Page 1

YASNAC PC NC

Operating Manual

Page 2

YASNAC PC NC Operating Manual Introduction

SAFETY INFORMATION

PRECAUTIONS

1. Read this instruction manual in its entirety before using the programming functions available in the

YASNAC PC NC.

2. The following warning symbols are used to indicate precautions that the user must be aware of to

safely use this equipment. Failure to follow these precautions can result in serious or possibly even

fatal injury and damage to products or related equipment or systems.

WARNING

WARNING

WARNING

This symbol indicates the presence of a potentially hazardous condition which, if not avoided, could

result in serious personal injury or death.

This precautionary symbol appears in labels attached to YASNAC products to alert the user to conditions requiring concern for safety.

SPECIAL SAFETY NOTE: This symbol indicates that ELECTRICAL SHOCK HAZARD con-

dition exists. DO NOT TOUCH any electrical connection terminals when the power is on, and for at

least 5 minutes after switching off the power supply. Warning label is located on the CNC enclosure

as shown:

PC NC Unit

xxxxxxxxx

xxxxxxxxx

xxxxxxxxx

xxxxxxxxx

xxxxxxxxx

WARNING LABEL

NOTICE

Printed _______. 2000. The information contained within this document is the proprietary property of

Yaskawa Electric America, Inc., and may not be copied, reproduced or transmitted to other parties without

the expressed written authorization of Yaskawa Electric America, Inc.

No patent liability is assumed with respect to the uses of the information contained herein. Moreover,

because Yaskawa is constantly improving its high quality product, the information contained in this manual

is subject to change without notice. Every precaution has been taken in the preparation of this document.

Nevertheless, Yaskawa assumes no responsibility for damages resulting from the use of the information contained within this publication.

i

Page 3

YASNAC PC NC Operating Manual Introduction

USING THIS MANUAL

This manual describes the procedures for programming the

RELATED INFORMATION SOURCES

For additional information, refer to the following manuals

TITLE OF DOCUMENT CONTENTS

YASNAC PC NC Operating Manual

(YEA-SIE-C844-2.1)

YASNAC PC NC Programming Manual

(YEA-SIE-C844-2.2)

YASNAC PC NC PLC Pr ogramming Manual

(YEA-SIE-C844-0.1)

YASNAC PC NC I/O Signal Function

(YEA-SIE-C844-2.3)

YASNAC PC NC Connecting Man ual

(YEA-SIE-C844-0.2)

YASNAC PC NC

Basic configuration and operating procedures

PC NC Program creation instructions

PLC Program creation instructions

Describes functions between PC NC and PLC

Instructions for connecting PC NC with machines,

machine interface and peripheral equipment

.

MEMOCON GL120,G130 120 Series

I/O Module User’s Manual

(Document No. SIEZ-C825-20.22)

MEMOCON GL120,G130 Hardware User’s Manual

(Document No. SIEZ-C825-20.1)

YASNAC PC NC Maintenance Manual

(YEA-SIE-C844-2.9)

Describes man-machine-interface (MMI) programming,

specifications and definitions.

Describes I/O power supply specifications

Describes the AC input power supply specifi catio ns for I/O.

Describes service and maintenance procedures.

ii

Page 4

YASNAC PC NC Operating Manual Introduction

INFORMATION INDICATORS

The following symbols are used in this programming manual to emphasize particular information t o the user:

Indicates important information to be remembered, i.e., precautionary alarm displays to prevent damaging devices.

Indicates supplementary material.

Indicates definitions of terminology that has not been explained before.

NOTES REGARDING SAFE OPERATION

It is important that the user should read this manual before installing, operating, performing any

maintenance or inspecting the

YASNAC PC NC.

Also, the functions and performance of a NC machine

tool are not determined by the CNC unit itself, therefore thoroughly read and familiarize yourself with the

machine builder’s documentation concerning the safe and most efficient ways to use the machine tool.

iii

Page 5

YASNAC PC NC Operating Manual Introduction

TABLE OF CONTENTS

Chapter 1

1.1 Outline of the YASNAC System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.1.1 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.1.2 Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.1.3 Machine Operation Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.1.4 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.2 Protective Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.2.1 Emergency Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.2.2 Overtravel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.2.3 Stored Stroke Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Chapter 2

1.2.4 Interlock Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

2.1 General Operation Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2 Inspection Before Turning the Power ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2.1 Inspection of the NC Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.2.2 Preparation before Turning the Power ON . . . . . . . . . . . . . . . . . . . . . . .2- 5

2.3 Turning the Power ON and Inspecting After Power ON . . . . . . . . . . . . . . . . . . 2-6

2.3.1 Procedure for Turning the Power ON . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.3.2 Checking the Motors for Abnormalities . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.3.3 Procedure for Turning Power OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.3.4 Inspection of the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.4 Manual Operation (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.4.1 Manual Rapid Traverse (RAPID) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.4.2 Jog Feed (JOG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.4.3 Step Feed (STEP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.4.4 Handle Feed (HANDLE)* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.5 Manual Operation (2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

iv

Page 6

YASNAC PC NC Operating Manual Introduction

2.5.1 Simultaneous 2 or 3-axis Handle Feed * . . . . . . . . . . . . . . . . . . . . . . . 2-13

2.5.2 Manual Reference Point Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.5.3 Manual Reference Point Return to the Second Reference Point* . . . . 2-16

2.5.4 1-line MDI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

2.6 Automatic Operation (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

2.6.1 Preparation of Automatic Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

2.6.2 MDI Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

2.6.3 Feed Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

2.6.4 Override . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

2.7 Automatic Operation (2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

2.7.1 Optional Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

2.7.2 Optional Block Skip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

2.7.3 Dry Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Chapter 3

2.7.4 Display Lock and Machine Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

2.7.5 Auxiliary Function Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

2.7.6 Z-axis Command Neglect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

2.7.7 4th-axis Command Neglect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

2.7.8 5th-axis Command Neglect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

2.8 Operation Intervention During Automatic Operation . . . . . . . . . . . . . . . . . . . 2-27

2.8.1 MDI Operation Intervention during Automatic Operation . . . . . . . . . 2-28

2.8.2 Automatic Handle Mode Offset * . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

2.8.3 Manual Absolute . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

3.1 USER INTERFACE OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.1.1 Status Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.1.2 Battery Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.1.3 NC Execution Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.1.4 Motion Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.1.5 Alarm Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3.1.6 Warning Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

v

Page 7

YASNAC PC NC Operating Manual Introduction

3.1.7 Time/Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3.1.8 Mode / MDI / Toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3.1.9 Mode Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.1.10 Menu Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

3.2 RECURRING COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

3.2.1 Position Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

3.2.2 Program Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

3.2.3 Nest Level Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

3.2.4 Shortcuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

3.2.5 Number Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

3.2.6 File Browser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

3.3 RUN MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

3.3.1 Production Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

3.3.2 Proveout Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

3.3.3 NC Switch Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-33

3.3.4 Timers Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

3.3.5 Tool Path Drawing Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

3.4 PROGRAM MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-40

3.4.1 File Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-40

3.4.2 Editor Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-46

3.4.3 List Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-53

3.4.4 Macro Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-55

3.5 TOOL MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-57

3.5.1 Offsets Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-57

3.5.2 Magazine Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-59

3.6 SETUP MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-61

3.6.1 Workshift Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-61

3.6.2 Four (4) Positions Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-63

3.6.3 One (1) Position Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-64

3.7 UTILITIES MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-65

3.7.1 Login Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-65

vi

Page 8

YASNAC PC NC Operating Manual Introduction

3.7.2 PC Settings Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-67

3.7.3 Maintenance Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-69

3.7.4 Configuration Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-70

3.7.5 Backup and Restore Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-72

3.7.6 CPU Monitor Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-74

3.7.7 Setting Parameters Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-75

3.7.8 NC Parameters Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-78

3.7.9 Machine Setup Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-79

3.7.10 Pitch Error Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-80

3.7.11 Solid Tap Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-82

3.7.12 Torque Ripple Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-83

3.7.13 Parameter Search Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-84

3.7.14 High Speed Cutting Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-86

3.7.15 User Install Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-87

3.7.16 MTB Install Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-90

3.7.17 PLC Parameters Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-91

3.7.18 PLC Diagnosis Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-92

3.7.19 Ladder Monitor Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-97

3.7.20 Switch Label Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-97

3.8 ALARM MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-100

3.8.1 NC Alarm Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-100

3.8.2 PLC Alarm Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-101

3.8.3 Alarm History Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-102

3.9 HELP MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-104

3.9.1 MMI Map Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-104

3.9.2 Manual Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-105

3.9.3 About Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-106

3.10 OFF LINE MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-107

3.10.1 The Offline Mode Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-107

vii

Page 9

YASNAC PC NC Operating Manual Introduction

Chapter 4

4.1 MAINTENANCE DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.1.1 Checking the Status of Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.1.2 Checking the NC Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.1.3 Display of Alarm Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.1.4 Cause of Alarm and Corrective Action . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.1.5 Troubleshooting (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.1.6 Troubleshooting (2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

4.1.7 Alarms Not Indicated by Alarm Numbers . . . . . . . . . . . . . . . . . . . . . . 4-15

4.1.8 PC NC Alarms Not Indicated By Alarm Numbers . . . . . . . . . . . . . . . 4-26

4.1.9 Touch Screen Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

4.1.10 Mode of Operation of PC NC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

4.1.11 Self - Diagnosis Function Specification . . . . . . . . . . . . . . . . . . . . . . . . 4-28

4.1.12 Hard Drive Mounting Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

viii

Page 10

YASNAC PC NC Operating Manual Chapter 1: Outline of the YASNAC System

1

Outline of the YASNAC System

Chapter 1 describes the outline of the YASNAC system and the operating

features and functions that should be thoroughly understood for the safe

and efficient operation of the system.

1.1 Outline of the YASNAC System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.1.1 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.1.2 Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.1.3 Machine Operation Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.1.4 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1.2 Protective Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.2.1 Emergency Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

1.2.2 Overtravel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

1.2.3 Stored Stroke Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

1.2.4 Interlock Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

1 - 1

Page 11

YASNAC PC NC Operating Manual Chapter 1: Outline of the YASNAC System

1.1 Outline of the YASNAC System

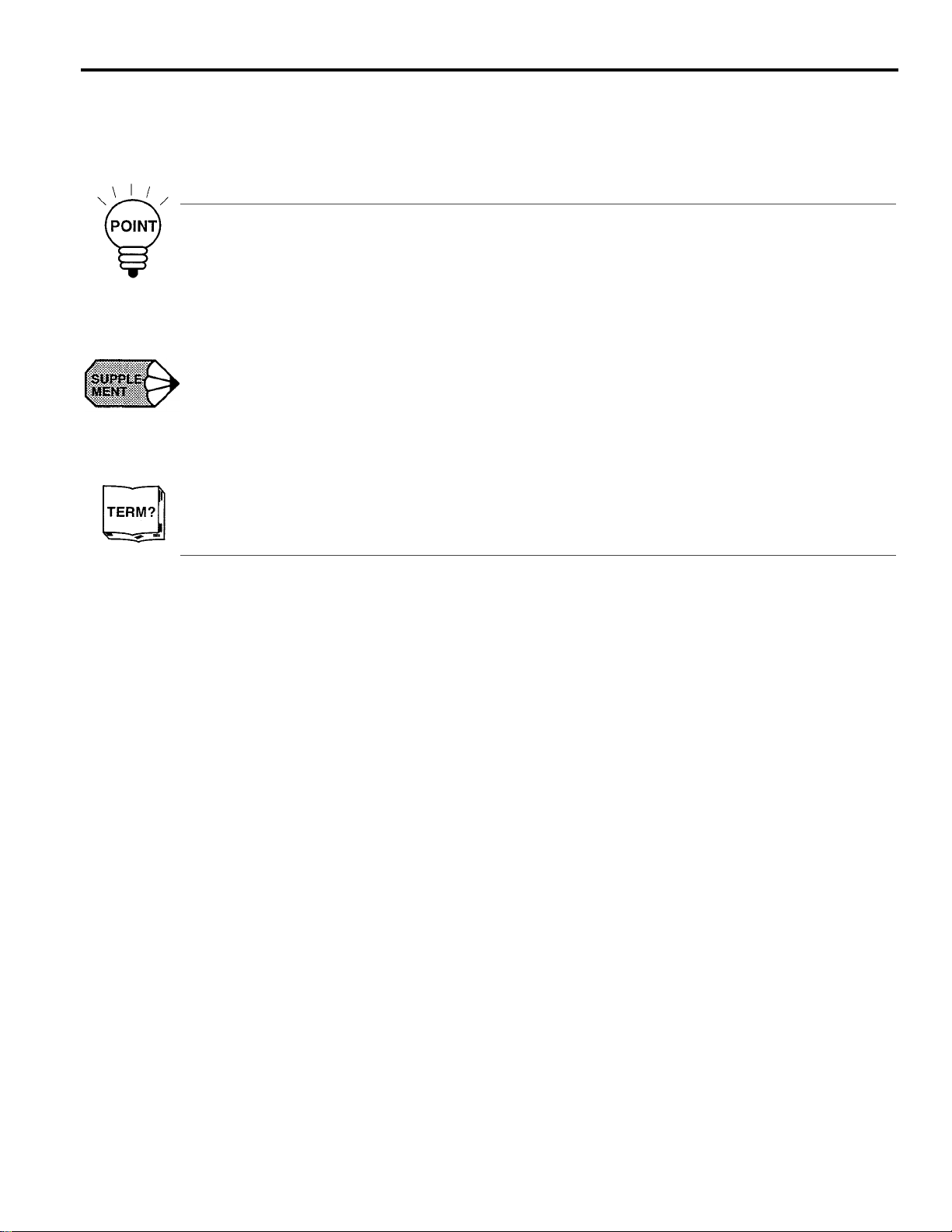

1.1.1 System Configuration

PC NC

Remote

Machine

Pendant

The configuration of the YASNAC PC NC system and the list of components are described

below.

Unit

YASNAC PC NC

Unit

Fig. 1.1.1.1 Standard Configuration of PC NC System

Table 1.1.1.1 List of YASNAC PC NC System Components

COMPONENT NAME MODEL NAME

CPU rack JZNC-JPCRKM---

NC Operation Panel JZNC-JPCOP--

SERVOPACK SGDC-

Spindle drive CIMR-M5

Servomotor SGM-

Spindle motor UAASKA-

Remote Pendant TBA

1 - 2

Page 12

YASNAC PC NC Operating Manual Chapter 1: Outline of the YASNAC System

1.1.2 Environmental Requirements

Requirements for the installation of an PC NC unit are indicated below. Install the PC NC unit in

a location where only these requirements are satisfied to avoid possible malfunctioning.

CAUTION!

Avoid using it in an environment where it may be subject to high temperatures, high humidity, dust,

corrosive gases, vibration or physical impacts that may cause fire, electric shock or malfunction.

• Use the product in an environment meeting the following conditions:

• Free from gases or vapors that create a potentially explosive atmosphere.

• Free from oil, organic solvents, etc.

• Relative humidity in the range 10 to 90% RH, with no condensation.

• Ambient temperature in the 0°C to 55°C with no freezing.

(Installation site must not be exposed to direct sunlight, must be distanced from heat generating devices,

and must be indoors.)

• Vibration not exceeding 4.9 m/s

2

.

• Do not store the product in locations subject to rain, water droplets, harmful gases or liquids.

Failure to observe this caution may result in product failure.

• Select a storage area indoors that is clean and meets the following temperature and humidity

requirements.

Ambient temperature: –15° C to 65° C (–5° F to 149° F)

Relative humidity: 10% to 90%

Failure to observe this caution may result in product failure.

(1) Ambient Temperature

For operation: 0°C to 55°C

For storage and transportation: –15° C to 65° C

Install the PC NC unit in a location not subject to direct sunlight, distant from heat sources,

and indoors.

(2) Humidity

Relative humidity must be in the range of 10 to 90%RH (non-condensing).

(3) Vibration

During operation: Max. 4.9 m/s

2

1 - 3

Page 13

YASNAC PC NC Operating Manual Chapter 1: Outline of the YASNAC System

(4) Atmosphere

Avoid the following locations:

• Dusty places

• Places where concentration of coolant and/or organic solvent mist is extremely high.

(5) Power Source

Input voltage: AC (single-phase) 180V ~ 264V

Frequency: 50/60 Hz –2 to +2 Hz

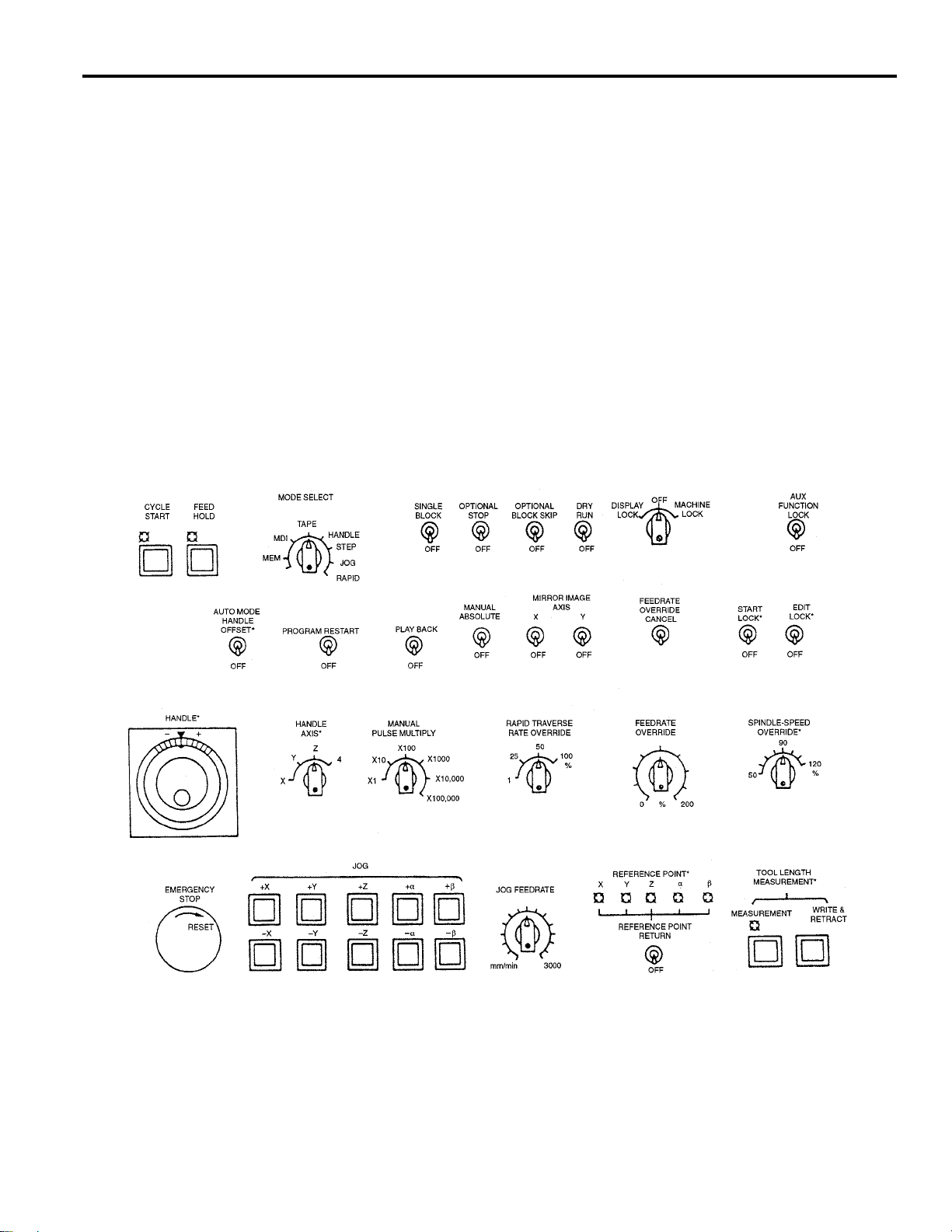

1.1.3 Machine Operation Panel

An example of the machine operation panel is indicated below. Arrangement and names of

switches and indicator lamps vary according to the machine model. For details, refer to the

machine tool manual.

Fig. 1.1.3.1 Example of Machine Operation Panel

1 - 4

Page 14

YASNAC PC NC Operating Manual Chapter 1: Outline of the YASNAC System

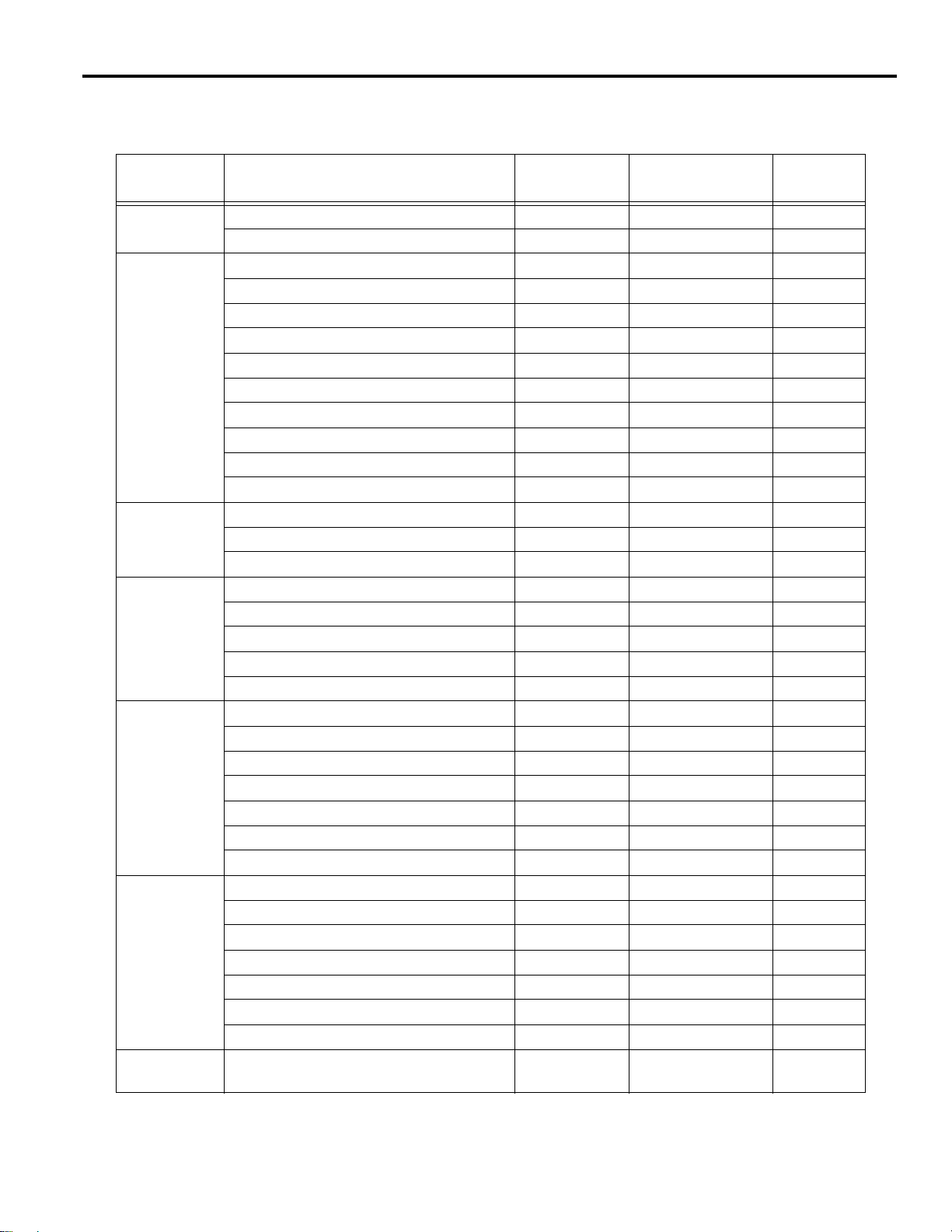

1.1.4 General Specifications

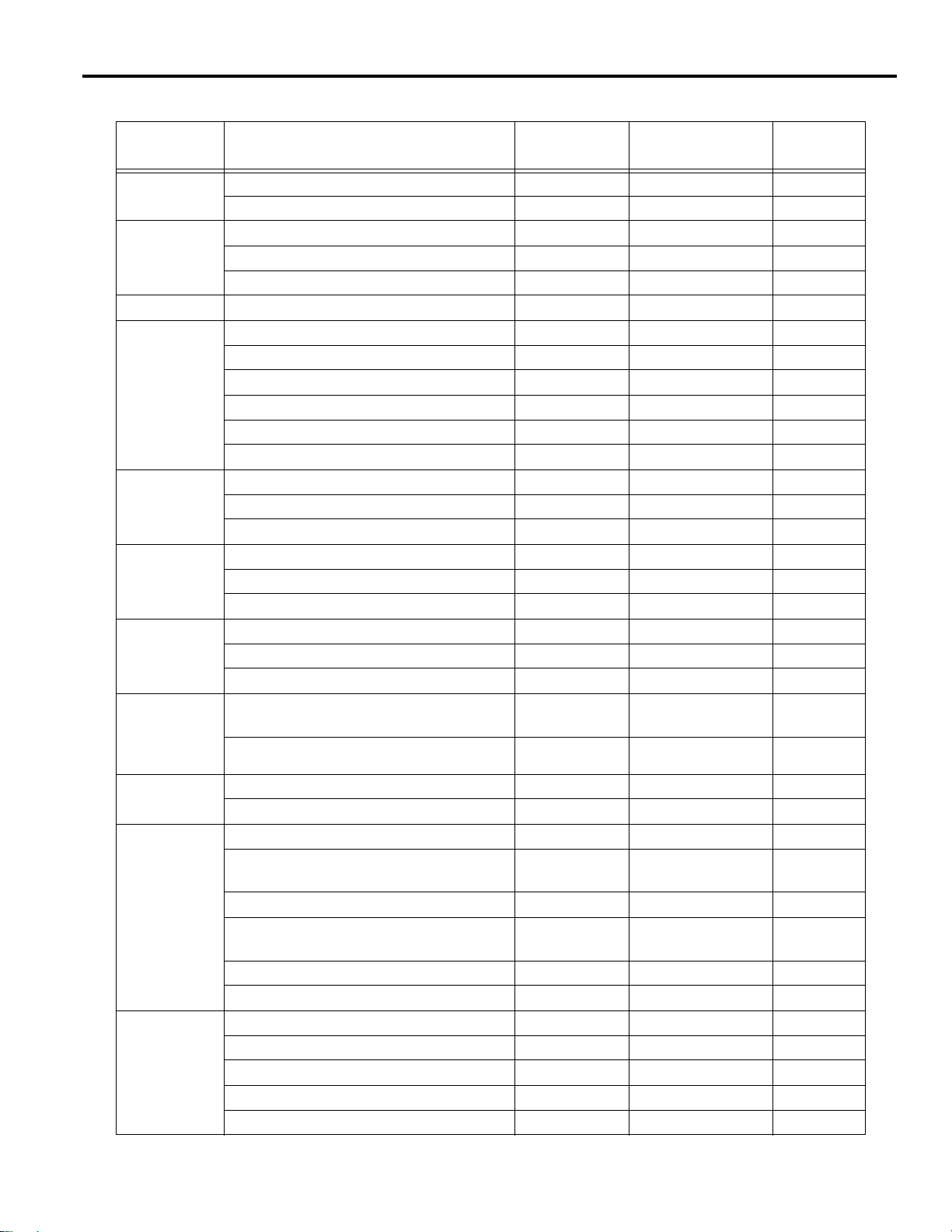

(1) Standard Specifications

CATEGOR ITEM AND FUNCTION

Controlled

axes

Input

command

Interpolation Positioning

Feed Rapid traverse

Storage and

editing of

program

Operation

and

display

Input/Output

function

Number of simultaneously controlled axes

Maximum programmable value

Absolute/incremental programming

Automatic acceleration and deceleration

Controlled axes

Least input increment

Least output increment

Decimal point input

Input unit 10 times

Tape code

NC tape

Input format

Buffer register

Linear interpolation

Circular interpolation

Cutting feed

Dwell

Incremental feed

Program storage capacity

Number of programs

Program editing

Program number search

Sequence number search

Address search

MDI editing

Operation panel

MDI function

l-line MDI

Operation and display

Calendar display

Pop-up me nu

Buzzer function

Input/Output interface

OPERATION

MANUAL

PROGRAMMING

MANUAL

SECTION

NO.

1 - 5

Page 15

YASNAC PC NC Operating Manual Chapter 1: Outline of the YASNAC System

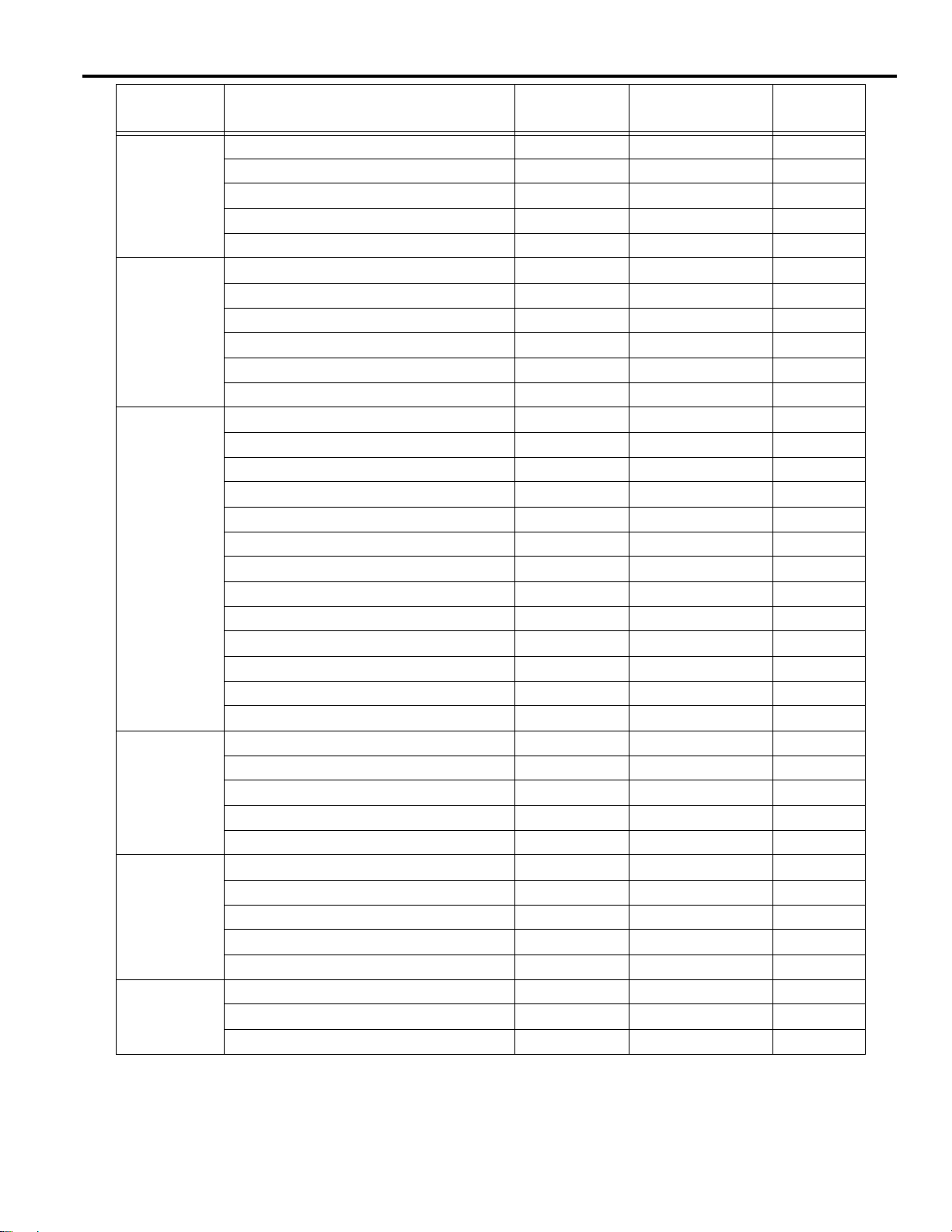

CATEGOR ITEM AND FUNCTION

Tool offset Tool function

Miscellaneous function

Tool length offset

Tool pos ition offset

Number of tool offset data sets

Coordinate

system

Operation

support

function

Programming

support

function

Safety and

maintenance

Environment

requirements

Manual return to reference point

Automatic return to reference point

Automatic return to second reference point

Reference point return check

Return from reference point

Base coordinate system setting

Label skip

Single block

Optional stop

Optional block skip

Dry run

Machine lock

Miscellaneous function lock

Display lock

Manual absolute

Numerical value set-up

Break-point functio n

Operation mode

Feed hold

Circular interpolation by R command

Repetitive circle interpolation

Subprogram

Exact stop check

Exact stop check mode

Emergency stop inpu t

Overtravel

Axis interlock

Stored stroke limit

Self-diagnostics (always displayed)

Power supply

Ambient temperature

Humidity

OPERATION

MANUAL

PROGRAMMING

MANUAL

SECTION

NO.

1 - 6

Page 16

YASNAC PC NC Operating Manual Chapter 1: Outline of the YASNAC System

(2) Option Specifications

CATEGOR ITEM AND FUNCTION

Controlled

axes

Input

command

Interpolation Helical interpolation

Feed Synchronized feed (solid tap)

Storage and

editing of

program

Operation

and display

Input/output

function and

device

Spindle, tool

and miscellaneous functions

Tool offset Tool radius offset

Coordinate

system

Operation

support

function

Least input/output increment of rotary axis

Expanded number of workpiece coordinate

Automatic tool length measurement (TLM)

Number of controlled axes

Rotary axis control

Inch/metric switching

Multi-active registers

High-speed mode operation

F1-digit

Simultaneous1-axis handle feed

Simultaneous 2-axis handle feed

Simultaneous 3-axis handle feed

Addition of program storage capacity

Addition of number of programs

Playback

Internal toggle switch

NC program drawing

Comment display function

Tape reader without take-up reels

Tape reader with take-up reels

RS-232C interface

T4-digit command

Second miscellaneous function

Addition of tool offset data sets

Manual second reference point return

Automatic third/fourth reference point

return

Workpiece coordinate system setting

systems

Local coordinate system

Rotation of workpiece coordinate system

Optional block skip B

Automatic mode handle offset

Program restart

Manual interruption point return

OPERATION

MANUAL

PROGRAMMING

MANUAL

SECTION

NO.

1 - 7

Page 17

YASNAC PC NC Operating Manual Chapter 1: Outline of the YASNAC System

CATEGOR ITEM AND FUNCTION

Programming

support

function

Accuracy

correction for

mechanical

system

Automation

support

function

Safety and

maintenance

Hole machining pattern cycle

Stored pitch error compens ation

Canned cycle

Canned cycle B

Circle cutting

Macroprogram

Programmable mirror image

Scaling

Coordinate system rotation

Automatic comer override

Programmab le data input

Program copy

Unidirectional approach

Skip function

Tool life control function

Program interruption

Stored stroke limit B

Stored stroke limit C

OPERATION

MANUAL

PROGRAMMING

MANUAL

SECTION

NO.

1 - 8

Page 18

YASNAC PC NC Operating Manual Chapter 1: Outline of the YASNAC System

1.2 Protective Functions

1.2.1 Emergency Stop

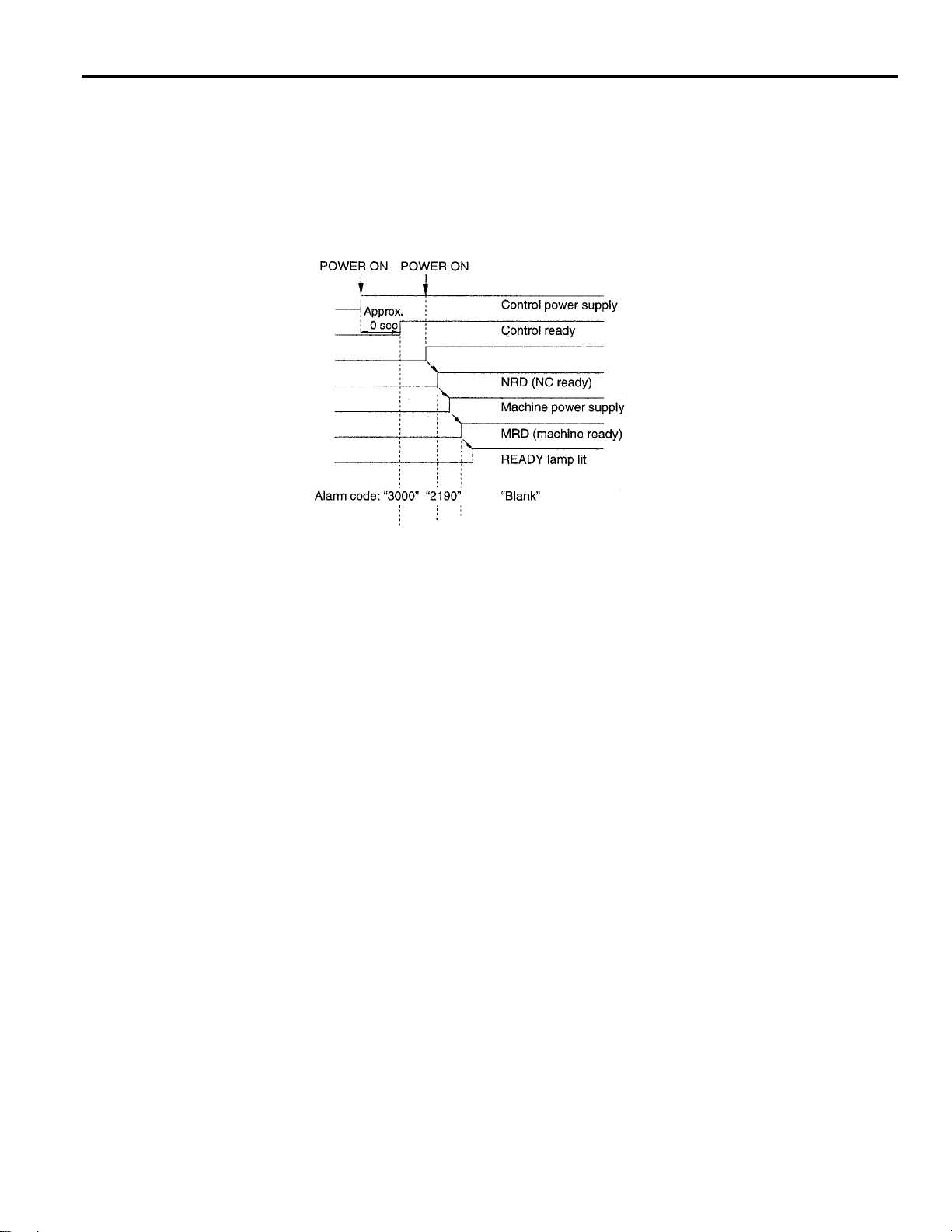

Press the emergency stop button immediately if a problem occurs with the system or line. The

execution of all commands stops instantaneously when the emergency stop button is pressed.

Servo power supply of the PC NC is shut OFF and dynamic brake is applied to stop all mechanical movement. In the emergency stop state, the PC NC is in the alarm state “3002”. If the emergency stop signal is “opened”, the PC NC stops the entire operation, and the SVMX and BKX

signals are “opened”.

PC NC

This operation is executed by setting the pins on the board. The pins di ffer between J300M

and J100M.

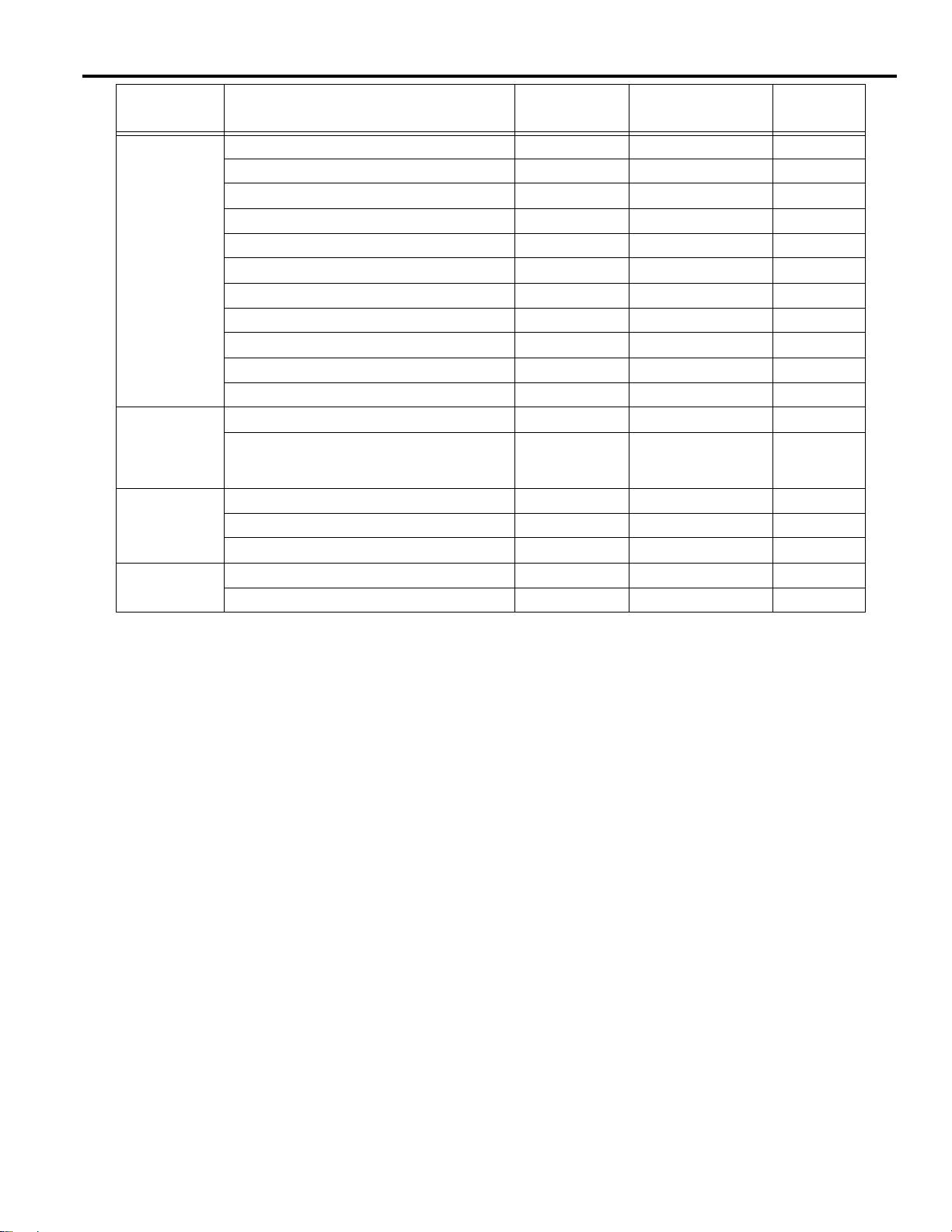

Table 1.2.1.1 Emergency Related Signals

1.2.2 Overtravel

The overtravel function stops axis feed operation when an axis reaches the travel limit; for the

detection of travel limit, a limit switch and a dog are used and if an axis reaches the travel limit,

the limit switch outputs a signal and the function stops axis feed operation in response to this

input. The axis reached and stopped at the travel limit can be moved manually into the axis movable range.

When the overtravel input is “opened”, axis movement is stopped in the manner as indicated in

Table 1.2.2.1. In response to this input, the alarm output (ALM) is “closed” and the corresponding alarm message is displayed on the screen.

Signal Name Pin Setting

Emergency Stop Input CN12-19 pin on JZNC-JFC 10 board

SVMX CN12-17 pin on JZNC-JFC 10 board

BKX CN12-16 pin on JZNC-JFC 10 board

Table 1.2.2.1 Axis Stop Direction with Overtravel Input “Opened”

Manual Operation Mode Automatic Operation Mode

*+X to *+5

input is “opened”

*-X to *-5

input is “opened”

* Normally closed contact

Movement in the *+X to *+5

direction is stopped.

Movement in the *-X to *-5

direction is stopped.

1 - 9

Movement of all axes is

stopped in all directions.

Page 19

YASNAC PC NC Operating Manual Chapter 1: Outline of the YASNAC System

If the overtravel input is “opened”, select the manual mode (jog, pulse handle) and move the axis

in the direction opposite to the direction for which the overtravel input is “opened” to “close” the

input. After that press the [RESET] key on the NC operation panel, the alarm output and display

are canceled.

1. After the occurrence of an alarm due to the “open” of the overtravel input, the M, S, and

T code read output signals (MF, SF and TF) are not turned OFF.

2. If it is necessary to interrupt the operation called by M, S and/or T code, set the interlock

by an external sequence.

3. The alarm numbers at the occurrence of overtravel are 2001 to 2005. If the overtravel

alarm occurs, axis move is stopped. Note that the servo is not turned OFF.1

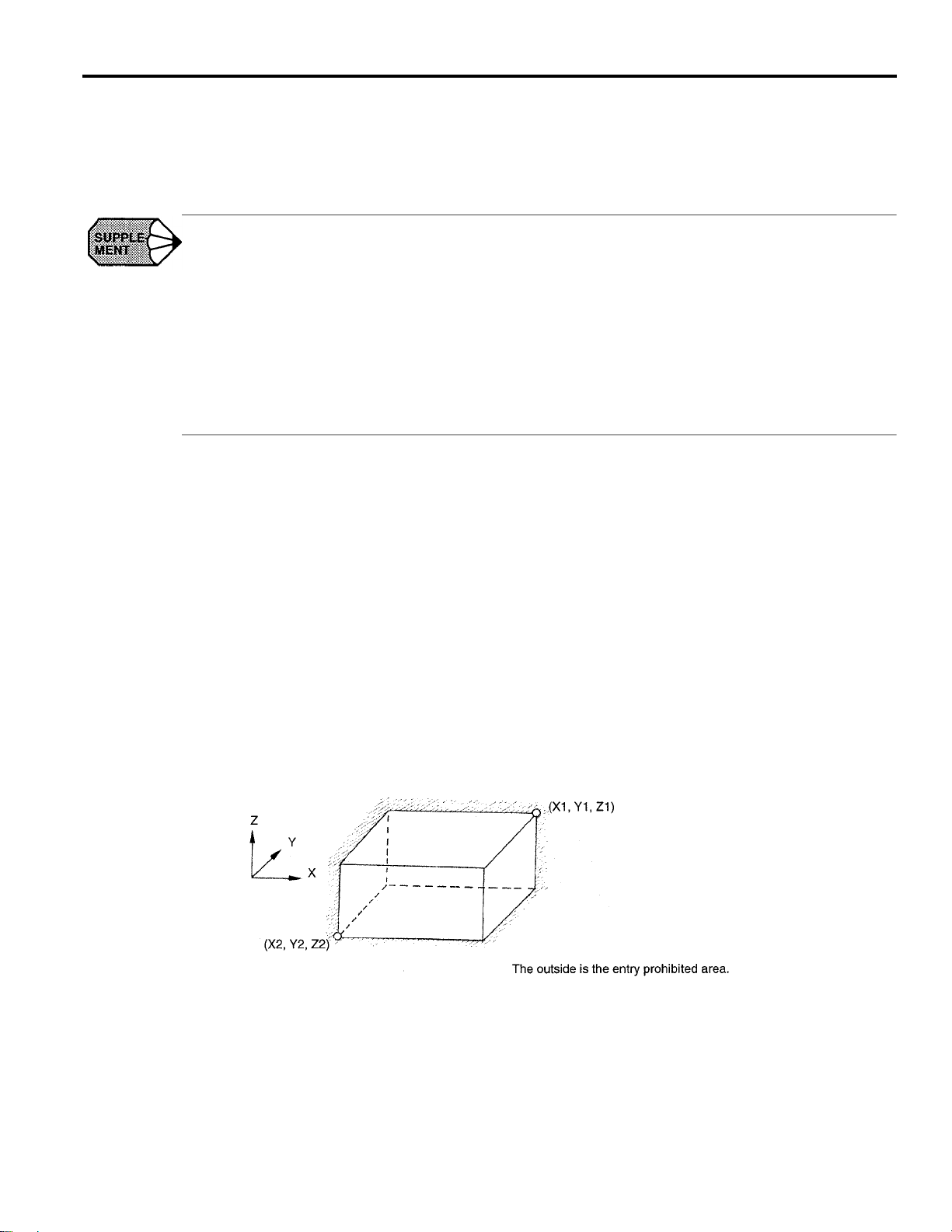

1.2.3 Stored Stroke Limit

To ensure improved safety in operation, this function prevents axis from entering the preset entry

prohibited areas both in manual and automatic operation.

(1) Stored Stroke Limit

To use the stored stroke limit function, the axis movable area is set by parameters with the

coordinate values in the machine coordinate system. The area outside the set boundary is

established as the entry prohibited area. If an axis enters the entry prohibited area, the function

stops axis movement and displays an alarm message. The function is made valid upon completion of the manual reference point return after the power is turned ON. In automatic operation, if even one axis causes the alarm, all axis are stopped.

In manual operation, only the axis that caused an alarm is stopped.

Fig. 1.2.3.1 Stored Stroke Limit

1 - 10

Page 20

YASNAC PC NC Operating Manual Chapter 1: Outline of the YASNAC System

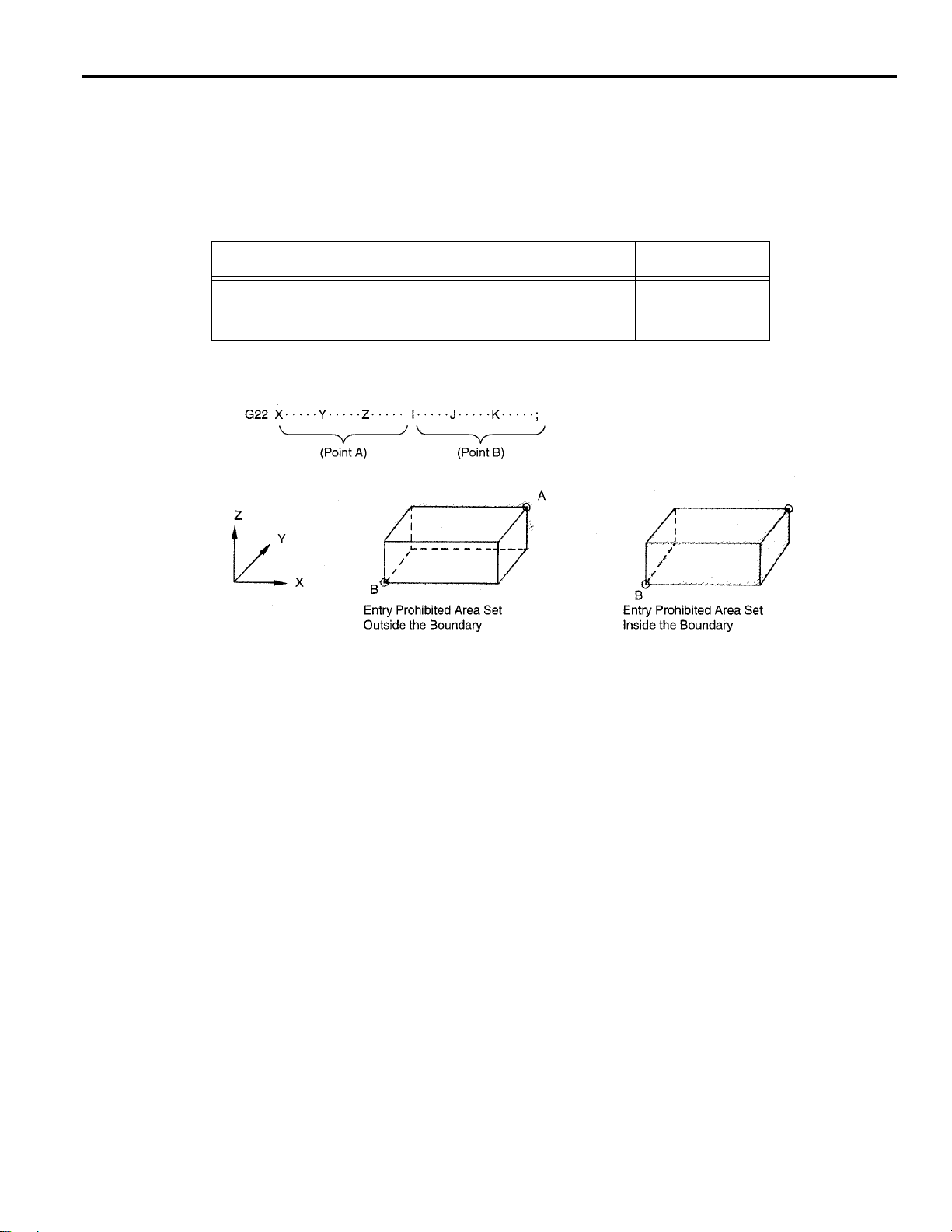

(2) Stored Stroke Limit B, C (G22, G23) *

The area either outside or inside the boundary set by parameters or by the commands in a

program is established as the entry prohibited area. The boundary is set with the coordinate

values in the machine coordinate system. Whether the entry prohibited area is established outside or inside the boundary can be determined by the setting for a parameter. The function is

made valid upon completion of the reference point return after turning ON the power.

G CODE FUNCTION GROUP

G22 Turning ON the stored stroke limit B 04

G23 Turning OFF the st ored stroke l i mit B 04

Fig. 1.2.3.2 Stored Stroke Limit B Function

• In addition to the stored stroke limits A and B, stored stroke limit C can be added.

• With the stored stroke limit C, set the boundary of the area and inside or outside the

boundary by parameters.

• According to the setting for the parameter or the input signal, one of the stored stroke limit

C (third to fifth prohibited area) can be made valid.

• For details of the stored stroke limit B, C, refer to 4.2.3 “Stored Stroke Limit B and C

(G22, G23)” in the PROGRAMMING MANUAL.

1 - 11

Page 21

YASNAC PC NC Operating Manual Chapter 1: Outline of the YASNAC System

1.2.4 Interlock Inputs

The interlock input is the signal used to disable axis movement, and is provided for each axis.

• When an axis is interlocked during movement, it is stopped after deceleration.

• When the interlock is released, the axis continues moving to comple te the r emainin g commands. Upon completion of the commands, the program advances to the next block.

• For simultaneous two or three axis interpolation commands, interpolation operation is disabled if one of these two or three axis is interlocked.

Fig. 1.2.4.1 Interlock Inputs

1 - 12

Page 22

YASNAC PC NC Operating Manual Chapter 2: PC NC System Outline

2

PC NC System Outline

Chapter 2 describes various operations including power ON procedure,

manual operation and automatic operation.

2.1 General Operation Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2 Inspection Before Turning the Power ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2.1 Inspection of the NC Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.2.2 Preparation before Turning the Power ON. . . . . . . . . . . . . . . . . . . . . . . 2- 5

2.3 Turning the Power ON and Inspecting After Power ON . . . . . . . . . . . . . . . . . . 2-6

2.3.1 Procedure for Turning the Power ON . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.3.2 Checking the Motors for Abnormalities . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.3.3 Procedure for Turning Power OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.3.4 Inspection of the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.4 Manual Operation (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.4.1 Manual Rapid Traverse (RAPID) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.4.2 Jog Feed (JOG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.4.3 Step Feed (STEP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.4.4 Handle Feed (HANDLE)* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.5 Manual Operation (2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2.5.1 Simultaneous 2 or 3-axis Handle Feed * . . . . . . . . . . . . . . . . . . . . . . . 2-13

2.5.2 Manual Reference Point Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.5.3 Manual Reference Point Return to the Second Reference Point* . . . . 2-16

2.5.4 1-line MDI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

2.6 Automatic Operation (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

2.6.1 Preparation of Automatic Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

2 - 1

Page 23

YASNAC PC NC Operating Manual Chapter 2: PC NC System Outline

2.6.2 MDI Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

2.6.3 Feed Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

2.6.4 Override . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

2.7 Automatic Operation (2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

2.7.1 Optional Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

2.7.2 Optional Block Skip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

2.7.3 Dry Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

2.7.4 Display Lock and Machine Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

2.7.5 Auxiliary Function Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

2.7.6 Z-axis Command Neglect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

2.7.7 4th-axis Command Neglect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

2.7.8 5th-axis Command Neglect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

2.8 Operation Intervention During Automatic Operation . . . . . . . . . . . . . . . . . . . 2-27

2.8.1 MDI Operation Intervention during Automatic Operation . . . . . . . . . 2-28

2.8.2 Automatic Handle Mode Offset * . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

2.8.3 Manual Absolute . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

2 - 2

Page 24

YASNAC PC NC Operating Manual Chapter 2: PC NC System Outline

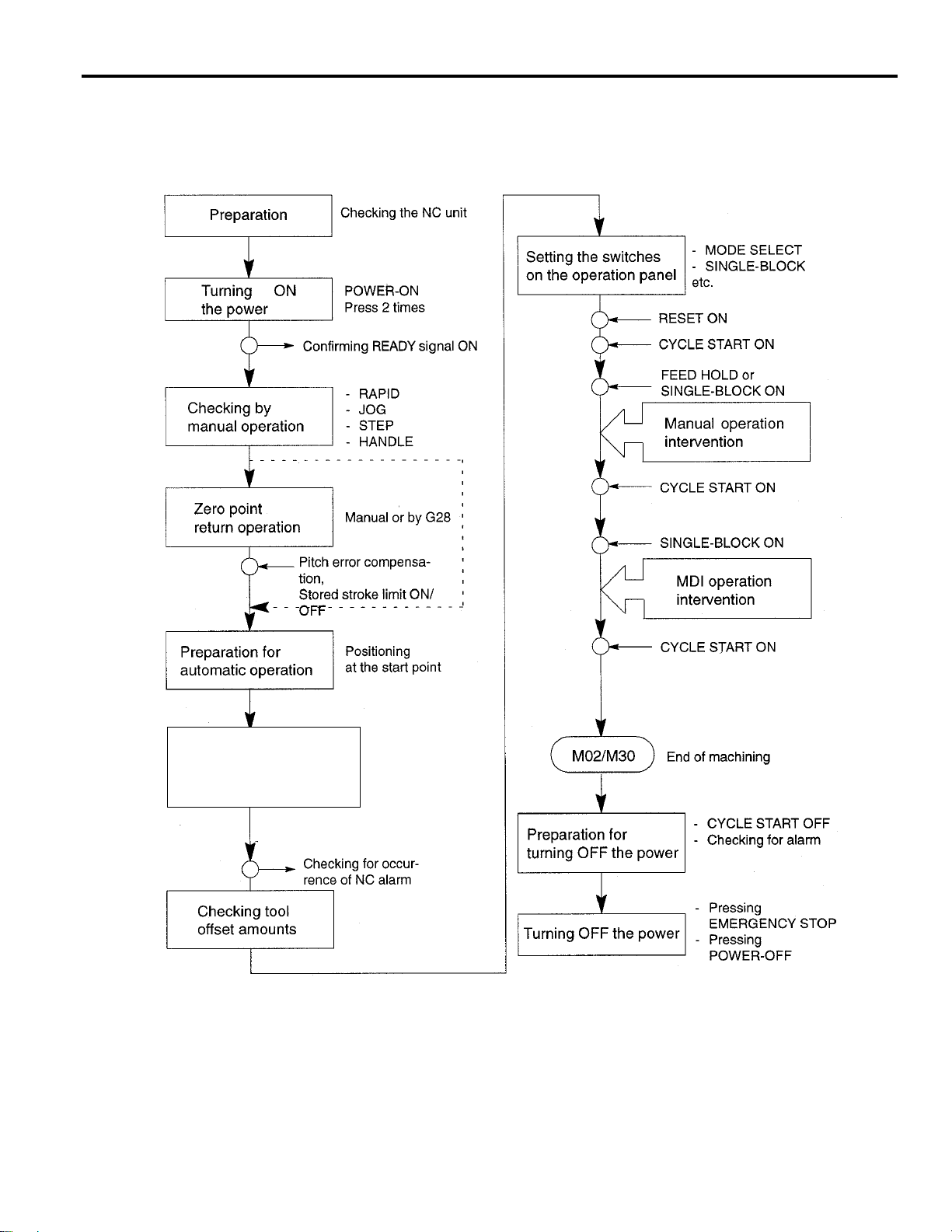

2.1 General Operation Flow

The operation procedure usually followed for daily operation is indicated in Fig.2.1.1. This chapter explains these operation items.

Setting Part Program

Loading NC program from PC

by Etherne t or from touch

screen and executing the

Program numbers

Fig. 2.1.1 Operation Procedure

2 - 3

Page 25

YASNAC PC NC Operating Manual Chapter 2: PC NC System Outline

2.2 Inspection Before Turning the Power ON

Before turning the power ON for YASNAC PC NC, it is necessary to carry out inspection to

Ensure safety. If the power is turned ON while the system has trouble, it could cause malfunctioning of the system itself and create a hazards conditions for the operations. Make sure to carryout daily inspection before turning the power ON.

WARNING!

• Always turn all power OFF (including the primary power supply) before carrying out daily

inspection.

Performing the inspection with the power ON may lead to electric shock.

• Wait 5 minutes after turning the power (including the primary power supply) OFF before

removing or replacing any unit or part.

• Failure to observe this warning could lead to electric shock and equipment failure.

• Do not touch any unit, terminals, etc., while the power is ON.

Failure to observe this war ning could lead to electric shock or device malfunction.

• Immediately after switching the power OFF, the product retains some electric charge. Do not

touch any parts (which are live when the power is ON) for 5 minutes after switching the power

OFF.

Failure to observe this war ning could lead to electric shock or device malfunction.

• Do not damage cables, subject them to excessive stress, or pinch them.

Excessive load on cables may cause electric shock.

• When the equipment is powered ON, never touch its rotating parts.

Failure to observe this warning could result in personal injury.

• Never modify the product.

2 - 4

Page 26

YASNAC PC NC Operating Manual Chapter 2: PC NC System Outline

CAUTION!

• To prevent personnel other than those involved in maintenance and inspection work from

turning the power ON while maintenance and inspection is in progress, place signs stating

“DO NOT TURN THE POWER ON” or words to that effect at the primary power

supplies of related control panels and other relevant locations.

Failure to observe this caution could lead to electric shock.

• Electronic devices such as CMOS ICs are used on the control boards. If you touch the IC’s

with your bare fingers, static electrical charge in your body could destroy these IC’ s, care must

be taken when handling these devices. Before handling these devices for maintenance purposes,

first discharge the static electricity in your body by touching a grounded metal device.

Failure to observe this caution could lead to personal injury and product failure.

• Do not install or remove boards, wiring, connectors, etc., while the power is ON.

Failure to observe this caution could lead to electric shock, product failure, and malfunction.

• Do not let foreign matter such as electrical wire scrap enter the unit.

Failure to observe this caution could result in fire, product failure or malfunction.

• Be sure to check the following points after completing maintenance and inspection work:

• Check that all fastening bolts are tightened.

• Check that no tools or other objects have been left inside the control panel.

• Check that the control panel door is closed properly.

Failure to carry out these checks could lead to electric shock, injuries, fire, and malfunction.

• Never attempt to disassemble the NC unit modify units/devices inside the PC NC unit.

Failure to observe this caution could lead to fire, product failure and malfunction.

• Do not change the set values of the devices, variable resistors, etc., in the control panel.

Failure to observe this caution could lead to fire, product failure, and malfunction.

2.2.1 Inspection of the NC Unit

In this subsection, the items to be inspected before turning ON the power are indicated for the

standard PC NC box supplied by Yaskawa. For the machine tool’s control box, refer to the

machine tool manuals.

(1) Inspecting the Machine Cabinet Doors

Make sure that the doors are securely closed before turning the power ON. The PC NC CPU

rack is not protected against oil mists or other airborne foreign matter. The door of the

machine cabinet doors must always be kept closed before powering ON.

2 - 5

Page 27

YASNAC PC NC Operating Manual Chapter 2: PC NC System Outline

(2) Inspecting the Shielding Parts in the Machine Cabinet

Inspect the shielding parts in the Machine Cabinet every month for gaps and/or damage.

Open the doors and check the packings installed around the door for damage.

Inspect the inside of the Machine Cabinet for abnormal contamination. If the inside is

abnormally dirty, clean it immediately after locating the cause of contamination.

Lock the doors securely and inspect the doors to make sure that there are no gaps.

By carrying out the inspection procedures indicated above at regular intervals, the YASNAC

PC NC can perform efficiently for a long time.

2.2.2 Preparation before Turning the Power ON

Before turning the power ON, confirm the following conditions:

• Make sure that the front side of the PC NC unit is closed. If the door is open or if there is a gap

between the door and the box panels, securely close and lock the door.

• Carry out the inspection for the machine and machine related controllers according to the

instructions in the machine tool manuals.

2 - 6

Page 28

YASNAC PC NC Operating Manual Chapter 2: PC NC System Outline

2.3 Turning the Power ON and Inspecting After Power ON

In this section, the procedure to be used for turning the power ON is explained. Inspection that

must be conducted after turning the power ON is also described.

WARNING!

• Be sure to turn the power OFF before replacing the battery.

Failure to observe this warning could lead to electric shock and product failure.

CAUTION!

• Replace fuses and batteries with the recommended products.

Failure to observe this caution could result in fire or product failure.

• Use the product with the “System Number Switch” of the CPU set to “0”.

Using while set to another number could lead to malfunction.

• Wait at least 2 seconds after turning the power OFF before turning it ON again.

Failure to observe this caution could lead to malfunction.

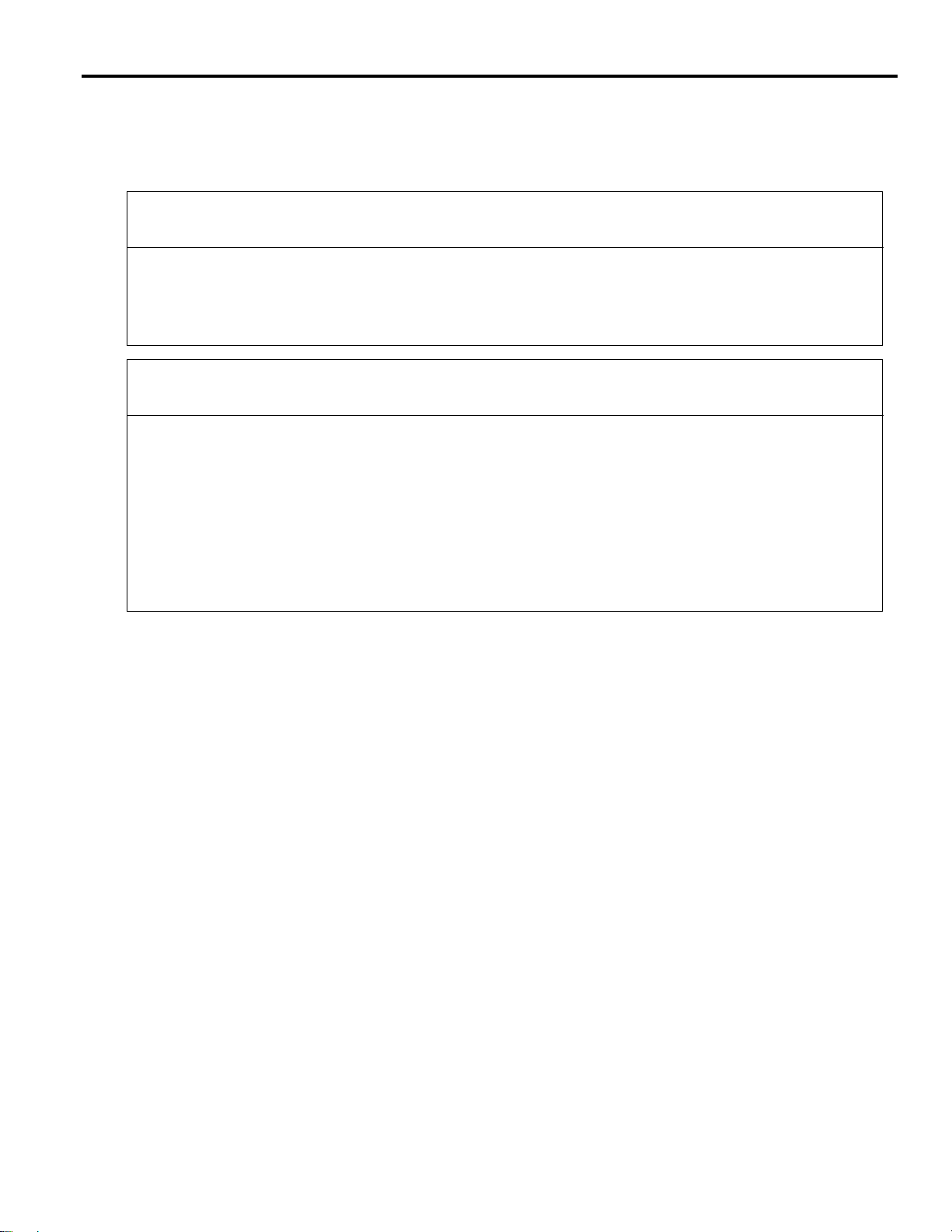

2.3.1 Procedure for Turning the Power ON

Turn the power ON in the following sequence.

Make sure that the power supplied to the PC NC unit is from an external power source.

Press the POWER ON button on the NC operation panel. Control power is turned ON and t he

cooling fan starts rotating.

Make sure that air is flowing out at the upper part on the side of the NC unit.

• In approximately 20 seconds, the control is ready for turning ON the servo power (alarm

code 3000).

Press the POWER ON button again - one time.

• The servo power is turned ON. When the machine is ready for operation, the NC enters

the ready state.

• When the power is correctly turned ON to the NC unit, the NRD (NC ready) signal is output.

• When the power is turned ON at the machine side in response to the NRD signal, the

MRD (machine ready) signal will be returned to the NC. The READY lamp goes on when

the MRD signal is returned. Note that a READY lamp is not used with some types of

machines.

2 - 7

Page 29

YASNAC PC NC Operating Manual Chapter 2: PC NC System Outline

• When the NC unit enters the ready state, the alarm message (displayed on the screen) will

go off.

If the NC unit fails to enter the ready state, locate the cause by referring to Section 7.2,

“ALARM DISPLAY JOB”, and take appropriate steps. For turning the power ON, there are

items that must be inspected at the machine side in addition to the NC unit related items. For

the former items, refer to the machine tool manuals.

5

PC NC Boots MMI screens

Fig. 2.3.1.1 Power ON Sequence

2.3.2 Checking the Motors for Abnormalities

Check the operation of the motors running. If abnormal vibration or noise occurs, turn the power

OFF and contact the maintenance personnel.

2.3.3 Procedure for Turning Power OFF

Turn the power OFF in the following sequence:

Make sure that the CYCLE START lamp on the machine operation panel is OFF with the

machine stopped.

Make sure that there is no alarm message displayed on the CRT screen. If an alarm message is

displayed, locate the cause by referring to Chapter 4, “MAINTENANACE” and take appropriate measures to clear it.

Carry out necessary STEPS for turning the power OFF at the machine side. For details, refer

to the machine tool manuals.

Press the EMERGENCY STOP button on the machine operation panel to turn the servo

power OFF.Press SHUTDOWN button to close all opened windows of PC NC.

When the safe SHUTDOWN message is displayed on CR T, Press the POWER OFF button on

the NC operation panel to shut off the power to PC NC.

2 - 8

Page 30

YASNAC PC NC Operating Manual Chapter 2: PC NC System Outline

Turn the power supply to the NC OFF by turning OFF a circuit breaker, etc.

PC NC Control Power Supp ly

PC NC Display

Shut Down button

Shut Down of PC Side

Closing Windows NT

Safe to Turn Off Windows NT

Fig. 2.3.3.1 Power OFF Sequence

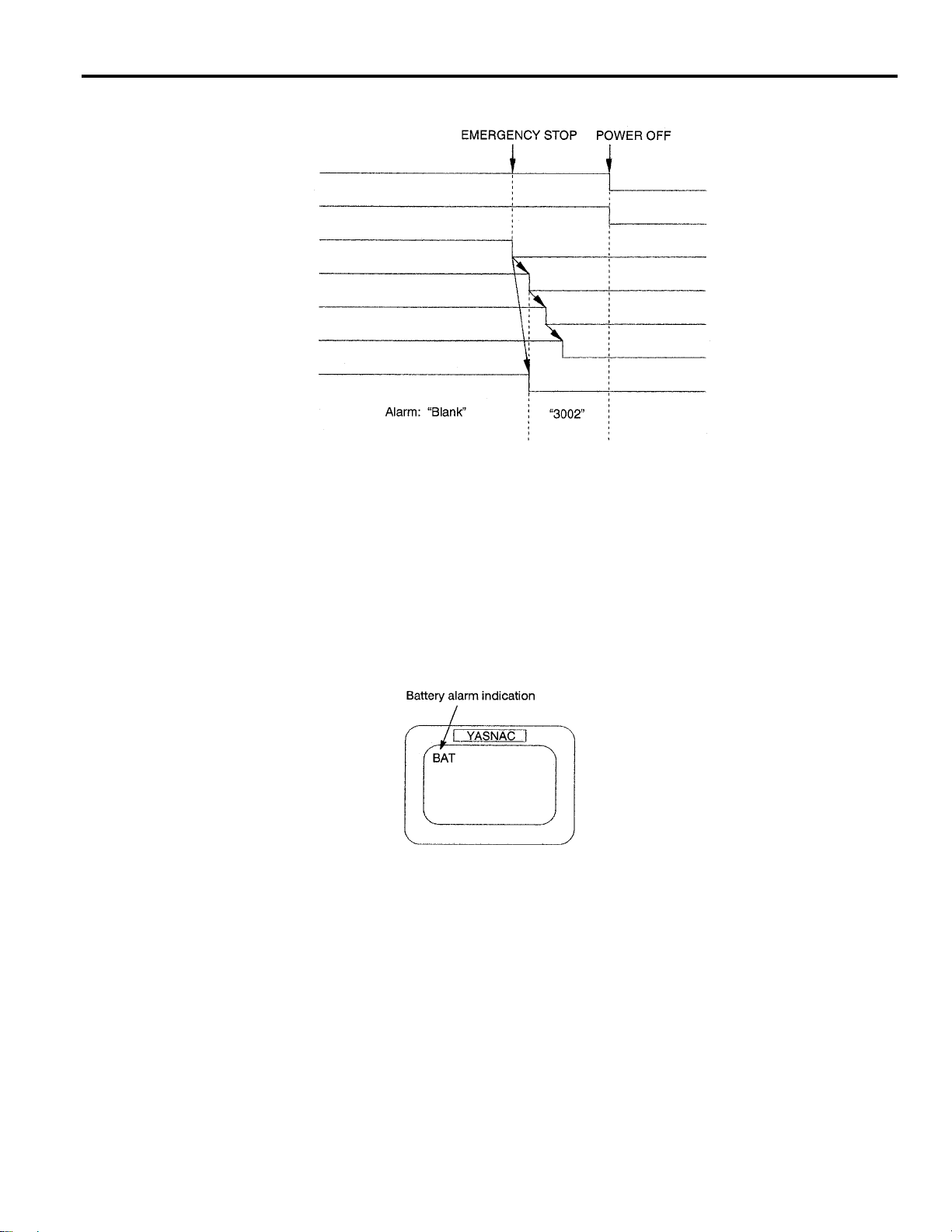

2.3.4 Inspection of the Battery

After turning the power ON, if there is a battery alarm, a br oken battery icon will be displayed, or

a solid battery is displayed to indicate everything is normal. After two minutes this normal battery indicator will disappear. When battery alarm is displayed by red battery icon, the battery

must be replaced immediately. Standard batteries cannot be used. For a replacement of battery,

contact your Yaskawa representative for Battery type: ER6VC3, Parts code: BA510

(1) Checking the Battery Which Needs Replacing

Follow the procedure indicated below to determine whether or not battery must be

replaced.

Press the POWER OFF button.

If a door interlock switch is installed, place the door interlock key in the OFF position.

This makes a power ON condition possible with the door opened.

Open the door so that the front part of the PC NC unit is visible.

Press the POWER ON button again - once.

2 - 9

Page 31

YASNAC PC NC Operating Manual Chapter 2: PC NC System Outline

Check the red color LED on the JANCD-JFC10 board. If it is lit, the battery must be

replaced.

Fuse (HM03, 0.3A)(F1)

I/O module power output

verification LED

I/O module power output

verification LED

Battery power supply

connector (CN06)

Battery

Fuse (5A) (F2)

(Behind Battery)

LITHIUM

Fig. 2.3.4.1 Location of the Battery on the PC NC board

2 - 10

Page 32

YASNAC PC NC Operating Manual Chapter 2: PC NC System Outline

(2) Replacing the Battery

Replace the battery easily with the following procedure.

Turn the PC NC power OFF.

Remove connector of Battery.Then, remove the battery from the holder by removing the

solder.

Fit the new battery in the holder and caref ully sold er RED( +) and BLACK ( -) wire s to the

Battery. Put the battery in its holder. Then put back battery connector, the connector may

be inserted in either direction, it must be securely inserted, otherwise, the power will not

be supplied by the battery. (See Fig. 2.7.)

Connect Red wire

( + )

B

A

T

T

E

R

Y

Connect Black wire ( - )

Fig. 2.3.4.2 Connecting the Battery Connector

Turn the power ON.

Make sure that “BAT” is not blinking on the CRT screen, and that the red color LED in

the board is OFF.

Note 1: Table/FigNote1

1. If the red color LED remains lit after replacing the battery, the connector might be inserted

incorrectly or the battery might be faulty.

2. Power OFF operation is allowed a few seconds after turning the power ON.

3. After turning the power OFF, replace the battery quickly. If the PC NC unit is left with the

battery removed, the data stored in the memory could be lost.

2 - 11

Page 33

YASNAC PC NC Operating Manual Chapter 2: PC NC System Outline

2.4 Manual Operation (1)

This section describes generally the manual operation. To move an axis manually, select the

operation mode of RAPID, JOG, STEP, or HANDLE with the MODE SELECT switch on

the machine operation panel.

2.4.1 Manual Rapid Traverse (RAPID)

An axis can be moved at a rapid traverse rate. Follow the procedure indicated below.

Select the rapid mode by placing the MODE SELECT switch on the machine operation panel

in the RAPID position.

Select the feedrate to be used for axis feed operation by the RAPID TRAVERSE and RATE

OVERRIDE switch on the machine operation panel.

• Override setting is possible in four steps of 100%, 50%, 25%, and F0. The feedrate corresponding to the setting at 100%, 50%, and 25% is set for parameters pm2801 to pm2805.

For the setting at F0, feedrate set for parameter pm2447 is used.

• Optionally, F1 and F2 positions are selectable. Feedrate to be selected according to the

switch setting at F1 and F2 is set for parameters pm2448 and pm2449.

On the machine operation panel, press the JOG button that corresponds to the axis and the

direction in which the axis should move. The axis moves at a rapid traverse rate while t he button is held pressed.

2.4.2 Jog Feed (JOG)

It is possible to move an axis in the jog feed mode. Follow the procedure indicated below.

Select the jog mode by placing the MODE SELECT switch on the machine operation panel in

the JOG position.

Select the feedrate with the JOG FEEDRATE switch on the machine operation panel.

2 - 12

Page 34

YASNAC PC NC Operating Manual Chapter 2: PC NC System Outline

• Feedrate can be selected from 32 steps, with actual feedrates of individual setting positions set for parameters pm2400 to pm2431. The actual number of steps and feedrates

selectable by the JOG FEEDRATE switch vary depending on the machine model. For

details, refer to the manuals published by the machine tool builder.

Press the JOG switch corresponding to the axis to be moved and the required axis move direc-

tion.

The axis moves at the selected feedrate while the JOG switch is held pressed.

2.4.3 Step Feed (STEP)

Manual step feed operation is possible. Follow the procedure indicated below.

Select the step mode by placing the MODE SELECT switch on the machine operation panel

in the STEP position.

Select the feed distance per step with the MANUAL PULSE MULTIPLY switch on the

machine operation panel.

Metric system: 0.001, 0.01, 0.1, 1.0, 10.0, 100.0 mm (per step)

Inch system: 0.0001, 0.001, 0.01, 0.1, 1.0, 10.0 inch (per step)

Press the JOG switch corresponding to the axis to be moved and the required axis move direc-

tion.

Each time the JOG switch is pressed, the selected axis moves in the selected direction by the

set feed distance per step.

2.4.4 Handle Feed (HANDLE)*

When the NC is equipped with a manual pulse generator, pulse handle feed operation is possible.

Follow the procedure indicated below.

Select the handle mode by placing the MODE SELECT switch on the machine operation

panel in the HANDLE position.

Select the axis to be moved by the HANDLE AXIS selection switch on the machine operation

panel.

With the MANUAL PULSE MULTIPLY switch on the machine operation panel, select the

axis feed distance per pulse (one division of the pulse handle).

Clockwise rotation: In the positive direction

Counterclockwise direction: In the negative direction

Metric system: 0.001, 0.01, 0.1 mm (per division)

Inch system: 0.0001, 0.001, 0.01 inch (per division)

Turn the pulse handle. The axis moves in the positive or negative direction according to the

direction in which the pulse handle is turned.

2 - 13

Page 35

YASNAC PC NC Operating Manual Chapter 2: PC NC System Outline

2.5 Manual Operation (2)

This section describes manual operations carried out in daily production using the manual

operation functions explained in 2.4 “MANUAL OPERATION (1)“.

2.5.1 Simultaneous 2 or 3-axis Handle Feed *

By installing the pulse handle for the individual axis, it is possible to move up to three axis among

the X-, Y-, Z-, α-, and β-axis simultaneously. Follow the procedure indicated below.

Fig. 2.5.1.1 Simultaneous 2 or 3-axis Pulse Handle Feed

Select the handle mode by placing the MODE SELECT switch on the machine operation

panel in the HANDLE position.

Select the axis feed distance per graduation of the pulse handle with the MANUAL PULSE

MULTIPLY switch on the machine operation panel. This switch is used in common for the

three pulse handles.

Turn the pulse handle. The sel ected axis is move d in the positive or negati ve dire cti on accord-

ing to the handle turning direction.

2 - 14

Page 36

YASNAC PC NC Operating Manual Chapter 2: PC NC System Outline

2.5.2 Manual Reference Point Return

Axes can be returned to the reference point in manual operation. Follow the procedure indicated

below.

Select the rapid or jog mode by placing the MODE SELECT switch on the machine operation

panel in the RAPID or JOG position.

Move an axis manually (manual rapid traverse or jog feed) to a position away from the refer-

ence point (within the reference point return enabled area). When an axis is located in range

A in Fig. 2.5.2.1, reference point return can be executed correctly.

Turn ON the REFERENCE POINT RETURN switch.

Keep the JOG switch pressed corresponding to the axis returning to the reference point and in

the return direction. When the JOG switch is held pressed, the corresponding axis starts moving in the same manner as ordinary manual axis feed operation.When the axis reaches the

deceleration point, feedrate is decelerated to a low feedrate and the axis stops automatically

at the reference point.

Upon completion of the reference point return, the REFERENCE POINT lamp of that axis

lights.

Fig. 2.5.2.1 Manual Reference Point Return

Reference Point is a specific position in the machine coordinate system. It is also called

the machine zero point or the machine reference point.

2 - 15

Page 37

YASNAC PC NC Operating Manual Chapter 2: PC NC System Outline

1. Once the reference point return is completed, point C indicated in Fig. 2.5.2.1 is stored to

the NC. Therefore, if reference point return is attempted while an axis is in area B, an error

occurs. In this case, the axis should first be returned to area A and then the reference point

return should be executed.

2. The axis for which the reference point return has been completed can be moved in

the reference point return direction manually only if the reference point return switch

is turned OFF.

3. If commands have been read to the buffer area during automatic operation, manual

reference point return must not be executed. If manual return operation is executed,

the data in the buffer area is cleared.

1. Immediately after the power is turned ON, the axis start manual or automatic reference

point return operation independent of the present axis position. However, reference point

return cannot be executed correctly if the axis is located in area B. In this case, the axis

must be returned to area A before executing reference point return.

2. If the MODE SELECT switch setting is changed while an axis is moving automatically to

the reference point, an alarm (alarm 2141 to 2145 reference point return interruption error)

occurs.

3. Reference point return cannot be executed when the MACHINE LOCK switch is ON.

4. With a rotary axis, it is possible to execute automatic reference point return as with a

linear axis.With a rotary axis, if it has been moved by more than ± 360.000° from the

reference point established first, reference point return is executed to the closest reference

point in the preset direction of reference point return.

The illustration below shows how the reference point return is executed from points A and

B. (The reference point return direction is determined by the setting for pm4002 D3 and

D4.)

5. Once the reference point return is completed, second and later reference point return is

executed at a high-speed mode. This is called “high-speed reference point return”. However, if the setting is so made to execute the reference point return at a low speed (pm4003

D6 = 1), second and later reference point return is executed at a low speed.

2 - 16

Page 38

YASNAC PC NC Operating Manual Chapter 2: PC NC System Outline

2.5.3 Manual Reference Point Return to the Second Reference Point*

The axis are automatically positioned at the second reference point. This operation allows positioning at the second reference point independent of the present axis position, whether it is in

the negative side or positive side from the second reference position. Follow the procedure indicated below.

Select the jog or rapid mode by placing the MODE SELECT switch in the JOG or RAPID

position.

Turn ON the ZRN2 (second zero point return request) switch on the machine operation panel.

Keep the JOG switch corresponding to the axis and direction of reference point return. The

corresponding axis is positioned at the second zero point at the jog feedrate or rapid traverse

rate according to the selected mode.

• If the ZRN2 switch is turned OFF while an axis is moving to the second reference point,

the axis stops moving. To restart the second reference point return operation, turn ON the

ZRN2 switch and turn OFF the JOG switch having been pressed once, then press it once

again.

• If the JOG switch is pressed again to be turn ed OFF while the X-a xis is moving t o the second zero point, the axis stops moving. In this case, press the JOG switch again to turn it

ON, and the X-axis restarts moving to the second zero point.With the Y- and Z-axis, this

is also applied.

1. If the JOG switches of [+] and [–] are pressed at the same time, the corresponding axis

stops moving since this operation is assumed to have turned OFF the JOG switch.

2. It is not allowed to use the first zero point return mode and the second reference point

return mode at the same time. If both input signals are ON at the same time, both of the

modes are invalid and neither jog nor rapid feed is executed. This feature is provided to

ensure safety.

3. If the NC is in either the machine lock state (including the machine lock for individual

axis) or the Z-axis command disregard state, the second zero point return operation cannot be executed. When a JOG switch is pressed under such a state, normal jog operation

is preformed.

4. With the axis for which second zero point return has been completed, manual axis move

operation is allowed only after the ZRN2 (second reference point return) switch is turned

OFF.

2 - 17

Page 39

YASNAC PC NC Operating Manual Chapter 2: PC NC System Outline

1. If the second zero point return input signal is turned ON in the state that the first zero point

return has not been completed, the input is invalid and the second reference point return

mode cannot be set.

2. In the second reference point return mode, input from the JOG switch [-X] ([-Y], [-Z]) is

valid. If the mode is changed, the ZRN2 switch is assumed to have been turned OFF.

2.5.4 1-line MDI

During the execution of manual operation, it is possible to execute one block of a part program by

directly entering it to the CR T screen. For this type of operation, a maximum of 40 characters can

be written and the function codes that are allowed are M, S, T, F, and E codes. However, M00,

M01, M02, M30, M90 to M99, and M190 to M199 cannot be specified. An offset command with

a T command is also disregarded. With the system that carries out set-up by using a T command,

a T command must not be specified for this 1-line MDI operation. Follow the procedure indicated

below.

Select the manual mode with the MODE SELECT switch on the machine operation panel. 1-

line MDI operation is not possible in the automatic or edit mode.

Enter the program from the operation panel.

Press the CYCLE ST ART switch on the machine operation panel, and the entered program is

executed. When the execution of the program is completed, the program displayed in the key

entry display area is cleared.

• If the mode is changed while the program is executed (waiting for FIN), the FIN is not

returned forcibly and the NC remains in the state waiting for the input of FIN.

2 - 18

Page 40

YASNAC PC NC Operating Manual Chapter 2: PC NC System Outline

2.6 Automatic Operation (1)

This section describes basic information necessary for performing automatic operation.

CAUTION!

• Before carrying out a cutting operation with a new program, confirm safety by performing the

single block operation and dry run operation.

If this pre operational check is not per for med, un expected o peration ma y result due to mis-setting of the amount of

offset, leading to tool damage due to interference. The resulting interference may cause injury to personnel.

• Strictly observe the cautions in the user’s manual when using programming functions.

Ignoring these cautions could lead to accidents involving injuries to personnel and malfu n c tions.

2.6.1 Preparation of Automatic Operation

After turning the power ON, the axis must be positioned at the start point defined in a program

before starting automatic operation. Set the coordinate system to be used for machining either

manually or by specifying appropriate commands in a program. Several examples are given

below to explain how the coordinate system should be set. For details, refer to the machine tool

manuals.

(1) Setting the Coordinate System

The origin of the coordinate system to be used for executing the commands should be set.

(a) When G92 is not specified in the program

The coordinate system for which the origin is set at other than the reference point for the

program not containing the coordinate system setting command (G92) is called a coordinate system for machining. The procedure for setting a coordinate system for machining

is indicated below.

Return the axis to the reference point by following the manual reference point return

procedure (see 2.4.2).

Select the MDI mode by placing the MODE SELECT switch on the machine operation

panel in the MDI position.

Write the program for setting the coordinate system.

For example,

2 - 19

Page 41

YASNAC PC NC Operating Manual Chapter 2: PC NC System Outline

G92X • • • Y • • • Z • • • ;

Fig. 2.6.1.1 Coordinate System for Machining

Execute the program by pressing the CYCLE ST ART switch on the machine operation

panel.

(b) When G92 is specified in the program, return the axis to the reference point by manual ref-

erence point return operation.

Example of Programming

EOR;

N1 G92X • • • Y • • • Z • • • ;

(c) When G28 (automatic reference program point return) and G92 are specified in the

program, move the axis manually to a position (in the area where reference point return

operation is allowed) away from the reference point.

Example of Programming

EOR;

N1 G28 • • • Y • • • Z • • • ;

N2 G92X • • • YO • • • Z • • • ;

(2) Start Lock

Keep the machine in the start lock state until it is confirmed that machine operation is permitted. Follow the procedure indicated below.

Before starting machine operation, turn the START LOCK switch on the machine opera-

tion panel ON.

After safety is confirmed, turn the START LOCK switch OFF.

Memory Operation

Memory mode operation is used to carry out automatic operation by using programs stored in

the PC NC memory. Follow the procedure indicated below.

2 - 20

Page 42

YASNAC PC NC Operating Manual Chapter 2: PC NC System Outline

Make sure that the alarm icon on the PC NC MMI is green. If the alarm icon is red, touch

the alarm icon button and locate the cause by referring to 9.1.4, “Cause of Alarm and Cor-

rective Action” and take appropriate measures to clear it.

Check the tool offset amounts and correct them if necessary, then position the axis at the

start point. For details of tool offset, refer to 5.3, “TOOL DATA CONTROL JOB”.

Carry out necessary settings with the switches on the machine operation panel.

• Select the memory mode by placing the MODE SELECT switch in the MEM position.

• Set the SINGLE-BLOCK switch ON or OFF. To execute the program block-by-

block, set it ON.

• Set the rapid traverse rate with the RAPID TRAVERSE RATE OVERRIDE switch.

• Set the MANUAL ABSOLUTE switch ON or OFF. Set the switch ON to return the

tool by manual operation intervention to the previously located position.

• Set the OPTIONAL BLOCK SKIP switch ON or OFF. Set the switch ON to disregard

the blocks that include the “/” (slash) code.

• Set the OPTIONAL STOP switch ON or OFF. To execute the optional stop function

(M01), set the switch ON.

• Set the DRY RUN switch. ON or OFF. Set the switch ON when checking the

program.

• With the FEEDRATE OVERRIDE and JOG FEEDRATE switches, set the feedrate.

Press the RESET button on the PC NC MMI operation panel. The program is rewound to

the beginning.

Press the CYCLE START switch on the machine operation panel to start automatic opera-

tion.

To suspend operation temporarily, press the FEED HOLD switch on the machine opera-

tion panel.

1. In case of emergency, press the EMERGENCY STOP button on the machine operation

panel to stop the machine immediately.

2. It is possible to start a program half way in the memory mode operation. Locate the cursor

at the required start block by using the Run This button, and press the CYCLE START

button. For this operation, however, the modal G codes must be set before starting the program.

3. In the memory mode, address search must always be executed by specifying “address +

nemeral”.

2 - 21

Page 43

YASNAC PC NC Operating Manual Chapter 2: PC NC System Outline

2.6.2 MDI Operation

Automatic operation is possible by inputting a program in the MDI mode. Follow the procedure

indicated below.

Select the MDI mode with the MODE SELECT switch on the machine operation panel.

Enter the block of commands from the keyboard. For details of program entry operation in

the MDI mode, refer to 6.2, “MDI OPERATION JOB”.

Press the CYCLE START switch on the machine operation panel and the execution of the

entered program is started.

2.6.3 Feed Hold

The feed hold function suspends automatic operation temporarily. Follow the procedure indicated below.

When the FEED HOLD switch on the machine operation panel is pressed while an axis is

moving, it stops after deceleration. The CYCLE START lamp on the machine operation

panel goes OFF and the FEED HOLD lamp lights.

After the completion of axis movement, the indicating lamp goes OFF.

1. If the execution of a drilling canned cycle is stopped halfway due to the single block

2. The setting of the FEED HOLD switch is disregarded while a tapping cycle is executed

3. If the FEEL HOLD switch is turned ON while M, S, T, or B* function not associated to

2.6.4 Override

The following provides a general description of the override function. For details of override,

refer to the machine tool manuals.

(1) Feedrate Override

function, the FEED HOLD lamp automatically goes ON to indicate that the operation

is suspended during the execution of a drilling canned cycle.

in the G84 mode.

be completed although the FEED HOLD lamp lights immediately. After the completion

of the function, the FEED HOLD lamp goes OFF and operation stops.

In the automatic mode (TAPE, MEM, MDI), feedrate specified by an F code can be over-

ridden in 21 steps in the range from 0 to 200% in increments of 10%, using the FEEDRATE

OVERRIDE switch on the machine operation panel. During the execution of a tapping cycle

(G74, G84), the setting is disregarded and the tapping cycle is executed in the feedrate specified by the program. If the OVERRIDE CANCEL switch is ON, the setting of the FEED

RATE OVERRIDE switch is disregarded and the axis are moved at the feedrate specified by

the F codes in a program.

2 - 22

Page 44

YASNAC PC NC Operating Manual Chapter 2: PC NC System Outline

Table 2.6.4.1 Feedrate Override Steps

STEP % STEP %

0 0 11 110

11012120

22013130

33014140

44015150

55016160

66017170

77018180

88019190

99020200

10 100 - -

Optionally, feedrate override range can be expanded to 0 to 540% (32 steps). In this case,

override increments are 10% in the range from 0 to 200%, 20% in the range from 220 to

300%, and 40% in the range from 340 to 540%.

2 - 23

Page 45

YASNAC PC NC Operating Manual Chapter 2: PC NC System Outline

2.7 Automatic Operation (2)

This section describes the switches used for automatic operation.

2.7.1 Optional Stop

The OPTIONAL ST OP switch is used to select whether or not the M01 (optional stop) command

should be executed in the automatic mode (MEM, MDI).

(1) OPTIONAL STOP Switch ON

When the OPTIONAL STOP switch is ON, the machine stops operating with the CYCLE

START lamp on the machine operation panel lit after the execution of the block that includes

M01. The CYCLE START lamp goes OFF if the FIN signal is returned. The operation

restarts when the CYCLE START switch is pressed.

(2) OPTIONAL STOP Switch OFF

The M01 command is disregarded. If the OP TIONAL ST OP switch setting is changed during

the execution of an automatic operation, it is disregarded for the block presently executed.

The new setting becomes valid from the block which is read after the switch setting has been

changed.

2.7.2 Optional Block Skip

The OPTIONAL BLOCK SKIP switch is used to set whether or not the data in the block which

includes the “/” (slash) code should be disregarded in automatic operation. Note that if the switch

setting is changed during operation, the new setting is not valid for the blocks having been read to

the buffer area.

(1) OPTIONAL BLOCK SKIP Switch ON

When the OPTIONAL BLOCK SKIP switch is ON, the commands specified after the “/”

(slash) code are disregarded (up to the end of the block). For the blocks in which the “/” code

is specified, the commands specified preceding the “/” code are executed.

(2) OPTIONAL BLOCK SKIP Switch OFF

The blocks which include the “/” (slash) code are executed. If the OP TIONAL BLOCK SKIP

switch setting is changed during the execution of an automatic operation, it is disregarded for

the block presently executed and also for the blocks having been read to the buffer area. The

new setting becomes valid from the block which is read after the switch setting has been

changed.

1. Specification of “/” is equivalent to”/ l“.

2. When the optional block skip 13 function is selected, the switches are provided corresponding to “/2” to “/9” individually and by using these switches, it is possible to turn ON

and OFF the block skip function for the individual designation of “/2” to “/9”.

2 - 24

Page 46

YASNAC PC NC Operating Manual Chapter 2: PC NC System Outline

2.7.3 Dry Run

When automatic mode operation (TAPE, MEM, MD1) is executed with the DRY RUN switch

set ON, feedrates specified in a program are disregarded and axis move commands are executed

at the feedrate set with the JOG FEEDRATE switch. Since the F code specified in a program is

displayed during the execution of a program, the program can be checked efficiently by using this

function.

Feedrate to be used in positioning (G00) can be selected from the rapid traverse rate or jog feedrate according to the setting for parameter pm2000 D0 as indicated in Table 2.7.3.1.

Table 2.7.3.1 Rapid Traverse in Dry Run

Parameter pm2000 D0 G00 in Dry Run

“0” Rapid traverse rate

“1” Jog feedrate set with JOG FEEDRATE switch

1. When the setting of the DRY RUN switch is changed during automatic operation, the

new setting becomes valid immediately. However, if it is changed while axis movement

is controlled in the “mm/rev” mode” or during the execution of a tapping cycle, the new

setting becomes valid after the completion of the presently executed block.

2. In the dry run mode, the setting of the RAPID ‘TRAVERSE RATE OVERRIDE switch

is valid for rapid traverse operation.

2.7.4 Display Lock and Machine Lock

The DISPLAY LOCK/MACHINE LOCK switch allows the program to be executed in the

following manner – to operate the machine with the present position data fixed, or to execute the

program to update the present position data without actually operating the machine. The switch

can be operated only while the operation is stopped in the block stop or feed hold state.

(1) DISPLAY LOCK/MACHINE LOCK Switch OFF