Page 1

YASNAC PC NC

I/O Signal Function Manual

Version: Beta 1.0

Page 2

YASNAC PCNC I/O Signal Function Manual

SAFETY INFORMATION

PRECAUTIONS

1. Read this instruction manual in its en ti ret y before using the I/O Sign al Functions available in the

YASNAC PCNC.

2. The following wa rni ng symbols are used to indicate precau ti ons th at the user must be aware of

to safely use this equipment. Failure to follow these pre cautions can result in seriou s or possi bly

even fatal injury and damage to products or related equipm e nt or systems.

WARNING

WARNING

WARNING

This sym b ol indica tes the pre sence of a po tentially hazardous condition which, if not avoided,

could result in serious personal injury or death.

This precautionary symbol appears in labels attached to YASNAC products to alert the user to

conditions requiri ng concern for safety.

SPECIAL SAFETY NOTE: This symbol indicates that ELECTRICAL SHOCK HAZARD

condition exists. DO NOT TOUCH any electrical connection terminals when the power is on, and

for at least 5 minutes after switching off the power supply. Warni ng l abe l is loc at ed on th e CN C

enclosure as shown:

PCNC Unit

xxxxxxxxx

xxxxxxxxx

xxxxxxxxx

xxxxxxxxx

xxxxxxxxx

NOTICE

Printed _______. 1999. The informatio n contained within this document is the proprietary property of

Yasakawa El ectric America, Inc. , and may not be copied, reproduced or transmit ted to other parties withou t

the expressed wr itte n authorization of Yasakawa Electric America, Inc .

WARNING LABEL

No pattent liability is assumed with respect to the uses of the information contained herein. Moreover,

because Yaskawa is constantly improving its high quality product, the information contained in this manaul

is subject to chan ge without notice. Every precaution has been taken in th e preparation of thi s document.

Nevertheless, Yasakawa assumes no responsibility for damages resulting from the use of the information

contained wit hi n thi s publication.

i

Page 3

YASNAC PCNC I/O Signal Function Manual

TABLE OF CONTENTS

1. Feed Function

1.1 F-1Digit Selection Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.2 No.2 G00 Mode Signal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.3 Feed Completed Output Signal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.4 Feedr at e O verride Input and Cancel Input Signal s. . . . . . . . . . . . . . . . . . . . . . . . .1-5

1.5 Pulse Handle Axis S election Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

1.6 Rapid Traverse Override Input Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

1.7 Manual Feed Axis/Direction Selection Input Sig nal . . . . . . . . . . . . . . . . . . . . . . .1-9

1.8 Solid Tap. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

2. Saving and Editing Programs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

3. Operation and Display

3.1 Calendar Output Signal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

4. M, S, T and B Functions

4.1 Input/Output Signals of M. S, T and B Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

4.2 S5-Digit Co mmand Input Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4- 5

4.3 Gear Range Selection Input and Output Signals . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4.4 Gear Shift Input and Spindle Fix ed Speed Input Signals . . . . . . . . . . . . . . . . . . . .4-11

4.5 Spindle Speed Agre ed Input Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4- 12

4.6 Spindle Speed Override Input Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

4.7 Binary Command Input Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

5. Coordinate Systems

5.1 Reference Point Return Control Input/Output Signals. . . . . . . . . . . . . . . . . . . . . .5-2

ii

Page 4

YASNAC PCNC I/O Signal Function Manual

6. Operation Support Functions

6.1 Input and Output Signals of CNC Operation Modes . . . . . . . . . . . . . . . . . . . . . . .6-2

6.2 Manual Jog Feedrate Selection Input Signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7

6.3 Manual Pulse/Step Mulitplication Ratio Setting Input Signals . . . . . . . . . . . . . . .6-9

6.4 Automatic Operation Start/Stop Input Signals

and Running/Stopped Output Signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-10

6.5 Single-Block Input Signal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-12

6.6 Manual Absolute Input Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-12

6.7 Display Lock Input Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-13

6.8 Program Restart Input Sig nal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

6.9 Dry Run Input Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-14

6.10 Machine Lock Input Signal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

6.11 Auxiliary Function Lock Inpout Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-15

6.12 Edit Lock Input Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-16

6.13 Automatic Mode Handle Offset Input Signal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

6.14 Interruption Point Return Input Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-16

6.15 Optional Stop Input Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-17

6.16 Axis Disconnection Designation Input Signals . . . . . . . . . . . . . . . . . . . . . . . . . . .6-17

7. Programming Support Functions

7.1 Time Count Input Signal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

7.2 Optional Block Delete Input Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

7.3 End of Program Input, Rewind Input and Output Signals . . . . . . . . . . . . . . . . . . .7-3

7.4 System Variable for Interface Input/Output Signals. . . . . . . . . . . . . . . . . . . . . . . .7-4

7.5 Mirror Image Input Signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-7

7.6 Canned Cycle Operation Status Monitor Output Signals. . . . . . . . . . . . . . . . . . . .7-7

8. Machin e S upp o rt Function

8.1 Internnal Toggle Switch Monito r Outpt Signals. . . . . . . . . . . . . . . . . . . . . . . . . . .8-2

iii

Page 5

YASNAC PCNC I/O Signal Function Manual

9. Automatic Support Functions

9.1 Servo-On Monitor Output Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-2

9.2 Brake-On Monitor Output Signal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-2

9.3 External Servo-On Input Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-2

9.4 Tool Life Management Input/Output Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-3

9.5 External Data Input/Output Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-5

9.6 Manual Skip Mod e Inp ut /Output Signals and Touch Sensor Input Signals . . . . .9-10

9.7 Manual Centering Mode Input Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-12

9.8 Program Interrupt Input Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-12

9.9 Direct Processing Signal Monitor Output Signal . . . . . . . . . . . . . . . . . . . . . . . . .9-13

9.10 Position Monitor Output Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-13

9.11 Hign-Speed Position Monitor Input Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-15

10. Safety and Maintenance Functions

10.1 Machine Ready Input Signal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

10.2 External Reset Input Signal and Resetting Output Signal . . . . . . . . . . . . . . . . . . .10-3

10.3 Start Interlock Input Sig nal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

10.4 Alarm State Output Signal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-4

10.5 External Error Detection Input Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-4

10.6 Servo Alarm Output Signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

10.7 Warning State Output Signal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

10.8 Absolute Position Detection Error Output Signal. . . . . . . . . . . . . . . . . . . . . . . . . .10-6

10.9 System Number Setting Monitor Output Signal. . . . . . . . . . . . . . . . . . . . . . . . . . .10-6

10.10 Operating Output Signal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-6

10.11 Power Loss Detection Monitor Output Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

10.12 Overtravel Input Signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-7

10.13 Stored Stroke Limit Check Input Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 0-8

10.14 Axis Interlock Input Signal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-9

10.15 Direction Specified Axis Interlock Input Signal. . . . . . . . . . . . . . . . . . . . . . . . . . .10-9

10.16 Servo Off Input Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-10

10.17 Servo Axis Load Monitor Output Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-11

iv

Page 6

YASNAC PCNC I/O Signal Function Manual

PURPOSE OF THIS MANUAL

This manual describe s the func tions of I/O signals between the YA SNA C PCNC and PLC. Read this

manual thoro ug h ly so that you wil l be able to use the YASNAC PCNC corr ec tly. Keep this manual in a

safe place and refer to it when ever necessa ry.

RELATED MA NUALS

Refer to the following manuals when neces sary.

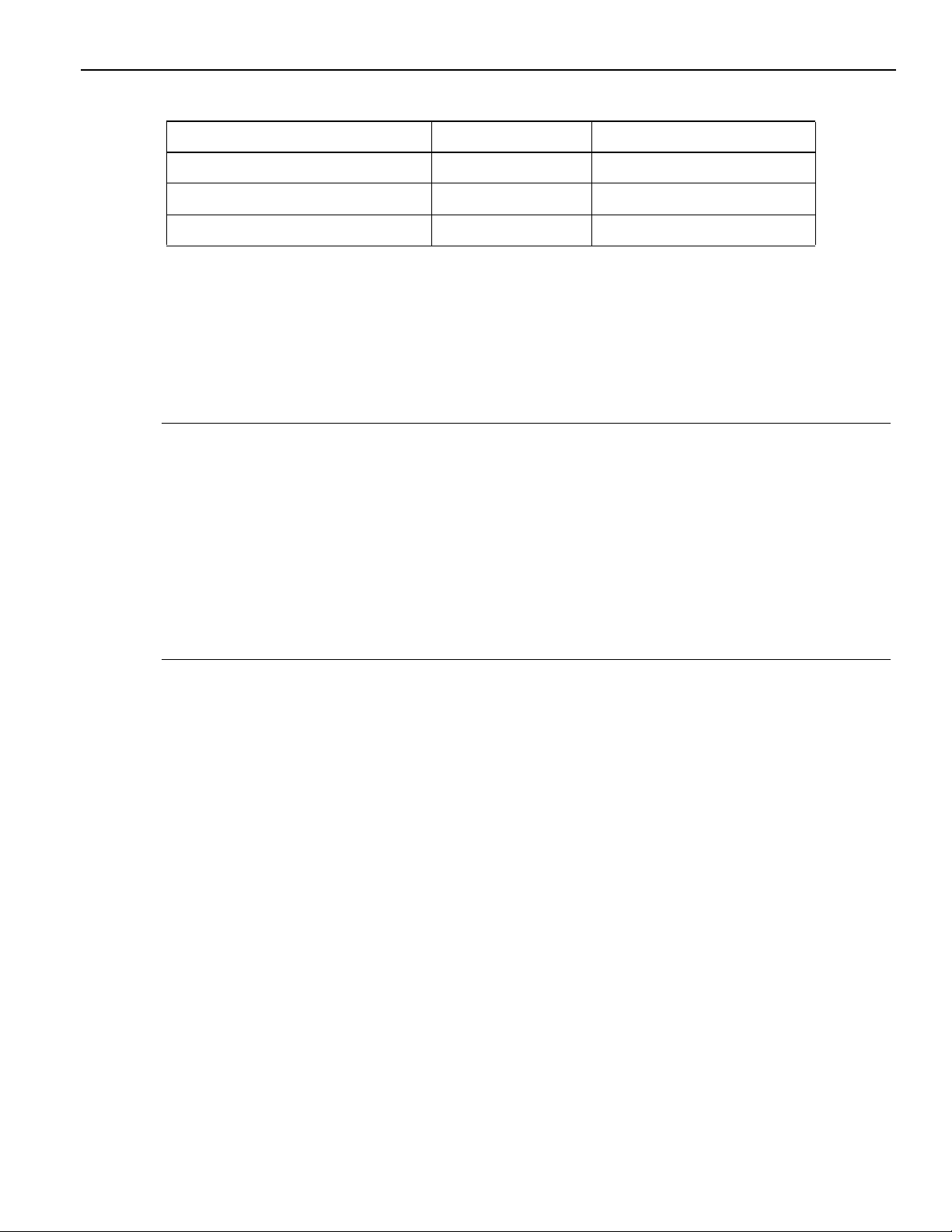

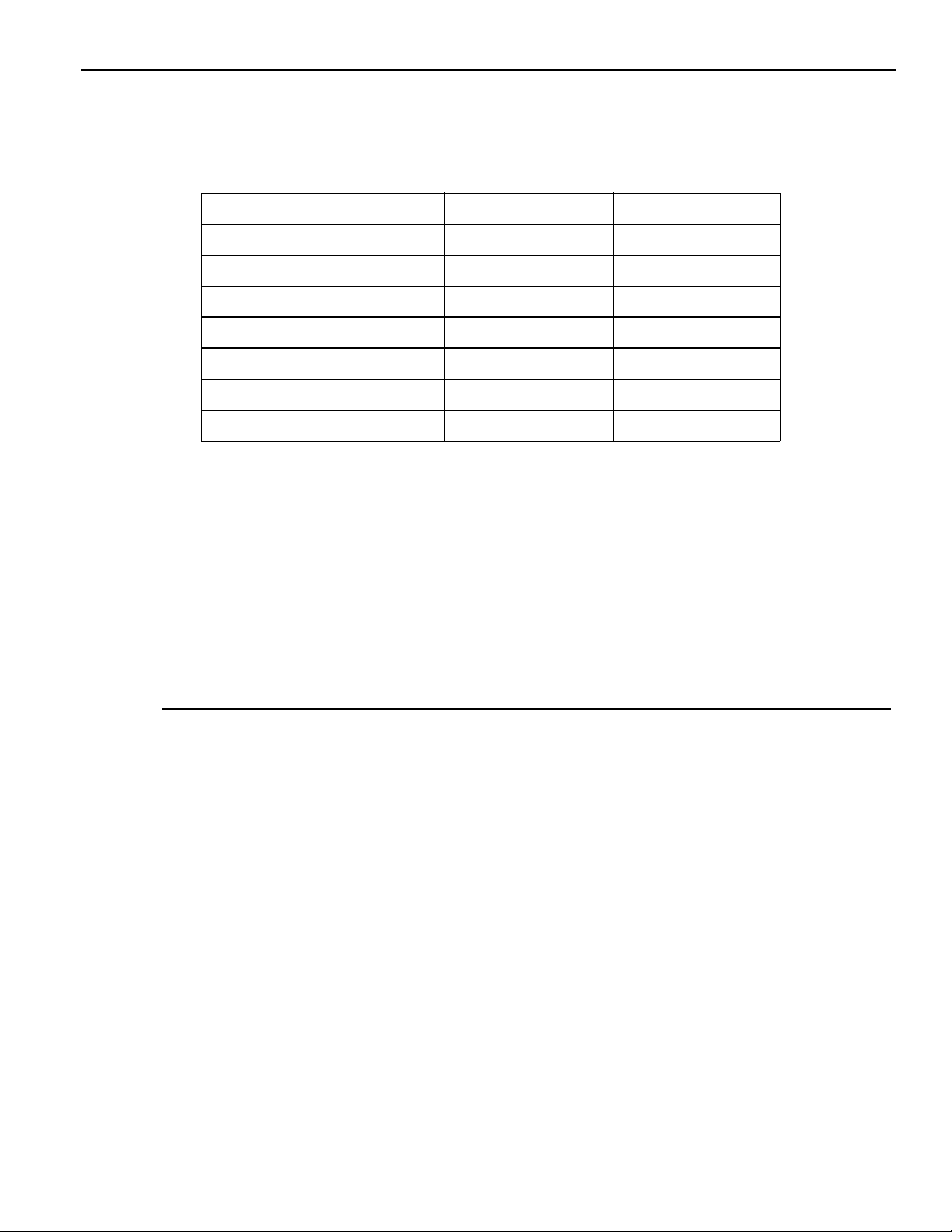

Name of Manual Manual Number Contents

YASNAC PCNC OPERAT ING MANUAL

YASNAC PCNC PROGRAMMING MANUAL

YASNAC PCNC/PLC PROGRAMMING MAN-

UAL

YASNAC PCNC CONNECTING MANUAL

YEA-SIE-C844-

2.1

YEA-SIE-C844-

2.2

YEA-SIE-C844-

0.1

YEA-SIE-C844-

0.2

Instrucions for connecting YASNAC to machines,

Descri bes the basic configuration

and operational procedures.

Describes the necessary information

how to create a PCNC program.

Describes the PLC instructions and

the process for developing PLC programs

machine interface and external equipment.

NOTES REGARDING SAFE OPERATION

Read this manual thoroughly before installing, operating, maintaining or inspecting the Y ASNAC

PCNC. Since the efficient and safe operation of a CNC machine tool is not d etermined by the CNC

only, it is important to also read the machine tool builder’s documentatio n about the machine to ol

itself.

SPECIAL SAFETY NOTE: This symbol ind icates that ELECTRICAL SHOCK HAZARD

condition exists. DO NOT TOUCH any electrical connection terminals when the power is on, and

for at least 5 minutes after switching off the power supply. Wa rni ng l abe l is located on the CNC

enclosure as shown:

PCNC Unit

v

xxxxxxxxx

xxxxxxxxx

xxxxxxxxx

xxxxxxxxx

xxxxxxxxx

WARNING LABEL

Page 7

YASNAC PCNC I/O Signal Function Manual

Warning label is located on the CN C operator pane l (wi th 14” CRT) as shown:

xxxxxxxxx

xxxxxxxxx

xxxxxxxxx

xxxxxxxxx

xxxxxxxxx

WARNING LABEL

REAR FACE

CAUTION

This symbol indicates that care should be used in this area.

This instruction label appears o n the enclosure as follows:

CAUTION

Use

proper

grounding

techniques

Warning labe l is loc ated on the PCNC enclosure as show n:

PCNC Unit

xxxxxxxxx

xxxxxxxxx

xxxxxxxxx

xxxxxxxxx

xxxxxxxxx

WARNING LABEL

vi

Page 8

YASNAC PCNC I/O Signal Function Manual Chapter 1: Feed Function

1

Feed Function

Chapter 1 describes the sign als related to the fe ed func ti on

1.1 F-1 Digit Selection Signal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.2 No. 2 G00 Mode Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.2.1 No. 2 G00 Mode Input Signals (#31019 to #31014) . . . . . . . . . . . . . . . . . . . .1-3

1.2.2 No. 2 G00 Mode Input Signals (#36280 to 36284) . . . . . . . . . . . . . . . . . . . . .1-3

1.3 Feed Completed Output Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.4 Feed Override I nput and Feedrate Override Cancel Input Signals . . . . . . . . . . . . . . . 1-5

1.5 Pulse Handle Axis S election Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

1.6 Rapid Traverse Override Input Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

1.7 Manual Feed Axis/Direction Selection Input Sig nal . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

1.8 Solid Tap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

1 - 1

Page 9

YASNAC PCNC I/O Signal Function Manual Chapter 1: Feed Function

1.1 F-1 Digit Selection Signal

F-1 Digit F-1 #30076

By the designation of a single-digit number (1 to 9) following address F, the feedrate corresponding to the designa ted numb er is selec ted. Actu al feedrates to be ca lled in res p ond to designated

one-digit numbers are set for setting parameters pm0820 to pm0828.

When the “F1” input signal is in the “closed state”, the currently selected feedrate can b e

increased or dec rea sed by turning the manu a l pu lse generator.

When the “F1” input signal is in the “ope n state”, it is not possible to change the feedrate by

turning the manua l pul se gene ra to r.

IMPORTANT!

1. If the F1 digit fe ed function is selected , it is not possible to designate feedrates of

1mm/min. to 9mm/min. by the F function. In this case, designation is only possible for

feedrates of 10mm/min. or greater.

2. If the dry run swit c h is O N, t he fee dra te set for dry run operation is valid.

3. The feed override functi on is invalid when the F-1 digit feed function is used.

4. Feedrates set f or sett ing parame ters pm08 20 to pm082 8 rema in v alid even if t he p ower

is turne d OFF.

5. Feedrat es ca lled by the designati on F1 di gi t codes are clamped in t he following manner:

If a parameter in the range from pm0820 to pm 0923 exceeds the value set for pm2864, the feedrate to be calle d is cl amped at the valu e set for pm 2865. If a paramet er se tt ing in the range from

pm0824 to pm0828 exceeds the value set for pm2866, the feedrate to be called is clamped at the

value set for pm28 67.

If the value set for the maximum feed rat e se tt in g parameter for F-1 figit fe ed function is greate r

than the valu e set for the maximum feedrate setting parameter for the nor mal F function, the maximum feedrate for the F-1 digit feed func tion is clamped at the feed ra te set fo r the ma ximum feedrate setting parameter for the normal F function.

1 - 2

Page 10

YASNAC PCNC I/O Signal Function Manual Chapter 1: Feed Function

1.2 No. 2 G00 Mode Signal

No. 2 G00 Mode Input G002X to G0025 #31010 to #31014

No. 2 G00 Mode Output G002XS to G0025S #36280 to #36284

Axis feed in the G00 mode is controlled by the setting for parameters, i.e. feedrates, acceleration/

deceleration, time constants and S-curve accel/decel coefficients. This funtion has two sets of

parameters rela te d to the execution of the G0 0 code to control feedrate, and the effect of the

accel/decel time constant and S-curve accel/decel according to theinput signal (G002X to G0025).

1.2.1 No. 2 G00 Mode Input Signal s (#31019 to #31014)

These signals cha nge over the control mode between the G00 and the second G00 cont rol

mode for the individual axes (X-axis to th e 5t h-axis).

If these sign als ar e “open” the G00 control mode is called.

If these sign als ar e “closed”, the second G00 control mode is called.

1.2.2 No. 2 G00 Mode Input Signal s (#36280 to 36284)

These signals are second G00 control mode out pt ut si gna ls for the individual axes

(X-axis to the 5th-axi s).

If these sign als ar e “open” the G00 control mode is called.

If these sign als ar e “closed”, the second G00 control mode is called.

1 - 3

Page 11

YASNAC PCNC I/O Signal Function Manual Chapter 1: Feed Function

1.3 Feed Completed Output Signal

Feed Completed Output Signal DEN #35374

For the execution of a part in th e automatic mode, if an axis movement command isdesignated

with a M, S, T and/or B command in the same block , th is outp ut signal indicates the completion

of axis movement.

In a block where axis mo vemen t comm and is designa ted wit h a M, S, T and/ or B comma nd, if th e

axis movemen t co m ma nd has been completed eve n th ough a M, S, T and/or B comman d has not

been completed, the feed completed output DEN is “closed”.

When the FIN input is “opened” from th e “closed” state after the closing if the feed completed

output DEN, the M, S, T and/or B command is assum ed t o have been executed and the feed

comple ted outpu t D EN is “opened”.

1 - 4

Page 12

YASNAC PCNC I/O Signal Function Manual Chapter 1: Feed Function

1.4 Feed Override Input and Feedrate Override Cancel Input Signals

Feed Override Input Signal OV1 to OV16 #30400 to #30404

Feed Override Input Cancel Signal OVC #30407

(1) Feedrate Override Input Signal

The feedrate override input signal ove rrri des feedrates specified in a part program in

increments of 10 % in the range from 0 to 549%. These input signals are valid in the

automatic mode.

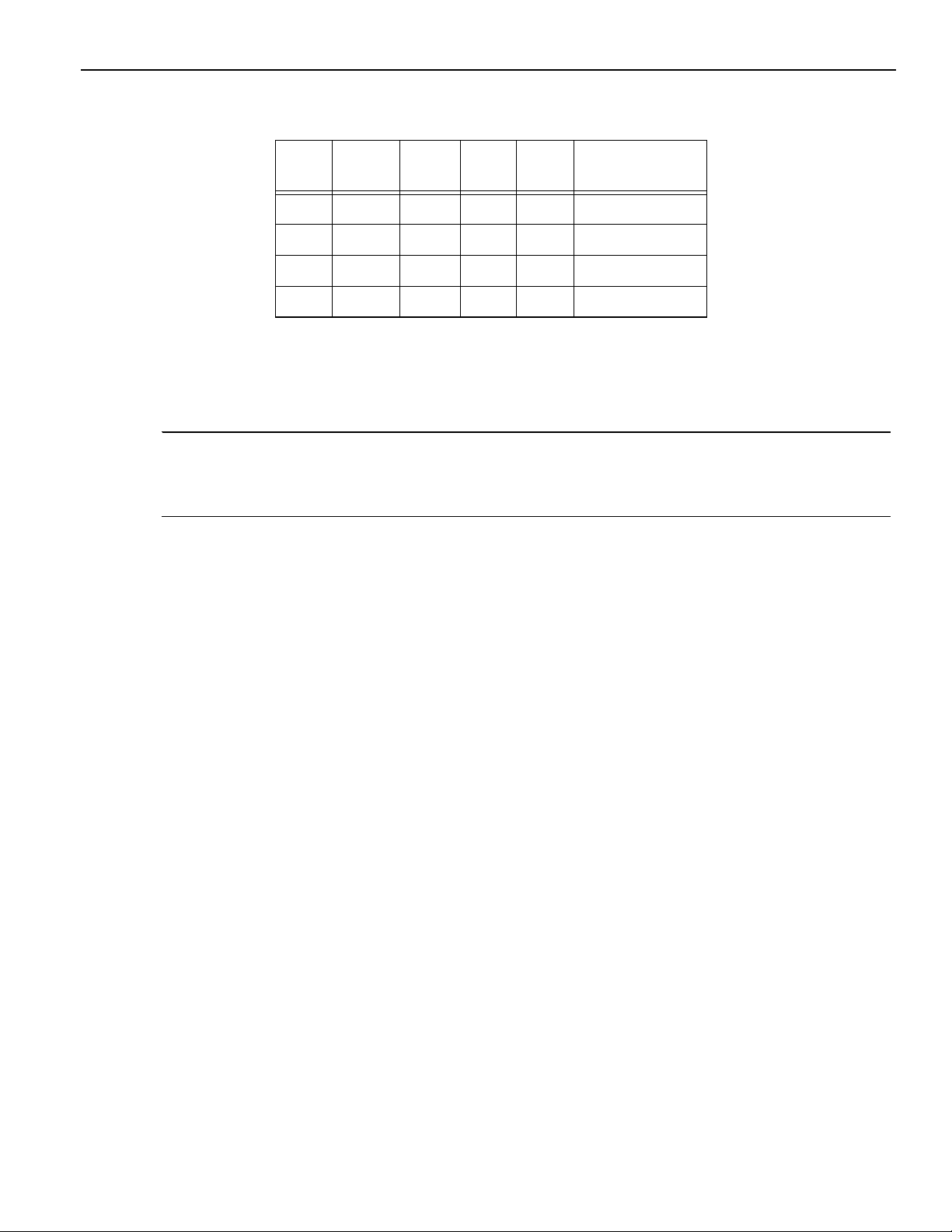

Feedrate Override Input Signal Table

OV1 OV2 OV4 OV8 OV16

00000 0%

1 0 0 0 0 10%

0 1 0 0 0 20%

1 1 0 0 0 30%

0 0 1 0 0 40%

1 0 1 0 0 50%

0 1 1 0 0 60%

1 1 1 0 0 70%

0 0 0 1 0 80%

1 0 0 1 0 90%

0 1 0 1 0 100%

1 1 0 1 0 110%

0 0 1 1 0 120%

1 0 1 1 0 130%

Feedrate Override

(Automatic Mode)

0 1 1 1 0 140%

1 1 1 1 0 150%

0 0 0 0 1 160%

1 0 0 0 1 170%

0 1 0 0 1 180%

1 1 0 0 1 190%

0 0 1 0 1 200%

1 0 1 0 1 220%

0 1 1 0 1 240%

1 1 1 0 1 260%

1 - 5

Page 13

YASNAC PCNC I/O Signal Function Manual Chapter 1: Feed Function

Feedrate Override Input Signal Table (conti nue d)

OV1 OV2 OV4 OV8 OV16

0 0 1 1 1 420%

1 0 1 1 1 460%

0 1 1 1 1 500%

1 1 1 1 1 540%

Note: The status of sign als is indicated by “0” or “1”.

0: Open

1: Closed

IMPORTANT!

Feedrate overr ide value of 200% and greate r is opt ional.

(2) Feedrate Override Cancel Input Signal

Feedrate Override

(Automatic Mode)

The feedra te override cancel input signal fixs the override value at “100%”.

If the “OVC” inut signal is “closed”, cutting feed designated in a part program is

executed at t he feedrate sp ec ified in the progra m, regardless of t he status of the

feedrate overr ide input signals.

1 - 6

Page 14

YASNAC PCNC I/O Signal Function Manual Chapter 1: Feed Function

1.5 Pulse Handle Axis Selection Signals

HX to H5 #30700 to #30704

Pulse Handle Axis Selection Signals

2HX to 2H5 #30800 to #30804

3HX to #H5 #30810 to #30814

(1) Pulse Handle Axis Selection Signal

The pulse han dle axis selection signals de sinate which of the ax es can be moved by the

operation of the pulse handle for mach ine s so equipped.

By “closing” the signal when the pul se ha ndle is selected, the corresponding axis can be

moved by turning the pul se ha ndl e. If more than one sign al is “closed” at the same time,

“closed ”signals is valid and the corresponding axis ca n be moved by turning the pulse

handle.

Prioriry of the Signals (highest to lowest): HX, HY, HZ, H4, H5

(2) Simultaneous 3-axis Pulse Handle Axis Selection Signal

If the machine is equipped with a simultaneous 3-axis feed pulse handle, up to three axes

can be moved at the same time when the signal is “closed”.

No. 1 pulse handle se lection (HX to H5)

No. 2 pulse handle sele ction (2HX to 2H5)

No. 3pulse handle selection (3HX to 3H5)

IMPORTANT!

For each pulse handle axis selection, selection is possible only for one ax is.

If more than one pulse handle is selected for one a xi s, fe ed di sta nces generated by the sele ct ed

pulse handles will overl ap.

1 - 7

Page 15

YASNAC PCNC I/O Signal Function Manual Chapter 1: Feed Function

1.6 Rapid T raverse Override Input Signal

Rapid Traverse Override Input Signal ROV1 to ROV4 #30034 to #30036

The rapid traverse override input signal determines the rapid traverse rate used in the execution

of positioning in automatic operation of CNC program, and also for manual rapid traverse

operation with the RT input “closed”.

IMPORTANT!

ROV4 can only be use d when the extension ov erride function (optio n) is sel ec ted.

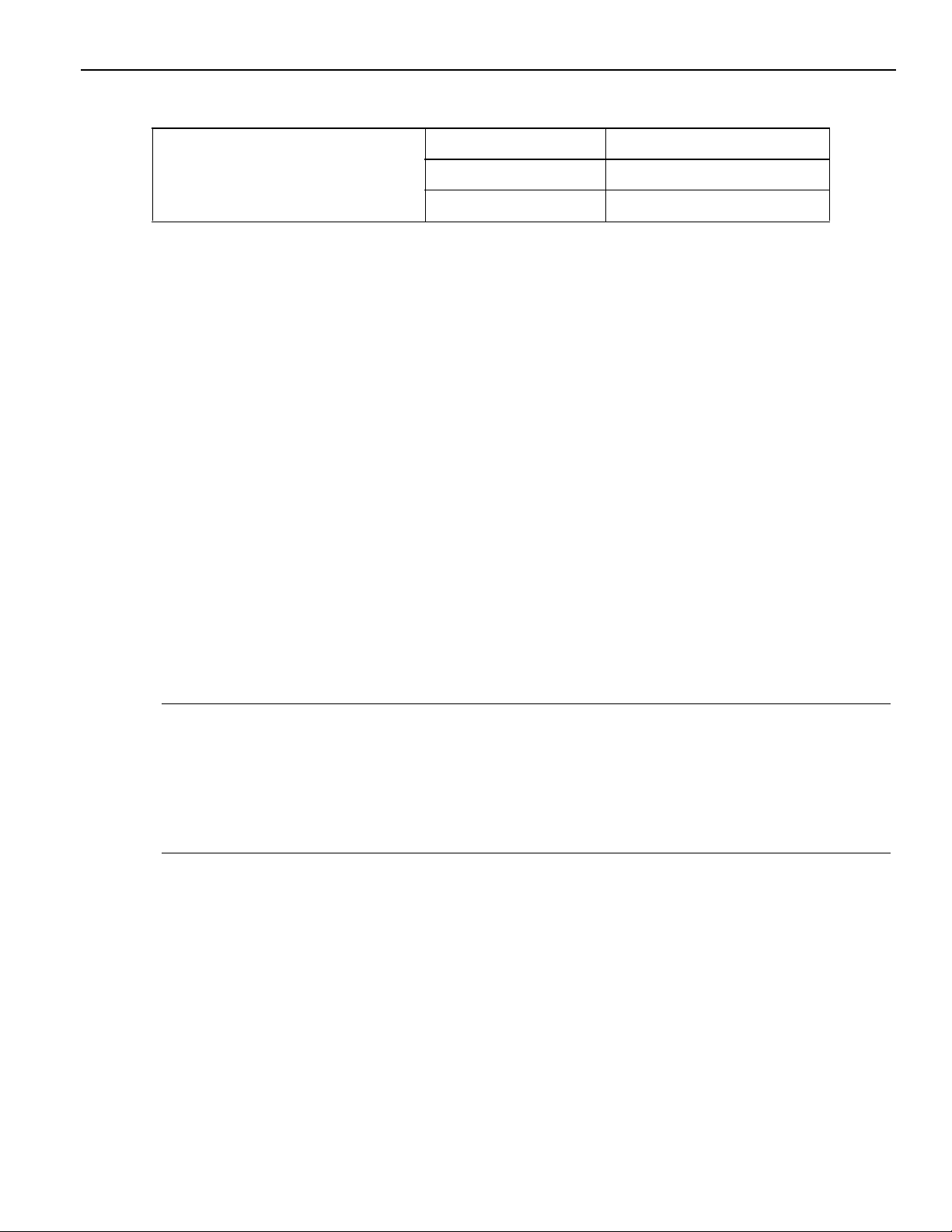

Input Signals and Rapid Traverse Rates

Input Signal Rapid Traverse Rates

ROV4 ROV2 ROV1 No. 1 Axis No. 2 Axis No. 3 Axis No. 4 Axis No. 5 Axis

0 1 1 Feedrate set

for pm2801

0 1 0 (Feedrate set for

pm2801) x 1/2

0 0 1 (Feedrate set for

pm2801) x 1/4

00 0F

10 0F

10 1F

pm2801 to pm2805 x pm2447 (%), or traverse set for pm2447 (see Note 2)

0

pm2801 to pm2805 x pm2448 (%)

0

pm2801 to pm2805 x pm2449 (%)

0

Note 1: The status of signals is indicated by “0” or “1”.

0: Open

1: Closed

Note 2: Interpretation of the val ue set fo r ppm 2447, used for determining the traverse rate F

is indicated below.

pm2000 D3= 0: The uni ts of the value set forpm2447 are “mm/min.”.

pm2000 D3= 1: The uni ts of the value set forpm2447 are “%”.

Feedrate set for

pm2802

(Feedrate set for

pm2802) x 1/2

(Feedrate set for

pm2802) x 1/4

Feedrate set for

pm2803

(Feedrate s et for

pm2803) x 1/2

(Feedrate s et for

pm2803) x 1/4

Feedrate set for

pm2804

(Feedrate se t f or

pm2804) x 1/2

(Feedrate se t f or

pm2804) x 1/4

Feedrate set for

pm2805

(Feedrate set for

pm2805) x 1/2

(Feedrate set for

pm2805) x 1/4

0

1 - 8

Page 16

YASNAC PCNC I/O Signal Function Manual Chapter 1: Feed Function

1.7Manual Feed Axis/Direction Selection Input Signal

+X to +5 #30710 to #30714

Manual Feed Axis/Direction Selection Input Signal

-X to -5 #30720 to #30724

The manual feed axis/direction selection input signals determine the direction of axis movement

and the axis to be m oved when the CNC is in t he jog mode, rapid traverse mode or manual step

feed mode.

When the “+” or “-” signals are “closed”, the correspondin g axes are move d. I f more than one

axis is selected, simultaneous axis movement is possible for up to the designated number or

simultaneously controllable axes.

IMPORTANT!

If both the “+” or “-” sig n als of the selec ted axis are “closed” or “opened” at the

same time, the axis cannot be moved. If this occu rs during axis movement, the axis

decelerate s and stops.

1 - 9

Page 17

YASNAC PCNC I/O Signal Function Manual Chapter 1: Feed Function

1.8 Solid Ta p

Solid Tap Mode G93M #35381

Spindle Position Loop Command SLPC #31174

Spindle Position Loop Mode SLPS #36512

Solid Tap Gear Selection STPGR #31155

(1) Solid Ta p Mod e Signal

The output signa l is in respon s e to the execution. At th e machin e, the spin dle start ( fo r w ard)

signal should be “opened” at this signal. Then return the spindle positin control loop command

input signal (SLPC ) aft er confirming that the spindle has been stopped by t he spind le ze rospeed signal.

IMPORTANT!

1. If the spindle controller has a soft start circuit, cancel it at the same time when the SLPC is

“opened”, since acceleration an d deceleration are controlled by the NC.

2. All of the following input signals must be “closed”.

Spindle reverse rota tion (SINV)

Gear shifting (GRO)

Spindle fixed speed (SO R)

(2) Spindle Position Loop Command

The signal is used to con fig ure the spindle position control loop in the NC.

When thi s input si gn al is “opened”, the CNC configur es the position control loop for the

spindle after confi rm ing that the spindle has stopped. It th en re turns the spindle positio n

control loop mode ou tp ut signa l (SL PS).

(3) Spindle Position Loop Mode Output Signal

The output signa l oc curs when the CNC has set the posit i on control loop for the spi ndl e t o

execute so l id tapping.

The executio n of the G93 block is com pleted by the outpu t of t his sig nal.

1 - 10

Page 18

YASNAC PCNC I/O Signal Function Manual Chapter 1: Feed Function

(4) Solid Tap Gear Selection Signal

For the machin e equipped withtw0-step gear range , it is possible to execute solid tapping in

both gear ranges A and B (Low and High ). When the signal is “open”, the A gear range is

selected, and when it is “closed”, the B gear range is se lected.

The signal must be set before the designation of the G93 (solid tap command) block. Once set,

the signal status must not b e changed until the solid tap mode is cancelled.

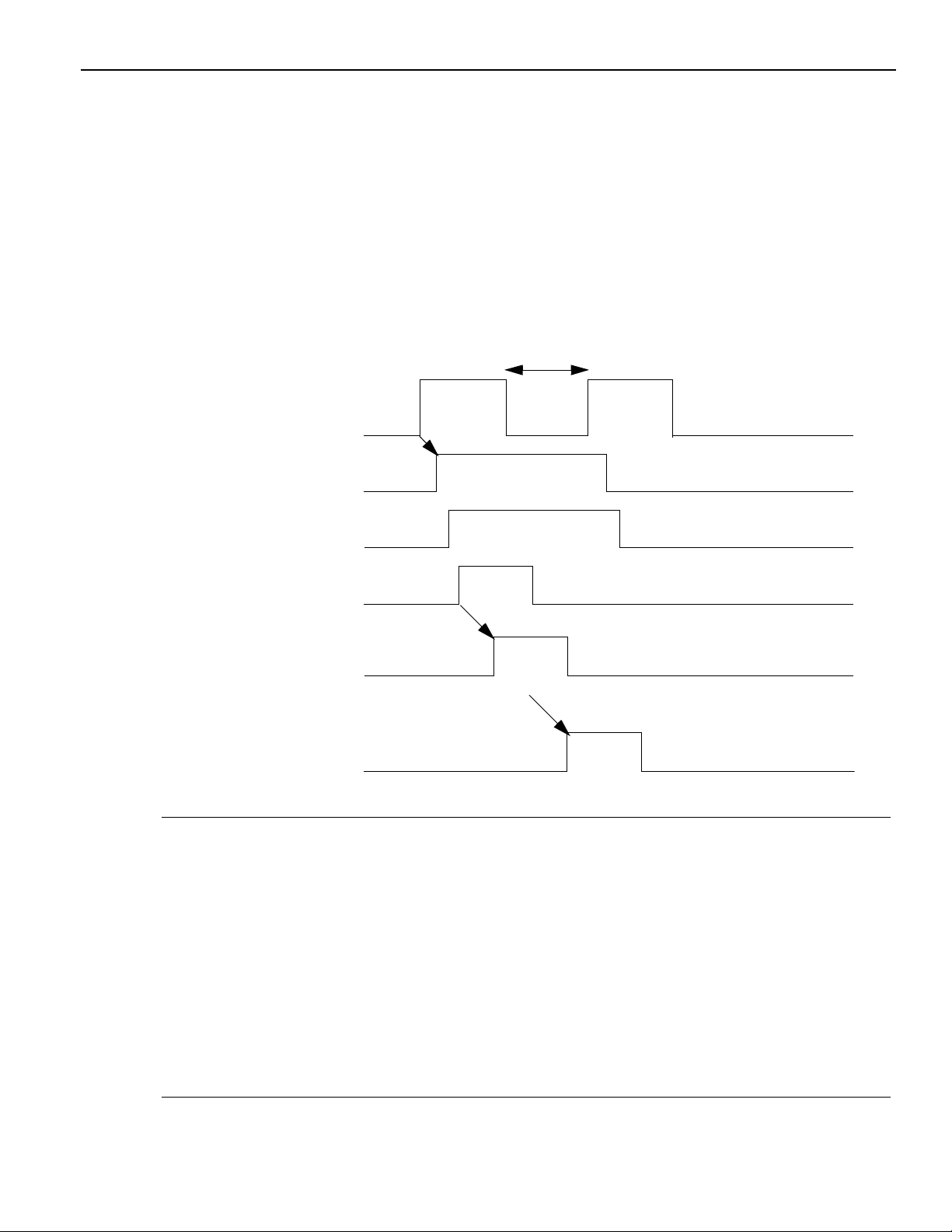

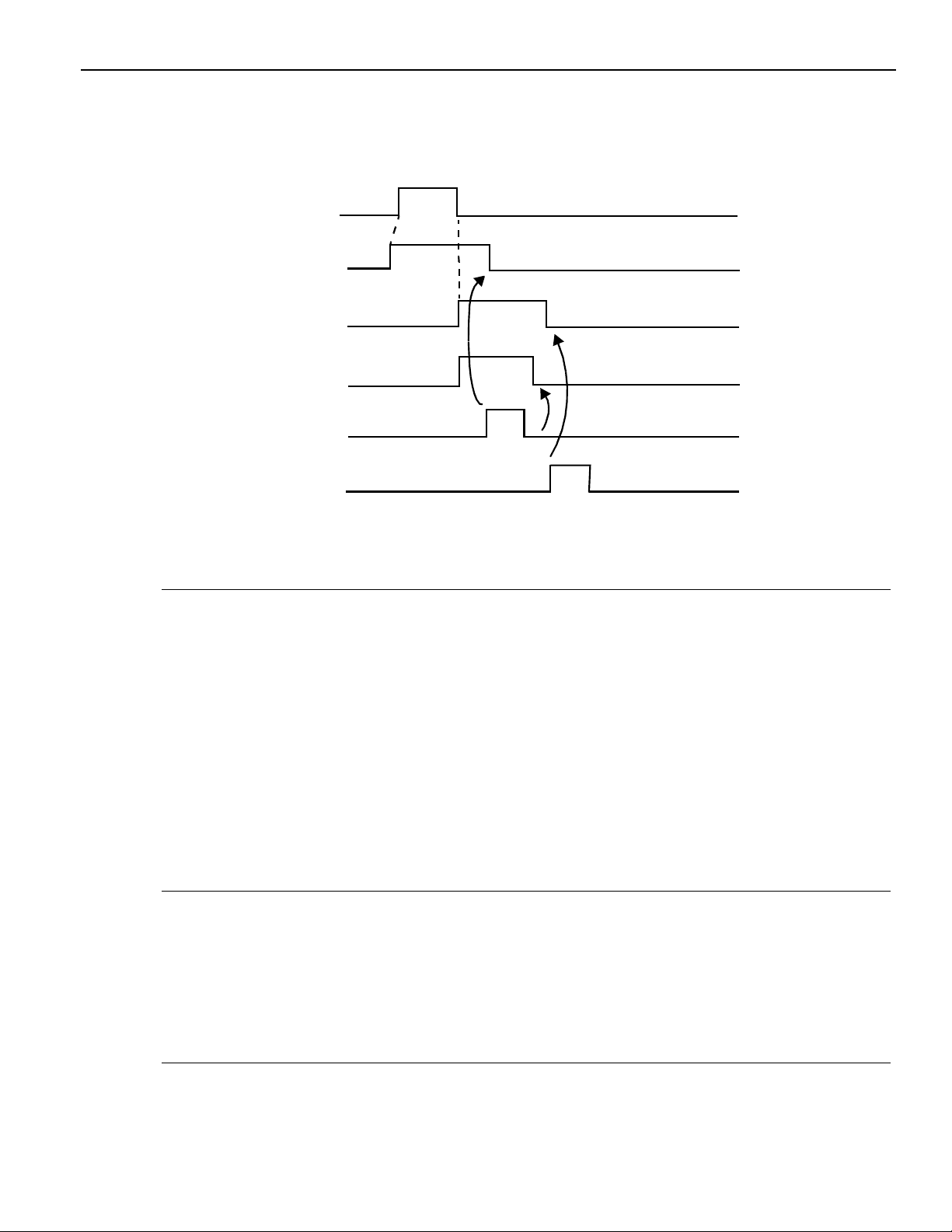

(5) Time Chart for Solid Tap Operation

Solid tap mode

G93 block G94 block

CNC program

G93M

Machine

Side

SUPPLEMENT

1. The G93M signal is “opened” when the G93 block is executed with both the dry run and MST

function lock OFF.

2. The G93M signal is “closed” when the execut io n of the G94 block starts or the CNC is reset.

Spindle start

(forward)

SLPC

Internal

processing (NC)

SLPS

Spindle

indexing

3. The G93 block is assumed to have been completed when the SLPS is “opened”, and the pro-

gram advances to the next block.

4. The G94 block is assumed to have been completed when the SLPS is “closed”, and the pro-

gram advances to the next block.

1 - 11

Page 19

YASNAC PCNC I/O Signal Function Manual Chapter 2: Saving And Editing Programs

2

SAVING AND EDITING PROGRAMS

Chapter 2 describes the signa ls for stori n g and e ditin g programs.

This Page is left Blank Intentionally.

2 - 1

Page 20

YASNAC PCNC I/O Signal Function Manual Chapter 3: Operation And Display

3

Operation And Display

Chapter 3 describes the signals related to operation and display.

3.1 Calendar Output Signal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3 - 1

Page 21

YASNAC PCNC I/O Signal Function Manual Chapter 3: Operation And Display

3.1 Calendar Output Signal

Calendar Output Signal CALEN1 TO CALEN4 #35064 TO #35067

By comparing the internal calendar of the CNC with the parameter (date) setting and by

out-pu tting the result of the comparison, it is possible to dispa ly a message such as a regular

maintenance warni n g by using the sequence program.

The calendar is in the CNC. By comp ari ng the ca le ndar t o the data par amete r sett in g, th e

result of the comparison is output. If the parameter setting is smaller than the CNC calendar

value, the signals (CALEN1 to CALEN4) are output corresponding to the pa ram eter used

for comparison.

For such processing, up to fou r parameters can be used to save the ca le ndar data.

The following shows an example of calendar data settin g for a parameter:

pm0905 = 19961 020 (October 20,1996)

pm0906 = 19960 301 (March1,1996 )

(1) Calendar O utput Signals (CALEN1 to CALEN 4)

The follow in g table shows th e relationship between the CNC calendar and the calendar signals to be output.

Signal Description

#35064 The status of No. 1 calendar

*Output when the CNC calendar data exceed the setting for pm0905

#35065 The status of No. 2 calendar

*Output when the CNC calendar data exceed the setting for pm0906

#35066 The status of No.3 calendar

*Output when the CNC calendar data exceed the setting for pm0907

#35067 The status of No. 1 calendar

*Output when the CNC calendar data exceed the setting for pm0908

3 - 2

Page 22

YASNAC PCNC I/O Signal Function Manual Chapter 3: Operation And Display

(2) Calendar Status

The relationship between the CNC calendar data and a parameter setting is indicated below.

Parame ter Value I/O

19960714 1

19960715 0

1995999 1

2000000 0

Since the calendar da ta tre at e d as bi nary data, comparison is possible even if the mo nt h value

exceeds “12”or day value exce ed s “31”.

For example, if the setting for a parameter is “19999999”, and if the CNC calendar data is

“19960715” (July 15 ,1 996), comparison is made as indicated below.

<

19960715 - 19999999

0

=

Since the result of compari son is negative, the output i s “0” (status of the calendar).

T o clear the calendar status, reset an appropriate value for a calendar parameter. When a

value greater than the CNC calendar data is et, t h e s tatus of the calendar is cleared.

The parameters used as the calendar parameter are indicated below.

pm0905 No. 1 calendar parameter

pm0906 No. 2 calendar parameter

pm0907 No. 3 calendar parameter

pm0908 No. 4 calendar parameter

3 - 3

Page 23

YASNAC PCNC I/O Signal Function Manual Chapter 4: M, S, T, and B Functio ns

4

M, S, T And B Functions

Chapter 4 desribes the signals for M, S, T, and B functions.

4.1 Input/Output Signals of M. S, T and B Code s4-2

4.2S5-Digit Command Input Signal4-5

4.3 Gear Range Se le ct ion Input and Output Signals4-9

4.4 Gear Shift Input and Spindle Fixed Speed Input Signals4-11

4.5 Spindle Speed Agre ed Input Signal4-12

4.6 Spindle Speed Override Input Signal s4-12

4.7 Binary Comma nd Input Signals4-14

4 - 1

Page 24

YASNAC PCNC I/O Signal Function Manual Chapter 4: M, S, T, and B Functio ns

4.1 Input/Output Signals of M,S,T and B Codes

(1) M, S, T and B Code Output Signals and M, S, T and B Code Re a d O ut put Signals

M code output MA0 to MA9 #35200 to #35211

S code output SD00 to SDO23 #36540 to #36567

Tcode output TO to T19 #35300 to #35323

B code output B0 to B15 #35330 to #35347

M code read output MF #35350

S code read output SF #36517 T code read output TF #35357 B code read output BF #35355

Kinds and Addresse s of M, S, T an d B Code Output Signals & Read Output Signals

These are output sign al s for the M, S, T and B commands specified in a program.

If a M, S, T and B command is read during the execution of a part program in the automatic

mode, then CNC outputs the signals according to the numeric value specified with address

M, S, T or B.

Then, the M, S, T or B code read ou tput sig nal is “closed” after the e lapse of the time se t fo r

a parameter.

IMPORTANT!

In the case of an S4 digit comm an d, an S cod e sig na l an d S code read signal are not outpu t

since the output is a 12 bit no-c ont act output or analog out put for a S4 digi t command.

1.M commands for logic circuit processing (M90 to M99)

Neither M code nor MFA code is output. M codes are those for interna l processing of the

CNC, and accordin gly, they cannot be used as external M codes.

2.M decode output signa ls (M00R, M01R, M02R and M30R)

Among the M codes, if M00, M01, M02 or M30 is executed, the corre sponding M decode

output signals (M00R(# 35214); M01R(#35215); M 02R(#35216); M30R( #35 217) appear

in addition to the M code and M code read output signals. The M decode output signal is

“opened” at th e start of automatic operation or when the CNC is res et.

If an M command with a dec ode out put signal is specified to gether/along with an a xis

movement com m and in the same block, the M de code output signal appe ars only after the

4 - 2

Page 25

YASNAC PCNC I/O Signal Function Manual Chapter 4: M, S, T, and B Functio ns

completion of the specified axis movement although th e M code out put signal ap pears at

the start of the execution o f th at block.

An example of the M decode ou tpt is shown in Fig. 4.1.

Axis movement

command

M code output

M decode output

DEN

FIN

Cycle start or

restart signal

Fig. 4.1 M Decode Output Time Chart

(2)M, S, T and B Function Completion Inut Signals

These input signal s indicate the com leti on of a M,S,T or B command to the CNC.

Output sign als MF, S F,TF and BF are “opened” if input signal FIN is “closed” while th e M,

S, T and B code read (MF A, SF,TF and BF) output signal is “open”. Then, when input signal

FIN is “opened” after the confirmation of “opening” of the output signal, the CNC assumes

that the execution of M,S,T or B command has been competed and execures t h ye next step

operation.

IMPORTANT!

1. The M code outptu signal is “opened” when the status of input signal FIN changes

from “closed” to “open”. For the S, T and B code outptut signals, the “open” or “closed ”

state is maintained.

2. For T and B codes, there are only bunary outputs and BCD outputs are not given.

4 - 3

Page 26

YASNAC PCNC I/O Signal Function Manual Chapter 4: M, S, T, and B Functio ns

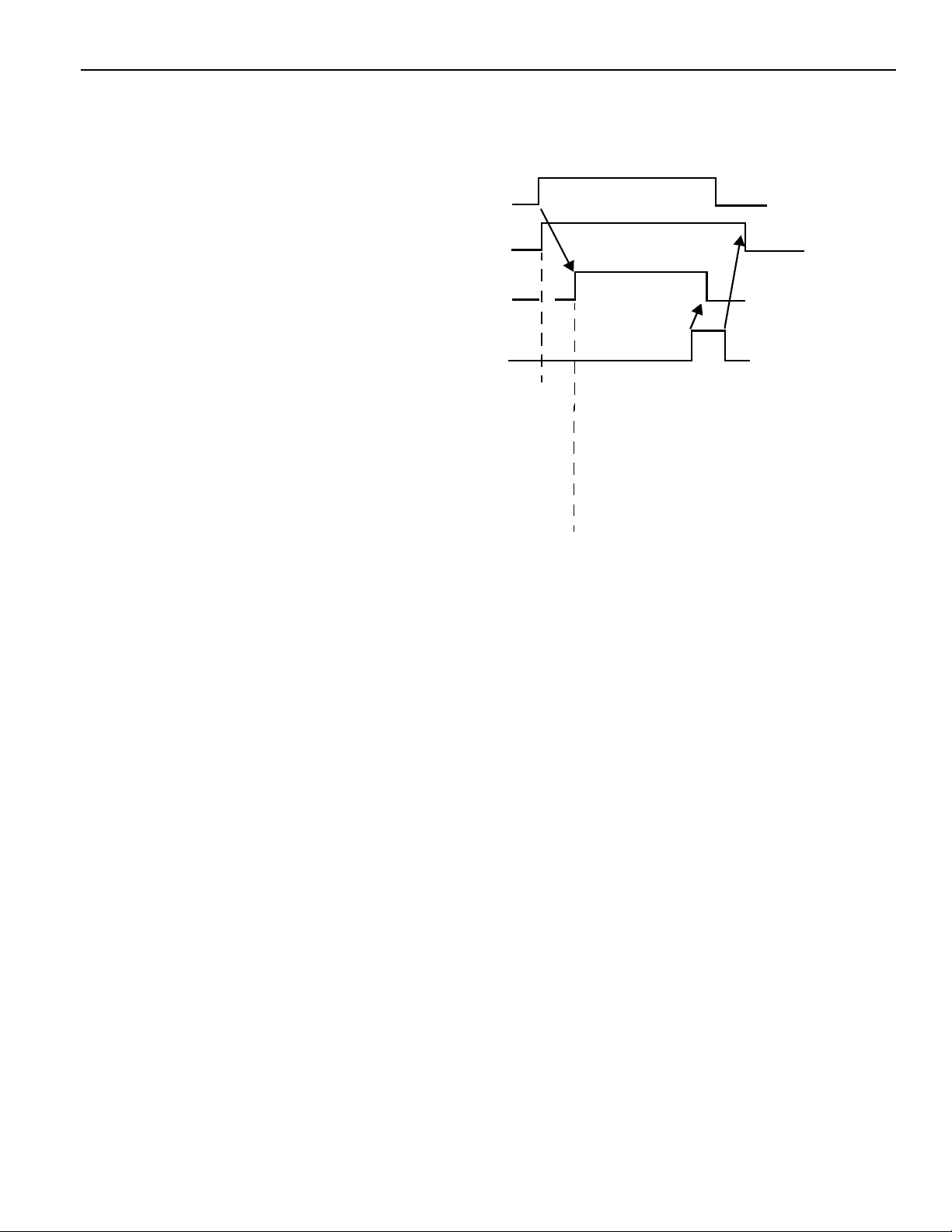

(3)Time Chart of M, S, T and B Signals

(a) When an M command is specified:

M code output

DEN

Read output

FIN input

Fig. 4.2 M Code Signal Time Chart

(b) When an S,T and/or B com m an d is spe ci fied

To the next step

Fig. 4.2 S/T/B Code Signal Time Chart

(c) When M/S/T/B command is specified with a n axis movement comma nd in the same

block.

4 - 4

Page 27

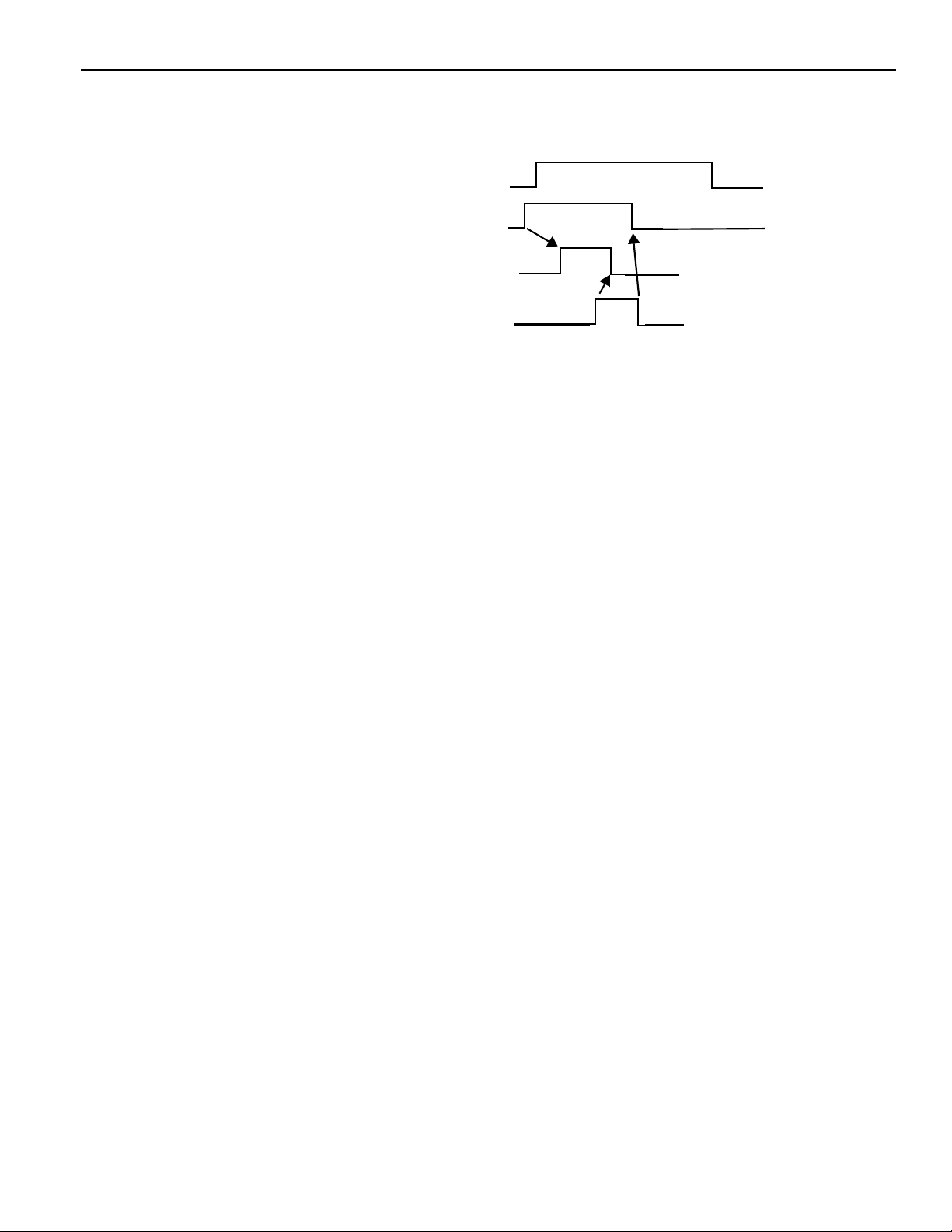

YASNAC PCNC I/O Signal Function Manual Chapter 4: M, S, T, and B Functio ns

If an M/S/T/B command is specified along with an axis movement command in the same

block, the M/S/T/ B command is ex ec ut ed simultaneously with the axis move me nt.

Axis movement

To the ne xt st ep

M code output

M code read output

FIN input

Fig. 4.4 M/S/T/B Code Signal Time Chart when Specified with

an Axis Movement Command in the Same Block

4 - 5

Page 28

YASNAC PCNC I/O Signal Function Manual Chapter 4: M, S, T, and B Functio ns

4.2 S5-Digit Command Input Signal

S Code Analog Output Inverse Input SINV #31104

S Code Analog Output Status Output SINVA #36500

Spindle Gear Range Input GR1 to GR4 #31100 to #31103

The CNC outputs these signals to determine the rotation speed of the spindle motor for “S5-

digit non-cont ac t ou tpu t” or “S5-digit analog outpu t” signals.

GR1 to GR4 (#31100 to #31103) signals input the statu s of gea r ra nge to t he CNC to determine the spindle m otoe speed accordi ng to the sp indle speed specified in a pa rt program.

Input signal SINV is used to invert the polartiy of the analog output signal for the S5-di gi t

analog output spe ci fication.

The M04s (#3538d0) is “opened” at the start of the M03 command, and i t is “closed” at the

start of the M04 command.

(1) 24-bit Non-contact Output for S5-digit Command

In response to the specifi e d sp in dle spe ed a nd th e gear range input (GR1 to GR4), a 23-bit

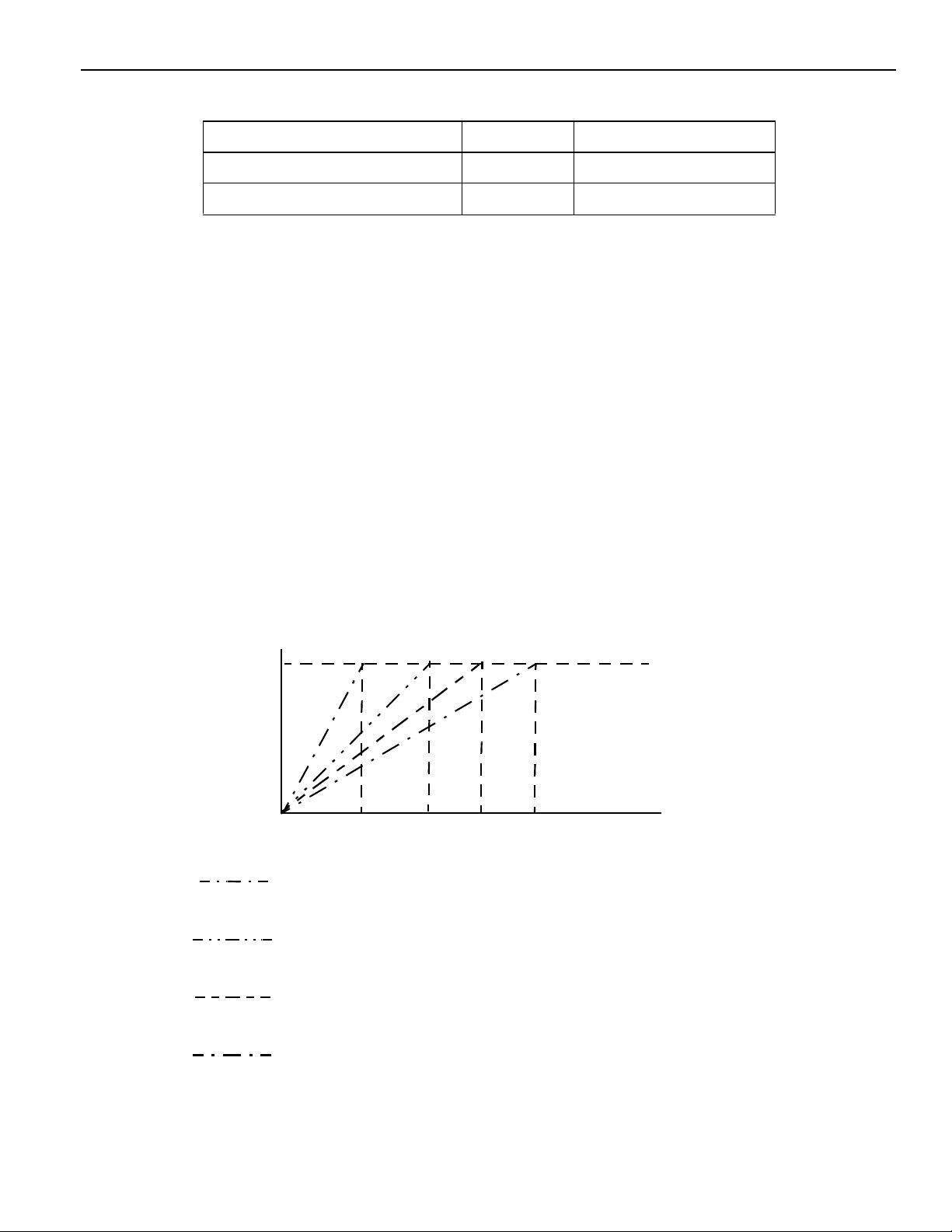

binary code (0 to +8 388608: spindle speed ) is out put as show n in Fig. 4.5.

.............................................................................................................................

Spindle Motor Speed

Command Output

8388608

.

Spindle Speed

GR1REV GR2REV GR3REV GR4REV

Fig. 4.5 Non-contact Output for S5-digit Command

: Output when GR1 is “closed”.

The saturated spindle m ot or speed of gear range “GR1”

shoul d be

set for parameter pm1408.

: Output ehen GR2 is “closed”.

The saturated spindle m otor speed of gear range “GR2”

shoul d be

set for parameter pm1409.

: Output ehen GR3 is “closed”.

The saturated spindle m otor speed of gear range “GR3”

S Command

4 - 6

Page 29

YASNAC PCNC I/O Signal Function Manual Chapter 4: M, S, T, and B Functio ns

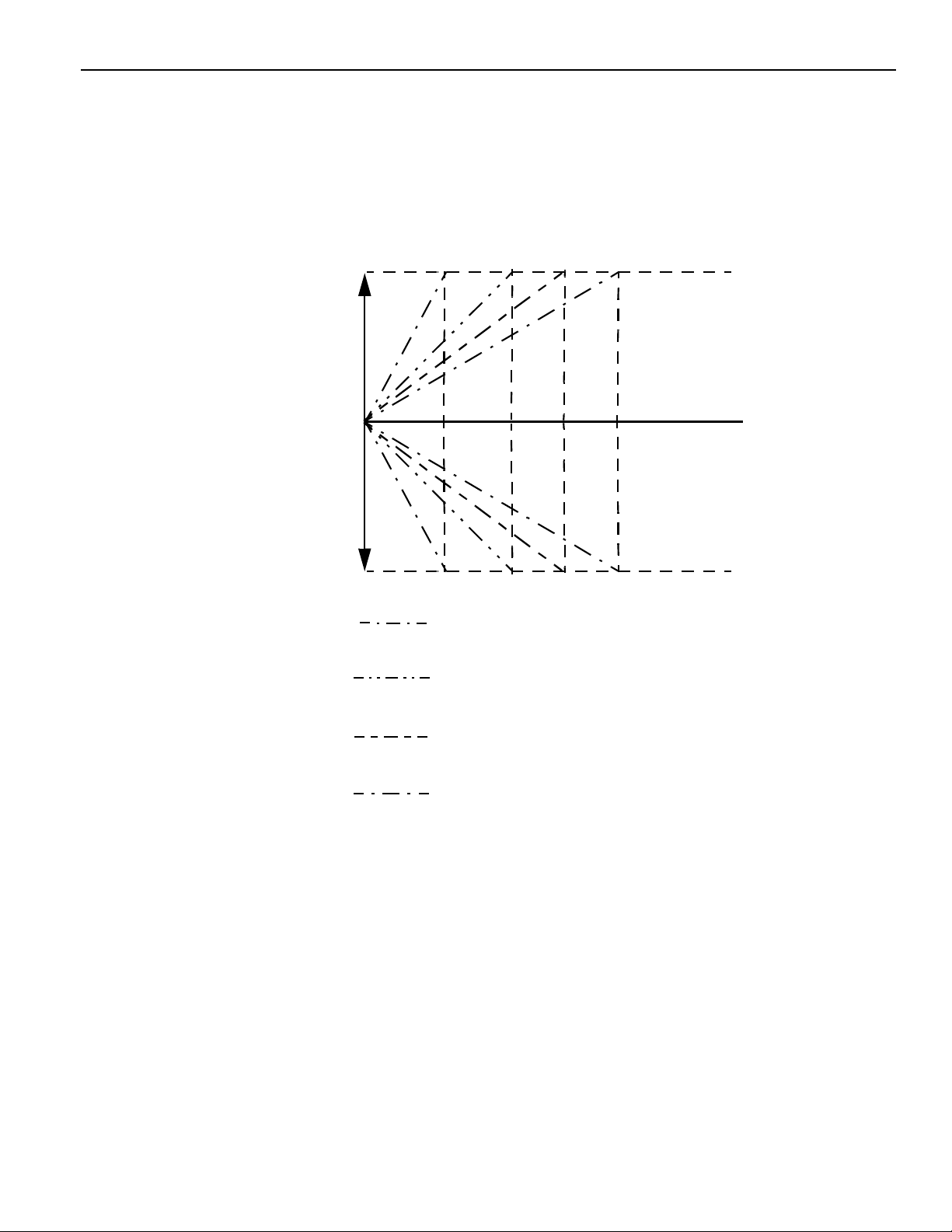

(2) Analog Output for S50-digit Command

In response to the specif ie d spindle speed and the gear range input (SINV), anal og voltage

(-10V to 0V to +10V) is ou tp ut a s shown in Fig. 4.6.

Spindle Motor Speed

Command Output

+10V

0V

-10V

GR 1REV GR2REV GR3REV GR4REV

Spindle Speed

S Comm an d

: Output when GR1 is “closed”.

: Output ehen GR2 is “closed”.

: Output ehen GR3 is “closed”.

: Output ehen GR2 is “closed”.

Fig. 4.6 Analog Output fo r S5-di gi t Command

4 - 7

Page 30

YASNAC PCNC I/O Signal Function Manual Chapter 4: M, S, T, and B Functio ns

(3) Time Chart of SINV Inut and SINV Ouput

Analog voltage

output

Plus

Minus

100 msec. or shorter

Fig. 4.7 Time Chart of SINV Inut and SINV Ouput

(4) Spindle Speed Clamp

It is possible to set the maximum and minimum spindle speed with parameters for each

of the gear ranges.

Setting the Maximum and Minimum Spindle Speeds

Parameter Description Nos. in

Chart

pm1404 Max. spindle speed when “GR1” input is “closed” pm1405 Max. spindle speed when “GR2” input is “closed” pm1406 Max. spindle speed when “GR3” input is “closed” pm1407 Max. spindle speed when “GR4” input is “closed” pm1400 Max. spindle speed when “GR1” input is “closed” pm1401 Max. spindle speed when “GR2” input is “closed” pm1402 Max. spindle speed when “GR3” input is “closed” pm1403 Max. spindle speed when “GR4” input is “closed”

ú

÷

ø

í

ó

ì

ö

An example of S5-digit analog output signa ls which are clamped by the set maximum and

minimum spindle speed is shown in Fig. 4.8.

4 - 8

Page 31

YASNAC PCNC I/O Signal Function Manual Chapter 4: M, S, T, and B Functio ns

Spindle Motor Speed

Command Output

+10V

.

0V

Output when

SINV input is

“closed”

GR1REV GR2REV GR3REV GR4REV

ó

ú

÷

öø

í

Spindle Speed

Command

Fig. 4.8 S5-digit Analog Outputs Clam pe d by th e Maximum and Minimum Spindle

Speeds Param Setting

IMPORTANT!

1. The spindl e mot or speed command ou tpu t is c al cu la te d by t he following formu la:

(Spindle speed command) x (223 or 10V)

Spindle gear ramge determined by the

Or, spindle speed that corresponds to 10V out put: #1408 to #1411

2. When analog si gn als appear for the spindl e motor, the polar ity can be changed by internally processing M03 (spindle forward rotation) a nd M04 (spindle reverse rotatio n) by

the NC.

4 - 9

Page 32

YASNAC PCNC I/O Signal Function Manual Chapter 4: M, S, T, and B Functio ns

4.3 Gear Range Selection Input and Output Signals

Gear Range Selection Command Output GR1S to GR4S #36504 to #36507

S Function Finish Input SFIN #31117

When an S command is executed, the CNC checks the maximum speed commands of the

individual gear ranges while at the same time it out puts the SF, an d then outputs the gear

selection co mman d (GR1S to GR4S) meet in g th e secified S command.

It then compares the pre s ent gear rang e and returns the FIN if the pres ent gear rang e i s the

same as th e out put gear sele ct ion command. If the gear range must be chang ed, the CNC

enters the gear rang e sel ec t ion sequence. If a fixed speed ou tp ut i s necessa ry for changing

the gear range, the CNC closes the GRO. The CNC outputs the fixed speed signal by giving

top prio rity to this signal.

“Open” the gera range se lection inut signa l ( G R1 to GR4 ) b efore the completi o n of gear

range selection and return the S gear range selection finish (SFIN) at the completion of gear

selection range. The specified spindle speed com m a nd is then output as the non -contact or

D/A output signal.

Then return the FIN when spindle speed agrees with the specified spindle speed.

(1) Gear Selection Sig na l Out put Timing

When an S command is re ad, the contro ller judges whether or no t th e gear range must

be changed and exceutes necessary range selection automatically. How this is exceuted

is shown in the time chart shown in Fig. 4.9.

In this example, gear range of GR@ is selected by the commands of “S1000 M03” and

a new spindle speed command “S2000” is specified which requires the gear range to be

changed to GR 3.

SEQUENCE:

1.The CNC judges tha t ge a r ran ge must be changed to GR 3 and and outputs GR3S signal .

2.At the machine side, this signal (GR3S) should be read by the read-command SF which

has a time delay of “t”, and the gear range should be changed. If the spindle motor must be

rotated to execute gear range change, “open” the GRO.

3.After the com pletion of gear range changing to GR 3, “open” GR3 input and then “open”

SFIN (S command finish in put ).

4.At the time the SFIN is “opened”, a new S command is calculated and sent.

4 - 10

Page 33

YASNAC PCNC I/O Signal Function Manual Chapter 4: M, S, T, and B Functio ns

5. ............................................................................................................................. FIN

should then be “opened” when actuall spin dle s peed agr ees wi th th e sp ecif ied s pin dle spe ed

(S2000, in this example).

Block in which a new

S command is specified

GR1S to Gr4S

Spindle gear range

specification out put

Read instruction

t

Gear range selection

operation (GRO input)

S command finish input

MSTcommand finish input

vo

DA output

Spindle gear rang e input

Fig. 4.9 Gear Range Sel ection Signal Outp ut Timing

SF

(GRO input)

SFIN

FIN

SM or VM

GR3

4.4 Gear Shift Input and Spindle Fixe d Spe ed Input Signals

Gear Shift Input Signal GRO #31107

Spindle Fixed Speed Input Signal SOR #31106

These input signals are used to output an S command (other than the one specified) in a

4 - 11

Page 34

YASNAC PCNC I/O Signal Function Manual Chapter 4: M, S, T, and B Functio ns

part program as analog or non-contact output si gna l for an S5-digit command.

If GRO input is “closed”, the vo lt age set f or pa rameter pm1413 is ou tput.

If SOR in put is “closed”, spindle speed set for parameter pm1412 resulting from the

spindle gear ran ge i nput and spindle moto r speed command vol ta ge that correspond to

the gear ranges, is out put .

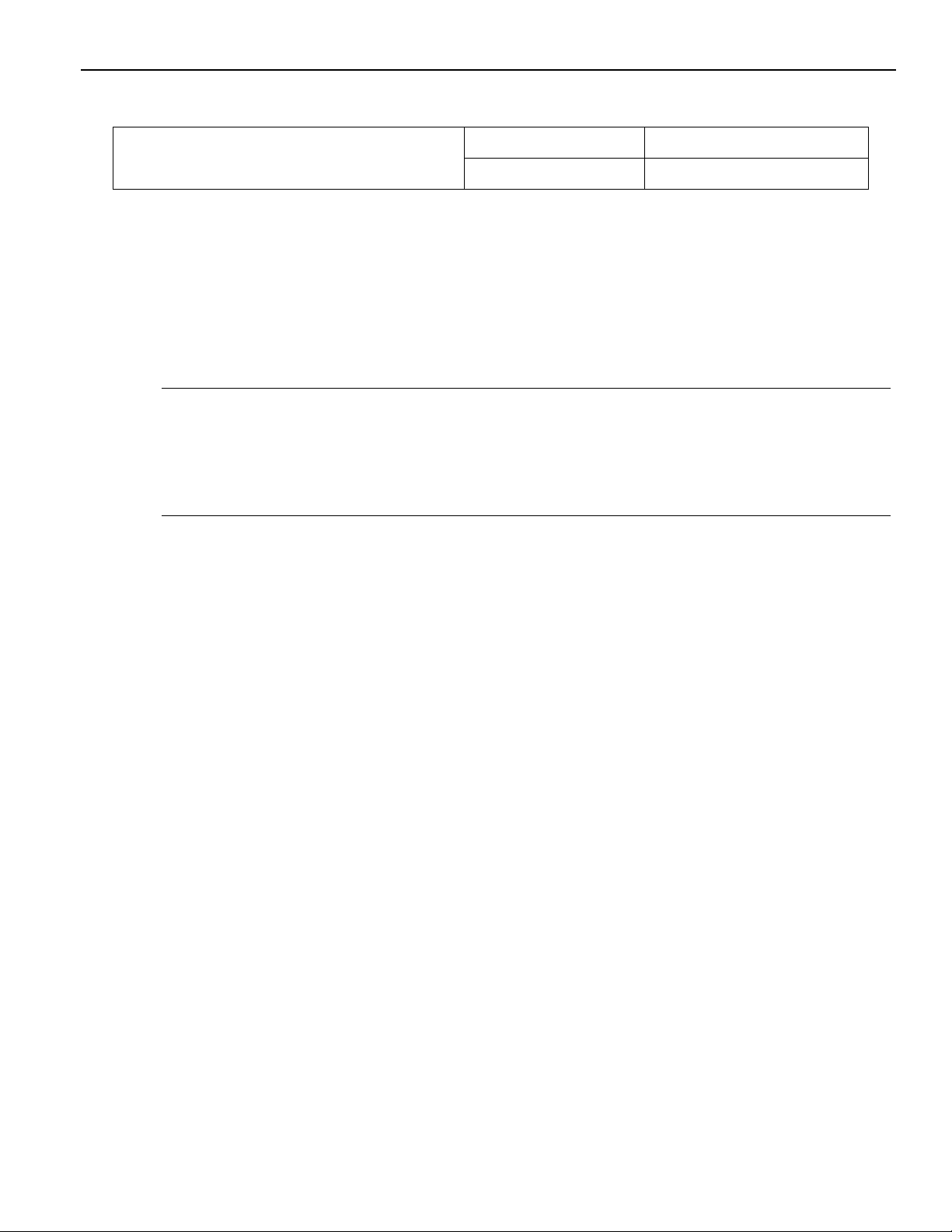

Setting of GRO and SOR Input Signals

GRO

Input

0 0 Voltage corresponding spindle speed specified in CNC program 0 1 Voltage set for parameter pm1412 1 0 Voltage set for parameter pm1413 1 1 Voltage set for parameter pm1413, 0 V

SOR

Input

Analog Voltage for S5-digit Command

Note: The status of signals is indica ted by “0” or “1”.

0: Op en

1: C losed

IMPORTANT!

1.It is possible to invert the voltage command (analog output for GRO, SOR input) by the

input of a S5-digit analog output inversion (S IN V#31104) input signal.

2.The length of time in wh ic h an analog voltage value responds to the setting of t he G RO

and SOR inputs is less than 100msec .

4.5 Spindle Speed Agreed Input Signal

Spindle Speed Agreed Input Signal SAGR #31116

If the CNC specific a ti on is a S5 -di git analog command or non-contact outpu t, thi s inp ut

signal in dicates that the spindle speed has reached the specified speed at the point where

cutting s tarts during the execution o f a p art program in auto matic mo de.

When cutting should sta rt (axis fee d m ode is changed from the positioni ng m ode to an

4 - 12

Page 35

YASNAC PCNC I/O Signal Function Manual Chapter 4: M, S, T, and B Functio ns

interpolation mo de), the CNC starts cutting aft er confirm ing that the SAGR inp ut signal

has been “closed”.

4.6 Spindle Speed Override Input Signals

Spindle Speed Override Input Signal SPA to SPE #31110 to #31114

If the CNC specific a ti on is a S5 -di git analog command or non-contact outpu t, the

spindle speed overri de input signal is used to overr ide an S-command specifi ed in a part

program in the range from 50 to 120%.

Spindle Speed Override Input Setting and Override Values

SPA Input SPB Input SPC Input Override

Value

11150% 01160% 01070% 11080% 10090% 0 0 0 100% 0 0 1 110% 1 0 1 120%

Note: The status of signals is indica ted by “0” or “1”.

0: Open

1: Closed

20-step override spec ification is optiona l.

Spindle Speed Override Input Setting and Override Values

SPA Input SPB Input SPC Input SPD Input SPE Input Override

Value

0001010%

0011020%

4 - 13

Page 36

YASNAC PCNC I/O Signal Function Manual Chapter 4: M, S, T, and B Functio ns

SPA Input SPB Input SPC Input SPD Input SPE Input Override

Value

0111030%

1111040%

1110050%

0110060%

0100070%

1100080%

1000090%

00000100%

00100110%

10100120%

10110130%

10010140%

10010150%

01010160%

01011170%

01001180%

00001190%

10001200%

Note: The status of signals is indica ted by “0” or “1”.

0: Open

1: Closed

IMPORTANT!

In a tap cycle in the solid ta p mo de , spi ndl e override is invalid if override value is fixed at

100%.

4.7 Binary S Command Input Signals

Binary S Command Input Signals SDI0 to SD123 #36540 to #36567

These input signals are used to specify spindle spe ed i n a 24-bit digital signal instea d of

analog voltage.

4 - 14

Page 37

YASNAC PCNC I/O Signal Function Manual Chapter 4: M, S, T, and B Functio ns

Note:Although the resol ut ion of the CNC is 24 bits, the resolution is restricte d by th e

input resolution of the spindle drive where the binary S command signal is output.

4 - 15

Page 38

YASNAC PCNC I/O Signal Function Manual Chapter 5: Coordinate Systems

5

Coordinate Systems

Chapter 5 describes the signals related to the coordinate system.

5.1 Reference Point Return Control Input/Output Signals. . . . . . . . . . . . . . . . . . . . . .5-2

5 - 1

Page 39

YASNAC PCNC I/O Signal Function Manual Chapter 5: Coordinate Systems

5.1 Reference Point Return Control Input/Output Signals

Reference Point Return Input Signal ZRN #30070

Reference Point Return Deceleration LS *DCX to *DC5 #30730 to #30734

Second Reference Point Return Input Signal ZRN2 #30071

At the Reference Point Output Signal ZPX TO ZP5 #36300 TO #36304

At the Second Reference Point Output Signal 2ZPX to 2ZP5 #36310 to #36314

At the Third Refere nce Point Output Signal 3ZPX to 3ZP5 #36320 to #36324

At the Fourth Refe rence Point Output Signal 4ZPX to 4ZP5 #36330 to #36334

These are input/ou tput signals used for the return function which positions the axes at the predetermined reference point when the CNC power is turned ON.

(1) Reference Po i n t R eturn Methods

For the execution of th e reference point retu rn, the fol lowing methods are provided:

Grid type

High-speed type

(a) Grid type Reference Point Return

With this method, the reference point is determined by the zero-point pulse of the position

encoder (1 pulse/turn).

After turning the CN C power ON, close the ZRN input with the manual jog operation

mode or rapid fee d mo de, and move the axis in th e refe re nce point return direct ion.

Then, the reference point return operation is executed in the sequence as shown in Fig.

5.1.

The G28 command in automatic mode is ex ecuted in the same manner as above.

Feedrate Rapid traverse (pm2801 to pm2805)

Decel. point

Approach speed (pm2521 to pm2525)

Creep speed (pm 2531 to pm2535)

Moved distance (pm4451 to pm 4455)

Feedrate sequence

Dog

width

(*DECX, *DECY, *DECZ, *DEC4, *DEC5)

Feedrate LS signal

Zero-point pulse

Fig. 5.1 Reference Point Return Sequenc e (Grid type)

5 - 2

Page 40

YASNAC PCNC I/O Signal Function Manual Chapter 5: Coordinate Systems

(b) High-speed type reference point ret urn

When the high-sp ee d ty pe (automatic, amunual) is selected, once the reference poi nt

return is executed, the second and later reference point returns are exe cuted by the

positioning mode to the reference point which is determined in the f irst reference

point operation.

Feedrate Rapid traverse

Feedrate sequenc e

Fig. 5.2 Reference Point Return Sequence

(High-speed type, Seco nd a nd Later Operation)

SUPPLEMENT

By setting parameters pm 4003D6 and D7, it is possible to select the gri d typ e for the se cond and

later reference poin t re tu rn ope rations.

(2) Reference Poi nt R etu r n S ig n als

The reference poi nt retu rn sig na ls are de scri bed as follows:

(a) Second reference point retur n input signal

When the second refe re nc e point is ste by the shift amount from the first refere nc e point.

(b) At the reference point output signal

When a nu me rica ll y co n tro lled a xis e xi sts at th e ref eren ce po int as a res ult of t he r efe r ence

point return operation or the positioning to the reference point, the co rre sponding output

signals (ZPX to ZP5) are closed. Note that the output signal is closed only when the corresponding axis ex it s in th e ra nge of +

3 pulse s f r om the refe rence po int posit io n.

(c) At the second r eference point ou tput signa l

In the automatic operation, when an axis is positioned at the second reference point by the

executio n of the “G30” command in a par t pro gra m, the corresponding out put signals

(2ZPX to 2ZP5) ar e cl o s ed to indicate that the axis is at the second reference point.

5 - 3

Page 41

YASNAC PCNC I/O Signal Function Manual Chapter 5: Coordinate Systems

(d) At the third reference point output signal

In automatic operation, when an axis is positioned at the third reference point through the

executio n of the “G30 P3” command in a part pro gram, the correspondi ng out put signals

(3ZPX to 3ZP5) are closed indicating that the axis is at the third reference point .

(e) At the fourth reference point output signal

In automatic opera tion, when an axis is posit ioned at t he four th refer ence poi nt thro ugh the

executio n of the “G30 P4” command in a part pro gram, the correspondi ng out put signals

(4ZPX to 4ZP5) are closed indicating that the axis is at th e fo u rth refere nce point.

5 - 4

Page 42

YASNAC PCNC I/O Signal Function Manual Chapter 6: Operation Support Functions

6

Operation Support Functions

Chapter 6 describes the signals related to the operation support functions

6.1 Input and Output Signals of CNC Operation Modes . . . . . . . . . . . . . . . . . . . . . . .6-2

6.2 Manual Jog Feedrate Selection Input Signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7

6.3 Manual Pulse/Step Mulitplication Ratio Setting Input Signals . . . . . . . . . . . . . . .6-9

6.4 Automatic Operation Start/Stop Input Signals

and Running/Stopped Output Signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-10

6.5 Single-Block Input Signal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-12

6.6 Manual Absolute Input Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-12

6.7 Display Lock Input Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-13

6.8 Program Restart Input Sig nal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

6.9 Dry Run Input Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-14

6.10 Machine Lock Input Signal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

6.11 Auxiliary Function Lock Inpout Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-15

6.12 Edit Lock Input Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-16

6.13 Automatic Mode Handle Offset Input Signal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

6.14 Interruption Point Return Input Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-16

6.15 Optional Stop Input Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-17

6.16 Axis Disconnection Designation Input Signals . . . . . . . . . . . . . . . . . . . . . . . . . . .6-17

6 - 1

Page 43

YASNAC PCNC I/O Signal Function Manual Chapter 6: Operation Support Functions

6.1 Input and Output Signals of CNC Operation Modes

(1) Operation Mode Input Signals

These input signals define the operation modes of the CNC by the programmable controller.

For the CNC, the followi ng eight (8) operation modes are provided.

RT #30000 Manual rapid traverse mode

JOG #30001 Manual jog feed mode

H #30002 Manual pulse handle mode

STP #30003 Manual skip feed mode

MDI #30005 Manual da ta input mode

MEM #30006 Memory mode

Manual mode

Automa tic mode

An operation mode is determined by closing one of these input signals.

(a) RT: Manual Rap id Traverse Input Mode

When the “RT” input signal is “closed” with other “open”, the CNC enters the manual

rapid traverse m o de. In this mode, i t controls axis feed accordin g to the inp ut signal of

the manua l fe ed direction and also the rapid override signal.

(b) JOG: Manual Jog Feedra te Sel ec ti on Input Signals

When the “JOG” input signal is “closed” with other inputs “open”, the CNC enters the

manua l jog feed mo d e. In this mode, it controls ax is feed acc o r ding to th e input signal

of the manual feed dire ction.

(c) H: Pulse Handle Mode Input

When the “H” input signal is “closed” with other inputs “open”, the CNC enters the

pulse handle mode. In this mode, it controls axis feed according to axis selection and

the multiply setting signals by operation of the manual pulse generator.

(d) STP: Manual Step Feed Mode Input

When the “STP” input signal is “closed” with other inputs “open”, the CNC enters the

tape mode. In this mode, operation using CNC tape which is read by the ta pe rea der is

enabled.

By setting the appropriate parame t er, it is possible to inp ut a part program from the

RS-232C interface instead of using the tape reader.

6 - 2

Page 44

YASNAC PCNC I/O Signal Function Manual Chapter 6: Operation Support Functions

(e) MDI: Manual Data Input Mode

When the “MDI” input signal is “closed” with other inputs “open”, the CNC enters the

MDI mode. In this mode, operation using a part program entered by the manual data

input op eration is enabled.

(f) MEM: Memory Mode Input

When the “MEM” input signal is “closed” with other in puts “open”, the CNC enters

the memory mode. In th is m ode, operation by usi ng a part stora ge program stored in

the CNC part progra m memory is enabled.

(2) Operation Mode Output Signals

The operation mode output signa ls in diacte the present CNC mode.

Manual Mode Output Signal MAN #35010

Automatic Mode Output Signal AUTO #35011

(a) MAN: Manual Mode Ouput

This signal is outpu t whe n the CNC is in any of the follow ing states:

H (handle mod e)

STP (manual step mode)

JOG (manual jog mode)

RT (rapid feed mode)

(b) AUTO: Automatic Mode Output

This signal is outpu t whe n the CNC is in any of the follow ing states:

TP (tape mode )

MEM (memory mode )

MDI (manual jog mode)

EDT (progr am edit mode)

6 - 3

Page 45

YASNAC PCNC I/O Signal Function Manual Chapter 6: Operation Support Functions

MEM

(Input)

MDI

(Input)

JOG

(Input)

AUTO

(Input)

MAN

(Input)

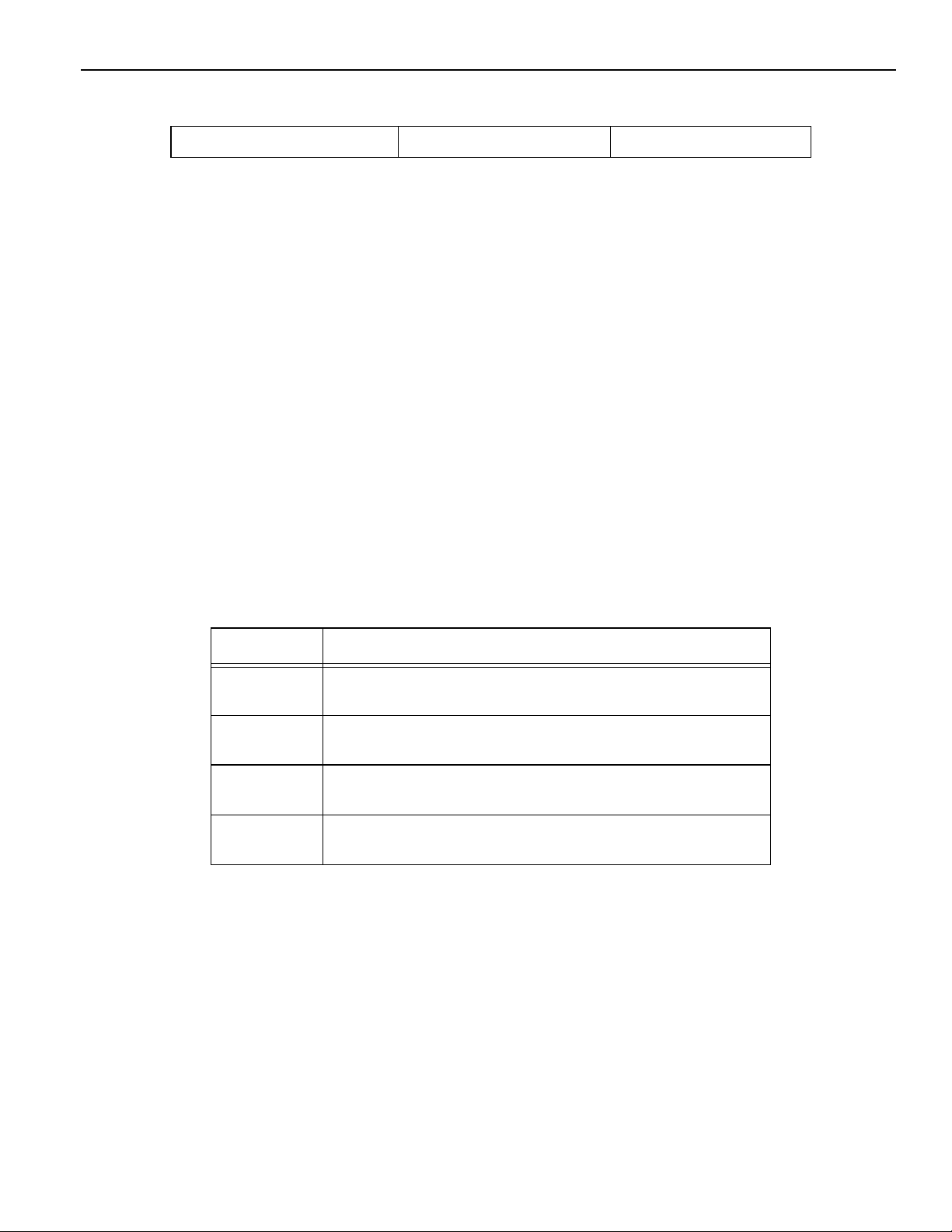

Fig. 6 Time Chart of Operation Mode Input and Output Signals

(3) Supplements to Operation Mode Input/Output Signals

The items that must be taken into consideration conce rni ng the operatio n mo de input/output

signals ar e indicated below:

1. If an operation mode input signal other than manual mode input signals is given during the

memory mode operation, the CNC stops execution of a part program after the completion

of the block present ly being execute d.

This is also true duri ng a part program executio n in t he tape or MDI mode.

2. If a manual mode input signal is given during the execution of a part program in the memory mode, the following occ urs:

• Axis movment commands

6 - 4

Page 46

YASNAC PCNC I/O Signal Function Manual Chapter 6: Operation Support Functions

The axes are decelerated and stopped, then the program is interrupted. The remaining

axis movement commands can be continuously executed by turning the automatic start

(ST) inp u t s ignal ON after retu r ning to th e automat ic mode.

• M, S and T commands

These commands are processed depending on the setting for pm 4009D7 (forced FIN

mode selection).

pm4009D7=0 (fo rce d FIN m ode set)

Both the sampling output (MFB to MFE) and the M code output are turned O F F,

and the M S and/or T comm a nd is assumed to have bee n completed. Therefore,

the interrupted M, S and/or T comm ands is not output even when a n automatic

mode is recovered. SPL indicator is not lit.

pm4009D7=1 (fo rce d FIN m ode not set)

The M, S and/or T command is saved and the SPL indicator is lit.

3. If an automatic mode input signal or program edit mode input si gna l is gi ve n w hi le an

axis is moved in a ma nual mode, the ax is is de celerated and stoppe d.

4. An operation mode input is valid if onl y one of the input signal s is “closed”. Under other

status c on ditions , the prev iously selected operation mode remains valid .

If there is no operation mode input signal or if more than one operation mode input signal

is given af ter the power is tur n ed ON, the P CNC ente rs the manual jog feed mode.

MEM

(Input)

TP

(Input)

JOG

(Input)

Operation

Mode of NC

Fig. 6.2 Operation Mode Input Signal

6 - 5

Page 47

YASNAC PCNC I/O Signal Function Manual Chapter 6: Operation Support Functions

5. If a manual operation mode input signal is given while a tapping cycle is executed in auto-

matic mode, the automatic mode is maintained until thread cutting is completed.

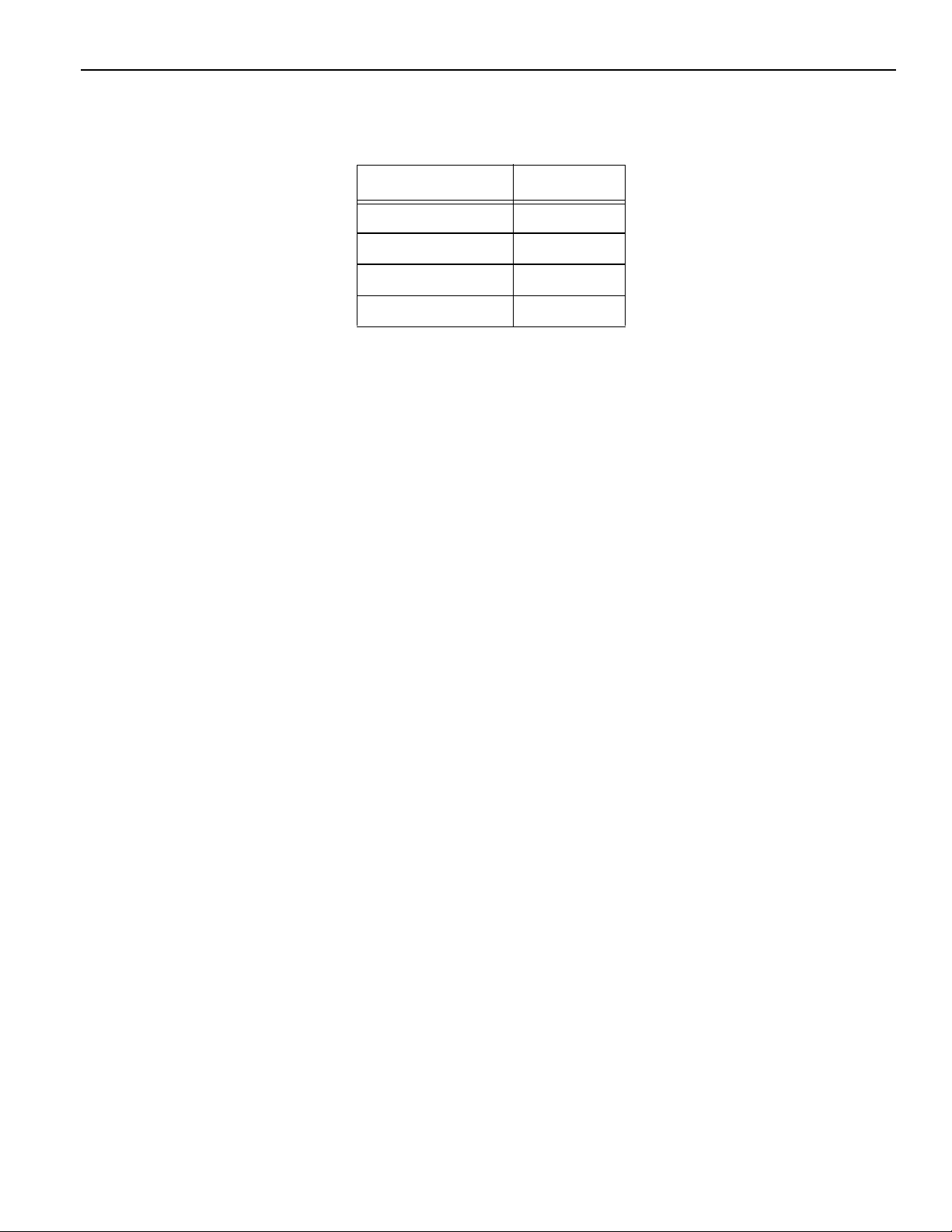

(4) System Number Switch Monitor Output Signals

The status (0 to F) of the rotary switch “SW2” on the JCP01 board is output by the system

number switch monitor outp ut signal.

CAUTION

The rotary switch SW2 de fines the CNC operation and must not be changed

without consulting your Yaska w a representative , or the ma chine tool builder.

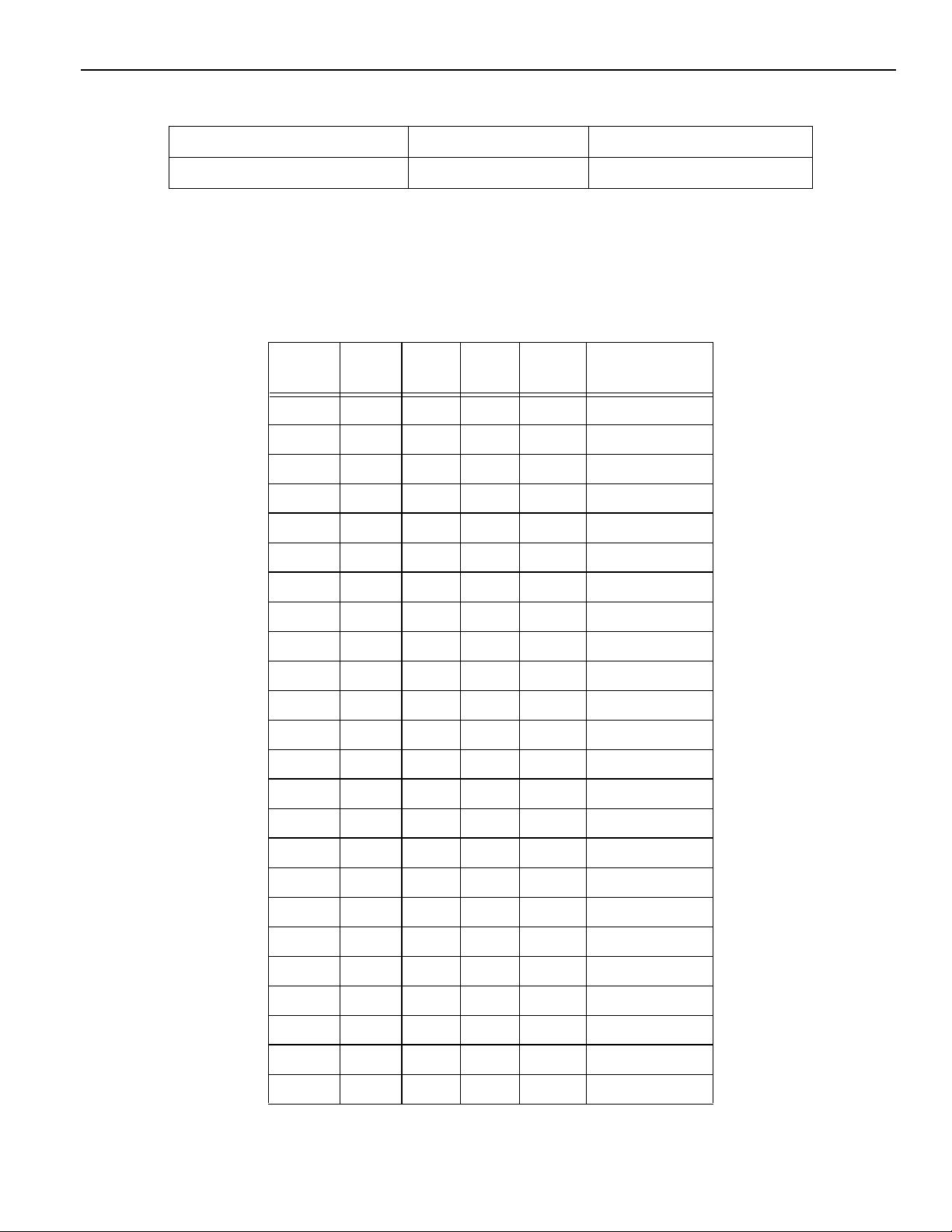

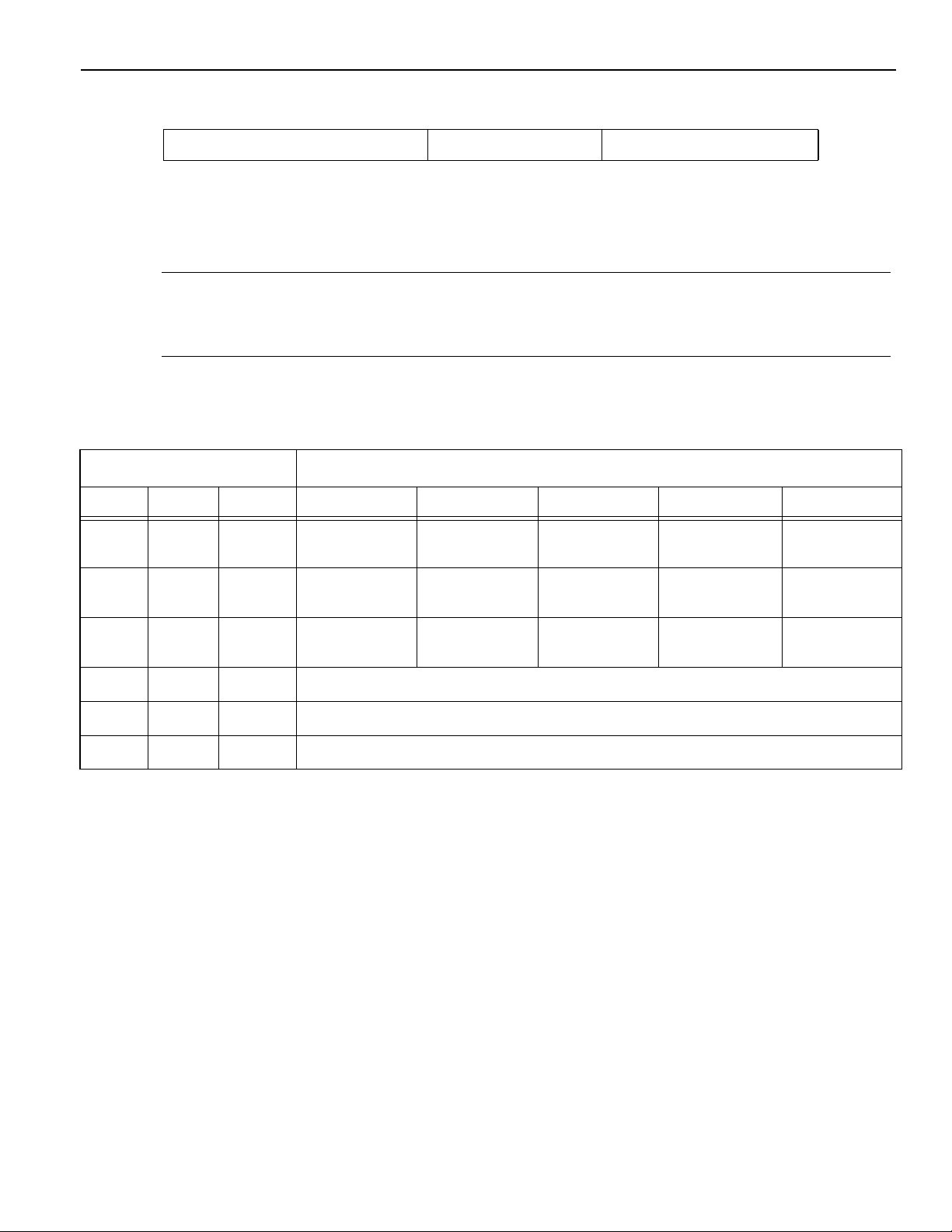

System Number Switch Functions Table

#35023

to

#35020

0000 0 Normal operation

0001 1 End user parameter change mode

0010 2 Standard/option parameter change mode

0011 3 Not used

0100 4 Ladder program exit mode

0101 5 Not Used

0110 6 Not Used

0111 7 Not Used

1000 8 On-line maintenance mode

1001 9 Software debug mode 1

1010 A Software debug mode 2

1011 B Running test mode

1100 C PCB test mode

Rotary

Switch

Setting

Function

ROM

Check

Watchdog Remarks

áá

áá

áá

áá

á

áá

á

With ladder debug function

With ladder debug function

With ladder debug function

With ladder debug function

These positions must not

be selected since they call

the modes on for Yaskawa.

1101 D Not used

1110 E Operation to check contents in memory

1111 F Total make made (f or maintenance)

Note: Rotar y swit ch settings 8 through F are for the Yaskawa Mode.

6 - 6

Page 48

YASNAC PCNC I/O Signal Function Manual Chapter 6: Operation Support Functions

6.2 Manual Jog Feedrate Selection Input Signal

Manual Jog Feedrate Selection Input Signal JV1 to JV16 #30020 to #30024

These signals determine feedrate for manual jog feed operation.

The manual feedrate is also used for the feedrate when executing a part program in automatic

mode with the dry run function set ON.

JOG mode

JV1 toJV16

Valid in this range

Fig. 6.3 Manua l Jog Fe edrate Time Chart

Manual Jog Feedrate Table

JV1 JV2 JV4 JV8 JV16 Jog Feedrate (Manual Mode)

00000Feedrate set for pm2400

10000Feedrate set for pm2401

01000Feedrate set for pm2402

01000Feedrate set for pm2403

00100Feedrate set for pm2404

10100Feedrate set for pm2405

01100Feedrate set for pm2406

11100Feedrate set for pm2407

00010Feedrate set for pm2408

10010Feedrate set for pm2409

01010Feedrate set for pm2410

11010Feedrate set for pm2411

00110Feedrate set for pm2412

10110Feedrate set for pm2413

01110Feedrate set for pm2414

11110Feedrate set for pm2415

00001Feedrate set for pm2416

10001Feedrate set for pm2417

6 - 7

Page 49

YASNAC PCNC I/O Signal Function Manual Chapter 6: Operation Support Functions

JV1 JV2 JV4 JV8 JV16 Jog Feedrate (Manual Mode)

01001Feedrate set for pm2418

11001Feedrate set for pm2419

00101Feedrate set for pm2420

10101Feedrate set for pm2421

01101Feedrate set for pm2422

11101Feedrate set for pm2423

00011Feedrate set for pm2424

10011Feedrate set for pm2425

01011Feedrate set for pm2426

11011Feedrate set for pm2427

00111Feedrate set for pm2428

10111Feedrate set for pm2429

01111Feedrate set for pm2430

11111Feedrate set for pm2431

Note: The status of signals is indicated by “0” or “1”.

0: Open

1: Closed

SUPPLEMENT

For a rotary axis, jog feedrate can be set 1/10 of the feedrate applied for a linear axis by setting the

parameter as indi cated below.

pm2000 D7=0: Fee dra te set for pm2400 to 2431 are appl ied to both linear and rotar y axe s.

pm2000 D7=1: For a rotary axis, 1/10 of the fee drate set for pm2400 to pm 2431 is applied.

6 - 8

Page 50

YASNAC PCNC I/O Signal Function Manual Chapter 6: Operation Support Functions

6.3 Manual Pulse/Step Multiplication Ratio Setting Input Signals

Manual Pulse/Step Multiplication Ratio Setting Input Signal MP1 to MP4 #30025 TO #30027

These sign als determine axis feed amount per step when the PCNC is in the manual handle

or manual step feed mode.

Manual Handle/Step Multiplication Ratio Setting Table

MP1 MP2 MP4 Manual Step Feed Manual Handle Feed

0 0 0 1 pulse/step

1 0 0 10 pulses/step

0 1 0 100 pulses/step

1 1 0 1000 pulses/step 100 pulses/step

0 0 1 10000 pulses/step 100 pulses/step

1 0 1 100000 pulses/step 100 pulses/step

011

111

Note: The status of signals is in di ca ted by “0” or “1”.

0 : Open

1 : Closed

Do not set

6 - 9

Page 51

YASNAC PCNC I/O Signal Function Manual Chapter 6: Operation Support Functions

6.4 Automatic Operation Start/Stop Input Signals and Running/Stopped Output Signals

Automatic Operation Start Input Signal ST #30030

Automatic Operation Stop Input Signal *SP #30031

Running Output Signal #35370

Stopped Output Signal #35371

(1) Automatic Operation Start Input Signal

By “closing” and the “opening” the ST input signal when the tape, memory, MDI or edit mode

is selected for PCNC operation, the PC NC starts automatic operation to execute a part p rogram. At the same time, it turns the running STL output signal ON.

Note that input of th e ST signa l is ignored in the following states:

• The PCN C is in an alarm state. (al ar m output o r input err or s ignal is ON).

• Automatic operation st op “*SP” input is “opened”.

• External reset “ERS” input is “closed”.

• The RESET button on the operation panel is “closed”.

• Emergency stop “*ESP” is not closed.

• STL signal is output dur ing automatic opera ti on.

(2)Automatic Operation Stop Input Signal

After start o f automatic operation, the PCNC completes automatic operation and turns the

automa tic start (STL) output signal OFF when any of the follow ing state s is satisfied.

• In the MDI mode, exe c ution of a part program is completed by the ma nually input data.

• Execution of one bl ock of a part program is completed with the single-block (SBK ) in put

is “closed”.

• The end of a program (EOP) input is “closed” by the execution of an M command in a part

program.

(3) Running Output Signal

If the automatic o p eration s top input “SP” is “opened” during auomatic operation, axis move ment, etc. is inter ru pt ed an d the r unn ing oupu t si gna l “STL” is opened. Then, the stopped output signal “SPL” is closed.

The input of auto ma tic operation stop signal is ignored if it is input in the fol lowing state.

• While a thread cut ti ng block is being ex ec uted.

6 - 10

Page 52

YASNAC PCNC I/O Signal Function Manual Chapter 6: Operation Support Functions

(4) Stopped Output Signal

If the automatic o peration s tart inpu t “ST” is “closed” and then “opened” with the automatic

operation stop input “*SP” closed, the stopped output “SPL” is opened and automatic operation is restarted.

The running ou put “ST L ” is cl osed.

Close

STP

Open

Close

STL

Open

Close

*SP

Open

Close

SPL

Open

PCNC status

Halt Running Halt Running

Fig. 6.4 Time Chart of ST and *SP Input Signal s and STL and SPL Out put Signals

IMPORTANT

1. The automatic operation start (ST) and automatic stop (*SP) input signals must be “closed” or

“opened” for more than 100msec. If it is less than 100 msec., such input signals may be

ignored.

2. If automatic operation stop (*SP) input signal is “closed” in the state where the CNC is waiting for the completio n of M, S,T or B c ommands (waiting for “FIN” input), the automatic

stopped (SPL) output signal is turned ON. If M,T or B command complete (FIN) input signal

is “opened”, the PCNC ent ers the autom a tic operation stopped state.

3. The STL is opened in the single-block stop state.

4. The S T L stays closed i n the alarm state (ALM).

6 - 11

Page 53

YASNAC PCNC I/O Signal Function Manual Chapter 6: Operation Support Functions

6.5 Single-Block Input Signal

Single-Block Inp ut Sign al SBK #30060

This input sign al is used to execute a part program block by bloc k in a utomatic operati on.

When the PCNC is in the automat ic mode with SBK input signal “closed”, if automatic operation

is star ted, the PCNC ex ecutes one block of a part prog r a m and stops, the closes the STL ( running,

#35370) output signal.

If the SBK input signal is “closed” during the execution of a part program, the PCNC stops after

the completion of the block presently being executed.

6.6 Manual Absolute Input Signal

Manual Absolute Input Signal ABS #30061

(1) When the Absolute Input Signal is “Open”

Tool path of a part program e xecuted continuously in automat ic mode after manual int e rruption of axis movement is shifted by the manually moved distance.

G90

G01 Z20. 000 F∆∆

X20. 000 Y30. 000

X10. 000 Y40. 000

.

.

.

X20. 000

{

Y30. 000

X10. 000

{

Y20. 000

X10. 000

{

Y40. 000

Fig.6.5 Tool Path in Automatic Mode Operation

X20. 000

{

Y30. 000

X10. 000

{

Y40. 000

X10. 000

{

Y20. 000

Manually operated axis movement

Fig.6.6 Tool Path after Manual Interrupti on (A BS Input Signal “Open”)

6 - 12

Page 54

YASNAC PCNC I/O Signal Function Manual Chapter 6: Operation Support Functions

(2) When the ABS Input Signal is “Closed”

X20. 000

{

X10. 000

{

Y20. 000

Y30. 000

X10. 000

{

Y40. 000

Fig.6.7 Tool Path with ABS Input Signal “Closed”

6.7 Display Lock Input Signal

Display Lock Input Signal DLK #30062

This input signal is used to prevent outp ut of the PCN C to the external po sition display.

If the DL K in put signa l is “closed”, al though axis move ment is executed (both in autom at ic and

manual modes), the position data pf the external position display (CRT, POS display “EXTER-

NAL”) are not updated.

6.8 Program Restart Input Signal

Program Restart Input Signal PRST #30063

This sig n al is used to r estart machinig fr om a desi gn ated point in a part p r ogram.

After “closing” the PRST input signal, select the memory mode and search the number for pr ogram restart at the PCNC operation panel.

The M,S and T codes existing in the blocks from start of the part program to the specifie d

sequence num be r are displayed on the sc reen.

6 - 13

Page 55

YASNAC PCNC I/O Signal Function Manual Chapter 6: Operation Support Functions

6.9 Dry Run Input Signal

Dry Run Input Signal DRN #30064

The input signal uses the manua l jog fe edrate selection input signals (JV 1, JV2, JV4, JV8, JV16)

for the execution of a part program in automatic mode.

When a part p rogram is exec uted in automatic mode w i th the DRN i nput signal “closed”, axis

feed is executed not by the feedrate specified in the part progra m but by the feedrate defi ned by

the man ual jog feed rate selection input signa ls .

If the DRN inp u t s ig n a l changes from “open” to “close” or from “closed” to “open” while the

PCNC ise xecuting automatic operation, feed rate is chang ed a ccording to t he s elected feed mode

as indicated below:

• In the “mm/rev” mode: The feedrate is not changed for the block presently executed.

• In the “mm/min” mode: Th e feedrate is chang ed even during th e execution of commands in a

block.

Note: During the execution of a tapping cycle, the feedrate is not changed during the execution

of commands in a block and a new feedra t e be comes valid after the com pl et ion of the

commands in the block.

Concerning a rapid feed, whether the rapid feedrate or jog feedrate is used can be selected

by the setting for a parameter. If rapid feedrate is selected, rapid feedrate override function

is not va lid.

The acceleration/deceleration time constant is not influenced by whether or not the dry run

is turne d ON.

<Parameters>

• Dry run internal toggl e sw i tc h ON /OFF pm0000 D3

• Valid/invalid dry run for rapid feed pm2000 D0

6 - 14

Page 56

YASNAC PCNC I/O Signal Function Manual Chapter 6: Operation Support Functions

6.10 Machine Lock Input Signal

Machine Lock Input Signal MLK #30066

Axis-depend ent Machine Lock

Input Signal

AMLKX to AMLK5 #30840 to #30844

The machine lock input signal is used to prevent output of the output pulses of the PCNC to servo

units.

The machine lock function is used to check a new program without actually moving the axes.

When the MLK input signal is “closed”, altho ug h t he log ic circui t distributes pulse s , th e axes are

not moved (both in aut om atic and manual mode operations).

Since the logic circuit distributes pulses, the position data is updated as the axis move commands

are executed.

To change the status of the ML K input signal from “closed” to “opened” o r from “opened” to

“closed”, the PCNC must be stopped. In other words, if the MLK input signal stat us should be

changed, the PCNC must be in the Block Stop state or Feed Hold state. If it is changed when the

PCNC is in other states, attempted change is ignor ed.

By using the AMLKX(#30840) to AMLK5(#30844) input signals, the machine lock function can

be called for the individual axes.

If the MLK input signal is “closed” during single-block mode operation, the machine lock function becomes valid afte r the blo ck stops.

6.11 Auxiliary Function Lock Input Signal

Auxiliary Function

Lock Input Signal

The auxiliary fun ct ion lock input signal is us ed to omit the execut ion of the M,S,T and B functions for th e ex ecution of a part program in aut om atic mode.

If the AFL inp ut signal is “closed”, the PCNC ignores the M,S,T and B commands specified in a

part program. The cod e/ de co de output sugnals (M00R, M01R, M02R and M30R) are ou tp ut,

however. Analog D/A signal is also output to the spin dle.

If the AFL input signal status is changed from “opened” to “closed” or from “closed” to “opened”

during the execution of a part program, the program is executed according to the selected AFL

input signal state from the block next to th e one currently bei ng executed.

ALK #30067

6 - 15

Page 57

YASNAC PCNC I/O Signal Function Manual Chapter 6: Operation Support Functions

6.12 Edit Lock Input Signal

Edit Lock Input Signal EDTLK #30072

The edit lock input sig na l pro te ct s part programs stored in the PC NC part program memory from

being altered.

When the ED TL K input signal is “closed”, key operation of the [IN SE T], [ALTER] and

[ERASE] keys, and the data storing opertion are ignored.

If program edit operation is attempted in this stat e, the following warning message is displayed:

“EDIT LOCK!”

6.13 Automatic Mode Handle Offset Input Signal

Automatic Mode Handle

Offset Input Signal

When the HOFS input signal is “closed”, axis m ovement generate d by the pulse handle ca n be

overlapped with the axis m ovement exec ut ed in the automa tic operation.

The axis for which overlapping of axis movement by the pulse handle is the one which

selected by the pulse handle feed axis selection input signal. Axis movement distance

per pulse can be changed by setting th e multiplication ratio setting switch.

IMPORTANT!

1. Axis mov em ent by the automa ti c mode handle offset func ti on is always valid even during

block stop or when a block which does not include axis movement commands is executed.

2. If the axis interlock input (*IT X to * I T5) signa l is “closed”, axis movement by the automatic

mode handle offset function is not possible .