Page 1

Instruction

Manual

Fiber-optic FA-bus Module and

Fiber-optic FA-bus Type 2 Module

IM 34M6H45-01E

Yokogawa Electric Corporation

IM 34M6H45-01E

1st Edition

Page 2

<Toc> <Ind> <Rev> <Preface>

Applicable Products:

● FA-M3 Range-free Multi-controllers

Model: F3LR01-0N

Model name: Fiber-optic FA-bus Module

Model: F3LR02-0N

Model name: Fiber-optic F A-bus T ype 2 Module

The document number and document model code for this manual are indicated below:

Document number: IM 34M6H45-01E

Document model code: DOCIM

Please refer to the document number in all communications; also refer to the document

number or document model code when purchasing additional manuals.

i

All Rights Reserved Copyright © 1999, Y okogawa Electric Corporation

IM 34M6H45-01E

1st Edition : Feb.28,1999-00Media No. IM 34M6H45-01E (CD) 1st Edition : Feb. 1999 (YK)

Page 3

<Toc> <Ind> <Rev> <Preface>

◆ Important

■ About This Manual

(1)This manual should be passed on to the end user.

(2)Before using the module, read this manual completely to get a thorough understand-

ing of the module.

(3)This manual explains the functions contained in this product, but does not warrant that

those will suit the particular purpose of the user.

(4)Under absolutely no circumstances may the contents of this manual be transcribed or

copied, in part or in whole, without permission.

(5)The contents of this manual are subject to change without prior notice.

(6)Every effort has been made to ensure accuracy in the preparation of this manual.

However, should any errors or omissions come to the attention of the user , please

contact the nearest Y okogawa Electric representative or sales office.

ii

IM 34M6H45-01E 1st Edition : Feb.28,1999-00

Page 4

<Toc> <Ind> <Rev> <Preface>

■ Safety Precautions when Using/Maintaining the Product

The following safety symbols are used on the product as well as in this manual.

CAUTION

This symbol indicates that the operator must follow the instructions laid out in this

manual in order to avoid the risk of personnel injuries or fatalities or damage to the

instrument. The manual describes what special care the operator must exercise to

prevent electrical shock or other dangers that may result in injury or the loss of life.

Protective ground terminal

Before using the instrument, be sure to ground this terminal.

Function ground terminal

Before using the instrument, be sure to ground this terminal.

iii

Indicates alternating current.

Indicates direct current.

(1) The following symbols are used only in the instruction manual.

WARNING

Indicates that the operator must refer to the instructions in this manual in order to

prevent the instrument (hardware) or software from being damaged, or a system

failure from occurring.

CAUTION

Draws attention to information essential for understanding the operation and functions.

TIP

Gives information that complements the present topic.

SEE ALSO

Identifies a source to which to refer.

(2)For the protection and safe use of the product and the system controlled by it, be sure

to follow the instructions and precautions on safety stated in this manual whenever

handling the product. Take special note that if you handle the product in a manner

other than prescribed in these instructions, safety cannot be guaranteed.

(3)If separate protection and/or safety circuits for this product or the system which is

controlled by this product are to be installed, ensure that such circuits are installed

external to the product.

(4)If component parts or consumables are to be replaced, be sure to use parts specified

by the company .

IM 34M6H45-01E 1st Edition : Feb.28,1999-00

Page 5

<Toc> <Ind> <Rev> <Preface>

(5)Do not attempt to make modifications or additions internal to the product.

■ Force Majeure

(1)Y okogawa Electric Corporation (hereinafter referred to as Yokogawa Electric) makes

no warranties regarding the product except those stated in the WARRANTY that is

provided separately .

(2)Y okogawa Electric assumes no liability to any party for any loss or damage, direct or

indirect, caused by the user or any unpredictable defect of the product.

■ Software Supplied by the Company

(1)Y okogawa Electric makes no other warranties expressed or implied except as pro-

vided in its warranty clause for software supplied by the company .

(2)Use the relevant software with one specified computer only . Y ou must purchase

another copy of the software for use with each additional computer.

(3)Copying the software for any purpose other than backup is strictly prohibited.

(4)Store the floppy disks (originals) of this software in a safe place.

iv

(5)Reverse engineering, such as decompiling of the software, is strictly prohibited.

(6)No portion of the software supplied by Y okogawa Electric may be transferred, ex-

changed, or sublet or leased for use by any third party without prior permission by

Y okogawa Electric.

IM 34M6H45-01E 1st Edition : Feb.28,1999-00

Page 6

<Toc> <Ind> <Rev> <Preface>

■ General Requirements for Using FA-M3 Controllers

● Avoid installing FA-M3 controllers in the following locations:

• Where the instrument will be exposed to direct sunlight, or where the operating tem-

perature is outside the range 08 to 558C.

• Where the relative humidity is outside the range 10 to 90%, or where sudden tempera-

ture changes may occur and cause condensation.

• Where corrosive or inflammable gases are present.

• Where the instrument will be exposed to direct mechanical vibration or shock.

● Securely tighten screws:

• Securely tighten module mounting screws and terminal screws to avoid problems

such as faulty operation.

● Securely fasten connectors of interconnecting cables:

• Securely fasten connectors of interconnecting cables, and check them thoroughly

before turning on the power.

v

● Interlock with emergency-stop circuitry using external relays:

• Equipment incorporating the F A-M3 controllers must be furnished with emergency-

stop circuitry that uses external relays. This circuitry should be set up to interlock

correctly with controller status (stop/run).

● Ground FA-M3 controllers to an independent Japanese Industrial Standard

(JIS) Class 3 Ground:

• Avoid grounding the FG terminal of the F A-M3 controller to the same ground as highvoltage power lines. Ground the terminal to an independent JIS Class 3 ground

(ground resistance up to 100 Ω).

● Observe countermeasures against noise:

• When assigning inputs/outputs, the user should avoid locating AC-supplied I/O modules in the vicinity of the CPU module.

● Keep spare parts on hand:

• Stock up on maintenance parts, including spare modules, in advance.

● Discharge static electricity before operating the system:

• Because static charge can accumulate in dry conditions, first touch grounded metal to

discharge any static electricity before touching the system.

● Never use solvents such as paint thinner for cleaning:

• Gently clean the surfaces of the F A-M3 controllers with a piece of soft cloth soaked in

water or a neutral detergent.

• Do not use solvents such as paint thinner for cleaning, as they may cause deformation, discoloration, or malfunctioning.

IM 34M6H45-01E 1st Edition : Feb.28,1999-00

Page 7

<Toc> <Ind> <Rev> <Preface>

● Avoid storing the FA-M3 controllers in places with high temperature or

humidity:

• Since the CPU module has a built-in battery , avoid storing it in places with high temperature or humidity.

• Since the service life of the battery is drastically reduced by exposure to high temperatures, so take special care (storage temperature can be from -208 to 758C).

● Always turn off the power before installing or removing modules:

• Turn of f power to the power supply module when installing or removing modules,

otherwise damage may result.

● When installing ROM packs and changing switch settings:

• In some modules you can remove the right-side cover and install ROM packs or

change switch settings. While doing this, do not touch any components on the printedcircuit board, otherwise components may be damaged and modules fail.

vi

IM 34M6H45-01E 1st Edition : Feb.28,1999-00

Page 8

<Toc> <Ind> <Rev> <Preface>

◆ Introduction

■ Overview of the Manual

The FA-M3 V ersatile Range Multi-controller builds on a new concept developed by

Y okogawa, a company specializing in measurement, control, and information processing.

The manual for Fiber-optic FA-bus Module and Fiber-optic F A-bus T ype 2 Module describes

their specifications as well as how to exchange data.

These modules are used to control I/O subunits installed approximately 100 to 500 meters

apart. Because fiber optic cables are used in communications lines, they will provide noise

immunity and can allow high-speed communications.

■ This manual consists of:

(1) Fiber-optic FA-bus Module

(2) Fiber-optic FA-bus Type 2 Module

vii

■ Other Instruction Manuals

Consult the following FA-M3 manuals as necessary when using this module:

• Sequence CPU Instruction Manual – Functions (IM 34M6P12-02E)

• Sequence CPU Instruction Manual – Instructions (IM 34M6P12-03E)

• Sequence CPU (Model F3FP36 Sequence CPU Module) (IM 34M6P22-01E)

• Personal Computer Link Command Module (IM 34M6P41-01E)

• Ladder Diagram Support Program M3 Instruction Manual (IM 34M6Q13-01E)

■ Trademarks

The product and company names used in this manual are the trademarks or registered

trademarks of their respective companies.

IM 34M6H45-01E 1st Edition : Feb.28,1999-00

Page 9

Blank Page

Page 10

<Int> <Ind> <Rev>

F A-M3

Fiber-optic F A-bus Module and

Fiber-optic F A-bus Type 2 Module

CONTENTS

◆ Important ......................................................................................................ii

◆ Introduction................................................................................................. vii

F3LR01-0N Fiber-optic F A-bus Module

A1. Overview ................................................................................................ A1-1

A1.1 Features .........................................................................................................A1-1

A1.2 Application Examples......................................................................................A1-2

Toc-1

IM 34M6H45-01E 1st Edition

A2. Specifications ......................................................................................... A2-1

A2.1 Function Specifications ................................................................................... A2-1

A2.2 Operating Environment ...................................................................................A2-1

A2.3 Components and Their Functions ...................................................................A2-2

A2.4 External Dimensions .......................................................................................A2-3

A3. System Configuration ............................................................................. A3-1

A3.1 Fiber-optic FA-bus System Configuration........................................................ A3-1

A3.1.1 Restrictions on System Configuration ............................................. A3-1

A3.1.2 Connecting Modules .......................................................................A3-2

A4. Preliminary Setting and Cable Connections.............................................A4-1

A4.1 Startup Procedures ......................................................................................... A4-1

A4.2 Setting Switches .............................................................................................A4-2

A4.2.1 Setting Unit Number Switches ........................................................ A4-2

A4.2.2 Setting Functional Set Switches...................................................... A4-3

A4.3 Attaching and Detaching Modules................................................................... A4-4

A4.3.1 Attaching Modules .......................................................................... A4-4

A4.3.2 Detaching Modules ......................................................................... A4-4

A4.3.3 Attaching Modules in Intense Vibration Environments..................... A4-5

A4.3.4 Depth of Installation ........................................................................ A4-5

A4.4 Connecting Fiber Optic Cables........................................................................ A4-6

A4.4.1 Preparation for Calbes ....................................................................A4-6

A4.4.2 Attaching and Detaching Connectors ............................................ A4-11

A4.4.3 Notice on Connecting Fiber Optic Connectors .............................. A4-12

A4.5 Preliminary Checks .......................................................................................A4-13

A5. Accessing the Module in the Subunit....................................................... A5-1

A5.1 Slot Numbers of FA-M3...................................................................................A5-1

IM 34M6H45-01E

1st Edition : Feb.28,1999-00

Page 11

<Int> <Ind> <Rev>

A6. I/O Refresh T ime..................................................................................... A6-1

A6.1 Estimation of I/O Refresh Time........................................................................ A6-1

A6.2 I/O Refresh Time Calculation Example............................................................A6-2

A7. RAS Function .........................................................................................A7-1

A7.1 Function for Detecting an Error Location ......................................................... A7-1

A7.1.1 Check the LED Display ................................................................... A7-1

A7.2 Output Shutdown Function due to a Communications Error ............................ A7-2

A7.2.1 Overview of Output Shutdown Function .......................................... A7-2

A7.2.2 Output Shutdown of Subunit ........................................................... A7-2

A7.2.3 Function Setting Operation Procedure ............................................ A7-3

A8. Error Handling ........................................................................................ A8-1

A8.1 Troubleshooting ..............................................................................................A8-1

A8.2 Troubleshooting Flowchart When ‘RDY’ LED Is Not ON .................................. A8-2

A8.3 Troubleshooting Flowchart When ‘ERR ’ LED Is ON........................................ A8-3

F3LR02-0N Fiber-optic F A-bus T ype 2 Module

B1. Overview ................................................................................................ B1-1

Toc-2

B1.1 Features .........................................................................................................B1-2

B2. Specifications .........................................................................................B2-1

B2.1 Function Specifications ................................................................................... B2-1

B2.2 Operating Environment ...................................................................................B2-1

B2.3 Components and Their Functions ...................................................................B2-2

B2.4 External Dimensions .......................................................................................B2-3

B3. System Configuration ............................................................................. B3-1

B3.1 Fiber-optic FA-Bus T ype 2 System Configuration ............................................ B3-1

B3.1.1 Slot Number ................................................................................... B3-1

B3.1.2 Restrictions on System Configuration ............................................. B3-2

B3.1.3 Connecting Modules .......................................................................B3-3

B3.2 System Configuration......................................................................................B3-7

B3.2.1 Items Required ............................................................................... B3-7

B3.2.2 System Configuration Procedures .................................................. B3-7

B3.3 Configuration of Substations ........................................................................... B3-8

B3.4 Maximum Total Cable Extension .....................................................................B3-9

B3.5 Precautions...................................................................................................B3-10

B4. Preliminary Setting and Cable Connections............................................. B4-1

B4.1 Startup Procedures ......................................................................................... B4-1

B4.2 Setting Switches .............................................................................................B4-2

B4.2.1 Setting Unit Numbers...................................................................... B4-3

B4.2.2 Setting Slot Numbers ...................................................................... B4-3

B4.2.3 Setting Output Shutdown During a Transmission Line Failure ......... B4-4

B4.2.4 Setting the Number of Ports ............................................................B4-5

IM 34M6H45-01E

1st Edition : Feb.28,1999-00

Page 12

<Int> <Ind> <Rev>

B5. I/O Refresh T ime..................................................................................... B5-1

Toc-3

B4.2.5 Setting Transmission Configuration ................................................ B4-5

B4.2.6 Setting the Quantity of Light ............................................................B4-5

B4.3 Attaching and Detaching Modules................................................................... B4-6

B4.3.1 Attaching Modules .......................................................................... B4-6

B4.3.2 Detaching Modules ......................................................................... B4-6

B4.3.3 Attaching Modules in Intense Vibration Environments..................... B4-7

B4.3.4 Depth of Installation ....................................................................... B4-7

B4.4 Connecting Fiber Optic Cables........................................................................ B4-8

B4.4.1 Preliminary ..................................................................................... B4-8

B4.4.2 Attaching and Detaching Connectors ............................................ B4-12

B4.4.3 Notice on Connecting Optical Connectors..................................... B4-13

B4.4.4 Connecting Fiber Optic Cables ..................................................... B4-14

B4.5 Preliminary Checks .......................................................................................B4-15

B4.6 Notice on Applying Power ............................................................................. B4-16

B5.1 Estimation of I/O Refresh Time........................................................................ B5-1

B5.2 I/O Refresh Time Calculation Example............................................................B5-2

B6. RAS Function ......................................................................................... B6-1

B6.1 Function for Detecting Error Location .............................................................. B6-1

B6.1.1 LED Display.................................................................................... B6-1

B6.1.2 Logging Transmission Line Error Location *1 to Error Log............... B6-8

B6.2 Output Shutdown Function due to a Communications Error .......................... B6-14

B6.2.1 Overview of Output Shutdown Function ........................................ B6-14

B6.2.2 Output Shutdown of Substation .................................................... B6-14

B6.2.3 Function Setting Operation Procedure .......................................... B6-16

B6.3 Switching Transmission Line due to a Communications Error........................ B6-19

B6.3.1 Loop Switch Function ................................................................... B6-19

B6.3.2 Transmission Line Data Return Function ......................................B6-21

B7. Error Handling ........................................................................................ B7-1

B7.1 Troubleshooting Flowchart.............................................................................. B7-1

B7.2 Troubleshooting Flowchart When 'RDY' LED Does Not Switch ON ................. B7-2

B7.3 Troubleshooting Flowchart When "ERR1" and "ERR2" LEDs Are ON............. B7-3

Revision History.......................................................................................................i

IM 34M6H45-01E 1st Edition : Feb.28,1999-00

Page 13

Blank Page

Page 14

F3LR01-0N

Fiber-optic FA-bus Module

IM 34M6H45-01E 1st Edition : Feb.28,1999-00

Page 15

Blank Page

Page 16

<Toc> <Ind> <A1. Overview >

A1. Overview

The Model F3LR01-0N Fiber-optic FA-bus Modules (hereinafter referred to as modules)

are interface modules to configure the distributed control system through a fiber-optic FA

bus. This bus connects F A-M3 main units and sub-units. Using this bus, users can configure an efficient remote I/O system.

If the above modules are installed on the FA-M3 main units and sub-units, and connected

with each other with fiber optic cables, modules on the subunits will be handled at the same

level as in the main units.

A1.1 Features

1

Features of remote I/O systems

(1) Users do not need to worry about I/O refresh time in ladder programming.

(2) Subunits can include contact input/output modules and other special modules such as

RS-232-C communications modules, excepting FA link modules and Ethernet modules.

(3) If subunits are configured with an FA-bus module, users can access those units in the

same way as the modules in the main units are accessed.

*

configured with the modules are:

A1-1

(4) Because of its optical communications, the system will not be influenced by noise.

(5) Maximum extended cable length is 200 meters.

1: I/O implies “Input” and “Output,” — stated as “contact input/output.” Remote I/Os are located far away from the CPU

*

module, but can be handled in the same way as for contact input/output modules close to a CPU module.

IM 34M6H45-01E 1st Edition : Feb.28,1999-00

Page 17

<Toc> <Ind> <A1. Overview >

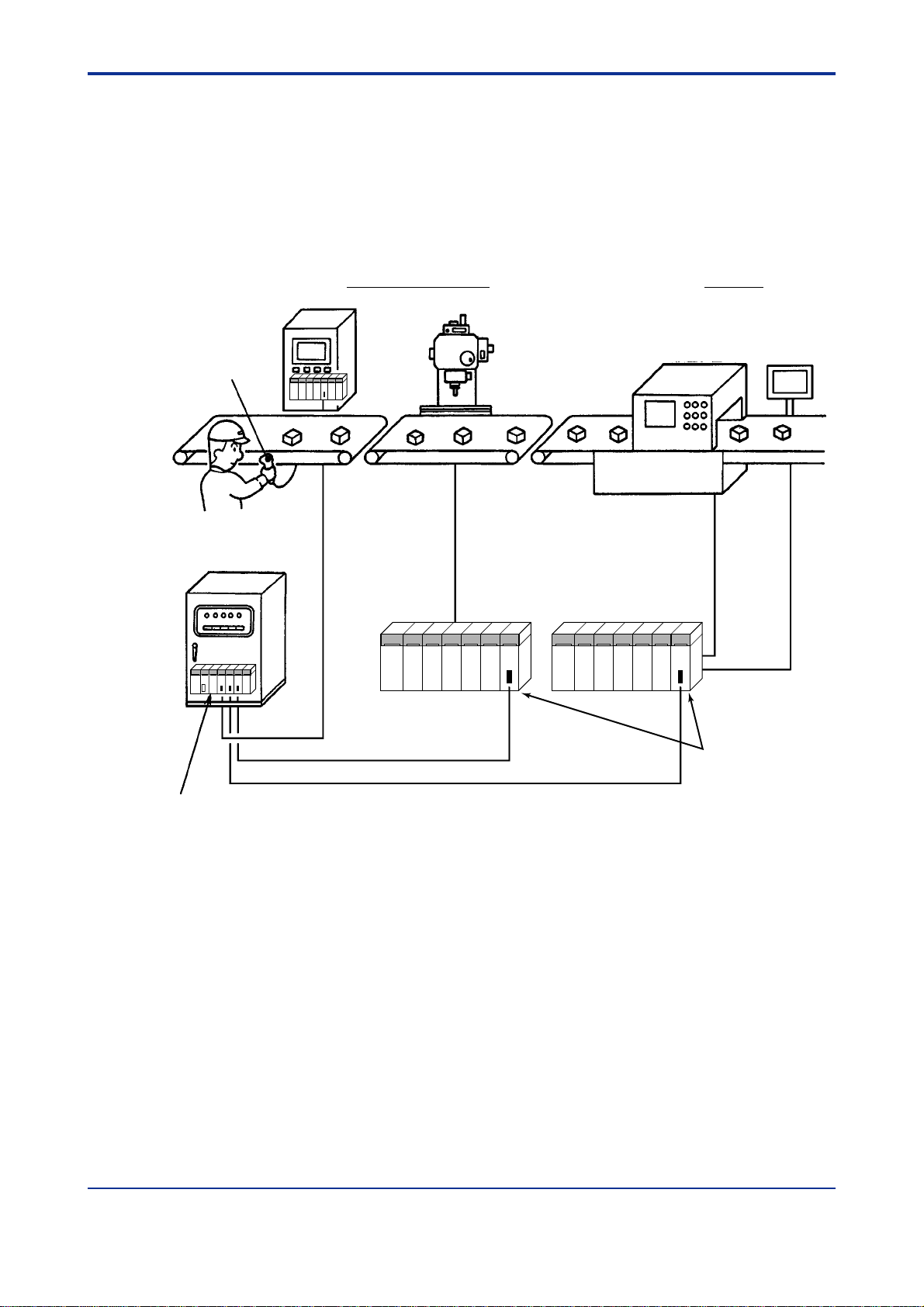

A1.2 Application Examples

If a remote I/O system is configured, some problems could occur, which include configuration (environment) setting, uses of specific remote I/O instructions, and I/O refresh time, or

the like.

Whereas if a remote I/O system is configured with a fiber-optic FA-bus module, the above

problems will not occur. The system configuration example is shown below.

Example of conveyer control:

Assembly and processing Inspection

Control panel

Test equipment

Bar-code reader

NC machine

A1-2

Conveyer control panel

FA-M3 main unit

Figure A1.1 System Configuration Example

RS-232-C

communication

interface

Fiber-optic FA bus

Fiber-optic FA bus

FA-M3 subunits FA-M3 subunits

Fiber-optic FA bus

GP-IB

interface

RS-232-C

communication

interface

Fiber-optic FA-bus module

FA0101.EPS

IM 34M6H45-01E

1st Edition : Feb.28,1999-00

Page 18

<Toc> <Ind> <A2. Specifications >

A2 . Specifications

A2.1 Function Specifications

■ General Specifications

Table A2.1 General Specifications

A2-1

Items

Current consumption 220 mA max. (5 V DC)

External dimensions 28.9 (W) × 100 (H) × 83.2 (D) mm

Weight 0.1 kg

Note: For other specifications, see applicable specifications for the FA-M3.

■ Communications Specifications

Table A2.2 Communications Specifications

Transmission speed 10 Mbps

Transmission media Two-conductor optical fiber (hard plastic clad quartz fiber H-PCF)

Transmission distance Max. total extension: 200 m

Max. interunit extension: 200 m

Transmission configuration Star configuration

Maximum number of subunits 7

connected

RAS functions • I/O contact shutdown due to a transmission channel error

• Error location reporting via a transmission channel

Specifications

F3LR01-0N

TA0201.EPS

SpecificationsItem

TA0202.EPS

A2.2 Operating Environment

No specific operating environmental limitations are required.

Logging of a transmission line error to an error log can be made either in the F3SP21,

F3SP25 or F3SP35 Module in Version 8 or later, or in the Ladder Diagram Support Program (M3) in Version 1.08 or later .

IM 34M6H45-01E 1st Edition : Feb.28,1999-00

Page 19

<Toc> <Ind> <A2. Specifications >

A2.3 Components and Their Functions

■ Front View

Indicators

RDY: Lit when the internal circuit is operating normally.

ERR: Lit when the module fails to detect an input signal from the port.

SUB UNIT

3

2

4

NO.

1

5

0

6

9

7

8

Unit No. Switch (SUB UNIT No.)

Set unit numbers 0 to 7:

0: Main unit number

1 to 7: Sub-unit numbers

7 to 9: Inhibited

A2-2

■ Right Side View

Figure A2.1 Locations of Components

Optical fiber port

FA0201-1.EPS

This figure shows where

the cover is removed.

Functions Set Switches

(4-pole DIP switch block)

Switch No. ON OFF Factory setting

1

Output

shutdown

Hold

ON

2

3

Always OFF.

4

(Valid only for the fiber-optic FA-bus modules that

are installed in a subunit.)

FA0201-2.EPS

IM 34M6H45-01E

1st Edition : Feb.28,1999-00

Page 20

<Toc> <Ind> <A2. Specifications >

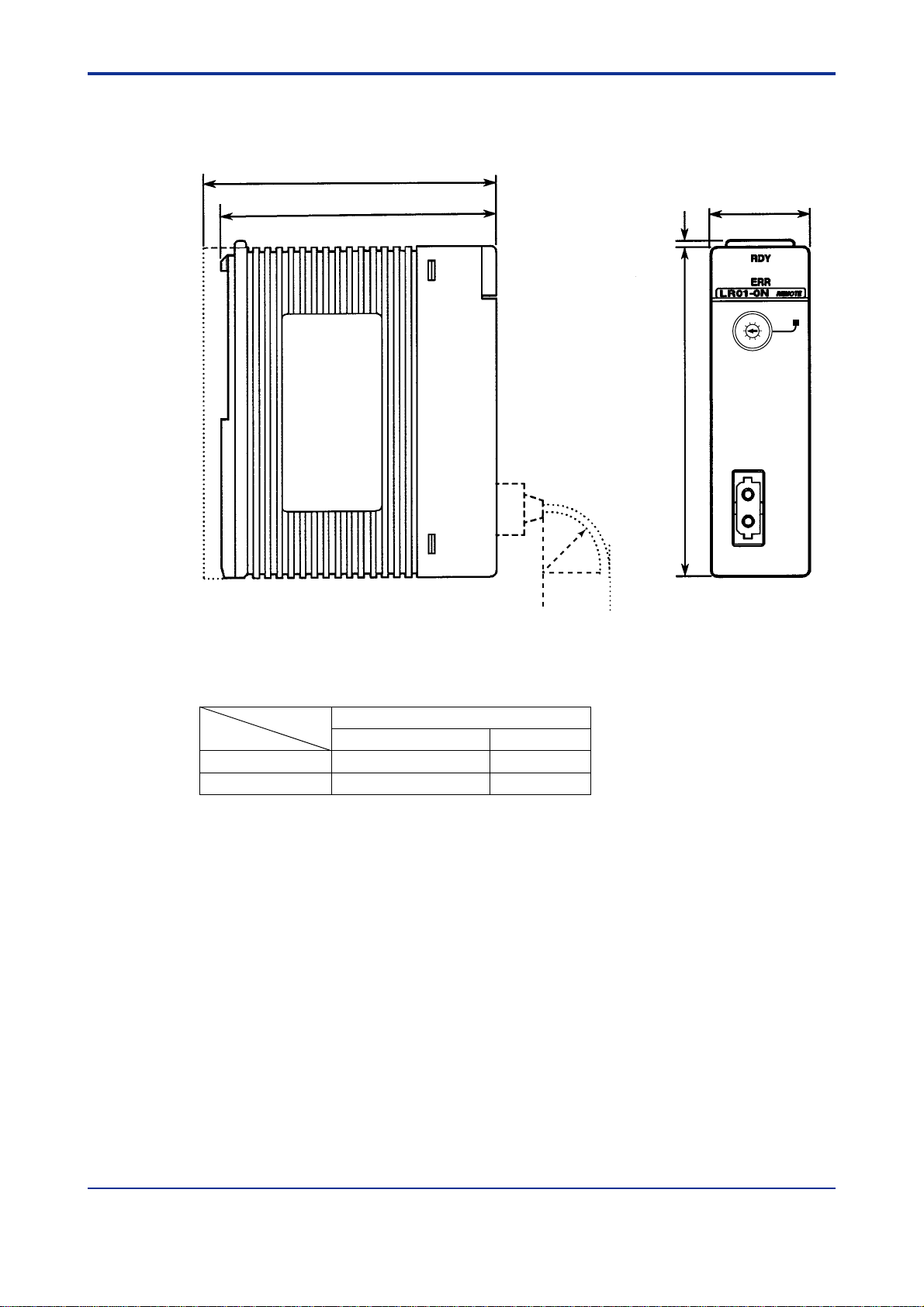

A2.4 External Dimensions

85.5

A2-3

(Unit: mm)

83.2 28.9

Figure A2.2 External Dimensions

2

SUB UNIT

3

2

4

NO.

1

5

0

6

9

7

8

100

r

FA0202.EPS

Allow for the following cable bending whenever the module is installed.

Table A2.3 Radius of Cable Bending

Radius (r) of cable bending, mm

During installation work When installed

Fiber optic cord 15 min. 50 min.

Fiber optic cable 50 min. 100 min.

TA0203.EPS

IM 34M6H45-01E 1st Edition : Feb.28,1999-00

Page 21

Blank Page

Page 22

<Toc> <Ind> <A3. System Configuration >

A3. System Configuration

A3.1 Fiber-optic FA-bus System Configuration

Fiber-optic FA-bus systems are so configured that fiber-optic F A-bus modules are installed

in main units and subunits, and the intermodules are connected with optical-fiber cables.

Main units: Units on which CPU modules are installed.

Sub units: Units for system expansion, on which CPU modules are not installed.

A3.1.1 Restrictions on System Configuration

Fiber-optic FA-buses are restricted in system configuration, as listed in Table A3.1.

Table A3.1 Restrictions on System Configuration

Item Specifications

Maximum total extension per system 200 m

No. of connectable subunits 7 max.

No. of fiber-optic FA-bus modules installable in main units

No. of fiber-optic FA-bus modules installable in subunits

Number of modules installable in subunits All I/O modules and special modules,

Unit no. setting Main unit: 0

(rotary switch on the module front panel) Subunit: 1 to 7 (no duplication allowed)

7 max.

1 max.

except FA link modules and Ethernet modules,

can be installed.

A3-1

TA0301.EPS

IM 34M6H45-01E 1st Edition : Feb.28,1999-00

Page 23

<Toc> <Ind> <A3. System Configuration >

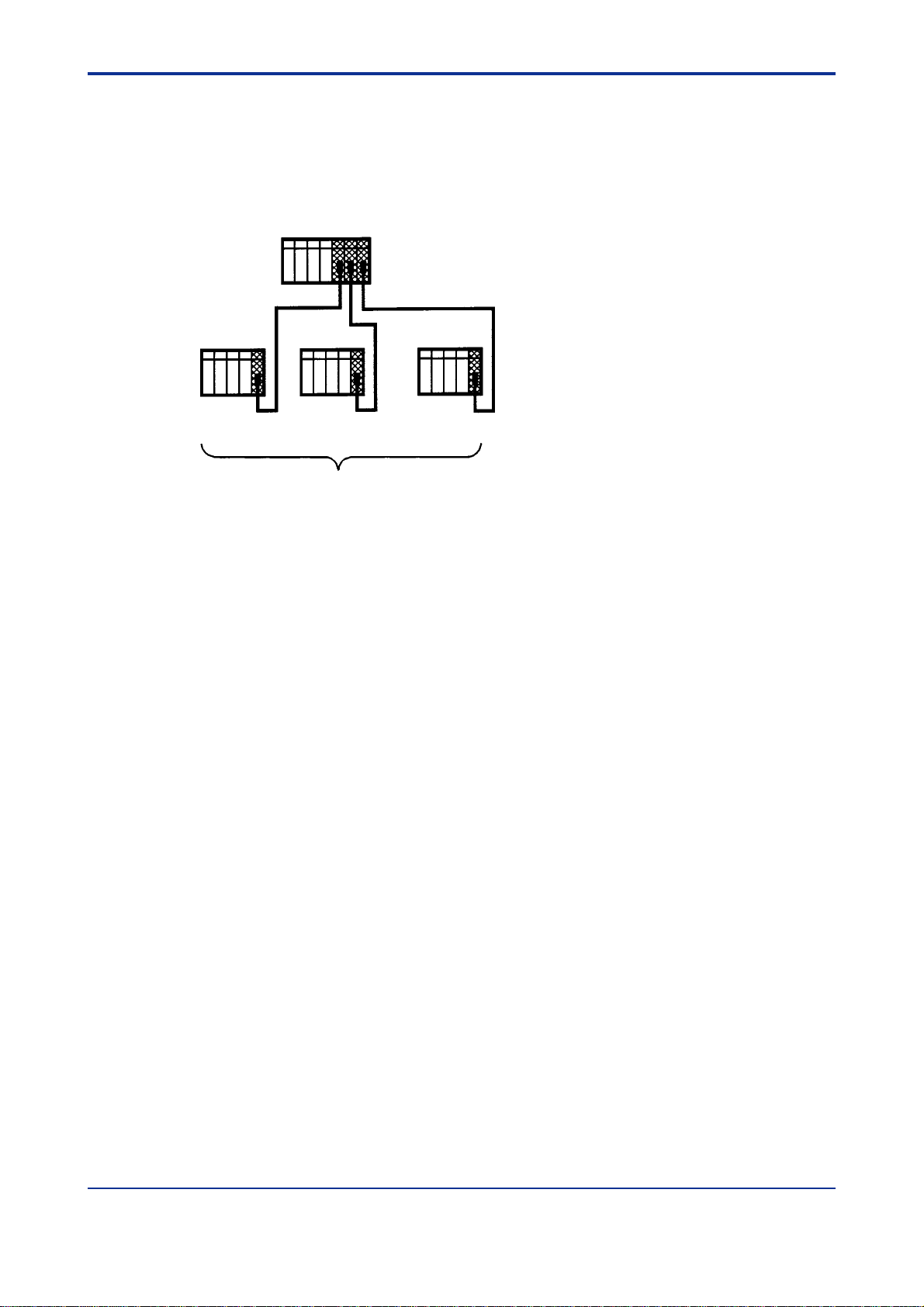

A3.1.2 Connecting Modules

The FA-M3 modules can be connected only in the star configuration as in Figure A3.1.

■ Star Configuration

A3-2

Unit No. 0

Unit No.1 Unit No.2 Unit No.3

Seven subunits max.

Figure A3.1 Connecting Modules

Main unit

FA0301.EPS

IM 34M6H45-01E 1st Edition : Feb.28,1999-00

Page 24

<Toc> <Ind> <A4. Preliminary Setting and Cable Connections >

A4. Preliminary Setting and Cable

Connections

A4.1 Startup Procedures

Figure A4.1 shows the system startup procedures when the fiber-optic FA-bus modules are

used.

Build-up system configuration

A4-1

Select an appropriate route for

laying fiber optic cables

Determine fiber optic cable

specifications and place an

order for cables

Carry out cable installation

Connect fiber optic codes or cables

Instrument layout

Set module setup switches

Refer to Sumitomo Electric

Industries, Ltd. Manual of how

to lay fiber optic cables.

Mount fiber-optic FA-bus

module on base module

Apply the power

Preliminary check

...

Refer to Sumitomo Electric

Industries, Ltd. Manual of how to

lay fiber optic cables.

(See Section A4.2)

(See Section A4.3)

(See Section A4.4)

(See Section A4.4)

Figure A4.1 System Startup Flow

Start operation

FA0401.EPS

IM 34M6H45-01E 1st Edition : Feb.28,1999-00

Page 25

<Toc> <Ind> <A4. Preliminary Setting and Cable Connections >

A4.2 Setting Switches

A4.2.1 Setting Unit Number Switches

Set the unit numbers for module installation using a decimal rotary switch on the front of the

module.

SUB UNIT

3

2

4

NO.

1

5

0

6

9

7

8

FA0402.EPS

Figure A4.2 Location of Unit Number Set Switch

A4-2

The unit number set ranges from 0 to 7 (see Note below). Do not duplicate unit numbers

with those of other fiber-optic FA-bus modules. Set unit number 0 to all modules installed

on the main unit.

Table A4.1 Setting Unit Number Switches

Setting switch Description

0 For modules installed on the main unit (default value: 0)

1 to 7 For modules installed on subunits

8 to 9 Not in use (prohibited)

TA0401.EPS

CAUTION

• If the unit numbers are duplicated, the fiber-optic FA-bus module will not operate

normally . Or if the module is accessed using a software package with the unit numbers duplicated, an RS-232-C communications error will occur and operation of that

package will stop.

• Do not install the F3LR01 module set as a subunit and a sequence CPU module on

the same base module. Otherwise, the sequence CPU module detects an error

causing its memory to clear.

IM 34M6H45-01E

1st Edition : Feb.28,1999-00

Page 26

<Toc> <Ind> <A4. Preliminary Setting and Cable Connections >

A4.2.2 Setting Functional Set Switches

A 4-bit DIP switch is provided on the right side of the module for functional features. Using

this switch, set the following:

■ Setting Output Shutdown During a Communications Error

Use SW1 for this setting. This switch is valid only for subunits. Use the switch in the off

position for the main unit (set to on at the factory).

For details on the output shutdown features, see Chapter A7, “RAS Function.”

Table A4.2 Setting Functional Set Switches

Switch numbers Functions ON OFF Factory setting

1 Output shutdown Hold On

2 to 4 * Not in use — Off

CAUTION

Output shutdown during

communications error

A4-3

TA0402.EPS

Use switches 2 through 4 set to off. If these switches remain on, the module will not operate

correctly .

IM 34M6H45-01E

1st Edition : Feb.28,1999-00

Page 27

<Toc> <Ind> <A4. Preliminary Setting and Cable Connections >

A4.3 Attaching and Detaching Modules

A4.3.1 Attaching Modules

Figure A4.3 shows how to attach this module to the base module. First hook the anchor

slot at the bottom of the module to be attached onto the anchor pin on the bottom of the

base module. Push the top of this module in the direction of the arrow shown in the figure

(toward the base module) until the yellow, spring-loaded anchor/release button clicks into

place.

Base module

Top button

Anchor pin

A4-4

This module

Figure A4.3 Attaching Modules

CAUTION

DO NOT bend the connector on the rear of the module by force during the above operation.

If the module is forcibly pushed with an improper connection, the connector may bend and

this damage will cause a module installation error during the self-diagnosis.

A4.3.2 Detaching Modules

T o remove this module from the base module, reverse the above operation by pressing the

yellow anchor/release button to unlock it, and tilting the module away from the base module. Then lift the module off of the anchor pin at the base.

FA0403.EPS

IM 34M6H45-01E

1st Edition : Feb.28,1999-00

Page 28

<Toc> <Ind> <A4. Preliminary Setting and Cable Connections >

A4.3.3 Attaching Modules in Intense Vibration Environments

If the modules are used in intense vibration environments, fasten the modules with a screw

directly beneath the yellow anchor/release button, as shown in Figure A4.4. For this, use a

12- to 14-mm long M4 binder screw. With a Phillips screwdriver , tighten the upper side of

the module with this screw. During this operation, the user must tilt the screwdriver somewhat using the guide channel at the top of the module. Allow a clearance of such an extent

that the screwdriver will access the screw, between the module and the duct above it.

FA0404.EPS

Figure A4.4 Tightening Module

A4-5

CAUTION

DO NOT overtighten the module fixing screw .

A4.3.4 Depth of Installation

The module’s installation depth is 85.5 mm-long between the rear of the base module and

the front of this module. However, if a cable with connectors is used, some extra space in

addition to this overall depth must be provided for the bend in the cable.

85.5

r

Figure A4.5 Installation Depth

Radius (r) of cable bending, mm

During installation work After installation

Fiber optic cord 15 min. 50 min.

Fiber optic cable 50 min. 100 min.

FA0405.EPS

IM 34M6H45-01E 1st Edition : Feb.28,1999-00

Page 29

<Toc> <Ind> <A4. Preliminary Setting and Cable Connections >

A4.4 Connecting Fiber Optic Cables

A4.4.1 Preparation for Calbes

Connect fiber optic cables between fiber-optic FA-bus modules.

(1) Specifications for fiber optic cables used

Table A4.3 Fiber Optic Cable Core Specifications

Item Specifications

Model HC-20/07 (manufactured by Sumitomo Electric)

Core diameter 200 ±5 µm

Clad diameter 230 µm

Transmission loss 7 dB/km max. (λ = 0.81 µm, Ta = 25°C) (HC)

Table A4.4 Fiber Optic Connector Specifications

Model Number Specifications

CF-2001H Bi-directional, lever-lock, adhesive and polishing

CF-2011 B-directional, lever-lock, pressurizing and cutting

+0

–10

TA0403.EPS

TA0404.EPS

A4-6

(2) Fiber optic cables supplied by the company

Fiber Optic Cable (for Panel Use)

Sufix

Style

Model

KM60

Code

-S60 — — For connections inside panels, cable length up to 0.6 m

-001 — — For connections inside panels, cable length up to 1 m

-003 — — For connections inside panels, cable length up to 3 m

Fiber Optic Cable (for Indoor Use) with Tension Members

Model

KM61

Sufix

Code

-010 — — For indoor connections, cable length up to 10 m

-100 — — For indoor connections, cable length up to 100 m,

-150 — — For indoor connections, cable length up to 150 m,

-200 — — For indoor connections, cable length up to 200 m,

Option

Code

Code

Note: For pulling eyes, see the pulling-eye assembly diagram later in this manual.

Style

Code

Option

Code

with a pulling eye (one end of the cable)

with a pulling eye (one end of the cable)

with a pulling eye (one end of the cable)

Description

Description

Applicable

Module

F3LR02

and

F3LP12

TAC040401_1.EPS

Applicable

Module

F3LR02

and

F3LP12

TAC040401_2.EPS

IM 34M6H45-01E 1st Edition : Feb.28,1999-00

Page 30

<Toc> <Ind> <A4. Preliminary Setting and Cable Connections >

Fiber Optic Cable (for Outdoor Use) with Tension Members

Sufix

Style

Model

KM62

KM67

Code

-100 — — For outdoor connections, cable length up to 100 m,

-200 — — For outdoor connections, cable length up to 200 m,

-300 — — For outdoor connections, cable length up to 300 m,

-400 — — For outdoor connections, cable length up to 400 m,

-500 — — For outdoor connections, cable length up to 500 m,

-600 — — For outdoor connections, cable length up to 600 m,

-700 — — For outdoor connections, cable length up to 700 m,

-800 — — For outdoor connections, cable length up to 800 m,

-900 — — For outdoor connections, cable length up to 900 m,

-L01 — — For outdoor connections, cable length up to 1000 m,

-300 — — For outdoor connections, cable length up to 300 m,

-400 — — For outdoor connections, cable length up to 400 m,

-500 — — For outdoor connections, cable length up to 500 m,

Code

Option

Code

Description

with a pulling eye (one end of the cable)

with a pulling eye (one end of the cable)

with a pulling eye (one end of the cable)

with a pulling eye (one end of the cable)

with a pulling eye (one end of the cable)

with a pulling eye (one end of the cable)

with a pulling eye (one end of the cable)

with a pulling eye (one end of the cable)

with a pulling eye (one end of the cable)

with a pulling eye (one end of the cable)

with a pulling eye (one end of the cable)

with a pulling eye (one end of the cable)

with a pulling eye (one end of the cable)

Note: For pulling eyes, see the pulling-eye assembly diagram later in this manual.

A4-7

Applicable

Module

F3LR02

(up to 200 m)

F3LP12

(up to 1000 m)

F3LR02

(up to 500 m)

TAC040401_3.EPS

IM 34M6H45-01E 1st Edition : Feb.28,1999-00

Page 31

<Toc> <Ind> <A4. Preliminary Setting and Cable Connections >

■ Outline Drawing (with dimensions)

KM60

Fiber optic connector Fiber optic connector

ID marking ID marking

Fiber optic cable

A4-8

Cable Length (L)

L≤5

KM61, KM62, KM67

Fiber optic connector ID marking

Cable Length (L)

5<L≤30

30<L

Tolerance +e (m)

0.20

ID marking

(Sheathless

terminal)

Tension

member

Tolerance +e (m)

0.50

L × 0.03 (3%)

L + tolerance

Tape or

protective covering

Fiber optic cable

L + tolerance

+e

–0

+e

–0

(Sheathless

terminal)

Tension

member

FAC040401_1.EPS

Fiber optic connector

200±50 mm200±50 mm

FAC040401_2.EPS

■ Corss-sectional Drawing

KM60

1

2

3

4

5

ID marking

1 Core (silica glass)

2 Clad (fluoroacylate resin)

3 Covering (fluorine resin)

4 Reinforcing material

(aromatic high-tensile-strength fiber)

5 Sheath (heat-resistant PVC, black)

FAC040401_3.EPS

IM 34M6H45-01E 1st Edition : Feb.28,1999-00

Page 32

<Toc> <Ind> <A4. Preliminary Setting and Cable Connections >

KM61, KM62, and KM67

A4-9

1

2

3

4

5

6

1 Fiber optic single-core cable

2 Tension member (plastic-covered copper wire)

3 Lacing (plastic lacing)

4 Inclusion (plastic yarn or fiber)

5 Holding tape (plastic fiber)

6 Heat-resistant PVC sheath (KM61), LAP sheath (KM62, KM67)

Fiber optic lead-in cable laying pulling-eye assembly diagram

15-mm

30

dia.

2-mm

dia.

6

1

Rigid section 70

6

3

78

Approx. 500

Rigid section 50

2

(3) Fiber optic cables from Sumitomo Electric Industries, Ltd.

FAC040401_4.EPS

Unit: mm

4

5

FAC040401_5.EPS

Manufacturer Type Specifications Applicable modules

Sumitomo

Electric

Industries, Ltd.

Fiber optic cord H-PCF2-core cord

Fiber optic cable 2-C-V (indoor use)

2-C-LAP (outdoor use)

DCV-HC-20/07

2 × CCV-HC-20/07

2 × CCV-HC-20/07

F3LR01, F3LR02, and F3LP12

F3LR01, F3LR02, and F3LP12

F3LR01, F3LR02, and F3LP12

TAC040401_4.EPS

Fiber optic cord and cable with connectors attached at both ends

Manufacturer Product Type Specifications P: L (m) Shape Applicable modules

Sumitomo

Electric

Industries,

Ltd.

2001H-MM-L

2001H-MM-0.2-L

2001H-MM-0.2/L

1: Modules and distance F3LR01 and F3LR02, 0 to 200 meters

*

2: Polling-eye: Use a polling eye for the cable length of 50 meters or above.

*

Fiber Optic Cord

2-C-V cable

(for indoor use)

2-C-LA cable

(for outdoor use)

F3LR12, 0 to 1000 meters

DCV-HC-20/07

2 × CCV-HC-20/07

2 × CCV-HC-20/07

-P

-P

2

*

2

*

Up to 5

1

*

1

*

2.2-mm dia. ×

2-core cord

8.4-mm dia. cable

10-mm dia. cable

F3LR01, F3LR02,

and F3LP12

F3LR01, F3LR02,

and F3LP12

F3LR01, F3LR02,

and F3LP12

TAC040401_5.EPS

CAUTION

For more details on fiber optic cables, contact Sumitomo Electirc Industries, Ltd. When

ordering, specify the above shaded areas.

1

*

1

*

1

*

IM 34M6H45-01E 1st Edition : Feb.28,1999-00

Page 33

<Toc> <Ind> <A4. Preliminary Setting and Cable Connections >

CAUTION

Be sure to use the specified cables, otherwise, the module may fail, or expected design

performance cannot be attained.

(4) Firber optic cables and tools required

When laying fiber optic cables, use Sumitomo Electric cables listed below.

Table A4.5 Fiber Optic Cables and Tools Required

Name Model

Fiber optic connector Adhered, polished and assembled CF-2001H

Pressurized, cut and assembled CF-2011

Toof for fiber optic connector Pressurizing, cutting and assembling CAK-1062

Optical power tester (for fiber optic connector inspection) CAT-2700

Master fiber set (for fiber optic connector inspection) CAT-2001H

Note: For the fiber optic cable installation, consult the Fiber Optic Installation Instructions (publication number IM 34M6C92-

01E).

A4-10

CAT2001H (HG)

TA0405.EPS

CAUTION

Use the specified cable connectors and tools, otherwise the module may fail or expected

disign performance cannot be attained.

IM 34M6H45-01E 1st Edition : Feb.28,1999-00

Page 34

<Toc> <Ind> <A4. Preliminary Setting and Cable Connections >

A4.4.2 Attaching and Detaching Connectors

■ Attaching Connectors

When completing an optical connection, always hold the connector and never the cable,

then insert it until it clicks into place. Then pull it slightly toward you to make sure that the

connector is correctly seated.

Fiber optic connector

FA0406.EPS

Figure A4.6 Attaching Connectors

A4-11

■ Detaching Connectors

FA0407.EPS

Figure A4.7 Detaching Connectors

Hold the center portion of the connector (indicated by the arrow in the figure) to unlock

connector and then pull it toward you.

IM 34M6H45-01E 1st Edition : Feb.28,1999-00

Page 35

<Toc> <Ind> <A4. Preliminary Setting and Cable Connections >

A4.4.3 Notice on Connecting Fiber Optic Connectors

Handle fiber optic cables with great care. When the fiber optic cables are laid, first read

Sumitomo Electric Industries Manual and then ask the workers for specific applications as

described in the manual.

CAUTION

• DO NOT touch optical connector core wires and protect them from dirt and dust.

Otherwise, transmission performance may deteriorate or a communications error

could occur.

T o store them, be sure that they are provided with appropriate cable covers.

• Each time the fiber optic cords or cables are connected, keep the cable extension

within 0.7% of permissible extension percentage. When the cable is fixed, also keep

the cable extension within 0.2% of permissible extension percentage. If the cable

extension is beyond these limitations, fiber optic cables or cords may be disconnected.

For this purpose, DO NOT cause excess tension, bending, or twisting or the like of the

cables or cords.

Table A4.3 General Mechanical Characteristics for Fiber Optic Codes and Cables

Tensile strength

Fiber optic cord During wiring<10 15 min. during wiring 0 kg <180°/2 m

When fixed = 0 50 min. when fixed

Fiber optic cable During wiring< 50 50 min. during wiring 100 kg/50 mm <90°/2 m

When fixed< 0 100 min. when fixed

Bend radius (mm) Lateral pressure Twisting

A4-12

TA0406.EPS

For the tension during wiring work, follow the allowable tensile strength specified by optical

fiber specifications or sales brochures.

When fixing cables, DO NOT create excess tension to connectors and cables.

Use a pressurizing and cutting type connector in the field work.

IM 34M6H45-01E

1st Edition : Feb.28,1999-00

Page 36

<Toc> <Ind> <A4. Preliminary Setting and Cable Connections >

A4.5 Preliminary Checks

After installing modules and wiring fiber optic cables, check that all electrical connections

have been completed and the modules are in communications-enabled states.

Apply power to the units and check the following two points:

(1) Check that the RDY (green) lamp lights up.

If this lamp does not light up, the fiber-optic FA-bus module may not be connected to

the base module correctly . T urn off the power and attach the module to the base

module correctly . Then apply the power and be sure that the RDY lamp lights up.

(2) Check that the ERR lamp remains turned off.

If the lamp lights up, communications will be disabled. If the power of the destination

unit is off, turn on its power and check that the ERR lamp is turned off. If it is still on,

transmission lines may be faulty . (Fiber optic cables may be disconnected).

A4-13

IM 34M6H45-01E

1st Edition : Feb.28,1999-00

Page 37

Blank Page

Page 38

<Toc> <Ind> <A5. Accessing the Module in the Subunit >

A5. Accessing the Module in the Subunit

A5.1 Slot Numbers of FA-M3

Slot numbers are used for accessing each module in the FA-M3.

These slot numbers indicate the position of the slot where the module is mounted and

consist of 3-digit integers as shown below.

1

Slot number within the unit

*

: 01 to 16

1 Sequentially from slot right of power

*

supply module, 01, 02, ......, 16

A5-1

Unit number main unit: 0

subunit: 1 to 7

FAC0501.EPS

Accessing modules mounted in the subunit is similar to that for modules mounted in the

main unit and can be accomplished by either a ladder diagram support program or a

BASIC program.

IM 34M6H45-01E 1st Edition : Feb.28,1999-00

Page 39

<Toc> <Ind> <A5. Accessing the Module in the Subunit >

Optical bus module

A5-2

Up to 7

units can be

connected

Slot number→

Main unit

Subunit 1

Subunit 2

001 002 003 004 005 006 007 008 009 010 011 012 013 014 015 016

Power

supply

module

Add-on sequence CPU

(3 CPUs maximum)

CPU module

101 102 103 104 105 106 107 108 109 110 111 112 113 114 115 116

Power

supply

module

201 202 203 204 205 206 207 208 209 210 211 212 213 214 215 216

Power

supply

module

.

.

.

.

.

.

.

.

701 702 703 704 705 706 707 708 709 710 711 712 713 714 715 716

Power

Subunit 7

supply

module

Figure A5.1 System Configuration and Slot Numbers

FA0501.EPS

IM 34M6H45-01E 1st Edition : Feb.28,1999-00

Page 40

<Toc> <Ind> <A6. I/O Refresh Time >

A6. I/O Refresh Time

A6.1 Estimation of I/O Refresh Time

Calculate the I/O refresh time separately for each port of the main unit.

For details, refer to the following calculation example.

A6-1

I/O refresh time =

• There are two types, namely, ‘input read’ and ‘output write.’

Calculate the I/O refresh time for each type using the following

formula and sum the values.

I/O refresh time for each

access

‘Access type’ ‘Formula’

F3SP21 F3SP25/35

Input read 11 µs 10 µs

Output read 27 µs 21 µs

=+

Sum of I/O refresh times

for each access

Time dependent on acces

• 1.0 µs ×

Time dependent on

transmission distance

ø (m)

100 (m)

ø: Transmission distance

Number of modules

×

converted to 16 points

‘Number of modules’

• Number of modules

corresponding to access type,

convert to a 16-point module.

FAC0601.EPS

IM 34M6H45-01E 1st Edition : Feb.28,1999-00

Page 41

<Toc> <Ind> <A6. I/O Refresh Time >

A6.2 I/O Refresh Time Calculation Example

Calculate I/O refresh time for the following system configuration.

A6-2

Main unit F3LR01-0N

module

Figure A6.1 Example of Calculation of I/O Refresh Time (for F3SP25 and F3SP35 Modules)

Master CPU

Power

supply

150 m

Subunit 1

Input 32-point module × 2

Output 32-point module × 1

FA0601.EPS

[Step 1] Calculating the time dependent on transmission distance

• 1.0 µs × = 1.5 µs

150 (m)

100 (m)

FAC0602_1.EPS

[Step 2] Calculate the number of modules, converted to 16 points

• Input read = 32 points × 2 → 2 × 2 = 4

• Output write = 32 points × 1 → 2 × 1 = 2

[Step 3] Calculating the total I/O refresh time

Input read = (10 µs +1.5 µs) × 4 = 46.0 µs

Output write = (21 µs +1.5 µs) × 2 = 45.0 µs(+

I/O Refresh Time = 91.0 µs

FAC0602_2.EPS

IM 34M6H45-01E 1st Edition : Feb.28,1999-00

Page 42

<Toc> <Ind> <A7. RAS Function >

A7. RAS Function

A7.1 Function for Detecting an Error Location

A7.1.1 Check the LED Display

When an error occurs in this module or when there is a cable break in the transmission line,

the error LED (ERR) or alarm LED (ALM) of the CPU module turns on.

The LED of this CPU module turns on, even when an error occurs in a module other than

this module.

To decide whether the cause of the lighted LED lies in this module, check the status of the

RDY and ERR LEDs of the Fiber-optic F A-bus module mounted on each unit.

The relation between the fiber optic cable break and the lighting of the LED in the module is

as shown below.

A7-1

[Disconnection example 1]

CPU MODULE

ERR ON

ALM ON

MAIN UNIT

Cable disconnected

Fiber-optic FA-bus module

ERR ON

Subunit

×

0

[Disconnection example 2]

[Disconnection example 3]

Figure A7.1 Relation between Fiber Optic Cable Break and Lighting of LED in the Module

CPU MODULE

ERR ON

ALM ON

Main unit

Fiber-optic

FA-bus module

ERR ON

0

CPU MODULE

ERR ON

ALM ON

Main unit

Fiber-optic

FA-bus module

ERR ON

0

×

Cable disconnected

×

×

1

Subunit

1

Cable disconnected

Optical FA Bus module

ERR ON

Subunit

1

FA0701.EPS

IM 34M6H45-01E 1st Edition : Feb.28,1999-00

Page 43

<Toc> <Ind> <A7. RAS Function >

A7.2 Output Shutdown Function due to a

Communications Error

A7.2.1 Overview of Output Shutdown Function

This module is equipped with a function which shuts down the output of the I/O module

when a communications error occurs.

When an error occurs in the fiber-optic FA-bus module, this function prevents it from af fecting the system or from resulting in hazardous operation or unstable operation of the system.

For example, when the transmission line breaks, it detects the error and immediately turns

off the output signals of each I/O module and avoids any risk.

The output shutdown function on a communications error is valid only on configurations

having one main CPU (with no add-on CPU).

A7.2.2 Output Shutdown of Subunit

A7-2

Subunit

CAUTION

• When it is necessary to reset the output due to power supply breakdown or transmission line error, use the output module with less than 32 points, turn on the shutdown

switch of the F3LR02 and set an Output Reset using the CPU configuration setting.

This setting cannot be used in a 64-point output module.

• When it is necessary to hold the output due to power supply breakdown and transmission line error, turn of f the shutdown switch of the F3LR02 and set an Output Hold

using the CPU configuration setting.

• The Output Reset function cannot be used in multiple CPU systems (systems loaded

with add-on CPU). Always use the Output Hold setting.

The operation of the output module corresponding to various combinations of setting is

shown below for your reference.

Shutdown SW of

F3LR01 mounted

in Subunit

ON Reset Short-circuited Open Reset Hold

OFF Reset Open Short-circuited Hold Hold

Configuration

Setting of

CPU module

Hold Short-circuited Open Hold Hold

Hold Open Short-circuited Hold Hold

Fail signal contact point Output module operation

FAIL 1 FAIL 2 32 points or less 64 points

TAC070202.EPS

IM 34M6H45-01E 1st Edition : Feb.28,1999-00

Page 44

<Toc> <Ind> <A7. RAS Function >

A7.2.3 Function Setting Operation Procedure

The procedure for using the output shutdown function for a communications error is shown

below.

[Step 1] Operating the function set switch on the right side of the module.

Function set switch

In order to operate this function, it is necessary to

set the function set switch on the right side of this

module mounted in the subunit. Turn the first bit

of the 4-bit DIP switch “ON” (It is already set to

ON at the time of shipment from the factory).

FA0702.EPS

Figure A7.2 Function Set Switch on the Right Side of the Module

[Step 2] Output during halt

A7-3

■ Setting the input/output conditions using the Ladder Diagram Support

Program M3

Setting is performed using the Ladder Diagram Support Program M3 for the FA-M3.

This method carries out the DIO settings using the Ladder Diagram Support Program M3

on a personal computer. The outline of the operation is as follows:

1. Select the configuration from the top level menu (initial menu) of the Ladder Diagram

Support Program M3.

2. Select the DIO definition in the configuration.

3. On the DIO Definition screen, set the output during halt item of the respective I/O

module to the reset.

IM 34M6H45-01E 1st Edition : Feb.28,1999-00

Page 45

<Toc> <Ind> <A7. RAS Function >

Configuration Configuration name: D:\TOOL\CONFIG

DI/O setting Base unit 1

BIN/BCD 17-32 BIN BCD BIN/BCD 17-32 BIN BCD

1 Input sampling 01-16 16 1.0 3 Input sampling 01-16 16 1.0

(ms) 17-32 16 1.0 (ms) 17-32 16 1.0

Output during halt Reset Hold Output during halt Reset Hold

BIN/BCD 17-32 BIN BCD BIN/BCD 17-32 BIN BCD

2 Input sampling 01-16 16 1.0 4 Input sampling 01-16 16 1.0

(ms) 17-32 16 1.0 (ms) 17-32 16 1.0

output during halt Reset Hold Output during halt Reset Hold

KEY IN:

Capacity

Trace

Run

Comm

01-16 BIN BCD Unused 01-16 BIN BCD Unused

33-48 BIN BCD 33-48 BIN BCD

49-64 BIN BCD 49-64 BIN BCD

33-48 16 1.0 33-48 16 1.0

49-64 16 1.0 49-64 16 1.0

01-16 BIN BCD Unused 01-16 BIN BCD Unused

33-48 BIN BCD 33-48 BIN BCD

49-64 BIN BCD 49-64 BIN BCD

33-48 16 1.0 33-48 16 1.0

49-64 16 1.0 49-64 16 1.0

Register

ROM

FALink NextUnit Previous Default ExitDIO

A7-4

SC0701.EPS

Screen A7.1 Setting of Input/Output Conditions in Ladder Diagram Support Program M3

Further, for details on the Ladder Diagram Support Program M3 and similar operations,

refer to the ‘Ladder Diagram Support Program M3 Instruction Manual’ (publication number

IM 34M6Q13-01E).

IM 34M6H45-01E 1st Edition : Feb.28,1999-00

Page 46

<Toc> <Ind> <A7. RAS Function >

■ Setting the input/output conditions using BASIC (F3BP20)

When an error occurs, ‘Do you want to hold output status of the output module’ or ‘Do you

want to reset’ is set using a CONTROL statement.

For 16-point and 32-point modules, setting can be performed every 8 terminals within the

control register.

The format of the statement is as follows:

A7-5

Format

CONTROL m, 1 : I

m: Slot number or numerical expression

I: Set data, integer or integer variable

Contents of control register

MSB LSB

15 12 8 4 0

Register 4 Register 3 Register 2 Register1

Not in use (usually 0)

Status setting on master CPU error,

on startup

(0: hold, 1: Reset)

Register 4: Terminals 25 to 32

Register 3: Terminals 17 to 26

Register 2: Terminals 9 to 16

Register 1: Terminals 1 to 8

• All the contents of the control register are “0” when the modules starts up.

Example CONTROL 206 , 1: $0010

: For the output module in slot number 206, when

there is a master CPU error, terminal numbers

9 to 16 are reset but status of the remaining

terminals is maintained.

IM 34M6H45-01E 1st Edition : Feb.28,1999-00

FAC070203.EPS

Page 47

Blank Page

Page 48

<Toc> <Ind> <A8. Error Handling >

A8. Error Handling

A8.1 Troubleshooting

If a problem occurs in this module, follow the troubleshooting flowchart below to solve the

problem.

CPU module ALM on

A8-1

Error in this module?

YES

Is ‘RDY’ LED of

this module on?

YES

Is ‘ERR’ LED of

this module on?

NO

Is unit number

setting correct?

NO

NO

YES

NO

Investigate the reason

why the ‘ALM’ LED of

a module is on and

take countermeasures.

Refer to A8.2,

“Procedure Flowchart”

when ‘RDY’ LED is

not on.

Find out the place of

breakdown referring to

the procedure in

Section A7.1, “Function

for Detecting an Error

Location.”

Refer to A8.3, “Flow

Chart when ‘ERR’

LED is on.”

YES

Is setting of

switch in the side

cover correct?

YES

Replace this module.

END

NO

Set the switch inside

Figure A8.1 Troubleshooting Flowchart (1)

Set the unit number

correctly.

the right side cover

correctly (SW 2 to 4

are off).

FA0801.EPS

IM 34M6H45-01E 1st Edition : Feb.28,1999-00

Page 49

<Toc> <Ind> <A8. Error Handling >

A8.2 Troubleshooting Flowchart When ‘RDY’ LED Is

Not ON

‘RDY’ LED is not on

A8-2

Is power

supply module being

supplied prescribed

voltage?

YES

Are other modules

in RDY state?

YES

Is it mounted in

proper slot?

YES

Does ‘RDY’

LED remain off even

if it is mounted

in another

slot?

YES

NO

Supply normal voltage.

NO

Replace power supply

module or base module.

NO

Push it in the slot till

‘click’ sound is heard

(refer to A4.3 of

this manual).

NO

NO

Is ‘RDY’ LED on?

Replace base module.

YES

Replace the module.

Figure A8.2 Troubleshooting Flowchart (2)

END

FA0802.EPS

IM 34M6H45-01E 1st Edition : Feb.28,1999-00

Page 50

<Toc> <Ind> <A8. Error Handling >

A8-3

A8.3 Troubleshooting Flowchart When ‘ERR ’ LED Is

ON

‘ERR’ LED on

Is optical fiber

connected?

YES

Is the power

supply of all other

units turned on?

YES

Is optical fiber

disconnected?

NO

Is setting of switch

in the side cover

correct?

YES

NO

Connect optical fiber.

NO

Turn on the power

of all the other units.

YES

Replace optical fiber.

NO

Set switch inside the

right side cover correctly

(SW 2 to 4 are off).

Replace this module.

Is ‘ERR’ LED still on?

NO

END

YES

Figure A8.3 Troubleshooting Flowchart (3)

FA0803.EPS

IM 34M6H45-01E 1st Edition : Feb.28,1999-00

Page 51

Blank Page

Page 52

F3LR02-0N

Fiber-optic FA-bus Type 2 Module

IM 34M6H45-01E 1st Edition : Feb.28,1999-00

Page 53

Blank Page

Page 54

<Toc> <Ind> <B1. Overview >

B1. Overview

The Model F3LR02-0N Fiber-optic FA-bus T ype 2 Modules are interface modules to configure the distributed control system through a type 2 fiber-optic FA bus. This bus connects

FA-M3 main units and sub-units. Using this bus, users can configure a remote I/O system

efficiently.

If the above modules are installed on the FA-M3 main units and sub-units, and connected

with each other with an optical fiber cable, modules in the subunits will be handled at the

same level as in the main units.

1: I/O implies “Input” and “Output,” -- stated as “contact input/output.”

*

This module is mainly used for:

• Distributed installations of I/O modules

• System expansion

B1-1

*

1

CPU Module

Power Supply Module

Main units Subunits

Figure B1.1 Remote I/O System

Fiber-optic

FA-bus Type 2 Module

Power Supply Module

Fiber optic cable

Fiber-optic

FA-bus Type 2 Module

IM 34M6H45-01E 1st Edition : Feb.28,1999-00

Page 55

<Toc> <Ind> <B1. Overview >

B1.1 Features

Features included in this module are:

• High-speed communications

10 Mbps high-speed communications. These relieve the user from worrying about the I/O

refresh time in ladder programming.

• Extended inter-station distance

1

*

The master station can control substations

meters

*2

apart as indicated in the figure below. A maximum cable extension of 1.4 km

available.

which are at a maximum distance of 500

B1-2

3

*

is

Master station

500 m max.

Substation 1 Terminal station

1.4 km max.

● Freely substitutable installation

Except for the FA-link and Ethernet modules, other I/O modules can be installed as substa-

4

*

tions

. Access to modules is the same as access to modules installed on master stations.

● Easy installation

Unlike that of a remote I/O, installation requires no environmental (configuration) settings.

● Use of optical transmission signals

The fiber optic cable in the signal transmission line is not affected by noise on the line.

Master station Substation

Fiber-optic cable

1 Subunit on which this module is installed

*

2 If modules are to be installed more than 200 meters apart, use a Type GI H-PCF fiber optic cable.

*

3 In the daisy chain configuration with three substations.

*

4: FA Link and Ethernet Modules are not included.

*

● Versatile system configurations

Two I/O ports provided on the module allow daisy-chaining and loop connections. Installation of multiple T ype 2 Fiber-optic F A-bus modules enables a variety of configurations. For

more details on this, see Section B3.1.3 later in this manual.

● Multiple distributed system installations

A maximum of 56 substations or 32 substations* for each system is available.

For applications where only F3BU04 modules are used.

*

IM 34M6H45-01E

1st Edition : Feb.28,1999-00

Page 56

<Toc> <Ind> <B1. Overview >

1

● RAS

The alarm monitor

*

functions -- help pinpoint a trouble spot quickly.

2

*

and error logging

2

*

features allow you to localize a disconnection or a

trouble spot. Once an error is detected, an ERR LED lights up to indicate a failure even in

the field. For more details, see Chapter B6, "RAS Function."

1: RAS stands for "Reliability, A vailability, Serviceability" to indicate how easy it is to use the automatic equipment.

*

2: Indicates specific features in the Ladder Diagram Support Program M3.

*

B1-3

IM 34M6H45-01E

1st Edition : Feb.28,1999-00

Page 57

Blank Page

Page 58

<Toc> <Ind> <B2. Specifications >

B2 . Specifications

B2.1 Function Specifications

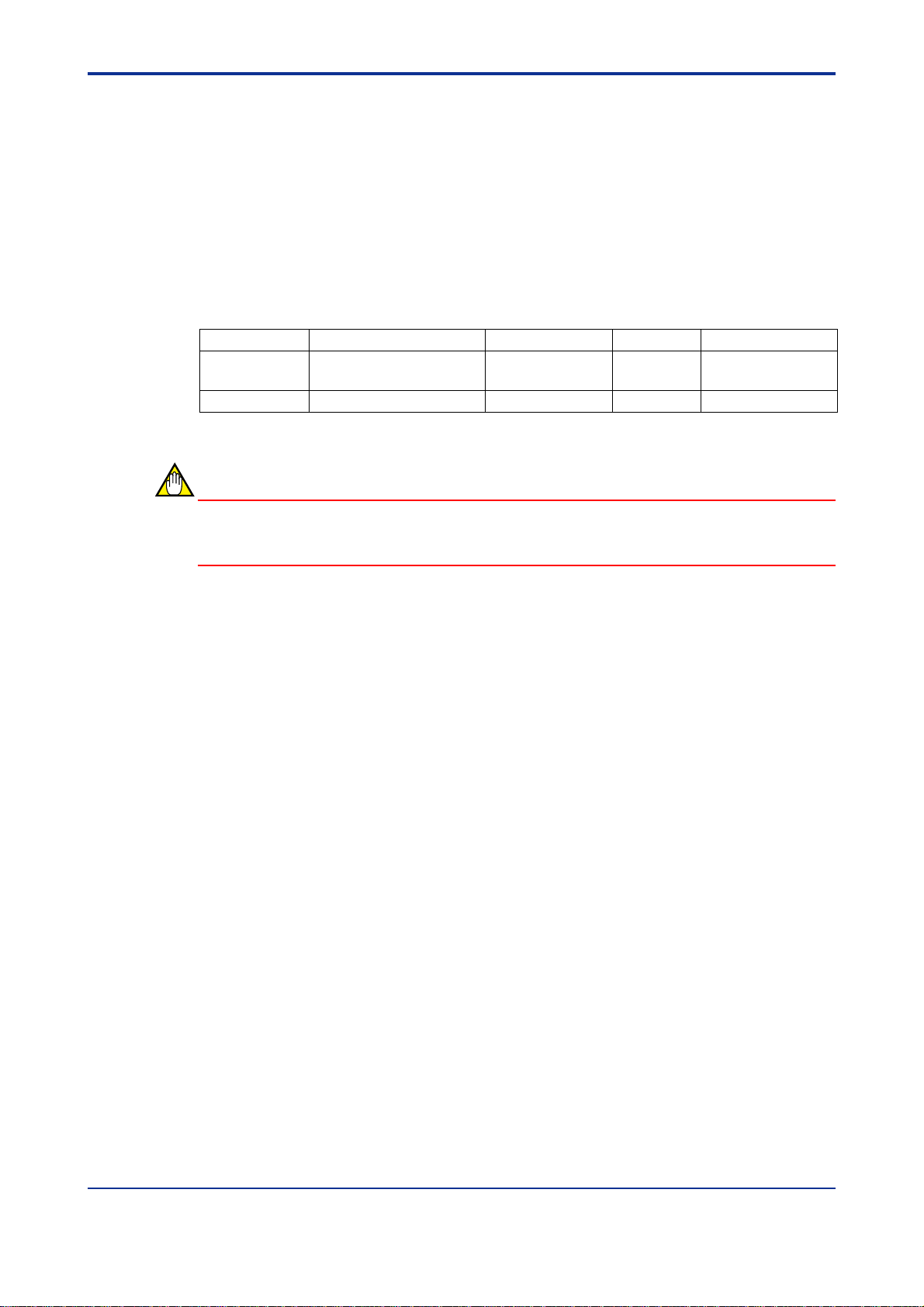

■ General specifications

Table B2.1 General Specifications

Item

Current consumption 460 mA max. (5V DC)

External dimensions 28.9 (W) 3 100 (H) 3 83.2 (D) mm

Weight 0.12 kg

■ Communications specifications

Specifications

F3LR02-0N

B2-1

Table B2.2 Communications Specifications

Item Specifications

Transmission speed 10 Mbps

Transmission media 2-conductor optical fiber (hard plastic clad quartz fiber H-PCF)

Transmission distance

Transmission configuration Star, daisy-chained or loop configuration

Maximum number of substations 56 stations

RAS features

Signal code Manchester code

I/O system Direct access to I/O

Number of I/O ports 2

1: A maximum of three stations available in daisy-chained interconnections.

*

2: A maximum of 32 stations per system available if all the F3BU04 subunits are connected.

*

500 m max. interunit extension

1.4 km total length

• I/O contact output shutdown due to a transmission channel error

• Error location reporting via transmission channel, and loop-back

functions

B2.2 Operating Environment

CPU modules that can be used with this module are:

F3SP21, F3SP25, F3SP35, F3BP20, and F3FP36.

1

*

2

*

IM 34M6H45-01E 1st Edition : Feb.28,1999-00

Page 59

<Toc> <Ind> <B2. Specifications >

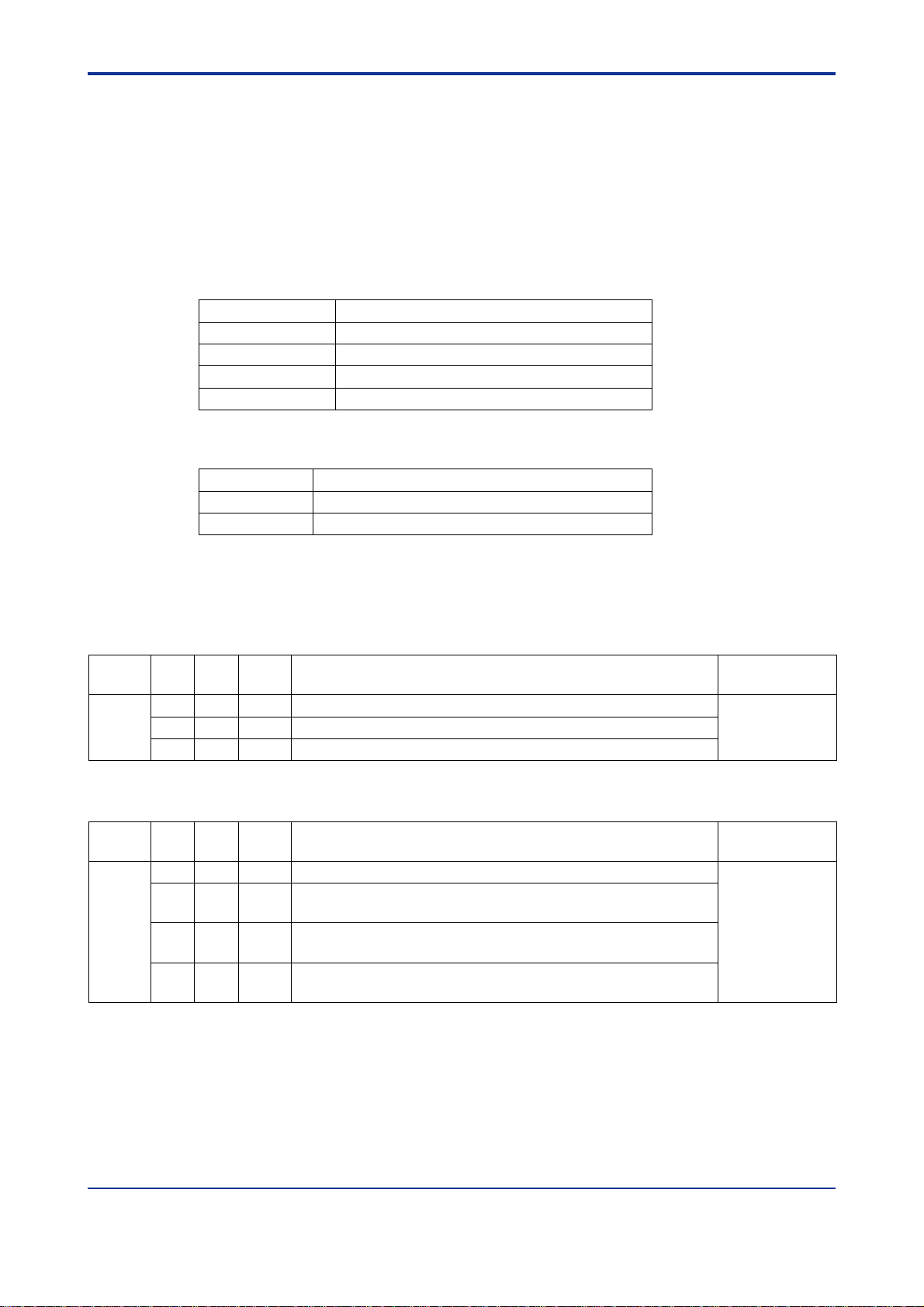

B2.3 Components and Their Functions

■ Front view

B2-2

RDY

ERR1

ERR2

LR02-0N

3

2

4

1

5

0

6

9

7

8

4

5

3

6

2

7

1

8

9

0

A

F

B

E

C

D

1

2

■ Right side view

REMOTE

SUB UNIT

NO.

LEFT SLOT

NO.

Indicators : RDY : Lit when the internal circuit is

operating normally.

ERR1 : Lit when the module fails to detect an

input signal from port 1.

ERR2 : Lit when the module fails to detect an

input signal from port 2.

Unit number switch (SUB UNIT NO.) :

Sets a unit number 0 to 7.

0 : Main unit number

1 to 7 : Subunit numbers

8 and 9 : Inhibited.

(Default value: 0)

Slot number switch (LEFT SLOT NO.)

Sets the left slot number of the base module on which this module is

installed.

(Default value: 1)

1, 3, 5, 7, 9, B, D and F: Slot numbers for F3BU04 module

1 and 9: Slot number for F3BU06 module

1: Slot number for base module

(F3BU09 or F3BU13)

Optical-fiber port

Status set switch

SW

Meaning

No.

1

*

Action in

1

communication

error occurrence

2

Port used

3

Channel

configuration

4

RearFront

Reserved

1: Valid only for the output modules in a subunit.

*

2: Both port 1 and port 2 are used.

*

ON OFF

Hold

Port 1

Daisy

chain/start

configuration

—

Shutdown

Both ports

Loop

configuration

—

2

*

Factory

set

ON

OFF

OFF

OFF

This figure is drawn with the

cover removed.

1

OFF

2

3

4

5

OFF

6

7

8

Functions set DIP switch

Quantity-of-light set switch

SW

No.

5

6

7

8

Meaning

Port 1 light

power

setting

Port 2 light

power

setting

Station-to-station distance

(fiber-optic cable length) (m)

OFF

0 to

200

OFF

OFF

OFF

0 to

200

OFF

OFF

ON

ON

200

to

300

200

to

300

OFF

OFF

Figure B2.1 Components on the Front and Right Side of F3LR02-0N Module

IM 34M6H45-01E

300

ON

to

ON

ON

ON

400

300

ON

to

ON

400

1st Edition : Feb.28,1999-00

400

to

500

400

to

500

Page 60

<Toc> <Ind> <B2. Specifications >

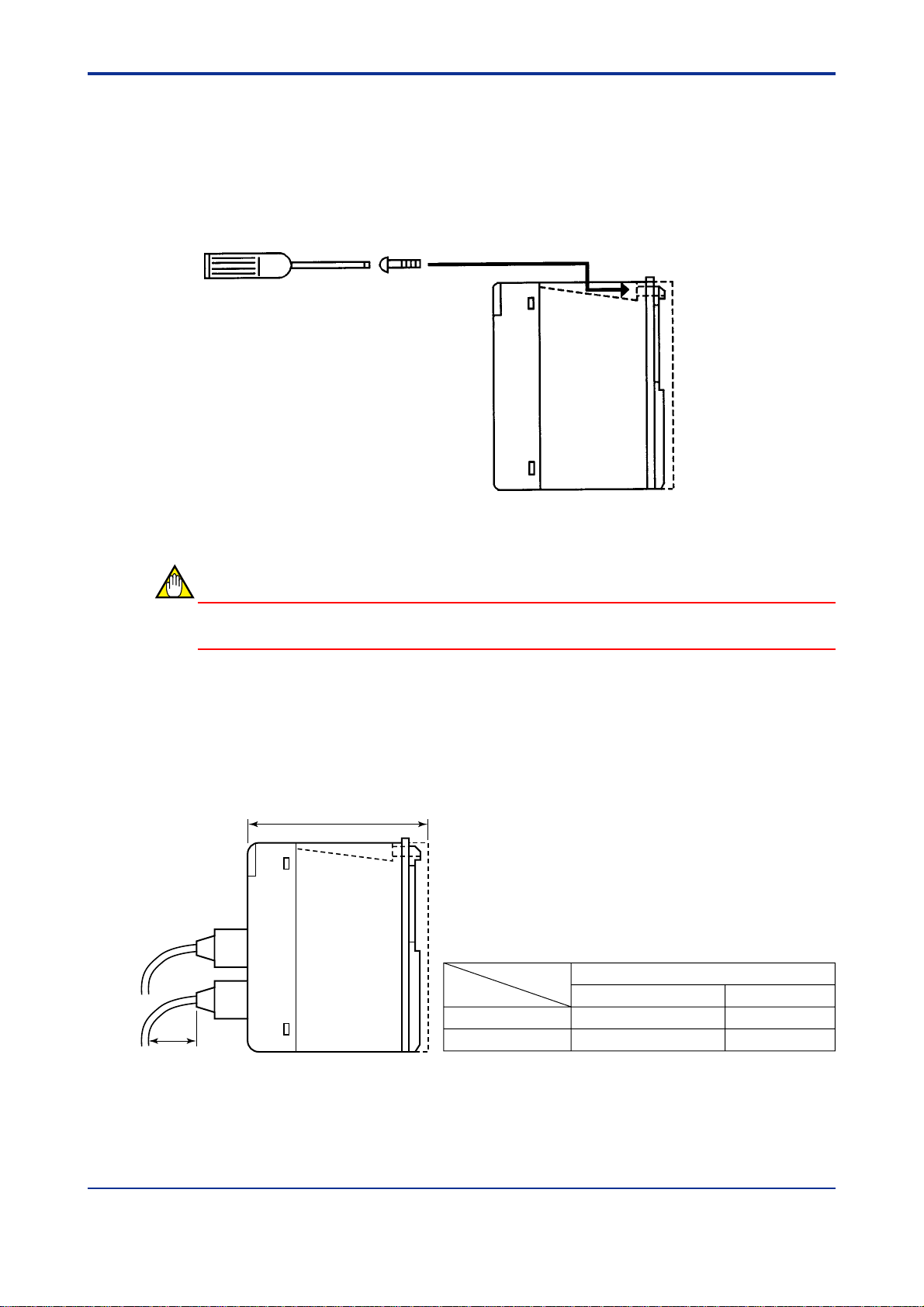

B2.4 External Dimensions

■ External dimensions

LR02-0N

1

0

1

0

1

2

9

8

4

3

2

F

E

D

RDY

ERR1

ERR2

3

5

C

SUB UNIT

4

NO.

5

6

7

LEFT SLOT

6

NO.

7

8

9

A

B

B2-3

Unit: mm

REMOTE

r

Figure B2.2 External Dimensions of F3LR02-0N Module

Allow for the following cable bending whenever the module is installed.

Table B2.3 Radius of Cable Bending

Radius (r) of cable bending, mm

During installation work When installed

Fiber optic cord 15 min. 50 min.

Fiber optic cable 50 min.

100 min.

2

IM 34M6H45-01E 1st Edition : Feb.28,1999-00

Page 61

Blank Page

Page 62

<Toc> <Ind> <B3. System Configuration >

B3-1

B3. System Configuration

B3.1 Fiber-optic FA-Bus Type 2 System Configuration

The Fiber-optic FA-bus T ype 2 systems are so configured that modules are installed in main

units and subunits, and the intermodules are connected with fiber optic cables.

The Fiber-optic FA-bus T ype 2 systems are configured as follows:

Components Description

Stations Units where this module is installed

Main units (master stations) Units where CPU modules are installed

Subunits System extension units where CPU modules are not installed

Substations Subunits where this module is installed

The following terms are used in the system configuration:

Term Description

Terminal station Substations at the end of daisy-chain connections

Station address Unit or slot numbers, or the like, to be added to stations

Master station A module installed on the master station

Substation A module installed on the substation

Terminal station module A module installed on the terminal station

B3.1.1 Slot Number

The FA-M3 controllers use slot numbers to access individual modules. These numbers

indicate slot positions where modules are installed. The following three digits are used to

indicate the slot positions.

Modules installed on subunits can be accessed in the same way as for those installed on

the main unit using either a Ladder or BASIC program.

Slot number * in the unit: 01 to 16

: 01, 02, .... ,16 in sequence from the right slot

*

Unit number: Main unit: 0

Subunit: 1 to 7

of the power supply module

IM 34M6H45-01E 1st Edition : Feb.28,1999-00

Page 63

<Toc> <Ind> <B3. System Configuration >

B3-2

Slot number

Main unit

Subunit 1

Subunit 2

Subunit

Subunit

001 002 003 004 005 006 007 008 009 010 011 012 013 014 015 016

CPU

101 102 103 104

201 202 203 204

301 302 303 304

3

401 402 403 404

4

105 106 107 108 109 110 111 112 113 114 115 116

205 206 207 208 209 210 211 212 213 214 215 216

305 306 307 308 309 310 311 312 313 314 315 316

405 406 407 408 409 410 411 412 413 414 415 416

Subunit

Subunit

Subunit

501 502 503 504

5

601 602 603 604

6

701 702 703 704

7

505 506 507 508 509 510 511 512 513 514 515 516

605 606 607 608 609 610 611 612 613 614 615 616

705 706 707 708 709 710 711 712 713 714 715 716

Figure B3.1 System Configuration and Slot Numbers

B3.1.2 Restrictions on System Configuration

The Fiber-optic FA-bus systems are restricted as in Table B3.1.

Table B3.1 Restrictions on System Configuration

Item Description

Number of fiber-optic FA-bus type 2 modules that

No restrictions

can be installed in a master station

Number of fiber-optic FA-bus type 2 modules that

Only one module

can be installed in a substation

Modules that can be installed in a subunit I/O and special modules excluding the F3LP■■ and F3LE01

*

Indicates that the rated current is within the limits speicfied in the power supply module.

*

IM 34M6H45-01E

1st Edition : Feb.28,1999-00

Page 64

<Toc> <Ind> <B3. System Configuration >

B3.1.3 Connecting Modules

The Fiber-optic FA-bus T ype 2 Modules can be loop-connected, daisy-chained, or starconnected. Examples of system configurations are shown below.

● Indication of the units in the examples

The following figure shows the unit number set switch (u) set to 3, the slot number set

switch set to 5, and this module installed on the F3BU04 base unit. With these settings, the

left slot of the F3BU04 module is changed to slot number 5, and the slot number where this

module is installed is 8.

B3-3

Substation

Unit 3

Slot nos. 5-8

module

Power supply

u3 - s5

(8)

This module

IM 34M6H45-01E 1st Edition : Feb.28,1999-00

Page 65

<Toc> <Ind> <B3. System Configuration >

■ Loop Configuration

This connects a vacant port of the substation (as in substation 1 or 4 in the figure below) to

a master station to configure a loop structure. Even if a disconnection or shutdown of a

substation occurs, built-in RAS functionality will work to increase system reliability .

• Configuration example

Master station

Unit no. 0

Slot nos. 1 to 6

module

Power supply

Substation

Unit no. 1

Slot nos. 1 to 4 u1-s1

u0-s1

Fiber optic cable

Fiber optic cable

Substation

Unit no. 4

Slot nos. 1 to 6 u4-s1

B3-4

This module

module

Power supply

Fiber optic cable

Substation

Unit no. 1

Slot nos. 9 to 12 u1-s9

module

Power supply

Substation

Unit no. 2

Slot nos. 1 to 9 u2-s1

module

Power supply

module

Power supply