Page 1

AC Servo Drives

Σ-II Series

SGMVH

/SGDM/SGDH

USER'S MANUAL

SGMVH Servomotor

SGDM/SGDH SERVOPACKs

POWER

8CN

O

P

E

CN3

R

A

T

O

R

T DATA/SEEMOD/

CN5

CN3

KSERVOPAC

S -HDG

****

AYASKAW

CN1

DC

480 V460

V

CHARGE

DC

400 V 0 V440

380

DU

DWDV B1

B2

24N

24P

V

V

CN2

MANUAL NO. SIEP S800000 59A

Outline

Selections

Servomotor Specifications and

Dimensional Drawings

SERVOPACK Specifications and

Dimensional Drawings

Specifications and Dimensional Drawings of

Cables and Peripheral Devices

Wiring

Digital Operator/Panel Operator

Operation

Adjustments

Inspection, Maintenance,

and Troubleshooting

Appendix

1

2

3

4

5

6

7

8

9

10

11

Page 2

Copyright © 2008 YASKAWA ELECTRIC CORPORATION

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system,

or transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording,

or otherwise, without the prior written permission of Yaskawa. No patent liability is assumed

with respect to the use of the information contained herein. Moreover, because Yaskawa is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this

manual. Nevertheless, Yaskawa assumes no responsibility for errors or omissions. Neither is

any liability assumed for damages resulting from the use of the information contained in this

publication.

Page 3

About this Manual

Intended Audience

This manual is intended for the following users.

•

Those selecting Σ-II Series servo drives or peripheral devices for Σ-II Series servo drives.

•

Those wanting to know about the ratings and characteristics of Σ-II Series servo drives.

•

•

•

•

Description of Technical Terms

The terms in this manual are defined as follows:

• Servomotor or motor = Σ-II Series SGMVH servomotor.

• SERVOPACK = Σ-II Series SGDM/SGDH amplifier.

• Servo drive = A set including a servomotor and servo amplifier.

• Servo system = A servo control system that includes the combination of a servo drive with a host

• Parameter number = Numbers that the user inputs toward the SERVOPACK.

designing Σ-II Series servo drive systems.

Those

Those installing or wiring Σ-II Series servo drives.

Those performing trial operation or adjustments of Σ-II Series servo drives.

Those maintaining or inspecting Σ-II Series servo drives.

controller and peripheral devices.

iii

Page 4

IMPORTANT

INFO

EXAMPLE

TERMS

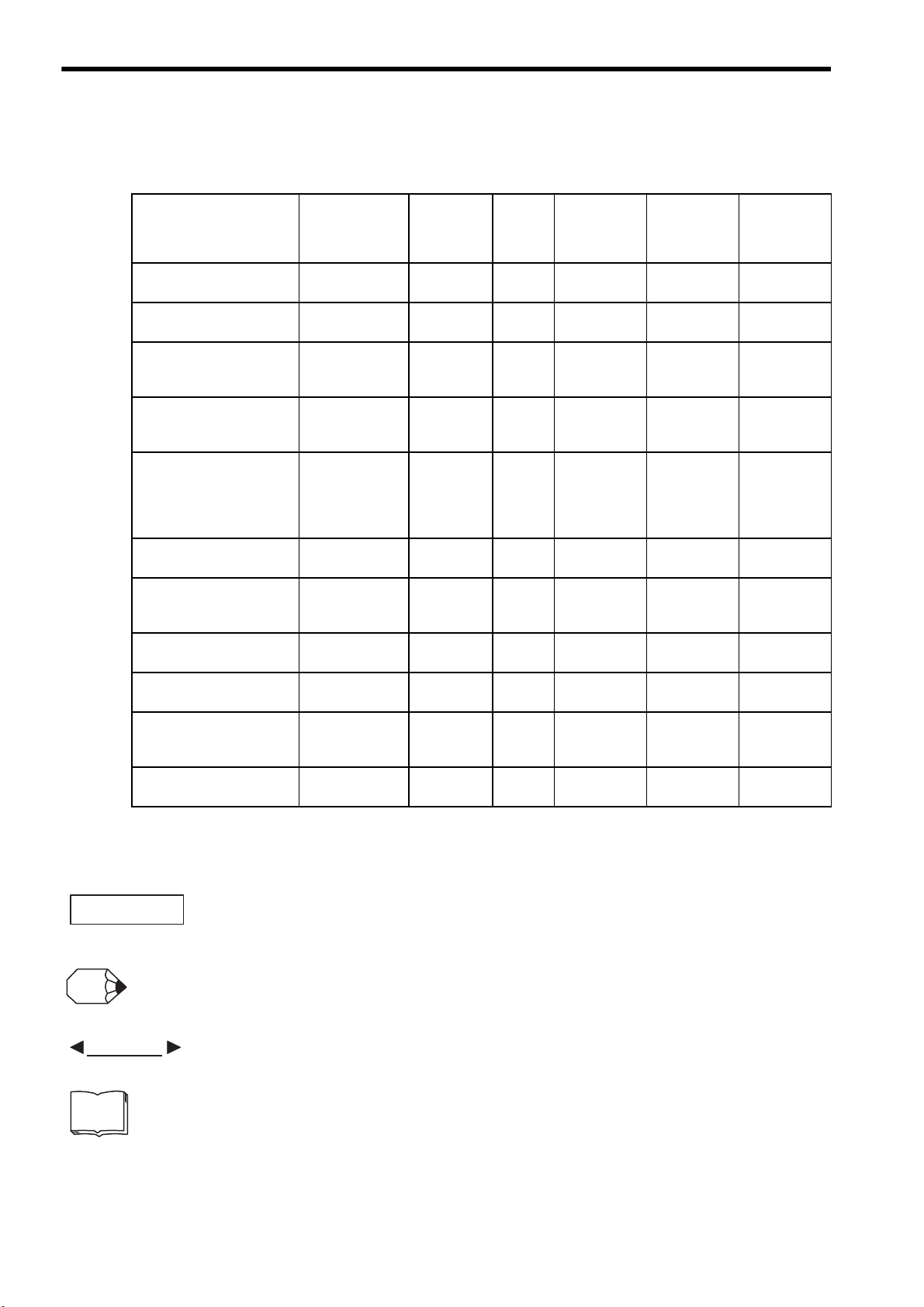

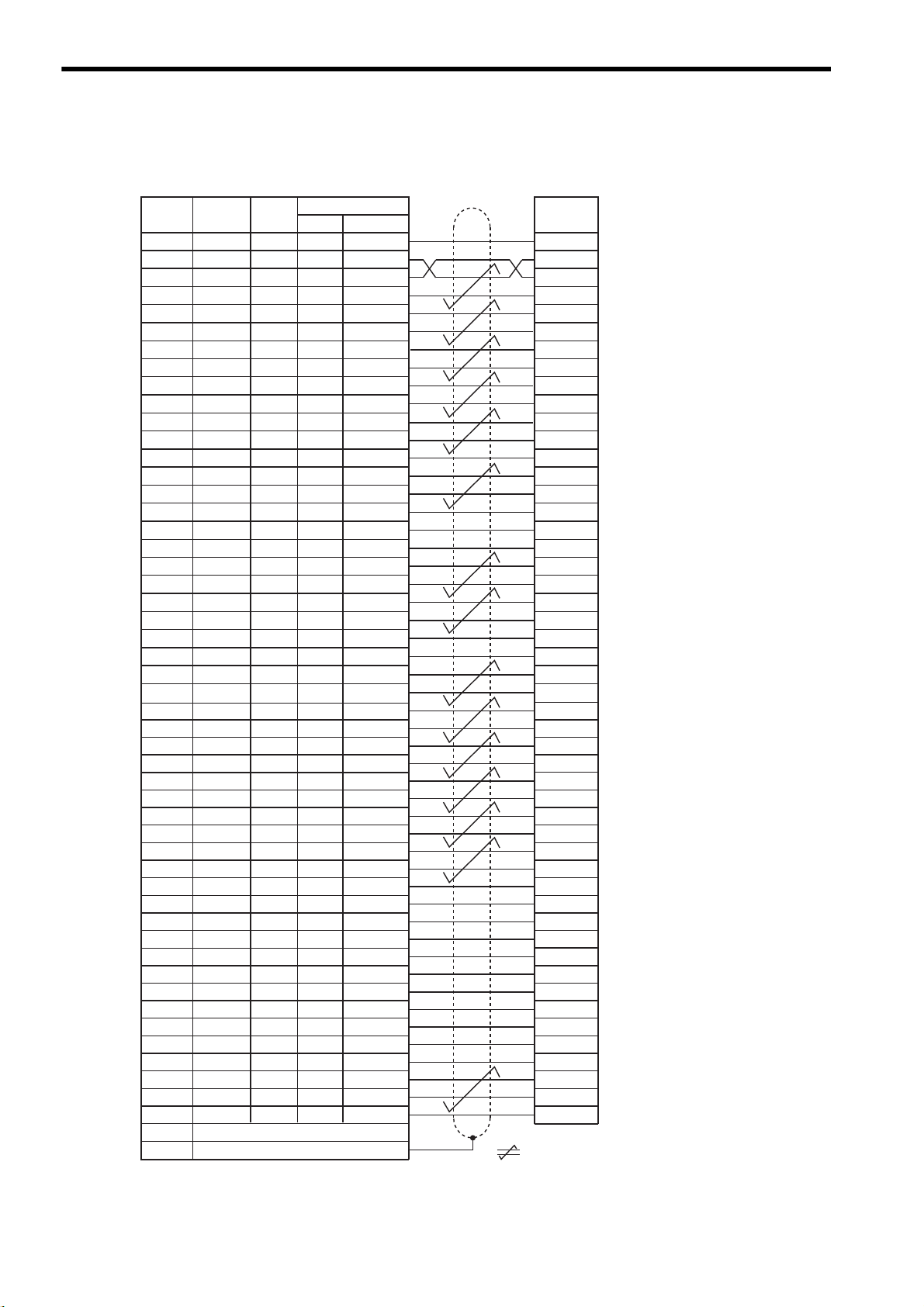

Quick access to your required information

Read the chapters marked with 9 to get the information required for your purpose.

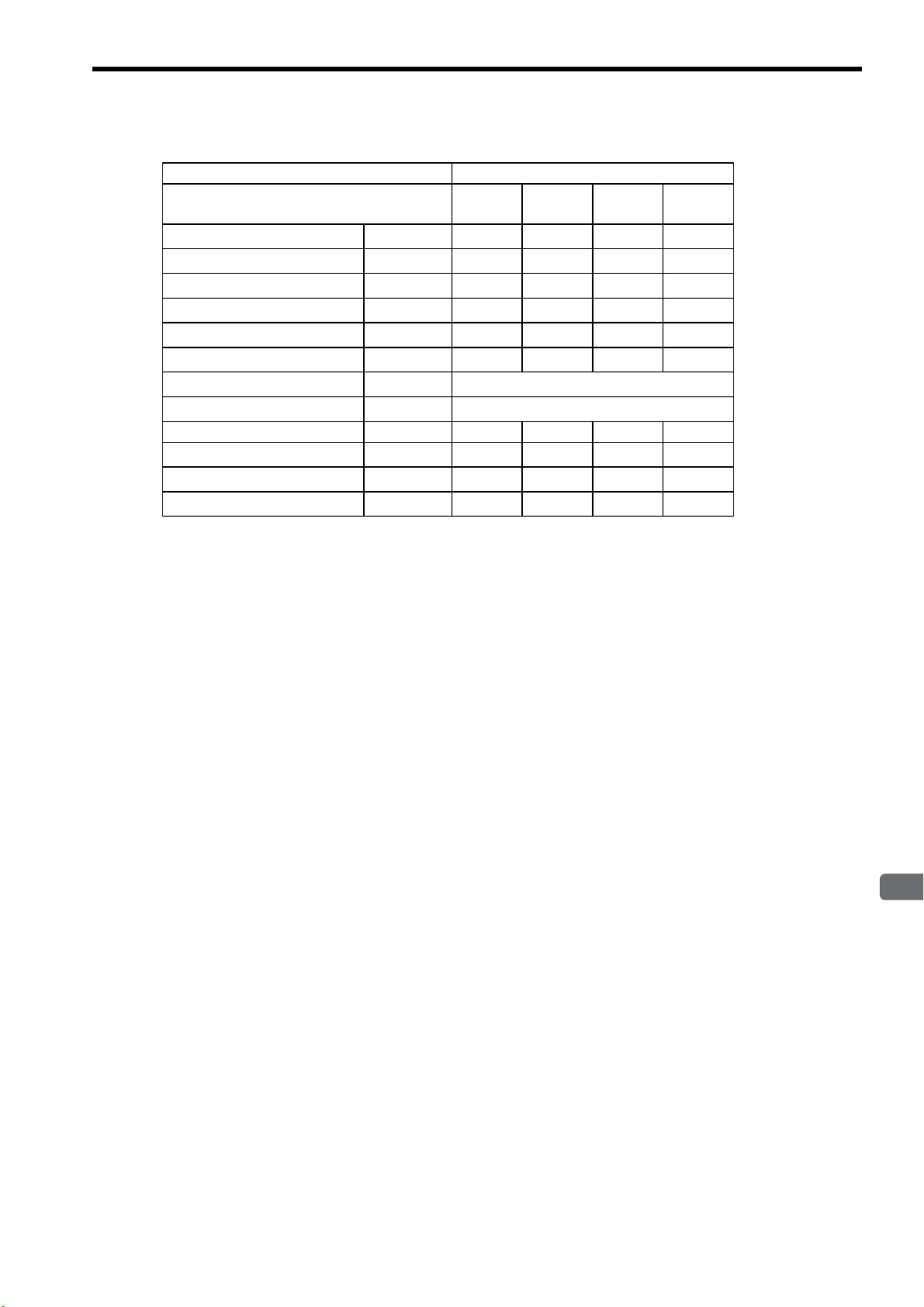

Chapter

Chapter 1

Outline

Chapter 2

Selections

Chapter 3

Servomotor Specifications

and Dimensional Drawings

Chapter 4

SERVOPACK Specifications

and Dimensional Drawings

Chapter 5

Specifications and

Dimensional Drawings of

Cables and Peripheral

Devices

Chapter 6

Wiring

Chapter 7

Digital Operator/Panel

Operator

Chapter 8

Operation

Chapter 9

Adjustments

Chapter 10

Inspection, Maintenance,

and Troubleshooting

Chapter 11

Appendix

SERVOPACKs,

Servomotors,

and Peripheral

Devices

Ratings and

Character-

istics

System

Design

Panel

Configura-tion

and Wiring

Trial Operation

and Servo

Adjustment

Inspection and

Maintenance

9

9

9999

9999

9999

99 9

99

9

9

9

9999

iv

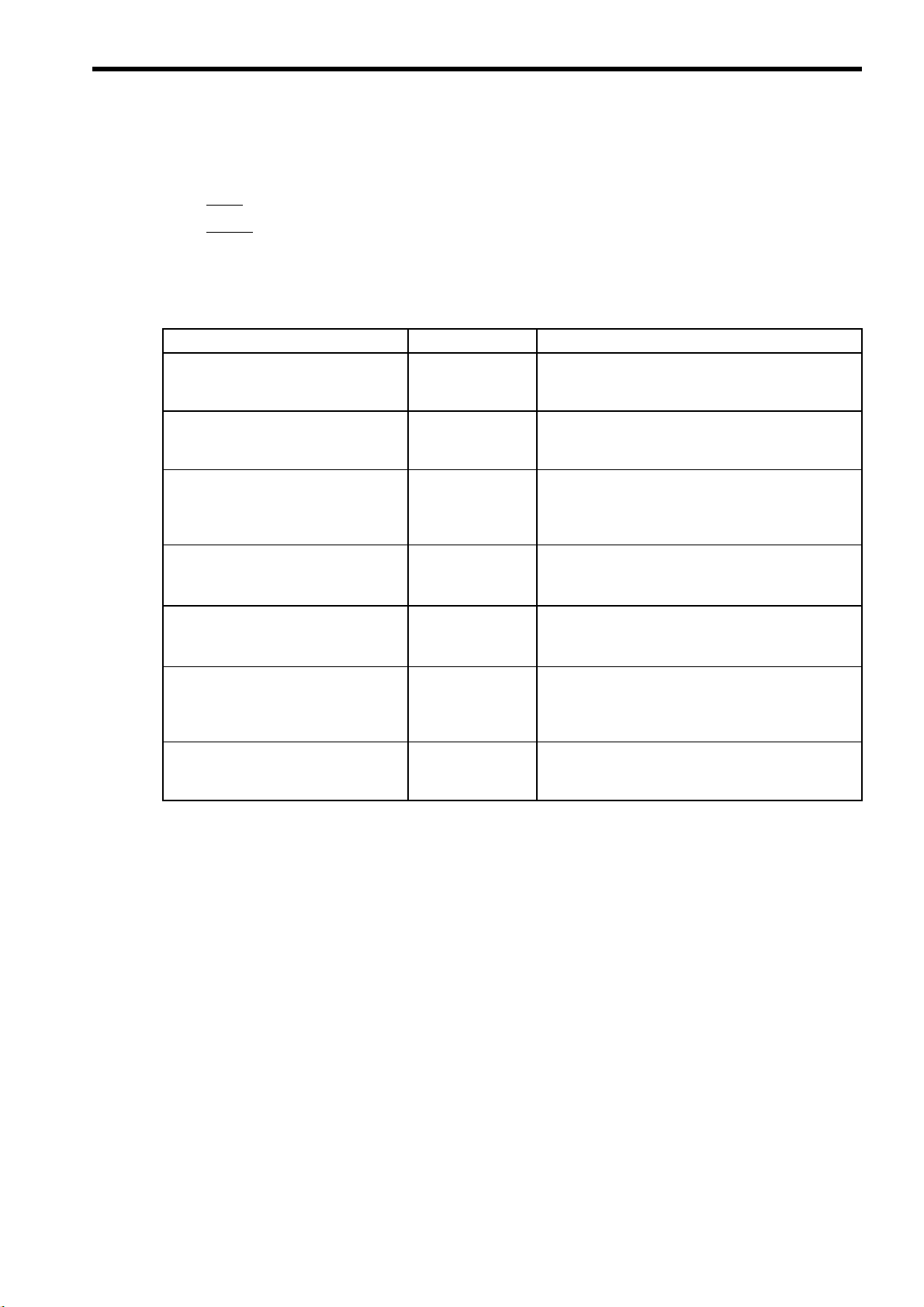

Visual Aids

■

The following aids are used to indicate certain types of information for easier reference.

• Indicates important information that should be memorized, including precautions such as alarm dis-

plays to avoid damaging the devices.

• Indicates supplemental information.

• Indicates application examples.

• Indicates definitions of difficult terms or terms that have not been previously explained in this man-

ual.

Page 5

Indication of Reverse Signals

■

In this manual, the names of reverse signals (ones that are valid when low) are written with a forward slash (/)

before the signal name, as shown in the following example:

• S-ON

=

/S-ON

• P-CON

Related Manuals

■

=

/P-CON

Refer to the following manuals as required.

Manual Name Manual Number Contents

-II Series SGMH/SGDH

Σ

Digital Operator Operation Manual

-II Series SERVOPACKs

Σ

Personal Computer Monitoring Software

Operation Manual

-II Series SGDH

Σ

Fully Closed Interface Unit

User’s Manual

Type: JUSP-FC100

-II Series SGDH MECHATROLINK

Σ

Application Module User’s Manual

Type: JUSP-NS100

-II Series SGDH MECHATROLINK-II

Σ

Application Module User’s Manual

Type: JUSP-NS115

-II Series SGDH

Σ

DeviceNet Application Module

User’s Manual

Type: JUSP-NS300

-II Series SGDH PROFIBUS-DP

Σ

Application Module User’s Manual

Type: JUSP-NS500

TOE-S800-34 Provides detailed information on the operating method

SIE-S800-35 Describes the using and the operating methods on soft-

SIE-C718-5 Provides detailed information on the fully closed con-

SIE-C718-4 Provides detailed information on MECHATROLINK

SIEPC71080001 Provides detailed information on MECHATROLINK-II

SIE-C718-6 Provides detailed information on DeviceNet communi-

SIE-C718-8 Provides detailed information on PROFIBUS-DP

of JUSP-OP02A-2 type Digital Operator (option

device).

ware that changes the local personal computer into the

monitor equipment for the Σ-II Series servomotor.

trol of the JUSP-FC100 interface unit.

communications.

communications.

cations.

communications.

v

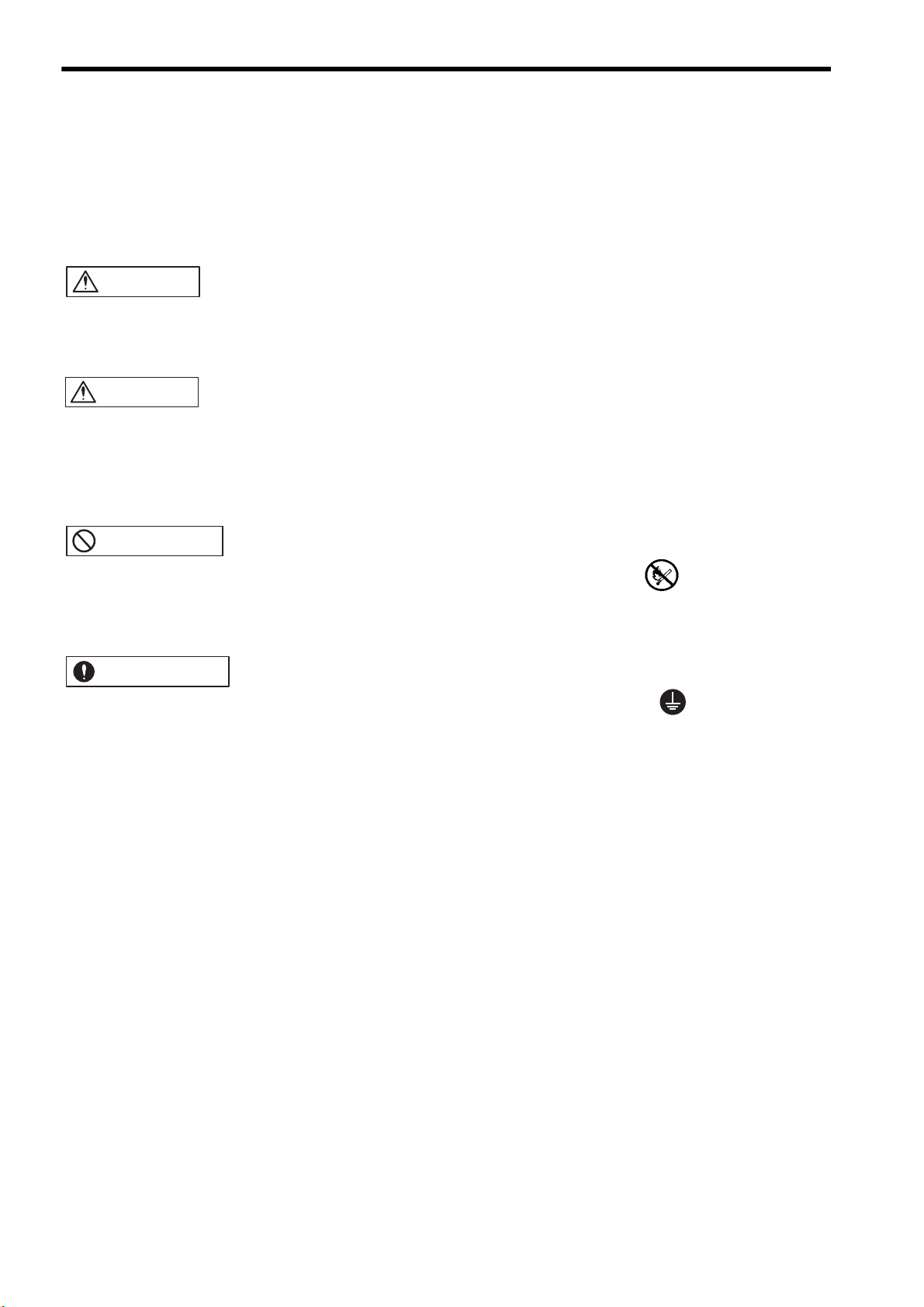

Page 6

WARNING

CAUTION

PROHIBITED

MANDATORY

Safety Information

The following conventions are used to indicate precautions in this manual. Failure to heed precautions provided

in this manual can result in serious or possibly even fatal injury or damage to the products or to related equipment

and systems.

Indicates precautions that, if not heeded, could possibly result in loss of life or serious

injury.

Indicates precautions that, if not heeded, could result in relatively serious or minor

injury, damage to the product, or faulty operation.

In some situations, the precautions indicated could have serious consequences if not heeded.

Indicates prohibited actions that must not be performed. For example, this symbol

would be used as follows to indicate that fire is prohibited: .

Indicates compulsory actions that must be performed. For example, this symbol would

be used as follows to indicate that grounding is compulsory: .

vi

Page 7

Notes for Safe Operation

WARNING

Read this manual thoroughly before checking products on delivery, storage and transportation, installation,

wiring, operation and inspection, and disposal of the AC servo drive.

• Never touch any rotating motor parts while the motor is running.

Failure to observe this warning may result in injury.

• Before starting operation with a machine connected, make sure that an emergency stop can

be applied at any time.

Failure to observe this warning may result in injury.

• Never touch the inside of the SERVOPACKs.

Failure to observe this warning may result in electric shock.

• Do not touch terminals for five minutes after the power is turned OFF.

Residual voltage may cause electric shock.

• Do not touch terminals for five minutes after voltage resistance test.

Residual voltage may cause electric shock.

• Follow the procedures and instructions for trial operation precisely as described in this

manual.

Malfunctions that occur after the servomotor is connected to the equipment not only damage the

equipment, but may also cause an accident resulting in death or injury.

• The multiturn limit value must be changed only for special applications.

Changing it inappropriately or unintentionally can be dangerous.

• If the Multiturn Limit Disagreement alarm (A.CC) occurs, check the setting of parameter

Pn205 in the SERVOPACK to be sure that it is correct.

If Fn013 is executed when an incorrect value is set in Pn205, an incorrect value will be set in the

encoder. The alarm will disappear even if an incorrect value is set, but incorrect positions will be

detected, resulting in a dangerous situation where the machine will move to unexpected positions.

• Do not remove the front cover, cables, connectors, or optional items while the power is ON.

Failure to observe this warning may result in electric shock.

• Installation, disassembly, or repair must be performed only by authorized personnel.

Failure to observe this warning may result in electric shock or injury.

• Do not damage, press, exert excessive force or place heavy objects on the cables.

Failure to observe this warning may result in electric shock, stopping operation of the product, or

burning.

• Provide an appropriate stopping device on the machine side to ensure safety.

A holding brake for a servomotor with brake is not a stopping device for ensuring safety.

Failure to observe this warning may result in injury.

• Do not come close to the machine immediately after resetting momentary power loss to

avoid an unexpected restart.

Take appropriate measures to ensure safety against an unexpected restart.

Failure to observe this warning may result in injury.

• Do not modify products.

Failure to observe this warning may result in injury or damage to products.

• Connect the ground terminal to electrical codes (ground resistance: 100

Improper grounding may result in electric shock or fire.

or less).

Ω

vii

Page 8

CAUTION

CAUTION

CAUTION

Checking on Delivery

• Always use the servomotor and SERVOPACK in one of the specified combinations.

Failure to observe this caution may result in fire or malfunction.

Storage and Transportation

• Do not store or install the product in the following places.

• Locations subject to direct sunlight.

• Locations subject to temperatures outside the range specified in the storage or installation temperature conditions.

• Locations subject to humidity outside the range specified in the storage or installation humidity conditions.

• Locations subject to condensation as the result of extreme changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust, salts, or iron dust.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

Failure to observe this caution may result in fire, electric shock, or damage to the product.

• Do not hold the product by the cables or motor shaft while transporting it.

Failure to observe this caution may result in injury or malfunction.

• Do not place any load exceeding the limit specified on the packing box.

Failure to observe this caution may result in injury or malfunction.

• If disinfectants or insecticides must be used to treat packing materials such as wooden frames, pallets, or

plywood, the packing materials must be treated before the product is packaged, and methods other than

fumigation must be used.

Example: Heat treatment, where materials are kiln-dried to a core temperature of 56

minutes or more.

If the electronic products, which include stand-alone products and products installed in machines, are packed with

fumigated wooden materials, the electrical components may be greatly damaged by the gases or fumes resulting from

the fumigation process. In particular, disinfectants containing halogen, which includes chlorine, fluorine, bromine, or

iodine can contribute to the erosion of the capacitors.

Installation

• Never use the products in an environment subject to water, corrosive gases, inflammable gases, or

combustibles.

Failure to observe this caution may result in electric shock or fire.

• Do not step on or place a heavy object on the product.

Failure to observe this caution may result in injury.

• Do not cover the inlet or outlet parts and prevent any foreign objects from entering the product.

Failure to observe this caution may cause internal elements to deteriorate resulting in malfunction or fire.

C for 30

°

viii

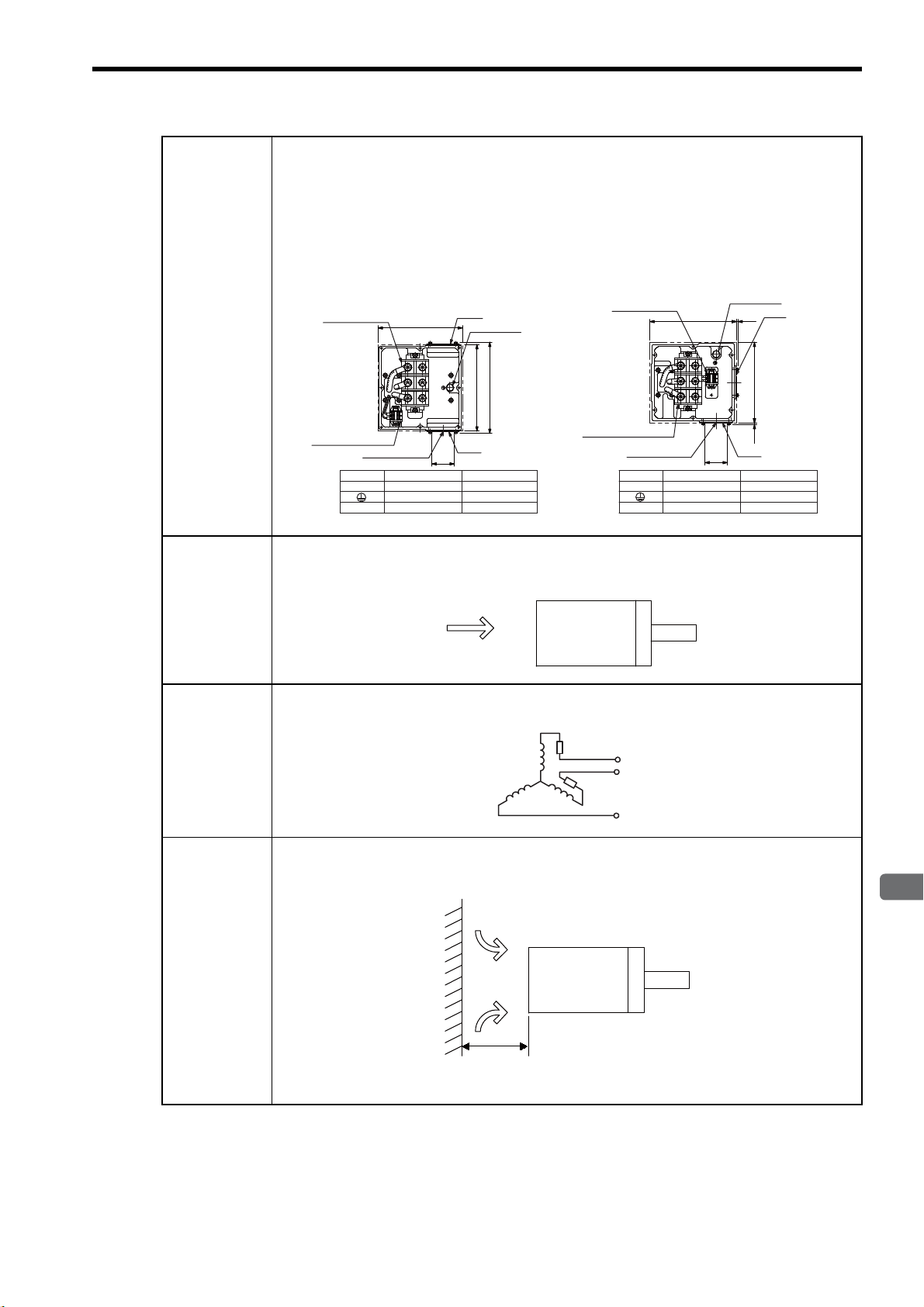

• Be sure to install the product in the correct direction.

Failure to observe this caution may result in malfunction.

Page 9

Installation(cont’d

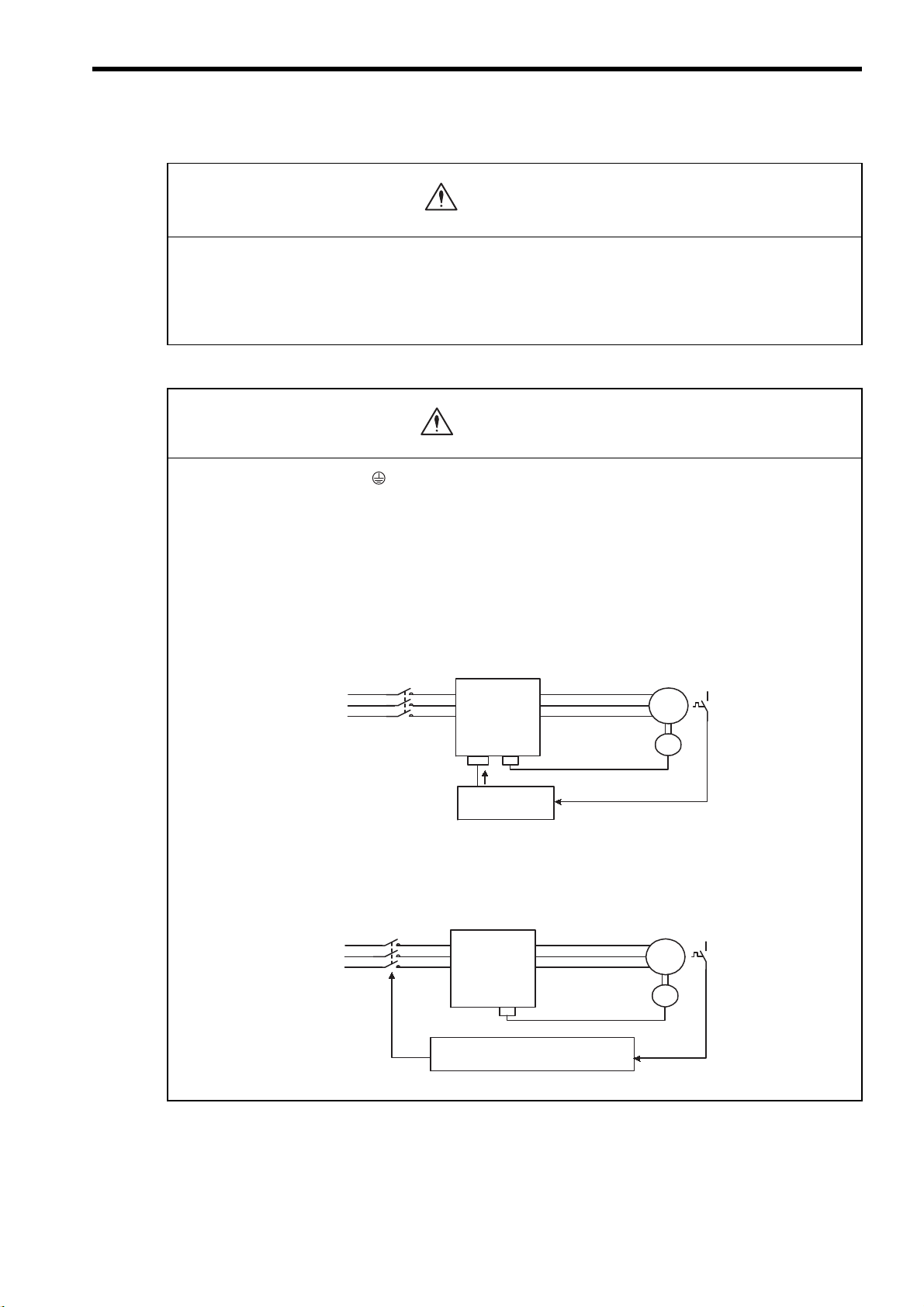

CAUTION

WARNING

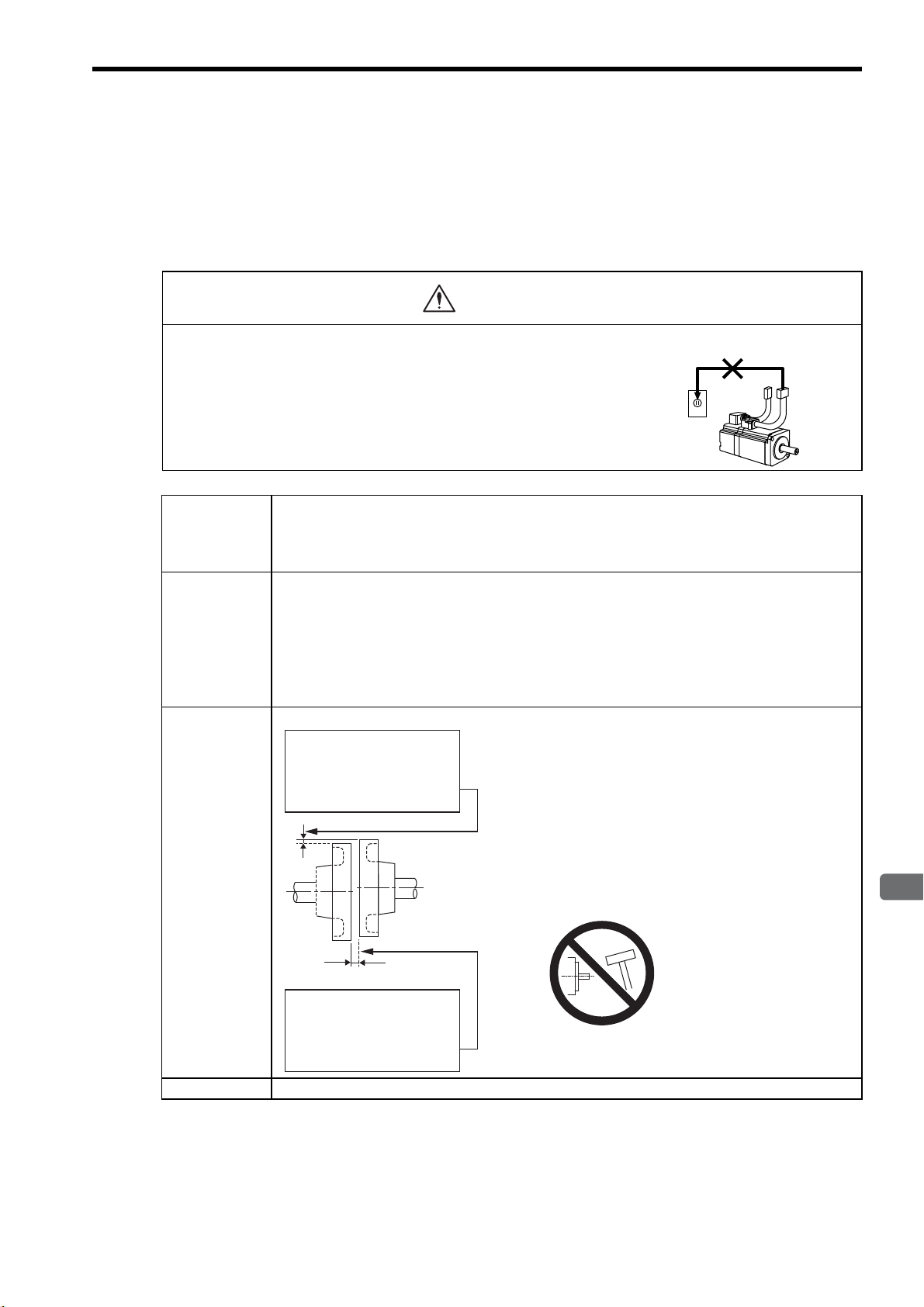

Host Controller

Servo OFF

PG

M

Thermal

protector

Main circuit

magnetic

contactors

Main circuit

power supply

SERVOPACK

• Provide the specified clearances between the SERVOPACK and the control panel or with

other devices.

Failure to observe this caution may result in fire or malfunction.

• Do not apply any strong impact.

Failure to observe this caution may result in malfunction.

Wiring

• Connect the ground terminal to electrical codes (ground resistance: 100 Ω or less).

Improper grounding may result in electric shock or fire.

• Use the thermal protector built into the servomotor according to either of the two following methods.

SGMVH servomotors are cooled by a fan. If the fan is defective or power to the fan is disconnected, heat from the

motor may result in burns or fire.

Method 1:

• Wire the output from the thermal protector to the host controller and turn OFF the servo when the thermal

protector operates.

)

Method 2:

• Wire the thermal protector to the operating circuit of the main circuit magnetic contactors or the host

controller and turn OFF the main circuit magnetic contactor when the thermal protector operates.

Main circuit

magnetic

Main circuit

power supply

To main circuit

magnetic contactors

contactors

SERVOPACK

Host controller or operating circuit

of main circuit magnetic contactors

M

PG

Thermal

protector

ix

Page 10

CAUTION

• Do not connect a three-phase power supply to the U, V, or W output terminals.

Failure to observe this caution may result in injury or fire.

• Securely connect the power supply terminals and motor output terminals.

Failure to observe this caution may result in fire.

• Do not bundle or run power and signal lines together in the same duct. Keep power and signal lines

separated by at least 30 cm.

• Use twisted-pair shielded wires or multi-core twisted pair shielded wires for signal and encoder (PG)

feedback lines.

The maximum length is 3 m for reference input lines and is 20 m for PG feedback lines.

• Do not touch the power terminals for five minutes after turning power OFF because high voltage may still

remain in the SERVOPACK.

Make sure the charge indicator is turned OFF first before starting an inspection.

• Avoid frequently turning power ON and OFF.

Since the SERVOPACK has a capacitor in the power supply, a high charging current flows for 0.2 seconds when

power is turned ON. Frequently turning power ON and OFF causes main power devices such as capacitors and fuses

to deteriorate, resulting in unexpected problems.

• Install the battery at either the host controller or the SERVOPACK.

It is dangerous to install batteries at both simultaneously, because that sets up a loop circuit between the batteries.

• Be sure to wire correctly and securely.

Failure to observe this caution may result in motor overrun, injury, or malfunction.

• Always use the specified power supply voltage.

An incorrect voltage may result in burning.

• Take appropriate measures to ensure that the input power supply is supplied within the specified voltage

fluctuation range. Be particularly careful in places where the power supply is unstable.

An incorrect power supply may result in damage to the product.

• Install external breakers or other safety devices against short-circuiting in external wiring.

Failure to observe this caution may result in fire.

• Take appropriate and sufficient countermeasures for each when installing systems in the following

locations.

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields and magnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies including power supply lines.

Failure to observe this caution may result in damage to the product.

• Do not reverse the polarity of the battery when connecting it.

Failure to observe this caution may damage the battery or cause it to explode.

x

Page 11

Operation

CAUTION

• Conduct trial operation on the servomotor alone with the motor shaft disconnected from machine to avoid

any unexpected accidents.

Failure to observe this caution may result in injury.

• Before starting operation with a machine connected, change the settings to match the parameters of the

machine.

Starting operation without matching the proper settings may cause the machine to run out of control or malfunction.

• Forward run prohibited (P-OT) and reverse run prohibited (N-OT) signals are not effective during zero point

search mode using parameter Fn003.

• When using the servomotor for a vertical axis, install the safety devices to prevent workpieces to fall off due

to occurrence of alarm or overtravel. Set the servomotor so that it will stop in the zero clamp state at

occurrence of overtravel.

Failure to observe this caution may cause workpieces to fall off due to overtravel.

• Do not touch the SERVOPACK heatsinks, regenerative resistor, or servomotor while power is ON or soon

after the power is turned OFF.

Failure to observe this caution may result in burns due to high temperatures.

• Do not make any extreme adjustments or setting changes of parameters.

Failure to observe this caution may result in injury due to unstable operation.

• When an alarm occurs, remove the cause, reset the alarm after confirming safety, and then resume

operation.

Failure to observe this caution may result in injury.

• Do not use the servo brake of the servomotor for ordinary braking.

Failure to observe this caution may result in malfunction.

• Do not turn the Servo ON or OFF unless necessary.

Failure to observe this caution may cause internal parts to deteriorate.

xi

Page 12

CAUTION

CAUTION

Maintenance and Inspection

• When replacing the SERVOPACK, transfer the previous SERVOPACK parameters to the new

SERVOPACK before resuming operation.

Failure to observe this caution may result in damage to the product.

• Do not attempt to change wiring while the power is ON.

Failure to observe this caution may result in electric shock or injury.

•

Do not disassemble the servomotor.

Failure to observe this caution may result in electric shock or injury.

Disposal

• When disposing of the products, treat them as ordinary industrial waste.

General Precautions

Note the following to ensure safe application.

• The drawings presented in this manual are sometimes shown without covers or protective guards. Always replace

the cover or protective guard as specified first, and then operate the products in accordance with the manual.

• The drawings presented in this manual are typical examples and may not match the product you received.

• This manual is subject to change due to product improvement, specification modification, and manual

improvement. When this manual is revised, the manual code is updated and the new manual is published as a next

edition.

• If the manual must be ordered due to loss or damage, inform your nearest Yaskawa representative or one of the

offices listed on the back of this manual.

• Yaskawa will not take responsibility for the results of unauthorized modifications of this product. Yaskawa shall

not be liable for any damages or troubles resulting from unauthorized modification.

xii

Page 13

CONTENTS

About this Manual - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -iii

Safety Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - vi

Notes for Safe Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - vii

1 Outline

1.1 Checking Products - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

1.1.1 Check Items - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

1.1.2 Servomotors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

1.1.3 SERVOPACKs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

1.2 Examples of Servo System Configurations - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-3

1.2.1 Three-phase, 200 V Series- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-3

1.2.2 Three-phase, 400 V Series- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-4

1.3 Applicable Standards - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-5

1.3.1 North American Safety Standards (UL) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-5

CE Marking- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-5

1.3.2

2 Selections

2.1 Servomotor Model Designations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-2

2.2 SERVOPACK Model Designations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-3

Σ-II Series SERVOPACKs and Applicable Servomotor - - - - - - - - - - - - - - - - - - - 2-4

2.3

2.4 Selecting Cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-5

2.4.1 Cables for SGMVH Servomotor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-5

2.5 Selecting Peripheral Devices - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-6

2.5.1 Special Options- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-6

2.5.2 Molded-case Circuit Breaker and Fuse Capacity - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-8

2.5.3 Noise Filters, Magnetic Contactors, and Brake Power Supply Units - - - - - - - - - - - - - - - - - - - 2-9

2.5.4 Regenerative Resistor Units - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-9

2.5.5 Dynamic Brake (DB) Units - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-10

2.5.6 Thermal Relays- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-11

3 Servomotor Specifications and Dimensional Drawings

3.1 Ratings and Specifications of SGMVH (1500 min-1) - - - - - - - - - - - - - - - - - - - - - 3-2

-1

3.2 Ratings and Specifications of SGMVH (800 min

) - - - - - - - - - - - - - - - - - - - - - - 3-6

3.3 Mechanical Specifications of Servomotors - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-9

3.3.1 Precautions on Servomotor Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-9

3.3.2 Allowable Radial and Thrust Loads - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-13

3.3.3 Mechanical Tolerance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-14

3.3.4 Direction of Servomotor Rotation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-14

3.3.5 Impact Resistance- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-14

3.3.6 Vibration Resistance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-14

xiii

Page 14

3.3.7 Vibration Class - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-15

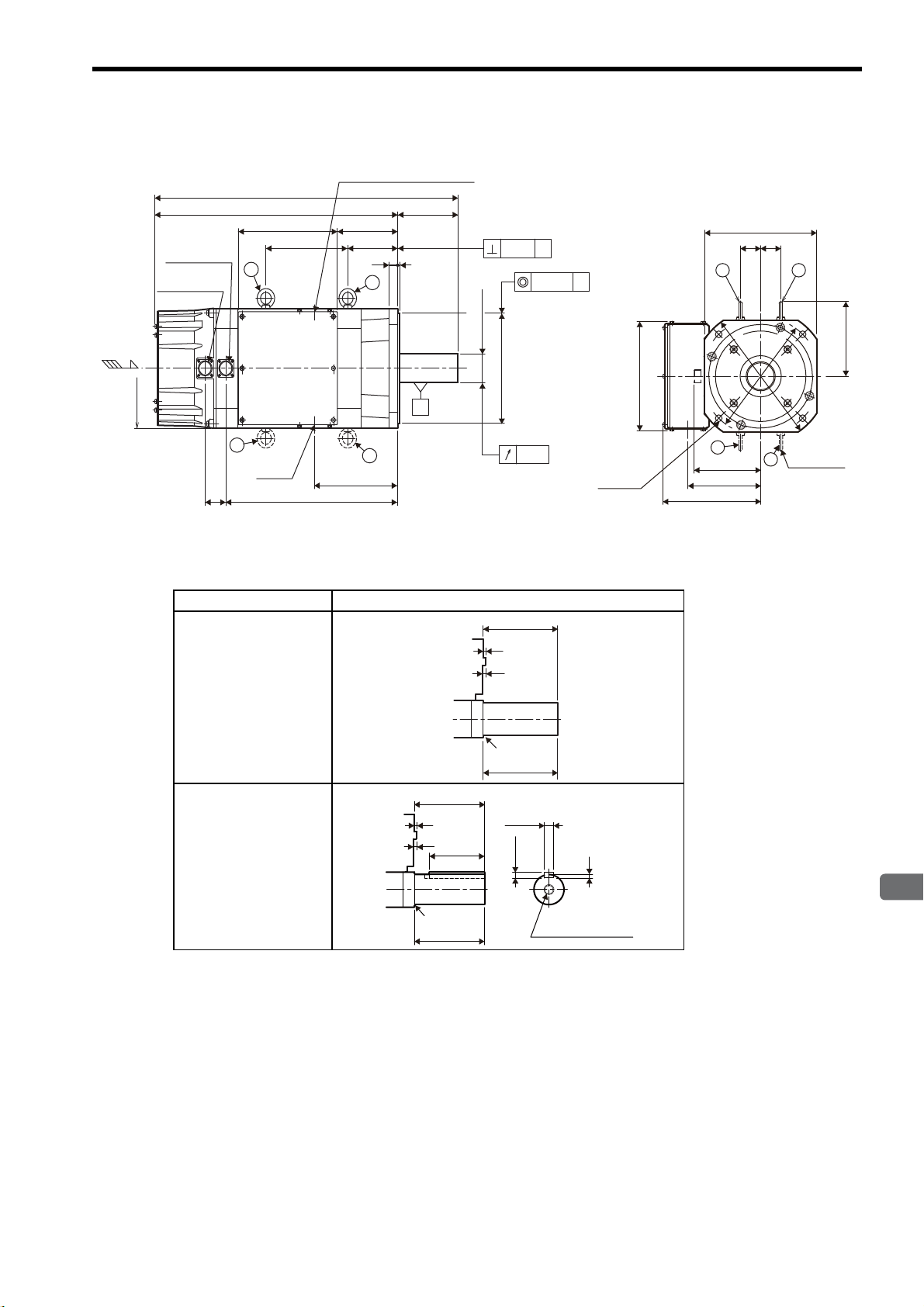

3.4 Dimensional Drawings of SGMVH Servomotors (1500 min-1) - - - - - - - - - - - - - 3-16

3.5 Dimensional Drawings of SGMVH Servomotors (800 min

-1

) - - - - - - - - - - - - - - 3-22

4 SERVOPACK Specifications and Dimensional Drawings

4.1 SERVOPACK Ratings and Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-2

4.1.1 Three-phase 200 V - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-2

4.1.2 Three-phase 400 V - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-2

4.1.3 SERVOPACK Ratings and Specific

4.2 SERVOPACK Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-5

4.3 SERVOPACK Internal Block Diagrams - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-7

4.3.1 Three-phase 200 V, 22 kW, 30 kW Models - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-7

4.3.2 Three-phase 200 V, 37 kW Model - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-8

4.3.3 Three-phase

4.3.4 Three-phase

4.3.5 Three-phase

4.3.6 Three-phase 400 V, 90 kW Model - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-10

400 V, 22 kW, 30 kW Models - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-9

400 V, 37 kW Model - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-9

400 V, 45 kW, 55 kW Models - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-10

4.4 SERVOPACK’s Power Supply Capacities and Power Losses - - - - - - - - - - - - - 4-11

4.5 SERVOPACK Overload Characteristics and Allowable Load Moment of Inertia 4-12

4.5.1 Overload Characteristics - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-12

4.5.2 Starting and Stopping Time - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-13

4.5.3 Load Moment of Inertia - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-14

ations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-3

4.6 SERVOPACK Dimensional Drawings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-16

4.6.1 Three-phase 200 V, 22 kW, 30 kW Models - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-16

4.6.2 Three-phase 200 V, 37 kW Model - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-17

4.6.3 Three-phase 400 V, 22 kW Model - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-18

Three-phase 400 V, 30 kW Model - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-19

4.6.4

4.6.5 Three-phase 400 V, 37 kW Model - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-20

4.6.6 Three-phase 400 V, 45 kW, 55 kW Models - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-20

4.6.7 Three-phase 400 V, 90 kW Model - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-21

5 Specifications and Dimensional Drawings of Cables and Peripheral Devices

5.1 SERVOPACK Main Circuit Wire Size - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-2

5.1.1 Wiring Cables to Main Circuit Terminals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-2

Three-phase 200 V - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-3

5.1.2

5.1.3 Three-phase 400 V - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-4

5.2 Encoder Cables for CN2 Connector - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-6

5.2.1 Encoder Cable with Connectors on Both Ends - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-6

5.2.2 Cable with Loose Wire at Encoder End- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-7

5.3 Connectors and Cables for Encoder Signals - - - - - - - - - - - - - - - - - - - - - - - - - - 5-8

xiv

Page 15

5.4 I/O Signal Cables for CN1 Connector - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-10

5.4.1 Standard Cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-10

5.4.2 Connector Type and Cable Size - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-10

5.4.3 Connection Diagram - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-12

5.5 Peripheral Devices - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-13

5.5.1 Cables for Connecting Personal Computers- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-13

5.5.2 Digital Operator- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-14

5.5.3 Cables for Analog Monitor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-15

5.5.4 Connector Terminal Block Converter Unit - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-16

5.5.5 Brake Power Supply Unit - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-17

5.5.6 Absolute Encoder Battery- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-18

5.5.7 Molded-case Circuit Breaker (MCCB) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-19

5.5.8 Noise Filter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-20

5.5.9 Surge Absorber- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-22

5.5.10 Regenerative Resistor Unit- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-23

5.5.11 Dynamic Brake (DB) Unit - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-29

5.5.12 Thermal Relays - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-36

5.5.13 Variable Resistor for Speed and Torque Setting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-39

5.5.14 Encoder Signal Converter Unit - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-40

5.5.15 MECHATROLINK Application Module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-41

5.5.16 DeviceNet Application Module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-42

5.5.17 PROFIBUS-DP Application Module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-43

5.5.18 Fully-closed Application Module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-44

6 Wiring

6.1 Wiring Main Circuit - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-2

6.1.1 Names and Functions of M

6.1.2 Typical Main Circuit Wiring Examples - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-4

6.2 Wiring Encoders - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-8

6.2.1 Connecting an Encoder (CN2) and Output Signals from the SERVOPACK (CN1) - - - - - - - - - 6-8

6.2.2 Encoder Connector (CN2) Terminal Layout - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-9

6.3 I/O Signal Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-10

6.3.1 Example of I/O Signal Connection- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-10

6.3.2 I/O Signal Connector (CN1) Terminal Layout - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-11

6.3.3 I/O Signal (CN1) Names and Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-12

6.3.4 Interface Circuit- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-14

6.4 Others - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-17

6.4.1 Wiring Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-17

6.4.2 Wiring for Noise Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-18

6.4.3 Using More Than One SERVOPACK- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-22

6.4.4 Extending Encoder Cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-24

ain Circuit Terminals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-2

xv

Page 16

7 Digital Operator/Panel Operator

7.1 Functions on Digital Operator/Panel Operator - - - - - - - - - - - - - - - - - - - - - - - - - 7-2

7.1.1 Connecting the Digital Operator - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-2

7.1.2 Key Names and Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-3

7.1.3 Basic Mode Selection and Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-4

7.1.4 Status Display - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-5

7.2 Operation in Utility Function Mode (Fn) - - - - - - - - - - - - - - - - - - - - - - - - - 7-7

7.2.1 List of Utility Function Modes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-7

7.2.2 Alarm Traceback Data Display (Fn000)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-8

7.2.3 Zero-point Search Mode (Fn003) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-9

7.2.4 Parameter Settings Initialization (Fn005)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-10

7.2.5 Alarm Traceback Data Clear (Fn006) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-11

7.2.6 Manual Zero Adjustment and Gain Adjustment of Analog Monitor Output (Fn00C, Fn00D) - -7-12

7.2.7 Offset Adjustment of Motor Current Detection Signal (Fn00E, Fn00F) - - - - - - - - - - - - - - - - -7-15

7.2.8 Password Setting (Protects Parameters from Being Changed) (Fn010) - - - - - - - - - - - - - - - -7-17

7.2.9 Motor Models Display (Fn011) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-18

7.2.10 Software Version Display (Fn012) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-19

7.2.11 Application Module Detection Results Clear (Fn014) - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-20

7.3 Operation in Parameter Setting Mode (Pn)- - - - - - - - - - - - - - - - - - - - - - 7-21

7.3.1 Setting Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-21

7.3.2 Input Circuit Signal Allocation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-24

7.3.3 Output Circuit Signal Allocation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-27

7.4 Operation in Monitor Mode (Un) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-29

7.4.1 List of Monitor Modes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-29

8 Operation

8.1 Trial Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-4

Trial Operation for Servomotor without Load - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-6

8.1.1

8.1.2 Trial Operation for Servomotor without Load from Host Reference - - - - - - - - - - - - - - - - - - - -8-9

Trial Operation with the Servomotor Connected to the Machine

8.1.3

8.1.4 Servomotor with Brakes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-16

8.1.5 Position Control by Host Controller - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-16

8.2 Control Mode Selection- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-17

8.3 Setting Common Basic Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-18

8.3.1 Setting the Servo ON Signal - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-18

8.3.2 Switching the Servomotor Rotation Direction- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-19

8.3.3 Setting the Overtravel Limit Function - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-20

8.3.4 Setting for Holding Brakes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-22

8.3.5 Selecting the Stopping Method After Servo OFF - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-26

8.3.6 Instantaneous Power Loss Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-27

- - - - - - - - - - - - - - - - - - - - -8-15

xvi

8.4 Absolute Encoders - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-28

8.4.1 Interface Circuits - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-29

8.4.2 Selecting an Absolute Encoder - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-30

8.4.3 Handling Batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-30

Page 17

8.4.4 Replacing Batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-31

8.4.5 Absolute Encoder Setup (Fn008) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-32

8.4.6 Absolute Encoder Reception Sequence- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-33

8.4.7 Multiturn Limit Setting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-36

8.4.8 Multiturn Limit Setting When Multiturn Limit Disagreement (A.CC) Occurred - - - - - - - - - - - - 8-37

8.5 Operating Using Speed Control with Analog Reference - - - - - - - - - - - - - - - - - 8-38

8.5.1 Setting Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-38

8.5.2 Setting Input Signals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-39

8.5.3 Adjusting Offset- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-40

8.5.4 Soft Start - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-43

8.5.5 Speed Reference Filter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-43

8.5.6 Using the Zero Clamp Function - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-43

8.5.7 Encoder Signal Output - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-45

8.5.8 Speed Coincidence Output- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-48

8.6 Operating Using Position Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-49

8.6.1 Setting Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-49

8.6.2 Setting the Electronic Gear- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-51

8.6.3 Position Reference - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-54

8.6.4 Smoothing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-57

8.6.5 Positioning Completed Output Signal - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-58

8.6.6 Positioning Near Signal - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-59

8.6.7 Reference Pulse Inhibit Function (INHIBIT) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-60

8.6.8 Reference Pulse Input Multiplication Switching Function - - - - - - - - - - - - - - - - - - - - - - - - - - 8-61

8.7 Operating Using Torque Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-63

8.7.1 Setting Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-63

8.7.2 Torque Reference Input - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-63

8.7.3 Adjusting the Reference Offset - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-64

8.7.4 Limiting Servomotor Speed during Torque Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-66

8.8 Operating Using Speed Control with an Internally Set Speed - - - - - - - - - - - - - 8-68

8.8.1 Setting Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-68

8.8.2 Input Signal Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-69

8.8.3 Operating Using an Internally Set Speed - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-69

8.9 Limiting Torque - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-71

8.9.1 Internal Torque Limit (Limiting Maximum Output Torque) - - - - - - - - - - - - - - - - - - - - - - - - - - 8-71

8.9.2 External Torque Limit (Output Torque Limiting by Input Signals) - - - - - - - - - - - - - - - - - - - - - 8-72

8.9.3 Torque Limiting Using an Analog Voltage Reference- - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-73

8.9.4 Torque Limiting Using an External Torque Limit and Analog Voltage Reference- - - - - - - - - - 8-74

8.9.5 Checking Output Torque Limiting during Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-75

8.10 Control Mode Selection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-76

8.10.1 Setting Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-76

8.10.2 Switching the Control Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-76

xvii

Page 18

8.11 Other Output Signals- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-77

8.11.1 Servo Alarm Output (ALM) and Alarm Code Output (ALO1, ALO2, ALO3) - - - - - - - - - - - - - 8-77

8.11.2 Warning Output (/WARN)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-78

8.11.3 Servomotor running Output Signal (/TGON) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-78

8.11.4 Servo Ready (/S-RDY) Output - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-79

9 Adjustments

9.1 Autotuning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-2

9.1.1 Servo Gain Adjustment Methods - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -9-2

9.1.2 List of Servo Adjustment Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -9-2

9.2 Online Autotuning- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-4

9.3 Manual Tuning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-4

9.3.1 Explanation of Servo Gain - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -9-4

9.3.2 Servo Gain Manual Tuning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -9-5

9.3.3 Position Loop Gain - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -9-5

9.3.4 Speed Loop Gain - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -9-6

9.3.5 Speed Loop Integral Time Constant - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -9-6

9.4 Servo Gain Adjustment Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-7

9.4.1 Feed-forward Reference - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -9-7

9.4.2 Torque Feed-forward- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -9-7

9.4.3 Speed Feed-forward - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -9-8

9.4.4 Proportional Control Operation (Proportional Operation Reference)- - - - - - - - - - - - - - - - - - - -9-9

9.4.5 Using the Mode Switch (P/PI Switching) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-10

9.4.6 Setting the Speed Bias - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -9-13

9.4.7 Speed Feedback Filter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -9-13

9.4.8 Speed Feedback Compensation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -9-13

9.4.9 Switching Gain Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -9-14

9.4.10 Torque Reference Filter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -9-16

9.5 Analog Monitor- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-20

10 Inspection, Maintenance, and Troubleshooting

10.1 Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-2

10.1.1 Alarm Display Table - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -10-2

10.1.2 Warning Display - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-4

10.1.3 Alarm Display Table when the Application Module is Used - - - - - - - - - - - - - - - - - - - - - - - -10-5

10.1.4 Warning Display Table when the Application Module is Used - - - - - - - - - - - - - - - - - - - - - - 10-6

10.1.5 Troubleshooting of Alarm and Warning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -10-7

10.1.6 Troubleshooting for Malfunction without Alarm Display - - - - - - - - - - - - - - - - - - - - - - - - - - 10-16

xviii

10.2 Inspection and Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-20

10.2.1 Servomotor Inspection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-20

10.2.2 SERVOPACK Inspection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-20

10.2.3 SERVOPACK’s Parts Replacement Schedule - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-21

Page 19

11 Appendix

11.1 Servomotor Capacity Selection Examples - - - - - - - - - - - - - - - - - - - - - - - - - - 11-2

11.1.1 Selection Example for Speed Control- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11-2

11.1.2 Selection Example for Position Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11-4

11.2 Connection to Host Controller - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11-7

Example of Connection to MP2200/MP2300 Motion Module SVA-01 - - - - - - - - - - - - - - - - 11-7

11.2.1

11.2.2 Example of Connection to MP920 4-axes Analog Module SVA-01 - - - - - - - - - - - - - - - - - - 11-8

11.2.3 Example of Connection to OMRON’s Motion Control Unit - - - - - - - - - - - - - - - - - - - - - - - - 11-9

11.2.4 Example of Connection to OMRON’s Position Control Unit - - - - - - - - - - - - - - - - - - - - - - -11-10

11.2.5 Example of Connection to MITSUBISHI’s AD72 Positioning

Unit (SERVOPACK in Speed Control Mode) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -11-11

11.2.6 Example of Connection to MITSUBISHI’s AD75 Positioning Unit

(SERVOPACK in Position Control Mode)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -11-12

11.3 List of Parameters- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11-13

11.3.1 Utility Functions List - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -11-13

11.3.2 List of Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -11-14

11.4 Parameter Recording Table - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11-29

INDEX

Revision History

xix

Page 20

1

Outline

1

Outline

1.1 Checking Products - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-2

1.1.1 Check Items - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

1.1.2 Servomotors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

1.1.3 SERVOPACKs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

1.2 Examples of Servo System Configurations - - - - - - - - - - - - -1-3

1.2.1 Three-phase, 200 V Series - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-3

1.2.2 Three-phase, 400 V Series - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-4

1.3 Applicable Standards - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-5

1.3.1 North American Safety Standards (UL) - - - - - - - - - - - - - - - - - - - - - - 1-5

CE Marking

1.3.2

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-5

1-1

Page 21

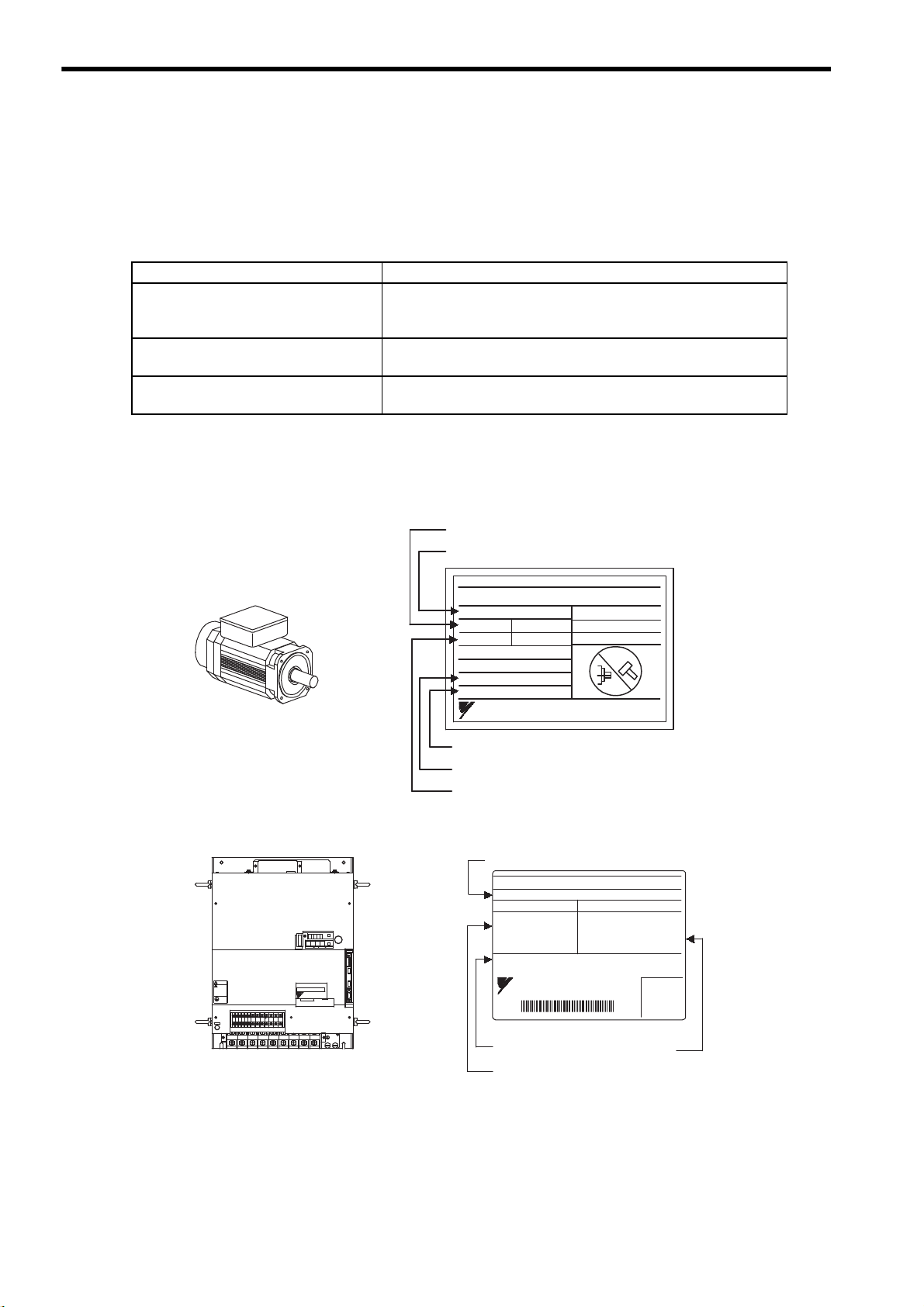

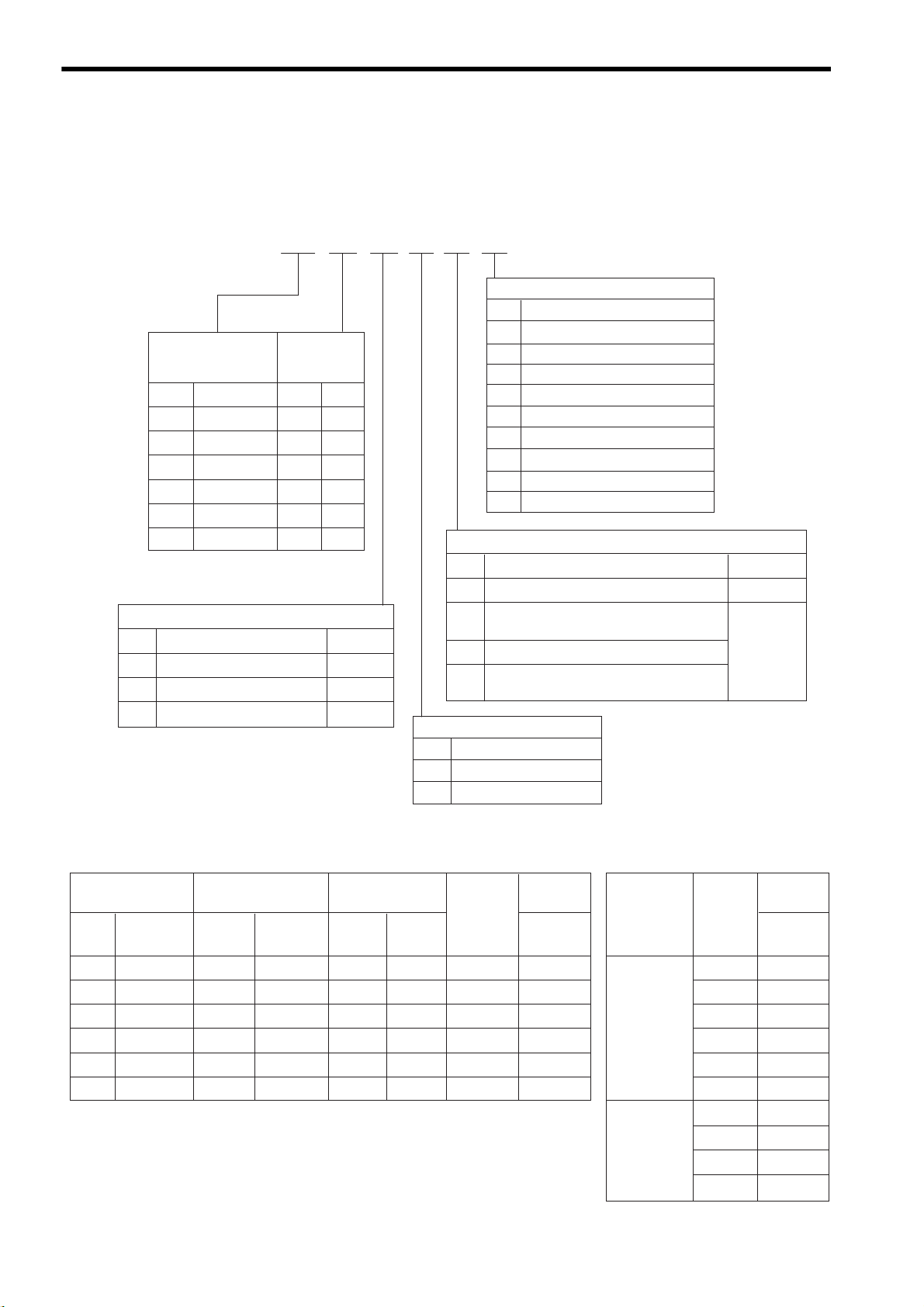

1 Outline

Manufacturing date

Serial number

Servomotor model

Rated output

Rated rotation speed

SGMVH

servomotor

AC SERVO MOTOR

TYPE

SGMVH - 2BDCA

kw N.m

min

SER.NO.

A

RATING

DATE

22

140

1500

58

CONT.

K7A500 101 - 004

9708

ENCODER

UTMAH- B12BDYR11

17 bit

YASKAWA ELECTRIC CORPORATION

JAPAN

-1

Σ-II Series SGDM and SGDH

SERVOPACKs

SERVOPACK model

Serial number

Output power

Applicable power supply

SERVOPACK

SGDH - 3ZDEB

AC-INPUT AC-OUTPUT

MODEL

VOLTS 380- 480

Hz 50/60

PHASE 3

AMPS 145

VOLTS 0 - 480

PHASE 3

AMPS 175

30.0 (40.2)

S / N R7C303 - 221 - 4

YASKAWA ELECTRIC

MADE IN JAPAN

kW (HP)

+2-+1

L1/R L2/S

L3/T

UVW

480 V460

V

DU

400 V 0 V440

V

DWDV B1

380

V

DC

24N

B2

DC

24P

CHARGE

S-HDG

㧖㧖㧖㧖

T DATA/SEEMOD/

KSERVOPAC

AYASKAW

R

O

P

E

R

A

T

O

CN3

8CN

POWER

CN5

WARNING

ෂޓ㒾

ㅢ㔚߮㔚Ḯࠝࡈᓟ5

ಽ㑆ޔ┵ሶㇱߦ⸅ࠆߥ!

electric shock.

Disconnect all power

May cause

ᗵ㔚ߩᕟࠇࠅ

before servicing.

and wait 5 min.

grounding techniques.

ធ⛯ߖࠃ

Use proper

ᔅߕࠕ㧙ࠬ✢ࠍ

1.1.1 Check Items

1.1 Checking Products

The following procedure is used to check the AC servo drives of Σ-ΙΙ Series products on delivery.

1.1.1 Check Items

Check the following items when Σ-ΙΙ Series products are delivered.

Check Items Comments

Are the delivered products the ones

that were ordered?

Does the servomotor shaft rotate

smoothly?

Is there any damage? Check the overall appearance, and check for damage or scratches that

If any of the above items are faulty or incorrect, contact your Yaskawa representative or the dealer from whom

you purchased the products.

1.1.2 Servomotors

Check the model numbers marked on the nameplates on the servomotor and SERVOPACK. (Refer to the descriptions of model numbers in

the following section.)

The servomotor shaft is normal if it can be turned smoothly by hand.

Servomotors with brakes, however, cannot be turned manually.

may have occurred during shipping.

1.1.3 SERVOPACKs

1-2

Page 22

1

Outline

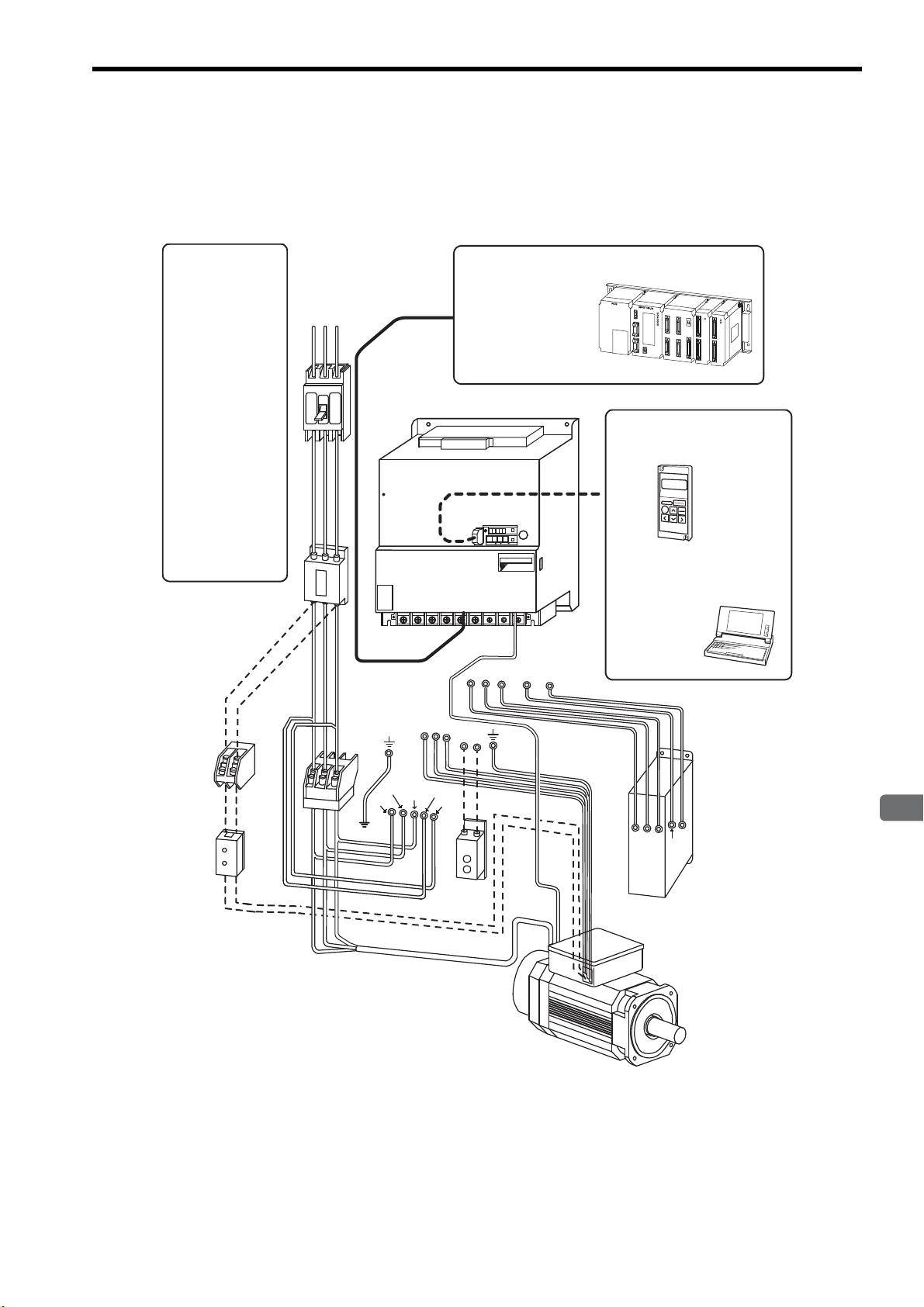

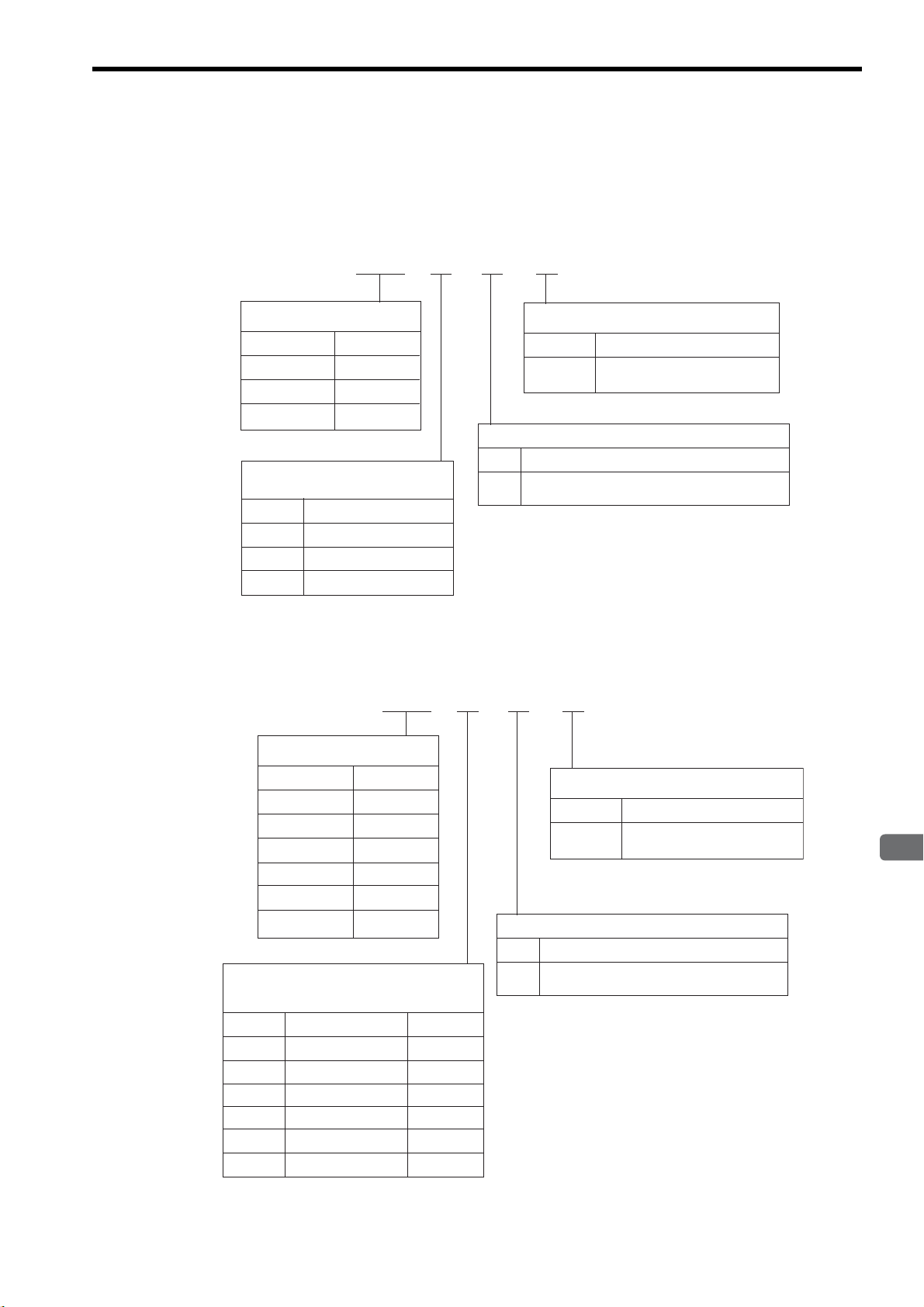

1.2 Examples of Servo System Configurations

U

V

W

B1

B2

RST

CN3

CN1

DB24

DU

DV

DW

DBON

DB24

DU

DV

DW

DBON

Regenerative

Resistor Unit

Power supply for

cooling fan

Power supply

Three-phase 200 VAC

SGMVH

servomotor

SGDM/SGDH SERVOPACK

Host controller

Connect the SGDM/SGDH SERVOPACK

to a Yaskawa or an other manufacturer’s

host controller.

Digital Operator

Allows the user to set parameters or

operation reference and display

operation status or alarm status.

(JUSP-OP02A-2)

Cable model:

Personal computer

Hand-held type

1-meter cable included

Molded-case circuit

breaker (MCCB)

Used to protect power

supply line.

Noise filter

Used to eliminate external noise from power

supply line.

Magnetic contactor *

Turns the servo ON or

OFF.

Brake power supply

Used for SGMVH

servomotor with brake.

LPSE-2H01

(For 200 V input)

Dynamic Brake (DB)

Unit

*

Use a surge absorber

for the magnetic contactor.

Brake power supply

Dynamic Brake Unit

Used if dynamic brake

function is required for the

SERVOPACK.

Note: The Dynamic Brake (DB) Unit DBON and

DB24 terminals can be used with SERVOPACKs of 37 kW or more only.

MP900/MP2000 Series

JZSP-CMS01 to 03

L1/R

L2/S

L3/T

L3C/t

L1C/r

- +1

+2 L1/R L2/S L3/T

UVW

CN2

CN3

CN1

TDATA/SEEMOD/

SERVOPACK

YASK AWA

R

O

P

E

R

A

T

O

CN3

8CN

POWER

CN5

SGDH-

㧖㧖㧖㧖

This section describes examples of basic servo system configuration.

1.2.1 Three-phase, 200 V Series

1.2 Examples of Servo System Configurations

1-3

Page 23

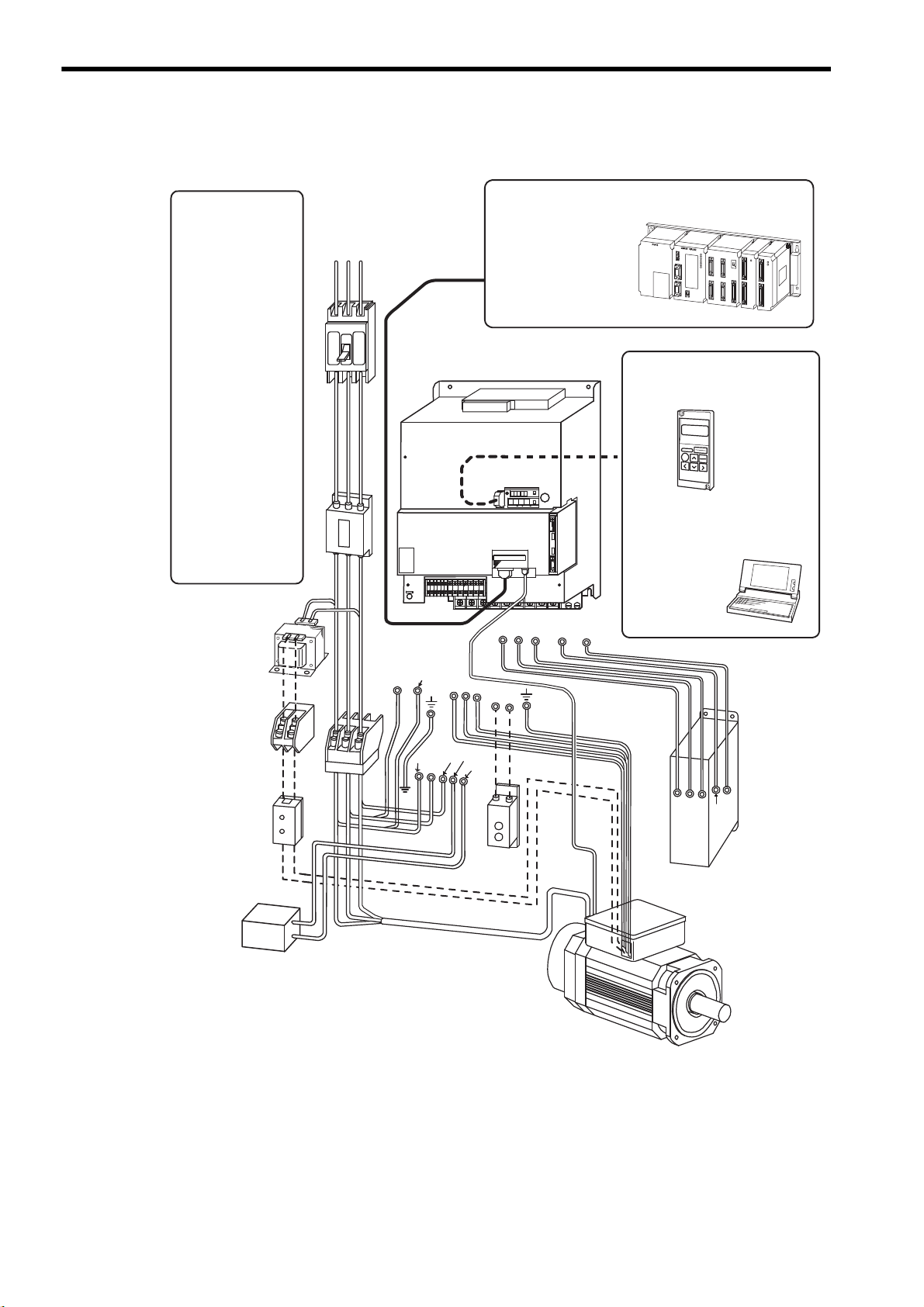

1 Outline

Regenerative

Resistor Unit

U

V

W

B1

B2

0V

Power supply for

cooling fan

Power supply

Three-phase 400 VAC

RST

SGMVH

servomotor

SGDH SERVOPACK

Host controller

Connect the SGDH SERVOPACK to a

Yaskawa or an other manufacturer’s

host controller.

Digital Operator

Allows the user to set parameters or

operation reference and display

operation status or alarm status.

(JUSP-OP02A-2)

Cable model:

Personal computer

Hand-held type

1-meter cable included

Molded-case circuit

breaker (MCCB)

Used to protect power

supply line.

Noise filter

Used to eliminate external noise from power

supply line.

Magnetic contactor *

Turns the servo ON or

OFF.

Brake power supply

Used for SGMVH

servomotor with brake.

LPSE-2H01

(For 200 V input)

Power transformer

Used to switch between

200 V to 400 V.

Dynamic Brake (DB)

Unit

*

Use a surge absorber

for the magnetic contactor.

CN3

CN1

Brake power supply

DB24

DU

DV

DW

DBON

Dynamic Brake Unit

DB24

DU

DV

DW

DBON

Used if dynamic brake

function is required for the

SERVOPACK.

Note: The Dynamic Brake (DB) Unit DBON and

DB24 terminals can be used with SERVOPACKs of 37 kW or more only.

MP900/MP2000 Series

JZSP-CMS01 to 03

380 to 480V

L1/R

L2/S

L3/T

DC24N

DC24P

DC power

supply

(24 VDC)

+

-

CN2

CN3

CN1

8

8

&7

88

8

&9&8 $

8

&%

0

$

&%

2

%*#4)'

5*&)

㧖㧖㧖㧖

6#5''/1&

-5'4812#%

#;#5-#9

4

1

2

'

4

#

6

1

%0

%0

219'4

%0

1.2.2 Three-phase, 400 V Series

1.2.2 Three-phase, 400 V Series

1-4

Page 24

1

Outline

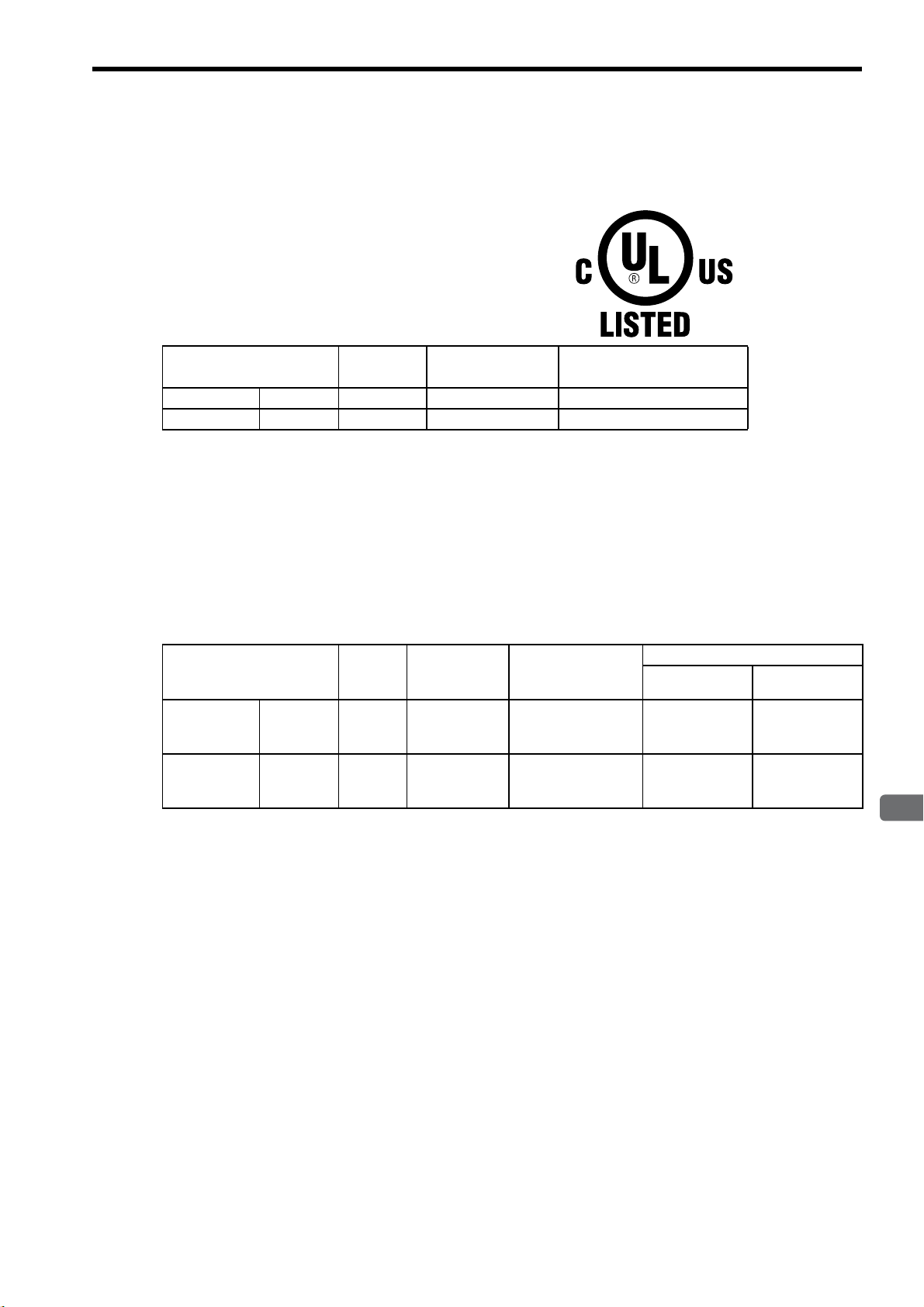

1.3 Applicable Standards

1.3.1 North American Safety Standards (UL)

Model

SERVOPACK SGDH

Servomotor SGMVH

* 1. 200 V SERVOPACKs and servomotors have not obtained certification showing compliance

with UL standards.

* 2. 75 kW SERVOPACKs and servomotors have not obtained certification showing compliance

with UL standards.

* 3. Underwriters Laboratories Inc.

∗1

Voltage

400 V 22 kW to 55 kW UL508C(E147823)

400 V 22 kW to 55 kW UL1004(E165827)

Capacity∗2

∗3

Standards

UL

(UL File No.)

1.3 Applicable Standards

1.3.2 CE Marking

The SGDH SERVOPACK and SGMVH servomotor have not obtained certification showing compliance with CE

marking, but, the following models comply with its standards.

Model

SERVOPACK SGDH

Servomotor SGMVH

* A low voltage directive-compliant model is in development.

Note: Because SERVOPACKs and servomotors are built-in type, reconfirmation is required after

being installed in the final product.

∗

Voltage

400 V 22 kW to 55 kW EN50178

400 V 22 kW to 55 kW

Capacity

∗

Low Voltage

Directive

(compliant)

–

EMC Directive (compliant)

EMI EMS

EN55011

class A group 1

∗

EN55011

class A group 1

EN50082-2

or

EN61000-6-2

EN50082-2

or

EN61000-6-2

1-5

Page 25

2

Selections

2

Selections

2.1 Servomotor Model Designations - - - - - - - - - - - - - - - - - - - - - 2-2

2.2 SERVOPACK Model Designations - - - - - - - - - - - - - - - - - - - 2-3

2.3 Σ-II Series SERVOPACKs and Applicable Servomotor - - - - - 2-4

2.4 Selecting Cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-5

2.4.1 Cables for SGMVH Servomotor - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-5

2.5 Selecting Peripheral Devices - - - - - - - - - - - - - - - - - - - - - - - 2-6

2.5.1 Special Options - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-6

2.5.2 Molded-case Circuit Breaker and Fuse Capacity - - - - - - - - - - - - - - - - 2-8

2.5.3 Noise Filters, Magnetic Contactors, and Brake Power

Supply Units - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-9

2.5.4 Regenerative Resistor Units - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-9

2.5.5 Dynamic Brake (DB) Units - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-10

2.5.6 Thermal Relays - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-11

2-1

Page 26

2 Selections

SGMVH − 2B A 2 B 2 N

4th digit: Serial Encoder

7th digit: Brake and Oil Seal

Code

N

1

S

B

C

D

E

F

G

Specifications

Standard (without options)

With dust seal

With oil seal

With 90-VDC brake

With 24-VDC brake

With oil seal and 90-VDC brake

With oil seal and 24-VDC brake

With dust seal and 90-VDC brake

With dust seal and 24-VDC brake

1st + 2nd digits:

Rated Output

(kW)

Code

2B

3Z

3G

4E

5E

7E

Rated Output A

−

−

−

D

3rd digit:

Voltage

A:200V,D:400V

Code

2

3

C

Remarks

Standard

ޓޓSpecifications

17-bit absolute encoder

20-bit absolute encoder

17-bit incremental encoder

: Available

Option

5th digit: Rated Speed

Code

B

D

Specifications

6th digit: Shaft End, Mounting Method

Code

6

RemarksޓޓSpecifications

Flange-mounted, straight without key

Flange-mounted, straight with key

and shaft end tap (

×1)

1st +

2nd

digits

3rd

digit

4th

digit

5th

digit

6th

digit

7th

digit

: Not available

−

1500 min

-1

800 min

-1

Foot-mounted, straight with key

and shaft end tap (

×1)

K

L

Foot-mounted, straight without key

2

Standard

Option

22

30

37

45

55

75

Standard

1st + 2nd digits:

Rated Output (kW)

Code

Rated

Output

BD

5th digit: Rated Speed

B: 1500 min

-1

,

D: 800 min

-1

Flangemounted

Mounting Method

: Available

With

Brake

With

Brake

Rated

Speed

(min

-1

)

Rated

Output

(kW)

With Oil

Seal and

Dust Seal

Foot-

mounted

1500

800

22

30

37

45

55

75

22

30

37

45

Flange-

mounted

22

30

37

45

55

75

2B

3Z

3G

4E

5E

7E

Foot-

mounted

: Not available

−

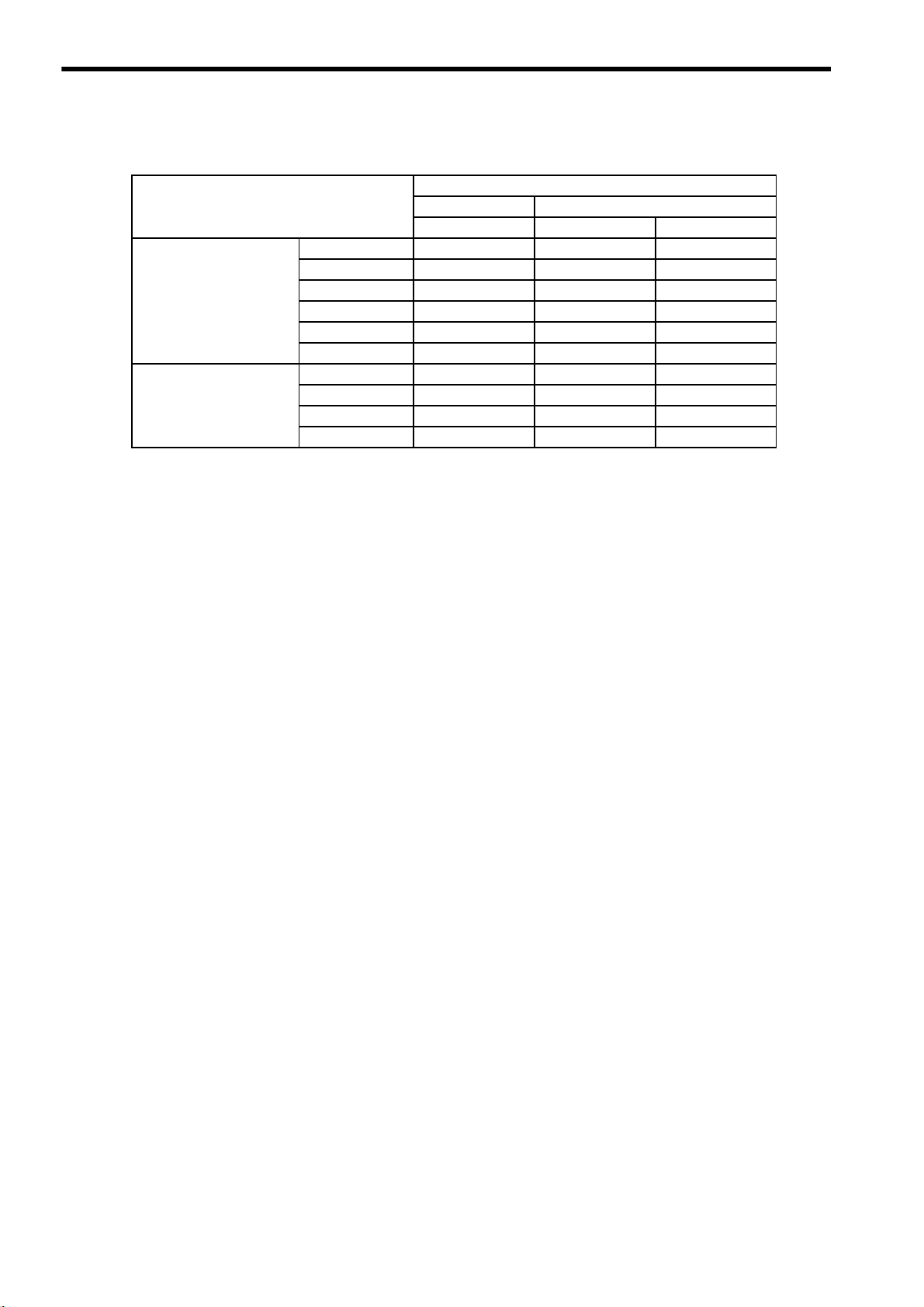

2.1 Servomotor Model Designations

(1) Available Models

2-2

Page 27

2

Selections

2.2 SERVOPACK Model Designations

Code

2B

3Z

3G

Rated Output

22

30

37

Code

D

Specificatioins

Code

2B

3Z

3G

A

Code

B

Specificatioins

2BSGDM - A D B

5th digit: Applicable Servomotor Model

1st + 2nd digits (kW)

3rd digit: Power Supply

Voltage A: 200 V

4th digit: Model

SGMVH

Servomotor

For torque, speed and position control

1st +

2nd

digits

3rd

digit

4th

digit

5th

digit

: Available

Code

2B

3Z

3G

4E

5E

9Z

Rated Output

22

30

37

45

55

75

D

Δ

Δ

Δ

2BSGDH - A E B

Code

2B

3Z

3G

4E

5E

9Z

A

1st +

2nd

digits

3rd

digit

4th

digit

5th

digit

Code

E

Specificatioins

Code

B

Specificatioins

5th digit: Applicable Servomotor Model

1st + 2nd digits (kW)

3rd digit: Power Supply Voltage

A: 200 V, D: 400 V

4th digit: Model

SGMVH

Servomotor

For torque, speed and position control

: Available

: Option

: Not available

Δ

Select the SERVOPACK according to the applied servomotor.

2.2 SERVOPACK Model Designations

2-3

Page 28

2 Selections

2.3 Σ-II Series SERVOPACKs and Applicable Servomotor

Servomotor

SGMVH-

2B

3Z

1500 min

800 min

Note: =A: 200 V, D: 400 V

Be sure to match the voltage ratio on the servomotor and the SERVOPACK.

-1

-1

3G

4ED

5ED

7ED

2B

3Z

3G

4ED

SGDM- SGDH-

200 V 200 V 400 V

2BADB 2BAEB 2BDEB

3ZADB 3ZAEB 3ZDEB

3GADB 3GAEB 3GDEB

– – 4EDEB

– – 5EDEB

– – 9ZDEB

2BADB 2BAEB 2BDEB

3ZADB 3ZAEB 3ZDEB

3GADB 3GAEB 3GDEB

– – 4EDEB

SERVOPACK

2-4

Page 29

2

Selections

2.4 Selecting Cables

CN2

Encoder

end

SERVOPACK

end

Encoder

end

SERVOPACK

end

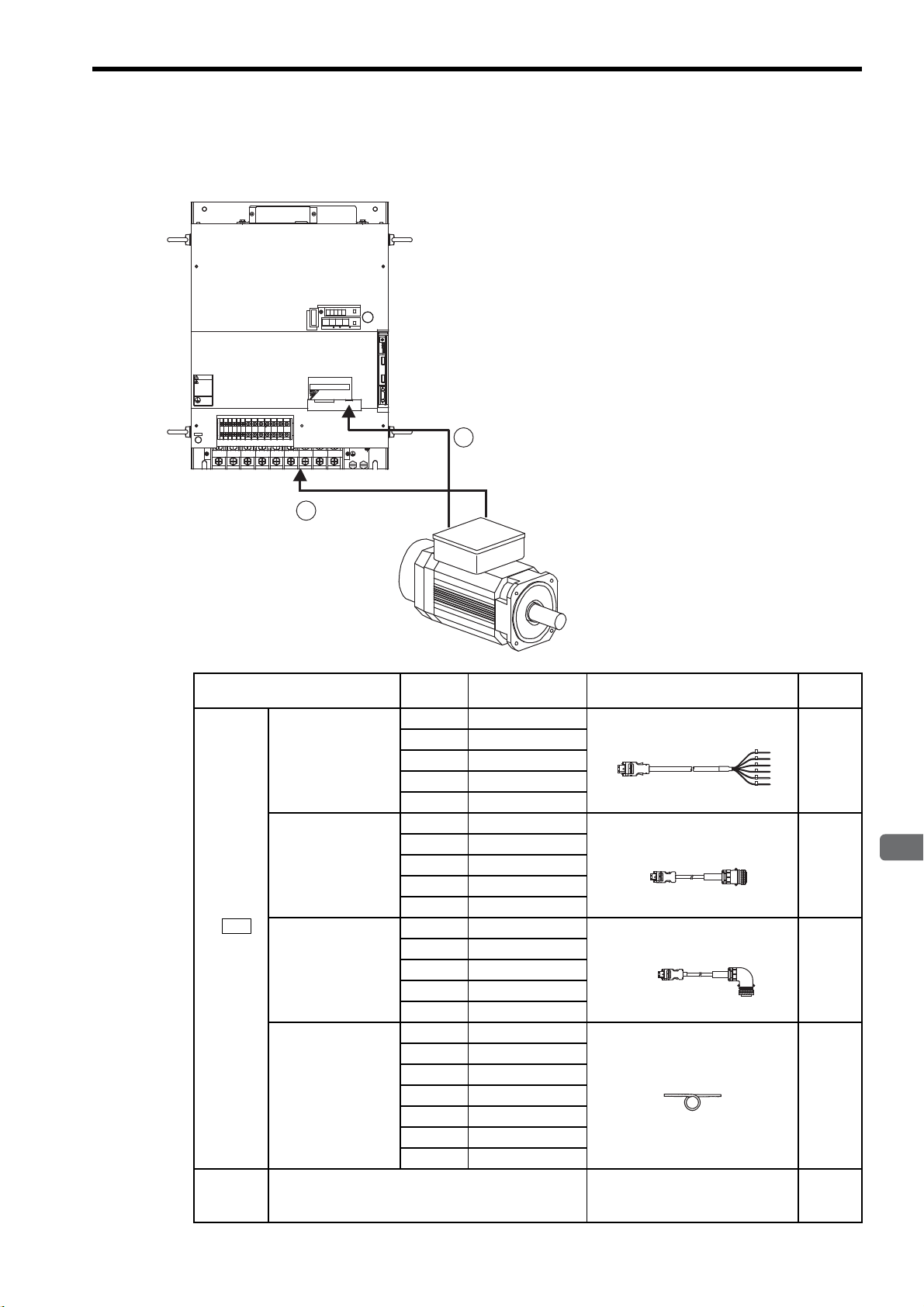

2.4.1 Cables for SGMVH Servomotor

219'4

%0

6 & #6#5''/1&

%0

%0

-5'4812#%

5*&)

㧖㧖㧖㧖

#;#5-#9

May cause

electric shock.

Disconnect all power

and wait 5 min.

before servicing.

grounding techniques.

%*#4)'

ෂޓ㒾

WARNING

ᗵ㔚ߩᕟࠇࠅ

ㅢ㔚߮㔚Ḯࠝࡈᓟ5

ಽ㑆ޔ┵ሶㇱߦ⸅ࠆߥ

ᔅߕࠕ㧙ࠬ✢ࠍ

ធ⛯ߖࠃ

Use proper

1

2

'

4

#

6

1

4

&%

8

88

8

8

8

&%

&7

&9&8 $

$

0

2

.4 .5

.6

789

2.4 Selecting Cables

1

c

Encoder

Cable

dMain

Circuit

Cable

2

Name Length Type Specifications

3 m JZSP-CMP23-03

Cable with loose

wire at encoder

end

5 m JZSP-CMP23-05

10 m JZSP-CMP23-10

15 m JZSP-CMP23-15

20 m JZSP-CMP23-20

3 m JZSP-CMP21-03

5 m JZSP-CMP21-05

Cable with a

straight plug

10 m JZSP-CMP21-10

15 m JZSP-CMP21-15

20 m JZSP-CMP21-20

3 m JZSP-CMP22-03

SERVOPACK

end

Cable with an

L-shaped plug

5 m JZSP-CMP22-05

10 m JZSP-CMP22-10

15 m JZSP-CMP22-15

20 m JZSP-CMP22-20

5 m JZSP-CMP29-05

10 m JZSP-CMP29-10

Cables

15 m JZSP-CMP29-15

20 m JZSP-CMP29-20

50 m max.

30 m JZSP-CMP29-30

40 m JZSP-CMP29-40

50 m JZSP-CMP29-50

Cables

Not available.

For details, refer to chapter 5.

Encoder

end

Refer-

ence

5.2.2

5.2.1

5.2.1

5.3

−

2-5

Page 30

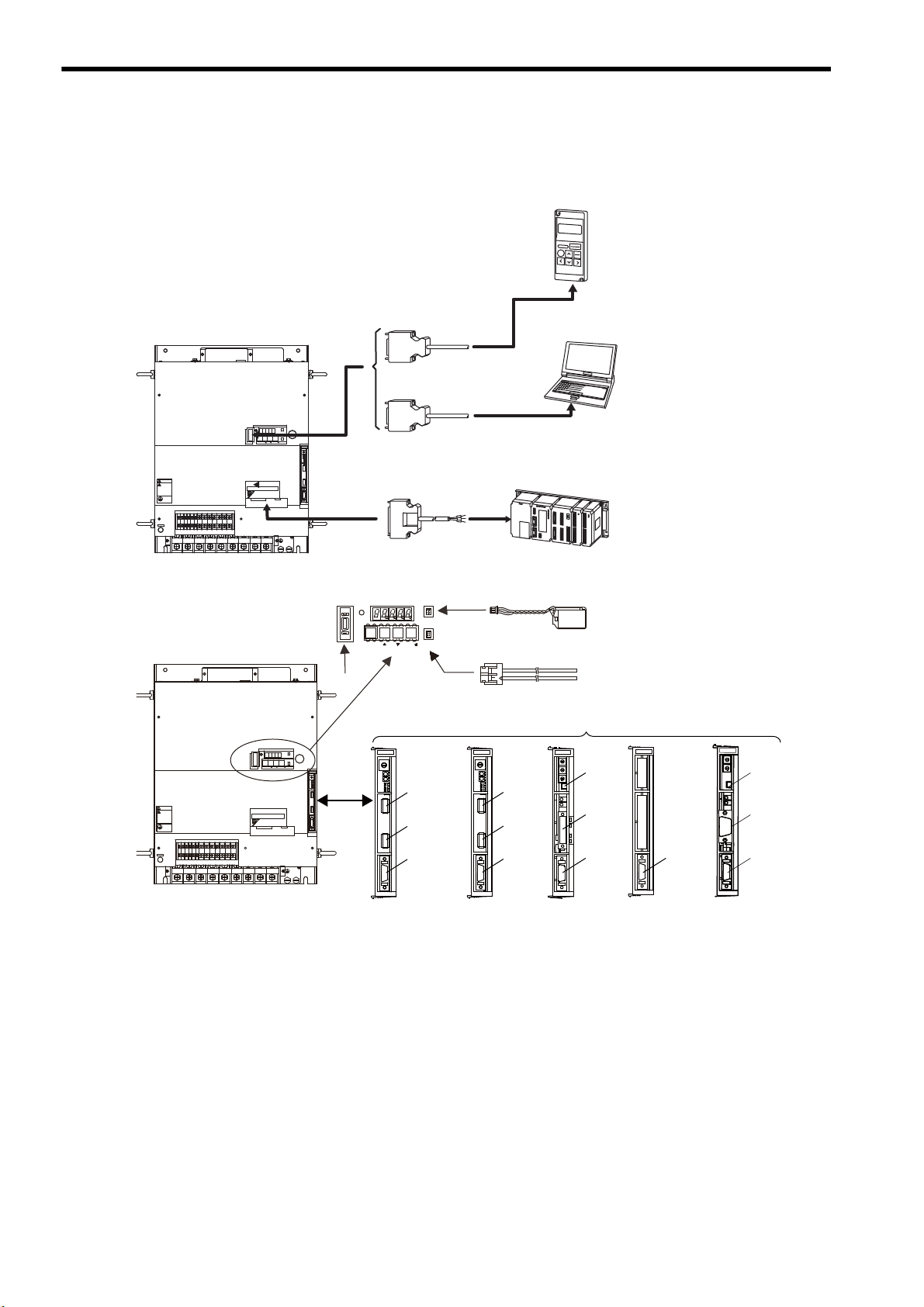

2 Selections

Personal

computer

Digital operator

Host controller

I/O signal cable

Connection cable

for digital operator

Connection cable

for personal computer

.4 .5

.6

789

8

8

&7

88

8

&9&8 $

8

&%

0

$

&%

2

%*#4)'

5*&)

㧖㧖㧖㧖

6#5''/1&

-5'4812#%

#;#5-#9

4

1

2

'

4

#

6

1

%0

%0

219'4

%0

WARNING

ෂޓ㒾

ㅢ㔚߮㔚Ḯࠝࡈᓟ5

ಽ㑆ޔ┵ሶㇱߦ⸅ࠆߥ

electric shock.

Disconnect all power

May cause

ᗵ㔚ߩᕟࠇࠅ

before servicing.

and wait 5 min.

grounding techniques.

ធ⛯ߖࠃ

Use proper

ᔅߕࠕ㧙ࠬ✢ࠍ

NS100

S

W

1

S

W

2

A

R

C

N

6

A

C

N

6

B

C

N

4

5

4

0

9

6

1

2

7

8

3

3

5

4

0

9

6

1

2

7

8

NS300

5

4

0

9

6

1

2

7

8

3

X

10

X

1

D

R

C

N

11

M

S

N

S

FC100

MECHATROLINK-I

application

module

(NS100)

DeviceNet

application

module

(NS300)

Fully-closed

application

module

(FC100)

PROFIBUS-DP

application

module

(NS500)

Connector

CN6A

CN11

CN6

CN4

CN11

CN6

CN4CN4

CN6B

CN4

6

NS500

NS115

S

W

1

S

W

2

A

R

C

N

6

A

C

N

6

B

C

N

4

MECHATROLINK-II

application

module

(NS115)

CN6A

CN6B

CN4

CN3

CN8

MODE/SET DATA/

POWER

CN5

.4 .5

.6

789

8

8

&7

88

8

&9&8 $

8

&%

0

$

&%

2

%*#4)'

5*&)

㧖㧖㧖㧖

6#5''/1&

-5'4812#%

#;#5-#9

4

1

2

'

4

#

6

1

%0

%0

219'4

%0

WARNING

ෂޓ㒾

ㅢ㔚߮㔚Ḯࠝࡈᓟ5

ಽ㑆ޔ┵ሶㇱߦ⸅ࠆߥ

electric shock.

Disconnect all power

May cause

ᗵ㔚ߩᕟࠇࠅ

before servicing.

and wait 5 min.

grounding techniques.

ធ⛯ߖࠃ

Use proper

ᔅߕࠕ㧙ࠬ✢ࠍ

Analog monitor cable

Battery for absolute encoder

2.5.1 Special Options

2.5 Selecting Peripheral Devices

2.5.1 Special Options

2-6

Page 31

2.5 Selecting Peripheral Devices

2

Selections

CN1

CN3

Operator

end

SERVOPACK

end

CN3

Personal

computer end

SERVOPACK

end

Personal

computer end

SERVOPACK

end

Personal

computer end

SERVOPACK

end

CN5

SERVOPACK end

Monitor end

CN8

Name Length Type Specifications

Connector terminal block

c

converter unit

I/O Signal

Cables

Cable with

loose wires at

one end

d Digital Operator

e

Connection Cable for Digital

Operator

JUSP-TA50PG

1 m JZSP-CKI01-1

2 m JZSP-CKI01-2

3 m JZSP-CKI01-3

JUSP-OP02A-2

1m JZSP-CMS00-1

1.5m JZSP-CMS00-2

2 m JZSP-CMS00-3

Terminal block and 0.5 m connection

cable

Loose wires at host controller end

With connection cable (1 m)

Required only when the digital operator model: JUSP-OP02A-1 for Σ-I

series is used.

D-Sub 25-pin (For PC98)

Refer-

ence

5.5.4

5.4.1

5.5.2

2 m JZSP-CMS01

f

Connection Cable for Personal

Computer

g

Analog Monitor Cable

2 m JZSP-CMS02

2 m JZSP-CMS03

1 m

JZSP-CA01 or

DE9404559

JZSP-BA01-1

h

Battery for Absolute Encoder

Application Module

⑦

∗

* For details, refer to the manuals of each application module.

ER6VC3

JUSP-NS100

JUSP-NS115

JUSP-NS300

JUSP-FC100

JUSP-NS500

D-Sub 9-pin (For DOS/V)

Half-pitch 14-pin (For PC 98)

To connect to a host controller,

3.6 V, 2000 mAh, manufactured by

Toshiba Battery Co., Ltd.

MECHATROLINK-I application

module (NS100)

MECHATROLINK-II application

module (NS115)

DeviceNet application module

(NS300)

Fully-closed application module

(FC100)

PROFIBUS-DP

application module (NS500)

5.5.1

5.5.3

5.5.6

5.5.15

5.5.15

5.5.16

5.5.18

5.5.17

2-7

Page 32

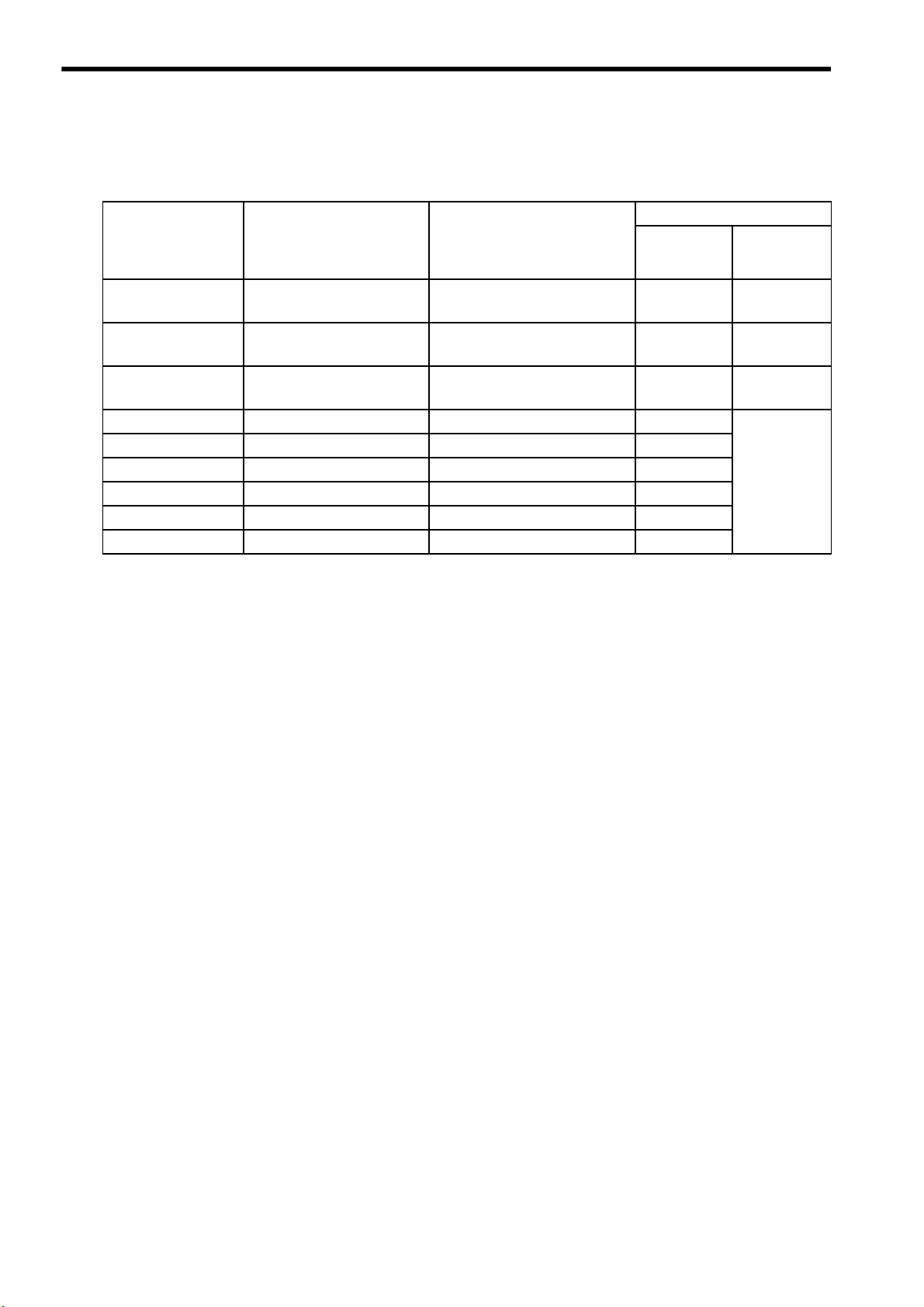

2 Selections

2.5.2 Molded-case Circuit Breaker and Fuse Capacity

2.5.2 Molded-case Circuit Breaker and Fuse Capacity

Select a input fuse or molded-case circuit breaker that comply with UL standard.

SERVOPACK Model

SGDM-2BADB

SGDH-2BAEB

SGDM-3ZADB

SGDH-3ZAEB

SGDM-3GADB

SGDH-3GAEB

SGDH-2BDEB

SGDH-3ZDEB

SGDH-3GDEB

SGDH-4EDEB

SGDH-5EDEB

SGDH-9ZDEB

* 1. Nominal value at the rated load.

* 2. Cutoff characteristics (25

* 3. The values will vary, depending on the 24 VDC control power supply used.

Note: Do not use a fast-acting fuse. Because the SERVOPACK’s power supply is a capacitor

input type, a fast-acting fuse may blow when the power is turned ON.

Power Supply

Capacity per

SERVOPACK

∗1

(kVA)

Current Capacity of the

Molded-case Circuit Breaker

and the Fuse (A)

∗2

Inrush Current (A)

Main Circuit

Power Supply

36.7 150 300 30

50.1 200 300 30

61.8 225 600 30

36.7 100 140

50.1 150 565

61.8 150 565

75.2 225 1130

91.9 225 1130

125.3 300 170

°C): 200% for two seconds min. and 700% for 0.01 seconds min.

Control Circuit

Power Supply

*3

(10)

2-8

Page 33

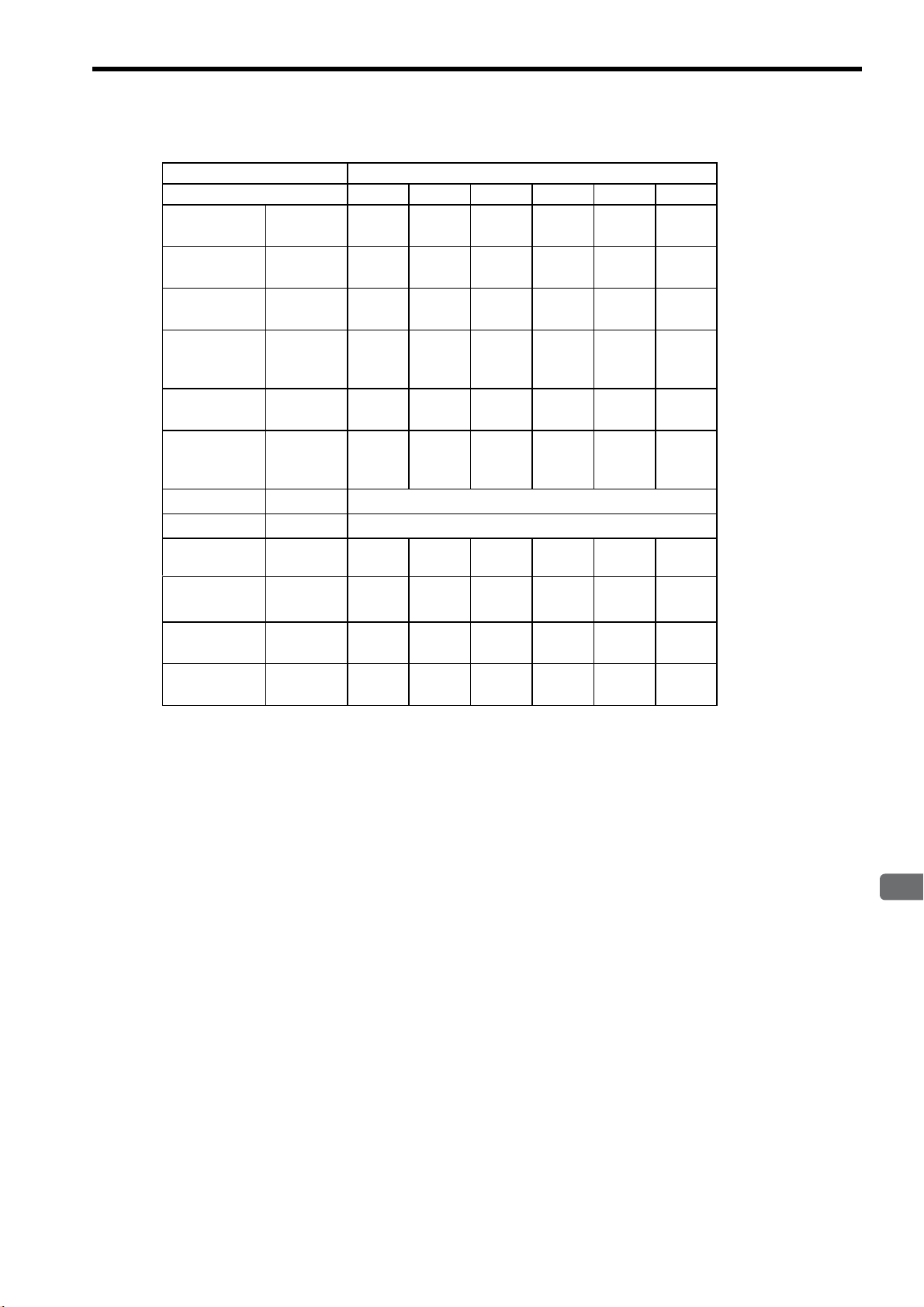

2.5 Selecting Peripheral Devices

2

Selections

2.5.3 Noise Filters, Magnetic Contactors, and Brake Power Supply Units

SERVOPACK Model Recommended Noise Filter Magnetic Contactor Brake Power Supply Unit

SGDM-2BADB

SGDH-2BAEB

SGDM-3ZADB

SGDH-3ZAEB

SGDM-3GADB

SGDH-3GAEB

SGDH-2BDEB

SGDH-3ZDEB

SGDH-3GDEB

FN258L-130-35 SC-N6 (125A)

FN258L-180-07 SC-N8 (180A)

FN359P-250-99 SC-N10 (220A)

FN258L-180-07 SC-N6 (125A)

FN258L-180-07 SC-N8 (180A)

FN258L-180-07 SC-N8 (180A)

c24 VDC brake (provided by a

customer)

d90 VDC brake

• LPDE-1H01 for 100 VAC input

• LPSE-2H01 for 200 VAC input

SGDH-4EDEB

SGDH-5EDEB

SGDH-9ZDEB

Note: 1. If some SERVOPACKs are wired at the same time, select the proper magnetic contactors accord-

ing to the total capacity.

2. The following table shows the manufacturers of each device.

Peripheral Device Manufacturer

Noise Filter Schaffner Electronic

Magnetic Contactor Fuji Electric Co., Ltd.

Brake Power Supply

Unit

FN359P-250-99 SC-N10 (220A)

FN359P-250-99 SC-N10 (220A)

FN359P-300-99 SC-N11 (300A)

Yaskawa Controls Co., Ltd.

2.5.4 Regenerative Resistor Units

SERVOPACK

Model

Regenerative

Resistor Unit

Model

Resistance (Ω)

Resistance

Capacity (W)

Allowable Load Moment of