Page 1

Digital Resistance Meter

IM 755601-01E

4th Edition

Page 2

Product Registration

Thank you for purchasing YOKOGAWA products.

YOKOGAWA provides registered users with a variety of information and services.

Please allow us to serve you best by completing the product registration form

accessible from our website.

http://tmi.yokogawa.com/

PIM 103-04E

Page 3

Notes

Trademarks

Revisions

Thank you for purchasing the YOKOGAWA Digital Resistance Meter 755601/755611.

This User’s Manual contains useful information about the functions, operating

procedures, and handling precautions of the instrument. To ensure correct use, please

read this manual thoroughly before operation.

Keep this manual in a safe place for quick reference in the event a question arises.

• The contents of this manual are subject to change without prior notice as a result of

continuing improvements to the instrument’s performance and functions. The figures

given in this manual may differ from the actual screen.

• Every effort has been made in the preparation of this manual to ensure the accuracy

of its contents. However, should you have any questions or find any errors, please

contact your nearest YOKOGAWA dealer.

• Copying or reproducing all or any part of the contents of this manual without

YOKOGAWA’s permission is strictly prohibited.

• MS-DOS is a registered trademark of Microsoft Corporation.

• PostScript is a registered trademark of Adobe Systems Incorporated.

• Other company and product names are trademarks or registered trademarks of their

respective holders.

1st edition: July 1999

2nd edition: September 2013

3rd edition: May 2014

4th edition: October 2017

4th Edition: October 2017 (YMI)

All Rights Reserved, Copyright © 1999 Yokogawa Electric Corporation

All Rights Reserved, Copyright © 2013 Yokogawa Test & Measurement Corporation

iIM 755601-01E

Page 4

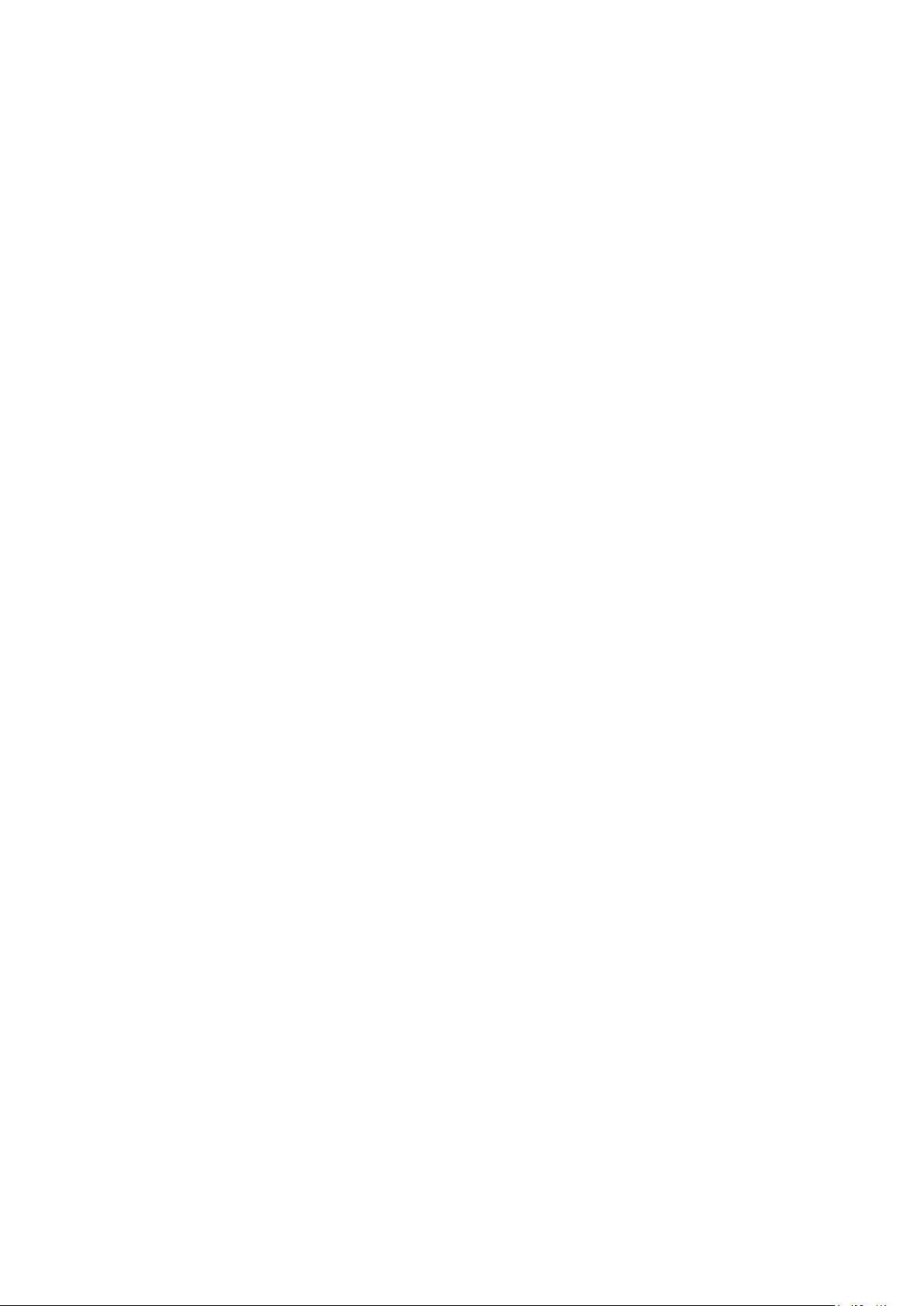

Checking the Contents of the Package

Unpack the box and check the contents before operating the instrument. If some of the

contents are not correct or missing or if there is physical damage, contact the dealer

from which you purchased them.

7556 Main Unit

Check that the model name and suffix code given on the name plate on the side panel

match those on the order. When contacting the dealer from which you purchased the

instrument, please quote the instrument No.

MODEL

SUFFIX

NO.

Madein Japan

MODEL and SUFFIX codes

Model Name Suffix Code Specifications

755601 0.01% resolution

755611 0.001% resolution

Power supply -1 100 VAC

-4 120 VAC

-6 220 VAC

-8 240 VAC

Power cord

Options /C1 GP-IB interface

1 Make sure that the attached power cord meets the designated standards of the country and

1

-D UL/CSA Standards Power Cord (Part No.: A1006WD)

-F VDE Standard Power Cord (Part No.: A1009WD)

-Q BS Standard Power Cord (Part No.: A1054WD)

-R SAA Standard Power Cord (Part No.: A1024WD)

-H GB Standard Power Cord (complies with the CCC)

/C2 Centronics interface

/C3 GP-IB & Centronics interface

area that you are using it in.

[Maximum Rated Voltage: 125 V, Maximum Rated Current: 7 A]

[Maximum Rated Voltage: 250 V, Maximum Rated Current: 10 A]

[Maximum Rated Voltage: 250 V, Maximum Rated Current: 10 A]

[Maximum Rated Voltage: 240 V, Maximum Rated Current: 10 A]

(Part No.: A1064WD)

[Maximum Rated Voltage: 250 V, Maximum Rated Current: 10 A]

MODEL

SUFFIX

NO.

Made in Japan

NO. (Instrument No.)

When contacting the dealer from which you purchased the instrument, please quote the

instrument No.

ii IM 755601-01E

Page 5

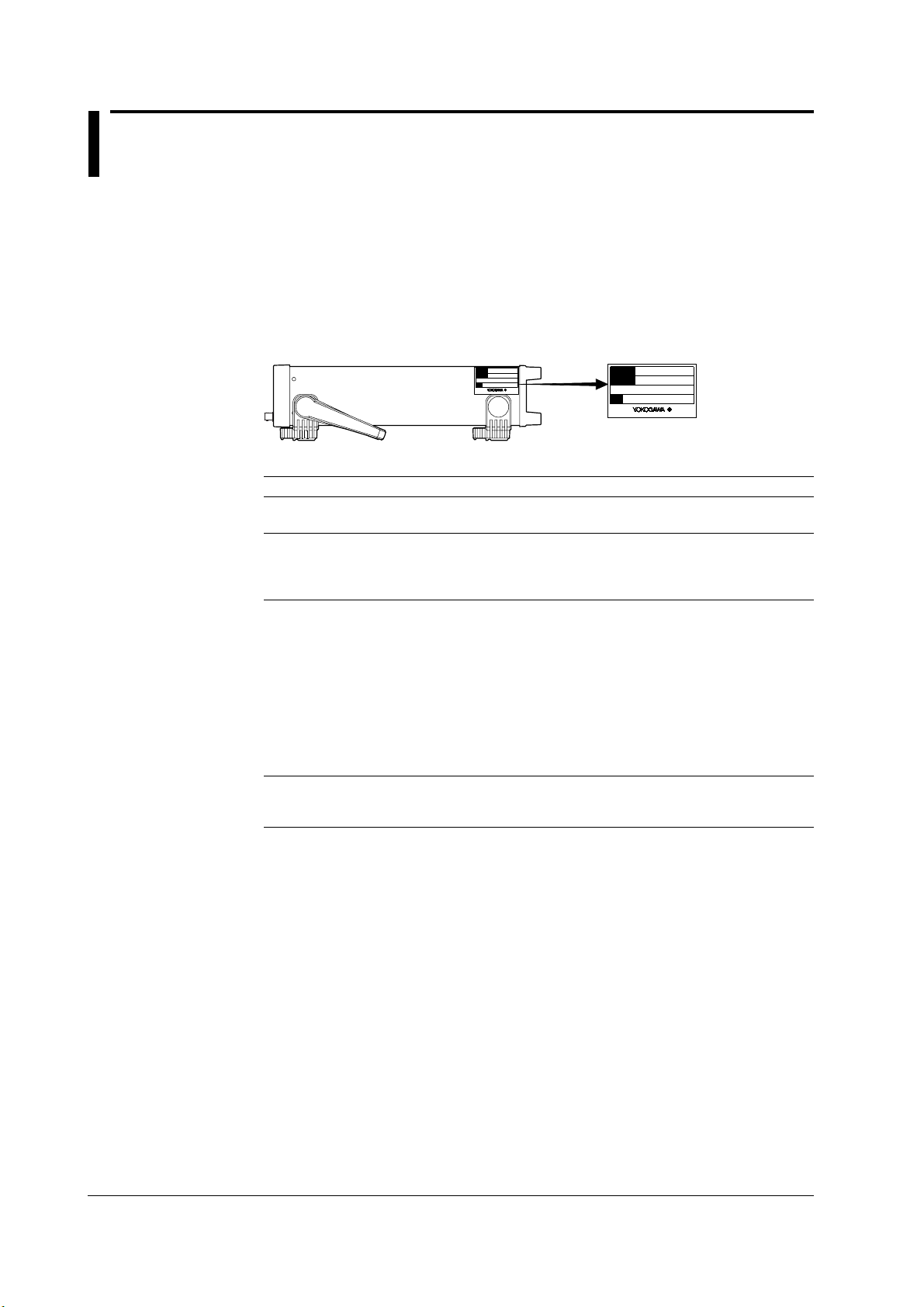

Standard Accessories

The following standard accessories are supplied with the instrument. Check that all

items are present and that they are undamaged.

Checking the Contents of the Package

1. Power cord (one of the following power cords

is supplied according to the instrument's suffix codes)

UL/CSA standard

A1006WD

D

Spare power fuse

for suffix code -1 & -4:

A1345EF (1 piece)

for suffix code -6 & -8:

A1342EF (1 piece)

1 Make sure that the attached power cord meets the designated standards of the

country and area that you are using it in.

VDE standard

A1009WD

F Q R

Rubber feet

(4 pieces)

A9088ZM 2 sets

BS standard

A1054WD

SAA standard

A1024WD

User's Manual (this manual) 1 piece

1

GB Standard

A1064WD

Note

• We recommend you keep the packing box. The box is useful when you need to transport the

instrument.

• For information regarding the fuse ratings, see section 11.5, “Replacing the Power Fuse.”

H

iiiIM 755601-01E

Page 6

Safety Precautions

This product is designed to be used by a person with specialized knowledge.

This instrument is designed for indoor use only.

The following general safety precautions must be observed during all phases of

operation. If the instrument is used in a manner not specified in this manual, the

protection provided by the instrument may be impaired.

This manual is an essential part of the product; keep it in a safe place for future

reference. YOKOGAWA assumes no liability for the customer’s failure to comply with

these requirements.

The following symbols are used on this instrument.

“Handle with care.” To avoid injury, death of personnel or damage to the

instrument, the operator must refer to the explanation in the User’s Manual or

Service Manual.

AC

ON (power)

OFF (power)

Make sure to comply with the following safety precautions. Not complying might

result in injury, death of personnel.

WARNING

Use the Instrument Only for Its Intended Purpose

This instrument is a resistance measuring device. Do not use this instrument for

anything other than as a resistance measuring device.

Check the Physical Appearance

Do not use the instrument if there is a problem with its physical appearance.

Power Supply

Ensure that the source voltage matches the voltage of the power supply before

turning ON the power.

Power Cord and Plug

• To prevent an electric shock or fire, be sure to use the power cord supplied by

YOKOGAWA. The main power plug must be plugged into an outlet with a

protective grounding terminal. Do not invalidate protection by using an extension

cord without protective grounding. Additionally, do not use the power cord

supplied with this instrument with another instrument.

• Do not use the power cord in a bundled condition.

• If you use a power plug with foreign substance on it, insulation may be

compromised by humidity or other factors and may cause a fire. Clean the

power plug regularly.

Protective Grounding

Make sure to connect the protective grounding to prevent electric shock before

turning ON the power.

iv IM 755601-01E

Page 7

Safety Precautions

Necessity of Protective Grounding

Never cut off the internal or external protective grounding wire or disconnect the

wiring of the protective grounding terminal. Doing so poses a potential shock

hazard.

Do Not Use When the Protection Functions Are Defective

Before using this instrument, check that the protection functions, such as the

protective grounding and fuse, are working properly. If you suspect a defect, do

not use the instrument.

Do Not Remove the Covers or Disassemble or Alter the Instrument

Only qualified YOKOGAWA personnel may remove the covers and disassemble

or alter the instrument. The inside of the instrument is dangerous because parts of

it have high voltages.

External Connection

Connect the protective grounding before connecting to the item under

measurement or external control circuit. If you need to touch the circuit, turn of its

power and make sure that there are no voltages being generated.

Measurement Category

The measurement category of this instrument signal input terminals is Other (O).

Do not use it to measure the main power supply or for Measurement Categories

II, III, and IV.

Install or Use the Instrument in Appropriate Locations

• This instrument is designed to be used indoors. Do not install or use it

outdoors.

• Install the instrument so that you can immediately remove the power cord if an

abnormal or dangerous condition occurs.

CAUTION

Operating Environment Limitations

This product is a Class A (for industrial environments) product. Operation of this

product in a residential area may cause radio interference in which case the user

will be required to correct the interference.

vIM 755601-01E

Page 8

Waste Electrical and Electronic Equipment

Waste Electrical and Electronic Equipment (WEEE), Directive

(This directive is valid only in the EU.)

This product complies with the WEEE directive marking requirement. This marking

indicates that you must not discard this electrical/electronic product in domestic

household waste.

Product Category

With reference to the equipment types in the WEEE directive, this product is classified as

a “Monitoring and control instruments” product.

When disposing of products in the EU, contact your local Yokogawa Europe B.V. office.

Do not dispose in domestic household waste.

EU Battery Directive

EU Battery Directive

(This directive is valid only in the EU.)

Batteries are included in this product. This marking indicates they shall be sorted out and

collected as ordained in the EU battery directive.

Battery type: Lithium battery

You cannot replace batteries by yourself. When you need to replace batteries, contact

your local Yokogawa Europe B.V. office.

vi IM 755601-01E

Page 9

How to Use this Manual

Structure of the Manual

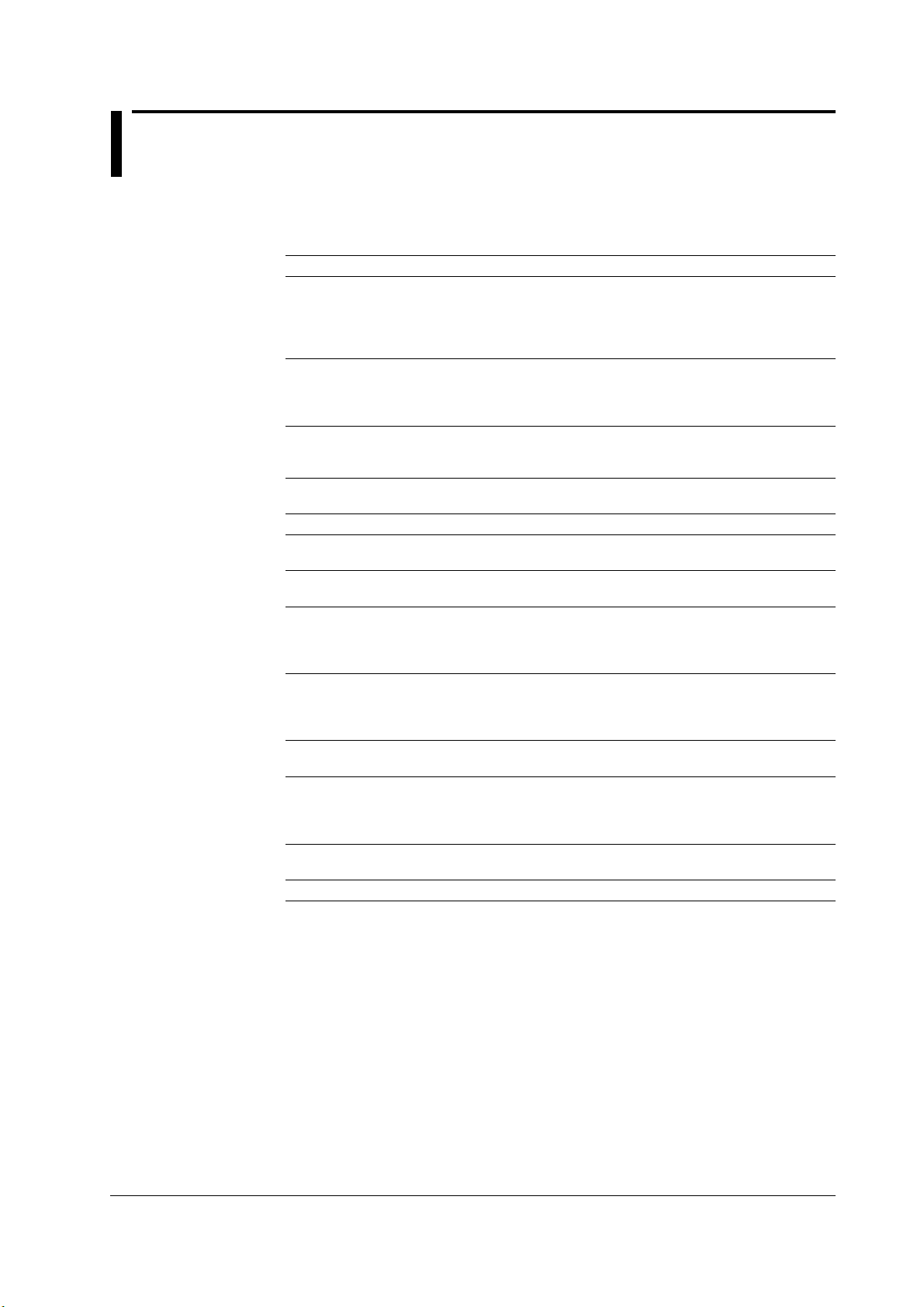

This User’s Manual consists of the following 12 chapters, and an index.

Chapter Title Description

1 Functions Describes the measurement principles and

2 Names and Uses of Parts Describes the names and uses of each part of the

3 Before Starting Measurements Describes precautions on use, how to install the

4 Setting the Measurement Conditions Describes how to set the measurement conditions

5 Making Measurements Describes how to make measurements.

6 Other Functions Describes how to save and recall measured data

7 Using the Handler Interface Describes the handler interface specifications, how

8 Using the Serial (RS-232) Interface Describes how to control this instrument from a

9 Using the GP-IB Interface Describes how to control this instrument from a

10 Using Communication Commands Describes communication commands and sample

11 Error Messages and Maintenance, Describes the possible causes of problems and

and Inspection their appropriate corrective measures. Describes

12 Specifications The specifications of the instrument are given on

Index Gives an Index.

functions of the instrument. Operating procedures

are not given in this chapter. However, reading

this chapter will help you understand the operating

procedures given in the chapters that follow.

instrument. For keys, references are given to

pages in the manual where operating procedures

are explained.

instrument, how to connect the power supply, turn

ON/OFF the power switch, and other operations.

such as measurement range and limits.

and how to print out the data.

to setup the handler interface, and the timing chart.

controller (such as a PC) and how to retrieve

measured data from the instrument via the serial

(RS-232) interface.

controller (such as a PC) and how to retrieve

measured data from the instrument via the GP-IB

interface.

programs.

the messages that are displayed on the screen.

Describes how to perform self-tests.

tables.

viiIM 755601-01E

Page 10

How to Use this Manual

Conventions Used in this Manual

Symbols

The following symbols are used in this manual.

Affixed to the instrument. Indicates danger to personnel or

instrument and the operator must refer to the User’s Manual. The

symbol is used in the User’s Manual to indicate the reference.

WARNING

CAUTION

Note

Characters displayed on the seven-segment LED

Because this instrument uses a seven-segment LED to display alphanumeric characters,

some of the characters are displayed using special characters. For details, see section

1.3, “Digital Numbers and Characters and A List of Menus” (page 1-4).

Symbols used on pages in which operating procedures are given

In chapters 3 through 9, on pages where operating procedures are given, the following

symbols are used to classify a description.

Keys

Procedure

Describes precautions that should be observed to prevent injury

or death to the user.

Describes precautions that should be observed to prevent minor

or moderate injury, or damage to the instrument.

Provides important information for the proper operation of the

instrument.

Indicates the keys and indicators related to the setting.

Describes the procedures using a flow diagram. For details on how

to read the flow diagram, see the example given on the next page.

The procedures are based on the premise that the user is carrying

them out for the first time. Therefore, in some cases, you may not

have to follow all the steps.

Explanation

viii IM 755601-01E

Describes the details of the settings and the restrictions that exist

with the operating procedure. A detailed description of the function

is not provided in this section. See chapter 1 for a detailed

description of the functions.

Page 11

How to Use this Manual

A Procedure Example

1. Pressing the SHIFT key then the MΩ key displays the contact check selection

menu.

2. Press the

REF

LIMIT

or

<

key until the desired item appears on the screen.

>

3. Press the ENTER key to confirm the selection.

4. If you selected bEF or AFt, enter the contact check level using the numerical keys.

Then, press the ENTER key to confirm.

1.

SHIFT

M

Ω

CHECK

2.

REF LIMIT

3.

Ω

,%

ENTER

Ω

,%

ENTER

(Contact check level)

4.

Ω

ENTER

,%

Symbols Used in the Syntax

The following table indicates symbols that are used in the syntax mainly in Chapter 10.

These symbols are referred to as BNF (Backus-Naur Form) symbols. For details, see

pages 10-5 and 10-6.

Symbol Meaning Example User Input Example

<> Defined value :PANel:RECall{<NRf>}<NRf>=0 to 9 →:PANEL:RECALL 3

{} Select a value from {} :MTIMe{NORMal|FAST|HSPeed} →:MTIME FAST

| Exclusive OR

[] Can be omitted :CHECK[:MODE]BEFore →:CHECK:BEFORE

ixIM 755601-01E

Page 12

Contents

Checking the Contents of the Package .........................................................................................ii

Safety Precautions .......................................................................................................................iv

Waste Electrical and Electronic Equipment ................................................................................. vi

EU Battery Directive .....................................................................................................................vi

How to Use this Manual .............................................................................................................. vii

Chapter 1 Functions

1.1 Block Diagram ........................................................................................................................... 1-1

1.2 Functions .................................................................................................................................. 1-2

1.3 Digital Numbers and Characters and A List of Menus .............................................................. 1-4

1.4 A List of Initial Values ................................................................................................................ 1-7

Chapter 2 Names and Uses of Parts

2.1 Names of Parts ......................................................................................................................... 2-1

2.2 Keys and Error Displays ........................................................................................................... 2-2

Chapter 3 Before Starting Measurements

3.1 Precautions on the Use of the instrument ................................................................................. 3-1

3.2 Installing the Instrument ............................................................................................................ 3-2

3.3 Connecting the Power Cord ...................................................................................................... 3-3

3.4 Wiring ........................................................................................................................................ 3-5

Chapter 4 Setting the Measurement Conditions

4.1 Switching the Limit Mode .......................................................................................................... 4-1

4.2 Changing the Range (Reference) ............................................................................................. 4-2

4.3 Using the Comparator Function ................................................................................................ 4-4

4.4 Using the Contact Check Function ........................................................................................... 4-7

4.5 Setting the Measurement Time ................................................................................................. 4-8

4.6 Using the Trigger Function ........................................................................................................ 4-9

Chapter 5 Making Measurements

5.1 Setting the Measurement Mode ................................................................................................ 5-1

5.2 Switching between Deviation (%) and Absolute (R) Displays ................................................... 5-3

Chapter 6 Other Functions

6.1 Store/Recall Measured Data ..................................................................................................... 6-1

6.2 Printing Data ............................................................................................................................. 6-3

6.3 Initializing the Setup Information ............................................................................................... 6-7

Chapter 7 Using the Handler Interface

7.1 Handler Interface Functions and Specifications ........................................................................ 7-1

7.2 Setting the Pulse Width of the EOM Signal .............................................................................. 7-4

7.3 Timing Chart.............................................................................................................................. 7-5

x IM 755601-01E

Page 13

Contents

Chapter 8 Using the Serial (RS-232) Interface

8.1 Serial (RS-232) Interface Functions and Specifications ........................................................... 8-1

8.2 Connecting the Serial (RS-232) Interface Cable ....................................................................... 8-2

8.3 Handshaking ............................................................................................................................. 8-4

8.4 Data Format .............................................................................................................................. 8-6

8.5 Serial Communication Settings ................................................................................................. 8-7

Chapter 9 Using the GP-IB Interface

9.1 GP-IB Interface Functions and Specifications .......................................................................... 9-1

9.2 Connecting the Interface Cable ................................................................................................ 9-3

9.3 Responses to Interface Messages ............................................................................................ 9-4

9.4 Switching to the Addressable Mode .......................................................................................... 9-6

9.5 Switching to the Talk-only Mode................................................................................................ 9-8

Chapter 10 Communication Commands

10.1 Before Programming ............................................................................................................... 10-1

10.1.1 Messages...................................................................................................................................... 10-1

10.1.2 Commands.................................................................................................................................... 10-3

10.1.3 Responses .................................................................................................................................... 10-4

10.1.4 Data .............................................................................................................................................. 10-5

10.1.5 Synchronization with the Controller .............................................................................................. 10-7

10.1.6 Programming of Various Functions ............................................................................................... 10-9

10.2 Commands ............................................................................................................................ 10-13

10.2.1 A List of Commands .................................................................................................................... 10-13

10.2.2 CHECk(contact CHECk) Group .................................................................................................. 10-15

10.2.3 COMMunicate Group .................................................................................................................. 10-16

10.2.5 HANDler Group ........................................................................................................................... 10-18

10.2.4 DISPlay Group ............................................................................................................................ 10-18

10.2.6 HEADer Group ............................................................................................................................ 10-19

10.2.7 LIMit Group ................................................................................................................................. 10-20

10.2.8 MEASure Group.......................................................................................................................... 10-22

10.2.9 MTIMe(Meas TIMe) Group.......................................................................................................... 10-23

10.2.10 PANel Group ............................................................................................................................... 10-23

10.2.11 PRINt Group (Option) ................................................................................................................. 10-24

10.2.12 READ Group ............................................................................................................................... 10-25

10.2.13 RECall Group .............................................................................................................................. 10-26

10.2.14 SELFtest Group .......................................................................................................................... 10-28

10.2.15 STATus Group ............................................................................................................................. 10-29

10.2.16 STORe Group ............................................................................................................................. 10-30

10.2.17 TRIGger Group ........................................................................................................................... 10-32

10.2.18 Common Command Group ......................................................................................................... 10-33

10.3 Status Report ........................................................................................................................ 10-36

10.3.1 About the Status Report.............................................................................................................. 10-36

10.3.2 Status Byte.................................................................................................................................. 10-37

10.3.3 Standard event register............................................................................................................... 10-38

10.3.4 Extended Event Register ............................................................................................................ 10-39

10.3.5 Output Queue and Error Queue.................................................................................................. 10-40

10.4 ASCII Character Codes ........................................................................................................ 10-41

10.5 About the IEEE.488.2-1992 Standard ................................................................................... 10-42

1

2

3

4

5

6

7

8

9

10

11

12

Index

xiIM 755601-01E

Page 14

Contents

Chapter 11 Error Messages, Maintenance, and Inspection

11.1 Troubleshooting ...................................................................................................................... 11-1

11.2 Messages and Corrective Actions........................................................................................... 11-2

11.3 Self Test .................................................................................................................................. 11-5

11.4 Adjustments ............................................................................................................................ 11-7

11.5 Replacing the Power Fuse ....................................................................................................11-12

Chapter 12 Specifications

12.1 Input Specifications ................................................................................................................. 12-1

12.2 Trigger Specifications.............................................................................................................. 12-3

12.3 Measurement Time Specifications .......................................................................................... 12-3

12.4 Contact Check Specifications ................................................................................................. 12-4

12.5 Comparator Specifications ...................................................................................................... 12-4

12.6 Other Specifications ................................................................................................................ 12-5

12.7 Handler Interface Specifications ............................................................................................. 12-5

12.8 Communication Specifications ................................................................................................ 12-6

12.9 General Specifications ............................................................................................................ 12-6

12.10 External Dimensions ............................................................................................................... 12-8

Index

xii IM 755601-01E

Page 15

Chapter 1 Functions

LOCAL key

GP-IB connector

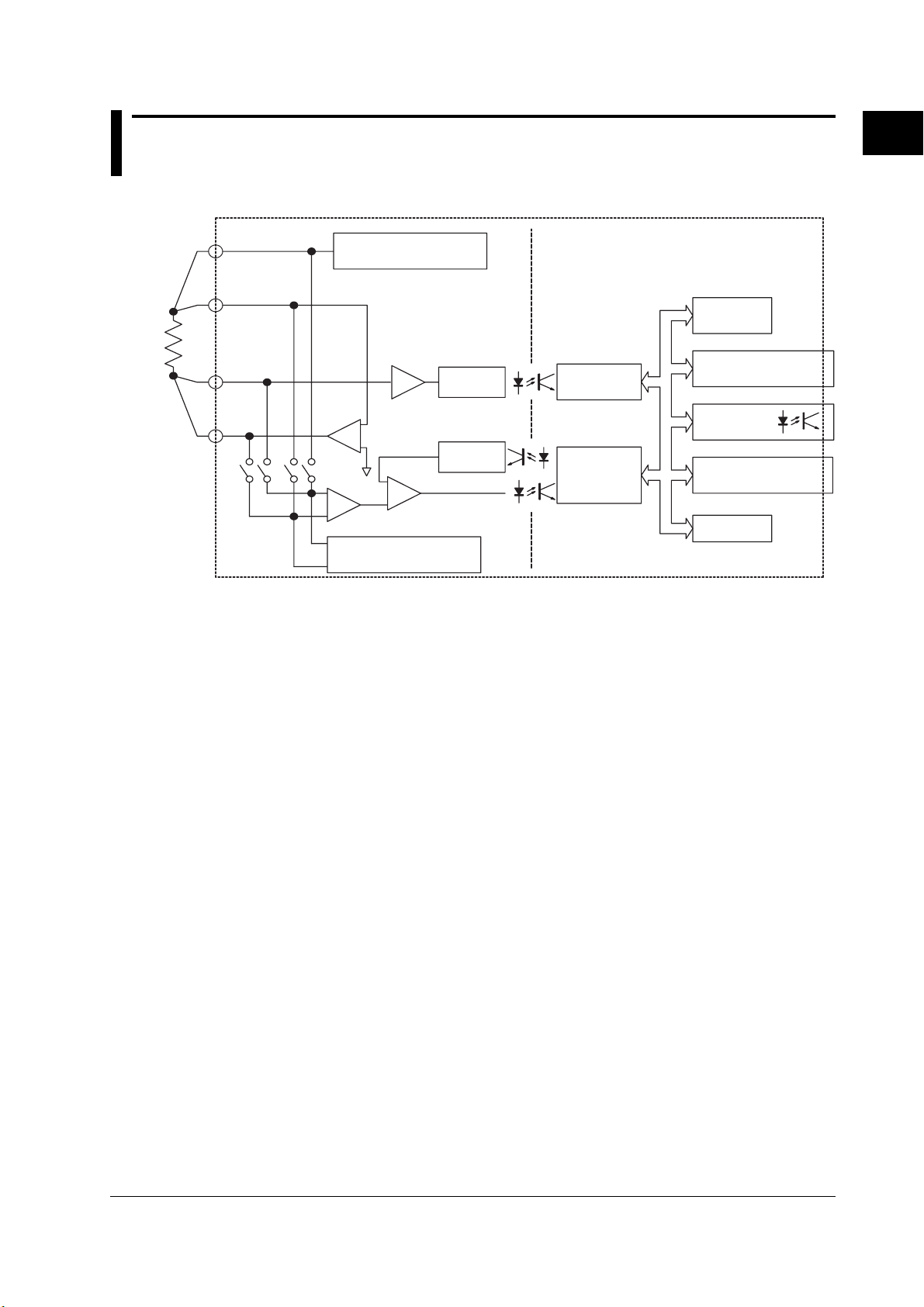

1.1 Block Diagram

Block Diagram

H

L

H

L

CUR

POT

POT

CUR

Constant current source

for measurement

-

+

Diff. amp.

Constant current source

for contact check

Analog section Digital section

A/D

converter

Pre-amp

D/A

converter

Comparator

A/D

interface

CPU

1

Functions

Display

interface

Printer

interface

Handler

interface

Communication

interface

Memory

Measurement Principle

A constant current is fed through the resistor under measurement from the H

to the L

measured. Because the electric potential at the H

equal to the circuit’s common electric potential, the resistance can be determined by

dividing the voltage at the L

In the contact check that is performed before or after the measurement, a constant

current is fed from the H

the L

reference voltage that was set by the D/A converter to check the connection to the

resistor under measurement.

Since the analog section is insulated from the digital section (electric potential of the

case), the circuit is robust against noise, resulting in a stable measurement. In addition,

the handler interface is also insulated from the case in order to minimize noise influence.

CUR

terminal, and the voltage difference between the H

CUR

terminal is controlled so that it is

POT

terminal by the current.

POT

terminal to the H

CUR

terminal. The voltage that appears across these terminals is compared with the

CUR

terminal and from the L

POT

POT

and L

terminals is

POT

terminal to

POT

terminal

1-1IM 755601-01E

Page 16

1.2 Functions

Comparator Function

Determines whether or not the measured result is within the comparison range set

arbitrarily by the user. HI, IN, or LO mark is turned ON to indicate the comparator result.

The result is also output via the handler interface.

Contact Check Function

Determines whether or not the item under measurement is properly connected to the

measurement input terminal, and the result is output via the handler interface. If an error

is detected, “ (no contact)” is displayed.

Trigger Function

Trigger Mode

The instrument has the following three types of trigger modes:

• External trigger: Makes a measurement when the instrument detects a rising or

• Manual trigger: Makes a measurement when the TRIG key on the front panel is

• Internal trigger: Makes measurements at intervals which depend on the specified

falling edge of a signal that is applied to the external trigger input

terminal or the number 8 pin (EXT TRIG) of the handler interface.

pressed or whenever a trigger is activated via the communication

interface.

measurement time (auto sampling).

Trigger Delay

The measurement can then be started the specified time after the trigger occurrence. A

trigger delay is enabled when the trigger mode is set to external trigger or manual trigger.

Communication Function

Handler and serial (RS-232) interfaces come standard with the instrument. A GP-IB

interface is also available as an option.

Printout Function

By using the optional Centronics interface, data stored in the memory, statistics collected

from those data, and other information can be printed to an external printer.

1-2 IM 755601-01E

Page 17

1.2 Functions

Handler Interface Function

The handler interface is used to output comparator results, contact check results, index

signals, and various other signals.

For the specifications of each pin, see section 12.7 “Handler Interface Specifications.”

Other Functions

Storing/Recalling Measured Data

Up to 2000 data sets can be stored. Each data set contains the measured value

obtained from each measurement.

A data set is stored or recalled at every trigger occurrence.

Initializing settings

The settings can be reset to factory default values or initial values.

Measurement Mode/SETUP mode

The instrument has two modes, measurement and SETUP modes. You can switch

between the modes as necessary.

Measurement mode: This mode measures and displays the resistance. Only the R/%

SETUP mode: This mode is used to change the instrument’s settings. No

1

Functions

key, SETUP/MEAS key (SHIFT+R/% key), and STORE DATA

key (SHIFT+0 key) are enabled. Since all other keys are locked,

an erroneous operation resulting from pressing the wrong keys

can be avoided.

However, the TRIG key is enabled when the trigger mode is set

to [MANUAL] and the RECALL DATA key is enabled when

recalling data.

measurements can be made in this mode.

Limit Mode (Deviation/Absolute)

You can select whether to use a deviation (%) or an absolute value (R) to specify the

limit value (LO, HI) that is used when determining the result with the comparator function.

The comparator determines the result using deviation (%) if you set the limit mode to

deviation. The measured value can then be displayed using % or Ω.

The comparator determines the result using absolute value (R) if you set the limit mode

to absolute mode (R). The measured value is displayed using Ω. In this mode, the

comparator function works only for the 1 Ω range.

1-3IM 755601-01E

Page 18

1.3 Digital Numbers and Characters and A List of Menus

Digital Numbers and Characters

Because the instrument’s display is a seven-segment LED, the following special

characters are used to represent the alphanumeric characters. Some characters are not

used by the instrument.

A List of Menus

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

G

H

I

J

Lower case c

Lower case h

K

L

M

N

O

P

Q

R

S

T

U

V

W

X

Y

Z

+

–

×

÷

∧ (power)

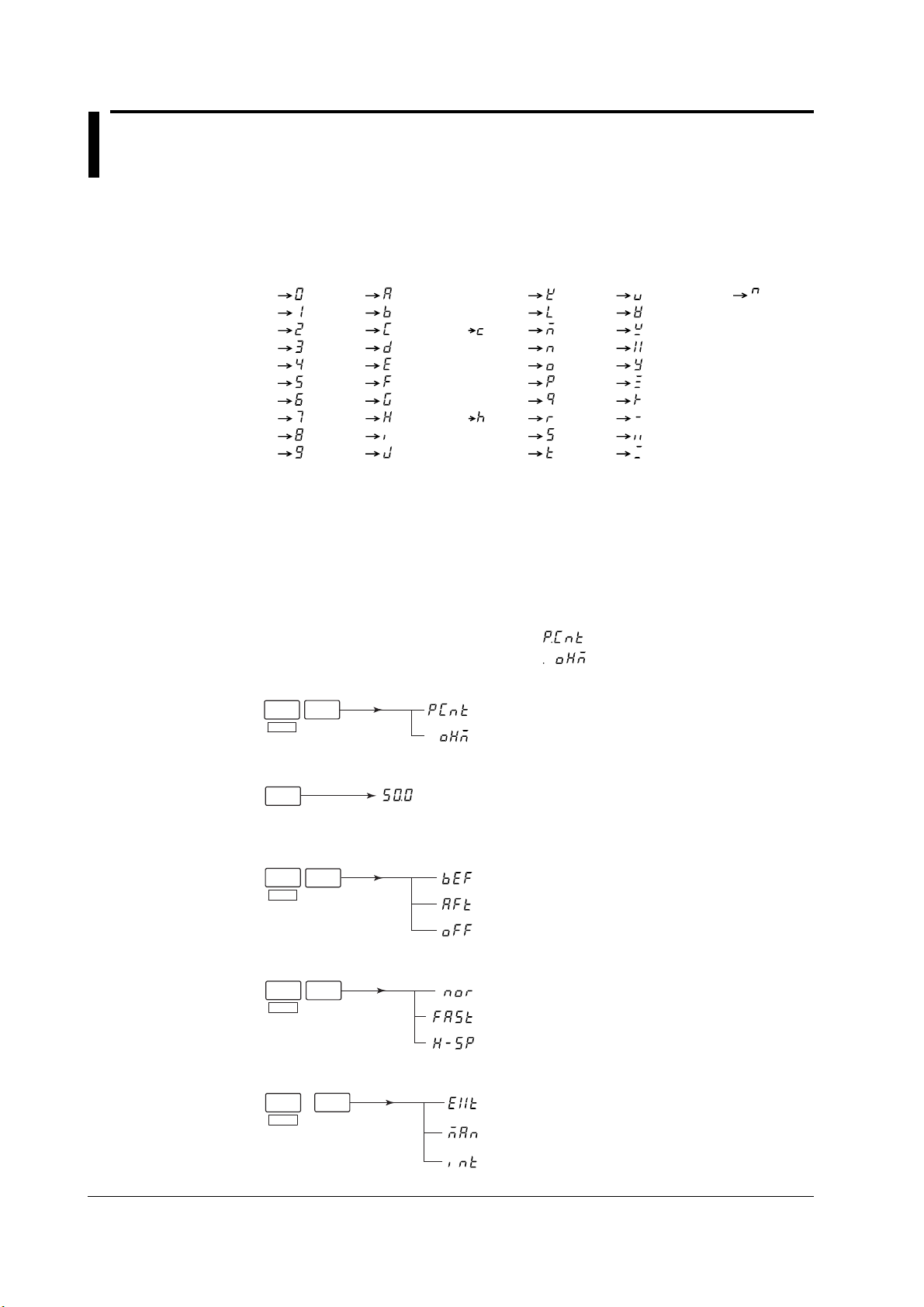

In this section, a list of menus for the SETUP mode is given for each operation key.

For information regarding the EXIT and < , > keys, see section 2.2, “Keys and Error Displays.”

Top menu of the SETUP mode

The first menu displayed in the main display in the SETUP mode is called the top menu.

The display returns to this menu when you confirm a setting or when you exit from a menu.

The top menu varies depending on the limit mode setting as follows:

When the limit mode is set to % (PCnt) :

When the limit mode is set to R (OHm) :

Limit mode setting menu (page 4-1)

SHIFT

8

LIMIT

MODE

(Deviation mode)

(Absolute mode)

Reference setting menu (page 4-2)

REF

(Set the reference)

Contact check setting menu (page 4-7)

M

SHIFT

Ω

CHECK

(Execute before measurement)

(Execute after measurement)

(Disable contact check)

Measurement time selection menu (page 4-8)

SHIFT

7

MEAS

TIME

(Normal)

(Fast)

(High speed)

Trigger mode setting menu (page 4-9)

SHIFT

TRIG

TRIG

MODE

(External trigger)

(Manual trigger)

(Internal trigger)

1-4 IM 755601-01E

Page 19

1.3 Digital Numbers and Characters and A List of Menus

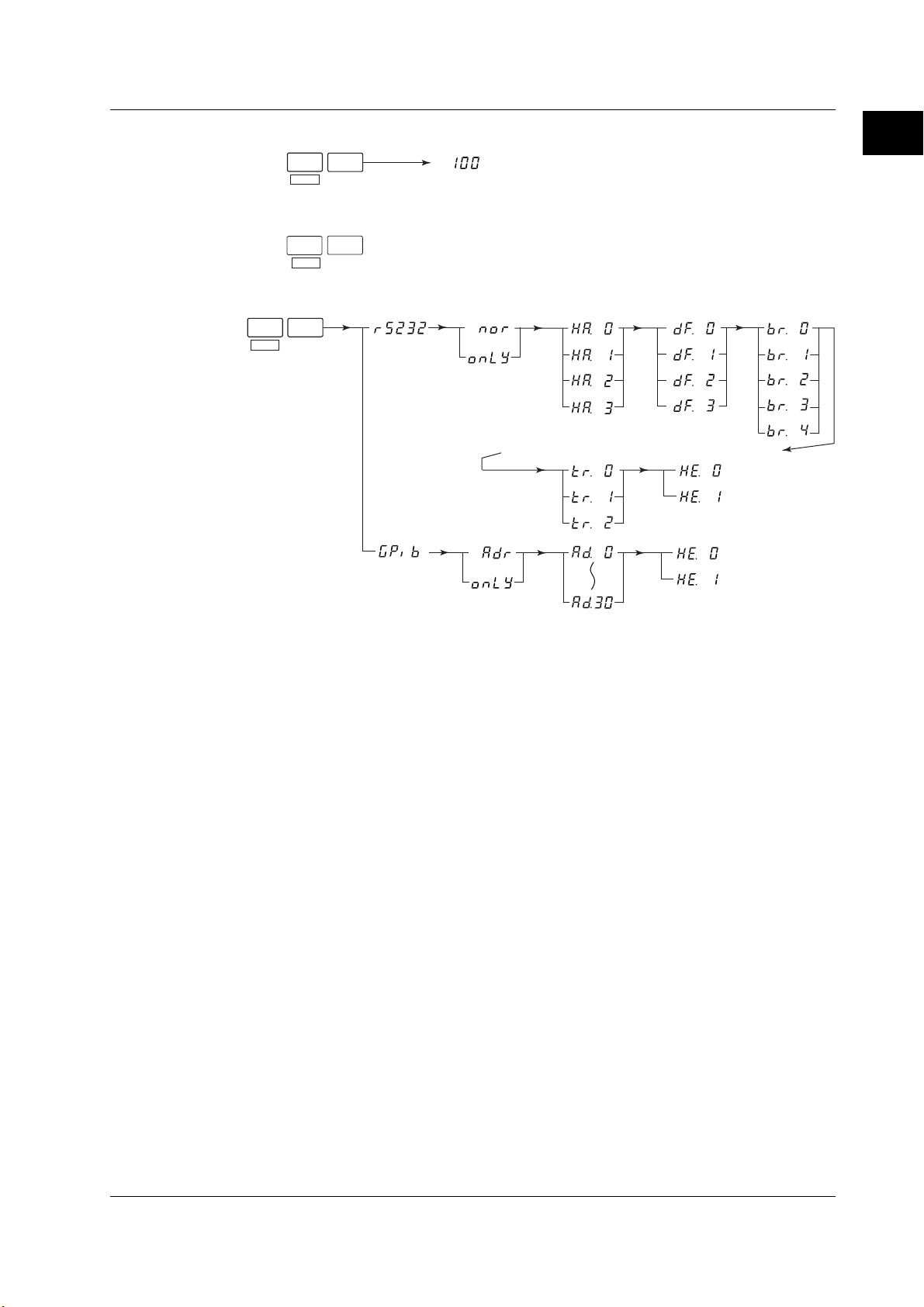

Measured data store menu (page 6-1)

0

STORE

SHIFT

DATA

(Number of stored data sets)

Measured data recall menu (page 6-1)

.

RECALL

SHIFT

DATA

Communication interface setting menu (page 8-7 and 9-6)

3

SHIFT

I/F

*

1

Functions

* Displayed only on instruments that have the optional GP-IB interface.

1-5IM 755601-01E

Page 20

1.3 Digital Numbers and Characters and A List of Menus

Misc menu (pages 4-5, 4-10, 4-11, 6-3, 6-4, 6-7, 7-4, and 11-6)

1

*

1

*

SHIFT

k

MISC

Ω

(Printer output)

(Output format)

(Start printing)

(Stop printing)

(40 characters, no measured data)

(40 characters, with measured data)

(A4 size, no measured data)

(A4 size, with measured data)

2

*

(Percent limit)

(Trigger delay)

(Trigger edge)

(EOM pulse width)

(Initialize setup information)

(Self-test)

3

*

3

*

(Delay time in units of ms)

(Rising)

(Falling)

(in units of ms)

*1 Displayed on instruments that have the optional Centronics interface.

*2 Not displayed when the limit mode is set to absolute mode (R).

*3 For the 755611. “9.99” or “99.9” is displayed on the 755601.

1-6 IM 755601-01E

Page 21

1.4 A List of Initial Values

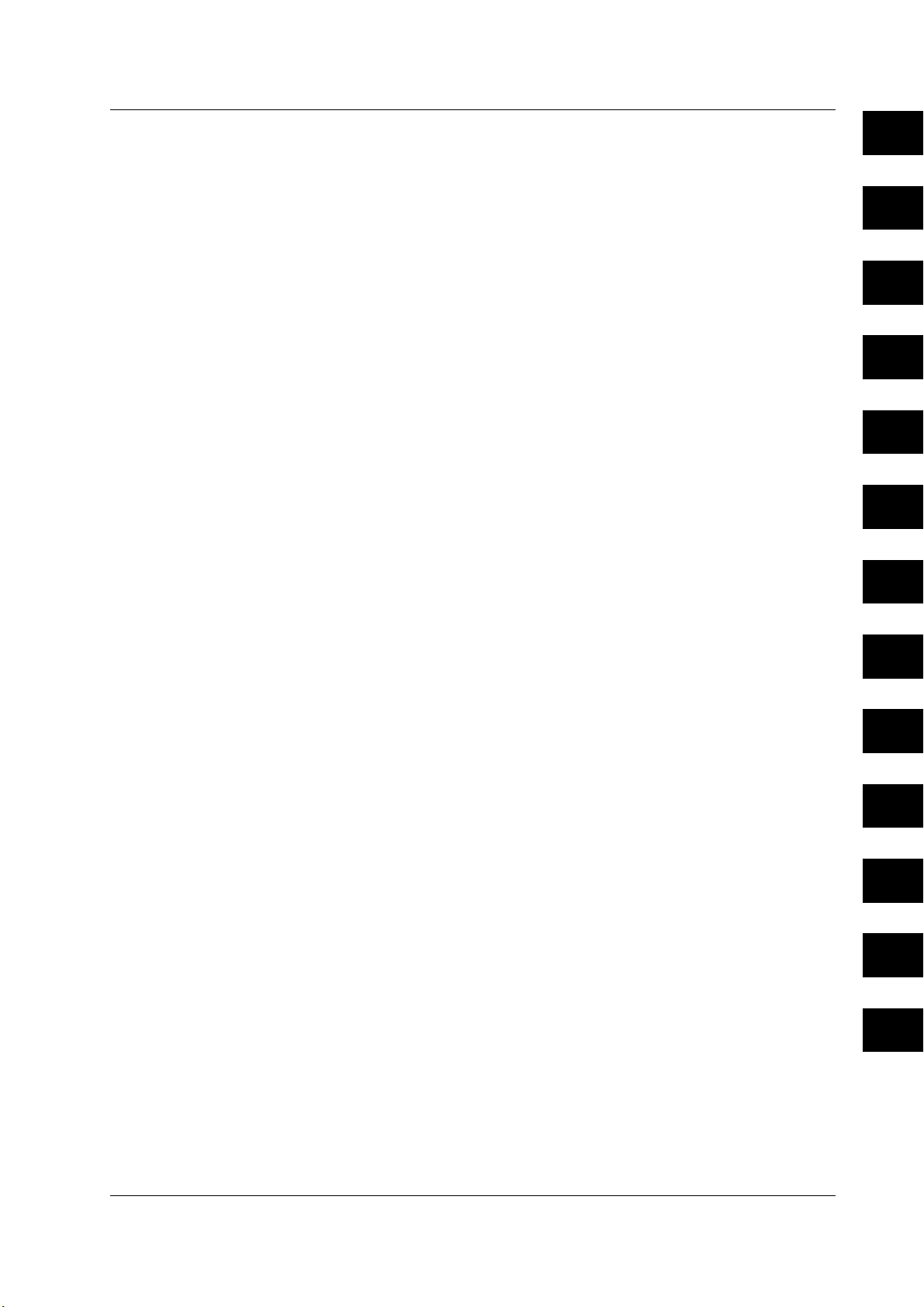

Parameter Factory Default Initial Settings Resume Function*

Display Deviation Deviation Yes

Deviation reference (REF) 100 kΩ 100 kΩ Yes

Measurement time NORMAL NORMAL Yes

Trigger mode EXTERNAL EXTERNAL Yes

Trigger delay 0 ms 0 ms Yes

Contact check function ON ON Yes

Contact check timing Before Before Yes

Contact check level 30 Ω 30 Ω Yes

HI limit 0% 0% Yes

LO limit 0% 0% Yes

Measured data store OFF OFF No

Number of stored data 100 100 Yes

Contents of the stored data Cleared Cleared No

Measured data recall OFF OFF No

SETUP/MEAS SETUP SETUP Yes

Limit mode PCNT PCNT Yes

Percent limit 9.99 9.99 Yes

EOM width 10 ms 10 ms Yes

Communication interface Serial (RS232) Previous condition Yes

Serial (RS232)

Mode Normal Previous condition Yes

Handshaking 0 Previous condition Yes

Data format 0 Previous condition Yes

Baud rate 3 Previous condition Yes

Terminator 0 Previous condition Yes

Header 0 Previous condition Yes

GP-IB

Mode Addressable Previous condition Yes

Address 1 Previous condition Yes

Header 0 Previous condition Yes

Printer (option) OFF OFF No

Print out of measured data OFF.rP OFF.rP Yes

Yes: enabled, No: disabled

* Resume function: A function in which the setup information is stored when the power is turned

OFF and recalled when it is turned ON again.

1

Functions

1-7IM 755601-01E

Page 22

LOCAL key

GP-IB connector

Chapter 2 Names and Uses of Parts

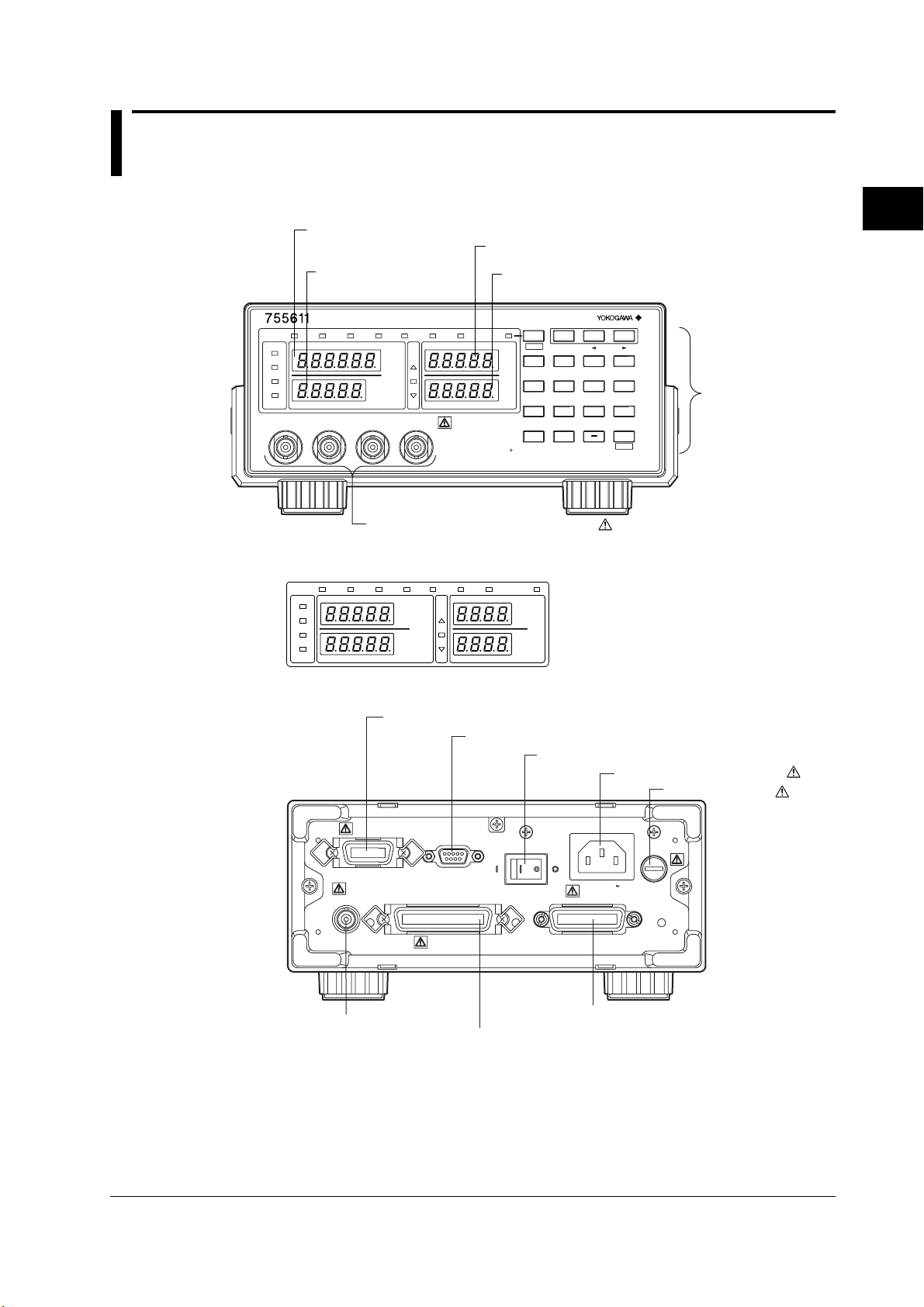

2.1 Names of Parts

Front Panel

Setting value/setting display (Main display, 5 digits on the 755601)

Reference display

DIGITAL RESISTANCE METER

HIGH

STORE

NORMAL

FAST

REFERENCE

UNKNOWN

SPEED

MEAS&

LOCK

SAMPLE

EXTERNAL

MANUAL

L

CUR L POT H POT H CUR

RECALL

DATA

DATA

HI

%

IN

MΩ

LO

kΩ

Ω

Measurement input terminal (page 3-5)

755601 Display Screen

HIGH

MEAS&

LOCK

SAMPLE

EXTERNAL

MANUAL

NORMAL

FAST

REFERENCE

SPEED

STORE

DATA

MΩ

kΩ

CHECK REMOTE

HI LIMIT

LO LIMIT

Do not connect a current/voltage

source to the UNKNOWN terminals.

It will damage the instrument.

ALL TERMINALS 42 V PEAK TO

RECALL

CHECK REMOTE

DATA

HI

%

IN

LO

Ω

HI LIMIT display (4 digits on the 755601)

LO LIMIT display (4 digits on the 755601)

SETUP/MEAS

REF LIMIT

R/%

SHIFT

HI LIMIT

LO LIMIT

EXIT

89

7

%

MEAS

LIMIT

TIME

Ω

MODE

546

1

23

.

0

STORE

RECALL

DATA

DATA

%

Ω

LOCAL

TRIG

TRIG

MODE

M

CHECK

MISCI/F

Ω,%

ENTER

Ω

k

Ω

2

Names and Uses of Parts

Numerical key/

setting key (page 2-2)

Rear Panel (for both 755601, 755611)

Handler interface connector (page 7-3)

HANDLER

TRIGGER IN

External trigger input

terminal (page 4-11)

Serial (RS-232) interface connector (chapter 8)

Power switch (page 3-4)

Power connector (page 3-3)

SERIAL

PRINTER

(RS-232)

POWER

ON

OFF

100V AC

25VA MAX

50/60Hz

GP-IB(IEEE488)

FUSE

250V T 315mA

GP-IB interface connector (chapter 9)

Centronics interface connector (page 6-4)

Fuse (page 11-12)

2-1IM 755601-01E

Page 23

2.2 Keys and Error Displays

Display

The selected measurement time lights

Lights while storing measured data

Lights while recalling measured data

Indicates the comparator result

Lights during contact check

Lights while operating under remote control

HIGH

STORE

RECALL

NORMAL

FAST

SPEED

MEAS&

LOCK

SAMPLE

EXTERNAL

MANUAL

REFERENCE

DATA

%

MΩ

kΩ

Ω

Lights when the trigger mode is set to MANUAL

Lights when the trigger mode is set to EXTERNAL

Lights every data sample

Lights during measurement mode

Switching between measurement mode and SETUP mode

SETUP/MEAS (SHIFT+R/%) key

This key is used to switch between measurement mode and SETUP mode. The

instrument is in the measurement mode when the “MEAS & LOCK” indicator is lit.

DATA

HI

IN

LO

CHECK REMOTE

HI LIMIT

LO LIMIT

SETUP/MEAS

SHIFT

7

%

MEAS

TIME

Ω

1

0

STORE

DATA

REF LIMIT

R/%

EXIT

LOCAL

TRIG

TRIG

MODE

M

CHECK

k

MISCI/F

,%

Ω

ENTER

Ω

Ω

89

LIMIT

MODE

546

23

.

RECALL

DATA

Keys used during the measurement mode

R/% key

This key is used to switch the unit between absolute (R) and deviation (%) in which the

measured value is displayed. When the limit mode is set to absolute (R), pressing this

key will have no effect.

2-2 IM 755601-01E

Page 24

Keys used during the SETUP mode

SHIFT key

Pressing this key once causes the keys to enter the shifted condition. Pressing it again

clears the shifted condition. During the shifted condition, the functions indicated in

purple characters are effective. The shifted condition is indicated by a lit indicator to the

left of the SHIFT key.

EXIT(R/%) key

Used to cancel the setting operation. Pressing this key cancels the specified settings

and causes the instrument to return to the top menu of the SETUP mode.

REF key

When the limit mode is set to deviation (%), this key is used to set the range (reference).

LIMIT key

Used to set the upper and lower limits.

<(REF) key

• When entering numbers (using the numerical keys), this key operates as a backspace

key.

• This key is also used when selecting a parameter in the SETUP menu.

>(LIMIT) key

• When entering numbers, this key operates as a clear key.

• It is also used when selecting a parameter in the SETUP menu.

Numerical keys

• Used when entering numerical values. These keys are valid only when entering

numbers.

• The MΩ, kΩ, Ω, and % keys are used to set a unit on the numerical value.

TRIG key

When the trigger mode is set to manual trigger, pressing this key activates a trigger.

MEAS TIME(SHIFT+7) key

Used to select the measurement time.

LIMIT MODE(SHIFT+8) key

Used to select the limit mode between deviation (%) and absolute (R).

CHECK(SHIFT+MW) key

Used to set the contact check function.

I/F(SHIFT+3) key

Used to set the serial (RS-232) interface or the optional GP-IB interface.

MISC(SHIFT+kW) key

Used to set the trigger delay and other parameters.

STORE DATA(SHIFT+0) key

Used when storing the measured data.

RECALL DATA(SHIFT+ .) key

Used when recalling the measured data.

LOCAL key

Clears the remote mode.

ENTER(Ω,%) key

Used to confirm a specified value or parameter.

2.2 Keys and Error Displays

2

Names and Uses of Parts

2-3IM 755601-01E

Page 25

2.2 Keys and Error Displays

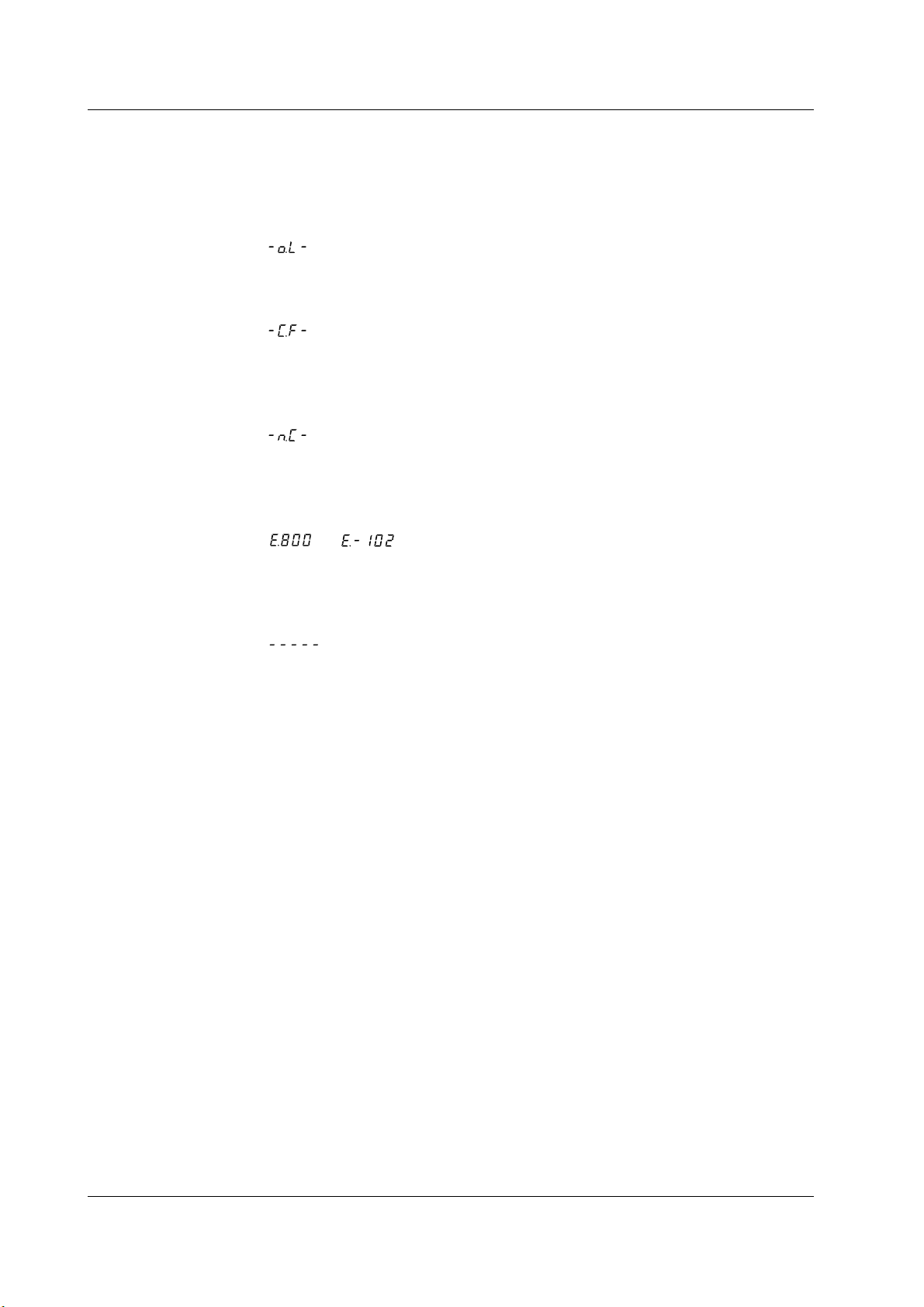

Error Display

Overrange display

When the measured value exceeds the display range or the maximum display value for

the corresponding measurement range, an overrange results. The display shows the

following when the measured value is over the range.

“ ”

Display when an abnormality is detected in the test current

The display when an abnormality is detected in the test current shows the following:

“ ”

Contact check error display

When using the contact check function to make measurements, the display shows the

following when a contact check error occurs.

“

Other error displays

When an error that is described in section 11.2 “Messages and Corrective Actions”

occurs, the corresponding error code is displayed as follows:

“

”

” or “ ”

Bar Display

When the mode is switched from the SETUP mode to the measurement mode, the

display shows the following until the first measured value is displayed.

“

”

2-4 IM 755601-01E

Page 26

Chapter 3 Before Starting Measurements

3.1 Precautions on the Use of the instrument

Safety Precautions

If you are using this instrument for the first time, make sure to thoroughly read the

“Safety Precautions” given on page iii.

• Do not remove the cover from the instrument. Some sections inside the instrument

have high voltages that are extremely dangerous. For internal inspection or

adjustment, contact your nearest YOKOGAWA dealer as listed on the back cover of

this manual.

• Never continue to use the instrument if there are any symptoms of trouble such as

strange smells or smoke coming from the instrument. In such cases, immediately turn

OFF the power and unplug the power cord. Then, contact your nearest YOKOGAWA

dealer as listed on the back cover of this manual.

• Nothing should be placed on top of the power cord. The power cord should also be

kept away from any heat sources. When unplugging the power cord from the outlet,

never pull the cord itself. Always hold the plug and pull it. If the power cord is

damaged, contact your dealer for replacement. Refer to page ii for the part number

when placing an order.

General Handling Precautions

• Never place any objects containing water on top of the instrument. This may cause problems.

• Do not apply shock to the input section. Applying shock to the input terminal or the

probe can cause electrical noise to enter the instrument.

• When the instrument is not being used for an extended period of time, unplug the

power cord from the outlet.

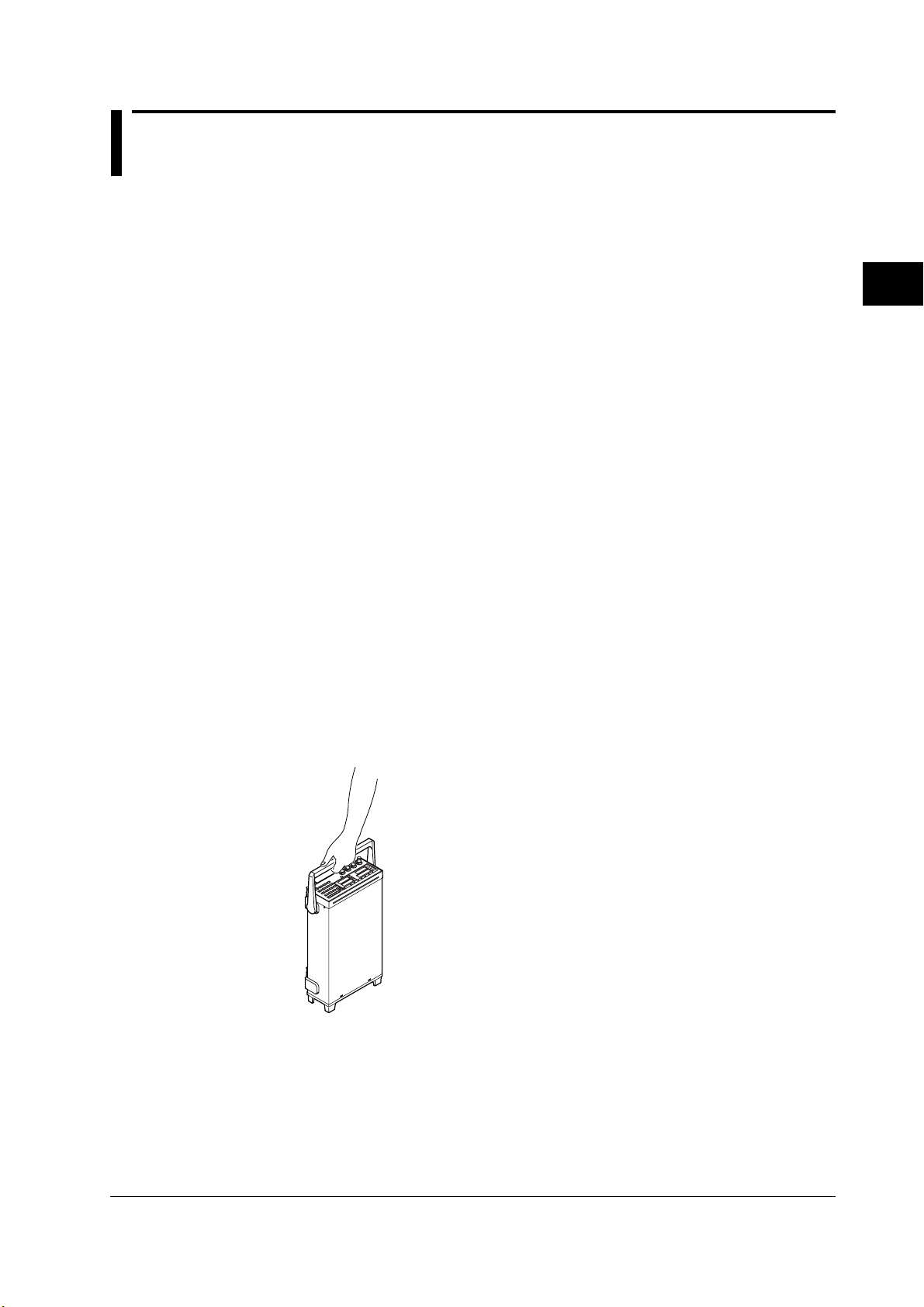

• When moving the instrument, first, turn OFF the devices under measurement and

remove all measurement wires and communication cables. Then, turn OFF the

instrument and remove the power cord from the outlet. To carry the instrument, use

the handle (see figure below) or carry it using both hands.

3

Before Starting Measurements

• Keep electrically charged objects away from the input terminals. They may damage

the internal circuitry.

• Do not pour volatile agents on the case nor leave the case in contact with rubber or

PVC products for long periods of time. The case is made of a thermoplastic resin, so

take care not to let anything hot such as a soldering iron touch the case.

• When cleaning the case or the operation panel, remove the instrument’s power cord

from the outlet. Then, wipe with a dry, soft cloth. Do not use volatile chemicals since

this might cause discoloring and deformation.

3-1IM 755601-01E

Page 27

3.2 Installing the Instrument

Installation condition

Install the instrument in a place that meets the following conditions.

Flat, even surface

Install the instrument on a stable horizontal surface. Otherwise, precise measurements

may be impeded.

Ambient temperature and humidity

Ambient temperature: 5 to 40°C

Ambient humidity: 20 to 80%RH (no condensation)

Do not install the instrument in the following places:

• Outdoor.

• In direct sunlight or near heat sources.

• Where an excessive amount of soot, steam, dust, or corrosive gases are present.

• Where the instrument is exposed to water or other liquids.

• Near strong magnetic field sources.

• Near high voltage equipment or power lines.

• Where the level of mechanical vibration is high.

• In an unstable place.

• In a place where the power switch cannot be accessed easily.

Note

• For the most accurate measurements, use the instrument in the following environment.

Ambient temperature: 23±3°C, ambient humidity: 30 to 75%RH (no condensation)

When using the instrument in a place where the ambient temperature is 5 to 18°C or 28 to

40°C, add the temperature coefficient to the accuracy of the module as specified in chapter

12, “Specifications.”

• When installing the instrument in a place where the ambient humidity is 30% or below, take

measures to prevent static electricity such as using an anti-static mat.

• Internal condensation may occur if the instrument is moved to another place where both the

ambient temperature and humidity are higher, or if the temperature changes rapidly. In this

case, let the instrument adjust to the new environment for at least one hour before using the

instrument. Check to see that there is no condensation.

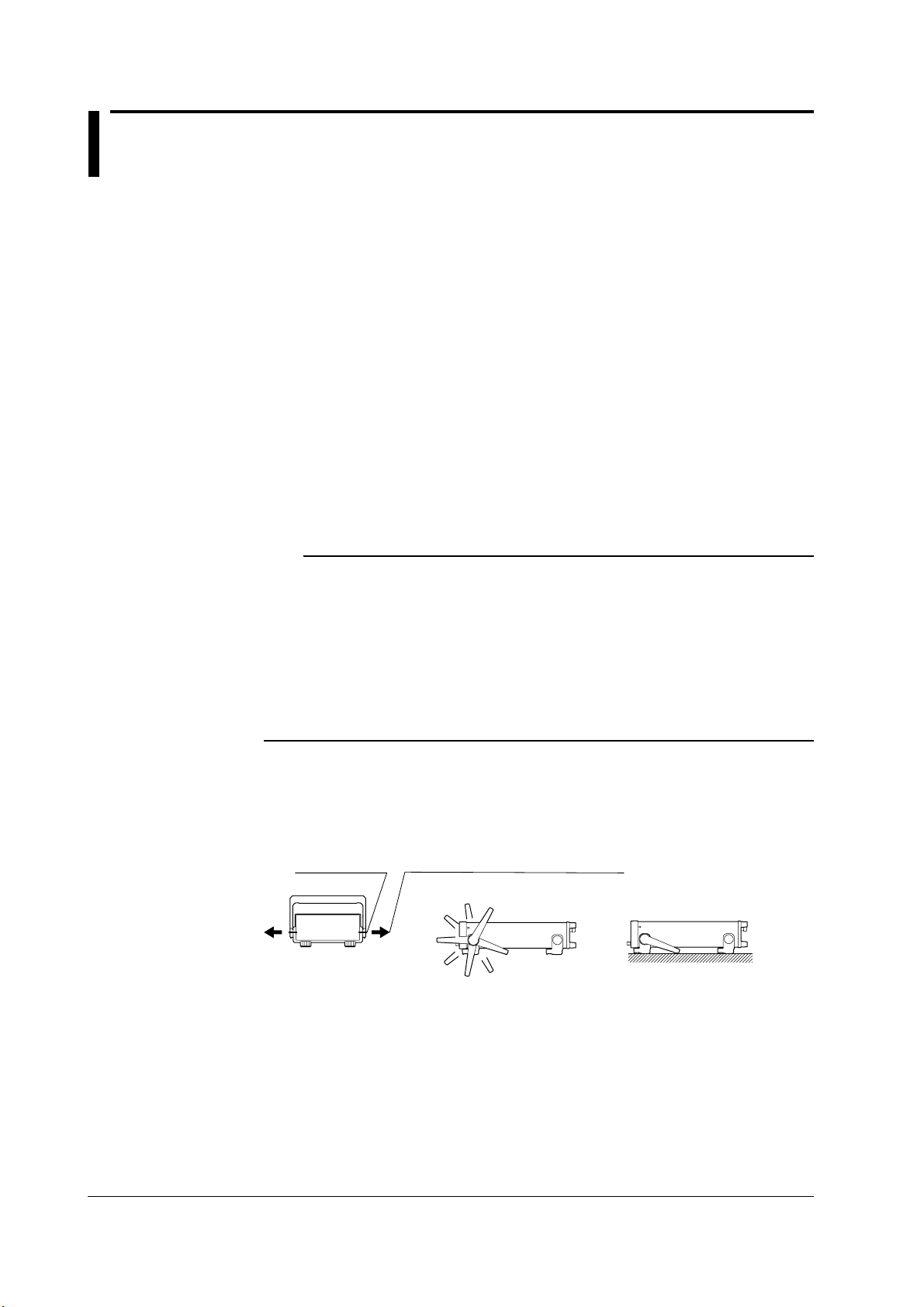

Installation position

Place the instrument on a flat, even surface as shown in the figure below. To adjust the

handle position, pull the handle outward on each side along the axis of rotation by 2 to 3

mm, then slowly rotate the handle to another locked position.

Axis of rotation

Pull the handle outward on each side

by 2 to 3 mm and rotate.

7

Locked positions of the handle

6

5

4

8

1

2

3

1

Storage Location

Do not store the instrument in the following kinds of places:

• Where the relative humidity is 80% or higher or where the temperature is 60°C or

higher

• In direct sunlight or near heat sources

• Where an excessive amount of dust, salt, or iron is present

• Where there are corrosive or explosive gases

• Where water, oil, or chemicals may splash

• Where the level of mechanical vibration is high

We recommend that the instrument be stored in an environment where the temperature

is between 5 and 40°C and the relative humidity is between 20 and 80% RH.

3-2 IM 755601-01E

Page 28

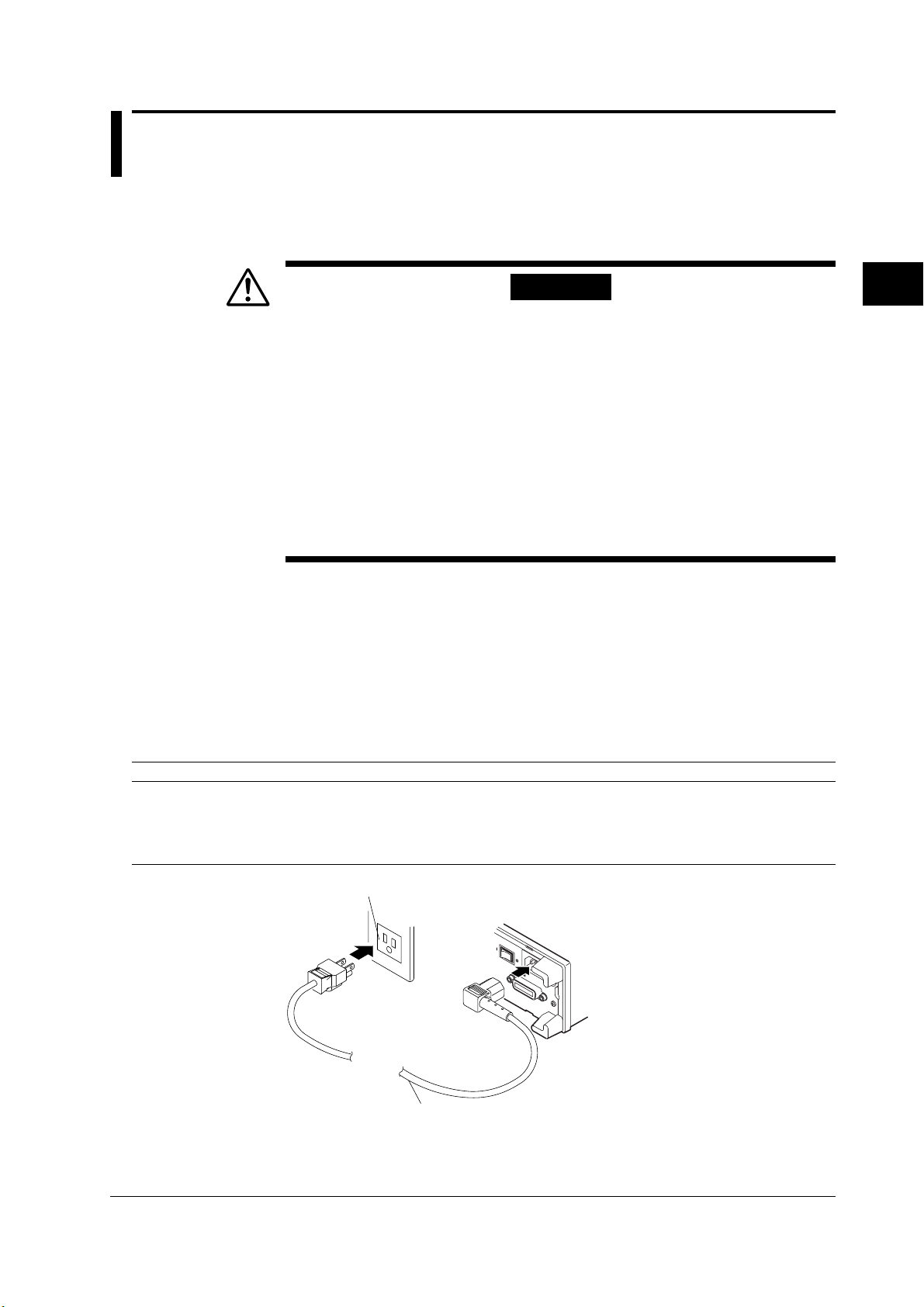

3.3 Connecting the Power Cord

Before connecting the power

Follow the warnings below to avoid electric shock and damage to the instrument.

Connecting Procedure

1. Check that the power switch on the rear panel is OFF.

2. Connect the plug of the power cord that is included in the package to the power

3. Plug the other end of the power cord into a power outlet that satisfies the conditions

WARNING

• Connect the power cord only after confirming that the voltage of the

power supply matches the rated electric power voltage for the

instrument.

• Connect the power cord after checking that the power switch of the

instrument is turned OFF.

• To prevent electric shock or fire, always use the power cord supplied by

YOKOGAWA.

• Always use protective grounding to prevent electric shock. Connect the

power cord of the instrument to a three-pole power outlet that has a

protective grounding terminal.

• Never use an extension cord that does not have protective grounding,

otherwise the protection function will be compromised.

connector on the rear panel of the instrument.

below. The AC outlet must be a three-pole type that has a protective grounding

terminal.

3

Before Starting Measurements

Item Suffix Code -1 Suffix Code -4 Suffix Code -6 Suffix Code -8

Rated supply voltage 100 VAC 120 VAC 220 VAC 240 VAC

Permitted supply voltage range 90 to 110 VAC 108 to 132 VAC 198 to 242 VAC 216 to 264 VAC

Rated supply voltage frequency 50/60 Hz 50/60 Hz 50/60 Hz 50/60 Hz

Permitted supply voltage frequency range 47 to 66 Hz 47 to 66 Hz 47 to 66 Hz 47 to 66 Hz

Maximum power consumption 25 VA 25 VA 25 VA 25 VA

Three-pole outlet

Power cord

(Standard accessory)

3-3IM 755601-01E

Page 29

3.3 Connecting the Power Cord

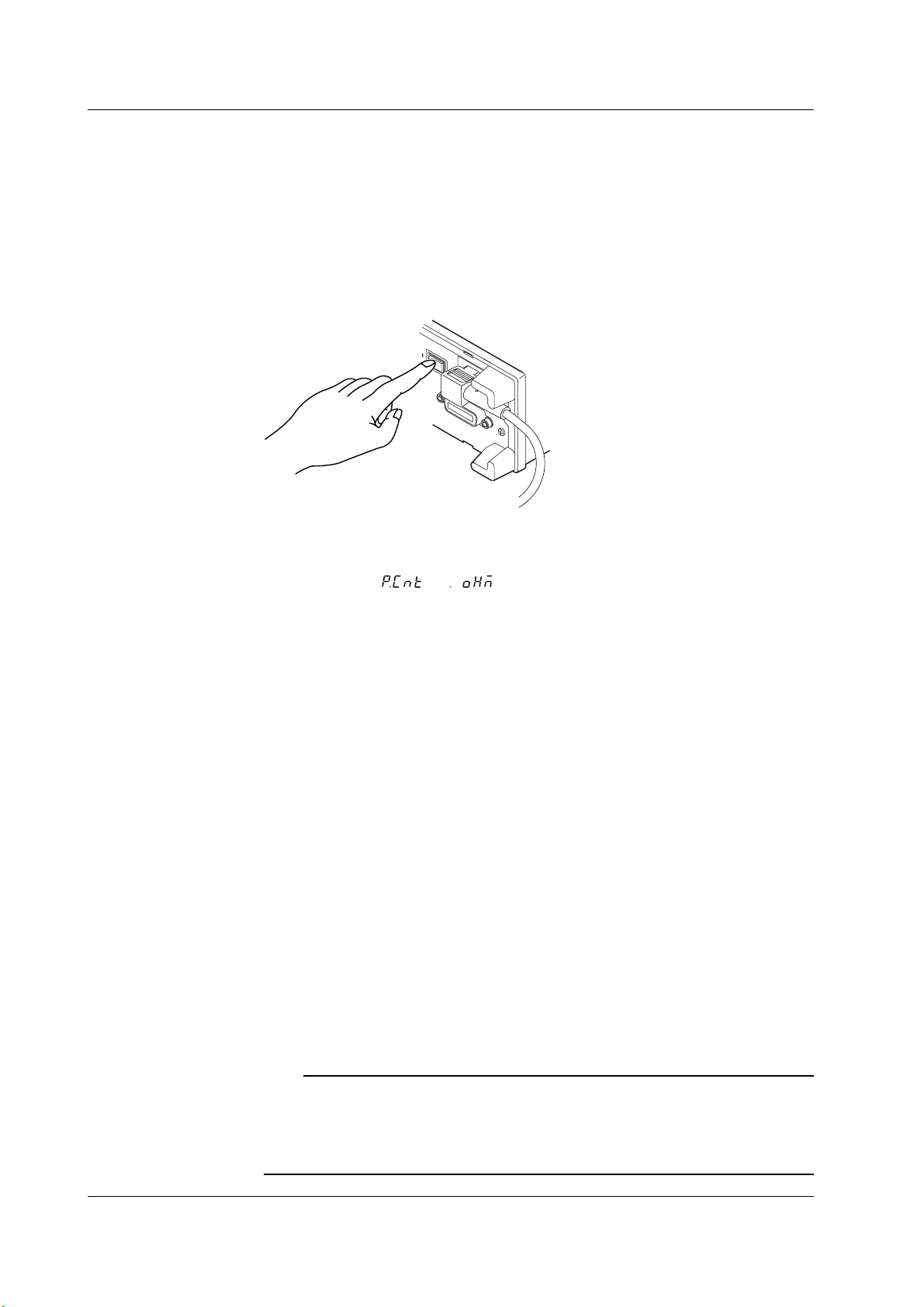

Turning the Power Switch ON/OFF

Points to Check before Turning ON the Power

• Is the instrument properly installed? See section 3.2, “Installing the Instrument.” (page 3-2)

•Is the power cord properly connected? See section 3.3, “Connecting the Power

Cord.” (page 3-3)

Turning ON/OFF the Power Switch

Turn ON the power by depressing the power switch on the rear panel to the “ON (|)” side

and OFF by depressing it to the “OFF (O) side.”

Power Up Operation

When the power switch is turned ON, the instrument automatically starts a self-test. The

self-test takes approximately 30 seconds. Upon successful completion, the top menu of

the SETUP mode (

measurement mode (the instrument recalls the condition that existed when the power

was turned OFF).

To make a measurement, press the SETUP/MEAS key (SHIFT+R/% key) to switch to

the measurement mode.

If the Instrument Does Not Start Normary When the Power Is Turned On

If the instrument fails to power up as described or the top menu does not appear, turn

OFF the power switch and check the following points.

• Is the power cord securely connected?

• Is the correct voltage coming to the power outlet? See page 3-3.

• If the power switch is turned ON while pressing the SHIFT key, the setup parameters

are initialized to their factory default values. For details regarding initialization, see

section 6.3, “Initializing Setup Parameters” on page 6-7.

If the instrument still fails to power up after checking these points, contact your nearest

YOKOGAWA dealer for repairs.

or ) appears or the instrument enters the

For Making Accurate Measurements

Allow the instrument to warm up for at least 30 minutes after turning ON the power switch.

Shut Down Operation

The setup parameters that exist immediately before the power switch is turned OFF are

stored in memory. The same is true when the power cord gets disconnected from the

outlet. The next time the power switch is turned ON, the instrument powers up using the

previous settings that existed immediately before the power was turned OFF.

Note

A lithium battery is used to retain the setup parameters. The battery has a limited lifetime. When

the lithium battery voltage falls below a certain level, a “901” error code is displayed on the screen

when the power switch is turned ON. When this error code appears, the battery must be

replaced quickly. The user cannot replace the battery. For battery replacement, contact your

nearest YOKOGAWA dealer.

3-4 IM 755601-01E

Page 30

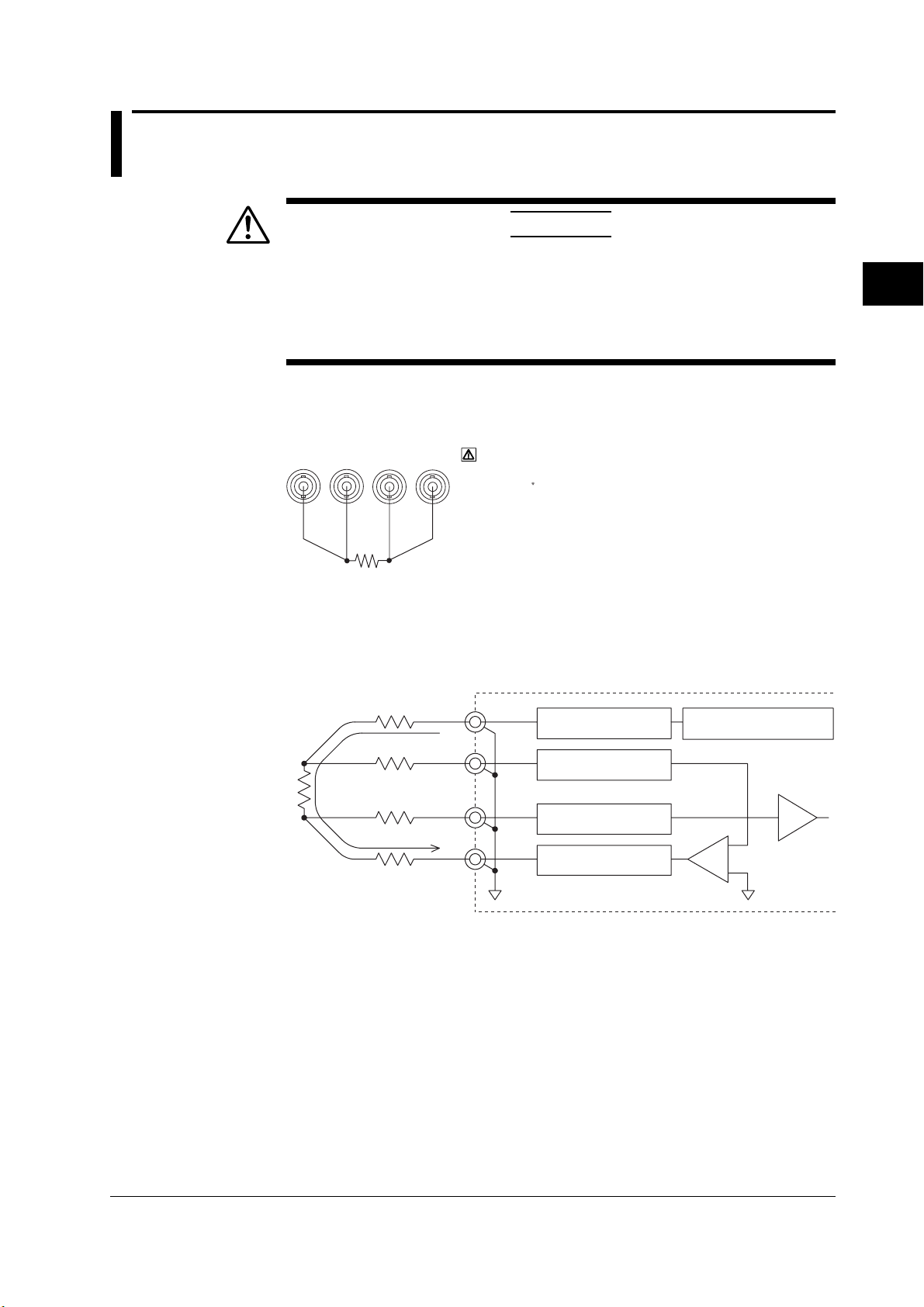

3.4 Wiring

CAUTION

Do not apply any voltage or current across the measurement input

terminals and across the measurement input terminal and the guard

(the outside of the BNC connector). The maximum common-mode

voltage across the case and input terminals is ±42 Vpeak. Not meeting

these conditions can damage the instrument.

Wiring Method

Connect BNC cables to each terminal as shown in the figure below.

L

CUR CURPOTPOT

Resistor under measurement

UNKNOWN

L H H

Do not connect a current/voltage

source to the UNKNOWN terminals.

It will damage the instrument.

ALL TERMINALS 42 V PEAK TO

3

Before Starting Measurements

Wiring Precautions

The accuracy specifications can only be met if the following conditions, given in the

wiring example below, are provided.

Wiring Example

r

1

r

2

H

CUR

Circuit used to

detect disconnection

H

POT

Circuit used to

Constant current source

for measurement

detect disconnection

I

R

s

x

r

2

L

POT

Circuit used to

detect disconnection

r

1

L

CUR

Circuit used to

detect disconnection

-

Pre-amp

+

Is: Test current

Rx: Resistor under measurement

r1, r2: Resistance of the lead wires (includes contact resistance)

Is × r1 ≤ 1.5 V: For checking the normal operation of the constant current

source

r2 ≤ 15 Ω (for 1 Ω range): Because the circuit used to detect disconnection feeds a

r2 ≤ 30 Ω (for other ranges) minimal amount of current so that it can detect disconnection

during measurement.

3-5IM 755601-01E

Page 31

3.3 Connecting the Power Cord

Note

• When measuring a resistor that contains capacitive components in parallel, the response

• Since this instrument applies a pulse current to make measurements, when measuring a

• To minimize the influence from noise, make the lead wires as short as possible, and use

• Keep the capacitance of the shielded cable between the measurement input terminal and

• Do not connect the input terminals and the guard. Measurements cannot be made, under this

• For absolute value display (R), drifting occurs near the zero point when the input is shorted,

becomes slow and correct measurements may not be obtained. In this case, turn OFF the

contact check function, and perform the measurement after the response is adequately stable.

resistor that has inductive components in series (wire wound resistor, for example), the

response becomes slow and correct measurements may not be obtained. In addition, if the

inductance exceeds 10 µH, it can cause resonance.

shielded cables. In addition, placing the resistor under measurement inside a shielded case

and connecting the guard (outside of the BNC connector) and the shielded case with shielded

cables are effective means of preventing noise.

guard (outside of the BNC connector) under 300 pF. Resonance can result if this value is

exceeded.

condition.

possibly resulting in the display of a negative value.

For deviation display (%), the display corresponding to -100% (when the input is shorted, for

example) is represented by -99.9%, -99.99%, or -99.999%.

3-6 IM 755601-01E

Page 32

LOCAL key

GP-IB connector

Chapter 4 Setting the Measurement Conditions

4.1 Switching the Limit Mode

Keys

Indicator is off during SETUP mode

HIGH

SPEED

MΩ

kΩ

STORE

DATA

%

Ω

Procedure

NORMAL

MEAS&

LOCK

SAMPLE

EXTERNAL

MANUAL

FAST

REFERENCE

The items that are specified or selected are confirmed when the ENTER (Ω,%) key is

pressed. To exit from a menu in the middle of the operation, press the EXIT (R/%) key.

RECALL

DATA

HI

IN

LO

CHECK REMOTE

HI LIMIT

LO LIMIT

SETUP/MEAS

SHIFT

7

%

MEAS

TIME

Ω

1

0

STORE

DATA

REF LIMIT

R/%

EXIT

LOCAL

TRIG

TRIG

MODE

M

CHECK

k

MISCI/F

,%

Ω

ENTER

Ω

Ω

89

LIMIT

MODE

546

23

.

RECALL

DATA

4

Setting the Measurement Conditions

Explanation

Switching to the SETUP mode

1. Press the

SHIFT

SETUP/MEAS

R/%

key to switch to the SETUP mode. If the “MEAS & LOCK”

indicator is off, this operation is not necessary.

Switching the limit mode

2. 4.

8

3.

LIMIT

SHIFT

MODE

REF LIMIT

[Main display]

(Deviation mode)

(Absolute mode)

Ω

,%

ENTER

There are two limit modes.

You can select whether to use a deviation (%) or an absolute value (R) for the

comparator function.

• Deviation (%) mode: The measured value is handled as a deviation from the

specified reference value. The comparator function is also

carried out in terms of the deviation.

• Absolute (R) mode: The measured value is handled as an absolute value. The

comparator function is also carried out in terms of the absolute

value.

Precautions to be taken when switching the limit mode

The following parameters are initialized when the limit mode is switched.

HI level, LO level, and REF (reference, when the limit mode is set to %)

4-1IM 755601-01E

Page 33

4.2 Changing the Range (Reference)

When the limit mode is set to deviation (%)

Keys

HIGH

STORE

RECALL

DATA

HI

IN

LO

CHECK REMOTE

HI LIMIT

LO LIMIT

Procedure

NORMAL

FAST

SPEED

MEAS&

LOCK

SAMPLE

EXTERNAL

MANUAL

REFERENCE

DATA

%

MΩ

kΩ

Ω

The items that are specified or selected are confirmed when the MΩ, kΩ, or ENTER

(Ω,%) key is pressed. When confirmed, the new reference is displayed.

To exit from a menu in the middle of the operation, press the EXIT (R/%) key. The

display returns to the top menu of the SETUP mode.

SETUP/MEAS

SHIFT

7

%

MEAS

TIME

Ω

1

0

STORE

DATA

REF LIMIT

R/%

EXIT

LOCAL

TRIG

TRIG

MODE

M

CHECK

k

Ω

MISCI/F

,%

Ω

ENTER

Ω

89

LIMIT

MODE

546

23

.

RECALL

DATA

Switching to the SETUP mode

1. Press the

SHIFT

SETUP/MEAS

R/%

key to switch to the SETUP mode. If the “MEAS & LOCK”

indicator is off (if PCnt or oHm is displayed on the main display), this operation is

not necessary.

Changing the reference value

2. 4.

REF

3. Numerical keys

[REFERENCE

display]

M

Ω

(Press when the unit is MΩ.)

CHECK

k

Ω

(Press when the unit is kΩ.)

MISC

Ω

,%

(Press when the unit is Ω.)

ENTER

If the value entered using the numerical keys is not correct, an error (810) is displayed

for approximately one second, and the display returns to step 3.

Explanation

When the reference value is entered, the range is automatically determined.

The range and the display range are set according to the specified reference as follows.

For the procedure to set the percent limit, see section 4.3, “Using the Comparator

Function.”

When the percent limit is set to 9.99%

Reference Range Display Range

0.0001 to 1.0009 Ω 1 Ω “-99.999%

1.001 to 10.009 Ω 10 Ω to

10.01 to 100.009 Ω 100 Ω 19.999%”

0.1001 k to 1.0009 kΩ 1 kΩ (for 755611)

1.001 k to 10.009 kΩ 10 kΩ

10.01 k to 100.09 kΩ 100 kΩ

0.1001 M to 1.0009 MΩ 1 MΩ

1.001 M to 10.009 MΩ 10 MΩ

10.01 M to 120.00 MΩ 100 MΩ

*1 “-99.99% to 19.99%” for 755601

4-2 IM 755601-01E

*1

Page 34

When the percent limit is set to 99.9%

Reference Range Display Range

0.001 to 1.009 Ω 10 Ω “-99.99%

1.01 to 10.09 Ω 100 Ω to

10.1 to 100.09 Ω 1 kΩ 199.99%”

0.101 k to 1.009 kΩ 10 kΩ (for 755611)

1.01 k to 10.09 kΩ 100 kΩ

10.1 k to 100.9 kΩ 1 MΩ

0.101 M to 1.009 MΩ 10 MΩ

1.01 M to 10.09 MΩ 100 MΩ

10.1 M to 120.0 MΩ 100 MΩ

*2 “-99.9% to 199.9%” for 755601

*2

4.2 Changing the Range (Reference)

When the limit mode is set to absolute (R)

When the limit mode is set to absolute (R), the range is fixed to 1 Ω. You cannot change

this value.

Maximum displayed value: 1.20000 (755611)

Measurement resolution: 10 µ Ω (755611)

4

Setting the Measurement Conditions

1.2000 (755601)

100 µ Ω (755601)

4-3IM 755601-01E

Page 35

4.3 Using the Comparator Function

When the limit mode is set to deviation (%)

Keys

Indicates the comparator result

Set/Display HI limit value

HIGH

STORE

RECALL

DATA

HI

IN

LO

CHECK REMOTE

HI LIMIT

LO LIMIT

Procedure

NORMAL

FAST

SPEED

MEAS&

LOCK

SAMPLE

EXTERNAL

MANUAL

REFERENCE

DATA

%

MΩ

kΩ

Ω

Set/Display LO limit value

The items that are specified or selected are confirmed when the ENTER (Ω,%) key is

pressed. When confirmed, the new limit is displayed.

To exit from a menu in the middle of the operation, press the EXIT (R/%) key. The

display returns to the top menu of the SETUP mode.

SETUP/MEAS

SHIFT

7

%

MEAS

TIME

Ω

1

0

STORE

DATA

REF LIMIT

R/%

EXIT

LOCAL

TRIG

TRIG

MODE

M

CHECK

k

Ω

MISCI/F

,%

Ω

ENTER

Ω

89

LIMIT

MODE

546

23

.

RECALL

DATA

Switching to the SETUP mode

1. Press the

SHIFT

SETUP/MEAS

R/%

key to switch to the SETUP mode. If the “MEAS & LOCK”

indicator is off, this operation is not necessary.

Changing the limit value (HI and LO values)

2. 4.

LIMIT

3. Numerical keys

[HI LIMIT display]

Ω

,%

ENTER

5. Numerical keys

[LO LIMIT display]

6.

Ω

,%

ENTER

If the value entered using the numerical keys is not correct, an error (810) is displayed

for approximately one second, and the display returns to step 3.

Selecting the percent limit

2.

k

Ω

3.

MISC

SHIFT

REF

[Main display]

LIMIT

(Plimit)

4.

Ω

,%

ENTER

5.

REF LIMIT

[Main display]

*

*

6.

Ω

,%

ENTER

* For 755611. For 755601, select either “9.99” or “99.9.”

4-4 IM 755601-01E

Page 36

Explanation

4.3 Using the Comparator Function

Setting range of limit values (HI and LO values)

The limit value is set in terms of the deviation (%) from the reference value that was set

in section 4.3, “Changing the Range (Reference).”

Limit Value Setting Range

When the percent limit is 9.99% When the percent limit is 99.9%

Applies to both LO, HI -9.999% to 9.999% (755611) -99.99% to 99.99% (755611)

-9.99% to 9.99% (755601) -99.9% to 99.9% (755601)

However, LO ≤ HI

Note

If the values are set so that HI is less than LI, an error (815) occurs.

Selecting the percent limit

Percent limit refers to the display resolution when the measured values are handled in

terms of deviation (%).

Select the percent limit from the following two choices.

9.99%

99.9%

Note that depending on the selected percent limit, the range of limit values (LO and HI

values) varies as indicated in the above section “Setting range of limit values (HI and LO

values).”

Note

• Changing the percent limit initializes the limit values (HI and LO) to 0%.

•If the percent limit is changed from 9.99% to 99.9%, the reference value is rounded to the least

significant digit. However, if the limit mode is 9.99% and the reference value is between 0.0001

Ω to 0.0004 Ω, changing the limit mode to 99.9% changes the reference value to 0.001 Ω.

Comparator function

The measured value is compared to the specified limit values (HI and LO) and the result

is indicated by turning ON the appropriate indicator.

The comparator result is also output from the handler interface.

The following comparison is made.

When the measured value > HI : “HI” (

When the measured value < LO : “LO” (

When the measured value is between LO and HI : “IN” (

“–OL–” (overrange), : “HI” (

“–nC–” (contact check error),

“–CF–” (Abnormality detected in the test current)

indicator) turns ON (red)

indicator) turns ON (red)

indicator) turns ON (green)

indicator) turns ON (red)

4

Setting the Measurement Conditions

Note

The comparator function is carried out using fractions with greater accuracy than those displayed.

4-5IM 755601-01E

Page 37

4.3 Using the Comparator Function

When the limit mode is set to absolute (R)

Keys

NORMAL

MEAS&

LOCK

SAMPLE

EXTERNAL

MANUAL

FAST

REFERENCE

Procedure

The items that are specified or selected are confirmed when the ENTER (Ω,%) key is

pressed. When confirmed, the new reference is displayed.

To exit from a menu in the middle of the operation, press the EXIT (R/%) key. The

display returns to the top menu of the SETUP mode.

HIGH

SPEED

Indicates the comparator result

STORE

RECALL

DATA

HI

IN

LO

CHECK REMOTE

LO LIMIT

DATA

%

MΩ

kΩ

Ω

Set/Display LO limit value

Set/Display HI limit value

SETUP/MEAS

HI LIMIT

SHIFT

7

%

MEAS

TIME

Ω

1

0

STORE

DATA

REF LIMIT

R/%

EXIT

LOCAL

TRIG

TRIG

MODE

M

CHECK

k

Ω

MISCI/F

,%

Ω

ENTER

Ω

89

LIMIT

MODE

546

23

.

RECALL

DATA

Explanation

Switching to the SETUP mode

1. Press the

SHIFT

SETUP/MEAS

R/%

key to switch to the SETUP mode. If the “MEAS & LOCK”

indicator is off, this operation is not necessary.

Changing the limit values

2.

LIMIT

3. Numerical keys 5. Numerical keys 6.

[HI LIMIT display] [LO LIMIT display]

4.

Ω

,%

ENTER

Ω

,%

ENTER

If the value entered using the numerical keys is not correct, an error (810) is displayed

for approximately one second, and the display returns to step 3.

Setting range of limit values

The setting range applies to both HI and LO.

Model Setting Range Resolution

755601 0.000 Ω to 1.200 Ω 1 mΩ

755611 0.0000 Ω to 1.2000 Ω 100 µ Ω

However, LO ≤ HI

Note

If the values are set so that HI becomes less than LI, an error (815) occurs.

Comparator function

Same as the description given in “When the limit mode is set to deviation (%).” See

page 4-5.

4-6 IM 755601-01E

Page 38

4.4 Using the Contact Check Function

2. 4.

3.

6.5. Numerical keys

(Contact check level)

CHECK

ENTER

SHIFT

REF

LIMIT

M

Ω

Ω

,%

ENTER

Ω

,%

ENTER

Ω

,%

[Main display]

Keys

Indicator is ON while contact check

is in progress

HIGH

STORE

RECALL

DATA

HI

IN

LO

CHECK REMOTE

HI LIMIT

LO LIMIT

%

Ω

Procedure

NORMAL

FAST

SPEED

MEAS&

LOCK

SAMPLE

EXTERNAL

MANUAL

REFERENCE

DATA

%

MΩ

kΩ

Ω

The items that are specified or selected are confirmed when the ENTER (Ω,%) key is

pressed. When confirmed, the display returns to the top menu of the SETUP mode.

To exit from a menu in the middle of the operation, press the EXIT (R/%) key. The

display returns to the top menu of the SETUP mode.

SETUP/MEAS

R/%

SHIFT

EXIT

89

7

MEAS

LIMIT

TIME

MODE

546

1

23

.

0

STORE

RECALL

DATA

DATA

REF LIMIT

TRIG

TRIG

MODE

M

CHECK

k

MISCI/F

Ω

ENTER

LOCAL

Ω

Ω

,%

4

Setting the Measurement Conditions

Explanation

Switching to the SETUP mode

1. Press the

SHIFT

SETUP/MEAS

R/%

key to switch to the SETUP mode. If the “MEAS & LOCK”

indicator is off, this operation is not necessary.

Using the contact check

If the value entered using the numerical keys is not correct, an error (810) is displayed

for approximately one second, and the display returns to step 5.

Contact check function

If the result of the contact check is larger than the specified check level, an error is

generated. The time duration of the check is 2 ms, and the check current is 50 mA.

The timing to perform the contact check can be selected from the following choices.

OFF: Contact check is not performed.

bEF: Contact check is performed before the measurement. If an error is detected, “–nC–” is

displayed and the “HI” indicator ( ) turns ON. “HI” “NO CONTACT” signal is output

from the handler interface.

AFt: Contact check is performed after the measurement. If an error is detected, “–nC–”

is displayed and the “HI” indicator (

) turns ON. “HI” “NO CONTACT” signal is

output from the handler interface.

Setting range of the check level

1 to 30 Ω (1 Ω resolution).

4-7IM 755601-01E

Page 39

4.5 Setting the Measurement Time

Keys

The appropriate indicator turns ON

HIGH

STORE

RECALL

DATA

HI

IN

LO

CHECK REMOTE

HI LIMIT

LO LIMIT

Procedure

NORMAL

FAST

SPEED

MEAS&

LOCK

SAMPLE

EXTERNAL

MANUAL

REFERENCE

DATA

%

MΩ

kΩ

Ω

The items that are specified or selected are confirmed when the ENTER (Ω,%) key is

pressed. When confirmed, the display returns to the top menu of the SETUP mode.

To exit from a menu in the middle of the operation, press the EXIT (R/%) key. The

display returns to the top menu of the SETUP mode.

SETUP/MEAS

SHIFT

7

%

MEAS

TIME

Ω

1

0

STORE

DATA

REF LIMIT

R/%

EXIT

LOCAL

TRIG

TRIG

MODE

M

CHECK

k

Ω

MISCI/F

,%

Ω

ENTER

Ω

89

LIMIT

MODE

546

23

.

RECALL

DATA

Explanation

Switching to the SETUP mode

1. Press the

SHIFT

SETUP/MEAS

R/%

key to switch to the SETUP mode. If the “MEAS & LOCK”

indicator is off, this operation is not necessary.

Selecting the measurement time

LIMIT

[Main display]

Ω

,%

ENTER

2.

7

TIME

3.

REF

SHIFT

MEAS

Measurement time

Select from the following choices.

Type Measurement Time* (when the measurement range is 1 Ω to 1 MΩ)

nor (NORMAL) 19.9 ms (for 60 Hz)

FASt (FAST) 5.7 ms

H-SP (HIGH SPEED) 2.8 ms

* Measurement time: When the trigger mode is set to EXTERNAL, the time from the trigger

23.2 ms (for 50 Hz)

input to the falling edge of the EOM signal of the handler interface is

called the measurement time.