GS610

Source Measure Unit

IM 765501-01E

5th Edition

Product Registration

Thank you for purchasing YOKOGAWA products.

YOKOGAWA provides registered users with a variety of information and services.

Please allow us to serve you best by completing the product registration form

accessible from our website.

http://tmi.yokogawa.com/

PIM 103-04E

List of Manuals

Notes

Thank you for purchasing the GS610 Source Measure Unit.

This user’s manual contains useful information about the instrument’s functions and

operating procedures and lists the handling precautions of the GS610. To ensure

correct use, please read this manual thoroughly before beginning operation. After

reading the manual, keep it in a convenient location for quick reference whenever a

question arises during operation.

The following manuals, including this one, are provided as manuals for the GS610.

Please read all manuals.

Manual Title Manual No. Description

GS610 Source Measure Unit IM 765501-01E This manual. Explains all the functions of

User’s Manual the GS610 and their operating procedures.

GS610 Source Measure Unit IM 765501-92 Document for China

The “E” in the manual number is the language code.

Contact information of Yokogawa offices worldwide is provided on the following sheet.

Document No. Description

PIM 113-01Z2 List of worldwide contacts

• The contents of this manual are subject to change without prior notice as a result of

continuing improvements to the instrument’s performance and functions. The figures

given in this manual may differ from those that actually appear on your screen.

• Every effort has been made in the preparation of this manual to ensure the accuracy

of its contents. However, should you have any questions or find any errors, please

contact your nearest YOKOGAWA dealer.

• Copying or reproducing all or any part of the contents of this manual without

YOKOGAWA’s permission is strictly prohibited.

• The TCP/IP software of this product and the document concerning the TCP/IP

software have been developed/created by YOKOGAWA based on the BSD

Networking Software, Release 1 that has been licensed from the University of

California.

The GS610 sources up to 110 V of DC voltage.

• To prevent electric shock, be sure to read this manual before use.

• Improper operation may lead to serious, life-threatening accidents. Keep this

manual close to the GS610 so that the operator can refer to it anytime

French

Le GS610 fournit jusqu’à 110 V de tension c.c.

• Afin d’éviter tout choc électrique, bien lire le présent manuel avant utilisation.

• Une utilisation incorrecte entrainerait des risques d’accidents graves voire

mortels. Conservez ce manuel à proximité du GS610, de sorte que l’opérateur

puisse le consulter à tout moment

5th Edition: October 2017 (YMI)

All Rights Reserved, Copyright © 2005 Yokogawa Electric Corporation

All Rights Reserved, Copyright © 2013 Yokogawa Test & Measurement Corporation

IM 765501-01E

High voltage

Haute tension

i

Trademarks

Revisions

• Microsoft, Internet Explorer, MS-DOS, Windows, Windows NT, and Windows XP are

either registered trademarks or trademarks of Microsoft Corporation in the United

States and/or other countries.

• Adobe, Acrobat, and PostScript are trademarks of Adobe Systems Incorporated.

• For purposes of this manual, the ® and TM symbols do not accompany their

respective registered trademark names or trademark names.

• Other company and product names are registered trademarks or trademarks of their

respective holders.

• 1st edition: August 2005

• 2nd edition: January 2009

• 3rd edition: September 2013

• 4th edition: March 2016

• 5th edition: October 2017

ii IM 765501-01E

Checking the Contents of the Package

Unpack the box and check the contents before operating the instrument. If some of the

contents are not correct or missing or if there is physical damage, contact the dealer

from which you purchased them.

GS610

Check that the model name and suffix code given on the name plate on the side panel

match those on your order.

MODEL and SUFFIX Codes

Model Suffix Code1Description

765501 100-240 VAC Source measure unit

Power cord

Options /C10 Ethernet interface

1 For products whose suffix code contains “Z,” an exclusive manual may be included. Please

2 Make sure that the attached power cord meets the designated standards of the country and

2

-D UL/CSA Standard Power Cord (Part No.: A1006WD)

-F VDE Standard Power Cord (Part No.: A1009WD)

-Q BS Standard Power Cord (Part No.: A1054WD)

-R AS Standard Power Cord (Part No.: A1024WD)

-H GB Standard Power Cord (Part No.: A1064WD)

read it along with the standard manual.

area that you are using it in.

[Maximum rated voltage: 125 V; Maximum rated current: 7A]

[Maximum rated voltage: 250 V; Maximum rated current: 10 A]

[Maximum rated voltage: 250 V; Maximum rated current: 10 A]

[Maximum rated voltage: 250 V; Maximum rated current: 10 A]

[Maximum rated voltage: 250 V; Maximum rated current: 10 A]

IM 765501-01E

NO. (Instrument Number)

When contacting the dealer from which you purchased the instrument, please give them

the instrument number.

iii

Checking the Contents of the Package

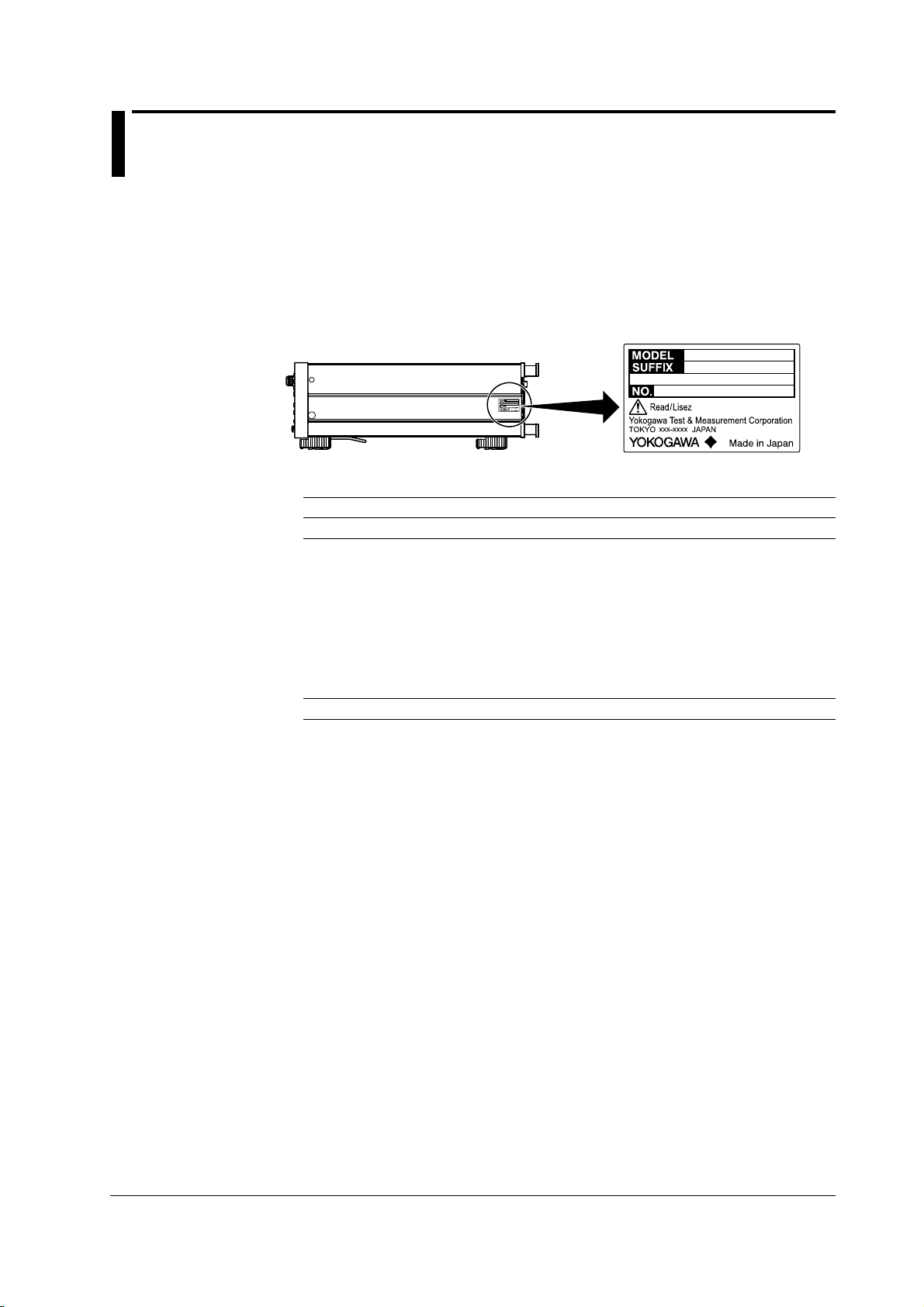

Standard Accessories

The standard accessories below are supplied with the instrument.

Name Model Qty. Notes

Power cord A1006WD 1 UL/CSA Standard Power Cord

Rubber Feet A9088ZM 2 Two rubber feet in one set

Measurement lead 758933 1

Alligator clip adapter 758922 1 set Safety terminal-to-alligator clip adapter. Red

D-sub connector for A1519JD/ 1 set 1 connector cover, 1

External I/O B8060KA 15-pin connectocer

Manuals IM 765501-01E 1 User’s manual (this manual)

/Part No.

Maximum rated voltage: 125 V;

Maximum rated current: 7A

A1009WD 1 VDE Standard Power Cord

Maximum rated voltage: 250 V;

Maximum rated current: 10 A

A1054WD 1 BS Standard Power Cord

Maximum rated voltage: 250 V;

Maximum rated current: 10 A

A1024WD 1 AS Standard Power Cord

Maximum rated voltage: 250 V;

Maximum rated current: 10 A

A1064WD 1 GB Standard Power Cord

Maximum rated voltage: 250 V;

Maximum rated current: 10 A

and black, 1 pc. each

IM 765501-92 1 Document for China

PIM 113-01Z2 1 List of worldwide contacts

One of these power cords is supplied according to the suffix code1.

UL, CSA Standard

A1006WD

D F

Measurement Lead

758933

D-sub connector for EXT. I/O

(15-pin, male)

B8060KA

1 Make sure that the attached power cord meets the designated standards of the country

and area that you are using it in.

VDE Standard

A1009WD

Alligator Clip Adapter Set

758922

A1519JD

BS Standard

A1054WD

Q

Manuals

• IM 765501-01E (this manual)

• IM 765501-92

• PIM 113-01Z2

AS Standard

A1024WD

R

Rubber Feet

A9088ZM

GB Standard

A1064WD

H

iv IM 765501-01E

Checking the Contents of the Package

Optional Accessories (Sold Separately)

The optional accessories below are available for purchase separately.

Name Model/ Min. Safety Notes Manual No.

Part No. Q’ty standard

Measurement lead 758917 1 set 1000 V CAT II Safety terminal cable with 2 leads (red and black) —

758933 1 set 1000 V CAT III Safety terminal cable with 2 leads (red and black) —

Alligator clip adapter 758922 1 set 300 V CAT II Safety terminal-to-alligator clip adapter. Red and —

(small) black, 1 pc each. Rating: 300 V, 15 A.

Alligator clip adapter 758929 1 set 1000V CAT II Safety terminal-to-alligator clip adapter. Red and —

(large) black, 1 pc each. Rating: 1000 V, 32 A.

Safety terminal adapter 758923 1 set 600 V CAT II Spring clamp type. Red and black, 1 pc. each. —

758931 1 set 1000 V CAT III Screw-in type. Red and black, 1 pc each. —

Conversion adapter 758924 1 500 V CAT II Safety BNC-to-banana adapter. Rating: 500 V. —

BNC cable 366924 1 — BNC-BNC, length: 1 m. Rating: 42 V. —

366925 1 — BNC-BNC, length: 2 m. Rating: 42 V. —

D-sub connector for A1519JD 1 — 15-pin connector cover —

External I/O B8060KA 1 — 15-pin connector —

in a set. Length: 0.75 m. Rating: 1000 V, 32 A.

in a set. Length: 1 m. Rating: 1000 V, 19 A.

Rating: 600 V, 10 A.

Rating: 1000 V, 36 A.

WARNING

• Use the accessories specified in this manual. Moreover, use the accessories of

this product only with Yokogawa products that specify them as accessories.

• Use the accessories of this product within the rated range of each accessory.

When using several accessories together, use them within the specification

range of the accessory with the lowest rating.

CAUTION

Use BNC cables 366924 and 366925 for the BNC I/O terminals.

French

AVERTISSEMENT

• Utiliser les accessoires spécifiés dans ce manuel. En outre, utiliser les

accessoires de ce produit uniquement avec des produits Yokogawa pour

lesquels ils sont spécifiés comme accessoires.

• Utilisez les accessoires de ce produit en fonction des valeurs nominales de

chacun.

Lorsque vous employez plusieurs accessoires en même temps, utilisez les

valeurs de l’accessoire ayant les valeurs nominales les plus faibles.

IM 765501-01E

ATTENTION

Utiliser les câbles BNC 366924 et 366925 pour les bornes E/S BNC.

v

Safety Precautions

This product is designed to be used by a person with specialized knowledge.

This instrument is an IEC safety class I instrument (provided with a terminal for

protective earth grounding). The general safety precautions described herein must be

observed during all phases of operation. If the instrument is used in a manner not

specified in this manual, the protection provided by the instrument may be impaired.

This manual is an essential part of the product; keep it in a safe place for future

reference. YOKOGAWA assumes no liability for the customer’s failure to comply with

these requirements.

The following symbols are used on this instrument.

Warning: handle with care. Refer to the user’s manual or service manual.

This symbol appears on dangerous locations on the instrument which require

special instructions for proper handling or use. The same symbol appears in

the corresponding place in the manual to identify those instructions.)

Alternating current

ON (power)

French

OFF (power)

ON (power) state

OFF (power)

Avertissement : À manipuler délicatement. Toujours se reporter aux manuels

d’utilisation et d’entretien. Ce symbole a été apposé aux endroits dangereux

de l’instrument pour lesquels des consignes spéciales d’utilisation ou de

manipulation ont été émises. Le même symbole apparaît à l’endroit

correspondant du manuel pour identifier les consignes qui s’y rapportent.

Courant alternatif

Marche (alimentation)

Arrêt (alimentation)

Marche

Arrêt

vi IM 765501-01E

Safety Precautions

Failure to comply with the precautions below could lead to injury or death or damage

to the instrument.

WARNING

• Use the Instrument Only for Its Intended Purpose

This instrument is equipped with current and voltage measurement.

Use the instrument only for measuring and generating current and voltage.

• Check the Physical Appearance

Do not use the instrument if there is a problem with its physical appearance.

• Use the Correct Power Supply

Before connecting the power cord, ensure that the source voltage matches the

rated supply voltage of the instrument and that it is within the maximum rated

voltage of the provided power cord.

• Use the Correct Power Cord and Plug

• To prevent the possibility of electric shock or fire, be sure to use the power

cord supplied by YOKOGAWA.

• The main power plug must be plugged into an outlet with a protective earth

terminal. Do not disable this protection by using an extension cord without

protective earth grounding.

• Additionally, do not use the power cord supplied with this instrument with

another instrument.

• Do not use the power cord in a bundled condition.

• If you use a power plug with foreign substance on it, insulation may be

compromised by humidity or other factors and may cause a fire. Clean the

power plug regularly.

• Connect the Protective Grounding Terminal

Make sure to connect the protective earth to prevent electric shock before

turning ON the power. The power cord that comes with the instrument is a threeprong type power cord. Connect the power cord to a properly grounded threeprong outlet.

• Do Not Impair the Protective Grounding

Never cut off the internal or external protective grounding wire or disconnect the

wiring of the protective grounding terminal. Doing so poses a potential shock

hazard.

• Do Not Use When the Protection Functions Are Defective

Before using this instrument, check that the protection functions, such as the

protective grounding and fuse, are working properly. If you suspect a defect, do

not use the instrument.

• Do Not Operate in an Explosive Atmosphere

Do not operate the instrument in the presence of flammable liquids or vapors.

Operation in such an environment constitutes a safety hazard.

• Do Not Remove the Covers or Disassemble or Alter the Instrument

Only qualified YOKOGAWA personnel may remove the covers and disassemble

or alter the instrument. The inside of the instrument is dangerous because parts

of it have high voltages.

IM 765501-01E

vii

Safety Precautions

• Ground the Instrument before Making External Connections

Securely connect the protective grounding before connecting to the item under

measurement or to an external control unit.

Before touching the target device, turn off this instrument and check that there is

no voltage or current being output.

• Measurement Category

The measurement category of this instrument signal input terminals is Other (O).

Do not use it to measure the main power supply or for Measurement Categories

II, III, and IV.

• Install or Use the Instrument in Appropriate Locations

• This instrument is designed to be used indoors. Do not install or use it

outdoors.

• Install the instrument so that you can immediately remove the power cord if

an abnormal or dangerous condition occurs.

• Using in a Floating Condition

• Depending on the connected external device, dangerous voltage may appear

at the terminals if the instrument is used in a floating condition. Be careful of

electric shock and electric discharge.

• To prevent electric shock, remove rings, watches, and other metallic

accessories and jewelry before operation.

• Wiring Correctly

Dangerous voltage may appear at the terminals if the instrument is used in a

floating condition. If you do not connect the devices correctly, not only will it

damage the instrument or the target device, it may also lead to electric shock or

fire. Be careful when you connect the lead wires, and be sure to check the

following points.

• When using the instrument in a floating condition, make sure that the electric

potential of each output terminal is within ±250 Vpeak relative to the ground.

Before output (before turning on the output), check that:

• Lead wires are connected to the instrument’s output terminals correctly.

• Lead wires are connected to the target device correctly.

During output, check that:

• Never touch the terminals and the connected lead wires when the item under

measurement is on.

CAUTION

Operating Environment Limitations

This product is a Class A (for industrial environments) product. Operation of this

product in a residential area may cause radio interference in which case the

user will be required to correct the interference.

viii IM 765501-01E

Safety Precautions

French

AVERTISSEMENT

• Utiliser l’instrument aux seules fins pour lesquelles il est prévu

Cet instrument est équipé d'une fonction de mesure de courant et de tension.

Utiliser cet instrument uniquement pour mesurer et générer un courant et une

tension.

• Inspecter l’apparence physique

Ne pas utiliser l'instrument si son intégrité physique semble être compromise.

• Vérifier l’alimentation

Avant de brancher le cordon d’alimentation, vérifier que la tension source

correspond à la tension d’alimentation nominale du GS610 et qu’elle est

compatible avec la tension nominale maximale du cordon d’alimentation.

• Utiliser le cordon d'alimentation et la fiche adaptés

• Pour éviter les risques de choc électrique ou d’incendie, utilisez le cordon

d’alimentation fourni par YOKOGAWA.

• La fiche doit être branchée sur une prise secteur raccordée à la terre. En cas

d’utilisation d'une rallonge, celle-ci doit être impérativement reliée à la terre.

• Par ailleurs, n’utilisez pas le cordon d’alimentation fourni pour cet instrument

avec un autre appareil.

• N’utilisez pas le cordon d’alimentation en faisceau.

• Si vous utilisez un cordon d’alimentation sur lequel se trouve une substance

étrangère, l’isolation risque d’être compromise par l’humidité ou d’autres

facteurs, ce qui peut provoquer un incendie. Nettoyez la fiche du cordon

d’alimentation régulièrement.

• Brancher la prise de terre

Avant de mettre l’instrument sous tension, penser à brancher la prise de terre

pour éviter tout choc électrique. Le cordon d’alimentation livré avec l’instrument

est doté de trois broches. Brancher le cordon d’alimentation sur une prise de

courant à trois plots et mise à la terre.

• Ne pas entraver la mise à la terre de protection

Ne jamais neutraliser le fil de terre interne ou externe, ni débrancher la borne de

mise à la terre. Cela pourrait entraîner un choc électrique ou endommager

l’instrument.

• Ne pas utiliser lorsque les fonctions de protection sont défectueuses

Avant d’utiliser l’instrument, vérifier que les fonctions de protection, telles que le

raccordement à la terre et le fusible, fonctionnent correctement. En cas de

dysfonctionnement possible, ne pas utiliser l’instrument.

• Ne pas utiliser dans un environnement explosif

Ne pas utiliser l’instrument en présence de gaz ou de vapeurs inflammables.

Cela pourrait être extrêmement dangereux.

• Ne pas retirer le capot, ni démonter ou modifier l’instrument

Seul le personnel YOKOGAWA qualifié est habilité à retirer le capot et à

démonter ou modifier l’instrument. Certains composants à l’intérieur de

l’instrument sont à haute tension et par conséquent, représentent un danger.

IM 765501-01E

ix

Safety Precautions

• Relier l’instrument à la terre avant de le brancher sur des connexions

externes

Connectez le conducteur de terre avant de raccorder le dispositif cible ou une

unité de commande externe. Avant de toucher le dispositif cible, mettez

l’instrument hors tension, et vérifiez qu’aucune tension ni aucun courant ne sont

émis.

• Catégorie de mesure

La catégorie de mesure des terminaux d’entrée de signal du GS610 est Autre

(O). Ne pas l’utiliser pour mesurer l’alimentation électrique, ni pour les

catégories de mesure II, III et IV.

• Installer et utiliser l’instrument aux emplacements appropriés

• L’instrument est prévu pour une utilisation en intérieur. Ne pas l’installer, ni

l’utiliser à l’extérieur.

• Installer l’instrument de manière à pourvoir immédiatement le débrancher du

secteur en cas de fonctionnement anormal ou dangereux.

• Utilisation d’une condition de flottement

• Selon le dispositif extérieur raccordé, une tension dangereuse peut survenir

sur les bornes si l’instrument est utilisé en condition de flottement. Faites

attention au choc électrique et à la décharge électrique.

• Afin d’éviter tout choc électrique, retirer les bagues, les montres et autres

accessoires métalliques ainsi que les bijoux avant la mise en service.

• Câblage correct

Une tension dangereuse peut survenir sur les bornes si l’instrument est utilisé

en condition de flottement. Si vous ne raccordez pas correctement les appareils,

non seulement cela risque d’endommager l’équipement ou l’appareil cible, mais

en plus cela risque d’entraîner un choc électrique ou un incendie. Branchez

toujours les câbles en plomb correctement et vérifiez les points suivants.

• Lorsque l’instrument est utilisé en condition de flottement, veiller à ce que le

potentiel électrique de chaque borne de sortie soit inférieur à ± 250 V de

crête par rapport à la masse.

Avant le sortie (avant la mise sous tension), vérifier que :

• Les câbles en plomb sont correctement raccordés aux bornes de sortie de

l’équipement.

• Les câbles en plomb sont correctement raccordés à l’appareil cible.

Pendant la sortie, vérifier que :

• Ne jamais toucher les bornes et les câbles branchés lorsque l’appareil à

mesurer est sous tension.

ATTENTION

Limitations relatives à l’environnement opérationnel

Ce produit est un produit de classe A (pour environnements industriels).

L’utilisation de ce produit dans un zone résidentielle peut entraîner une

interférence radio que l'utilisateur sera tenu de rectifier.

x IM 765501-01E

Sales in Each Country or Region

Waste Electrical and Electronic Equipment

Waste Electrical and Electronic Equipment (WEEE), Directive

(This directive is valid only in the EU.)

This product complies with the WEEE directive marking requirement. This

marking indicates that you must not discard this electrical/electronic product in

domestic household waste.

Product Category

With reference to the equipment types in the WEEE directive, this product is

classified as a “Monitoring and control instruments” product.

When disposing of products in the EU, contact your local Yokogawa Europe B.V.

office. Do not dispose in domestic household waste.

EU Battery Directive

EU Battery Directive

(This directive is valid only in the EU.)

Batteries are included in this product. This marking indicates they shall be sorted

out and collected as ordained in the EU battery directive.

Battery type: Lithium battery

You cannot replace batteries by yourself. When you need to replace batteries,

contact your local Yokogawa Europe B.V. office.

Authorized Representative in the EEA

Yokogawa Europe B.V. is the authorized representative of Yokogawa Test &

Measurement Corporation for this product in the EEA. To contact Yokogawa Europe

B.V., see the separate list of worldwide contacts, PIM 113-01Z2.

IM 765501-01E

xi

Conventions Used in This Manual

Safety Markings

The following markings are used in this manual.

Improper handling or use can lead to injury to the user or damage

to the instrument.

indicate that the user must refer to the user’s manual for special

instructions. The same symbol appears in the corresponding place

in the user’s manual to identify those instructions. In the manual,

the symbol is used in conjunction with the word “WARNING” or

“CAUTION.”

This symbol appears on the instrument to

WARNING

CAUTION

French

AVERTISSEMENT

ATTENTION

Note

Calls attention to actions or conditions that could cause serious or

fatal injury to the user, and precautions that can be taken to prevent

such occurrences.

Calls attentions to actions or conditions that could cause light injury

to the user or damage to the instrument or user’s data, and

precautions that can be taken to prevent such occurrences.

Attire l’attention sur des gestes ou des conditions

susceptibles de provoquer des blessures graves (voire

mortelles), et sur les précautions de sécurité pouvant

prévenir de tels accidents.

Attire l’attention sur des gestes ou des conditions susceptibles

deprovoquer des blessures légères ou d’endommager l’instrument

ou lesdonnées de l’utilisateur, et sur les précautions de sécurité

susceptiblesde prévenir de tels accidents.

Calls attention to information that is important for proper operation

of the instrument.

xii IM 765501-01E

Subheadings

Conventions Used in This Manual

On pages that describe the operating procedures in chapters 3 through 17 and appendix,

the following symbols are used to distinguish the procedures from their explanations.

Procedure

Explanation

<<Corresponding Command Mnemonic>>

Follow the numbered steps. All procedures are written with

inexperienced users in mind; experienced users may not need to

carry out all the steps.

This subsection describes the setup parameters and the limitations

on the procedures. It may not give a detailed explanation of the

function. For a detailed explanation of the function, see chapter 2.

Indicates a communication command that corresponds to the

function described on the procedural explanation page.

Displayed Characters and Terminology Used in the Procedural Explanations

Panel Keys and Rotary Knob

Bold characters used in the procedural explanations indicate characters that are marked

on the panel key or the rotary knob.

SHIFT+Key

SHIFT+key

the operation key. In this state, the items marked in purple characters below the keys

are controlled.

means you will press the SHIFT key to turn ON the SHIFT key followed by

IM 765501-01E

xiii

Contents

List of Manuals ................................................................................................................................ i

Checking the Contents of the Package ..........................................................................................iii

Safety Precautions .........................................................................................................................vi

Sales in Each Country or Region ...................................................................................................xi

Conventions Used in This Manual................................................................................................. xii

Chapter 1 Part Names and Functions

1.1 Front Panel ...................................................................................................................... 1-1

1.2 Rear Panel ....................................................................................................................... 1-2

1.3 Names and Description of the Displayed Contents ......................................................... 1-3

1.4 Key Groups and Menus ................................................................................................... 1-5

Chapter 2 Explanation of Functions

2.1 System Configuration and Block Diagram ....................................................................... 2-1

2.2 Source Measure Cycle ..................................................................................................... 2-3

2.3 Source .............................................................................................................................. 2-5

2.4 Measurement ................................................................................................................. 2-10

2.5 Triggers .......................................................................................................................... 2-13

2.6 Sweep ............................................................................................................................ 2-14

2.7 Computation ................................................................................................................... 2-17

2.8 Store and Recall (Statistical Computation Value Display).............................................. 2-19

2.9 USB Storage Function ................................................................................................... 2-20

2.10 Other Functions ............................................................................................................. 2-22

Chapter 3 Instrument Preparation and Common Operations

3.1 Handling Precautions ....................................................................................................... 3-1

3.2 Installing the GS610 ......................................................................................................... 3-3

3.3 Connecting to the Power Supply ...................................................................................... 3-7

3.4 Turning the Power Switch ON/OFF .................................................................................. 3-9

3.5 Wiring Precautions ......................................................................................................... 3-11

3.6 Setting the Power Frequency ......................................................................................... 3-14

3.7 Setting the Date, Time, and the Time Difference from GMT (Greenwich Mean Time) ... 3-15

3.8 Basic Operation of Keys and Rotary Knob .................................................................... 3-17

3.9 Entering Values .............................................................................................................. 3-19

Chapter 4 Trigger Setting, Connection Type (Remote Sense and Local Sense),

and USB Storage Function

4.1 Setting the Trigger ............................................................................................................ 4-1

4.2 Connection Type (Remote Sense and Local Sense) ....................................................... 4-3

4.3 USB Storage Function ..................................................................................................... 4-5

Chapter 5 Source

5.1 Switching the Source Function ........................................................................................ 5-1

5.2 Setting the Source Range Setting .................................................................................... 5-2

5.3 Setting the Limiter ............................................................................................................ 5-4

5.4 Setting the DC Source Mode ........................................................................................... 5-6

5.5 Setting the Pulse Source Mode ....................................................................................... 5-8

5.6 Setting the Source Delay ............................................................................................... 5-11

5.7 Turning the Output ON/OFF........................................................................................... 5-13

xiv IM 765501-01E

Contents

3

12

11

10

15

14

13

18

17

16

Index

App

5.8 Zero Generation ............................................................................................................. 5-14

5.9 Offset Calibration ........................................................................................................... 5-16

Chapter 6 Sweep

6.1 Setting the Linear or Log Sweep ...................................................................................... 6-1

6.2 Setting the Program Sweep ............................................................................................. 6-5

6.3 Selecting the Termination Mode ....................................................................................... 6-7

6.4 Setting the Repeat Count ................................................................................................. 6-9

6.5 Starting the Sweep Operation ........................................................................................ 6-10

6.6 Program Pattern File ...................................................................................................... 6-11

Chapter 7 Measurement

7.1 Turning the Measurement ON/OFF ................................................................................. 7-1

7.2 Selecting the Measurement Function .............................................................................. 7-2

7.3 Turning ON/OFF the Auto Range function of the Measurement Range Settings ............ 7-3

7.4 Setting the Measurement Delay ....................................................................................... 7-4

7.5 Setting the Integration Time ............................................................................................. 7-6

7.6 Auto Zero Function .......................................................................................................... 7-7

7.7 Turning Auto V/I ON/OFF ................................................................................................. 7-8

Chapter 8 Computation

8.1 Averaging ......................................................................................................................... 8-1

8.2 NULL Computation ........................................................................................................... 8-3

8.3 Computation Using Equations ......................................................................................... 8-4

8.4 Comparison Operation ..................................................................................................... 8-7

8.5 User-Defined Computation .............................................................................................. 8-9

1

2

3

4

5

6

7

8

9

10

Chapter 9 Storing Measured Results and Recalling Statistical Computation

Values

9.1 Storing the Measured Results .......................................................................................... 9-1

9.2 Recalling Statistical Computation Values ......................................................................... 9-4

Chapter 10 BNC Input/Output and External Input/Output

10.1 Setting the Input/Output Signals of the BNC Input/Output Terminal and the External Input/

Output Connector ........................................................................................................... 10-1

10.2 Synchronized Operation ................................................................................................ 10-7

Chapter 11 Other Functions

11.1 Saving the Setup Data ................................................................................................... 11-1

11.2 Loading the Setup Data ................................................................................................. 11-3

11.3 Selecting the Settings Applied at Power ON .................................................................. 11-4

11.4 Turning the Beep Sound ON/OFF .................................................................................. 11-5

11.5 Displaying the Error Log ................................................................................................ 11-6

11.6 Selecting the Display Brightness and Turning the Display OFF .................................... 11-7

11.7 Key Lock ........................................................................................................................ 11-8

11.8 Selecting the Decimal Point and Separator Notations of CSV Files .............................. 11-9

Chapter 12 Ethernet Interface (Option)

12.1 Ethernet Interface Functions and Specifications ............................................................ 12-1

12.2 Connecting to the Network ............................................................................................. 12-2

12.3 Setting the TCP/IP ......................................................................................................... 12-3

12.4 Checking the Ethernet Settings ..................................................................................... 12-6

12.5 Web Server Function ..................................................................................................... 12-7

IM 765501-01E

11

12

13

14

15

16

17

18

App

Index

xv

Contents

Chapter 13 GP-IB Communications

13.1 About the IEEE.488.2-1992 Standard ............................................................................ 13-1

13.2 GP-IB Interface Functions and Specifications ............................................................... 13-3

13.3 Connecting the GP-IB Cable .......................................................................................... 13-4

13.4 Setting the GP-IB Address ............................................................................................. 13-5

13.5 Responses to Interface Messages ................................................................................. 13-6

Chapter 14 RS-232 Communications

14.1 RS-232 Interface Functions and Specifications ............................................................. 14-1

14.2 Serial (RS-232) Interface Connection ............................................................................ 14-2

14.3 Handshaking Method ..................................................................................................... 14-4

14.4 Combination of Data Formats ........................................................................................ 14-5

14.5 Setting the RS-232 Interface .......................................................................................... 14-6

Chapter 15 USB Interface

15.1 USB Interface Functions and Specifications .................................................................. 15-1

15.2 Selecting the USB Interface Function ............................................................................ 15-2

Chapter 16 Communication Commands

16.1 Program Format ............................................................................................................. 16-1

16.1.1 Symbols Used in the Syntax ........................................................................... 16-1

16.1.2 Messages ........................................................................................................ 16-1

16.1.3 Commands ...................................................................................................... 16-3

16.1.4 Responses ...................................................................................................... 16-5

16.1.5 Data................................................................................................................. 16-5

16.2 Commands ..................................................................................................................... 16-6

16.2.1 A List of Commands ........................................................................................ 16-6

16.2.2 Output Commands (OUTPut Group)............................................................. 16-14

16.2.3 Source Commands (SOURce GRoup).......................................................... 16-15

16.2.4 Sweep Commands (SWEep Group) ............................................................. 16-23

16.2.5 Measurement Commands (SENSe GRoup) ................................................. 16-24

16.2.6 Trigger Commands (TRIGger Group) ........................................................... 16-26

16.2.7 Computation Commands (CALCulate Group)............................................... 16-27

16.2.8 Store/Recall Commands (TRACe Group) ..................................................... 16-29

16.2.9 External Input/Output Commands (ROUTe Group)....................................... 16-31

16.2.10 System Commands (SYSTem Group)........................................................... 16-34

16.2.11 Measured Value Read Commands (INITiate, FETCh, and READ Group) .... 16-38

16.2.12 Status Commands (STATus Group) .............................................................. 16-39

16.2.13 Common Command Group ........................................................................... 16-40

16.3 Status Reports ............................................................................................................. 16-42

16.3.1 Overview of the Status Report ...................................................................... 16-42

16.3.2 Status Byte .................................................................................................... 16-43

16.3.3 Standard Event Register ............................................................................... 16-44

16.3.4 Source Event Register .................................................................................. 16-46

16.3.5 Measure Event Register................................................................................ 16-47

16.3.6 Output Queue and Error Queue .................................................................... 16-48

16.4 Sample Programs ........................................................................................................ 16-49

16.4.1 Before Programming ..................................................................................... 16-49

16.4.2 GP-IB Access Function ................................................................................. 16-50

16.4.3 Sample 1 (Example of Reading the Measured Results during Free Run Using

Internal Trigger) ............................................................................................. 16-53

xvi IM 765501-01E

Contents

3

12

11

10

15

14

13

18

17

16

Index

App

16.4.4 Sample 2 (Example of generating a trigger from the PC and reading the

measured results) ......................................................................................... 16-55

16.4.5 Sample 3 (Example of Updating the Source Level from a PC) ..................... 16-57

16.4.6 Sample 4 (Example of Updating the Source Level with

the Sweep Function) ..................................................................................... 16-59

16.4.7 Sample 5 (Example of Carrying Out the Storage Function and Reading the

Statistical Values) .......................................................................................... 16-62

16.5 ASCII Character Codes ............................................................................................... 16-63

Chapter 17 Troubleshooting and Maintenance

17.1 Troubleshooting ............................................................................................................. 17-1

17.2 Error Code Description and Corrective Action ............................................................... 17-3

17.3 Self Test ......................................................................................................................... 17-6

17.4 Checking the System Status .......................................................................................... 17-8

17.5 Updating the System Firmware ...................................................................................... 17-9

17.6 Recommended Replacement Parts ............................................................................. 17-11

Chapter 18 Specifications

18.1 Source Section ............................................................................................................... 18-1

18.2 Measurement Section .................................................................................................... 18-3

18.3 Functions ....................................................................................................................... 18-4

18.4 External Input/Output Section (TRIG/SWEEP/CTRL IN and OUT)................................ 18-5

18.5 Interface ......................................................................................................................... 18-5

18.6 General Specifications ................................................................................................... 18-6

18.7 External Dimensions ...................................................................................................... 18-9

1

2

3

4

5

6

7

8

9

10

Appendix

Appendix 1 Computation Definition Specifications ..................................................................App-1

Appendix 2 Application Examples ...........................................................................................App-6

Appendix 3 Contents of the Factory Default Setup File (Default.txt) .....................................App-18

11

Index

IM 765501-01E

12

13

14

15

16

17

18

App

Index

xvii

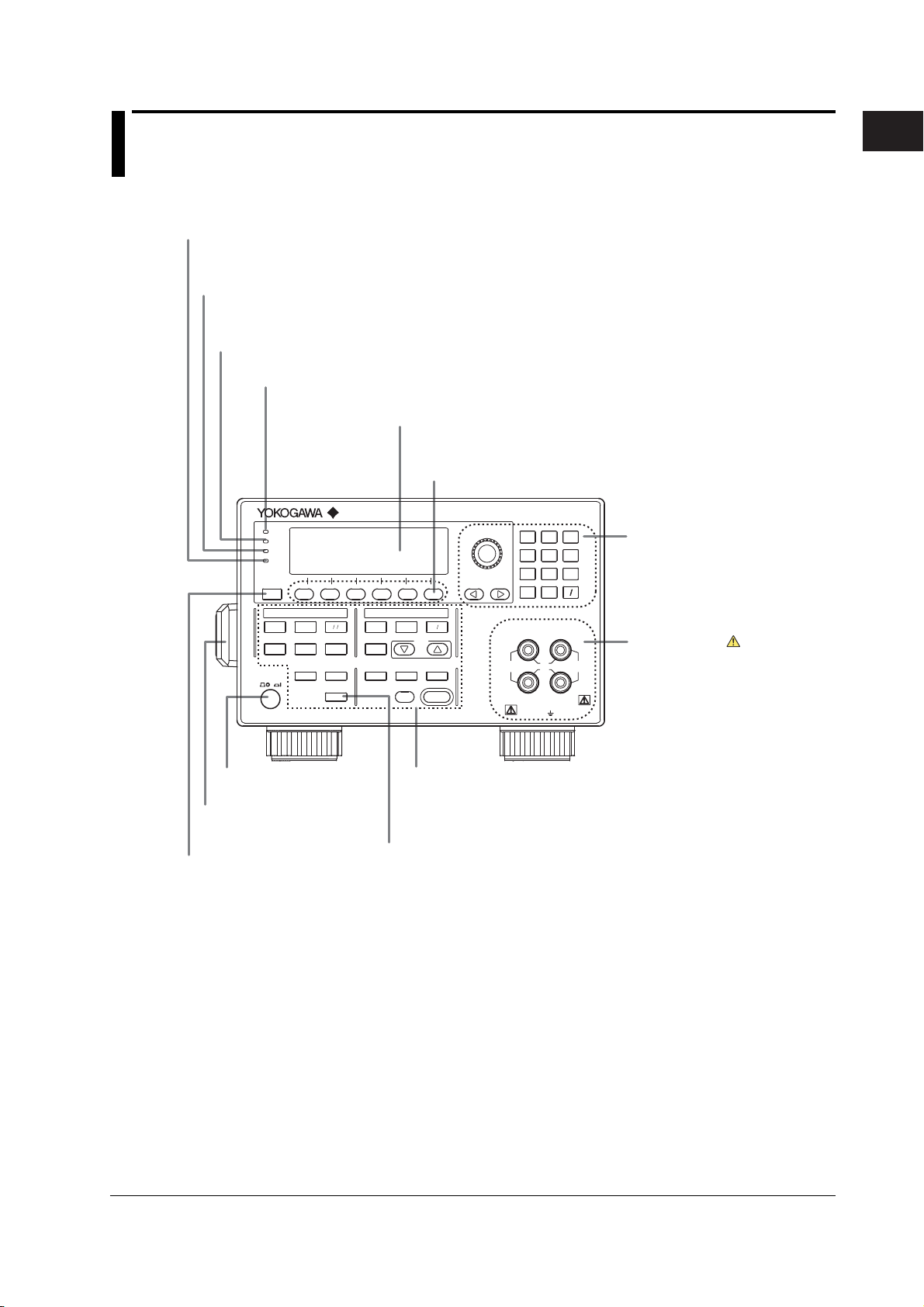

GS 61 0

SOU RCE MEAS URE UNIT

Chapter 1 Part Names and Functions

1.1 Front Panel

Remote indicator

Illuminates when the GS610 is in remote mode (controlled via communications).

See sections 13.2 and 14.1.

KEY LOCK indicator

Illuminates when key lock is ON.

See section 11.7.

Remote sense indicator

Illuminates when remote sense (four-terminal connection).

See section 4.2.

Average indicator

Illuminates when averaging is ON. See section 8.1.

GS610

AUTO

RANGE

MATH

COMPARE

LOCAL

MISC

SOURCE MEASURE UNIT

I

Ω

V

MEASURE

NULL

VALUE

TIME

KEY LOCK

SHIFT

AVERAGE

4 WIRE

KEY LOCK

REMOTE

DISPLAY

ESC

STORE

MENU

RECALL

POWER

MEASURE

Display

See section 1.3.

SOURCE

LIMIT

MODE

MENU

RANGE

AUTO

RANGE

OUTPUT CONTROL

START

SWEEP

ZERO

Soft keys

Used to select items on the soft key menu that appears

when setting up the GS610. See section 3.8.

VS IS

SOURCE

TRIG

MODE

OUTPUT

789

456

BS

123

.

0

SENSE

Hi

110V

1V

MAX

MAX

Lo

ALL TERMINALS

250V MAX TO

+

OUTPUT

-

110V

MAX

Rotary knob, numeric keys, and

cursor keys

Used to set values and select setup

data or items.

See sections 3.8 and 3.9.

Output terminal

Connect the measurement lead that

comes with the package.

See sections 3.5 and 4.2.

1

Part Names and Functions

IM 765501-01E

Power switch.

See section 3.4.

Handle

Used when carrying the GS610.

See section 3.1.

ESC (DISPLAY) key

Used to clear the soft key menu.

See section 3.8.

Setup and execution keys

Keys used to change the settings or carry out an operation.

Press a setup key to show the respective setup item.

See sections 1.4 and 3.9.

SHIFT key

The keys enter the shifted state when you press the SHIFT key and

the SHIFT key illuminates. In this state, the items marked in purple

characters below the keys are controlled.

1-1

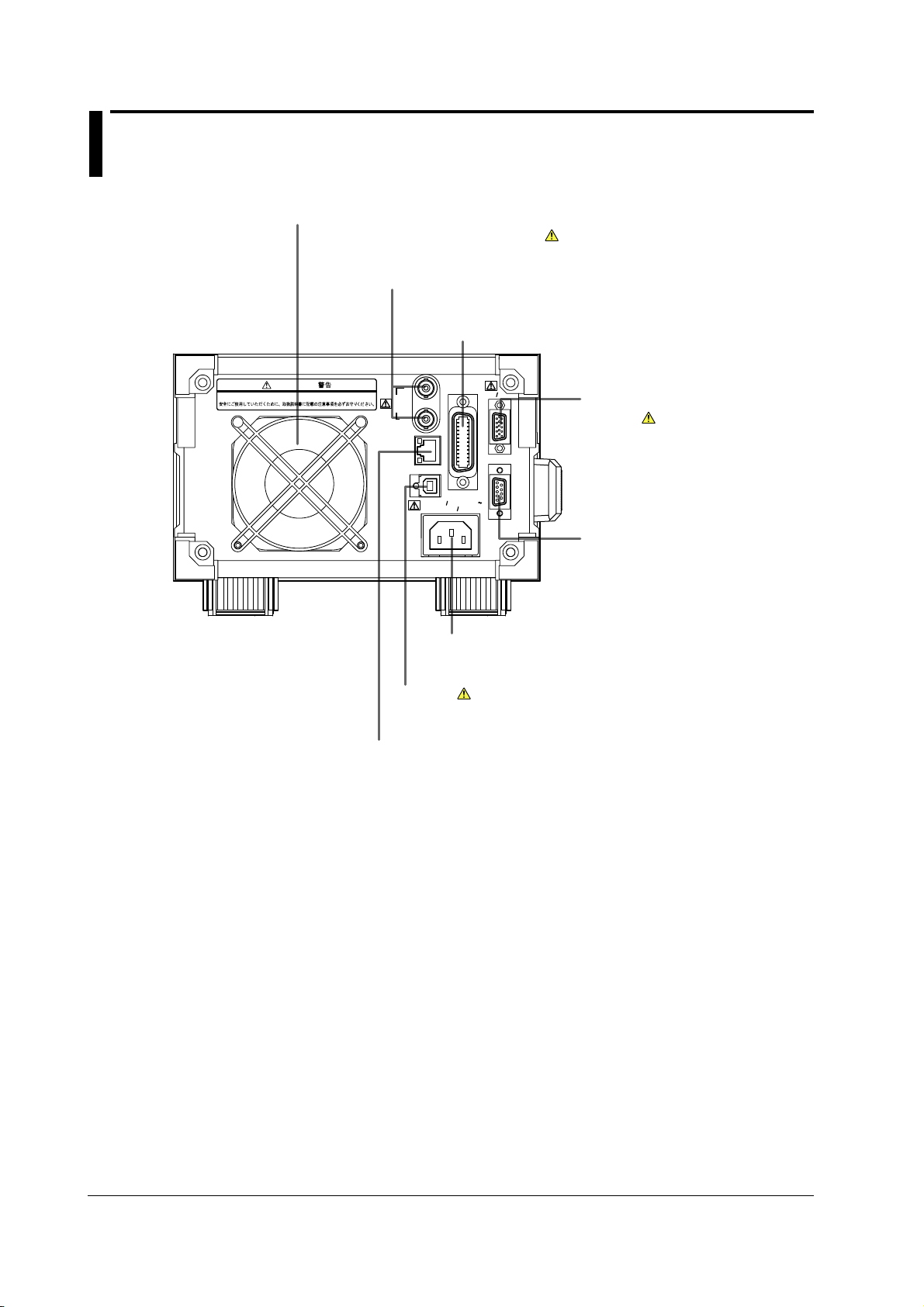

1.2 Rear Panel

Cooling fan

See section 3.2.

BNC input/output terminal

Used to input/output signals such as trigger, sweep, and control

signals and deliver the output signal of the comparison result.

See chapter 10.

GP-IB connector

Used to perform communications via the GP-IB interface.

See section 13.3.

Do not operate without reading the safety precautions in the user’s manual.

WARNING

100 - 120V

200VA MAX

GP-IB

(IEEE488)

220 - 240V AC

60Hz

50

EXT I

O

SERIAL (RS-232)

External input/output connector

(15 pins)

Used to input/output signals such

as trigger, sweep, and control

signals and deliver the output signal

of the comparison result.

See chapter 10.

TRIG /

SWEEP /

CTRL

ETHERNET

100BASE-TX

USB

IN

OUT

ACT

LINK

RS-232 connector (9 pins)

Used to perform communications

with a PC via the RS-232 interface.

See section 14.2.

Power connector

Used to connect the GS610 to a power supply.

See section 3.3.

USB port

Used to connect to a PC with a USB interface when running

the GS610 as a USB storage device.

Ethernet port

Used to connect to a LAN.

1-2 IM 765501-01E

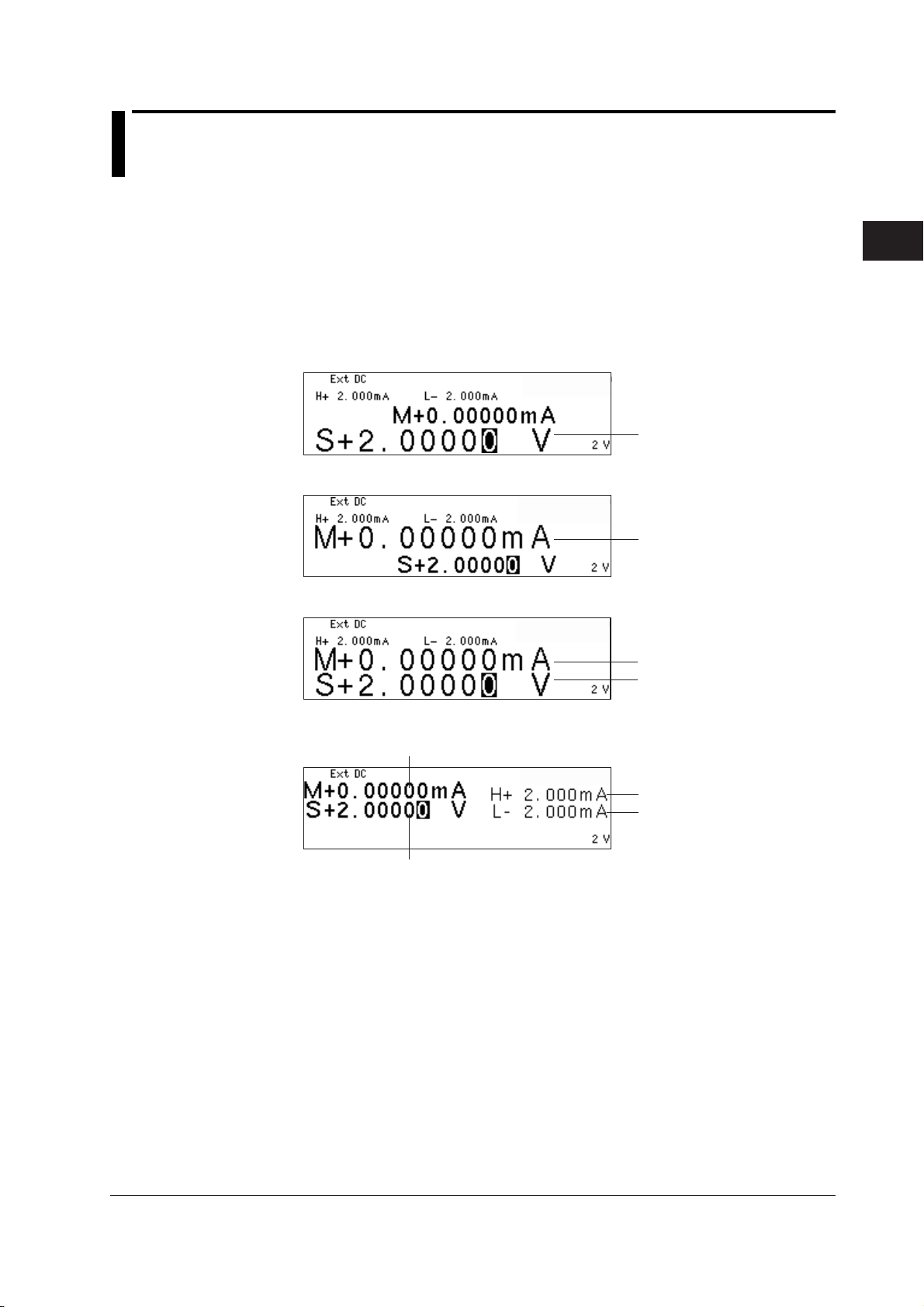

1.3 Names and Description of the Displayed Contents

The contents shown on the display are as follows:

Status display area

Comparison result display

Trigger setting display

Source mode and sweep

mode displays

Wait indicator

High limiter indicator

Low limiter indicator

Sampling error indicator

Error indicator

1

Part Names and Functions

Measured value

Source value

Source range

High limiter value

Information Shown in the Status Display Area

Comparison Result Display (For the procedures, see section 8.4)

Displays the judgement result of the comparison.

High: Over the upper limit

In: Within the limits

Low: Under the lower limit

Trigger Mode Display (For the procedures, see section 4.1)

Displays the selected trigger mode.

Int: Internal trigger

Ext: External trigger

Imm: Immediate (no trigger wait)

Source Mode and Sweep Mode Displays (For the procedures, see sections 5.4, 5.5,

6.1, and 6.2)

Displays the combination of the source mode and sweep mode. The following eight

combinations are available.

DC: DC source

Pls: Pulse source

DCLinr: Source mode = DC and sweep mode = Linear

DCLog: Source mode = DC and sweep mode = Log

DCProg: Source mode = DC and sweep mode = Program

PlsLinr: Source mode = pulse and sweep mode = Linear

PlsLog: Source mode = pulse and sweep mode = Log

PlsProg: Source mode = pulse and sweep mode = Program

Low limiter value

IM 765501-01E

Wait Indicator (For the procedures, see section 2.5 and 6.5)

Displays the various wait conditions during operation.

WaitTrigger: Waiting for trigger

WaitStart: Waiting for sweep start

Calculating: Calculating sweep data

1-3

1.3 Names and Description of the Displayed Contents

High Limiter Indicator (For the procedures, see section 5.3)

Turns ON when the high limiter is active.

Low Limiter Indicator (For the procedures, see section 5.3)

Turns ON when the low limiter is active.

Sampling Error Indicator (For the procedures, see section 2.5)

Turns ON when the trigger timing is not synchronized to the source measure cycle

period (the starting point) such as when a trigger is activated in the middle of a source

measure cycle.

Error Indicator (For the procedures, see section 11.5)

Turns ON when there is one or more errors in the error memory.

1-4 IM 765501-01E

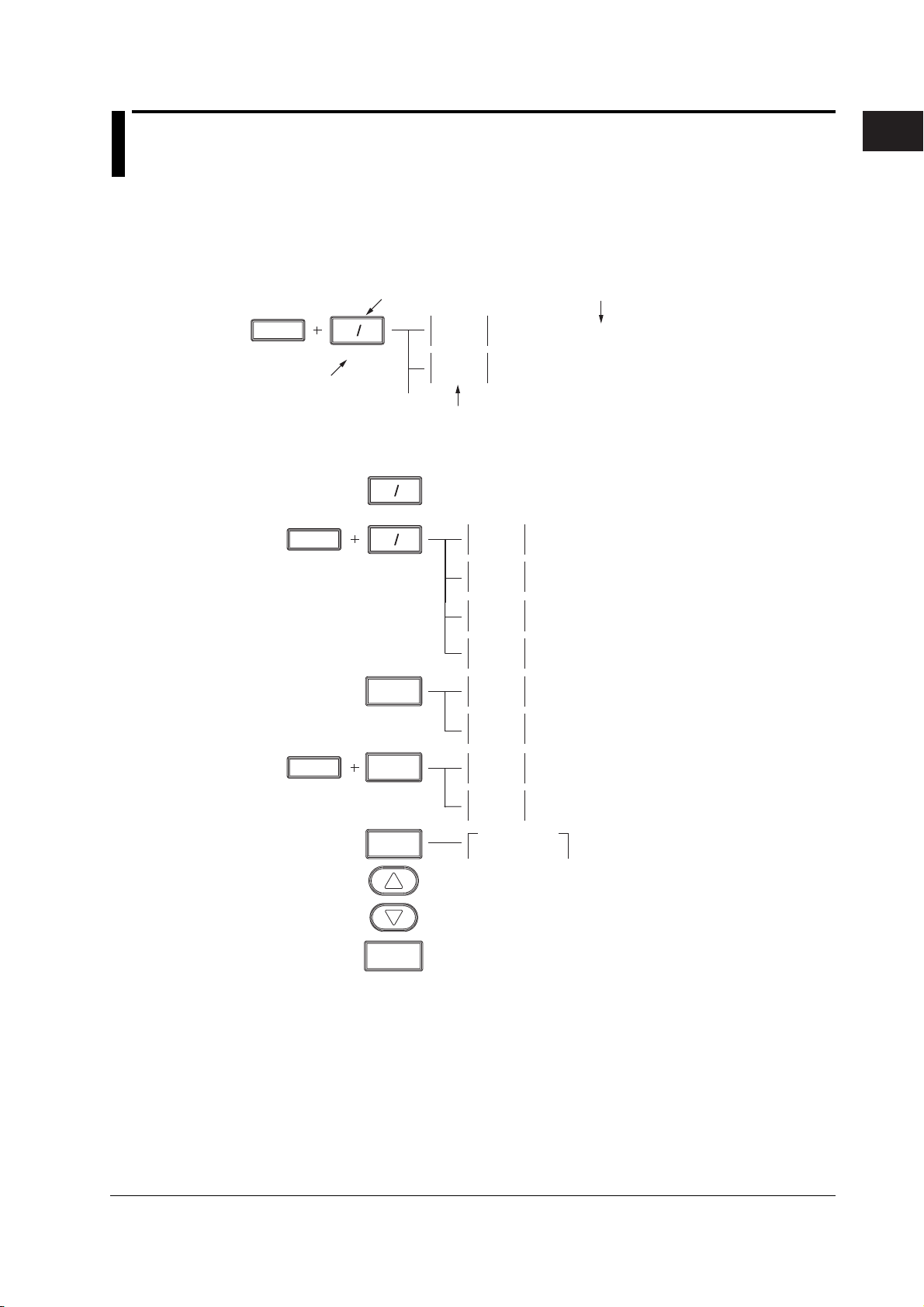

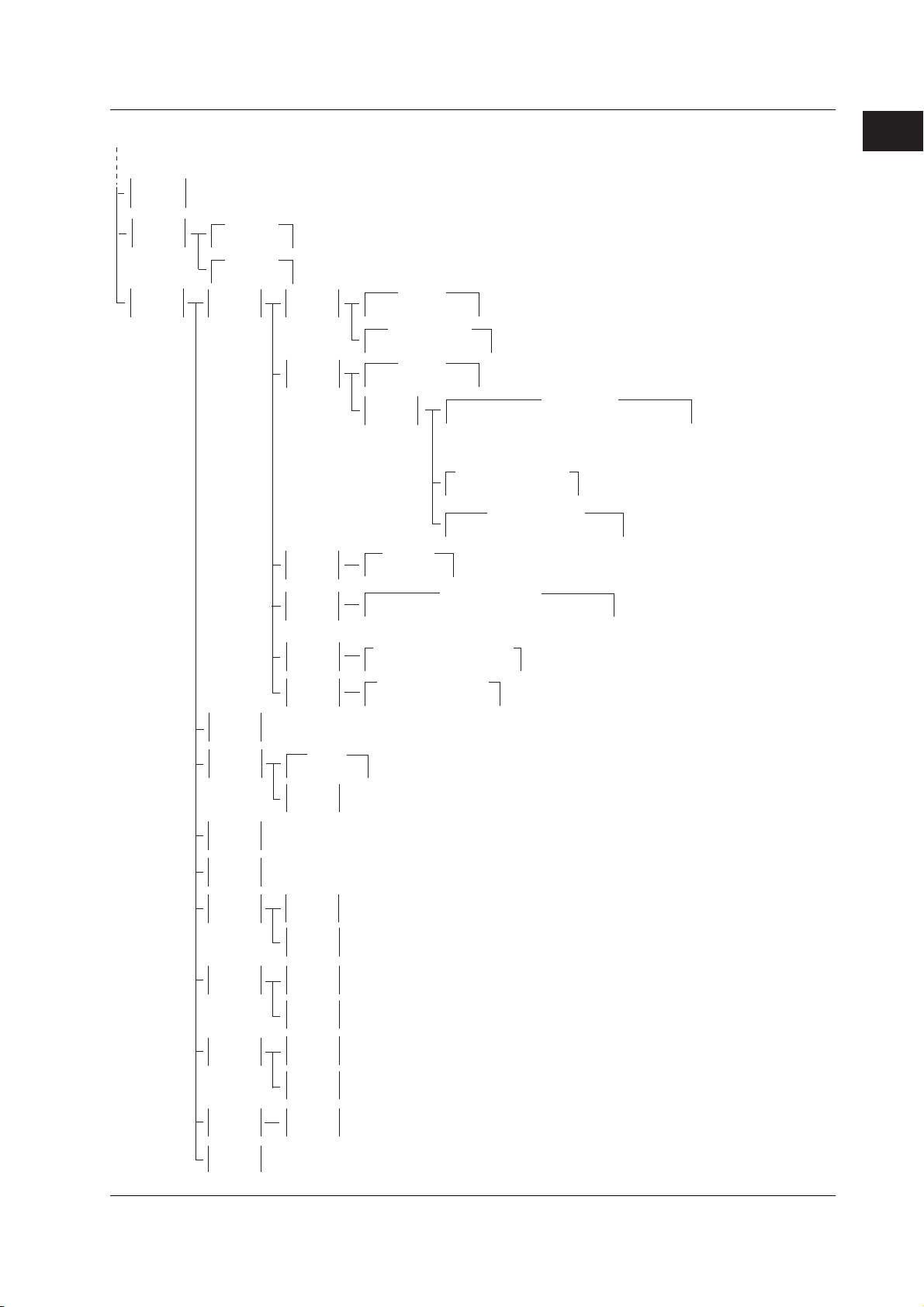

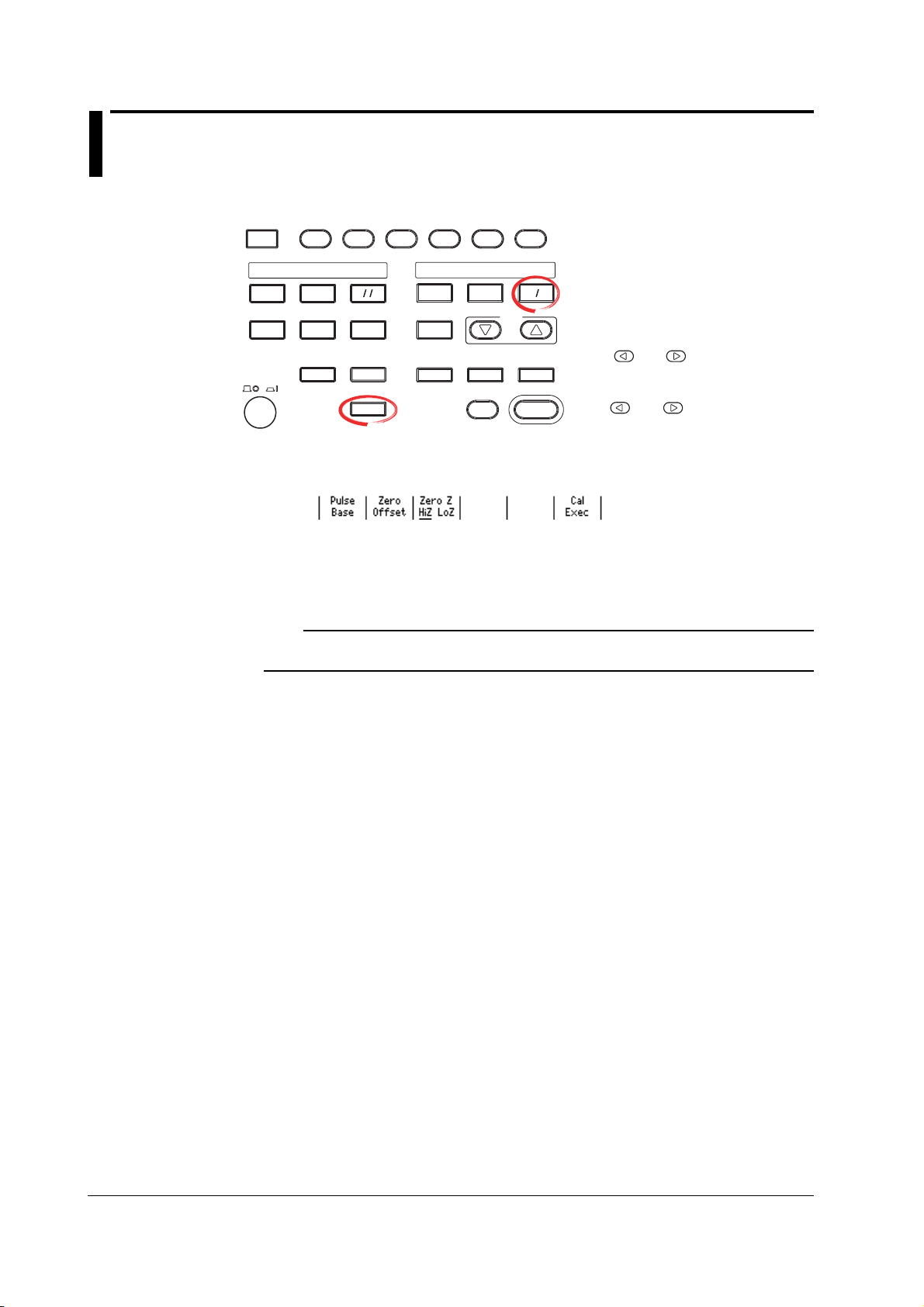

1.4 Key Groups and Menus

There are four functional key groups on the GS610. This section introduces each key

group in a tree format.

Viewing the Tree Structure

1

Part Names and Functions

SHIFT

Activated when the

SHIFT key is pressed

followed by the key

VS IS

SOURCE

SOURCE Group

SHIFT

SHIFT

Keys

VS IS

SOURCE

VS IS

SOURCE

LIMIT

MENU

LIMIT

MENU

MODE

Setup description and reference section

Pulse

Base

Zero

Offset

Switches the source function (voltage (VS) or current (IS))

(section 5.1)

Sets the pulse base when generating pulses (section 5.2)

Sets the zero source offset (section 5.8)

Soft key menu shown on the display

Pulse

Base

Zero

Offset

Zero Z

Hiz Loz

Cal

Exec

High

Limit

Low

Limit

Limit

On Off

Tracking

On Off

SourceMode

DC Pulse

Sets the pulse base when generating pulses

(section 5.5)

Sets the zero source offset (section 5.8)

Switches the zero source impedance

(high or low) (section 5.8)

Executes offset calibration (section 5.9)

Sets the upper limiter value (section 5.3)

Sets the lower limiter value (section 5.3)

Turns ON/OFF the limiter (section 5.3)

Turns ON/OFF the limiter tracking (section 5.3)

Selects the source mode (DC or pulse)

(sections 5.4 and 5.5)

IM 765501-01E

AUTO

RANGE

Increases the source range (section 5.2)

Decreases the source range (section 5.2)

Turns ON/OFF the auto source range (section 5.2)

1-5

1.4 Key Groups and Menus

MEASURE Group

I

V

Ω

MEASURE

I

V

SHIFT

Ω

MEASURE

Switches the measurement function (voltage (V), current (I), or resistance (Ω) (section 7.2)

Measure

On Off

IntgTime

Average

AutoZero

On Off

Turns ON/OFF the measurement function (section 7.1)

***

***

250µs 1ms 4ms *** 100ms 200ms

Mode

***

Count

***

Turns ON/OFF the auto zero function (section 7.6)

IntegrationTime

AverageMode

Off Block Moving

Sets the average count (section 8.1)

Sets the integration time

(section 7.5)

Switches the average mode

(Off, Block, or Moving)

(section 8.1)

SHIFT

SHIFT

AUTO

RANGE

NULL

VALUE

NULL

VALUE

MATH

COMPARE

MATH

COMPARE

AutoZero

Exec

Auto V/I

On Off

Turns ON/OFF the auto measurement range (section 7.3)

Turns ON/OFF the NULL computation (section 8.2)

Sets the NULL reference (section 8.2)

Math

On Off

Param

Param

Param

View

Select

File

Compare

On Off

Upper

Execute auto zero (section 7.6)

Turns ON/OFF auto V/I (section 7.7)

Turns ON/OFF computation (section 8.3)

Sets equation parameter A (section 8.3)

A

Sets equation parameter B (section 8.3)

B

Sets equation parameter C (section 8.3)

C

Displays the equation (section 8.3)

Selects the equation definition file (section 8.3)

Turns ON/OFF the comparison operation (section 8.4)

Sets the upper limit of the comparison operation (section 8.4)

SHIFT

STORE

MENU

STORE

MENU

RECALL

Lower

Turns ON/OFF the storage function (section 9.1)

Count

Auto

On Off

Displays the statistical computation result (section 9.2)

Sets the lower limit of the comparison operation (section 8.4)

***

Sets the number of points to be stored (store count) (section 9.1)

Turns ON/OFF the auto storage function (section 9.1)

1-6 IM 765501-01E

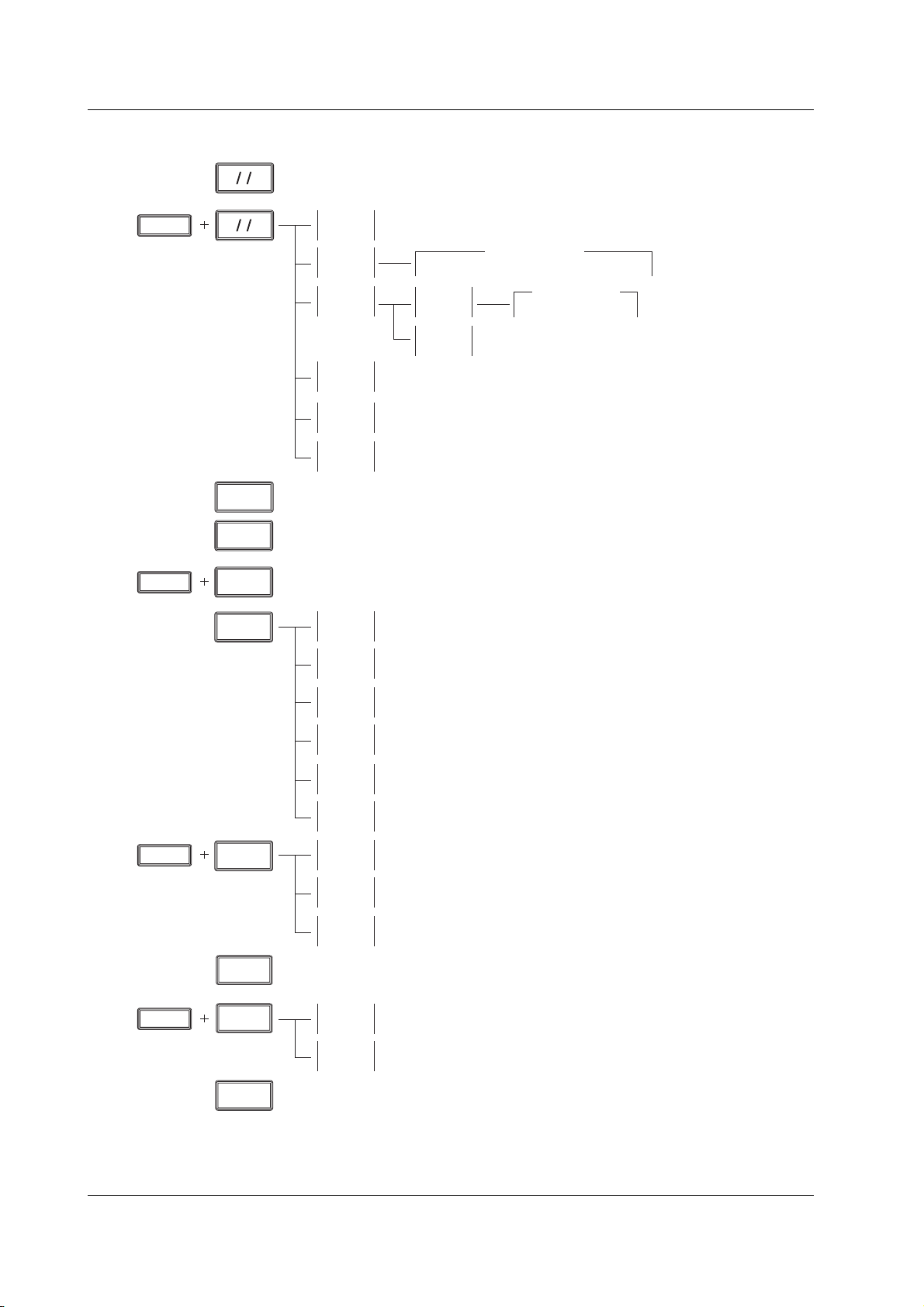

1.4 Key Groups and Menus

OUTPUT CONTROL Group

SHIFT

TRIG

MODE

TRIG

MODE

Generates a manual trigger (section 4.1)

SWEEP

START

Starts the sweep operation (section 6.5)

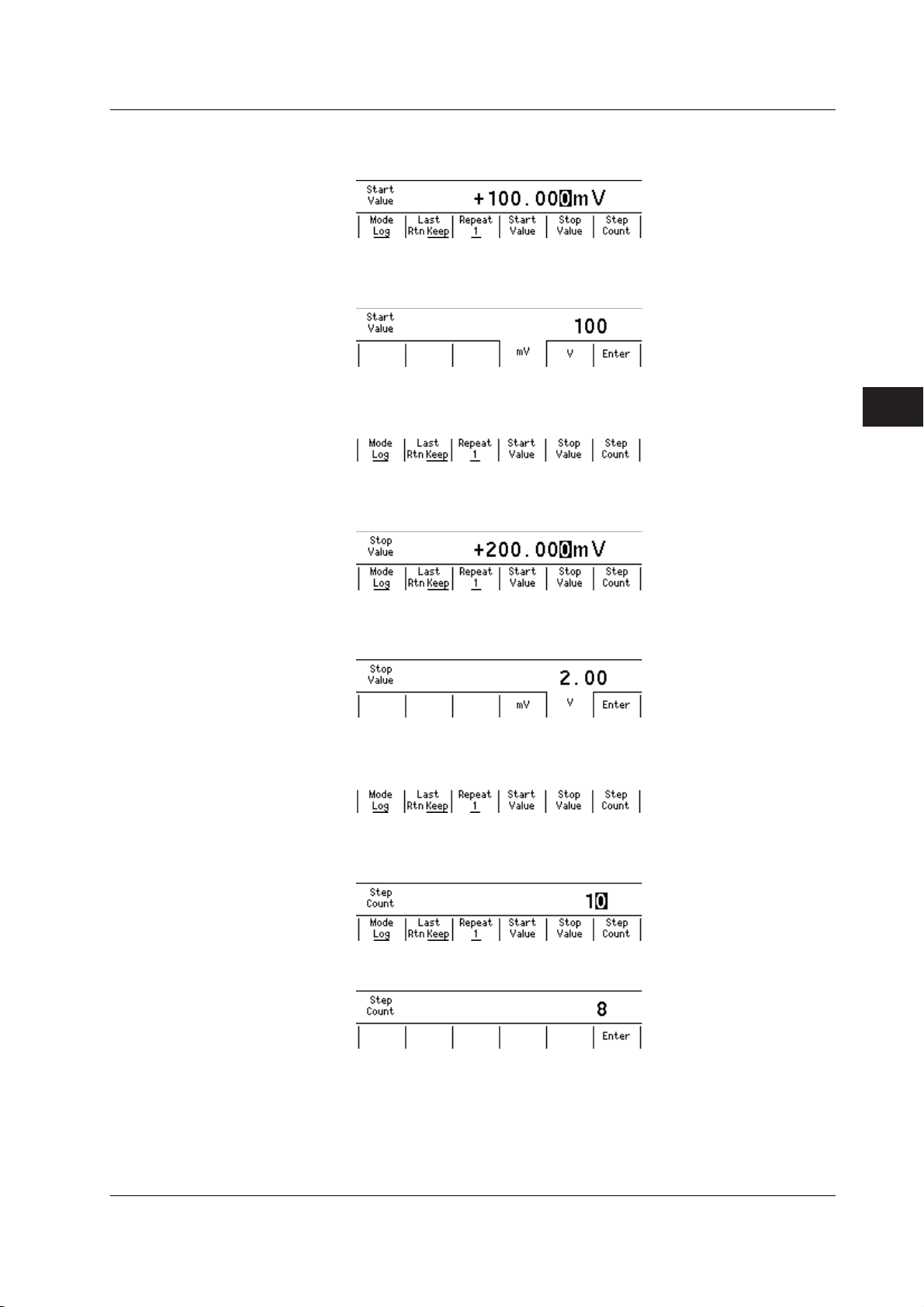

TrigMode

Int Ext Imm

Mode

***

Last

Rtn Keep

Repeat

Start

Value

Stop

Value

Step

Value

Step

Count

Select

File

Switches the sweep termination mode (return on keep) (section 6.3)

Sets the sweep repeat count (section 6.4)

***

Sets the sweep start value (section 6.1)

Sets the sweep stop value (section 6.1)

Sets the sweep step value (displayed only when linear sweep is selected)

(section 6.1)

Sets the sweep step count (displayed only when log sweep is selected)

(section 6.1)

Selects the pattern file (displayed only when program sweep is selected)

(section 6.2)

Selects the trigger mode (internal, external, or immediate) (section 4.1)

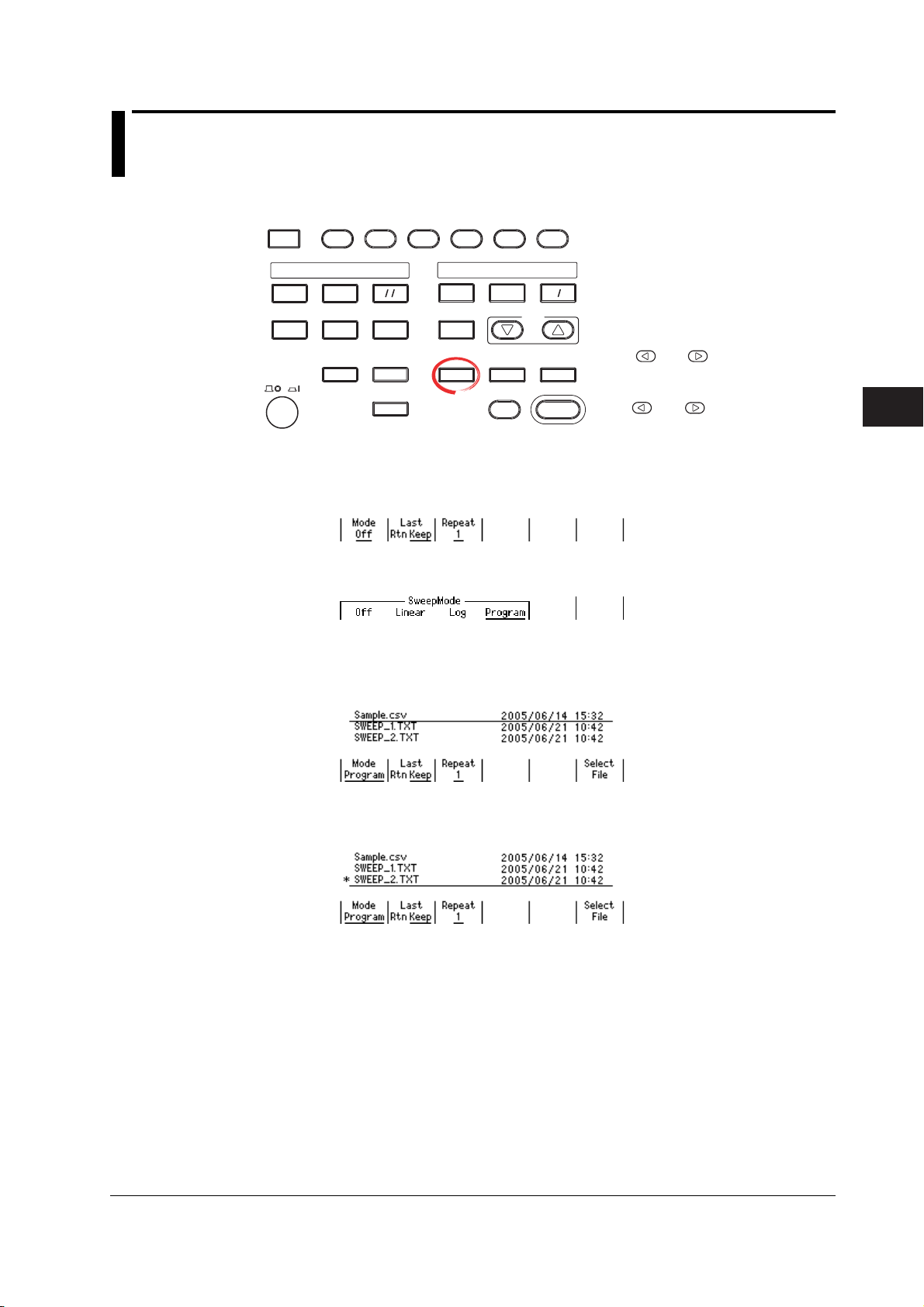

SweepMode

Off Linear Log Program

Selects the sweep mode

(off, linear, log, or program)

(sections 6.1 and 6.2)

1

Part Names and Functions

OUTPUT

ZERO

Turns ON/OFF the output mode (section 5.7)

Turns ON/OFF the zero state (section 5.8)

IM 765501-01E

1-7

1.4 Key Groups and Menus

MISC Group

TIME

KEY LOCK

SHIFT

TIME

KEY LOCK

Turns ON/OFF key lock (section 11.6)

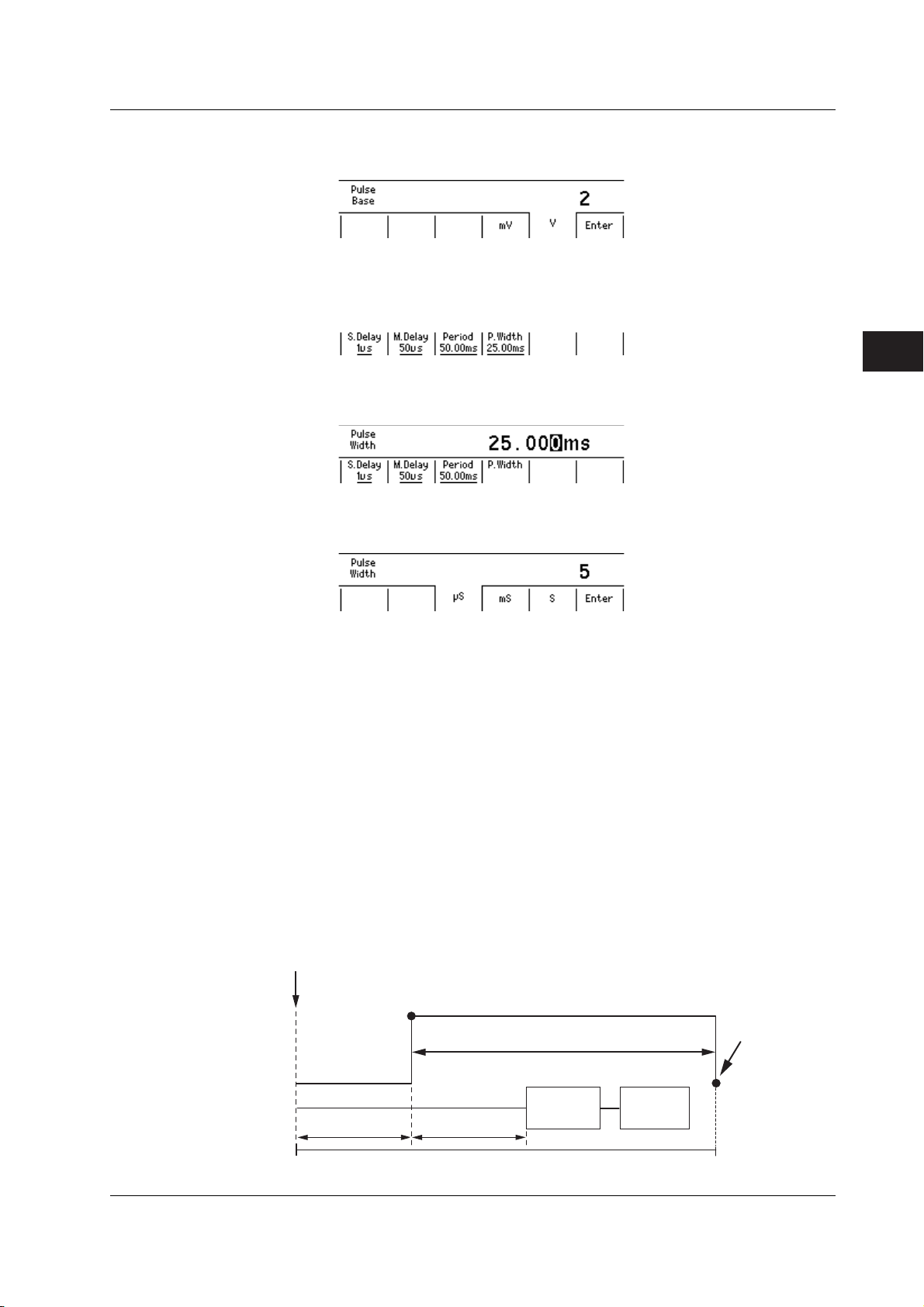

MISC

S.Delay

***

M.Delay

***

Period

***

P. Wi dth

***

Remote

I/F

Setup

Error

Log

Sets the source delay (section 5.6)

Sets the measure delay (section 7.4)

Sets the repeat period of the internal trigger (section 4.1)

Sets the pulse width (section 5.5)

GPIB

RS232

LAN

USB

Save

Setup

Load

Setup

PowerOn

Setup

Clear

Sets the GP-IB address (section 13.4)

***

BaudRate

***

DataBit

7 8

Parity

***

StopBit

1 2

Flow

***

Term

***

DHCP

On Off

IP

Address

Subnet

Mask

Default

Gateway

Term

***

Overview

USB Mode

***

Storage USB-TMC

Save

RamDisk

Save

Setup1

Save

Setup2

Save

Setup3

Save

Setup4

Loads the setup (section 11.2)

Selects the setup used when the GS610 is powered up (section 11.3)

Shows and clears error log (section 11.5)

9600 14400 19200 38400 57600 115200

Switches the RS-232 data length (7 or 8) (section 14.5)

Parity

None Even Odd

Switches the RS-232 stop bit (1 or 2) (section 14.6)

FlowControl

None XON CTS/RTS

Terminator

CR LF CR+LF

Turns ON/OFF the Ethernet DHCP function (section 12.3)

Enter

Enter

Enter

Terminator

CR LF CR+LF

Shows a list of Ethernet settings (section 12.4)

Selects the USB function (storage function

or USB communication function)

(section 15.2)

Saves the settings to the RAM disk (GS610RAM)

(section 11.1)

Saves the settings to Setup 1 (section 11.1)

Saves the settings to Setup 2 (section 11.1)

Saves the settings to Setup 3 (section 11.1)

Saves the settings to Setup 4 (section 11.1)

BaudRate

Selects the RS-232 parity

(none, odd, or even) (section 14.5)

Selects the RS-232 transmission

delimiter (CR, LF, or CR+LF)

(section 14.5)

Sets the fixed Ethernet IP address

(section 12.3)

Sets the fixed Ethernet subnet mask

(section 12.3)

Sets the fixed Ethernet default gateway

(section 12.3)

Sets the Ethernet transmission

delimiter (CR, LF, or CR+LF)

(section 12.3)

Selects the

RS-232

baud rate

(section 14.5)

Selects the RS-232 flow control

(none, XON-OFF, CTS-RTS)

(section 14.5)

Continues to the next page

1-8 IM 765501-01E

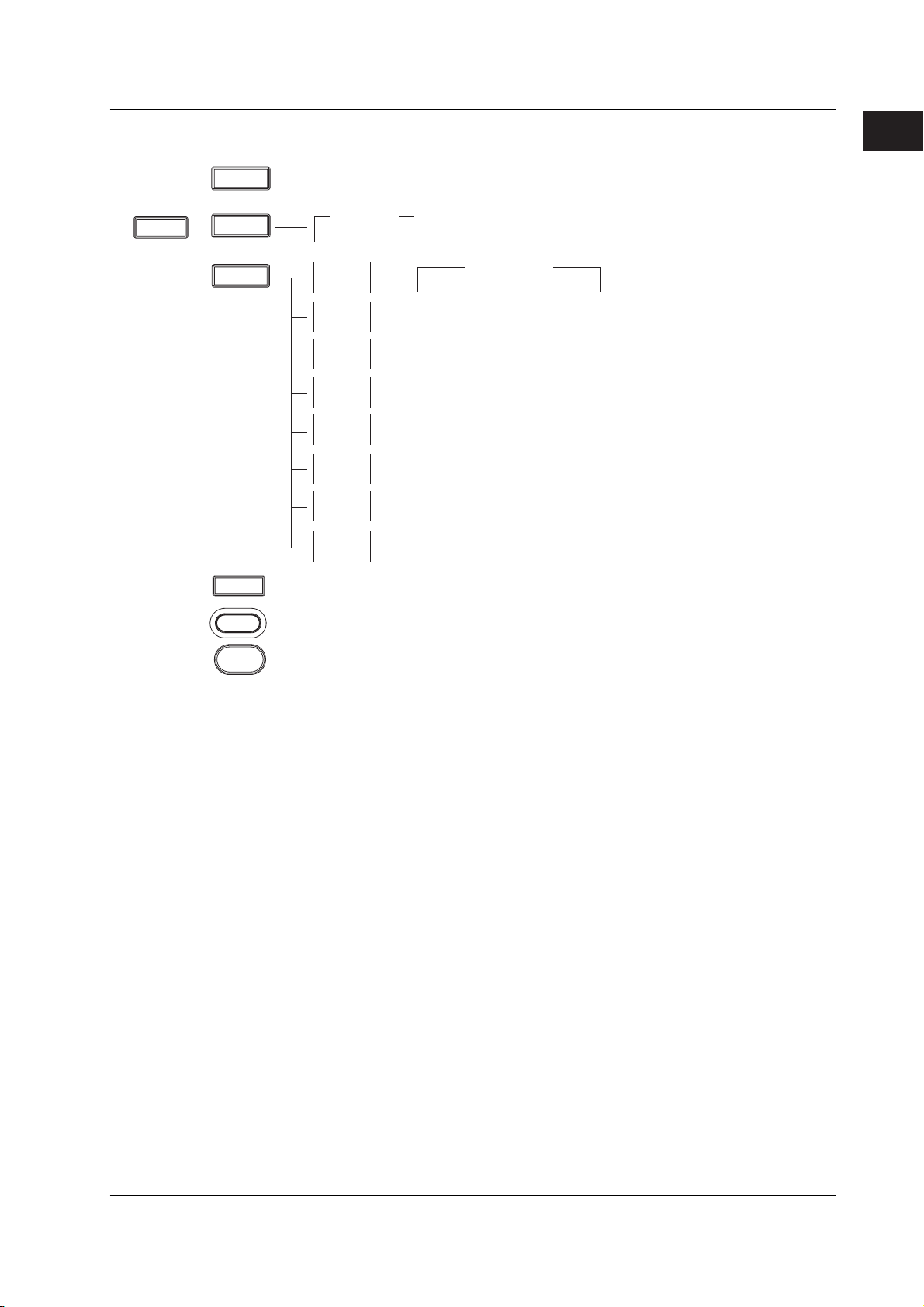

1.4 Key Groups and Menus

Continued from the previous page

Wire

2W 4W

CSV

Setting

Selects sensing (two-wire or four-wire) (section 4.2)

DecPoint

. ,

Separate

, ;

System

External

I/O

Beep

On Off

Display

***

LineFreq

50 60

Product

Info

Time

Adjust

Turns ON/OFF the beep sound (section 11.4)

Selects the power frequency (50 Hz or 60 Hz) (section 3.6)

Shows the product information (section 17.4)

Selects the decimal point for CSV files (section 11.8)

Selects the separator for CSV files (section 11.8)

BNC IN

***

BNC OUT

***

DIO5

***

DIO6

***

DIO7

***

DIO8

***

Bright

1 2 3 4

Off

Exec

Edit

Turns OFF the display (section 11.6)

Edits the time (section 3.7)

BNC IN

Trig Sweep Ctrl

ControllType

IntLock Output Zero

BNC OUT

Trig Sweep Ctrl

Type

***

DIO 5pin

Output Zero

DIO 6pin(TrigOut)

Origin ScrChg MeasBgn MeasEnd PlsEnd

DIO 7pin(SweepSyncOut)

Origin TurnEnd AllEnd

DIO 8pin(ControlOut)

IntLock Output Zero

Selects the display brightness (section 11.6)

Selects the BNC input

(trigger, sweep start, or control) (section 10.1)

Selects the BNC control input

(interlock, output relay control, or zero source) (section 10.1)

Selects the BNC output (trigger, sweep start, or control)

(section 10.1)

Origin ScrChg MeasBgn MeasEnd PlsEnd

SweepSyncOutType

Origin TurnEnd AllEnd

ControlOutType

IntLock Output Zero Program

Selects the external input/output connector pin 5 function

(output relay control or zero source control) (section 10.1)

Selects the external input/output connector pin 7 function

(sweep start, 1 turn end, or all end) (section 10.1)

Selects the external input/output connector pin 8 function

(interlock, output, or zero) (section 10.1)

TrigOutType

Selects the BNC sweep synchronization output

(sweep start, 1 turn end, or all end)

(section 10.1)

Selects the BNC control output

(interlock, relay output, zero source,

or programmable) (section 10.1)

Selects the external input/output

connector pin 6 function (trigger, source

change, measure begin, measure end,

or pulse end) (section 10.1)

Selects the BNC trigger

output (trigger, source

change, measure begin,

measure end, or falling

edge of pulse) (section 10.1)

1

Part Names and Functions

IM 765501-01E

Time

Zone

SelfTest

Disk

Format

Firmware

Update

Sets the time (section 3.7)

Set

Edits the GMT offset (section 3.7)

Edit

Sets the GMT offset (section 3.7)

Set

Display

Exec

Updates the system firmware (section 17.5)

Executes the display test (section 17.3)

Executes the key test (section 17.3)

Key

Executes the GS610ROM disk format (section 4.3)

1-9

1

GS6 10

SOURCE MEA SURE UNI T

Chapter 2 Explanation of Functions

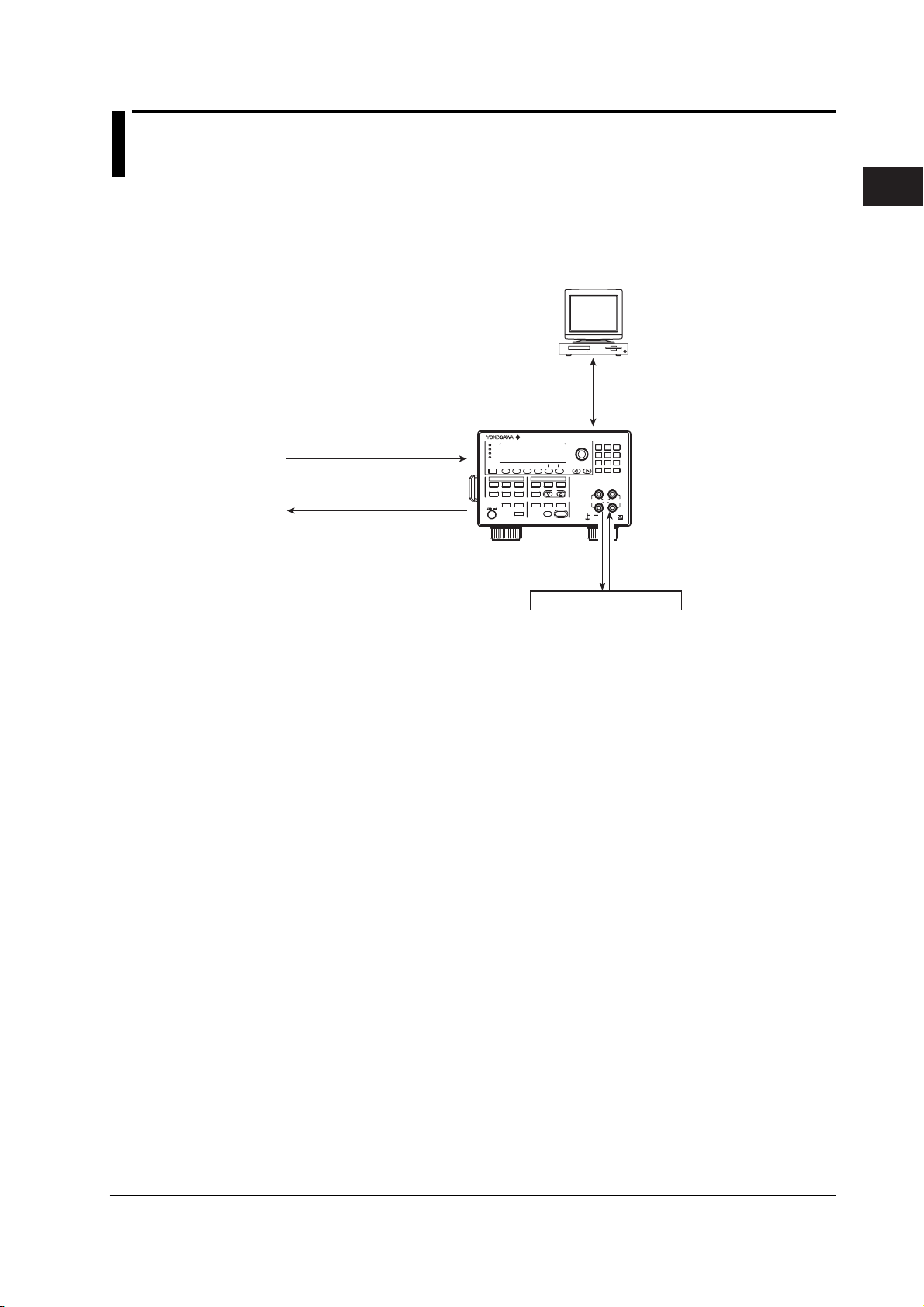

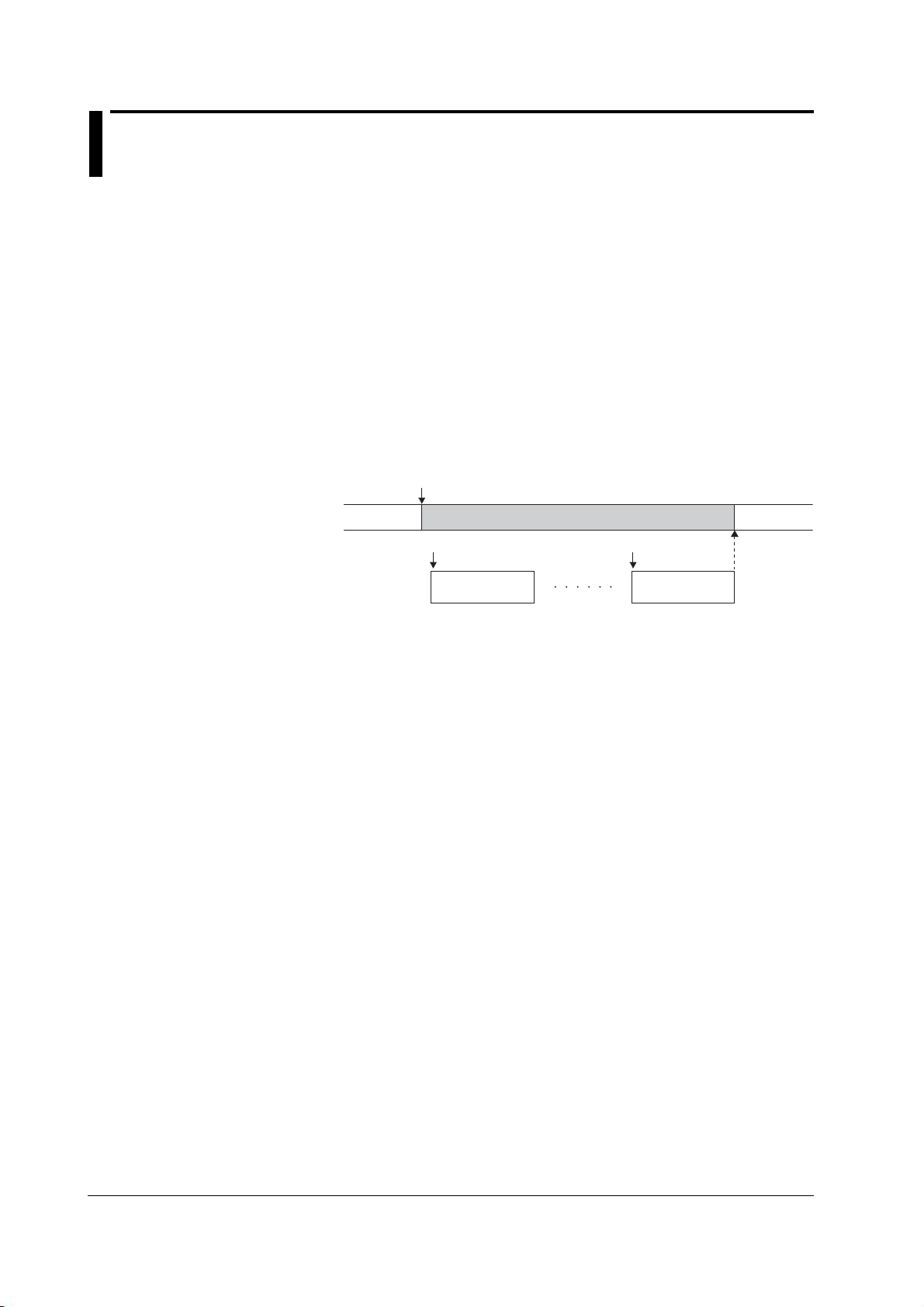

2.1 System Configuration and Block Diagram

System Configuration

PC

• USB storage (store setup parameters,

recall statistical computation values, and

save/load equations, programs, and panel settings)

• Remote control

Trigger input

Sweep start input

Interlock input

Output ON/OFF (relay)

control input

GS610

Zero source control input

POWER

Trigger output

Source change timing output

Measure start timing output

Measure end timing output

(Voltage or current)

Pulse end timing output

Sweep synchronization output

Sweep 1 turn end timing output

Sweep all end timing output

Interlock through output

Output ON/OFF (relay) status output

Zero source status output

Programmable output

Comparison result output

Comparison end output

USB (USB storage)

Communication

(Ethernet, GP-IB, and RS-232*)

GS610

SOURCE MEASURE UNIT

Source

Measured value

DUT (device under test)

* Conforms to EIA-574.

EIA-574 is an EIA-232 (RS-232) standard

for the 9-pin interface.

2

Explanation of Functions

IM 765501-01E

2-1

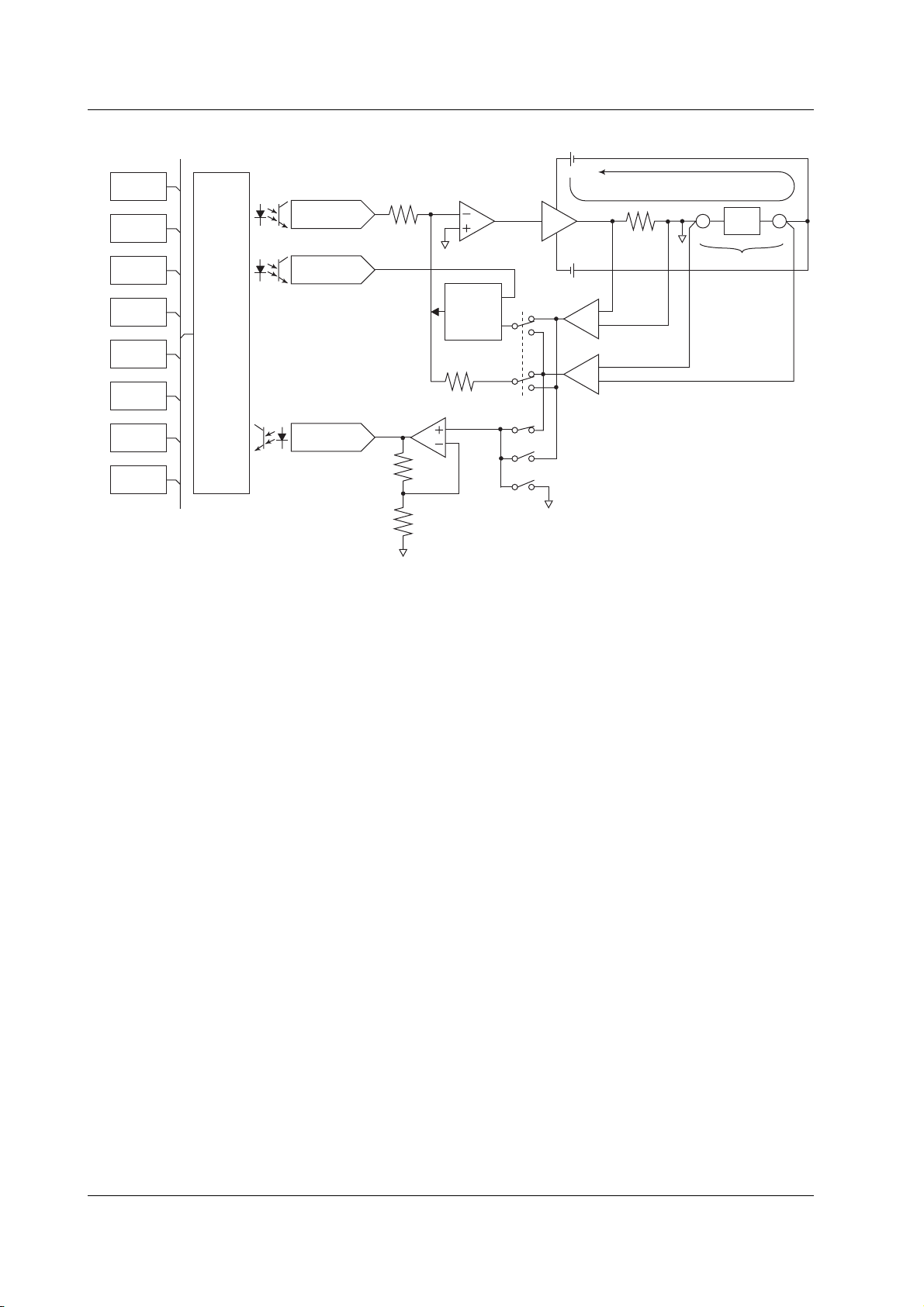

2.1 System Configuration and Block Diagram

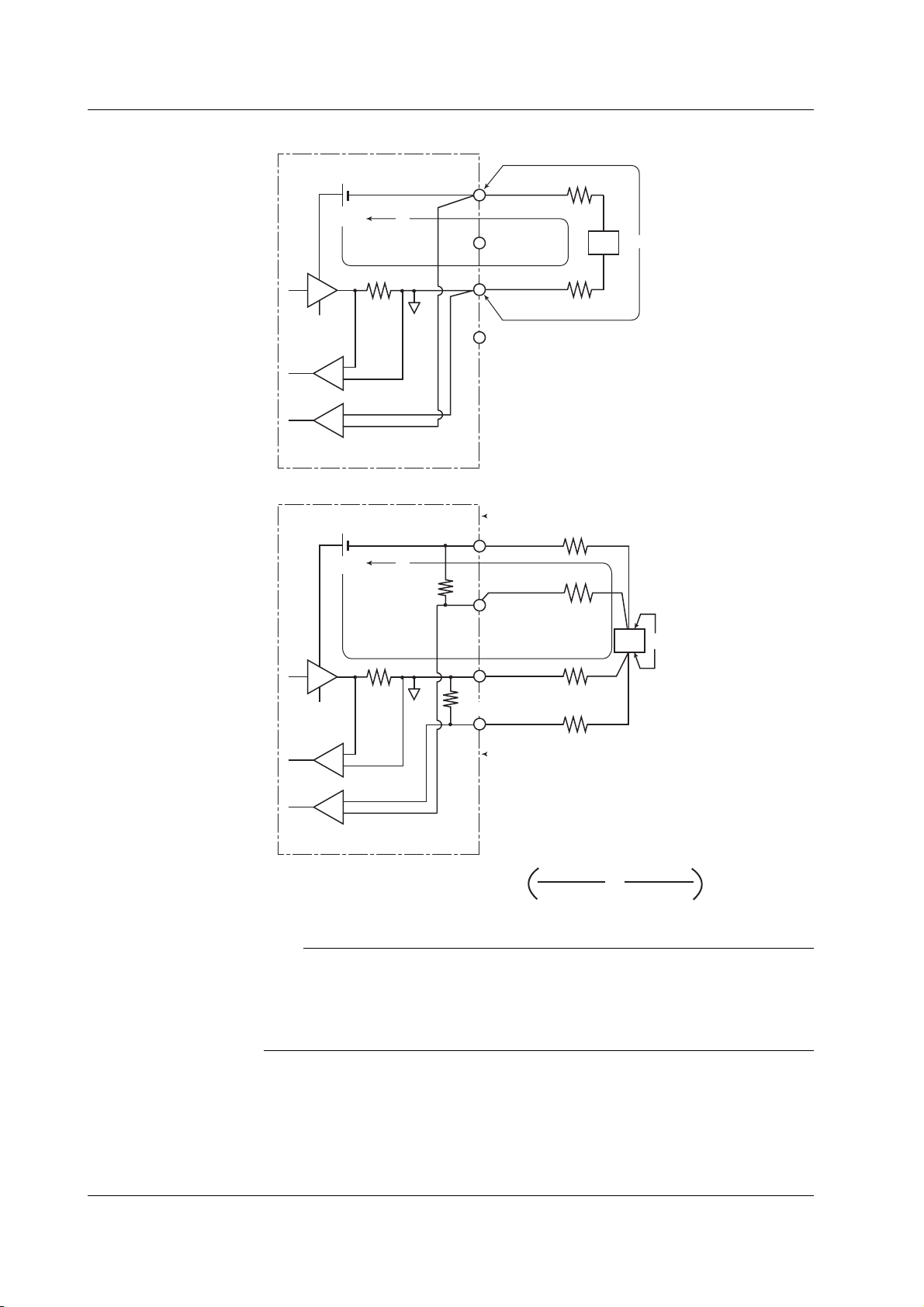

Block Diagram

CPU

VFD

KEY

EXT I/O

RS-232

GP-IB

USB

ETHER

(option)

Analog

control

Io

Source DAC

Limiter DAC

ADC

Limiter

control

circuit

Current sense

amplifier

Voltage sense amplifier

DUT: Device Under Test

DUT

LO HI

Vo

Voltage Vo that appears across output terminals HI and LO is converted to normalized

voltage by a differential amplifier (voltage sense amplifier) that has different gains for

different voltage ranges. In addition, current Io that flows through output terminals HI

and LO is converted to normalized voltage by different shunt resistors and differential

amplifiers (current sense amplifiers) for different current ranges.

The analog section consists of the source block, limiter block, and measurement block.

The source block controls the voltage sense amplifier or the current sense amplifier so

that its output is equal to the source DAC output, and delivers the specified source value

across HI and LO. Two D/A converters are used in the source DAC to achieve a 5.5digit resolution.

The limiter control circuit in the limiter block controls the output across HI and LO so that it is

equal to the specified limiter value when the output from the voltage sense amplifier or

current sense amplifier exceeds the specified limiter value. When generating voltage, the

output from the current sense amplifier is compared with the limiter value; when generating

current, the output from the voltage sense amplifier is compared with the limiter value.

The measurement block measures the output from the voltage sense amplifier or current

sense amplifier. In addition, if the auto zero function is enabled, the internal zero

reference is measured every measurement cycle (measurement operation), and the

offset drift of the measurement pre-amplifier and A/D converter is cancelled while

measurements proceed. A feedback pulse width modulation (an integration type) is

employed for the A/D converter (ADC).

The analog control section transfers data to the D/A converter (DAC), controls various

switches, controls the width measurement of the pulse transferred from the A/D

converter, and so on. To achieve high-speed sweep of 100 µs steps, a high-speed

photocoupler is employed for the transferring of data to the source DAC.

The display employs a 256 × 64 dot VFD

*

to improve the visibility.

The GS610 comes with GP-IB and RS-232 interfaces that provide compatibility with

conventional systems as well as a USB port that is convenient for writing to or reading

data from a PC. An Ethernet port is also provided as an option if you wish to use the

existing network for data communication.

* Vacuum Fluorescent Display

2-2 IM 765501-01E

1

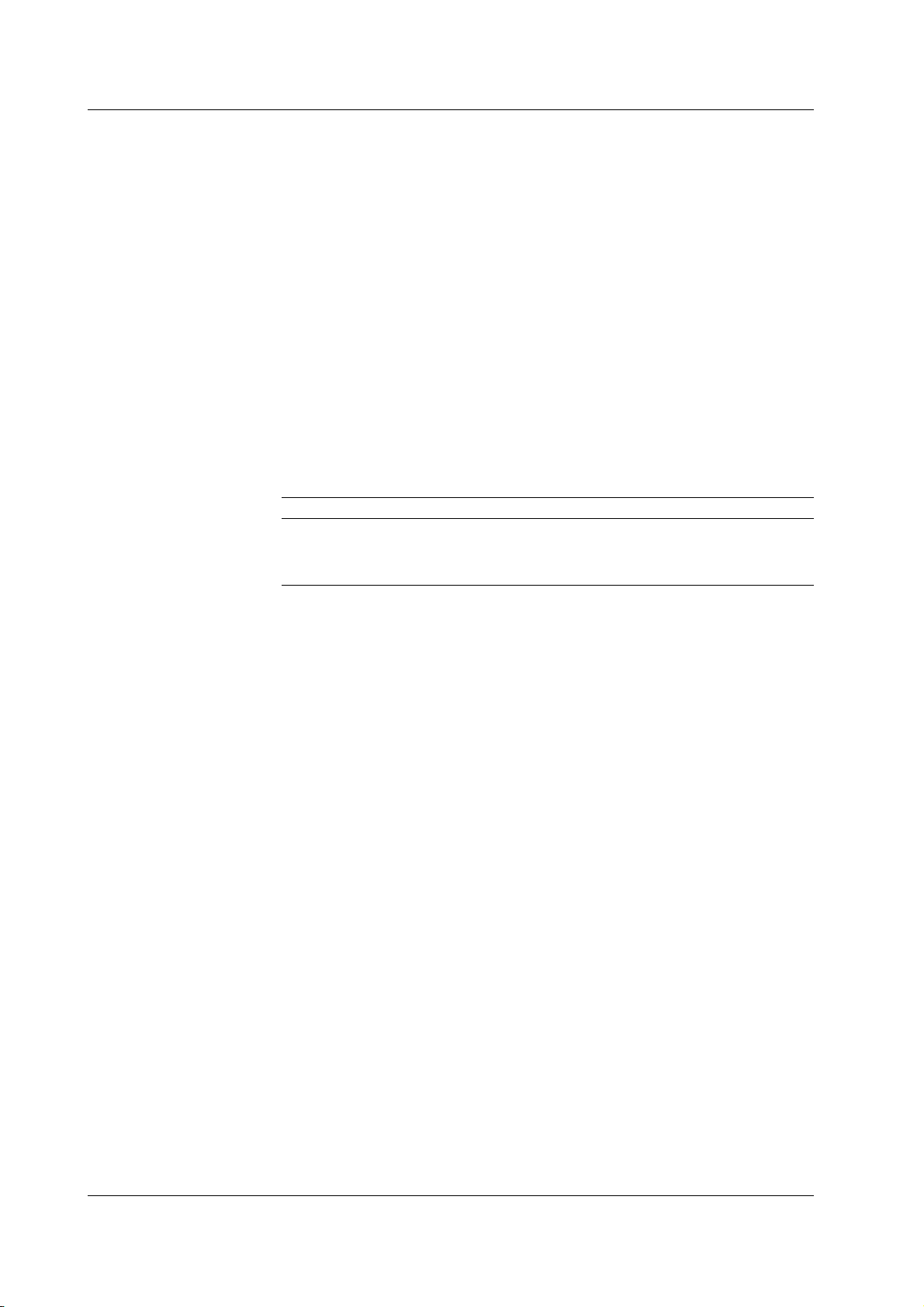

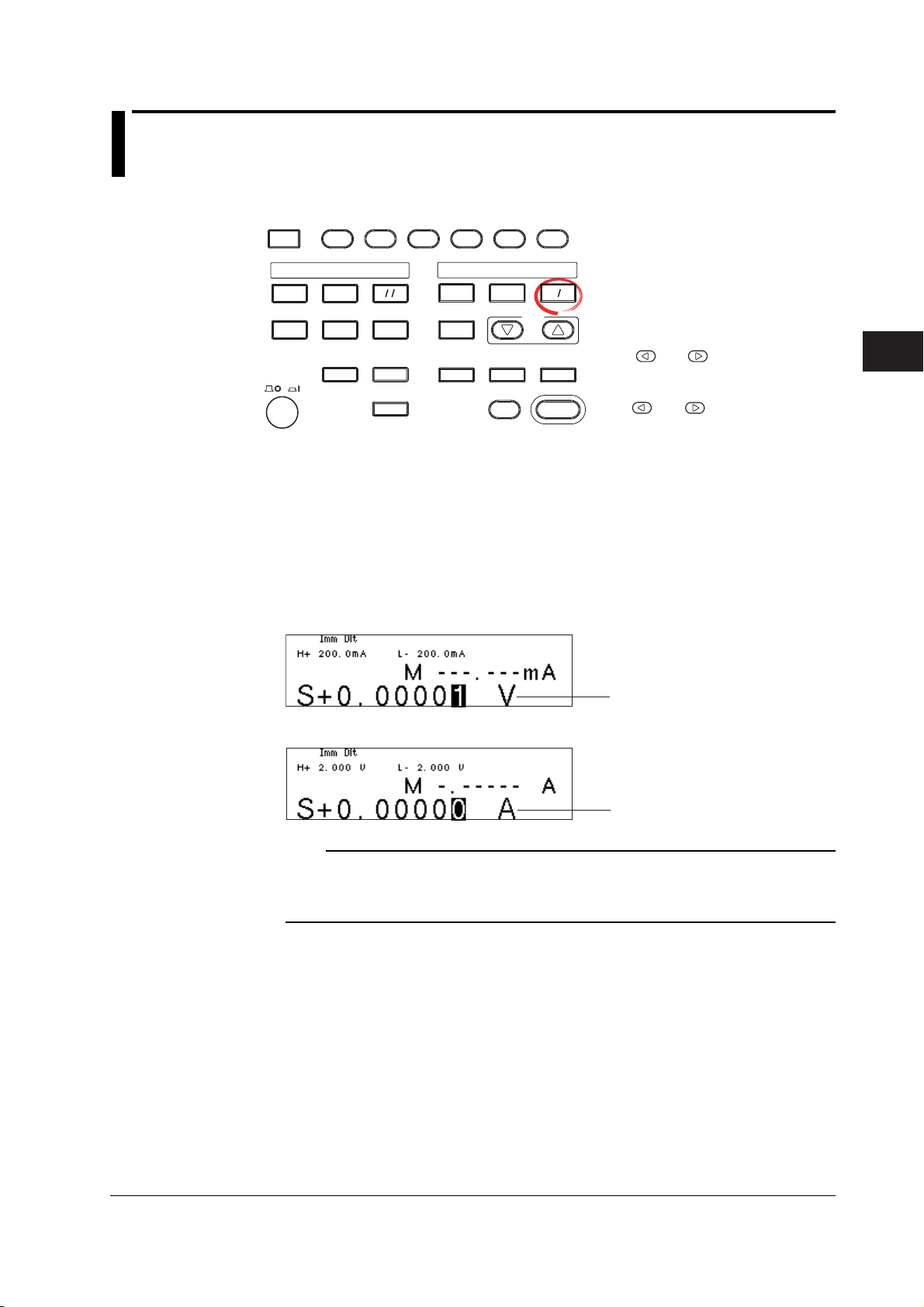

2.2 Source Measure Cycle

Source measure cycle

trigger (see section 2.5, “Triggers”). When the GS610 output is ON, the source measure

cycle is constantly repeated.

In a source measure cycle, the source level changes after a time specified by the source

delay elapses from the point in which the trigger is activated. Furthermore, the

measurement starts after a time specified by the measurement delay elapses. When the

measurement and computation are complete, one source measure cycle is finished.

However, if you change the source level with a key or a communication command in the

middle of a source measure cycle, the source level changes immediately without waiting

for the source delay or measure delay, and the internal trigger phase is reset.

If the measurement function is turned OFF, measure delay, measurement, and

computation are not carried out. The way in which a source measure cycle ends varies

depending on the source mode (see sections 5.4, “DC Source Mode” and 5.5, “Pulse

Source Mode).

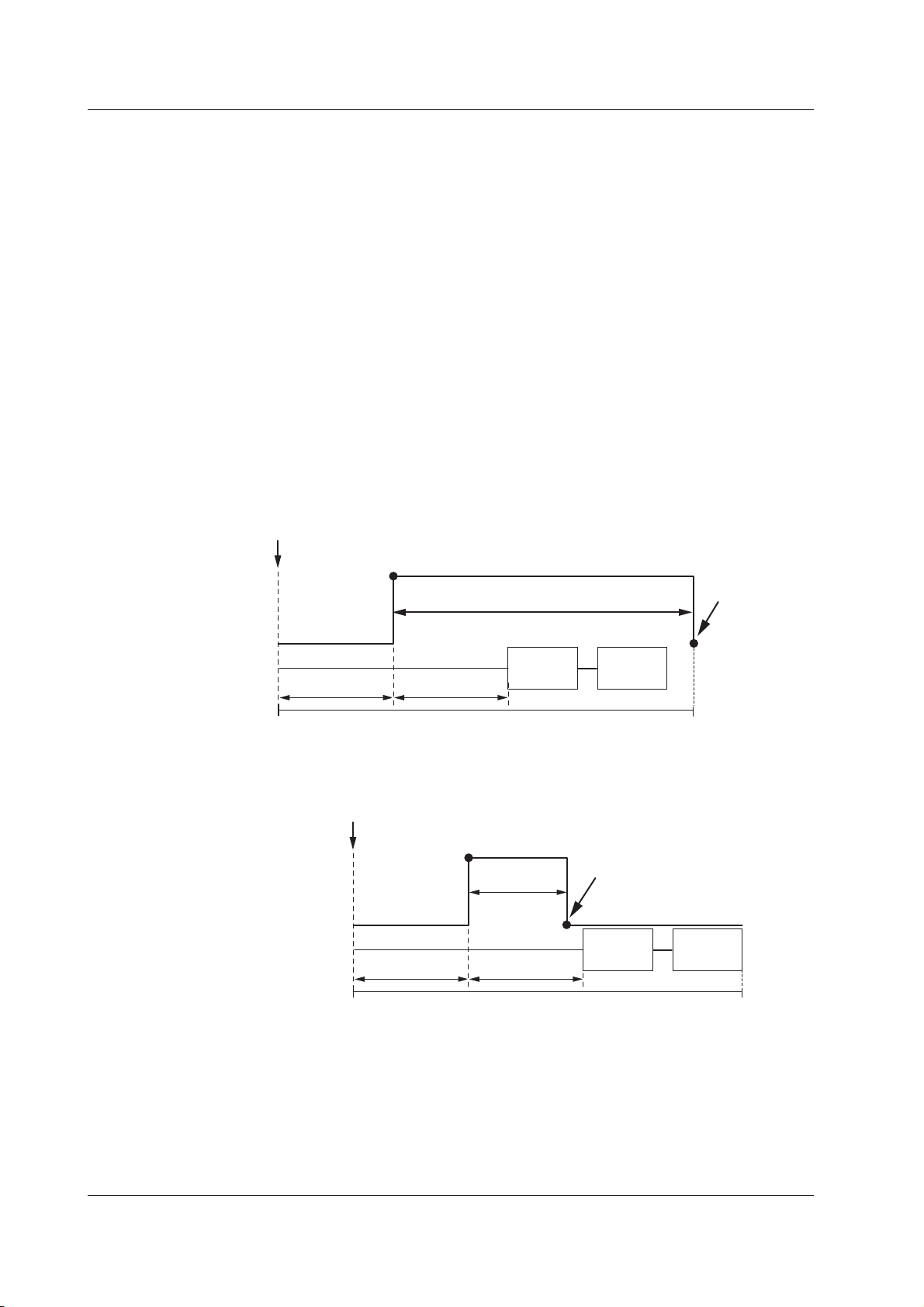

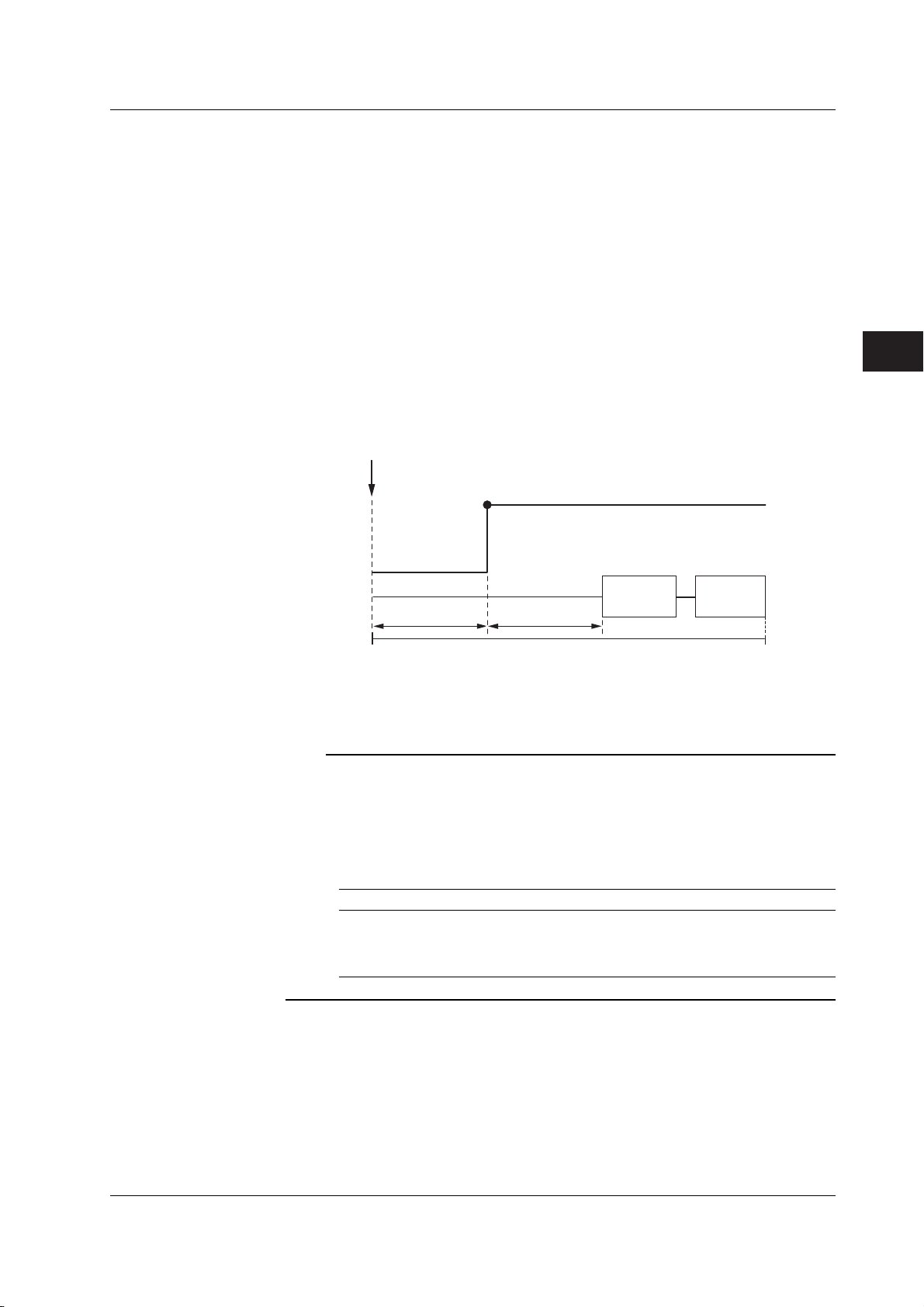

Source Measure Cycle Example

(When the Source Mode Is DC and Sweep Mode Is Linear)

Trigger

Source

on the GS610 refers to the basic operation that starts with a

Current source level

Previous source

level

2

Explanation of Functions

Measurement

Source delay

Measurement

delay

Source measure cycle

Measurement

Computation

IM 765501-01E

2-3

2.2 Source Measure Cycle

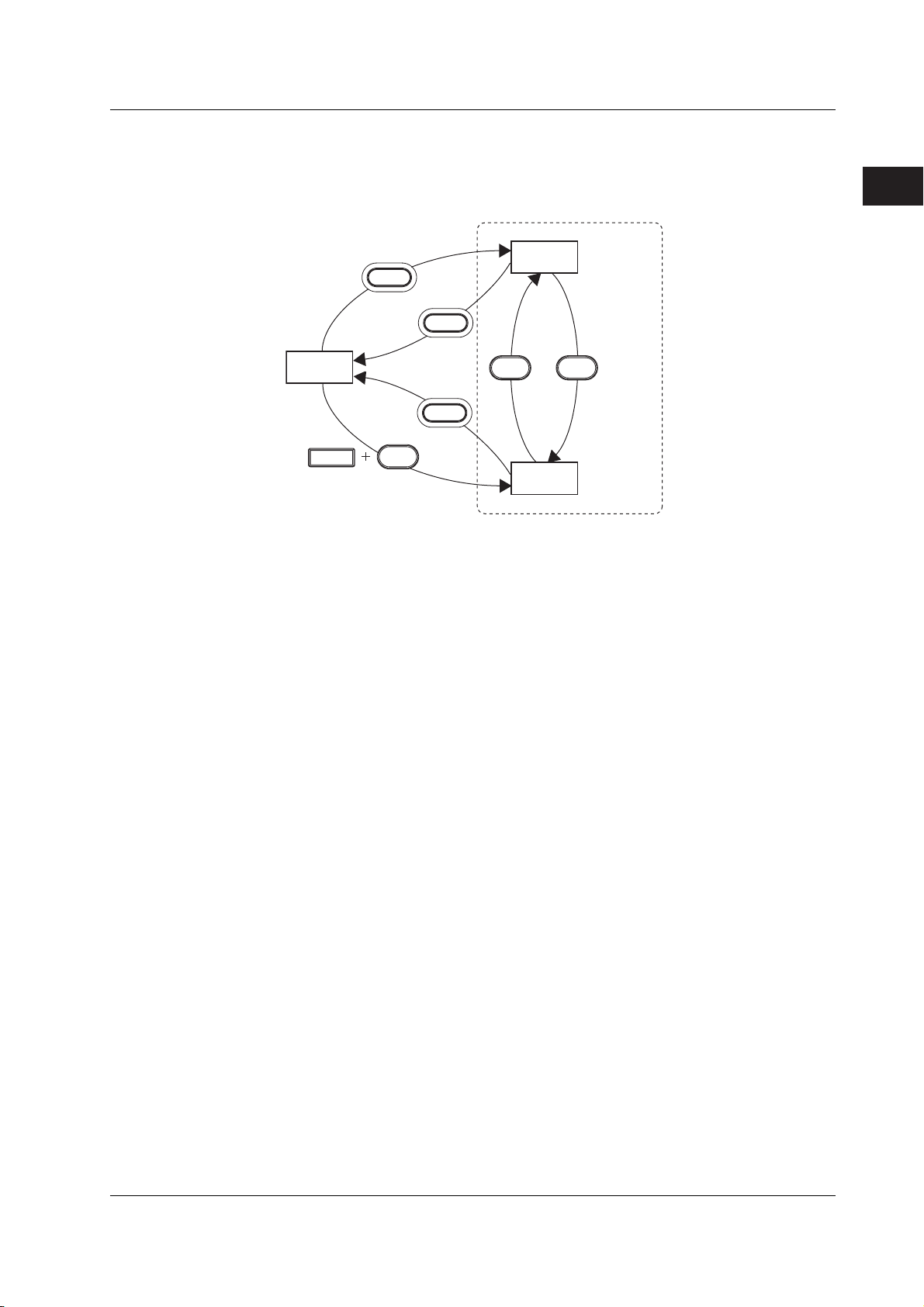

Flow Chart of a Source Measure Cycle

The time indicated in the chart is a typical time needed for its processing. The averaging

time varies depending on the average count, and the computation time varies depending

on the complexity of the equation.

Tri gg er

Source delay

+S. Delay

Change to optimal range

+2 ms

No

mismatched when auto

source range is

Change source range

Update source level

Is measurement ON?

Measurement delay

A/D operation

Yes

mismatched when auto

measurement range

No

A/D operation

Zero compensation

Range

selected?

+3 ms

+10 µs

+M. Delay

+IntgTime*

Range

is selected?

Auto zero?

+IntgTime*

Yes

No

Yes

No

Yes

Block average

operation?

No

Yes

No

Average count

finished?

Yes

Resistance

measurement?

No

Yes

Calculate resistance

+100 µs

Moving average (+moving

average count × 1.5 µs)

Computation

+150 µs

NULL computation

+20 µs

Comparison

+20 µs

End source

measure cycle

Computation

+150 µs

* Integration time + 200 µs when the integration time is 250 µs, 1 ms, or 4 ms.

Integration time + 520 µs when the integration time is 20 ms, 100 ms, or 200 ms.

2-4 IM 765501-01E

1

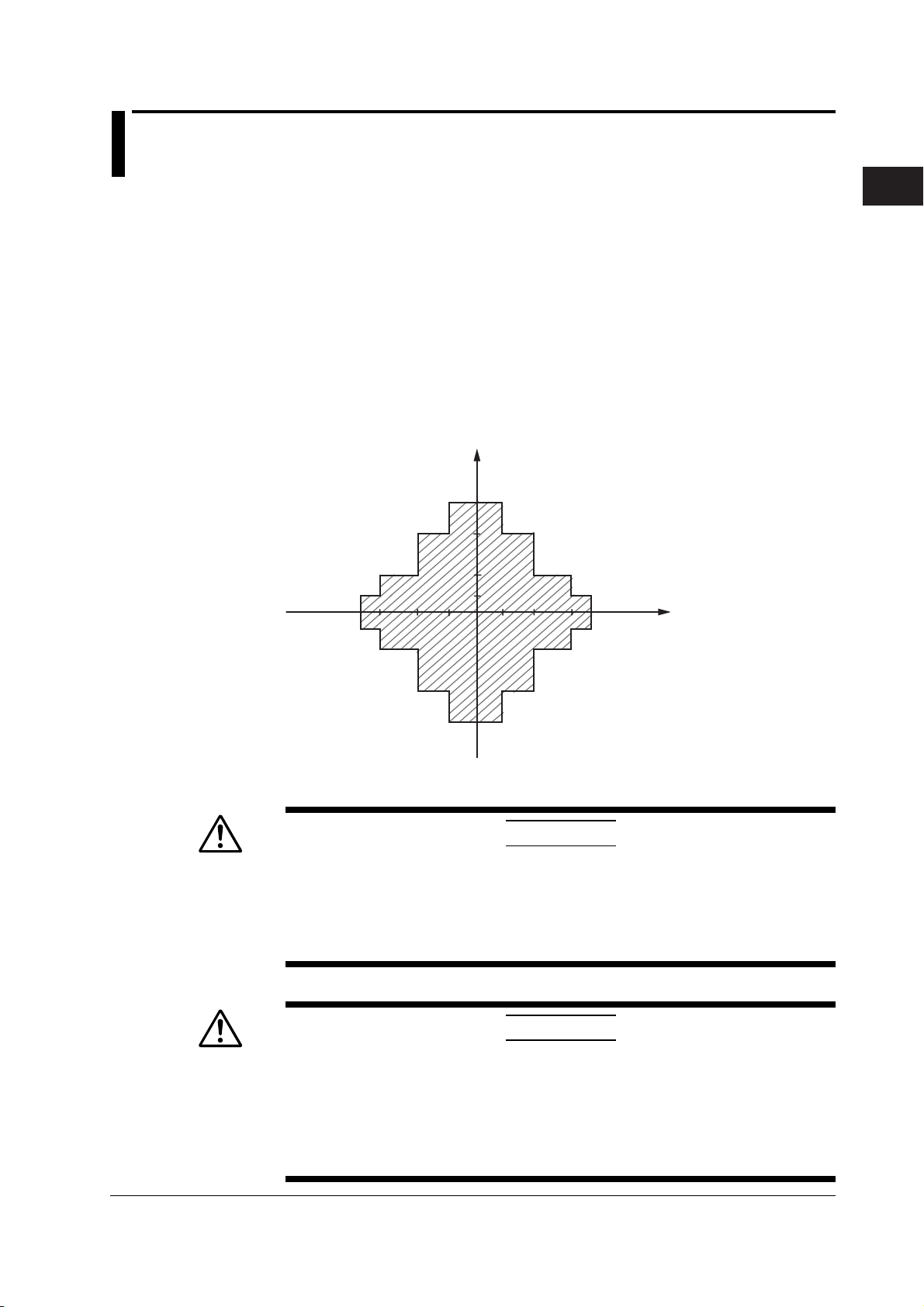

2.3 Source

Source Function (See section 5.1 for the procedure)

You can select voltage source (VS) or current source (IS).

Source Range

The GS610 generates voltage or current in the range specified by the hatched lines in

the figure below. The performance limitations of the GS610 place constraints on the

current and voltage when generating voltage and current, respectively. For example, the

voltage is limited to 30 V or less when 1.5 A is specified when generating current. If the

voltage or current source level is at the boundary of the source range and is limited, a

high limiter indicator (H) illuminates if the level is positive and a low limiter indicator (L)

illuminates if the level is negative.

I

3.2

2

1

0.5

12 30

60

110

V

2

Explanation of Functions

Limiter (See section 5.3 for the procedure)

CAUTION

If a load exceeding the source range above is connected such as a current

source exceeding the current limiter setting when generating voltage or a

voltage source exceeding the voltage limiter setting when generating current,

abnormal load is detected, and the output is turned OFF. Do not connect a load

exceeding the range above to the GS610. Doing so may cause malfunction.

French

ATTENTION

Si vous raccordez une source de courant en mode source de tension dépassant

le paramètre du limiteur de courant, ou une source de tension en mode source

de courant dépassant le paramètre du limiteur de tension, ou encore une charge

dépassant la plage de la source ci-dessus, une charge anormale est détectée et

la sortie est mise hors tension. Ne connectez pas ces types de charge au

GS610, ce dernier risquerait de ne pas fonctionner correctement.

IM 765501-01E

2-5

2.3 Source

If a limiter is set, an additional limit can be placed within the source range. This limit can

prevent damage to the connected device due to overcurrent or overvoltage. The current

limiter is automatically selected when generating voltage, and the voltage limiter is

automatically selected when generating current.

If the limiter is turned OFF, the voltage or current can be generated up to the maximum

value of the source range regardless of the limiter setting.

Voltage Limiter Operation

I

I

Low limiter High limiter

Current Limiter Operation

3.2

0.5

3.2

0.5

2

1

2

1

I

12 30

12 30

60

60

110

110

V

High limiter

V

Low limiter

The high and low limiter values can be set independently. If tracking is turned ON, an

absolute value can be set for the high and low limits, and the limiter functions in the

positive and negative ranges around zero.

If the high limiter is active, the high limiter indicator (H) is shown on the display. If the

low limiter is active, the low limiter indicator (L) is shown on the display.

2-6 IM 765501-01E

1

2.3 Source

Source Range Setting and Auto Range (See section 5.2 for the procedure)

Source Range Setting

The source range settings during voltage generation and current generation are listed below.

• Voltage Source Range Settings

Source Range Setting Source Range Resolution

200 mV ±205.000 mV 1 µV

2 V ±2.05000 V 10 µV

12 V ±12.0000 V 100 µV

20 V ±20.5000 V 100 µV

30 V ±30.000 V 1 mV

60 V ±60.000 V 1 mV

110 V ±110.000 V 1 mV

• Current Source Range Settings

Source Range Setting Source Range Resolution

20 µA ±20.5000 µA 100 pA

200 µA ±205.000 µA1 nA

2 mA ±2.05000 mA 10 nA

20 mA ±20.5000 mA 100 nA

200 mA ±205.000 mA 1 µA

0.5 A ±0.50000 A 10 µA

1 A ±1.00000 A 10 µA

2 A ±2.00000 A 10 µA

3 A ±3.20000 A 10 µA

2

Explanation of Functions

Auto Range

If auto range is turned ON, the range setting with the highest resolution that contains the

source level is automatically selected, eliminating the need for you to manually select the

range setting. However, switching the range setting takes time, and the source level becomes

discontinuous, if the range setting switches as a result of changing the source level.

Source Mode (See sections 5.4 and 5.5 for the procedure)

There are two source modes available.

DC Source Mode

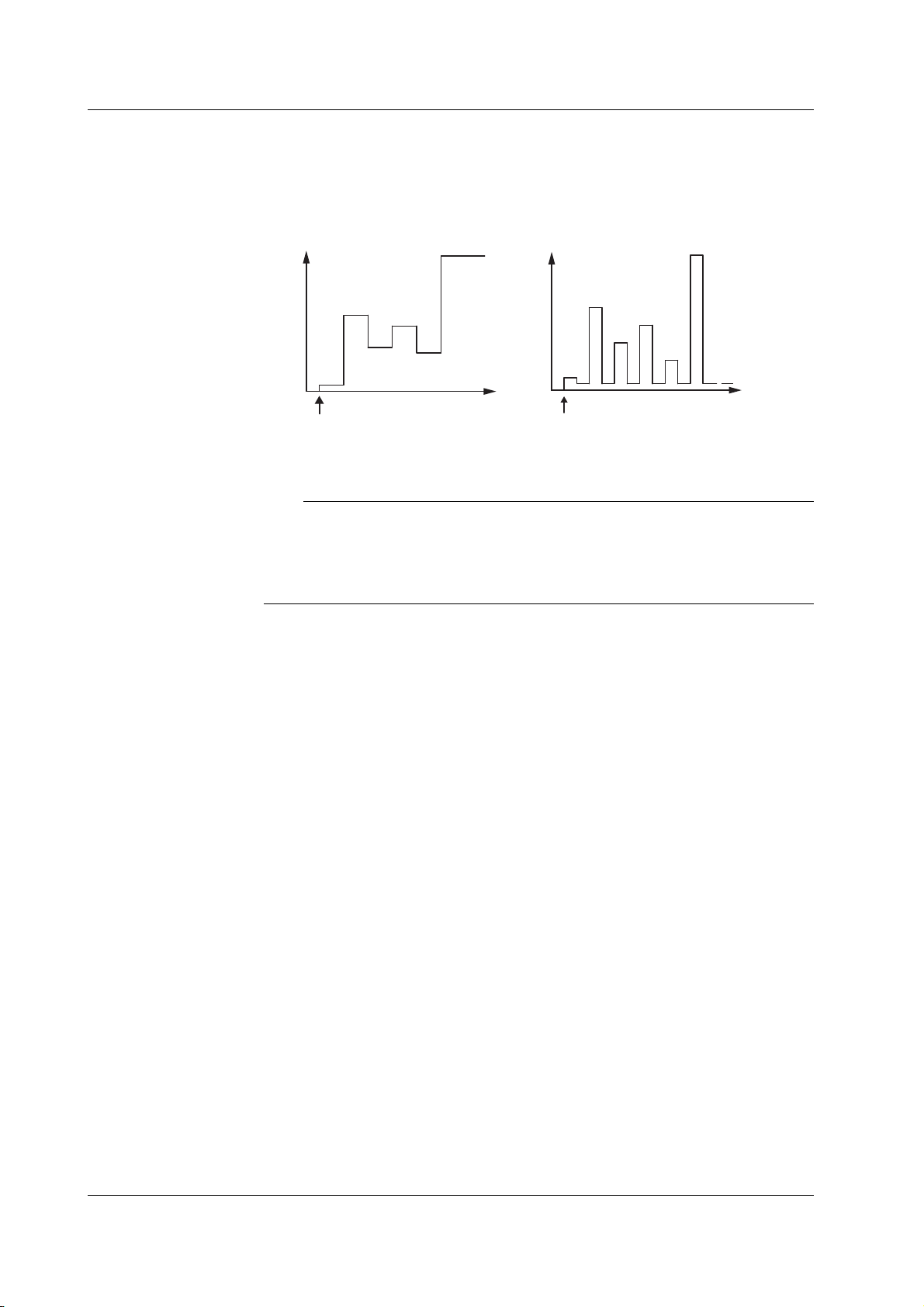

If the sweep mode (see section 2.6, “Sweep”) is ON in DC source mode, the source level

changes after a time specified by the source delay elapses from the point in which the

trigger is activated. Then, measurement starts after a time specified by measurement

delay elapses. When the measurement and computation are complete, one source

measure cycle is finished.

If the sweep mode is OFF, the source level is maintained, and the source measure cycle

is carried out.

If the measurement function (see section 2.4, “Measurement”) is turned OFF, measure

delay, measurement, and computation are not carried out. The source measure cycle is

finished when the source level changes.

Trigger

Current source level

Source

Previous source

level

IM 765501-01E

Measurement

Source delay

Measurement

delay

Source measure cycle

Measurement

Computation

2-7

2.3 Source

Pulse Source Mode

Pulse source mode can be used to improve the reproducibility of measurements on

DUTs that change in characteristics due to the heat generation that results from applying

the source such as a resistor with large temperature coefficient. It is also effective for

evaluation of display devices that use pulse width to control the brightness.

The pulse is specified by two values, the pulse base value and the source level. The

minimum pulse width is 100 µs.

As with the DC source, the source level changes after a time specified by the source

delay elapses from the point in which the trigger is activated. Furthermore, the

measurement starts after a time specified by the measurement delay elapses. The

source level changes at the same the measure delay is activated and returns to the

pulse base value after the pulse width. A source measure cycle is finished at the end of

the pulse or at the end of the measurement and computation, whichever comes later.