Page 1

AC Servo Drives

-V Series

USER’S MANUAL

Design and Maintenance

Rotational Motor

MECHATROLINK-III Communications Reference

SGDV SERVOPACK

SGMJV/SGMAV/SGMPS/SGMGV/SGMSV/SGMCS Servomotors

MANUAL NO. SIEP S800000 64H

Outline

Panel Display and

Operation of Digital Operator

Wiring and Connection

Operation

Adjustments

Utility Functions (Fn)

Monitor Displays (Un)

Fully-closed Loop Control

Troubleshooting

Appendix

1

2

3

4

5

6

7

8

9

10

Page 2

Copyright © 2008 YASKAWA ELECTRIC CORPORATION

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system,

or transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording,

or otherwise, without the prior written permission of Yaskawa. No patent liability is assumed

with respect to the use of the information contained herein. Moreover, because Yaskawa is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this

manual. Nevertheless, Yaskawa assumes no responsibility for errors or omissions. Neither is

any liability assumed for damages resulting from the use of the information contained in this

publication.

Page 3

About this Manual

This manual describes information required for designing, testing, adjusting, and maintaining Σ-V Series

SERVOPACKs.

Keep this manual in a location where it can be accessed for reference whenever required. Manuals outlined on

the following page must also be used as required by the application.

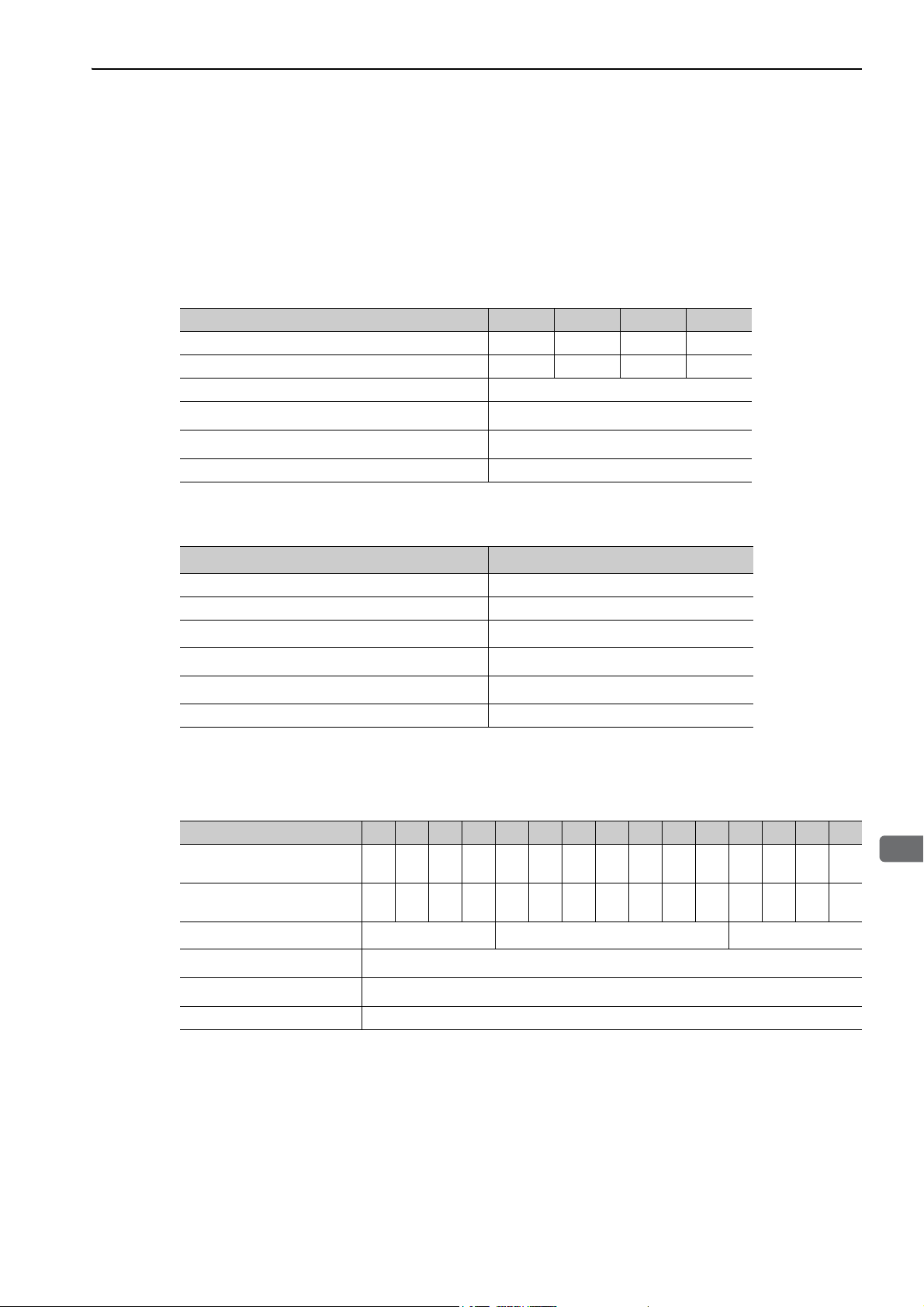

Description of Technical Terms

The following table shows the meanings of terms used in this manual.

Te rm Meaning

Cursor Input position indicated by Digital Operator

Servomotor

SERVOPACK Σ-V Series SGDV servo amplifier

Servo Drive

Servo System

M-III Model

Servo ON Power to motor ON

Servo OFF Power to motor OFF

Base Block (BB)

Servo Lock

Main Circuit Cable

Σ-V Series SGMJV, SGMAV, SGMPS, SGMGV, SGMSV, or SGMCS

(Direct Drive) servomotor

A set including a servomotor and SERVOPACK (i.e., a servo amplifier)

A servo control system that includes the combination of a servo drive

with a host controller and peripheral devices

MECHATROLINK-III communications reference used for SERVOPACK interface

Power supply to motor is turned OFF by shutting off the base current

to the power transistor in the current amplifier.

A state in which the motor is stopped and is in position loop with a

position reference of 0.

Cables which connect to the main circuit terminals, including main

circuit power supply cables, control power supply cables, servomotor

main circuit cables, and others.

IMPORTANT Explanations

The following icon is displayed for explanations requiring special attention.

• Indicates important information that should be memorized, as well as precautions, such as

alarm displays, that do not involve potential damage to equipment.

iii

Page 4

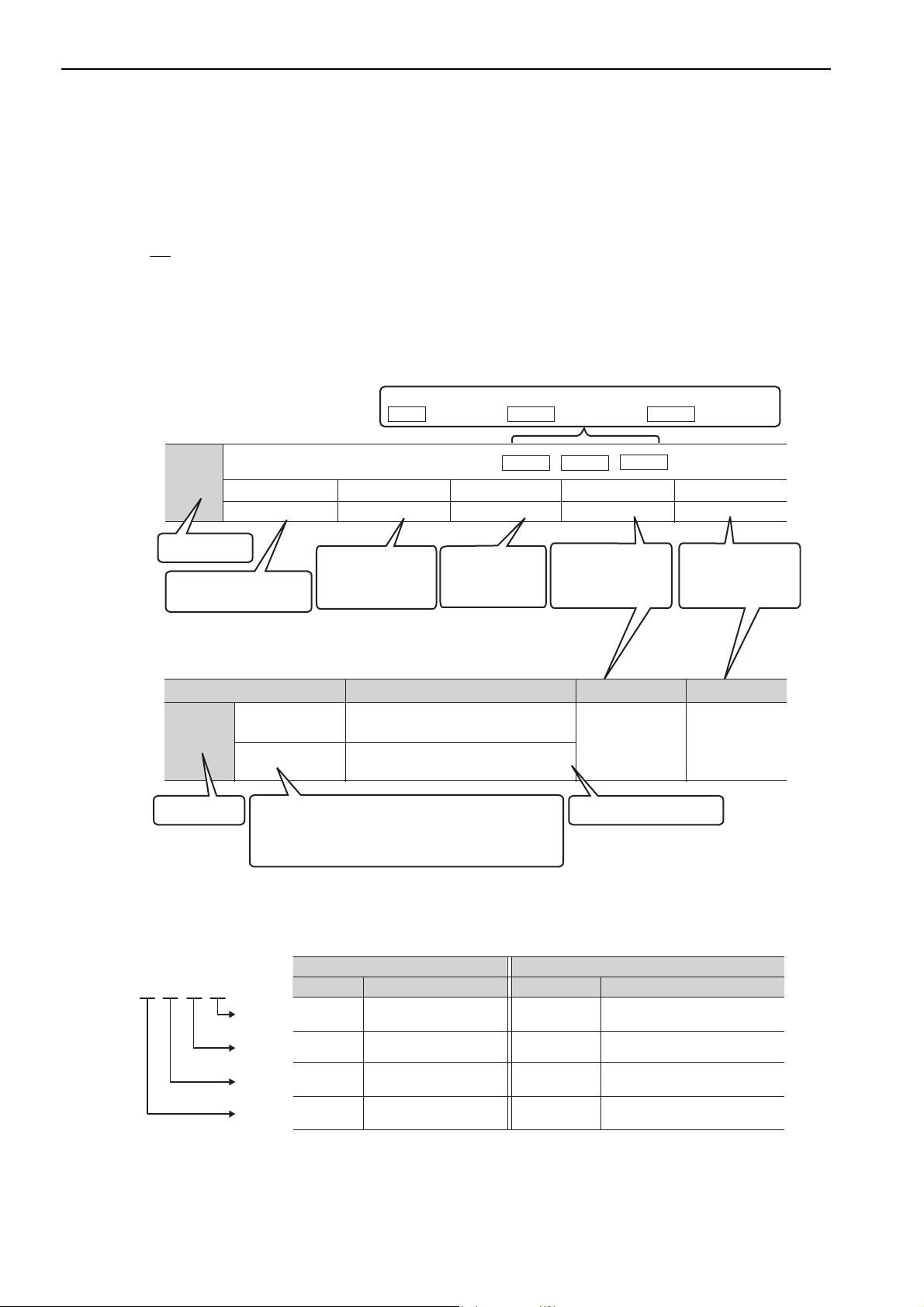

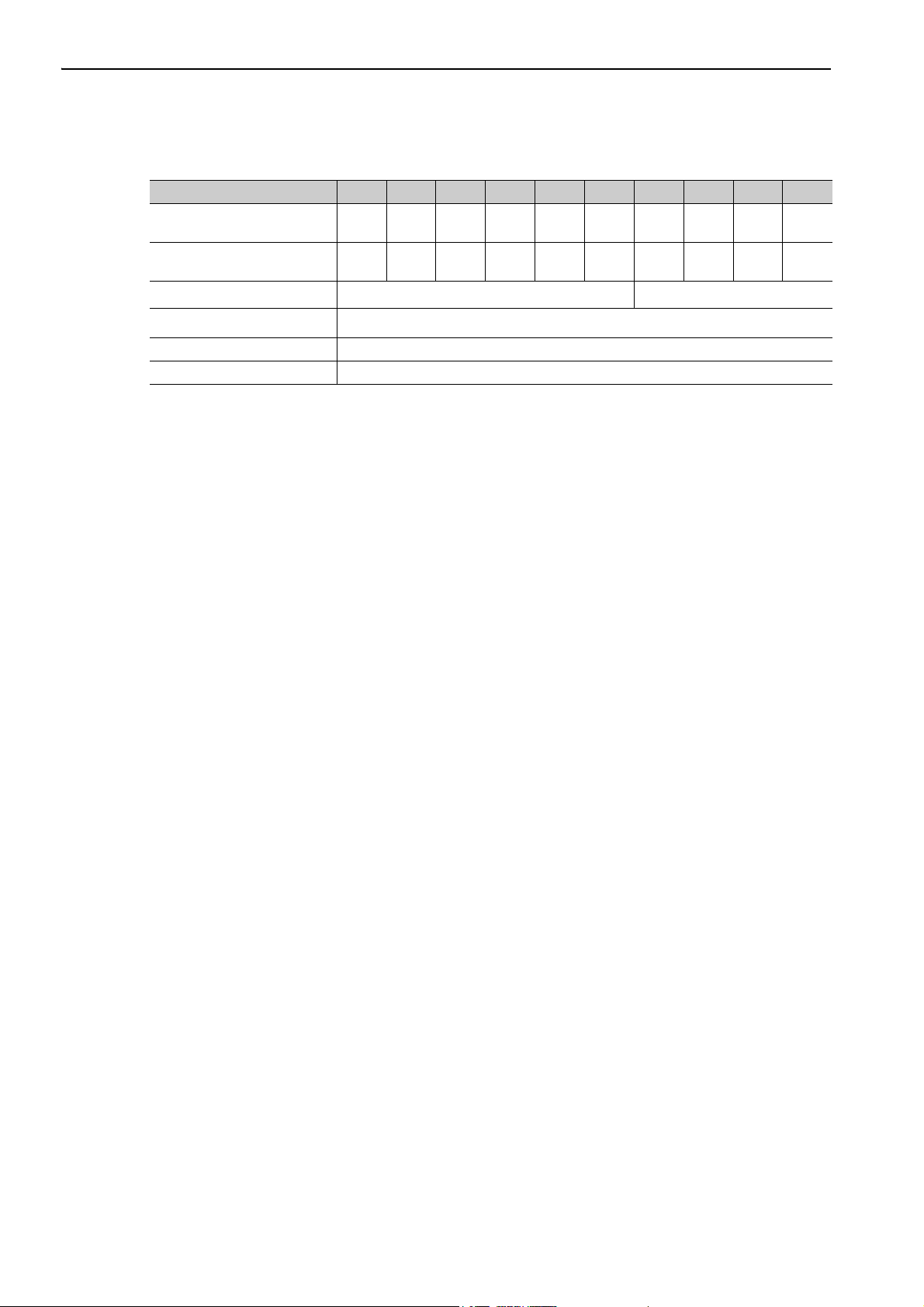

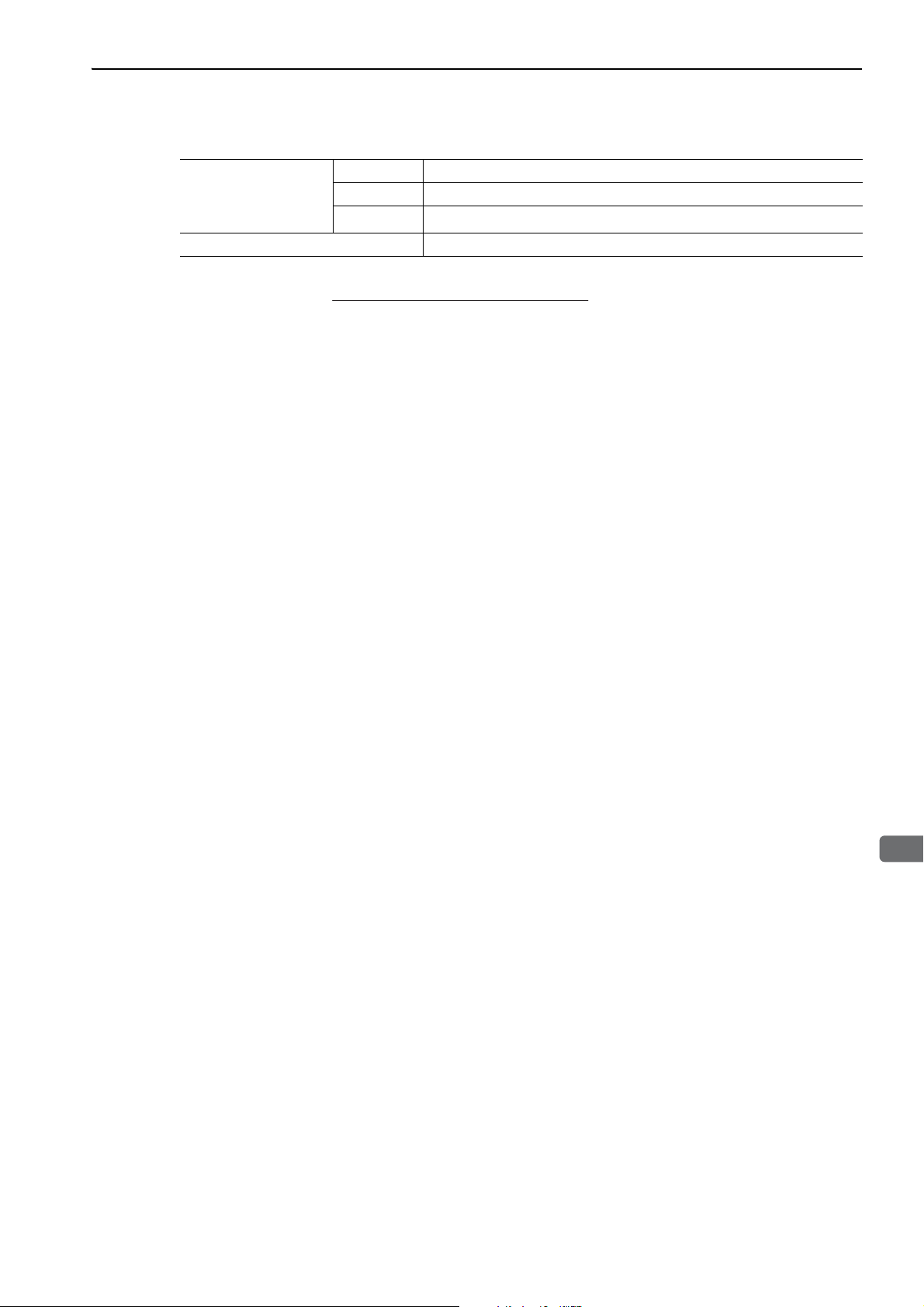

Pn406

Emergency Stop Torque

Setting Range

0% to 800% 1% 800 After change

Setting Unit Factory Setting When Enabled

Classification

Setup

Parameter Meaning When Enabled Classification

Pn002

After restart

n.0

[Factory setting]

n.1

Uses the absolute encoder as an

incremental encoder.

Uses the absolute encoder as an

absolute encoder.

Setup

Parameter

number

Parameter

number

Position

Torque

Control methods for which the parameter applies.

Speed

: Speed control

: Position control

: Torque control

Indicates the

parameter setting

before shipment.

Indicates when a

change to the

parameter will be

effective.

Indicates the

parameter

classification.

Indicates the

minimum setting unit

for the parameter.

Torque

Position Speed

Indicates the setting

range for the parameter.

The notation “n.” indicates a parameter

for selecting functions. Each corresponds to

the setting value of that digit. The notation shown

here means that the third digit is 1.

This section explains the

selections for the function.

• Parameters for Selecting Functions

Rotation

1st digit

2nd digit

3rd digit

4th digit

Digital Operator Display

(Display Example for Pn002)

Digit Notation Setting Notation

Meaning Notation Meaning

Pn002.0

Pn002.1

Pn002.2

Pn002.3

Indicates the value for the

1st digit of parameter Pn002.

Indicates the value for the

2nd digit of parameter Pn002.

Indicates the value for the

3rd digit of parameter Pn002.

Indicates the value for the

4th digit of parameter Pn002.

Pn002.0 = x

or n.x

Pn002.1 = x

or n.x

Indicates that the value for the

1st digit of parameter Pn002 is x.

Indicates that the value for the

2nd digit of parameter Pn002 is x.

Pn002.2 = x

or n.x

Pn002.3 = x

or n.x

Indicates that the value for the

3rd digit of parameter Pn002 is x.

Indicates that the value for the

4th digit of parameter Pn002 is x.

Notation

MECHA

Notation Used in this Manual

• Notation for Reverse Signals

The names of reverse signals (i.e., ones that are valid when low) are written with a forward slash (/) before the

signal name.

Notation Example

BK

= /BK

• Notation for Parameters

The notation depends on whether the parameter requires a value setting (parameter for numeric settings) or

requires the selection of a function (parameter for selecting functions).

• Parameters for Numeric Settings

iv

Notation Example

Page 5

Manuals Related to the Σ-V Series

Refer to the following manuals as required.

Name

Σ-V Series

User's Manual

Setup

Rotational Motor

(No.: SIEP S800000 43)

Σ-V Series

Product Catalog

(No.: KAEP S800000 42)

Σ-V Series

User's Manual

Design and Maintenance

Rotational Motor/

MECHATROLINK-III

Communications Reference

(this manual)

Σ-V Series

User’s Manual

MECHATROLINK-III

Standard Servo Profile

Commands

(No.: SIEP S800000 63)

Σ-V Series

User’s Manual

Operation of Digital Operator

(No.: SIEP S800000 55)

Σ-V Series

AC SERVOPACK SGDV

Safety Precautions

(No.: TOBP C710800 10)

Σ Series

Digital Operator

Safety Precautions

(No.: TOBP C730800 00)

AC SERVOMOTOR

Safety Precautions

(No.: TOBP C230200 00)

Selecting

Models and

Peripheral

Devices

Ratings and

Specifications

System

Design

Panels and

Wiring

Trial

Operation

Trial

Operation

and Servo

Adjustment

Maintenance

and

Inspection

Trademarks

MECHATROLINK is a trademark of the MECHATROLINK Members Association.

v

Page 6

WARNING

CAUTION

PROHIBITED

MANDATORY

Safety Information

The following conventions are used to indicate precautions in this manual. Failure to heed precautions provided in this manual can result in serious or possibly even fatal injury or damage to the products or to related

equipment and systems.

Indicates precautions that, if not heeded, could possibly result in loss of

life or serious injury.

Indicates precautions that, if not heeded, could result in relatively serious

or minor injury, damage to the product, or faulty operation.

In some situations, the precautions indicated could have serious

consequences if not heeded.

Indicates prohibited actions that must not be performed. For example,

this symbol would be used to indicate that fire is prohibited as follows:

Indicates compulsory actions that must be performed. For example, this

symbol would be used to indicate that grounding is compulsory as

follows:

vi

Page 7

Safety Precautions

This section describes important precautions that must be followed during storage, transportation, installation,

wiring, operation, maintenance, inspection, and disposal. Be sure to always observe these precautions thoroughly.

• Never touch any rotating servomotor parts during operation.

Failure to observe this warning may result in injury.

• Before starting operation with a machine connected, make sure that an emergency stop can be

applied at any time.

Failure to observe this warning may result in injury or damage to the equipment.

• Never touch the inside of the SERVOPACKs.

Failure to observe this warning may result in electric shock.

• Do not remove the cover of the power supply terminal block while the power is ON.

Failure to observe this warning may result in electric shock.

• After the power is turned OFF or after a voltage resistance test, do not touch terminals while the

CHARGE lamp is ON.

Residual voltage may cause electric shock.

• Follow the procedures and instructions provided in the manuals for the products being used in the

trial operation.

Failure to do so may result not only in faulty operation and damage to equipment, but also in personal injury.

• The output range of the rotational serial data for the Σ-V absolute position detecting system is different from that of earlier systems for 12-bit and 15-bit encoders. As a result, the infinite-length positioning system of the Σ Series must be changed for use with products in the Σ-V Series.

• The multiturn limit value need not be changed except for special applications.

Changing it inappropriately or unintentionally can be dangerous.

• If the Multiturn Limit Disagreement alarm occurs, check the setting of parameter Pn205 in the SERVOPACK to be sure that it is correct.

If Fn013 is executed when an incorrect value is set in Pn205, an incorrect value will be set in the encoder. The

alarm will disappear even if an incorrect value is set, but incorrect positions will be detected, resulting in a

dangerous situation where the machine will move to unexpected positions.

• Do not remove the top front cover, cables, connectors, or optional items from the SERVOPACK

while the power is ON.

Failure to observe this warning may result in electric shock.

• Do not damage, pull, exert excessive force on, or place heavy objects on the cables.

Failure to observe this warning may result in electric shock, stopping operation of the product, or fire.

• Do not modify the product.

Failure to observe this warning may result in injury, damage to the equipment, or fire.

• Provide appropriate braking devices on the machine side to ensure safety. The holding brake on a

servomotor with a brake is not a braking device for ensuring safety.

Failure to observe this warning may result in injury.

• Do not come close to the machine immediately after resetting an instantaneous power interruption

to avoid an unexpected restart. Take appropriate measures to ensure safety against an unexpected

restart.

Failure to observe this warning may result in injury.

• Connect the ground terminal according to local electrical codes (100 Ω or less for a SERVOPACK

with a 100 V, 200 V power supply, 10 Ω or less for a SERVOPACK with a 400 V power supply).

Improper grounding may result in electric shock or fire.

WARNING

• Installation, disassembly, or repair must be performed only by authorized personnel.

Failure to observe this warning may result in electric shock or injury.

• The person who designs a system using the safety function (Hard Wire Baseblock function) must

have full knowledge of the related safety standards and full understanding of the instructions in this

manual.

Failure to observe this warning may result in injury or damage to the equipment.

vii

Page 8

Storage and Transportation

CAUTION

• Do not store or install the product in the following locations.

Failure to observe this caution may result in fire, electric shock, or damage to the equipment.

• Locations subject to direct sunlight

• Locations subject to temperatures outside the range specified in the storage/installation temperature conditions

• Locations subject to humidity outside the range specified in the storage/installation humidity conditions

• Locations subject to condensation as the result of extreme changes in temperature

• Locations subject to corrosive or flammable gases

• Locations subject to dust, salts, or iron dust

• Locations subject to exposure to water, oil, or chemicals

• Locations subject to shock or vibration

• Do not hold the product by the cables, motor shaft, or encoder while transporting it.

Failure to observe this caution may result in injury or malfunction.

• Do not place any load exceeding the limit specified on the packing box.

Failure to observe this caution may result in injury or malfunction.

• If disinfectants or insecticides must be used to treat packing materials such as wooden frames, pallets, or plywood, the packing materials must be treated before the product is packaged, and methods other than fumigation must be used.

Example: Heat treatment, where materials are kiln-dried to a core temperature of 56

minutes or more.

If the electronic products, which include stand-alone products and products installed in machines, are packed

with fumigated wooden materials, the electrical components may be greatly damaged by the gases or fumes

resulting from the fumigation process. In particular, disinfectants containing halogen, which includes chlorine, fluorine, bromine, or iodine can contribute to the erosion of the capacitors.

°C for 30

Installation

• Never use the product in an environment subject to water, corrosive gases, flammable gases, or

combustibles.

Failure to observe this caution may result in electric shock or fire.

• Do not step on or place a heavy object on the product.

Failure to observe this caution may result in injury or malfunction.

• Do not cover the inlet or outlet ports and prevent any foreign objects from entering the product.

Failure to observe this caution may cause internal elements to deteriorate resulting in malfunction or fire.

• Be sure to install the product in the correct direction.

Failure to observe this caution may result in malfunction.

• Provide the specified clearances between the SERVOPACK and the control panel or with other

devices.

Failure to observe this caution may result in fire or malfunction.

• Do not apply any strong impact.

Failure to observe this caution may result in malfunction.

CAUTION

viii

Page 9

Wiring

CAUTION

• Be sure to wire correctly and securely.

Failure to observe this caution may result in motor overrun, injury, or malfunction.

• Do not connect a commercial power supply to the U, V, or W terminals for the servomotor connection.

Failure to observe this caution may result in injury or fire.

• Securely connect the main circuit terminals.

Failure to observe this caution may result in fire.

• Do not bundle or run the main circuit cables together with the I/O signal cables or the encoder

cables in the same duct. Keep the main circuit cables separated from the I/O signal cables and the

encoder cables with a gap of at least 30 cm.

Placing these cables too close to each other may result in malfunction.

• Use shielded twisted-pair cables or screened unshielded twisted-pair cables for I/O signal cables

and the encoder cables.

• The maximum wiring length is 3 m for I/O signal cables, 50 m for encoder cables or servomotor

main circuit cables, and 10 m for control power supply cables for the SERVOPACK with a 400-V

power supply (+24 V, 0 V).

• Do not touch the power supply terminals while the CHARGE lamp is ON after turning power OFF

because high voltage may still remain in the SERVOPACK.

Make sure the charge indicator is OFF first before starting to do wiring or inspections.

• Be sure to observe the following precautions when wiring the SERVOPACK main circuit terminal

blocks.

• Do not turn the SERVOPACK power ON until all wiring, including the main circuit terminal blocks, has

been completed.

• Remove detachable main circuit terminals from the SERVOPACK prior to wiring.

• Insert only one power line per opening in the main circuit terminals.

• Make sure that no part of the core wire comes into contact with (i.e., short-circuits) adjacent wires.

• Install a battery at either the host controller or the SERVOPACK, but not both.

It is dangerous to install batteries at both ends simultaneously, because that sets up a loop circuit between the

batteries.

• Always use the specified power supply voltage.

An incorrect voltage may result in fire or malfunction.

• Make sure that the polarity is correct.

Incorrect polarity may cause ruptures or damage.

• Take appropriate measures to ensure that the input power supply is supplied within the specified

voltage fluctuation range. Be particularly careful in places where the power supply is unstable.

An incorrect power supply may result in damage to the equipment.

• Install external breakers or other safety devices against short-circuiting in external wiring.

Failure to observe this caution may result in fire.

• Take appropriate and sufficient countermeasures for each form of potential interference when

installing systems in the following locations.

• Locations subject to static electricity or other forms of noise

• Locations subject to strong electromagnetic fields and magnetic fields

• Locations subject to possible exposure to radioactivity

• Locations close to power supplies

Failure to observe this caution may result in damage to the equipment.

• Do not reverse the polarity of the battery when connecting it.

Failure to observe this caution may damage the battery, the SERVOPACK or servomotor, or cause an explosion.

• Wiring or inspection must be performed by a technical expert.

• Use a 24-VDC power supply with double insulation or reinforced insulation.

ix

Page 10

Operation

CAUTION

• Always use the servomotor and SERVOPACK in one of the specified combinations.

Failure to observe this caution may result in fire or malfunction.

• Conduct trial operation on the servomotor alone with the motor shaft disconnected from the

machine to avoid accidents.

Failure to observe this caution may result in injury.

• During trial operation, confirm that the holding brake works correctly. Furthermore, secure system

safety against problems such as signal line disconnection.

• Before starting operation with a machine connected, change the parameter settings to match the

parameters of the machine.

Starting operation without matching the proper settings may cause the machine to run out of control or malfunction.

• Do not turn the power ON and OFF more than necessary.

Do not use the SERVOPACK for applications that require the power to turn ON and OFF frequently. Such

applications will cause elements in the SERVOPACK to deteriorate.

As a guideline, at least one hour should be allowed between the power being turned ON and OFF once actual

operation has been started.

• When carrying out JOG operation (Fn002), origin search (Fn003), or EasyFFT (Fn206), forcing

movable machine parts to stop does not work for forward overtravel or reverse overtravel. Take

necessary precautions.

Failure to observe this caution may result in damage to the equipment.

• When using the servomotor for a vertical axis, install safety devices to prevent workpieces from falling due to alarms or overtravels. Set the servomotor so that it will stop in the zero clamp state when

overtravel occurs.

Failure to observe this caution may cause workpieces to fall due to overtravel.

• When not using the turning-less function, set the correct moment of inertia ratio (Pn103).

Setting an incorrect moment of inertia ratio may cause machine vibration.

• Do not touch the SERVOPACK heat sinks, regenerative resistor, or servomotor while power is ON

or soon after the power is turned OFF.

Failure to observe this caution may result in burns due to high temperatures.

• Do not make any extreme adjustments or setting changes of parameters.

Failure to observe this caution may result in injury or damage to the equipment due to unstable operation.

• When an alarm occurs, remove the cause, reset the alarm after confirming safety, and then resume

operation.

Failure to observe this caution may result in damage to the equipment, fire, or injury.

• Do not use the holding brake of the servomotor for braking.

Failure to observe this caution may result in malfunction.

• An alarm or warning may occur if communications are performed with the host controller while the

SigmaWin+ or Digital Operator is operating.

If an alarm or warning occurs, it may stop the current process and stop the system.

Maintenance and Inspection

CAUTION

• Do not disassemble the SERVOPACK and the servomotor.

Failure to observe this caution may result in electric shock or injury.

• Do not attempt to change wiring while the power is ON.

Failure to observe this caution may result in electric shock or injury.

• When replacing the SERVOPACK, resume operation only after copying the previous SERVOPACK

parameters to the new SERVOPACK.

Failure to observe this caution may result in damage to the equipment.

Disposal

CAUTION

• When disposing of the products, treat them as ordinary industrial waste.

x

Page 11

General Precautions

Observe the following general precautions

• The products shown in illustrations in this manual are sometimes shown without covers or protective guards.

Always replace the cover or protective guard as specified first, and then operate the products in accordance with

the manual.

• The drawings presented in this manual are typical examples and may not match the product you received.

• If the manual must be ordered due to loss or damage, inform your nearest Yaskawa representative or one of the

offices listed on the back of this manual.

to ensure safe application.

xi

Page 12

Warranty

(1) Details of Warranty

Warranty Period

Warranty Scope

(2) Limitations of Liability

The warranty period for a product that was purchased (hereinafter called “delivered product”) is one year from

the time of delivery to the location specified by the customer or 18 months from the time of shipment from the

Yaskawa factory, whichever is sooner.

Yaskawa shall replace or repair a defective product free of charge if a defect attributable to Yaskawa occurs

during the warranty period above. This warranty does not cover defects caused by the delivered product reaching the end of its service life and replacement of parts that require replacement or that have a limited service

life.

This warranty does not cover failures that result from any of the following causes.

1. Improper handling, abuse, or use in unsuitable conditions or in environments not described in product catalogs or manuals, or in any separately agreed-upon specifications

2. Causes not attributable to the delivered product itself

3. Modifications or repairs not performed by Yaskawa

4. Abuse of the delivered product in a manner in which it was not originally intended

5. Causes that were not foreseeable with the scientific and technological understanding at the time of shipment from Yaskawa

6. Events for which Yaskawa is not responsible, such as natural or human-made disasters

1. Yaskawa shall in no event be responsible for any damage or loss of opportunity to the customer that arises

due to failure of the delivered product.

2. Yaskawa shall not be responsible for any programs (including parameter settings) or the results of program

execution of the programs provided by the user or by a third party for use with programmable Yaskawa

products.

3. The information described in product catalogs or manuals is provided for the purpose of the customer purchasing the appropriate product for the intended application. The use thereof does not guarantee that there

are no infringements of intellectual property rights or other proprietary rights of Yaskawa or third parties,

nor does it construe a license.

4. Yaskawa shall not be responsible for any damage arising from infringements of intellectual property rights

or other proprietary rights of third parties as a result of using the information described in catalogs or manuals.

xii

Page 13

(3) Suitability for Use

1. It is the customer’s responsibility to confirm conformity with any standards, codes, or regulations that

apply if the Yaskawa product is used in combination with any other products.

2. The customer must confirm that the Yaskawa product is suitable for the systems, machines, and equipment

used by the customer.

3. Consult with Yaskawa to determine whether use in the following applications is acceptable. If use in the

application is acceptable, use the product with extra allowance in ratings and specifications, and provide

safety measures to minimize hazards in the event of failure.

• Outdoor use, use involving potential chemical contamination or electrical interference, or use in conditions or environments not described in product catalogs or manuals

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, vehicle systems, medical equipment, amusement machines, and installations subject to separate industry or government regulations

• Systems, machines, and equipment that may present a risk to life or property

• Systems that require a high degree of reliability, such as systems that supply gas, water, or electricity, or

systems that operate continuously 24 hours a day

• Other systems that require a similar high degree of safety

4. Never use the product for an application involving serious risk to life or property without first ensuring that

the system is designed to secure the required level of safety with risk warnings and redundancy, and that the

Yaskawa product is properly rated and installed.

5. The circuit examples and other application examples described in product catalogs and manuals are for reference. Check the functionality and safety of the actual devices and equipment to be used before using the

product.

6. Read and understand all use prohibitions and precautions, and operate the Yaskawa product correctly to

prevent accidental harm to third parties.

(4) Specifications Change

The names, specifications, appearance, and accessories of products in product catalogs and manuals may be

changed at any time based on improvements and other reasons. The next editions of the revised catalogs or

manuals will be published with updated code numbers. Consult with your Yaskawa representative to confirm

the actual specifications before purchasing a product.

xiii

Page 14

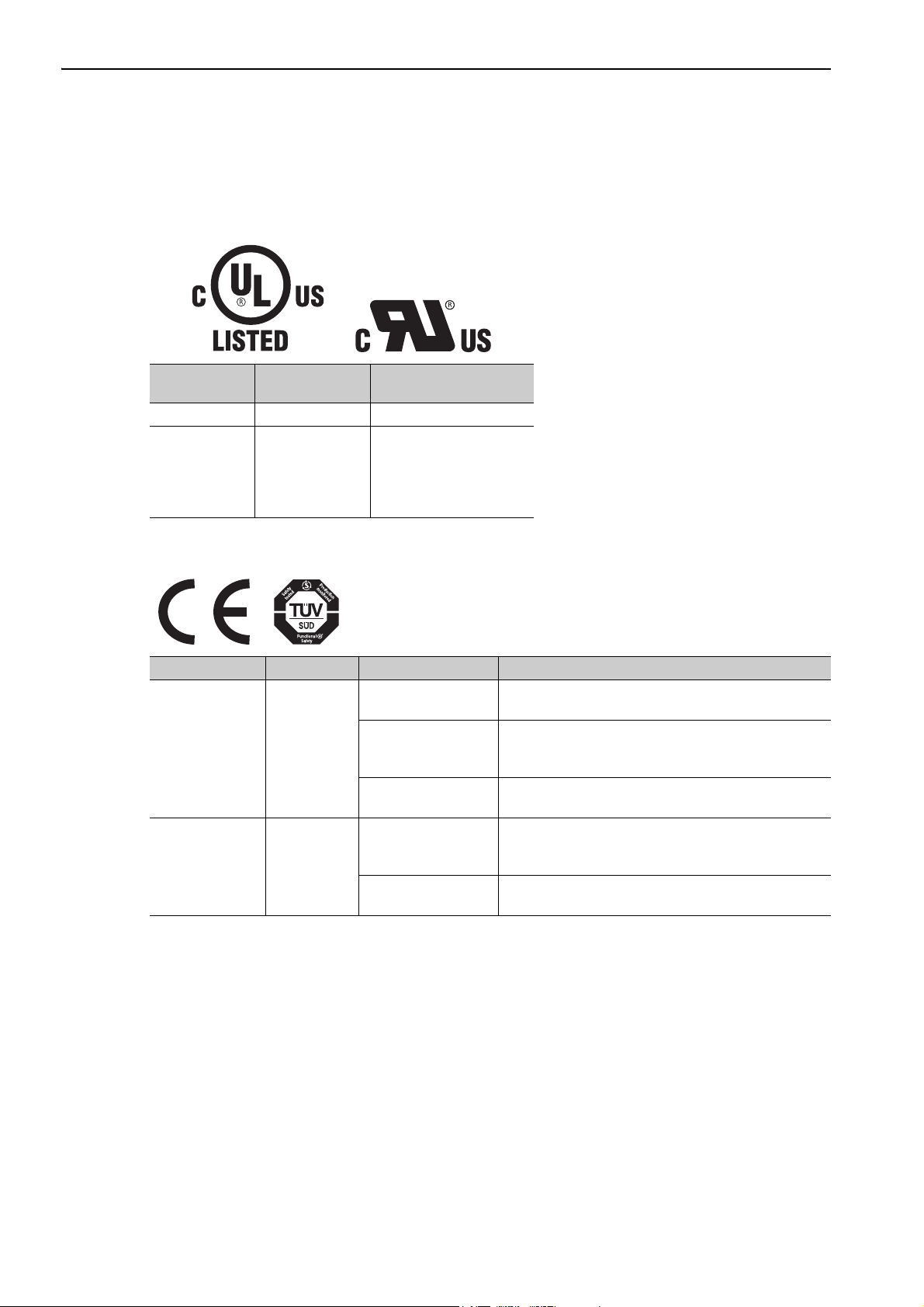

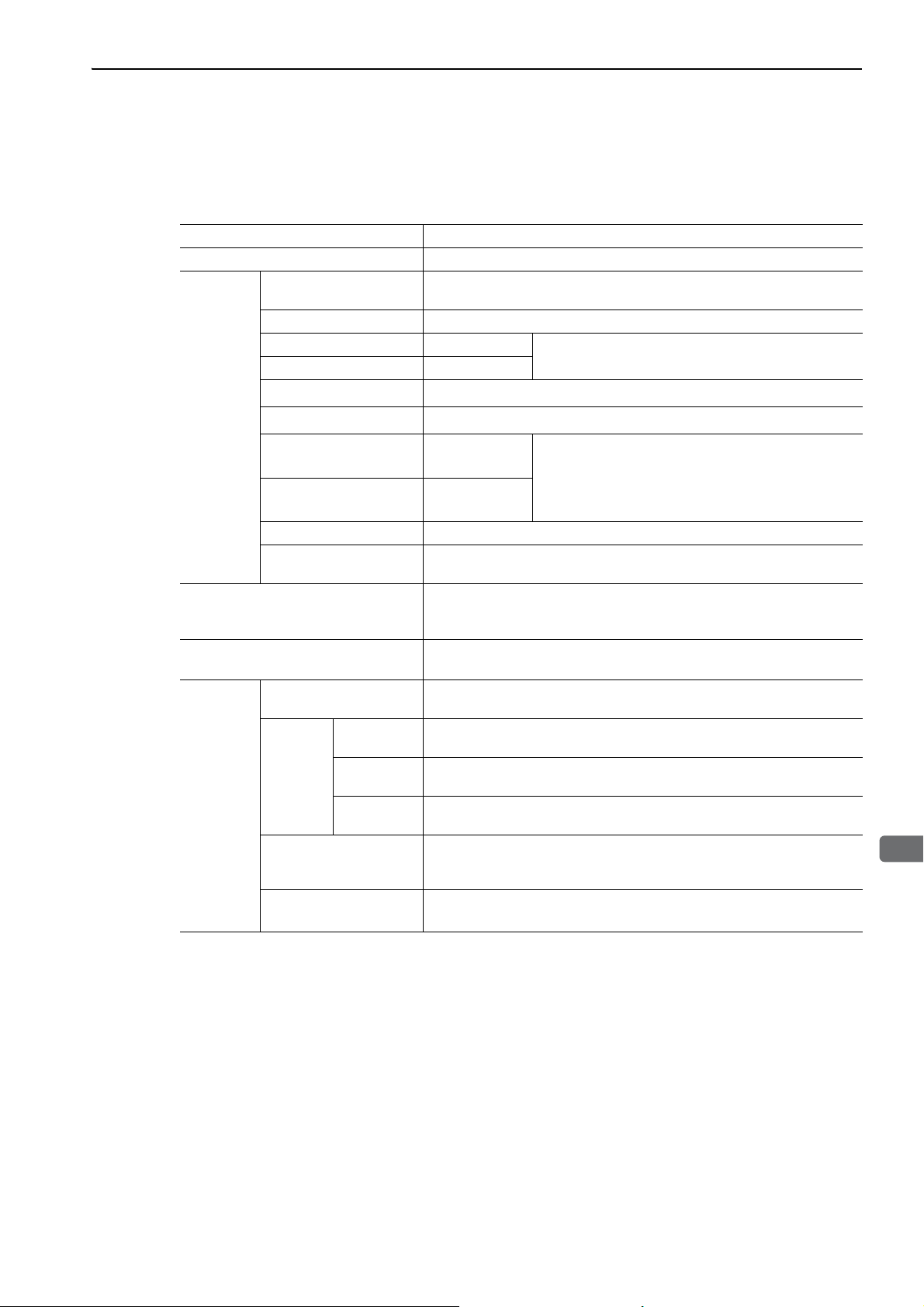

Harmonized Standards

North American Safety Standards (UL)

Model

SERVOPACK SGDV UL508C (E147823)

•SGMJV

•SGMAV

Servomotor

•SGMPS

• SGMGV

•SGMSV

UL Standards

(UL File No.)

UL1004 (E165827)

European Directives

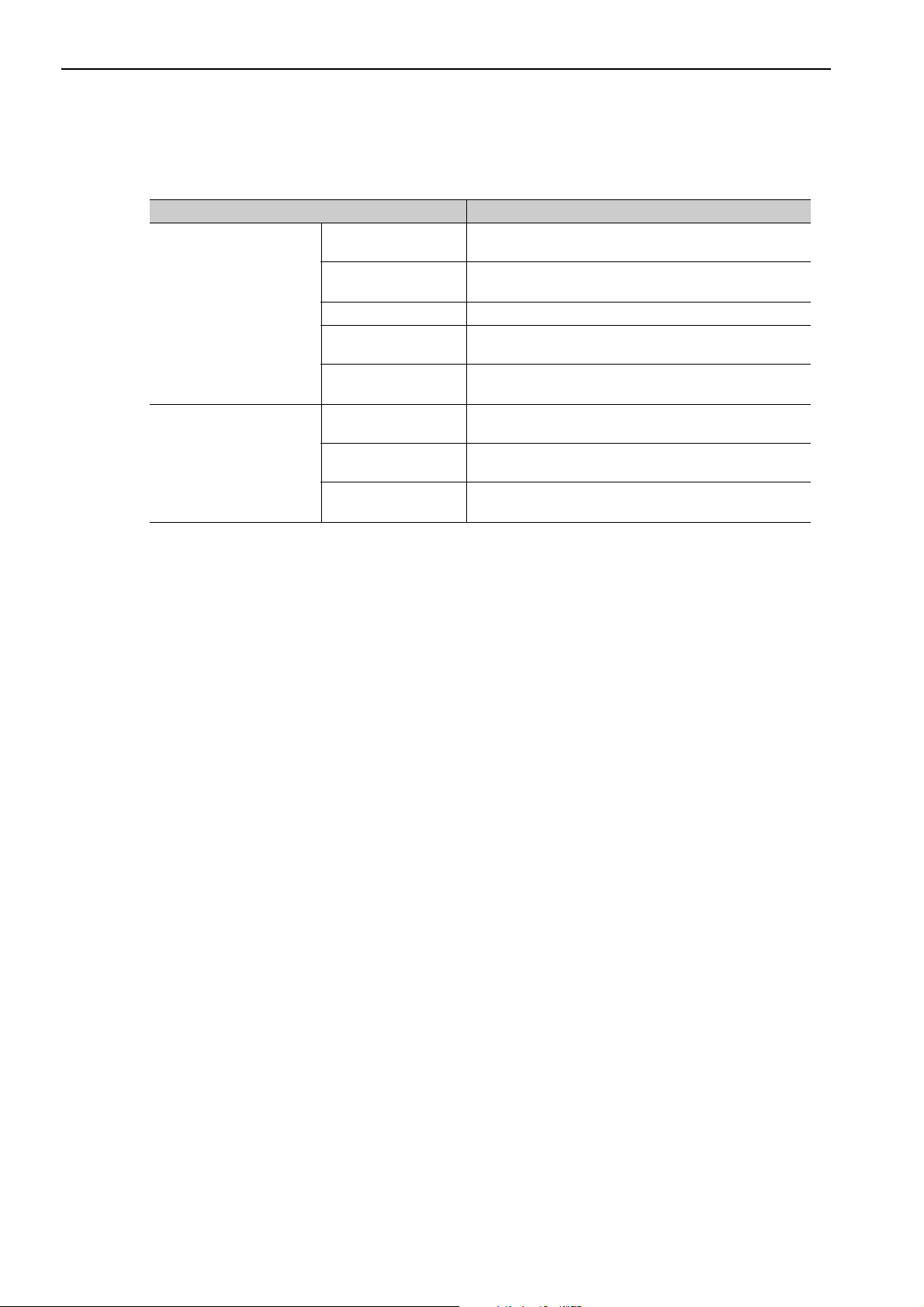

Model European Directives Harmonized Standards

Machinery Directive

2006/42/EC

SERVOPACK SGDV

•SGMJV

•SGMAV

Servomotor

•SGMPS

• SGMGV

•SGMSV

EMC Directive

2004/108/EC

Low Voltage Directive

2006/95/EC

EMC Directive

2004/108/EC

Low Voltage Directive

2006/95/EC

EN ISO13849-1: 2008

EN 954-1

EN 55011 group 1 class A

EN 61000-6-2

EN 61800-3

EN 50178

EN 61800-5-1

EN 55011 group 1 class A

EN 61000-6-2

EN 61800-3

EN 60034-1

EN 60034-5

xiv

Page 15

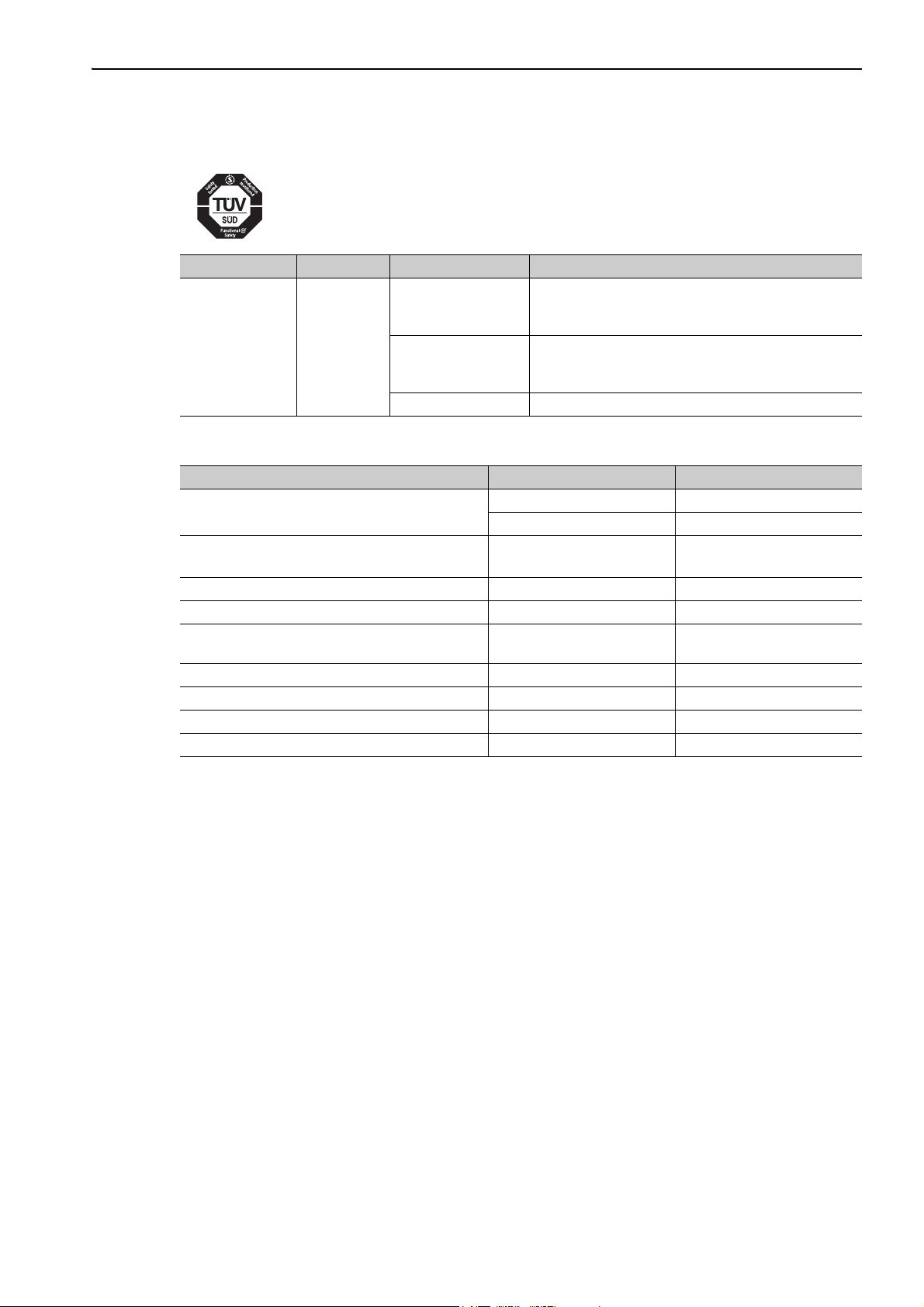

Safety Standards

Model Safety Standards Standards

EN ISO13849-1: 2008

Safety of Machinery

SERVOPACK SGDV

Functional Safety

EMC IEC 61326-3-1

EN 954-1

IEC 60204-1

IEC 61508 series

IEC 62061

IEC 61800-5-2

Safe Performance

Items Standards Performance Level

Safety Integrity Level

Probability of Dangerous Failure per Hour

Category EN 954-1 Category 3

Performance Level EN ISO 13849-1 PL d (Category 3)

Mean Time to Dangerous Failure of Each

Channel

Average Diagnostic Coverage EN ISO 13849-1 DCave: Low

Stop Category IEC 60204-1 Stop category 0

Safety Function IEC 61800-5-2 STO

Proof test Interval IEC 61508 10 years

IEC 61508 SIL2

IEC 62061 SILCL2

IEC 61508

IEC 62061

EN ISO 13849-1 MTTFd: High

PFH ⇐ 1.7×10

(0.17% of SIL2)

-9

[1/h]

xv

Page 16

Contents

Chapter 1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.1 Σ-V Series SERVOPACKs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.2 Part Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 SERVOPACK Ratings and Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.3.1 Ratings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.3.2 Basic Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.3.3 MECHATROLINK-III Function Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.4 SERVOPACK Internal Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.4.1 Single-phase 100 V, SGDV-R70F21A, -R90F21A, -2R1F21A Models . . . . . . . . . . . . . . . 1-9

1.4.2 Single-phase 100 V, SGDV-2R8F21A Model. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.4.3 Single-phase 200 V, SGDV-120A21A008000 Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1.4.4 Three-phase 200 V, SGDV-R70A21, -R90A21, -1R6A21 Models . . . . . . . . . . . . .1-10

1.4.5 Three-phase 200 V, SGDV-2R8A21 Model. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

1.4.6 Three-phase 200 V, SGDV-3R8A21A, -5R5A21A, -7R6A21A Models . . . . . . . . . . . . . . 1-11

1.4.7 Three-phase 200 V, SGDV-120A21A Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

1.4.8 Three-phase 200 V, SGDV-180A21A, -200A21A Models . . . . . . . . . . . . . . . . . . . . . . . . 1-12

1.4.9 Three-phase 200 V, SGDV-330A21A Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-13

1.4.10 Three-phase 200 V, SGDV-470A21A, -550A21A Models . . . . . . . . . . . . . . . . . . . . . . . 1-13

1.4.11 Three-phase 200 V SGDV-590A21A, -780A21A Models . . . . . . . . . . . . . . . . . . . . . . . . 1-14

1.4.12 Three-phase 400 V, SGDV-1R9D21A, -3R5D21A, -5R4D21A Models . . . . . . . . . . . . . 1-14

1.4.13 Three-phase 400 V, SGDV-8R4D21A, -120D21A Models . . . . . . . . . . . . . . . . . . . . . . . 1-15

1.4.14 Three-phase 400 V, SGDV-170D21A Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

1.4.15 Three-phase 400 V, SGDV-210D21A, -260D21A Models . . . . . . . . . . . . . . . . . . . . . . . 1-16

1.4.16 Three-phase 400 V, SGDV-280D21A, -370D21A Models . . . . . . . . . . . . . . . . . . . . . . . 1-16

1.5 Examples of Servo System Configurations . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

1.5.1 Connecting to SGDV-F21A SERVOPACK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

1.5.2 Connecting to SGDV-A21 SERVOPACK. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

1.5.3 Connecting to SGDV-D21A SERVOPACK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

1.6 SERVOPACK Model Designation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

1.7 Inspection and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Harmonized Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

xvi

Chapter 2 Panel Display and Operation of Digital Operator . . . . . . . . . . . .2-1

2.1 Panel Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.1.1 Status Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.1.2 Alarm and Warning Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.1.3 Hard Wire Base Block Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.1.4 Overtravel Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2 Operation of Digital Operator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.3 Utility Functions (Fn). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.4 Parameters (Pn) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.4.1 Parameter Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.4.2 Notation for Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.4.3 Setting Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2.5 Monitor Displays (Un) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Page 17

Chapter 3 Wiring and Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.1 Main Circuit Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.1.1 Main Circuit Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.1.2 Using a Standard Power Supply

(Single-phase 100 V, Three-phase 200 V, or Three-phase 400 V) . . . . . . . . . . . . . . . . . .3-3

3.1.3 Using the SERVOPACK with Single-phase, 200 V Power Input . . . . . . . . . . . . . . . . . . . 3-11

3.1.4 Using the SERVOPACK with a DC Power Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

3.1.5 Using More Than One SERVOPACK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

3.1.6 General Precautions for Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

3.2 I/O Signal Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

3.2.1 I/O Signal (CN1) Names and Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

3.2.2 Safety Function Signal (CN8) Names and Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . .3-19

3.2.3 Example of I/O Signal Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

3.3 I/O Signal Allocations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

3.3.1 Input Signal Allocations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

3.3.2 Output Signal Allocations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

3.4 Examples of Connection to Host Controller. . . . . . . . . . . . . . . . . . . . . . . . . 3-24

3.4.1 Sequence Input Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

3.4.2 Sequence Output Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-25

3.5 Wiring MECHATROLINK-III Communications . . . . . . . . . . . . . . . . . . . . . . . 3-27

3.6 Encoder Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

3.6.1 Encoder Signal (CN2) Names and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-28

3.6.2 Encoder Connection Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-28

3.7 Connecting Regenerative Resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

3.7.1 Connecting Regenerative Resistors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-30

3.7.2 Setting Regenerative Resistor Capacity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

3.8 Noise Control and Measures for Harmonic Suppression. . . . . . . . . . . . . . . 3-33

3.8.1 Wiring for Noise Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-33

3.8.2 Precautions on Connecting Noise Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-35

3.8.3 Connecting a Reactor for Harmonic Suppression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

Chapter 4 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4.1 MECHATROLINK-III Communications Settings . . . . . . . . . . . . . . . . . . . . . . 4-3

4.1.1 Setting Switches S1, S2, and S3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.2 MECHATROLINK-III Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.3 Basic Functions Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.3.1 Servomotor Rotation Direction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.3.2 Overtravel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.3.3 Software Limit Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

4.3.4 Holding Brakes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4.3.5 Stopping Servomotors after SV_OFF Command or Alarm Occurrence. . . . . . . . . . . . . . 4-14

4.3.6 Instantaneous Power Interruption Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

4.3.7 SEMI F47 Function (Torque Limit Function for Low DC Power Supply Voltage

for Main Circuit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17

4.3.8 Setting Motor Overload Detection Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-20

4.4 Trial Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

4.4.1 Inspection and Checking before Trial Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

4.4.2 Trial Operation via MECHATROLINK-III . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-23

4.4.3 Electronic Gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-24

4.4.4 Encoder Output Pulses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-26

4.4.5 Setting Encoder Output Pulse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-27

4.5 Test Without Motor Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

4.5.1 Motor Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-28

4.5.2 Motor Position and Speed Responses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-29

4.5.3 Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-30

4.5.4 Digital Operator Displays during Testing without Motor . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

xvii

Page 18

4.6 Limiting Torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

4.6.1 Internal Torque Limit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

4.6.2 External Torque Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-33

4.6.3 Checking Output Torque Limiting during Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

4.7 Absolute Encoders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

4.7.1 Connecting the Absolute Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-36

4.7.2 Absolute Data Request (SENS ON Command) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

4.7.3 Battery Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

4.7.4 Absolute Encoder Setup and Reinitialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-41

4.7.5 Absolute Data Reception Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

4.7.6 Multiturn Limit Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-47

4.7.7 Multiturn Limit Disagreement Alarm (A.CC0) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-48

4.7.8 Absolute Encoder Origin Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-49

4.8 Other Output Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-50

4.8.1 Servo Alarm Output Signal (ALM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-50

4.8.2 Warning Output Signal (/WARN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-50

4.8.3 Rotation Detection Output Signal (/TGON) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-51

4.8.4 Servo Ready Output Signal (/S-RDY) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-51

4.8.5 Speed Coincidence Output Signal (/V-CMP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-52

4.8.6 Positioning Completed Output Signal (/COIN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-53

4.8.7 Positioning Near Output Signal (/NEAR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-54

4.8.8 Speed Limit Detection Signal (/VLT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-55

4.9 Safety Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-57

4.9.1 Hard Wire Base Block (HWBB) Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-57

4.9.2 External Device Monitor (EDM1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-63

4.9.3 Application Example of Safety Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-65

4.9.4 Confirming Safety Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-66

4.9.5 Connecting a Safety Function Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-67

4.9.6 Precautions for Safety Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-69

Chapter 5 Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.1 Type of Adjustments and Basic Adjustment Procedure . . . . . . . . . . . . . . . . .5-3

5.1.1 Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.1.2 Basic Adjustment Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.1.3 Monitoring Operation during Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.1.4 Safety Precautions on Adjustment of Servo Gains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5.2 Tuning-less Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

5.2.1 Tuning-less Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

5.2.2 Tuning-less Levels Setting (Fn200) Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

5.2.3 Related Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

5.3 Advanced Autotuning (Fn201) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

5.3.1 Advanced Autotuning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-17

5.3.2 Advanced Autotuning Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

5.3.3 Related Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

5.4 Advanced Autotuning by Reference (Fn202) . . . . . . . . . . . . . . . . . . . . . . . . 5-27

5.4.1 Advanced Autotuning by Reference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-27

5.4.2 Advanced Autotuning by Reference Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-29

5.4.3 Related Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-33

5.5 One-parameter Tuning (Fn203) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-34

5.5.1 One-parameter Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-34

5.5.2 One-parameter Tuning Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-35

5.5.3 One-parameter Tuning Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-41

5.5.4 Related Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-42

5.6 Anti-Resonance Control Adjustment Function (Fn204) . . . . . . . . . . . . . . . . 5-43

5.6.1 Anti-Resonance Control Adjustment Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-43

5.6.2 Anti-Resonance Control Adjustment Function Operating Procedure . . . . . . . . . . . . . . . . 5-44

5.6.3 Related Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-48

xviii

Page 19

5.7 Vibration Suppression Function (Fn205) . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-49

5.7.1 Vibration Suppression Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-49

5.7.2 Vibration Suppression Function Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . .5-50

5.7.3 Related Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-53

5.8 Additional Adjustment Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-54

5.8.1 Switching Gain Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-54

5.8.2 Manual Adjustment of Friction Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-58

5.8.3 Current Control Mode Selection Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-60

5.8.4 Current Gain Level Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-60

5.8.5 Speed Detection Method Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-60

5.8.6 Backlash Compensation Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-61

5.9 Compatible Adjustment Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-67

5.9.1 Feedforward Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-67

5.9.2 Mode Switch (P/PI Switching) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-68

5.9.3 Torque Reference Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-70

5.9.4 Position Integral . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-72

Chapter 6 Utility Functions (Fn) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

6.1 List of Utility Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.2 Alarm History Display (Fn000). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.3 JOG Operation (Fn002) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6.4 Origin Search (Fn003) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6.5 Program JOG Operation (Fn004) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

6.6 Initializing Parameter Settings (Fn005) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

6.7 Clearing Alarm History (Fn006) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

6.8 Offset Adjustment of Analog Monitor Output (Fn00C) . . . . . . . . . . . . . . . . . 6-15

6.9 Gain Adjustment of Analog Monitor Output (Fn00D) . . . . . . . . . . . . . . . . . . 6-17

6.10 Automatic Offset-Signal Adjustment of the Motor Current Detection Signal

(Fn00E) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

6.11 Manual Offset-Signal Adjustment of the Motor Current Detection Signal

(Fn00F) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

6.12 Write Prohibited Setting (Fn010) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

6.13 Servomotor Model Display (Fn011) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-24

6.14 Software Version Display (Fn012) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

6.15 Resetting Configuration Errors in Option Modules (Fn014). . . . . . . . . . . . 6-26

6.16 Vibration Detection Level Initialization (Fn01B) . . . . . . . . . . . . . . . . . . . . . 6-27

6.17 Display of SERVOPACK and Servomotor ID (Fn01E) . . . . . . . . . . . . . . . . 6-29

6.18 Display of Servomotor ID in Feedback Option Module (Fn01F) . . . . . . . . 6-31

6.19 Origin Setting (Fn020) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-33

6.20 Software Reset (Fn030). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-34

6.21 EasyFFT (Fn206). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-35

6.22 Online Vibration Monitor (Fn207). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-39

Chapter 7 Monitor Displays (Un) . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

7.1 List of Monitor Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7.2 Viewing Monitor Displays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

7.3 Monitoring Input Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

7.3.1 Interpreting Input Signal Display Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

7.3.2 Input Signal Display Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

xix

Page 20

7.4 Monitoring Output Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

7.4.1 Interpreting Output Signal Display Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-6

7.4.2 Output Signal Display Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-6

7.5 Monitoring Safety Input Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

7.5.1 Interpreting Safety Input Signal Display Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

7.5.2 Safety Input Signal Display Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-7

Chapter 8 Fully-closed Loop Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

8.1 System Configuration and Connection Example for SERVOPACK

with Fully-closed Loop Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8.1.1 System Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8.1.2 Internal Block Diagram of Fully-closed Loop Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

8.1.3 Serial Converter Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

8.1.4 Example of Connections to External Encoders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

8.1.5 Encoder Output Pulse Signals from SERVOPACK with an External Encoder

by Renishaw plc. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-7

8.1.6 Precautions When Using an External Incremental Encoder by Magnescale . . . . . . . . . . . 8-8

8.2 SERVOPACK Startup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

8.3 Parameter Settings for Fully-closed Loop Control . . . . . . . . . . . . . . . . . . . . 8-13

8.3.1 Motor Rotation Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-14

8.3.2 Sine Wave Pitch (Frequency) for an External Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

8.3.3 Setting Encoder Output Pulses (PAO, PBO, and PCO) . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

8.3.4 External Absolute Encoder Data Reception Sequence . . . . . . . . . . . . . . . . . . . . . . . . . .8-17

8.3.5 Electronic Gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-20

8.3.6 Alarm Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-21

8.3.7 Analog Monitor Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-22

8.3.8 Speed Feedback Method during Fully-closed Loop Control . . . . . . . . . . . . . . . . . . . . . . 8-22

Chapter 9 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

9.1 Alarm Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

9.1.1 List of Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

9.1.2 Troubleshooting of Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-7

9.2 Warning Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-23

9.2.1 List of Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-23

9.2.2 Troubleshooting of Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-25

9.3 Monitoring Communication Data on Occurrence of an Alarm or Warning . . 9-30

9.4 Troubleshooting Malfunction Based on Operation and

Conditions of the Servomotor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-31

Chapter 10 Appendix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-1

10.1 List of Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

10.1.1 Utility Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-2

10.1.2 Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-3

10.1.3 MECHATROLINK-III Common Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-37

10.2 List of Monitor Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-45

10.3 Parameter Recording Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-46

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Index-1

xx

Revision History

Page 21

1

Outline

1

Outline

1.1 Σ-V Series SERVOPACKs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.2 Part Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 SERVOPACK Ratings and Specifications . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.3.1 Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.3.2 Basic Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1.3.3 MECHATROLINK-III Function Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.4 SERVOPACK Internal Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

1.4.1 Single-phase 100 V, SGDV-R70F21A, -R90F21A, -2R1F21A Models . . . . . . . . . . . . 1-9

1.4.2 Single-phase 100 V, SGDV-2R8F21A Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.4.3 Single-phase 200 V, SGDV-120A21A008000 Model . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1.4.4 Three-phase 200 V, SGDV-R70A21, -R90A21, -1R6A21 Models . . . . . . . . . . 1-10

1.4.5 Three-phase 200 V, SGDV-2R8A21 Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

1.4.6 Three-phase 200 V, SGDV-3R8A21A, -5R5A21A, -7R6A21A Models . . . . . . . . . . . 1-11

1.4.7 Three-phase 200 V, SGDV-120A21A Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

1.4.8 Three-phase 200 V, SGDV-180A21A, -200A21A Models . . . . . . . . . . . . . . . . . . . . . 1-12

1.4.9 Three-phase 200 V, SGDV-330A21A Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

1.4.10 Three-phase 200 V, SGDV-470A21A, -550A21A Models . . . . . . . . . . . . . . . . . . . . 1-13

1.4.11 Three-phase 200 V SGDV-590A21A, -780A21A Models . . . . . . . . . . . . . . . . . . . . 1-14

1.4.12 Three-phase 400 V, SGDV-1R9D21A, -3R5D21A, -5R4D21A Models . . . . . . . . . . 1-14

1.4.13 Three-phase 400 V, SGDV-8R4D21A, -120D21A Models . . . . . . . . . . . . . . . . . . . 1-15

1.4.14 Three-phase 400 V, SGDV-170D21A Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

1.4.15 Three-phase 400 V, SGDV-210D21A, -260D21A Models . . . . . . . . . . . . . . . . . . . . 1-16

1.4.16 Three-phase 400 V, SGDV-280D21A, -370D21A Models . . . . . . . . . . . . . . . . . . . . 1-16

1.5 Examples of Servo System Configurations . . . . . . . . . . . . . . . . . . . . . . .1-17

1.5.1 Connecting to SGDV-F21A SERVOPACK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

1.5.2 Connecting to SGDV-A21 SERVOPACK . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

1.5.3 Connecting to SGDV-D21A SERVOPACK . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

1.6 SERVOPACK Model Designation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-21

1.7 Inspection and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

1-1

Page 22

1 Outline

Refer to 1.6 SERVOPACK Model Designation.

Refer to 4.1.1 Setting Switches S1, S2, and S3.

Refer to 4.1.1 Setting Switches S1, S2, and S3.

Refer to 3.1 Main Circuit Wiring.

Refer to 3.1 Main Circuit Wiring.

Refer to 3.8.3 Connecting a Reactor for Harmonic

Suppression.

Refer to 3.1 Main Circuit Wiring.

Refer to 3.1 Main Circuit Wiring.

Note: When not using the safety function, use the SERVO-

PACK with the safety function’s jumper connector

(JZSP-CVH05-E, provided as an accessory) inserted.

For the connecting method, refer to 3.2.2 Safety Func-

tion Signal (CN8) Names and Functions.

For details on how to use the safety function, refer to

4.9 Safety Function.

Refer to 5.1.3 Monitoring Operation during Adjustment.

Refer to 2.1.1 Status Display.

Refer to 3.5 Wiring MECHATROLINK-III Communications.

Refer to 3.2 I/O Signal Connections.

Refer to 3.6 Encoder Connection.

64

Refer to 3.7 Connecting Regenerative Resistors.

1.1 Σ-V Series SERVOPACKs

The Σ-V Series SERVOPACKs are designed for applications that require frequent high-speed, high-precision positioning. The SERVOPACK makes the most of machine performance in the shortest time possible, thus contributing to improving productivity.

1.2 Part Names

This section describes the part names of SGDV SERVOPACK for MECHATROLINK-III communications

reference.

Serial number

DIP switch (S3)

Used to set MECHATROLINK communications.

Rotary switches (S1 and S2)

Used to set MECHATROLINK station address.

Nameplate (Found on side of SERVOPACK.)

Indicates the SERVOPACK model and ratings.

Charge indicator

Lights when the main circuit power supply is

ON and stays lit as long as the internal

capacitor remains charged. Therefore, do not

touch the SERVOPACK even after the power

supply is turned OFF if the indicator is lit. It may

result in electric shock.

Main circuit power supply terminals

Used for main circuit power supply input.

Control power supply terminals

Used for control power supply input.

Regenerative resistor connecting

terminals

Connects external regenerative resistors.

DC reactor terminals for harmonic

suppression

Connects a DC reactor for harmonic suppression.

Servomotor terminals

Connects the main circuit cable for servomotor.

Ground terminal

Be sure to connect to protect against electrical shock.

With front cover open

LED indicator (CN)

Lights when the SERVOPACK normally receives

a CONNECT command.

Communications LED indicators (L1 and L2)

Indicates that data is being transmitted between

the SERVOPACK and the MECHATROLINK system.

CN5 Analog monitor connector

Used to monitor motor speed, torque reference,

and other values through a special cable (option).

Panel display

Indicates the servo status with a seven-segment

LED display.

Input voltage

Front cover

SERVOPACK model

MECHATROLINK-III communications connectors

Connects MECHATROLINK-III-supported devices.

CN3 Connector for digital operator

Connects a digital operator (option, JUSP-OP05A-1-E) or

a personal computer (RS422).

Refer to Σ-V Series Product Catalog (No. KAEPS 800000 42)

and Σ-V Series User’s Manual, Operation of Digital Operator

(No. SIEP S800000 55).

CN7 Connector for personal computer (USB connector)

Communicates with a personal computer.

Use the connection cable (No: JZSP-CVS06-02-E).

CN1 I/O signal connector

Used for reference input signals and sequence I/O signals.

CN8 Connector for safety function devices

Connects a safety function device.

CN2 Encoder connector

Connects the encoder in the servomotor.

1-2

Page 23

1.3 SERVOPACK Ratings and Specifications

1

Outline

+10%

–15%

+10%

–15%

+10%

–15%

+10%

–15%

+10%

–15%

+10%

–15%

1.3 SERVOPACK Ratings and Specifications

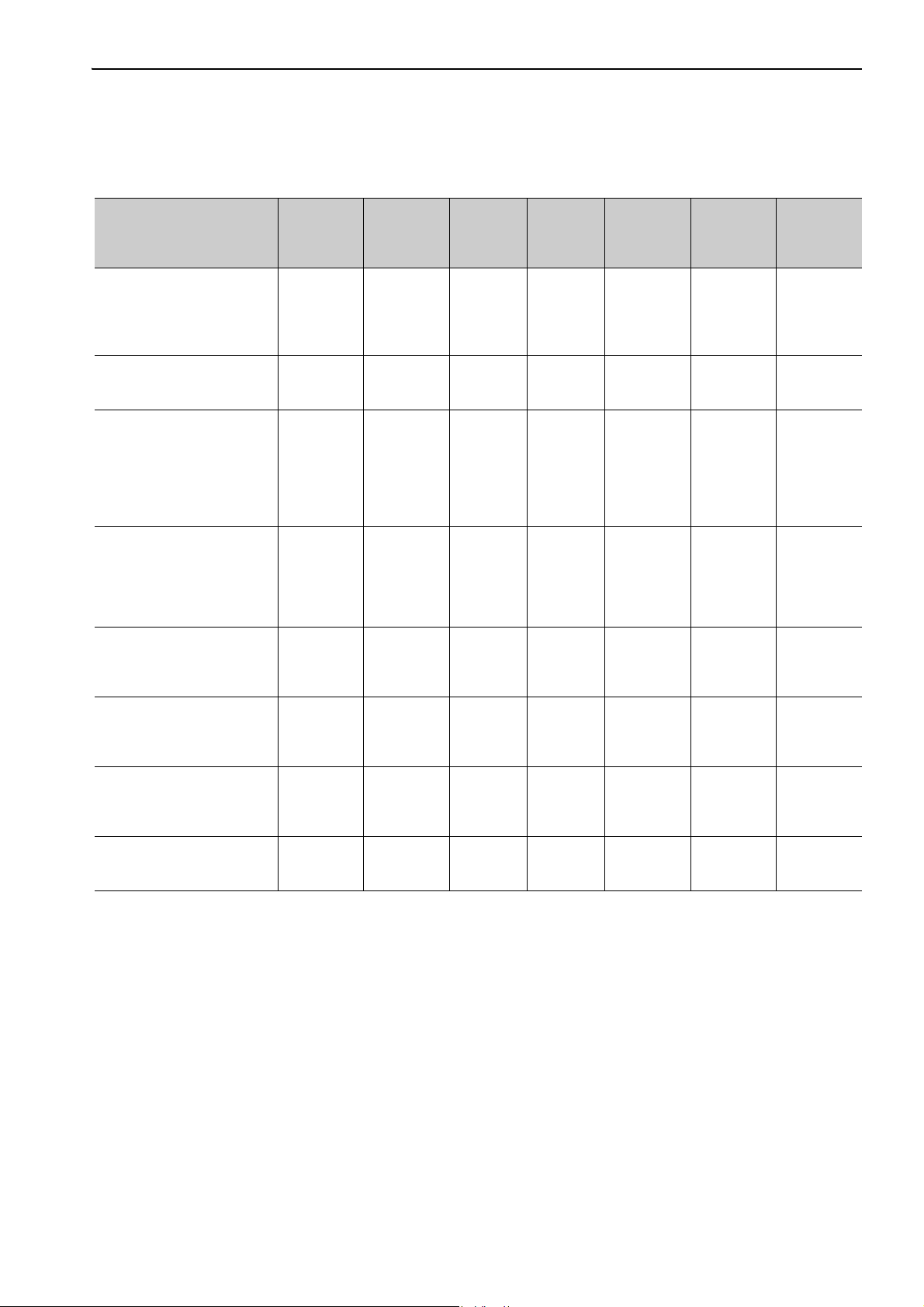

This section describes the ratings and specifications of SERVOPACKs.

1.3.1 Ratings

Ratings of SERVOPACKs are as shown below.

(1) SGDV with Single-phase, 100-V Rating

SGDV (Single Phase, 100 V) R70 R90 2R1 2R8

Continuous Output Current [Arms] 0.66 0.91 2.1 2.8

Instantaneous Max. Output Current [Arms] 2.1 2.9 6.5 9.3

Regenerative Resistor * None or external

Main Circuit Power Supply

Control Power Supply

Overvoltage Category III

∗ Refer to 3.7 Connecting Regenerative Resistors for details.

Single-phase, 100 to 115 VAC , 50/60 Hz

Single-phase, 100 to 115 VAC , 50/60 Hz

(2) SGDV with Single-phase, 200-V Rating

SGDV (Single Phase, 200 V)

Continuous Output Current [Arms] 11.6

Instantaneous Max. Output Current [Arms] 28

Regenerative Resistor

*2

Main Circuit Power Supply

Control Power Supply

Built-in or external

Single-phase, 220 to 230 VAC , 50/60 Hz

Single-phase, 220 to 230 VAC , 50/60 Hz

Overvoltage Category III

∗1. The official model number is SGDV-120A21A008000.

∗2. Refer to 3.7 Connecting Regenerative Resistors for details.

120

*1

(3) SGDV with Three-phase, 200-V Rating

SGDV (Three Phase, 200 V) R70 R90 1R6 2R8 3R8 5R5 7R6 120 180 200 330 470 550 590 780

Continuous Output Current

[Arms]

Instantaneous Max. Output

Current [Arms]

Regenerative Resistor

Main Circuit Power Supply

Control Power Supply

Overvoltage Category III

0.66 0.91 1.6 2.8 3.8 5.5 7.6 11.6 18.5 19.6 32.9 46.9 54.7 58.6 78.0

2.1 2.9 5.8 9.3 11.0 16.9 17 28 42 56 84 110 130 140 170

*

None or external Built-in or external External

Three-phase, 200 to 230 VAC , 50/60 Hz

Single-phase, 200 to 230 VAC , 50/60 Hz

∗ Refer to 3.7 Connecting Regenerative Resistors for details.

1-3

Page 24

1 Outline

+10%

–15%

1.3.1 Ratings

(4) SGDV with Three-phase, 400-V Rating

SGDV (Three Phase, 400 V) 1R9 3R5 5R4 8R4 120 170 210 260 280 370

Continuous Output Current

[Arms]

Instantaneous Max. Output

Current [Arms]

Regenerative Resistor

*

1.9 3.5 5.4 8.4 11.9 16.5 20.8 25.7 28.1 37.2

5.5 8.5 14 20 28 42 55 65 70 85

Built-in or external External

Main Circuit Power Supply

Three-phase, 380 to 480 VAC , 50/60 Hz

Control Power Supply 24 VDC ±15%

Overvoltage Category III

∗ Refer to 3.7 Connecting Regenerative Resistors for details.

1-4

Page 25

1

Outline

1.3.2 Basic Specifications

Basic specifications of SERVOPACKs are shown below.

Drive Method Sine-wave current drive with PWM control of IGBT

Feedback Encoder: 13-bit (incremental), 17-bit, 20-bit (incremental/absolute)

Surrounding Air Temperature

Storage Temperature -20°C to +85°C

Ambient Humidity 90% RH or less

Storage Humidity 90% RH or less

Vibration Resistance

Operating

Conditions

Shock Resistance

Protection Class IP10

Pollution Degree 2

0°C to +55°C

2

4.9 m/s

19.6 m/s

2

1.3 SERVOPACK Ratings and Specifications

With no freezing or condensation

An environment that satisfies the following conditions.

• Free of corrosive or flammable gases

• Free of exposure to water, oil, or chemicals

• Free of dust, salts, or iron dust

Altitude 1000 m or less

Others

Harmonized Standards

Mounting

Speed Control Range

Speed

Regu-

*1

Performance

lation

Torque Control

Tolerance

(Repeatability)

Soft Start Time

Setting

Load

Regulation

Volta ge

Regulation

Temperature

Regulation

Free of static electricity, strong electromagnetic fields, magnetic fields or

exposure to radioactivity

UL508C

EN50178, EN55011 group1 class A, EN61000-6-2, EN61800-3, EN61800-

5-1, EN954-1, IEC61508-1 to 4

Standard: Base-mounted

Optional: Rack-mounted or duct-ventilated

1:5000 (The lower limit of the speed control range must be lower than the

point at which the rated torque does not cause the servomotor to stop.)

0% to 100% load: ±0.01% max. (at rated speed)

Rated voltage ±10%: 0% (at rated speed)

25 ± 25

°C: ±0.1% max. (at rated speed)

±1%

0 to 10 s (Can be set individually for acceleration and deceleration.)

1-5

Page 26

1 Outline

1.3.2 Basic Specifications

I/O

Signals

Communications

Function

LED Display Panel display (seven-segment), CHARGE, L1, L2, and CN indicators

MECHATROLINK-III

Communications Setting Switches

Analog Monitor (CN5)

Dynamic Brake (DB)

Regenerative Processing

Overtravel Prevention (OT)

Protective Function

Utility Function Gain adjustment, alarm history, JOG operation, origin search, and so on.

Encoder Output Pulse

Sequence

Input

Sequence

Output

RS422A

Communications

(CN3)

USB

Communications

(CN7)

Input

Signals

which can

be allocated

Fixed Output Servo alarm (ALM) output

Output

Signals

which can

be allocated

Interface

1:N

Communications

Axis

Address

Setting

Interface Personal computer (can be connected with SigmaWin+)

Communications

Standard

(cont’d)

Phase A, B, C: line driver

Encoder output pulse: any setting ratio (Refer to 4.4.5.)

Number of

Channels

Functions

Number of

Channels

Functions

Digital operator (JUSP-OP05A-1-E), personal computer (can be connected

with SigmaWin+)

N = Up to 15 stations possible at RS422A

Set by parameter

Complies with standard USB1.1. (12 Mbps)

Rotary Switch

(S1, S2)

DIP Switch (S3) Number of pins: Four pins (Refer to 4.1.1)

Number of points: 2

Output voltage: ± 10VDC (linearity effective range ± 8 V)

Resolution: 16 bits

Accuracy:

Max. output current: ± 10 mA

Settling time (

Activated when a servo alarm or overtravelling occurs or when the power

supply for the main circuit or servomotor is OFF.

Included

Dynamic brake stop, deceleration to a stop, or free run to a stop at P-OT or

N-OT

Overcurrent, overvoltage, insufficient voltage, overload, regeneration error,

and so on.

± 20 mV (Typ)

*2

7 ch

• Homing deceleration switch (/DEC)

• External latch (/EXT 1 to 3)

• Forward run prohibited (P-OT), reverse run prohibited

(N-OT)

• Forward external torque limit (/P-CL), reverse external

torque limit (/N-CL)

Signal allocations can be performed, and positive and

negative logic can be changed.

3 ch

• Positioning completion (/COIN)

• Speed coincidence detection (/V-CMP)

• Rotation detection (/TGON)

• Servo ready (/S-RDY)

• Torque limit detection (/CLT)

• Speed limit detection (/VLT)

• Brake (/BK)

• Warning (/WARN)

• Near (/NEAR)

Signal allocations can be performed, and positive and

negative logic can be changed.

Position: 16 positions × 2 (Refer to 4.1.1)

± 1%): 1.2 ms (Typ)

1-6

Page 27

1.3 SERVOPACK Ratings and Specifications

1

Outline

Speed regulation =

No-load motor speed Total load motor speed

Rated motor

speed

×

100%

-

Rotation

Input /HWBB1, /HWBB2: Baseblock signal for power module

Safety Function

Output EDM1: Monitoring status of internal safety circuit (fixed output)

*3

Standards

EN954 Category 3, IEC61508 SIL2

Option Module Fully-closed module, safety module

∗1. Speed regulation by load regulation is defined as follows:

∗2. Refer to 1.3.1 Ratings for details on regenerative resistors.

∗3. Perform risk assessment for the system and be sure that the safety requirements are fulfilled.

(cont’d)

1-7

Page 28

1 Outline

1.3.3 MECHATROLINK-III Function Specifications

1.3.3 MECHATROLINK-III Function Specifications

The following table shows the specifications of MECHATROLINK-III.

Function Specifications

MECHATROLINK-III

Communication

Reference Method

Communication Protocol

Station Address

Baud Rate 100 Mpbs

Transmission Cycle

Number of Transmission Bytes

Control Method

Reference Input

Profile

MECHATROLINK-III

03H to EFH (Max. number of stations: 62)

Use the rotary switches S1 and S2 to set the station address.

125 μs, 250 μs, 500 μs, 750 μs, and 1.0 ms to 4.0 ms (increments of 0.5 ms)

16, 32, or 48 bytes per station

Use the DIP switch S3 to select the number of words.

Position, speed, or torque control with MECHATROLINKIII communication

MECHATROLINK commands (sequence, motion, data setting/reference, monitoring, or adjustment)

MECHATROLINK-III standard servo profile

MECHATROLINK-II-compatible profile

1-8

Page 29

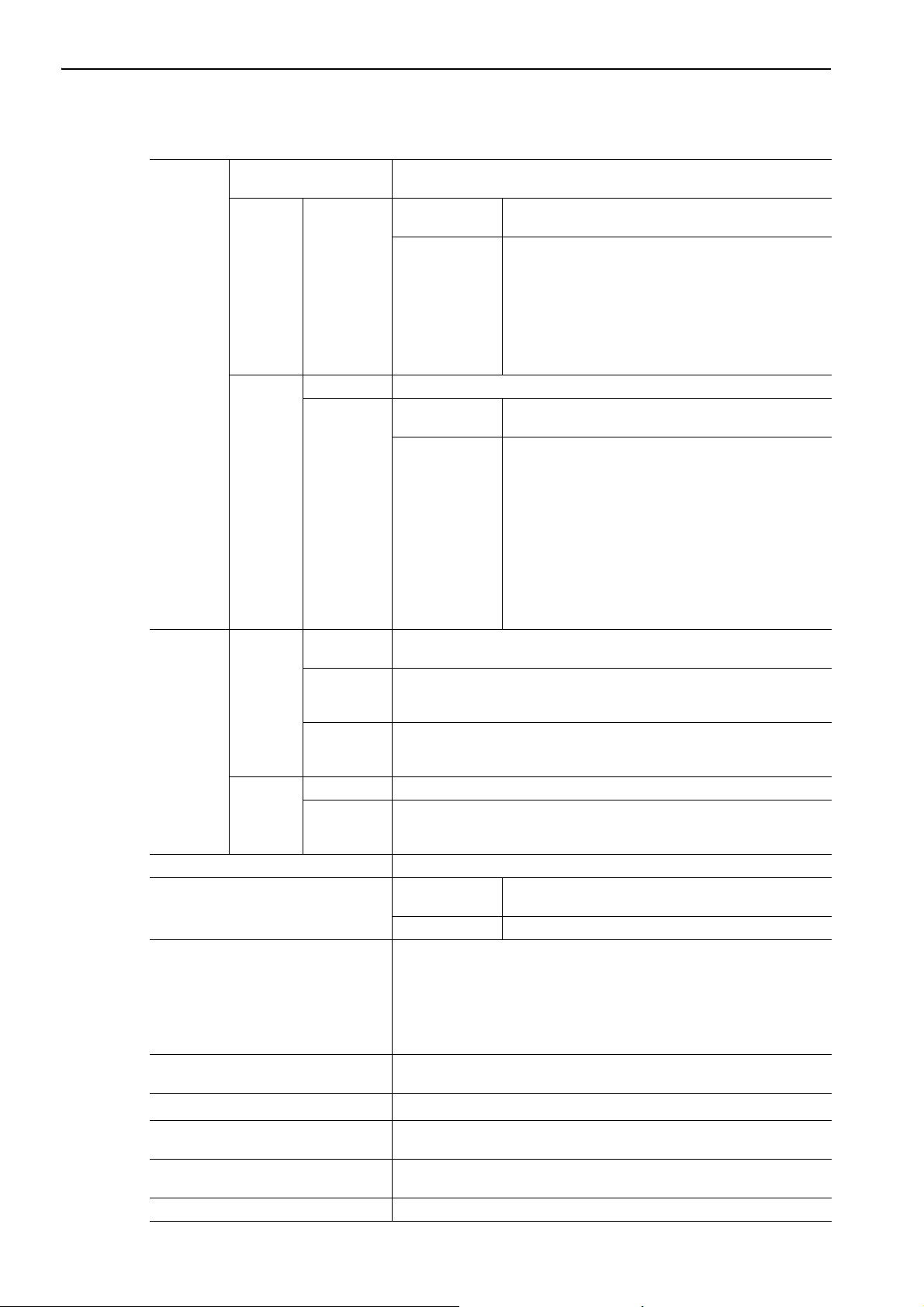

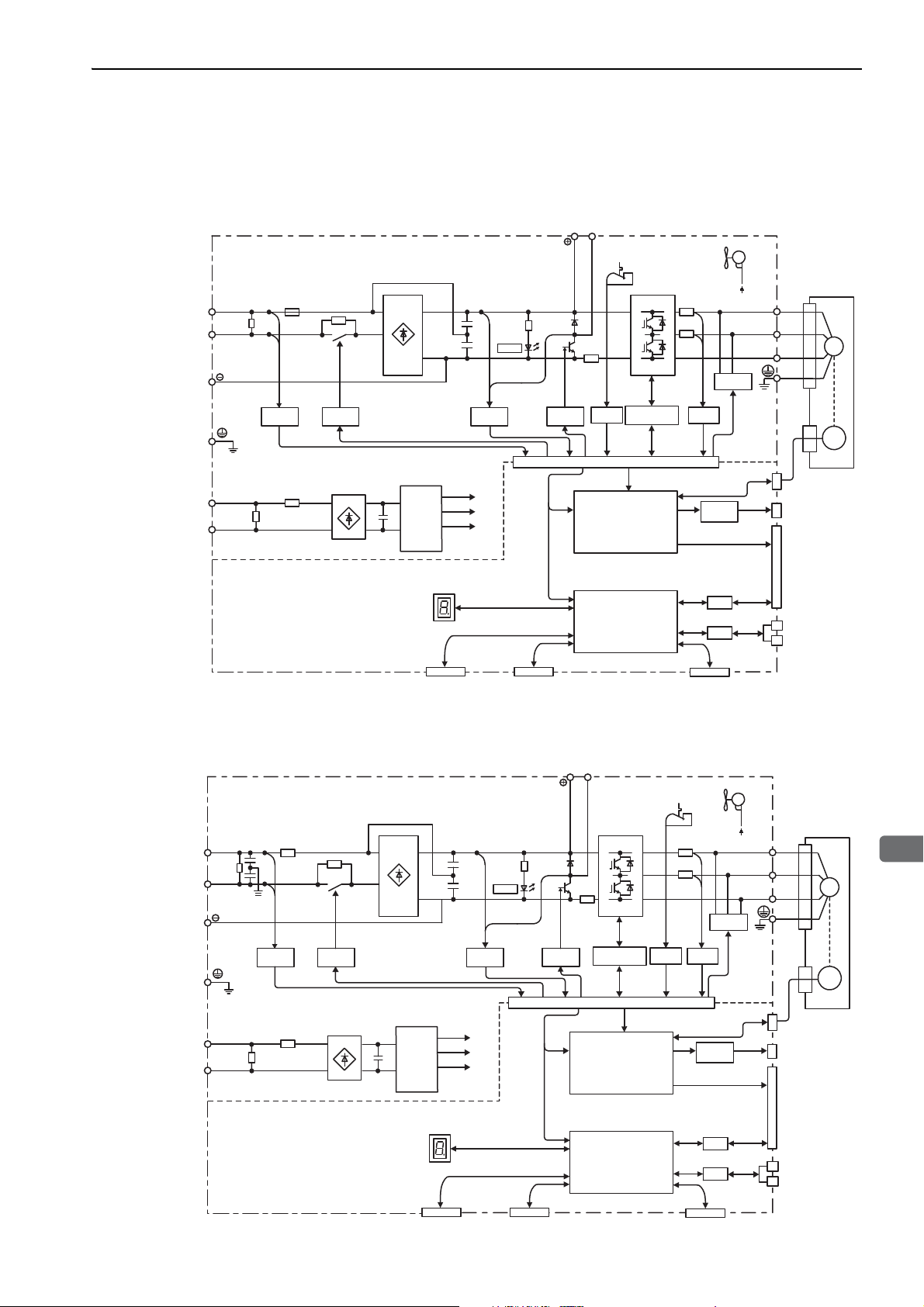

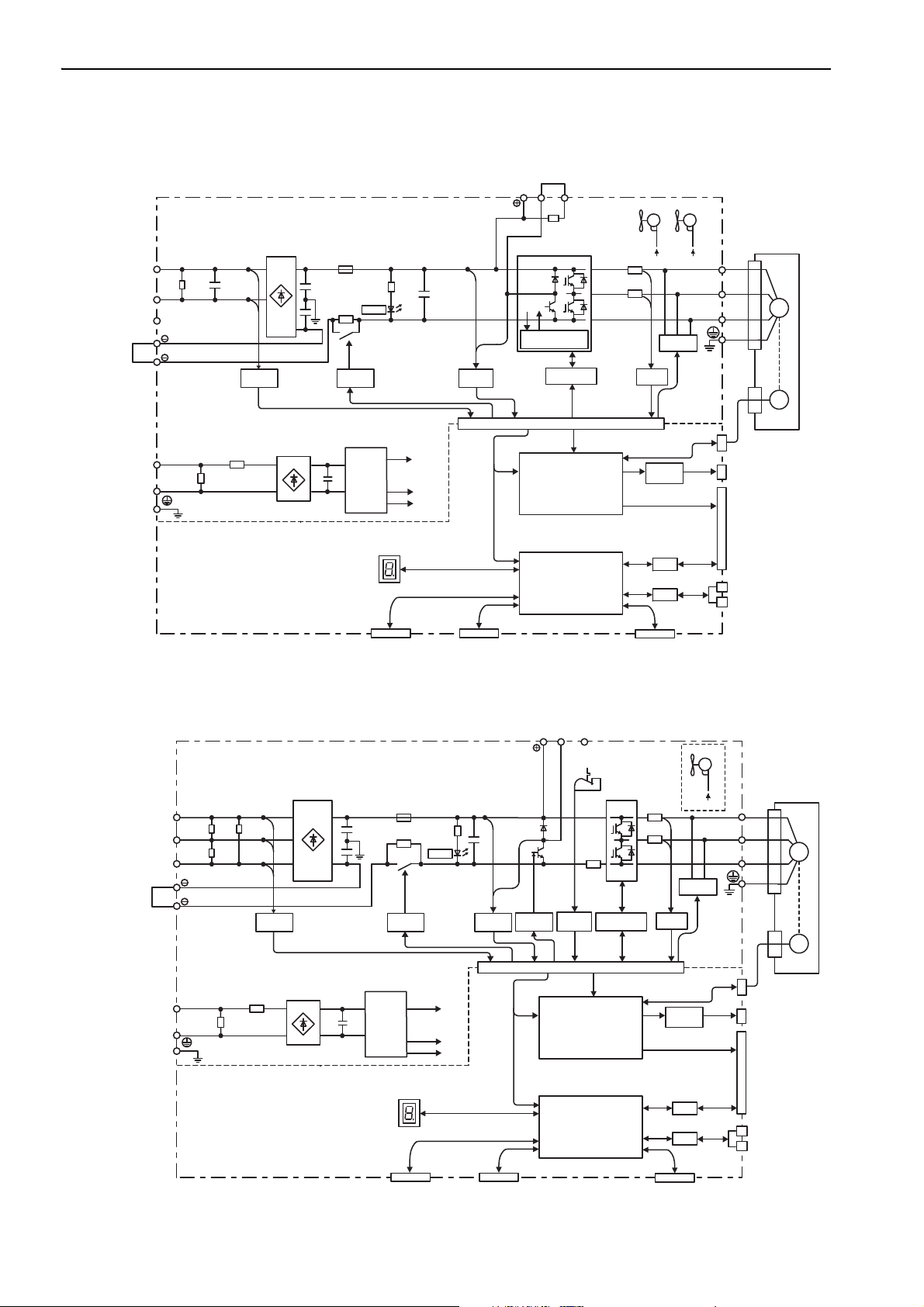

1.4 SERVOPACK Internal Block Diagrams

1

Outline

L1

B1/ B2

L2

L1C

L2C

U

V

W

CHARGE

M

ENC

Control power

supply

Main circuit

power supply

Control

power

supply

±12 V

+5 V

+17 V

Current

sensor

Dynamic

brake circuit

Servomotor

Gate

drive

Voltage

sensor

Voltage

sensor

Varistor

Varistor

Gate drive

overcurrent

protector

Temperature

sensor

Relay

drive

+

12 V

Fan

+

–

+

–

+

–

CN3 CN7 CN8

CN2

I/O

I/F

CN1

CN6A

CN6B

CN5

MECHATROLINK-III

communications

CPU

(Position/speed

calculation, etc.)

Panel display

Digital operator

Personal

computer

Signal for safety fuction

Encoder output

pulse

I/O signal

Analog monitor

output

ASIC

(PWM control, etc.)

Analog

voltage

converter

M-III

M-III

1.4 SERVOPACK Internal Block Diagrams