YASKAWA SGD7S-2R8F20A023F40B, SERVOPACK Sigma 7 Series, SGD7S-2R8A20A023F40B, SGD7S-1R6A20A023F40B, SGD7S-3R8A20A023F40B Product Manual

...Page 1

-7-Series AC Servo Drive

-7S SERVOPACK with

FT/EX Specification

for Press and Injection

Molding Application

Product Manual

Model: SGD7S-20F40, and -20F41

MANUAL NO. SIEP S800001 94C

Basic Information on

SERVOPACKs

SERVOPACK Ratings and

Specifications

Pressure Feedback Control

Speed/Torque (Pressure)

Table Operation

Maintenance

Parameter Lists

1

2

3

4

5

6

Page 2

Copyright © 2016 YASKAWA ELECTRIC CORPORATION

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system, or transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission

of Yaskawa. No patent liability is assumed with respect to the use of the information contained herein. Moreover, because Yaskawa is constantly striving to

improve its high-quality products, the information contained in this manual is subject to change without notice. Every precaution has been taken in the preparation

of this manual. Nevertheless, Yaskawa assumes no responsibility for errors or

omissions. Neither is any liability assumed for damages resulting from the use of

the information contained in this publication.

Page 3

About this Manual

This manual describes the press and injection molding application option for Σ-7-Series AC Servo

Drive Σ-7S SERVOPACKs.

Read and understand this manual to ensure correct usage of the Σ-7-Series AC Servo Drives.

Keep this manual in a safe place so that it can be referred to whenever necessary.

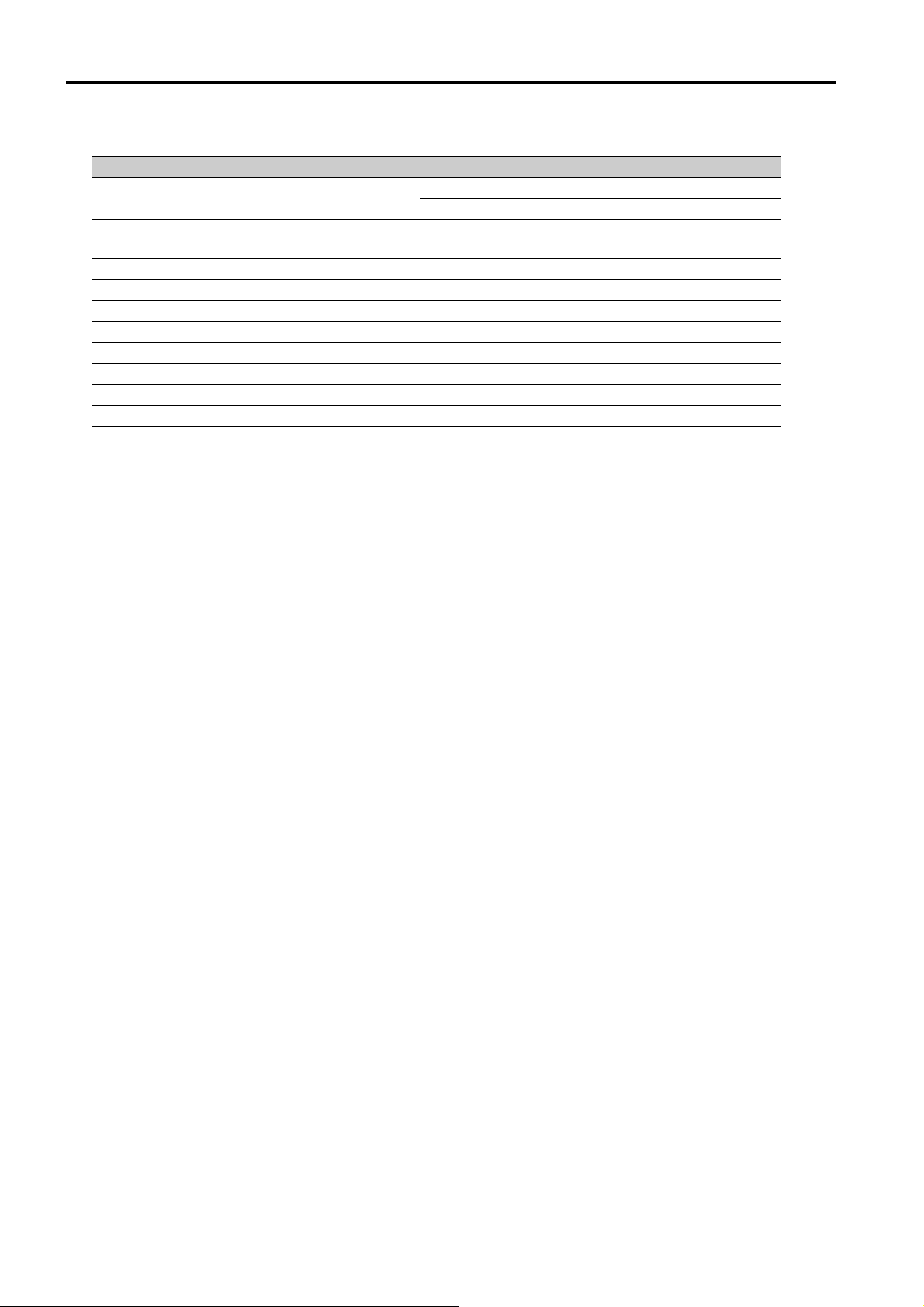

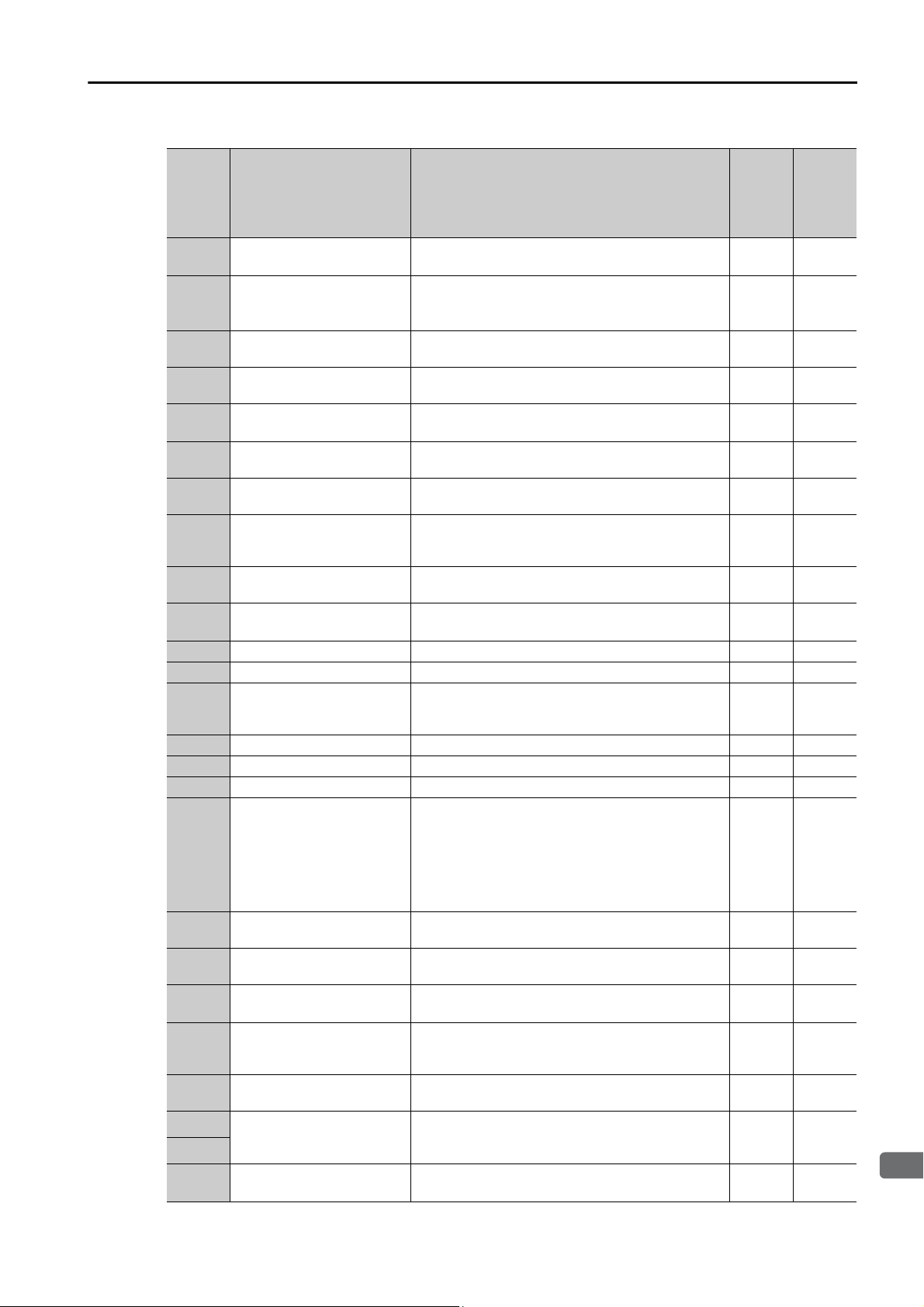

Outline of Manual

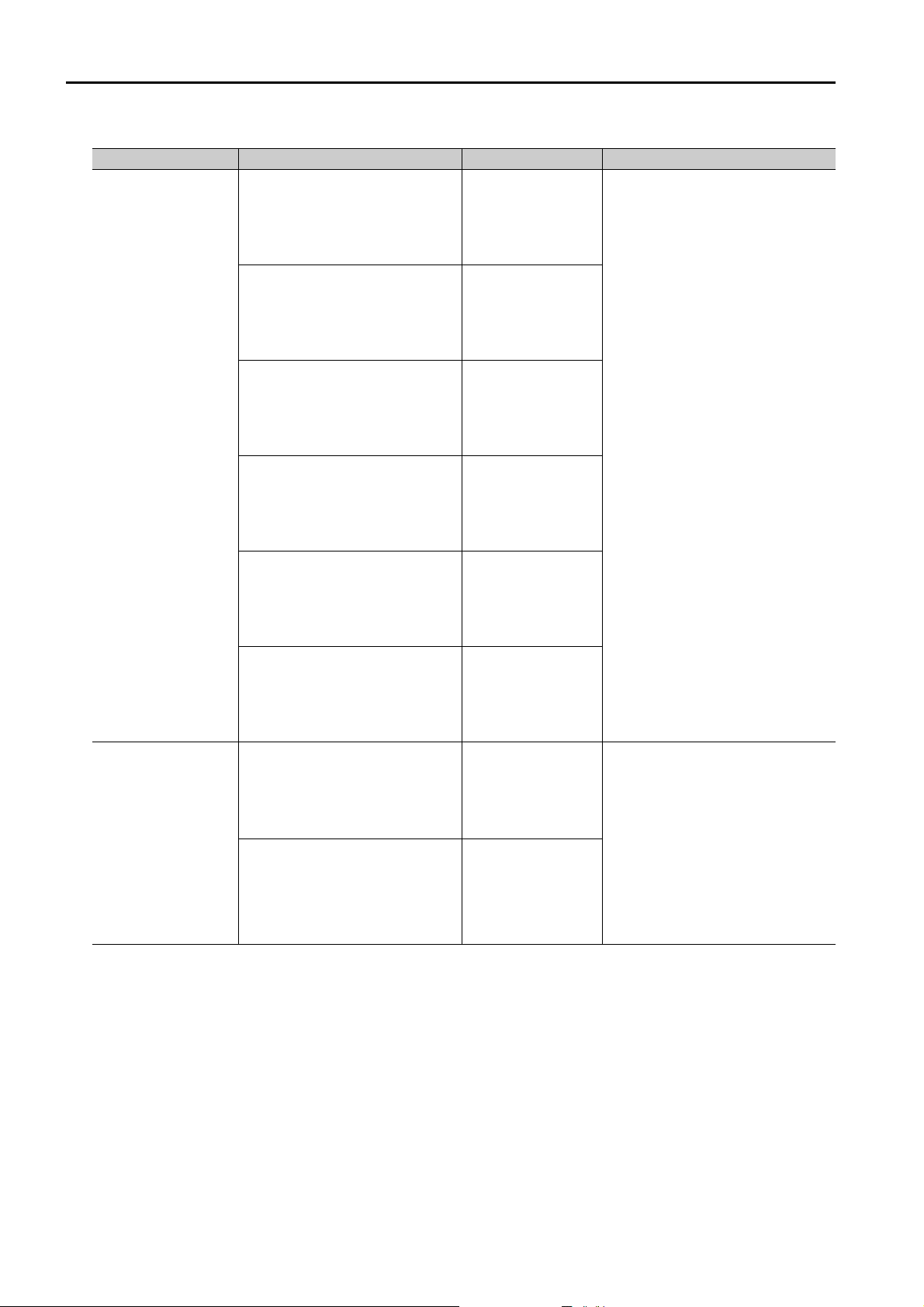

The contents of the chapters of this manual are described in the following table.

When you use the SERVOPACK, read this manual and the relevant product manual given in the following table.

Σ

-7S SERVOPACK with

Item

The Σ-7 Series – 1.1

Product Introduction 1.1 –

Interpreting the Nameplates – 1.2

Part Names – 1.3

Model Designations 1.2 –

Basic Information

on SERVOPACKs

Selecting a SERVOPACK

SERVOPACK Installation – Chapter 3

Wiring and Connecting SERVOPACKs – Chapter 4

Basic Functions That Require Setting before Operation – Chapter 5

Application Functions – Chapter 6

Trial Operation and Actual Operation – Chapter 7

Tuning – Chapter 8

Monitor

Combinations of SERVOPACKs and Servomotors

Functions 1.4 –

Restrictions 1.5 –

SigmaWin+ 1.6 –

Combining the SERVOPACKs with MPSeries Machine Controllers and the

MPE720 Engineering Tool

Ratings 2.1 –

SERVOPACK Overload Protection Characteristics

Specifications 2.3 –

Block Diagrams – 2.2

External Dimensions – 2.3

Examples of Standard Connections

between SERVOPACKs and Peripheral

Devices

Monitoring Product Information – 9.1

Monitoring SERVOPACK Status – 9.2

Monitoring Machine Operation Status and

Signal Waveforms

Monitoring Product Life – 9.4

This

Manual

–1.5

1.7 –

2.2 –

–2.4

3.7, 4.5 9.3

Communications References Product

MECHATROLINK-III

Manual

(Manual No.: SIEP S800001 28)

Continued on next page.

iii

Page 4

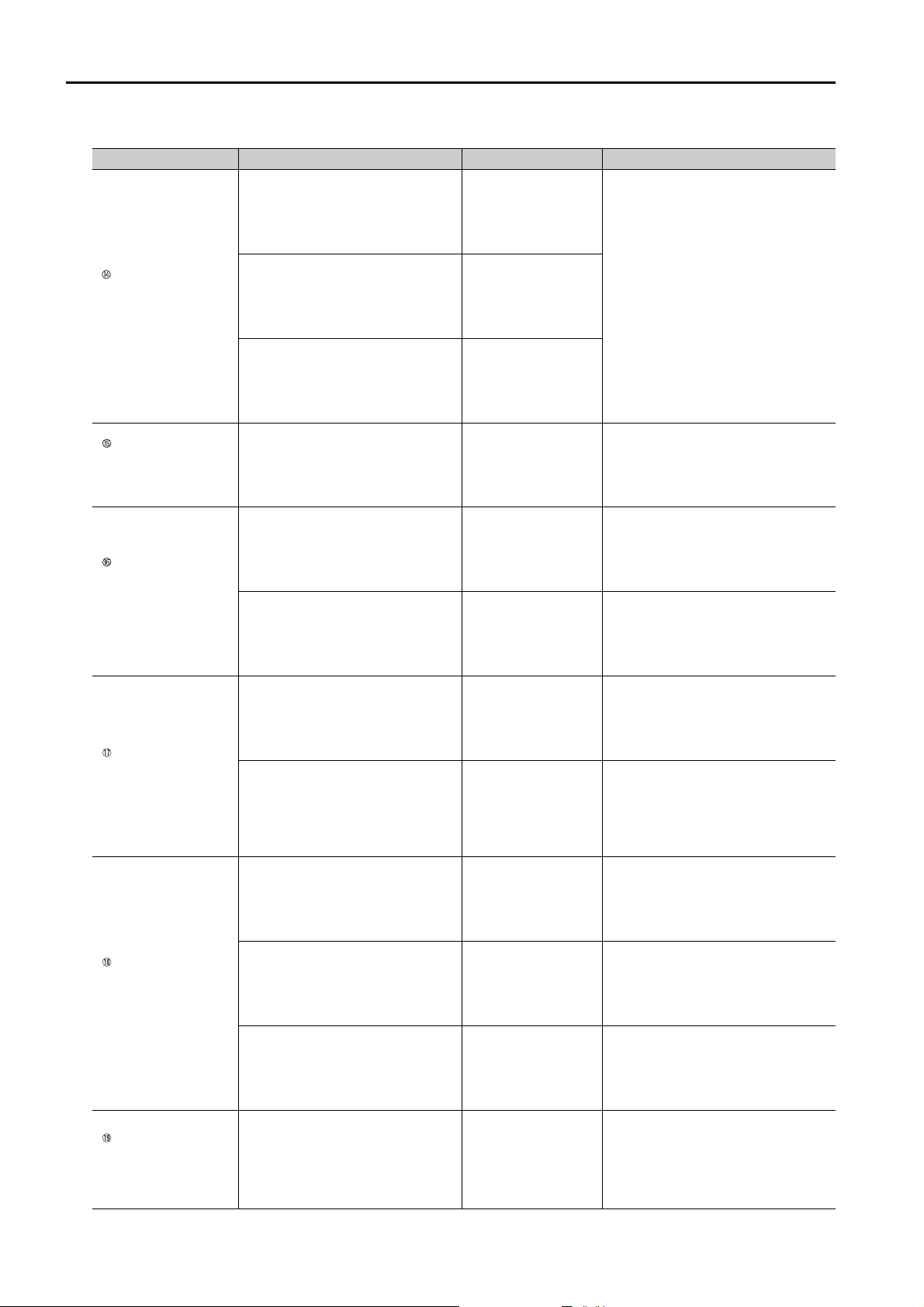

Continued from previous page.

Σ

-7S SERVOPACK with

Item

This

Manual

Communications References Product

MECHATROLINK-III

(Manual No.: SIEP S800001 28)

Fully-Closed Loop Control – Chapter 10

Safety Function – Chapter 11

Introduction 3.1 –

Input Signal Connections 3.2 –

Pressure Feedback Control

Operation Patterns for Pressure Feedback

Control

Changing from Torque Control to Pressure

Feedback Control

3.3 –

3.4 –

Control Block Diagrams 3.5 –

Setup Procedure 3.6 –

Monitoring 3.7 –

Introduction 4.1 –

Speed/Torque

(Pressure) Table

Operation

Operation Patterns for Speed/Torque (Pressure) Table Operation

Table Parameter Settings for Speed/Torque

(Pressure) Table Operation

4.2 –

4.3 –

Operating Procedure 4.4 –

Monitoring 4.5 –

Inspections and Part Replacement – 12.1

Alarm Displays

List of Alarms

Troubleshooting Alarms

5.1.1,

5.2.1

5.1.2,

5.2.2

5.1.3,

5.2.3

Resetting Alarms – 12.2.3

Display Alarm History – 12.2.4

Clearing the Alarm History – 12.2.5

Maintenance

Resetting Alarms Detected in Option

Modules

– 12.2.6

Resetting Motor Type Alarms – 12.2.7

Warning Displays

List of Warnings

Troubleshooting Warnings

Monitoring Communications Data during

Alarms or Warnings

Troubleshooting Based on the Operation

and Conditions of the Servomotor

5.1.4,

5.2.4

5.1.5,

5.2.5

5.1.6,

5.2.6

–12.4

5.1.7,

5.2.7

Interpreting the Parameter Lists 6.1 –

6.2.1,

6.3.1

6.2.2,

6.3.2

6.2.3,

6.3.3

Parameter Lists

List of Servo Parameters

List of MECHATROLINK-III Common

Parameters

Parameter Recording Table

Appendices – Chapter 14

Manual

–

–

–

–

–

–

–

–

–

–

iv

Page 5

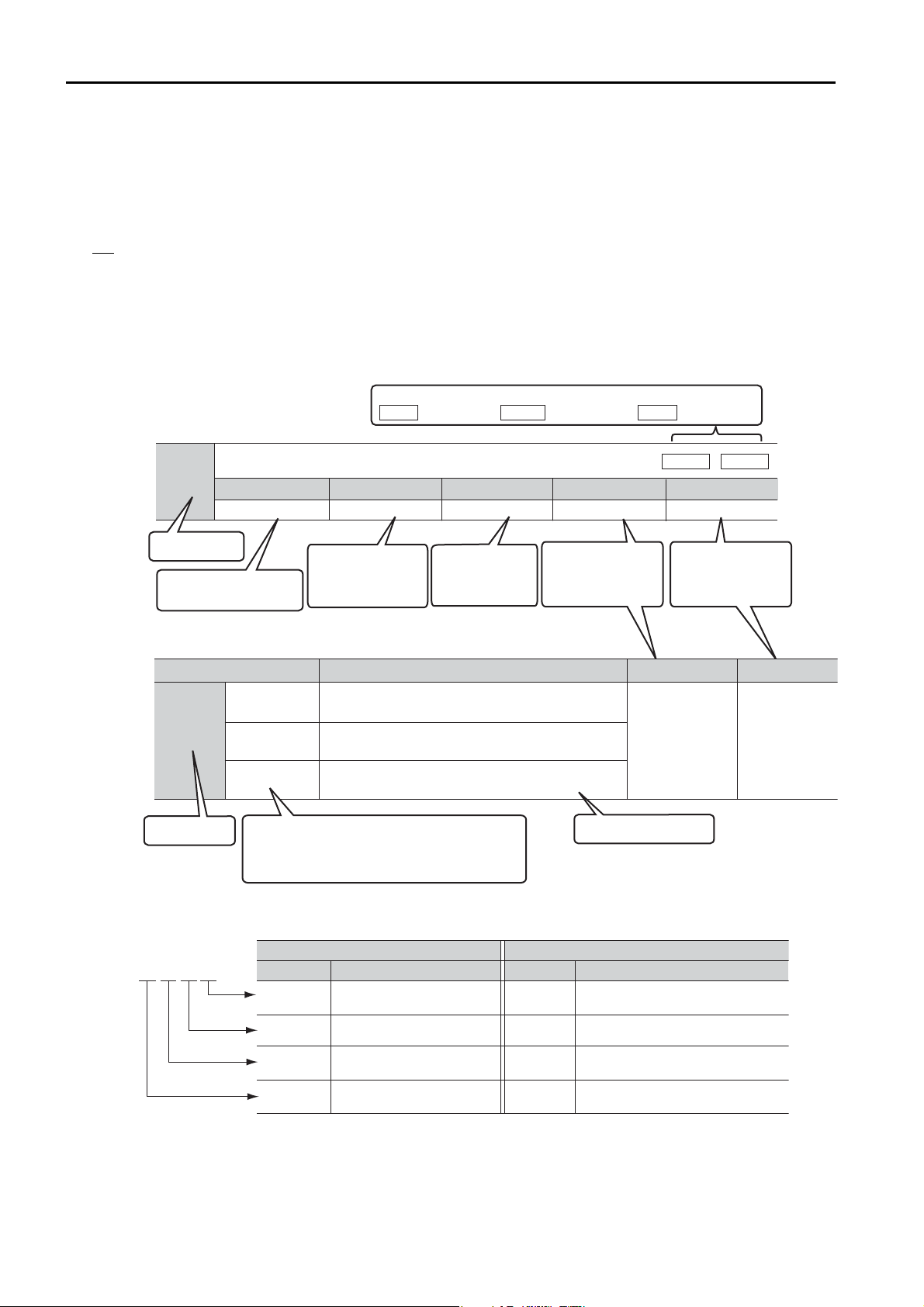

Related Documents

Manuals Catalogs

System Components

Machine

Controller

and

Servo Drive

General

Catalog

MP3300

Catalog

Machine Controllers

Σ-7-Series

Catalog

Servo Drives

Machine Controllers

SERVOPACKs:

Σ-7S and Σ-7W

SERVOPACKs with Built-in Controllers:

Σ-7C

Servomotors

Other Documents

Built-in

Function

Manuals

Σ-7-Series

Σ-7S/Σ-7W

SERVOPACK

Product

Manuals

Σ-7-Series

Σ-7S/Σ-7W

SERVOPACK

Hardware Option

Product Manuals

Option

Module

User’s

Manuals

Σ-7-Series

Σ-7S/Σ-7W

SERVOPACK

FT/EX

Product Manuals

(This manual)

Option

Module

User’s

Manual

Σ-7-Series

Servomotor

Product

Manuals

Σ-7-Series

Σ-7C

SERVOPACK

Product Manual

Σ-7-Series

Σ-7C

SERVOPACK

Troubleshooting

Manual

Enclosed

Documents

Enclosed

Documents

Built-in

Function

Manuals

Enclosed

Documents

Σ-7-Series

Peripheral

Device

Selection

Manual

Σ-7-Series

Operation

Interface

Operation

Manuals

Σ-7-Series

MECHATROLINK

Communications

Command

Manuals

Programming

Manuals

Distributed

I/O Module

User’s

Manual

The relationships between the documents that are related to the Servo Drives are shown in the following

figure. The numbers in the figure correspond to the numbers in the table on the following pages. Refer

to these documents as required.

v

Page 6

Classification Document Name Document No. Description

Machine Controller

and Servo Drive

General Catalog

MP3300 Catalog

Σ-7-Series Catalog

Built-in Function

Manuals

Option Module

User’s Manuals

Machine Controller and

AC Servo Drive

Solutions Catalog

Machine Controller

MP3300

AC Servo Drives

Σ-7 Series

Σ-7-Series AC Servo Drive

Σ-7C SERVOPACK

Motion Control

User’s Manual

Machine Controller

MP3000 Series

Communications

User’s Manual

Machine Controller

MP2000 Series

Communication Module

User’s Manual

Machine Controller

MP2000 Series

262IF-01 FL-net

Communication Module

User’s Manual

Machine Controller

MP2000 Series

263IF-01 EtherNet/IP

Communication Module

User’s Manual

Machine Controller

MP2000 Series

I/O Module

User’s Manual

Machine Controller

MP2000 Series

Analog Input/Analog Output Module AI-01/AO-01

User’s Manual

Machine Controller

MP2000 Series

Counter Module CNTR-01

User’s Manual

KAEP S800001 22

KAEP C880725 03

KAEP S800001 23

SIEP S800002 03

SIEP C880725 12

SIEP C880700 04

SIEP C880700 36

SIEP C880700 39

SIEP C880700 34

SIEP C880700 26

SIEP C880700 27

Describes the features and application examples for combinations of

MP3000-Series Machine Controllers and Σ-7-Series AC Servo

Drives.

Provides detailed information on

MP3300 Machine Controllers,

including features and specifications.

Provides detailed information on Σ-

7-Series AC Servo Drives, including

features and specifications.

Provides detailed information on

the specifications, system configuration, and application methods of

the Motion Control Function Modules (SVD, SVC4, and SVR4) for Σ-

7-Series Σ-7C SERVOPACKs.

Provides detailed information on

the specifications, system configuration, and communications connection methods for the Ethernet

communications that are used with

MP3000-Series Machine Controllers and Σ-7-Series Σ-7C SERVOPAC Ks.

Provide detailed information on the

specifications and communications methods for the Communications Modules that can be mounted

to MP3000-Series Machine Controllers and Σ-7-Series Σ-7C

SERVOPACKs.

Provide detailed information on the

specifications and communications methods for the I/O Modules

that can be mounted to MP3000Series Machine Controllers and Σ-

7-Series Σ-7C SERVOPACKs.

Continued on next page.

vi

Page 7

Continued from previous page.

Classification Document Name Document No. Description

Enclosed Documents

Σ-7-Series AC Servo Drive

Σ-7S and Σ-7W SERVOPACK

Safety Precautions

Σ-V-Series/Σ-V-Series

for Large-Capacity Models/

Σ-7-Series

Safety Precautions

Option Module

Σ-V-Series/Σ-V-Series

for Large-Capacity Models/

Σ-7-Series

Installation Guide

Command Option Module

Σ-V-Series/Σ-V-Series

for Large-Capacity Models/

Σ-7-Series

Installation Guide

Fully-closed Module

TOMP C710828 00

TOBP C720829 00

TOBP C720829 01

TOBP C720829 03

Provides detailed information for

the safe usage of Σ-7-Series

SERVOPACKs.

Provides detailed information for

the safe usage of Option Modules.

Provides detailed procedures for

installing the Command Option

Module in a SERVOPACK.

Provides detailed procedures for

installing the Fully-closed Module in

a SERVOPACK.

Σ-7-Series

Σ-7C SERVOPACK

Product Manual

Σ-7-Series

Σ-7C SERVOPACK

Troubleshooting

Manual

Σ-V-Series/Σ-V-Series

for Large-Capacity Models/

Σ-7-Series

Installation Guide

Safety Module

Σ-V-Series/Σ-V-Series

for Large-Capacity Models/

Σ-7-Series

Installation Guide

INDEXER Module

Σ-V-Series/Σ-V-Series

for Large-Capacity Models/

Σ-7-Series

Installation Guide

DeviceNet Module

Σ-7-Series AC Servo Drive

Σ-7C SERVOPACK

Product Manual

Σ-7-Series AC Servo Drive

Σ-7C SERVOPACK

Troubleshooting Manual

TOBP C720829 06

TOBP C720829 02

TOBP C720829 07

SIEP S800002 04

SIEP S800002 07

Provides detailed procedures for

installing the Safety Module in a

SERVOPACK.

Provides detailed procedures for

installing the INDEXER Module in a

SERVOPACK.

Provides detailed procedures for

installing the DeviceNet Module in a

SERVOPACK.

Provides detailed information on

selecting Σ-7-Series Σ-7C SERVOPACKs; installing, connecting, setting, testing in trial operation, and

tuning Servo Drives; writing, monitoring, and maintaining programs;

and other information.

Provides detailed troubleshooting

information for Σ-7-Series Σ-7C

SERVOPACKs.

Continued on next page.

vii

Page 8

Classification Document Name Document No. Description

Σ-7-Series

Σ-7S/Σ-7W

SERVOPACK

Product Manuals

Σ-7-Series AC Servo Drive

Σ-7S SERVOPACK with

MECHATROLINK-III

Communications References

Product Manual

Σ-7-Series AC Servo Drive

Σ-7S SERVOPACK with

MECHATROLINK-II

Communications References

Product Manual

Σ-7-Series AC Servo Drive

Σ-7S SERVOPACK with

Analog Voltage/Pulse Train

References

Product Manual

Σ-7-Series AC Servo Drive

Σ-7S SERVOPACK

Command Option Attachable

Type with INDEXER Module

Product Manual

SIEP S800001 28

SIEP S800001 27

SIEP S800001 26

SIEP S800001 64

Continued from previous page.

Provide detailed information on

selecting Σ-7-Series SERVOPACKs and information on installing, connecting, setting, performing

trial operation for, tuning, and monitoring the Servo Drives.

Σ-7-Series

Σ-7S/Σ-7W

SERVOPACK with

Hardware Option

Specifications

Product Manuals

Σ-7-Series AC Servo Drive

Σ-7S SERVOPACK

Command Option Attachable

Type with DeviceNet Module

Product Manual

Σ-7-Series AC Servo Drive

Σ-7W SERVOPACK with

MECHATROLINK-III

Communications References

Product Manual

Σ-7-Series AC Servo Drive

Σ-7S/Σ-7W SERVOPACK with

Hardware Option Specifications

Dynamic Brake

Product Manual

Σ-7-Series AC Servo Drive

Σ-7W/Σ-7C SERVOPACK with

Hardware Option Specifications

HWBB Function

Product Manual

SIEP S800001 70

SIEP S800001 29

SIEP S800001 73

Provide detailed information on

Hardware Options for Σ-7-Series

SERVOPACKs.

SIEP S800001 72

Continued on next page.

viii

Page 9

Continued from previous page.

Classification Document Name Document No. Description

Σ-7-Series AC Servo Drive

Σ-7-Series

Σ-7S/Σ-7W SERVO-

PAC K

FT/EX

Product Manuals

Option Module

User’s Manual

Σ-7S SERVOPACK with

FT/EX Specification for Indexing

Application

Product Manual

Σ-7-Series AC Servo Drive

Σ-7S SERVOPACK with

FT/EX Specification for Tracking

Application

Product Manual

Σ-7-Series AC Servo Drive

Σ-7S SERVOPACK with

FT/EX Specification

for Application with Special Motor,

SGM7D Motor

Product Manual

Σ-7-Series AC Servo Drive

Σ-7S SERVOPACK with FT/EX

Specification for Press and

Injection Molding Application

Product Manual

Σ-7-Series AC Servo Drive

Σ-7S SERVOPACK with

FT/EX Specification

for Transfer and Alignment

Application

Product Manual

Σ-7-Series AC Servo Drive

Σ-7S SERVOPACK with

FT/EX Specification

for Torque/Force Assistance

for Conveyance Application

Product Manual

Σ-7-Series AC Servo Drive

Σ-7S SERVOPACK with

FT/EX Specification

for Cutting Application

Feed Shaft Motor

Product Manual

AC Servo Drives

Σ-V Series/Σ-V Series

for Large-Capacity Models/

Σ-7 Series

User’s Manual

Safety Module

SIEP S800001 84

SIEP S800001 89

SIEP S800001 91

This manual

(SIEP S800001 94)

SIEP S800001 95

SIEP S800002 09

SIEP S800002 10

SIEP C720829 06

Provide detailed information on the

FT/EX Option for Σ-7-Series

SERVOPACKs.

Provides details information

required for the design and maintenance of a Safety Module.

Enclosed Documents

AC Servo Drive

Rotary Servomotor

Safety Precautions

AC Servomotor

Linear Σ Series

Safety Precautions

TOBP C230260 00

TOBP C230800 00

Provides detailed information for

the safe usage of Rotary Servomotors and Direct Drive Servomotors.

Provides detailed information for

the safe usage of Linear Servomotors.

Continued on next page.

ix

Page 10

Continued from previous page.

Classification Document Name Document No. Description

Σ-7-Series AC Servo Drive

Rotary Servomotor

Product Manual

SIEP S800001 36

Σ-7-Series

Servomotor

Product Manuals

Σ-7-Series

Peripheral Device

Selection Manual

Σ-7-Series

MECHATROLINK

Communications

Command Manuals

Programming

Manuals

Σ-7-Series AC Servo Drive

Linear Servomotor

Product Manual

Σ-7-Series AC Servo Drive

Direct Drive Servomotor

Product Manual

Σ-7-Series AC Servo Drive

Peripheral Device

Selection Manual

Σ-7-Series AC Servo Drive

MECHATROLINK-II

Communications

Command Manual

Σ-7-Series AC Servo Drive

MECHATROLINK-III

Communications

Standard Servo Profile

Command Manual

Machine Controller

MP3000 Series

Ladder Programming

Manual

Machine Controller

MP3000 Series

Motion Programming

Manual

Machine Controller

MP2000/MP3000 Series

Engineering Tool

MPE720 Version 7

User’s Manual

SIEP S800001 37

SIEP S800001 38

SIEP S800001 32

SIEP S800001 30

SIEP S800001 31

SIEP C880725 13

SIEP C880725 14

SIEP C880761 03

Provide detailed information on

selecting, installing, and connecting

the Σ-7-Series Servomotors.

Describes the peripheral devices

for a Σ-7-Series Servo System.

Provides detailed information on

the MECHATROLINK-II communications commands that are used

for a Σ-7-Series Servo System.

Provides detailed information on

the MECHATROLINK-III communications standard servo profile commands that are used for a Σ-7-

Series Servo System.

Provides detailed information on

the ladder programming specifications and instructions for MP3000Series Machine Controllers and Σ-

7-Series Σ-7C SERVOPACKs.

Provides detailed information on

the motion programming and

sequence programming specifications and instructions for MP3000Series Machine Controllers and Σ-

7-Series Σ-7C SERVOPACKs.

Describes in detail how to operate

MPE720 version 7.

Σ-7-Series

Operation Interface

Operating Manuals

Distributed

I/O Module

User’s Manuals

Σ-7-Series AC Servo Drive

Digital Operator

Operating Manual

Servo Drive

AC

Engineering Tool

SigmaWin+

Operation Manual

MECHATROLINK-III

Compatible I/O Module

User’s Manual

SIEP S800001 33

SIET S800001 34

SIEP C880781 04

Describes the operating procedures for a Digital Operator for a

Σ-7

-Series Servo System.

Provides detailed operating procedures for the SigmaWin+ Engineering Tool for a Σ-7-Series Servo

System.

Describes the functions, specifications, operating methods, and

MECHATROLINK-III communications for the Remote I/O Modules

for MP2000/MP3000-Series

Machine Controllers.

x

Page 11

Using This Manual

Technical Terms Used in This Manual

The following terms are used in this manual.

Ter m Meaning

Servomotor A Σ-7-Series Rotary Servomotor, Direct Drive Servomotor, or Linear Servomotor.

A generic term used for a Σ-7-Series Rotary Servomotor (SGMMV, SGM7J, SGM7A, SGM7P,

Rotary Servomotor

Linear Servomotor

SERVOPACK

Servo Drive

Servo System

servo ON

servo OFF

base block (BB)

servo lock

Main Circuit Cable

SigmaWin+

or SGM7G) or a Direct Drive Servomotor (SGM7E, SGM7F, SGMCV, or SGMCS).

The descriptions will specify when Direct Drive Servomotors are excluded.

A generic term used for a Σ-7-Series Linear Servomotor (SGLG, SGLF, or SGLT).

A Σ-7-Series Σ-7S Servo Amplifier with MECHATROLINK-III Communications References.

The combination of a Servomotor and SERVOPACK.

A servo control system that includes the combination of a Servo Drive with a host controller

and peripheral devices.

Supplying power to the motor.

Not supplying power to the motor.

Shutting OFF the power supply to the motor by shutting OFF the base current to the power

transistor in the SERVOPACK.

A state in which the motor is stopped and is in a position loop with a position reference of 0.

One of the cables that connect to the main circuit terminals, including the Main Circuit Power

Supply Cable, Control Power Supply Cable, and Servomotor Main Circuit Cable.

The Engineering Tool for setting up and tuning Servo Drives or a computer in which the Engineering Tool is installed.

Differences in Terms for Rotary Servomotors and Linear Servomotors

There are differences in the terms that are used for Rotary Servomotors and Linear Servomotors.

This manual primarily describes Rotary Servomotors. If you are using a Linear Servomotor, you

need to interpret the terms as given in the following table.

Rotary Servomotor Linear Servomotor

torque force

moment of inertia

rotation movement

forward rotation and reverse rotation forward movement and reverse movement

CW and CCW pulse trains forward and reverse pulse trains

rotary encoder linear encoder

absolute rotary encoder absolute linear encoder

incremental rotary encoder incremental linear encoder

unit: min

unit: Nmunit: N

-1

mass

unit: mm/s

xi

Page 12

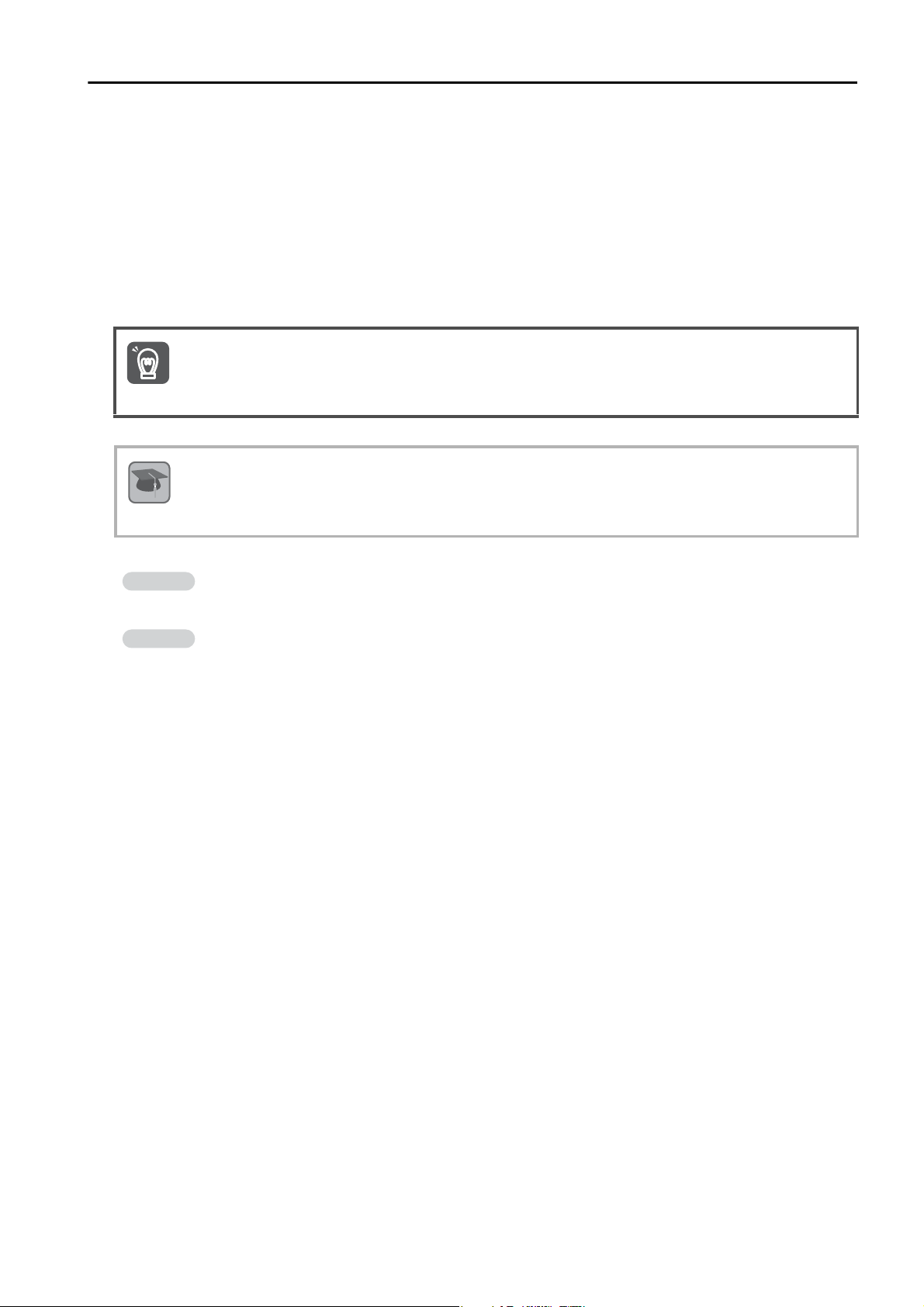

Pn100

Speed Loop Gain

Setting Range

10 to 20,000 0.1 Hz 400 Immediately

Setting Unit Default Setting When Enabled

Classication

Tuning

(default setting)

Use the encoder according to encoder specications.

Use the encoder as an incremental encoder.

Use the encoder as a single-turn absolute encoder.

This is the setting range

for the parameter.

Parameter

number

This column explains the

selections for the function.

Position

Torque

The control methods for which the parameters apply are given.

Speed

: Speed control : Position control : Torque control

This is the

parameter setting

before shipment.

This is when any

change made to the

parameter will

become effective.

This is the parameter

classication.

This is the minimum

unit (setting increment)

that you can set for

the parameter.

Position

Speed

Parameter Meaning When Enabled Classication

Pn002

n.

0

After startup Setup

n.1

n.2

Parameter

number

The notation “n.” indicates a parameter for

selecting functions.

Each

indicates the setting for one digit.

The notation shown here means that the third digit

from the right is set to 2.

• Parameters for Selecting Functions

Notation Examples for Pn002

Pn002 =

n.

X

Indicates the rst digit from

the right in Pn002.

Pn002 =

n.

1

Indicates that the rst digit from

the right in Pn002 is set to 1.

Pn002 =

n.

X

Indicates the second digit

from the right in Pn002.

Pn002 =

n.

1

Indicates that the second digit from

the right in Pn002 is set to 1.

Pn002 =

n.

X

Indicates the third digit from

the right in Pn002.

Pn002 =

n.

1

Indicates that the third digit from

the right in Pn002 is set to 1.

Pn002 =

n.X

Indicates the fourth digit from

the right in Pn002.

Pn002 =

n.1

Indicates that the fourth digit from

the right in Pn002 is set to 1.

n.0 0 0 0

Notation

Digit Notation Numeric Value Notation

Meaning Notation Meaning

Notation Used in this Manual

Notation for Reverse Signals

The names of reverse signals (i.e., ones that are valid when low) are written with a forward slash (/)

before the signal abbreviation.

Notation Example

BK

is written as /BK.

Notation for Parameters

The notation depends on whether the parameter requires a numeric setting (parameter for numeric

setting) or requires the selection of a function (parameter for selecting functions).

•

Parameters for Numeric Settings

Notation Example

xii

Engineering Tools Used in This Manual

This manual uses the interfaces of the SigmaWin+ for descriptions.

Page 13

Trademarks

Important

Term

Example

Information

• MECHATROLINK is a trademark of the MECHATROLINK Members Association.

• QR code is a trademark of Denso Wave Inc.

• Other product names and company names are the trademarks or registered trademarks of the

respective company. “TM” and the

® mark do not appear with product or company names in this

manual.

Visual Aids

The following aids are used to indicate certain types of information for easier reference.

Indicates precautions or restrictions that must be observed.

Also indicates alarm displays and other precautions that will not result in machine damage.

Indicates definitions of difficult terms or terms that have not been previously explained in this manual.

Indicates operating or setting examples.

Indicates supplemental information to deepen understanding or useful information.

xiii

Page 14

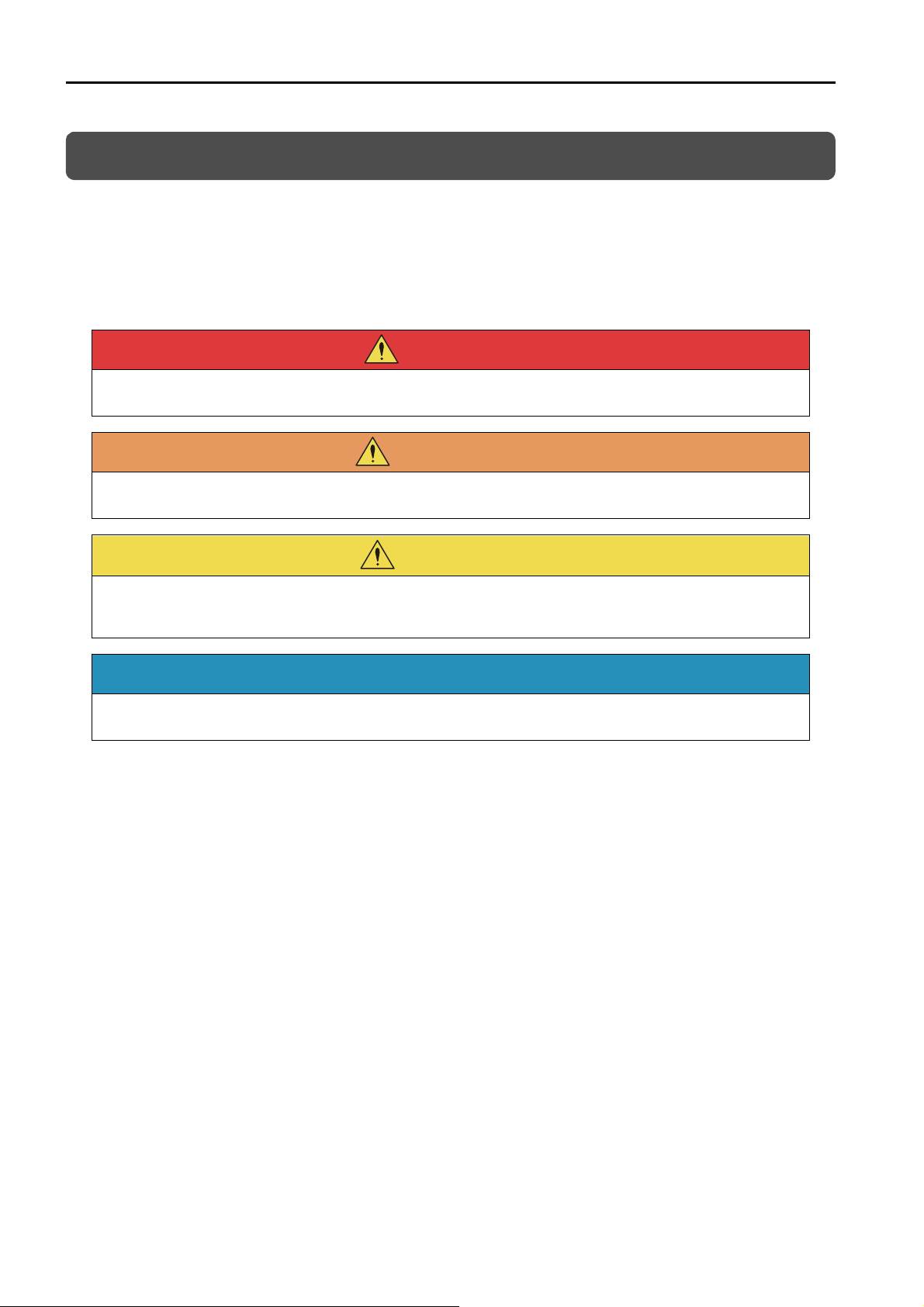

DANGER

WARNING

CAUTION

NOTICE

Safety Precautions

Safety Information

To prevent personal injury and equipment damage in advance, the following signal words are used

to indicate safety precautions in this document. The signal words are used to classify the hazards

and the degree of damage or injury that may occur if a product is used incorrectly. Information

marked as shown below is important for safety. Always read this information and heed the precautions that are provided.

Indicates precautions that, if not heeded, are likely to result in loss of life, serious injury, or fire.

Indicates precautions that, if not heeded, could result in loss of life, serious injury, or fire.

Indicates precautions that, if not heeded, could result in relatively serious or minor injury, or in

fire.

Indicates precautions that, if not heeded, could result in property damage.

xiv

Page 15

Safety Precautions That Must Always Be Observed

DANGER

WARNING

CAUTION

General Precautions

Read and understand this manual to ensure the safe usage of the product.

Keep this manual in a safe, convenient place so that it can be referred to whenever necessary.

Make sure that it is delivered to the final user of the product.

Do not remove covers, cables, connectors, or optional devices while power is being supplied to

the SERVOPACK.

There is a risk of electric shock, operational failure of the product, or burning.

Use a power supply with specifications (number of phases, voltage, frequency, and AC/DC

type) that are appropriate for the product.

There is a risk of burning, electric shock, or fire.

Connect the ground terminals on the SERVOPACK and Servomotor to ground poles according

to local electrical codes (100 Ω or less for a SERVOPACK with a 100-VAC or 200-VAC power

supply, and 10 Ω or less for a SERVOPACK with a 400-VAC power supply).

There is a risk of electric shock or fire.

Do not attempt to disassemble, repair, or modify the product.

There is a risk of fire or failure.

The warranty is void for the product if you disassemble, repair, or modify it.

The SERVOPACK heat sinks, regenerative resistors, External Dynamic Brake Resistors, Servo-

motors, and other components can be very hot while power is ON or soon after the power is

turned OFF. Implement safety measures, such as installing covers, so that hands and parts

such as cables do not come into contact with hot components.

There is a risk of burn injury.

For a 24-VDC power supply, use a power supply device with double insulation or reinforced

insulation.

There is a risk of electric shock.

Do not damage, pull on, apply excessive force to, place heavy objects on, or pinch cables.

There is a risk of failure, damage, or electric shock.

The person who designs the system that uses the hard wire base block safety function must

have a complete knowledge of the related safety standards and a complete understanding of

the instructions in this document.

There is a risk of injury, product damage, or machine damage.

Do not use the product in an environment that is subject to water, corrosive gases, or flamma-

ble gases, or near flammable materials.

There is a risk of electric shock or fire.

xv

Page 16

NOTICE

CAUTION

NOTICE

CAUTION

Do not attempt to use a SERVOPACK or Servomotor that is damaged or that has missing parts.

Install external emergency stop circuits that shut OFF the power supply and stops operation

immediately when an error occurs.

In locations with poor power supply conditions, install the necessary protective devices (such as

AC reactors) to ensure that the input power is supplied within the specified voltage range.

There is a risk of damage to the SERVOPACK.

Use a Noise Filter to minimize the effects of electromagnetic interference.

Electronic devices used near the SERVOPACK may be affected by electromagnetic interference.

Always use a Servomotor and SERVOPACK in one of the specified combinations.

Do not touch a SERVOPACK or Servomotor with wet hands.

There is a risk of product failure.

Storage Precautions

Do not place an excessive load on the product during storage. (Follow all instructions on the

packages.)

There is a risk of injury or damage.

Do not install or store the product in any of the following locations.

• Locations that are subject to direct sunlight

• Locations that are subject to ambient temperatures that exceed product specifications

• Locations that are subject to relative humidities that exceed product specifications

• Locations that are subject to condensation as the result of extreme changes in temperature

• Locations that are subject to corrosive or flammable gases

• Locations that are near flammable materials

• Locations that are subject to dust, salts, or iron powder

• Locations that are subject to water, oil, or chemicals

• Locations that are subject to vibration or shock that exceeds product specifications

• Locations that are subject to radiation

If you store or install the product in any of the above locations, the product may fail or be damaged.

Transportation Precautions

Transport the product in a way that is suitable to the mass of the product.

Do not use the eyebolts on a SERVOPACK or Servomotor to move the machine.

There is a risk of damage or injury.

When you handle a SERVOPACK or Servomotor, be careful of sharp parts, such as the corners.

There is a risk of injury.

Do not place an excessive load on the product during transportation. (Follow all instructions on

the packages.)

There is a risk of injury or damage.

xvi

Page 17

NOTICE

Do not hold onto the front cover or connectors when you move a SERVOPACK.

CAUTION

There is a risk of the SERVOPACK falling.

A SERVOPACK or Servomotor is a precision device. Do not drop it or subject it to strong shock.

There is a risk of failure or damage.

Do not subject connectors to shock.

There is a risk of faulty connections or damage.

If disinfectants or insecticides must be used to treat packing materials such as wooden frames,

plywood, or pallets, the packing materials must be treated before the product is packaged, and

methods other than fumigation must be used.

Example: Heat treatment, where materials are kiln-dried to a core temperature of 56°C for 30

minutes or more.

If the electronic products, which include stand-alone products and products installed in machines,

are packed with fumigated wooden materials, the electrical components may be greatly damaged

by the gases or fumes resulting from the fumigation process. In particular, disinfectants containing

halogen, which includes chlorine, fluorine, bromine, or iodine can contribute to the erosion of the

capacitors.

Do not overtighten the eyebolts on a SERVOPACK or Servomotor.

If you use a tool to overtighten the eyebolts, the tapped holes may be damaged.

Installation Precautions

Install the Servomotor or SERVOPACK in a way that will support the mass given in technical

documents.

Install SERVOPACKs, Servomotors, regenerative resistors, and External Dynamic Brake Resis-

tors on nonflammable materials.

Installation directly onto or near flammable materials may result in fire.

Provide the specified clearances between the SERVOPACK and the control panel as well as

with other devices.

There is a risk of fire or failure.

Install the SERVOPACK in the specified orientation.

There is a risk of fire or failure.

Do not step on or place a heavy object on the product.

There is a risk of failure, damage, or injury.

Do not allow any foreign matter to enter the SERVOPACK or Servomotor.

There is a risk of failure or fire.

xvii

Page 18

NOTICE

DANGER

WARNING

Do not install or store the product in any of the following locations.

• Locations that are subject to direct sunlight

• Locations that are subject to ambient temperatures that exceed product specifications

• Locations that are subject to relative humidities that exceed product specifications

• Locations that are subject to condensation as the result of extreme changes in temperature

• Locations that are subject to corrosive or flammable gases

• Locations that are near flammable materials

• Locations that are subject to dust, salts, or iron powder

• Locations that are subject to water, oil, or chemicals

• Locations that are subject to vibration or shock that exceeds product specifications

• Locations that are subject to radiation

If you store or install the product in any of the above locations, the product may fail or be damaged.

Use the product in an environment that is appropriate for the product specifications.

If you use the product in an environment that exceeds product specifications, the product may fail

or be damaged.

A SERVOPACK or Servomotor is a precision device. Do not drop it or subject it to strong shock.

There is a risk of failure or damage.

Always install a SERVOPACK in a control panel.

Do not allow any foreign matter to enter a SERVOPACK or a Servomotor with a Cooling Fan and

do not cover the outlet from the Servomotor’s cooling fan.

There is a risk of failure.

Wiring Precautions

Do not change any wiring while power is being supplied.

There is a risk of electric shock or injury.

Wiring and inspections must be performed only by qualified engineers.

There is a risk of electric shock or product failure.

Check all wiring and power supplies carefully.

Incorrect wiring or incorrect voltage application to the output circuits may cause short-circuit failures. If a short-circuit failure occurs as a result of any of these causes, the holding brake will not

work. This could damage the machine or cause an accident that may result in death or injury.

Connect the AC and DC power supplies to the specified SERVOPACK terminals.

• Connect an AC power supply to the L1, L2, and L3 terminals and the L1C and L2C terminals on the

SERVOPACK.

• Connect a DC power supply to the B1/ and 2 terminals and the L1C and L2C terminals on the

SERVOPACK.

There is a risk of failure or fire.

If you use a SERVOPACK that supports a Dynamic Brake Option, connect an External Dynamic

Brake Resistor that is suitable for the machine and equipment specifications to the specified

terminals.

There is a risk of unexpected operation, machine damage, burning, or injury when an emergency

stop is performed.

xviii

Page 19

CAUTION

Wait for at least six minutes after turning OFF the power supply (with a SERVOPACK for a 100-

NOTICE

VAC power supply input, wait for at least nine minutes) and then make sure that the CHARGE

indicator is not lit before starting wiring or inspection work. Do not touch the power supply terminals while the CHARGE lamp is lit after turning OFF the power supply because high voltage

may still remain in the SERVOPACK.

There is a risk of electric shock.

Observe the precautions and instructions for wiring and trial operation precisely as described in

this document.

Failures caused by incorrect wiring or incorrect voltage application in the brake circuit may cause

the SERVOPACK to fail, damage the equipment, or cause an accident resulting in death or injury.

Check the wiring to be sure it has been performed correctly.

Connectors and pin layouts are sometimes different for different models. Always confirm the pin

layouts in technical documents for your model before operation.

There is a risk of failure or malfunction.

Connect wires to power supply terminals and motor connection terminals securely with the

specified methods and tightening torque.

Insufficient tightening may cause wires and terminal blocks to generate heat due to faulty contact,

possibly resulting in fire.

Use shielded twisted-pair cables or screened unshielded multi-twisted-pair cables for I/O Sig-

nal Cables and Encoder Cables.

Observe the following precautions when wiring the SERVOPACK’s main circuit terminals.

• Turn ON the power supply to the SERVOPACK only after all wiring, including the main circuit terminals, has been completed.

• If a connector is used for the main circuit terminals, remove the main circuit connector from the SERVOPACK before you wire it.

• Insert only one wire per insertion hole in the main circuit terminals.

• When you insert a wire, make sure that the conductor wire (e.g., whiskers) does not come into con-

tact with adjacent wires.

Install molded-case circuit breakers and other safety measures to provide protection against

short circuits in external wiring.

There is a risk of fire or failure.

Whenever possible, use the Cables specified by Yaskawa.

If you use any other cables, confirm the rated current and application environment of your model

and use the wiring materials specified by Yaskawa or equivalent materials.

Securely tighten cable connector screws and lock mechanisms.

Insufficient tightening may result in cable connectors falling off during operation.

Do not bundle power lines (e.g., the Main Circuit Cable) and low-current lines (e.g., the I/O Sig-

nal Cables or Encoder Cables) together or run them through the same duct. If you do not place

power lines and low-current lines in separate ducts, separate them by at least 30 cm.

If the cables are too close to each other, malfunctions may occur due to noise affecting the low-current lines.

Install a battery at either the host controller or on the Encoder Cable.

If you install batteries both at the host controller and on the Encoder Cable at the same time, you

will create a loop circuit between the batteries, resulting in a risk of damage or burning.

When connecting a battery, connect the polarity correctly.

There is a risk of battery rupture or encoder failure.

xix

Page 20

WARNING

CAUTION

Operation Precautions

Before starting operation with a machine connected, change the settings of the switches and

parameters to match the machine.

Unexpected machine operation, failure, or personal injury may occur if operation is started before

appropriate settings are made.

Do not radically change the settings of the parameters.

There is a risk of unstable operation, machine damage, or injury.

Install limit switches or stoppers at the ends of the moving parts of the machine to prevent

unexpected accidents.

There is a risk of machine damage or injury.

For trial operation, securely mount the Servomotor and disconnect it from the machine.

There is a risk of injury.

Forcing the motor to stop for overtravel is disabled when the Jog (Fn002), Origin Search

(Fn003), or Easy FFT (Fn206) utility function is executed. Take necessary precautions.

There is a risk of machine damage or injury.

When an alarm occurs, the Servomotor will coast to a stop or stop with the dynamic brake

according to the SERVOPACK Option specifications and settings. The coasting distance will

change with the moment of inertia of the load and the resistance of the External Dynamic Brake

Resistor. Check the coasting distance during trial operation and implement suitable safety measures on the machine.

Do not enter the machine’s range of motion during operation.

There is a risk of injury.

Do not touch the moving parts of the Servomotor or machine during operation.

There is a risk of injury.

Design the system to ensure safety even when problems, such as broken signal lines, occur.

For example, the P-OT and N-OT signals are set in the default settings to operate on the safe

side if a signal line breaks. Do not change the polarity of this type of signal.

When overtravel occurs, the power supply to the motor is turned OFF and the brake is released.

If you use the Servomotor to drive a vertical load, set the Servomotor to enter a zero-clamped

state after the Servomotor stops. Also, install safety devices (such as an external brake or

counterweight) to prevent the moving parts of the machine from falling.

Always turn OFF the servo before you turn OFF the power supply. If you turn OFF the main cir-

cuit power supply or control power supply during operation before you turn OFF the servo, the

Servomotor will stop as follows:

• If you turn OFF the main circuit power supply during operation without turning OFF the servo, the

Servomotor will stop abruptly with the dynamic brake.

• If you turn OFF the control power supply without turning OFF the servo, the stopping method that is

used by the Servomotor depends on the model of the SERVOPACK. For details, refer to the manual

for the SERVOPACK.

• If you use a SERVOPACK with the Dynamic Brake Hardware Option, the Servomotor stopping methods will be different from the stopping methods used without the Option or with other Hardware

Options. For details, refer to the following manual.

Σ-7-Series Σ-7S/Σ-7W SERVOPACK with Dynamic Brake Hardware Option Specifications Product Manual

(Manual No.: SIEP S800001 73)

Do not use the dynamic brake for any application other than an emergency stop.

There is a risk of failure due to rapid deterioration of elements in the SERVOPACK and the risk of

unexpected operation, machine damage, burning, or injury.

xx

Page 21

NOTICE

When you adjust the gain during system commissioning, use a measuring instrument to monitor

DANGER

WARNING

CAUTION

NOTICE

the torque waveform and speed waveform and confirm that there is no vibration.

If a high gain causes vibration, the Servomotor will be damaged quickly.

Do not frequently turn the power supply ON and OFF. After you have started actual operation,

allow at least one hour between turning the power supply ON and OFF (as a guideline).

Do not use the product in applications that require the power supply to be turned ON and OFF

frequently.

The elements in the SERVOPACK will deteriorate quickly.

An alarm or warning may occur if communications are performed with the host controller while

the SigmaWin+ or Digital Operator is operating.

If an alarm or warning occurs, it may interrupt the current process and stop the system.

After you complete trial operation of the machine and facilities, use the SigmaWin+ to back up

the settings of the SERVOPACK parameters. You can use them to reset the parameters after

SERVOPACK replacement.

If you do not copy backed up parameter settings, normal operation may not be possible after a

faulty SERVOPACK is replaced, possibly resulting in machine or equipment damage.

Maintenance and Inspection Precautions

Do not change any wiring while power is being supplied.

There is a risk of electric shock or injury.

Wiring and inspections must be performed only by qualified engineers.

There is a risk of electric shock or product failure.

Wait for at least six minutes after turning OFF the power supply (with a SERVOPACK for a 100-

VAC power supply input, wait for at least nine minutes) and then make sure that the CHARGE

indicator is not lit before starting wiring or inspection work. Do not touch the power supply terminals while the CHARGE lamp is lit after turning OFF the power supply because high voltage

may still remain in the SERVOPACK.

There is a risk of electric shock.

Before you replace a SERVOPACK, back up the settings of the SERVOPACK parameters. Copy

the backed up parameter settings to the new SERVOPACK and confirm that they were copied

correctly.

If you do not copy backed up parameter settings or if the copy operation is not completed normally,

normal operation may not be possible, possibly resulting in machine or equipment damage.

Discharge all static electricity from your body before you operate any of the buttons or switches

inside the front cover of the SERVOPACK.

There is a risk of equipment damage.

xxi

Page 22

DANGER

WARNING

CAUTION

Troubleshooting Precautions

If the safety device (molded-case circuit breaker or fuse) installed in the power supply line oper-

ates, remove the cause before you supply power to the SERVOPACK again. If necessary, repair

or replace the SERVOPACK, check the wiring, and remove the factor that caused the safety

device to operate.

There is a risk of fire, electric shock, or injury.

The product may suddenly start to operate when the power supply is recovered after a momen-

tary power interruption. Design the machine to ensure human safety when operation restarts.

There is a risk of injury.

When an alarm occurs, remove the cause of the alarm and ensure safety. Then reset the alarm

or turn the power supply OFF and ON again to restart operation.

There is a risk of injury or machine damage.

If the Servo ON signal is input to the SERVOPACK and an alarm is reset, the Servomotor may

suddenly restart operation. Confirm that the servo is OFF and ensure safety before you reset an

alarm.

There is a risk of injury or machine damage.

Always insert a magnetic contactor in the line between the main circuit power supply and the

main circuit power supply terminals on the SERVOPACK so that the power supply can be shut

OFF at the main circuit power supply.

If a magnetic contactor is not connected when the SERVOPACK fails, a large current may flow,

possibly resulting in fire.

If an alarm occurs, shut OFF the main circuit power supply.

There is a risk of fire due to a regenerative resistor overheating as the result of regenerative transistor failure.

Install a ground fault detector against overloads and short-circuiting or install a molded-case

circuit breaker combined with a ground fault detector.

There is a risk of SERVOPACK failure or fire if a ground fault occurs.

The holding brake on a Servomotor will not ensure safety if there is the possibility that an exter-

nal force (including gravity) may move the current position and create a hazardous situation

when power is interrupted or an error occurs. If an external force may cause movement, install

an external braking mechanism that ensures safety.

xxii

Disposal Precautions

When disposing of the product, treat it as ordinary industrial waste. However, local ordinances

and national laws must be observed. Implement all labeling and warnings as a final product as

required.

Page 23

General Precautions

Figures provided in this document are typical examples or conceptual representations. There

may be differences between them and actual wiring, circuits, and products.

The products shown in illustrations in this document are sometimes shown without covers or

protective guards. Always replace all covers and protective guards before you use the product.

If you need a new copy of this document because it has been lost or damaged, contact your

nearest Yaskawa representative or one of the offices listed on the back of this document.

This document is subject to change without notice for product improvements, specifications

changes, and improvements to the manual itself.

We will update the document number of the document and issue revisions when changes are

made.

Any and all quality guarantees provided by Yaskawa are null and void if the customer modifies

the product in any way. Yaskawa disavows any responsibility for damages or losses that are

caused by modified products.

xxiii

Page 24

Warranty

Details of Warranty

Warranty Period

The warranty period for a product that was purchased (hereinafter called the “delivered product”) is

one year from the time of delivery to the location specified by the customer or 18 months from the

time of shipment from the Yaskawa factory, whichever is sooner.

Warranty Scope

Yaskawa shall replace or repair a defective product free of charge if a defect attributable to

Yaskawa occurs during the above warranty period.

This warranty does not cover defects caused by the delivered product reaching the end of its service life and replacement of parts that require replacement or that have a limited service life.

This warranty does not cover failures that result from any of the following causes.

• Improper handling, abuse, or use in unsuitable conditions or in environments not described in

product catalogs or manuals, or in any separately agreed-upon specifications

• Causes not attributable to the delivered product itself

• Modifications or repairs not performed by Yaskawa

• Use of the delivered product in a manner in which it was not originally intended

• Causes that were not foreseeable with the scientific and technological understanding at the time

of shipment from Yaskawa

• Events for which Yaskawa is not responsible, such as natural or human-made disasters

Limitations of Liability

• Yaskawa shall in no event be responsible for any damage or loss of opportunity to the customer

that arises due to failure of the delivered product.

• Yaskawa shall not be responsible for any programs (including parameter settings) or the results of

program execution of the programs provided by the user or by a third party for use with programmable Yaskawa products.

• The information described in product catalogs or manuals is provided for the purpose of the customer purchasing the appropriate product for the intended application. The use thereof does not

guarantee that there are no infringements of intellectual property rights or other proprietary rights

of Yaskawa or third parties, nor does it construe a license.

• Yaskawa shall not be responsible for any damage arising from infringements of intellectual property rights or other proprietary rights of third parties as a result of using the information described

in catalogs or manuals.

xxiv

Page 25

Suitability for Use

• It is the customer’s responsibility to confirm conformity with any standards, codes, or regulations

that apply if the Yaskawa product is used in combination with any other products.

• The customer must confirm that the Yaskawa product is suitable for the systems, machines, and

equipment used by the customer.

• Consult with Yaskawa to determine whether use in the following applications is acceptable. If use

in the application is acceptable, use the product with extra allowance in ratings and specifications, and provide safety measures to minimize hazards in the event of failure.

• Outdoor use, use involving potential chemical contamination or electrical interference, or use

in conditions or environments not described in product catalogs or manuals

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems,

vehicle systems, medical equipment, amusement machines, and installations subject to separate industry or government regulations

• Systems, machines, and equipment that may present a risk to life or property

• Systems that require a high degree of reliability, such as systems that supply gas, water, or

electricity, or systems that operate continuously 24 hours a day

• Other systems that require a similar high degree of safety

• Never use the product for an application involving serious risk to life or property without first

ensuring that the system is designed to secure the required level of safety with risk warnings and

redundancy, and that the Yaskawa product is properly rated and installed.

• The circuit examples and other application examples described in product catalogs and manuals

are for reference. Check the functionality and safety of the actual devices and equipment to be

used before using the product.

• Read and understand all use prohibitions and precautions, and operate the Yaskawa product

correctly to prevent accidental harm to third parties.

Specifications Change

The names, specifications, appearance, and accessories of products in product catalogs and

manuals may be changed at any time based on improvements and other reasons. The next editions of the revised catalogs or manuals will be published with updated code numbers. Consult

with your Yaskawa representative to confirm the actual specifications before purchasing a product.

xxv

Page 26

Compliance with UL Standards, EU Directives, and Other Safety Standards

Certification marks for the standards for which the product has been certified by certification bodies

are shown on nameplate. Products that do not have the marks are not certified for the standards.

North American Safety Standards (UL)

Product Model North American Safety Standards (UL File No.)

SERVOPACKs SGD7S

• SGMMV

Rotary

Servomotors

Direct Drive Servomotors

Linear

Servomotors

*1. Certification is pending.

*2. SGM7F-B, -C, and -D: Certified; SGM7F-A: Certification is pending.

• SGM7A

• SGM7J

• SGM7P

• SGM7G

• SGM7E

• SGM7F

• SGMCV

• SGLGW

• SGLFW

• SGLFW2

• SGLTW

*1

*2

*1

UL 61800-5-1 (E147823)

CSA C22.2 No.274

UL 1004-1

UL 1004-6

(E165827)

UL 1004-1

UL 1004-6

(E165827)

UL 1004

(E165827)

xxvi

Page 27

European Directives

Product Model EU Directive Harmonized Standards

Machinery Directive

2006/42/EC

SERVOPACKs

SGD7S

EMC Directive

2014/30/EU

Low Voltage Directive

2014/35/EU

EMC Directive

SGMMV

2004/104/EC

Low Voltage Directive

2006/95/EC

Rotary

Servomotors

• SGM7J

• SGM7A

EMC Directive

2014/30/EU

• SGM7P

• SGM7G

Low Voltage Directive

2014/35/EU

*1

*1

B, C,

D, E

EMC Directive

2004/108/EC

Low Voltage Directive

2006/95/EC

Direct Drive

Servomotors

• SGM7E

• SGM7F

• SGMCV

• SGMCS-

(Small-Capacity, Coreless

Servomotors)

Linear

Servomotors

• SGLF

• SGLFW2

• SGLT

*1. Certification is pending.

*2. Certification is pending for the SGM7F and SGMCV. No application has been made for SGMCS certification.

*3. No application has been made for SGMCS certification.

Note: 1. We declared the CE Marking based on the harmonized standards in the above table.

2. These products are for industrial use. In home environments, these products may cause electromagnetic interference and additional noise reduction measures may be necessary.

• SGLG

EMC Directive

2004/108/EC

Low Voltage Directive

2006/95/EC

EN ISO13849-1: 2015

EN 55011 group 1, class A

EN 61000-6-2

EN 61000-6-4

EN 61800-3 (Category C2, Second

environment)

EN 50178

EN 61800-5-1

EN 55011 group 1, class A

EN 61000-6-2

EN 61800-3

EN 60034-1

EN 60034-5

EN 55011 group 1, class A

EN 61000-6-2

EN 61000-6-4

EN 61800-3 (Category C2, Second

environment)

EN 60034-1

EN 60034-5

EN 55011 group 1, class A

EN 61000-6-2

EN 61000-6-4

EN 61800-3

*2

*3

EN 60034-1

EN 60034-5

EN 55011 group 1, class A

EN 61000-6-2

EN 61000-6-4

EN 60034-1

Safety Standards

Product Model Safety Standards Standards

EN ISO13849-1: 2015

IEC 60204-1

IEC 61508 series

IEC 62061

IEC 61800-5-2

SERVOPACKs SGD7S

Safety of Machinery

Functional Safety

EMC IEC 61326-3-1

xxvii

Page 28

Safety Parameters

Item Standards Performance Level

Safety Integrity Level

Probability of Dangerous Failure per Hour

Performance Level EN ISO 13849-1 PLe (Category 3)

Mean Time to Dangerous Failure of Each Channel EN ISO 13849-1 MTTFd: High

Average Diagnostic Coverage EN ISO 13849-1 DCavg: Medium

Stop Category IEC 60204-1 Stop category 0

Safety Function IEC 61800-5-2 STO

Mission Time IEC 61508 10 years

Hardware Fault Tolerance IEC 61508 HFT = 1

Subsystem IEC 61508 B

IEC 61508 SIL3

IEC 62061 SILCL3

IEC 61508

IEC 62061

PFH = 4.04×10

(4.04% of SIL3)

-9

[1/h]

xxviii

Page 29

1

Contents

About this Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Outline of Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Using This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xi

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiv

Compliance with UL Standards, EU Directives, and Other Safety Standards . . xxvi

Basic Information on SERVOPACKs

2

1.1

1.2

1.3

1.4

1.5

1.6

1.7

Product Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Model Designations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.2.1 Interpreting SERVOPACK Model Numbers with the FT40 Specification . . . . 1-3

1.2.2 Interpreting SERVOPACK Model Numbers with the FT41 Specification . . . . 1-4

1.2.3 Interpreting Servomotor Model Numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Combinations of SERVOPACKs and Servomotors . . . . . . . . . . . 1-5

Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.5.1 Function Application Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.5.2 Restrictions on Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

SigmaWin+ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Combining the SERVOPACKs with MP-Series Machine Controllers and the MPE720 Engineering Tool

SERVOPACK Ratings and Specifications

. . 1-11

3

2.1

2.2

2.3

Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

SERVOPACK Overload Protection Characteristics . . . . . . . . . . 2-5

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Pressure Feedback Control

3.1

3.2

3.3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Connecting Pressure Sensor Amplifiers. . . . . . . . . . . . . . . . . . . 3-4

3.2.1 FT40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.2.2 FT41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Operation Patterns for Pressure Feedback Control. . . . . . . . . . 3-5

xxix

Page 30

4

3.4

3.5

3.6

3.7

Changing from Torque Control to Pressure Feedback Control . 3-6

3.4.1 Mode 2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

3.4.2 Mode 1 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Control Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.5.1 Pressure Feedback Control 2 (Pn458 = n.1) . . . . . . . . . . . . . . . . . . . .3-7

3.5.2 Pressure Feedback Control 1 (Pn458 = n.0) . . . . . . . . . . . . . . . . . . . .3-8

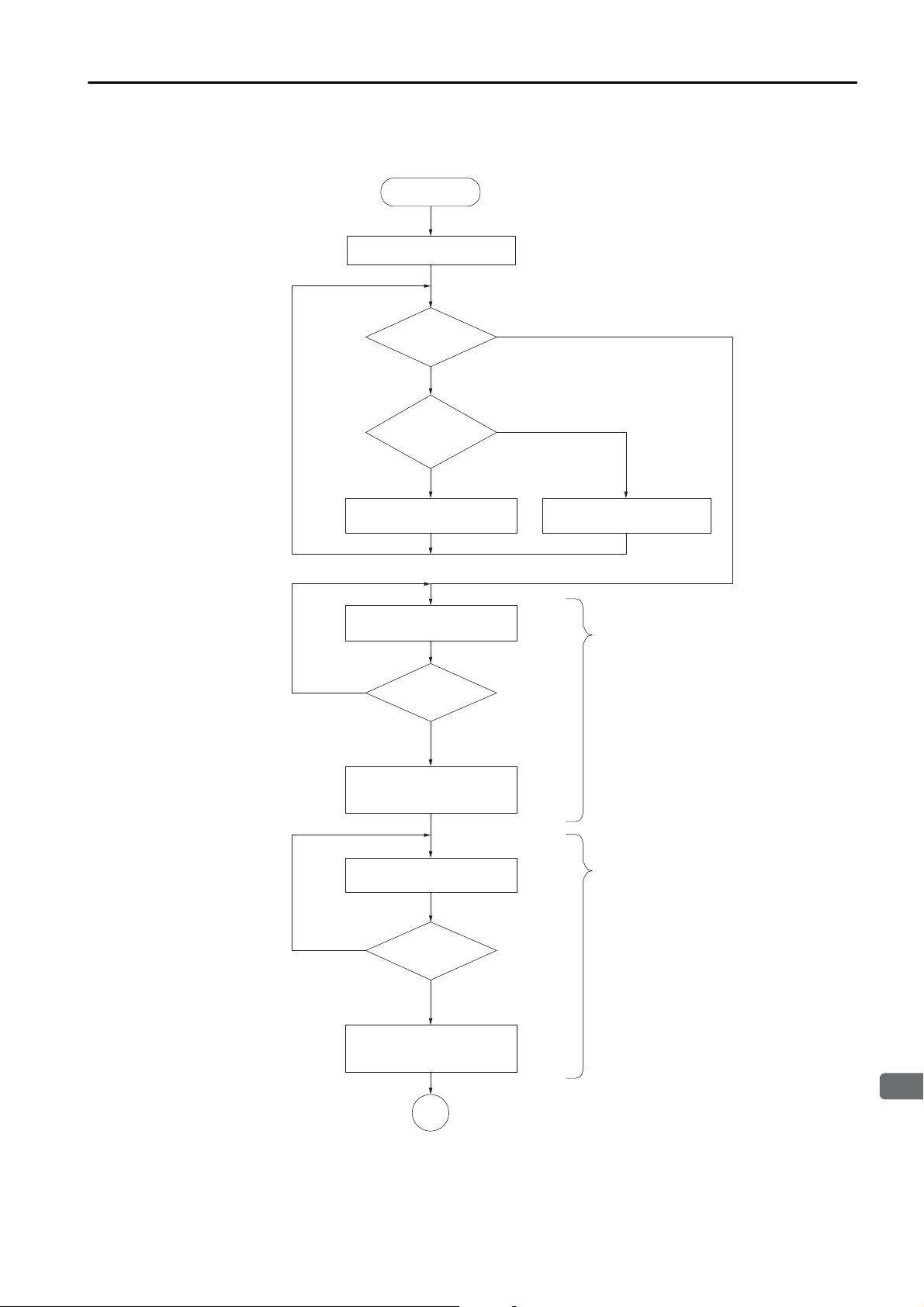

Setup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3.6.1 Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

3.6.2 Disabling Tuning-Less Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

3.6.3 Setting and Checking Other Station Monitoring . . . . . . . . . . . . . . . . . . . . .3-10

3.6.4 Settings for the System That Uses Pressure Feedback Control . . . . . . . . .3-13

3.6.5 Automatic Offset Adjustment for Pressure Feedback Detection

Input Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

3.6.6 Settings prior to Pressure Feedback Control Operation . . . . . . . . . . . . . . . 3-16

3.6.7 Gain Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Speed/Torque (Pressure) Table Operation

5

4.1

4.2

4.3

4.4

4.5

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Operation Patterns for Speed/Torque (Pressure) Table Operation

Table Parameter Settings for Speed/Torque (Pressure) Table Operation

4.3.1 Setting the Number of Speed Table References

4.3.2 Settings for Speed Table Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

4.3.3 Setting Condition for Changing from Speed Table Operation

4.3.4 Settings for Torque (Pressure) Table Operation . . . . . . . . . . . . . . . . . . . . . . 4-11

Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Maintenance

5.1

FT40 Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.1.1 Alarm Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

5.1.2 List of Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

5.1.3 Troubleshooting Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

5.1.4 Warning Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-39

5.1.5 List of Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-39

5.1.6 Troubleshooting Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-42

5.1.7 Troubleshooting Based on the Operation

. . 4-3

. . 4-4

and the Number of Torque (Pressure) References. . . . . . . . . . . . . . . . . . . . .4-4

to Torque (Pressure) Table Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

and Conditions of the Servomotor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-49

xxx

Page 31

6

5.2

FT41 Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-58

5.2.1 Alarm Displays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-58

5.2.2 List of Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-58

5.2.3 Troubleshooting Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-64

5.2.4 Warning Displays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-95

5.2.5 List of Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-95

5.2.6 Troubleshooting Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-98

5.2.7 Troubleshooting Based on the Operation

and Conditions of the Servomotor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-105

Parameter Lists

6.1

6.2

6.3

List of Servo Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.1.1 Interpreting the Parameter Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.1.2 List of MECHATROLINK-III Common Parameters . . . . . . . . . . . . . . . . . . . . 6-3

FT40 Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6.2.1 List of Servo Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6.2.2 List of MECHATROLINK-III Common Parameters . . . . . . . . . . . . . . . . . . . 6-48

6.2.3 Parameter Recording Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-56

FT41 Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-70

6.3.1 List of Servo Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-70

6.3.2 List of MECHATROLINK-III Common Parameters . . . . . . . . . . . . . . . . . . 6-116

6.3.3 Parameter Recording Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-124

Index

Revision History

xxxi

Page 32

Basic Information on SERVOPACKs

This chapter provides information required to select

SERVOPACKs, such as the SERVOPACK models.

1

1.1

1.2

1.3

1.4

1.5

1.6

1.7

Product Introduction . . . . . . . . . . . . . . . . . . 1-2

Model Designations . . . . . . . . . . . . . . . . . . 1-3

1.2.1 Interpreting SERVOPACK Model Numbers

with the FT40 Specification . . . . . . . . . . . . . . . . . 1-3

1.2.2 Interpreting SERVOPACK Model Numbers

with the FT41 Specification . . . . . . . . . . . . . . . . . 1-4

1.2.3 Interpreting Servomotor Model Numbers . . . . . . 1-4

Combinations of SERVOPACKs and Servomotors . . . 1-5

Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.5.1 Function Application Restrictions . . . . . . . . . . . . 1-9

1.5.2 Restrictions on Specifications . . . . . . . . . . . . . . . 1-9

SigmaWin+ . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Combining the SERVOPACKs with MP-Series Machine Controllers and the MPE720 Engineering Tool . . 1-11

Page 33

1.1 Product Introduction

1.1

Product Introduction

The SERVOPACKs described in this manual provide the following two functions to achieve

high-precision pressing control for molding equipment, compressors, and other machines that

require press and injection molding.

Function Description Reference

The value input from a pressure sensor is used to perform fullyclosed loop control of a torque reference.

Pressing Feedback

Control

Speed/Torque

(Pressure) Table

Operation

For the values input from a pressure sensor, you can select either of

the following two types.

• FT40 (11th to 13th digits in SERVOPACK model number: F40):

Analog signals

• FT41 (11th to 13th digits in SERVOPACK model number: F41):

Data via network connected with MECHATROLINK-III

Operation is automatically switched between speed references and

torque references based on information set in the SERVOPACK.

page 3-1

page 4-1

1-2

Page 34

1.2 Model Designations

1

Basic Information on SERVOPACKs

F40

Press and injection molding option

023

Specification

Code

FT/EX Specification

None

B

None

BTO

specification

Specification

Code

BTO Specification

*3

MECHATROLINK-III

communications references

20

A 200 VAC

SGD7S

-

R70

A 20 A

023

A

Maximum Applicable

Motor Capacity

Voltage

Interface

*2

Code

Code

Specication

Specication

Design Revision Order

Hardware Options

Specication

ThreePhase,

200 VAC

1st+2nd+3rd digits

4th digit

5th+6th digits

7th digit

8th+9th+10th digits

Σ-7-Series

Σ-7S

SERVOPACKs

4th

digit

1st+2nd+3rd

digits

5th+6th

digits

8th+9th+10th

digits

7th

digit

R70

*1

R90

*1

1R6

*1

2R8

*1

3R8

5R5

*1

7R6

120

180

200

330

470

550

590

780

R70

R90

2R1

2R8

0.05 kW

0.1 kW

0.2 kW

0.4 kW

0.5 kW

0.75 kW

1.0 kW

1.5 kW

2.0 kW

3.0 kW

5.0 kW

6.0 kW

7.5 kW

11 kW

15 kW

0.05 kW

0.1 kW

0.2 kW

0.4 kW

Voltage Code Specication

Analog sensor input All models

Code

Specication

Applicable

Models

F40

B

11th+12th+13th

digits

14th

digit

11th+12th+13th digits

14th digit

F 100 VAC

SinglePhase,

100 VAC

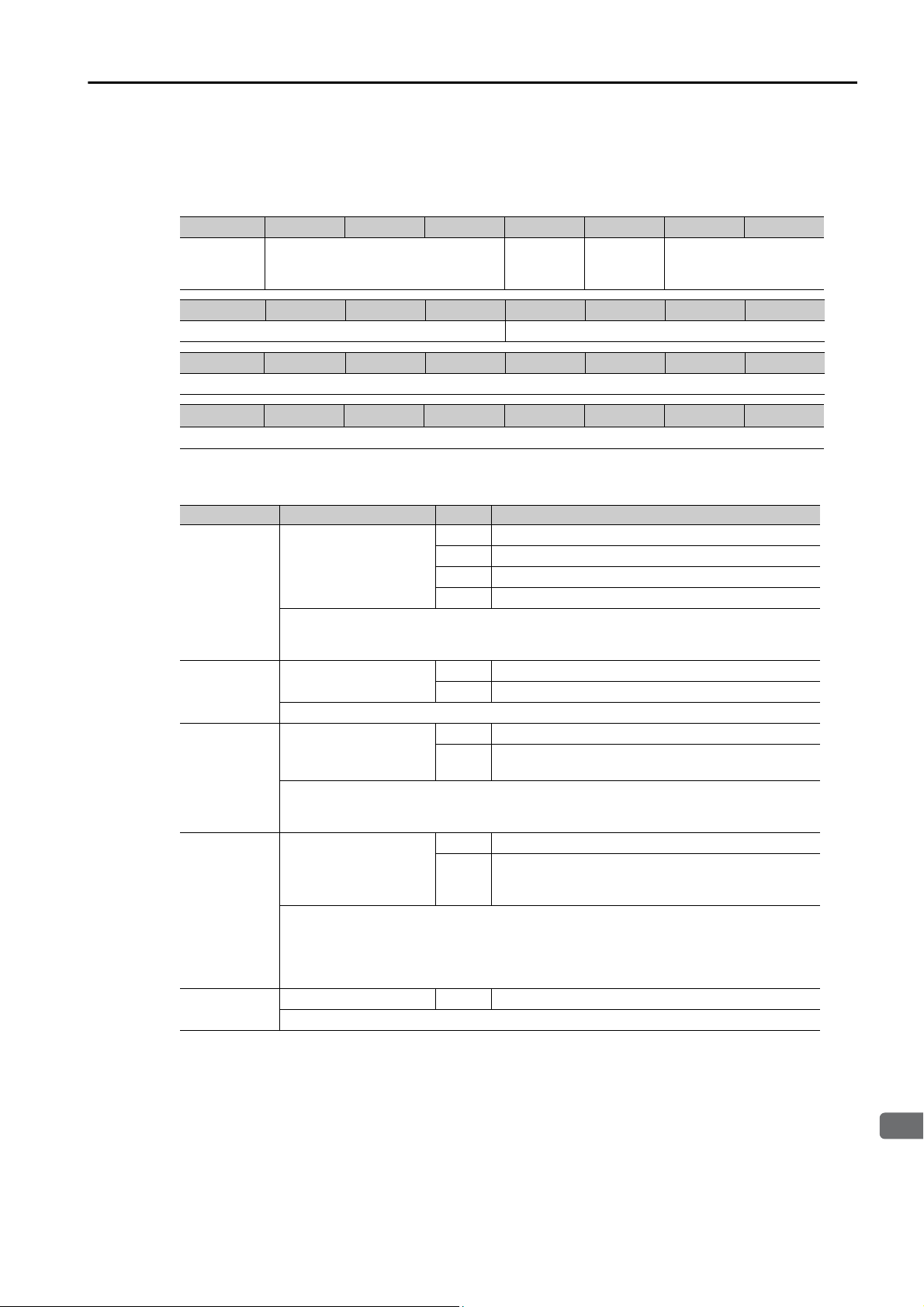

1.2.1 Interpreting SERVOPACK Model Numbers with the FT40 Specification

1.2

1.2.1

Model Designations

Interpreting SERVOPACK Model Numbers with the FT40

Specification

*1. You can use these models with either a single-phase or three-phase input.

*2. The same interface is used for both Rotary Servomotors and Linear Servomotors.

*3. The BTO specification indicates if the SEVOPACK is customized by using the MechatroCloud BTO service. You

need a BTO number to order SERVOPACKs with customized specifications.

Refer to the following catalog for details on the BTO specification.

AC Servo Drives Σ-7 Series (Manual No.: KAEP S800001 23)

1-3

Page 35

1.2 Model Designations

F41

Press and injection molding option

000

Specification

Code

FT/EX Specification

None

B

None

BTO

specification

Specification

Code

BTO Specification

*3

MECHATROLINK-III

communications references

20

A 200 VAC

SGD7S

-

R70

A 20 A

000

A

Maximum Applicable

Motor Capacity

Voltage

Interface

*2

Code

Code

Specication

Specication

Design Revision Order

Hardware Options

Specication

ThreePhase,

200 VAC

1st+2nd+3rd digits

4th digit

5th+6th digits

7th digit

8th+9th+10th digits

Σ-7-Series

Σ-7S

SERVOPACKs

4th

digit

1st+2nd+3rd

digits

5th+6th

digits

8th+9th+10th

digits

7th

digit

R70

*1

R90

*1

1R6

*1

2R8

*1

3R8

5R5

*1

7R6

120

180

200

330

470

550

590

780

R70

R90

2R1

2R8

0.05 kW

0.1 kW

0.2 kW

0.4 kW

0.5 kW

0.75 kW

1.0 kW

1.5 kW

2.0 kW

3.0 kW

5.0 kW

6.0 kW

7.5 kW

11 kW

15 kW

0.05 kW

0.1 kW

0.2 kW

0.4 kW

Voltage Code Specication

No hardware options

Code

Specication

F41

B

11th+12th+13th

digits

14th

digit

11th+12th+13th digits

14th digit

F 100 VAC

SinglePhase,

100 VAC

1.2.2 Interpreting SERVOPACK Model Numbers with the FT41 Specification

1.2.2

Interpreting SERVOPACK Model Numbers with the FT41

Specification

*1. You can use these models with either a single-phase or three-phase input.

*2. The same interface is used for both Rotary Servomotors and Linear Servomotors.

*3. The BTO specification indicates if the SEVOPACK is customized by using the MechatroCloud BTO service. You

1-4

1.2.3

Interpreting Servomotor Model Numbers

Refer to the following manuals for information on interpreting Σ-7-Series Servomotor model

numbers.

need a BTO number to order SERVOPACKs with customized specifications.

Refer to the following catalog for details on the BTO specification.

AC Servo Drives Σ-7 Series (Manual No.: KAEP S800001 23)

Σ-7-Series Rotary Servomotor Product Manual (Manual No.: SIEP S800001 36)

Σ-7-Series Linear Servomotor Product Manual (Manual No.: SIEP S800001 37)

Σ-7-Series Direct Drive Servomotor Product Manual (Manual No.: SIEP S800001 38)

Page 36

1.3 Combinations of SERVOPACKs and Servomotors

1

Basic Information on SERVOPACKs

1.3

Combinations of SERVOPACKs and Servomotors

Refer to the following manuals for information on combinations with Σ-7-Series Servomotors.

Σ-7-Series Rotary Servomotor Product Manual (Manual No.: SIEP S800001 36)

Σ-7-Series Linear Servomotor Product Manual (Manual No.: SIEP S800001 37)

Σ-7-Series Direct Drive Servomotor Product Manual (Manual No.: SIEP S800001 38)

1-5

Page 37

1.4 Functions

1.4

Functions

This section lists the functions provided by SERVOPACKs. Refer to the following manual for

details on the functions.

Σ-7-Series Σ-7S SERVOPACK with MECHATROLINK-III Communications References Product Manual (Manual No.:

SIEP S800001 28)

Functions given inside bold lines in the functions tables are restricted for the SERVOPACKs

described in this manual. Refer to the following section for details on restrictions to these functions.

1.5 Restrictions

•

Functions Related to the Machine

Power Supply Type Settings for the Main Circuit and Control Circuit

Automatic Detection of Connected Motor

Motor Direction Setting

Linear Encoder Pitch Setting

Writing Linear Servomotor Parameters

Selecting the Phase Sequence for a Linear Servomotor

Polarity Sensor Setting

Polarity Detection

Overtravel Function and Settings

Holding Brake