Page 1

YASNAC PC NC

Connecting Manual

Version: Beta 1.0

Page 2

YASNAC PCNC Connecting Manual Preface/Table of Contents

SAFETY INFORMATION

PRECAUTIONS

1. Read this instruct io n ma nual in its entirety before using the YASNAC PC N C Connecting Manu al .

2. The following warning symbols are used to indicate precautions that the user must be aware of

to safely use this equipment. Failure to follo w thes e pre cautions can result in serious or possibl y

even fatal injury and damage to products or related equipment or system.

WARNING

WARNING

WARNING

This sym b ol indica tes the pre s en ce of a potentially hazardous condition which, if not avoided,

could result in serious personal injury or death.

This precau tionary symbol appear s in la be ls attached to YA SN AC products to alert th e use r to

conditions requiring concern for safety.

SPECIAL SAFE TY N O TE: This symbol indicates that ELECTRICAL SHOCK HAZARD

condition exi s ts. D O N O T TO U CH a ny electrical connection termin al s w hen the power is ON,

and for at least 5 minutes after switching off the power supply.

CAUTION

This symbol indicates the presence of a potentially hazardous condition which, if not avoided,

could result in mino r or moderate personal in jury and/or damage to eq uipment.

NOTICE

Printed _______. 1999. The information contained within this document is the proprietary property of

Yasakawa Electric America, Inc., and may not be copied, reproduced or transmitted to other parties without

the expressed wr itte n authorization of Yasakawa Electric Americ a, Inc.

No pattent liabil ity is assumed with respect to the uses o f the information con tained herein. Mo r eover,

because Yaskawa is constant ly im proving its high quali ty product, the informa ti on contained in this ma nual

is subject to chan ge w ithout notice. Every precaution has been taken in th e preparation of this document.

Nevertheless, Yasakawa assumes no responsibilit y for da m ag es resu ltin g from th e use of the inf orm a tion

contained within this publication.

i

Page 3

YASNAC PCNC Connecting Manual Preface/Table of Contents

Table of Contents

1. GENERALS

1.1 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

1.1.1 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

1.1.2 Connection between Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

1.1.3 Connector Layout NC side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4

1.1.4 Connector Layout PC side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 5

1.2 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 6

1.3 Thermal Design of Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 7

1.3.1 Thermal Design. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 7

1.3.2 Dust Proof Design. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 11

1.3.3 Countermeasure Against Magnetic Fields . . . . . . . . . . . . . . . . . . . . . . . . 1 - 12

1.4 Cable Clamp and Shielding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 13

1.5 Packaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 14

1.5.1 General Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 14

1.5.2 Installation of CNC Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 15

1.5.3 Installation of Feed/Spindle Servopacks. . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 16

2. POWER SUPPLY CONNECTIONS

2.1 Connection between Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

2.1.1 Power Supply specifications for PCNC and I/O units . . . . . . . . . . . . . . 2 - 2

2.1.2 Power Supply connections to PCNC . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 3

2.1.3 Power Supply Connections to PCNC and I/O units . . . . . . . . . . . . . . . . . 2 - 3

2.1.4 Power Supply to Converter unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 4

2.2 Detailed Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 5

2.2.1 Power Supply to PCNC unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 5

ii

Page 4

YASNAC PCNC Connecting Manual Preface/Table of Contents

2.2.2 Power Supply to Converter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 7

2.2.3 Example of Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 8

2.3 LED for Power Input /Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 9

2.3.1 LED for PCNC Power Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 10

3. CONNECTION OF PCNC OPERATION PANEL

3.1 Connection between Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2

3.1.1 Connection with the Operation panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 2

3.2 Detailed Connection of PCNC Operation panel. . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 3

3.2.1 Connection with Operation panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 3

3.3 General notes on Connection with operation Panel . . . . . . . . . . . . . . . . . . . . . . . . .3 - 8

3.3.1 JANCD-JSPO4/JANCD-J861. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 8

3.3.2 PCNC Connections Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 9

4. CONNECTION OF MANUAL PULSE GENERATOR

4.1 Connection between Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

4.1.1 Connection with CNC Operation Panel . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

4.2 Detailed Connection of Manual Pulse Generator . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

4.2.1 Parallel I/F. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

4.2.2 Non-Parallel I/F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 4

5. CONNECTION OF POWER ON/OFF EXCLUSIVE SIGNAL

5.1 Connection between Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 2

5.1.1 Connection to PCNC Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 2

5.2 Detailed Connection of Power ON/OFF Exclusive Signal . . . . . . . . . . . . . . . . . . 5 - 3

5.2.1 Connection to PCNC Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 3

5.3 Details of Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 4

iii

Page 5

YASNAC PCNC Connecting Manual Preface/Table of Contents

5.3.1 Servo Power ON (SVMX), Brake Release (BKX) Output. . . . . . . . . . . . 5 - 4

5.3.2 Emergenc y Stop (*ESP) Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 5

5.3.3 External Power ON/OFF (EON, EOF, ECOM) Input. . . . . . . . . . . . . . . . 5 - 5

6. CONNECTION WITH SERVOPACK

6.1 Connection between Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 2

6.1.1 Con ne ction between PCNC U nit, Servopack and M otor . . . . . . . . . . . . . 6 - 2

6.2 Connection Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 3

6.2.1 Connection between PCNC Unit and Servopack . . . . . . . . . . . . . . . . . . . 6 - 3

6.2.2 Connection of the Servomotor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 4

6.2.3 Connection of the Spindle Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 7

6.2.4 Selection of the Converter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 9

7. CONNECTION OF RS-232C

8. CONNECTION OF DIRECT IN/OUT SIGNALS TO THE PCNC UNIT

8.1 Connection between Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 2

8.1.1 Connection to the CNC Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 2

8.2 Detailed Connection of Direct IN/OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 2

8.2.1 Connection to the CNC Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 2

8.2.2 Description of Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 4

8.2.3 I/O Circuits on CNC side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 4

9. CONNECTION OF I/O MODULE

9.1 Connection between Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 2

9.1.1 Connection between Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 2

iv

Page 6

YASNAC PCNC Connecting Manual Preface/Table of Contents

9.2 Detailed Connection of I/O Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 3

9.2.1 Connection between Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 3

9.3 Connection between Additional I/O Module devices. . . . . . . . . . . . . . . . . . . . . . 9 - 4

9.3.1 Connection between Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 4

9.4 Detailed Connection of Additinal I/O Module . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 5

9.4.1 Connection between Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 5

10. CONNECTION OF GENERAL PURPOSE I/O

10.1 Connection between Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 2

10.1.1 Connection of Signal Line with I/O Module . . . . . . . . . . . . . . . . . . . . . . 10 - 2

10.1.2 Connection between Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 3

10.2 Detailed Connection of General Purpose I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 4

10.2.1 FC810/FC815/FC860 Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 4

10.2.2 FC861 Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 27

10.2.3 JSP02/JSP04 Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 36

10.3 Description of General Purpose I/O Signal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 45

10.3.1 I/O Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 45

10.3.2 /O Circuit of I/O Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 47

10.3.3 Power Supply for I/O Signal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 57

11. REPLACEMENT OF BA TTERY/FUSE

11.1 Battery Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11 - 2

11.1.1 Checking the battery life. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11 - 2

11.1.2 Replacement procedure of battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11 - 3

11.2 Fuse Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11 - 4

v

Page 7

YASNAC PCNC Connecting Manual Preface/Table of Contents

APPENDIX 1. DIMENSIONS

1.1 PCNC Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A1-3

1.1.1 PCNC UNIT (JZNC-JPCRKM

oooo

-

oo

)A1-3

o

-

1.2 Power Supply Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A1-4

1.2.1 Power Supply Unit type ( UPS00004) . . . . . . . . . . . . . . . . . . . . . . . . . . . .A1-4

1.3 Operation Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A1-5

1.3.1 Display Unit Type ( JZNC-JPCOP-

ooo -oo

) . . . . . . . . . . . . . . . . . . .A1-5

1.4 I/O Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A1-6

1.4.1 ANCD-FC810/FC815/FC860 Model-A1-6

1.4.2 JZNC-IAU59 (JANCD-FC861) Model. . . . . . . . . . . . . . . . . . . . . . . . . . . .A1-6

1.5 AC Servopack (including Converter and Spindle Drive) . . . . . . . . . . . . . . . . . . . A1-7

1.6 AC Servomotor S Series (Model SGMG, for 200VAC) . . . . . . . . . . . . . . . . . . . . A1-9

1.6.1 Standard Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A1-9

1.6.2 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A1-10

1.7 Spindle Motor M5 Series (Model UAASKA for 200VAC) . . . . . . . . . . . . . . . . . A1-11

1.7.1 Flange-mounted type Motor Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . .A1-11

1.7.2 Foot-mounted type Motor Dimensions(Drwg. 1.1.1). . . . . . . . . . . . . . . . .A1-13

1.8 Power Supply Unit for Brake (OPR109F, OPR109A) . . . . . . . . . . . . . . . . . . . . . A1-15

1.9 Noise Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A1-16

1.10 Manual Pulse Generator (OSM-01-2GA-15) . . . . . . . . . . . . . . . . . . . . . . . . . . . . A1-17

1.11 Spindle Pulse Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A1-18

1.11.1 NE-1024-2MDF-068-11 (6000 r/min) . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NE-1024-2MDF-068-12 (6000 r/min) . . . . . . . . . . . . . . . . . . . . . . . . . . . A1-18

1.11.2 NE-1024-2MD-11 (6000 r/min) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A1-19

1.12 Heat Exchanger. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A1-20

1.12.1 External Dimensions of REX1550 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A1-20

1.12.2 HEATEX02. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A1-21

1.13 AC Reator (UZBA-B: for Input, for 50.60Hz) . . . . . . . . . . . . . . . . . . . . . . . . . . . A1-22

vi

Page 8

YASNAC PCNC Connecting Manual Preface/Table of Contents

APPENDIX 2.CABLE SPECIFICATIONS

2.1 Cable Manufacturing Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A2-3

2.1.1 Connection with the Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A2-3

2.1.2 Connection with the Operation Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A2-5

2.1.3 Connection with the Pulse Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A2-11

2.1.4 Connection with the Power ON/OFF Circuit . . . . . . . . . . . . . . . . . . . . . . .A2-11

2.1.5 Connection of the Direct IN Signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A2-12

2.1.6 Connection with I/O Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A2-12

2.1.7 Connection between I/O Boards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A2-13

2.1.8 Connection with the Servo Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A2-15

2.2 Cable Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A2-17

2

2.2.1 Cable Drwg. No. DE 8400093 (KQVV-SB Type, 0.2mm

2.2.2 Cable D rw g. N o. DE 8402398 (VCT Type, 0.2mm

2

x 20 pairs) . . .A2-17

x 5 pairs) . . . . . . . . .A2-18

2.2.3 Cable Drwg. No. DE9405671. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A2-19

2.3 Cable and Connector Details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A2-2

2.3.1 Main Power Cable (UWR00264-1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A2-3

2.3.2 Floppy D i sk da ta cable (U W R00265-1) . . . . . . . . . . . . . . . . . . . . . . . . . . .A2-4

2.3.3 Floppy D i sk Power Cable (UWR0026 6-1 ) . . . . . . . . . . . . . . . . . . . . . . . .A2-5

2.3.4 Touchscreen Power Cable (UWR00267-1). . . . . . . . . . . . . . . . . . . . . . . . .A2-6

2.3.5 Video Extension cable (UWR00270-1) . . . . . . . . . . . . . . . . . . . . . . . . . . .A2-7

2.3.6 Touchscreen Data Cable (UWR00271-1 ) . . . . . . . . . . . . . . . . . . . . . . . . .A2-8

2.3.7 Servo ON/OFF Main Cable (UWR00272-1 ). . . . . . . . . . . . . . . . . . . . . . .A2-9

2.3.8 Push-button switch harness cable (UWR00273-1). . . . . . . . . . . . . . . . . . .A2-10

2.3.9 PS/2 Port Ext ension Cable (UWR00275- 1 ). . . . . . . . . . . . . . . . . . . . . . . .A2-11

2.3.10 CPU Rack Power cable (UWR00276-1) . . . . . . . . . . . . . . . . . . . . . . . . . .A2-12

vii

Page 9

YASNAC PCNC Connecting Manual Preface/Table of Contents

2.3.11 CRT Power Cable (UW R00262-1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A2-13

2.3.12 Serial Mouse Data Cable (UWR00318-1) . . . . . . . . . . . . . . . . . . . . . . . . .A2-14

2.3.13 NC Pow e r Supply AC Input Cable (UW R00229-1). . . . . . . . . . . . . . . . . .A2-15

2.3.14 NC Power Supply Output Cable (UWR00228-3). . . . . . . . . . . . . . . . . . . .A2-16

2.3.15 Yenet Servo Cable (UWR00249-2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A2-17

2.3.16 Yenet I/O Cable (UWR00251-4). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A2-18

2.3.17 Servo Drive I/O Cable (UWR00214-2) . . . . . . . . . . . . . . . . . . . . . . . . . . .A2-19

2.3.18 Power ON Sequence Cable (UWR00263-1). . . . . . . . . . . . . . . . . . . . . . . .A2-20

2.3.19 I/O Board Power Output Cable (UWR00258-7). . . . . . . . . . . . . . . . . . . . .A2-21

2.3.20 Drive Jumper Connectors (UWR00219-2). . . . . . . . . . . . . . . . . . . . . . . . .A2-22

2.3.21 I/O Cable (UWR00305-7). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A2-23

2.3.22 I/O Cable (UWR00306-3). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A2-24

2.3.23 I/O Cable (UWR00307-3). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A2-25

viii

Page 10

YASNAC PCNC Connecting Manual Preface/Table of Contents

USING THIS MANUAL

This manual decribes the procedures for connecting the

<$61$&3&1&

to machines, mach ine i nter fac es an d

peripheral equipment.

Connections provided by the machine tool builder differ from the types provided in Yaskawa CNC enclosures. Therefore, i t m ay be necessary to make co nne ction changes in ac cordance with the ne e ds of sta nda rd

cabinets an d int e grated equipment.

The programmable controller system (hereafter called PLC) is installed in the

For PLC details, refer to the

<$61$&3&1&

PLC Programming Manual.

<$61$&3&1&

unit.

RELATE D INFORMATION SOURCES

For additonal inform ation, refer to the follow ing manuals:

Title Of Docume nt Contents

YASNAC P C N C Operating Ma n u a l

( YEA-SIA-C844-2.1 )

YASNAC PCNC Programming Manual

( YEA-SIA-C844-2.2 )

Basic configuration and operating procedures

also describes Human machine interface(HMI)

PCNC Program creation instructions

YASNAC PCNC PLC Programming Manual

( YEA-SIA-C844-0.1 )

YASNAC PCNC I/O Signal Function

( YEA-SIA-C844-2.3 )

YASNAC PCNC Connecting Manual

( YEA-SIA-C844-0.2 )

MEMOCON GL120,G130 120 Series I/O Module User’s Manual

(Document No. SIEZ-C825-20.22)

MEMOCON GL120,G130 Hardware User’s Manual

(Document No. SIEZ-C825-20.1)

YASNAC PCNC Maintenance Manual

( YEA-SIA-C844-2.9 )

PLC Program creation instructions

Describes functions between PCNC, PLC

and Machine Tool

Instructions for connecting PCNC with machines,

machine interface and peripheral equipment

Describes I/O connections and power supply

specifications

Describes the AC input power supply specifications for I/O.

Describes servi ce and maint enance procedures.

ix

Page 11

YASNAC PCNC Connecting Manual Preface/Table of Contents

NOTES FOR SAFE OPERATION

It is important that the user should read this conn ec ti ng manual before insta ll ing , operating, performing any

maintenance o r inspecti ng the

<$61$&3&1&

Also, the functions and performance of a NC machine tool are

not determined by the PCNC unit itself, therefore, thoroughly read and familiarize yourself with the machine

builder’s documentation concerning the safe and most efficient ways to use the m achine tool.

The following symbols are used in this connection manual to emphasize particular information to the

user:

Indicates important information to be remembered, i.e., precautionary alarm displays

POINT

to prevent damaging devices.

x

Page 12

YASNAC PCNC Connecting Manual Preface/Table of Contents

OPERATING SAFETY WARNINGS

In this

<$61$&3&1&

&RQQHFWLQJ0DQXDO

warnings regarding safe use are categorized as WARNING and

CAUTION (refer to Page 1 for an explanation of these terms) . An example of this warning method is as fol-

lows:

PCNC Unit

Read all Warning label’s

of PCNC Unit.

WARNING

CAUTION

WARNING LABEL

BE SURE TO CONNECT

GROUNDING LINE TO

GROUNDING TERMINAL

WARNING

PCNC Opeartion panel

with 14” CRT U ni t

14 “ CRT UNIT or

May cause electrical sho c k .

Do not touch inside.

( Make sure to connect grounding )

Read all the cautions and warnings

24 DC Power supply unit ( UPS 000004 )

xi

LCD ( Expected)

rear side warning

Label

(Make sure to connect grounding )

Page 13

YASNAC PCNC Connecting Manual Preface/Table of Contents

TRANSPORT PRECAUTONS

CAUTION

• When movin g the product, do not lift by the ca ble .

• Once the product has been installed on the machine and the eyebolts have been removed, insert

suitable size machine bolts in the mounting holes.

• The product should not be exposed to harmful environmental conditions, i.e., water, harmful

gases or liquids.

Failure to observe these precautions may result in personal injury or product damage.

STORAGE

CAUTION

• This product should not be exxposed to harmful environmental conditions, i.e, water, harmful

gases or liquids.

• Product should be stored in a clean indoor area that meets the following temperature and humidity

conditions:

• Ambient te mperature: -15

• Relative humidity : 10% to 90%

• Altitude : 1000 m or less ( 10000ft or less )

Failure to observe these precautions may result in personal injury or product damage.

o

C to 65oC (-5oF to 149oF)

xii

Page 14

YASNAC PCNC Connecting Manual Preface/Table of Contents

INSTALLATION

CAUTION

• Install peri pheral equipment in accordance with th e following:

1. A rust preventative substance has been applied to the motor shaft’s end an d flange. Remove

the substance using a cl ean cloth.

2. When connecting the motor shaft to a dr iven machine, be sur e to cente r-align accurately t o

prevent vibration.

3. Mount the servo unit(Converter,Inverter and A m plifier ) vertcally and faste n fir ml y in pla ce

with screws or bolts.

4. Since the servo unit (Converter,Inverter and Amplifier ) will generate heat, install the unit with

sufficient clearance for cooling air flow.

5. In order to reduce heat generation, position the servo unit’s(Converter,Inverter and Amplifier)

cooling fan outside of the enclosure for exposure to the exte rnal atmosphere for cool ing.

6. When circulating air inside of the enclosure, do not blow air directly onto the servo unit since

dust cont amination could occur.

7. Position and mount components so that they are easily accessible for inspection and maintenance.

Failure to observe these precautions may result in product failure.

CAUTION

• When installing this pro duc t, do not close the intake or exhaust port s, bu t take precautions to

prevent foreign matter fro m e nt eri ng this device

• Do not subject this pr oduct to any strong physical im pa cts.

• Set the power line capacity higher than this produ ct ’s power consumption level.

Failure to observe these precautions may result in personal injury or product damage.

xiii

Page 15

YASNAC PCNC Connecting Manual Preface/Table of Contents

WIRING

CAUTION

• Use the shortest wires when making connections.This helps prevent malfunction.

• Connect the +24V D C power supply to the PC NC unit .

1. The power supply shoul d be provided at the custome r’s site.

(The power supply unit , UPS000004, is available as an option.)

2. Supply the power in the range of +24V DC +

• Do not run the I/O signal wires with power wires or in the same duct. Ample separation of signal

wires from power wires will reduce the noi se i nfl uence.

• If noise occurs, use a noise suppressor to eliminate it. Refer to th e sec ti on in this connection

manual for noise filter specifications and capacities.Us e o f the correct n oise filter will reduce

noise influence.

• Be sure to complete the end-terminal-proc essing to the la st module of the remote I/O modul e .

Set the “TERMINATION” shorting pin to “ON”.

10% to the PC NC unit ’s inlet (CN 05).

Failure to follow these instructions could result in malfunction.

CAUTION

• Electrical wiring and connections should be performed by qualified personnel only.

Failure to observe this precaution could result in product failure, fire and/ or

personal injury or death due to electrical shock.

• Never connect a three-phase power supply to mot or output terminals, U,V or W of th e dri ve unit.

Damage to the device will occur if incorrectly connected.

• Select the type and size of wire based on your requirements and current capacity. When the

ambient temperature exceeds 30

conform to the local electrical codes and cable manufacturer’s specifications.

Failure to comply could result in an electrical fire.

o

C (86oF), the allowable current drops. Select the cable size to

• Use twis ted wire o r multi-core twisted p air shield ed wire for general signal wires and feedback

signal wires for the encode r.

These wire types help prevent malfunction.

xiv

Page 16

YASNAC PCNC Connecting Manual Preface/Table of Contents

CAUTION

• The current cap ac ity of 24V DC (external pow e r unit for input/output con ta ct s ) is de te rmined by

the number of contact points to be used. When the current ca pa city is low, install an additional

external power un it .

• A n enclosure for this product should be designed and const ruc t ed t o me e t th e fol lo w in g:

1. Use an airtight enclosure.

2. Limit the aver age temperat ure rise of air within the enclosure to less than 10

compared to the ambient te mperature.

3. Use a UL approved fan to circuate the air in a closed enclosure to improve cooling efficiency,

and to prevent abnorm al hea t ri se.

4. Seal the cable inlet, door, etc. completely.

5. Since a CRT display attracts airborne particles due to its high voltage that could result in

malfunction, therefore, provide an enclosure capable of preventing dust from entering the CPU.

6. Ambient magnetic field may cause CRT screen fluctuations, therefore, prevent this with a

layout and magentism shield.

7.In PC NC Unit,printe d c irc ui t bo ards,various units may ac cumlate dust from air,may result in

malfunctio n, therfore ,mak e s tructures to prevent the entry o f du s t.

8.Install packing on the cable inlet,doors,back covers,etc. to eliminate gaps or openings.

Failure to observe these precautions m ay result in product failure.

o

C (50oF)

xv

Page 17

YASNAC PCNC Connecting Manual Preface/Table of Contents

CAUTION

• Connect ea ch unit’s grounding line individually to the housing or grounding plat e.

See the followin g example:

V

,

S

200VA C

LF

.

.

U

M

V

External

Box

.

.

Operation relay

sequence

LF

W

N

C

N

C

AVR

E

E

B

,

F

Grounding at one

point (100Ω / less)

• Select the wire for grou n di n g in conf ormance with local electrical codes.

• Be sure to connect the motor’s grounding terminal to the drive unit’s grounding terminal.

• Ground at one point. (Ground resistance 100 Ω or less).

• Be sure to seperate the grounding line of the unit from the pow e r unit’s grounding line.

Failure to perform correct grounding can lead to malfunction.

xvi

Page 18

YASNAC PCNC Connecting Manual Preface/Table of Contents

APPLICATION SAFETY PRECAUTIONS

CAUTION

• When operating the unit, be sure to obs erve the fol lo w ing electrical safety procedure s

1.Do not touch the unit or terminal wire while the unit is ope rating.

2. Even though the unit has been turned OFF, it is still in charged status, so do not touch any

component parts for a minimum of five minutes.

Failure to observe this precaution could result in product failure, fire and/ or personal injury

or death due to electrical shock.

• Do not mishandle, pinch or ca use exc essive stress to cables.

Excessive load on the cable could cause electric shock.

• While the unit is turned O N, never touch any rotati ng pa rts.

Failure to observe this precaution could result in personal injury.

Never modify t he product

Free from explosiv e gases or steam

Free from oil,organic solv ent,corrosive liqui ds et c.

Vibration under (0.5 G).

Never disassmb le or modi fy the compon ents of the unit.

Never change the set values of the components and any variable resistors used in control panel.

Failure to observe this warning could result product failure, fire and/ or personal injury

or death due to electrical shock.

xvii

Page 19

YASNAC PCNC Connecting ManualChapter 1: General

Installation And Electrical Connection

This section addresses the basic system: configuration, specifications,

enclosure design, electrical connections and installation.

1

General

1.1 System Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 2

1.1.1 System Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 2

1.1.2 Connection between Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 3

1.1.3 Connector Layout NC side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 4

1.1.4 Connector Layout PC side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 5

1.2 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 6

1.3 Thermal Design of Enclosure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 7

1.3.1 Thermal Design. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 7

1.3.2 Dust Proof Design. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 11

1.3.3 Countermeasure Against Magnetic Fields . . . . . . . . . . . . . . . . . . . . . . . . .1 - 12

1.4 Cable Clamp and Shielding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 13

1.5 Packaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 14

1.5.1 General Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 14

1.5.2 Installation of PCNC Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 15

1.5.3 Installation of Feed/Spindle Servopacks. . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 16

1 - 1

Page 20

YASNAC PCNC Connecting ManualChapter 1: General

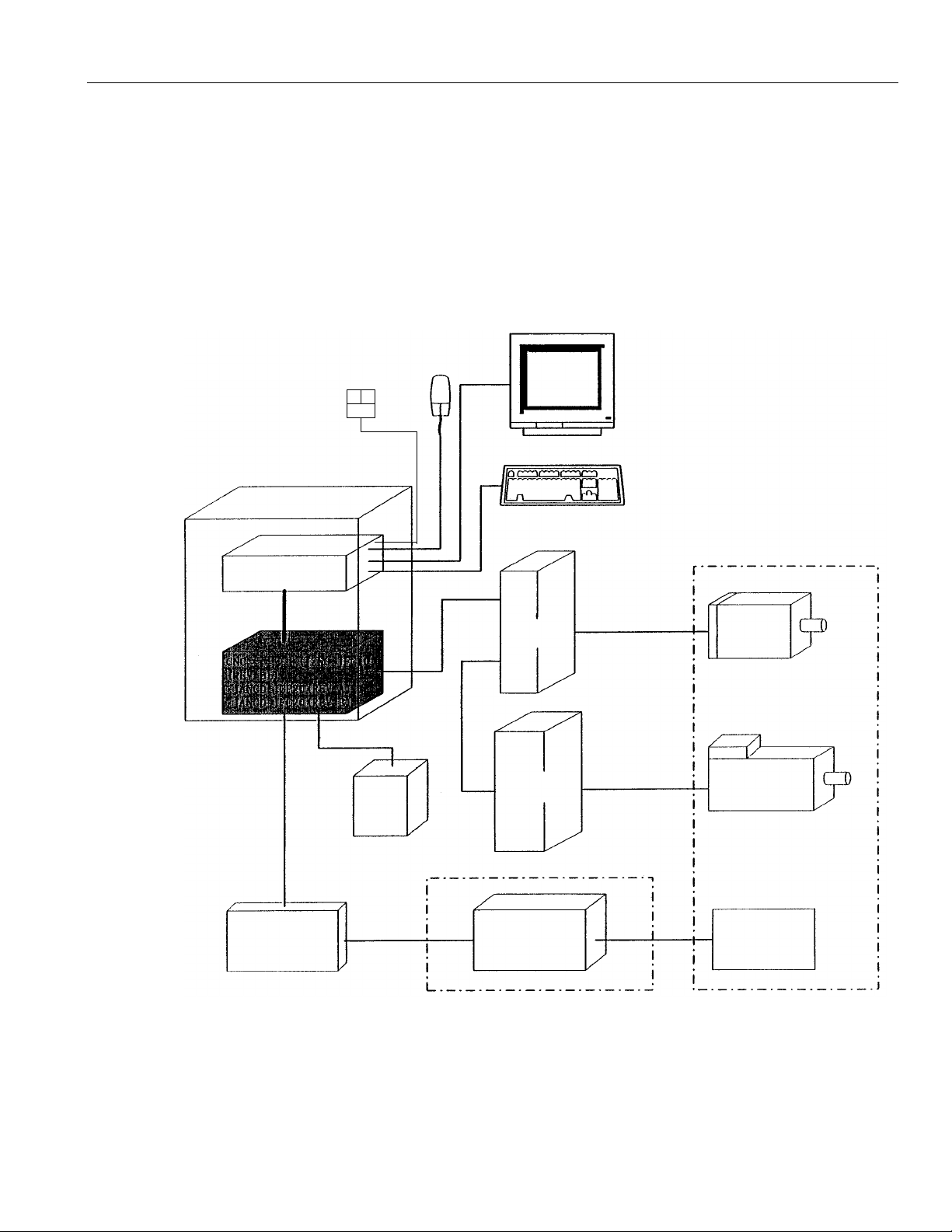

1.1 Syste m C onfi gur ati on

1.1.1 System Confi gur ati on

The PCNC unit of the YASNAC which i s hat che d i n the dia gram below is compo sed of two

boards: JCP20 and JFC20 (JZNC-JFC10). It is inserted to a PC extended bus (ISA) inside PC

case.

Its I/O module, servo uni t, spi ndl e dri ve and motor are the same as those of the YASNAC

J100 CNC UNIT.

FDD

PC NC case

PC

ISA bus

JFC10

DC

+24V

power

Mouse

Monitor with Touch screen

Keyboard

Feeding

servo unit

Spindle

drive unit

Machine

Feeding

motor

Spindle mo tor

I/O Module

High voltage

Device

machine side

Figure 1.1.1 YASNAC PCNC System Structure Diagram

1 - 2

on

Page 21

YASNAC PCNC Connecting ManualChapter 1: General

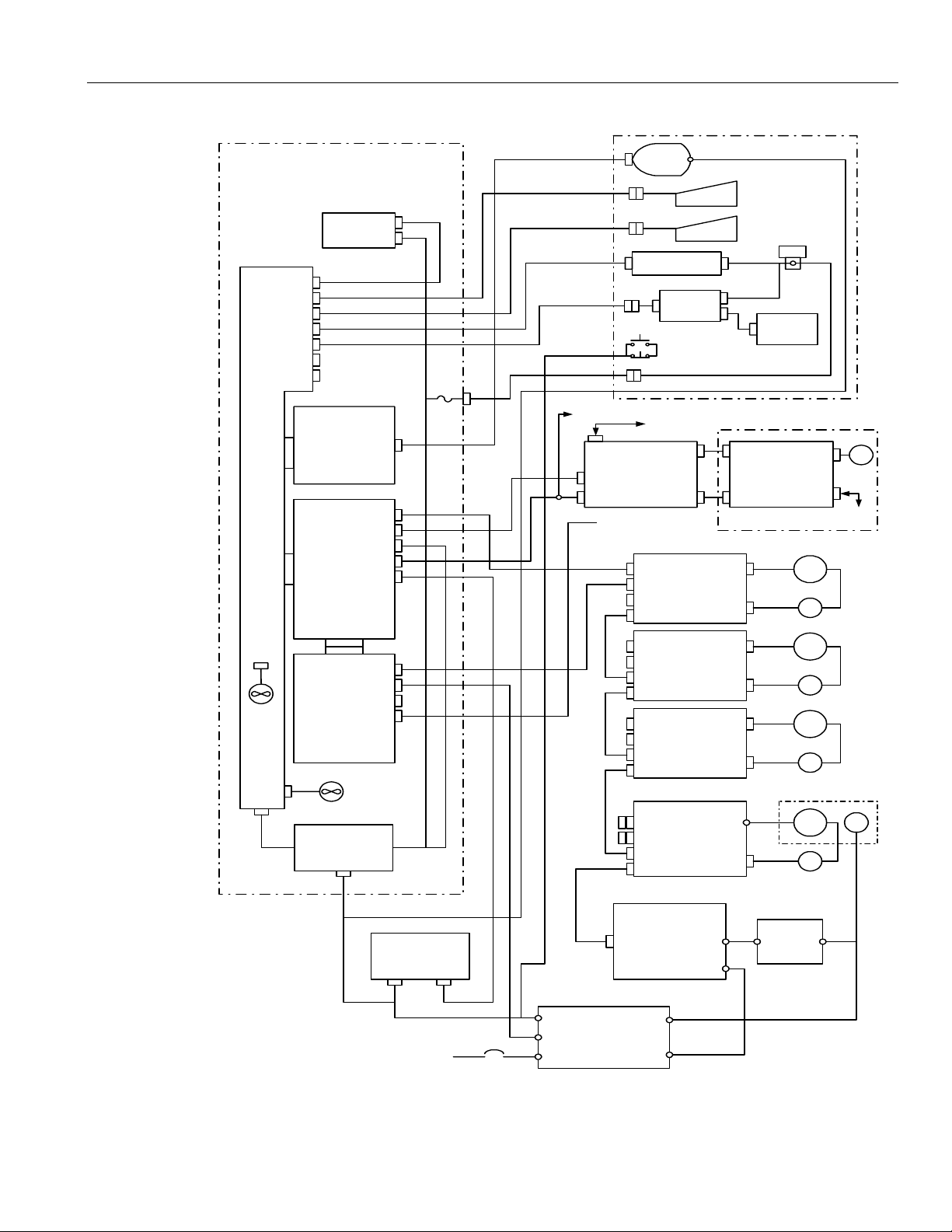

1.1.2 Connection Between Devices

CPU RACK UNIT

DATA

HDD

INP UT

PWR

VIDEO

CN01

CN02

CN03

CN04

CN05

CN11

CN12

CN13

CN14

CASE FAN

OUTOUT

PGS

(PO W E R

GOOD

SIGNAL)

NC POWER

SUPPLY

INPU T OUTPUT

AC230V

DC

OUT

NFB

ATX

MOTHER

BOARD

PS/2 MOUSE

PCI

ISA

FAN1

CPU

FAN

FAN3

IDE I/F

KBD

COM2

FDD

COM1

LPT1

VIDEO

CARD

JFC 20

JCP 20-1

PC PO W E R

SUPPLY

24VDC FOR

MACHINE I/O

CN1~6

I/O BOARD

FOR MACHINE SIGNAL

(FC8 X X )

CN11

CN13

SENSOR SIGNAL

CONVERTER UNIT

5CN

INPUT POWER UNIT

TB2

TB1

SVM

CRT

KEYBOARD

MOUSE

FDD

TS

CONTROL

SERVO ON

SHUT DOWN

MACHINE

CONTROL

SIGNALS

CN14

CN12

SERVO UNIT

SGDC-**AJA

4CN

1CN

Z AXIS

52CN

51CN

SGDC-**AJA

4CN

1CN

Y AXIS

52CN

51CN

SGDC-**AJA

4CN

1CN

X AXIS

52CN

51CN

C1MR-M5N

4CN

1CN

52CN

51CN

C1MR-MR5N

SVM

A1/A2

PWRDATA

TOUCH

SCREEN

MAC HINE O P . PAN EL I/O

CN5

I/O BOARD

FOR MACH INE

OP. PNL.

(JSP02/04)

CN3

3CN

2CN

3CN

2CN

3CN

2CN

2CN

REACTOR

R/S/T

A1/A2

X0100**

TB3

CN1

CN7,8,9

MACHINE PANEL

M

PG

M

PG

M

PG

UAASK*-**FZ*INVERTER UNIT

M

PG

SIGNALS

SGMG -

**A2AB *

FA

HPG

N

Figure 1.1.2.1 Detail Con nection of PCNC Unit wit h various devices.

1 - 3

Page 22

YASNAC PCNC Connecting ManualChapter 1: General

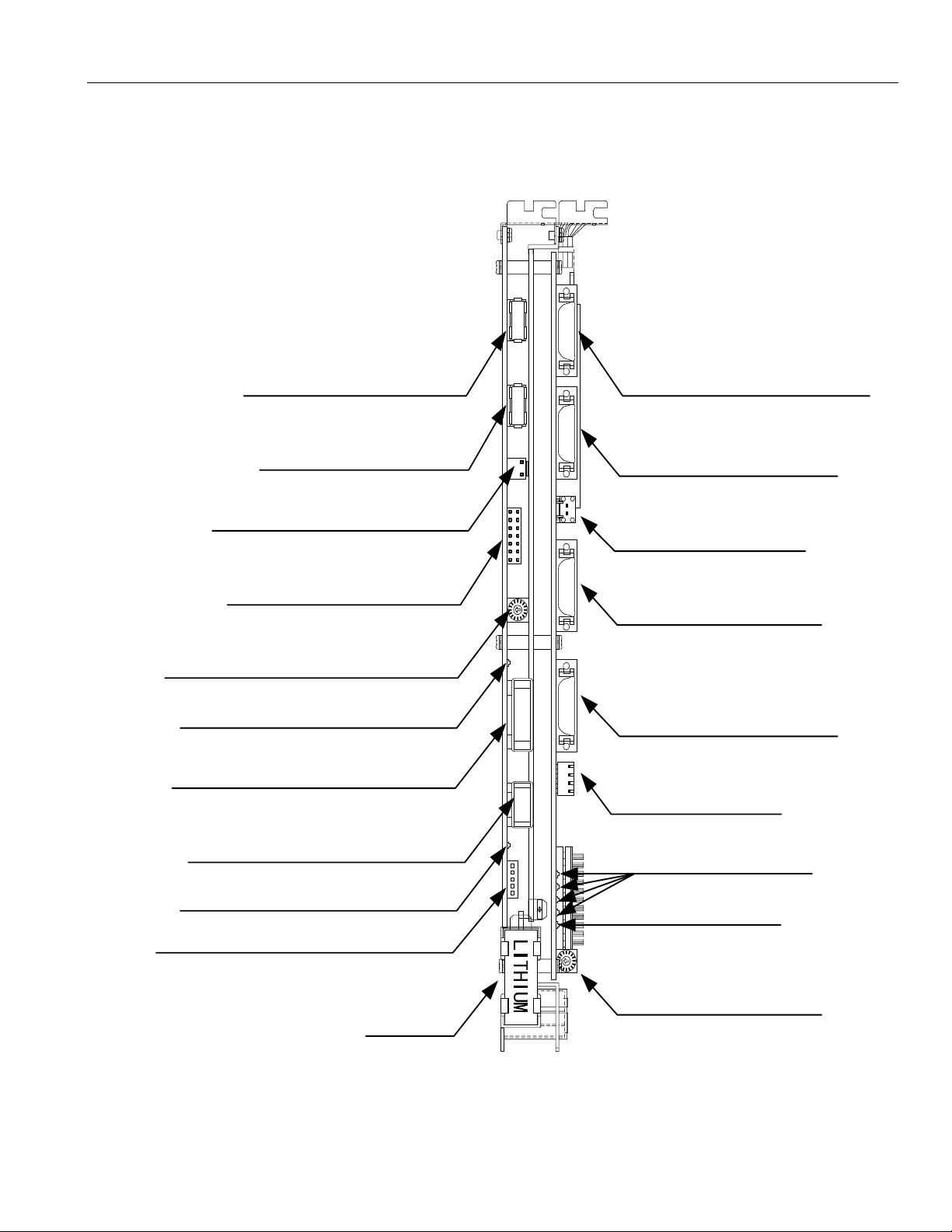

1.1.3 Connector Layout NC Side

The following figure gives the detail Conne ct ors Layout of YASN A C JZNC-JFC10 board.

Servo controller connector (CN01)

I/O module connecto r (CN02)

Power good signal connector (CN03)

Interruption setting short pi n (S11)

Memory address setting r otary swi t ch (S12)

I/O module po wer output ver ificati on L ED

I/O module power o utput connector (CN04)

Servo controller I/O connector (CN11)

Power On/Off connect or (CN12)

Fuse (HM03, 0.3A) (F1)

RS232C connector (CN14)

Direct IN/OUT connector (CN14)

System load switch (S1)

I/O module power input connector (CN 05)

I/O module power in put verif icat ion LED

Battery power reply supply connector (CN06)

Battery

FIGURE 1.1.3.1: Details Layout of YASNAC JZNC-JFC10 Board

System load switch (S1)

(from top: 1, 2, 3, 4)

Battery alarm LED

System load rotary switch (S1)

1 - 4

Page 23

YASNAC PCNC Connecting ManualChapter 1: General

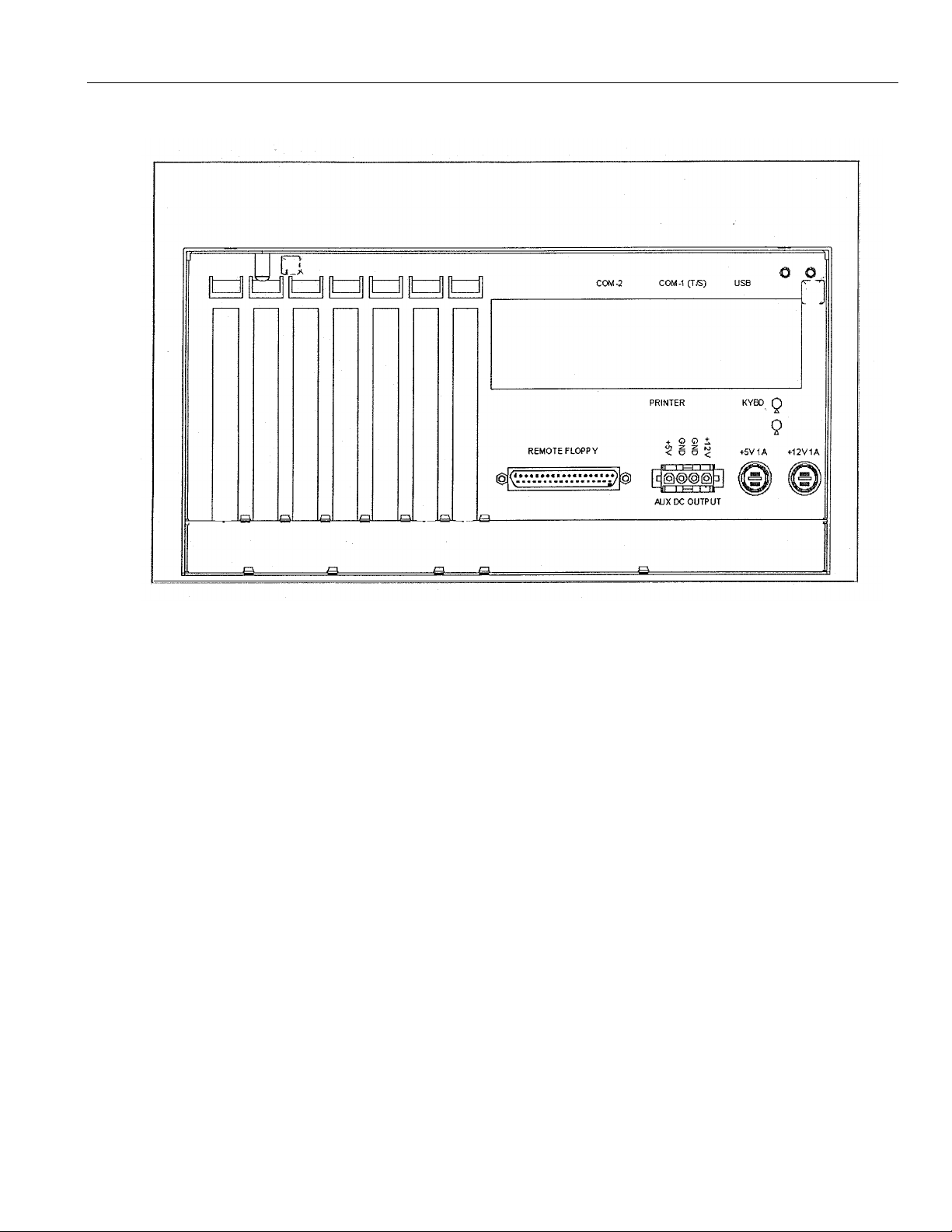

1.1.4 Connector Layout PC Side

FIGURE 1.1.4.1: Connector Layout on the top view of the PCNC CPU rack

1 - 5

Page 24

YASNAC PCNC Connecting ManualChapter 1: General

1.2 G ene ral Specifications

The enclosure shoul d be designed to meet all of th e following conditi ons.

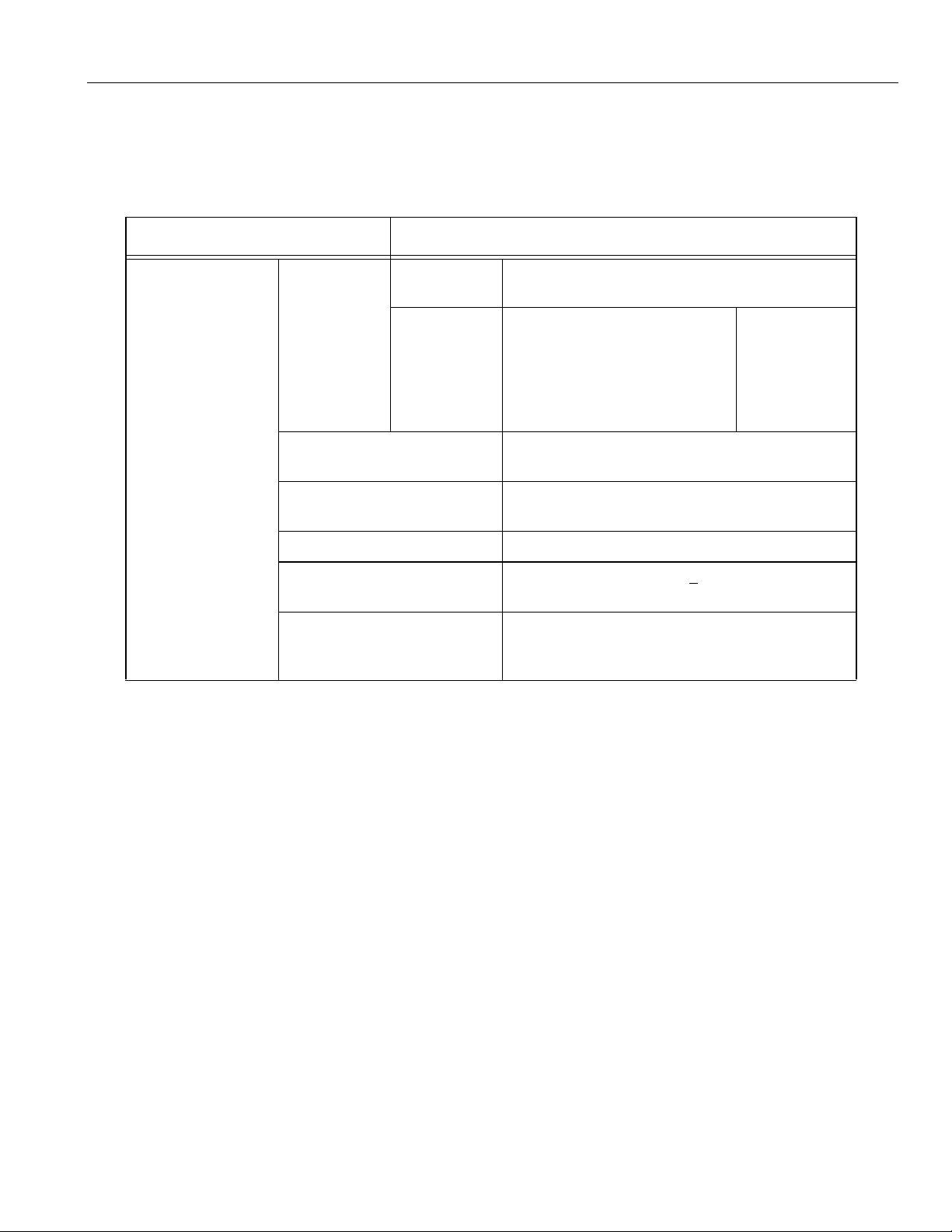

Table 1.2.1: Specifica t i o ns

Item Specifications

Ambient Conditions

Storage and

Transportation

Temperature*

Humidity 20% to 80% RH (with operation)

Vibration

during operation

PCNC Unit input power supply

Power Supply Unit UPS000004

Operating

(around

enclosure)

Others Free from dust, coolant or organic solvent

PCNC unit

I/O module

Servopack

14” Color mon itor with

touch screen

10% to 90% RH (with non-operation)

• Input power supply voltage: 180V-264VAC

• Frequency: 47 Hz to 63 Hz

• Momentary interruption: 0.5 cycle (0 VDC)

o

C to +65oC

-15

Less than 4.9m/s

+24VDC+

180V-264V AC

10%

o

0

Note: Avoid installing th e control panel in a loca t ion subject to direct sunlight, ne ar heat

generating devices or outdoors even if the ambient temperature is within the specified

range.

C to +53oC

1 - 6

Page 25

YASNAC PCNC Connecting ManualChapter 1: General

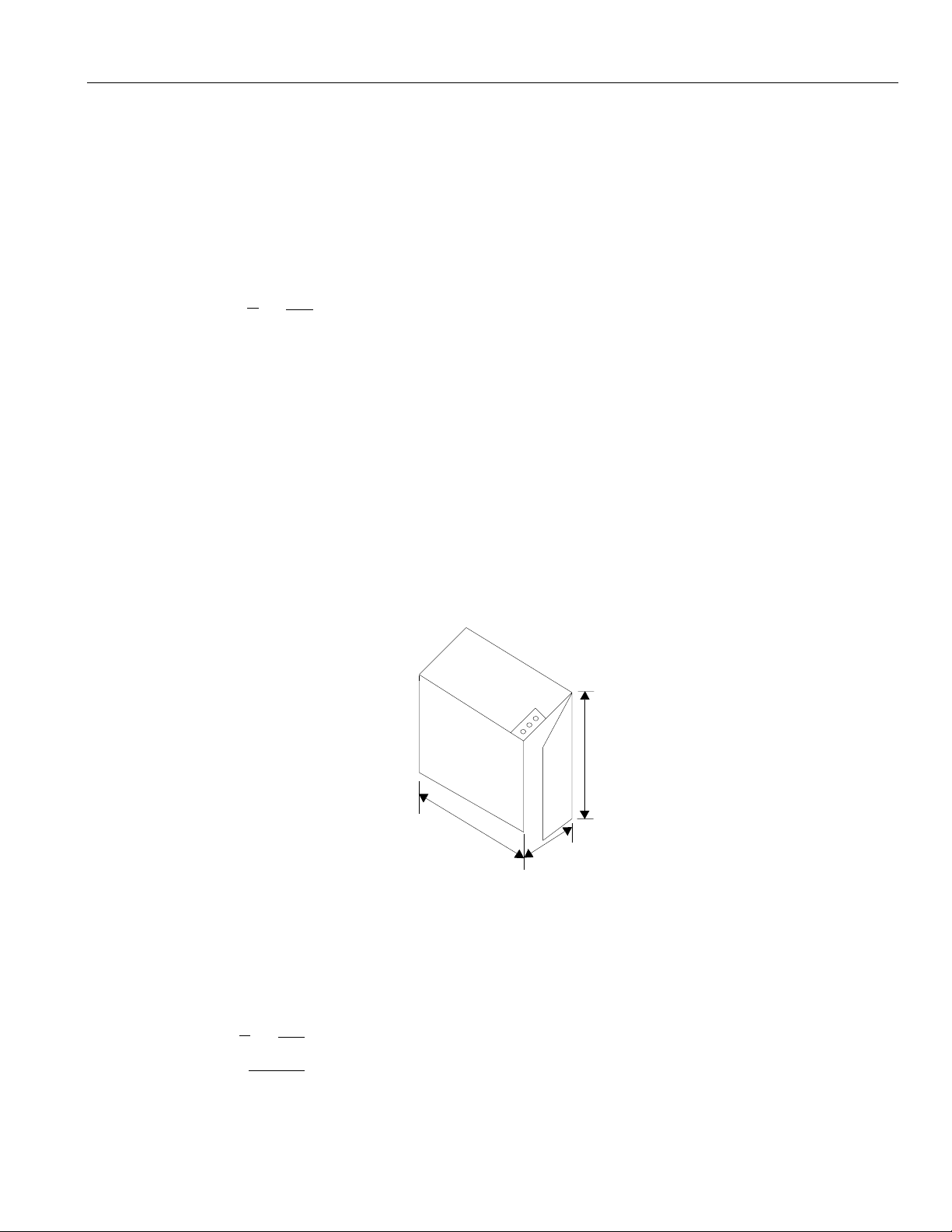

1.3 The rm al Design of Enclosure

1.3.1 Thermal Design

Design of the encl osure shoul d be made on the basis that the ave rage temperature increase of

air within the encl osure (containing t he PC NC unit and other components) should be 10

below the external air temperature.

(1) Temperatu re In cre ase within th e Enclosure (Average Temperature Increase )

The internal temperature increase (sheet metal enclosure) is generally as follows:

P

∆Τ=

P

=

qe

.

k A

where,

o

C

∆Τ : Interna l temperature incr e ase (

o

C)

P : Heat generation in enclosure (W)

qe : Enclosure heat percolation ratio (W/

k : Heat transit ratio of sheetmetal (W/m

6W/m

A : Efficient heat diffusion area of enclosure (m

2o

C: With interna l c o oling fan

4W/m

2o

C: Without internal cooling fan

o

C)

2o

C)

2

)

1200

All dimensions in millime te rs

800

Fig 1.5 Dim ensions of Enclosu re

700

Efficient heat diffusion a rea is in dependently loca ted, so bottom area is excluded.

A=4.16m

2.

If the heat gener at ion in the enclosure i s supposed to be 246W (113 W in CNC

portion, 104 W in servo portion, and 29 W in I/o portion),

P

∆Τ=

=

P

=

qe

246

6 x 4.16

.

k A

= 9.9 (oC)

1 - 7

Page 26

YASNAC PCNC Connecting ManualChapter 1: General

(2) Heat Exchanger Cooling Capacity

Where coolin g capacity is insufficie nt eve n wit h a c irc ulating fan mount ed in the

enclosur e, Yaskawa can provide heat exchangers.

Table 1.3. 1.1: Heat Exchang e rs

Heat Exchanger Cooling Capacity External Dimensions (mm)

o

REX1550 100W /10

HEATEX02 250W /10

C 295 width x 890 height x 50 depth

o

C 440 width x 924 height x 50 depth

The heat generation indicat ed in the above tabl e is the allowabl e heat generated wh en the

internal tempe ra ture increase in the enclosure is limited t o unde r 10

o

C.

Example: Allowable Heat Generated in the Enclosure with Heat Exchanger

The amount of internal heat generated to make th e internal temperature under 10

o

the enclosur e is e quipped with a HEATEX02 Heat E xchanger is expre ssed by the

following equation:

.....................................................

P= k.A.∆Τ+ 250 W/10oC

= 6 x 4.16 x 10 + 250

o

= 499 W/10

C

therefore, it is ne ce ssary to be under 499W.

(3) Mounting Heat Exchanger

Heat exchange r should be mounted on the enclosure pro vided by the machine tool

builder. Fig. 1.5 shows a mounting examp le . Mo unt the exc ha nger so that the internal air

is drawn from the upper portion and discha rged th rough the lower port ion, while external

air is drawn in from th e lo w er portion and discharged thro ugh the upper portion.

C when

Internal air

Enclosure

External air

Heat exchanger

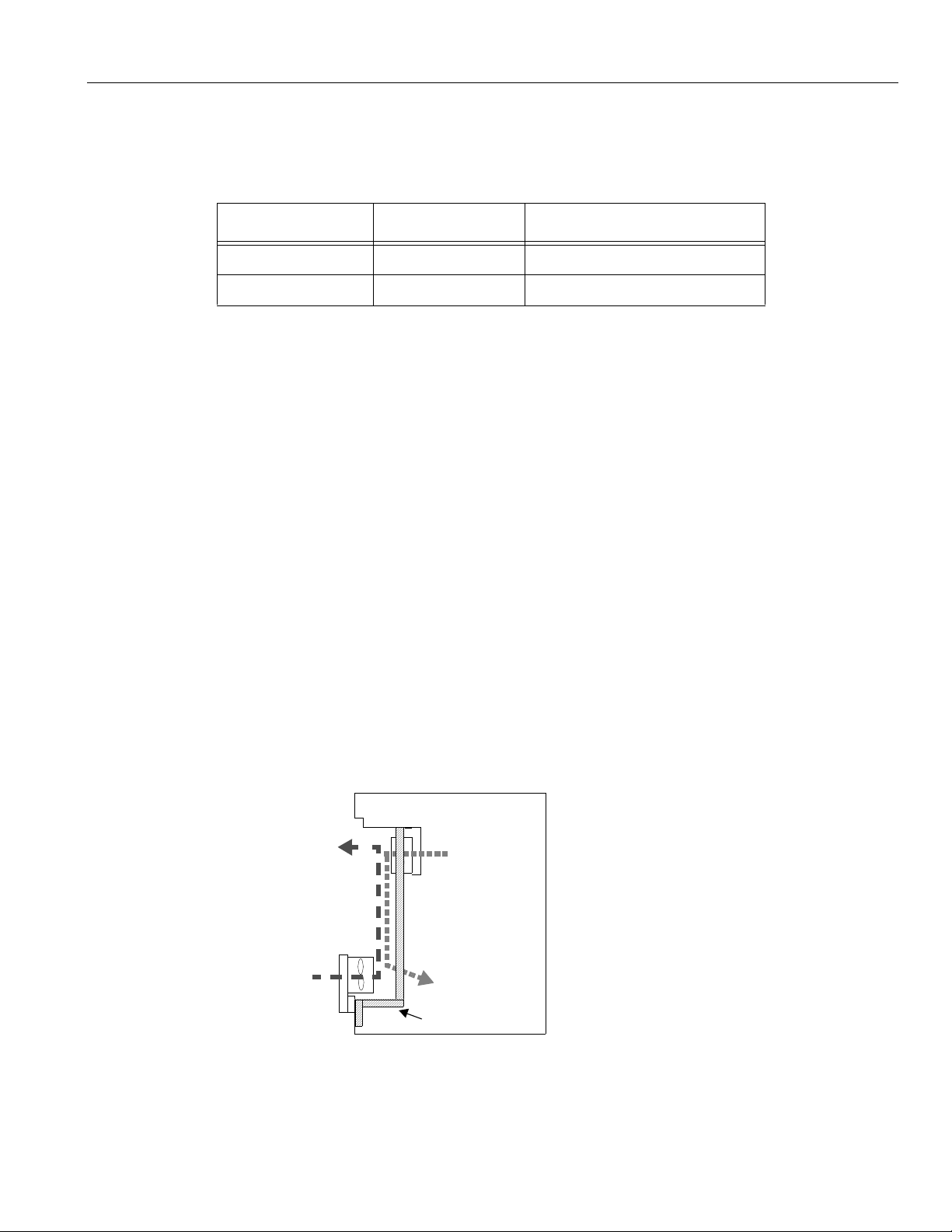

Fig 1.3.1.1: Mounting of Heat Exchanger on the enclosure made by Machine builder

1 - 8

Page 27

YASNAC PCNC Connecting ManualChapter 1: General

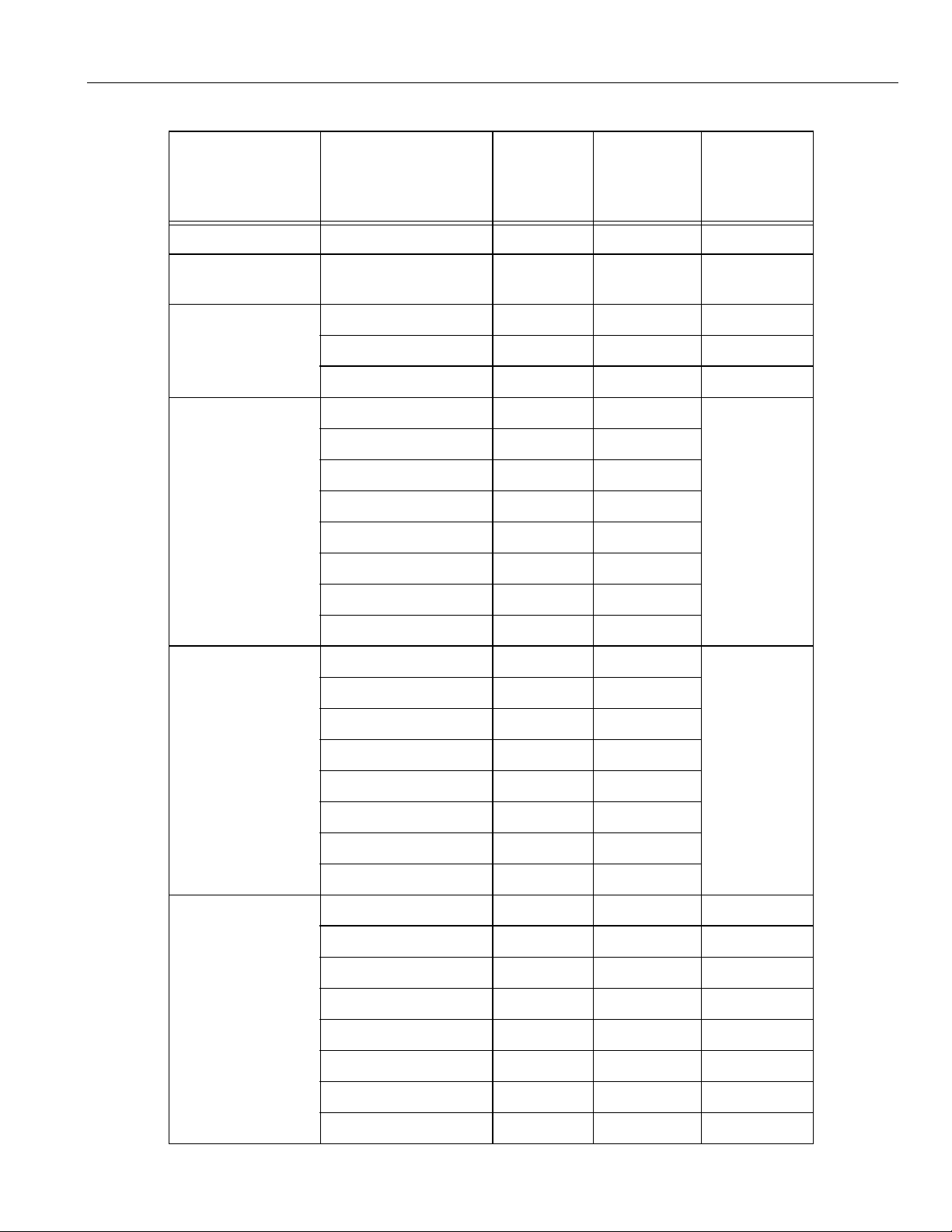

(4)Heat Gene rat ion by Respective Units

Unit Type Total Heat

PCNC rack JZNC-JPCRKM_-_

14” Color CRT with

Touchscreen

I/O Module

Converter

JZNC-JPCOP-_ _ _

JANCD-FC810* 29 29 0 JANCD-FC860* 29 29 0

JANCD-FC861* 14.5 14.5 0 CIMR-MR5N23P7 84 44 CIMR-MR5N25P5 84 44 CIMR-MR5N27P5 119 61 CIMR-MR5N2011 152 70 CIMR-MR5N2015 204 88 CIMR-MR5N2018 273 108 CIMR-MR5N2022 335 132

Generation

(W)

Internal

Heat

Generation

(W)

Minimum

Wind

Velocity for

Cooling

2.5

Spindle Inverter

Reactor

CIMR-MR5N2030 392 160 CIMR-MR5N23P7 84 44 CIMR-MR5N25P5 185 58 CIMR-MR5N27P5 244 77 CIMR-MR5N2011 307 89

2.5

CIMR-MR5N2015 454 119 CIMR-MR5N2018 565 144 CIMR-MR5N2022 717 180 CIMR-MR5N2030 869 219

UZBA-B 20A 0.53 mH 35 35 0 UZBA-B 30A 0.35 mH 45 45 0

UZBA-B 40A 0.2 65 mH 50 50 0

UZBA-B 60A 0.18 mH 65 65 0 UZBA-B 80A 0.13 mH 75 75 0

UZBA-B 90A 0.12 mH 90 90 0 UZBA-B 120A 0.09 mH 90 90 0 UZBA-B 160A 0.07 mH 100 100 0

1 - 9

Page 28

YASNAC PCNC Connecting ManualChapter 1: General

Unit Type Total Heat

SGDC-05AJ A 28 10 SGDC-10AJ A 48 12

Servo Unit

SGDC-15AJ A 73 15 SGDC-20AJ A 108 18 SGDC-30AJ A 148 22 SGDC-50AJ A 208 28

1. The heat generated by the CNC unit varies depending on the addition

POINT

of options. The heat generated by the I/O module varies with I/O

status.

2. Internal heat generation is the heat remaining inside of the enclosure

when the servo uni t’s fin is exposed outside of the enclosure, and

when the external air is applied to the fin at greater than 2.5m/s

Generation

(W)

Internal

Heat

Generation

(W)

Minimum

Wind

Velocity for

Cooling

2.5

3. Thermal design of th e e nclosure to house the servo unit varies with

machine specifications, but is acknowledged to use a value of 70% of

the load fa ctor.

1 - 10

Page 29

YASNAC PCNC Connecting ManualChapter 1: General

1.3.2 Dust proof Design

Dust proof Design and Construction

PCNC units and other components (especially CRTs) housed in a machine tool enclosure are

exposed to an environment with airbo rne matter, e.g., dust. oil, coolant mi st, etc.Since these

elements could cause control component malfunction, enclosures should be designed and built

to prevent such m atter from entering as follo w s:

• Use an air-tight enclosure.

• Seal the cabine t inlet with packin g mat erial. Refer to Fig. 1.3.2.1.

• Secure the rear do or li d w ith packing material . Refe r to Fig, 1.3.2.2.

• The enclosure’s front surfa ce s w ith PCN C operating panels and are dust proof, but do not

install them where liquid coolants are present. The periphery should be sealed with suitable

materials.

The CRT unit’s high voltage will attract airbo r ne dust, so w hen mounting the CRT unit’s

pendant box please take note of the following:

1. Seal the cab le inl et , do or, rear lid op ening clearance s w it h packing materi al .

2. The CRT Unit’s mounting surface has been factory sealed.

3. Seal any other op enings.

4. Since oil wil l enter the encl osure through screw holes an d collect on the

internal ceiling surface, apply suitable packing material to seal these holes.

Metal fitting

Packing

Cable

Fig. 1.3.2.1 Cable Inlet

1 - 11

Page 30

YASNAC PCNC Connecting ManualChapter 1: General

Pendant box

Fig. 1.3.2.2 Door Packing

1.3.3 Counterme asures against Magne ti c Fields

The CRT screen’s d isp lay may fluctua te due to ambien t magnetic fiel d s. To prevent this, keep

magnetic generating materials, e.g., transformers, reactors, fans, electro-magnetic switches,

solenoid relays, exchange power cables, etc. a minimum of 300mm from the CRT.

The value of 300mm is a general standard and coul d va ry depending on the situation,

therefore, be aw a re of the presence of magnetic generating sou rces when positioning the

Packing

CRT unit.

1 - 12

Page 31

YASNAC PCNC Connecting ManualChapter 1: General

1.4 Cable Clamp and Shielding

If the cables wired to the PCN C un it nee d to be shiel de d, the y mu st be grounded using the

grounding plate wit h cable clamp hardware. Because this cl amp serves both as cable support

and shielding, they must be installed carefully so that safe system motion can be assured.

1. Peel the cable coating to expose the cable where it connects the grounding plate with the

cable clam p.

2. The cable clamps (with the cables) must be installed to the grounding plate as shown in the

following diagram :

VGA

POWER

DATA

POWER

DATA

CRT

Touch

Panel

FDD

Keyboard

Mouse

2m max.

VGA

EX.DC

PARALLEL CD-ROM ZIP

24VDC

COM1

YENET IO

FDD

PS/2

SERIAL

CARD

(OPTION)

CPU

RACK

IPU

Drive IO

YENET D

IPU

Drive IO

YENET

YENET

24VDC

Drive

Pack

IO

Ferrite Core

Shield Clamp

YENET

24VDC

Last IO

FIGURE 1.4.1: Yasnac PCNC Shielding and Ferrite core clamping points

1 - 13

Page 32

YASNAC PCNC Connecting ManualChapter 1: General

1.5 Packaging

When designing the enc l osure to house the CNC unit and ot he r equipment, the con struction

should provide for th e fol l ow ing:

1.5.1 Genera l Notes:

• The enclos ure must be ai r-t ight.

• Internal layout of c omponents should pr ovi de for ease of mounting, inspection maintenance,

and removal.

• There should be a physical gap of 100mm be tween component s and the enclosure’s wall so

not to restrict air flow for coolin g.

• If the operation panel is built into the machine’s enclosure door, provisions to prevent vibra-

tion from the machine is necessary.

• The average temperature increase in the enclosure should be limited to 10

o

C compared to the

external ai r.

• Use a fan to cir cula te ai r to impr ove co oli ng e f fi cien cy w ith in t he encl os ure . As a g ener al r ule,

the fan should blow a ir upward at 1m/s over the p. c. boa rd ’s surface.

• The fan should not bl ow ai r directly onto the p.c . board.

• To prevent malfunctions due to noises, kee p noi se generating eleme nt s 10m aw ay from AC

power supply cables an d com ponents (over 90VDC).

• When wiring, separate AC from DC lines, and separate primary side from the transfor mers’s

secondary side, line filter, etc.

1 - 14

Page 33

YASNAC PCNC Connecting ManualChapter 1: General

1.5.2 Installing the PCNC Unit

• The PCNC unit has a bui lt -i n fan that blows air (1 m/s) over the upper side of the PCNC unit.

• Provide clear ances of 50 mm min imum above the 100 mm minimum bel ow the PCNC unit for

ventilation and maintenanc e.

JZNC - JFC10

)

P

)

S

/

O

/

I

V

S

V

(

R

1

D

0

(

N

1

C

1

N

C

)

O

I

R

(

2

0

)

N

U

C

P

I

(

2

)

1

S

N

C

G

P

(

3

0

N

C

1

F

)

C

L

P

M

O

C

(

3

1

N

C

V

5

+

)

)

V

N

4

I

2

D

+

(

/

4

0

V

4

5

1

N

+

N

C

C

T

U

O

(

1

W

S

)

V

4

5

2

0

+

N

C

N

I

(

V

4

2

+

)

T

A

B

(

6

0

1

N

C

2

3

4

T

A

B

3

W

S

DETAIL 1

]

0

4

.

0

[

6

1

.

0

1

R2.54 [0.10]

R6.35 [0.25]

Y

R

E

T

T

A

B

FIGURE 1.5.2. 1: Mounting of PCNC Unit

1 - 15

Page 34

YASNAC PCNC Connecting ManualChapter 1: General

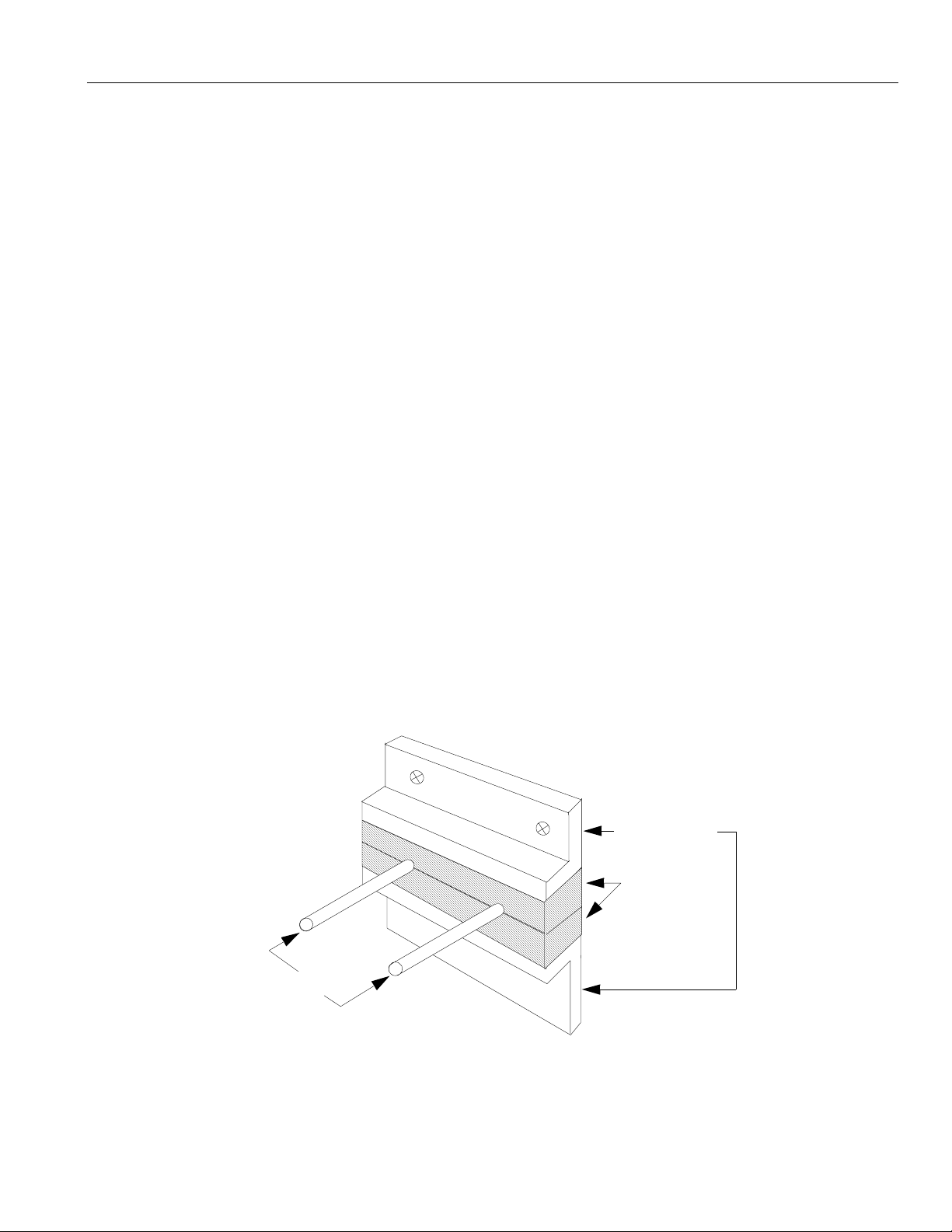

1.5.3 Installing the Feed/Spindle Servopacks (Amplifiers)

• The Servopack is t o be w all-mounted vert ically using screws or bolts.

• Locate the Servopack so that inspection, maintena nc e and part replacem e nt can be easily

made.

• The Servopack w i ll generate some heat, so mou nt wi th sufficient space around the unit .

• To reduce heat gene rat ion, mount the cooling fin external to the Serv opa ck’s enclosure with

the fan blowing air on the cooling fin @ 2.5m/s.

• Internal air should not be blown directly ont o th e Servopack since this could cause dust contamination.

Cooling fin

External Air

Fig. 1.5.3.1 Cooling Fin Installed Outside of Enclosure

Feed Servopack

Converter & Inverter

1 - 16

Page 35

YASNAC PCNC Connecting Manual Chapter 2: Power Supply

2

Power Supply Connection

Connecting Power Supply To Compo nent s.This section addresses the following electrical

connections: power supply to components, detailed connections and LED connections.

2.1 Connection between Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 2

2.1.1 Power Supply specifications for PCNC and I/O units . . . . . . . . . . . . . . . .2 - 2

2.1.2 Power Supply connections to PCNC . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 3

2.1.3 Power Supply Connections to PCNC and I/O units . . . . . . . . . . . . . . . . . .2 - 3

2.1.4 Power Supply to Converter unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 4

2.2 Detailed Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 5

2.2.1 Power Supply to PCNC unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 5

2.2.2 Power Supply to Converter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 7

2.2.3 Example of Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 8

2.3 LED for Power Input /Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 9

2.3.1 LED for PCNC Power Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 10

2 - 1

Page 36

YASNAC PCNC Connecting Manual Chapter 2: Power Supply

2.1 Connection between Devices

This section descri bes connections betw ee n devices, connector nu m be rs and connector type. For

power supply connection use a commercially available standard power supply or Power Supply

Model UPS000004.

2.1.1 Power Supply specifications for PCNC Unit and I/O units.

Power supply connec ti on to the PCNC unit differs depend ing on whether using a

commercially a vai l abl e standard power supply for both PCNC and I/O units or use a

recommended po w er suppl y uni t on ly fo r PCN C a nd use ano th er power supply for I/O units.

(1) Selection of Power Supply

(a) U sin g a Standard Power Supply

Excluding +24 V pow e r supply for I/O input and out put,90W is required for the total

PCNC system. Select a suitable power supply with consideration for temperature

derating charac te ri sti cs.

• Power supply for I/O input and output

Select a suitable power supply by referring to the calculation example shown in

Section 10.3.3 “Power Supply for I/O Signal”.

•Power supply for PCNC Unit

In order to provid e 90W power capacit y or greater when th e in te rnal panel

temperature is 55oC, a +24V output power supply with ca pa city of 150W and

greater is required: (Recommended UPS000004 is rated for 150 Watts.)

Select a power supply with the following specifi ca tions:

Power capacity of 150W or greater.

Power supply with the derating characteristics of 60% or greater when the internal

panel temperat ure is 55

o

C. (150W x .06 = 90W)

•Recommended Power Supply:

UPS000004

Operating Condi tions:

o

At 50

At 55

C - 100% ( Out put rated Curre nt 6.5 Amps)

o

C - 80 % ( Derated Output Current )

For more details conta ct the pow e r su ppl y manufacturer.

2 - 2

Page 37

YASNAC PCNC Connecting Manual Chapter 2: Power Supply

2.1.2 Power Supply Connections to PCNC

CNC unit Power supply unit(UPS00004)

JANCD-JFC10 CN05(1-178293-2)

+24VDC

1+24V

Stabilized power supply

20

3 FANALM

V

24

*Note : Derating for ambient te m pe r at ure should be considered.

FIGURE 2.1.2.1 Power Supply to PCNC Unit when using recommended Power Supply Unit.

2.1.3 Power Supply Connections to PCNC and I/O Units

UWR00306

PCNC UNIT

JANCD-JIF10

CN05 CN04

+24VDC

5V DC & GND

*

Terminal

Block

5V

UWR00307

+24VDC+

3.0 A min. (Note*)

24V

10%

CN 13

JANCD-FC8_ _

CN 14

UWR00305

CN 13

JANCD-FC8_ _

AC Power Supply

180V-264V AC

Single phase

CN 14

24V DC

+24V supply

(UPS00004)

GND

CN 05

JSP04/JSP02

Machin e Tool

Builder supply

CN 06

+24V according

to I/O

requirements.

* To be provided by Mach ine Tool builder

FIGURE 2.1.3.1 Power Supply to PCNC unit when using re c omm e nded Power Supply Unit

2 - 3

Page 38

YASNAC PCNC Connecting Manual Chapter 2: Power Supply

2.1.4 Power Supply to Converter Unit

Converter unit

MC

CIMR-MR5

L

FIGURE 2.1.4.2 Connection between Devices

Table 2.1.4.2 Component Selection for Power Supply Circuit

Converter

Type CIMR-

MR5N2

ooo

3P7 3.7 4.6 7 30A 20A

Applicable

Capacity

(kW)

Output

Capacity

(kW)

Power

Source

Capacity

(KVA)

Breaker

1MCCB

TXR

MCCB

Electro-

magnetic

Contactor

1MC

Power supply

Reator*

1L

20 A 0.53 mH

(x 002491)

(x 010057)

5P5 5.5 6.8 9 40A 30A

7P5 7.5 9.3 12 50A 40A

011 11 13.6 19 75A 60A

015 15 18.6 24 100A 75A

018 18.5 22.9 30 125A 100A

022 22 27.2 36 150A 125A

030 30 37.1 48 175A 150A

30 A 0.35 mH

(x 002492)

(x 010058)

40 A 0.265 mH

(x 002493)

(x 010059)

60 A 0.18 mH

(x 002495)

(x 010060)

80 A 0.13 mH

(x 002497)

(x 010061)

90 A 0.12 mH

(x 002498)

(x 010062)

120 A 0.09 mH

(x 002555)

(x 010063)

160 A 0.07 mH

(x 002556)

(x 010064)

*Note: Code in upper row: with leads

Code in lower row : with terminals

2 - 4

Page 39

YASNAC PCNC Connecting Manual Chapter 2: Power Supply

2.2 Detailed Connection

This section desc rib es th e de ta iled connection of power supply.

2.2.1 Power Supply to PCNC unit

CNC unit Power Supply Unit (UPS000004)

JANCD-JFC10 CN05(1-178293-2)

1+24V 20 3 FANALM

V

24

+24VDC Stabilized

power supply

+24VDC+

3.0 A min. (Note*)

10%

ó

AC Power Supply

180V-264V AC

Single phase

*Note: Derating for ambient temperature should be considered.

JANCD-JFC10 CN05

Connector specifications

Connector : 1-178288-3

(3PIN)

Manufacturer : AMP

UPS000004

Connector specification

Criimp terminal : 1.25 -4

Recommended cable : VCT type, 2mm2 x 5 cores (DE8402398)

L

N

FG

+24V

0

V

24

1

Select proper

cable fit for the

power supply

2

terminal.

200 VAC Single-phase

FIGURE 2.2.1.1 Power supply connections to PCNC Unit and 24V DC Power supply unit.

2 - 5

Page 40

YASNAC PCNC Connecting Manual Chapter 2: Power Supply

ó

UPS000004

24 DC Power

Supply

L

N

LF

180V~264V

1Ph AC

PCNC CPU

L

N

FIGURE 2.2.1.2 Power supply connections to PCNC Unit and 24V DC Power supply

PCNC Power Socket and Frame ground details

JZNC - JFC10

)

P

)

S

/

O

/

V

I

S

(

V

R

1

D

0

(

N

1

C

1

N

C

)

O

I

R

(

2

0

)

N

U

C

P

I

(

2

)

1

S

N

C

G

P

(

3

0

N

C

1

F

)

C

L

P

M

O

C

(

3

1

N

C

V

5

+

)

)

V

N

4

I

2

D

+

(

/

4

0

4

V

1

5

N

+

N

C

C

T

U

O

(

1

W

S

)

V

4

5

2

0

+

N

C

N

I

(

V

4

2

+

)

T

A

B

(

6

0

1

N

C

2

3

4

T

A

B

3

W

S

FG

LF - Line F ilter. Use line filter. For select ion of Line f ilter

refer Appendix-1.

Note: Use 3.5mm sq or more for the Frame ground wire

DETAIL 1

]

0

4

.

0

[

6

1

.

0

1

R2.54 [0.10]

R6.35 [0.25]

Y

R

E

T

T

A

B

FIGURE 2.2.1.3 PCNC unit frame ground wire to be connected

2 - 6

Page 41

YASNAC PCNC Connecting Manual Chapter 2: Power Supply

Note: Please follow the Frame Ground connection details for the machine and electrical

cabinet.

1. Connect FG Cable from custom e rs ma in grounding point to Machine’s electrical

cabinet where PCN C i s mounted.

2. Connect FG cable from customers ma i ns

FIGURE 2.2.1.4 YASNAC PCNC CRT Power and Ground Wiring

Note: 1. Connect CRT ground wire only to the CRT chassis ground terminal. Do NOT

connect ground wire to terminal “E” on the main p ower terminal block of the CRT

unit.

2. CRT G round wire must be a separate wire directly co nnected to the main cabinet

ground plate or grou nd ba r. Any other connections to the machine operation box

should be done using sep ar at e gro und wires.

2 - 7

Page 42

YASNAC PCNC Connecting Manual Chapter 2: Power Supply

2.2.2 Power Supply to Converter Unit

Converter unit

TXR MCCB

CIMR-MR5

R/L1

1L

1L

S/L2

MC

.

MC TXR MCCB

R

200/220 / 230 VAC-15% to 10%

50/60 Hz +

S

2Hz

1L

T/L3

A1

A2

FIGURE 2.2.2.1 Detailed Connection of Power

MC TXR MCCB

.

Fig. 2.2.2.1 Detailed Connection of Power

r

t

T

2 - 8

Page 43

YASNAC PCNC Connecting Manual Chapter 2: Power Supply

2.2.3 Circuit Diagram Example (Power magnets & PCNC CN12 Control Signals)

To Customer PWR supply

To fan for air circulation

inside panel

CN12 (IPU)

FIGURE 2.2.3. 2 Circuit Diagram Example

2 - 9

Page 44

YASNAC PCNC Connecting Manual Chapter 2: Power Supply

2.3 LED for Power Input/Output

I/O module power output verification LED

I/O module power input verification LED

FIGURE 2.3.0.1 LED for PCNC Input/Output Power Indication on JCNC-JFC10 Board

2 - 10

Page 45

YASNAC PCNC Connecting Manual Chapter 2: Power Supply

2.3.0 LED for PCNC Power input

The status of +24V pow er supply to the CNC uni t ca n be confirmed by the LED.

The LED is lit when +24V power is supplied properly.

When +24V powe r is not supplied or when the fuse in side the PCNC unit is blown ou t du e to a

fault of PCNC unit, the LED will be unlit.

2 - 11

Page 46

YASNAC PCN C Connecting Manual Chapter 3: Connect i on of PCNC Operation Pan el

3

Connection of PCNC Operation Panel

CONNECTING PCNC OPERATOR PANEL AND PCNC

This section addresses the electrical connection between the PCNC unit

and the CNC Operator panel.

3.1 Connection between Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2

3.1.1 Connection with the Operation panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2

3.2 Detailed Connection of PCNC Operation panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 3

3.2.1 Connection with Operation panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 3

3.3 General notes on Connection with operation Panel . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 8

3.3.1 JANCD-JSPO4/JANCD-J861 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 8

3.3.2 PCNC Connections Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 9

3.3.3 Extended I/O board FC861 and Remote Machine Pen da n t connections . . . 3 - 10

3 - 1

Page 47

YASNAC PCN C Connecting Manual Chapter 3: Connect i on of PCNC Operation Pan el

3.1 C onne cti on Be tw e en Devices

3.1.1 Connecti on with Operation Panel

CPU RACK UNIT

ATX

MOTHER

BOARD

IDE I/ F

KBD

COM2

FDD

COM1

PS/2 MOUSE

LPT1

PCI

ISA

VIDEO

CARD

JFC20

HDD

DATA

PWR

VIDEO

CN01

CN02

CN03

CN04

CN05

DC

OUT

(a)

(b)

(c)

(d)

(e)

(h)

(f)

(g)

CRT

KEYBOARD

FDD

CONTROL

SERVO ON

SHUT DOWN

MOUSE

PWRDATA

TS

TB3

TOUCH

SCREEN

FAN1

CPU

FAN

JCP20-1

FAN3 CASE FAN

PC POWER

SUPPLY

INP U T

CN11

CN12

CN13

CN14

OUTOUT

(PO W E R

SIGNAL)

NC POWER

SUPPLY

INP U T OUTPUT

AC230V

PGS

GOOD

NFB

INPUT POWER UNIT

TB2

TB1

SVM

3 - 2

Page 48

YASNAC PCN C Connecting Manual Chapter 3: Connect i on of PCNC Operation Pan el

3.2Detailed Connection of PCNC Operation Panel

3.2.1 Connection with Operation P anel

(a) Connection det ai ls be twe en PCN C CPU unit and CRT display unit

ATX MOTHERBOARD

PCI1

PCI BUS

DISPLAY CARD (PT75)

J1

RED -1 -1 R E D

GREEN -2 -2 G R E E N

BLUE -3 -3 B L U E

GND -4 -4 G N D

GND -5 -5 G N D

RED GND -6 -6 R E D G N D

GREEN GND -7 -7 G R E E N G N D

BLUE GND -8 -8 B L U E G N D

N/A -9 -9 N /A

GND -10 -10 G ND

GND -11 -11 G ND

N/A -12 -12 N/A

HSYNC -13 -13 HSYN C

VSYNC -14 -14 VSYNC

N/A -15 -15 N/A

SHELL

FROM C RT PO W ER

(2-10 E)

N.C.

14 INCH CRT

VIDEO

SHELL

POWER

L

N

E

(b) Connection detail between PCN C CPU Unit and Key board

ATX MOTH ERBO ARD

KB

KBD DATA -1 -1 KB D D A T A

GND -3 -3 G N D

KBD PW R -4 -4 K B D PW R

KBD CLK -5 -5 K B D C L K

-2

-6

SHELL

3 - 3

KEYBOARD

Page 49

YASNAC PCN C Connecting Manual Chapter 3: Connect i on of PCNC Operation Pan el

(c) Connection detail between PC N C CPU U ni t and Se rial Mo use

ATX MOT HE RB O ARD

COM2

DCD -1

RX -2

TX -3

DTR -4

GND -5

DSR -6

RTS -7

CTS -8

RI -9

SHELL

FERRITE

CORE

FERRITE

CORE

PS/2 T O S E RIAL

ADAPTER

RZD

-1 DCD

-2 RX D

-3 TXD

-4 DTR

-5 GND

-6 DS R

-7 RTS

-8 CTS

-9 RI

SHELL

GND -3

DATA -1

+5V -4

CLK -5

SERIAL

MOUSE

-2

-6

3 - 4

Page 50

YASNAC PCN C Connecting Manual Chapter 3: Connect i on of PCNC Operation Pan el

(d) Connection details betwe en PCNC CPU unit and FDD

ATX MOTHER BOAR D

GND -1, 3 ,5,7,9,11,13

-15,17,19,21,23

-25,27,29,31,33

NORMAL/-HD -2 -2 NORMAL/-HD

IN USE/-SIDE LD . -4 -4 IN USE/-SIDE L D.

-DRIVE SELECT 3 -6

-DRIVE SELECT 0 -10

-DRIVE SELECT 1 -12

-DRIVE SELECT 2 -14

-MOTOR ON -16

-DIR ECT ION -1 8

WR ITE DATA -2 2

-WRITE ENABLE -24

-TRACK00 -2 6

-WRITE PROTECT -28

READ DATA -30

-SIDE SELECT -32

DISK CHG./-READY -34

FDC FDD DATA

-INDE X -8

-STEP -20

FDD PORT

FDD PORT

-1,2, 3 ,4,5,6,7 G ND

-8,9,10,11,12

-13,14,15,16,17

-20 NORMAL/-HD

-21 IN US E/-SIDE L D.

-22 -DRIVE SELECT 3

-23 -IN DEX

-24 -DRIVE SELECT 0

-25 -DRIVE SELECT 1

-26 -DRIVE SELECT 2

-27 -MOTO R ON

-28 DIR SELECT

-29 -S T EP

-30 WRITE DATA

-31 -WRITE ENA BLE

-32 -T R ACK00

-33 -WRITE PROTEC T

-34 READ DATA

-35 -SIDE SELECT

-36 DISK CHG./-READY

-18

-19

-37

SHELL

FERRITE

CORE

FERRITE

CORE

FLOPPY DISK DR IVE UNIT

3.5" 1.44MB

-1,3, 5,7 ,9 ,1 1, 13 G ND

-15,17,19,21,23

-25,27,29,31,33

-6 -DRIVE SELE CT 3

-8 -INDEX

-10 -DRIVE SELECT 0

-12 -DRIVE SELECT 1

-14 -DRIVE SELECT 2

-16 -MOTO R ON

-18 DIR SELECT

-20 -S T EP

-22 WR ITE D AT A

-24 -WRITE ENA BLE

-26 -T R ACK00

-28 -WRITE PROTEC T

-30 READ DATA

-32 -SIDE SELECT

-34 DISK CHG./-READY

FROM A UX

DC OUTPUT

(3-8B)

-4 +12V

-3 G N D

-2 G N D

-1 +5V

FERRITE

CORE

TB3

+12V

GND

GND

+5V

FDD POWER

-1

-2

-3 GND

-4 +5V

CONTROLLER

POWER

TO T/S

(7-13E)

3 - 5

Page 51

YASNAC PCN C Connecting Manual Chapter 3: Connect i on of PCNC Operation Pan el

(e) Connection details Betw e en PCNC CPU unit and Touch screen

ATX MO THERBO ARD

COM1 P2

DCD -1

RX -2

TX -3

DTR -4

GND -5

DSR -6

RTS -7

CTS -8

RI -9

SHELL

FERRITE

CORE

CONTROLLER

FROM T/S

POW ER

(6-14B )

FERRITE

CORE

-1 D C D

-2 R X

-3 T X

-4 D T R

-5 G N D

-6 D S R

-7 R T S

-8 C T S

-9 R I

SHELL

-1 + 5V

-2 G N D

-3

-4

TOUCHSCREEN

CONTROLLER

-1 D C D

-3 R X D

-5 T X D

-7 D T R

-9 G ND

-2 D S R

-4 R T S

-6 C T S

-8 R I

-10 key

P4

-1 + 5V

-2 G N D

P3

TOUCHSCREEN

H -1

X -2

S -3

Y -4

L -5

(f) Connection detailed between PCNC CPU UNIT and SERVO ON/ SHUT DOWN

MACHINE CONTROL CABINET

CPU RACK

AUX DC

OUTPUT

(5/12 VDC)

WIRE DUCT

MAIN DC

POWER

CABLE

UWR00264

MACHINE OPERATION BOX

12V

GND

JUMPER

GND

JUMPER

5V

Shield

GND

GND

5V

5V

FDD POWER

CABLE

UWR00266

6P DOUBLE ROW COVERED TERMINAL STRIP

(SUCH AS BEAU # 18006-10A OR E Q U I VALENT)

TOUCH SCREEN POWER

CABLE UWR00267

TOUCH SCREEN

SERIAL

CONTROLLER

POWER

TOUCH

SCREEN

POWER MIDCABLE

UWR00298

FLOPPY DISK DRIVE

POWER

Terminal block

To be arranged by MTB

3 - 6

Page 52

YASNAC PCN C Connecting Manual Chapter 3: Connect i on of PCNC Operation Pan el

(g) CRT Power Cable

PCNC CRT

(Touch Screen)

(h) Servo ON/OFF

Rear Sid e

ON

1 Phase, AC

Power Supply

OE

OL FG

(Ground wire to be connected to FG)

N to N

L to L

G to FG

3 - 7

Page 53

YASNAC PCN C Connecting Manual Chapter 3: Connect i on of PCNC Operation Pan el

3.3 General Notes on Connection with Operation Panel

3.3.1 JANCD-JSP04 and Operator Panel

MACHINE OPERATOR PANEL

BA C K SIDE V IEW PCNC

CN 0 2

URW 00205-1

JA N C D-JSP0 4

CN 7 C N 8 C N9

CN A

CN 0 4

URW 00205-1

YENE T

JANCD-FC861 URW00251-2

CN1 1 CN 1 2

YENET URW00251-2

This figure gives the gene ra l I/ O ca rd connections with PCN C.

1. Extended I/O board, FC 861 , nee d s to be connected by a YENET ca ble from CN02 of PCNC

unit to the CN11 of FC 861 unit

2. Extended I/O board FC 861 is th en connected by a YENET cable from CN 04 of JSP04 to

CN12 of FC 861 unit.

3 - 8

Page 54

YASNAC PCN C Connecting Manual Chapter 3: Connect i on of PCNC Operation Pan el

3.3.2 PCNC Connection Layout (Top View)

FIGURE 3.3.2.1 PCNC Connections Layout to CRT and PC Accessories

3 - 9

Page 55

YASNAC PCN C Connecting Manual Chapter 3: Connect i on of PCNC Operation Pan el

3.3.3 Extended I/O board FC861 and Remote m ach ine pendent connectio ns

REMOTE MACHINE PENDENT

Manual Pulse

Generator

power supply

Connector

Emergency signal

Male Female

YENET Cable

JANCD-FC861 (I/O Board)

CN11 CN12

PCNC UNIT

CN02

UWR00251-2

YENET Cable

FIGURE 3.3.3.1 External FC861, Remote Machine Pendant, and PCNC connections

The figure illustrates the general I/O card and Remote Machine Pendant card connections with

the PCNC Unit.

Note: 1. FC861 board needs to be connected by a YEN E T cable from CN02 o f the PCN C

Unit to CN11 of the FC861 I/O board.

2. Remote Machine Pendant is connected vi a a Y E N ET cable from CN12 of the

FC861 I/O board to femal e connector for the Remote Machine Penda nt.

3 - 10

Page 56

YASNAC PCN C Connecting Manual Chapter 4: Connec ti on of Manual Pulse Generato r

4

Connection of Manual Pulse Generator

Connecting PCNC Operation Panel And Manual Pulse Generator

This section addresses the electrical connection of the Manual Pulse Generator.

4.1 Connection between Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 2

4.1.1 Connection with PCNC Operation Panel . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 2

4.2 Detailed Connection of Manual Pulse Generator. . . . . . . . . . . . . . . . . . . . . . . . . .4 - 3

4.2.1 Parallel I/F. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 3

4.2.2 Non-Parallel I/F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 4

4 - 1

Page 57

YASNAC PCN C Connecting Manual Chapter 4: Connec ti on of Manual Pulse Generato r

4.1 Connection Between Devices

This section describes the connection between the PCN C Operator Panel and th e Ma nual

Pulse Generato r, the type of co nnector and cable spec ifi ca tions.

4.1.1 Connection of the PCNC operator Panel to the Manual Pulse Generator.

PCNC Operator Panel

JANCD-JSP02

JANCD-JSP04

UL20276 AWG28 x 10 pairs

CN01

10220-6202JL

.

10120-3000VE

(10120-52A0-008)

.

Manual pulse generator No.1

1HPG

Manual pulse generator No.2

2HPG

Manual pulse generator No.3

3HPG

FIGURE 4.1.1.1 Co nnection Between De vices

4 - 2

Page 58

YASNAC PCN C Connecting Manual Chapter 4: Connec ti on of Manual Pulse Generato r

4.2 Connection Details of Manual Pulse Generator

Following conne ction details between the PC N C Operator Panel and the Manua l pu lse

generator

4.2.1 Parallel I / F

FIGURE 4.2.1.1 Detailed Connection of Manual Pulse Generat or (Par al lel I/F)

4 - 3

Page 59

YASNAC PCN C Connecting Manual Chapter 4: Connec ti on of Manual Pulse Generato r

4.2.2 Non - paral le l I / F

PCNC Operator Panel

JANCD-JSP02-1,-2

-JSP04-1,-2,-4

CN01-1 6 PAH1

CN01-1 7 0V

CN01-18

CN01-19

CN01-3

CN01-6

CN01-12

CN01-13

CN01-14

CN01-15

CN01-2

CN01-5

CN01-8

CN01-7

PBH1

0V

0V

5V

FG

P AH2

0V

PBH2

0V

0V

5V

FG

PAH3

0V

.

.

A

P

P

B

P

MPG NO 1

1PHG

.

0V

.

.

+5V ~ 12V

A

B

MPG NO 2

2PHG

P

P

P

.

0V

P

+5V ~ 12V

A

P

MPG NO 3

POINT

CN01-10

CN01-9

PBH3

0V

B

P

.

3PHG

.

CN01-1

CN01-4

FIGURE 4.2.2.1 Manual Pulse Generator Connection Detail s

1. JSP02-1, JSP02-2, JSP04-1, JSP04-2, JSP04-4 are provided with non-para ll el I/F. Wi th

JSP02-1, JSP04-1 only one manual pulse generator can be connected (one axis) . With

JSP02-2, JSP04-2, JSP04-4 three manual pulse generators can be connected (three axis).

2. Use the cab le wi t hin 5 meters for non-paralle l type I/F. Connect FG and th e c abl e to the

case using a metal cable clamp fitting.

0V

5V

FG

.

0V

P

+5V ~ 12V

4 - 4

Page 60

YASNAC PCNC Connecting Manual Chapter 5: Connection of Power ON/OFF Excluisve Signal

5

Connection of Power ON/OFF Exclusive Signal

This section addresses the connection of the Power On/Off Exclusive Signal

5.1 Connection between Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 2

5.1.1 Connection to PCNC Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 2