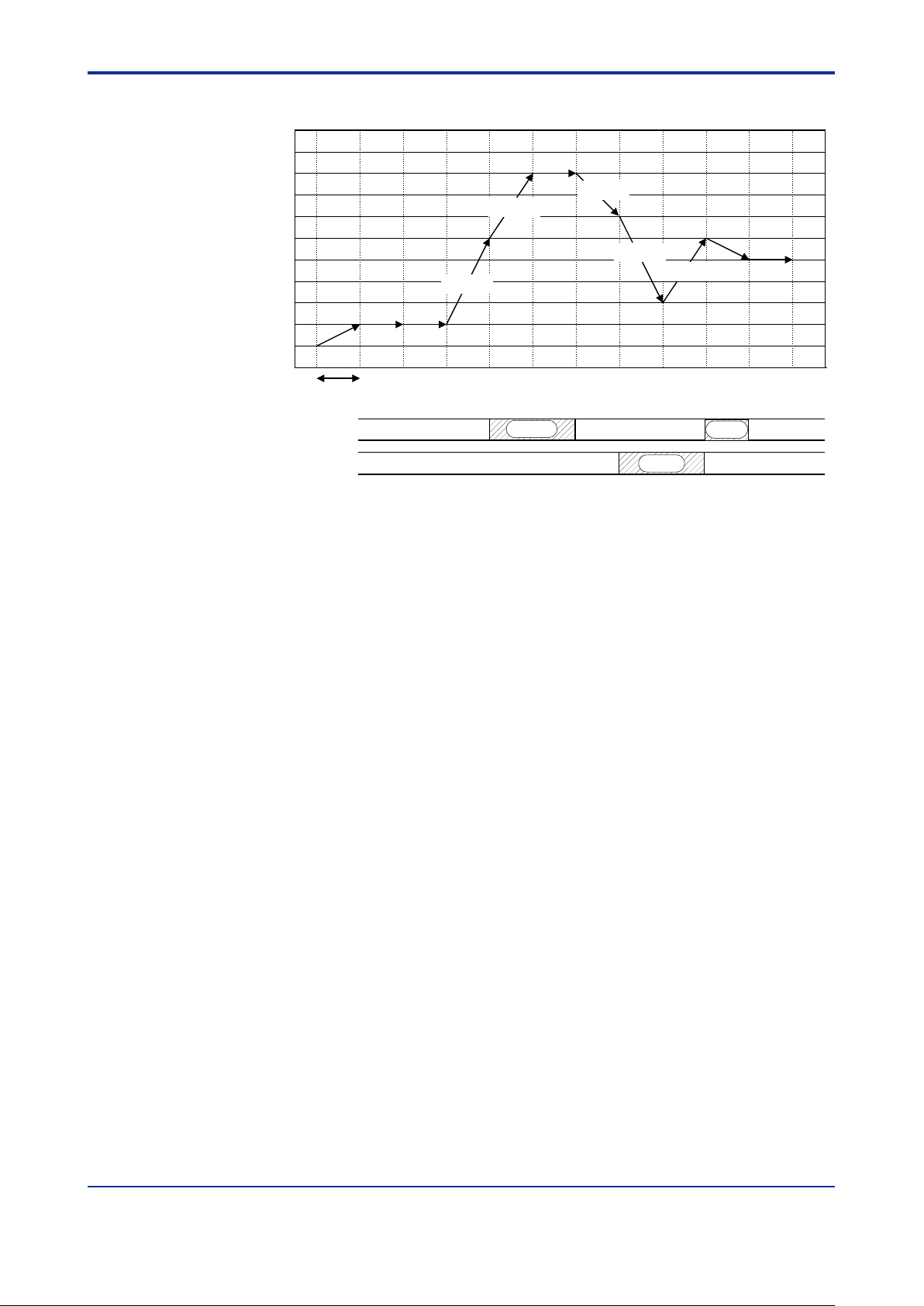

Figure 4.7 Action to be Taken When Input is Rate-of-change Alarm

4.3.2 Alarm Connection/Output Sections

There are two alarm connection/output sections (four for the /RLY4 option), which set

each of the following items (see Figure 4.5).

Those in parentheses show parameter symbols to be displayed in the display setter. "n"

takes value 1 or 2 (up to 4 for the option /RLY4).

• Alarm output connection (ALn_H, ALn_L): ALn_H specifies whether to connect the

high-limit alarm detection results of MOD1 to MOD3. ALn_L specifies whether to

connect the low-limit alarm detection results of MOD1 to MOD3.

• Alarm AND/OR specification (AN.OR.n): Specifies if the results of alarm output

connections are AND-connected or OR-connected.

• Alarm timer mode (TM.M): Selects the alarm timer mode. This is common to alarm

outputs 1 and 2 (or alarm outputs 1 to 4 for the /RLY4 option).

0: Alarm output timer (timer causing alarm output to delay: equivalent to SDAU*E)

1: ON/OFF delay timer (alarm dead time)

Page 24

<4. FUNCTIONS >

4-8

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

TMn setpoint (sec.)

Alarm output resolution (sec.)

0 to 39

0.15

40 to 79

0.3

80 to 159

0.6

160 to 319

1.2

320 to 600

2.4

• Alarm output timer (TMn): Sets the alarm output delay for alarm n. The alarm unit

outputs an alarm when the time period set in TMn has elapsed after the connection

of alarm n resulted in an alarm status. Time can be specified in the range of 0 to 600

seconds (in 1 sec. intervals). However, a time lag of approx. 0.2 second will be

added to this setting as dead time to prevent erroneous alarm action.

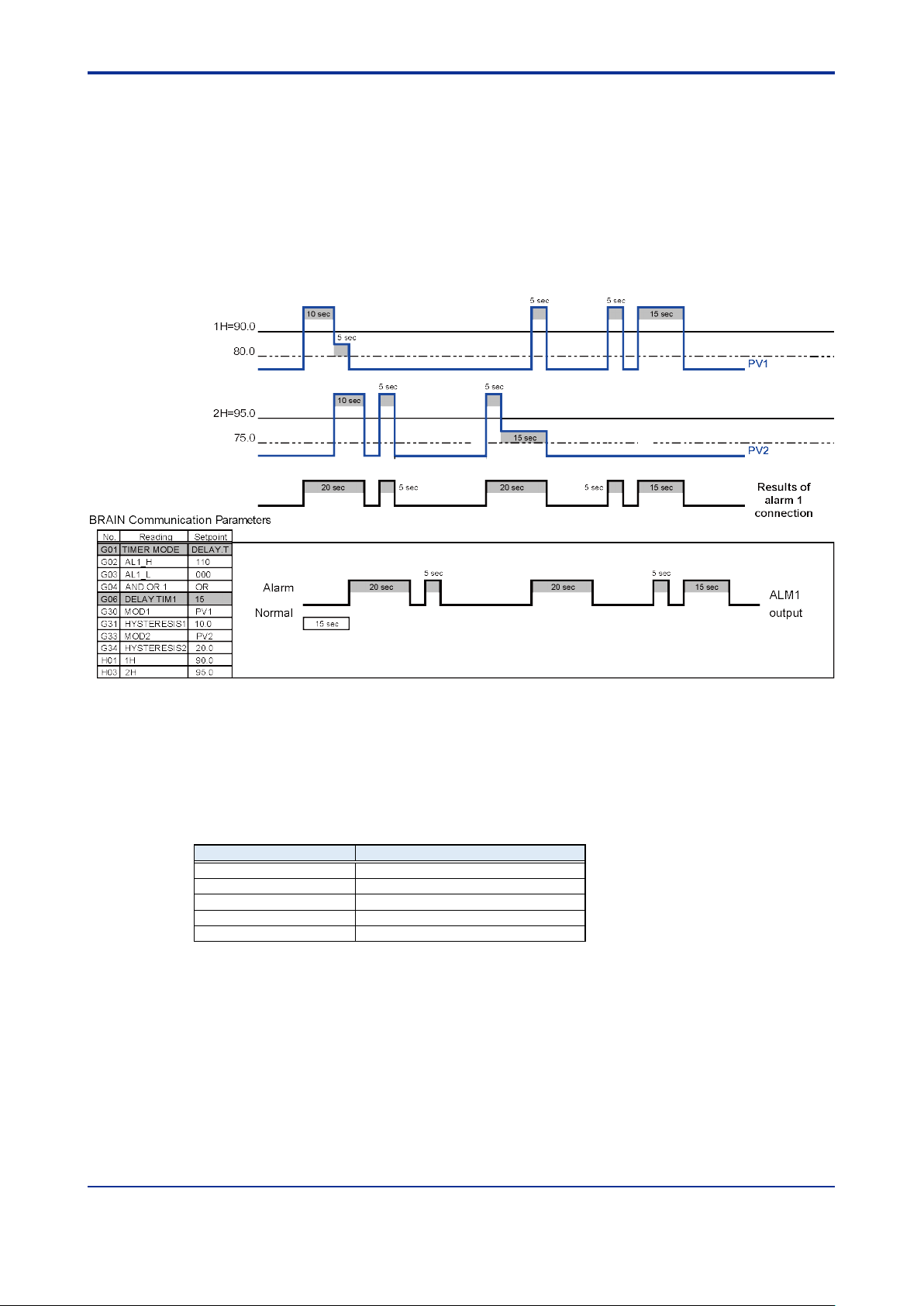

Figure 4.8 shows an example of the alarm actions taken by ALM1 when the alarm

output timer is set so that alarms to be output to ALM1 are delayed by 15 seconds if

an alarm is detected for either the 90.0 (hysteresis: 10.0) high limit alarm setpoint of

PV1 or the 95.0 (hysteresis: 20.0) high limit alarm setpoint of PV2.

Figure 4.8 Alarm Output Actions to be Taken When Alarm Output Timer is Set

Moreover, if a timer setpoint is changed, alarm status becomes identical with the

alarm status of that time, causing the timer function to work from that time on. The

alarm output resolution is as shown in the following table according to the setpoint

of the alarm output timer.

For example, if an alarm status occurs for one second with the alarm output timer set at

600 sec., an alarm is output for 2.4 seconds, between 597.6 to 602.4 seconds later.

ALM1 and ALM2 can be HOT started, while ALM3 and ALM4 are always COLD started.

(For HOT/COLD starts, see Section 4.6, "Function of Recovery from Power Failure.")

Page 25

<4. FUNCTIONS >

4-9

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

• Alarm-n ON delay timer (ON.TMn): Sets dead time after which the alarm turns ON.

If an input value is within an alarm range for a time set by ON.TMn, an alarm status

occurs. If the input returns to the normal range before the time set by ON.TMn

elapses, no alarm turns ON.

• Alarm-n OFF delay timer (OF.TMn): Sets dead time after which the alarm turns OFF.

If an input value is within a normal range for a time set by OF.TMn, a normal status

is brought about. If the input returns to an alarm range before the time set by

OF.TMn elapses, the alarm does not turn OFF.

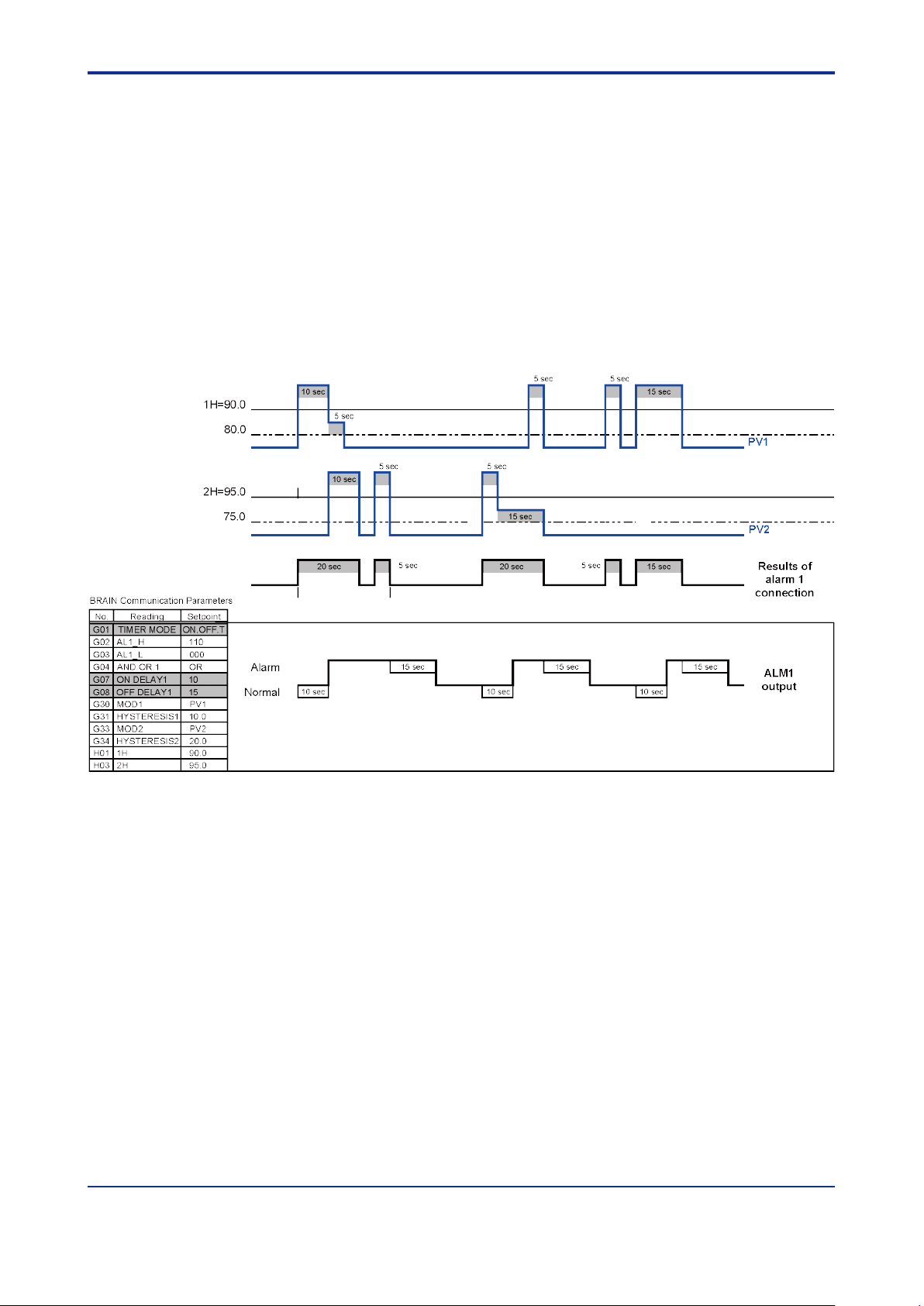

Figure 4.9 shows an example of the alarm actions taken by ALM1 when the alarm n

OFF delay timer is set so that the dead time of alarms to be output to ALM1 is 10

seconds and the dead time before these alarms are canceled is 15 seconds if an

alarm is detected for either the 90.0 (hysteresis: 10.0) high limit alarm setpoint of

PV1 or the 95.0 (hysteresis: 20.0) high limit alarm setpoint of PV2.

Figure 4.9 Alarm Actions to be Taken When Alarm-n ON/OFF Delay Timers are Set

• Direction of relay action (ACTn): Specifies energized/de-energized status of a relay

in a condition where no alarm has occurred.

Energized at normal operation (ACTn=1)

A relay is energized when the alarm n detection result is in a normal state.

De-energized at normal operation (ACTn=0)

A relay is energized when the alarm n detection result is in an alarm state.

• RLYn TEST: Relay action test (exclusive to a PC (VJ77) or the JHT200 Handy

Terminal)

This is the relay action test function. It allows a relay to turn ON/OFF regardless of

the current alarm detection results. (Note: Make sure that your process is not

affected by the relay action test before using this function.)

One set of transfer contacts are provided for each output section. An alarm state can be

checked with the ALM lamp on the front panel of the alarm unit (which lights up if an

alarm occurs) and by checking the ALMn parameter displayed on the display setter.

Page 26

<4. FUNCTIONS >

4-10

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

PV1

PV1 - PV2

PV2

AN.OR.1

AND

OR

AL1_H

AL1_L

TM1

ACT1

ALM1

AN.OR.2

AND

OR

AL2_H

AL2_L

TM2

ACT2

ALM2

MOD1

HYS1

1H=80

1L

MOD2

HYS2

2H=50

2L=40

MOD3

HYS3

3H=70

3L

PV1 rate-of-change

PV2 rate-of-change

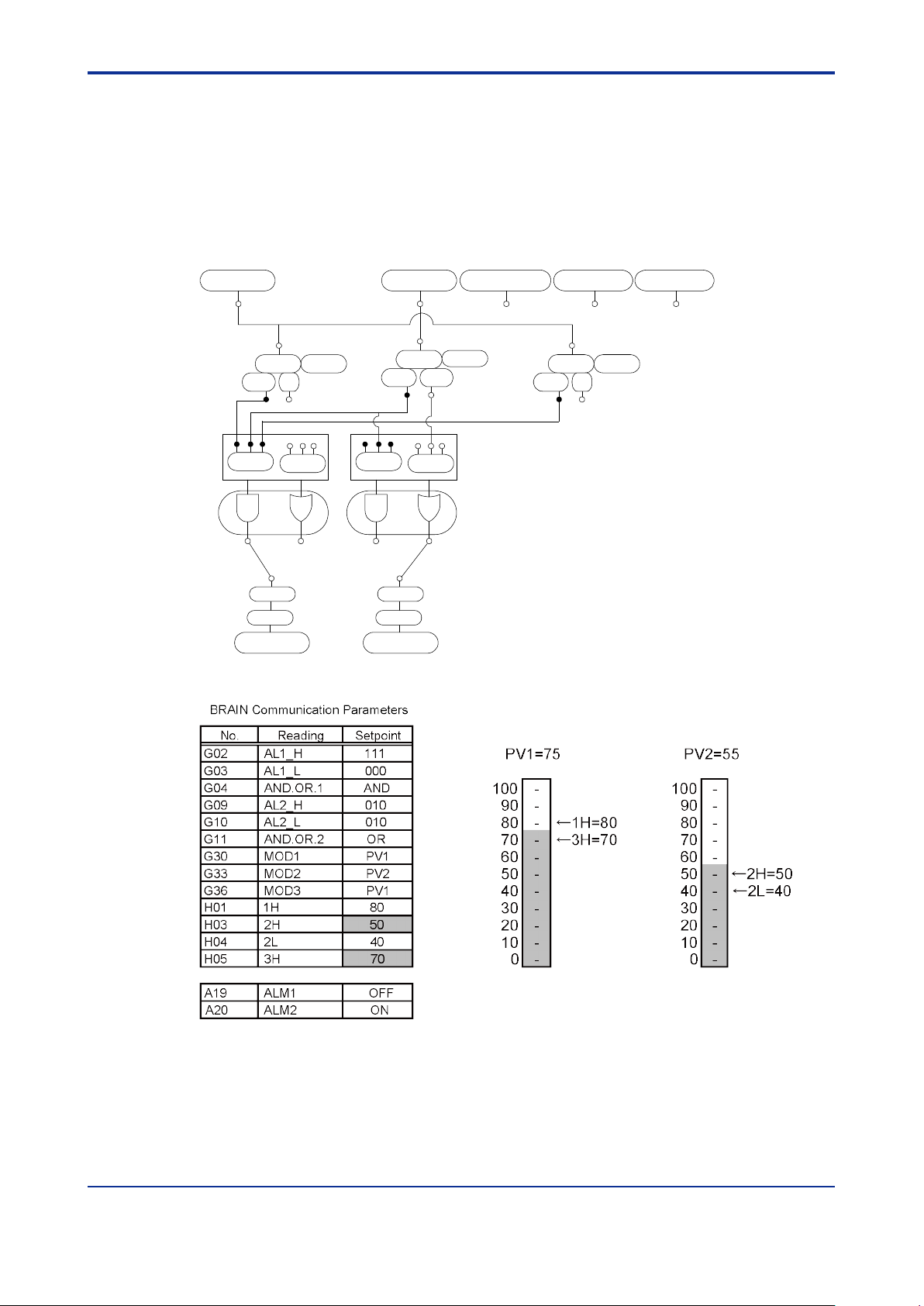

4.3.3 Example of Setting the Alarm Functions

Example of Setting 1

Condition A)

ALM1: ALM1 alarm is output if all of the following are generated: the high high-limit

alarm of input 1 (1H = 80), the high-limit alarm of input 1 (3H = 70), and the

high-limit alarm of input 2 (2H = 50).

ALM2: ALM2 alarm is output if either the high-limit alarm (2H = 50) or low-limit alarm

(2L = 40) of input 2 is generated.

Figure 4.10 Alarm Connections for Condition A

Figure 4.11 Details of Parameter Settings

The parameter settings for condition A are as shown in the table above. When input 1

and input 2 are in the condition as shown in the figure above, the 2H and 3H parameters

enter the alarm state and only ALM2 outputs an alarm. (ALM1 outputs no alarm because

1H has not been in the alarm state.)

Page 27

<4. FUNCTIONS >

4-11

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

mV input

Thermocouple input

RTD input

Span

10 to 100 mV DC

10 to 63 mV

elect romotive force)

50 to 500°C

Zero elevation

Three times the span

whichever is smaller

Three times the span or within ±25 mV,

Five t imes or less

4.4 Retransmission Output Function (for /VLT

and /CUR Options)

The SDAU digital alarm unit with the /VLT or /CUR option can output an input signal as

retransmission output in order to use it in a recorder, etc.

The retransmission output function is set using the following parameters.

For more information on each parameter, see Chapter 6, "PARAMETERS."

RET: Selects the retransmission output type (selectable from None, PV1, PV2, and

PV1 - PV2)

RTH: Maximum value of retransmission output scale

RTL: Minimum value of retransmission output scale

Retransmission Output Accuracy Guaranteed Range:

(RTH-RTL)

(RTL)

Note1: The retransmission output accuracy guaranteed range is within the noted accuracy range and within 0.0 to 100.0% of

the span (RTH - RTL ).

or within ±50 mV,

(converted based on thermo

whichever is smaller

the s pan

Page 28

<4. FUNCTIONS >

4-12

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

PC

A maximum of 1,200 m ; up to 31 slave stations connected.

Programmable logic

controller (FA-M3, etc.)

or

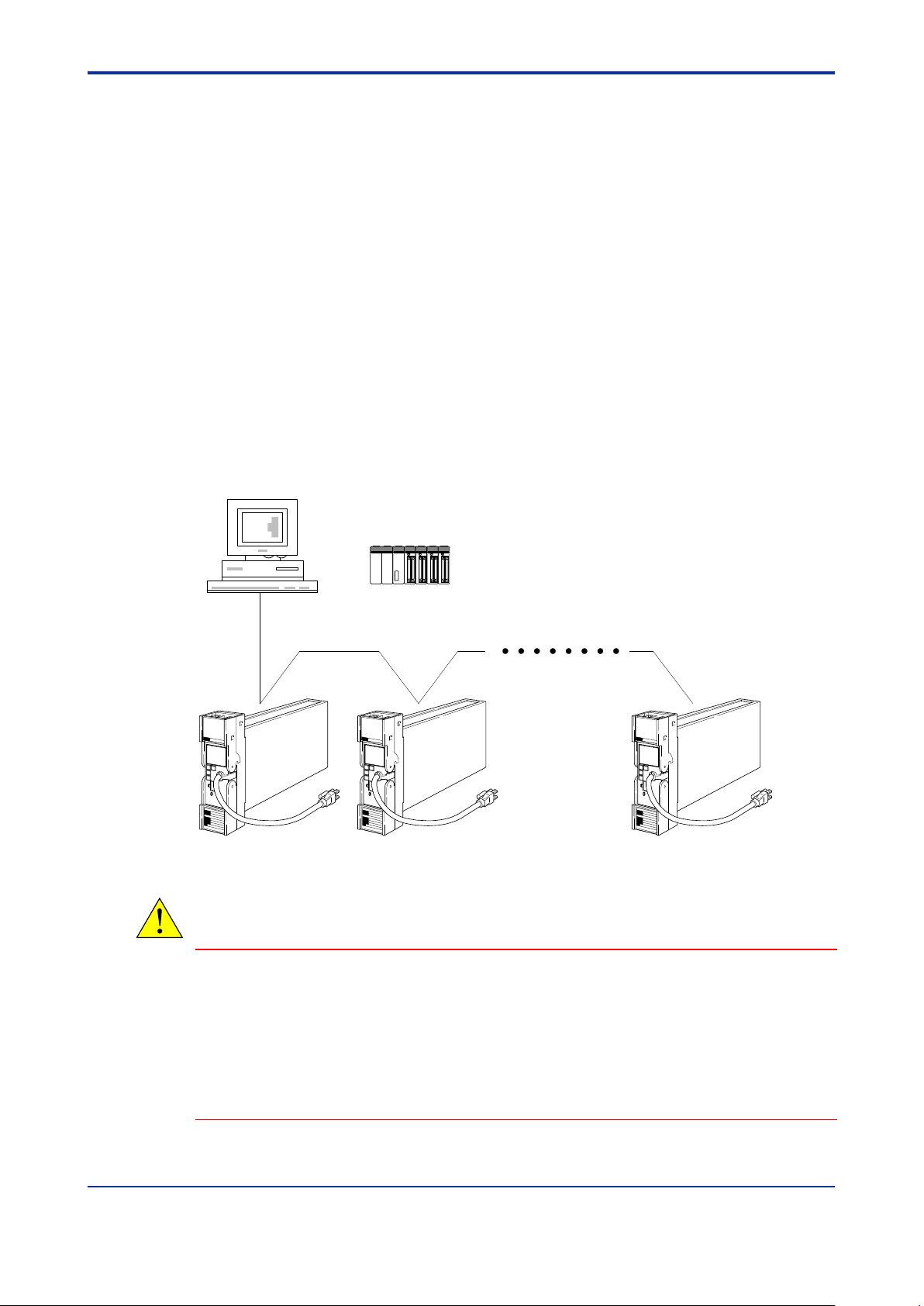

4.5 Communication Function (for /COM Option)

The SDAU alarm unit can communicate with a device with an RS-485 communication

interface, allowing input values to be read out and/or parameters to be read out or

written in.

For more information, see YS80*R Rack-Mounted Instruments Communication

Functions User’s Manual (IM 01B04F01-20E).

- Communication Interface : 1 channel

- Standards : EIA RS-485

- Communication System : 2-wire, half-duplex

- Baud Rate : 1200, 2400, 4800 and 9600 bps

- Communication Protocol : MODBUS, PC-Link, and Ladder

- Maximum Units Connectable : 31 units

- Maximum Communication Distance : 1200 m

- Communication Cable : Twist pair cable with shield (Wire size: AWG24 or

equivalent.)

Figure 4.12 Connection with a PC

CAUTION

• RS-485 communication is not available when a PC (VJ77) or the Handy Terminal is connected to

the BRAIN connector on the front panel.

When using a PC (VJ77) or the Handy Terminal, connect a PC (VJ77) or the Handy Terminal after

removing the RS-485 connector so that a PC (VJ77) or the Handy Terminal connector can be

easily disconnected.

• Writing via RS-485 communication is not possible if the Parameter Write Protect jumper (W.P.) is

set to ON or the Communication Write Protect Setting parameter (COMMU) is set to “1: Protect”.

Page 29

<4. FUNCTIONS >

4-13

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

H=75.0

POWER OFF

POWER ON

HYS=10%

10

seconds

POWER ON

Normal

When HOT start is set:

When COLD start is set:

Normal

Normal

Alarm

10

seconds10seconds

Parameter Symbol

Setpoint

H (alarm setpoint nH)

75.0%

HYS (hysteresis)

10.0%

TM ( alarm output timer)

30 seconds

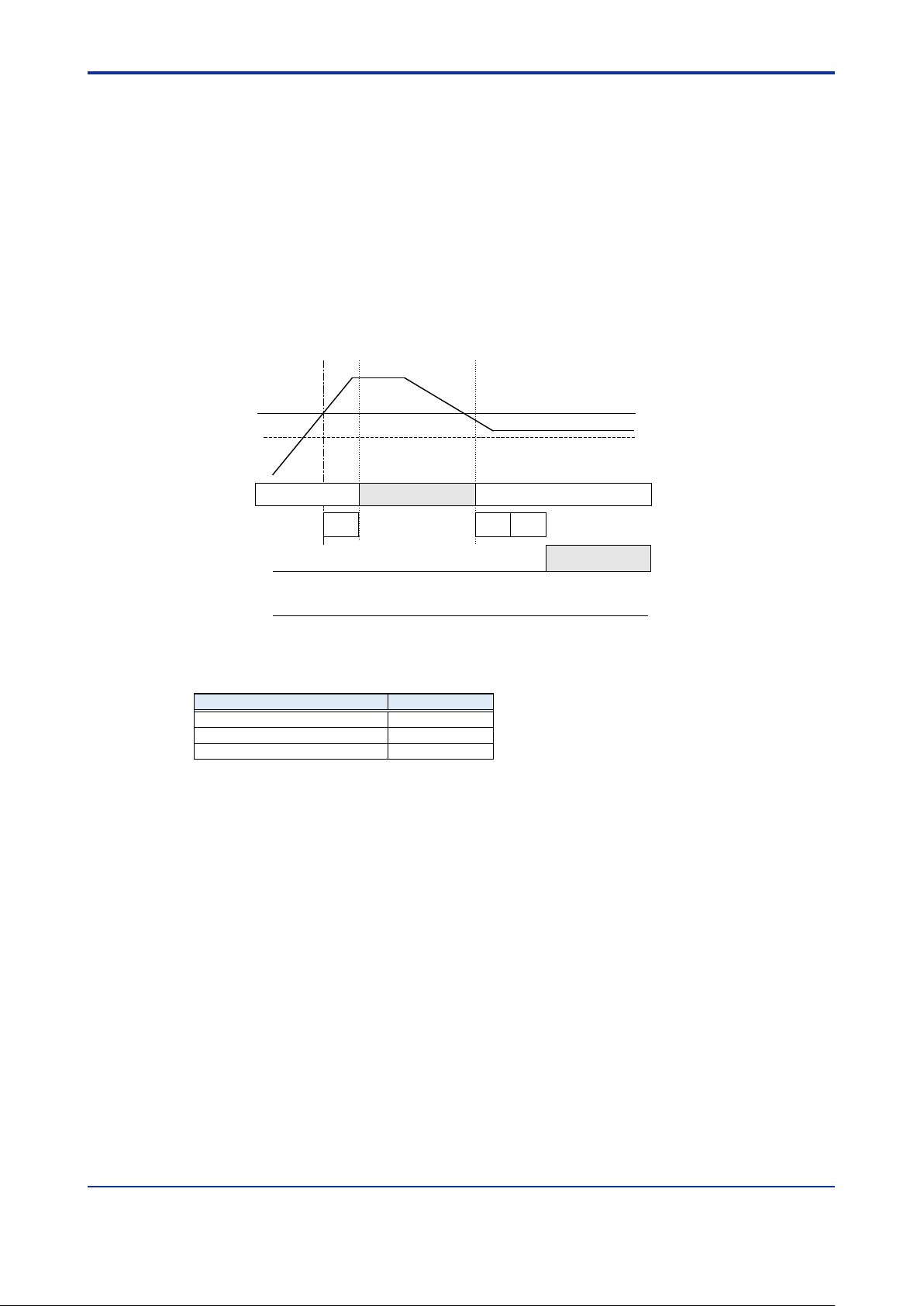

4.6 Function of Recovery from Power Failure

The SDAU alarm unit's recovery from power failure function operates as described

below, depending on the setting of the HOT start/COLD start parameter.

HOT start: Continues operation from the alarm status just before a power failure.

Note1: W hen t he alarm t im er m ode is set to alarm output tim er, ALM3 and ALM4 cann ot be HOT started.

Note2: HOT start s also cannot be m ade for rate-of-change alarm s. F or these alarm s, the S DAU judges if an alarm has

COLD start: Starts operation by assuming that power-on input has been continued

(provided that hysteresis has not been activated).

The following shows differences in alarm actions between HOT and COLD setpoints.

occurred at the instant when the change time of a rate-of-change alarm has elapsed, by regarding the value at

recovery from pow er failure as the previous value.

Figure 4.13 Alarm Action for HOT and COLD Starts

Parameter Setting Conditions for the Conditions in the Figure Above

Note: Even when the HOT start parameter is set, if a power failure occurs during any of

the following procedures, a HOT start is not possible.

• During input adjustment

• While a parameter is being changed (with a key switch, a PC (VJ77), JHT200

Handy Terminal, or through RS-485 communication)

• During initial setting at power ON

Page 30

<4. FUNCTIONS >

4-14

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

1

ALM

2 E F

Lower half section of

the digital display

Fail (F) lamp

Error (E) lamp

4.7 Self-Diagnostic Function

The SDAU alarm unit has a self-diagnostic function capable of detecting a failure or

error in the unit itself.

If an error/failure is detected, notification is made by the following means: an error

indication appears on the lower half of the digital display, a parameter is displayed on

the upper half of it, a lamp on the front panel of the alarm unit is lit, the failure output

contact is de-energized (when /RLY4, /CUR, or /VLT is not specified), and/or an alarm

output contact is activated.

For details about the lamps on the front panel of an alarm unit with the /RLY4 option, see

Section 5.2, “Part Names of the Display Setter.”

The following describes actions to be taken in the event of error. (For more information,

see Section 8.2, "Actions under Fault Conditions.")

• Lighting of F lamp: CPU failure, A/D conversion failure, EEPROM failure, or RJC

error

(When the /RLY4 option is specified, this lamp is an indicator for ALM4.)

• Lighting of E lamp: Input signal overrange (Note)

(This lamp lights up if the input is more than 106.25% or less than -6.25% of the

input range high limit (RH1) or the input range low limit (RL1).)

Input burnout (Note)

HOT start is disabled (see Section 4.6, "Function of Recovery from Power Failure").

(When the /RLY4 option is specified, this lamp is an indicator for ALM3.)

Note: For input signal overrange or input burnout, the E lamp lights up and a failure output is sent out when the target input

signal is connected to an alarm output section.

• Failure output: (only when /CUR, /VLT, or /RLY4 option is not specified)

A failure contact output is provided if the F lamp comes on or the power supply fails.

Using the point-of-error failure output action parameter (front display parameter:

FAIL.M; BRAIN communication parameter: F40:FAIL MODE), define the action of

the failure contact to be taken when the E lamp comes on.

ON (0) = Provides a failure contact output when the E lamp comes on.

OFF (1) = Provides no failure contact output when the E lamp comes on.

(This parameter defaults to ON (0), as with SDAU*E.)

Page 31

<4. FUNCTIONS >

4-15

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

Off

O

n

Alarm output

Failure output

Energization

(normal state)

De-energization

(alarm)

Energization

(normal state)

De-energization

(alarm)

Approx. 75 msec

At power-on

Approx. 40 msec

At power failure

0 (normal)

Unable to

communicate

Reading of the FAILST (D0022)

failure output by RS-485

communication

0 (normal)

Unable to communicate

Off

Off

F lamp

Power supply

24VDC

0V

Approx. 2 to 3 sec

Off

Off

E lamp

4.8 Alarm/Failure Outputs at Power-on and

Power Failure

The alarm and failure outputs function as explained below when the power is turned on

or if the power fails.

The following example explains a case where the action is defined as RLYn

ACTION=NRM ENERGIZED (normal-state energization) and no alarms or failures have

occurred.

When the power is turned on:

(1) The alarm output starts alarm action in approximately 2 to 3 seconds after power-on.

(2) The failure output is energized (normal state) in approximately 75 milliseconds after

the start of alarm action.

If the power fails:

(1) The failure output is de-energized (failure state) immediately after the power is cut

off.

(2) The alarm output is also de-energized in approximately 40 milliseconds after the

failure output is de-energized.

(3) The E lamp remains lit for approximately 40 milliseconds after the failure output is

de-energized.

Figure 4.14 Alarm/Failure Outputs at Power-on and Power Failure

Page 32

Blank Page

Page 33

<5. SETTING>

5-1

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

5. SETTING

WARNING

When setting parameters, do not turn off the SDAU alarm unit.

Items to Confirm before Start of Operation

Before you start operation, inspect and confirm the following items:

(1) Draw out the internal unit from the rack case, and make sure that the specified fuses

are properly mounted in the fuse holders at the rear of the internal unit.

Make sure that the specified power supply fuse is properly mounted in the fuse

holder on the front for /TB option.

(2) W hen inserting the internal unit into the rack case, firmly connect the multi-pin

connectors for connecting the internal unit and the case.

(3) Make sure that power plugs are properly connected to the power outlet.

(4) Make sure that external wiring to the terminal block is properly connected.

(5) Make sure the parameter setpoint and change the setpoint if necessary. Set the

parameter following the steps (1) through (3) described below.

Setting procedure required for basic use

(1) Set the Input-Related Parameters.

For details on parameters, refer to Input-Related Parameters in Section 6.3, “Display

on Front Panel: List of Parameters” or parameter numbers F** SET (I/O) in Section

6.4, “BRAIN communication parameter: List of Parameters.”

For details on input processing function, refer to Section 4.2, “Input Processing

Function.”

(2) Set the Alarm-Related Parameters.

Note: Alarm setting parameters (1H, 1L, 2H, 2L, 3H and 3L) are not displayed because they are not c onnec ted for

fact ory-set default.

Set the alarm setpoint after completing the wiring for alarm.

For details on parameters, refer to Alarm Connection/Output Parameters and Alarm

Detection-Related Parameters in Section 6.3, “Display on Front Panel: List of

Parameters” or parameter numbers G** SET (ALM) and H** (ALM H/L) in Section

6.4, “BRAIN communication parameter: List of Parameters.”

For details on the alarm processing function, refer to Section 4.3, “Alarm Processing

Function.”

Before defining the alarm setting parameters, determine the method of alarm

connection by referring to Figure 4.5 “Alarm Processing Function Block Diagram” in

Section 4.3, “Alarm Processing Function.”

Page 34

<5. SETTING>

5-2

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

(3) Set the Parameters for Optional Suffix Codes (for /VLT, /CUR or /COM only)

For details on parameters for “/ VLT” or “/CUR” option, refer to Retransmission

Output-Related Parameters in Section 6.3, “Display on Front Panel: List of

Parameters” or parameter numbers J** SET (RET) in Section 6.4, “BRAIN

communication parameter: List of Parameters.”

For details on retransmission output function, refer to Section 4.4, “Retransmission

Output Function.”

For details on parameters for “/COM” option, refer to Communication-Related

Parameters in Section 6.3, “Display on Front Panel: List of Parameters” or parameter

numbers K** SET (COM) in Section 6.4, “BRAIN communication parameter: List of

Parameters.”

For details on communication function, refer to Section 4.5, “Communication

Function.”

(4) Set the Point-of-error Failure Output Action Parameter (FAIL MODE).

(For options other than /RLY4, /VLT and /CUR)

For details on this parameter, see Section “Other Parameters” in 6.3, “Display on

Front Panel: List of Parameters” or see parameter number F40 in Section 6.4,

“BRAIN communication parameter: List of Parameters.”

For details on actions in case of failure, see Section 8.2, “Actions under Fault

Conditions.”

Page 35

<5. SETTING>

5-3

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

5.1 Name of Components

The following shows the name of SDAU components.

Figure 5.1 Names of Components

Page 36

<5. SETTING>

5-4

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

ALM

1 2 3

4

ALM

ALM3 and ALM4 lamps

(Alarm status indicator lamps)

<Digital display for /RLY4 option>

5.2 Part Names of the Display Setter

Figure 5.2 Part Names of the Display Setter

Note1: When using a PC (VJ77) or the Handy Terminal, connect a PC (VJ77) or the Handy Ter m i nal aft er rem oving the RS-

485 connector.

Note2: W hen the /RLY4 option is specified, the ALM3 and ALM4 lamps take the place of the E and F lamps.

Page 37

<5. SETTING>

5-5

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

Display/indication

Function

Parameter display section

Displays a parameter symbol in an 11-segment indication.

Symbols in the following table.

Setpoint display s ect ion

Displays the status of a parameter displayed in the parameter display

setpoint .

ALM (Alarm-1 and -2 status

indicator) lamps (yellow)

Light up in the event of an alarm.

ALM (Alarm-3 and -4 status

indicator) lamps (yellow)

Provided only for the /RLY4 option. These lamps light up in the event

of an alarm.

E (Error) lamp (yellow)

Not provided for the /RLY4 option.

Conditions."

F (Fail) lamp (red)

Not provided for the /RLY4 option.

Conditions."

LED

Signal

LED

Signal

LED

Signal

A N 1

B O 2

C P 3 D Q 4

E R

indicator)

5

F S 6 G T 7 H U 8

I

V 9

J W 0 K X

L Y

M Z

Functions of the Digital Display Section

Table 5.1 Functions of the Digital Display Section

For the display of letters in 11 segments, see a List of LED Dis play

section (such as an input value, alarm status, self -diagnostic result) or

This lamp lights up in the event of an internal er ror such as input

burnout.

For more information, see Sec tion 8.2, "Actions under Fault

This lamp lights up in the event of failur e such as A/D conversion

failure.

For more information, see Sec tion 8.2, "Actions under Fault

List of LED Display Signal

Table 5.2 List of LED Display Signal

Alphabetic

character

Display

Alphabetic

character

(Upper side

digital

indicator)

r

(Lower side

digital

Display

Numeral

character

Display

Page 38

<5. SETTING>

5-6

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

Name

Jumper Name

Optional Suffix

Parameter write-protect jumper

W . P. ―

Alarm output contact

ALM1

RY. 1

With /RLY4 specified

ALM2

RY. 2

With /RLY4 specified

ALM3

RY. 3

With /RLY4 specified

ALM4

RY. 4

With /RLY4 specified

Failure output contact action setting jumper

Without /RLY4, /VLT, or /CUR

5.3 Setting Jumpers

The SDAU alarm unit has the following jumpers.

Table 5.3 Setting Jumpers

action setting jumper

• Parameter write-protect jumper

W hen this jumper is set to ON, key switch-based parameter changes, parameter

changes via a PC (VJ77) or the JHT200 Handy Terminal, and RS-485

communication-based parameter changes will be disabled. In this case, pressing

the [→] key switch with a setting parameter displayed on the digital display causes

"LOCK" to appear in the upper half of the display setter. Press any key to return to

the status that was set before the "LOCK" indication.

• Failure output contact action setting jumper (jumper name: RY.4)

Set this jumper only when the /RLY4, /VLT, or /CUR option is not specified.

A failure output contact is always energized during normal operations.

This jumper is used to set the action to be taken in the event of failure (for more

information on CPU failure, and others, see Section 8.2, "Actions under Fault

Conditions.").

For NC setting: Closed if a relay is de-energized.

For NO setting: Open if a relay is de-energized.

• Alarm output contact action setting jumpers (jumper names: RY.1, RY.2, RY.3, RY.4)

Set these jumpers if the /RLY4 option is specified.

ALM1 is set with RY.1, ALM2 with RY.2, ALM3 with RY.3, and ALM4 with RY.4.

For NC setting: Closed if the relay is de-energized.

For NO setting: Open if the relay is de-energized.

Page 39

<5. SETTING>

5-7

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

Jumper Name

BRAIN Communication

Parameter Name

Parameter write protect

A55: WRT PROTECT

Factory-shipped condition

RY.1 RY.2 RY.3 RY.4

NO

NC

NO NC NO NC NO NC

NO setting NO setting NO setting NO setting

RY.1 RY.2 RY.3 RY.4

NO NC NO NC NO NC NO NC

NC setting NC setting NC setting NC setting

Parameter write-protect

Setting jumper (factory-shipped condition)

When this jumper is set to ON,

parameter change is disabled.

Note: RY.1, RY.2 and RY.3 jumpers are provided only

when /RLY4 option is specified.

5.3.1 Checking Setting Jumpers and their Locations

The setting jumpers are located on the main board of the internal unit.

Pull out the internal unit and check the current settings.

Moreover, the current status of the parameter write-protect jumper can be checked via a

PC (VJ77) or the JHT200 Handy Terminal without pulling the internal unit out.

Figure 5.3 Jumper Settings

CAUTION

Operation is not guaranteed if the jumper is not set.

Page 40

<5. SETTING>

5-8

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

5.3.2 Change of Setting Jumper

Follow the procedure below to change the setting jumpers:

(a) Pull the terminal block cover toward you to draw out the internal unit from the rack

case.

(b) Check the jumpers on the main board of the internal unit and change their settings

as desired. Use tweezers or another fine-tipped object to change the setting

jumpers.

(c) Return the internal unit to the rack case.

(d) Return the terminal block cover to its original position.

Page 41

<5. SETTING>

5-9

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

Key

Functions

Display Mode

Setting Change Mode

Setting Fix Mode

Display Shutoff

Mode

Displays the next parameter.

Canc els a changed

parameter.

Canc els a changed

the next par ameter.

The SDAU enters this

→

Advances the SDAU to detailed

enable s tat e. ( Note 1)

Moves digit for setting.

Returns the SDAU

↑

Displays the previous parameter.

Changes a s etpoint.

No operation

SET

Canc els disabled HOT start

FLAG parameter is displayed.

Advances the SDAU to

Fixes a setpoint and

to display mode.

Enable

The SDAU enters a setting-and-change enable state.

If t he Par ameter W rite-Protect jumper has been set to ON, the ENBL s witch will be disabled.

Display

mode

(Moves the SDAU to

setting change mode)

(Moves digit for setting)

(Increments a setpoint)

(Displays the next parameter)

(Displays the previous parameter)

(Moves the SDAU

to setting fix mode)

Detailed alarm

status display

mode

(Enabled only when ALMn = 1

during display of ALMn)

(Cancels disabled HOT start impossible status flag if a FLAG parameter

is displayed)

(Displays error

description)

SET

SET

SET

Press any key switch to

return to display mode.

Display shutoff

mode

(The SDAU enters this mode if no

key switch is operated for more

than 30 min. while the display

mode parameter set to OFF.)

(Cancels a changed

setpoint, returns the SDAU

to display mode, and

displays the next

parameter.)

(Fixes a setpoint and moves the

SDAU to display mode)

Setting fix mode

(All-digits flashing)

(Cancels a changed

setpoint, returns the SDAU

to display mode, and

displays the next

parameter)

Setting change mode

(Single-digit flashing)

(Returns the SDAU to setting

change mode and moves

flashing to the next digit)

(Enabled only when FLAG ≠ 0000

during display of FLAG)

Error display

mode

(Displays an alarm setpoint

when an alarm has occurred)

5.4 Settings Done from the Front Panel of the

Alarm Unit

Using the display setter on the front panel of the alarm unit, you can display input values

and set parameters. For more information on the parameters, see Section 6.3, "Display

on Front Panel: List of Parameters."

5.4.1 How to Operate the Key Switches

Table 5.4 Key Switch Functions

Switch

value, ret urns t he

SDAU to display mode,

and displays the next

value, ret urns t he

SDAU to display

mode, and displays

mode if a key switch

is not oper ated for

more than 30 min.

while the display

mode paramet er is

alarm status dis play mode when

ALMn=1 is indicated.

Advances the SDAU to error

display mode if FLAG ≠ 0000 is

indicated.

Advances the SDAU to s etting

to setting change

mode and moves

flashing to the next

digit.

set to 0 = OFF.

When a key switch is

pressed in display

shutoff mode, the

SDAU ret urns to

display mode.

change mode when a settable or

changeable parameter is

displayed in setting and change

(ENBL)

impossible status flag when

If a password has been set, the SDAU enters a s etting-enable s tate only when a c orr ect password has

setting fix mode.

advances the SDAU

been entered after pr ess ing the ENBL switch.

Note 1: If the P arameter W ri te-Protect jumper on the main board has been set to ON, the SDA U does not advance t o the

setting change mode, but displays "LOCK" in the upper half of the digital display.

Figure 5.4 Key Switch Operations and Mode Transitions

Page 42

<5. SETTING>

5-10

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

→

(2) Press the ENBL switch to bring about a setting and the change enable state.

(3) Alarm-1 high-limit alarm connection (AL1_H) appears.

Press the [ r] key several times.

SET

ALM

1 2 E F

SET

ALM

1 2

E F

(1) An input value (60.00) appears at power ON.

(4) Set alarm-1 high-limit alarm connection (AL1_H).

This causes the most significant digit of the display to flash.

Continuing to press the key causes the flashing indicator to move to

a digit on the right.

Press the [→] key

once.

Press the [] key.

This causes the value of a flashing digit to increment. Press this

key to bring about "1."

Press the [SET]

key.

This causes all the digits to flash. Press the [SET] key again to

cause "100" to light up. (This completes the setting.)

→

→

5.4.2 Settings Using Key Switches (Example)

The following describes how to set a parameter using the key switches. Put the SDAU

into a parameter setting-and-change enable state and follow the procedure below to set

the parameter.

CAUTION

If the Parameter Write-Protect jumper on the main board has been set to ON, the SDAU does not

advance to the setting change mode even if you press the [→] key switch in step (4) of the parameter

setting procedure. Thus, the flashing indicator cannot move to the next digit. In this case, "LOCK"

appears in the upper half of the digital display. To return to the display mode, press any key switch.

Parameter Setting Procedure

Figure 5.5 Parameter Setting Procedure

Page 43

<5. SETTING>

5-11

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

How to set disable f unction

How to cancel disable

funct ion

Operations to be disabled

Parameter

Set the j umper (W. P.) on the

Set the j umper (W. P.) on

- Change of a parameter using key

485 communication

ENBL switch

If no key s witch is operated for

the change dis able s tate.

Press ENBL switch.

- Change of a parameter using key

Passwor d

parameter

Set a password using the SET

parameter.

Enter a correct passwor d

to the PASS parameter.

- Change of a parameter using key

switches

COMMU

parameter

Set the COMMU parameter to

"1."

Set the COMMU

parameter to "0."

- Change of a parameter through RS485 communication

Press ENBL switch Entry of a pass word: accepted

Setting and c hange disabl ed Setting and c hange enabled

When a pass word

has been set

W

hen no password

is set

Setting and c hange enabled

Last operation of a key switc h

Press ENBL switch

For 30 min.

Last operation of a key switc h

For 30 min.

Set ting and

change disabled

Set ting and

change disabled

Set ting and

change disabled

5.5 Parameter Change Disable Function

The SDAU alarm unit has four parameter-change-disable functions as shown in the

table below. They are used to prevent a parameter from being changed inadvertently.

Table 5.5 Parameter Change Disable Function

Write-Protect

jumper

main board to ON.

the main board to OFF.

switches

- Change of a parameter via a PC

(VJ77) or the Handy Terminal

- Change of a parameter through RS-

30 min. since the last operation

switches

of a key switch on the front

panel in the setting-and-change

enable s tat e, t he SDAU enters

Figure 5.6 Relationship between the ENBL Switch and Password Function

Page 44

<5. SETTING>

5-12

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

ALM

Press any key switch.

Normal operation mode

ALM

Display shutoff mode

Only decimal points light up.

If no key switch is operated for

more than 30 minutes, the SDAU

moves to the display shutoff mode.

1 2

E F

1 2

E F

5.6 Various Display Modes

This section describes various display modes.

5.6.1 Display at Power ON

The model with display setter displays REV NO. (revision number of software for the

SDAU) for about 2 seconds after power ON.

Example of display (REV NO.2)

5.6.2 LOCK Display

If the upper half of the digital display shows "LOCK," the Parameter Write-Protect

jumper on the main board has been set to ON. Thus, no parameters can be set or

changed. The lower half of the digital display indicates nothing. Press any key switch to

return to the status that was set before "LOCK" was displayed.

5.6.3 Display in Display Shutoff Mode

If the upper and lower halves of the digital display show decimal points only, the SDAU

is in the display shutoff mode. This mode is activated if no key switch is operated for

more than 30 minutes with the display mode parameter (DSPM) set to 0 = OFF.

To return to the display mode, press any key switch in the display shutoff mode.

If an A/D conversion failure, EEPROM failure, EEPROM SUM failure or RJC error

occurs in the display shutoff mode, error indication has priority over the display shutoff

mode.

Moreover, during the occurrence of an A/D conversion failure, EEPROM failure,

EEPROM SUM failure or RJC error, the SDAU does not enter the display shutoff mode.

Figure 5.7 Display in Display Shutoff Mode

Page 45

<5. SETTING>

5-13

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

ALM

1 2 E F

ALM

1 2

E F

5.6.4 Error Display

When the upper half of the digital display shows a PV parameter (PVn, DV, PVn.VL), the

lower half of the digital display indicates an error description. For more information, see

Section 8.2, "Actions under Fault Conditions."

Figure 5.8 Error Display

5.6.5 Display of Self-Diagnostic Results

If the result of self-diagnosis (FLAG) is any value other than "0000," pressing the [→]

key switch while the FLAG parameter is displayed causes the upper half of the digital

display to show an error description. Nothing appears on the lower half of the digital

display.

If multiple errors are present, press the [→] key switch to show the description of the

next error. For more information, see Section 8.2, "Actions under Fault Conditions."

Figure 5.9 Display of Self-diagnostic Results

Page 46

<5. SETTING>

5-14

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

ALM

1 2 E F

5.6.6 Detailed Alarm Status Display

The detailed alarm status display shows the type of input for which alarm has occurred

and the relevant alarm setpoint.

To switch to the detailed alarm status display, press the [→] key switch while the alarm

status is "1." Each time the [→] key switch is pressed, the display switches to the next

alarm status by the number of alarm setpoints where an alarm has occurred.

The Detailed Alarm Status Display is not updated until the [→] key switch is pressed the

next time.

Note: In the detai led al arm status di splay, you cannot change an alarm setpoint. Information provi ded on the Detailed Alarm

The display condition is as shown in the figure below.

Stat us Di splay is not updated even if the on-display alarm is cancel ed when th e display is ac tive.

Nor is the i nformation up dated even if the on-display alarm setpoint is c hanged by paramet er set ting via BRAIN or

RS-485 communication.

Figure 5.10 Display Condition of Detailed Alarm Status Display

1. Upper three digits of the upper half of digital display: Shows the input connected to

an alarm point where an alarm has occurred. (PV1, PV2, DV, VL1, VL2)

2. Lower two digits of the upper half of digital display: Shows the alarm setpoint (1H,

1L, 2H, 2L, 3H, and 3L) where an alarm has occurred.

3. Lower half of digital display: Shows the setpoint of an alarm point where an alarm

has occurred.

The following shows an example of the detailed alarm status display.

Setting 1:

ALM1: ALM1 alarm is output if all of the following are generated: the high high-limit

alarm (1H) of input 1, the high-limit alarm (3H) of input 1, and the high-limit

alarm (2H) of input 2.

ALM2: ALM2 alarm is output if either the high-limit alarm (2H) or the low-limit alarm

(2L) of input 2 is generated.

Setting 2:

ALM1: ALM1 alarm is output if one of the following is generated: the high high-limit

alarm (1H) of input 1, the high-limit alarm (3H) of input 1, or the high-limit alarm

(2H) of input 2 is generated.

ALM2: ALM2 alarm is output if either the high-limit alarm (2H) or the low-limit alarm

(2L) of input 2 is generated.

Page 47

<5. SETTING>

5-15

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

For setting 1:

For setting 2:

ALM

1 2

E F

ALM

1 2

E F

ALM

1 2

E F

ALM

1 2

E F

ALM

1 2 E F

ALM

1 2

E F

ALM

1 2 E F

ALM

1 2 E F

→

No change (right arrow key switch is disabled because ALM1 = 0)

→

→

→ →

→

→

→

Figure 5.11 Detailed Alarm Status Display

The detailed alarm status display and its display procedure are as shown below when

parameters in the table are set in an input condition as shown in the figure above.

Figure 5.12 Examples of Detailed Alarm Status Display

Page 48

<5. SETTING>

5-16

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

5.7 Settings Using the JHT200 Handy Terminal

The SDAU alarm unit has BRAIN communication parameters used to specify a function

or to adjust inputs/outputs. To display or set/change a parameter, connect the JHT200

Handy Terminal (*1) to this unit.

*1: The BT200 BRA IN Terminal of Yokogawa El ectric Corporation can also be used.

CAUTION

For details of operation and adjusting procedures of JHT200 Handy Terminal, refer to the

instruction manual “JHT200 Handy Terminal” (IM 77J50H01-01EN).

Figure 5.13 Connecting the Handy Terminal

Page 49

<5. SETTING>

5-17

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

5.8 Settings Using a PC (VJ77)

The SDAU alarm unit has BRAIN communication parameters used to specify a function

or to adjust inputs/outputs. To display or set/change a parameter, connect a PC (VJ77) to

this unit.

CAUTION

For details of operation and adjusting procedures of VJ77 Parameters Setting Tool, refer

to the instruction manual “Model VJ77 PC-based Parameters Setting Tool” (IM

77J01J77-01E).

Figure 5.14 Connecting a PC (VJ77)

Page 50

Blank Page

Page 51

<6. PARAMETERS >

6-1

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

6. PARAMETERS

6.1 Configuration of Parameters

The SDAU's parameters include display-only parameters (those shown in the shaded

areas of the parameter chart) and parameters that can be set and changed.

A parameter can be set in two ways: one is to set it using the key switches and the other

is to set it via a PC (VJ77) or the JHT200 Handy Terminal.

(For SDAU with the /COM option, a parameter can also be set through RS-485

communication.)

There are differences between the parameter symbols that are displayed on the display

setter on the front panel of the unit and those that are displayed on a PC (VJ77) or the

Handy Terminal due to some bearing on the display units. Moreover, there are also

parameters that can be set only via a PC (VJ77) or the Handy Terminal. Parameters

marked with “-” in Symbol appearing on digital display in Section 6.4, "BRAIN

Communication Parameter: List of Parameters" are applicable to it.

Of parameters that can be set and changed, those required to be set at setup can be

displayed on the display setter on the front panel by setting the SKIP parameter to "0."

If the SKIP parameter is set to "1," the parameters that can be set and changed,

excepting alarm setpoints (1H, 2H, 3H, 1L, 2L, 3L), are not displayed on the display

setter. A PC (VJ77) or the JHT200 Handy Terminal can display any parameters

regardless of the setting of the SKIP parameter.

Page 52

<6. PARAMETERS >

6-2

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

PV1

PV2

DV

PV1.VL

PV2.VL

ALM1

ALM2

Setting of MODn determines the parameters to be displayed (PV1

and PV2 are always displayed)

Parameter DV is displayed also when parameter RET=3 (PV1-PV2)

/RLY4

provided?

ALM3

ALM4

In the event of an alarm (ALMn = 1), use key switches

to display an alarm setpoint where the alarm has

occurred.

Password

already set?

FLAG

No

Yes

In the event of an error (FLAG ≠ 0000), use key switches to

display an error description.

PASS

SKIP

No

Yes

SKIP=1

1H

1L

2H

2L

3H

3L

(To "F1" on the next page)

(From "SET" on the next page)

No

Yes

6.2 Display on Front Panel: Development View of

Parameters

SDAU-1xx Type Parameters

Figure 6.1 Chart of Parameters to be Displayed on SDAU-1xx Type Front-Panel Digital Display

Note: "nH" is displayed when an alarm is connected with ALn_H, while "nL" is di splayed when it is connected with ALn_L.

Page 53

<6. PARAMETERS >

6-3

IM 01B04K03-02E

8th Edition: Jan.29,2021-00

F1

Type of input-1

signal

1 to 5V

Yes

SQR1

RH1

RL1

UNIT1

TC or RTD

mV

SQR1=1

L.CUT1

RH1

RL1

TC

No

DP1

SCH1

SCL1

DP1

SCH1

SCL1

RJC

RJC=OFF

R.CNST

PV1

BIAS1

F2

SQR2

SQR2=1

Yes

L.CUT2

No

DP2

SCH2

SCL2

PV2

BIAS2

TM.M

AL1_H

AL1_L

AN.OR.1