Page 1

INSTRUCTION

MANUAL

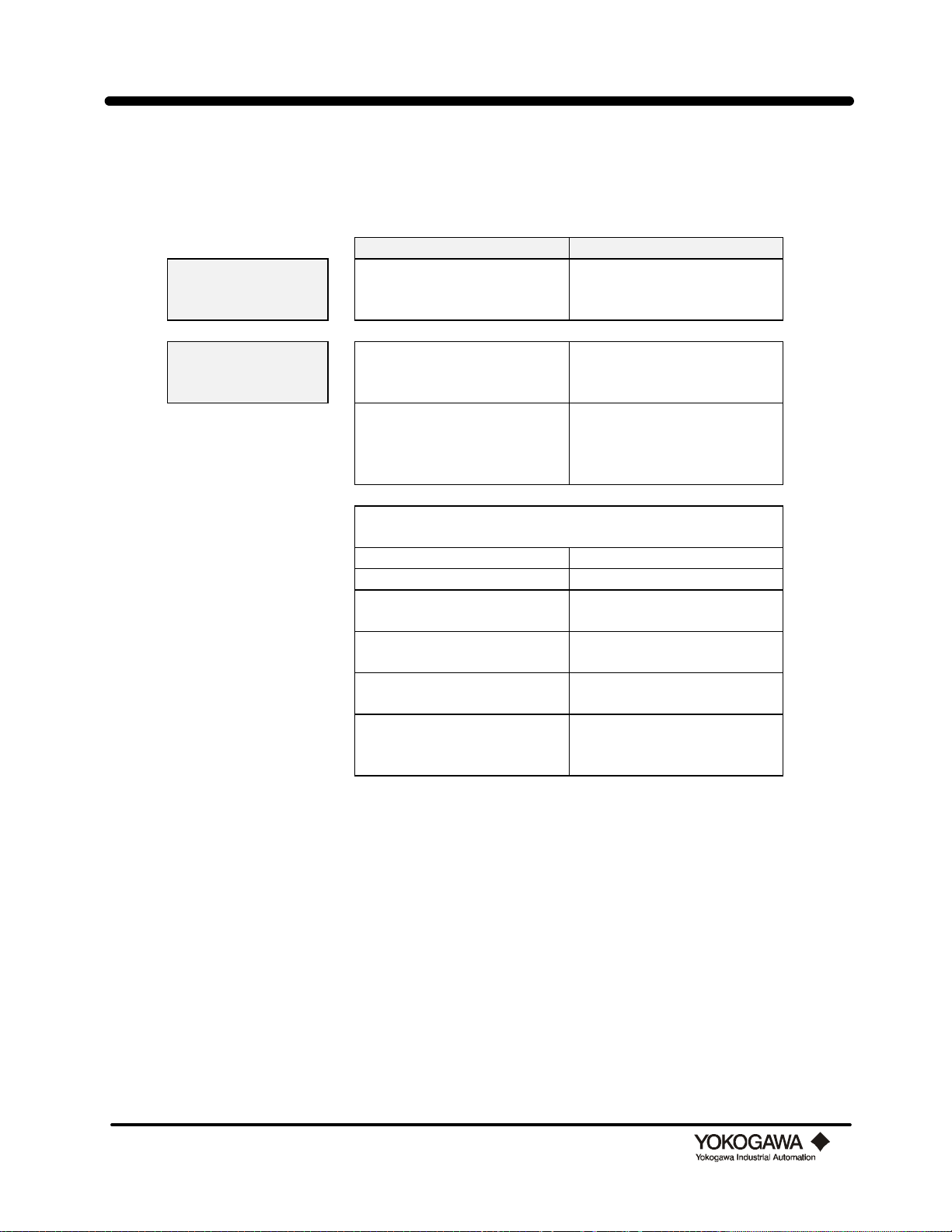

Model YF100

Vortex Flowmeter

(Integral Type, Remote Type)

Model YFA11

Vortex Flow Converter

(Remote Type)

(Style E)

IM 1F2B4-01-YIA

IM 1F2B4-01-YIA

1st Edition, March 1998

Printed in U.S.A.

Page 2

TABLE OF CONTENTS

I. INTRODUCTION ....................................................................................................... 1

1.1 General Overview ............................................................................................. 1

1.2 Principle of Operation ....................................................................................... 1

1.2.1 Vortex shedding .................................................................................... 1

1.2.2 K-factor................................................................................................ 2

1.2.3 Qmin .................................................................................................... 3

1.2.4 Uniquely vortex .................................................................................... 3

1.2.5 Vortex frequency .................................................................................. 3

1.2.6 Available outputs .................................................................................. 3

1.3 Standard Specifications ..................................................................................... 4

1.4 Basic Sizing...................................................................................................... 7

1.4.1 Flowmeter sizing .................................................................................. 7

1.5 Model and Suffix Codes ................................................................................... 9

II. QUICK START ......................................................................................................... 22

2.1 Parameter Setting in BRAIN Communications................................................ 22

2.2 YEWFLO Setup ............................................................................................. 25

2.2.1 Liquid, gas or steam in mass flow units .............................................. 26

2.2.2 Steam flow in energy units ................................................................. 28

2.2.3 Gas volumetric referenced to standard conditions............................... 30

2.2.4 Liquid, gas, or steam in volumetric units at flowing conditions .......... 32

2.3 Parameter Setting in HART Communications ................................................. 34

2.3.1 Communication Specifications ........................................................... 34

2.3.2 Hardware Recommendations .............................................................. 35

III. INSTALLATION ....................................................................................................... 36

3.1 Piping Requirements ....................................................................................... 36

3.1.1 Pipe schedule ..................................................................................... 37

3.1.2 Flow direction and orientation............................................................ 37

3.1.3 Pressure and temperature taps ............................................................ 37

3.1.4 Flushing the pipe ................................................................................ 38

3.1.5 Gaskets .............................................................................................. 38

3.2 Installing the Vortex Meter .............................................................................. 38

3.2.1 Installing the wafer style vortex meter ................................................ 38

3.2.2 Installing the wafer style vortex meter horizontally ............................ 39

3.2.3 Installing the wafer style vortex meter vertically ................................ 39

3.2.4 Installing the flanged vortex meter ..................................................... 40

3.2.5 Insulating vortex meters with integral converter ................................. 40

3.2.6 Rotating the meter housing ................................................................. 41

3.2.7 Remote converter terminal box rotation.............................................. 41

3.2.8 Integral converter rotation .................................................................. 41

3.2.9 Installing the remote converter ........................................................... 42

3.3 Wiring ........................................................................................................... 43

3.3.1 Cables and wires (analog or pulse output wires only) ......................... 43

3.3.2 Analog output, 2-wire type (4-20 mADC)........................................... 43

3.3.3 Pulse output, 3-wire type .................................................................... 44

3.3.4 Interconnection for remote converter .................................................. 45

3.4 Cable ........................................................................................................... 46

3.4.1 Field terminating the signal cable (YF011-0*E) .................................. 46

3.5 Wiring Cautions.............................................................................................. 49

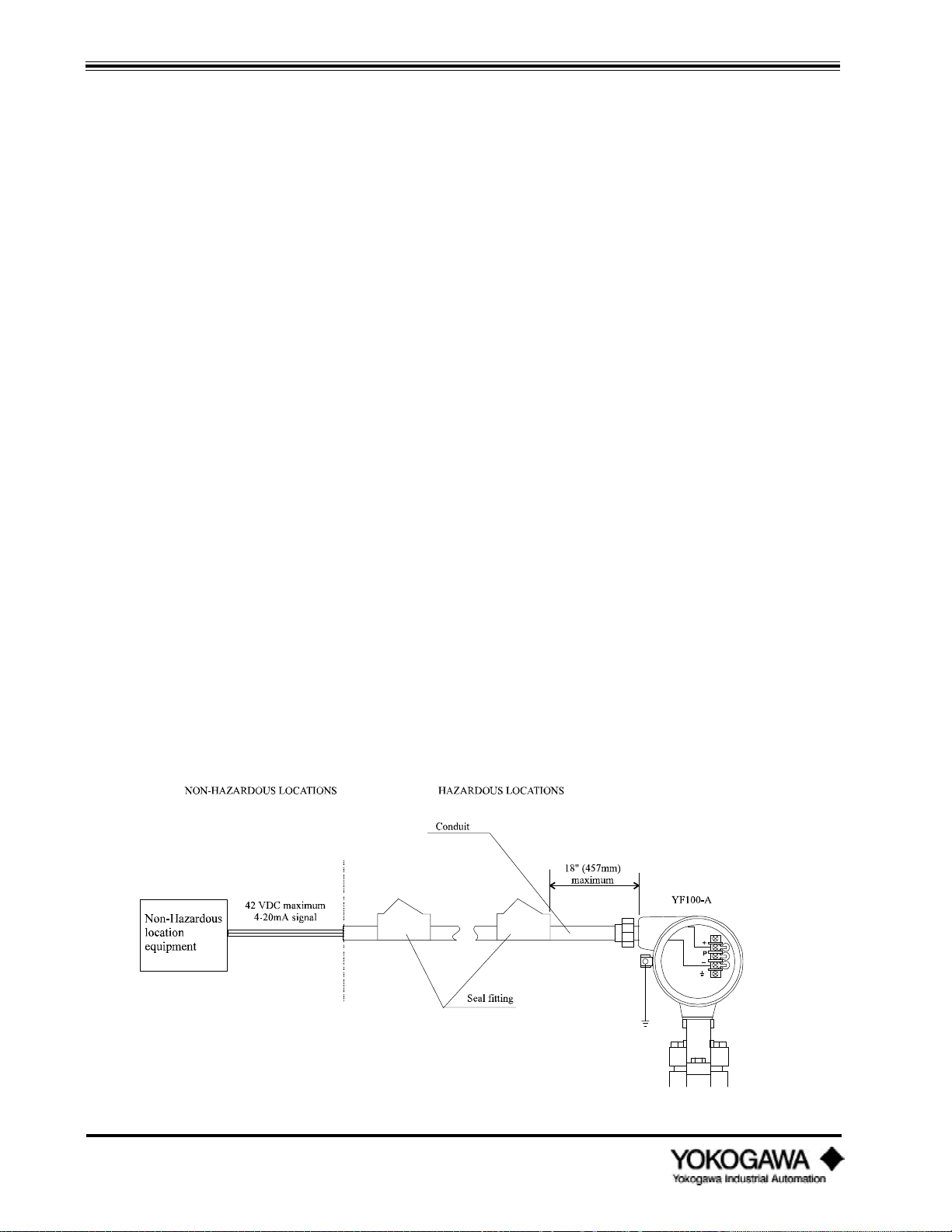

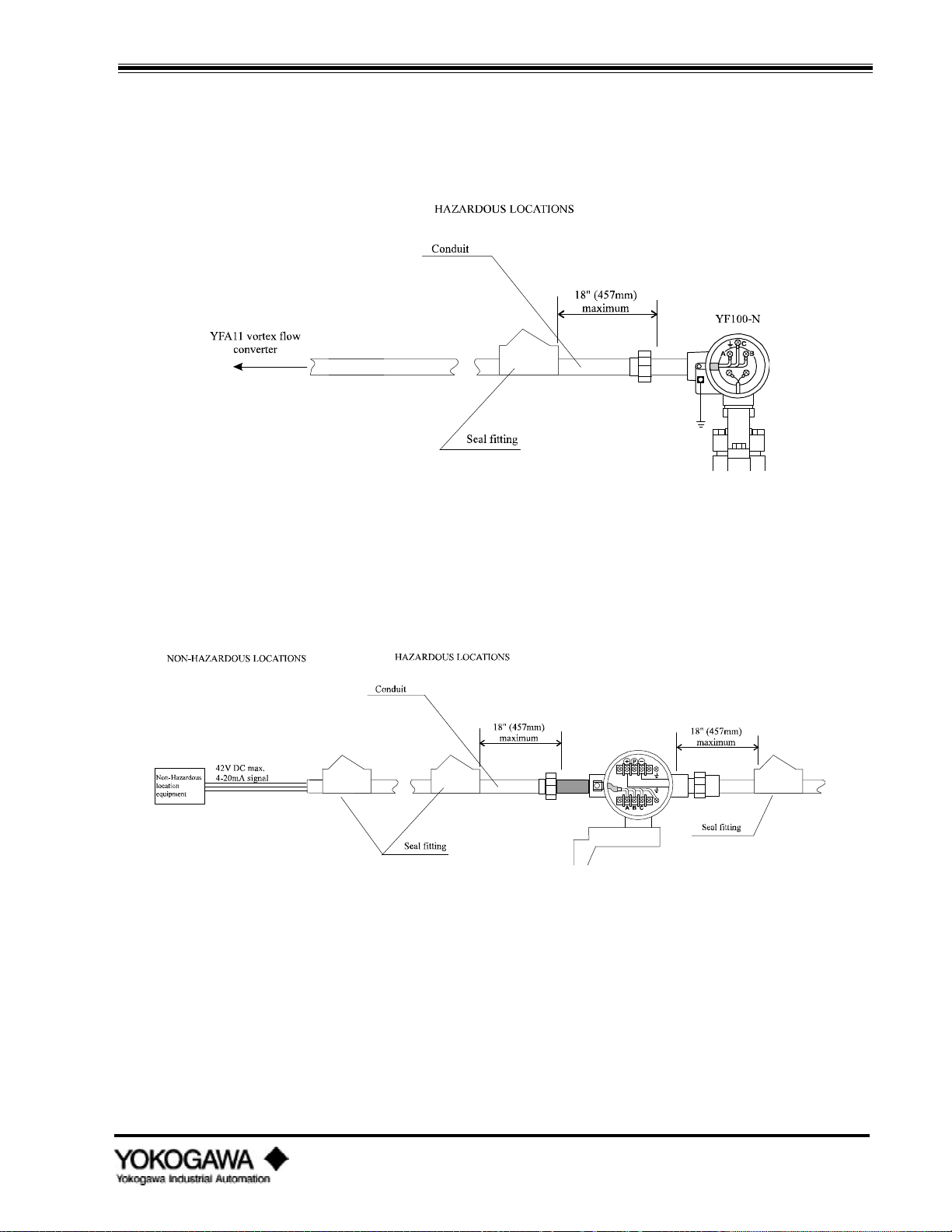

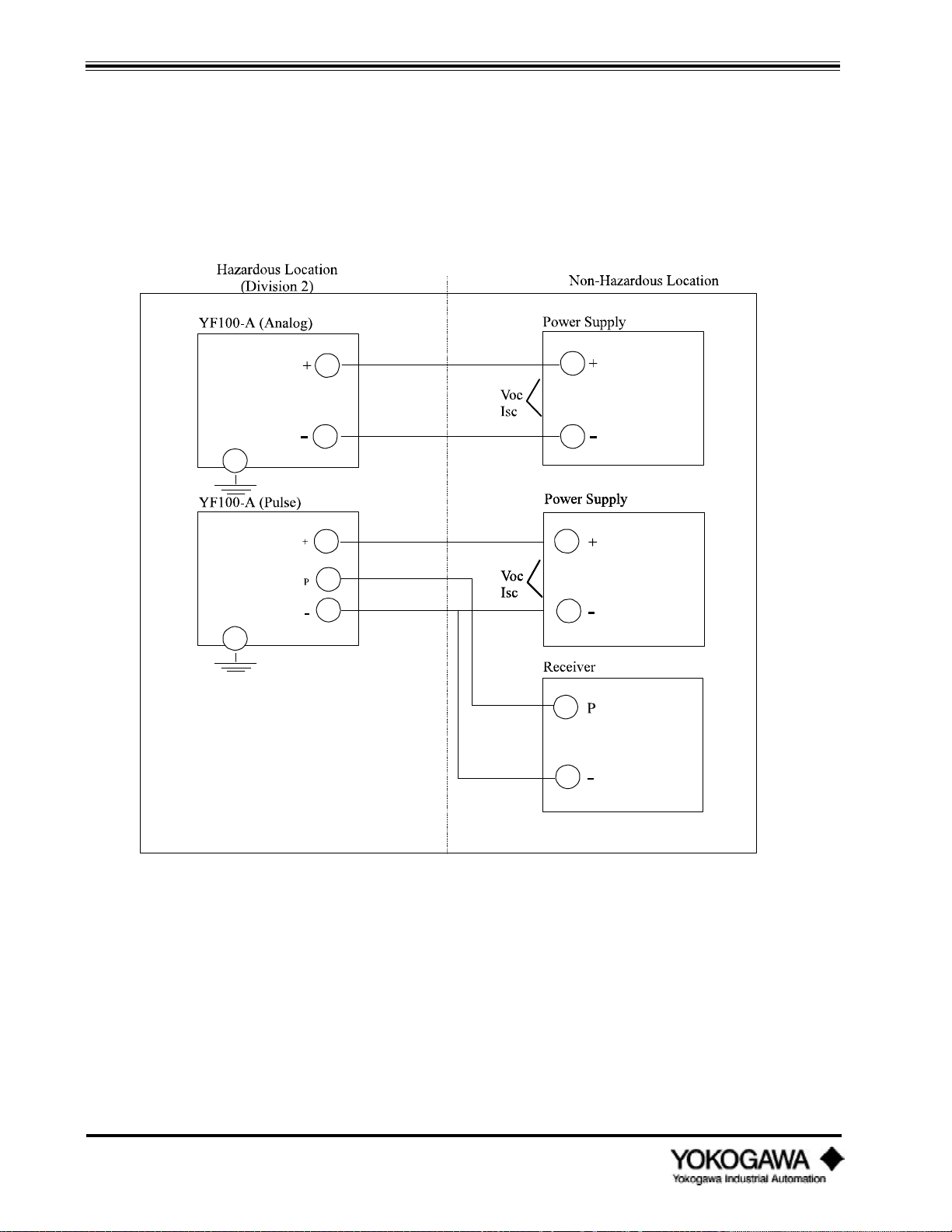

3.5.1 Flameproof transmitter installation ..................................................... 49

3.5.2 Cautions for insulation and dielectric strength testing......................... 49

3.5.3 Instruction document for FM explosionproof instruments ................... 50

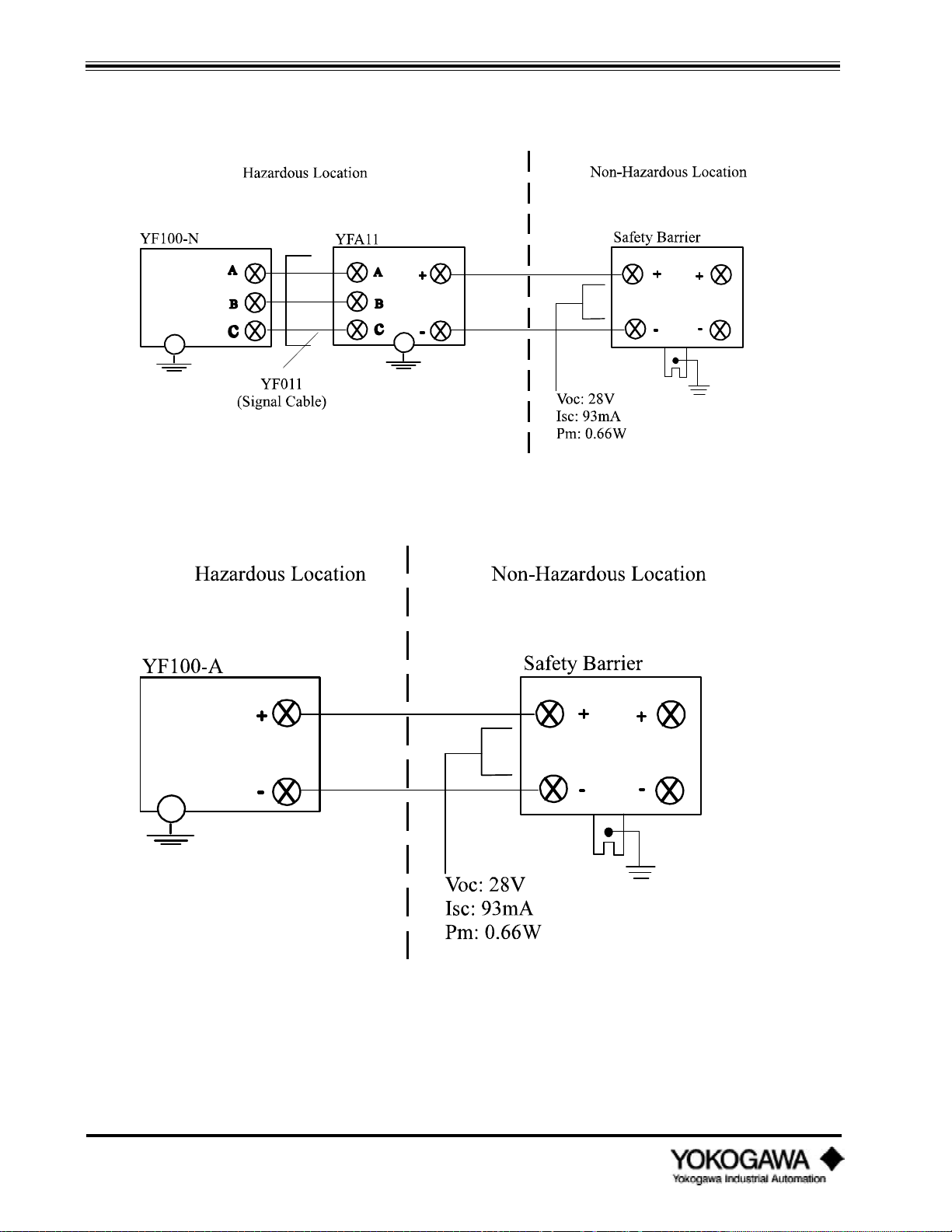

3.5.4 Wiring cautions for CSA intrinsic safety ............................................. 52

3.5.5 Wiring cautions for FM intrinsic safety .............................................. 54

IM 1F2B4-01-YIA

i

Page 3

TABLE OF CONTENTS

IV. MAINTENANCE ...................................................................................................... 58

4.1 How to ........................................................................................................... 58

4.1.1 Communicating with the YEWFLO remotely ..................................... 59

4.1.2 Adjusting zero and span ..................................................................... 60

4.1.3 Using self-diagnostics ........................................................................ 61

4.1.4 Simulating an output/performing a loop check.................................... 62

4.1.5 Changing the output mode to analog or pulse ..................................... 63

4.1.6 Increasing gas and steam flow measurement accuracy by correcting

for gas expansion ............................................................................... 64

4.1.7 Activating Reynolds number correction .............................................. 65

4.1.8 Activating mismatched pipe schedule (bore) correction...................... 66

4.1.9 Setting up and resetting the internal totalizer ...................................... 67

4.1.10 Scaling the pulse output ..................................................................... 68

4.1.11 Setting up user defined flow units ...................................................... 69

4.1.12 Setting up the local LCD indicator display mode ................................ 70

4.1.13 Setting the low cut flowrate................................................................ 71

4.1.14 Trimming the 4-20 mA analog output ................................................. 72

4.1.15 Using the upload/download feature .................................................... 74

4.2 Disassembly and Reassembly .......................................................................... 75

4.2.1 Indicator/Totalizer removal ................................................................ 75

4.2.2 Amplifier replacement ........................................................................ 75

4.3 Vortex Shedder Assembly Removal ................................................................ 76

4.3.1 Removal of shedder from remote converter type ................................. 76

4.3.2 Removal of the shedder from integral type ......................................... 77

4.4 Reassembly Cautions ...................................................................................... 78

4.4.1 YEWFLO shedder bolt torque procedures .......................................... 78

4.5 YEWFLO Style "E" Amplifier Calibration Procedure ..................................... 81

4.5.1 General amplifier checkout ................................................................ 82

4.5.2 Analog output test .............................................................................. 82

4.5.3 Pulse output test ................................................................................. 83

V. PARAMETER SETTING/CONFIGURATION ....................................................... 84

5.1 Notes on the TBL optional digital display ....................................................... 84

5.1.1 Display contents in display section ..................................................... 85

VI. TROUBLESHOOTING ............................................................................................ 88

6.1 Error Code Listing .......................................................................................... 88

6.2 Operating Procedures ...................................................................................... 89

6.3 Flow Computation .......................................................................................... 92

6.3.1 Variable definitions ............................................................................ 92

6.3.2 Flow conversion factor ....................................................................... 93

6.4 Signal Conditioning ........................................................................................ 94

6.4.1 YEWFLO Style "E" signal adjustment procedure ............................... 94

6.4.2 Problem solving ................................................................................. 94

6.4.3 Piping checkout procedure ................................................................. 94

6.4.4 Noise balance adjustment ................................................................... 95

6.4.5 Noise judge ........................................................................................ 96

6.4.6 TLA adjustment ................................................................................. 96

6.4.7 Low-cut flowrate adjustment .............................................................. 97

6.4.8 High-frequency filter adjustment ........................................................ 97

6.5 Flowcharts ...................................................................................................... 98

6.5.1 No flowmeter output under flowing conditions ................................... 98

6.5.2 Flowmeter output with no flow ......................................................... 100

6.5.3 Large flowmeter errors ..................................................................... 101

6.5.4 Output is unstable when flowrate is low ........................................... 102

IM 1F2B4-01-YIA

ii

Page 4

TABLE OF CONTENTS

VII. GLOSSARY ......................................................................................................... 103

APPENDIXES:

Appendix A: Parameter Details ............................................................................. 107

Appendix B: HART Parameter Details ...................................................................115

Appendix C: Customer Maintenance Parts List

Appendix D: Dimensional Diagrams

INDEX

IM 1F2B4-01-YIA

iii

Page 5

INTRODUCTION

I. INTRODUCTION

1.1 GENERAL OVERVIEW

This manual provides installation, parameter setting, calibration, maintenance and troubleshooting

instructions for the YEWFLO Vortex flowmeter. Also included are standard specifications, model code

definitions, dimensional drawings and a parts lists.

All YEWFLO’s are shipped pre-configured for your application. Therefore, if you included correct

process conditions with your order, no electronic setup or parameter setting is required. For piping

and wiring connections, refer to the Installation section.

If your process conditions have changed since your order was placed, please refer to the ‘QUICK

START’ section which is designed to simplify configuration of the YEWFLO software parameters.

Please refer to the index for immediate access to a specific procedure or the glossary located at the end

of this manual for further information on a specific term.

If you have any questions concerning the YEWFLO you received, please contact your local Yokogawa

Industrial Automation Representative or our headquarters office in Newnan, GA at 770-254-0400.

If you have technical questions regarding the installation, operation, setup or application of a

YEWFLO, please contact our Technical Assistance Center (TAC) at 800-524-SERV.

Yokogawa has manufactured this instrument according to rigorous ISO 9000 quality standards. To

ensure quality performance we recommend referencing our YEWFLO sizing program to determine the

level at which your application should be run as well as a straight meter run of 20 diameters upstream

and 5 diameters downstream. In addition to these suggestions, please follow the instructions in this

manual carefully.

We are not responsible for any instrument’s performance, if that instrument has not been properly

applied or installed in accordance with this manual, nor can we be responsible for the performance of

any instrument which has been modified or repaired by an unauthorized service center.

Note: Existing YEWFLO Style C vortex flowmeters may be upgraded to provide the features and benefits

of the New microprocessor-based Style "E" YEWFLO.

1.2 PRINCIPLE OF OPERATION

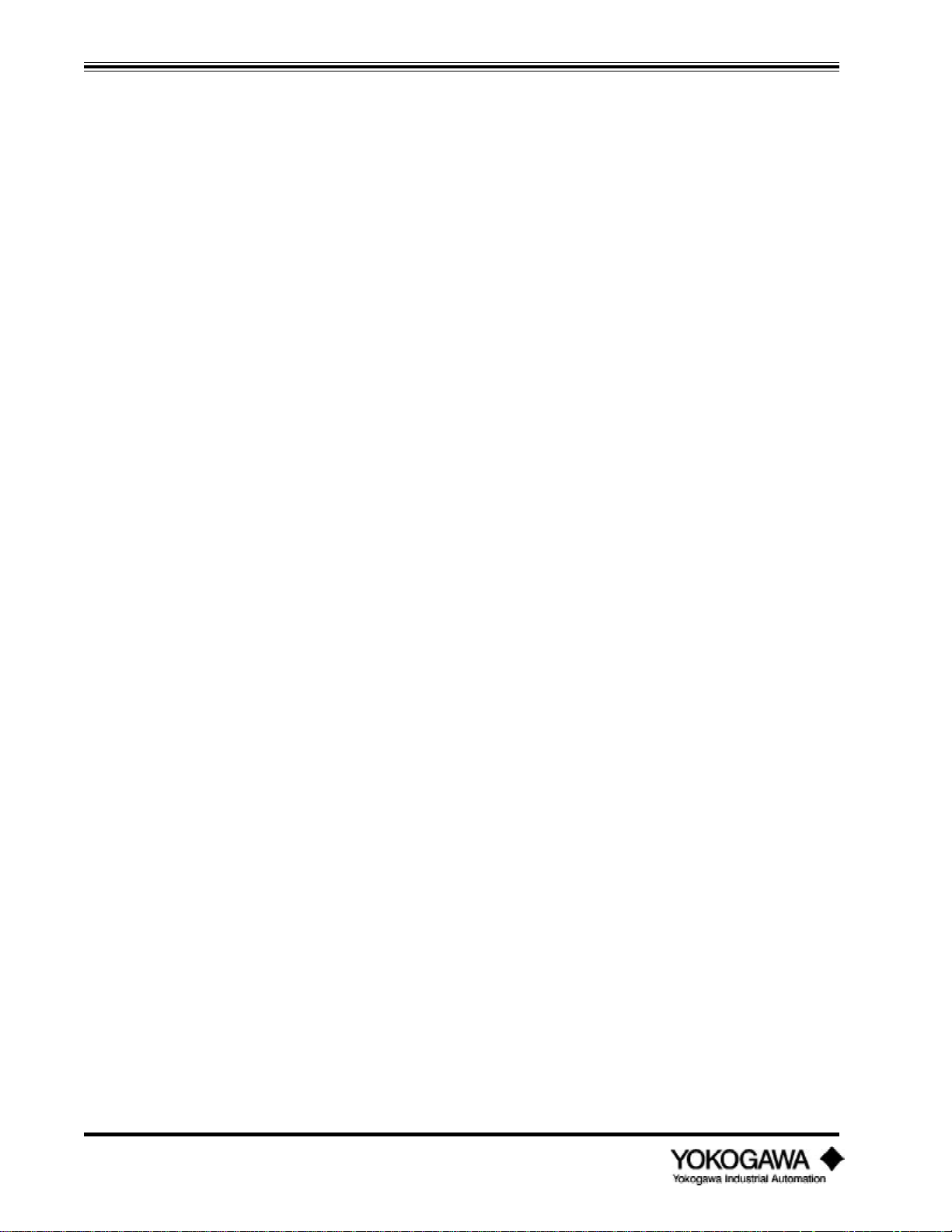

1.2.1 Vortex shedding

How many of you have seen a flag flapping in the breeze on a windy day? Everybody has. How many

of you have noticed that the flag flaps faster as the wind blows faster? Few haven’t. When you see a

flag flapping in the breeze, you are witnessing the same phenomenon that makes a vortex flowmeter

work. The flapping frequency is proportional to the velocity of the wind, and it’s linear! The flapping

is caused by a vortex alternately being created on either side of the flag, and moving downstream with

the wind. The vortex is a swirl of low pressure, like a tornado, that pulls the flag in the direction of the

vortex. The passing of alternating vortices down the length of the flag causes it to flap. The faster the

wind blows, the faster these vortices are created, and the faster the flag flaps. Frequency is

proportional to velocity.

IM 1F2B4-01-YIA

Page 1

Page 6

INTRODUCTION

The flapping flag is a familiar example of vortex shedding that everyone should be comfortable with.

Here’s how it’s used in a vortex flowmeter. A non-streamlined part (bluff body) is inserted in the flow

stream, this obstruction in the pipe causes vortices to be alternately created (shed). We call this part

the ‘shedder bar’. The shedder bar in a YEWFLO performs two functions, it creates the vortices, and

with the addition of our piezoelectric crystals senses them too. The crystals generate an alternating

voltage waveform whose frequency is proportional to fluid velocity. The rest of the magic is taken care

of in the electronics.

Figure 1.2.1: Karman Vortices

1.2.2 K-factor

The most important fact about vortex shedding is that once the physical geometry, (pipe I.D., shedder

bar width, etc.), are fixed, the frequency vs. flowrate (K-factor (pulse/gallon)) is unaffected by

changes in viscosity, density or pressure over the operating range of the specific application. To

determine the operating range use the YEWFLO Sizing program. On the other hand, an orifice plate is

directly affected by changes in any of these parameters. There is a very small temperature effect due to

expansion or contraction of the shedder bar width, which is easily compensated. Therefore, the Kfactor created in our flow stand (all YEWFLOs are wet flow calibrated) on water, is accurate for gas

too! Not so with an orifice plate. The benefit here is simplified calculations, and fewer things that

can effect accuracy .

IM 1F2B4-01-YIA

Page 2

Figure 1.2.2: Relationship between K-factor and Reynolds Numbers

Page 7

INTRODUCTION

1.2.3 Qmin

Those of you who haven’t used many vortex flowmeters may be wondering, ‘Why do we need to know

viscosity, density, pressure and temperature?’. While the K-factor is unaffected by changes in

viscosity, density and pressure, the velocity at which vortices begin to be created and become stable

enough to measure accurately will vary. We refer to this velocity as Qmin, stated in desired flow units

GPM, SCFH, etc. Here’s an example to help you understand. Let’s go back to the flag example.

We’ve all seen the flag flapping in the breeze; however, on some days we can feel the breeze blowing,

but the flag isn’t flapping. Why not? For the flag to flap, there must be enough breeze blowing, or

energy, to lift the flag and create fully developed vortices. This is the same thing that happens in the

vortex flowmeter.

The higher the fluid viscosity, the higher the velocity (more energy) required to start vortex shedding.

On the other hand, the higher the density, the lower the velocity needed to start vortex shedding. In

gases, viscosity and density can vary with pressure and temperature. Sounds complicated, but

compared to an orifice plate it’s quite simple. By using the YEWFLO sizing program, vortex meter

selection is simple. Simply enter the process conditions, the program will prompt you for them, and

presto, a performance table for all meter sizes is generated. This performance table will help you

select the best YEWFLO for the application.

1.2.4 Uniquely vortex

Vortex shedding flowmeters measure flow digitally. This means, amplitude of the vortex signal is

unimportant. As long as the flow is above the Qmin threshold, only the presence or absence of a

vortex is important. Just like digital electronics, as long as the voltage is above or below a threshold

value, it is either on or off. Digital flow measurement means no zero drift or span shift . Orifice plate

flowmeters, for example, cannot make this claim, even if they are using microprocessor-based digital

D/P transmitters, they still measure the small amplitude of deflection caused by differential pressure,

and changes in temperature or pressure can shift zero and span.

1.2.5 Vortex frequency

The YEWFLO uses piezoelectric crystals embedded in the shedder bar . Note that they are 1)

hermetically sealed, and 2) surrounded by a heavy wall thickness, to protect them from the

environment and the process. The positioning of the crystals is important. Although one crystal

primarily measures flow frequency, it unfortunately picks up some pipe vibration noise. The other

crystal is positioned such that it picks up primarily the pipe vibration noise. By electronically

subtracting these two signals, we are able to obtain a high signal to noise ratio for the flow signal .

The new Style "E" body design also improves the signal to noise ratio, by stiffening the shedder bar

mounting in the measurement plane, further isolating it from pipe vibration.

1.2.6 Available outputs

After processing the digital vortex frequency as described above, what outputs can you get? You can

select either 4-20 mA output or voltage pulse, digital output. Output is selected by setting jumpers on

the amplifier board, and the setting the software for pulse or analog output. Analog output is twowire, and pulse output is a three-wire connection (for details see the wiring section). The pulse output

can be scaled over a range of 0-6000 Hz, down or up to maximize pulse resolution. Scaling up the

frequency output can be done to improve resolution. The pulse output is also capable of driving many

electromechanical totalizers directly without additional power.

IM 1F2B4-01-YIA

Page 3

Page 8

INTRODUCTION

1.3 STANDARD SPECIFICATIONS

NOTE: For special applications, please contact your local Yokogawa Industrial Automation representative to

discuss possible enhancements to these standard specifications.

Fluids to be measured: Liquid, gas or steam

Performance specifications:

Repeatability: 0.2% of reading

Accuracy and velocity range :

Fluid Accuracy: Pulse Output Accuracy: Analog Output Velocity

Liquid ±0.8% of reading ±0.8% of reading plus up to 32 ft/sec

Gas or ±0.8% of reading ±0.8% of reading plus up to 115 ft/sec

Steam ±0.1% of full scale

±1.5% of reading ±1.5% of reading plus from 115 ft/sec

Note: Gas accuracy can be improved to 0.8% over the full range by built-in software compensation. (See

how to section 4.10.)

Output signal:

Analog: 4 to 20 mADC

Pulse: Low level 0 to 2 V

High level Vs - 2V ( Vs = input supply voltage)

Pulse width 50% duty cycle

±0.1% of full scale

±0.1% of full scale to 262 ft/sec

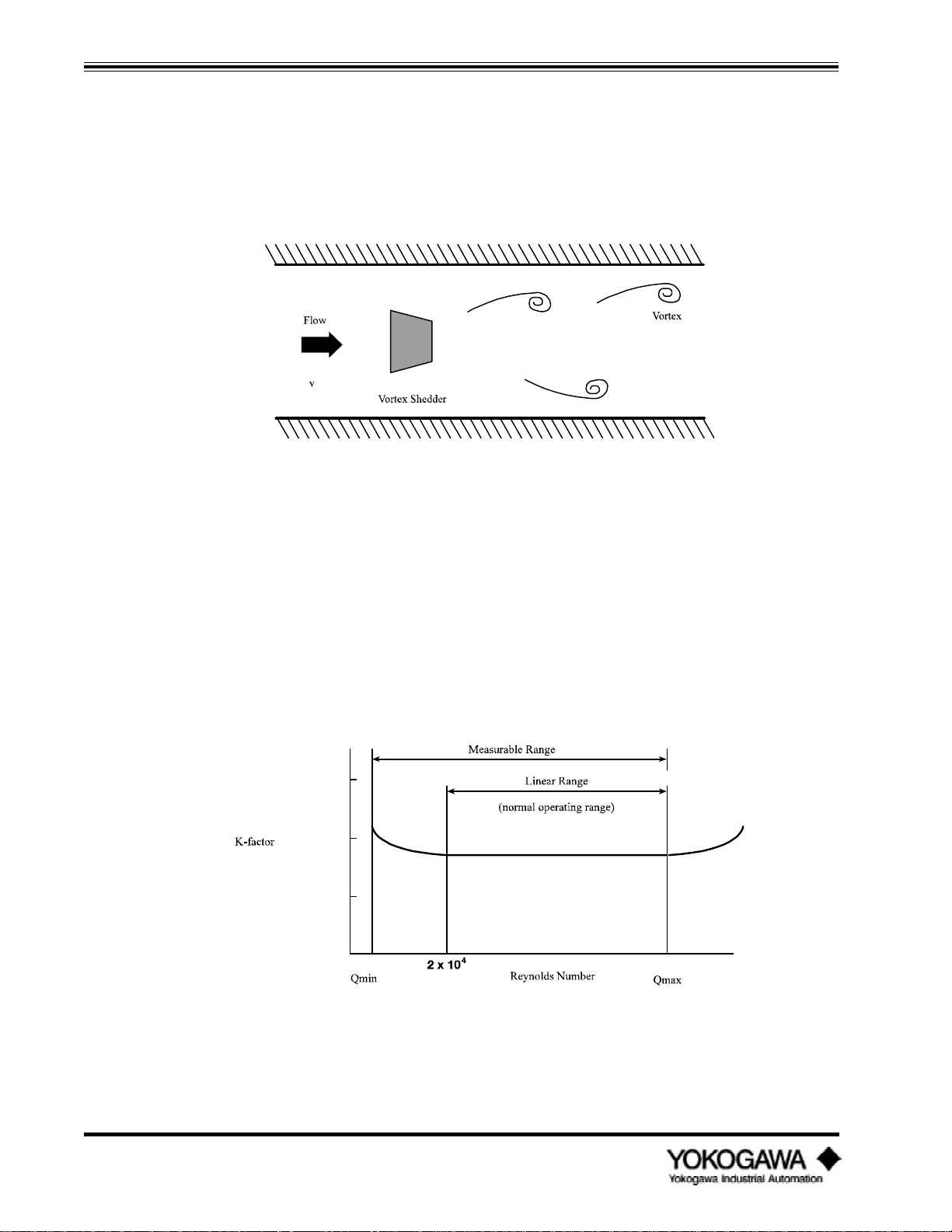

Ambient temperature limits:

-40º to 175ºF (-40º to 80ºC): standard unit w/o agency approval ratings

-20º to 175ºF (-30º to 80ºC): with optional digital indicator

-40º to 140ºF (-40º to 60ºC): with FM explosion-proof rating

-40º to 120ºF (-40º to 50ºC): with CSA intrinsically safe rating for integral converter

-40º to 175ºF (-40º to 80ºC): with CSA intrinsically safe rating for remote converter

Process temperature limits:

Standard remote converter: -40º to 575ºF (-40º to 300ºC)

HPT remote converter: -40º to 755ºF (-40º to 402ºC)

Cryogenic remote converter: -320º to 300ºF (-200º to 150ºC)

Integral converter: See Figure 1.3.1

Storage temperature limits:

Integral or remote standard unit: -40º to 176ºF (-40º to 80ºC)

With integral indicator or totalizer: -22º to 80ºF (-30º to 140ºC)

IM 1F2B4-01-YIA

Page 4

Page 9

INTRODUCTION

Figure 1.3.1: Operating temperature range for integral type converter

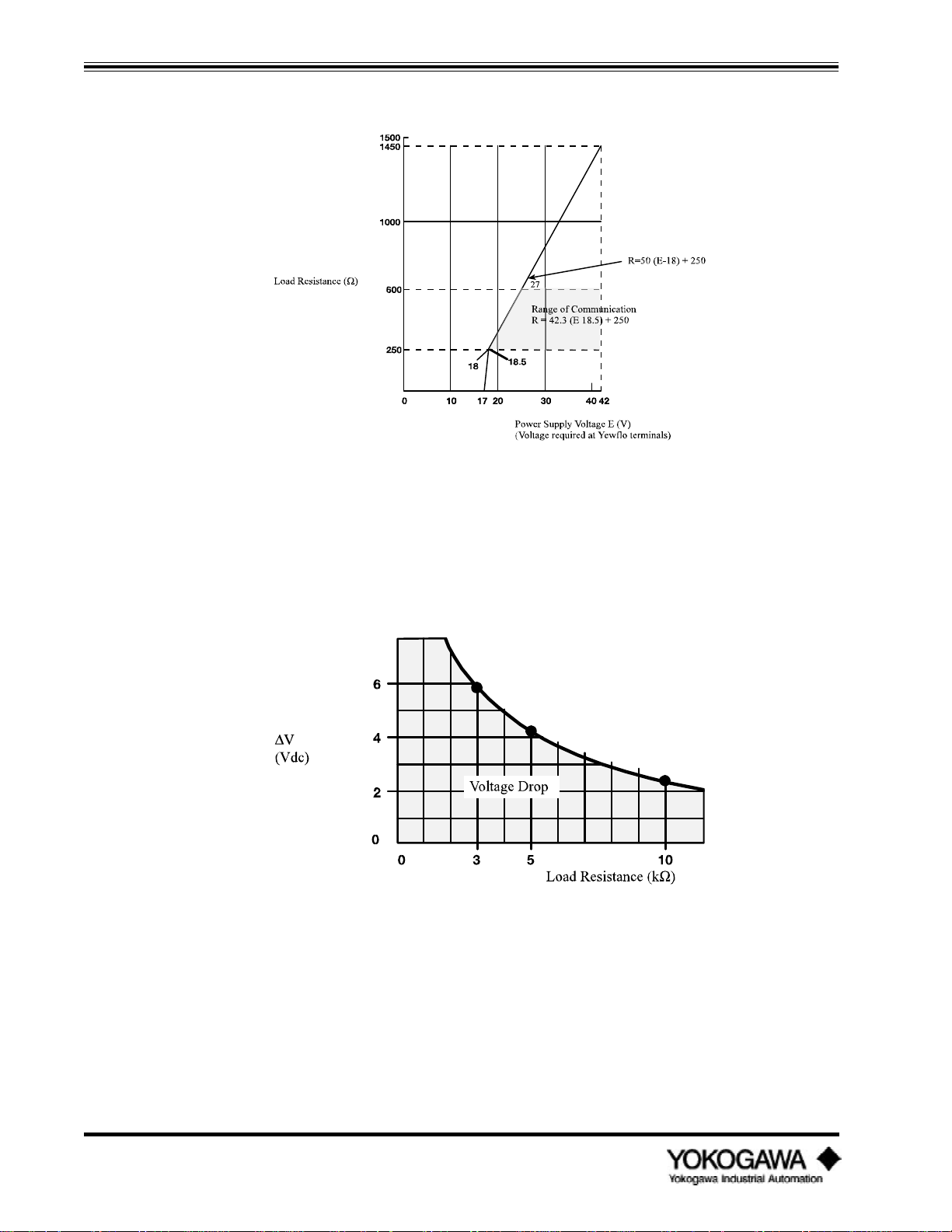

Power supply and load resistance:

Analog output: 17 to 42 VDC (see Figure 1.3.2)

Pulse output: 14 to 30 VDC

Maximum output wire resistance: 50 ohms

Maximum line capacitance: 0.22 microfarad

Ambient humidity limits:

5 to 100% relative humidity

Process pressure limits:

-14.7 psi (full vacuum) to flange rating

Materials of construction:

Process wetted parts:

Body: CF8M (ANSI 316 stainless steel) or Hastelloy C (equivalent of

ASTM494, CW12MW)

Shedder bar: Duplex stainless steel (CD4MCU equivalent to ANSI 329 stainless

steel) or Hastelloy C (equivalent of ASTM494, CW12MW)

Non-wetted parts:

Amplifier housing: Aluminum alloy casting

Paint: Case - Polyurethane resin baked coating, frosty white

Cover - Polyurethane resin baked coating, deep, sea moss green

IM 1F2B4-01-YIA

Page 5

Page 10

INTRODUCTION

Analog Output :

Figure 1.3.2: Relationship between power supply voltage and load resistance for analog output version

Pulse Output: Pulse output voltage = Vs-2v-∆v

where ∆v = due to external load resistance

Vs = Power Supply Voltage

2v = 2 volts

IM 1F2B4-01-YIA

Page 6

Figure 1.3.3: Load resistance vs. pulse output voltage drop

Page 11

INTRODUCTION

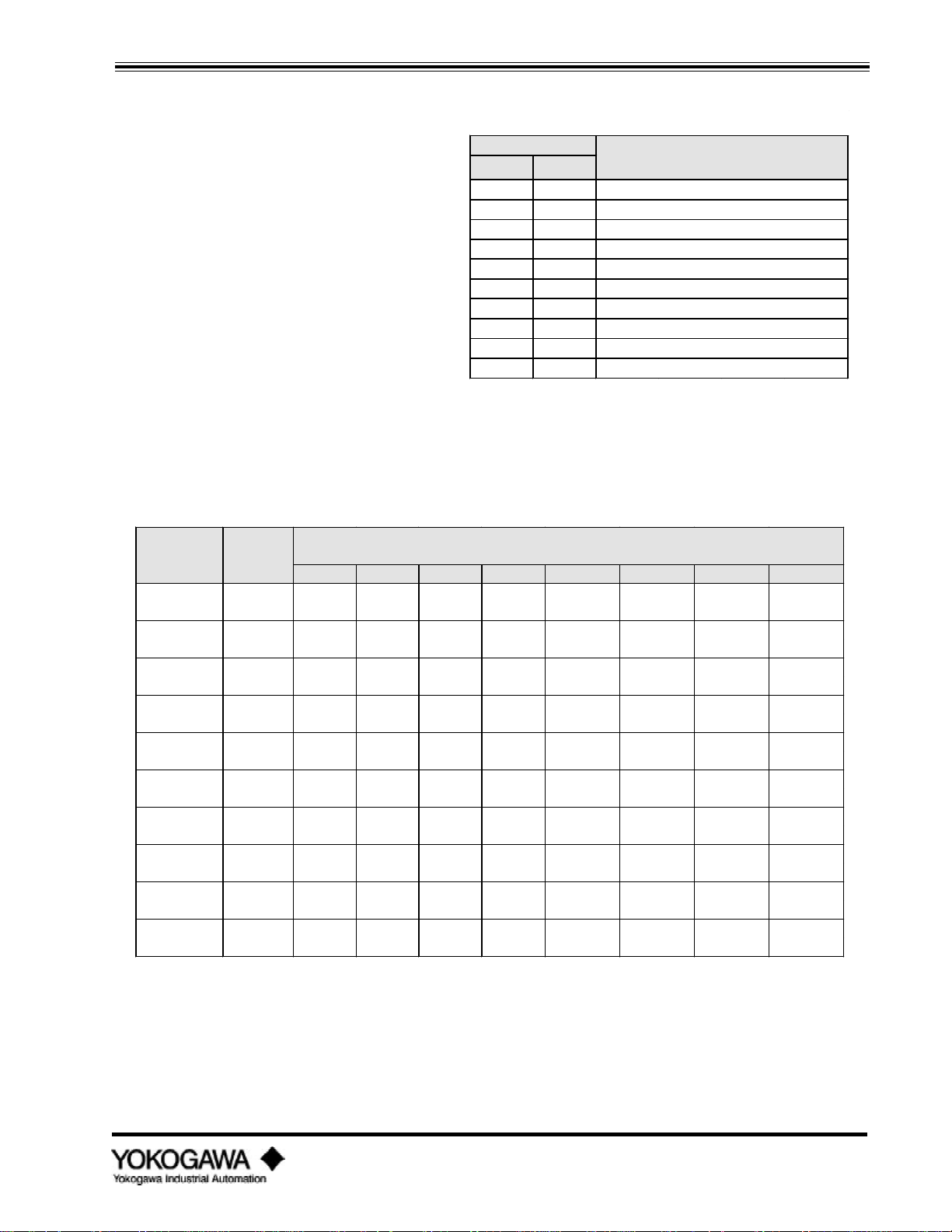

1.4 BASIC SIZING

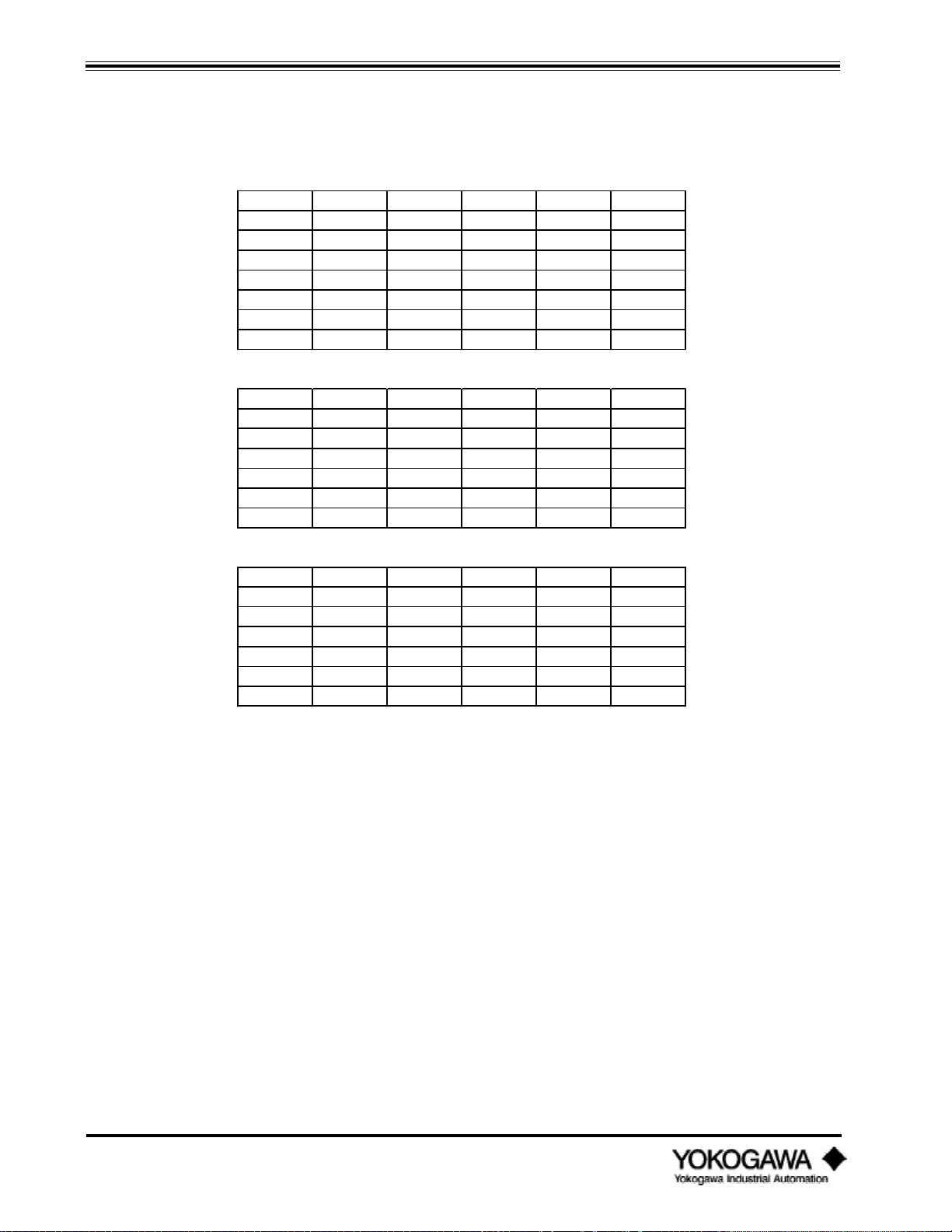

Measurable Flow Rates in U.S. gpm

Nominal Size

1.4.1 Flowmeter sizing

LIQUID

Nominal Size Minimum and Maximum

Notes: 1) This table assumes standard

conditions of 59ºF (15ºC).

2) Maximum flowrates are based

on 32 ft/sec.

3) These figures are

approximations. Refer to the

Yewflo sizing program for the

exact minimum and maximum

for your application.

4) The values shown in parenthesis

is the minimum linear flowrate.

5) Proper pipe bracing may be

required to obtain minimum

mm inch

15 ½ 1.3 -4.2 and 27

25 1 2 -7.3 and 82

40 1½ 5.9 -11.3 and 196

50 2 9.8 -14.5 and 324

80 3 20 and 628

100 4 33 and 1100

150 6 79 and 2400

200 8 150 and 4290

250 10 265 and 6460

300 12 300 and 9260

flowrate.

Table 1.4.1: Water -Flowmeter Range

GAS

Flow Rate Minimum Linear and Maximum Measurable Air Flow Rates in SCFH

(inches) Limits (Standard conditions are 59ºF and 14.7 psia) at process line pressure

0 psig 50 psig 100 psig 150 psig 200 psig 300 psig 400 psig 500 psig

½ min 172 361 500 719 939 1379 1822 2266

max 1700 7492 13302 19128 24967 36692 48454 60266

1 min 400 839 1118 1486 1940 2851 3765 4683

max 5267 23215 41217 59268 77362 113692 150137 186737

1½ min 792 1919 3037 4061 5026 6838 8970 11157

max 1267 55397 98355 141428 184604 271296 358263 445599

2 min 1313 2756 4080 5867 7658 11254 14862 18485

max 20821 91779 162951 234313 305846 449474 593557 738253

3 min 2534 5321 7877 11326 14784 21726 28691 35685

max 40196 177182 314580 452347 590443 867720 1145876 1425214

4 min 4423 10710 16953 22670 28055 38174 50076 62283

max 70157 309249 549061 789516 1030544 1514497 1999984 2487535

6 min 9685 29678 46977 64927 84749 124548 164473 204567

max 153618 677145 1202247 1728757 2256524 3316208 4379250 5446812

8 min 20851 68121 107827 144185 178437 242799 303286 265774

max 274675 1010761 2149664 3091086 4034753 5929510 7830269 9739113

10 min 37370 122437 193804 259153 320716 436397 545115 649056

max 424752 1872295 3324193 4779987 6239253 9169263 12108556 15060351

12 min 53518 175343 277549 371134 459300 624968 780663 929518

max 608291 2681328 4760604 6845457 8935284 13131375 17340759 21568047

1

Notes: 1) Maximum flowrates are based on 262 ft/sec.

Table 1.4.2: Air-Flowmeter Range

2) These figures are approximations. Refer to the sizing program for the exact minimum and

maximum flowrates for your application.

IM 1F2B4-01-YIA

Page 7

Page 12

INTRODUCTION

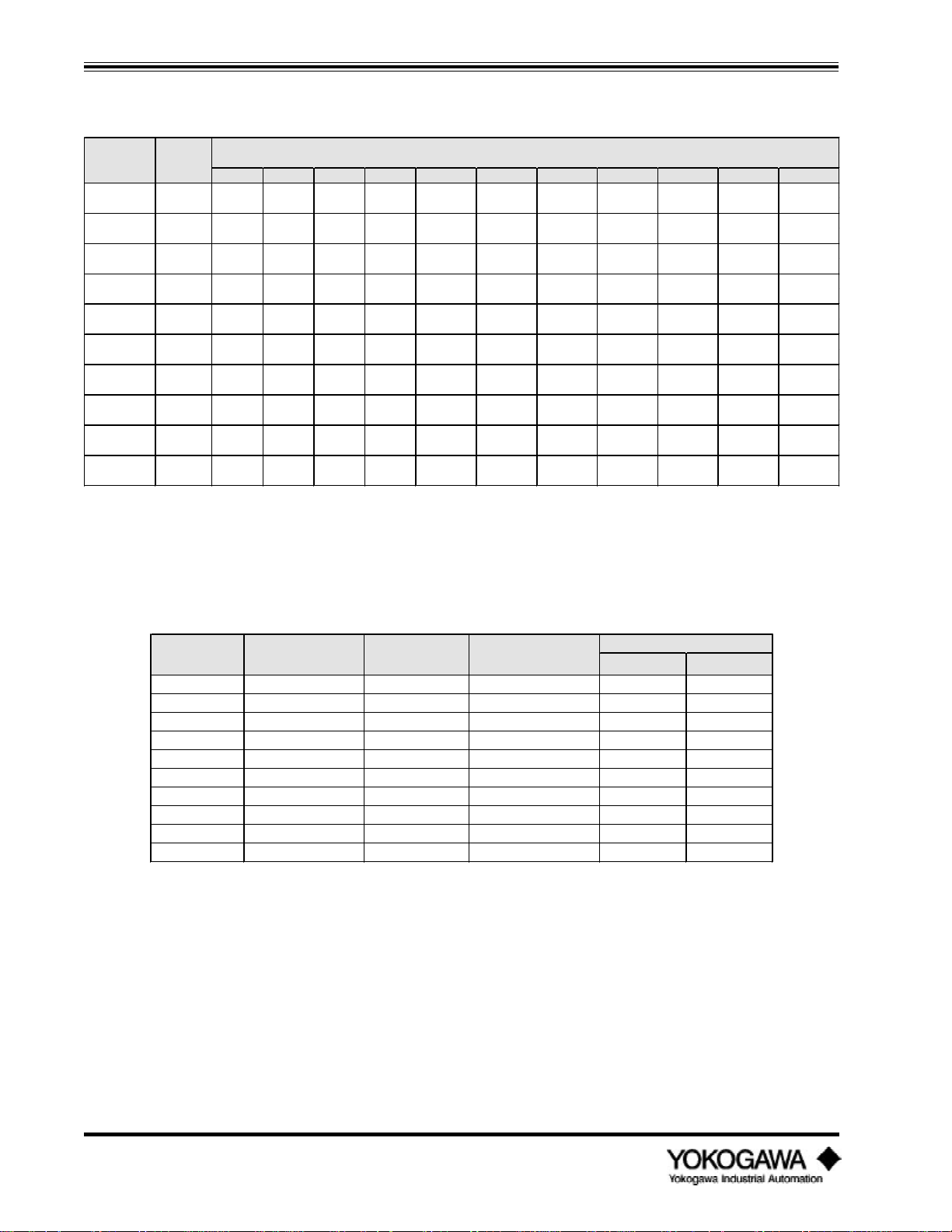

STEAM

Nominal Size Flow Rate Minimum Linear and Maximum Measurable Saturated Steam Flow Rates in lb/hr

(inches) Limits at process line pressure

½ min 12.8 14.6 18.4 21.5 24.1 26.5 28.7 30.7 32.6 36.6 43.4

1 min 29.7 34 42.8 49.9 56.1 61.6 66.6 71.3 75.7 83.7 91.2

1½ min 58.7 67.3 84.6 98.6 118 137 156 173 191 224 257

2 min 97.5 111 140 164 184 202 219 234 248 298 354

3 min 188 216 271 316 355 390 422 452 480 576 683

4 min 328 376 472 551 659 766 869 967 1065 1251 1434

6 min 719 824 1184 1515 1827 2122 2407 2681 2951 3467 3974

8 min 1549 1885 2720 3477 4193 4872 5525 6153 6773 7958 9122

10 min 2725 3387 4888 6249 7536 8756 9930 11060 12174 14304 16396

12 min 3903 4851 7000 8949 10793 12539 14220 15839 17434 20485 23481

15 psig 25 psig 50 psig 75 psig 100 psig 125 psig 150 psig 175 psig 200 psig 250 psig 300 psig

max 122 161 254 346 437 527 616 705 765 973 1154

max 379 498 788 1071 1353 1632 1910 2185 2464 3014 357

max 905 1188 1879 2554 3228 3894 4557 5215 5879 7192 8530

max 1500 1969 3113 4232 5349 6452 7550 8639 9740 11916 14133

max 2895 3800 6010 8170 10326 12455 14576 16678 18804 23004 27283

max 5054 6633 10490 14260 18023 21739 25440 29109 32820 40150 47620

max 11065 14523 22969 31224 39463 47600 55705 63739 71864 87914 104270

max 19785 25968 41070 55830 70561 85111 99603 113968 128496 157194 186439

max 30596 40157 63509 86334 109114 131614 154024 176238 198703 243081 288305

max 43816 57590 90952 123640 156263 188485 220578 252392 284564 348119 412883

Table 1.4.3: Steam - Flowmeter Range

Notes: 1) Maximum flowrates are based on 262 ft/sec.

2) These figures are approximations. Refer to the sizing program for the exact minimum and

maximum flowrates for your applications.

Nominal Size Internal Diameter Cross Sectional Nominal Pulse Rate Nominal K-factor

(inches) (inches) Area (ft2) (Hz/ft/s) Pulse/US gal Pulse/ft

½

1

1½

2

3

4

6

8

10

12

0.57 0.0018 19.1 1423 10645

1.01 0.0056 10.8 259 1940

1.56 0.133 7.05 70.8 530

2.01 0.022 5.59 33.9 253

2.8 0.043 4.02 12.6 94.3

3.69 0.074 3 5.39 40.3

5.46 0.163 2.03 1.67 12.5

7.31 0.291 1.52 0.7 5.24

9.09 0.45 1.23 0.366 2.74

10.9 0.645 1.03 0.213 1.59

Table 1.4.4: Nominal K-factor and general flowmeter information

3

IM 1F2B4-01-YIA

Page 8

Page 13

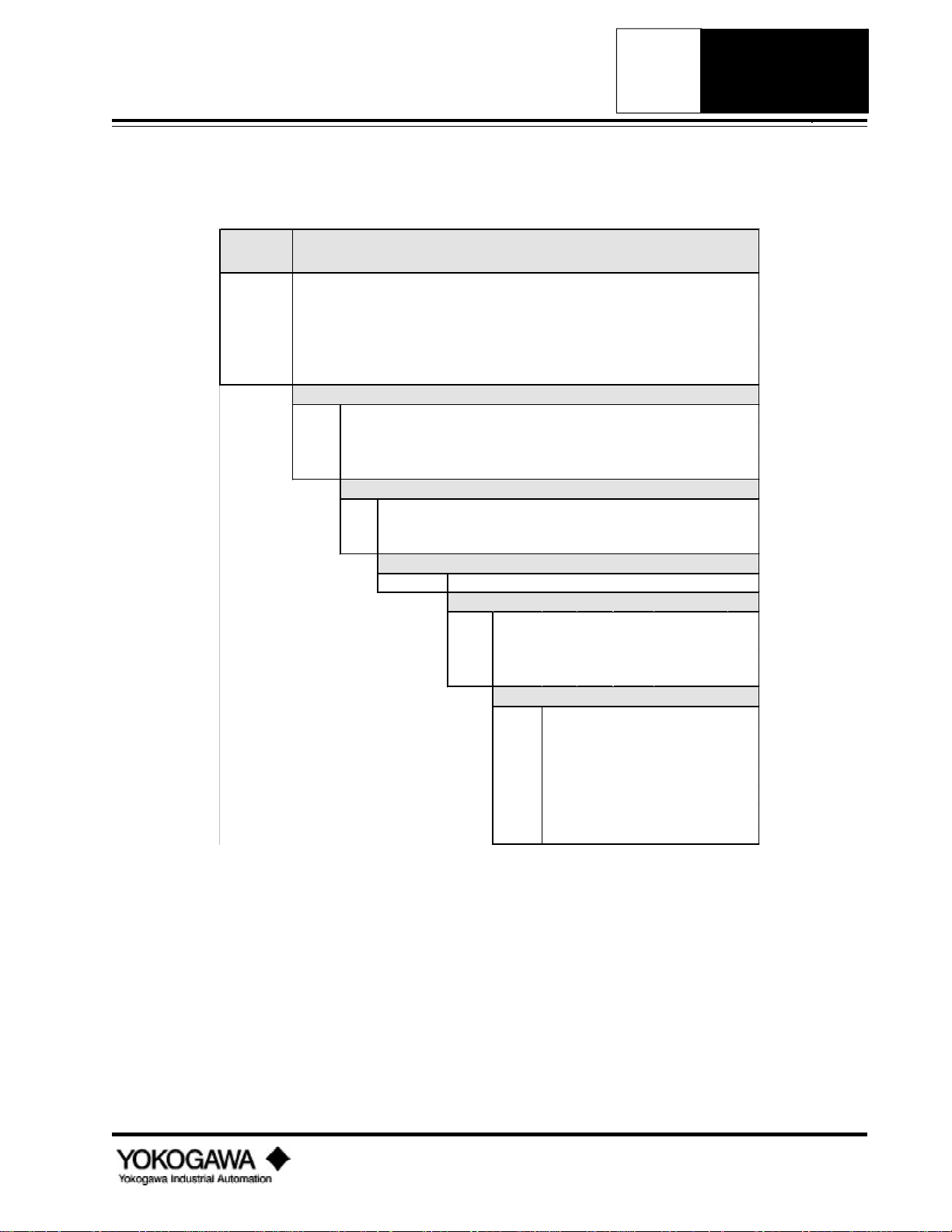

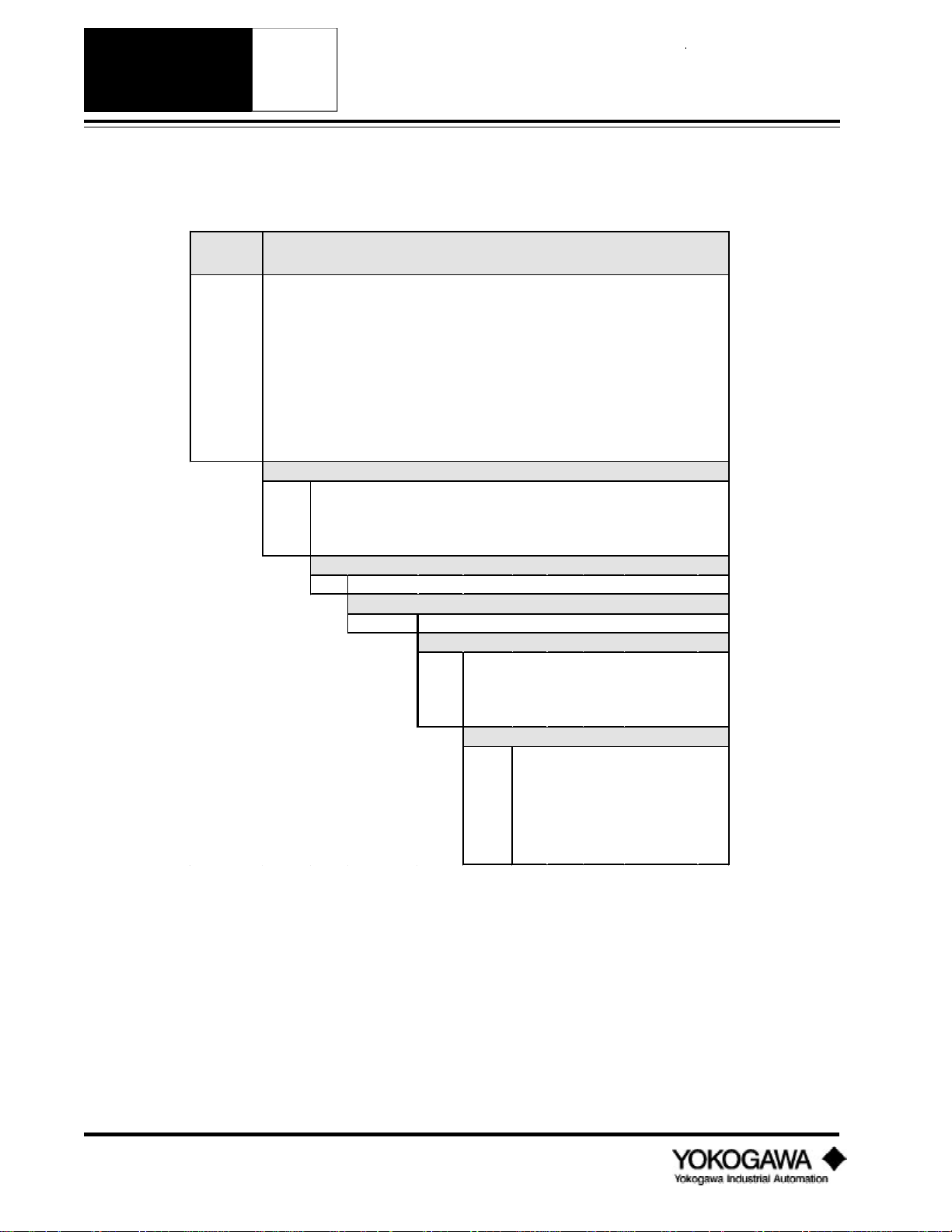

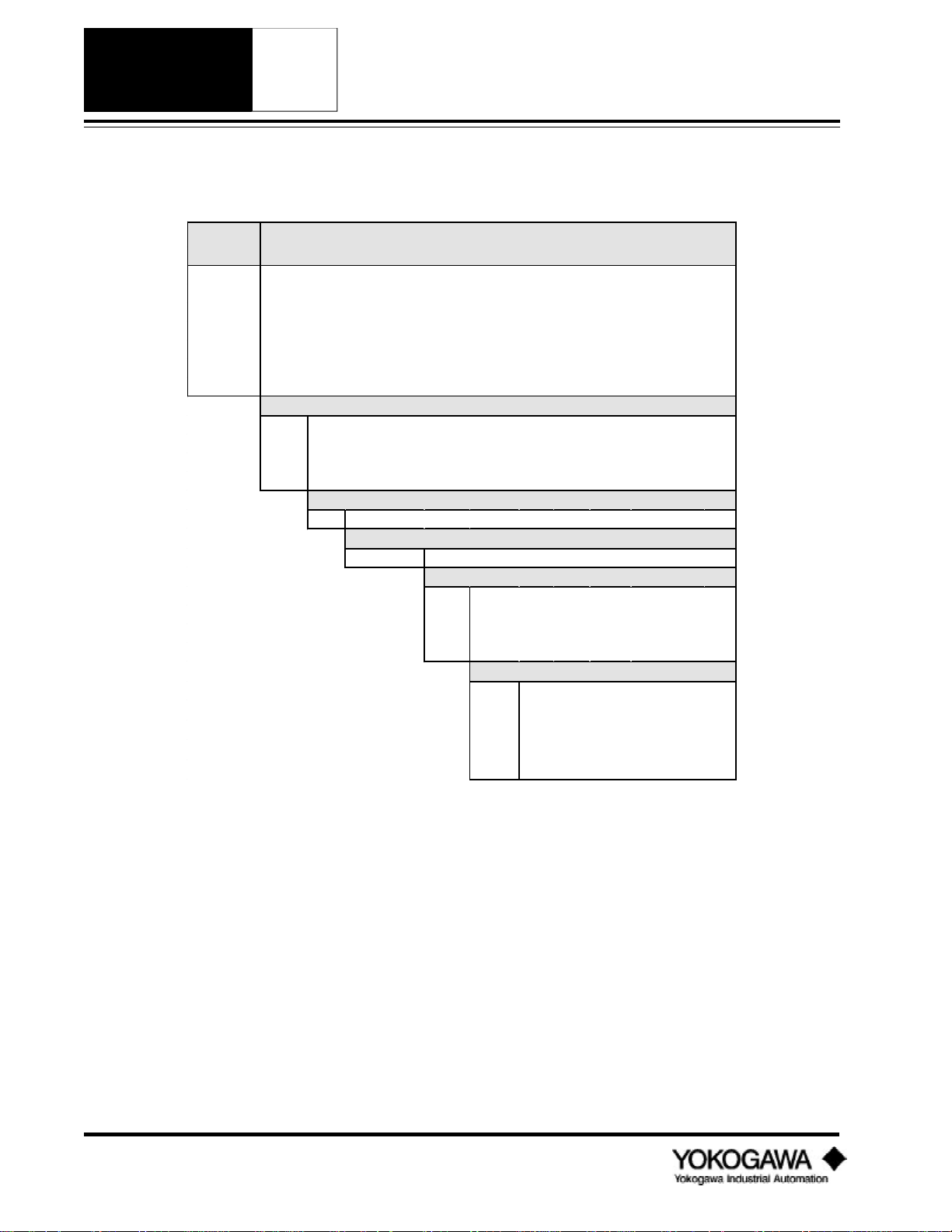

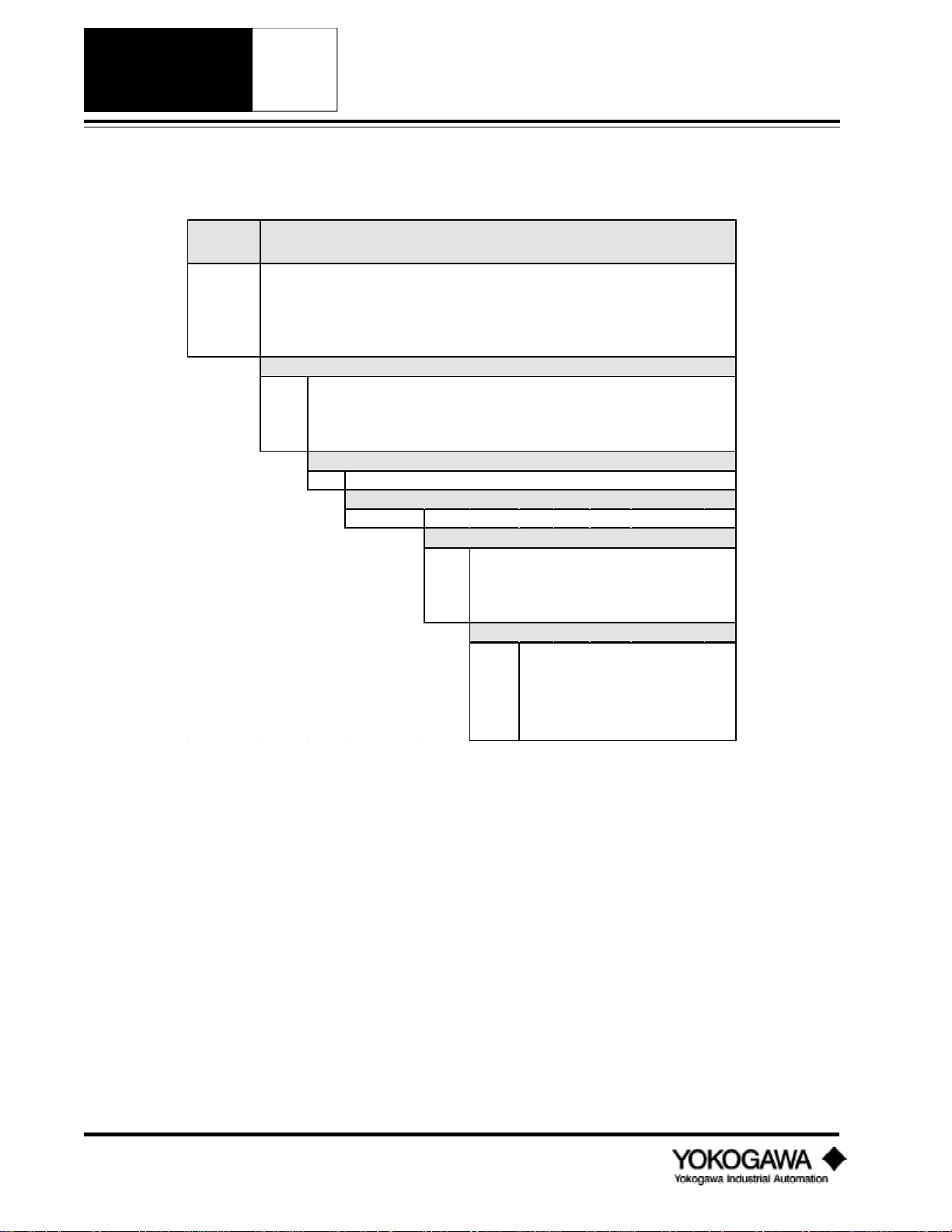

YEWFLO

B3

ANSI 600 lb Wafer Flanges

*E VORTEX FLOWMETERS

*E

STAINLESS

WAFER

MODEL

CODE

YF101 0.5" I.D. Stainless Steel Wafer

YF102 1.0" I.D. Stainless Steel Wafer

YF104 1.5" I.D. Stainless Steel Wafer

YF105 2.0" I.D. Stainless Steel Wafer

YF108 3.0" I.D. Stainless Steel Wafer

YF110 4.0" I.D. Stainless Steel Wafer

-AAU Integral, 4-20 mA or pulse

-AAD Integral, 4-20 mA for intrinsic safety

-AAR Integral, pulse output for intrinsic safety

-NNN Remote converter

YEWFLO *E - STAINLESS WAFER

PROCESS CONNECTIONS (wafer style for mounting between)

B1 ANSI 150 lb Wafer Flanges

B2 ANSI 300 lb Wafer Flanges

A-S3S3*E Stainless Steel shedder bar & body

/FMF FM explosionproof housing w/FM stamp

/FMS FM intrinsic safety w/FM stamp

/CSF CSA explosionproof housing w/CSA stamp

/CSS CSA intrinsic safety w/CSA stamp

CERTIFICATION

MATERIALS

CERTIFICATION

OPTIONS

/HART HART communications

/HPT High temperature

/TBL Local interface

/EPF Epoxy-coated electronics housing

/OSW Oxygen cleaning

/BLT 304 SS nuts and bolts

/SCT Stainless Steel tags wired into place

IM 1F2B4-01-YIA

Page 9

Page 14

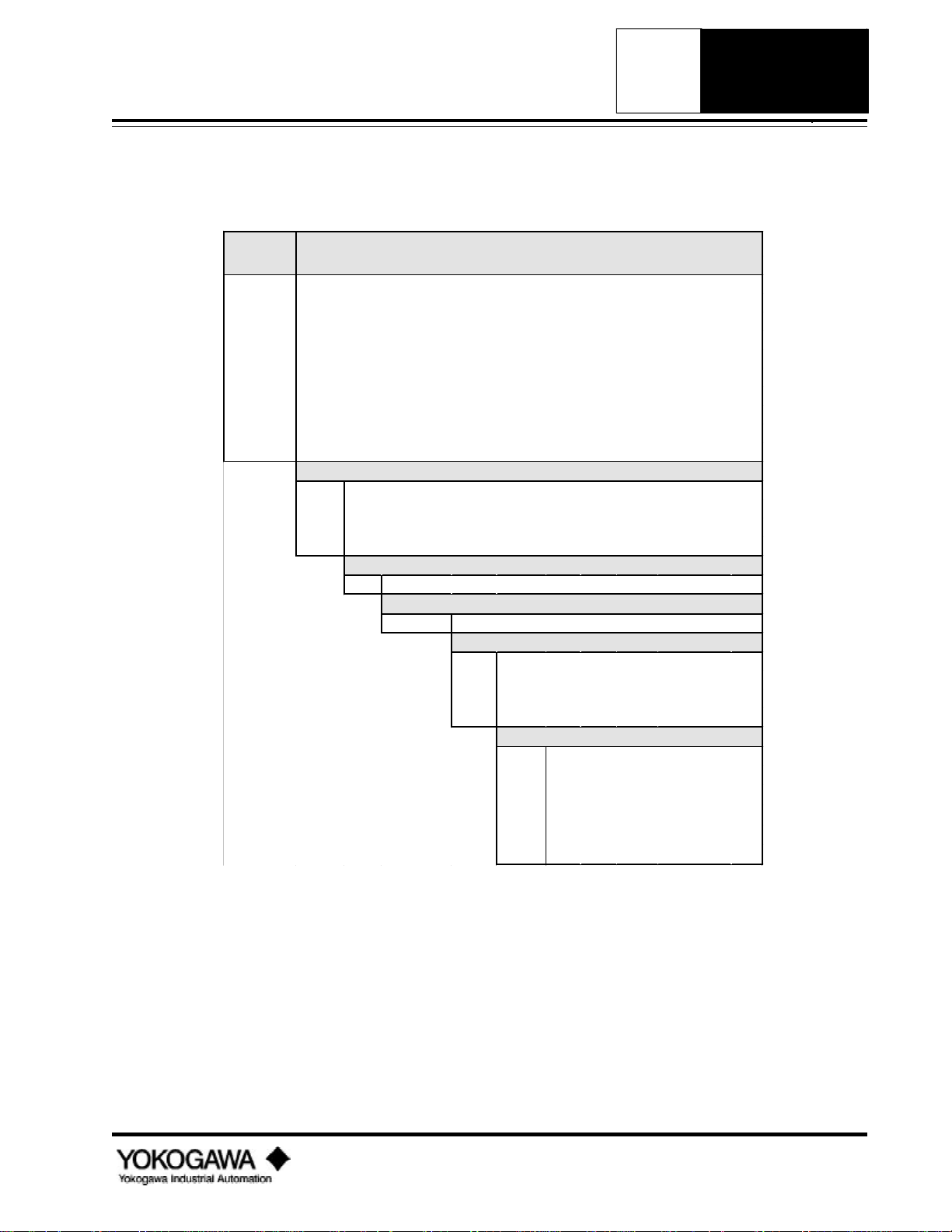

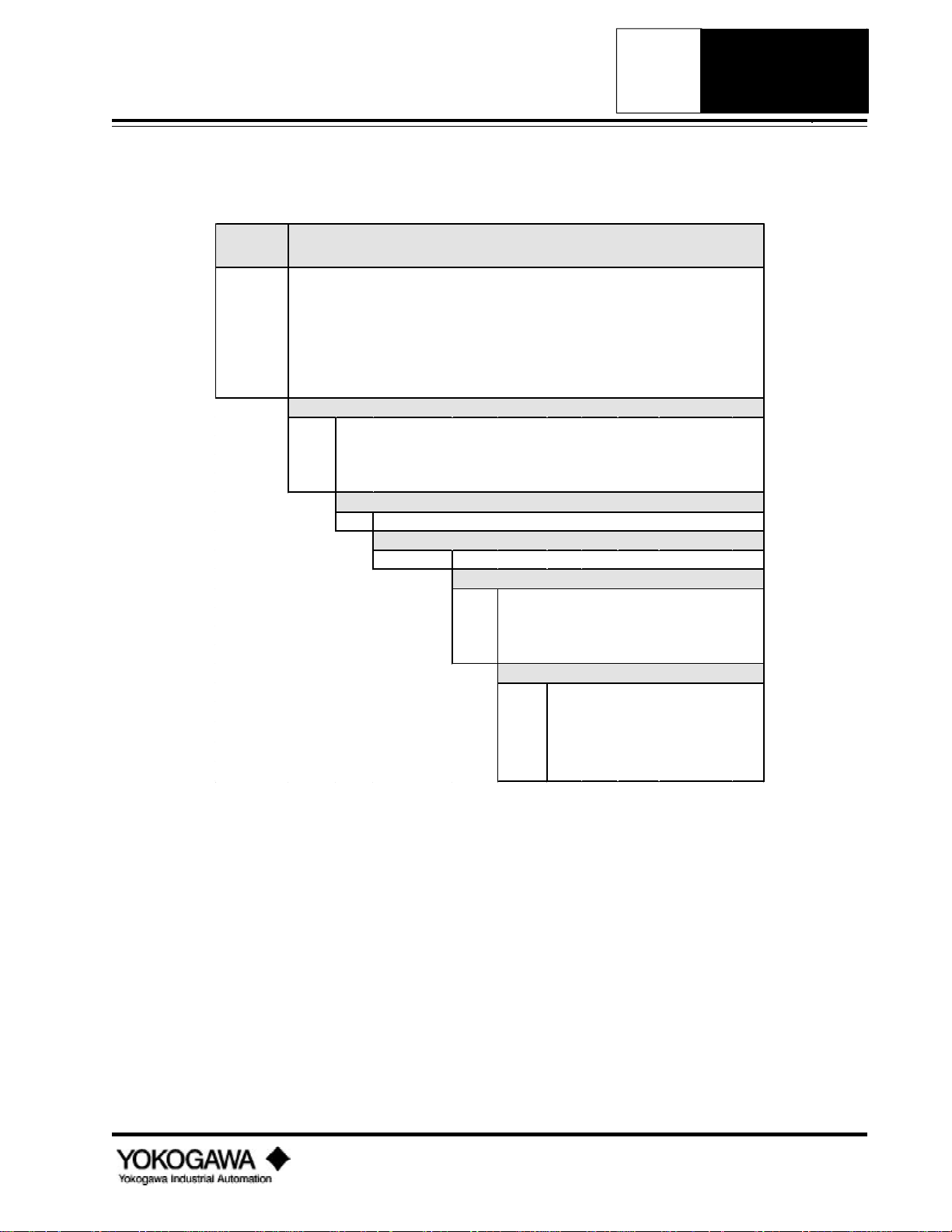

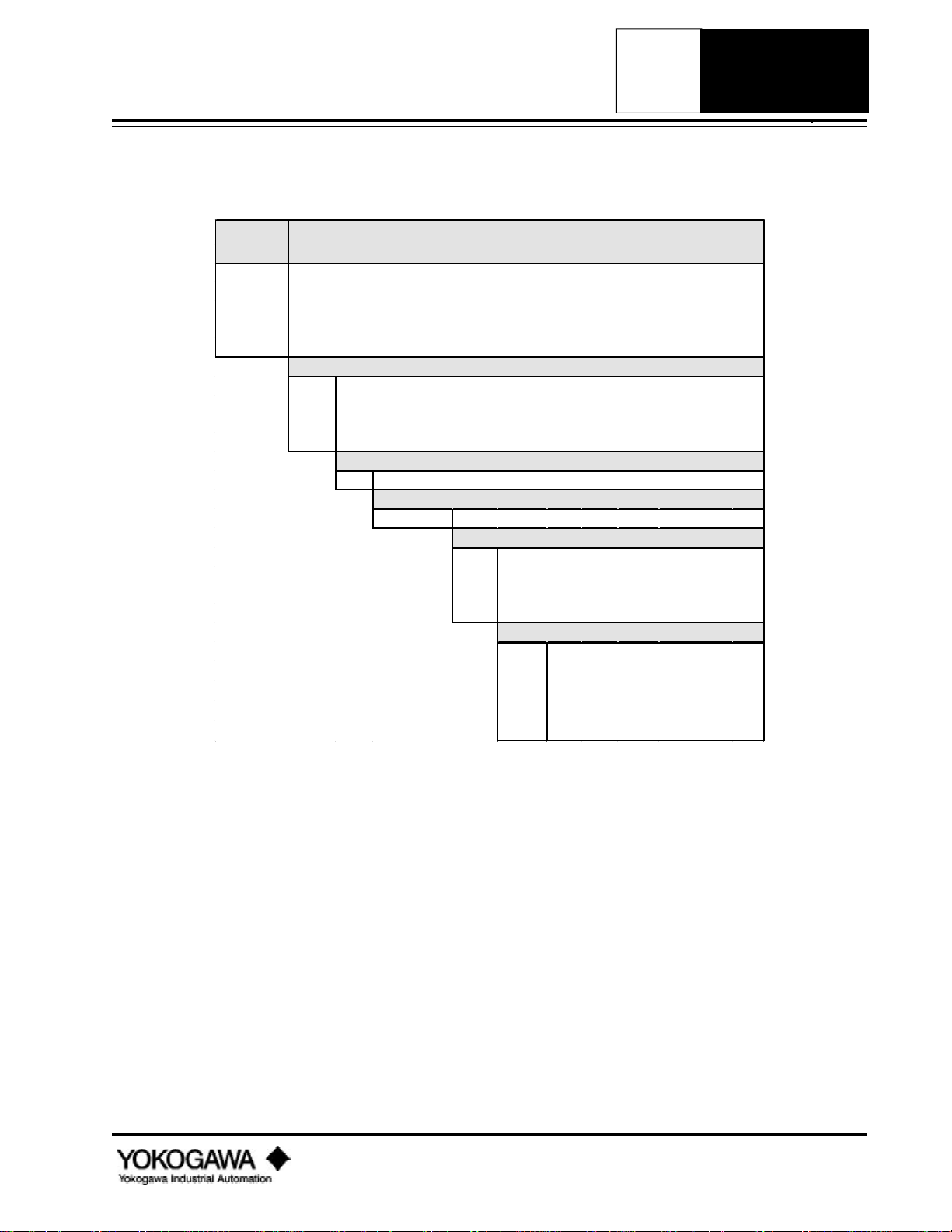

STAINLESS

FLANGED 150#

*E

YEWFLO

*E VORTEX FLOWMETERS

MODEL

CODE

YF101 0.5" I.D. Stainless Steel 150 lb RF flange

YF102 1.0" I.D. Stainless Steel 150 lb RF flange

YF104 1.5" I.D. Stainless Steel 150 lb RF flange

YF105 2.0" I.D. Stainless Steel 150 lb RF flange

YF108 3.0" I.D. Stainless Steel 150 lb RF flange

YF110 4.0" I.D. Stainless Steel 150 lb RF flange

YF115 6.0" I.D. Stainless Steel 150 lb RF flange

YF120 8.0" I.D. Stainless Steel 150 lb RF flange

YF125 10.0" I.D. Stainless Steel 150 lb RF flange

YF130 12.0" I.D. Stainless Steel 150 lb RF flange

-AAU Integral, 4-20 mA or pulse

-AAD Integral, 4-20 mA for intrinsic safety

-AAR Integral, pulse output for intrinsic safety

-NNN Remote converter

YEWFLO *E - STAINLESS 150# FLANGE

CONFIGURATION

PROCESS CONNECTIONS

A1 ANSI 150 lb RF flanges

A-S3S3*E Stainless Steel shedder bar & body

/FMF FM explosionproof housing w/FM stamp

/FMS FM intrinsic safety w/FM stamp

/CSF CSA explosionproof housing w/CSA stamp

/CSS CSA intrinsic safety w/CSA stamp

/HART HART communications

/HPT High temperature

/TBL Local interface

/EPF Epoxy-coated electronics housing

/OSW Oxygen cleaning

/SCT Stainless Steel tags wired into place

MATERIALS

CERTIFICATION

OPTIONS

IM 1F2B4-01-YIA

Page 10

Page 15

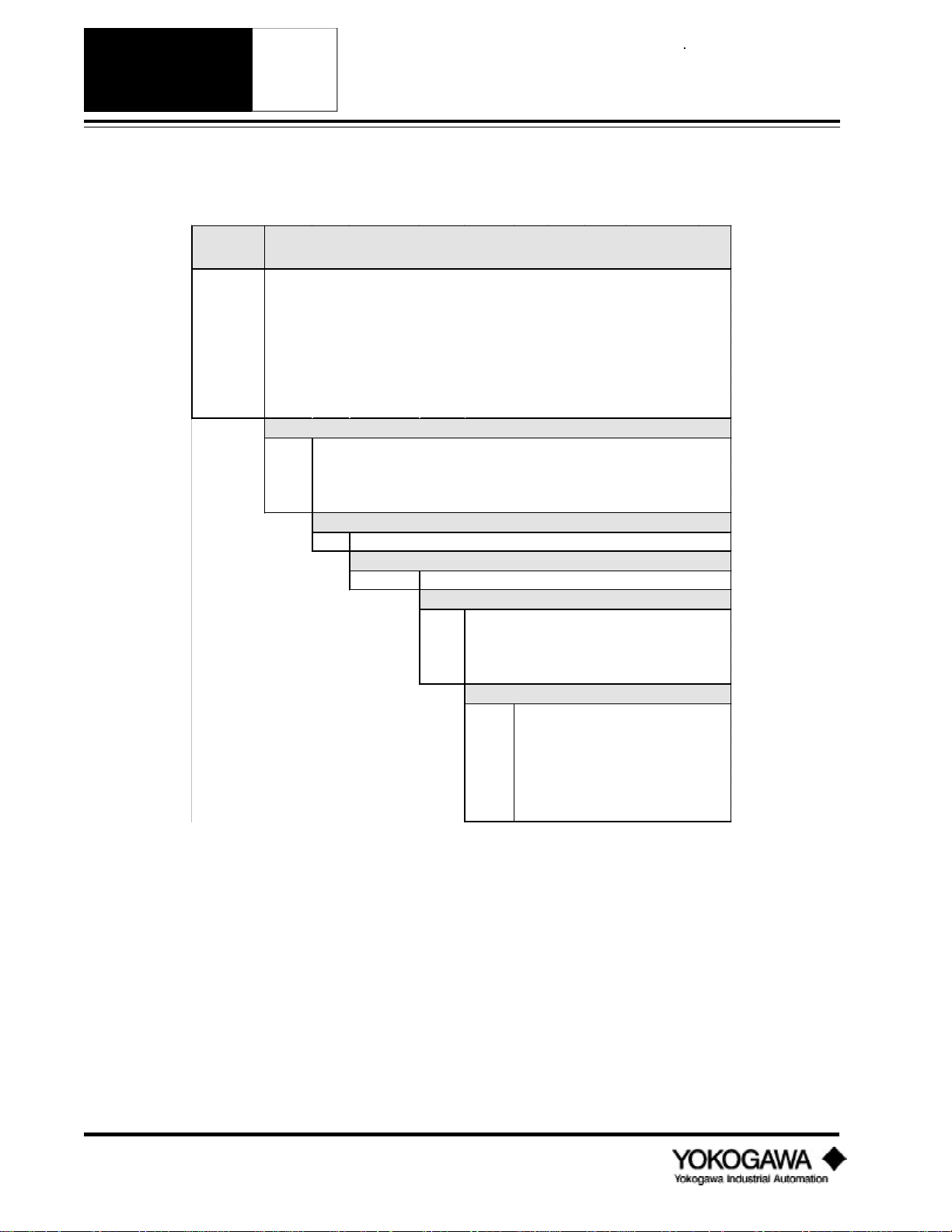

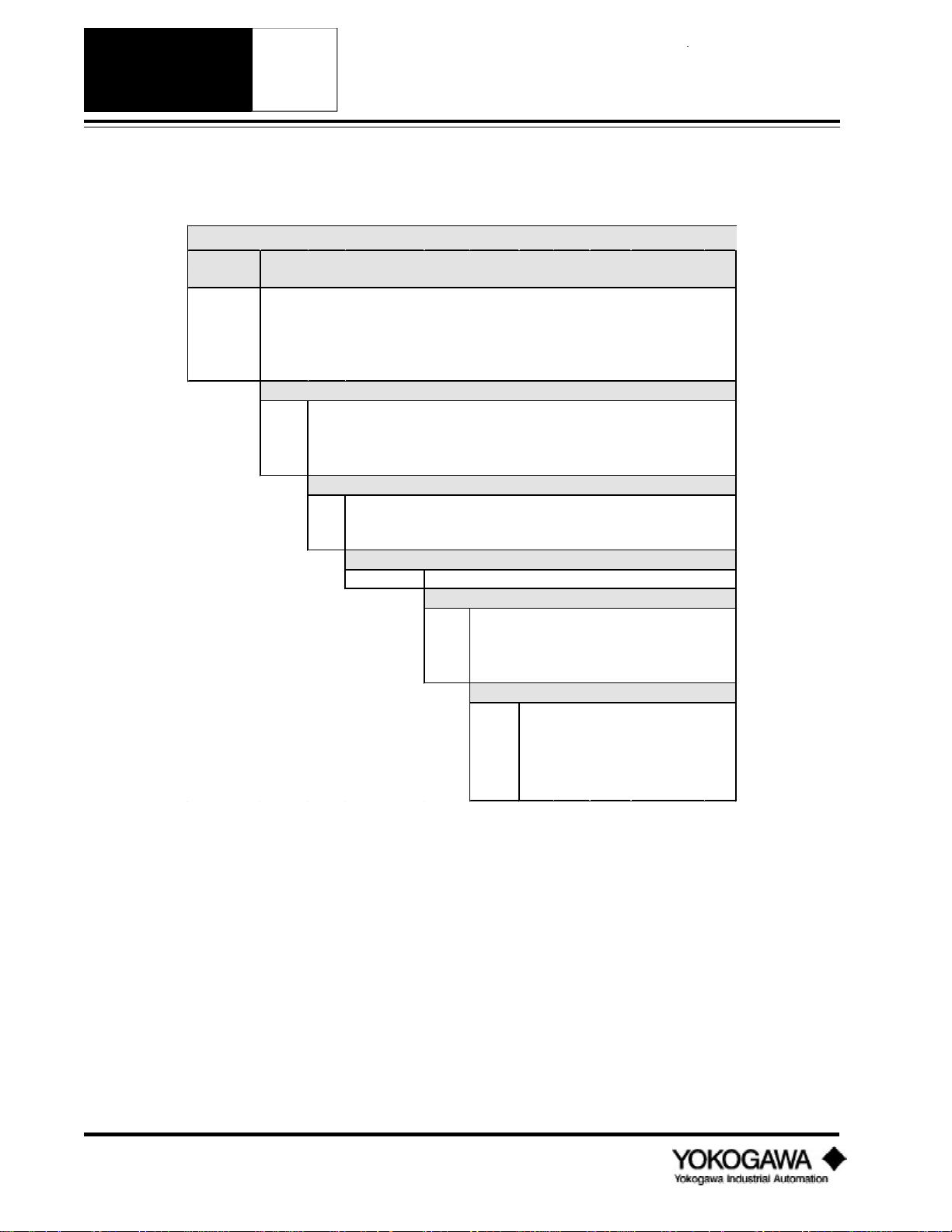

YEWFLO

*E VORTEX FLOWMETERS

*E

STAINLESS

FLANGED 300#

MODEL

CODE

YF101 0.5" I.D. Stainless Steel 300 lb RF flange

YF102 1.0" I.D. Stainless Steel 300 lb RF flange

YF104 1.5" I.D. Stainless Steel 300 lb RF flange

YF105 2.0" I.D. Stainless Steel 300 lb RF flange

YF108 3.0" I.D. Stainless Steel 300 lb RF flange

YF110 4.0" I.D. Stainless Steel 300 lb RF flange

YF115 6.0" I.D. Stainless Steel 300 lb RF flange

YF120 8.0" I.D. Stainless Steel 300 lb RF flange

YF125 10.0" I.D. Stainless Steel 300 lb RF flange

YF130 12.0" I.D. Stainless Steel 300 lb RF flange

-AAU Integral, 4-20 mA or pulse

-AAD Integral, 4-20 mA for intrinsic safety

-AAR Integral, pulse output for intrinsic safety

-NNN Remote converter

YEWFLO *E - STAINLESS 300# FLANGE

CONFIGURATION

PROCESS CONNECTIONS

A2 ANSI 300 lb RF flanges

A-S3S3*E Stainless Steel shedder bar & body

/FMF FM explosionproof housing w/FM stamp

/FMS FM intrinsic safety w/FM stamp

/CSF CSA explosionproof housing w/CSA stamp

/CSS CSA intrinsic safety w/CSA stamp

/HART HART communications

/HPT High temperature

/TBL Local interface

/EPF Epoxy-coated electronics housing

/OSW Oxygen cleaning

/SCT Stainless Steel tags wired into place

MATERIALS

CERTIFICATION

OPTIONS

IM 1F2B4-01-YIA

Page 11

Page 16

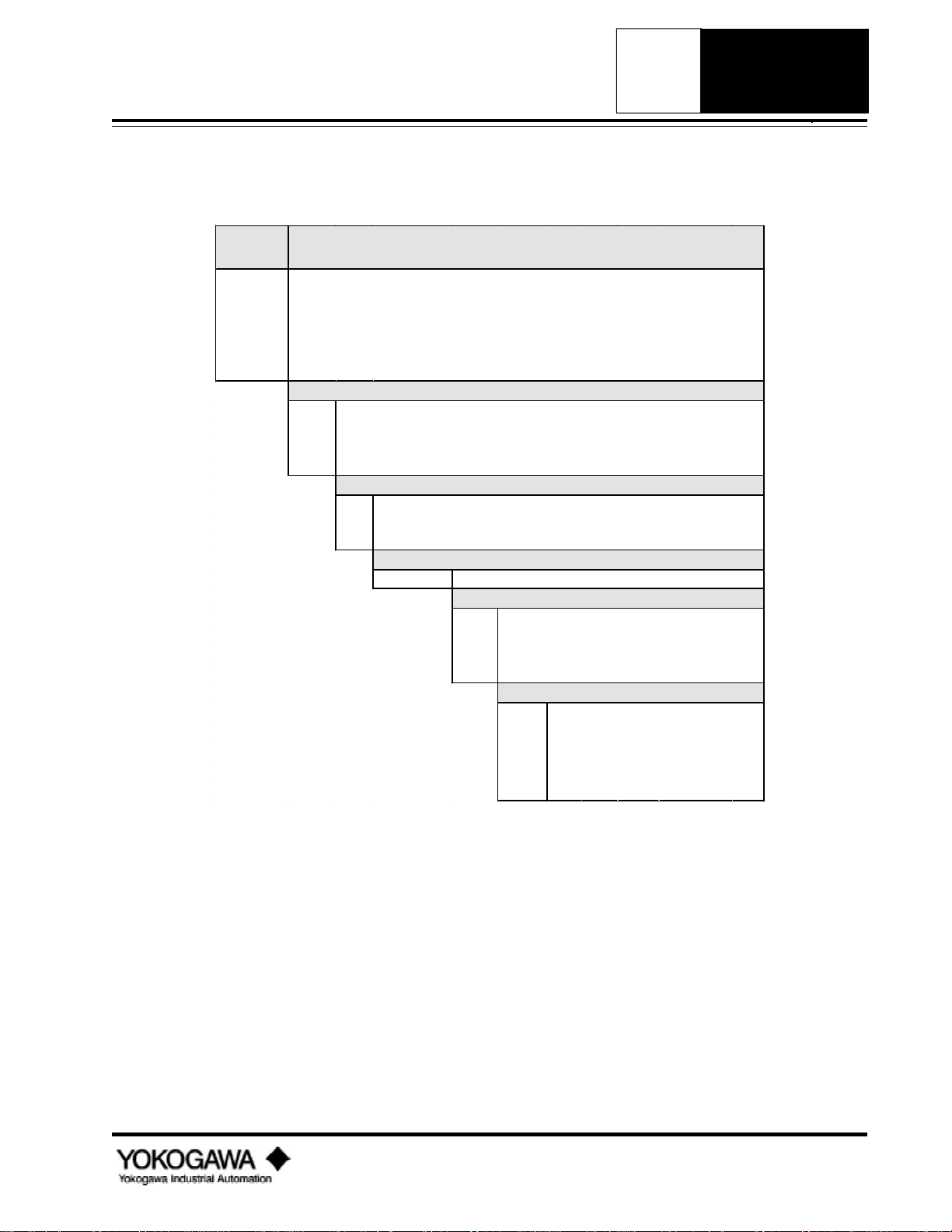

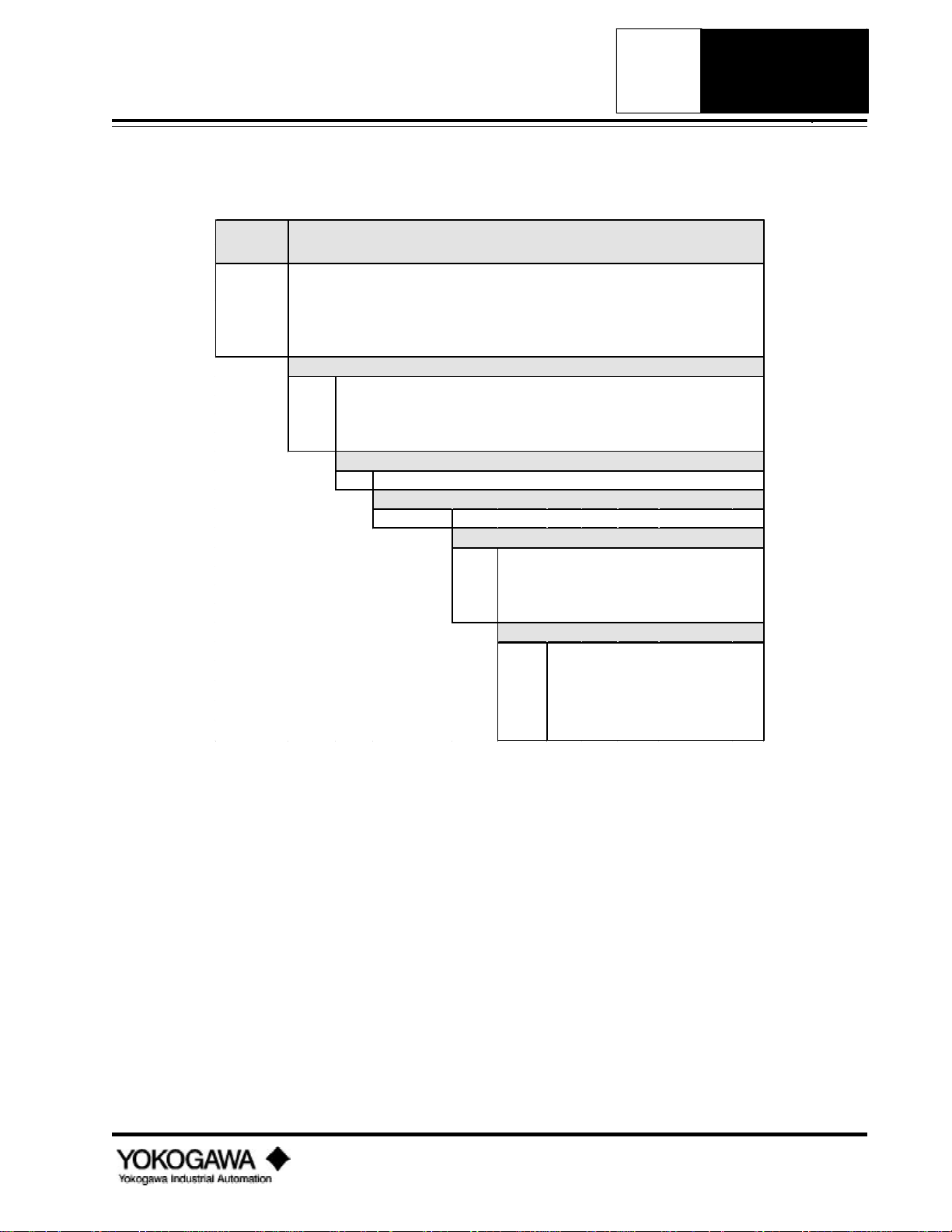

STAINLESS

FLANGED 600#

*E

YEWFLO

*E VORTEX FLOWMETERS

MODEL

CODE

YF101 0.5" I.D. Stainless Steel 600 lb RF flange

YF102 1.0" I.D. Stainless Steel 600 lb RF flange

YF104 1.5" I.D. Stainless Steel 600 lb RF flange

YF105 2.0" I.D. Stainless Steel 600 lb RF flange

YF108 3.0" I.D. Stainless Steel 600 lb RF flange

YF110 4.0" I.D. Stainless Steel 600 lb RF flange

YF115 6.0" I.D. Stainless Steel 600 lb RF flange

YF120 8.0" I.D. Stainless Steel 600 lb RF flange

-AAU Integral, 4-20 mA or pulse

-AAD Integral, 4-20 mA for intrinsic safety

-AAR Integral, pulse output for intrinsic safety

-NNN Remote converter

YEWFLO *E - STAINLESS 600# FLANGE

CONFIGURATION

PROCESS CONNECTIONS

A3 ANSI 600 lb RF flanges

A-S3S3*E Stainless Steel shedder bar & body

/FMF FM explosionproof housing w/FM stamp

/FMS FM intrinsic safety w/FM stamp

/CSF CSA explosionproof housing w/CSA stamp

/CSS CSA intrinsic safety w/CSA stamp

/HART HART communications

/HPT High temperature

/TBL Local interface

/EPF Epoxy-coated electronics housing

/OSW Oxygen cleaning

/SCT Stainless Steel tags wired into place

MATERIALS

CERTIFICATION

OPTIONS

IM 1F2B4-01-YIA

Page 12

Page 17

YEWFLO

B3

ANSI 600 lb RF flanges

*E VORTEX FLOWMETERS

*E

HASTELLOY C

WAFER

MODEL

CODE

YF101 0.5" I.D. Hastelloy C Wafer

YF102 1.0" I.D. Hastelloy C Wafer

YF104 1.5" I.D. Hastelloy C Wafer

YF105 2.0" I.D. Hastelloy C Wafer

YF108 3.0" I.D. Hastelloy C Wafer

YF110 4.0" I.D. Hastelloy C Wafer

-AAU Integral, 4-20 mA or pulse

-AAD Integral, 4-20 mA for intrinsic safety

-AAR Integral, pulse output for intrinsic safety

-NNN Remote converter

YEWFLO *E - HASTELLOY C WAFER

PROCESS CONNECTIONS (wafer style for mounting between)

B1 ANSI 150 lb RF flanges

B2 ANSI 300 lb RF flanges

A-HCHC*E Hastelloy C Shedder wetted parts

CERTIFICATION

MATERIALS

CERTIFICATION

/FMF FM explosionproof housing w/FM stamp

/FMS FM intrinsic safety w/FM stamp

/CSF CSA explosionproof housing w/CSA stamp

/CSS CSA intrinsic safety w/CSA stamp

OPTIONS

/HART HART communications

/TBL Local interface

/EPF Epoxy-coated electronics housing

/OSW Oxygen cleaning

/SCT Stainless Steel tags wired into place

IM 1F2B4-01-YIA

Page 13

Page 18

HASTELLOY C

FLANGED 150#

*E

YEWFLO

*E VORTEX FLOWMETERS

MODEL

CODE

YF101 0.5" I.D. Hastelloy C 150 lb RF flange

YF102 1.0" I.D. Hastelloy C 150 lb RF flange

YF104 1.5" I.D. Hastelloy C 150 lb RF flange

YF105 2.0" I.D. Hastelloy C 150 lb RF flange

YF108 3.0" I.D. Hastelloy C 150 lb RF flange

YF110 4.0" I.D. Hastelloy C 150 lb RF flange

YF115 6.0" I.D. Hastelloy C 150 lb RF flange

-AAU Integral, 4-20 mA or pulse

-AAD Integral, 4-20 mA for intrinsic safety

-AAR Integral, pulse output for intrinsic safety

-NNN Remote converter

YEWFLO *E - HASTELLOY C 150# FLANGE

CERTIFICATION

PROCESS CONNECTIONS (wafer style for mounting between)

A1 ANSI 150 lb RF flanges

A-HCHC*E Hastelloy C Shedder wetted parts

/FMF FM explosionproof housing w/FM stamp

/FMS FM intrinsic safety w/FM stamp

/CSF CSA explosionproof housing w/CSA stamp

/CSS CSA intrinsic safety w/CSA stamp

MATERIALS

CERTIFICATION

OPTIONS

/HART HART communications

/TBL Local interface

/EPF Epoxy-coated electronics housing

/OSW Oxygen cleaning

/SCT Stainless Steel tags wired into place

IM 1F2B4-01-YIA

Page 14

Page 19

YEWFLO

*E VORTEX FLOWMETERS

*E

HASTELLOY C

FLANGED 300#

MODEL

CODE

YF101 0.5" I.D. Hastelloy C 300 lb RF flange

YF102 1.0" I.D. Hastelloy C 300 lb RF flange

YF104 1.5" I.D. Hastelloy C 300 lb RF flange

YF105 2.0" I.D. Hastelloy C 300 lb RF flange

YF108 3.0" I.D. Hastelloy C 300 lb RF flange

YF110 4.0" I.D. Hastelloy C 300 lb RF flange

YF115 6.0" I.D. Hastelloy C 300 lb RF flange

-AAU Integral, 4-20 mA or pulse

-AAD Integral, 4-20 mA for intrinsic safety

-AAR Integral, pulse output for intrinsic safety

-NNN Remote converter

YEWFLO *E - HASTELLOY C 300# FLANGE

CERTIFICATION

PROCESS CONNECTIONS (wafer style for mounting between)

A2 ANSI 300 lb RF flanges

A-HCHC*E Hastelloy C wetted parts

/FMF FM explosionproof housing w/FM stamp

/FMS FM intrinsic safety w/FM stamp

/CSF CSA explosionproof housing w/CSA stamp

/CSS CSA intrinsic safety w/CSA stamp

MATERIALS

CERTIFICATION

OPTIONS

/HART HART communications

/TBL Local interface

/EPF Epoxy-coated electronics housing

/OSW Oxygen cleaning

/SCT Stainless Steel tags wired into place

IM 1F2B4-01-YIA

Page 15

Page 20

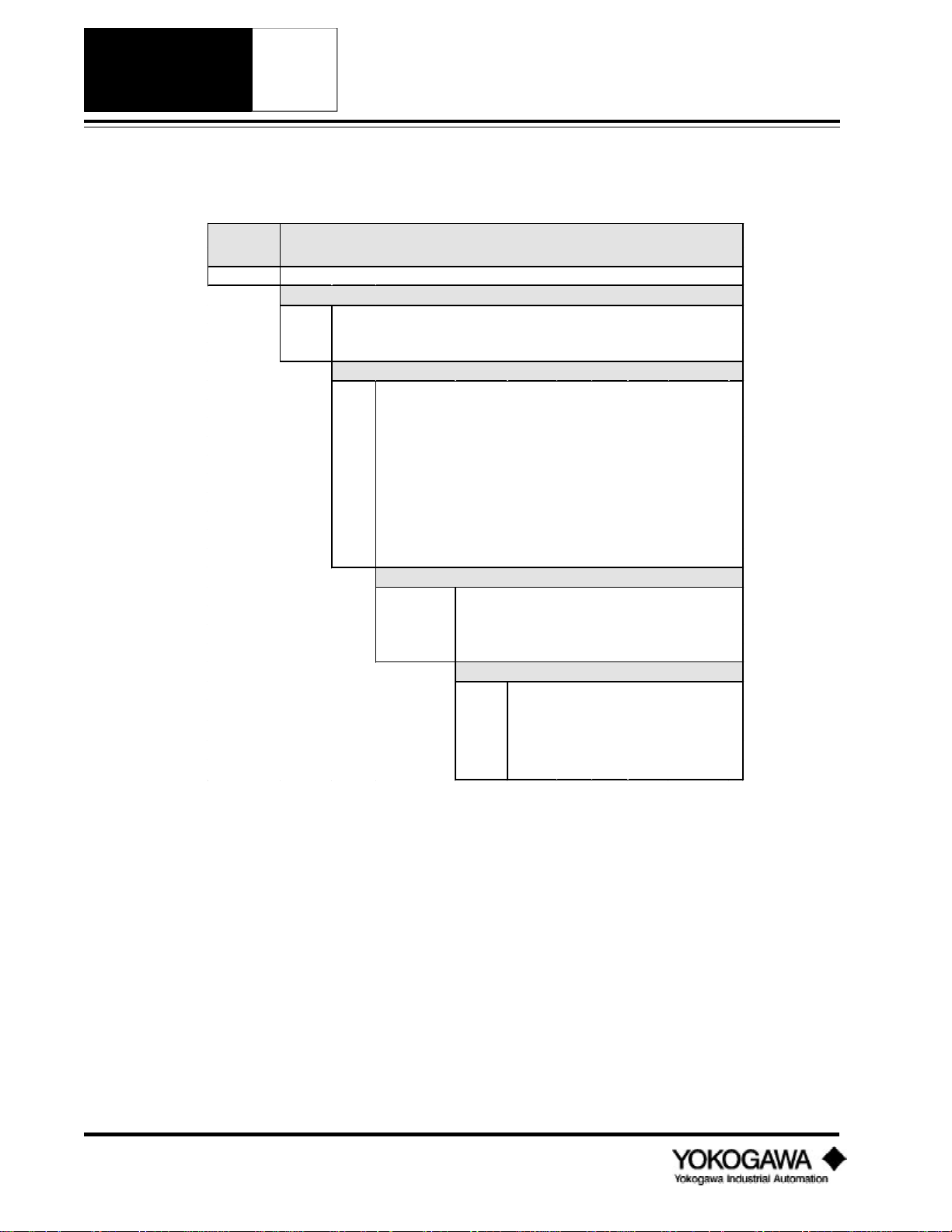

NACE MTLS

B3

ANSI 600 lb RF flanges

WAFER

MODEL METER SIZES

CODE

YF101 0.5" I.D. NACE Wafer

YF102 1.0" I.D. NACE Wafer

YF104 1.5" I.D. NACE Wafer

YF105 2.0" I.D. NACE Wafer

YF108 3.0" I.D. NACE Wafer

7

*E

*E VORTEX FLOWMETERS

YEWFLO *E - NACE MATERIALS WAFER

CERTIFICATION

-AAU Integral, 4-20 mA or pulse

-AAD Integral, 4-20 mA for intrinsic safety

-AAR Integral, pulse output for intrinsic safety

-NNN Remote converter

PROCESS CONNECTIONS (wafer style for mounting between)

B1 ANSI 150 lb RF flanges

B2 ANSI 300 lb RF flanges

YEWFLO

MATERIALS

A-HCS3*E Hastelloy C shedder bar w/stainless steel body

CERTIFICATION

/FMF FM explosionproof housing w/FM stamp

/FMS FM intrinsic safety w/FM stamp

/CSF CSA explosionproof housing w/CSA stamp

/CSS CSA intrinsic safety w/CSA stamp

OPTIONS

/HART HART communications

/TBL Local interface

/EPF Epoxy-coated electronics housing

/OSW Oxygen cleaning

/SCT Stainless Steel tags wired into place

IM 1F2B4-01-YIA

Page 16

Page 21

YEWFLO

*E VORTEX FLOWMETERS

*E

NACE MTLS

7

FLANGED 150#

MODEL

CODE

YF101 0.5" I.D. NACE 150 lb RF Flange

YF102 1.0" I.D. NACE 150 lb RF Flange

YF104 1.5" I.D. NACE 150 lb RF Flange

YF105 2.0" I.D. NACE 150 lb RF Flange

YF108 3.0" I.D. NACE 150 lb RF Flange

YEWFLO *E - NACE MATERIALS 150# FLANGE

-AAU Integral, 4-20 mA or pulse

-AAD Integral, 4-20 mA for intrinsic safety

-AAR Integral, pulse output for intrinsic safety

-NNN Remote converter

PROCESS CONNECTIONS

A1 ANSI 150 lb RF flanges

A-HCS3*E Hastelloy C shedder bar w/stainless steel body

/FMF FM explosionproof housing w/FM stamp

/FMS FM intrinsic safety w/FM stamp

/CSF CSA explosionproof housing w/CSA stamp

/CSS CSA intrinsic safety w/CSA stamp

CERTIFICATION

MATERIALS

CERTIFICATION

OPTIONS

/HART HART communications

/TBL Local interface

/EPF Epoxy-coated electronics housing

/OSW Oxygen cleaning

/SCT Stainless Steel tags wired into place

IM 1F2B4-01-YIA

Page 17

Page 22

NACE MTLS

7

FLANGED 300#

*E

YEWFLO

*E VORTEX FLOWMETERS

MODEL

CODE

YF101 0.5" I.D. NACE 300 lb RF Flange

YF102 1.0" I.D. NACE 300 lb RF Flange

YF104 1.5" I.D. NACE 300 lb RF Flange

YF105 2.0" I.D. NACE 300 lb RF Flange

YF108 3.0" I.D. NACE 300 lb RF Flange

YEWFLO *E - NACE MATERIALS 300# FLANGE

-AAU Integral, 4-20 mA or pulse

-AAD Integral, 4-20 mA for intrinsic safety

-AAR Integral, pulse output for intrinsic safety

-NNN Remote converter

PROCESS CONNECTIONS

A2 ANSI 300 lb RF flanges

A-HCS3*E Hastelloy C shedder bar w/stainless steel body

/FMF FM explosionproof housing w/FM stamp

/FMS FM intrinsic safety w/FM stamp

/CSF CSA explosionproof housing w/CSA stamp

/CSS CSA intrinsic safety w/CSA stamp

CERTIFICATION

MATERIALS

CERTIFICATION

OPTIONS

/HART HART communications

/TBL Local interface

/EPF Epoxy-coated electronics housing

/OSW Oxygen cleaning

/SCT Stainless Steel tags wired into place

IM 1F2B4-01-YIA

Page 18

Page 23

YEWFLO

*E VORTEX FLOWMETERS

*E

NACE MTLS

7

FLANGED 600#

MODEL

CODE

YF101 0.5" I.D. NACE 600 lb RF Flange

YF102 1.0" I.D. NACE 600 lb RF Flange

YF104 1.5" I.D. NACE 600 lb RF Flange

YF105 2.0" I.D. NACE 600 lb RF Flange

YF108 3.0" I.D. NACE 600 lb RF Flange

YEWFLO *E - NACE MATERIALS 600# FLANGE

-AAU Integral, 4-20 mA or pulse

-AAD Integral, 4-20 mA for intrinsic safety

-AAR Integral, pulse output for intrinsic safety

-NNN Remote converter

PROCESS CONNECTIONS

A3 ANSI 600 lb RF flanges

A-HCS3*E Hastelloy C shedder bar w/stainless steel body

/FMF FM explosionproof housing w/FM stamp

/FMS FM intrinsic safety w/FM stamp

/CSF CSA explosionproof housing w/CSA stamp

/CSS CSA intrinsic safety w/CSA stamp

CERTIFICATION

MATERIALS

CERTIFICATION

OPTIONS

/HART HART communications

/TBL Local interface

/EPF Epoxy-coated electronics housing

/OSW Oxygen cleaning

/SCT Stainless Steel tags wired into place

IM 1F2B4-01-YIA

Page 19

Page 24

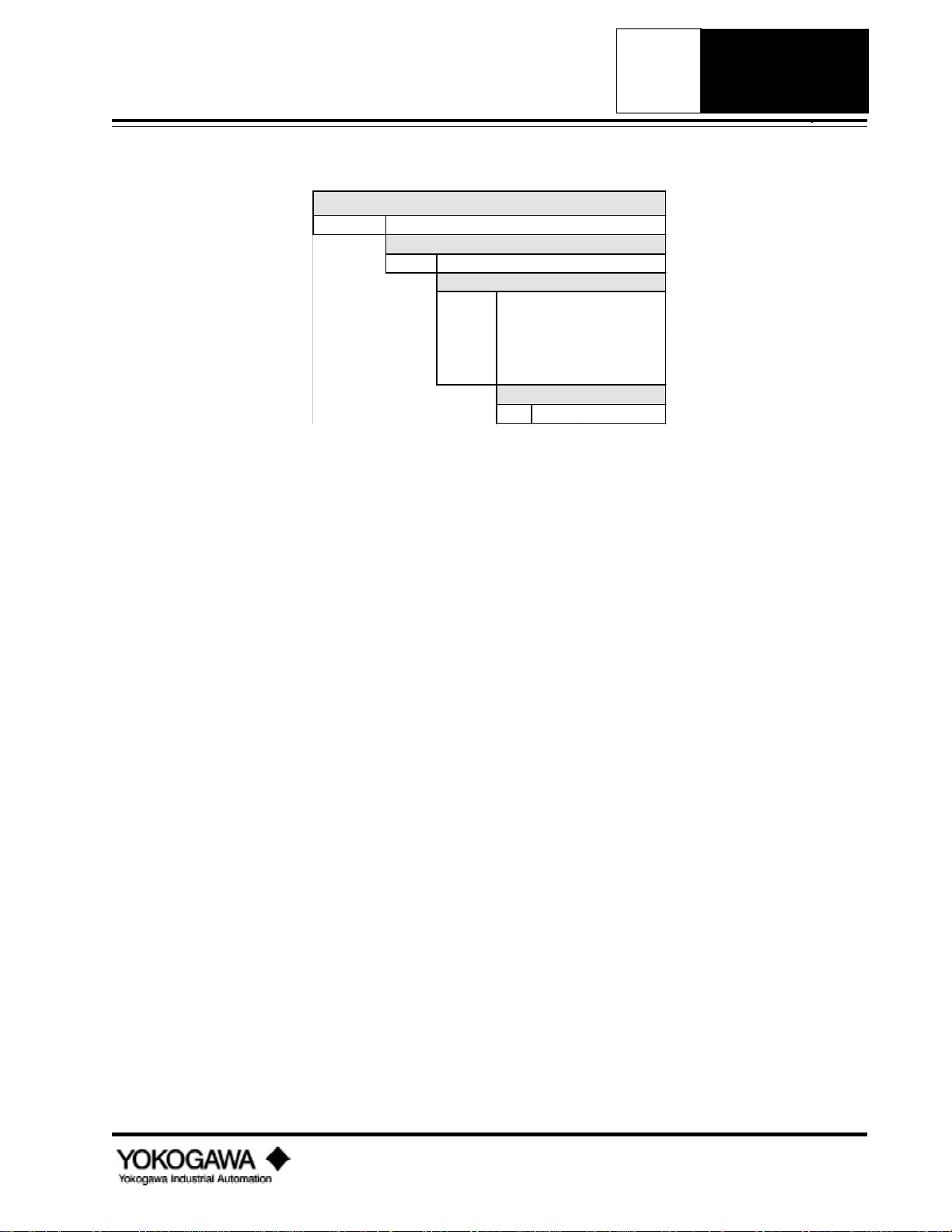

REMOTE

CONVERTER

*E

YEWFLO

*E VORTEX FLOWMETERS

MODEL

CODE

YFA11 Remote Converter

-AUPA 4-20 mA or pulse output

-ADPA 4-20 mA for intrinsic safety

-ARPA Pulse output for intrinsic safety

YEWFLO *E - REMOTE CONVERTER

-01*E 0.5" body

-02*E 1.0" body

-04*E 1.5" body

-05*E 2.0" body

-08*E 3.0" body

-10*E 4.0" body

-15*E 6.0" body

-20*E 8.0" body

-25*E 10.0" body

-30*E 12.0" body

CONFIGURATION

METER SIZES

CERTIFICATION

/FMF FM explosionproof housing w/FM stamp

/FMS FM intrinsic safety w/FM stamp

/CSF CSA explosionproof housing w/CSA stamp

/CSS CSA intrinsic safety w/CSA stamp

OPTIONS

/HART HART communications

/TBL Local interface

/EPF Epoxy-coated electronics housing

/SCT Stainless Steel tags wired into place

/Z Additional cable, per foot

IM 1F2B4-01-YIA

Page 20

Page 25

YEWFLO

*E VORTEX FLOWMETERS

CABLE TYPE, *E

YF011 Remote meter interconnecting cable

CONFIGURATION

-1 Terminated ends

-0010F 10 feet

-0015F 15 feet

-0030F 30 feet

-0050F 50 feet

-0065F 65 feet

METER SIZES

CERTIFICATION

*E Style E

*E

PARTS

METERS

CABLE

IM 1F2B4-01-YIA

Page 21

Page 26

QUICK START USING THE BT100/200

II. QUICK START

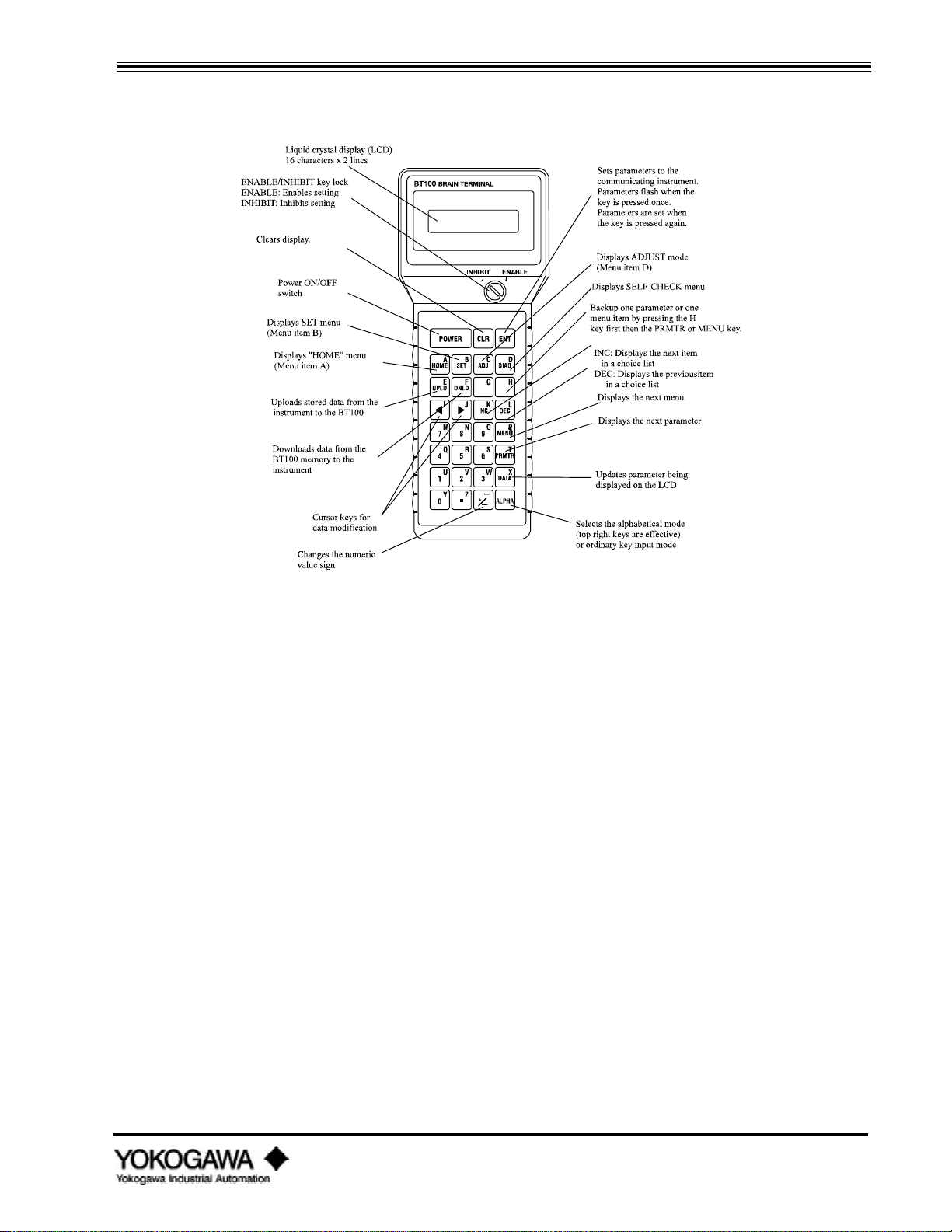

BT100/BT200 HANDHELD TERMINAL

Note: If you specified the correct process conditions on your order, these parameters have been preset at the

factory; therefore, there is no need to re-enter the data.

The Style E YEWFLO is a smart communicating device with microprocessor-based technology.

When used with Yokogawa’s BT100 or BT200 handheld terminal (HHT), YEWFLO can be

configured to meet specific application needs. In addition, the optional local indicator/totalizer (TBL

option) allows setting of various parameters.

When in the analog output mode, the HHT may be connected at any point on the instrument's

4-20 mA loop. This connection superimposes a digital signal on top of the instrument’s 4-20 mA

signal making communications completely transparent to your process signal. On the other hand,

since there are no 4-20 mA wires in the pulse mode, direct connection of the HHT to the HHT

PULSE and HHT COM test points on the amplifier is necessary. Once connected, flowrate and total

can be read, tag numbers entered, meter size or any other parameter modified as required.

Additionally, you may activate or deactivate many features of the YEWFLO as necessary to meet

the requirements of your application.

The HHT will enable you to scroll through the program until you locate the parameter that you wish

to change. For communication information, see “How to communicate with the YEWFLO remotely”

in the maintenance section. Please refer to the appropriate HHT instruction manual for details on

each HHT.

To change a parameter using the BT100, insert the removable key in the lock and turn it clockwise

to the ENABLE position. If the key is not in place or if it is in the INHIBIT position, you will receive an

OPERATION ERR message on the display when you press either the INC or DEC key or try to enter

an alphanumeric value in any parameter. If this occurs, insert the key in the lock, turn it clockwise to

the ENABLE position then press either the INC, DEC or alphanumeric key as before.

2.1 PARAMETER SETTING IN BRAIN™ COMMUNICATIONS

The Model YF100*E Vortex flowmeter incorporates BRAIN™ communication functions. These

functions enable the Vortex converter to remotely carry out the following functions by

communicating with the BRAIN™ Terminal (BT100 or BT200), µXL, or Centum-XL distributed

control systems.

• Setting or changing parameters required for vortex meter operation such as tag number, flow span

and process conditions for example.

• Monitoring flowrate, totalized flow and self-diagnostics.

• 4-20 mA loop check (simulated output) and totalizer reset.

Note: When the pulse/analog jumpers are set for a pulse output, Remote BRAIN™ communication on the

4-20 mA wires is not available. Therefore parameters cannot be set or read remotely. For the BT100

to operate in the pulse output mode, the instrument must be connected to the test points labeled HHT

Pulse and HHT Com. This allows access to all parameters.

Note: Only the position of the jumpers affects remote communication ability, the software setting of pulse or

4-20 mA has no effect.

IM 1F2B4-01-YIA

Page 22

Page 27

QUICK START USING THE BT100/200

BT100 Basic Operation

1) POWER on.

2) First three key strokes will always display “Model No.”, Tag No.”, and “Self-check”.

3) Press MENU key to select desired main menu.

4) Press PMTR key to move down through the selected menu.

5) Once a parameter has been selected, use the INC or DEC keys to review options within the

parameter list. When data input is required, use the alpha key to toggle between the alpha and

numeric characters (A to Z, 0 to 9).

6) Once a parameter has been selected, push ENT twice to save the changes.

Notes: A) Use the ALPHA key to move between alpha and numeric characters.

B) To back up in the programming sequence, push H key and then PMTR when in parameter

mode or MENU when in main menu mode.

C) UPLD and DNLD keys permit copying settings from one instrument in BT100 non-volatile

memory to another instrument.

D) The automatic power-off of the BT100 automatically turns off the power when no key has been

pressed for about 5 minutes. This function is not active during the display A10: Flowrate %, A20:

Flowrate, or A30: Total. The display of these values is updated every 5 seconds.

IM 1F2B4-01-YIA

Page 23

Page 28

QUICK START USING THE BT100/200

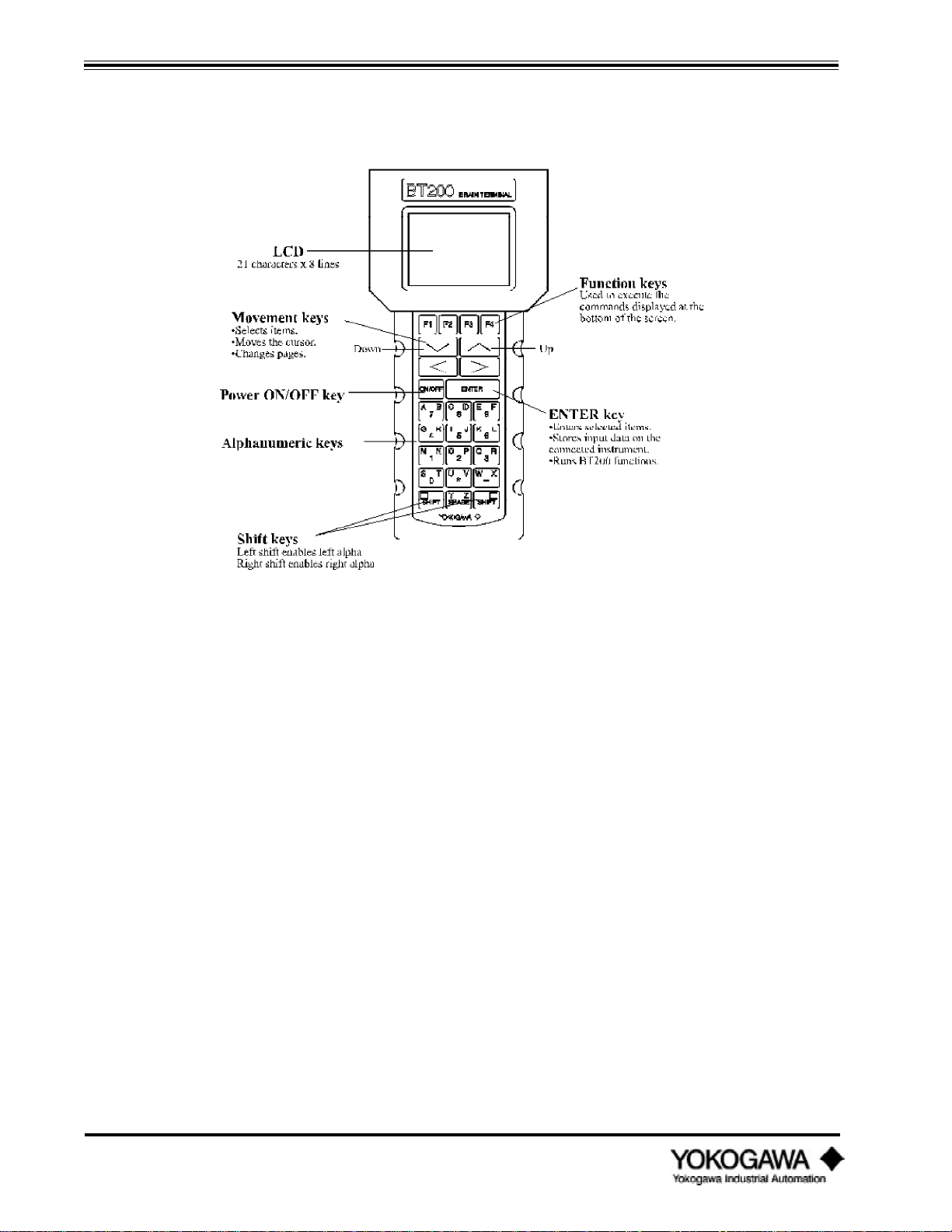

BT200 Basic Operation

1) Press ON/OFF to activate power.

2) Press ENTER key when prompted.

3) “Model”, “Tag No.”, and “Self-check” will always be displayed next.

4) Press F4 to continue. The main menu list will be displayed next.

5) Highlight the desired menu by using the up and down movement keys. Press ENTER to

access the selected menu.

6) Use the up and down movement keys to highlight the desired parameter and press ENTER to

access.

7) Once a parameter has been selected either:

a) Use the up and down movement keys to review options within the parameter. Once the

appropriate option has been selected, press ENTER twice to edit the selection.

b) Where data input is required, use the alpha key to toggle between the alpha and numeric

characters. Press ENTER twice to save the changes.

Notes: A) The function keys (F1-F4) are used to execute the commands displayed at the bottom of the

screen.

B) Use the left (<) and right (>) movement keys to change whole page of displayed information. The

“<“ key shows the preceding page and the “>“ key the following page.

C) To select a desired alpha character, always use the appropriate SHIFT key. Use the green

shift key to select letters marked in green and the black shift key to select letters marked in black.

If the alpha/numeric keys are not used in conjunction with the SHIFT key, the numeric value

shown on the key will be displayed.

D) To go directly to a particular parameter anywhere in the menu tree while working in a menu, press

either SHIFT key and then press F4. Type the parameter designation (example B24) to be

displayed and press ENTER.

IM 1F2B4-01-YIA

Page 24

Page 29

QUICK START USING THE BT100/200

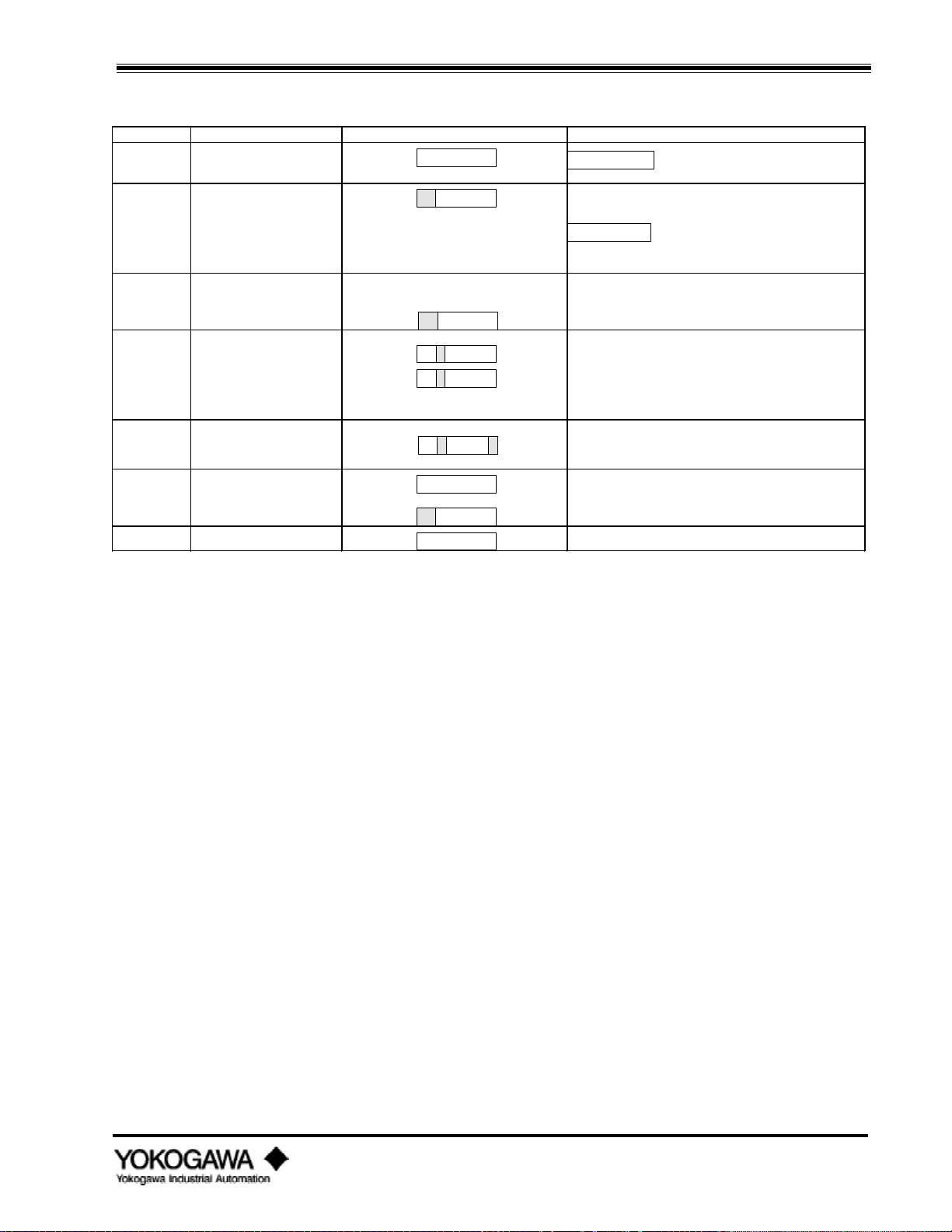

2.2 YEWFLO SETUP

Note: If you specified the correct process conditions on your order, these parameters have been preset at the

factory; therefore, there is no need to re-enter the data.

The purpose of a Quick Start is to address only those parameters which must be set to establish the

operation of a meter for this application. Follow the parameters listed below and enter the data for

your particular application.

With the BT100 or BT200 properly connected to the Vortex meter begin communicating by pressing

the power button. After the power up sequence is complete, go to “ Menu B: SET 1”. The operation of

the BT100 and BT200 are slightly different. Please refer to the ‘Basic Handheld Terminal Operation’

if you are unfamiliar with how to move through the menus and parameters. The following flow chart

identifies only the parameters to be set, you may have to skip several parameters or menus to get to

the parameters shown below. Be sure to enter all values and selections shown below or they will

not be saved. If you make a typing error, use the CLR key to clear and re-enter.

IM 1F2B4-01-YIA

Page 25

Page 30

QUICK START USING THE BT100/200

2.3 PARAMETER SETTING IN HART™ COMMUNICATIONS

When specified, the model YF100*E vortex flowmeter can be provided with HART™

communication functions. (To determine if this field communication protocol has been

incorporated in your instrument, confirm the “HART” suffix is a part of the YEWFLO model code.)

These functions enable the vortex converter to remotely carry out the following by communicating

with the HART communicator:

· Setting or changing parameters required for vortex meter operation such as tag number, flow span

and process conditions.

· Monitoring flowrate, totalized flow and self-diagnostics.

· 4-20 mA loop check (simulated output) and totalizer rest

The HART communicator can interface with YEWFLO from the control room, via direct connection

to the amplifier, or any other wiring termination point on the 4-20 mA loop. Polarity does not matter.

There must be a minimum of 250 ohms between the connection and the power supply. Refer to

Figure 1.3.2 on page 7 for power supply voltage requirements and load resistance.

Note1: The output jumpers on the amplifier must be set to the analog position to communicate. Only the

position of the jumpers affects remote communication ability, the software setting of pulse or 4-20 mA

has no effect.

Note2: When Yewflo is supplied with the HART option, the TBL digital display/local operator interface

cannot be used for parameter setting and configuration. Only two parameters are supported by the

TBL:

Parameter E01: Total reset

Parameter E02: Display Select

The amplifier has been pre-configured at the factory, so no setup should be required prior to

installation. If your process conditions have changed and reprogramming is required, the menu/

parameter configuration list for YEWFLO/HART can be found in Appendix B in the back of this

manual. Refer to the instructions provided with your HART communicator or operation details. The

QUICK START section of this manual will address only those parameters which must be set to

establish the operation of the meter for a particular application. Appendix B will cross-reference the

BRAIN parameters to the corresponding HART parameters.

2.3.1 Communication Specifications

Method of communication: Frequency shift keying (FSK). Conforms with Bell 202 Modem standard

with respect to baud rate and digital “1” and “0” frequencies.

Baud Rate: 1,200 bps

Digital “0” Frequency: 2,200 Hz

Digital “1” Frequency: 1,200 Hz

Data Byte Structure: 1 start bit, 8 data bits, 1 odd parity bit, 1 stop bit

IM 1F2B4-01-YIA

Page 34

Page 31

QUICK START USING THE BT100/200

Single Digital Process Variable Rate:

Poll/Response Mode: 2.0 per second

Burst Mode: 3.7 per second

Maximum Number of Multi-drop Devices:

Loop Powered: 15

Multivariable Specification:

Maximum process variable per smart device: 256

Maximum Number of Communication Masters: Two

2.3.2 Hardware Recommendations:

Supply Voltage: 17-42 VDC

Load Resistance: 250 to 600 ohms (includes cable resistance)

Refer to Figure 1.3.2 on page 7 for power

supply voltage requirements and load

resistance.

Minimum cable size: 24 AWG, (0.51 mm diameter)

Cable Type: Single pair shielded or multiple pair with

overall shield

Maximum Twisted-Pair Length: 10,000 ft. (3,048 m)

Maximum Multiple Twisted-Pair Length: 5,000 ft (1,524 m)

Use the following formula to determine cable length for a specific application:

L = 65 x 106 - (Cr + 10,000)

(R x C) C

where:

L = length in feet or meters

R = resistance in ohms (current sense resistance plus barrier resistance)

C = cable capacitance in pF/ft or pF/m

Cf = maximum shunt capacitance of field device in pF

IM 1F2B4-01-YIA

Page 35

Page 32

INSTALLATION

III. INSTALLATION

Before installing your YEWFLO you will need to gather the following tools:

Wafer Style:

1. Gaskets - self-centering preferred. In no case should the I.D. of the gaskets be smaller than

the I.D. of the meter.

2. Wrenches - Two of a size appropriate for the nuts supplied.

3. Screw driver - A small Phillips or flat blade type may be used to connect lead wires.

4. Sufficient wire to reach from the meter signal converter to the power source, receiving

device. See the Wiring Section of this manual for wire recommendations.

5. Stud bolts, washers and nuts are supplied with the meter

Flanged Style:

1. Nuts, bolts and washers appropriate in type, size, material and quantity for the flange as

specified by ANSI standards.

2. Gaskets - self-centering preferred. In no case should the I.D. of the gaskets be smaller than

the I.D. of the meter.

3. Wrenches - Two of a size appropriate for the nuts supplied.

4. Screw driver - A small Phillips or flat blade type may be used to connect lead wires.

5. Sufficient wire to reach from the meter signal converter to the power source, receiving

device. See the Wiring Section of this manual for wire recommendations.

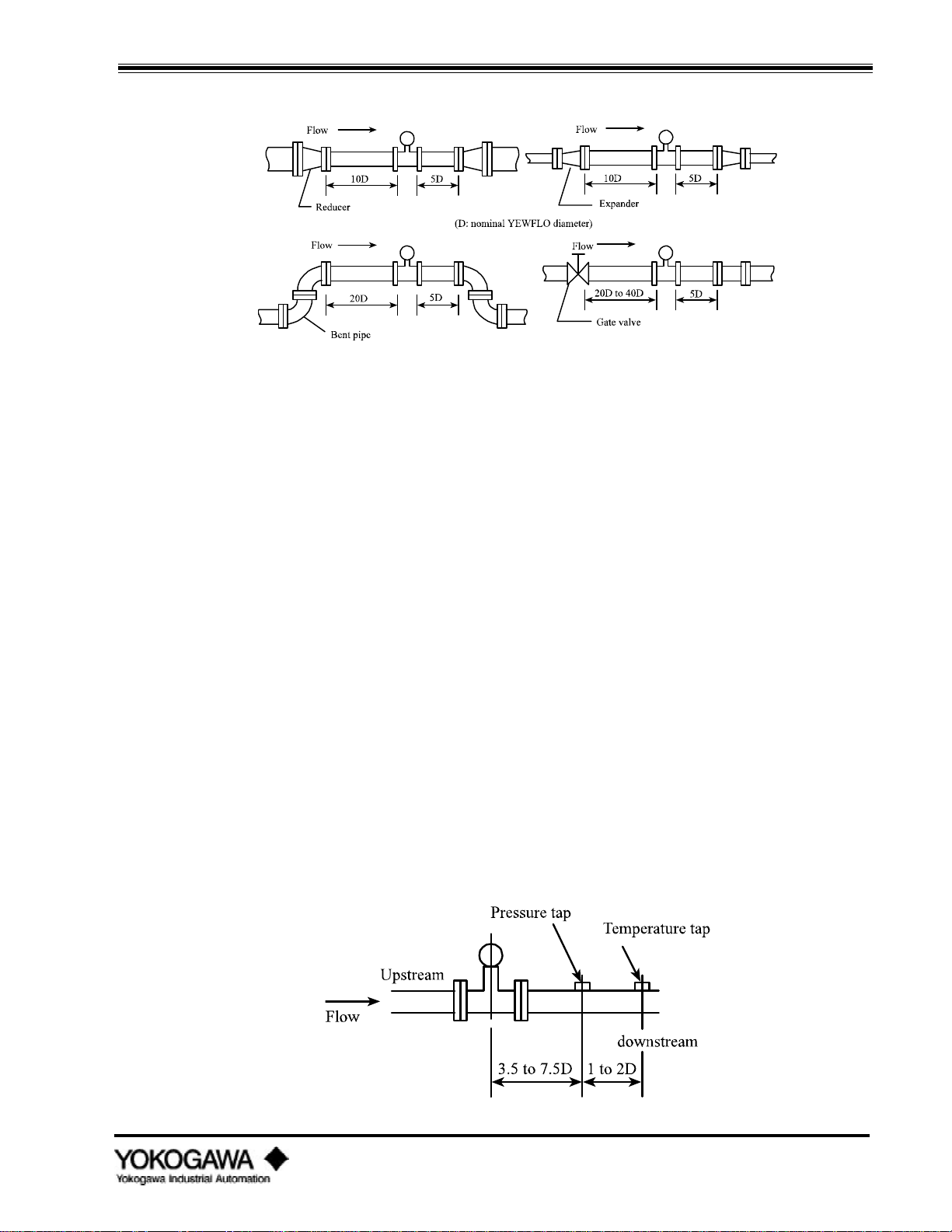

3.1 PIPING REQUIREMENTS

To obtain maximum performance, the vortex flowmeter should be installed in a pipe with a straight

run the same size as the nominal size of the meter. On the upstream side, the straight run depends on

what is in the pipe ahead of the meter. In most installations a maximum of 20 diameters will be

sufficient. The pipe on the downstream side of the meter should always be at least 5 diameters. The

combination of flowmeter with upstream and downstream pipe is referred to as the metering run.

Refer to the following illustrations for the minimum straight pipe for your installation. Note that in

all installations the mating pipe on either side of the vortex meter must match the meter size. In many

applications proper sizing may recommend using one meter size smaller than the existing pipe.

When this is the case, concentric reducers should not be directly attached to the flowmeter, but

installed on either end of the metering run as shown. In any case, the guidelines for orifice plate

installations as published by the ASME will be safe to follow.

IDEAL

Figure 3.1.1: YEWFLO upstream side of valve

IM 1F2B4-01-YIA

Page 36

Page 33

INSTALLATION

ACCEPTABLE

Figure 3.1.2: Reducer, expander, elbow and valve

If the meter cannot be located in the piping where the minimum straight run requirements can be

met, it may be possible to install flow conditioning equipment upstream of the vortex meter and

reduce the upstream piping without significantly reducing the accuracy. Contact your local

representative or Yokogawa Industrial Automation for recommendations regarding flow conditioners.

3.1.1 Pipe schedule

We recommend pipe schedule 40 for ½" through 2" meter sizes. For meters larger than 2", use

schedule 80 pipe or smaller. If pipe schedule other than above is used, please refer to Parameter D05

to correct errors due to mismatched pipe schedule.

3.1.2 Flow direction and orientation

Before installing the vortex meter verify the arrow on the meter body is facing the same

direction as the direction of the flow. The direction of flow can be determined by the arrow on the

shedder bar or clamping plate. The meter may be installed with the converter located above, below

or to the side of the piping, whatever suits the selected installation location best. Flow may be

horizontal or vertical, as long as the pipe is completely full. For liquid applications vertical flow up

is preferred, as this guarantees a full pipe at all times.

3.1.3 Pressure and temperature taps

If you are metering a gas where pressure and temperature compensation is required, pressure and

temperature taps must be located downstream of the vortex meter. See Figure 3.1.3.

Figure 3.1.3: Pressure and Temperature taps

IM 1F2B4-01-YIA

Page 37

Page 34

INSTALLATION

3.1.4 Flushing the pipe

On a new installation we recommend flushing the pipeline and removing any and all scales on the

inside of the pipe before installing the vortex meter. The bypass piping should be installed around the

vortex meter to facilitate pipe cleaning. When there is no bypass piping, the vortex meter should be

temporarily removed and a spool piece installed in its place.

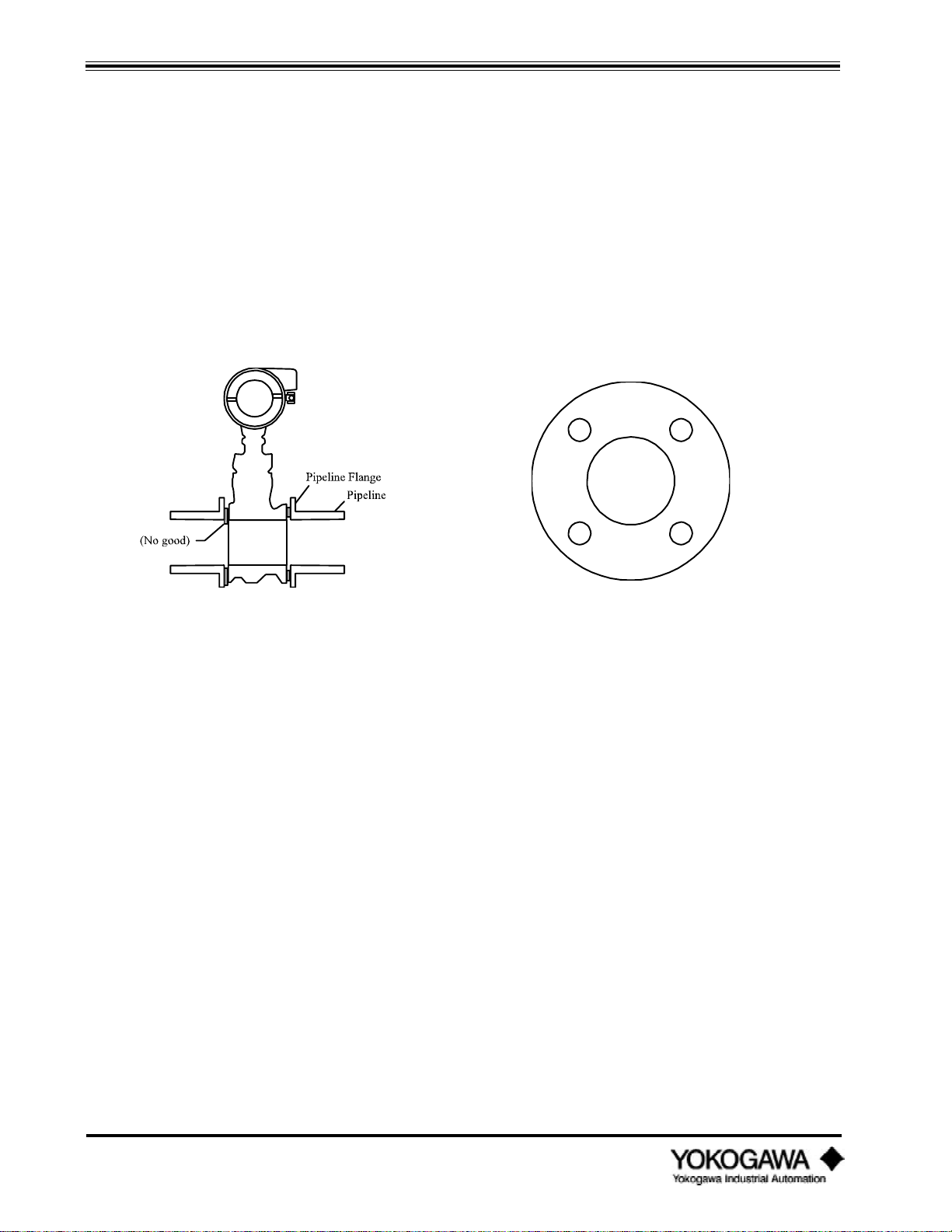

3.1.5 Gaskets

The ID of the gaskets must be equal to or larger than the ID of the meter and mating pipe. The

gaskets should be the self-centering type. It is important that the gaskets not protrude into the flow

stream, otherwise accuracy will be adversely affected.

Figure 3.1.4: Gasket cross section Figure 3.1.5: Typical gasket with bolt holes

3.2 INSTALLING THE VORTEX METER

Before installing the vortex meter, verify the arrow on the meter body is facing the same direction as

the direction of the flow.

3.2.1 Installing the wafer style vortex meter

When installing the wafer type vortex meter it is important to align the instrument bore with the

inner diameter of the adjacent piping. For meters in sizes ½" through 3", four alignment collars are

supplied. These collars establish a predetermined spacing between the mounting bolts and the

outside diameter of the vortex meter body. The bolts must be of the proper diameter to establish

alignment. Carbon steel stud bolts and nuts are supplied as standard. Stainless steel (304) stud bolts

and nuts are optional. Gaskets are supplied by the user. Check all mating flanges ensuring all weld

slag is ground off and the inside surface is clean and smooth.

IM 1F2B4-01-YIA

Page 38

Page 35

INSTALLATION

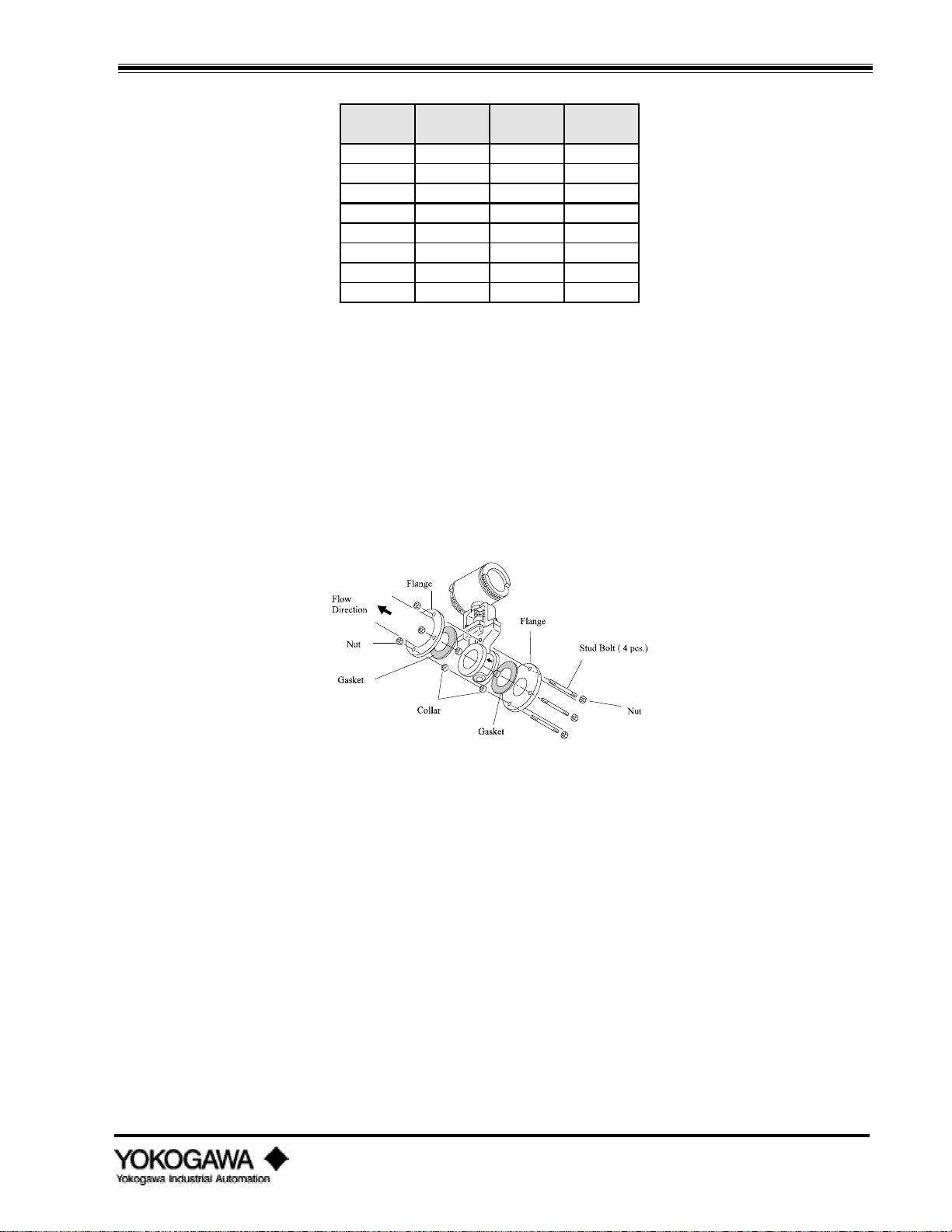

Meter Flange Collar Kit Mark on

Size Rating (4 per set) collar

0.5" 150# F9322GC GL

0.5" 300#, 600# F9322GD GM

1.0" 150# F9322HC HL

1.0" 300#, 600# F9322GA GJ

1.5" 150# F9322GC GL

1.5" 300#, 600# F9322JD JM

2.0" 150# F9322KA KC

3.0" 150# F9322KM KP

Table 3.2.1: Dimensions

Note: Only the above indicated meter sizes require collars

3.2.2 Installing the wafer style vortex meter horizontally

1) Insert two collars (see dimensions table above) on each of the two lower bolts.

2) Place the vortex meter on the collars located on the lower two bolts making sure the arrow

on the side of the meter body is facing in the same direction as the flow.

3) Insert the remaining bolts and tighten all bolts and nuts uniformly.

4) Check for leakage between the meter body and the flanges.

Figure 3.2.1: Wafer type - horizontal installation

3.2.3 Installing the wafer style vortex meter vertically

1) Insert one collar (if required, see table 3.2.1) on each bolt, being certain that the collars are

in contact with the outside diameter of the vortex meter body. Make sure the arrow on the

side of the meter body is facing the same direction as the flow.

2) Tighten all bolts uniformly.

3) Check for leakage between the meter body and the flanges.

IM 1F2B4-01-YIA

Page 39

Page 36

INSTALLATION

CAUTION:

When installing the vortex meter in a vertical pipe

outdoors we recommend rotating the conduit

connection to face downward reducing the chance of

rain and condensate running down the conduit into

the housing.

Fig 3.2.2: Wafer type - vertical installation

3.2.4 Installing the flanged vortex meter

Use bolts, nuts and gaskets in accordance with ANSI B16.5 (user supplied). The ID of the gasket

must be equal to or greater than the ID of the meter bore. Self-centering gaskets are highly

recommended.

Figure 3.2.3: Flanged type - horizontal installation Figure 3.2.4: Flanged type - vertical installation

3.2.5 Insulating vortex meters with integral converter

When installing a vortex meter with an integral converter in a pipe to measure high temperature

fluids, do not insulate the converter housing or mounting bracket. If it is necessary to insulate the

entire installation, use a remote mounted converter. Custom steam jackets are available if necessary,

please contact your Yokogawa Industrial Automation Representative for more information.

IM 1F2B4-01-YIA

Page 40

Page 37

INSTALLATION

3.2.6 Rotating the meter housing

The terminal box or converter housing may be rotated in 90º increments with respect to the pipe for

viewing or wiring convenience.

3.2.7 Remote converter terminal box rotation

1) Turn the power off.

2) Remove the terminal box cover.

3) Disconnect the lead wires from the sensor, Red (A) and White (B).

4) For 1" through 4" meter sizes, remove the bracket mounting bolts and the terminal box from

the meter body. Remove the four Allen bolts securing the terminal box to the bracket,

rotate to the desired position and reassemble.

5) On larger meters remove the 4 hex bolts securing the terminal box, rotate to the desired

position and reassemble.

3.2.8 Integral converter rotation

1) Turn the power off.

2) Remove the converter cover.

3) Remove the amplifier.

4) Disconnect the wires from the sensor, Red (A) and White (B).

5) For 1" through 4" meter sizes, remove the bracket mounting bolts and the amplifier housing

6) On larger meters remove the 4 hex bolts securing the amplifier housing, rotate to the desired

Figure 3.2.5: Changing the terminal box orientation

from the meter body. Remove the four Allen bolts securing the housing to the bracket, rotate

to the desired position and reassemble.

position and reassemble.

IM 1F2B4-01-YIA

Page 41

Page 38

INSTALLATION

Figure 3.2.6: Changing the converter orientation

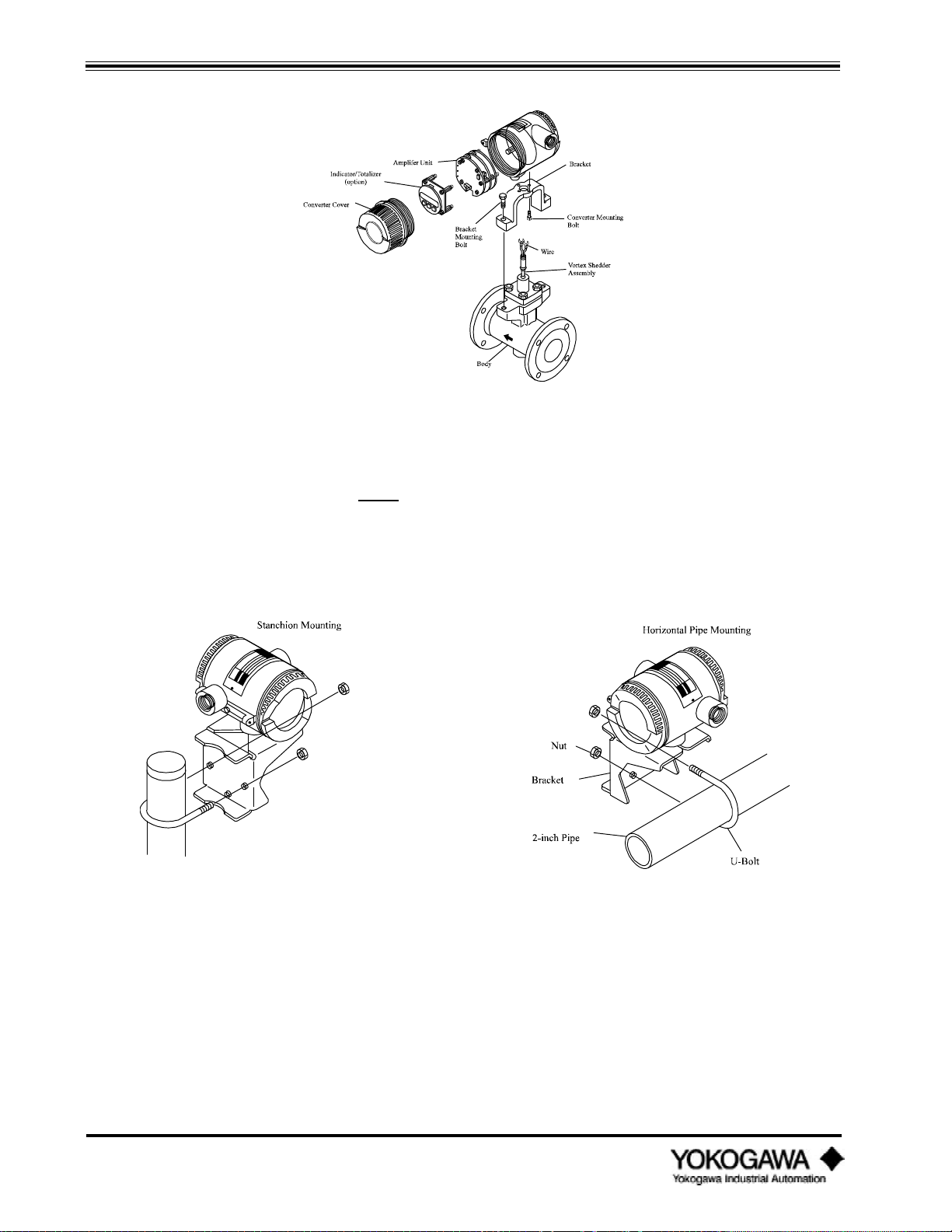

3.2.9 Installing the remote converter

A special signal cable (YF011) must be used between the vortex meter body and the remote

electronics. The maximum cable length is 65 feet (20 meters). Do not splice additional cable to

extend the length. The converter may mounted on 2" nominal pipe stand (horizontal or vertical)

using the supplied mounting bracket. The converter orientation may be rotated in 90º increments if

necessary to simplify wiring or viewing. To shorten the cable in the field please refer to the section

on cable.

Figure 3.2.7: Converter installation Figure 3.2.8: Converter installation

vertical pipe mounting horizontal pipe mounting

Note: If there is a local indicator (option /TBL) included on the remote amplifier, its display may be rotated

IM 1F2B4-01-YIA

Page 42

in 90º increments to facilitate reading the display.

Page 39

INSTALLATION

3.3 WIRING

3.3.1 Cables and wires (analog or pulse output wires only)

The following recommendations should be considered when selecting output wire for YEWFLO, and

installing it in the field.

1) Use 600 V PVC insulated wire or equivalent.

2) Use shielded wire in areas susceptible to electrical noise.

3) Use wire and cable suitable for the ambient environment, especially temperature and

4) Lay wires as far as possible from electrical noise sources such as large transformers, motors,

5) When wiring in a vertical position, a drip loop with a drain should be installed in the conduit

6) We recommend using crimp-on solderless type lugs for the output wire termination.

7) For industrial installations, we recommend using conduit or cable tray to protect wiring from

8) Safety grounding should meet National Electrical Code Class 3 requirements (resistance to

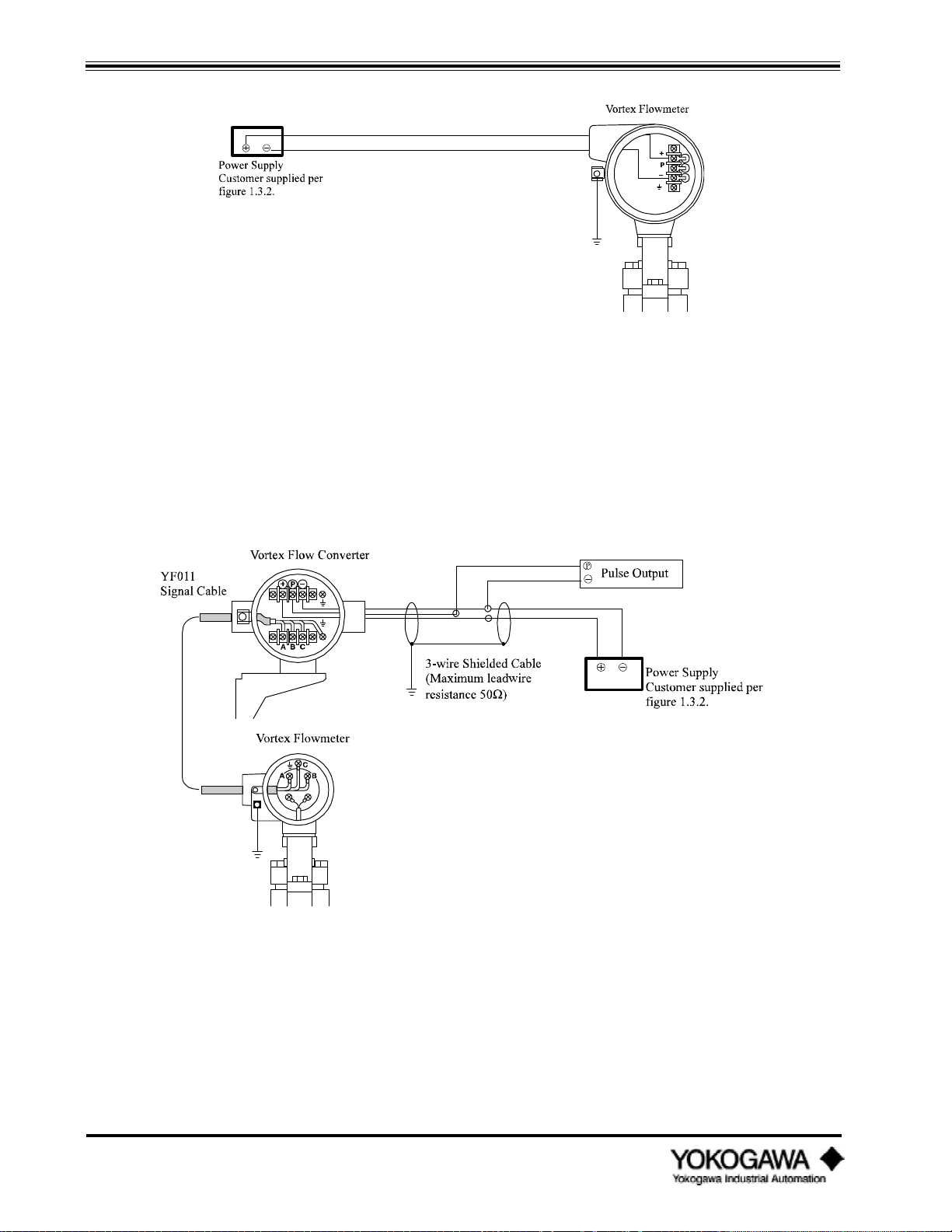

3.3.2 Analog output, 2-wire type (4-20 mADC)

When configured for analog output, the two instrument output wires also provide power. A DC

power supply (user supplied) is required in the loop. The power supply voltage required is

determined by the total instrument loop resistance including output wires. The permissible resistance

versus required power supply voltage is shown in figures 3.3.1 and 3.3.2.

chemical compatibility.

and power supplies.

so that water does not run down the wire and into the converter housing.

water or mechanical damage. A rigid steel conduit or flexible metal conduit is acceptable.

ground of 100 ohms or less). Ground wires should be 600 V PVC insulated wire.

Note: The field chassis ground and minus (-) power supply terminal are isolated from each other and should

not be connected.

Figure 3.3.1: Wiring Connections (Analog) Remote Converter

IM 1F2B4-01-YIA

Page 43

Page 40

INSTALLATION

Figure 3.3.2: Wiring Connections (Analog) Integral Converter

3.3.3 Pulse output, 3-wire type

When configured for pulse output mode, the converter requires three wires between the converter

and the power supply. The required power should be between 18 and 30 VDC (allowable ripple +1.5

V or less). The pulse output (P terminal) is connected to a remote totalizer. The minimum load

resistance of the pulse output loop is 10k ohms (maximum capacitance 0.22F, 0.1F for output

frequency above 2.5 kHz), and interconnection wire resistance must be less than 50 ohms.

IM 1F2B4-01-YIA

Page 44

Figure 3.3.3: Wiring Connections (Pulse) - Remote Converter Type

Page 41

INSTALLATION

Figure 3.3.4: Wiring Connections (Pulse) - Integral Type

3.3.4 Interconnection for remote converter

When the converter is remotely mounted from the meter body, a special signal cable (YFO11) must

be used. The maximum length of this cable is 65 feet (20 meters). The signal cable transmits a low

level sensor signal from the remote flowmeter to the remote converter. The remote converter

provides the output signals as described above. The remote signal wire connections are the same for

either Analog or Pulse output units. The A, B and C terminals on the flowmeter are connected via the

red, white and black wires (respectively) to the A, B and C terminals on the converter. The blue wire

is connected on the converter end only to chassis ground. See figure 3.3.5.

For remote mounted converters there are two electrical conduit connections. Use the left connection,

as viewed from the terminal side, for the signal wire (YFO11 cable) and the right connection for the

output wiring. If the connection directions are reversed, the cover shield for the signal terminals

cannot be installed.

Figure 3.3.5: Shield Converter -Remote Type

IM 1F2B4-01-YIA

Page 45

Page 42

INSTALLATION

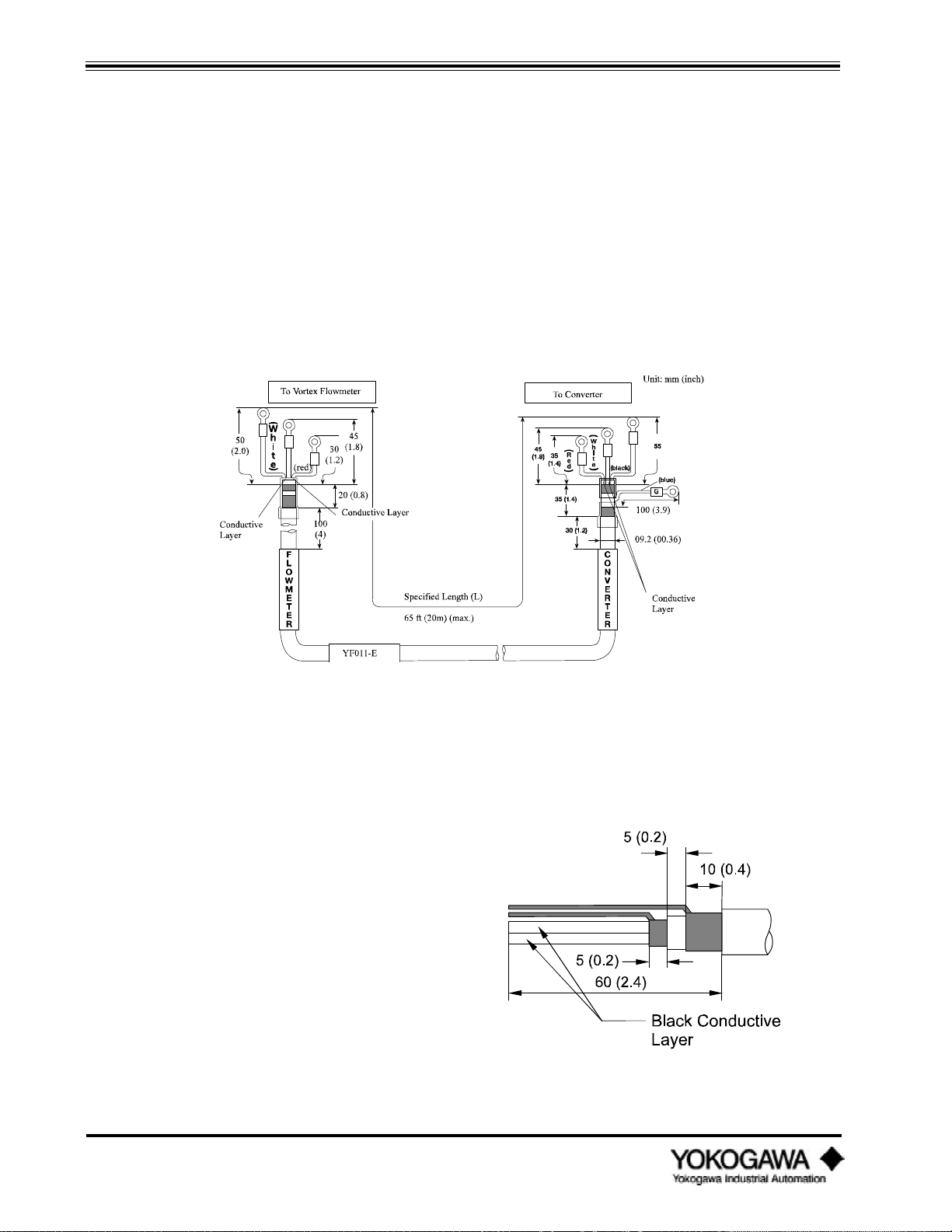

3.4 CABLE

3.4.1 Field terminating the signal cable (YF011-0*E)

Both ends of the cable must be finished in accordance with the following instructions. The maximum

cable length is 65 feet (20 meters). The YEWFLO cable is a special double-shielded cable available

only from Yokogawa Industrial Automation. Proper termination is critical to ensure the meter

performs as specified. Do not splice additional cable to add length. Please follow all steps

completely.

If you are shortening the cable in the field, to simplify your work, cut off excess length from the

flowmeter end of the cable only and re-terminate. The flowmeter end requires only three (3)

termination’s, while the converter end requires four (4).

Figure 3.4.1: YF011 Signal Cable

Caution: Do not allow the “conductive layer” (black covering over signal wires A & B) to short to case

ground or any other conductor. Please follow the termination procedure to insure proper termination

and flowmeter performance.

Flowmeter end of the cable

1. Strip the outer polyethylene jacket,

outer braided shield, inner jacket,

and inner braided shield to the

dimensions shown.

Caution: Don’t cut the uninsulated drain wires.

2. Strip off the black conductive layer

on each wire exposing the red or

white insulation underneath to the

IM 1F2B4-01-YIA

Page 46

Page 43

INSTALLATION

dimensions shown. Cut the length

of each wire to the dimensions

shown. Twist the strands of each

wire and drain wire so there are no

free strands.

3. Do not allow the black conductive

layer to short circuit to wires A, B,

C or the metal Case.

4. Strip off the red or white insulation

to the dimensions indicated. Twist

the outer and the inner drain wires

(shields) together. You should now

have 3 individual conductors.

5. Insert insulating tubing over the

twisted drain wires, wire C, as far

as possible. Cut the tubing off

leaving only 0.2 inches (5 mm) of

the drain wire exposed. Strip 0.2

inches (5 mm) of insulation from

the tips of the remaining two wires,

A and B.

6. Slide heat shrinkable tubing over

the wire bundle such that it covers

the braided shields, overlaps the

outer jacket and the loose wires A,

B, and C as shown. Be certain that

this tubing insulates all shield wires

from chassis ground, this will insure

that the field ground remains

isolated from the control room

ground.

7. Install insulated crimp lugs on each

wire A, B, and C.

8. Attach identifying labels to the

outside of the signal cable.

IM 1F2B4-01-YIA

Page 47

Page 44

INSTALLATION

Confirm that the insulation between each wire including the inner shield is 10 Mega Ohm or greater

at 500 VDC. Maintain both ends of the wires disconnected (open circuit) during insulation resistance

(Hi-Pot) test.

Converter end of the cable

1. Strip the outer polyethylene jacket,

outer braided shield, inner jacket,

and inner braided shield to the

dimensions shown. Caution: don’t

cut the drain wires.

2. Strip off the black conductive layer

on each wire exposing the red or

white insulation underneath to the

dimensions indicated. Twist the

strands of each wire and drain wire

so there are no free strands.

3. Do not allow the black conductive

layer to short circuit to wires A, B,

C, G or the metal case.

4. Strip off the red or white insulation

to the dimensions indicated, and cut

each wire to length as shown.

5. Insert blue insulating tubing over the

outer shield drain wire (G), and

black insulating tubing over the

inner shield drain wire (C) as

shown. Cut the tubing off exposing

0.2 inches (5 mm) of each drain

wire. Strip 0.2 inches (5 mm) of

insulation from the tips of the

remaining two wires (A and B).

6. a) Slide heat shrinkable tubing over

the entire wire bundle such that it

overlaps the outer jacket, outer

shield and the blue wire (G) as

shown. Be certain that the outer

shield is fully protected.

IM 1F2B4-01-YIA

Page 48

Page 45

INSTALLATION

b) Slide another heat shrinkable tubing

over the wire bundle such that it covers

the inner braided shield, overlaps the

inner jacket and the loose wires A, B,

and C as shown. Be certain that the heat

shrink tubing protects all shield wires

from chassis ground. Heat the tubing as

necessary to shrink it for a tight fit.

7. Install insulated crimp lugs on each wire A, B, C and G.

8. Attach identifying labels to the outside of each signal cable.

Confirm that the insulation between each wire including the inner shield is 10 Mega Ohm or greater

at 500 VDC. Maintain both ends of the wires disconnected (open circuit) during insulation resistance

(Hi-Pot) test.

3.5 WIRING CAUTIONS

When installing the YEWFLO in a hazardous area, particular care must be taken when wiring the

meter not violate any of the requirements of the hazardous area approvals.

For explosionproof installations, the wiring must be protected by conduit and proper seals so

hazardous material exposure is limited and consistent with the requirements of the approving agency

(FM or CSA). If you are unsure about the requirements of the approving agency, consult their

appropriate standards handbook.

3.5.1 Flameproof transmitter installation

The model YF100 vortex flowmeters and YFA11 vortex flow converters are designed to be used in

hazardous areas, divisions 1 and 2. Their specific uses are outlined in “Recommended practice for

explosion-protected electrical installations in general industries (Gas Explosion Protection, 1985).”

To avoid damaging the flameproof equipment, connecting bolts, wiring and pipes should be installed

with care. Caution should also be used for maintenance and repair of the equipment. For further

information, refer to “Operating precautions for instruments of flameproof construction conforming

to technical criteria (IEC-Compatible Standards)”

3.5.2 Cautions for insulation and dielectric strength testing