Page 1

User’s

Manual

IM 34M06H62-02E

Temperature Control and

PID Module

IM 34M06H62-02E

3rd Edition

Yokogawa Electric Corporation

Applicable Modules:

Model Code Model Name

F3CU04-0S Temperature control and PID module

F3CU04-1S Temperature control and PID module

Addendum

See at the end of this manual.

Page 2

Blank Page

Page 3

Applicable Product

Range-free Multi-controller FA-M3

- Model : F3CU04-0S, F3CU04-1S

- Name : Temperature Control and PID Module

The document number for this manual is given below.

Refer to the document number in all communications, including when purchasing

additional copies of this manual.

- Document No.: IM 34M06H62-02E

i

Media No. IM 34M06H24-06E (CD) 1st Edition :Mar. 2015 (YK)

All Rights Reserved Copyright © 2014, Yokogawa Electric Corporation

IM 34M06H62-02E 3rd Edition : Jul.16, 2015-00

Page 4

Important

About This Manual

- This Manual should be passed on to the end user.

- Before using the controller, read this manual thoroughly to have a clear

understanding of the controller.

- This manual explains the functions of this product, but there is no guarantee that

they will suit the particular purpose of the user.

- Under absolutely no circumstances may the contents of this manual be transcribed

or copied, in part or in whole, without permission.

- The contents of this manual are subject to change without prior notice.

- Every effort has been made to ensure accuracy in the preparation of this manual.

However, should any errors or omissions come to the attention of the user, please

contact the nearest Yokogawa Electric representative or sales office.

Safety Symbols

ii

- Danger. This symbol on the product indicates that the operator must follow the

instructions laid out in this user's manual to avoid the risk of personnel injuries,

fatalities, or damage to the instrument. Where indicated by this symbol, the manual

describes what special care the operator must exercise to prevent electrical shock

or other dangers that may result in injury or the loss of life.

- Protective Conductor Terminal

This terminal is to prevent electric shock. Before using the instrument, connect to

the Protective earth (Comply with the regulation of each country.), and route the line

through the shortest path possible.

- Functional Earth T erminal

This terminal is for stable operation. Before using the instrument, be sure to ground

this terminal.

- Alternating current. Indicates alternating current.

- Direct current. Indicates direct current.

IM 34M06H62-02E 3rd Edition : Jul.16, 2015-00

Page 5

The following symbols are used only in the user's manual.

iii

WARNING

- Indicates a “Warning”.

Draws attention to information essential to prevent hardware damage, software

damage or system failure.

CAUTION

- Indicates a “Caution”

Draws attention to information essential to the understanding of operation and

functions.

TIP

- Indicates a “TIP”

Gives information that complements the present topic.

SEE ALSO

- Indicates a “SEE ALSO” reference.

Identifies a source to which to refer.

Safety Precautions when Using/Maintaining the Product

- For the protection and safe use of the product and the system controlled by it, be

sure to follow the instructions and precautions on safety stated in this manual

whenever handling the product. Take special note that if you handle the product in

a manner other than prescribed in these instructions, the protection feature of the

product may be damaged or impaired. In such cases, Yokogawa cannot guarantee

the quality, performance, function and safety of the product.

- When installing protection and/or safety circuits such as lightning protection devices

and equipment for the product and control system as well as designing or installing

separate protection and/or safety circuits for fool-proof design and fail-safe design of

processes and lines using the product and the system controlled by it, the user

should implement it using devices and equipment, additional to this product.

- If component parts or consumable are to be replaced, be sure to use parts specified

by the company.

- This product is not designed or manufactured to be used in critical applications

which directly affect or threaten human lives and safety — such as nuclear power

equipment, devices using radioactivity, railway facilities, aviation equipment,

shipboard equipment, aviation facilities or medical equipment. If so used, it is the

user’s responsibility to include in the system additional equipment and devices that

ensure personnel safety.

- Do not attempt to modify the product.

- To avoid electrical shock, turn off the power before wiring.

- This product is classified as Class A for use in industrial environments. If used in a

residential environment, it may cause electromagnetic interference (EMI).

In such situations, it is the user's responsibility to adopt the necessary measures

against EMI.

Exemption from Responsibility

- Yokogawa Electric Corporation (hereinafter simply referred to as Yokogawa Electric)

makes no warranties regarding the product except those stated in the WARRANTY

that is provided separately.

- Yokogawa Electric assumes no liability to any party for any loss or damage, direct or

indirect, caused by the use or any unpredictable defect of the product.

IM 34M06H62-02E 3rd Edition : Jul.16, 2015-00

Page 6

Software Supplied by the Company

- Yokogawa Electric makes no other warranties expressed or implied except as

provided in its warranty clause for software supplied by the company.

- Use the software with on e computer only. You must purchase another copy of the

software for use with each additional computer.

- Copying the software for any purposes other than backup is strictly prohibited.

- Store the original media that contain the software in a safe place.

- Reverse engineering, such as decompiling of the software, is strictly prohibited.

- Under absolutely no circumstances may the software supplied by Yokogawa Electric

be transferred, exchanged, or sublet or leased, in part or as a whole, for use by any

third party without prior permission by Yokogawa Electric.

iv

IM 34M06H62-02E 3rd Edition : Jul.16, 2015-00

Page 7

General Requirements for Using the FA-M3 / e-RT3 Controller

Set the product in a location that fulfills the following requirements:

- Where the product will not be exposed to direct sunlight, and where the operating

surrounding air temperature is from 0°C to 55°C (32°F to 131°F).

There are modules that must be used in an environment where the operating

surrounding air temperature is in a range smaller than 0°C to 55°C (32°F to 131°F).

Refer to “Hardware Manual” (IM 34M06C11-01E) or the applicable user's manual. In

case of attaching such a module, the entire system's operating surrounding air

temperature is limited to the module's individual operating surrounding air

temperature.

- Where the relative humidity is from 10 to 90%.

In places where there is a chance of condensation, use a space heater or the like to

constantly keep the product warm and prevent condensation.

- For use in Pollution Degree 2 Environment.

- Where there are no corrosive or flammable gases.

- Where the product will not be exposed to mechanical vibration or shock that exceed

specifications.

- Where there is no chance the product may be exposed to radioactivity.

v

Use the correct types of wire for external wiring:

- USE COPPER CONDUCTORS ONLY.

- Use conductors with temperature rating above 75°C.

Securely tighten screws:

- Securely tighten module mounting screws and terminal screws to avoid problems

such as faulty operation.

- Tighten terminal block screws with the correct tightening torque as given in this

manual. Refer to the “Hardware Manual” (IM 34M06C11-01E) or the applicable

user's manual for the appropriate tightening torque.

Securely lock connecting cables:

- Securely lock the connectors of cables, and check them thoroughly before turning

on the power.

Interlock with emergency-stop circuitry using external relays:

- Equipment incorporating the FA-M3 / e-RT3 controller must be furnished with

emergency-stop circuitry that uses external relays. This circuitry should be set up to

interlock correctly with controller status (stop/run).

Ground for low impedance:

- For safety reasons, connect the [FG] grounding terminal to a protective earth

(Comply with the regulation of each country.). For compliance to CE Marking, use

braided or other wires that can ensure low impedance even at high frequencies for

grounding.

Configure and route cables with noise control considerations:

- Perform installation and wiring that segregates system parts that may likely become

noise sources and system parts that are susceptible to noise. Segregation can be

achieved by measures such as segregating by distance, installing a filter or

segregating the grounding system.

IM 34M06H62-02E 3rd Edition : Jul.16, 2015-00

Page 8

Configure for CE Marking Conformance:

- For compliance to CE Marking, perform installation and cable routing according to

the description on compliance to CE Marking in the “Hardware Manual” (IM

34M06C11-01E).

- The list of CE conforming models is available in Appendix A2. of “Hardware

Manual”.

Keep spare parts on hand:

- We recommend that you stock up on maintenance parts, including spare modules,

in advance.

- Preventive maintenance (replacement of the module) is required for using the

module beyond 10 years.

Discharge static electricity before touching the system:

- Because static charge can accumulate in dry conditions, first touch grounded metal

to discharge any static electricity before touching the system.

Wipe off dirt with a soft cloth:

- Gently wipe off dirt on the product's surfaces with a soft cloth.

- If you soak the cloth in water or a neutral detergent, tightly wring it out before wiping

the product. Letting water enter the module interior can cause malfunctions.

- Do not use volatile solvents such as benzine or paint thinner or chemicals for

cleaning, as they may cause deformity, discoloration, or malfunctioning.

vi

Avoid storing the FA-M3 /e-RT3 controller in places with high

temperature or humidity:

- Since the CPU module has a built-in battery, avoid storage in places with high

temperature or humidity.

- Since the service life of the battery is drastically reduced by exposure to high

temperatures, take special care (storage surrounding air temperature should be

from -20°C to 75°C).

- There is a built-in lithium battery in a Sequence CPU module which serves as backup

power supply for programs, device information and configuration information.

The service life of this battery is more than 10 years in standby mode at room

temperature. Take note that the service life of the battery may be shortene d when

installed or stored at locations of extreme low or high temperatures. Therefore, we

recommend that modules with built-in batteries be stored at room temperature.

Always turn off the power before installing or removing modules:

- Failing to turn off the power supply when installing or removing modules, may result

in damage.

Do not touch components in the module:

- In some modules you can remove the right-side cover and install ROM packs or

change switch settings. While doing this, do not touch any components on the

printed-circuit board, otherwise components may be damaged and modules may fail

to work.

Do not use unused terminals:

- Do not connect wires to unused terminals on a terminal block or in a connector.

Doing so may adversely affect the functions of the module.

IM 34M06H62-02E 3rd Edition : Jul.16, 2015-00

Page 9

Use the following power source:

- Use only F3PU- as the power supply module.

- If using this product as a UL-approved product, for the external power supply, use a

limited voltage / current circuit power source or a Class 2 power source.

Refer to the user's manual before connecting wires:

- Refer to the “Hardware Manual” (IM 34M06C11-01E) or the applicable user’s

manual for the external wiring drawing.

- Refer to “A3.6.5 Connecting Output Devices” in the “Hardware Manual” before

connecting the wiring for the output signal.

- Refer to “A3.5.4 Grounding Procedure” in the “Ha rdware Manual” for attaching the

grounding wiring.

Authorized Representative:

- The Authorized Representative for this product in the EEA is:

Yokogawa Europe B. V.

Euroweg 2, 3825 HD Amersfoort, The Netherlands

vii

IM 34M06H62-02E 3rd Edition : Jul.16, 2015-00

Page 10

How to dispose the batteries

This is an explanation about the new EU Battery Directive. This directive is only valid in

the EU.

Batteries are included in some modules of this product. The procedure is different when

the user can remove or cannot remove.

Batteries the user can remove

The battery of F3RP6 can be removed by yourself.

When you remove the battery from F3RP6 and dispose it, discard them in accordance

with domestic law concerning disposal. See the User's Manual of F3RP6 for the

removal procedure. Take a right action on waste batteries, because the collection

system in the EU on waste batteries are regulated. If you don't remove the battery from

this product, please see .

Batteries the user cannot remove

Dispose the battery together with this product.

When you dispose this product in the EU, contact your local Yokogawa Europe

B.V.office.

Do not dispose them as domestic household waste.

Battery category: Lithium battery

viii

Note: With reference to Annex II of the new Battery Directive 2006/66/EC, the above

symbol indicates obligatory separate collection.

IM 34M06H62-02E 3rd Edition : Jul.16, 2015-00

Page 11

Introduction

Overview of the Manual

This instruction manual describes the specifications, functions and use of the

Temperature Control and PID Module. The information is especially useful when you

are performing pre-operation engineering.

ToolBox for Temperature Control and PID Modules

A dedicated ToolBox software is provided for this module. With this software, you can

easily set up various parameters of the module, as well as perform action tests, tuning

and monitoring by following screen instructions. For details, see the “ToolBox for

Temperature Control and Monitoring Modules User’s Manual” (IM34M06Q31-02E).

Notation

References to chapters and sections are denoted by the chapter or section number,

followed by the chapter or section title enclosed within double-quotation marks.

Relay names and register names are shown with Initial caps.

States or setting values are enclosed within double quotation marks, or displayed with

initial caps.

ix

Other User’s Manuals

Read the following manuals, as required.

For information on the specifications, configuration*, installation,

wiring, trial operation, maintenance and inspection of the e-RT3, as well

as information on the system-wide limitation of module installation,

refer to:

- Hardware Manual (IM 34M06C11-01E).

*: For information on the specifications of products other than the power supply module, base module, I/O module, cable

and terminal block unit, refer to their respective user’s manuals.

IM 34M06H62-02E 3rd Edition : Jul.16, 2015-00

Page 12

Copyrights and Trademarks

Copyrights

The copyright of the programs and online manuals contained in the software medium of

the Software Product shall remain in YOKOGAWA.

You are allowed to print the required pages of the online manuals for the purposes of

using or operating the Product; however, reprinting or reproducing the entire document

is strictly prohibited by the Copyright Law.

Except as stated above, no part of the online manuals may be reproduced, transferred,

sold, or distributed to a third party in any manner (either in electronic or written form

including, without limitation, in the forms of paper documents, electronic media, and

transmission via the network). Nor it may be registered or recorded in the media such as

films without permission.

Trademarks

The trade names and company names referred to in this manual are either trademarks

or registered trademarks of their respective companies.

x

IM 34M06H62-02E 3rd Edition : Jul.16, 2015-00

Page 13

Temperature Control and PID Module

CONTENTS

Applicable Product .................................................................................... i

Important ................................................................................................... ii

Introduction .............................................................................................. ix

Copyrights and T rademarks .................................................................... x

PART-A Function Overview

A1 Overview .................................................................................... A1-1

TOC-1

IM 34M06H62-02E 3rd Edition

A2 Specifications ............................................................................. A2-1

A2.1 Model and Suffix Codes ........................................................................ A2-1

A2.2 Compatibility with CPU Modules ........................................................ A2-1

A2.3 General Specifications .......................................................................... A2-2

Input Specifications .............................................................................. A2-2

A2.4

Output Specifications ........................................................................... A2-7

A2.5

Backup Function ................................................................................... A2-7

A2.6

Function Specifications ........................................................................ A2-8

A2.7

Components and Functions ............................................................... A2-10

A2.8

External Dimensions ........................................................................... A2-11

A2.9

A3 Startup Procedure ...................................................................... A3-1

Hardware Preparation ................................................................ A4-1

A4

A4.1 Selecting Input T ypes and Power Frequency ..................................... A4-2

A4.2 Attaching/Detaching Modules .............................................................. A4-6

A4.3 Wiring ..................................................................................................... A4-8

Wiring Precautions .................................................................. A4-8

A4.3.1

A4.3.2 Terminal Wiring Diagram ....................................................... A4-10

PART-B Parameter Description

B1 Accessing the Module .............................................................. B1-1

B1.1 Accessing Using Sequence Instructions ............................................ B1-2

Accessing Using BASIC ....................................................................... B1-5

B1.2

B1.3 Writing and Reading after Powering On ............................................. B1-6

B2 Types of Relays and Registers .................................................. B2-1

B2.1 T ypes of Relays ..................................................................................... B2-1

B2.2 T ypes of Registers ................................................................................ B2-2

IM 34M06H62-02E 3rd Edition : Jul.16, 2015-00

Page 14

TOC-2

B2.2.1 Common Process Data ........................................................... B2-4

Analog Output Settings ........................................................... B2-5

B2.2.2

B2.2.3 Setup Control Parameters ....................................................... B2-6

B2.2.4 SP Backup Parameters ............................................................ B2-7

B2.2.5 Function Control Parameters .................................................. B2-7

B2.2.6 EEPROM Write Counter .......................................................... B2-7

B2.2.7 Controller Parameters ............................................................. B2-8

B2.2.8 Process Data .......................................................................... B2-10

B2.2.9 Operation Control Parameters .............................................. B2-12

B2.2.10 I/O Parameters ....................................................................... B2-13

B2.2.11 Operation Parameters ........................................................... B2-15

B2.3 How to Enable Settings ...................................................................... B2-22

How to Back up SP Values to EEPROM ............................................ B2-33

B2.4

Initializing All Settings ........................................................................ B2-33

B2.5

B3 Setup and Operation .................................................................. B3-1

B3.1 Setting Controller Parameters ............................................................. B3-2

Power Frequency Selection .................................................... B3-2

B3.1.1

Input Sampling Period ............................................................. B3-2

B3.1.2

B3.1.3 Controller Mode........................................................................ B3-3

B3.1.4 Setting Output Terminals .......................................................... B3-5

B3.1.5 Sample Program for Setting Controller Parameters ............... B3-6

B3.2 Setting I/O Parameters .......................................................................... B3-8

Input Type Selection ............................................................... B3-8

B3.2.1

Control Type Selection ............................................................ B3-8

B3.2.2

B3.2.3 Sample Program for Setting I/O Parameters ........................... B3-9

B3.3 Setting Operation Parameters ............................................................ B3-12

Preparing for Dynamic Auto-tuning ........................................ B3-12

B3.3.1

Preparing for PID Control ...................................................... B3-14

B3.3.2

B3.3.3 Sample Program for Setting Operation Parameters .............. B3-16

B3.4 Operation .............................................................................................. B3-18

B4 Sample Program ......................................................................... B4-1

PART-C Function Description

C1 Controller Mode ......................................................................... C1-1

C1.1 Single Loop ............................................................................................ C1-1

C1.2 Cascade Control ................................................................................... C1-4

Cascade Control Operation .................................................... C1-6

A1.2.1

C1.3 Two-input Changeover Control ............................................................ C1-8

Disabled Mode ..................................................................................... C1-11

C1.4

C2 Output-related Functions .......................................................... C2-1

C2.1 Control Type Selection.......................................................................... C2-5

C2.2 Output Type Selection .......................................................................... C2-5

C2.3 Output Terminal Selection .................................................................... C2-6

IM 34M06H62-02E 3rd Edition : Jul.16, 2015- 00

Page 15

TOC-3

C2.4 Control T ypes and their Operations .................................................... C2-7

ON/OFF Control Output .......................................................... C2-7

C2.4.1

C2.4.2 PID Control Output .................................................................. C2-9

C2.4.3 Heating/Cooling PID Control .................................................. C2-13

C2.4.4 Heating/Cooling ON/OFF Control ......................................... C2-21

Analog Output ...................................................................................... C2-23

C2.5

External Output.................................................................................... C2-24

C2.6

C3 PV-related Functions ................................................................. C3-1

C3.1 Input T ype Selection.............................................................................. C3-4

C3.2 Power Frequency Selection ................................................................ C3-7

C3.3 Input Range Setting .............................................................................. C3-8

PV Range Setting (for use in two-input changeover mode only) ..... C3-9

C3.4

C3.5 Burnout Detection .............................................................................. C3-10

C3.6 Reference Junction Compensation ................................................... C3-11

Broken-line Biasing ............................................................................. C3-12

C3.7

C3.8 Fixed Biasing ....................................................................................... C3-13

C3.9 Square Root Extraction ...................................................................... C3-14

Input Filtering ....................................................................................... C3-15

C3.10

C3.11 Two-input Changeover

(for use in two-input changeover mode only) ................................. C3-16

C3.12 External Input ....................................................................................... C3-18

C4 SP-Related Functions ................................................................ C4-1

C4.1 Set Point (SP) ......................................................................................... C4-2

C4.2 Remote Set Point ................................................................................... C4-3

C4.3 Limiting the Set Point ........................................................................... C4-4

Setting SP Gradient ............................................................................... C4-5

C4.4

C4.5 PV Tracking ............................................................................................ C4-7

C4.6 SP Tracking ............................................................................................ C4-8

C5 Auto-Tuning Function ................................................................ C5-1

C5.1 Dynamic Auto-tuning ............................................................................ C5-1

C5.2 Auto-tuning ............................................................................................ C5-3

C5.2.1 Tuning Points and Stored PID Number ................................... C5-5

C6 Control and Computation Function .......................................... C6-1

C6.1 Forward Operation and Reverse Operation ........................................ C6-1

C6.2 Proportional Band ................................................................................. C6-2

C6.3 Integral Time and Manual Reset Values .............................................. C6-4

C6.4 Derivative Time ...................................................................................... C6-6

C6.5 Manual Adjustment PID Constants ...................................................... C6-8

C6.6 PID Control Mode .................................................................................. C6-9

C6.7 "Super" Overshooting Suppression Function ................................. C6-11

C6.8 Anti-reset Windup................................................................................ C6-12

C6.9 PID Selection Method

(SP Number Selection, Zone PID Selection) .................................... C6-13

IM 34M06H62-02E 3rd Edition : Jul.16, 2015-00

Page 16

TOC-4

C6.9.1 SP Number Selection ............................................................ C6-14

C6.9.2 Zone PID Selection ................................................................ C6-15

C7 Operation Control ....................................................................... C7-1

C7.1 Run/Stop Switch .................................................................................... C7-1

Operation after Switching from Stop Mode to Run Mode ........ C7-2

C7.1.1

C7.2 Automatic/Manual Switch ..................................................................... C7-4

Operation after Switching from Manual Mode to Automatic

C7.2.1

Mode ........................................................................................ C7-5

C7.3 Remote/Local Switch ............................................................................ C7-6

C7.4 Automatic/Manual/Cascade Switch ..................................................... C7-7

Cascade Mode ......................................................................... C7-8

C7.4.1

Automatic Mode ....................................................................... C7-8

C7.4.2

C7.4.3 Manual Mode ........................................................................... C7-9

C7.5 Preset Output Function ...................................................................... C7-10

C8 Alarm Function ........................................................................... C8-1

C8.1 Alarm Types ........................................................................................... C8-4

Wait Function ......................................................................................... C8-6

C8.2

Alarm Delay Timer ................................................................................. C8-7

C8.3

Selecting Alarm Preset Values ............................................................. C8-7

C8.4

C9 Disable Backup Function .......................................................... C9-1

C10 Self-diagnosis Function ........................................................... C10-1

C10.1 How to Check for Errors ..................................................................... C10-2

List of Error Statuses .......................................................................... C10-2

C10.2

C11 Selecting Temperature Unit ..................................................... C11-1

PART-D Troubleshooting

D1 Before Performing Checks ....................................................... D1-1

D2 Troubleshooting a Specific Problem ........................................ D2-1

(1) Input does not change, or fluctuates excessively ............................. D2-2

(2) Any LED indicator other than RDY and 60 Hz is lit or flashing ........ D2-3

(3) The loop is out of control (with an oscillating response) ................. D2-4

Output does not respond to or follow a changed set point value .... D2-5

(4)

Excessive overshooting ....................................................................... D2-5

(5)

Settings are not enabled ....................................................................... D2-5

(6)

PART-E Relays and Registers

E1 List of Registers ........................................................................ E1-1

List of Relays .............................................................................. E2-1

E2

Index .......................................................................................................... Index-1

Revision Information .......................................................................................... xi

IM 34M06H62-02E 3rd Edition : Jul.16, 2015- 00

Page 17

Temperature Control and PID Module

PART-A Function Overview

TOC A-1

IM 34M06H62-02E 3rd Edition

PART-A provides an overview of the module functions.

A1. Overview

A2. Specifications

A2.1 Model and Suffix Codes

A2.2 Compatibility with CPU Modules

A2.3 General Specifications

A2.4 Input Specifications

A2.5 Output Specifications

A2.6 Backup Function

A2.7 Function Specifications

A2.8 Components and Functions

A2.9 External Dimensions

A3. Startup Procedure

A4. Hardware Preparation

A4.1 Selecting Input Types and Power Supply Frequency

A4.2 Attaching/Detaching Modules

A4.3 Wiring

IM 34M06H62-02E 3rd Edition : Jul.16, 2015-00

Page 18

Blank Page

Page 19

A1. Overview

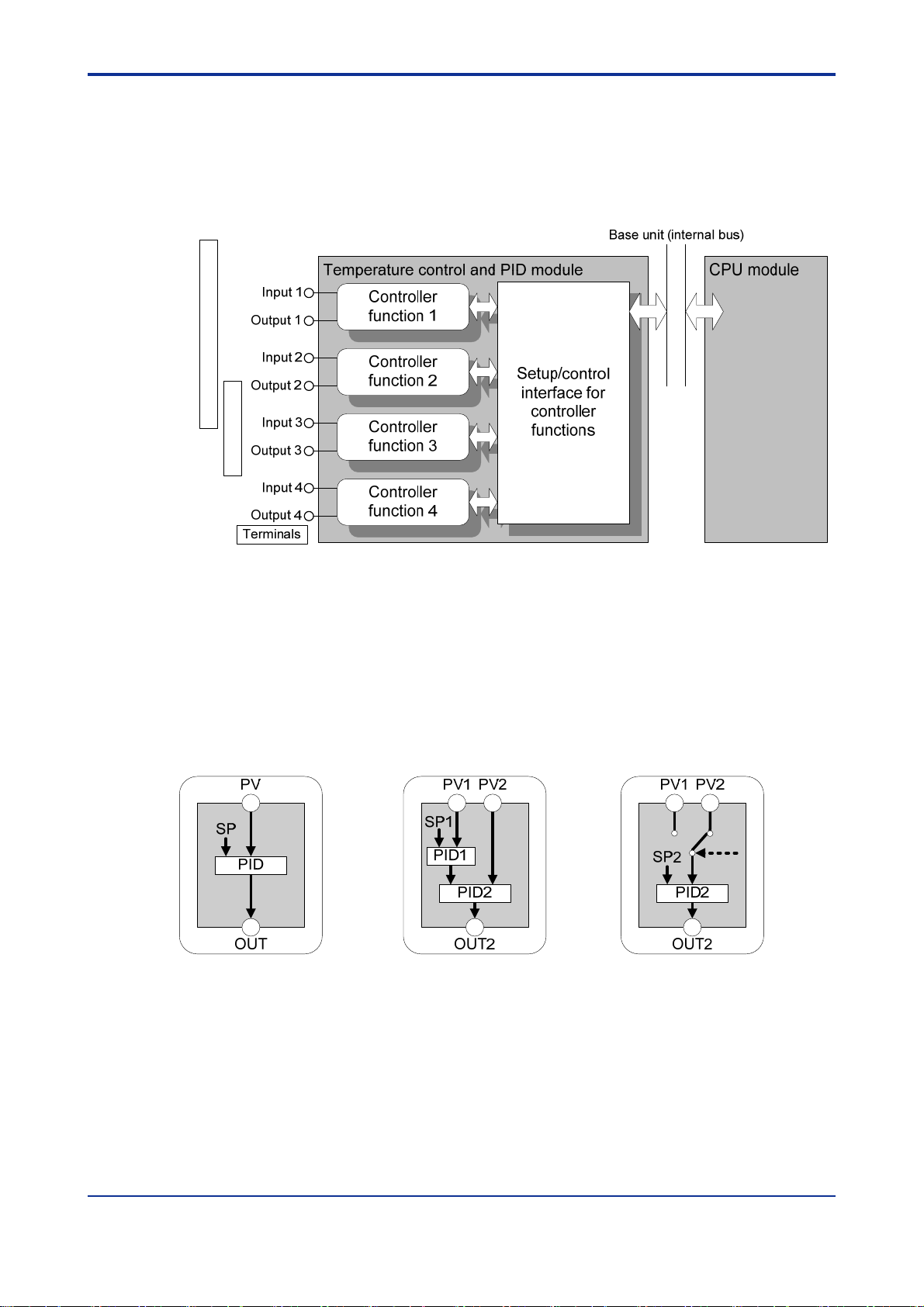

The temperature control and PID module (hereafter called “the module”) is an I/O

module to be mounted on the FA-M3 base unit. The module is provided with

multiple input and output circuits and performs multiple PID control functions.

Figure A1.1 shows a schematic diagram of a system containing the module.

Thermocouple/RTD/Signal Converter

SSR/Relay/SCR

A1-1

Figure A1.1 Schematic Diagram Showing the Relationship between Sensors, Actuators,

Temperature Control and PID Module and CPU Module

The module is provided with four controller functions and one setup and control

interface for the controller functions for controlling four loops. The controller

functions can be configured to act inter-dependently or independently to support a

wide variety of applications.

Three controller modes are available: single loop, cascade control, and two-input

changeover control. In the single loop mode (default), individual controller

functions operate independently. In the cascade or two-input changeover control

mode, two controller functions are combined to act as a single controller function.

(1) Single Loop (2) Cascade Control (3) Two-input Changeover Control

Figure A1.2 Controller Modes

Controller mode, instrument ranges, set points and other parameter values

required for module operation can be stored in the module to simplify operation

setup at each module startup. A program will then only need to run/stop operation

and switch between set points from the CPU module to achieve operation.

IM 34M06H62-02E 3rd Edition : Jul.16, 2015-00

Page 20

Features

- High accuracy, high resolution, high speed

The input sampling period for four loops is 200 ms. The sampling period may be set

to 100 ms if only two loops are used. The input conversion accuracy is 0.1% of full

scale, and the input resolution is 0.1C (using 5-digit representation). Low-resolution

operation (using 4-digit representation) is also available.

- Universal input

The input type may be set to thermocouple, RTD, or DC voltage for each loop.

- Dynamic auto-tuning

In the dynamic auto-tuning mode, what you have to do before starting operation is to

simply set the input type, output type, and set point. The dynamic auto-tuning

function automatically determines and tunes the PID parameters during operation.

You may disable the function, where appropriate.

Main Differences between F3CU04-N and F3CU04-S

With the F3CU04-S module, a specific SP backup procedure needs to be executed to

store set points to the EEPROM. Otherwise, set points are not stored to the EEPROM

when updated.

With the F3CU04-N module, however, set points are always stored automatically when

updated. This approach of storing set points unconditionally regardless of whether it is

required by an application allows for easier programming and operation, but may

damage the EEPROM storage media in an application where set points are constantly

updated.

A1-2

IM 34M06H62-02E 3rd Edition : Jul.16, 2015-00

Page 21

A2. Specifications

A2.1 Model and Suffix Codes

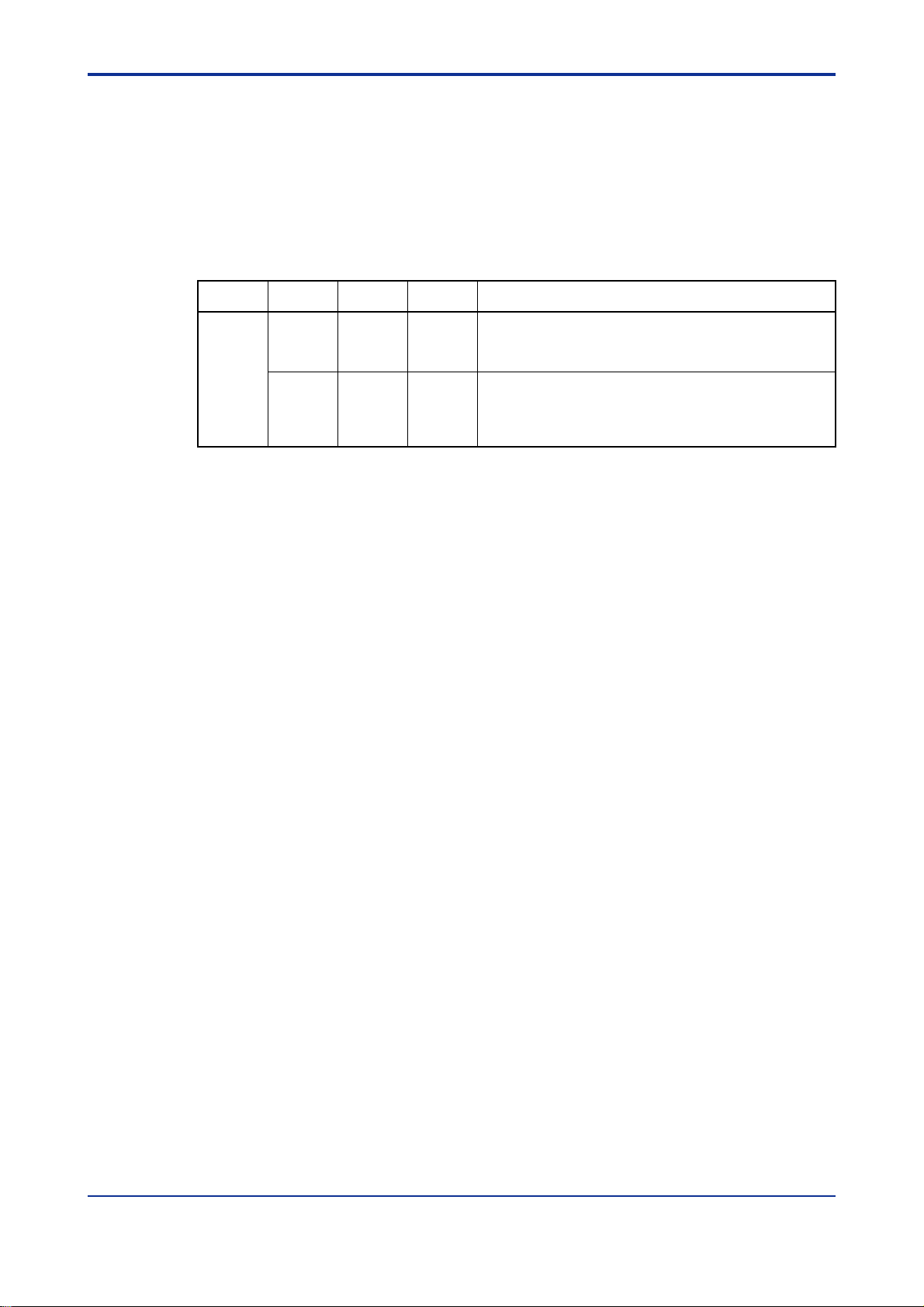

Table A2.1 shows the model name and suffix code of the module.

Table A2.1

Model

F3CU04

Model and Suffix Codes

Suffix

Code

-0S — —

-1S — —

Style

Code

Option

Code

4 loops

Universal input

Time-proportional PID output (open collector)

Single-slot size

4 loops

Universal input

Universal output (open collector, 4-20 mA continuous

output)

Double-slot size

A2-1

Description

A2.2 Compatibility with CPU Modules

There is no restriction on the type of CPU modules that can be used with this module.

IM 34M06H62-02E 3rd Edition : Jul.16, 2015-00

Page 22

* 2

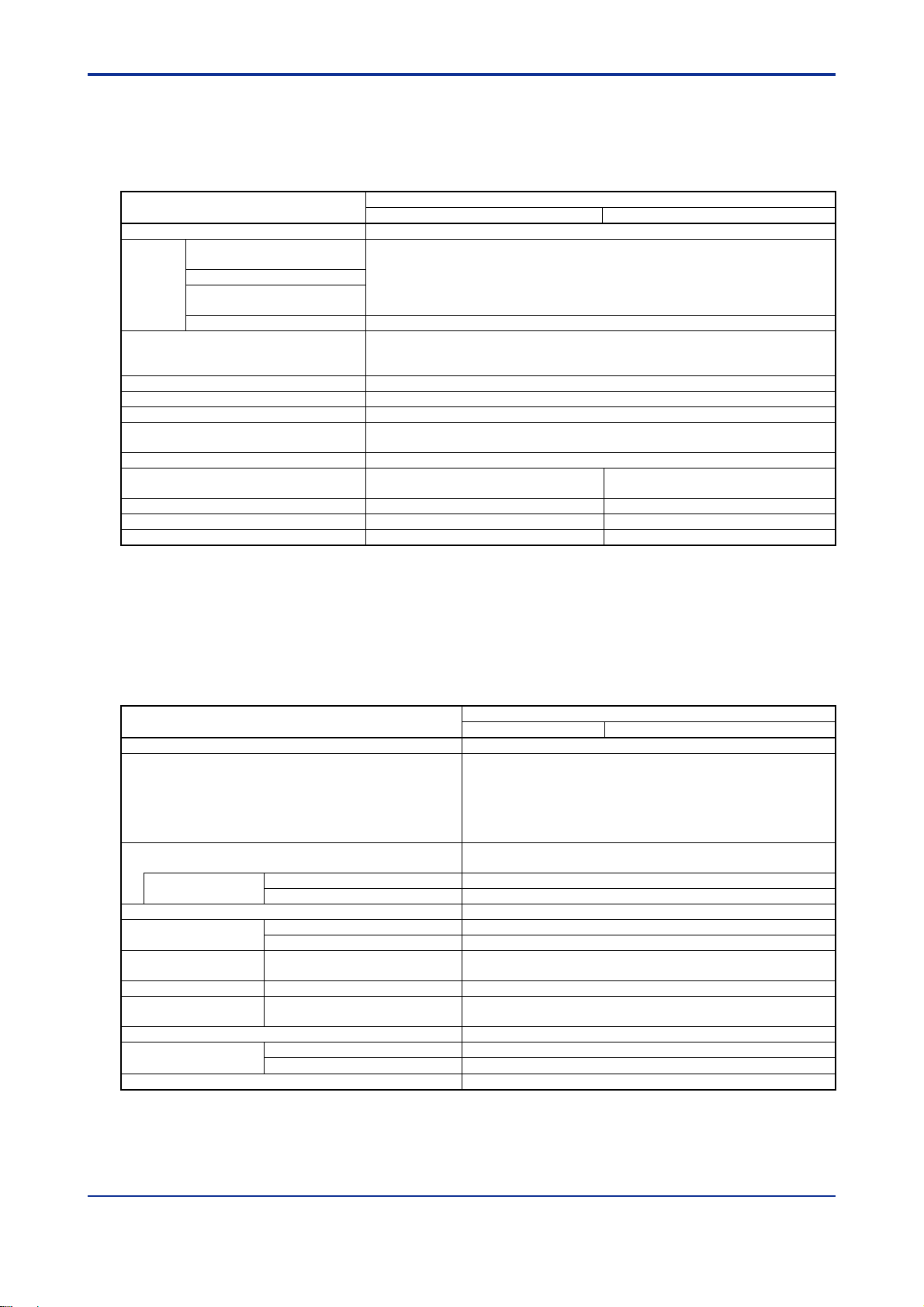

A2.3 General Specifications

Table A2.2 lists the general specifications of the F3CU04-0S and F3CU04-1S

temperature control and PID modules.

Table A2.2 General Specifications

Item

Number of loops 4

Isolation Between input terminals

Alarm types

Number of alarm outputs (input relays) 4 points per loop (only alarms 1 and 2 have input relays)

Alarm delay timer Yes

Warm-up time 30 minutes min.

Max. allowable ambient temperature

change rate

Mounting position Horizontal or inverted orientation not allowed

External connection

External dimensions

Current consumption 460 mA at 5 V DC 470 mA at 5 V DC

Weight 200 g 350 g

and internal circuit

Between input terminals

Between output terminals

and internal circuit

Between output terminals Not isolated.

*1

28.9 (W) x 100 (H) x 106.1 (D) mm 58 (W) x 100 (H) x 106.1 (D) mm

*1: The stated accuracy for the reference junction for thermocouple input deteriorates if the ambient temperature change

exceeds this rate.

*2: External dimensions excluding protrusions (for details, see the External Dimensions drawing).

Isolated by photocouplers and transformers

(tested for 1500 V AC voltage withstanding for 1 minute)

12 types of alarm:

Upper input limit, lower input limit, upper deviation limit, lower deviation limit,

upper/lower deviation limit, and deviation range, all with or without waiting

10C/h max.

One 18-point terminal block with

M3.5 screws

F3CU04-0S

Specification

Two 18-point terminal blocks with

M3.5 screws

A2-2

F3CU04-1S

A2.4 Input Specifications

Table A2.3 lists the input specifications of the F3CU04-0S and F3CU04-1S temperature

control and PID modules.

Table A2.3 Input Specifications

Item

Input sampling period*1 200ms for 4 loops, or 100ms for 2 loops

Input types and ranges

Burnout detection

Detection current

Input insulation resistance 1 M min.

Allowable signal

Source resistance

Allowable wiring

resistance

Measuring current RTD Approx. 270 μA

Reference junction

Compensation

Allowable input voltage range -20 to 20 V DC

Noise reduction

Effect of ambient temperature

*3*4

*1: If input sampling period is set to 100 ms for 2 loops, only loops 1 and 2 are available.

*2: This value assumes that all input terminals are correctly wired (that is, solderless termination, wire diameters and

connections are correct).

*3: This value assumes that the power supply frequency is correctly selected.

*4: This module continues to operate at a input accuracy of ±0.5% max. of F.S. during the radiated electromagnetic field test.

Thermocouple 100 nA max.

RTD 100 nA max.

Thermocouple or DC mV input 250

DC voltage input 2 k max.

RTD

*2

Thermocouple

Common mode 120 dB (50/60 Hz) min.

Normal mode 40 dB (50/60 Hz) min.

2.0C (0 to 55C)

F3CU04-0S

See Table A2.4, “Instrument Range and Accuracy”.

Individual inputs separately configurable by software or

collectively by hardware

Thermocouple input : 15 ranges

RTD input : 9 ranges

DC voltage input : 6 ranges

Thermocouples or RTDs are checked for burnout.

Up-scale, down-scale, or none may be selected.

max.

max. per wire

10

(three wires must have the same resistance)

0.01%/C or 1μV/C, whichever is greater

Specification

F3CU04-1S

IM 34M06H62-02E 3rd Edition : Jul.16, 2015-00

Page 23

*

6

*

6

*

7

*

7

*

8

*

8

*

9

*

9B*

10

*

10

*

10S*

11

*

11

*

11R*

11

*

11

*

11

*

12

*

12

*

13

*

13

*1

4

14

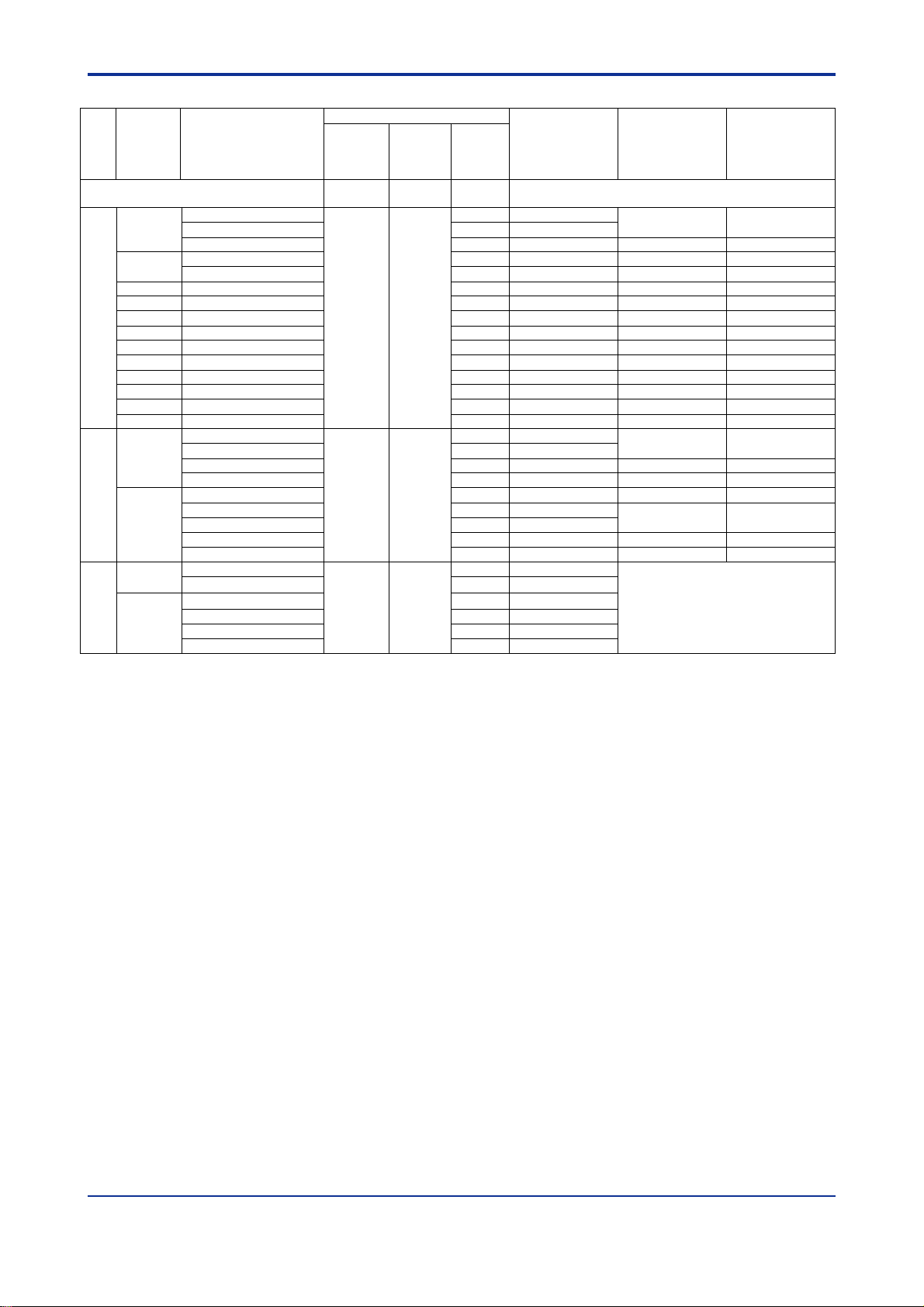

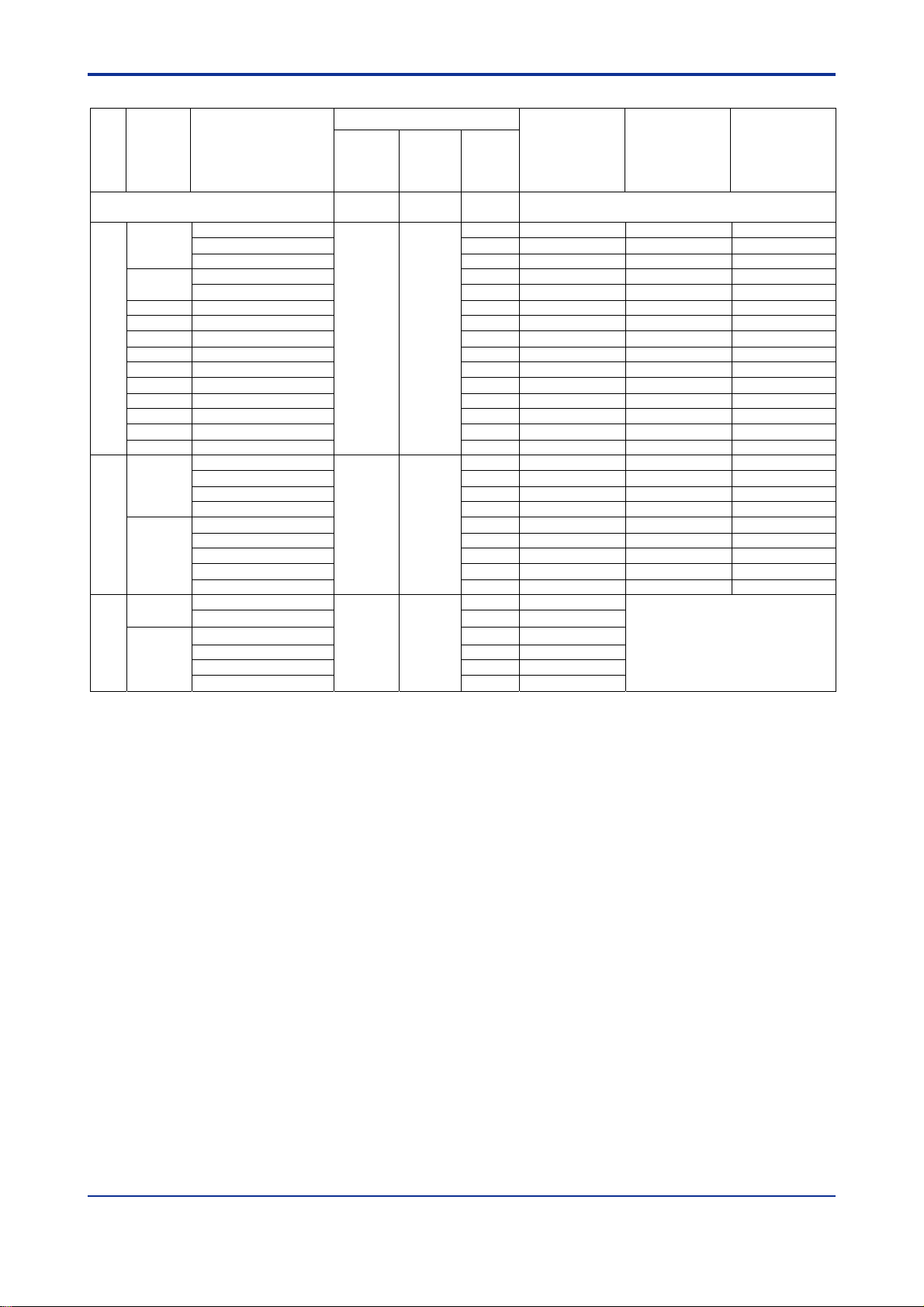

Table A2.4 Instrument Range and Accuracy (for high resolution operation with SW1-1 set to OFF) 1/4

Input Type Selector Switch

Input

Input

Type

Category

*1

Instrument Range

*2

SW1-3 SW1-4 SW5

*3

Software Setting

Accuracy*4 Resolution*2

A2-3

Software setting (factory setting) OFF OFF 0

-200.0 to 1370.0C

K*5

-200.0 to 1000.0C 2 2 ($02)

Instrument ranges

following codes.

1 1 ($01)

-200.0 to 500.0C 3 3 ($03)

J

-200.0 to 1200.0C 4 4 ($04)

-200.0 to 500.0C 5 5 ($05)

T -270.0 to 400.0C 6 6 ($06)

0.0 to 1600.0C 7 7 ($07)

0.0 to 1600.0C 8 8 ($08)

OFF OFF

0.0 to 1600.0C 9 9 ($09)

N -200.0 to 1300.0C A 10 ($0A)

Thermocouple

E -270.0 to 1000.0C B 11 ($0B)

L -200.0 to 900.0C C 12 ($0C)

U -200.0 to 400.0C D 13 ($0D)

W

0.0 to 1600.0C E 14 ($0E)

Platinel 2 0.0 to 1390.0C F 15 ($0F)

JPt100

-200.0 to 500.0C

-200.0 to 200.0C 1 17 ($11)

0.0 to 300.0C 2 18 ($12)

0 16 ($10)

0.00 to 150.00C 3 19 ($13)

RTD

Pt100

-200.0 to 850.0C 4

OFF ON

-200.0 to 500.0C 5 21 ($15)

-200.0 to 200.0C 6 22 ($16)

20 ($14)

0.0 to 300.0C 7 23 ($17)

0.00 to 150.00C 8 24 ($18)

DC mV

input

DC V

input

DC voltage

*1: Applicable standard is JIS/IEC/DIN (ITS-90) for thermocouples and RTD.

*2: For thermocouples K, B, S, R, and W, input ranges may be set wider than their instrument range (see the notes below). However, if the

input range width exceeds 1600C, the resolution becomes twice the indicated value. Furthermore, the actual range for an acceptable

input is the input range5%.

*3: When you turn on the power after changing the hardware switch settings, data stored in the EEPROM is initialized to follow the switch

settings.

*4: This accuracy applies if the ambient temperature is 25 5C and the input value is within the instrument range. If the input type is

thermocouple and reference junction compensation is used, you should also take into consideration the accuracy of the reference

junction compensation.

*5: For K-type thermocouples, the input range may be set from -270.0 to 1370.0C beyond its instrument range. The accuracy and

resolution depend on measured temperatures as follows:

-270.0 to -200.0C: Neither accuracy or resolution is guaranteed.

-200.0 to 0.0C: 1.0C accuracy, 0.2C resolution

*6: For K-type thermocouples, the accuracy and resolution depend on measured temperatures as follows:

-200.0 to -180.0C: 0.9C accuracy, 0.2C resolution

-180.0 to -100.0C: 0.6C accuracy, 0.1C resolution

*7: For J-type thermocouples, the accuracy and resolution depend on measured temperatures as follows:

-200.0 to -100.0C: 1.0C accuracy, 0.2C resolution

*8: For J-type thermocouples, the accuracy and resolution depend on measured temperatures as follows:

-200.0 to -150.0C: 0.6C accuracy, 0.1C resolution

*9: For T-type thermocouples, the accuracy and resolution depend on measured temperatures as follows:

-270.0 to -200.0C: 3.5C accuracy, 0.5C resolution

-200.0 to -100.0C: 1.0C accuracy, 0.1C resolution

*10: For B-type thermocouples, the input range may be set from 0.0 to 1800.0C beyond its instrument range. The accuracy and resolution

depend on measured temperatures as follows:

0.0 to 300.0C: Neither accuracy nor resolution is guaranteed.

300.0 to 900.0C: 2.5C accuracy, 0.3C resolution

*11: For S-type and R-type thermocouples, the input range may be set from 0.0 to 1700.0C beyond its instrument range. The accuracy and

resolution depend on measured temperatures as follows:

0.0 to 200.0C: 1.5C accuracy, 0.2C resolution

*12: For N-type thermocouples, the accuracy and resolution depend on measured temperatures as follows:

-200.0 to 0.0C: 1.3C accuracy, 0.3C resolution

*13: For E-type thermocouples, the accuracy and resolution depend on measured temperatures as follows:

-270.0 to -200.0C: 6.5C accuracy, 2.0C resolution

-200.0 to -100.0C: 1.0C accuracy, 0.2C resolution

*14: For W-type thermocouples, the input range may be set from 0.0 to 2300.0C beyond its instrument range. The accuracy and resolution

depend on measured temperatures as follows:

0.0 to 100.0C: 1.0C accuracy, 0.2C resolution

*15: Resolution is determined by the upper and lower limits for the input range, as well as the upper and lower scaling limits. It is represented

by one digit.

*16: "" means that the value is ignored.

0 to 10.00 mV DC

*15

0 to 100.0 mV DC A 26 ($1A)

0.000 to 1.000 V DC B 27 ($1B)

0.000 to 5.000 V DC D 29 ($1D)

*15

1.000 to 5.000 V DC E 30 ($1E)

*16

ON

0.00 to 10.00 V DC F 31 ($1F)

9 25 ($19)

may be specified by software using one of the

*5

0.5C

0.1C*5

0.5C

0.1C

0.5C

0.1C

0.5C

0.1C

0.5C

0.1C

1.0C

0.1C

1.0C

0.1C

1.0C

0.1C

0.6C

0.1C

0.5C

0.1C

0.6C 0.1C

0.6C 0.1C

0.8C14 0.1C

0.6C 0.1C

0.4C 0.1C

0.3C 0.1C

0.20C 0.03C

0.4C 0.1C

0.4C 0.1C

0.3C 0.1C

0.20C 0.03C

0.1% of instrument range

*15

1 digit

IM 34M06H62-02E 3rd Edition : Jul.16, 2015-00

Page 24

*

6

*

7

*

7

*

7

*

8

*

9

*

9

*

10

*

10

*

11

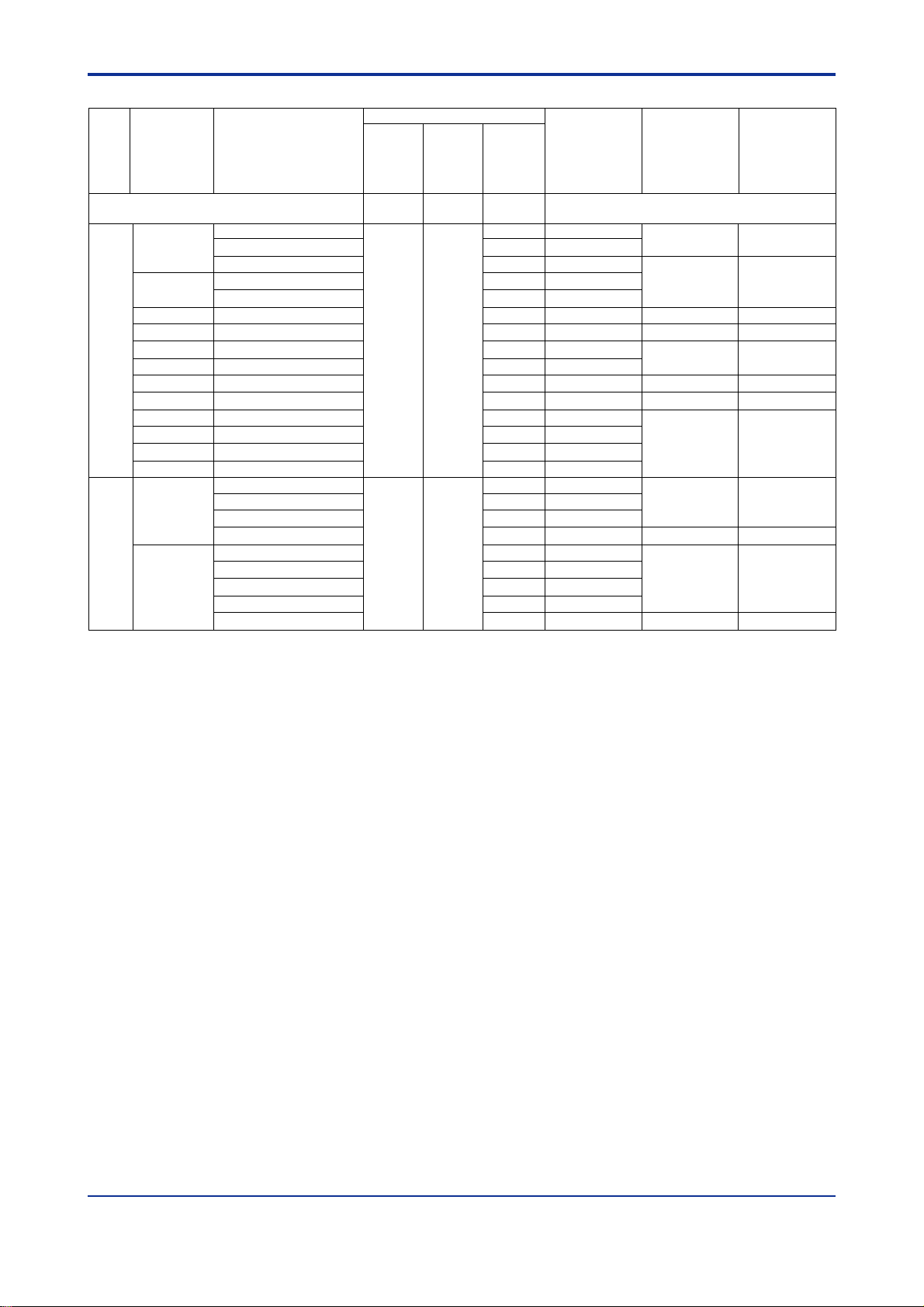

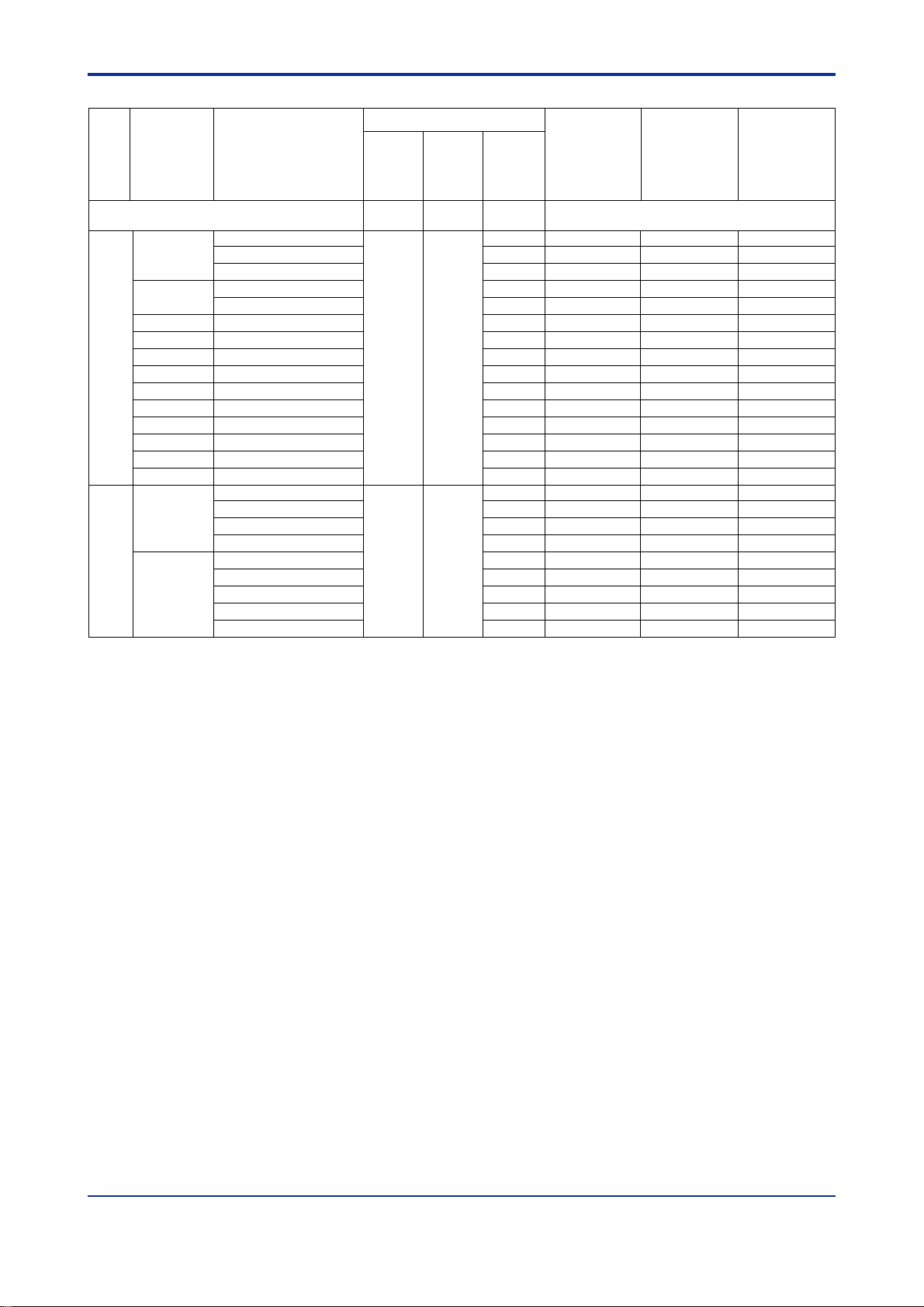

Table A2.4 Instrument Range and Accuracy (for low resolution operation with SW1-1 set to OFF) 2/4

Input

Category

Input Type

Input Type Selector Switch

*1

Instrument Range

SW1-3 SW1-4 SW5

*3

Software

Setting

Accuracy

*4

Resolution*2

A2-4

Software setting ON OFF 0

-200 to1370C

K*5

-200 to1000C 2 34 ($22)

Instrument ranges may be specified by

software using one of the following codes.

1 33 ($21)

2C

*5

1C*5

-200 to500C 3 35 ($23)

J

-200 to 1200C 4 36 ($24)

-200 to 500C 5 37 ($25)

T -270 to 400C 6 38 ($26)

B

0 to 1600C 7 39 ($27)

S

0 to 1600C 8 40 ($28)

R

0 to 1600C 9 41 ($29)

N -200 to 1300C A 42 ($2A)

Thermocouple

ON OFF

E -270 to 1000C B 43 ($2B)

2C 1C

2C

1C

2C

1C

2C 1C

2C

1C

2C

1C

L -200 to 900C C 44 ($2C)

U -200 to 400C D 45 ($2D)

W

0 to 1600C E 46 ($2E)

2C 1C

Platinel 2 0 to 1390C F 47 ($2F)

RTD

JPt100

Pt100

-200 to 500C

-200 to 200C 1 49 ($31)

0 to 300C 2 50 ($32)

0.0 to 150.0C 3 51 ($33)

-200 to 850C 4 52 ($34)

ON ON

-200 to 500C 5 53 ($35)

-200 to 200C 6 54 ($36)

0 48 ($30)

2C 1C

0.3C 0.1C

2C 1C

0 to 300C 7 55 ($37)

0.0 to 150.0C 8 56 ($38)

*1: Applicable standard is JIS/IEC/DIN (ITS-90) for thermocouples and RTD.

*2: For thermocouples K, B, S, R, and W, input ranges may be set wider than their instrument range (see the notes below). Furthermore, the

actual range for an acceptable input is the input range5%.

*3: When you turn on the power after changing the hardware switch settings, data stored in the EEPROM is initialized to follow the switch

settings.

*4: This accuracy applies if the ambient temperature is 25 5C and the input value is within the instrument range. If the input type is

thermocouple and reference junction compensation is used, you should also take into consideration the accuracy of the reference

junction compensation.

*5: For K-type thermocouples, the upper and lower input range limits may be set from -270 to 1370C. The accuracy and resolution depend

on measured temperatures as follows:

-270 to -200C: Neither accuracy nor resolution is guaranteed.

*6: For T-type thermocouples, the accuracy and resolution depend on measured temperatures as follows:

-270 to -200C: 4C accuracy, 1C resolution

*7: For B-type thermocouples, the upper and lower input range limits may be set from 0 to 1800C. The accuracy and resolution depend on

measured temperatures as follows:

0 to 300C: Neither accuracy nor resolution is guaranteed.

300 to 900C: 3C accuracy, 1C resolution

*8: For S-type and R-type thermocouples, the upper and lower input range limits may be set from 0 to 1700C.

*9: For N-type thermocouples, the accuracy and resolution depend on measured temperatures as follows:

-200 to 0C: 3C accuracy, 1C resolution

*10: For E-type thermocouples, the detailed accuracy and resolution are as follows:

-270 to -200C: 8C accuracy, 2C resolution

-200 to 1000C: 2C accuracy, 1C resolution

*11: For W-type thermocouples, the upper and lower input range limits may be set from 0 to 2300C.

0.3C 0.1C

IM 34M06H62-02E 3rd Edition : Jul.16, 2015-00

Page 25

*

5

*

5

*

5

*

5

*

6

*

6

*

7

*

7

*

8

*

9

*

9

*

10

*

10

*

10

*

11

*

11

*

11

*

11

*

12

*

12

*

13

*

13

*1

4

Table A2.4 Instrument Range and Accuracy (for high resolution operation with SW1-1 set to ON) 3/4

*3

Software

Setting

Accuracy

*4

Resolution*2

Input

Category

Input

Type

*1

Instrument Range

Input Type Selector Switch

*2

SW1-3 SW1-4 SW5

A2-5

Software setting (factory setting) OFF OFF 0

-328.0 to 2498.0F

K*5

-328.0 to 1832.0F

-328.0 to 932.0F

J

T

B

S

R

N

Thermocouple

E

L

U

W

Platinel 2

-328.0 to 2192.0F

-328.0 to 932.0F

-454.0 to 752.0F

32 to 2912F

32 to 2912F

32 to 2912F

-328.0 to 2372.0F

-454.0 to 1832.0F

-328.0 to 1652.0F

-328.0 to 752.0F

32 to 2912F

32.0 to 2534.0F

OFF OFF

-328.0 to 932.0F

JPt100

-328.0 to 392.0F

32.0 to 572.0F

32.0 to 302.0F

RTD

Pt100

-328.0 to 1562.0F

-328.0 to 932.0F

-328.0 to 392.0F

OFF ON

32.0 to 572.0F

32.0 to 302.0F

DC mV

*15

input

DC V

*15

input

DC voltage

*1: Applicable standard is JIS/IEC/DIN (ITS-90) for thermocouples and RTD.

*2: For thermocouples K, B, S, R, and W, input ranges may be set wider than their instrument range (see the notes below). However, if the

input range width exceeds 2880F, the resolution becomes twice the indicated value. Furthermore, the actual range for an acceptable

input is the input range5%.

*3: When you turn on the power after changing the hardware switch settings, data stored in the EEPROM is initialized to follow the switch

settings.

*4: This accuracy applies if the ambient temperature is 77F9F and the input value is within the instrument range. If the input type is

thermocouple and reference junction compensation is used, you should also take into consideration the accuracy of the reference

junction compensation.

*5: For K-type thermocouples, the input range may be set from -454.0 to 2498.0F beyond its instrument range. The accuracy and resolution

depend on measured temperatures as follows:

-454.0 to -328.0F: Neither accuracy or resolution is guaranteed.

-328.0 to 32.0F: 2.0F accuracy, 0.4F resolution

*6: For K-type thermocouples, the accuracy and resolution depend on measured temperatures as follows:

-328.0 to -292.0F: 2.0F accuracy, 0.4F resolution

-292.0 to -148.0F: 1.2F accuracy, 0.2F resolution

*7: For J-type thermocouples, the accuracy and resolution depend on measured temperatures as follows:

-328.0 to -148.0F: 2.0F accuracy, 0.4F resolution

*8: For J-type thermocouples, the accuracy and resolution depend on measured temperatures as follows:

-328.0 to -238.0F: 1.2F accuracy, 0.2F resolution

*9: For T-type thermocouples, the accuracy and resolution depend on measured temperatures as follows:

-454.0 to -328.0F: 6.5F accuracy, 1.0F resolution

-328.0 to -148.0F: 2.0F accuracy, 0.2F resolution

*10: For B-type thermocouples, the input range may be set from 32 to 3272F beyond its instrument range. The accuracy and resolution

depend on measured temperatures as follows:

32 to 572F: Neither accuracy nor resolution is guaranteed.

572 to 1652F: 5F accuracy, 1F resolution

*11: For S-type and R-type thermocouples, the input range may be set from 32 to 3092F beyond its instrument range. The accuracy and

resolution depend on measured temperatures as follows:

32 to 392F: 3F accuracy, 1F resolution

*12: For N-type thermocouples, the accuracy and resolution depend on measured temperatures as follows:

-328.0 to 32.0F: 2.5F accuracy, 0.6F resolution

*13: For E-type thermocouples, the accuracy and resolution depend on measured temperatures as follows:

-454.0 to -328.0F: 12.0F accuracy, 4.0F resolution

-328.0 to -148.0F: 2.0F accuracy, 0.4F resolution

*14: For W-type thermocouples, the input range may be set from 32 to 4172F beyond its instrument range.

*15: Resolution is determined by the upper and lower limits for the input range, as well as the upper and lower scaling limits. It is represented

by one digit.

*16: "" means that the value is ignored.

0 to 10.00 mV DC

0 to 100.0 mV DC

0.000 to 1.000 V DC

0.000 to 5.000 V DC

1.000 to 5.000 V DC

0.00 to 10.00 V DC

*16

ON

Instrument ranges may be specified by software

using one of the following codes.

1.0F

1 1 ($01)

2 2 ($02) 1.0F

3 3 ($03) 1.0F

4 4 ($04) 1.0F

5 5 ($05) 1.0F

6 6 ($06) 1.0F

7 7 ($07) 2F

8 8 ($08) 2F

9 9 ($09) 2F

A 10 ($0A) 1.2F

B 11 ($0B) 1.0F

0.2F

0.2F

0.2F

0.2F

0.2F

0.2F

1F

1F

1F

0.2F

0.2F

C 12 ($0C) 1.2F 0.2F

D 13 ($0D) 1.2F 0.2F

E 14 ($0E) 2F 1F

F 15 ($0F) 1.2F 0.2F

0 16 ($10)

1 17 ($11)

2 18 ($12)

3 19 ($13)

4 20 ($14)

5 21 ($15)

6 22 ($16)

7 23 ($17)

0.8F 0.2F

0.8F 0.2F

0.6F 0.2F

0.4F 0.2F

0.8F 0.2F

0.8F 0.2F

0.8F 0.2F

0.6F 0.2F

8 24 ($18) 0.4F 0.2F

9 25 ($19)

A 26 ($1A)

B 27 ($1B)

D 29 ($1D)

0.1% of instrument range

1 digit

*15

E 30 ($1E)

F 31 ($1F)

IM 34M06H62-02E 3rd Edition : Jul.16, 2015-00

Page 26

*

5

*

5

*

5

*

5

*

6

*

7

*

7

*

7

*

8

*

8

*

8

*

8

*

9

*

10

*

10

*

11

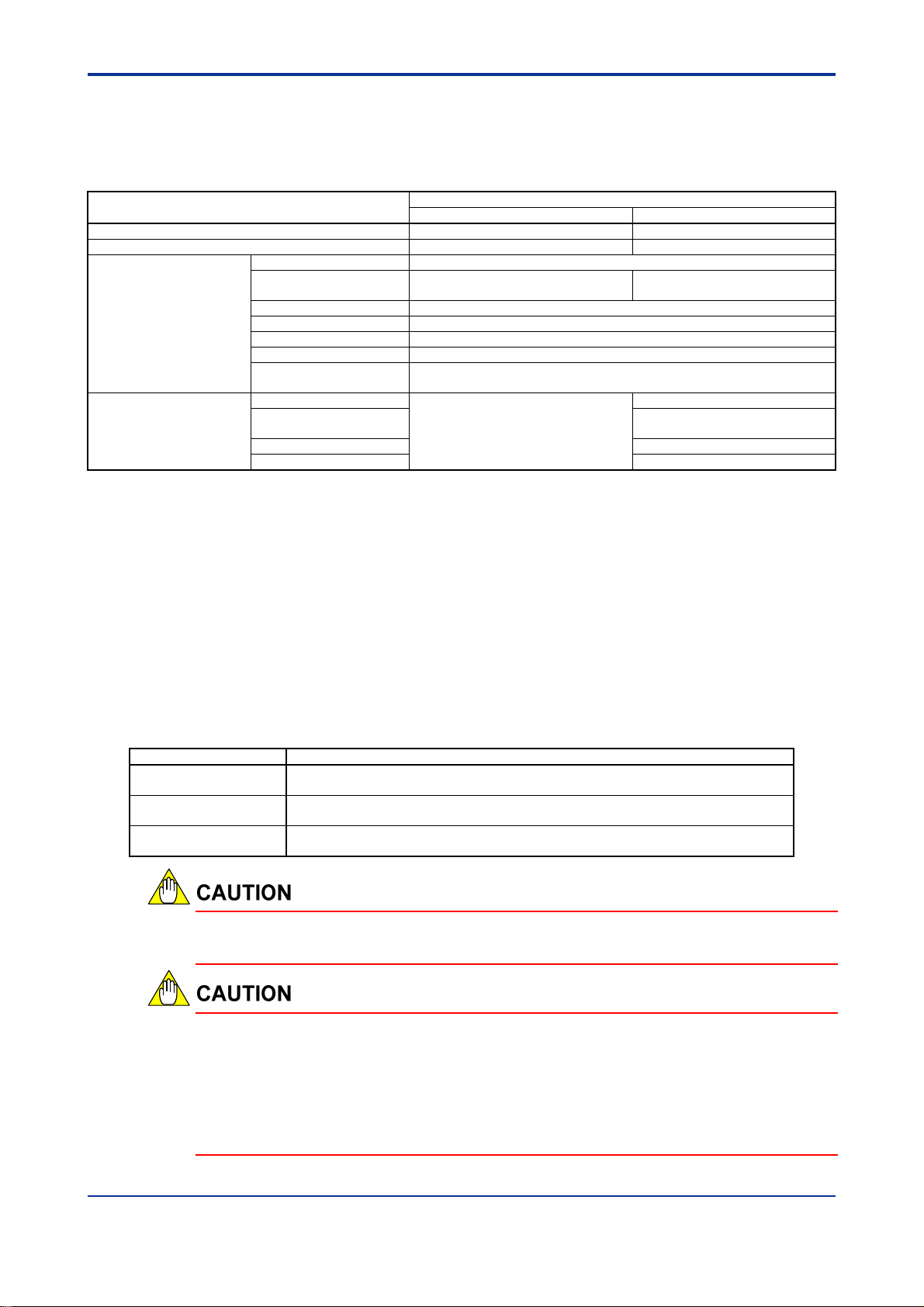

Table A2.4 Instrument Range and Accuracy (for low resolution operation with SW1-1 set to ON) 4/4

Input

Category

Input Type

Input Type Selector Switch

*1

Instrument Range

SW1-3 SW1-4 SW5

*3

Software

Setting

Accuracy

*4

Resolution*2

A2-6

Software setting ON OFF 0

-328 to 2498F

K*5

-328 to 1832F

-328 to 932F

-328 to 2192F

-328 to 932F

-454 to 752F

32 to 2912F

32 to 2912 F

32 to 2912F

-328 to 2372F

-454 to 1832F

-328 to 1652F

-328 to 752F

32 to 2912F

32 to 2534F

ON OFF

Thermocouple

J

T

B

S

R

N

E

L

U

W

Platinel 2

-328 to 932F

JPt100

-328 to 392F

32 to 572F

32 to 302F

RTD

Pt100

-328 to 1562F

-328 to 932F

-328 to 392F

ON ON

32 to 572F

32 to 302F

*1: Applicable standard is JIS/IEC/DIN (ITS-90) for thermocouples and RTD.

*2: For thermocouples K, B, S, R, and W, input ranges may be set wider than their instrument range (see the notes below). Furthermore, the

actual range for an acceptable input is the input range5%.

*3: When you turn on the power after changing the hardware switch settings, data stored in the EEPROM is initialized to follow the switch

settings.

*4: This accuracy applies if the ambient temperature is 77F9F and the input value is within the instrument range. If the input type is

thermocouple and reference junction compensation is used, you should also take into consideration the accuracy of the reference

junction compensation.

*5: For K-type thermocouples, the upper and lower input range limits may be set from -454 to 2498F. The accuracy and resolution depend

on measured temperatures as follows:

-454 to 328F: Neither accuracy nor resolution is guaranteed.

*6: For T-type thermocouples, the accuracy and resolution depend on measured temperatures as follows:

-454 to -328F: 7F accuracy, 1F resolution

*7: For B-type thermocouples, the upper and lower input range limits may be set from 32 to 3272F. The accuracy and resolution depend on

measured temperatures as follows:

32 to 572F: Neither accuracy nor resolution is guaranteed.

572 to 1652F: 5F accuracy, 1F resolution

*8: For S-type and R-type thermocouples, the upper and lower input range limits may be set from 32 to 3092F. The accuracy and

resolution depend on measured temperatures as follows:

32 to 392F: 3F accuracy, 1F resolution

*9: For N-type thermocouples, the accuracy and resolution depend on measured temperatures as follows:

-328 to 32F: 4F accuracy, 1F resolution

*10: For E-type thermocouples, the detailed accuracy and resolution are as follows:

-454 to 328F: 12F accuracy, 4F resolution

-328 to 148F: 3F accuracy, 1F resolution

*11: For W-type thermocouples, the upper and lower input range limits may be set from 32 to 4172F.

Instrument ranges may be specified by

software using one of the following codes.

1 33 ($21)

2 34 ($22)

3 35 ($23)

4 36 ($24)

5 37 ($25)

6 38 ($26) 2F

7 39 ($27) 2F

8 40 ($28) 2F

9 41 ($29) 2F

A 42 ($2A) 2F

B 43 ($2B) 2F

2F

1F

2F

1F

2F 1F

2F 1F

2F 1F

1F

1F

1F

1F

1F

1F

C 44 ($2C) 2F 1F

D 45 ($2D) 2F 1F

E 46 ($2E) 2F 1F

F 47 ($2F) 2F 1F

0 48 ($30)

1 49 ($31)

2 50 ($32)

3 51 ($33)

4 52 ($34)

5 53 ($35)

6 54 ($36)

7 55 ($37)

8 56 ($38)

2F 1F

2F 1F

2F 1F

2F 1F

2F 1F

2F 1F

2F 1F

2F 1F

2F 1F

IM 34M06H62-02E 3rd Edition : Jul.16, 2015-00

Page 27

A2.5 Output Specifications

Table A2.5 lists the output specifications of the F3CU04-0S and F3CU04-1S temperature

control and PID modules.

Table A2.5 Output Specifications

Item

Number of outputs 4 8

External power supply * 24 V DC 10%, 10 mA 24 V DC 10%, 250 mA

Rated load voltage 24 V DC

Maximum load current 0.1 A per point

Time-proportional PID

output (open collector

output)

Continuous PID output

(analog output)

* External power supply is not required if no output terminal is used (that is, if only input terminals are used).

ON residual voltage 0.5 V DC max.

OFF leakage current 0.1 mA max.

Response time OFFON: 1 ms max., ONOFF: 1 ms max.

Cycle time 0.5 to 240 s

Time-proportional

resolution

Output range

Allowable load

resistance

Output accuracy

Output resolution 0.05% of F.S.

10 ms or 0.05% of F.S., whichever is greater

N.A.

F3CU04-0S

Specification

F3CU04-1S

0.1 A per point and 0.4 A for 8

points

4-20 mA (3.2-20.8 mA)

600 max.

1.0% of F.S.

A2-7

A2.6 Backup Function

The F3CU04-0S or F3CU04-1S temperature control and PID module provides a backup

function for storing input type, input range, set points and other parameter values, and

hence retaining their values even after power off and on. Parameters designated for

backup are stored whenever their corresponding registers are updated, provided the

backup function is not disabled. However, you need to execute a specific procedure

every time to back up set point values. Otherwise, stored set points will not be updated.

Even so, beware that set points will not be updated if the backup function is disabled.

Take note that there is a maximum limit to the number of write operations allowed for the

backup function.

Table A2.6 Backup Function

Description

Stored parameters

Number of write

operations

Disable backup function

For details on the I/O data registers that are stored by the backup function and their data

position numbers, see Section B2, "Types of Relays and Registers."

Controller parameters, I/O parameters, and operation parameters. For details, refer

to the list of registers.

Up to 100,000 write operations allowed

This parameter disables the backup function. It may be used, if required, to avoid

reaching the maximum limit for write operations.

In situations where the CPU module frequently overwrites the I/O data registers

earmarked to be stored by the backup function, the maximum limit for write operations

(100,000 times) may be reached. To prevent this, turn on the Disable Backup Function

parameter. Once the write limit is reached, data backup is no longer allowed and the

system enters hardware failure mode. Furthermore, parameter data may be reset at

system startup to the default values given in Section B2, "Types of Relays and

Registers."

IM 34M06H62-02E 3rd Edition : Jul.16, 2015-00

Page 28

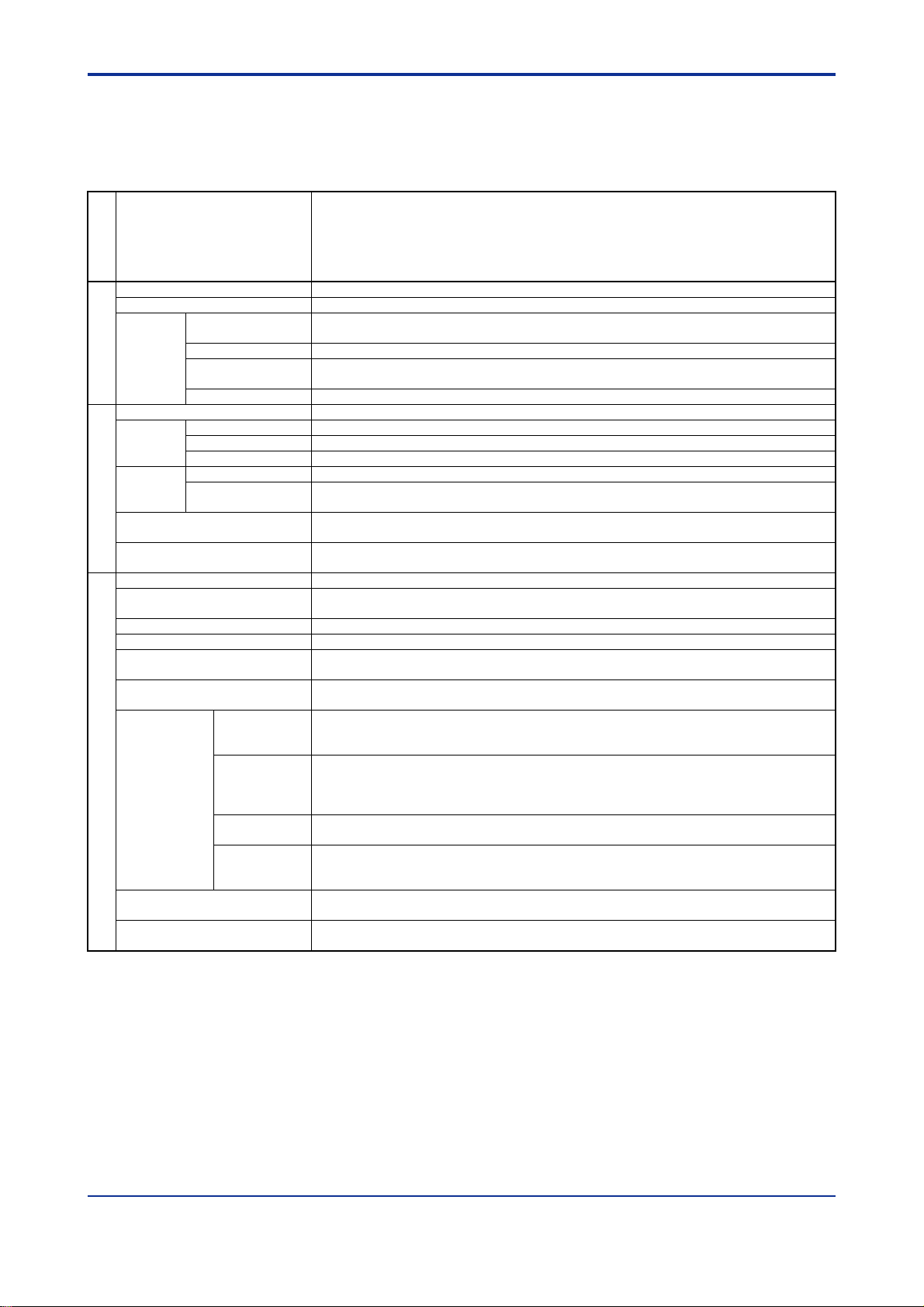

A2.7 Function Specifications

Table A2.7 shows the function specifications of the F3CU04-0S and F3CU04-1S

temperature control and PID modules.

Table A2.7 Function List (1/2)

Functions Description

Category

Input sampling period Sets the input sampling period (this affects the number of available loops).

Controller mode selection Specifies the controller mode for a pair of 2 loops.

Single loop

Controller

Controller

mode

Control type selection Selects from on/off, PID, and heating/cooling control types.

Control

type

Output

limiter

Output type selection *2

Output processing

Cascade control Two control and computation functions perform cascade control (using 2 loops of input and output).

Two-input

changeover

Disabled Loops specified as ‘disabled’ are not used.

ON/OFF

PID Controls output according to PID computation results.

Heating/cooling Controls both heating and cooling outputs according to PID computation results.

Output limiter

Rate-of-change

limit

Analog output *2

Input type selection Sets input type using switches (for all loops) or software (for individual loops).

Power supply frequency

specification

Input range setting Sets input ranges.

PV range setting Sets PV range for two-input changeover mode.

Burnout selection

Reference junction

compensation

Broken-line

biasing

Input

Input processing

computation

Fixed biasing

Input filtering

Square root

extraction

Two-input changeover

External PV input

*1: Numbers within parentheses (100% and 0%) applies when the output is configured as a continuous output

(for F3CU04-1S only).

*2: Available for F3CU04-1S only.

*3: When burnout selection is set to OFF, the measured input value at the time of burnout (open circuit) is unpredictable and

may approach either the upper limit or the lower limit. Furthermore, the burnout relay is not set.

However +OVER or -OVER detection is performed.

Basic controller mode with one control and computation function where two loops operate

independently.

Switches between two measured inputs (using a register or measured value range) and handles

them as one measured input (using 2 loops of input).

Performs control by turning on (100% output) or turning off the output (0% output). *

Sets the upper and lower limits for the control output.

Sets the maximum allowable rate-of-change for the control output.

Selects between time-proportional output (open collector) and continuous output (4-20 mA analog

output).

Specifies a fixed value output for any output terminal not used in a control loop (e.g. when

disabled).

Specifies the power supply frequency. An appropriate setting value will reduce the effect of common

mode noise.

Selectable from Up-scale, Down-scale, or OFF (no burnout detection) for thermocouple or RTD

input open-circuit detection. *3

Sets thermocouple reference junction compensation to ‘On’ or ‘Fixed Value’.

Specifies any temperature and its bias value. A compensation value based on the linear

interpolation of the specified bias values is automatically added to a measured input. This function

is particularly useful for a deteriorated sensor, for which input compensation is desirable.

Specifies a fixed bias value to be automatically added to measured input values. This function is

useful when a measured input suffers a fixed deviation due to a known physical problem with a

sensor, or when fine adjustment of measured input is desirable for better consistency with values

indicated by other equipment, even though data deviation is within tolerance.

Filtering can be used to remove high frequency noise from measured inputs such as flow rate and

pressure. Filtering is a first order delay numerical operation.

Performs square root extraction on measured inputs. This function is useful for converting

differential pressure signals (of orifice, nozzle, or other types of restriction flowmeter) to flow rate

signals.

Sets the two-input changeover mode to perform changeover based on temperature range, preset

temperature value, or register value.

External values may be used as control input values. Measured input values that have undergone

required processing by a CPU module or other means, may be used as input values.

A2-8

1

IM 34M06H62-02E 3rd Edition : Jul.16, 2015-00

Page 29

Table A2.7 Function List (2/2)

Functions Description

Category

Four set points can be predefined for each loop. A predefined set point can be selected using the

SP number parameter.

Defines acceleration and deceleration independently for varying the control set point at a fixed rate

or to prevent an abrupt change in the control set point.

When a switchover is made from Stop to Run, from Manual to Automatic, or from one SP number to

another, the control set point is first set to the current PV value and then gradually changed to the

required value at the rate defined by the SP gradient parameters.

Automatically recalculates PID constants to achieve continuous stable control at the beginning of a

control operation or when control becomes unstable.

When a start tuning instruction is issued, measures the characteristics of a control object by

switching on and then switching off the output, and automatically determines and sets optimal PID

constants.

Defines the direction of output change (increase or decrease) corresponding to a positive deviation.

The combination of the CMD parameter (0: standard PID control mode, 1: fixed-point control mode)

and the remote/local switch determines the PID control method (PV derivative type PID control or

deviation derivative type PID control) with or without bumping.

Prevents excessive integration and hence overshooting by suspending PID computation. The

deviation width for resuming PID computation can be set using a parameter.

Set point

Autotuning

Control

and

Control and computation

computation

Set points

Remote set point Can be used to continually change the set point value from the CPU module or by other means.

SP tracking Retains the set point value when switching from remote to local mode.

SP limiter Limits the set point within specified limits in remote or cascade control mode.

SP gradient

setting

PV tracking

Dynamic

auto-tuning

Auto-tuning

Forward/reverse

operation

PID control mode

Super Suppresses overshooting using fuzzy logic.

Anti-reset windup

PID selection Selects one of the four PID parameter groups belonging to each loop.

PID

selection

method

SP number

selection

Zone PID selection

Switches between four PID parameter groups according to the value of the SP Number Selection

parameter.

Automatically switches between PID parameter groups according to PV value. In addition, allows

switching to a specific PID parameter group when the deviation is large.

Operation control Switches between run/stop, automatic/manual/cascade, remote/local, and other operating modes.

Alarm setup

Alarm

Alarm

Waiting Suppresses alarms during the startup period after power on until the operation stabilizes.

Delay timer Reports an alarm only if an alarm condition persists for a minimum duration.

Backup function

(Storing of preset values)

Defines four alarms for each loop. Alarms may be defined to trigger with respect to the upper or

lower input limit or differential upper or lower limit.

Stores parameters to the EEPROM, which is writable up to 100,000 times.

A2-9

IM 34M06H62-02E 3rd Edition : Jul.16, 2015-00

Page 30

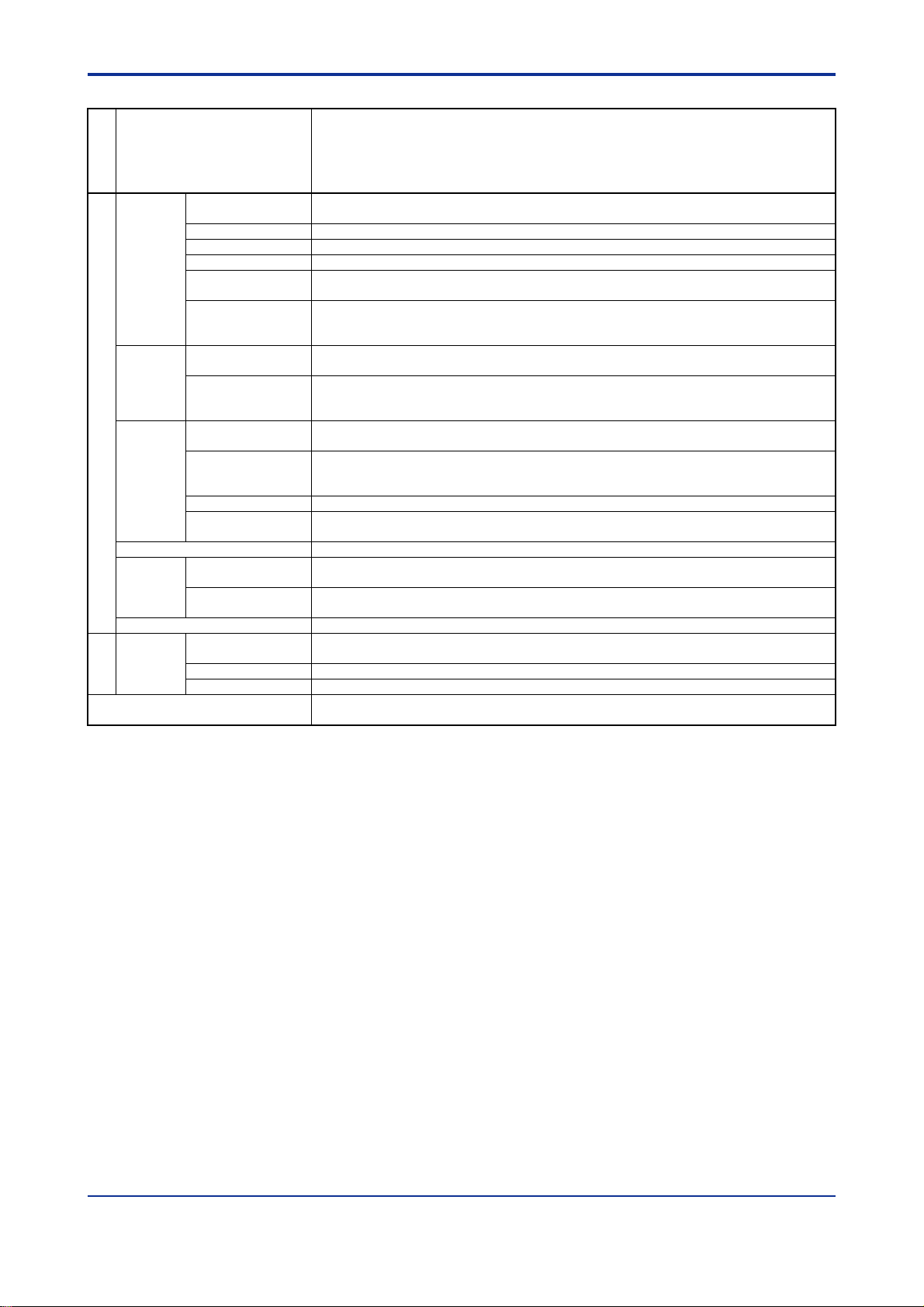

A2.8 Components and Functions

F3CU04-0S

RDY

CU04-0S

IN4

IN3

A

b

+

B

-

IN2

IN1

A

b

+

B

-

4

3

2

1

OUT

COM

60Hz

ALM

ERR

PID

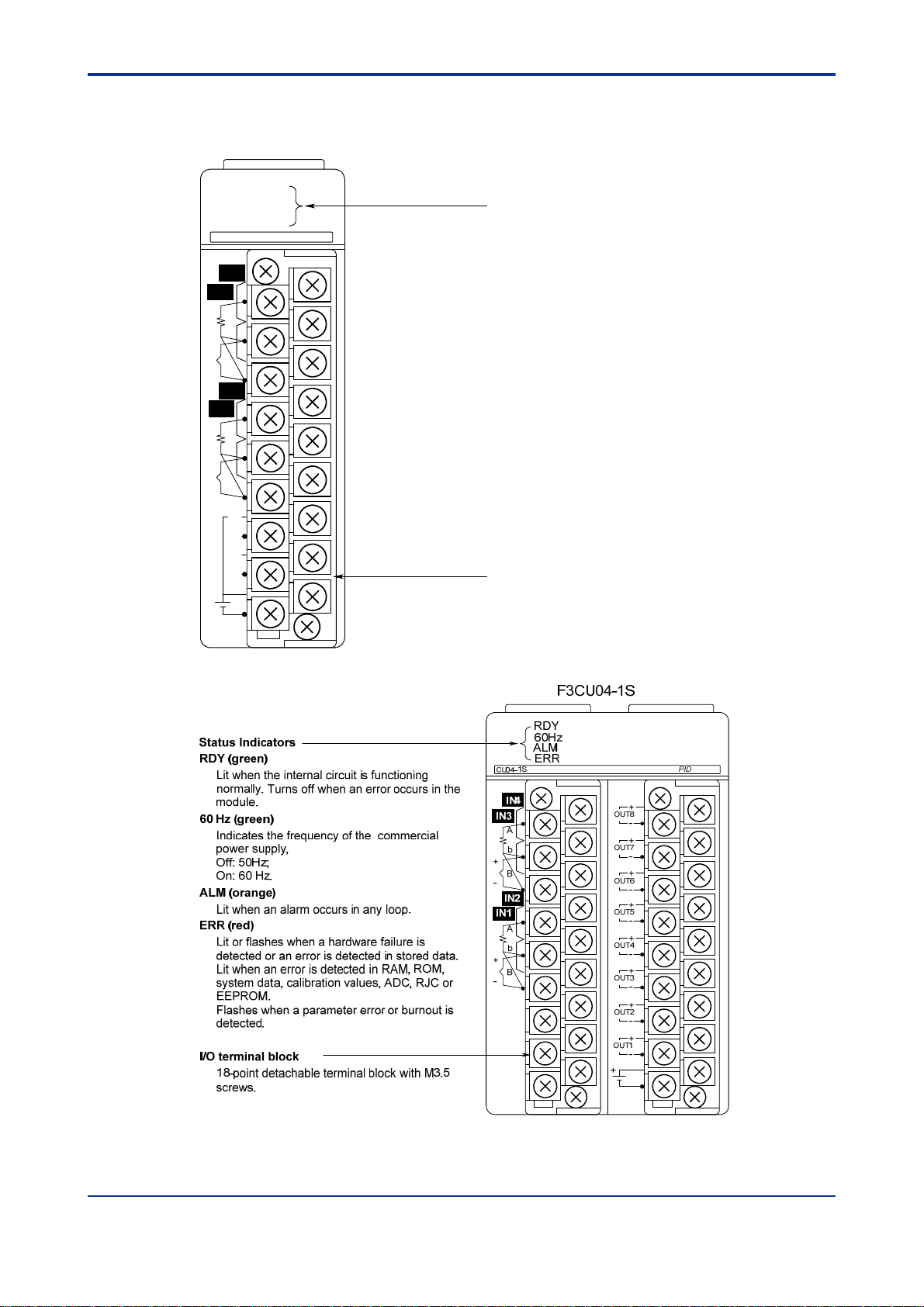

Status Indicators

RDY (green)

Lit when the internal circuit is functioning

normally. Turns off when an error occurs in the

module.

60 Hz (green)

Indicates the frequency of the commercial

power supply,

Off: 50Hz;

On: 60 Hz.

ALM (orange)

Lit when an alarm occurs in any loop.

ERR (red)

Lit or flashes when a hardware failure is

detected or an error is detected in stored data.

Lit when an error is detected in RAM, ROM,

system data, calibration values, ADC, RJC or

EEPROM.

Flashes when a parameter error or burnout is

detected.

I/O terminal block

18-point detachable terminal block with M3.5

screws.

A2-10

Figure A2.1 F3CU04-0S, F3CU04-1S Front View

IM 34M06H62-02E 3rd Edition : Jul.16, 2015-00

Page 31

Figure A2.2 Right Side View Showing Input Type and Power Supply Frequency Selector

A2-11

Switches

You may switch the temperature unit between C and F using SW1-1. For details, see

Section C11, “Selecting Temperature Unit.”

A2.9 External Dimensions

Figure A2.3 External Dimensions

IM 34M06H62-02E 3rd Edition : Jul.16, 2015-00

Page 32

Blank Page

Page 33

A3. Startup Procedure

Install the module into your system and perform the following startup procedure.

Figure A3.1 Startup Procedure

Before you use the module, you must first design the overall system

configuration, set the switches, install the module on the base unit, and perform

required wiring and other hardware preparation. Following that, you will set the

controller modes and input ranges using software. The software here refers to the

FA-M3 Programming Tool WideField3, the BASIC Programming Tool M3 or the

ToolBox for Temperature Control and Monitoring modules. The required system

components when performing setup are the power supply module, the base

module, the CPU module, software and a personal computer for running the

software. For details on the required environment for executing the software,

including specifications for the personal computer and compatible CPU modules,

as well as details on how to operate the software, see the relevant software

manuals.

After software setup, perform trial runs to tune parameters for optimal

performance. Now, you are ready for actual operation.

Sections A4, "Hardware Preparation" and B3, "Setup and Operation" describe

these procedures in detail. For details on how to access the module using

software to perform setup and for more information on relays and registers, see

Section B1, "Accessing the Module," and B2, "Types of Relays and Registers,"

respectively.

A3-1

IM 34M06H62-02E 3rd Edition : Jul.16, 2015-00

Page 34

Blank Page

Page 35

A4. Hardware Preparation

To use the temperature control and PID module, you must set the operation

switches and perform wiring connections. In this chapter, we describe the details

of hardware preparation.

Figure A4.1 shows the workflow for hardware preparation. For details on each

operation, refer to the sections indicated in the column on the right.

Figure A4.1 Workflow for Hardware Preparation

A4-1

IM 34M06H62-02E 2nd Edition : June 2008-00

Page 36

A4.1 Selecting Input Types and Power

Frequency

This section describes how to select appropriate input types for given temperature ranges

and how to select a suitable power frequency for a given power supply environment.

Figure A4.2 shows the hardware switches for selecting input types and power frequency.

SW1-1: Temperature unit selector switch

SW1-2: Power frequency selector switch

SW1-3: Input type selector switch

SW1-4: Input type selector switch

SW5: Input type selector switch

(Input type is determined by the

combined values of SW1-3, SW1-4, and SW5.)

A4-2

Note: This is the right side view of the module with its cover removed.

Figure A4.2 Input Types and Power Frequency Selector Switches

Use switches SW1-1, SW1-3, SW1-4 and SW5 to perform input setup. SW1-4 and SW5

together specifies an input type, which apply to all loops, while SW1-3 specifies a

resolution and SW1-1 specifies the temperature unit for all loops. For the various switch

combinations and their corresponding input type and resolution values, see Table 4.1,

“Input Type Selection”.

Use SW1-2 to select a power frequency corresponding to the AC power used in the